Patents

Literature

47results about How to "Fully glued" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

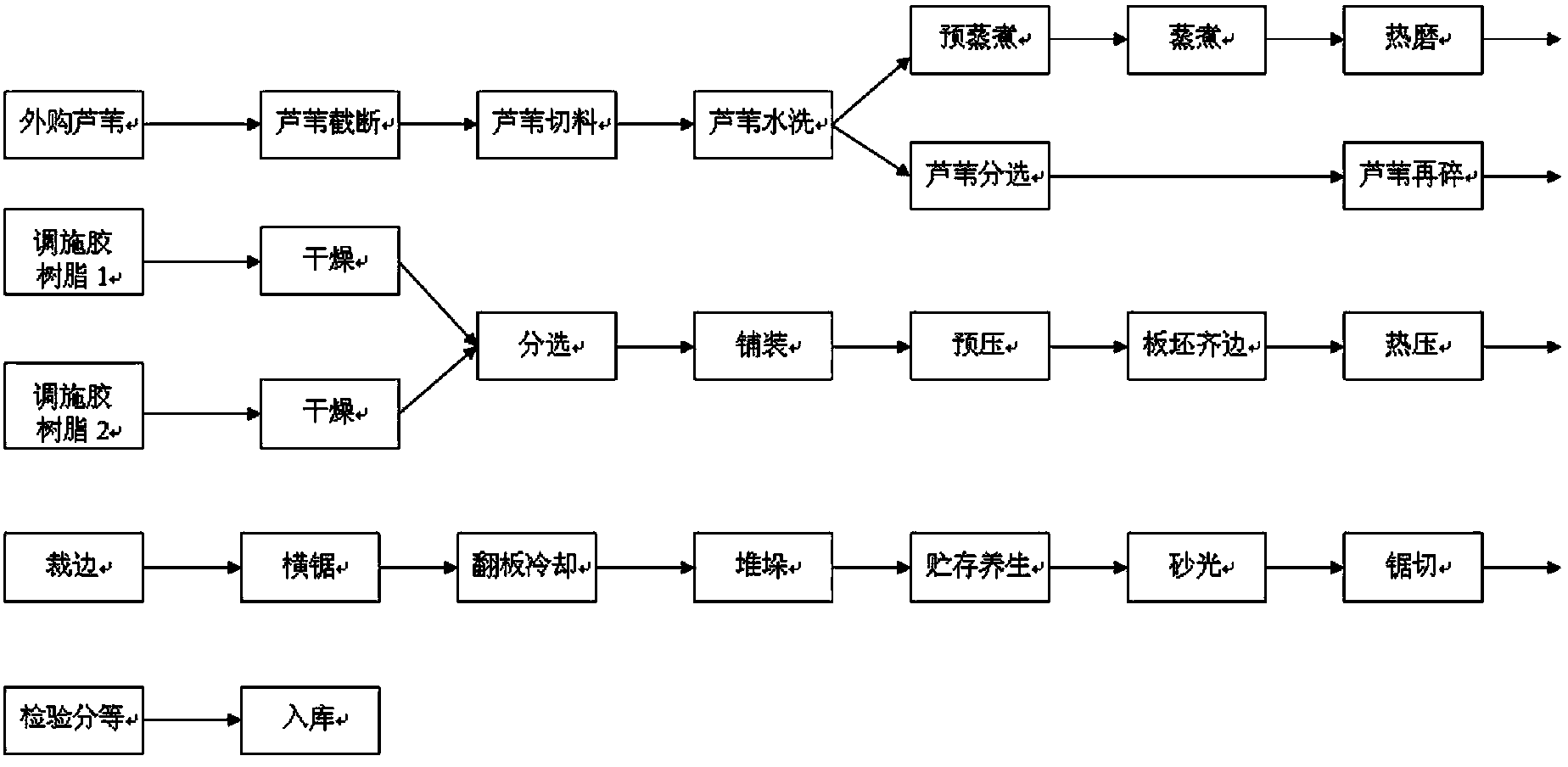

Preparation method for reed fiber particle board

ActiveCN104227819AReduce the effects of gluingReduce releaseLaminationLamination apparatusFiberWood shavings

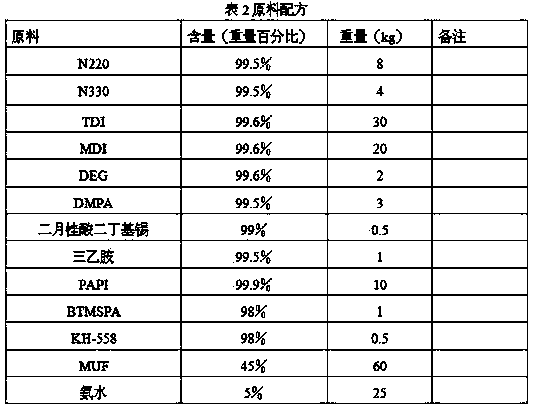

The invention discloses a preparation method for reed fiber particle board. The preparation method comprises the following steps: cutting a reed raw material by using a circular sawing machine to prepare stem-shaped reeds with certain sizes; cutting the material by using a reed cutting machine, wherein one part of the cut material is cooked and softened to obtain the reed fibers, and the other part of the cut material crushed again to obtain fine reed shavings; respectively applying different resin adhesives to the reed fibers and the shavings, and drying, air-sorting and paving to form three-layer or multi-layer structural board blank; pre-pressing the three-layer or multi-layer structural board blank into a continuous flat-pressing hot press to press and produce the environment-friendly reed fiber particle board. The preparation method has the advantages that the influence of a wax layer on the surface of a reed on gluing performance is reduced to the greatest extent by graded pavement treatment; the production cost of the reed fiber particle board prepared by the process is moderate; both the physical and chemical properties of the reed fiber particle board meet related national standard requirements; the free formaldehyde release amount reaches the level-E1 standard requirement. According to the preparation method, reed resources of a wet land are fully utilized; the source of production raw materials of artificial boards is enlarged; the requirements on building resource-saving and environment-friendly society of China are met.

