Patents

Literature

306results about "Track maintainence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

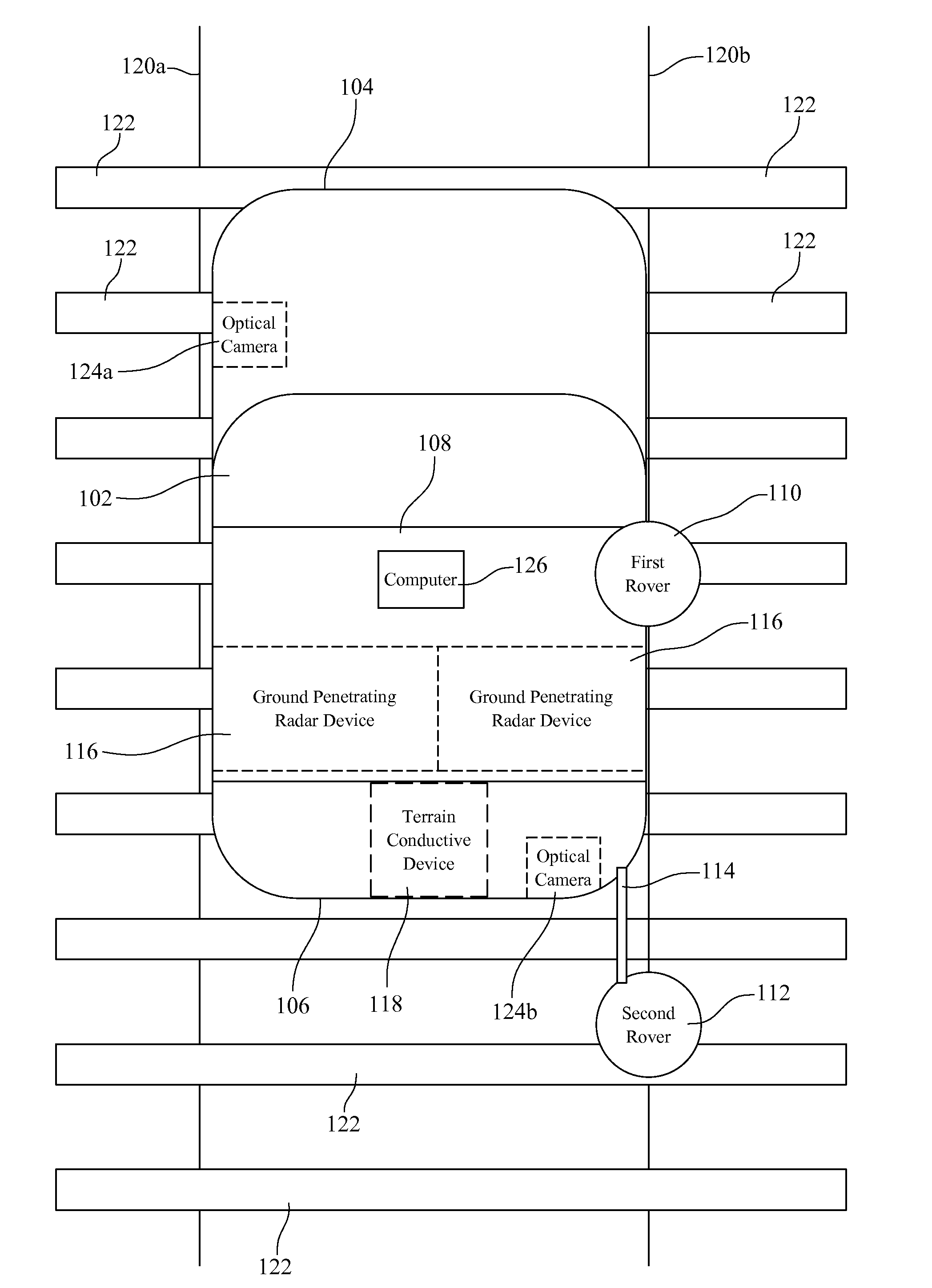

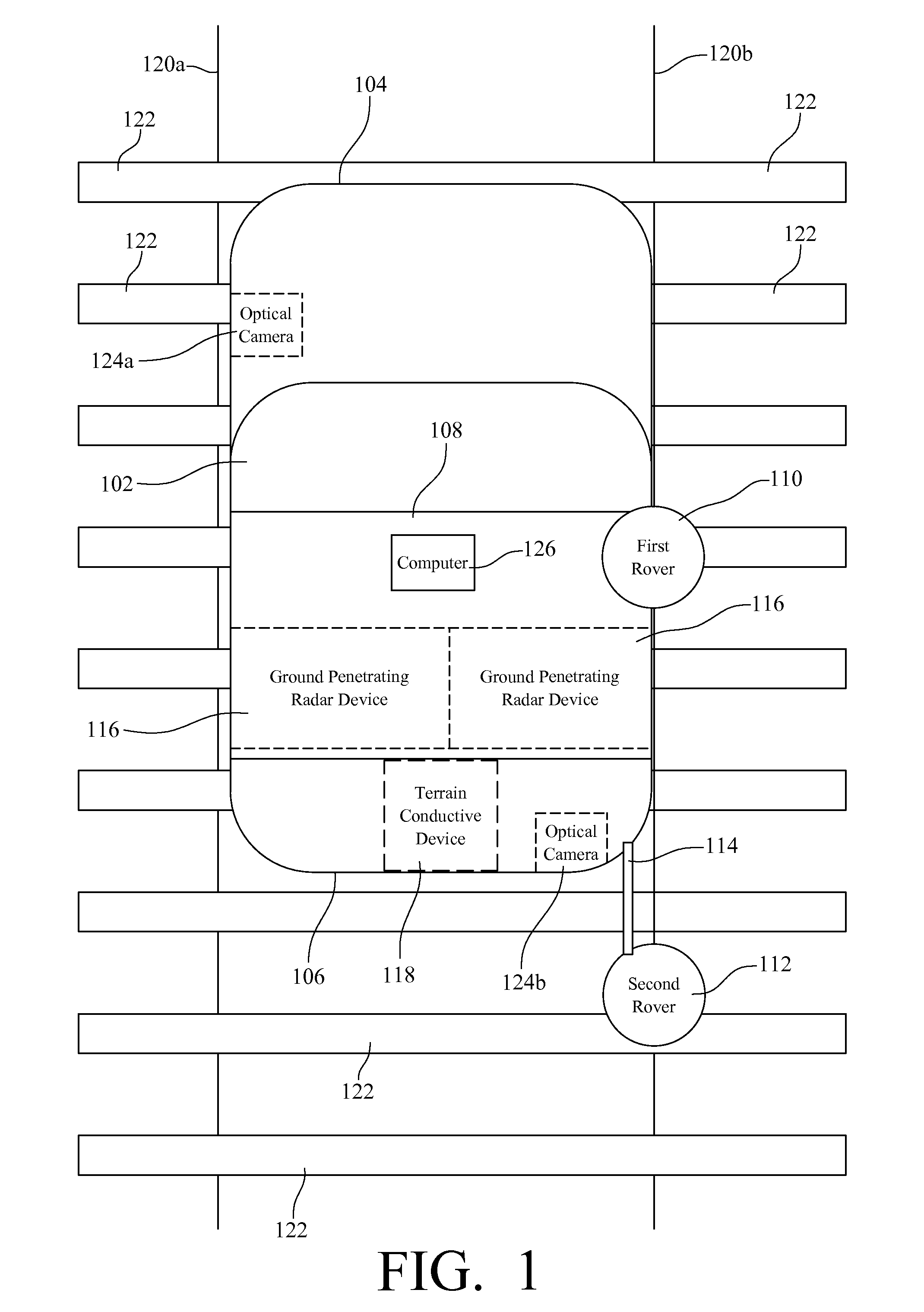

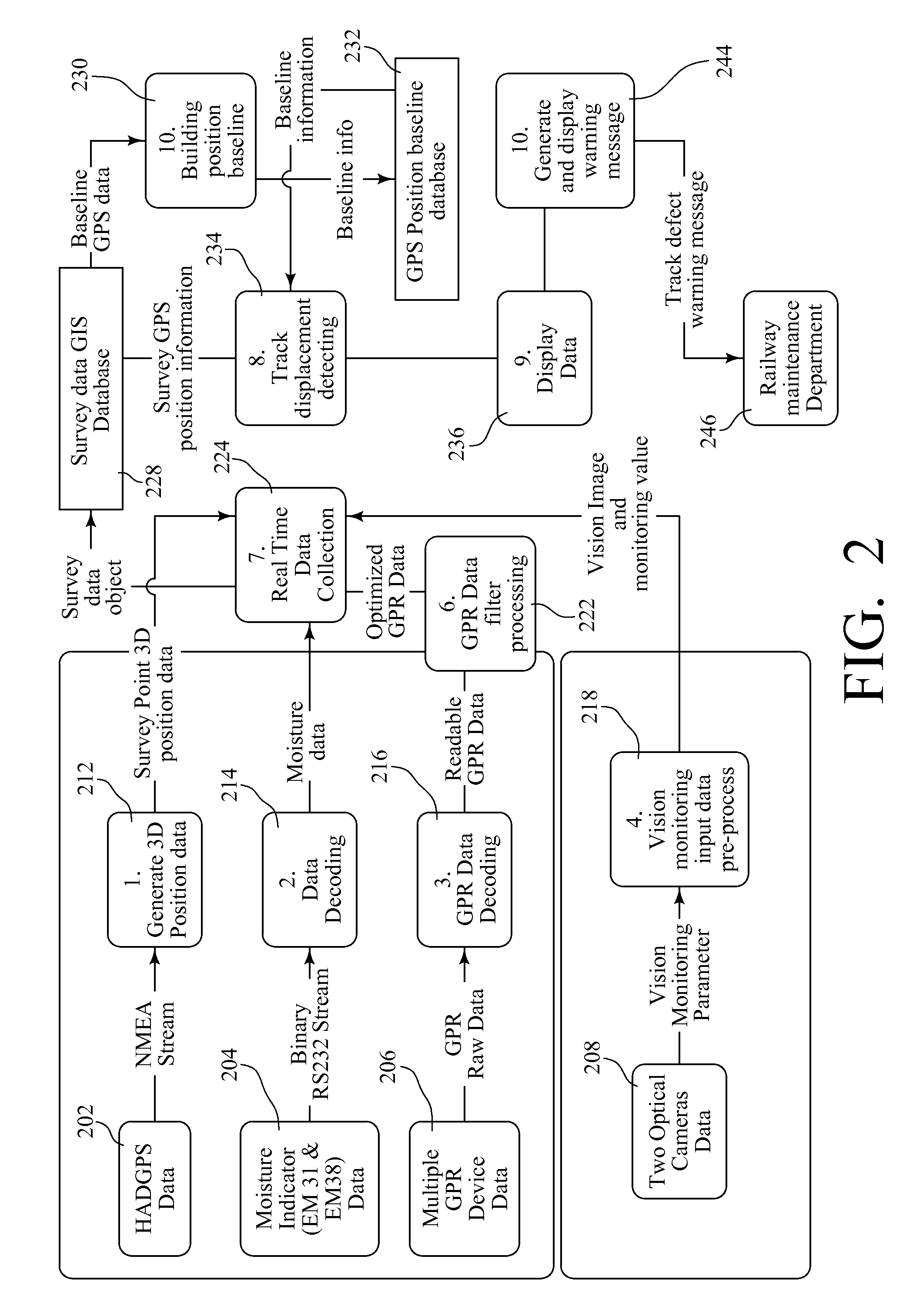

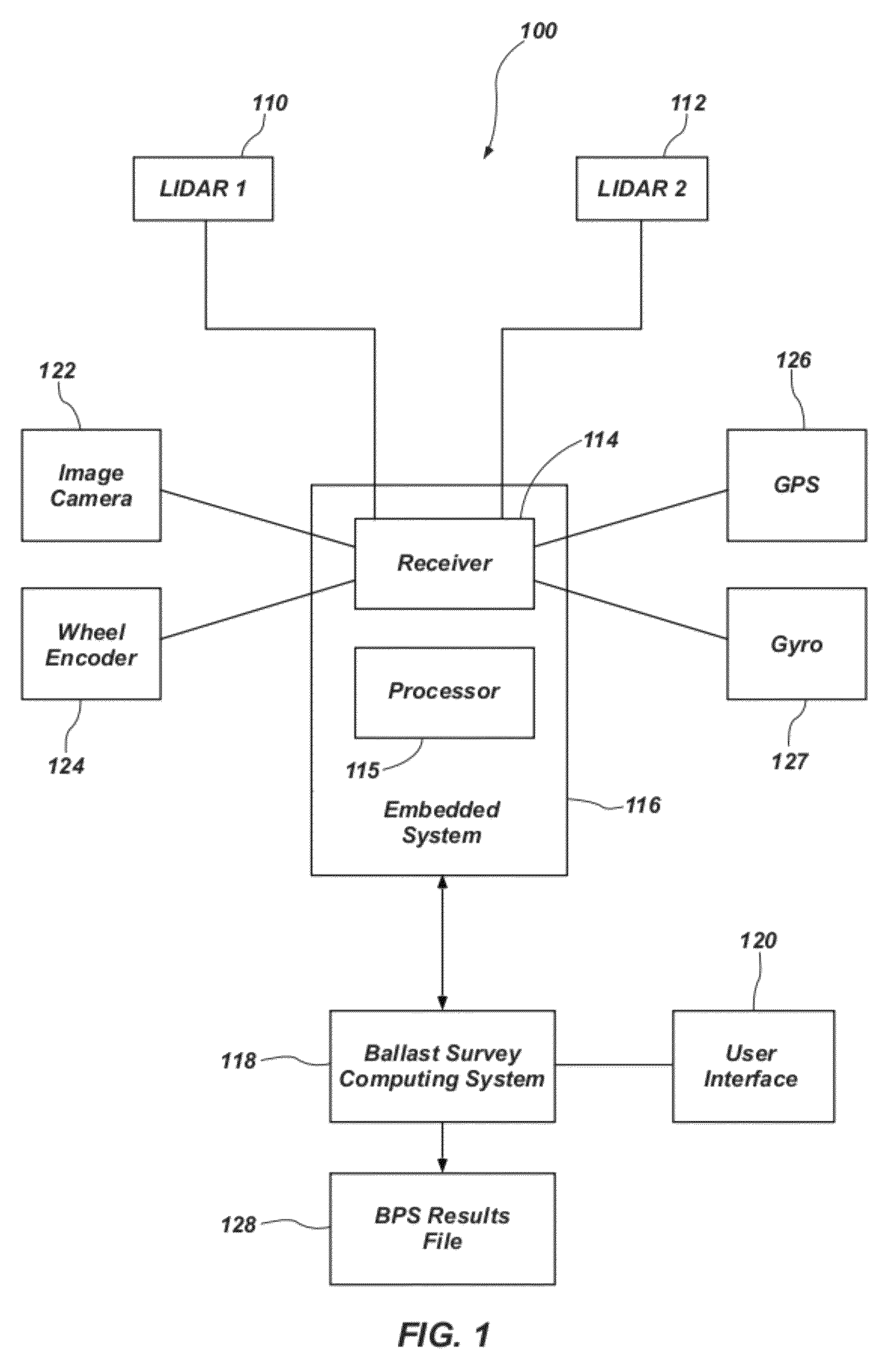

Railroad surveying and monitoring system

InactiveUS20100026551A1Easy to adaptOptimizationPosition fixationTesting/calibration of speed/acceleration/shock measurement devicesTerrainLandform

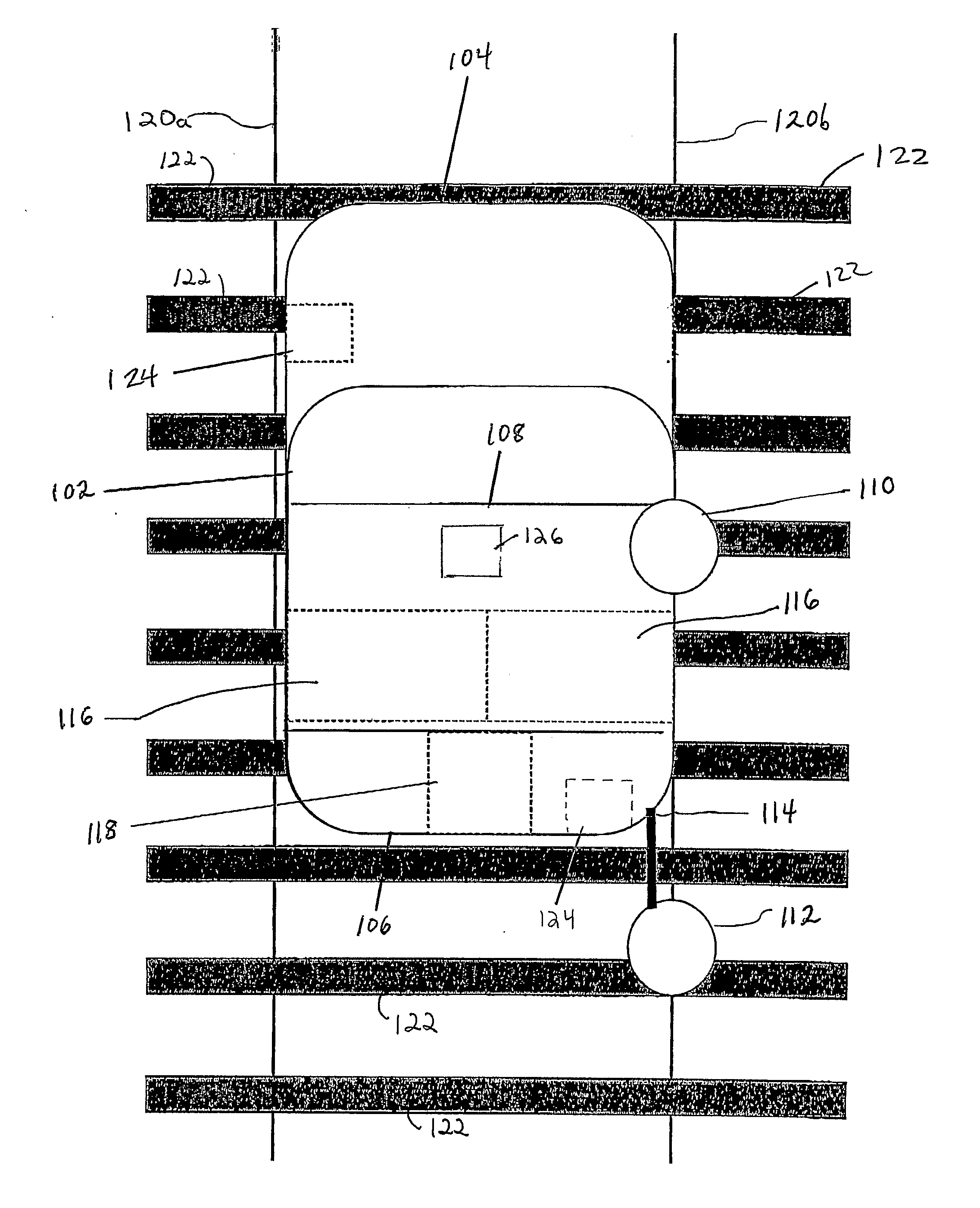

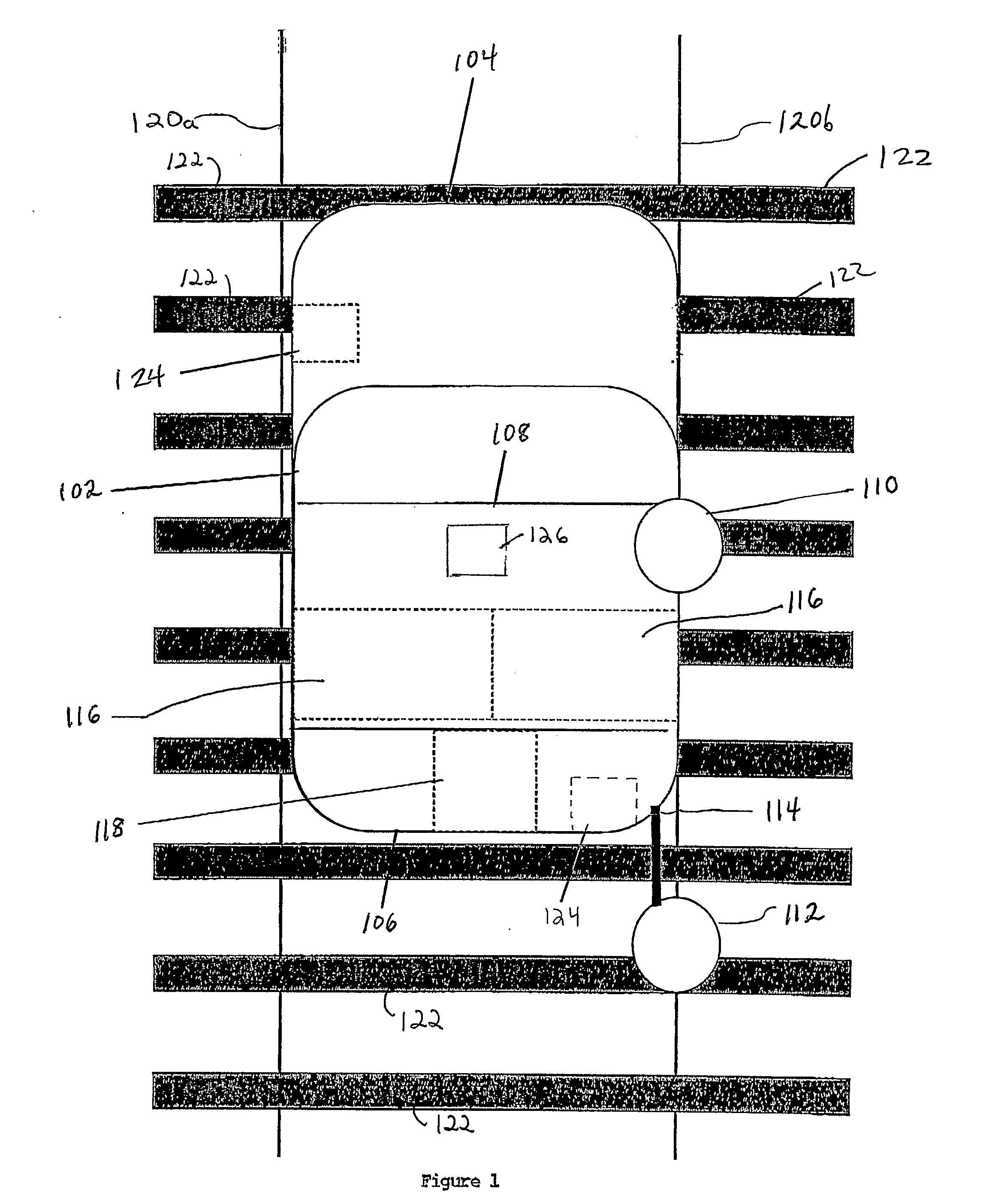

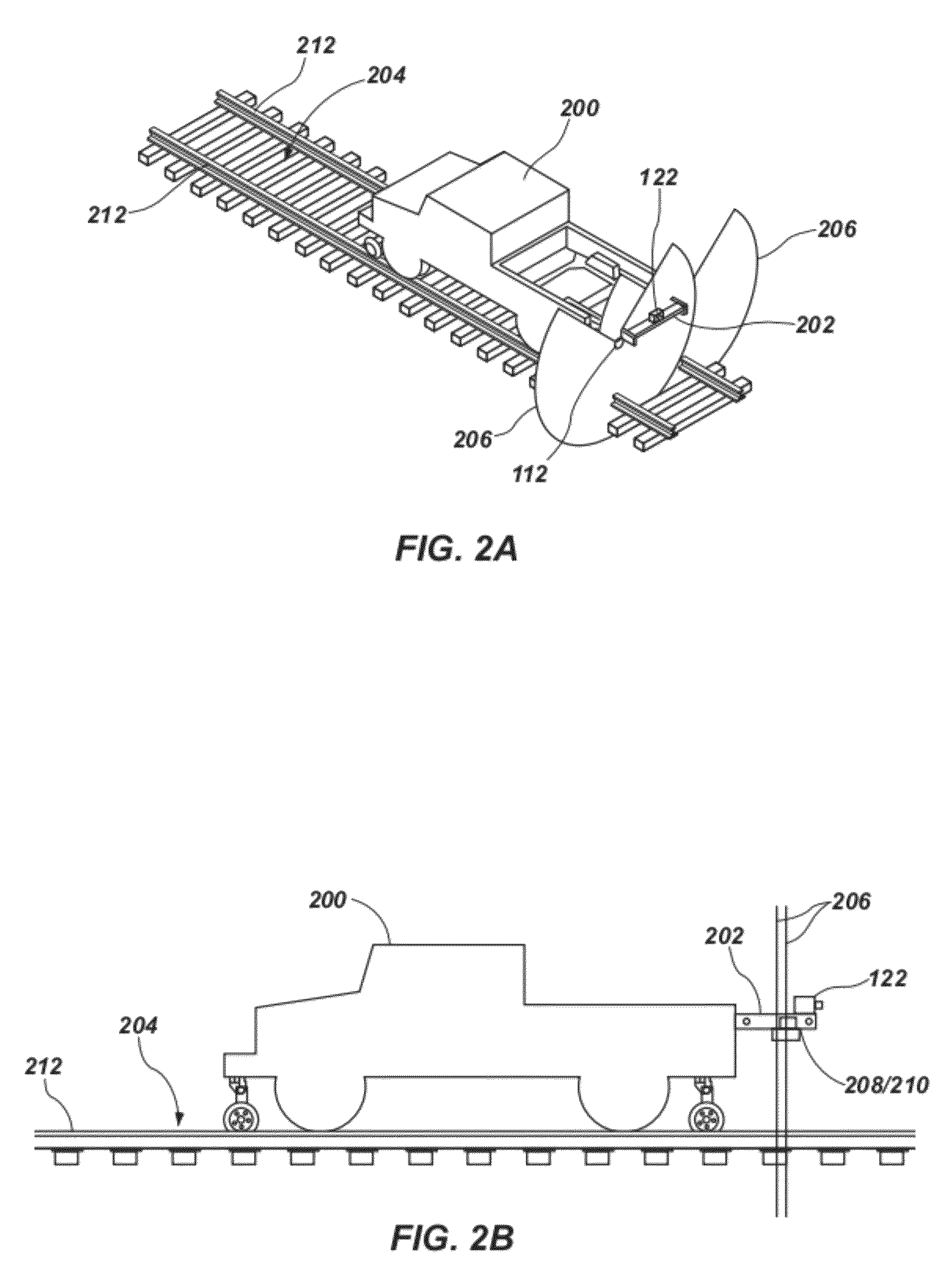

A Railroad Surveying and Monitoring System configured on a mobile platform for surveying, monitoring, and analyzing rail position and superstructure and terrain substructure of railroad tracks (20a,b) or other structures. The system employs two or more High Accuracy Differential Global Positioning System devices (110,112), ground penetrating radar devices (116), terrain conductivity instruments (118), optical cameras (124), and data receivers and processors (126), which in turn process, display, and store the data in a usable database. Precise coordinate data generated from a High Accuracy Global Positioning System provides both location data for subsurface sensors and surface sensors and rail position coordinates to monitor track displacements during track inspection in real time.

