Patents

Literature

571results about How to "Easy to glue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultraviolet curable organic silicon-acrylic resin electronic adhesive and application thereof

InactiveCN101812278AFast curingIncrease elasticityOther chemical processesCoatingsNon toxicityAdhesive

The invention provides an ultraviolet curable organic silicon-acrylic resin electronic adhesive, which comprises the following components: (1) 100 parts of doublebond-containing acrylic monomers or prepolymer, (2) 5 to 500 parts of doublebond-containing organic silicon resin with a molecular weight of 1,000 to 10,000, (3) 1 to 100 parts of vinyl compound modified inorganic nano particle, (4) 1 to 50 parts of radical ultraviolet initiator, (5) 1 to 100 parts of organosilan, (6) 0 to 200 parts of inorganic reinforcing agent, and (7) 0 to 50 parts of auxiliary agent, wherein the ultraviolet curable organic silicon-acrylic resin is prepared by carrying out ultraviolet curing on the materials, and the solid content thereof is 100 weight percent. The product produced by the invention has the excellent characteristics of firm bonding with metal, glass and plastic materials and electronic devices, good optical property, good elasticity, good weather resistance, safety, non-toxicity, convenient construction and the like, can replace traditional solvent electronic adhesives, and is used for protective coatings, protective adhesives, packaging materials and the like of electronic devices, integrated circuits, printed circuits, LED chips and the like.

Owner:SHANGHAI XIYI NEW MATERIAL SCI & TECHCO

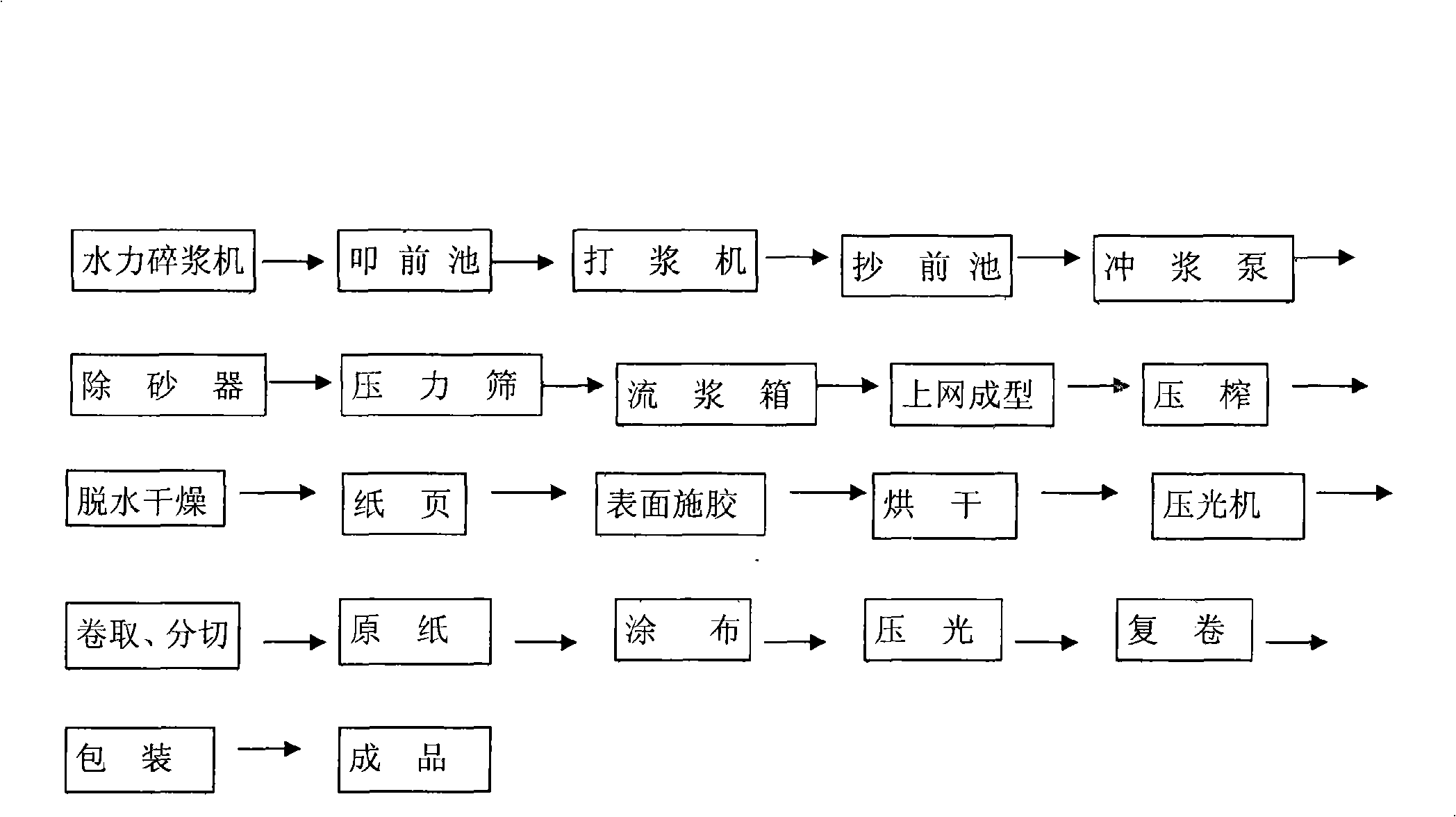

Paper making process for precoating water transfer printing base paper

ActiveCN101289824AHigh mechanical strengthImprove surface propertiesCoatings with pigmentsWater-repelling agents additionPulp and paper industryWater transfer

The invention relates to paper and a process for making the same, in particular to a process for making precoated water transfer printing paper base paper. The process comprises the following steps that: after steps of crushing, pulp beating, pulp mixing, screening and purification, on-screen forming, dewatering and drying, surface glue blending and winding and parting cut, materials are turned into base paper; after steps of base paper coating, press finishing and rewinding, the base paper is turned into the precoated water transfer printing paper base paper. The process of the invention has the advantages of simple technological flow, smooth paper surface, good stiffness, stable printing dimension, big differences of both paper surfaces on water absorption, good tensile strength, short decoating time and even decoating.

Owner:WEIFANG HENGLIAN SPECIALTY PAPER

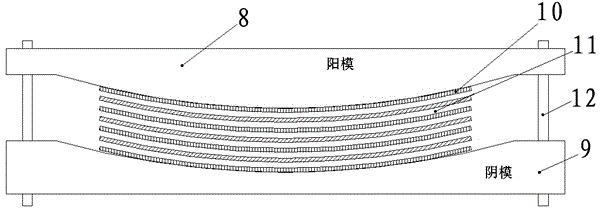

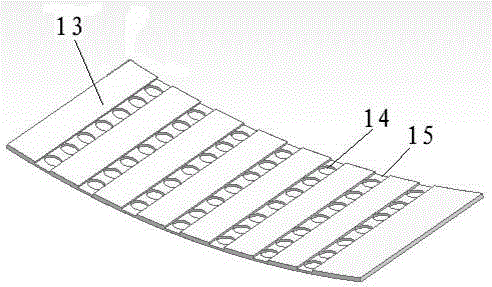

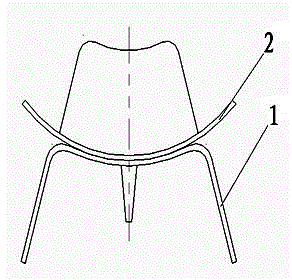

Manufacturing method of bent bamboo furniture and bent bamboo rod pieces

The invention provides a manufacturing method of bent bamboo furniture and bent bamboo rod pieces. The manufacturing method involves manufacturing of the bent bamboo rod pieces and bent bamboo plate pieces. According to the method, bamboo is divided into long-strip-shaped bamboo filaments or bamboo splits after bamboo skin and bamboo pith which can affect the bonding performance are removed; adhesives are arranged on the surfaces of the bamboo filaments or the bamboo splits after the bamboo filaments or the bamboo splits are dried; plate blank is formed in a planar cold press in a cold pressing mode; the plate blank is arranged in a bending forming die in an overlaying mode, pressing is conducted to enable the plate blank to form bent-plate-shaped bent bamboo rod plates, the bent bamboo rod plates and the die are sent into a heating chamber to be heated and cured, after the die is disassembled, according to the requirements of bent bamboo rods, the plates are cut into bent bamboo rods in a sawing mode in the bending direction of the bamboo filaments, and the bent bamboo rod pieces are formed after the surfaces are smoothed; meanwhile, the bamboo is sawed off at fixed length and divided into rectangular bamboo strips, assembly is conducted according to the requirements of the plate blank, the plate blank is arranged in a drying and shaping die to be compressed, and drying, heating and shaping are conducted to form bent bamboo plate piece panels; the surfaces of the panels are coated with adhesives, the panels are laid in a heat curing die, and pressing, heating and curing are conducted to obtain the bent bamboo plate pieces.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

