Patents

Literature

667results about How to "Strong resistance to deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

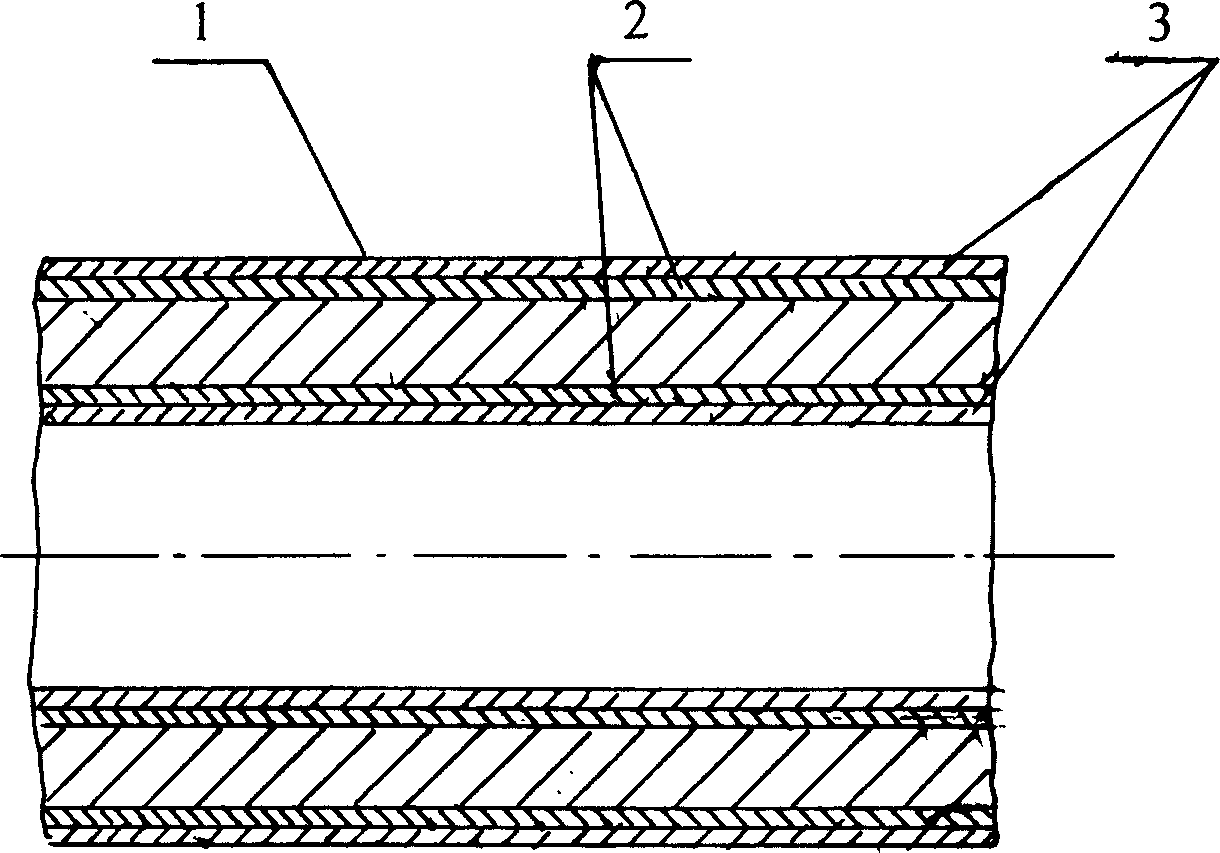

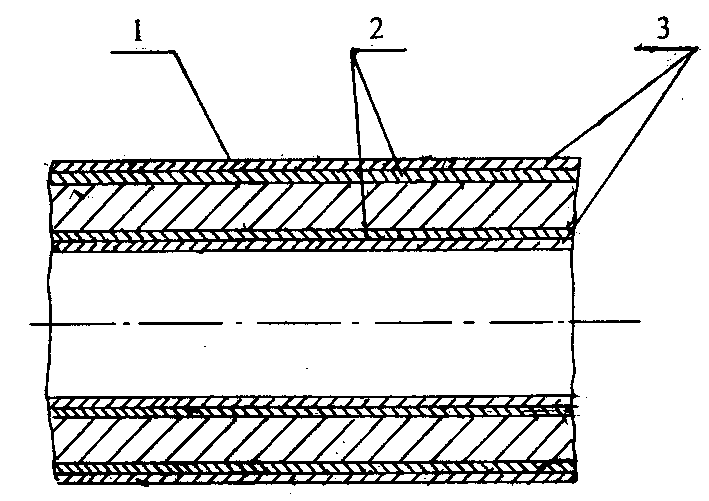

High-polymer modified pitch, its water-proof roll material and use thereof

ActiveCN101070434AImprove standardsHigh standard waterproof functionOther chemical processesRoof covering using flexible materialsPolymer modifiedCrack resistance

The invention provides a polymer modified asphalt, and the weight of the components comprising as follows :45-55% matrix asphalt, 4 - 8% blend oil, 12 - 14% of SBS ,5-9 % APAO, 2-7% of High-temperature improvement and 15-20% filler. It also offers polymer modified asphalt, which made of waterproof membrane and the railway bridge, highway bridge deck waterproofing project applications. The invention of these waterproofing membrane have a high standard of waterproof function, it can withstand high intensity of railway bridge and particularly high stress dynamic load .It also have excellent performance on water-resistance, high and low temperature resistance, adhesion, crack resistance, fatigue resistance and other aspects .it can be used for railway bridge and the road deck waterproofing works.

Owner:JINZHOU DONGFANG YUHONG BUILDING MATERIALS +1

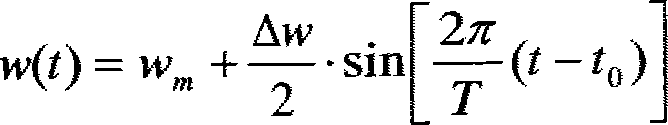

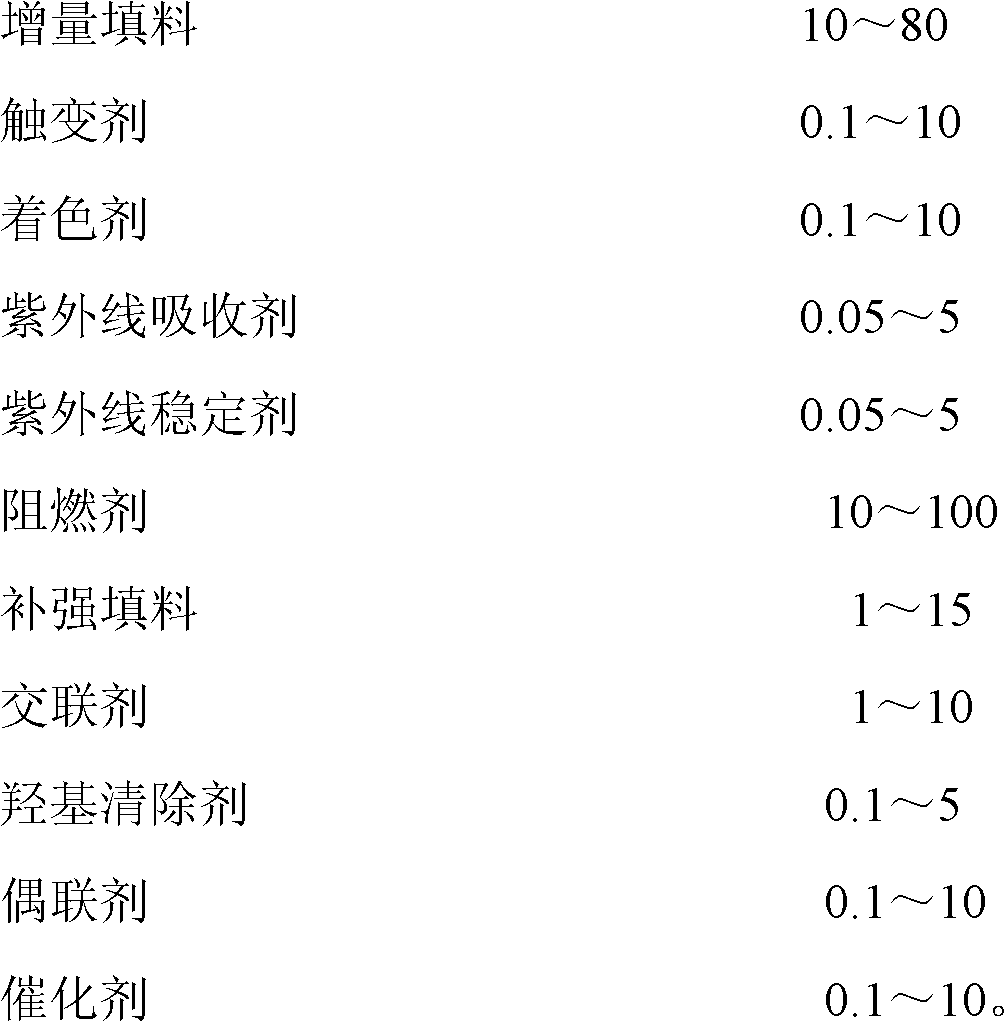

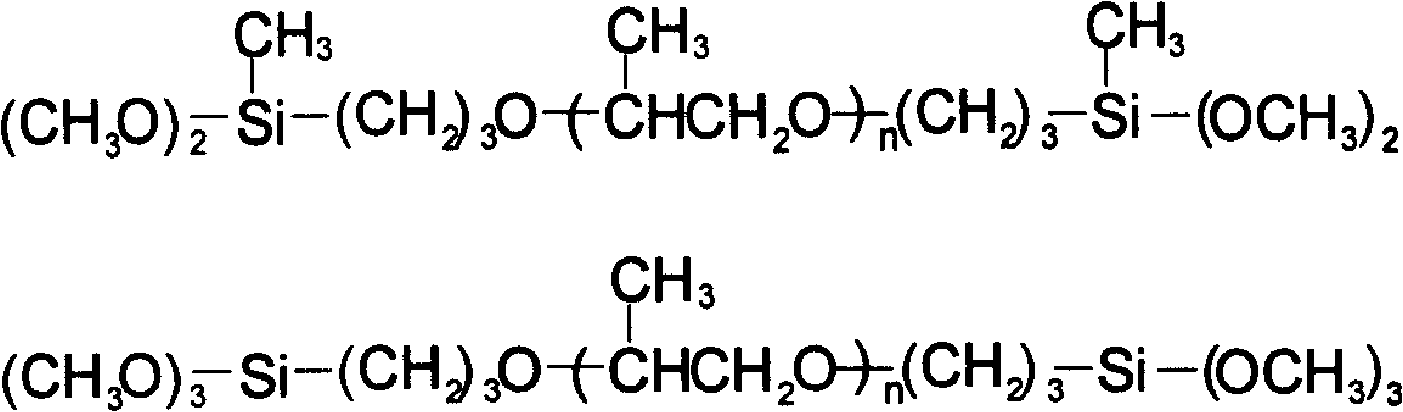

Monocomponent flame-retardant silane modified polyether sealant and preparation method thereof

InactiveCN102660214AImprove flame retardant performanceFast curingNon-macromolecular adhesive additivesPolyether adhesivesPolymer resinWeather resistance

The invention relates to a monocomponent flame-retardant silane modified polyether sealant and a preparation method thereof. The sealant of the invention comprises an MS-polymer resin, a plasticizer, a reinforcement filler, a thixotropic agent, an ultraviolet ray absorbing agent, an ultraviolet ray stabilizing agent, a flame retardant, a crosslinking agent, a hydroxy group scavenger, a coupling agent, an organic tin catalyst and the like. The obtained monocomponent flame-retardant silane modified polyether sealant has the advantages of flame retardation, fast solidification, strong strength, and high weather resistance.

Owner:JIANGSU TIANCHEN NEW MATERIALS

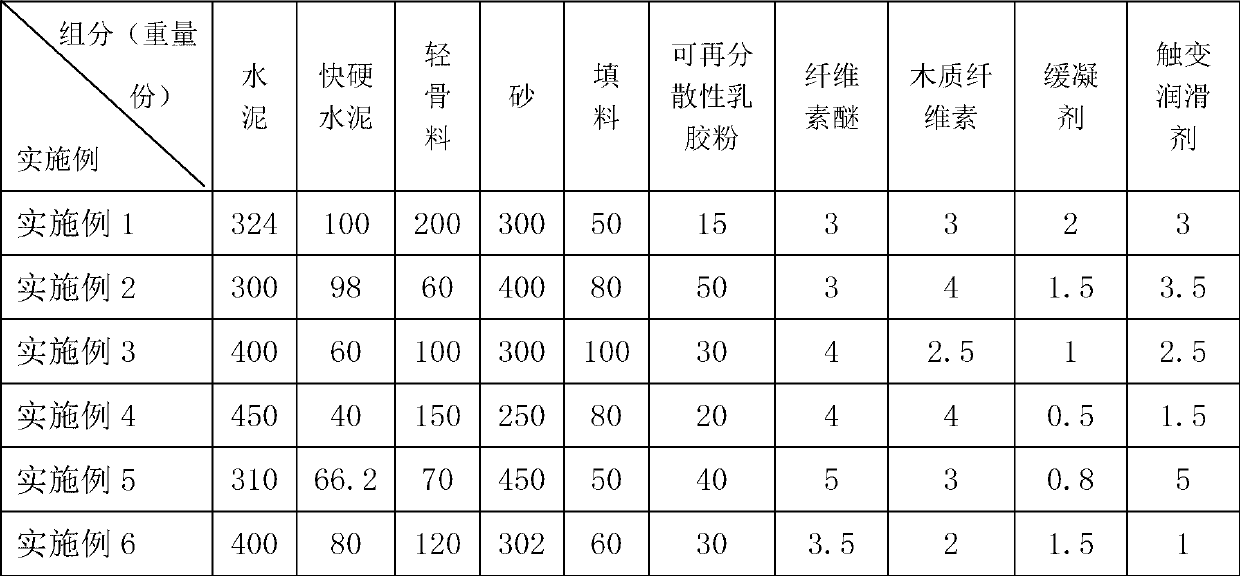

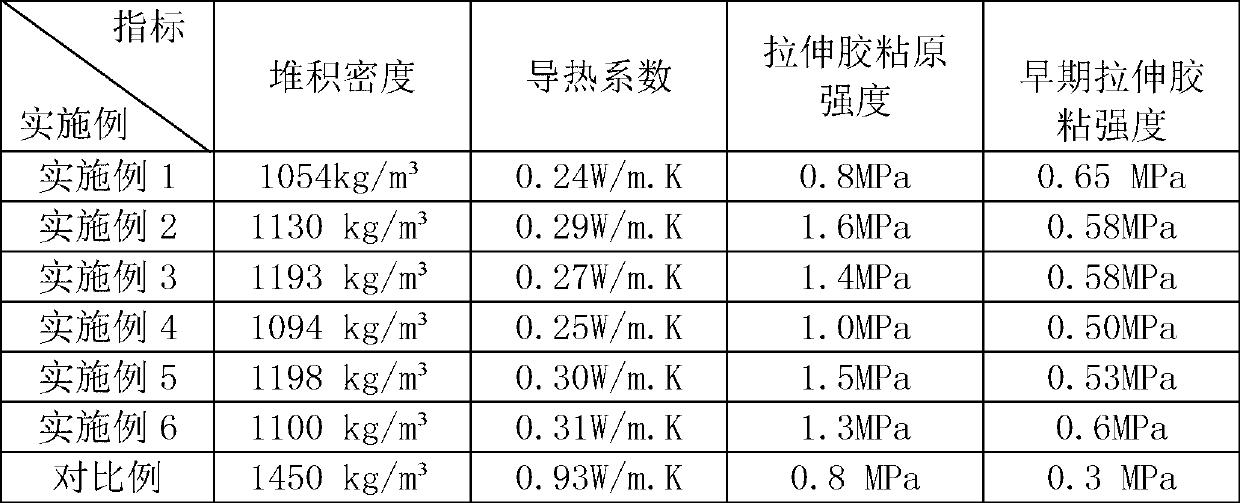

Binding mortar with light weight and high droop resistance and preparation and use methods

The invention provides binding mortar with light weight and high droop resistance, which consists of the following components in parts by weight: 300-450 parts of cement, 40-100 parts of rapid hardening cement, 60-200 parts of lightweight aggregate, 250-450 parts of sand, 50-100 parts of filling material, 15-50 parts of re-dispersible emulsion powder, 3-5 parts of cellulose ether, 2-4 parts of lignocellulose, 0.5-2 parts of retarder and 1-5 parts of thixotropic lubricant. The lightweight aggregates are glass microspheres, or hollow glass microspheres or ceramsite sand, of which the particle size is below 1.2mm and loose bulk density is below 0.8Kg / L. The invention has lower mortar density, good droop resistance, lower thermal conductivity and certain thermal insulation performance; the binding mortar can be hardened quickly, and the requirement of carrying out subsequent construction quickly is satisfied; the elastic modulus of the mortar is small, and deformation resistance is strong; and the mortar uses multiple polymer additives, and base materials have strong adaptability and strong binding performance.

Owner:深圳广田高科新材料有限公司

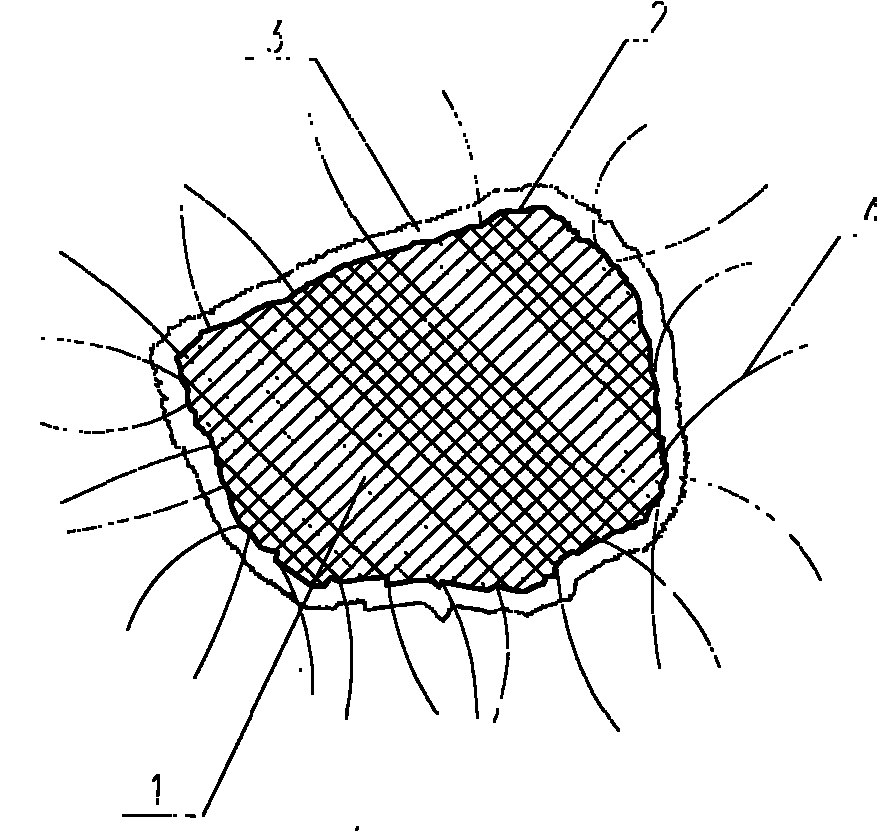

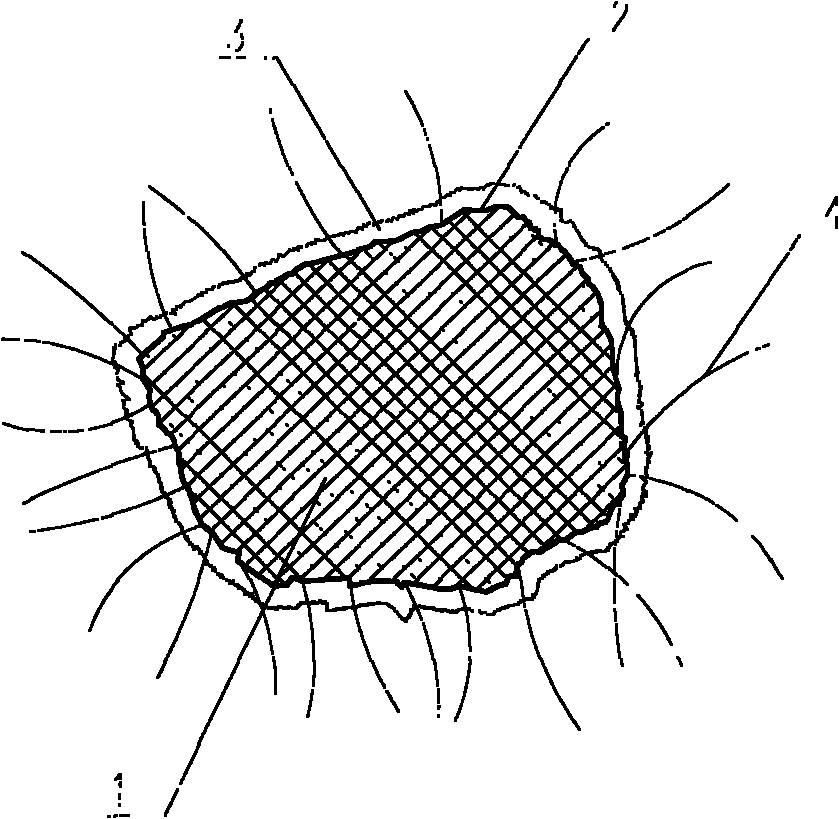

Stone aggregate wrapped by microfine fibre polymer mortar thin layer and preparation method thereof

InactiveCN101863631AHigh compressive strengthStrong resistance to deformationSilica fumeVolcanic ash

The invention discloses a stone aggregate wrapped by a microfine fibre polymer mortar thin layer and a preparation method thereof; the stone aggregate is formed by stone aggregate inner cores, an adhesive inner wrapping layer, a polymer cement mortar outer wrapping layer and an adhesive microfine fibre hair layer, wherein the adhesive inner wrapping layer and the stone aggregate are adhered firmly; microfine fibre filaments are anchored and rooted on the adhesive inner wrapping layer; and the polymer cement mortar outer wrapping layer and the adhesive inner wrapping layer are soluble mutually and can effectively form a whole body. Active powder in the polymer cement mortar outer wrapping layer contains silica fume, zeolite powder, finely-ground mineral slag, pulverized coal ash and the like, and can generate volcanic ash reaction with Ca(OH)2 crystal at the interface position of the set cement so as to generate gelled materials, and further carry out improved treatment on the weakest interfaces of set cement and the stone aggregate in concrete. The modified stone aggregate of the invention has good affinity with the set cement, and has higher binding power with the set cement.