Owner:MARSHALL UNIV RES

Polyurethane resin composition, preparation method and application thereof

InactiveCN101735595AImprove water resistanceImprove featuresBallastwayTrack maintainencePolyolefinAlcohol

The invention provides a polyurethane resin composition, a preparation method and application thereof. The polyurethane resin composition comprises a component A and a component B, wherein the component A contains polyolein polyatomic alcohol, a plasticizer, an anti-settling agent and other auxiliary agents; the component B is isocyanate or prepolymer of the isocyanate; and the mass ratio of the A to the B is 10:1-1:10. A pouring material containing the resin composition can be used as a patching material for a cement road bed, a boss resin layer and a mortar packing layer of a railway plate-type unballasted track and has the advantages of high water resistance, ageing resistance and low temperature resistance, long service life and capability of being used at a low temperature.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI

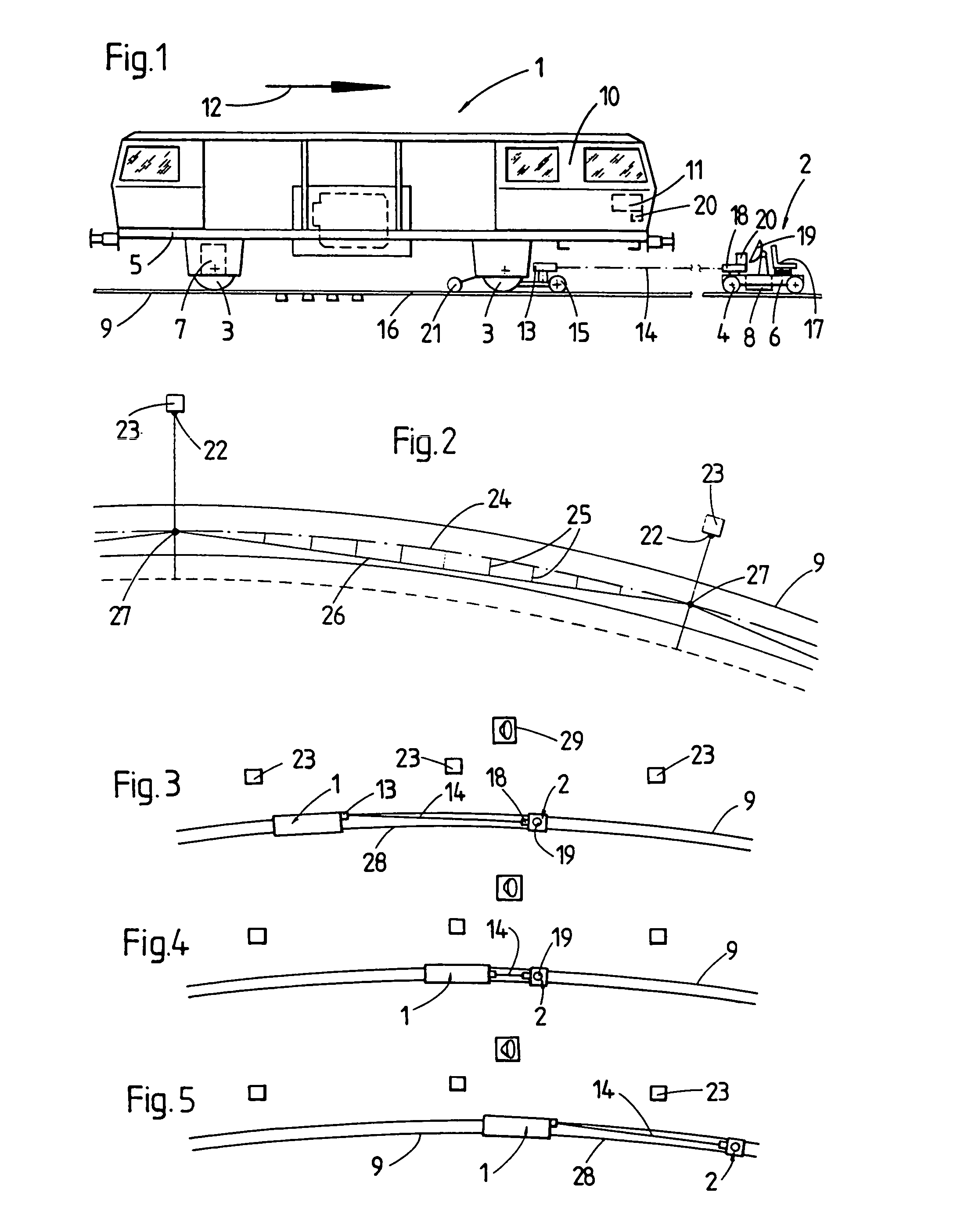

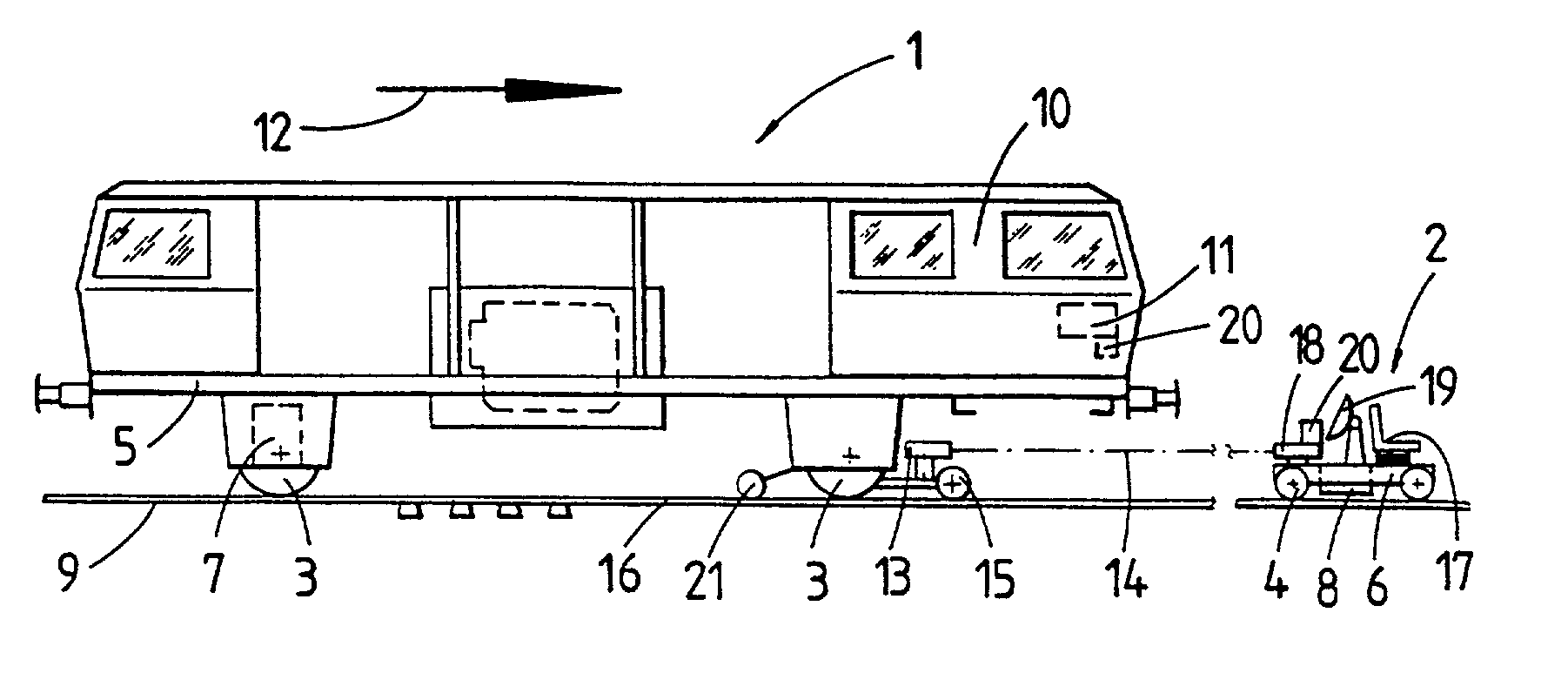

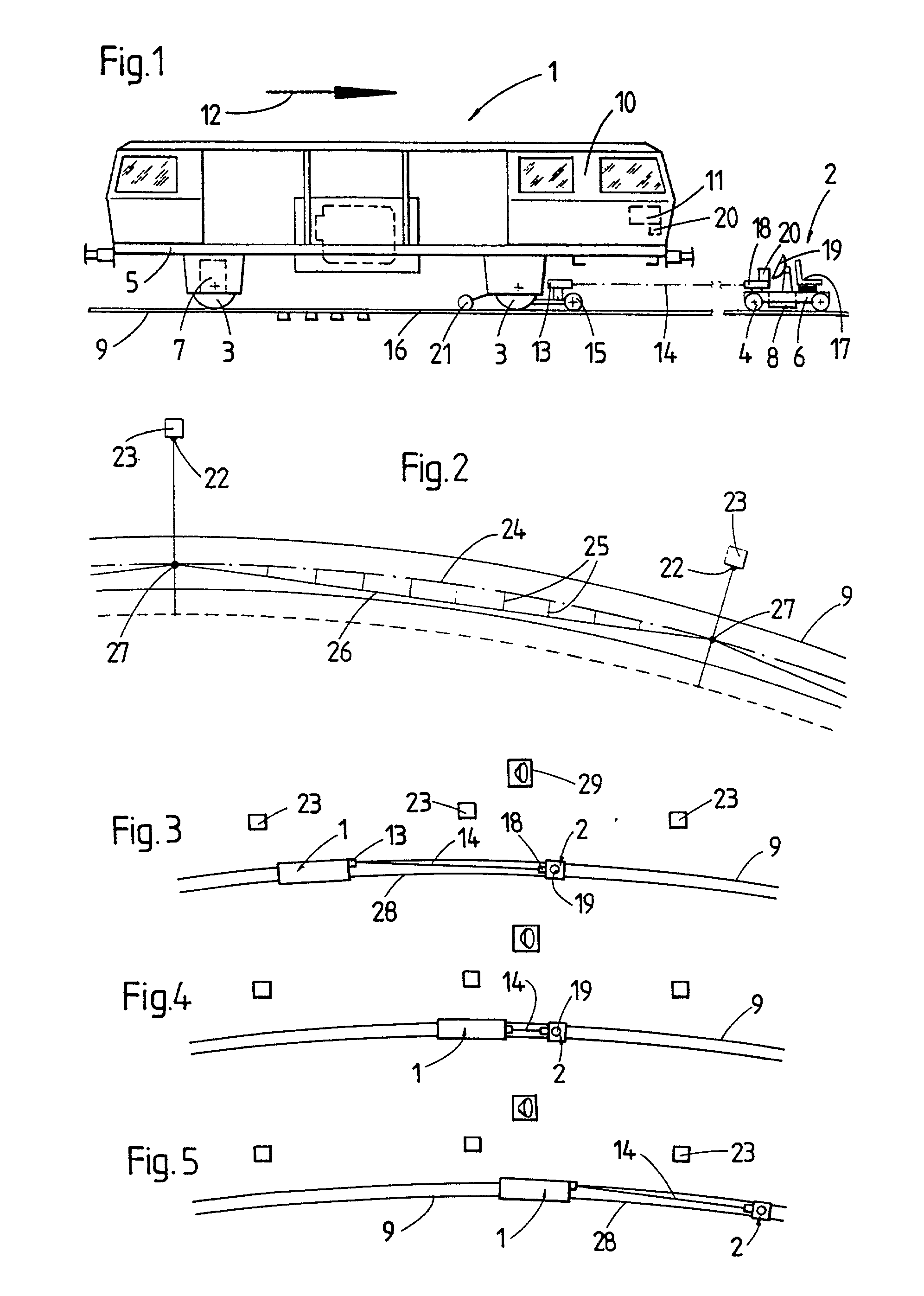

Method of surveying a track

InactiveUS7050926B2Improve accuracyFast progressBallastwayDigital data processing detailsGps receiverEngineering

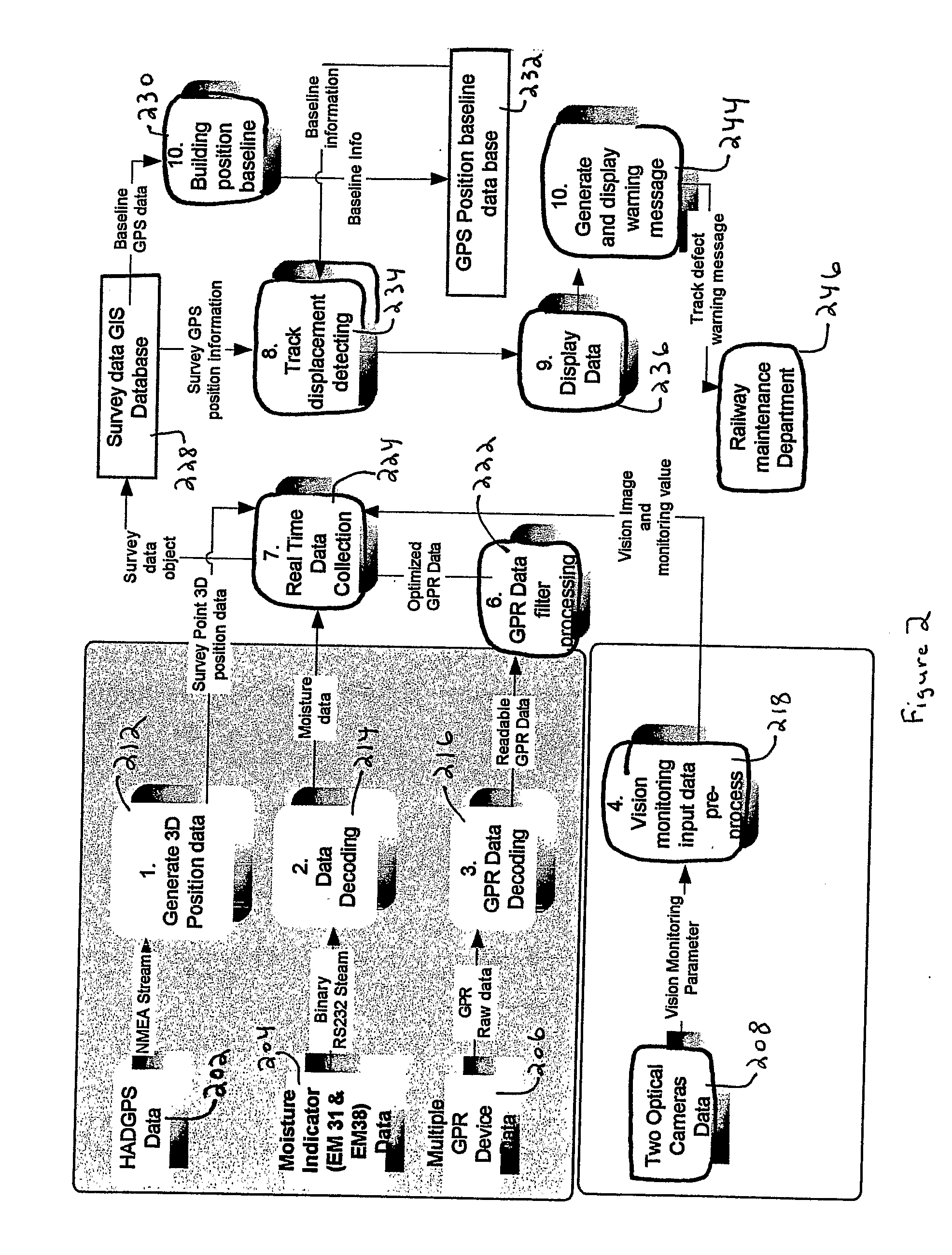

In a method of surveying a track (9), a first or mobile measuring vehicle (1) and a second or stationary measuring vehicle (2) are placed at a distance apart from one another on a track section to be measured. A reference line (14) is formed by a laser beam emitted from the stationary measuring vehicle (2). At the start of each measuring cycle, by using a GPS receiver (19), the relative position of the stationary measuring vehicle (2) with reference to a fixedly installed GPS reference station (29) located adjacent to the track section is determined, the said GPS reference station being known within a terrestrial coordinate system. The reference line (14) is aligned with the mobile measuring vehicle (1) on the basis of the determined position data, and the track surveying operation is carried out by advancing the mobile measuring vehicle (1) while changes of the actual track position relative to the reference line (14) are registered.

Owner:FRANZ PLASSER BAHNBAUMASCHINEN IND GMBH

Railroad surveying and monitoring system

InactiveUS8180590B2Avoid large vibrationsPosition fixationTesting/calibration of speed/acceleration/shock measurement devicesTrackwayMonitoring system

A Railroad Surveying and Monitoring System configured on a mobile platform for surveying, monitoring, and analyzing rail position and superstructure and terrain substructure of railroad tracks (20a,b) or other structures. The system employs two or more High Accuracy Differential Global Positioning System devices (110,112), ground penetrating radar devices (116), terrain conductivity instruments (118), optical cameras (124), and data receivers and processors (126), which in turn process, display, and store the data in a usable database. Precise coordinate data generated from a High Accuracy Global Positioning System provides both location data for subsurface sensors and surface sensors and rail position coordinates to monitor track displacements during track inspection in real time.

