Patents

Literature

111results about How to "Improve effective operation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

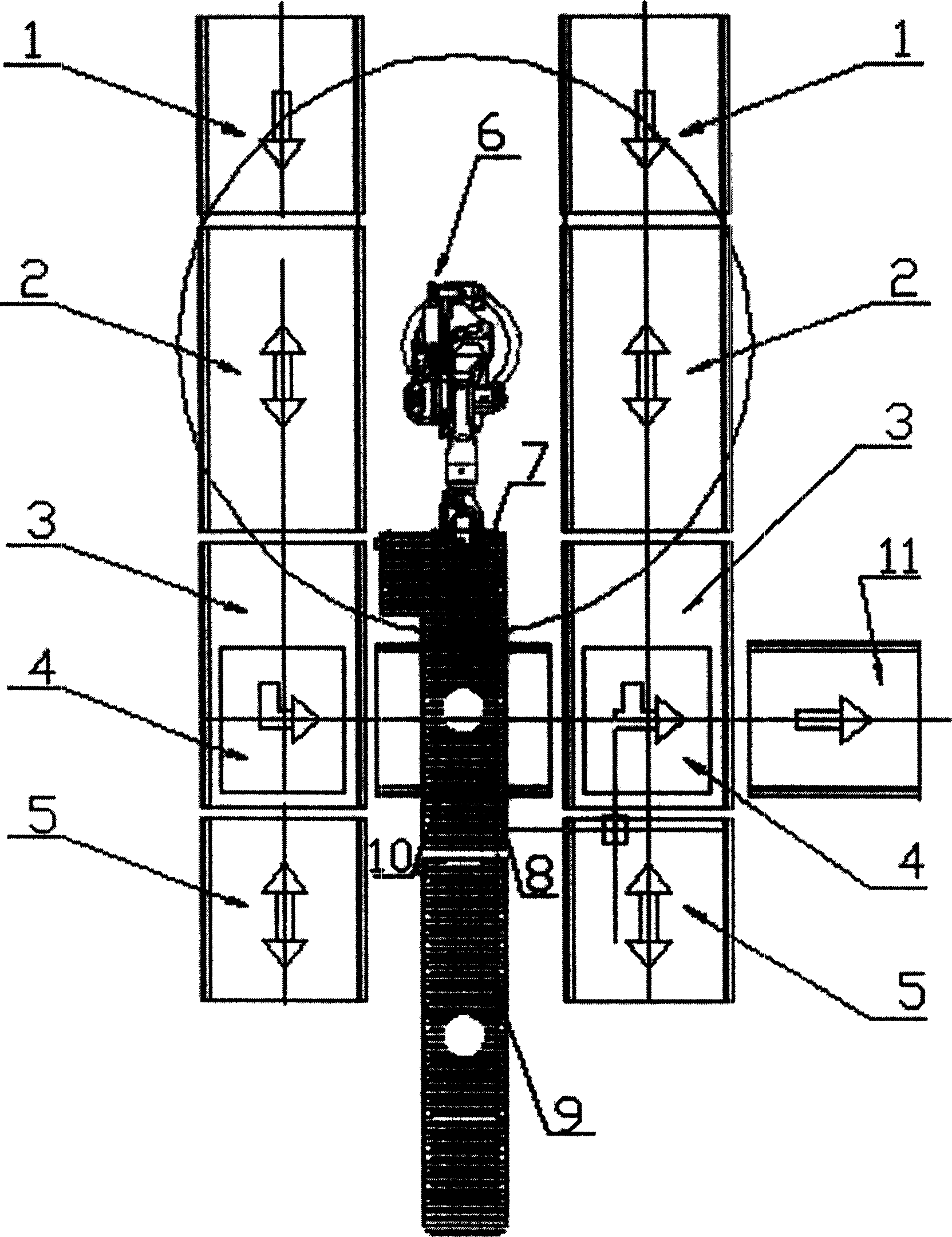

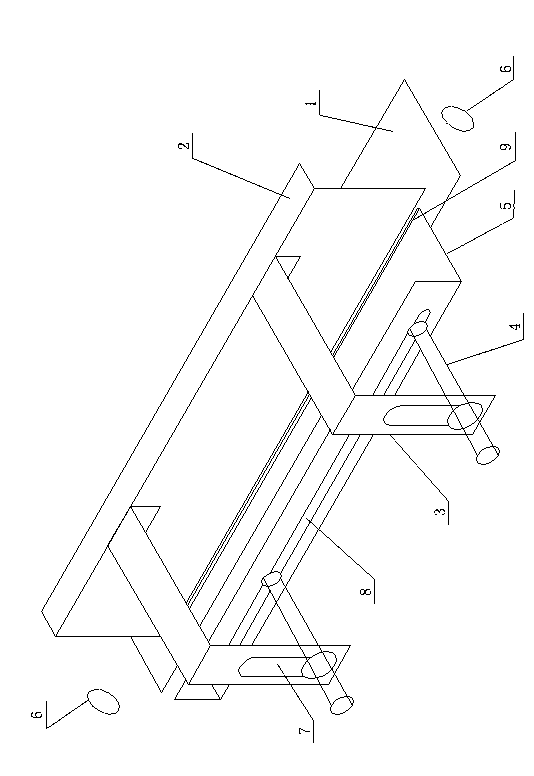

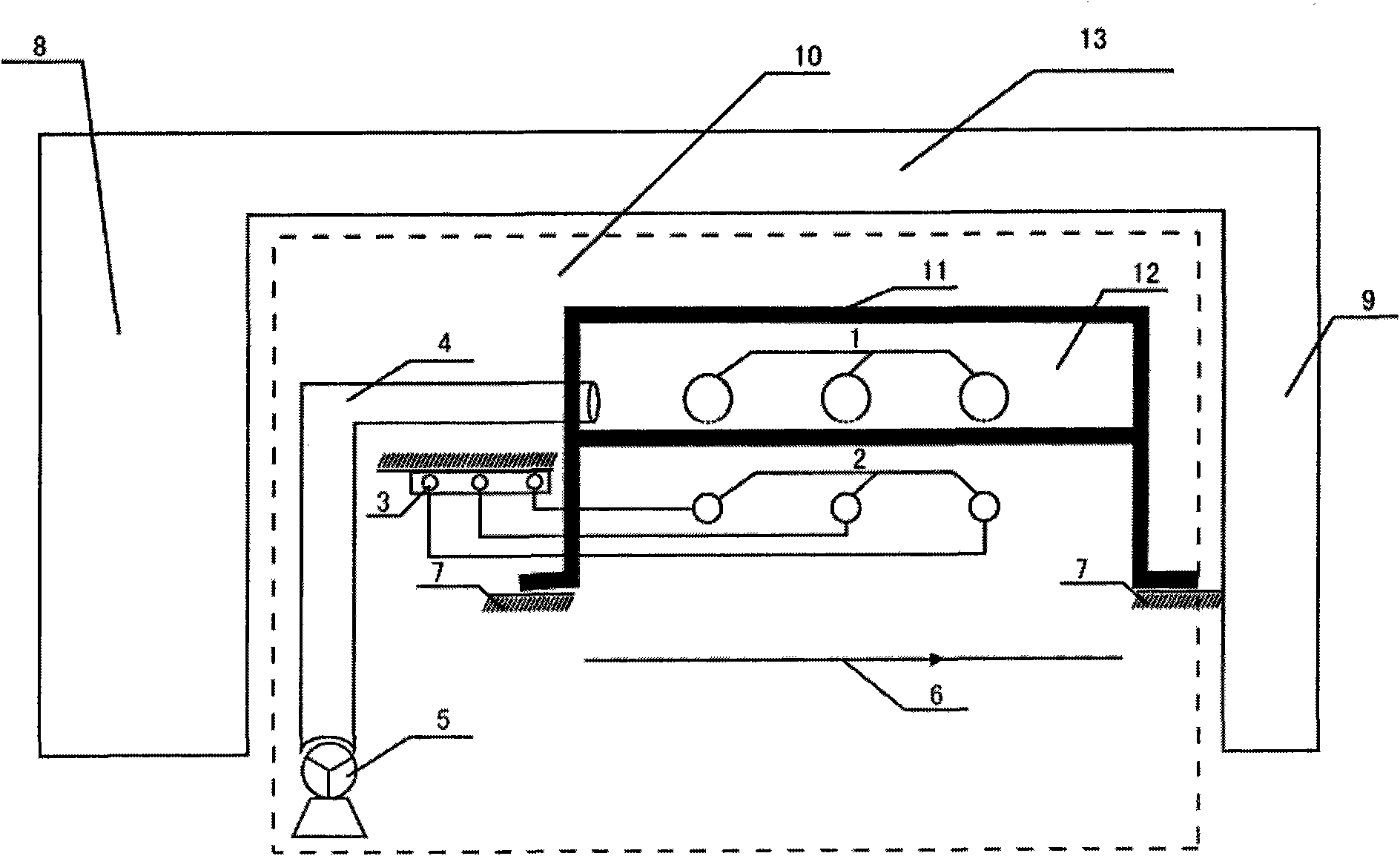

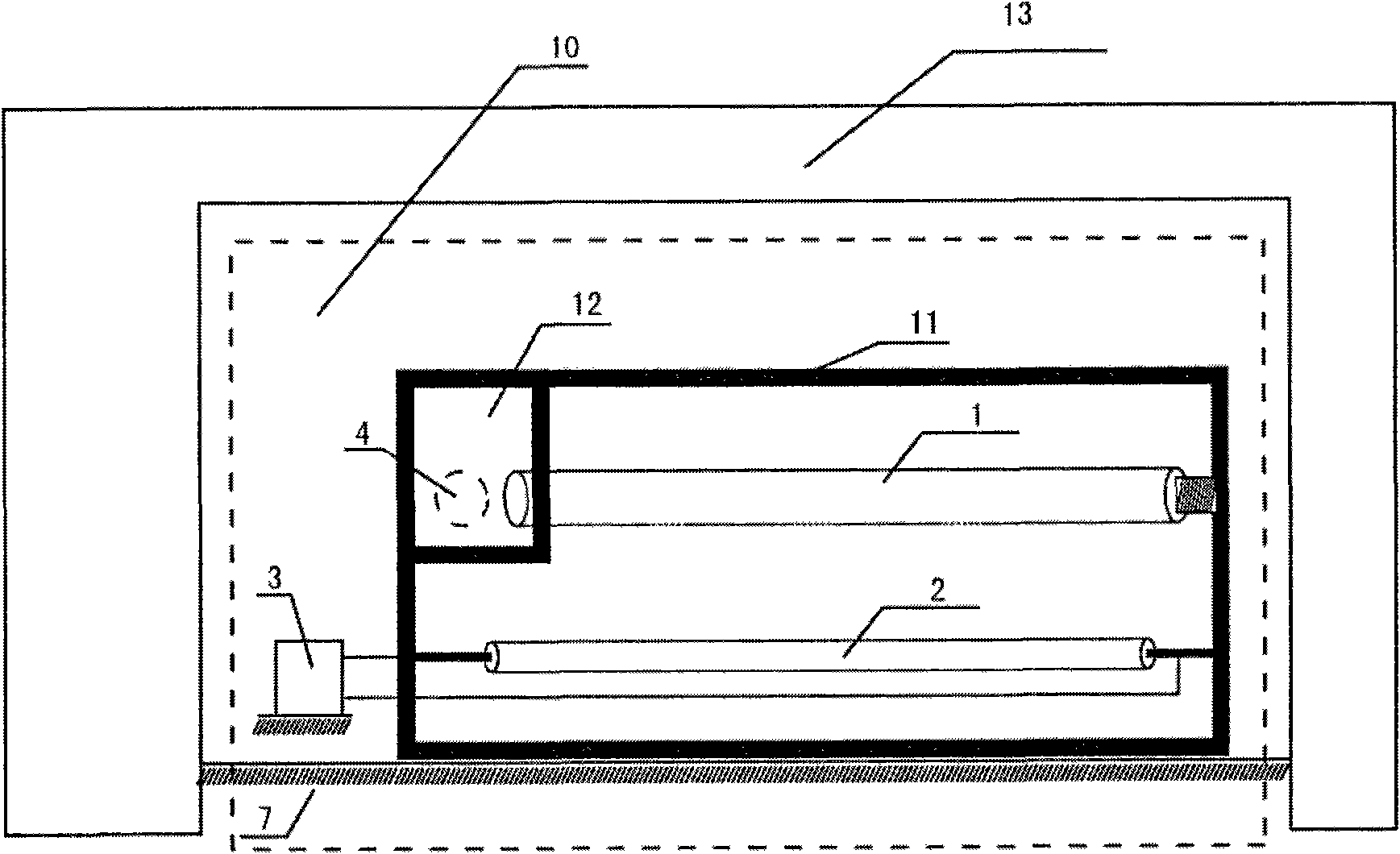

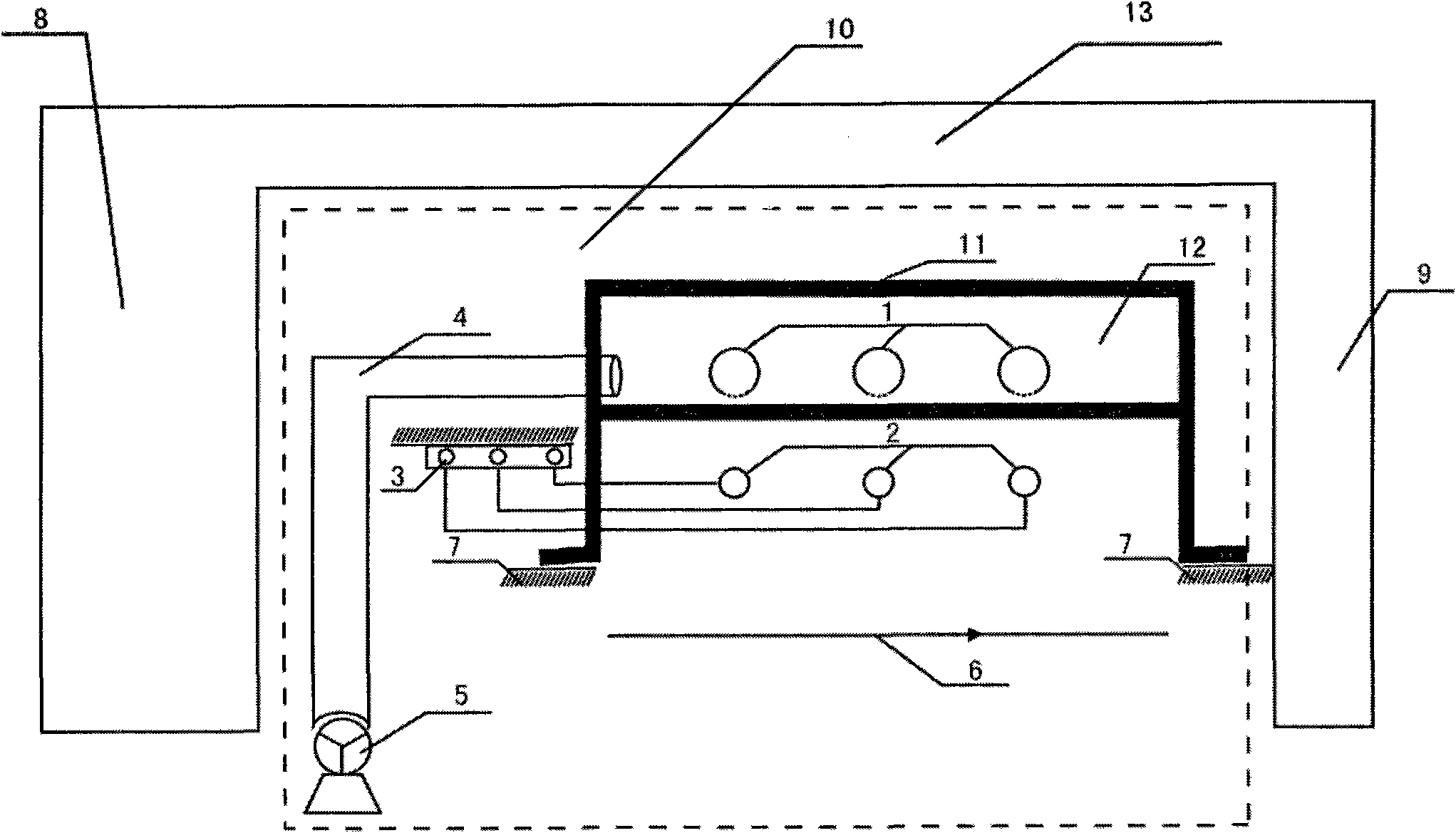

Fall apart tray treatment system in smoke box solid tray stack disassembling process

InactiveCN1590256AAvoid inefficient workImprove effective operation rateDe-stacking articlesConveyor partsCartonEngineering

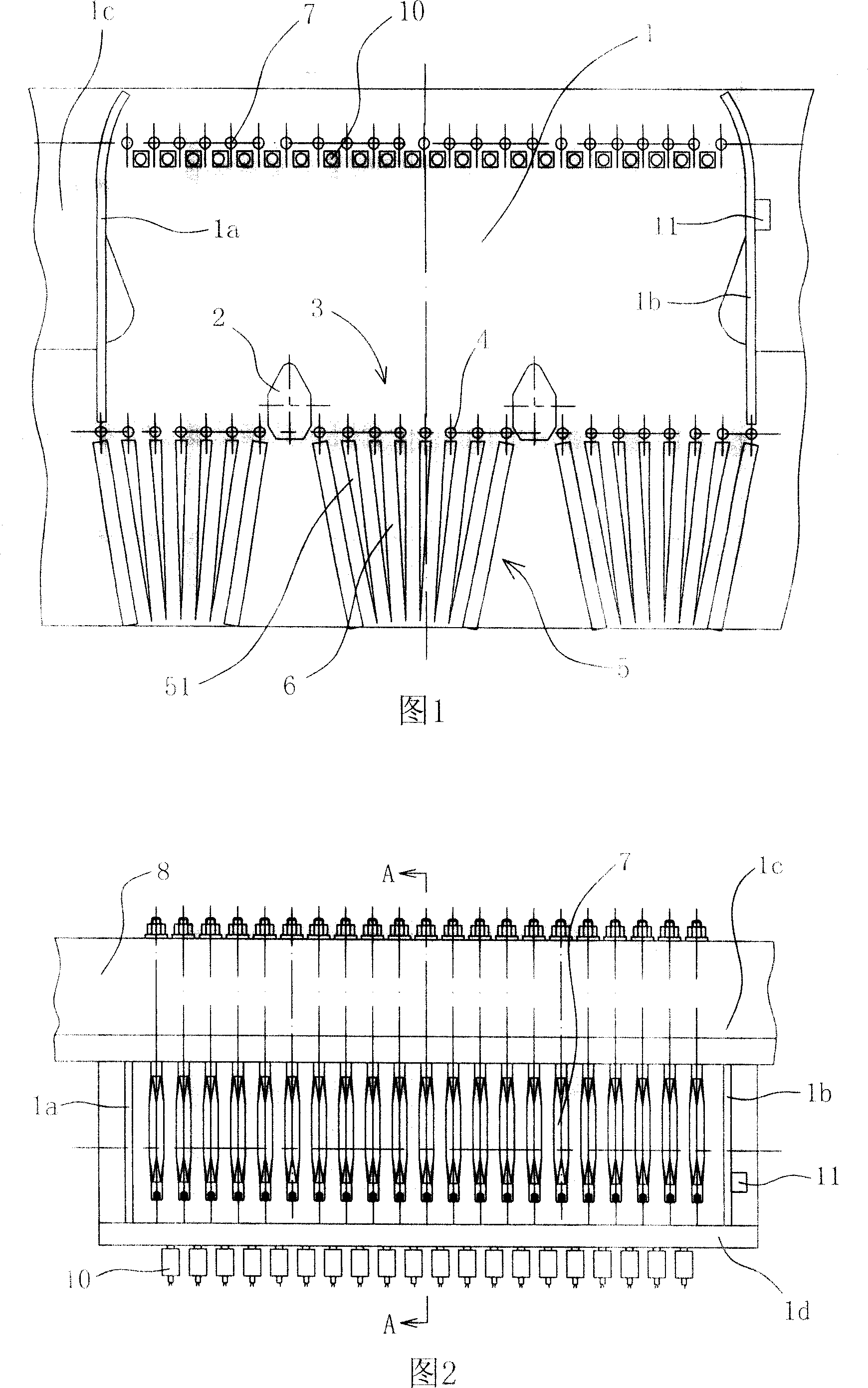

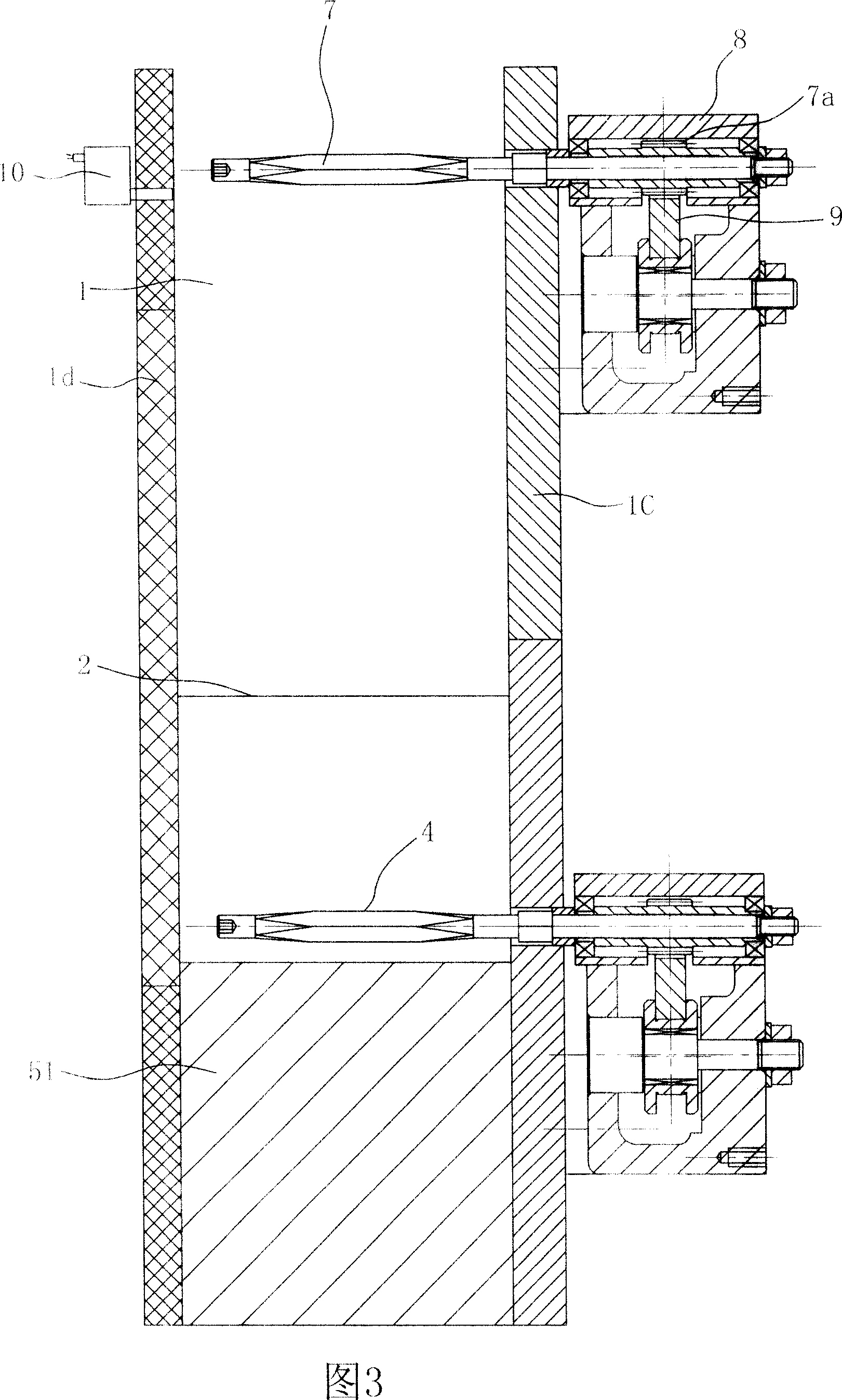

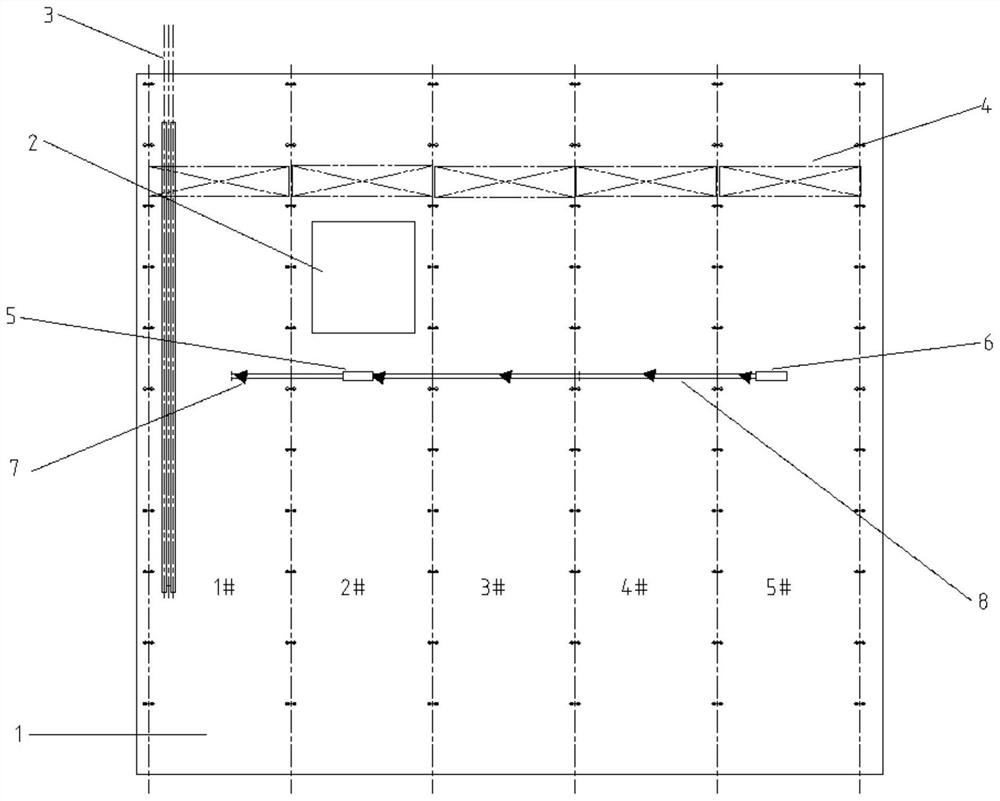

An idle pallets treating system used in detaching the stack of cigarette cartons is composed of a chain conveyer, the chain conveyer for the stack-detaching position, the chain conveyer for idle pallet channel, robot, the roller conveyers for cigarette cartons, and the chain conveyer for idle pallet. It features that a chain conveyer for the temporary storage position and a bidirectional chain conveyer used as the storage position of idle pallets are additionally used.

