Patents

Literature

97results about How to "Washout" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

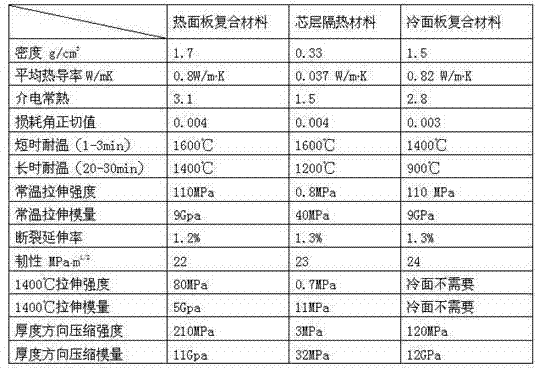

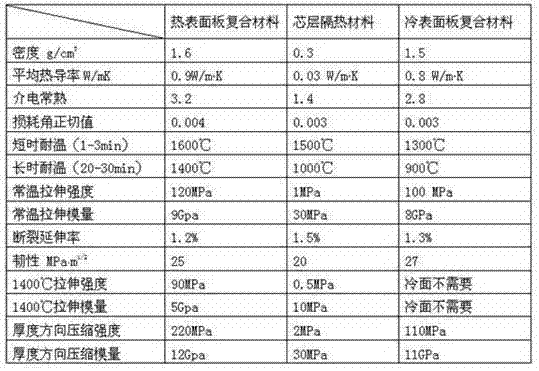

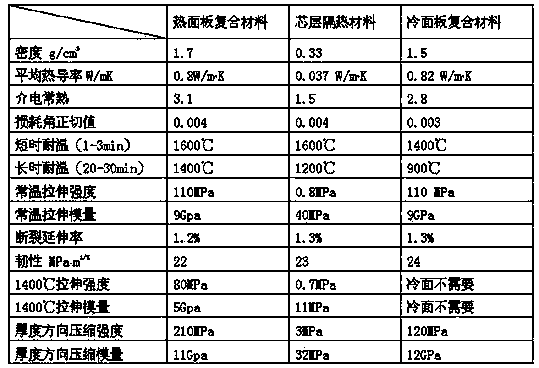

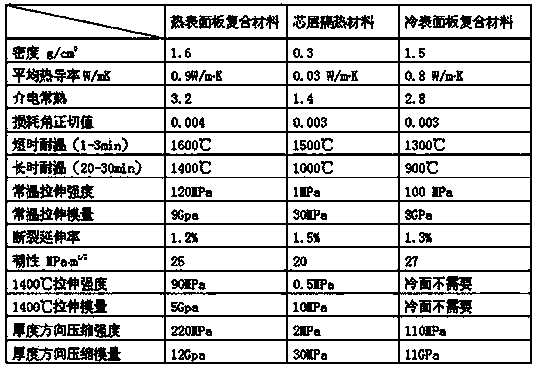

Ceramic composite material of high temperature insulation sandwich structure and method for preparing ceramic composite material

ActiveCN102642350AImprove toughnessImprove thermal conductivityLaminationLamination apparatusOxide ceramicCeramic composite

Disclosed are a ceramic composite material of a high temperature insulation sandwich structure and a method for preparing the ceramic composite material. A core layer of the composite material is an aerogel composite material layer reinforced by high temperature resistant inorganic fibers, oxide ceramic composite material surface plates reinforced by high temperature resistant inorganic fibers are compounded on the upper surface and the lower surface of the core layer, the thickness of the core layer is larger than or equal to 2mm, and the thicknesses of the upper surface plate and the lower surface plate respectively range from 0.1mm to 3.0mm. The method for preparing the ceramic composite material of the high temperature insulation sandwich structure includes the steps: (1) selecting aerogel composite materials reinforced by the high temperature resistant inorganic fibers as materials of the core layer with the thickness larger than or equal to 2mm; (2) tiling high temperature resistant inorganic fiber cloth or thin-layer fabrics on the upper surface and the lower surface of the core layer to perform needling, puncture or sewing; (3) sucking sol in a vacuum manner and gelating the sol at the temperature of 30-200 DEG C; and (4) performing heat treatment. The ceramic composite material of the high temperature insulation sandwich structure integrates the functions of heat insulation, bearing, wave penetration and the like.

Owner:NAT UNIV OF DEFENSE TECH

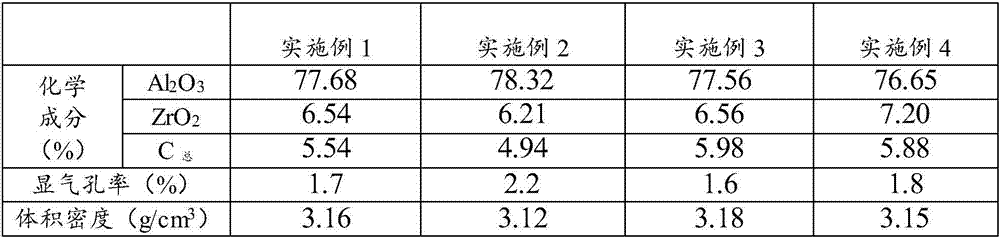

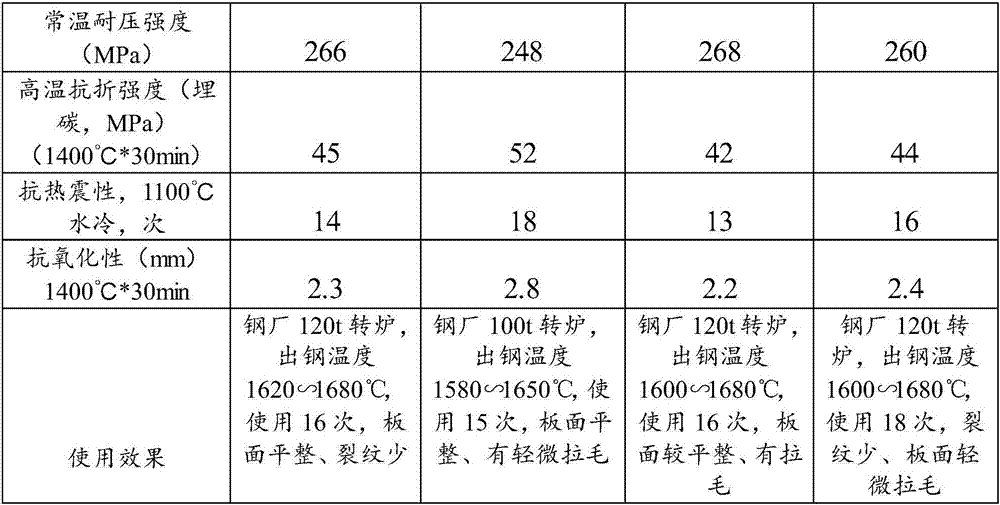

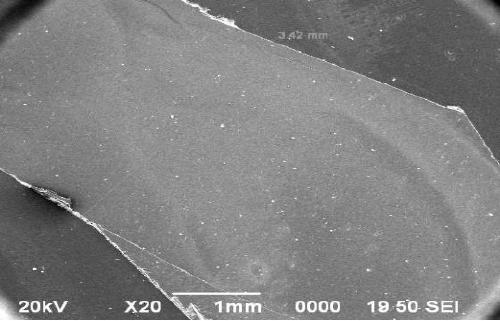

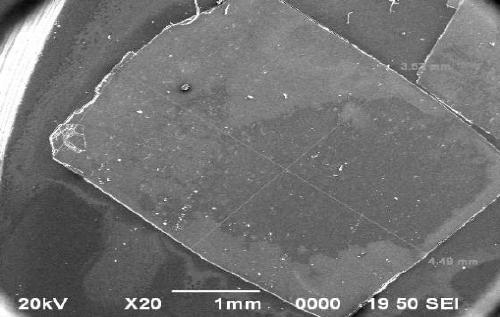

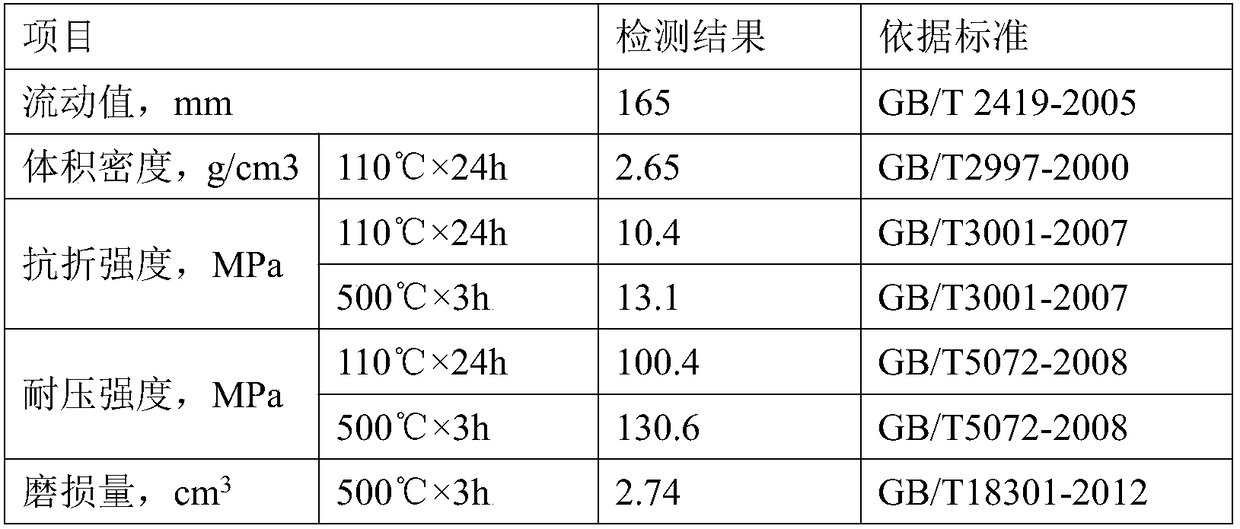

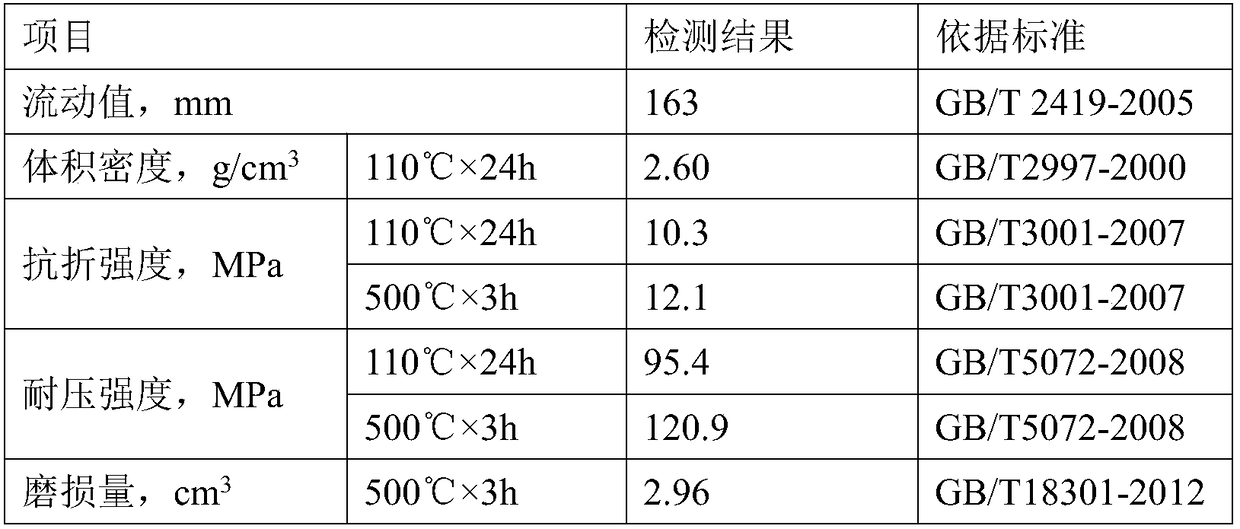

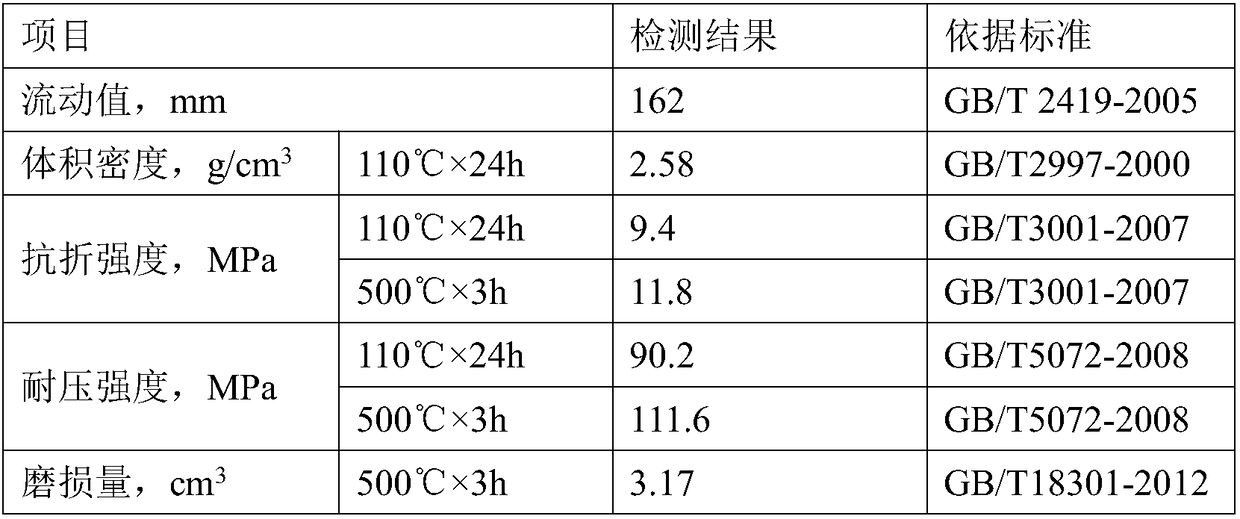

Slide plate brick for slag stopping of converter, and production method thereof

The invention provides a slide plate brick for slag stopping of a converter. The slide plate brick is produced from, by mass, 45-60% of tabular corundum, 10-30% of zirconia mullite, 6-14% of alumina micro-powder, 4-10% of metallic aluminum powder, 2-8% of silicon carbide, 1-3% of clay, 1-3% of carbon black, 0.5-1.5% of boron carbide, 0.5-1.5% of aluminum fibers and 4-6% of a composite resin binder. The slide plate brick for slag stopping of the converter is produced through selecting specific kinds and proportions of the raw materials without high temperature calcination, can be used multiple times, and has good resistance to corrosion, scour, oxidation and thermal shock.

