Patents

Literature

1719 results about "Labelling machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

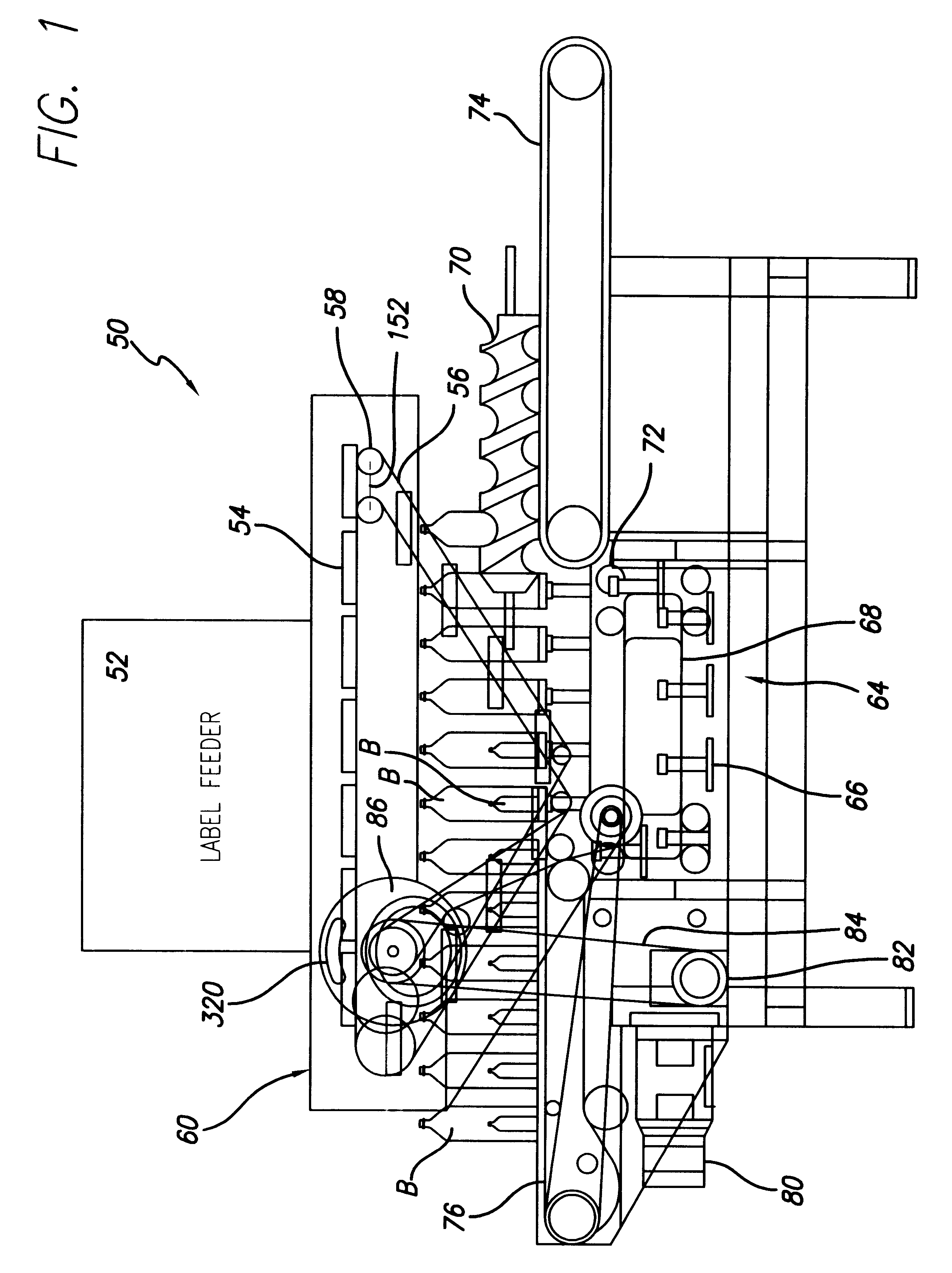

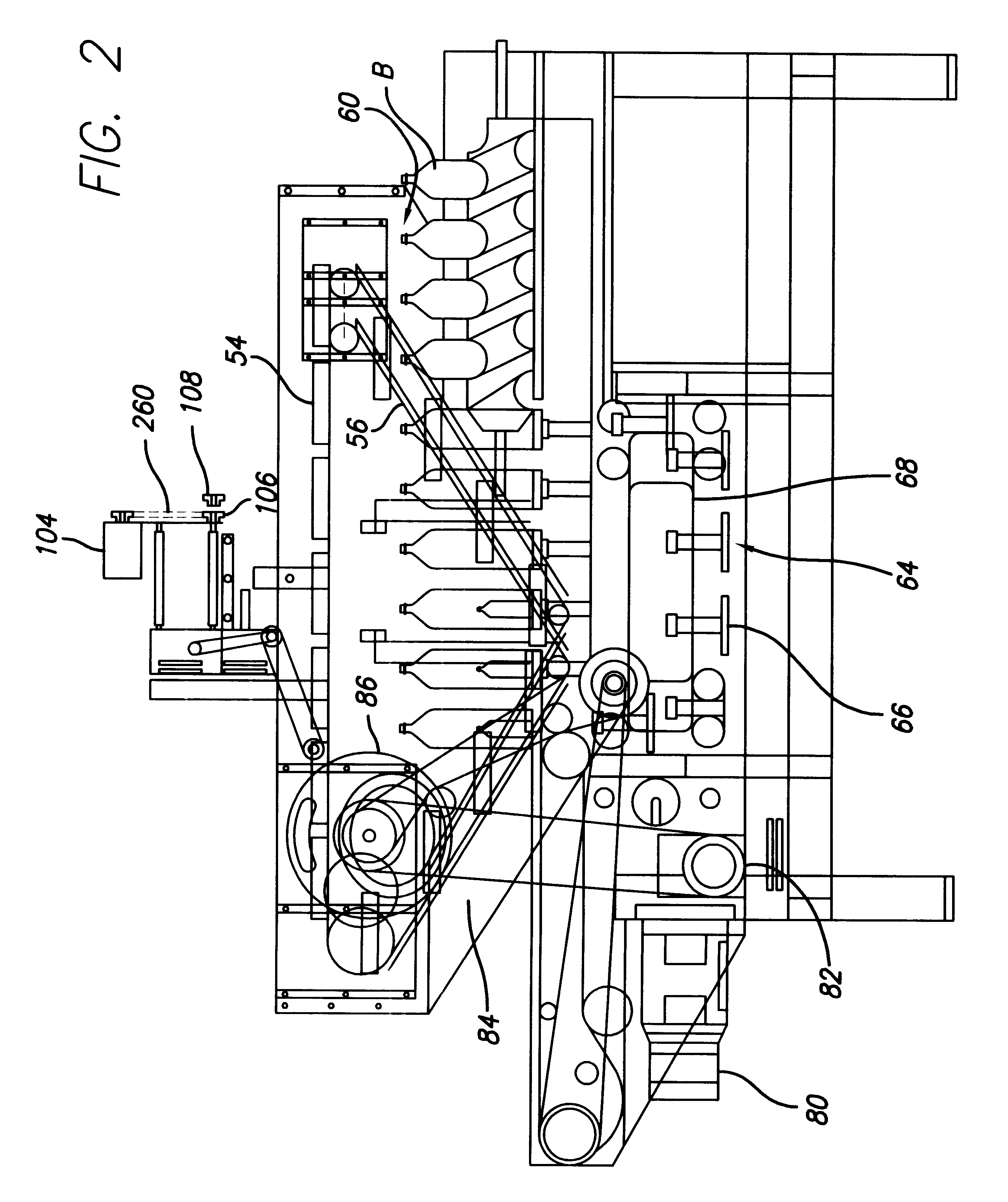

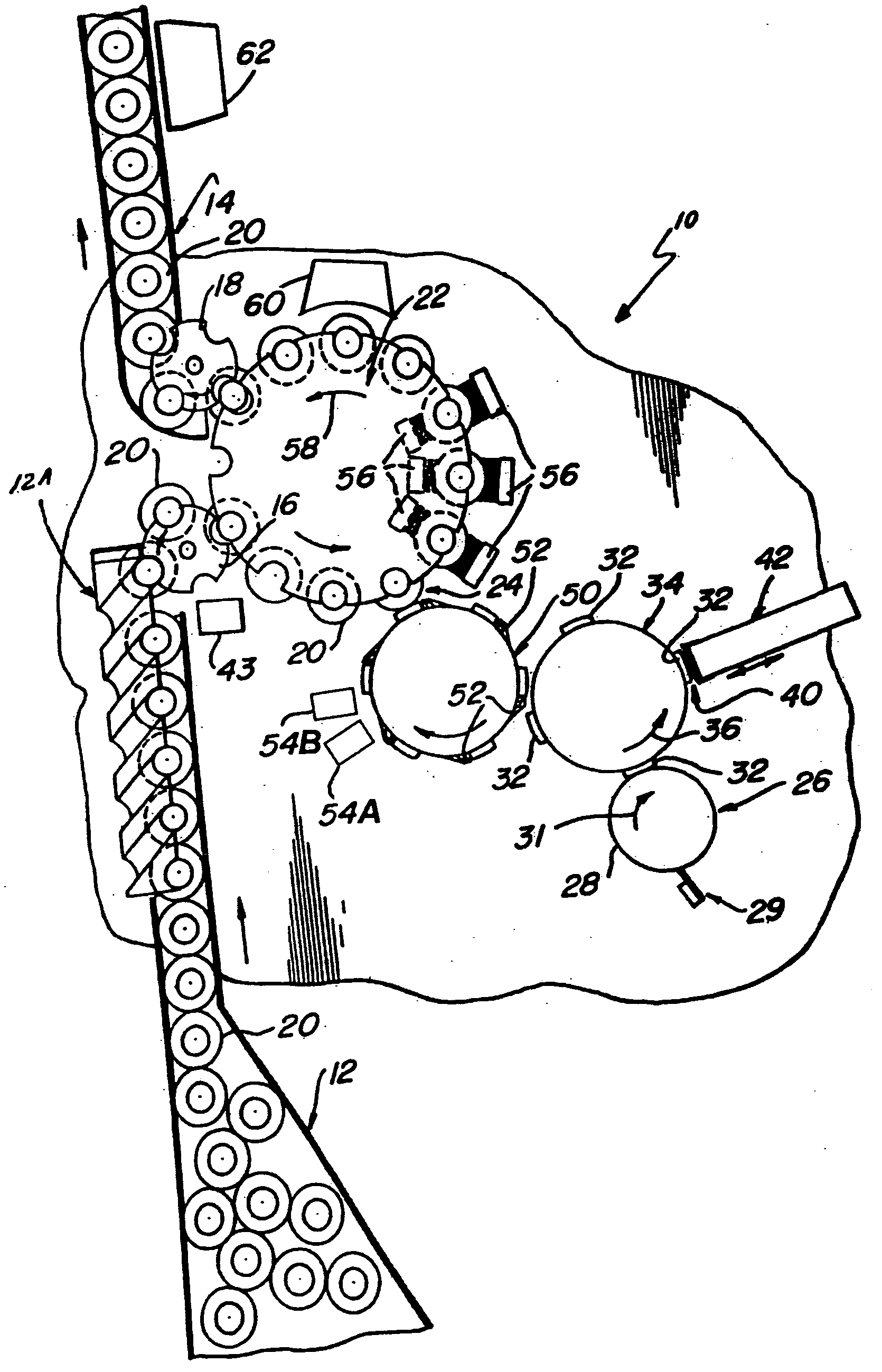

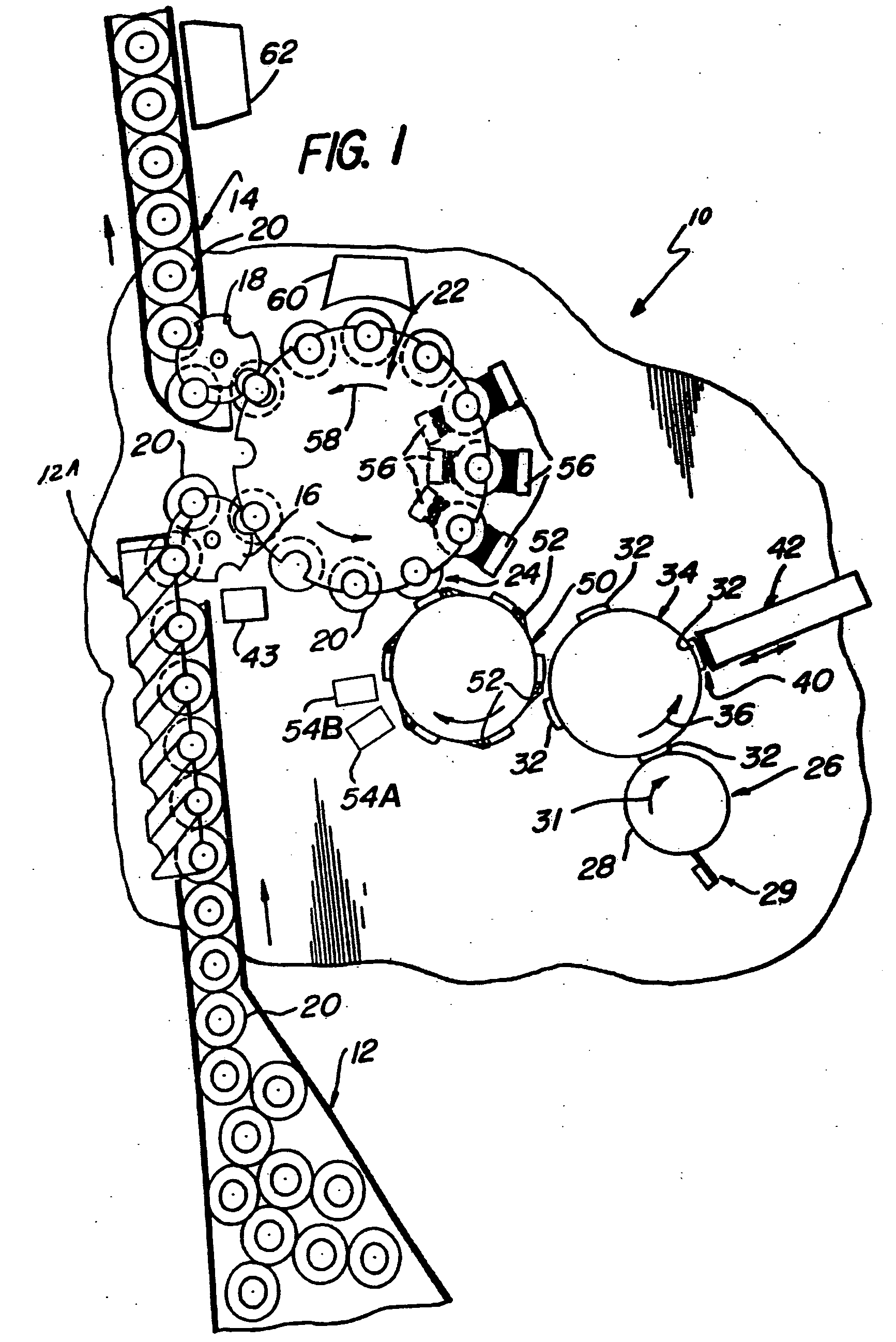

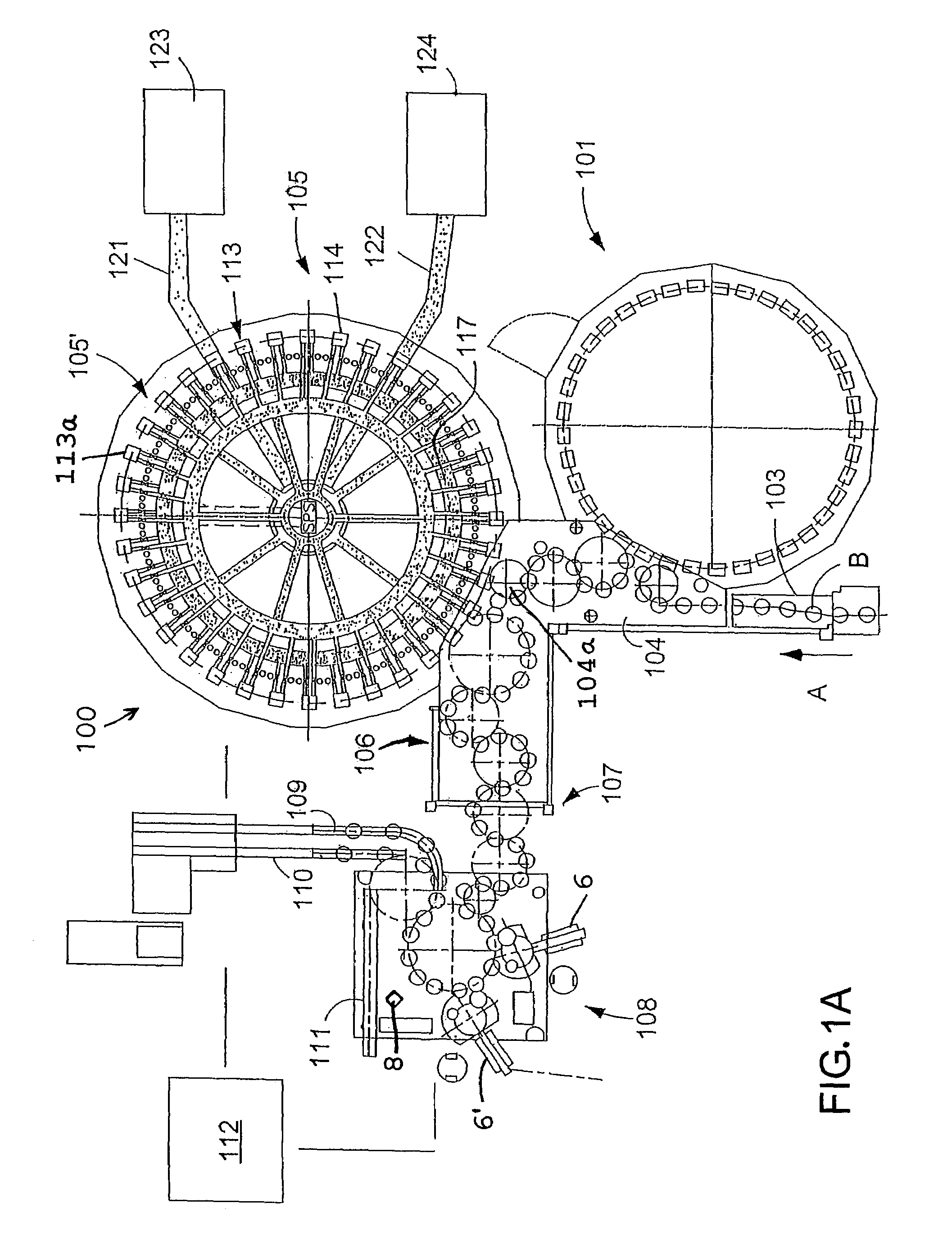

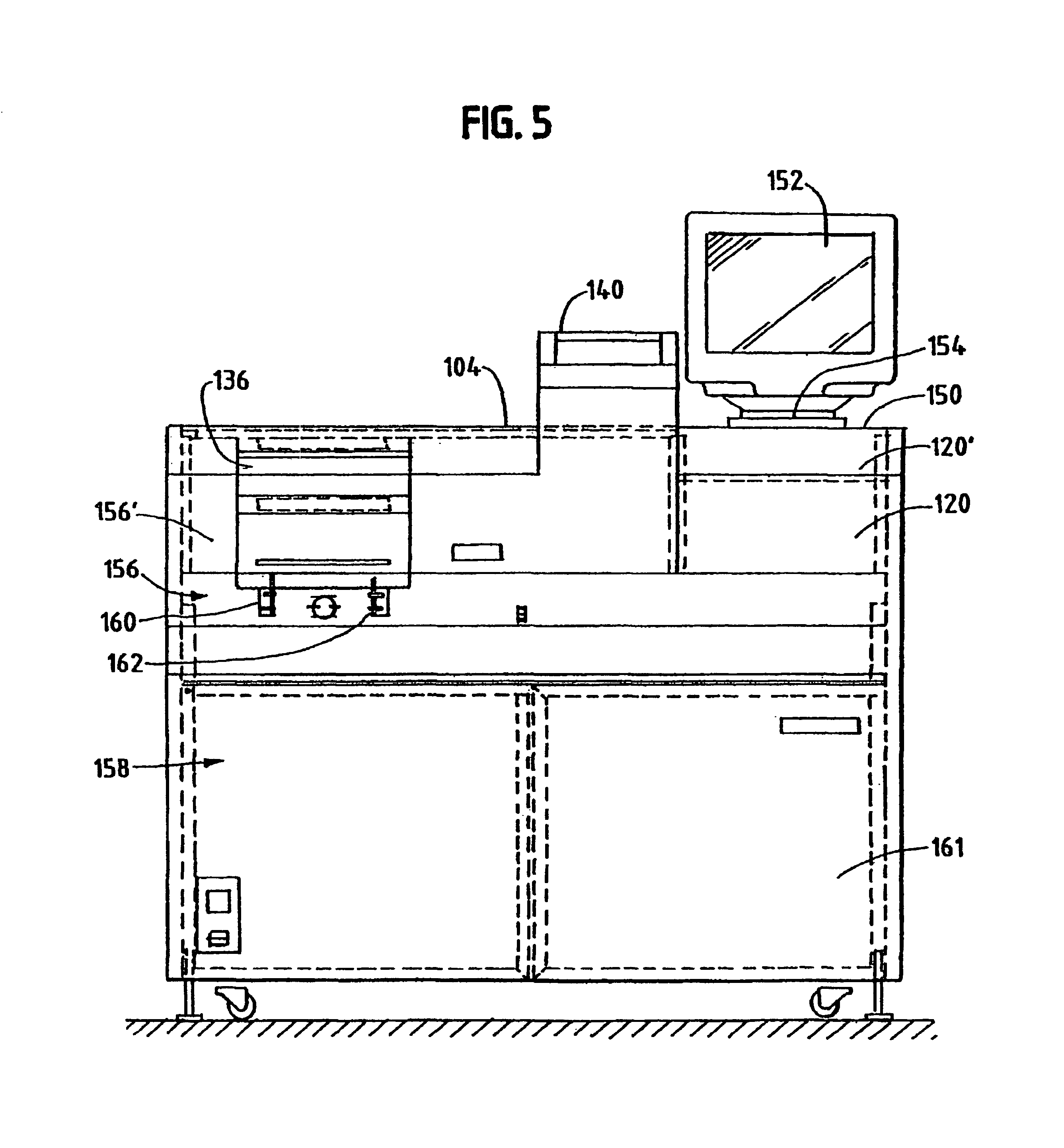

In-line continuous feed sleeve labeling machine and method

InactiveUS20010002614A1Wrappers shrinkageMechanical working/deformationUltrasonic weldingEngineering