Owner:NANTONG ZHONGRUN CONCRETE +1

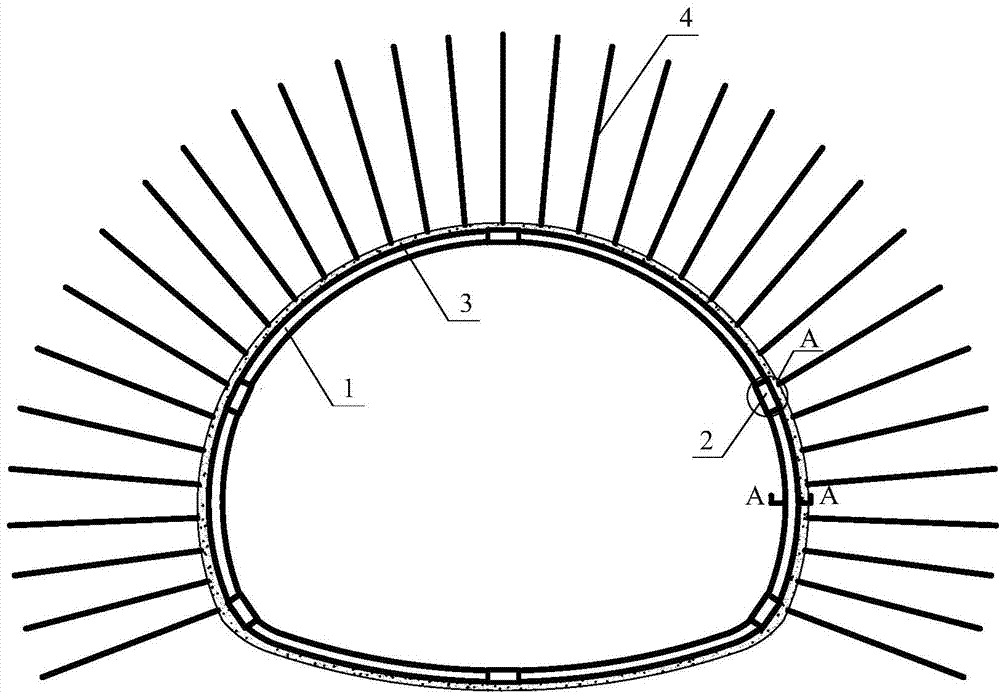

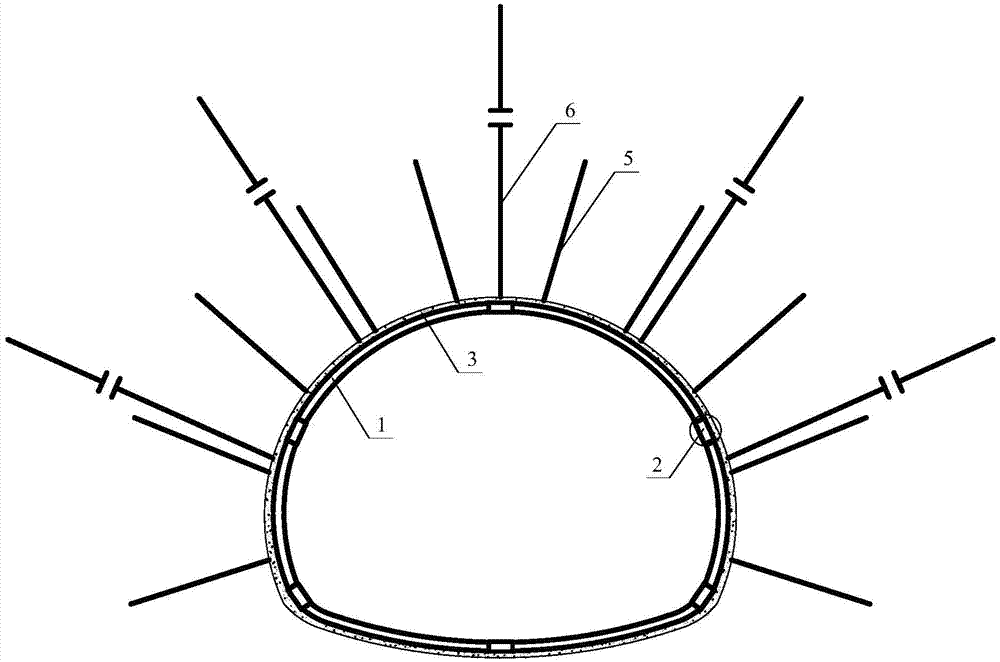

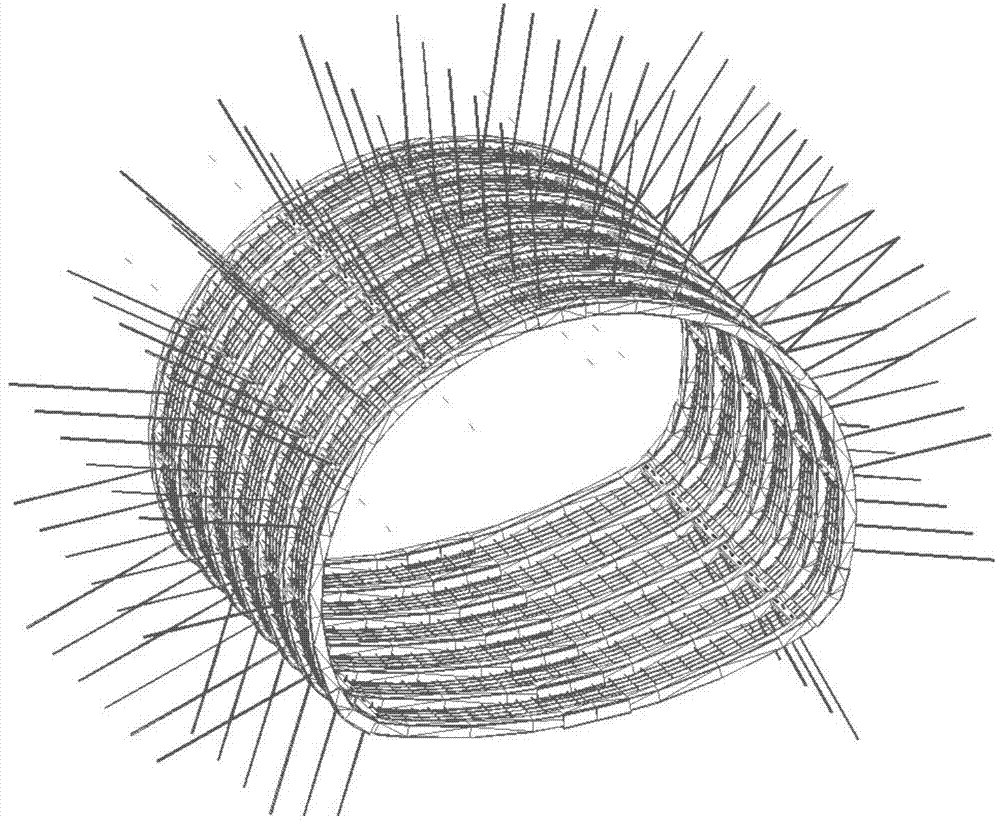

Square steel confined concrete arch center wall back filling bolting-grouting support system and construction method

InactiveCN103615273AImprove self-supporting capacityFill in timeAnchoring boltsSupporting systemRock tunnel

The invention discloses a square steel confined concrete arch center wall back filling bolting-grouting support system and a construction method. The square steel confined concrete arch center wall back filling bolting-grouting support system comprises high-strength anchor rods, grouting anchor rods, grouting anchor cables and multiple square steel confined concrete arch centers, wherein adjacent square steel confined concrete arch centers are connected through longitudinal beams, anchor rod holes are formed in the longitudinal beams, longitudinal beam anchor rods penetrate the longitudinal beams through the anchor rod holes to be anchored into a surrounding rock, a wall back filling layer is arranged between the square steel confined concrete arch centers and the surrounding rock, and the square steel confined concrete arch centers, the wall back filling layer and the tunnel surrounding rock are connected through the longitudinal beam anchor rods. The high-strength anchor rods, the grouting anchor rods and the grouting anchor cables are constructed before the square steel confined concrete arch centers are erected. The square steel confined concrete arch center wall back filling bolting-grouting support system and the construction method are applicable to supporting of underground projects including weak broken surrounding rock tunnels and the like, the square steel confined concrete arch center wall back filling bolting-grouting support system has the advantages of being high in strength, good in stability, reasonable in stress and the like, and the square steel confined concrete arch center wall back filling bolting-grouting support system and the construction method can effectively improve the primary supporting strength after tunnel excavation and ensure the stability of the tunnel surrounding rock.

Owner:SHANDONG UNIV

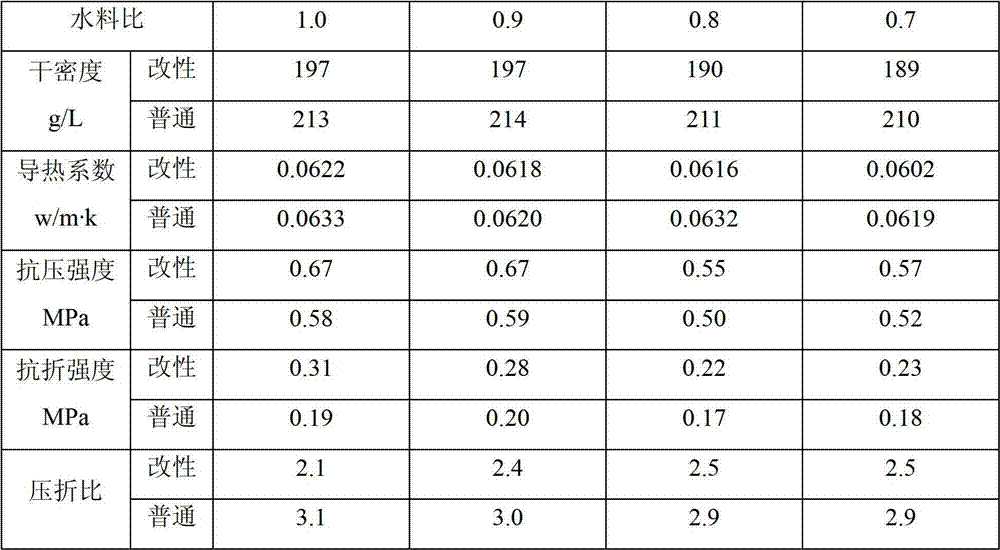

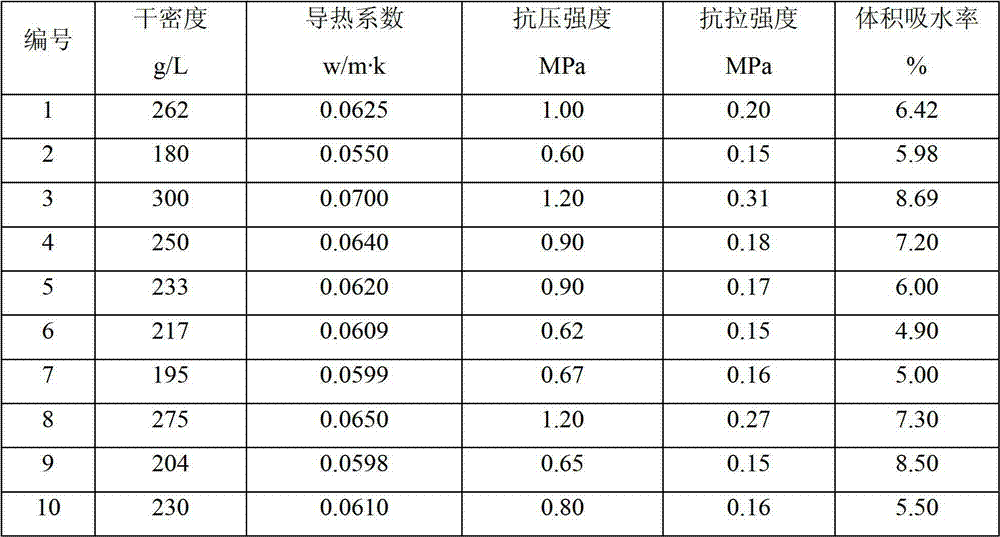

Dual organic modified cement-base expanded perlite fireproof thermal-insulation board and preparation method thereof

InactiveCN102815906AStrong resistance to deformationImprove crack resistancePolymer scienceCrack resistance

The invention relates to a dual organic modified cement-base expanded perlite fireproof thermal-insulation board and a preparation method thereof. The dual organic modified cement-base expanded perlite fireproof thermal-insulation board mainly comprises the following components in percentage by weight: 50-80% of organic modified expanded perlite, 20-35% of Portland cement, 5-10% of polymer emulsion, 0-3% of active filler and 0.5-1% of additive. The preparation method comprises the following steps: evenly mixing raw materials, adding water, stirring to obtain a semidry material, filling the semidry material into a mold, compacting into a fireproof thermal-insulation board, and finally, carrying out high temperature steam curing for several hours. The dual organic modified cement-base expanded perlite fireproof thermal-insulation board not only has the advantages of strong deformation resistance, favorable crack resistance, shock resistance, favorable weather resistance, long service life, favorable fire resistance (Grade A) and the like in the Portland cement-base expanded perlite inorganic thermal-insulation board, but also has the advantages of high strength, low density and low elastic modulus. The invention has the characteristic of high production efficiency, and can implement large-scale production.

Owner:宁波荣山新型材料有限公司

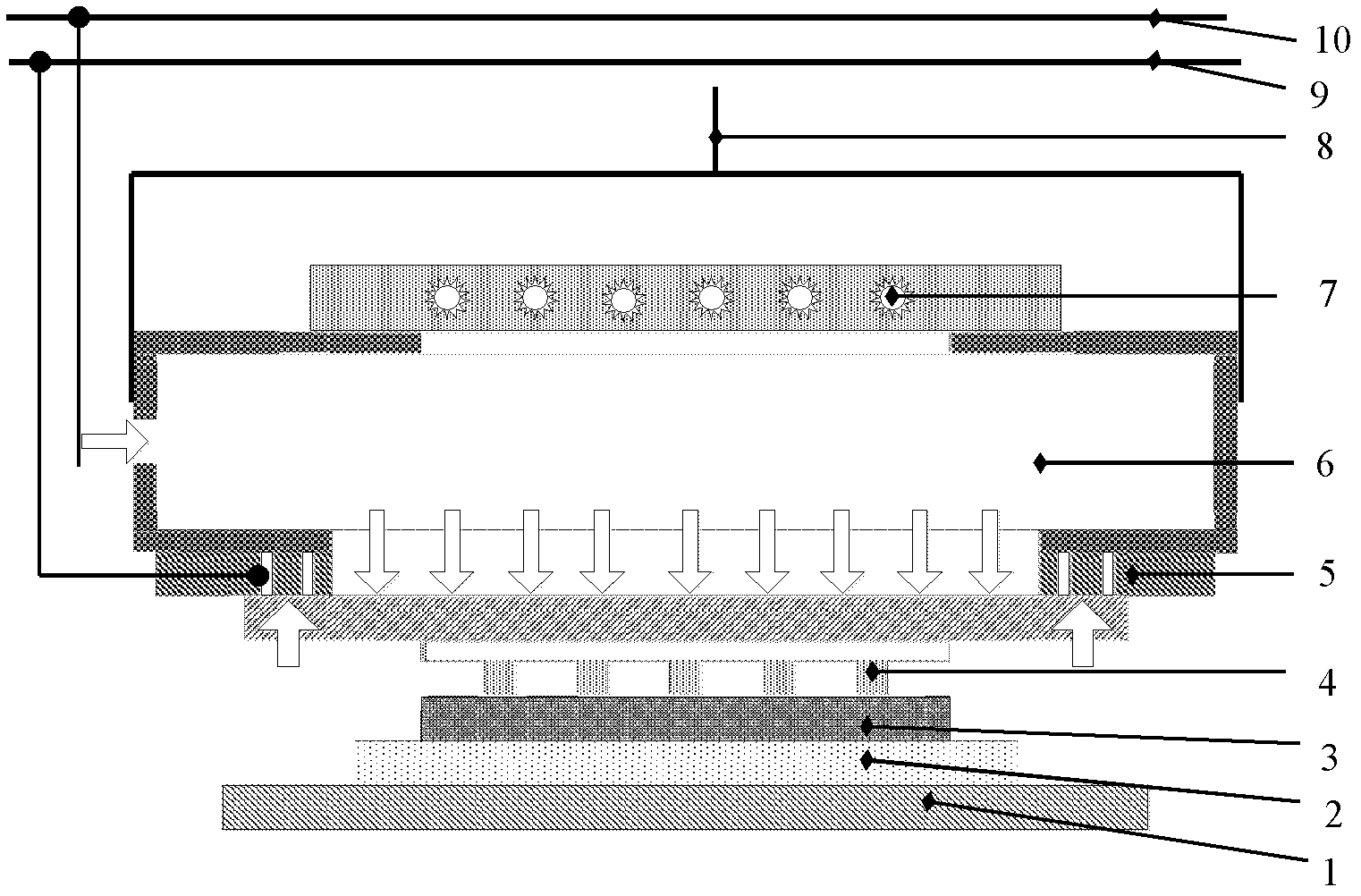

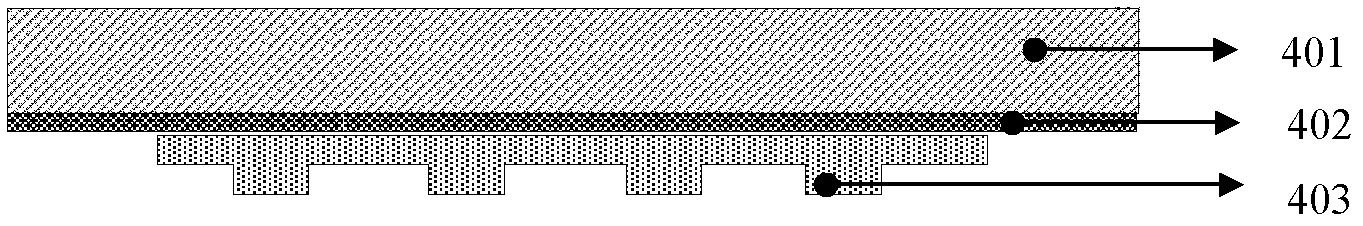

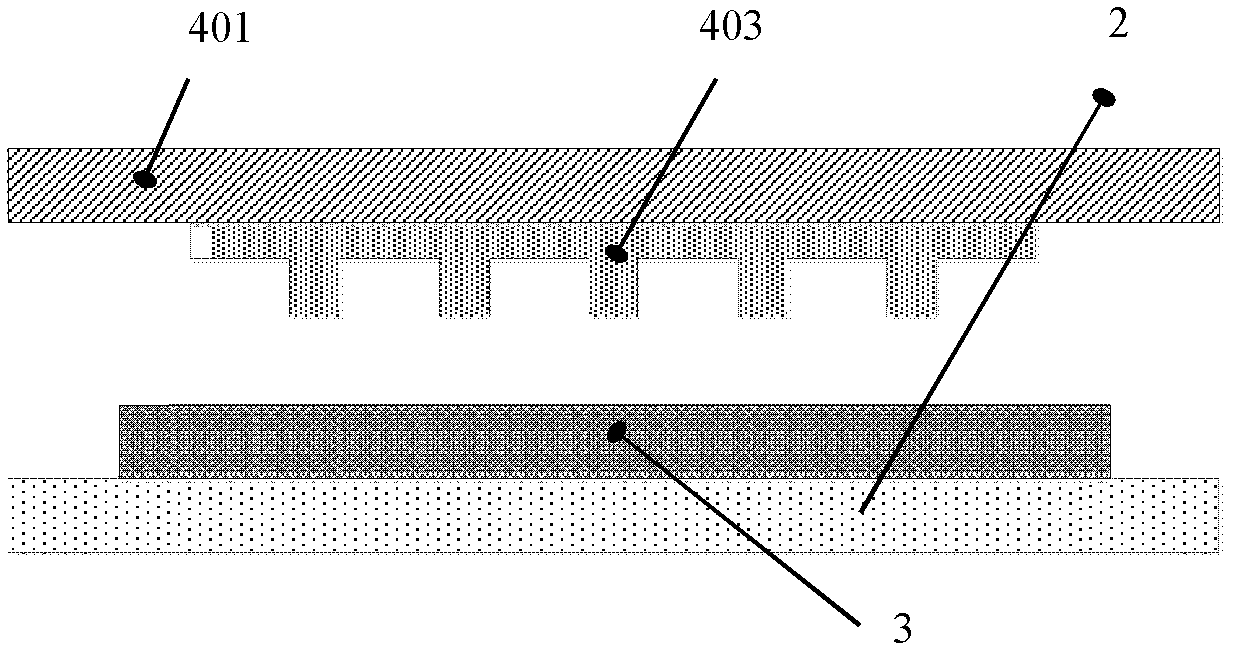

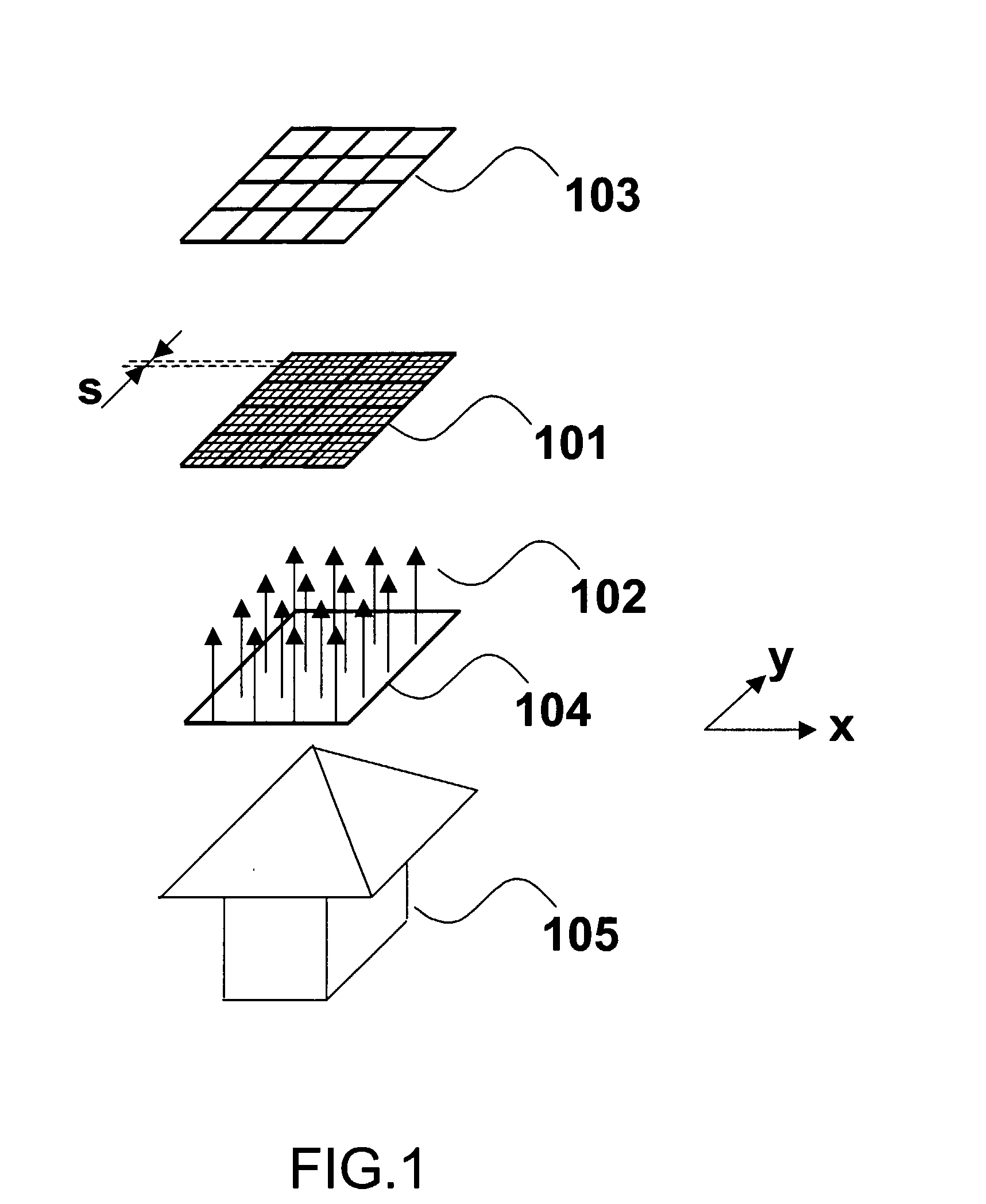

Device and method for large-area nano imprinting photoetching

ActiveCN102591143AHigh elastic modulusHigh complex precisionPhotomechanical apparatusNano structuringFluid control