Owner:云南紫金科贸有限公司

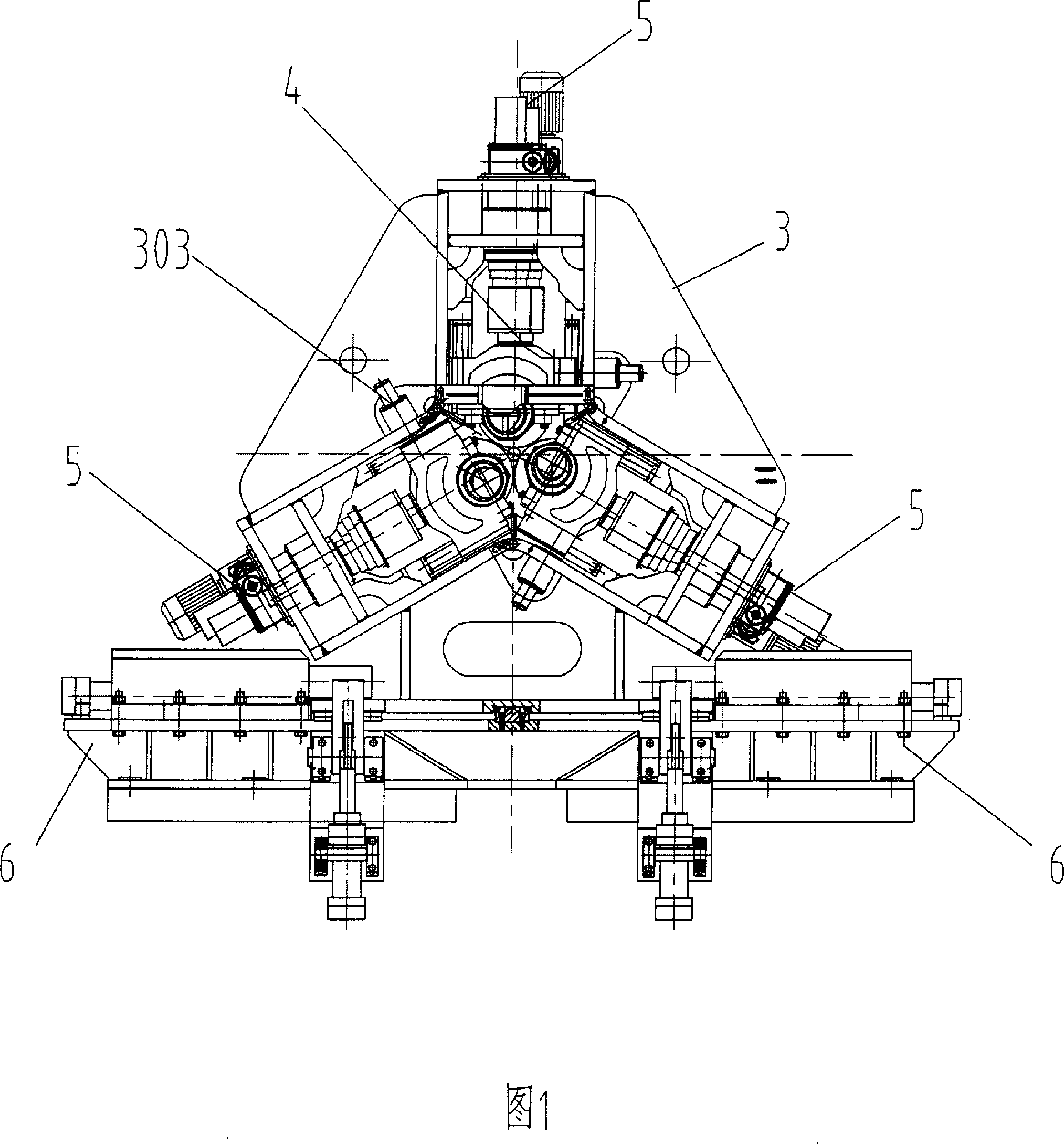

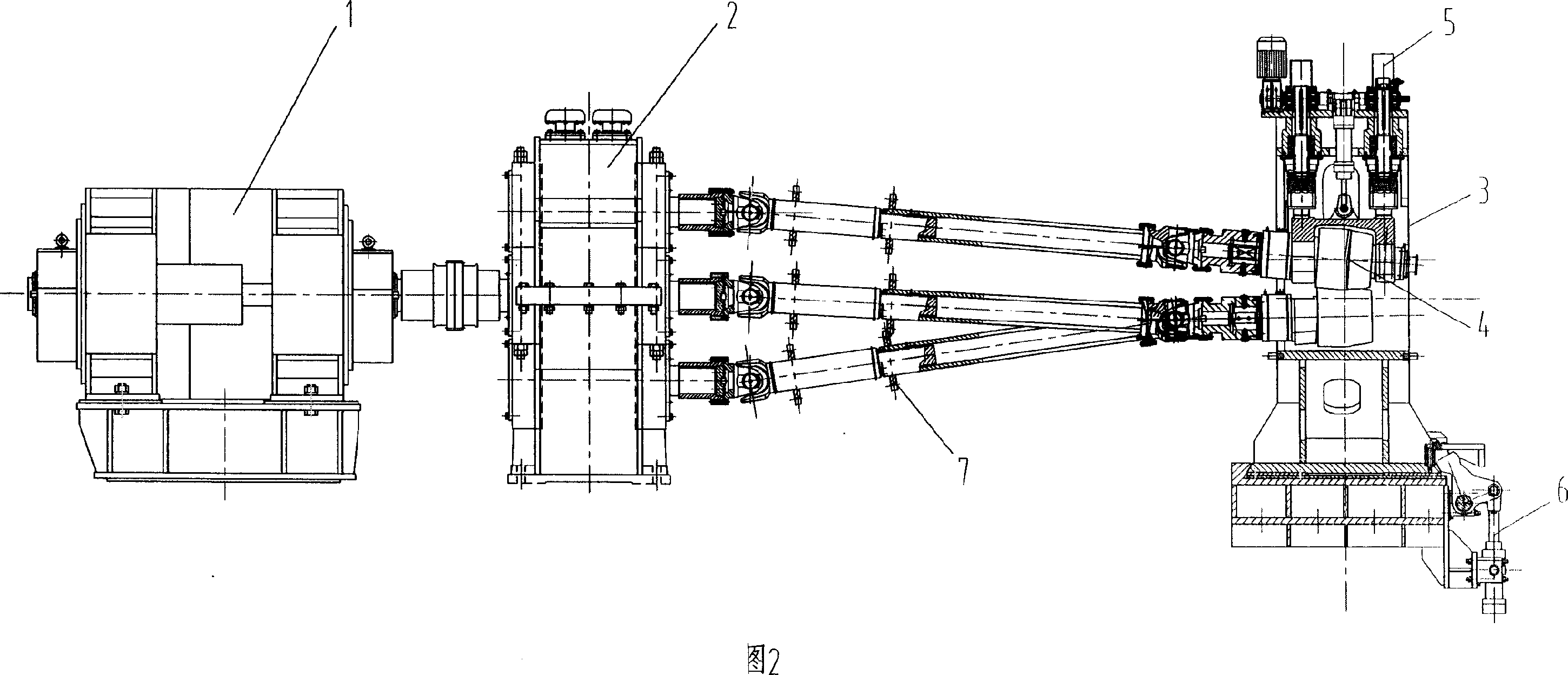

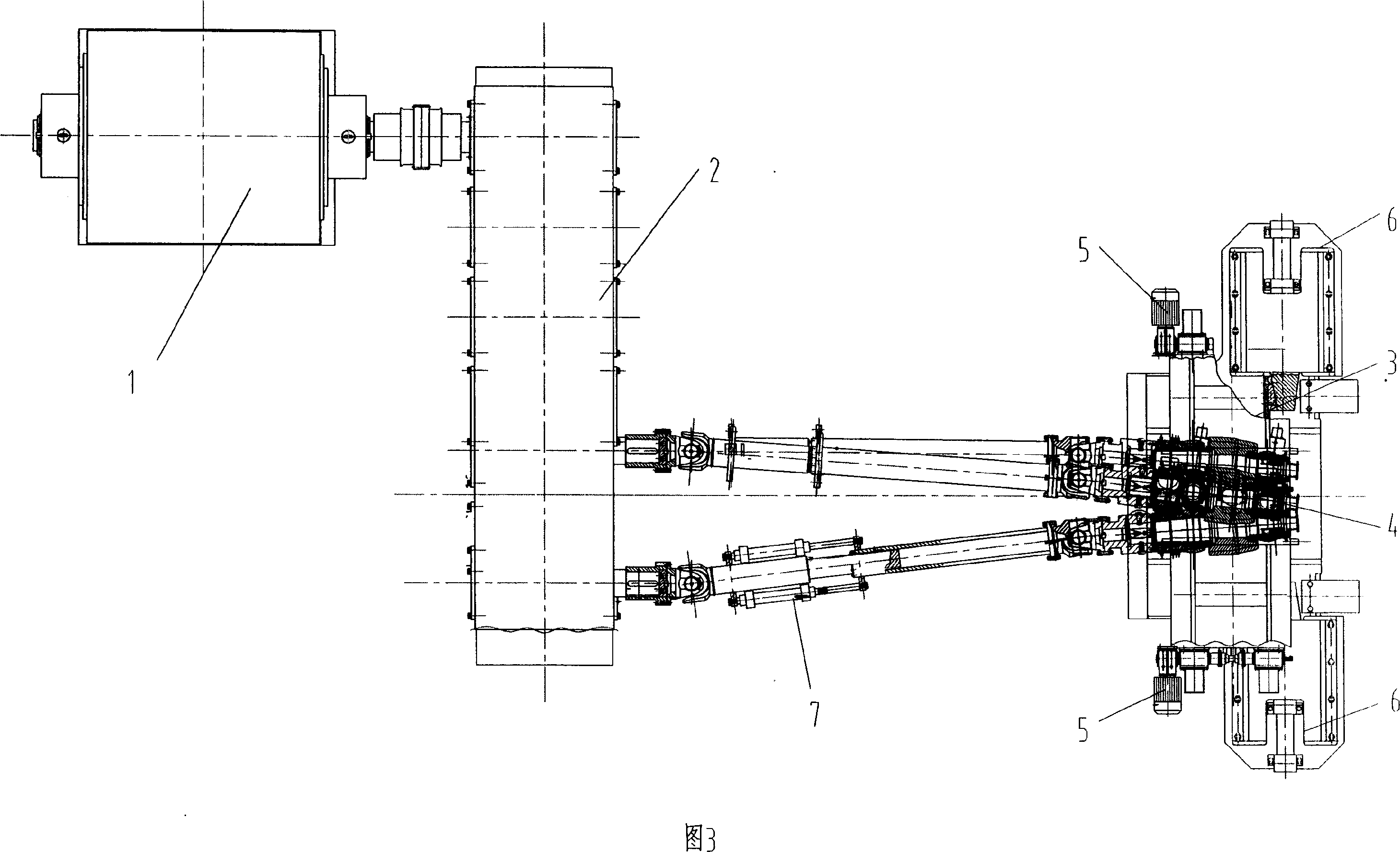

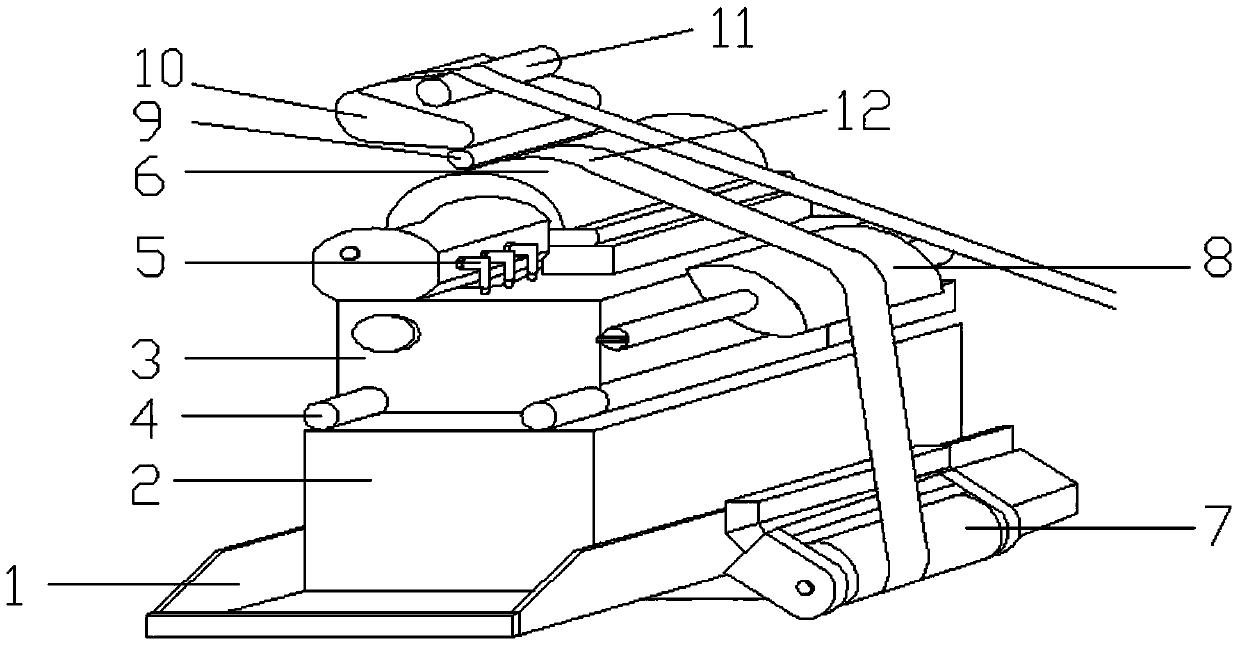

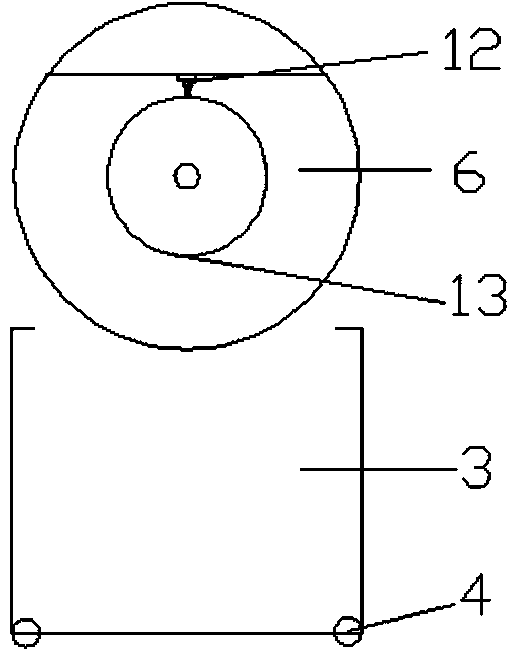

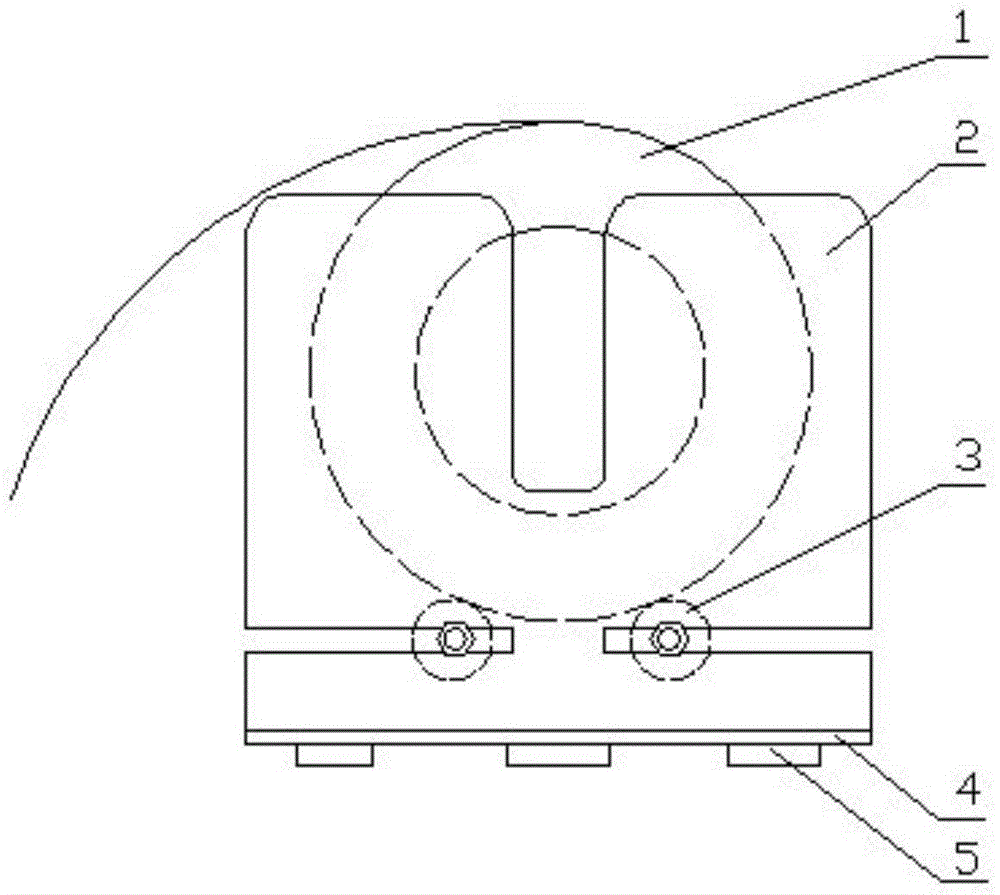

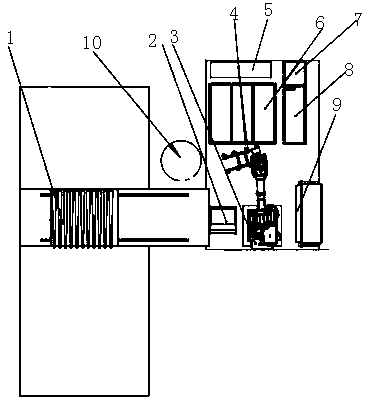

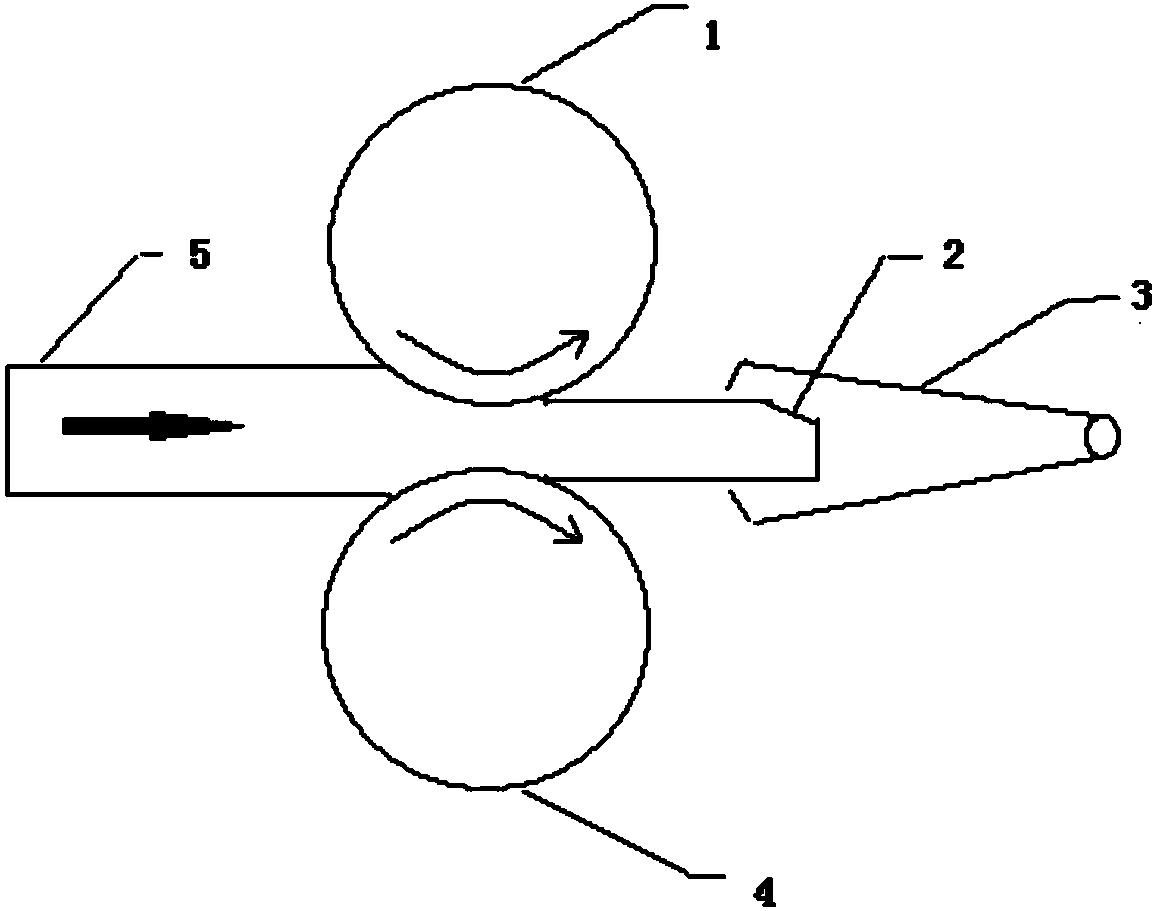

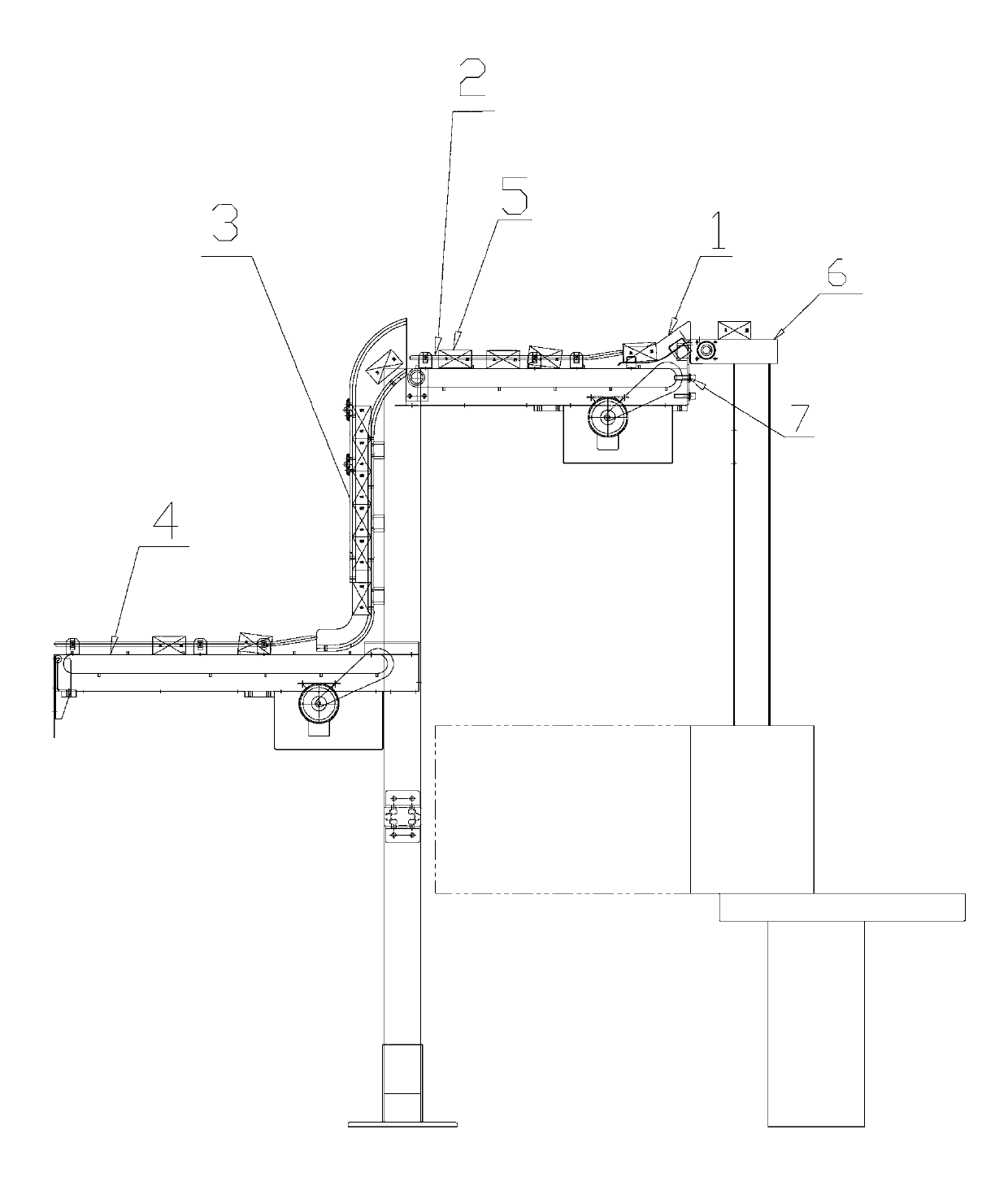

Three-roller pipe rolling apparatus

ActiveCN1981948AOvercome the tail triangle defectConvenience guaranteedMetal rolling stand detailsRollsPush pullEngineering

