Patents

Literature

235results about How to "Consider performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Optimization of channel equalizer

InactiveUS6954495B2Improve channel performanceImprove performanceMultiple-port networksError preventionWeight coefficientRadio receiver

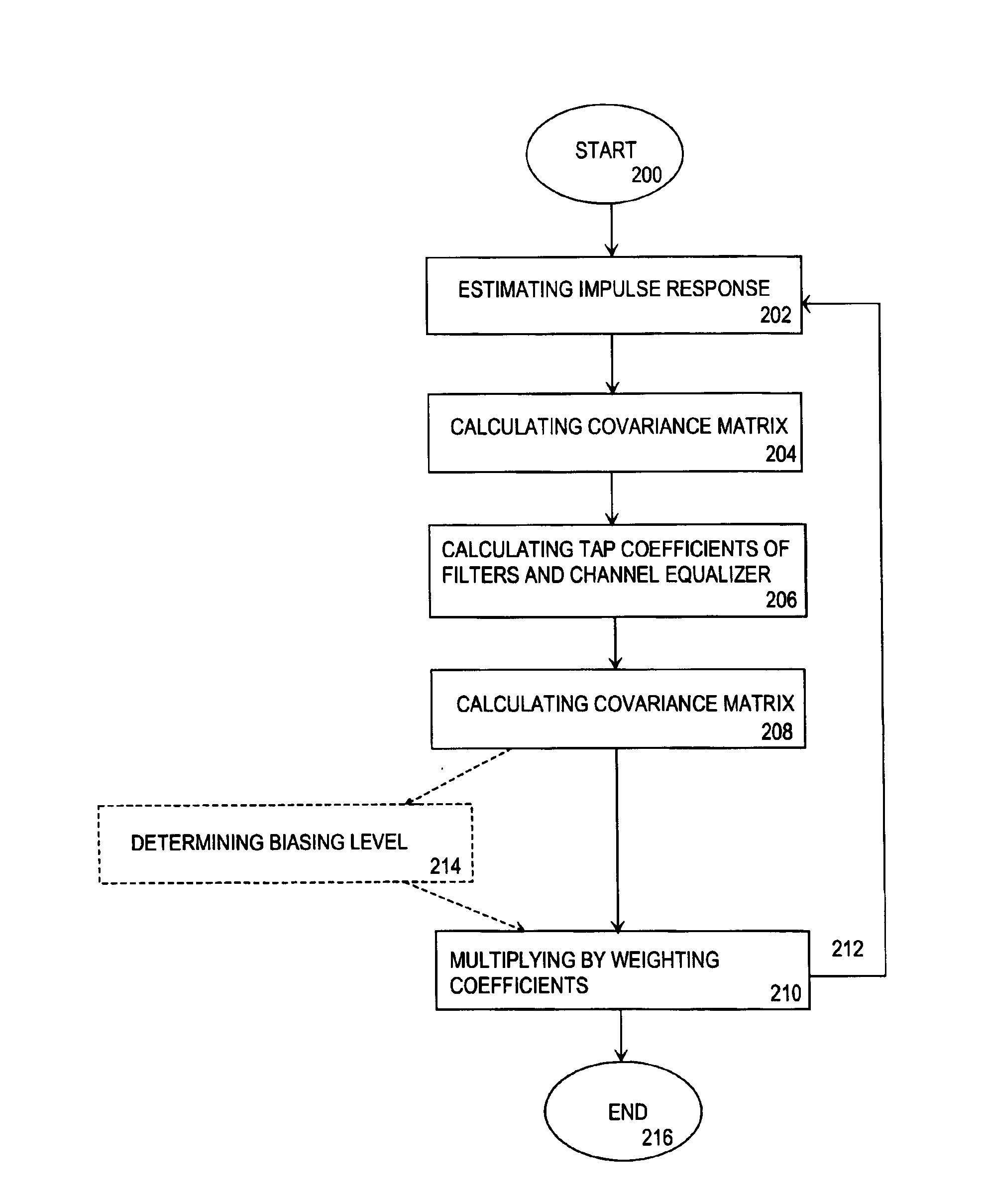

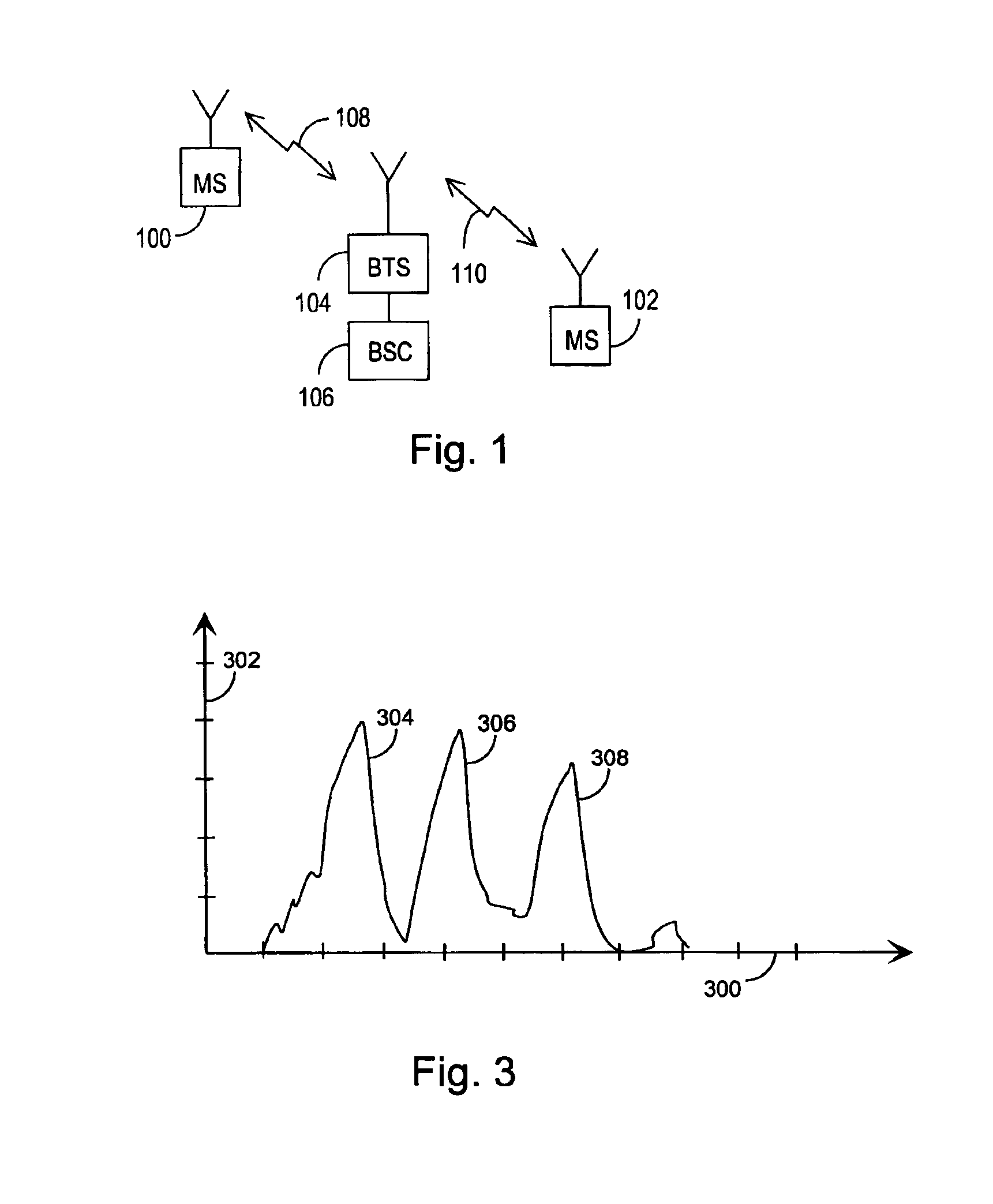

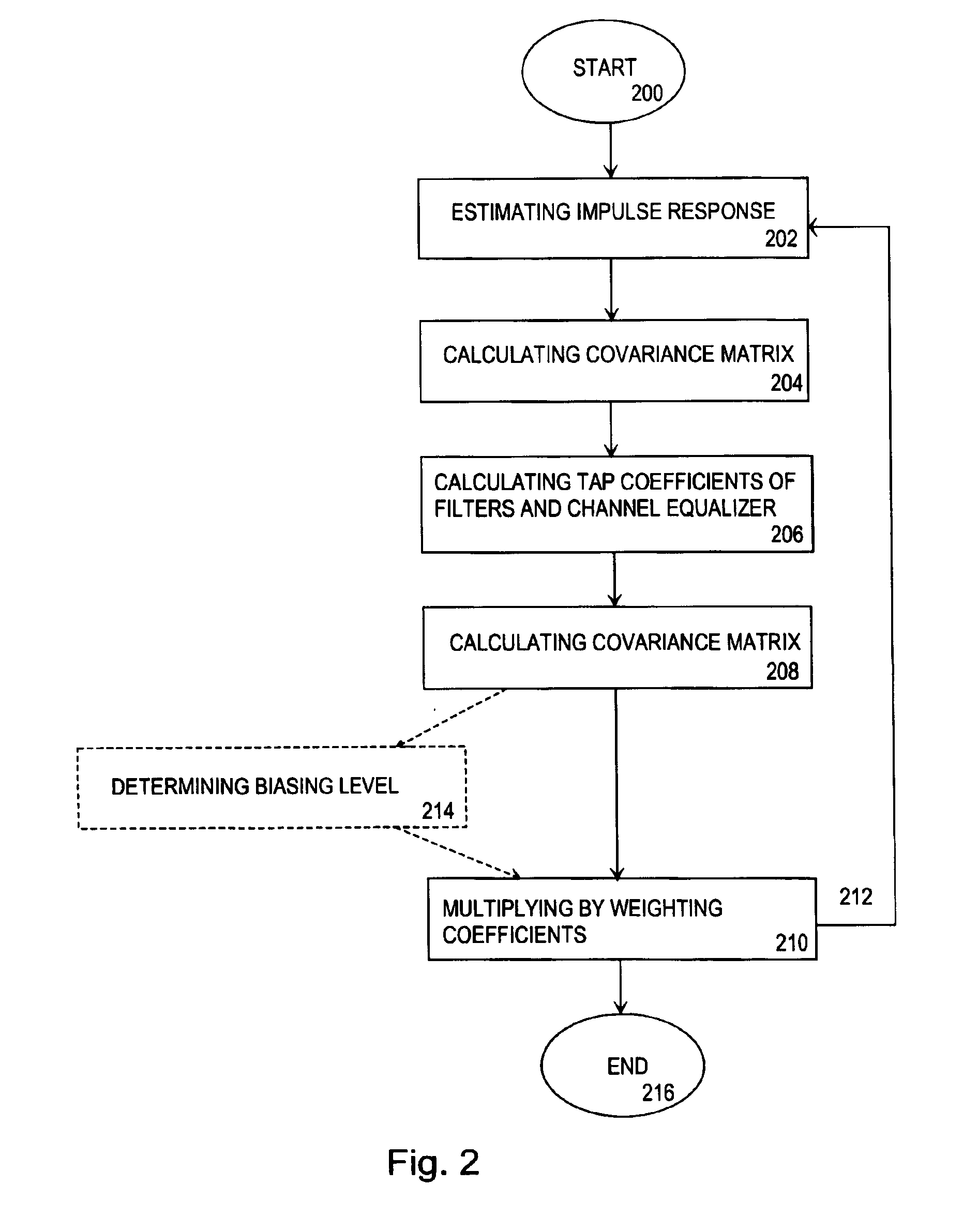

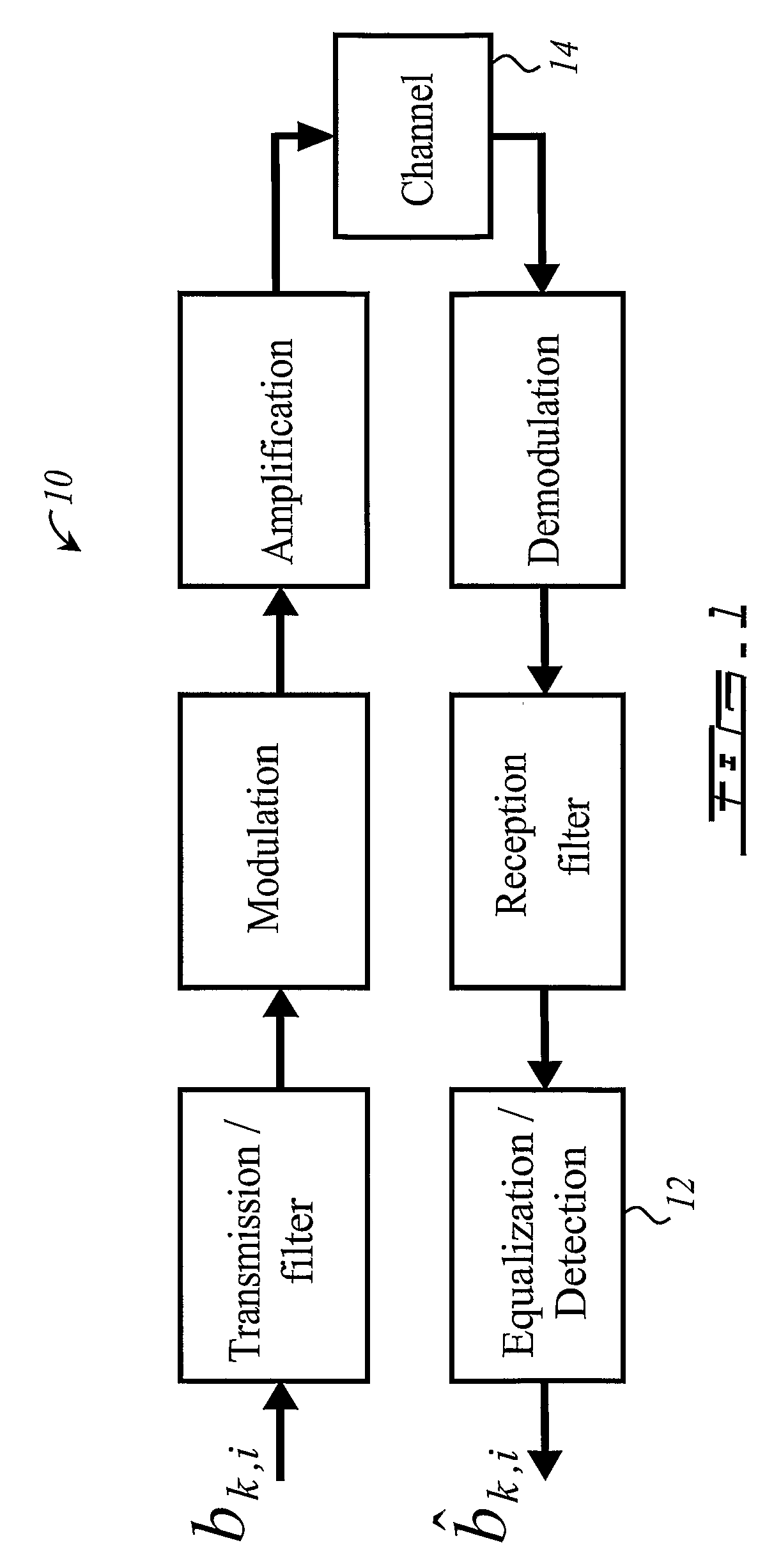

A method for carrying out channel equalization in a radio receiver wherein an impulse response is estimated, noise power is determined by estimating a co-variance matrix of the noise contained in a received signal before prefiltering, and tap coefficients of prefilters and an equalizer are calculated. The method comprises determining the noise power after prefiltering by estimating a noise covariance matrix, after which input signals of the channel equalizer are weighted by weighting coefficients obtained from the noise covariance estimation.

Owner:NOKIA CORP

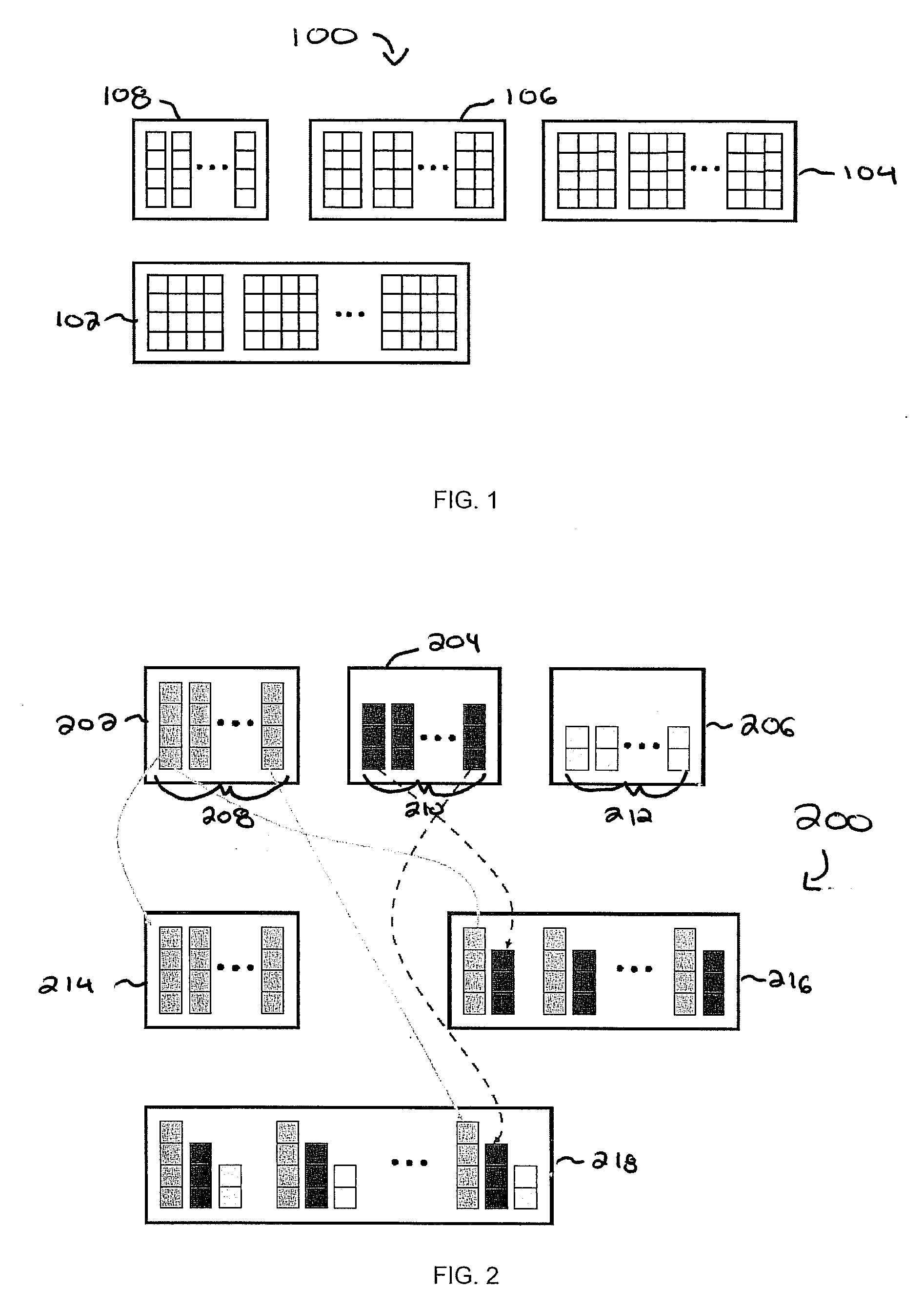

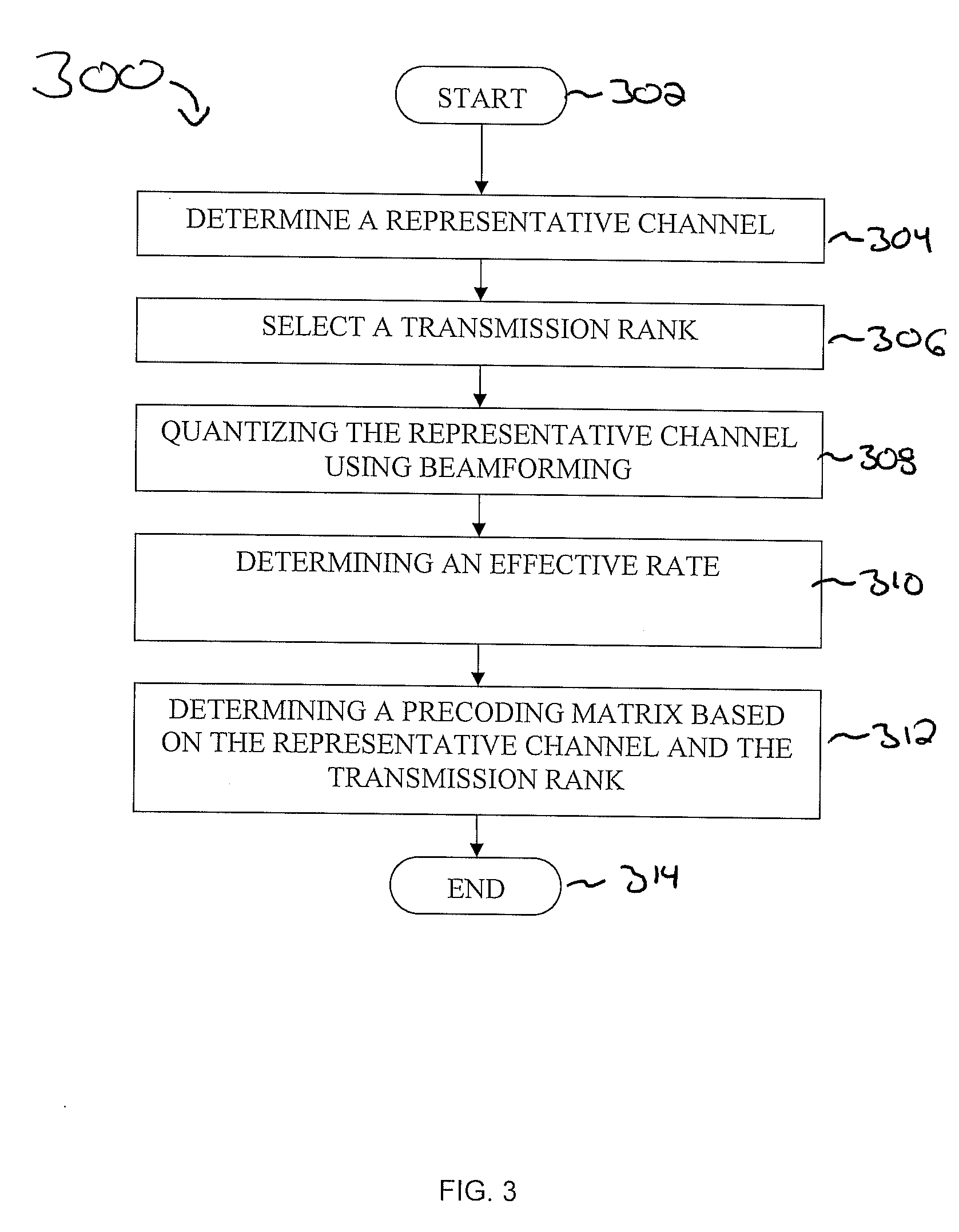

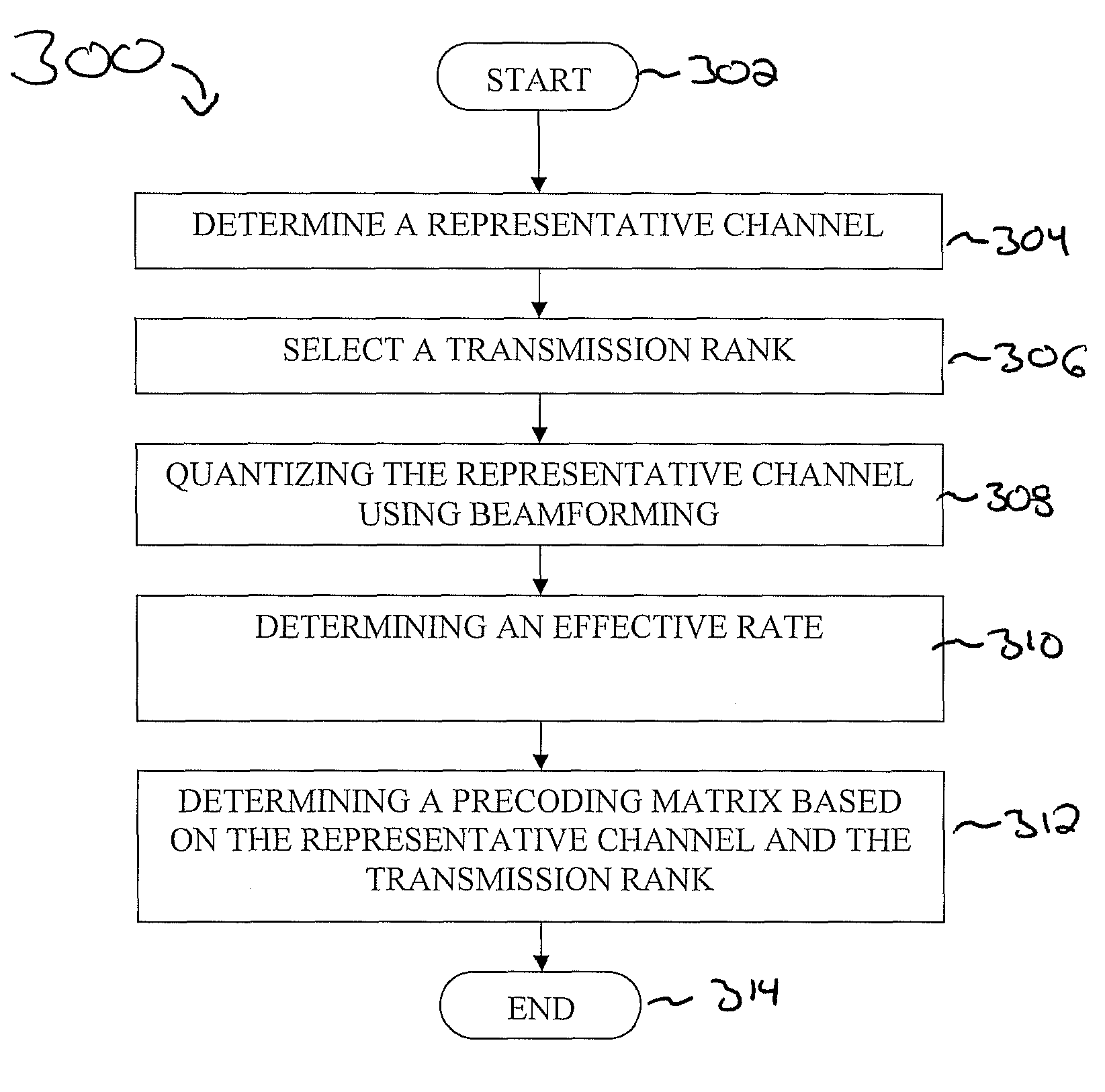

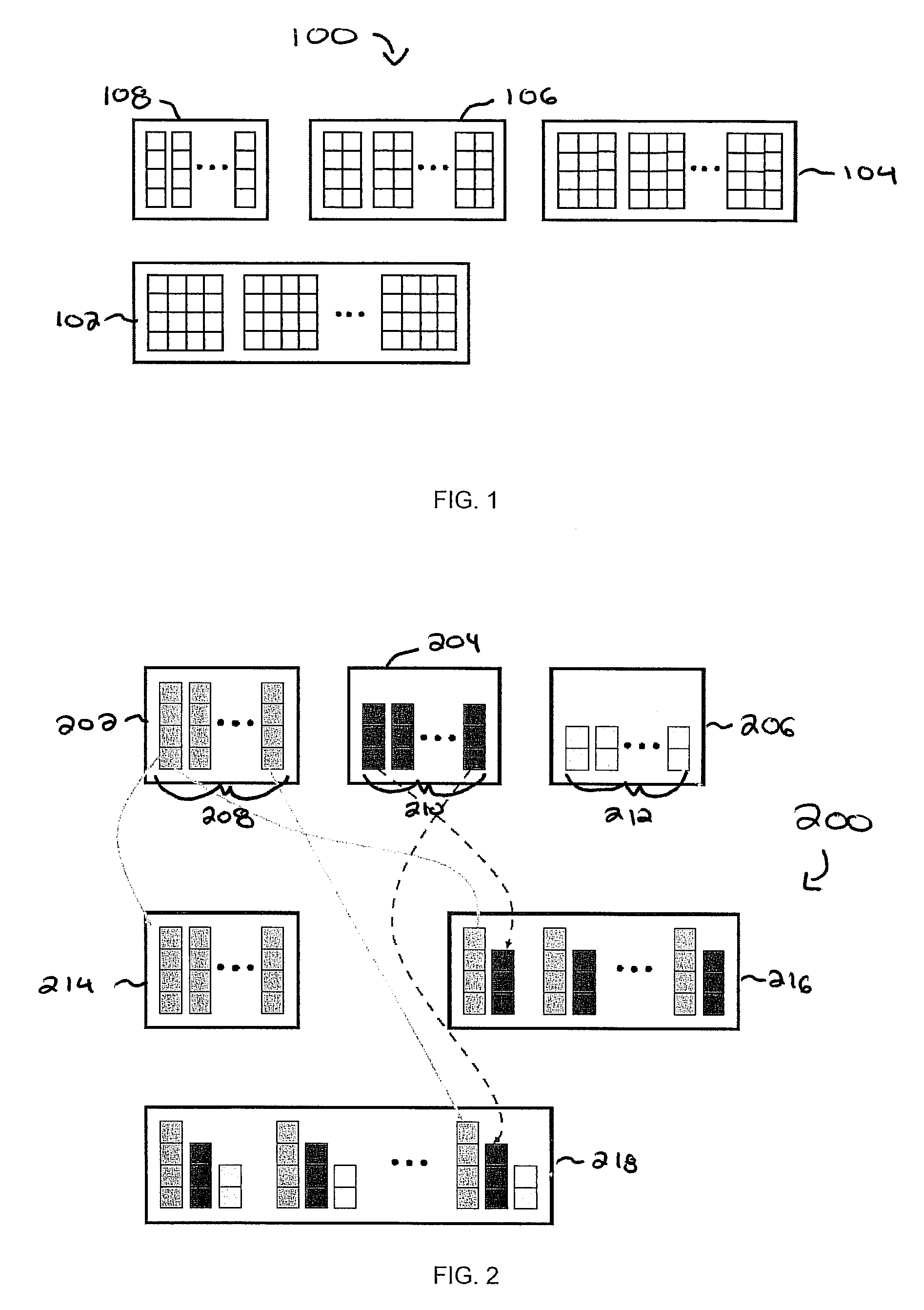

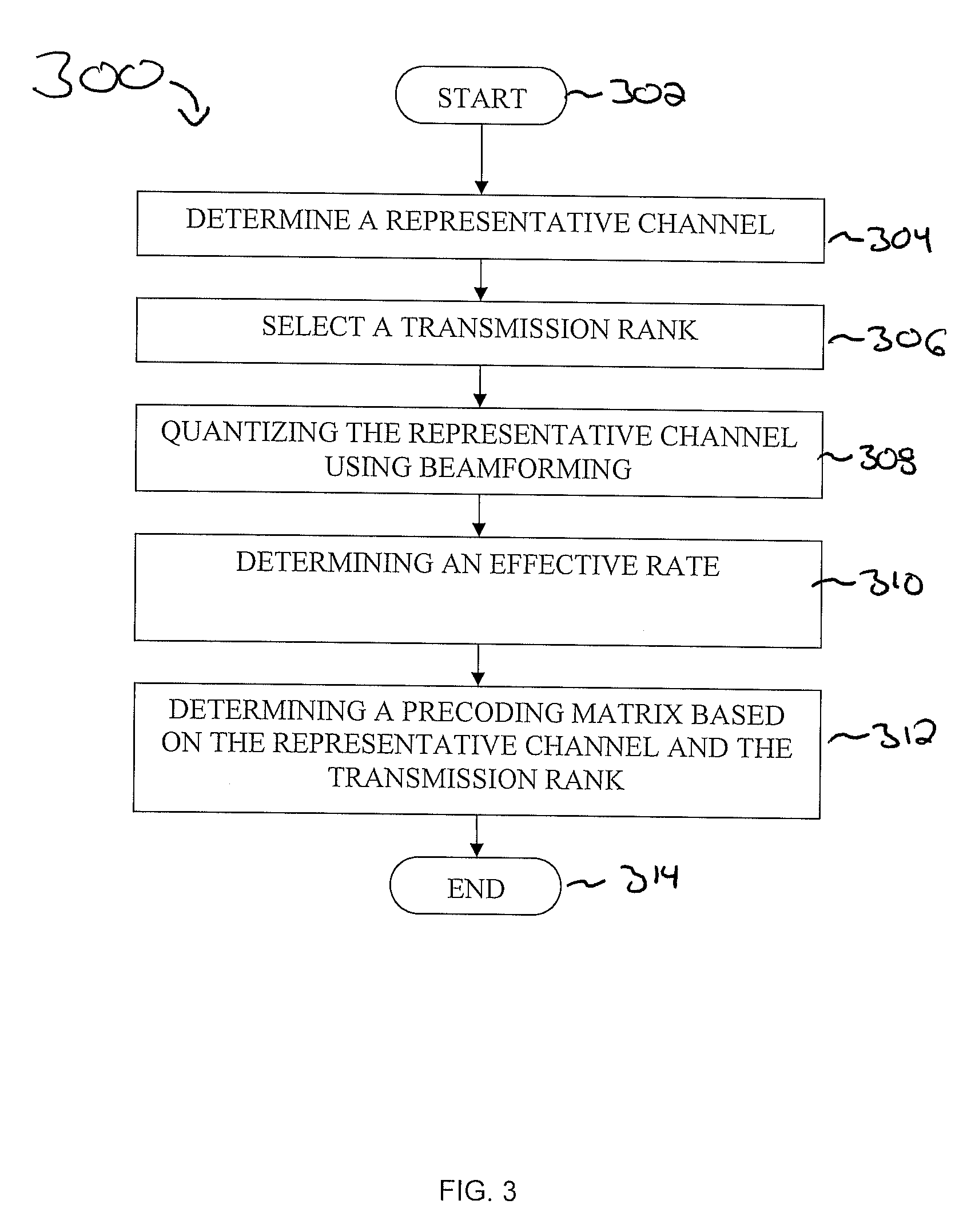

Quantized Precoding Over a Set of Parallel Channels

ActiveUS20080049596A1Reduce computational complexityImprove performanceFrequency-division multiplexRadio transmissionRound complexityEngineering