Owner:DONGYING ZHENGHE WOOD IND

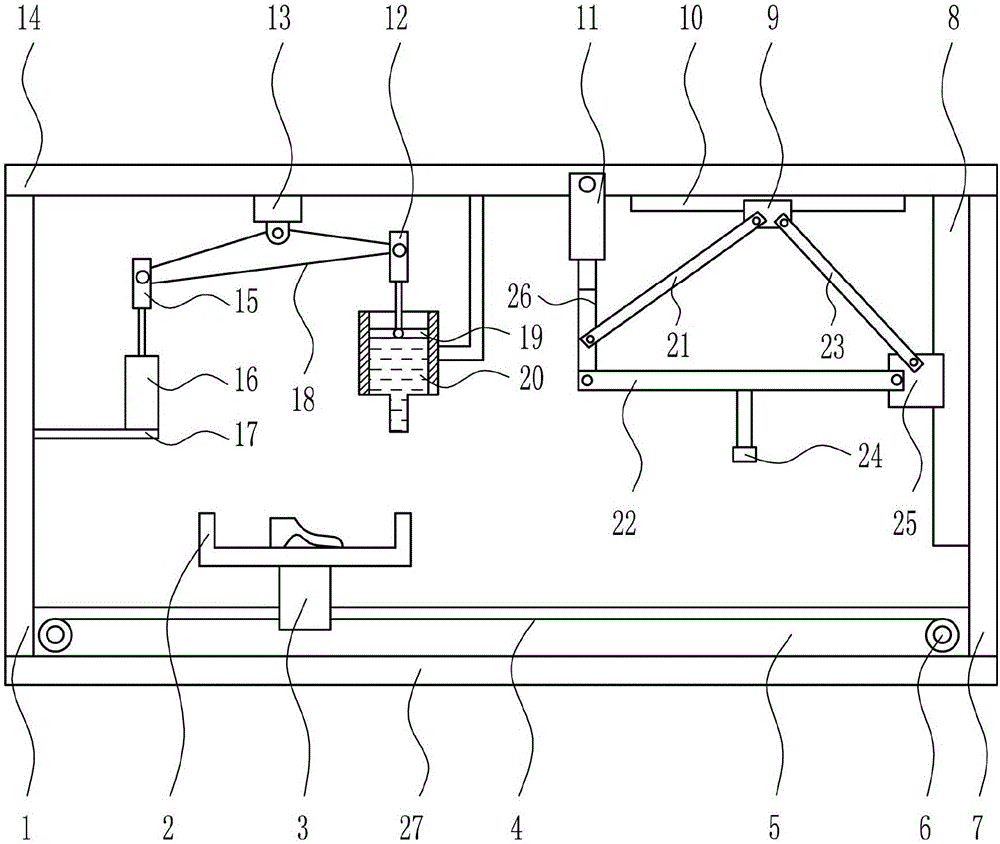

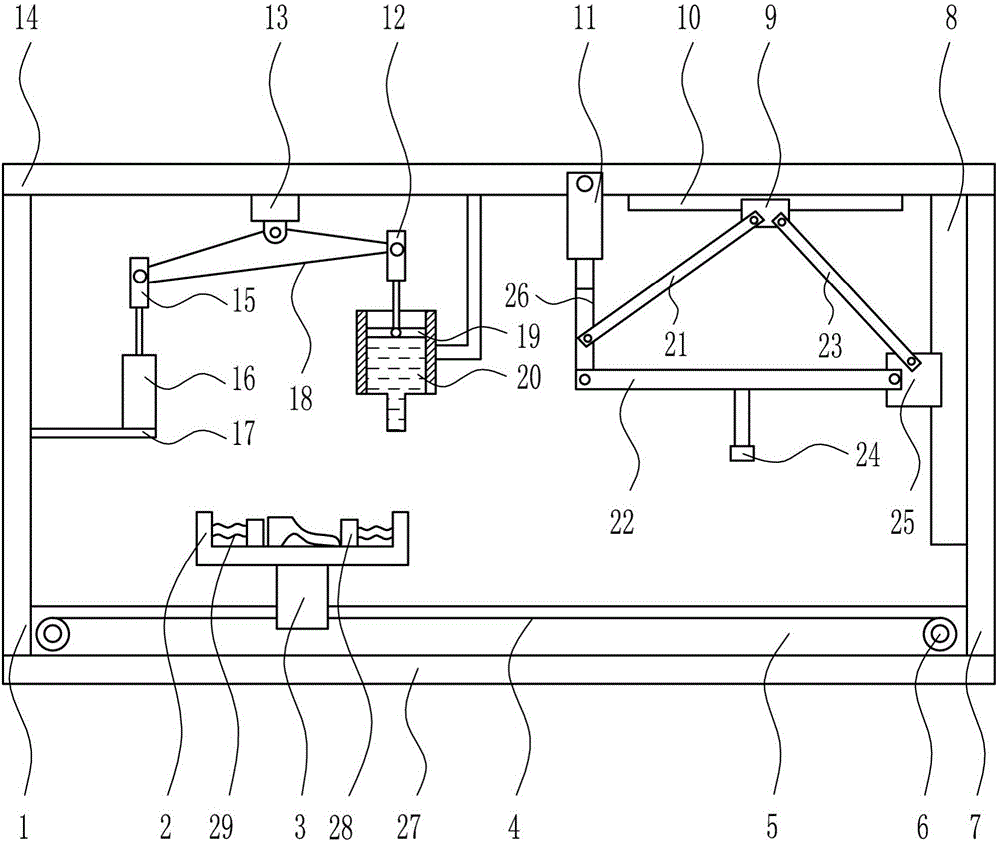

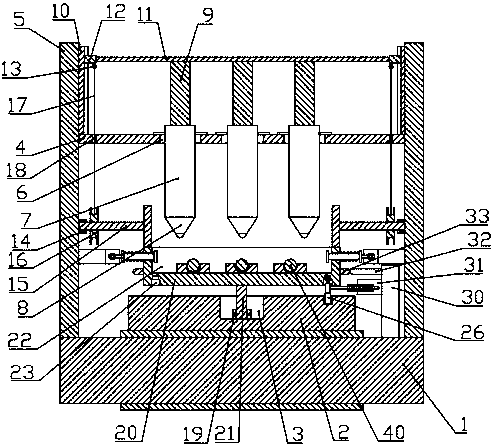

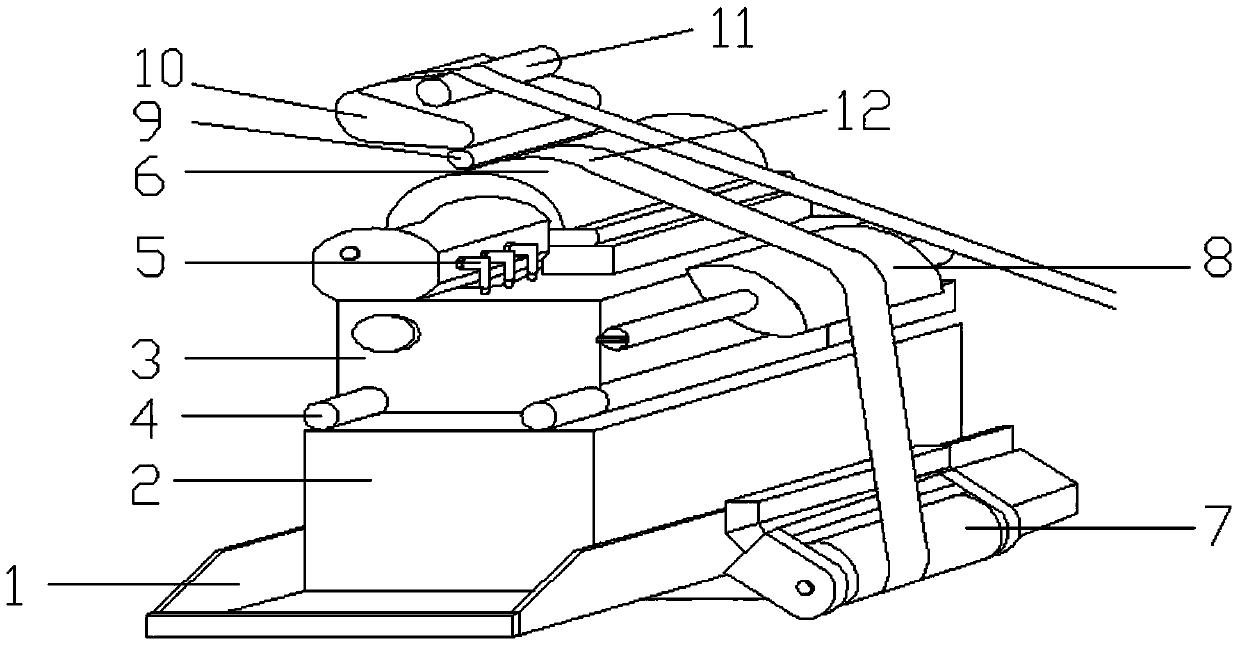

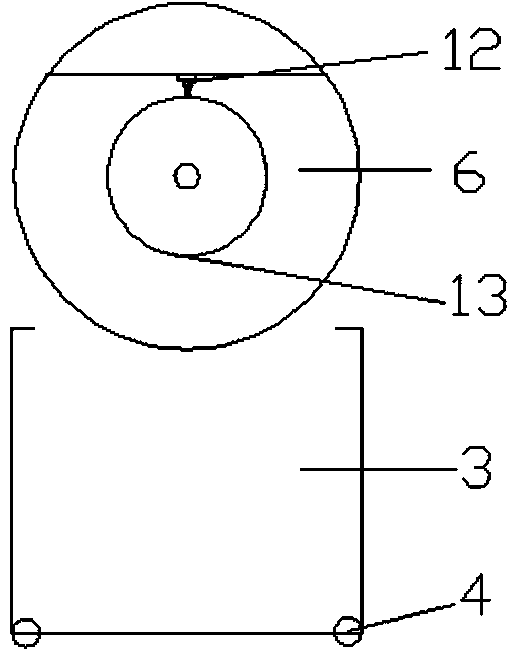

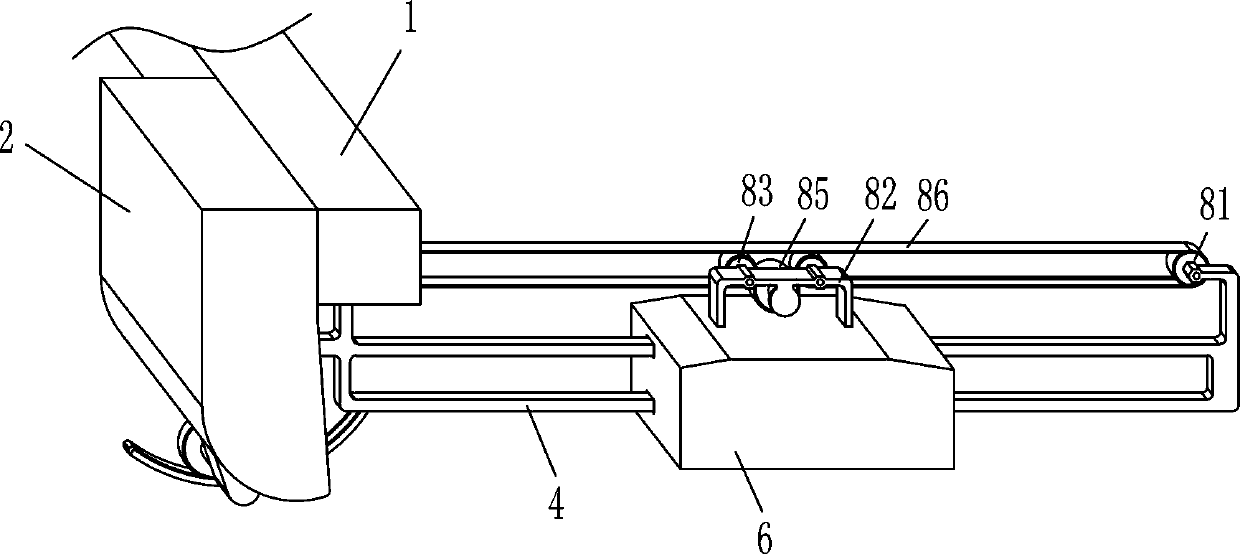

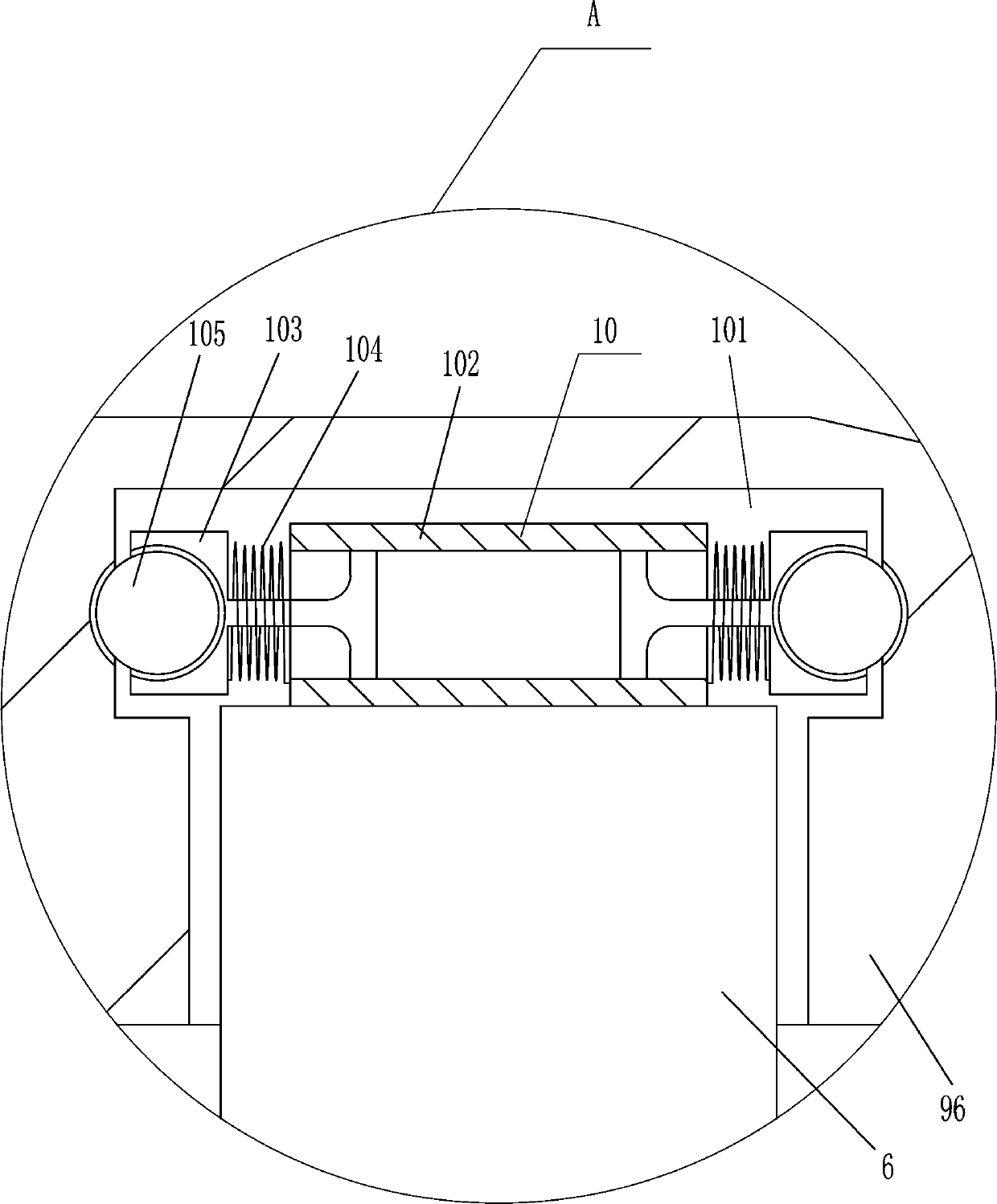

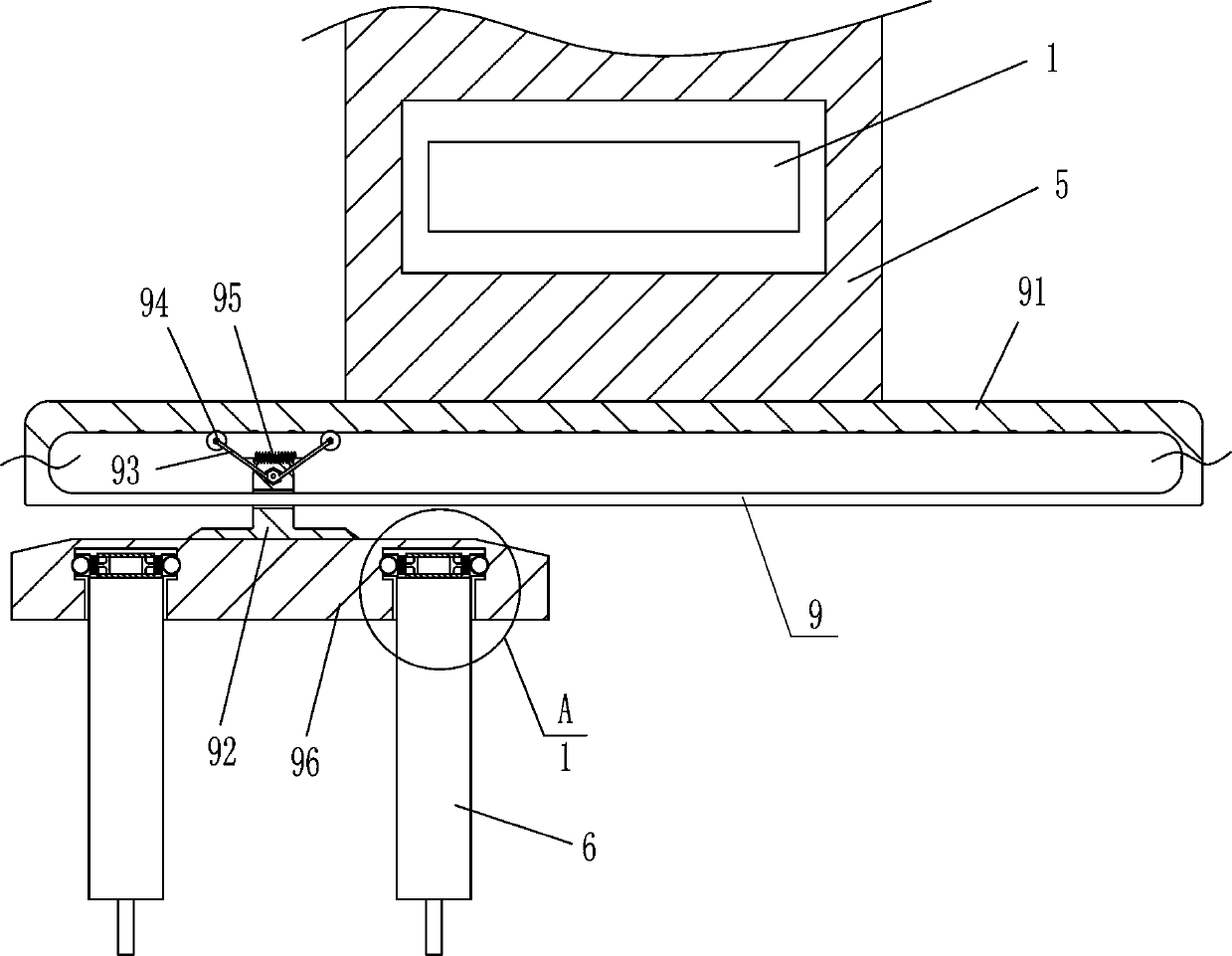

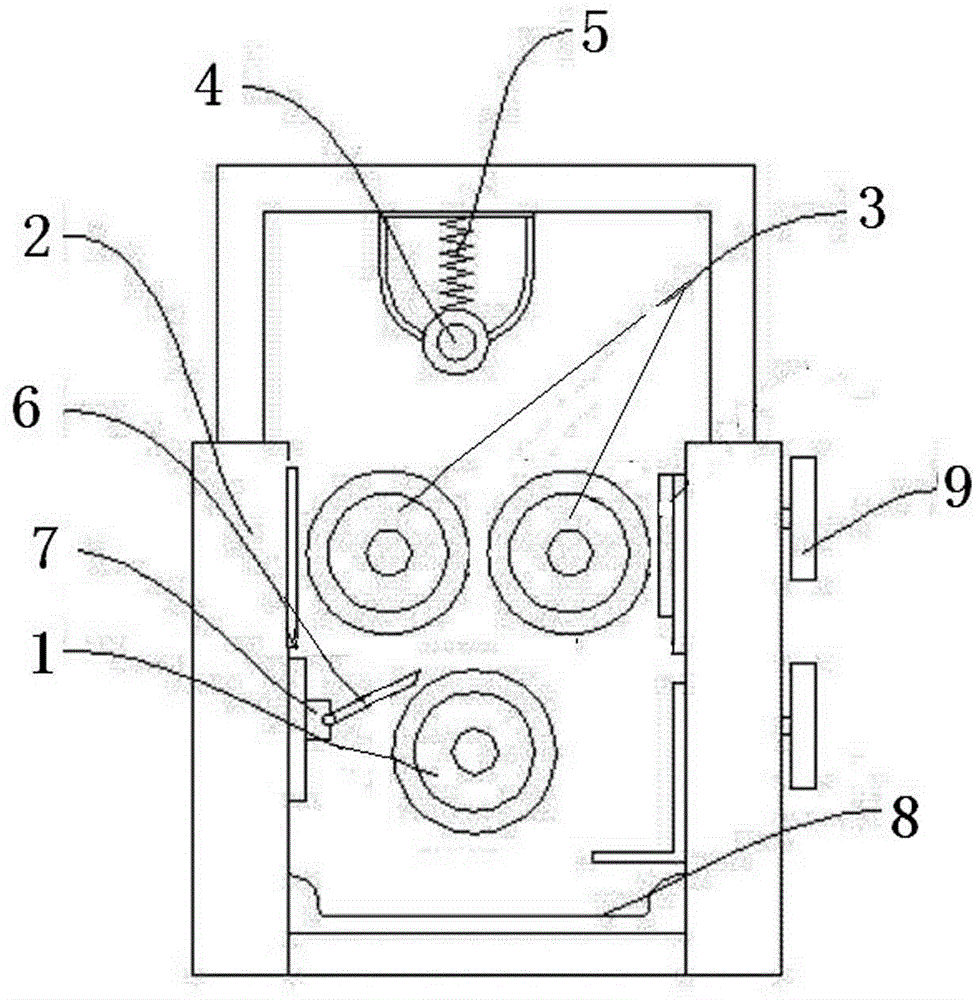

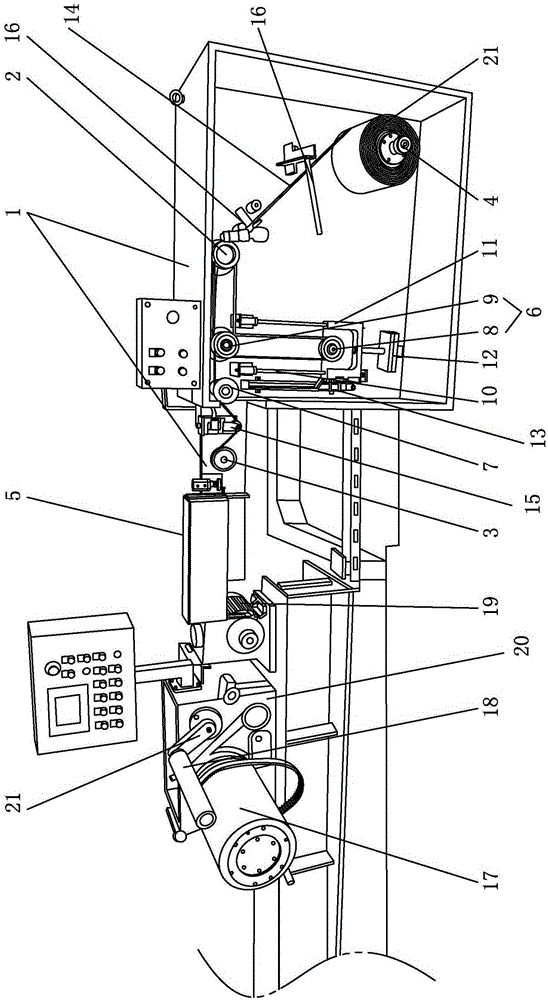

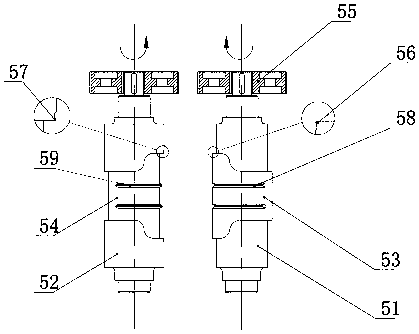

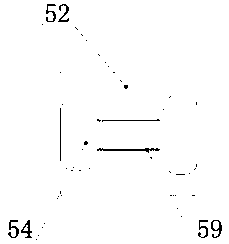

Shoemaking gumming device

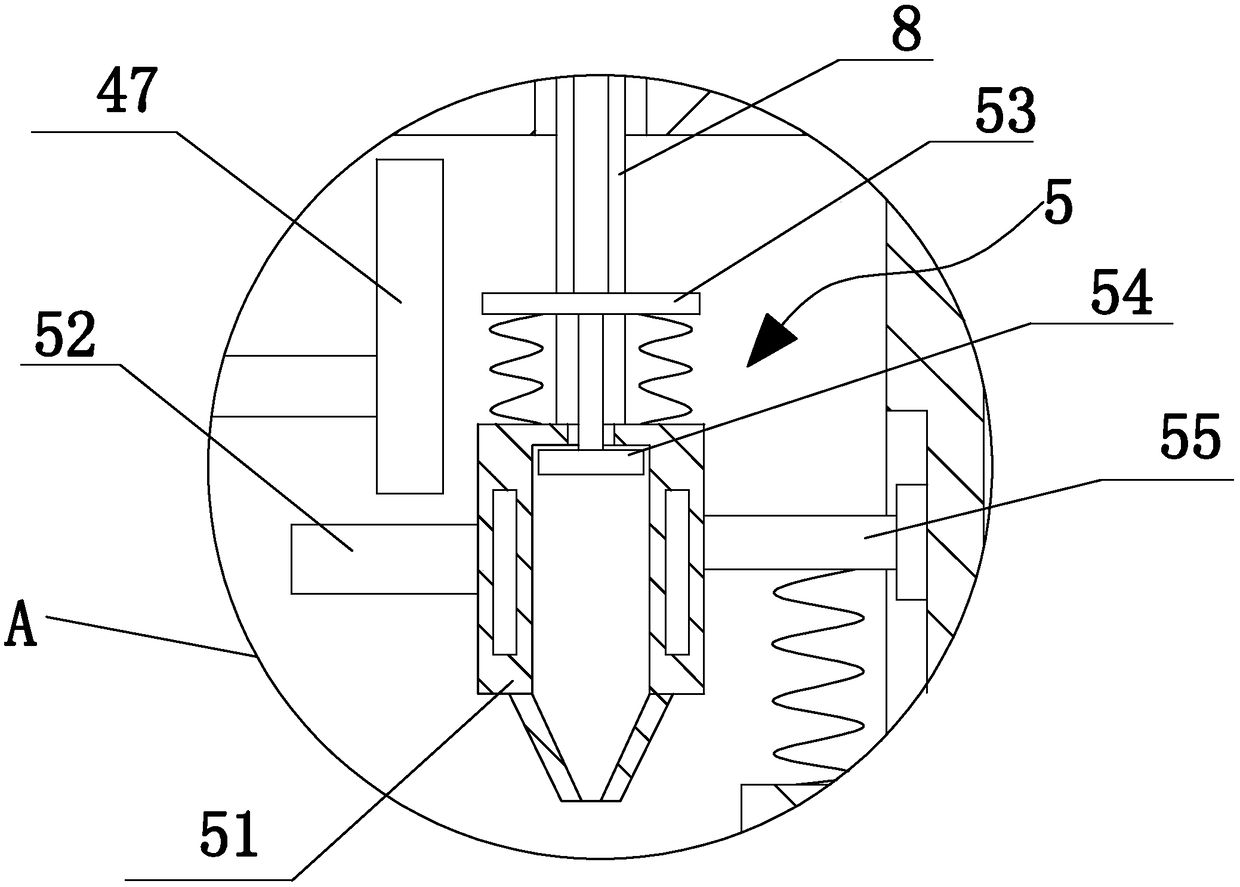

InactiveCN106108264APrevent sliding left and rightFully gluedShoe gluingMechanical engineeringPiston

The invention relates to a gumming device, in particular to a shoemaking gumming device, and aims to provide the shoemaking gumming device being accurate in gumming position, comprehensive in gumming, and visual enough for observation. The shoemaking gumming device comprises a left bracket, an accommodating rack, a first slider, a stay wire, a first slide rail, an electric reel, a right bracket, a second slide rail, a third slider, a third slide rail, a first electric push rod, a fifth connecting rod, a supporting seat, a top plate, a fourth connecting rod, a cylinder, a fixing plate, a swing rod, a piston, a cylinder body, a third connecting rod, a second connecting rod, a first connecting rod, a pressing block, a second slider, a lifting rod and a bottom plate. The shoemaking gumming device has the effects of being accurate in gumming position, comprehensive in gumming, and visual enough for observation; being fast in gumming speed, reasonable in design, and convenient to use, the shoemaking gumming device is highly practical.