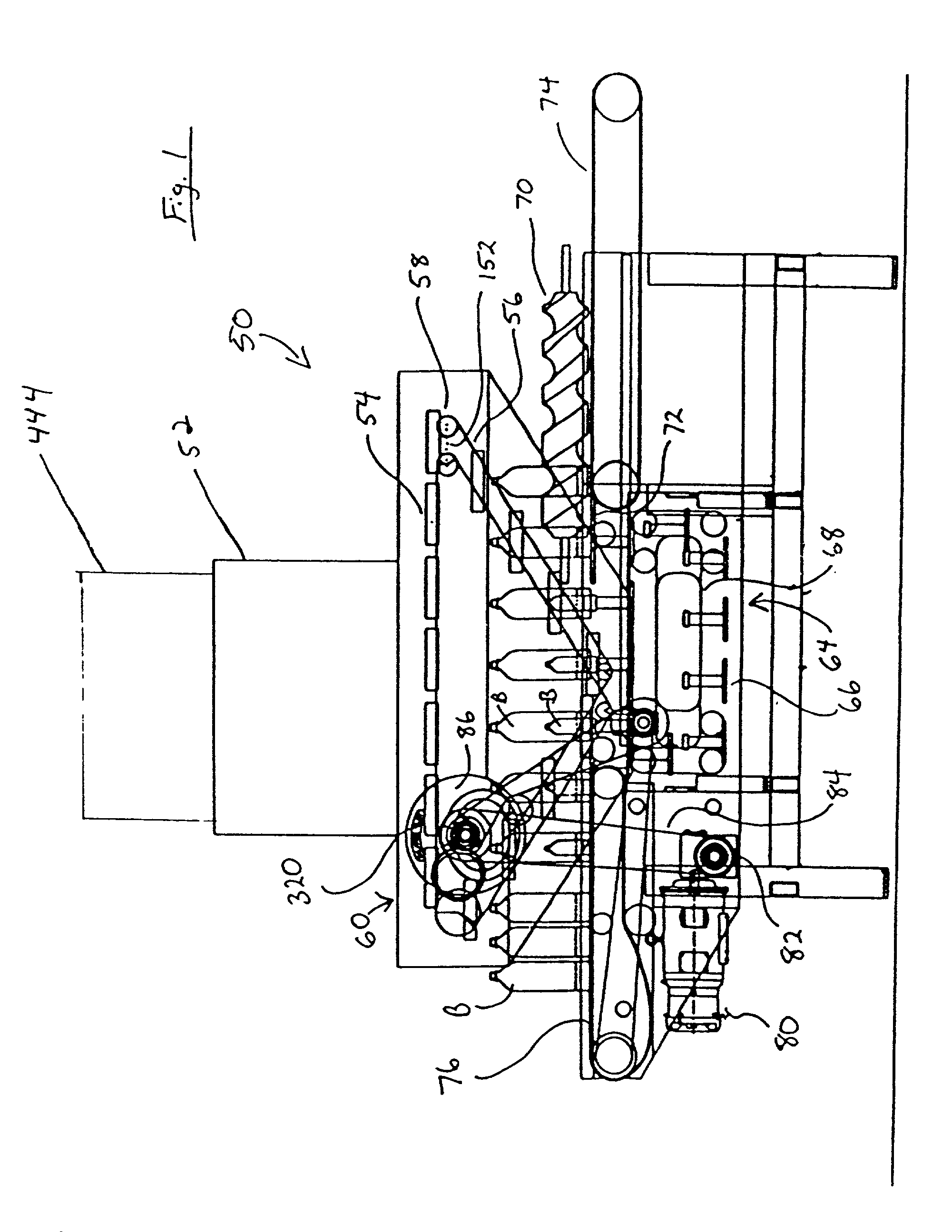

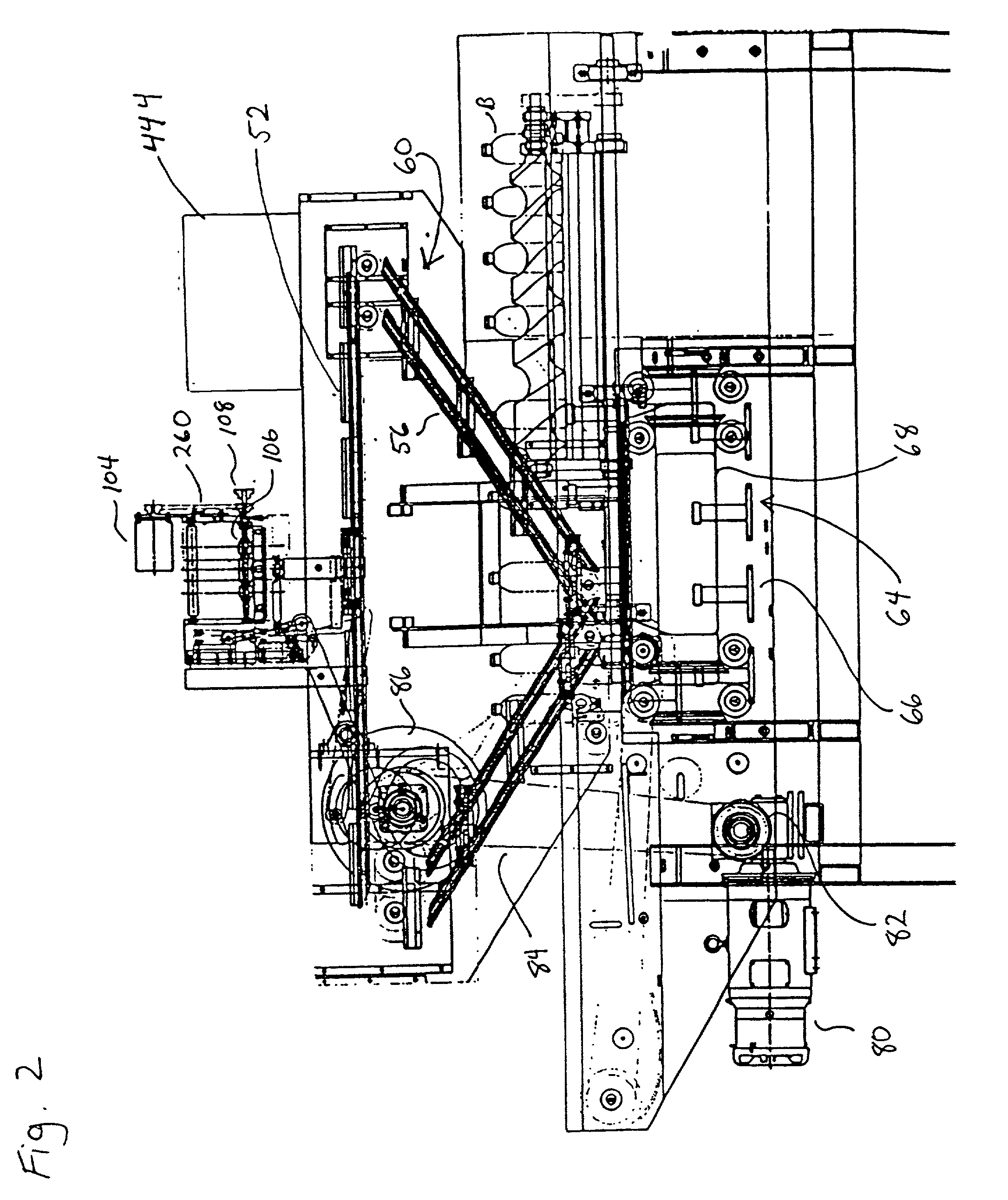

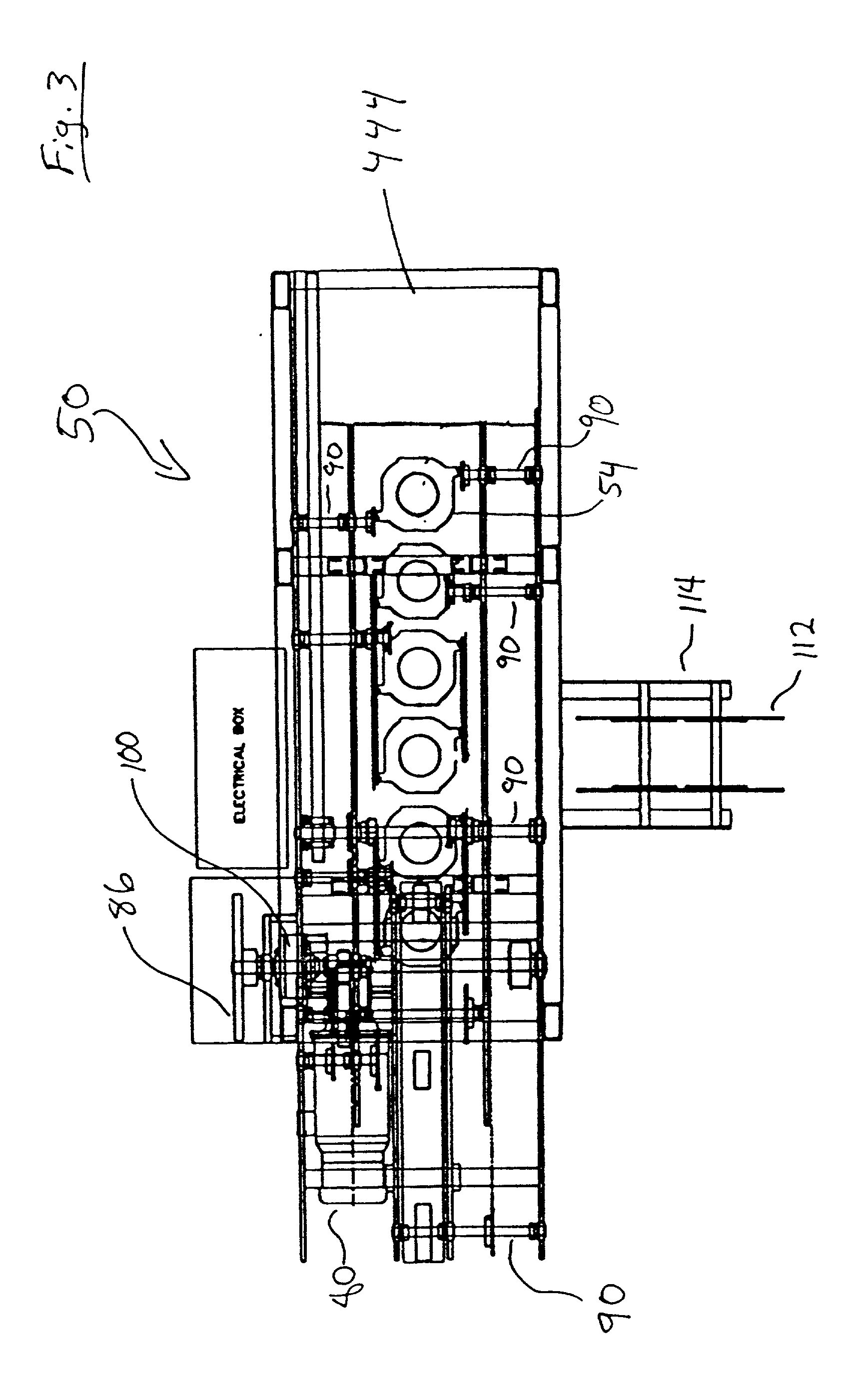

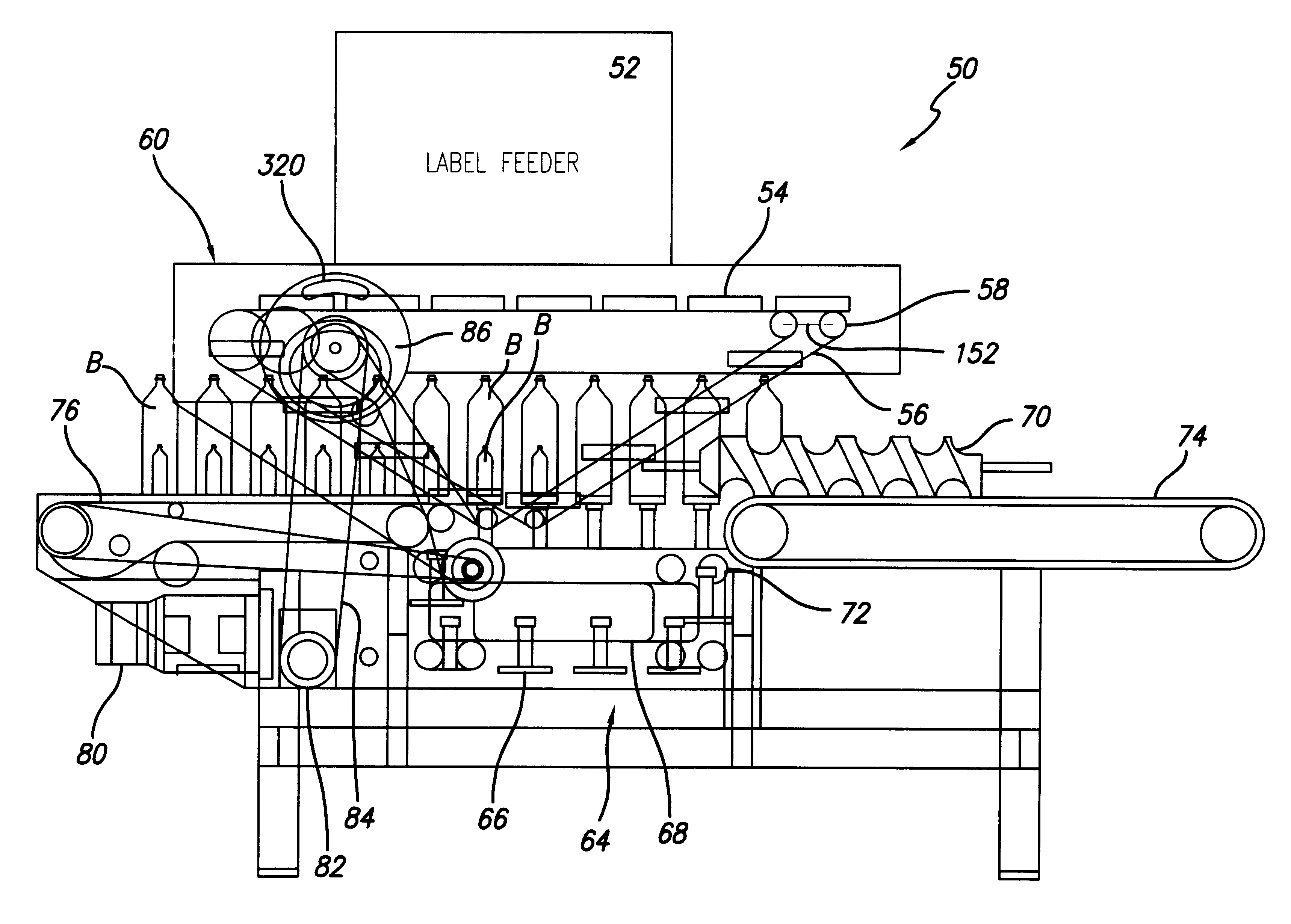

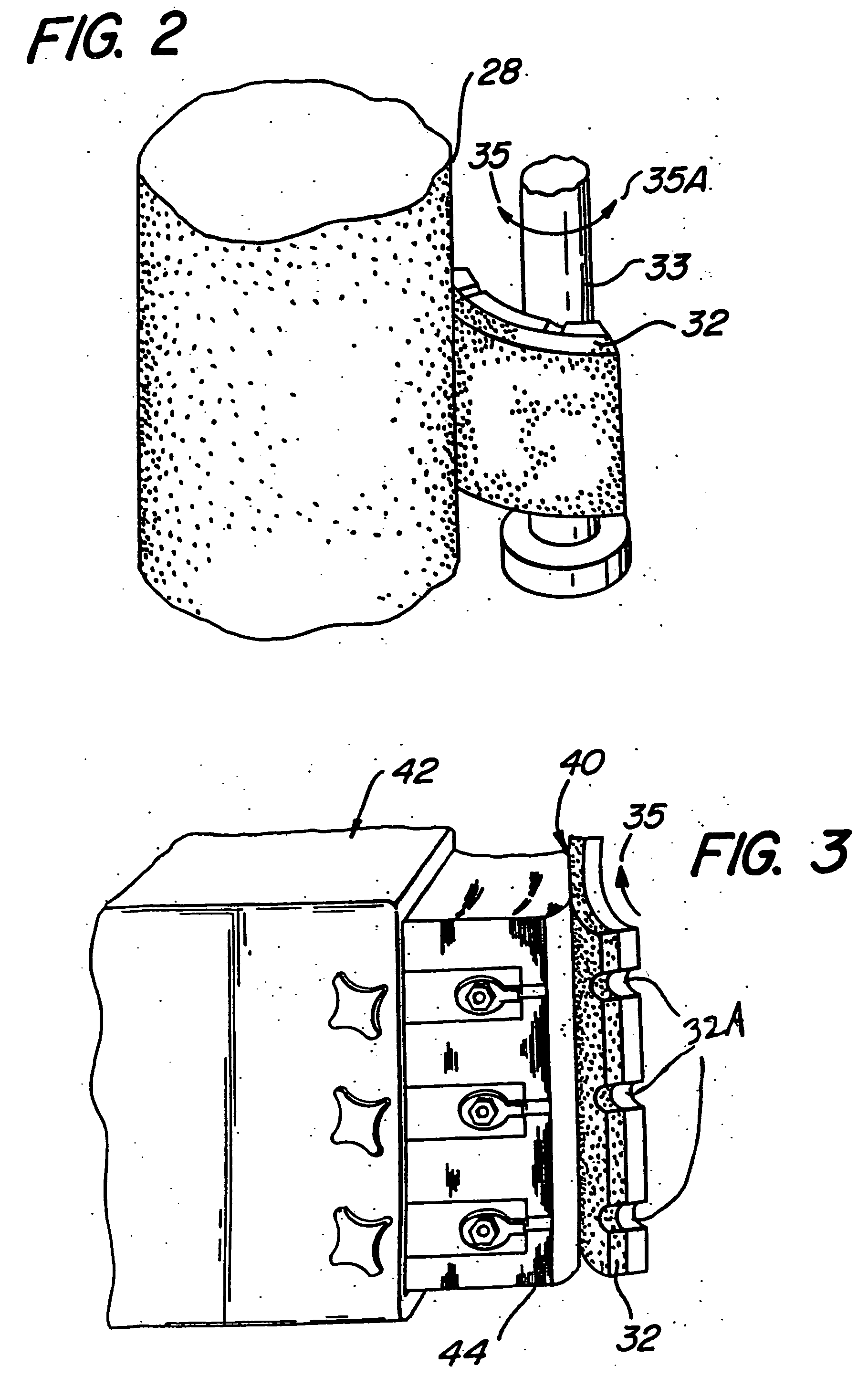

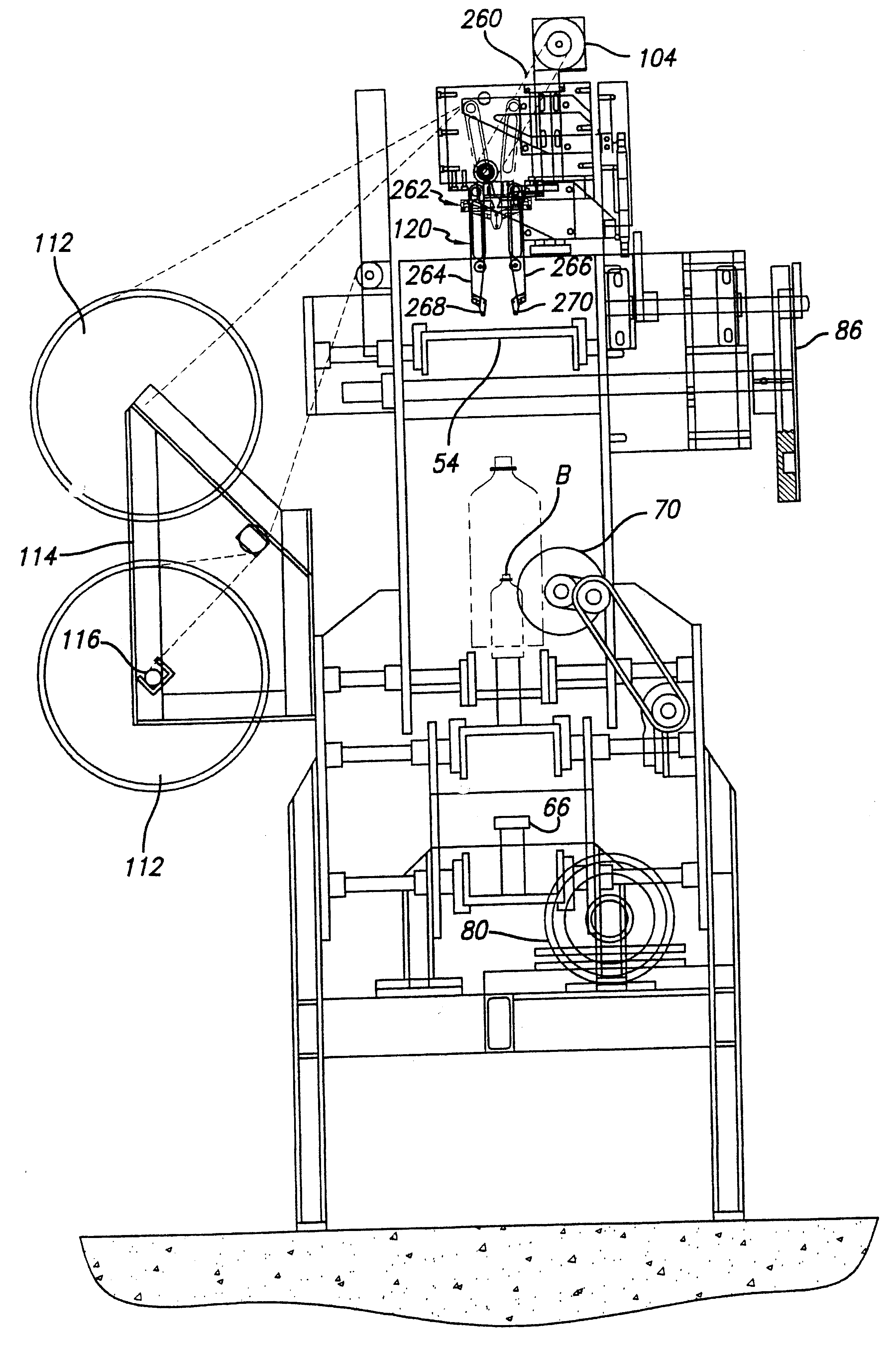

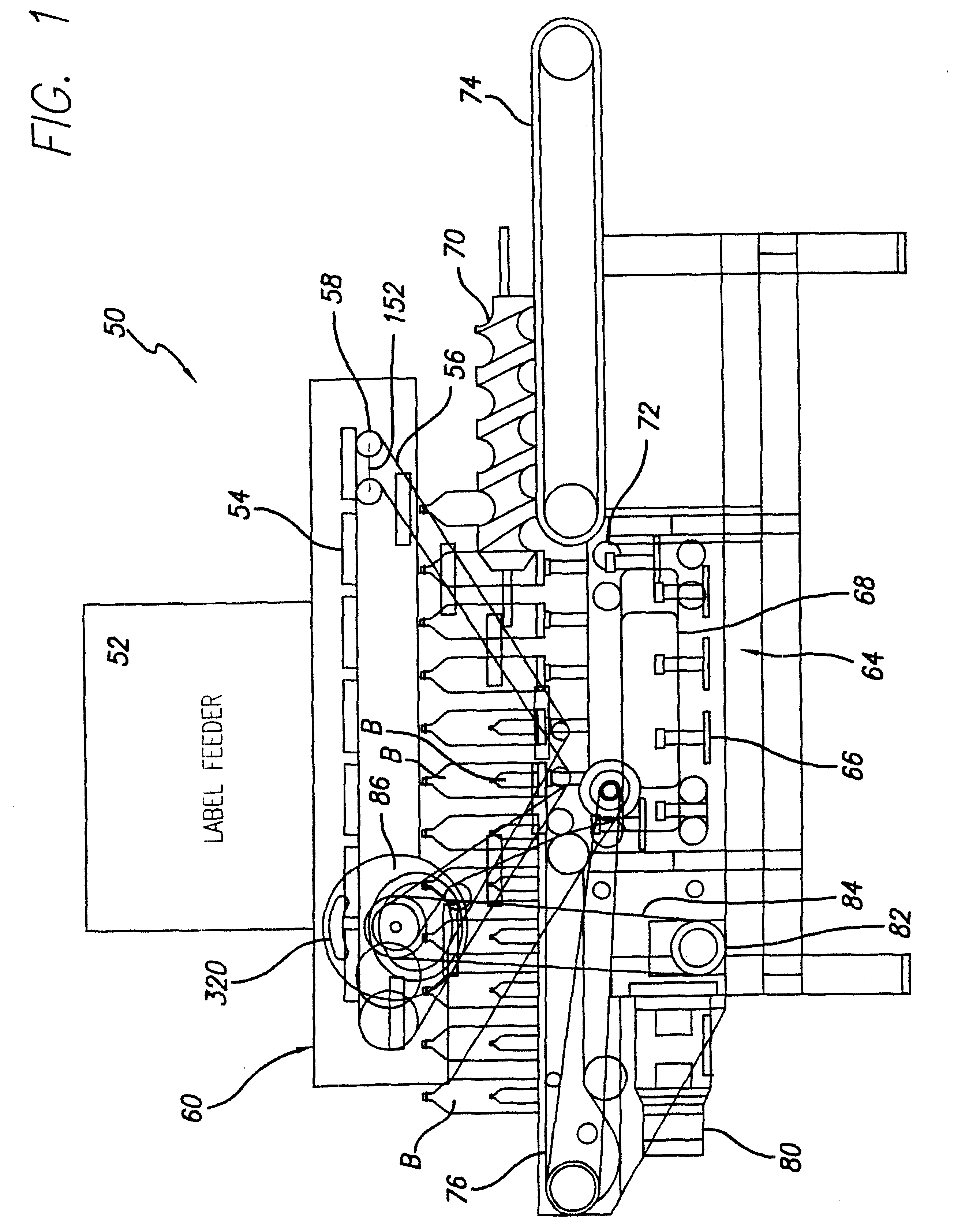

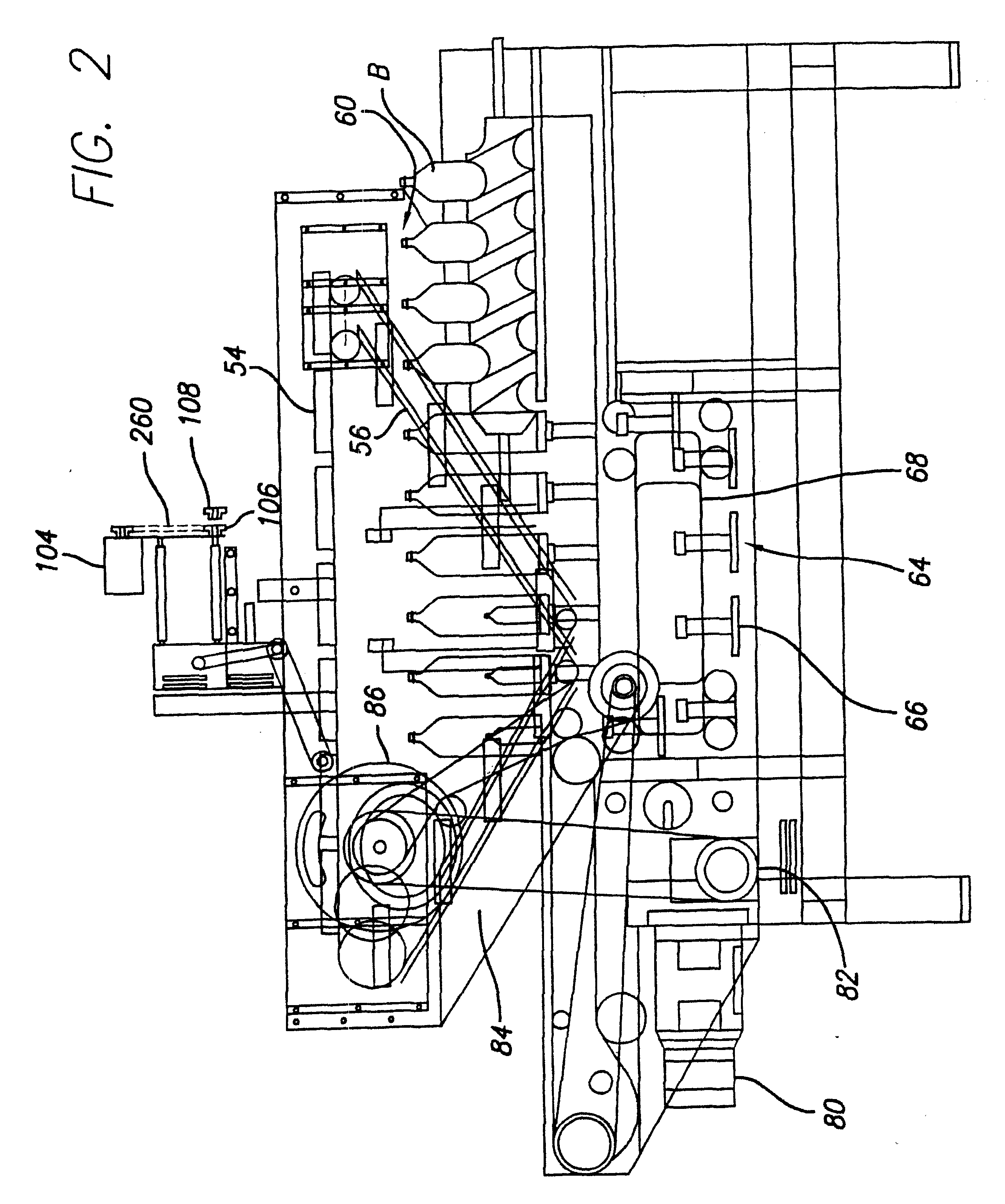

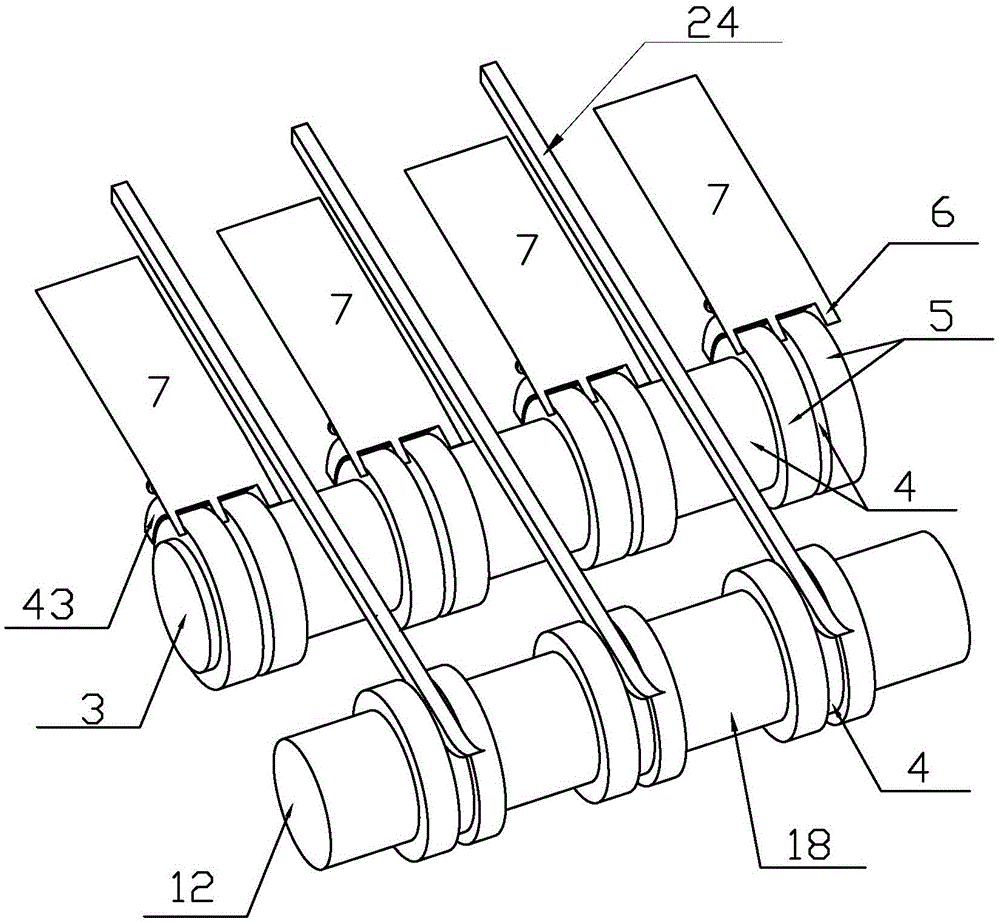

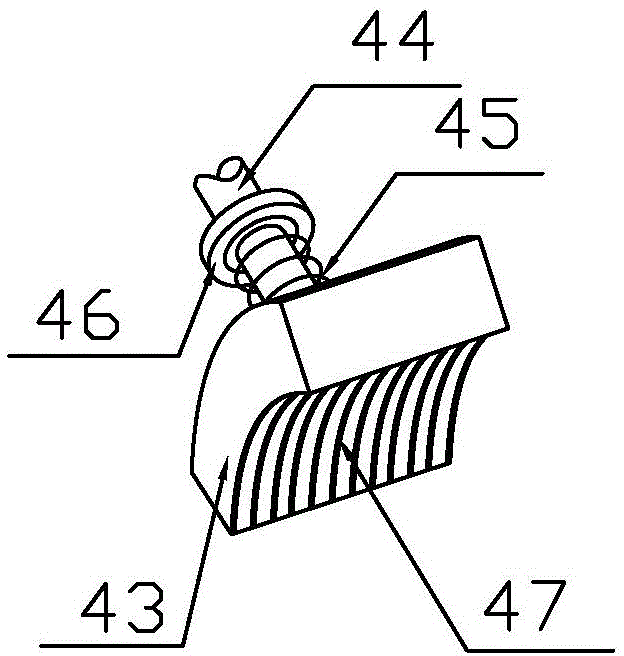

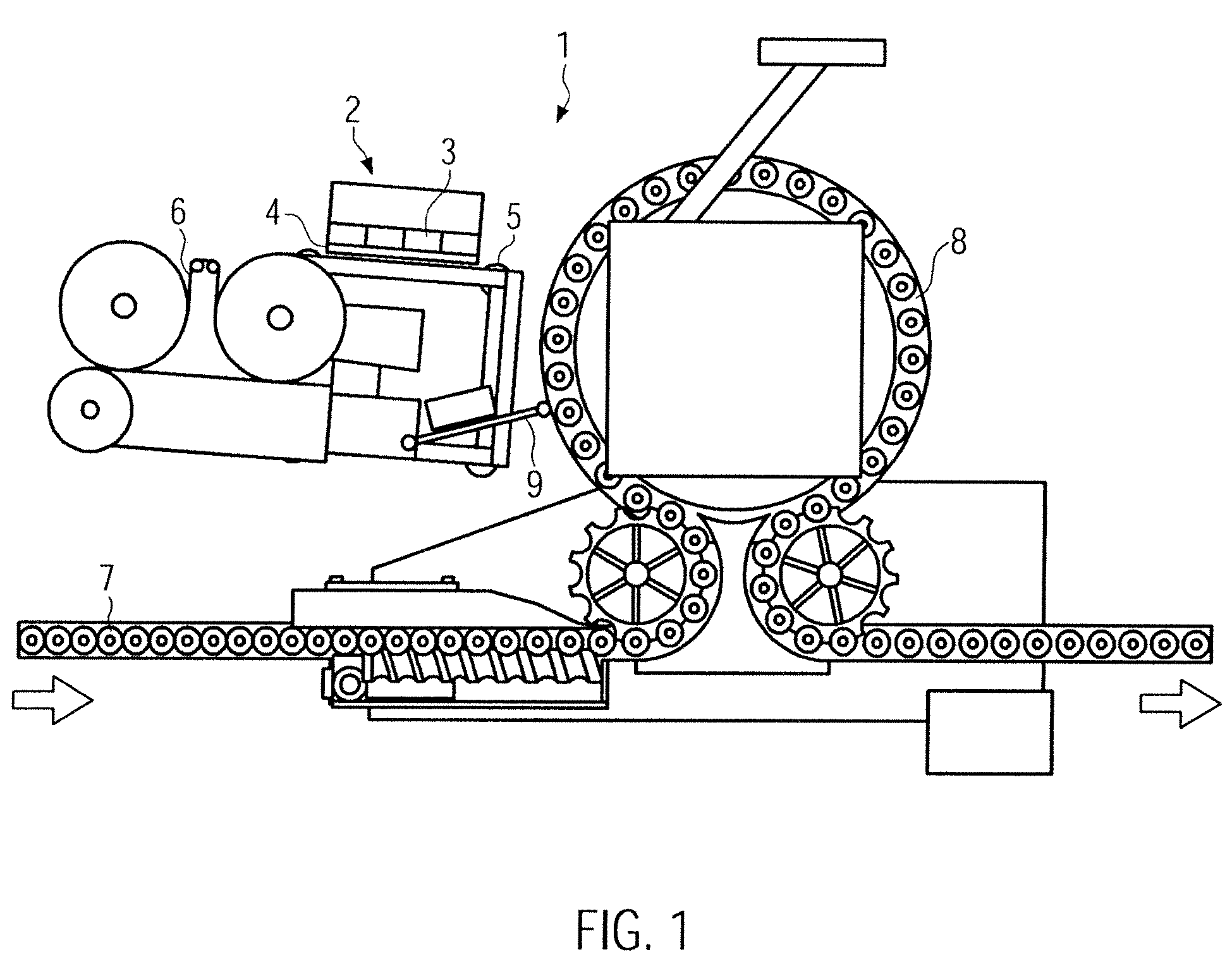

An in-line continuous feed sleeve labeling machine labels containers, such as beverage containers, in an in-line fashion maintaining the elevation of the containers during their linear transport. The in-line continuous feed sleeve labeling machine of the present invention receives bottles in flood feeder or linear fashion. A timing screw or the like properly separates, and both spatially and temporally disposes, the containers for sleeving. The timing screw propels the containers onto a pedestal system. The pedestals of the pedestal system maintain their horizontal nature due to offset pivotable attachments to the track system upon which they travel. A sheet of film is unspooled from an unwind roll and passed through a tube forming apparatus that overlaps the edges of the film. The overlapping edges completing the tube enclosure are connected using ultrasonic welding or the like. The sleeve is then passed to an iris carrier. In coordinated fashion with the travel of the pedestal system, iris carriers carrying sleeves upon articulating radial arms descend upon the bottles. Once the label sleeve has reached the appropriate point (generally adjacent to the central portion of the bottle), the iris carrier allows the label sleeve to engage the central portion of the bottle. Frictional attachment or otherwise allows the finger rods of the iris carrier to pull away from the sleeve as the iris carrier continues to descend down towards the pedestal. The sleeve then becomes attached to or engaged by the bottle until the finger rods of the iris carrier free themselves from the sleeve label. A container stabilizer may provide lateral bottle support and aid the ensleevement process. The finger rods then dilate to better disengage the bottle as the iris carrier ascends up and away from the bottle. The bottle is then transported to an exit conveyor having been properly sleeved, while the iris carrier returns to transport another sleeve.

