Ultrahigh molecular weight polyethylene short fiber and preparation method thereof

A technology of ultra-high molecular weight and polyethylene, applied in the direction of single-component polyolefin rayon, fiber chemical characteristics, single-component synthetic polymer rayon, etc., can solve the problem of single-filament fineness and low yarn strength and other problems, to achieve the effect of easy gluing, wide application and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

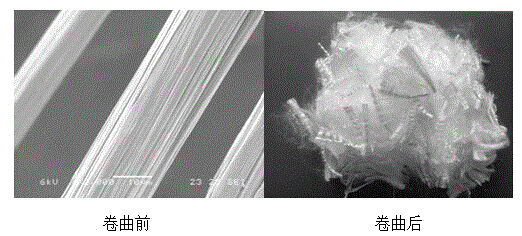

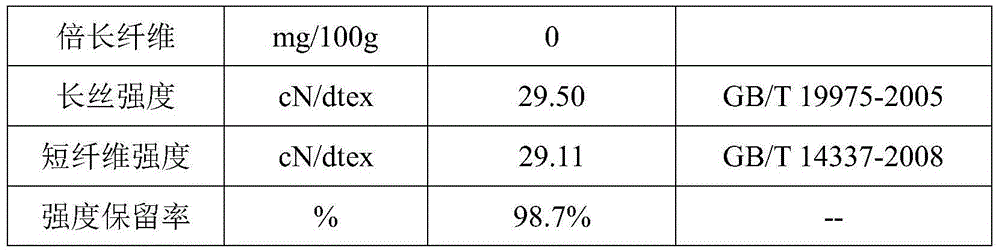

[0027] Example 1: Ultra-high molecular weight polyethylene with an intrinsic viscosity of 23.6dl / g is extruded with a twin-screw extruder after being swollen with decahydronaphthalene, spun through a spinneret, desolvated by a hot air circulation system, and the temperature in the front zone of nitrogen flow is It is 115°C, and the temperature in the middle and rear areas is 70-110°C and gradually decreases. Then it is pre-drawn, the pre-drawing temperature is 125°C, and the draw ratio is 3.14, and then it is subjected to three-stage thermal stretching. Relaxation stretching, the relaxation temperature is 146° C., and the relaxation ratio is 1.0 to prepare ultra-high molecular weight polyethylene filaments. The filament is bundled, the bundle fineness is 200,000 denier, the crimp wheel width bears 3,000 dtex per mm, the bundle tension is 0.1cN / dtex, and then the filament oil is washed with warm water and oiled by spraying oil rollers. The oil is anionic Type high-strength pol...

Embodiment 2

[0031] Embodiment 2: roughly the same as Embodiment 1, the difference is that the intrinsic viscosity of ultra-high molecular weight polyethylene is 20dl / g, and after swelling with paraffin, it is extruded with a twin-screw extruder, sprayed through a spinneret, and passed through a spinneret. The hot air circulation system desolventizes, the temperature in the front zone of the nitrogen flow is 150°C, and the temperature in the middle and rear zone is 110-140°C and gradually decreases. 84 2400D / 1380f ultra-high molecular weight polyethylene staple fibers are assembled into a large tow of 200,000 deniers. The crimping wheel width per mm bears 10,000 dtex, and the bundle tension is 0.15cN / dtex. The large tow is desalted Soak in a water bath to wash away the filament oil, and then immerse the tow in the short fiber anionic high-strength polyethylene staple fiber oil on the oil tank to control the oil content to 0.5%. The feeding wheel of the crimper is sent into the stuffing ext...

Embodiment 3

[0032] Embodiment 3: roughly the same as Example 1, the difference is that the intrinsic viscosity of ultra-high molecular weight polyethylene is 25dl / g, and after swelling with kerosene, it is extruded with a twin-screw extruder, sprayed through a spinneret, and passed through a spinneret. The hot air circulation system desolventizes, the temperature in the front area of the nitrogen flow is 110 ° C, and the temperature in the middle and rear area is 70 ~ 100 ° C and gradually decreases. 135 ultra-high molecular weight polyethylene staple fibers of 1500D / 1380f are assembled into a large tow of 200,000 deniers. The crimping wheel width per mm bears 5,000 dtex, and the bundle tension is 0.08cN / dtex. The large tow is washed Wash off the filament oil in the oil tank, then immerse in the oil tank for oiling, control the oil content to 0.2%, send it into the stuffing extrusion crimping tank through the feeding wheel of the crimper for crimping, the tension of the crimped tow is 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com