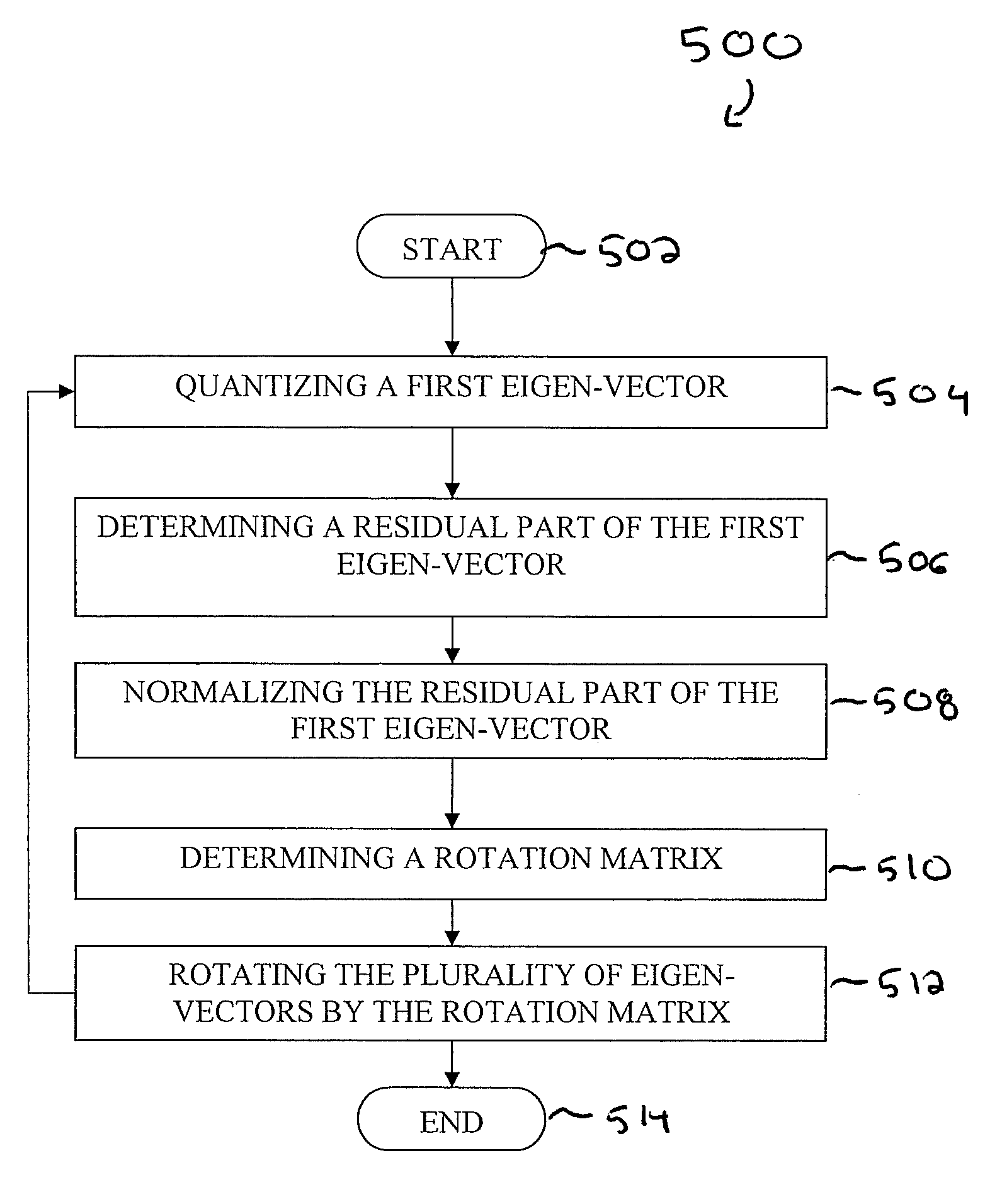

Methods and apparatus are disclosed for applying successive multi-rank beamforming strategies (e.g., successive preceding strategies) for the design of precoders over a set of parallel channels. Successive beamforming is applied to a narrow band channel model and is also applied for finer quantization of a single beamforming vector (e.g., recursive beamforming). A first embodiment provides the optimal approach with high complexity. An alternative embodiment provides successive beamforming for near optimal preceding selection with medium complexity. A low complexity method for precoder selection is also provided wherein a channel representative matrix for the set of parallel channels is determined and successive beamforming on the calculated channel representative is applied.

Owner:NEC CORP

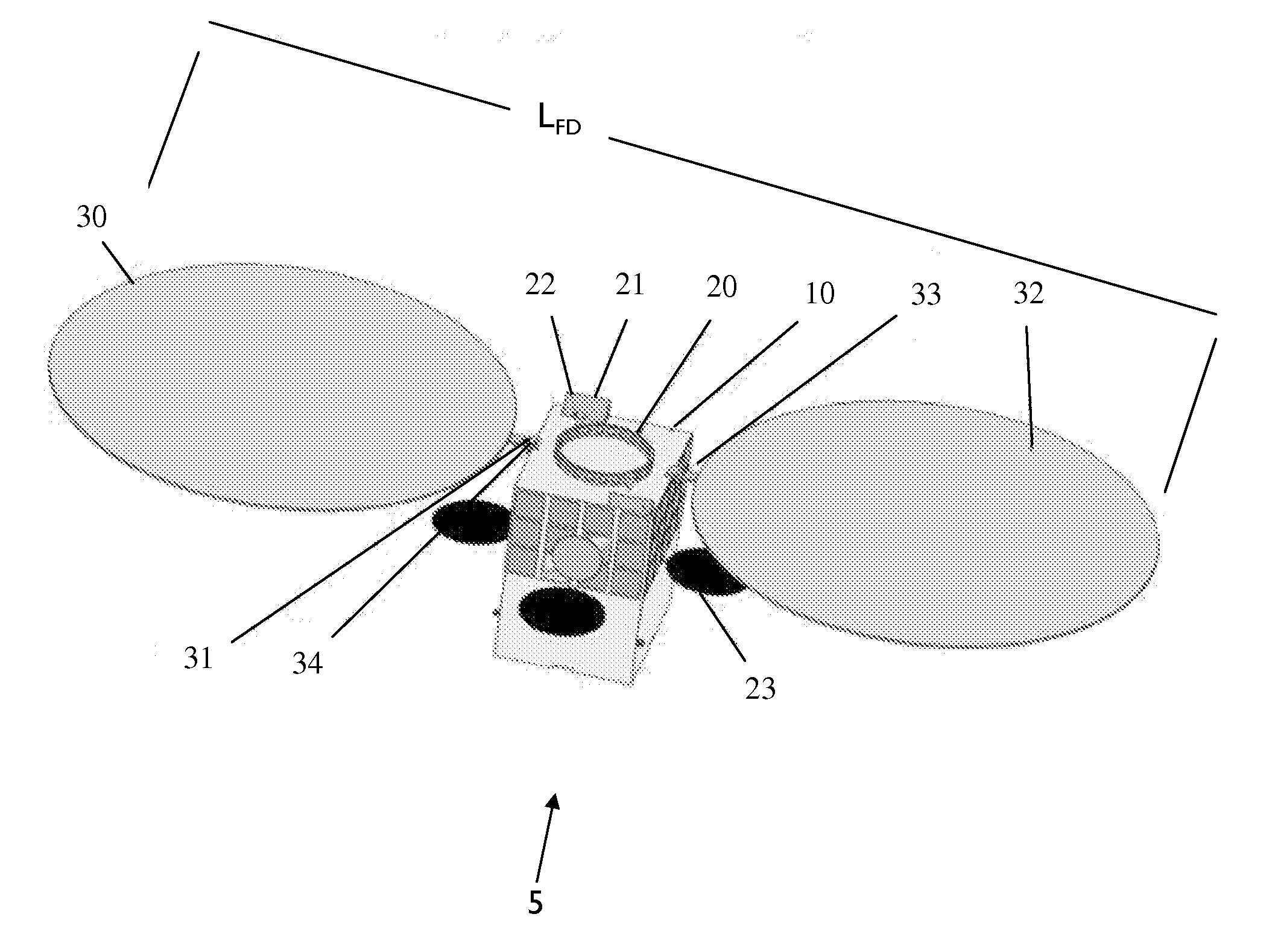

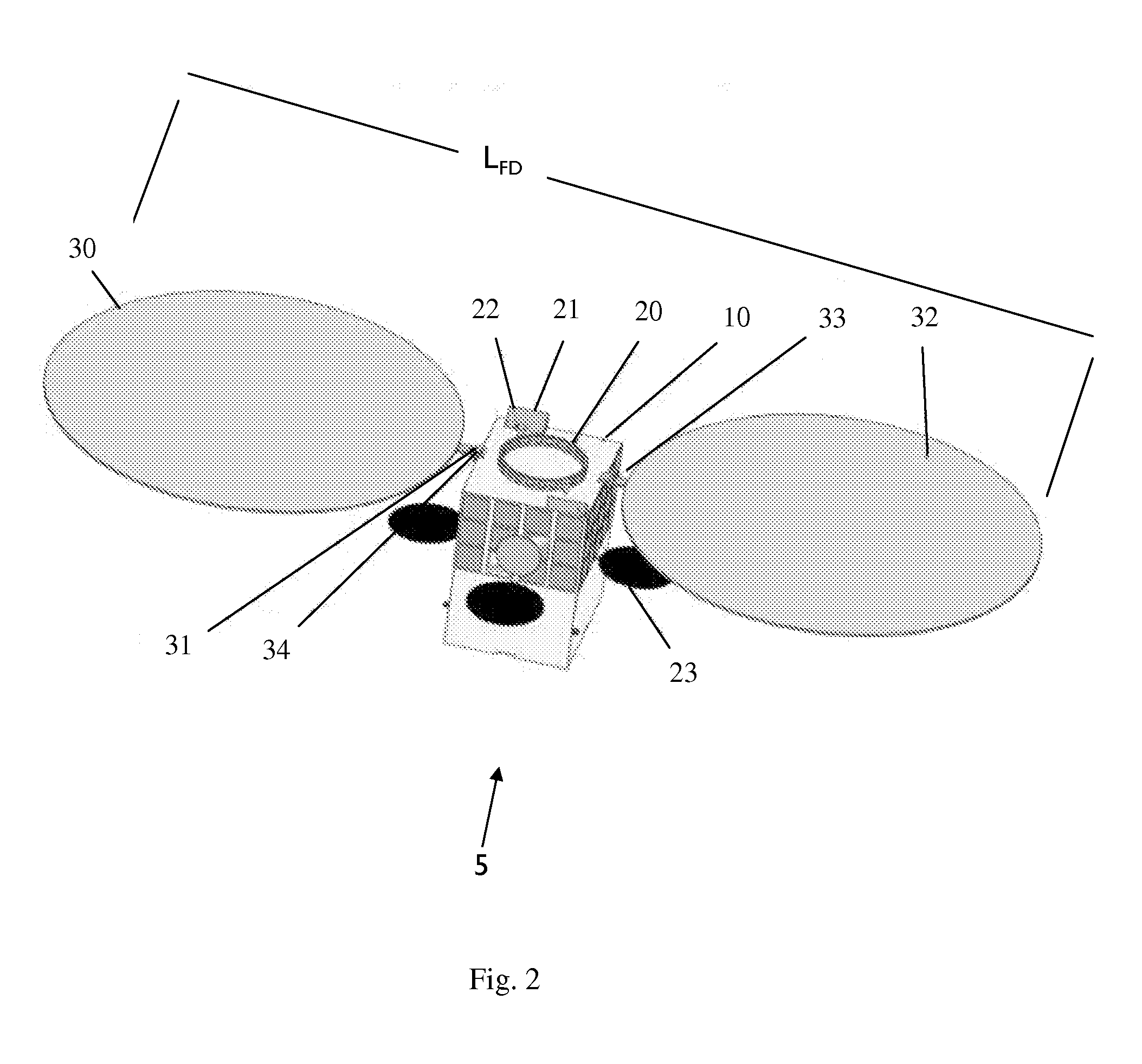

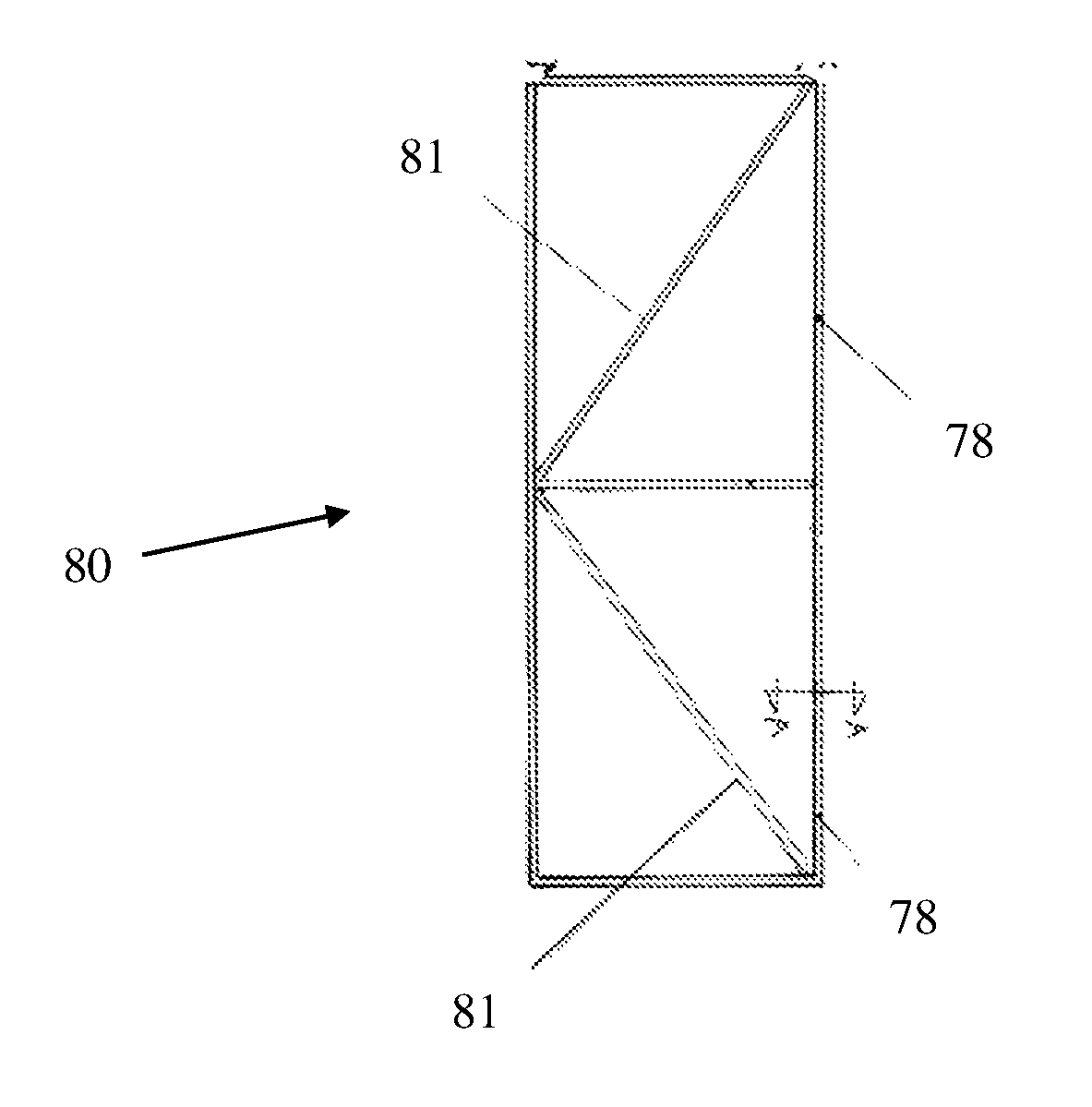

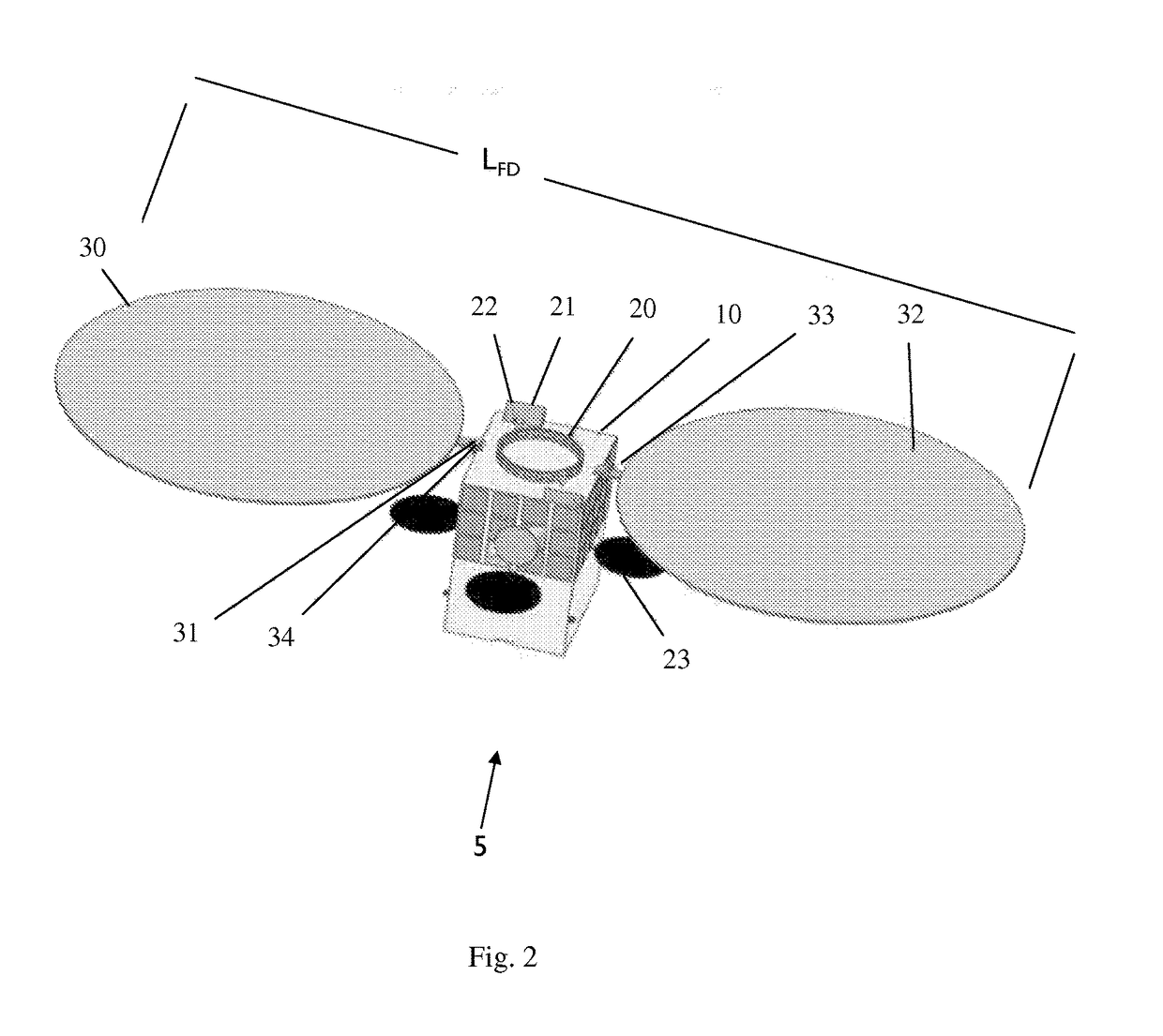

Low volume micro satellite with flexible winded panels expandable after launch

ActiveUS20150217876A1Improve performanceLow costCosmonautic power supply systemsPhotovoltaicsNatural satelliteMicrosatellite

Micro satellite is disclosed with foldable solar panels that may be winded around the body of the micro satellite so that the growth in outer dimensions of the satellite is no more than 10-20 mm along each one of the length, width and height of the microsatellite so that the micro satellite may be launched in an auxiliary payload volume of a launcher. The foldable solar panels may be deployed to employ area that exceeds 9 times the product of the length by the width of the satellite and 6 times the product of the height by the length. The solar power produced by the solar panel and their light weight enable carrying of cargo that is at least 0.6 of the of the total mass of the satellites.

Owner:ASTROSCALE ISRAEL LTD

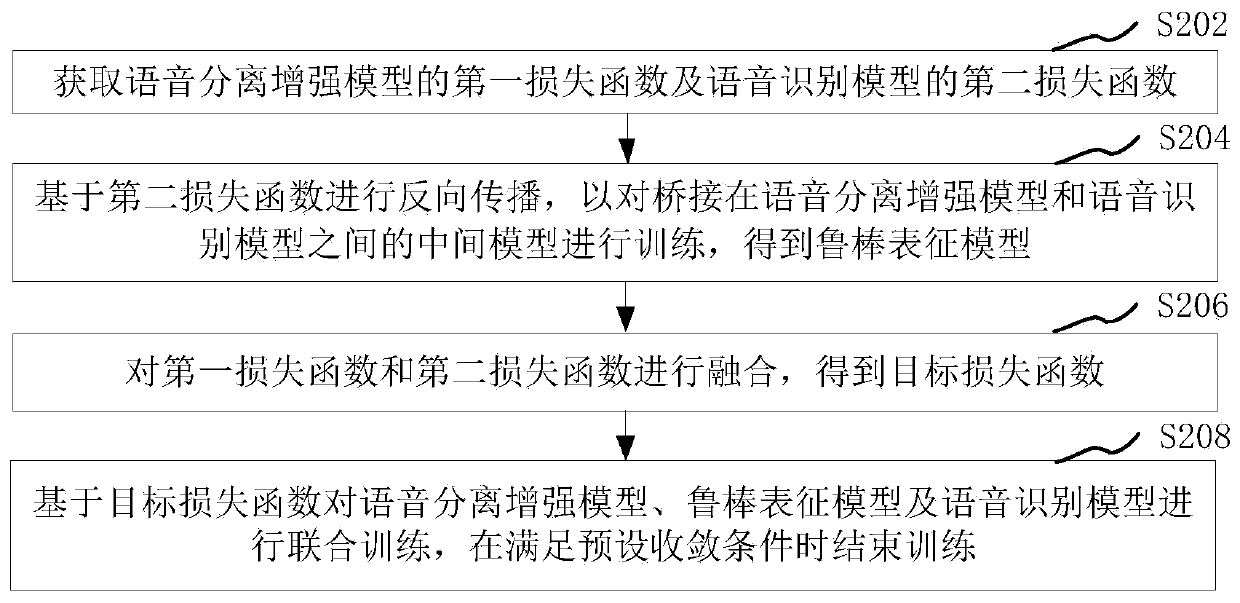

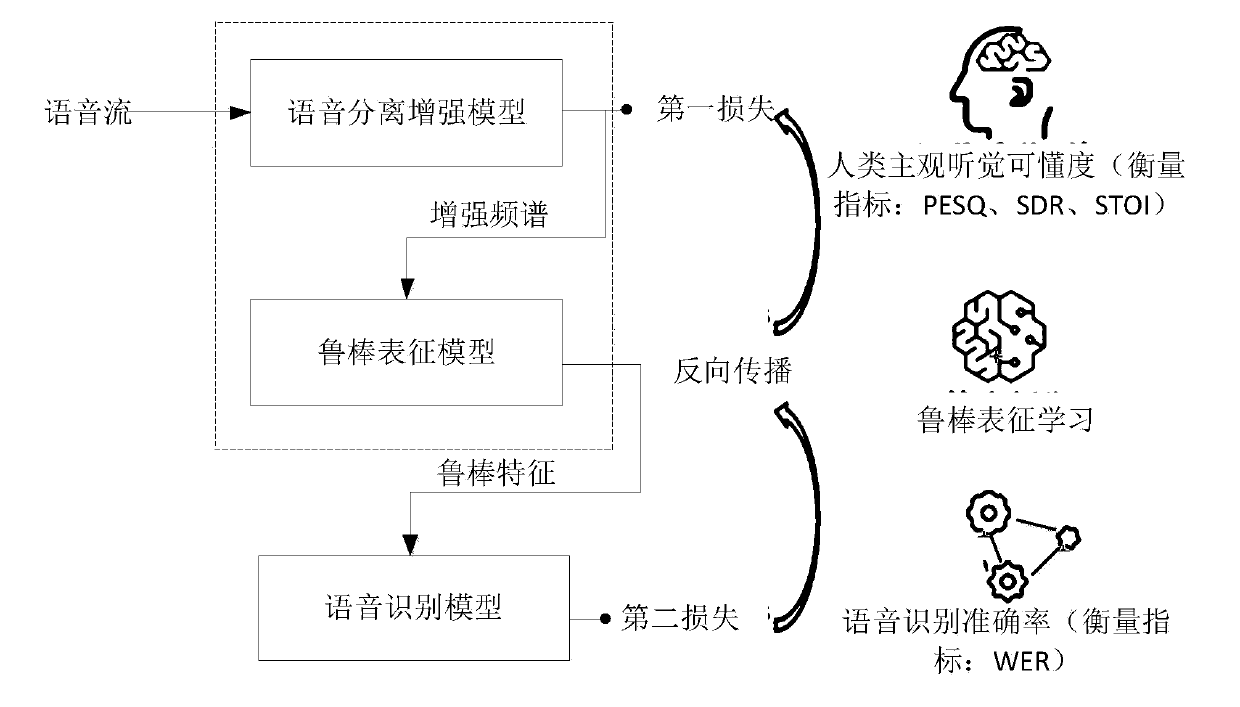

Speech recognition and model training method, device and computer readable storage medium

ActiveCN111261146AImprove accuracyGuaranteed performanceSpeech recognitionNeural architecturesEngineeringSpeech sound

The invention relates to a speech recognition and model training method, a device and a computer readable storage medium. The method comprises the steps: obtaining a first loss function of a speech separation enhancement model and a second loss function of a speech recognition model; performing back propagation based on the second loss function to train an intermediate model bridged between the speech separation enhancement model and the speech recognition model to obtain a robust representation model; fusing the first loss function and the second loss function to obtain a target loss function; and performing joint training on the speech separation enhancement model, the robust representation model and the speech recognition model based on the target loss function, and ending the trainingwhen a preset convergence condition is satisfied. According to the scheme provided by the invention, the speech recognition accuracy can be improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Quantized precoding over a set of parallel channels

ActiveUS7839835B2Consider performanceLoss of performanceFrequency-division multiplexTransmission monitoringRound complexityEngineering

Methods and apparatus are disclosed for applying successive multi-rank beamforming strategies (e.g., successive preceding strategies) for the design of precoders over a set of parallel channels. Successive beamforming is applied to a narrow band channel model and is also applied for finer quantization of a single beamforming vector (e.g., recursive beamforming). A first embodiment provides the optimal approach with high complexity. An alternative embodiment provides successive beamforming for near optimal preceding selection with medium complexity. A low complexity method for precoder selection is also provided wherein a channel representative matrix for the set of parallel channels is determined and successive beamforming on the calculated channel representative is applied.

