Patents

Literature

55 results about "Railway embankment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

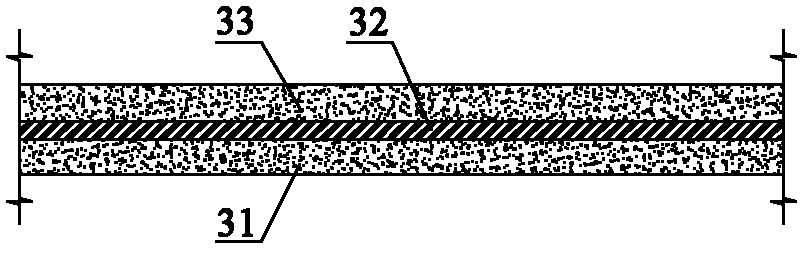

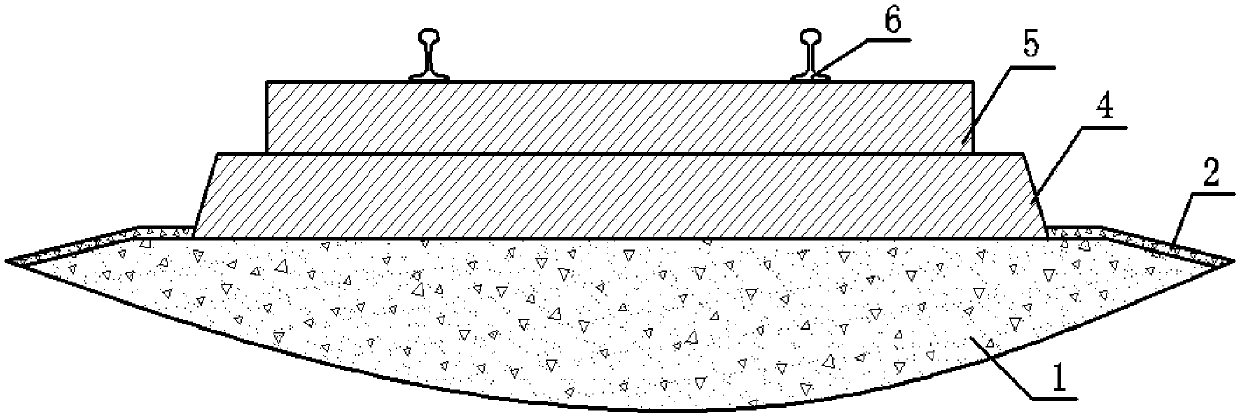

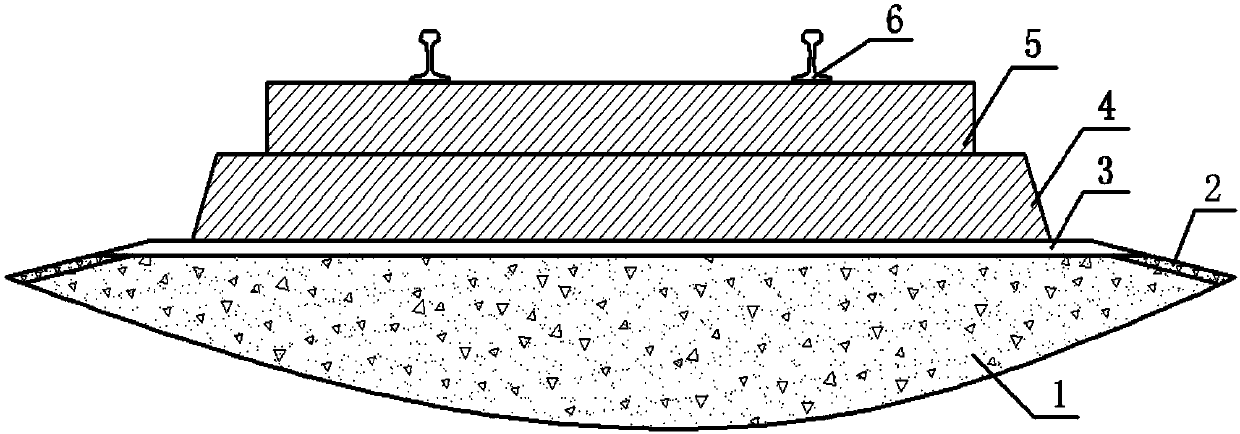

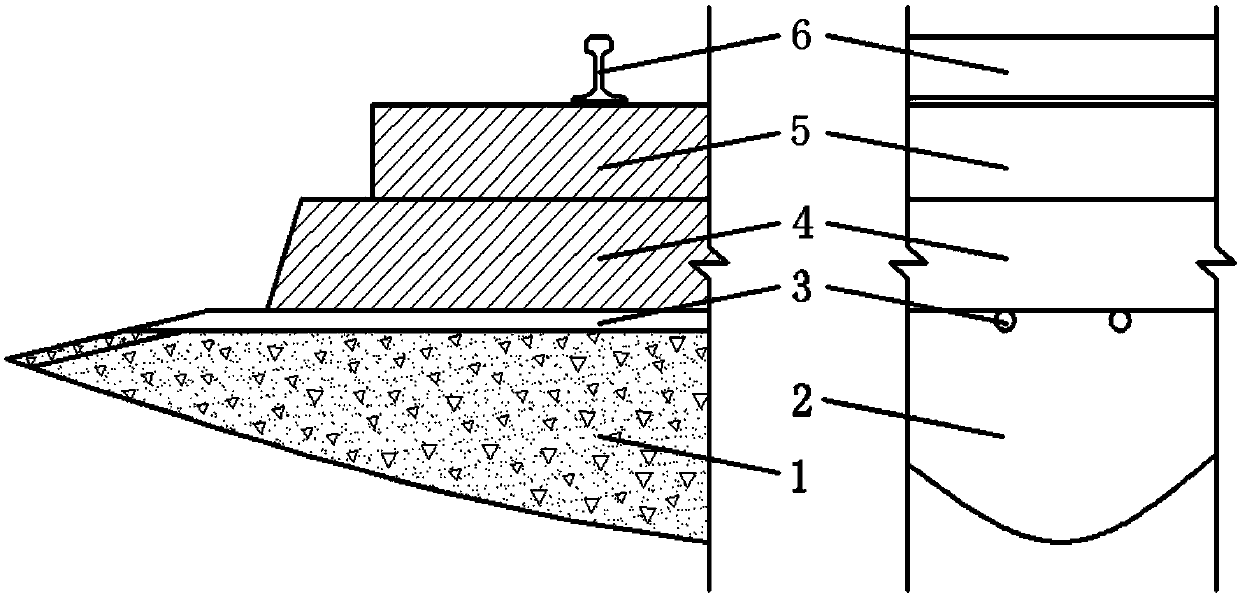

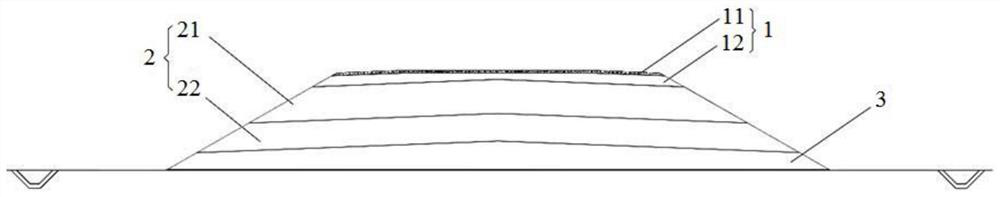

High speed railway embankment structure in salty soil regions

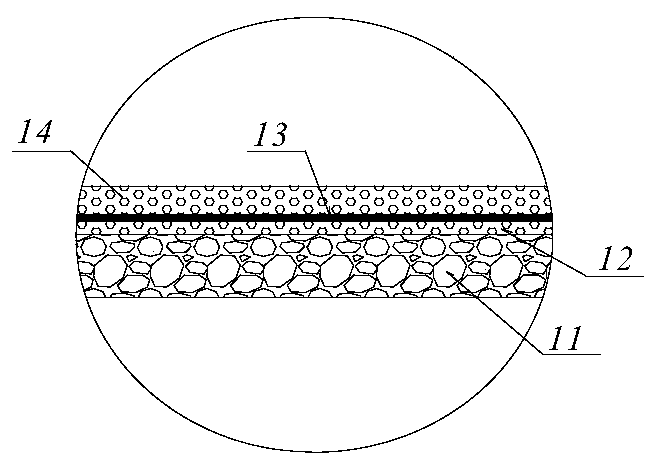

The invention discloses a high speed railway embankment structure in salty soil regions. The high speed railway embankment structure comprises a ground stabilization body arranged in soft foundation, wherein a reinforced mattress layer is laid above the ground stabilization body; a salty soil isolation layer is laid above the reinforced mattress layer; a filling embankment is laid above the salty soil isolation layer. The high speed railway embankment structure is simple in structure and convenient to construct, the reinforced mattress layer on the base is fully utilized as a carrier, the isolation measures are taken through the salty soil isolation layer made by taking a composite geomembrane or a capillary drain board as a main body, the high speed railway embankment structure is small in layer thickness and relatively low in material price and has obvious advantages compared with the measures of excavating a great quantity of salty oil, reducing underground water level, permeating water and soil or isolating asphaltic sand, the project investment can be obviously reduced, the environmental pollution is alleviated, capillary water of the salty oil can be effectively prevented from eroding the embankment body, and high service performance and long-term stability of the embankment engineering are guaranteed.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

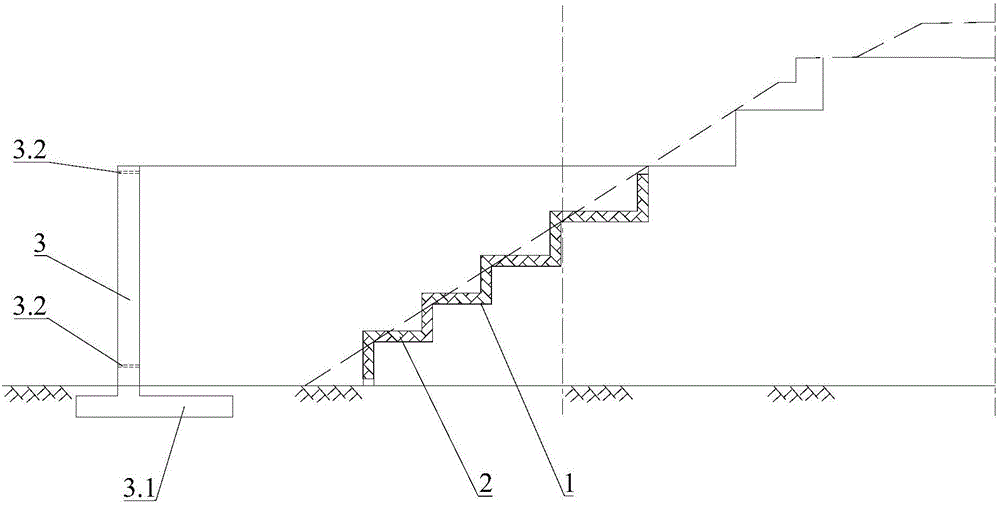

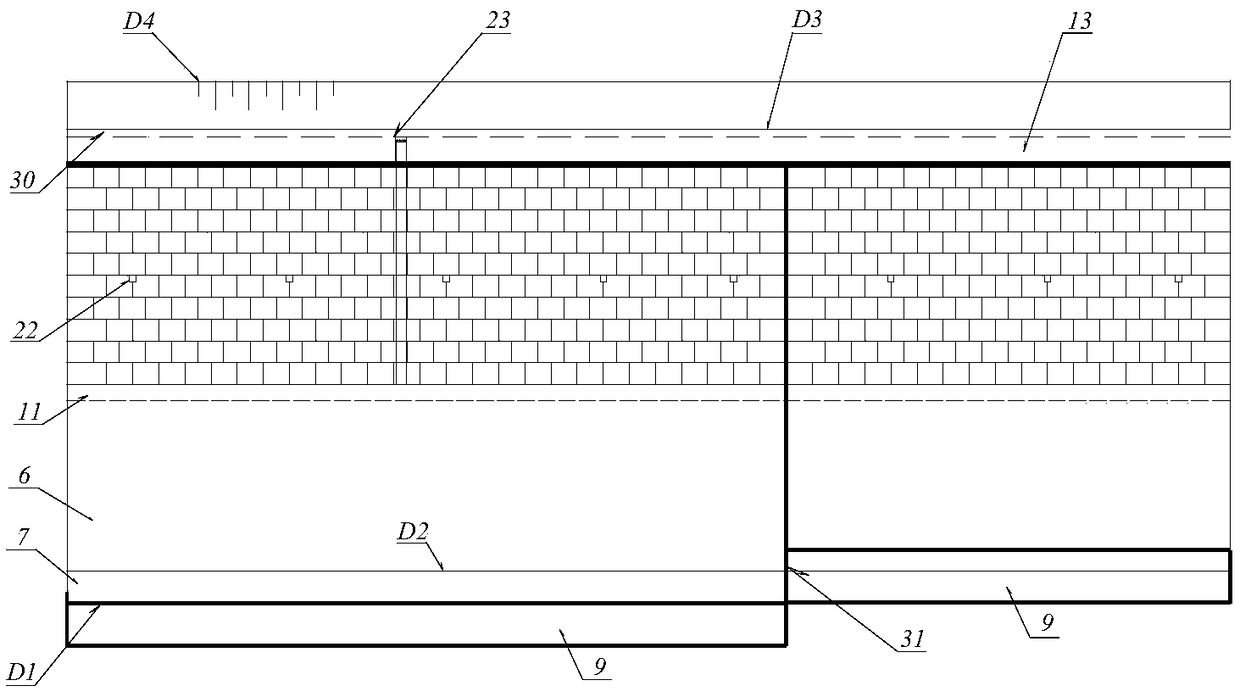

Widening subgrade structure based on existing railway subgrade and construction method of widening subgrade structure

The invention discloses a widening subgrade structure based on an existing railway subgrade. The widening subgrade structure comprises a step arranged on the side slope of the existing railway subgrade, an inverted filter arranged on the step, and a retaining wall poured on the outer side of a widening railway embankment. The space between the inverted filter and the retaining wall is filled with light soil. A crack-prevention steel bar mesh is laid at the preset height in the light soil. A subgrade filler is constructed on the light soil. The invention further provides a widening subgrade method of the existing railway subgrade. According to the subgrade widening structure based on the existing railway subgrade, the load of the widening subgrade can be reduced greatly through the characteristic of small density of the light soil, the stability of the widening subgrade is improved, and extra sedimentation of a railway operation subgrade is reduced. Through the retaining wall on the outer side of the light soil, the usage quantity of the light soil can be reduced, construction land is saved, and the retaining wall can serve as a template for construction of the light soil.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