Owner:ZHEJIANG KAJIALI SHOES CO LTD

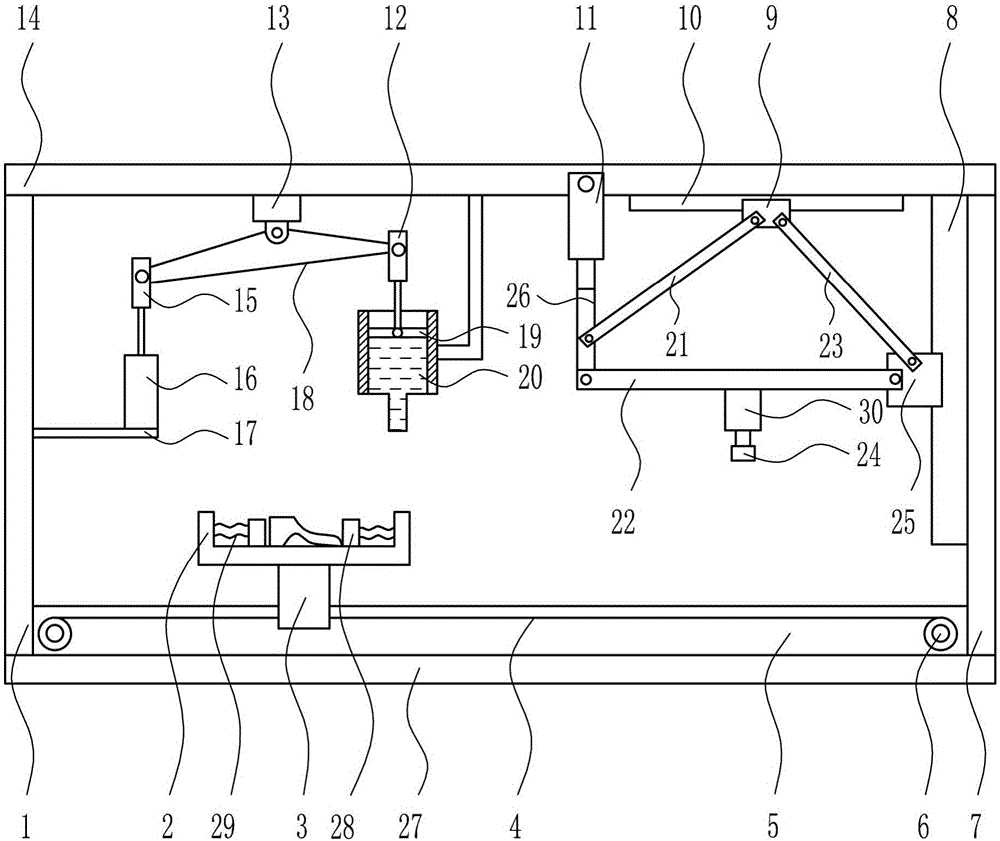

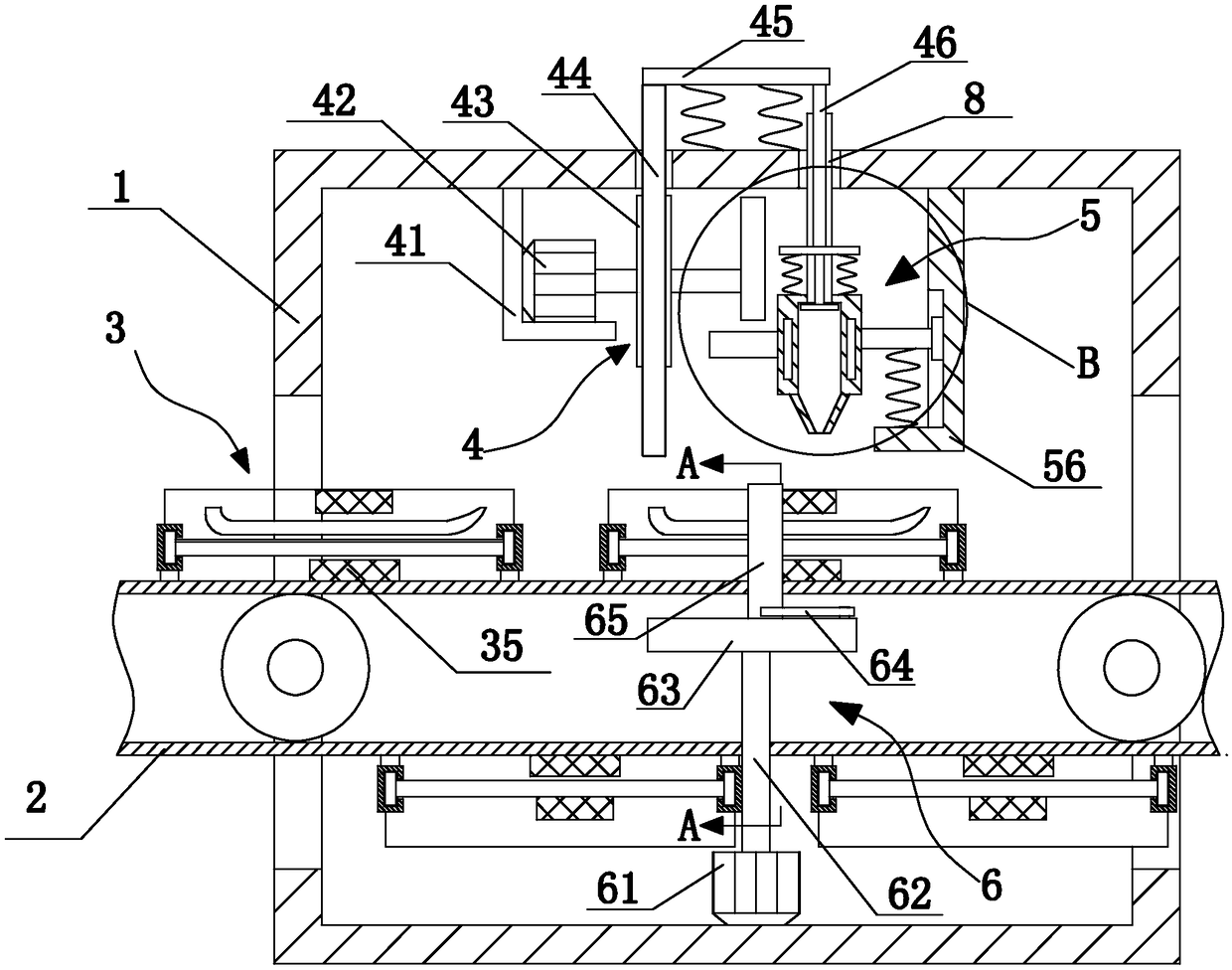

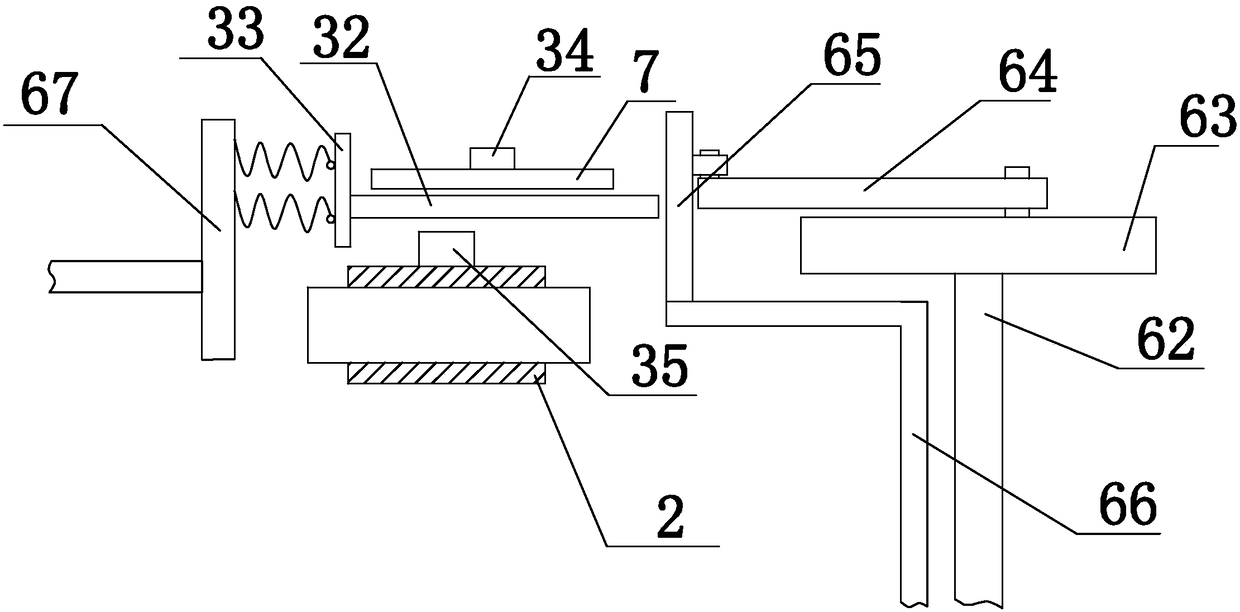

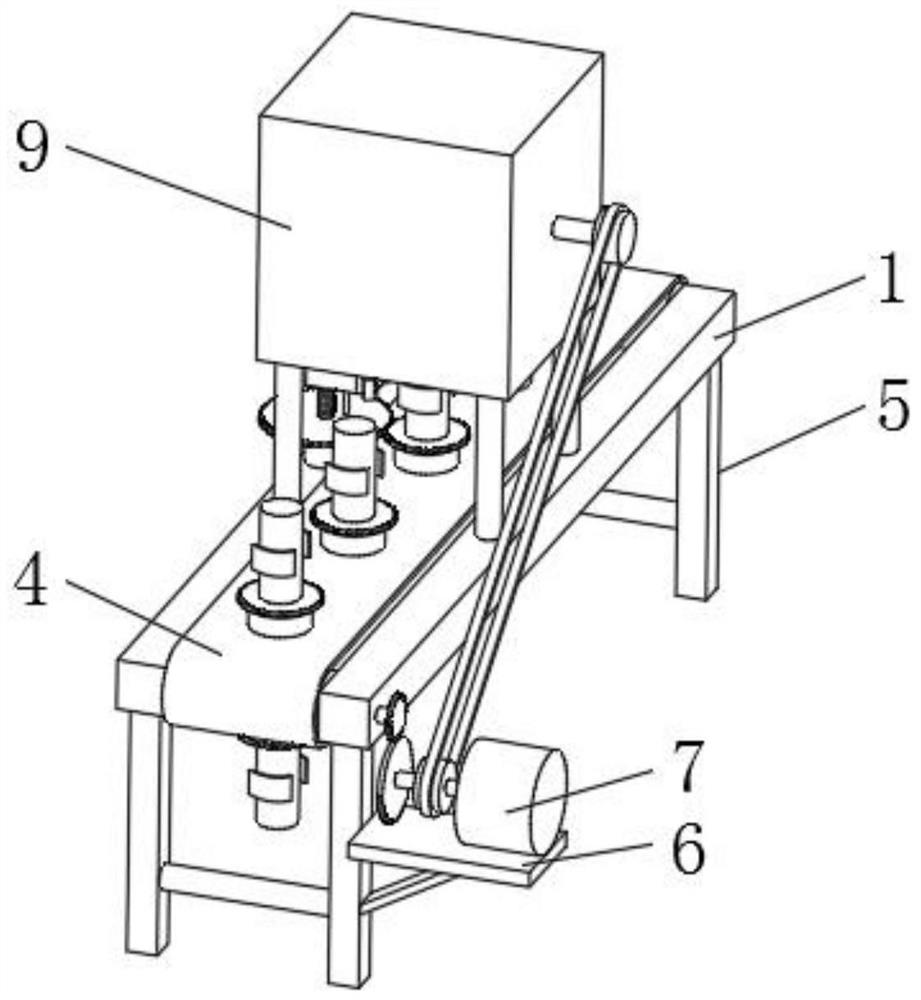

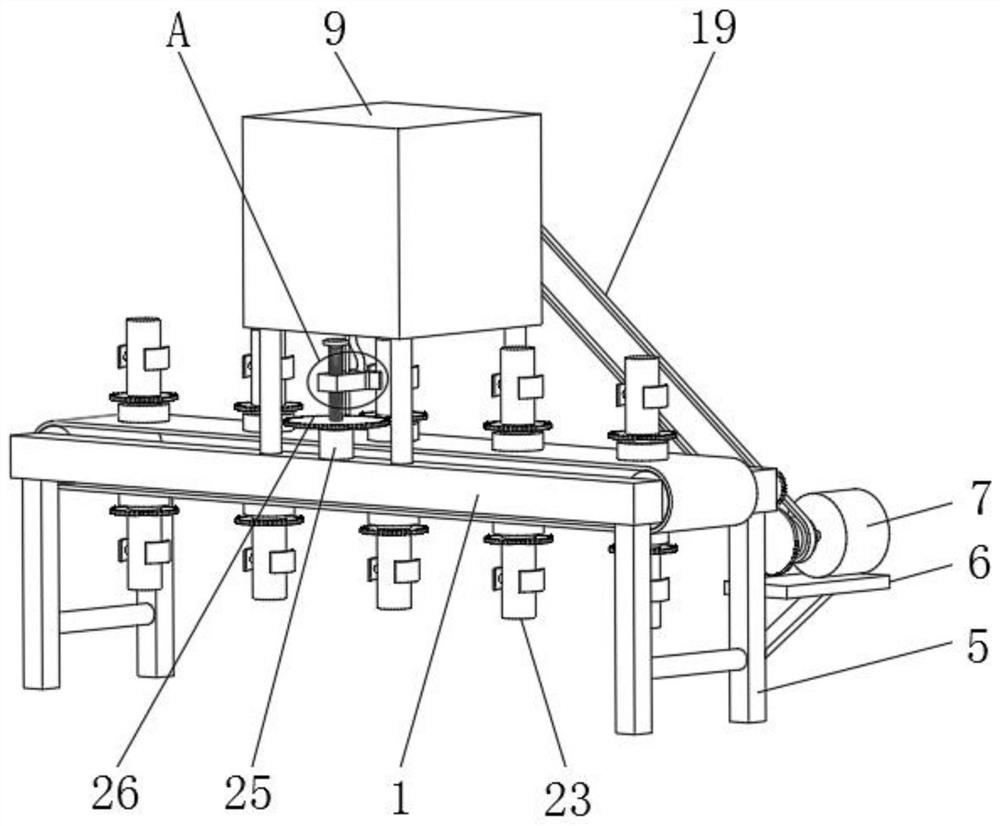

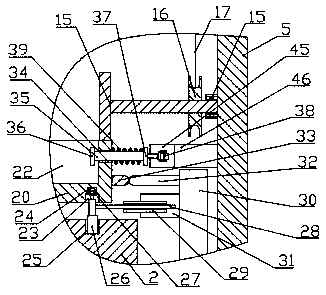

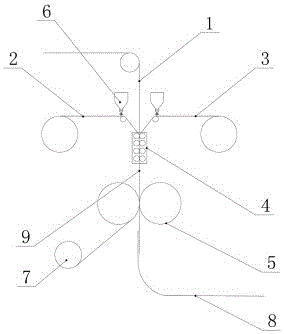

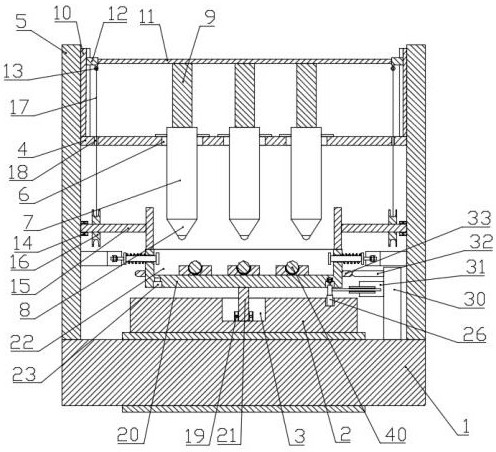

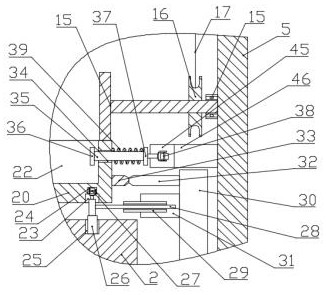

Automatic and efficient gluing device for shoemaking

ActiveCN109123917AThe amount of glue applied is stableGuaranteed work efficiencyShoe gluingPistonEngineering

The invention discloses an automatic and efficient gluing device for shoemaking, including a device box, a conveyor and a placement mechanism, wherein first openings are arranged on both side walls ofthe device box, both ends of the conveyor are movable through the first opening, a plurality of placement mechanisms are fixedly connected to the conveyor belt of the conveyor device, the sole is arranged on the placing mechanism located above the conveying drive. By the combination of the glue squeezing device and the glue discharging device, when the glue loading cylinder approaches the sole downward, the piston will be pressed down by the pressure rod to realize the glue discharging, thus effectively ensuring the stability of the glue coating amount, and by intermittently moving the glue loading cylinder up and down, it can ensure that the glue discharging of the glue loading cylinder will not continue, effectively avoiding glue discharging excess and affecting glue bonding.

Owner:泉州卓展商贸有限公司

Production method of bamboo plywood coated with film

InactiveCN101830025AWide variety of sourcesReduce wasteWood working apparatusFlat articlesNational standardColloid

The invention discloses a production method of bamboo plywood coated with a film. The production method comprises the processes of: sheet cutting, curtain or mat knitting, drying and sizing, glue dipping, glue airing, re-drying, blank assembling, hot pressing and blank edge processing and is characterized by comprising the specific steps: drying a bamboo curtain or a bamboo mat knitted by bamboo with small diameter at 100-200 DEG C firstly till water content is 10-14% and sizing; dipping in glue and then drying at 100-120 DEG C till the water content is 6-14%; adding veneers, covering film paper, dipping in glue separately and airing; assembling blanks of mat and short and long curtains alternately; hot pressing and processing edges of the blanks. The invention has wide raw material sources and less raw material waste, shortens drying time, improves working efficiency, achieves more firm gluing among plies, has no foaming and flaking phenomenon, and overcomes the defects of surface hole shrinking and incomplete gluing due to colloids seepage, which are generated when drying is carried out below 95 DEG C in the traditional method. All indexes of the product provided by the invention meet or exceed national standards.

Owner:南充富达竹业有限公司

Uniformly gelatinizing gluing device for folding filter element

InactiveCN112439646AAvoid cloggingAvoid uniformityLiquid surface applicatorsCoatingsElectric machineEngineering

The invention discloses a uniformly gelatinizing gluing device for a folding filter element and relates to the field of folding filter element processing devices. The uniformly gelatinizing gluing device comprises two horizontal square columns, wherein two rotating shafts are jointly and rotatably mounted on the sides, close to each other, of the two horizontal square columns, transfer rollers arefixedly connected to the two rotating shafts in a sleeving manner, and a same conveyor belt is movably mounted and connected to the two transfer rollers in a sleeving manner. When a rotating motor isstarted, the conveyor belt is driven to move intermittently, so that the folding filter element stops moving when arriving at a glue spraying position and glues. By adopting assembly line operation,the working hours are saved, and meanwhile, a stirring rod is further driven to rotate to stir and scatter a glue solution in a glue storage box, so that a phenomenon that the glue solution is solidified and agglomerated can be avoided effectively. When the servo motor is started, a glue spray head is driven to move up and down, and meanwhile, a sleeving column and the folding filter element can be further driven to rotate, so that the folding filter element can be gelatinized comprehensively with good gluing effect and can be gelatinized uniformly.

Owner:高永胜

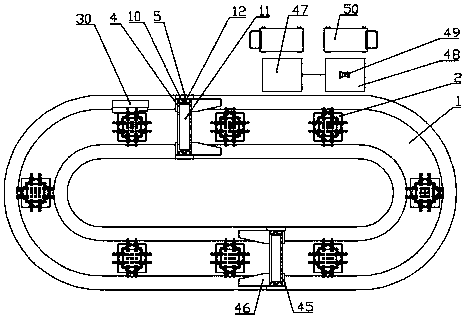

Automatic glue injecting device for LED lamp production

ActiveCN111203367AImprove work efficiencySmooth rotationLiquid surface applicatorsCoatingsEngineeringLED lamp

The invention discloses an automatic glue injecting device for LED lamp production, and relates to the technical field of LED lamp devices. The device mainly solves the problems of inconvenience during LED lamp production, inconvenience for glue injecting through glue injecting needle cylinders and over-low working efficiency. The device mainly comprises a rotating conveying belt, and a limiting mechanism, a pushing mechanism, a feeding and discharging mechanism, an automatic glue injecting mechanism and a rotating mechanism are arranged on the rotating conveying belt. According to the device,LED lamp containing trays are placed on fixing tables, the rotating conveying belt drives the LED lamp containing trays to pass through the positions below the glue injecting needle cylinders and drives winding wheels to rotate, a lifting plate is pulled downwards through connecting wires, glue in the glue injecting needle cylinders is guided to the LED lamp containing trays through glue injecting heads, and glue injecting is carried out; and when the fixing tables move, the LED lamp containing trays can be driven to rotate through meshing of strip-shaped racks and annular racks, and when theLED lamp containing trays pass through the glue injecting needle cylinders again, glue injecting is carried out in another direction. The device has the beneficial effects that glue injecting can berapidly carried out, and the working efficiency is improved.

Owner:ZHEJIANG HAIHONG IND PROD DESIGN CO LTD

Cigarette filter tip assembling machine glue spray system device

InactiveCN104174543APrevent moisture from evaporatingImprove performanceLiquid surface applicatorsSpraying apparatusAdhesive glueMechanical engineering

The invention discloses a cigarette filter tip assembling machine glue spray system device which comprises a nozzle paper roll component, a glue spray auxiliary system and a cleaning maintenance system, wherein the glue spray auxiliary system comprises a base, a glue pump, a rubber tube, a paper guide roll, a paper guide block and the like; the nozzle paper roll component is formed by manufacturing a glue spray head and the paper roll together; the position of the glue spray head can be changed along with rotation of the paper roll; the cleaning maintenance system comprises a water pool, a cleaning device and a supporting rod; the water pool and the cleaning device are fixed on the supporting rod; the supporting rod can move up and down under the action of a cylinder; and cleaning maintenance operation of the glue spray head can be finished by rotating the glue spray head and lifting the water pool and the water level. The cigarette filter tip assembling machine glue spray system device disclosed by the invention is uniform in gluing, firm in adhesion and high in cigarette yield, integrates glue spray and cleaning into a whole and is high in degree of automation and convenient to use, and waste of glue water is reduced.

Owner:ANHUI YITONG MACHINERY

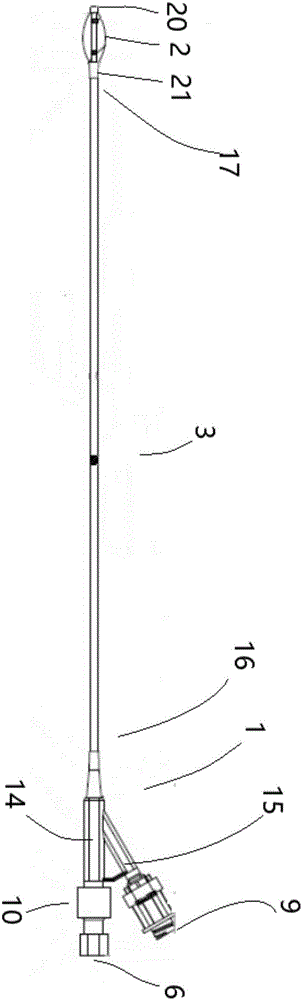

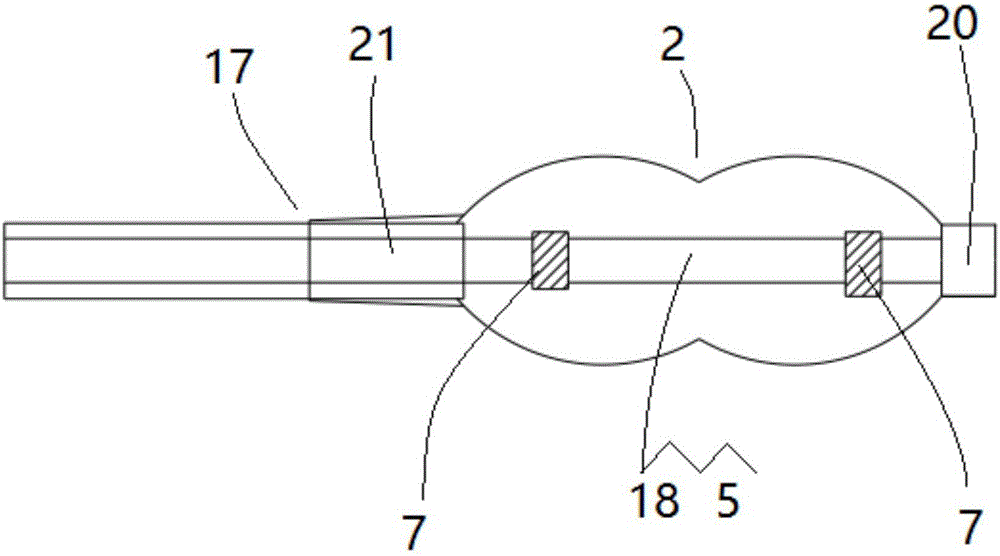

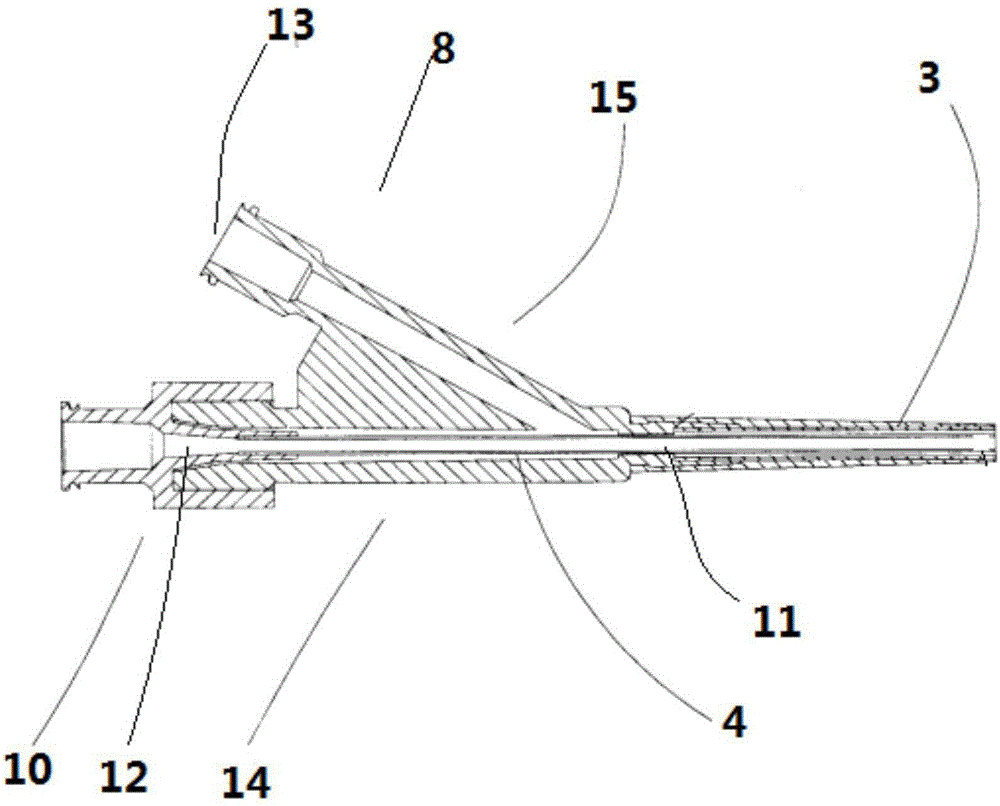

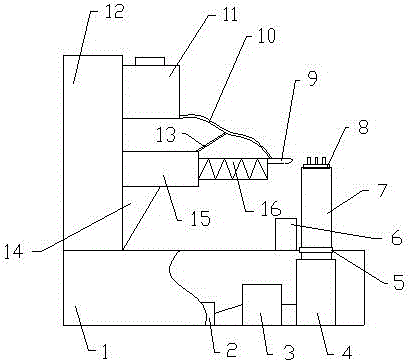

Balloon catheter for vertebral expansion and preparation method of balloon catheter for vertebral expansion