Owner:NEC CORP

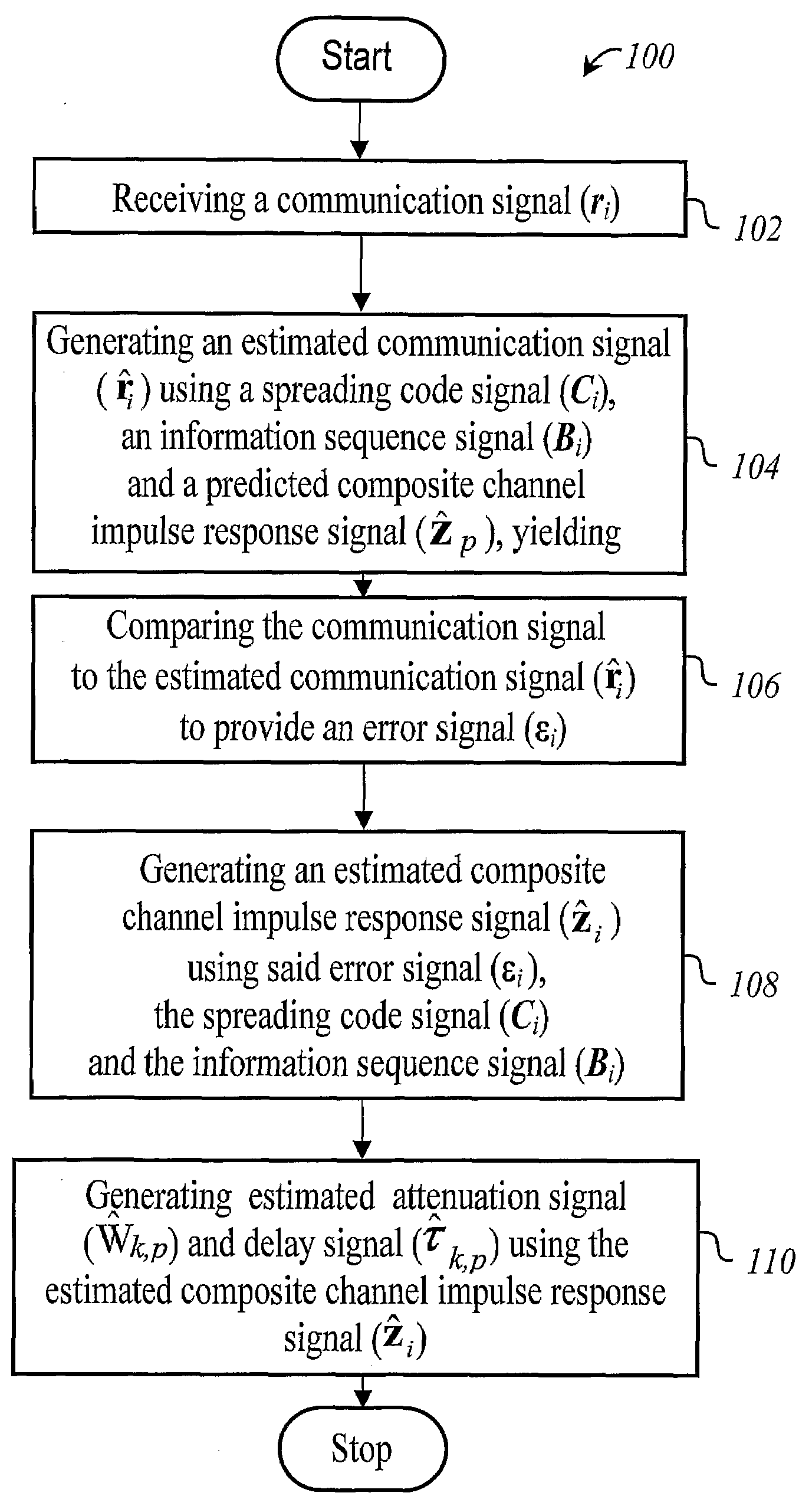

Method and System For Multi-User Channel Estimation in Ds-Cdma Systems

InactiveUS20080130674A1Improve tracking qualityReduce computational complexityRadio transmissionChannel estimationSequence signalComposite channel

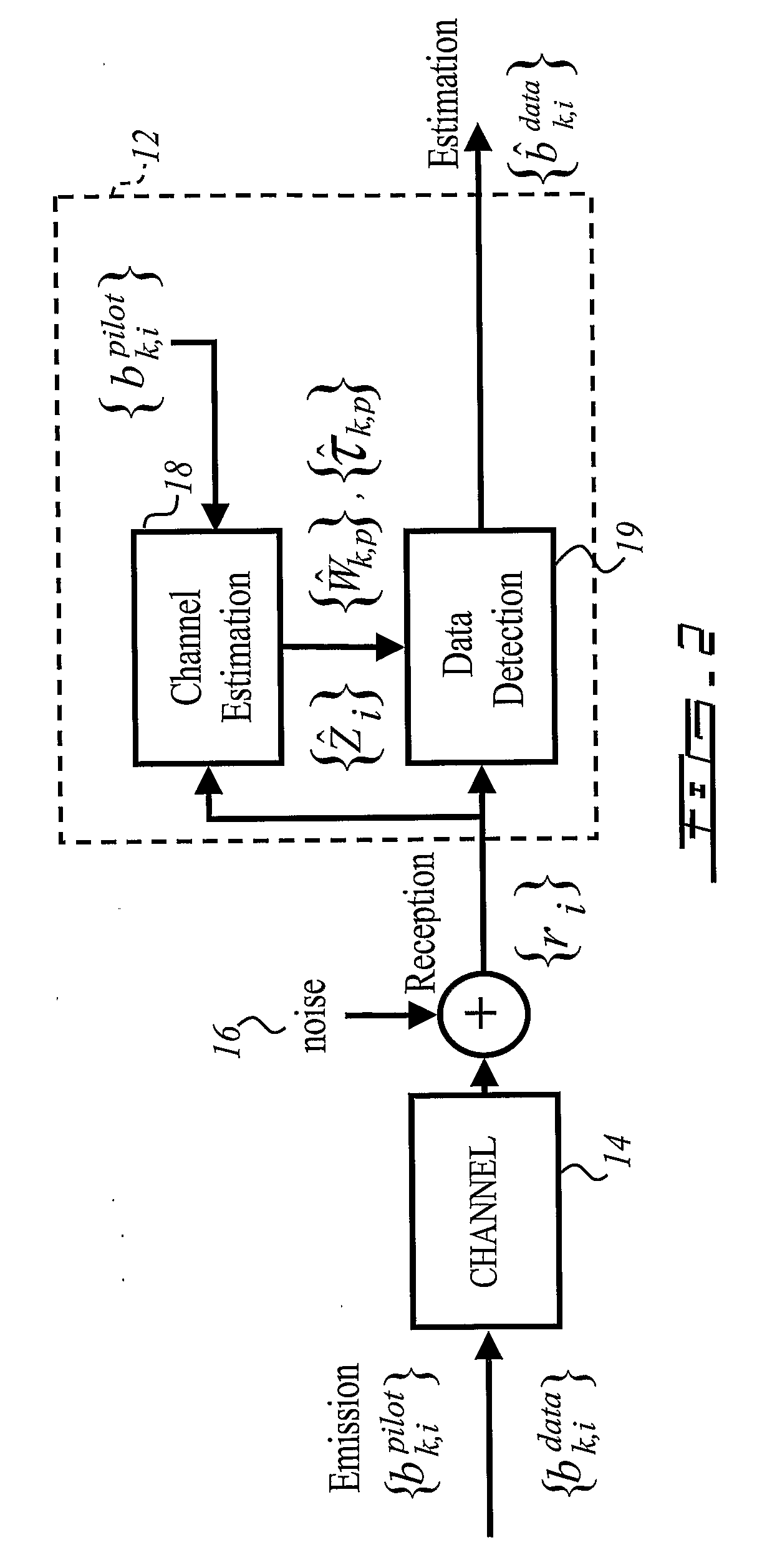

The method and system for multi-user channel estimation in a multi-access network comprises: providing a communication signal (ri) providing an estimated communication signal Formula (I) generated using a spreading code signal (Ci), an information sequence signal (Bi) and a predicted composite channel impulse response signal Formula (II); comparing the communication signal (ri) to the estimated communication signal Formula (I) to provide an error signal (εi); and generating an estimated composite channel impulse response signal Formula (III) using the error signal (εi), the spreading code signal (Ci) and the information sequence signal (Bi); the predicted composite channel impulse response signal Formula (II) providing the multi-user channel estimation. The proposed method, which is based on a LMS like algorithm, is an efficient and low complexity method allowing estimating and tracking even fast times varying multi-path channels. Instantaneously, the composite channel impulse response is computed and estimates of all possible path energies are computed to be used as an indicator of the significant paths (delays).

Owner:AXIOCOM

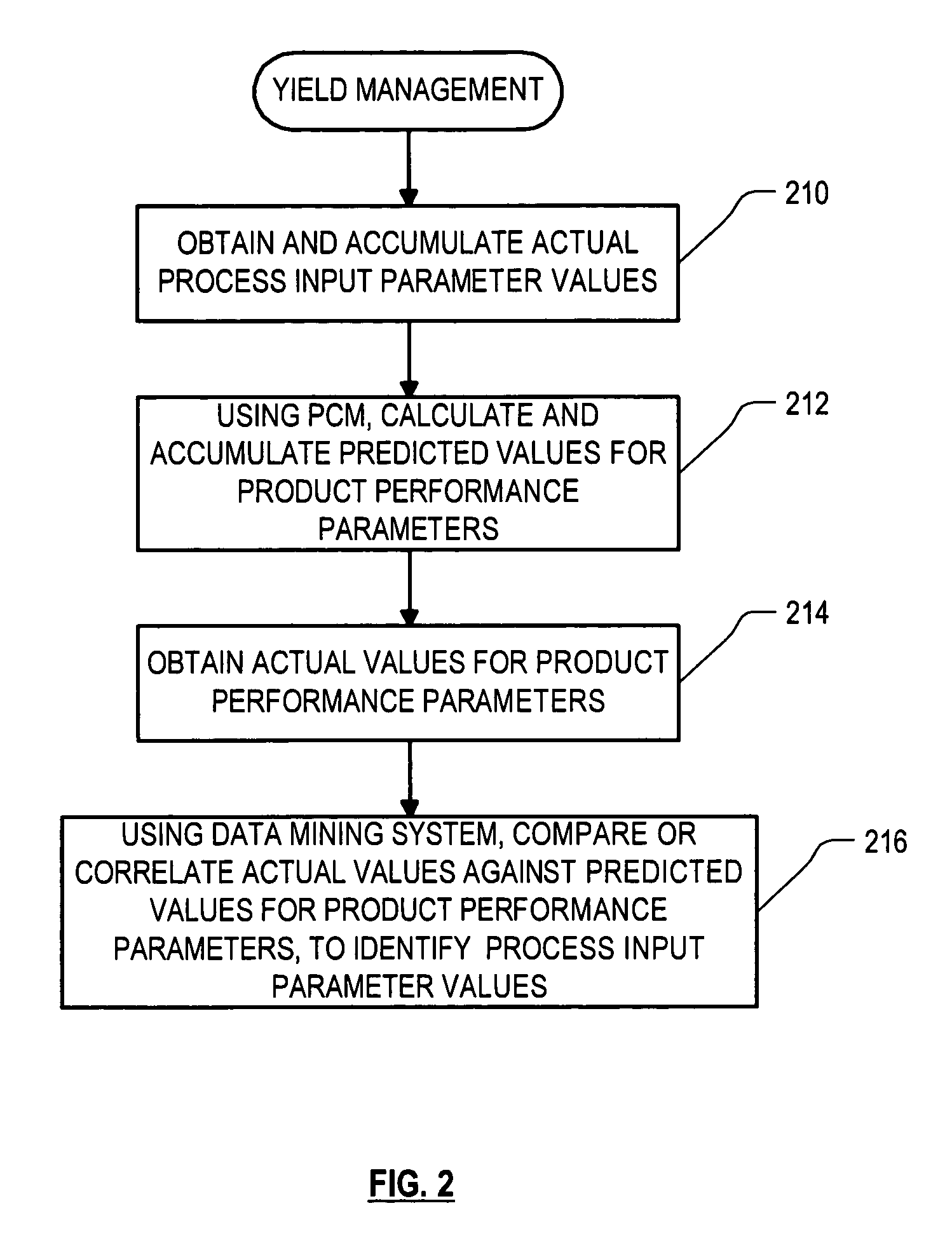

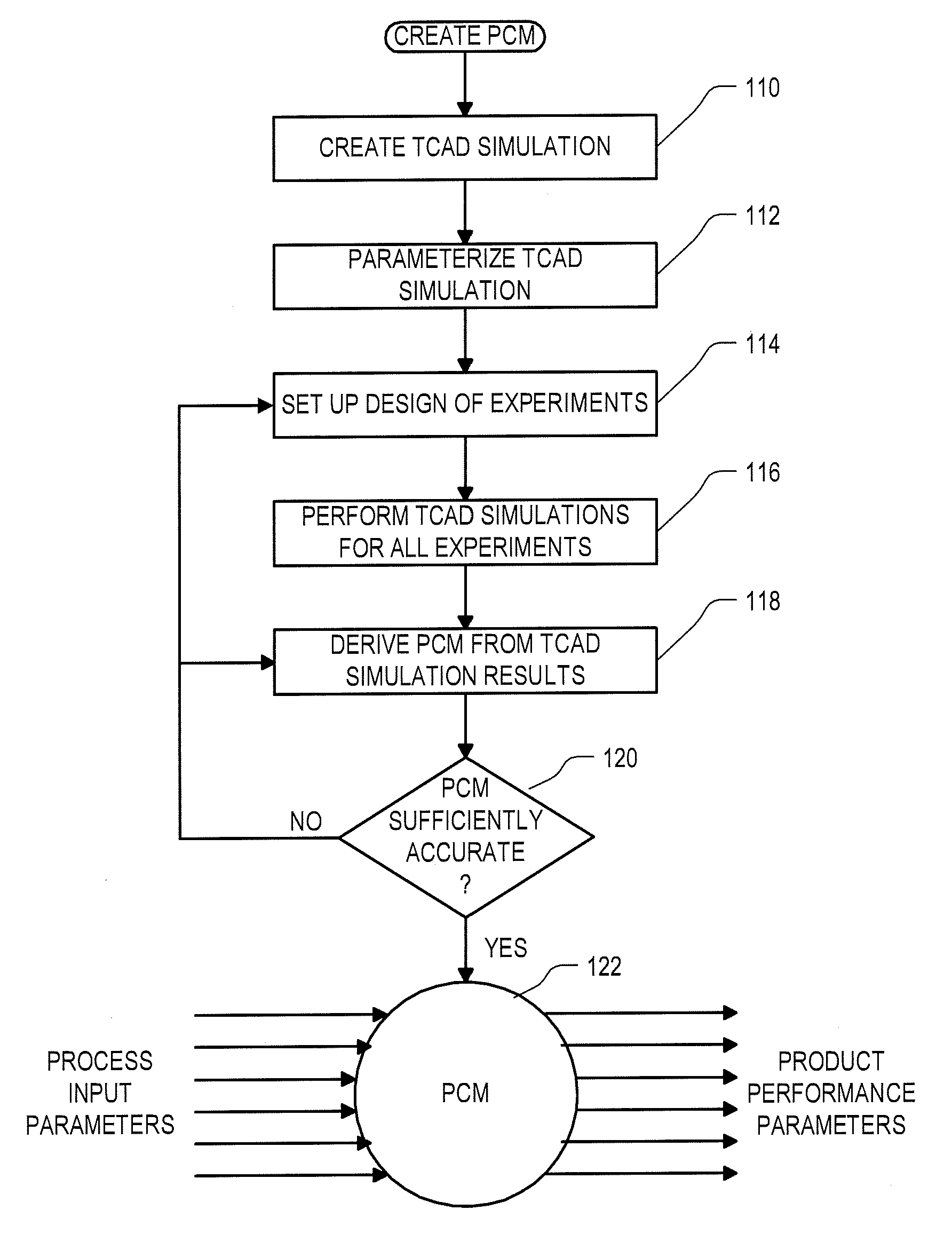

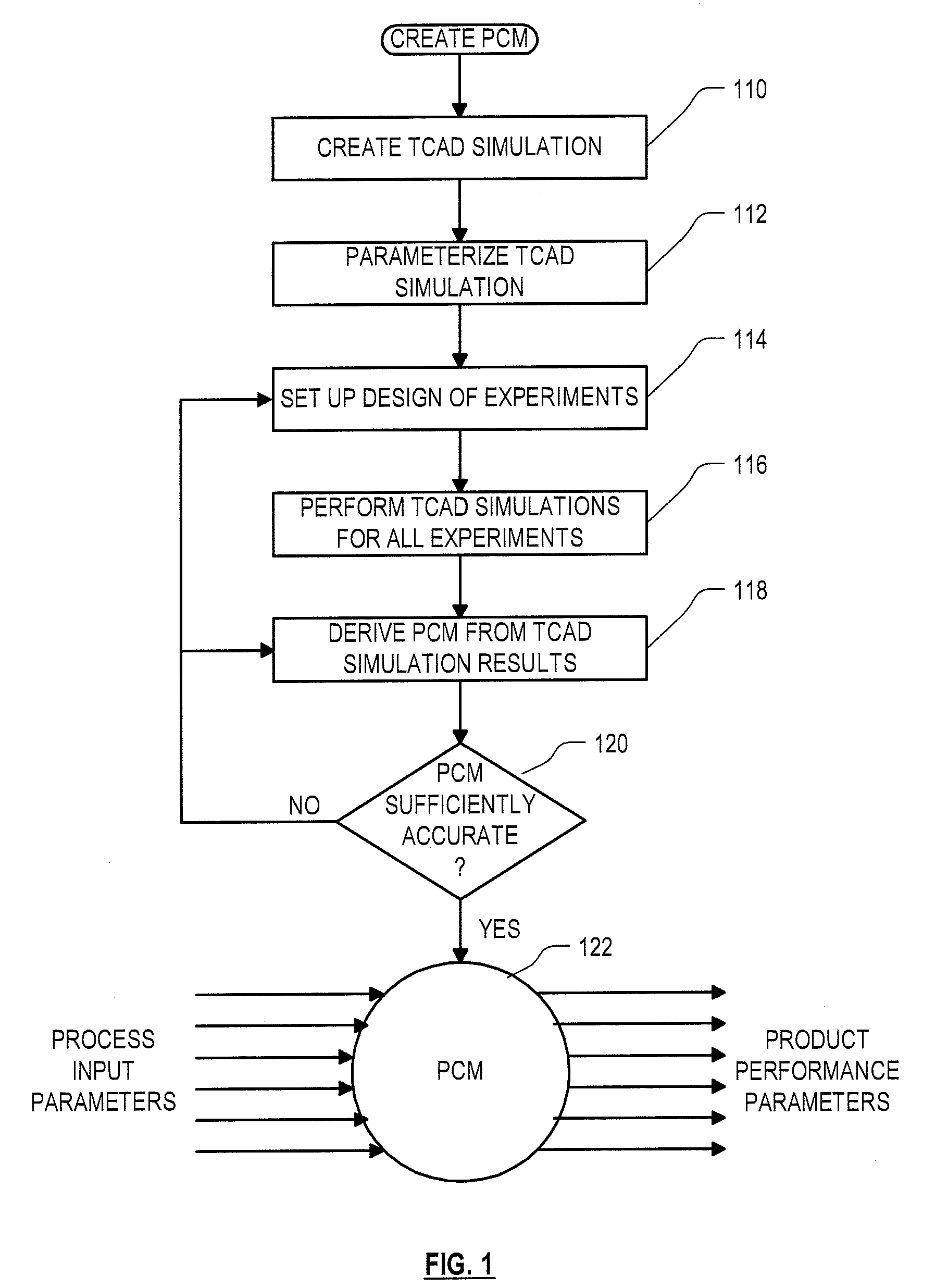

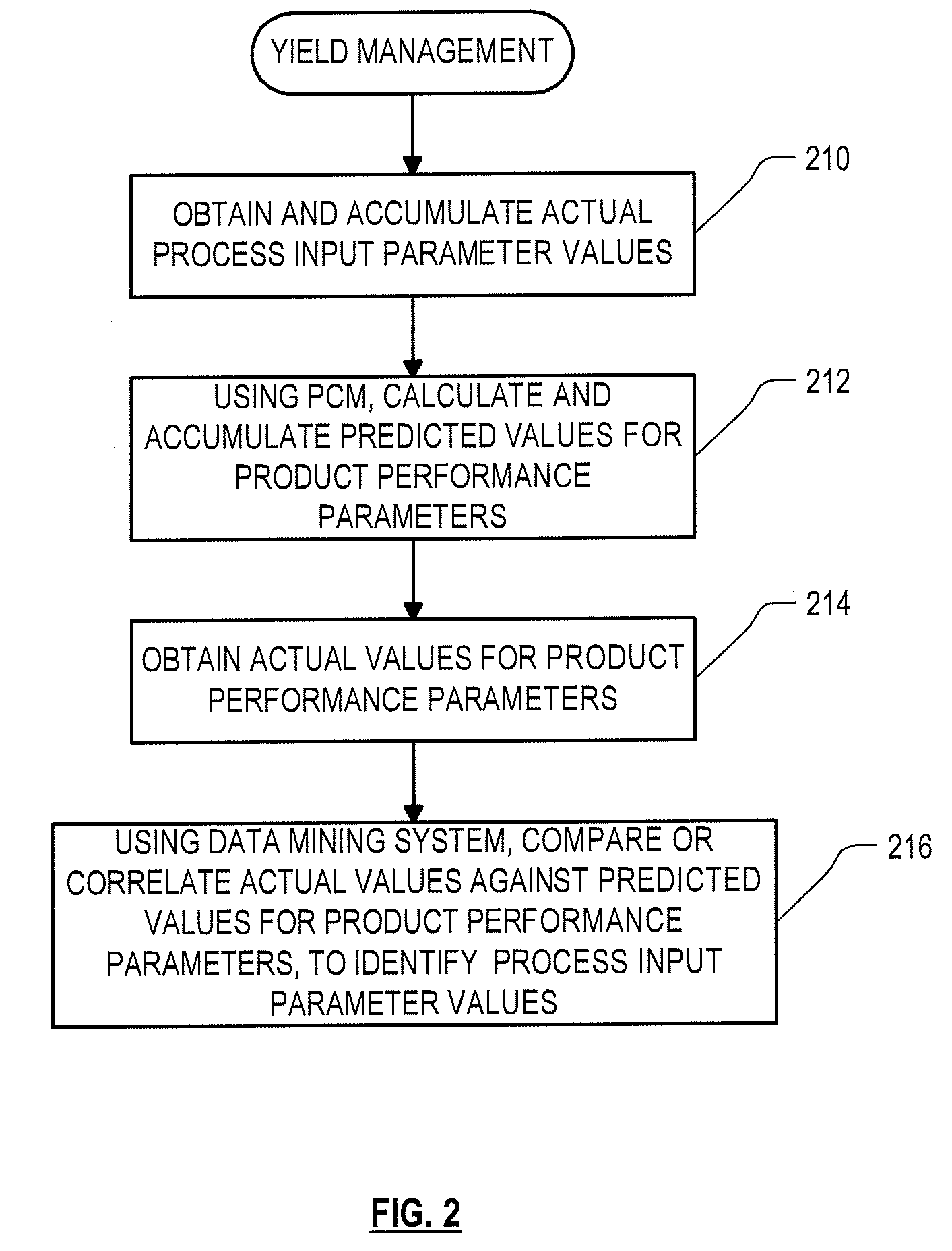

Method and system for enhancing the yield in semiconductor manufacturing

ActiveUS7792595B1Low costReduce in quantityProgramme controlAnalogue computers for electric apparatusSemiconductorSystems engineering

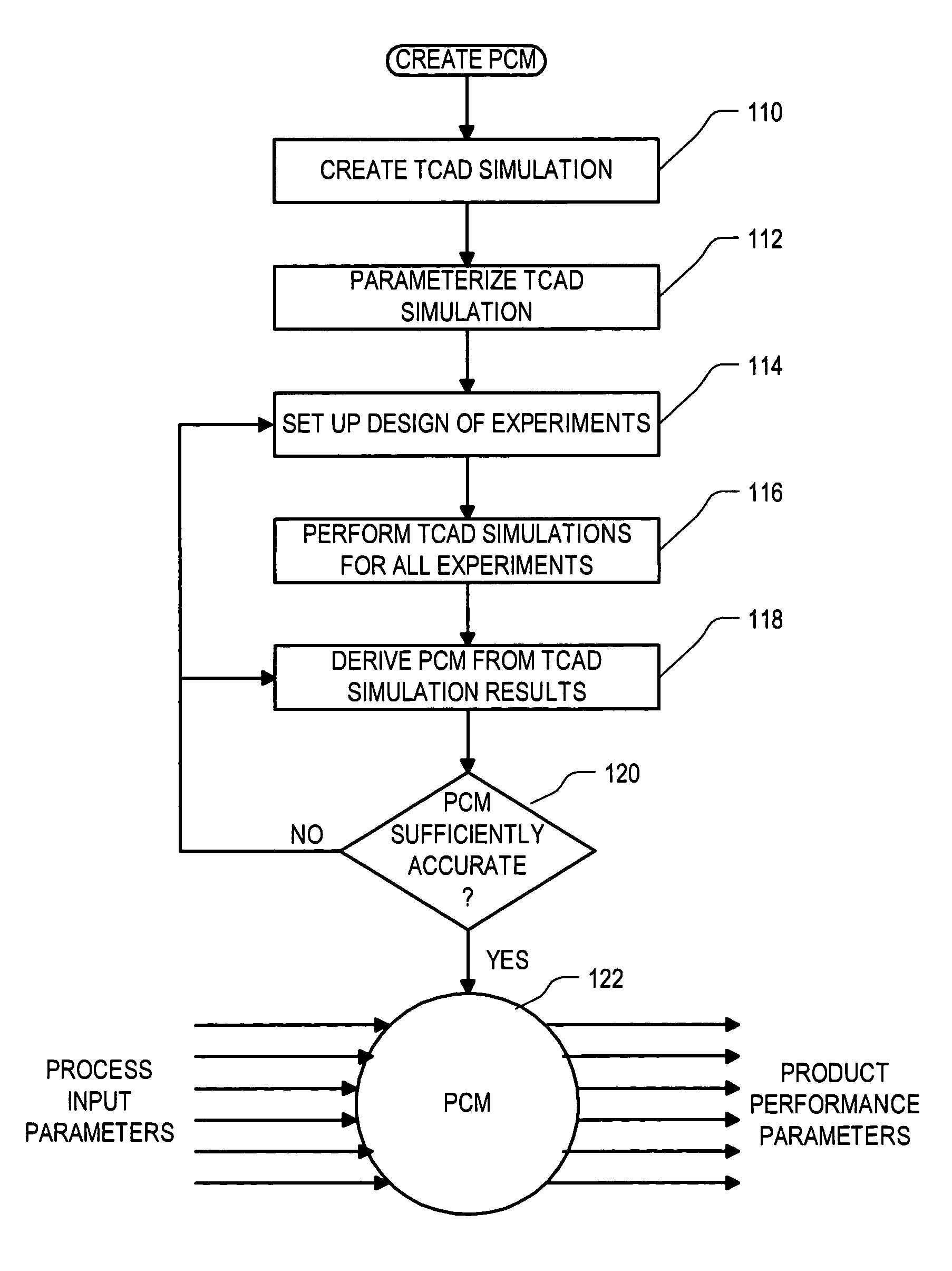

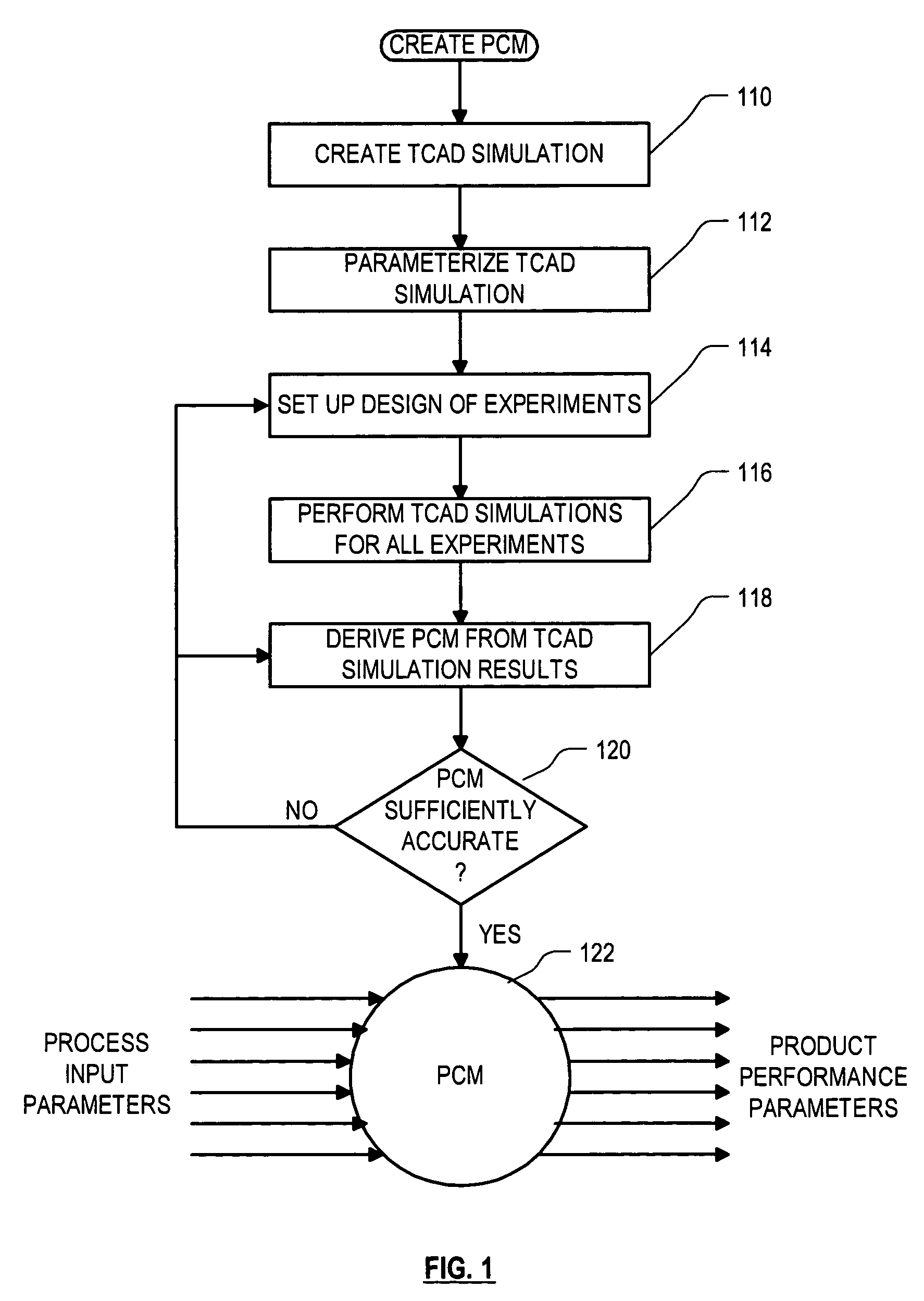

Roughly described, a manufacturing process is enhanced by using TCAD and TCAD-derived models. A TCAD simulation model of the process is developed, which predicts, in dependence upon a plurality of process input parameters, a value for a performance parameter of a product to be manufactured using the process. Estimated, predicted or desired values for a calculated subset of the parameters (including either process input parameters or product performance parameters or both), are determined in dependence upon the process model, and further in dependence upon actual, estimated or desired values for a different subset of the parameters (again either process input parameters or product performance parameters or both). The determination is preferably made using a process compact model of the process, itself developed in dependence upon the simulation model.