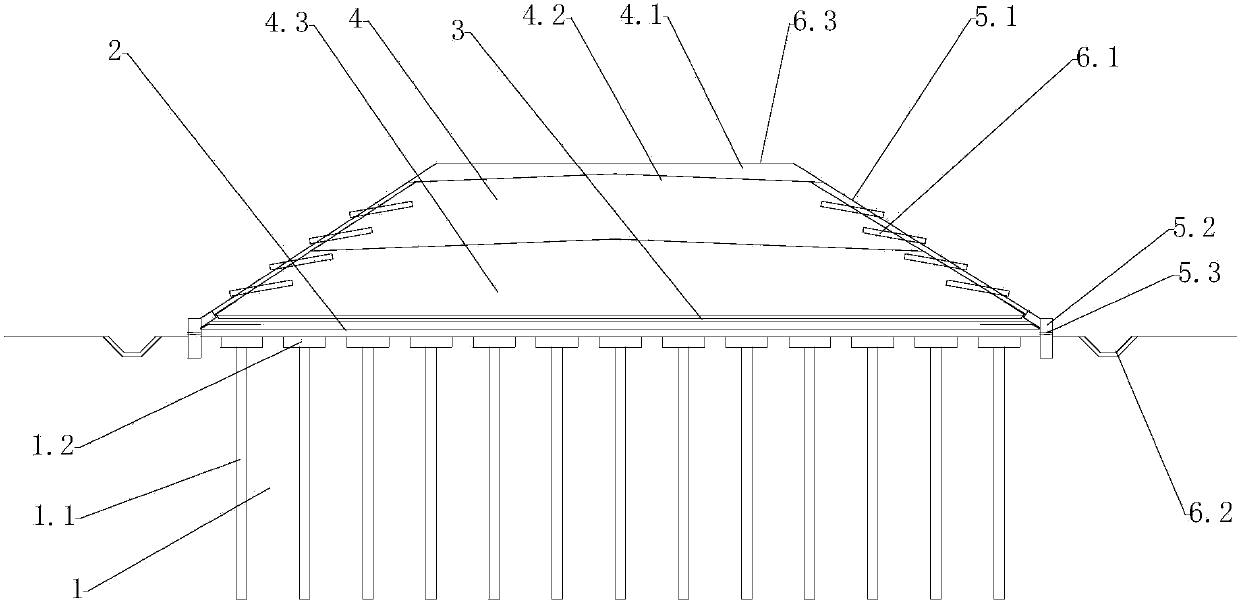

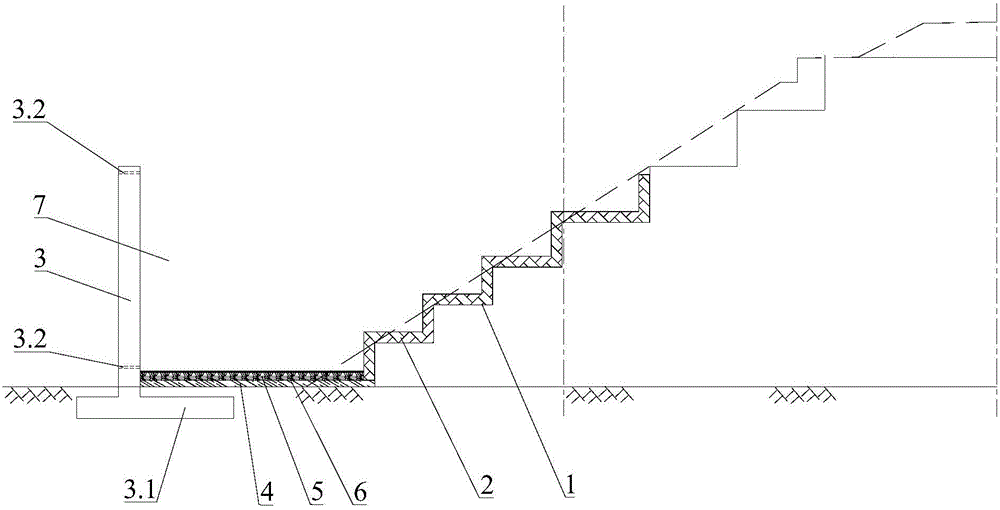

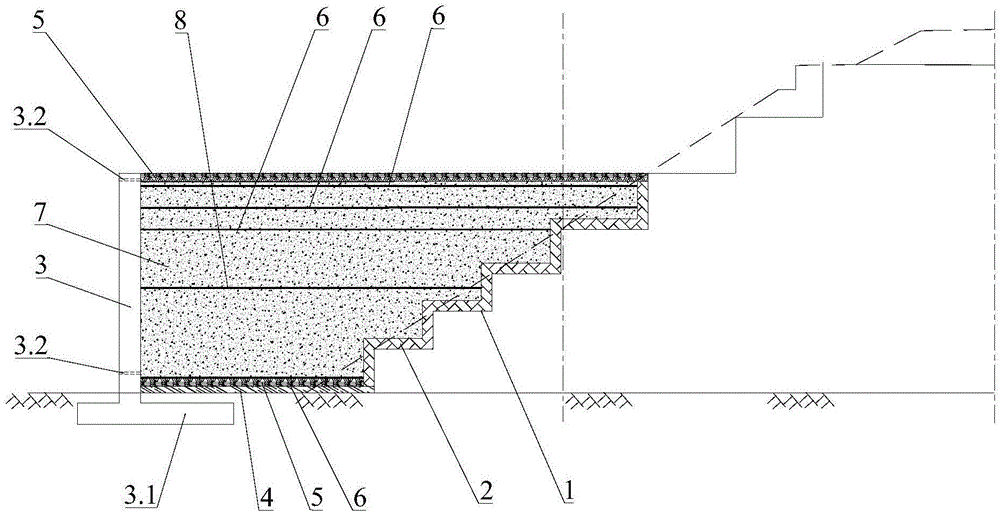

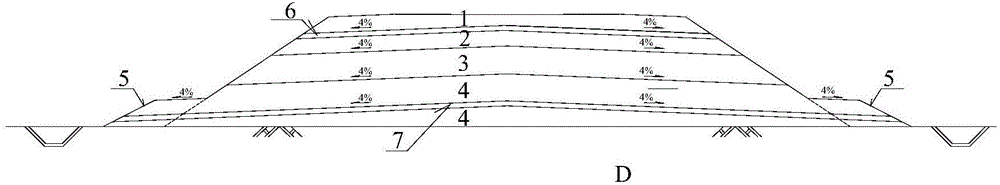

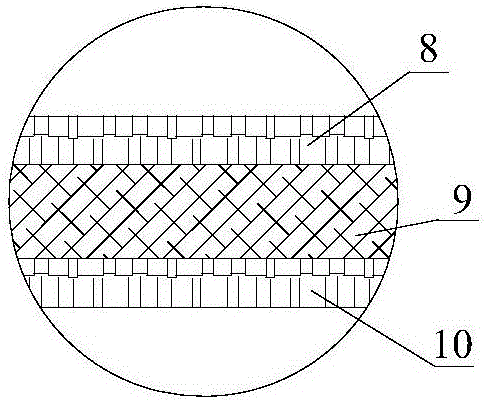

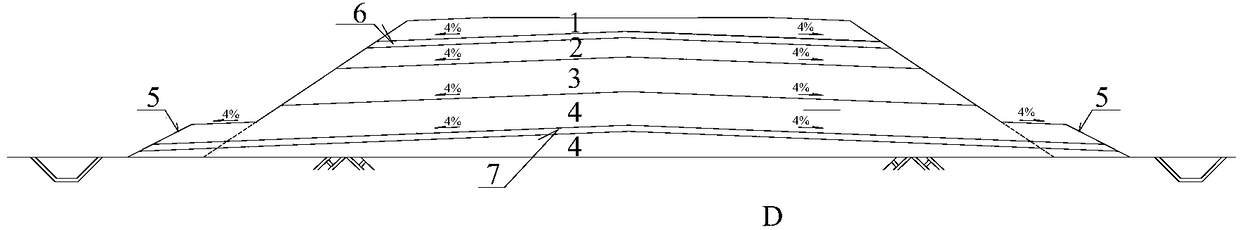

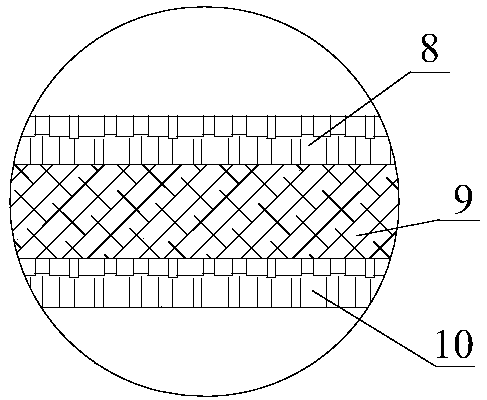

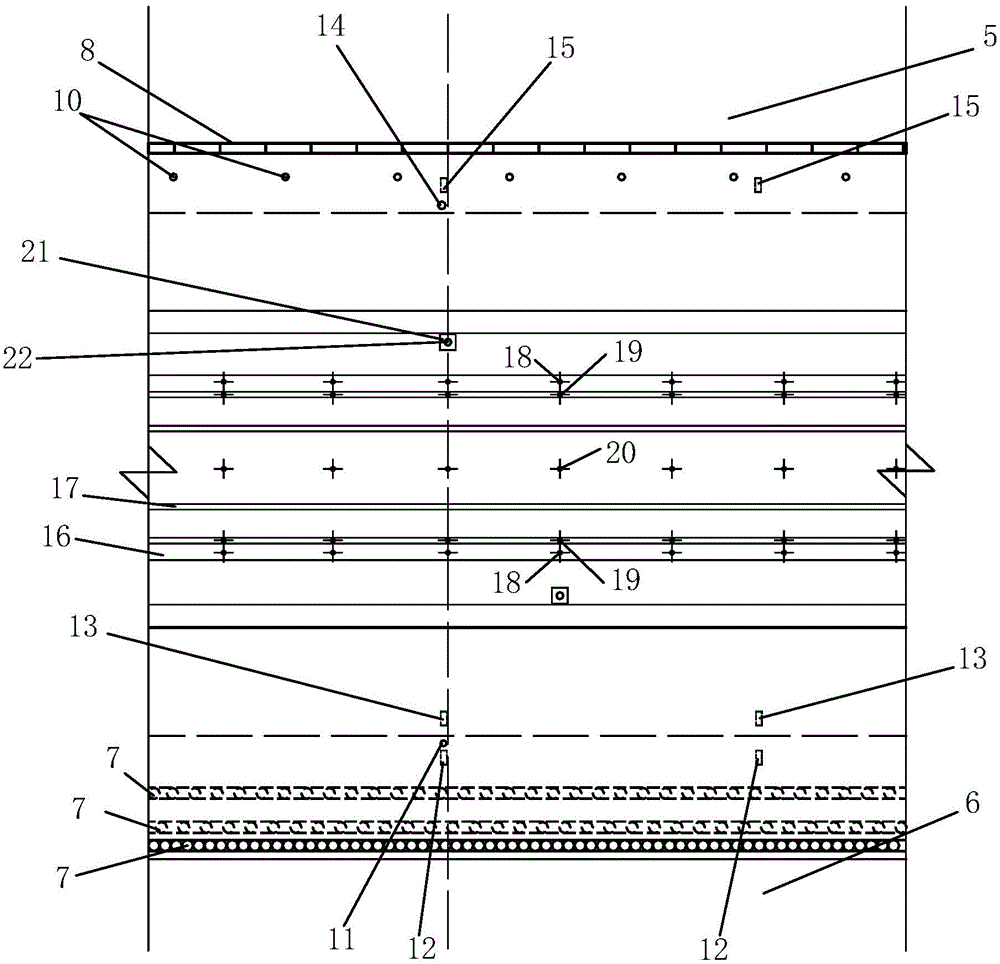

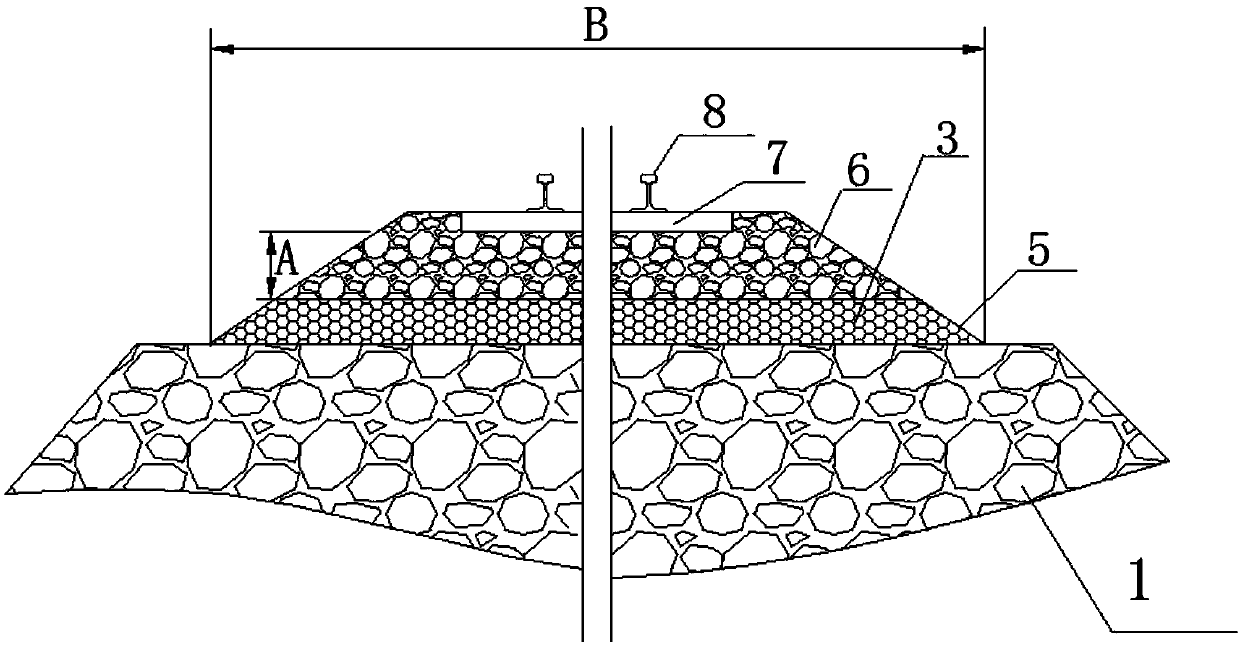

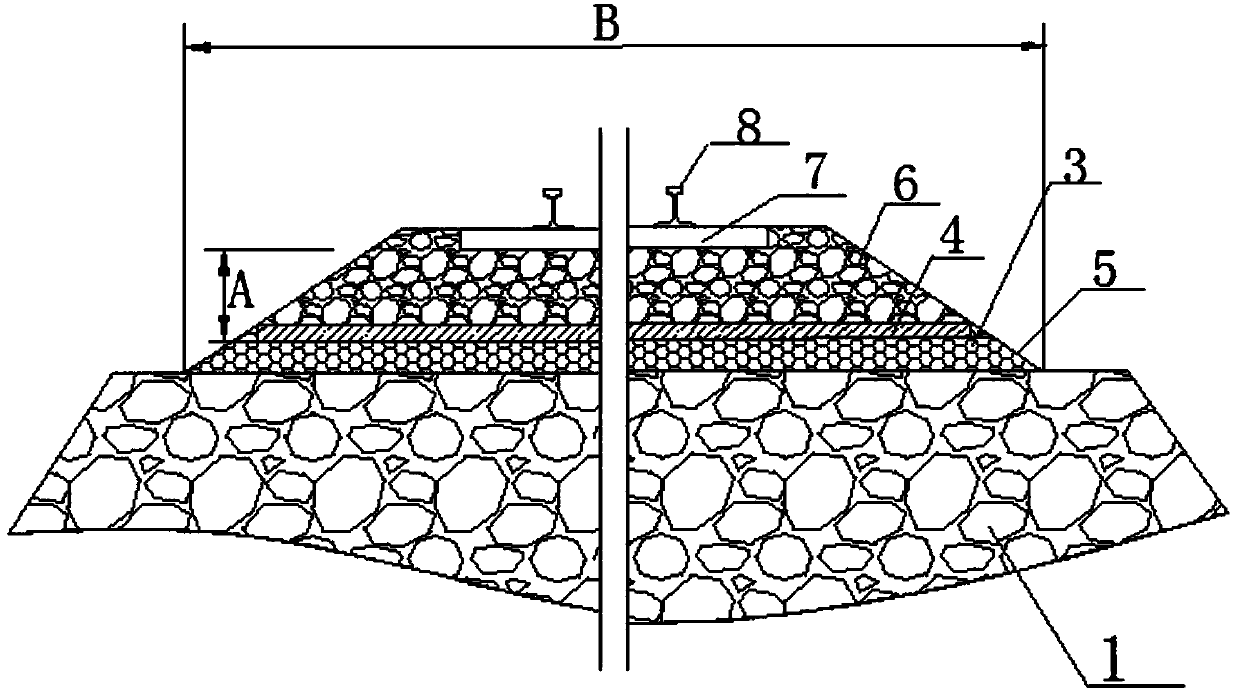

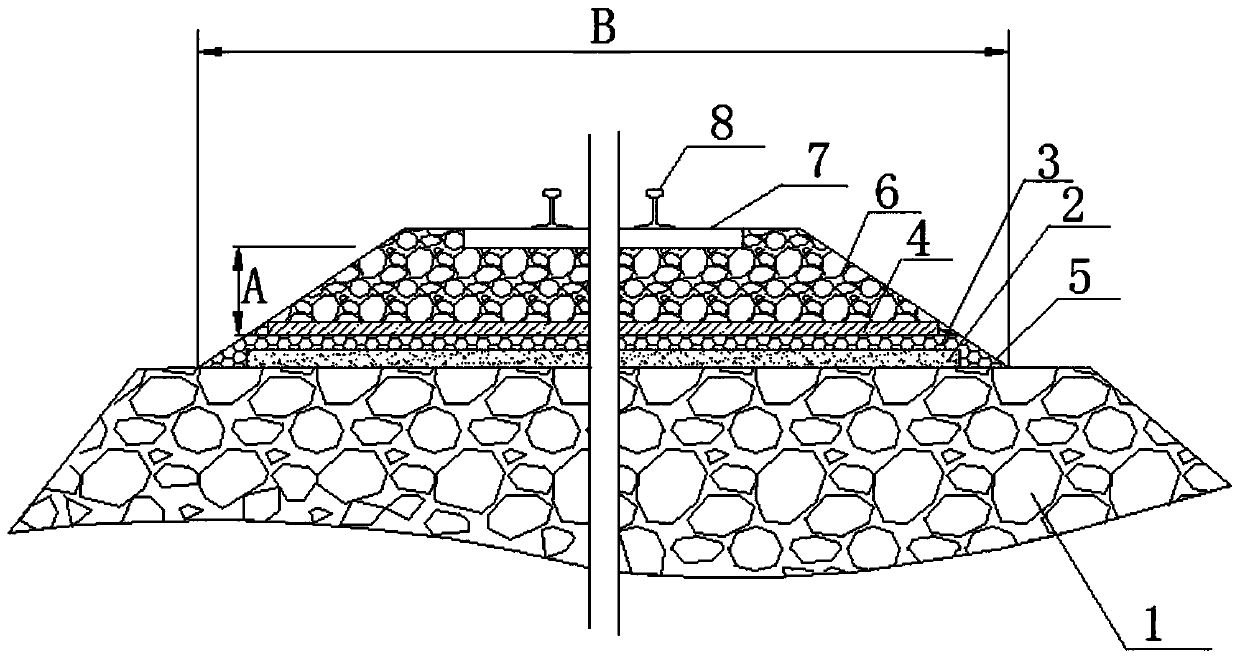

High speed railway embankment reinforcement structure of salinized soil area

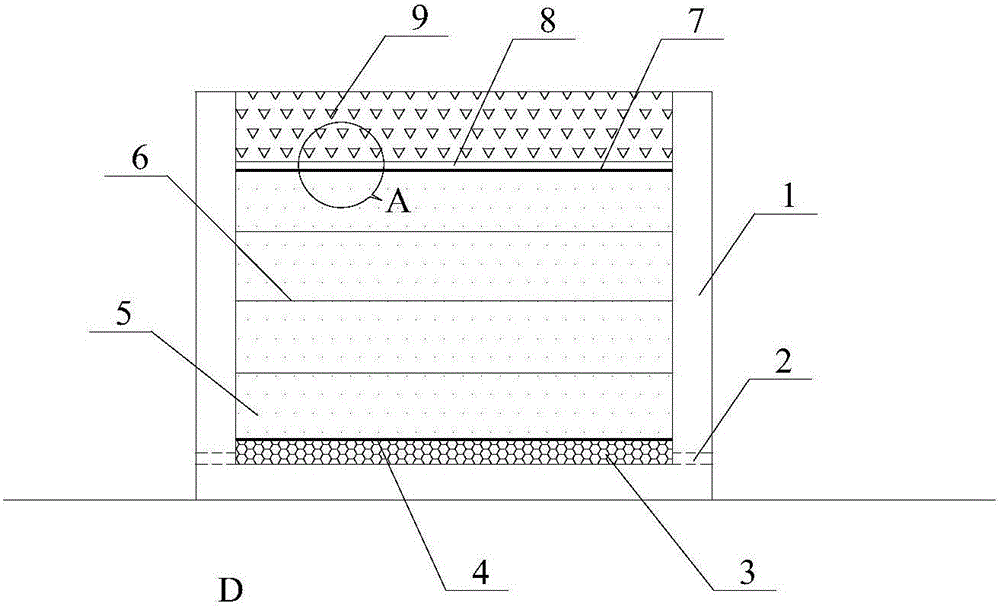

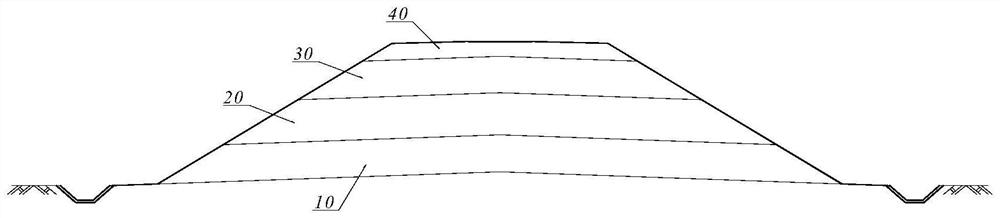

ActiveCN106555368ASolve the collapseSolve the problem of salt swellingRoadwaysBallastwayRailway embankmentInsulation layer

The invention discloses a high speed railway embankment reinforcement structure of a salinized soil area. The problems of collapsibility and salt expansion of a salinized soil foundation are effectively solved, and the foundation treatment work amount and building cost of a high speed railway foundation of the salinized soil area are greatly reduced. The high speed railway embankment reinforcement structure comprises a foundation bed surface layer, a foundation bed bottom layer upper structural layer, a foundation bed bottom layer lower structural layer, a foundation body, water insulation berm structures, an upper water insulation layer and a lower water insulation. The foundation bed surface layer is arranged on the foundation face, and graded broken stone including no soluble salt is adopted for filling. The foundation bed bottom layer upper structural layer is arranged below the foundation bed surface layer, the thickness is 1.0 m, and coarse-particle soil with the soluble salt content being smaller than 0.3% is adopted for filling. The foundation bed bottom layer lower structural layer is arranged below the foundation bed bottom layer upper structural layer, the thickness is 1.3 m, and coarse-particle soil with the soluble salt content being smaller than 1.5% and the fine particle content being smaller than 5% is adopted for filling. In the foundation body, coarse-particle soil with the soluble salt content being smaller than 1.5% and the fine particle content being smaller than 5% is adopted for filling. The water insulation berm structures are arranged on slope toes on the two sides of an embankment, and coarse-particle soil with the soluble salt content being smaller than 1.5% and the fine particle content being smaller than 5% is adopted for filling. The upper water insulation layer is arranged between the foundation bed surface layer and the foundation bed bottom layer upper structural layer. The lower water insulation layer is arranged in the foundation body, and the two sides of the lower water insulation layer extend to the water insulation berm structures.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

High-speed railway embankment reinforcement structure in saline soil area

The invention discloses a high speed railway embankment reinforcement structure of a salinized soil area. The problems of collapsibility and salt expansion of a salinized soil foundation are effectively solved, and the foundation treatment work amount and building cost of a high speed railway foundation of the salinized soil area are greatly reduced. The high speed railway embankment reinforcement structure comprises a foundation bed surface layer, a foundation bed bottom layer upper structural layer, a foundation bed bottom layer lower structural layer, a foundation body, water insulation berm structures, an upper water insulation layer and a lower water insulation. The foundation bed surface layer is arranged on the foundation face, and graded broken stone including no soluble salt is adopted for filling. The foundation bed bottom layer upper structural layer is arranged below the foundation bed surface layer, the thickness is 1.0 m, and coarse-particle soil with the soluble salt content being smaller than 0.3% is adopted for filling. The foundation bed bottom layer lower structural layer is arranged below the foundation bed bottom layer upper structural layer, the thickness is 1.3 m, and coarse-particle soil with the soluble salt content being smaller than 1.5% and the fine particle content being smaller than 5% is adopted for filling. In the foundation body, coarse-particle soil with the soluble salt content being smaller than 1.5% and the fine particle content being smaller than 5% is adopted for filling. The water insulation berm structures are arranged on slope toes on the two sides of an embankment, and coarse-particle soil with the soluble salt content being smaller than 1.5% and the fine particle content being smaller than 5% is adopted for filling. The upper water insulation layer is arranged between the foundation bed surface layer and the foundation bed bottom layer upper structural layer. The lower water insulation layer is arranged in the foundation body, and the two sides of the lower water insulation layer extend to the water insulation berm structures.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

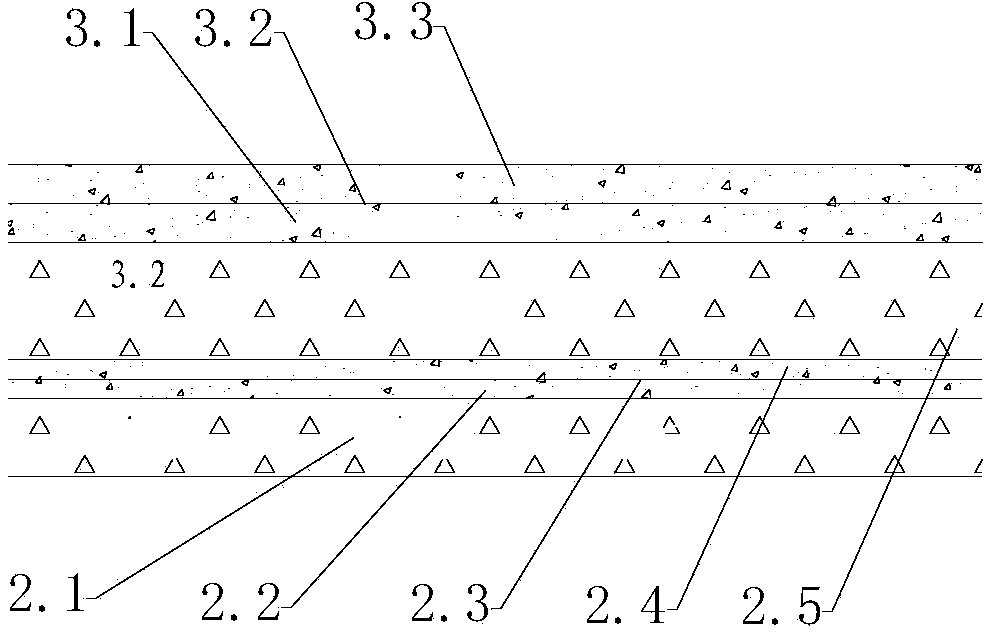

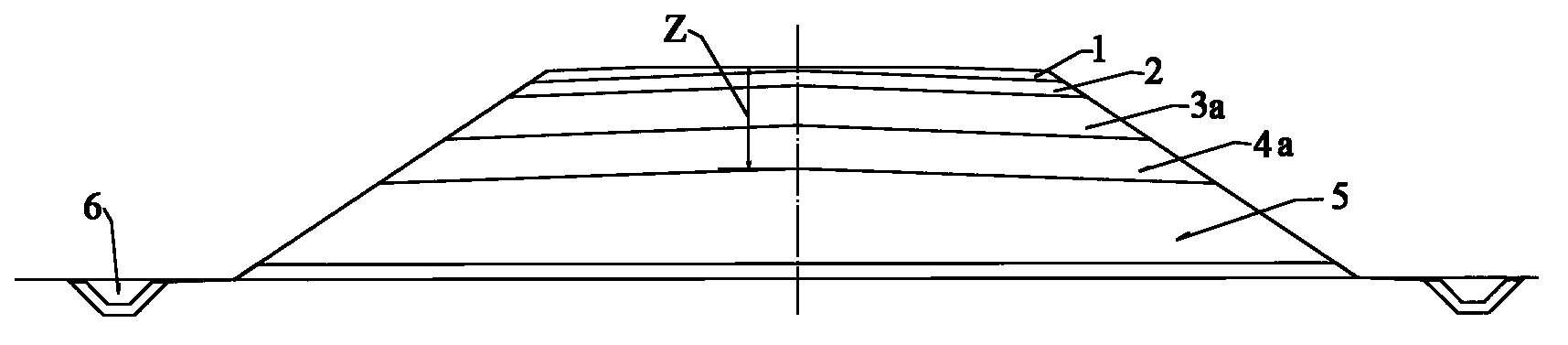

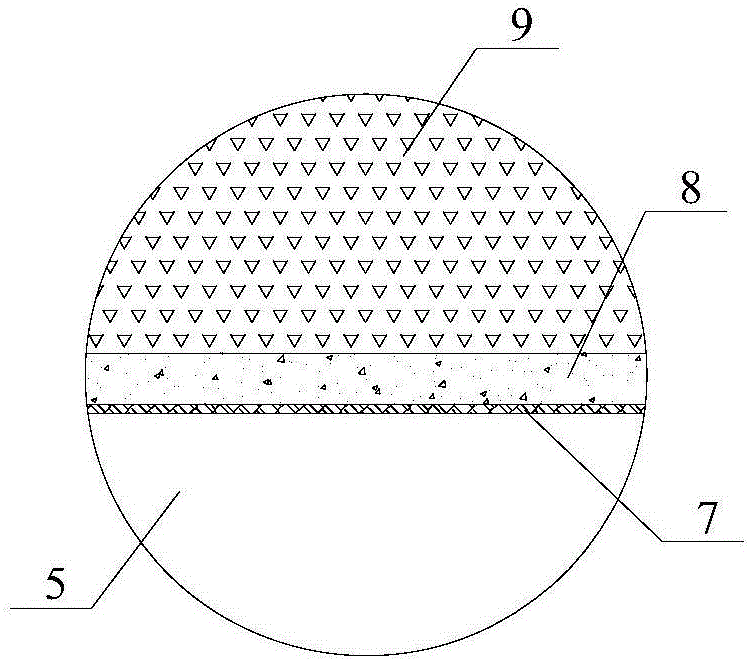

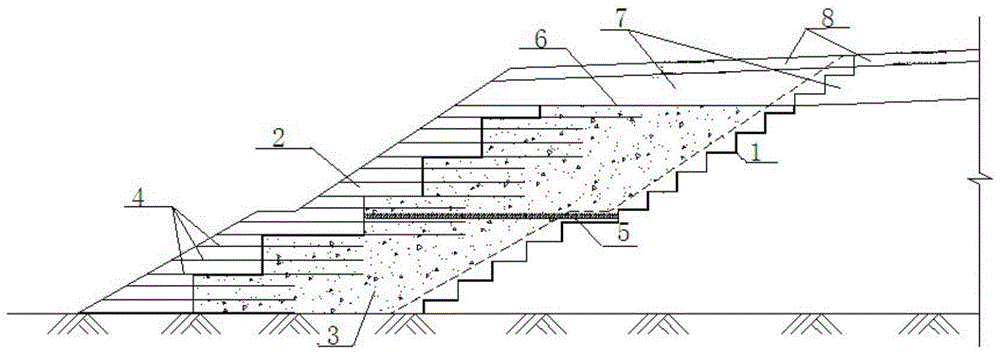

Embankment bedding structure of ballastless track high speed railway in seasonally frozen earth area