The invention discloses a device and a method for large-area nano imprinting photoetching. A fluoropolymer-based thin film structure composite soft mould is introduced, and a gas assisting pressing mode and a mould micro-feed pressure pressing mode are adopted in the imprint process. The demoulding is carried out on the basis of low surface energy of a fluoropolymer base by a two-time solidifying and revealing type demoulding method, and thus the large area demoulding can be realized by small demoulding power. The device and the method for the large-area nano imprinting photoetching, disclosed by the invention, realize that a large-area nano-structure can be manufactured on various kinds of substrates, such as uneven (bent, cocked or stepped) substrates, curved substrates, or fragile substrates, and have the obvious advantages of high complex precision, large imprinting area, high efficiency, and low cost and a mould is long in service life. The device and the method for the large-area nano imprinting photoetching are suitable for LED (light emitting diode) nano-imaging technology and manufacturing of optical devices (such as optical lenses), butterfly solar condensers, micro-fluid control devices and the like.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Polyurethane cement mortar and preparation method thereof

InactiveCN103420657ASmall volume shrinkageStrong resistance to deformationPolymer scienceCrack resistance

The invention discloses polyurethane cement mortar and a preparation method thereof. The polyurethane cement mortar comprises the following materials: 50 to 70 parts of cement, 100 to 140 parts of 30 to 150 meshes' silver sand, 10 to 35 parts of water, 1.5 to 6 parts of early strength agent, 0.9 to 2.4 parts of water-reducing agent, and 20 to 25 parts of one-component polyurethane, wherein the one-component polyurethane comprises isocyanate, polyether 220, polyether 330, catalyst and solvent. The invention further discloses the corresponding preparation method which comprises the following steps: leading a small quantity of polyurethane resin in cement mortar, uniformly dispersing the cement mortar in the cement substrate, and carrying out hydration of cement and solidification of polyurethane simultaneously to form an integral structure through mutual filling. The polyurethane cement mortar prepared according to the preparation method overcomes the defects of large air shrinkage deformation, poor impermeability, crack resistance and corrosion resistance, high density and the like of common mortar which is low in tension or compression ratio, and has the excellent performances of high freezing resistance, leakage resistance, corrosion resistance, ductility ratio, and deformation resistance, low volume shrinkage ratio, and the like.

Owner:安徽省思维新型建材有限公司

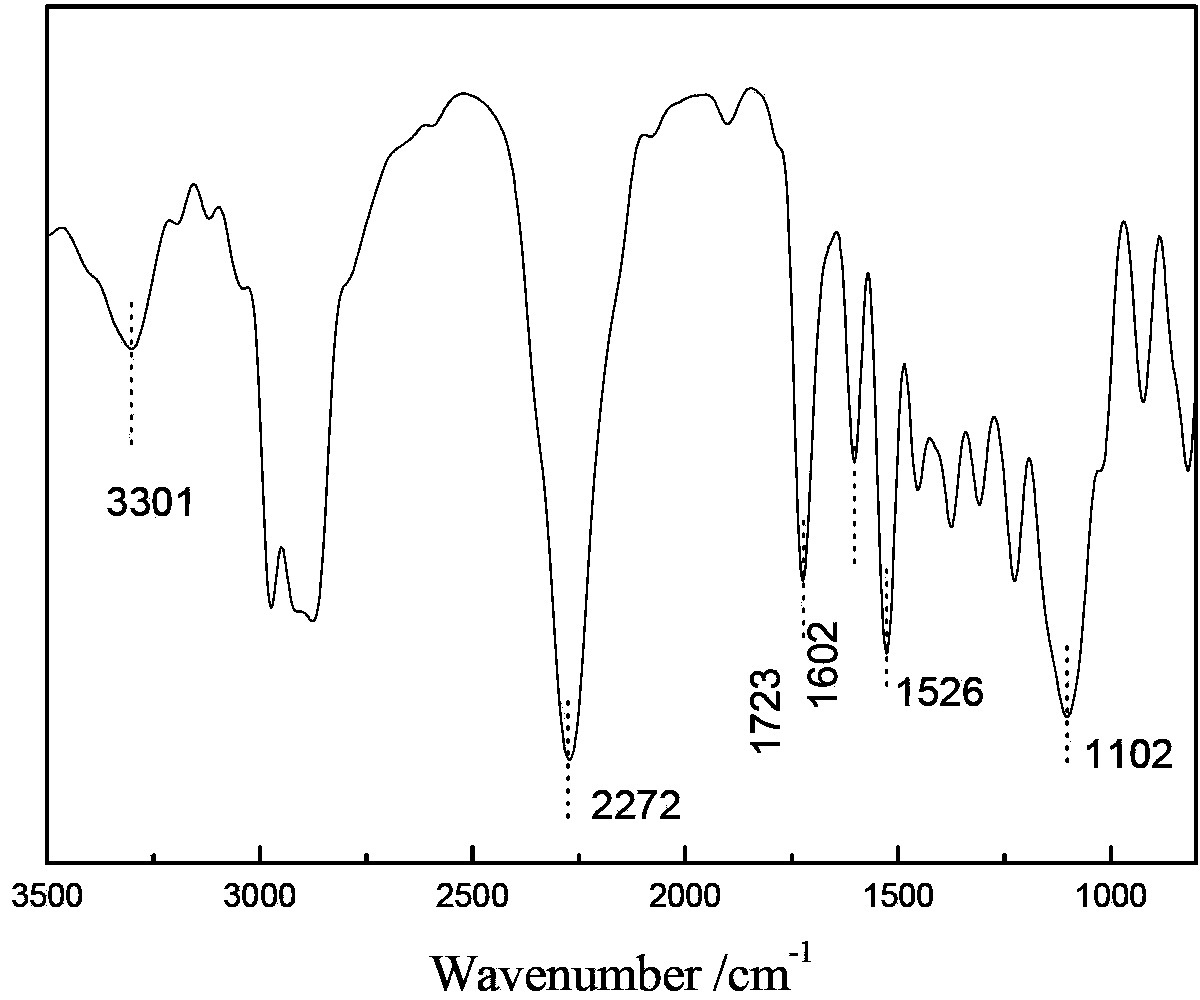

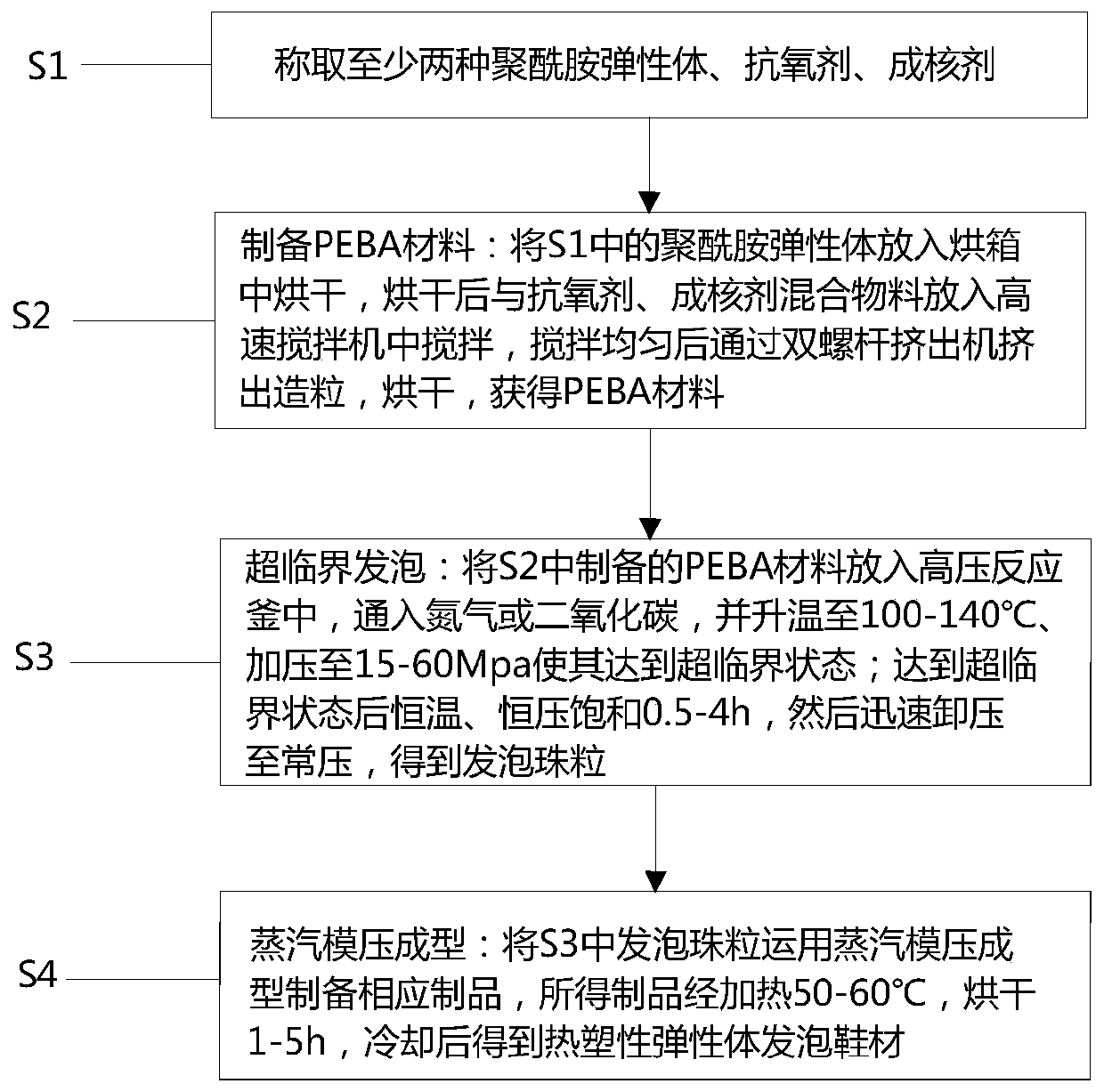

Thermoplastic elastomer foamed shoe material and preparation method thereof

The invention belongs to the technical field of shoe material manufacturing, and particularly relates to a thermoplastic elastomer foaming shoe material and a preparation method thereof. The thermoplastic elastomer foaming shoe material is prepared from the following raw materials in parts by mass: 100 parts of a modified polyamide elastomer, 0.1 to 0.5 part of an antioxidant and 0 to 10 parts ofa nucleating agent, the modified polyamide elastomer at least comprises two polyamide elastomers so that the regulated and controlled melt strength is more excellent, a series of shoe foaming materials with higher foaming ratios and better elasticity are prepared through a supercritical fluid foaming technology, the foaming material has the advantages of low density, excellent resilience, excellent deformation resistance and the like, meanwhile, the material is applied to the field of sneakers, a force feedback mechanism is started for the whole running process, energy in each step of a weareris recycled and then released again, the light and efficient resilience property is guaranteed, and power can be provided for the wearer.

Owner:LI NING CHINA SPORTS GOODS

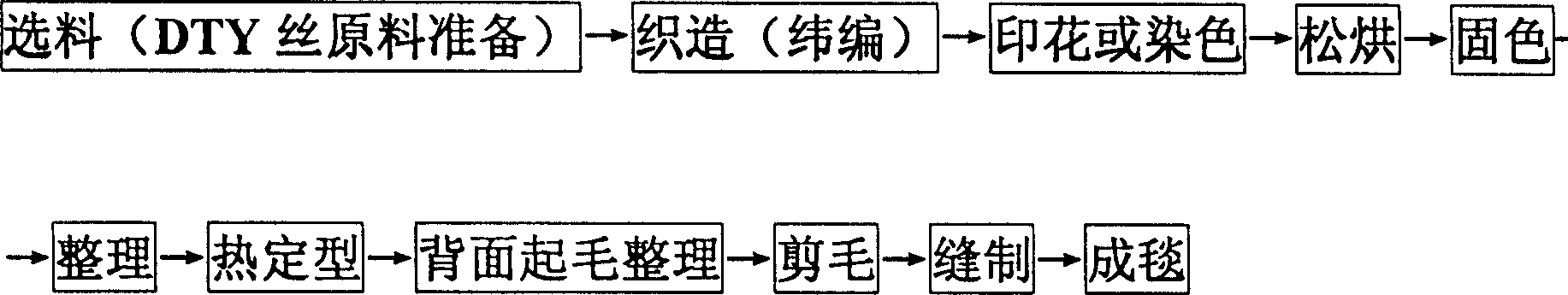

Process for producing polyester fiber blanket

The process of producing polyester fiber blanket includes the following steps: sortig cationic DTY yarn; and warp knitting or weft knitting. The present invention has the advantages of no need of re-networking step to simplify the technological process, the universality of DTY yarn on both warp knitting loom and weft knitting loom, blotch warp knitting, less deformation of the blanket, and blanket fluff height of 4.0-12 mm, unit area weight of 280-550 g / sq m.

Owner:常熟市锦绣经纬编有限公司

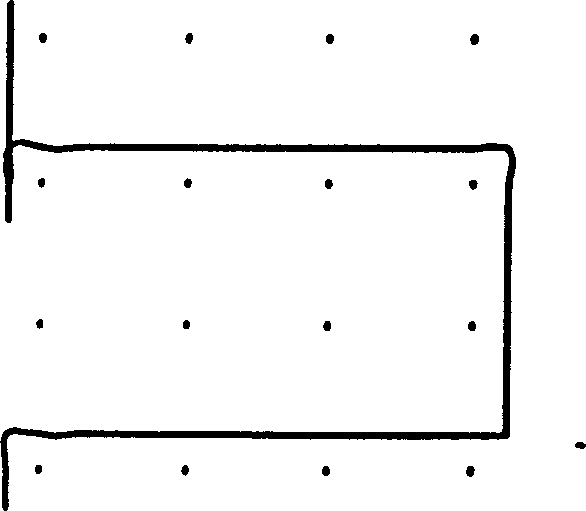

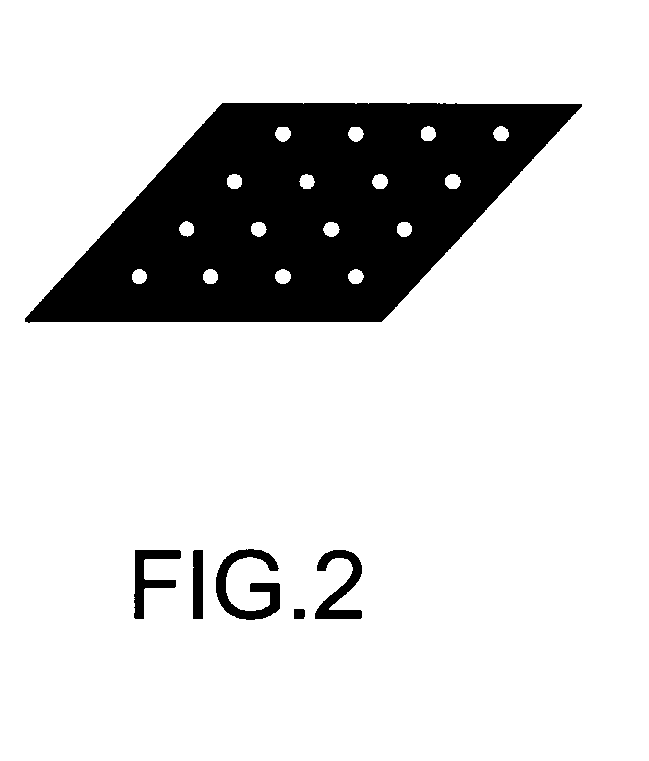

Information Carrier, System and Apparatus for Reading Such an Information Carrier

InactiveUS20080100892A1Easy Data RecoveryStrong resistance to deformationOptical beam sourcesRecord information storageComputer science

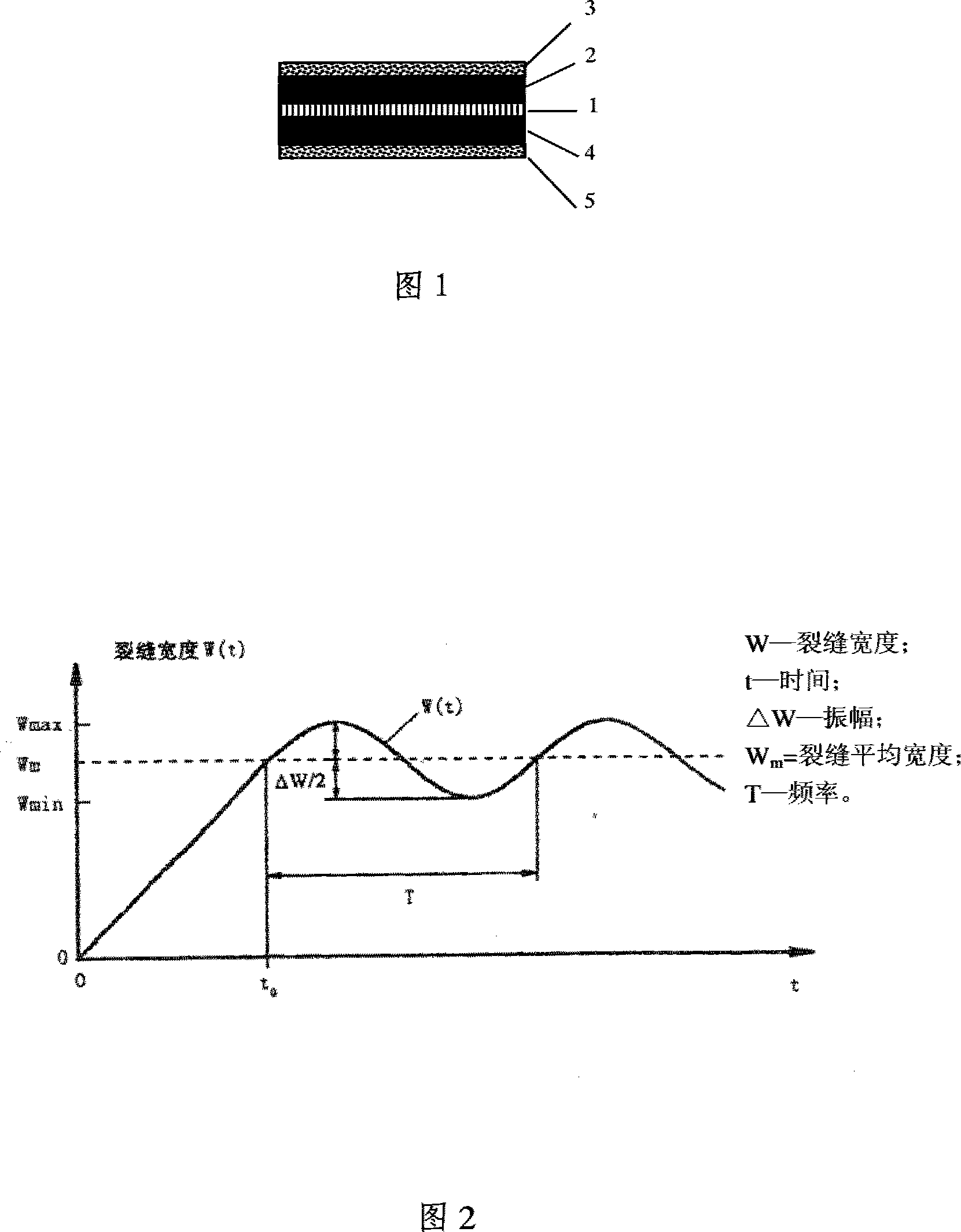

The invention relates to an information carrier (801) comprising: a data layer (802) intended to store a set of elementary data, a layer (803) comprising an array of apertures (804) placed parallel to said data layer (802) for generating an array of light spots intended to be applied to said data layer (802). The invention also relates to a system and apparatus for reading such an information carrier.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Support method for bolt-grouting composite crushing dynamic-pressure roadway soft rock roof by high-pre-stressed anchor cable

The invention discloses a support method for bolt-grouting a composite crushing dynamic-pressure roadway soft rock roof by a high-pre-stressed anchor cable. The support method comprises the following steps of: after excavating a roadway, keeping up with a roadway driving head for drilling a deep part in a roadway roof, sending a deep hole camera shooting detecting instrument to the bottom of a drilled hole, recording inner wall lithological characters, fracture spacing and crushing region thickness range of surrounding rocks of different depths; keeping up with the roadway driving head, firstly drilling grouted holes in the surfaces of surrounding rocks, installing grouting pipes, then spraying thin-layer concrete on the surfaces of the surrounding rocks of the roadway for closing the surfaces of the surrounding rocks of the roadway to prevent slurry from overflowing; grouting the insides of the surrounding rocks through the grouting pipes, after slurry is solidified, drilling anchor cable holes in the surfaces of the surrounding rocks of the roadway, and when the depths of the anchor cable holes exceed the range of a crushing region, installing an anchor cable for reinforcing. The support method has the advantages of being simple in operation, bringing convenience for construction, saving secondary or multi-time support procedure, lowering the cost, saving the time and manpower, increasing the working efficiency, realizing dual-anchoring, and achieving the strong support effect, and is especially suitable for the roof which is difficult to support under the condition of dynamic pressure.