Owner:MARSHALL UNIV RES

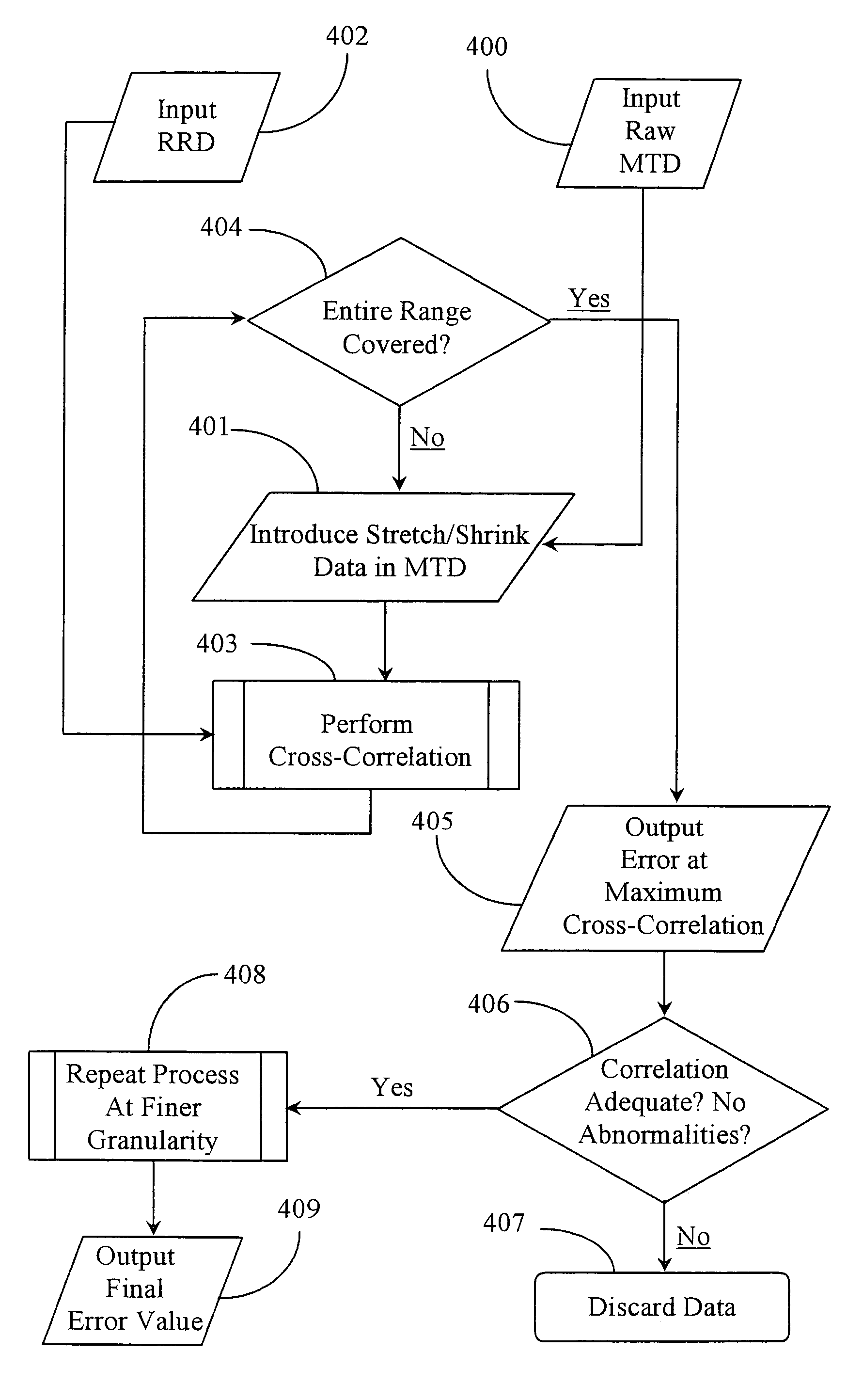

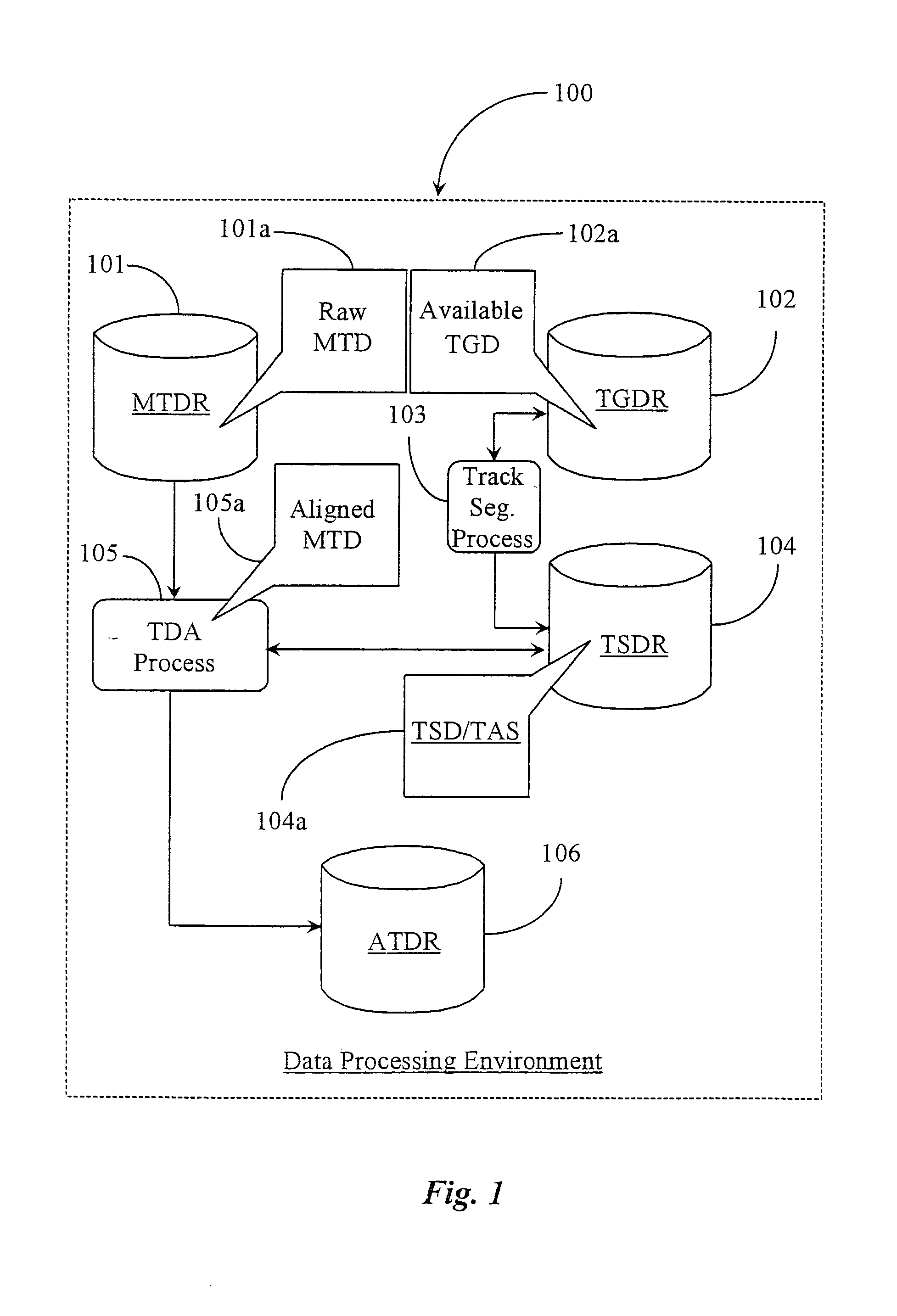

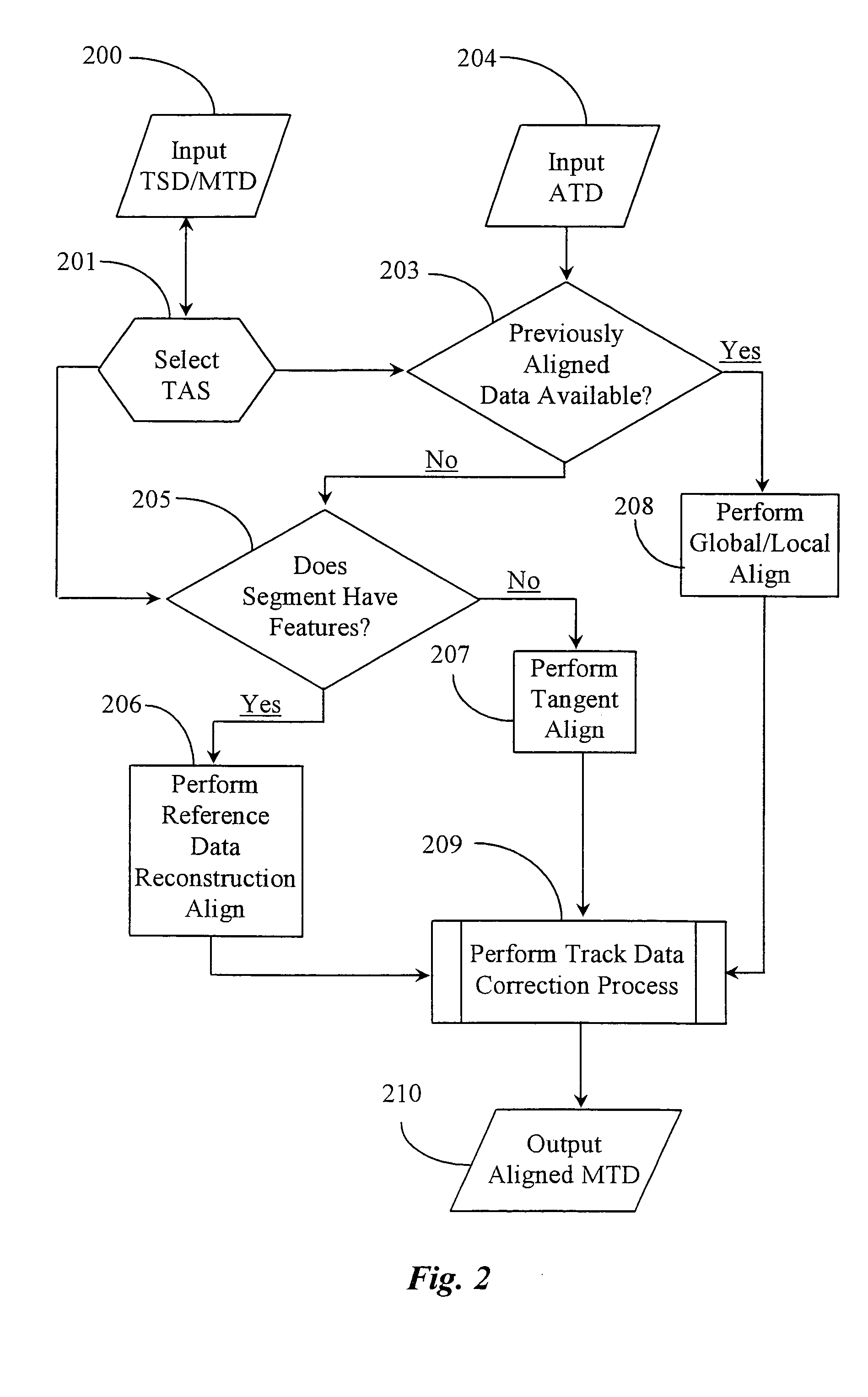

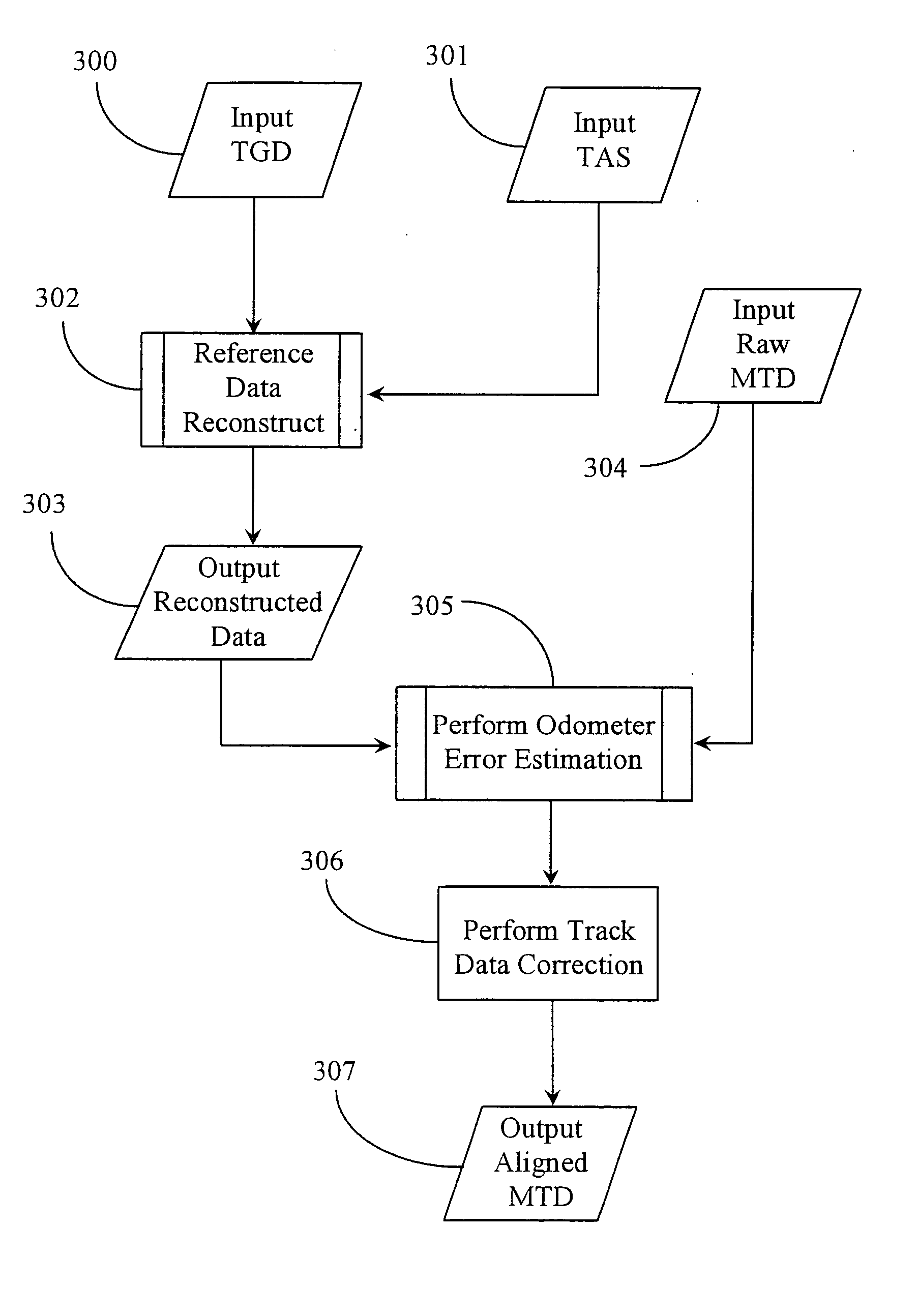

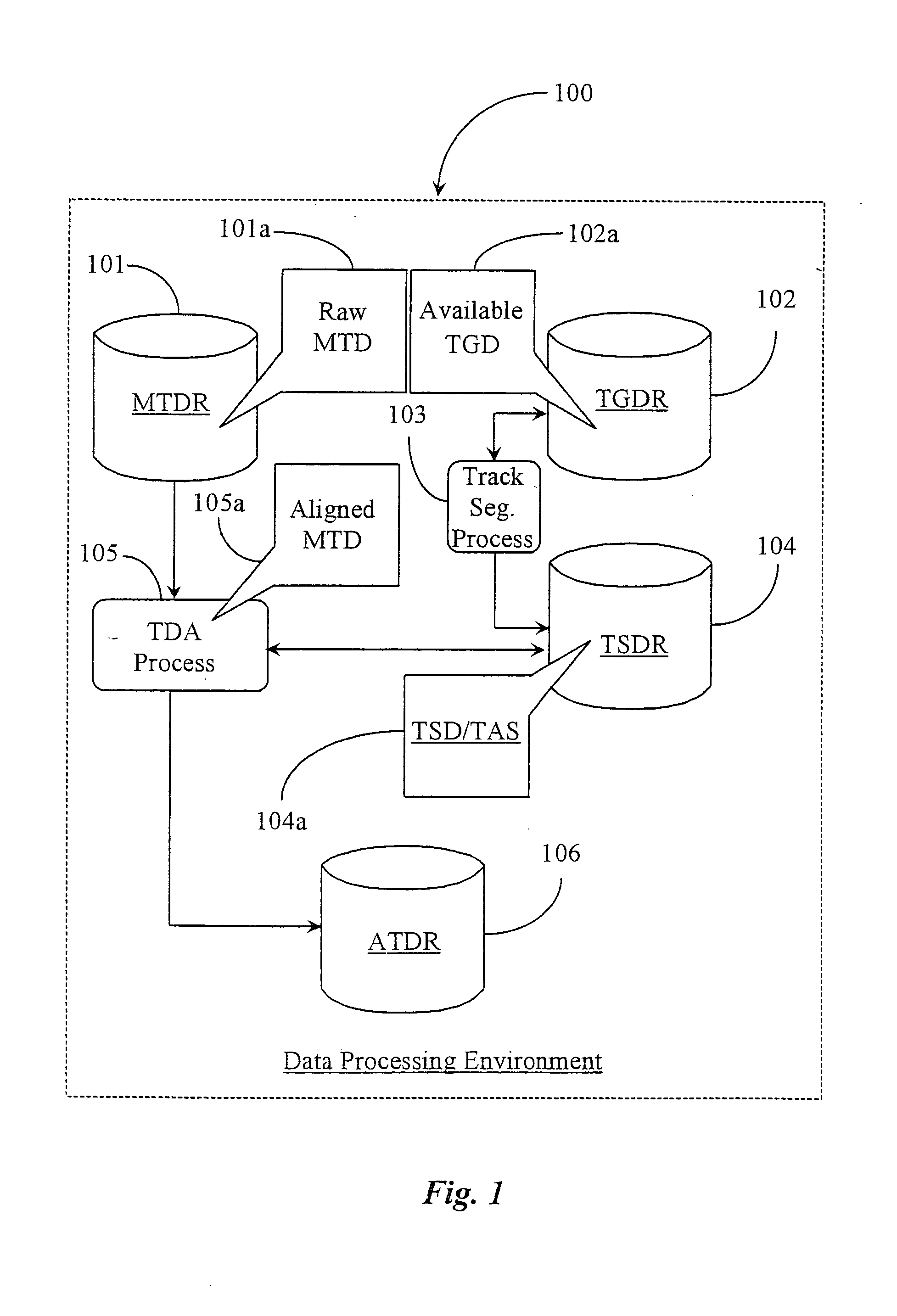

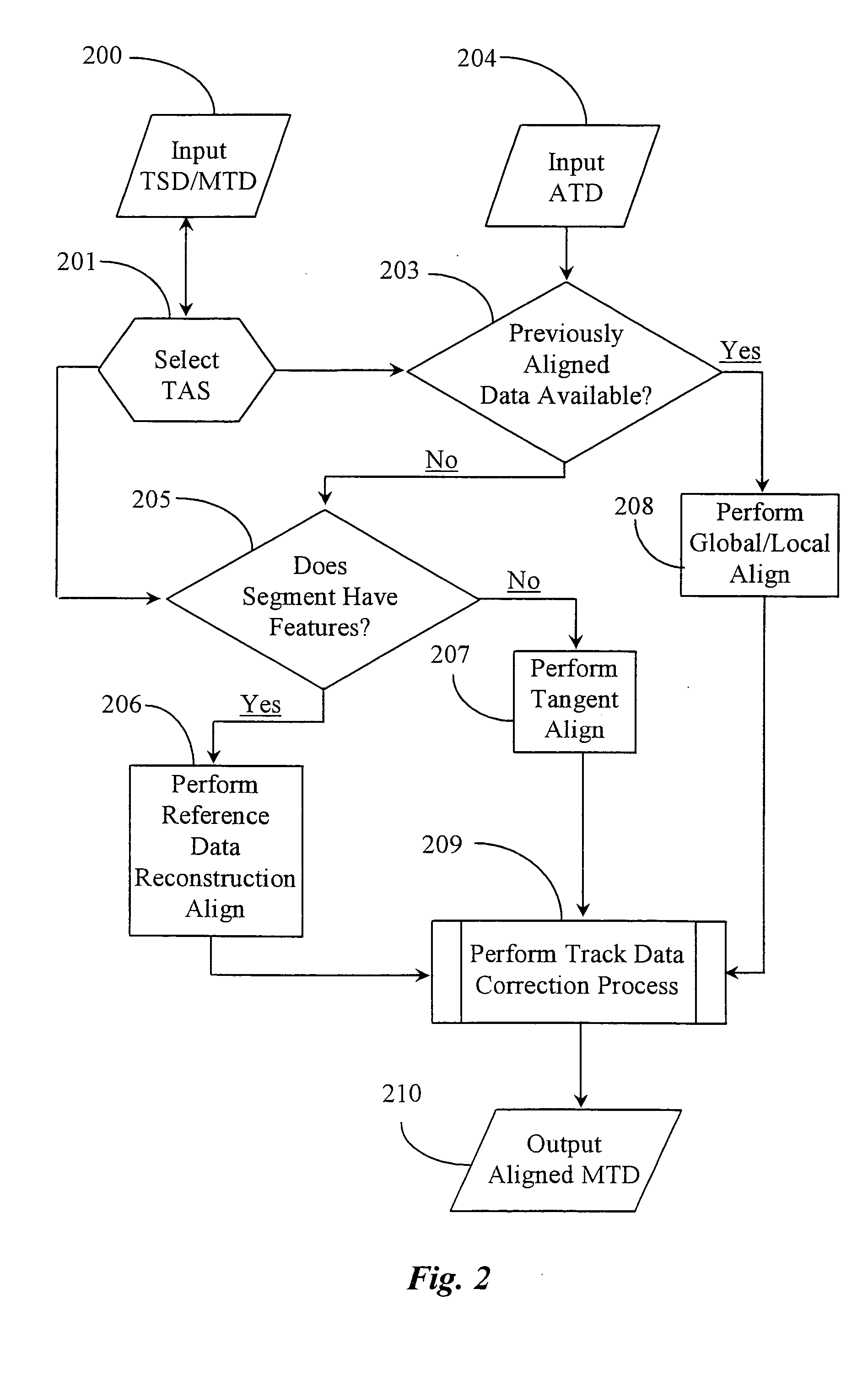

Methods for aligning measured data taken from specific rail track sections of a railroad with the correct geographic location of the sections

InactiveUS7130753B2Electrical measurementsTesting/calibration of speed/acceleration/shock measurement devicesGeolocationComputer science

Owner:TATA CONSULTANCY SERVICES LTD

Unsaturated resin composition as well as preparation method and a purpose thereof

ActiveCN101724218AImprove low temperature resistanceEasy to useBallastwayTrack maintainenceAcrylic resinTemperature resistance

The invention provides an unsaturated resin composition as well as a preparation method and a purpose thereof, wherein the unsaturated resin composition contains a component A and a component B, the component A contains an acrylic resin or a prepolymer thereof, a diluent, a toughening agent, a thixotropic agent and other assistants; the component B contains a peroxide initiator and a plasticizer,and the mass ratio of A to B is 100:1 to 100: 50. The preparation method of the composition is simple and is beneficial to rapid production. A repairing material containing the composition and used as a railway plate type ballastless track cement road bed, a boss resin layer and a mortar filling layer solves the problems of poor water resistance, impact resistance, aging resistance and low temperature resistance existing in the traditional repairing material.

Owner:BEIJING RAILWELD NEW MATERIAL TECH CO LTD +2

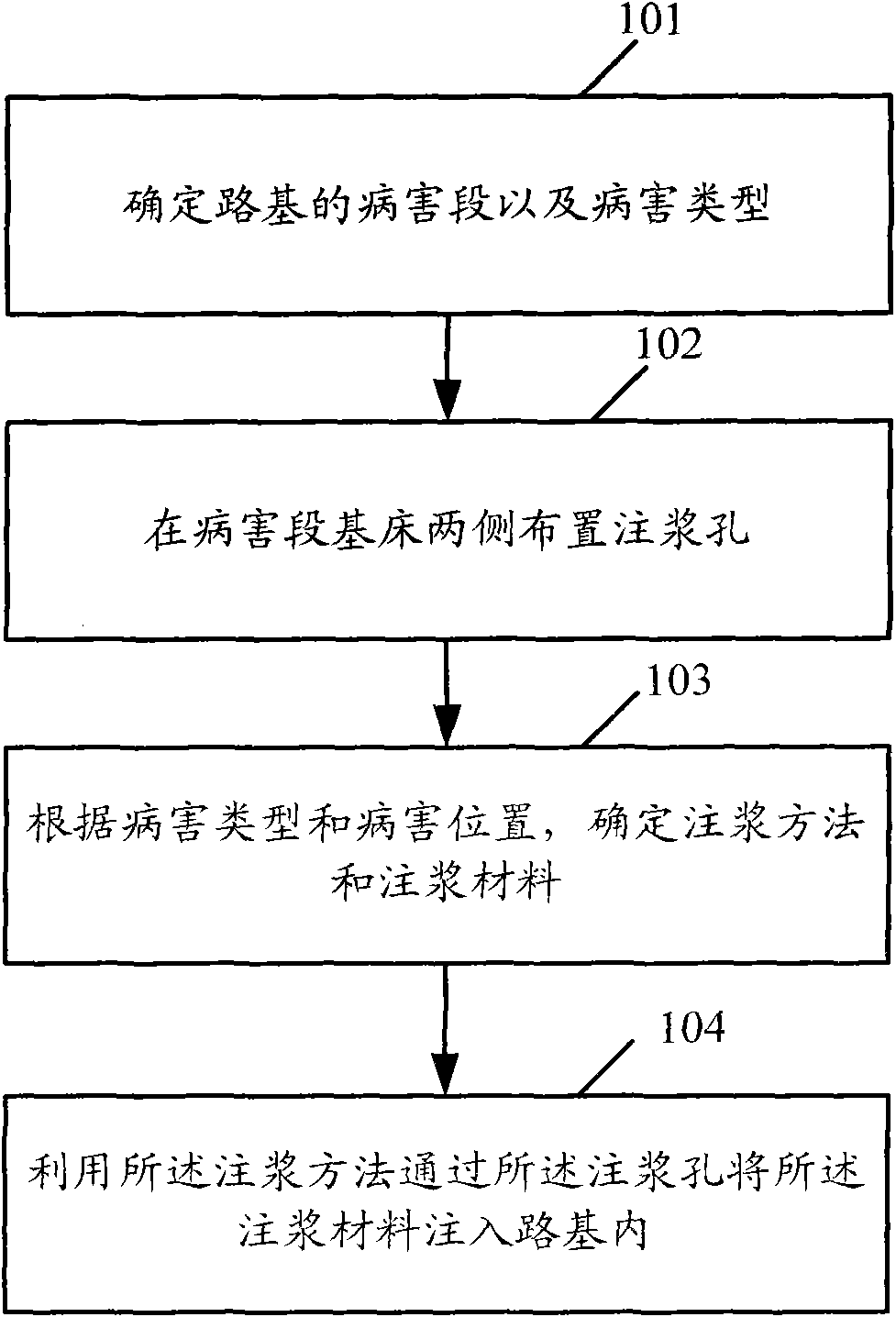

Railroad bed repair method without affecting existing running conditions

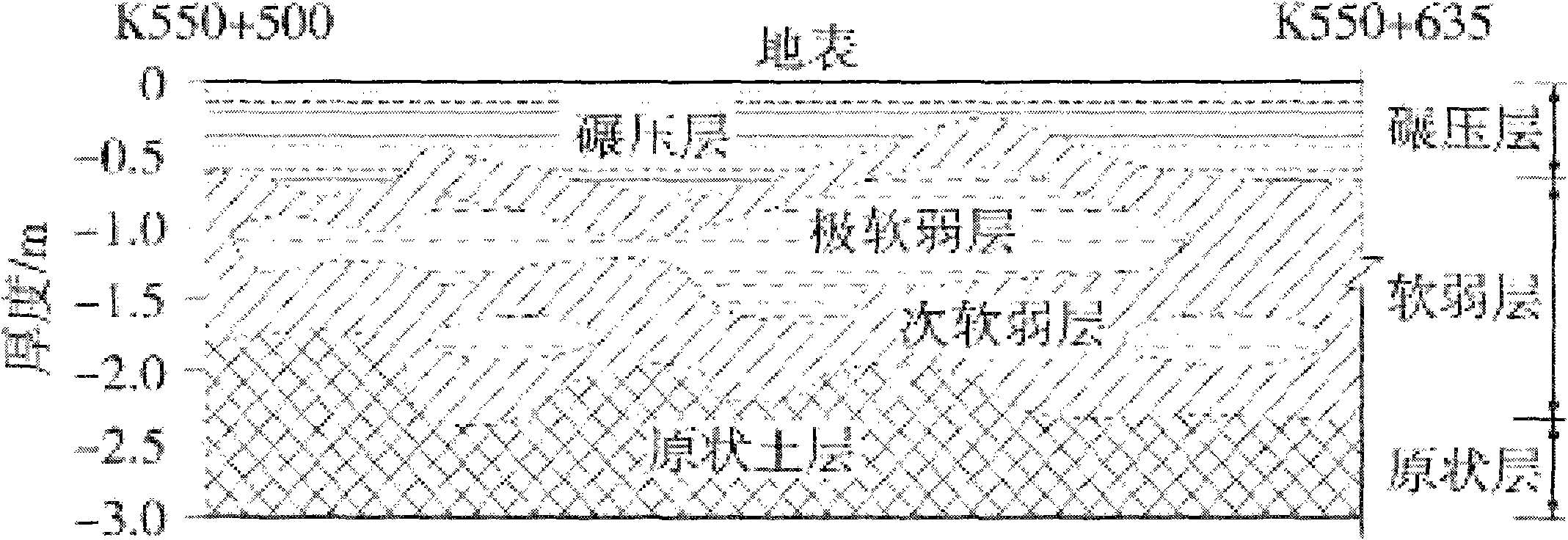

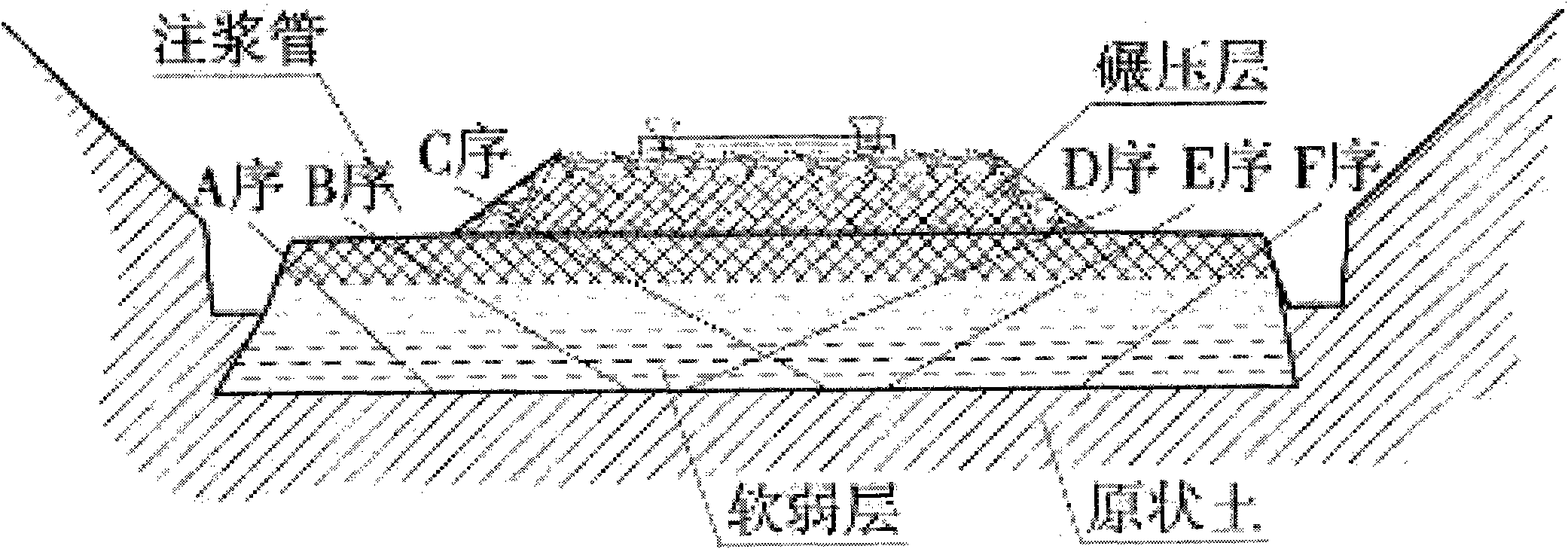

InactiveCN102071607AImprove waterproof and drainage performanceImprove bearing capacityTrack maintainenceSoil preservationFrostFreeze injury

The invention discloses a railroad bed repair method without affecting existing running conditions. The method comprises the following steps of: determining the destroy section position and the destroy type of a bed; drilling grouting holes on two sides of the destroy section bed; determining a grouting method and a grouting material according to the destroy type and the destroy section position; and grouting the grouting material into the bed by using the grouting method through the grouting holes. The construction of the scheme does not occupy the railway running space, does not affect normal running of the railway, and can perform reinforcement from the surface of the bed to the deep place of dozens of meters below the bed. The foundation and the ground surface do not need to be dug during construction, so the method has low labor intensity, high mechanization degree and short construction period, effectively treats frost boiling, sinking, extrusion, freezing injury and the like, improves the bearing capacity of the bed and improves the drainage resistance of the bed.