ActiveCN103266546AMeet the deformation control requirementsGuaranteed stabilityRoadwaysSurface layerRailway embankment

The invention relates to an embankment bedding structure of a ballastless track high speed railway in a seasonally frozen earth area to effectively control the water content of filling in a bedding scope not to exceed the initial frost heaving water content to prevent frost heaving deformation from a source so as to meet the control requirements on bedding structure deformation by the ballastless track high speed railway and ensure the high smoothness, the stability and the durability of a track structure. The embankment bedding comprises a lower bedding bottom layer, an upper drainage type bedding bottom layer, a drainage type bedding surface layer and a subgrade surface waterproof layer sequentially filled on an embankment body from bottom to top. Drainage ditches are arranged horizontally on both sides of the embankment body. The design frozen depth of the embankment bedding is from the upper surface of the subgrade surface waterproof layer to the upper surface of the embankment body.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

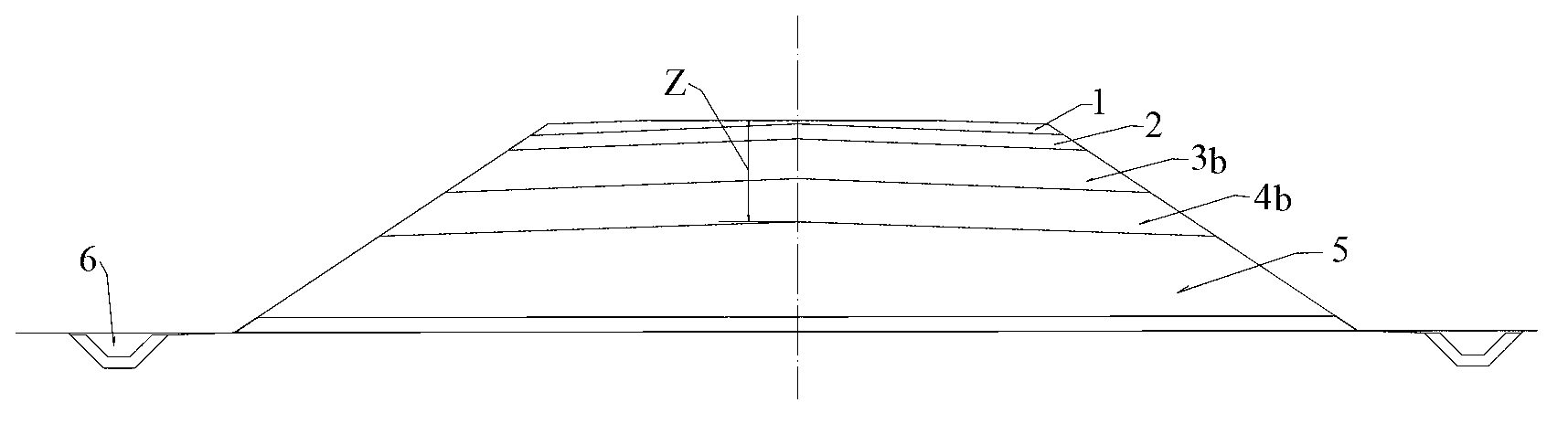

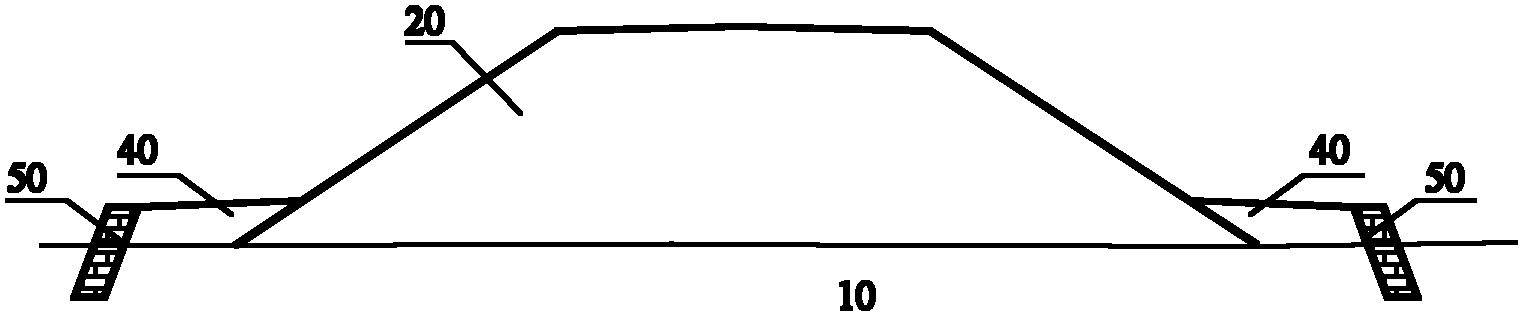

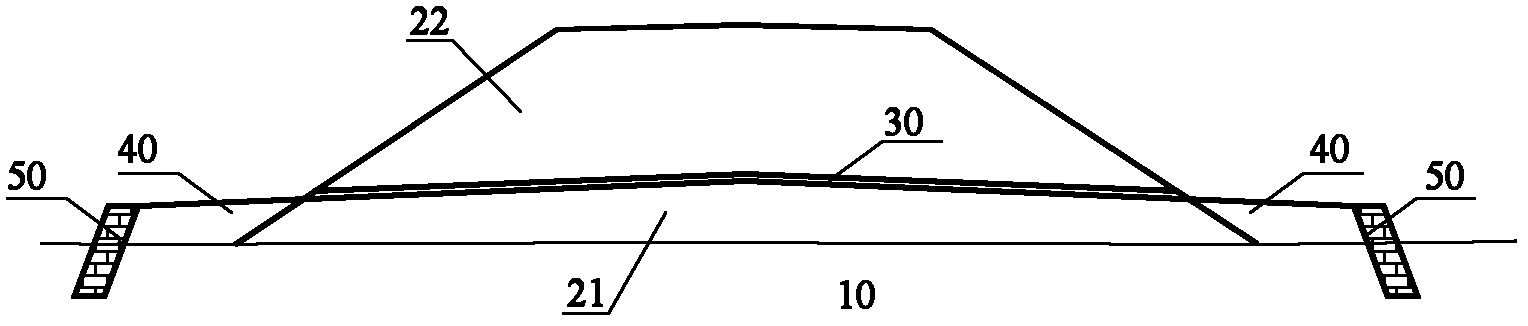

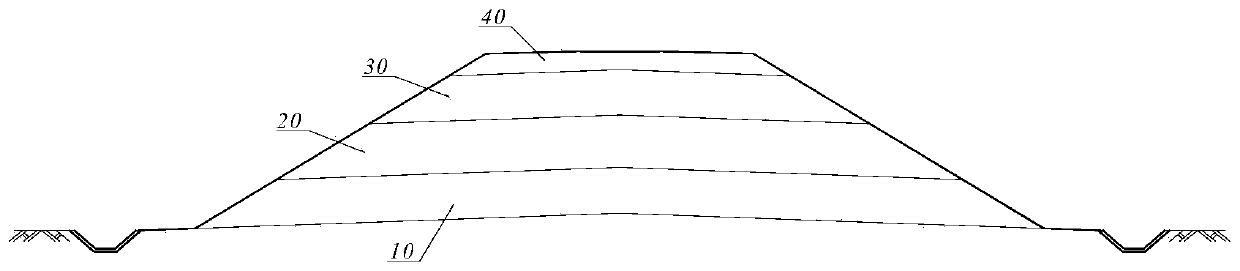

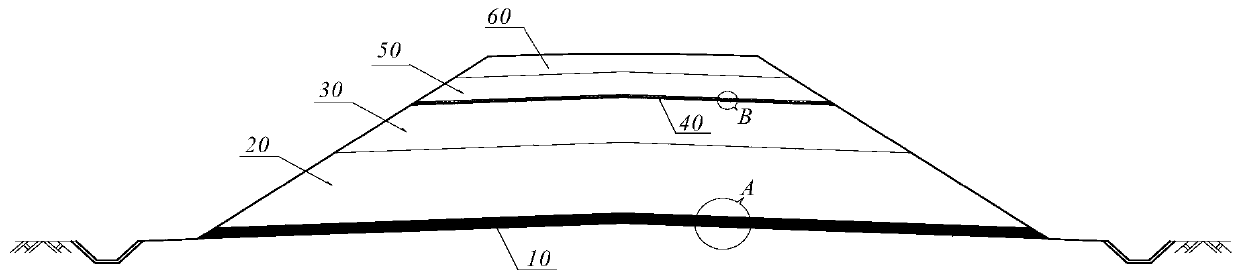

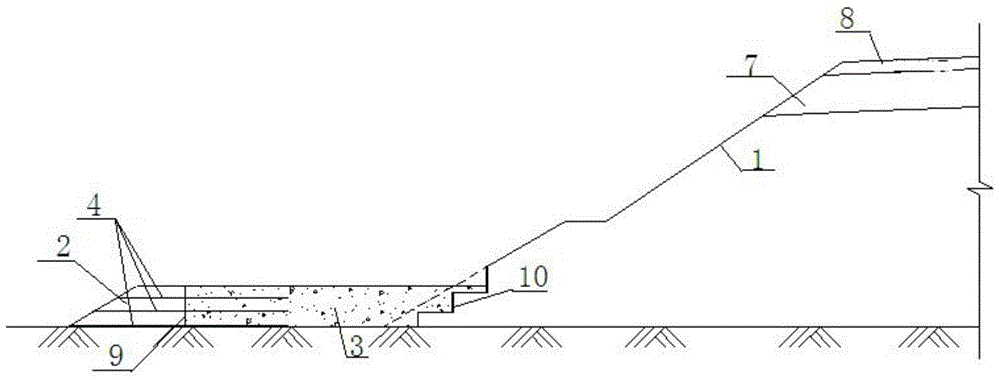

High-speed railway roadbed structure of unsaturated soil foundation in plain region

InactiveCN102330398AControlling the Effects of SettlementImprove riding performanceRoadwaysClimate change adaptationRailway embankmentEngineering

The invention discloses a high-speed railway roadbed structure of an unsaturated soil foundation in a plain region. The structure has the characteristics of strong integrity and good stability, can effectively control roadbed settlement, and meets the requirements of a high-speed railway for high smoothness, stability and durability of a line. The structure comprises an unsaturated soil foundation (10) and a road embankment filling body (20) filled in the unsaturated soil foundation, two sides of the slope toe of the road embankment filling body (20) are provided with back pressure road protection waterproof layers (40), a protective toe wall (50) is arranged at the outer side of the road embankment filling body, and the back pressure road protection waterproof layers (40) are compactly filled by non-permeable soil. The structure effectively solves the technical problems of the field; the high-speed railway embankment is directly constructed on the unsaturated soil foundation, so that the construction cost of the high-speed railway roadbed can be greatly reduced; the structure has the characteristics of strong integrity and good stability, can effectively control the influence of rainfall accumulated water on the roadbed settlement, and meets the requirements of the high-speed railway for high smoothness, stability and durability of the line; and the construction process is simple and meets the requirement of environmental protection.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

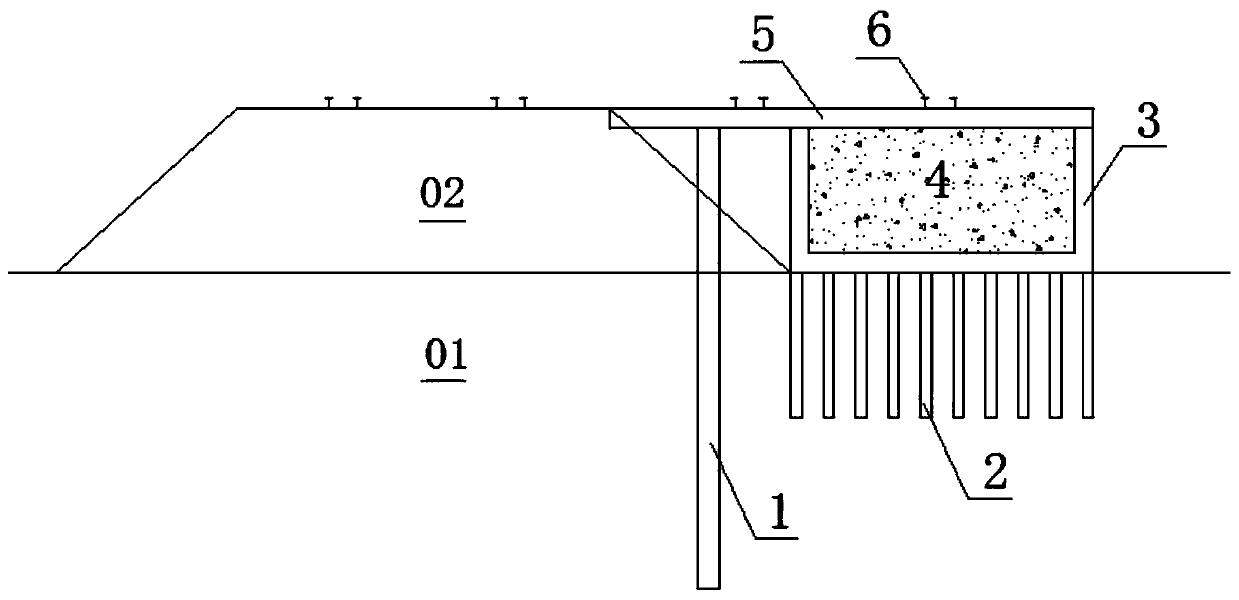

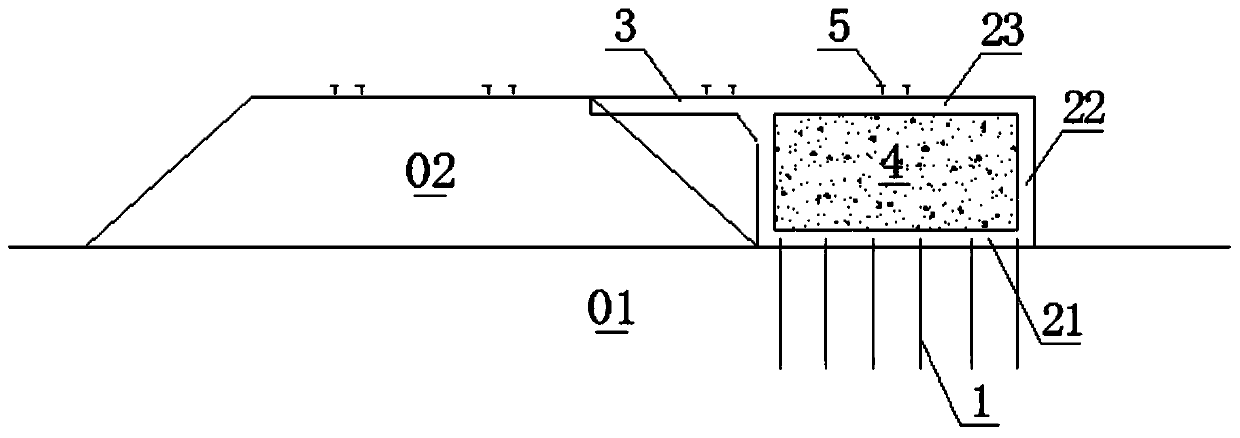

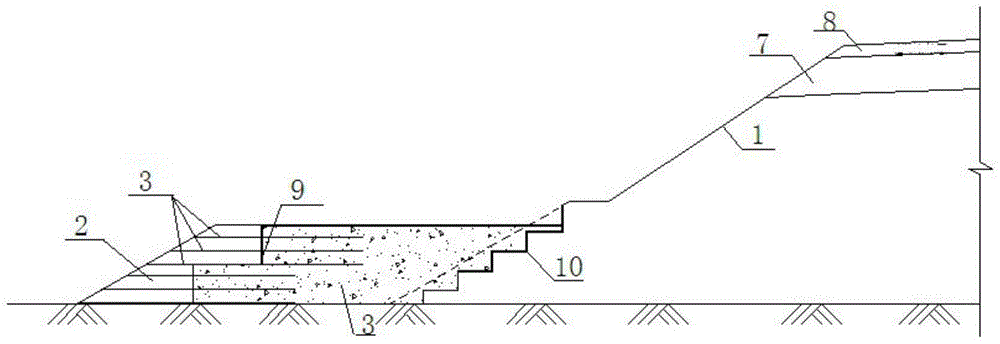

Hard plastic soil foundation existing high-speed railway embankment side width structure a construction method

PendingCN110820432AAvoid additional settlementAvoid influenceRailway tracksRailway embankmentStructural engineering

The invention discloses a hard plastic soil foundation existing high-speed railway embankment side width structure and a construction method. The side width structure comprises a plurality of isolation supporting piles, a plurality of CFG piles, a groove-shaped structure, a light concrete body and a bearing plate, wherein the isolation supporting piles are used for being arranged on an existing fill side slope at intervals along a line, and the bottoms of the isolation supporting piles go deep into a hard plastic soil foundation; the CFG piles are used for being arranged in the hard plastic soil foundation on the outer side of the existing fill slope toe at intervals; the groove-shaped structure is used for being arranged on the hard plastic soil foundation on the outer side of the existing fill slope toe, an opening of the groove-shaped structure is arranged upwards, and all the CFG piles are connected to the bottom of the groove-shaped structure; the light concrete body is poured inside the groove-shaped structure, and the top surface of the light concrete body is flush with a groove opening of the groove-shaped structure; and the bearing plate is connected to the tops of the isolation supporting piles, the groove-shaped structure and the light concrete body, the top surface of the bearing plate is flush with the top surface of an existing fill, and one end of the bearing plate is placed on an existing fill road shoulder structure. According to the side width structure, the influence on the existing high-speed railway fill is effectively avoided.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