Owner:SYNOPSYS INC

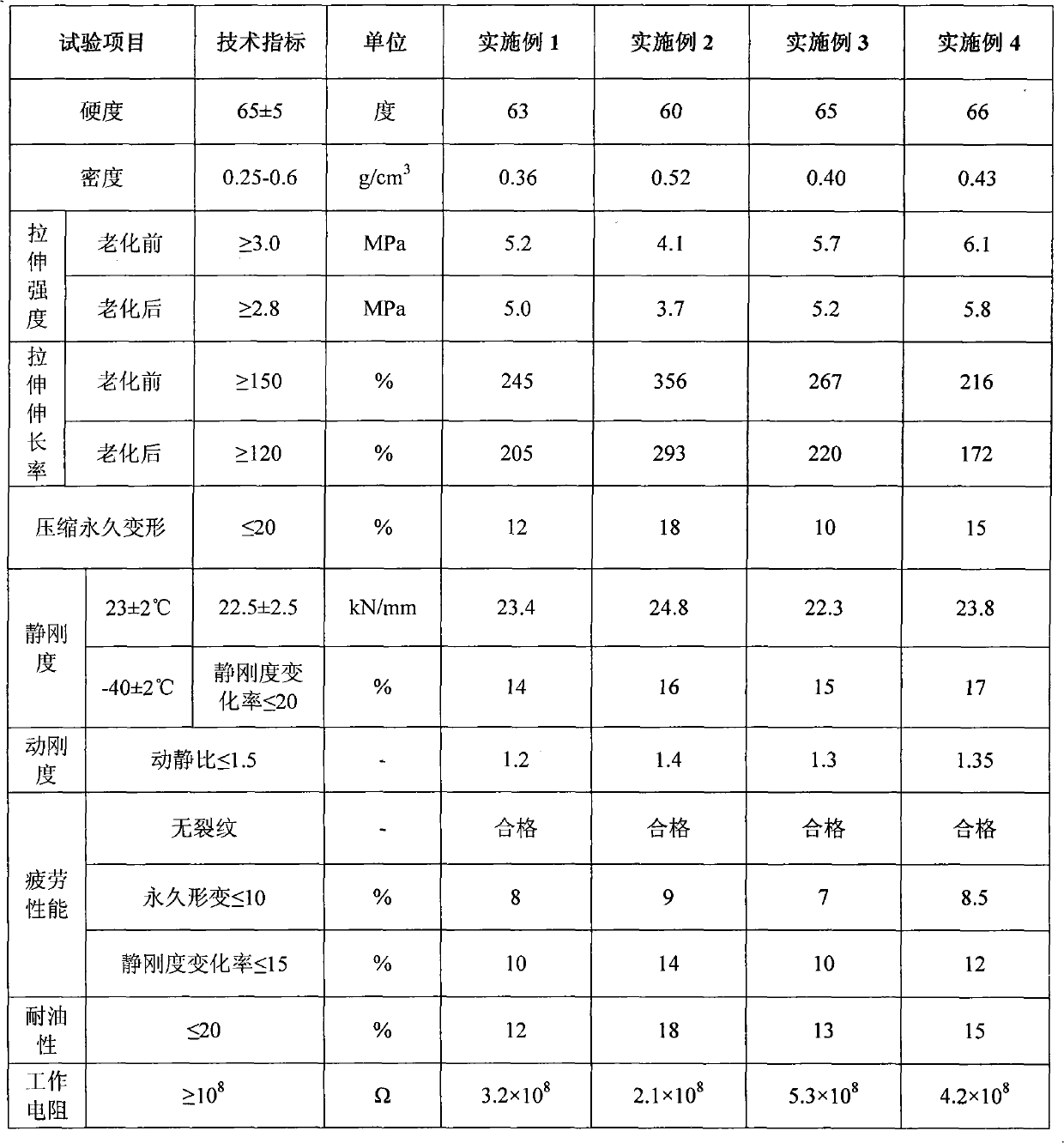

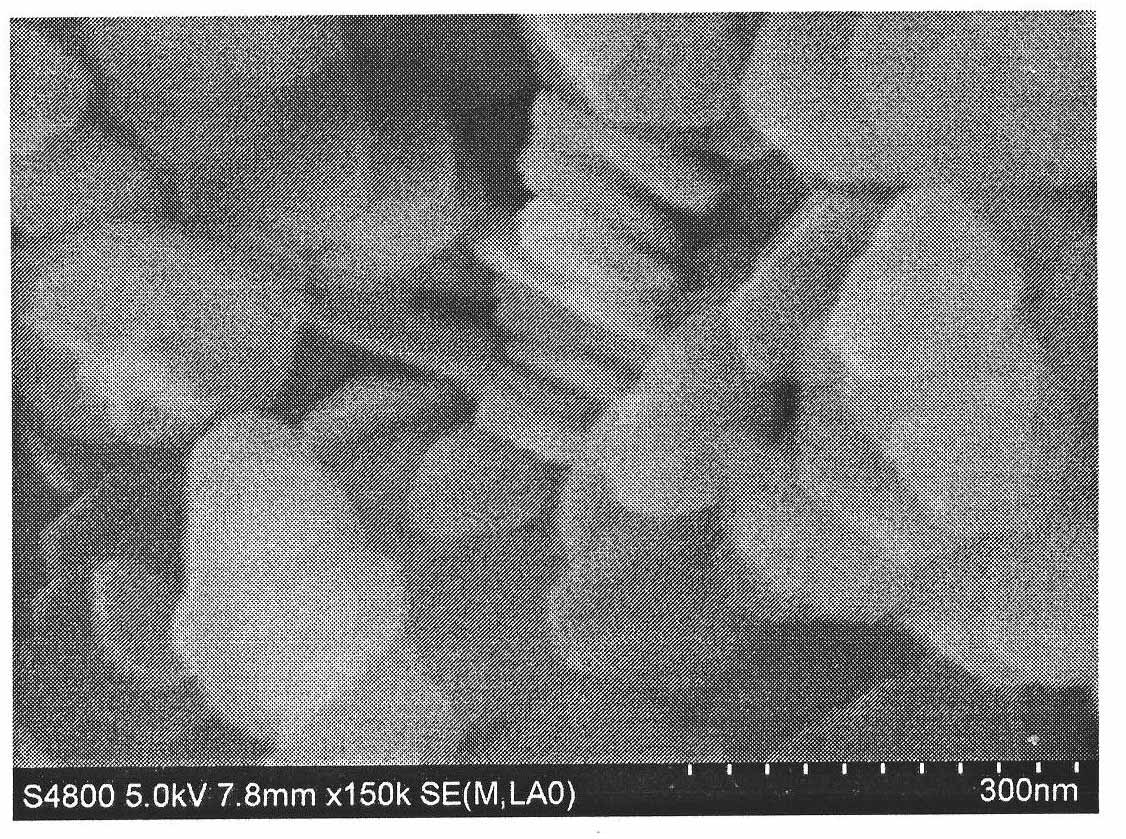

Microporous polyurethane elastomer shock absorption element for high-speed railway and preparation method thereof

The invention discloses a microporous polyurethane elastomer shock absorption element for a high-speed railway. The shock absorption element is characterized by being prepared by stirring and mixing a mixture I and a quasi-prepolymer II at the temperature of between 35 and 55 DEG C for 2 to 5 minutes to obtain a mixture, wherein the mixture I consists of the following components in part by weight: 23 to 40 parts of polyether polyol A, 5 to 10 parts of chain extender, 0.1 to 0.5 part of water, 0.2 to 0.55 part of silicone oil foam homogenizing agent and 0.15 to 0.3 part of catalyst, and the quasi-prepolymer II is prepared by reacting 2.5 to 8 parts of modified nanokaolin, 24 to 30 parts of polyether glycol and 30 to 40 parts of polyisocyanate; pouring the mixture into a die which is pre-heated to 45 to 70 DEG C and is coated with a de-molding agent for molding, de-molding, and curing at the temperature of between 80 and 100 DEG C for 10 to 20 hours. The indexes of the shock absorption element meet the requirements of the HE / 3328-2006 standard.

Owner:ANHUI UNIVERSITY +1

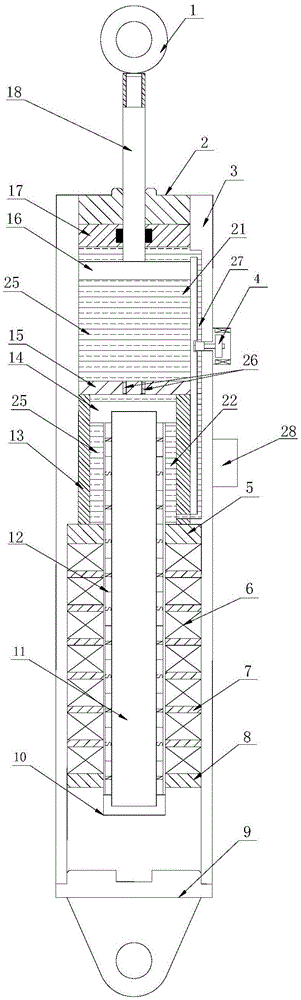

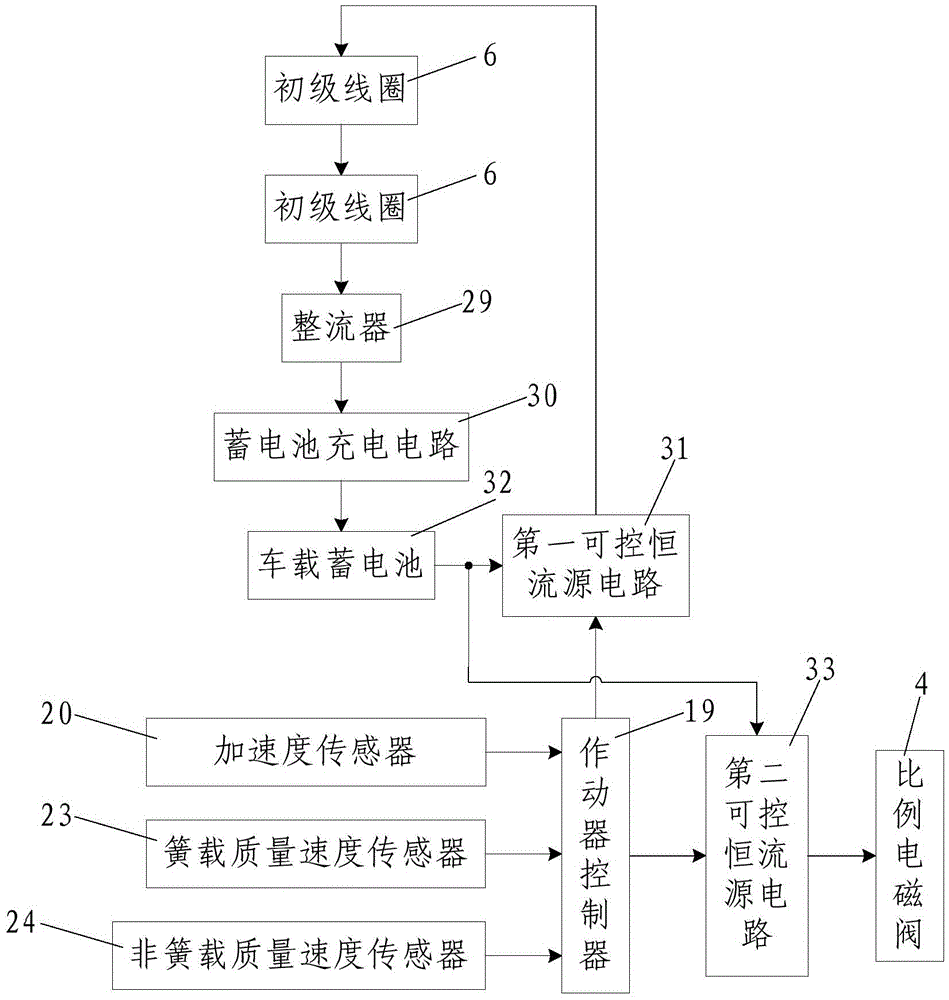

Multi-mode electromagnetic energy-regenerative vehicle active suspension actuator and control method thereof

ActiveCN105480043ASimple structureNovel and reasonable designResilient suspensionsPermanent magnet linear motorSprung mass

The invention discloses a multi-mode electromagnetic energy-regenerative vehicle active suspension actuator. The multi-mode electromagnetic energy-regenerative vehicle active suspension actuator comprises an actuator main body and an actuator controller, wherein the actuator main body comprises a piston cylinder, a permanent magnet linear motor module, an adjustable damping vibration absorber module, an actuator upper end cover and a lower lifting lug. The permanent magnet linear motor module comprises a secondary piston rod, a linear motor upper end cover, a linear motor lower end cover, a plurality of silicon steel sheets, a plurality of primary coils and a permanent magnet; the adjustable damping vibration absorber module comprises a vibration absorber piston rod, a sleeve, an upper lifting lug, a sealing separation plate, a big piston, a small piston, a damping liquid passage and a proportional electromagnetic valve; and an input end of the actuator controller is connected with an acceleration sensor, a sprung mass speed sensor and an unsprung mass speed sensor. The invention further discloses a control method for the multi-mode electromagnetic energy-regenerative vehicle active suspension actuator. The invention is advantaged in that the energy-regenerative efficiency of the multi-mode electromagnetic energy-regenerative vehicle active suspension actuator is high, the service life of a vehicle-mounted storage battery can be effectively prolonged and an active suspension is in an optimal vibration absorbing state.

Owner:XIAN UNIV OF SCI & TECH

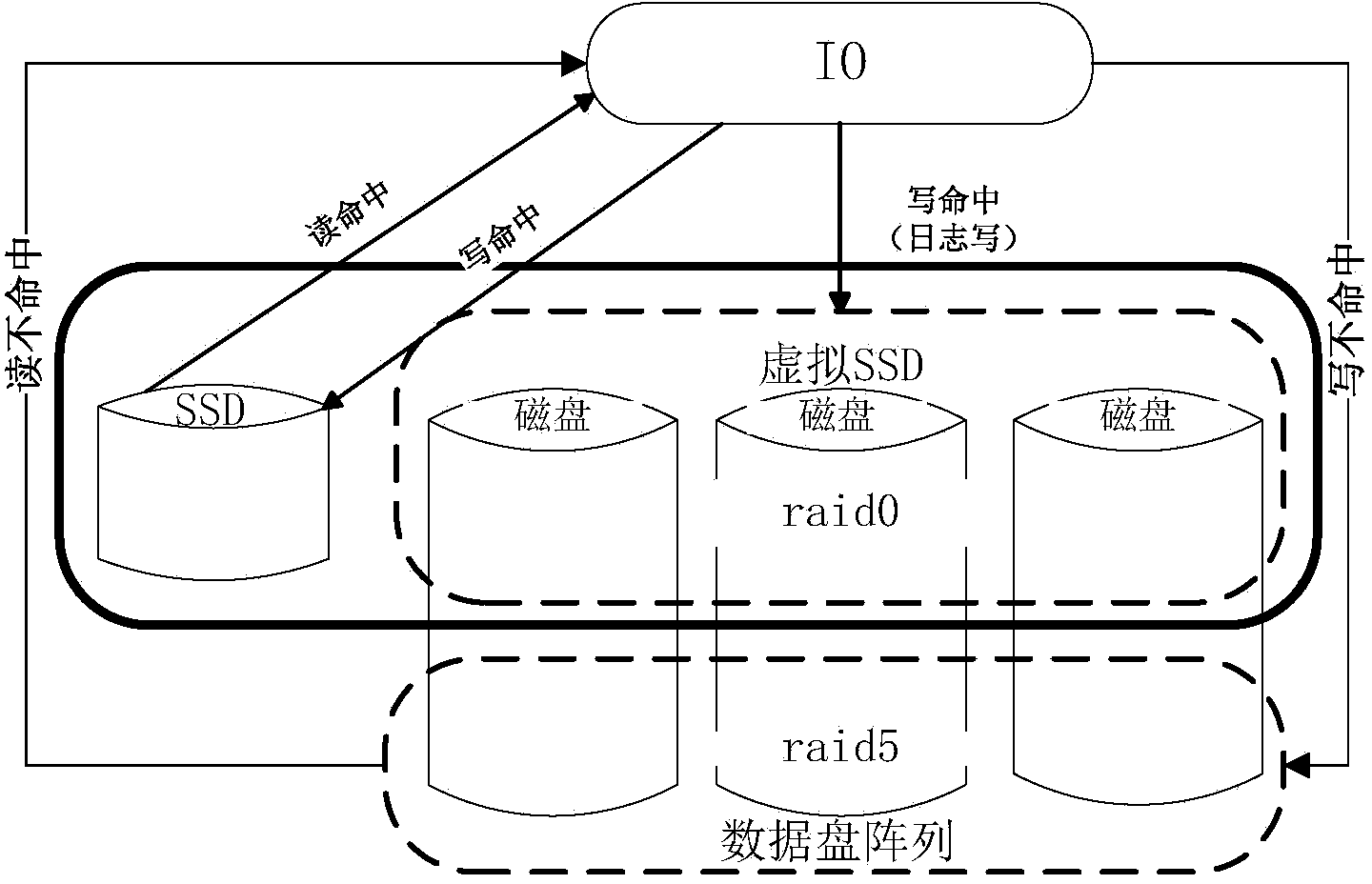

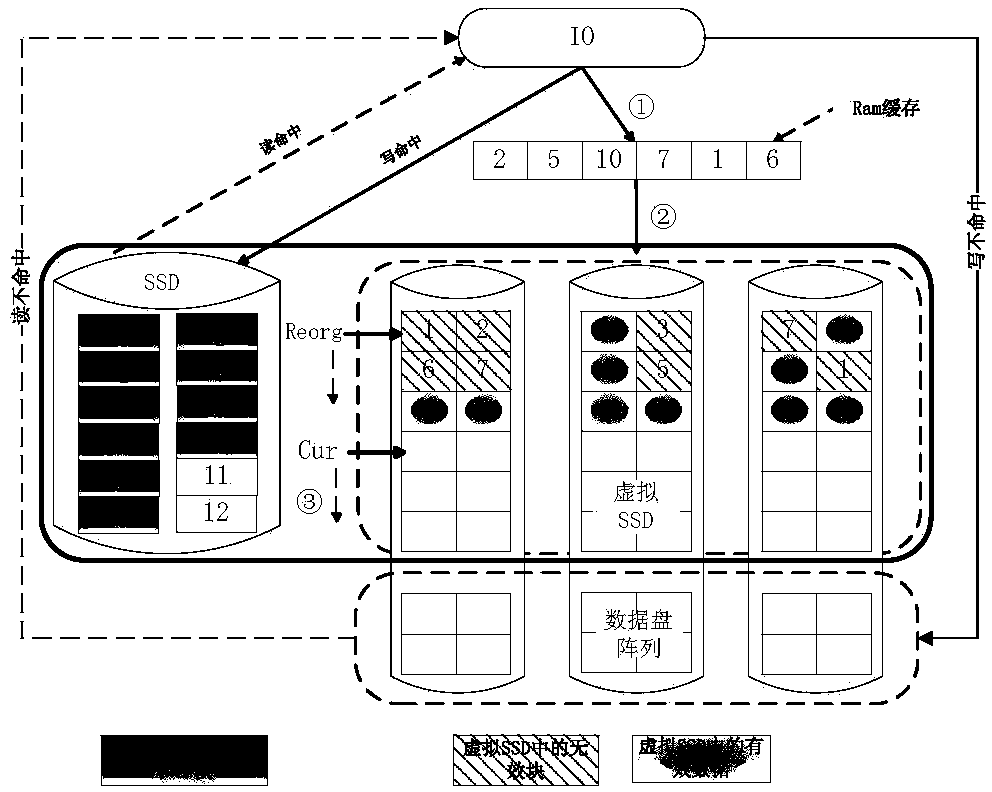

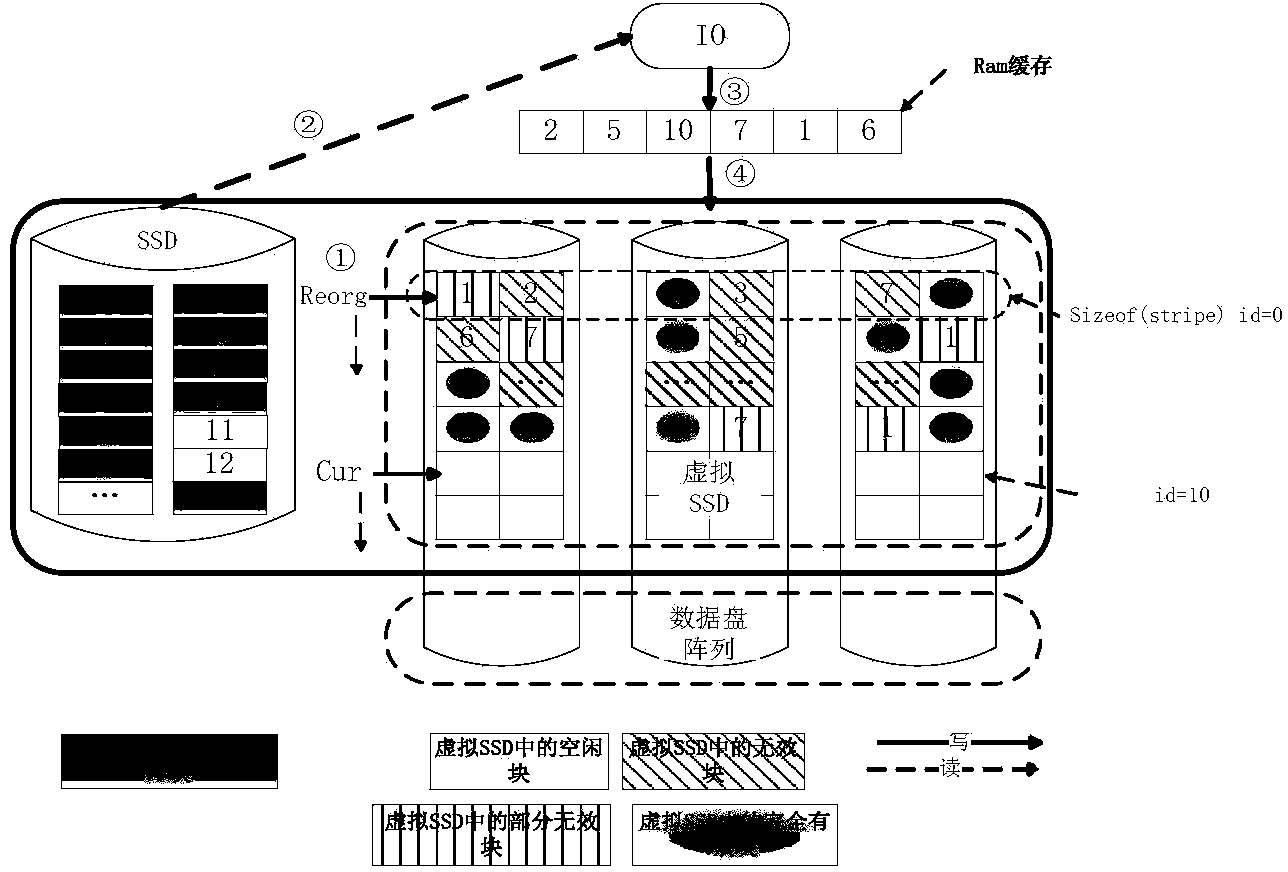

Disk array caching method for virtual SSD and SSD isomerous mirror image

ActiveCN103645859AReduce the number of writesReduce overheadInput/output to record carriersRAIDDirty data

The invention discloses a disk array caching method for a virtual SSD and an SSD isomerous mirror image. The disk array caching method comprises the steps that a disk is logically divided into two parts, wherein the upper half part forms an RAID0 or RAID5 structure to serve as the virtual SSD so as to back up dirty data in a real SSD, the virtual SSD is in a log writing mode, a ram writing cache is set, and the lower half portion is assembled to be of different RAID structures according to needs of users, and is used as a data array so as to store cold data; an address mapping Hash locating table between a data disk and the cache of the real SSD is built; a timer is set so as to regularly write data cached in the ram writing cache of the virtual SSD into the virtual SSD; a request from an upper layer file system is received; for a reading request, when the reading request is not hit in the real SSD, data are read from the data array. The disk array caching method gives consideration to performance, reliability and cost.