InactiveCN106422032AAvoid fracturesFirmly connectedBalloon catheterGuide wiresThermal expansionInjection moulding

The invention discloses a balloon catheter for vertebral expansion and a preparation method of the balloon catheter for vertebral expansion. The preparation method includes steps: S10, performing injection moulding to obtain a Y-shaped catheter body and a catheter cap; S20, adhering a supporting guide wire and a guide wire cap; S30, preparing a balloon, marking an outer tube, enabling the balloon to sleeve one end of the outer tube, enabling a tube sleeve to sleeve the joint of the outer tube and the balloon, and firmly welding the tube sleeve; S40, connecting the outer tube with the Y-shaped catheter body; S50, connecting the inner tube with the catheter cap of the Y-shaped catheter body; S60, mounting radiopaque marks on the inner tube; S70, connecting the Y-shaped catheter body with the catheter cap; S80, sealing a far end of the balloon; S90, inserting the supporting guide wire into the inner tube, mounting a needleless connector at a third connection port, and evacuating the balloon to finish assembly. Due to synchronous execution of multiple procedures, production efficiency is improved.

Owner:SHANGHAI KINETIC MEDICAL

Absorbing material rolling-cut device of numerical control adult paper diaper production line

InactiveCN105943246AEasy to separateExtended service lifeSevering textilesAbsorbent padsNumerical controlHigh pressure gas

The invention belongs to the technical field of hygienic product production. An absorbing material rolling-cut device of a numerical control adult paper diaper production line comprises an absorbing core transport unit, a surface film transport unit, a base film transport unit, a hot glue laminating unit, and a rolling-cut unit. The rolling-cut unit comprises a male die cutting roller and a bottom die cutting roller. The surface of a roller body of the male die cutting roller is provided with a male die. The surface of the roller body of the bottom die cutting roller is provided with a die cavity. The side edge of the male die is provided with a right cutting edge. The side edge of the die cavity is provided with a left cutting edge. The device can realize uniform mixing and atomization of an emulsifying sizing material under action of high pressure gas, so gas and liquid are fully mixed and blended, so as to show atomization uniform spraying in a certain region, and a rolling-cut structure is further optimized. Thus, the rolling-cut technology of the absorbing material of the paper diaper is further improved, and uninterruptable continuous production of a whole numerical control adult paper diaper production line is realized.

Owner:QUANZHOU ZHIZAOZHE MECHANICAL EQUIP CO LTD

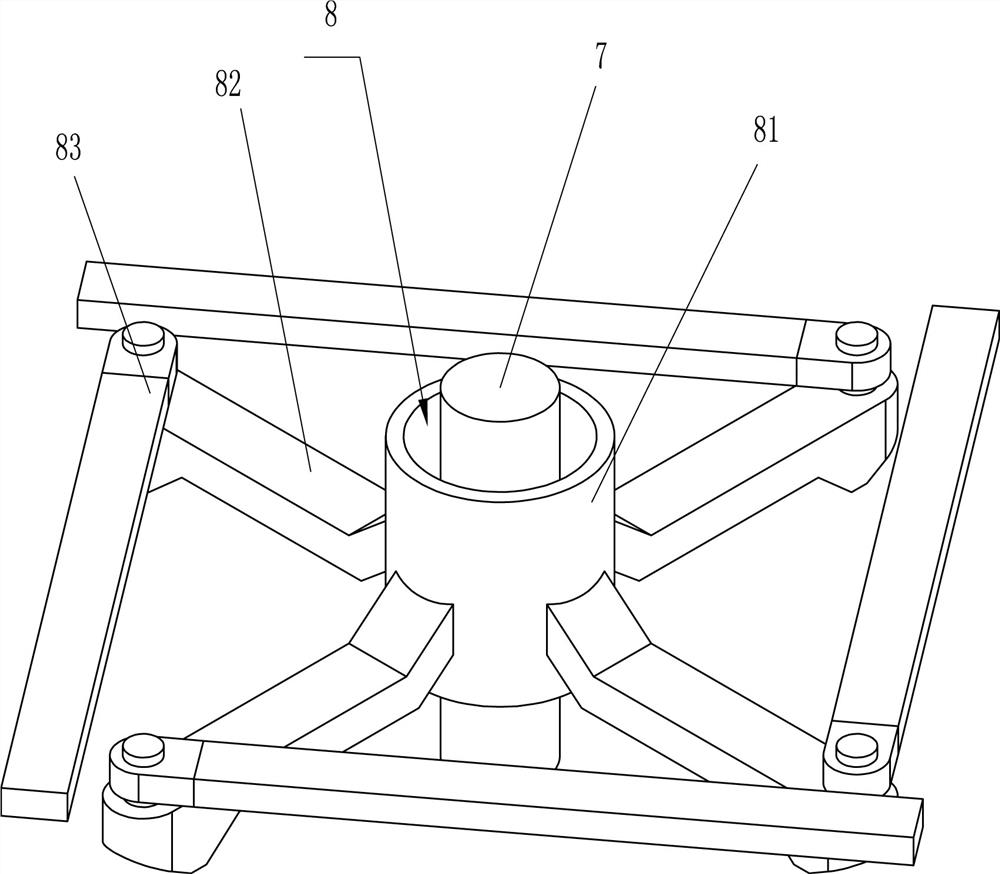

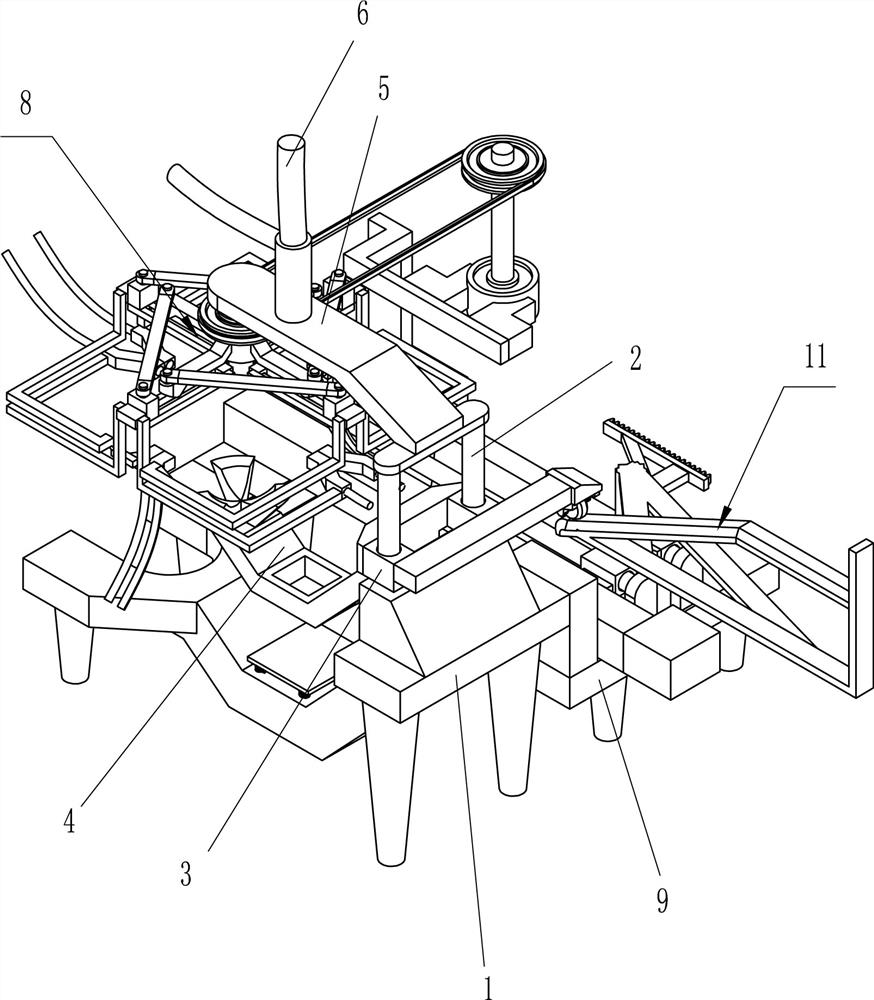

Backlight lamp inclination surface glue dispenser for television production back plate

ActiveCN110756396ALow costFully gluedLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses a backlight lamp inclination surface glue dispenser for a television production back plate, and relates to the field of television production. The technical problem is to design the backlight lamp inclination surface glue dispenser for the television production back plate, wherein the glue dispenser can adjust a glue dispensing pipe according to the angle of the back plateand can adapt to back plates with different sizes. The backlight lamp inclination surface glue dispenser for the television production back plate comprises a mounting frame, a mounting plate, a universal ball, a guide rod, a sliding block and the like, wherein the mounting plate is fixedly connected to the left part of the outer side of the upper part of the mounting frame; the universal ball is rotationally arranged at the lower part of the right side surface of the mounting plate; the guide rod is connected to the universal ball; and the sliding block is arranged on the guide rod in a sliding mode. According to the glue dispenser, the glue dispenser is erected on a conveying belt of the back plate, when the back plate moves to the position below the glue dispensing pipe, a driving motoris started to enable the glue dispensing pipe to be in contact with the back plate to glue the back plate, so that the glue dispenser can adapt to the back plates placed at different angles, then a servo motor is started to enable the glue dispensing pipe to move left and right, and comprehensive gluing is carried out on the back plate.

Owner:永康市陌桐电子科技有限公司

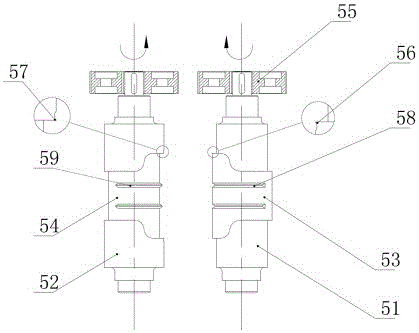

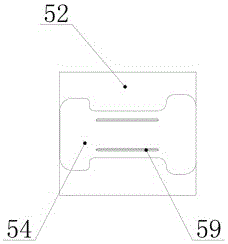

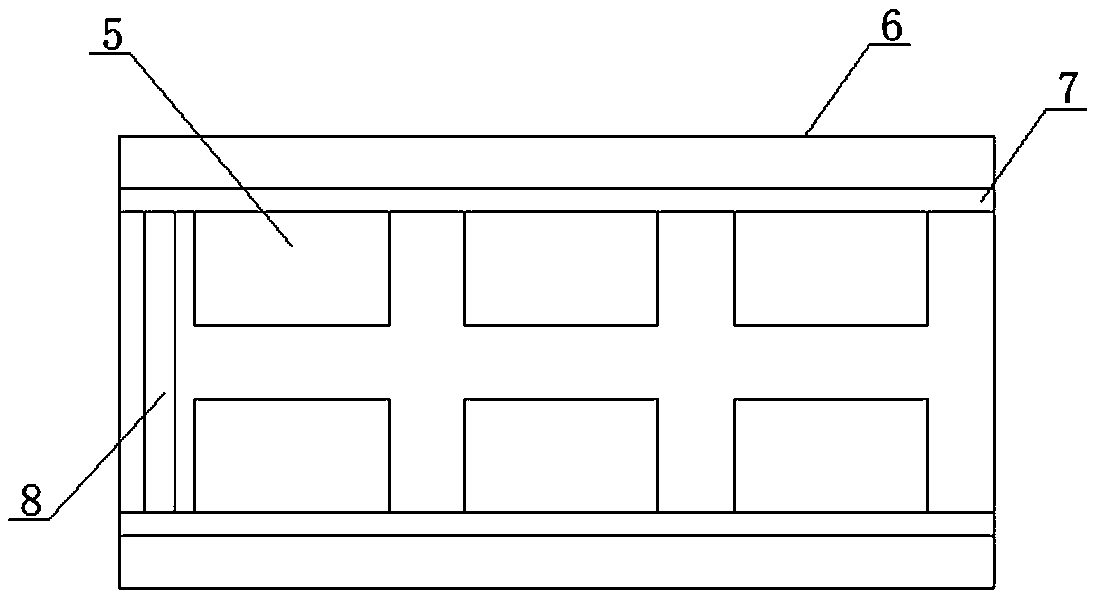

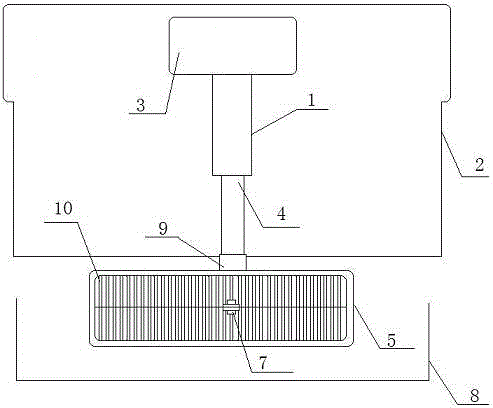

LED light group heat-conducting glue coating and scraping box

PendingCN107638999AUniform thicknessFully gluedLiquid surface applicatorsCoatingsHeat conductingEngineering

The invention relates to an LED light group heat-conducting glue coating and scraping box which comprises a lower mold, an upper mold and a glue scraping mold, wherein a plurality of positioning holesfor placing LED light groups are uniformly formed in the lower mold, the upper mold with replaceable different thicknesses is correspondingly arranged on the lower mold, glue coating holes corresponding to the positioning holes are formed in the upper mold, and the glue scraping mold capable of uniformly scraping heat-conducting glue in the glue coating holes is arranged on the upper mold.

Owner:JIANGSU HUACHENG TECH

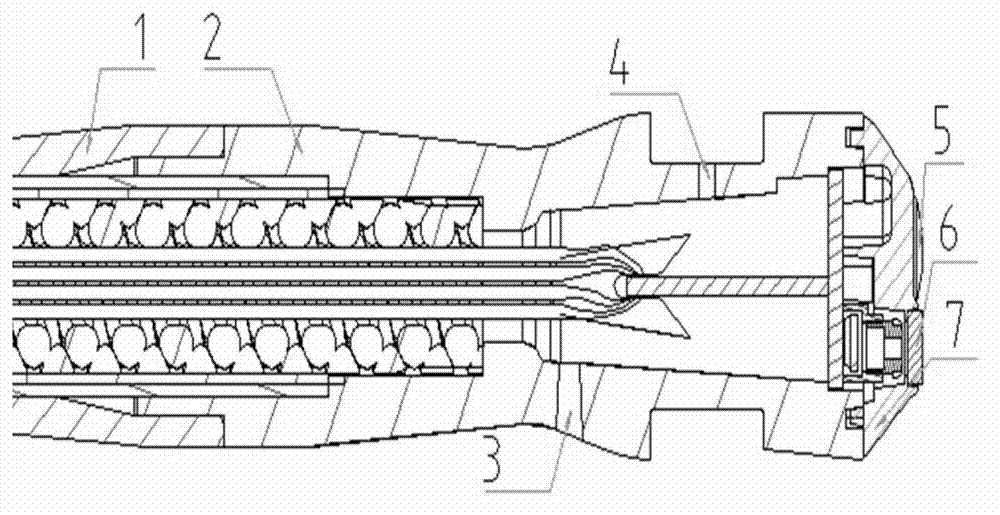

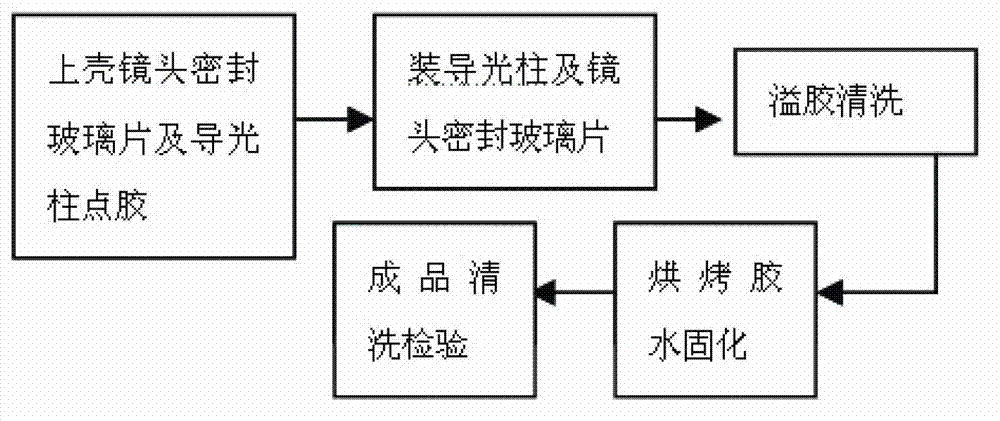

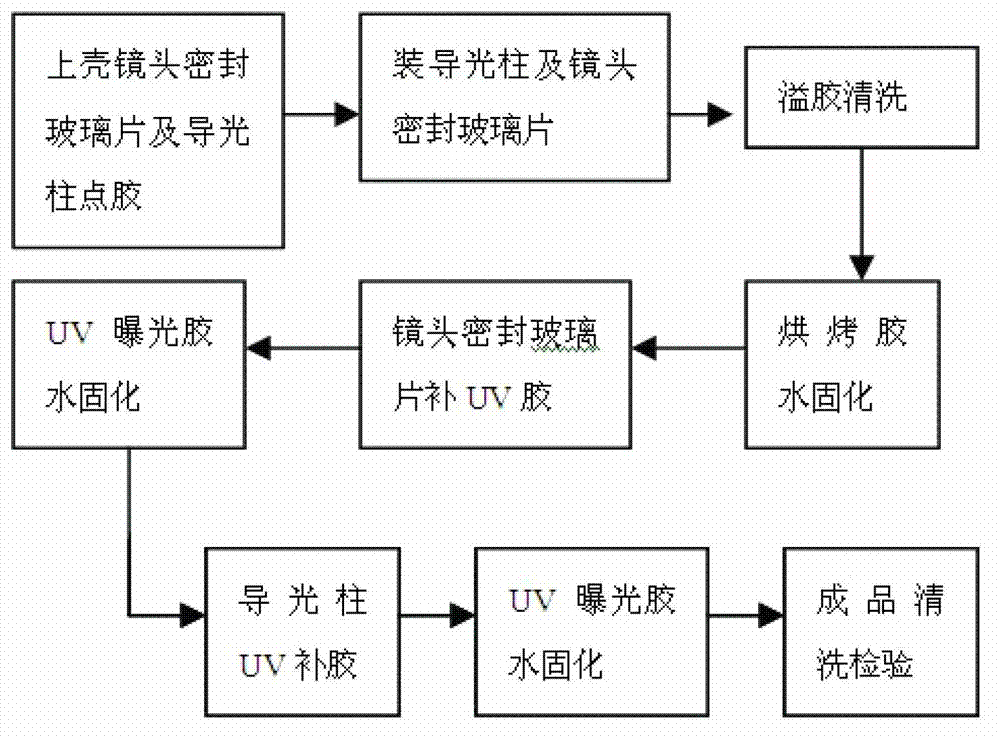

Improved method for high-pressure resistance test process of endoscope

ActiveCN102818976AImprove high pressure performanceImprove glue filling methodTesting dielectric strengthMountingsRubber ringEngineering

The invention provides an improved method for a high-pressure resistance test process of an endoscope. The method comprises the following steps that 1) after a light guide post and lens sealing glass are arranged on an upper casing of a lens, the reinforcement is carried out on UV (ultraviolet) glue of the upper casing of the lens, the light guide post and the lens sealing glass; 2) before the glue is filled inside the endoscope, beautiful grain additive tapes are pasted on a glue outlet hole part; and 3) when an insulation rubber ring is pasted with a soft stem lower casing of the casing, spot gluing is carried out at a generated gap part. The final qualification rate of the process endoscope after the high-pressure resistance test is obviously improved.