Owner:HUNAN XIANGGANG RUITAI TECH

Preparation method of superlight closed-pore ceramic

InactiveCN104016703ASimple preparation processSave the debinding processCeramicwareCeramic particleMetallic materials

The invention discloses a preparation method of a superlight closed-pore ceramic, belonging to the technical field of inorganic nonmetallic materials. The superlight closed-pore ceramic comprises the following raw materials by weight percent: 5%-60% of ceramic particles, 0.01%-5% of a foaming agent and the balance of water. The preparation method comprises the steps of mixing the ceramic particles and a long-chain surfactant with the water according to a ratio to obtain granular stable foam; directly drying the foam, and sintering at high temperature to obtain the superlight closed-pore ceramic. The superlight closed-pore ceramic is uniform in pore, high in closed porosity, low in density and high in strength, and is suitable for preparing foam ceramic materials with different sizes and complicated shapes. In addition, the superlight closed-pore ceramic is relatively high in strength and relatively low in volume density and heat conductivity coefficient; the preparation method has the characteristics of low cost, simple process, environmental friendliness and the like, and has wide application prospects.

Owner:TSINGHUA UNIV

Carbon-free ladle brick and preparation method thereof

ActiveCN102515794ASolve the problem of non-scouring resistance and aggregate powder separationGood structural flexibilityThermal expansionConstruction aggregate

The invention discloses a carbon-free ladle brick and a preparation method thereof. The carbon-free ladle brick is prepared by using bauxite chamotte, a corundum raw material, magnesium oxide and alumina micro powder as main raw materials, adding iron oxide, a magnesium chloride solution, sodium hexametaphosphate and canary dextrin, mixing the above-mentioned materials by using special procedures, storing an obtained mixed for 30 min, carrying out compression molding and drying the mixture at a temperature of 200 DEG C for 24 h. According to the invention, iron oxide and alumina micro powder are enabled to exist in gaps between aggregate and powder and form hercynite with a low thermal expansion coefficient at a medium-high temperature, and no excess iron oxide enters into a matrix, which enables the ladle brick to have good high temperature stability and anti-stripping performance; therefore, the problem that molten steel carburetting caused by high temperature melting loss of a refractory brick influences smelting quality is overcome, and the prepared carbon-free ladle brick has excellent performances of high strength, washing resistance, a long service life, etc.

Owner:山西高科耐火材料股份有限公司

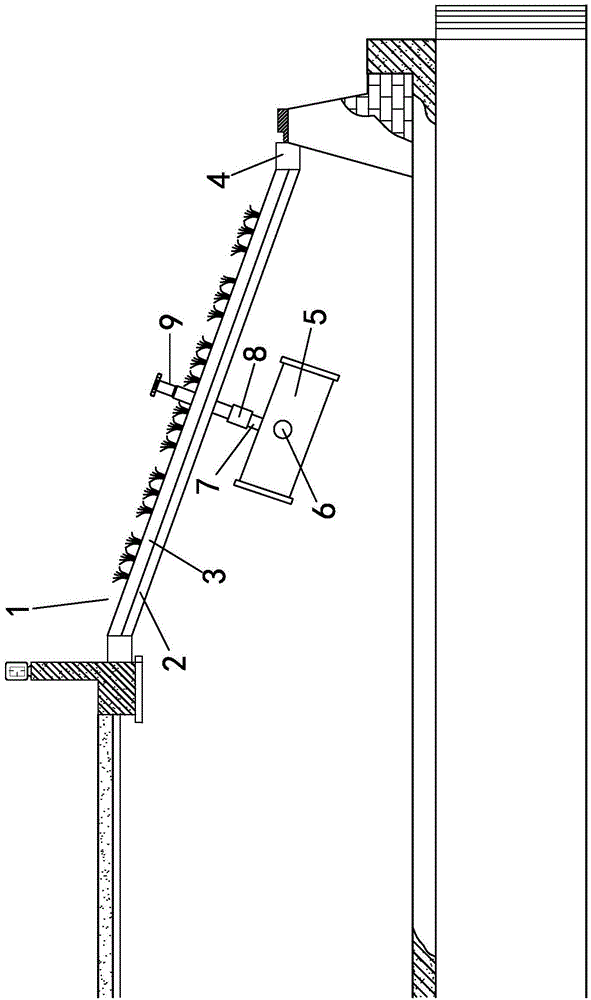

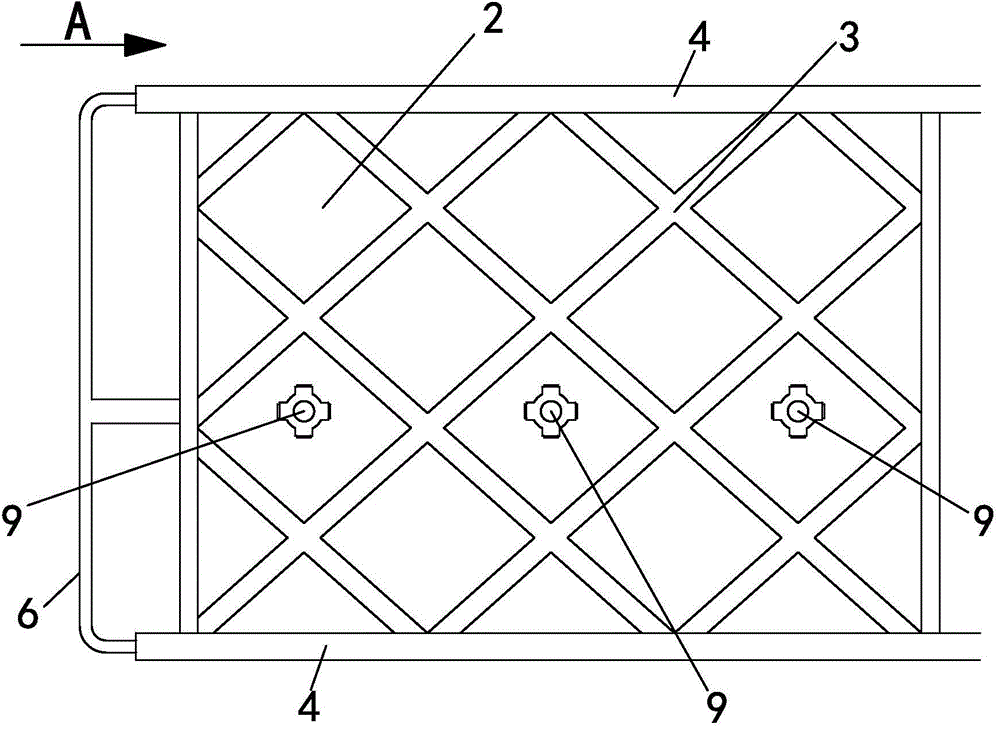

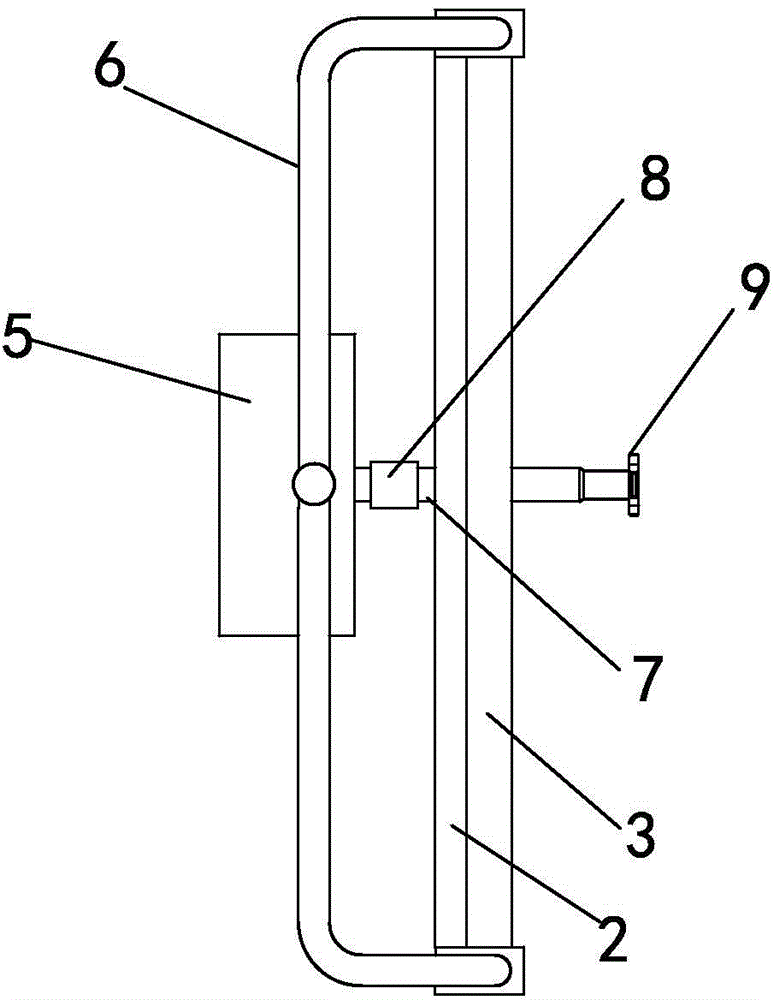

Vegetation bag ecological slope protection construction method and vegetation bag rainwater treatment system

ActiveCN104652360ARelieve stressFlushing helpsCoastlines protectionExcavationsGrowth plantVegetation

The invention discloses a vegetation bag ecological slope protection construction method and a vegetation bag rainwater treatment system. The vegetation bag ecological slope protection construction method comprises the following steps: (a) performing construction preparation; (b) measuring and lining; (c) excavating a foundation pit; (d) pouring concrete to obtain a slope foundation; (e) performing primary rainwater treatment system construction; (f) performing whole slope construction; (g) manufacturing beam grillages; (h) performing secondary rainwater treatment system construction; (i) stacking vegetation bags; (j) planting plants. According to a vegetation bag ecological slope protection system, plant growth substrates are fixed to the interiors of vegetation bags, so that a side slope is more stable and has erosion resistance by utilizing the anchoring effect of the roots of plants; the slope protection foundation which is erosion-resistant, firm and breathable, and suitable for the growth of the plants is formed by combining the characteristics of the beam grillages and the vegetation bags. Meanwhile, the rainwater treatment system is added, so that rainwater is stored in a rainy season and can be used for irrigating the plants in a dry season; on one hand, the slope protection pressure is relieved, and the water and soil loss is further prevented; on the other hand, the rainwater treatment system is favorable to the growth of the plants.

Owner:CHENGLONG CONSTR GROUP

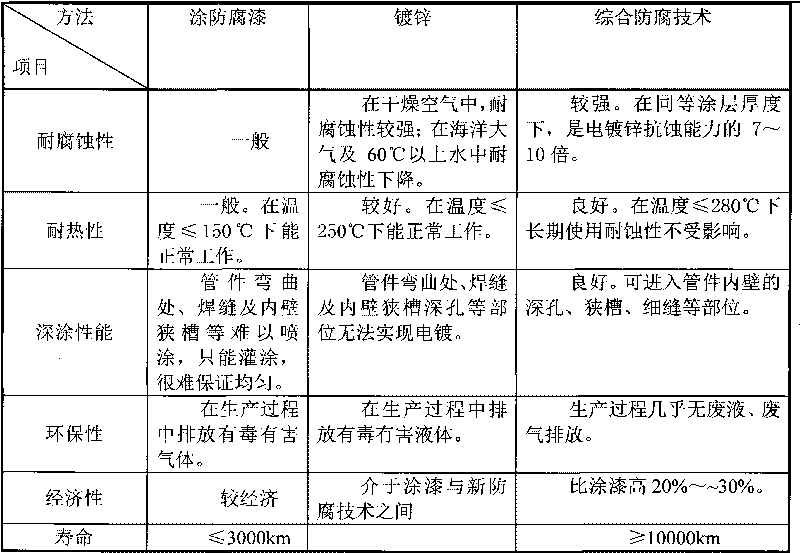

Comprehensive anticorrosive method of metal pipe fitting

InactiveCN101724801AStrong adhesionHigh temperature resistantHot-dipping/immersion processesPipe fittingBinding force

The invention relates to a comprehensive anticorrosive method of a metal pipe fitting, in particular to a comprehensive anticorrosive method combined with a plurality of anticorrosive treatments on the surface of a vehicle metal pipe fitting. The pipe fitting needed to be treated is sequentially treated by the following steps: A, oil removal and derusting; B, Zn-Cr coating; and C, top layer closing, wherein composite phosphating treatment is carried out before the step B. In the anticorrosive method, based on a Zn-Cr coating and aiming at the advantages and the disadvantages of the Zn-Cr coating as well as the structural and using particularity of a water system pipe fitting, a new comprehensive anticorrosive technology combined composite phosphating, Zn-Cr coating and top layer closing is adopted, so that an obtained composite coating achieves the advantages of strong adhesive force, high temperature resistance (280 DEG C) and flushing resistance, obviously enhances the anticorrosion ability of a pipeline, and has stronger binding force and flushing resistance compared with the ordinary Dacromet treatment technology.

Owner:CHINA NORTH VEHICLE RES INST

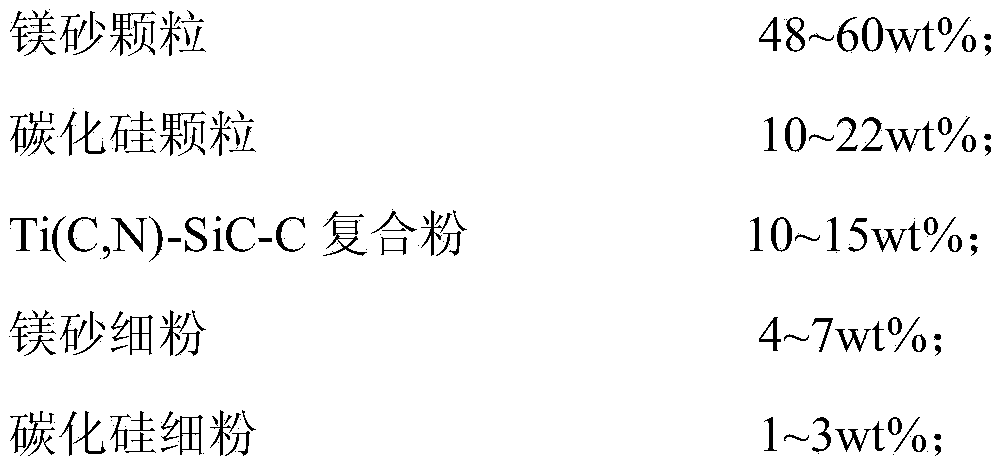

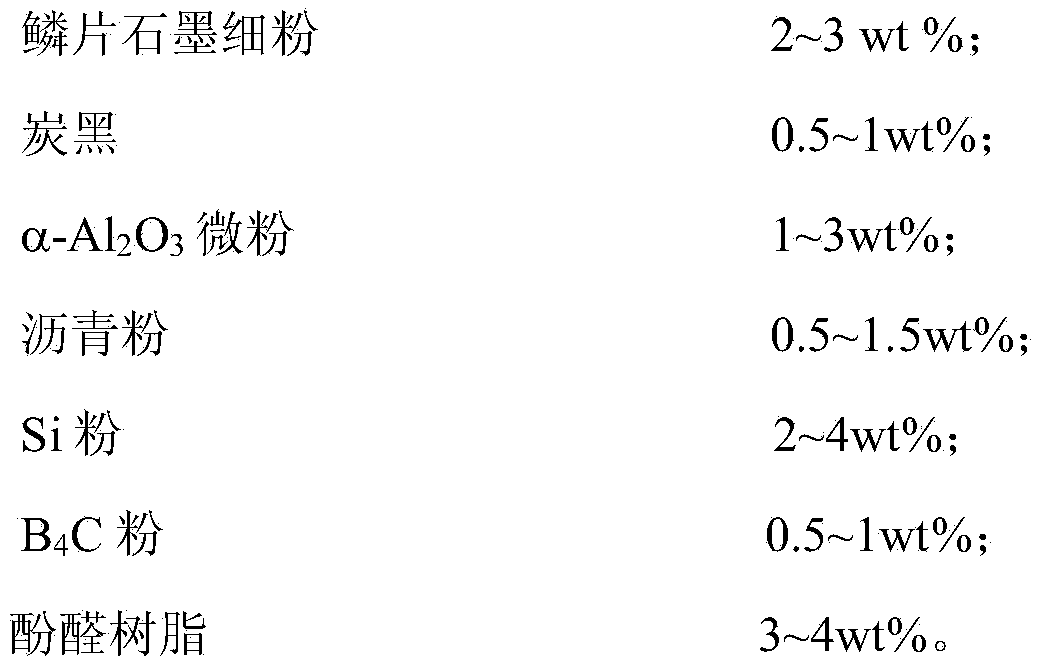

Smelting separation furnace lining material and preparation method thereof

InactiveCN104003738AGood antioxidant propertiesGood thermal shock stabilityTemperature resistanceCarbon black