Owner:HUAZHONG UNIV OF SCI & TECH

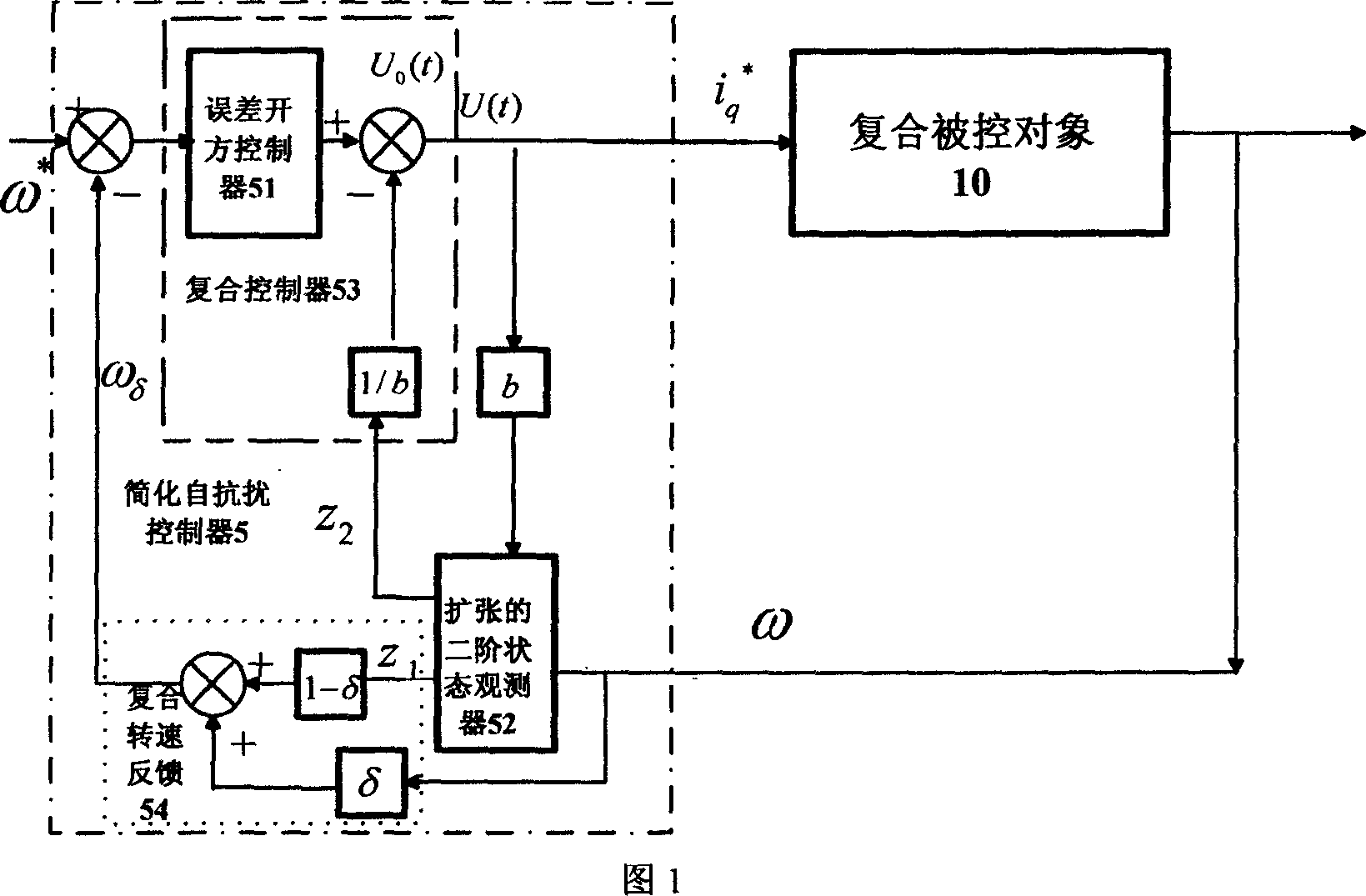

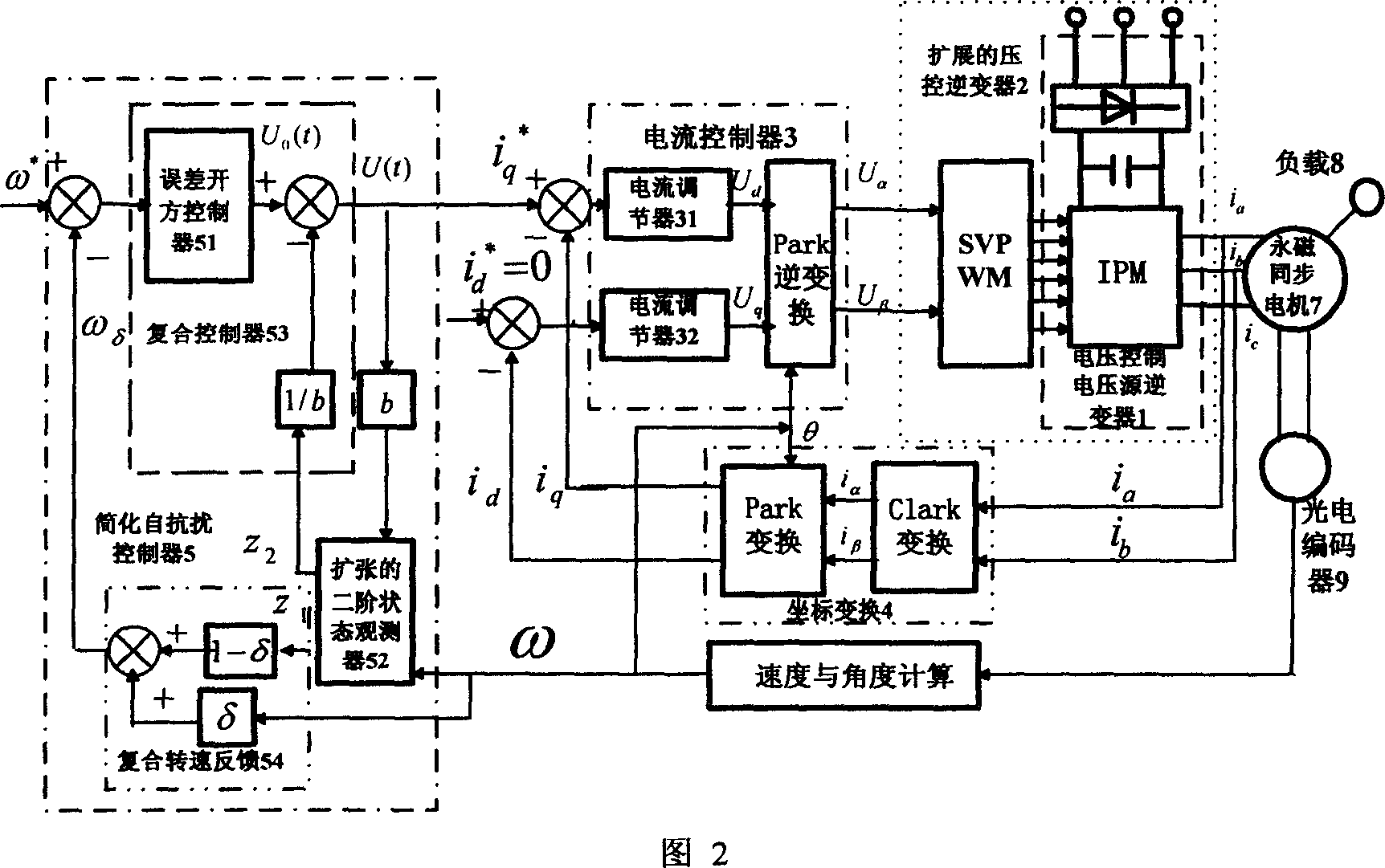

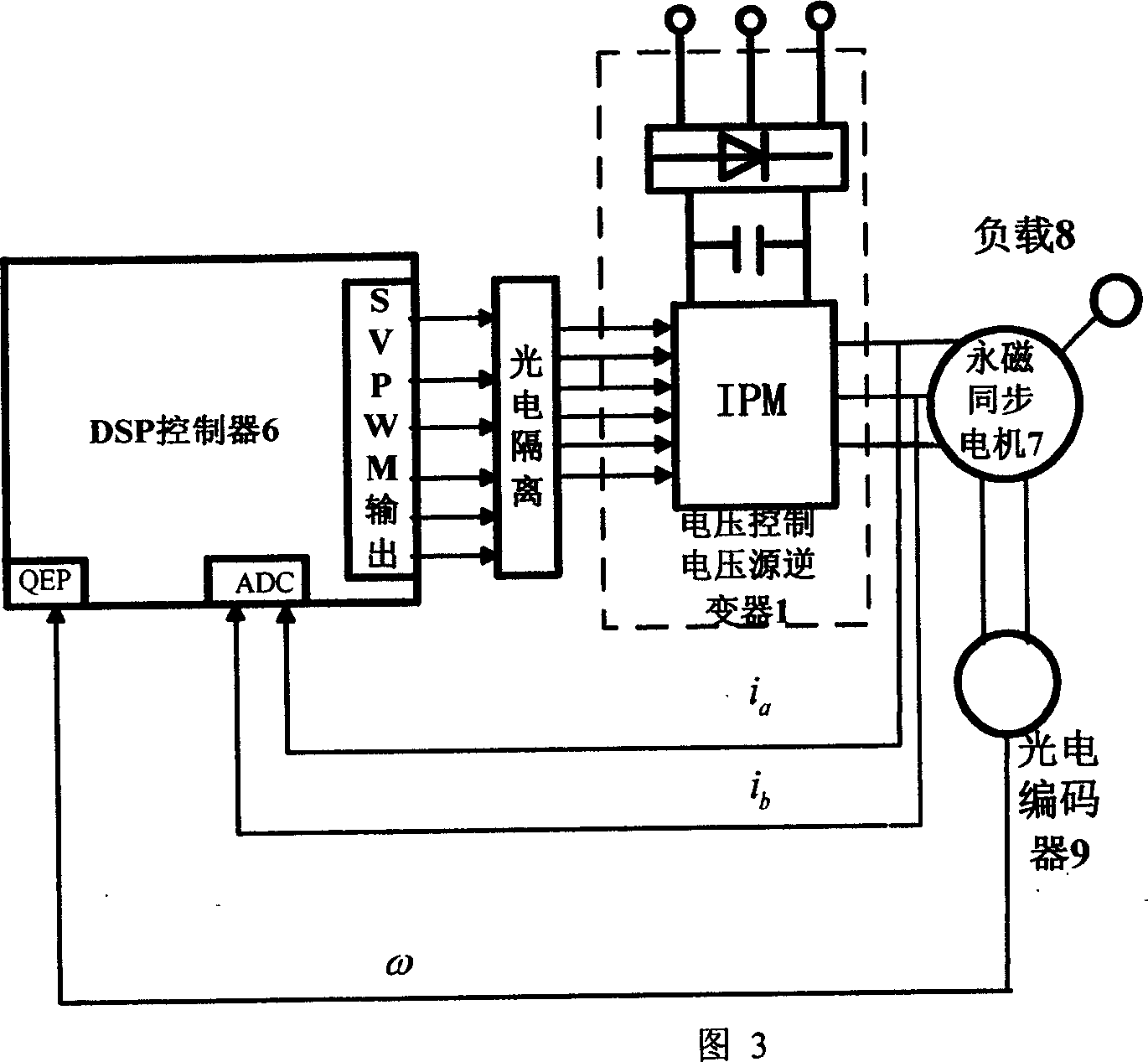

Method for building simplified self interference rejection controller of permanent magnet synchronous machine

ActiveCN1967414AImprove adaptabilityImprove performanceControllers with discontinuous output signalSelf interferencePermanent magnet synchronous motor

A simplified self noise-immunity controller formation method of PMSM (permanent magnet synchronous motor) is applicable to the high performance control of PMSM. It constructs the expanding voltage-controlled inverter (2) by the voltage control voltage source inverter (1) and space vector pulse width modulation; it constructs a composite controlled object (10) by the expanding voltage-controlled inverter and current controller (3), the coordinate transformation (4), the permanent magnet synchronous motor (7), the workload (8) and the photoelectric encoder (9); it constructs the second-order state observer (52) by compositing the input and output signals of the controlled object; It constructs the composite speed feedback (54) by the weighted sum of the two speed measurement value; it constructs the composite controller (53) by the superposition of the generalized rate error square controller (51) and the compensation value of the system perturbation (-z2 / b); it series connects the composite controller before the composite controlled object, and finally, it constructs the simplified self noise-immunity controller (5) by the composite controller and the expanding second-order state observer.

Owner:SOUTHEAST UNIV +1

Method and system for enhancing the yield in semiconductor manufacturing

ActiveUS20090005894A1Less complexShort timeProgramme controlPhotomechanical apparatusSemiconductorSystems engineering

Roughly described, a manufacturing process is enhanced by using TCAD and TCAD-derived models. A TCAD simulation model of the process is developed, which predicts, in dependence upon a plurality of process input parameters, a value for a performance parameter of a product to be manufactured using the process. Estimated, predicted or desired values for a calculated subset of the parameters (including either process input parameters or product performance parameters or both), are determined in dependence upon the process model, and further in dependence upon actual, estimated or desired values for a different subset of the parameters (again either process input parameters or product performance parameters or both). The determination is preferably made using a process compact model of the process, itself developed in dependence upon the simulation model.

Owner:SYNOPSYS INC

Low volume micro satellite with flexible winded panels expandable after launch

ActiveUS9758260B2Improve performanceLow costCosmonautic power supply systemsArtificial satellitesNatural satelliteMicrosatellite

Micro satellite is disclosed with foldable solar panels that may be winded around the body of the micro satellite so that the growth in outer dimensions of the satellite is no more than 10-20 mm along each one of the length, width and height of the microsatellite so that the micro satellite may be launched in an auxiliary payload volume of a launcher. The foldable solar panels may be deployed to employ area that exceeds 9 times the product of the length by the width of the satellite and 6 times the product of the height by the length. The solar power produced by the solar panel and their light weight enable carrying of cargo that is at least 0.6 of the of the total mass of the satellites.

Owner:ASTROSCALE ISRAEL LTD

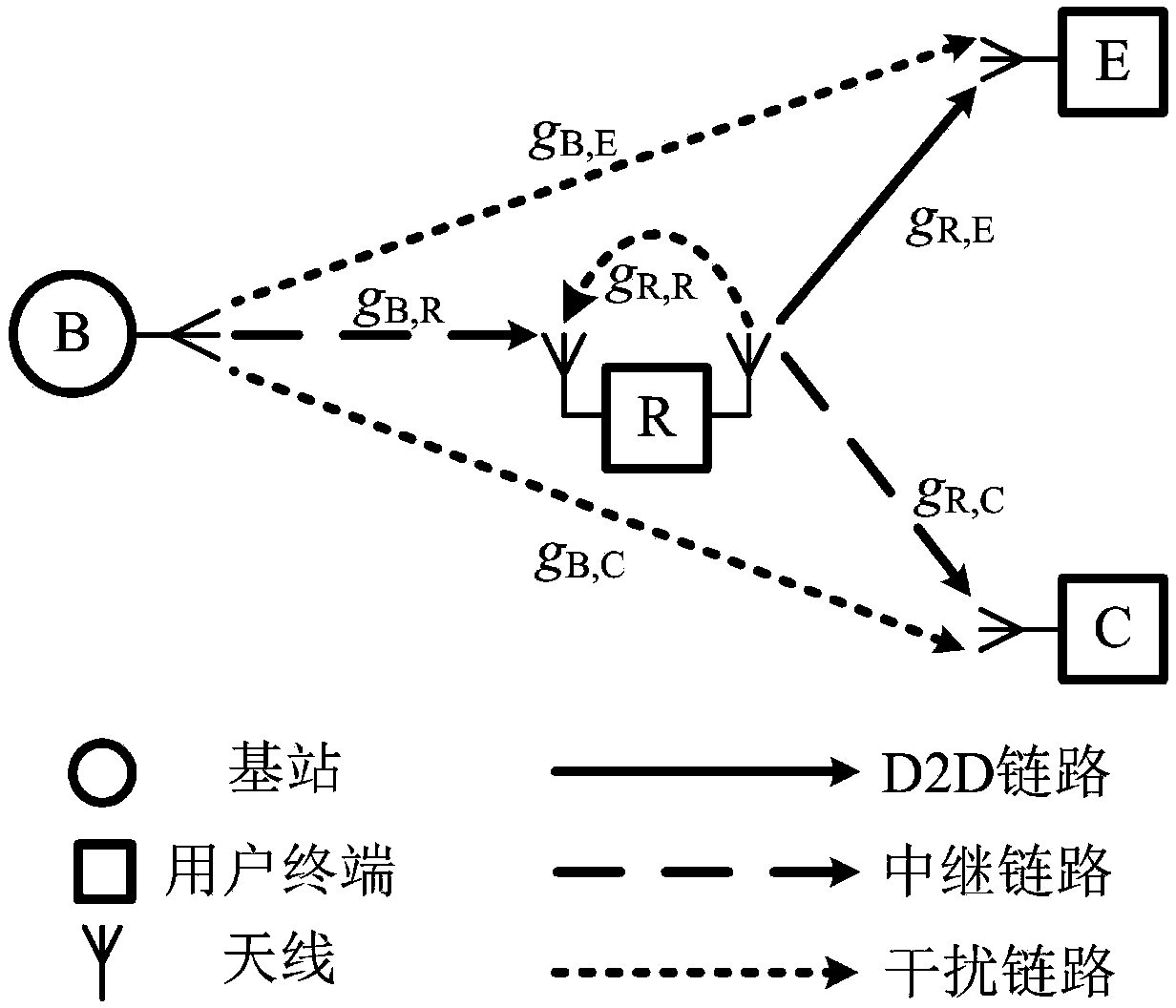

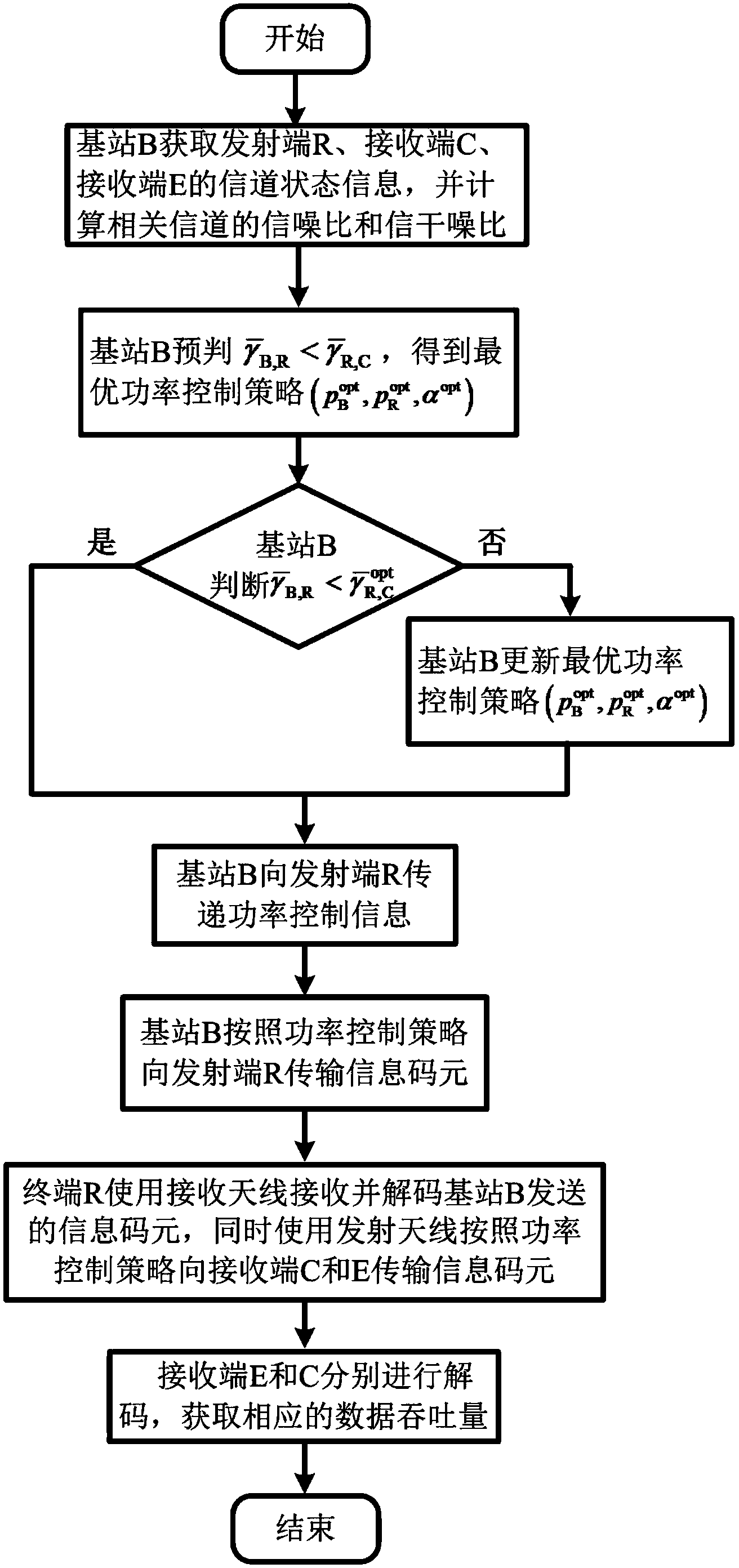

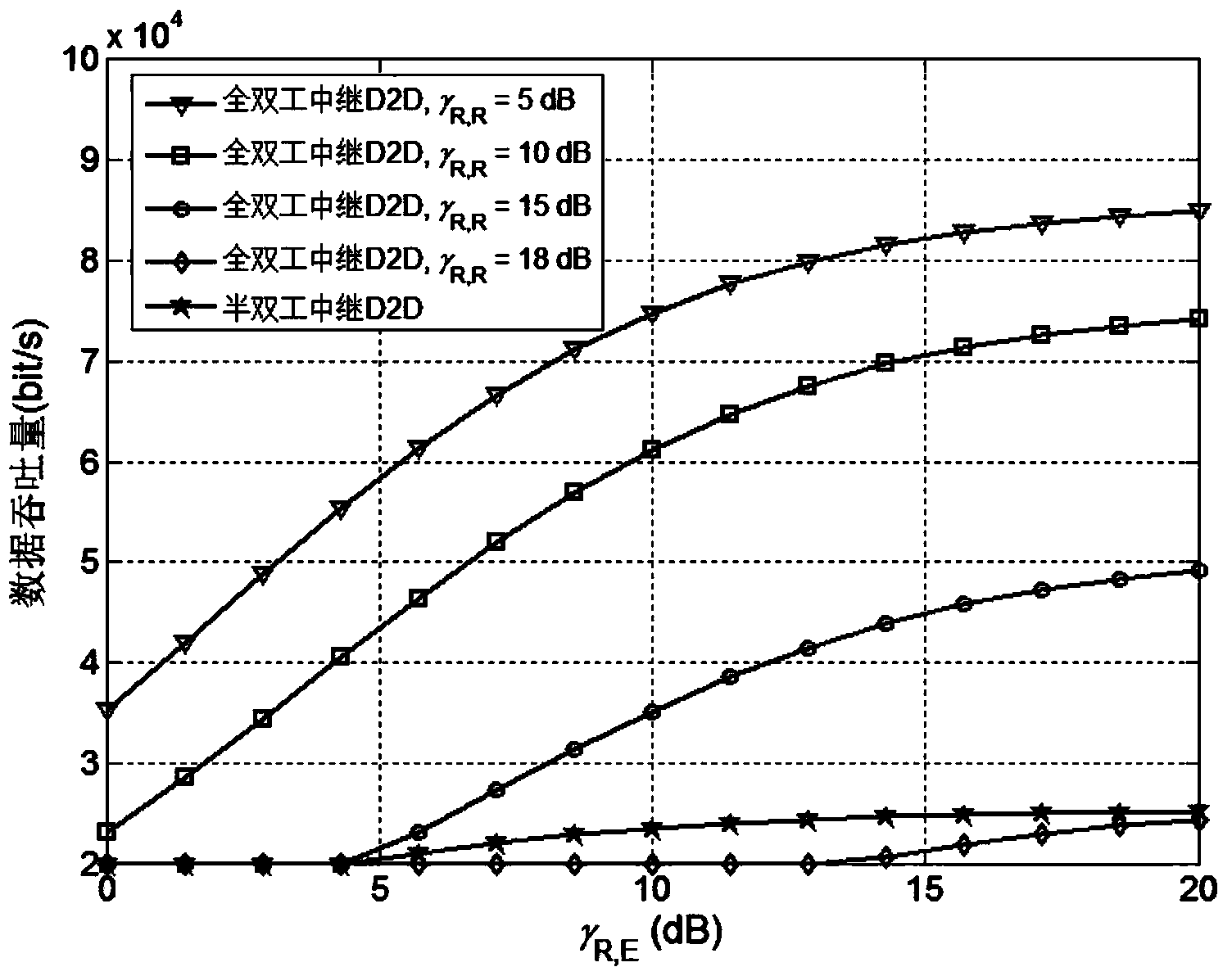

Power control method embedded into D2D cellular network and based on full-duplex relay

InactiveCN104284407AMaximize data throughputMinimum Data Throughput MaximizationPower managementTime domainFrequency spectrum

The invention discloses a power control method embedded into a D2D cellular network and based on a time domain half-duplex relay, and belongs to the technical field of wireless communications. The method relates to a base station B using a point-to-multipoint topological structure cellular network for transmitting, a cellular network receiving terminal C, a D2D transmitting terminal R used as a cellular communication relay and a D2D receiving terminal E; the D2D transmitting terminal is used as a cellular communication relay between the base station B and the receiving terminal C, cellular communication and D2D communication are subjected to combined power control, the full-duplex wireless relay technology is used for achieving orthogonal communication channel frequency spectrum multiplex of the cellular communication and the D2D communication, the minimum data throughout requirement of the cellular communication is met, meanwhile, the throughout of the D2D communication is maximized, hence, the overall performance of the system and the individual performance of users can be considered at the same time, and good balance can be achieved between the system layer and the user layer.

Owner:CHINA UNIV OF MINING & TECH

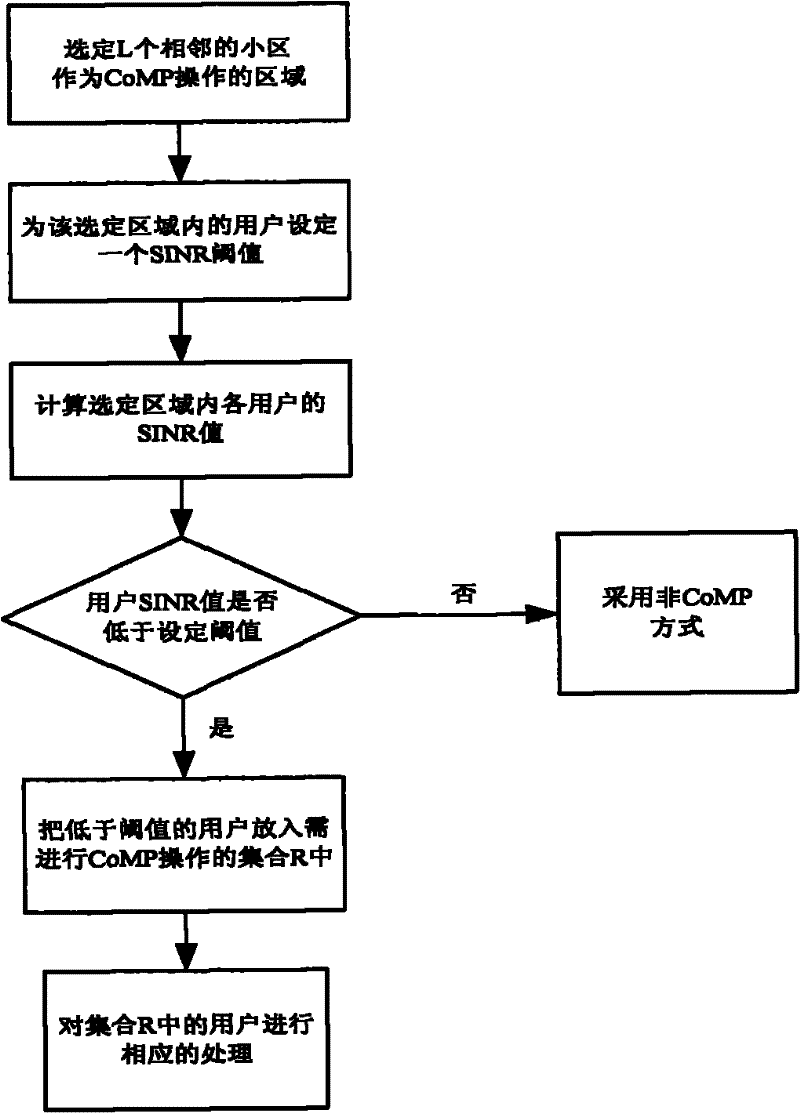

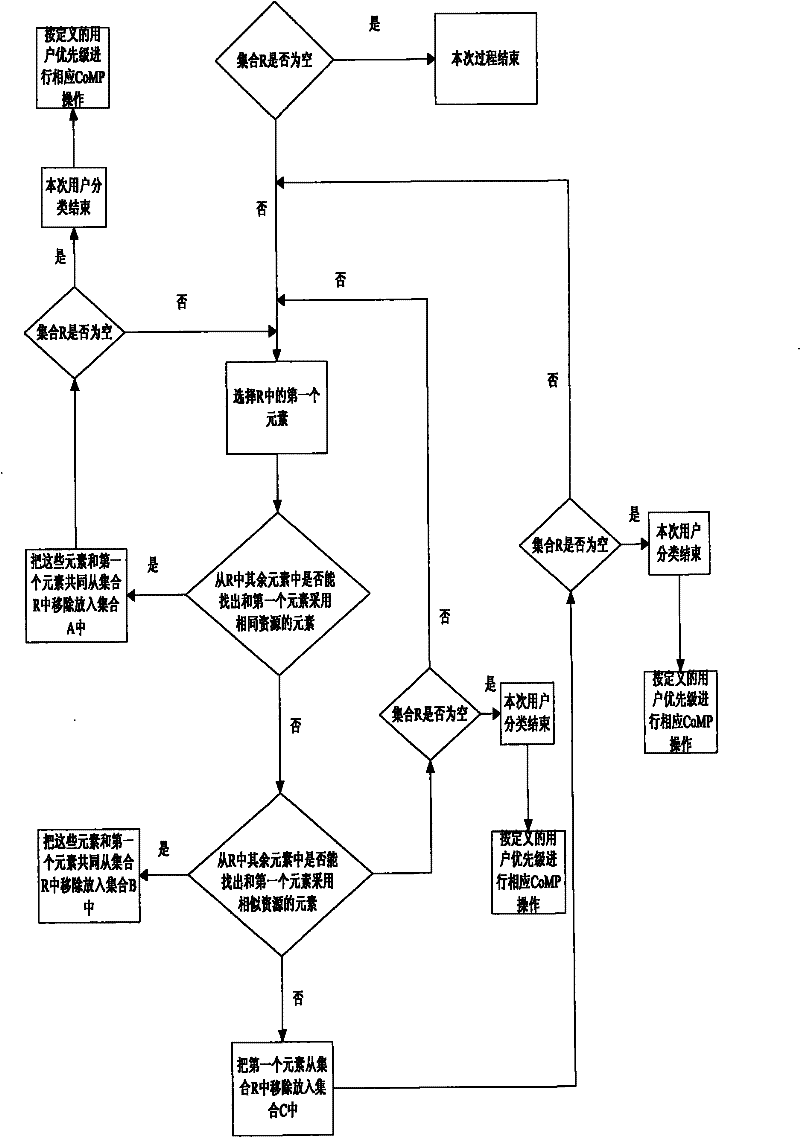

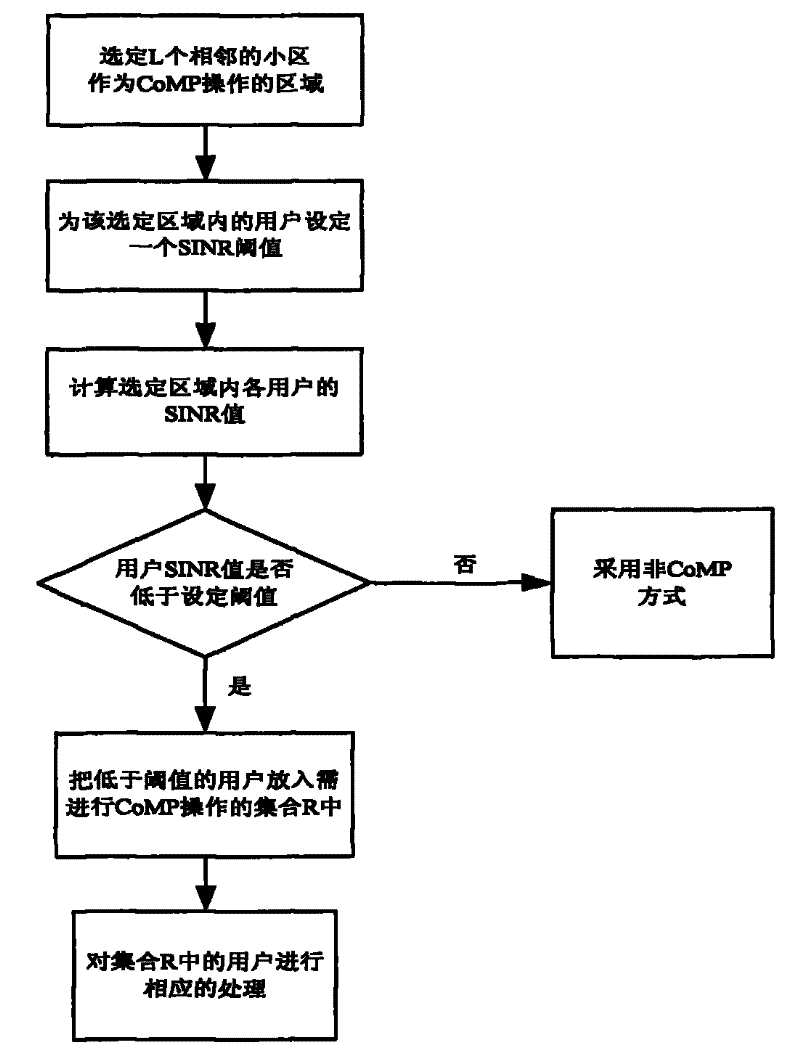

Structuring method of CoMP cell cluster

ActiveCN101754383AImprove performanceConsider performanceWireless communicationUser needsLibrary science

The invention provides a structuring method of a CoMP cell cluster, which comprises the steps of: selecting an area to be carried out the structuring of the CoMP cell cluster from a wireless communication network, and preliminarily determining mobile users needing the CoMP operation in the area; sequentially finding out same users adopting same communication resources, similar users adopting partial same communication resources and different users adopting completely different communication resources from the preliminarily determined mobile users needing the CoMP operation; and structuring the CoMP cell cluster for the same users, the similar users and the different users according to the priority level from high to low. The CoMP operation performed by the structuring method of the CoMP cell cluster not only improves the performance of edge users, but also simultaneously considers the overall performance of the system.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