Owner:AXON LLC

In-line continuous feed sleeve labeling machine and method

An in-line continuous feed sleeve labeling machine labels containers, such as beverage containers, in an in-line fashion maintaining the elevation of the containers during their linear transport. The in-line continuous feed sleeve labeling machine of the present invention receives bottles in flood feeder or linear fashion. A timing screw or the like properly separates, and both spatially and temporally disposes, the containers for sleeving. The timing screw propels the containers onto a pedestal system. The pedestals of the pedestal system maintain their horizontal nature due to offset pivotable attachments to the track system upon which they travel. In coordinated fashion with the travel of the pedestal system, iris carriers carrying sleeves upon articulating radial arms descend upon the bottles. Once the label sleeve has reached the appropriate point (generally adjacent to the central portion of the bottle), the iris carrier allows the label sleeve to engage the central portion of the bottle. Frictional attachment or otherwise allows the finger rods of the iris carrier to pull away from the sleeve as the iris carrier continues to descend down towards the pedestal. The sleeve then becomes attached to or engaged by the bottle until the finger rods of the iris carrier free themselves from the sleeve label. A container stabilizer may provide lateral bottle support and aid the ensleevement process. The finger rods then dilate to better disengage the bottle as the iris carrier ascends up and away from the bottle. The bottle is then transported to an exit conveyor having been properly sleeved, while the iris carrier returns to transport another sleeve.

Owner:AXON LLC

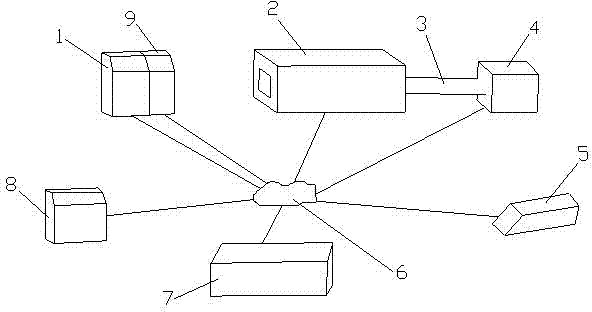

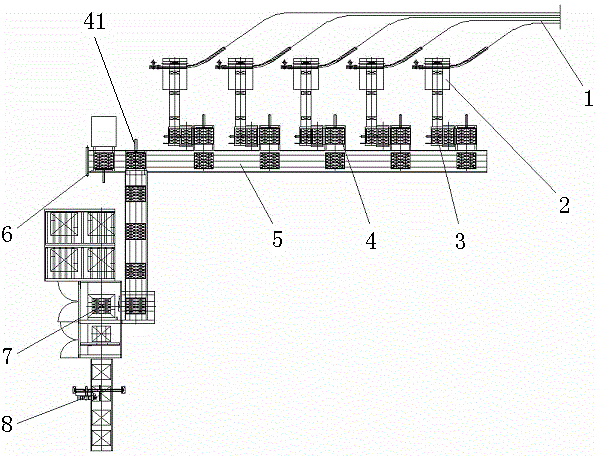

SMT material conveying method and system

ActiveCN104843486AImprove accuracySave human effortCharge manipulationConveyor partsProduction lineProcess engineering

The invention discloses an SMT material conveying method and system. The SMT material conveying method includes the steps of identity marking of materials, automatic warehousing and delivery in an intelligent warehouse, task distribution outside the warehouse, automatic conveying to a production line for use and re-identification warehousing of tailing. The SMT material conveying system comprises an automatic supplying machine, an automatic printing and labeling machine, the intelligent warehouse, an automatic printing and labeling module, a material conveying belt, an automatic feeding cart and automatic measurement and counting equipment, wherein the automatic supplying machine, the automatic printing and labeling machine, the intelligent warehouse and the automatic printing and labeling module are sequentially and linearly distributed, and the intelligent warehouse and the automatic printing and labeling module are connected through the material conveying belt. The SMT material conveying method and system can largely reduce labor, and are high in automation degree. The efficiency of storing, taking and conveying materials to the production line is high. The material management accuracy is high. The production cost is largely reduced. The production efficiency is improved.

Owner:SUZHOU I STOCK INTELLIGENT TECH

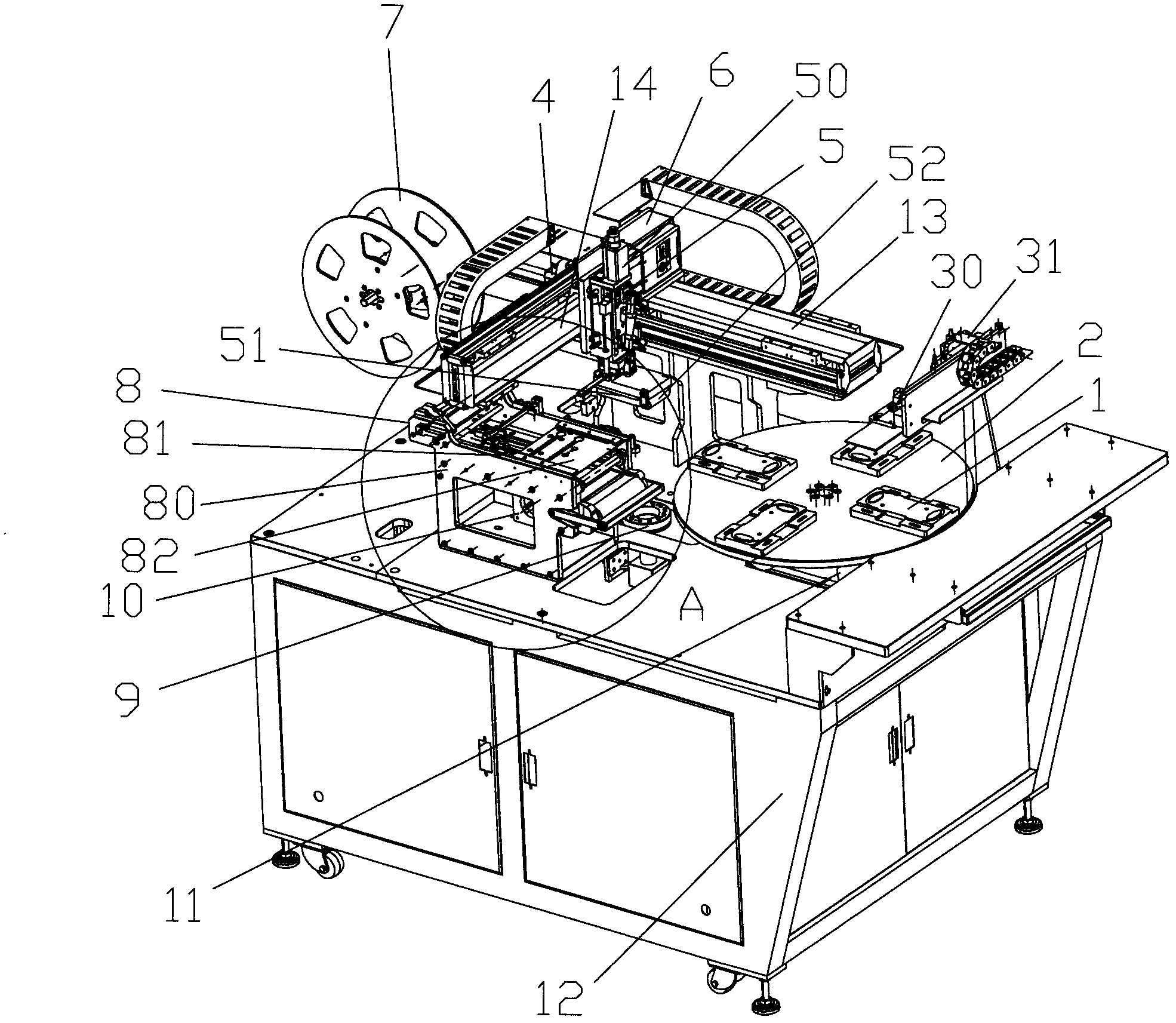

Labeling machine

InactiveCN102530336AReduce manual interventionSave human resourcesLabelling flat rigid surfacesLabelling machinesAxis cylinderEngineering

The invention provides a labelling machine which comprises a machine frame, a rotating bedplate, a material belt wheel disc, a material conveying device. a material pressing device and a material taking device, wherein the rotating bedplate is arranged at one end of the machine frame; the material belt wheel disc is arranged at the other end of the machine frame; the material conveying device and the material pressing device are arranged between the rotating bedplate and the material belt wheel disc; the material taking device is arranged on one side of the material belt wheel disc; a positioning jig for positioning a mobile phone screen is arranged on the rotating bedplate; the material conveying device comprises a sliding platform, a motor arranged below the sliding platform, and a sensor arranged between the sliding platform and the material belt wheel disc; and the material pressing device comprises a Y-axis slide track arranged on the machine frame, an X-axis slide track arranged on the Y-axis slide track, a Y-axis cylinder used for driving the X-axis slide track, a sliding suck head arranged on the X-axis slide track, and an X-axis cylinder used for driving the sliding suck head. The manual intervention is less in the manufacturing process, the human resources are saved, the working efficiency and the rate of good products are improved greatly, and the labor cost is saved.

Owner:杨传军

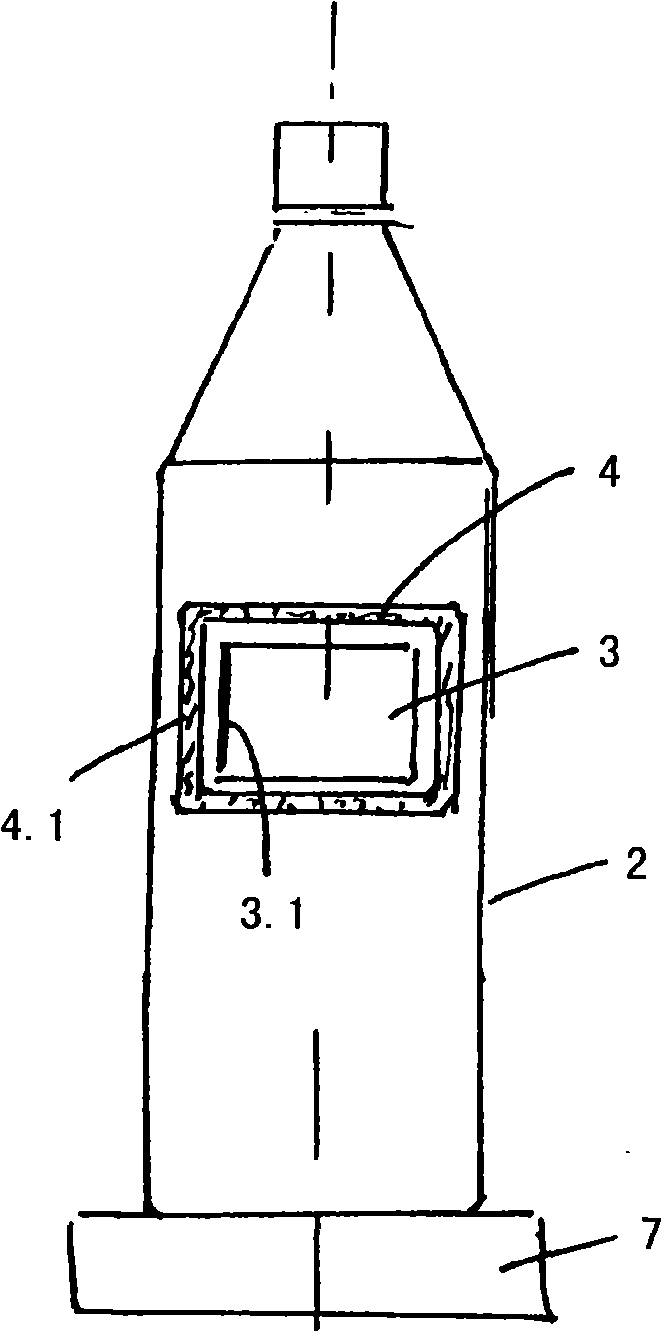

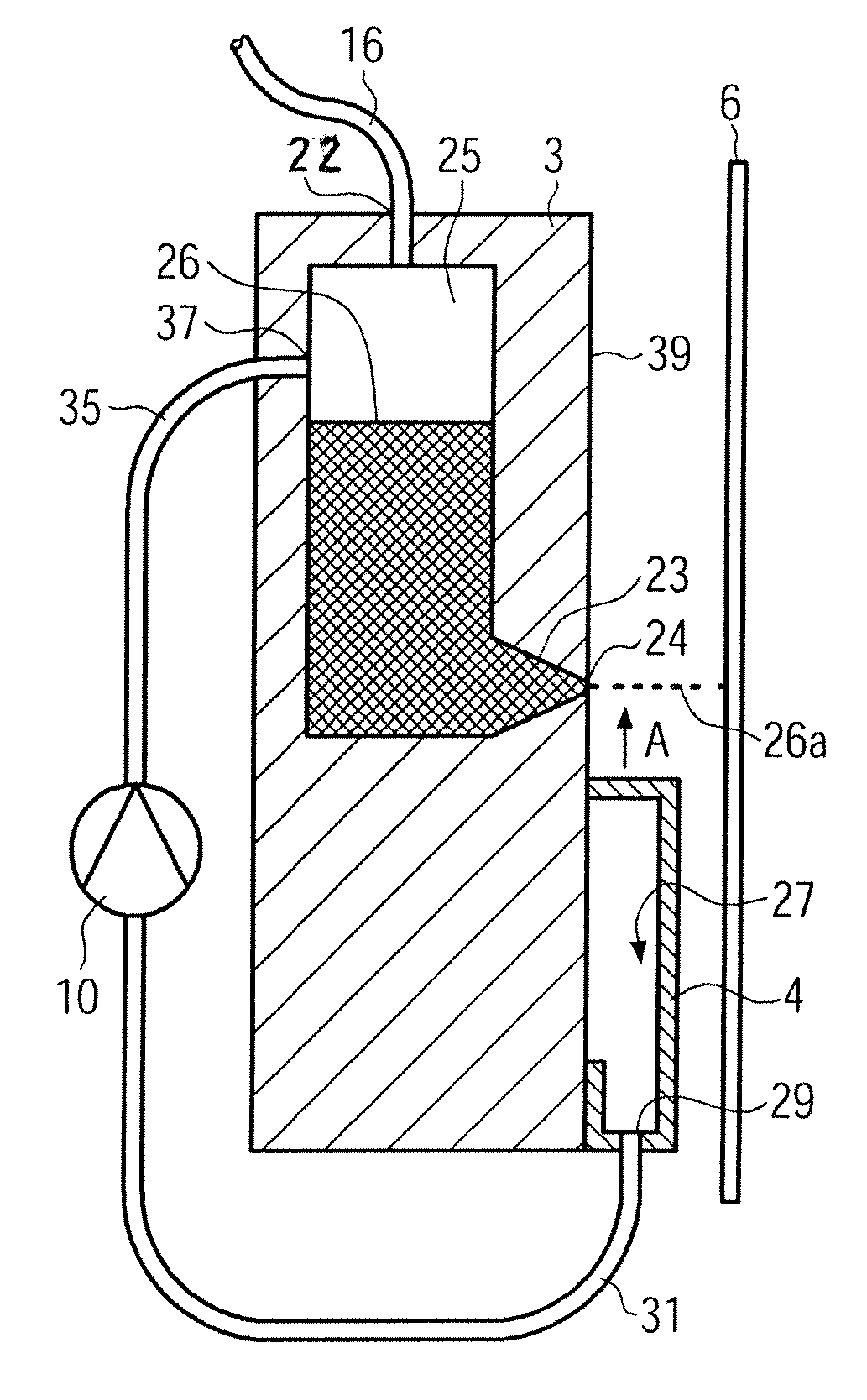

Labeling apparatus and method employing radiation curable adhesive

InactiveUS20040200566A1Guaranteed uptimeMechanical working/deformationDead plant preservationAdhesiveEngineering

A labeling apparatus and method for continuously applying a layer of a radiation curable adhesives to plastic, sheet fed, cut and stack, labels, irradiating the adhesive on the labels, prior to and / or subsequent to adhering the labels to containers, e.g., a bottle, to render the adhesive sufficiently tacky to effectively permanently seal the labels to containers in a commercial labeling machine. The plastic labels can be clear, opaque (including metallized) plastic films and can be retained in a dispensing magazine prior to the application of the radiation curable adhesive to the labels.