The invention relates to a smelting separation furnace lining material and a preparation method thereof. According to the technical scheme, the preparation method of the smelting separation furnace lining material comprises the following steps: mixing 48-60wt% of magnesite particles and 10-22wt% of silicon carbide particles, adding 3-4wt% of phenolic resin, mixing, then adding mixed powder, mixing, moulding, and then drying for 24 hours at the temperature of 180-220 DEG C, so that the melting separation furnace lining material is obtained; the mixed powder is obtained by mixing 10-15wt% of Ti(C,N)-SiC-C composite powder, 4-7wt% of magnesite fine powder, 1-3wt% of silicon carbide fine powder, 2-3wt% of crystalline flake graphite fine powder, 0.5-1wt% of carbon black, 1-3wt% of alpha-Al2O3 micro powder, 0.5-1.5wt% of asphalt powder, 2-4wt% of Si powder and 0.5-1wt% of B4C powder. The smelting separation furnace lining material has the characteristics of high temperature resistance, washing resistance, strong FeO and TiO2 corrosion resistance, good oxidation resistance and excellent thermal shock performance.

Owner:WUHAN UNIV OF SCI & TECH

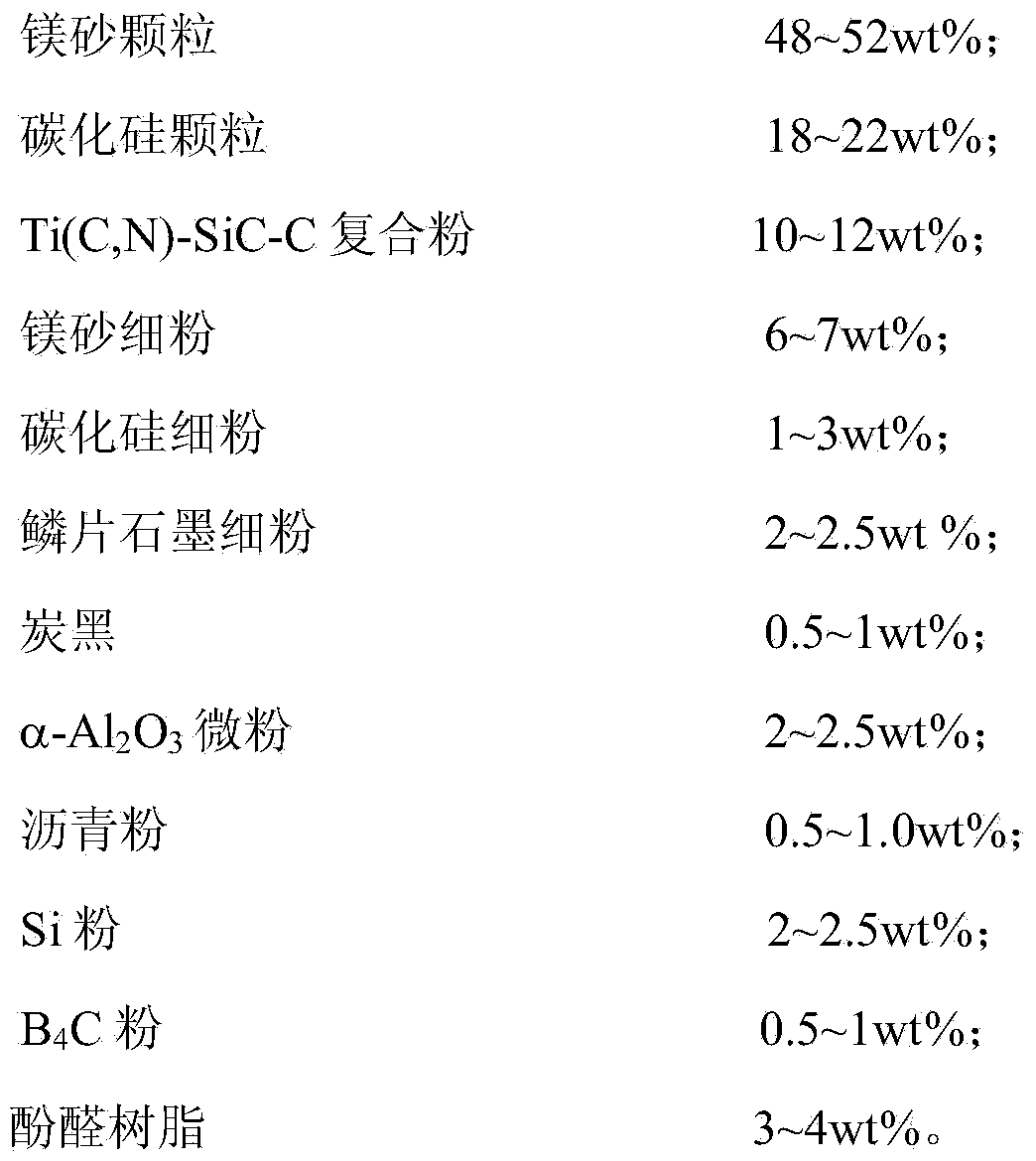

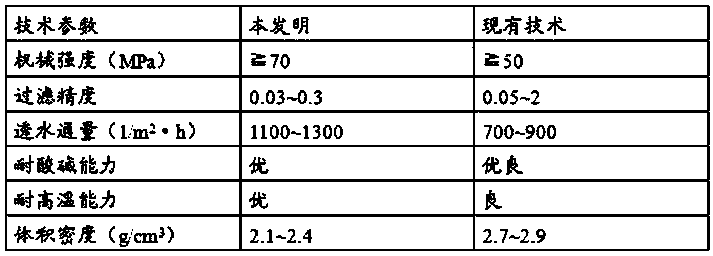

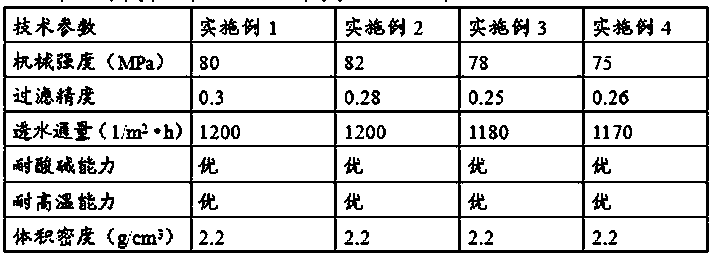

Inorganic film tube and making method thereof

ActiveCN103566778AHigh thermal conductivityImprove high temperature resistanceSemi-permeable membranesFlue gasSewage treatment

The invention discloses an inorganic film tube. The inorganic film tube is made through the extrusion molding and high temperature sintering of silicon carbide as a primary raw material. The invention also discloses a making method of the inorganic film tube. The making method comprises the following steps: uniformly mixing and granulating primary raw materials for making the inorganic film tube to obtain granules; carrying out extrusion molding of the granules in an extruder to obtain a carrier tube blank; drying and sintering the carrier tube blank; coating the sintered carrier tube blank; and drying and sintering the coated carrier tube blank to obtain the inorganic film tube. The inorganic film tube has the advantages of low cost, high strength, scour resistance, erosion resistance, high water flux, strong infiltration capacity and long service life, and is especially suitable for the sewage treatment and high-temperature flue gas filtering separation of environmental protection fields.

Owner:佛山市金刚材料科技有限公司 +1

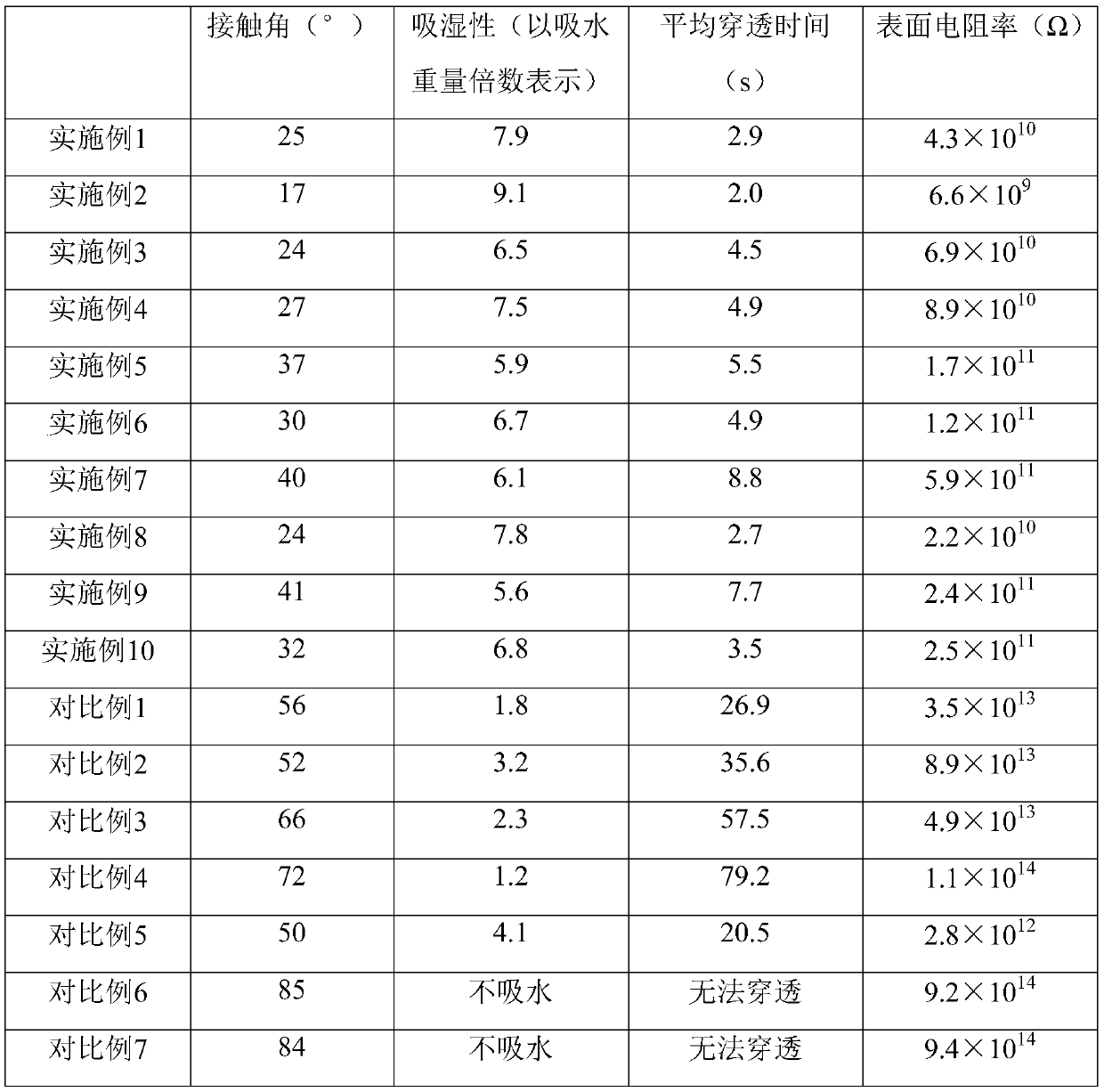

Hydrophilic antistatic polypropylene composition and preparation method and application thereof

ActiveCN111020870AImprove hydrophilicityShort penetration timeElectroconductive/antistatic filament manufactureNon-woven fabricsMasterbatchPolymer science

The invention discloses a hydrophilic antistatic polypropylene composition and a preparation method and application thereof. The composition is prepared from the following components in parts by weight: 30-75 parts of polypropylene, 0.5-15 parts of compatilizer, 2-25 parts of hydrophilic accelerant and 5-70 parts of hydrophilic agent, wherein the hydrophilic agent comprises a non-ionic surface active agent and an anionic surface active agent. The composition also includes optionally a dispersant, a lubricant, and an antioxidant. The obtained hydrophilic antistatic material can be used as a master batch to be directly added into polypropylene resin for melt spinning, the obtained polypropylene non-woven fabric is good in hydrophilic performance, capable of absorbing multiple times of wateramount of the non-woven fabric and short in penetration time, and good hydrophilicity can still be kept after multiple times of scouring, and the material has scouring resistance and durable hydrophilic effects. The product prepared by the method also has an excellent antistatic effect and is simple in preparation process and low in cost and is beneficial to large-scale commercial production.

Owner:联泓(江苏)新材料研究院有限公司 +1

Fire-resistant pouring material used for bottom of lead smelting furnace

The invention relates to a fire-resistant pouring material used for the bottom of a lead smelting furnace. The fire-resistant pouring material comprises the following components: 10-5mm special-grade alumina clinker, 5-3mm special-grade alumina clinker, special-grade alumina clinker with d90 being less than 0.088mm, 3-1mm brown aluminium oxide, 1-0.088mm brown aluminium oxide, alpha-alumina micro powder with d95 being less than 0.020mm, silica powder, and industrial-grade chromium oxide green; in addition, an additive consisting of compound hardening accelerator and aluminium phosphate solution is also used. The magnesium-aluminium-chrome spinel castable disclosed by the invention can be sintered and shows excellent thermal shock resistance, stripping resistance, erosion resistance, slag bonding prevention and the like under a low temperature process condition during copper smelting, thereby meeting the use requirement of long-term use of a fireproof lining of a copper smelting tundish.

