A mixed single denier tow with O-shaped cross-section for reduced-focus cigarette filter rods and its preparation method and application

A cigarette filter rod and tow technology, which is applied in the field of mixed single-denier tow for reduced-focus cigarette filter rods and its preparation, can solve the problems of complex production process, low production efficiency, and high cost of special-shaped filter rods, and achieve the efficiency of reduced-focus cigarettes Stability, high effective operation rate, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

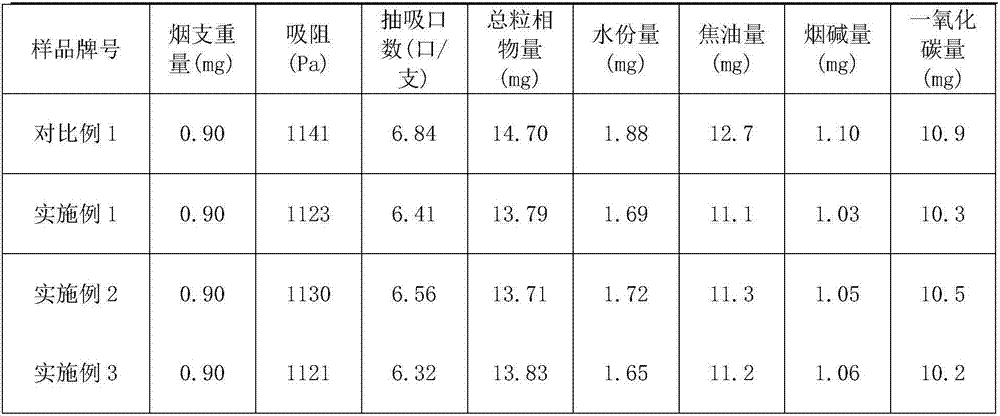

Embodiment 1

[0022] A method for preparing mixed single-denier tows for reduced-focus cigarette filter rods with O-shaped cross-sections. Dissolving vinegar slices in acetone to form a slurry, filtering the slurry, entering spinning equipment, and passing through the same spinneret. The spinneret holes of different apertures are spun to form three kinds of monofilaments with different linear densities. The spinnerets of the three different apertures are evenly distributed in the same spinneret according to the weight ratio; The thread densities are 2.3dtex, 2.7dtex, 3.0dtex respectively, and the ratio is 1:1:1. The cross-sectional shape of the monofilament is O-shaped, and the material of the monofilament is acetate fiber. A finished mixed monodenier fiber tow is produced. The breaking strength of the mixed single denier tow is ≥18.0N / Ktex, the water content is (6.0±1.6)%, the oil content is (0.70~1.50)%, the residual acetone content is ≤0.30%, and the titanium dioxide content is (0.40 ±0...

Embodiment 2

[0024] A method for preparing mixed single-denier tows for reduced-focus cigarette filter rods with O-shaped cross-sections. Dissolving vinegar slices in acetone to form a slurry, filtering the slurry, entering spinning equipment, and passing through the same spinneret. The spinneret holes of different apertures are spun to form three kinds of monofilaments with different linear densities. The spinnerets of the three different apertures are evenly distributed in the same spinneret according to the weight ratio; The thread densities are 1.5dtex, 2.0dtex, 2.5dtex respectively, and the ratio is 1:1:1. The cross-sectional shape of the monofilament is O-shaped, and the material of the monofilament is acetate fiber. A finished mixed monodenier fiber tow is produced. The breaking strength of the mixed single denier tow is ≥18.0N / Ktex, the water content is (6.0±1.6)%, the oil content is (0.70~1.50)%, the residual acetone content is ≤0.30%, and the titanium dioxide content is (0.40 ±0...

Embodiment 3

[0026] A method for preparing mixed single-denier tows for reduced-focus cigarette filter rods with O-shaped cross-sections. Dissolving vinegar slices in acetone to form a slurry, filtering the slurry, entering spinning equipment, and passing through the same spinneret. The spinneret holes of different apertures are spun to form three kinds of monofilaments with different linear densities. The spinnerets of the three different apertures are evenly distributed in the same spinneret according to the weight ratio; The thread densities are 2.0dtex, 2.5dtex, 3.0dtex, the ratio is 1:1:1, the cross-sectional shape of the monofilament is O-shaped, and the material of the monofilament is acetate fiber. A finished mixed monodenier fiber tow is produced. The breaking strength of the mixed single denier tow is ≥18.0N / Ktex, the water content is (6.0±1.6)%, the oil content is (0.70~1.50)%, the residual acetone content is ≤0.30%, and the titanium dioxide content is (0.40 ±0.20)%. Mixed sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com