Prestressed concrete sleepers and method for transporting and installing a switch with prestressed concrete sleepers

A concrete and prestressed technology, applied in the direction of switch, track, road, etc., can solve the problems of complexity, economical use, high cost, etc., and achieve the effect of simplifying transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

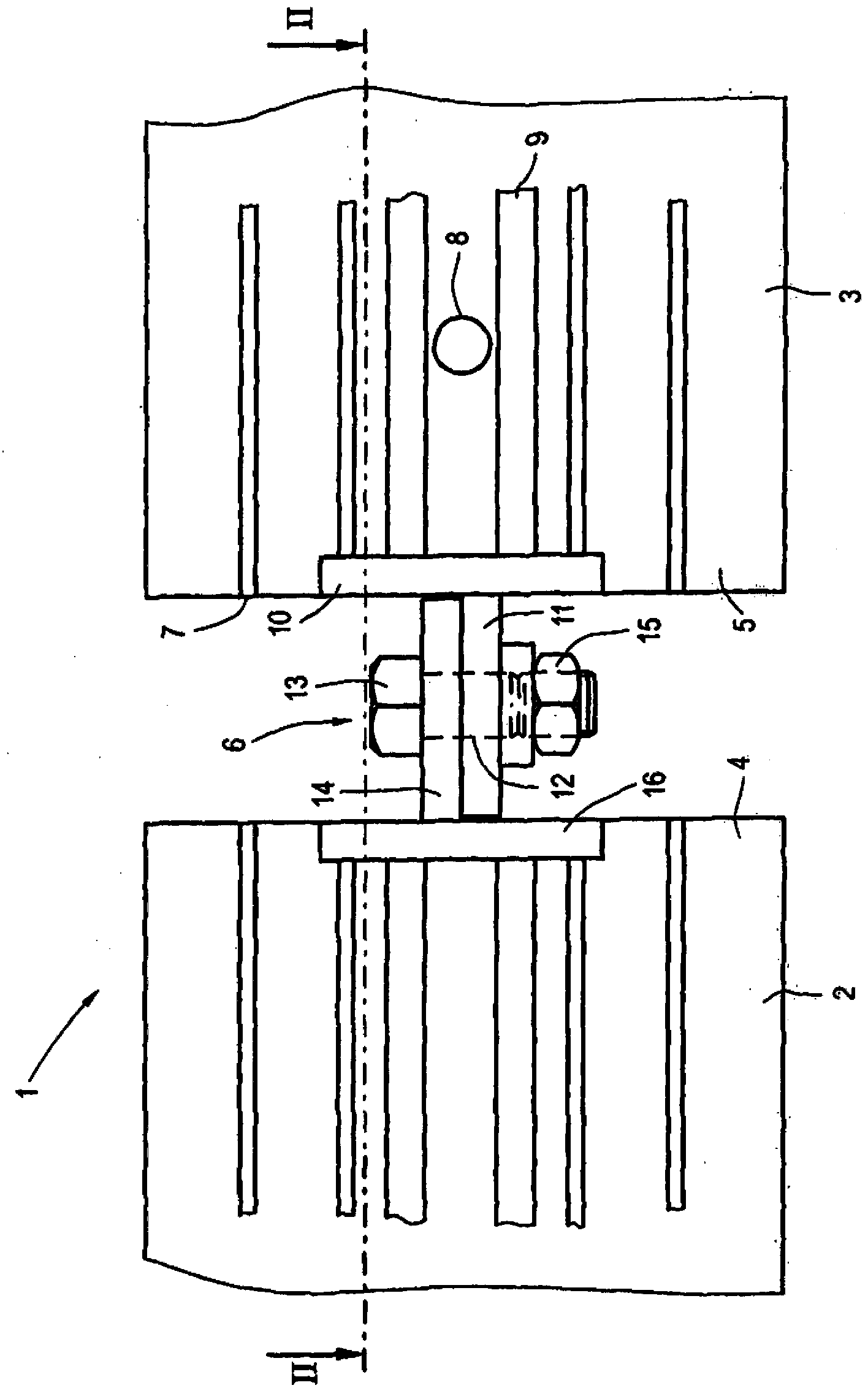

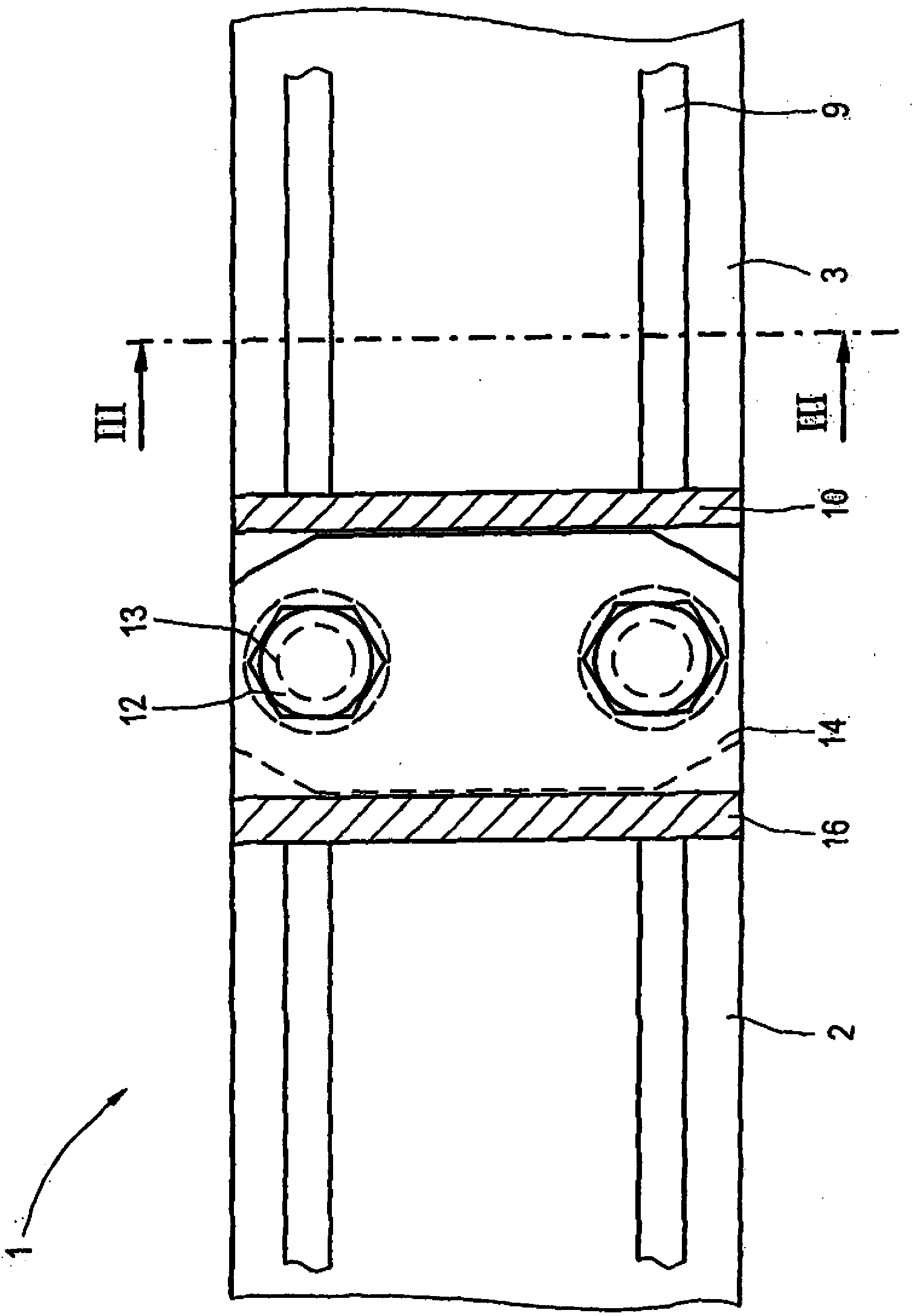

[0026] figure 1 A plan view of a prestressed concrete sleeper 1 is shown, which has sleeper sections 2 , 3 which are connected in a flexurally rigid manner by connecting devices 6 embedded in the sleeper ends 4 , 5 .