Owner:APPLIED EXTRUSION TECH

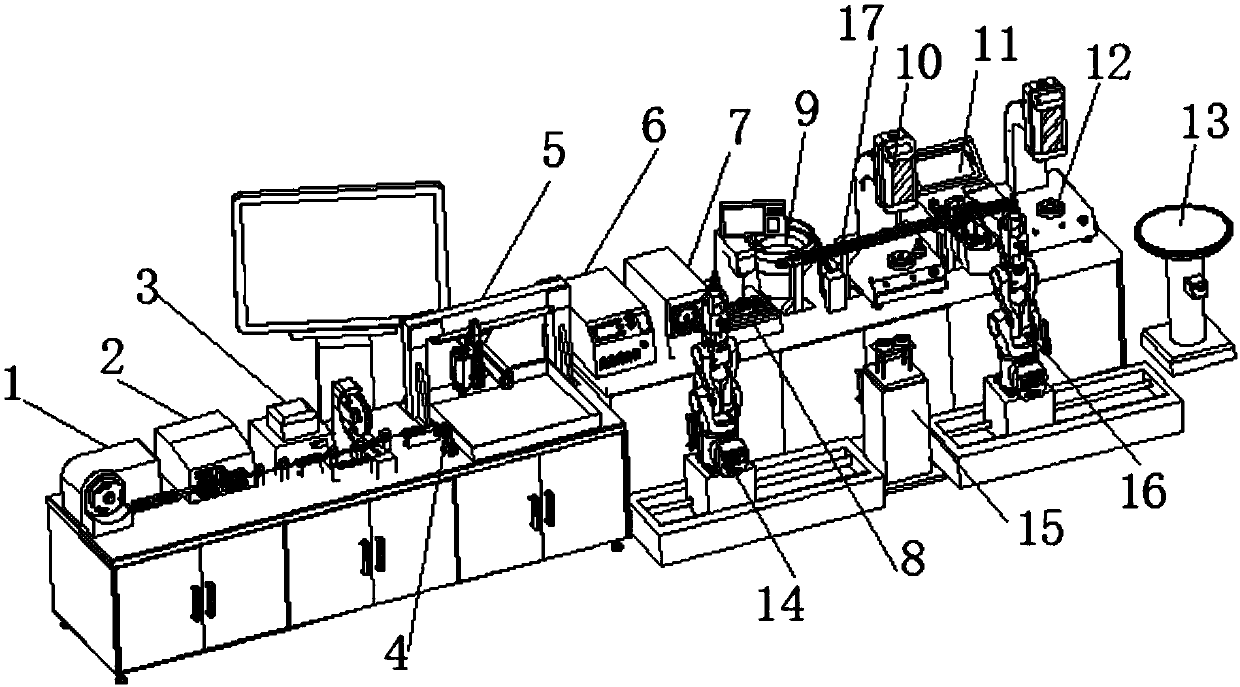

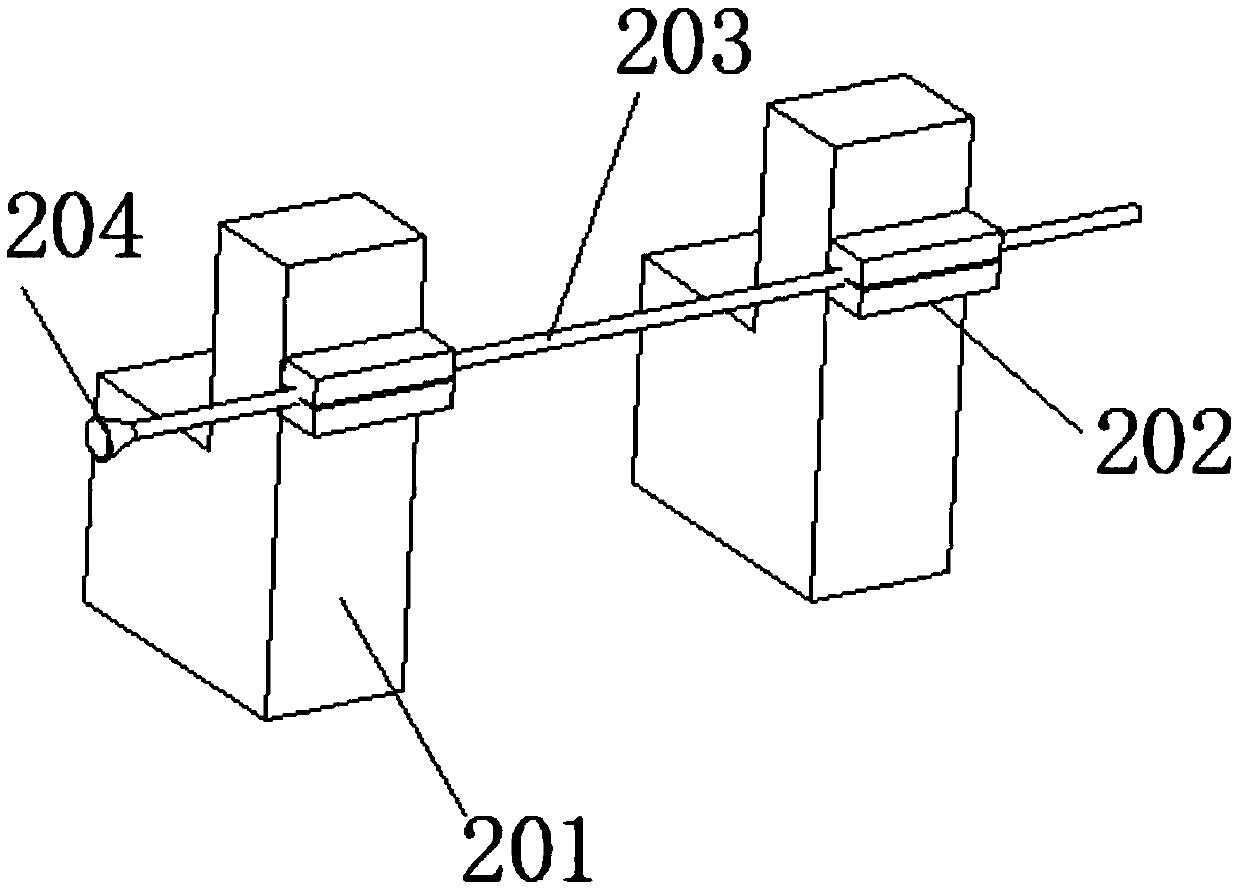

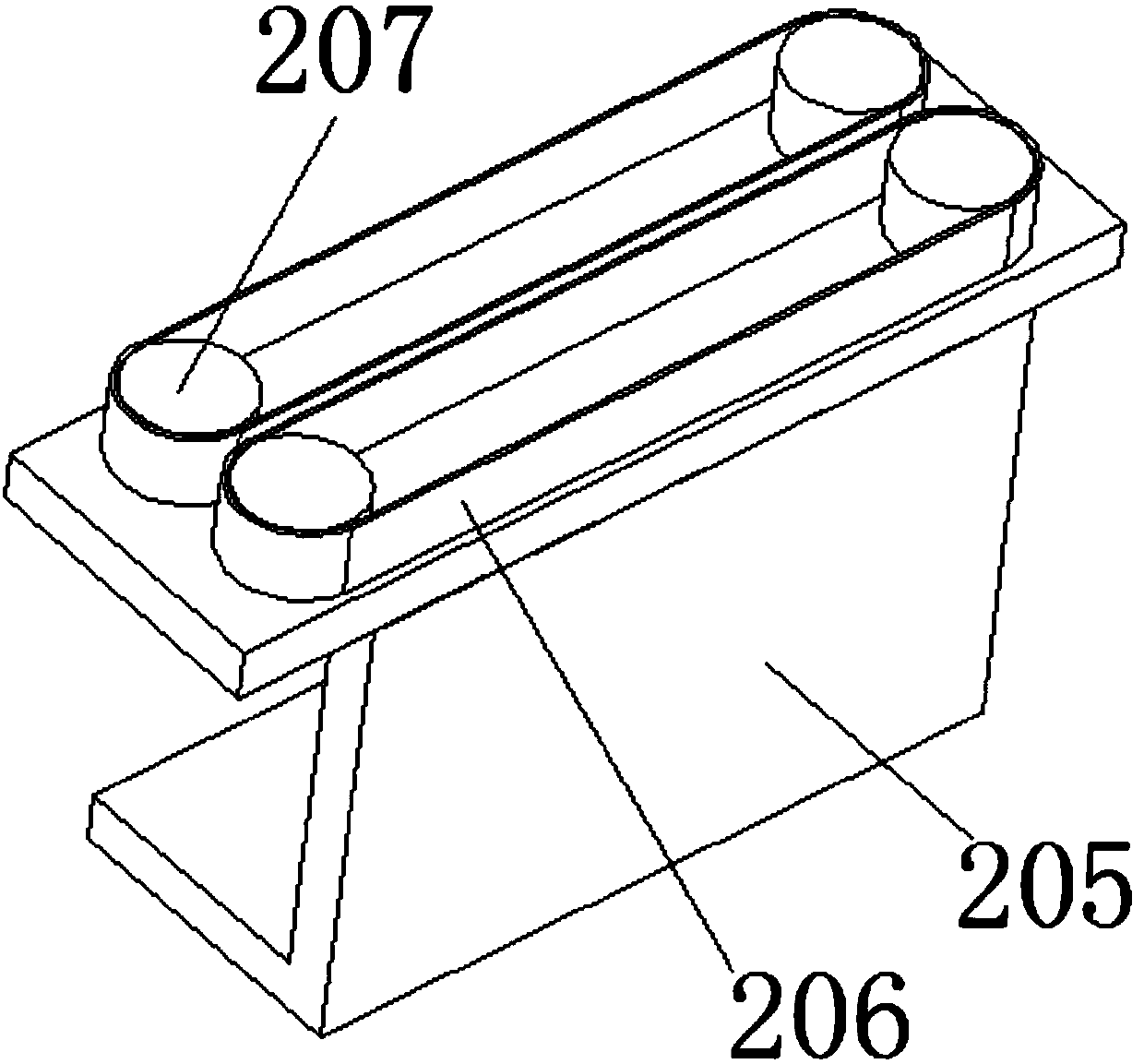

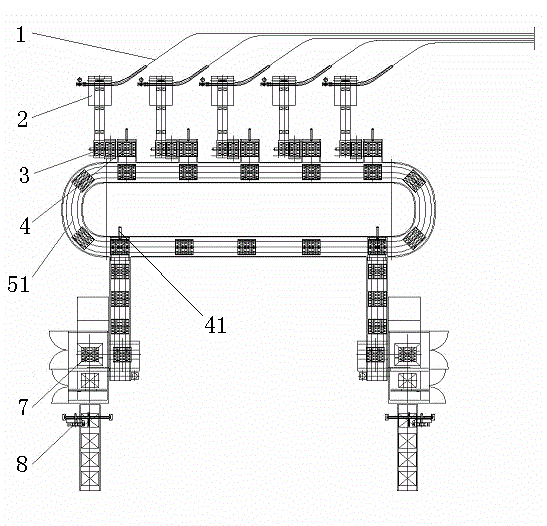

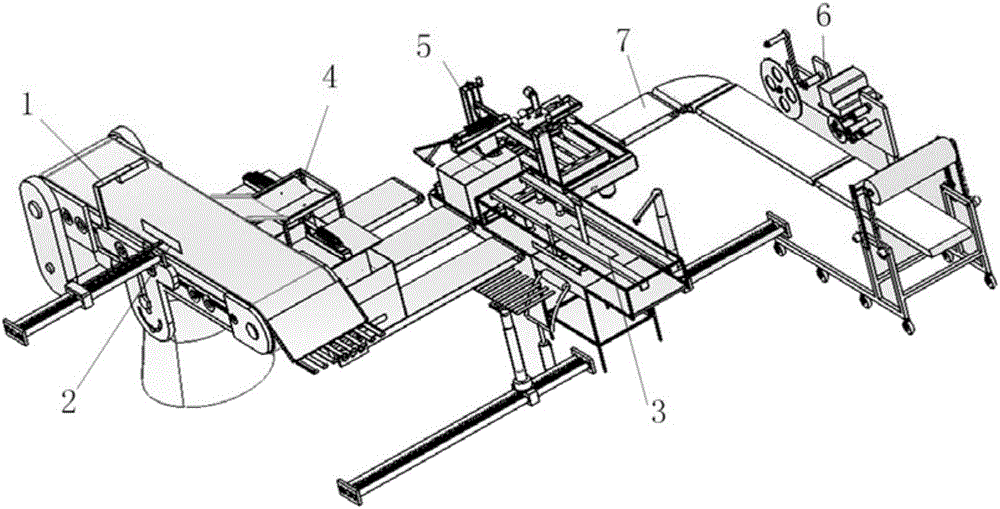

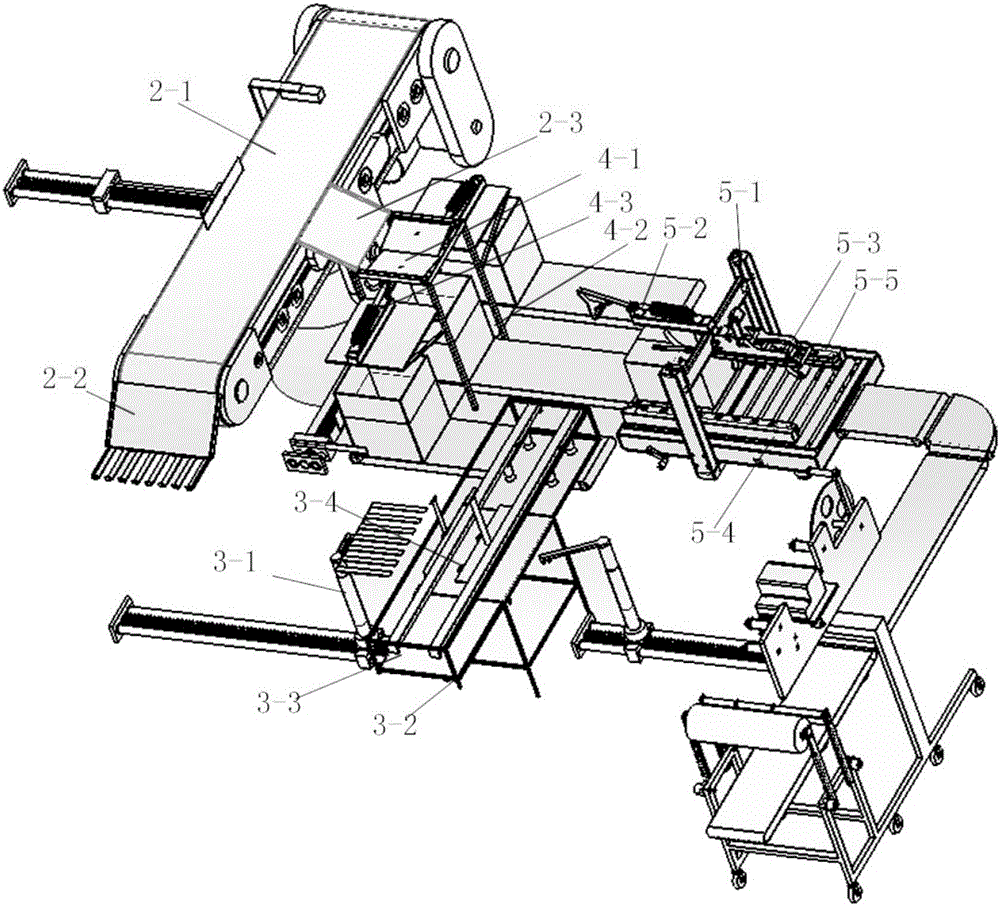

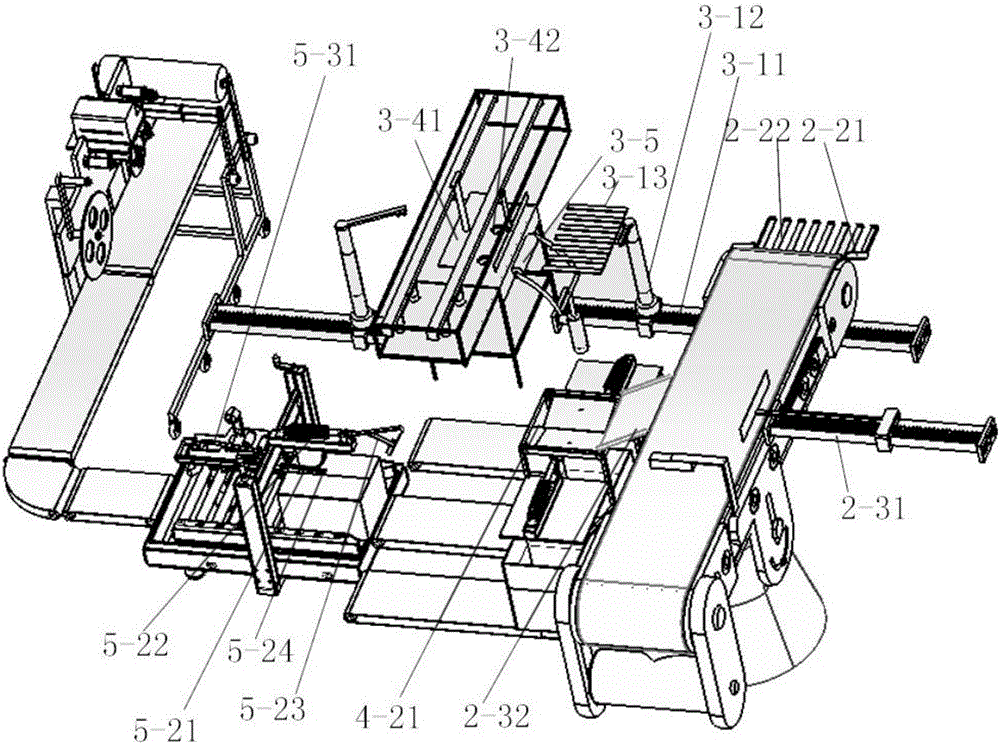

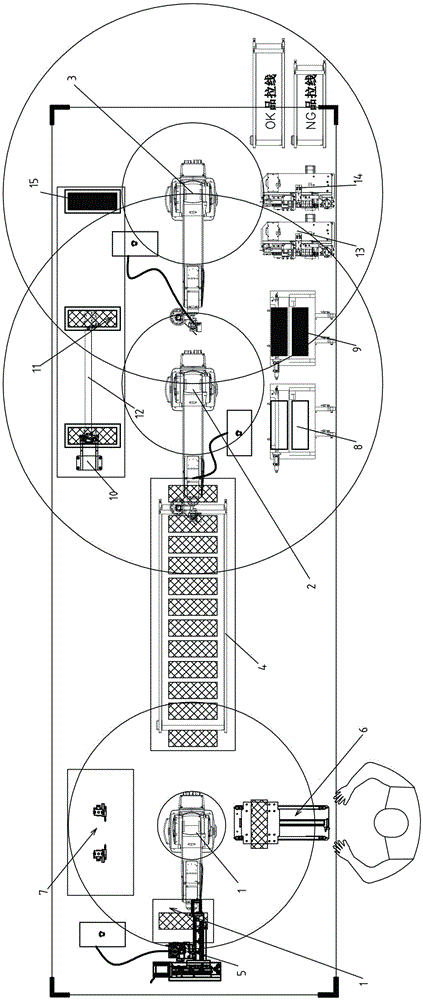

Low-voltage cable assembly intelligent crimping system production line

PendingCN107834338AFully automatedSave spaceConnection formation by deformationLow voltageEngineering

The invention discloses a low-voltage cable assembly intelligent crimping system production line which comprises a fully automatic wire laying marking unit and a wire intelligent crimping unit. The fully automatic wire laying marking unit successively includes an automatic wire laying machine, an automatic wire cutting machine, an automatic cable labeling machine, a label scan gun, and a rectangular coordinate conveying robot from left to right. The wire intelligent crimping unit successively includes, from left to right, a laser wire stripper, a two-axis rotary peeler, a cable detection device, and a vibration plate feeding device, a multi-axis slipway mechanical arm device, a first visual inspection device, a crimping detection device, a second visual inspection device, and a cable collection device. A first electrical apparatus control system six-degree-of-freedom robot and a second electrical apparatus control system six-degree-of-freedom robot are disposed on a side of wire intelligent crimping unit. A conventional apparatus is adjusted and improved so that the high-precision and high-efficiency fully automatic cable assembly automated production line is designed to replace anartificial production method.

Owner:无锡胜维电气有限公司

Labeling machine

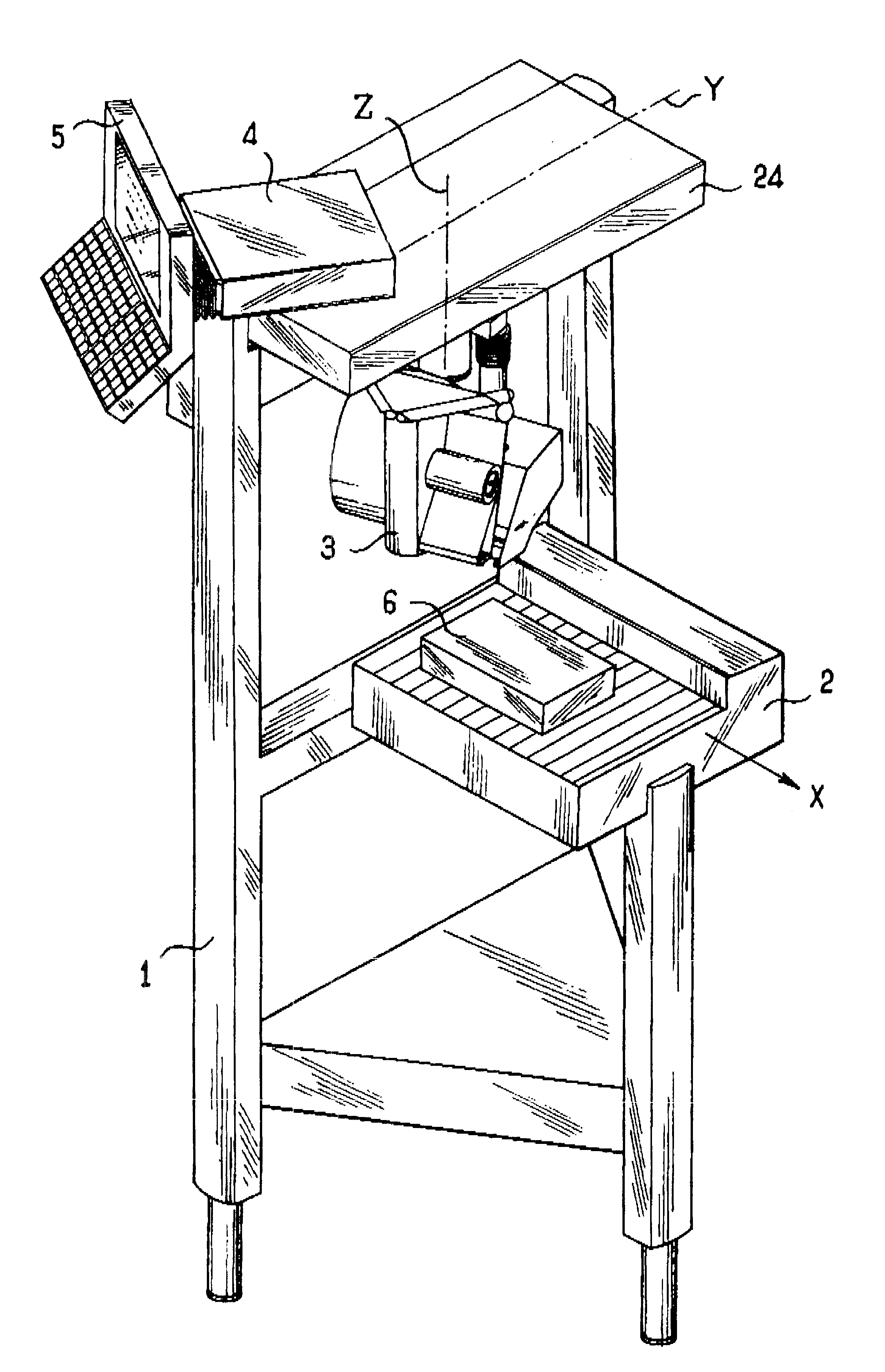

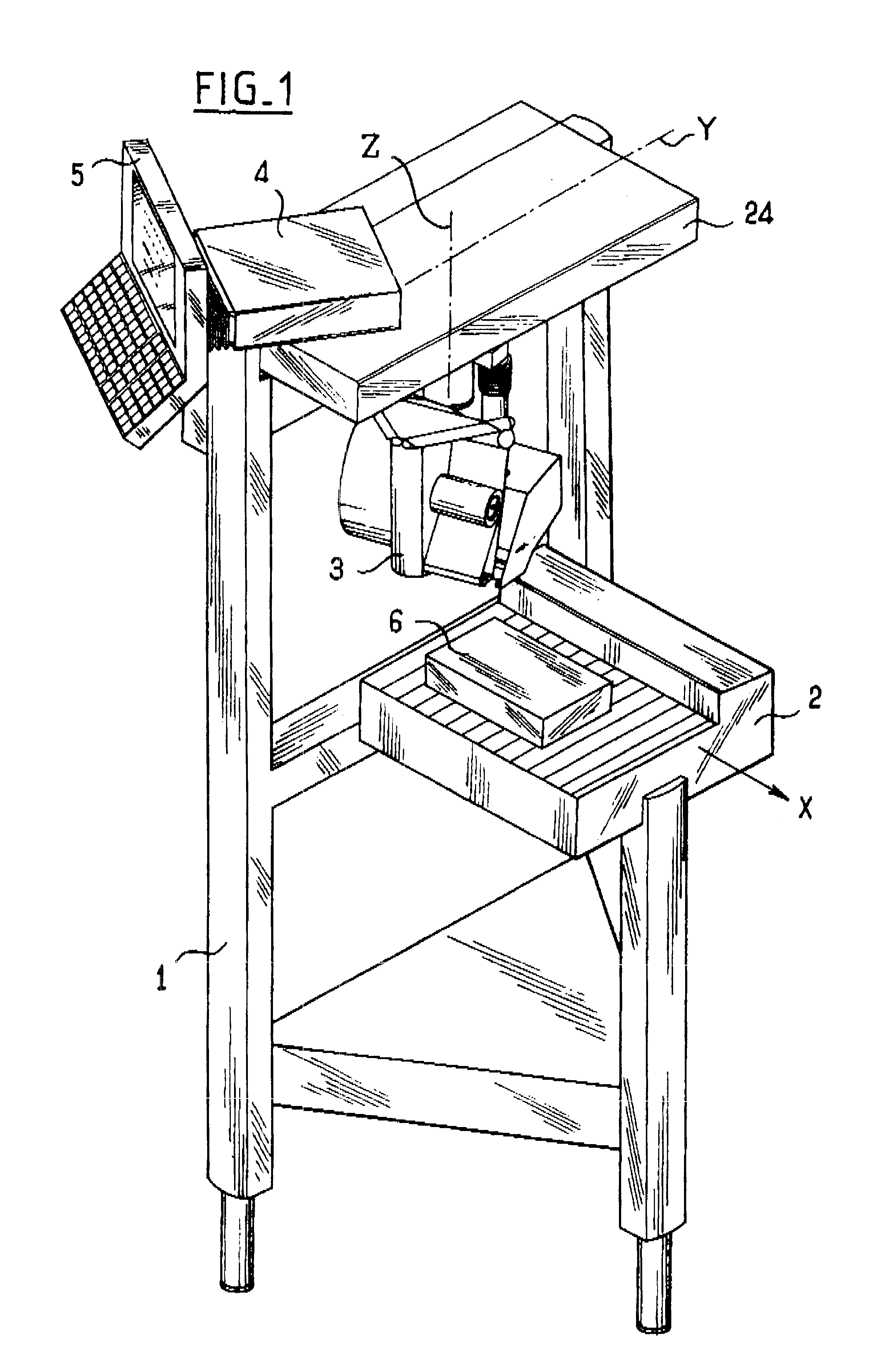

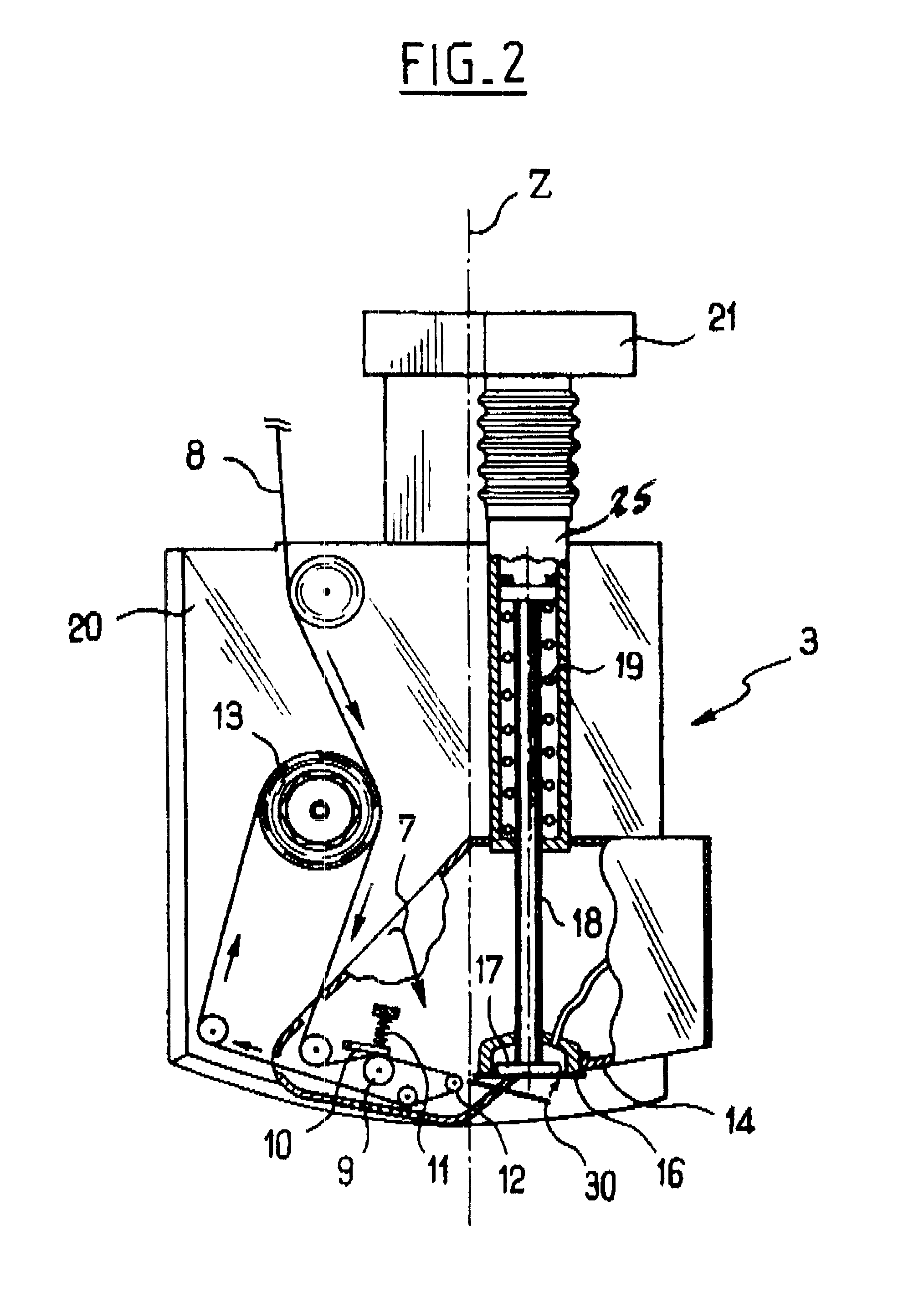

InactiveUS6634400B2Avoids incessant go-and-return tripSimple designMechanical working/deformationManual label dispensersEngineeringLabelling machine

The invention provides a labeling machine comprising a structure, a labeling head capable of pivoting relative to the structure about a pivot axis, the labeling head being fitted with gripper means for gripping a label holding it in a plane that is substantially normal to the pivot axis of the labeling head, and placing means carried by the labeling head and adapted to take the label held by the gripper means and place it on an article to be labeled that is present on the labeling machine. According to the invention, the gripper means hold a label in such a manner that a corner thereof coincides substantially with the point of intersection of the pivot axis and the plane of the label.

Owner:NS TESTUT

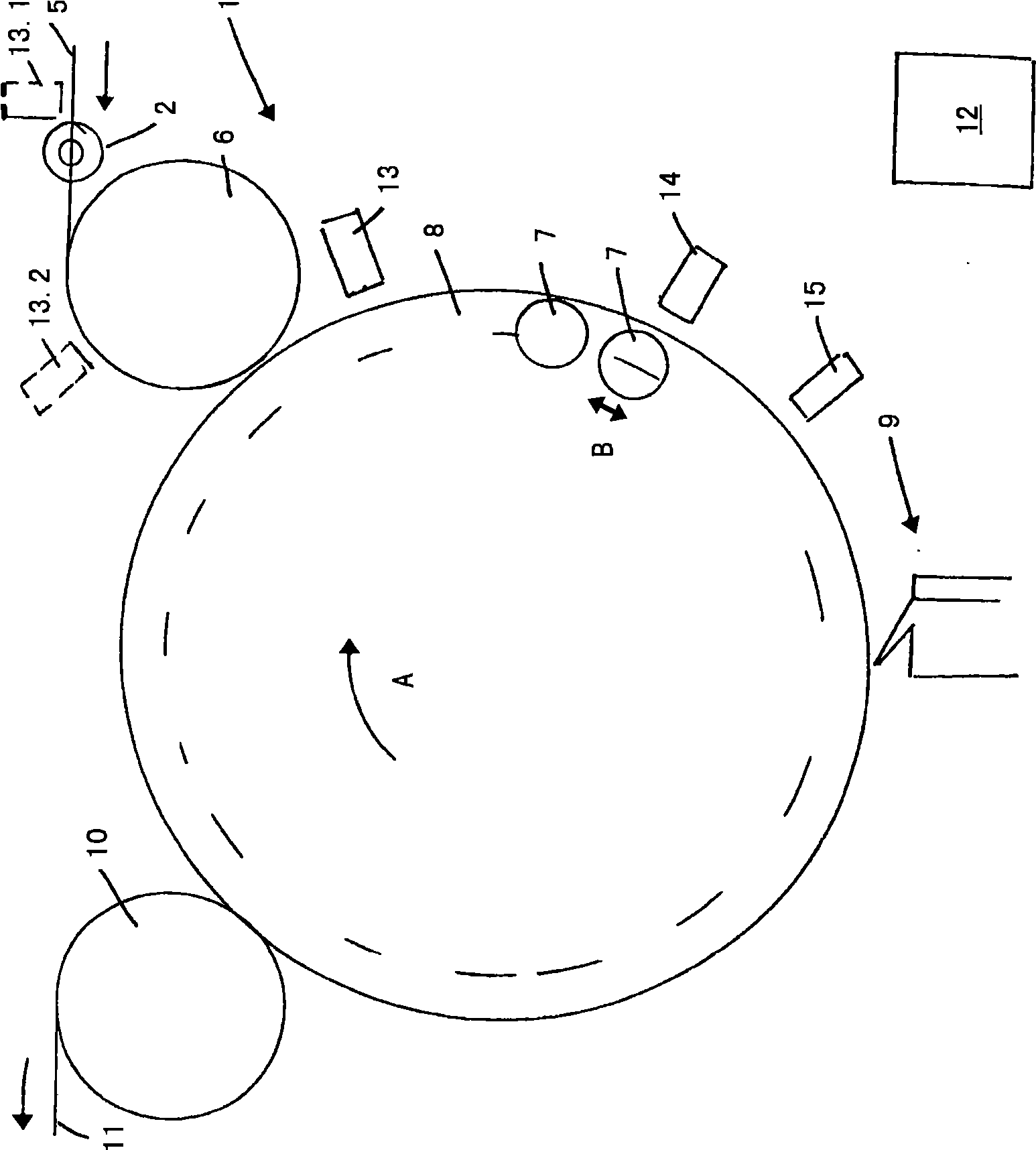

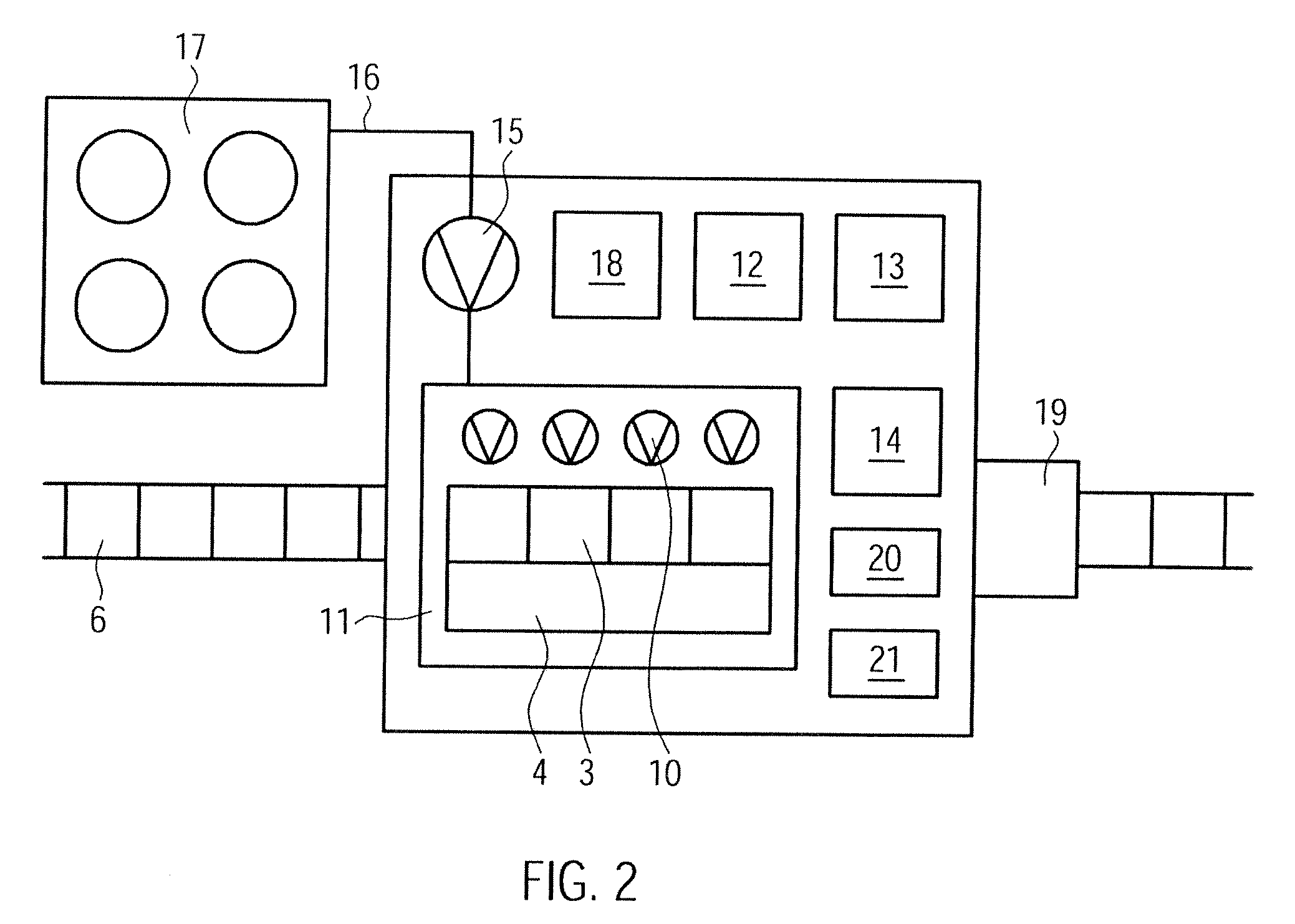

Method for the positionally accurate application of labels, and labelling machine

In a method for the positionally accurate application of labels (3) on bottles, cans or similar containers in relation to at least one container-typical design feature (4), the container-typical design feature of each container (2) which is moved past at least one camera (15) on a transport element (8) is detected using at least one image detection and processing system by way of said camera. The orientation and / or the actual form of the container-typical design feature on each container are / is detected by way of the image detection and processing system (4, 15) and the transfer instant of the label to the respective container is controlled from this in such a way that the label is positioned there in an optimum manner in relation to the design feature after the application.

