Patents

Literature

282results about How to "Simplify construction procedures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

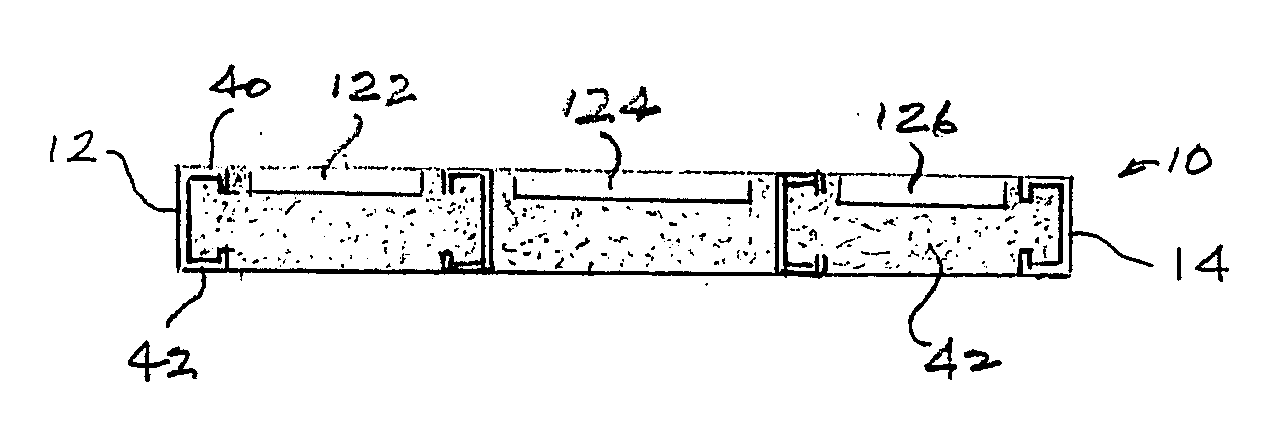

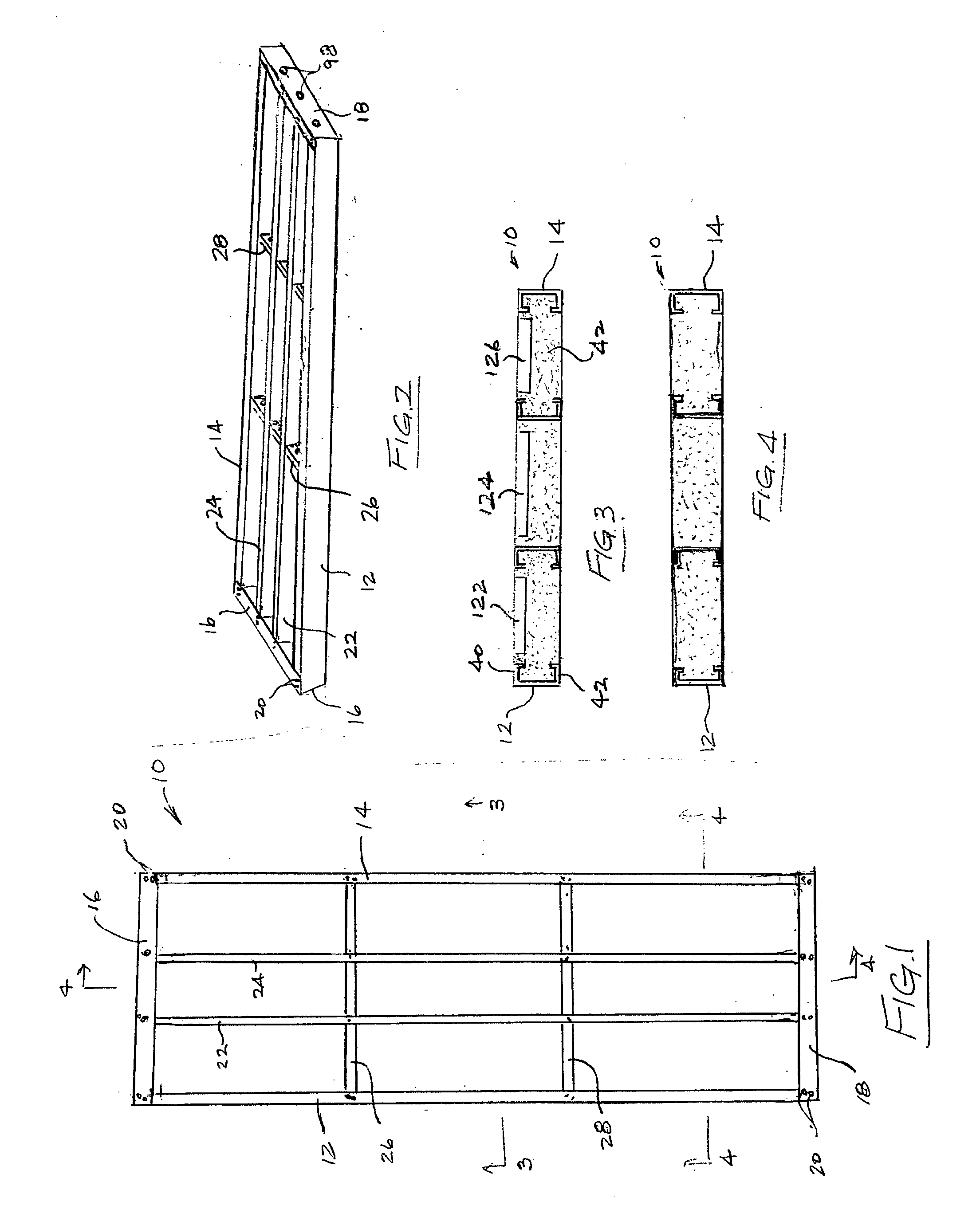

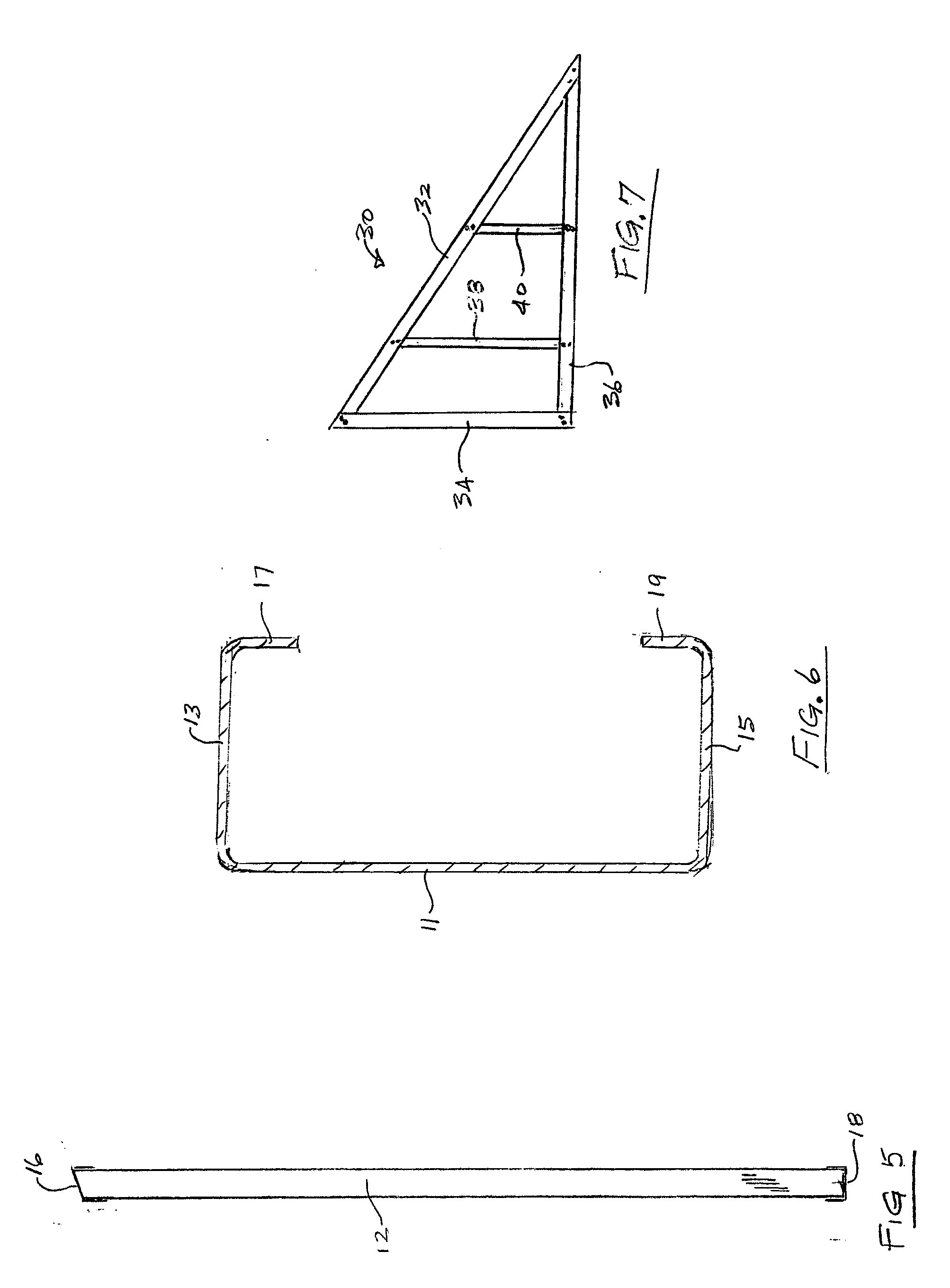

Insulated wall panel for building construction and method and apparatus for manufacture thereof

InactiveUS20060265985A1Minimization requirementsHigh densityBuilding componentsMetal frameworkFilling materials

Pre-fabricated wall, ceiling and roof panels for use in building construction have a metal framework, metal interior bracing as needed and may include internal electrical, water and gas supply conduits enabling simple and efficient building construction. A method for manufacturing the pre-fabricated building panels includes constructing a metal panel framework with internal structural bracing and placing the framework in a machine having relatively moveable foam containment plates. Polyurethane foam panel filler material having efficient thermal insulating quality is injected into the panel frame between the foam containment plates and expands during curing to fill the voids within the panel frame and define parallel exterior and interior panel surfaces. The light-weight polymer foam filled panels are then secured to the panel connectors of a building foundation and are secured to one another to define the walls, ceiling and roof a building structure and provide resistance to storm damage, insect and water damage and heat reflection.

Owner:NICHOLS MICHAEL P

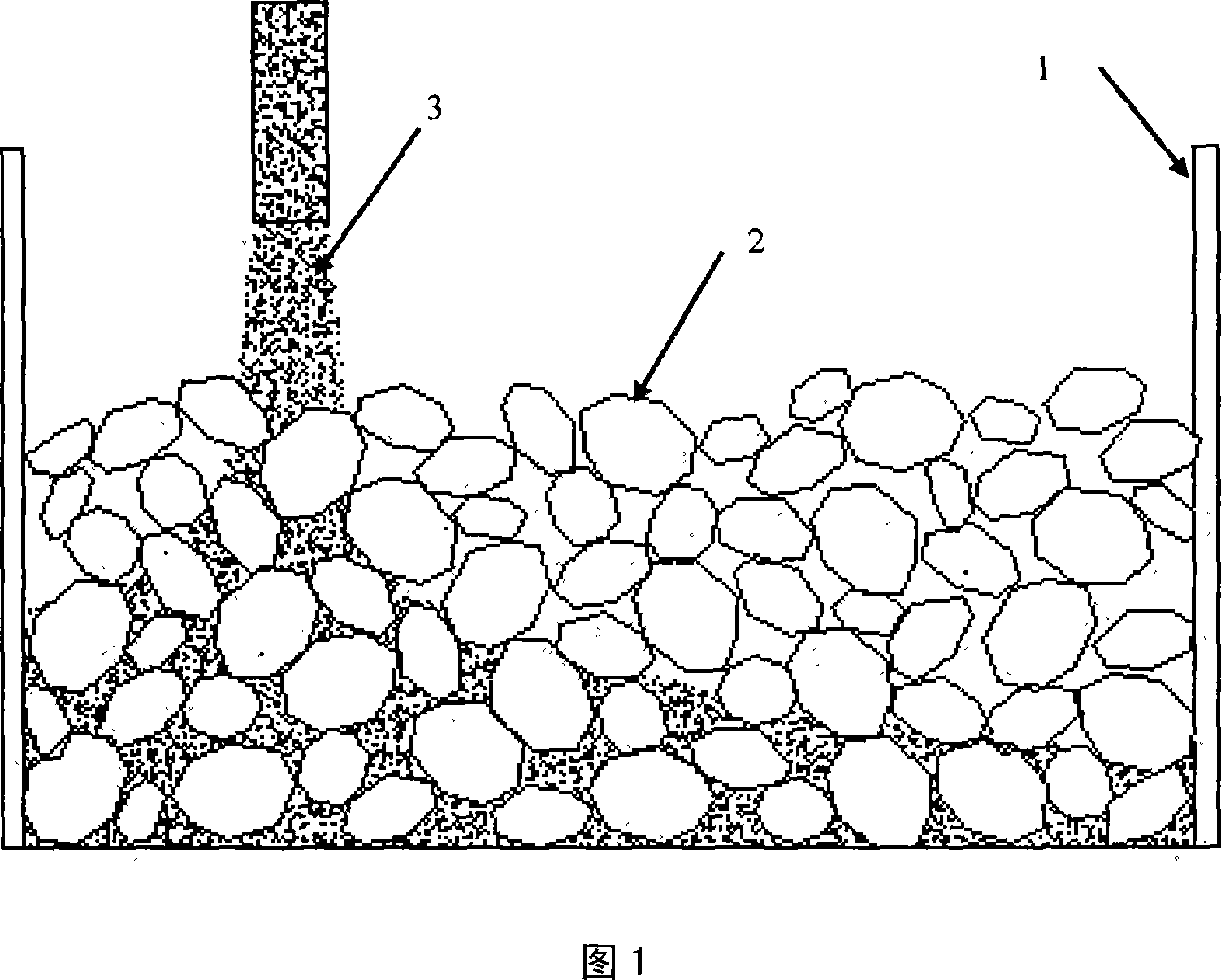

Method for constructing normal piled concrete

ActiveCN101074560APouring is flexible and fastReduce usageFoundation engineeringUltimate tensile strengthWater temperature

The invention relates to a construction method to pour the natural moraine by the concrete. The invention transforms the scree or rock block with 15cm particle to the storehouse, then to pour the compact concrete into the moraine from the surface. The invention has the simple construction and improved the efficiency and saved cost. The moraine concrete uses little cement and low water temperature, good volume stability.

