Organosilicon-modified aqueous polyurethane-acrylate composite coating agent and preparation method thereof

A water-based polyurethane and acrylate technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of high environmental protection requirements, poor mechanical properties, poor compatibility of composite systems, etc. Poor compatibility, the effect of strengthening the force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

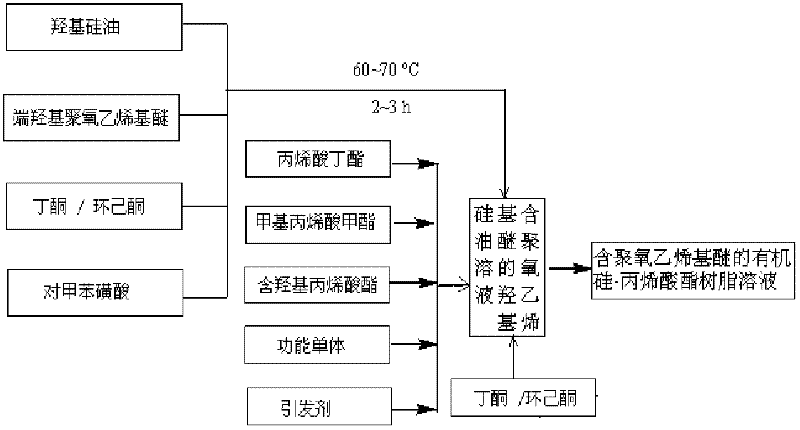

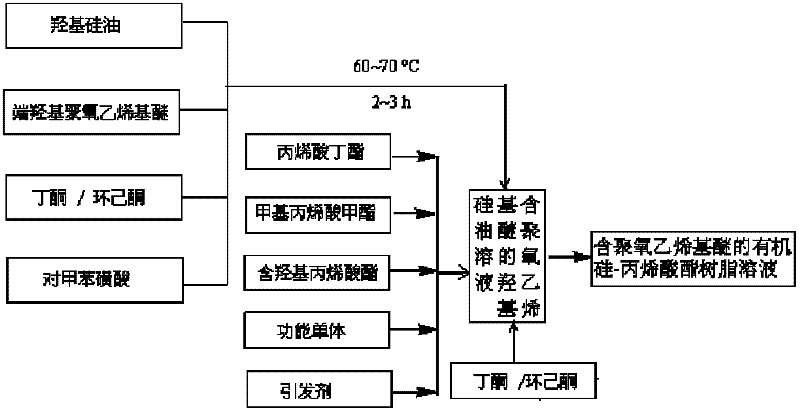

[0038] Dissolve 100 mg of hydroxy silicone oil (molecular weight: 2000), 80 mg of hydroxy-terminated polyoxyethylene ether, 150 mg of methyl ethyl ketone, 150 mg of cyclohexanone, and 2.5 mg of p-toluenesulfonic acid, and heat up to 70 o C was reacted for 2 hours to prepare a hydroxyl silicone oil solution containing polyoxyethylene ether.

[0039] Dissolve 100 mg of polyoxyethylene ether-containing hydroxyl silicone oil in a mixed solvent of 100 mg methyl ethyl ketone and 90 mg cyclohexanone, and heat to 75 o C, mix 85 mg methyl methacrylate, 50 mg butyl acrylate, 15 mg diacetone acrylamide and 6 mg β-hydroxyethyl methacrylate, and add 1.5 mg dibenzoyl peroxide to fully dissolve After that, slowly add it dropwise into the above-mentioned hydroxyl silicone oil solution containing polyoxyethylene base ether, control the dropping time for 2.5 hours, and then add it at 85 o C for 1.5 hours to prepare a polyoxyethylene-containing silicone-acrylate resin solution...

Embodiment 2

[0044] The same as in Example 1, but the amount of hydroxyl-terminated polyoxyethylene ether in step (1) was changed from 80 mg to 60 mg, and the others remained unchanged.

Embodiment 3

[0046] Same as Example 1, but the amount of hydroxyl-terminated polyoxyethylene ether in step (1) was changed from 80 mg to 100 mg, and the others remained unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com