Owner:北京中铁瑞威基础工程有限公司

Repair method for ballastless track foundation settlement

InactiveCN104452484AControl extensionControl Lifting AccuracyBallastwayTrack maintainenceEngineeringRepair method

The invention relates to a repair method for ballastless track foundation settlement. The method includes the first step of lifting a supporting layer of a settlement area to make a corresponding track board lifted by a preset rising amount, the second step of conducting grouting and compacting on the lower portion of the lifted supporting layer, and the third step of finishing grouting and completing repair. By means of the method, the lifting accuracy can be accurately controlled.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

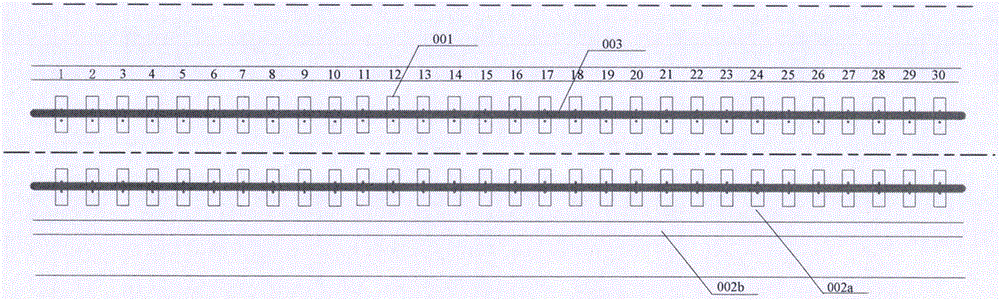

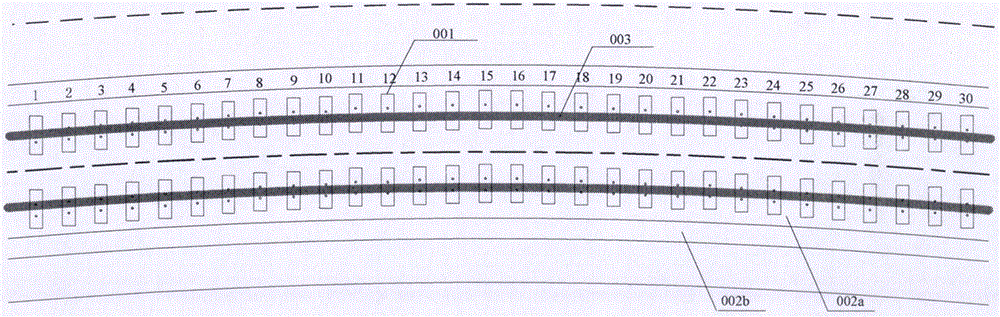

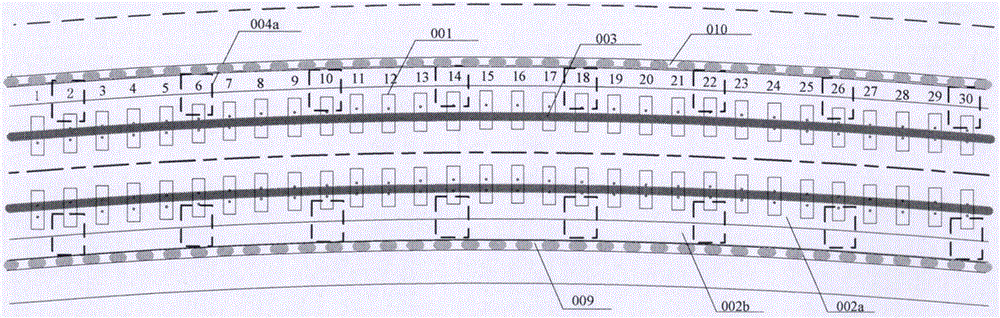

Center line deviation rectifying method for ballastless track of high-speed railway of roadbed segment

ActiveCN106049193AGuaranteed alignmentGuaranteed smoothnessBallastwayTrack maintainenceMiddle lineFastener

The invention provides a center line deviation rectifying method for a ballastless track of a high-speed railway of a roadbed segment. The method includes the following steps that the center line deviation amount and settling amount of a ballastless track line are measured; measured data are analyzed, and in combination of the track structure characteristics, lifting points and jacking points are arranged at the lower portion and the side face of a whole roadbed of a ballastless track structure; lifting devices are installed on the lifting points, the whole roadbed of the ballastless track and an upper structure are finely lifted, after an interface between the whole roadbed and graded gravel is jacked to be loosened, the lifting devices are unloaded, and the whole roadbed falls back; jacking devices are installed on the jacking points, and through grouped loading and level-by-level jacking, the ballastless track line is rectified to a designed position; and after line center line deviation rectification is finished, line restoration operation is conducted, a gap in the lower portion of the whole roadbed of the ballastless track is filled with polymer cement mortar, and line smoothness is restored through a fine adjustment fastener system. By the adoption of the method, the problem of center line deviation of the ballastless track line of the roadbed segment can be safely, rapidly and effectively solved within a skylight time, and line smoothness is restored.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +3

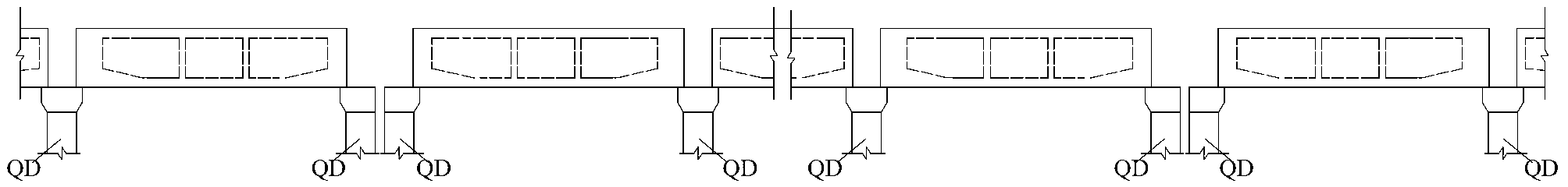

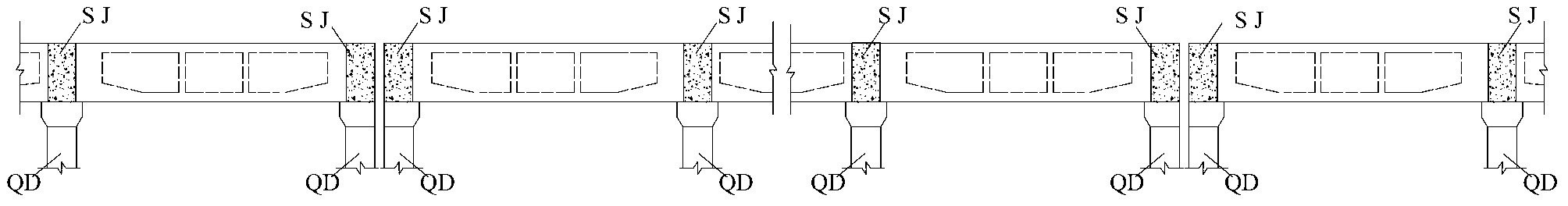

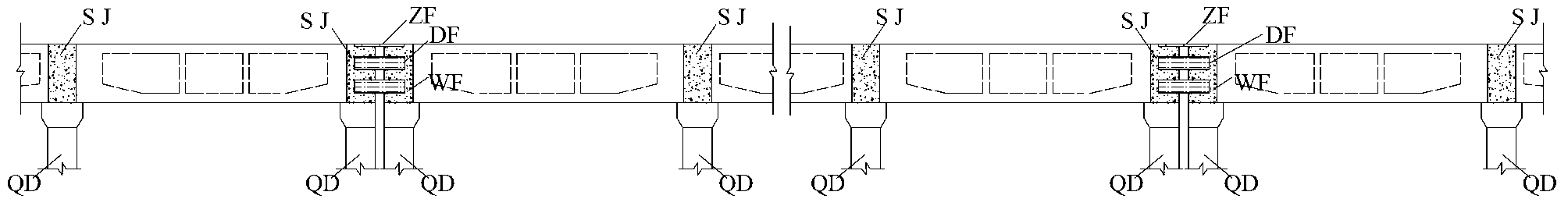

Straddle type monorail transportation rigid framework system

InactiveCN103161101AReduce the number of expansion jointsImprove riding performanceBridge erection/assemblyTrack maintainenceStraddleExpansion joint

The invention discloses a straddle type monorail transportation rigid framework system, and relates to track beams and piers in a straddle type monorail transportation system. In order to increase smooth of lines, reduce the number of monorail transportation track beam expansion joints, eliminate cast steel tension supports, reduce abrasion to rubber wheels and construction cost, and prolong service life of vehicles, the straddle type monorail transportation rigid framework system is designed. The straddle type monorail transportation rigid framework system is composed in a multi-connected rigid frame bridge mode, a rigid frame bridge is formed by connecting concrete track beams which are prefabricated by a workshop on pier bent cap top surfaces through wet joints in a simple support into continuous method, the track beams are prefabricated by the workshop, adjacent two-connected rigid frame bridges are connected through seamless expansion joints or joint plates or plate type rubber expansion joints, and seamlessness of the straddle type monorail transportation lines is achieved.

Owner:BEIJING JIAOTONG UNIV

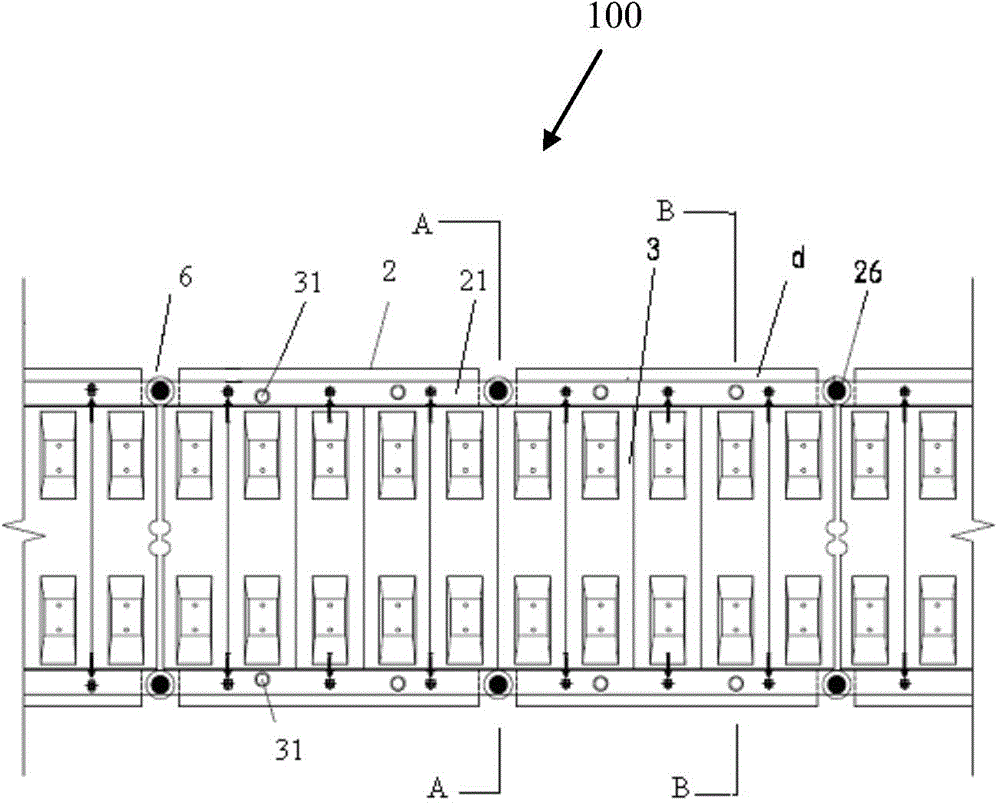

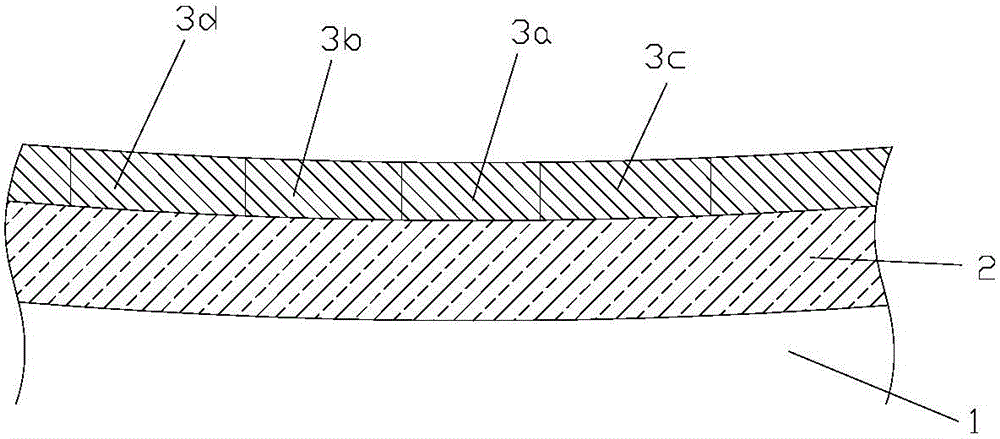

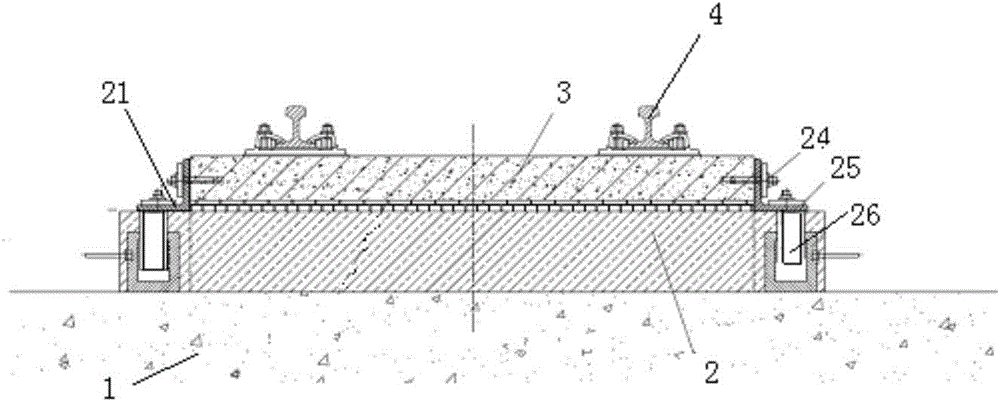

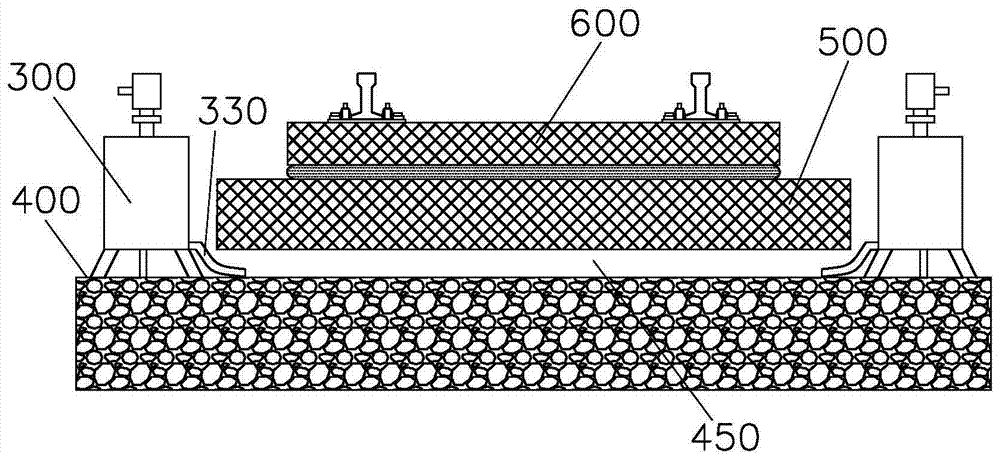

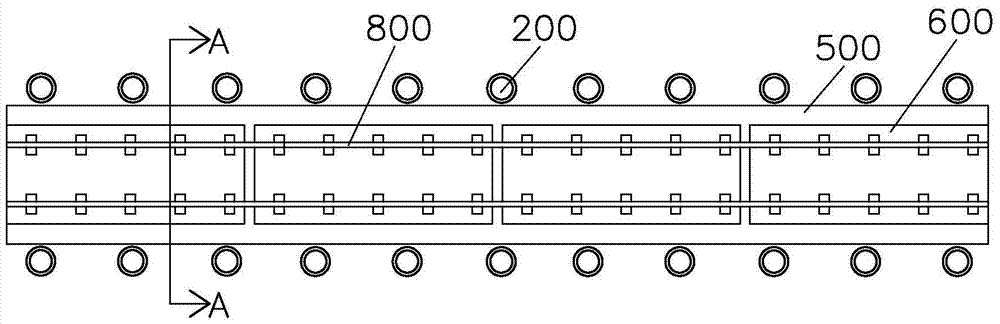

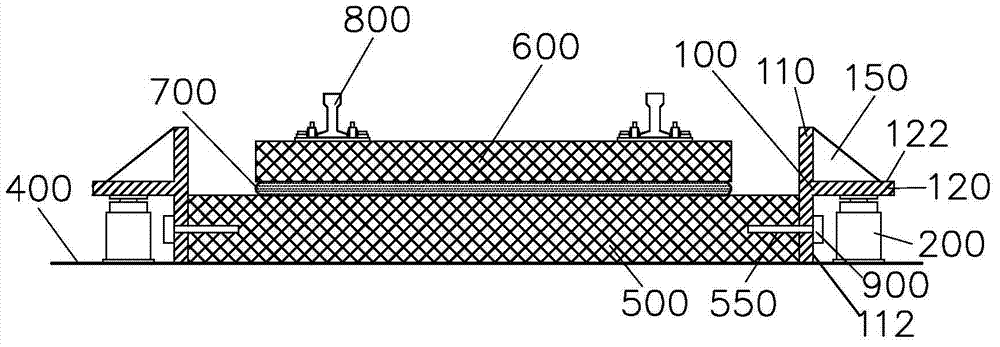

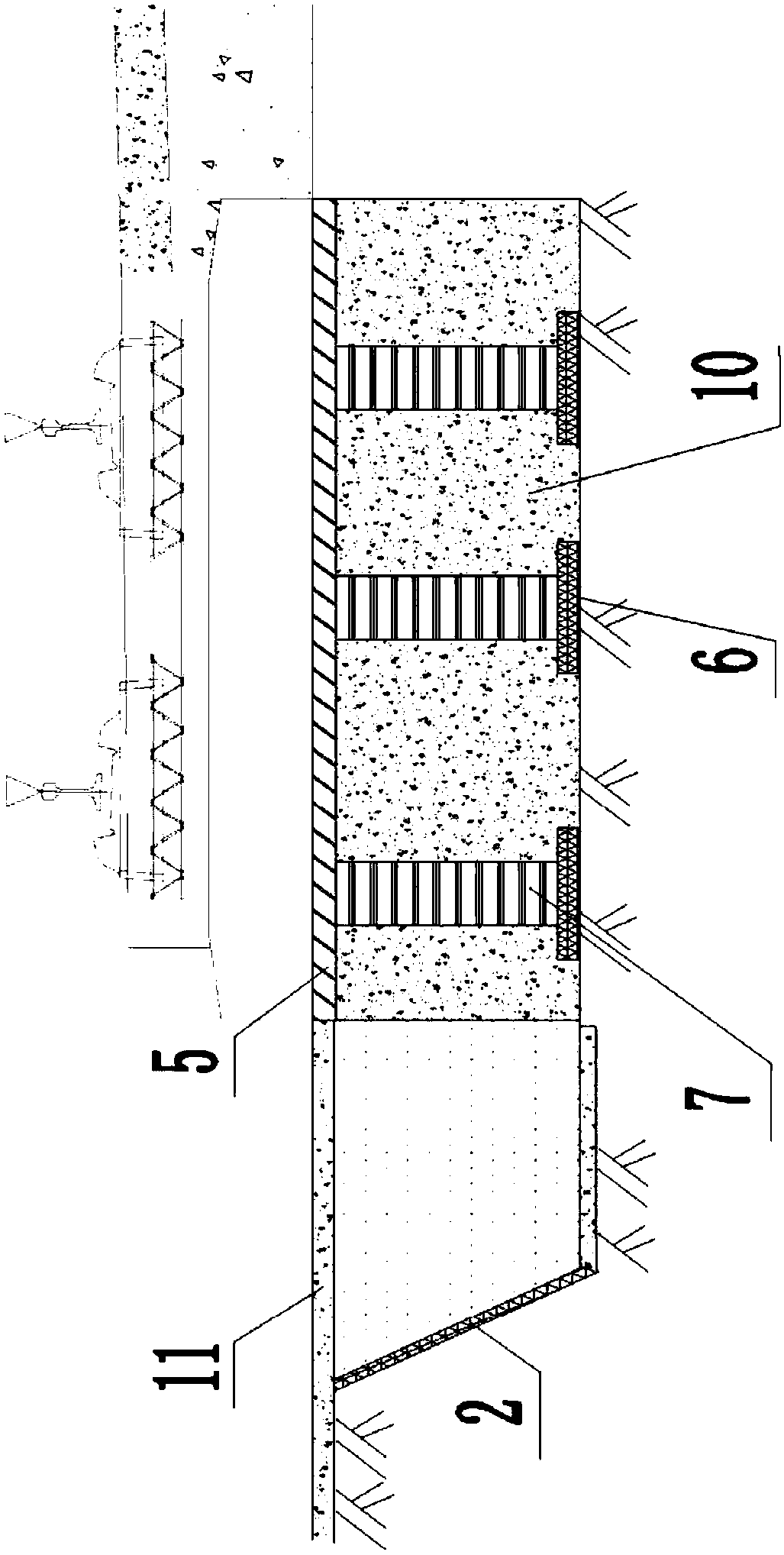

System and method for high-speed railway subgrade settlement restoration

InactiveCN103757993AGuaranteed not to breakMeet job requirementsBallastwayTrack maintainenceAutomatic controlEngineering

The invention discloses a system and method for high-speed railway subgrade settlement restoration. The system comprises at least eight lifting components, at least eight hydraulic lifting devices, a hydraulic distribution device, an automatic control system and a grouting device, wherein the at least eight lifting components are arranged at preset lifting points on a base plate, and every lifting component comprises a connecting part and a lifting part; every hydraulic lifting device is arranged between a high-speed railway subgrade and the lifting part of the lifting component; the hydraulic distribution device is connected with every hydraulic lifting device through hydraulic pipelines; the automatic control system controls the hydraulic distribution device to provide preset hydraulic pressure for every hydraulic lifting device so as to lift the base plate to a preset height of the high-speed railway subgrade; and the grouting device pours slurry in gaps formed between the base plate and the high-speed railway subgrade through slurry pipelines so as to support the base plate after the slurry is solidified. The invention further provides a method for track plate and base plate integrated lifting type high-speed railway subgrade settlement restoration.

Owner:北京中铁瑞威基础工程有限公司

Method of surveying a track

InactiveUS20030097235A1Time-consume taskImprove accuracyBallastwayDigital data processing detailsGps receiverReference line

In a method of surveying a track (9), a first or mobile measuring vehicle (1) and a second or stationary measuring vehicle (2) are placed at a distance apart from one another on a track section to be measured. A reference line (14) is formed by a laser beam emitted from the stationary measuring vehicle (2). At the start of each measuring cycle, by using a GPS receiver (19), the relative position of the stationary measuring vehicle (2) with reference to a fixedly installed GPS reference station (29) located adjacent to the track section is determined, the said GPS reference station being known within a terrestrial coordinate system. The reference line (14) is aligned with the mobile measuring vehicle (1) on the basis of the determined position data, and the track surveying operation is carried out by advancing the mobile measuring vehicle (1) while changes of the actual track position relative to the reference line (14) are registered.

Owner:FRANZ PLASSER BAHNBAUMASCHINEN IND GMBH

Girder-exchange construction method for existing railway bridge by successively incremeantal launching framework process

ActiveCN101200881AReduce the impact of operationsReduce investmentBridge erection/assemblyBridge strengtheningEngineeringBallast

The invention relates to a girder replacement construction method of the existing railway line bridges, which applies a method of incremental launching framework. The girder replacement construction method is fulfilled according to seven steps: (1) A split slideway is respectively arranged on one side of the existing line and a framework is respectively prefabricated on the split type slideway; (2) Temporary rest piers are arranged under the existing line bridge and used to upbear a track skeleton, and the locking of seamless lines and the installation of a crossarm track are carried out on the two sections of a grider-replaced section; (3) The temporary rest piers are used to upbear the girder body of the existing line, and the bearings under the existing girder are disassembled; (4) the prefabricated framework is connected with the existing girder by a steel stranded wire; (5) A continuous jack is utilized to tow the steel stranded wire to haul the cascaded framework and the existing girder to the position required by the design; (6) The bearing side under the bottom plate of the prefabricated framework is grouted and reinforced; (7) After dropping the track and replenishing ballast, the line is resumed. The present invention has the advantages that the construction is safe and stable, the cost is reduced, the construction procedures are simplified, the construction period is shortened and the engineering cost is saved.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD

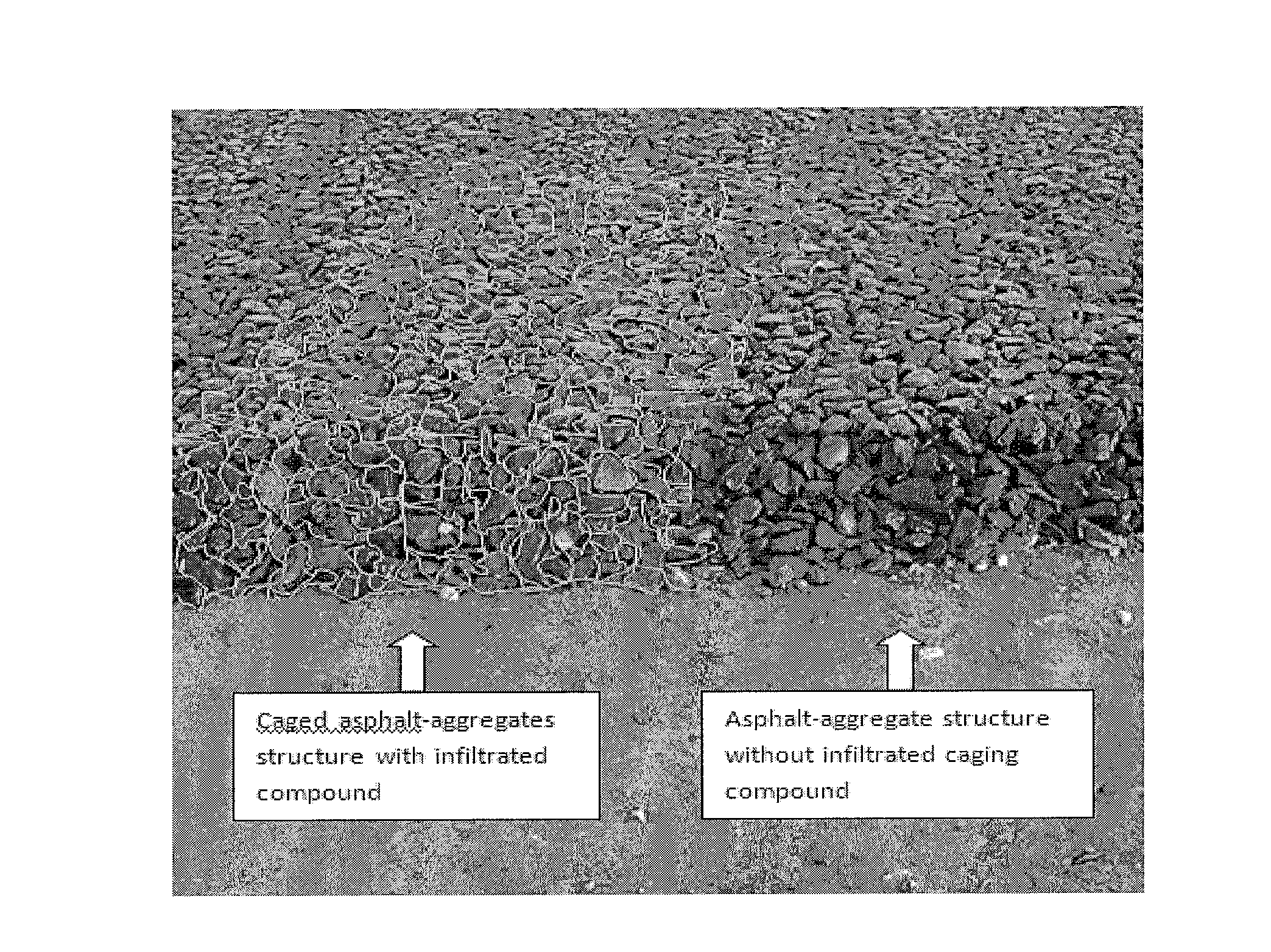

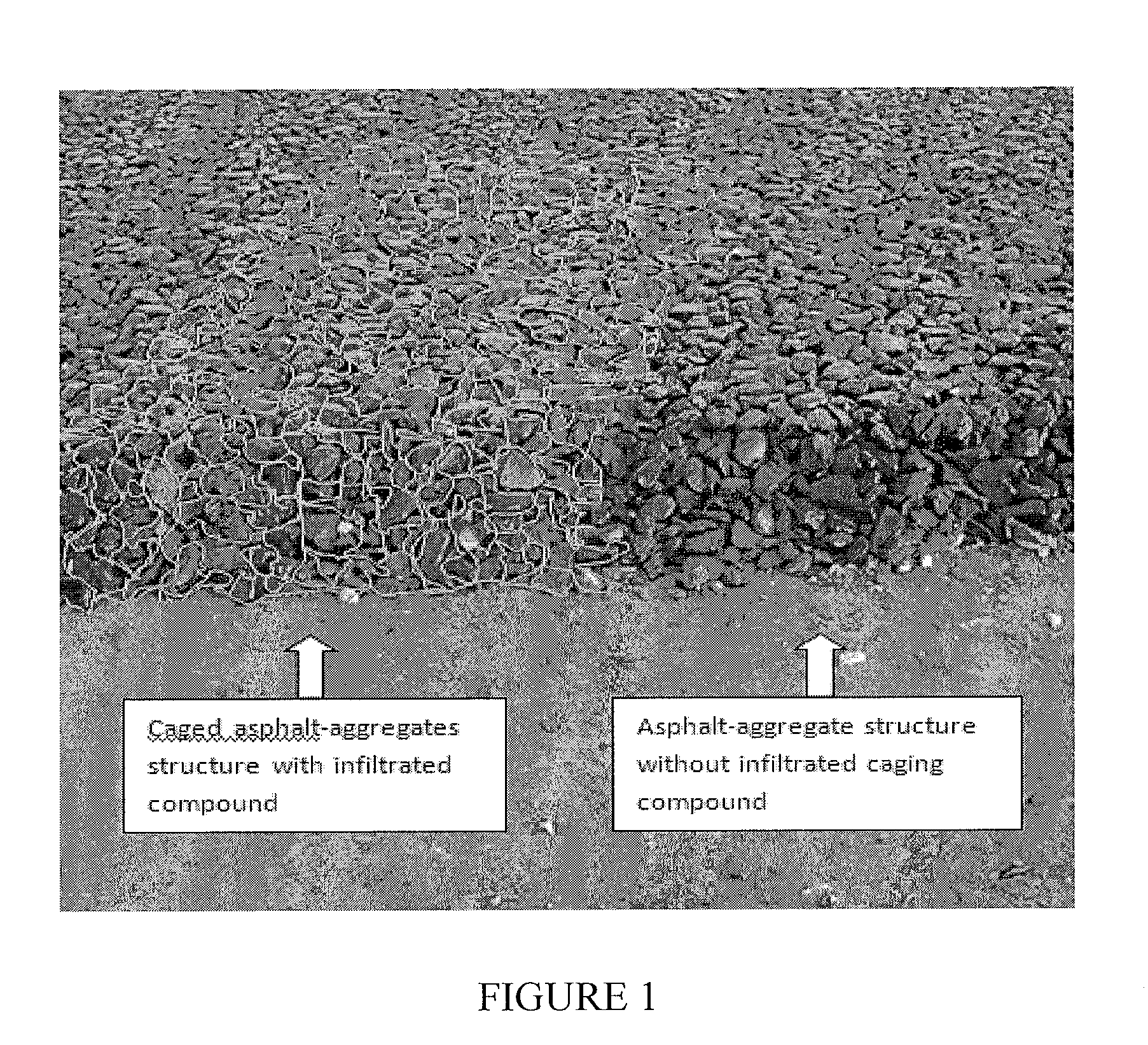

Application of high toughness, low viscosity nano-molecular resin for reinforcing pothole patching materials in asphalt and concrete base pavement

ActiveUS20110293954A1Increased durabilityHigh strengthSolid waste managementBallastwayRoad surfaceViscosity

Described herein are methods of improving the durability of concrete by the infusion of the concrete with a low-viscosity oligomeric solution, and subsequent curing of the oligomeric solution to form a high toughness polymer. Also described herein are compositions containing concrete and high toughness polymers, and formed articles made from concrete and high toughness polymers. The methods and compositions are useful for improving the durability of concrete roads and structures, as well as the durability of repairs to concrete roads.

Owner:RGT UNIV OF CALIFORNIA

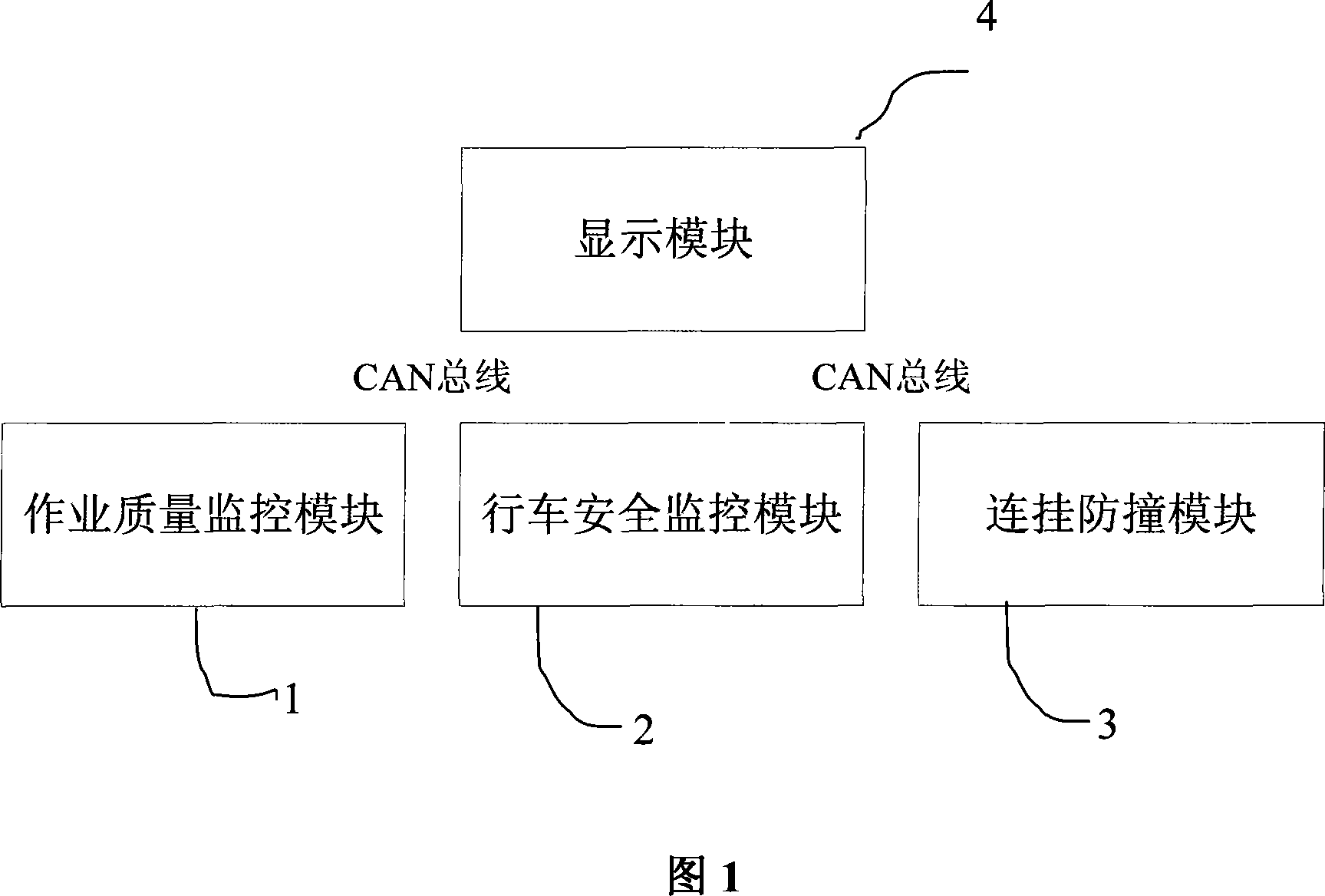

Monitor system for operation safety and operation quality of railway large-scale maintenance machinery

A monitor system for the operation safety and operation quality of large railway maintenance machines is provided, which comprises an operation quality monitoring module, a run safety montoring module, a connection / hanging anti-collision module and a display module. The modules are connected with the display module through a CAN bus. The operation quality monitoring module monitors and records the operation parameters to ensure accuracy in operation, which can also be taken as the basis for acceptance of railway; the run safety mentoring module monitors and records the info concerning the safety of running, prevents occurrence of accident; the connection / hanging anti-collision module will automatically judge any danger source in front, prevent any accident; the display module plays the role for man-machine interaction. In each module, special way is used for monitoring the operation quality, run safety and the anti-collision in connection / hanging.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD +1

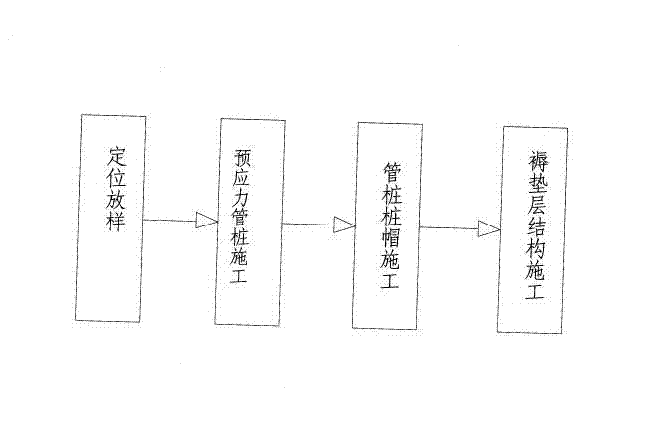

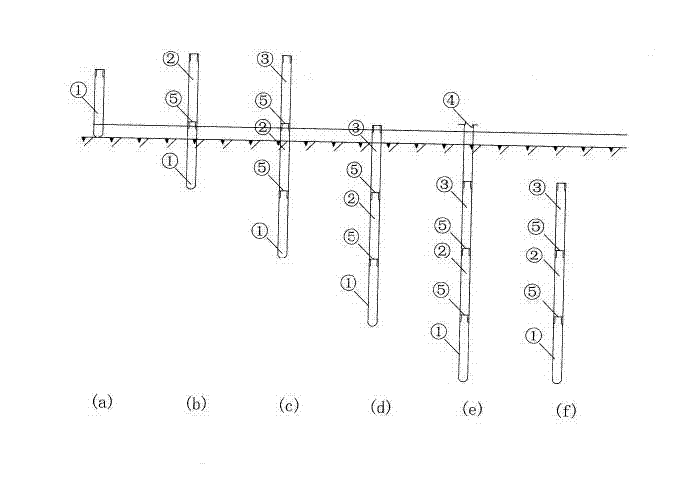

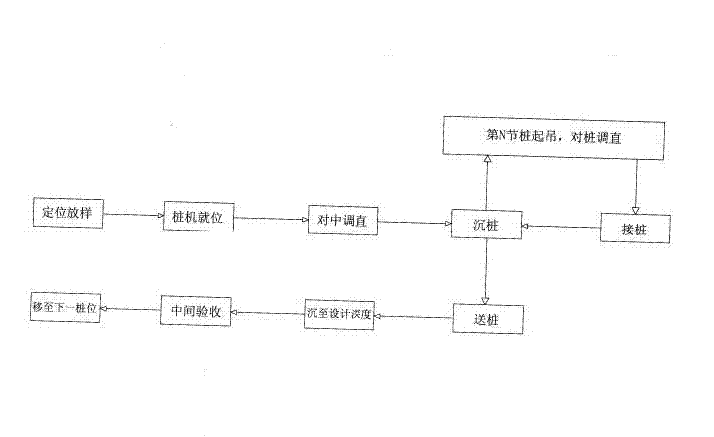

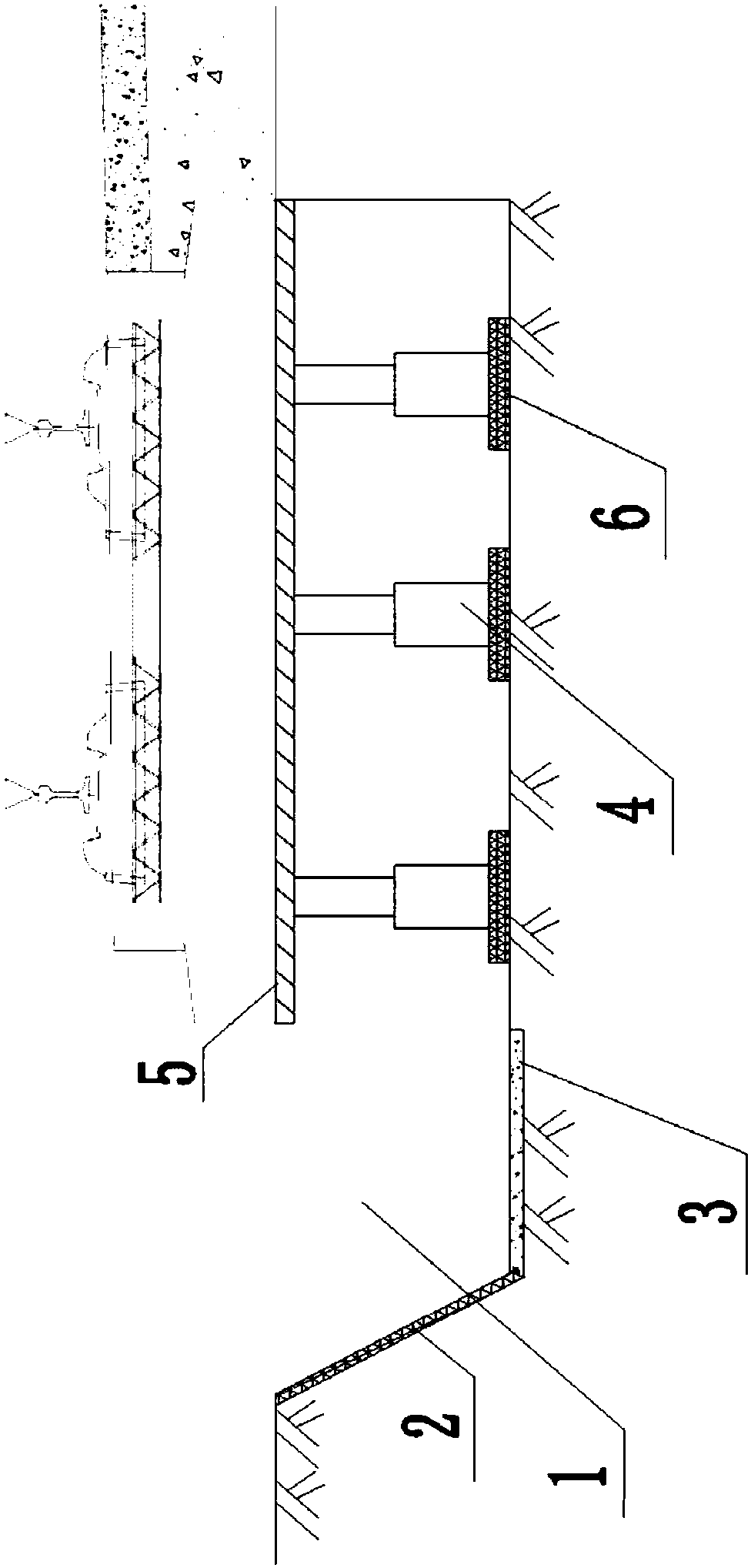

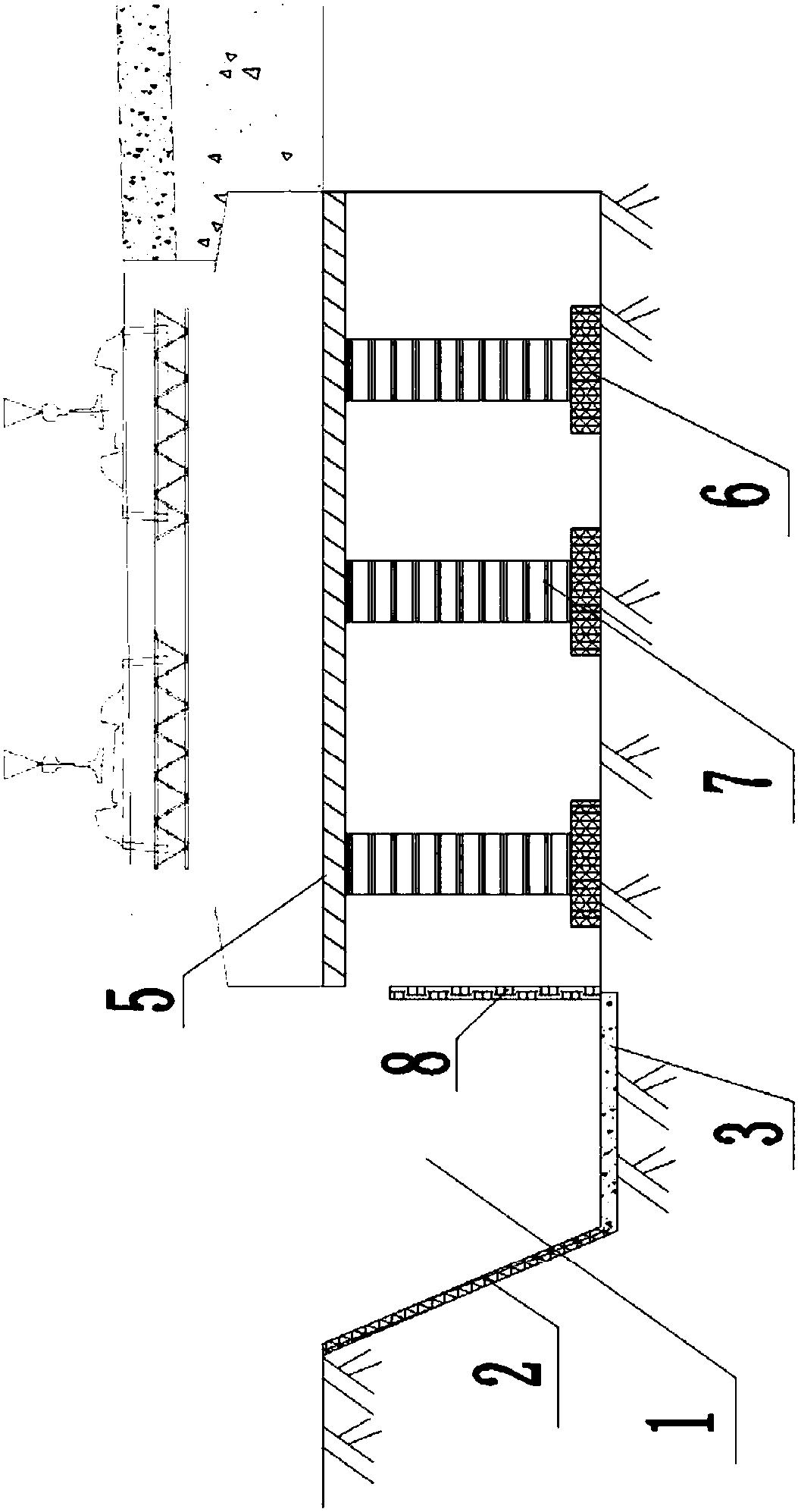

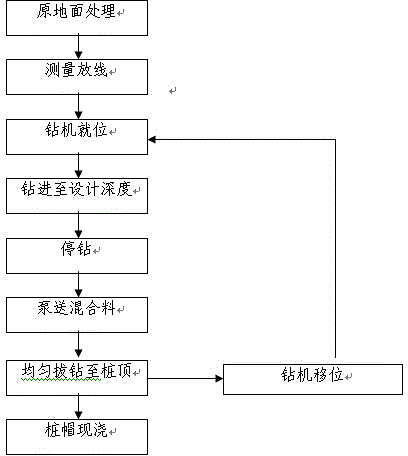

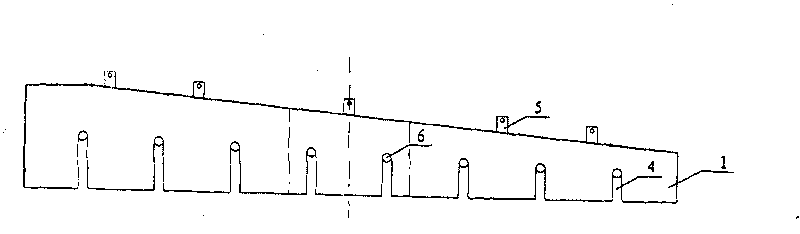

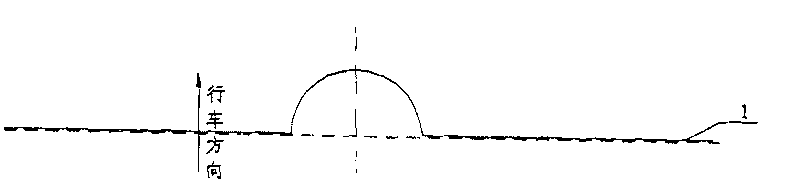

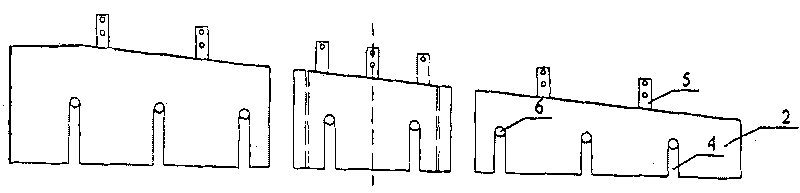

Roadbed having pile-net combination structure and construction method thereof

ActiveCN102535263AReach carrying capacityMeet the requirementsTrack maintainenceBulkheads/pilesChipsealSubgrade

The invention provides a roadbed having a pile-net combination structure and a construction method thereof, which solves the technical problems that soft-soil foundation in superlarge area cannot be treated effectively and post-construction settlement cannot be effectively overcome in the prior art. The roadbed comprises prestress tubular piles (1), prestress tubular pipe caps (2), a prestress tubular pile ground beam (3) and a cushion layer (4), wherein the cushion layer (4) sequentially consists of a first gravel cushion layer (5), a first medium-coarse sand cushion layer (6), a geogrid (7), a second medium-coarse sand cushion layer (8) and a second gravel cushion layer (9) from bottom to top. The thickness of each gravel cushion layer is 25mm, the grain diameter of gravel in the gravel cushion layers is smaller than or equal to 3mm, the silt content of the gravel cushion layers is smaller than or equal to 5%, the thickness of each medium-coarse cushion layer is 5mm, the silt content of the medium-coarse cushion layers is smaller than or equal to 5%, bidirectional tension strength of the geogrid (7) is larger than or equal to 80 kilonewton / m, extension rate of the geogrid (7) is smaller than or equal to 15%, and compacting factor of the cushion layer (4) is smaller than 0.9. The invention further discloses a construction method of the roadbed. The roadbed is low in general manufacturing cost and has excellent economic benefits and popularization value.

Owner:CHINA RAILWAY 19 BUREAU GRP CO LTD

Treatment method for ballastless track roadbed arching

ActiveCN108951307AAvoid destructionEnsure structural safetyTrack maintainenceCrushed stoneRisk stroke

The invention relates to the field of railway roadbed engineering, in particular to a treatment method for a ballastless track roadbed arching disaster. The disaster is treated in the way that firstly, concrete of an arching section sealing layer on one side or two sides of a road shoulder is broken, a working groove is excavated downwards, and waterproof treatment is conducted on the groove bottom; then, foundation bed padding below a supporting layer is excavated, adjustable supporting devices are used for supporting after excavation is conducted, and a crossbeam and cushion blocks are arranged at the upper ends and the lower ends of the adjustable supporting devices; after excavation is finished, the elevation of track slabs is reduced through reduction of the height or the stroke of the adjustable supporting devices, then simple supports are used for replacing the adjustable supporting devices, and finally a packing material is poured; and the working groove is tamped and filled with graded broken stones layer by layer, and the sealing layer is repaired through concrete. The elevation of the track slabs is recovered to the original designed elevation, and the smoothness of a line is recovered. The provided method has the beneficial effects that construction is convenient and quick, economic cost is low, railway normal operation is not affected, and therefore the method is more practical.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

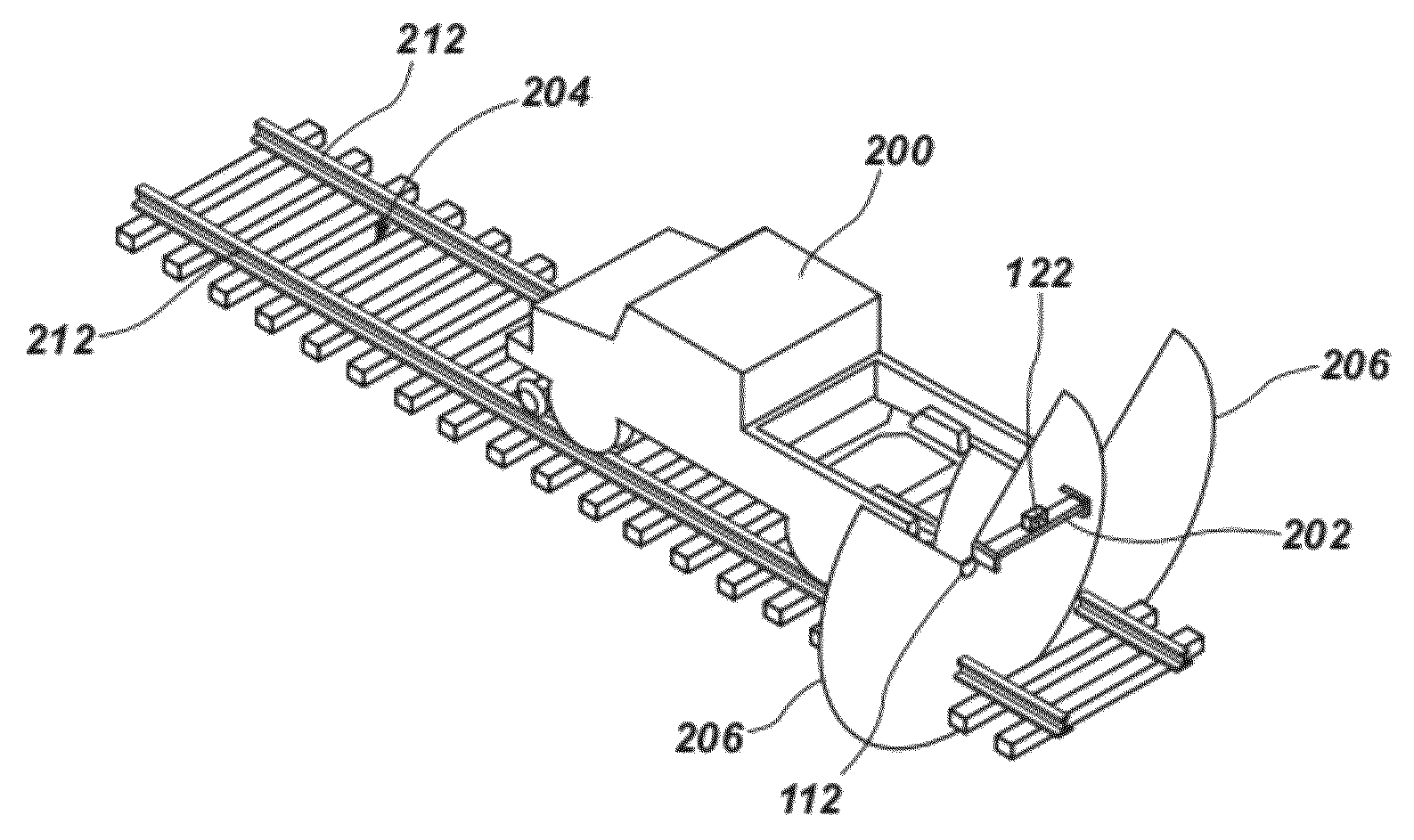

Ballast delivery and computation system and method

ActiveUS8875635B2Vehicle testingRegistering/indicating working of vehiclesEngineeringComputing systems

A method for delivering ballast to a section of railroad track includes measuring an existing ballast profile of a section of railroad track using a remote sensing system, and providing a signal indicative thereof to a first computer. Using the first computer, the existing ballast profile is compared with an ideal ballast profile to compute a track file representing a volume of additional ballast needed as a function of linear position along the section of railroad track, and data representing the track file is transmitted to a second computer of an automatic ballast dump train. Ballast is dumped along the section of railroad track according to the track file under control of the second computer.

