Preparation method of urban river polluted bottom mud active covering plate

A technology for polluting bottom mud and covering plates, applied in water pollutants, sludge treatment, polluted waterways/lakes/ponds/rivers, etc., can solve the problem of thinning and failure of covering layers, suspension of covering materials, and high flow rate of river water To achieve the effect of good water permeability, uniform coverage and simple construction procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 Experimental research on the permeability coefficient, water retention, and erosion loss ratio of bottom mud active covering slabs

[0027] (1) Implementation process

[0028] In this example, the variation ranges of the permeability coefficient, water retention and scouring loss ratio of the bottom sludge active covering board made of different mass ratios of calcined modified sludge particles, cement and fly ash were studied.

[0029] In this example, a total of 16 mass ratios of calcined modified sludge particles, cement and fly ash were taken. The calcined modified sludge particles were all 180g, and the quality of cement and fly ash was appropriately changed. The change in cement quality was divided into: 4 groups, number 1~4#; 1#: cement 40g, fly ash respectively 50, 60, 70, 80g; 2#: cement 50g, fly ash respectively 50, 60, 70, 80g; 3#: 60g of cement, 50, 60, 70, 80g of fly ash; 4#: 70g of cement, 50, 60, 70, 80g of fly ash; the water-binder ratio is 0....