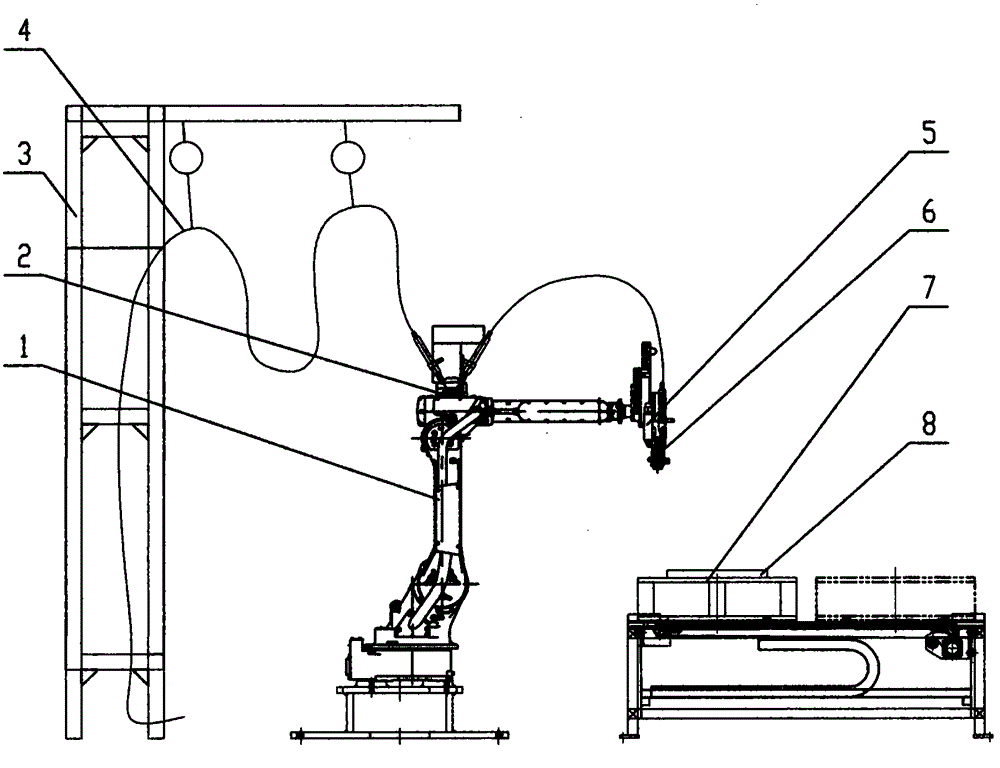

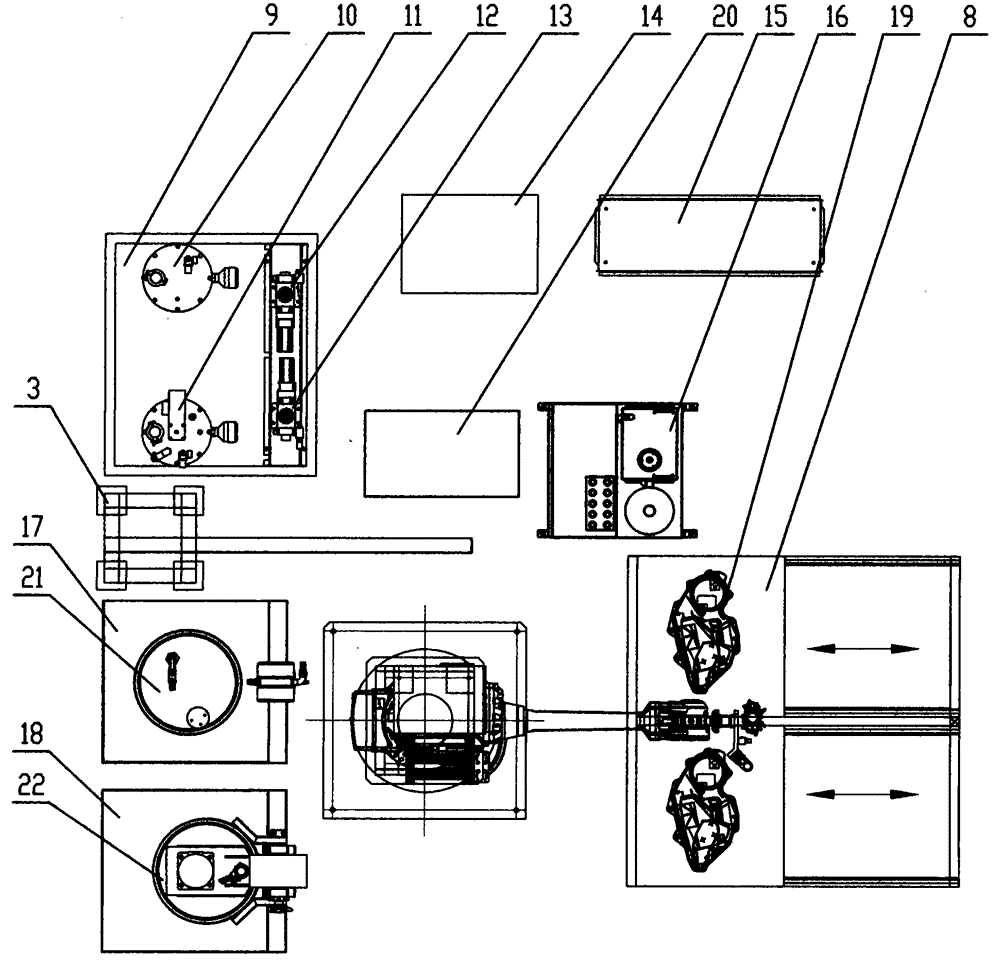

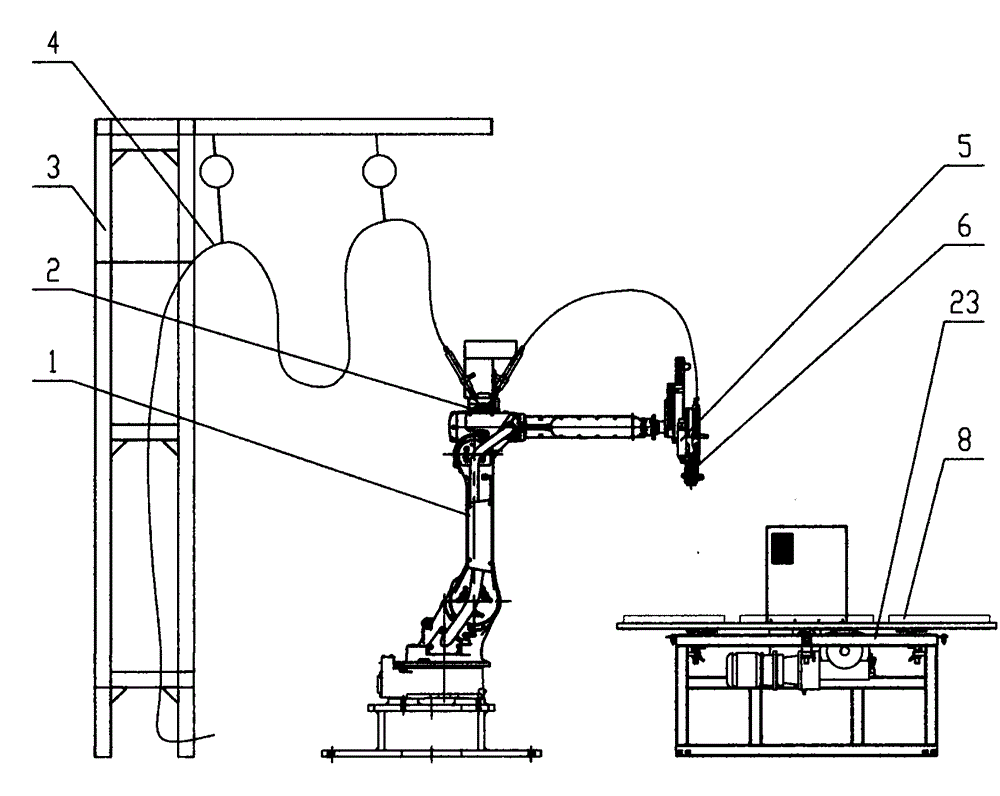

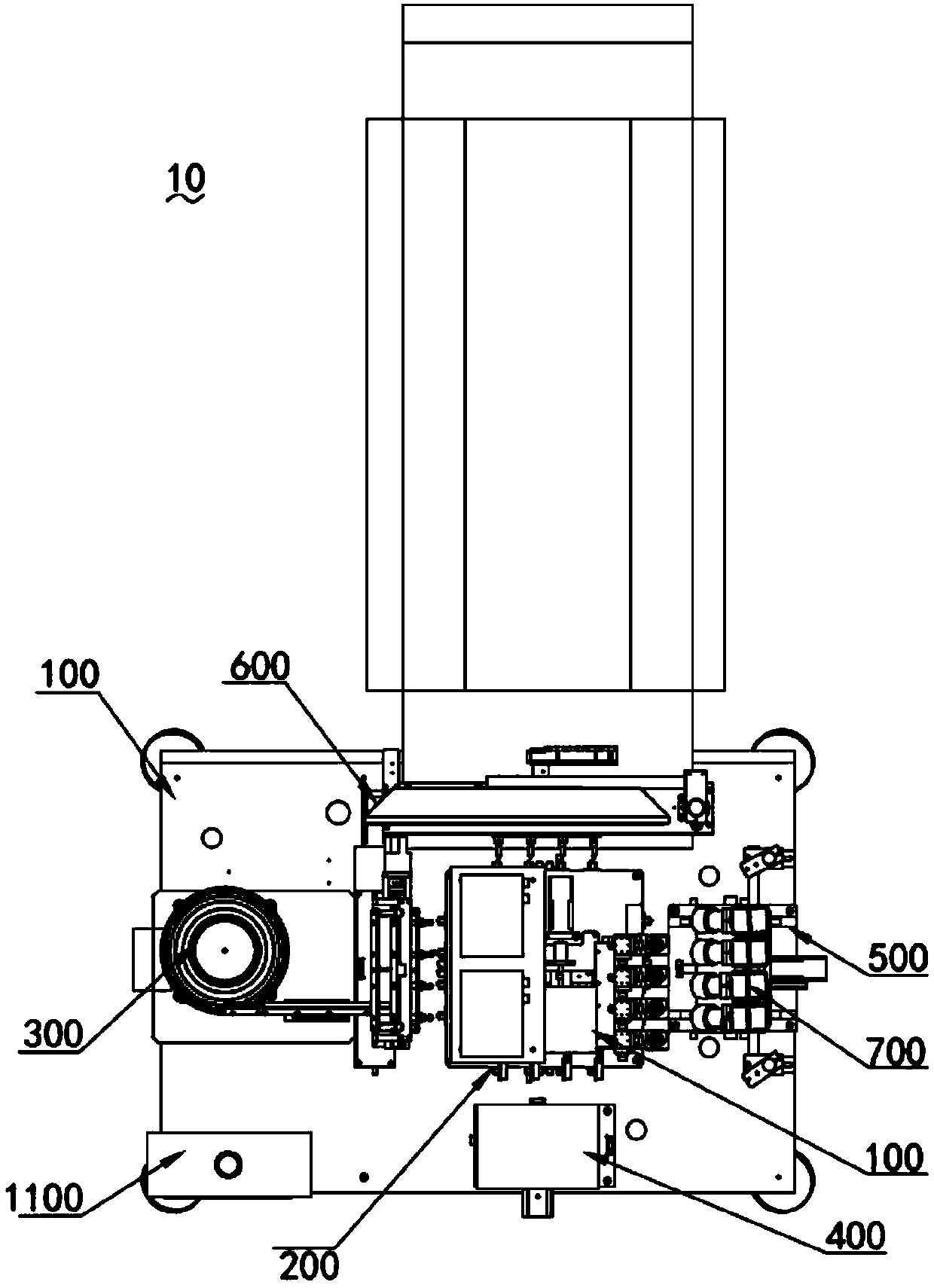

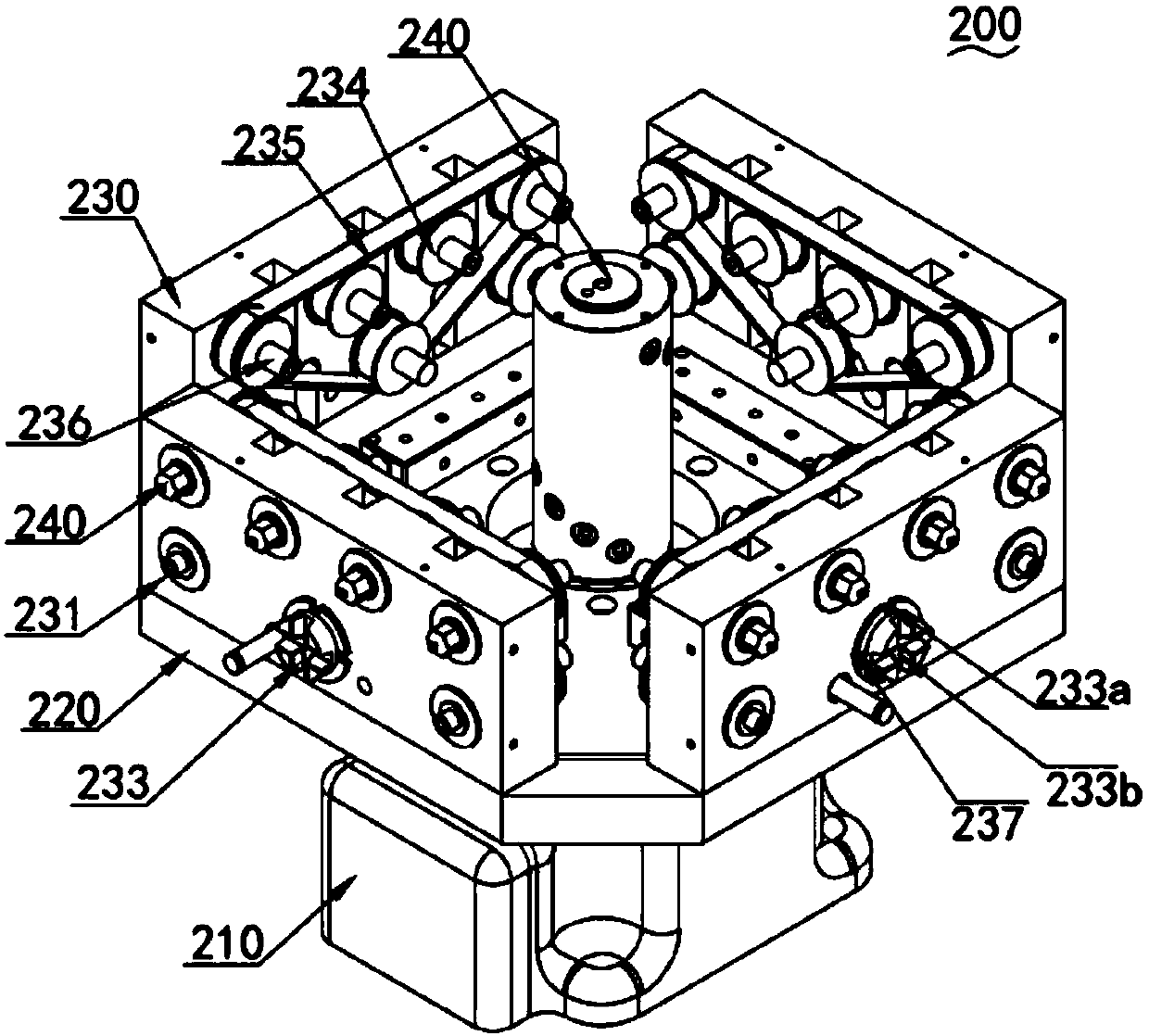

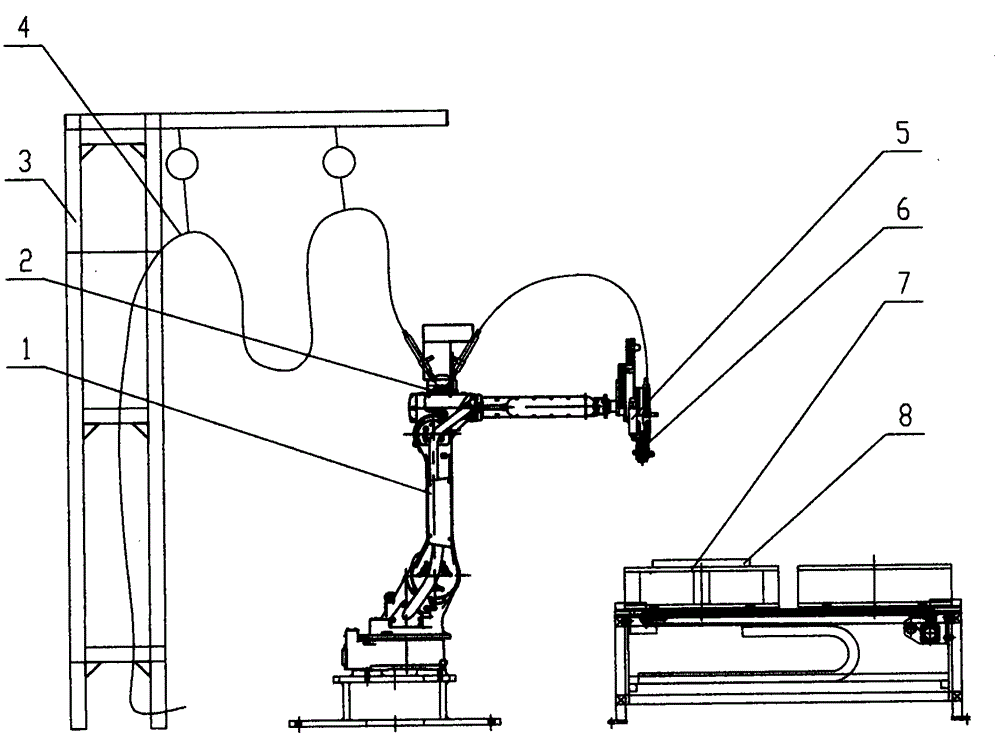

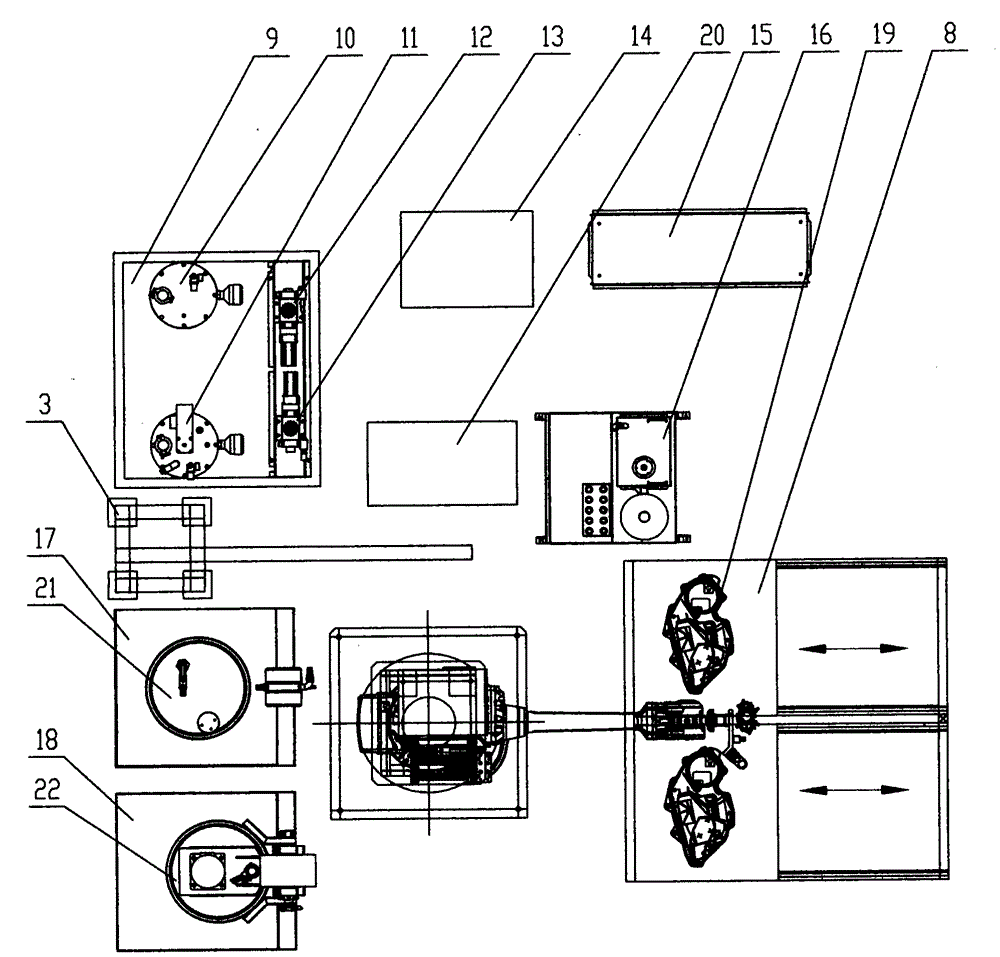

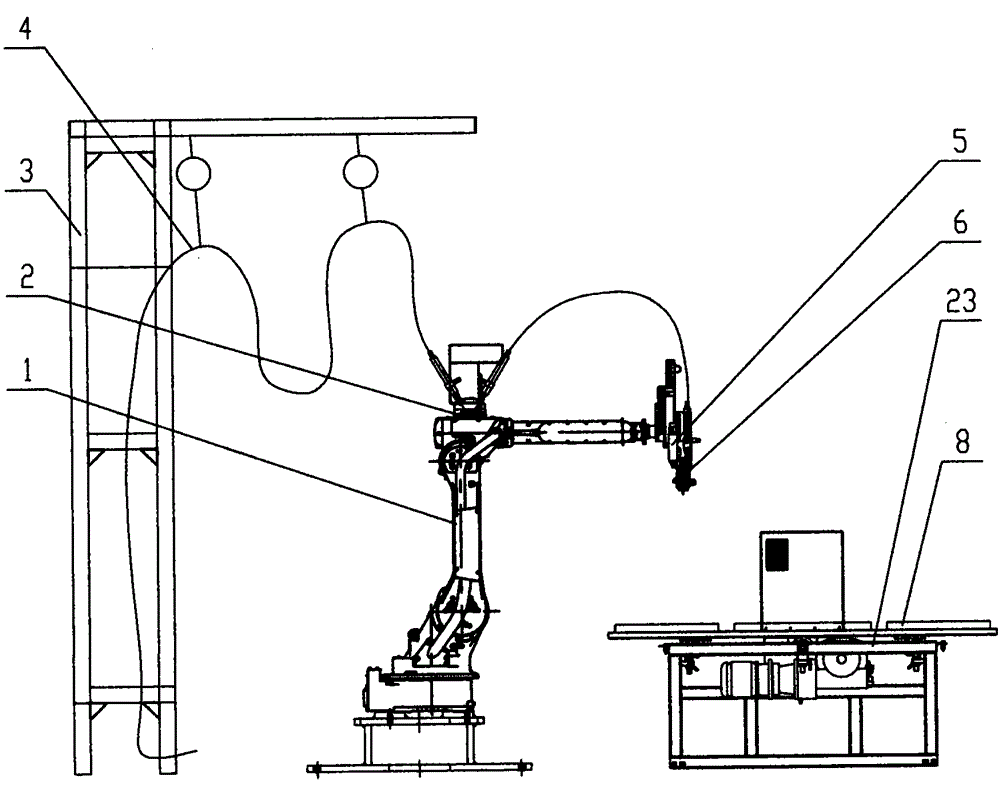

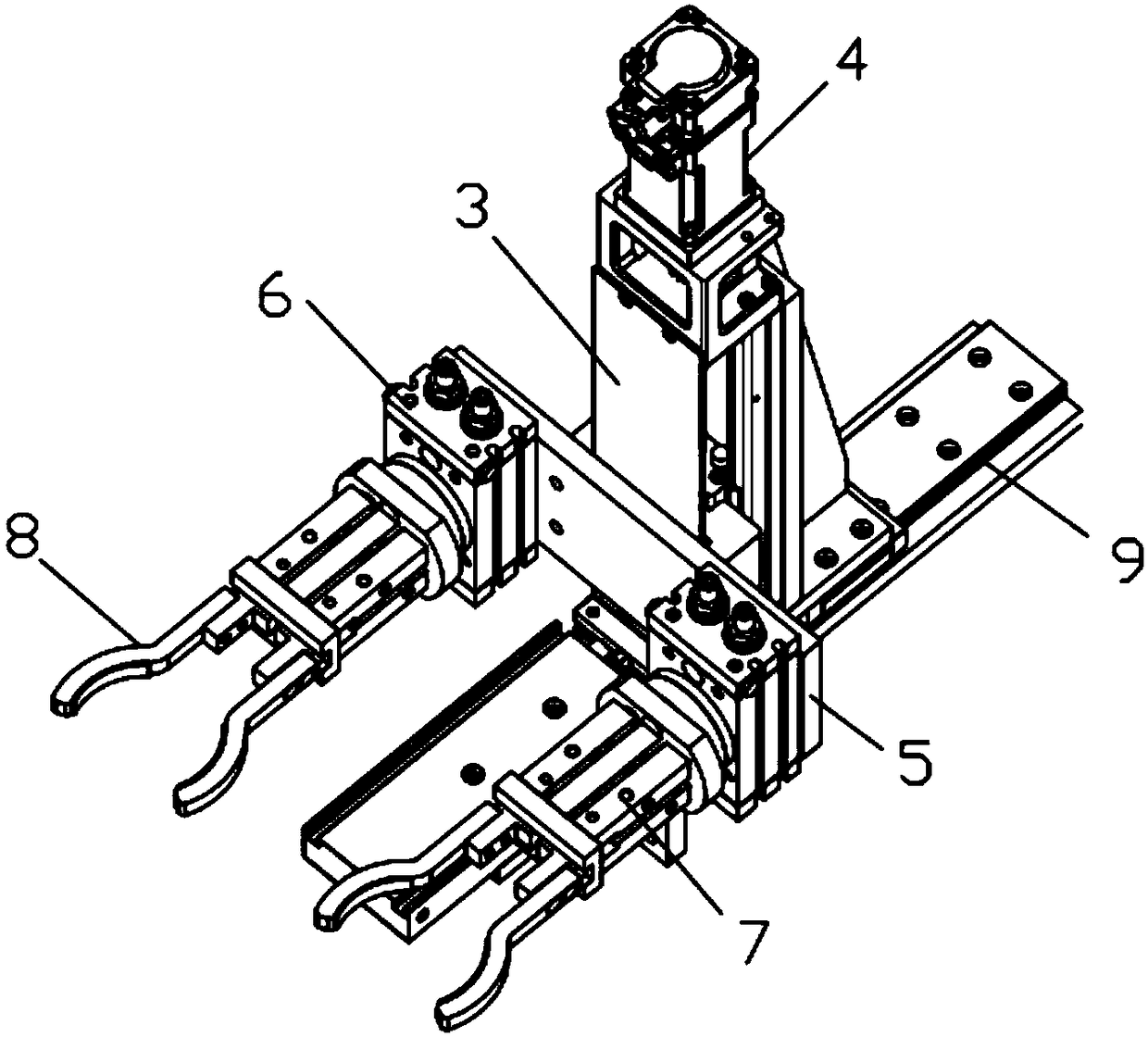

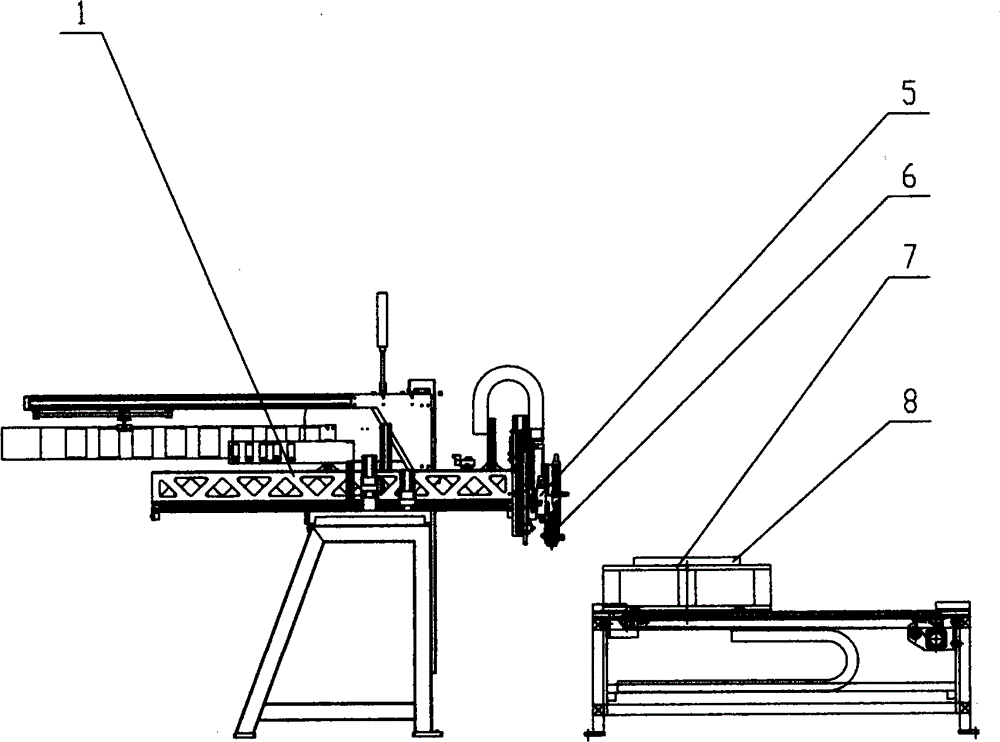

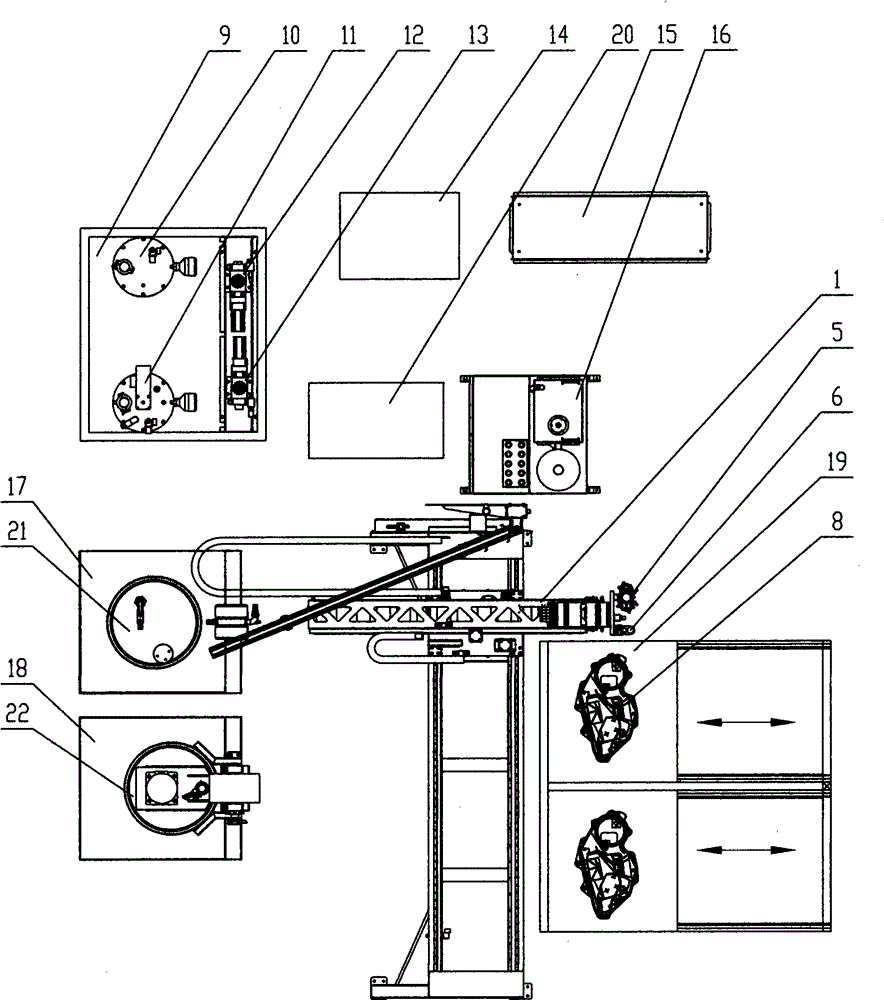

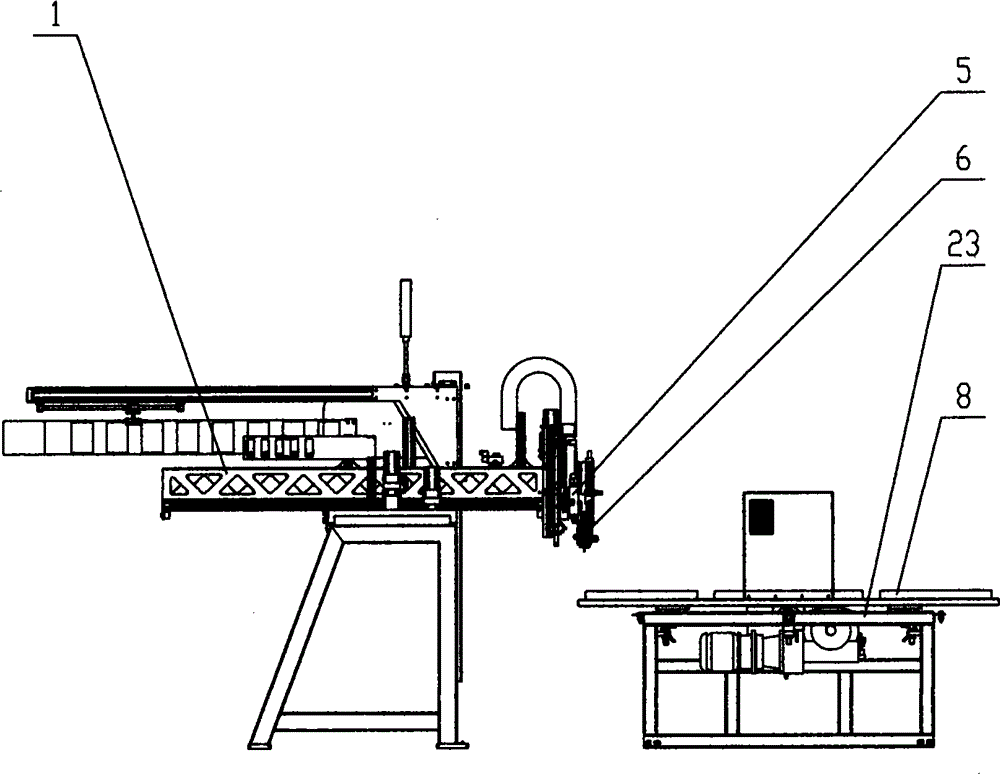

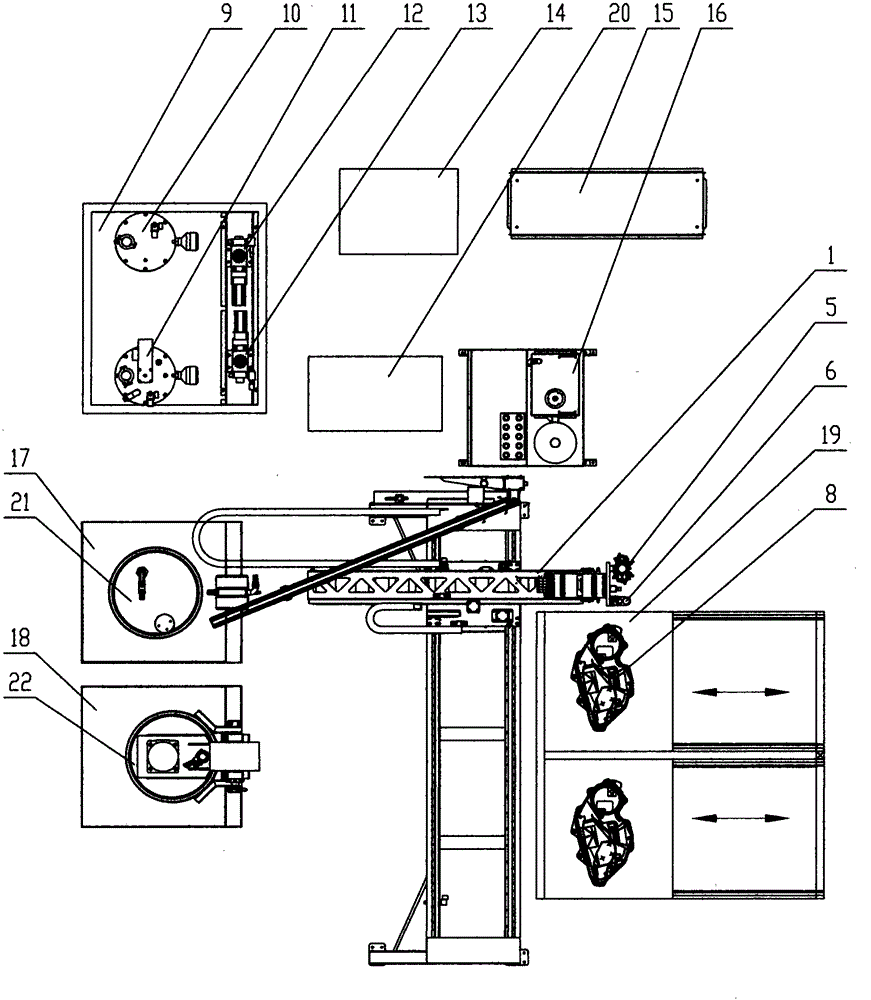

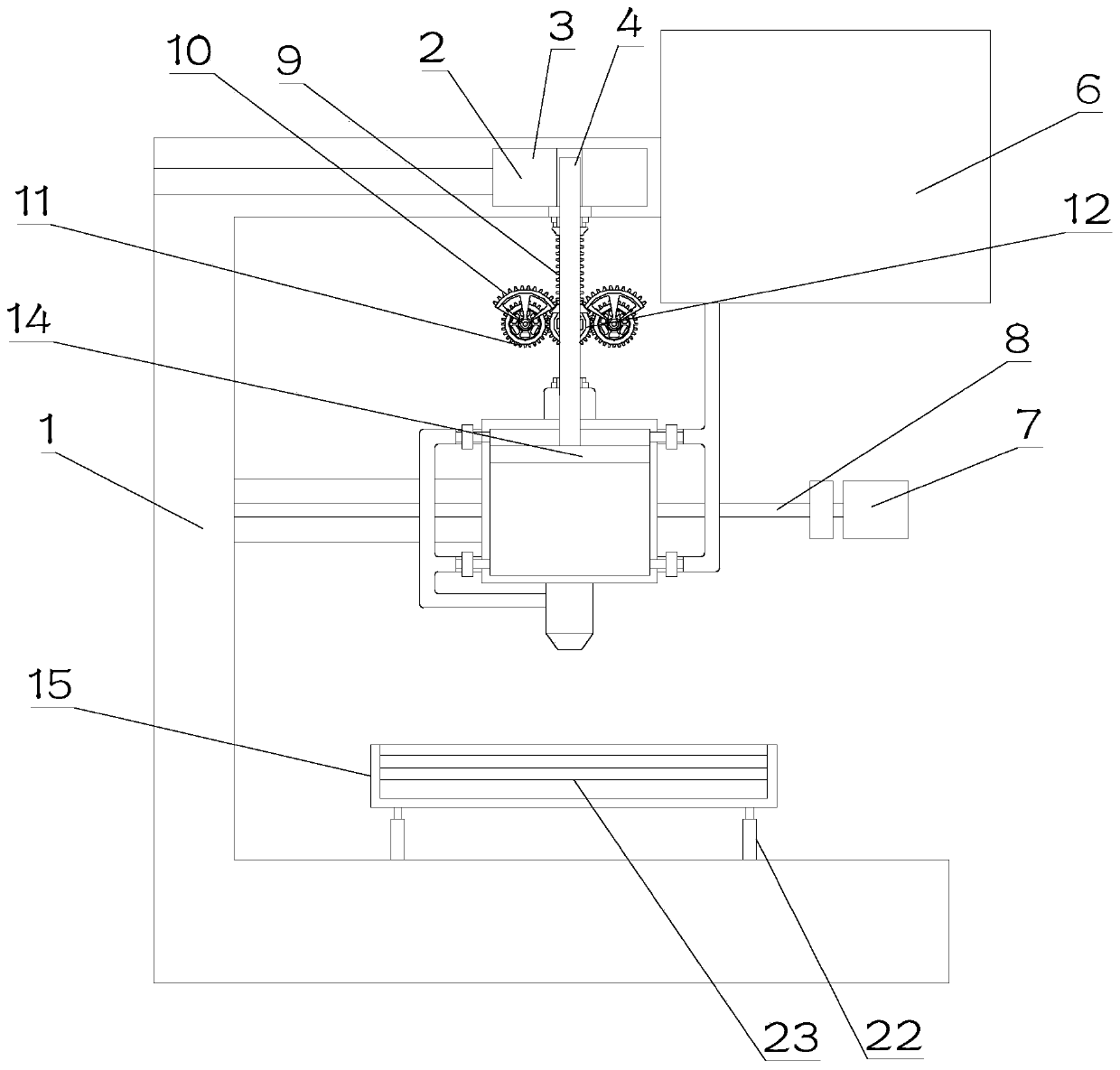

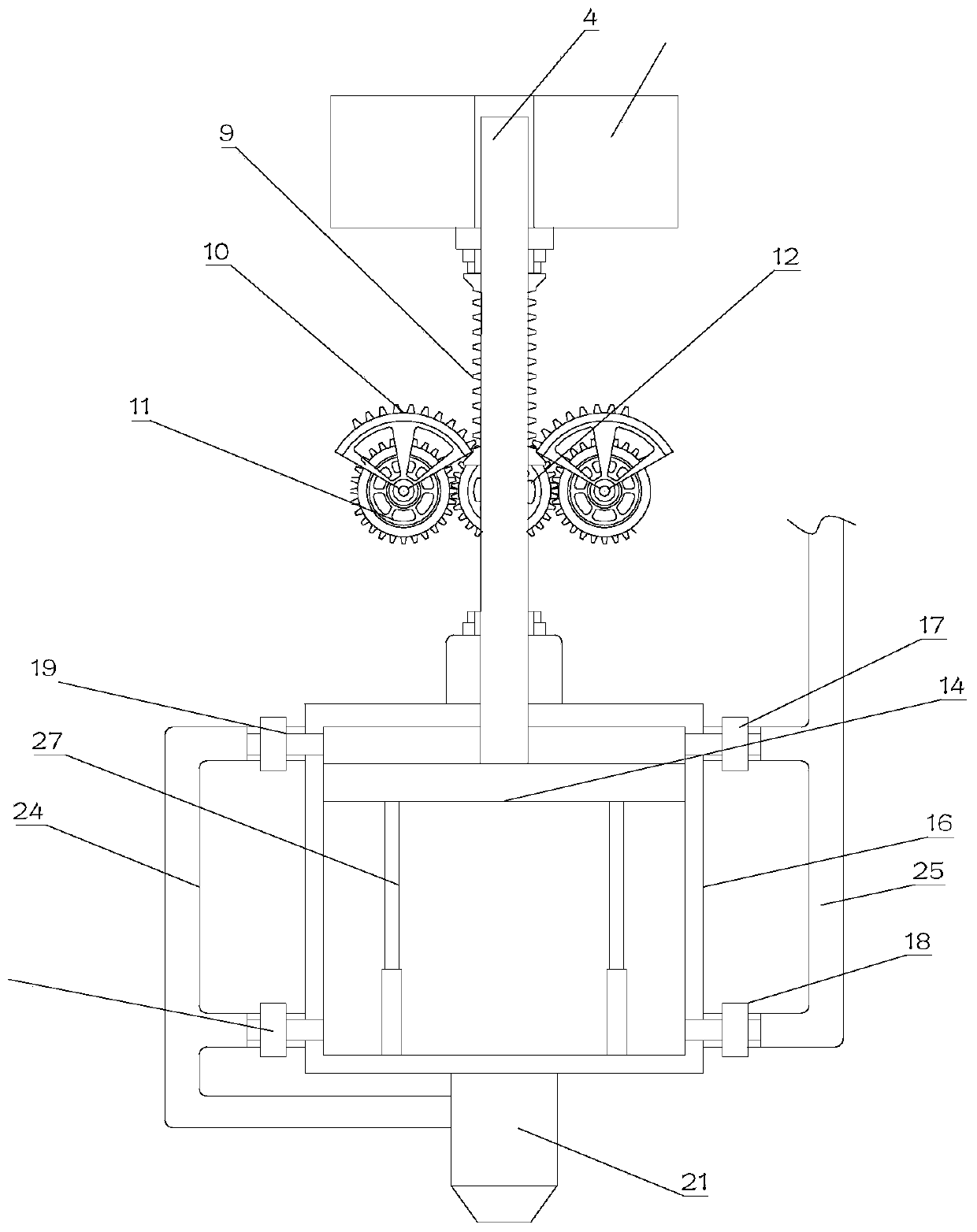

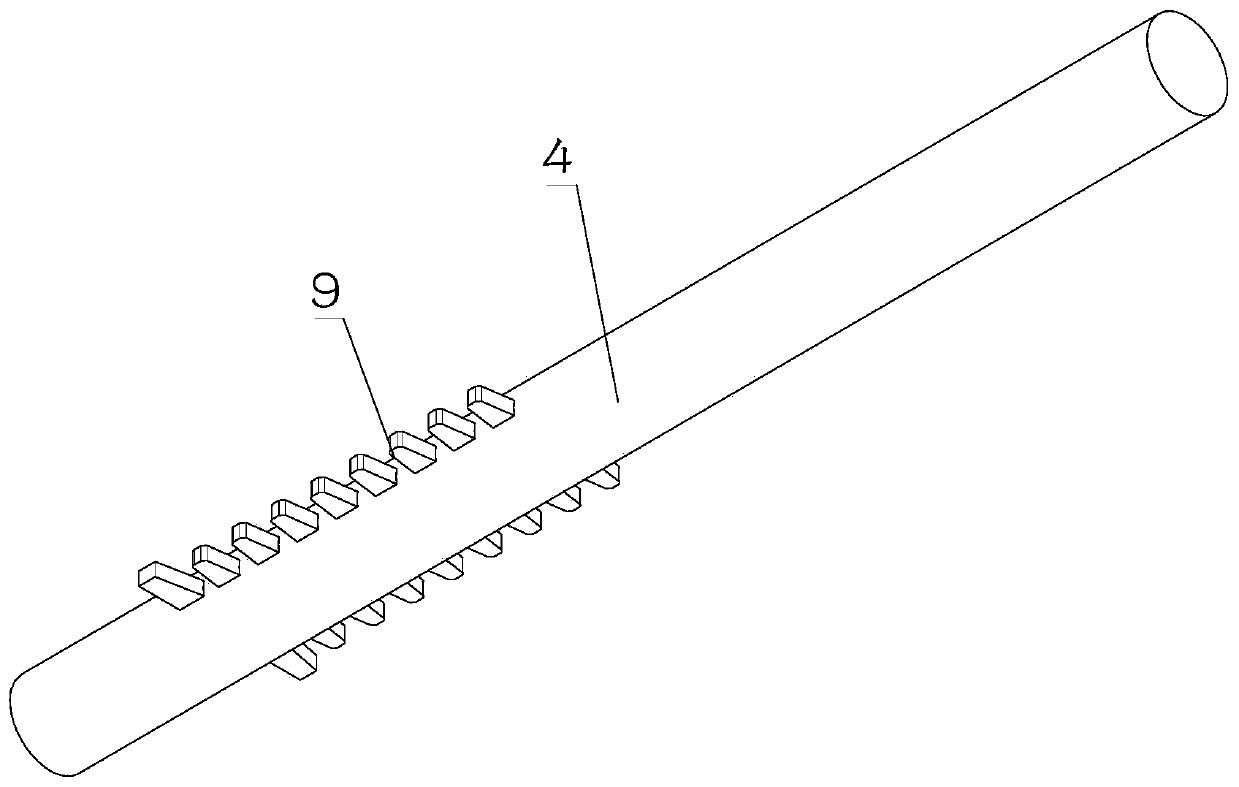

Full-automatic robot gluing equipment and process technology

The invention relates to the technical field of gluing, in particular to full-automatic robot gluing equipment and a process technology which are used for two-component polyurethane gluing. The full-automatic robot gluing equipment is characterized in that the equipment comprises a three-axis robot or a four-axis robot or a five-axis robot or a six-axis robot, a glue supply device, a two-component gluing head, a two-station automatic gluing workbench or a multi-station automatic rotary gluing workbench, plasma treatment equipment, a waste cleaning solution recovery device and an intelligent control system. The three-axis robot or the four-axis robot is of a gantry type or cantilever type structure. The two-component gluing head and a plasma treatment head are fixed to the three-axis robot or the four-axis robot and can be linked in the X axis, the Y axis and the Z axis. The five-axis robot or the six-axis robot is an articulated robot, and five-axis linkage or six-axis linkage of the two-component gluing head and the plasma treatment head can be achieved. According to the novel polyurethane gluing equipment and the process technology, the proportion is precise, glue tape performance is stable, and the sealing effect is good.

Owner:DALIAN HUAGONG INNOVATION TECH

Method for producing bamboo fibre artificial board without glue glued adhesion

InactiveCN101214678AEmission reductionReduce the degree of water condensationDomestic articlesFlat articlesPressure decreasePulp and paper industry

The present invention relates to a production method of self-bonding artificial bamboo fibre board, which includes the following technical processes: (1) bamboo particles, (2) high-temperature steam softening, (3) hot grinding, (4) drying, (5) the spraying of additive, (6) the spreading of material, (7) prepressing, (8) hot pressing, (9) the releasing of a board, (10) cooling, and (11) a finished product. Moreover, in the process of high-temperature steam softening, a softening method of gradually increasing temperature and pressure and momentarily decreasing