Owner:郑州瑞泰耐火科技有限公司

Al2O3-SiO2 tundish permeable brick and preparation method thereof

InactiveCN102320845AAvoid room temperature decompositionGuaranteed decentralizationAluminum fluorideBrick

The invention relates to an Al2O3-SiO2 tundish permeable brick and a preparation method thereof. 65-78 wt% of tabular corundum particles, 7-20 wt% of mullite particles, 2-10 wt% of white corundum fine powder, 1-4 wt% of rho-Al2O3 fine powder, and 1-3 wt% of silicon micropowder are used as raw materials; 0.10-0.20 wt% of mixtures of sodium hexametaphosphate and sodium tripolyphosphate, 0.05-0.20 wt% of yellow dextrin, 0.01-0.20 wt% of azodicarbonamide, 1-4 wt% of Al2O3-SiO2 gel powder, and 0.20-1.0 wt% of aluminium fluoride are used as additives. The preparation method comprises the following steps: premixing the additives and silicon micropowder uniformly according to the contents, adding the tabular corundum particles and the mullite particles, mixing and grinding, adding the white corundum fine powder and rho-Al2O3 fine powder, mixing and grinding, adding 5-7 wt% of water, stirring, casting, molding, performing heat preservation at 110-200 DEG C for 12-48 hours, and finally sintering at 1200-1500 DEG C for 3 hours. The prepared permeable brick has good permeability and high strength, and is erosion-resistant and environment-friendly.

Owner:WUHAN UNIV OF SCI & TECH

Chromium corundum-silicon carbide-carbon castable for iron troughs

The invention relates to a chromium corundum-silicon carbide-carbon castable for iron troughs. The castable comprises, by mass, 45-75 % of chrome corundum, 10-30 % of silicon carbide, 1-6% of spherical asphalt, 1-10% of alpha-Al2O3 powder, 1-5% of silicon micro-powder, 1-7% of a binder, 0.1-2% of a composite antioxidant and 2-6% of a composite additive. The prepared castable for iron troughs has the characteristics of good erosion resistance, good wear resistance, good thermal shock stability, high erosion resistance and long service life, and can increase the iron influx of blast furnace iron troughs in order to reduce consumption of a refractory material.

Owner:上海新泰山高温工程材料有限公司

High temperature wear-resistant coating for metal surface, and its preparing mand using method

ActiveCN1850917AHigh refractorinessImprove thermal conductivityLiquid surface applicatorsCoatingsWear resistantPhosphoric acid

The invention discloses a high temperature antifriction dope for metal surface and the using method. It is made up from 85% thickness phosphoric acid 22-28 portions, aluminum hydroxide 3-5 portions, water 5-8 portions, chrome 0.01-0.02 portions, thinned silica solution 6-10 portions, white steel 10-18 portions, zirconia 12-18 portions, alumina 8-12 portions, magnesia 0.03-0.05 portions, and coagulant 4-7 portions and stainless steel wire 0.3-0.6 portions.

Owner:枣庄市新达节能技术开发有限责任公司

High abrasion-proof anti-heat vibration high-alumina brick and preparation thereof

The invention discloses a high abrasion-resistance and thermal shock-resistance high alumina brick, comprising the following compositions, by weight: 5 to 15 parts of 3 to 5mm special grade bauxite aggregate, 30 to 40 parts of 1 to 3mm special grade bauxite aggregate, 10 to 20 parts of 0 to 1mm special grade bauxite aggregate, 20 to 30 parts of special grade bauxite fine powder, 5 to 7 parts of zircon sand fine powder, 1 to 3 parts of Suzhou No.2 mud, 8 to 10 parts of complex binding agent and 4 to 6 parts of water. The invention also discloses a manufacturing method of the high abrasion-resistance and thermal shock-resistance high alumina brick. The high abrasion-resistance and thermal shock-resistance high alumina brick has properties of high intensity, refractoriness and high abrasion-resistance and thermal shock resistance. The high alumina brick and the manufacturing method are applied to circulating fluidized bed boiler cyclone separator flues, cyclone separator straight sections and cones, return feeders, metallurgical industrial furnaces and other heat equipment, and have advantages of simple manufacturing process and easy realization.

Owner:江苏耐基炉衬有限公司

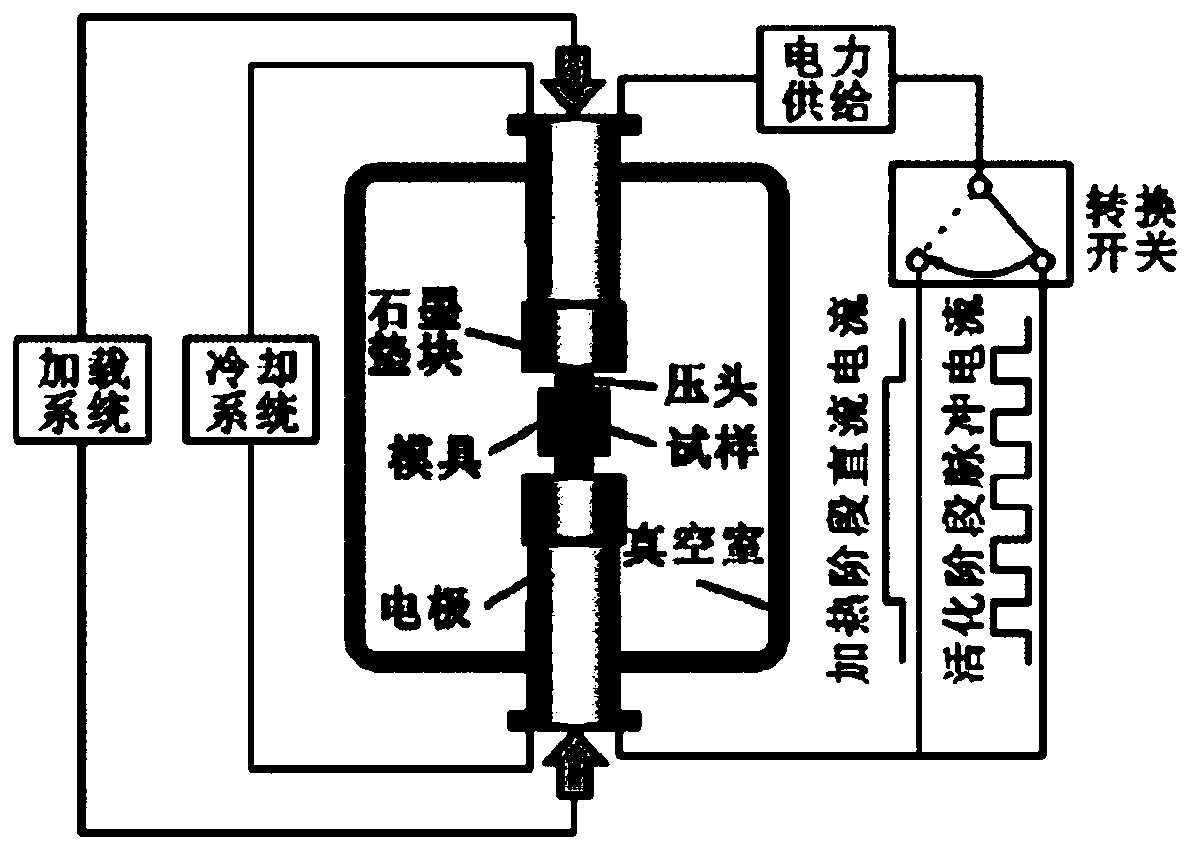

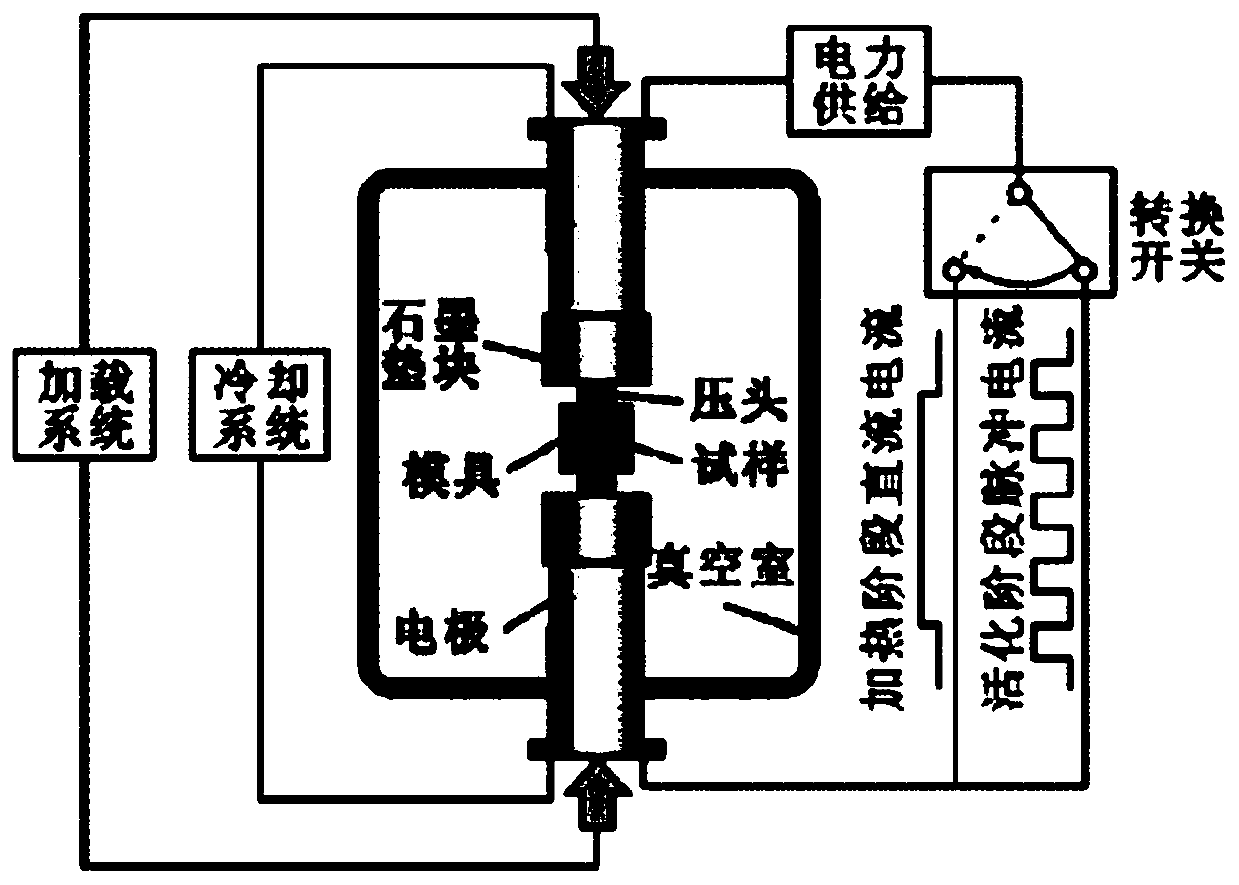

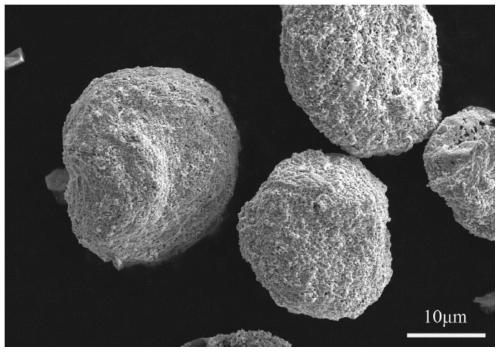

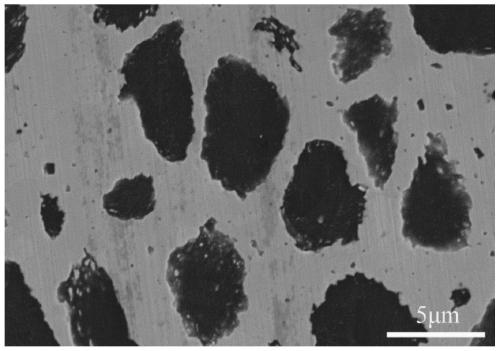

Tungsten carbide reinforced carbon matrix composite material and preparation method

The invention discloses a tungsten carbide reinforced carbon matrix composite material and a preparation method. Mesocarbon microbeads are adopted as the matrix, and tungsten carbide ceramic is adopted as the reinforcement phase and is evenly distributed among the carbon microbeads so as to form a three-dimensional network tungsten carbide skeleton reinforced isotropic structure. The preparation method includes: firstly taking tungsten oxide particles and mesocarbon microbeads as the raw materials to prepare uniform and thickness controllable tungsten carbide coating coated mesocarbon microbead powder by molten salt process, then performing pre-press molding, and conducting discharge plasma sintering at 1500-1900DEG C to form a uniform three-dimensional network tungsten carbide ceramic skeleton, which can significantly improve the strength, ablation resistance and oxidation resistance of the carbon matrix, thus forming the isotropic carbon matrix composite material characterized by lowcost, low density and excellent mechanical properties, sintering performance and ablation resistance. Because of the excellent comprehensive performance, the tungsten carbide reinforced carbon matrixcomposite material can be widely applied to aerospace, national defense and other fields, and has broad application prospects.

Owner:XI AN JIAOTONG UNIV

High-temperature-resistant environment-friendly metal casting coating and preparation method thereof

InactiveCN105642821AImprove high temperature resistanceImprove crack resistanceFoundry mouldsFoundry coresSodium BentoniteCrack resistance

The invention discloses high-temperature-resistant environment-friendly metal casting coating and a preparation method thereof. The coating comprises, by weight, 3-5 parts of attapulgite clay, 12-15 parts of quartz powder, 5-12 parts of talcum powder, 4-10 parts of superfine glass powder, 1.5-4 parts of sodium silicate, 3-5 parts of bauxite, 3-8 parts of diatomaceous earth, 2-4 parts of bentonite, 6-10 parts of polyethylene glycol, 3-9 parts of organic siloxane, 5-9 parts of silicon resin, 6-12 parts of linseed oil water-soluble alkyd resin, 4-6 parts of triphenyltin hydroxide, 2-6 parts of lignosulfonic acid, 1-3 parts of oxidizing agents, 1-2 parts of wetting agents, 2-5 parts of defoaming agents, 4-9 parts of preservatives, 2-6 parts of bonding agents, 5-8 parts of curing agents and 75-90 parts of deionized water. Compared with the prior art, the casting coating prepared through the method has excellent high temperature resistance, crack resistance and scouring resistance, and is good in adhesiveness and air permeability; meanwhile, the produced coating is uniform, environmentally friendly, free of pollution, good in stability and adsorbability, and capable of meeting the requirements for mass production of large castings, and improves the surface quality of the castings.

Owner:TONGLING ANDONG CAST STEEL

Corundum mullite crucible and preparation method thereof

The invention discloses a corundum mullite crucible and a preparation method thereof, and belongs to the technical field of refractory materials. The corundum mullite crucible comprises the followingraw materials in parts by weight: 25-33 parts of 3-1 mm tabular corundum, 18-27 parts of 1-0 mm tabular corundum, 7-12 parts of 80-mesh corundum sand, 6-12 parts of 320-mesh zircon powder, 6-14 partsof 240-mesh vice-white corundum, 7-14 parts of 150-mesh sillimanite, 1.5-5 parts of 180-mesh Suzhou soil, 3.5-6 parts of Al2O3 micropowder 370C, 3.8-5.8 parts of 200-mesh quartz and 2-5 parts of a binding agent. The crucible made from corundum mullite materials has advantages of small thermal expansion coefficient, good acid and alkali resistance and good thermal shock stability; the corundum mullite materials are ideal materials suitable for ceramic industry; and the crucible is cast and molded by gypsum, and has advantages of low production costs, high efficiency and excellent product performance and overall effect.