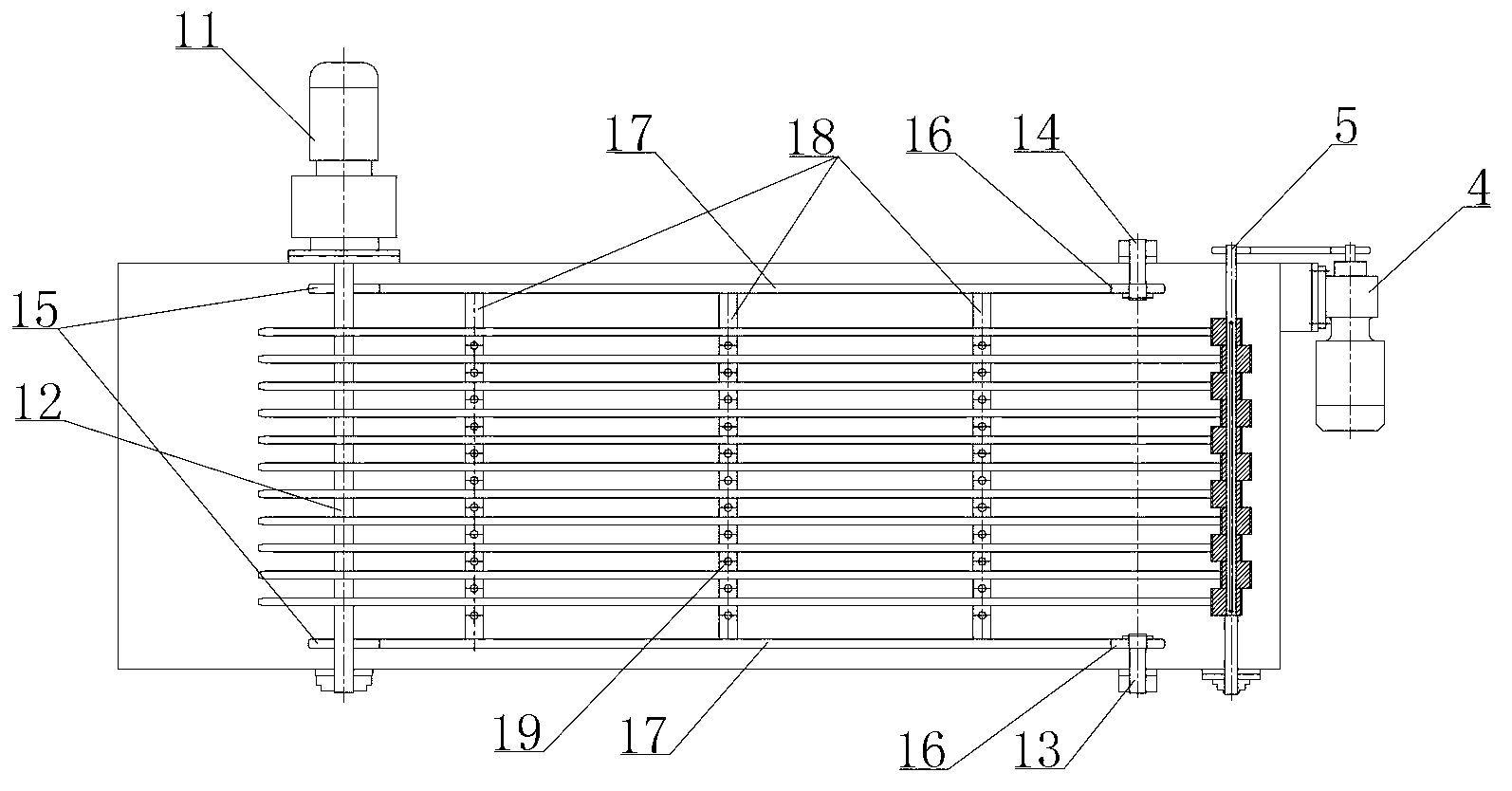

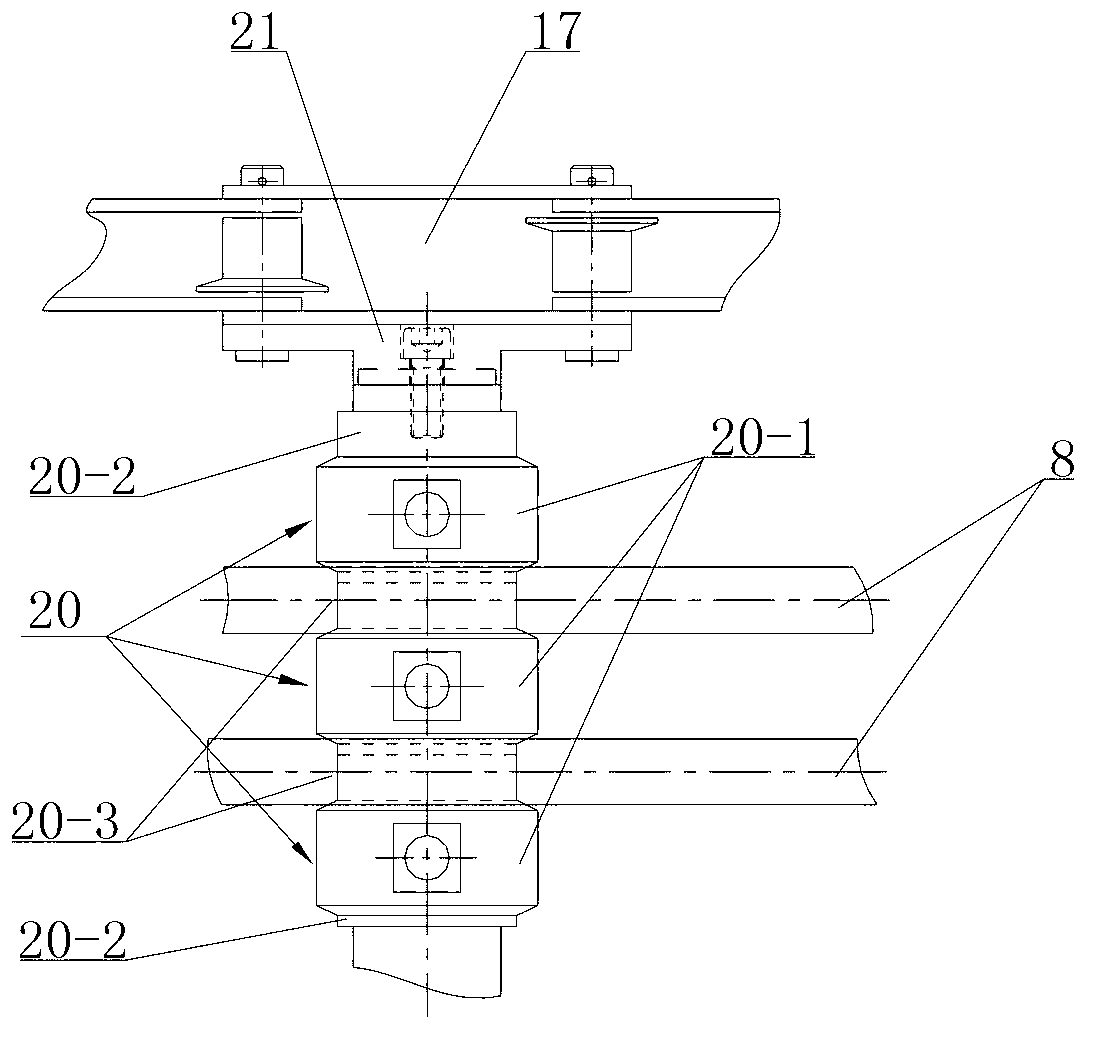

A 3-roller tube rolling mill is composed of a base, a closed machine frame with hydraulic push-pull and locking unit and lubricating tube, a motor, three roller units, three roller drive and balance regulators an electric controller.

Owner:TAIYUAN TONGZE HEAVY IND

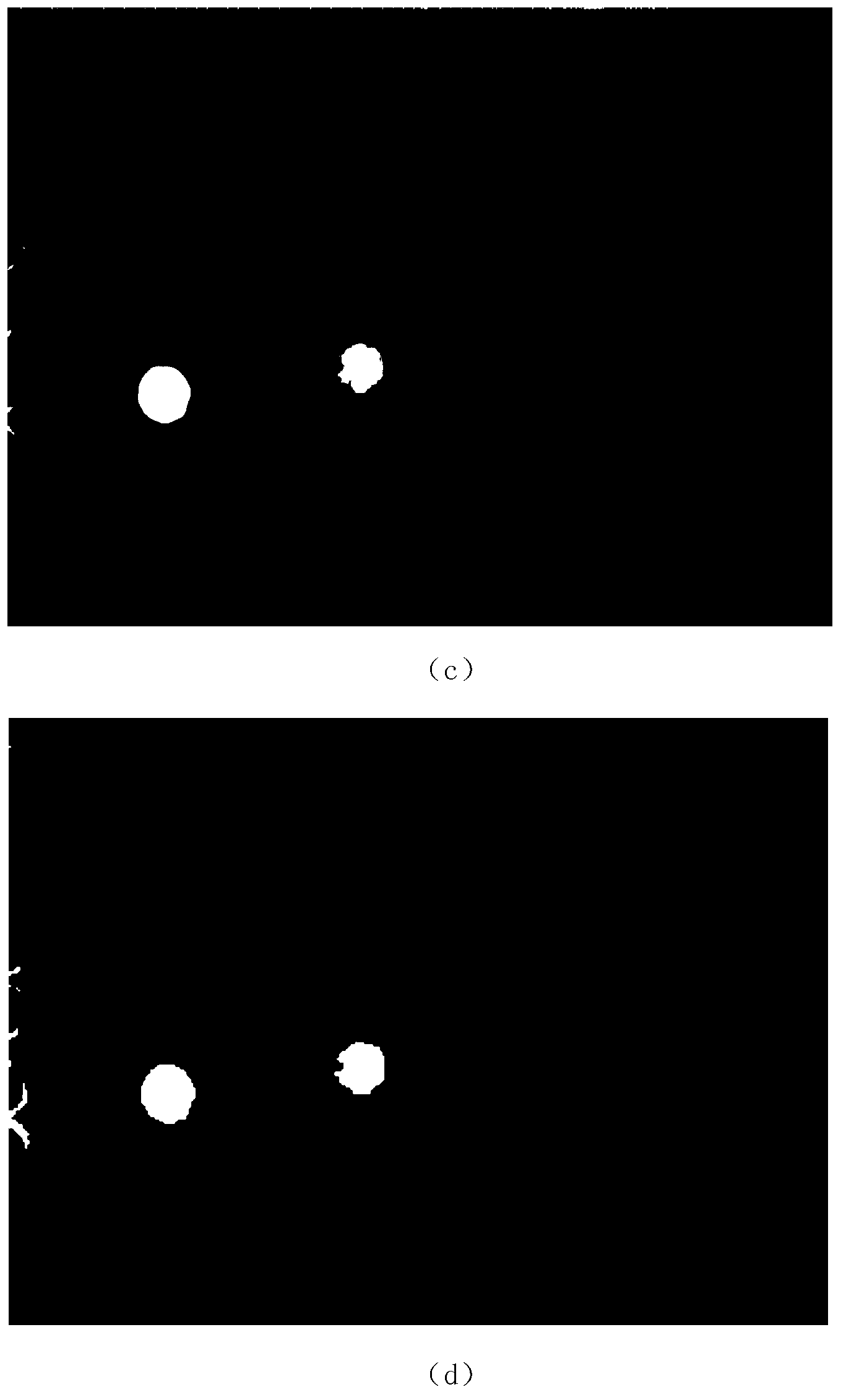

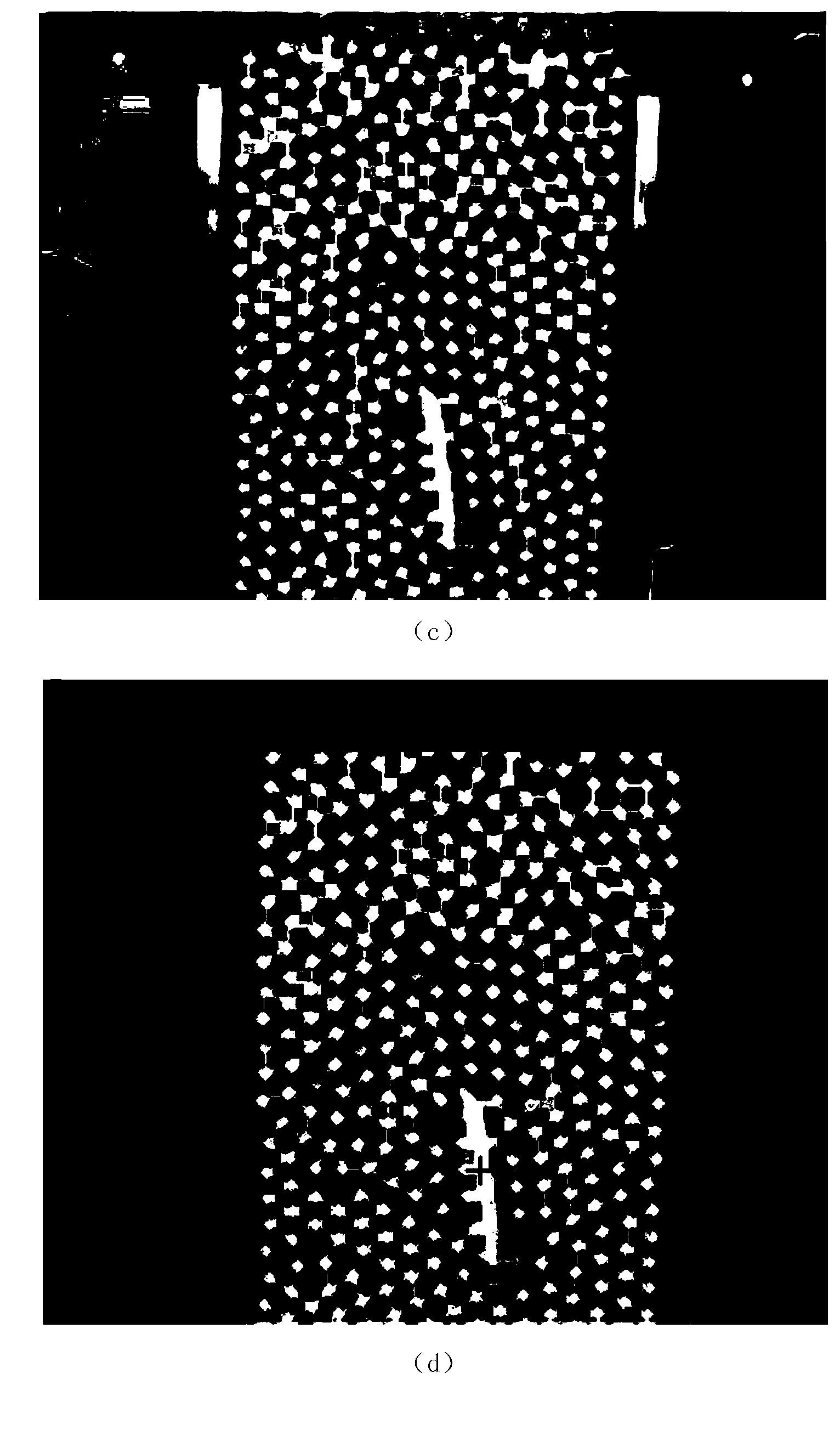

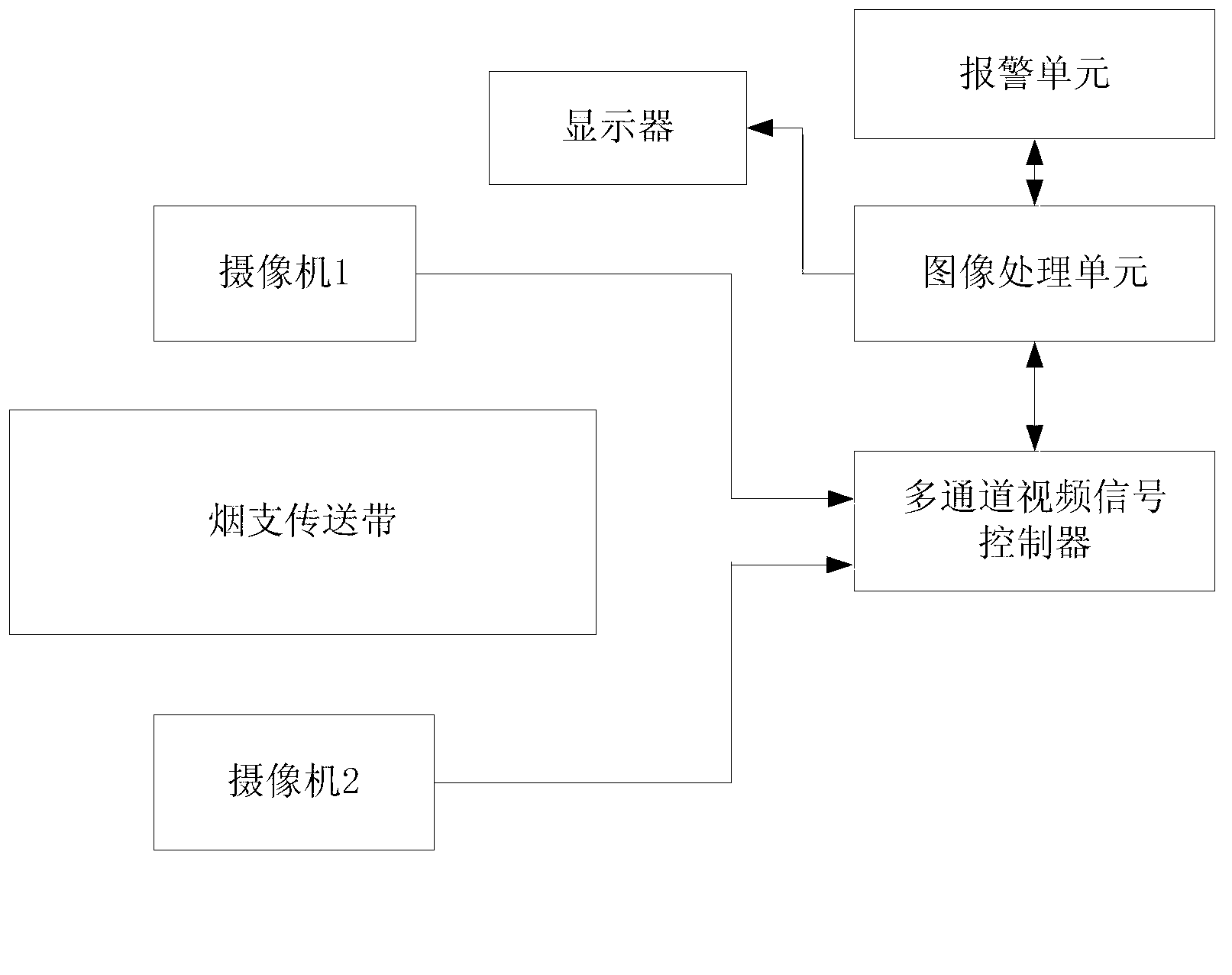

System and method for detecting arrangement confusion and inverted arrangement of cigarettes in cigarette warehouse

ActiveCN103010531AFully automatedRelease energyPackaging automatic controlImaging processingDisplay device

The invention discloses a system and a method for detecting arrangement confusion and inverted arrangement of cigarettes in a cigarette warehouse. The system comprises an image acquisition unit, a display, an image processing unit, a multichannel video signal controller and an alarm unit; both the display and the image processing unit are connected with the image acquisition unit; and both the multichannel video signal controller and the alarm unit are connected with the image processing unit. The method comprises the following steps of: carrying out gray processing on cigarette arrangement images acquired by the detection system. carrying out pixel statistics on each white connected domain in the images which are subjected to corrosion and expansion processing, and obtaining a pixel area value S; comparing the S with a cigarette end pixel area M in a cigarette image of cigarettes which are normally arranged; judging whether the cigarettes in the current image are abnormal; and timely triggering alarm. The integral system has a simple structure and is low in cost; the cigarette arrangement detection method on the basis of the system is simple and efficient; labor intensity of workers is reduced; detection efficiency is improved; and detection on invertedly arranged cigarettes fills up a gap of cigarette packaging equipment.