pressure is applied; in the softening method, the bamboo particles with a water ratio less than 18 percent are loaded into a sealable pressure container, the temperature-increasing rate is controlled within 60 DEG C per hour, when the temperature is raised to 130 DEG C, the pressure is controlled at more than 0.4Mpa, and the temperature and the pressure are maintained for over one hour; later, a steam valve is opened, and the pressure is rapidly decreased to zero, and the pressure-decreasing period is controlled within three hundred and sixty seconds. Consequently, the condensation degree of condensed water can be decreased, the discharging quantity of the condensed water and the loss of carbohydrate and lignin degradation products in the discharging process can be reduced, the bamboo fibres can be sufficiently inflated and rapidly separated, the rate is increased, the concentration of free radical is increased, and the high-strength bonding requirement is satisfied.

Owner:张胜先

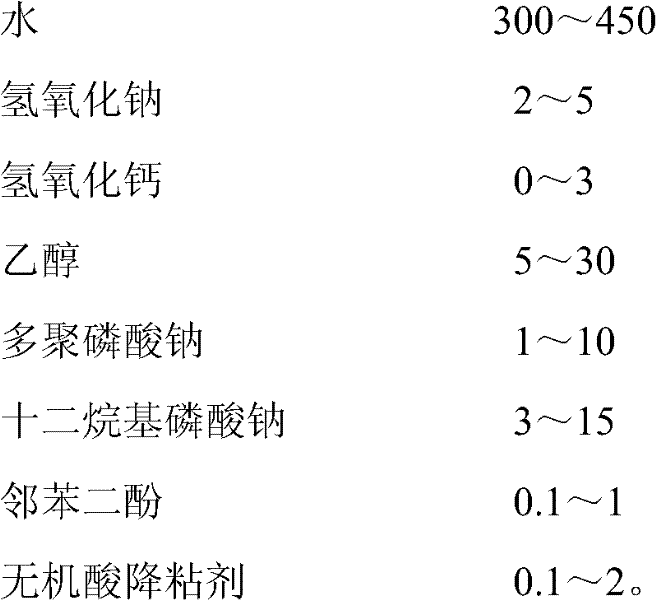

Aldehyde-free soybean modified wood bonding agent and method for preparing same

InactiveCN102212329ASolve the strength problemAddress water resistanceProtein adhesivesGlue/gelatin preparationCross-linkAdhesive

The invention provides an aldehyde-free soybean modified wood bonding agent and a method for preparing the same. The aldehyde-free soybean modified wood bonding agent belongs to the protein-based bonding agent. The bonding agent is characterized in that: the soybean meal undergoes the three-step modification treatment which comprises the modification treatment by using mixed solution of alkali and ethanol in the early stage, the cross-linking modification by using a compound cross-linking agent in the intermediate stage and cutting by using an inorganic acid thinning agent to reduce viscosityin the final stage to prepare the bonding agent, wherein the compound cross-linking agent is the mixture of polyphosphate, sodium dodecyl sulfate and catechol containing a defoaming agent in propertyquantity; and the cutting thinning agent is the water-soluble inorganic acid. The invention provides an aldehyde-free soybean modified wood bonding agent having the advantages of low cost of raw materials, high bonding strength, high water resistance, easy coating and unnecessary high-temperature hot pressing and a method for preparing the same. The bonding agent provided by the invention solves the problems of low bonding strength and poor water resistance existing in the commercially available aldehyde-free soybean protein bonding agent, is environment-friendly and resource-saving, also solves the problems of high viscosity and poor coating process existing in the soybean protein bonding agent and is applied to the bonding of various wood products.