Owner:NINGBO SUNNY OPOTECH CO LTD

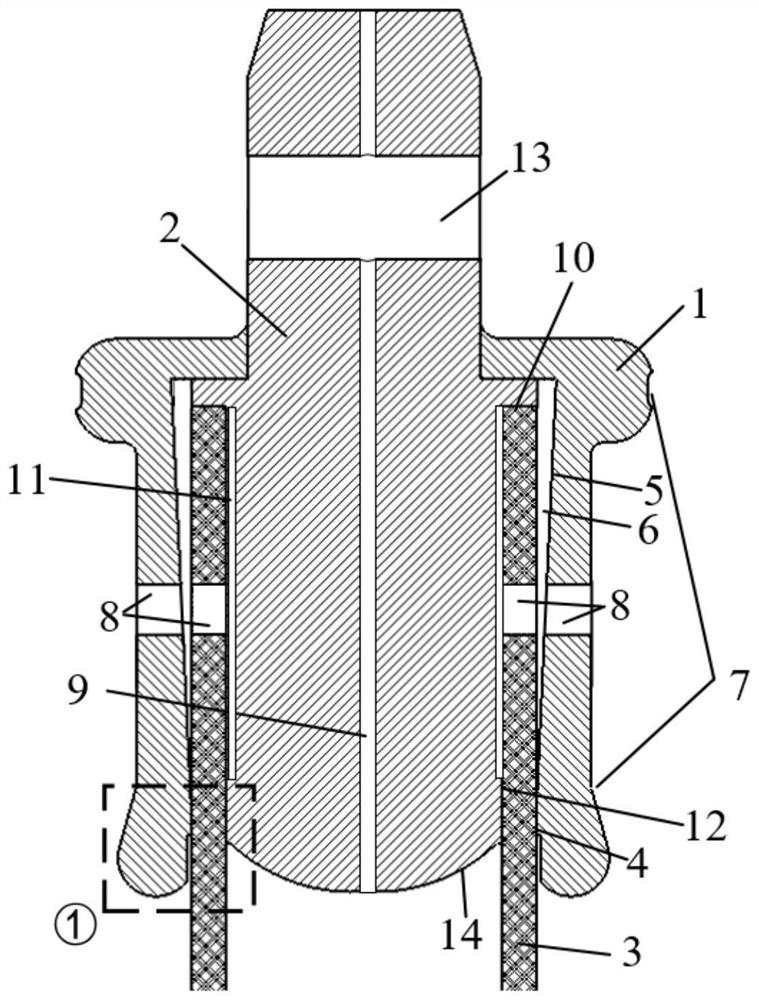

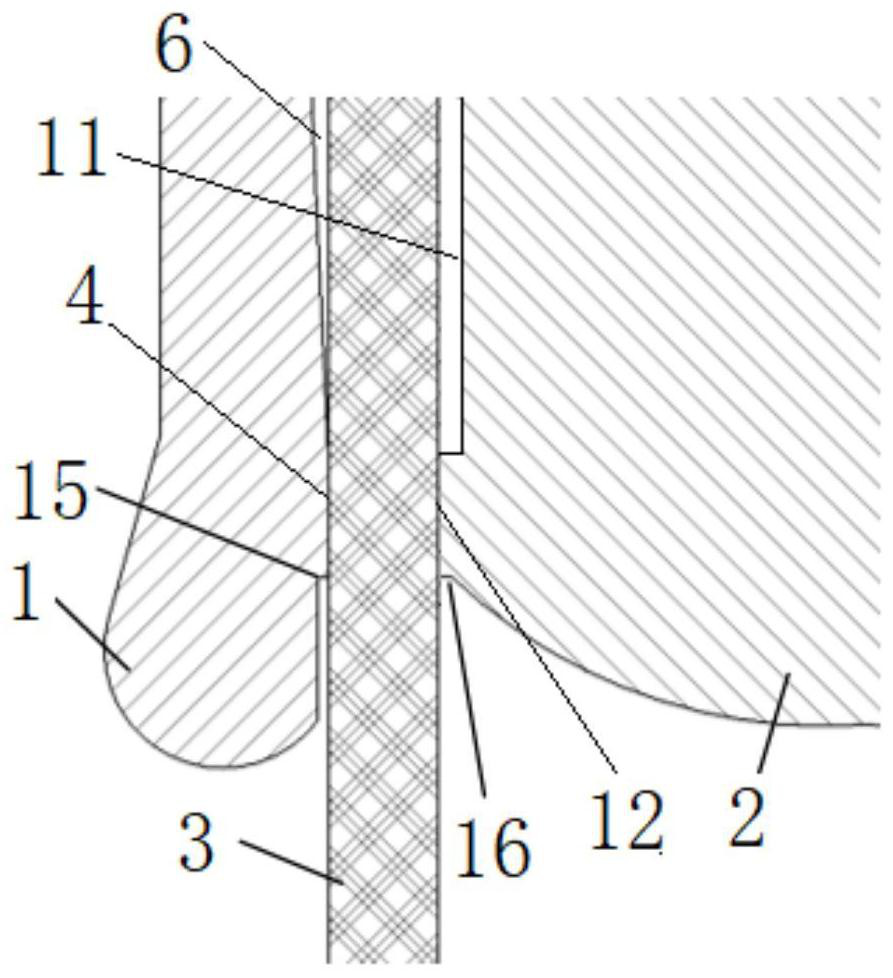

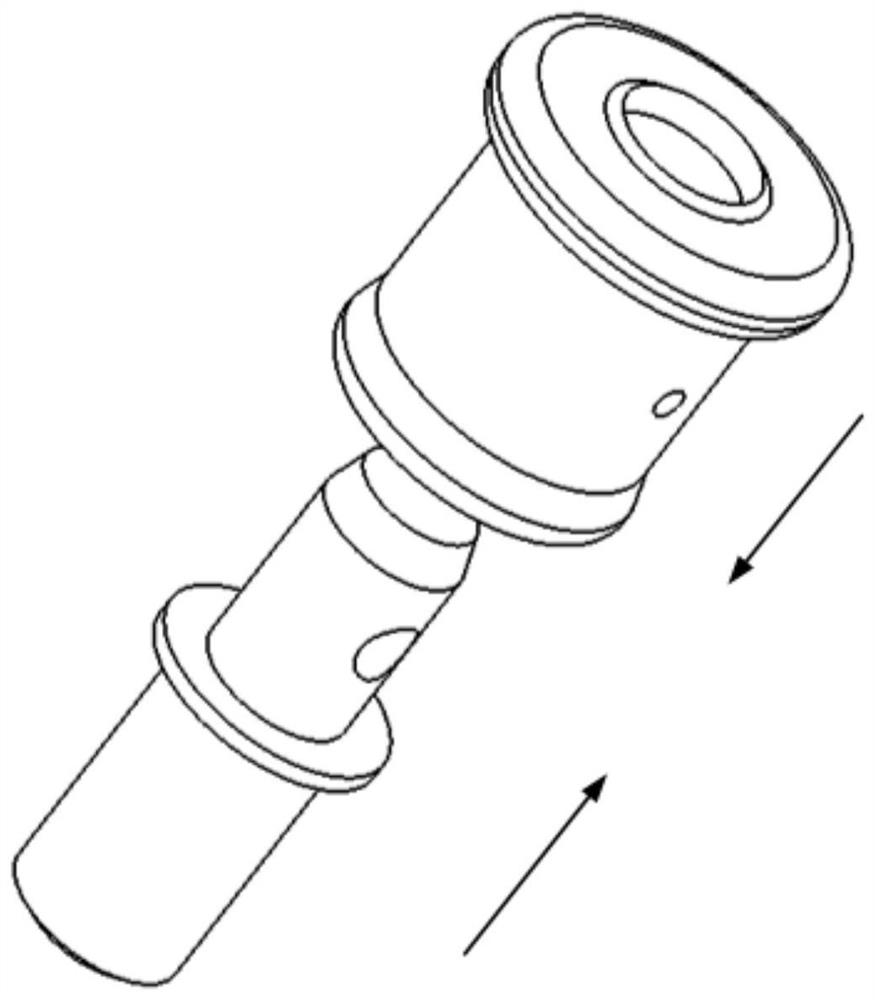

End part metal piece structure for transmission insulating rod of gas insulated switchgear and manufacturing method of end part metal piece structure

ActiveCN112768267AFirmly connectedReduce tensionSwitchgear arrangementsContact driving mechanismsEngineeringSwitchgear

The invention discloses an end metal piece structure for a transmission insulating rod of gas insulated switchgear and a manufacturing method of the end metal piece structure. An outer sleeve of the end metal piece structure sleeves the outside of a metal insert, one end of the metal insert extends out of the outer sleeve, a pin hole is formed in the part, outside the outer sleeve, of the end of the metal insert; a first annular gap is formed between the other end of the metal insert and the other end of the outer sleeve; one end of a fiber reinforced epoxy composite pipe is inserted into an inner cavity of the outer sleeve from the first annular gap; a glue injection cavity is formed between the outer surface of the fiber reinforced epoxy composite pipe and the inner wall of the outer sleeve; the longitudinal section of the glue injection cavity is in a shape with one large end and one small end; and the small end of the glue injection cavity is the end close to the first annular gap, and the glue injection cavity is filled with a binder. According to the end part metal piece structure of the invention, the mechanical and insulation problems caused by poor interface bonding performance between the metal piece and the fiber reinforced epoxy composite pipe are solved.

Owner:XI AN JIAOTONG UNIV +2

Gluing device for aluminum shell cover plate of power capacitor

InactiveCN106252105AGuaranteed service lifeAvoid gluing effectsLiquid surface applicatorsEncapsulating capacitors apparatusEngineeringElectric power

The invention discloses a gluing device for an aluminum shell cover plate of a power capacitor. The gluing device comprises a base, wherein a power supply, a controller and a rotating motor are arranged inside the base, the power supply, the controller and the rotating motor are all connected by a circuit, an output shaft of the rotating motor stretches out from an upper surface of the base, a power capacitor locating component is connected above the output shaft, a connecting seat is further arranged above the base, a fixing seat and a material storage box are sequentially connected to the connecting seat from bottom to top, a spring expansion link is connected to the fixing seat, a gluing opening is connected to the spring expansion link, and the material storage box is connected with the gluing opening by a pipeline. The device is simple to operate, can be used for coating capacitor aluminum shell cover plates with different shapes, and moreover, the coating effect is relatively good, thereby ensuring the sealing property of the aluminum shell cover plate of the power capacitor and avoiding safety accidents of the power capacitors in practical use.

Owner:铜陵市铜创电子科技有限公司

Plywood double-glue-spreader gluing machine

InactiveCN104941862AIncrease contact surfaceFully gluedLiquid surface applicatorsCoatingsEngineeringSilica gel

The invention discloses a plywood double-glue-spreader gluing machine. The plywood double-glue-spreader gluing machine comprises a glue feeding device, a gluing device, a silica gel roller and a rack, wherein the glue feeding device is arranged above the rack; the gluing device is arranged in the rack via a lifting adjusting device; the silica gel roller is fixedly arranged below glue spreaders; the gluing device comprises the two glue spreaders arranged side by side; the silica gel roller is arranged below the part between the two glue spreaders. According to the invention, based on an existing gluing machine, an original single glue spreader is changed into the double glue spreaders, so that the contact surface of the glue spreaders and a core plate is increased, which is equivalent to that gluing is carried out twice on one gluing machine, so that the surface of a core plate is glued fully and uniformly; moreover, the plywood double-glue-spreader gluing machine is simple in structure, is high in practicability, and is suitable for popularization and use.

Owner:SIYANG XIANGHE WOOD IND

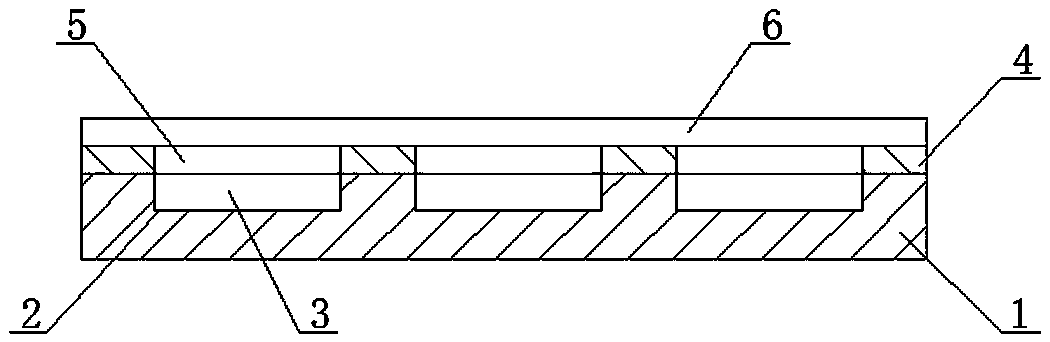

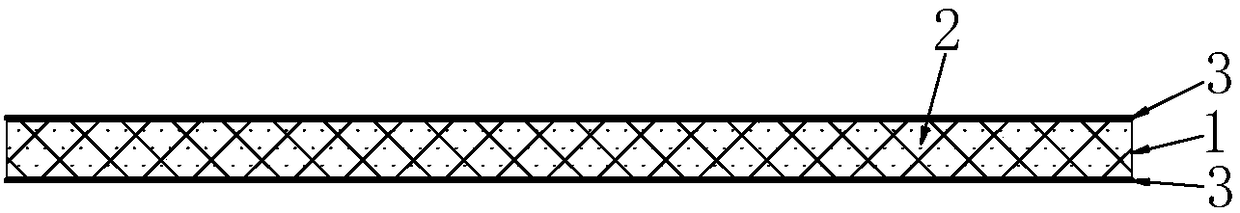

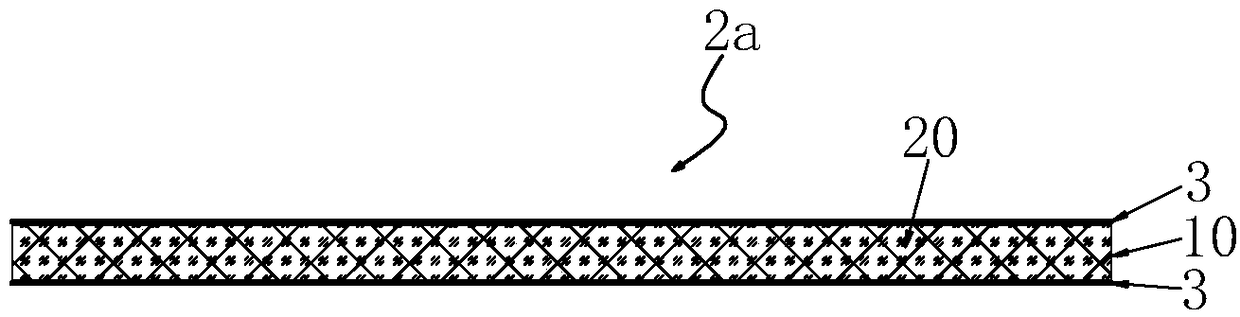

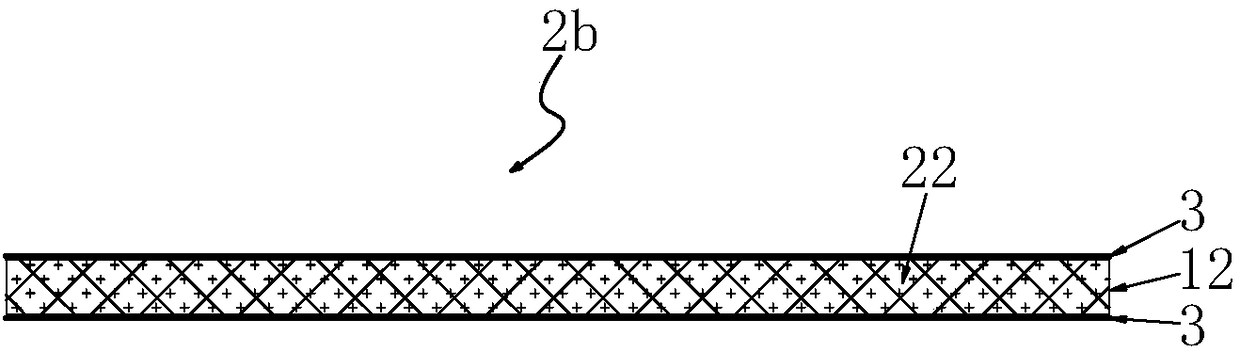

Sheet glue and gluing method thereof

The invention relates to sheet glue and a gluing method thereof. The sheet glue is prepared from a sheet carrier, a glue body and an isolating membrane, wherein a plurality of non-sealed accommodatingspaces are densely distributed in the sheet carrier, the glue body is coated to the sheet carrier and permeates to fill all the accommodating spaces, and the sheet carrier coated by the glue body issealed and wrapped by the isolating membrane; thus, the problems that an existing adhesive is prone to being wasted and is prone to forming foams to cause poor adhesion are solved.