Owner:CHINA TOBACCO HUNAN INDAL CORP

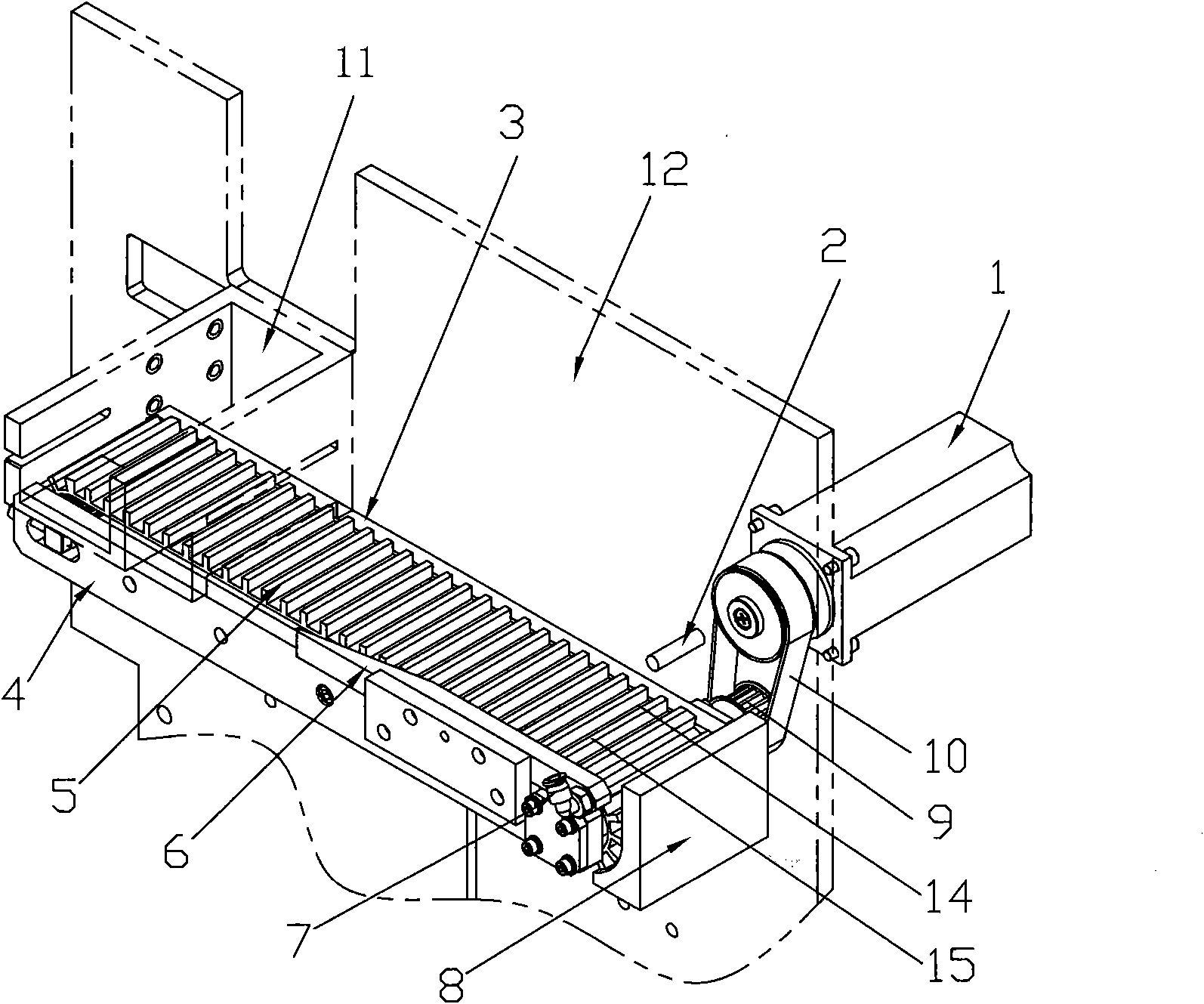

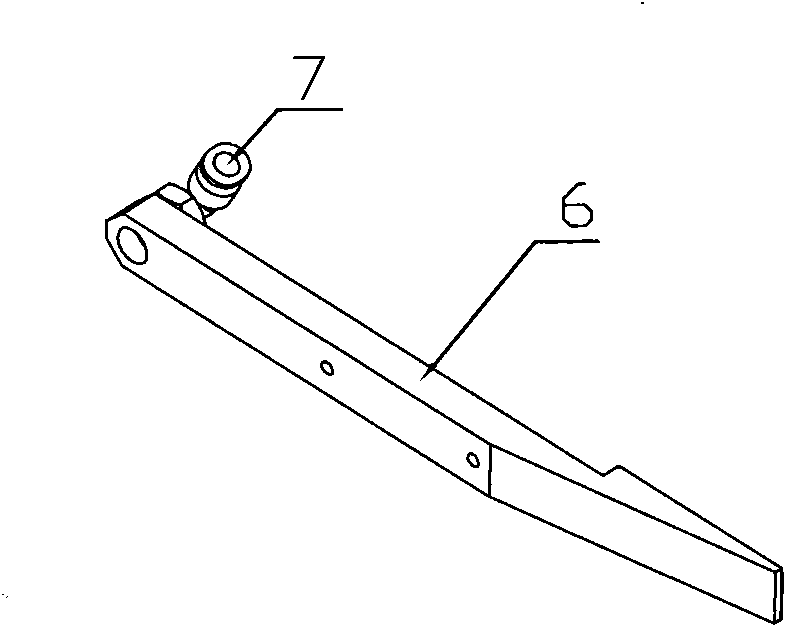

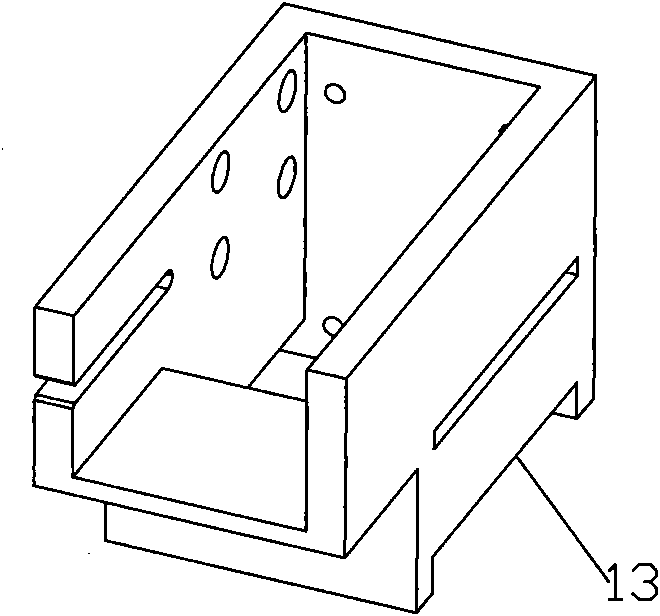

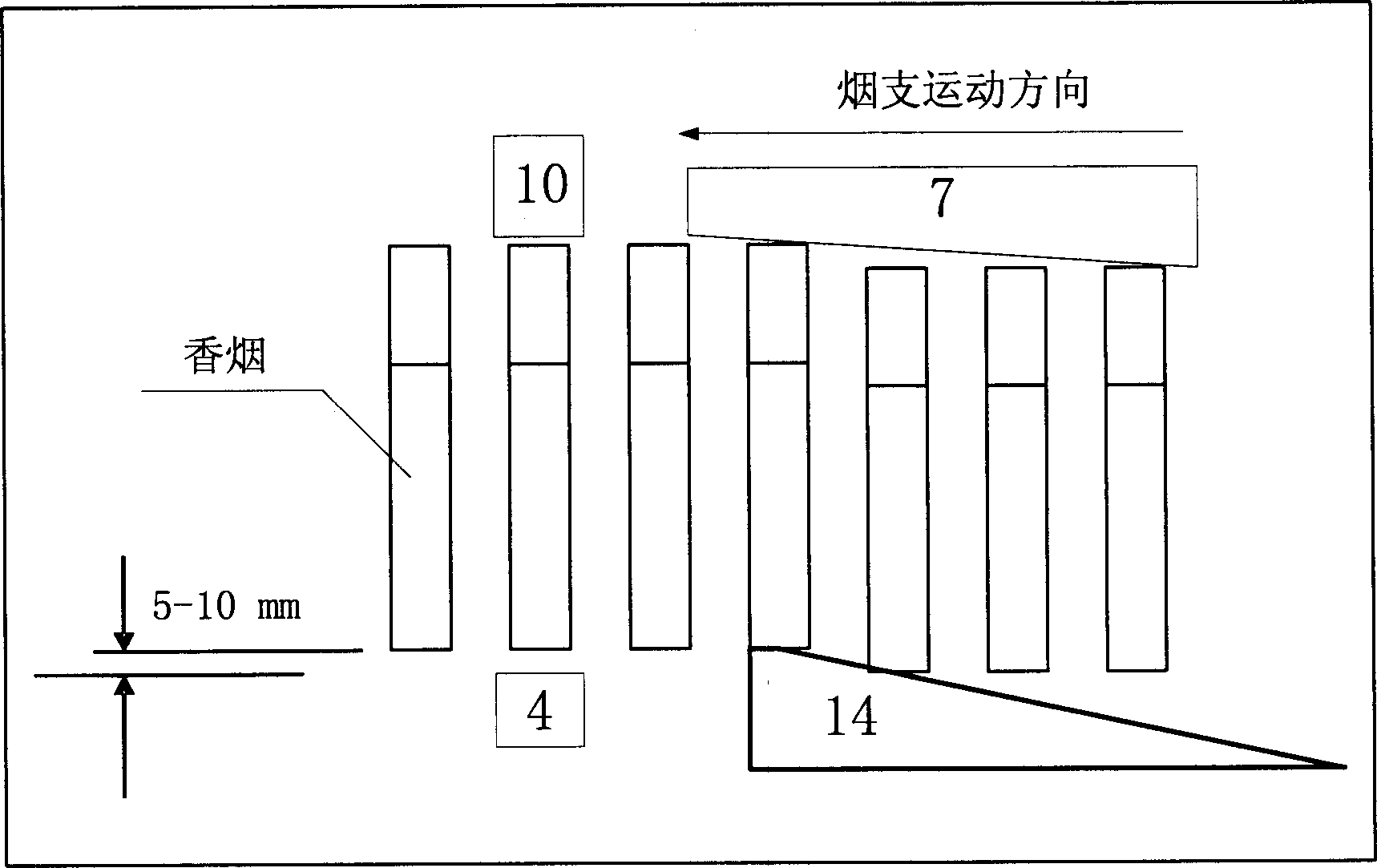

On-line detection and rejection device for cigarette packaging machine to reject cigarette

InactiveCN102431668AOrderly rowsReduce wastePackaging cigarettePackaging cigarsDrive shaftEngineering

The invention discloses an on-line detection and rejection device for a cigarette packaging machine to reject cigarettes and belongs to the technical field of cigarette making machines. The on-line detection and rejection device comprises a detection belt, a drive motor, a baffle, a wedge-shaped stop dog, side plates arranged on two sides of the detection belt and a hollow-head detection sensor, wherein a motor output shaft and the drive shaft of the detection belt are connected by virtue of a driving belt; one end of the detection belt is positioned below the smoke outlet of a baiting hopper; the other end of the detection belt is provided with the baffle; the side plate on one side of the detection belt is provided with the wedge-shaped stop dog; the end part, adjacent to the baffle, of the wedge-shaped stop dog is provided with a rejection air tap; and the part, which corresponds to the wedge-shaped stop dog, of the side plate on the other side is provided with the hollow-head detection sensor. According to the on-line detection and rejection device, hollow-head cigarettes in the baiting hopper of a recovery plant can be detected and rejected to reduce waste in the cigarette package and improve the effective operation rate. In addition, a plurality of cigarettes can be simultaneously discharged so as to improve the detection and rejection efficiencies.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

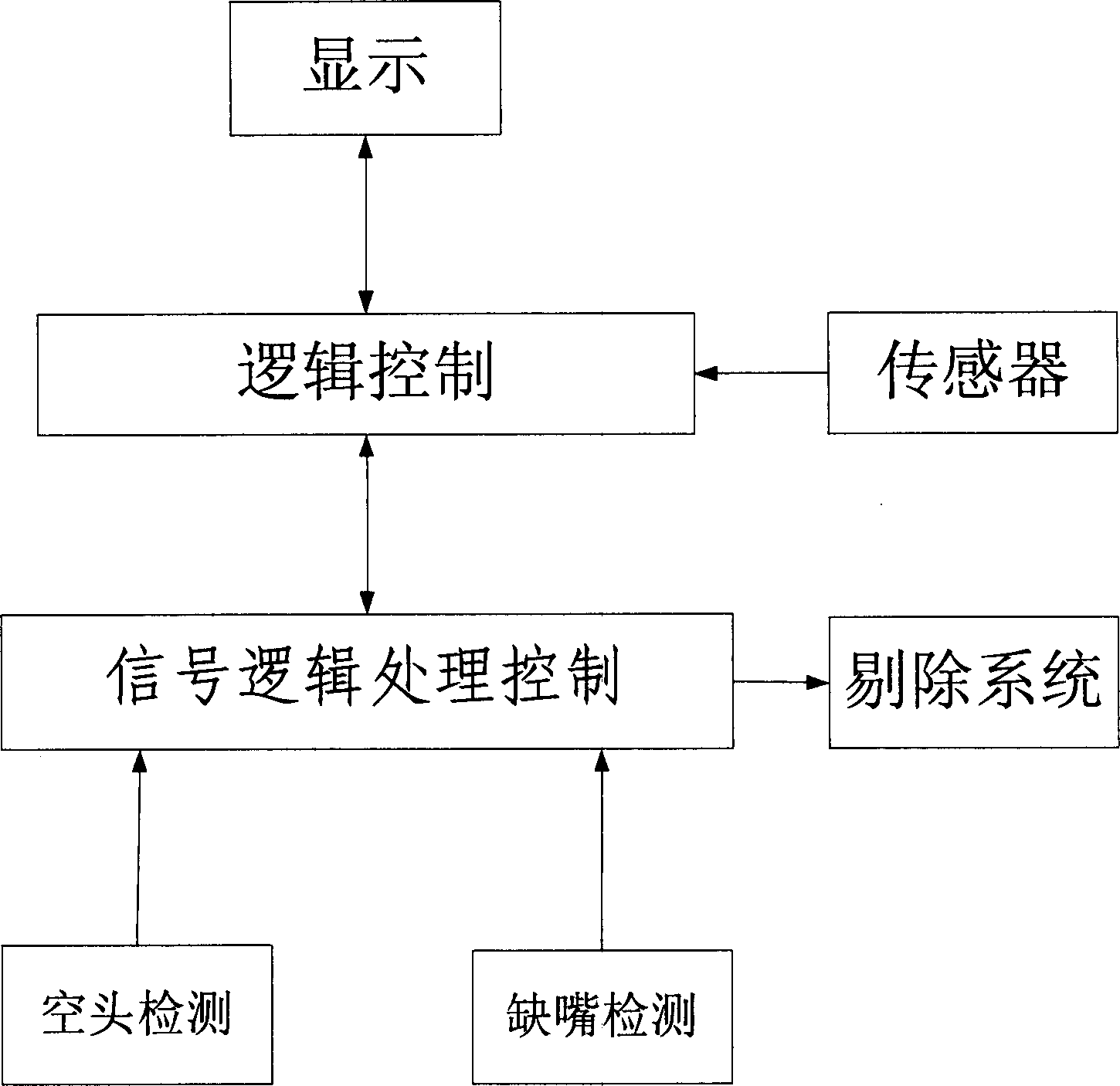

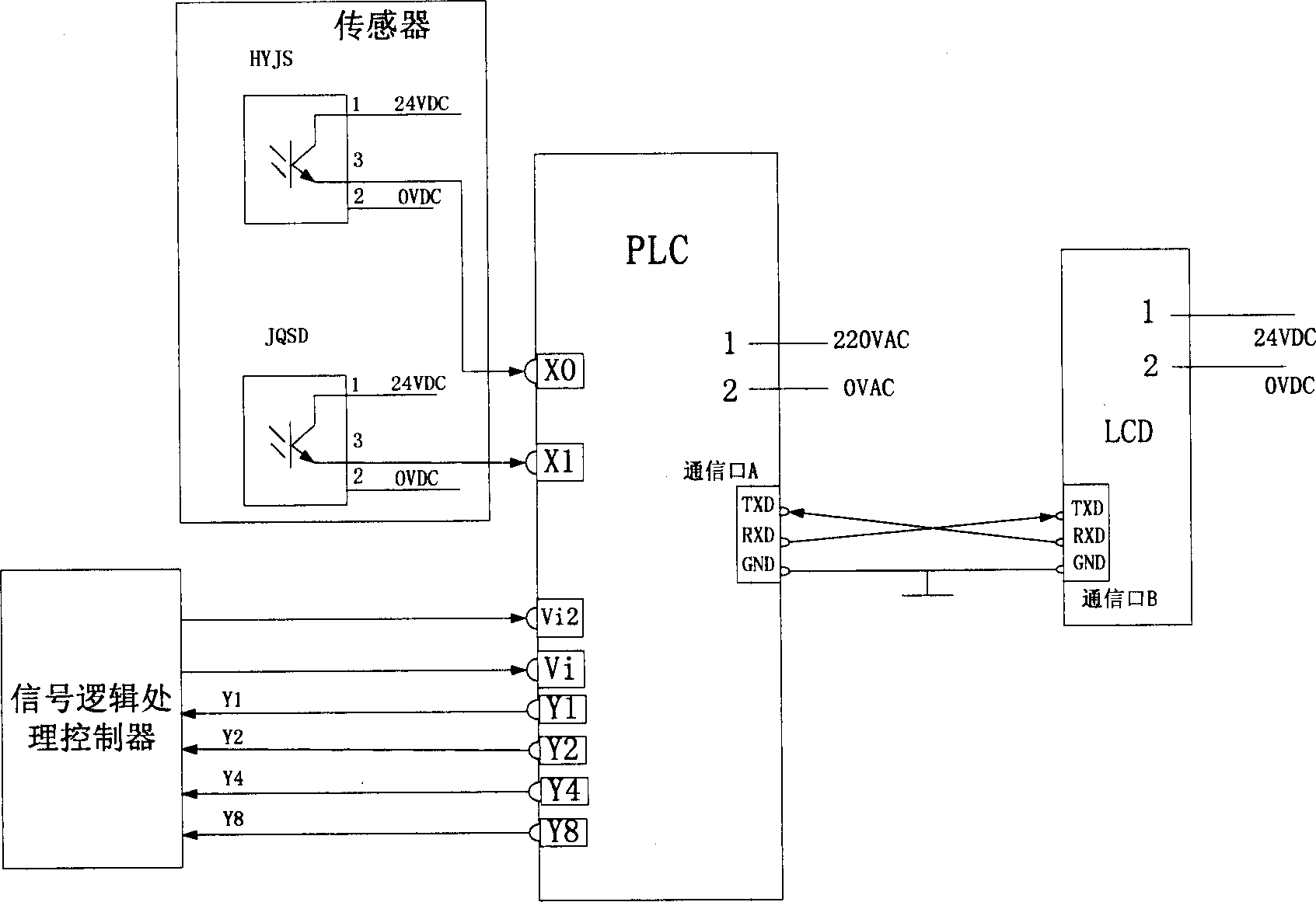

Cigarette quality on-line detecting device of cigarette machine

InactiveCN1788634AReduce complexityImprove stabilityCigarette manufactureElectric cablesEmbedded system

The on-line cigarette quality detection set includes one electric part and one mechanical part. The electric part includes a display and a logic control unit connected via serial shielded communication cable and as the kernels, as well as a signal acquiring system and a signal logic treating and controlling unit. The signal logic treating and controlling unit comprising signal logic treating and controller receives the signal from the signal acquiring system and has output connected to the logic control unit and an eliminating system. The signal acquiring system consists of an empty head detecting unit and a no-filter tip monitoring unit and a sensor. The eliminating system is the mechanical part including an eliminating drum unit and a sensor installing unit. The present invention can eliminate cigarettes with loose head or no filter tip to raise cigarette quality.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

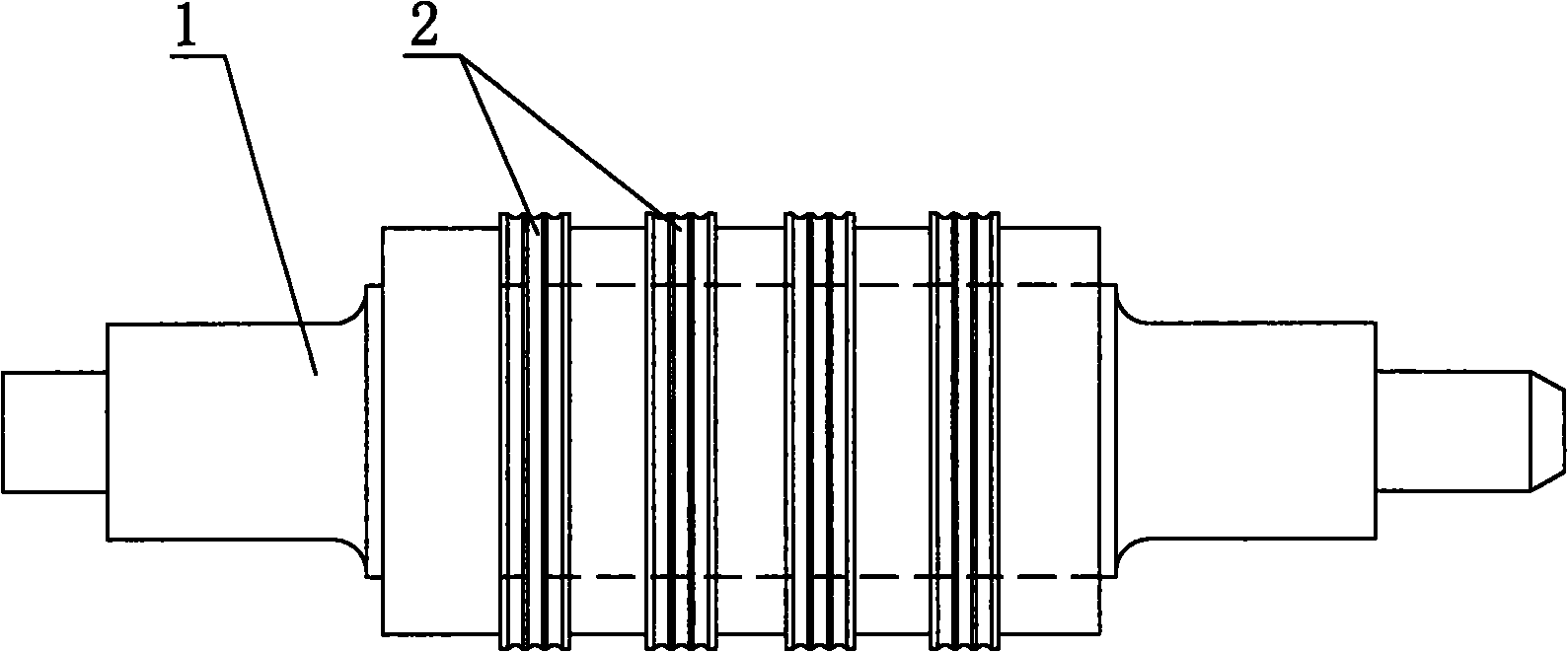

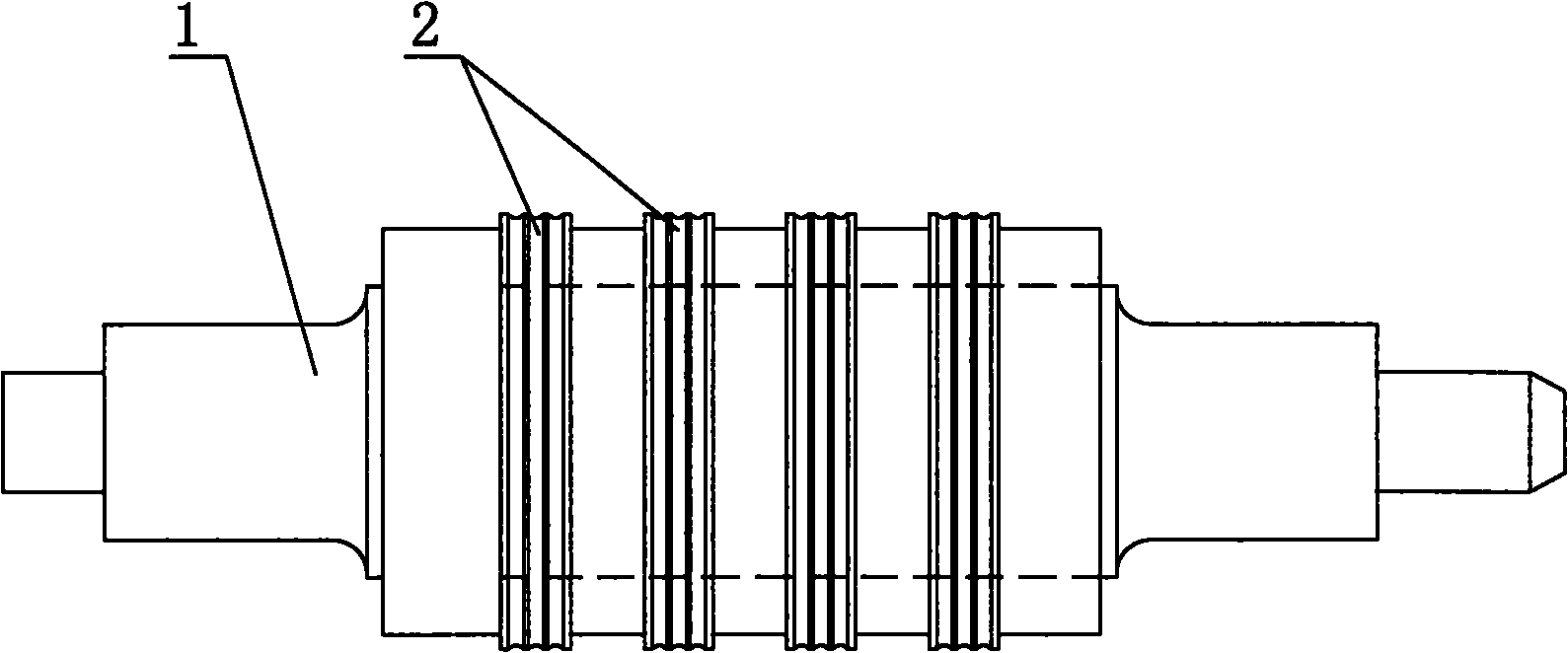

Hard alloy composite roll

InactiveCN101966531AImprove wear resistanceExtend your lifeRollsMetal rolling arrangementsAlloy compositeDuctile iron

The invention discloses a hard alloy composite roll. The hard alloy composite roll comprises a mandrel and more than two roll collars, wherein the roll collars are sleeved on the mandrel and are made of tungsten carbide hard alloy; and the mandrel is made of tough alloy steel. Due to the adoption of the technical scheme, the hard alloy roll collars replace the original spicule nodular cast iron roll, and the tungsten carbide hard alloy roll collars are applied, the abrasive resistance of the roll is high, and the service life is long, so that the effective operation rate is improved; therefore, the yield of rolling mills is improved.