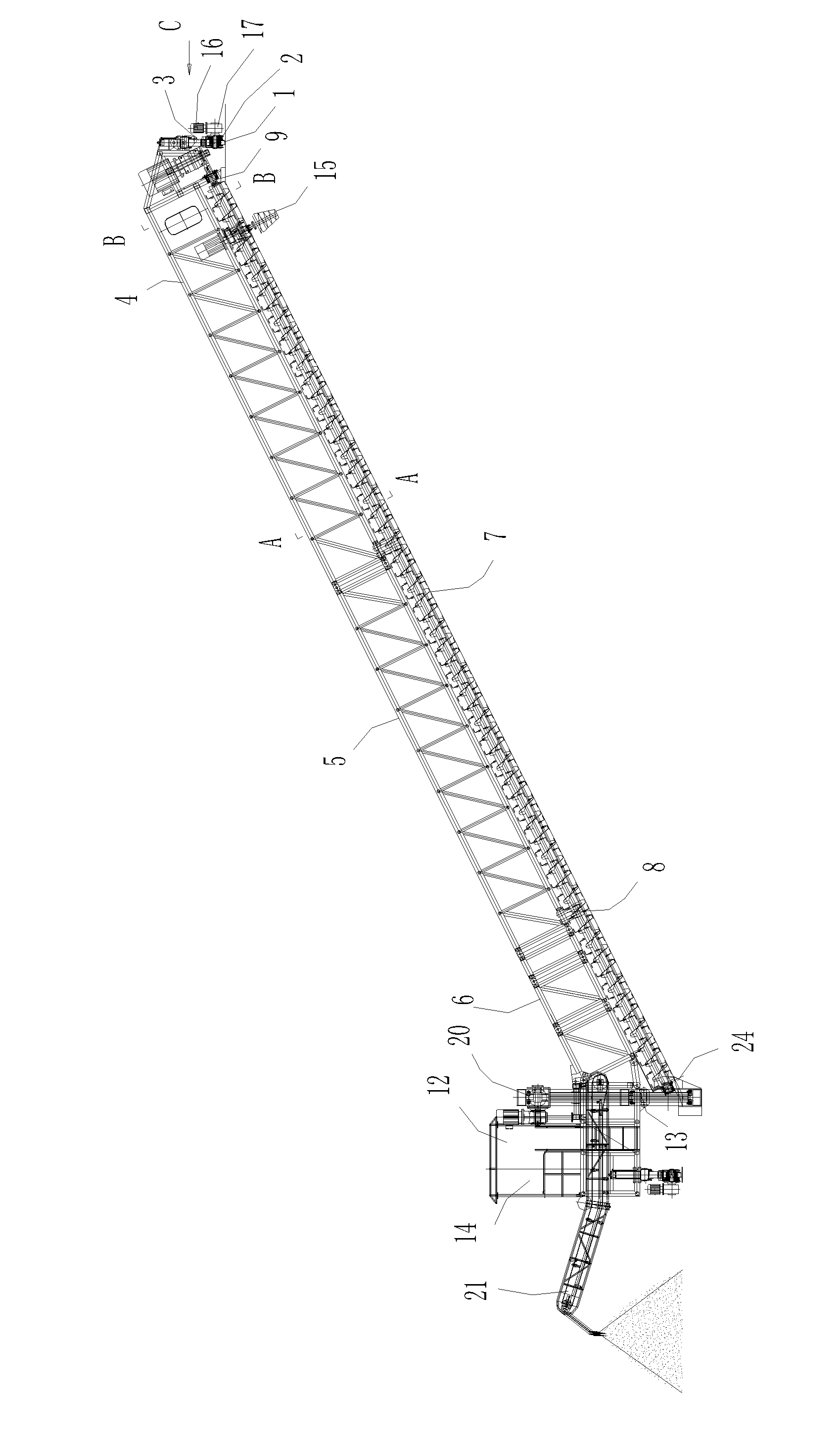

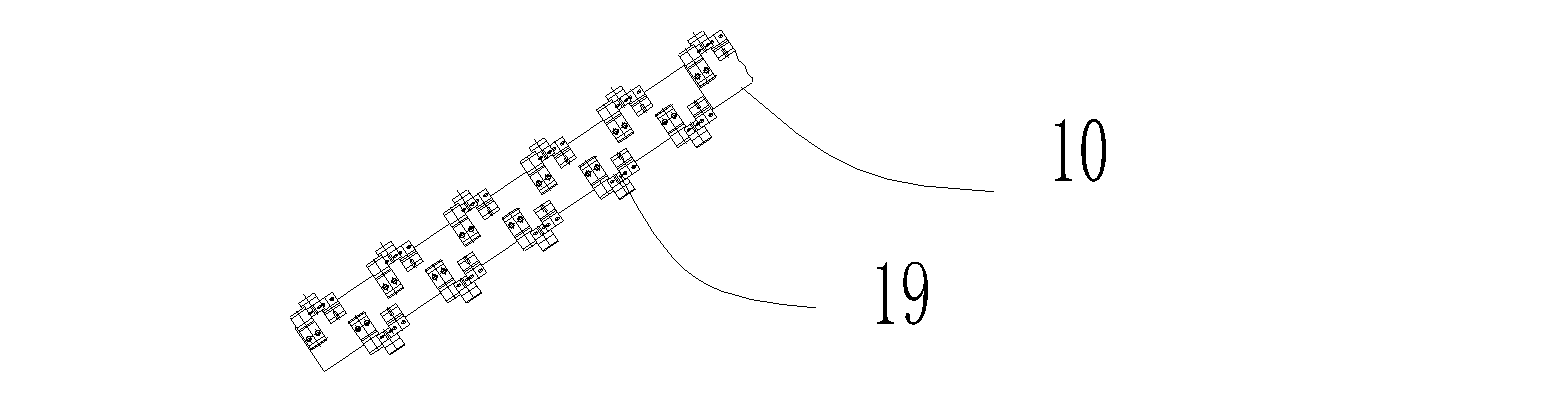

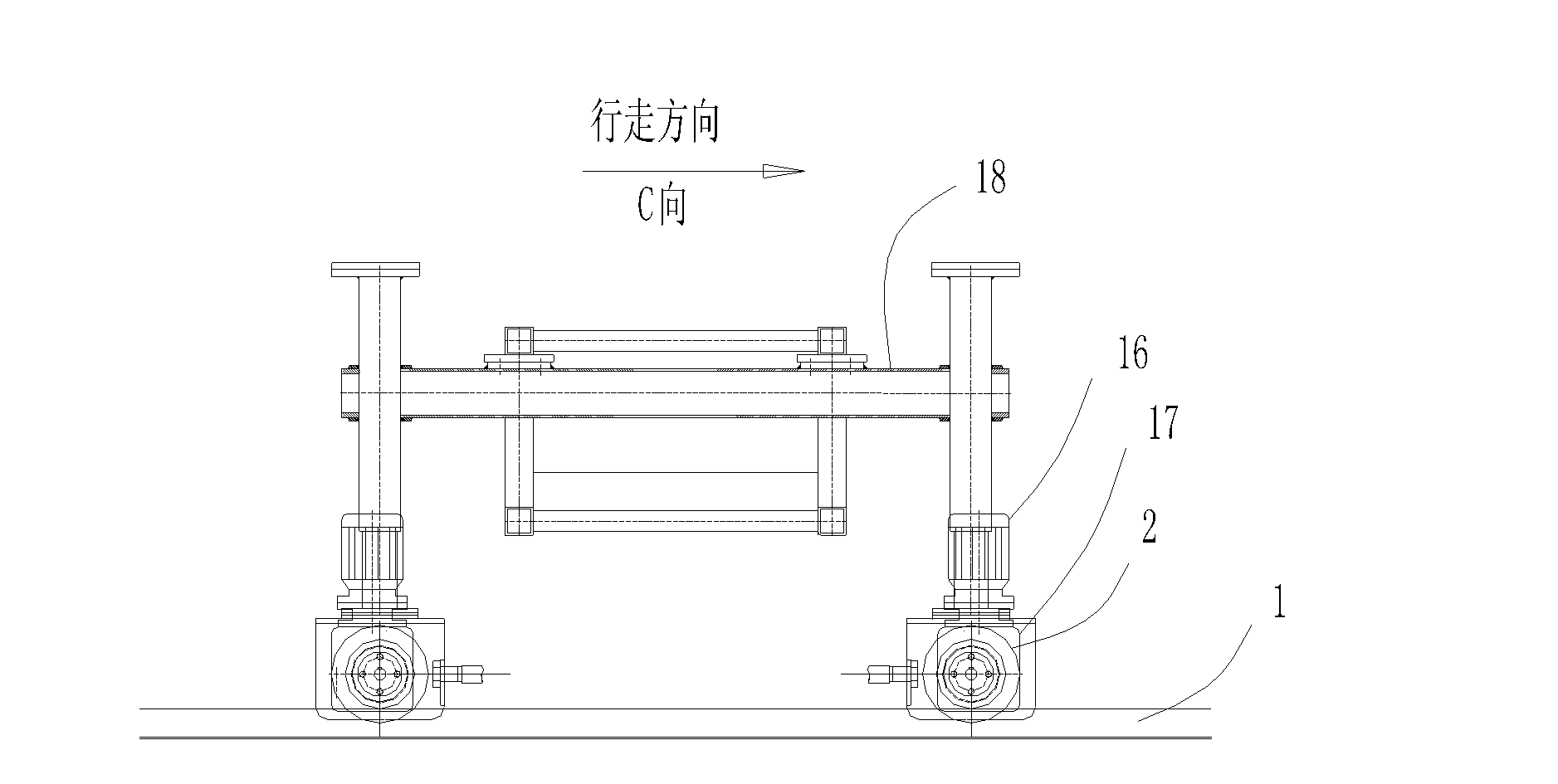

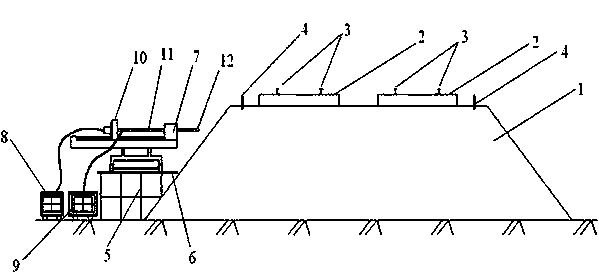

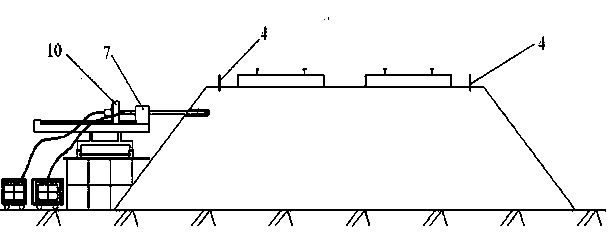

Multifunctional semi-section channel finishing machine

InactiveCN102561269AQuality improvementLabor savingArtificial water canalsExcavationsRailway embankmentEngineering

The invention discloses a finishing machine, which is applied to channel slops or railway embankment side slopes and comprises a framework, a running device, a lifting device and a finishing device. The running device drives the finishing machine to run along the extension direction of a channel, the finishing device is mounted on the framework and is transversely arranged on a slope from the upper portion to the lower portion, and the lifting device is arranged between the running device and the framework and capable of adjusting the distance and parallelism between the finishing device and the slope. The finishing device of the finishing machine crosses the integral slope and runs along with the running finishing machine, so that the slope can be finished in a uniform standard and the finished slope is uniform. Besides, the slope finishing quality is improved greatly and work efficiency is improved.

Owner:韩其华 +3

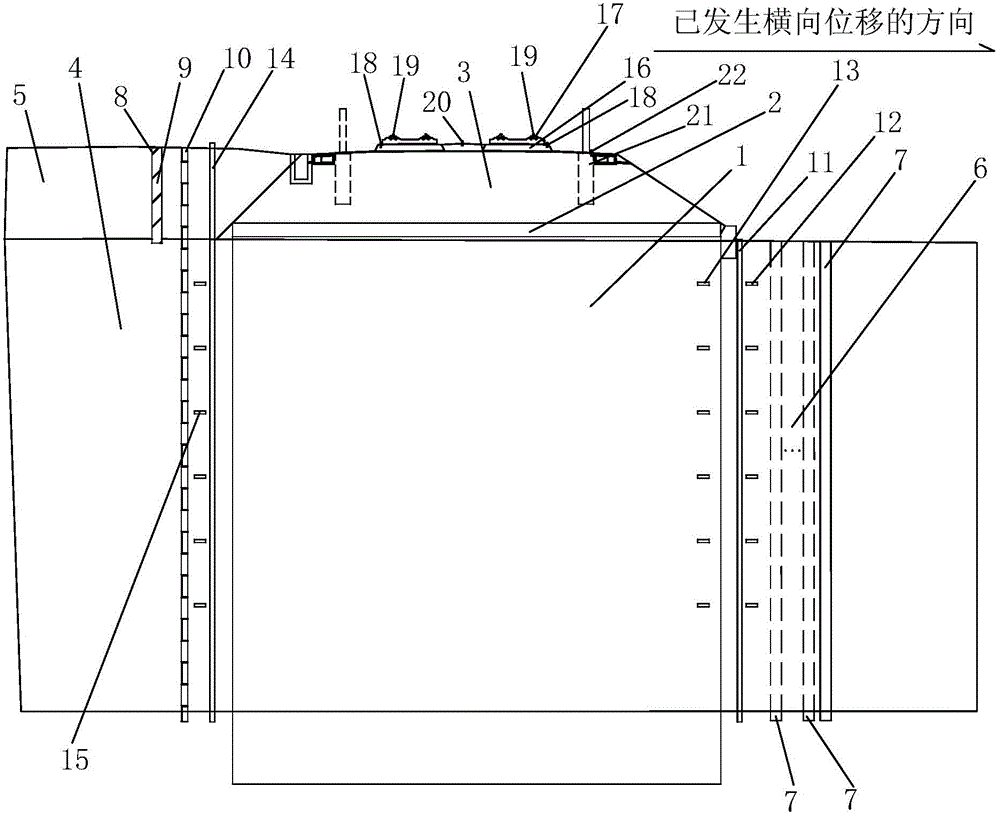

Correcting method for high speed railway ballastless track subgrade in soft soil area

ActiveCN103821039BRotary grouting pile technology is matureConstruction quality is easy to controlRailway tracksInjection pressureRailway embankment

The invention discloses a correcting method for high speed railway ballastless track subgrade in a soft soil area. The correcting method comprises the following steps that 1, when the lateral displacement of the high speed railway embankment occurs , a deformation groove and a plurality of stress relief apertures are formed in an asymmetrical load region, the deformation groove is filled with rigid foam, and the stress relief apertures are filled with grits and rubbles; 2, a first row jet-grouting pile is arranged in a second soft stratum area, the instantaneous injection pressure generated by the construction of the first row jet-grouting pile is utilized to drive a pile foundation reinforcement area located at the bottom of the high speed railway embankment to conduct the displacement from the second soft stratum area to a first soft stratum area, the pile foundation reinforcement area drives a subgrade reinforcement bed course located above the pile foundation reinforcement area and the high speed railway embankment to move simultaneously, and the correcting for the high speed railway subgrade is achieved; 3, the deformation groove is densely filled with the rubbles plus 5% of cement. An acting force is applied on subgrade deeps, the subgrade drives the subgrade body to conduct a movement, so that the purpose of correcting the lateral displacement of the subgrade is achieved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Rock foundation existing high-speed railway embankment force balance assisting widening structure and construction method

PendingCN110761127AAvoid Vertical DistortionAvoid disadvantagesRailway tracksRailway embankmentRc frames

The invention discloses a rock foundation existing high-speed railway embankment force balance assisting widening structure and a construction method. The assisting widening structure comprises a plurality of grouting anchor rods, a reinforced concrete frame structure, a reinforced concrete cantilever plate and a filling body, wherein the plurality of grouting anchor rods are used for being arranged in a rock foundation outside a slope foot of an existing embankment at intervals, the reinforced concrete frame structure is used for being arranged on the rock foundation outside the slope foot ofthe existing embankment, all the grouting anchor rods are connected to the bottom of the frame structure, one end of the reinforced concrete cantilever plate is connected to the top of the frame structure, the other end of the reinforced concrete cantilever plate is arranged on an existing embankment road shoulder structure, the top surface of the frame structure, the top surface of the cantilever plate and the top surface of the existing embankment are flush, and the filling body fills a cavity in the frame structure. By using the assisting widening structure, the high bearing capacity and anchoring force of the rock foundation are fully utilized, the weight of the frame structure and the internal filling body of the frame structure are utilized, pulling force generated by the grouting anchor rods is combined, and load acting on the cantilever plate by a train is resisted, so that adverse vertical deformation generated when the train passes through the cantilever plate can be avoided, and an existing high-speed railway is not influenced.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

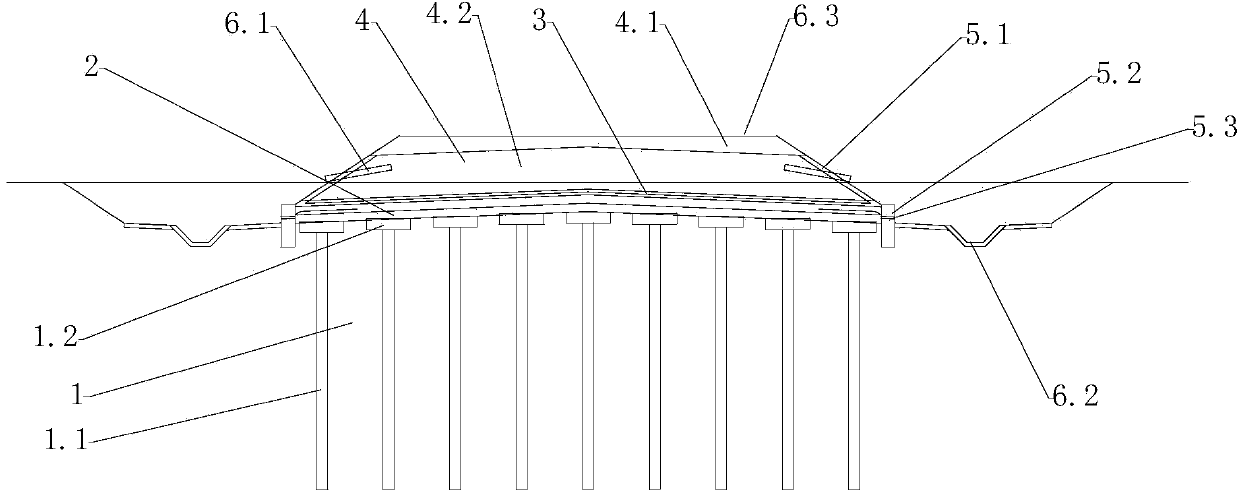

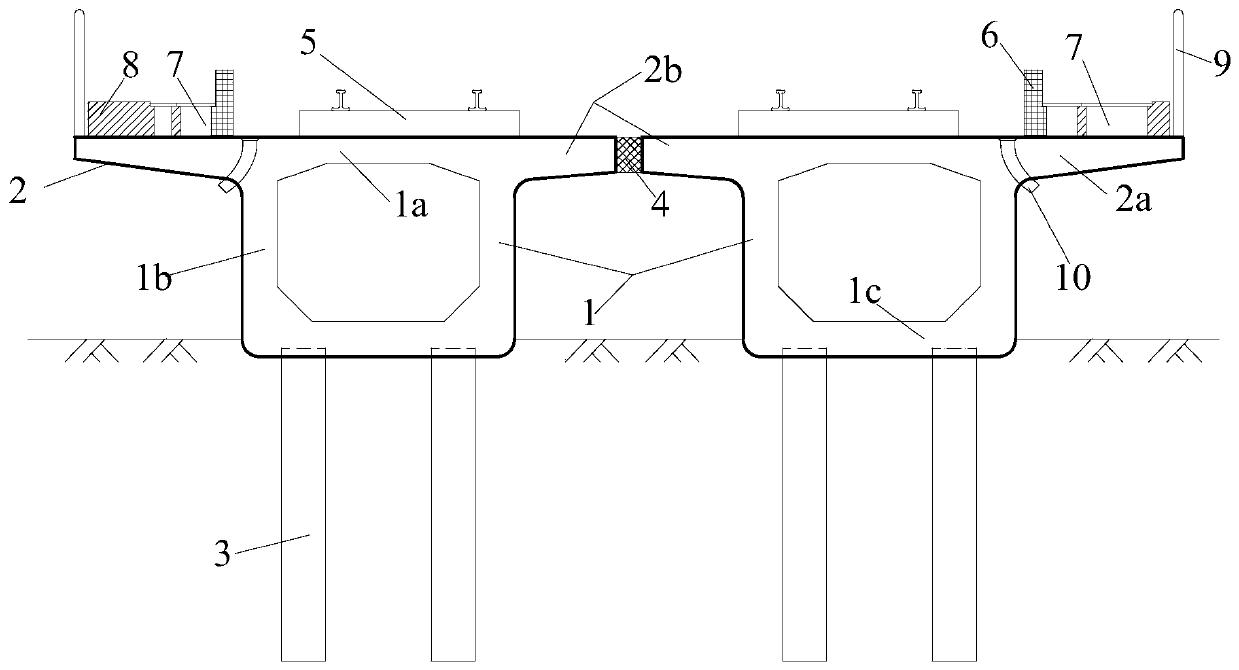

Light roadbed structure of high-speed railway

PendingCN111058338ALight weightReduce reinforcement rangeBallastwayBridge structural detailsRubber materialSupporting system

The invention discloses a light roadbed structure of a high-speed railway. The light roadbed structure comprises a box type roadbed, a cantilever structure and a rigid pile foundation, wherein the boxtype roadbed comprises a top plate which is integrally formed and horizontally arranged, two side wall plates which are vertically arranged and a bottom plate which is horizontally arranged, all thecomponents are fixedly connected to form a closed box-shaped structure, and the section of the closed box-shaped structure is in a closed rectangular shape; and the two ends of the top plate extend outwards to form outer cantilevers and extend towards the center line of the roadbed to form inner cantilevers, and damping rubber materials are filled between the adjacent inner cantilevers to seal andstop water. A track plate and a track supporting system are arranged on the top plate, an anti-collision wall, a cable trough and a contact net stand column base are sequentially arranged on the outer cantilevers, and a protective fence is arranged at the ends of the outer cantilevers. Vertical drainage ducts are formed in the positions, close to the outer side wall plates, of the top plate of the box type roadbed; a rigid pile foundation is arranged at the bottom of the box type roadbed. According to the method, the sloping range of the slope of the high-speed railway embankment is greatly reduced, the foundation reinforcement work amount is reduced, and the use amount of rigid piles and the filling amount of railway roadbed filler are reduced.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

Double-side cantilever retaining wall pop-up package opposite-pull type reinforced earth railway embankment structure

PendingCN109235156AIncreased durabilityReduce erosionRailway tracksReinforced concreteRailway embankment

The invention provides a double-side cantilever retaining wall pop-up package opposite-pull type reinforced earth railway embankment structure, which not only meets the safety and stability requirements of high embankment slope retaining in railway flooding section, but also solves the problems of deep soft soil foundation treatment and structural durability under flooding condition. At the same time, it can effectively shorten the construction period and make the construction more convenient, especially suitable for the case of large width of embankment top surface. Comprises two side panelsand a filter layer located on the back of the filter layer, an inclusion and a road basic body filled between the two side inclusions, wherein the road basic body is layered with a wrapping geogrid, and the wrapping geogrid forms a reverse wrapping on the inclusions at both ends of the wrapping geogrid. A double-side cantilever retaining wall construction body is arranged below the wrapping opposite-tension reinforced earth structure body, The two-side cantilever retaining wall structure is composed of two-side cantilever retaining walls and a lower road basic body filled in between. A reinforced concrete foundation is arranged on the upper inner side of the two-side cantilever retaining wall vertical arms on the lower road basic body, and the lower ends of the two-side slabs are respectively located on the same-side reinforced concrete foundation. The bottom plate composed of the toe plate and the heel plate of the double-side cantilever retaining wall is located on a sand cushion layer, and the sand cushion layer is laid on a consolidated foundation.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

A treatment method for controlling the mud and slopping of the subgrade of slab ballastless track railway

The invention discloses a renovation method for treating mud pumping of a plate-type ballastless track railway roadbed. Drilling is conducted on the surface layer of a foundation bed through a special horizontal drilling machine, and then the method that hot air is injected into grouting hole passageways is adopted; accumulated water in a mud pumping disease area is subjected to treatment, and grouting is conducted in grouting holes after accumulated water treatment is completed; before grouting, telescopic seams of a base plate, cracks of the side edges and orifices of the opposite sides of the grouting holes are subjected to sealing treatment, and then grouting is successively conducted in the hole passageways according to a certain sequence; a uniform and compact water insulation layer with the certain strength is formed between the base plate and the surface layer of the foundation bed after grouting is completed; and the water insulation layer can obstruct water of cracks on the upper portion from invading into the surface layer of the foundation bed and can also block fine particle soil in the surface layer of the foundation bed on the lower portion to move upwards. According to the novel renovation method for treating mud pumping of the plate-type ballastless track railway roadbed, the mud pumping disease of the plate-type ballastless track railway roadbed can be well governed.