Owner:SHANDONG XINGANG ENTERPRISE GRP CO LTD

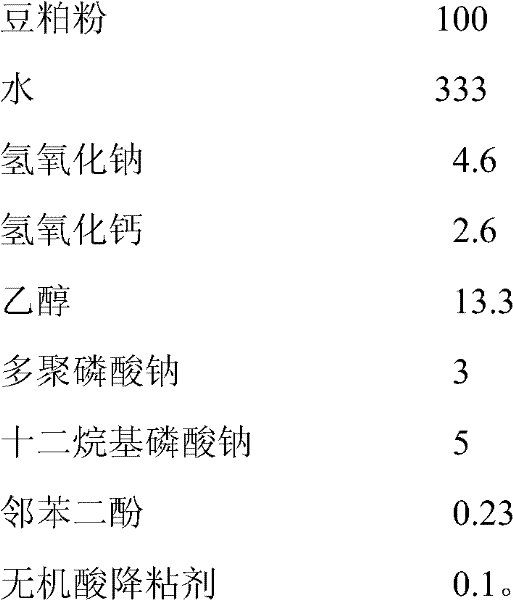

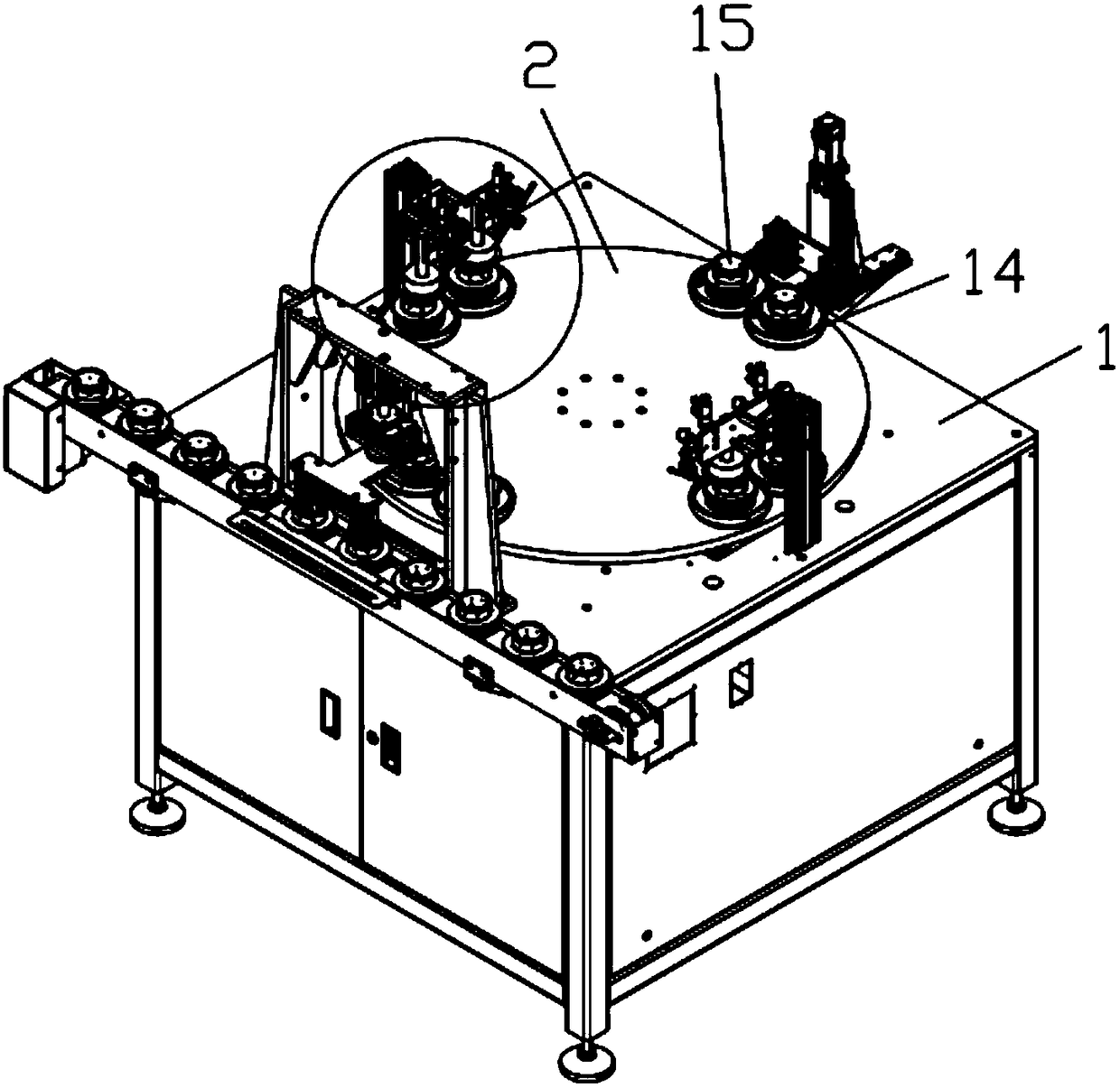

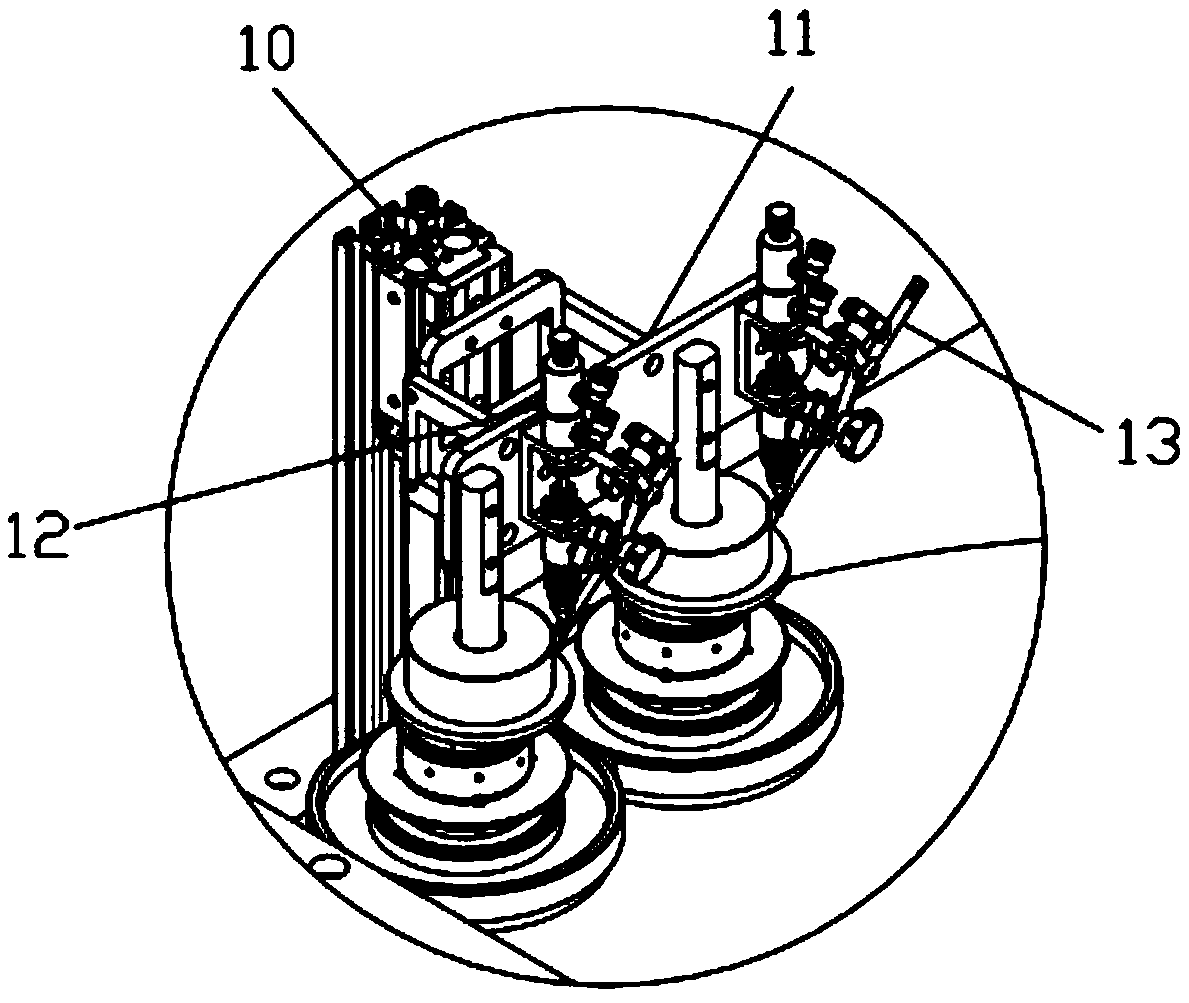

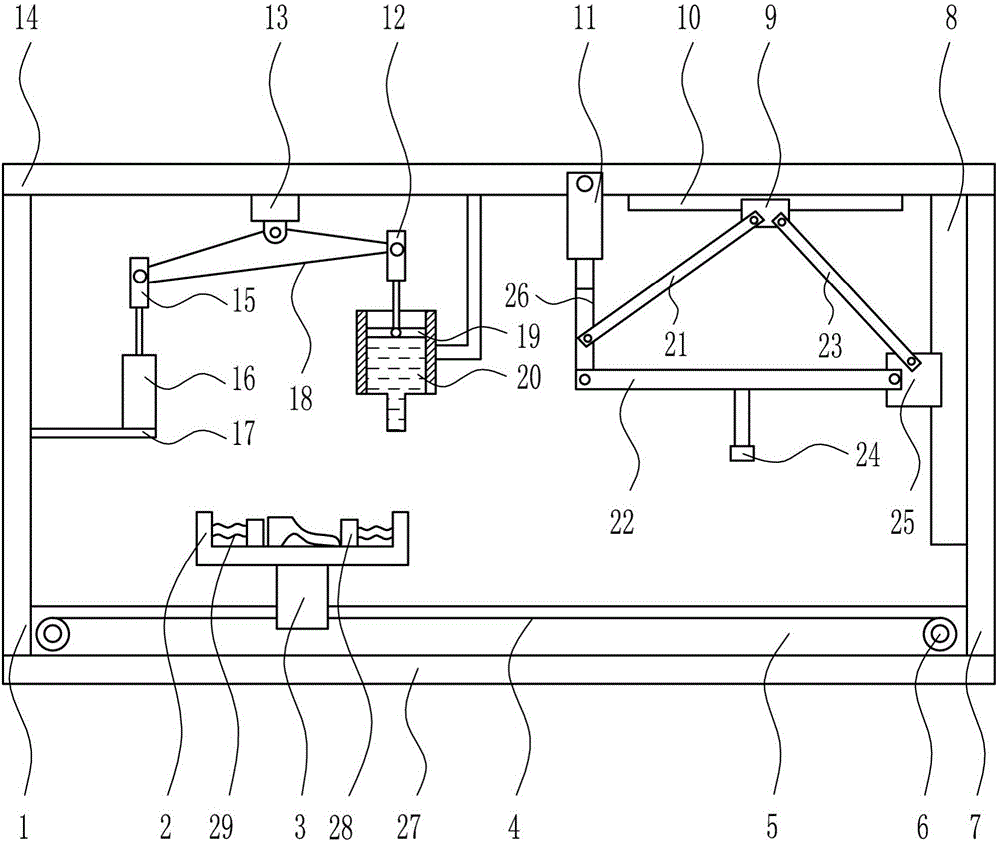

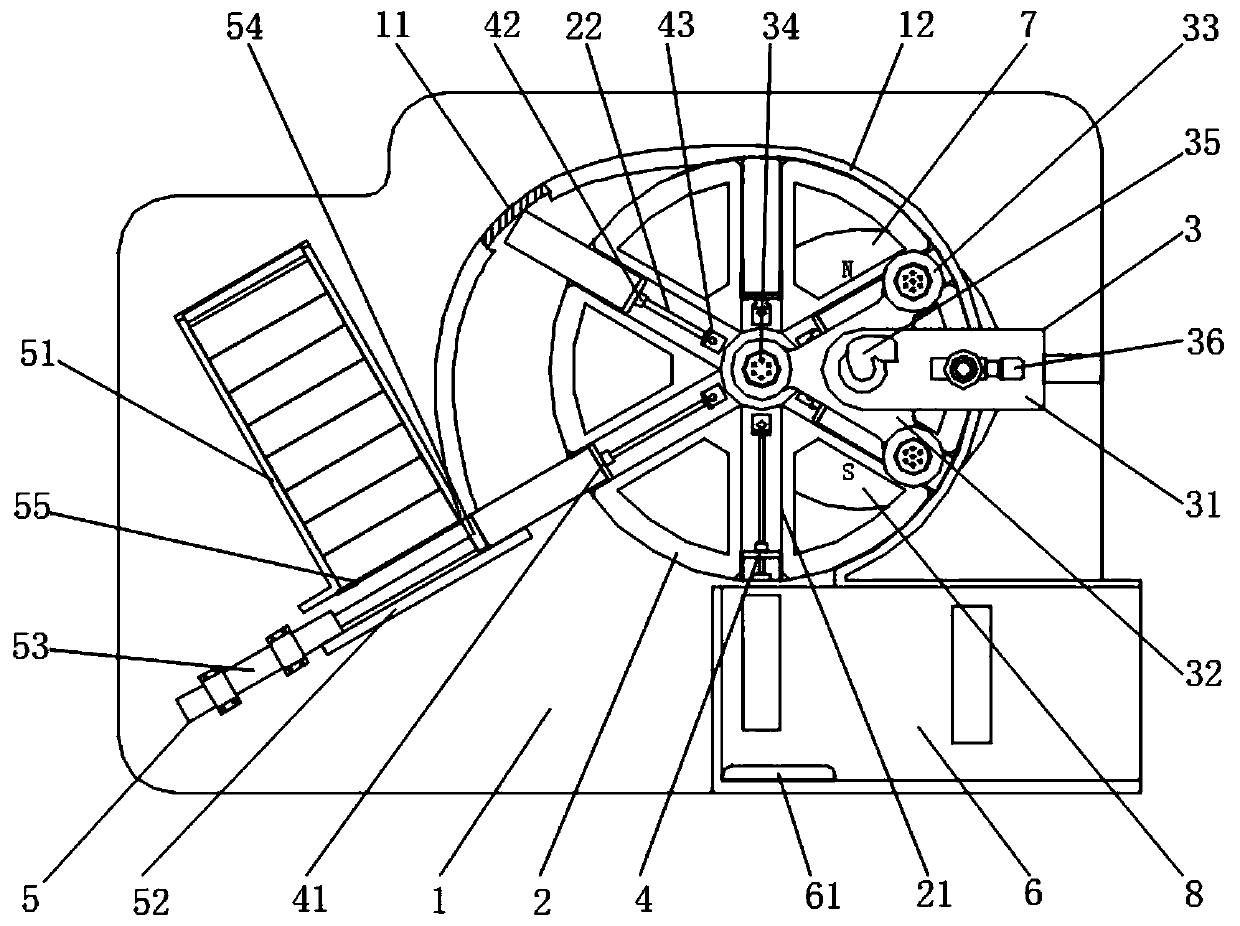

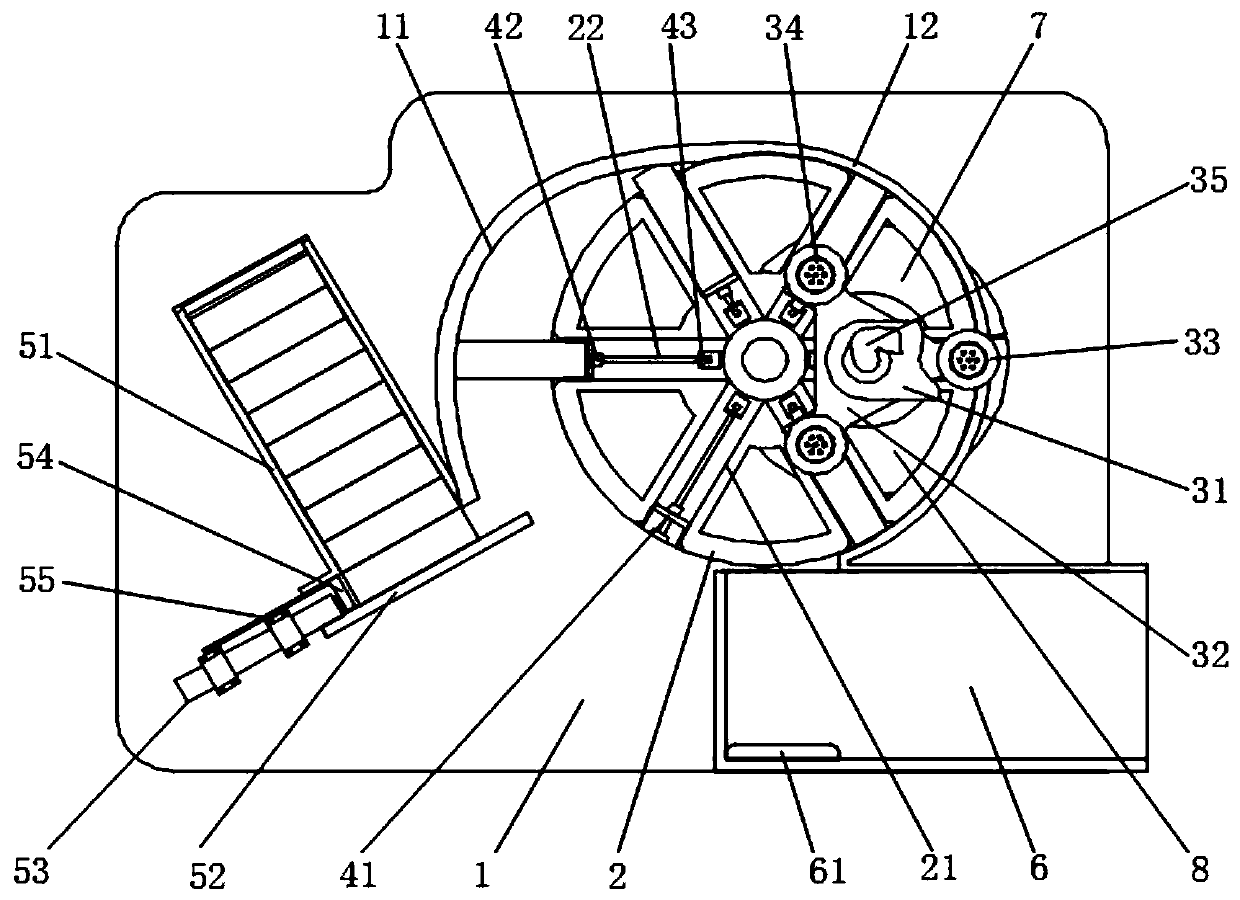

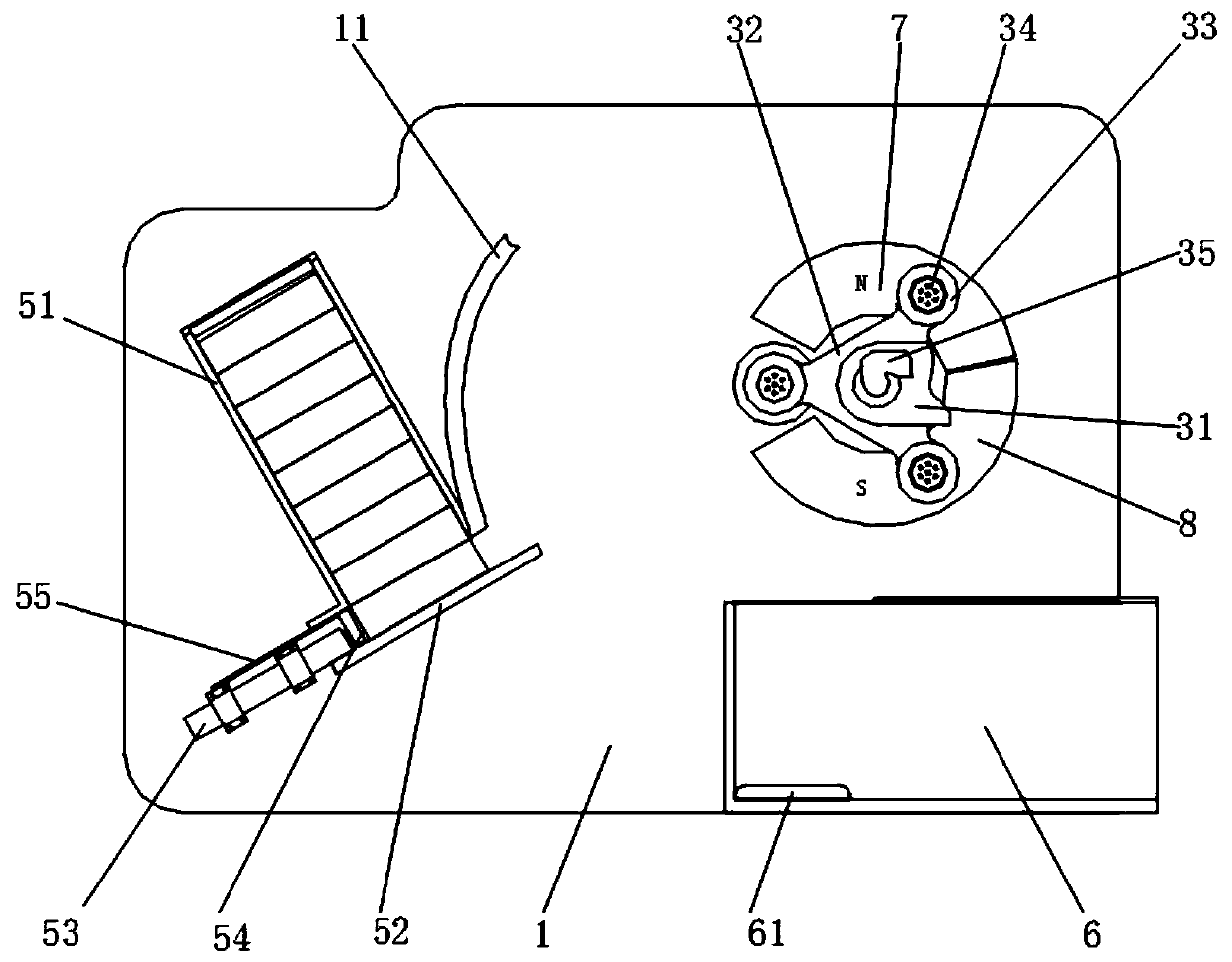

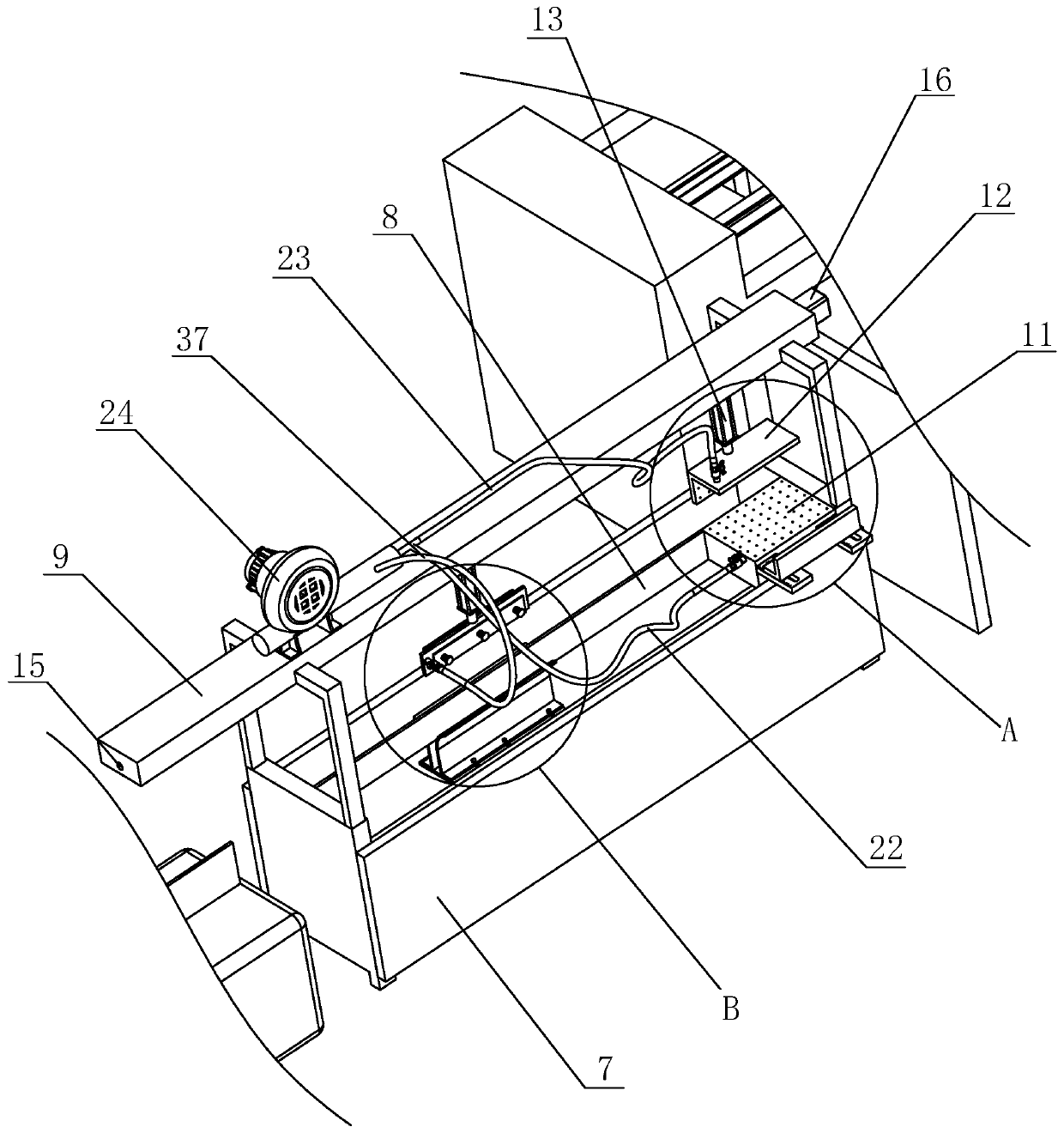

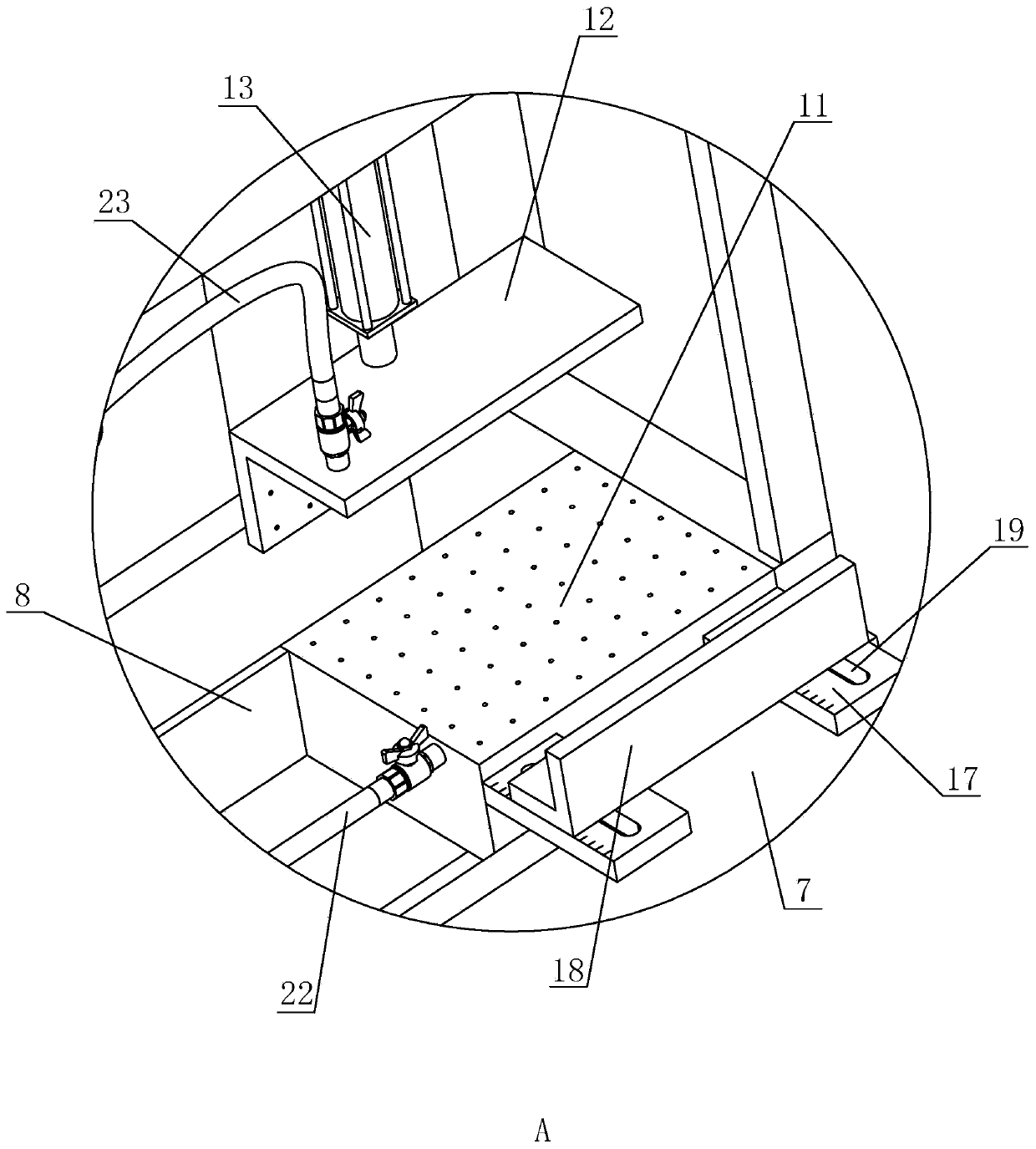

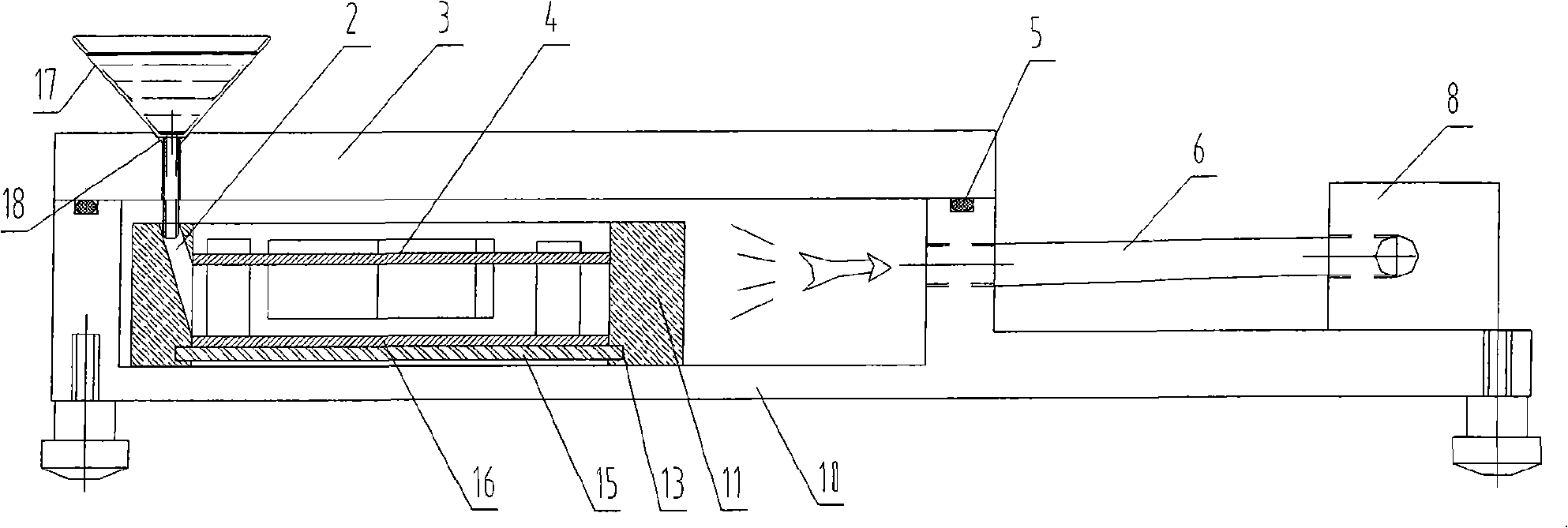

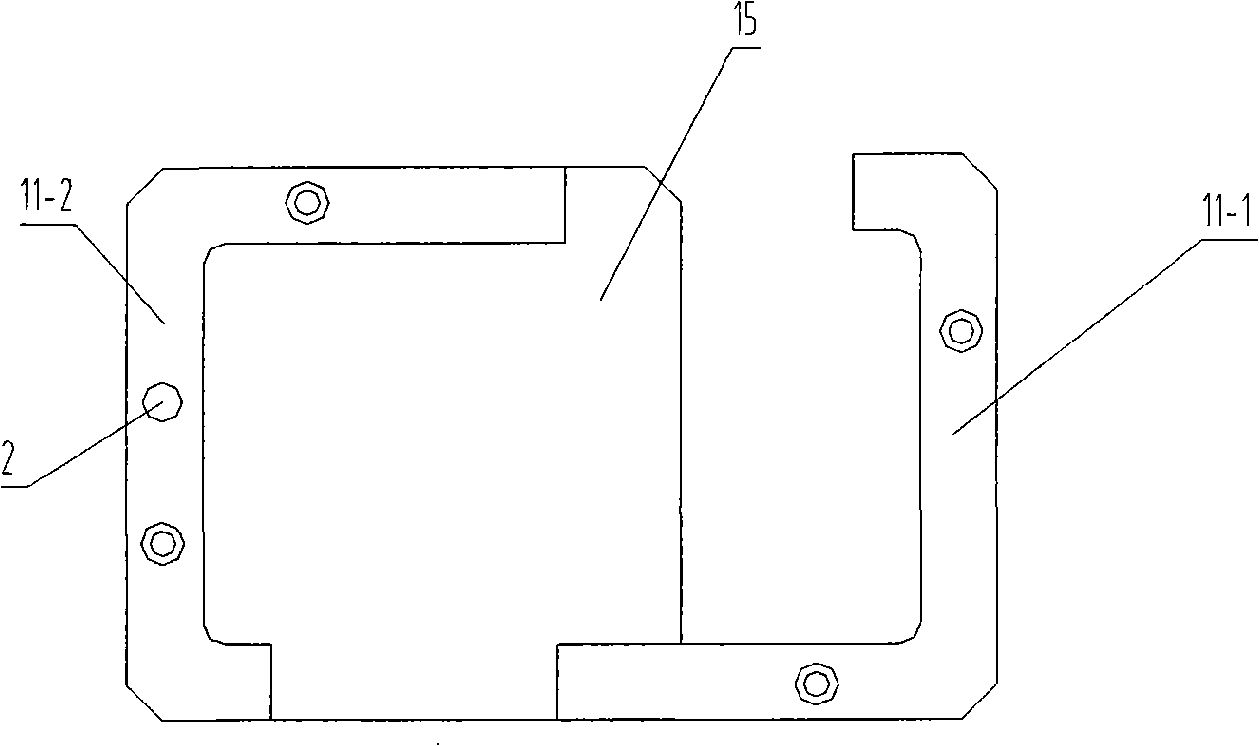

Electronic element high-efficiency vacuum gluing equipment

PendingCN107742573AImprove gluing qualityEasy to absorb and grabEncapsulation/impregnationElectricityEngineering

The invention relates to the technical field of electronic element gluing, and particularly relates to electronic element high-efficiency vacuum gluing equipment, which comprises a rack, a turntable mechanism, a loading mechanism, a positioning mechanism, a rotating mechanism, an unloading mechanism, a detecting mechanism, a gluing mechanism, a vacuum mechanism, an electric control mechanism and acontrol mechanism, wherein the turntable mechanism is arranged on the rack; the loading mechanism, the positioning mechanism, the rotating mechanism and the unloading mechanism are arranged on the rack and around the turntable mechanism; the detecting mechanism is fixed on the rack and above the rotating mechanism; the gluing mechanism is mounted on the rack and above the turntable mechanism; thevacuum mechanism and the electric control mechanism are arranged in the rack; the control mechanism is connected with the electric control mechanism and is fixed on the rack; the vacuum mechanism isconnected with the loading mechanism, the unloading mechanism and the turntable mechanism; the electric control mechanism is electrically connected with the turntable mechanism, the loading mechanism,the positioning mechanism, the rotating mechanism, the unloading mechanism, the vacuum mechanism and the control mechanism. The equipment provided by the invention has the advantages of full-automatic overall operation, high gluing quality of electronic elements, high gluing efficiency and high automation degree.