Owner:LORAM TECH INC

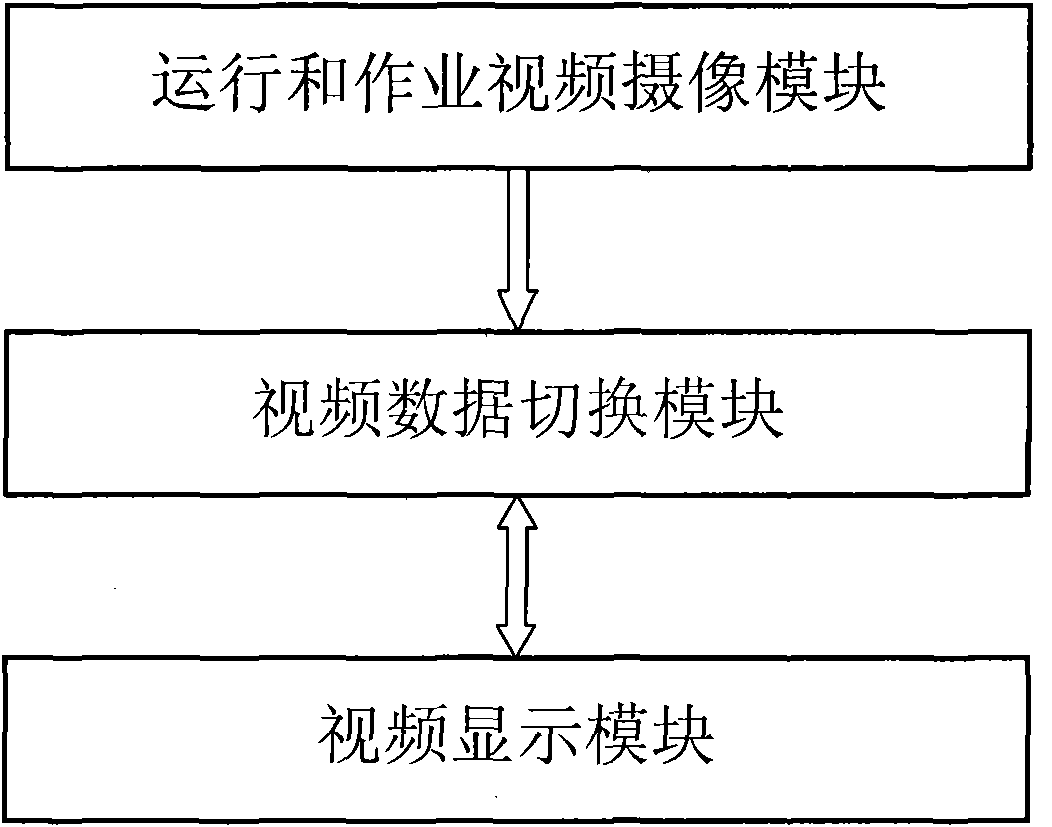

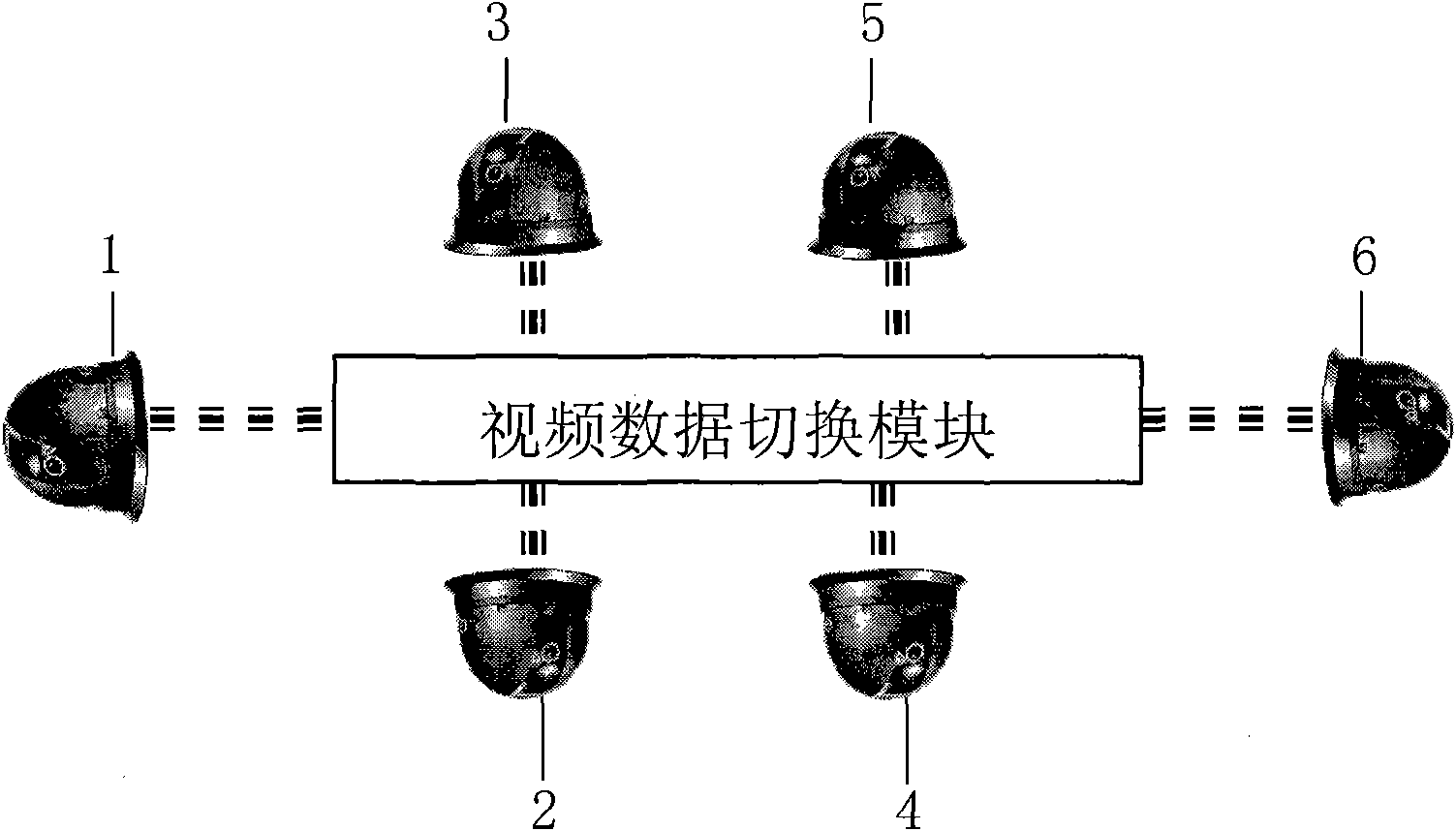

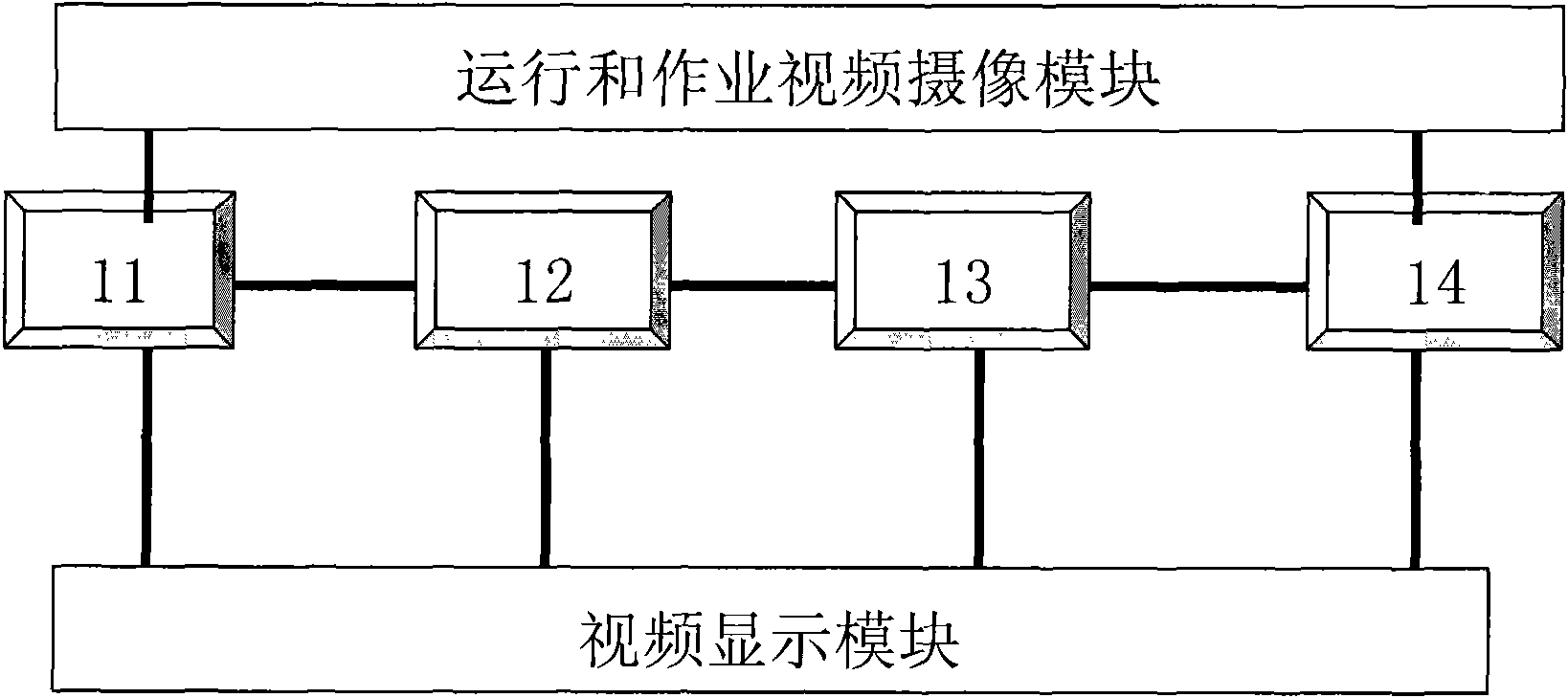

Auxiliary driving and operating system for large road maintenance machine for railways

ActiveCN101899803AChange work modeReduce operating errorsClosed circuit television systemsTrack maintainenceComputer moduleCritical position

The invention provides an auxiliary driving and operating system for a large road maintenance machine for railways. The system comprises a vehicle body, a running and operating video pickup module, a video data switching module and a video display module, wherein the running and operating video pickup module is used for acquiring a running condition of the vehicle body in a running and operating state and a video image of a corresponding key operating part from each predetermined angle; the video data switching module is used for switching the video image acquired by the a running and operating video pickup module to the video display module; and the video display module is used for displaying the image switched by the video data switching module. The system can assist a large road maintenance machine operator in observing the running and operating state of the vehicle body at any time during working and accurately judging the condition of the vehicle body, changes the traditional operating mode of the operator, reduces operation error, equipment damage or personnel injury because the operator cannot directly observe the corresponding key position of the vehicle body, reduces the working strength of the operator, and improves the operating efficiency of the vehicle.

Owner:北京捷信安通科技有限公司

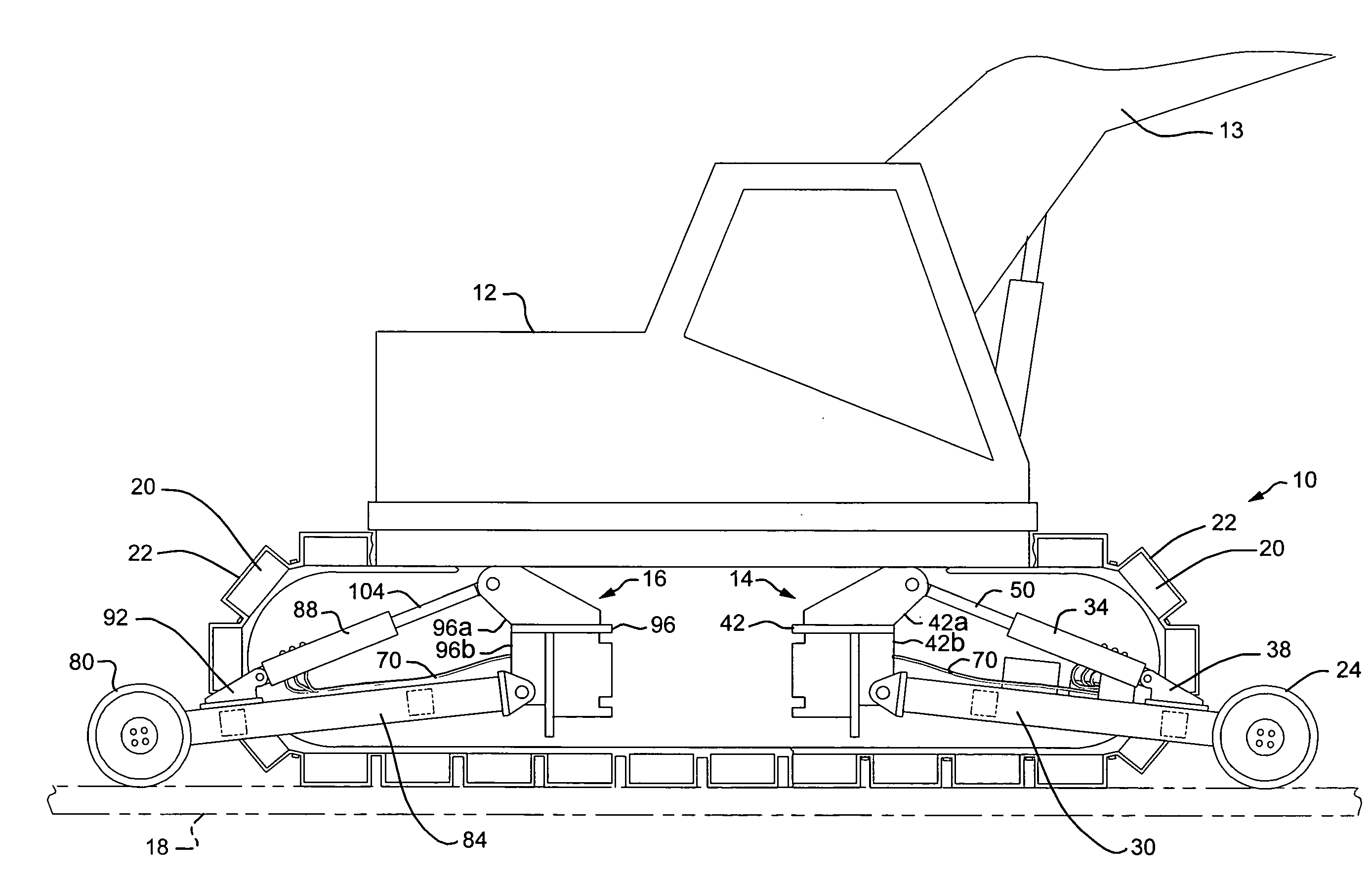

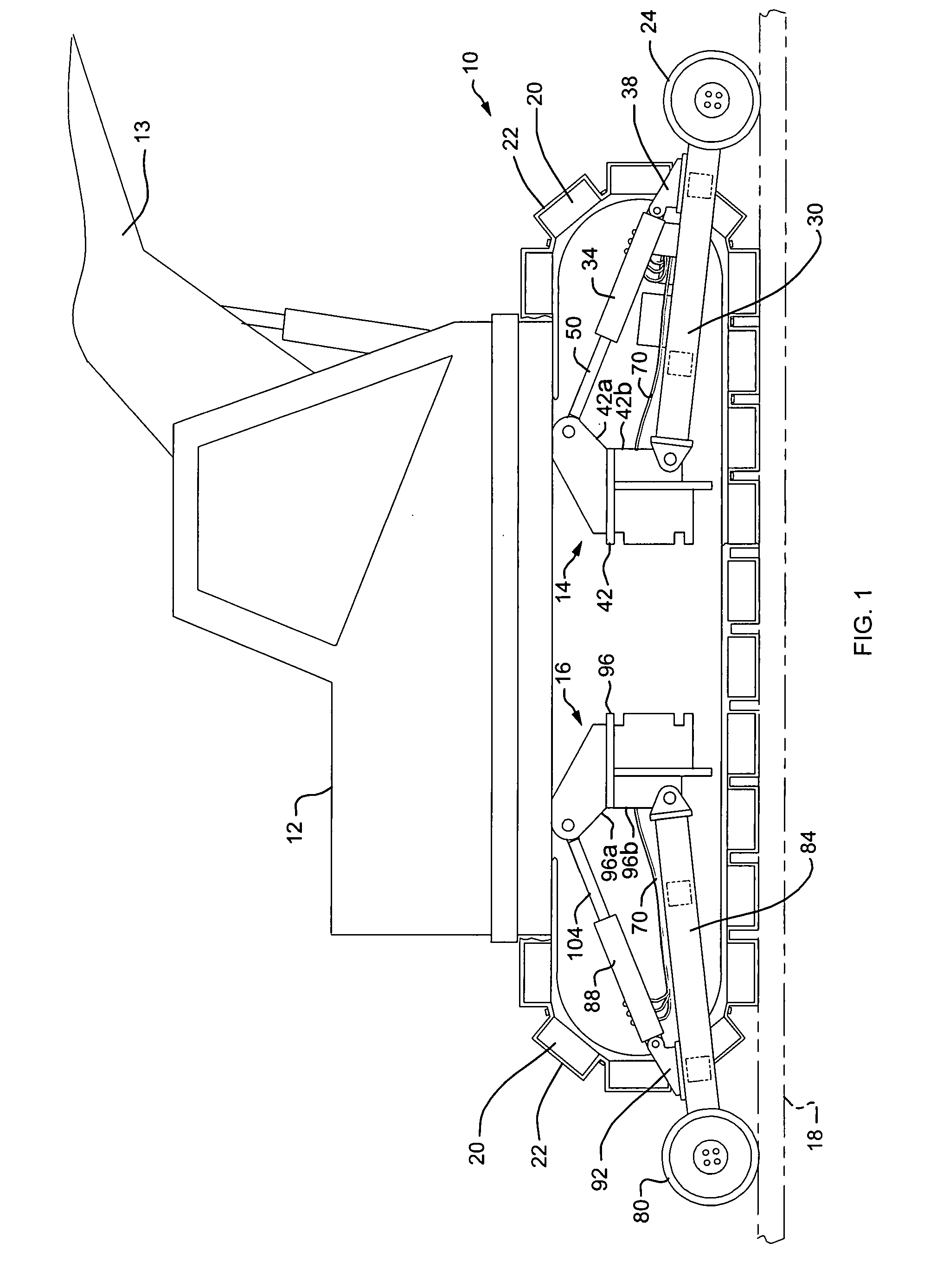

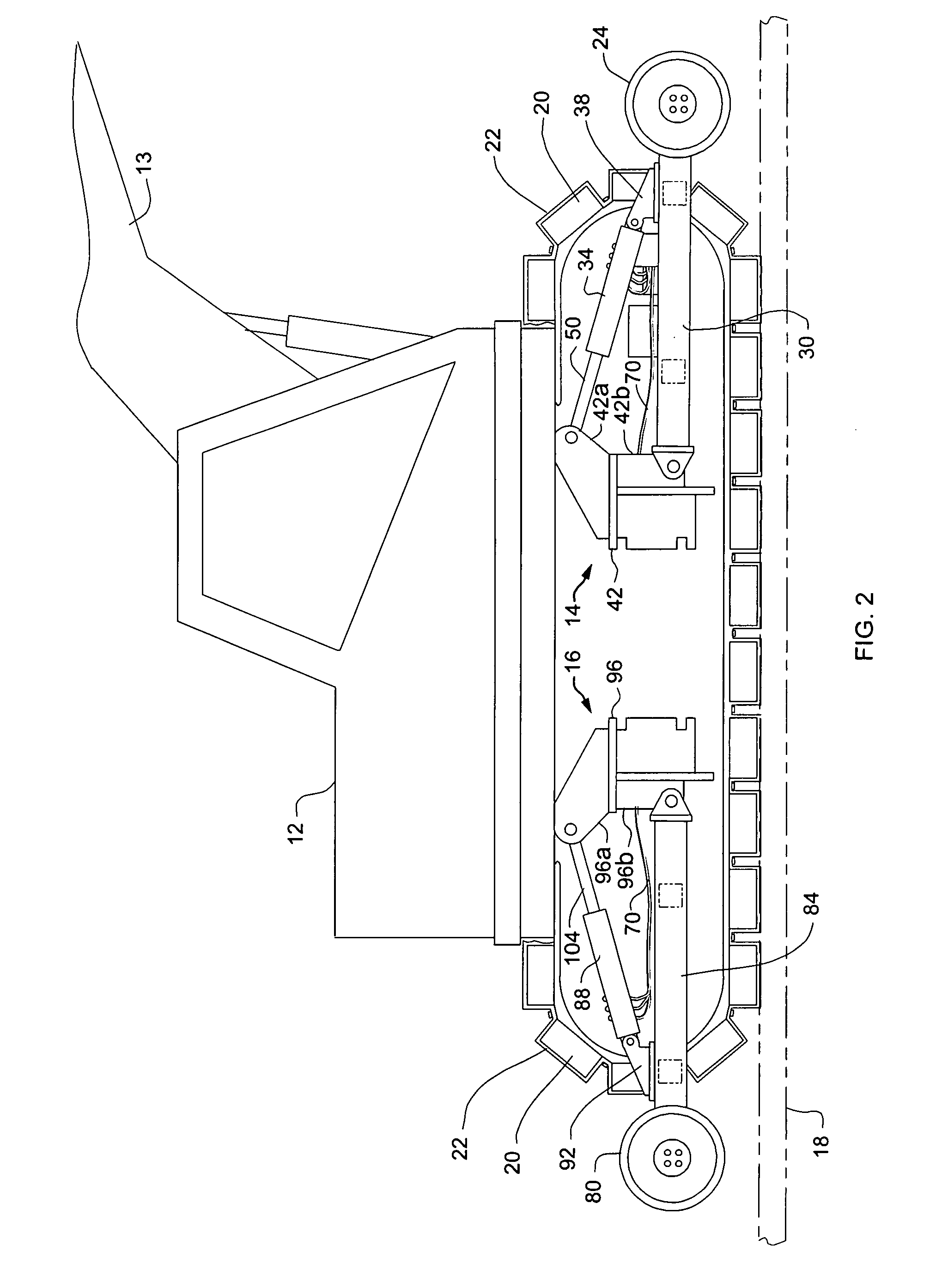

Apparatus for enabling an excavator to mount, demount and travel on railroad tracks

InactiveUS20080053332A1Soil-shifting machines/dredgersRail and road vehiclesHydraulic cylinderEngineering

A glyde-rail apparatus removably attached to a carrier such as an excavator to enable the excavator to mount and demount at any point along a railroad track and to travel along the railroad track without damaging the railroad track. The glyde-rail apparatus comprises a front swing arm assembly having a pair of rail wheels which removably attaches to one end of a frame of the excavator and a back swing arm assembly having a pair of rail wheels which removably attaches to a second end of the frame of the excavator. A pair of hydraulic cylinders positioned on the front swing arm assembly and another pair of hydraulic cylinders positioned on the back swing arm assembly enable the rail wheels to be raised or lowered onto the railroad track. A hard rubber cover attaches to the track of the excavator.