Owner:ZHEJIANG HENGCHENG CEMENTED CARBIDE

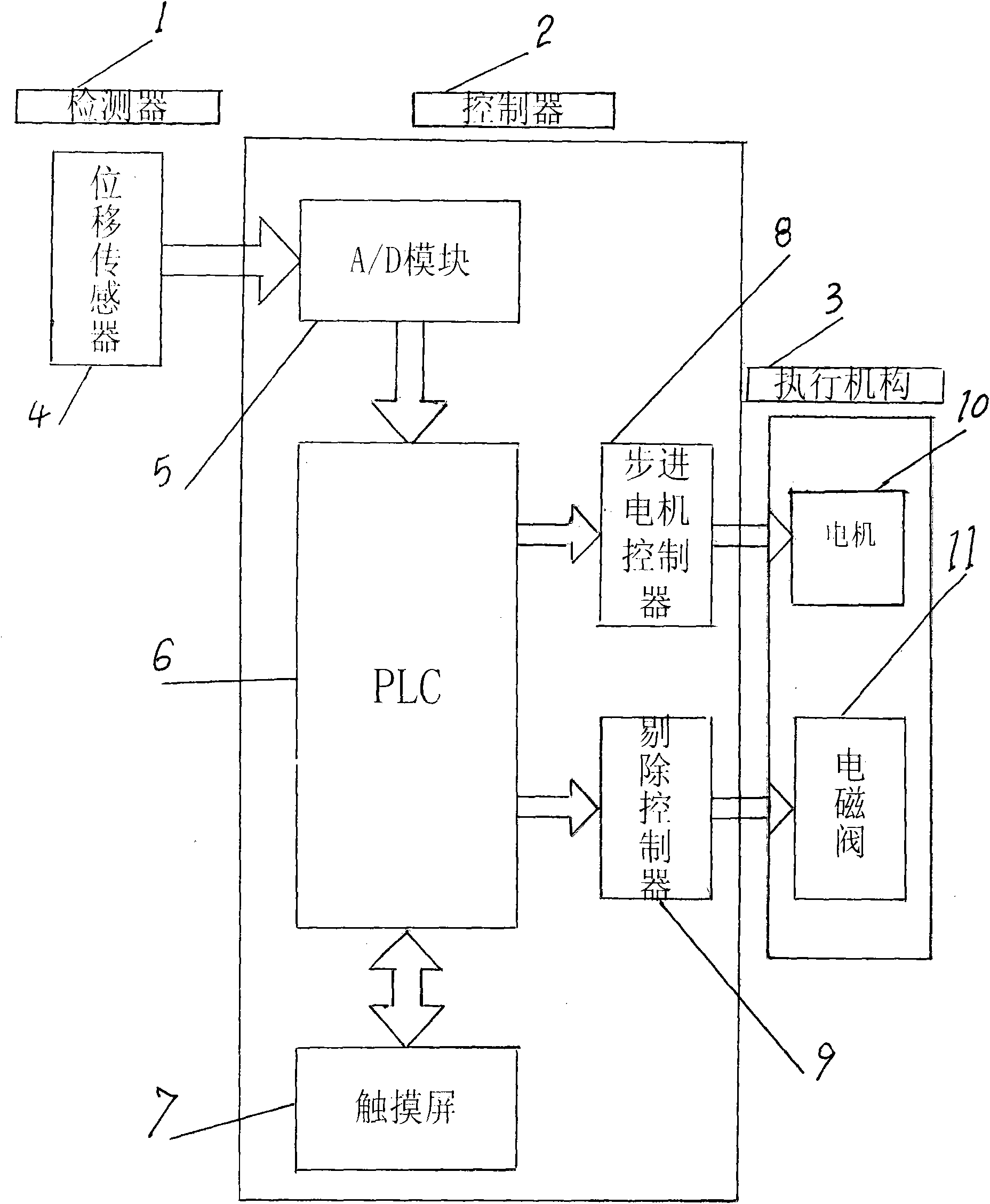

Automatic control device for correcting tipping paper of plug assembler

InactiveCN101658326AWith automatic replacement functionEasy to adjustCigarette manufactureWebs handlingAutomatic controlSolenoid valve

The invention discloses an automatic control device for correcting tipping paper of a plug assembler, which comprises a glue postheating plate and a drum; displacement sensors are arranged on the gluepostheating plate and at a position in front of the tipping paper drum; the displacement sensors receive tipping paper deviating signals and output the signals; and the signals are converted into a digital quantity by an A / D module, and then transmitted to a PLC; the PLC processes and outputs the signals; the signals are received by a step motor and an elimination controller, and the step motor and the elimination controller feed running information back; the running information is displayed by a touch screen; and the elimination controller controls the power-on and power-off of a solenoid valve. The automatic control device has the functions of automatically adjusting the tipping paper which follows the speed of the motor under various speeds of a main machine, automatically replacing the tipping paper, manually feeding paper, and manually cutting paper.

Owner:新乡东方工业科技有限公司

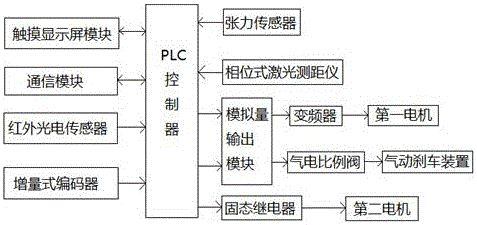

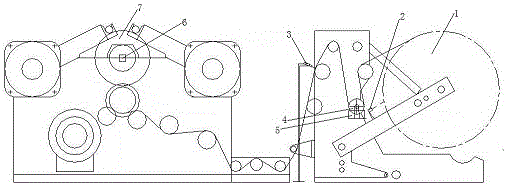

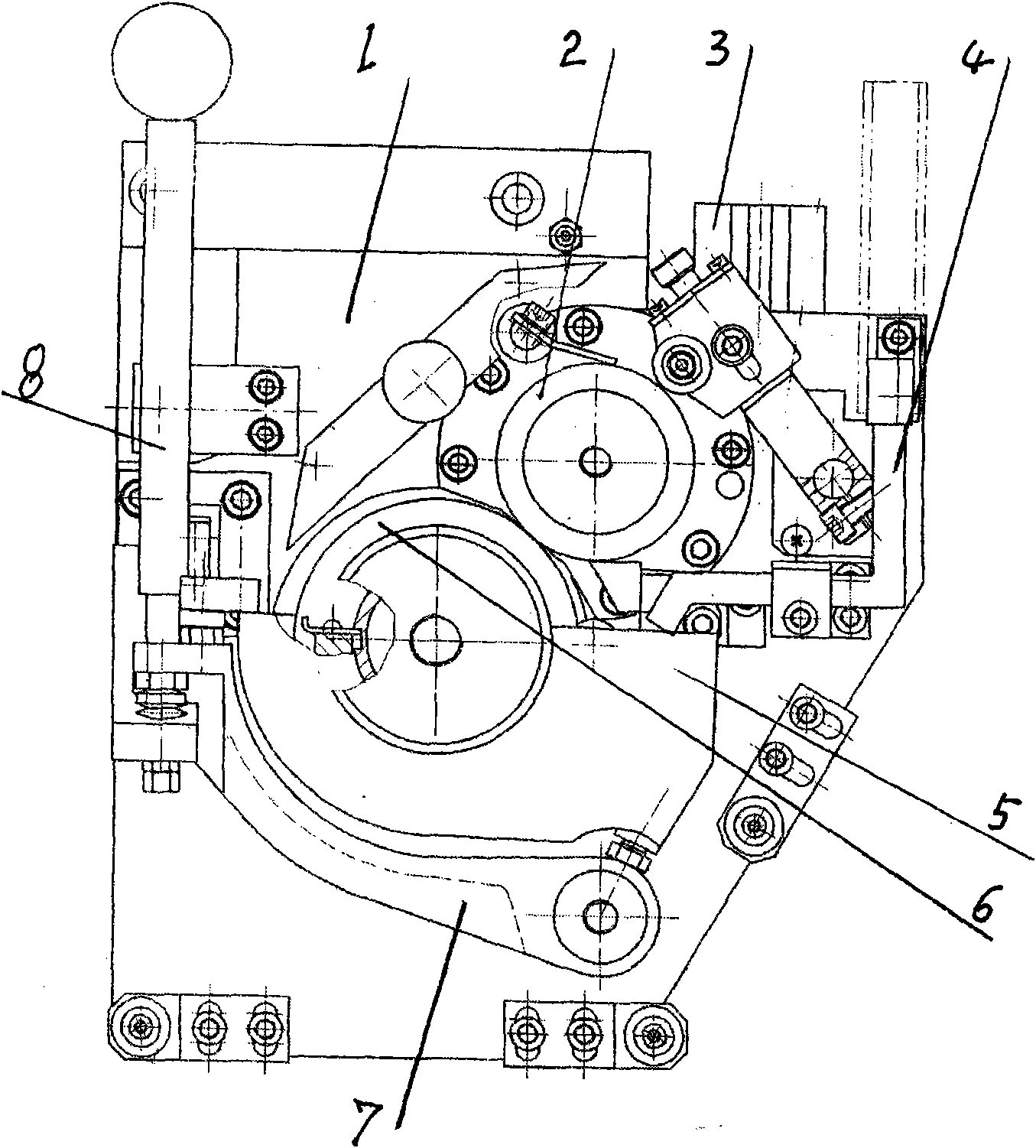

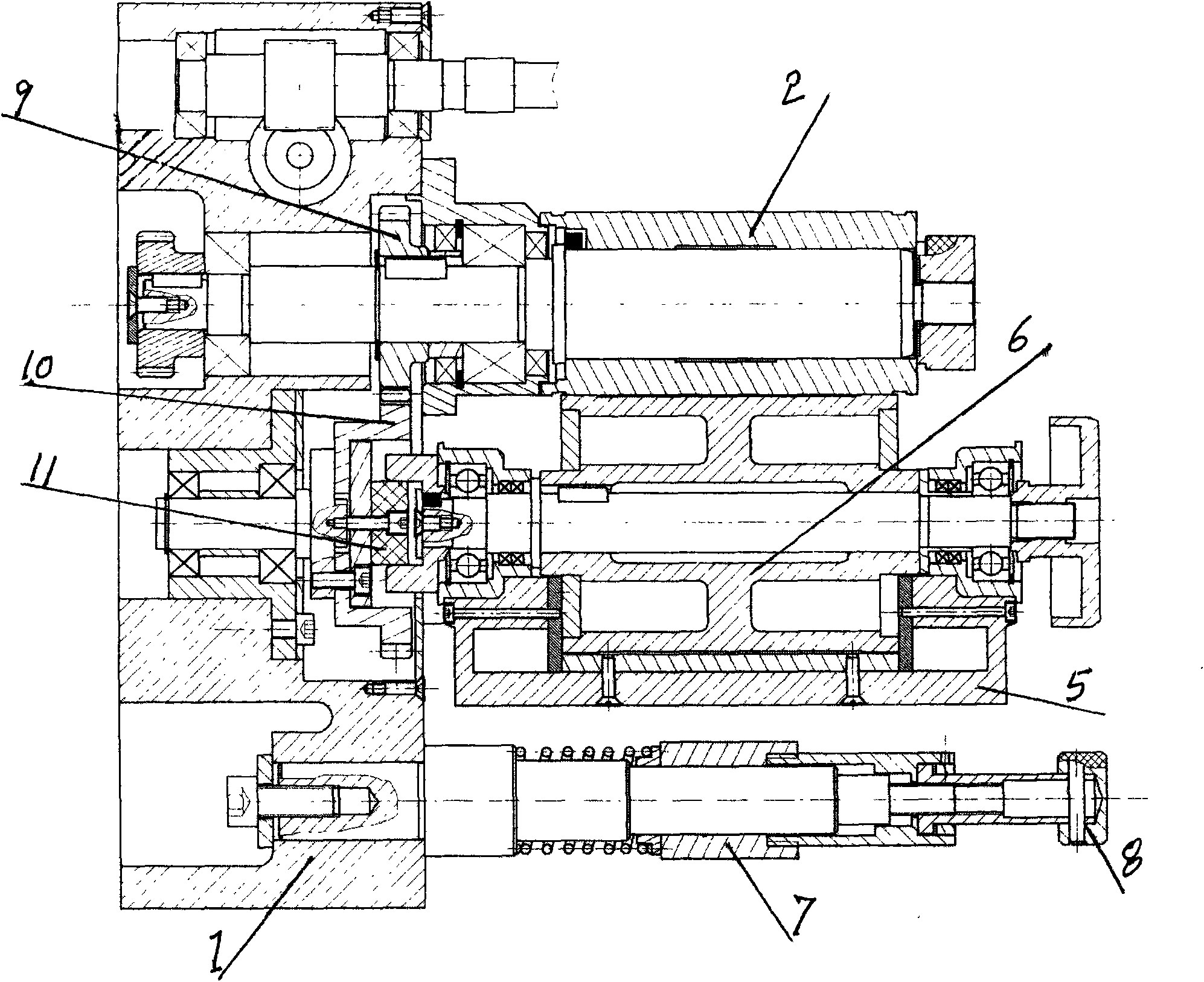

Automatic control system of aluminum soil splitting machine

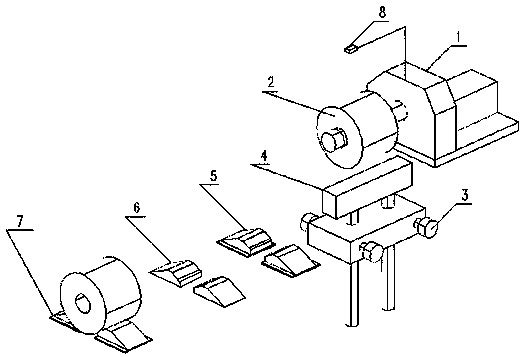

InactiveCN106671174AImprove effective operation rateReduce scrap rateMetal working apparatusAutomatic controlLaser ranging

The invention discloses an automatic control system of an aluminum soil splitting machine, and relates to the technical field of splitting machine automatic control. According to the automatic control system, a tension signal of a coiled material and the current diameter of a coiling block are detected in real time through a tension sensor and a phase type laser range finder correspondingly, an electrical proportional valve is controlled in real time, and therefore a pneumatic brake device is controlled, and tension of the equipment is automatically and stably controlled. Operating data of a wind-up roll is detected in real time through an incremental encoder, the operating linear speed of the equipment can be stably controlled, and meter number control can also be achieved. Control over the left-right movement of a wind-up seat and a pay-off seat is achieved through an infrared photoelectric sensor, it is guaranteed that the wind-up seat and the pay-off seat are oppositely flushed all the time. According to the automatic control system, under stable control over the tension and the operating speed of the equipment, the effective work rate of the splitting machine is increased, and the rejection rate is reduced. The automatic control system is high in control precision, good in reliability and capable of effectively preventing equipment overspeed accidents, and the safe and stable work of the equipment is guaranteed.

Owner:GUANGXI ZHENLONG IND

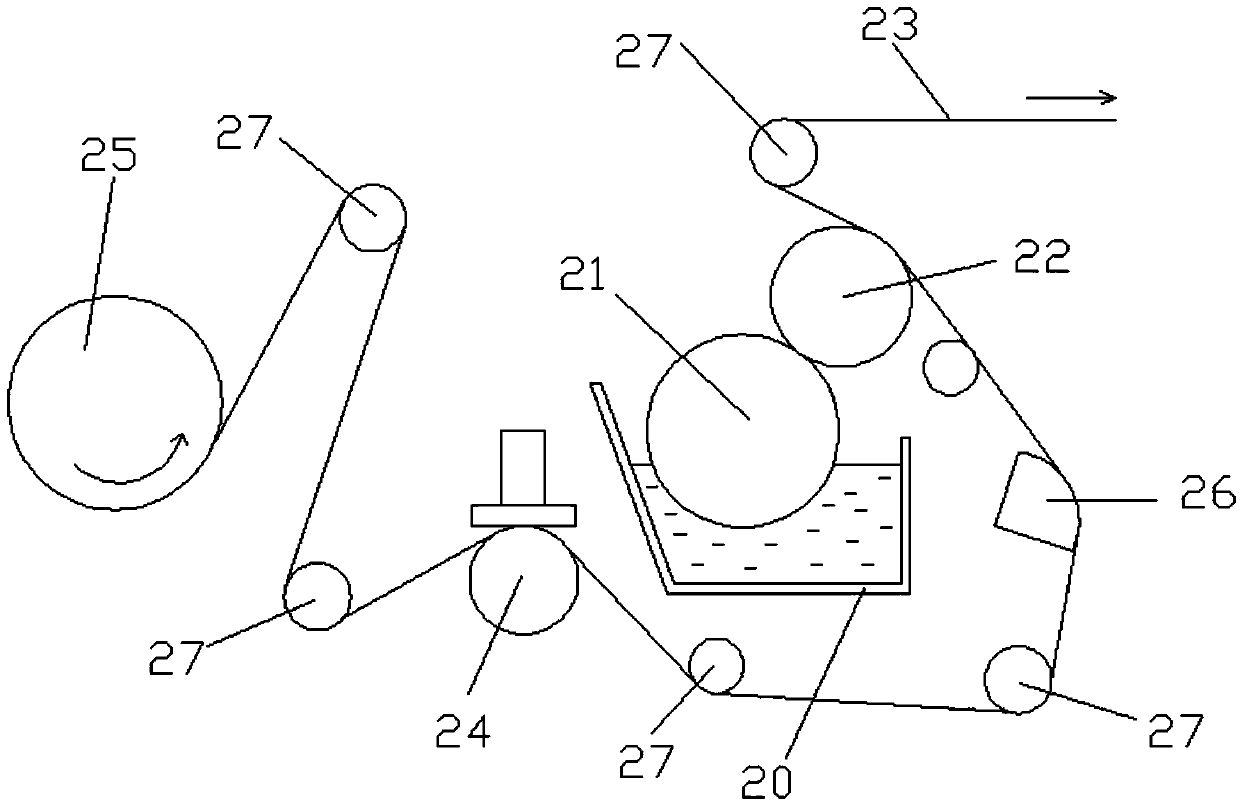

Glue feed mechanism on cigarette making machine

InactiveCN101658324AIncrease contactImprove effective operation rateLiquid surface applicatorsCigarette manufactureCouplingEngineering

The invention discloses a glue feed mechanism on a cigarette making machine, which comprises upper and lower rubber rolls, a glue cylinder and an air cylinder, wherein the upper rubber roll is arranged on a box body and is directly driven by a spindle; the lower rubber roll is supported on the glue cylinder through sealing bearings at two ends of the spindle; the upper part of the glue cylinder isprovided with a glue surface detecting photoelectric tube; rear parts of the upper and lower rubber rolls are respectively connected with a pair of gears in meshed transmission; the lower rubber rollis connected with the gears through a slider coupling; the spindle on a bent arm of the box body is provided with an adjusting handle; the air cylinder is arranged on the lateral surface of the box body and a rack on the air cylinder drives the gears to transmit; a lower part of the periphery of the lower rubber roll is buried in the glue cylinder; and the glue cylinder is supported by a lower bracket. The glue feed mechanism has the advantages of reducing labor intensity of personnel for a machine set and improving the quality of products.

Owner:新乡东方工业科技有限公司

On-line detection system of tobacco rod aluminum-foil paper

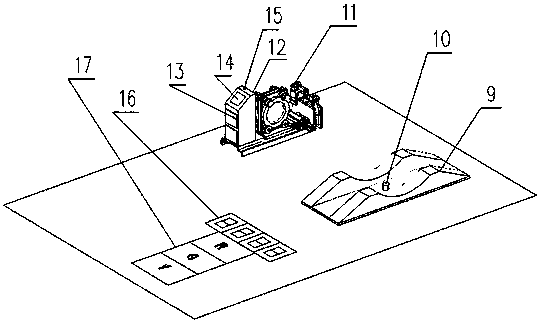

InactiveCN106853876ASolve the undetectable puzzleImprove effective operation ratePackaging cigarettePackaging cigarsVisual technologyMachine vision

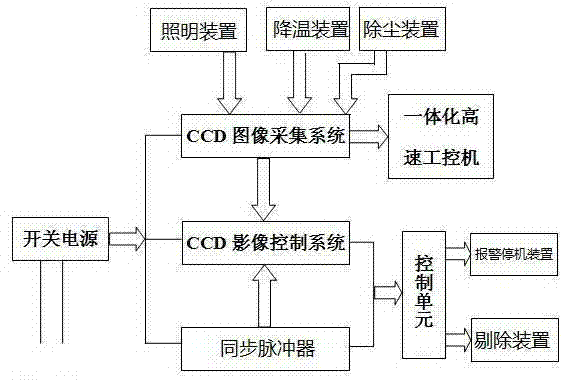

The invention provides an on-line detection system of tobacco rod aluminum-foil paper. The on-line detection system of the tobacco rod aluminum-foil paper comprises a CCD image acquisition system, a CCD image control system, a control unit and a processing unit; the CCD image control system and an integral high speed industrial control computer are connected to the CCD image acquisition system respectively, and the CCD image control system and the processing device are connected to the control system separately; the CCD image control system is provided with a synchronous pulser, and the synchronous pulser is connected to the CCD image control system and the control unit respectively. The on-line detection system of the tobacco rod aluminum-foil paper adopts a noncontact type machine visual technology, the difficult problem is thoroughly solved that through a sensor adopting a traditional electrical inductance principle cannot detect novel aluminum-foil paper, and the effective work rate of equipment is fully improved.