Owner:ZHEJIANG UNIV

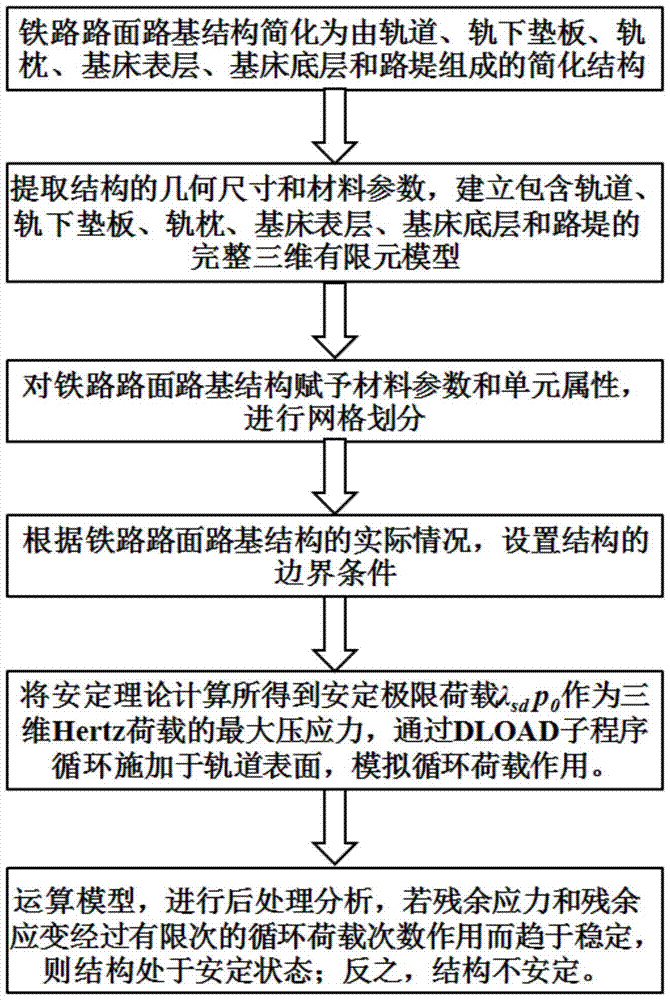

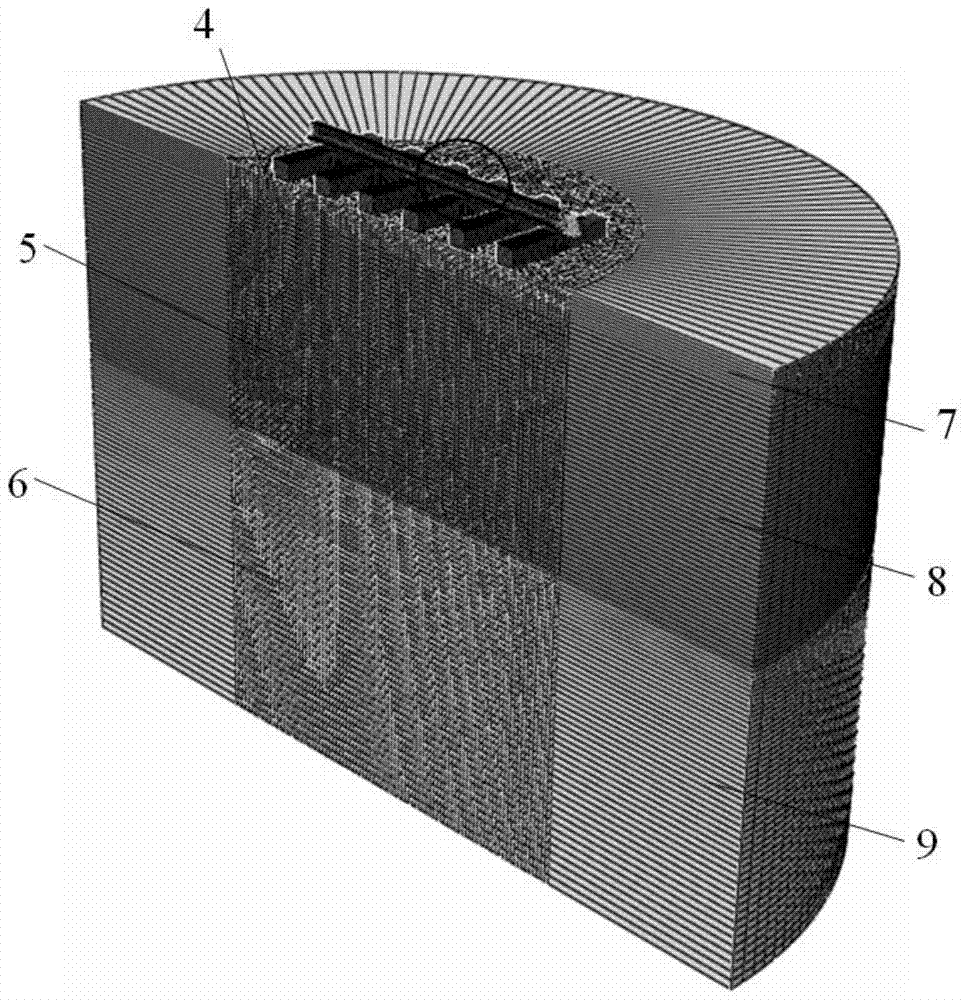

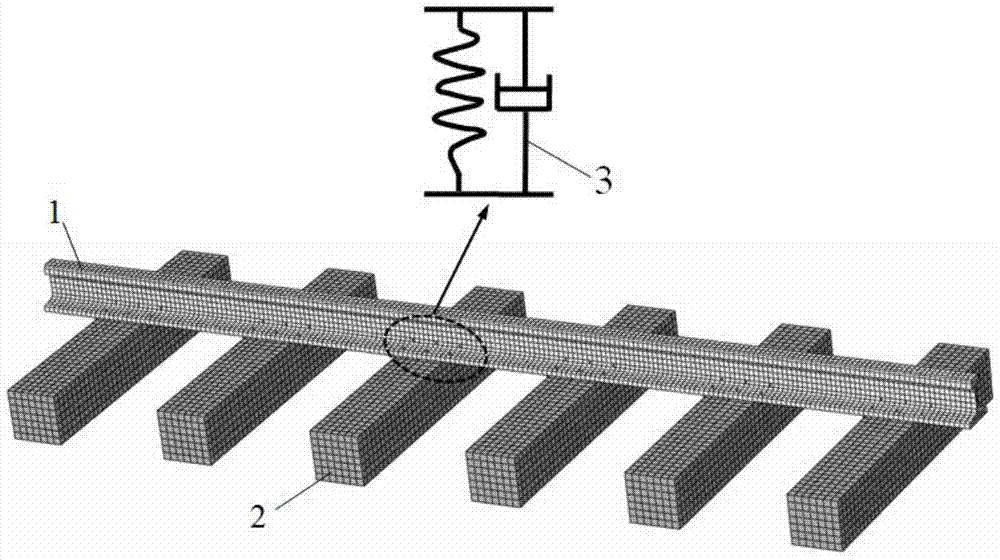

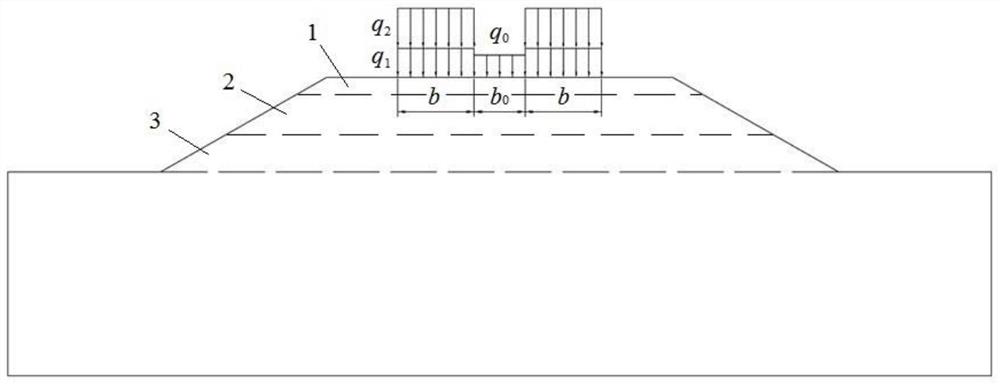

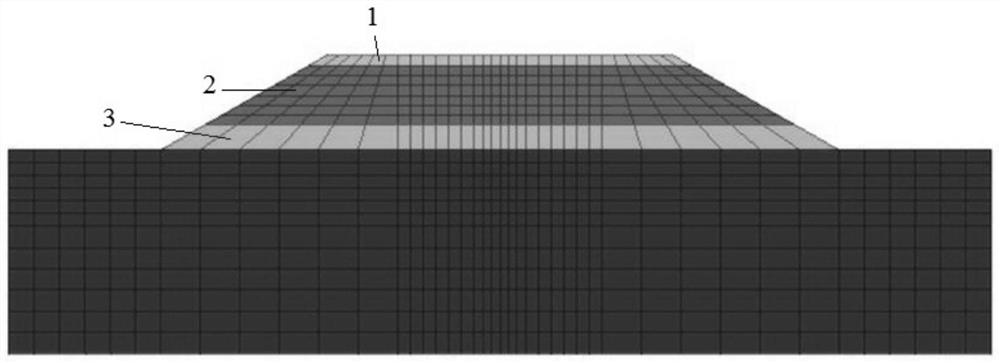

A three-dimensional finite element verification method for structural stability analysis of multi-storey railway subgrade

ActiveCN105302953BTrue elastic-plastic deformation propertiesEasy post-processingSpecial data processing applicationsElement modelRailway embankment

The invention discloses a three-dimensional finite element verification method for the stability analysis of multi-layer railway subgrade structure. The method uses ABAQUS finite element software to apply a dynamic cyclic load equal to the stability limit of multi-layer railway subgrade structure calculated by stability theory on the track surface , by analyzing the relationship between the residual stress field of the structure and the number of load cycles, it is verified whether the railway structure is in a stable state under the load. The specific steps include: simplifying the subgrade structure of railway pavement; extracting the geometric parameters of the structure; assigning material properties and unit properties to the subgrade structure of the pavement respectively; setting the boundary conditions of the structure; The present invention simplifies the actual structure of the railway pavement subgrade, establishes a three-dimensional finite element model of the multi-layer railway pavement subgrade structure, and verifies the stability limit of the multi-layer railway pavement subgrade structure obtained by the stability theory, which can be used for the construction of the railway pavement subgrade Design provides useful reference.

Owner:HOHAI UNIV

U-shaped groove foundation of immersed soft foundation wrapped with opposite-tension reinforced earth railway embankment structure

PendingCN109235157AIncreased durabilityReduce erosionRailway tracksRailway embankmentReinforced concrete

The invention provides a U-shaped groove foundation of the immersed soft foundation wrapped with an opposite-tension reinforced earth railway embankment structure, which not only meets the safety andstability requirements of high embankment slope retaining engineering in railway flooding section, but also solves the structural durability problem under flooding condition. At the same time, it hasstrong integrity and large structural stiffness, which is conducive to reduce the uneven settlement of subgrade foundation on deep and thick soft soil foundation, and can adapt to lower foundation bearing capacity conditions. Comprises two side panels and a filter layer located on the back of the filter layer, an inclusion and a road basic body filled between the two side inclusions, wherein the road basic body is provided with a wrapping geogrid layered with the wrapping geogrid, and the wrapping geogrid forms a reverse wrapping on the inclusions at both ends of the wrapping geogrid transversely. A U-shape reinforced concrete groove foundation is arrange below that wrapped-up opposite-tension reinforced soil structure body, a lower road basic body is filled in the U-shaped reinforced concrete groove foundation, a reinforced concrete foundation is arranged on the lower road basic body inside the opening, and the lower ends of the two side panels are respectively located on the same side reinforced concrete foundation; The bottom of the reinforced concrete U-shaped groove foundation extends transversely outward to form a bottom plate and is seated on a sand cushion layer which is laid on the consolidated foundation.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

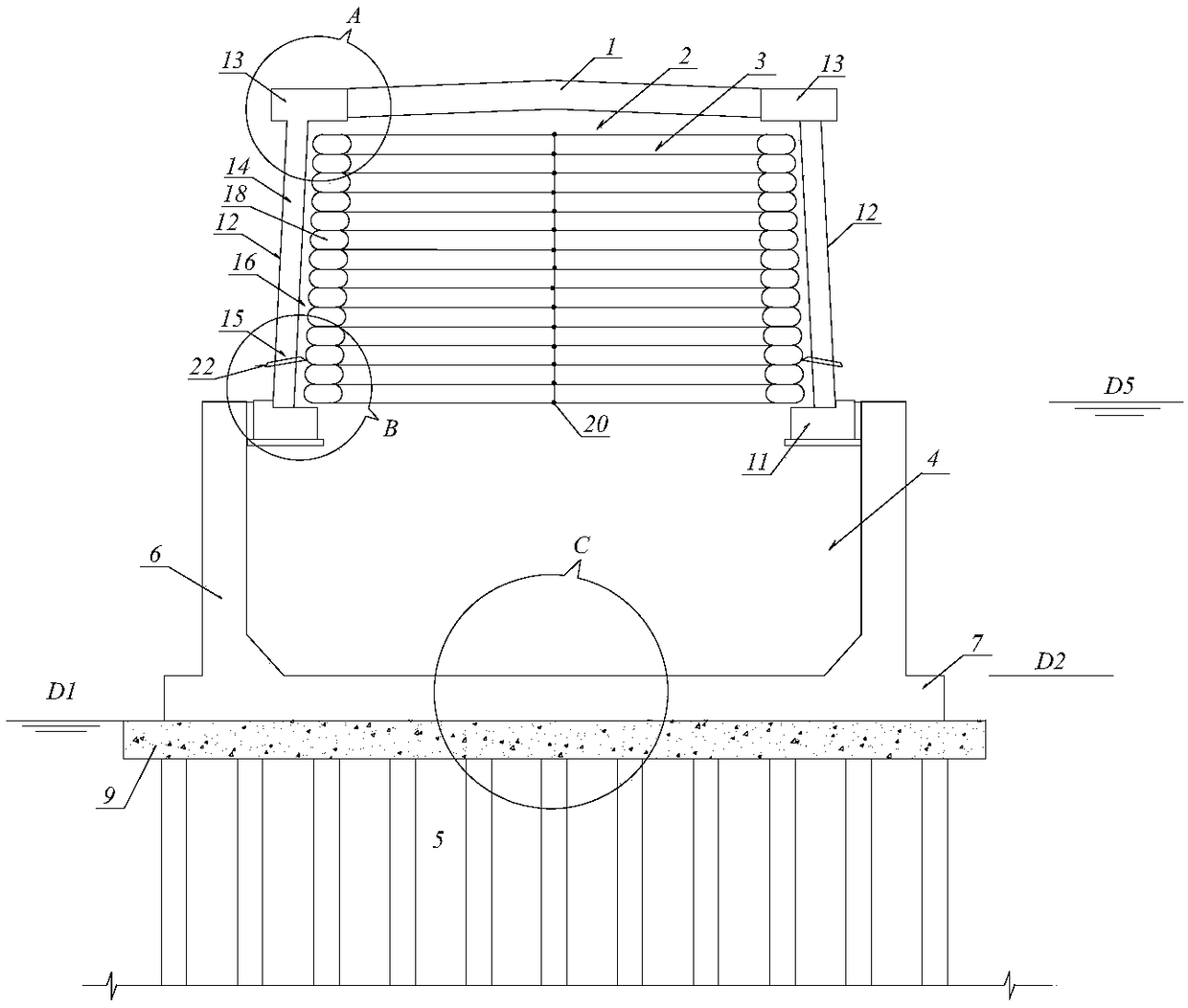

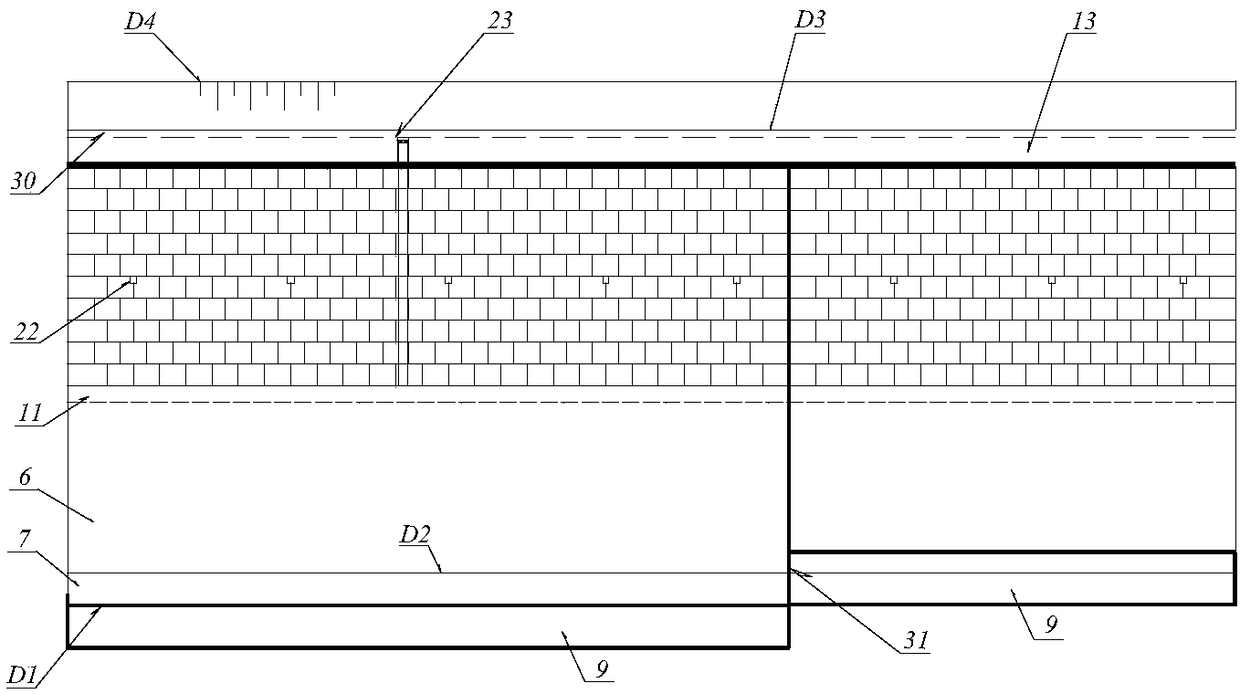

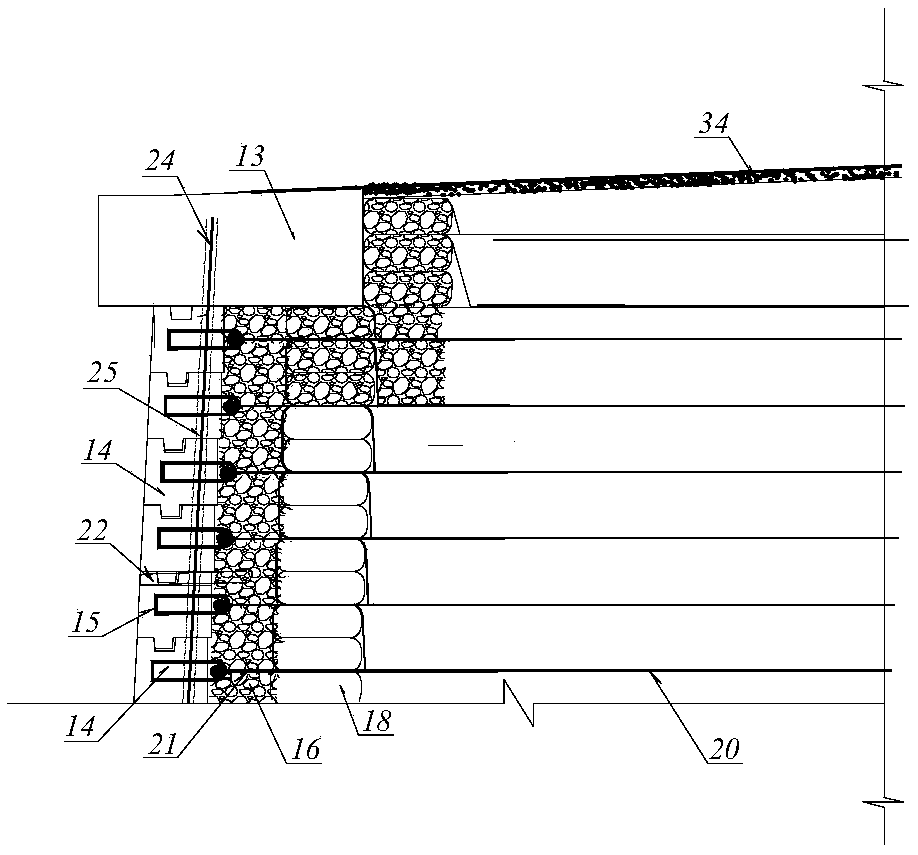

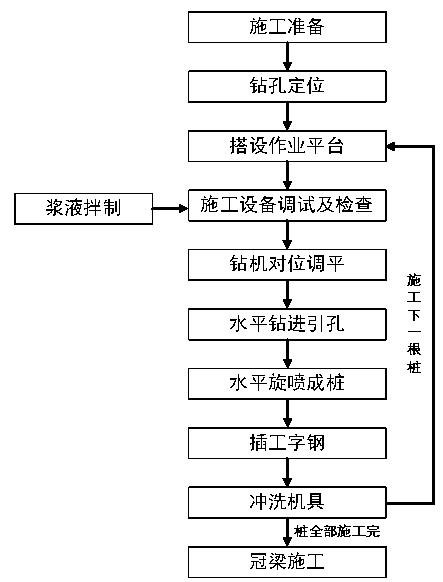

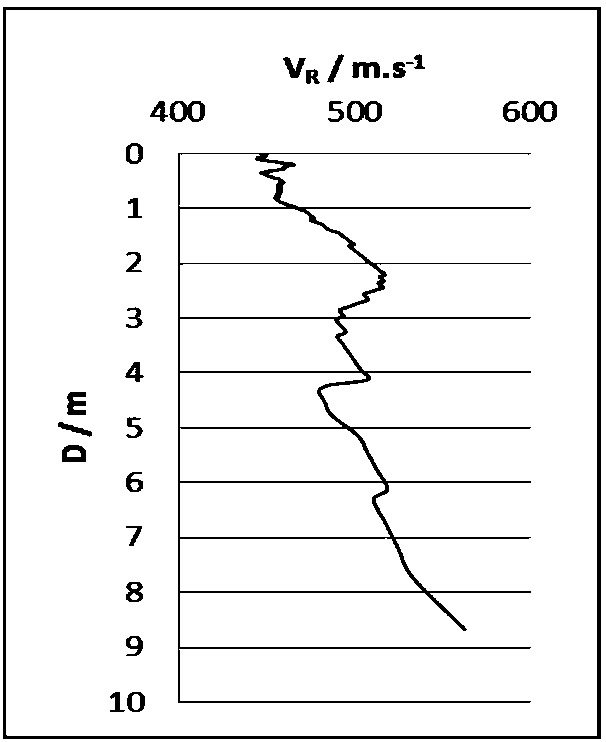

Construction method for reinforcing railway embankment with horizontal reinforced soil-cement piles

ActiveCN104294831AReduce construction difficultyImprove construction qualityRoadwaysExcavationsRailway embankmentSoil cement

The invention discloses a construction method for reinforcing a railway embankment with horizontal reinforced soil-cement piles. The method includes the sequentially-implemented steps of construction preparation, drilling and position, I-beam work platform setting up, construction equipment debugging and checking, horizontal rotary jet grouting drill rig alignment and leveling, horizontal lead hole drilling, horizontal rotary jet grouting file-forming, I-beam insertion, machine and tool washing and top beam construction. By the construction method, the horizontal rotary jet grouting pile-forming method is adopted, construction difficulty of the horizontal reinforced soil-cement piles is lowered effectively, and the relative position for pile-forming of the reinforced soil-cement piles can be ensured effectively; by the method of I-beam insertion, I-beams are prevented from self deflection deformation in the process of being inserted into the soil-cement jet grouting piles, and construction quality of railway embankment reinforcement by the horizontal reinforced soil-cement piles is improved remarkably.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