Owner:DONGGUAN TB ELECTRONICS TECH CO LTD

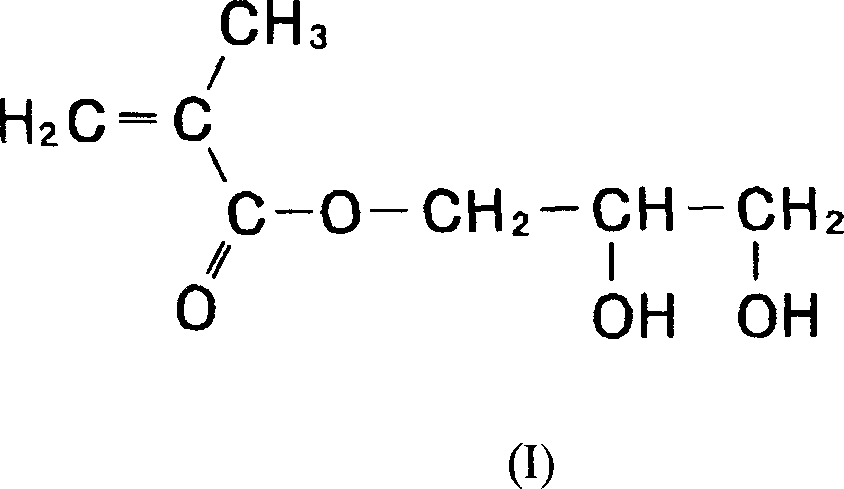

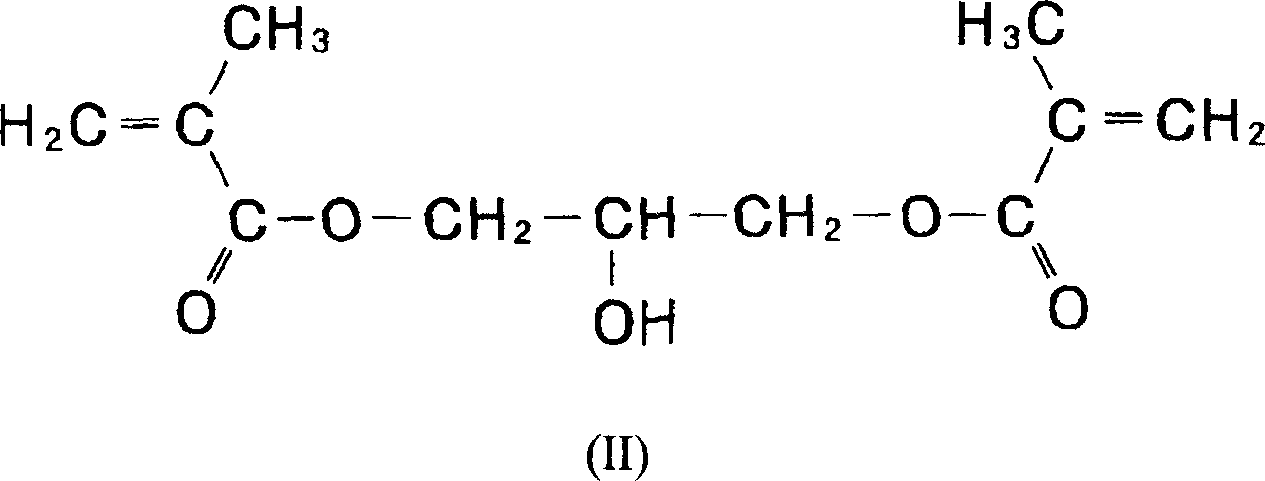

Printing ink using ultraviolet cured resin composition as active ingradient

The present invention relates to one kind of printing ink, and the printing ink has ultraviolet cured resin composition as the effective component. The ultraviolet cured resin composition contains glyceryl monomethacrylate and / or glyceryl dimethacrylate as light reactive diluent, and may be used in printing, spraying or adhering polypropylene, polyethylene and other polyolefin, ethylene-vinyl alcohol copolymer and other un-adhesive plastic material. In addition, it may be used in printing, spraying or adhering polycarbonate, polyester, paper, metal and other adhesive material.

Owner:SEIKO ADVANCE

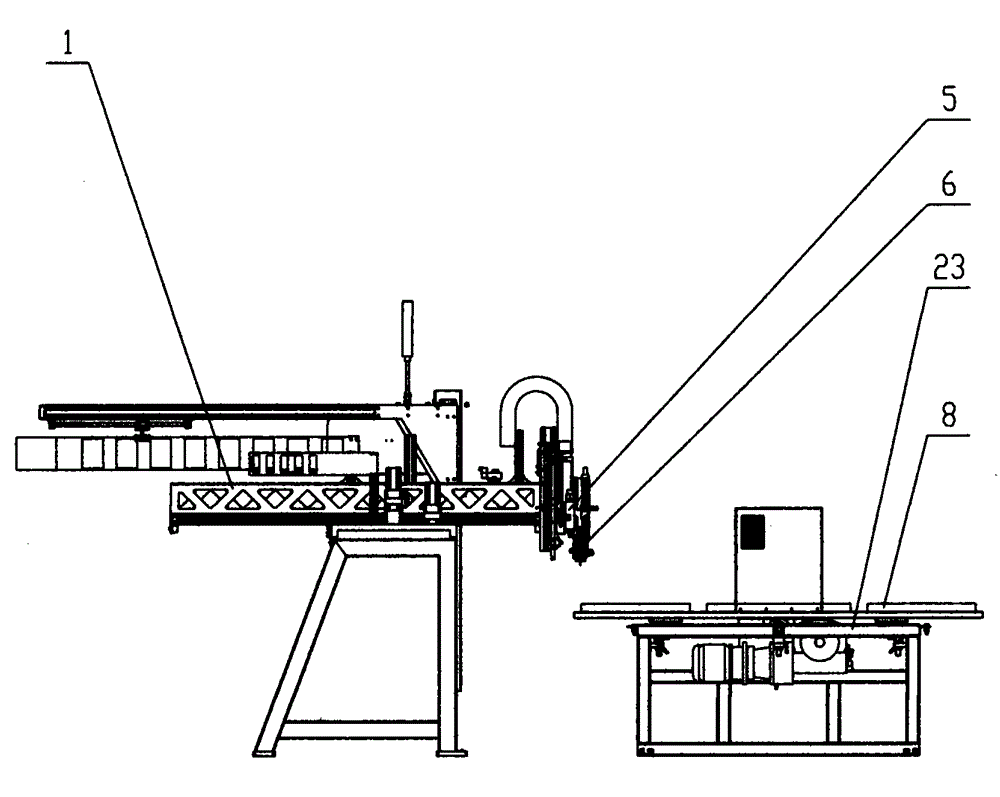

Five-axis robot gumming equipment and technology

ActiveCN104971862ASimple processFast processingProgramme-controlled manipulatorSpraying apparatusMetering pumpArthrobotrys

The invention relates to the technical field of gumming, in particular to five-axis robot gumming equipment and a technology which are used for two-component polyurethane gumming. The five-axis robot gumming equipment is characterized by comprising a five-axis robot, a gum supply device, a two-component gumming head, a double-station automatic gumming workbench or multi-station automatic and rotary gumming workbench, plasma processing equipment, a waste washing liquid recycling device and an intelligent control system. The five-axis robot is a five-joint robot. A workpiece is put on the double-station automatic gumming workbench or multi-station automatic and rotary gumming workbench. The workpiece is fixed or can rotate or swing or move along one axis. The two-component gumming head and aplasma processing head can achieve five-axis linkage. The gum supply device comprises a gum A barrel, a gum B barrel, a gum A metering pump, a gum B metering pump, a gum pipe, a gum supply pipeline, a pipeline support, a gum A material barrel and a gum B material barrel. The polyurethane gumming equipment and the technology are novel, accurate in matching ratio, stable in adhesive tape performance and good in sealing effect.

Owner:DALIAN HUAGONG INNOVATION TECH

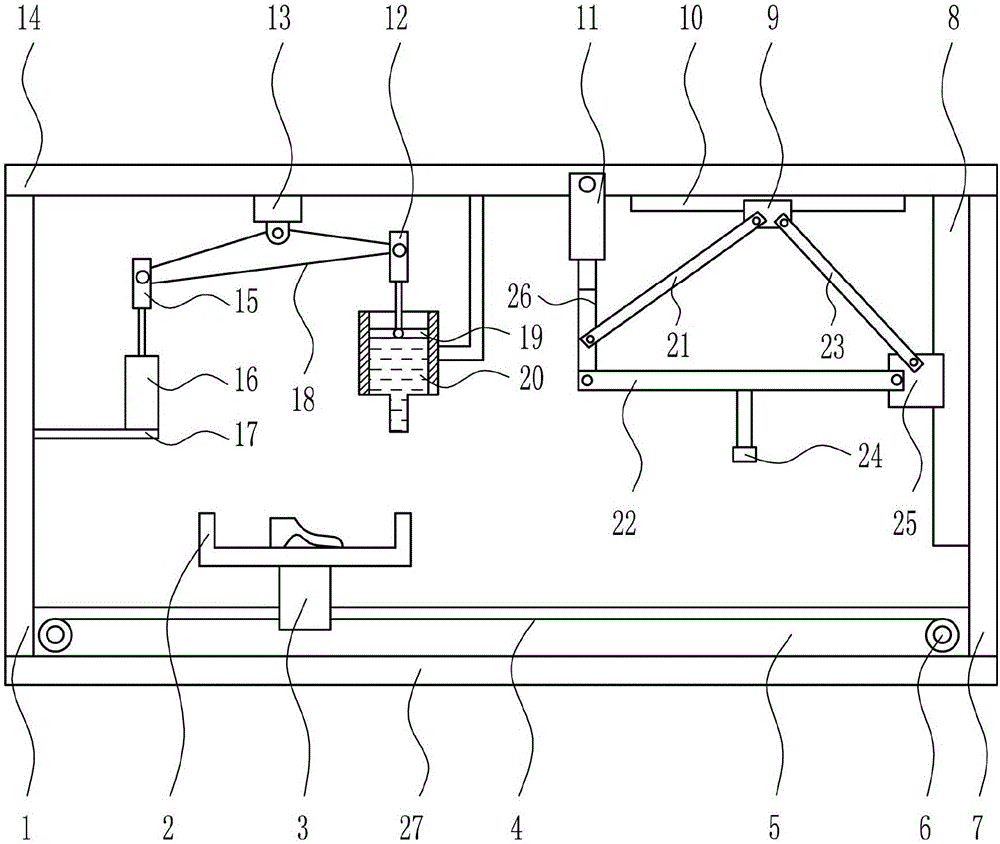

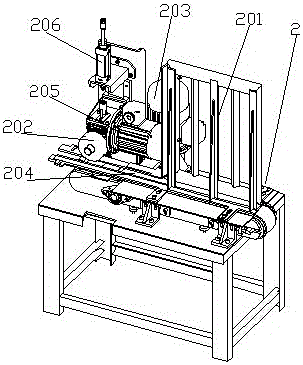

Automatic glue spreader

PendingCN109332079AEasy to glueSmall footprintLiquid surface applicatorsCoatingsIndustrial engineering

The invention discloses an automatic glue spreader, and relates to the technical field of glue spreaders. The automatic glue spreader comprises a working table and a dividing plate arranged on the working table, wherein four stations are arranged on the working table; a clamping device, a first glue spreading device, a turnover device and a second glue spreading device are sequentially arranged onthe four stations along the circumferential direction of the dividing plate; the turnover device comprises a lifting sliding table; a lifting air cylinder is arranged on the top part of the lifting sliding table; a lifting plate connected with the lifting air cylinder is arranged on the lifting sliding table; a rotary motor is arranged on the lifting plate and is connected with a clamping air cylinder; a pneumatic clamping jaw is arranged at the end part of the clamping air cylinder; an extending table is arranged on one side of the working table; and the lifting sliding table slides on the extending table along the horizontal direction. According to the automatic glue spreader provided by the invention, through arranging the two glue spreading devices and the turnover device between thetwo glue spreading devices, two sides of a workpiece can be conveniently glued; and meanwhile, by adopting the dividing plate, the workpiece can be conveyed to each station, so that the floor space ofequipment can be reduced.

Owner:JIANGSU YUBO AUTOMATION EQUIP CO LTD

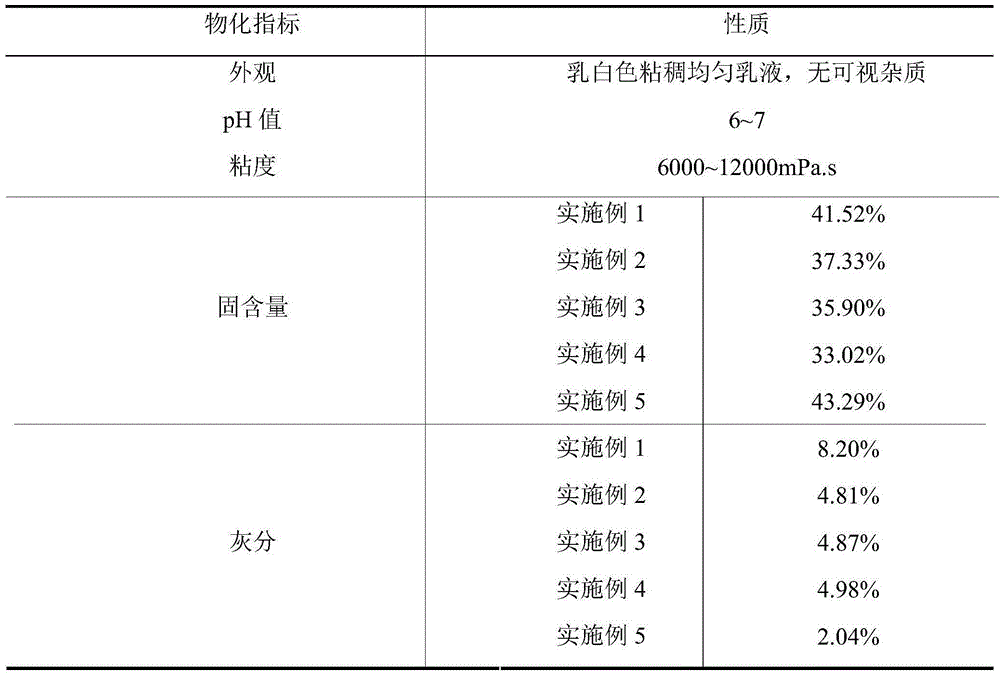

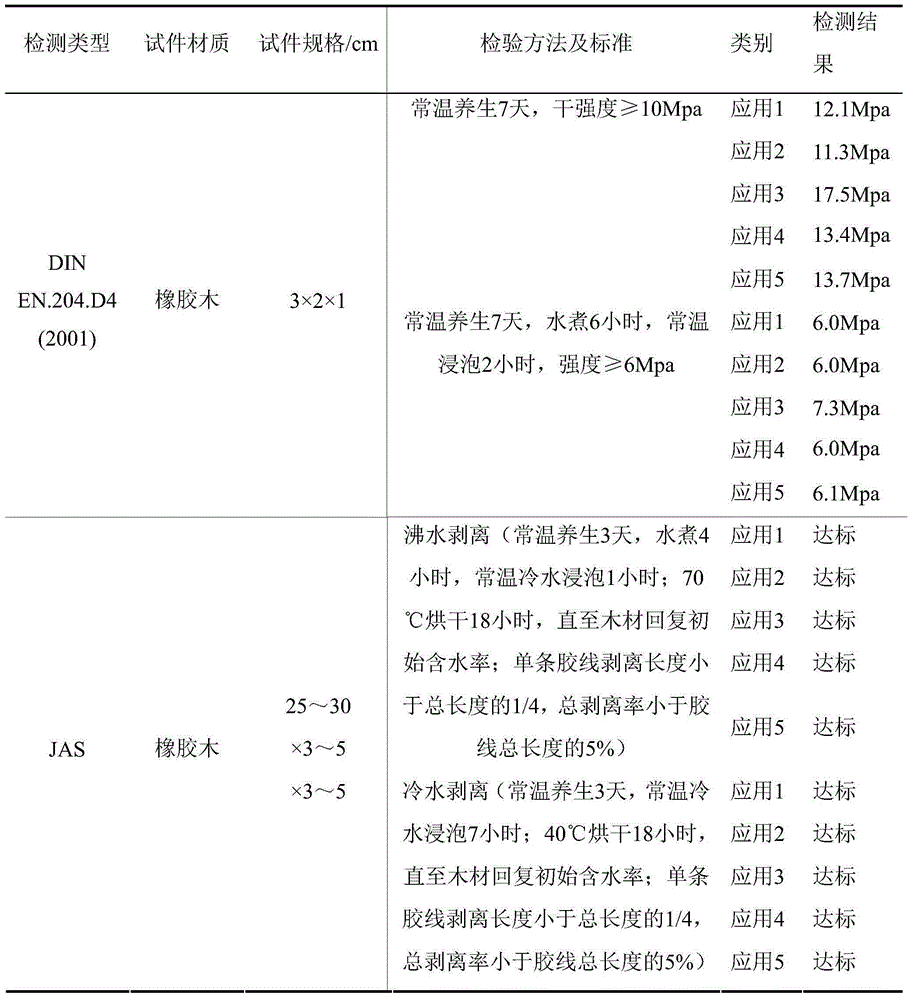

Water-based environment-friendly plate splicing adhesive and preparation method thereof

ActiveCN104479596APromote cleaner productionEasy to useMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesWater basedAdhesive

The invention relates to a water-based environment-friendly plate splicing adhesive and a preparation method thereof, belonging to the technical field of adhesives. The water-based environment-friendly plate splicing adhesive comprises the following raw materials in parts by mass: 0.1-1 part of polyvinyl alcohol, 0.5-10 parts of polyvinyl acetate emulsion, 0.5-10 parts of polyvinyl acetate-ethylene emulsion, 0.5-2 parts of calcium carbonate powder, 0.01-0.1 part of nano oxide, 0.001-0.02 part of carboxymethyl cellulose, 0.1-1 part of styrene-butadiene latex, 0.01-0.1 part of defoaming agent, 0.01-0.08 part of preservative, 6-12 parts of water and 1.34-3.46 parts of crosslinking agent. The polyvinyl acetate emulsion and polyvinyl acetate-ethylene emulsion are used as the base, and the prepared main agent is free of formaldehyde, and thus, is a water-based environment-friendly adhesive. All the monomers and components belong to low-toxicity environment-friendly chemicals which are beneficial to clean production.

Owner:康菲胶粘剂技术(广东)有限公司

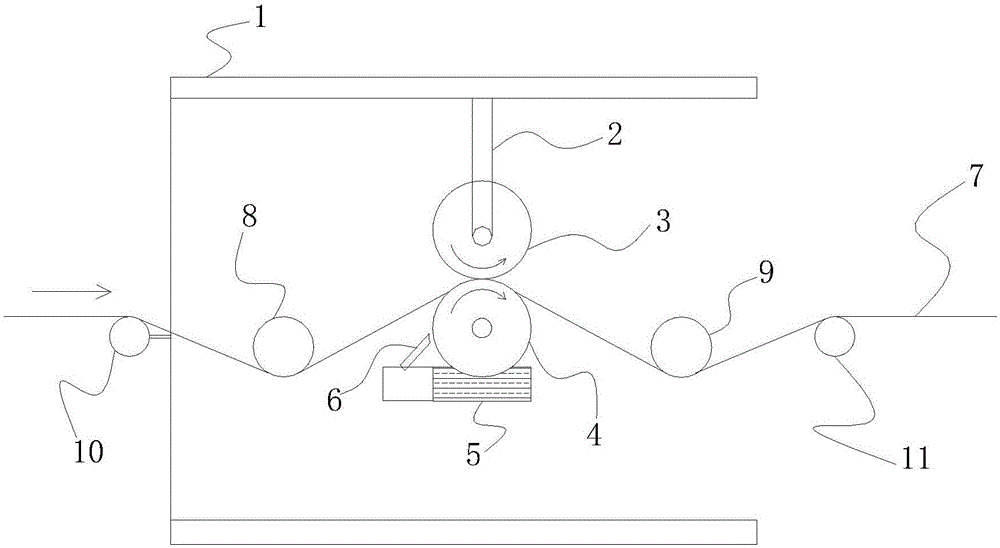

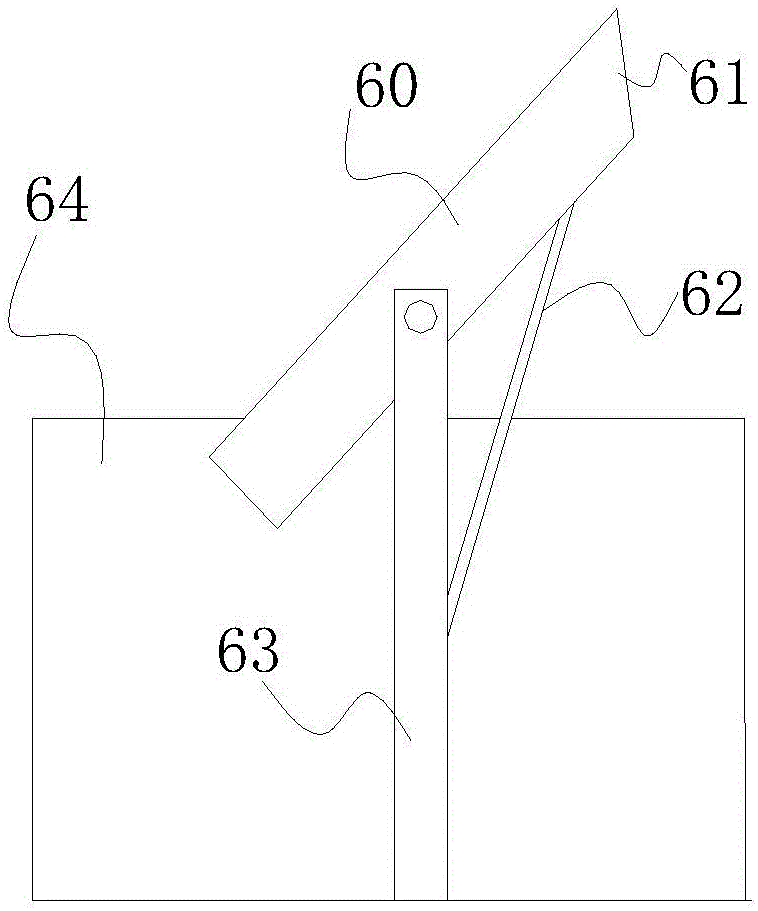

Paperboard gluing device

InactiveCN106040522ASimple structureReduce manufacturing costLiquid surface applicatorsCoatingsPaperboardPulp and paper industry

The invention relates to a paperboard gluing device. The paperboard gluing device comprises a glued paperboard, a coating support, guide rollers, a gluing roller and a transmission roller. The gluing roller is arranged under the transmission roller. A gap is reserved between the gluing roller and the transmission roller, and a channel for the glued paperboard to exactly pass is formed. The transmission roller is arranged on the top of the gluing support in a vertical adjusting manner through a hanging rod. A glue box is arranged at the bottom of the gluing roller and internally contains glue. Part of the wall barrel of the gluing roller is immersed in the glue, a glue scraping device is arranged at the position close to the gluing roller and comprises a scraper, a glue recycling box and a supporting rod arranged in the glue recycling box, the supporting rod is vertically arranged in the glue recycling box in a telescopic manner, and the scraper is movably arranged on the supporting rod. According to the paperboard gluing device, gluing is easy, the gluing amount is even, and the glue is not likely to pollute the gluing device; and the gluing device can be applied to the logistics field and other fields.