Owner:SHANDONG UNIV OF SCI & TECH

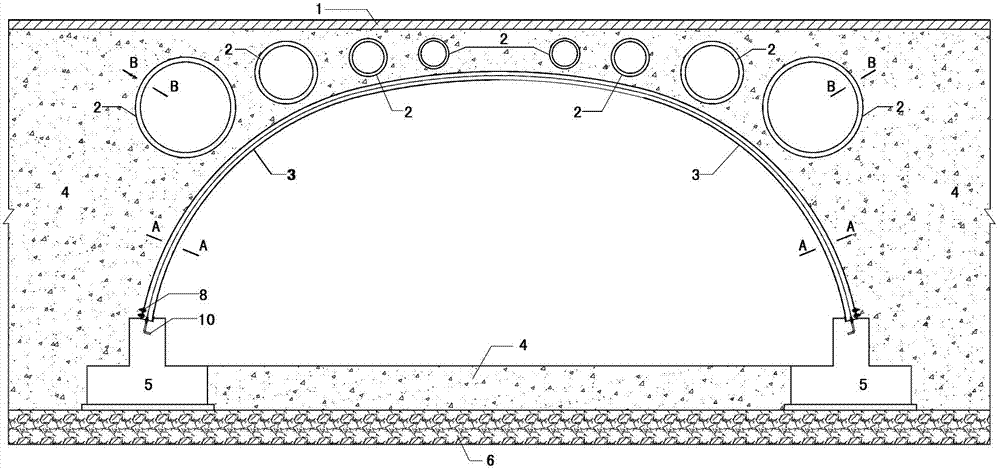

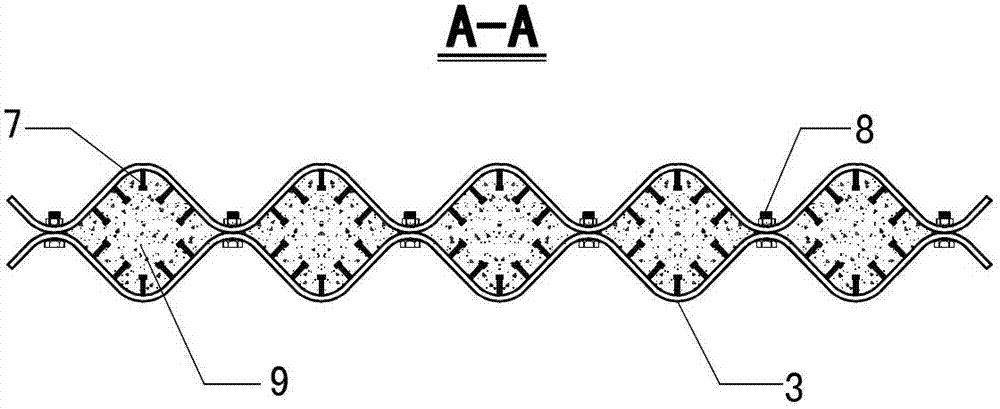

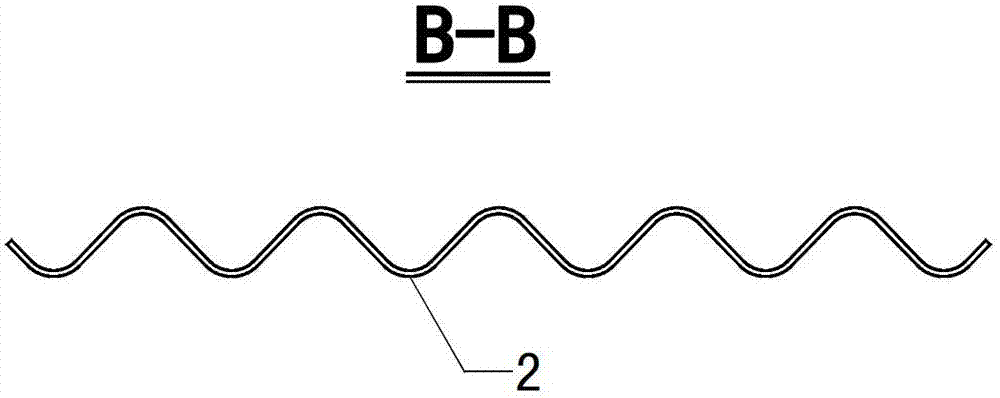

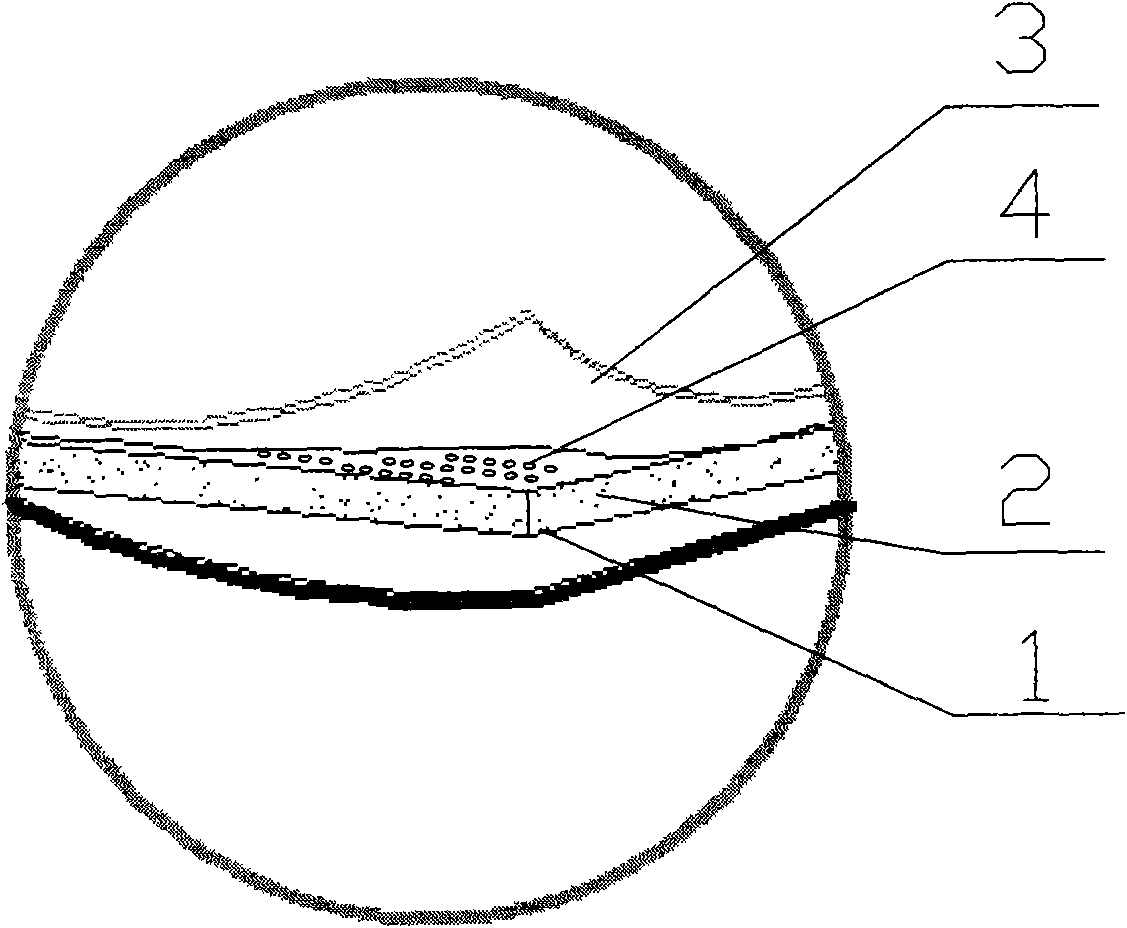

Lattice-type large-span soil-filling composite corrugated steel arch bridge structure

InactiveCN103114520ASimplify the assembly processReduce weightBridge erection/assemblyArch-type bridgeReinforced concreteEconomic benefits

The invention relates to a novel composite arc bridge structure, and particularly discloses a lattice-type large-span soil-filling composite corrugated steel arch bridge structure. Sandwich mortar composite corrugated steel plates are adopted as large-span main arch rings of the composite structure. The corrugated steel plates are connected to form a reversely arranged double-layer plate through bolts, studs are arranged in an interlayer, and filled high-strength mortar forms an integral sandwich composite corrugated steel plate. Corrugated steel tubes are adopted by gastropore. Load is conveyed between the main arch rings and the gastropore by filling soil. The lattice-type large-span soil-filling composite corrugated steel arch bridge structure has the advantages of being low in weight, durable, high in strength, good in flexibility, high in performance, rapid in construction, good in economic benefit and the like, is an ideal alternative to reinforced concrete bridges, can be widely used in the construction of middle-sized bridges (20-50m), and can certainly generate good social economic benefit.

Owner:HUNAN UNIV

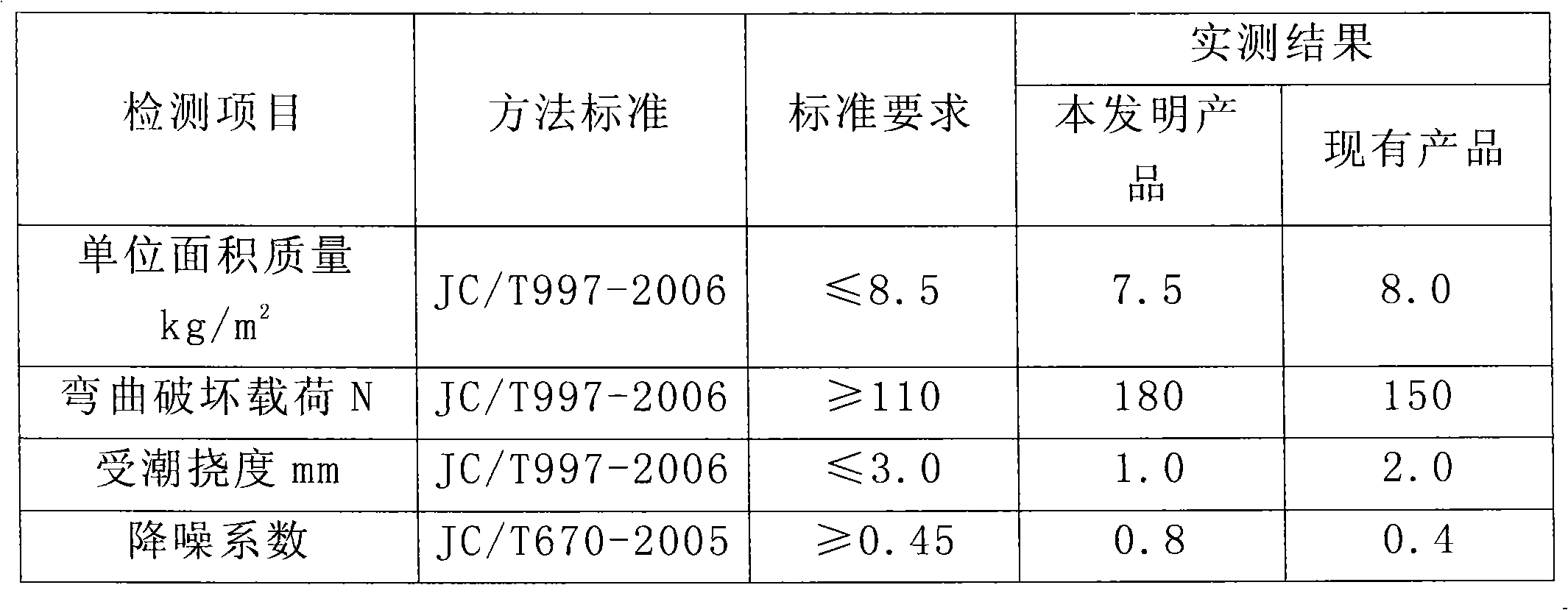

Sound absorbing decorative gypsum board and production method thereof

ActiveCN101649669ASolve the shortcomings of sagging deformation after decorationLow costCovering/liningsLamination ancillary operationsFiberNoise reduction

The invention provides a sound absorbing decorative gypsum board and a production method thereof, and relates to a decorative panel. The sound absorbing decorative gypsum board comprises an aluminiumfoil (1), a paper-faced gypsum board (2), and an embossing relief (3). The paper-faced gypsum board (2) is prepared by the following raw materials according to the proportioning rate: 60 parts of desulfurization gypsum, 4 parts of modified starch, 1 part of foaming agent, namely lauryl sodium sulfate, 1 part of glass fiber and 34 parts of water. The product is manufactured by the following steps:rotary drum embossing, film adhering of coating and drying. Compared with the existing sound absorbing board with the material quality, such as sound absorbing fiber or mineral wool and the like, thesound absorbing decorative gypsum board has the advantages of simple manufacturing process, high strength, dampproof performance, long service life and good effect of noise reduction and sound absorption.

Owner:TAISHAN GYPSUM CO LTD

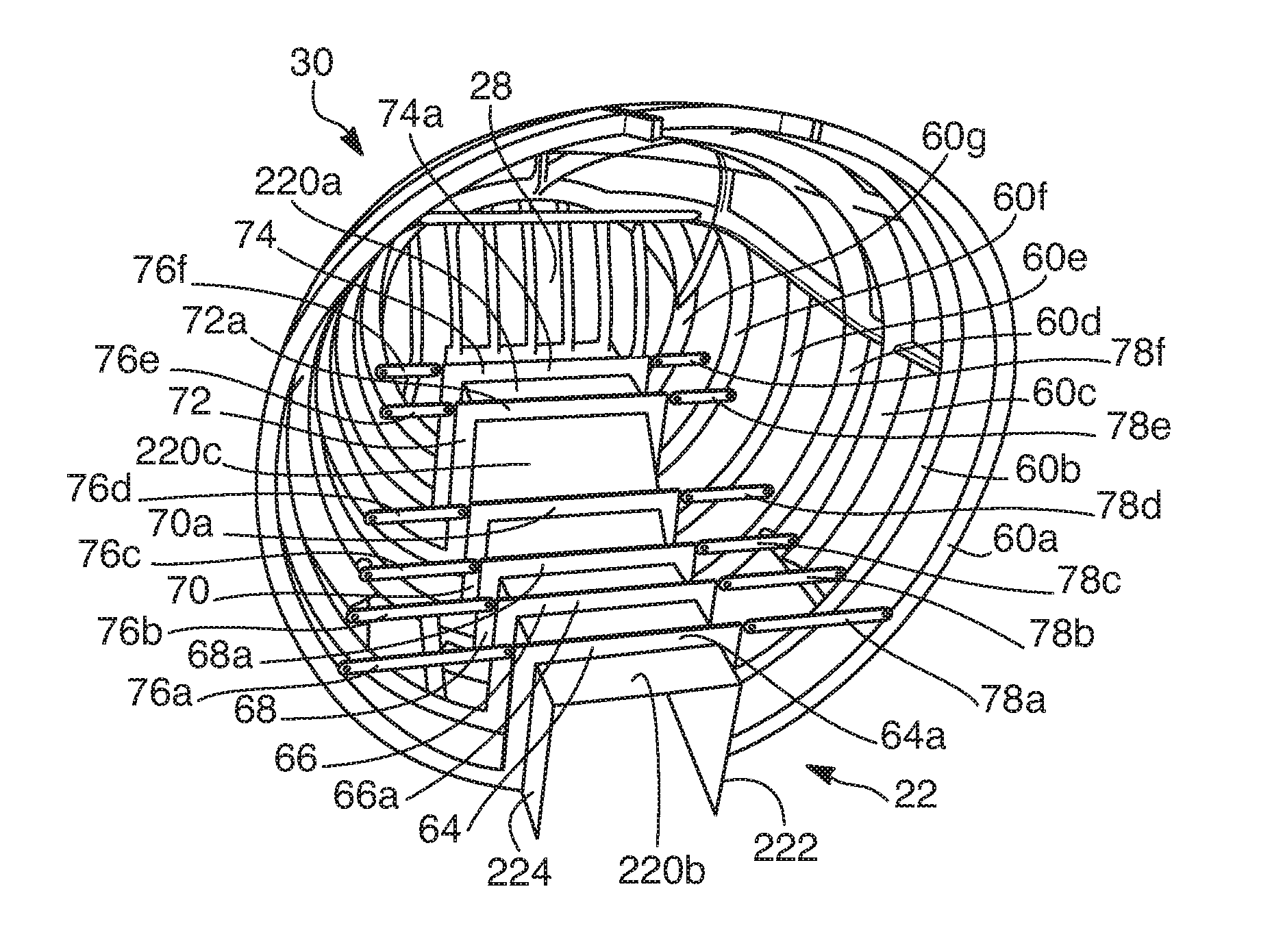

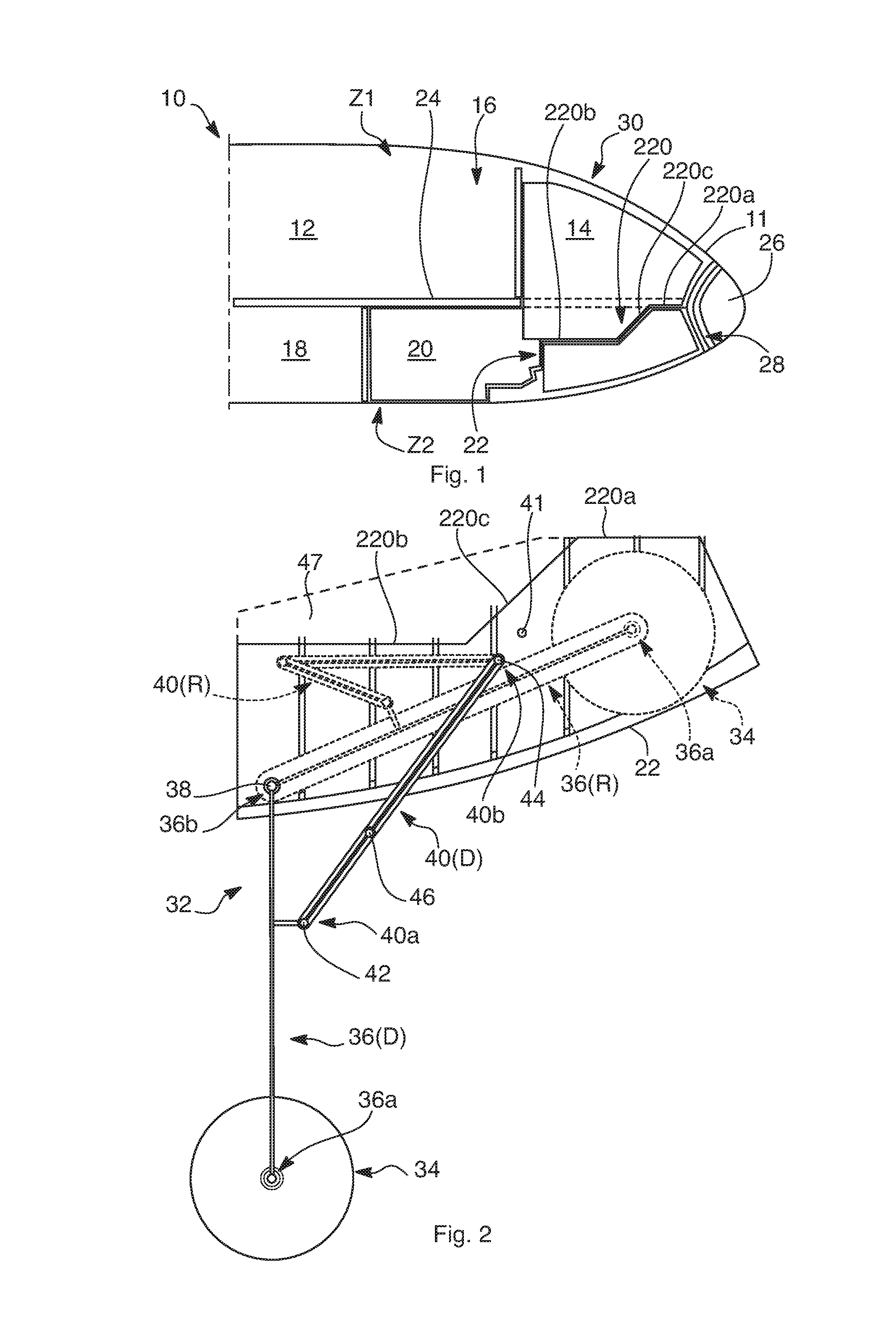

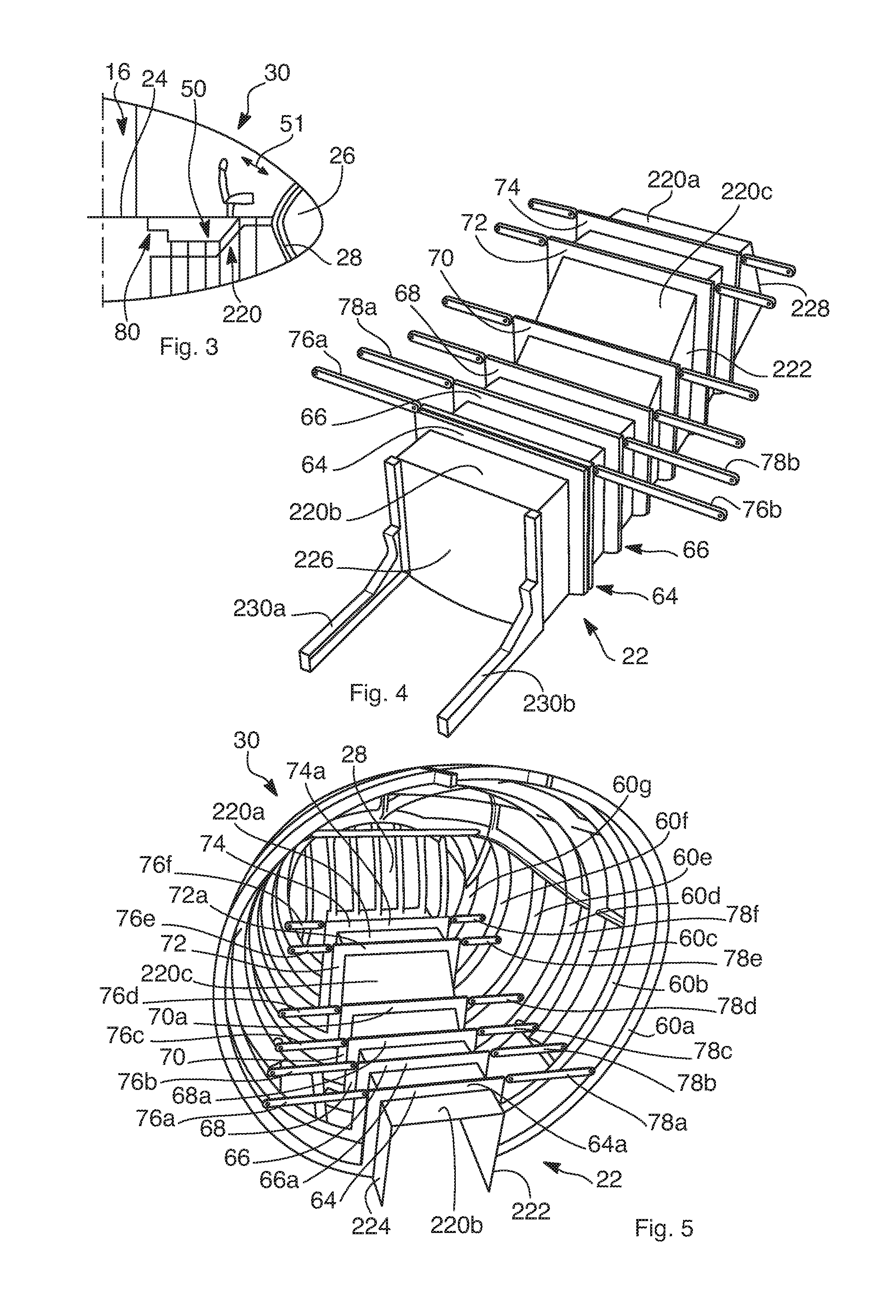

Aircraft front portion having an improved landing gear bay

InactiveUS20140175223A1Strong resistance to deformationStay in shapeFuselagesAircraft crew accommodationFuselageAirplane

An aircraft front portion in which the landing gear storage bay is arranged under a cockpit floor. The landing gear bay is mechanically connected to the fuselage frames of the aircraft front portion in order to perform the function of taking up the mechanical forces acting on the fuselage frames under the effect of pressurization. The cockpit floor is thus simplified since it serves solely as a plane for the crew to walk on and it can be lowered so as to release space in the cockpit.