Owner:XIAMEN ZL DIAMOND TECH CO LTD

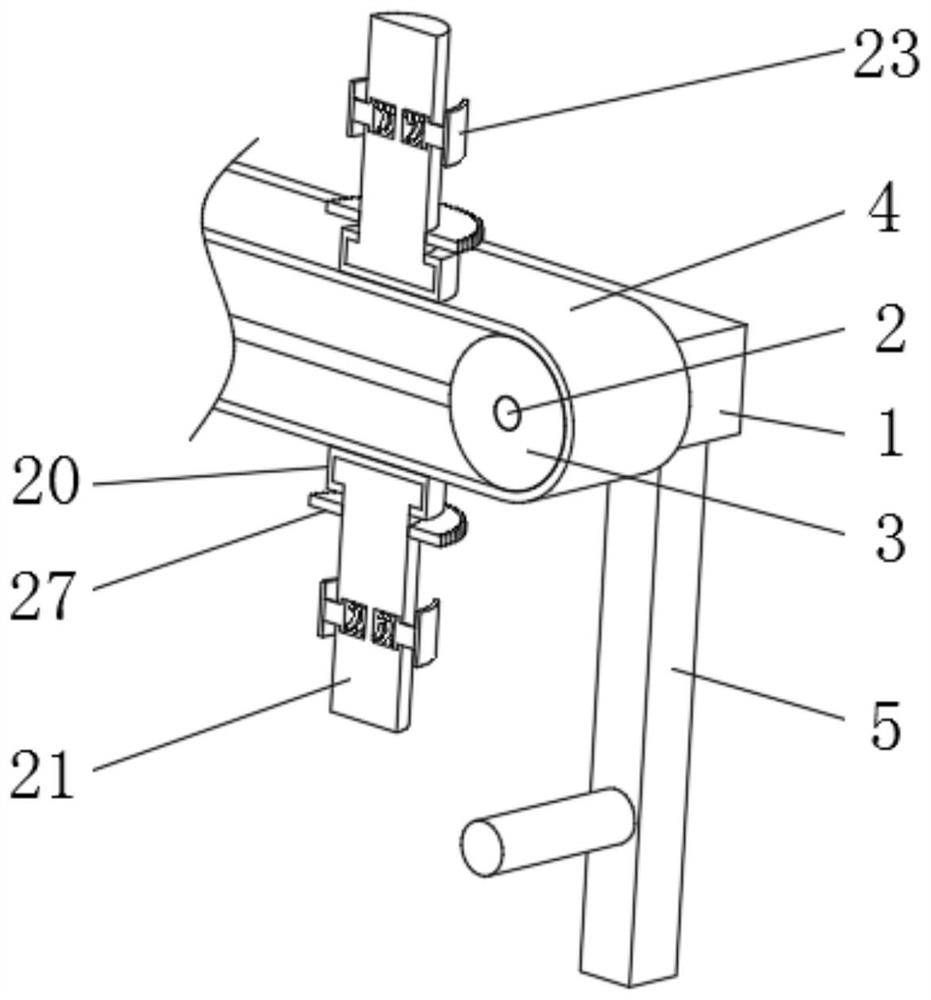

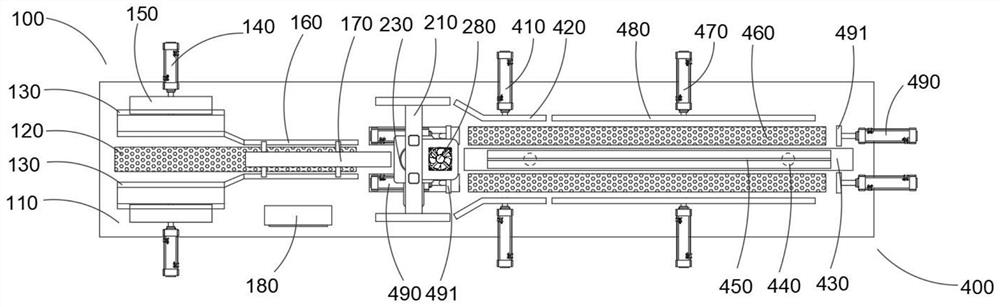

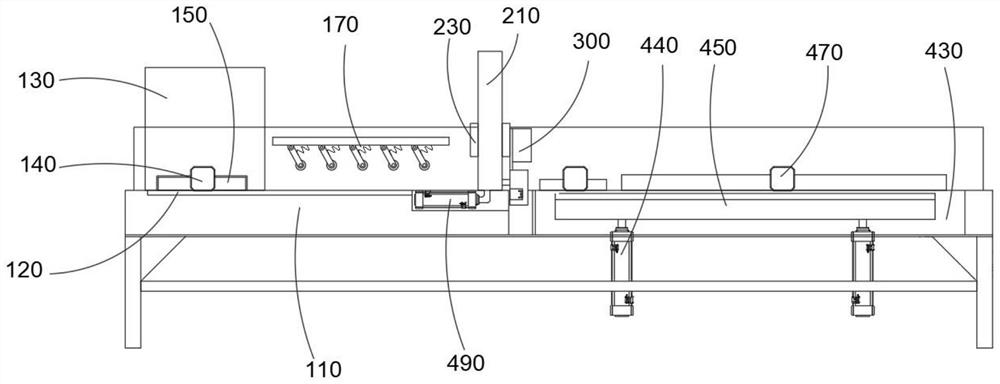

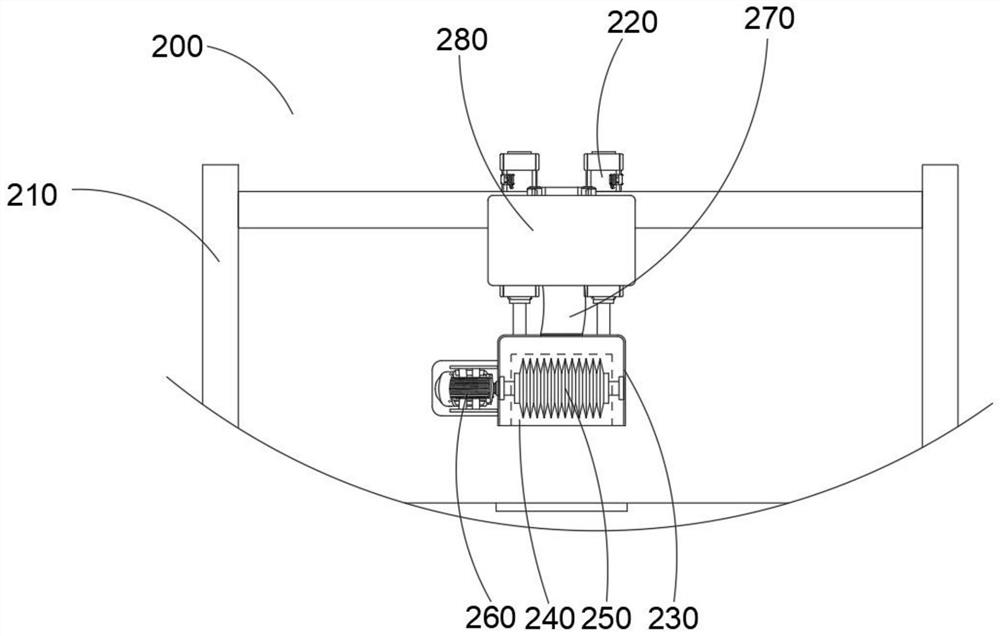

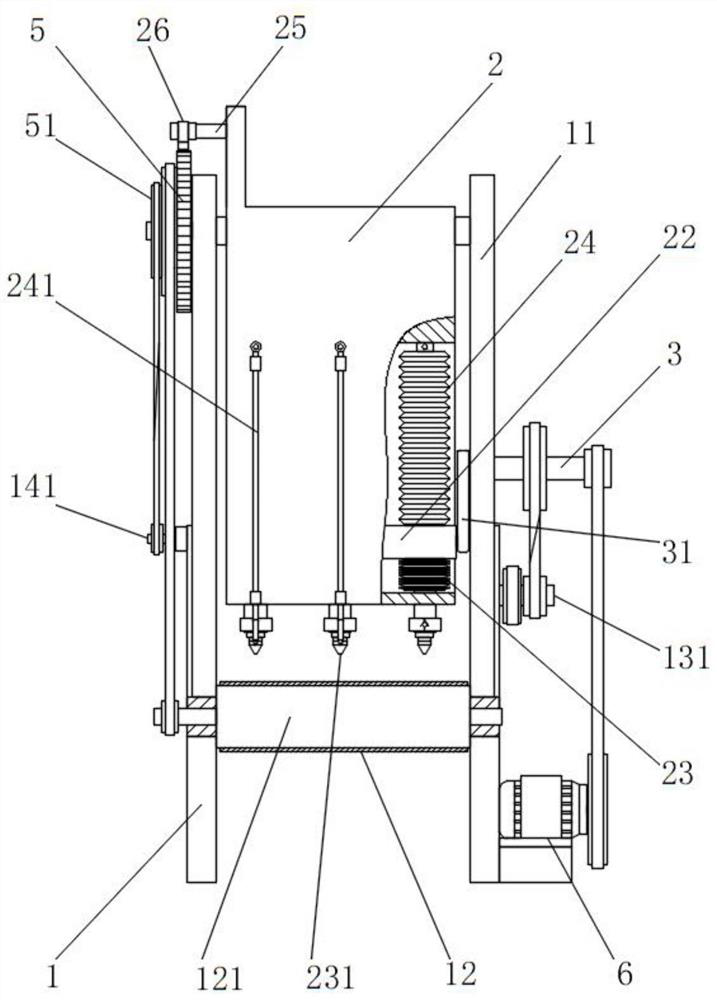

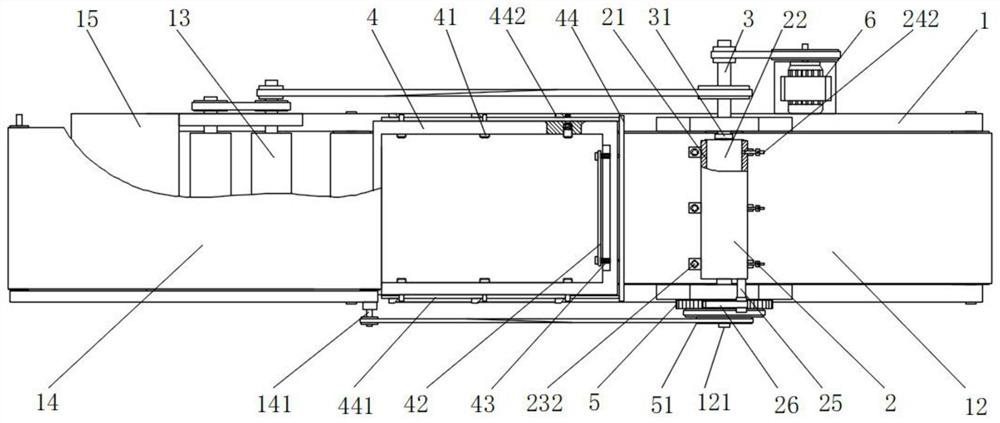

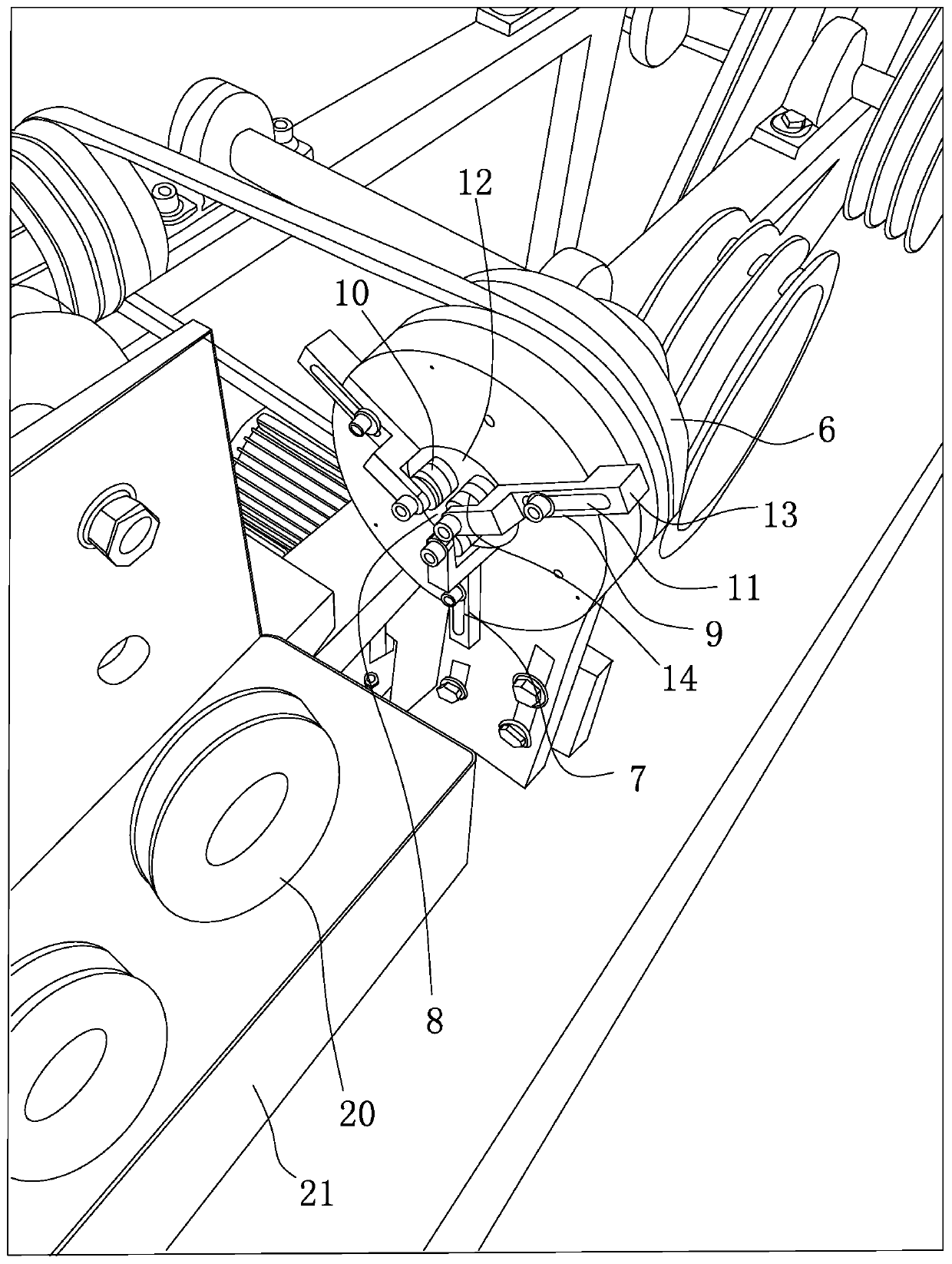

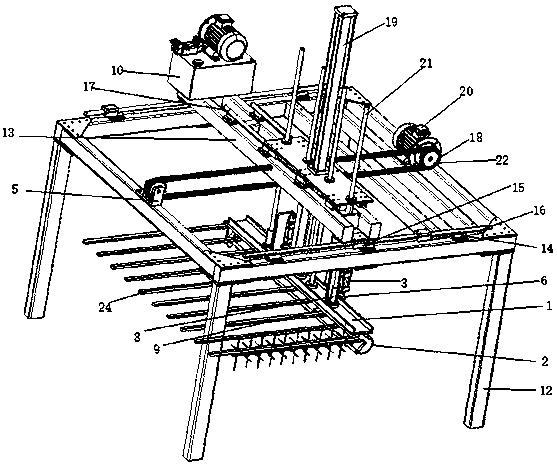

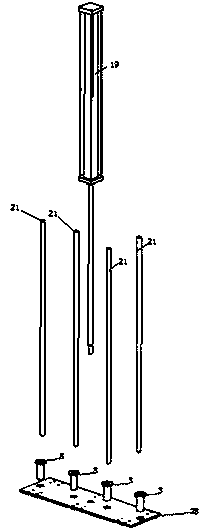

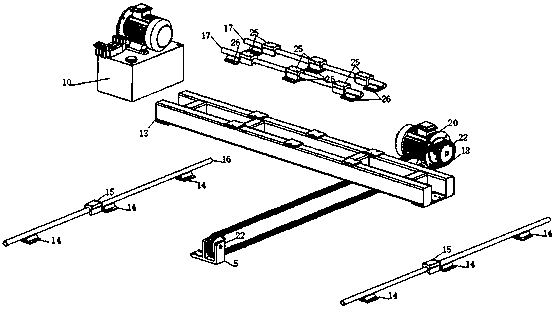

Full-automatic wood splicing machine for door edge material short square timber

ActiveCN114701024AImprove practicalityConvenient nestingWood veneer joiningBark-zones/chip/dust/waste removalMolding machineStructural engineering

The invention belongs to the technical field of wood splicing machines, and particularly relates to a door edge material short square wood full-automatic wood splicing machine which comprises a feeding mechanism, a comb tooth mechanism, a gluing mechanism and a forming mechanism. The feeding mechanism comprises a working table, a feeding conveying belt arranged on the working table and used for feeding, a storage bin installed on the working table, located on the side of the feeding conveying belt and used for storing materials, a pushing air cylinder installed on the side of the working table, and a pushing plate fixed to the driving end of the pushing air cylinder and located below the storage bin. The limiting plate is connected to the inner side edge of the material storage bin, the material pressing wheel set is installed on the limiting plate, and the controller is arranged on the working table. By means of the feeding mechanism and the forming mechanism, synchronous and alternate pressing connection of two sets of plates can be carried out in cooperation with different sizes of prepared materials in the feeding mechanism, waiting is not needed, the machining sizes can be different, the practicability of the wood connecting machine is greatly improved, meanwhile, discharging is convenient, and the design is novel and reasonable.

Owner:丰县泰宏全屋定制有限公司

Plywood forming machine

ActiveCN112025876ARealize the blowing cleaning functionImprove gluing effectWood veneer joiningBark-zones/chip/dust/waste removalRatchetMolding machine

The invention discloses a plywood forming machine. The plywood forming machine comprises a machine frame, mounting frames are fixedly mounted on the two sides of the middle of the top end of the machine frame correspondingly, a lower plate conveying belt assembly is arranged in the top end of the machine frame, and a swing frame is arranged on the inner sides of the two mounting frames; the two sides of the top end of the swing frame are rotationally connected with the inner sides of the top ends of the two mounting frames correspondingly, a sliding groove cavity is formed in the swing frame,and an extrusion sliding block is slidably connected into the sliding groove cavity; and a main shaft is rotationally connected to the middle of one mounting frame, and a driving motor is fixedly mounted at the bottom of the outer side of the rack. According to the plywood forming machine, a rocker is arranged to drive the extrusion sliding block, the swing frame is driven to swing, and a pawl rodat the top end of the swing frame is used for driving a ratchet wheel at intervals in a one-way mode, so that the plate surface cleaning and gluing function is achieved, two layers of wood plates areconveyed at intervals, the gluing effect of plate synthesis is improved, and the bonding strength of the plywood is improved.

Owner:临沂国正木业有限公司

LED decorative light strip outer surface acrylic particle coating device

The invention belongs to the technical field of LED decorative light strip production, and relates to an LED decorative light strip outer surface acrylic particle coating device. The coating device includes a machine frame. The machine frame is provided with a light strip feeding mechanism and a double-side adhesive tape coating mechanism, the machine frame is further provided with an acrylic particle coating mechanism, the acrylic particle coating mechanism includes a coating motor fixed to the machine frame and a coating rotary disc connected with the coating motor, the coating rotary disc is detachably provided with a plurality of rubbing components capable of rotating in the circumferential direction, rubbing channels are formed between the rubbing components, thus light strips can penetrate through the rubbing channels, and when the light strips penetrate through the rubbing channels, contact matching of the rubbing components and the outer surfaces of the light strips is formed.According to the LED decorative light strip outer surface acrylic particle coating device, the defect of many personal errors of manual operation is overcome, and the work efficiency is improved.

Owner:TAIZHOU CITY DADI LIGHT DECORATIONS

Production method of bamboo plywood coated with film

InactiveCN101830025BWide variety of sourcesReduce wasteWood working apparatusDomestic articlesEngineeringColloid

The invention discloses a production method of bamboo plywood coated with a film. The production method comprises the processes of: sheet cutting, curtain or mat knitting, drying and sizing, glue dipping, glue airing, re-drying, blank assembling, hot pressing and blank edge processing and is characterized by comprising the specific steps: drying a bamboo curtain or a bamboo mat knitted by bamboo with small diameter at 100-200 DEG C firstly till water content is 10-14% and sizing; dipping in glue and then drying at 100-120 DEG C till the water content is 6-14%; adding veneers, covering film paper, dipping in glue separately and airing; assembling blanks of mat and short and long curtains alternately; hot pressing and processing edges of the blanks. The invention has wide raw material sources and less raw material waste, shortens drying time, improves working efficiency, achieves more firm gluing among plies, has no foaming and flaking phenomenon, and overcomes the defects of surface hole shrinking and incomplete gluing due to colloids seepage, which are generated when drying is carried out below 95 DEG C in the traditional method. All indexes of the product provided by the invention meet or exceed national standards.

Owner:南充富达竹业有限公司

Glue tool

PendingCN110700425AFill evenly and fullyFully gluedBuilding insulationsEngineeringMechanical engineering

The invention discloses a glue tool. The tool comprises at least two sets or more outer tool bodies and at least two sets or more inner tool bodies, flow dividing holes are formed in the outer tool bodies, the inner tool bodies are connected with the outer tool bodies through fixing parts, floor pipeline gaps can be filled more evenly and sufficiently, glue coating of the glue tool is more uniformand sufficient, the glue quality of the project construction is improved, the quality problem caused by uneven glue coating can be completely solved, construction efficiency is improved, and construction cost is saved.

Owner:GOLD MANTIS CONSTR DECORATION

Gluing equipment for electroplating hanger

PendingCN109926280AFully gluedGlue evenlyLiquid surface applicatorsCoatingsHydraulic cylinderEngineering

The invention relates to the technical field of gluing equipment, in particular to gluing equipment for an electroplating hanger. The gluing equipment comprises a machine frame, front and rear slidingrails and left and right movable plates are arranged at the top of the machine frame, left and right sliding rails and a mounting bottom plate are arranged at the tops of the left and right movable plates, upper and lower guide columns and upper and lower hydraulic cylinders are arranged on the mounting bottom plate, a clamp bucket upper plate base is arranged at the output ends of the upper andlower hydraulic cylinders, a clamp bucket lower plate base is arranged on one side of the bottom of the clamp bucket upper plate base, a cantilever frame base and a cantilever frame rod are arranged at the bottom of the clamp bucket upper plate base, and an adjusting device for adjusting the rotation opening and closing angles of the clamp bucket lower plate base and the clamp bucket upper plate base is arranged on one side of the top of the clamp bucket upper plate base. The gluing equipment is simple in structure and uniform in gluing, has a market prospect and is suitable for popularization.