Owner:SHANDONG VOCATIONAL COLLEGE OF IND

Preparation method of tundish air brick

InactiveCN103787670AHigh Durability Thermal Shock ResistantExcellent thermal shock resistanceAzodicarbonamideCorundum

The invention discloses a preparation method of a tundish air brick. The preparation method comprises the following steps of: (1) placing 45-55 parts by weight of tabular corundum granules, 10-14 parts by weight of mullite granules and 5-8 parts by weight of chromic oxide granules into a mixer, and mixing for 5-8 minutes; (2) placing 4-6 parts by weight of white corundum fine powder, 2-3 parts by weight of alpha-Al2O3 fine powder and 1.5-3.5 parts by weight of silica micropowder into the mixer, and mixing for 10-15 minutes; (3) adding a mixture prepared from the step (1) to the mixer used in the step (2), mixing for 10-15 minute again, adding 0.4-0.6 part by weight of sodium hexametaphosphate, 0.3-0.5 part by weight of yellow dextrin, 0.1-0.3 part by weight of azodicarbonamide, 0.2-0.4 part by weight of boric acid and 0.1-0.3 part by weight of aluminum fluoride, and then mixing for 10-15 minutes again; (4) ageing for 1-2 hours, pressing for forming by using a press machine, and drying into a drying kiln at 200 DEG C for 24 hours; (5) firing under the condition of 1250-1350 DEG C for 2-3 hours.

Owner:WUXI CHENGBO SCI & TECH DEV

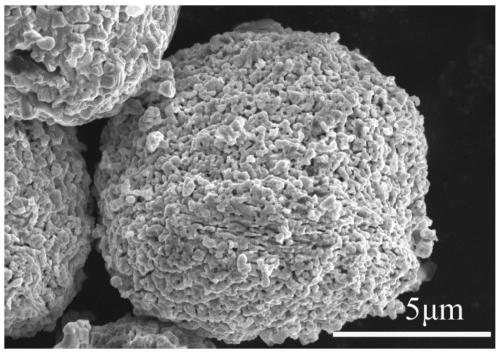

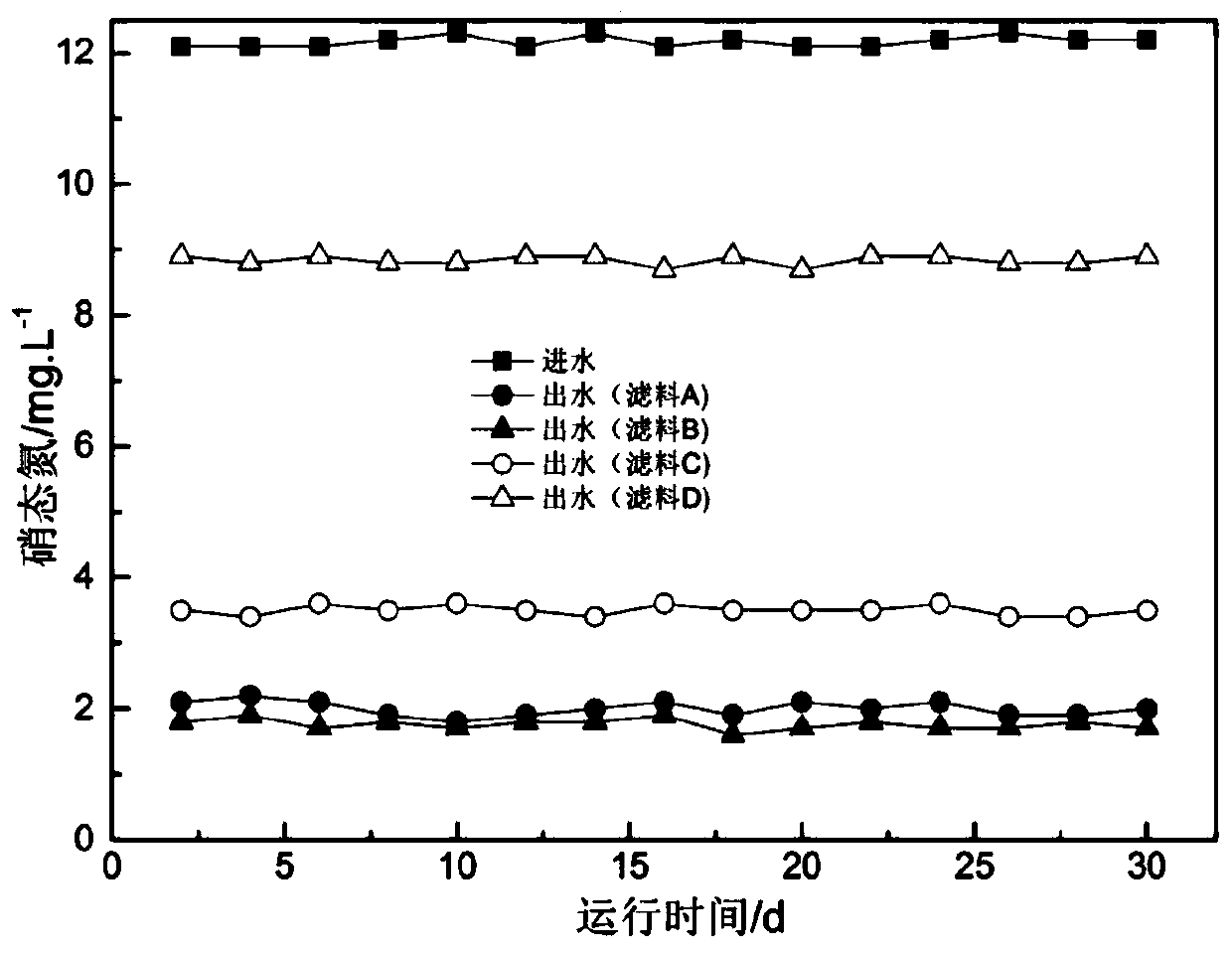

Filtering material with micropore and film for treating water

InactiveCN1481922AHigh mechanical strengthWashoutTreatment using aerobic processesSustainable biological treatmentPhosphateExpanded clay aggregate

The porous filming material for water treatment consists of clay 30-60 wt%, loess 30-60 wt%, kaolin 5-20 wt% and pore creating material 5-20 wt%. The product of the present invention is spherical haydite, and has high mechanical strength, high erosion resistance, high wear resistance and stable physical and chemical properties as well as rich pores, rough surface, great specific surface area, long service life, high adsorption performance, etc. It has high dirt intercepting capacity and high filming efficiency, is suitable for the growth and propagation of microbe and may be used to eliminate organic matter, suspension, nitride, phosphate, etc from water.

Owner:骆福全

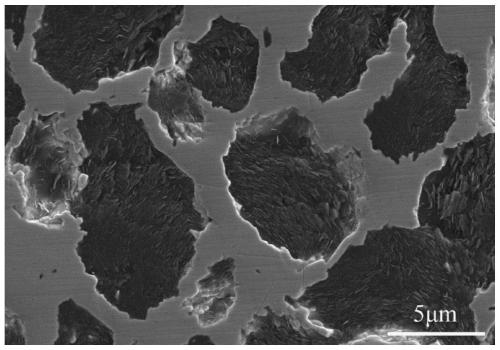

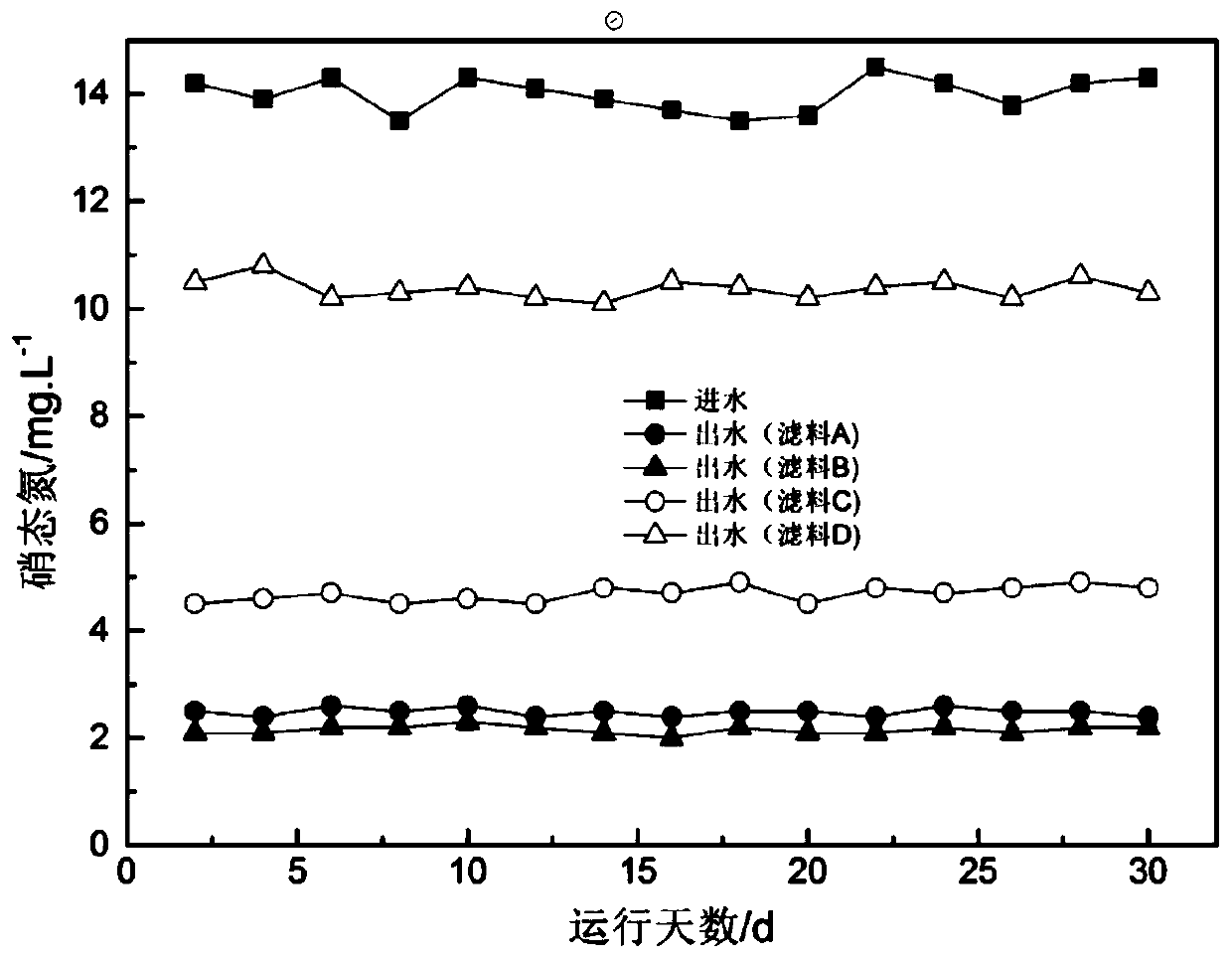

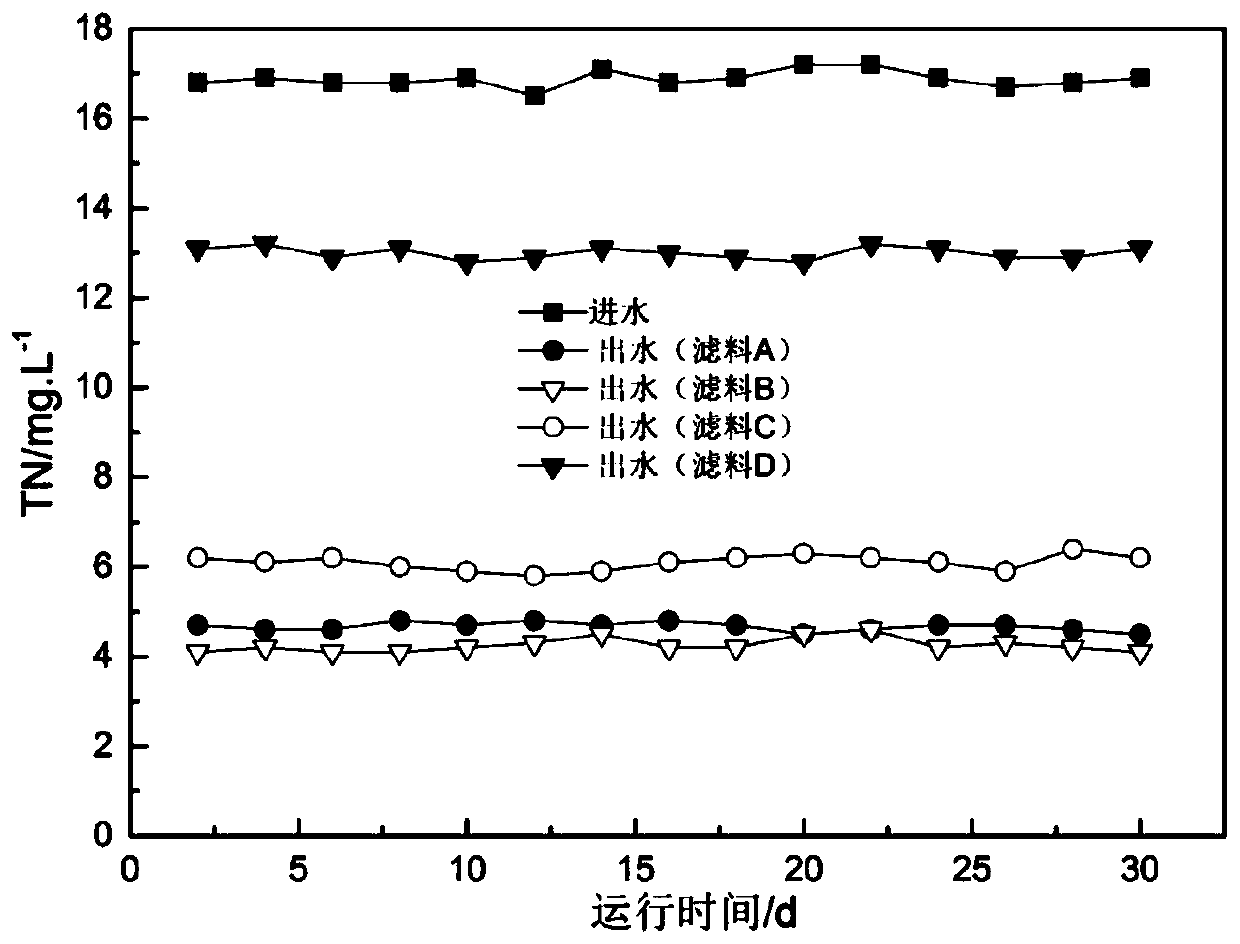

Biological filter material based on sulfur-containing tailings as well as preparation method and application thereof