Owner:AIRBUS OPERATIONS (SAS)

Large-strain X80 dual-phase steel plate produced by virtue of process at low temperature and under high pressure

The invention belongs to the field of the low-alloy high-strength pipeline steel and more specifically relates to a large-strain X80 dual-phase steel plate produced by virtue of a process at a low temperature and under a high pressure. The large-strain X80 dual-phase steel plate is composed of the following components in percentage by weight: 0.05-0.07% of C, 0.25-0.35% of Si, 1.40-1.80% of Mn, less than or equal to 0.01% of P, less than or equal to 0.003% of S, 0.01-0.04% of Nb, 0.01-0.02% of Ti, less than or equal to 0.035% of Mo, less than or equal to 0.30% of Cu, less than or equal to 0.035% of Cr, less than or equal to 0.030% of Ni, less than or equal to 40ppm of N, less than or equal to 20ppm of O, less than or equal to 1.2ppm of H and the balance of Fe and inevitable impurities. The large-strain X80 dual-phase steel plate has the beneficial effects that the steel plate is subjected to accelerated cooling by virtue of high-pressure water in the adopted rolling process so that the crystalline grain are effectively refined and the production efficiency is improved, and multi-pass cooling and rolling at a low temperature and under high pressure are not carried out in a non-recrystallization zone, and finally, a proeutectoid ferrite-lath bainite structure is obtained, the obtained steel plate has the yield strength Rt0.5 of 480-560MPa, the tensile strength Rm of 770-800MPa, the yield ratio Rt0.5 / Rm being less than or equal to 0.75, the Charpy impact energy at -20 DEG C being greater than or equal to 350J, the drop shear area at -15 DEG C being greater than or equal to 95% and the Uniform elongation UEL being greater than or equal to 12, and the steel plate is high in anti-deforming capability, and furthermore, the stress ratios of the steel plate are as follows: Rt2.0 / Rt1.0 is greater than or equal to 1.09 and Rt1.5 / Rt0.5 is greater than or equal to 1.15.

Owner:JIGANG GRP

Composite modified asphalt for high-grade high road and preparation thereof

InactiveCN101508789AImprove performanceImprove stabilityBuilding insulationsDistillationMixed materials

The invention relates to composite modified pitch used for high-grade highways and a preparation method thereof. The technical proposal is as follows: firstly, 10-45 weight percent of concocted coal pitch and 55-90 weight percent of petroleum pitch are mixed uniformly by a colloid mill to be heated up to 120-220 DEG C; 1-10 weight percent of the above mixed material of styrene-butadiene-styrene block copolymer and 0.1-0.3 weight percent of stabilizing agent are added to be mixed for 0.5 to 2 hours at the temperature as above; and then the materials are stirred and kept warm in a development tank for 2 to 8 hours and then are placed in a storage tank. The concocted coal pitch is prepared by the step as follows: 40-70 weight percent of mesothermal coal pitch and 30-60 weight percent of coal tar or coal tar distillation cut or 85-95 weight percent of the mesothermal coal pitch and 5-15 weight percent of phenolic resin are added into a reactor to be mixed for 0.5 to 3 hours at 100-160 DEG C. the invention has low cost and simple technology, and a product has the characteristics of unlikely crack at low temperature, uneasy softening at high temperature, good elasticity, high strength and long service life.

Owner:WUHAN UNIV OF SCI & TECH

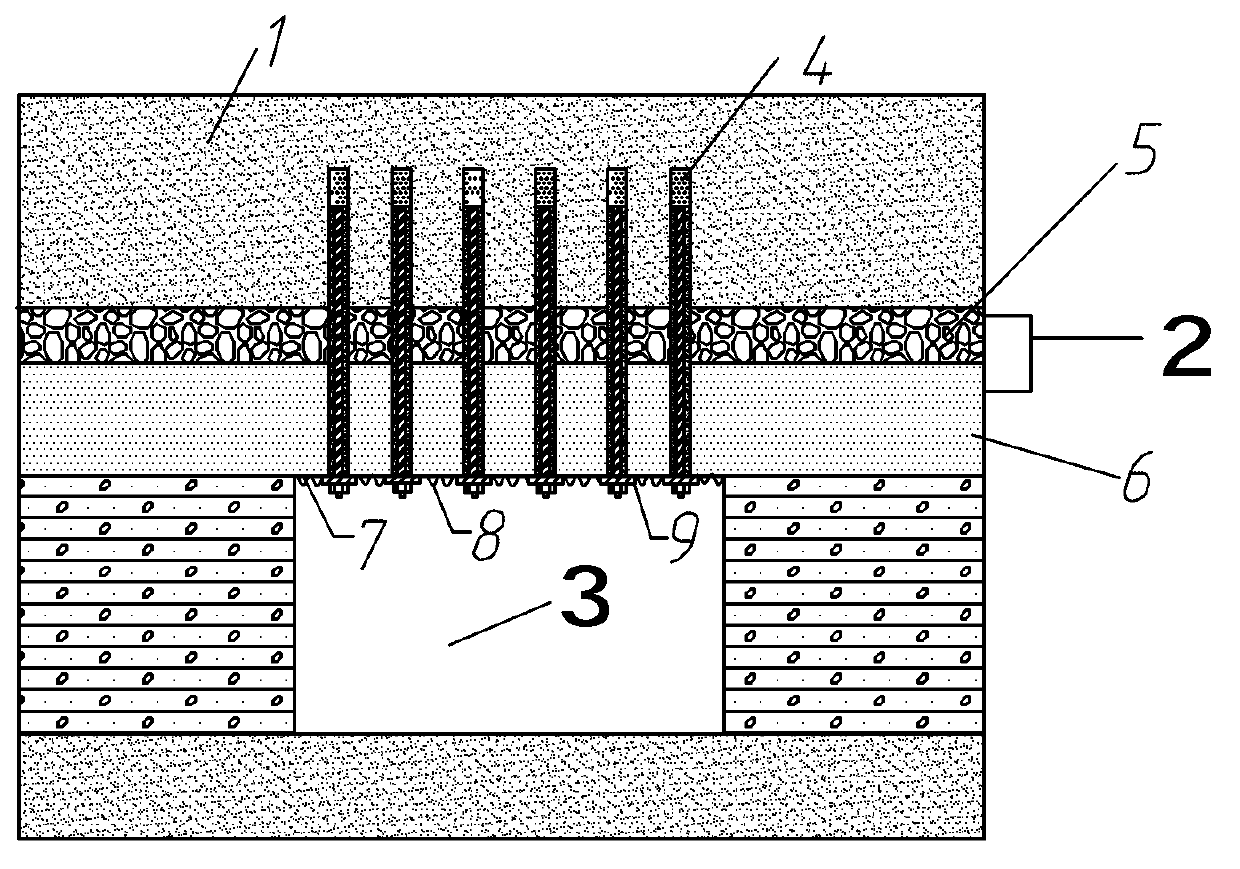

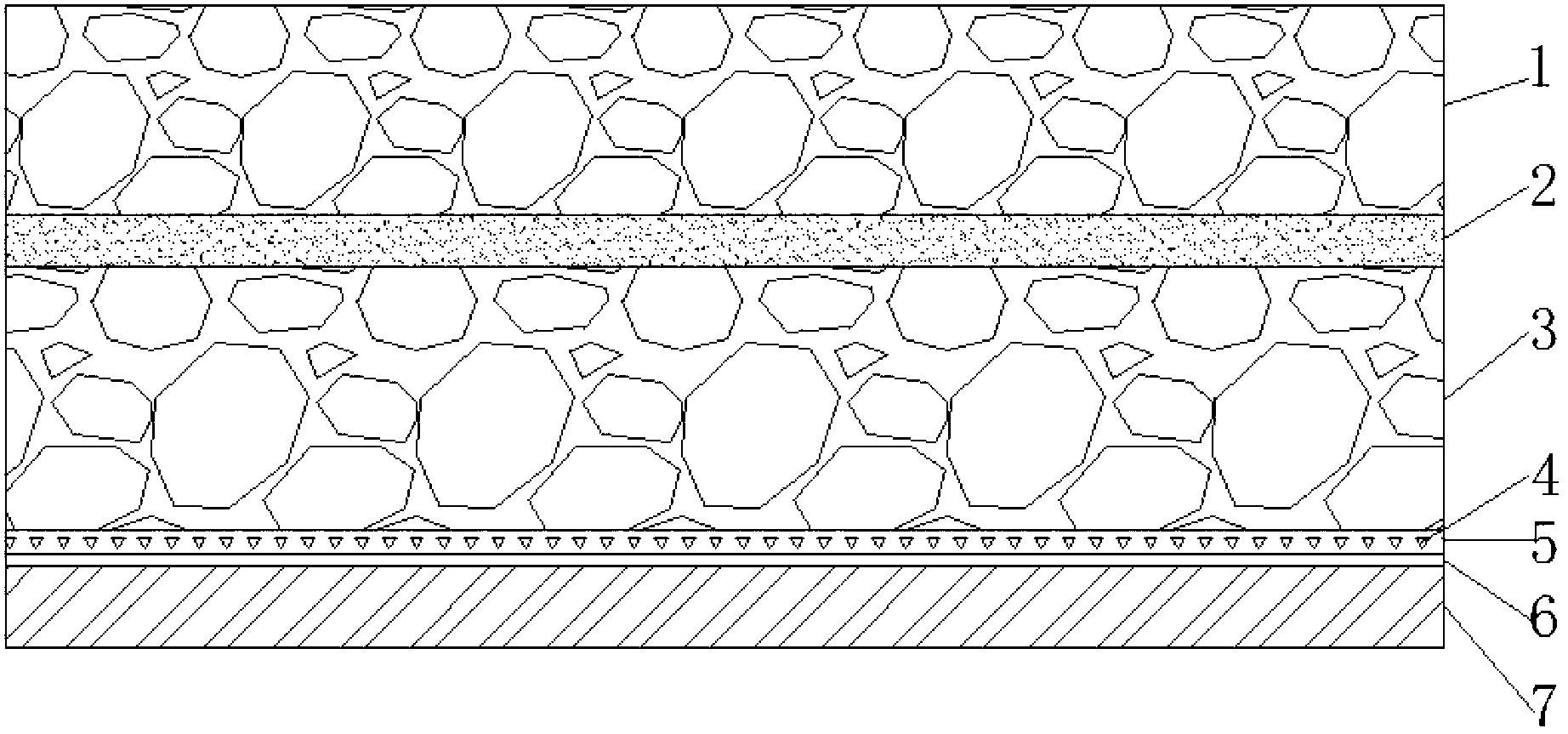

Asphalt concrete steel bridge pavement structure and pavement method thereof

ActiveCN103015316ASolve the problem of permanent deformationStrong adhesionBridge structural detailsBridge erection/assemblySand blastingViscosity

The invention discloses an asphalt concrete steel bridge pavement structure comprising a steel bridge (7) derusted by sandblast, an anticorrosive coating (6), a binding layer (5), high-viscosity asphalt embedded compact granular composition concrete bottom layer (3), an oil sticking layer (2) and a high-viscosity asphalt embedded and compact granular composition concrete top layer (1) which are arranged from bottom to top; and furthermore, the invention also provides a pavement method of the asphalt concrete steel bridge pavement structure. According to the asphalt concrete steel bridge pavement structure, the high-viscosity asphalt embedded compact granular composition concrete layers are used as main pavement layers, so that concrete has favorable interlayer binding force and deformation following performance, the generation of cracks can be restrained, so that the whole steel bridge pavement structure has the advantages of favorable track resistance and water seepage resistance.

