Patents

Literature

178results about How to "Reduce manual errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

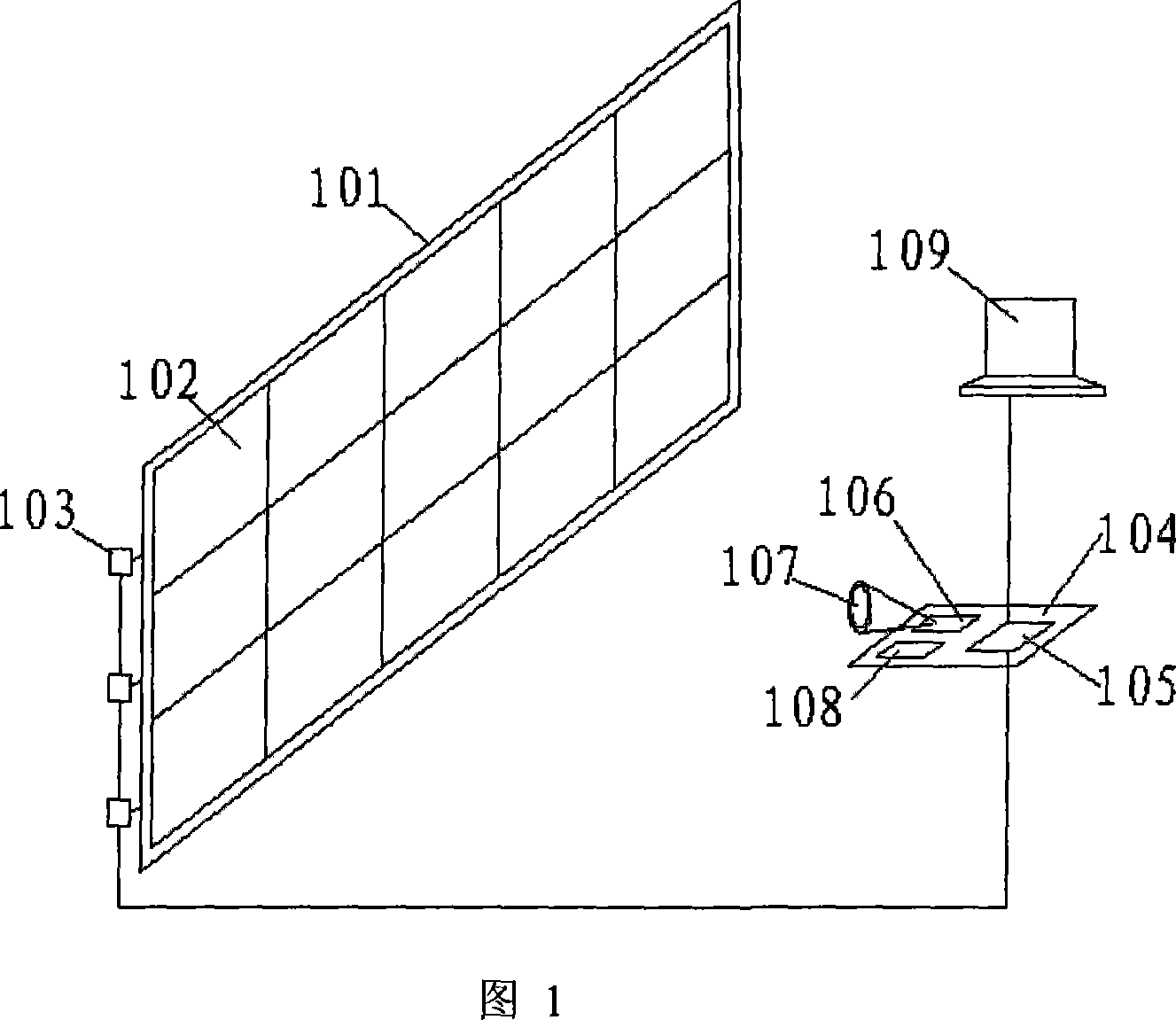

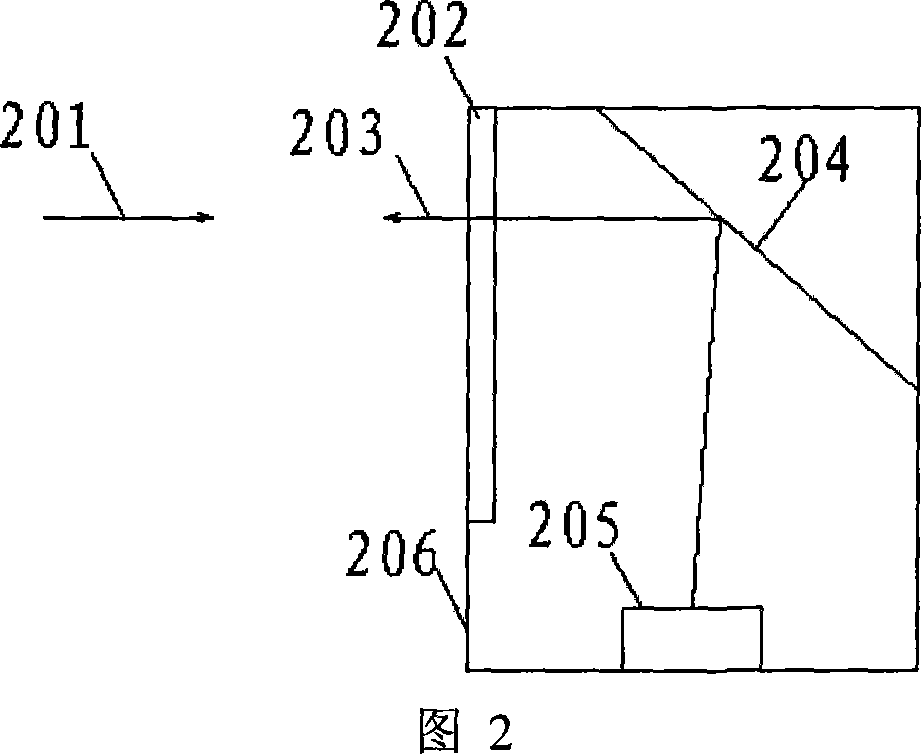

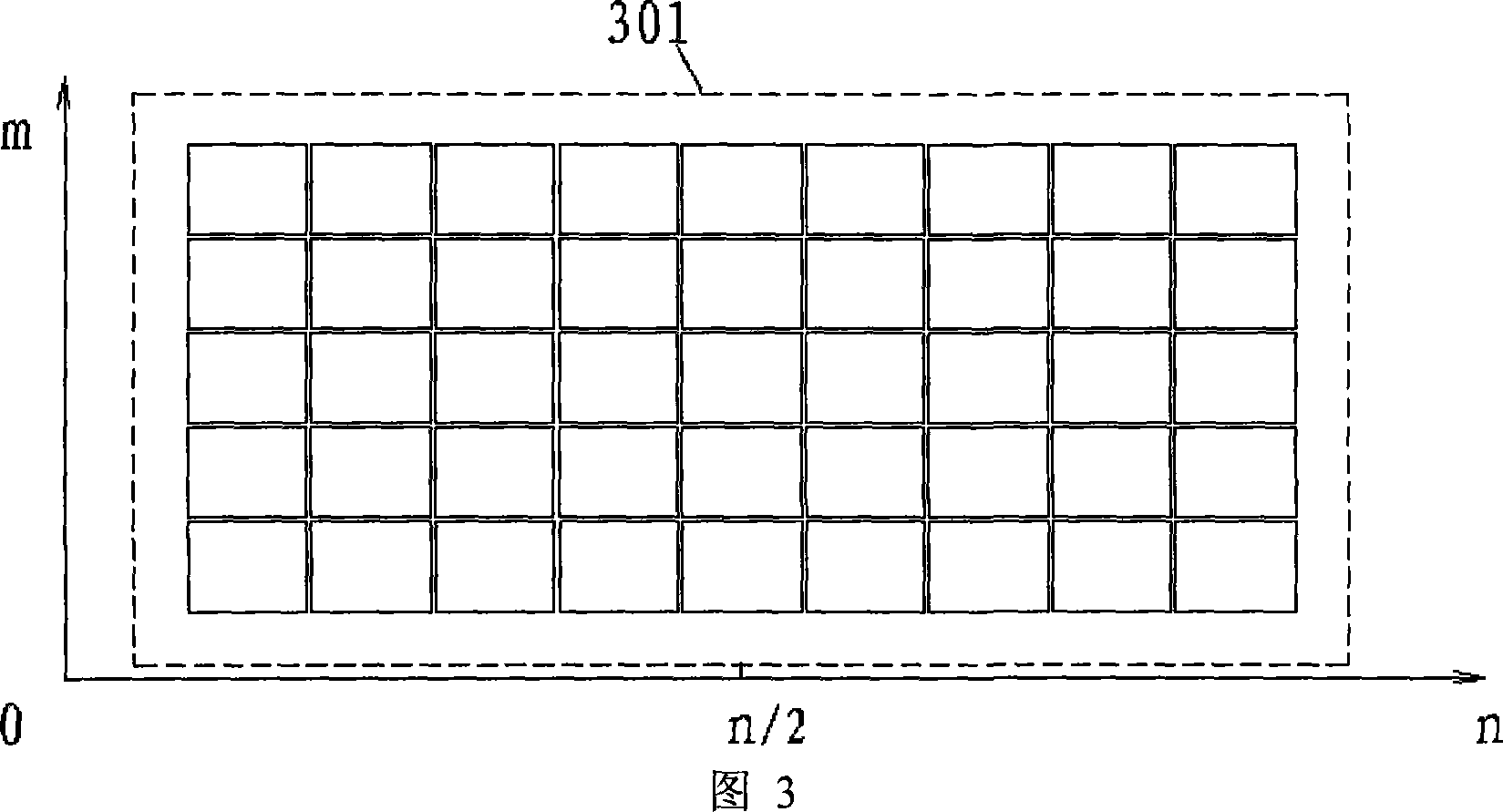

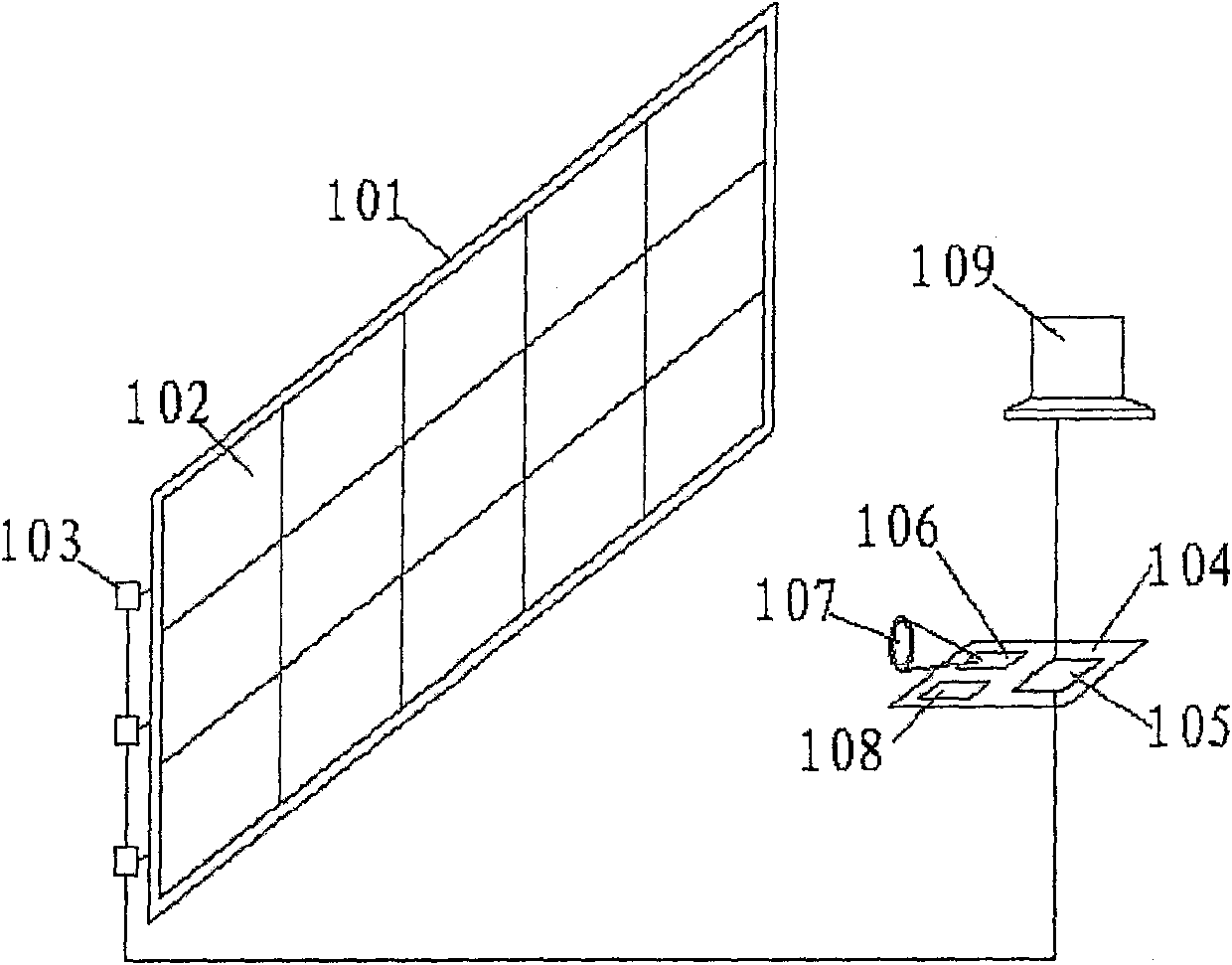

