Method for the positionally accurate application of labels, and labelling machine

A labeling machine, labeling technology, applied in the direction of labeling machine, labeling, packaging, etc., can solve problems such as short time intervals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

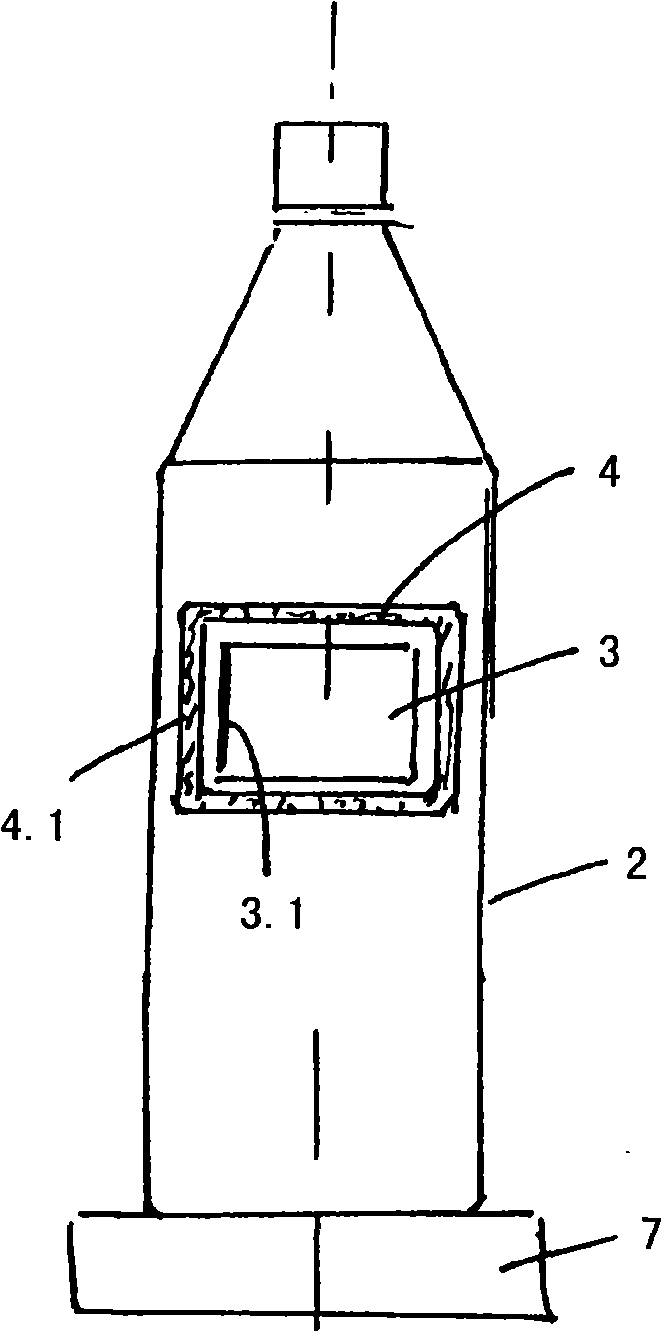

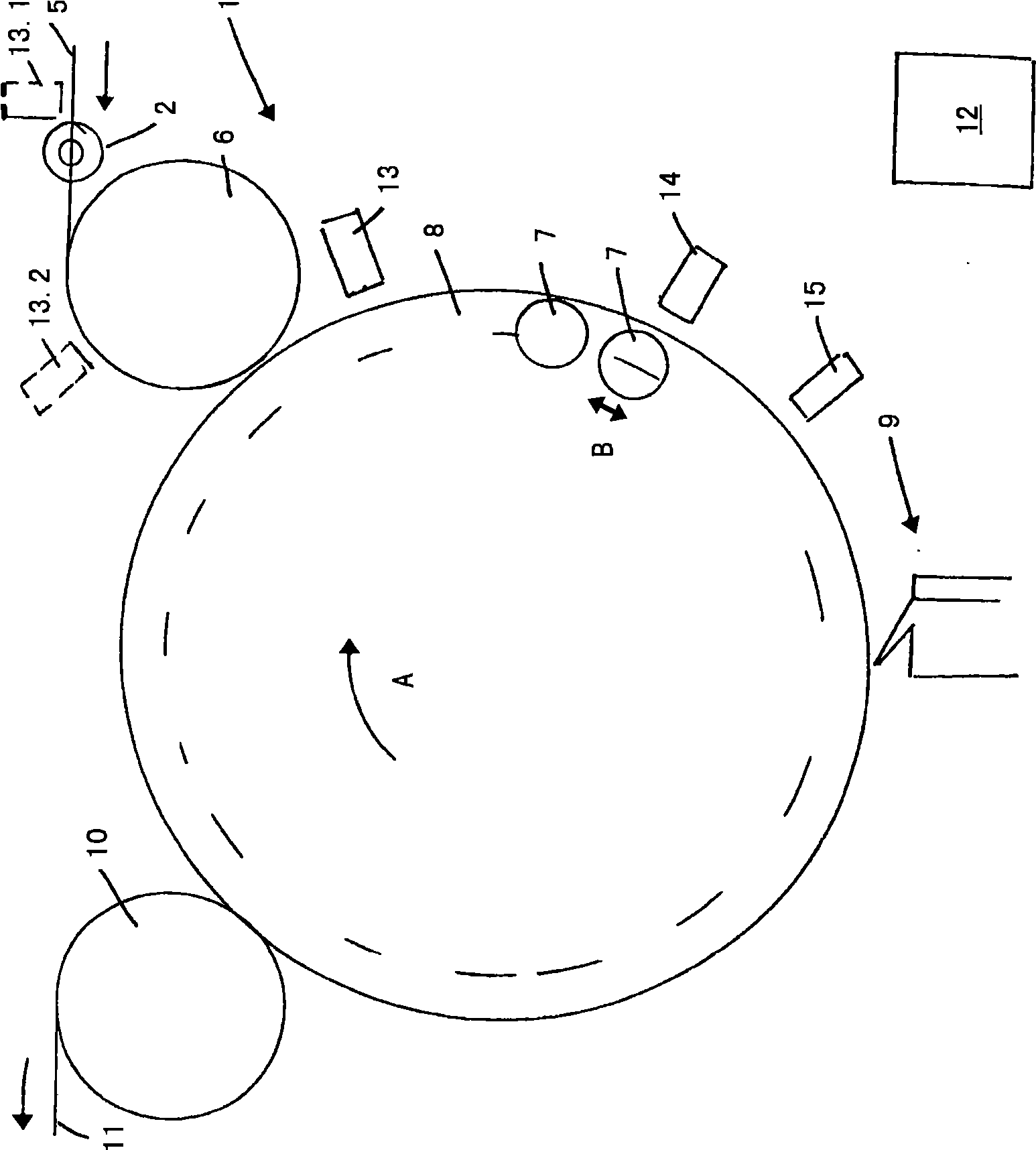

[0018] exist figure 2 A labeling machine of rotary construction generally characterized by 1 is used for labeling bottles 2, i.e. for applying labels 3 to On the circumference of bottle 2. This geometrical feature 4 is, in the illustrated embodiment, an imprinted surface, in the middle of which the corresponding label 3 should be located precisely.

[0019] The application of the label 3 should be carried out with the highest possible precision with respect to the geometrical features 4 , which can also have other configurations, for example in the form of decorative patterns, embossments or other raised text on the outer surface.

[0020] The bottles 2 to be labeled are conveyed to the labeling machine 1 vertically, ie with their bottle or container axis oriented in the vertical direction, via a conveyor 5 in a single bottle flow to the labeling machine 1, and then through the conveying star wheel which serves as the bottle or container inlet 6 respectively to a bottle car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com