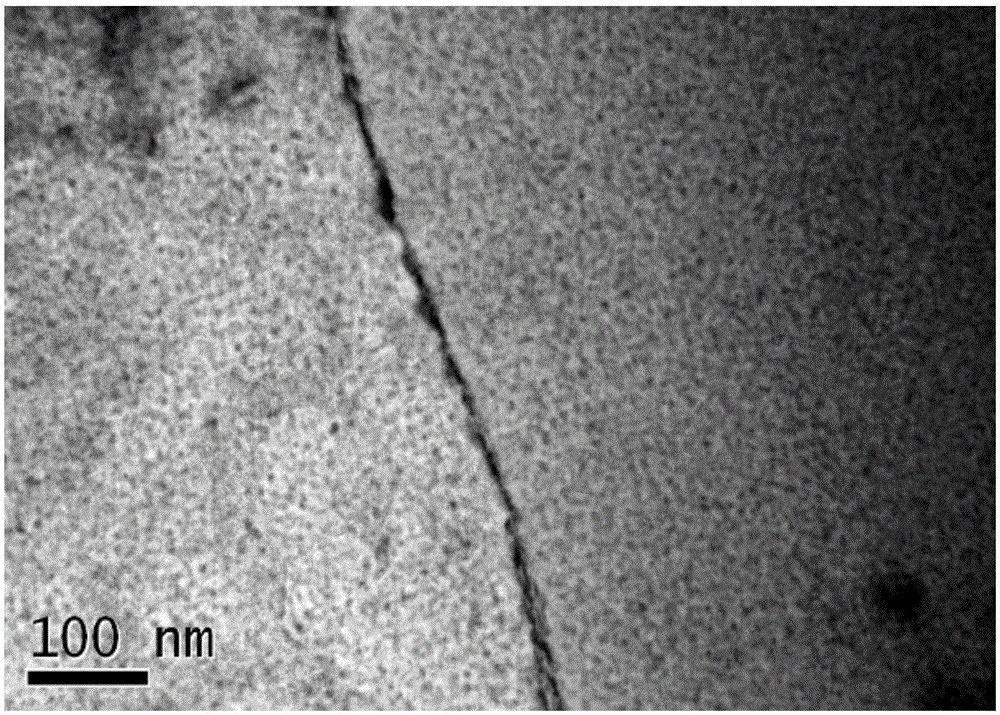

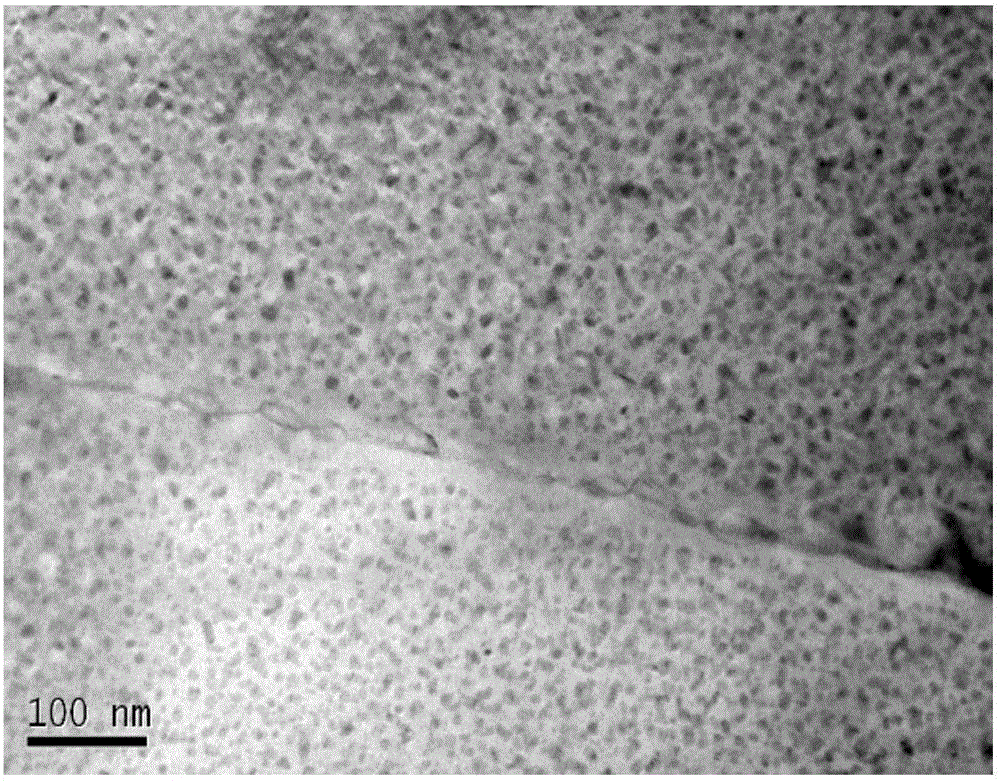

High-damping magnesium alloy containing quasicrystal reinforcing phase and preparation method thereof

The invention discloses a high-damping magnesium alloy containing quasicrystal reinforcing phase and a preparation method thereof. The high-damping magnesium alloy containing quasicrystal reinforcing phase comprises the following alloy components in percentage by weight: 0.9%-1.0% of zinc, 0.15-0.2% of yttrium and 0.6% of zirconium, wherein, zinc and magnesium are industrial pure zinc and industrial pure magnesium; alloy elements, namely, yttrium and zirconium respectively adopt the preliminary alloy form of magnesium-30% of yttrium and magnesium-30% of zirconium to be added in; the high-damping magnesium alloy containing quasicrystal reinforcing phase is prepared by preheating, smelting and shaping. The invention takes zinc, yttrium and zirconium as alloy elements, the atom content ratio of zinc to yttrium in the alloy is controlled to 5-6, so that the formed icosahedron quasicrystal phase has special crystal structure, which ensures the stability of interface combination. The high-damping magnesium alloy containing quasicrystal reinforcing phase of the invention can effectively prevent dislocation slippage and twin crystal expansion, performs favourable strengthening function, effectively overcomes the contradictoriness between the strength and the damping performance in the magnesium base high-damping structure material, has favourable anti-corrosion performance and is a magnesium alloy with comprehensive performance.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

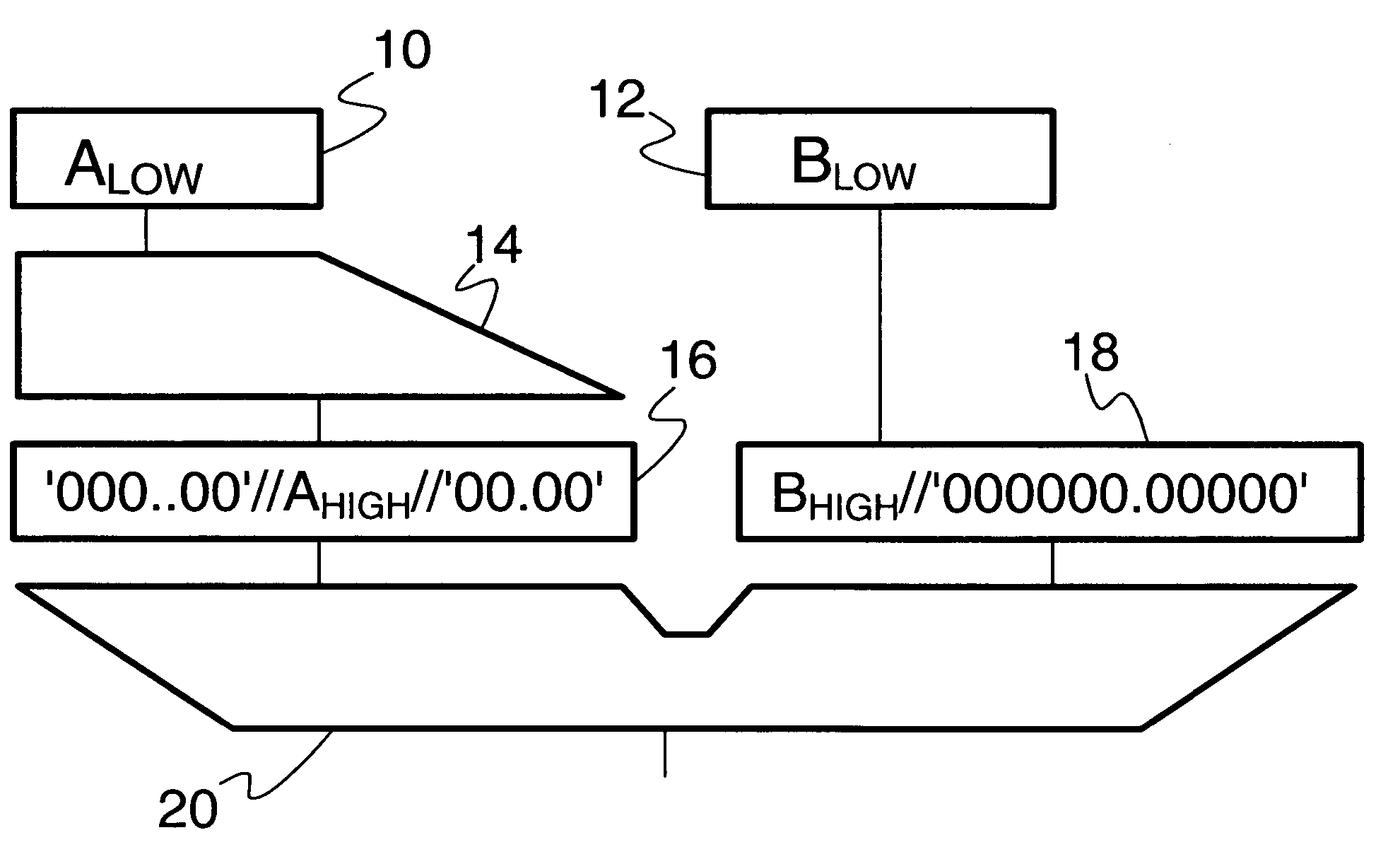

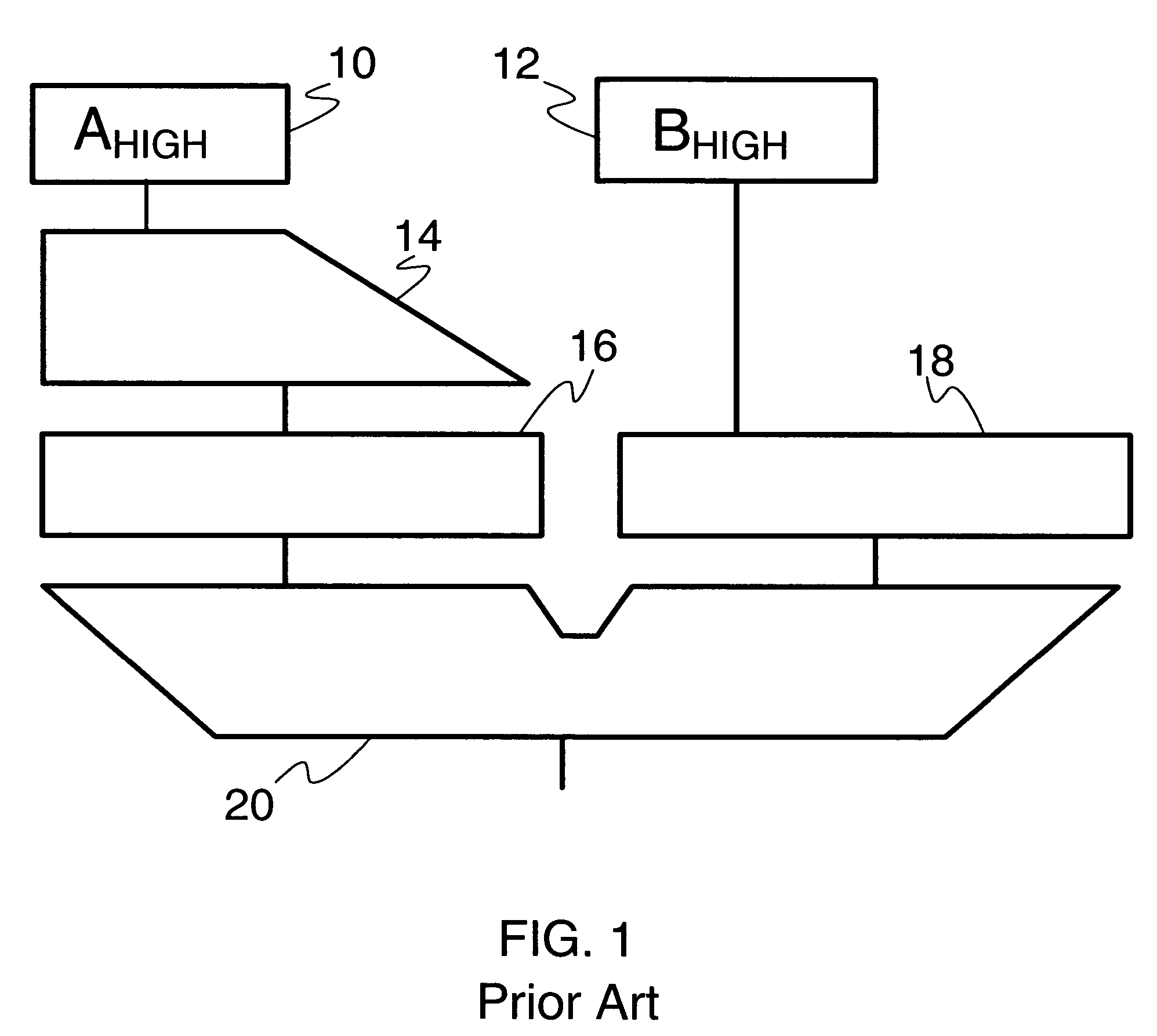

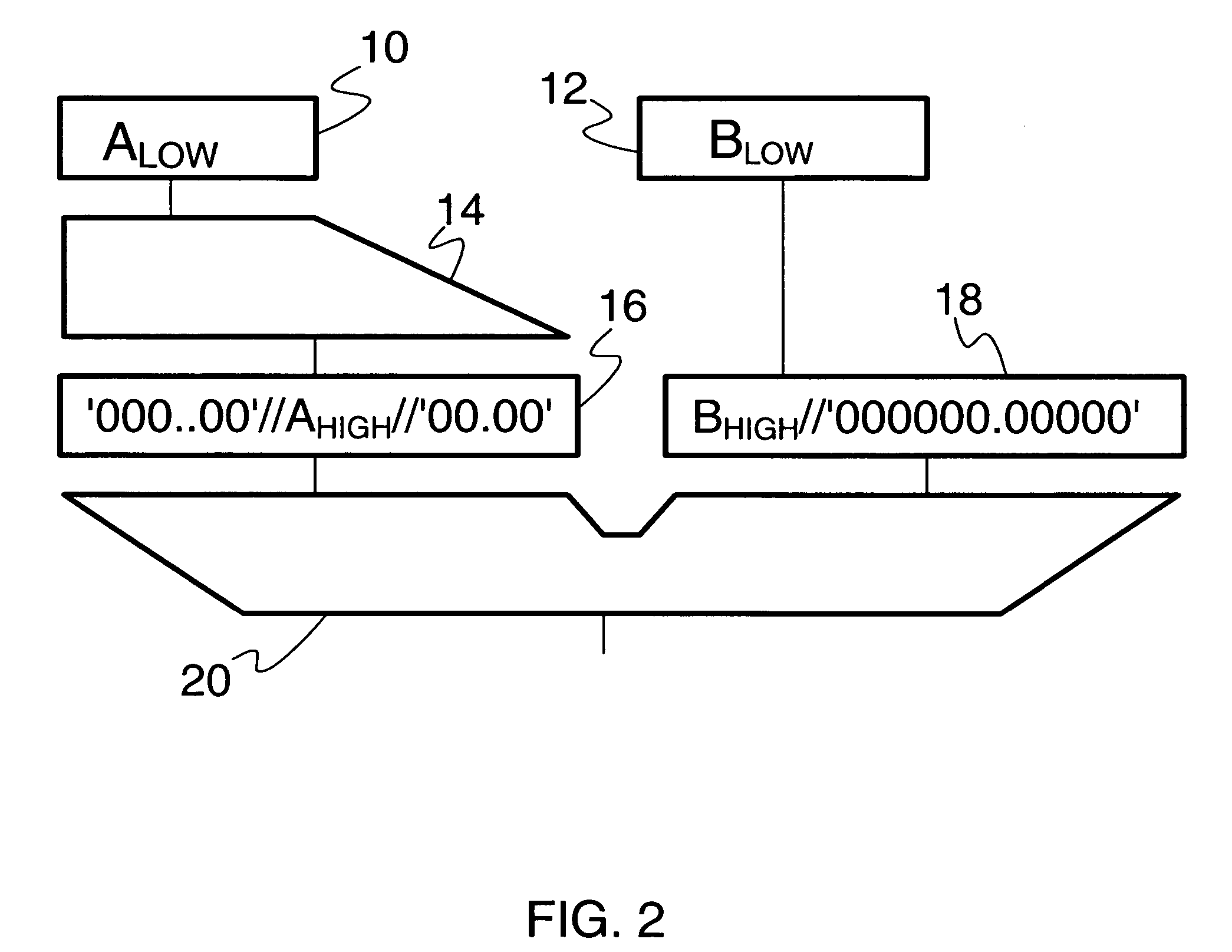

Advanced execution of extended floating-point add operations in a narrow dataflow

InactiveUS7373369B2Improve executionEfficient additionComputations using contact-making devicesComputation using non-contact making devicesProcessor registerOperand

A method and system for performing floating point additive arithmetic operations of long operands in a narrow dataflow. The operands include first and second floating point numbers having first and second mantissas, respectively, the second operand greater than the first operand. The mantissas are both separated into a low portion and a high portion, the high portions are loaded into N-bit operand registers. The high portion of the first mantissa is aligned with respect to the high portion of the second mantissa, the high portions are then moved into 2N-bit registers. The low portion of the first mantissa is aligned in accordance with the alignment of the first mantissa high portion. The low portions of both mantissas are then concatenated into the registers, the first mantissa concatenated using a hold-function circuit. A 2N-bit-wide adder performs the additive arithmetic operation on the concatenated mantissas.

Owner:IBM CORP

Large-strain X80 dual-phase steel plate produced by virtue of process at low temperature and under high pressure

The invention belongs to the field of the low-alloy high-strength pipeline steel and more specifically relates to a large-strain X80 dual-phase steel plate produced by virtue of a process at a low temperature and under a high pressure. The large-strain X80 dual-phase steel plate is composed of the following components in percentage by weight: 0.05-0.07% of C, 0.25-0.35% of Si, 1.40-1.80% of Mn, less than or equal to 0.01% of P, less than or equal to 0.003% of S, 0.01-0.04% of Nb, 0.01-0.02% of Ti, less than or equal to 0.035% of Mo, less than or equal to 0.30% of Cu, less than or equal to 0.035% of Cr, less than or equal to 0.030% of Ni, less than or equal to 40ppm of N, less than or equal to 20ppm of O, less than or equal to 1.2ppm of H and the balance of Fe and inevitable impurities. The large-strain X80 dual-phase steel plate has the beneficial effects that the steel plate is subjected to accelerated cooling by virtue of high-pressure water in the adopted rolling process so that the crystalline grain are effectively refined and the production efficiency is improved, and multi-pass cooling and rolling at a low temperature and under high pressure are not carried out in a non-recrystallization zone, and finally, a proeutectoid ferrite-lath bainite structure is obtained, the obtained steel plate has the yield strength Rt0.5 of 480-560MPa, the tensile strength Rm of 770-800MPa, the yield ratio Rt0.5 / Rm being less than or equal to 0.75, the Charpy impact energy at -20 DEG C being greater than or equal to 350J, the drop shear area at -15 DEG C being greater than or equal to 95% and the Uniform elongation UEL being greater than or equal to 12, and the steel plate is high in anti-deforming capability, and furthermore, the stress ratios of the steel plate are as follows: Rt2.0 / Rt1.0 is greater than or equal to 1.09 and Rt1.5 / Rt0.5 is greater than or equal to 1.15.

Owner:JIGANG GRP

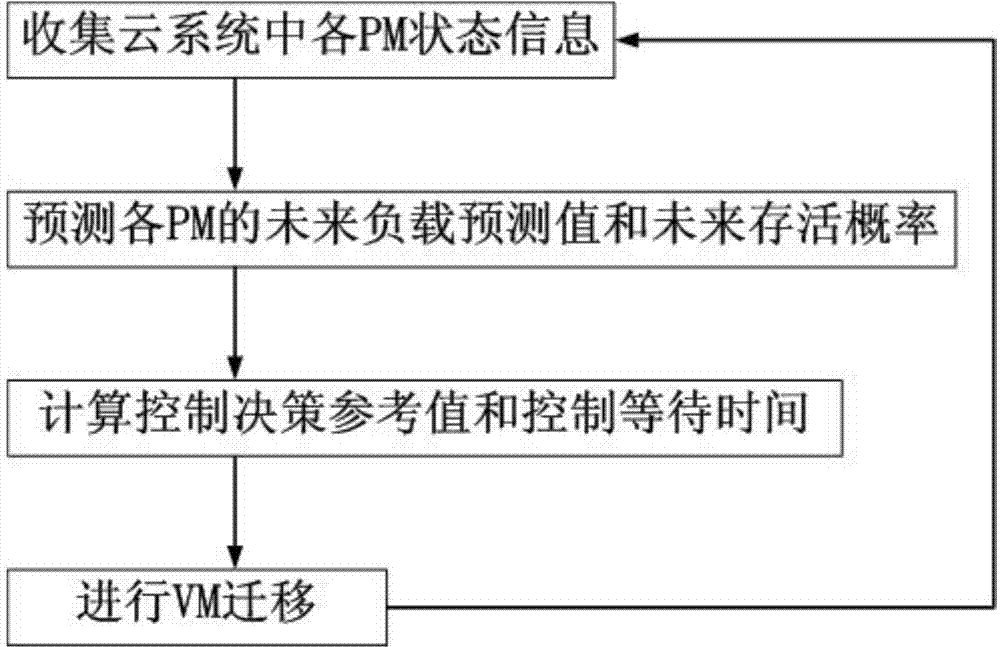

Method, device and system for migrating cloud virtual machine

InactiveCN103685542AImprove load balancingConsider performanceData switching networksComputing systemsVirtual machine

The invention discloses a method for migrating a cloud virtual machine, and belongs to the field of cloud computing. The runtime load change of each host machine of a cloud computing system and the reliability performance of the cloud computing system are dynamically tracked, then the control opportunity is self-adaptively determined, and the virtual machine is migrated among the host machines for responding for the load and reliability change of the system in real time, thus the load balance degree of the system and the task reliability are improved. According to the method, the device and the system, dynamic fluctuation of cloud system load is taken into full consideration, the prospective trend change of the system is predicted by tracking the trend, and the load balance is improved by carrying out VM (Virtual Machine) migration in advance. The failure possibility of PM (Physical Machine) is taken into consideration of the load balance, so that the strategy of VM migration can give consideration to performance and task reliability; meanwhile, variable control interval time is dynamically calculated according to system status, so that two extremes of 'control over-density' and ' control over-sparseness' are avoided.

Owner:CHONGQING RADIO & TV UNIV

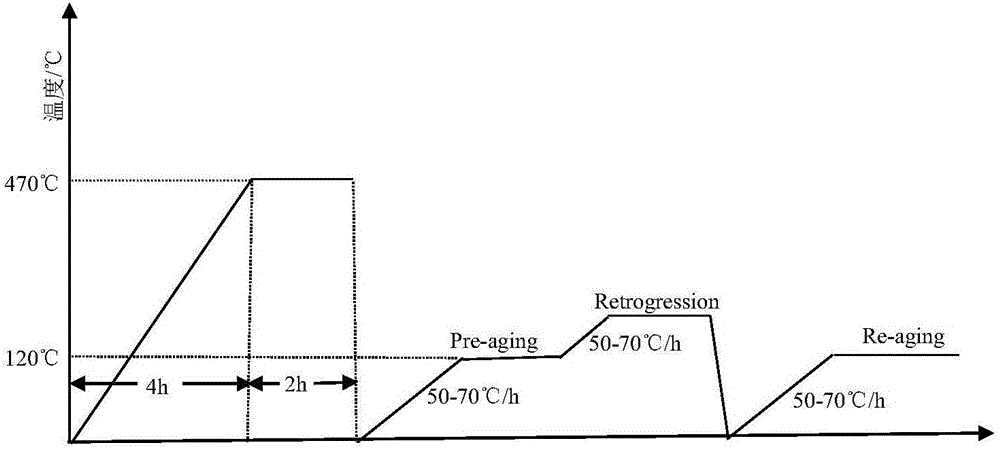

Thermal treatment process for high-strength anticorrosion aluminum alloy

ActiveCN105951008AImprove corrosion resistanceInhibition of recrystallizationThree levelSolution treatment

The invention provides a thermal treatment process for a high-strength anticorrosion aluminum alloy and belongs to the technical field of thermal treatment of aluminum alloy materials. The thermal treatment process includes the following specific steps that the aluminum alloy deformed through hot extrusion is subjected to low-speed temperature-rising solution treatment and then subjected to three-level aging treatment; in the three-level aging process, the temperature rises to 120 DEG C from the room temperature at the temperature rising speed of 50 DEG C / h to 70 DEG C / h, and then the temperature is kept for 24 hours; then the temperature rises to 170 DEG C to 190 DEG C from 120 DEG C at the temperature rising speed of 50 DEG C / h to 70 DEG C / h with a furnace, then the temperature is kept for 40 min to 120 min, and then the alloy is cooled to the room temperature; and finally, the temperature of the obtained alloy rises to 120 DEG C from the room temperature at the temperature rising speed of 50 DEG C / h to 70 DEG C / h, then the temperature is kept for 24 hours, and then the alloy is cooled to the room temperature. By the adoption of the thermal treatment process, the anticorrosion performance of the alloy is improved on the premise of guaranteeing the strength, low-speed temperature rising in the solution and aging processes is more beneficial to diffusion of atoms, the purpose that large thick components are uniformly heated is more easily achieved, and the thermal treatment process is more suitable for industrial production.

Owner:BEIJING UNIV OF TECH

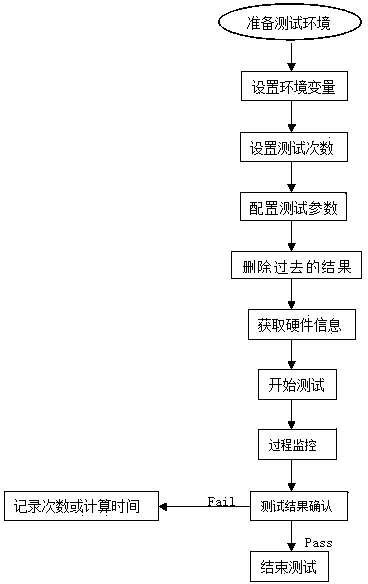

Verification method for HDD detecting failure and HDD out-of-order defect of server

InactiveCN104133749AAchieve double-layer verification effectTo achieve the purpose of stability testingDetecting faulty computer hardwareValidation methodsData recording

The invention discloses a verification method for HDD (Hard Disk Drive) detecting failure and an HDD out-of-order defect of a server, and belongs to an HDD test method. According to the method, a product serial number of the HDD is captured to be used for HDD recording; the HDD ordering in each time is subjected to data recording and comparison; record data and comparison results are stored into a record table; and whether the HDD detecting failure or the HDD out-of-order defect occurs or not is judged through checking the record table. The verification method for the HDD detecting failure and the HDD out-of-order defect of the server provided by the invention has the advantages that the operation is simple; the practicability is higher; the stability of the server is effectively ensured; and the method belongs to a very effective method for verifying the product quality.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

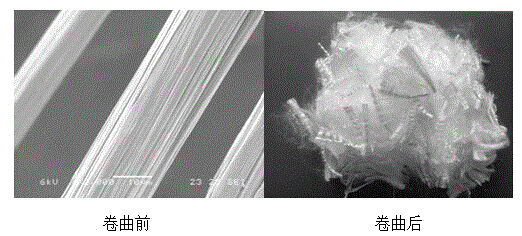

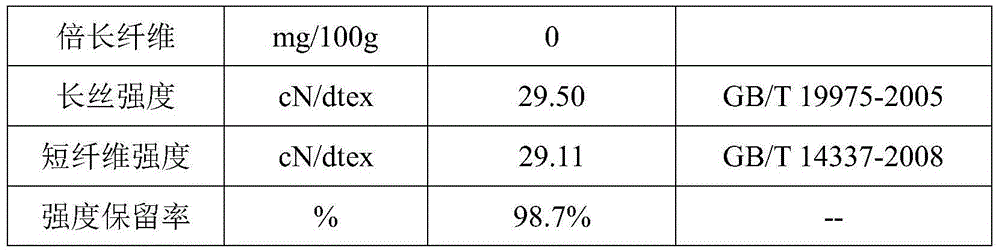

Ultrahigh molecular weight polyethylene short fiber and preparation method thereof

InactiveCN106283246AMeet the requirements of different styles of spinning processEasy to combSevering to form staple fibresArtificial filament heat treatmentFiberPolymer science

The invention discloses ultrahigh molecular weight polyethylene short fiber and a preparation method thereof. The preparation method includes: preparing protofilament of the ultrahigh molecular weight polyethylene short fiber, subjecting the protofilament to assembly winding and bundling, and cleaning oil on the protofilament; applying anionic high-strength polyethylene short fiber oil, performing cold crimping, and loosening and setting the crimped fiber at 80-120 DEG C, wherein drying time is 5-30min, and drying thermosetting temperature is 90-100 DEG C; adjusting tension, and cutting to obtain ultrahigh molecular weight polyethylene short fiber of 3-10 / 25mm in crimp number, wherein cutting length is 3-102mm. The section of the ultrahigh molecular weight polyethylene short fiber is special-shaped, the short fiber has certain natural crimping characteristic and is easy to comb and glue, and cohesion, spinnability and blending performance of the short fiber are improved; fiber number of the short fiber is 0.5-2.5dtex, cutting length is 3-102mm, and strength is 10-40cN / dtex, so that requirements on different styles of subsequent spinning processes can be met.