Owner:陈剑

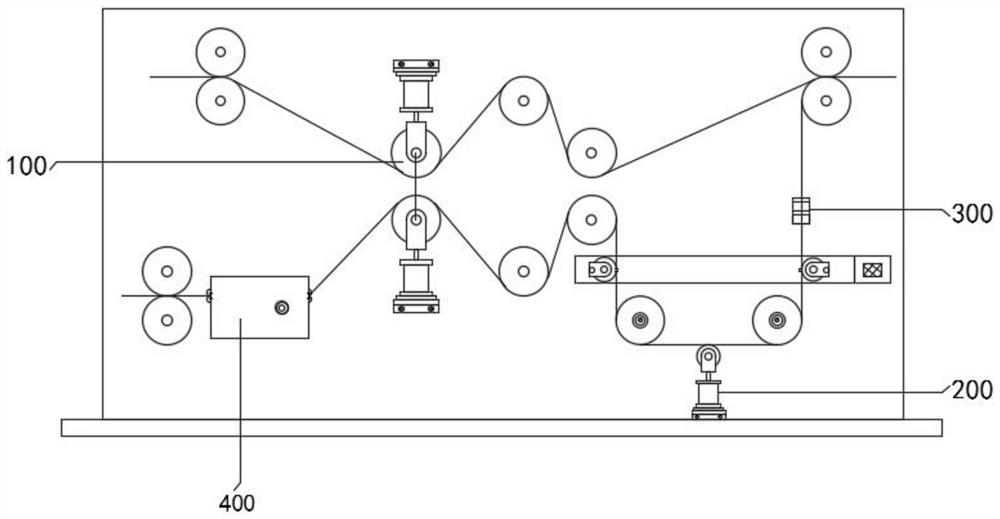

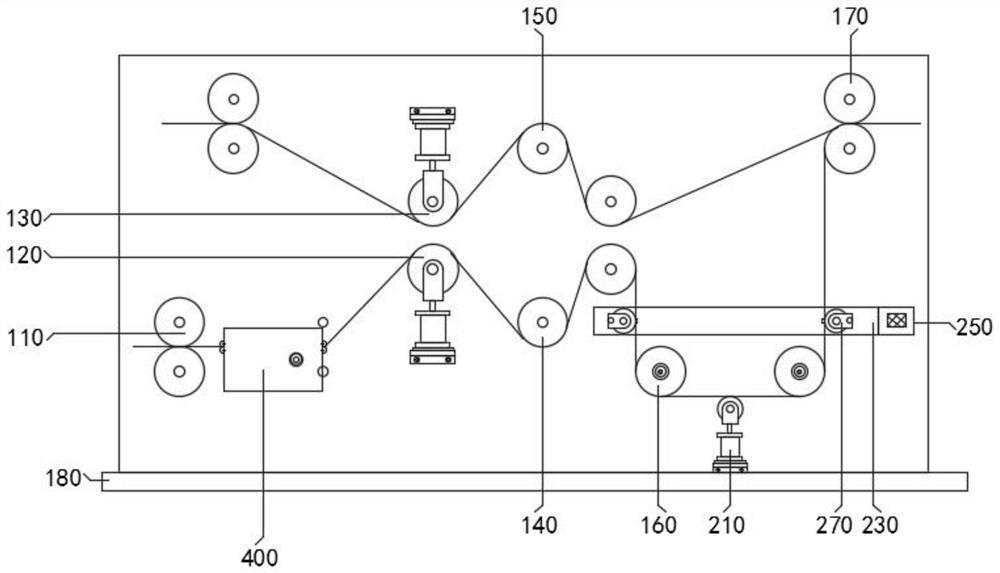

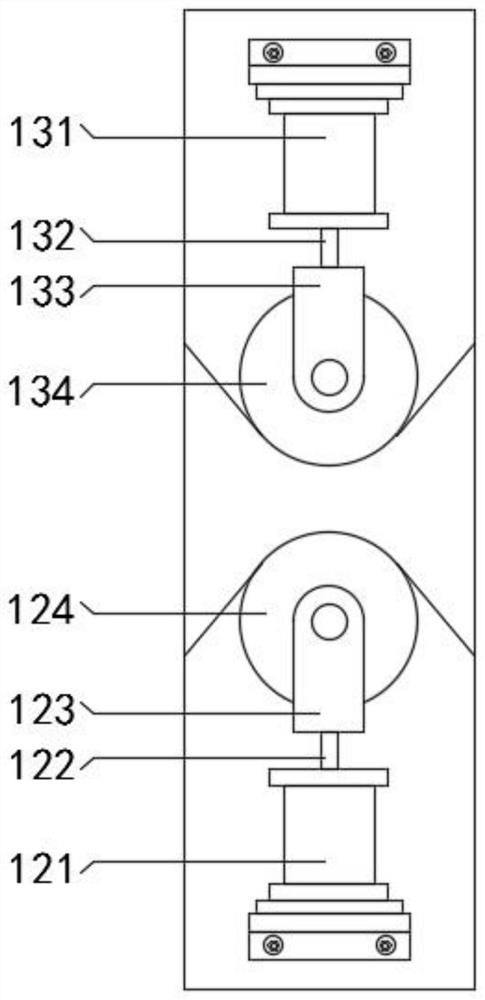

An automatic heat insulating glass side edge sealing equipment

ActiveCN111203366BFully gluedAvoid uneven glue applicationLiquid surface applicatorsCoatingsStructural engineeringMechanical engineering

The invention relates to glass processing, in particular to an automatic heat-insulating glass side edge sealing device. The technical problem of the present invention is how to provide an automatic heat-insulating glass side edge sealing device that improves efficiency, proceeds at a constant speed during the gluing process, and ensures the uniformity of gluing. An automatic heat-insulating glass side edge banding equipment, including a mounting frame, a first guide rail, a first guide sleeve, etc.; First guide bush. The present invention adopts eight groups of gluing heads to apply gluing to the sides fully, so that gluing can be applied to the sides of the glass at a comprehensive and uniform speed, avoiding uneven gluing, and there is no artificial direct contact during the gluing process. Participation, the glass can be glued automatically, and the manual will not be hurt by the side of the glass.

Owner:赣州海发中空玻璃工程有限公司

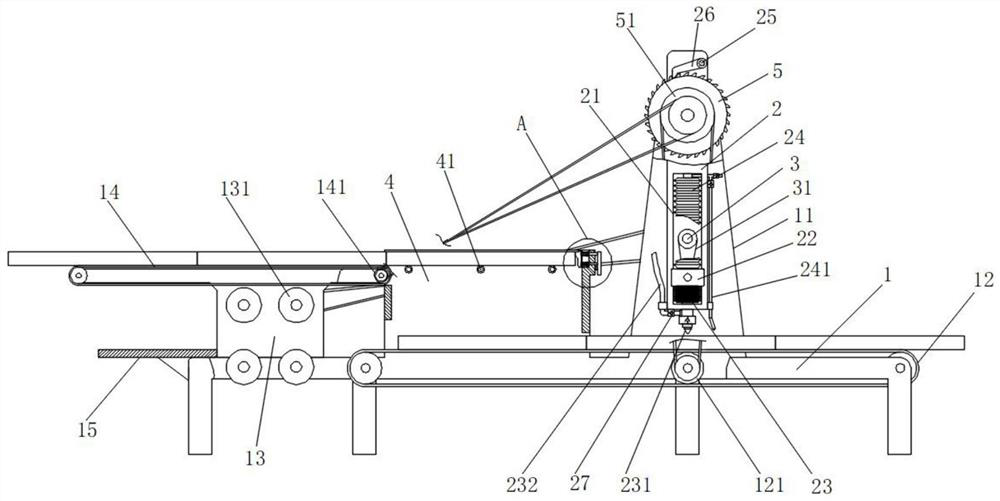

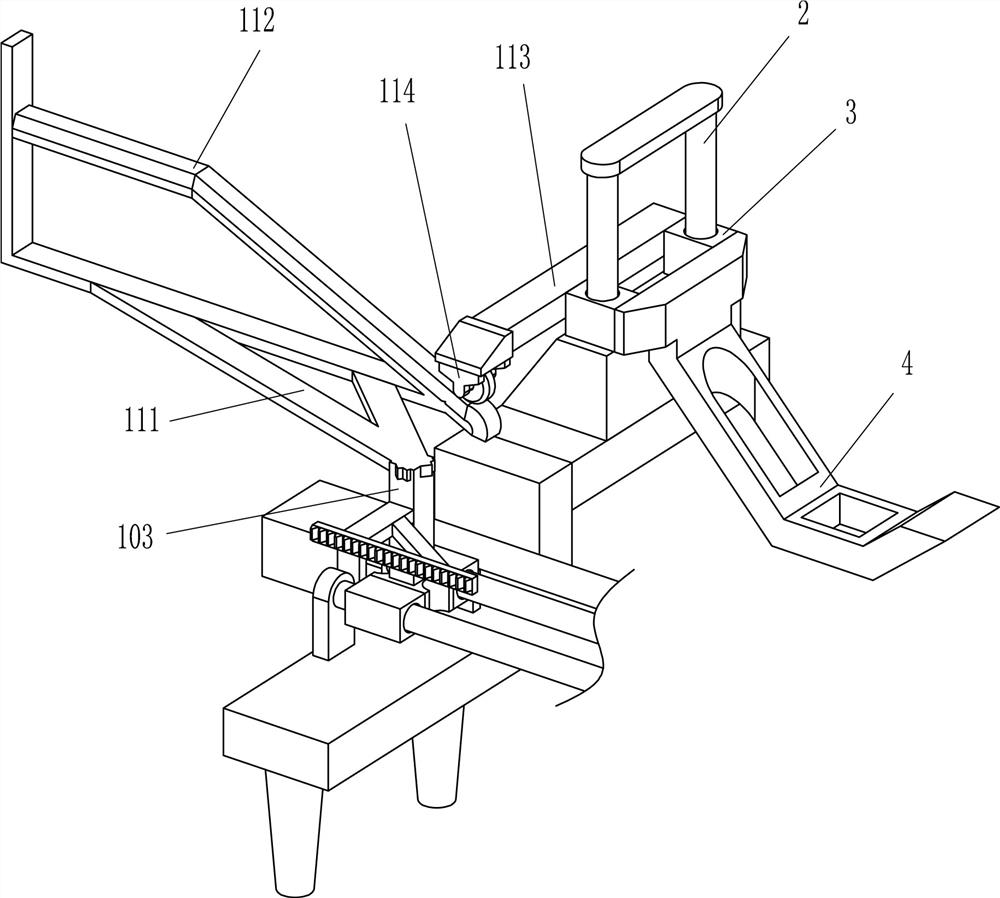

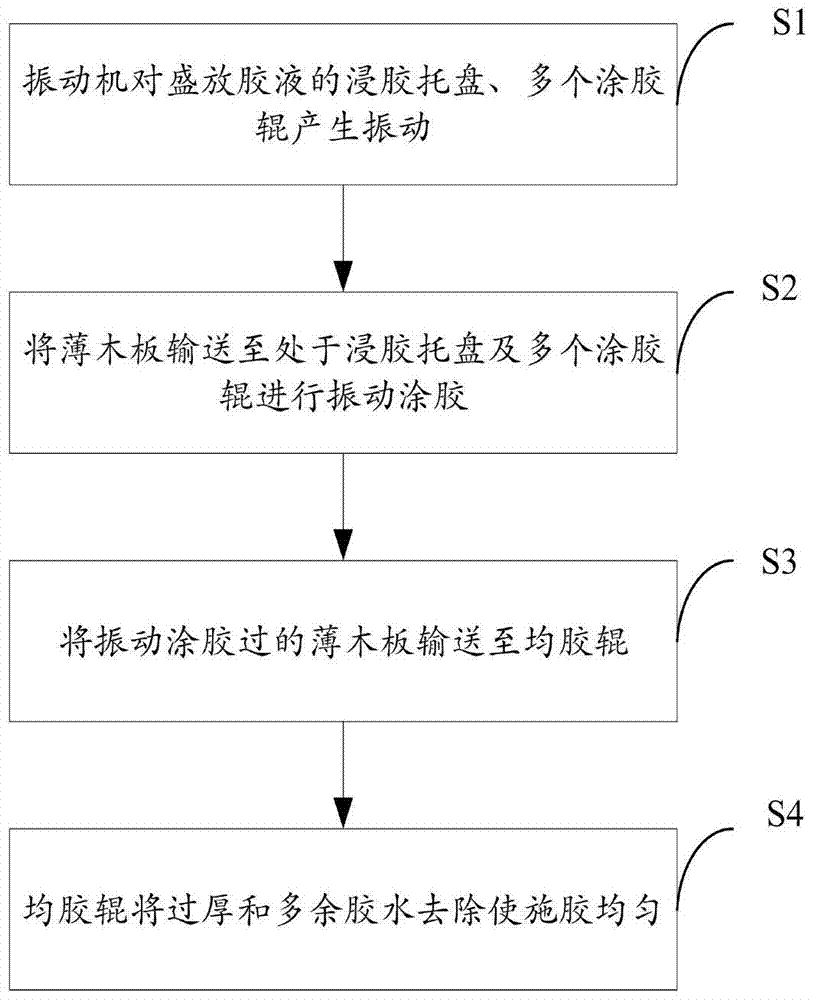

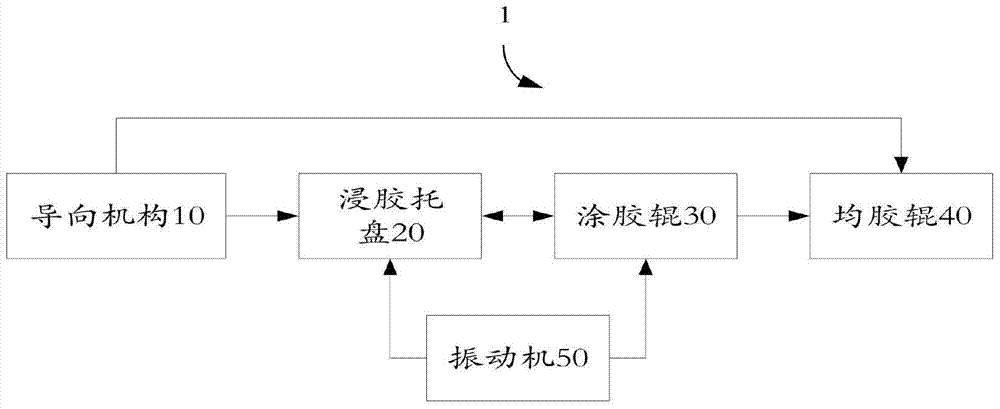

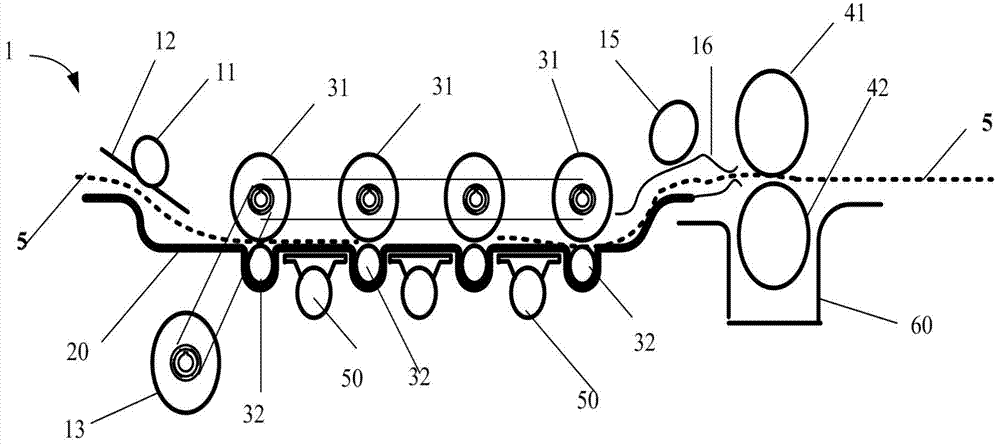

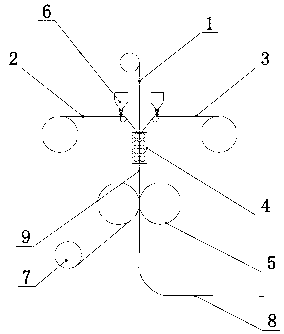

A method and device for vibrating gluing

InactiveCN105014759BFully gluedApply glue evenlyAdhesive application devicesWood impregnation detailsQuality assuranceEngineering

The invention discloses a vibrating gluing method, comprising: S1. A vibrating machine vibrates a gluing tray containing glue liquid and a plurality of gluing rollers; S2. Transporting veneer to the gluing tray in a vibrating state and a plurality of gluing rollers for vibrating gluing; S3. Conveying the vibrating gluing veneer to the gluing roller; S4. The gluing roller removes excessive thickness and excess glue to make the gluing uniform. The invention also discloses a vibration gluing equipment. The method and equipment for vibrating gluing provided by the invention can overcome the disadvantage that ordinary gluing machines cannot make glue soak into cracks, and ensure the quality of subsequent processed products.