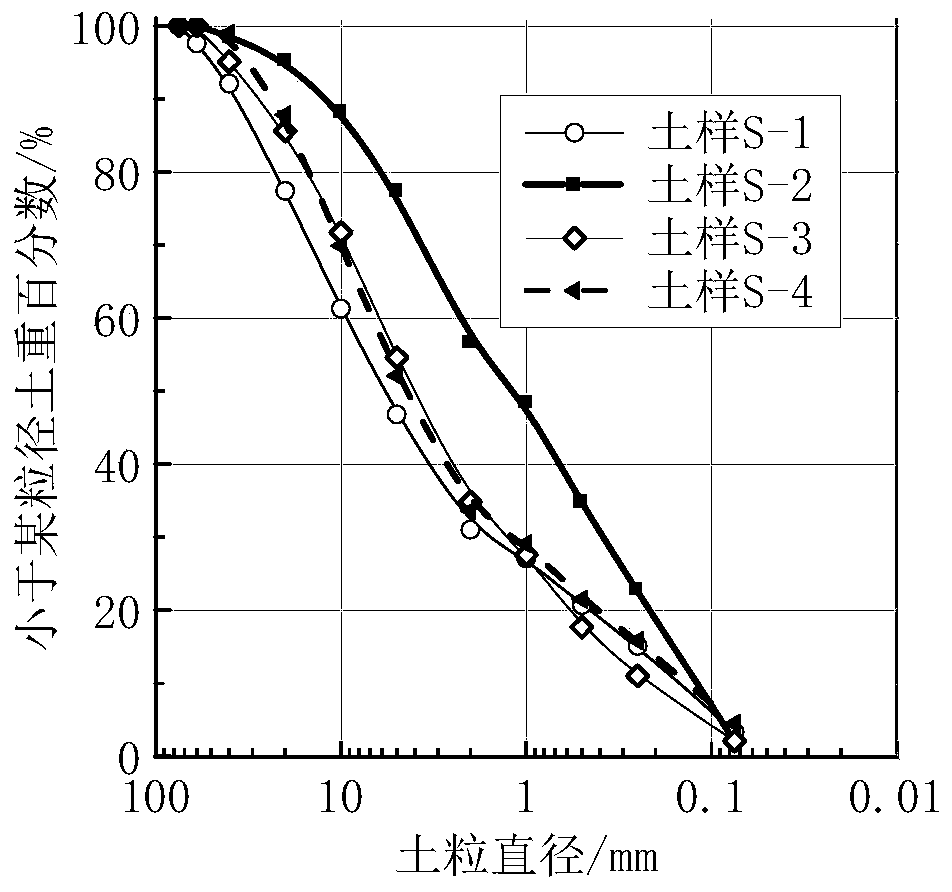

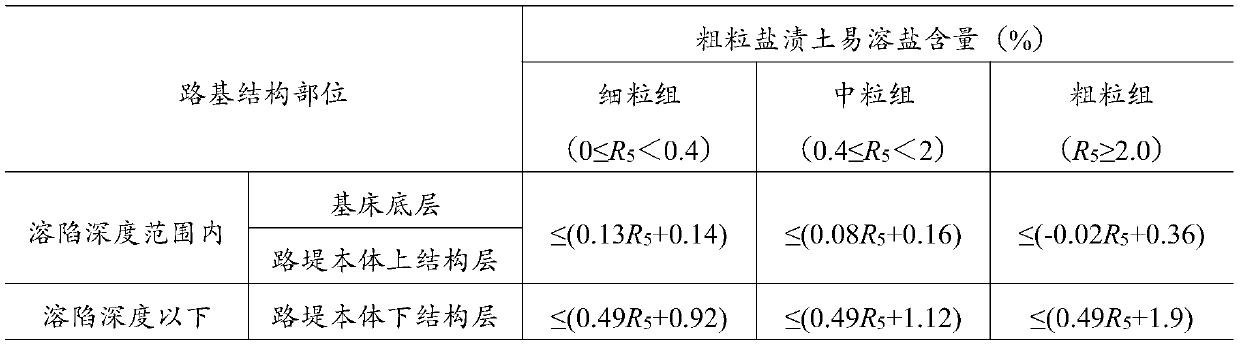

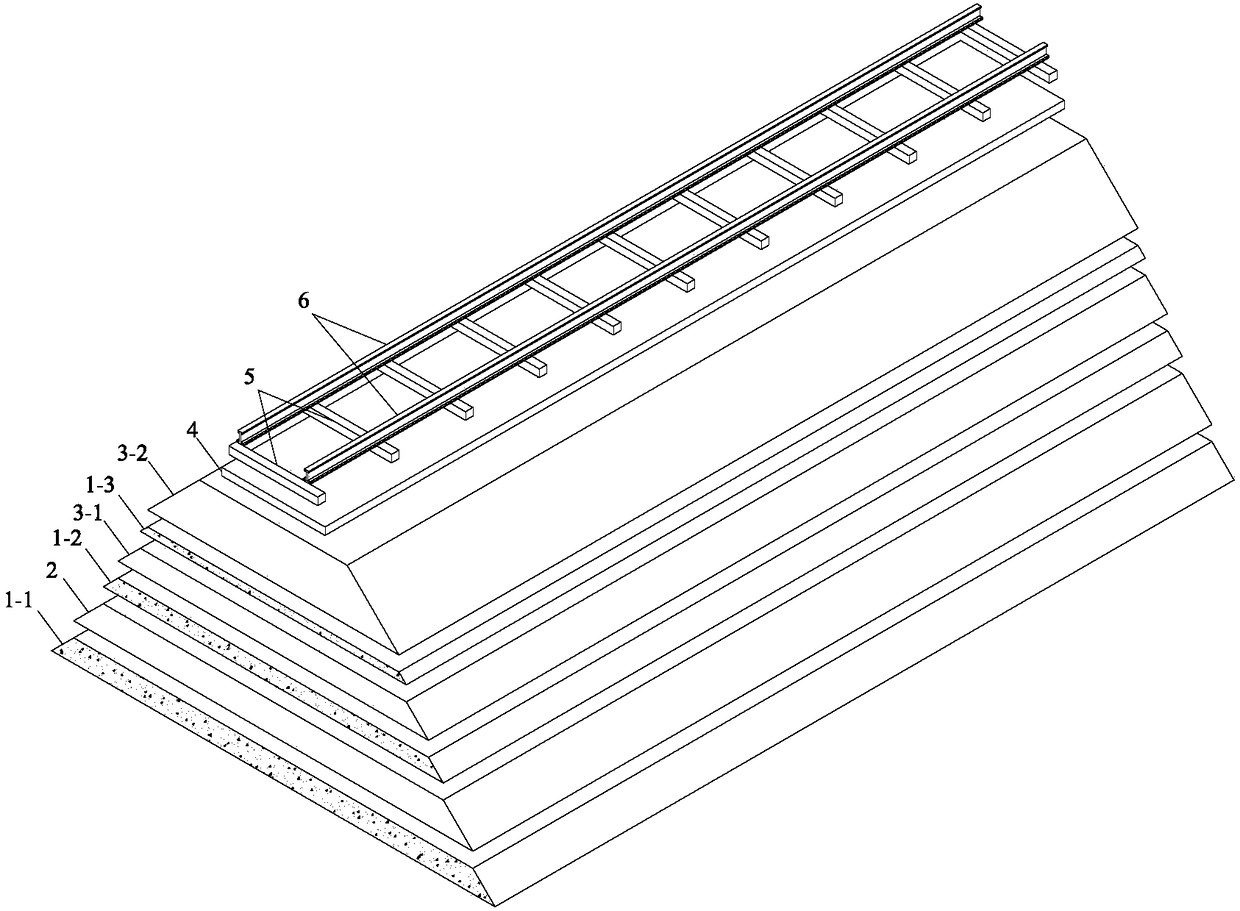

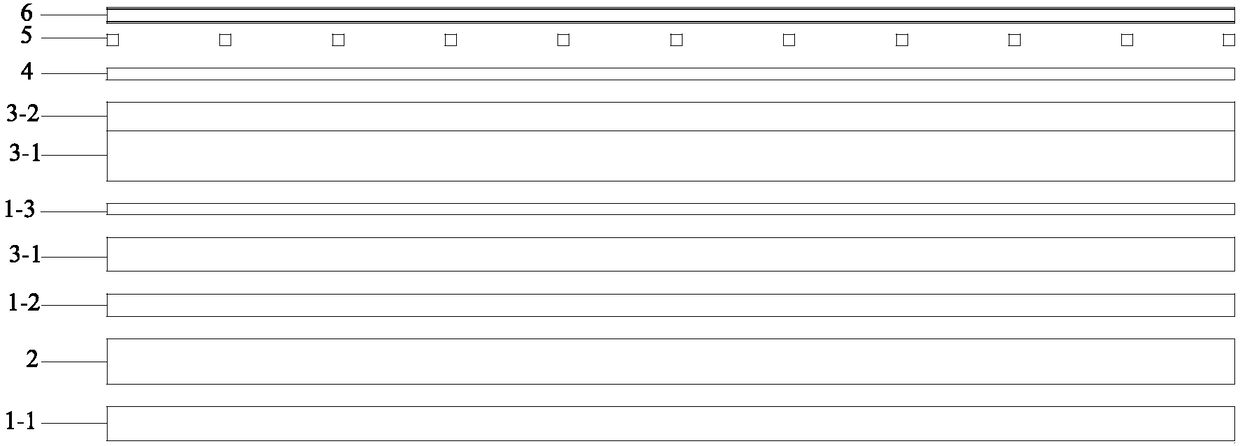

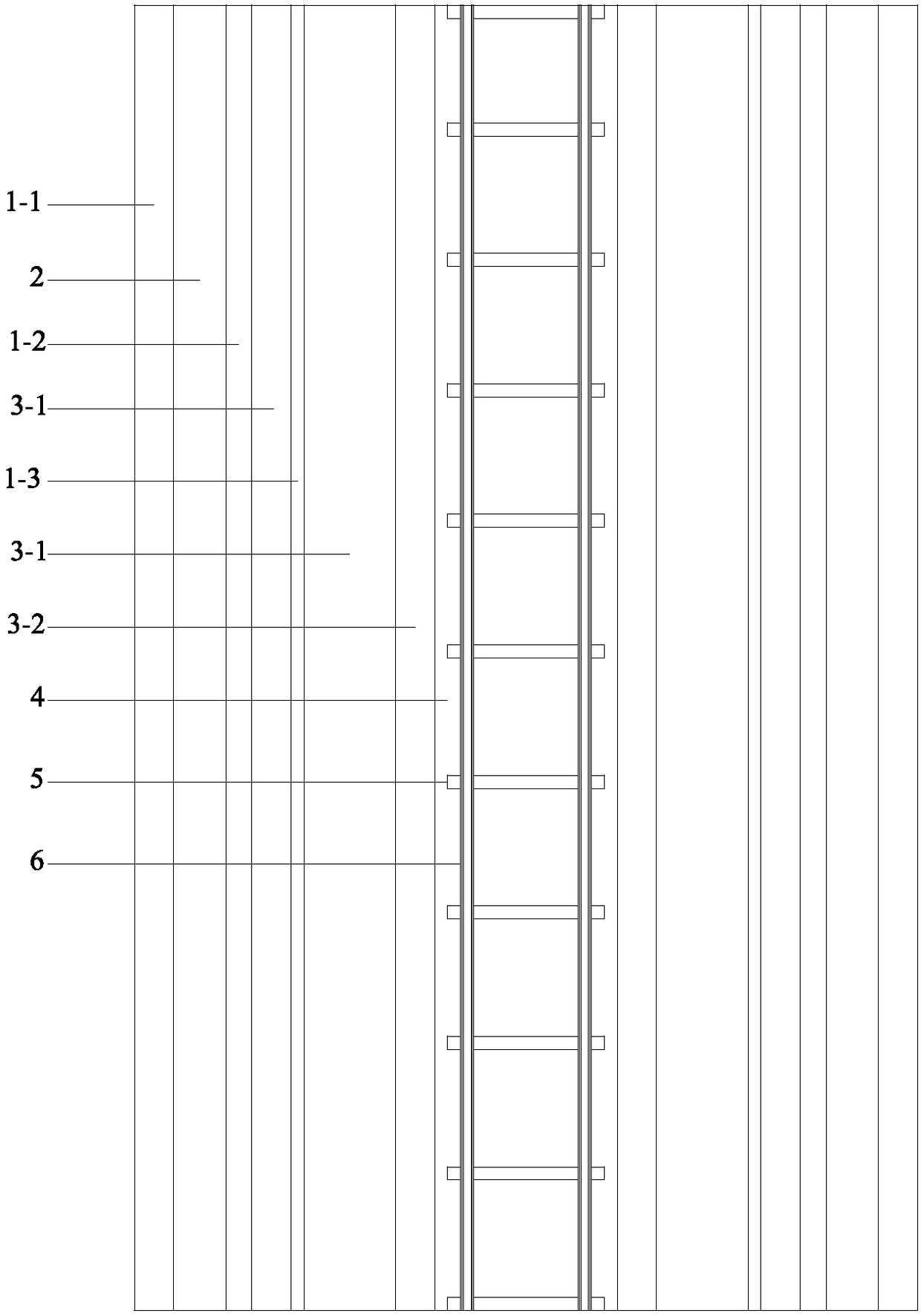

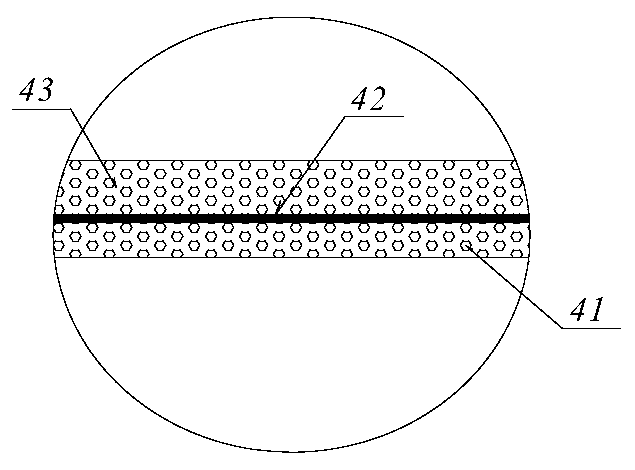

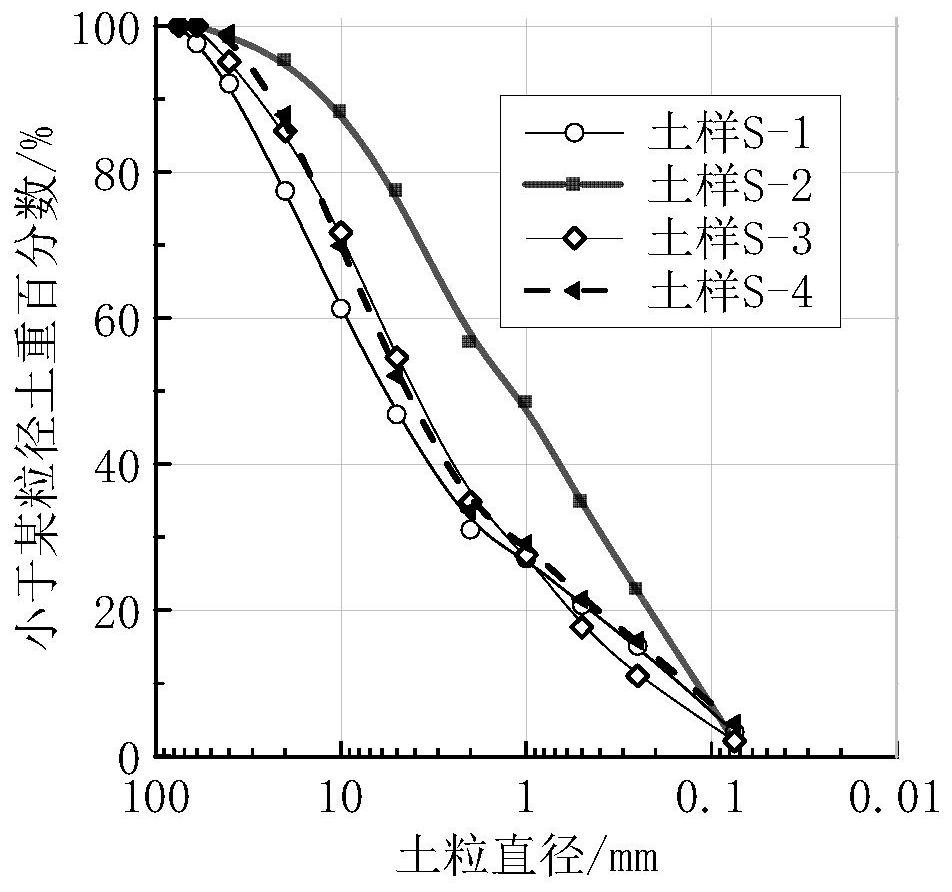

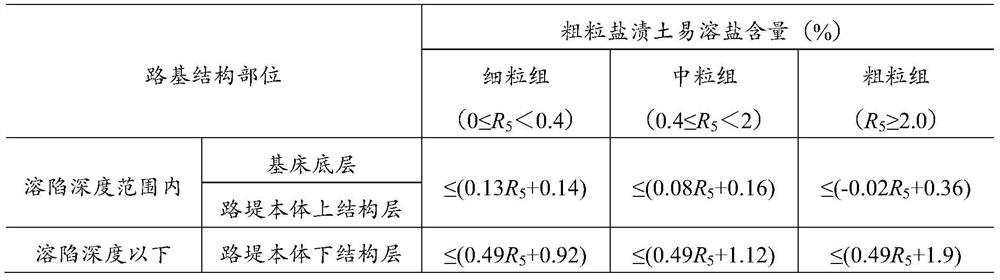

Coarse-grained saline soil roadbed structure of ballastless track with speed being 250-350 km/h and construction method

ActiveCN110158368ASolve the technical problems facedMeet the design requirementsBallastwayRailway embankmentSurface layer

The invention relates to a coarse-grained saline soil roadbed structure of a ballastless track with the speed being 250-350 km / h and a construction method. The arching and sinking deformation of an embankment is effectively controlled, it is ensured that salt expansion, melting sinking and compression deformation of the embankment meet the design requirement of a high-speed ballastless railway, and the technical problem caused when coarse-grained saline soil serves as a high speed railway embankment padding face is effectively solved. An embankment structure is composed of an embankment body lower structural layer, an embankment body upper structural layer, a foundation bed bottom layer and a foundation bed surface layer which are sequentially paved above a foundation from bottom to top; the embankment body lower structural layer, the embankment body upper structural layer and the foundation bed bottom layer are constructed through the coarse-grained saline soil, and the foundation bedsurface layer is constructed through non-saline soil; and the soluble salt content of the coarse-grained saline soil of the embankment body lower structural layer, the embankment body upper structural layer and the foundation bed bottom layer meets the requirements in the following table.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

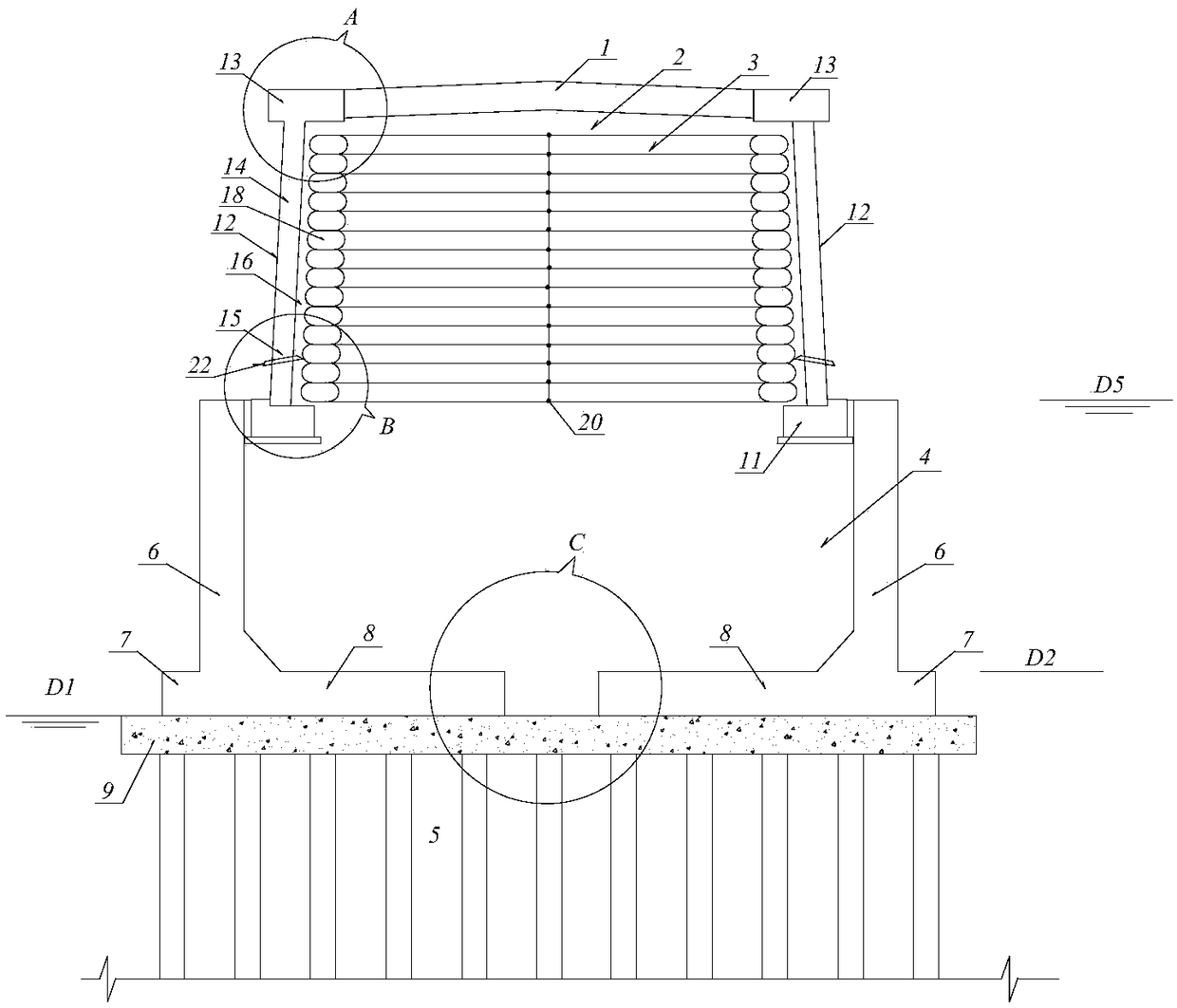

Reinforced damping railway embankment structure

The invention provides a reinforced damping railway embankment structure, and belongs to the technical field of railway environmental vibration control. The reinforced damping railway embankment structure comprises a multi-layer reinforced layer, embankment filling, a roadbed and a ballast bed. Combined with railway subgrade construction, the multi-layer reinforced layer is arranged in a subgradestructure, the strength of the embankment structure is effectively enhanced, and the uneven settlement and deformation of the roadbed are alleviated. At the same time, the multi-scattering phenomenonof a vibration wave is used for enabling the vibration wave to reflect back and forth between the reinforcement layers to consume energy, a damping material is used for transforming the vibration waveinto heat energy to absorb energy; furthermore, the reinforced damping railway embankment structure is tightly connected with a CFG pile, the vibration wave can be transmitted to the depth of the foundation, the vibration response caused by train operation is subjected to vibration-reducing and vibration-isolating treatment. The reinforced damping railway embankment structure is applicable to thevibration sensitive areas along rail transit lines which are newly built or subjected to expanding and rebuilding capability, especially for the situation that when a railway passes through dense buildings and the line sections which are close to the building.