Owner:TSINGHUA UNIV +1

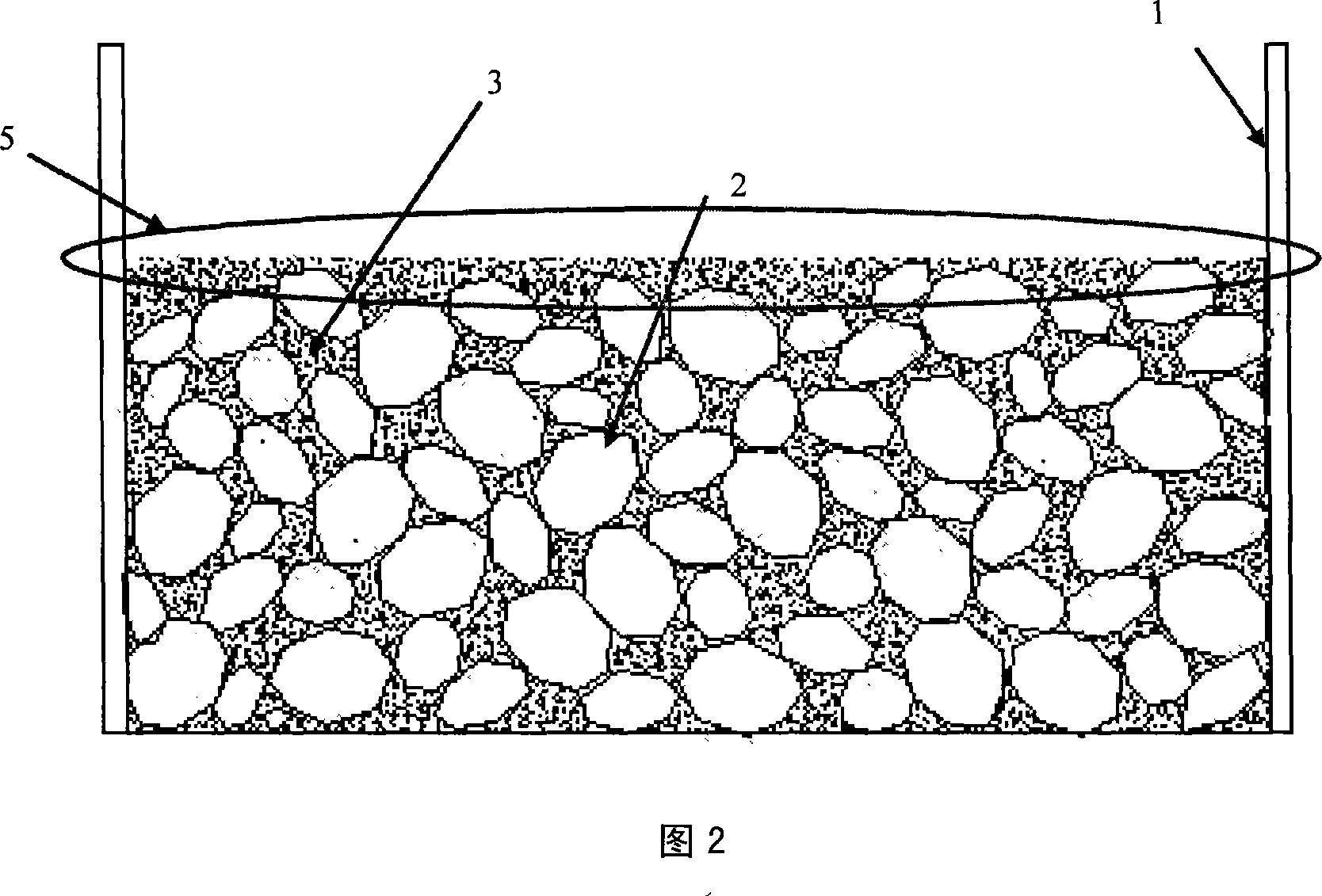

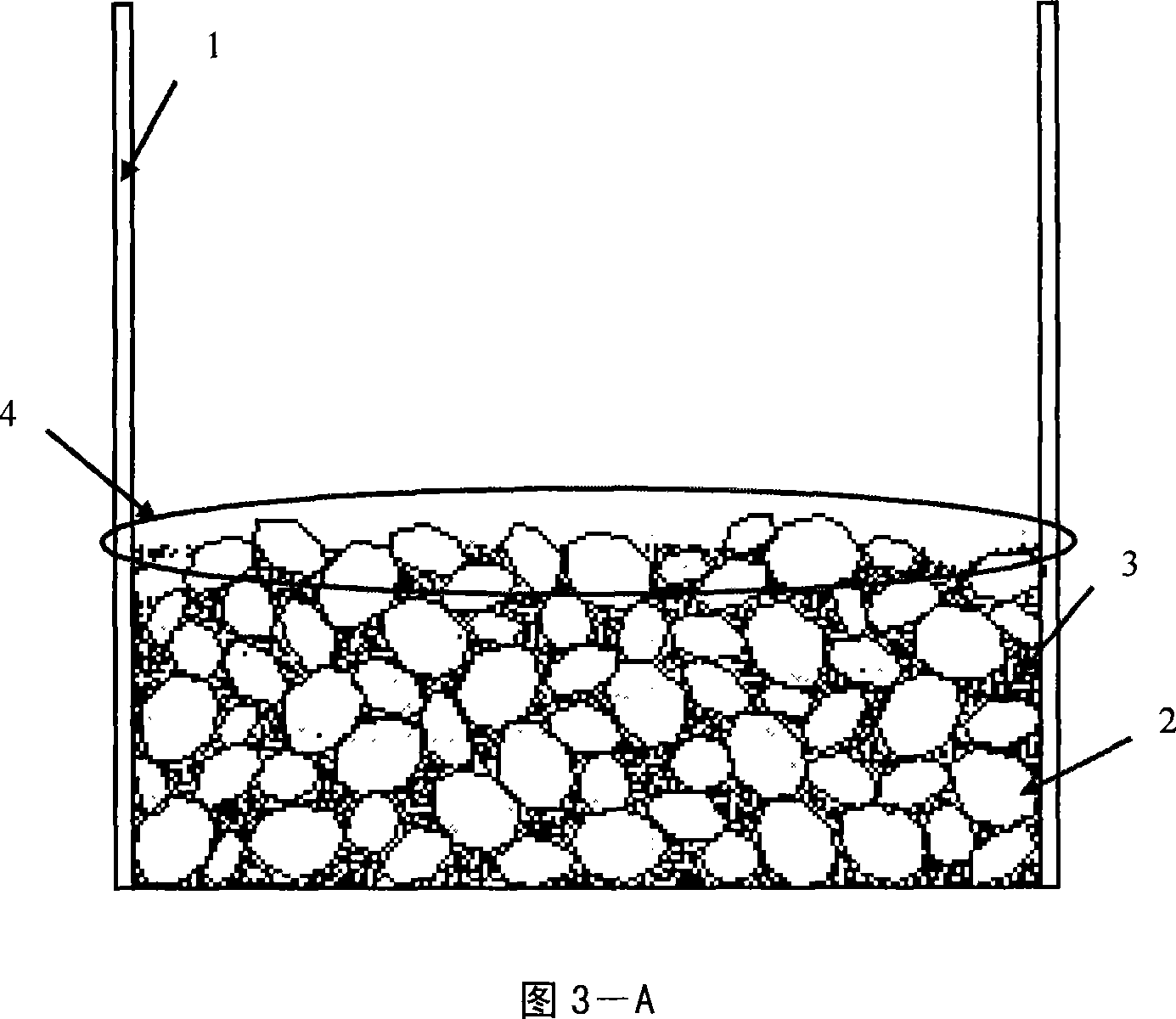

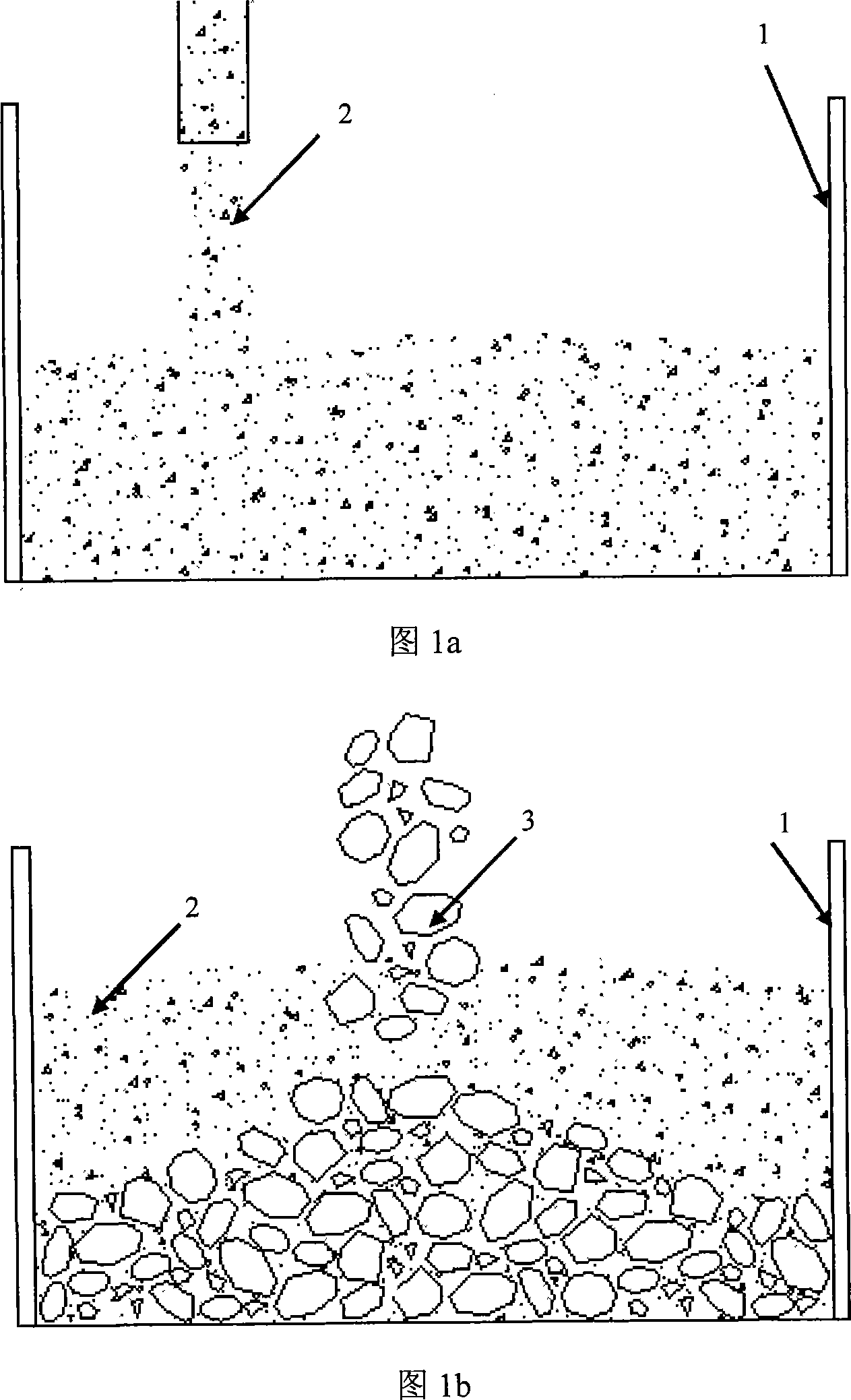

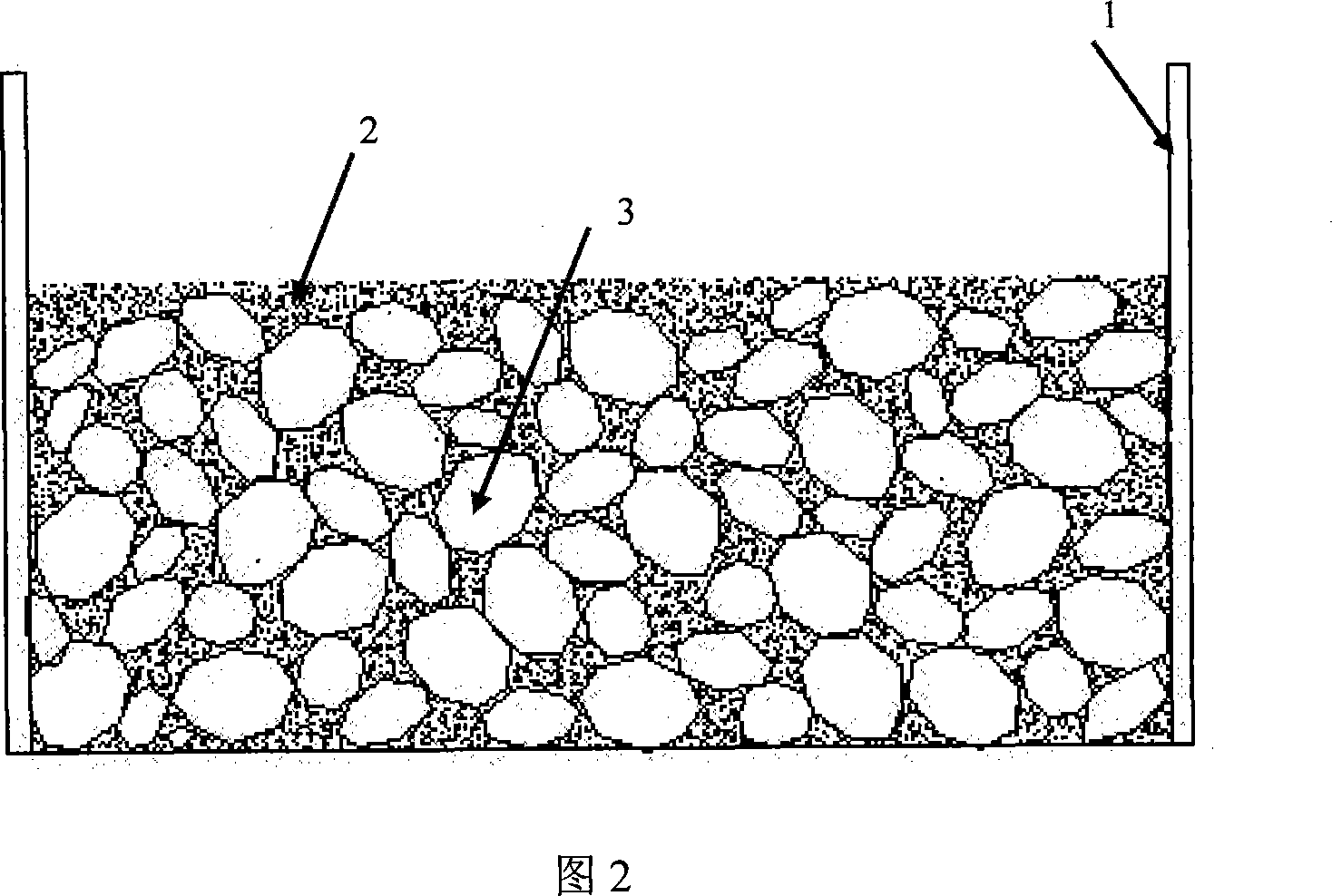

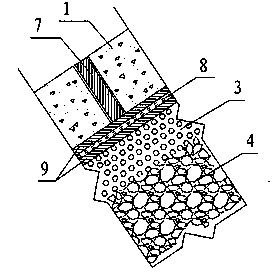

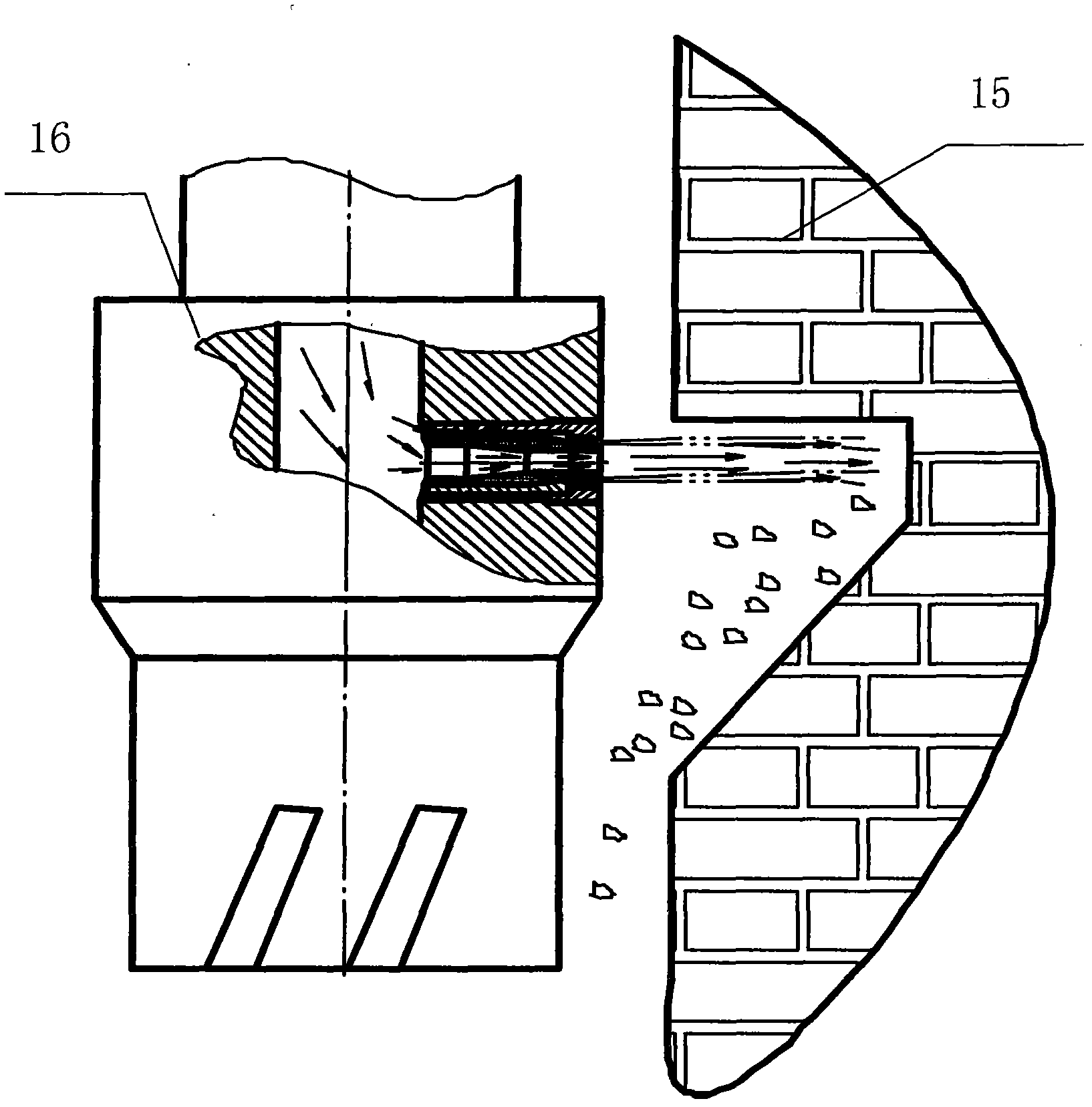

Jackstone-type rockfill concrete construction method

ActiveCN101144279APouring is flexible and fastReduce usageFoundation engineeringEarth-fill damsHigh intensityUltimate tensile strength

The present invention discloses a riprap rock-fill concrete construction method, which relates to a construction method for the large volume concrete. The present invention adopts self-compacting concrete having superior anti-segregation performance and good plasticity-retention performance, and firstly the concrete is poured into a bin, and then block stones or pebbles with the particle size smaller than 4 cm are poured into the poured self-compacting concrete in a mechanical way or a manual way, and the self-compacting concrete can fill up and compact the vacancies caused in the block stone settlement path at any time, the high anti-segregation performance ensures that the self-compacting concrete does not segregate and bleed water under the impact of the block stones, and finally the self-compacted rock-fill concrete with high intensity is formed. The method has the advantages that the construction is convenient, and the present invention has significant effects on the aspects of improving the construction efficiency and saving the construction cost, and the rock-fill concrete formed has high degree of compaction, the cement used is less, the hydration temperature rise is low, the volume stability is good, and the comprehensive performance is excellent, meanwhile, the present invention also has the advantages of energy-saving, environmental protection and being easy for continuous construction.

Owner:TSINGHUA UNIV +1

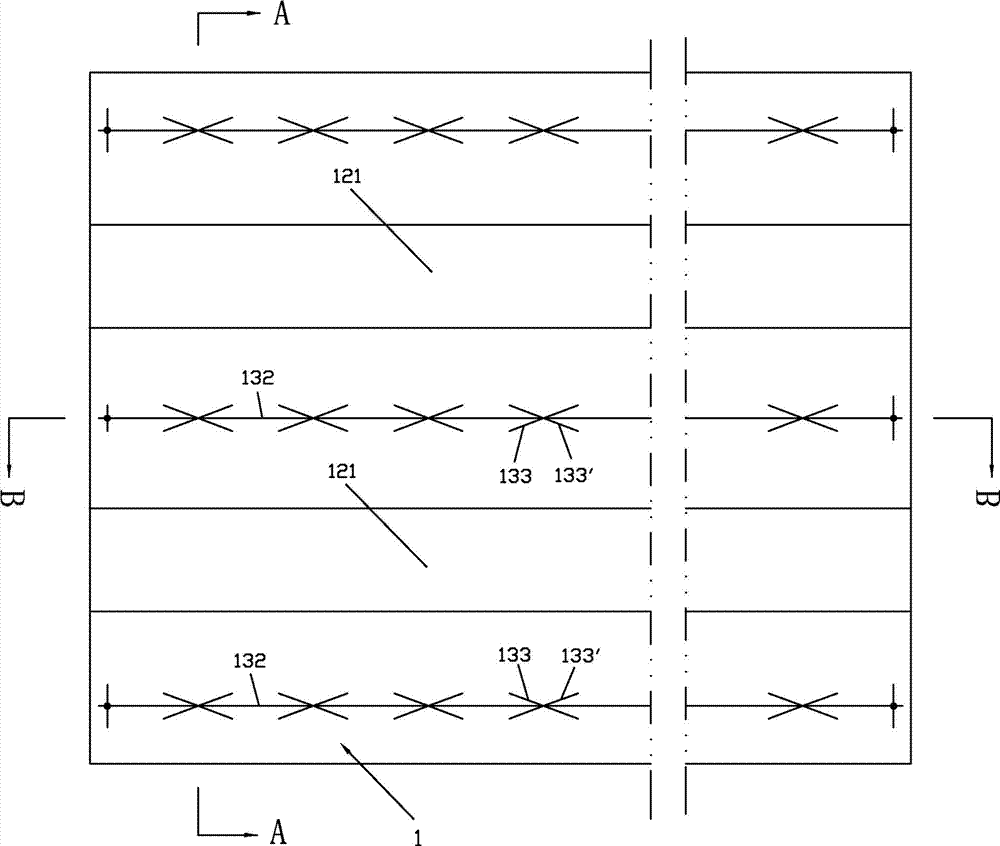

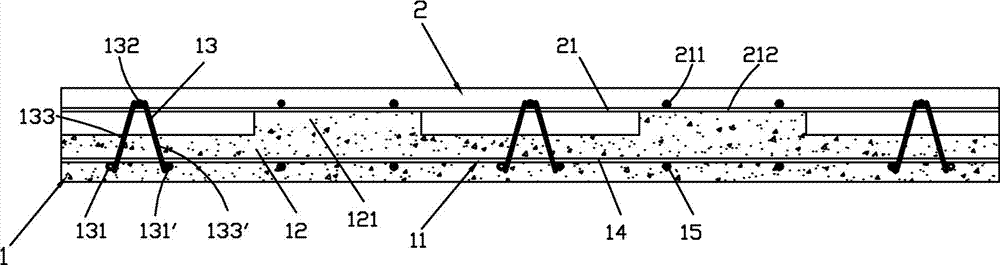

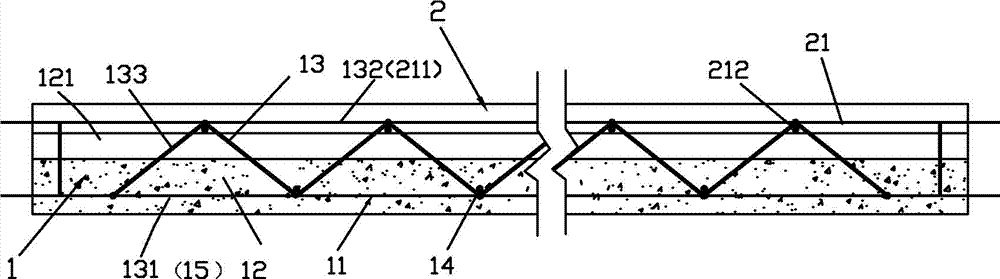

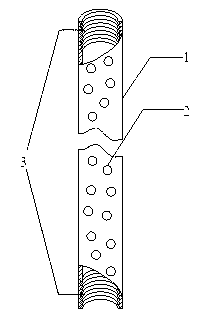

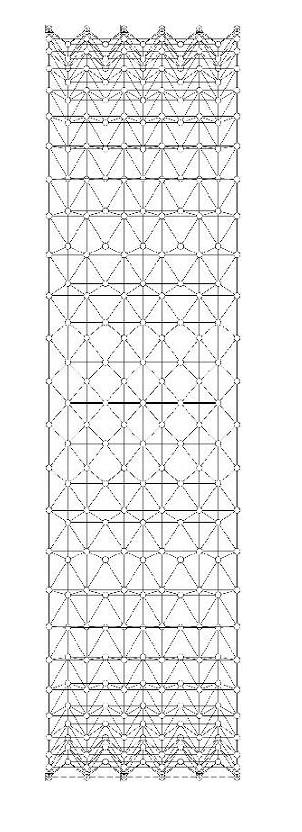

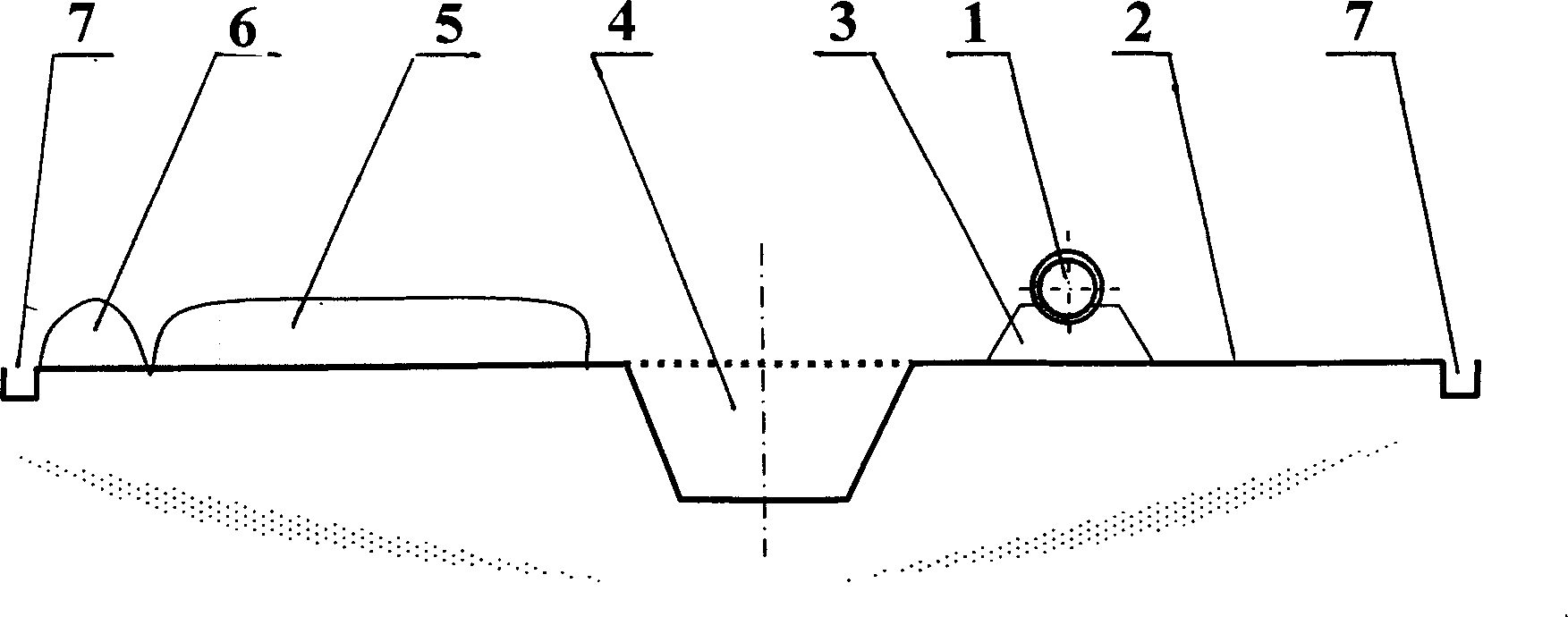

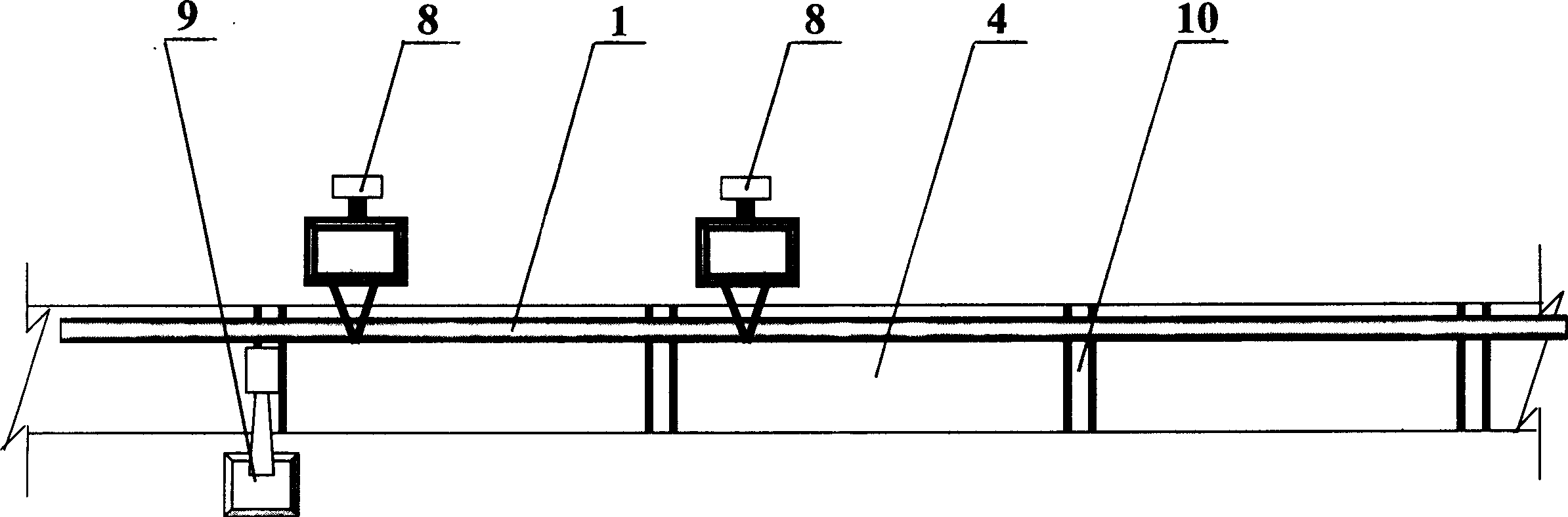

Ribbed steel bar truss concrete superimposed sheet and construction method thereof