Owner:GLYDE RAIL LICENSING

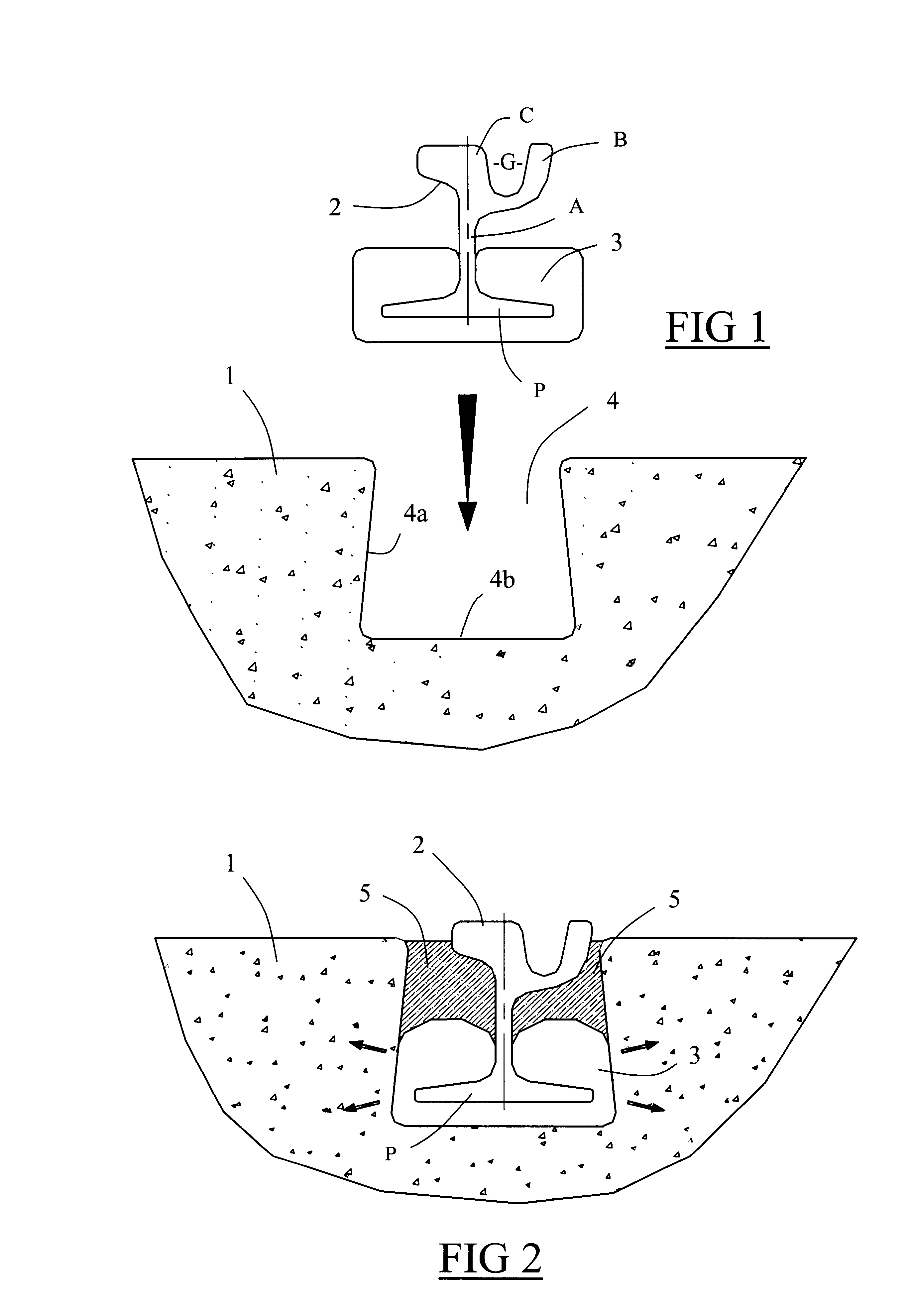

Method of constructing a rail track on a track-receiving concrete slab

Owner:ALSTOM TRANSPORT TECH SAS

Fast production method of track beams different in size and shape

ActiveCN103321113AFor quick replacementResume operationsBridge erection/assemblyTrack maintainenceTurn angleBridge engineering

The invention relates to a fast production method of track beams and belongs to the technical field of bridge engineering. The production method includes: combining and assembling prefabricated steel box segments (1), prefabricated connecting slabs (2), cast-in-place concrete (3) or prefabricated metal contact surface structures (4), which are designed preliminarily, thus quickly producing track beams which meet the field requirements and which are optional in length, height, curve radius and plane turning angle and optional in wheel-track contact surface linearity and size. The method has the advantages that the track beams different in size and shape can be quickly produced by the production method, and used as the substitute for track beams damaged in operation of straddle monorail transit, or used as a temporary track-beam structure for passage of bridge girder erection machines, on construction sites such as tunnels and deep trenches that a crane approaches with difficulty or at which the crane functions with difficulty during construction of monorail transit systems.

Owner:BEIJING JIAOTONG UNIV

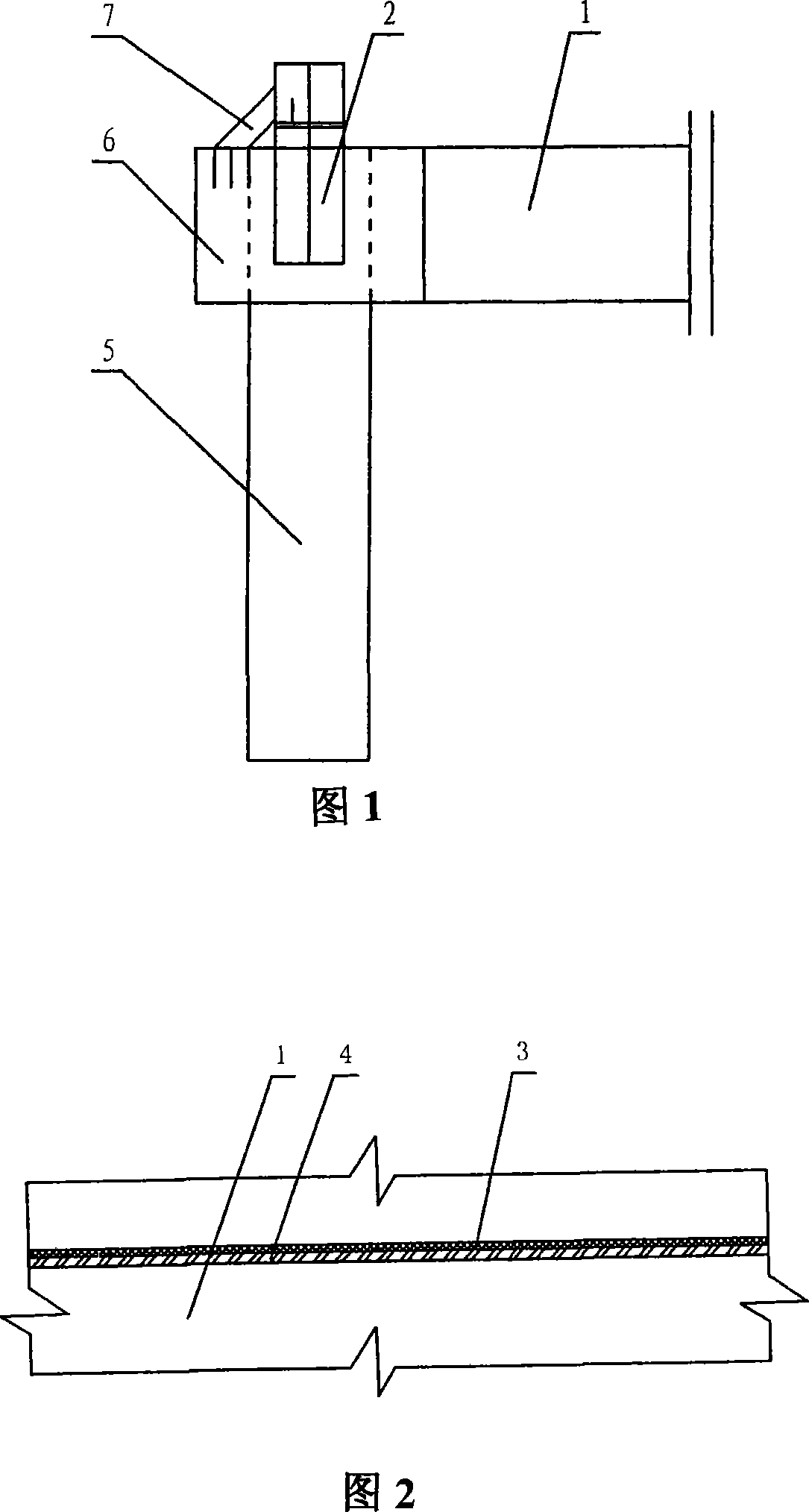

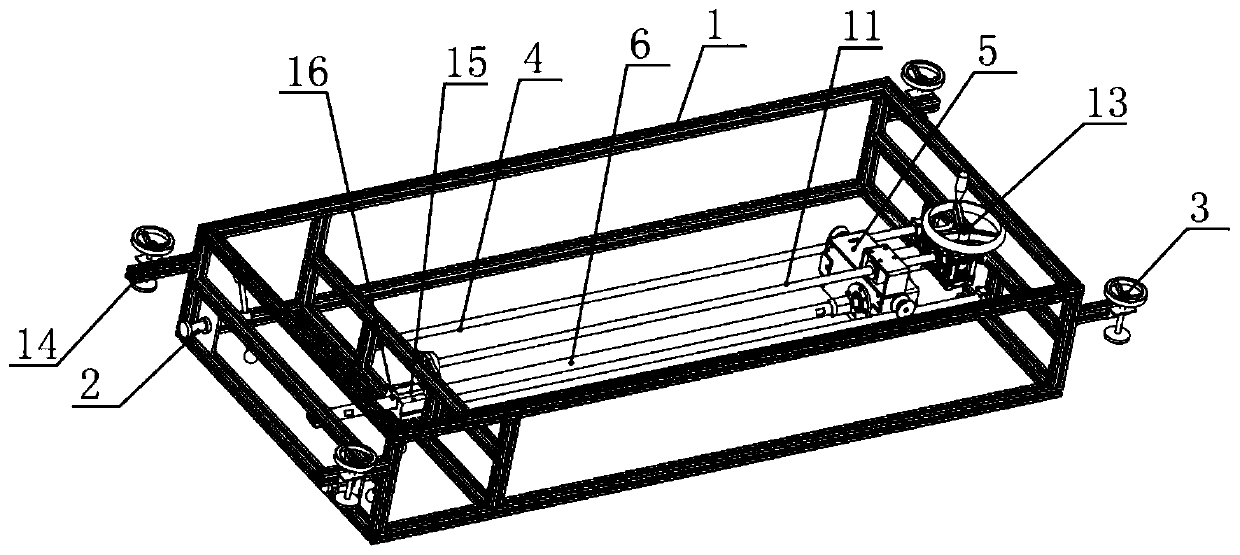

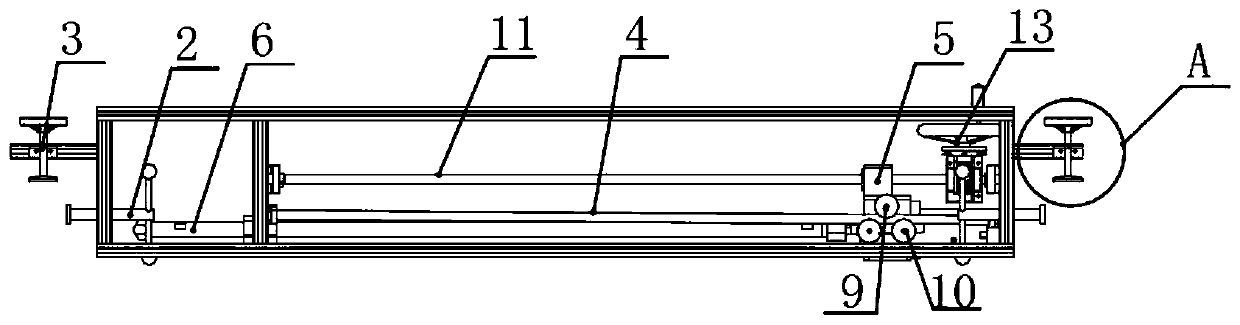

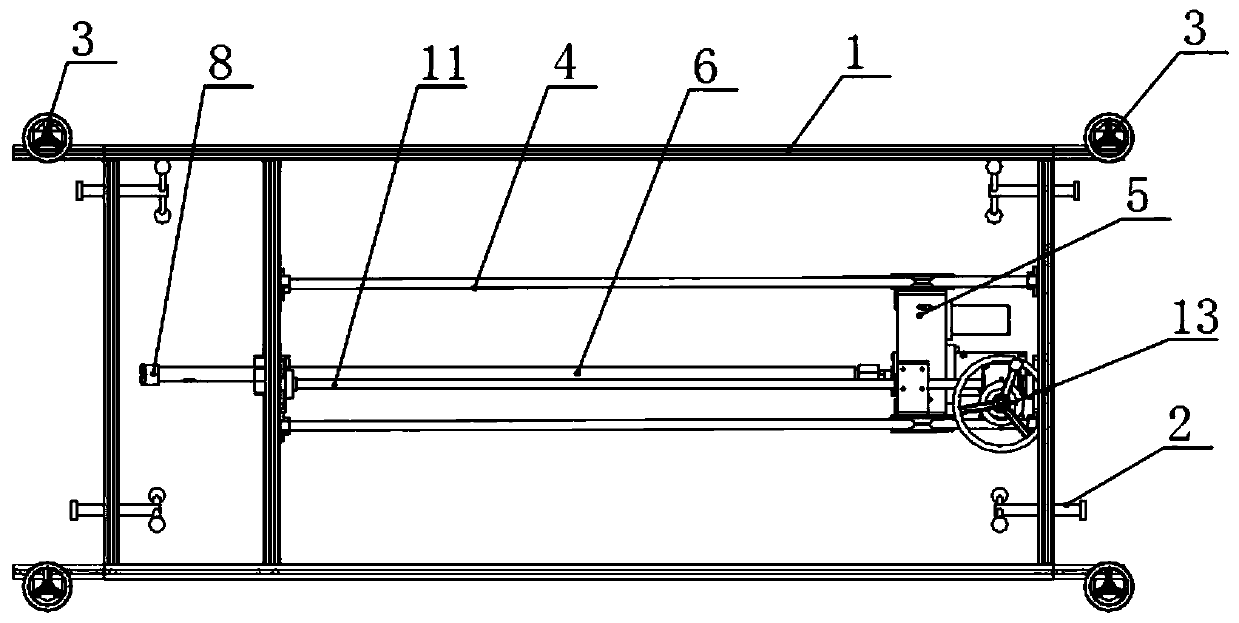

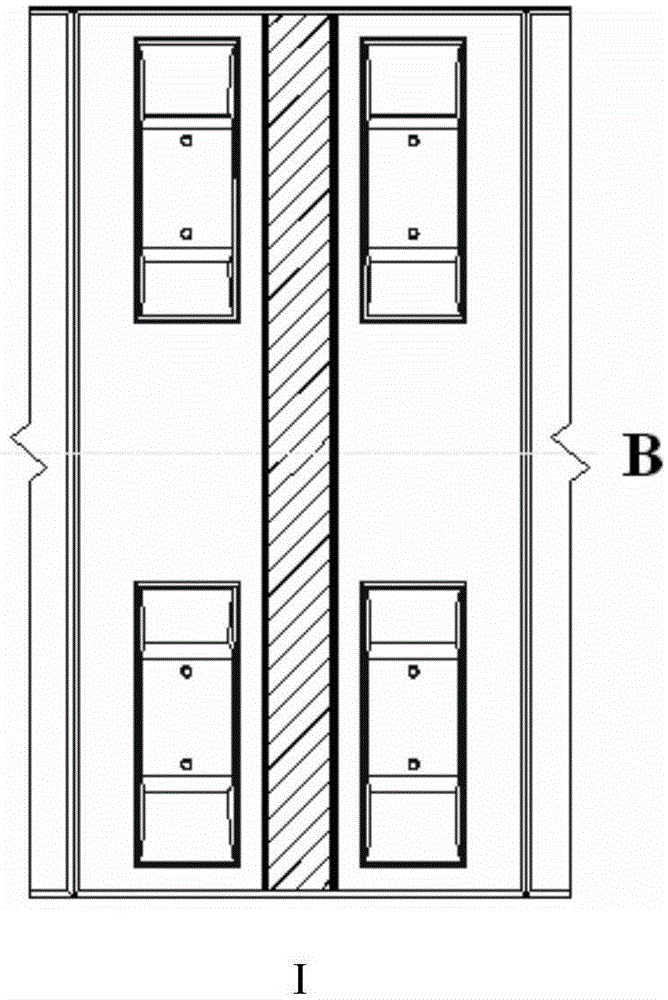

Ballastless track base plate post-cast strip breaking device, system and method

PendingCN110359329AWill be damagedDoes not cause crack growthTrack maintainenceLocking mechanismEngineering

The invention discloses a ballastless track base plate post-cast strip breaking device, system and method, and relates to the technical field of concrete breaking equipment. The device comprises a lateral locking mechanism which is fixed on a rack. The rack is also fixedly provided with a guide shaft, and the rack is further provided with a driving mechanism which slides along the guide shaft anda lifting mechanism which enables the driving mechanism to move up and down. The output end of the driving mechanism is provided with a hollow shaft, and the input end of the hollow shaft is is connected with a rotary joint; and the output end of the hollow shaft is further fixedly provided with a high-pressure spray head, wherein the high-pressure spray head communicates with the interior of thehollow shaft. According to the ballastless track base plate post-cast strip breaking device, system and method, a post-cast strip can be broken without using an oppositely-cover plate, and during theconstruction, a reinforcement cage structure can be maximally retained, so that a concrete structure is removed without damaging reinforcing steel bar, and accordingly the breaking speed of the post-cast strip is improved by 20 times-50 times.

