Novel blanking column of hot charging type energy-saving airtight submerged arc furnace and manufacturing method thereof

A closed mine and hot-loading technology, which is applied in the field of metallurgical equipment, can solve the problems of easy cracks, softening, and leakage of metal columns, and achieve the effects of good high-temperature chemical stability, improved insulation performance, and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

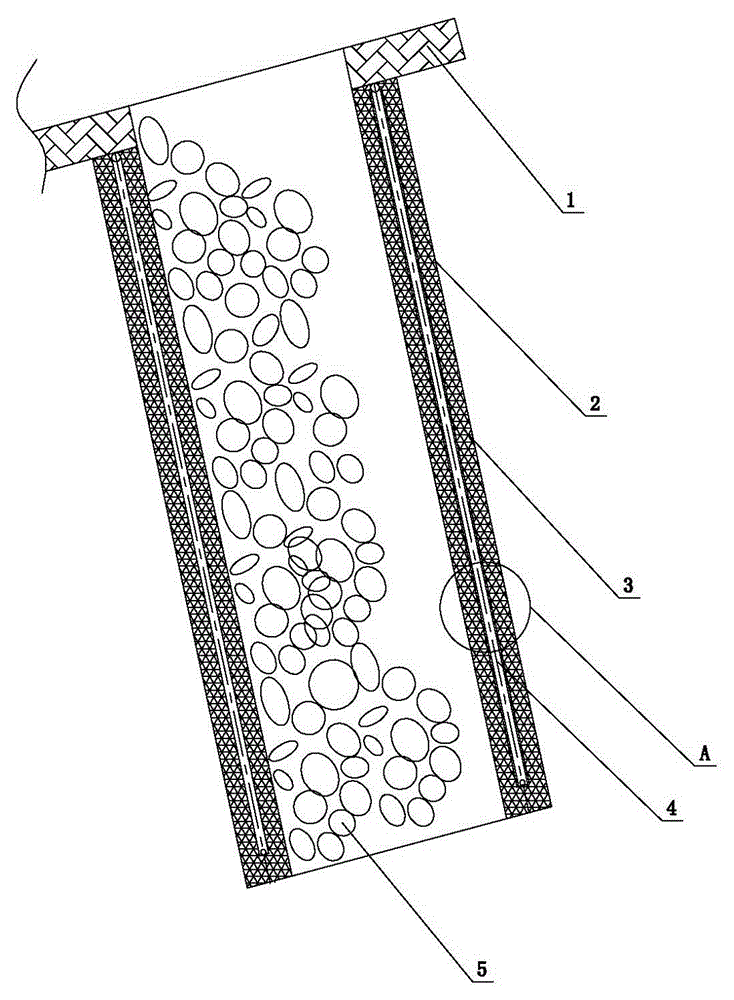

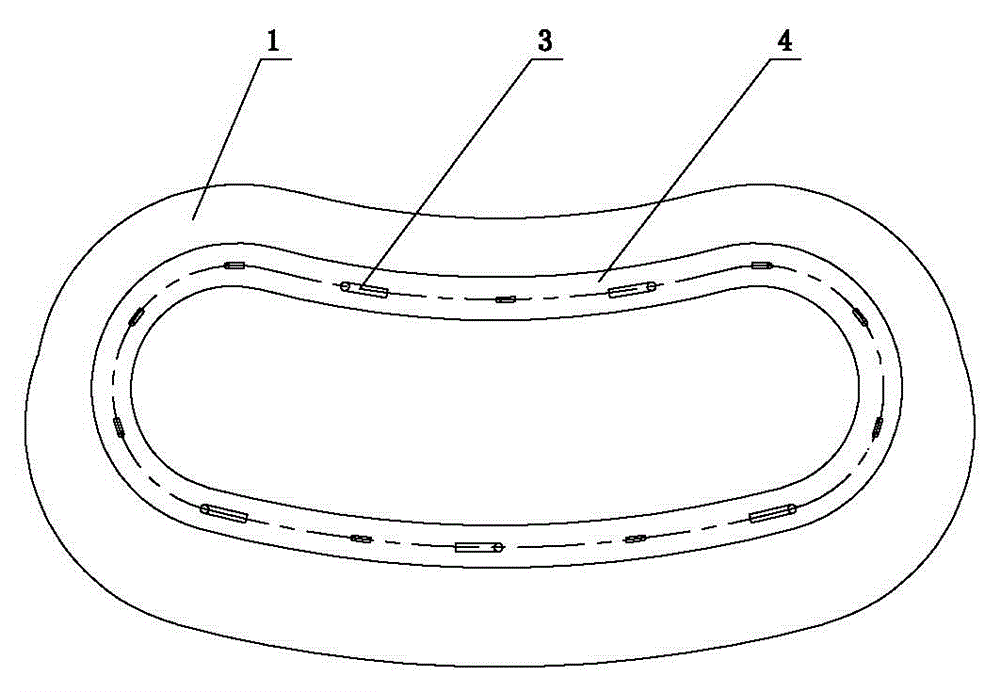

[0022] A novel method for manufacturing a blanking column of a heat-loading energy-saving sealed submerged arc furnace, the process of which is as follows:

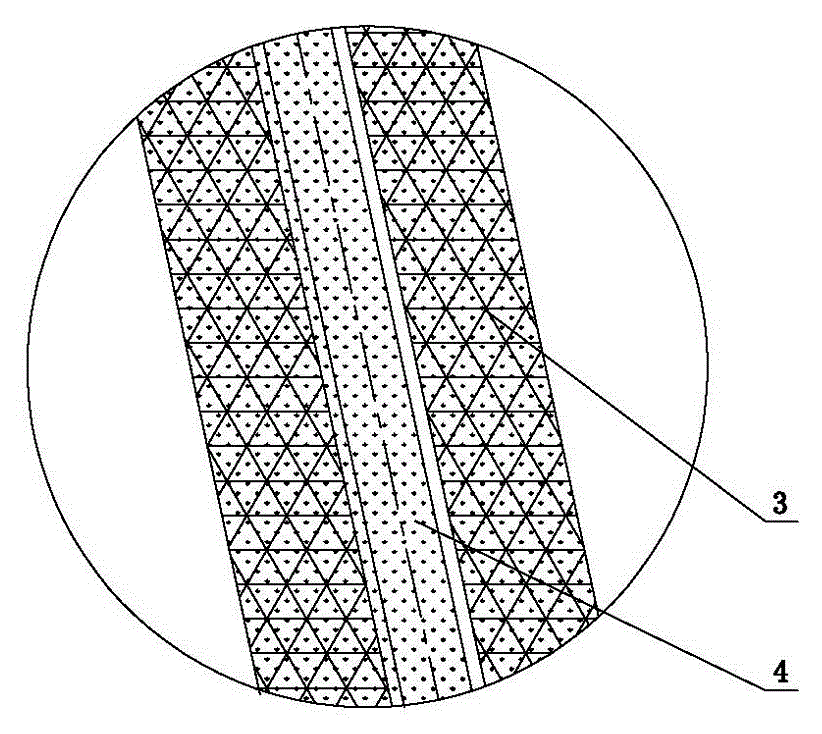

[0023] (1) Weld the heat-resistant metal reinforced grid 3 and the connecting flange 1 of the support seat, and coat the outer surface of the heat-resistant metal reinforced grid 3 with a high-temperature insulating coating 4. On the one hand, the material of the heat-resistant metal reinforced grid 3 There is a certain difference in the linear expansion coefficient of the cavity material of the non-metallic feeding column 2, and the organic coating separates them to reduce the thermal stress caused by temperature changes; the high temperature resistant insulating coating 4 improves the insulating performance of the metal grid. The heat-resistant metal reinforced grid 3 has high strength and toughness, and acts as an internal support for the skeleton, so that there is a good mechanical bite force between the cavities of th...

Embodiment 2

[0028] A novel method for manufacturing a blanking column of a heat-loading energy-saving sealed submerged arc furnace, the process of which is as follows:

[0029] (1) Weld the heat-resistant metal reinforced grid 3 and the connecting flange 1 of the support seat, and coat the outer surface of the heat-resistant metal reinforced grid 3 with a high-temperature insulating coating 4. On the one hand, the material of the heat-resistant metal reinforced grid 3 There is a certain difference in the linear expansion coefficient of the cavity material of the non-metallic feeding column 2, and the organic coating separates them to reduce the thermal stress caused by temperature changes; the high temperature resistant insulating coating 4 improves the insulating performance of the metal grid. The heat-resistant metal reinforced grid 3 has high strength and toughness, and acts as an internal support for the skeleton, so that there is a good mechanical bite force between the cavities of th...

Embodiment 3

[0034] A novel method for manufacturing a blanking column of a heat-loading energy-saving sealed submerged arc furnace, the process of which is as follows:

[0035] (1) Weld the heat-resistant metal reinforced grid 3 and the connecting flange 1 of the support seat, and coat the outer surface of the heat-resistant metal reinforced grid 3 with a high-temperature insulating coating 4. On the one hand, the material of the heat-resistant metal reinforced grid 3 There is a certain difference in the linear expansion coefficient of the cavity material of the non-metallic feeding column 2, and the organic coating separates them to reduce the thermal stress caused by temperature changes; the high temperature resistant insulating coating 4 improves the insulating performance of the metal grid. The heat-resistant metal reinforced grid 3 has high strength and toughness, and acts as an internal support for the skeleton, so that there is a good mechanical bite force between the cavities of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com