Owner:SHANGHAI PUDONG ROAD & BRIDGE GRP CO LTD

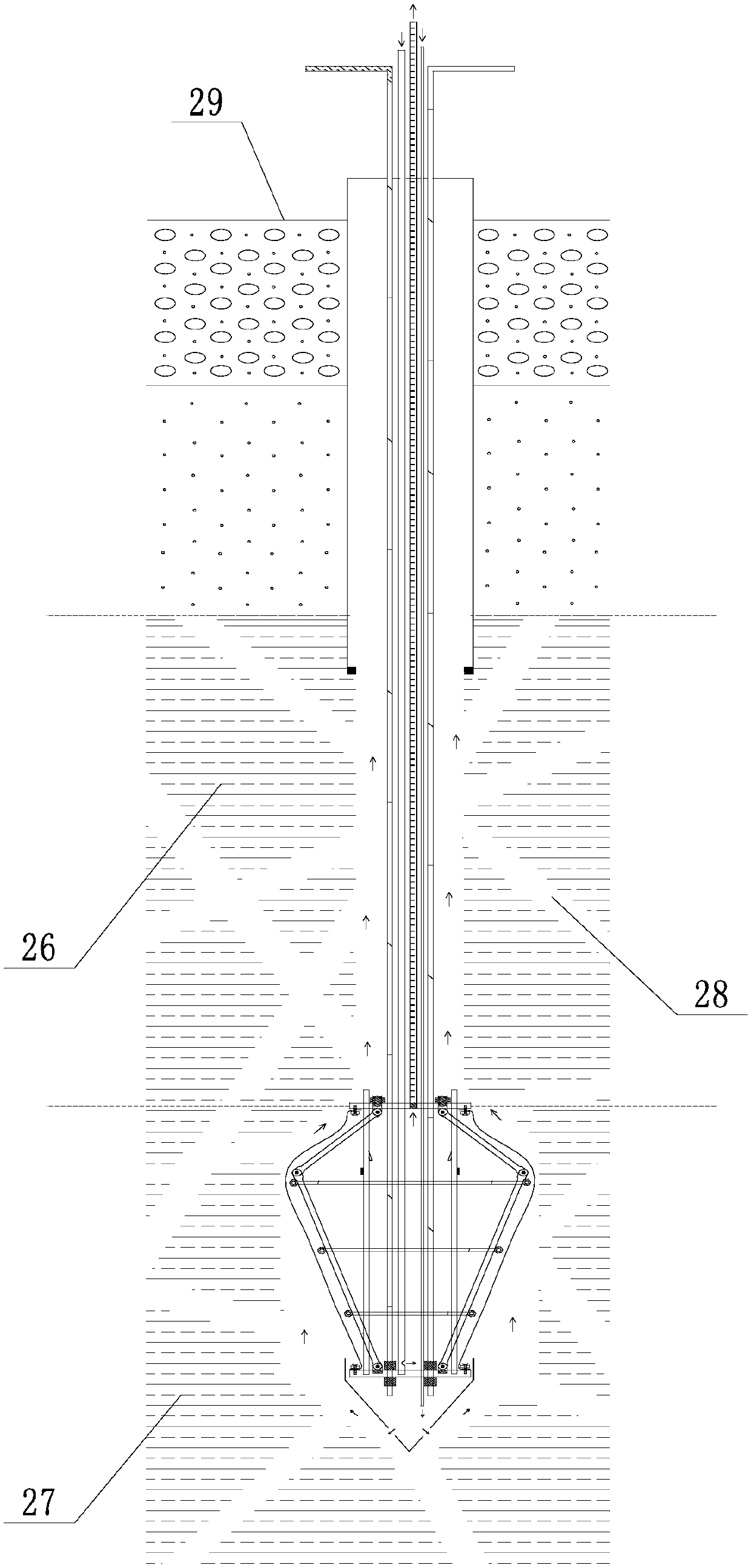

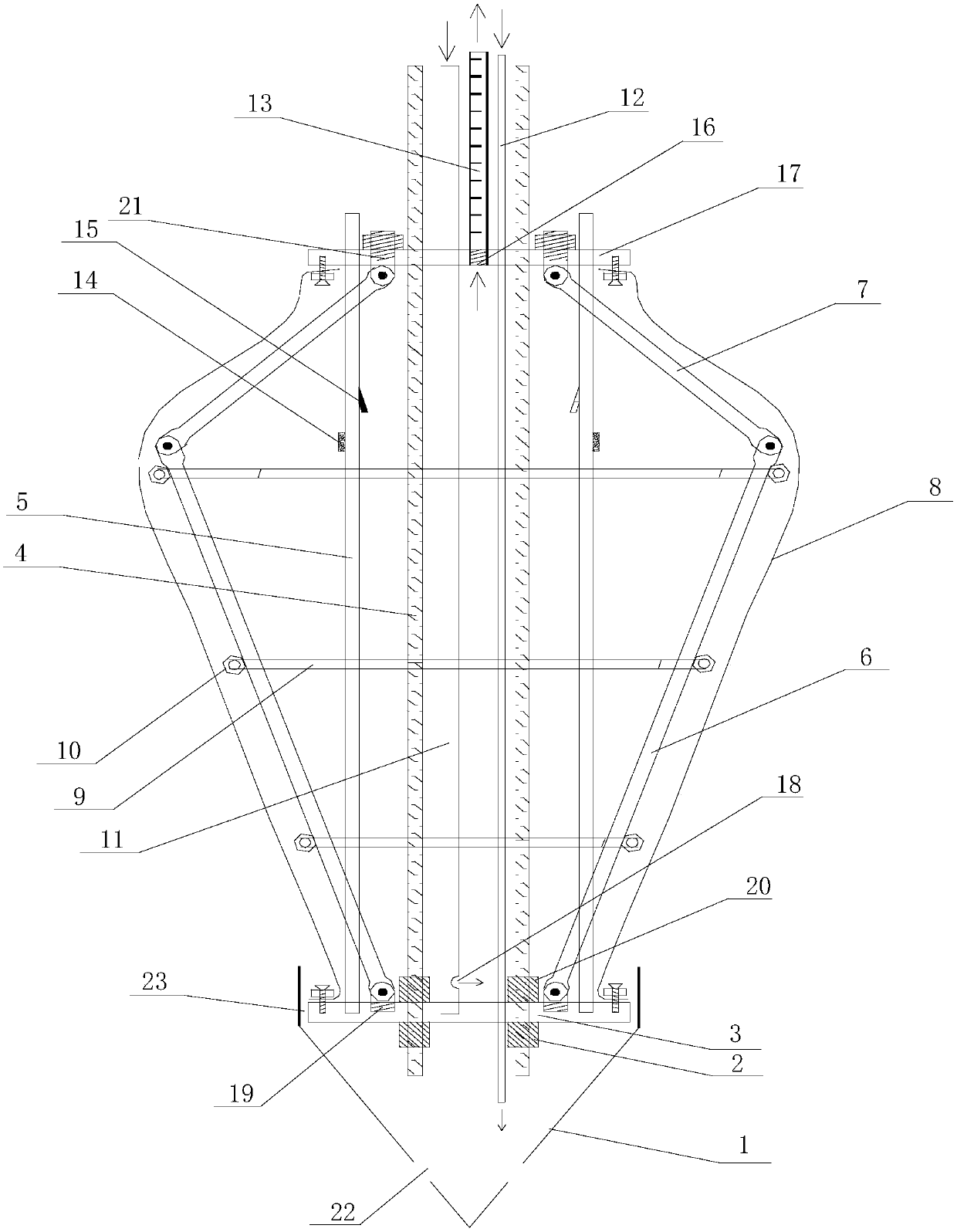

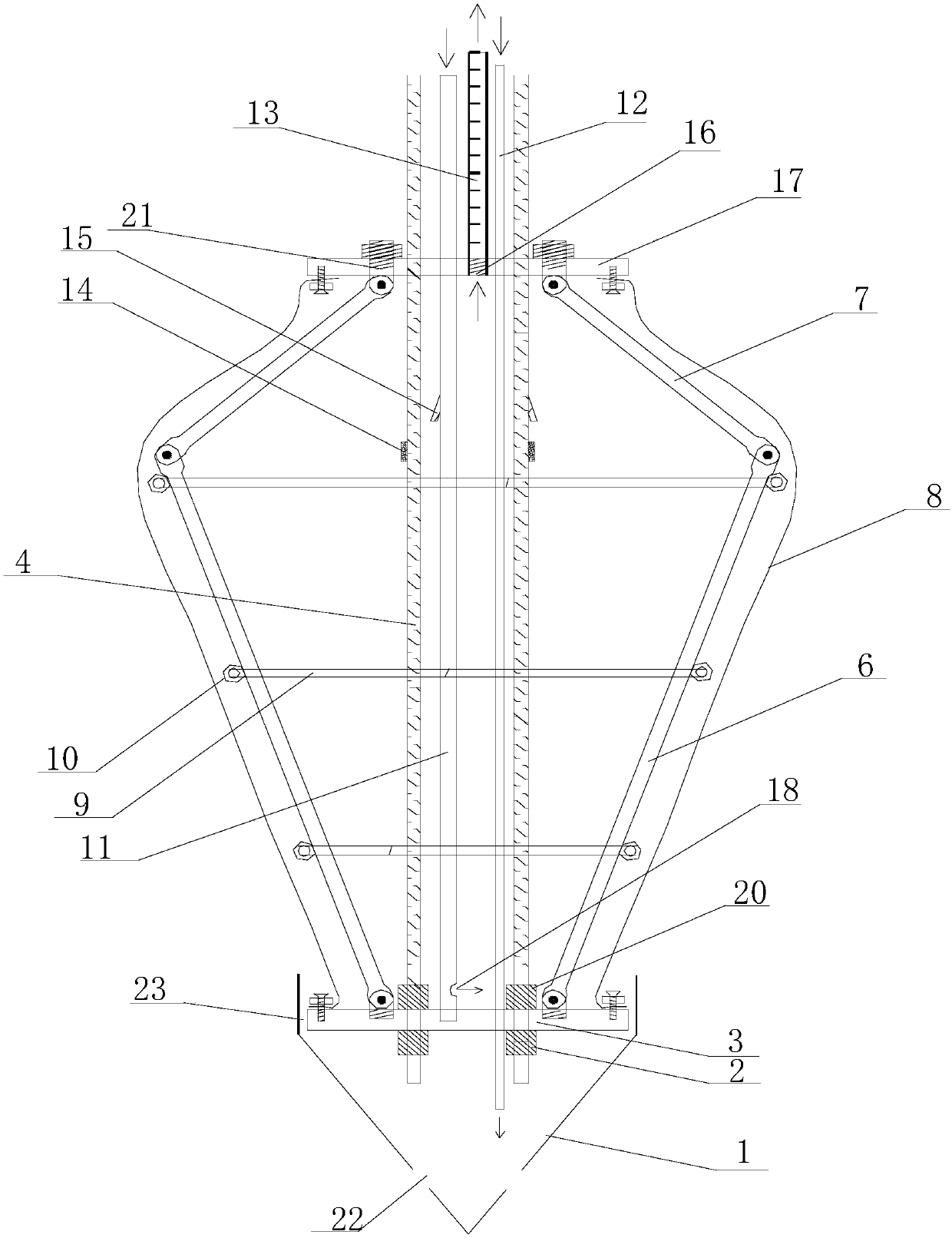

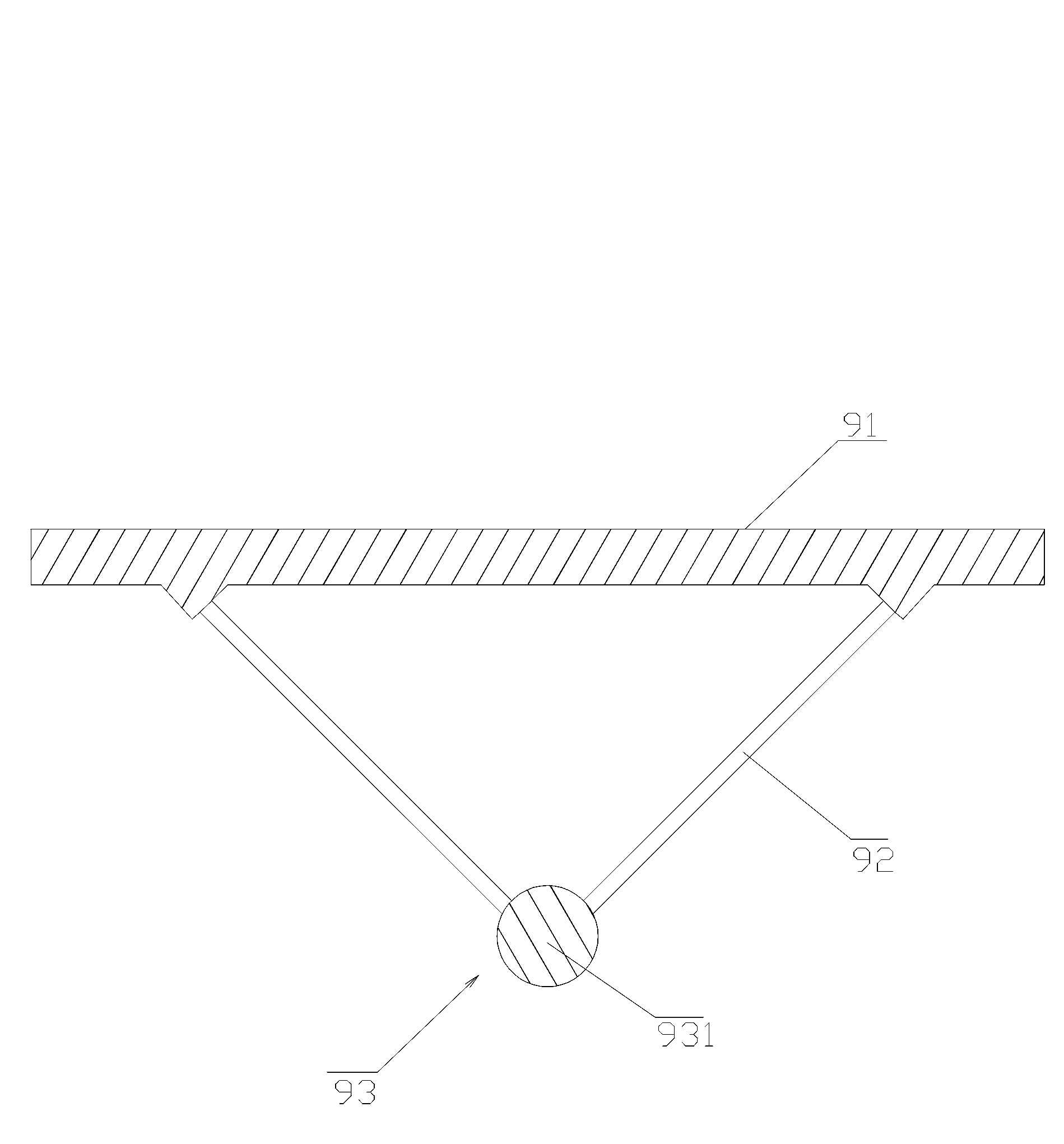

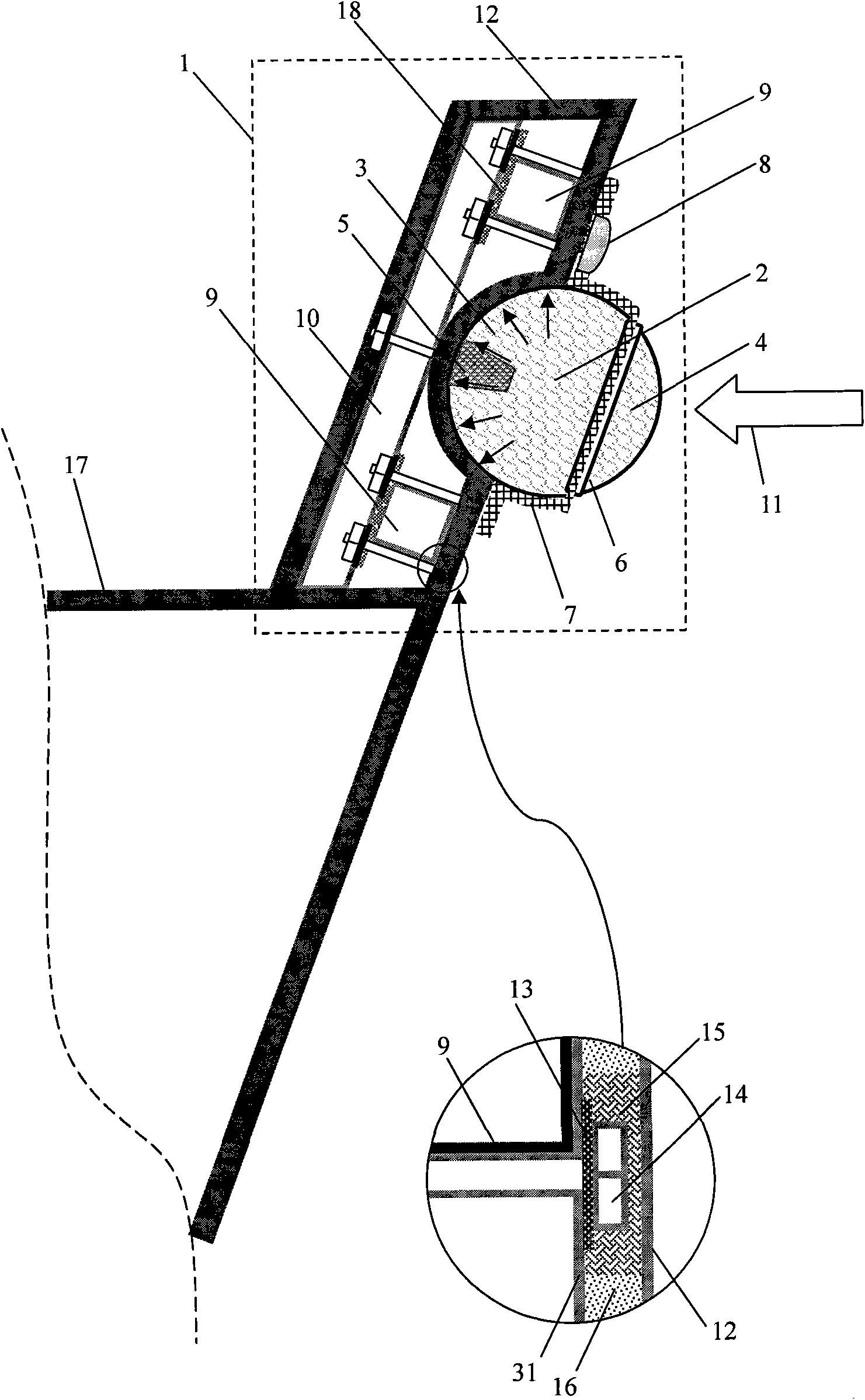

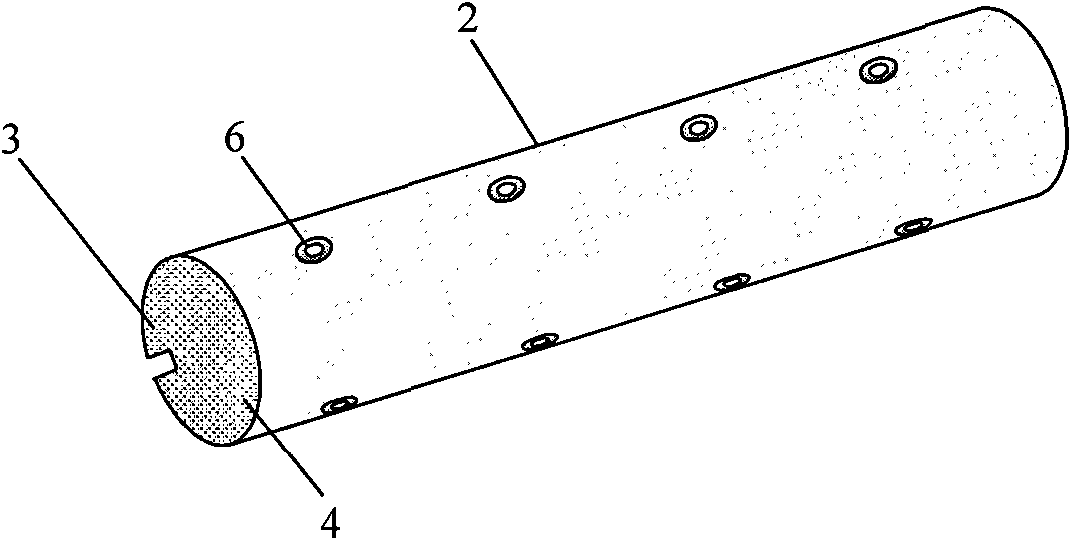

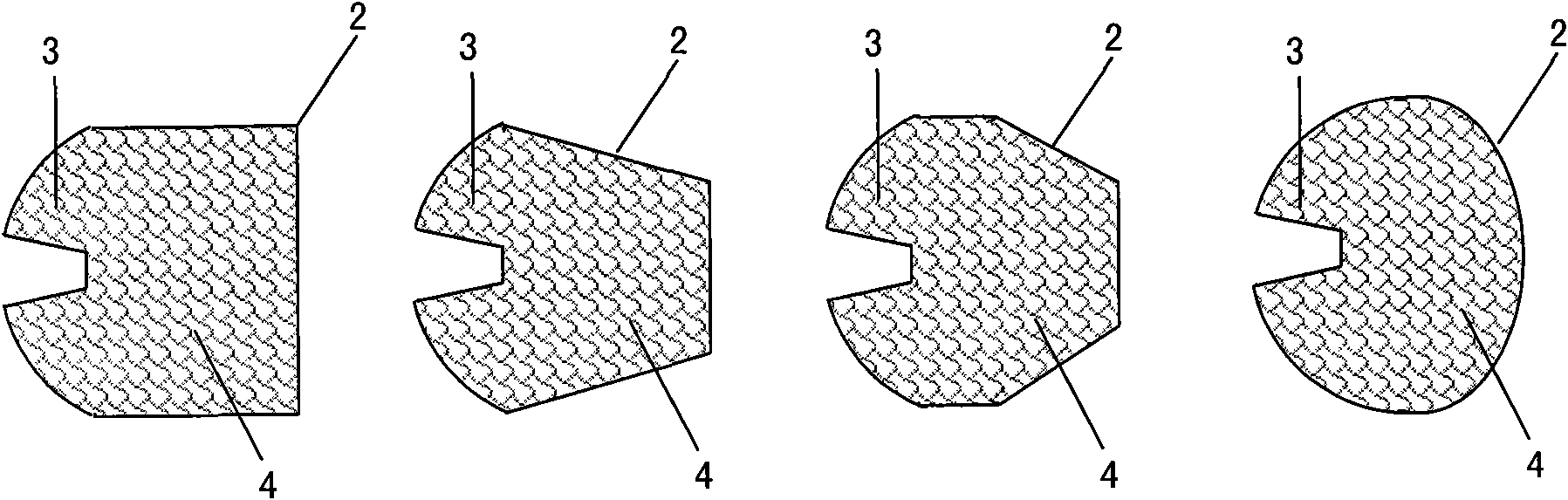

Rear-embedded film bag-type umbrella-shaped expansion tip used for pre-reaming and construction method thereof

PendingCN109518690AQuality improvementLow costExcavationsBulkheads/pilesEngineeringUltimate tensile strength

The invention discloses a rear-embedded film bag-type umbrella-shaped expansion tip used for pre-reaming and a construction method thereof. The rear-embedded film bag-type umbrella-shaped expansion tip used for pre-reaming comprises an umbrella-shaped expansion body device, a plurality of anchor bars penetrating through the umbrella-shaped expansion body device and a grouting pipe II. The umbrella-shaped expansion body device is sleeved with a film bag. A grout outlet of the grouting pipe is located in the film bag. A bar drawing disc, an umbrella-shaped folding rod set and a bar penetration disc are sequentially arranged in the umbrella-shaped expansion body device from front to back. By adoption of the rear-embedded film bag-type umbrella-shaped expansion tip used for pre-reaming and a construction method thereof, the problems that the work of rotary-jetting hole cleaning in a hard clay bed is complex and high in labor and machine consumption, mud in fractures of fracture-developed rock mass flows back into the umbrella-shaped expansion tip and consequentially affects the elements and strength of a grouting consolidated body, and the construction efficiency is reduced due to theadoption of the umbrella-shaped tip technique and the rotary jetting technique for drilling and reaming and synchronous carrying of the umbrella-shaped expansion tip are solved.

Owner:刘晓理

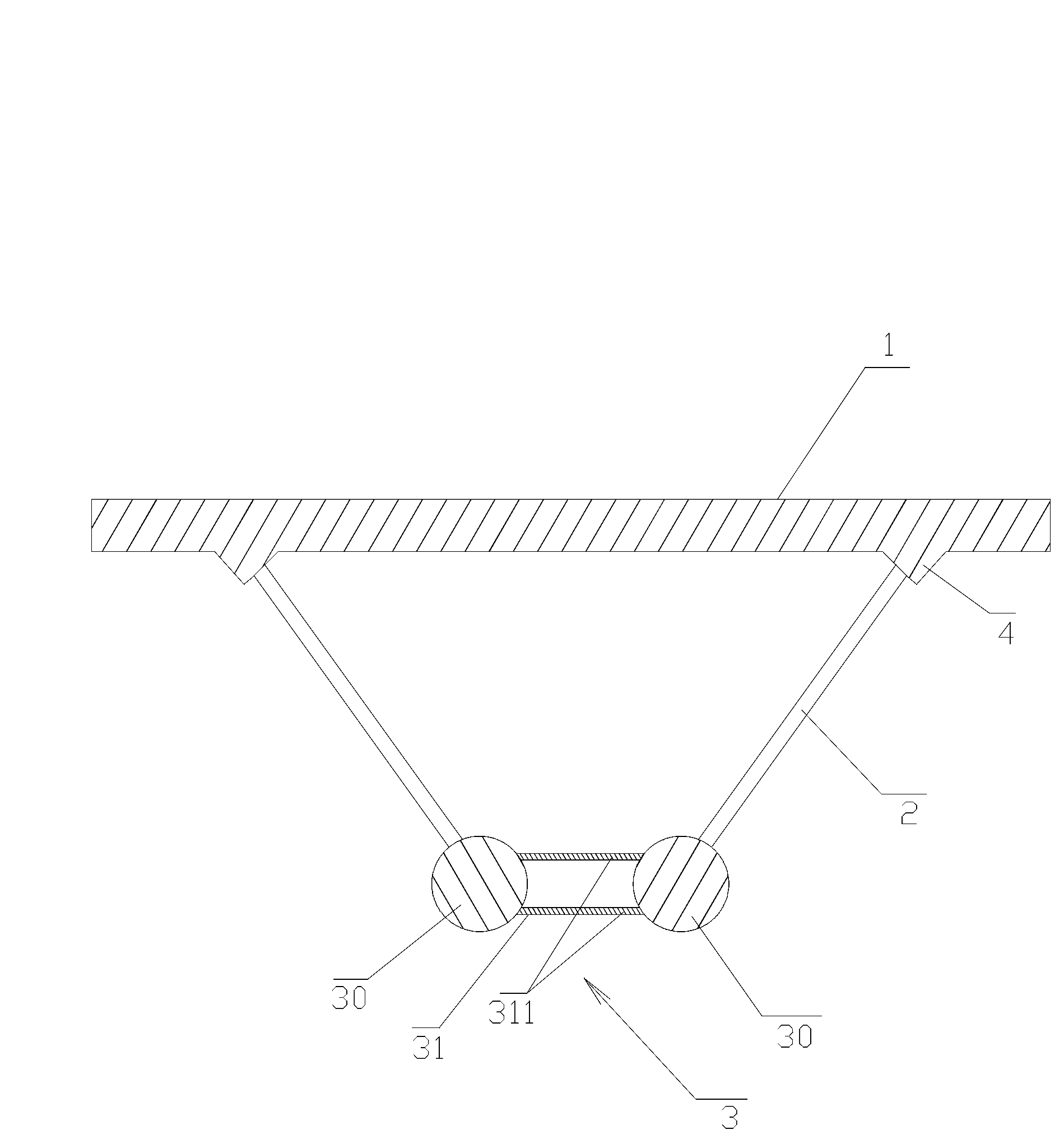

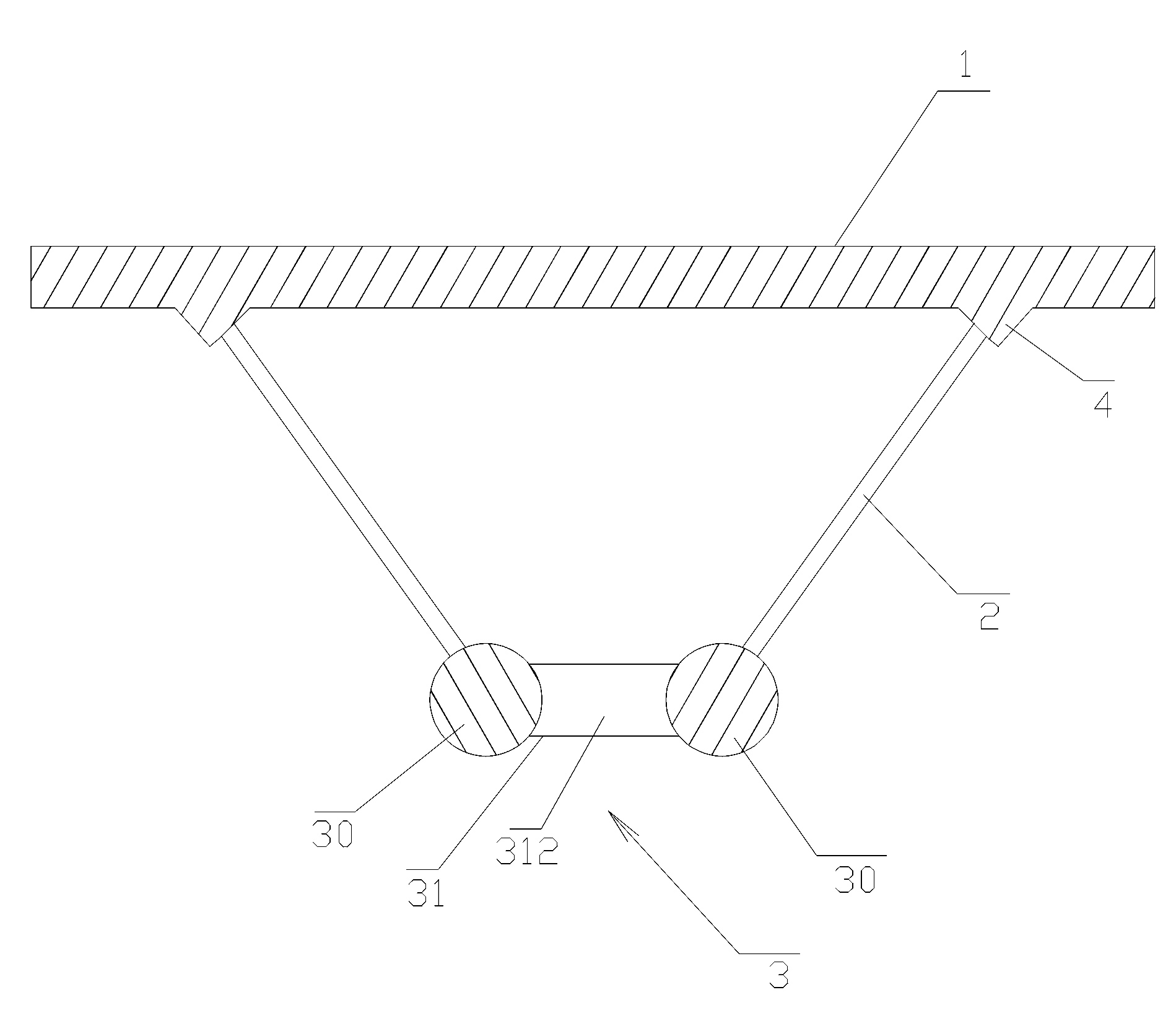

Multi-chord combined beam structure

ActiveCN102140777AIncrease stiffnessImprove bearing capacityBridge structural detailsReinforced concreteRebar

The invention discloses a multi-chord combined beam structure. A multi-chord combined beam mainly comprises a reinforced concrete top plate, a corrugated steel web and a chord bottom plate, wherein the reinforced concrete top plate is connected with one end of the corrugated steel web through a shear-resistant connecting piece; the other end of the corrugated steel web is connected and fixed to the chord bottom plate; the chord bottom plate consists of at least two chords of which the extending direction is the same as that of the reinforced concrete top plate and which are parallel to each other; and the chords are connected through a connecting piece. By the multi-chord combined beam structure in the embodiment of the invention, the rigidity and ultimate bearing capacity of the multi-chord combined beam are greatly improved, and the multi-chord combined beam has high deformation resistance and ductility; and the chord bottom plate is convenient to construct and subsequently maintaindue to a large operation space.

