Biological sandstone preparation method and device based on MICP (Microbial Induced Carbonate Precipitation) technology

A biological and sandstone technology, applied in the direction of fertilization devices, chemical instruments and methods, soil protection, etc., can solve the problems of reducing the utilization rate of urea and mineral calcium salts, increasing construction difficulty and construction cost, so as to promote practical application and Promote, reduce construction difficulty and cost, and improve the effect of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

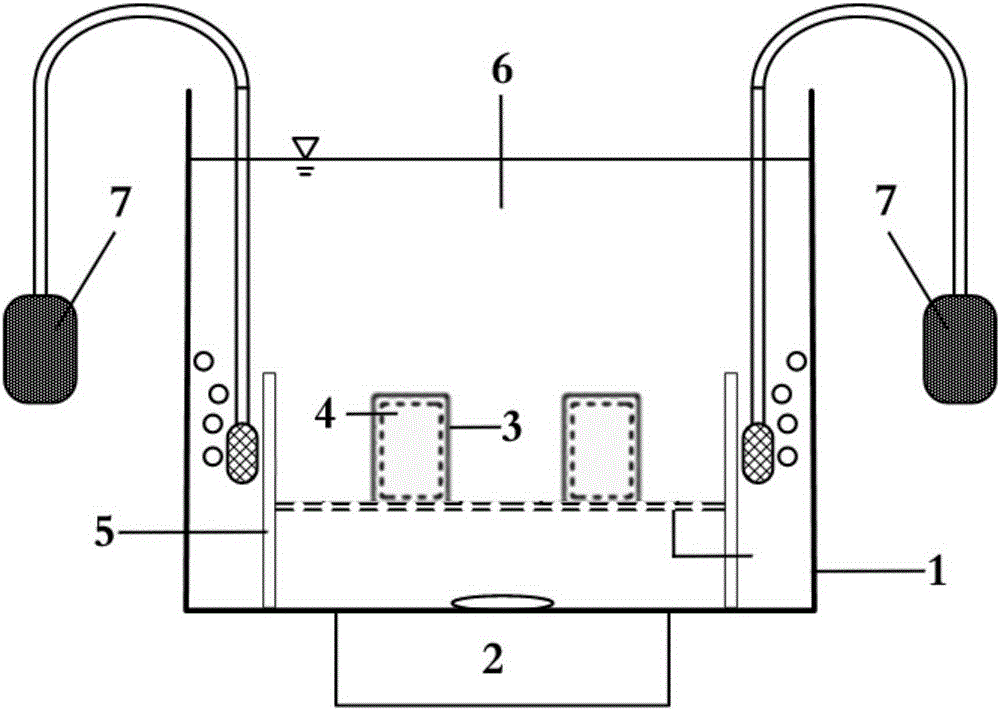

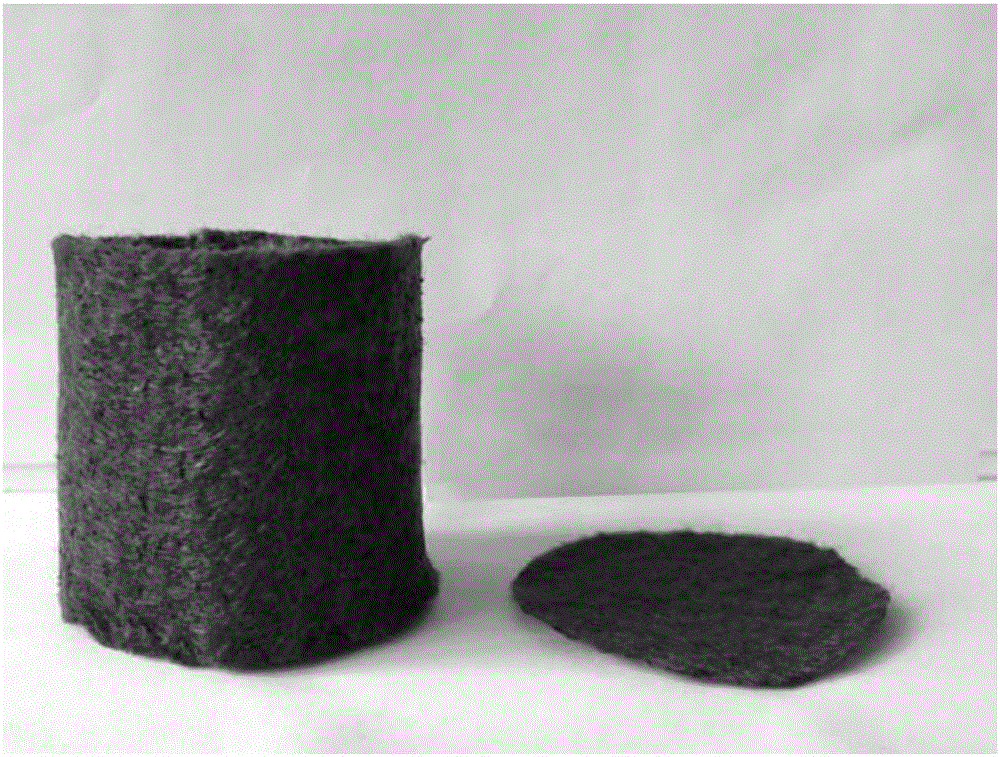

[0042] Embodiment 1: Fine-grained biological sandstone is made

[0043] Mold is cylindrical, and the diameter d=50mm of mold, height h=50mm, place particle diameter 0.5-1mm standard sand 47.3g in each mold, and particle diameter is 0.25mm-0.1mm natural desert sand (fine sand) 110g, Median particle size D of mixed sand 50 is 0.22. Mix 40ml of bacteria