Embodiment 2

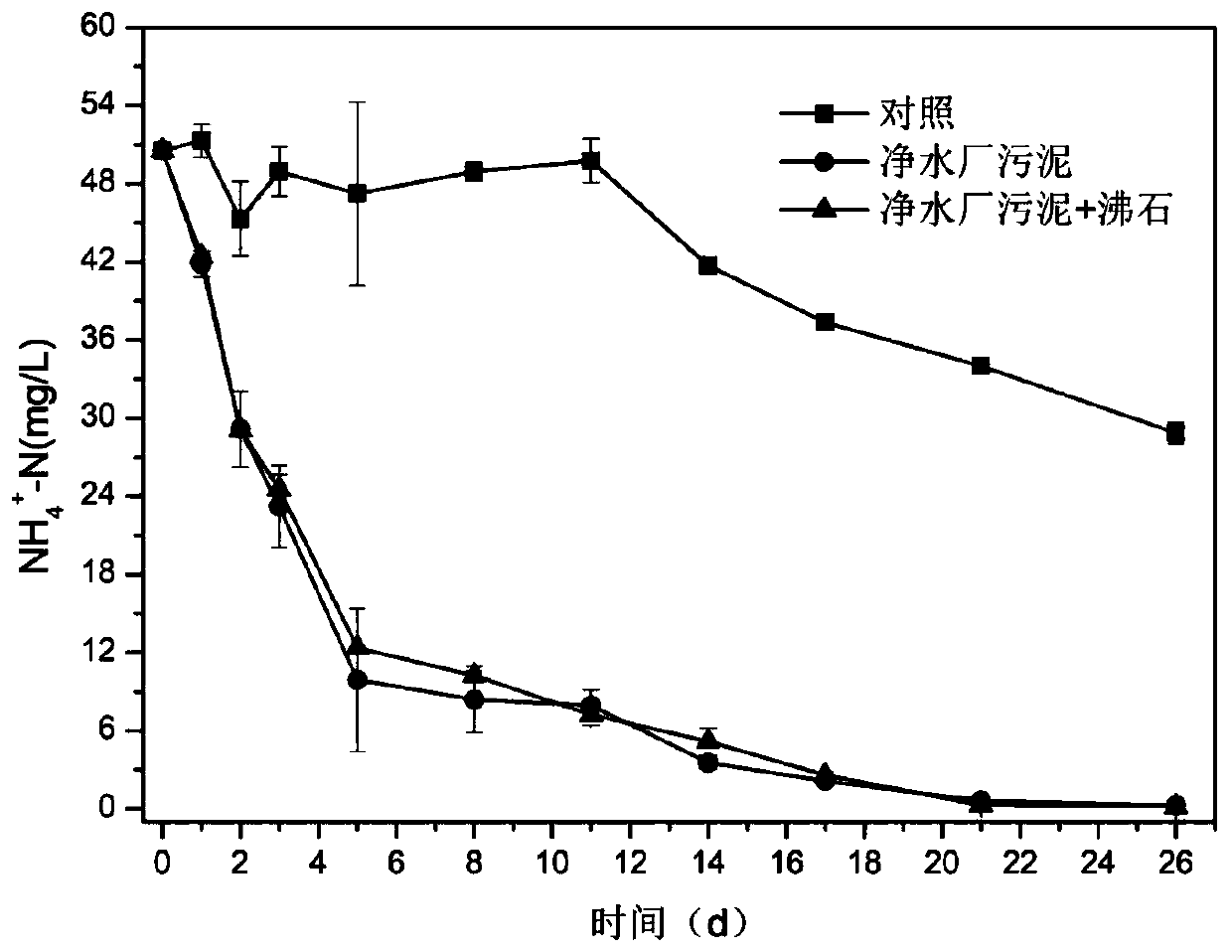

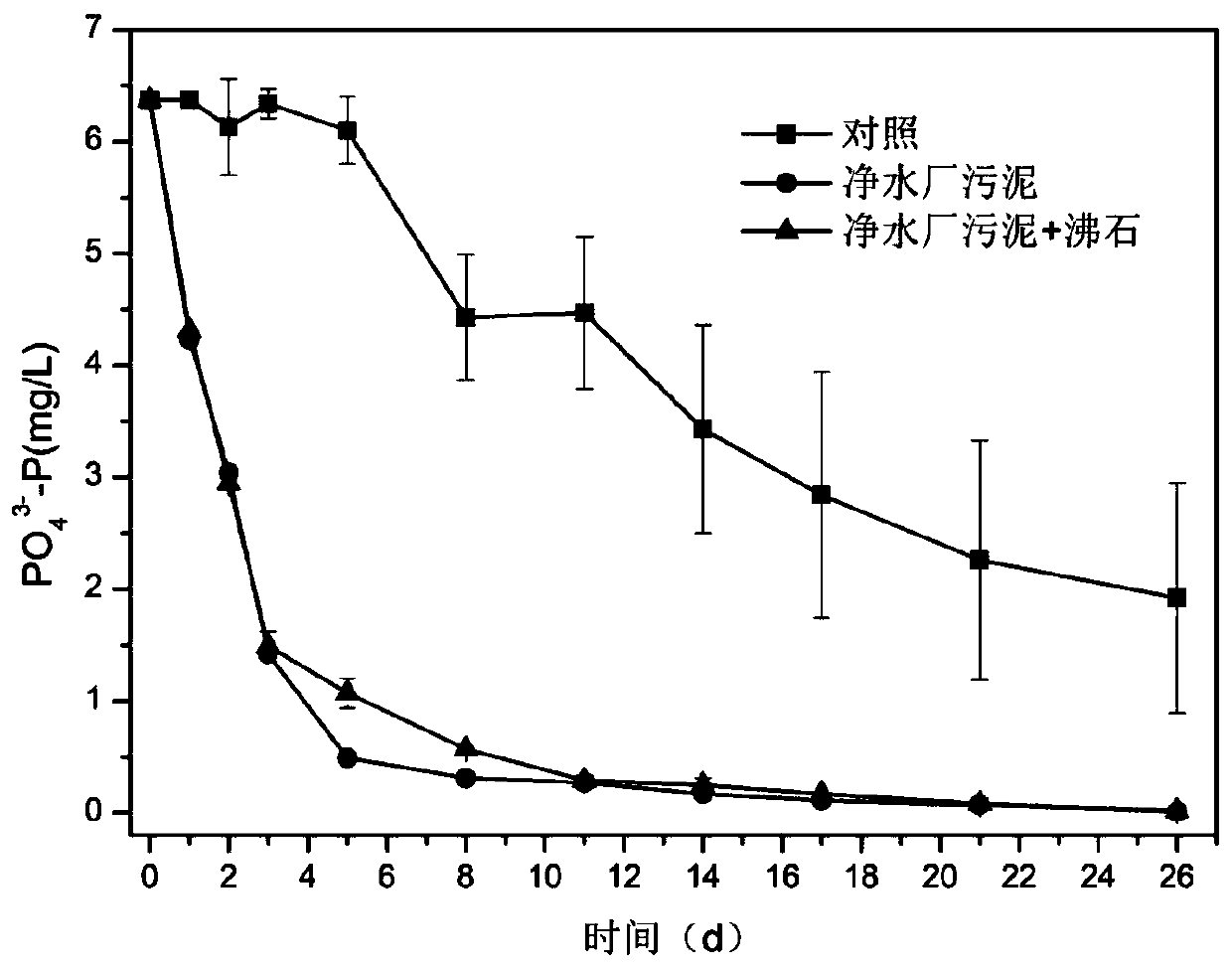

[0045] Example 2 Research on the Effect of Bottom Sludge Active Cover Board on Nitrogen and Phosphorus Reduction in Water

[0046] (1) Test plan

[0047]The test was carried out in a transparent square plexiglass cylinder of 16cm×16cm×16cm; the test water was self-mixed water, the concentration of ammonia nitrogen in the water was 48.06mg / L, and the concentration of orthophosphate was 4.98mg / L.

[0048] The covering boards used in the test are: ① Made of calcined modified sludge particles, cement and fly ash as raw materials, in which 180g of calcined modified sludge particles, 50g of cement, and 70g of fly ash are called calcined modified sludge. Sludge group; ②Using calcined modified sludge particles, zeolite, cement and fly ash as raw materials, in which calcined modified sludge particles 150g, zeolite 70g, cement 50g, fly ash 70g, called calcined modified sludge Mud + zeolite group.