Owner:SHENZHEN MUNICIPAL DESIGN & RES INST +1

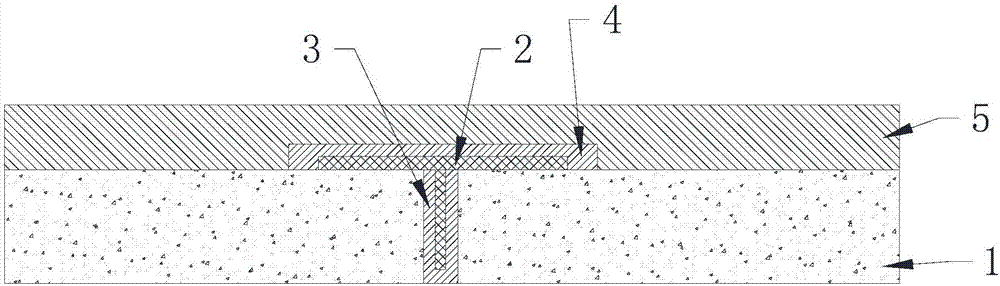

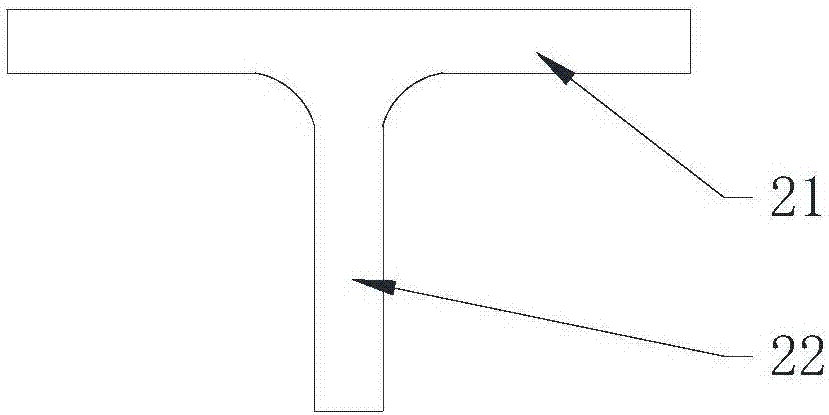

Anti-reflection crack asphalt pavement structure and construction method thereof

The invention discloses an anti-reflection crack asphalt pavement structure and a construction method thereof. The anti-reflection crack asphalt pavement structure is paved on the surface of a roadbase with cracks. The anti-reflection crack asphalt pavement structure comprises a T-shaped reinforcing part and an asphalt joint sealing material layer filling the cracks. The T-shaped reinforcing part comprises a transverse plate piece and a vertical plate piece arranged in the middle along the width direction of the lower surface of the transverse plate piece; the vertical plate piece of the T-shaped reinforcing part is embedded into and fixed in the asphalt joint sealing material layer and the lower surface of the transverse plate piece is adhered and fixed to the surface of each roadbase on each side of the crack; the asphalt pavement structure also comprises an asphalt coating and an asphalt concrete surface layer covering the asphalt coating. The asphalt coating coats the surface of a combination formed by adhering the roadbase and the T-shaped reinforcing piece. The structure disclosed by the invention has the advantages of good stability and high anti-reflection crack ability and the service life of the pavement can be prolonged effectively.

Owner:广东金长成桥梁隧道科技有限公司

Arrangement method of ecological gabion chamber revetment type

InactiveCN102704441ARestoring Biodiversity TraitsRestoring Diversity TraitsCoastlines protectionReceptacle cultivationRiver routingEngineering

The invention relates to an arrangement method of an ecological gabion chamber revetment type, and belongs to a revetment structure type in river training works. A stepped sandstone cushion layer is laid on the revetment of a river; a sinuous ecological gabion chamber is arranged on the stepped sandstone cushion layer; and plants are planted in the sinuous ecological gabion chamber. The arrangement method has the advantages of novel structure, reliable operation, wide application range, capabilities of improving the engineering safety and favorably improving water eco-environments of rivers and lakes and great application prospect.

Owner:CHINA WATER NORTHEASTERN INVESTIGATION DESIGN & RES

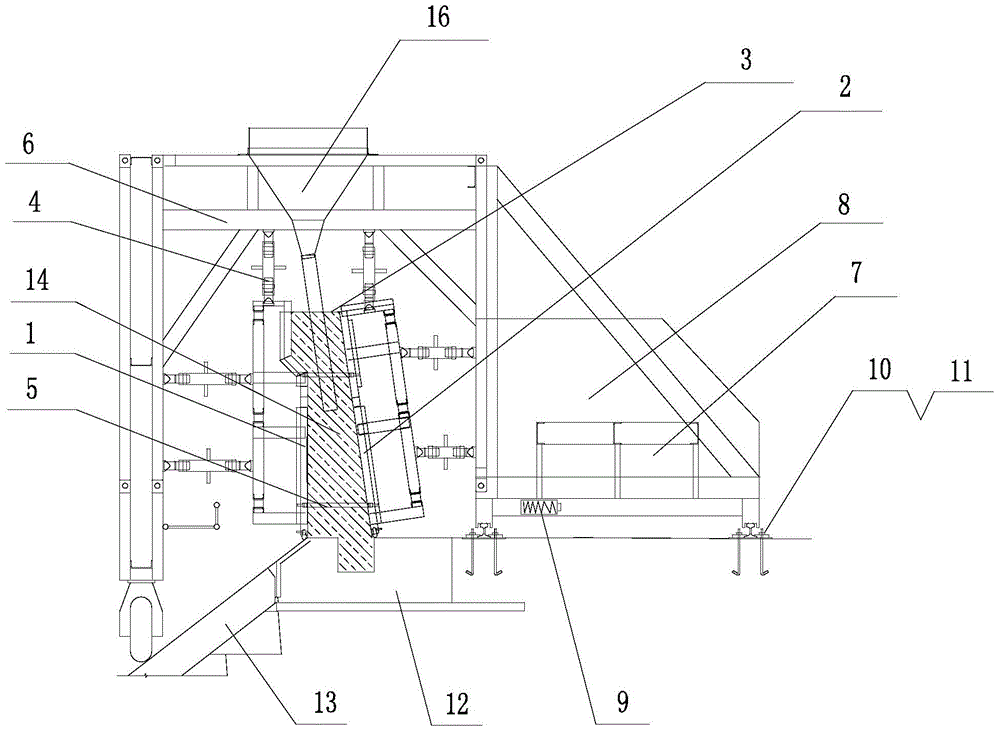

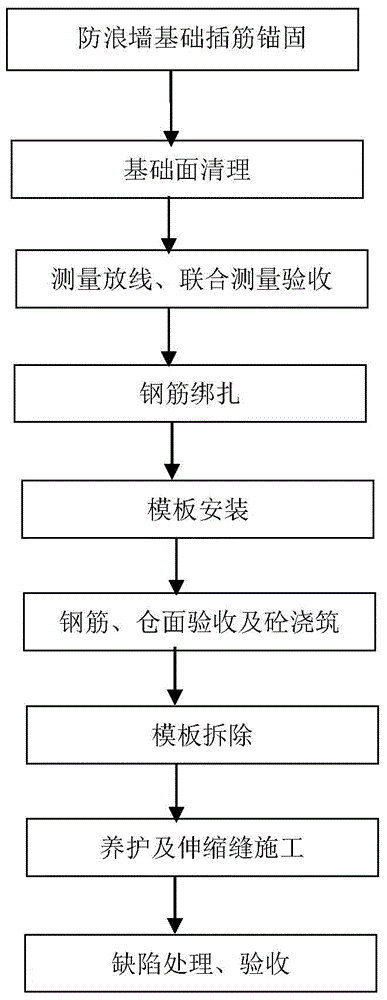

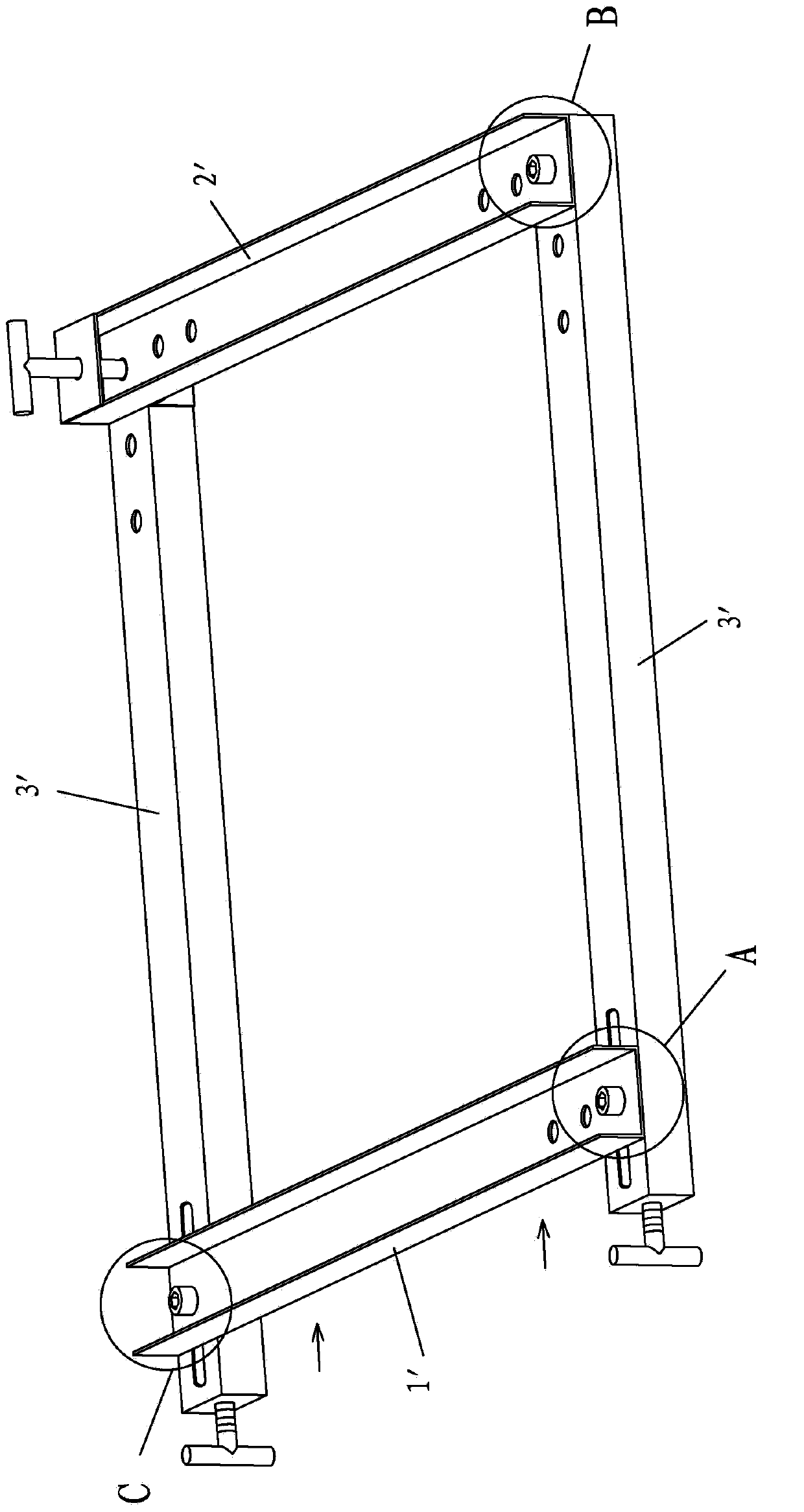

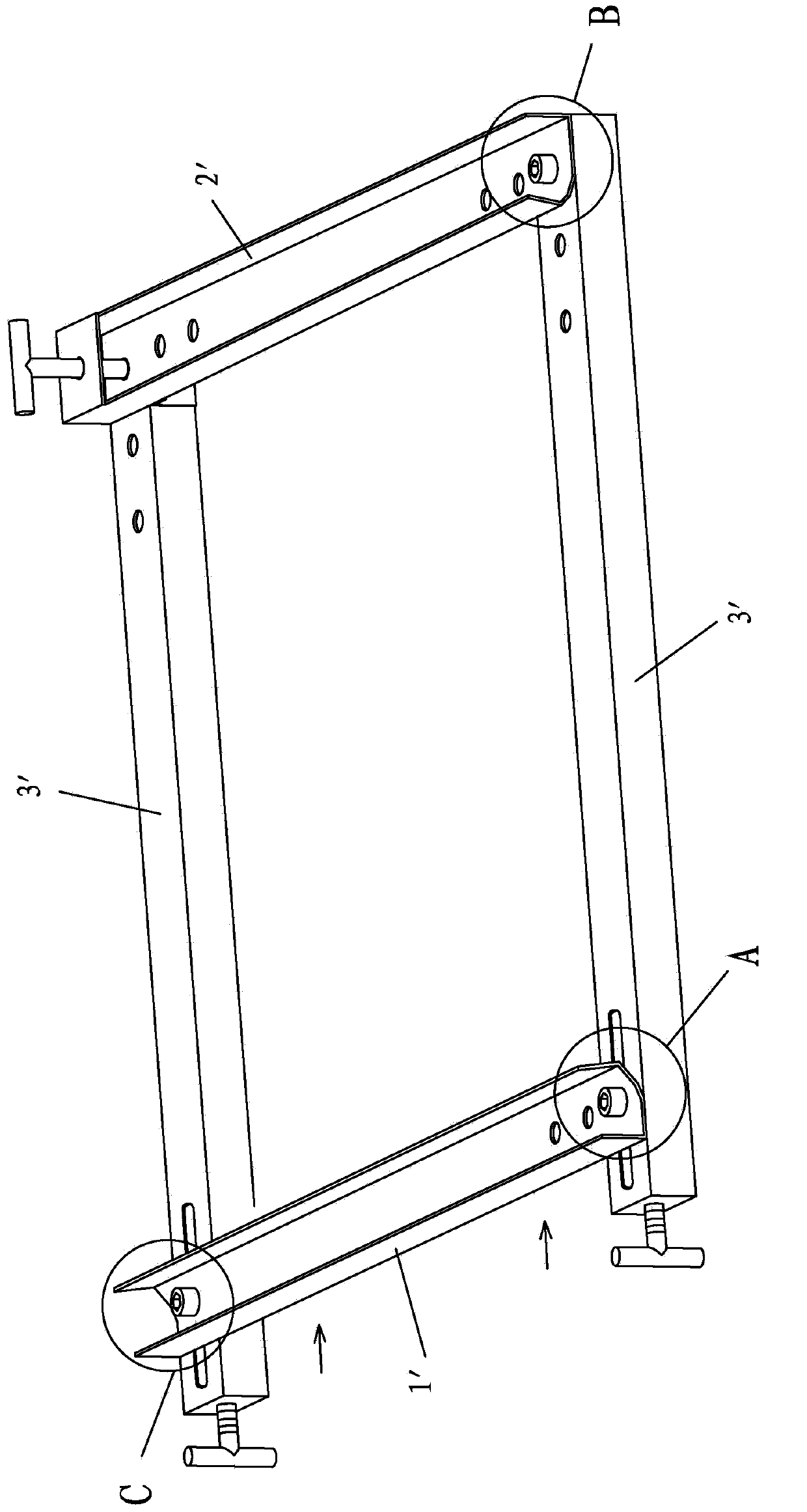

Quick formwork erecting construction method for cast-in-place wave wall

InactiveCN105178244AGood overall rigidityStrong deformation resistanceBreakwatersQuaysRebarSupport system

The invention provides a quick formwork erecting construction method for a cast-in-place wave wall. According to the method, a base of the wave wall is cast and then a special casting device is used for erecting a formwork for a wall body and casting the wall body. The method includes the following steps that firstly, insertion ribs are anchored to the cast base; secondly, a foundation face is cleaned; thirdly, a measuring line is released out of a start pile of a branch bin of the wave wall body; fourthly, a bound reinforcing steel bar net of the wave wall body is fixed to the anchored insertion ribs; fifthly, the formwork is installed through a shaping formwork system of the special casting device; sixthly, the wave wall body is cast through a sequential construction method; seventhly, the formwork is detached; eighthly, a curing agent is sprayed after the formwork is detached; and ninthly, defects are repaired. By the adoption of the method, the formwork installation procedure is simplified, the problems that a formwork supporting system can hardly be erected on the upstream face and a working face is not available are solved, operation is easy and convenient, the concrete quality is good, concrete sequential construction is performed, an engineering construction period is shortened, engineering cost is reduced, the labor intensity of workers is relieved, and potential safety hazards are eliminated.

Owner:SINOHYDRO BUREAU 7 CO LTD

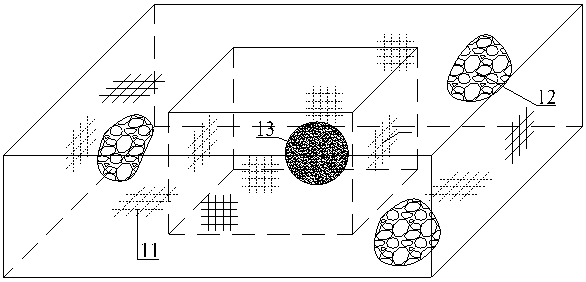

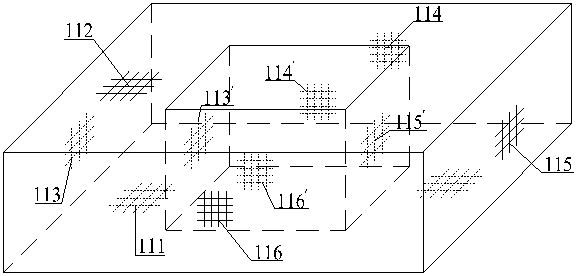

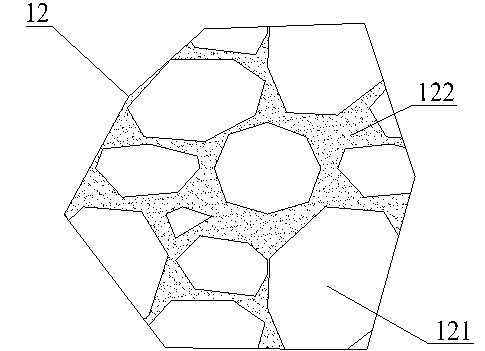

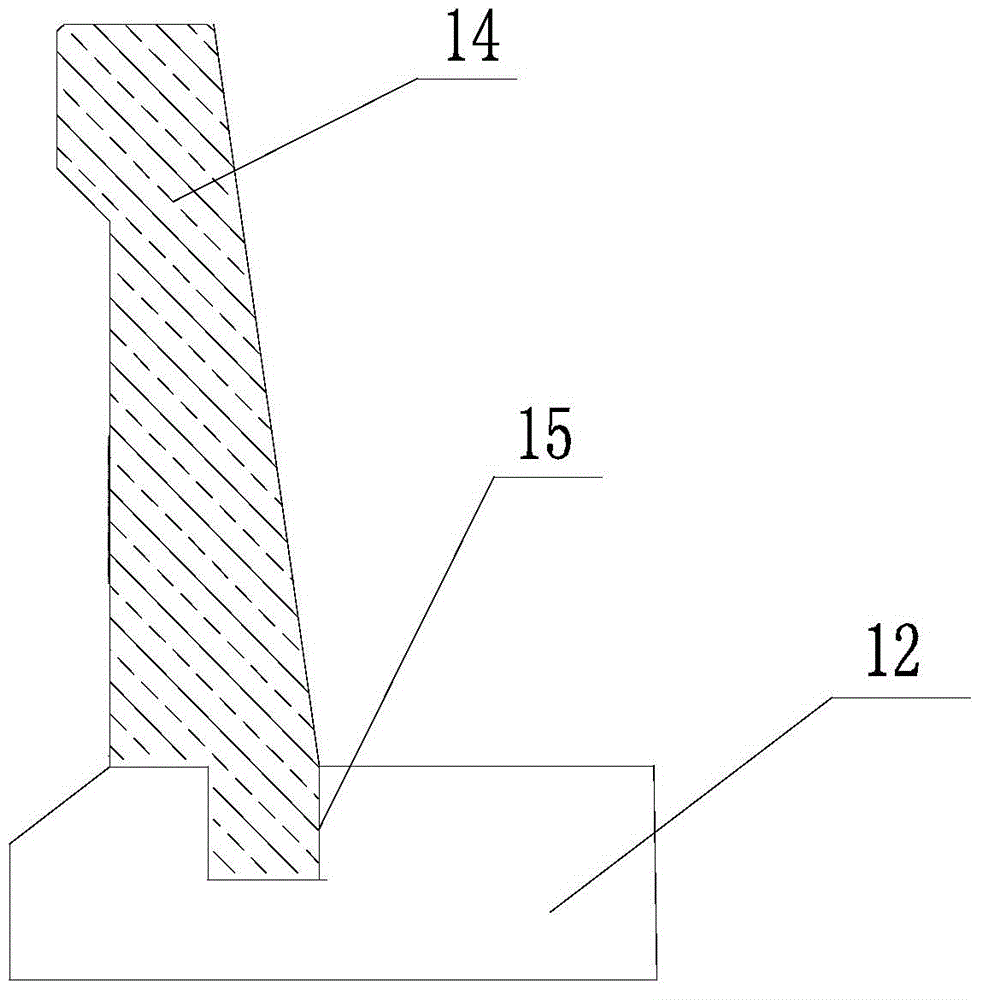

Anti-collision method of ship made of composite materials and hull structure

ActiveCN101898621AImprove protectionImprove rigidityVessel cleaningHull partsHull structureMarine engineering

The invention discloses an anti-collision method of a ship made of composite materials and a hull structure. The invention is mainly characterized in that sandwich plates (12) made of the composite materials are used as the outer walls of the hull, an integrated anti-collision bulwark (1) is adopted, the hull is in a 'cage type' structure, annular reinforced ribs are arranged on the side surfaces of the hull, and an energy-absorbing bow is adopted. The hull structure has the characteristics of light weight and high strength, and simultaneously, the overall anti-collision performance of the ship made of the composite materials is effectively improved through the comprehensive anti-collision structure design. When the ship has a collision on a front surface or a side surface, the comprehensive passive safety protection hull structure provided by the invention can effectively buffer an impact force caused by the collision of the ship, has good energy-absorbing effect and strong anti-deformation capacity, and is favorable for preventing or reducing casualties and property loss caused by the collision of the ship. The invention is especially suitable for the anti-collision design of the ship made of composite materials and has better application and popularization prospects.