A ribbed steel bar truss concrete superimposed sheet and a ribbed steel bar truss concrete construction method comprise a prefabricated layer and a superimposed layer. The prefabricated layer comprises a steel bar truss net and a concrete layer arranged on the lower portion of the prefabricated layer. A steel bar truss is composed of a lower chord steel bar, an upper chord steel bar and a web member steel bar connecting the lower chord steel bar and the upper chord steel bar. The steel bar truss net is composed of the steel bar truss, an additional steel bar shelved on the lower chord steel bar and vertical to the steel bar truss and a longitudinal steel bar in the lower portion of the prefabricated layer and parallel to the lower chord steel bar of the steel bar truss in the same plane. A plurality of concrete ribs are arranged on the upper end face of the concrete layer along the longitude direction and arranged in parallel. The superimposed layer is a cast-in-place concrete layer arranged on the prefabricate layer. A steel rib net is buried in the superimposed layer. The superimposed layer is connected with the upper chord steel bar in the steel bar truss of the prefabricate layer. The superimposed layer comprises an upper longitudinal bar and the additional steel bar vertical to the upper chord steel bar, and poured into a whole with the upper chord steel bar in the steel bar truss of the prefabricate layer and the web member steel bar. The ribbed steel bar truss concrete superimposed sheet and the ribbed steel bar truss concrete construction method have the advantages of being reasonable in steel bar overall arrangement, good in economy, convenient to hoist and transport, and effective in solving problem of sheet joint cracking.

Owner:SHANGHAI IRON & STEEL TECHN INST

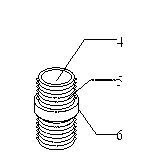

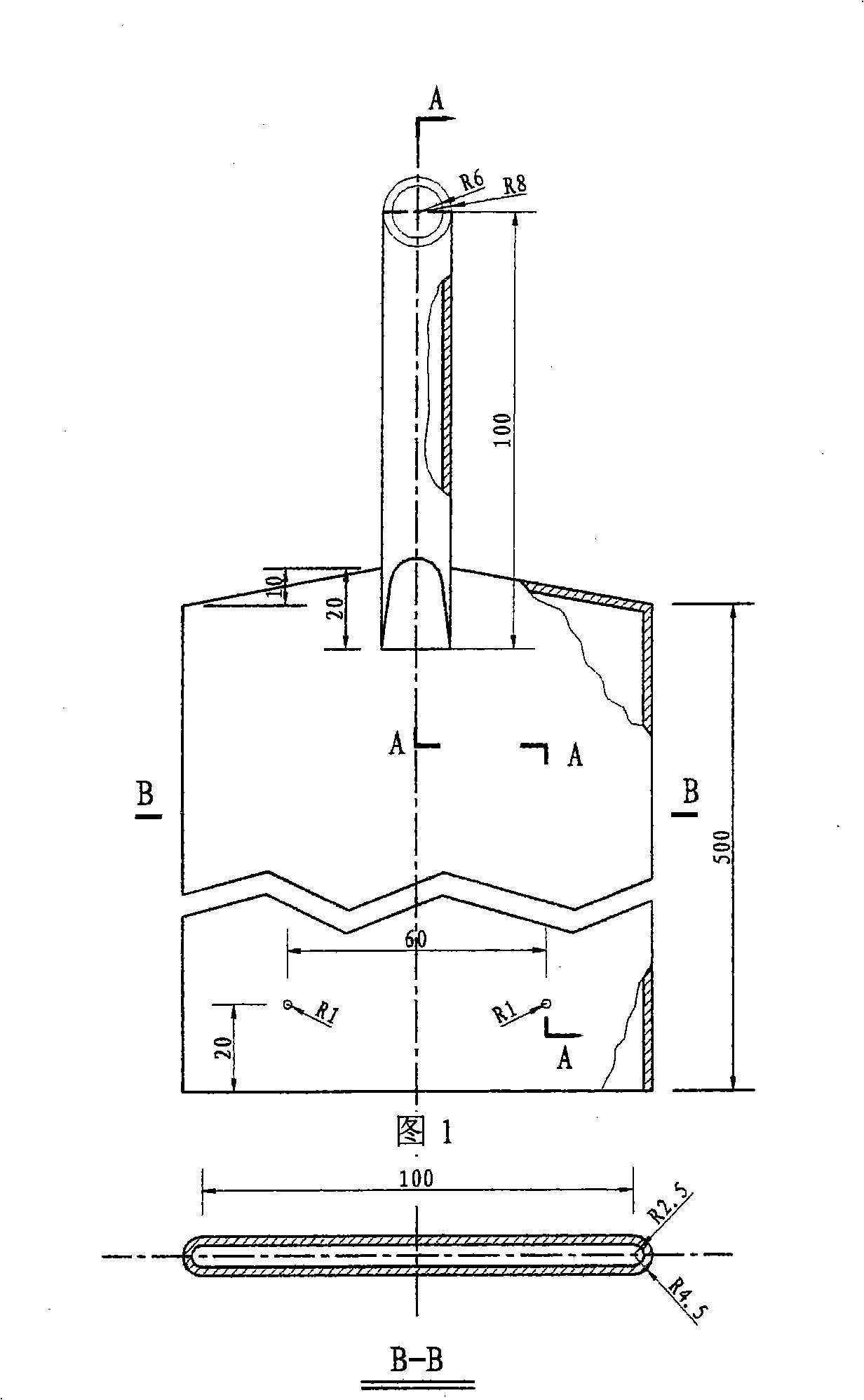

Electroosmosis electrode and electroosmosis draining system thereof

ActiveCN103215946ASimplify construction proceduresImprove work efficiencySoil preservationTechnical supportCorrosion resistant

The invention discloses an electroosmosis electrode and an electroosmosis draining system thereof, which comprise sectional draining electrode pipes, conductive filter cloth, a programmable direct current power supply, a draining pipe, a timing controller, a cable, a vacuum pump, a region optimizing device and a seismic wave real-time monitoring alarm, wherein the sectional draining electrode pipes are in thread connection by soft conductive connectors, are wrapped by the conductive filter cloth on the outside, meet the requirements of construction environments on mechanical properties and corrosion resistant property, and can still be used for a long time after multiple times of earthquakes and electroosmosis, and the use efficiency of electroosmosis equipment during soft base treatment can be improved by the uninterruptible electrifying of an electroosmosis instrument, thus reducing the construction cost. Excess pore water pressure generated by earthquake action can be timely discharged from a draining channel by the electroosmosis and vacuum negative actions, thus avoiding the shock damage to upper-part soil body and the earthquake liquefaction of a liquefied soil layer caused by the excess pore water pressure. The electroosmosis electrode and the electroosmosis draining system thereof are simple in structure, convenient to construct, durable and practical, and provides technical support and guarantee for promotion and application of an electroosmosis method on the fields such as soft base reinforcing and earthquake fortification of buildings.

Owner:HOHAI UNIV

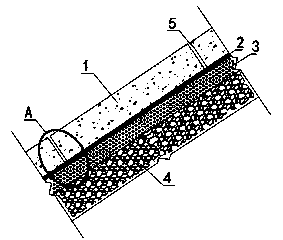

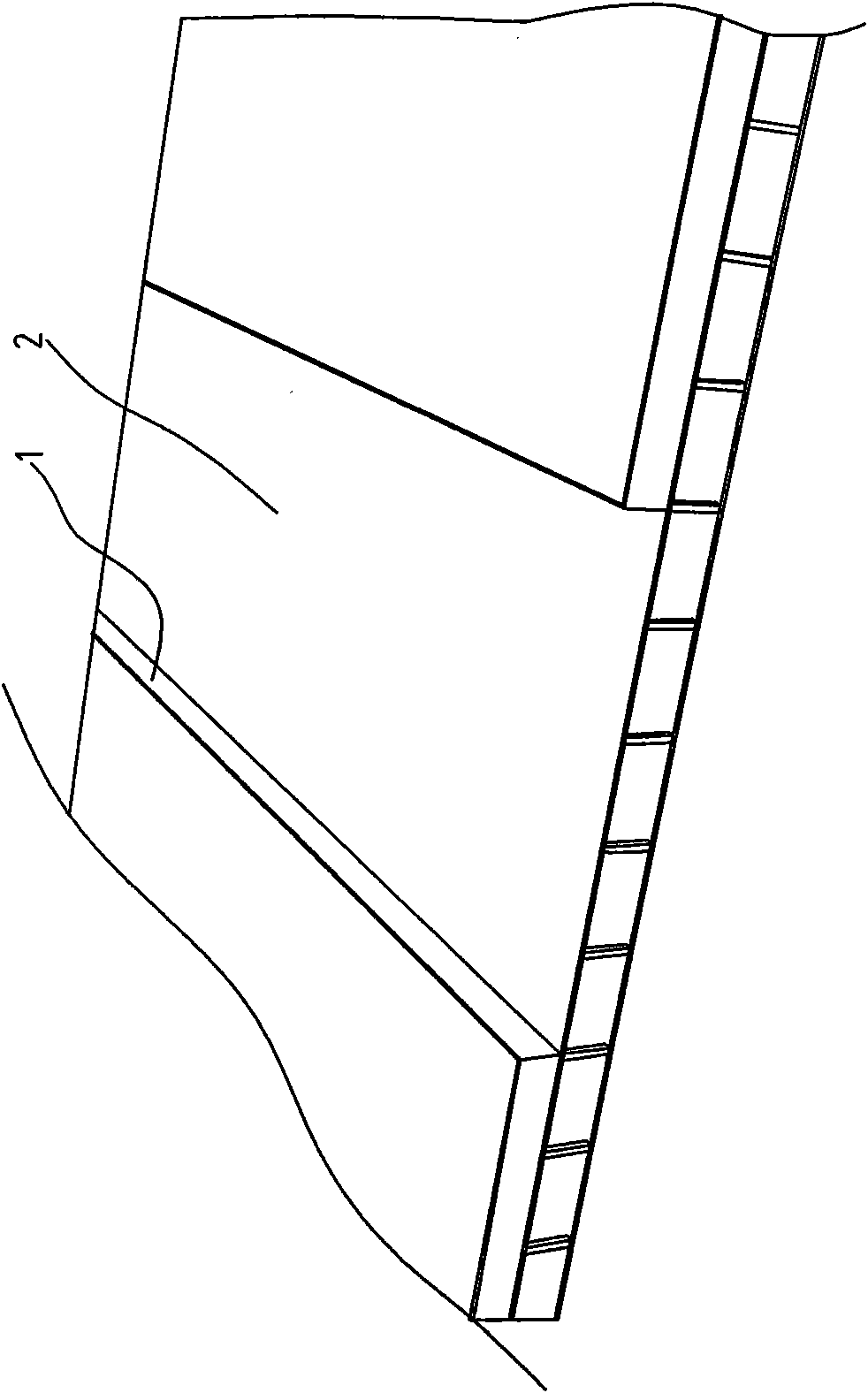

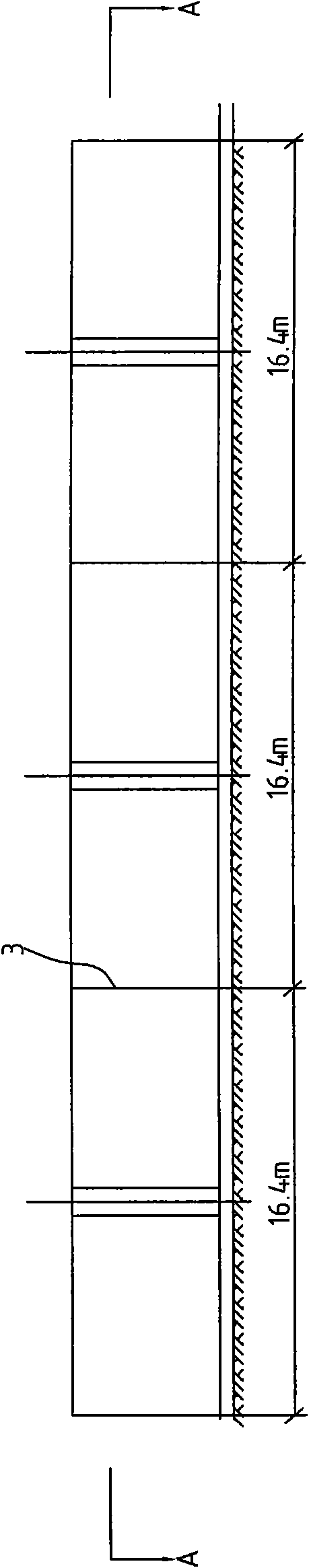

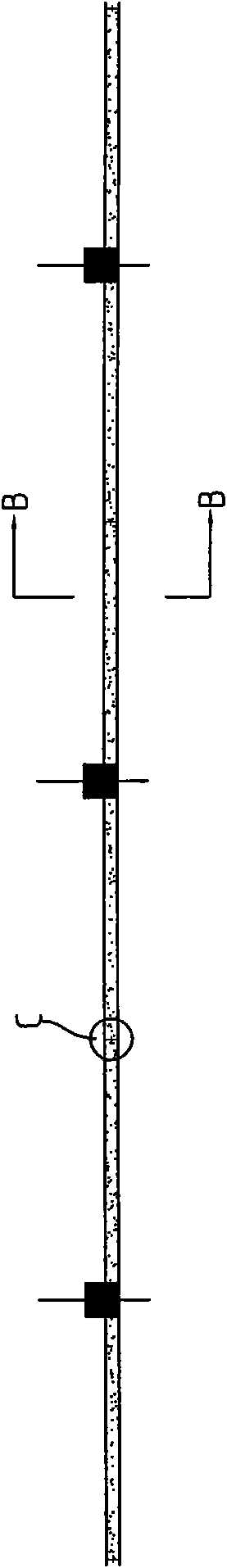

High rock-fill dam membrane anti-seepage body on deep coverage layer and construction method of high rock-fill dam membrane anti-seepage body

InactiveCN103643656AStrong adaptability to deformationNo crackEarth-fill damsRock-fill damsOverburdenFiber

The invention discloses a high rock-fill dam membrane anti-seepage body on a deep coverage layer and a construction method of the high rock-fill dam membrane anti-seepage body. The membrane anti-seepage body is composed of a concrete protection layer, a geomembrane anti-seepage layer, a flexibility cushion layer and a transition layer. The concrete protection layer is a cast-in-place fiber concrete layer for a reserved cross joint and a vertical joint and located on a surface layer to protect a geomembrane. The geomembrane anti-seepage layer is a two-cloth and one-membrane composite geomembrane and is located in the middle to play a role of preventing seepage. The flexibility cushion layer is a polyurethane pervious concrete layer and located at the bottom of the anti-seepage body to support the geomembrane and to transmit and disperse water loads. The rough granule transition layer is arranged between the flexibility cushion layer and a rock-fill dam body. The construction method comprises the technical steps of filling and building the transition layer, pouring the flexibility cushion layer, paving the composite geomembrane, pouring the concrete protection layer and the like. The membrane anti-seepage body can keep stable on a high rock-fill dam slope, the ability of adapting to deformation of a coverage layer dam foundation and the dam body is high, the structural form is simple, construction is fast, and the anti-seepage problem of the high rock-fill dam on the deep coverage layer can be effectively solved.

Owner:HOHAI UNIV

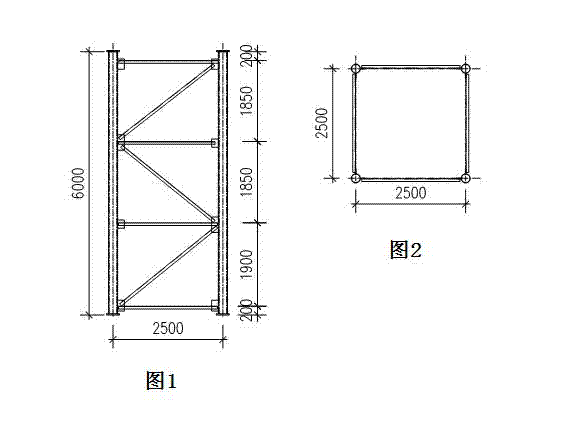

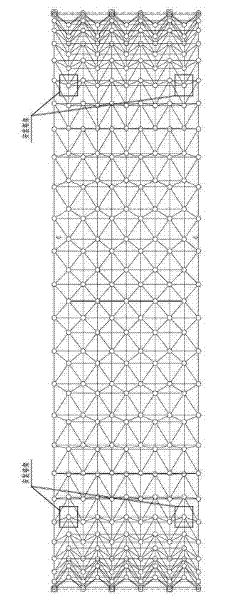

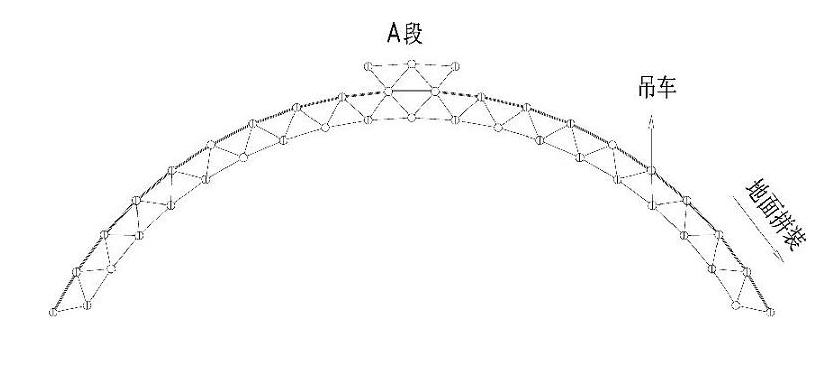

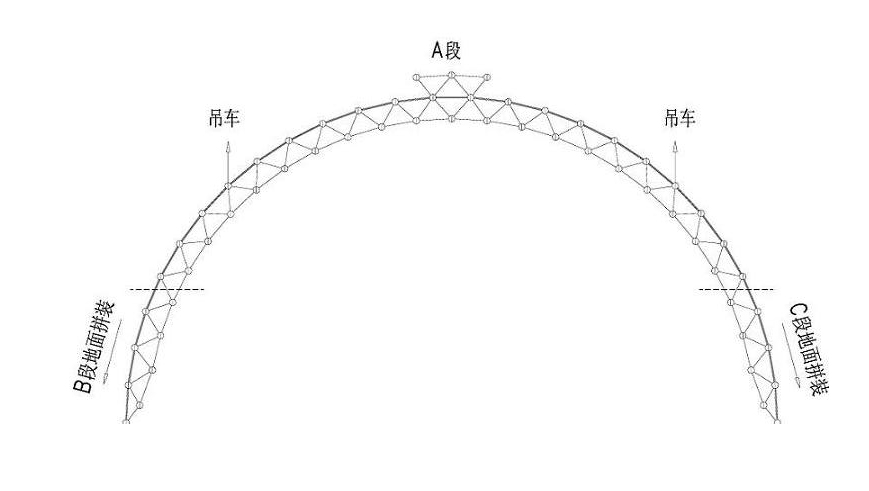

Construction process of ultra-large-span net-frame arch-shaped shed type storage silo

ActiveCN102337785AImprove accuracyShorten the timeLoad-supporting elementsBuilding material handlingFinite element algorithmEngineering

The invention relates to a construction process of an ultra-large-span net-frame arch-shaped shed type storage silo, which is characterized by comprising: obtaining dimensions of node rods of a net frame via a CFD (computational fluid dynamic) numerical wind tunnel computing technology and a finite element algorithm at first according to local weather conditions, the most adverse weather conditions and physical parameters of an arch-shaped shed, i.e. the ball head diameter of each node and geometric parameters of the rods on each node, and preparing a construction drawing, wherein the construction drawing at least comprises the serial number of each node and the number of rods on each node; and dividing construction steps into installation of basic units and installation of overhead cantilever units. Scaffolds are not needed to be erected in a whole house. The invention has the advantages that the time and materials can be saved, and the process is safe and reliable.

