Roadbed having pile-net combination structure and construction method thereof

A composite structure and pile network technology, which is applied in the direction of infrastructure engineering, roads, buildings, etc., can solve the problem of super-large soft soil foundation that cannot be effectively treated after construction settlement, and achieve simple and effective treatment methods, solve technical problems, and solve The effect of post-construction settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

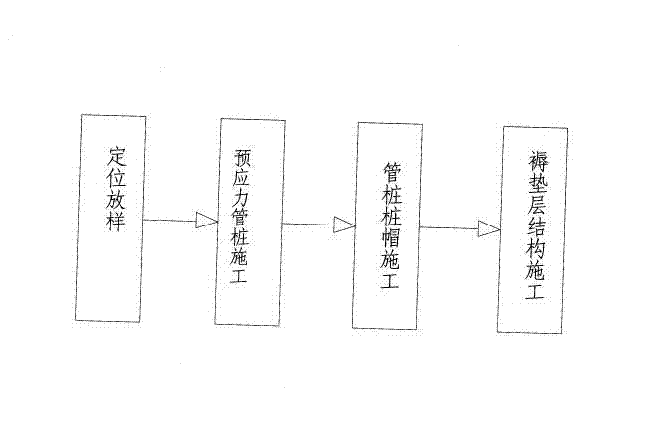

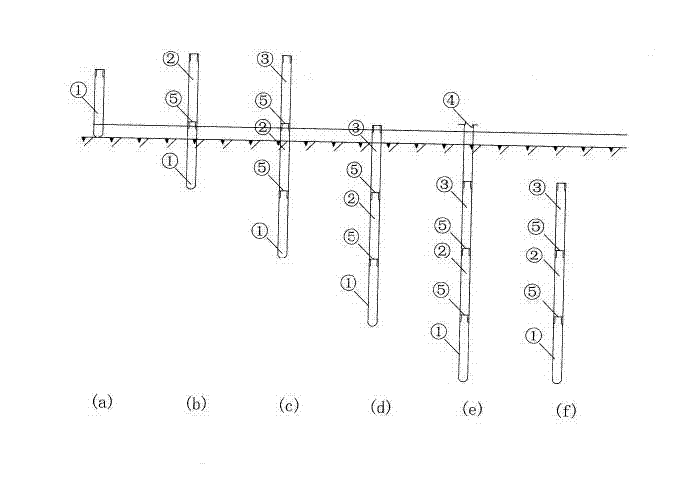

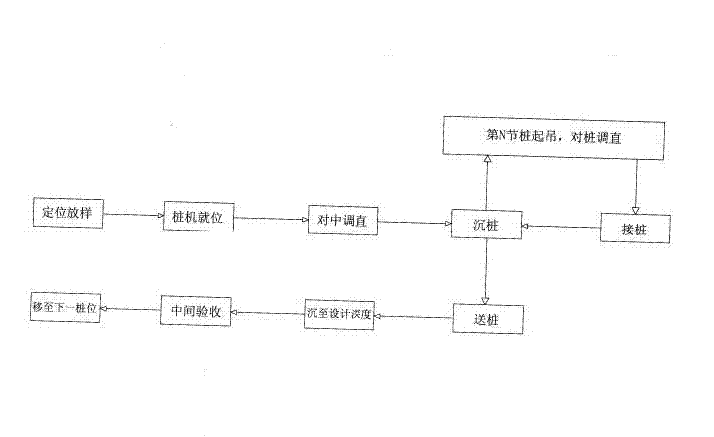

[0025] A roadbed with a pile-net composite structure, comprising a prestressed pipe pile 1, a prestressed pipe pile cap 2, a prestressed pipe pile ground beam 3 and a cushion layer 4. The cushion layer 4 includes a gravel cushion layer 5 , a medium-coarse sand cushion layer 6 , a geogrid 7 , a second medium-coarse sand cushion layer 8 and a second gravel cushion layer 9 . Prestressed pipe pile 1 is a PHC pipe pile, which is mainly composed of cylindrical pile body, end plate and steel hoop, etc. It is constructed by static pressure method. The construction process mainly includes hanging pile, inserting pile, sinking pile, and connecting pile , Sending piles, cutting pile heads, terminating pile pressing and pile driver shifting, etc. After the construction of prestressed pipe pile 1 is completed, the construction of prestressed pipe pile cap 2 shall be carried out. First, the size of the pile cap according to the design requirements is 1.4m×1.4m×0.35m. , C35 concrete pouring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com