[0049] In the test, there were 9 plexiglass cylinders, which were divided into 3 groups...

Embodiment 3

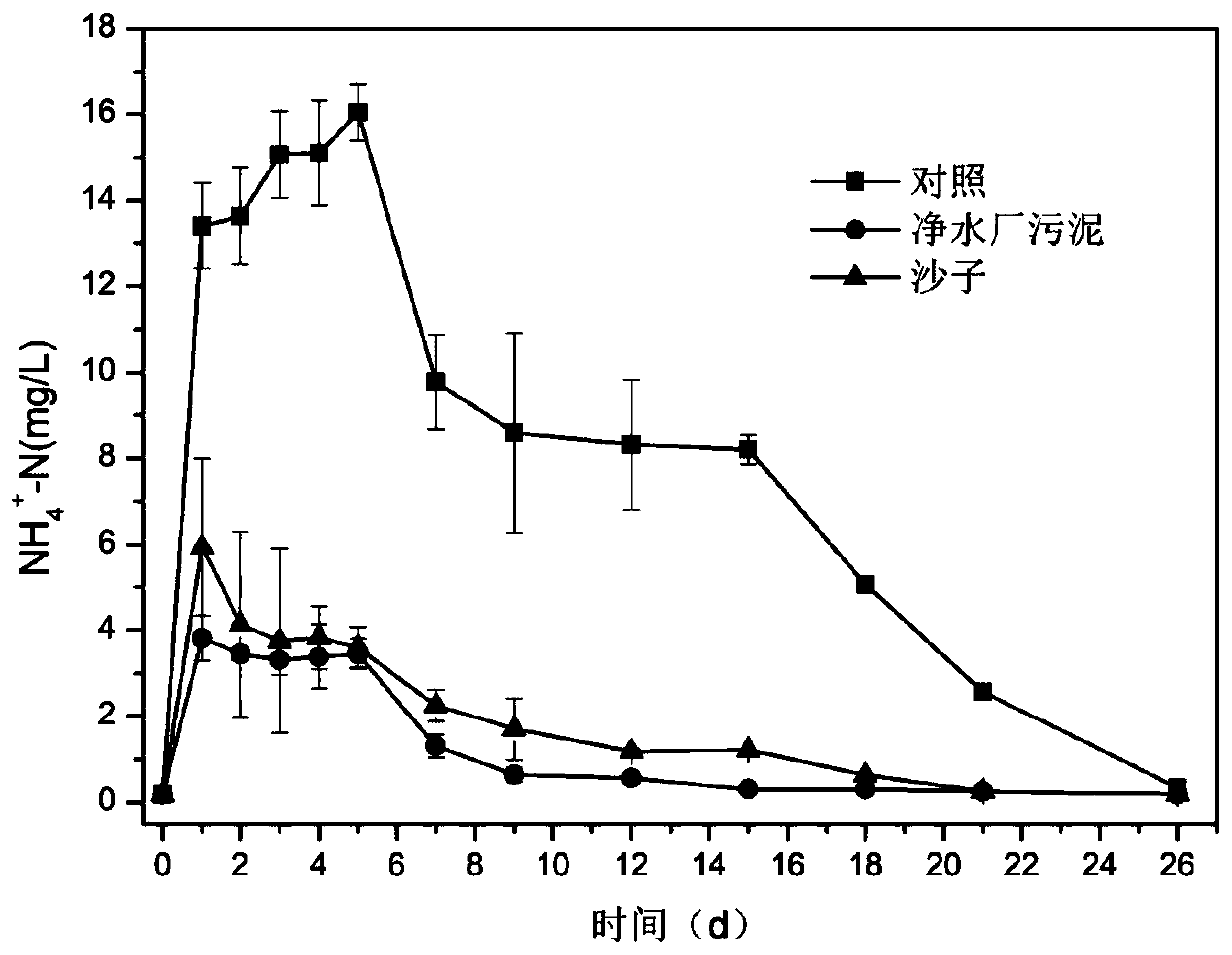

[0057] Example 3 Study on the effect of active covering plate on controlling the release of nitrogen and phosphorus from sediment

[0058] (1) Test plan

[0059] The test was carried out in a transparent square plexiglass tank of 16cm×16cm×16cm; the sediment in each plexiglass tank was about 1.15kg, and the thickness was about 5cm. The mud is covered with a board covering length×width=15cm×15cm and the thickness is about 0.5cm; the overlying water is tap water; using the principle of siphon, tap water is slowly added into the tank along the tank wall through a plastic hose, and the volume of the overlying water is about 2L.

[0060] The active cover plates used in the test are: ① Made of calcined modified sludge particles, cement and fly ash as raw materials, including 180g of calcined modified sludge particles, 50g of cement, and 70g of fly ash, which is called calcined modified sludge. Sludge group; ② It is made of sand, cement and fly ash as raw materials, and the amount ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com