Owner:成都交大铁发轨道交通材料有限公司 +1

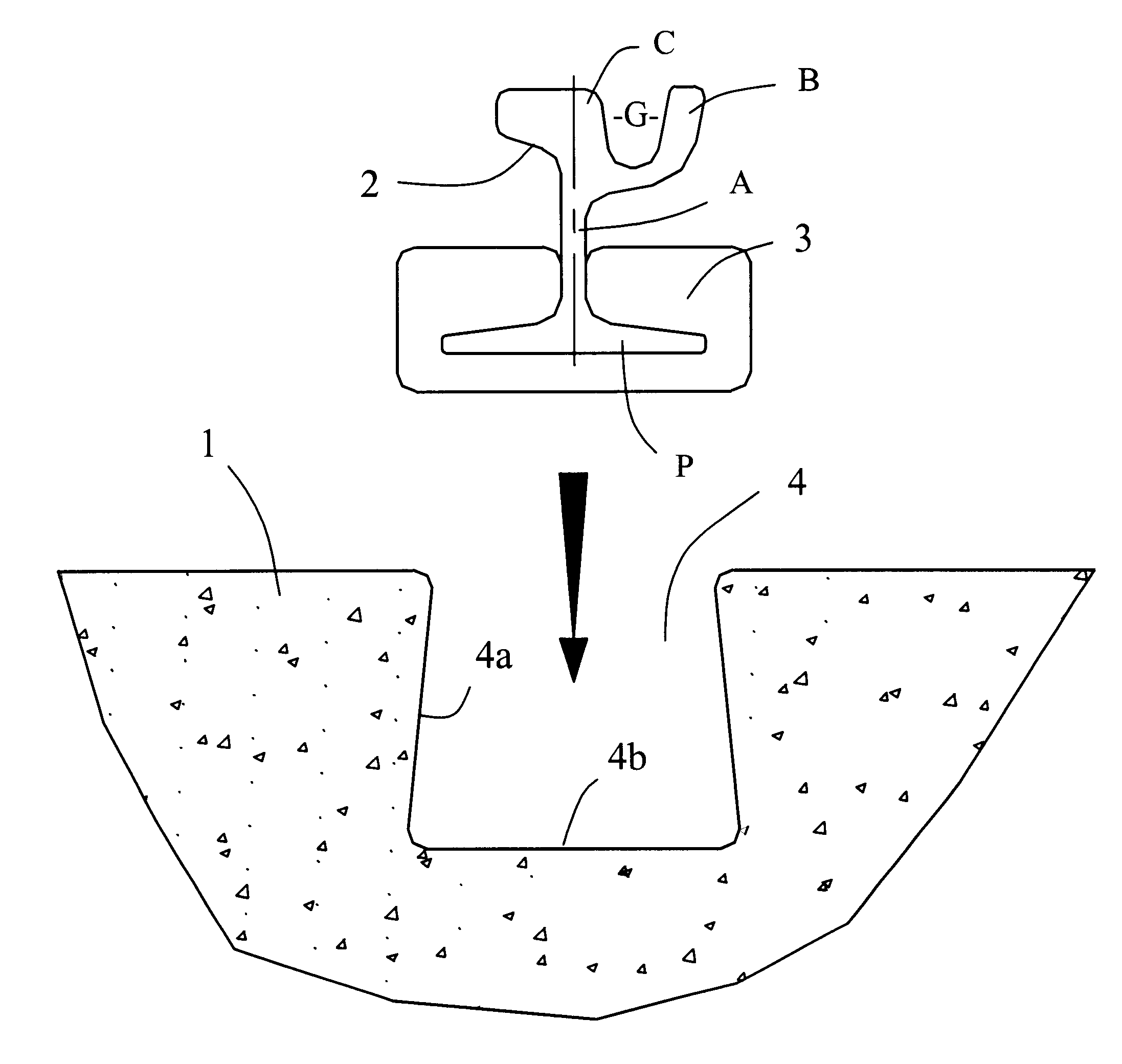

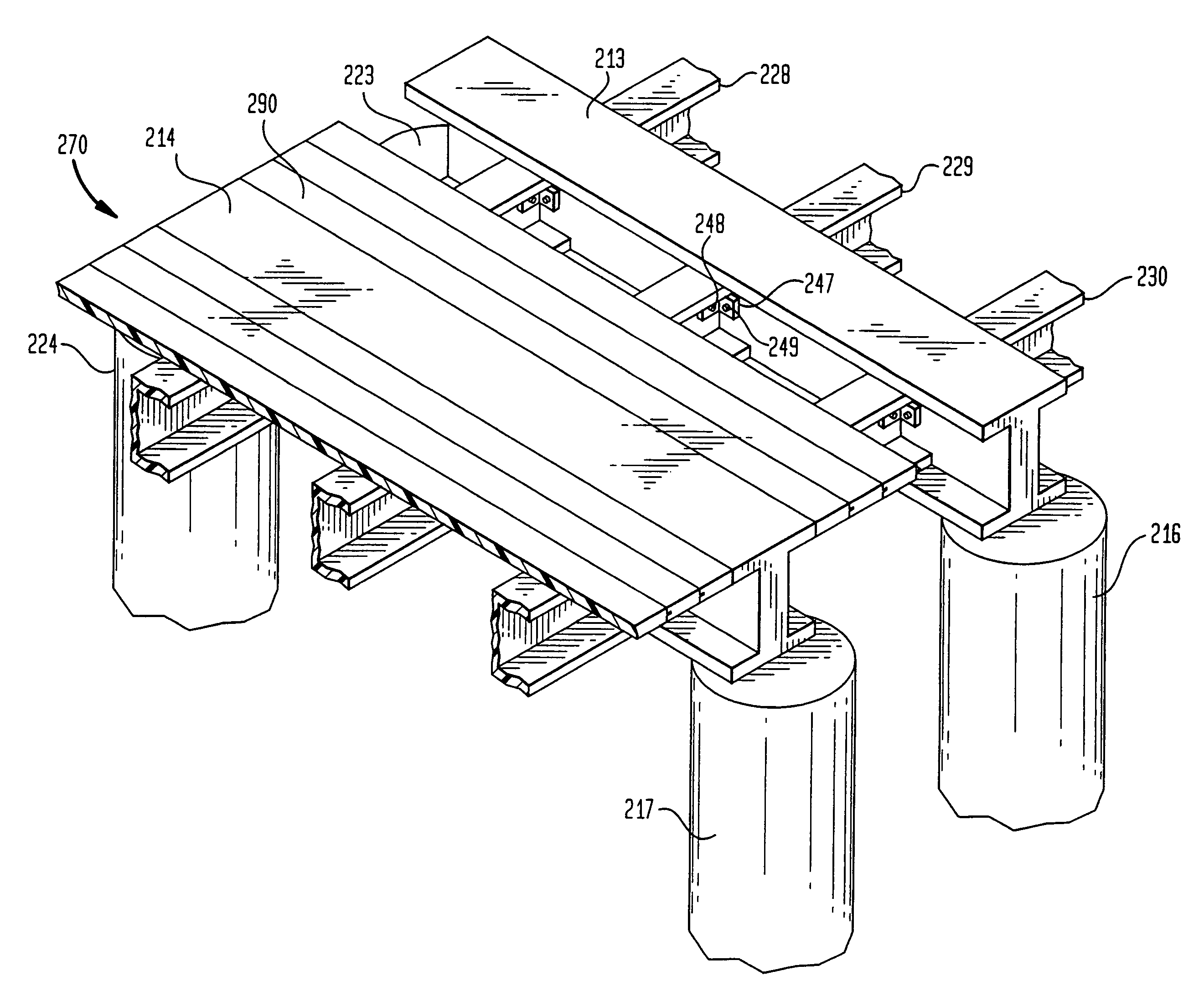

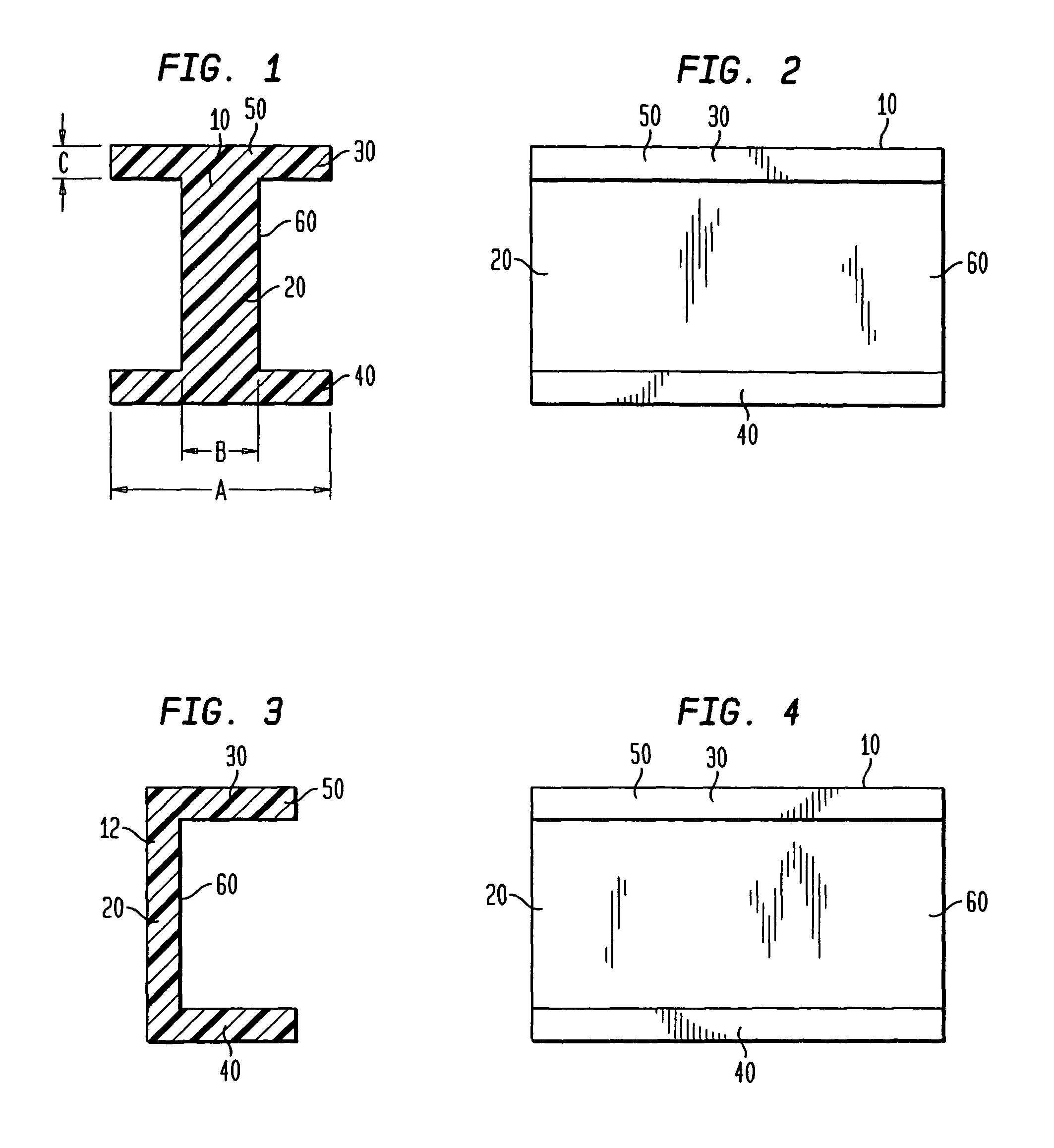

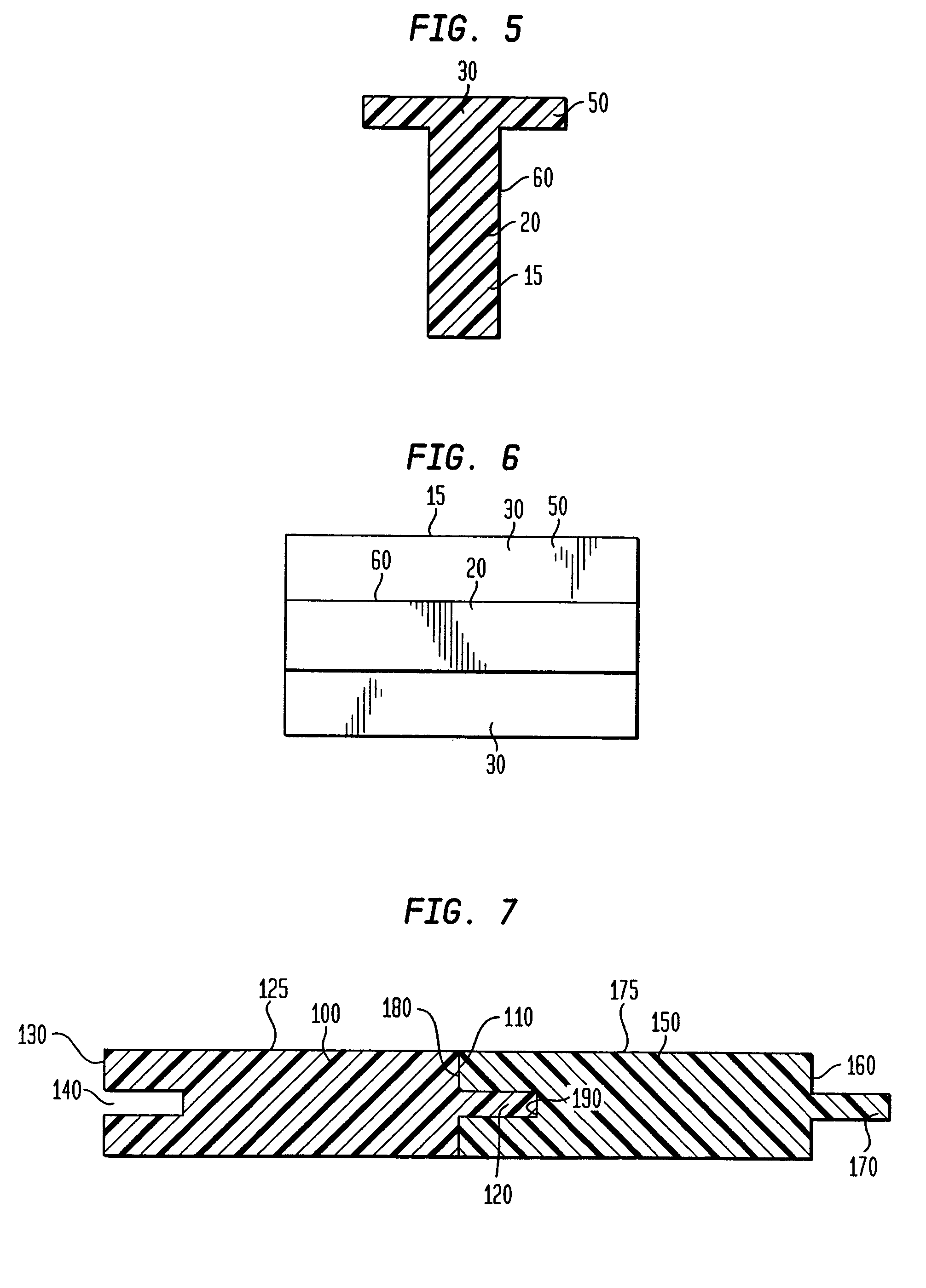

Use of recycled plastics for structural building forms

Modular plastic structural composites having a web section disposed along a horizontal axis and at least one flange section disposed along a horizontal axis parallel thereto and integrally molded to engage the top or bottom surface of the web section, wherein said composite is formed from a mixture of (A) high density polyolefin and (B) a thermoplastic-coated fiber material, polystyrene, or a combination thereof. Composites molded in the form of I-Beams and bridges constructed therefrom are also disclosed.

Owner:RUTGERS THE STATE UNIV

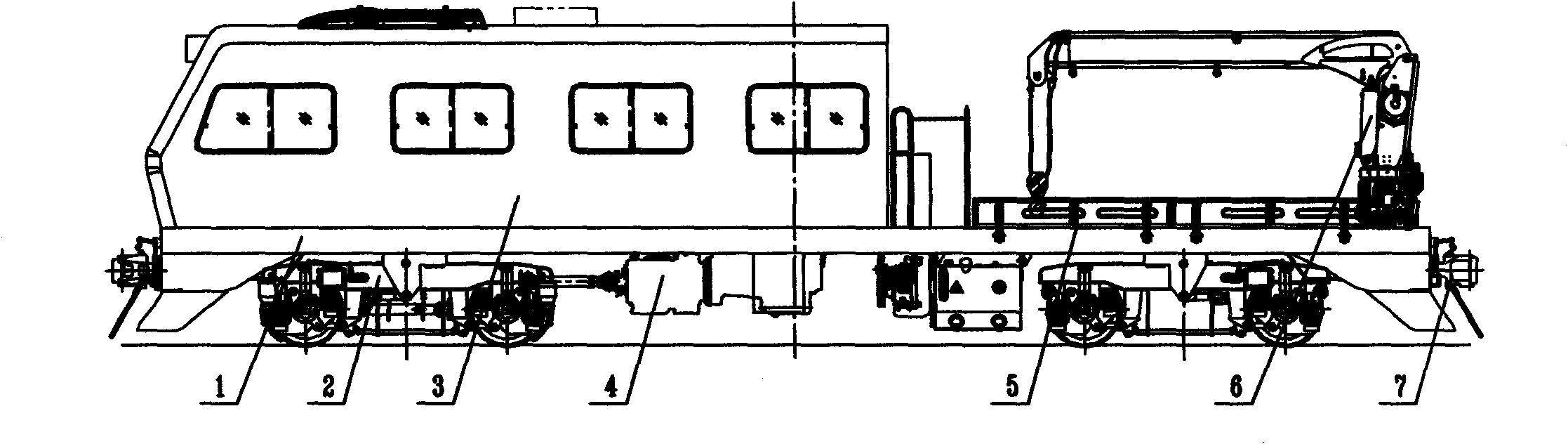

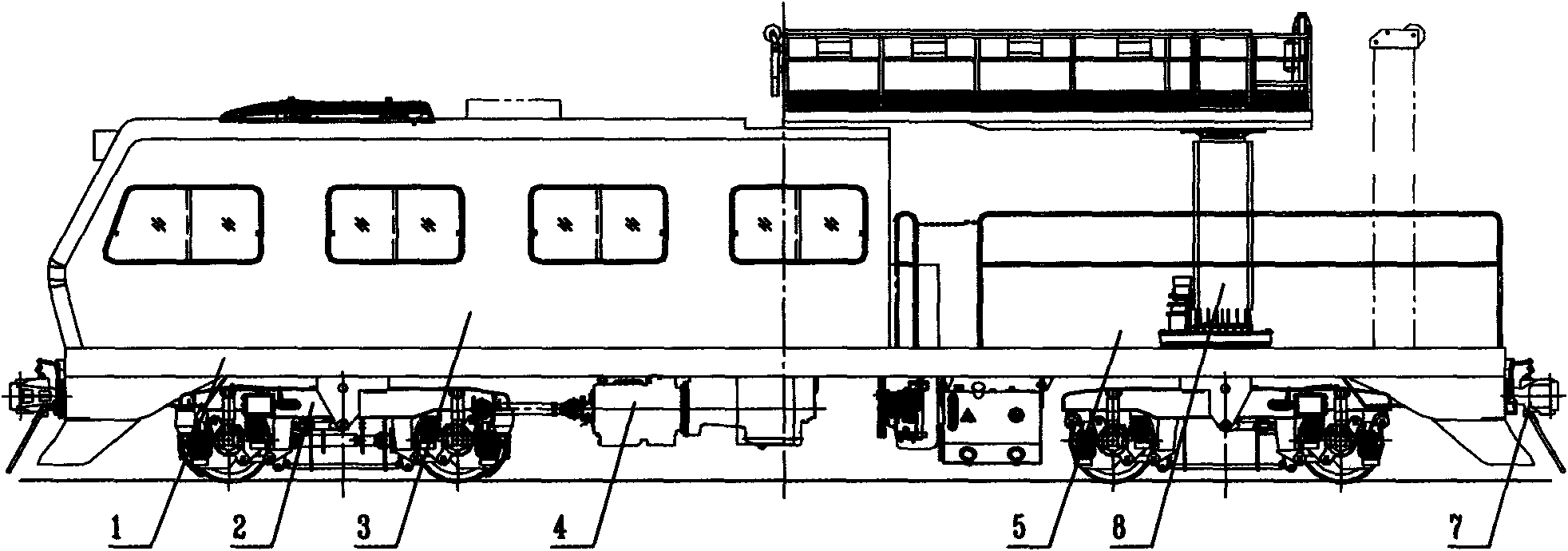

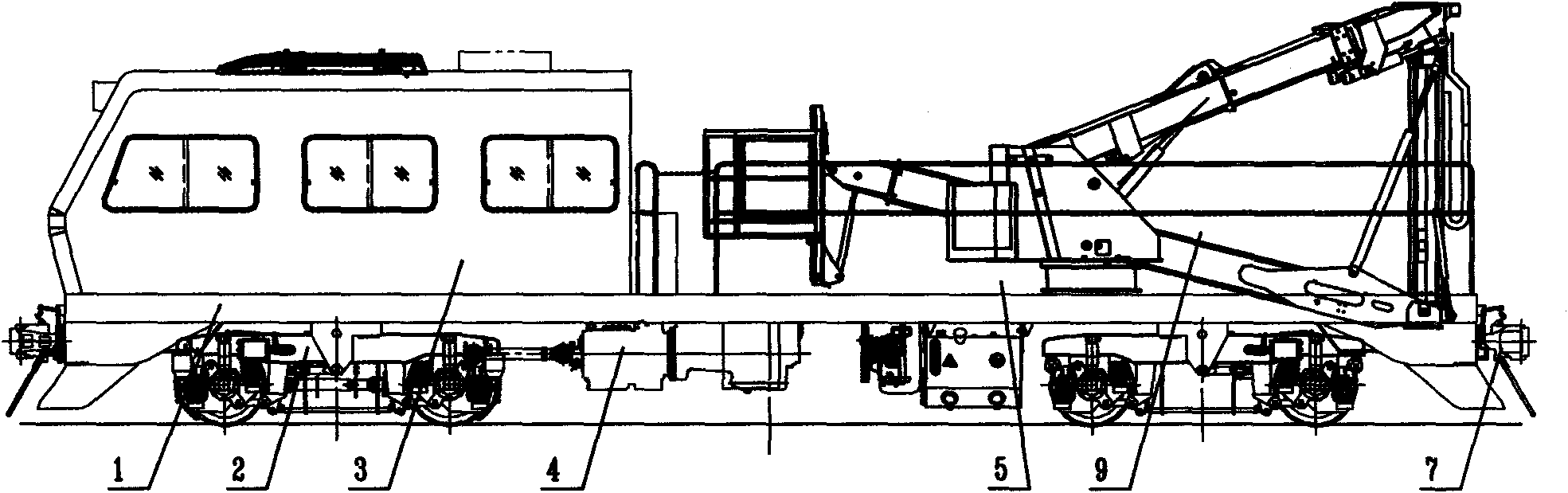

Comprehensive maintenance car for railways

The invention provides a comprehensive maintenance operation car for railways. The invention adopts the following technical scheme: two bogies are arranged below a car body; a hydrodynamic drive device for providing power hangs below the car body; a cab is arranged at the front end of the car body; a maintenance operation material platform is arranged at the rear end of the cab; different operation devices can be installed on the maintenance operation material platform to form the maintenance operation cars with different functions; and the different operation devices mainly include a whole-carriage heavy track car, a permanent way maintenance car, an operation car for contact wire, a bridge inspection car, a high-altitude operation car and the like. The comprehensive maintenance operation car has the following advantages: the comprehensive maintenance operation car realizes the functions of singly transporting the staff and the operation equipment to the operation site and completing relevant maintenance operations and simultaneously can transport the waste materials after operations.

Owner:GEMAC ENG MACHINERY

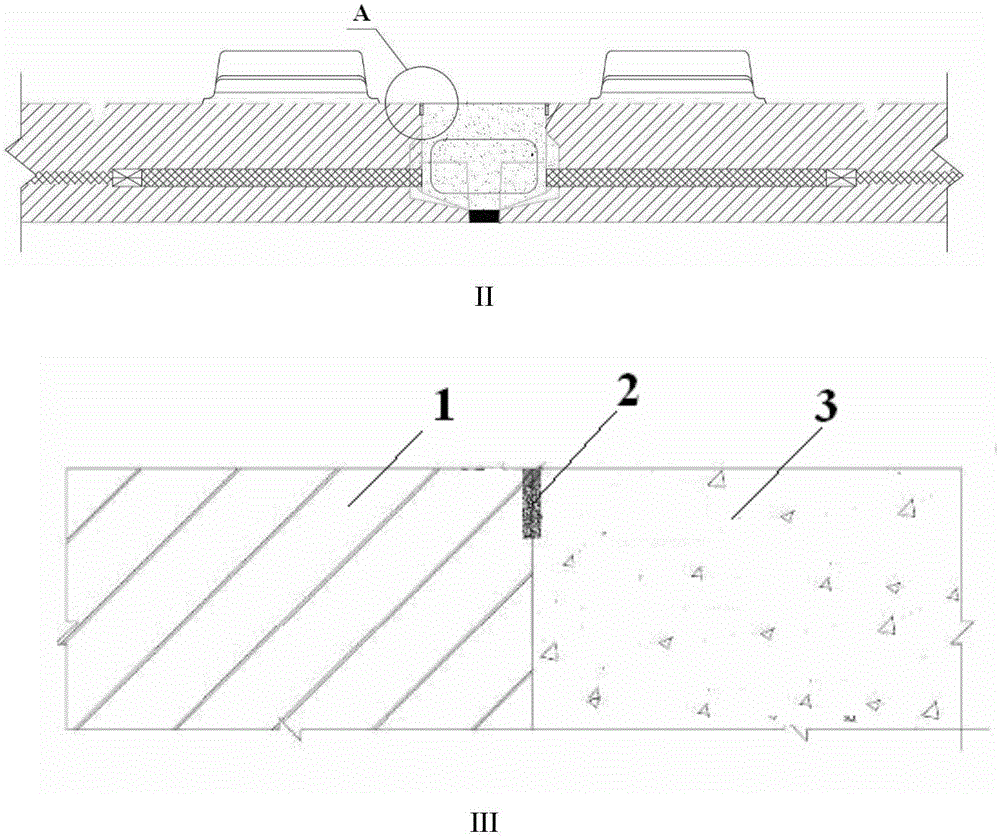

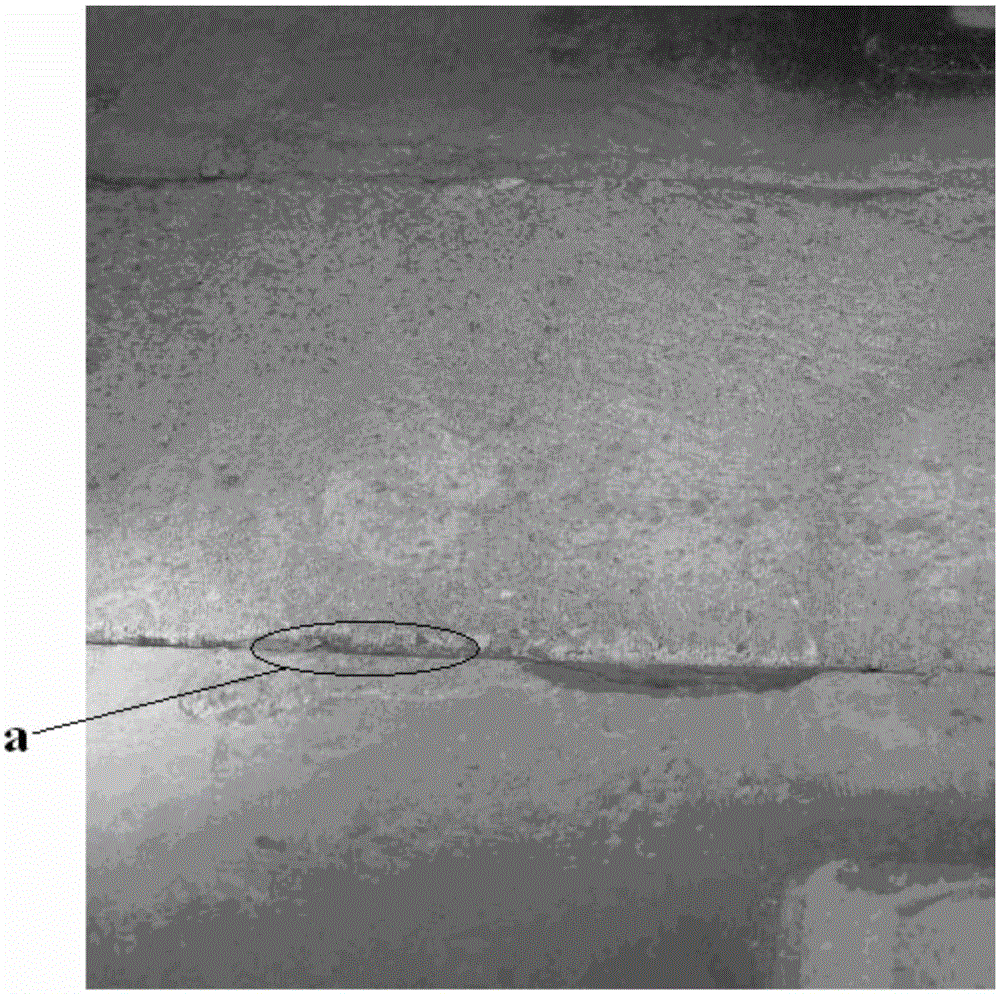

Method for treating cracks at seam positions of CRTS II ballastless track plates

InactiveCN105064153AImprove protectionMaintain mechanical propertiesBallastwayTrack maintainenceReinforced concreteRebar

The invention discloses a method for treating cracks at seam positions of CRTS II ballastless track plates. Based on special laws of cracks, the method guarantees the durability of a ballastless track structure by performing special waterproof treatment on cracks. The method for treating cracks comprises the following steps: cutting cracks; treating base surfaces; and pouring low-viscosity polyurethane waterproof material and high-viscosity organosilicon material in the cut cracks. The method is simple in construction, is convenient, economic, durable and reliable, and is suitable for the repairing operation of skylight points of cracks at seam positions of CRTS II ballastless track plates. Through the adoption of the method, the durability of the ballastless track structure can be significantly improved, so that the method is suitable for improving the durability of reinforced concrete structures with a large crack-width variation range.

Owner:CENT SOUTH UNIV

Methods for aligning measured data taken from specific rail track sections of a railroad with the correct geographic location of the sections

InactiveUS20050080569A1Electrical measurementsTesting/calibration of speed/acceleration/shock measurement devicesOrbitComputer science

Owner:TATA CONSULTANCY SERVICES LTD

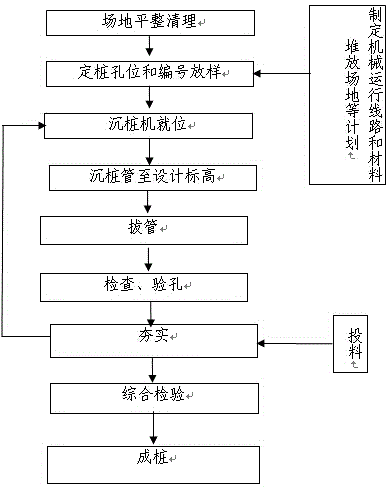

Collapsed loess subgrade base treatment method for railway with speed more than 200km

ActiveCN104404838AMeet the constructionFulfil requirementsTrack maintainenceBulkheads/pilesCulvertDrilling machines

The invention discloses a collapsed loess subgrade base treatment method for a railway with speed more than 200km, and belongs to the technical field of railway construction. The collapsed loess subgrade base treatment method for the railway with speed more than 200km comprises the following steps of 1, using two culverts or two bridges as a construction unit; firstly using a cement soil compaction pile to eliminate the collapsibility of the loess on a foundation in a way of first two sides and then middle part and row separation construction; then, adopting a pipe sinking method to form a hole in the cement soil compaction pile; 2, adopting a CFG (cement flyash gravel) pile to reinforce the foundation, wherein the CFG pile is drilled by a long spiral drilling machine; 3, cleaning the soil between the piles, forming a cement bedding layer, testing and checking, and entering the subgrade body filling procedure after qualification is confirmed. The collapsed loess subgrade base treatment method mainly solves the technical problems that the setting requirement is high, the collapsed loess is generally in the saturation state, and the difficulty in control of settling amount is higher after the construction of the subgrade of the railway with speed more than 200km.

Owner:CHINA RAILWAY NO 8 ENG GRP CO LTD

Method for constructing expansion joints of foundation in plate type ballastless track and templates for expansion joints

InactiveCN101725097AImprove construction efficiencyPrecise positioningMould separation apparatusBallastwayArchitectural engineeringExpansion joint

The invention discloses templates for expansion joints of a foundation in a plate type ballastless track. A second-layer template is positioned between a first-layer template and a third-layer template and keeps a distance from both the first-layer template and the third-layer template; the first-layer template and the second-layer template are similar and are both a vertical steel plate which is high on the left, low on the right and provided with a steel plate bent in a running direction in the middle, the lower part of the vertical steel plate is provided with notches, and the upper part of the vertical steel plate is connected with ear plates; and the second-layer template consists of three sections of vertical steel plates which are high on the right, low on the right and disconnected, the middle section is a steel plate bent in the running direction, the left and right sections are flat steel plates, the lower parts of the three sections of vertical steel plates are provided with notches and the upper parts of the three sections of vertical steel plates are connected with ear plates. The invention also discloses a method for constructing the expansion joints of the foundation in the plate type ballastless track. The method contributes to the realization of streamlined construction operation, improves construction efficiency, realizes the accurate control over water drainage counter slopes on two sides of the foundation and ensures the height smoothness of a top face of the foundation.

Owner:THE 8TH GRP OF CHINA RAILWAY 1ST ENG CO LTD

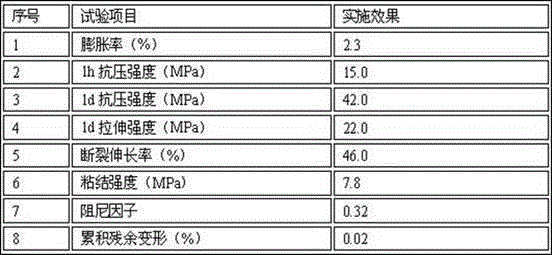

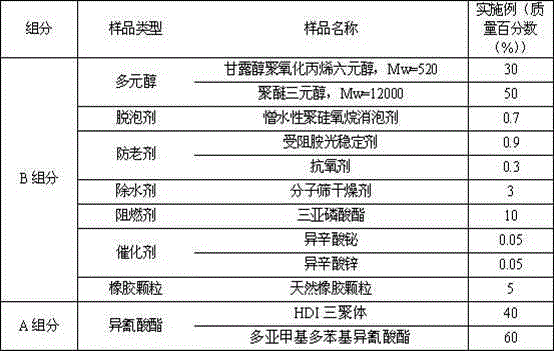

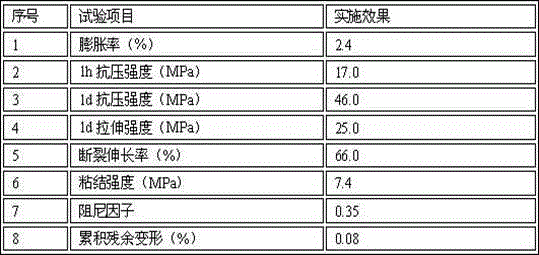

Cured track bed sinking repairing high-viscosity vibration attenuation polyurethane repairing material

The invention relates to a high-viscosity vibration attenuation polyurethane repairing material for sinking repairing of a polyurethane cured track bed of a high speed railway or a heavy haul railway. The high-viscosity vibration attenuation polyurethane repairing material consists of a component A and a component B which are mixed and stirred together mechanically, wherein the mass ratio of the component A to the component B is (1:0.9)-(1:1.5); the component A is a mixture of an HDI tripolymer and polymethylene polyphenyl isocyanate ester; the mass ratio of the HDI tripolymer to polymethylene polyphenyl isocyanate ester is (3:7)-(6:4); the content of -NCO is 27-29%; and the component B consists of polyhydric alcohol, a catalyst, a defoaming agent, a moisture scavenger, an anti-aging agent, a flame retardant and rubber granules. The high-viscosity vibration attenuation polyurethane repairing material is characterized in that the polyhydric alcohol is a mixture which consists of 6-functionality-degree mannitol poly(propylene oxide polyol) and 3-functionality-degree high molecular weight polyether polyol with the molecular weight of 12000. According to the polyurethane repairing material provided by the invention, the volume expansion ratio is 1-3%, the compressive strength of 1 hour is greater than or equal to 12MPa, the adhesion strength is greater than or equal to 6MPa, the damping factor is 0.25-0.40, the accumulated residual deformation is less than or equal to 0.5% after 5 million times of fatigue loading, and the polyurethane repairing material can be applied to polyurethane cured track bed sinking repairing and railway ballast cured track bed sinking repairing as well.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +2

Popular searches

Special data processing applications Incline measurement Railway auxillary equipment Radio wave reradiation/reflection Mechanical counters/curvatures measurements Digital computer details Speed measurement using gyroscopic effects Satellite radio beaconing Railway signalling and safety Gyroscopes/turn-sensitive devices

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com