Owner:XUZHOU ZM BESTA HEAVY STEEL STRUCTURE

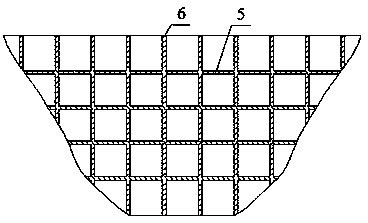

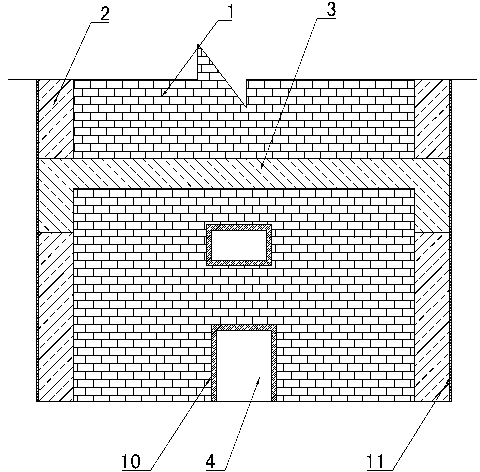

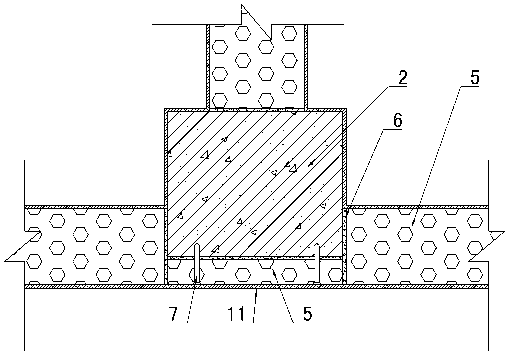

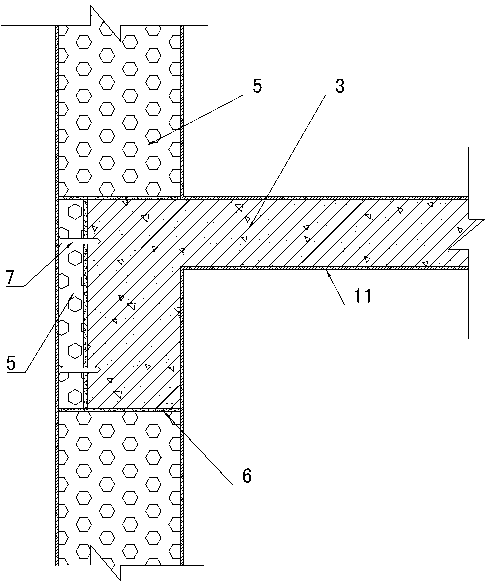

Low-density AAC (autoclaved aerated concrete) precise-masonry self-thermal insulation system and construction method

InactiveCN103074936ASimple structure designSolve thermal insulationWallsClimate change adaptationThermal insulationThin layer

The invention discloses a low-density AAC (autoclaved aerated concrete) precise-masonry self-thermal insulation system and a construction method, and belongs to the field of construction energy saving and structure integration. The system is characterized in that a wall body (1) is built by AAC building blocks (5) of which the density grade is B03-B05 grade; two adjacent AAC building blocks (5) are bonded by a building block binder layer (6); and one layer of stacked AAC building blocks (5) are built on the outer side surface of each column body (2). The construction method for the low-density AAC precise-masonry self-thermal insulation system mainly comprises the following steps of: stirring the building block binder layer (6); building the AAC building blocks (5); bonding an L-shaped bonding piece (8); and plastering thin-layer plaster mortar (11). According to the low-density AAC precise-masonry self-thermal insulation system and the construction method, the thermal insulation, fire prevention and energy saving requirements of a building can be satisfied without a composite thermal insulation layer, and construction working procedures are reduced, thereby being favorable for the engineering construction quality and shortening the days for construction.

Owner:山东高阳建材有限公司

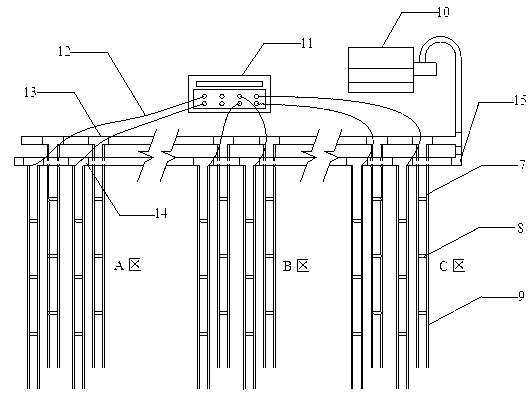

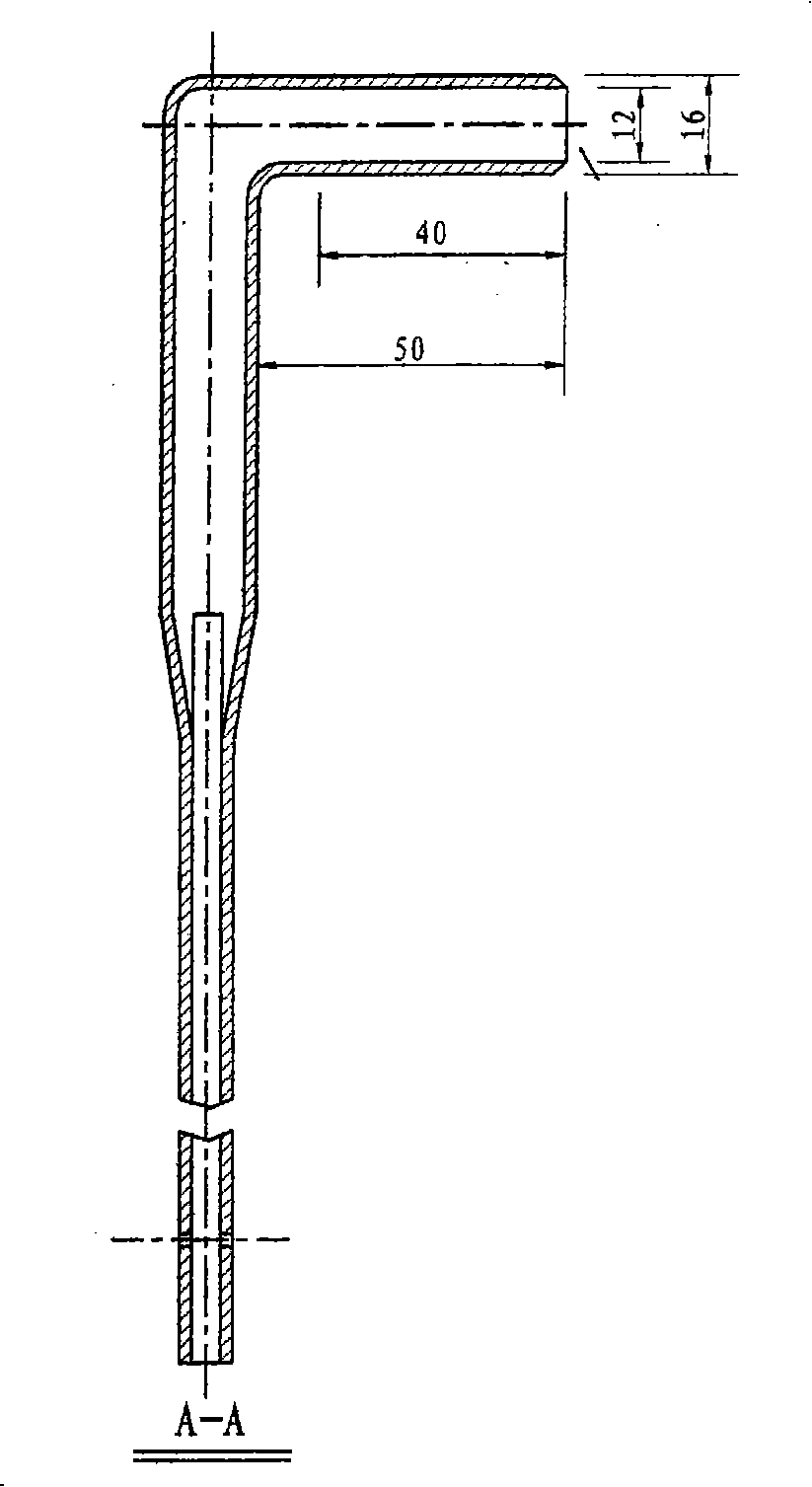

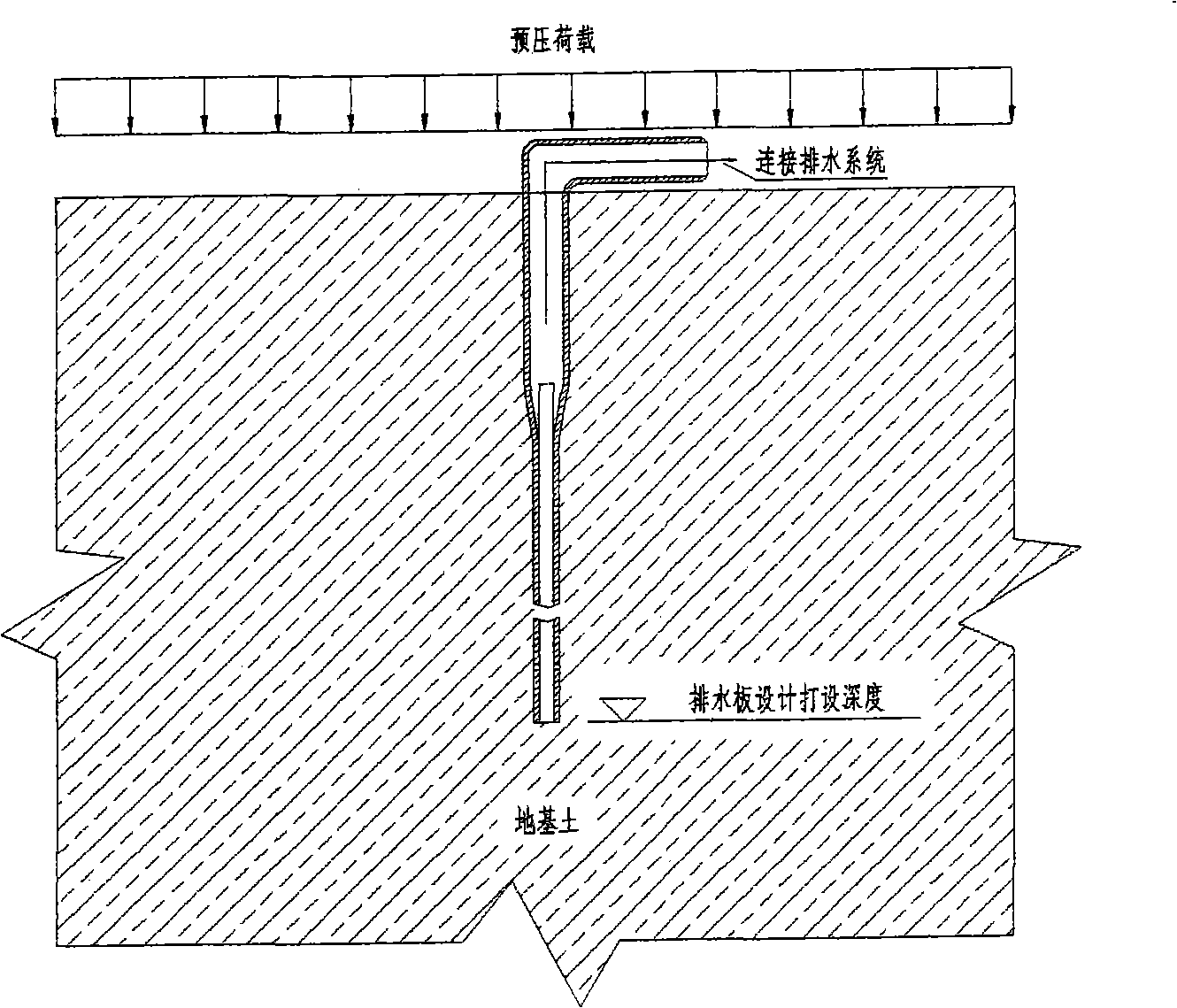

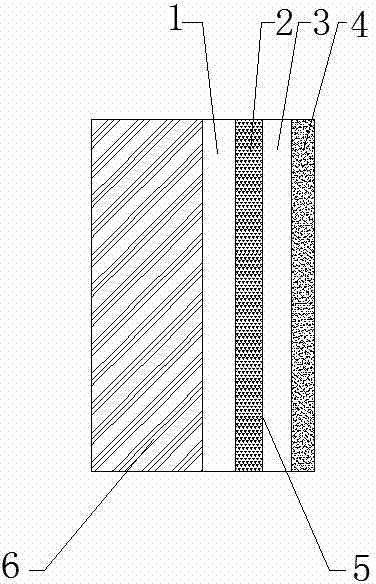

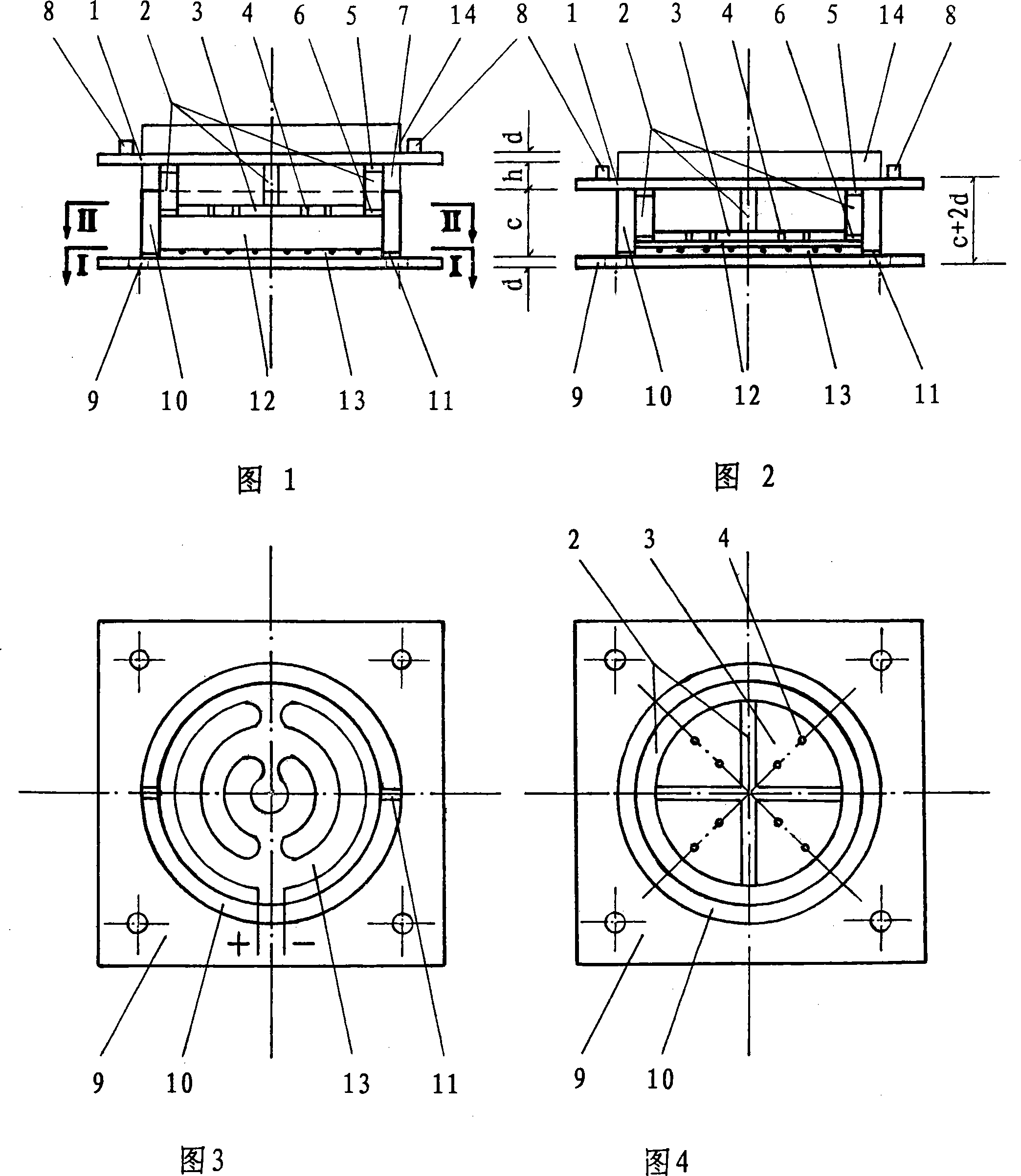

Self-seal vacuum pre-press reinforcing foundation technical method

InactiveCN101349054ASimplify construction proceduresEasy constructionSoil preservationEarth surfaceVacuum pump

The invention relates to a technical method for reinforcing foundation by self-sealing and vacuum prepressing, which adopts a mode of mounting a drainage plate self-sealing device and connecting an air suction and drainage connecting pipe system to discharge pore water in soft soil foundation for reinforcing the foundation; drainage plates and the drainage plate self-sealing device are driven into the foundation needing drainage and reinforcement in rank; and the drainage plate self-sealing device is connected to the air suction and drainage connecting pipe system and then a vacuum pump. The drainage plates and the drainage plate self-sealing device are arrayed according to a matrix and driven to the foundation; the vacuum pump is connected with a main pipe of the air suction and drainage connecting pipe system; the main pipe is connected with a plurality of rows of parallel branched pipes; two sides of the branched pipes are connected with a plurality of connecting branched pipes which are connected with a water and air suction pipe of the air suction and drainage plate self-sealing device. The method saves a plastic sealed film for reinforcing the ground surface, a horizontal drainage undercourse, total filter pipes, a film outgoing device and a film pressing sealed ditch in the common vacuum prepressing, simplifies the construction procedure, has convenient and rapid construction, shortens the construction period, saves mass engineering material, manpower and engineering investment.

Owner:TIANJIN PORT ENG INST LTD OF CCCC FIRST HARBOR ENG

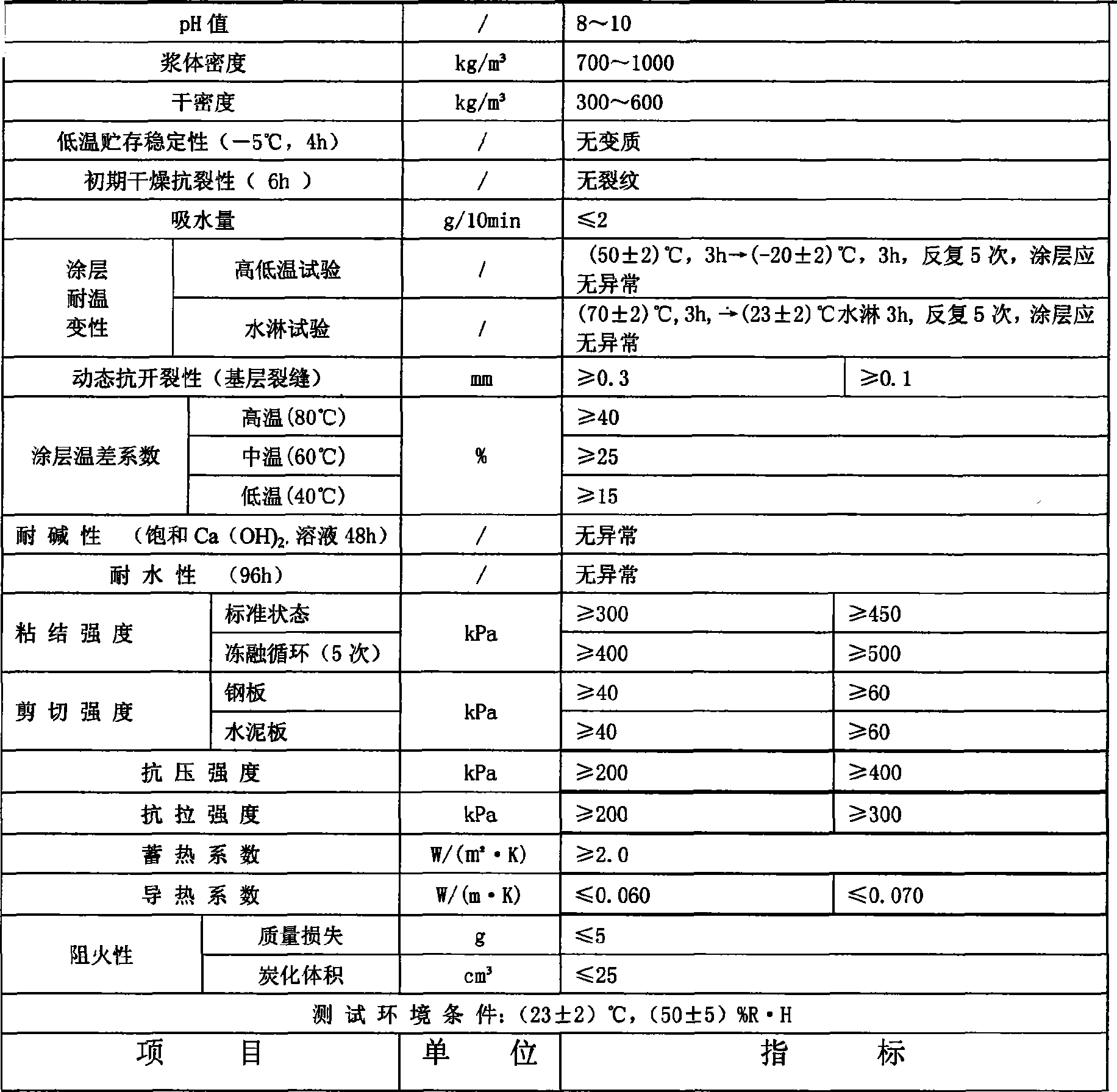

Insulation mortar reflective insulation coating external wall insulation system and construction process thereof

ActiveCN103572845AImprove the protective effectSimplify construction proceduresFilling pastesHeat proofingInsulation layerWeather resistance

The invention discloses an insulation mortar reflective insulation coating external wall insulation system and construction process thereof. The system comprises an insulation layer and a coating layer system, wherein the coating system is composed of a primary coat, a putty layer and a reflective insulation coating decorating face layer. The construction process comprises a preparation stage and a construction stage. The Insulation mortar reflective insulation coating external wall insulation system is low in manufacturing cost and excellent in durability, has good weather fastness, and can meet the use standard on an outer wall in terms of water absorption, impact strength, resistance to freezing, thawing and wear resistance.