Owner:HUNAN RUNPU TECH DEV

Kitchen waste vibrating screen classifier

InactiveCN102935426AAvoid contactSolve the entanglementSievingScreeningMechanical engineeringEngineering

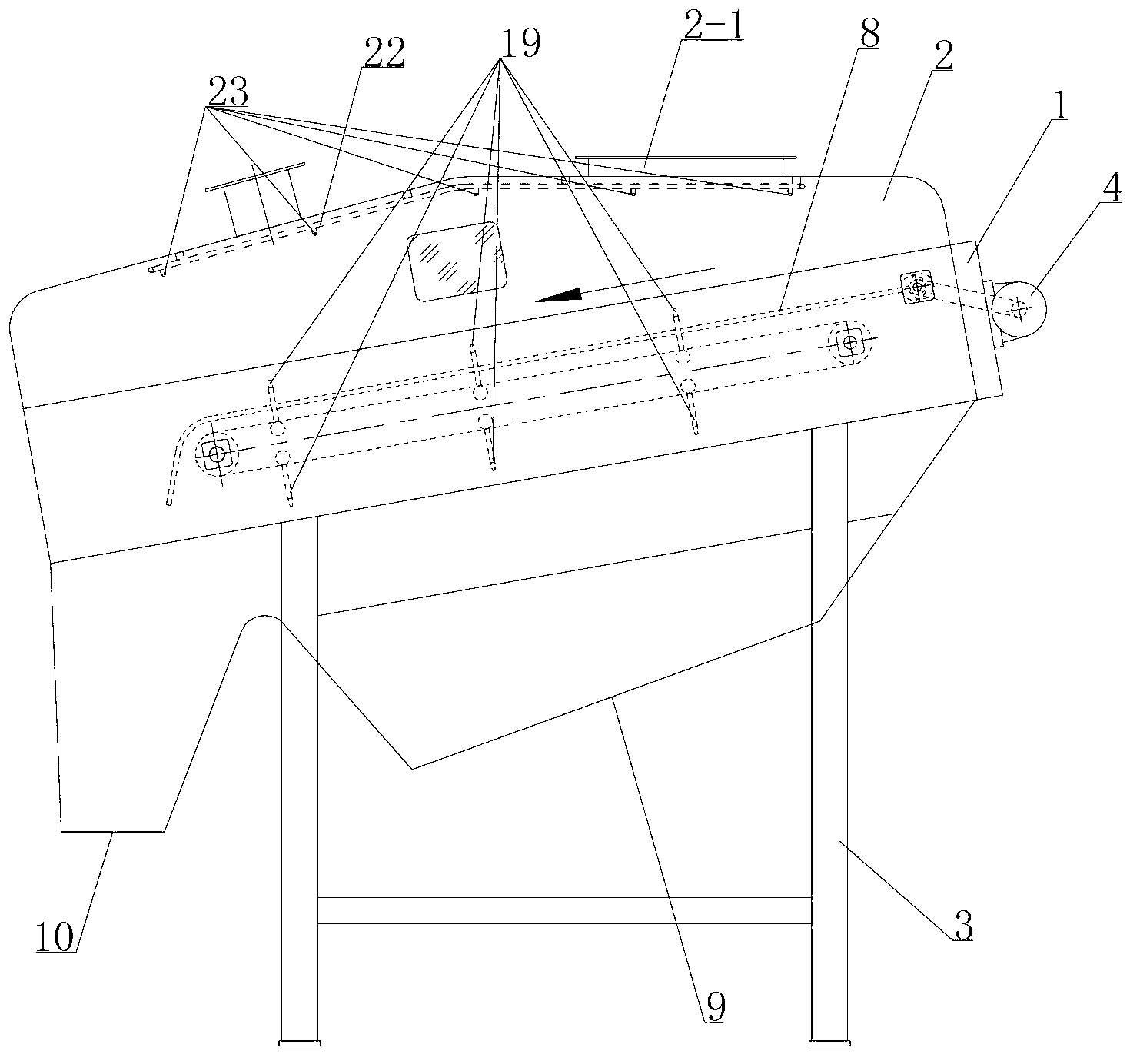

The invention relates to a kitchen waste vibrating screen classifier comprising a box body part, a tooth rake transmission device and a grizzly bar vibrating device. The tooth rake transmission device and the grizzly bar vibrating device are supported in a box body, and the grizzly bar vibrating device is composed of a first motor reducer, a transmission shaft, an eccentric sleeve, a connection sleeve, and a plurality of grizzly bars arranged in parallel. The kitchen waste vibrating screen classifier is characterized in that the tooth rake transmission device comprises a second motor reducer, a driving shaft, a first driven shaft and a second driven shaft; driving chain wheels are respectively installed at both ends of the driving shaft; one driven chain wheel is installed on each of the two driven shaft; the driven chain wheels are transmitted with the driving chain wheels by two transmission chains; a plurality of tooth rake shafts are fixedly connected between the two transmission chains; a plurality of rake teeth are uniformly distributed on each tooth rake shaft; and the grizzly bars are supported on the tooth rake shafts and are in staggered arrangement with the rake teeth. The driven shafts of the tooth rake transmission device are composed of the first driven shaft and the second driven shaft, and compared with the existing single driven shaft structure, according to the kitchen waste vibrating screen classifier, garbage is prevented form being contacted with the driven shafts so that the problem of plastic garbage winding is solved, the normal work of the device is ensured, and the effective operation rate of the device is improved.

Owner:天津百利阳光环保设备有限公司

Cigarette filter tip assembling machine glue spray system device

InactiveCN104174543APrevent moisture from evaporatingImprove performanceLiquid surface applicatorsSpraying apparatusAdhesive glueMechanical engineering

The invention discloses a cigarette filter tip assembling machine glue spray system device which comprises a nozzle paper roll component, a glue spray auxiliary system and a cleaning maintenance system, wherein the glue spray auxiliary system comprises a base, a glue pump, a rubber tube, a paper guide roll, a paper guide block and the like; the nozzle paper roll component is formed by manufacturing a glue spray head and the paper roll together; the position of the glue spray head can be changed along with rotation of the paper roll; the cleaning maintenance system comprises a water pool, a cleaning device and a supporting rod; the water pool and the cleaning device are fixed on the supporting rod; the supporting rod can move up and down under the action of a cylinder; and cleaning maintenance operation of the glue spray head can be finished by rotating the glue spray head and lifting the water pool and the water level. The cigarette filter tip assembling machine glue spray system device disclosed by the invention is uniform in gluing, firm in adhesion and high in cigarette yield, integrates glue spray and cleaning into a whole and is high in degree of automation and convenient to use, and waste of glue water is reduced.

Owner:ANHUI YITONG MACHINERY

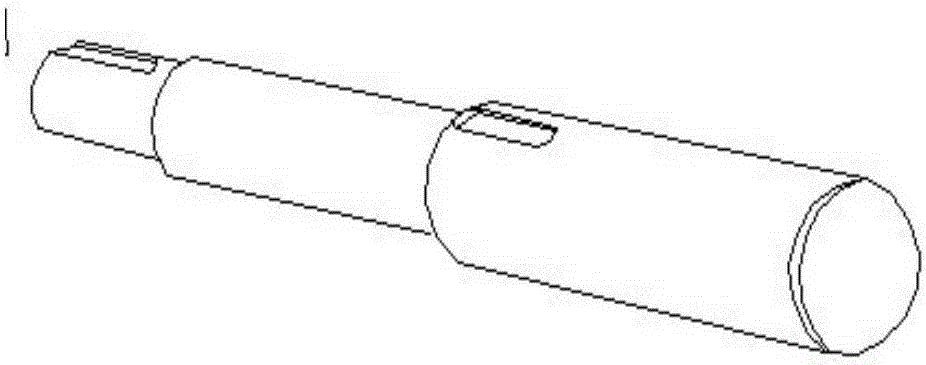

Guardrail tube deburring machine

The invention provides a guardrail tube deburring machine which comprises a machine table. A floating grinding device and a rotating device are arranged above the machine table, and a supporting frame is arranged between the floating grinding device and the rotating device. The floating grinding device comprises a support, a knife rest, a swing rod, a pull rod, a knife rod and a knife holder, wherein the support is arranged on the machine table, the knife rest is arranged above the support, the upper end of the swing rod is fixed on the knife rest through a first bolt, and the lower end of the swing rod is hinged to the middle of the knife rod. A pin shaft is arranged at the upper end of the knife rod, and a through hole is formed in the pin shaft. The upper end of the pull rod is hinged to the upper end of the swing rod, and the lower end of the pull rod penetrates through the through hole. An anti-falling part is arranged at the lower end of the pull rod, and a spring is arranged on the pull rod in a sleeving mode. The lower end of the knife rod is connected with the knife holder, and a knife is arranged on the knife holder. The guardrail tube deburring machine solves the problems that machining is not complete and knife biting and breakage occur due to the fact that the knife does not float, knife consumption is reduced, the knife replacement time is shortened, the machining quality of guardrail tubes is improved, the effective operation rate of equipment is increased, and the service life is prolonged.

Owner:GUIZHOU HUAYOU METAL PROD

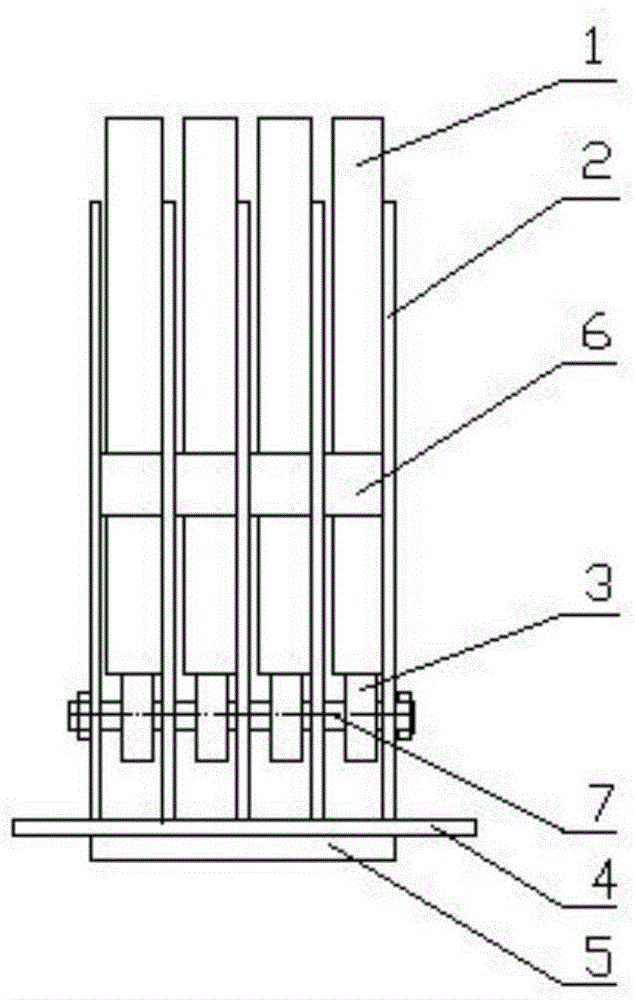

A binding steel belt storage rack

The invention relates to a binding steel belt storage rack. A square bottom plate is fixedly mounted to a base; separation plates are fixedly, vertically and uniformly mounted on the bottom plate at intervals; the two sides of the separation plates are connected via baffles; the bottom portions of the two side edges of each separation plate are provided with grooves in mirror symmetry; rolling shafts in mirror symmetry are connected with the separation plates after penetrating the grooves; rollers are arranged between the separation plates and on the rolling shafts; the two ends of each rolling shaft are fastened via nuts; binding steel belts are arranged between every two adjacent separation plates, located on the rollers and supported by the rollers. The binding steel belt storage rack is compact in design, enables a plurality of bundles of binding steel belts to be stored and used at the same time, can store binding belts of different models, facilitates use of operators and reduces the binding belt replacing efficiency.

Owner:TIANJIN SHENGLIDA MECHANICAL EQUIP CO LTD

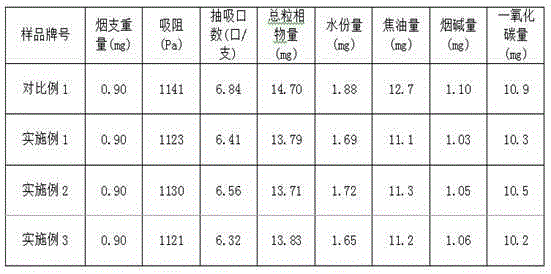

Mixed single denier strand for tar-reduced cigarette filter stick and preparing method and application of mixed single denier strand

ActiveCN104153080ASame defocus efficiencyStable defocusing efficiencyCigar manufactureTobacco smoke filtersPolymer scienceSpinning

The invention relates to a mixed single denier strand for a tar-reduced cigarette filter stick with an X-shaped cross section and a preparing method and application of the mixed single denier strand. The mixed single denier strand is composed of single fibers with different single fiber densities, wherein the single fibers are formed by at least three different specifications of spinneret orifices of the same spinneret plate in a spinning mode, the different specifications of spinneret orifices are different in aperture or section shape or aperture and section shape. The single fiber density ranges from 1.0 dtex to 3.5 dtex, the variable coefficients of the single fiber density range from 0.10 to 0.50, the cross sections of the single fibers are in at least two of an X shape, a Y shape and an O shape. The breaking strength of the mixed single denier strand is equal to or larger than 18.0 N / Ktex, the moisture content of the mixed single denier strand is (6.0+ / -1.6) percent, the tar content of the mixed single denier strand ranges from 0.70 percent to 1.50 percent, the remaining acetone content of the mixed single denier strand is smaller than or equal to 0.30 percent, and the titanium dioxide content of the titanium dioxide is (0.40+ / -0.20) percent. The mixed single denier strand has the advantages of being easier to process, high in effective working efficiency and more stable in tar reducing efficiency.

Owner:CHINA TOBACCO ZHEJIANG IND

Cigarette anti-block filtering device of cigarette packing machine

InactiveCN101024426AAvoid enteringSmoke smoothlyPackaging cigarettePackaging cigarsEngineeringAlarm device

The invention relates to a cigarette block-proof filtering device that includes cigarette hopper, splitter box, whisking bar group, and cigarette separating storeroom. The feature is that: one or plural level arranged whisking bars are set between two sides of cigarette hopper, and each group of whisking bar is made up of plural whisking bars, cigarette sensor is installed under the whisking bar, and alarming device is set beside the cigarette hopper. The whisking bar could remove the blocked or deficient cigarette without stopping the device, and it sharply improves the working efficiency of the machine.