Owner:SHENZHEN HISPEED BOATS TECH

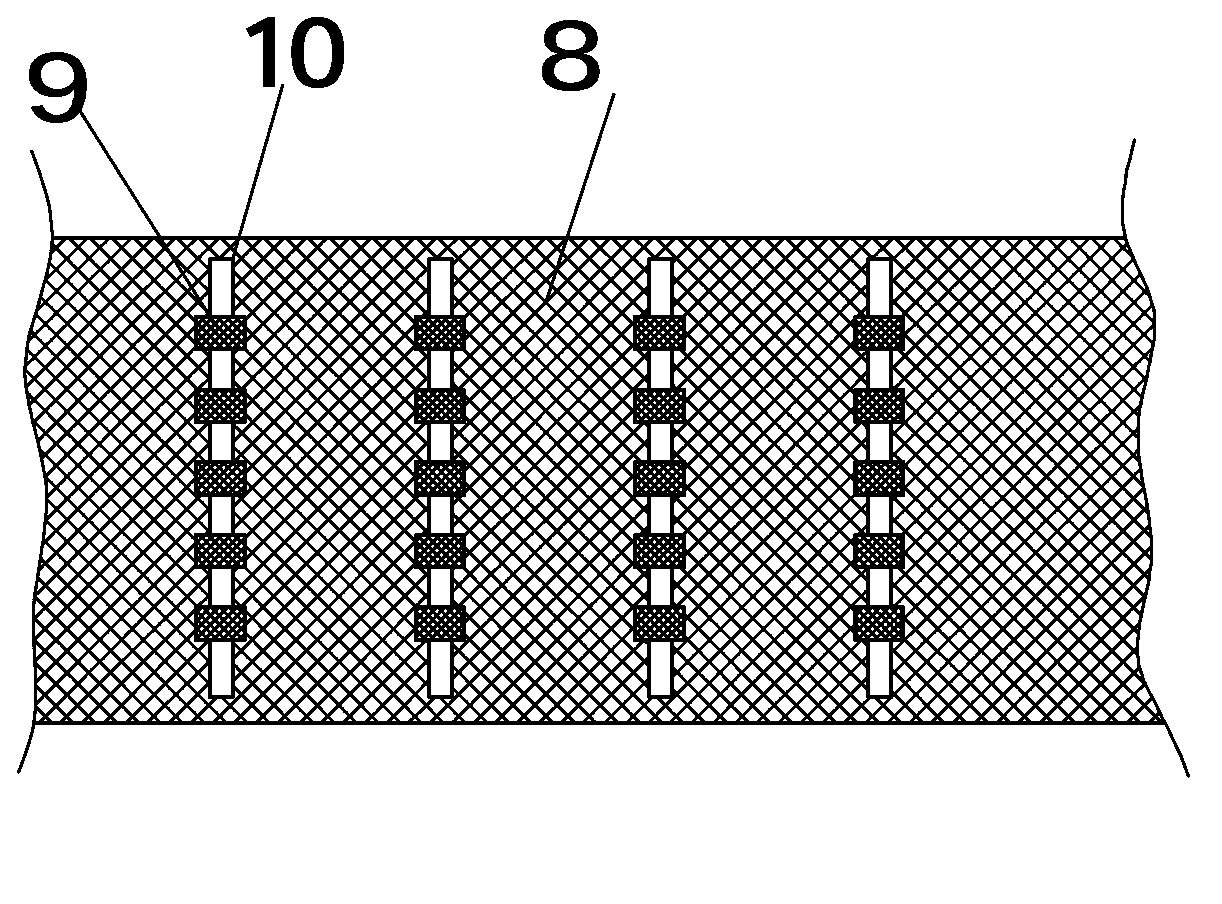

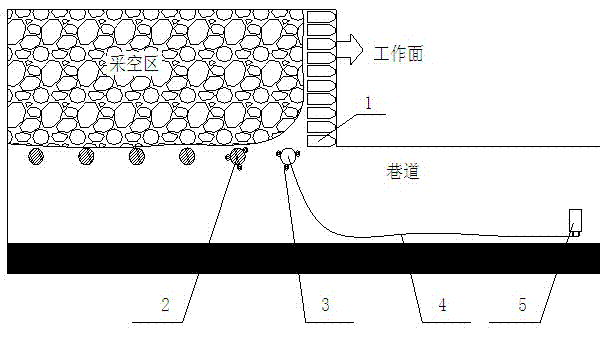

Gob-side entry retaining method using high-water material filling columns

InactiveCN102852551AAuxiliary transport volume is smallEasy constructionMaterial fill-upFilling materialsSlurry

A gob-side entry retaining method using high-water material filling columns belongs to the field of mine supports. With advancing of actual mining working faces, filling column structures are produced near end hydraulic supports at designed intervals, and two to three single hydraulic supports are fixed on the periphery of each filling column structure to assist forming of filling columns; and evenly-mixed high-water material slurry is filled into constructed filling column structures, and the single hydraulic supports are removed 4 hours after the filled slurry solidifies to finish construction of the filling columns. Road-side supports are formed by the filling columns in a row, the roadway is retained, and gob-side entry retaining is achieved. By the method, a huge amount of filling materials is saved, downhole auxiliary transport amount is low, and cost is low. The constructed filling columns are simple in construction and high in bearing capacity. An operator can operate below a top plate supported by bolt-mesh-cable in the roadway without entering a gob, and accordingly safety and reliability are high.

Owner:CHINA MINING & CIVIL NEW MATERIAL SCI & TECH LTD

Anti-pitting abrasion-resistant oil pipe and manufacture thereof

InactiveCN1439838ATemperature resistantAnti-stressCorrosion preventionSolid state diffusion coatingHigh resistanceChemical plating

An antiwear oil pipe resisting tubercular corrosion is prepared through pretreating oil pipe, gas-phase nitrifying to form the ferric nitride or carbon-contained ferric nitride on the surface of oil pipe, activating, washing, chemical plating a sacrificial anode type protecting layer, and post-treating. Its advnatages are high surface hardness and high resistance to tubercular corrosion, high temp. compression and deformation.

Owner:ZHEJIANG UNIV

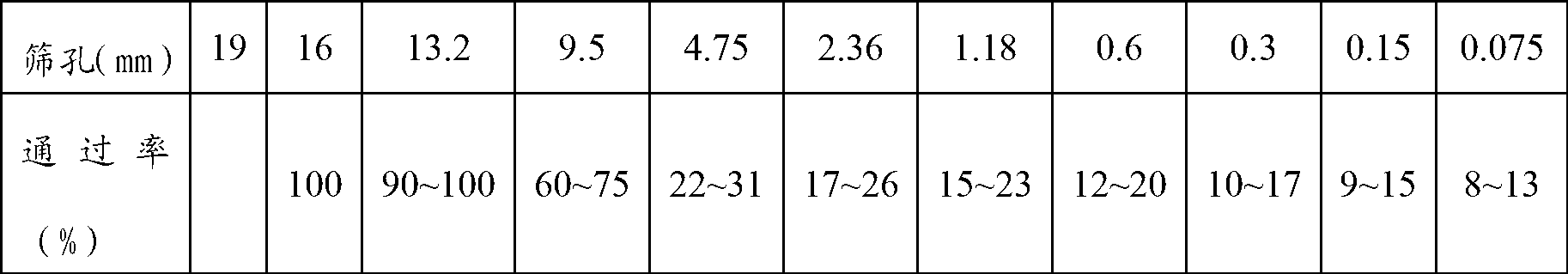

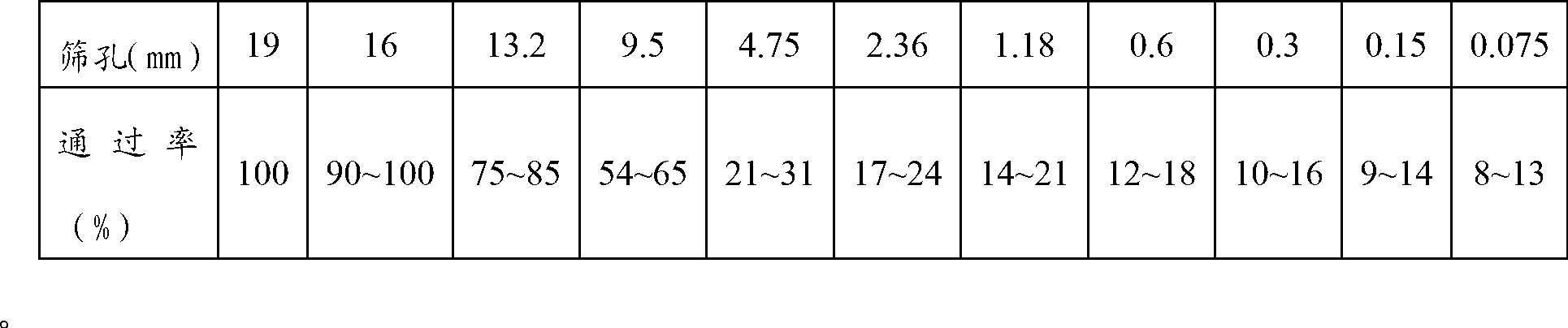

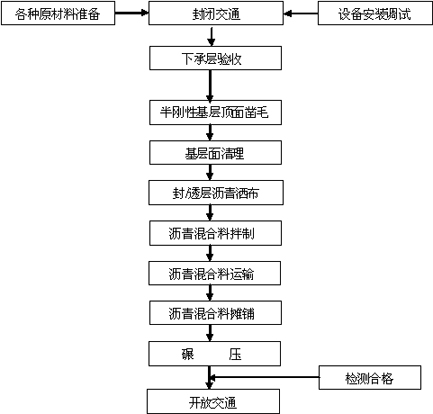

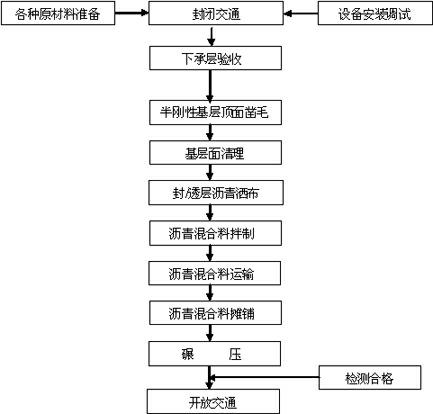

Asphalt-treated permeable-base (ATB) construction process

The invention relates to an asphalt-treated permeable-base (ATB) construction process. The ATB construction process is characterized in that: each raw material is obtained in a way that: coarse aggregate comprises crushed limestone produced by an impact crusher, fine aggregate comprises the crushed limestone with the particle sizes of less than 2.36mm, and a filler is produced by levigating hydrophobic stones such as highly-basic rocks and the like in limestone or magmatite; the asphalt distribution of a prime coat is 0.6 to 1.2 L / m<2>, and the asphalt distribution of a seal coat is 0.8 to 1.0 L / m<2>; when an asphalt mixture is mixed, asphalt is heated at the temperature of 155 to 165 DEG C, the mineral aggregate is heated at the temperature of 170 to 190 DEG C, the mixture is produced at the temperature of 155 to 170 DEG C, and reduction in the mixture storage temperature is not more than 10 DEG C; when the asphalt mixture is transported and charged, a vehicle is required to be moved forwards and backwards to realize balanced charging, and the temperature of the mixture is not lower than 150 DEG C when arriving at a pavement site; the temperature of an asphalt mixture paver screed is not lower than 80 DEG C, and the mixture is paved at the temperature of not lower than 140 DEG C at the pavement speed of 3 to 5 m / min; and rolling compaction is performed by three rolling compaction stages. The ATB construction process is simple and convenient to construct, and ensures relatively lower cost and high performance.

Owner:CCCC SHEC DONGMENG ENG CO LTD

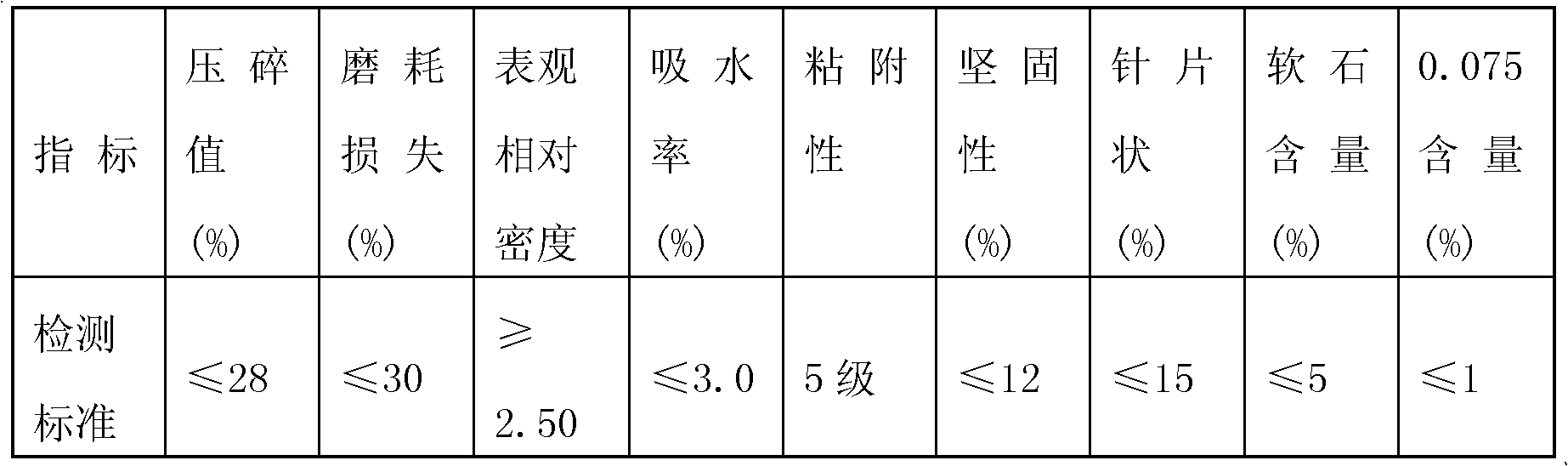

Quick insertion clamping frame of concrete blinding and method for clamping concrete blinding

The invention discloses a quick insertion clamping frame of concrete blinding. The clamping frame comprises a first square pipe, a second square pipe, a third square pipe and a fourth square pipe which are inserted and connected together in sequence to form a square frame shape. The invention further discloses a method for clamping the concrete blinding with the above clamping frame. Since the first square pipe, the second square pipe, the third square pipe and the fourth square pipe are mutually inserted and connected together to form the square frame, the clamping frame is convenient and quick in dismounting and mounting. The clamping frame can be dismounted to be pieces when not in use, so the clamping frame does not occupy large space and is convenient to carry, and square pipe structure is higher than a U-steel in non-deformability. The square pipes are mutually inserted and connected during pouring and do not bend and distort due to pressing of mortar in the concrete blinding. The concrete blinding do not incline outwardly, shape and size of a post formed by pouring is close to a set size, and furthermore, piecing clearances between neighboring concrete blinding do not crack too much, the mortar in the concrete blinding does not flow out along the piecing clearances, and accordingly trouble of cleaning the mortar is omitted.

Owner:富于安(福建)环保模版有限公司

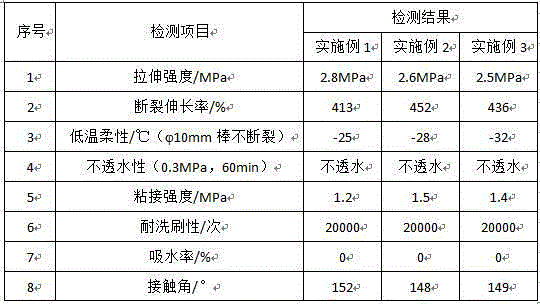

Fumed silica modified acrylate waterproof paint, and preparation method thereof

The invention provides a fumed silica modified acrylate waterproof paint. The fumed silica modified acrylate waterproof paint comprises, by weight, 40 to 50 parts of a polymer emulsion, 20 to 30 parts of modifying fumed silica, 0.2 to 0.6 part of a wetting dispersant, 0.2 to 0.5 part of an antifoaming agent, 0.1 to 0.2 part of a preservative, 0.2 to 0.5 part of a thickening agent, 5 to 10 parts of kaoline, 20 to 30 parts of heavy calcium carbonate powder, 2 to 5 parts of titanium dioxide powder, and 1 to 5 parts of water. Acrylate waterproof paint water resistance is improved greatly, water absorption rate is reduced, waterproofing is realized at 0.3MPa in 60min, and water absorption rate is zero.

Owner:WEIFANG HONGYUAN WATERPROOF MATERIAL

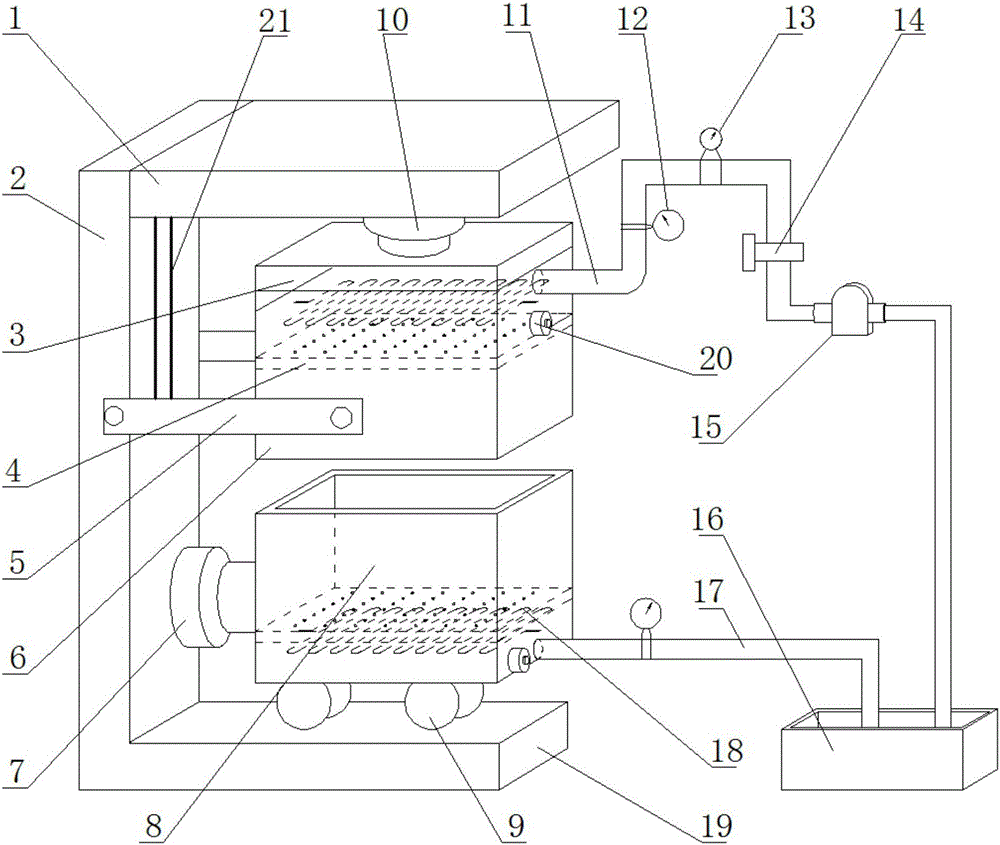

Rock and earth mass shear apparatus taking water-rock interaction into consideration

InactiveCN106442169AHigh strengthStrong resistance to deformationMaterial strength using steady shearing forcesInlet valveWater circulation

The invention provides a rock and earth mass shear apparatus taking water-rock interaction into consideration. Porous plates are arranged in an upper shear box and in a lower shear box respectively. An inner cavity of the upper shear box is divided into an action cavity and a shear cavity by the corresponding porous plate, and an inner cavity of the lower shear box is divided into an action cavity and a shear cavity by the corresponding porous plate. The action cavities are closed cavities and close to the bottoms of the boxes, the shear cavities are open cavities and close to the openings of the boxes. A dry-wet circulation system comprises a water tank, a water pump, a water inlet pipe, a backflow pipe, a flow meter, a water inlet valve, a pressure adjusting valve and two sets of electric heating wires with insulating sleeves. The water inlet pipe is communicated with the action cavity of the upper shear box, the backflow pipe is communicated with the action cavity of the lower shear box, the water inlet pipe, the upper shear box, the lower shear box, the backflow pipe and the water tank form a water circulation loop, and the two sets of electric heating wires with the insulating sleeves are installed in the action cavity of the upper shear box and the action cavity of the lower shear box respectively. The upper shear box and the lower shear box are transformed, early stage treatment is conducted on an installed rock sample under different conditions, interference caused by repeatedly detachment of the rock sample is avoided, and influence factor analysis is conveniently carried out on the rock sample in the testing process.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com