Owner:SINOPEC YIZHENG CHEM FIBER +1

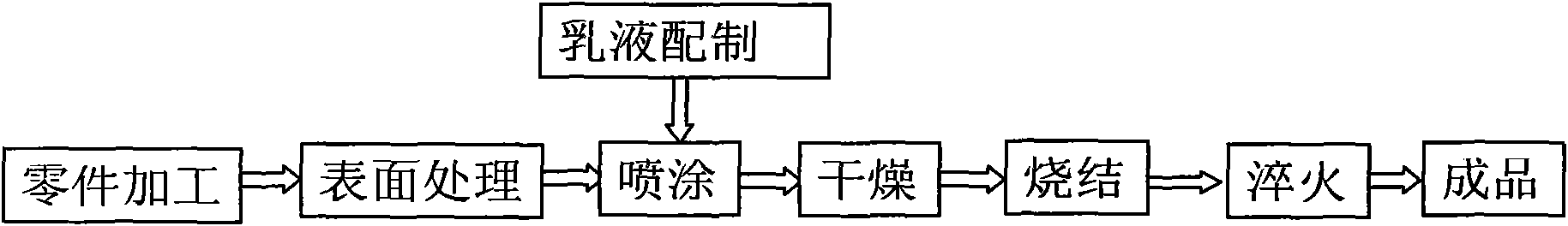

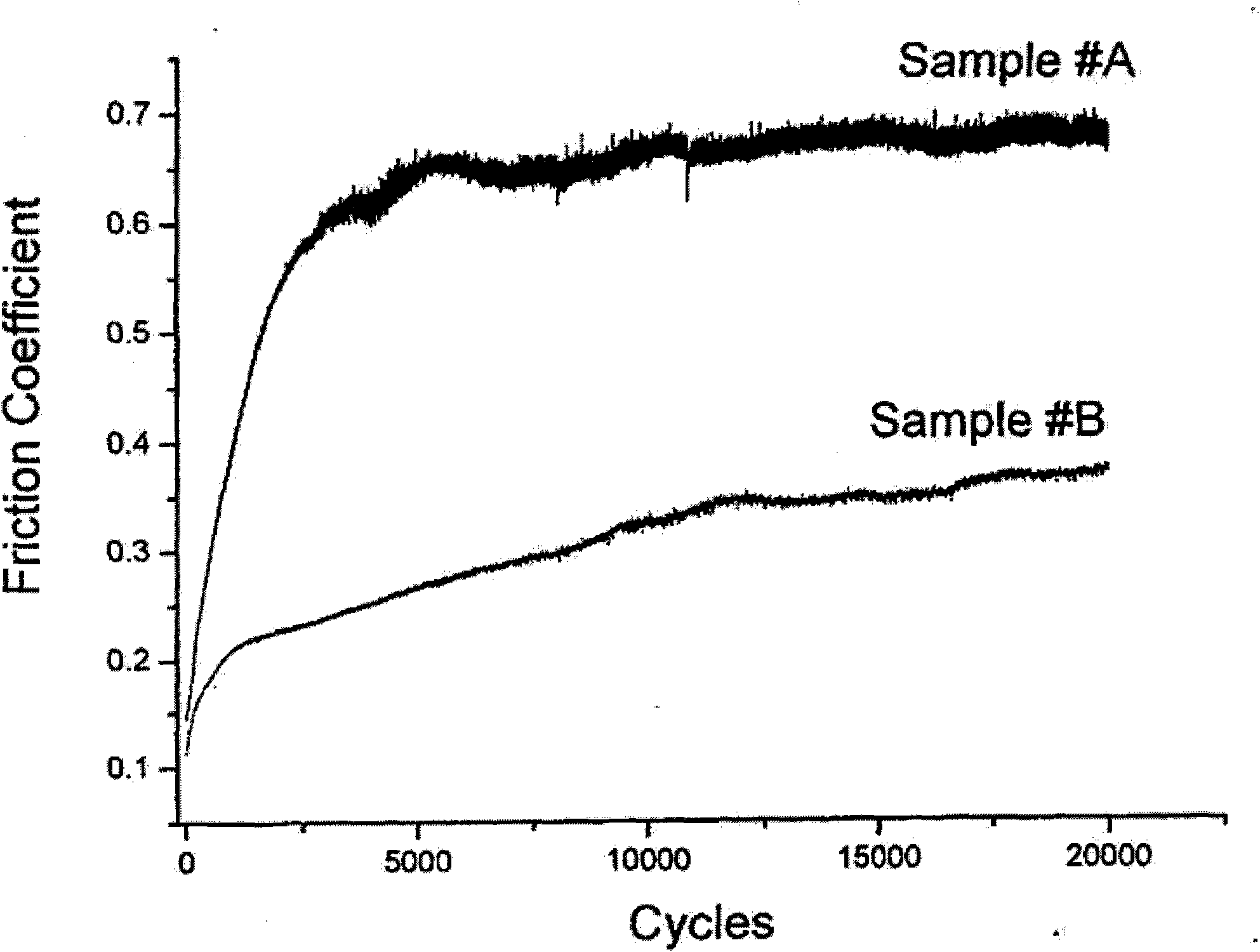

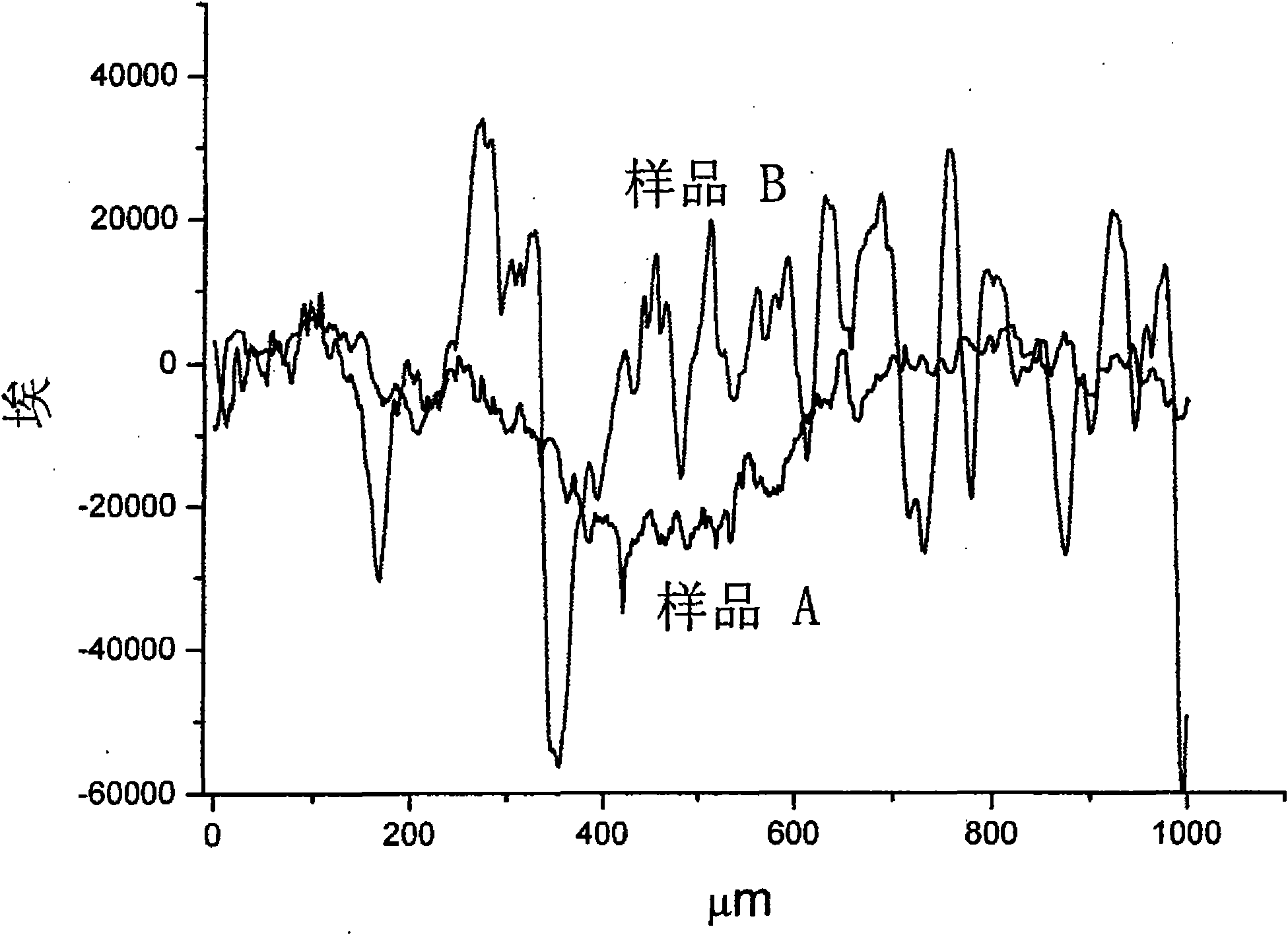

Abrasion-resistant and friction-reducing emulsion and preparation method for spraying same on surface of soft metal

InactiveCN101831222AExtended service lifeReasonable thicknessPretreated surfacesSpecial surfacesPhosphoric acidAlloy

The invention discloses abrasion-resistant and friction-reducing emulsion. The abrasion-resistant and friction-reducing emulsion comprises 50 to 69 parts of polytetrafluoroethylene emulsion, 2.0 to 5.9 parts of chromium oxide, 2.5 to 5.4 parts of phosphoric acid, 0.2 to 0.4 part of lauryl sodium sulfate, 0.5 to 3.0 parts of abrasion-resistant additive and 20 to 40 parts of distilled water. The invention also relates to a preparation method for spraying the abrasion-resistant and friction-reducing emulsion on the surface of a soft metal. The method comprises the following steps of: preparing the abrasion-resistant and friction-reducing emulsion with the components; treating the surface of soft metal matrix; spraying the emulsion on the surface of the soft metal; drying the soft metal; sintering the soft metal; and quenching the soft metal. When the abrasion-resistant and friction-reducing emulsion of the technical scheme of the invention is coated on the surface of the soft metal, the friction coefficient can be reduced by 20 percent, and the abrasion amount ratio of the soft metal to the basis material is less than or equal to 0.5. The abrasion-resistant and friction-reducing emulsion can be widely used for surface treatment of the soft metal such as copper, aluminum and alloy thereof and the like at a friction and abrasion part of a gear pump side plate, a bearing bush, a bearing block hole, a cylinder barrel and the like, and has novel structure and originality.

Owner:LUZHOU GUOBANG MACHINERY

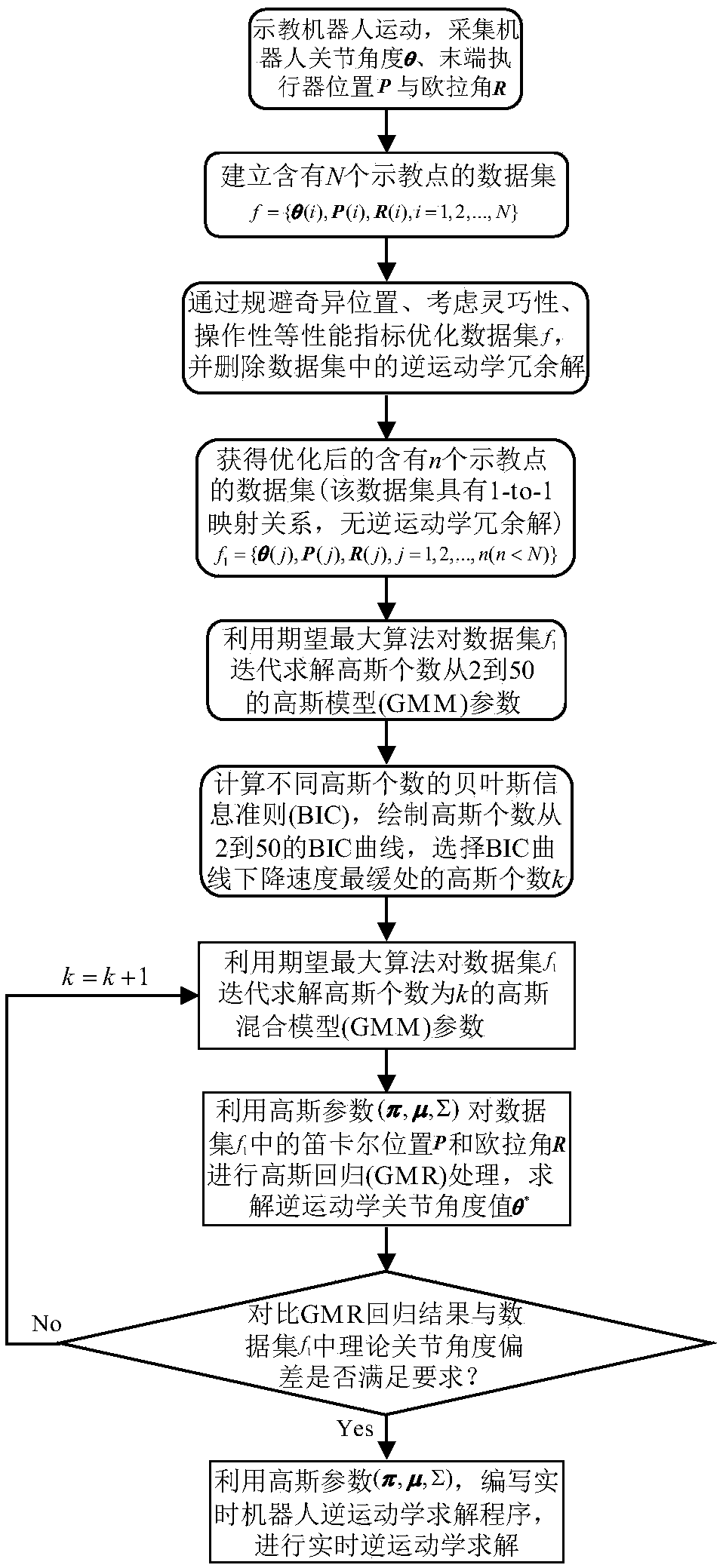

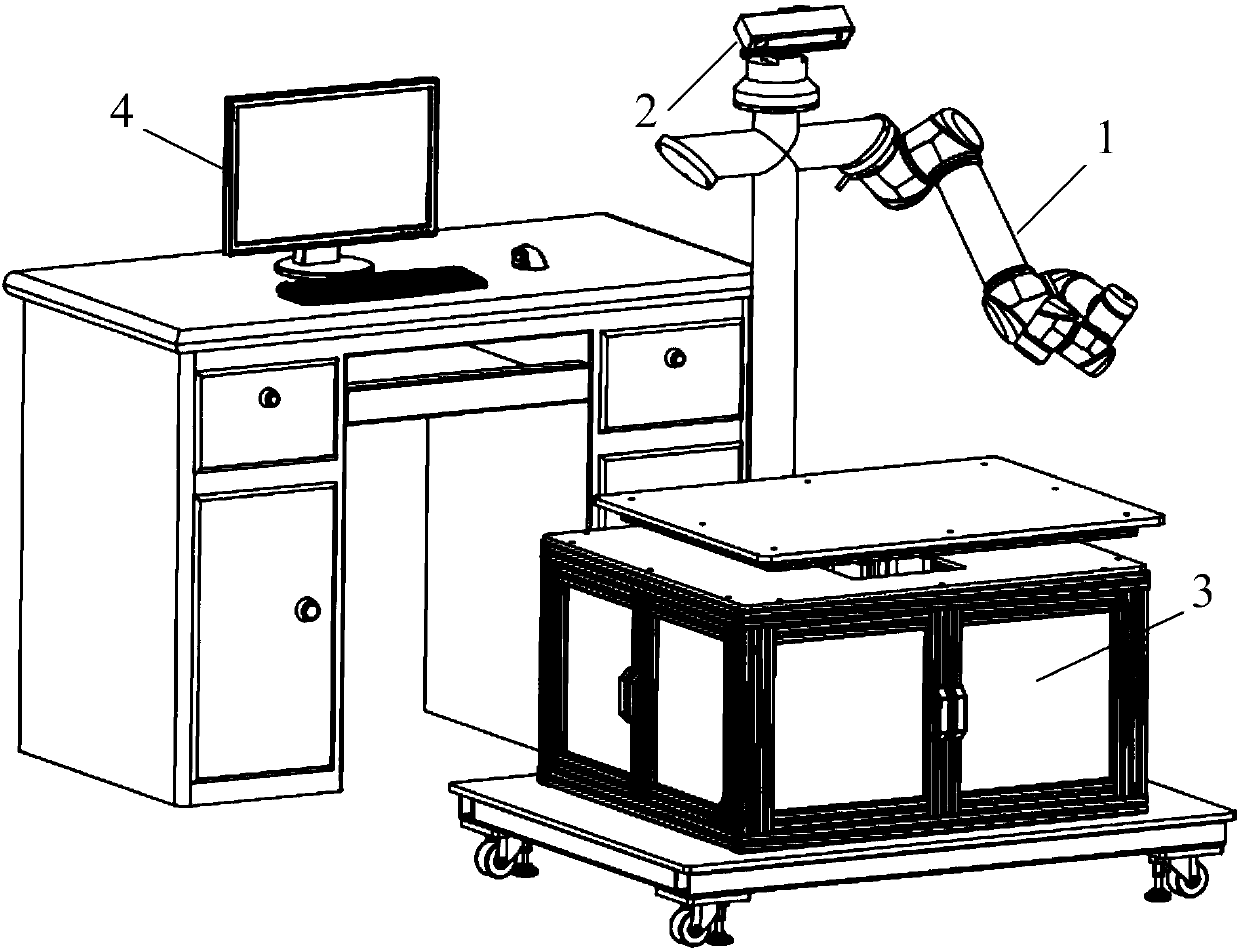

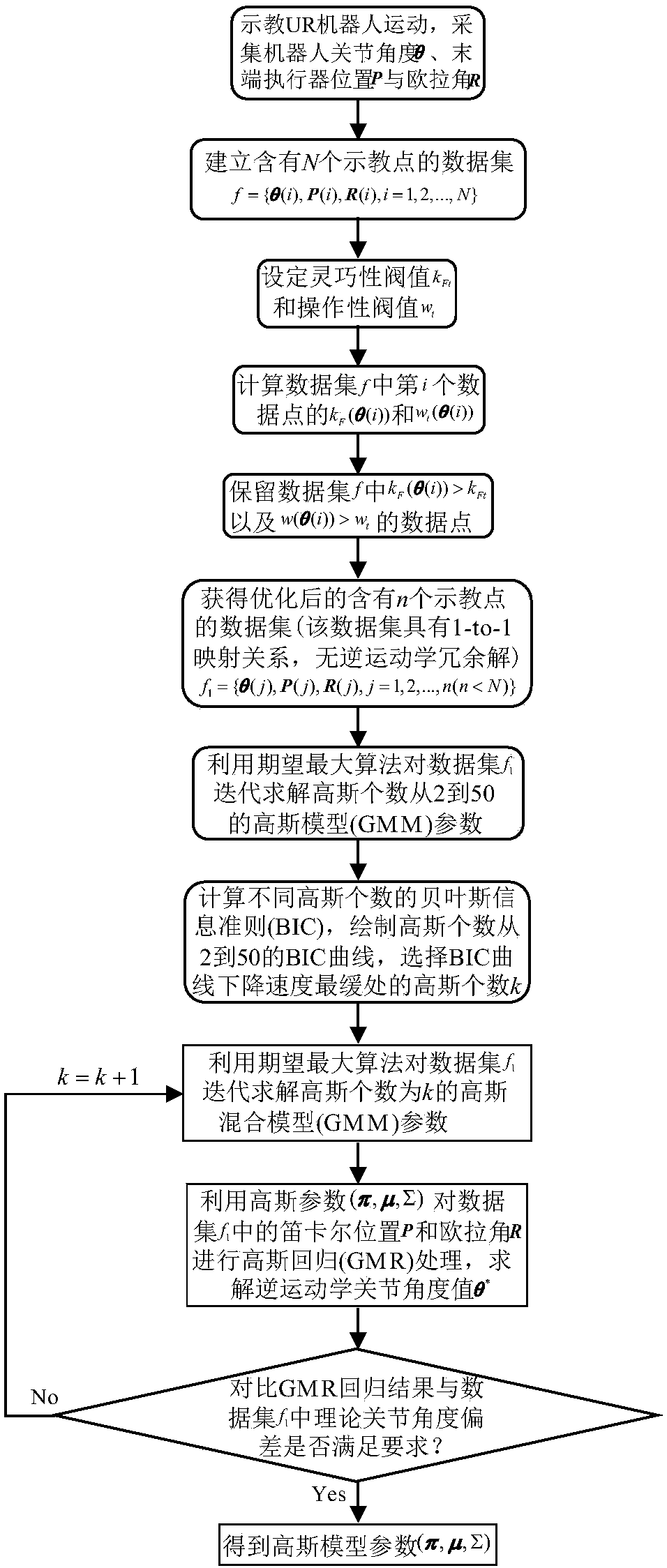

Inverse kinematics solution method for robot based on teaching learning

InactiveCN108427282ACalculation speedRealize high real-time computingAdaptive controlBayesian meldingEuler angles

The invention belongs to the field of robot kinematics solution, and particularly discloses an inverse kinematics solution method for a robot based on teaching learning. The method comprises the following steps of collecting the joint angle of N sets of robots and the Cartesian position and Euler angle of an end effector, and obtaining a data set f; optimizing the data set f to obtain the data setf1; iteratively solving the data set f1 to obtain Gaussian mixture model parameters with 2-50 Gaussian models; calculating Bayesian information criterion values corresponding to Gaussian mixture models, drawing a Bayesian information criterion curve, and determining a Gaussian number k according to the curve; solving the Gaussian mixture model with the Gaussian models of which the number is k; using the model parameters to conduct Gaussian regression treatment on the Cartesian position and the Euler angle of the data set f1, and solving an inverse kinematic joint angle value; comparing the joint angle value with the joint angle value in the data set f1, and correcting the number of the Gaussian models to obtain desired solution accuracy. The method has the advantages of fast calculation speed, strong applicability, good real-time control effect and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

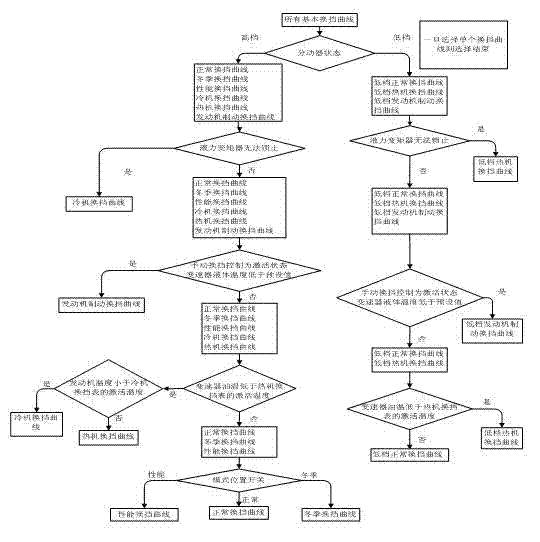

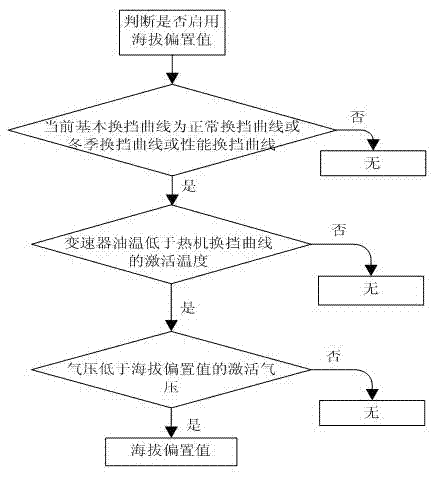

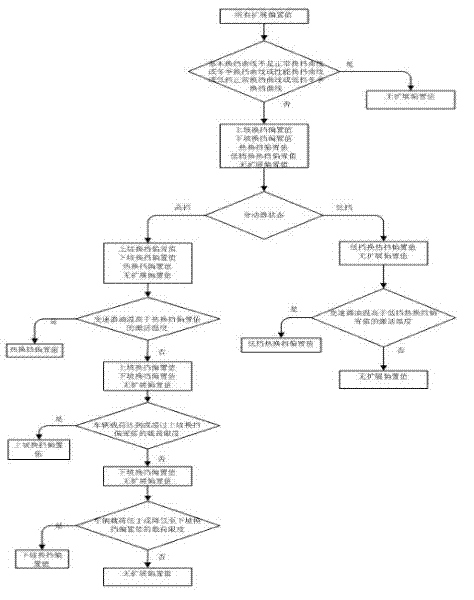

Shift control method of automobile transmission

The invention discloses a shift control method of an automobile gearbox, and aims to provide a shift control method of an automobile gearbox capable of setting different shift points according to the current driving environment. The shift control method comprises the following steps: a, selecting a basic shift curve according to the transfer case state, the engine temperature and the transmission oil temperature; b, selecting an elevation offset value according to the air pressure, the transmission oil temperature and the basic shift curve; c, selecting an expanding offset value according to the car load and the transmission oil temperature; d, using the elevation offset value and the expanding offset value to revise the basic shift curve; and e, monitoring the pedal position when a vehicle runs, and determining the corresponding shift point according to the revised shift curve. An optimal shift table can be selected according to the transfer case state, the transmission temperature, the engine temperature, the air density and the car load, thereby providing the best driving state. The shift control method provided by the invention is suitable for all automobile automatic gearboxes.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

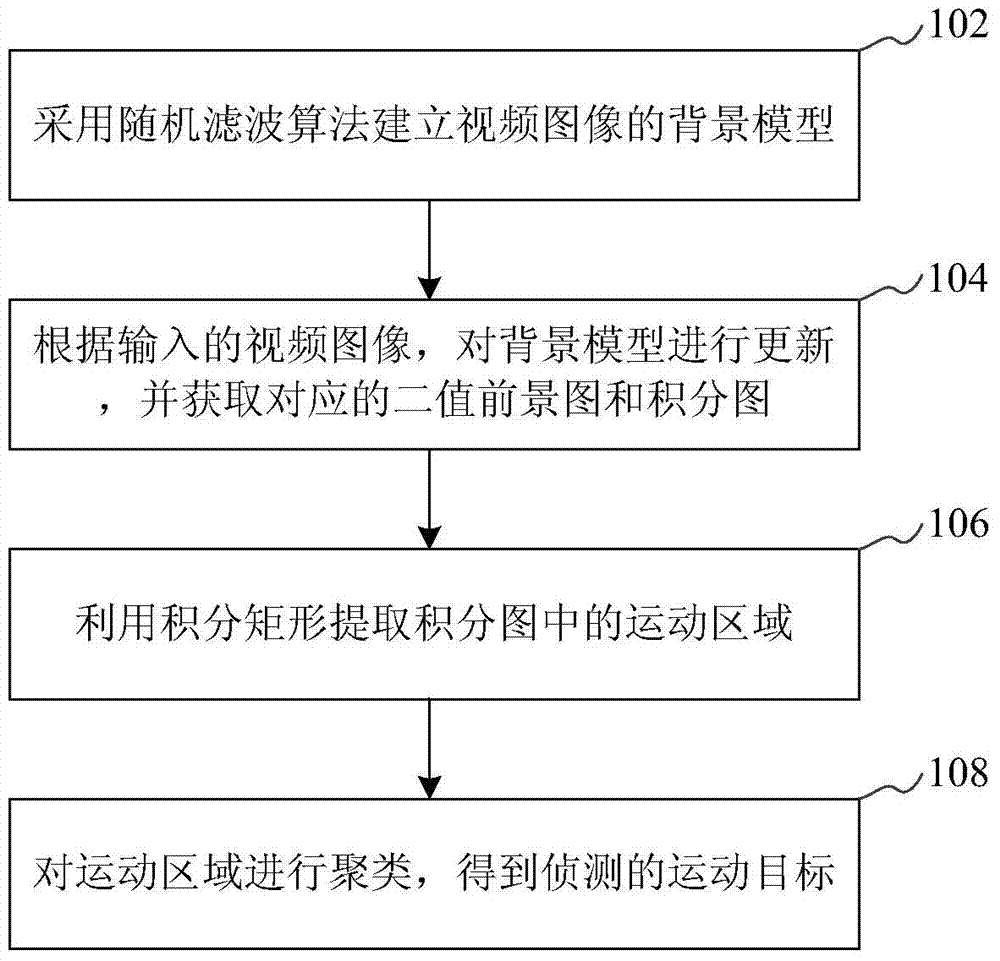

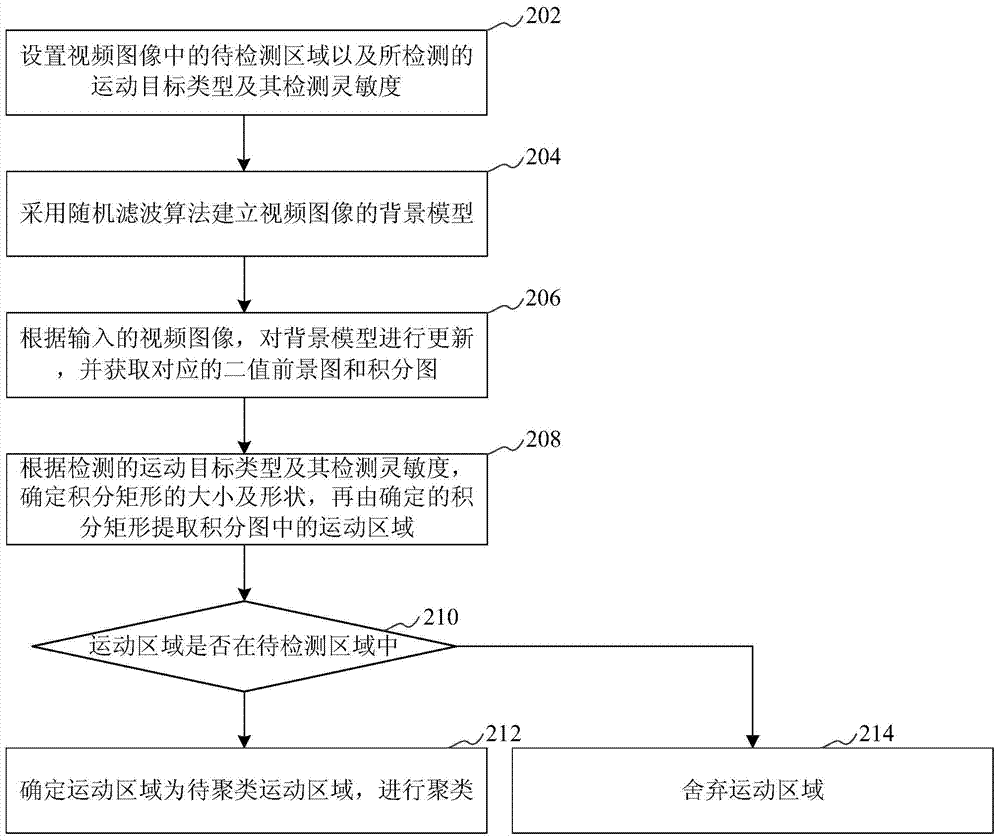

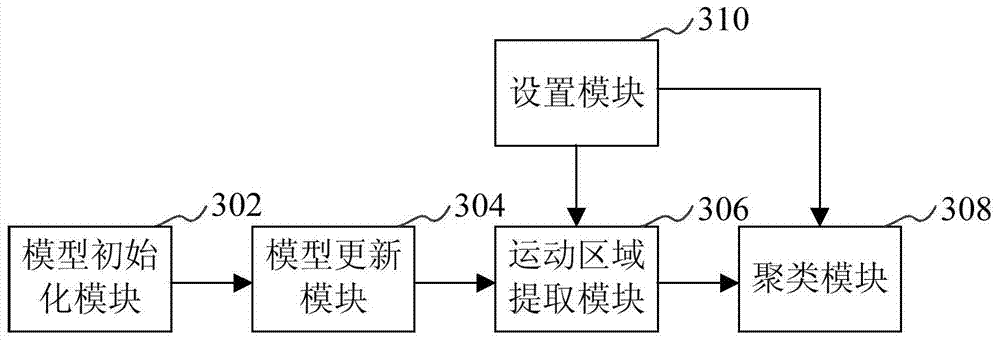

Motion detection method and device

ActiveCN103700087AImprove robustnessImprove detection accuracyImage analysisFilter algorithmMonitor equipment

The invention discloses a motion detection method which comprises the following steps: establishing a background model of a video image by using a random filtering algorithm; updating the background model according to the input video image, and acquiring a corresponding binary foreground picture and an integrogram of the binary foreground picture; extracting motion areas in the integrogram by using integral rectangles; clustering the motion areas so as to obtain a motion target. The invention further discloses a motion detection device. By adopting the technical scheme, the accuracy in motion detection is improved, both the property and the speed are taken into account, higher calculation cost is needless, and the method and the device are particularly applicable to embedded type monitoring equipment.

