Insulation mortar reflective insulation coating external wall insulation system and construction process thereof

A technology of reflective heat insulation coating and exterior wall insulation, which is applied in the direction of heat preservation, filling slurry, and processing of building materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

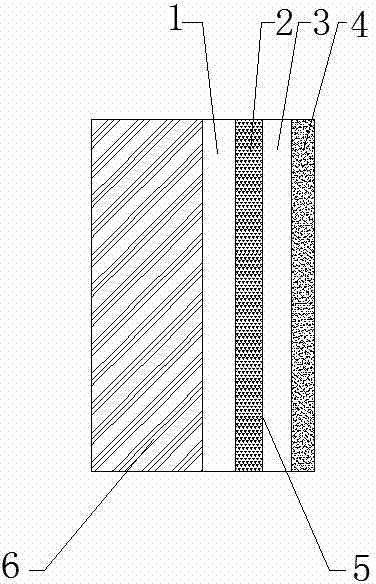

[0026] A thermal insulation system for thermal insulation mastic reflective heat insulation coatings for external walls, comprising a thermal insulation layer 1 and a coating system 5, the coating system 5 is composed of a primer layer 2, a putty layer 3 and a finishing layer 7 of reflective thermal insulation coatings. The thermal insulation plaster reflective thermal insulation paint exterior wall thermal insulation system is constructed on the base layer 6, and the thermal insulation layer 1 is connected to the base layer 6.

[0027] Among them, the insulation layer 1 is thermal insulation and waterproof cement, and its formula is: 18.0%~19.0% of styrene-acrylic emulsion, 15.5%~16% of silica sol, 0.9%~1.0% of ester alcohol, 0.2%~0.3% of thickener, anti-mildew Agent 0.1%~0.2%, ammonia water 0.1%~0.2%, dispersant 0.2%~0.3%, polystyrene particles 1.5%~2.2%, vitrified microbeads 12~19%, aluminum silicate 15%~26%, functional Fiber 0.7%~0.9%, coupling agent 0.1%~0.3%, wetting age...

Embodiment 2

[0082] All the other are identical with described embodiment 1, and difference is that described putty layer is waterproof putty, and is made of polymer rubber powder, portland cement, ground calcium carbonate, quartz powder, talcum powder, defoamer and hydroxyl Propyl methyl cellulose is made, and the addition amount of described polymer milk powder is 25%

Embodiment 3

[0084] The rest is the same as that of Example 2, except that the hydroxypropyl methylcellulose is 100,000 Pa·S, and the added amount of the polymer milk powder is not less than 35%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com