Owner:北京英格条码技术发展有限公司

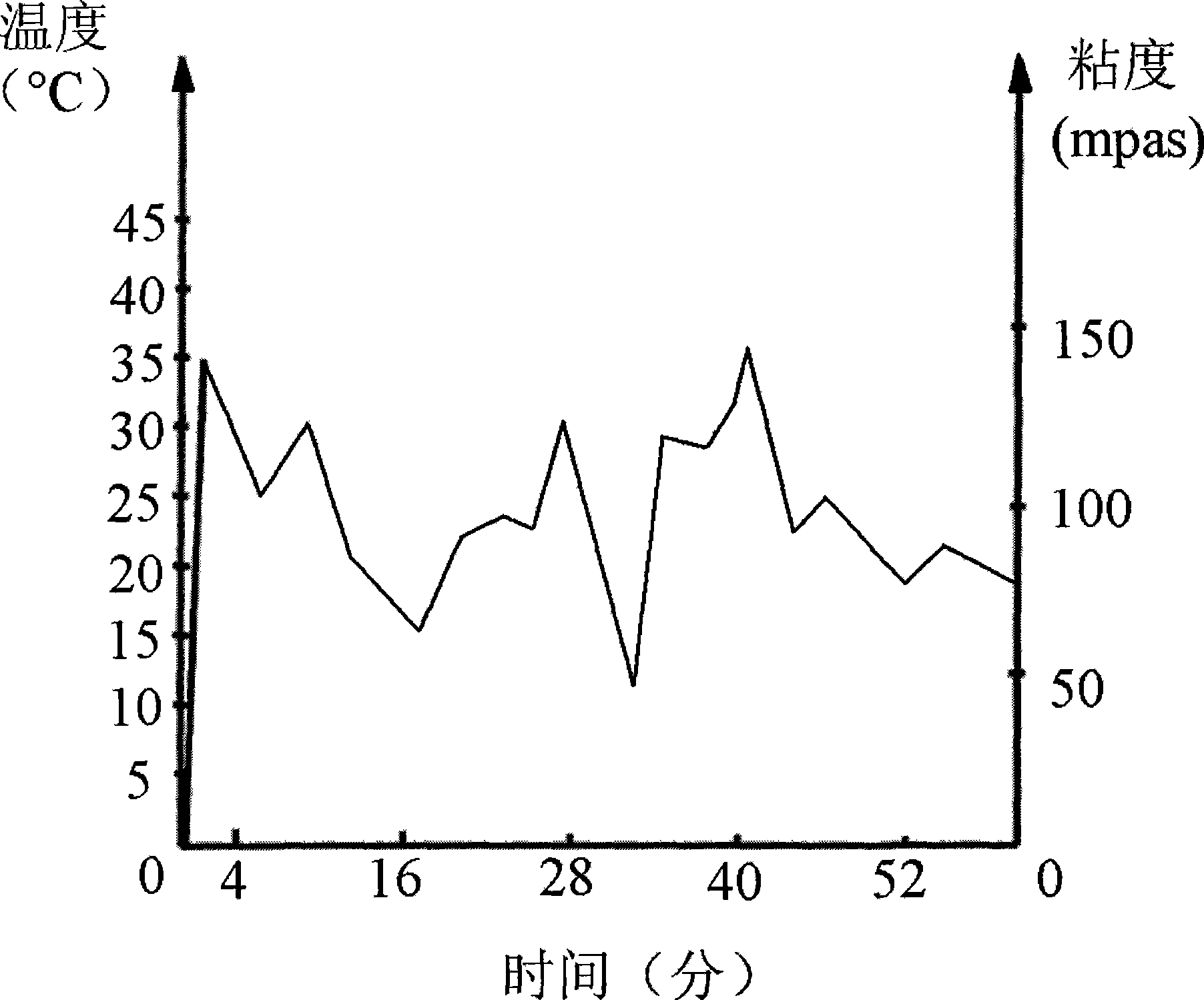

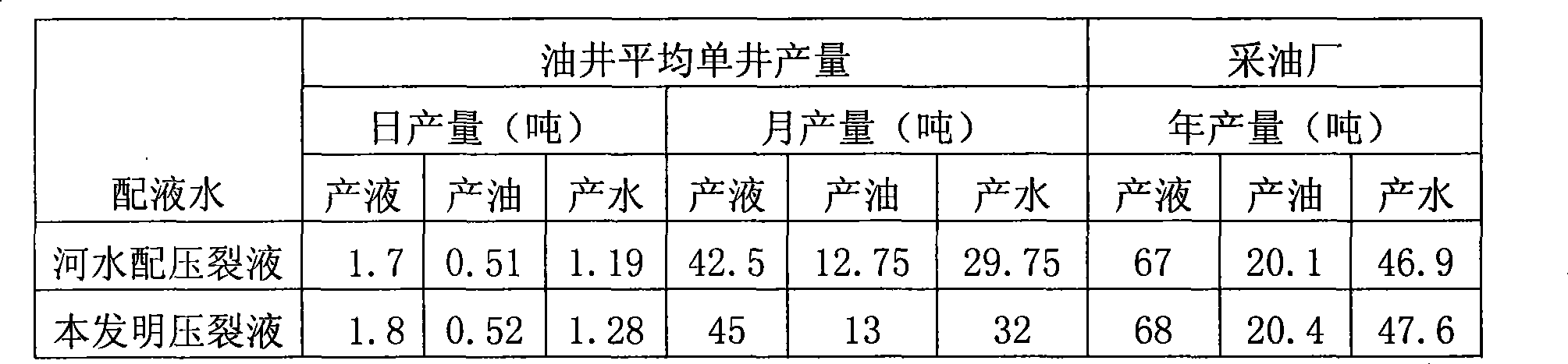

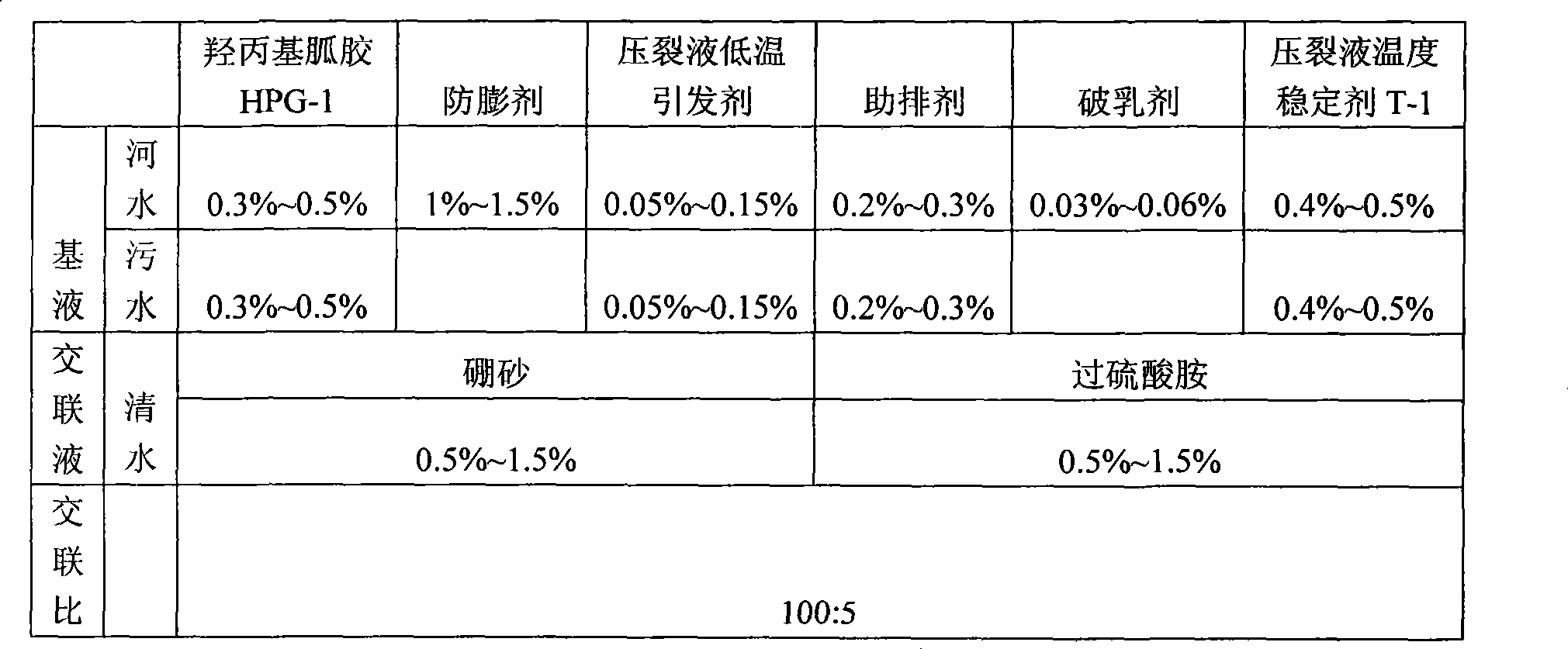

Fracture liquid and preparation method thereof

InactiveCN101381598AHigh salinityGood compatibilityDrilling compositionSweep efficiencyFracturing fluid

The invention discloses fracturing fluid and a preparation method thereof. The fracturing fluid is formed by mixing base fluid and crosslinked fluid according to the crosslinking ratio of 100 to 5; the base fluid consists of the following compositions according to mass percentage: 03 to 0.5 percent of hydroxypropyl guanidine gum HPG-1, 0.4 to 0.5 percent of a temperature stabilizer for the fracturing fluid, 0.05 to 0.15 percent of a low temperature evocating agent for the fracturing fluid, 0.2 to 0.3 percent of a cleanup additive and the balance being sewage water from a crude oil layer; and the crosslinked fluid consists of the following compositions according to mass percentage: 0.5 to 1.5 percent of borax, 0.5 to 1.5 percent of ammonium persulfate and the balance being clear water. The method for preparing the fracturing fluid comprises the following steps: the prepared base fluid and the prepared fracturing fluid are respectively placed for 100 to 120 minutes and are mixed according to the crosslinking rate of 100 to 5 to form the fracturing fluid. The method adopts the sewage water for matching the fracturing fluid, saves cost, has small pollution to the environment and improves the wave and volume of a water-driven reservoir and the oil-sweeping efficiency.

Owner:YANCHANG OIL FIELD

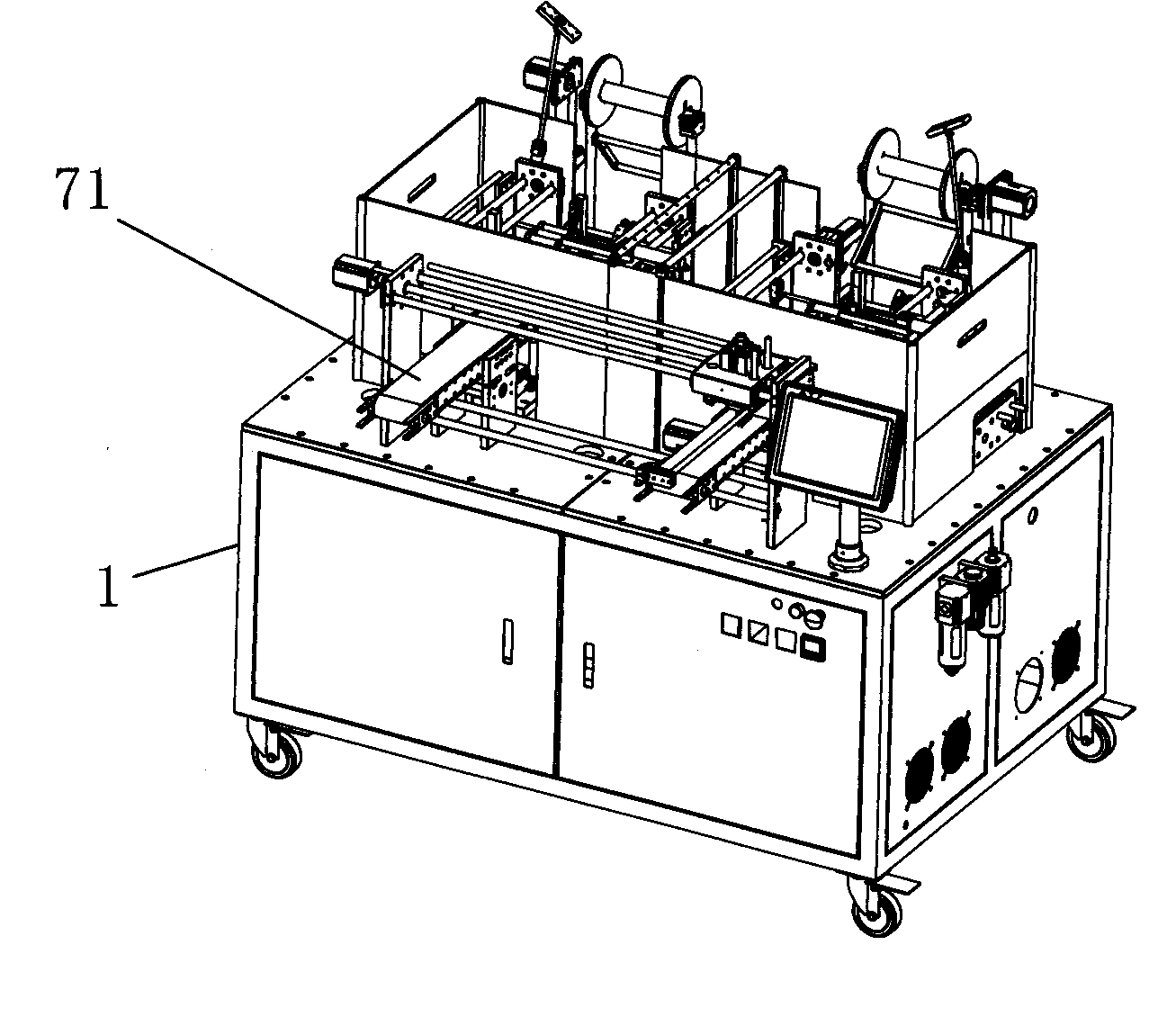

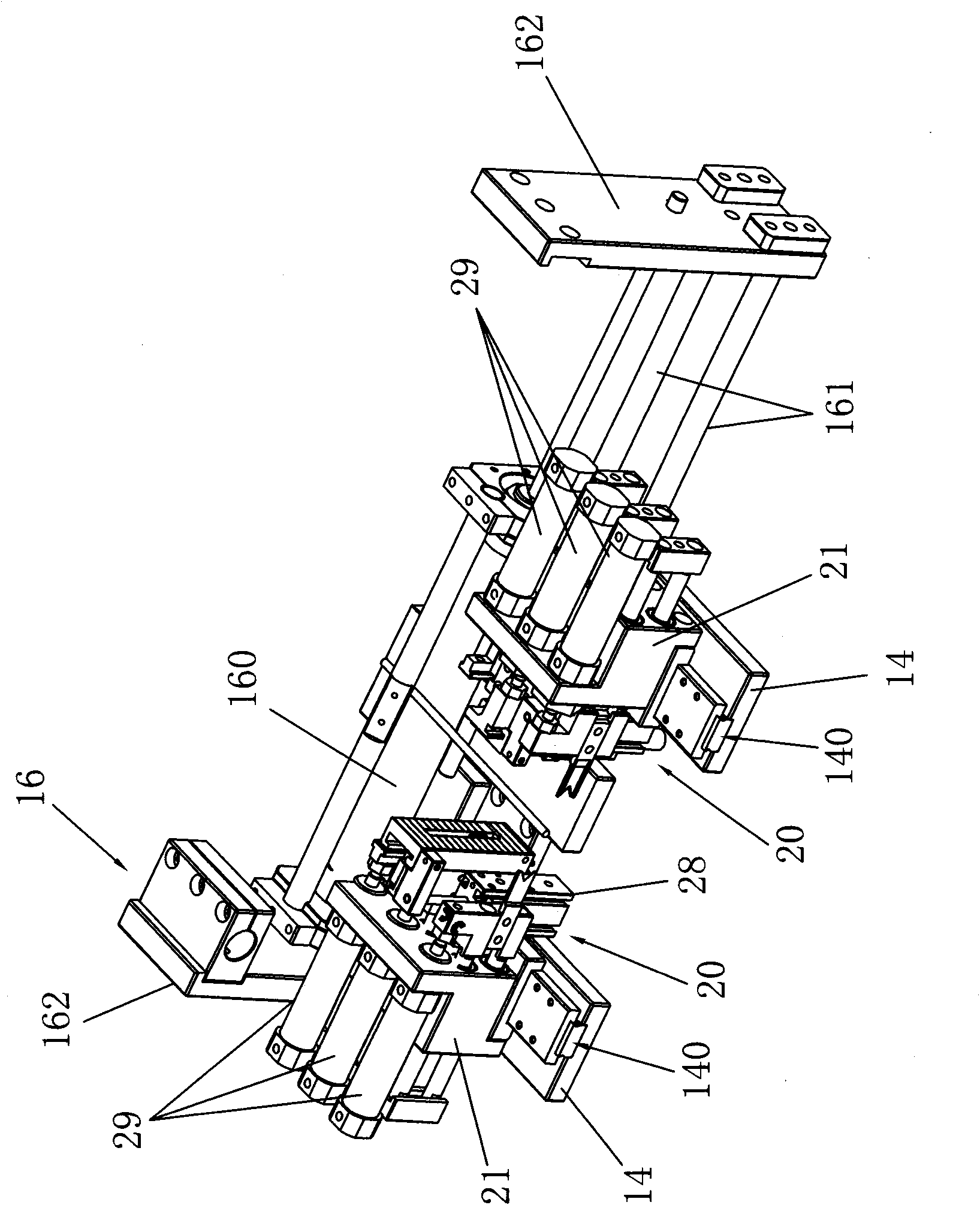

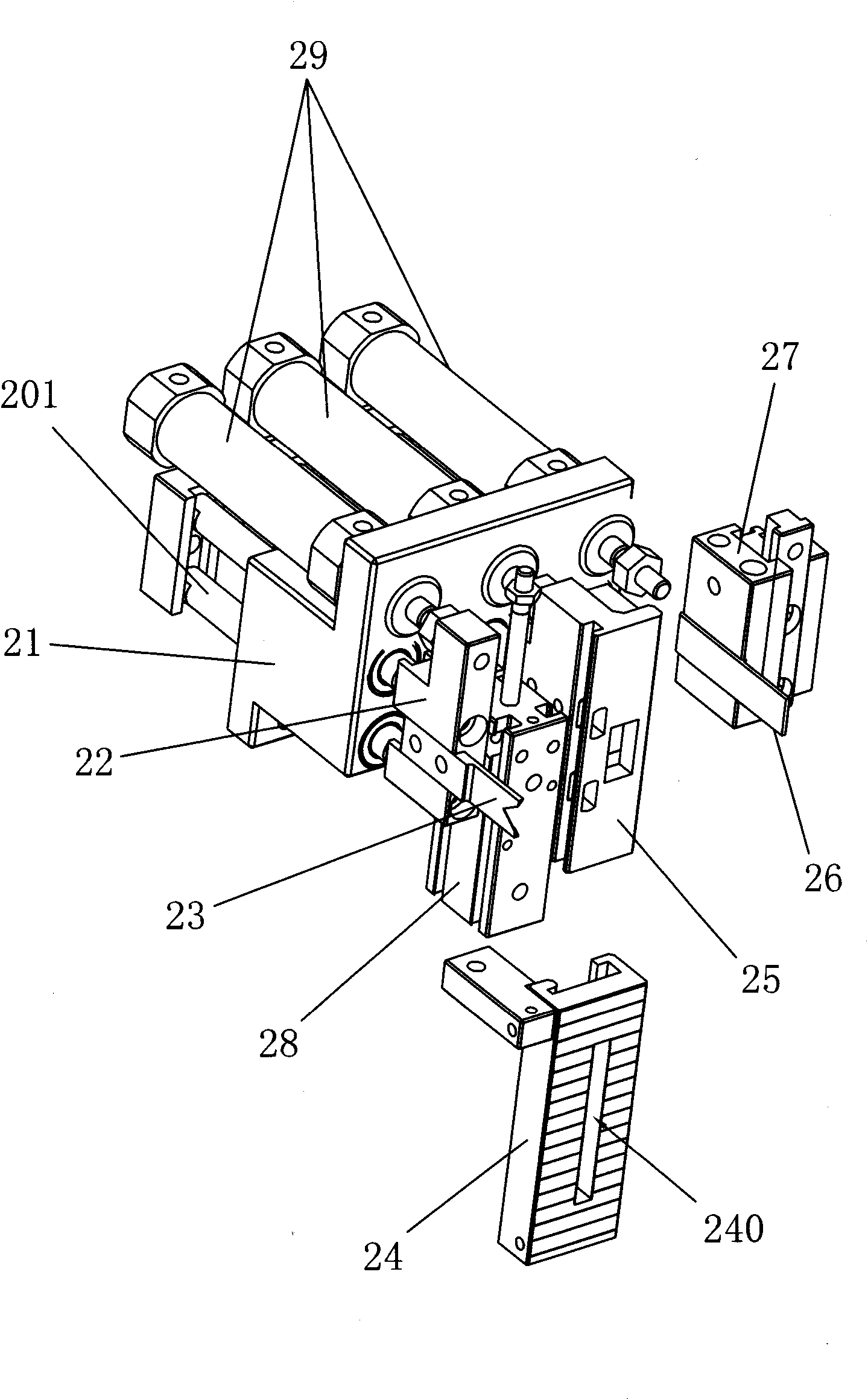

Automatically cutting and adhering machine

InactiveCN101863129AStrong jointImprove work efficiencyDomestic articlesElectric machineryManipulator

The invention relates to the technical field of cutting and adhering equipment, in particular to an automatically cutting and adhering machine. The automatically cutting and adhering machine comprises a machine frame, a control system, and a gear feeding device, a hot-press cutting device, a mechanical arm feeding and clamping device, a rotary glue-feeding device and a conveying device which are arranged on the machine frame sequentially, wherein the control system is connected with the gear feeding device, the hot-press cutting device, the mechanical arm feeding and clamping device, the rotary glue-feeding device and the conveying device; the hot-press cutting device comprises a pedestal and two groups of hot-press cutting mechanisms which are symmetrically arranged on the pedestal; the mechanical arm feeding and clamping device comprises two mechanical arms, an upper driving motor and a lower driving motor; each mechanical arm is provided with a clamping part; and the upper driving motor and the lower driving motor are used for driving the two mechanical arms respectively to move backwards and forwards. The automatically cutting and adhering machine has the advantages of capacity of automatically completing the whole production manufacturing process of a hair band, high degree of automation and great improvement on the production capacity and the quality of products.

Owner:LIVINGSTYLE ENTERPRISES

Four-axis robot gumming equipment and technology

ActiveCN104971863ASimple processFast processingProgramme-controlled manipulatorSpraying apparatusEngineeringCantilever

The invention relates to the technical field of gumming, in particular to four-axis robot gumming equipment and a technology which are used for two-component polyurethane gumming. The four-axis robot gumming equipment is characterized by comprising a four-axis robot, a gum supply device, a two-component gumming head, a double-station automatic gumming workbench or multi-station automatic and rotary gumming workbench, plasma processing equipment, a waste washing liquid recycling device and an intelligent control system. The four-axis robot is of a gantry type or cantilever type structure. The two-component gumming head and aplasma processing head are fixed on the four-axis robot and can achieve X-axis, Y-axis and Z-axis linkage. A workpiece is put on the double-station automatic gumming workbench or multi-station automatic and rotary gumming workbench and is fixed. The two-component gumming head and the plasma processing head are linked along the X-axis, Y-axis and Z-axis to achieve gumming. The polyurethane gumming equipment and the technology are novel, accurate in matching ratio, stable in adhesive tape performance and good in sealing effect.