Owner:TONGJI UNIV

400km-hour high-speed railway embankment structure suitable for Sichuan and Chongqing layer mudstone area

InactiveCN111608026ASimple structureFix stability issuesRailway tracksSoil scienceRailway embankment

The invention discloses a 400km-hour high-speed railway embankment structure suitable for a Sichuan and Chongqing layer mudstone area, which comprises an embankment body layer, a subgrade bed lower bottom layer, a subgrade bed upper bottom layer, a subgrade bed lower surface layer and a subgrade bed upper surface layer sequentially filled from bottom to top. The embankment body layer and the subgrade bed lower bottom layer are filled with red mudstone cement improved soil, the subgrade bed upper bottom layer is filled with filler A and filler B, the subgrade bed lower surface layer is filled with graded broken stone, and the subgrade bed upper surface layer is filled with asphalt concrete. The high-speed railway embankment structure is simple in structure and can meet the design requirement of a high-speed railway subgrade with the speed of 400 kilometers per hour.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Ballastless track coarse-grain salty soil embankment structure considering acute air temperature influence and construction method

PendingCN110195379AReduce the possibilityAddressing the lack of quality embankment fillBallastwaySurface layerRailway embankment

The invention provides a ballastless track coarse-grain salty soil embankment structure considering acute air temperature influence and a construction method, so that a high-speed railway ballastlesstrack arching and settlement deformation control target is achieved, the situation that water and salt are transferred and gathered to the top of a roadbed is avoided, and the technical defects existing when coarse-grain salty soil serves as high-speed railway embankment padding are effectively overcome. The embankment structure is composed of a foundation bottom separation layer, an embankment body, a foundation bed bottom layer lower structural layer, a foundation bed separation layer, a foundation bed bottom layer upper structural layer and a foundation bed surface layer, all of which are sequentially laid from bottom to top above a foundation. The embankment body and the foundation bed bottom layer lower structural layer are constructed through the coarse-grain salty soil, the salt expansion coefficient of the coarse-grain salty soil is not larger than 0.01, and the foundation bed bottom layer upper structural layer and the foundation bed surface layer are filled with non-salty soil. The burial depth of the foundation bed separation layer is not smaller than the depth of an acute air temperature influence layer. The depth of the acute air temperature influence layer is the depth at which atmosphere air temperature influence is quite remarkable or salt expansion deformation is acute.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

High-speed railway powder soil and sandy silt embankment structure and construction method

The invention discloses a high-speed railway powder soil and sandy silt embankment structure and a construction method to effectively solve the problems of difficulty in filling and compacting powder soil and sandy silt and poor stability, so that the powder soil and the sandy silt can serve as a high-speed railway embankment bottom structure, and engineering investment is greatly saved. The embankment structure is characterized in that a trench structure body longitudinally extending along a line is arranged above a geotechnical foundation, and the bottoms of two sides of the trench structure body are provided with longitudinally spaced drain holes. The inner bottom of the trench structure body is filled with a broken stone hardcore, a composite drain board is laid at the top of the broken stone hardcore, the upper portion of the composite drain board is filled with powder soil and sandy silt filling, a composite geo-membrane is laid at the top of the powder soil and sandy silt filling, a medium-coarse sand cushion is laid at the top of the composite geo-membrane, and the upper portion of the medium-coarse sand cushion is filled with an embankment surface layer structure. Stress tie bars are arranged in the powder soil and sandy silt filling in a longitudinally spaced and vertically layered manner, and two ends of each stress tie bar are fixedly connected with the side wall of the trench structure body.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

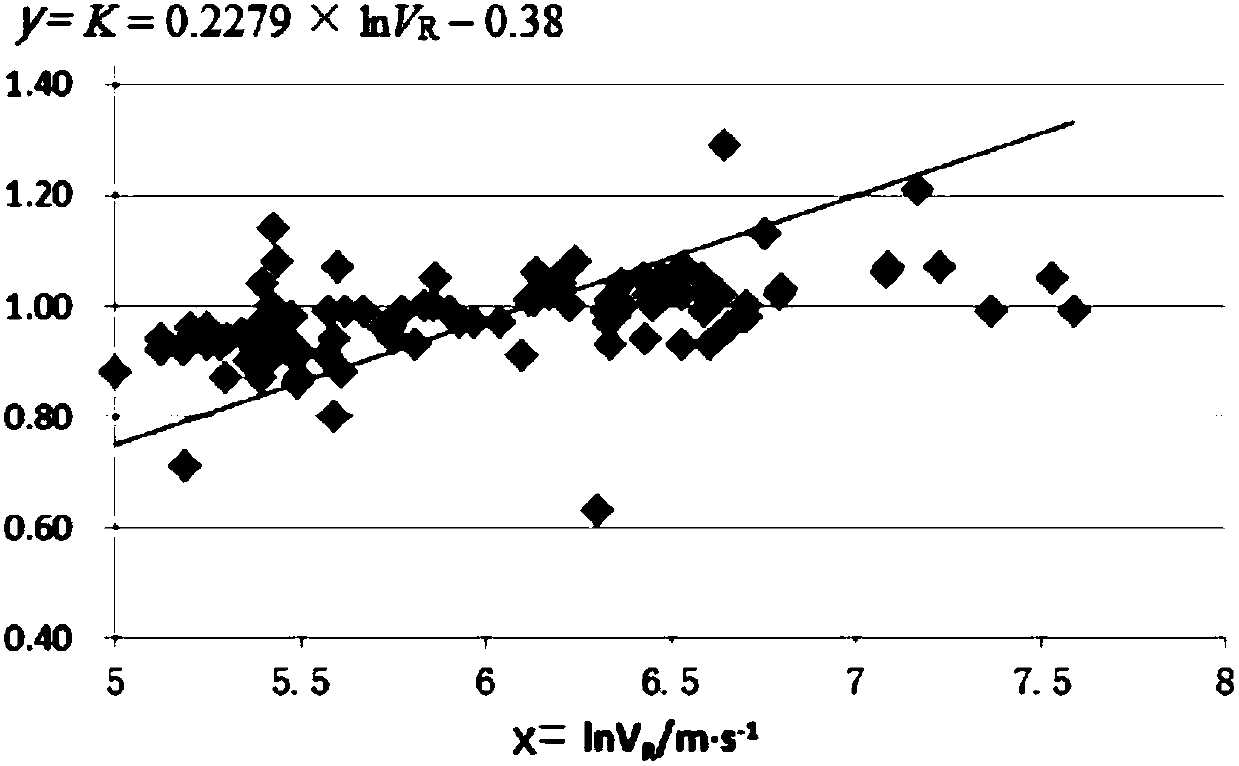

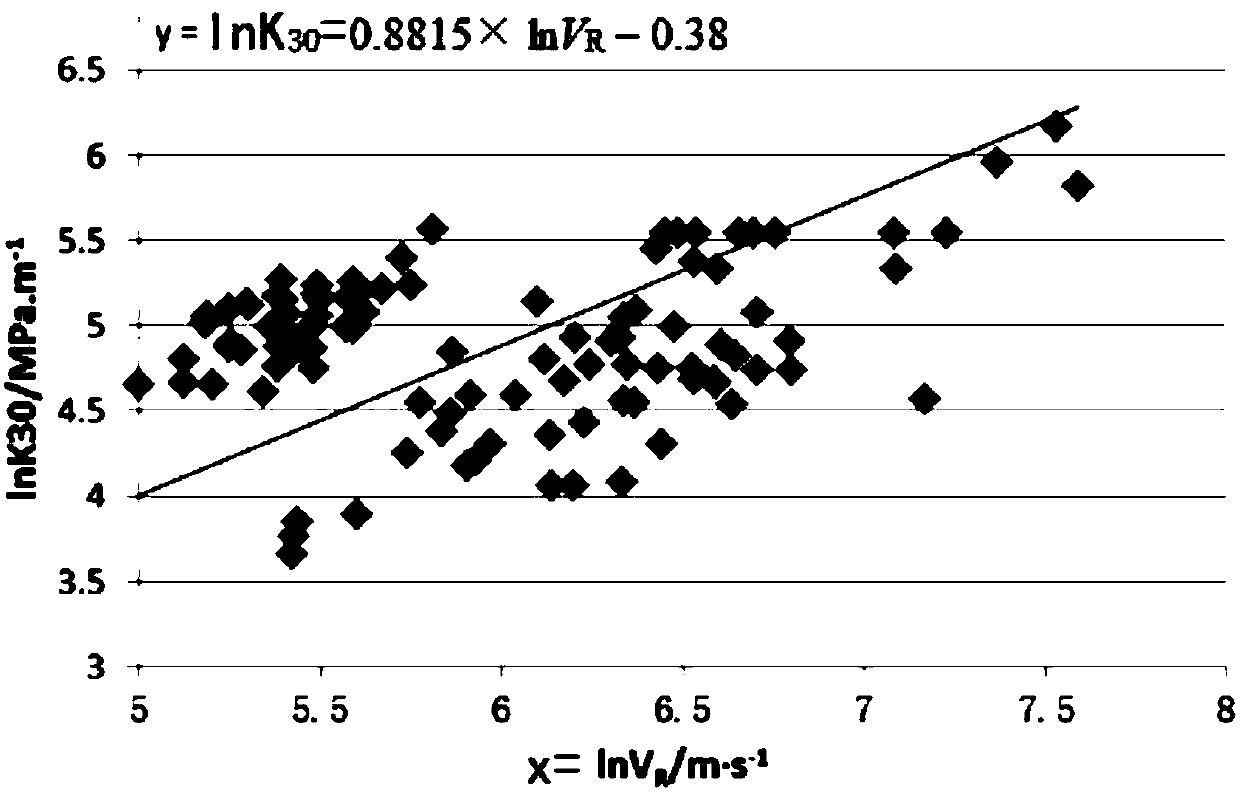

Surface wave detection method and device for railway embankment filling quality

InactiveCN107741456AFilling Quality ControlImprove detection efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesRailway embankmentClassical mechanics

The invention relates to the technical field of railway construction, in particular to a surface wave detection method and a surface wave detection device for railway embankment filling quality. The method provided by the invention comprises the following steps: adopting an n-channel detector to carry out surface wave detection in a roadbed site; obtaining a surface wave velocity-depth curve distribution chart of n-1 embankments; obtaining compaction coefficients and foundation coefficients at different depth positions of the embankments; obtaining a relational expression between an embankmentsurface wave velocity and a compaction coefficient and a relational expression between an embankment surface wave velocity VR and a foundation coefficient by analyzing the embankment surface wave velocity and the compaction coefficient and the foundation coefficient of a corresponding position; and according to standard values in existing railway bed design specifications, respectively and correspondingly substituting the relational expression between the embankment surface wave velocity and the compaction coefficient and the relational expression between the embankment surface wave velocityand the foundation coefficient to obtain the surface wave velocity of the filling quality of two railway embankments, wherein the larger surface wave velocity of the filling quality of the railway embankments is used as a standard value for surface wave detection of the compaction quality of embankment fillers.

Owner:CONSTR COMPANY OF CHINA RAILWAY NO 8 ENGNEERING GRP

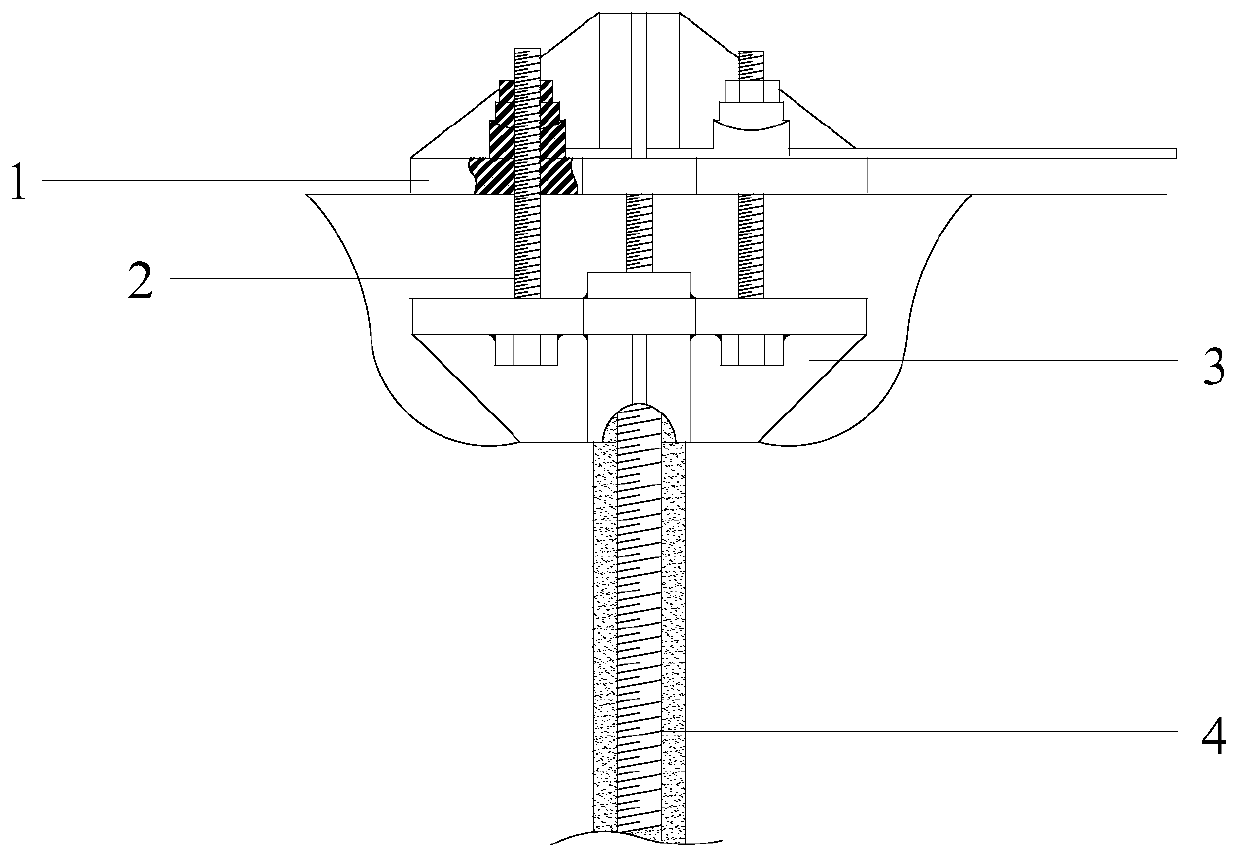

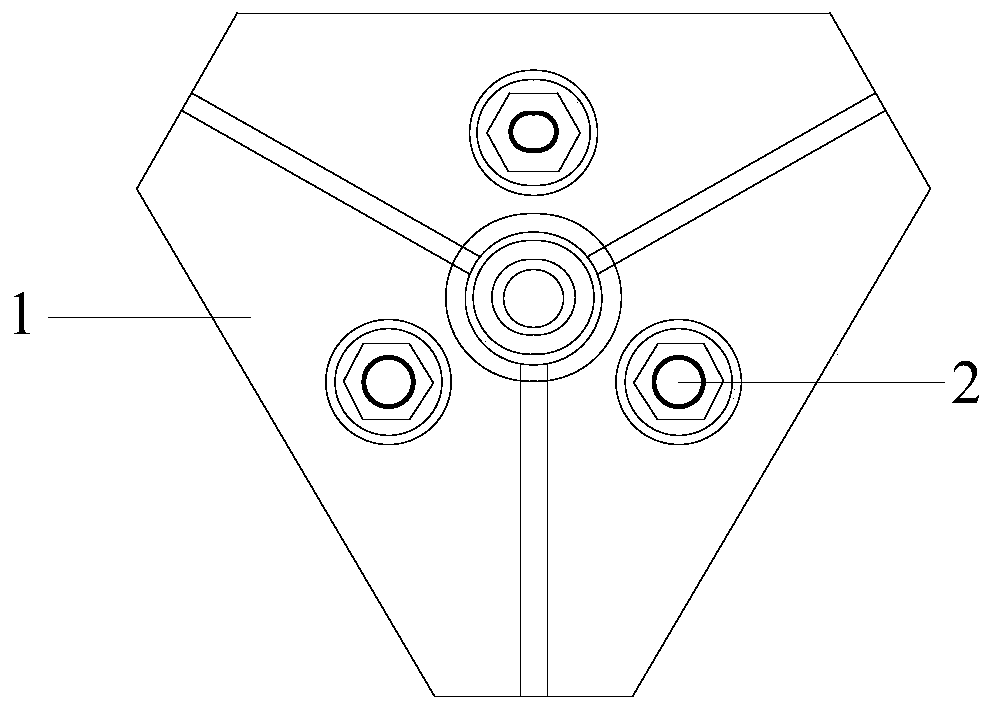

Anchor rod supporting structure for reinforcing railway embankment slope and construction method thereof

ActiveCN111519640ASmall construction equipmentReduce noiseExcavationsBulkheads/pilesRailway embankmentArchitectural engineering

The invention discloses an anchor rod supporting structure for reinforcing a railway embankment slope and a construction method thereof, and belongs to the technical field of anchor rod supporting. The anchor rod supporting structure for reinforcing the railway embankment slope is characterized in that a pressure bearing plate is fixed on a mounting component and arranged on the ground, tensile reinforcements and connecting pieces are alternately fixed up and down, the uppermost tensile reinforcement is connected with the mounting component, and the lowermost connecting piece is connected witha rotary shaft with a bulge on the lower end surface and a stirring wing, anti-rotating wings and excavating wings on the circumferential surface. According to the construction method, design valuesand specifications of bending moment, shearing force and axial force borne by an anchor rod body are calculated; a top end digging and cutting mechanism is connected with a drilling machine, cement isinjected and stirred during drilling, and the top end digging and cutting mechanism stops working after complete drilling and is reversely screwed out; the top end digging and cutting mechanism is connected with the tensile reinforcements, meanwhile, cement is injected and stirred, and working is stopped after complete drilling; and the tensile reinforcements are added, drilling is repeated tillthe preset depth is reached, and the anchor rod supporting structure is fixed. According to the anchor rod supporting structure for reinforcing the railway embankment slope and the construction methodthereof, the number of pipelines is reduced, the construction time is shortened, the number of anchoring parts are reduced, the stability of a track is ensured, and the stirring efficiency of the soil and the cement is improved.

Owner:HARBIN INST OF TECH

A kind of structure and laying method for preventing railway subgrade from muddling

ActiveCN105839476BShorten the setting timeFully solidifiedBallastwayRailway embankmentStone clearance

The invention discloses a structure capable of preventing railroad bed mud pumping and a paving method thereof. The structure is positioned between a railroad bed and a rail roadway ballast and comprises a first protective layer and a second protective layer. The paving method of the structure comprises the following steps of: 1) paving sand aggregate with an average grain diameter of 0.05-5mm on the surface of the railroad bed so as to form a sand cushion with the a the thickness of 4-6cm; 2) paving the broken stone with an average grain diameter of 5-7mm on the surface of the sand cushion, wherein the a the paving thickness of the broken stone is 3-6cm; 3) filling broken stone clearances with a polymer waterproof coating, wherein thea first protective layer is obtained after the polymer waterproof coating is solidified; 4) spraying a polyurea waterproof coating onto the surface of the first protective layer so as to form thea second protective layer with the thickness of 2-4 mm. Water infiltrating to the second protective layer is discharged through a dewatering slope of the first protective layer; ascending mud is isolated by the first protective layer, and the second protective layer forms thea second protection, so that the mud is effectively prevented from being pumped and extruded towards the railway railroad ballast or towards the outside through the railway ballast.

Owner:GUYUAN CHENTONG TECH DEV CO LTD

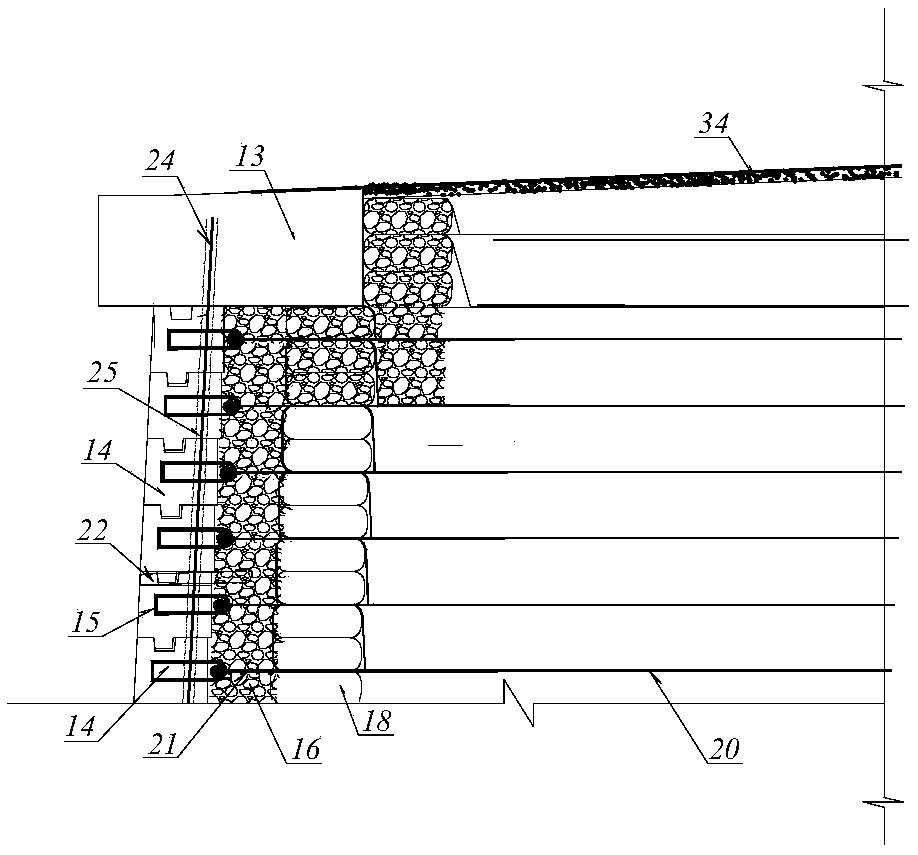

Railway Lightweight Soil Side Wide Subgrade Structure

ActiveCN104928996BReduce loadImprove stabilityRailway tracksExcavationsRailway embankmentSurface layer

The invention provides a light soil side wide roadbed structure for a railway. The light soil side wide roadbed structure comprises a conventional railway slope and a new side width filling road embankment, wherein light soil layers are poured between the conventional railway slope and the new side width filling road embankment; geogrids are arranged in the light soil layer and the side width filling road embankment; bottom layers of subgrade beds and surface layers of subgrade beds are sequentially paved on the conventional railway slope, the light soil layers, and the top surface of the new side width filling road embankment from bottom to top. The light soil side wide roadbed structure disclosed by the invention effectively reduces side filling loads, maintains the stability of a conventional road embankment, and reduces the sedimentation of new line foundations and the additional sedimentation of conventional lines.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