ActiveCN110818077AIncrease microbial biomassReduce thicknessWater treatment parameter controlWater contaminantsBiofilmMicroorganism

The invention relates to a biological filter material based on sulfur-containing tailings as well as a preparation method and application of the biological filter material, and belongs to the technical field of sewage treatment. The biological filter material is prepared by taking sulfur-containing tailings as a raw material, carrying out mechanical force treatment, chemical activation and thermalactivation, compounding the sulfur-containing tailings with sludge biochar prepared from excess sludge, and limestone, and taking aluminum dihydrogen phosphate as a binder. The biological filter material can be used for advanced treatment of secondary effluent with low C / N, no additional organic carbon source is needed, thiobacillus denitrificans are adopted to utilize sulfur in tailings for self-oxidation denitrification, the TN concentration can be reduced to 5 mg / L or below, and the purpose of treating waste with waste is achieved. The sulfur-containing tailings activated by limestone andsludge biochar are used as biofilm carriers, so that the specific surface area of the biological filter material is increased, and the self-oxidation denitrification mass transfer rate of microorganisms is also increased; and aluminum dihydrogen phosphate is used as a binder, so that the operation is convenient, the biological filter material can form a uniform structure, the structural defects ofthe biological filter material are reduced, and the application prospect is good.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE +1

Silicon carbide reinforced carbon matrix composite material and preparation method

The invention discloses a silicon carbide reinforced carbon matrix composite material and a preparation method. Mesocarbon microbeads are adopted as the matrix, and silicon carbide ceramic is adoptedas the reinforcement phase and is evenly distributed among the carbon microbeads so as to form a three-dimensional network silicon carbide skeleton reinforced isotropic structure. Technically, siliconpowder particles and the mesocarbon microbeads are taken as the raw materials to prepare uniform and thickness controllable silicon carbide coating coated mesocarbon microbead powder by molten salt method, after pre-press molding, discharge plasma sintering is carried out at 1600-1900DEG C to form a uniform three-dimensional network silicon carbide ceramic skeleton, while the strength, ablation resistance, oxidation resistance and thermal shock resistance of the carbon matrix are improved, the thermal conductivity of the matrix is also improved, therefore the isotropic carbon matrix compositematerial characterized by low cost, low density and excellent mechanical properties, sintering properties, thermal shock resistance, ablation resistance and thermal conductivity can be formed. Because of the excellent comprehensive performance, the silicon carbide reinforced carbon matrix composite material can be widely applied to aerospace, national defense, electronic packaging and other fields, and has broad application prospects.

Owner:XI AN JIAOTONG UNIV

High-abrasion high-alumina brick with heat shock resistance and manufacturing method thereof

InactiveCN104030707AImprove erosion resistanceImprove thermal shock resistanceCycloneChromium carbide

The invention discloses a high-abrasion high-alumina brick with heat shock resistance. The high-abrasion high-alumina brick comprises the following components in parts by weight: 5-15 parts of 3-5mm super alum aggregate, 30-40 parts of 1-3mm super alum aggregate, 10-20 parts of 0-1mm super alum aggregate, 20-30 parts of super alum powder, 5-7 parts of zirconium carbide fine powder, 2 parts of chromium carbide powder, 1-3 parts of Suzhou mud NO.2, 8-10 parts of compound binder and 4-6 parts of water. The invention also discloses a manufacturing method of the high-abrasion high-alumina brick with heat shock resistance. The high-abrasion high-alumina brick with heat shock resistance disclosed by the invention has high strength, refractoriness, high abrasion and heat shock resistance, and is applicable to a circulating fluid bed boiler cyclone separator flue, cyclone separator straight section and cone body, a return feeder, a metallurgical furnace and other thermal equipment. The high-abrasion high-alumina brick is simple in manufacturing process and easy to realize.

Owner:张婷

Dry high temperature resistant furnace lining material and preparation method and application thereof

PendingCN109503184AImprove high temperature resistanceImprove wear resistanceTemperature resistanceBoric acid

The invention discloses a dry high temperature resistant furnace lining material and a preparation method and application thereof. The dry high temperature resistant furnace lining material comprisesthe following raw materials in parts by weight: 97-99.5 parts of quartz sand and 0.5-3 parts of boric acid. According to the high temperature resistance property of the quartz sand, an appropriate amount of boric acid is added according to a different particle size ratio, components are further added according to the situation, uniform mixing is carried out, and a furnace lining is constructed; and the obtained dry high temperature furnace lining has significant thermal shock resistance, enhanced refractory properties and wear resistance. Through adding the boric acid, the mixing of the quartzsand with the other components is more uniform; and sodium tripolyphosphate can be matched to effectively promote the smoothness of the lining and enhance the telescopic strength of the lining.

Owner:云南永昌硅业股份有限公司

Preparation method of high-purity transparent crystal fused magnesia

The invention discloses a preparation method of high-purity transparent crystal fused magnesia. According to the preparation method, salt lake water chloromagnesite is adopted as a raw material, magnesium chloride generates magnesium hydrate sediments through an ammonia-lime method, magnesium hydrate is separated from a solution, and then the high-purity magnesium hydrate is slightly roasted to become slightly roasted magnesium oxide; the slightly roasted magnesium oxide is pressed into spheres to serve as raw materials, the spheres are smelted through an electric-arc furnace of 5000 KVA, andfusion is carried out through a high-voltage and high-current operation method; and at the later period of fusion, refining operation needs to be carried out, the temperature of fused liquid is increased to reach 3000 DEG C or above, after melting is completed, a molten lump has to be cooled slowly, and a high-purity transparent crystal fused magnesia clinker is obtained, wherein MgO is larger than or equal to 99%, SiO2 is smaller than or equal to 0.1%, Fe2O3 is smaller than or equal to 0.1%, and CaO is smaller than or equal to 0.1%.

Owner:HENAN TENAI SPECIAL REFRACTORIES CO LTD +2

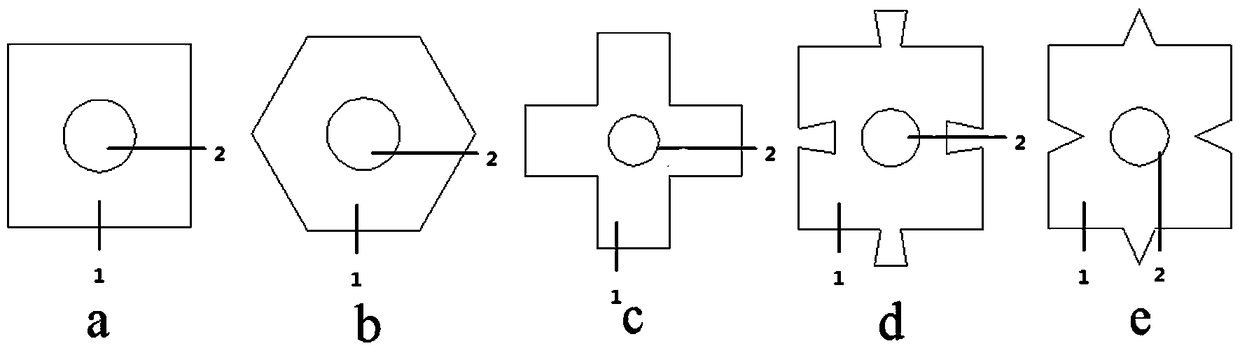

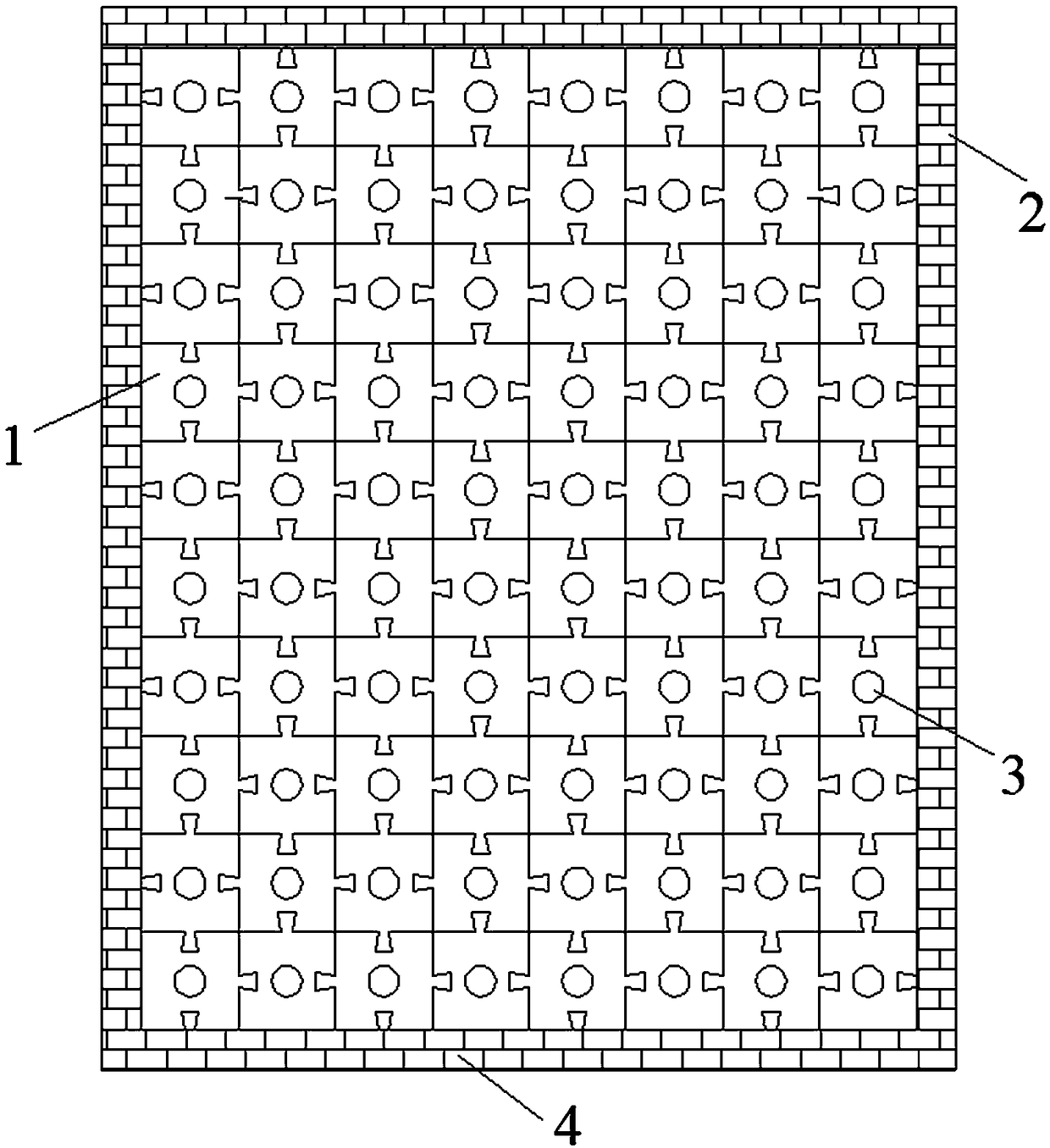

Method for protecting arsenic sand rock side slope by adopting arsenic sand rock modified building blocks

ActiveCN108218308ARealize on-site resource utilizationSolve problems that require constant re-protection every yearCoastlines protectionWoody plantGeomorphology

The invention discloses a method for protecting an arsenic sand rock side slope by adopting arsenic sand rock modified building blocks. The method comprises the following steps: 1, dividing slope surfaces into steep slopes and gentle slopes according to slope gradient of a side slope; 2, roughly flattening the slope surfaces with different slope gradients and building the arsenic sand rock modified building blocks on the flattened slope surfaces in a grouping manner; 3, planting herbal plants or woody plants in plant-growing holes of the arsenic sand rock modified building blocks which are built in a grouping manner in the step 2, planting grass in building block plant-growing holes of the steep slope section, and planting the grass or trees on the steep slope. According to the method disclosed by the invention, the arsenic sand rock side slope is protected by using the arsenic sand rock modified building blocks, so that in-place resource utilization of the arsenic sand rock is realized, and the problem that an existing side slope protection way needs to be continuously and renewedly protected every year is also solved; moreover, by adopting the method, the characteristic of the arsenic sand rock is comprehensively utilized, materials are taken in place, and protection of the side slope by using green planting and preparation of the modified building blocks are combined effectively, so that a protection effect is enhanced.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