Owner:KHS GMBH

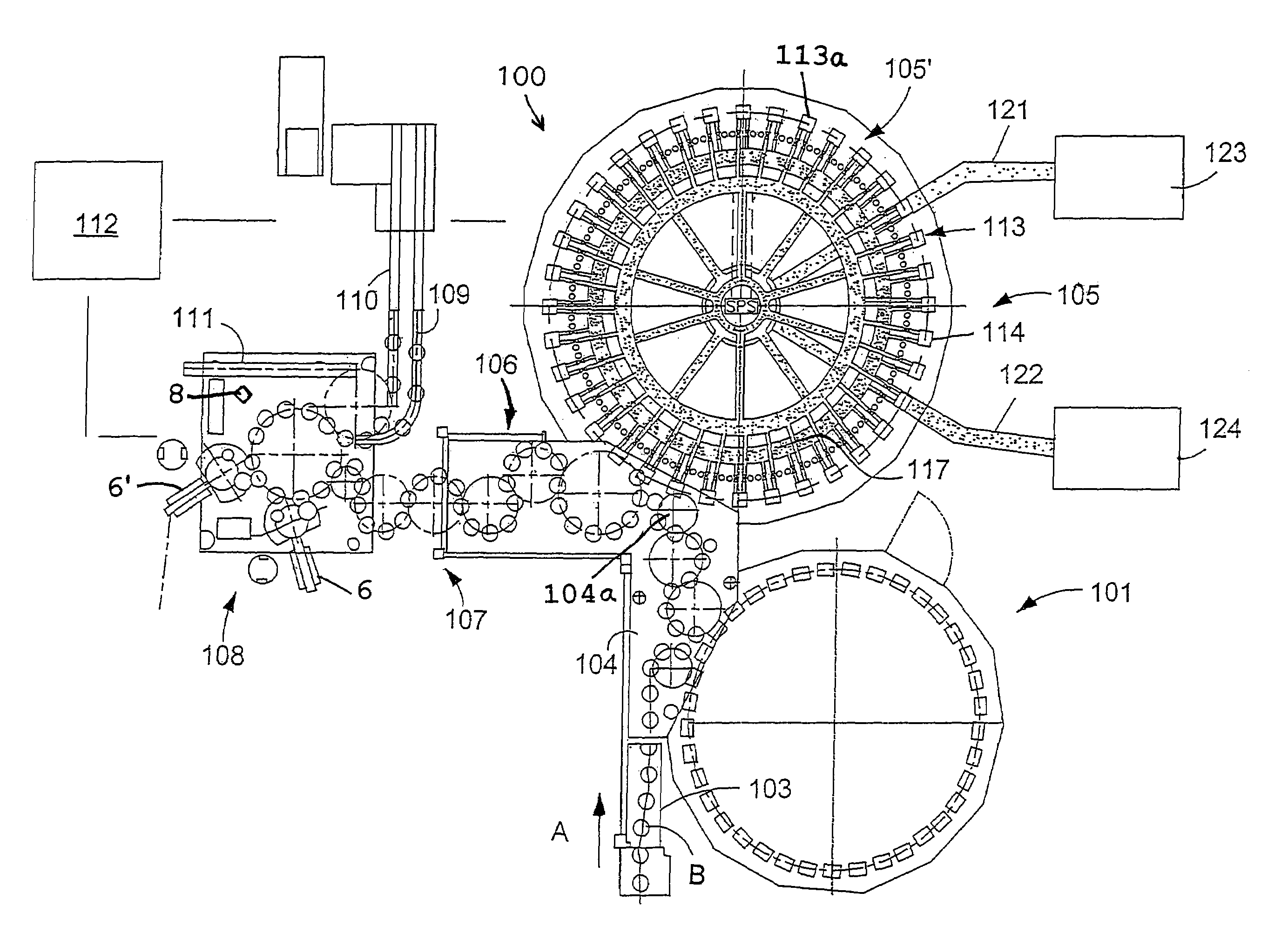

Beverage bottling plant for filling bottles with a liquid beverage filling material, a container filling plant container information adding station, such as, a labeling station, configured to add information to containers, such as, bottles and cans, and modules for labeling stations

A beverage bottling plant for filling bottles with a liquid beverage filling material, a container filling plant container information adding station, such as, a labeling station, configured to add information to containers, such as, bottles and cans, and modules for labeling stations proposed a labeling machine. Each module comprises a first coupling structure to permit interchangeable position of a module at one of a plurality of second coupling structures. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, the abstract is not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

Packaging box process for strip box packaging production and device for implementing packaging box process

ActiveCN104477426ALow investment costLow running costPackaging automatic controlIndividual articlesControl systemCarton

The invention provides a packaging box process for strip box packaging production and a device for implementing the packaging box process, strip boxes from a packaging unit are stacked to be a strip box stack in the manner of five layers in one stack and five strips in one layer twenty five strips in total, when a bar code reading and writing head reads that no information is in the bar code on corresponding conveying section of a tray conveyer, the whole strip box stack is pushed to the corresponding conveying section of the tray conveyer, and the bar code reading and writing head writes the corresponding strip box plate, packaging table number and other information into a readable and writable bar code on the corresponding conveying section of the tray conveyer, the strip box stack is conveyed into a cartoning sealing machine, after the bar code is identified by a control system, a corresponding paper box is selected for packaging the strip box stack, the plate, machine number, strip lack and other information of the strip box are provided to a labelling machine, the readable and writable bar code on the corresponding conveying section of the tray conveyer is decoded, and then the paper box full of strip boxes is labelled by the labelling machine and is discharged. The packaging box investment and operation cost are reduced, the packaging box process is simplified, and the quality is convenient to trace.

Owner:东方机器制造(昆明)有限公司

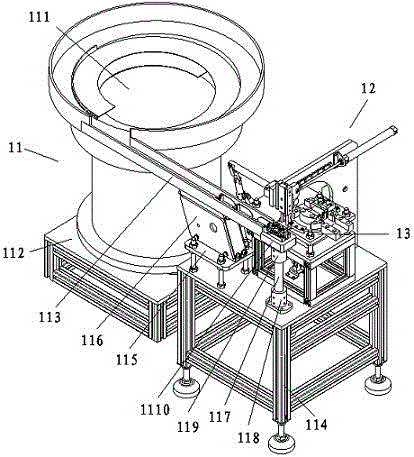

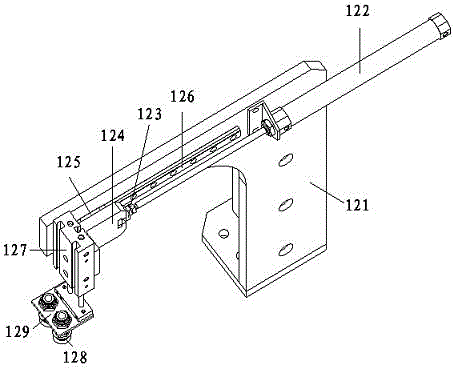

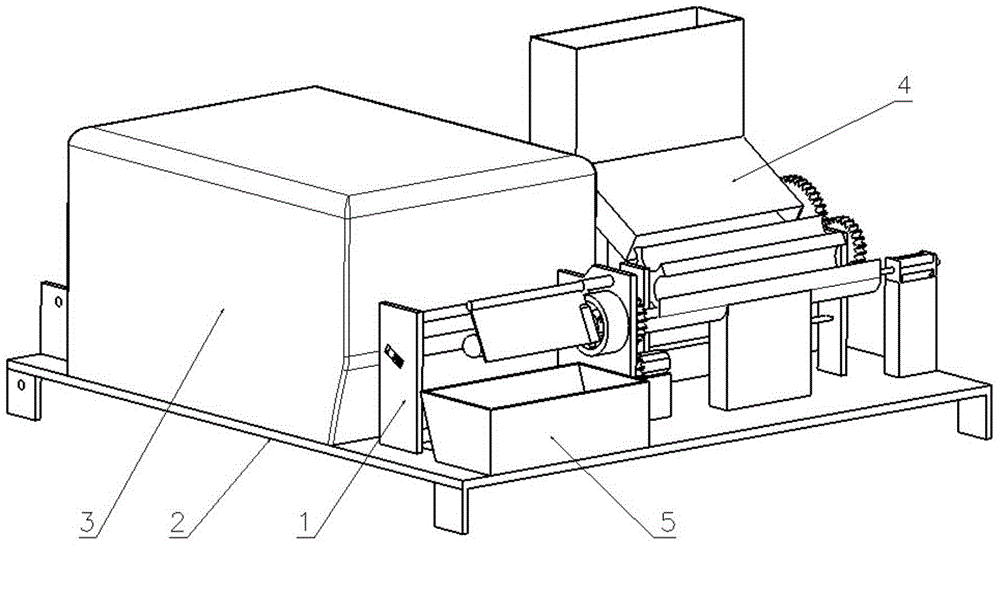

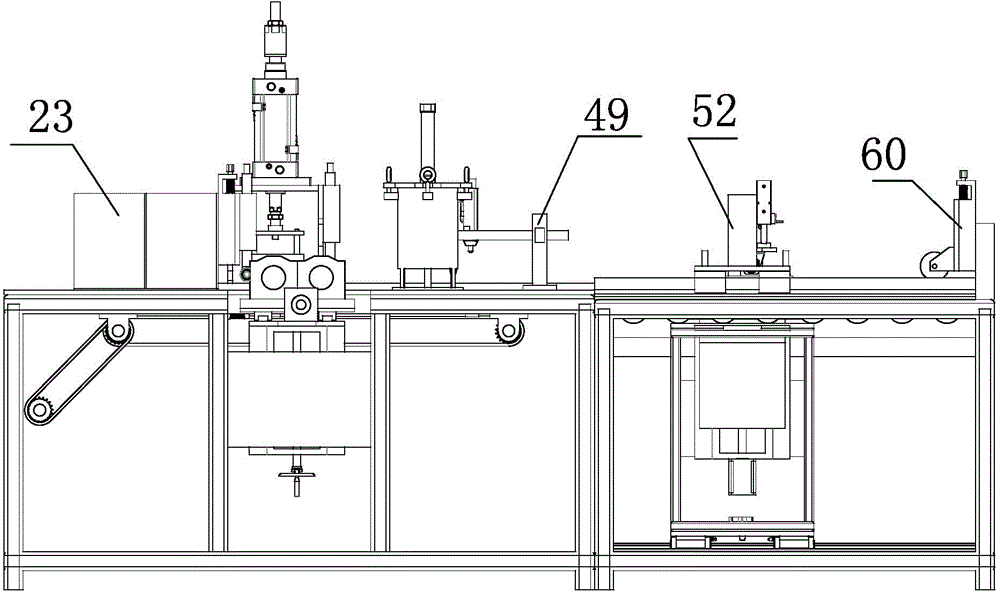

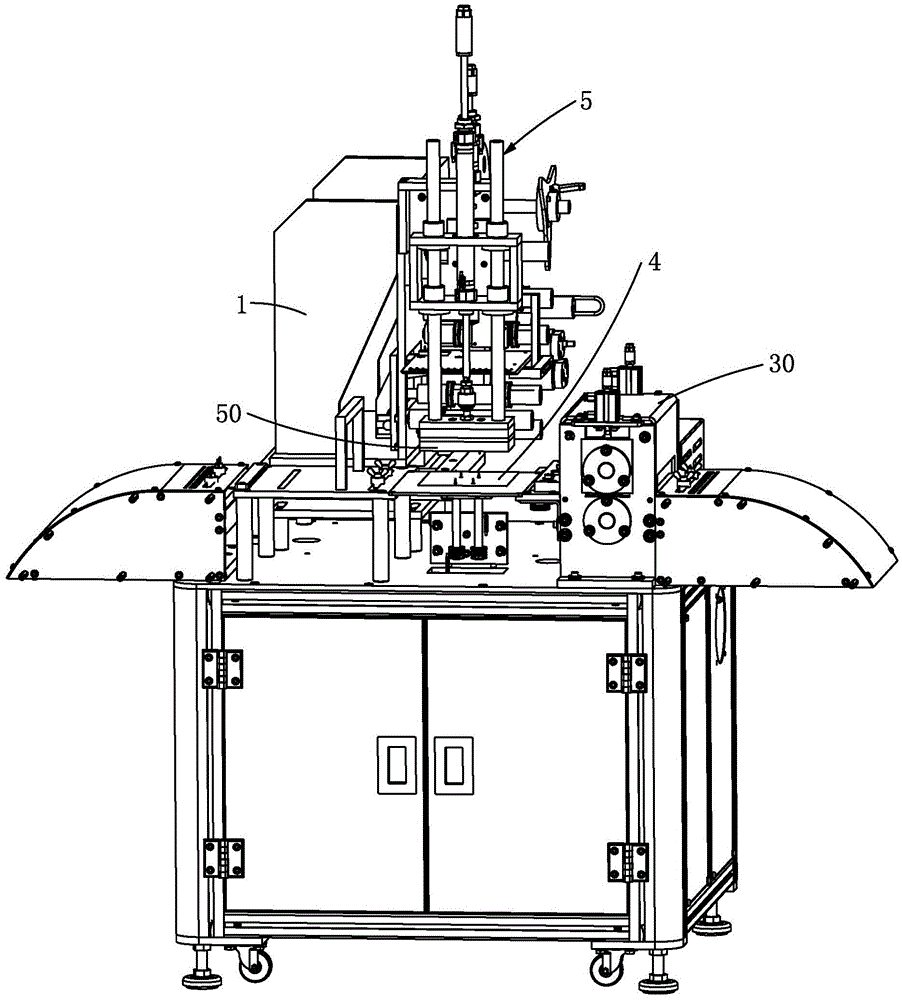

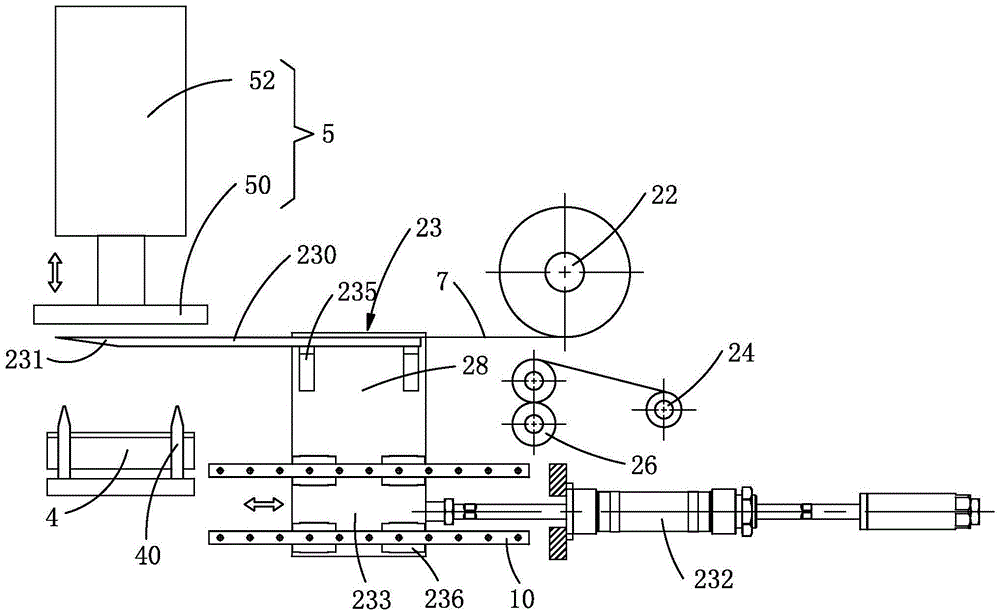

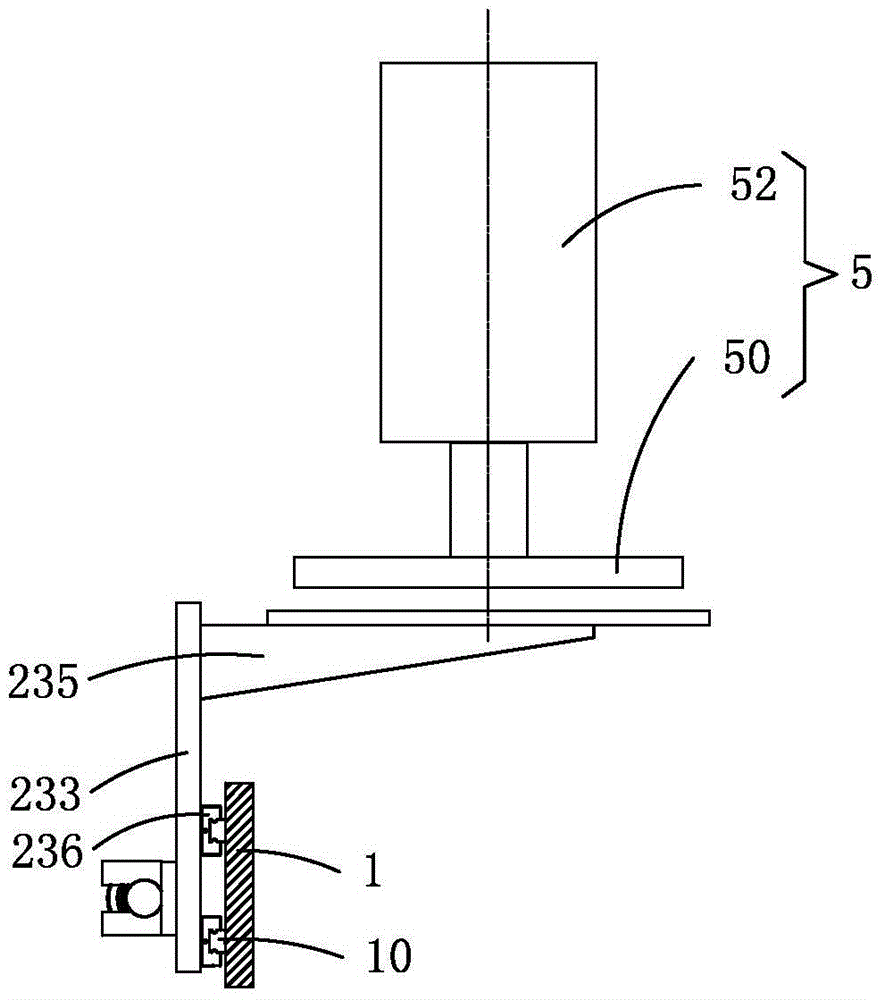

Limit switch labeling machine

ActiveCN105883119ACompact structureLabor savingMetal working apparatusConveyor partsEngineeringTransfer mechanism

The invention discloses a limit switch labeling machine. The limit switch labeling machine comprises a protective cover feeding mechanism, a transfer mechanism, a labeling mechanism and a damping sleeve feeding mechanism, wherein the protective cover feeding mechanism and the damping sleeve feeding mechanism are arranged in front of the transfer mechanism, and the labeling mechanism is arranged on the left side of the transfer mechanism. The protective cover feeding mechanism is used for conveying protective covers to the transfer mechanism, the labeling mechanism is used for labeling the protective covers in the transfer mechanism position, and the damping sleeve feeding mechanism is used for conveying damping sleeves to the protective covers in the transfer mechanism position. The limit switch labeling machine is compact in structure and capable of substituting automatic workpiece assembly and labeling for manual operation, so that labor is saved and production cost is reduced.

Owner:SUZHOU JUHUIBANG NEW MATERIAL TECH CO LTD

Automatic packaging method and device for expressage

InactiveCN105857784AImprove efficiencyImprove reliabilityWrapper twisting/gatheringLabelling machinesProcess engineeringIndustrial engineering

The invention discloses an automatic packaging method and device for expressage. The automatic packaging method for expressage is characterized in that commodities to be packaged are classified manually, whether a bagging mode or a boxing mode is suitable for the commodities to be packaged is judged, then corresponding identification codes are stuck on the commodities, and after the identification codes are scanned, the commodities to be bagged are conveyed by a commodity distributing mechanism to a commodity bagging mechanism to be bagged and sealed; the commodities to be boxed are conveyed to a commodity boxing mechanism to be boxed and sealed; and the packaged commodities are conveyed by a conveying device into a labeling mechanism, so that express waybills are stuck on the packaged commodities. The automatic packaging method and device for expressage are high in working efficiency and low in investment cost.

Owner:FOSHAN UNIVERSITY

Fusible adhesives crosslinkable by radiation

To obtain an adhesive having both a high initial adhesive capacity and high heat resistance, a fusible adhesive which can be cross-linked by radiation and a low tendency to creep is provided. The adhesive contains 0 to 40 weight percent of at least one elastomer which cannot be cross-linked by radiation, 15 to 40 weight percent of at least one compound containing at least two olefinic double bonds, and 20 to 85 weight percent of at least one tackifier. The adhesive is especially suitable for use on high speed labeling machines.

Owner:HENKEL KGAA

Automatic labeling machine

ActiveCN104354944AReduce utilizationControl speedLabelling machinesWebs handlingEngineeringFully automated

The invention discloses an automatic labeling machine and belongs to the field of labeling machines. The automatic labeling machine comprises a base, a mounting plate and a jig, wherein the mounting plate and the jig are mounted on the base; a label conveying path, a driven roller wheel set and a slide rail fixing frame are arranged on the mounting plate; the label conveying path and the driven roller wheel set are arranged on the front surface of the mounting plate; a discharging device, a sucking plate, a stripping plate, a main drive wheel module and a waste recovery device are arranged on the label conveying path in sequence from a starting point to an ending point; the roller wheels of the driven roller wheel set are arranged between the discharging device and the sucking plate, between the sucking plate and the stripping plate and between the stripping plate and the main drive wheel module respectively; a label sucking and moving mechanism capable of moving between the stripping plate and the jig is mounted on the slide rail fixing frame. As the whole labeling process is fully automated and the working process is accurate, the labeling stability and accuracy are really improved.

Owner:SHENZHEN DAYUCNC TECH

Auto labeler

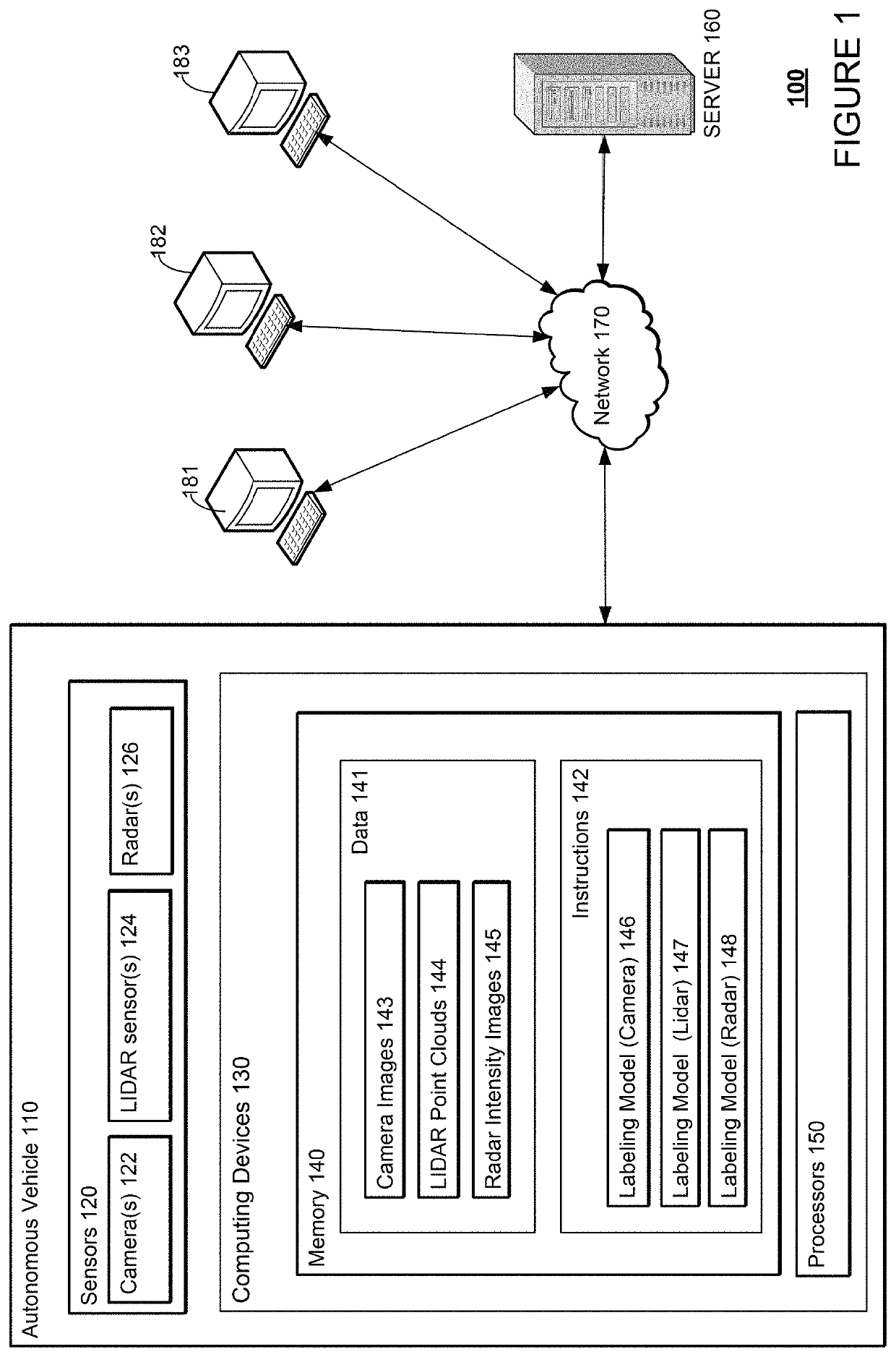

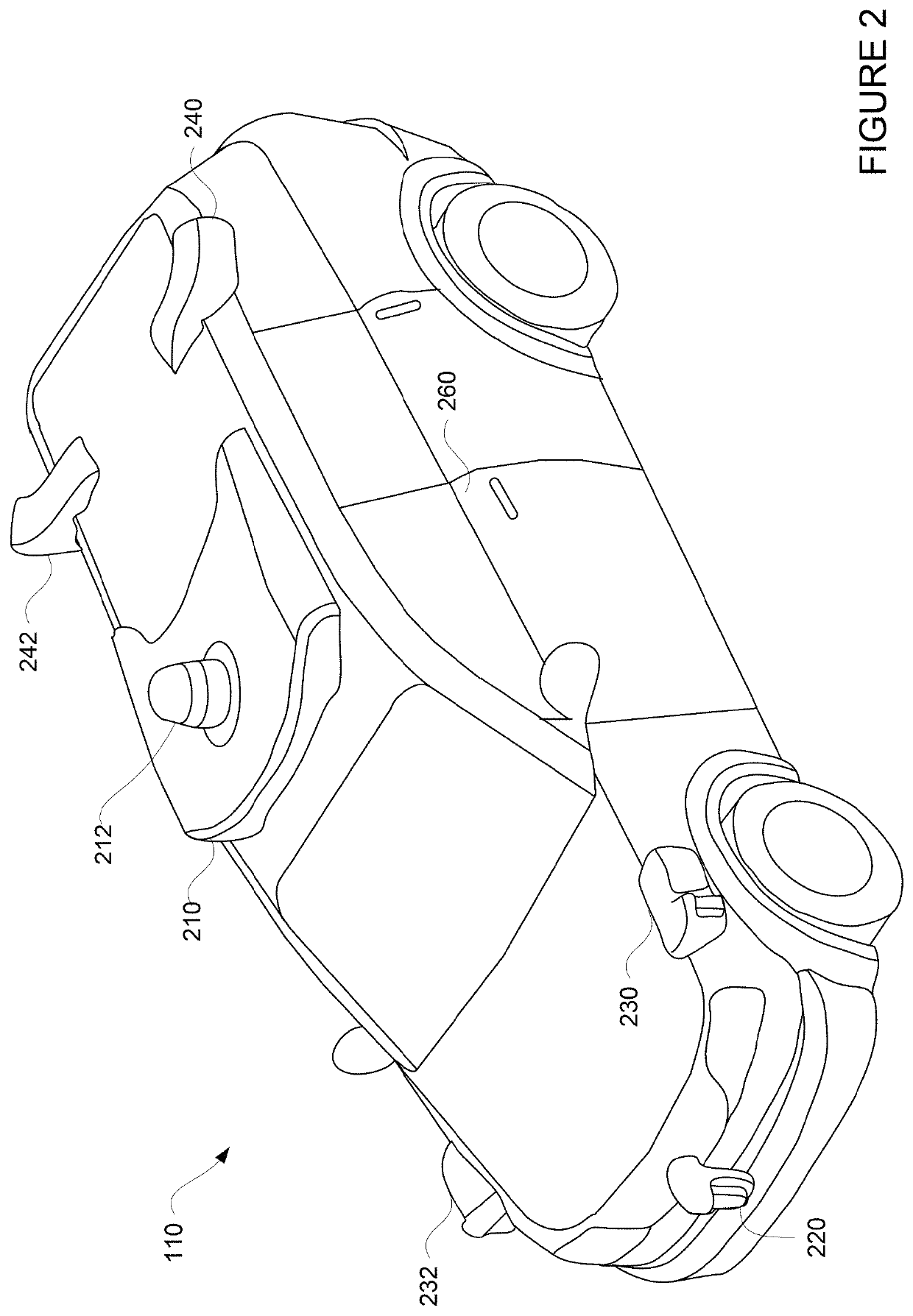

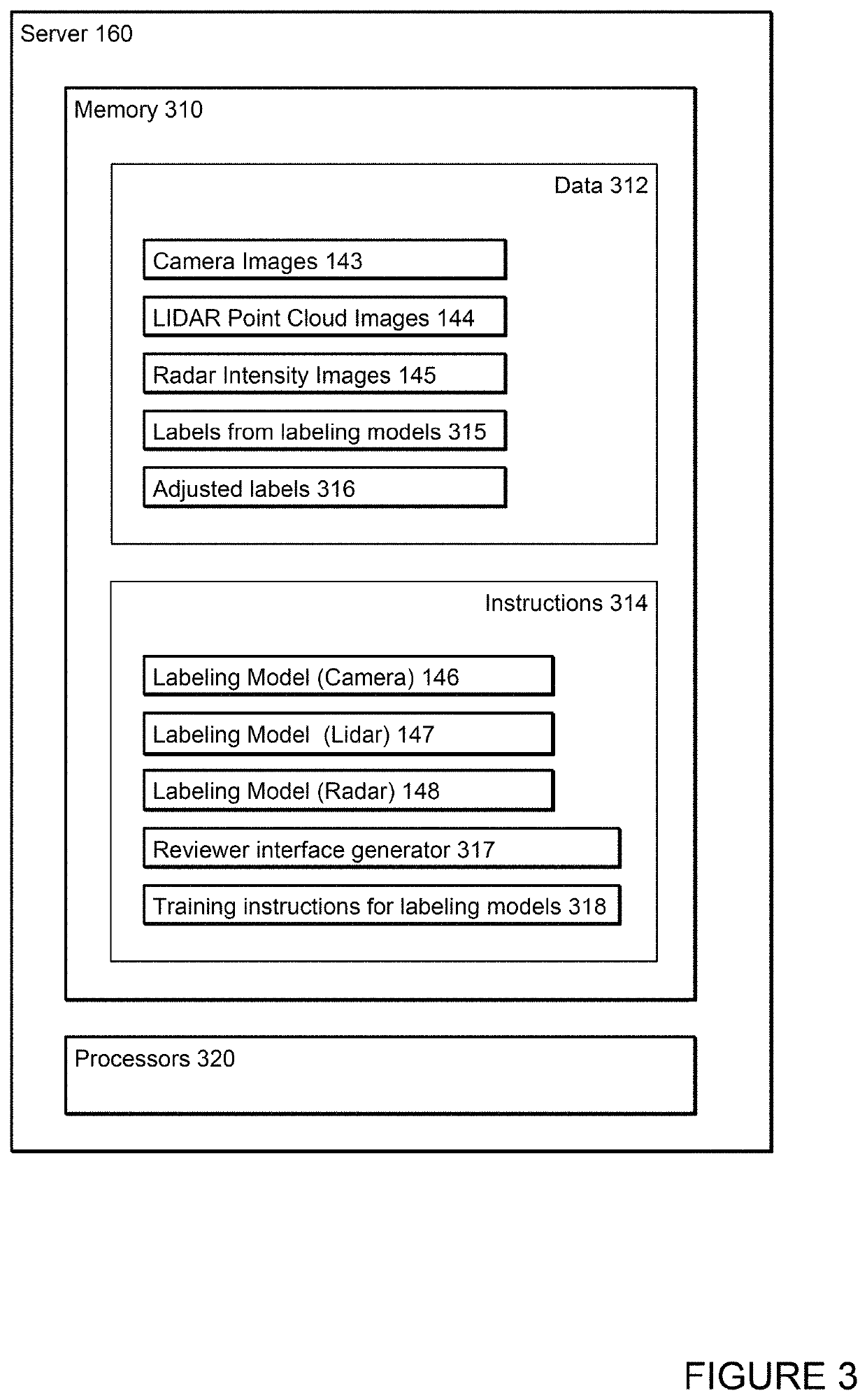

ActiveUS10891518B1Improve accuracyEnsemble learningScene recognitionSimulationArtificial intelligence

Aspects of the disclosure relate to training a labeling model to automatically generate labels for objects detected in a vehicle's environment. In this regard, one or more computing devices may receive sensor data corresponding to a series of frames perceived by the vehicle, each frame being captured at a different time point during a trip of the vehicle. The computing devices may also receive bounding boxes generated by a first labeling model for objects detected in the series of frames. The computing devices may receive user inputs including an adjustment to at least one of the bounding boxes, the adjustment corrects a displacement of the at least one of the bounding boxes caused by a sensing inaccuracy. The computing devices may train a second labeling model using the sensor data, the bounding boxes, and the adjustment to increase accuracy of the second labeling model when automatically generating bounding boxes.