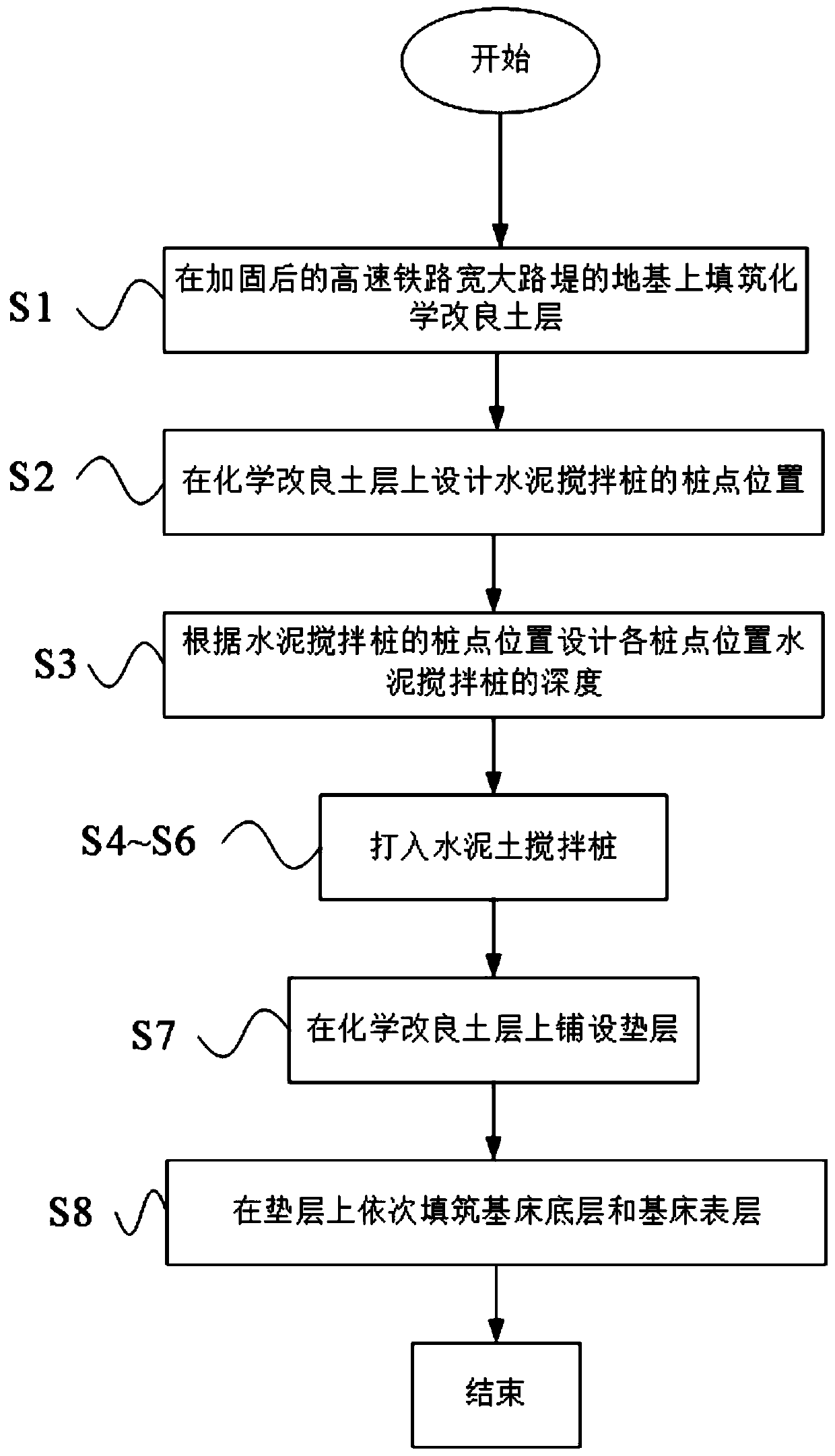

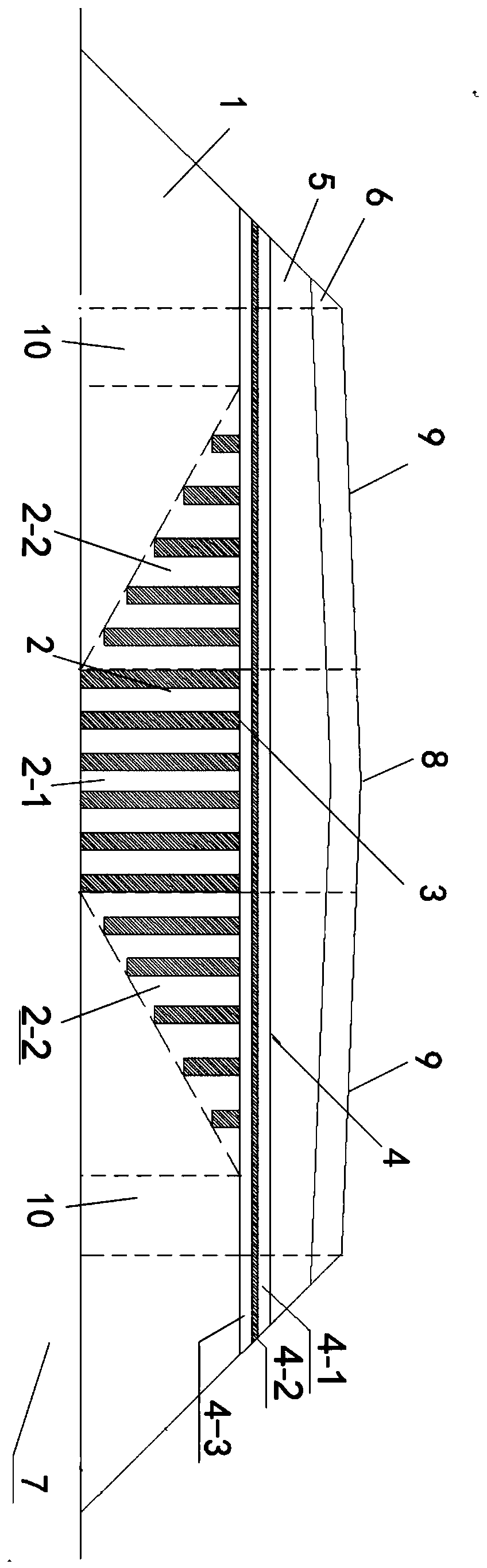

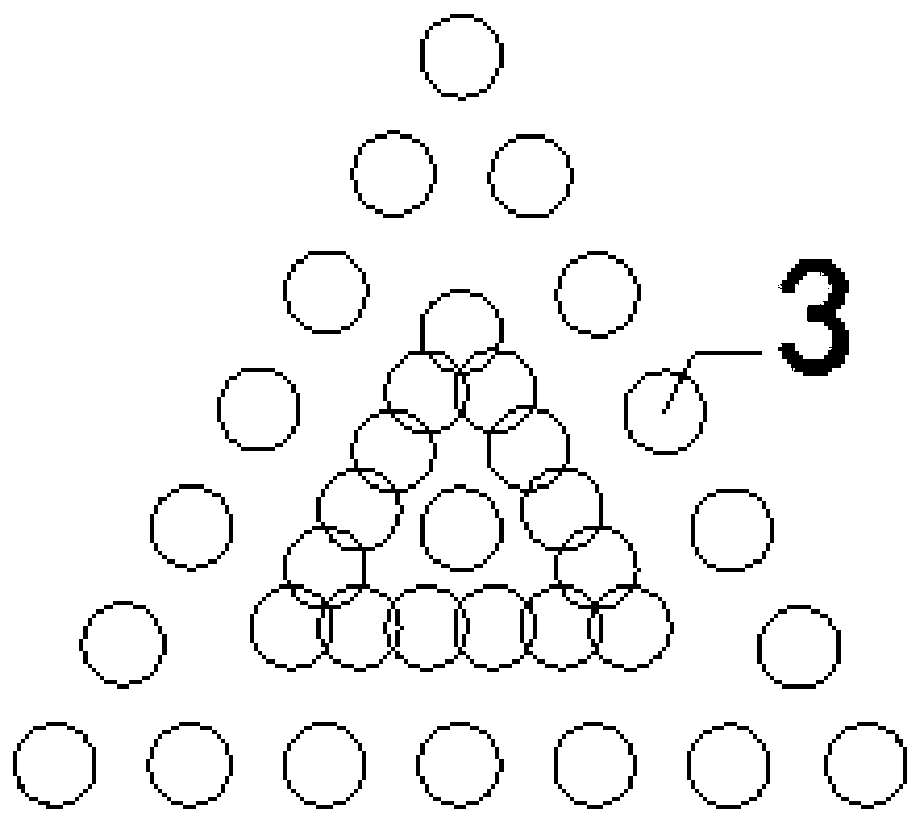

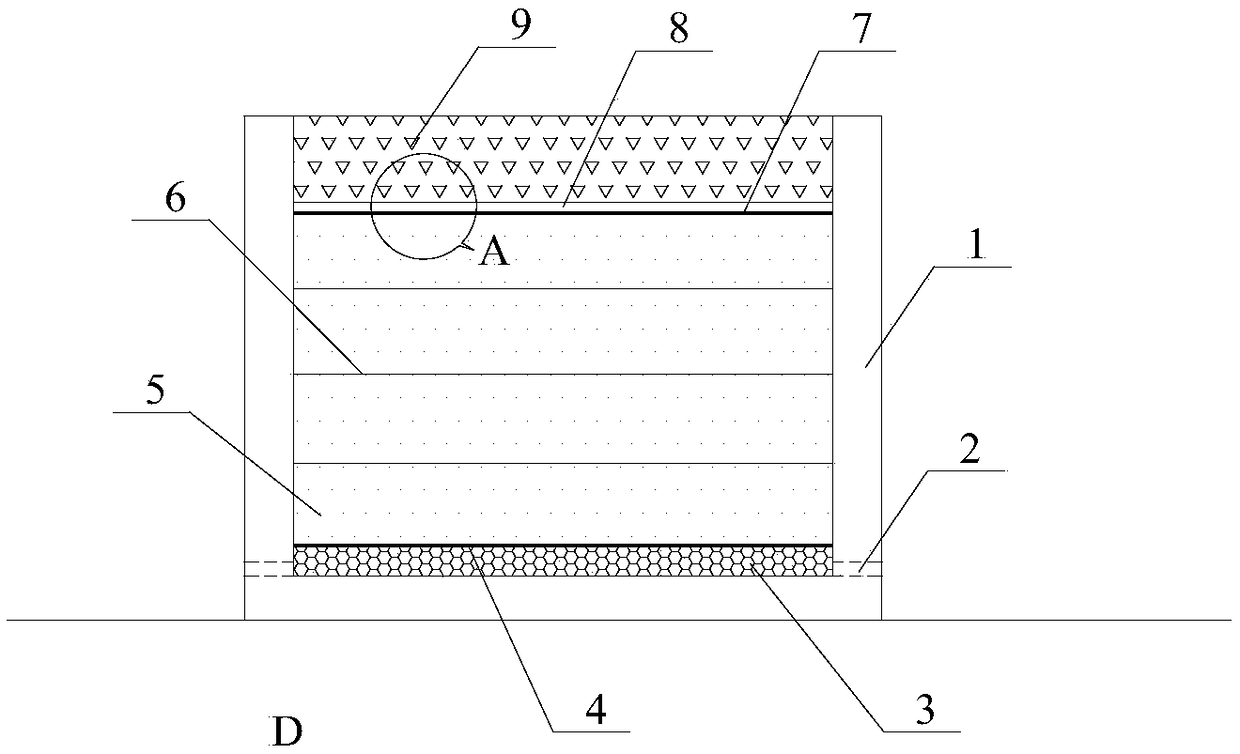

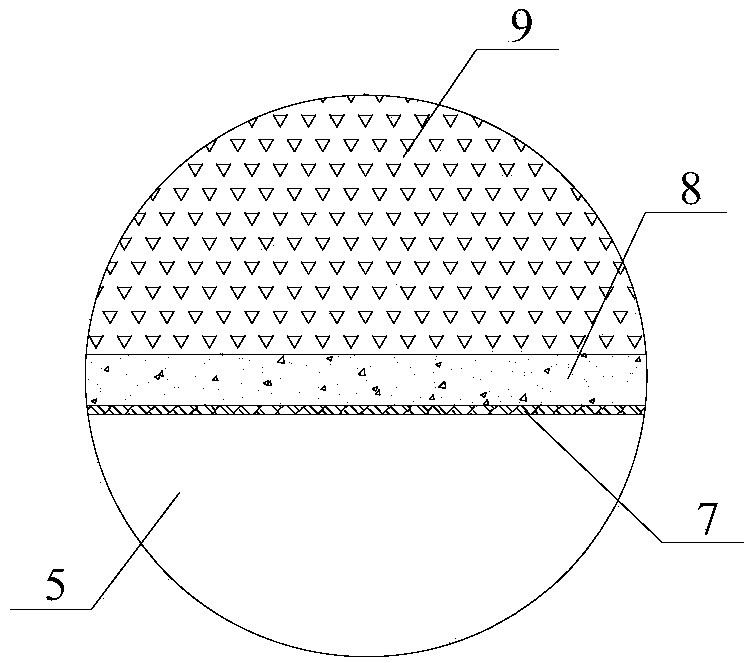

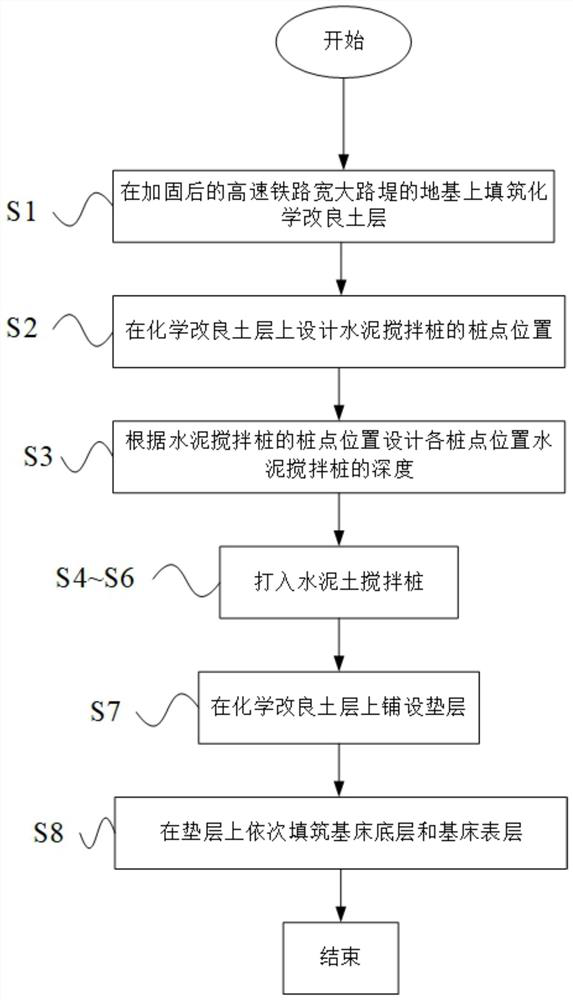

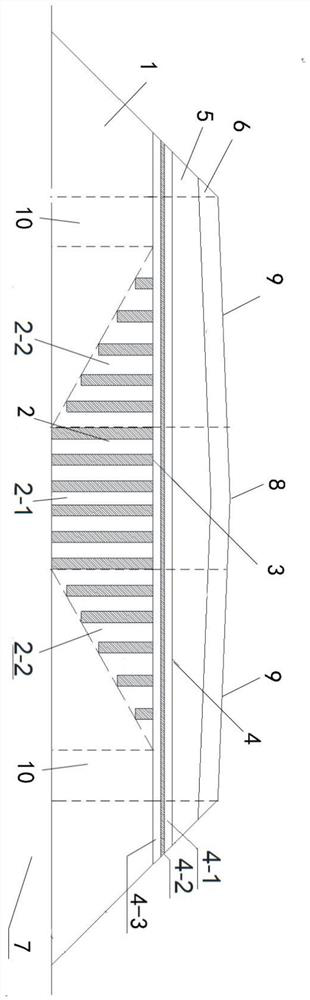

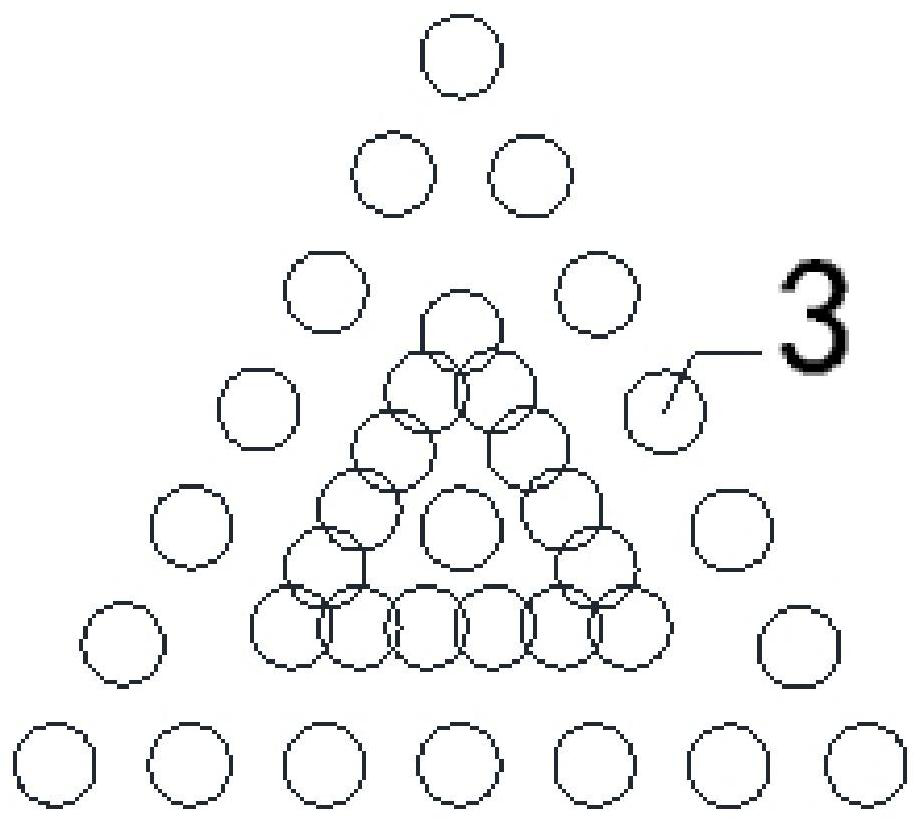

High-speed railway wide and large embankment settlement control method adopting cement mixing piles

ActiveCN110952387AReduce economic costsTo avoid settlement exceeding the requirements of "Code for Design of High-Speed Railways"Railway tracksBulkheads/pilesSoil scienceRailway embankment

The invention relates to a high-speed railway wide and large embankment settlement control method adopting cement mixing piles. The reinforcing method comprises the following steps: a chemical improved soil layer is filled on the foundation of the reinforced high-speed railway embankment; pile point positions of cement mixing piles are designed on the chemical improvement soil layer, the depths of the cement mixing piles at all the pile point positions are designed according to the pile point positions of the cement mixing piles, the cement mixing piles are driven into all the pile point positions, a cushion layer is laid on the chemical improvement soil layer, and a foundation bed bottom layer and a foundation bed surface layer are sequentially filled on the cushion layer. Compared withthe prior art, chemical improved soil is used as embankment filler under a foundation bed layer; the cement mixing piles are used for reinforcing the chemically-improved soil layer, the depth and density of the cement mixing piles are reduced along with increase of the distance between the pile point positions and the reinforcing area under the main line, on the premise that the safety performanceof the embankment is guaranteed, the economic cost of the embankment is reduced, and the embankment settlement amount is prevented from exceeding the high-speed railway design specification requirement.

Owner:TONGJI UNIV

A method for constructing high-speed railway silt and silt embankment structures

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

A Settlement Control Method of Wide Embankment of High-speed Railway Using Cement Mixing Pile

ActiveCN110952387BReduce economic costsAvoid exceeding the requirements of the "High-speed Railway Design Code"Railway tracksBulkheads/pilesSoil scienceRailway embankment

The invention relates to a high-speed railway wide and large embankment settlement control method adopting cement mixing piles. The reinforcing method comprises the following steps: a chemical improved soil layer is filled on the foundation of the reinforced high-speed railway embankment; pile point positions of cement mixing piles are designed on the chemical improvement soil layer, the depths of the cement mixing piles at all the pile point positions are designed according to the pile point positions of the cement mixing piles, the cement mixing piles are driven into all the pile point positions, a cushion layer is laid on the chemical improvement soil layer, and a foundation bed bottom layer and a foundation bed surface layer are sequentially filled on the cushion layer. Compared withthe prior art, chemical improved soil is used as embankment filler under a foundation bed layer; the cement mixing piles are used for reinforcing the chemically-improved soil layer, the depth and density of the cement mixing piles are reduced along with increase of the distance between the pile point positions and the reinforcing area under the main line, on the premise that the safety performanceof the embankment is guaranteed, the economic cost of the embankment is reduced, and the embankment settlement amount is prevented from exceeding the high-speed railway design specification requirement.

Owner:TONGJI UNIV

Structure and Construction Method of Coarse Saline Soil Embankment for Ballastless Track at 250-350km/h

ActiveCN110158368BSolve the technical problems facedMeet the design requirementsBallastwaySoil scienceRailway embankment

The invention relates to a coarse-grained saline soil roadbed structure of a ballastless track with the speed being 250-350 km / h and a construction method. The arching and sinking deformation of an embankment is effectively controlled, it is ensured that salt expansion, melting sinking and compression deformation of the embankment meet the design requirement of a high-speed ballastless railway, and the technical problem caused when coarse-grained saline soil serves as a high speed railway embankment padding face is effectively solved. An embankment structure is composed of an embankment body lower structural layer, an embankment body upper structural layer, a foundation bed bottom layer and a foundation bed surface layer which are sequentially paved above a foundation from bottom to top; the embankment body lower structural layer, the embankment body upper structural layer and the foundation bed bottom layer are constructed through the coarse-grained saline soil, and the foundation bedsurface layer is constructed through non-saline soil; and the soluble salt content of the coarse-grained saline soil of the embankment body lower structural layer, the embankment body upper structural layer and the foundation bed bottom layer meets the requirements in the following table.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

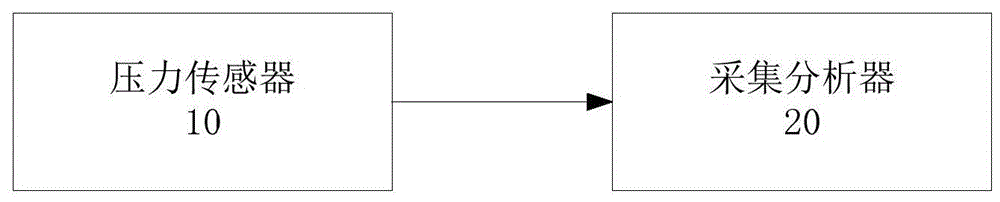

Calibration method and device for dynamic stress test of railway subgrade

ActiveCN104372782BImprove accuracyRailway tracksIn situ soil foundationRailway embankmentEngineering

The invention discloses a calibration method and device for a railroad bed dynamic stress test. The calibration method comprises the steps that a pressure sensor arranged in a railroad bed responds to the pressure borne by the railway bed to output a corresponding sensor signal, a bearing plate is arranged on the surface of the railway bed, and media with known weight are loaded on the bearing plate in a stacked mode; the relation between the actual pressure and the sensor signal is determined according to the weight of the media and the sensor signal to determine a calibration coefficient. The calibration coefficient obtained through the calibration method is accurate, and the test accuracy is improved.

Owner:CHINA SHENHUA ENERGY CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com