Owner:吴为荣

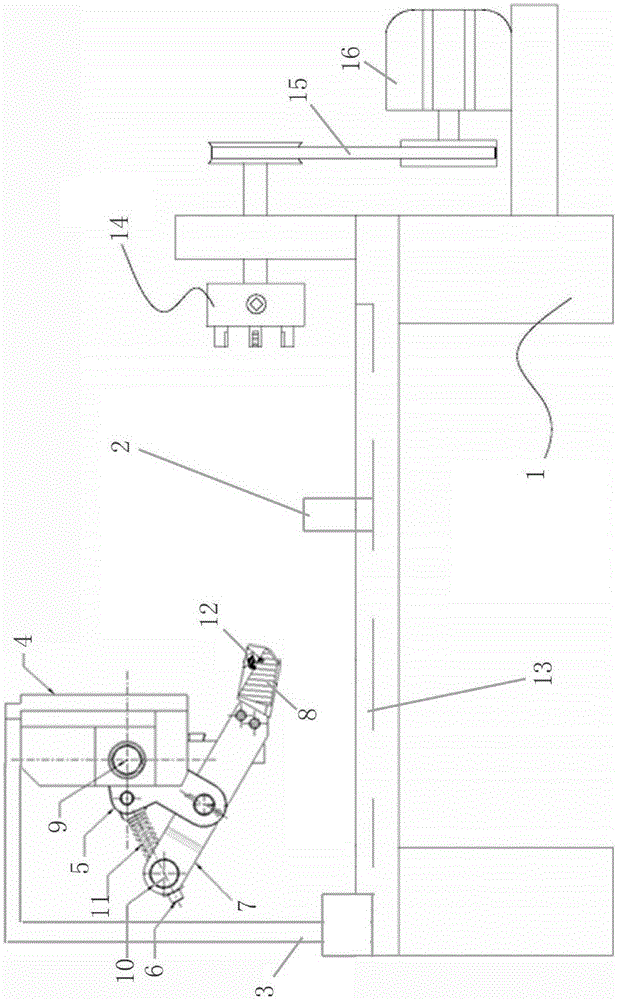

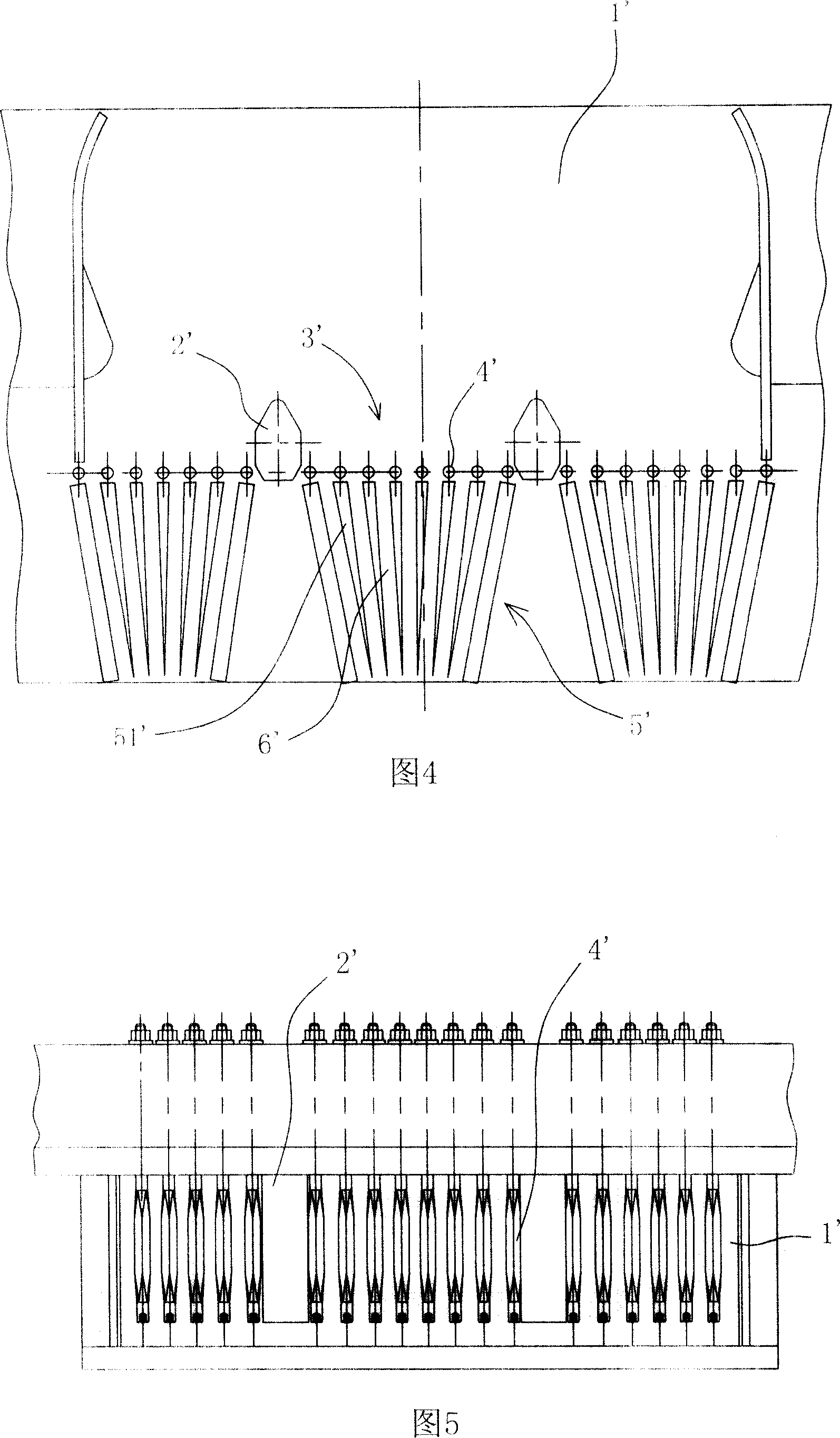

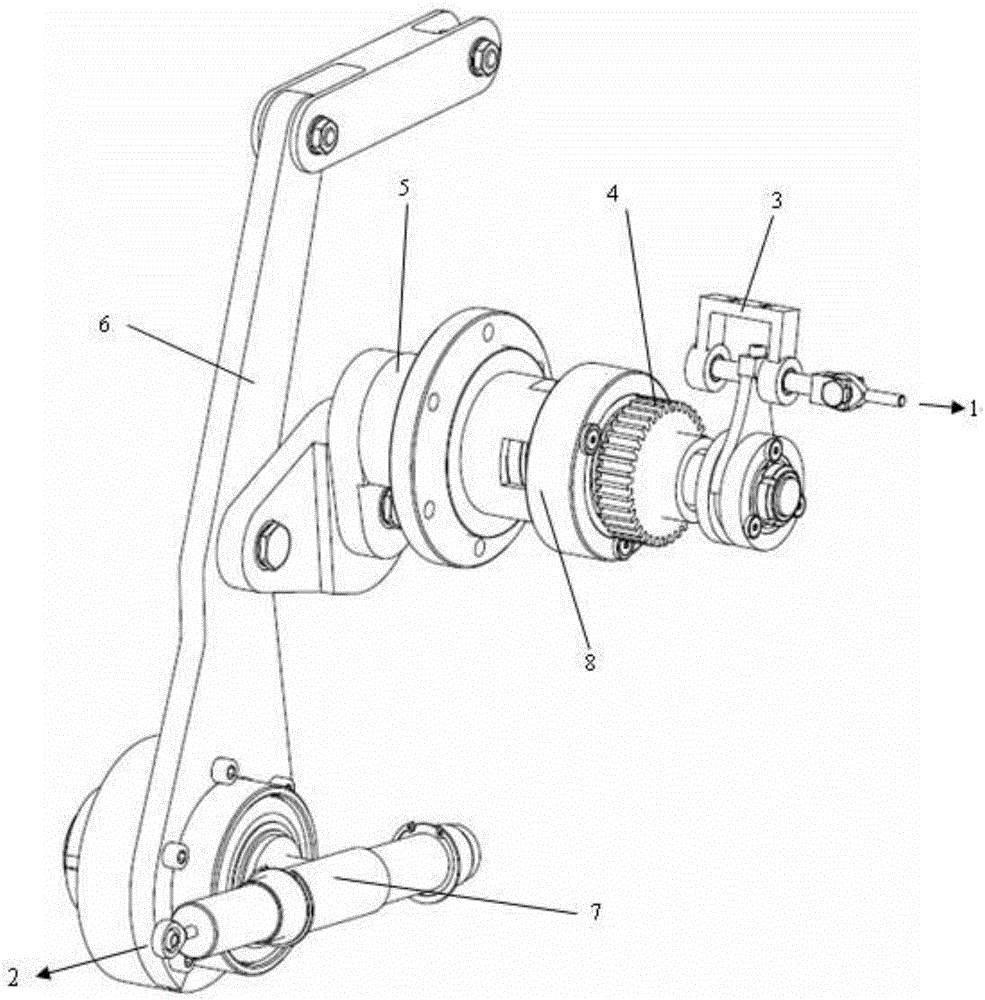

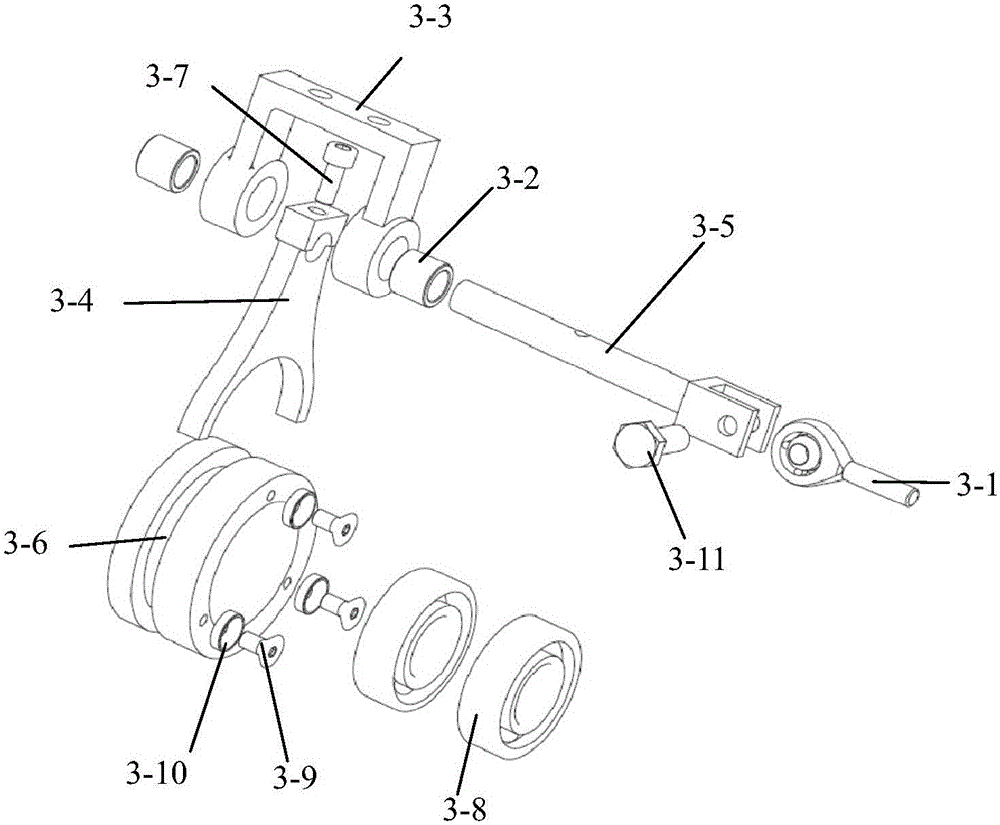

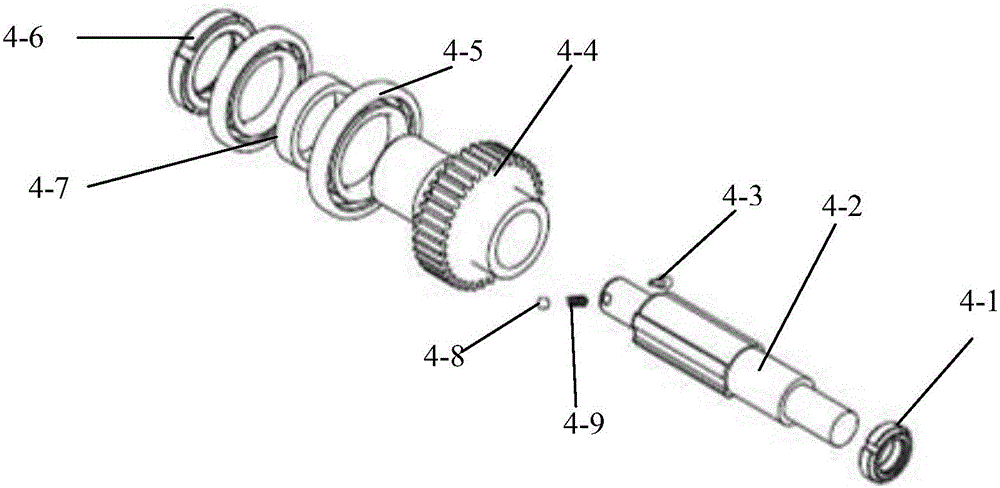

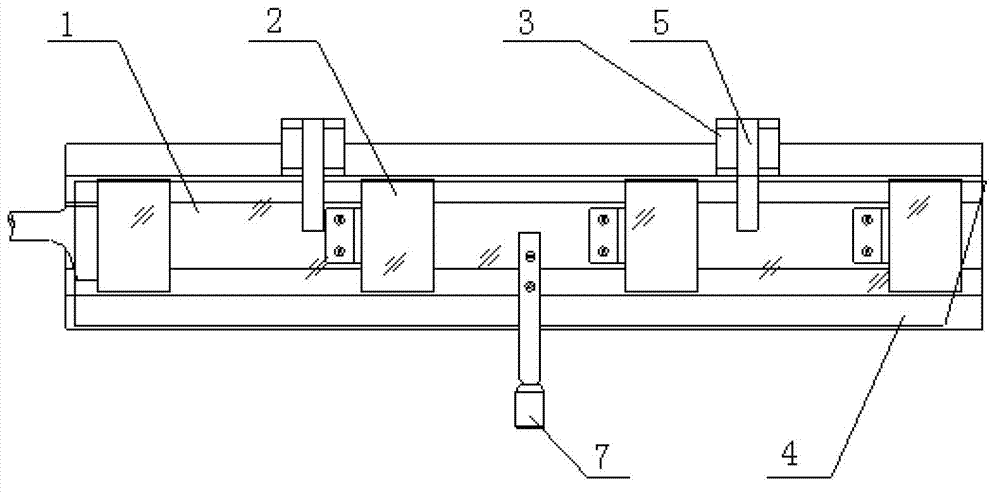

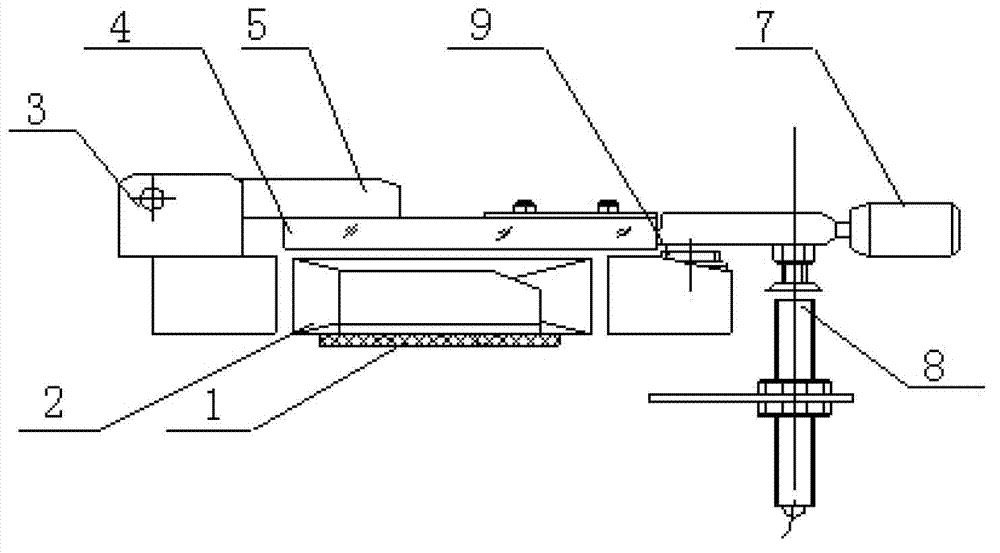

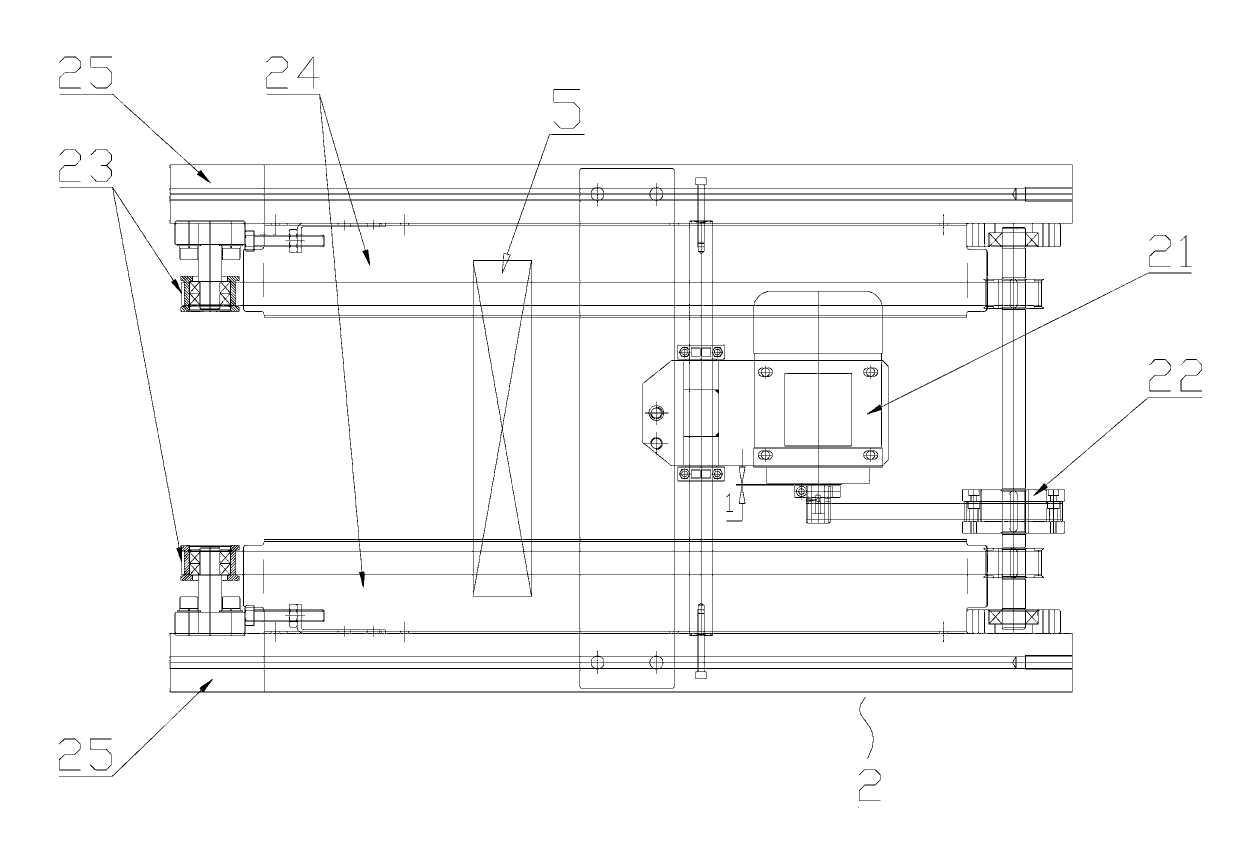

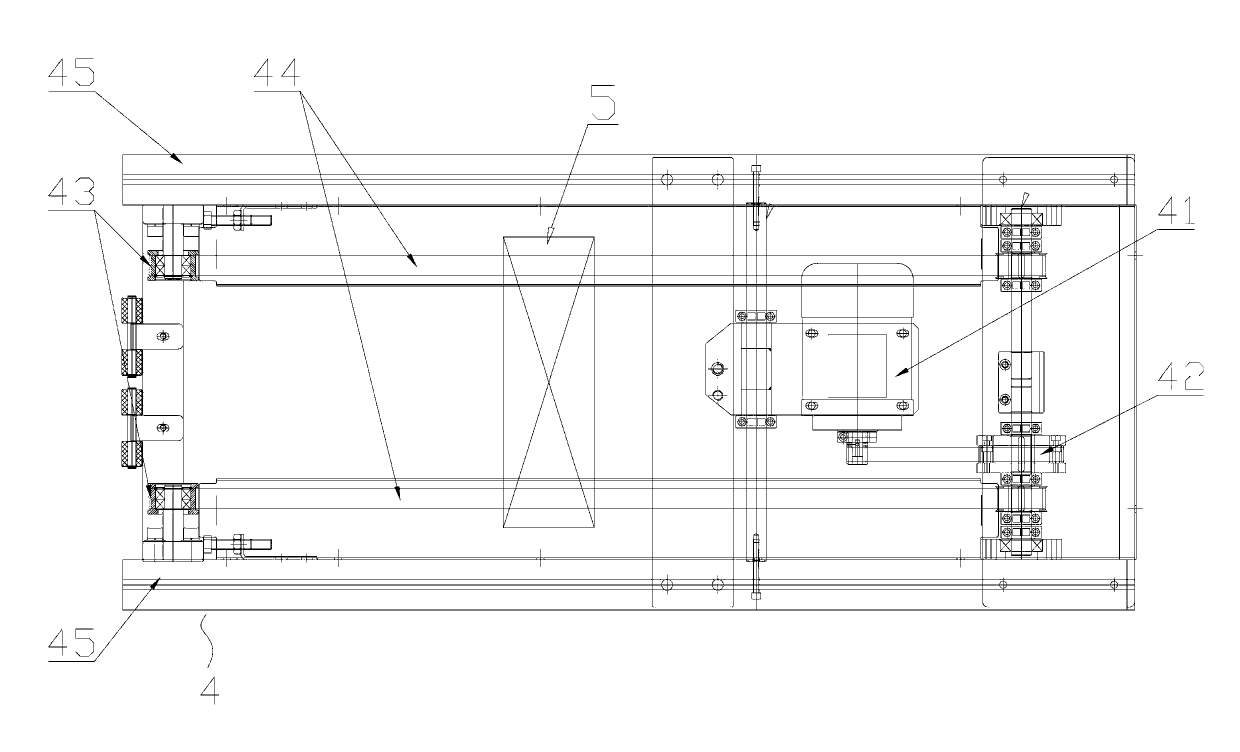

Mechanical pushing mechanism capable of realizing separate pushing

ActiveCN106314854AImprove effective operation rateReduce manufacturing costPackaging cigaretteLinear motionDrive shaft

The invention discloses a mechanical pushing mechanism capable of realizing separate pushing. The mechanism comprises a first oil cylinder, a shifting fork assembly, a driving shaft assembly, a driven shaft assembly, a crank rocker assembly, a supporting shaft assembly, a flange sleeve assembly and a second oil cylinder; a driving shaft is driven by the first oil cylinder through the shifting fork assembly to reciprocate in the axial direction; when the driving shaft assembly is connected with the driven shaft assembly, a driving gear rotates to drive the driving shaft and a driven shaft to rotate synchronously; and the driven shaft rotates to drive a rocker of the crank rocker assembly to swing with the lower end serving as a rotating center, a push rod is driven to move horizontally forwards and backwards, and the rotating motion of the driving gear is changed into the reciprocating linear motion of the push rod. The mechanism can quit work separately without shutdown when a machine breaks down locally; and once the fault is eliminated, the mechanism can run synchronously with other associated parts, the efficiency of a tobacco machine is correspondingly increased, and the production cost of tobacco bale products is reduced.

Owner:CHINA TOBACCO MACHINERY TECH CENT

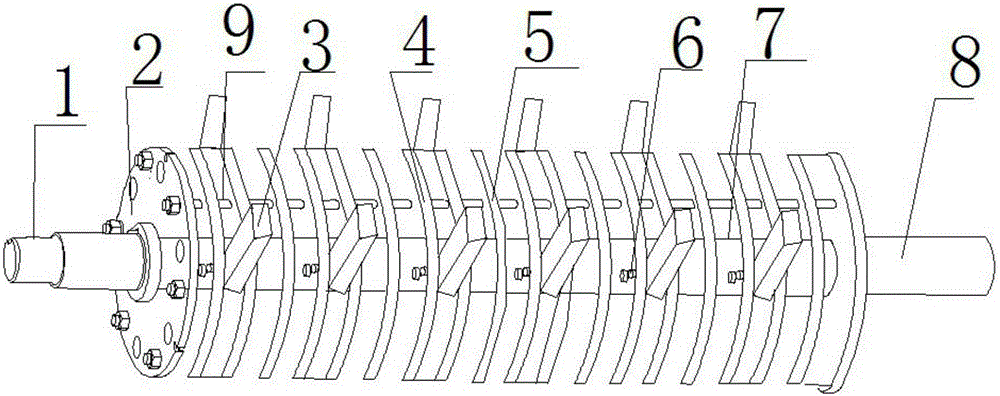

Beating roller for defoliator

The invention relates to the field of equipment manufacture, in particular to a beating roller for a defoliator. The beating roller comprises a belt pulley end shaft, beating roller end covers, a separating cutter cutterhead, beating cutter cutterheads, a roller, a beating cutter and a locating pin. The belt pulley end shaft is located at the front end of the integral beating roller, and the tail end of the belt pulley end shaft is inserted in the center of the beating roller end covers. The beating cutter cutterheads and the separating cutter cutterhead sleeve the roller in sequence, the cutter locating pin fixes the tail of the beating cutter between the two beating cutter cutterheads, and the number of pull rods is six. The pull rods and the roller parallelly penetrate the beating cutter cutterheads and a separating cutter cutterhead sleeve, the two ends of the pull rods and the two ends of the roller are fastened between the front beating roller end cover and the rear beating roller end cover, and the end shaft is located at the tail end of the beating roller. The beating roller is simple and practical, the cutterhead type beating cutter is convenient to dismantle, the beating cutter is stable and does not shake easily, a fixed pin does not break easily, the beating cutter replacing time is short, and the leaf beating line throughput is improved.

Owner:彭永军

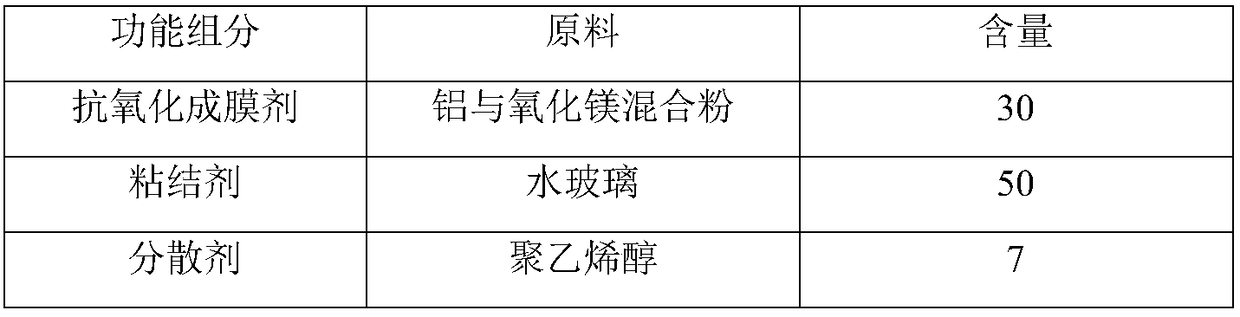

Method of prolonging service life of oxygen lance of converter

ActiveCN108642233AHigh temperature resistantImprove adhesionManufacturing convertersSlagBoron nitride

The invention relates to a method of prolonging the service life of an oxygen lance of a converter. The method comprises the following steps: carrying out treatment on bottom end surface of a spray head of the oxygen lance and treatment on side wall of an oxygen lance body, coating a high-temperature-resistant antioxidant coating to the bottom end surface of the spray head of the oxygen lance, carrying out induction heating or flame heating treatment on the end surface, spraying a first layer with a coal gas type flame high pressure spray gun, and spraying a second layer with an oxygen-acetylene flame high pressure spray gun; derusting the side wall of the gun body to a range 2-10 m far from the bottom end surface by taking the bottom end surface of the spray head of the oxygen lance as the starting point, and then smearing a coating; and spraying boron nitride powder to the coating by using the oxygen-acetylene flame high pressure spray gun. The method has the advantages that the service life of the oxygen lance is prolonged, and the labor intensity of workers is alleviated to a great extent; the deslagging treatment time as slag is attached to the oxygen lance is saved, the blowing rhythm is more compact, the effective operating efficiency of the converter is increased, and the output of steel is improved.

Owner:ANGANG STEEL CO LTD

Conveyor device of packing machine for small tobacco packets made of transparent paper

ActiveCN103708060AReduced probability of entering the forming wheelLow failure ratePackaging automatic controlControl systemPaper sheet

The invention provides a conveyor device of a packing machine for small tobacco packets made of transparent paper. The conveyor device comprises a conveyor belt and an equipment support. The conveyor belt is used for conveying the tobacco packets, the equipment support is used for mounting the conveyor belt, a cover plate is arranged above the conveyor belt and is divided into a first cover plate and a second cover plate in the front-back direction along a tobacco packet conveying direction, one end of the first cover plate is hinged to one end of the second cover plate, and the other end of the second cover plate is fixed; a detecting device for detecting whether the height of the first cover plate changes or not is arranged on the first cover plate and is electrically connected with a control system for driving the conveyor belt to move. When unqualified tobacco packets are conveyed on the conveyor belt, a lifting moment arm can be formed for the first cover plate, the first cover plate is lifted, the detecting device detects that the first cover plate is lifted, a signal is transmitted to the control system, the control system transmits an alarm signal and a command for stopping the conveyor belt from running, and accordingly a protection effect can be realized. The conveyor device has the advantages that the probability that the unqualified tobacco packets are fed into forming wheels can be greatly reduced, and accordingly an effective operation rate of equipment can be increased.

Owner:CHINA TOBACCO GUIZHOU IND

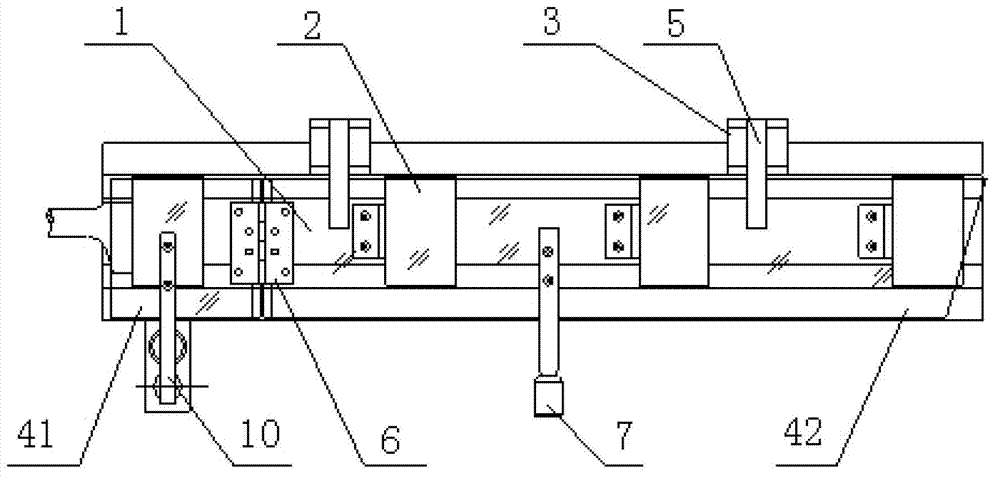

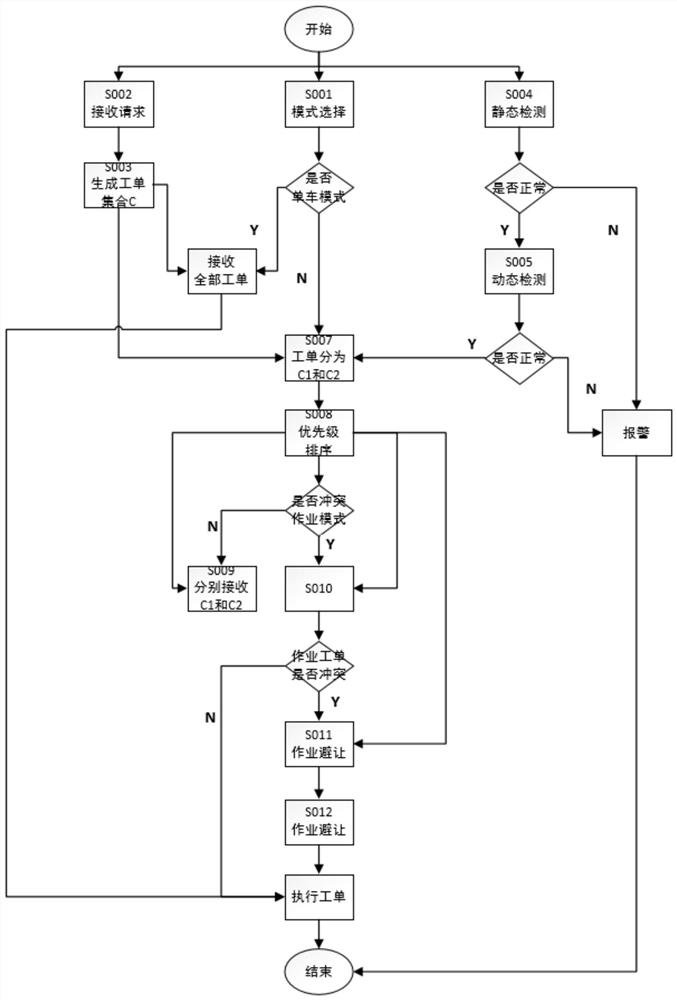

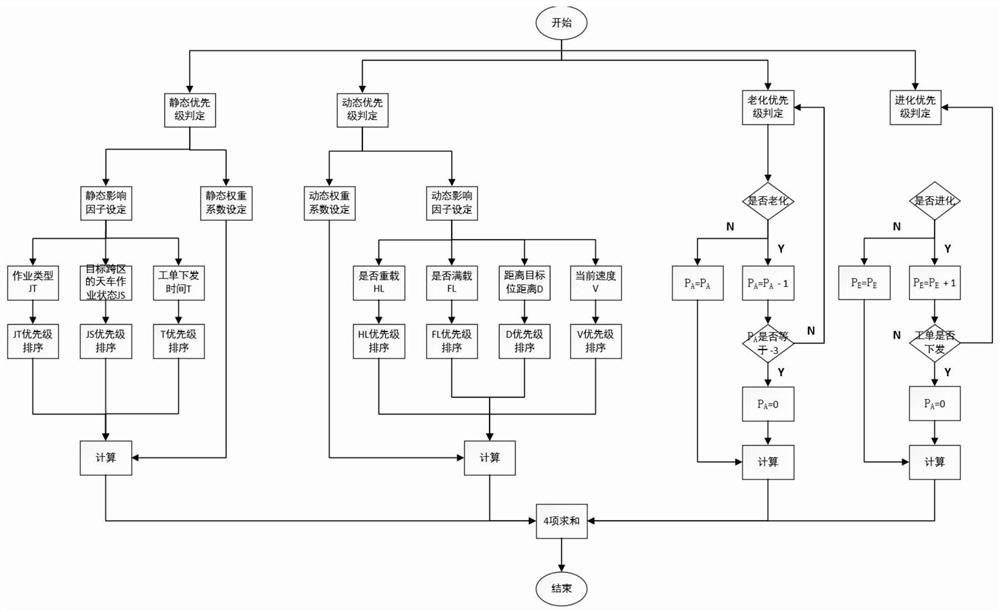

Same-rail double-crossing vehicle intelligent scheduling method

ActiveCN112016810AReduce downtimeImprove effective operation rateResourcesLogisticsStop timeReal-time communication

The invention relates to a same-rail double-crossing vehicle intelligent scheduling method, which comprises the following steps of: receiving a request of carrying a steel coil in each crossing area through real-time communication with a workshop secondary system, generating a work order, respectively issuing the work order to two crossing vehicles according to a priority sequence, and intelligently scheduling the two crossing vehicles to ensure that the two crossing vehicles run without conflict. According to the method, a reasonable, accurate and unique operation instruction can be issued tothe straddle carrier, the stopping time of mutual avoidance of the double straddle carriers is shortened, and meanwhile, the probability of conflict emergency stop of the double straddle carriers isreduced, so that the effective operation rate of the same-rail double straddle carriers is greatly improved. Two straddle vehicles arranged on the same rail are automatically dispatched for automaticoperation according to the reservoir area management requirement, the multi-span multi-task operation requirement is met, efficient, stable and conflict-free operation of the multi-span double-straddle vehicles is achieved, and the problem that the same-rail double-straddle vehicles are difficult to dispatch is solved.