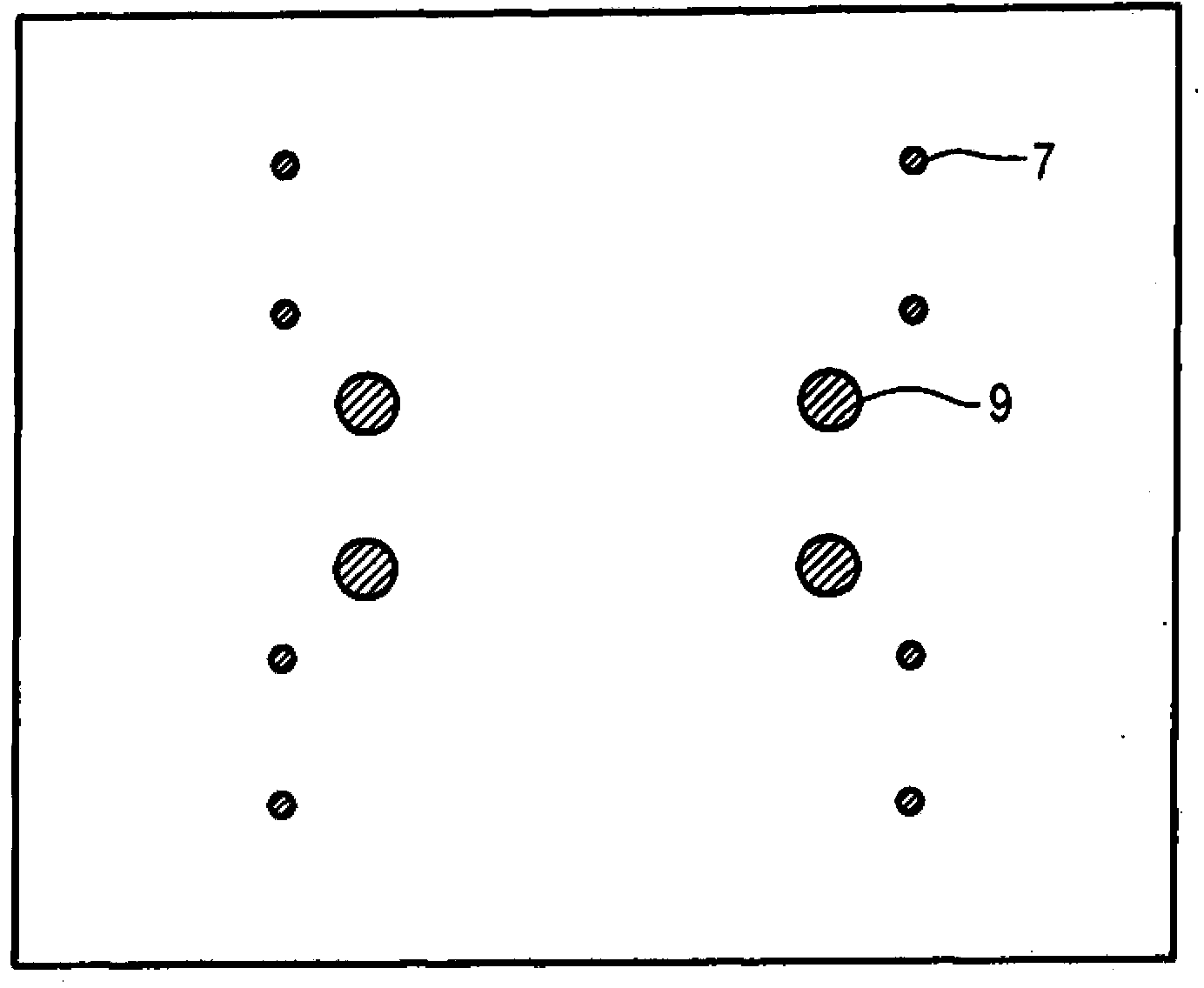

[0027] Each sleeper section 2 , 3 has a plurality of prestressing wires 7 via which the sleeper sections 2 , 3 are acted upon with a prestressing force in the form of pressure. The mounting of the rails takes place via a plurality of through holes, of which only one through hole 8 in the sleeper 3 is shown for the sake of simplicity.

[0028] In the exemplary embodiment shown, the welded steel connection means 6 each comprise four steel bars 9 which are arranged in the longitudinal direction of the prestressed concrete sleeper 1 and which are welded to the end plates 10 . The end plate 10 ends flush with the outer sides of the sleeper sections 2 , 3 . On the outer side of the end plate 10 there are welded webs 11 through which fastening screws 13 can be insert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com