Girder-exchange construction method for existing railway bridge by successively incremeantal launching framework process

A construction method and technology of existing lines, applied in bridges, bridge construction, bridge maintenance, etc., can solve problems such as large jacking force device requirements, the inability to guarantee the requirement of blocking the construction time for 6 hours, and the limited construction site, etc. The effect of bearing capacity, saving investment and simplifying construction procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

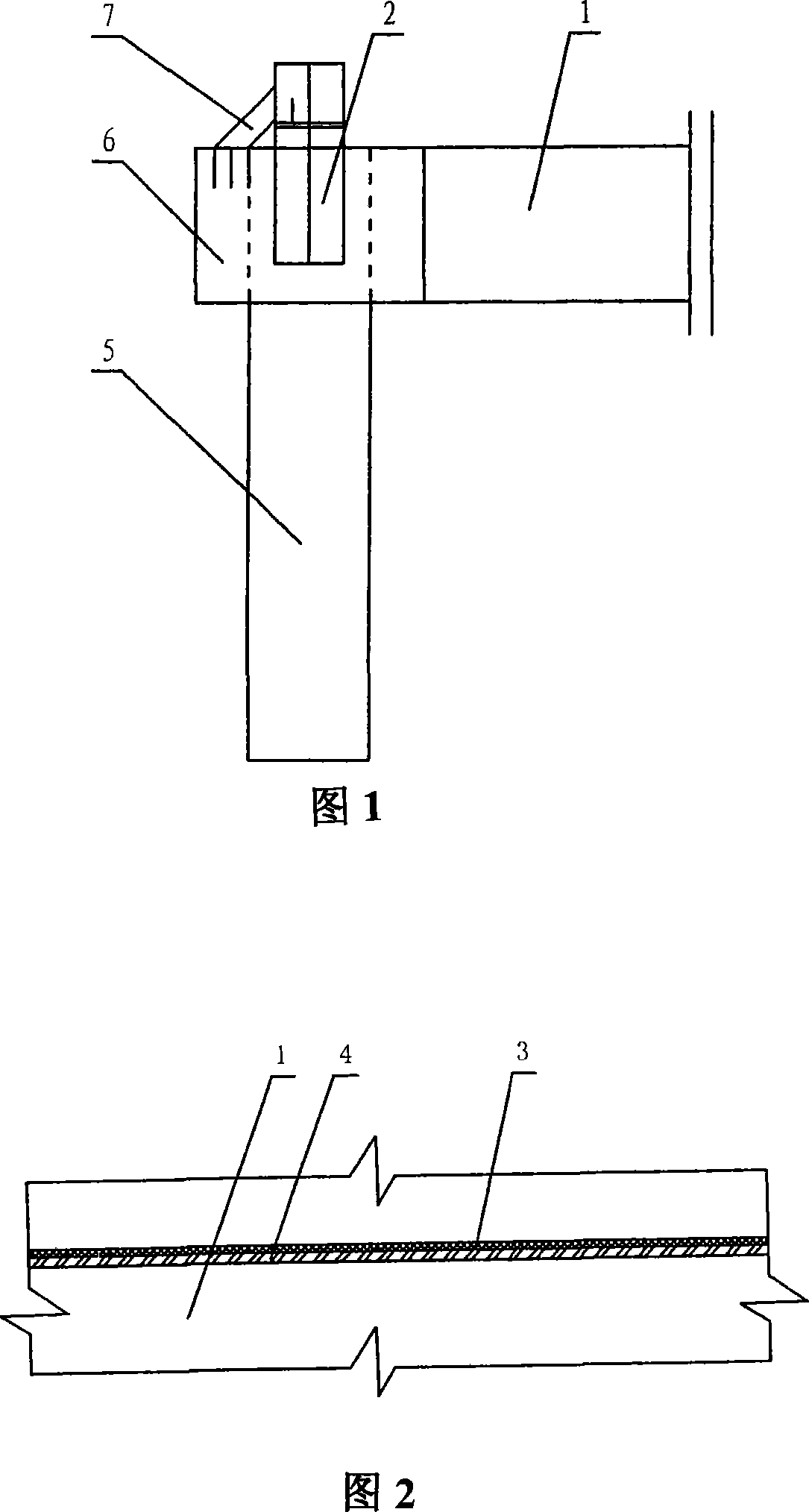

[0010] The Construction Method of Continuous Pushing Frame Method for Beam Replacement of Bridges on Existing Railway Lines

[0011] Overall construction plan:

[0012] 1. On one side of the existing line, separate slides are set up, and frames are prefabricated on the separate slides.

[0013] ① Slideway construction: There are 3 holes in this frame bridge, and 3 sets of slideways are arranged in each hole. Each set of slideways is composed of a main slideway and two auxiliary slideways. A reaction seat 2 is set at the other end of the prefabricated slideway 1 of the frame. . The sliding layer between the slideway and the frame adopts polytetrafluoroethylene slider 3, the size of the slider is 300×300×10mm, the distance is 1.1m, and the middle is filled with 15mm thick foam board 4.

[0014] The foundation is constructed with high-pressure rotary grouting piles. According to the different load conditions of the slideway foundation, the foundation of the existing beam moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com