Owner:WEIER AUTOMATION CO LTD TANGSHAN IRON & STEELGRP +1

Steel coil packing station and control method

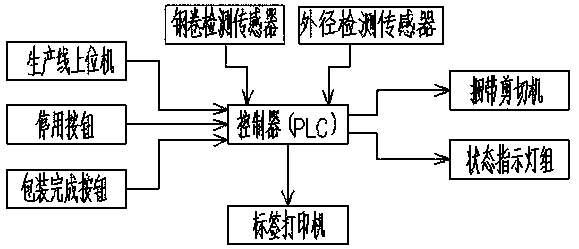

InactiveCN109775026AImprove work efficiencyReasonable arrangementPackaging automatic controlBundling machine detailsHuman–machine interfaceLogistics management

The invention relates to a steel coil packing station. The packing station comprises a packing saddle, a control cabinet and a binding belt shearing machine, wherein a steel coil detecting sensor is arranged in the center of the bottom part of the packing saddle; a label printer and a man-machine interface are arranged in the control cabinet; and a countdown display and a state indicator light setare arranged beside the packing saddle. According to the scheme, the steel coil packing station has the advantages that the packing logistics resource is allocated based on the automatic acquiring ofthe steel coil data and the monitoring of the packing time in the steel coil packing process, so that the utilization rate of the packing station is increased, and as a result, the packing station quantity is decreased, and the packing efficiency is improved.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Improved structure of small box cigarette packer seal label conveying structure

InactiveCN101108665AReduce manufacturing costImprove delivery capacityArticle feedersLabelling machinesMachiningCoefficient of friction

The invention discloses an improved device of the small box packing machine seal conveying structure of the cigarette, which namely uses a cylindrical gluing conveying wheel instead of the original flaky gluing conveying wheel, adopts polyurethane rubber with high coefficient of friction to machine a conveyor roller and improves the structure of the original speeding roller. Through the above improvement, the invention enhances the stability of conveying while prolonging the service life of the gluing conveying wheel. In addition, because of adopting the polyurethane rubber to make seal conveyor rollers, when the conveying track has adhesive scale, the conveying resistance in the passage is increased and the surface coefficient of the friction of the seal of different specifications is reduced, the conveyor roller can ensure stable conveying of the seal and adopt the coordination of round holes and shafts for the original speeding roller, which avoids the defects of circular runout easily produced by the original parts and requirement of high machining precision.

Owner:CHINA TOBACCO GUANGXI IND

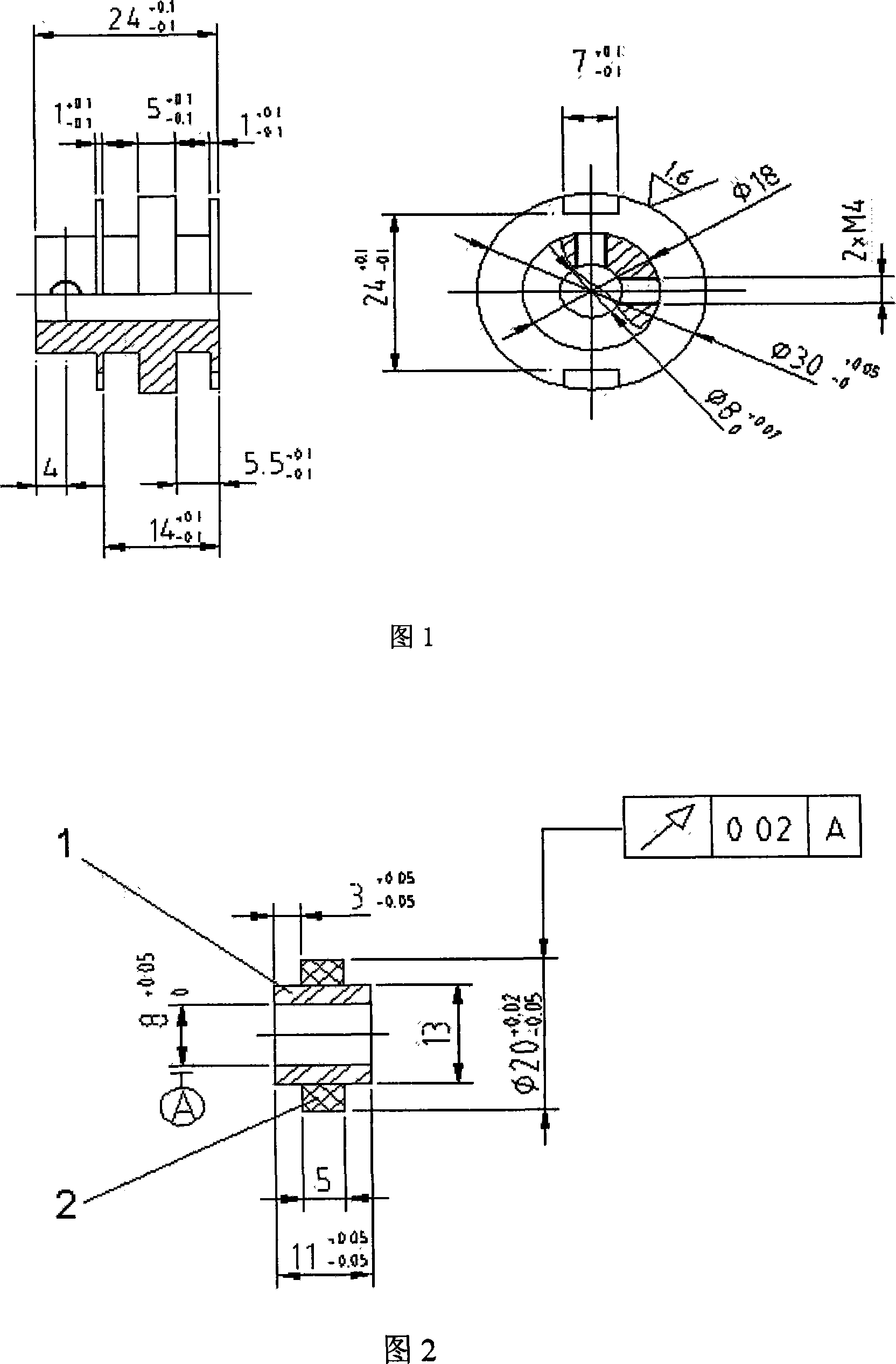

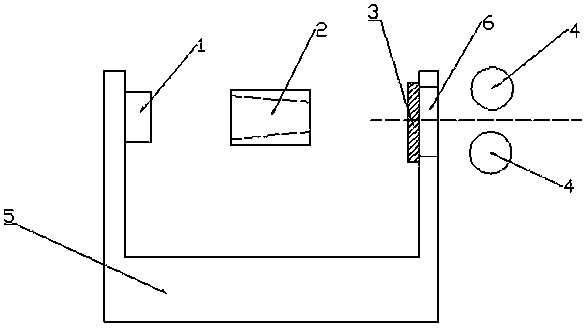

Device for achieving checking and laser adjusting on rollers and guide template and application method

InactiveCN108188187AEasy to adjustSimple structureGuiding/positioning/aligning arrangementsMechanical engineeringEnergy conservation

The invention provides a device for achieving checking and laser adjusting on rollers and a guide template and an application method. The device comprises a laser support, a laser device arranged on the laser support and used for checking a drawing and a guide plate and the drawing detachably fixed to the laser support, wherein standard guide outlet size patterns are printed on the drawing. A clearance used for storing the guide plate is reserved between the laser device and the drawing. The rollers and the guide plate can be accurately adjusted simply by replacing the drawing where the standard guide outlet size patterns are printed, time and labor are saved, the waiting time is shortened, energy is saved, and the product capacity is improved.

Owner:XINXING PIPES ZHEJIANG COPPER

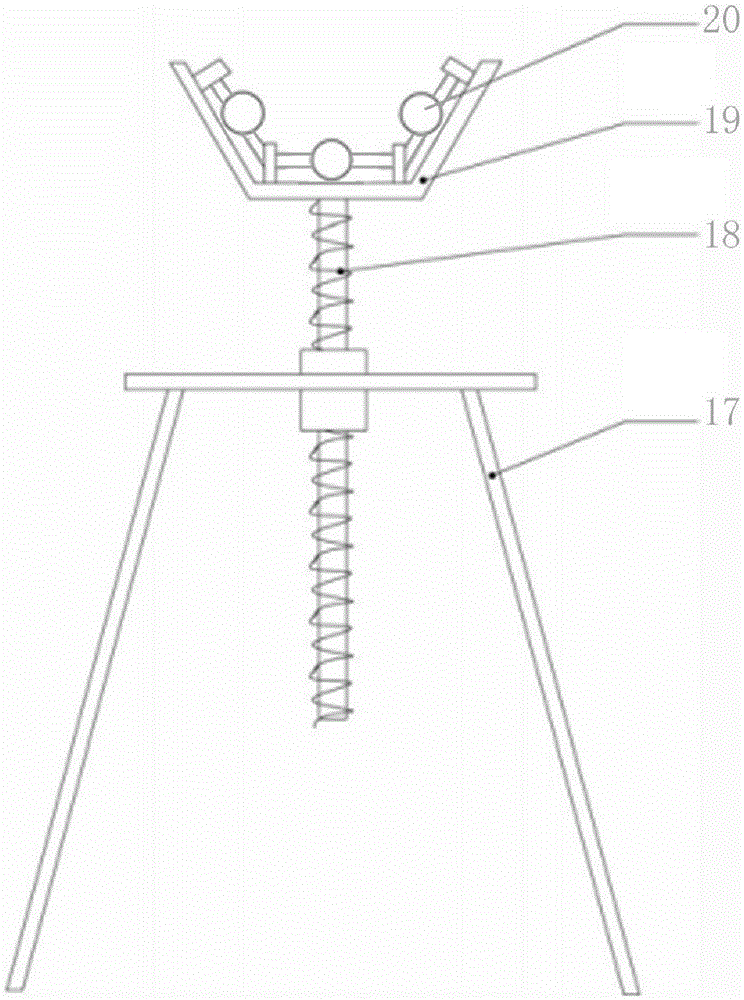

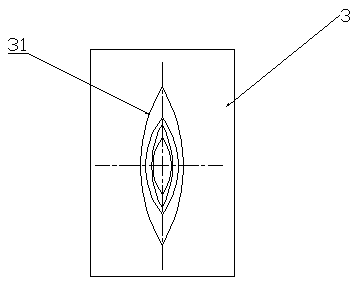

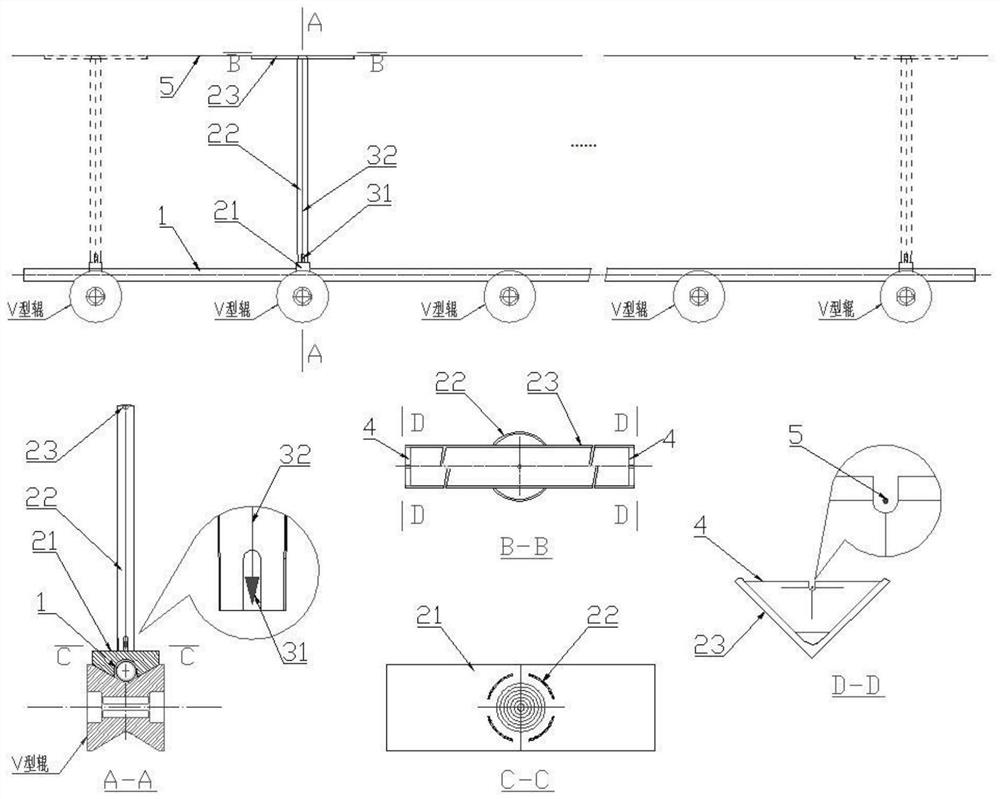

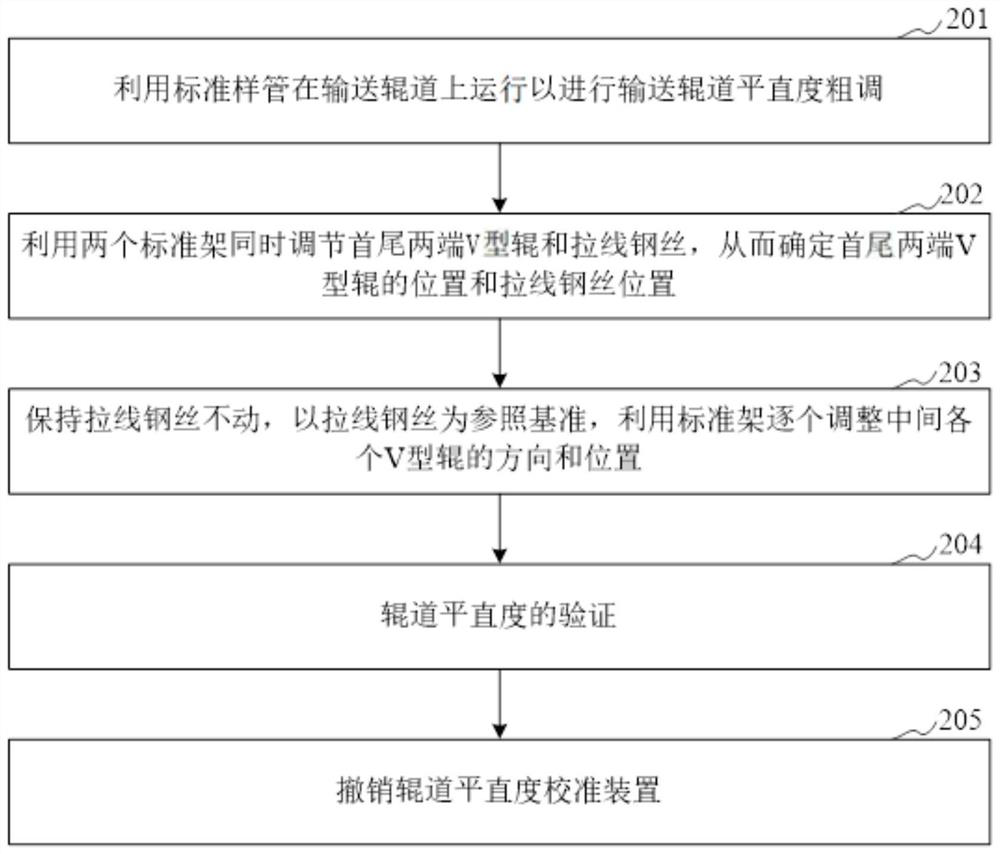

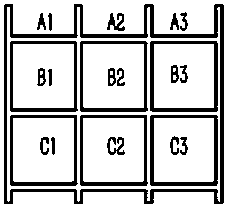

Straightness calibration device for V-shaped conveying roller way and using method thereof

ActiveCN112577400ASimple structureEasy to processMechanical measuring arrangementsRoller-waysClassical mechanicsEngineering

The invention relates to a straightness calibration device for a V-shaped conveying roller way. The straightness calibration device comprises a standard sample pipe, a standard frame, a hanger, a V-shaped piece and a stay wire steel wire. The standard frame comprises bases, vertical pipes and longitudinal rods, the bases are perpendicular in pairs, the bottom ends of the vertical pipes are perpendicularly connected with the bases, a plurality of observation holes are formed in the bottom ends of the vertical pipes, the top ends of the vertical pipes are perpendicularly connected with the longitudinal rods, the bottoms of the bases are conical surfaces matched with the conical surfaces of the V-shaped rollers, and inverted first U-shaped grooves are formed in the middles of the bottoms of the bases. Cross-shaped scales are arranged on the top surface of the base. The hanger is arranged in the vertical pipe and comprises a hanging cone and a hanging wire, the hanging cone is connected with a longitudinal rod located at the top end of the vertical pipe through the hanging wire, V-shaped pieces are arranged at the two ends of the longitudinal rod respectively, second U-shaped grooves are formed in the tops of the V-shaped pieces, and the connecting line of the groove bottom circle centers of the second U-shaped grooves of the V-shaped pieces at the two ends is parallel to the longitudinal rod. Straightness calibration is carried out on the conveying roller way composed of the multiple V-shaped rollers, and compared with the prior art, the calibration precision is improved.

Owner:BAOSTEEL SPECIAL STEEL SHAOGUAN CO LTD

Robot sample sheet taking and placing and labeling and material frame buffering system and working method thereof

PendingCN111086814AImprove securityImprove effective operation rateStorage devicesConveyor partsLabelling machineRobot control

The invention relates to a robot sample sheet taking and placing and labeling and material frame buffering system. A movable trolley, a robot control cabinet, a buffering material frame, a labeling table and a manual sample sheet taking and placing table are separately located on two sides and the front part of a robot. A labeling manipulator and a printer are arranged on the labeling table; a PLCcontrol cabinet is connected to the movable trolley and controls the movable trolley to move to the side of the robot, the PLC control cabinet is connected to the robot control cabinet and controls the robot to drive a sucking disc clamp to take and place a sample sheet through the robot control cabinet, the PLC control cabinet is connected to the labeling table and controls the labeling table toposition and correct the sample sheet secondarily automatically, and the PLC control cabinet is connected to the labeling manipulator and the printer and controls the labeling manipulator to label the corresponding position of the sample sheet automatically. The system provided by the invention alleviates the labor strength of a unit operator in a production process and reduces mistakes caused bymanual labeling.

Owner:SHANGHAI ZHONGYE HENGTIAN AUTOMATION ENG

Method for measuring distance between rollers in rolling mill

InactiveCN108188185AAccurate measurementAvoid running pile steel accidentsMeasuring devicesMetal rolling arrangementsCalipersMaterials science

The invention discloses a method for measuring the distance between rollers in a rolling mill. The method comprises the steps of preparing a pre-rolling sample, heating the pre-rolling sample, then starting the rolling mill, and rolling the heated pre-rolling sample through the upper roller and the lower roller to obtain a rolled sample; and measuring the rolled sample through a pair of calipers to obtain the distance between the upper roller and the lower roller. By means of the method, the problem that if the rolling mill adopted has a certain amount of bounce, a traditional measurement method has large errors when used for measuring the distance between the rollers, and consequently the steel stacking accident is easily caused in the subsequent steel feeding process is solved.

Owner:WUHU XINXING DUCTILE IRON PIPES

Electronic belt scale tobacco scrap automatic removal device for tobacco

ActiveCN103063280AHigh measurement accuracyImprove effectivenessWeighing apparatus for continuous material flowInfraredLight beam

Disclosed is an electronic belt scale tobacco scrap automatic removal device for tobacco. The electronic belt scale tobacco scrap automatic removal device for the tobacco comprises a belt scale belt and a belt scale frame arranged above the belt scale belt. A gap is arranged between the belt scale belt and the belt scale frame. A fixed plate is fixedly connected with the belt scale frame. The fixed plate is provided with an air cylinder which is horizontally arranged. A movable push plate is arranged at the front end of the air cylinder, and the movable plate is corresponding to the gap between the belt scale belt and the belt scale frame. Miniature infrared permeance type light beam type detector detecting switches are arranged at two ends of the belt scale belt and two ends of the belt scale frame and are corresponding to the gap between the belt scale belt and the belt scale frame. When the electronic belt scale tobacco scrap automatic removal device for the tobacco is in use and when clamped tobacco scraps appear in the gap between the belt scale belt and the belt scale frame, light beams emitted by the miniature infrared permeance type light beam type detector detecting switches are incapable of smoothly penetrating, the air cylinder receives an action signal, pushes the movable push plate forward, and pushes the clamped tobacco scraps away by using a flanging at the front end of the movable push plate. The electronic belt scale tobacco scrap automatic removal device for the tobacco has the advantages of being simple in structure, simple and convenient to operate, convenient to achieve, capable of greatly improving measuring accuracy of an electronic belt scale and an effective operation rate of equipment, and capable of effectively guaranteeing quality of products.

Owner:CHINA TOBACCO HENAN IND

Z type cigarette falling device of high-speed packaging machine outlet

InactiveCN103101645AEasy to sample for self-inspectionEasy to observe onlinePackagingCartonEngineering

The invention discloses a Z type cigarette falling device of a high-speed packaging machine outlet which is connected with a high-position belt conveyor through an outlet sliding plate installed in an inclined mode, and the high-position belt conveyor is connected with a low-position belt conveyor through a cigarette falling air cushion vertical channel. A high-position XL type synchronous belt of the high-position belt conveyor and a low-position XL type synchronous belt of the low-position belt conveyor are independently controlled through a high-position belt motor and a low-position belt motor, and cigarette cartons are kept to be stationary relative to the high-position XL type synchronous belt and the low-position XL type synchronous belt in a conveying process. The horizontal section of the cigarette falling air cushion vertical channel is a square which is matched with the appearances of the cigarette cartons, the size of each edge of the square is 1 to 5 millimeters larger than that of each edge of the appearance of each corresponding cigarette carton. The Z type cigarette falling device achieves smooth conveying of the cigarette cartons from a high position to a low position. The Z type cigarette falling device facilitates sampling and self-checking by operation personnel and on-line observation of product quality, facilitates emergent manual packaging when a downstream machine is halted, improves an effective operating rate of a unit, and effectively protects product appearance quality.

Owner:XIAMEN TOBACCO IND

Automatic drying system of monochromatic gravure press

InactiveCN101973161AAvoid scrappingDry fastRotary intaglio printing pressPrinting press partsInfrared lampPulp and paper industry

The invention relates to an automatic drying system of a monochromatic gravure press, which is used for accelerating pattern drying of the monochromatic gravure press. An automatic drying system is installed on a stand between a printing part and a paper collecting part; a hood of the automatic drying system is installed on a slideway on the stand; a shared air channel of the hood is communicated with a main air pipe connected with a fan; air in the main air pipe is blown into an air pipe with a hole at the bottom; the lower part of the air pipe in the hood is provided with infrared lamp tubes; the on-off of each infrared lamp tube is controlled by an air break switch installed on the stand; and the automatic drying system is provided with two or more air pipes and infrared lamp tubes. The air flows through the air pipe for spreading pressure air by the main air pipe through the fan to blow the infrared lamp tubes under the air pipe; and after being heated, the air blows the surface of paper passing through the monochromatic gravure press to automatically dry the paper. The automatic drying system rapidly dries a product by carrying out infrared automatic drying on a printed product pattern, thereby rapidly and continuously running equipment, improving the effective operation rate of the equipment and the yield of products and effectively preventing the discarding of the product pattern due to dirty sticking.

Owner:襄阳金飞环彩色包装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com