Owner:MAANSHAN TIANJINYUN PAINT IND

Installation construction process of bolt net rack cylindrical shell storage bin

ActiveCN102425326AImprove accuracyShorten the timeBuilding roofsBuilding material handlingFinite element algorithmStructural engineering

The invention discloses an installation construction process of a bolt net rack cylindrical shell storage bin, which is characterized by comprising the steps of: firstly, according to local meteorological conditions, obtaining sizes of net rack node rod members by adopting a CFD (Computational Fluid Dynamics) numerical value wind tunnel calculation technology and a finite element algorithm according to most disadvantageous conditions and tunnel physical parameters, namely, drawing a construction drawing by using a bulb diameter of each node and a geometric parameter of the rod members arranged on each node, wherein the construction drawing at least comprises a number of each node and the quantity of rod members of each node; and then dividing the construction step into a starting unit installation and an air overhanging unit installation. Due to no need of erecting an accomplished scaffold, the installation construction process has the characteristics of time and material saving, safety and reliability.

Owner:XUZHOU ZM BESTA HEAVY STEEL STRUCTURE

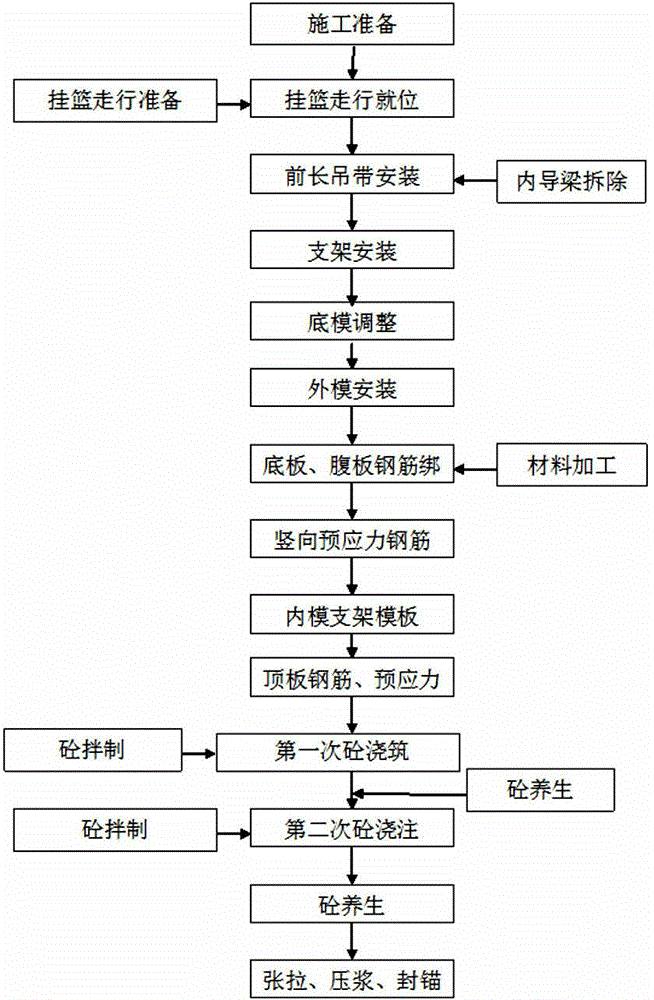

Girder-exchange construction method for existing railway bridge by successively incremeantal launching framework process

ActiveCN101200881AReduce the impact of operationsReduce investmentBridge erection/assemblyBridge strengtheningEngineeringBallast

The invention relates to a girder replacement construction method of the existing railway line bridges, which applies a method of incremental launching framework. The girder replacement construction method is fulfilled according to seven steps: (1) A split slideway is respectively arranged on one side of the existing line and a framework is respectively prefabricated on the split type slideway; (2) Temporary rest piers are arranged under the existing line bridge and used to upbear a track skeleton, and the locking of seamless lines and the installation of a crossarm track are carried out on the two sections of a grider-replaced section; (3) The temporary rest piers are used to upbear the girder body of the existing line, and the bearings under the existing girder are disassembled; (4) the prefabricated framework is connected with the existing girder by a steel stranded wire; (5) A continuous jack is utilized to tow the steel stranded wire to haul the cascaded framework and the existing girder to the position required by the design; (6) The bearing side under the bottom plate of the prefabricated framework is grouted and reinforced; (7) After dropping the track and replenishing ballast, the line is resumed. The present invention has the advantages that the construction is safe and stable, the cost is reduced, the construction procedures are simplified, the construction period is shortened and the engineering cost is saved.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD

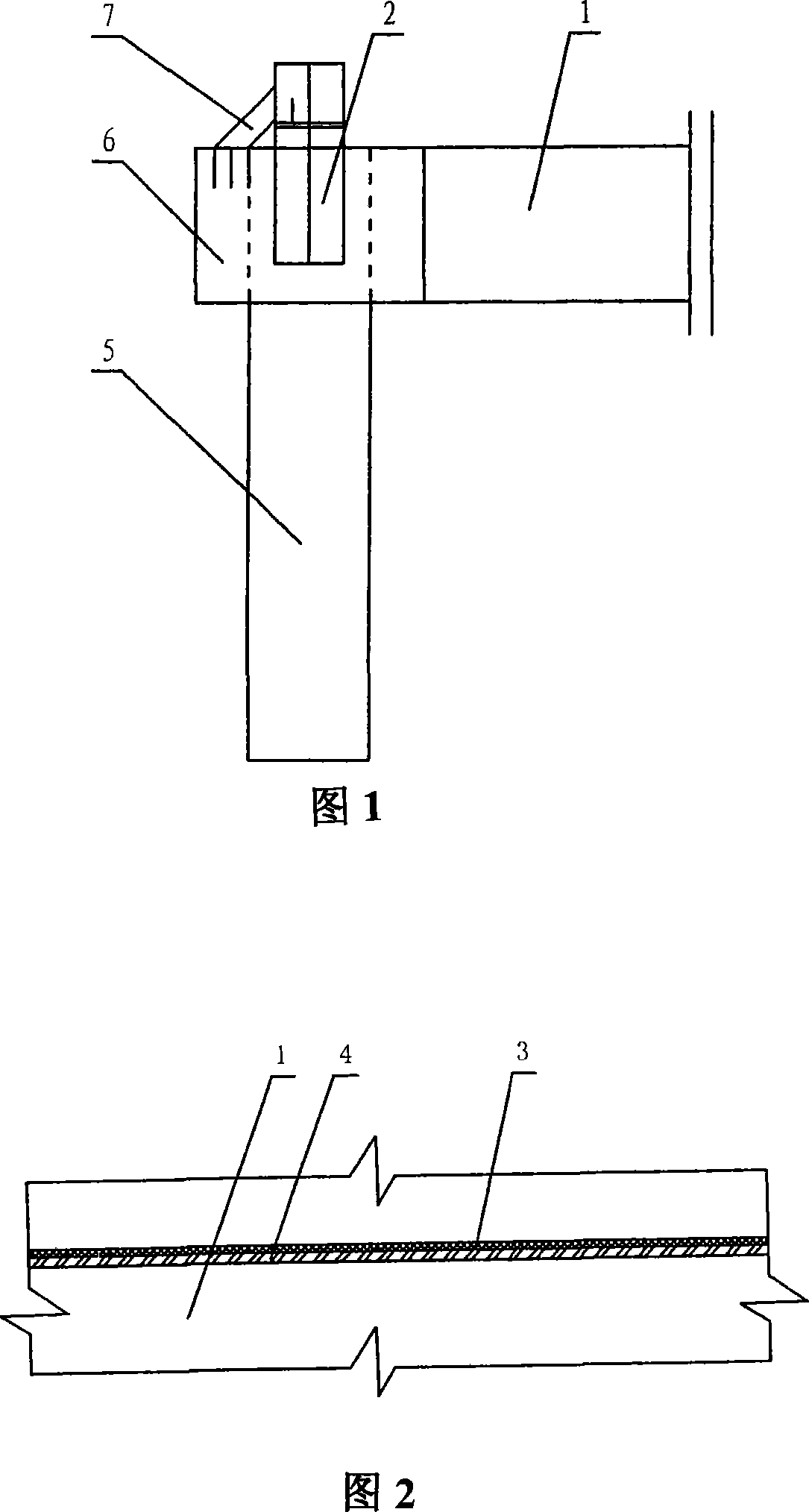

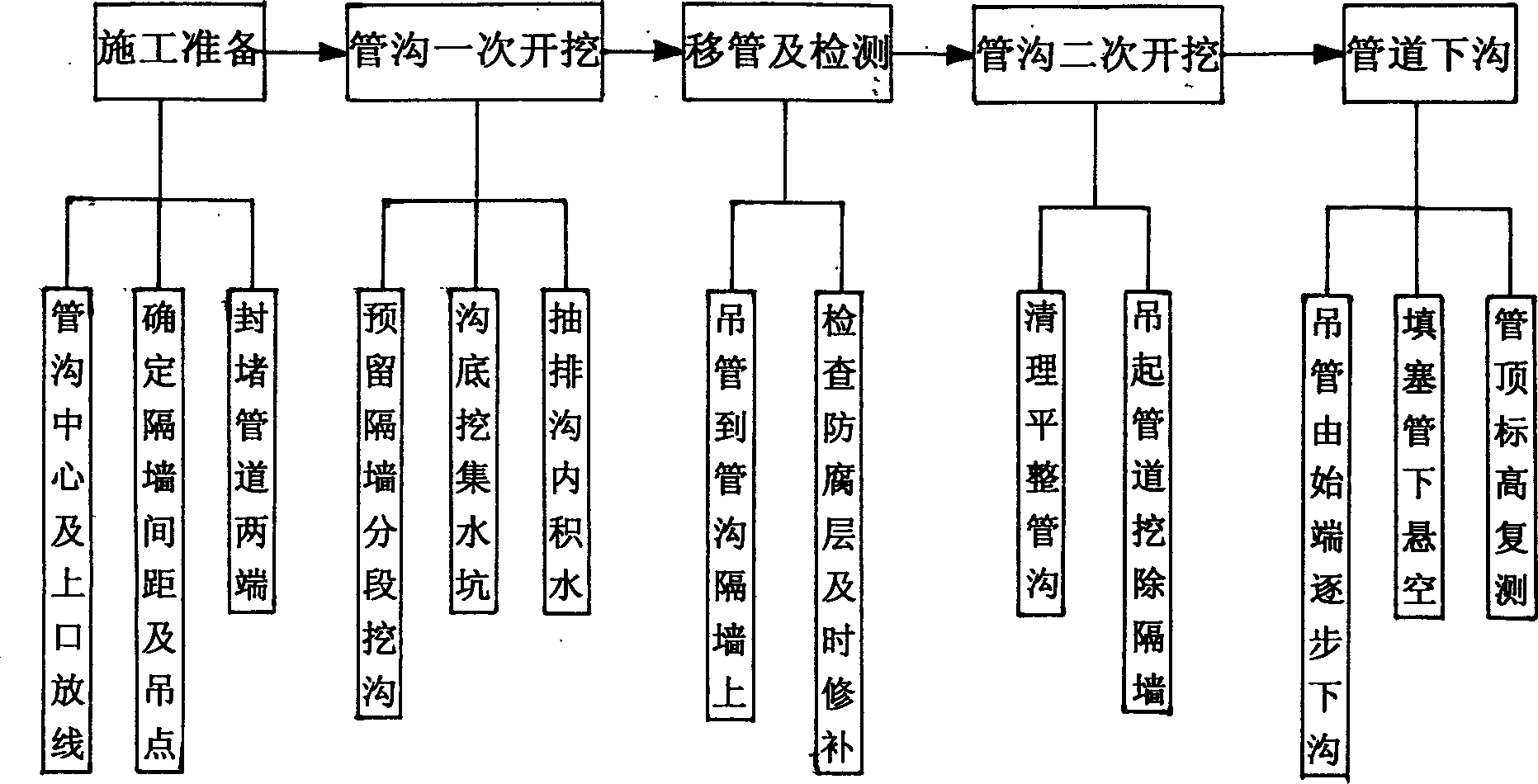

Down-ditch construction method for laying heavy caliber pipeline

InactiveCN1558130AAvoid tipping accidentsGuarantee the quality of workPipe laying and repairDitchPipe layer

The present invention is the construction process of laying wide bore pipe into pipe canal and relates to one important pipeline construction step. The present invention features that during excavating pipe canal, one soil partition wall is preserved in each certain distance; the pipe is first hoisted with two pipe layers and settled on the partition walls, and the initial end of the pipe is lifted before the soil partition wall is dug out with excavator and then settled slowly into the pipe canal; and all the partition walls are dug out successively and the pipes are settled in the pipe canal. The construction process includes the main steps of: preparation, the first pipe canal excavation, shifting pipes and detection, the second pipe canal excavation, and laying the pipes. The main advantages includes using two pipe layers only, low cost, low power consumption, simplified construction process, short construction period, etc.

Owner:NO 3 BRANCH OF SHENGLI PETROCHEM BUILDING CO LTD SHENGLI OIL FIELD

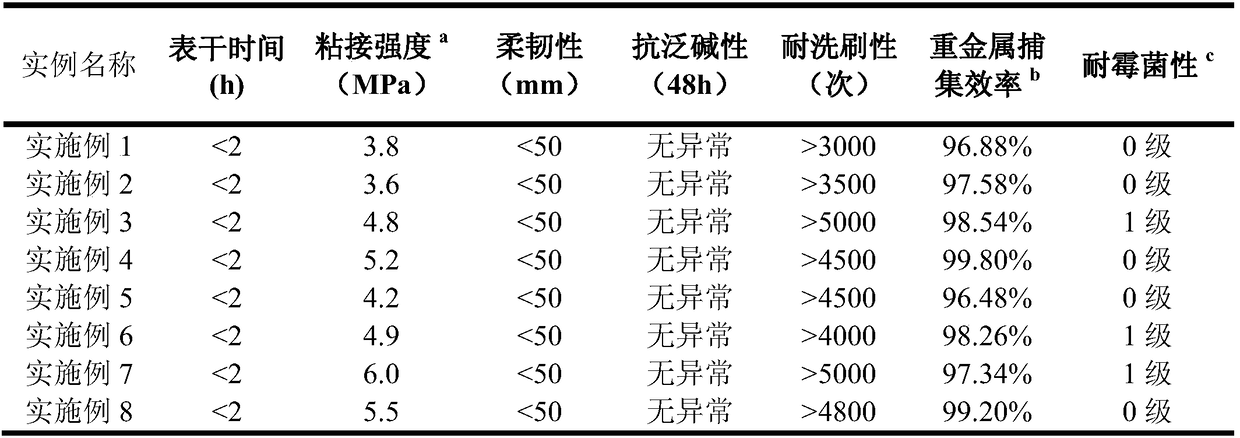

Geopolymer-based mold-proof antibacterial interior wall coating and preparation method thereof

InactiveCN108892978AReduce pollutionGood and long-lasting inhibitory effectAntifouling/underwater paintsPaints with biocidesWater basedBond strength

The invention discloses a geopolymer-based mold-proof antibacterial interior wall coating which is composed of a solid phase S and a liquid phase L, wherein the solid phase S comprises the following components in parts by weight: 10-90 parts of a gel binder, 5-85 parts of pigments and fillers, 0.1-5 parts of a film-forming agent, 0.5-10 parts of an anti-cracking additive and 0.4-5 parts of an anti-settling agent; and the liquid phase L comprises the following components in parts by weight: 5-90 parts of an alkali activator, 0.5-6 parts of a rheological modifier, 0.2-3 parts of an antifoaming agent and 2-90 parts of water. The invention further discloses a preparation method of the geopolymer-based mold-proof antibacterial interior wall coating. The geopolymer-based mold-proof antibacterialinterior wall coating disclosed by the invention realizes the zero-VOC (Volatile Organic Compound) advantage and high-efficiency mold-proof antibacterial functions of the novel water-based inorganicinterior wall coating, and has the advantages of being high in bonding strength with the base plane, excellent in scrubbing resistance, excellent in water resistance and penetration resistance, low inprice and the like, and the mold-proof antibacterial functions have long-term properties.

Owner:浙江航通舟新材料科技股份有限公司

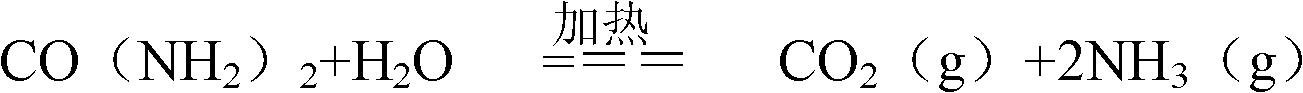

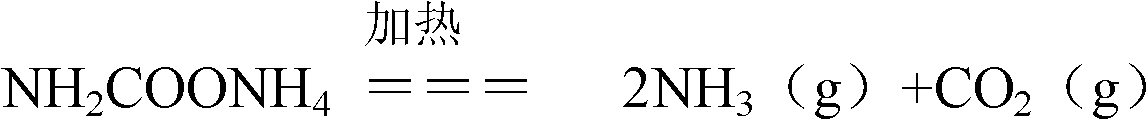

Gas self-production agent, use of the gas self-production agent, and self-produced gas foam acidizing method for oil wells and water wells

InactiveCN102373036ASimplify construction proceduresReduce construction costsCleaning apparatusFluid removalProduct gasAmmonium carbamate

The invention discloses a gas self-production agent, a use of the gas self-production agent, and a self-produced gas foam acidizing method for oil wells and water wells. The gas self-production agent can produce gas in an acid environment or at an oil well bottom temperature. An active ingredient of the gas self-production agent is ammonium carbamate. The gas self-production agent has the advantages of low requirement on gas production conditions, large gas yield, simplification of foam acidizing processes for oil wells and water wells, reduction of a foam acidizing cost, and improvement of acidizing effects.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

Resistance reducing agent

InactiveCN1988053AReduce generationReduce pollutionConductive materialConnection contact member materialGraphiteMoisture

This invention discloses a resistance-reducing agent including the following components in weight portions: conductive graphite 45-55, conductive cement: 5-12, sea-foam: 2-10, retarder: 0.1-1.5, moisture agent: 1-3, moisture: 20-35 and others: 5-15. This invention applies a new formula to prepare a grease resistance agent, which can reduce environment pollution and harm to operating persons.

