Mixed single denier strand for tar-reduced cigarette filter stick and preparing method and application of mixed single denier strand

A technology for cigarette filter rod and tow, which is applied in the field of mixed single-denier tow for decoking cigarette filter rod and its preparation, can solve the problems of high cost, low production efficiency, complicated production process of special-shaped filter rod, etc., and achieve effective operation High efficiency, stable coke reduction efficiency and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

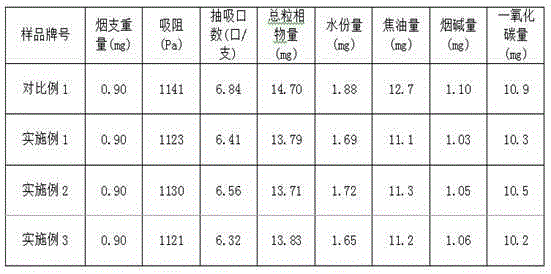

Embodiment 1

[0022] A preparation method with a mixed single -dan beam with a mixed -scorched cigarette filter with X -shaped section is used to dissolve the vinegar tablets with acetone to form a slurry, filter the slurry, enter the spinning device, and go through the three types of the same spray plate.The three different cross -section shapes and single -wire density of the spray holes of different pores and single -wire density, three different holes of different pores are evenly distributed in the same spray plate according to the weight ratio;The density of the single wire wires is 2.3Dtex, 2.7Dtex, 3.0Dtex, the proportion is 1: 1: 1, the single -silk section shape is X, Y, and O -type.Beams, dry, swing, and packaging finally produce a mixed single -dan fiber beam finished product.The fracture strength of the mixed Shan Dan beam is ≥18.0N / Ktex, the water content is (6.0 ± 1.6)%, the oil content is (0.70 ~ 1.50)%, the content of residual acetone is ≤0.30%, and the titanium dioxide content...

Embodiment 2

[0024] A preparation method with a mixed single -dan beam with a mixed -scorched cigarette filter with X -shaped section is used to dissolve the vinegar tablets with acetone to form a slurry, filter the slurry, enter the spinning device, and go through the three types of the same spray plate.The three different cross -section shapes and single -wire density of the spray holes of different pores and single -wire density, three different holes of different pores are evenly distributed in the same spray plate according to the weight ratio;The density of the single wire wires is 2.3Dtex, 2.7Dtex, and 3.0dtex, respectively, the ratio is 1: 1: 1, the single -silk section shape is X, X, and O -type.Beams, dry, swing, and packaging finally produce a mixed single -dan fiber beam finished product.The fracture strength of the mixed Shan Dan beam is ≥18.0N / Ktex, the water content is (6.0 ± 1.6)%, the oil content is (0.70 ~ 1.50)%, the content of residual acetone is ≤0.30%, and the titanium di...

Embodiment 3

[0026] A preparation method with a mixed single -dan beam with a mixed -scorched cigarette filter with X -shaped section is used to dissolve the vinegar tablets with acetone to form a slurry, filter the slurry, enter the spinning device, and go through the three types of the same spray plate.The three different cross -section shapes and single -wire density of the spray holes of different pores and single -wire density, three different holes of different pores are evenly distributed in the same spray plate according to the weight ratio;The density of the single wire wires is 2.3Dtex, 2.7Dtex, and 3.0dtex, respectively, the ratio is 1: 1: 1, the single -silk section shape is Y, Y, and O -type.Beams, dry, swing, and packaging finally produce a mixed single -dan fiber beam finished product.The fracture strength of the mixed Shan Dan beam is ≥18.0N / Ktex, the water content is (6.0 ± 1.6)%, the oil content is (0.70 ~ 1.50)%, the content of residual acetone is ≤0.30%, and the titanium di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coefficient of variation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com