Owner:WAYMO LLC

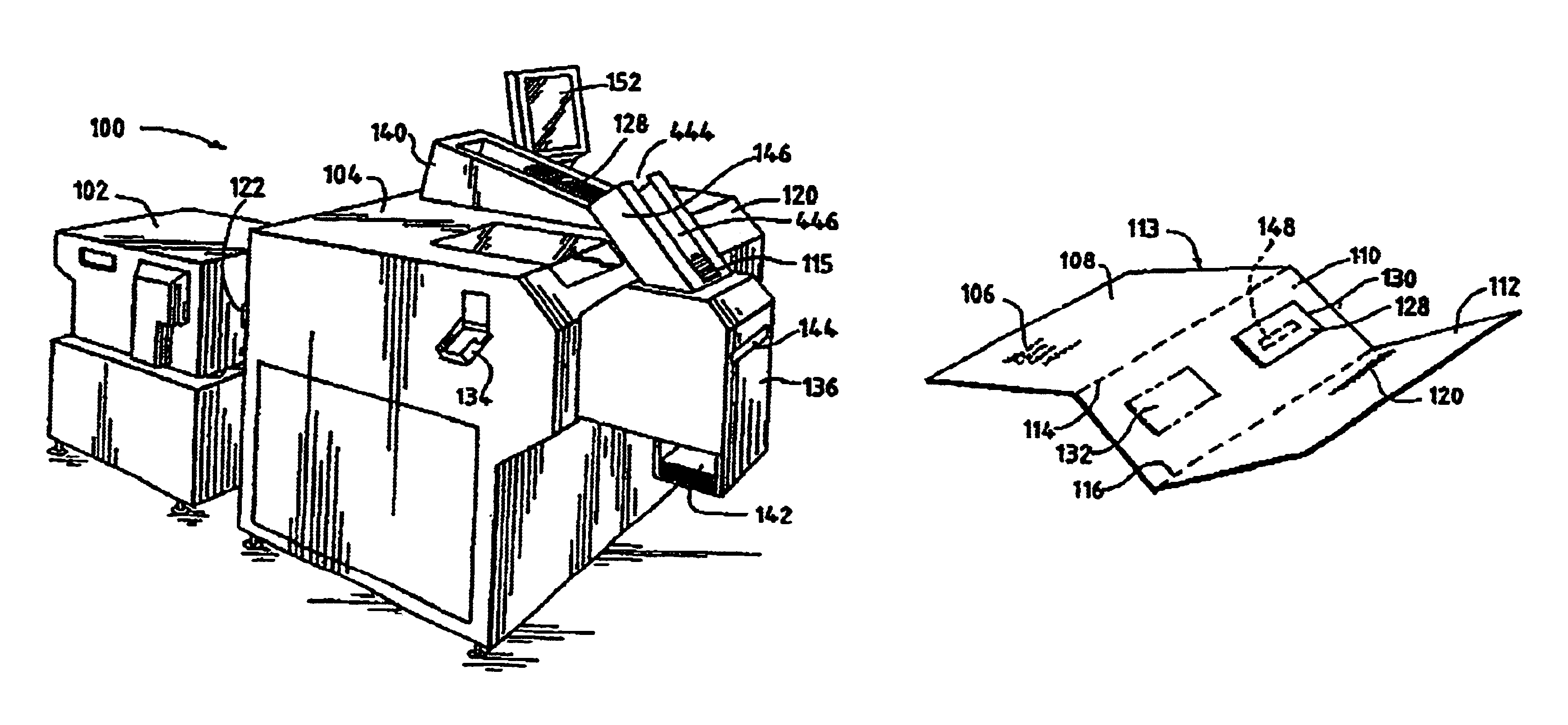

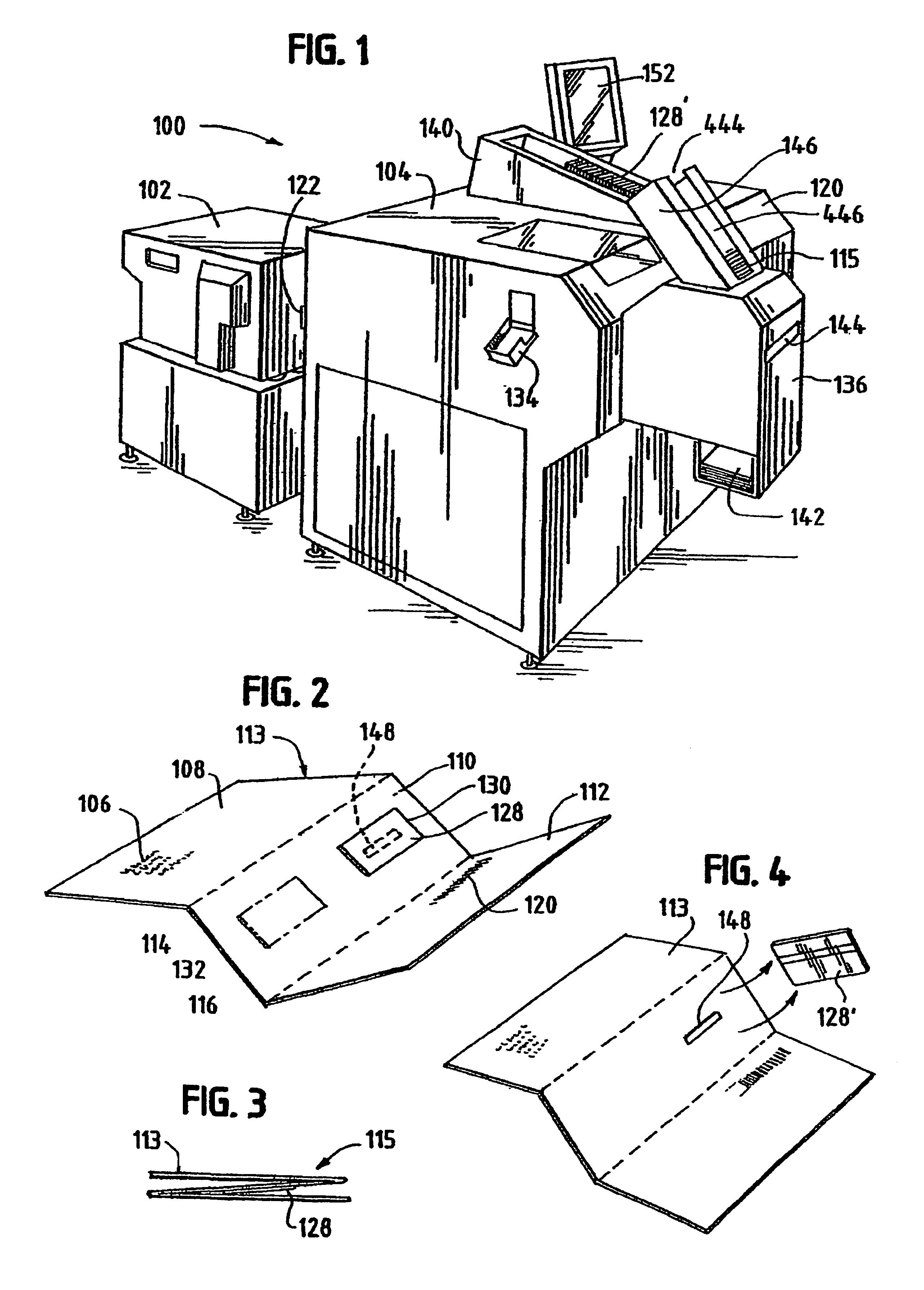

Card package production system with adhesive card attachment station and method

InactiveUS6902518B2Envelopes/bags making machineryLamination ancillary operationsAdhesiveElectrical and Electronics engineering

A card package production system (100) for producing card packages (115) composed of cards (128) attached to carriers (113) has an adhesive label attachment station (358, FIG. 34) with a heating platen (361) having a width for heating at least two labels (148) simultaneously that are passed over the platen (361) and a labeler downstream from the heating platen (361) with a pressing member (372) for pressing the heated adhesive label (128) against a card (128) at an attachment position. The heating platen (361) heats only an intermediate section of the adhesive to activate the adhesive and leaves end portions of the label relatively unheated and unactivated to facilitate subsequent removal of the label (148) from the card (128).

Owner:DYNETICS ENG

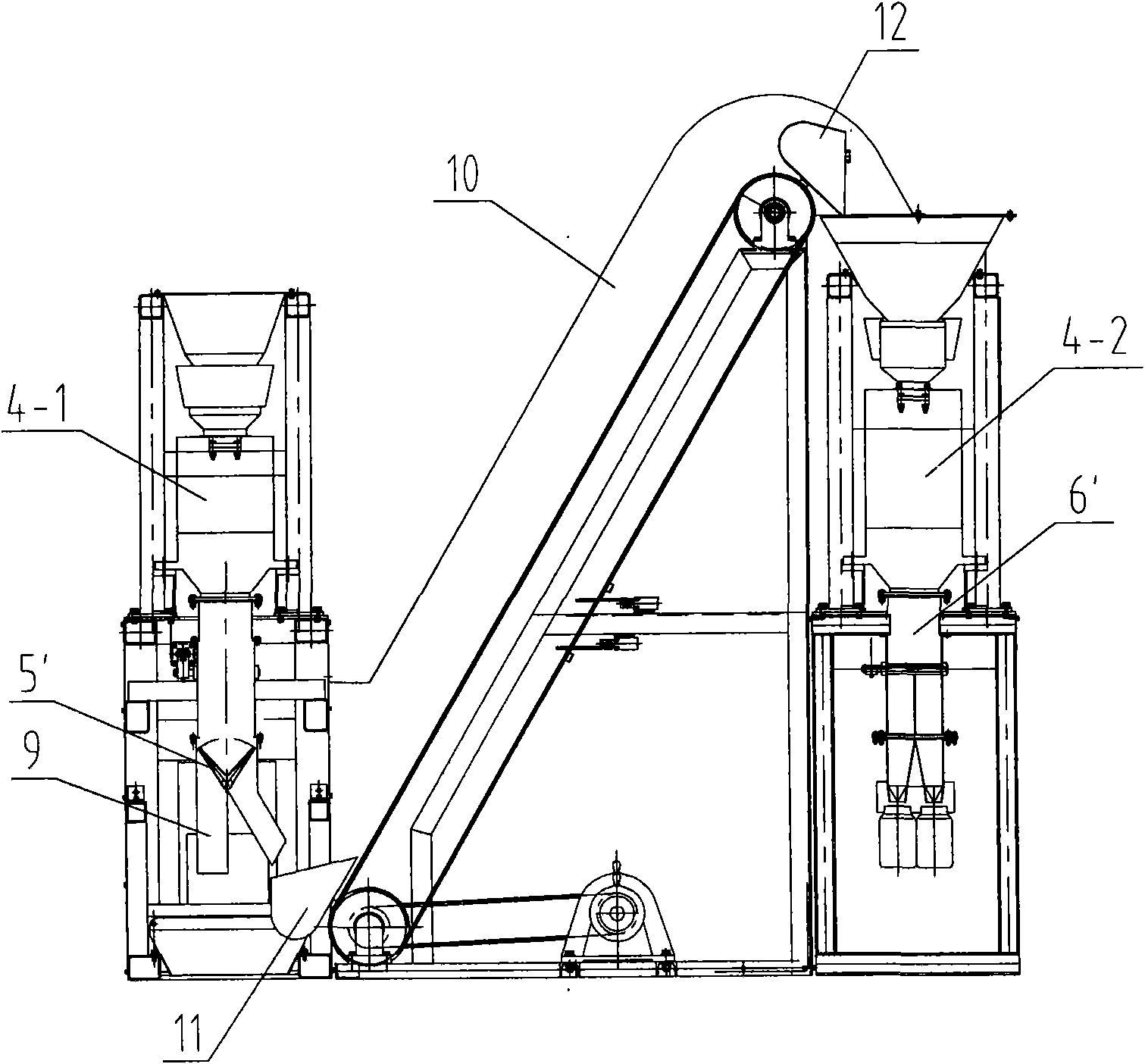

Coal coking automatic sample preparation system

InactiveCN101556221AGuarantee product qualityIncrease the level of automationPreparing sample for investigationComputer monitoringData acquisition

The invention relates to a coal coking automatic sample preparation system which comprises a sample-preparation working station, an automatic delivery unit, a discharging unit and a controlling unit, wherein the sample-preparation working station, the automatic delivery unit and the discharging unit are interlocked in sequence under the controlling action of the controlling unit, automatic feeding, crushing, shrinkage, canning, automatic delivery, sample sealing, information identification code spraying and rejected sample collection are performed to the raw material ore; and the controlling unit takes a PLC control system as a core part and comprises a data acquisition device, a system controller, an operating panel, a labelling machine controller, a jet printer controller, a packaging machine controller and a computer monitoring system, and the PLC control system is communicated with the seven parts through a filed bus. The invention has the advantages that the automatic feeding, the crushing, the shrinkage, the canning, the sample sealing, the information identification code spraying and the rejected sample collection automatization are finished for the raw material ore.

Owner:辽宁同辉科技发展有限公司

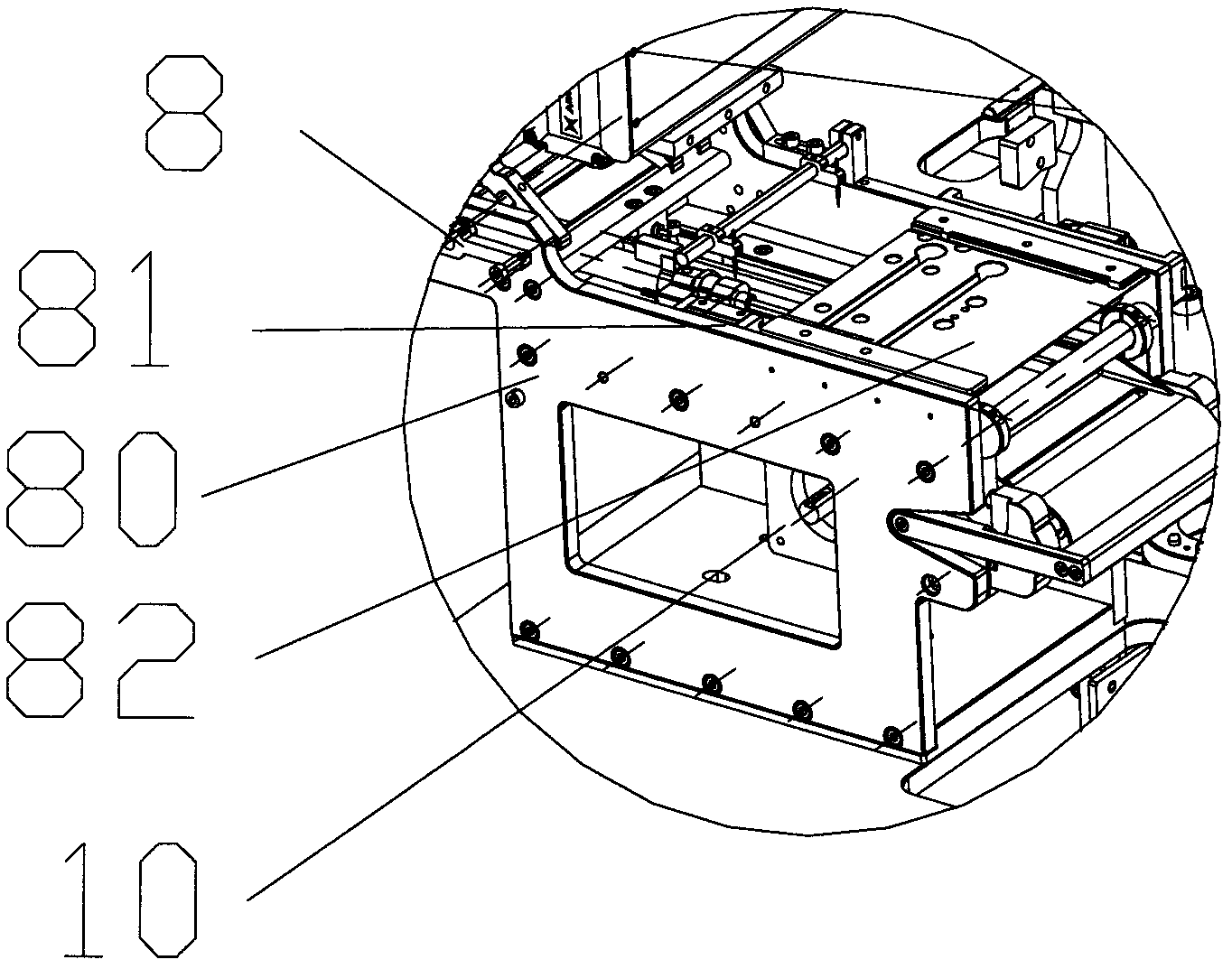

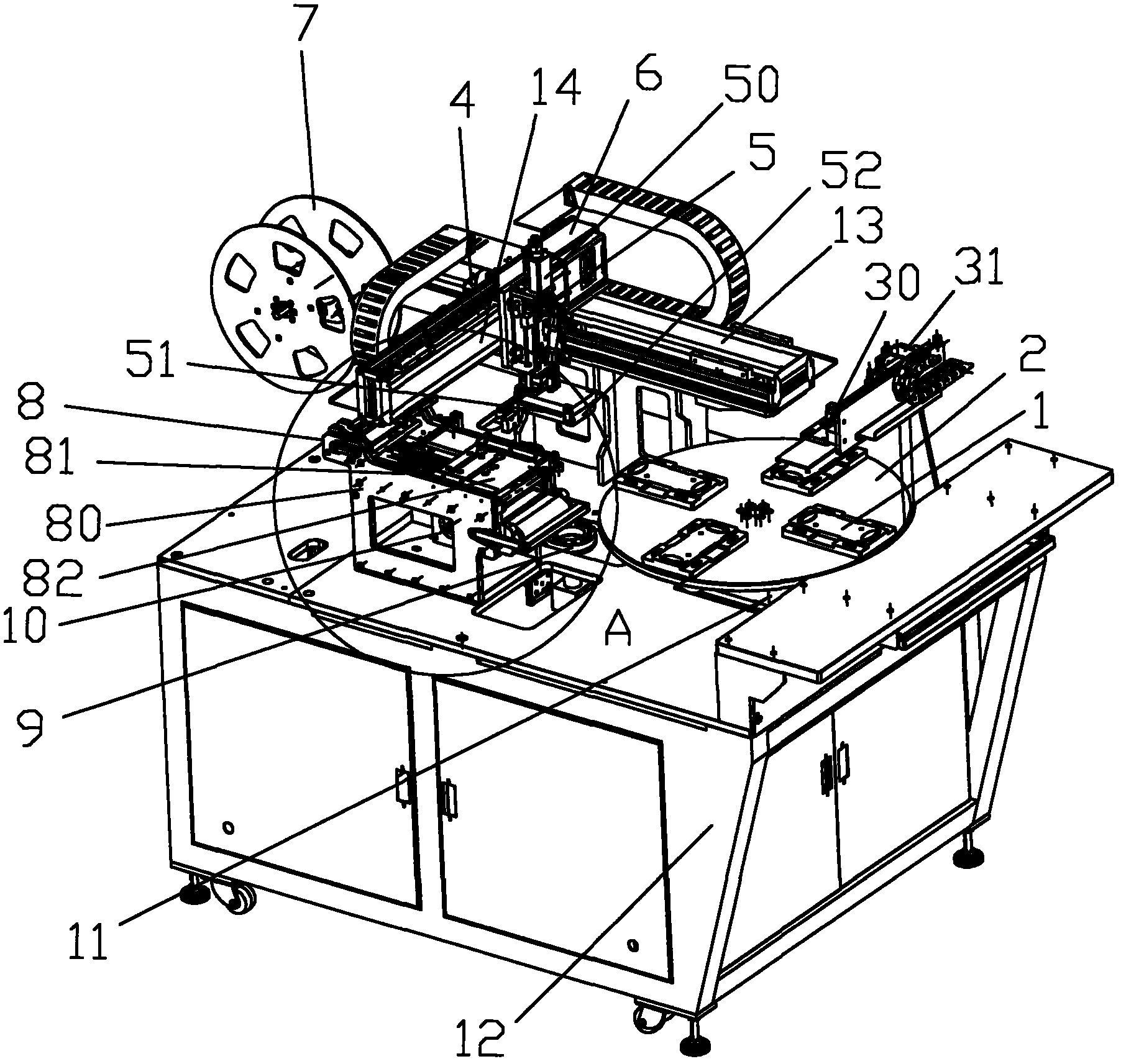

Automatic labeling machine and labeling method

ActiveCN107284780AHigh controllable precisionImprove detection accuracyLabelling machinesComputer graphics (images)Engineering

The invention discloses an automatic labeling machine and a labeling method. The labeling machine comprises a conveying module for conveying products from an identifying position to a labeling position, a label printing device, a robot and a CCD camera, wherein a slide table is arranged in a label outlet of the label printing device, and is provided with a horizontal support surface; a cylinder is connected below the slide table, and is acted on the slide table to move in the vertical direction; the robot comprises a vacuum label sucking head; the vacuum label sucking head moves between the label printing device and the labeling position; and the CCD camera is arranged below the vacuum label sucking head for acquiring images of labels absorbed on the vacuum label sucking head. The automatic labeling machine is high in control precision and detecting precision, generates no bubbles in labeling, and is fast in labeling.

Owner:苏州有泰精密自动化有限公司

Making method of three-dimensional relief anti-fake pattern mother set

ActiveCN104309272ALow costSimplify the plate making processForme preparationControl systemComputer vision

The invention discloses a making method of a three-dimensional relief anti-fake pattern mother set. The making method sequentially comprises the following steps: (1) design of a three-dimensional relief anti-fake pattern source file, sequentially comprising the steps of (1-1) performing relief treatment on a plane pattern to obtain a relief pattern; (1-2) performing multiple times of selected region establishment on the relief pattern, splitting the relief pattern into a plurality of selected regions; (1-3) filling lines into all selected regions to obtain the three-dimensional relief anti-fake pattern source file; (2) importing the three-dimensional relief anti-fake pattern source file obtained in the step (1) into a control system of a laser labeling machine; and (3) spreading a printing plate material on a working platform of the laser labeling machine and positioning the printing plate material, then starting the laser labeling machine to perform photoetching on the printing plate material, and forming stripes corresponding to the lines in the three-dimensional relief anti-fake pattern source file on one surface of the printing plate material to obtain the three-dimensional relief anti-fake pattern mother set. The making method is simple in making process; equipment with low input cost can realize direct processing and making of the three-dimensional relief anti-fake pattern mother set.

