Cigarette filter tip assembling machine glue spray system device

A cigarette filter and system device technology, which is applied in spraying devices, devices for coating liquid on the surface, coatings, etc., can solve the problem of poor adhesion of tipping and warping edges, open or warped edges of the interface, and influence on cigarettes Appearance and other problems, to achieve the effect of reducing the preparation time for starting up, preventing water evaporation, and avoiding uneven gluing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention patents a cigarette filter tipping machine glue spraying system device, which directly replaces the original tipping paper glueing structure of the cigarette machine, and the original power transmission system associated with the tipping paper glueing mechanism of the cigarette machine remains unchanged.

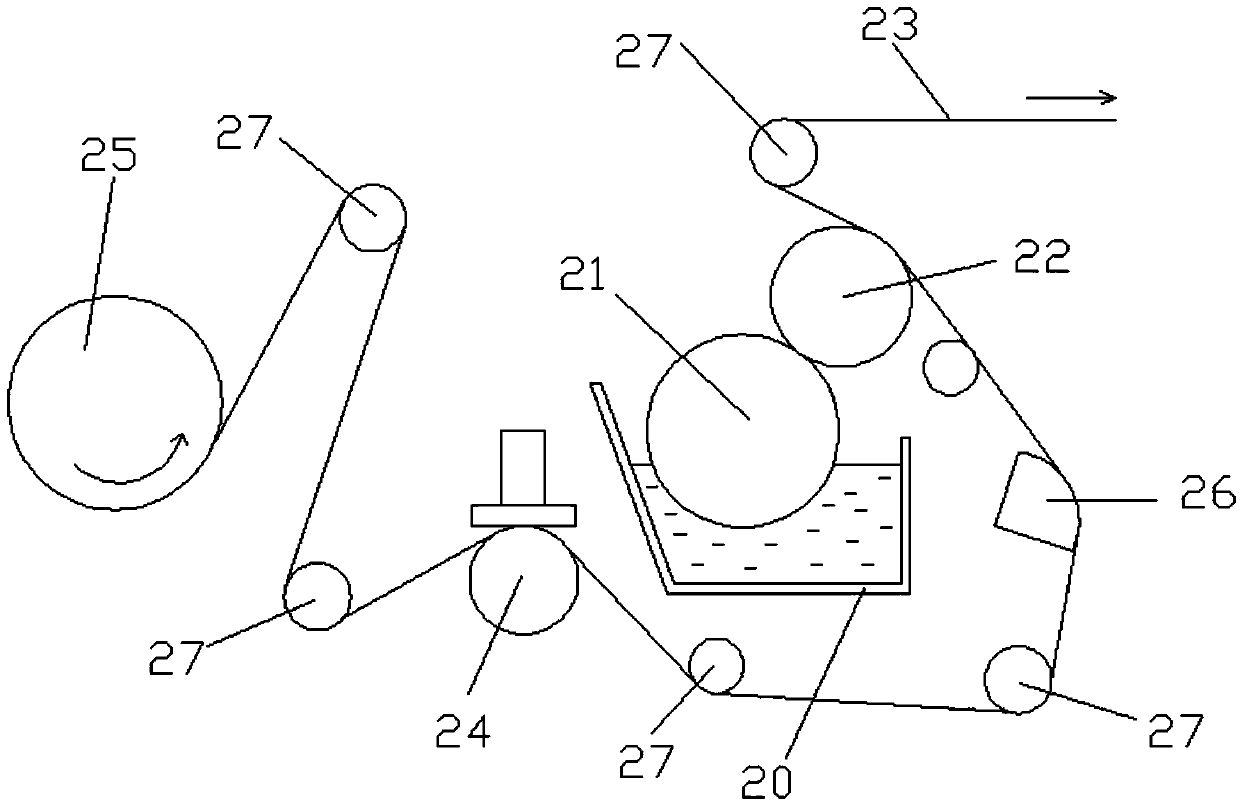

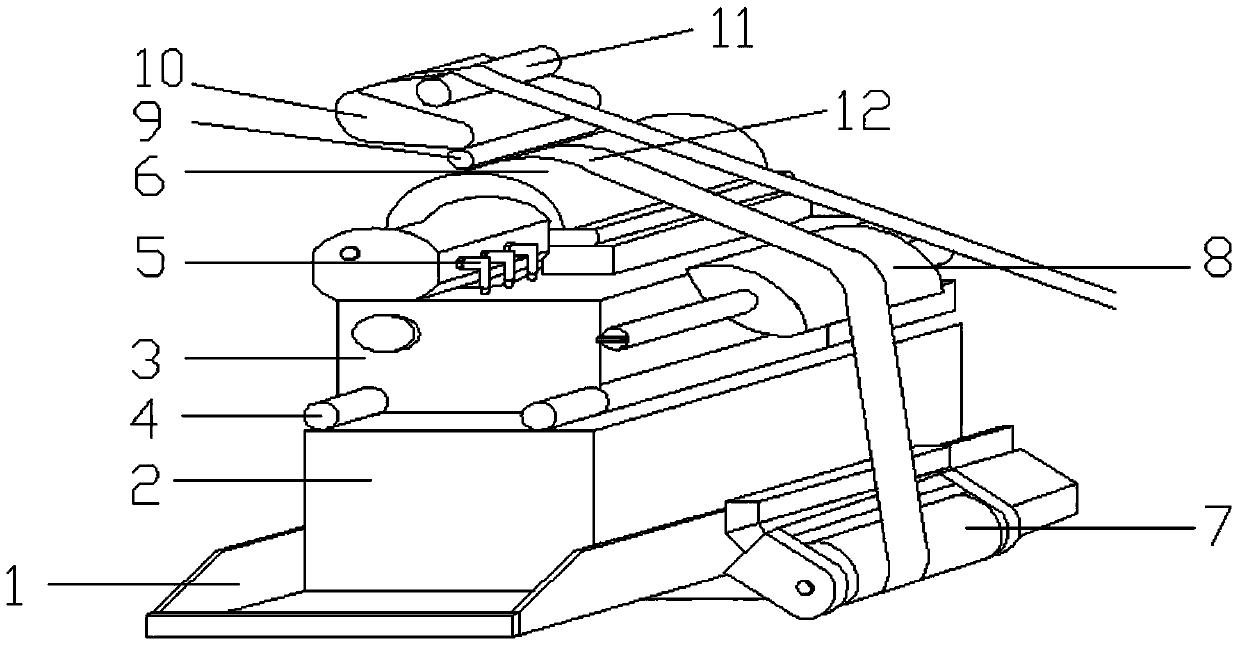

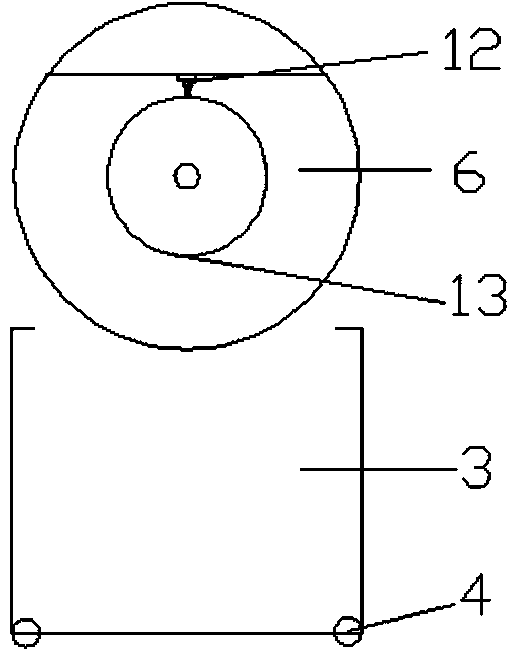

[0019] Such as figure 2 , image 3 , Figure 4 , Figure 5 As shown, the patent of the present invention is a cigarette filter tipping machine glue spraying system device, including a spray head paper roll assembly 6, a glue spray auxiliary system, and a cleaning and maintenance system. The spray head paper roll assembly 6 is a glue spray head 12 and a paper roll 13. Made together, the glue spray head 12 can change its position along with the rotation of the paper roller 13; , the second paper guide roller 9, the second paper guide block 10, the third paper guide roller 11, the rubber pump 2 is fixed on the base 1, the first paper guide block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com