Owner:SICHUAN SUNLIGHT INTELLIGENT ELECTRIC EQUIP CO LTD

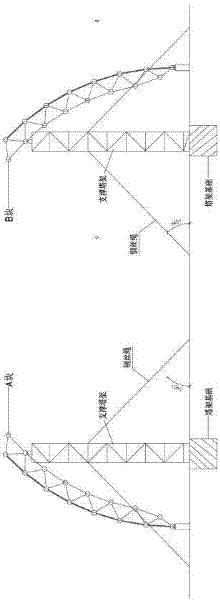

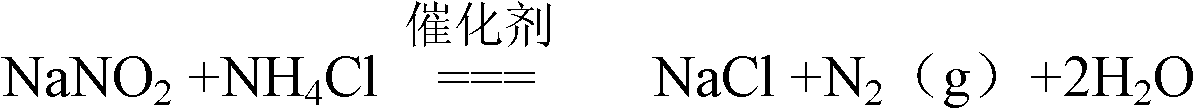

Hanging-basket and bent-cap-support matched integral construction method for side span linear segment of high-pier continuous rigid frame bridge

ActiveCN104790302ASimplify construction proceduresShorten the construction periodBridge erection/assemblyRigid frameRebar

The invention discloses a hanging-basket and bent-cap-support matched integral construction method for a side span linear segment of a high-pier continuous rigid frame bridge. Reinforcing steel bars are bound at a time; pouring is carried out twice; in other words, a section is formed in a pouring mode through a hanging basket in the first time of pouring, and a left solid section is formed in a pouring mode in the second time of pouring. Most of the solid section formed in the second time of pouring is located on a bent cap, and a fraction of the solid section is located on the hanging basket. The hanging-basket and bent-cap-support matched integral construction method has the advantages that the construction procedure can be simplified, the construction period can be saved, and the construction cost can be saved.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

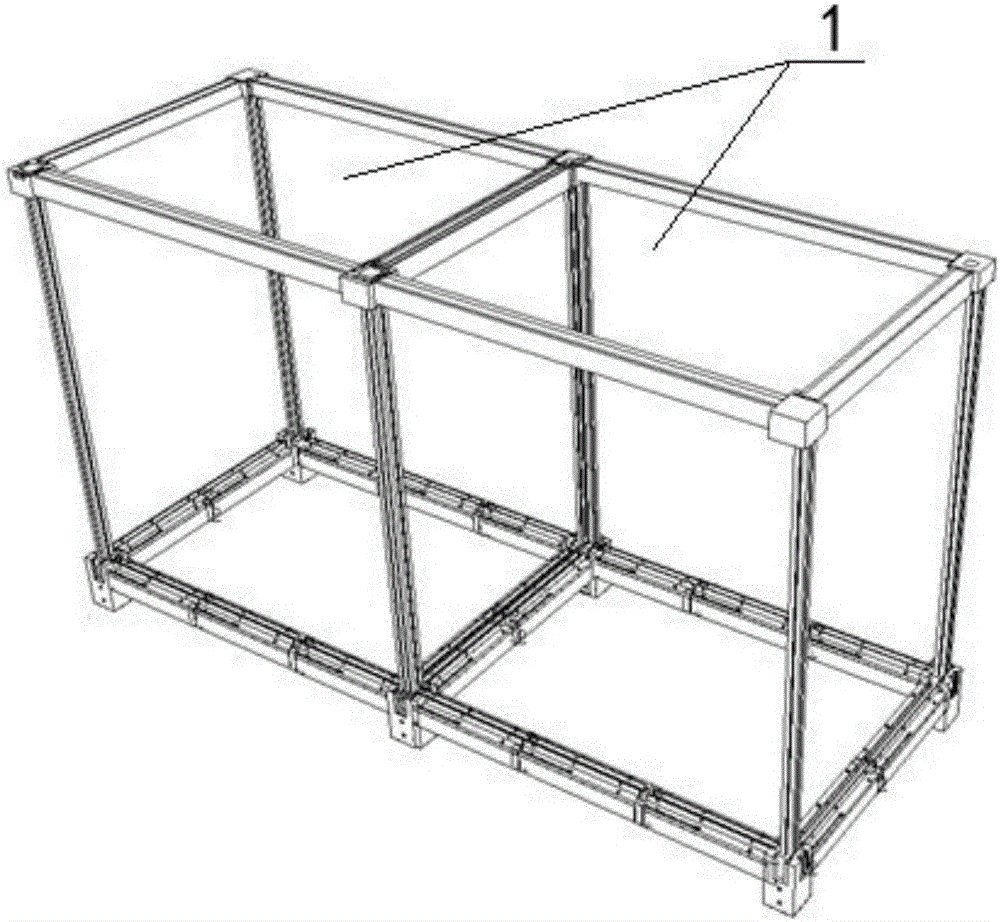

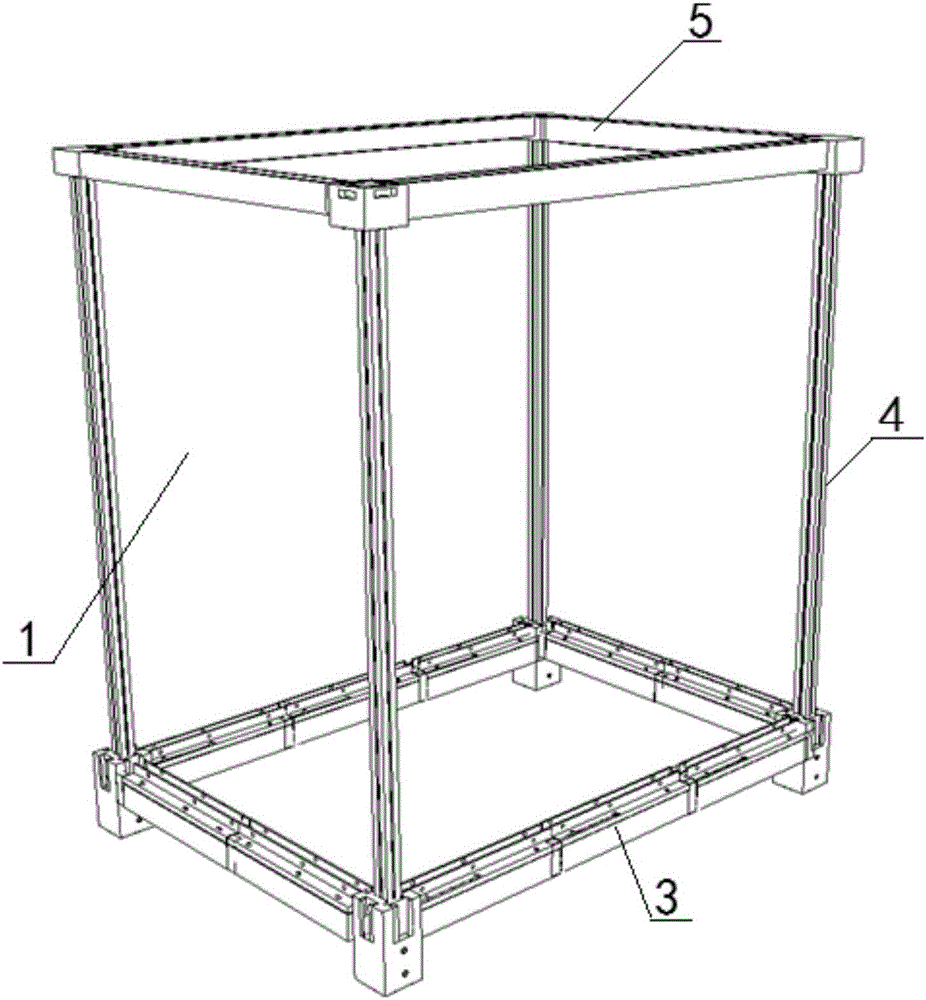

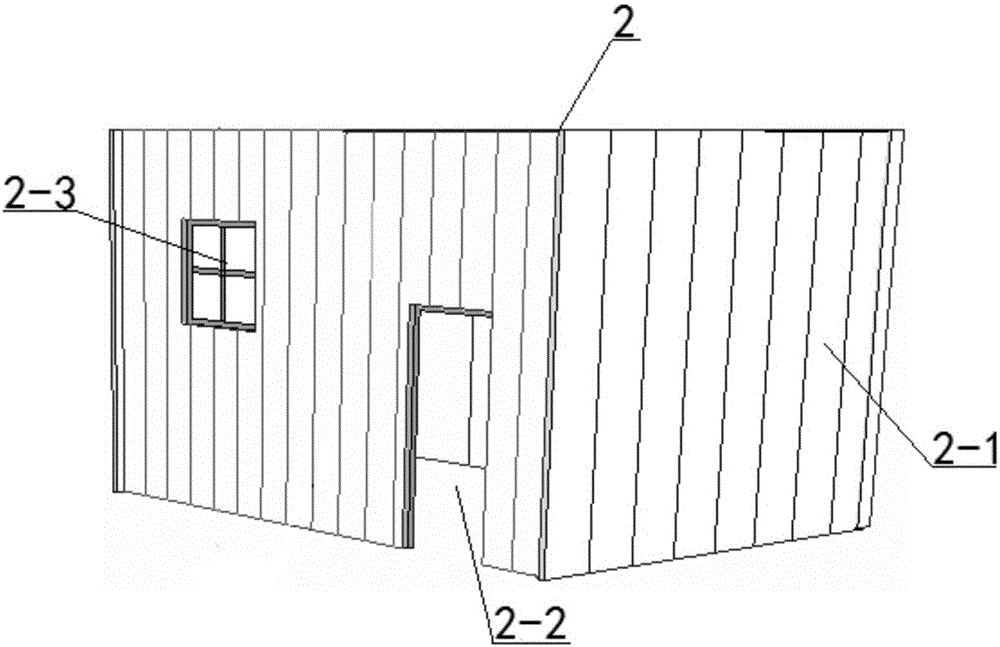

Easy installation type movable plank house with combined basic member

InactiveCN106065666ASimple construction processEasy to installBuilding constructionsMechanical engineering

The invention discloses an easy installation type movable plank house with a combined basic member. The movable plank house comprises at least one movable plank house main body frame, the multiple movable plank house main body frames can be mutually connected, and each movable plank house main body frame is provided with a movable plank house exterior-protected member; each movable plank house main body frame comprises a bottom support member, and each bottom support member is connected with a top support member through four support four-way upright columns; each movable plank house exterior-protected member comprises a side exterior-protected plate and a top exterior-protected plate, and each side exterior-protected plate is also provided with a plank house door and a plank house window; each side exterior-protected plate is arranged to surround the four support four-way upright columns and is connected with the four support four-way upright columns to form an integral body; and each top exterior-protected plate is connected with each top support member to form an integral body. The easy installation type movable plank house has the advantages of firmness, durability, convenient assembling, convenient transport and low manufacturing cost.

Owner:XIAN UNIV OF SCI & TECH

Compound cave making method of open hole of coalbed gas well

InactiveCN102425371AReduce the risk of hole making operations with the naked eyeReduce the risk of caving operationsLiquid/gas jet drillingEngineeringUltimate tensile strength

The invention relates to a compound cave making method of an open hole of a coalbed gas well, which is mainly used for reaming operation or open hole cave making operation of an open hole well section of the coalbed gas well. Hydraulic jet is utilized for destroying a coalbed, thereby reducing the operating strength of a mechanical cave making tool; and then a mechanical tool is further utilized for finishing the coalbed at a cave making section, the size of a cave is expanded to the designed value, and the cave making is continuously performed through the mechanical tool on the basis of hydraulic jet cave making, thereby overcoming the defects and the insufficiencies caused by the single cave making method, meeting the demands of the reaming operation or the cave operation of the open hole well section of the coalbed gas well and achieving the purpose of high-efficient oil and gas production.

Owner:CNPC BOHAI DRILLING ENG

Production process of novel concrete-filled steel tube composite structure

InactiveCN102628305ASolve the shortcomings of difficulty in vibrating and difficult to guarantee the quality of concreteSolve the shortcomings that the quality is difficult to guaranteeStrutsPillarsHigh strength concreteFiber

The invention relates to a production process of a novel concrete-filled steel tube composite structure, comprising the following steps of: (1) mixing self-stressing cement, fiber, superfine admixture, and an additive evenly; (2) adding concrete mixing water to the mixture obtained by step 1 and stirring to produce cement slurry; (3) adding a fine aggregate to the cement slurry obtained by the step 2 and mixing evenly to produce cement mortar slurry; (4) adding a coarse aggregate to the cement mortar slurry obtained by the step 3 and mixing evenly to produce fiber self-stressing self-compacting high-strength concrete; and (5) pouring the fiber self-stressing self-compacting high-strength concrete obtained by the step 4 into a steel pipe and allowing the concrete set and stick to the steel pipe to form a steel tube fiber self-stressing self-compacting high-strength concrete composite structure. The production process provided by the invention has the advantages that: tensile strength, bending strength, toughness, impact resistance and fatigue resistance of concrete can be improved, ductility of components can be improved, long-term performance degradation of the components can be effectively reduced, construction procedures can be simplified, construction period can be shortened, and engineering cost can be significantly lowered.

Owner:WUHAN UNIV

Method for coating and sealing fracture of bed rock in uncovered heavy consolidation grouting

InactiveCN103046513ASmall amount of workReduce distractionsMarine site engineeringWater leakageChisel

The invention discloses a method for coating and sealing a fracture of a bed rock in uncovered heavy consolidation grouting. The method comprises the steps of: firstly cleaning to remove impurities in the fracture of a rock body after the evenness of a base rock body to be grouted reaches to a design requirement; then coating a cement base waterproof material on the fracture of the rock body after keeping the surface of the rock body wet for 1-2 hours; checking an appearance effect of the coating layer after the final setting time of the cement base waterproof material arrives and coating the cement base waterproof material again on the places with empty holes or fractures; and then performing pressurized-water check, marking the fractures of the rock body with water seepage and water emission, and coating the cement base waterproof material again on the fractures of the rock body until the pressurized-water check shows that the fractures of the rock body have no water leakage. The method for coating and sealing the fracture of the bed rock in the uncovered heavy consolidation grouting, disclosed by the invention, not only overcomes the disadvantages of convenient fracture processing ways such as concrete sealing, spraying thin layer structure sealing, chisel groove and caulking sealing, and bare rock without sealing, and realizes a relative good consolidation grouting effect, but also has the characteristics of being convenient and rapid in construction, low in interference, economic, safe and reliable.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

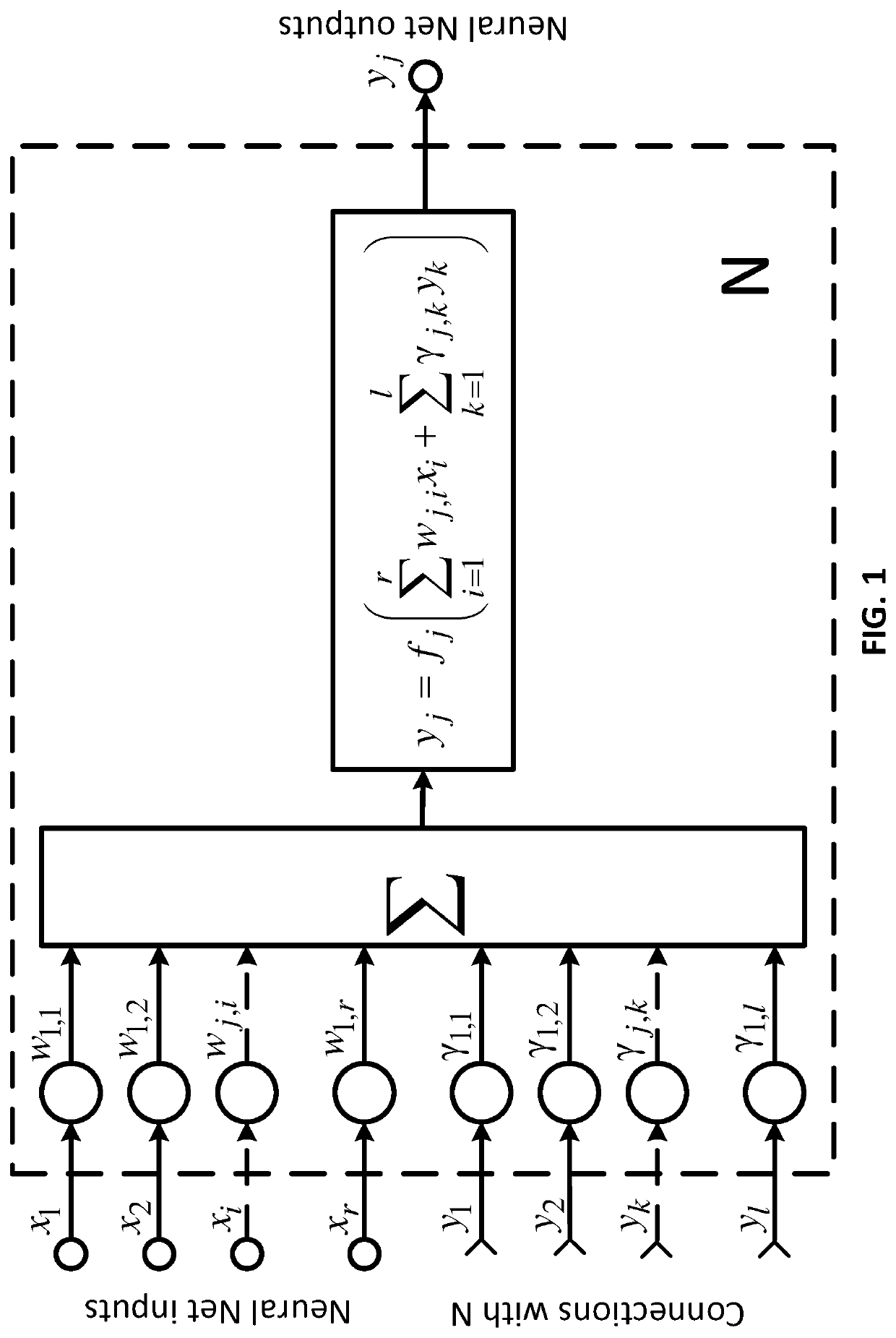

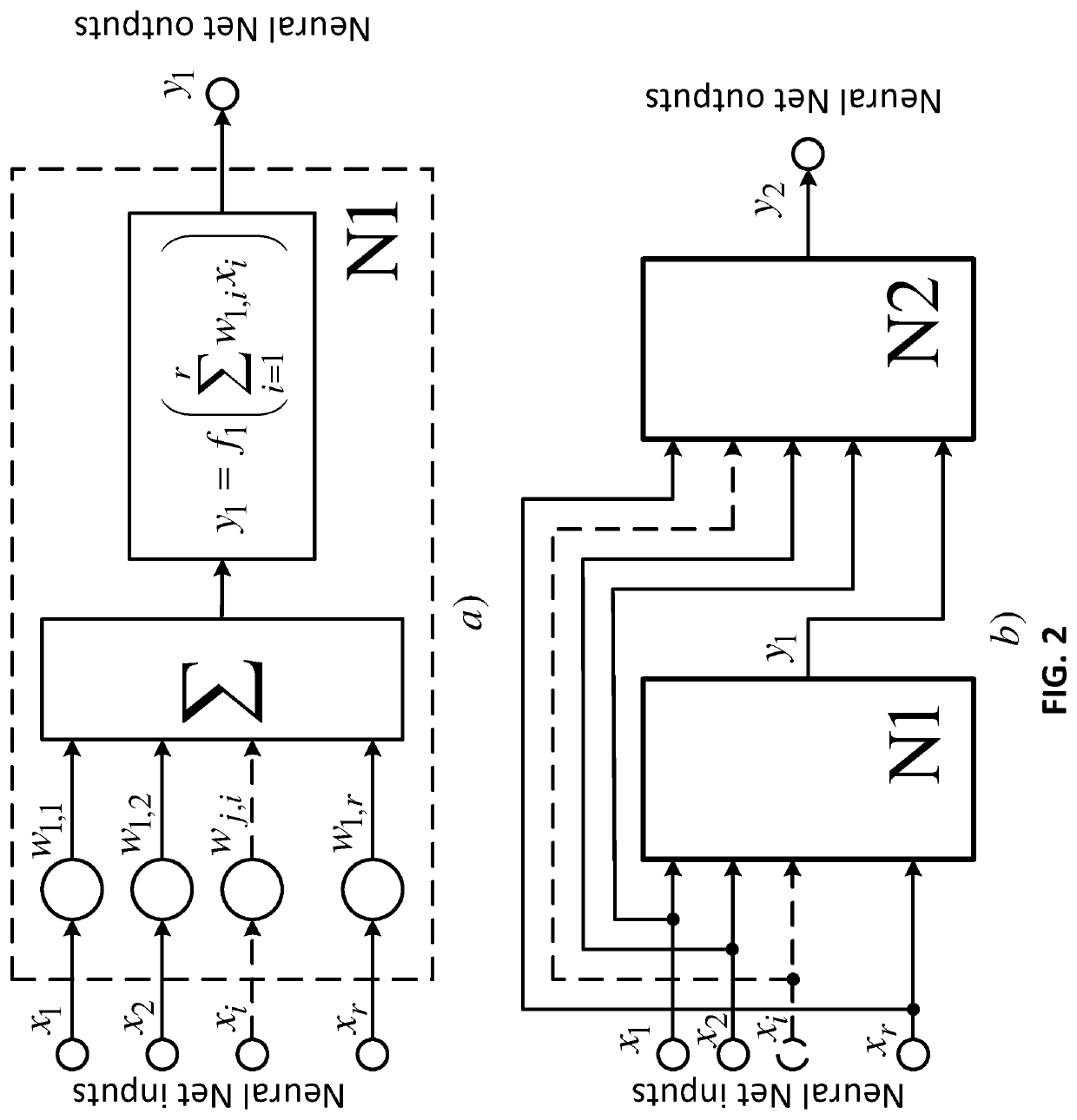

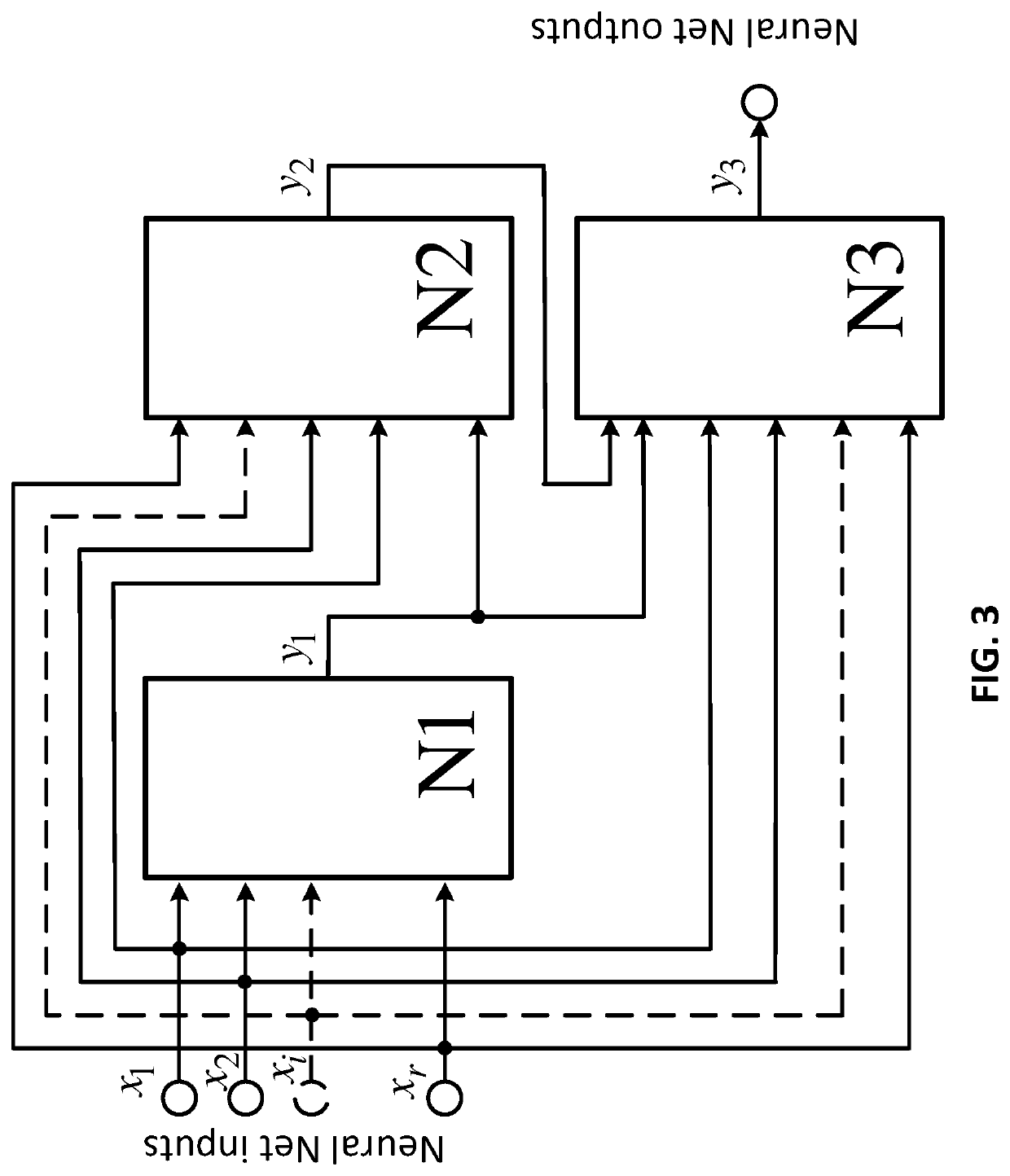

Method for training and self-organization of a neural network

ActiveUS10783433B1Improve performanceShorten operation timeMachine learningPhysical realisationActivation functionEngineering

Method of training a neural network, including receiving sets of digital attributes representing multidimensional regression at inputs; expanding the network by adding neurons and defining their activation functions and interconnections; any neuron of the neural network is capable of being directly connected to any other neuron; (i) when a training speed falls below predefined threshold, and accuracy does not improve, identifying a neuron with highest error value; (ii) adding a neuron directly between the identified neuron and a corresponding output; (iii) setting only a connection coefficient between the added neuron and the identified neuron to zero before it is modified by the training, while other coefficients of the added neuron are set the same as coefficients of the identified neuron, before they are modified. After at least one iteration, either (iv) finishing the training of the neural network or (v) continuing to train the network to reach a predefined depth.

