Straightness calibration device for V-shaped conveying roller way and using method thereof

A technology for calibrating device and conveying roller table, applied in the direction of roller table, measuring device, transportation and packaging, etc., can solve the problem that the horizontality and verticality of the V-shaped roller shaft cannot be guaranteed, and the smooth transportation and straightness of round bars of various specifications cannot be guaranteed. In order to achieve the effect of good promotion and application value, reducing the frequency of roller table calibration and manpower time investment, and improving the effective operation rate of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0032] It is worth noting that the orientation words such as "up" and "down" involved in this article are all determined relative to the perspective of the drawings, and are only for the convenience of description, and cannot be understood as limitations on the technical solution.

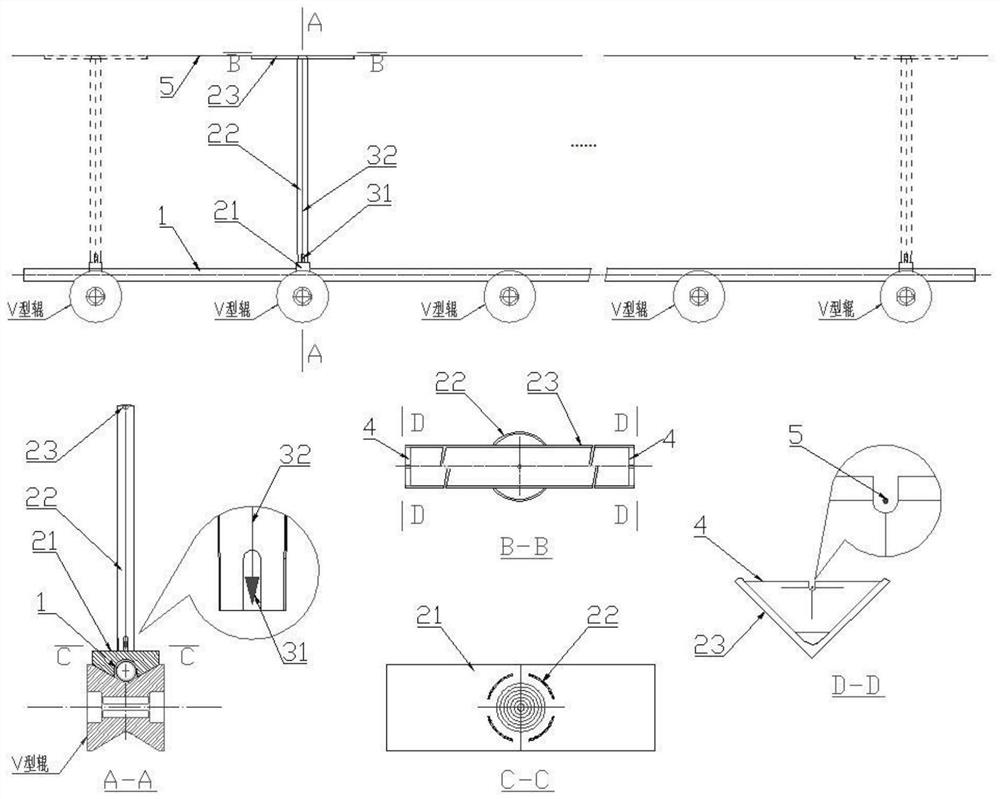

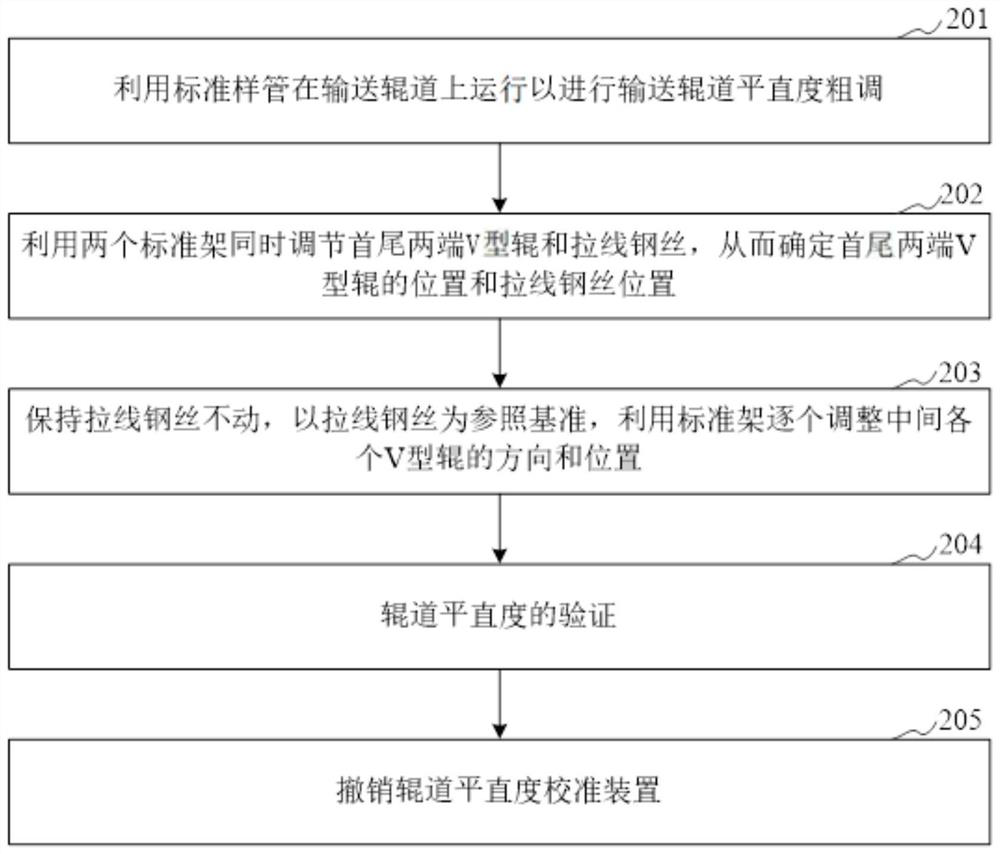

[0033] Such as figure 1 As shown, the present invention provides a V-shaped conveying roller flatness calibration device, which includes a standard sample tube 1, a standard frame, a hanger, a V-shaped piece and a wire 5 for a stay.

[0034]The standard frame comprises two vertical bases 21, standpipes 22 and longitudinal bars 23, the bottom of the standpipe 22 is vertically connected with the base 21, the bottom of the standpipe 22 is provided with a plurality of observation holes, the top of the standpipe 22 is connected to the vertical The rods 23 are vertically connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com