Owner:GUANGDONG ZHUANGLI COLOR PRINTING

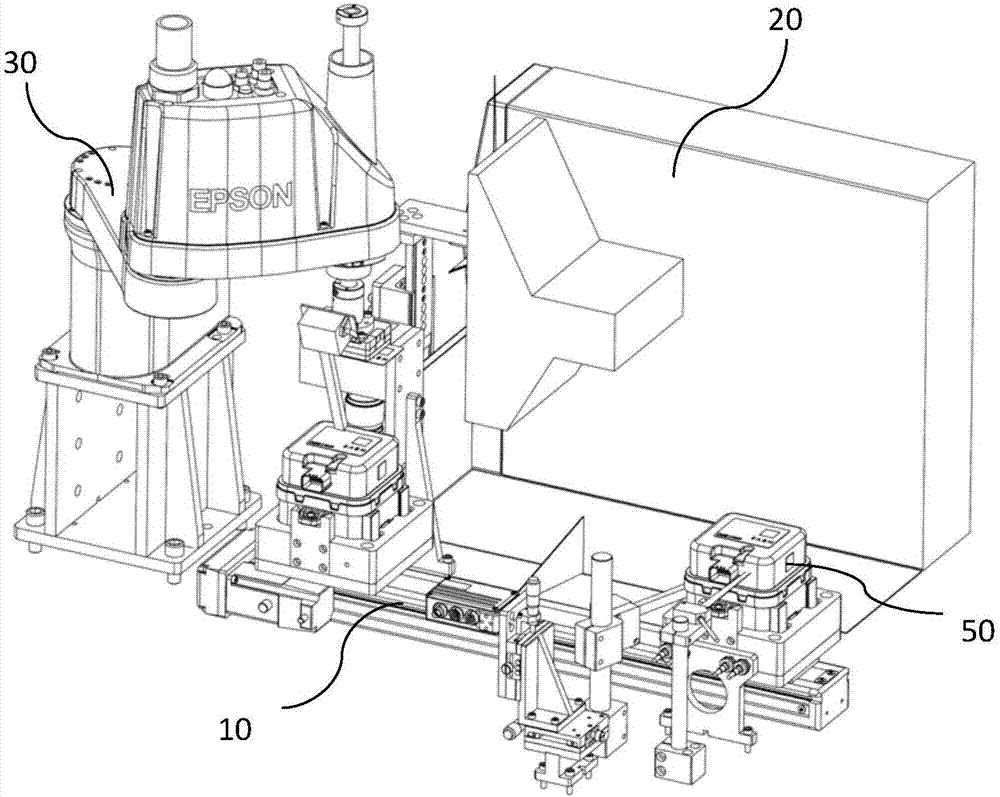

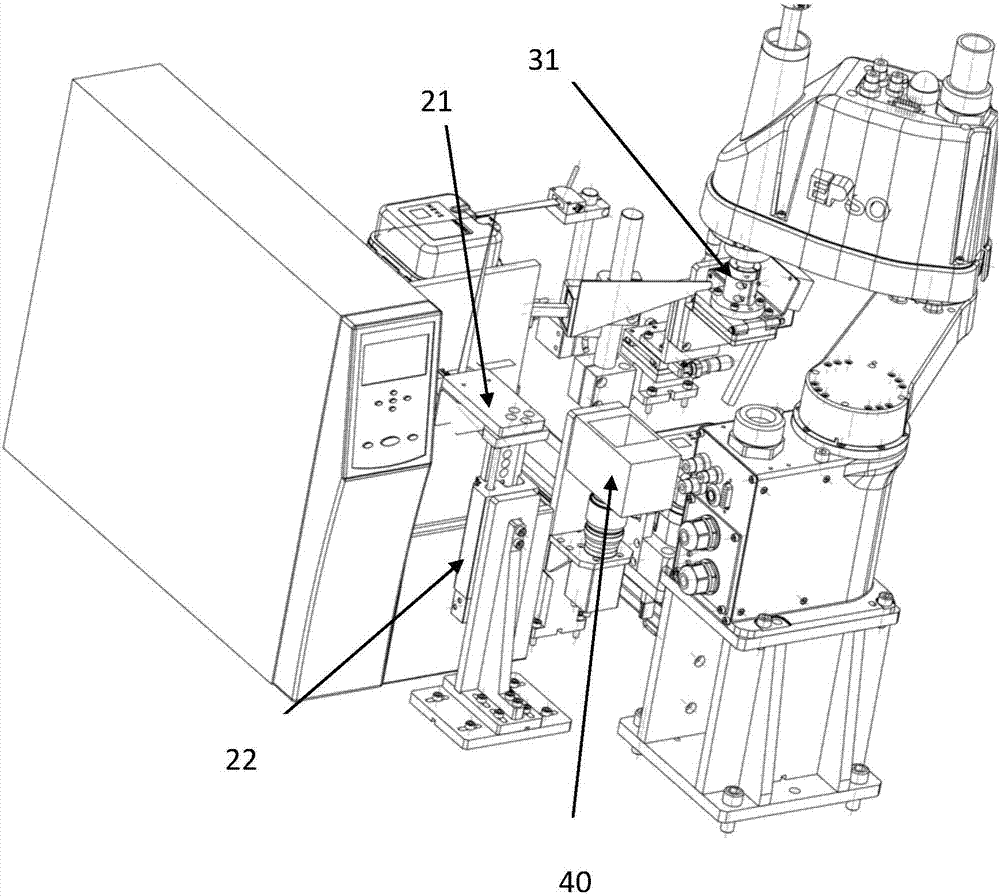

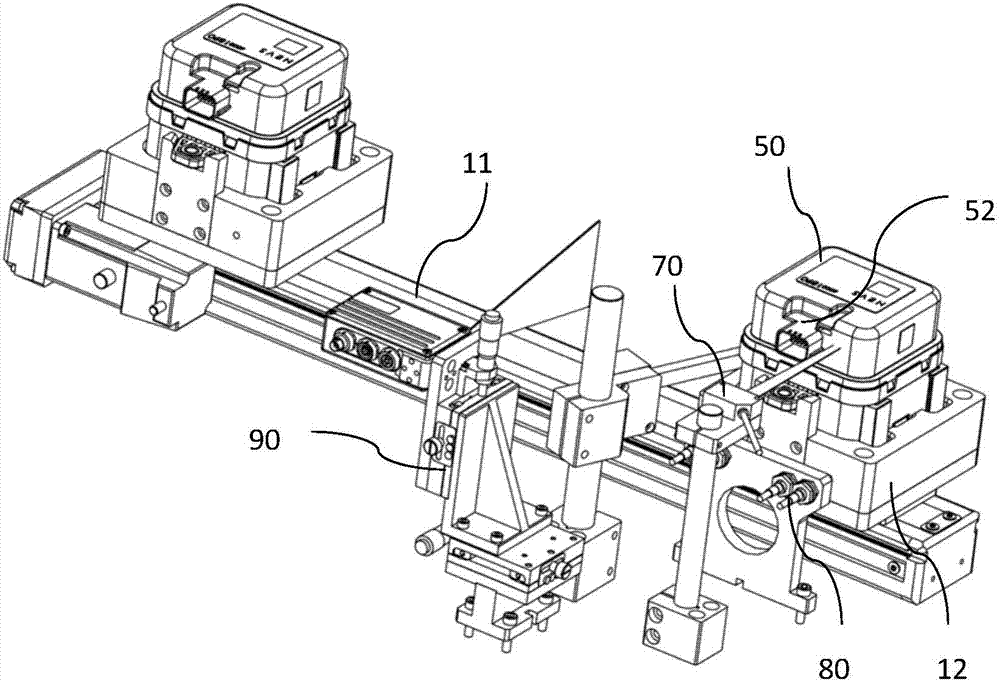

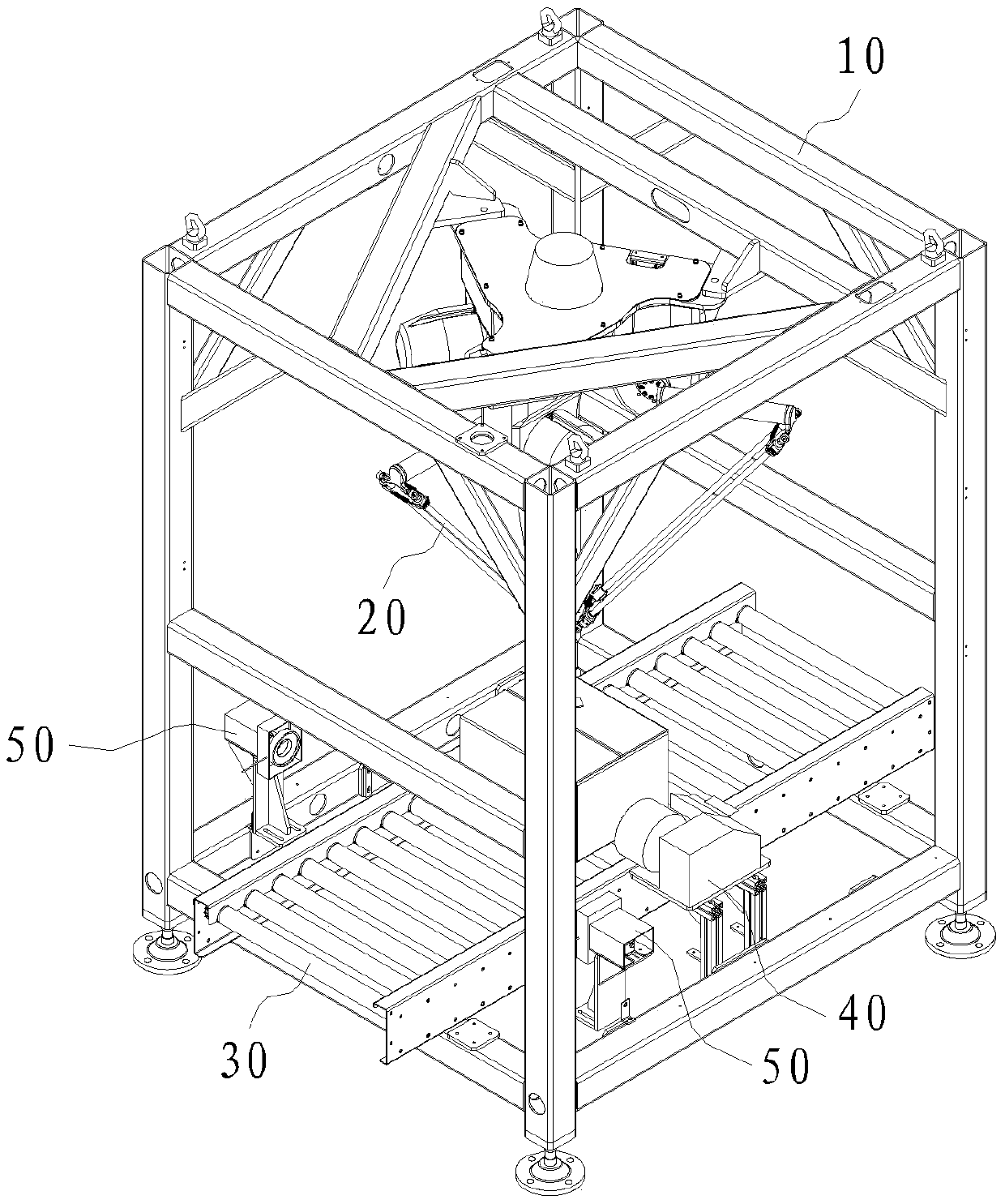

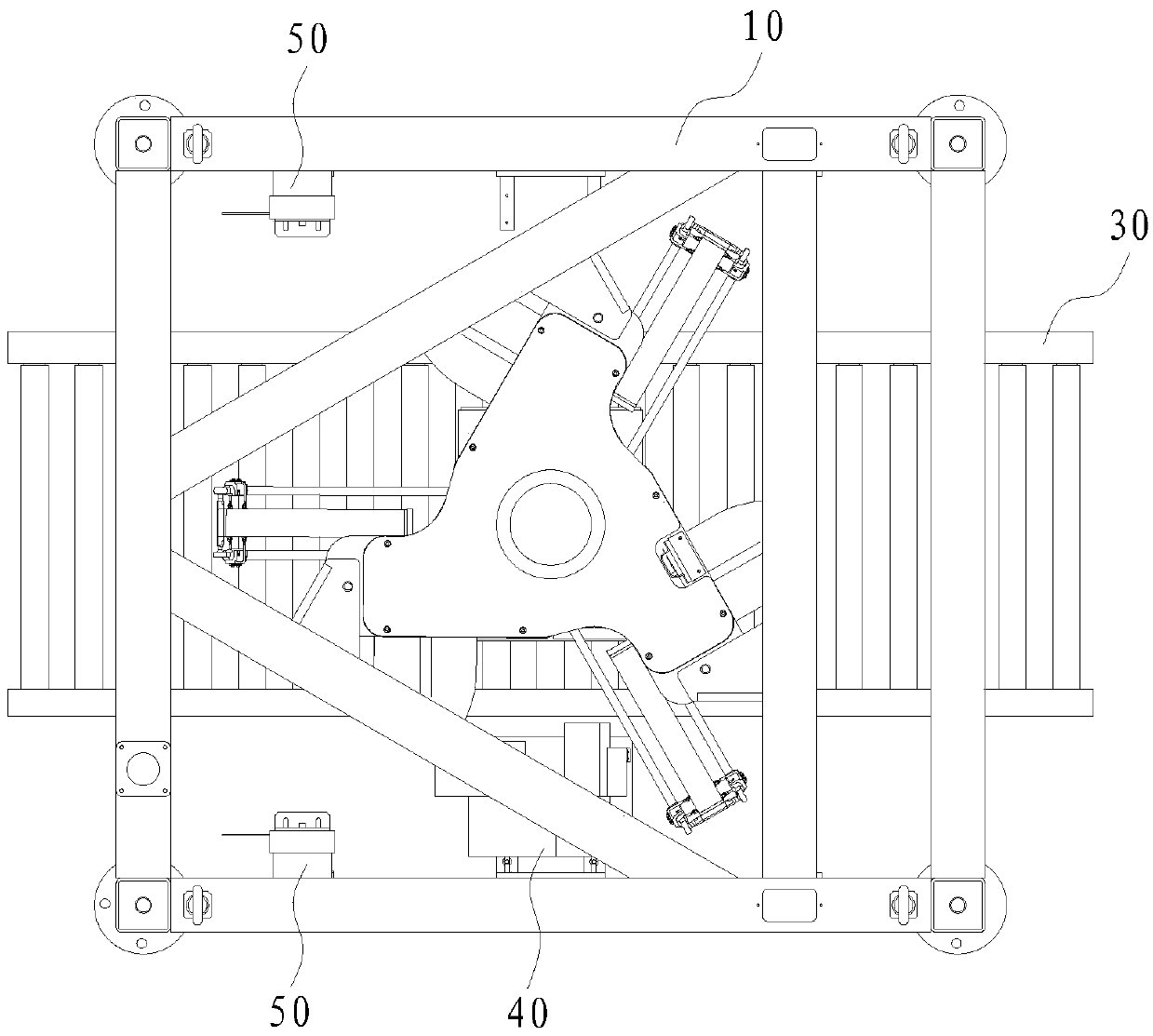

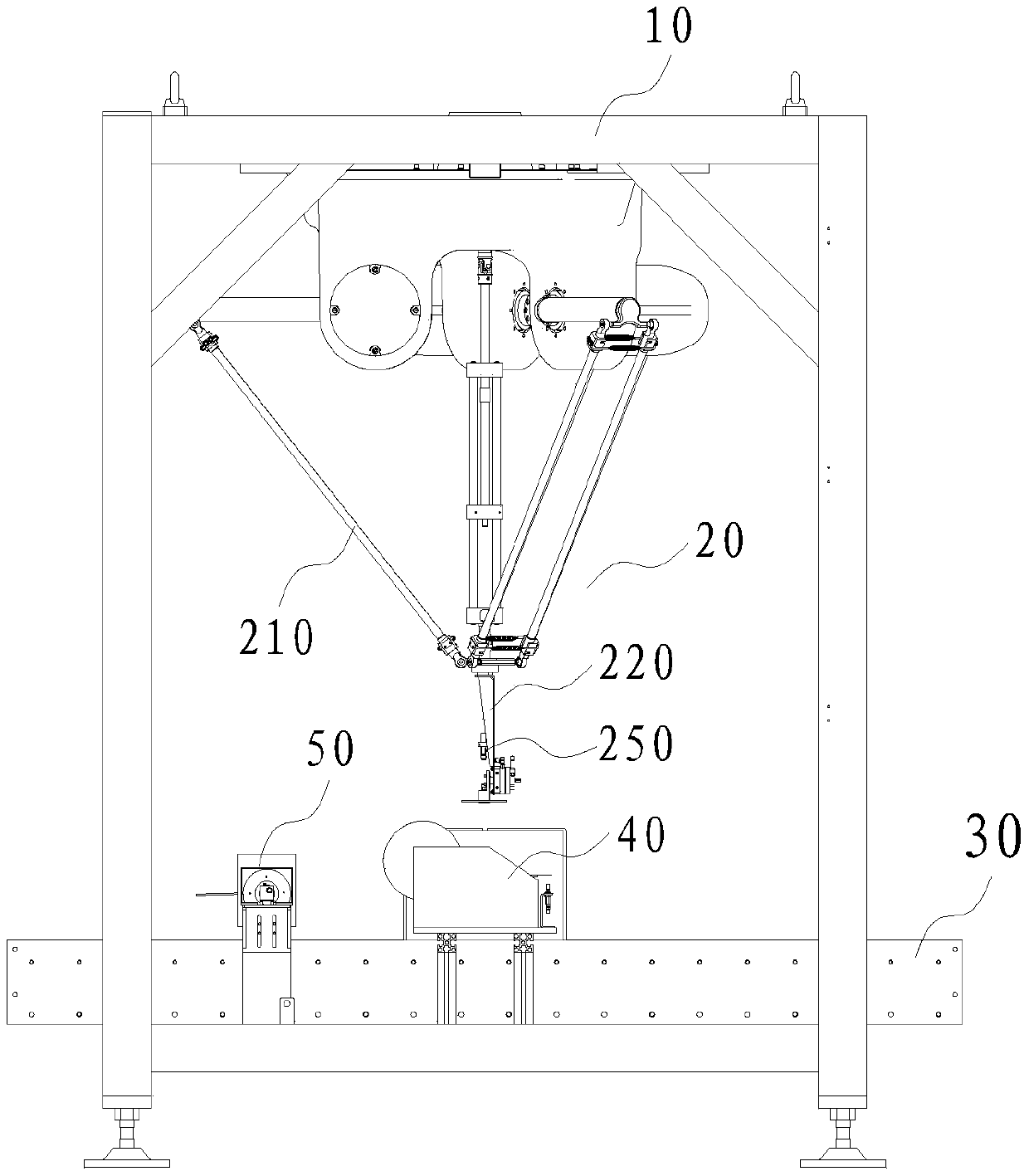

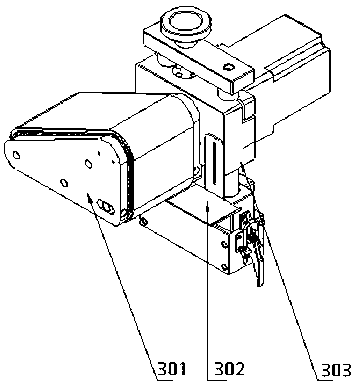

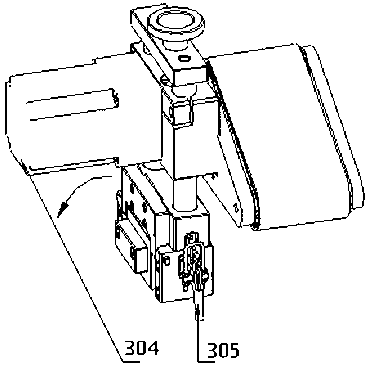

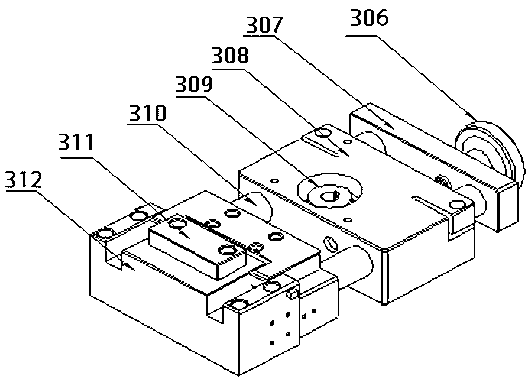

Labeling robot, labeling machine and labeling method of labeling machine

ActiveCN105501589AIncrease the level of automationIncrease productivityLabelling machinesCartonAutomation

The invention discloses a labeling robot, a labeling machine and a labeling method of the labeling machine. The label robot comprises a spider claw robot body, an installation support, a rotary support, a swing mechanism, a label taking mechanism and a controller, wherein the installation support is installed at the lower end of a rotary shaft of the spider claw robot body, the rotary support is installed at the lower end of the installation support in a rotary mode, the swing mechanism is connected with the rotary support, the label taking mechanism is installed on the rotary support, and the controller is electrically connected with the spider claw robot body, the swing mechanism and the label taking mechanism. According to the labeling robot, the labeling machine and the labeling method of the labeling machine, labeling of cartons in different specifications can be achieved, the automation degree is high, and production efficiency is high.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

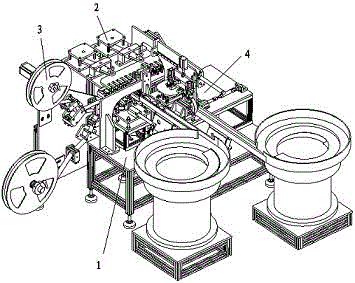

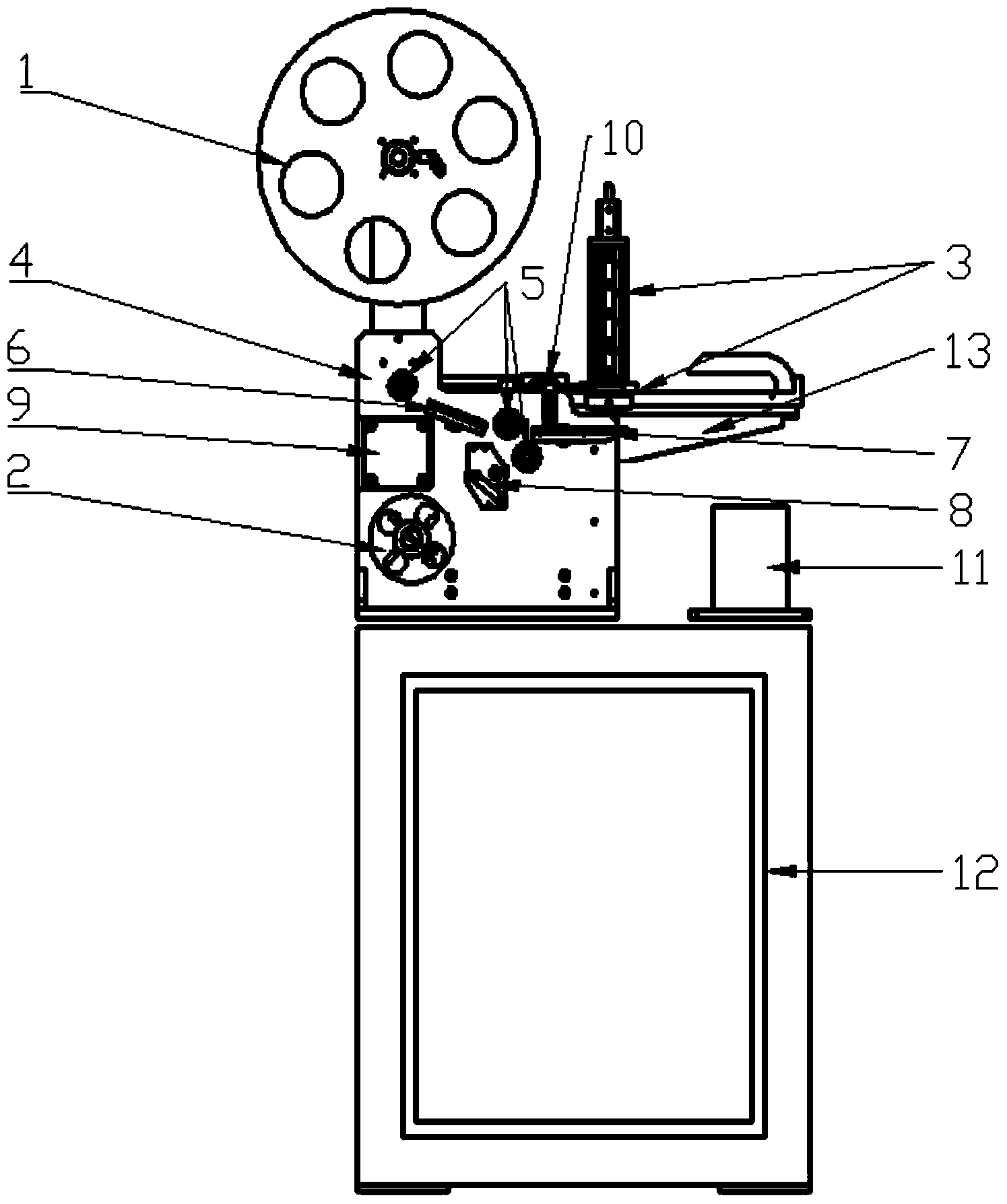

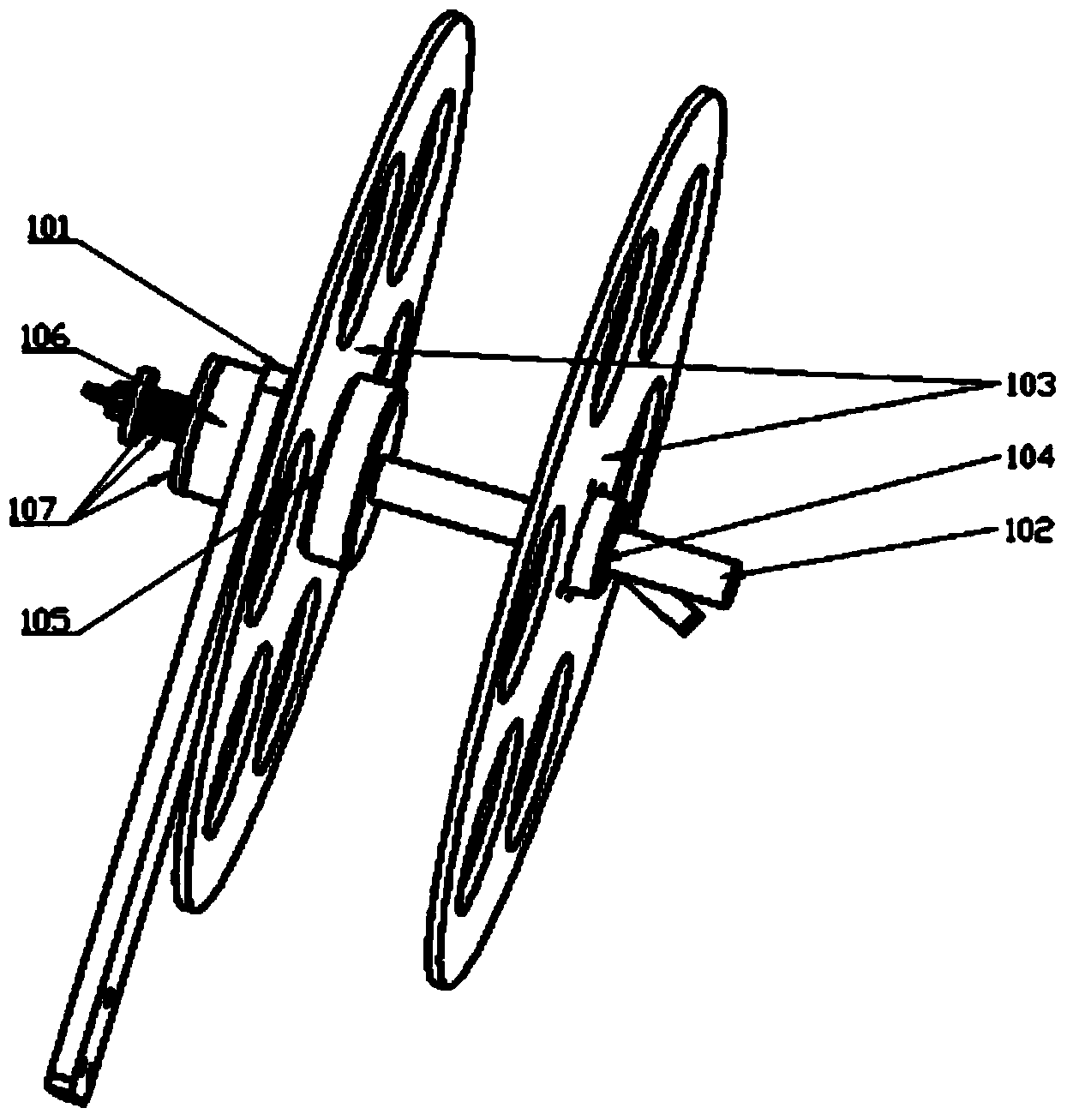

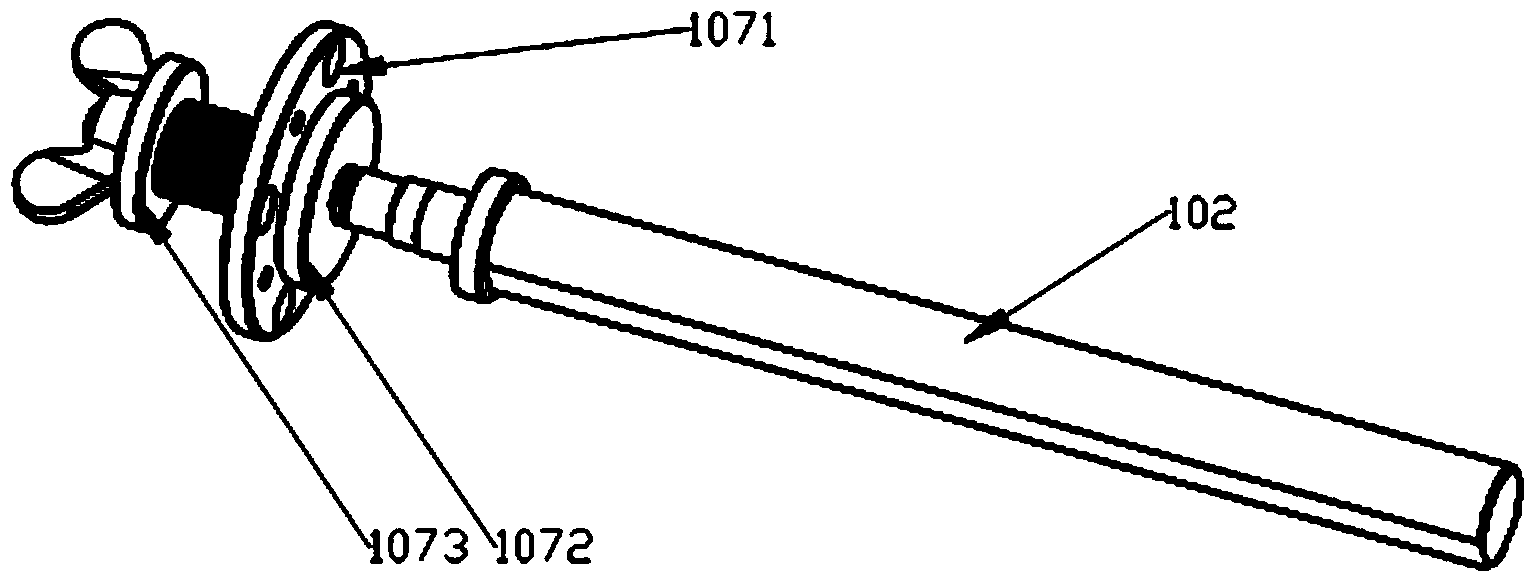

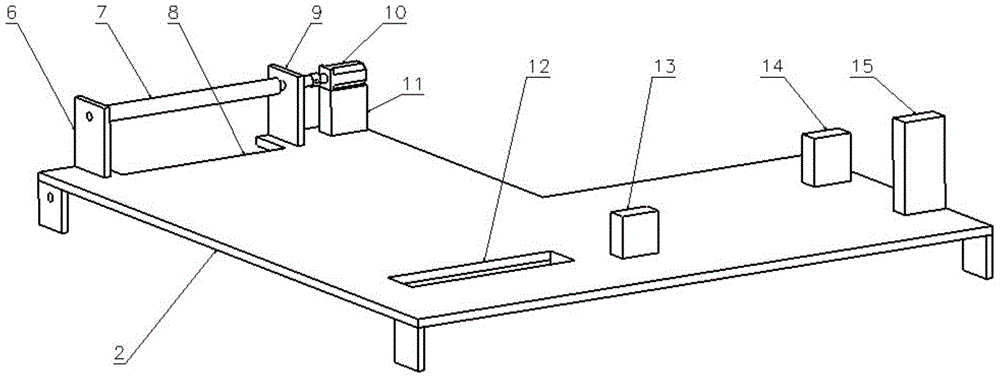

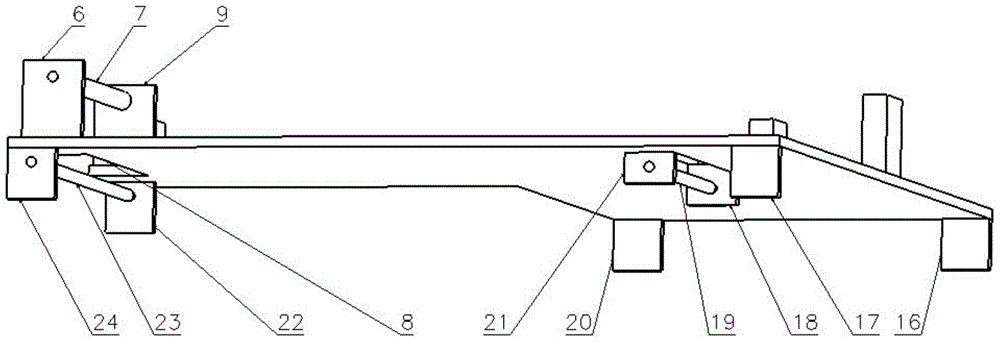

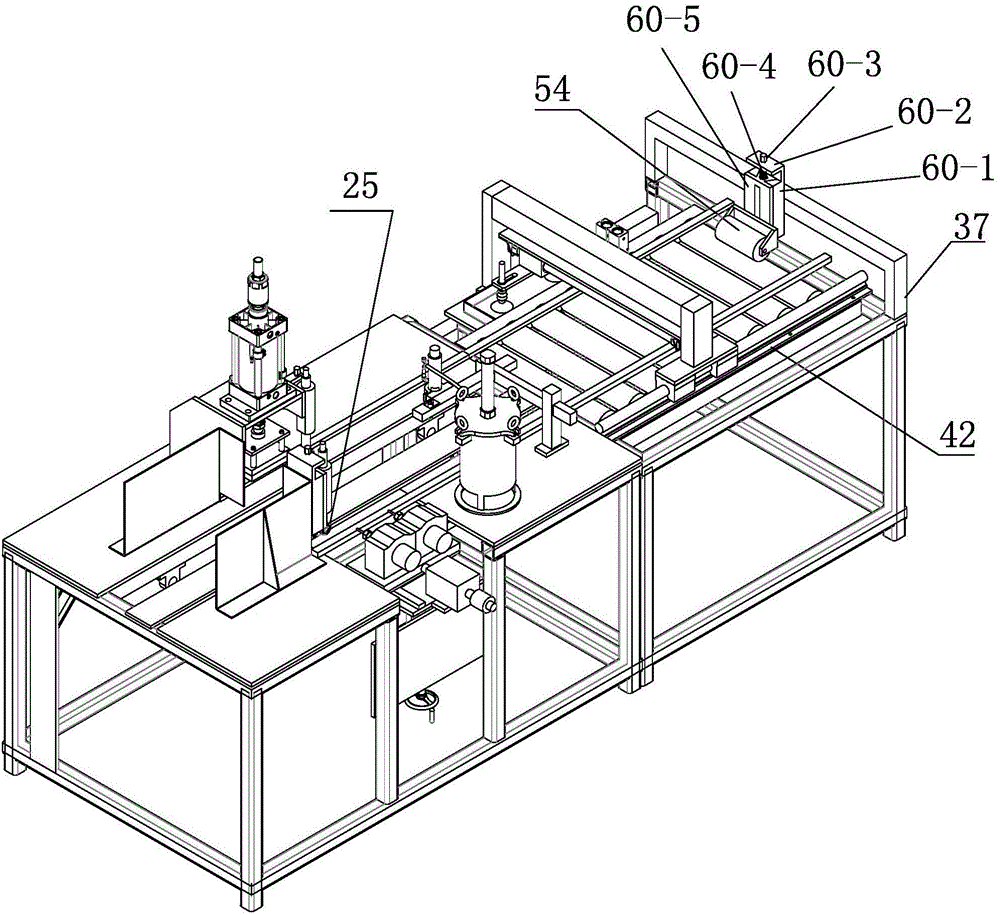

Test tube labeling machine with capabilities of automatic feeding and blanking

InactiveCN104691880ARealize automatic feeding processRealize blankingLabelling machinesLabelling elongated objectsDrive motorEngineering

The invention belongs to the field of labeling, relates to a test tube labeling machine with the capabilities of automatic feeding and blanking and aims at solving the problem of low efficiency of a labeling machine in the prior art. The test tube labeling machine mainly comprises a labeling mechanism, a bottom plate, a feeding mechanism and a blanking cabin, wherein the labeling mechanism consists of a turntable mechanism, a label pressing mechanism, a rotation mechanism and a rack assembly; the turntable mechanism consists of a turntable, a gear ring, a turntable driving gear, a turntable driving motor and a driving motor support seat; the feeding mechanism consists of a plate pushing mechanism, a rotary wheel mechanism and a feeding cabin mechanism which are fixed to the bottom plate sequentially. According to the test tube labeling machine, automatic feeding and blanking of a test tube can be realized, the labeling efficiency can be improved, test tubes with different diameters can be clamped, the test tubes stored in a feeding cabin can successfully enter the rotary wheel mechanism without the blockage phenomenon by adopting a cam mechanism, and the test tubes in a feeding cabin can singly and orderly enter a U-shaped groove for labeling by adopting the rotary wheel mechanism, the structure is simple, the debugging is convenient, the cost is low and the operation is convenient.