Owner:DALIAN HUAGONG INNOVATION TECH

Shoemaking gumming device

InactiveCN106108264APrevent sliding left and rightFully gluedShoe gluingMechanical engineeringPiston

The invention relates to a gumming device, in particular to a shoemaking gumming device, and aims to provide the shoemaking gumming device being accurate in gumming position, comprehensive in gumming, and visual enough for observation. The shoemaking gumming device comprises a left bracket, an accommodating rack, a first slider, a stay wire, a first slide rail, an electric reel, a right bracket, a second slide rail, a third slider, a third slide rail, a first electric push rod, a fifth connecting rod, a supporting seat, a top plate, a fourth connecting rod, a cylinder, a fixing plate, a swing rod, a piston, a cylinder body, a third connecting rod, a second connecting rod, a first connecting rod, a pressing block, a second slider, a lifting rod and a bottom plate. The shoemaking gumming device has the effects of being accurate in gumming position, comprehensive in gumming, and visual enough for observation; being fast in gumming speed, reasonable in design, and convenient to use, the shoemaking gumming device is highly practical.

Owner:ZHEJIANG KAJIALI SHOES CO LTD

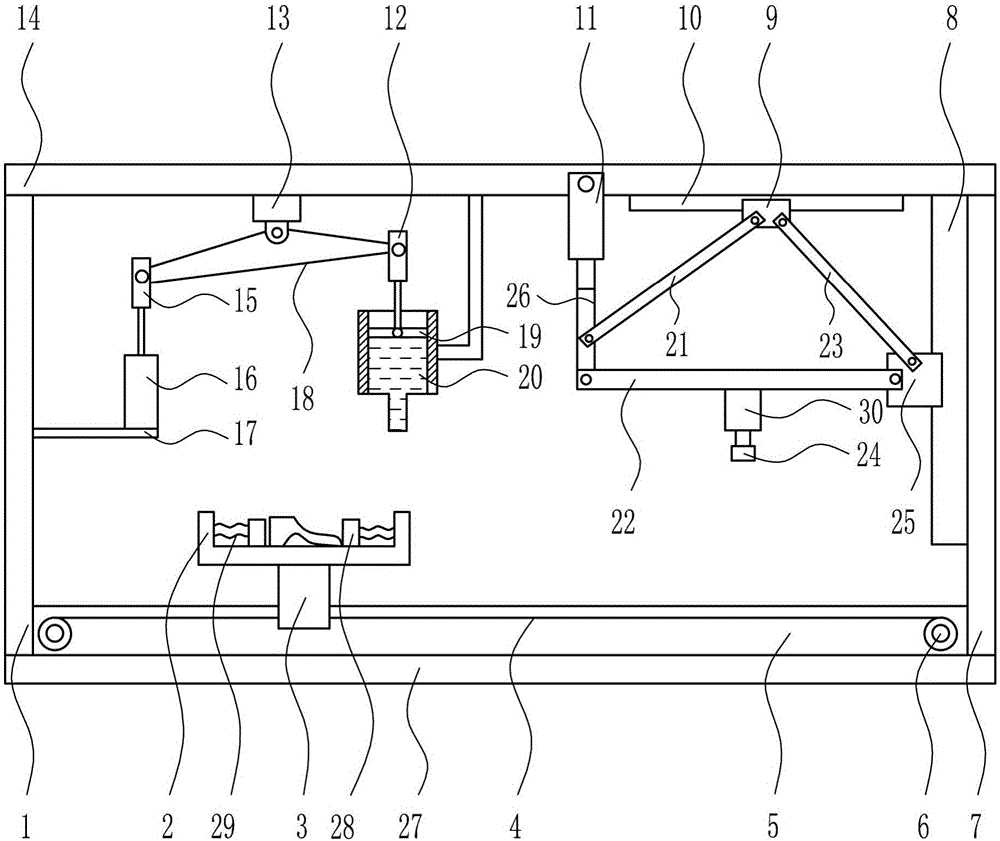

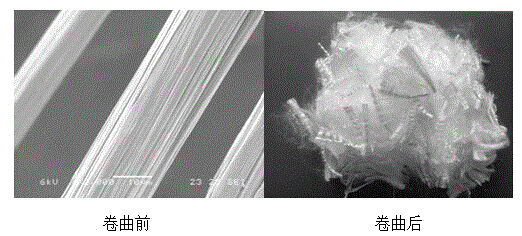

Ultrahigh molecular weight polyethylene short fiber and preparation method thereof

InactiveCN106283246AMeet the requirements of different styles of spinning processEasy to combSevering to form staple fibresArtificial filament heat treatmentFiberPolymer science

The invention discloses ultrahigh molecular weight polyethylene short fiber and a preparation method thereof. The preparation method includes: preparing protofilament of the ultrahigh molecular weight polyethylene short fiber, subjecting the protofilament to assembly winding and bundling, and cleaning oil on the protofilament; applying anionic high-strength polyethylene short fiber oil, performing cold crimping, and loosening and setting the crimped fiber at 80-120 DEG C, wherein drying time is 5-30min, and drying thermosetting temperature is 90-100 DEG C; adjusting tension, and cutting to obtain ultrahigh molecular weight polyethylene short fiber of 3-10 / 25mm in crimp number, wherein cutting length is 3-102mm. The section of the ultrahigh molecular weight polyethylene short fiber is special-shaped, the short fiber has certain natural crimping characteristic and is easy to comb and glue, and cohesion, spinnability and blending performance of the short fiber are improved; fiber number of the short fiber is 0.5-2.5dtex, cutting length is 3-102mm, and strength is 10-40cN / dtex, so that requirements on different styles of subsequent spinning processes can be met.

Owner:SINOPEC YIZHENG CHEM FIBER +1

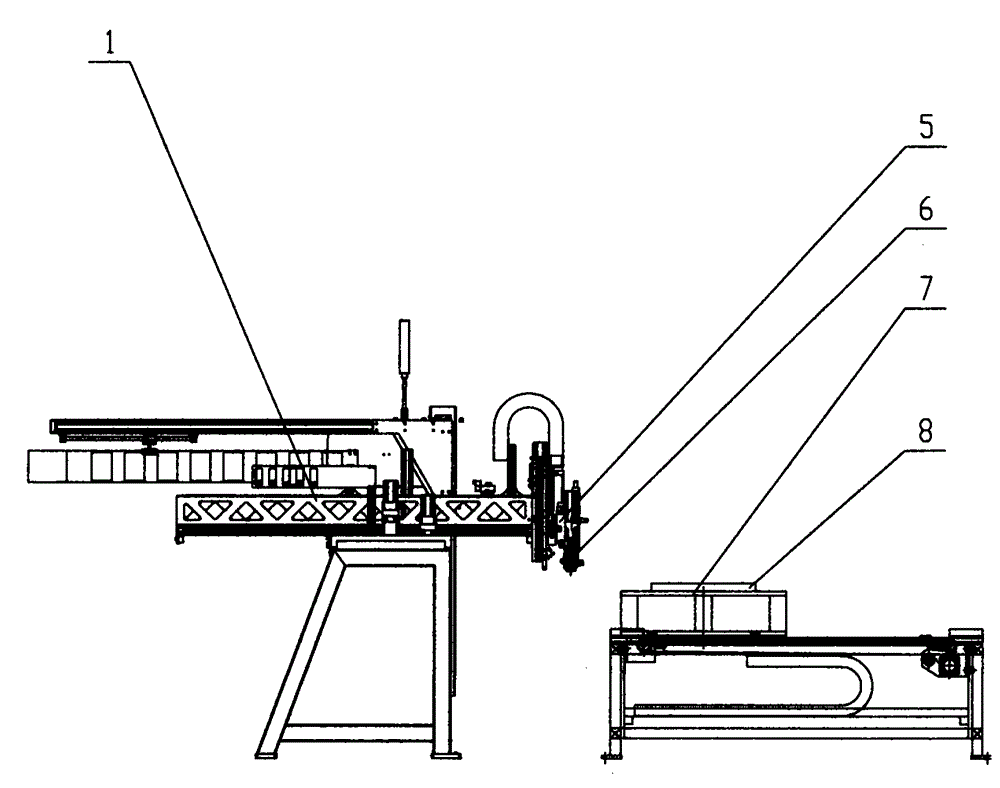

Three-axis robot gluing equipment and process technology

The invention relates to the technical field of gluing, in particular to three-axis robot gluing equipment and a process technology which are used for two-component polyurethane gluing. The three-axis robot gluing equipment is characterized in that the equipment comprises a three-axis robot, a glue supply device, a two-component gluing head, a two-station automatic gluing workbench or a multi-station automatic rotary gluing workbench, plasma treatment equipment, a waste cleaning solution recovery device and an intelligent control system. The three-axis robot is of a gantry type or cantilever type structure. The two-component gluing head and a plasma treatment head are fixed to the three-axis robot and can be linked in the X axis, the Y axis and the Z axis. Workpieces are fixedly placed on the two-station automatic gluing workbench or the multi-station automatic rotary gluing workbench, and therefore gluing is achieved. The glue supply device comprises a glue A barrel, a glue B barrel, a glue A metering pump, a glue B metering pump, glue pipes, glue supply pipelines, a glue A bucket and a glue B bucket. According to the novel polyurethane gluing equipment and the process technology, the proportion is precise, glue tape performance is stable, and the sealing effect is good.

Owner:DALIAN HUAGONG INNOVATION TECH

Method of treating bamboo floor using plasma

InactiveCN1718391AImprove wettabilityEasy to glueWood treatment detailsWood veneer joiningEngineeringBamboo floor

A method for treating bamboo floor boards by plasma includes such steps as drying bamboo strips, plasma treating to make its surface wet angle less than 25 deg, coating resin, laminating and hot pressing.

Owner:NANJING FORESTRY UNIV

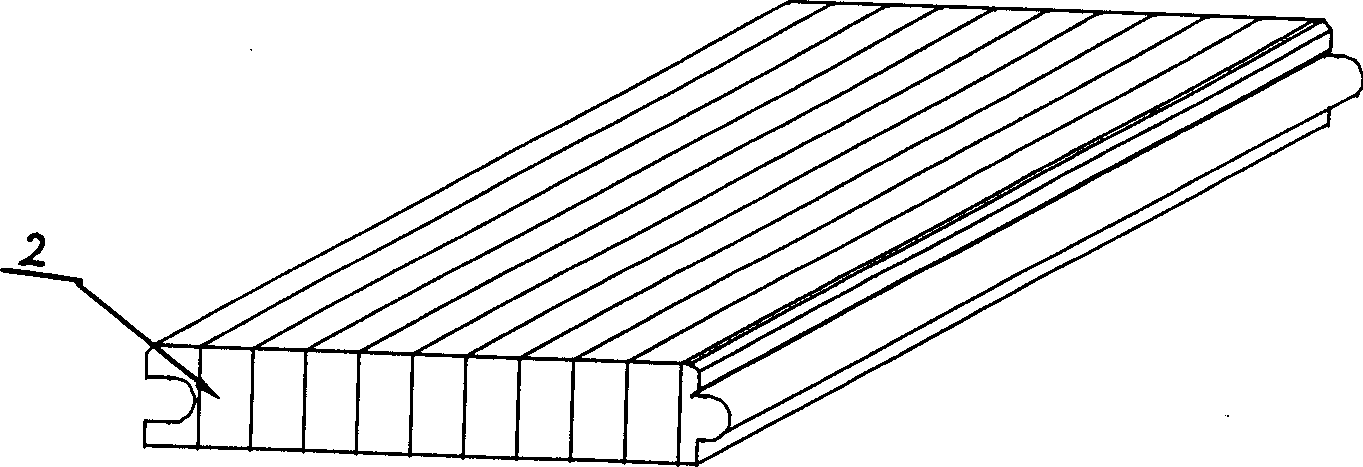

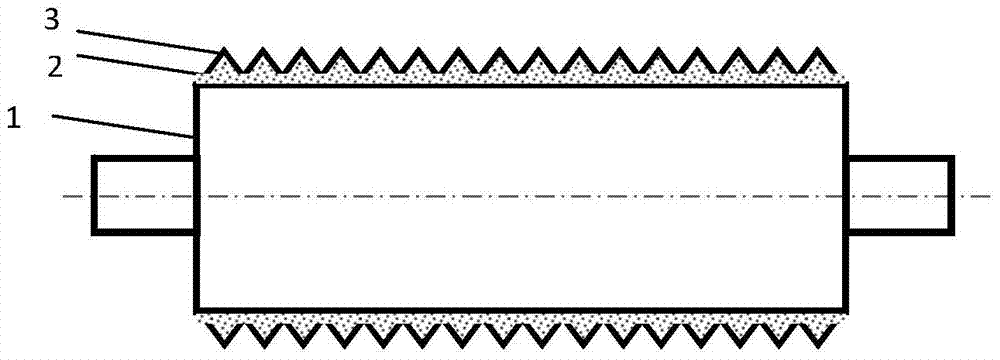

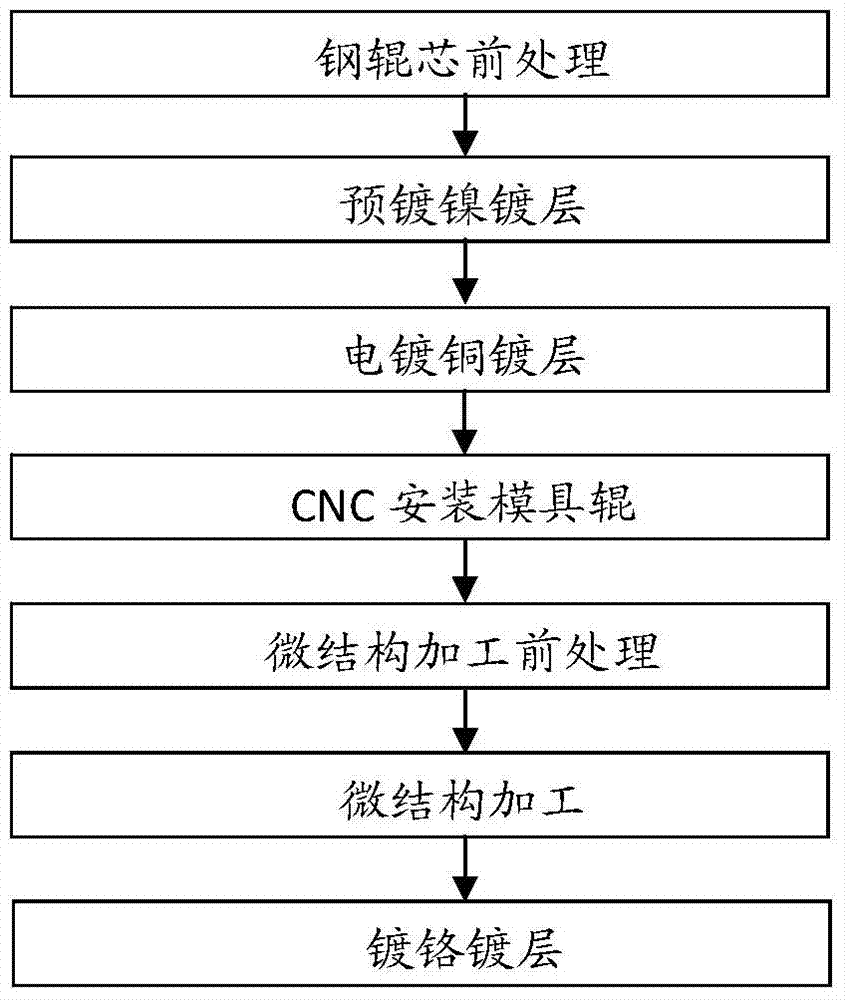

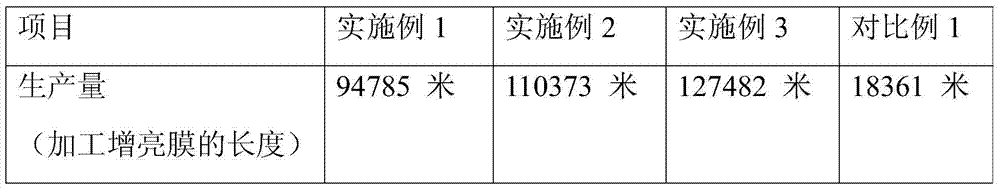

Mould roller for brightening film forming and manufacturing method thereof

The invention relates to a mould applied to composite brightening film forming processing and a manufacturing method thereof, in particular to a mould roller for brightening film forming and a manufacturing method thereof. According to the mould roller, the problems that an existing nickel plated mould roller for forming a prism structure has high hardness, abrasion of a diamond tool is large, and processing is difficult are solved. The mould roller comprises a steel roller core, the surface of the steel roll core is pre-plated with a nickel coating, a copper coating is arranged on the surface of the nickel coating, a prism structure is carved on the copper coating, and a chrome coating is arranged on the surface of the prism structure. The thickness of the nickel coating is 8-10 [mu]m; the thickness of the copper coating is 350-1000 [mu]m; the hardness of the copper coating is HV 200 to HV 280; the thickness of the chrome coating is 1-5 [mu]m; and the hardness of the chrome coating is HV 800 to HV 1000. The mould roll provided by the invention is easy to process and low in cost.

Owner:NINGBO CHANGYANG TECH

Gluing device for continuous glue feeding of PCB

InactiveCN111085396AEasy to glueGuarantee the quality of gluingLiquid surface applicatorsCoatingsAdhesive gluePiston

The invention discloses a gluing device for continuous glue feeding of a PCB, and relates to the technical field of PCB production. The device comprises a main body frame, a glue outlet mechanism is arranged on the main body frame, a bearing seat is arranged below the glue outlet mechanism, the bottom of the bearing seat is mounted on a lifting cylinder, the lifting cylinder is fixedly mounted onthe main body frame, the glue outlet mechanism comprises a glue box and a supporting block slidably arranged on the main body frame, a piston sliding up and down is arranged in the glue box, and a one-way valve C and a one-way valve A communicating with each other are arranged on the upper portion of the piston. A one-way valve D and a one-way valve B communicating with each other are arranged onthe lower portion of the piston. The output end of the one-way valve C and the output end of the one-way valve D communicate with a first pipeline, the output end of the first pipeline is connected tothe input end of a glue nozzle, and the glue nozzle is fixedly installed at the bottom of the glue box. The input end of the one-way valve A and the input end of the one-way valve B communicate witha second pipeline, and the input end of the second pipeline is externally connected with glue. The gluing device is stable in glue discharge and can achieve continuous glue discharge.

Owner:南京奥亚美电子科技有限公司

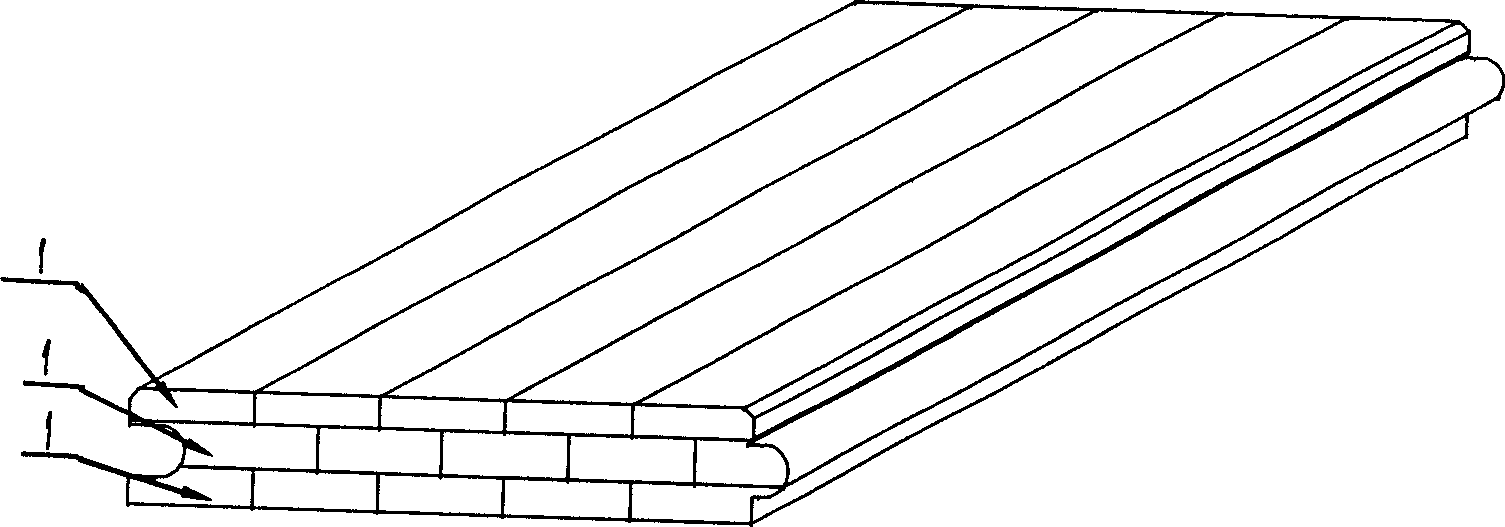

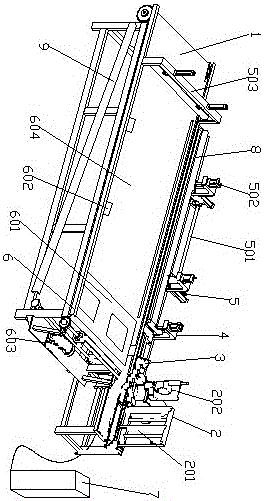

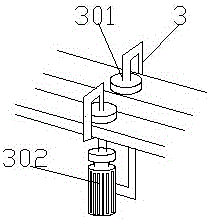

Batten splicing device

ActiveCN106042089ALabor savingCost savingsOther plywood/veneer working apparatusWood veneer joiningElectrical controlEngineering

The invention relates to a batten splicing device. The batten splicing device comprises a working frame, an electric control box, a main conveyor belt, a feeding mechanism, a gluing mechanism, a saw cutting mechanism, a long batten push mechanism and a board push mechanism. The gluing mechanism, the saw cutting mechanism and the long batten push mechanism are sequentially arranged on one side of the main conveyor belt in the conveying direction of the main conveyor belt. The feeding mechanism conveys battens to the gluing mechanism through the main conveyor belt to be glued, the glued battens are conveyed to the saw cutting mechanism through the main conveyor belt to be saw-cut, and the saw-cut battens are conveyed to the long batten push mechanism through the main conveyor belt for long batten splicing, and the spliced long battens are pushed outwards through the board push mechanism. The batten splicing device is reasonable in structure and ingenious in design, automatic gluing is achieved, fast and in-place board arrangement is achieved, no manual board arrangement is needed, the technical problems that by means of an existing board splicing device, the gluing function cannot be achieved, extra workers are needed in board arrangement, time and manpower are consumed, and the manual cost is high. For the prior art, the batten splicing device has very good market prospects and development space.

Owner:PINGDINGSHAN ANTAIHUA MINING SAFETY EQUIP MFG

Herbal thermal patch and production method thereof

The invention relates to a herbal thermal patch and a production method thereof. A spontaneous-heating agent in the thermal patch comprises 40-60% of iron powder, 10-30% of active carbon, 3-5% of salt, 5-15% of herbal medicine and 15-20% of water. The herbal medicine comprises 3-5 parts of lavender, 3-5 parts of mentha haplocalyx, 1-3 parts of barbados aloe, 1-3 parts of motherwort and 1-3 parts of sandalwood. The production method includes crushing the herbal medicine, mixing the crushed herbs with the iron powder, the active carbon and the salt, adding water into the mixture and stirring the mixture uniform to prepare particles, and drying the particles and packing the same with package bags. A heater is combined with the herbal medicine organically, so that the herbal thermal patch can warm a user in winter, has functions of refreshing and medical hot compress, and also has obvious healthcare and therapy effects to diseases such as gall and inhibited bending and stretching, stomach cold, stomachache and the like caused by rheumatism, rheumatoid arthritis, joint sprains, joint surrounding soft tissue strain and the like. In addition, the herbal thermal patch is convenient to carry, good in heating effect, free of side effect, free of polluting clothes, and high in practicability.