solution and growth medium, prepare 10 samples, put them on the plexiglass bracket, immerse in 20L cementing nutrient solution, turn on the air pump and magnetic stirrer, after 7 days of MICP curing, demould, take out Formed coarse-grained biological sandstone.

Embodiment 2

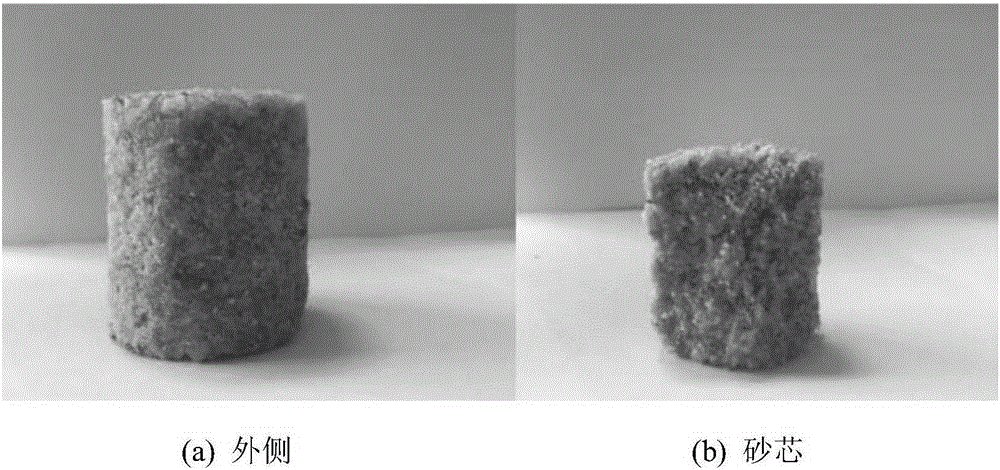

[0044] Embodiment 2: making of coarse-grained biological sandstone

[0045] The diameter of the mold is d=50mm, and the height is h=50mm. In each mold, 139.7g of standard sand with a particle size of 0.5mm-1mm and 15.5g of natural desert sand (fine sand) with a particle size of 0.25mm-0.1mm are placed in each mold. , the median particle size D of the mixed sand 50 is 0.87. Mix 40ml of bacteria and growth medium, prepare 10 samples, put them on the brackets, immerse in 20L cementing solution, turn on the air pump and magnetic stirrer, take it out after 7 days of experiment, take off the mold, and take out the formed coarse-grained organisms sandstone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com