Owner:JILIN UNIV

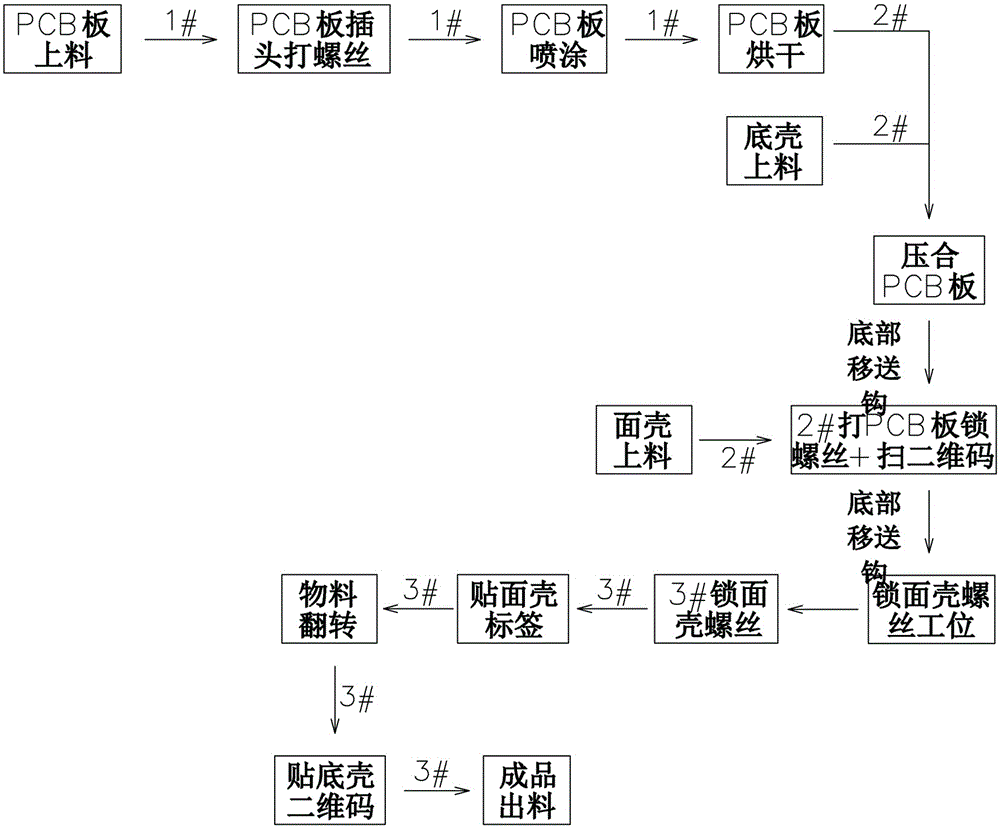

PCB and shell assembling machine and assembling process thereof

ActiveCN105127736AIncrease production capacityImprove the excellent rateAssembly machinesRobot handStructural engineering

The invention discloses a PCB and shell assembling machine. A drying box is arranged between a first six-axis mechanical arm and a second six-axis mechanical arm. The second six-axis mechanical arm corresponds to a third six-axis mechanical arm. The left end of the first six-axis mechanical arm is provided with a screw supplier and a screw hitting machine. A PCB feeding sliding table is arranged in front of the first six-axis mechanical arm, and a spraying box is arranged behind the first six-axis mechanical arm. The first six-axis mechanical arm corresponds to the spraying box, the screw hitting machine, the PCB feeding sliding table and the drying box. A bottom shell material bin and a face shell material bin are arranged in front of the second six-axis mechanical arm. A pressing mechanism and a PCB screw locking mechanism are arranged behind the second six-axis mechanical arm. A bottom transferring hook is arranged between the pressing mechanism and the PCB screw locking mechanism. A glue tearing mechanism and a two-dimension code labeling storage bin are arranged in front of the third six-axis mechanical arm. The third six-axis mechanical arm corresponds to the glue tearing mechanism, the two-dimension code labeling storage bin and a face shell screw locking and labeling mechanism. The invention further discloses a process for assembling a PCBA bard and a shell through the assembling machine. By means of the PCB and shell assembling machine, a PCB and shell assembling production line is achieved intelligently, the PCB and shell assembling machine is high in efficiency and yield, and manpower is saved.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

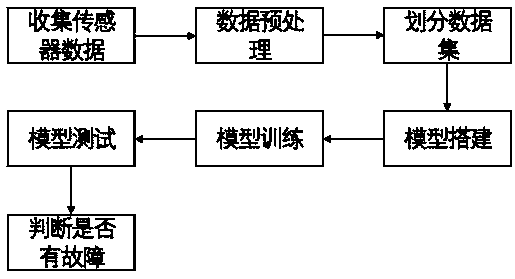

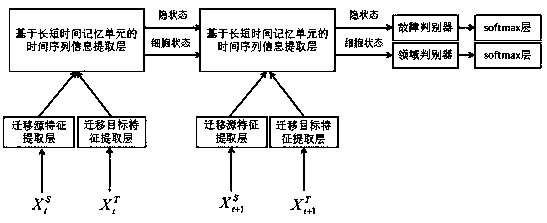

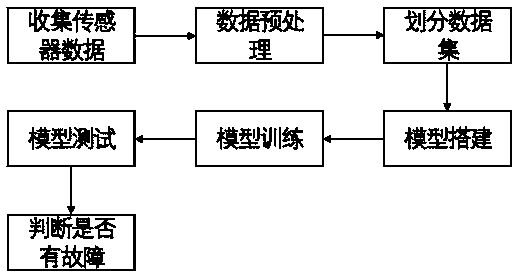

An unsupervised industrial system anomaly detection method based on deep transfer learning

ActiveCN109710636AProgramme controlDigital data information retrievalIndustrial systemsAnomaly detection

The invention discloses an unsupervised industrial system anomaly detection method based on deep transfer learning. According to the invention, labeled machine sensor sequence data from a migration source and unlabeled sensor sequence data from a migration target are utilized to train an industrial system abnormality detection model with good generalization ability, and the industrial system abnormality detection model is trained and tested to finally generate a trained industrial system abnormality discrimination model. By means of the model, the received machine sensor sequence data can be analyzed, and whether the machine is abnormal or not can be judged.

Owner:GUANGDONG UNIV OF TECH

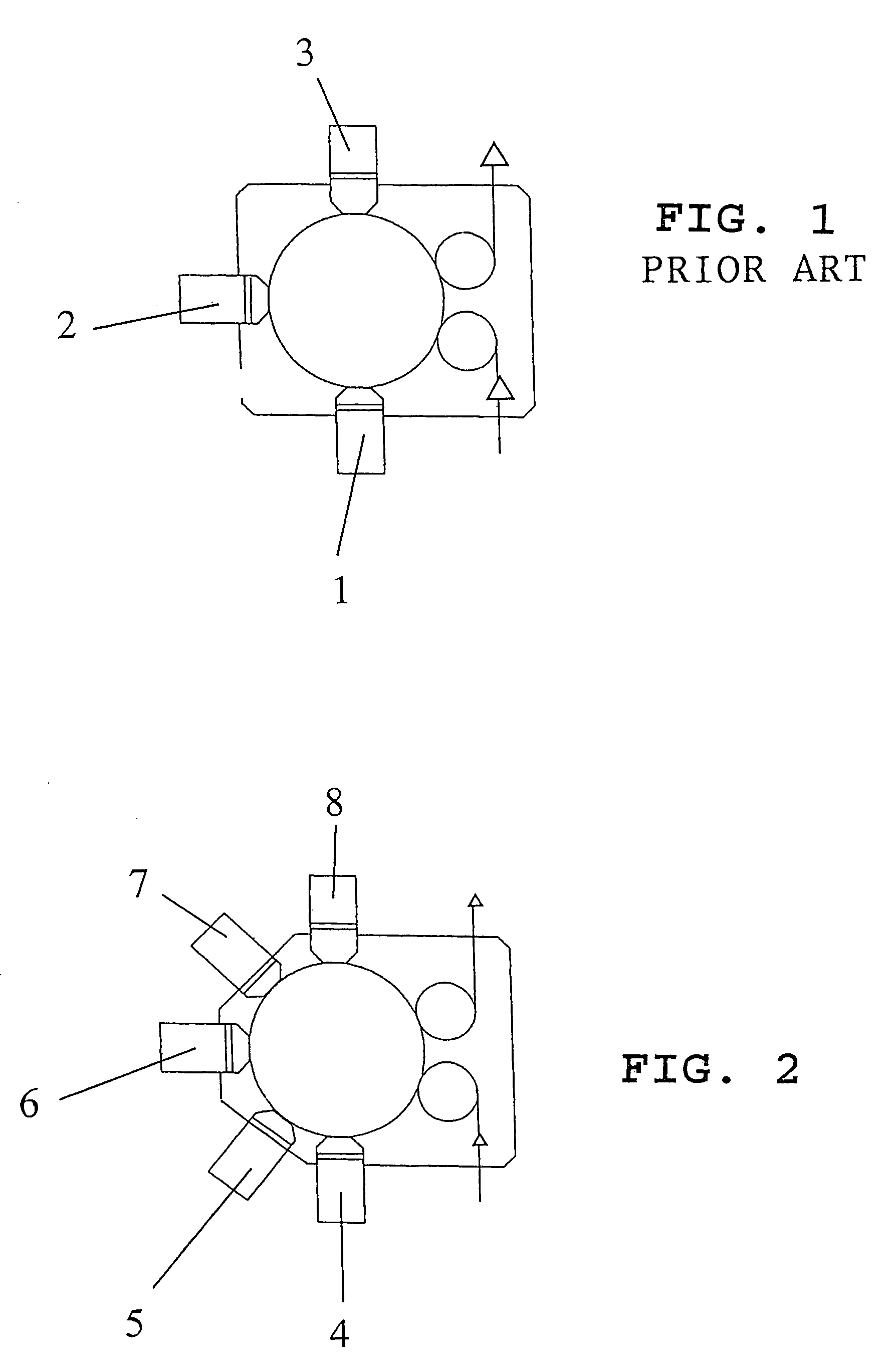

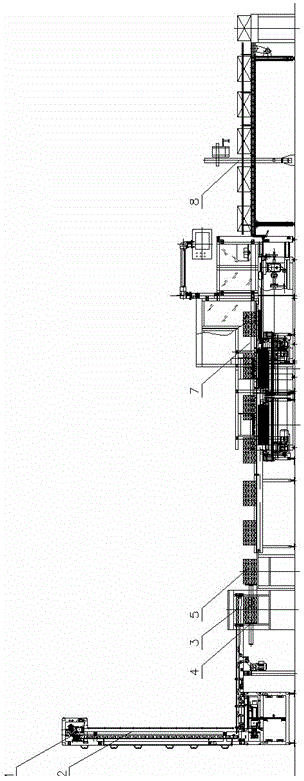

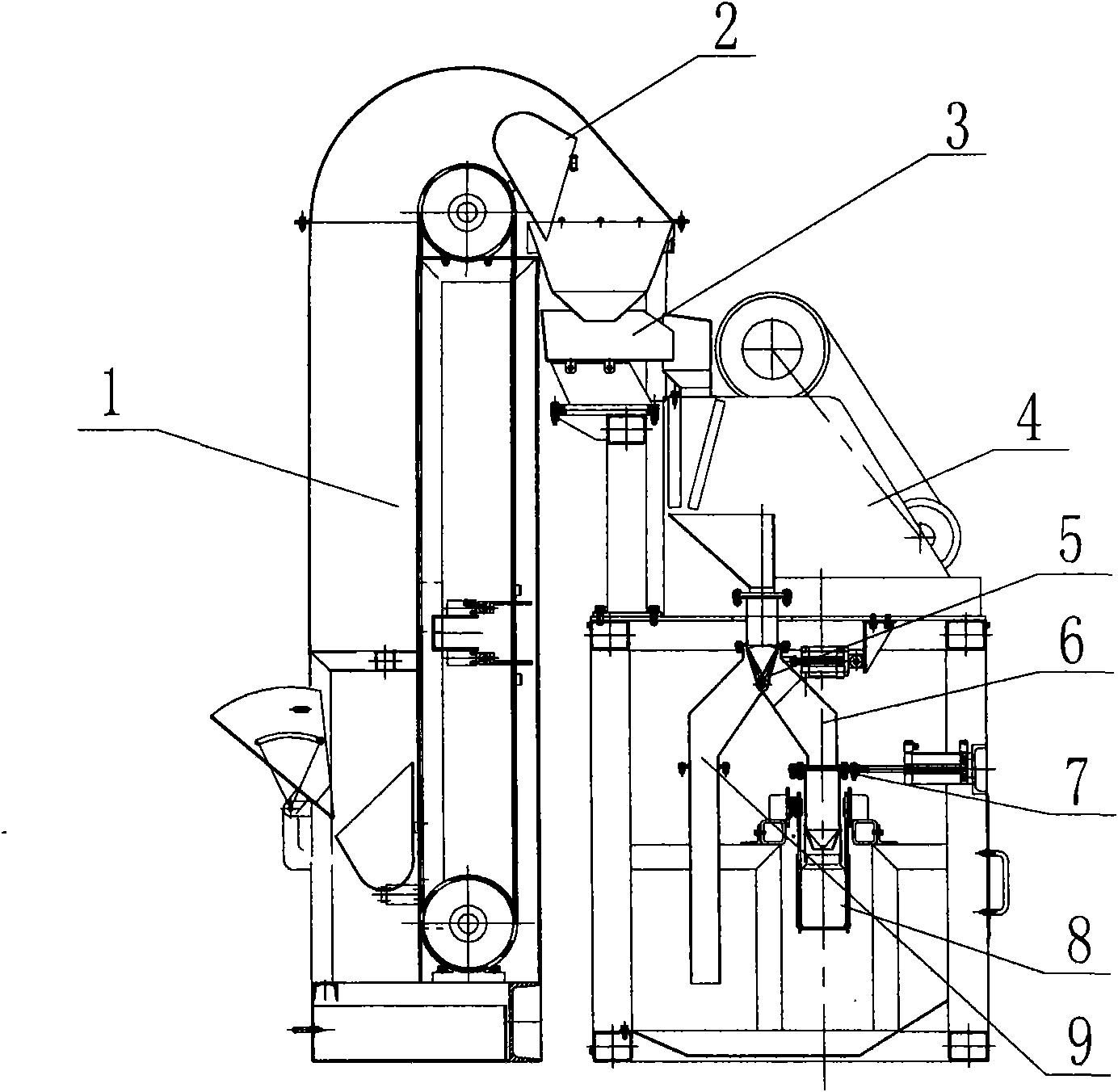

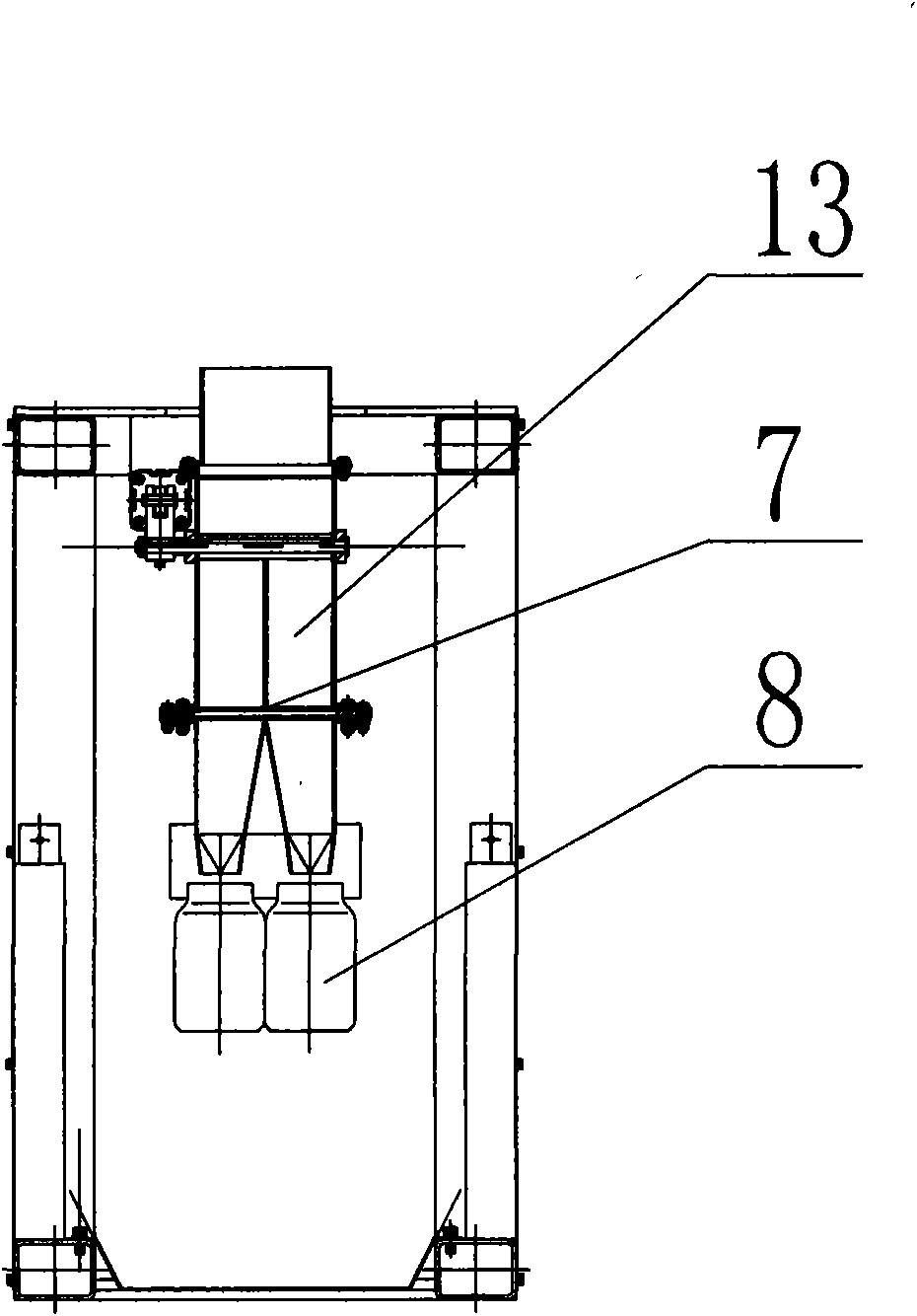

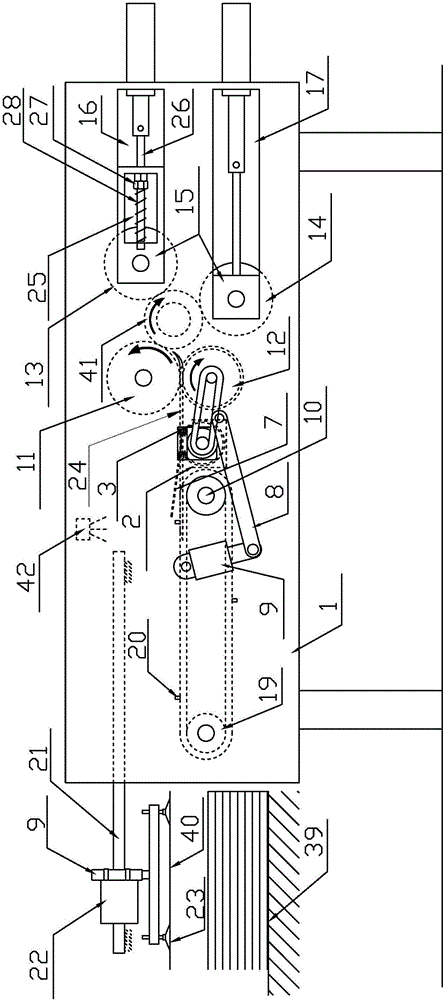

Labeling machine

ActiveCN103010541ACompact structureEasy to operateLabelling machinesLabelling short rigid containersBottleFault rate

The invention relates to a labeling machine which is characterized by comprising a vertical-to-horizontal mechanical synchronous device (1), a roller conveyer belt (2), a synchronous rejecting and bottle shifting device (9) and a bottle body horizontal-to-vertical device (8) which are connected in sequence, wherein a bottle coiling belt device (7) is further installed beside the roller conveyer belt (2); and a label feeding mechanism (3) is further installed beside the bottle coiling belt device (7) so as to accomplish the labeling in match with the bottle coiling belt device (7). Tests prove that the labeling machine provided by the invention is compact in structure, easy to operate, reliable to work and very lower in fault rate, and is applicable to rapid and automatic labeling and character printing on packages of oral liquid bottles, penicillin bottles and ampere bottles.

Owner:GUANGZHOU PHARMA INTELLIGENT EQUIP CO LTD

Cylindrical material labeling machine and labeling method

InactiveCN104085575AHigh speedLow costLabelling machinesLabelling elongated objectsRolling paperGear wheel

The invention relates to a cylindrical material labeling machine and labeling method. A piece of cylindrical product packaging paper is pasted manually in a rolling manner, and the cost is high. The cylindrical material labeling machine comprises a rack, a paper feeding device, a gumming mechanism and a roll paper pasting mechanism, wherein the gumming mechanism comprises a hot melt glue groove and a gumming roller; the gumming roller is provided with multiple ring grooves to be divided into multiple annular gumming surfaces, paper pressing bulges are arranged above the gumming roller, and the two ends of the gumming roller are respectively provided with a lifting device; an upper fixed roller and a lower fixed roller are linked in the same direction by a meshing gear so as to form a paper pulling roller group, a paper drum group is composed of the upper fixed roller, an upper moving roller and a lower moving roller, the paper feeding device comprises a movable paper absorbing mechanism and a conveying chain mechanism, and the conveying chain mechanism is arranged on the upper stream of the gumming roller. The invention also relates to the cylindrical material labeling method. The cylindrical material labeling machine and method provided by the invention have the advantages that the speed is high, the cost is low, a pasted label is smooth and firm and the glue dosage is low, and can be used for pasting labels of party cannon, fireworks or other paper materials, plastics and metal materials.

Owner:王丽娜

Labeling machine

InactiveUS20160031582A1Compact configurationLower the volumeLabelling machinesEngineeringMechanical engineering

A labeling machine including a substrate, an assembling element, a carrying shaft, a driving module, a labeling module, a peeling unit and a furling shaft is provided. The assembling element is disposed at one side of the substrate allowing it to be installed onto a robot. The carrying shaft is disposed on the substrate, and a label base with multiple labels is assembled on the carrying shaft. The driving module and the labeling module are disposed on the substrate. The peeling unit, the carrying shaft and the furling shaft are all disposed at the same side of the substrate. The furling shaft controlled by the driving module is used to furl the label base. When the label base wraps around the peeling unit and the driving module drives the furling shaft to rotate, the labeling module near by the pressing unit would capture the label protruded from the label base.

Owner:CENZ AUTOMATION

Labelling Machine

InactiveUS20090160901A1Amount of ink can be minimizedQuantity minimizationTypewritersLabelling machinesLabelling machineInkjet printing

A labelling machine and a method of applying information onto containers and / or labels by means of an ink jet printer which has at least one print head with at least one nozzle and in the case of which a cover can selectively be moved to a position in front of the discharge opening of the nozzle so as to recirculate ink discharged from the nozzle into the ink circuit. The printer can also be operated during a printing pause whereby the ink is prevented from drying up in the print head.

Owner:KRONES AG

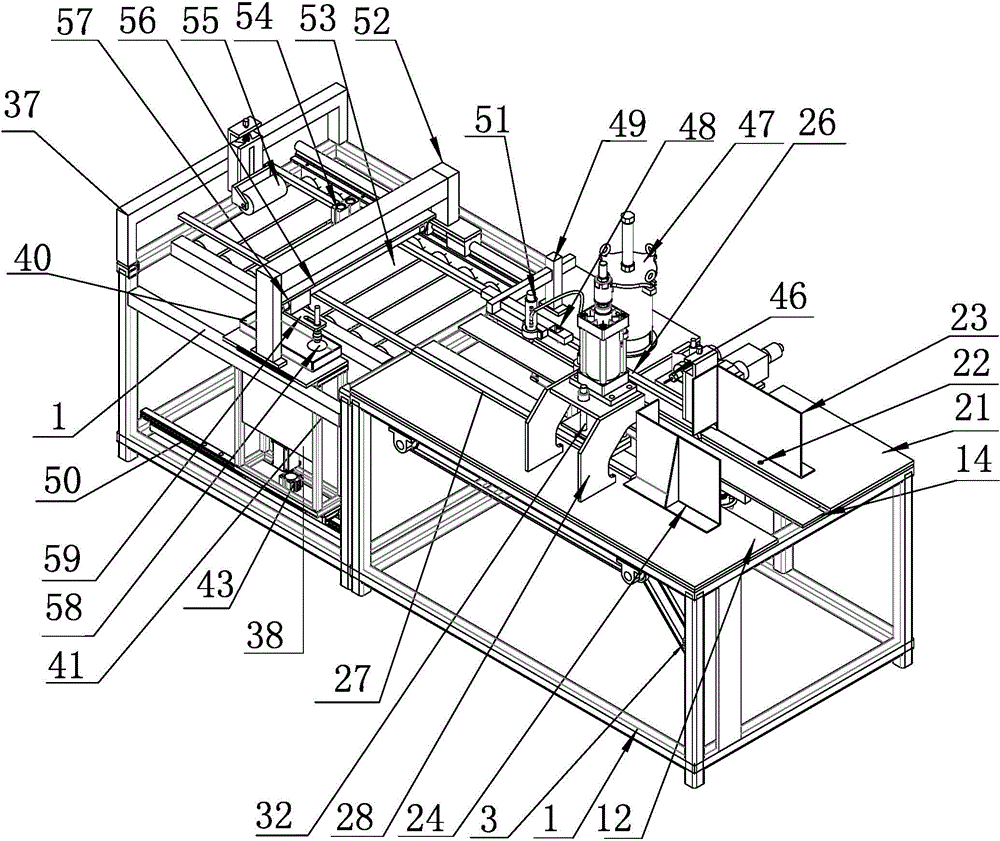

Automatic branding, drilling and labelling machine

InactiveCN104385420AContinuous brandingContinuous drillingBranding equipmentStationary drilling machinesButt jointWorkbench

The invention relates to an automatic branding, drilling and labelling machine, which can be used for sequentially finishing the procedures of conveying, branding, drilling, glue dripping, labelling and the like, can be used for machining products of various specifications and has the characteristics of high working efficiency, convenience in adjustment, and the like. According to the technical scheme, the automatic branding, drilling and labelling machine comprises a front half part and a back half part, wherein the front half part comprises a feeding mechanism arranged on the front segment of a frame, a fixed workbench arranged on the left side of the feeding mechanism, and a movable workbench arranged on the right side of the feeding mechanism; a hand drill hole lifting mechanism and a glue dripping mechanism are arranged on the fixed workbench; a branding mechanism is arranged on the movable workbench; the back half part comprises a drum group arranged on the back segment of the frame, a labelling device arranged above the drum group, a label lifting mechanism arranged on the right side of the drum group, and a label pressing mechanism arranged at the back end of the drum group; the front end of the drum group is in butt joint with the back end of the feeding mechanism.

Owner:ZHEJIANG TIANZHU IND & TRADE

Labeling machine and labeling method

The invention discloses a labeling machine and a labeling method. The labeling machine comprises a rack, a label supply mechanism, a product material strap supply mechanism, a joint platform and a label suction mechanism. The label suction mechanism and the joint platform directly face each other, the label suction mechanism is located above the middle segment of a product material strap passing path, and the joint platform is located below the middle segment of the product material strap passing path; the label suction mechanism comprises a label suction plate and a lifting drive part; the label supply mechanism comprises a discharging assembly, a label peeling plate assembly and a receiving assembly; the label peeling plate assembly comprises a label peeling plate and a horizontal displacement driving part, one end, close to the label suction mechanism, of the label peeling plate serves as a label peeling end, the label peeling end is located between the lower surface of the label suction plate and the upper surface of a product material strap, the label suction plate is driven by the lifting drive part to move downwards to suck the label material strap from the label peeling end and peel a label, and after the label peeling plate returns, the label suction plate further descends so as to enable the label to be attached to the product material strap. The label peeling plate horizontally moves to be matched with the lifting motion of the label suction mechanism to achieve label peeling, the transverse moving error of the label suction mechanism can be reduced, speed matching is avoided, control is simple, and the cost is relatively low.

Owner:GUANGDONG FXD INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com