Owner:深圳嘉汉林业科技有限公司 +1

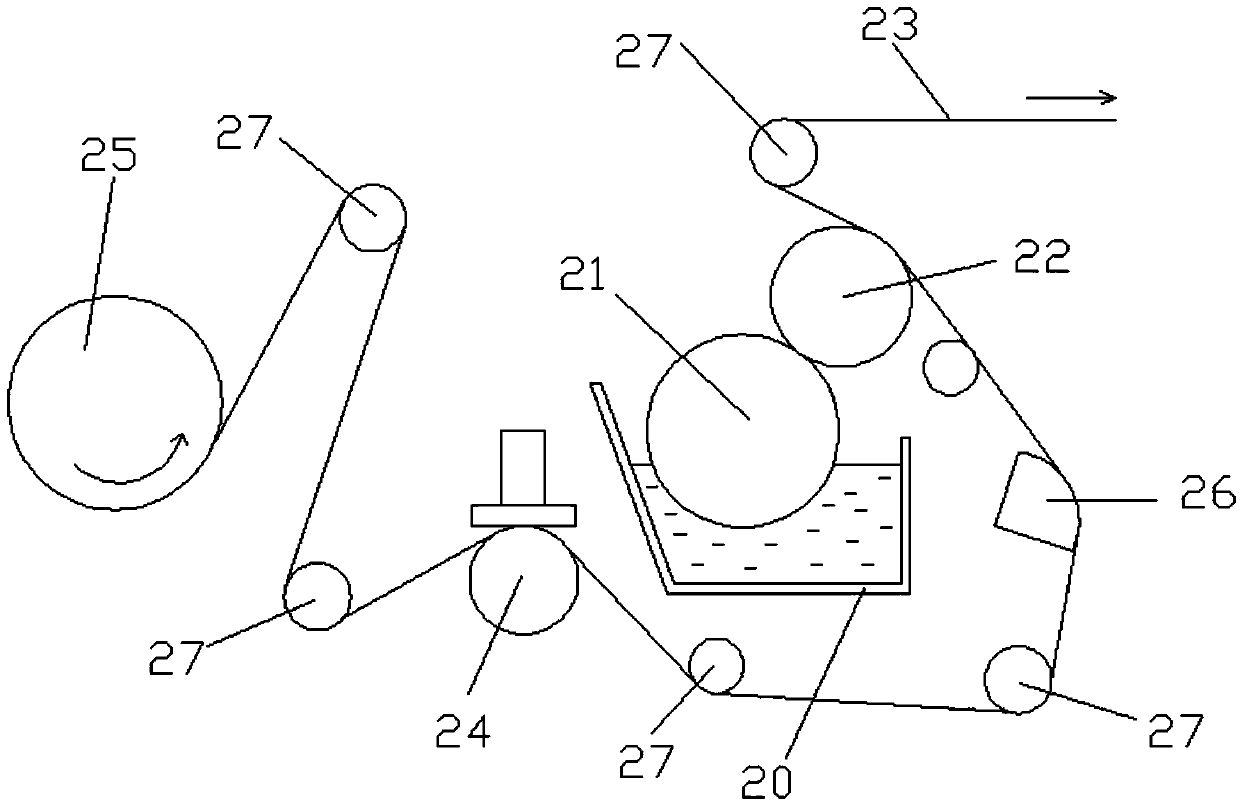

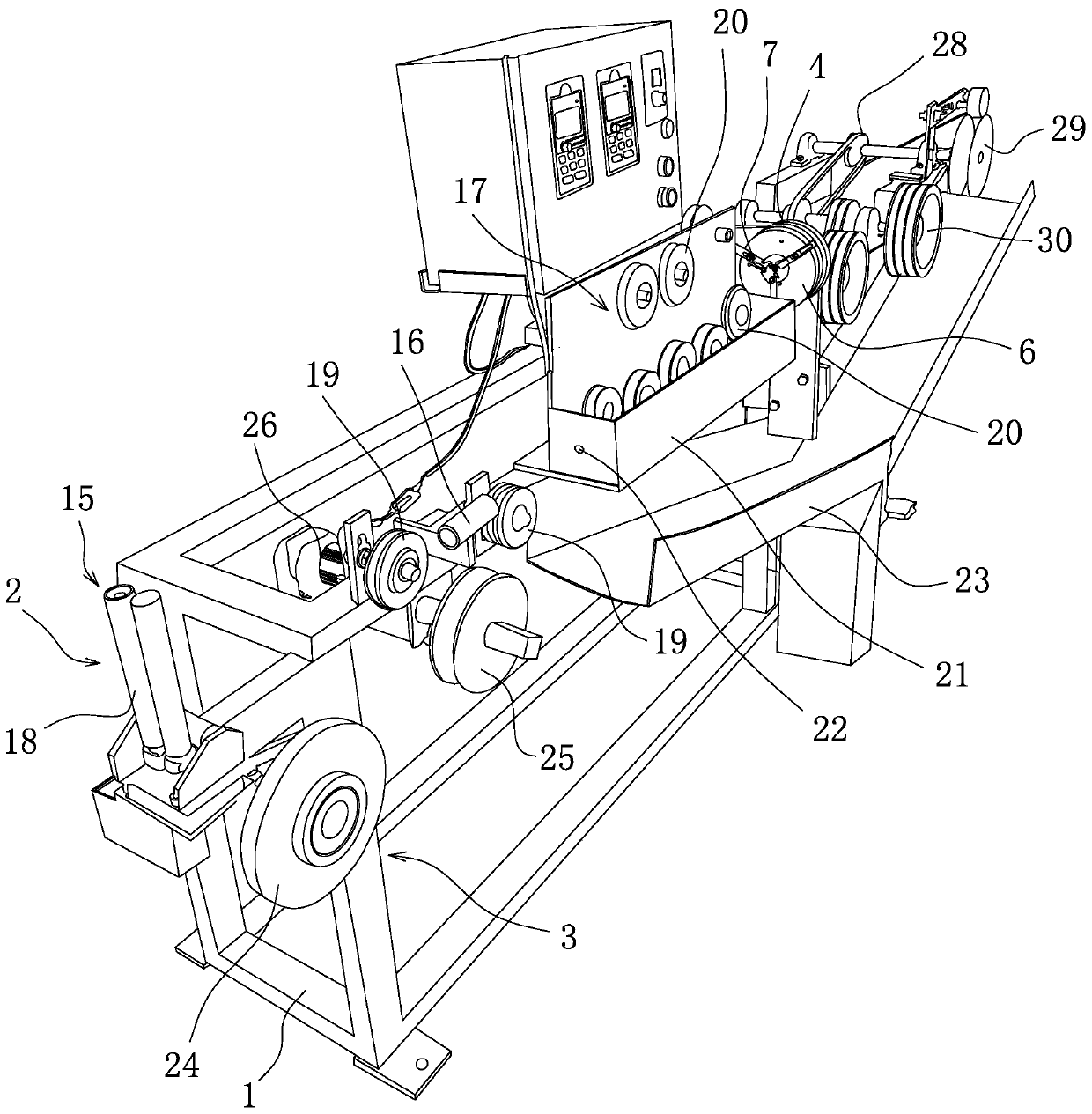

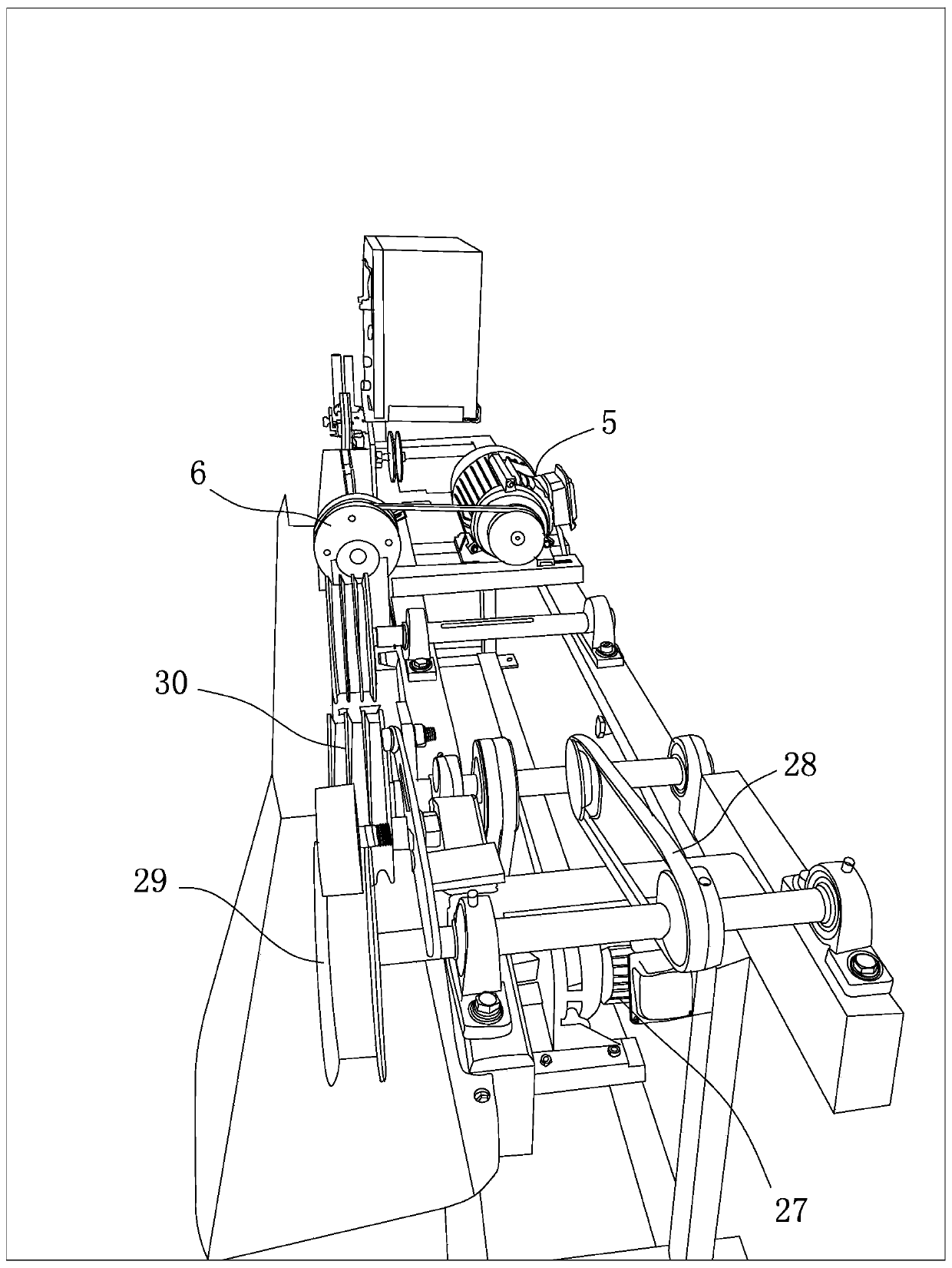

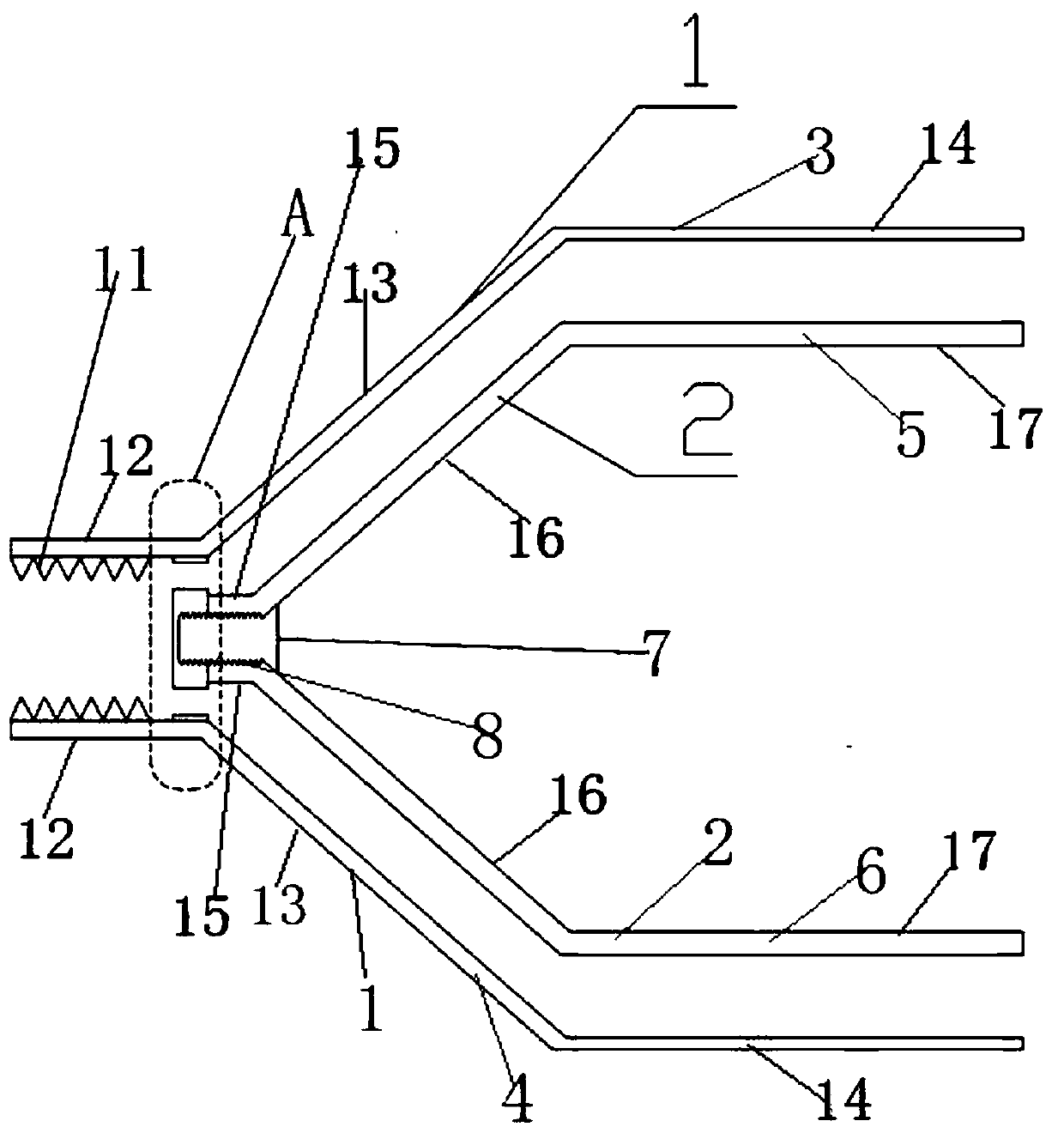

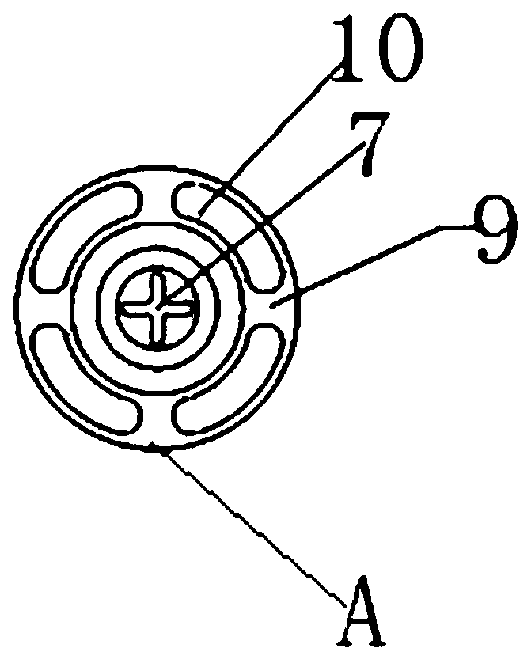

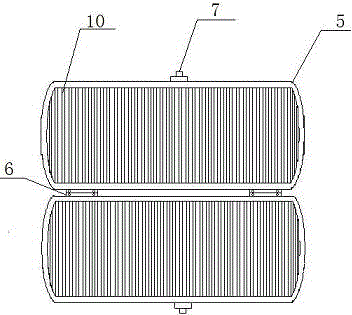

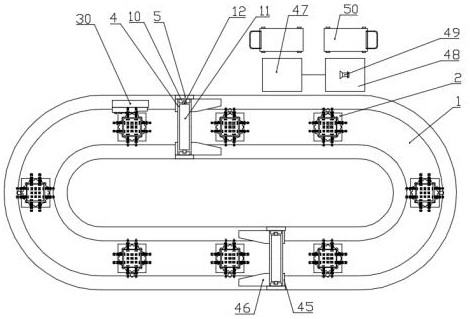

One-time molding device for cord gluing and conveyor belt cord layer

ActiveCN103506244BRealize one-time moldingFast molding speedLiquid surface applicatorsCoatingsAdhesiveConveyor belt

The invention belongs to the technical field of conveyor belt cord layer forming devices and particularly relates to a device for applying an adhesive to a cord and forming a conveyor belt cord layers in one step. An input roller and an output roller are arranged on a frame, a plurality of rollers are arranged between the input roller and the output roller, a cord roller is arranged on one side of the input roller, a liquid rubber container is arranged on one side of the output roller, a winding drum is arranged on one side of a molten rubber container, and the winding drum is powered to rotate. According to the invention, a cord is at a tensioned state after passing through the rollers, is applied with an adhesive after passing through the molten rubber accommodating cavity, and then is wound and formed, so that the effect of applying the adhesive to the cord and forming the conveyor belt cord layer in one step can be achieved, the forming speed is quick, the efficiency is high and the effect is excellent; the cord is enabled to be in the tensioned state by the cooperation of the lower roller and the upper roller and through the cord pressing wheel and the cord pressing bar, so that the cord is applied with the adhesive fully and the forming process is simple.

Owner:TAIZHOU BAIHUA RUBBER BELT

A gluing device for bamboo canes

This invention relates to a gluing device for bamboo canes. The device comprises a cylinder, a main support and a motor. The motor is arranged on the main support. The lower part of the motor is connected with the cylinder. The lower part of the cylinder is connected with a stirring arm. The lower part of the stirring arm is connected with a stirring wheel. The upper part and the lower part of the inner side of the stirring wheel are provided with a hinge which is convenient to open from the inside, respectively. The upper part and the lower part of the outer side of the stirring wheel are provided with a tension bolt, respectively. A glue pool is placed below the stirring wheel. Through the above improvement, the device of this invention has features of complete gluing, simple structure, labor saving, compact bamboo cane lamination and long service life.

Owner:季叶俊

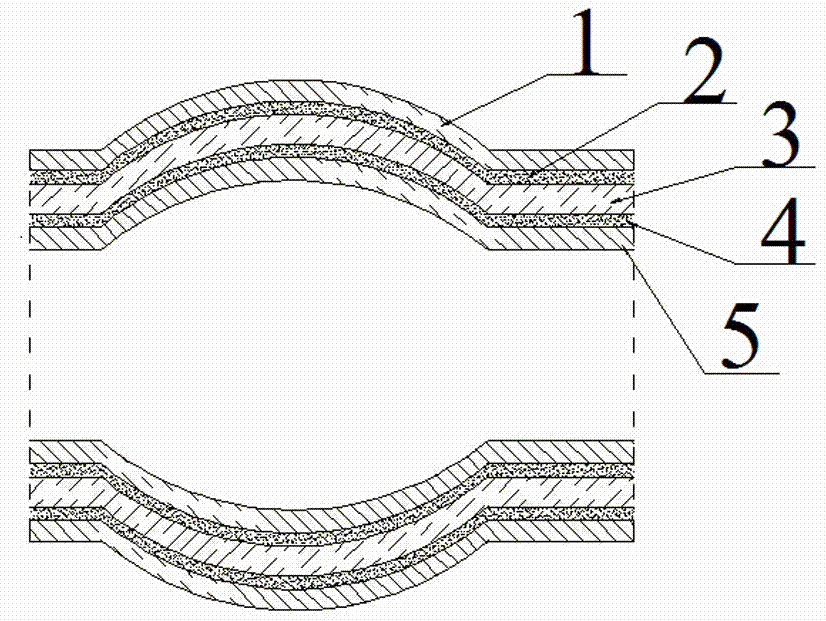

Viton synthetic rubber joints

ActiveCN105020511BImprove mechanical propertiesIncrease elasticityAdjustable jointsOxidation resistantEngineering

The invention relates to a fluororubber synthetic rubber joint. The pipe wall of the fluororubber synthetic rubber joint successively comprises an outer rubber external layer, an outer rubber internal layer, a composite frame layer, an inner rubber internal layer and an inner rubber external layer from the outside to the inside. The raw material ratio of each layer of the pipe wall is also disclosed. The fluororubber synthetic rubber joint can resist a high temperature of 140 to 180 DEG C, is fatigue-resistant and oxidation-resistant and is excellent in mechanical performance. The layers are closely combined, the molecular chain is fully gummed, the intensity is high, and the elasticity is good.

Owner:昌茂阀门集团有限公司

Composite plastic woven bag self-cleaning composite processing system and composite method thereof

InactiveCN113606915AImprove composite effectGuarantee the firmness of the bondLiquid surface applicatorsDrying gas arrangementsElectric machineDrive shaft

The invention discloses a composite plastic woven bag self-cleaning composite processing system. Before gluing, a plastic woven film material belt penetrates through a processing box, a drying motor is started, the drying motor is used for driving blowing blades and a transmission shaft to rotate, the transmission shaft drives a circulating shaft to rotate, an impeller on the circulating shaft drives cleaning liquid in a cleaning cavity to flow, impurities carried in the cleaning liquid can be retained in a collecting net bag when the cleaning liquid flows through the collecting net bag, the blowing blades drive air flow in an air guide barrel to flow, heat generated through an electric heating wire carried in the air flow is blown to the plastic woven film material belt, the cleaning water on the surface of the cleaned plastic woven film material belt is dried up, the surface of the plastic woven film material belt is cleaned in time, when the surface of the cleaned and dried plastic woven film material belt is glued, the bonding firmness between glue and the plastic woven film material belt can be guaranteed, and the compounding effect of the plastic woven film material belt is improved.

Owner:袁娜

Absorbent material roller cutting equipment for CNC adult diaper production line

InactiveCN105943246BEasy to separateExtended service lifeSevering textilesAbsorbent padsProduction lineNumerical control

The invention belongs to the technical field of hygienic product production. An absorbing material rolling-cut device of a numerical control adult paper diaper production line comprises an absorbing core transport unit, a surface film transport unit, a base film transport unit, a hot glue laminating unit, and a rolling-cut unit. The rolling-cut unit comprises a male die cutting roller and a bottom die cutting roller. The surface of a roller body of the male die cutting roller is provided with a male die. The surface of the roller body of the bottom die cutting roller is provided with a die cavity. The side edge of the male die is provided with a right cutting edge. The side edge of the die cavity is provided with a left cutting edge. The device can realize uniform mixing and atomization of an emulsifying sizing material under action of high pressure gas, so gas and liquid are fully mixed and blended, so as to show atomization uniform spraying in a certain region, and a rolling-cut structure is further optimized. Thus, the rolling-cut technology of the absorbing material of the paper diaper is further improved, and uninterruptable continuous production of a whole numerical control adult paper diaper production line is realized.

Owner:QUANZHOU ZHIZAOZHE MECHANICAL EQUIP CO LTD

An automatic glue injection equipment when producing led lights

ActiveCN111203367BImprove work efficiencySmooth rotationLiquid surface applicatorsCoatingsInjection equipmentEngineering

The invention discloses an automatic glue injecting device for LED lamp production, and relates to the technical field of LED lamp devices. The device mainly solves the problems of inconvenience during LED lamp production, inconvenience for glue injecting through glue injecting needle cylinders and over-low working efficiency. The device mainly comprises a rotating conveying belt, and a limiting mechanism, a pushing mechanism, a feeding and discharging mechanism, an automatic glue injecting mechanism and a rotating mechanism are arranged on the rotating conveying belt. According to the device,LED lamp containing trays are placed on fixing tables, the rotating conveying belt drives the LED lamp containing trays to pass through the positions below the glue injecting needle cylinders and drives winding wheels to rotate, a lifting plate is pulled downwards through connecting wires, glue in the glue injecting needle cylinders is guided to the LED lamp containing trays through glue injecting heads, and glue injecting is carried out; and when the fixing tables move, the LED lamp containing trays can be driven to rotate through meshing of strip-shaped racks and annular racks, and when theLED lamp containing trays pass through the glue injecting needle cylinders again, glue injecting is carried out in another direction. The device has the beneficial effects that glue injecting can berapidly carried out, and the working efficiency is improved.

Owner:ZHEJIANG HAIHONG IND PROD DESIGN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com