Coal coking automatic sample preparation system

An automatic sample preparation and coal coking technology, which is applied in the preparation of test samples, etc., can solve the problems of inability to guarantee the accuracy of the sample preparation process, reduce the reliability of experimental results, manual errors and misoperation, and reduce personal injury and improve Reliability and scientificity, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

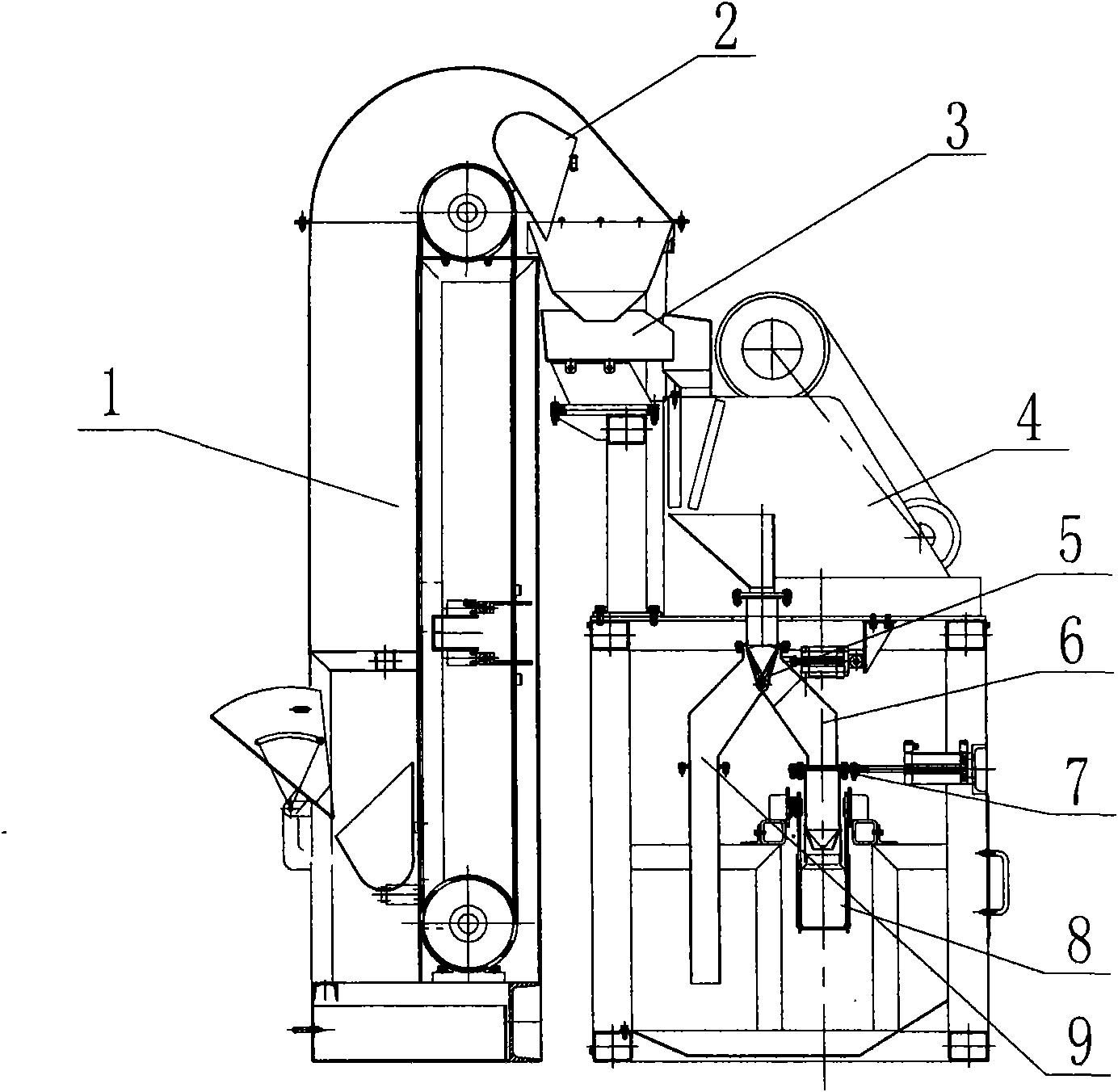

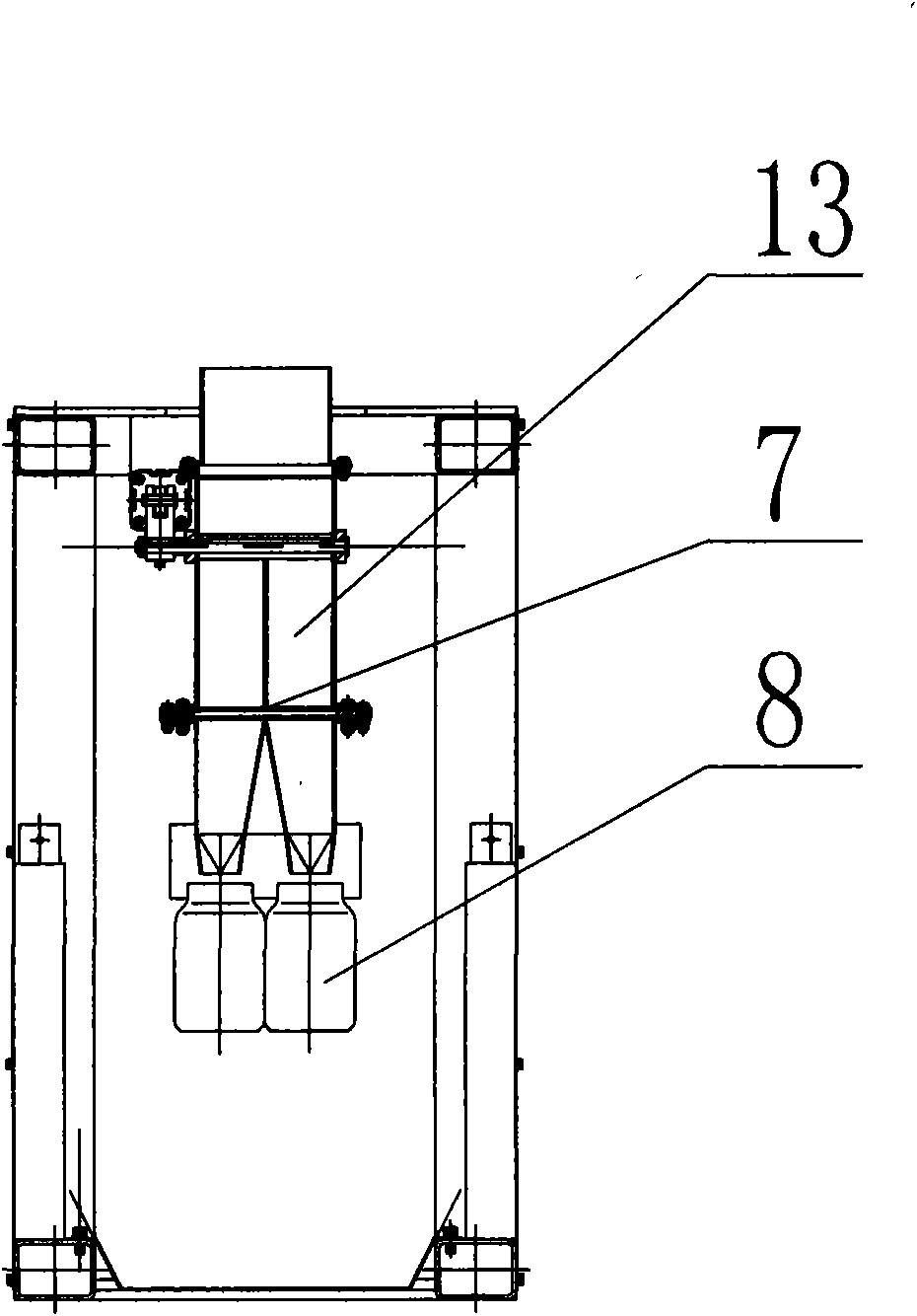