Owner:BELL INTEGRATOR INC

Method for controlling crack of super-long wall body

InactiveCN101608476AThe mechanism of action is clearConcise construction proceduresWallsBuilding material handlingSteel platesWall plate

The invention relates to a method for controlling a crack of a super-long wall body. The method is characterized by comprising the following steps: the super-long wall body is vertically divided by a thin steel plate along the longer inner core concrete of the wall; then a water stop steel plate is arranged on the axial position vertical to a separation steel plate; the separation steel plate divides the water stop steel plate into two parts and leads the two parts to be vertical to each other; and the separation steel plate and the water stop steel plate are positioned between meshes reinforcement at two sides of the wall body, and are bound and fixed with the meshes reinforcement. Compared with the prior art, the method for controlling the crack of the super-long wall body has simple and clear construction procedure, is advantageous to reduction of shrinkage stress of the wall body, can effectively play a role in controlling the crack matched with prestressed reinforcement, can be applied to any wall body structure requiring crack control, in particular to construction of the wall body of an underground garage, the side wall plates of overground and underground artificial channels, a super-long large water pool, side wall of a sewage treating pond and a retaining wall.

Owner:NINGBO CONSTR +2

Sedimentation support for bridge

InactiveCN101250850ANo need to expand the disposal areaRestoration Flatness IndexBridge structural detailsCompression deviceEngineering

The invention relates to a bridge settlement support, which comprises a product support, further comprises an upper settlement compression device which is located on the bottom portion of the product support, the device comprises an upper settlement body and a lower bottom basin, the upper settlement body comprises a top plate, an inner support plate and a middle carrier plate, the top plate is located at the lever direction, the middle carrier plate is fixed on the lower portion of the top plate and is parallel to the top plate through the inner support plate, the middle carrier plate is equipped with a plurality of rheological channels, the inner support plate comprises a ring plate and a baffle which is fixed in the ring plate to form a plurality of cavities, and the upper portion of the ring plate is equipped with a plurality of vent holes. The lower bottom basin comprises a bottom plate and an outer support plate which is fixed on the upper portion of the bottom plate, an overflow orifice is arranged between the bottom plate and the outer support plate, the outer support plate is a ring cylinder which is tightly sleeved on the outer side of the inner support plate, an electric heating disk is laid on the bottom plate, and a compression body is filled between the electric heating disk and the middle carrier plate. The bridge settlement support has the beneficial effects that the disease of bumping at bridge-head is effectively eliminated through that the self settlement drives the floor elevation reduce.

Owner:郝贤成

Protection mortar specially used on building insulating layer and preparing method thereof

InactiveCN101234870AHigh impact strengthSimplify construction proceduresSolid waste managementFiberCrack resistance

The invention relates to protection mortar specially used in heat preservation layer in building and a preparation method. The protection mortar is a dry mixed powder somatotype mortar or ready-mixed somatotype mortar. The weight portions of each component is 4-30 portions of short steel fiber, 10-25 portions of powder material, 0.5-8 portions of water retaining agent 5-35 portions of aggregate, 0.5-30 portions of polymer cement modification material, 10-30 portions of water and 10-30 portions of cement. The protection mortar not only simplifies the operation process, but also has the advantages of strong impact resistance, low press-breaking rate, strong durability and excellent crack resistance.

Owner:CANADA CARA INSULATION TECH

High-density glass fiber board and production method thereof

The invention relates to a high-density glass fiber board and a production method thereof which are used for reinforcing and protecting surface layers of soft heat-insulating materials of shipboard cabins and belong to the technical field of inorganic materials. The preparation method comprises the following steps of: preparing alkali-free glass fibers into an alkali-free glass fiber blanket; and taking a bonding agent, a thickening agent and a water repellent agent to prepare a bonding agent; centrifugally drying, rolling, compounding and setting alkali-free glass fiber cloth and the alkali-free glass fiber blanket to obtain the high-density glass fiber board. The high-density glass fiber board is formed by needling continuous fibers, so that the fiber blanket has a three-dimensional network structure and has strong tensile strength; and in addition, the bonding agent is used for compressing and setting, so that the strength of the product can be greatly improved. After the surface is impregnated with the alkali-free glass fiber cloth and is integrally formed with a fiber board, the product has functions of reinforcing boards and fireproof boards; and a heat insulating layer is integrated with a protecting layer, so that the construction procedure is simplified and the construction cost of projects is reduced.

Owner:无锡市明江保温材料有限公司

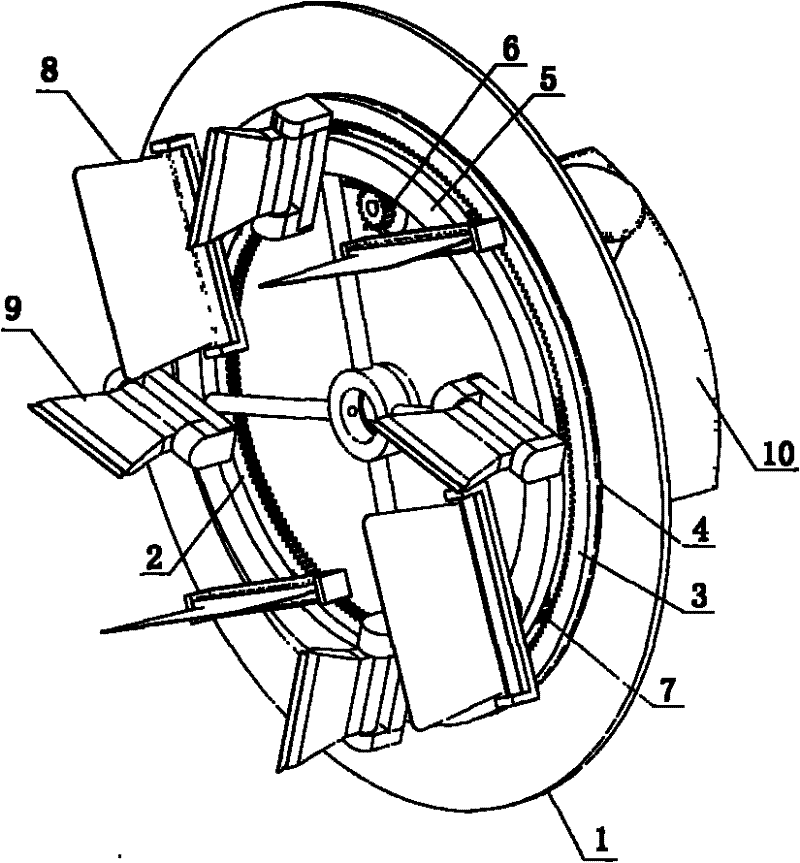

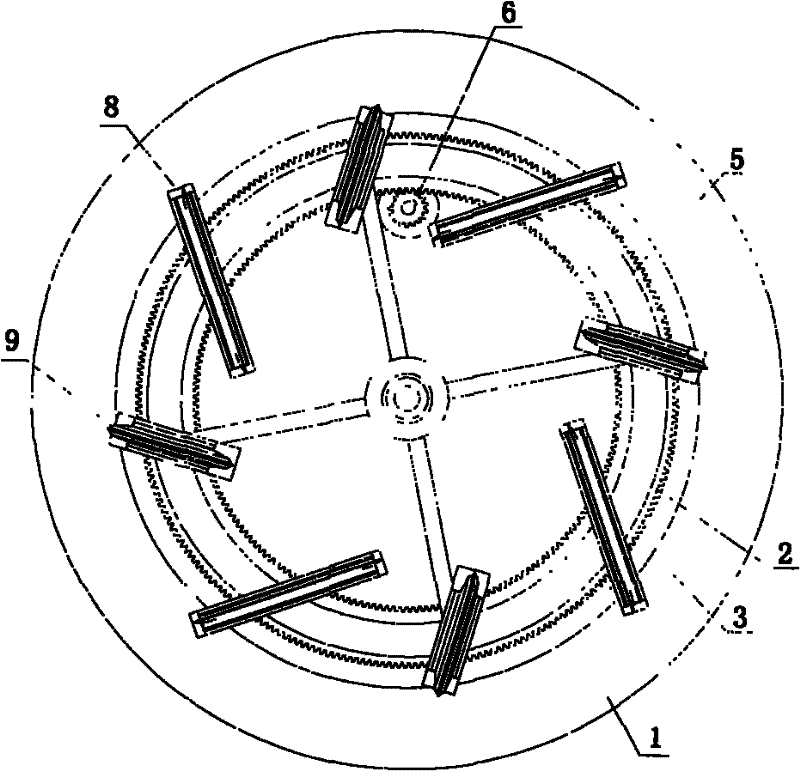

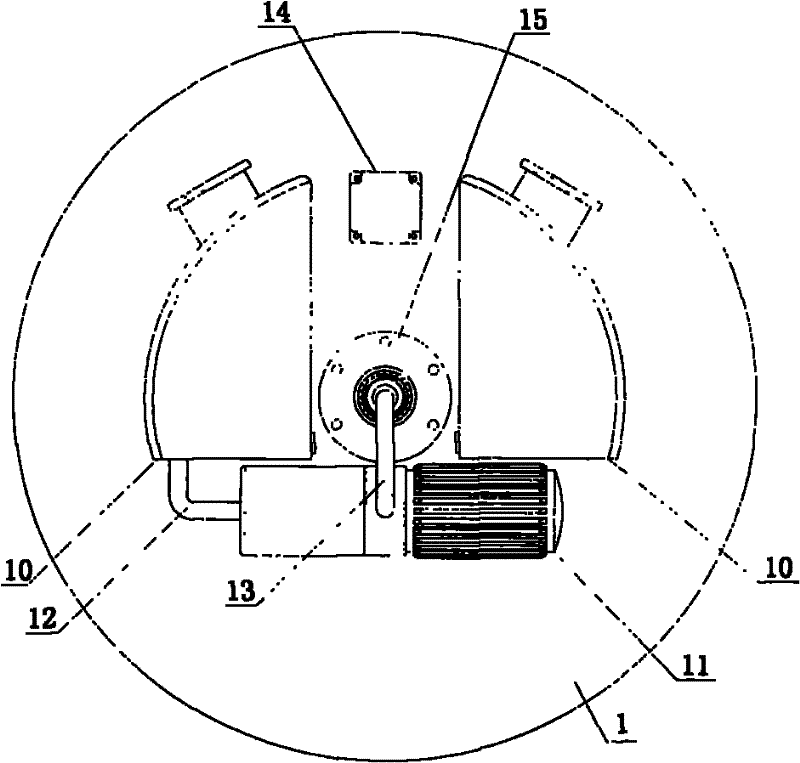

Automatic wall-scraping device

The invention discloses an automatic wall-scraping device, which can be used to scrape and plaster putty or mortar on a wall surface continuously and uniformly and comprises a bearing mounting plate (1), a driving internal toothed ring (2), a driven internal toothed ring (3), a toothed ring fixing wheel disc (4), a fly-cutter mounting wheel disc (5), a motor-driven gear (6), a direction adjusting planetary gear (7), a scraping and plastering fly cutter (8), a feeding fly cutter (9), a slurry box (10), a feeding pump (11), a suction pipe (12), a discharge pipe (13), a driving motor (14) and a carrier bearing body (15), wherein the feeding fly cutter and the scraping and plastering fly cutter are used for compressing the wall surface at an inclined angle; and when the wall-scraping device is rotated integrally, the feeding fly cutter is used for conveying and initially plastering putty in advance, and then the scraping and plastering fly cutter is used for plastering the putty uniformly and quickly; and in this manner, multiple fly cutters are operated continuously to scrape and plaster the putty on the wall surface uniformly at high speed. After the automatic wall-scraping device is mounted on an automatic bearing platform, the wall-scraping device can do the rectilinear motion along the wall surface, adjust the angle of the cutters, and perform feeding, scraping and plastering automatically, thereby realizing the full-automatic operation in the wall-scraping process.

Owner:朱建彬

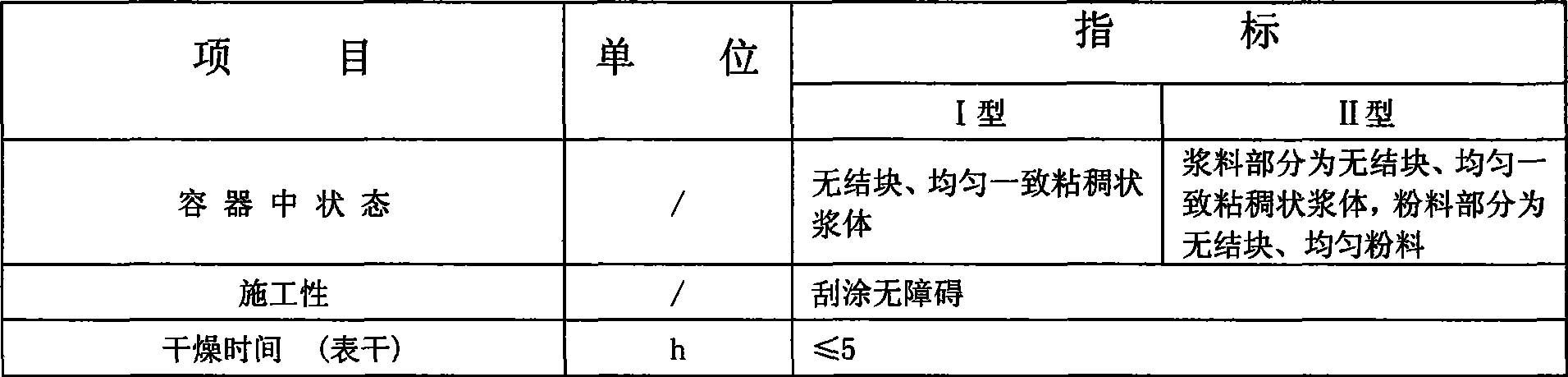

Microhollow super-fibre heat insulation coatings for building insulation and method of use thereof

InactiveCN101381546ACreate pollutionHealth hazardFireproof paintsCovering/liningsNoise removalThermal coefficient

The invention provides a micro hollow fiber thermal insulating coating for buildings and an application method thereof. The micro hollow fiber thermal insulating coating for buildings is divided into a I-type single-component micro hollow fiber thermal insulating coating for buildings and a II-type double-component micro hollow fiber thermal insulating coating for buildings, and is used as an exterior wall thermal insulating coating or used to pipes and other various places needing coating the thermal insulating coating. The coating is added with super hollow fibers and aramid fibers with high-temperature resistance, acid and alkali resistance and light weight, so that the coating has the advantages of low thermal coefficient and heat storage coefficient, obvious heat retaining effect, nontoxic formula, environmental protection, excellent fire resistance, super-strong chemical stability, high cohesional strength, noise removal, high cost performance, long service life, wide application, simple and easy construction, good effect, labor and physical resource conservation, and obvious economic and environment-friendly benefits.