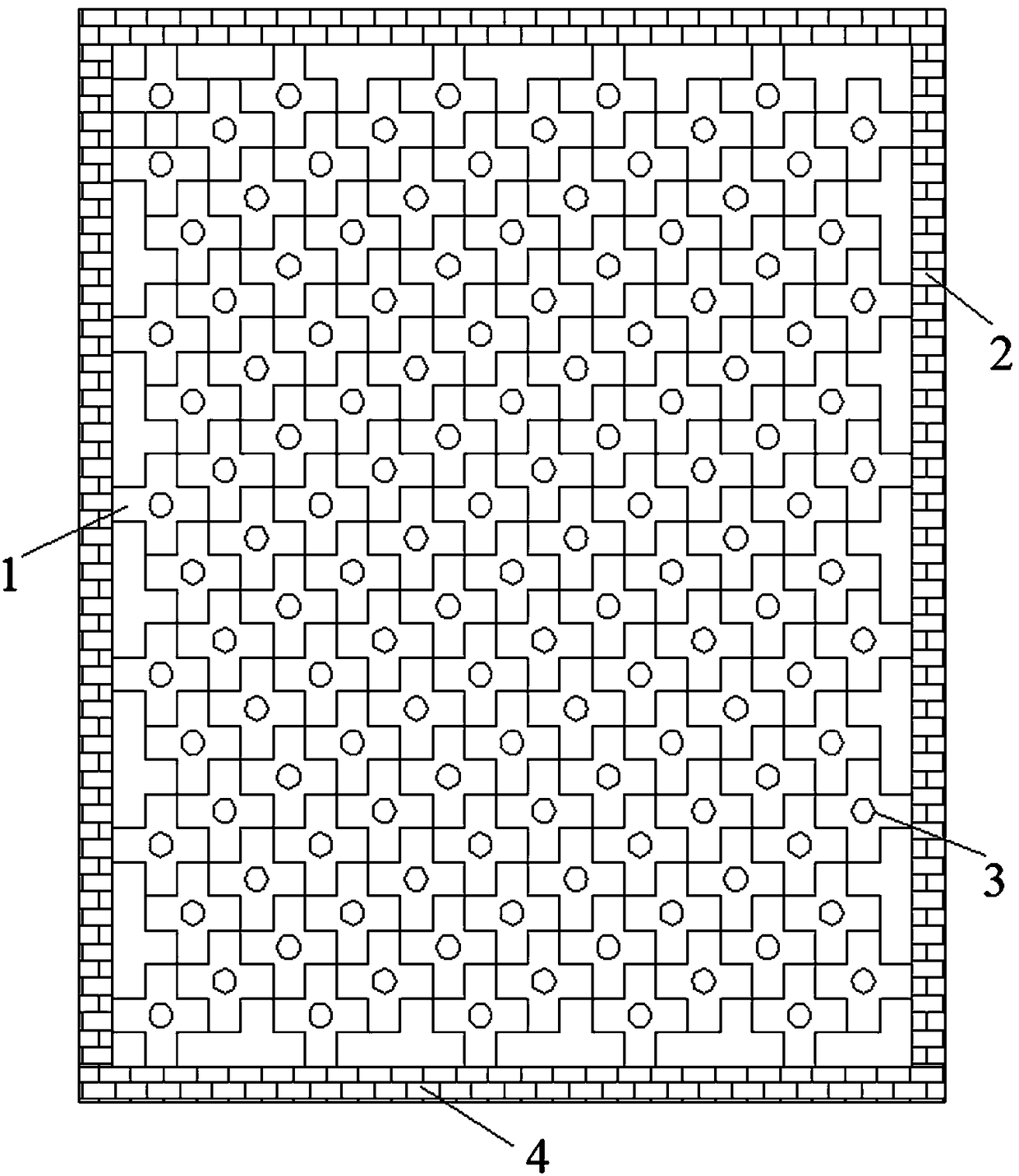

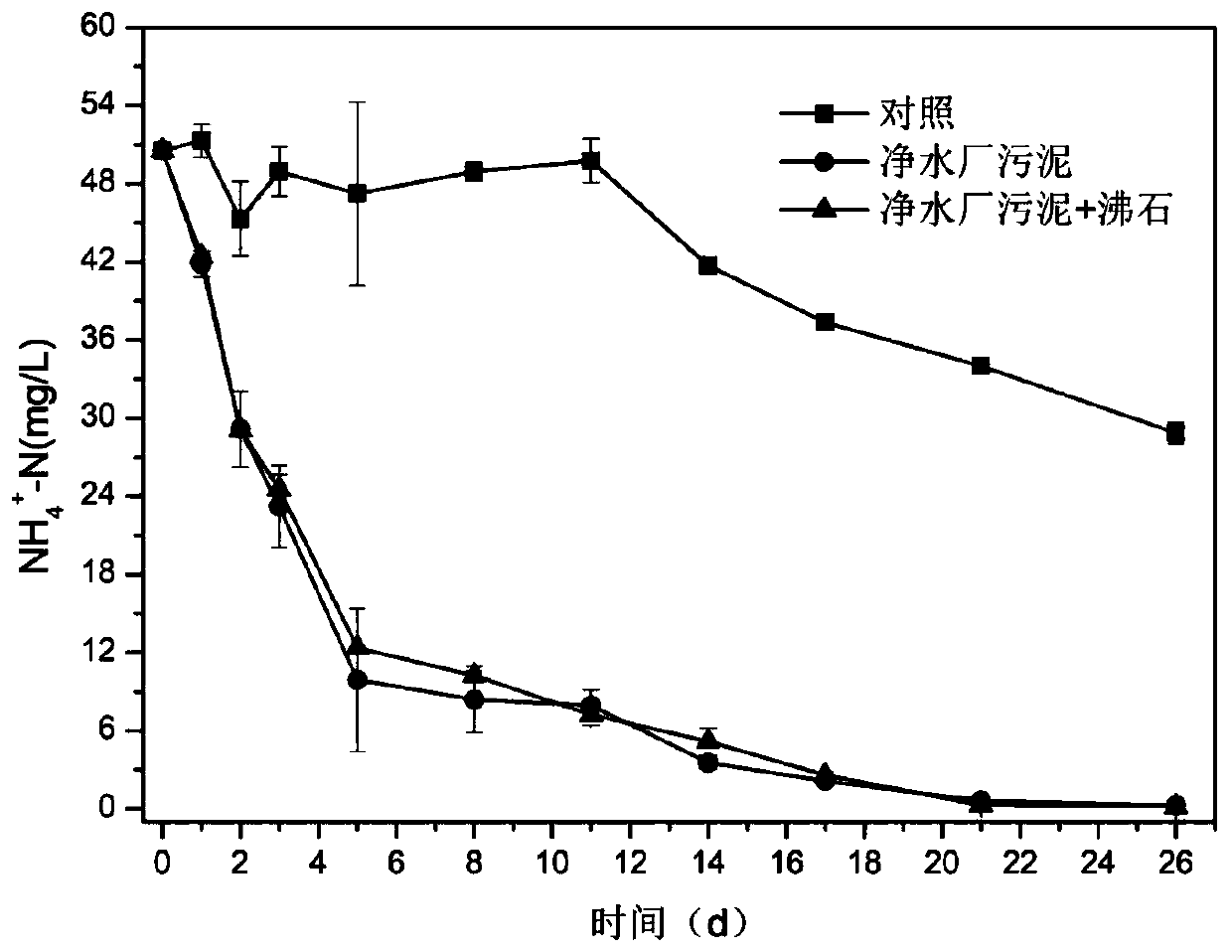

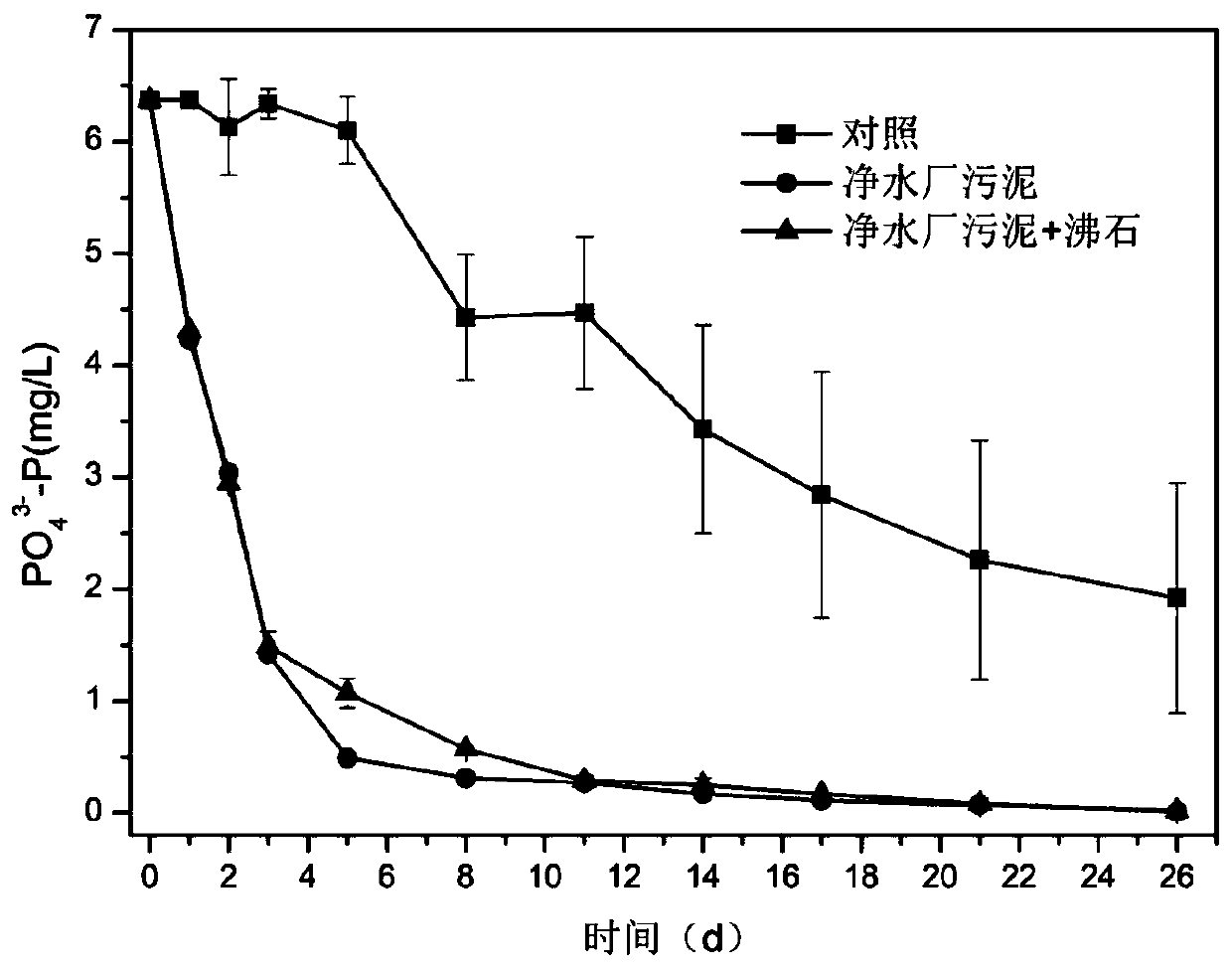

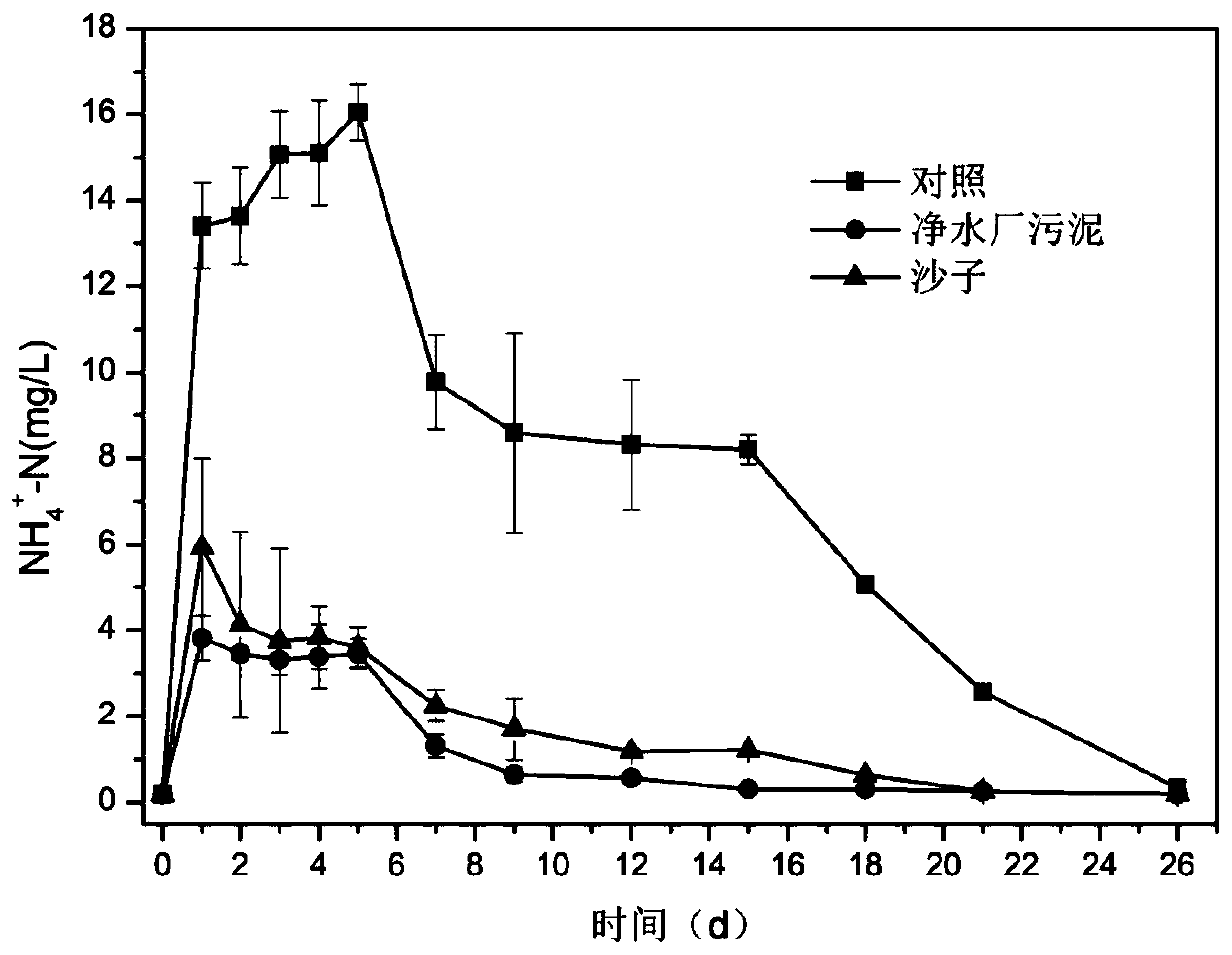

Preparation method of urban river polluted bottom mud active covering plate

ActiveCN110152591AGood water permeabilityImprove water retentionWater treatment parameter controlSludge treatmentMechanical crushingEngineering

The invention discloses a preparation method of an urban river polluted bottom mud active covering plate. The preparation method comprises the following steps: (1) collecting sludge of water purification plants to prepare sludge cakes, and calcining the sludge cakes at 380-450 DEG C for 3.5-4.5 hours to prepare sludge blocks; (2) carrying out mechanical crushing and mechanical vibration screeningon the sludge blocks to prepare the calcining modified sludge particles with a particle size of 1-5 mm; (3) adding 17-18 parts of the calcining modified sludge particles, 4-6 parts of cement and 5-8 parts of fly ash into a stirrer according to a water-cement ratio of 0.26-0.29, uniformly carrying out mixing, and carrying out standing to enable the aggregate and the binder to be fully mixed; (4) adding the stirred bottom material into a mold frame for pressing, wherein the pressing time is 60-80 seconds, and the pressing pressure is 0.75-0.8 MPa; (5) carrying out demolding to obtain a coveringplate 12-16 hours after compression molding; and (6) standing the covering plate finished product under a natural outdoor condition at a temperature of 20-25 DEG C for 12-16 days, wherein the obtainedcovering plate can be used for engineering application. The covering plate prepared by the method has the advantages of good water permeability, high water retention, washing resistance and the like.

Owner:HUAQIAO UNIVERSITY

High-strength and wear-resistant castable for middle back section of blast furnace water slag punching groove

The invention discloses a high-strength and wear-resistant castable for a middle back section of a blast furnace water slag punching groove. The castable comprises the following raw material components in parts by mass: 40 to 70 parts of waste ceramic aggregate, 3 to 25 parts of brown aluminum oxide, 1 to 5 parts of silicon carbide fine powder, 10 to 25 parts of calcium aluminate cement, 0.5 to 5parts of chromium sesquioxide fine powder, 1 to 4 parts of heat-resistant steel fiber and 1 to 8 parts of silicon dioxide micropowder; based on the mass percentage of the raw material components, theadditional components comprise 0.05 to 0.5 percent of organic explosion-proof fiber, 0.5 to 1.5 percent of boron carbide, 0.05 to 0.5 percent of water reducer and 0.02 to 0.2 percent of retarder. Thewaste ceramic serves as the main raw material to produce the wear-resistant castable of the middle back section of blast furnace punching slag by utilizing the characteristics that the waste ceramic material is compact in structure, high in hardness and washing-out resistant, so the characteristics of low cost, high strength, high wear resistance, long service life and the like are achieved, and energy saving and emission reduction are realized.