Owner:艾智科技技术(深圳)有限公司

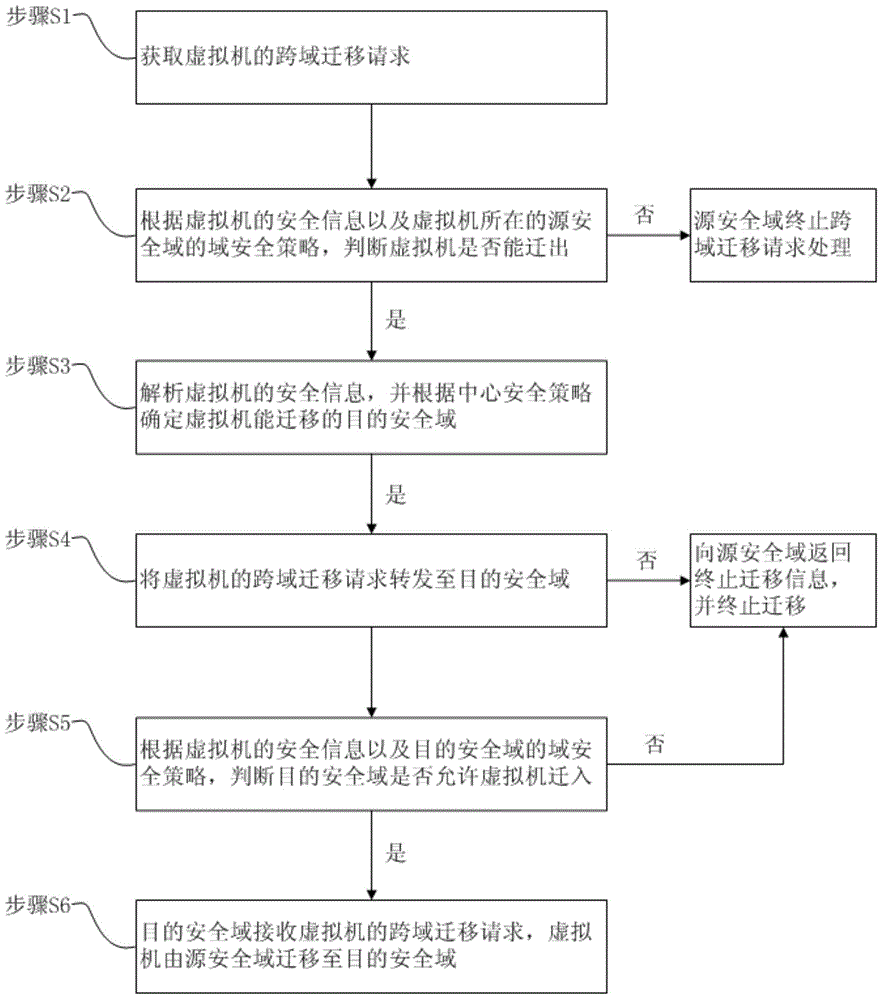

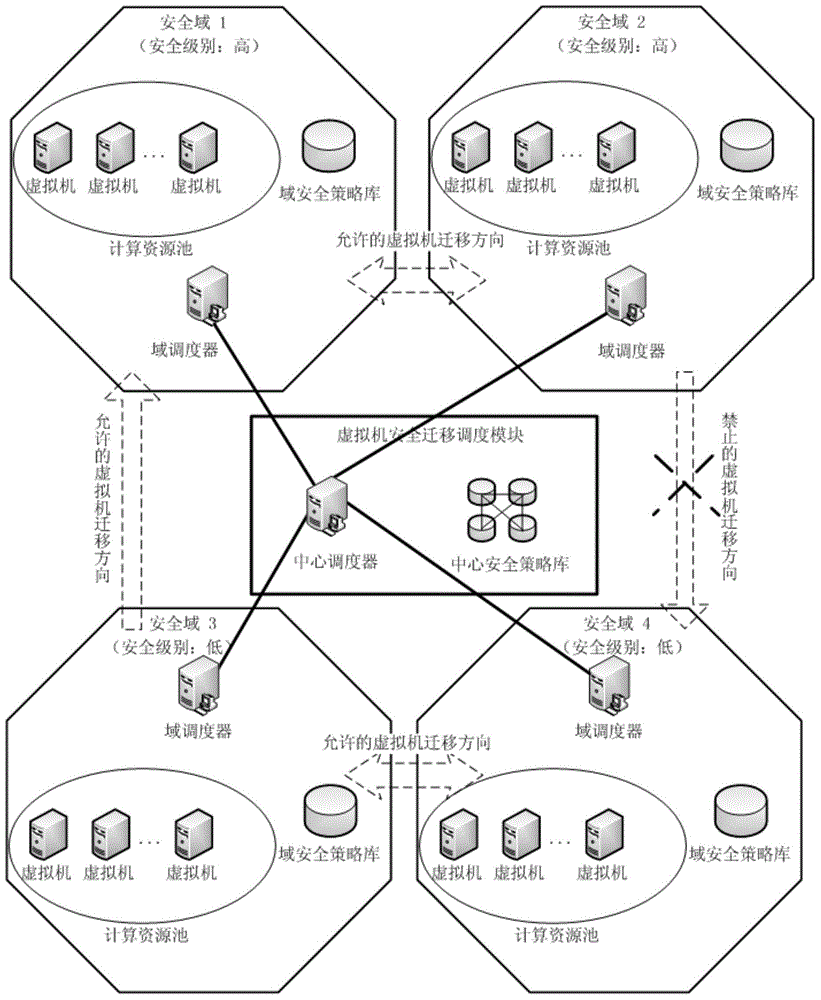

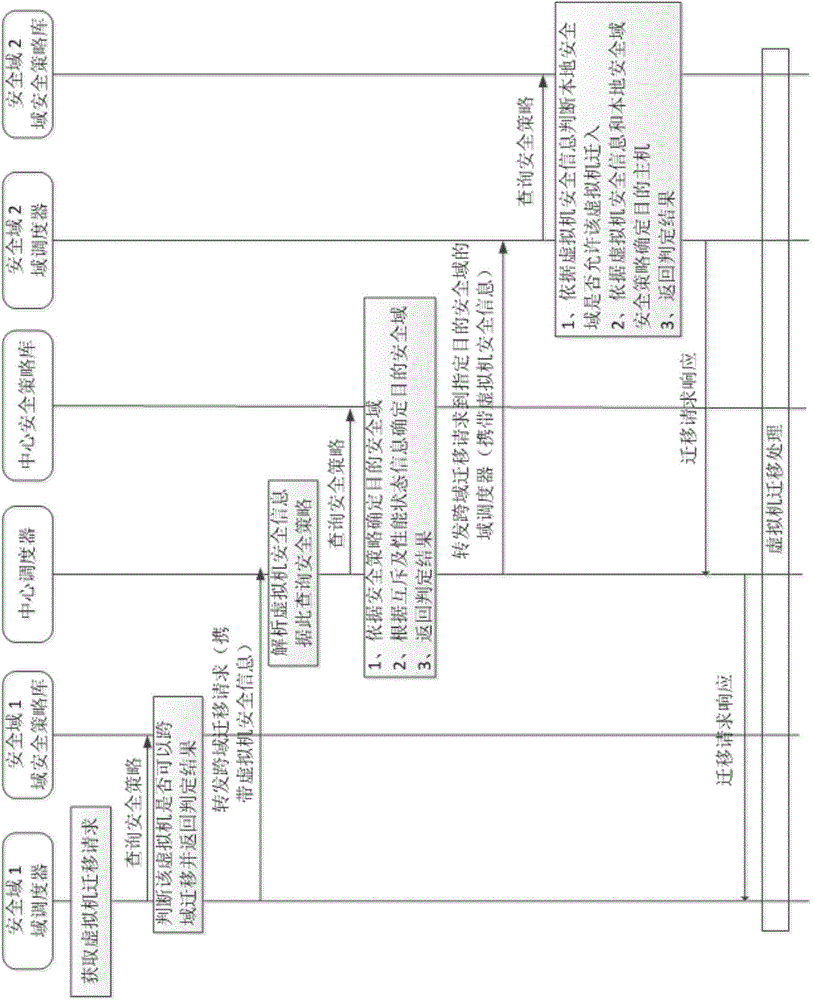

Scheduling method for virtual machine migration and system

ActiveCN104158826AAvoid safety hazardsGuarantee security strengthResource allocationTransmissionSecurity policyVirtual machine

The invention provides a scheduling method for virtual machine migration. The scheduling method includes the flowing steps that S1, a cross-domain migration request of a virtual machine is obtained; S2, whether the virtual machine can be migrated out or not is judged according to safety information of the virtual machine and the domain safety strategy of a source safety domain where the virtual machine is located; S3, if yes, the safety information of the virtual machine is parsed, and the target safety domain to which the virtual machine can be migrated is determined according to the central safety strategy; S4, the cross-domain migration request of the virtual machine is transferred to the target safety domain; S5, whether the target safety domain allows the virtual machine to be migrated to the target safety domain or not is judged according to the safety information of the virtual machine and the domain safety strategy of the target safety domain; S6, if yes, the target safety domain receives the cross-domain migration request of the virtual machine, and the virtual machine is migrated to the target safety domain from the source safety domain. By means of the scheduling method and system for virtual machine migration, potential safety hazards caused by migration of the virtual machine can be avoided, optimizing operation of system overall performance and load balance are guaranteed, and service safety and performance of the system are taken into consideration as well.

Owner:CEC CYBERSPACE GREAT WALL

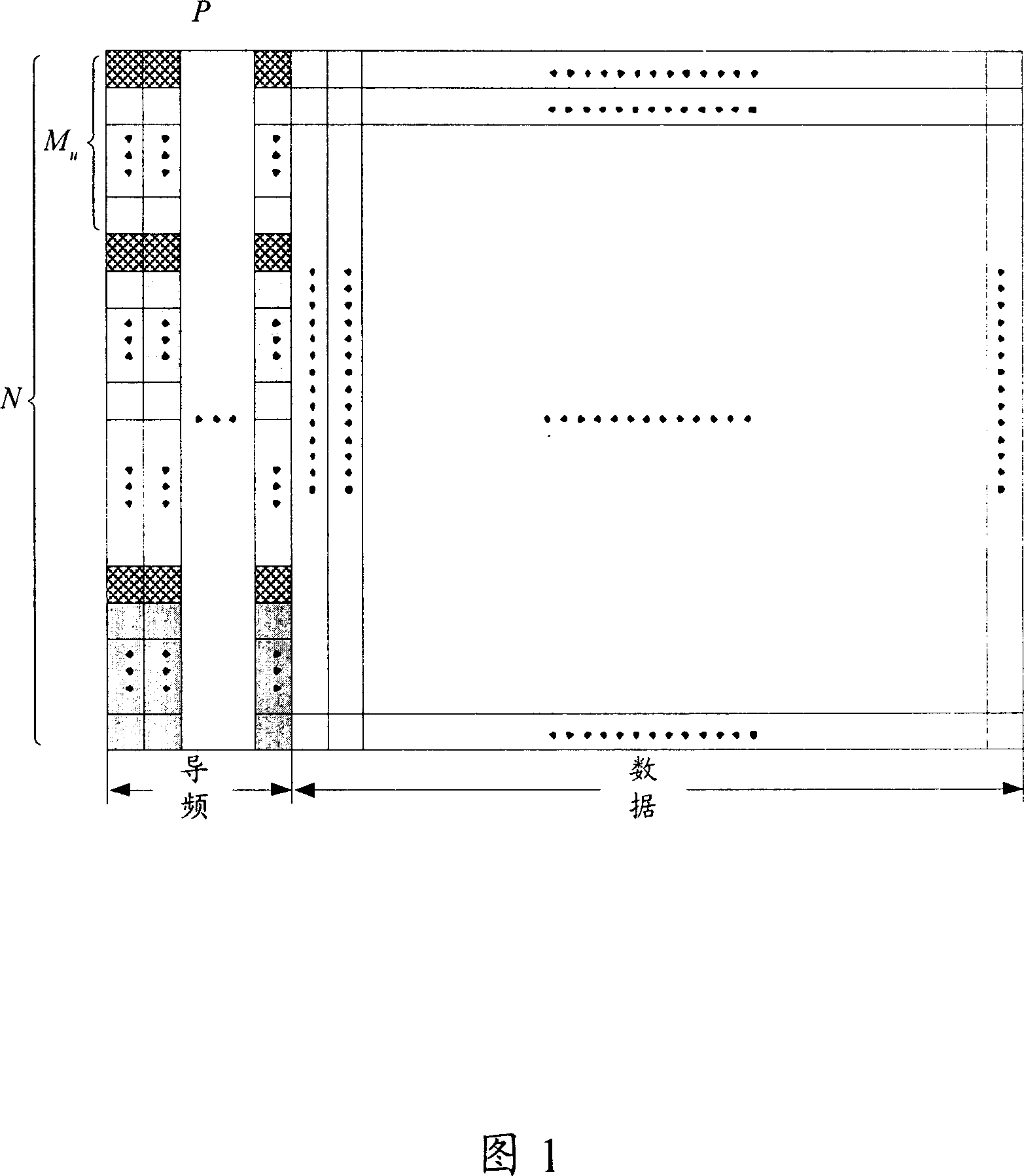

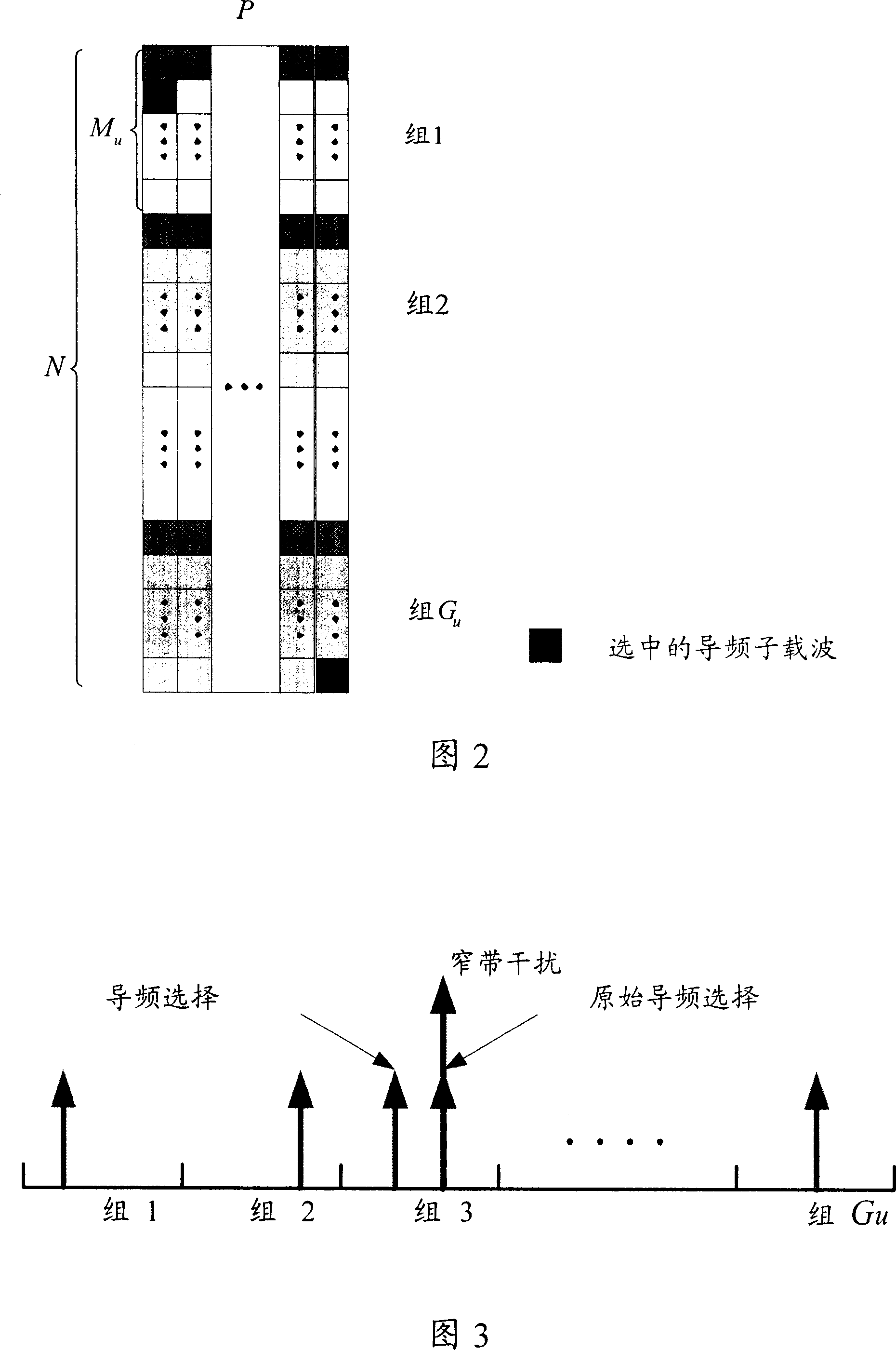

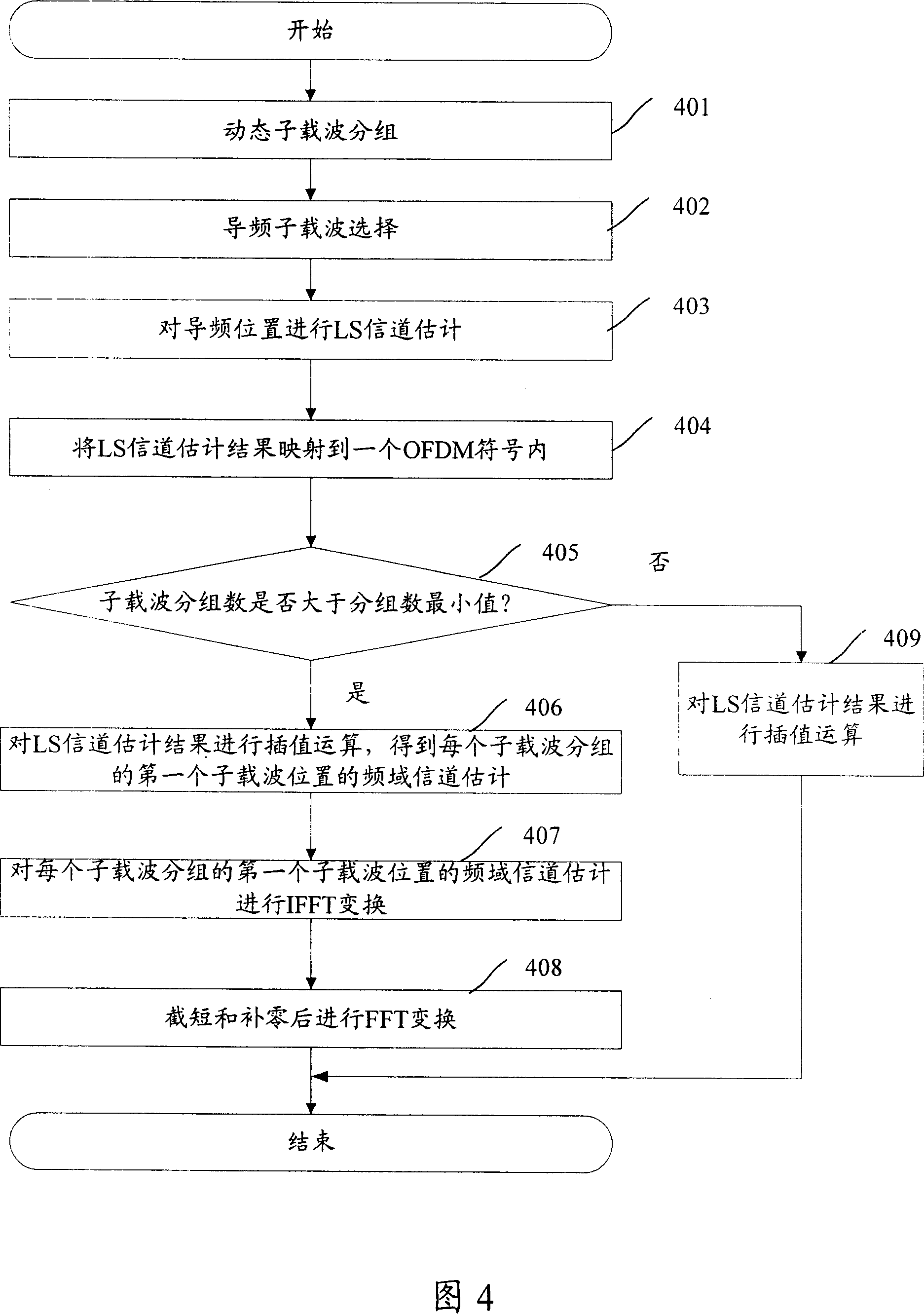

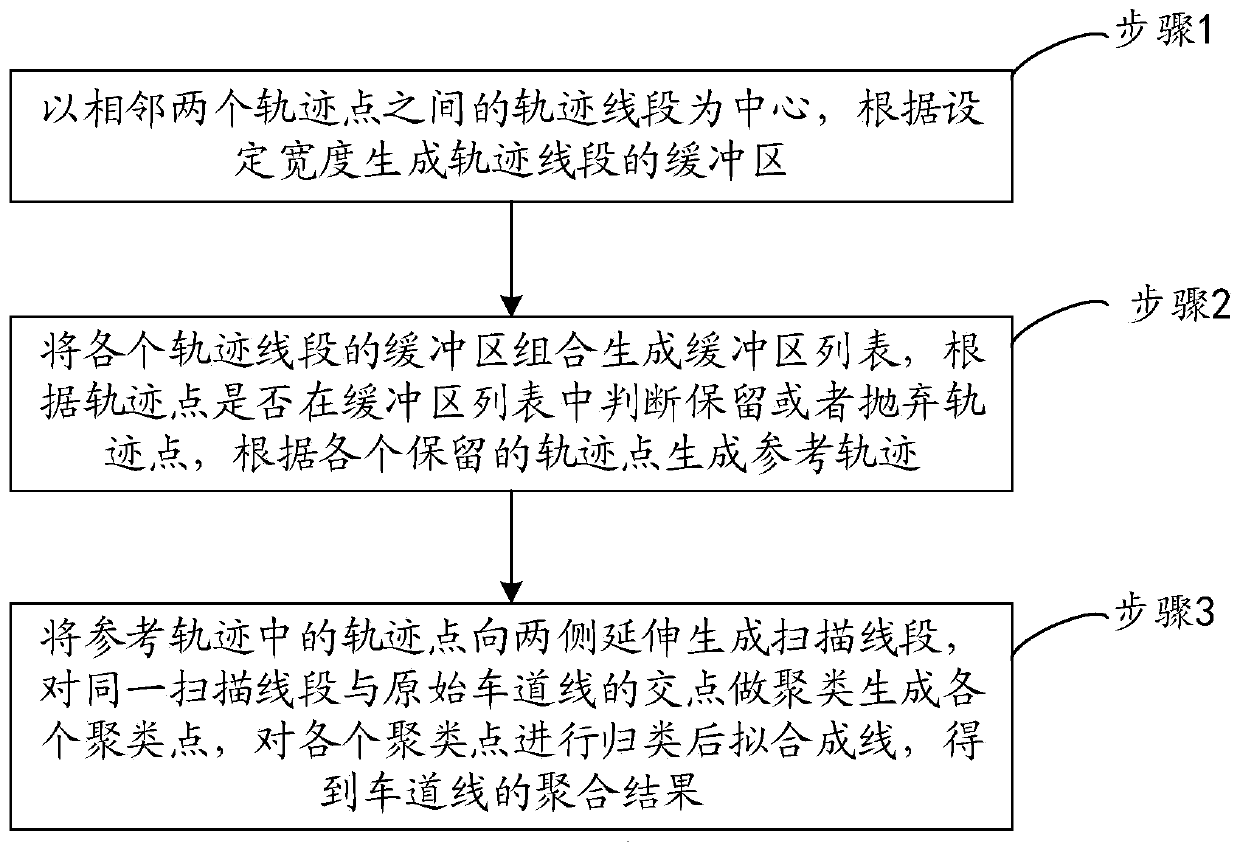

Pilot frequency sub carrier grouping method in orthogonal frequency division multiple access system

InactiveCN1988434AImprove estimation performanceConsider performanceSignal channelsRound complexityEstimation methods

This invention relates to a packeting method for pilot sub-cariers in an OFDMA system, which packets sub-carriers in pilot symbols against user U, in which, the pilot packet number and symbols of U are variable and the sub-carrier numbers are equal, and the value sphere is 1-U, U is all the user number in the OFDMA system, besides, this invention also puts forward a channel estimation method, by this invention, user numbers and / or antennas supported simultaneously can be increased at the most and complete frequency domain channel response of all antennas of all users can be got with the help of part frequency resources distributed to each user, besides, it can avoid or reduce influence of narrow band interference.

Owner:NTT DOCOMO INC

Preparation method of hollow fiber internal pressure composite film

ActiveCN102489176AGood separation performance and mechanical propertiesAvoid filament ruptureSemi-permeable membranesWater soluble polymersWater soluble

The invention discloses a preparation method of a hollow fiber internal pressure composite film, and aims to provide a preparation method of a hollow fiber internal pressure composite film with high supporting property and high pressure resistance. The preparation method comprises the following steps of: uniformly blending an outer layer film forming material, an outer layer film forming diluent and an outer layer film forming additive in a fusing process to obtain a thermally induced phase separation method outer layer film forming system; dissolving and uniformly mixing an inner layer film forming material, an inner layer film forming solvent and an inner layer film pore forming agent to obtain a non-solvent induced phase separation method inner layer film forming system, wherein the inner layer film pore forming agent contains over 70 percent of water-soluble polymer; and extruding and spinning in a composite way by introducing a core liquid into a central pipe, taking the inner layer film forming system as a middle layer and taking the outer layer film forming system as the outside, quickly soaking into a coagulation bath, fully curing an outer layer and an inner layer under the actions of the coagulation bath and the core liquid, and extracting and washing to obtain the hollow fiber internal pressure composite film. The large-inner-diameter hollow fiber internal pressure composite film prepared with the method disclosed by the invention can be used for replacing a tubular film during application.

Owner:TIANJIN MOTIMO MEMBRANE TECH

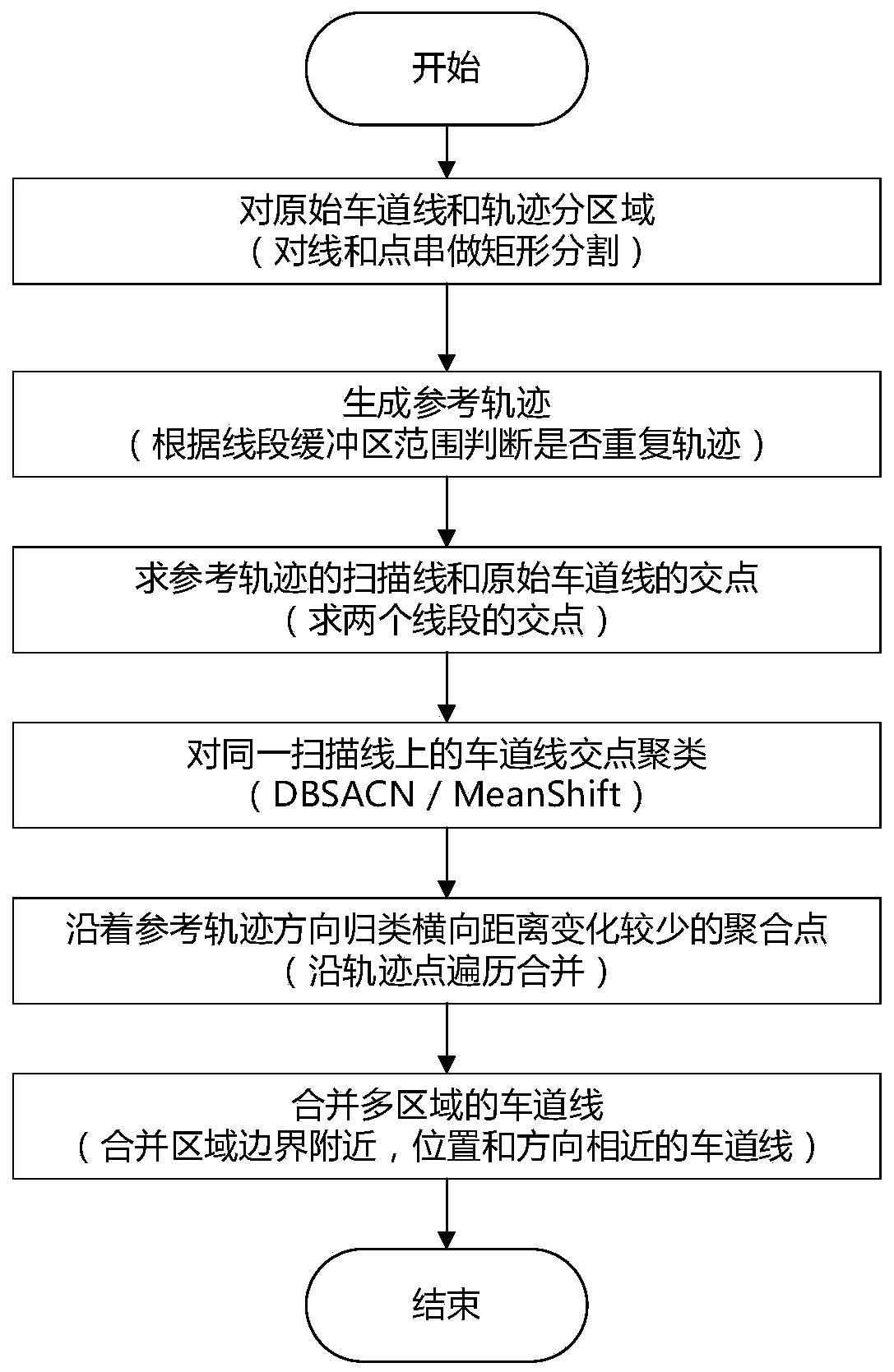

Lane sideline aggregation method based on track direction

ActiveCN110906940AIncrease inputAvoid participating in calculationsInstruments for road network navigationCharacter and pattern recognitionComputer graphics (images)Engineering

The invention relates to a lane line aggregation method based on a track direction, which comprises the following steps of: generating a buffer area of a track line segment according to a set width bytaking the track line segment between two adjacent track points as a center; combining the buffer areas of the track line segments to generate a buffer area list, judging whether track points are reserved or abandoned in the buffer area list or not according to whether the track points are in the buffer area list or not, and generating a reference track according to the reserved track points; andextending track points in the reference track to two sides to generate scanning line segments, clustering intersection points of the same scanning line segment and the original lane line to generateclustering points, classifying the clustering points, and fitting the clustering points into a line to obtain an aggregation result of the lane line. Tracks in characteristic directions are extractedfrom a large number of tracks, so that a large number of original tracks can be prevented from participating in calculation, and calculation efficiency is improved; the intersection point of the trackscanning line and the lane side line is introduced as a new clustering element, so that the finally generated lane shape, especially the lane shape of the miscellaneous line and the curve, conforms to the actual situation.

Owner:WUHAN ZHONGHAITING DATA TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com