Owner:FUJIAN OUNUO PAINT TECH

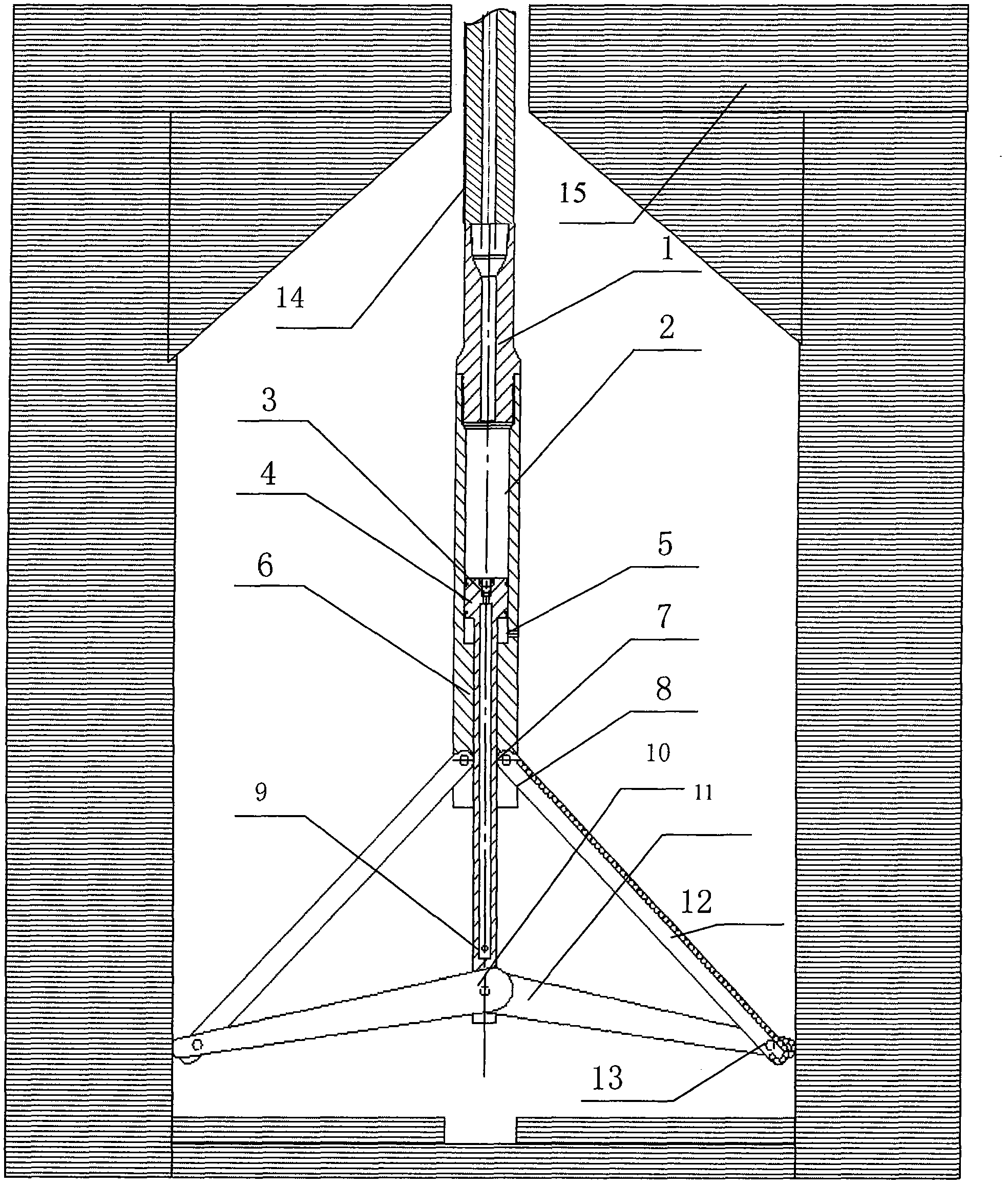

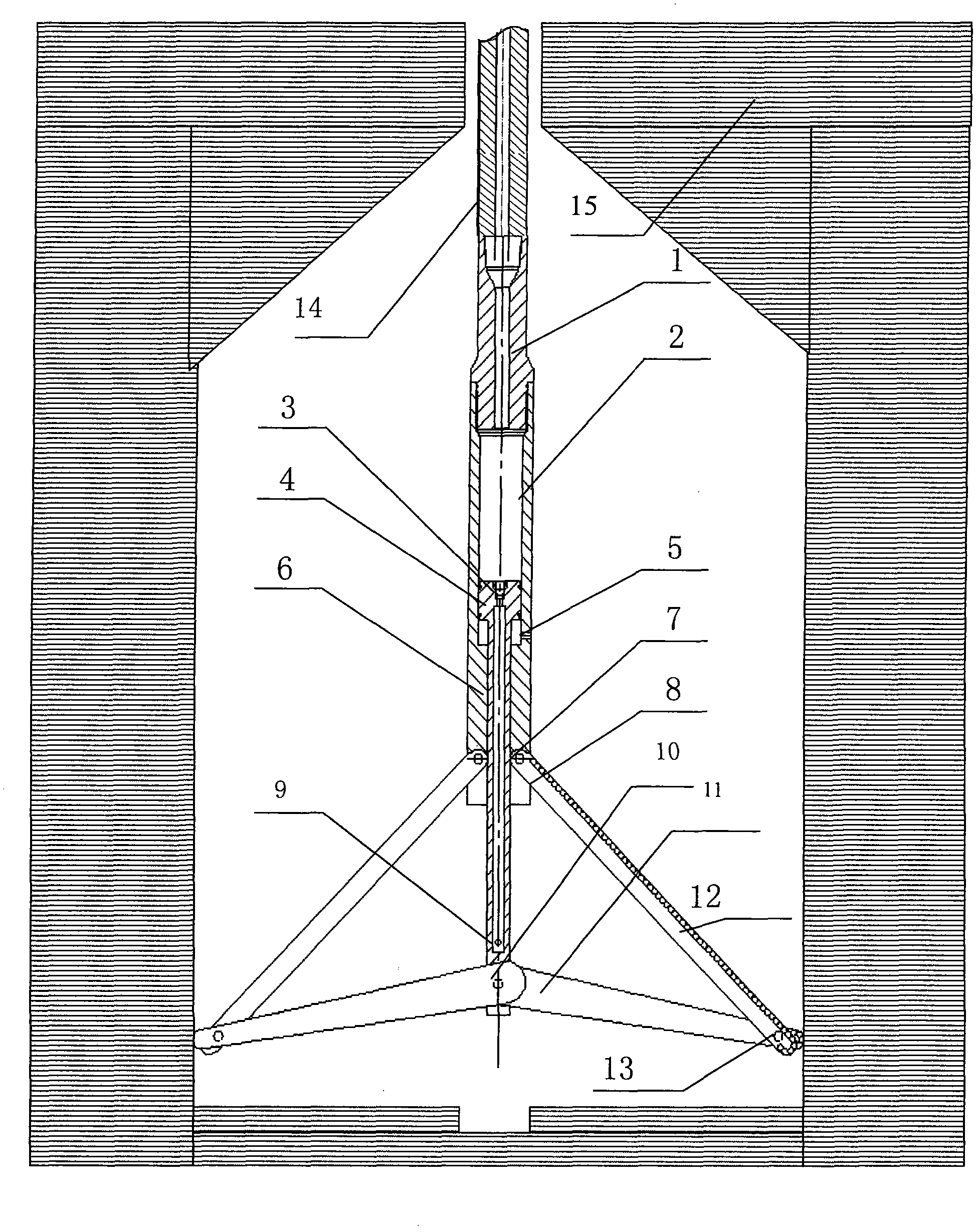

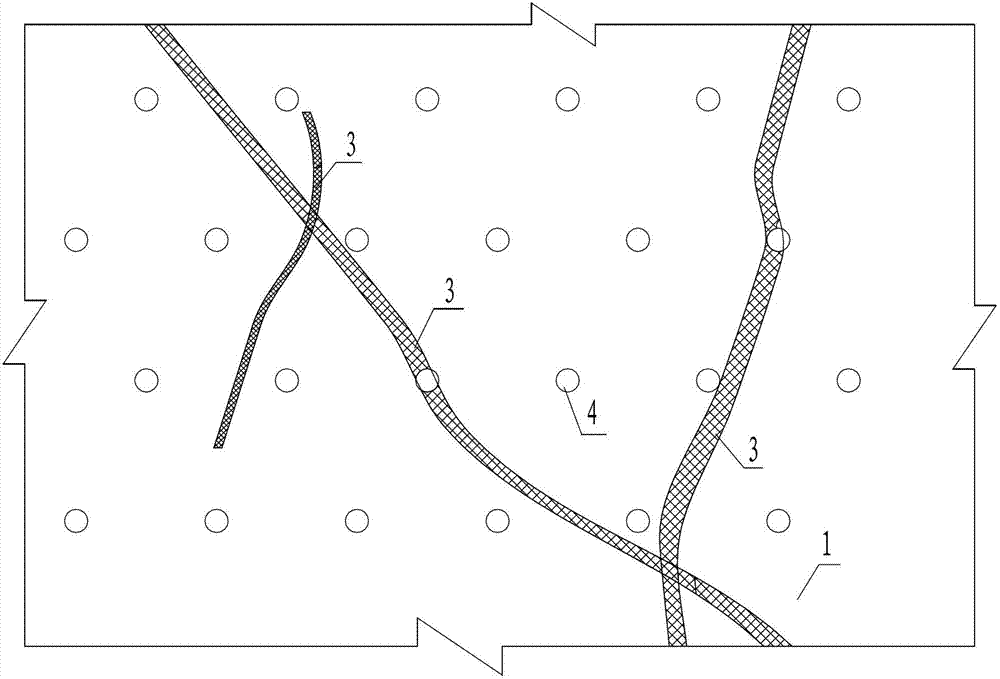

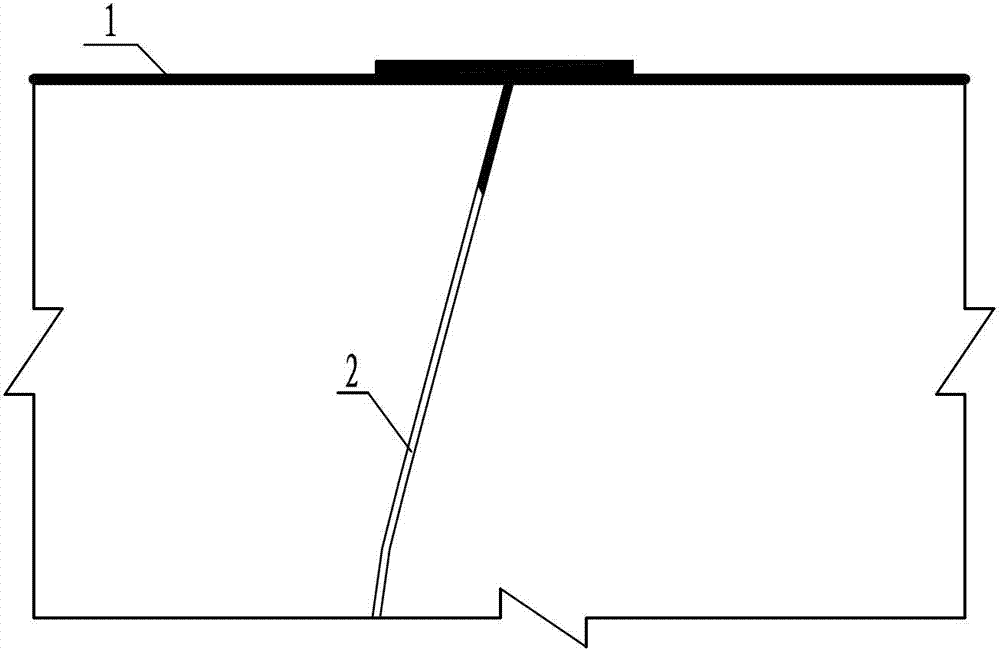

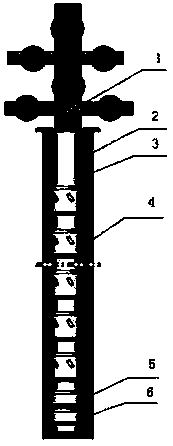

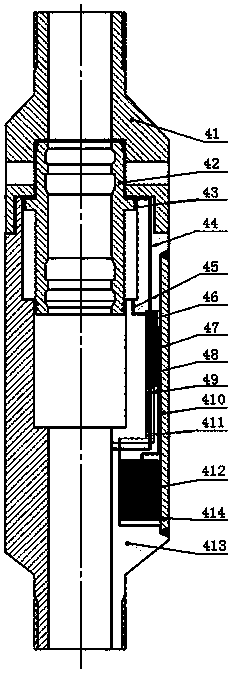

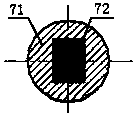

Intelligent well cementation slide sleeve separate-layer fracturing transformation process pipe column without stage limitation

ActiveCN103696748ASimplify construction proceduresShorten the construction periodFluid removalWell/borehole valve arrangementsWell cementingUltimate tensile strength

The invention discloses an intelligent well cementation slide sleeve separate-layer fracturing transformation process pipe column without stage limitation. The pipe column is designed for realizing the separate layer transformation of a straight well of an oil-gas well without stage limitation and meeting the process requirements of multi-stage fracturing transformation of oil-gas fields, the pipe column is arranged in a cement ring, the upper end of the pipe column is connected with a well opening, the pipe column consists of multi-stage intelligent well cementation slide sleeves, a floating hoop and a floating shoe, the multi-stage intelligent well cementation slide sleeves are connected through a sleeve, and the floating hoop and the floating shoe are arranged at the tail end of the pipe column. A piston is arranged in the intelligent well cementation slide sleeve cavity, an upper tube body is provided with a radial fracturing end opening, and a hydraulic pipeline for communicating a two-position four-way electromagnetic valve, a battery, a wireless sensing receiving device, an antenna, a water tank, an upper cavity of the tube body and a lower cavity of the tube body is buried in a groove formed in the tube wall of the lower tube body. The pipe column has the advantages that the separate-layer fracturing transformation without stage limitation can be realized, the construction period can be greatly shortened, the cost is saved, the international products can be replaced, the drilling work intensity can be reduced, electronic balls can be directly thrown for opening the first layer well cementation slide sleeve, the perforation is not needed, after the fracturing completion, all slide sleeves can be opened through ball throwing, the full through diameter can be realized, and the drilling and grinding well control risk can be reduced.

Owner:PETROCHINA CO LTD

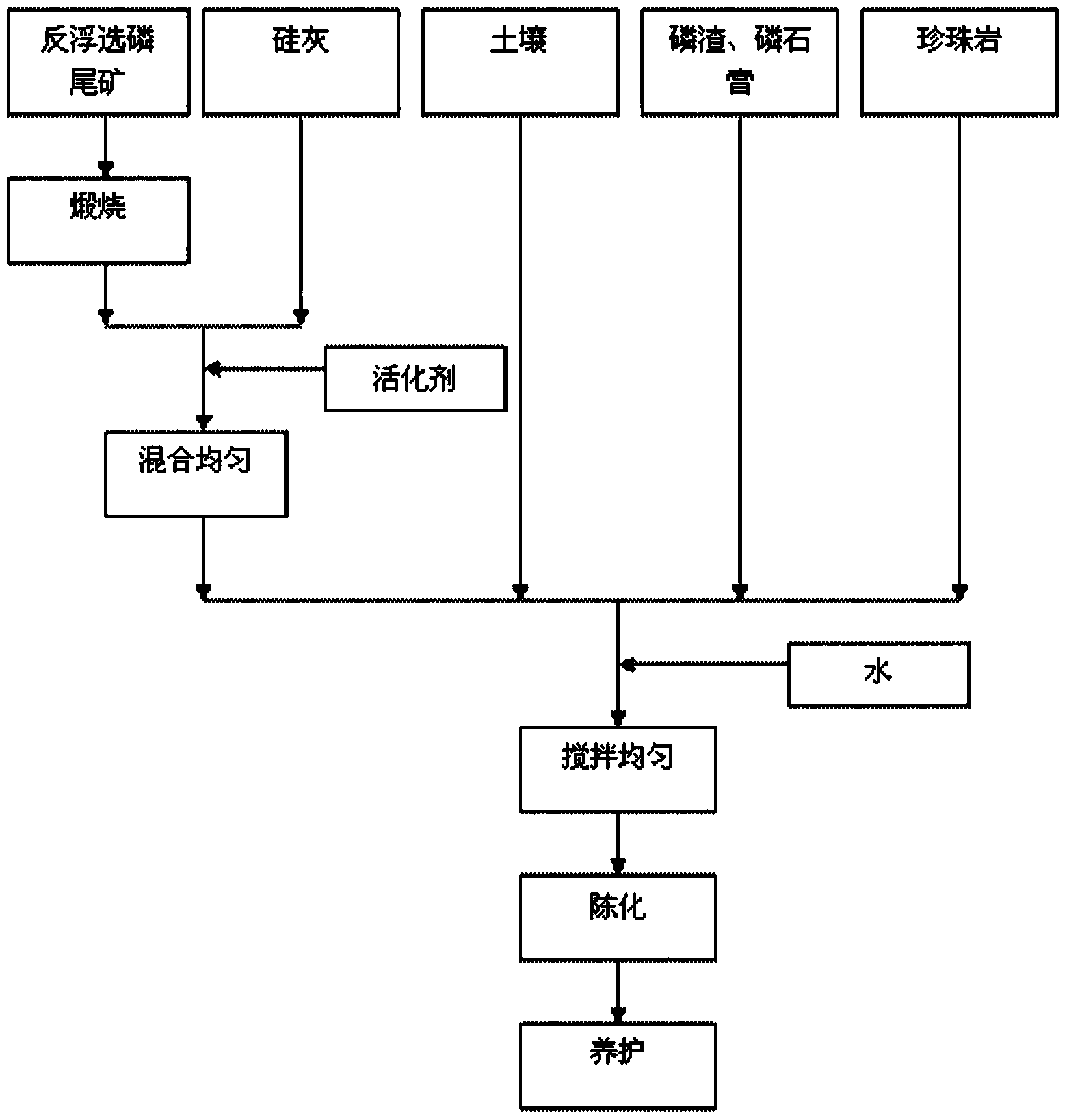

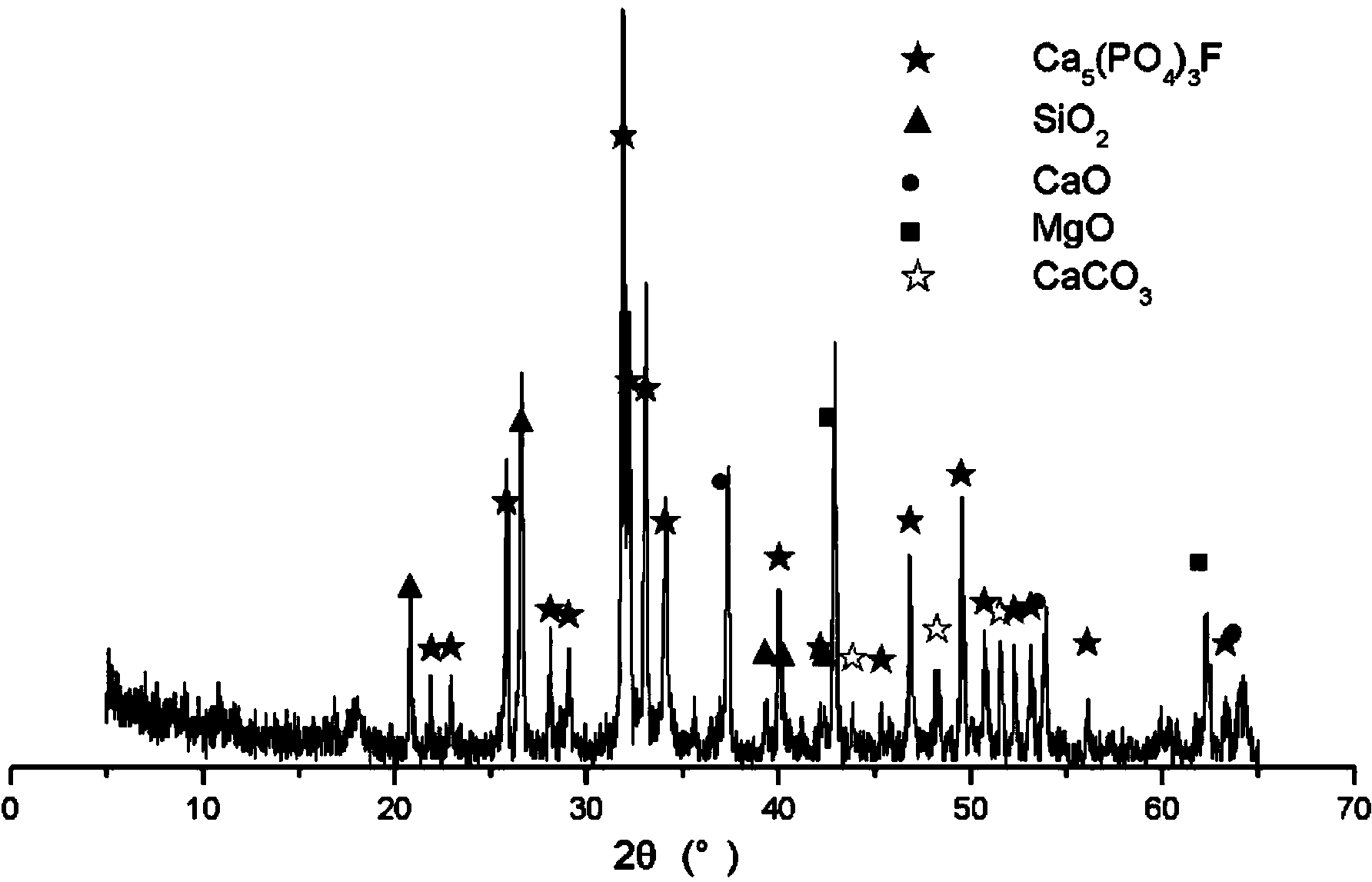

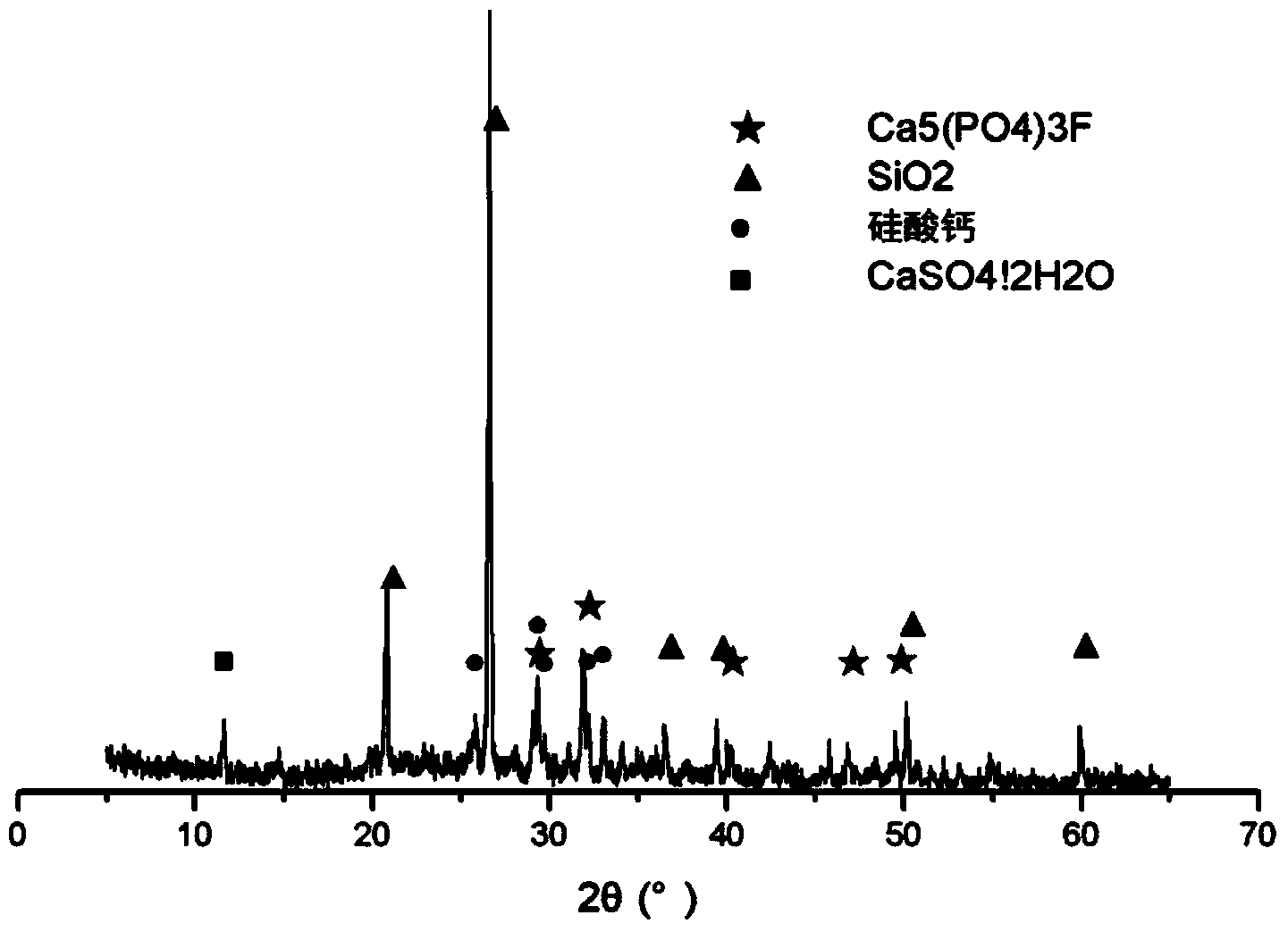

Plant growing medium produced by using reverse flotation phosphate tailing and preparation method thereof

InactiveCN104109050ALow costImprove fertilityFertilisers by pryogenic processesFertilizer mixturesPhosphateApatite

The invention relates to a plant growing medium produced by using reverse flotation phosphate tailing, which is used on a rock slope and comprises active phosphate tailing, soil and water, wherein active phosphate tailing is calcinined by reverse flotation phosphate tailing, the mass ratio of the active phosphate tailing to soil is 1:3-3:1, water mass accounts for 20-25% of total amount of active phosphate tailing and soil, the active phosphate tailing, soil and water are uniformly stirred and aged, and then are injected on the rock slope to obtain the plant growing medium. According to the invention, calcining is carried out so that phase composition of the reverse flotation phosphate tailing is changed; hydrated silicate composed of magnesium and calcium, which is more difficult than that of apatite, so that P2O5 in hydrated silicate can be directly absorbed by plant. The processed phosphate tailing is mixed with soil to obtain the plant growing medium. The plant growing medium can fully use the phosphate tailing, and has wide application prospect in mine reclamation and local agriculture production.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com