Owner:中冶武汉冶金建筑研究院有限公司

Ceramic composite material of high temperature insulation sandwich structure and method for preparing ceramic composite material

ActiveCN102642350BImprove toughnessImprove thermal conductivityLaminationLamination apparatusOxide ceramicCeramic composite

Disclosed are a ceramic composite material of a high temperature insulation sandwich structure and a method for preparing the ceramic composite material. A core layer of the composite material is an aerogel composite material layer reinforced by high temperature resistant inorganic fibers, oxide ceramic composite material surface plates reinforced by high temperature resistant inorganic fibers are compounded on the upper surface and the lower surface of the core layer, the thickness of the core layer is larger than or equal to 2mm, and the thicknesses of the upper surface plate and the lower surface plate respectively range from 0.1mm to 3.0mm. The method for preparing the ceramic composite material of the high temperature insulation sandwich structure includes the steps: (1) selecting aerogel composite materials reinforced by the high temperature resistant inorganic fibers as materials of the core layer with the thickness larger than or equal to 2mm; (2) tiling high temperature resistant inorganic fiber cloth or thin-layer fabrics on the upper surface and the lower surface of the core layer to perform needling, puncture or sewing; (3) sucking sol in a vacuum manner and gelating the sol at the temperature of 30-200 DEG C; and (4) performing heat treatment. The ceramic composite material of the high temperature insulation sandwich structure integrates the functions of heat insulation, bearing, wave penetration and the like.

Owner:NAT UNIV OF DEFENSE TECH

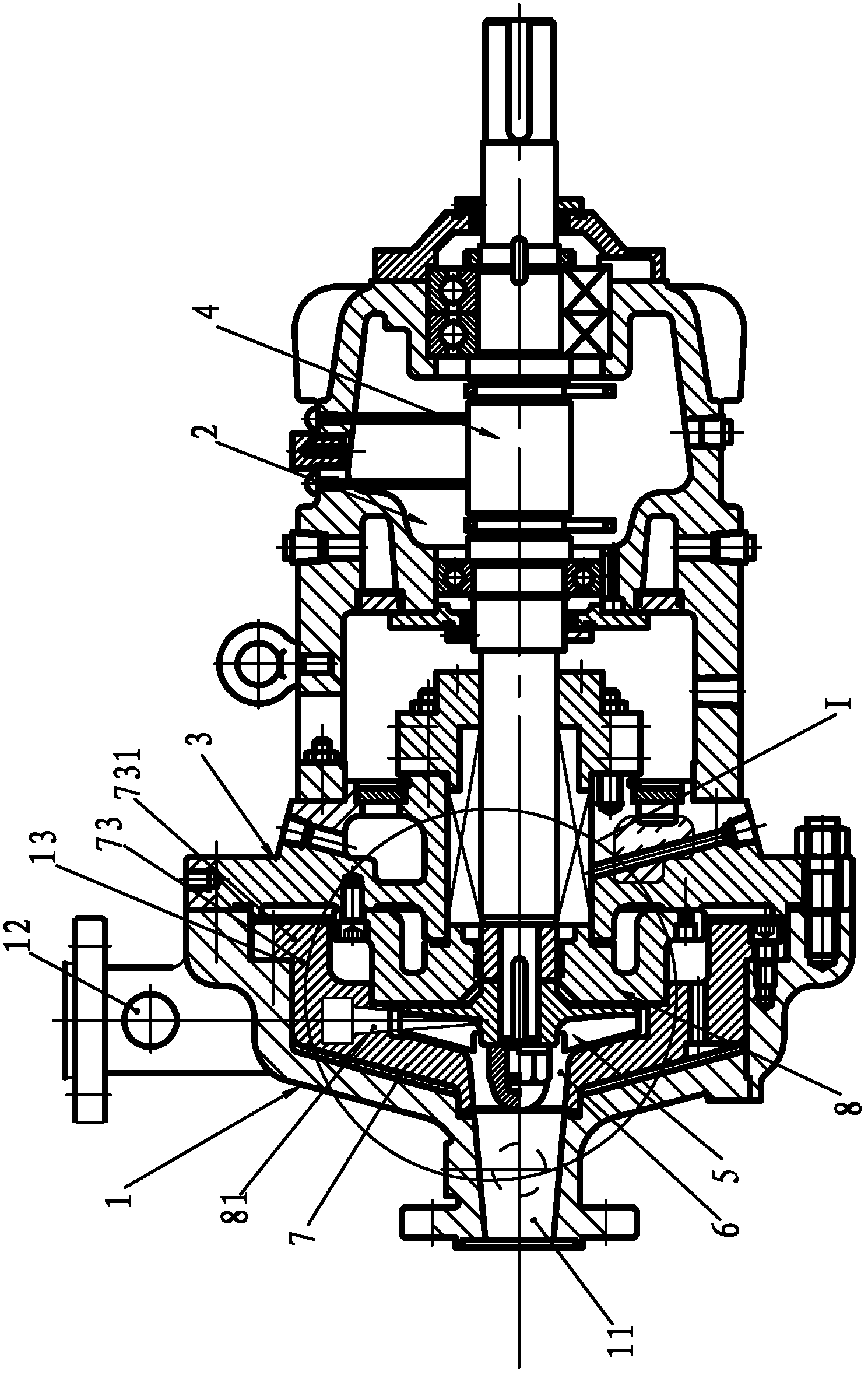

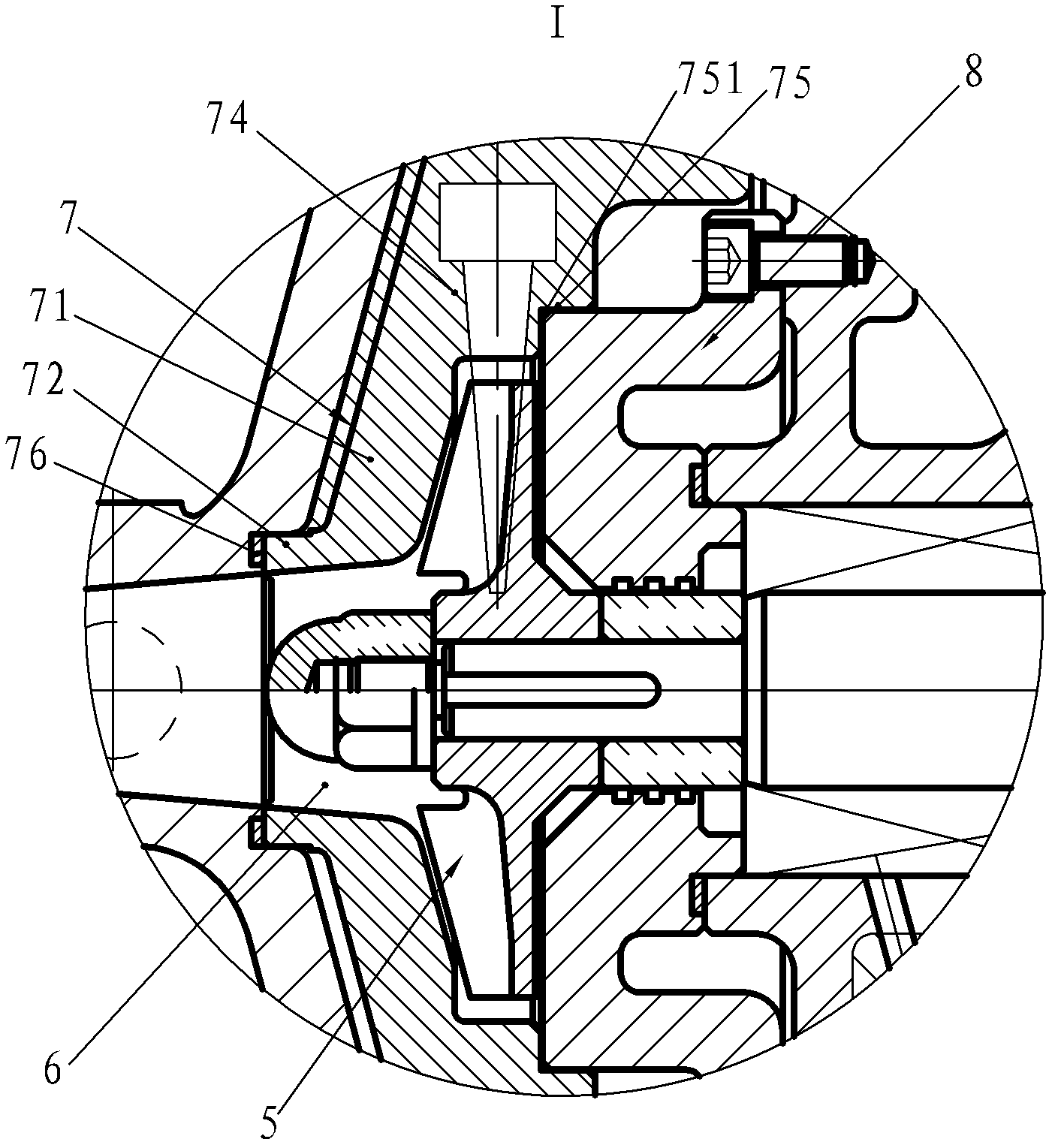

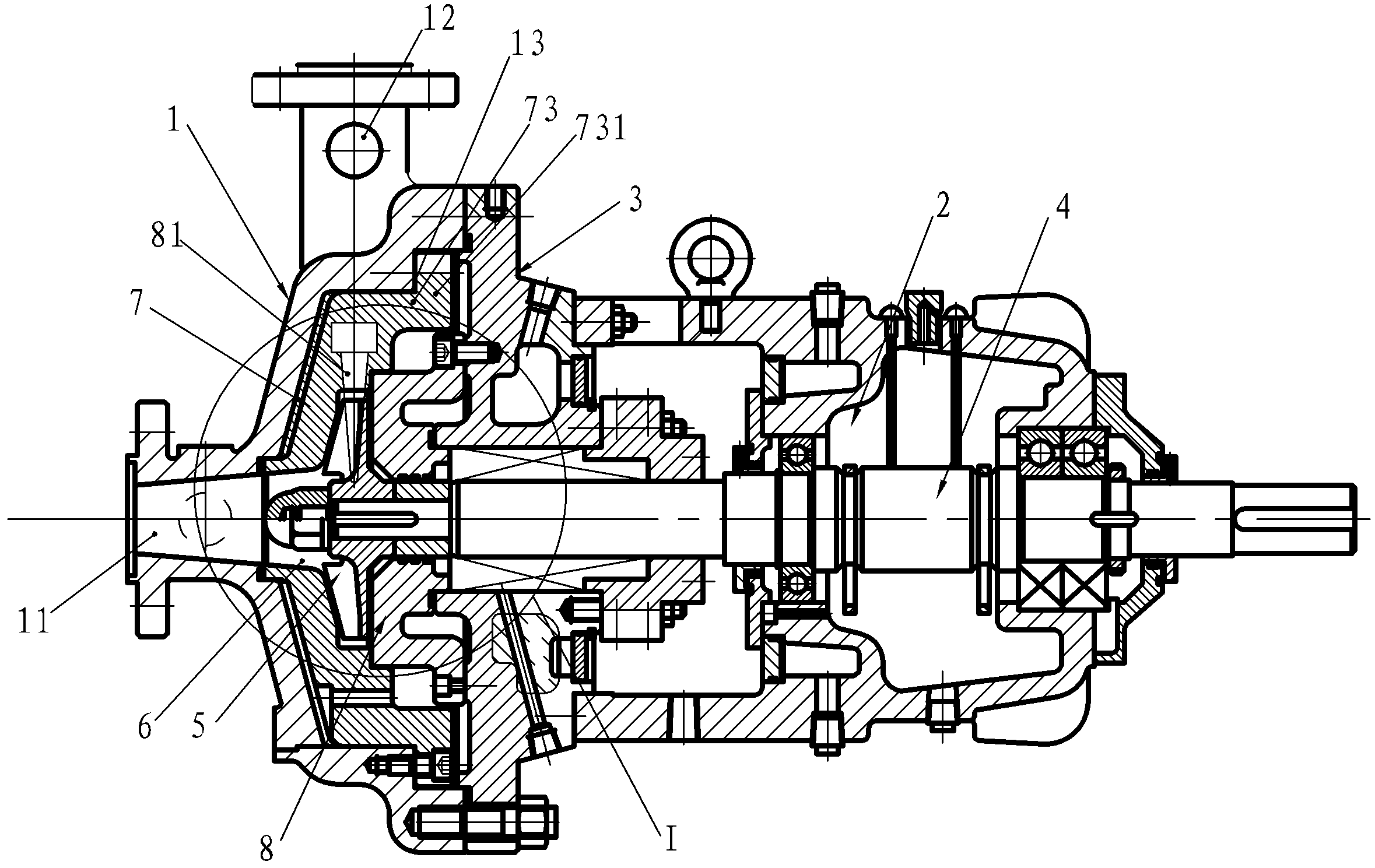

Dual-shell small-flow centrifugal pump

InactiveCN102425551AExtended service lifeMachining accuracy is easy to guaranteeSpecific fluid pumpsPump componentsStreamflowLinkage concept

The invention relates to a pump, in particular to a dual-shell small-flow centrifugal pump. The technical scheme provided by the invention is that: the dual-shell small-flow centrifugal pump comprises a pump body, a shaft seal device, a pump cover, a revolving shaft and an impeller, wherein the pump cover is arranged between the pump body and the shaft seal device; a flow channel is formed between the pump body and the pump cover; the pump body is provided with a medium inlet and a medium outlet which are communicated with each other through the flow channel; the impeller is in linkage connection with the revolving shaft and extends into the flow channel; the impeller is an open impeller; a pump body lining and a pump cover lining are arranged in the flow channel; the medium outlet is communicated with the flow channel through a diffusion hole formed on the pump body lining; the diffusion hole is conical; one end which is connected with the medium outlet is a large end, and one end which is connected with the flow channel is a small end; the flow channel is matched with the profile of the impeller; and the cross section of the flow channel is cylindrical. Due to the adoption of the technical scheme, a dual-shell small-flow centrifugal pump which has long service life and a simple structure, and is suitable for conveying particle mediums is provided.

Owner:EBARA GREAT PUMPS

High-alumina brick and manufacturing method thereof

InactiveCN104003743AGood wear resistance and thermal shock resistanceImproved erosion and thermal shock resistanceFlueStraight segment

The invention discloses a high-alumina brick. The high-alumina brick comprises, by weight, 5-15 parts of 3 mm-5 mm super alumina aggregate, 30-40 parts of 1 mm-3 mm super alumina aggregate, 10-20 parts of 0 mm-1 mm super alumina aggregate, 20-30 parts of super alumina powder, 5-7 parts of zirconium carbide powder, 1-3 parts of Guangxi mud, 8-10 parts of composite bonding agents and 4-6 parts of water. The invention further discloses a manufacturing method of the high-alumina brick. The high-alumina brick is of high strength, high refractoriness, high abrasion resistance and high thermal shock resistance and is applicable to a cyclone separator flue, a cyclone separator straight segment and a cone of a circulating fluidized bed boiler, a back-feeder, a metallurgical industrial furnace and other thermal equipment. The manufacturing process of the high-alumina brick is simple and easy to implement.

Owner:张婷

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com