A method for constructing high-speed railway silt and silt embankment structures

A technology of high-speed railway and silt, which is applied to the project of silt filling high-speed railway embankment. The use of silt field can solve the problems of poor stability and difficult filling and compaction, and achieve good stability, strong deformation resistance, Quality guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

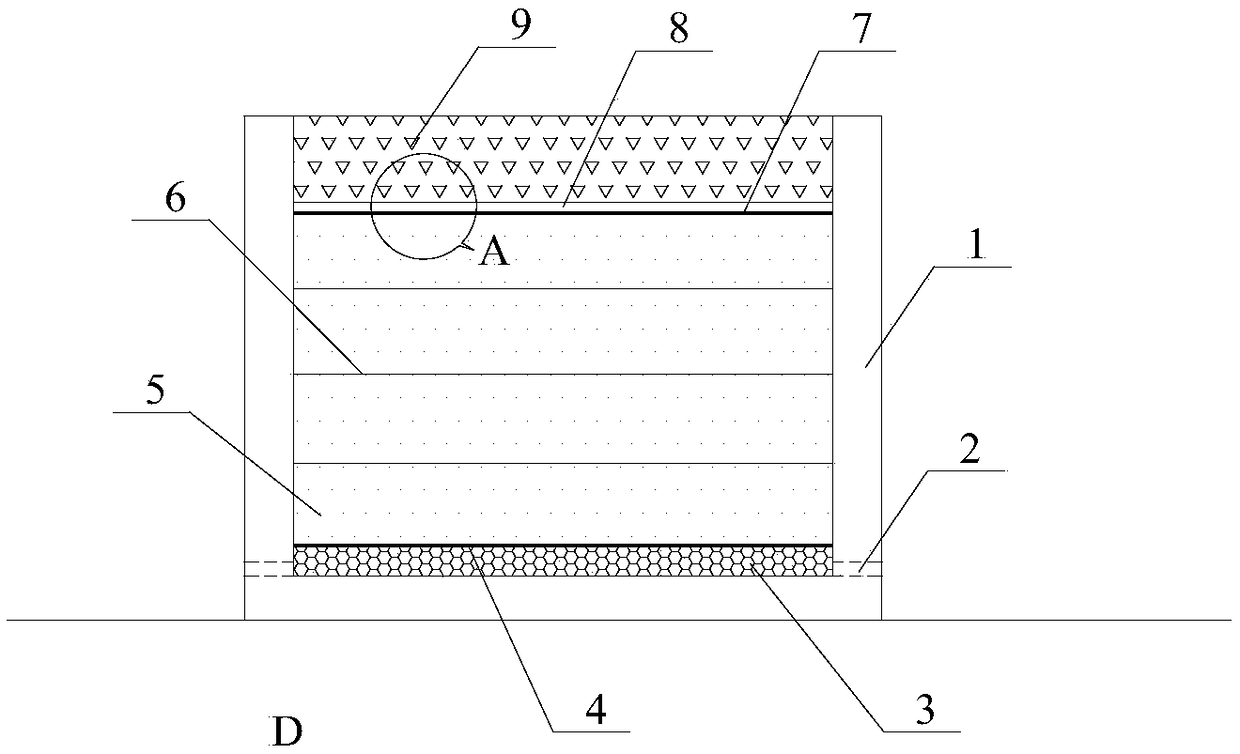

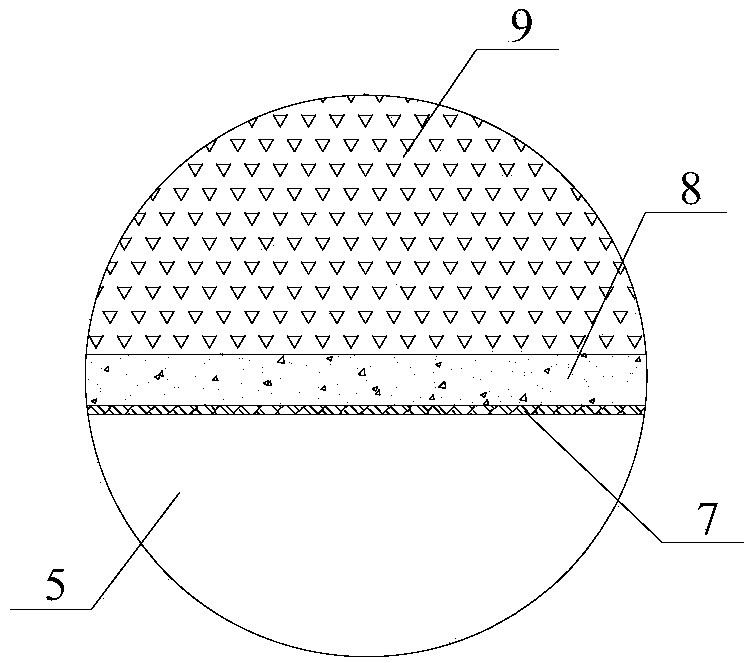

[0022] refer to figure 1 with figure 2 A high-speed railway silt and silt embankment structure is provided with a trough-shaped structure 1 extending longitudinally along the line on the foundation rock D, and the bottoms of both sides of the trough-shaped structure 1 have vertically spaced weep holes 2 . In the trough-shaped structure 1, a gravel cushion 3 is filled at the bottom, the composite drainage board 4 is laid on the top of the gravel cushion 3, and the silt and silt filling body 5 is filled above the composite drainage board 4 , the composite geomembrane 7 is laid on the top of the silt and silt filling body 5, the medium-coarse sand cushion layer 8 is laid on the top of the composite geomembrane 7, and the embankment surface structure 9 is layered and filled on the medium-coarse sand cushion layer 8. The silt and silt filling body 5 is longitudinall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com