Owner:珠海市宝丽金化妆品有限公司

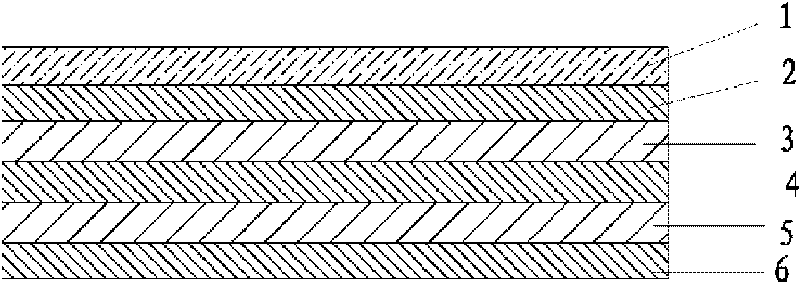

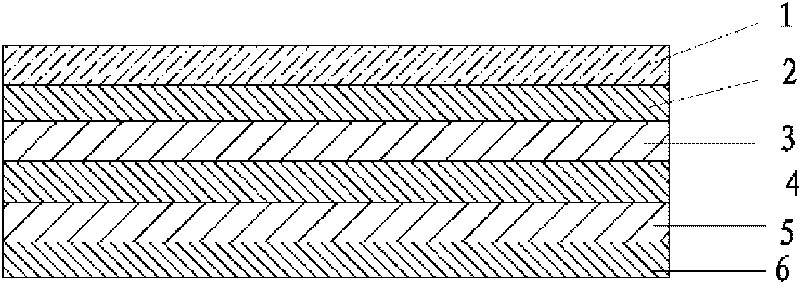

Antiflaming floor and manufacture method thereof

InactiveCN101761213AHigh level of anti-combustion performanceImprove flame retardant performanceLaminationLamination apparatusSingle plateEngineering

The invention relates to an antiflaming floor and a manufacture method thereof, belonging to wood processing industry. The antiflaming floor comprises a decoration layer, single plate layers and anitflaming layers. The antiflaming floor is characterized in that the layers of the antiflaming floor are arranged in an order of the decoration layer, the single plate layer, the antiflaming layer, the single plate layer, the antiflaming layer and the single plate layer form outside to inside, and all layers are adhered mutually by adhesives. The invention has the advantages of high antiflaming performance degree, good antiflaming effect and available humidity resistance. The advantage of good adhesion between the antiflaming layer and the single plate layer of the antiflaming floor is achieved, and both adhesion strength and impregnation stripping reach state standards.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Nanometer material surface glue spreading device

ActiveCN111451077AEasy glue applicationImprove functionality and convenienceLiquid surface applicatorsCoatingsElectric machineryPiston

The invention discloses a nanometer material surface glue spreading device comprising a workbench. A rotating disk is arranged on the top of the workbench. Six T-shaped sliding grooves are evenly formed on the top of the rotating disk and distributed on the top of the rotating disk in the radial direction. A rotating shaft is fixedly connected to the bottom of the rotating disk. The bottom end ofthe rotating shaft penetrates through the workbench and is rotationally connected with the workbench. The outer portion of the bottom end of the rotating shaft is fixedly provided with a gear ring. Adrive motor is fixedly installed at the bottom of the workbench and in transmission connection with the gear ring through a gear. According to the nanometer material surface glue spreading device, therotating disk is arranged and in linkage with an equilateral triangle rotating disk, when the rotating disk rotates, three glue spraying barrels can move back and forth in a reciprocating manner on two plate grooves in the same radial direction, through cooperation of vertical position change of magnetic pistons, the glue spreading function on nanometer plates is achieved, cleaning of the nanometer plates before glue spreading is also achieved, and the filling efficiency for glue spreading by equipment is greatly improved.

Owner:山东恒信科技服务有限公司

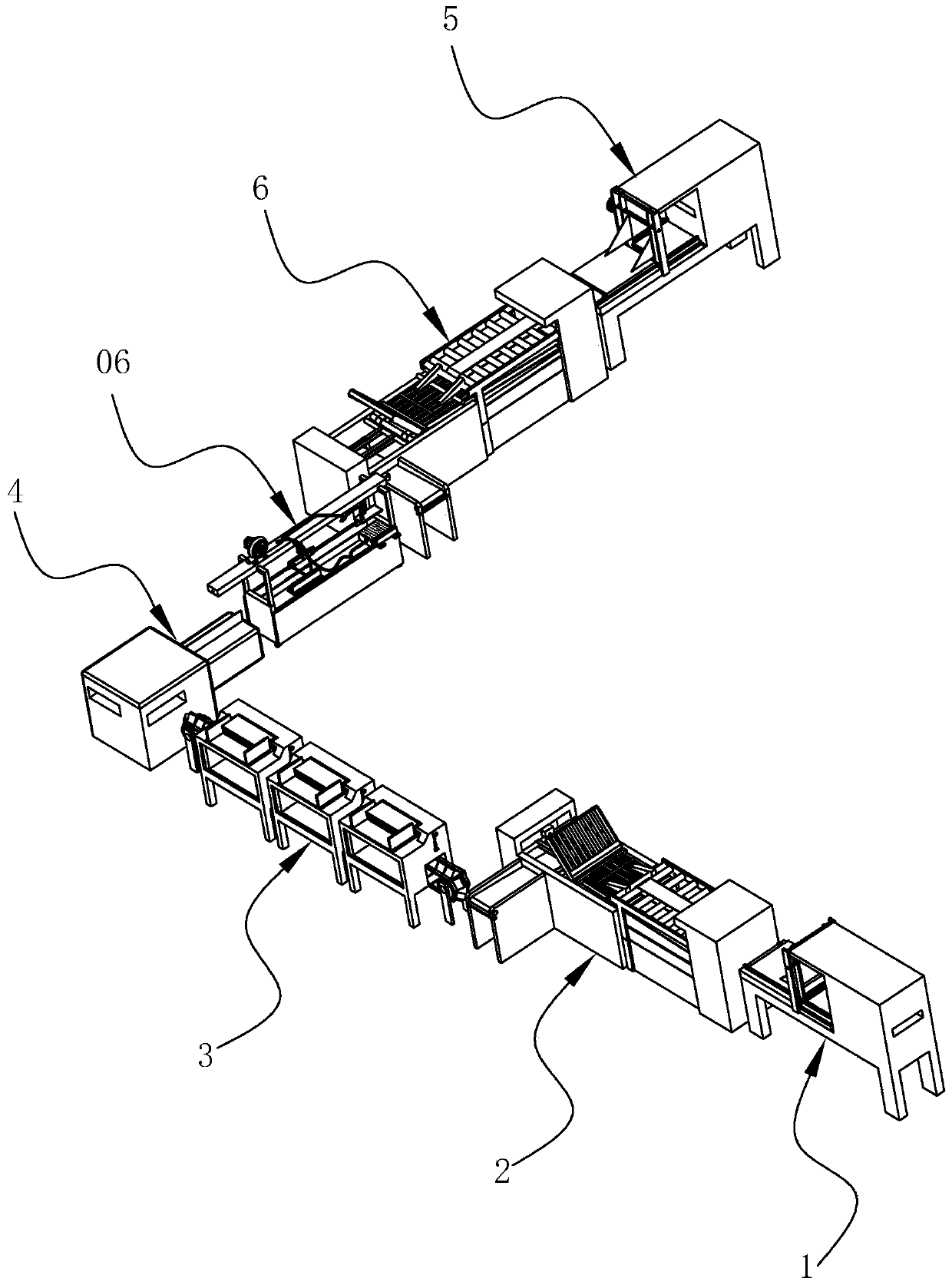

Book printing production technology and book printing production line

ActiveCN110450532AImprove product qualityIncrease productivityBook making processesRotary pressesProduction linePulp and paper industry

The invention discloses a book printing production technology and a book printing production line, and relates to the technical field of book printing. The production line comprises a bookblock manufacturing assembly, a book cover manufacturing assembly and an adhesive binding machine, the bookblock manufacturing assembly comprises a bookblock printer, a folding machine and a collating machine, the collating machine is connected with the adhesive binding machine, the book cover manufacturing assembly comprises a book cover printer and a paper cutting machine, and further comprises a mark folding device connected with the paper cutting machine, the mark folding device comprises a rack and a supporting sheet, and the rack is provided with a middle seam folding assembly and an adhesive-binding face folding assembly; the middle seam folding assembly comprises a connecting plate and a pressing plate, and the connecting plate is provided with a measuring assembly; and the adhesive-binding face folding assembly comprises two indentation plates, an abutting plate is arranged at the end, away from the indentation plates, of the supporting sheet, two positioning plates are arranged on the two sides of the abutting plate, a crossbeam is fixed to the upper end of the rack and provided with a sliding groove, and the abutting plate and the pressing plate are slidably connected to the slidinggroove. Binding of bookblocks and covers is facilitated, generation of defective books is effectively reduced, and the phenomenon of waste of raw materials is reduced.

Owner:湖北金港彩印有限公司

Method for preparing thick type shaving board through waste outdoor heat-treated wood and conventional wood and shaving board

ActiveCN105216089ALow hygroscopicityDimensionally stableLaminationLamination apparatusWood shavingsSurface layer

The invention provides a method for preparing a thick type shaving board through waste outdoor heat-treated wood and conventional wood. The thick type shaving board prepared through the method is small in hygroscopicity, stable in size and good in comprehensive mechanical property. According to the method, the waste outdoor heat-treated wood and the conventional wood are crushed into wood shavings respectively, and the two wood shavings are dried until the moisture content is 2%-4%, and then sizing and stirring are conducted; the wood shavings are made into a board blank through mat formation and are formed through hot pressing; when the mat formation is conducted, the wood shavings of the waste outdoor heat-treated wood are paved in a sandwich layer of the board blank, and the wood shavings of the conventional wood are paved in a surface layer of the board blank; in the sizing process, the adhesive is a urea-formaldehyde resin adhesive, or a phenolic resin adhesive, or a isocyanate adhesive; in the hot pressing process, the hot pressing pressure is 2.5-3.5 Mpa, the hot pressing time is 0.2-0.5 min / mm, and if the urea-formaldehyde resin adhesive is used, the hot pressing temperature is 110 DEG C to 160 DEG C; and if the phenolic resin adhesive or the isocyanate adhesive is used, then the hot pressing temperature is 150 DEG C to 200 DEG C.

Owner:广西东林木业有限公司

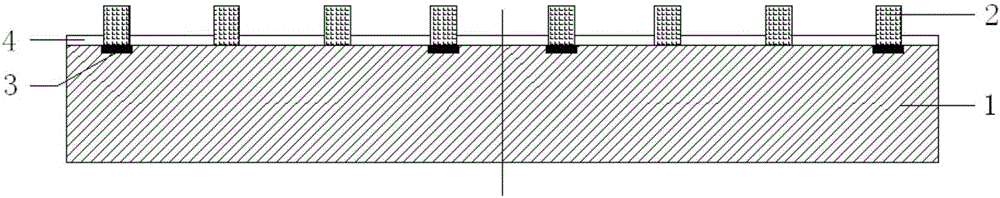

Plasma scribing chip packaging structure and manufacturing method

ActiveCN106098625APrevent leakageEasy to coverSemiconductor/solid-state device manufacturingEngineeringDielectric layer

The invention discloses a plasma scribing chip packaging structure and a manufacturing method. The structure comprises a chip, and the front surface of the chip is covered by one dielectric layer. The dielectric layer comprises at least one conductive pad, and at least one side wall of the chip is shaped like a rack which extends in an up / down direction. Moreover, each tooth slot of the rack is shaped like an arc. The side walls and back of the chip are completely coated by a passivation layer. In the structure, the passivation layer wraps the back and side walls of the chip, thereby avoiding the electric leakage, caused by the exposing of the base body of the chip, of the chip. The side walls of the chip are shaped like the rack, thereby facilitating the hanging and gluing, and increasing the binding force of the passivation layer with the side walls. The method employs a plasma dry method for etching, scribing and segmenting of a wafer, solves a problem of edge breakage when a blade mechanically cuts the chip, also solves a problem that the side walls of the chip are exposed because of a plasma separation method, and improves the feasibility of the technology.

Owner:HUATIAN TECH KUNSHAN ELECTRONICS

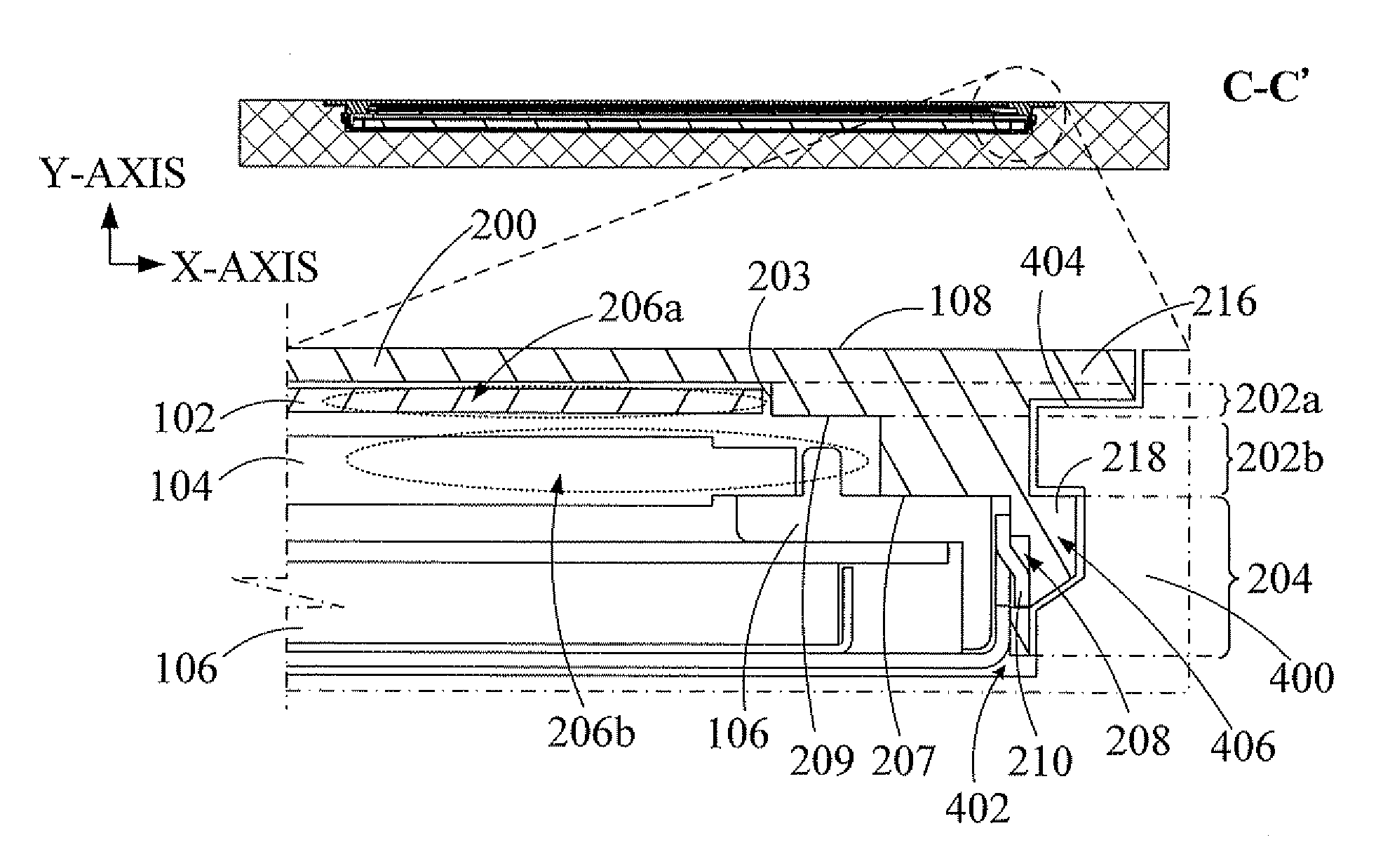

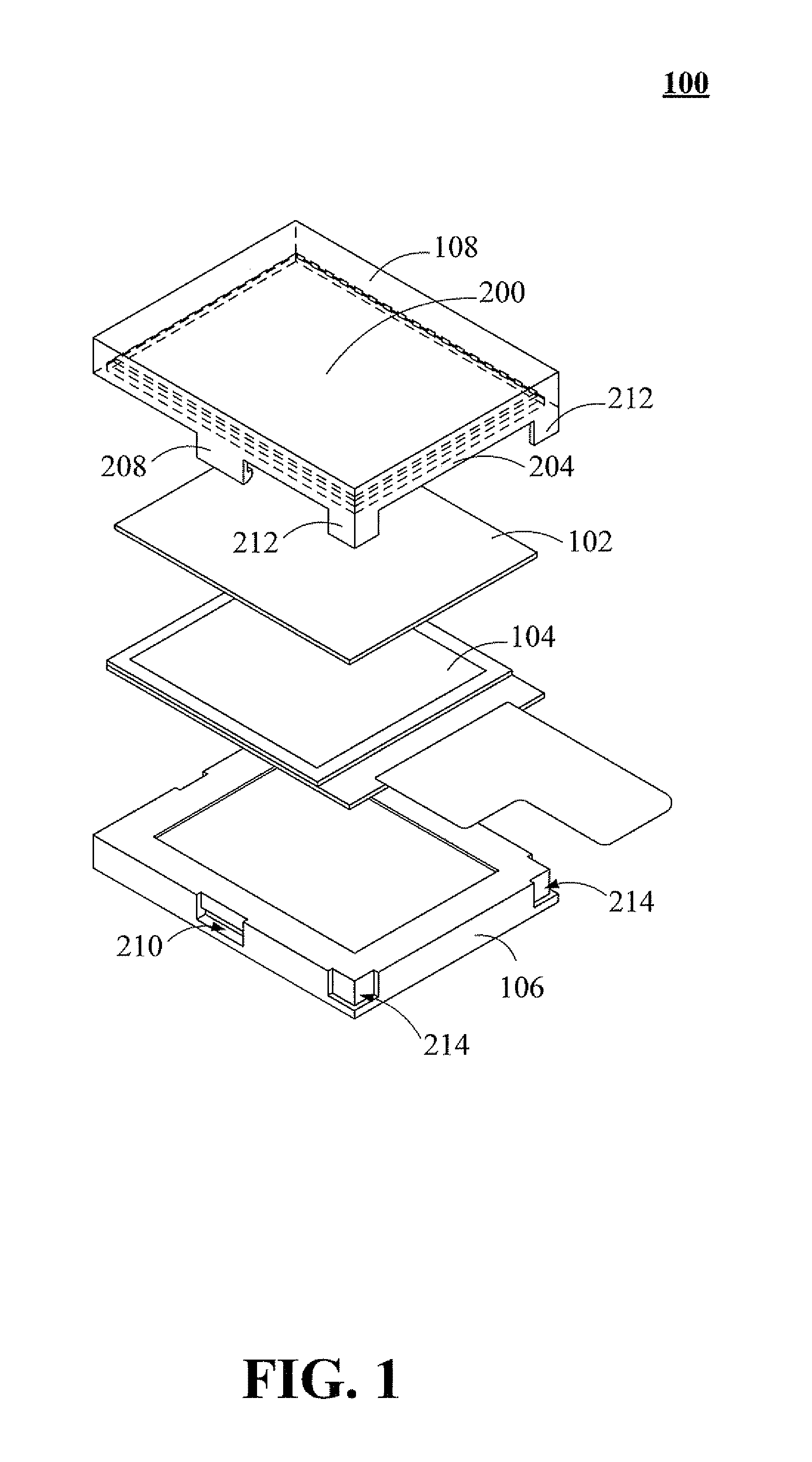

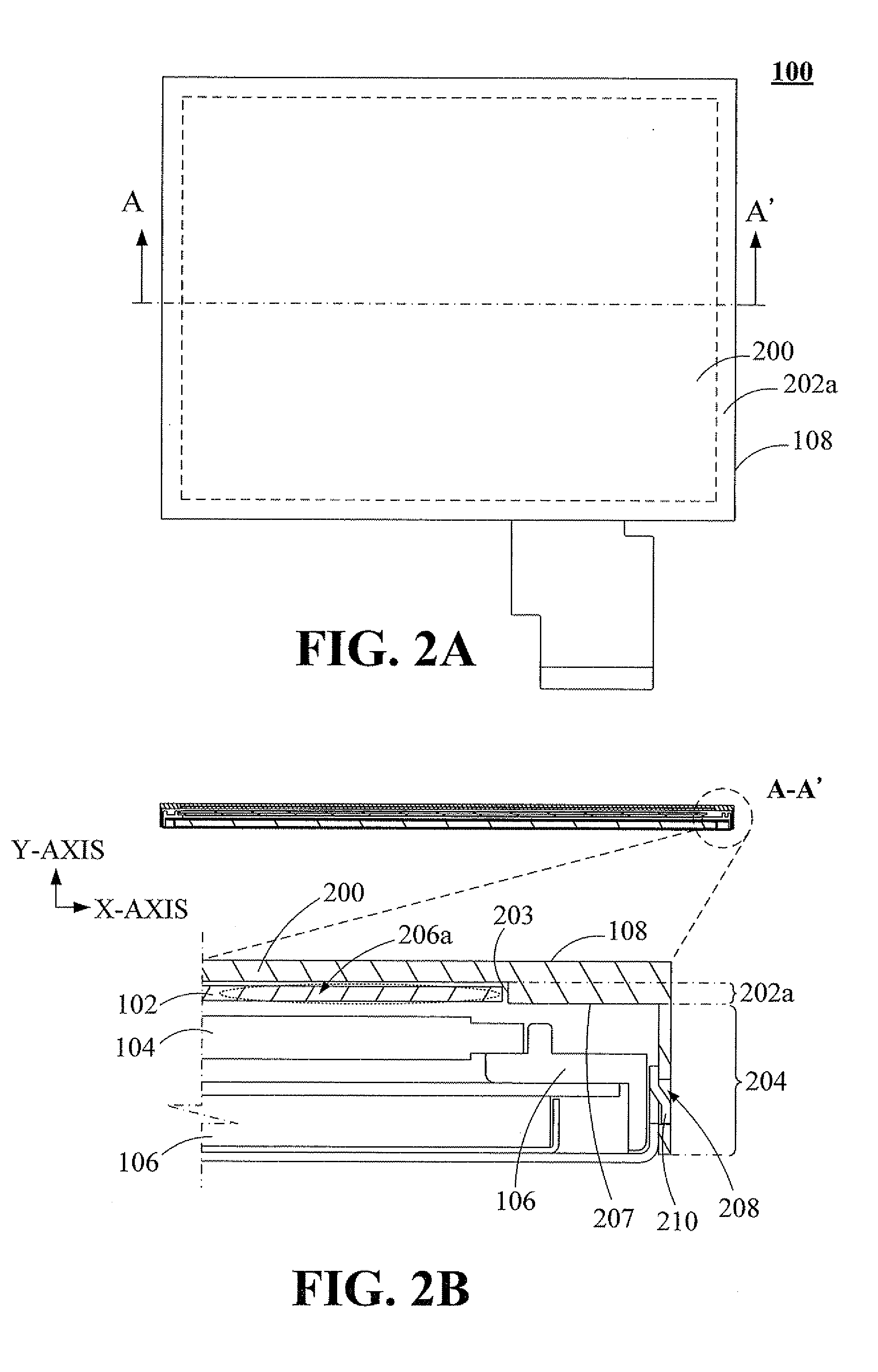

Touch display apparatus having cover lens structure

InactiveUS20120223896A1Reduce manufacturing costEasy to glueDigital data processing detailsElectrical apparatus contructional detailsTouch SensesComputer science

Owner:HANNSTAR DISPLAY CORPORATION

Tool for filling glue of power module and filling method

InactiveCN101262757AGuaranteed working temperatureCuring does not affectCooling/ventilation/heating modificationsHeat conductingPower module

The invention discloses a tool used for filling rubber into a power module and a rubber filling method thereof, wherein, the tool for filling rubber comprises a filling box and a rubber limiting mould that can seal the inner space of the power module, the filling box is communicated with a vacuum generator, the rubber limiting mould is put in the filling box and connected with a rubber filling device. The rubber filling method for a power module is that: in vacuum condition, the heat-conducting rubber is pumped and filled between two PCB plates of the power module. The tool used for filling rubber into a power module, which is clean, convenient and practical, can fill the heat-conducting rubber between the two PCB plates of the power module. The rubber filling method for a power module is simple, and fast and has good filing effect.

Owner:ASTEC POWER SUPPLY (SHENZHEN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com