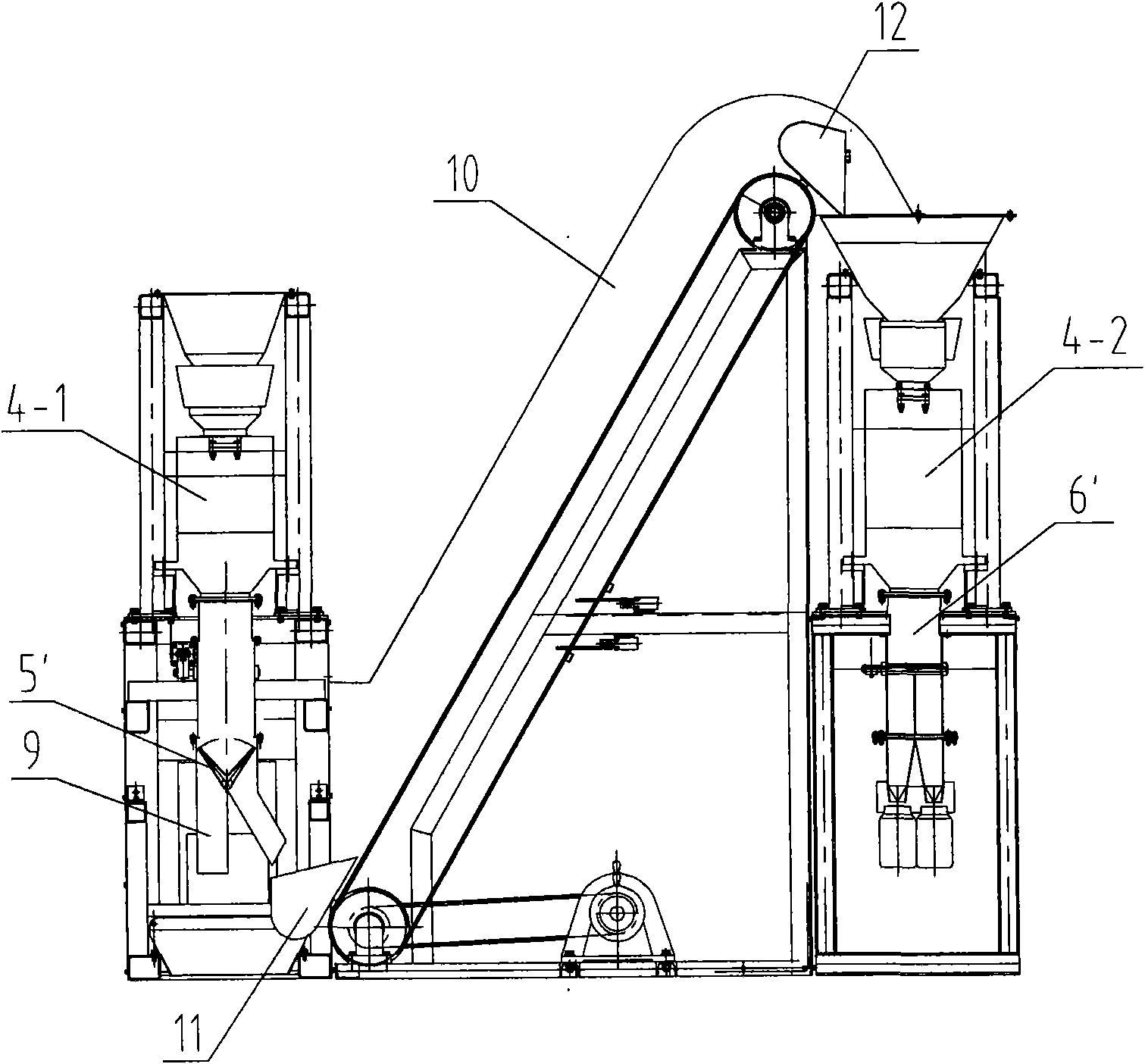

[0022] Will figure 1 - Fig. 7, coal coking automatic sample preparation system, the system includes a sample preparation workstation, an automatic conveying unit, a discharge unit, and a control unit. Through the control of the control unit, the sample preparation workstation, the automatic conveying unit, and the discharge unit are sequentially linked, Complete automatic feeding, crushing, shrinking, automatic conveying, sample sealing, information identification and coding, and collection of discarded samples for raw ores.

[0023] See figure 1 , the sample preparation workstation is composed of a vertical bucket elevator 1, an automatic feeder 3, a crusher 4, and a shrinker 6. The automatic feeder 3 is located at the lower part of the bucket dumping level 2 of the lifting mechanism. The vibration of the automatic feeder The hopper corresponds to the upper port of the crusher 4, the lower part of the outlet of the crusher 4 is connected to the shrinking and dividing two-way...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com