Construction method for reinforcing railway embankment with horizontal reinforced soil-cement piles

A technology of cement-soil piles and construction methods, applied in roads, excavations, roads, etc., can solve problems such as difficult construction, inability to form regular reinforced cement-soil piles, and affect the effect of embankment reinforcement, so as to ensure the relative position and avoid Effects of deflection deformation and improvement of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The construction method of the railway embankment reinforced with horizontal reinforced cement-soil piles of the present invention will be further described below with reference to the accompanying drawings and specific embodiments. The following examples are only used to illustrate the present invention but not to limit the present invention.

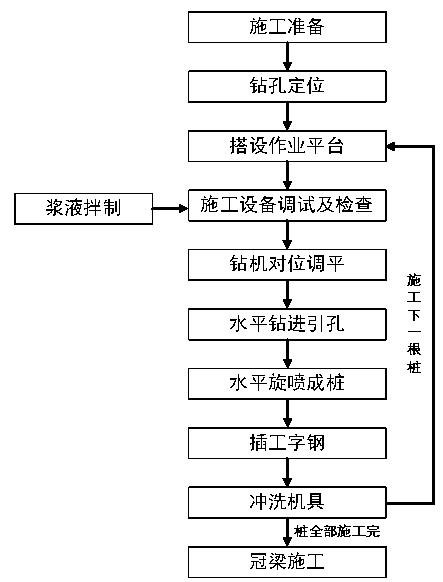

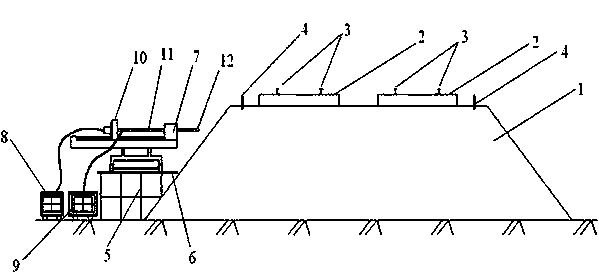

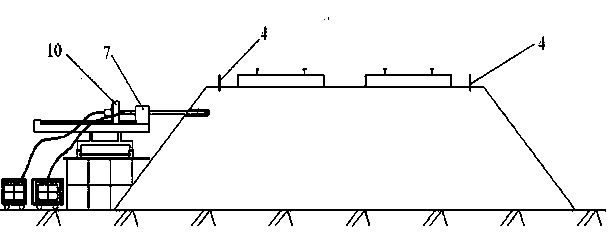

[0056] figure 1 It is a flow chart of the construction method of the horizontal reinforced cement-soil pile of the present invention to reinforce the railway embankment; Figure 2 to Figure 11It is a structural diagram of a certain construction stage in the construction process of the present invention. like Figure 1 to Figure 11 Shown, the construction method of horizontal reinforced cement-soil pile of the present invention strengthens railway embankment, specifically comprises the following steps:

[0057] The first step: construction preparation

[0058] Within the scope of the railway embankment 1 that needs to be rein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com