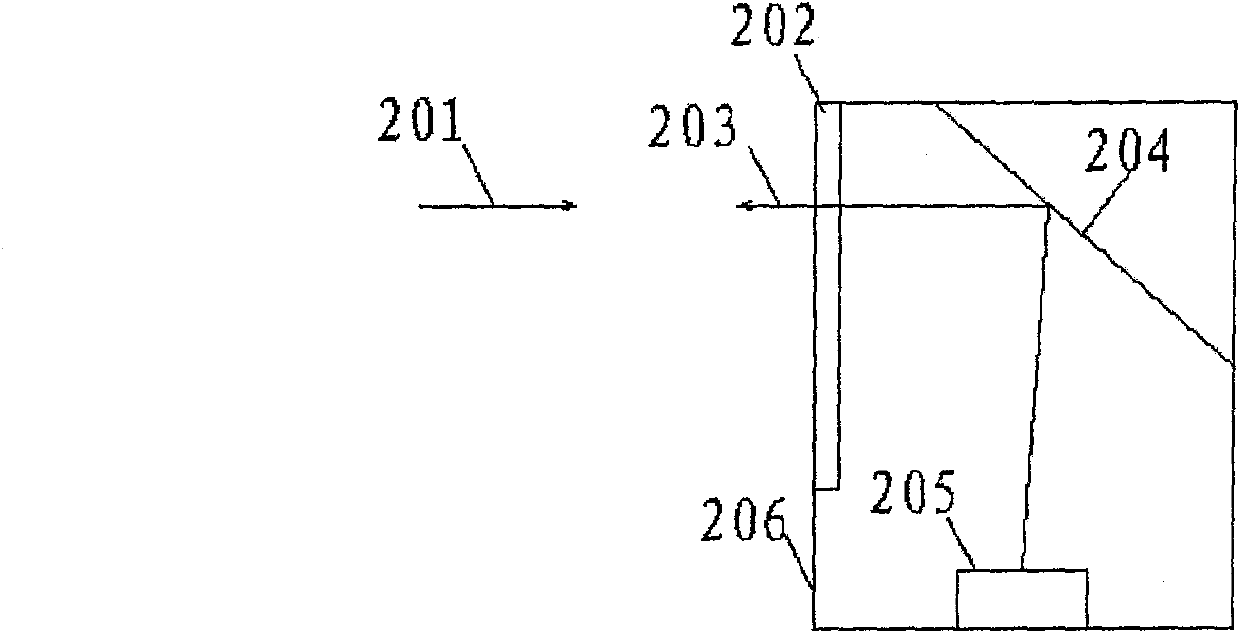

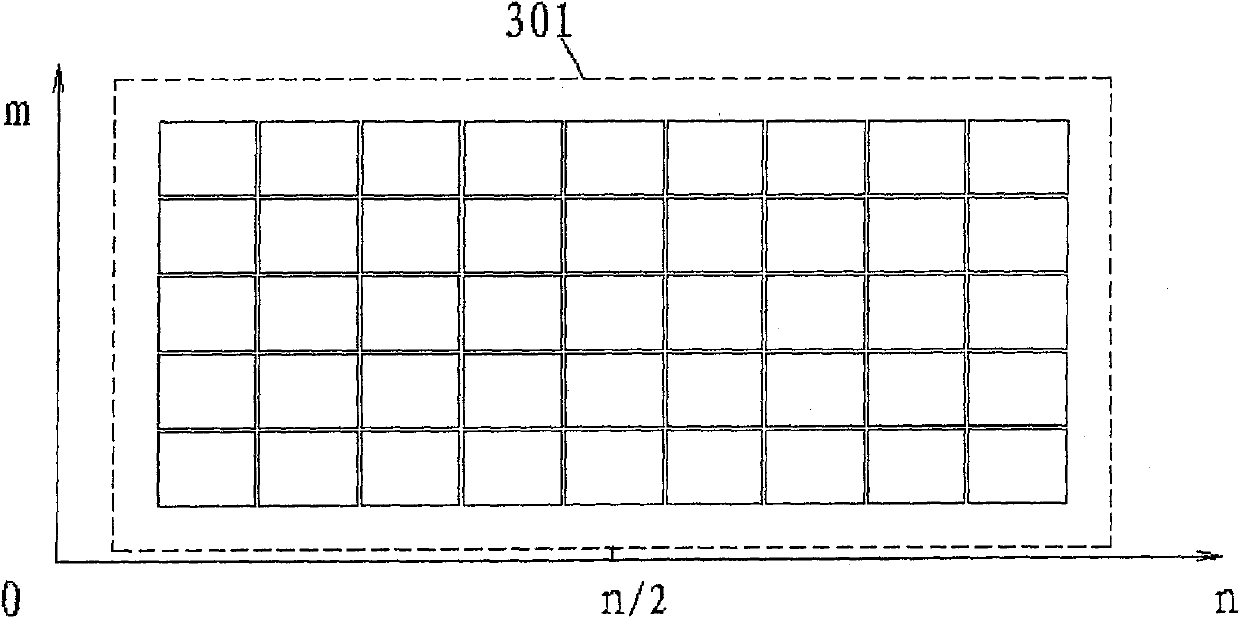

Method and apparatus for correcting multi-screen connected wall

InactiveCN101076128ASimple structureLow costPicture reproducers using projection devicesCathode-ray tube indicatorsComputer graphics (images)Computer module

The apparatus comprises a correction unit composed of a video camera module for capturing the color information of the screen, an image data buffer module, and a main control module used for receiving and executing the computer command. Said video camera module and image data buffer module are respectively connected to the multi-screen display wall and computer via the main control module. The method comprises: appointing the image displayed by each display unit on the multi-screen display wall; said video camera module shoots at least one picture and saves it in the image data buffer module; the computer extracts the color information from each display unit; according to the color of each display unit, the computer corrects the difference between said display units.

Owner:GUANGDONG VTRON TECH CO LTD

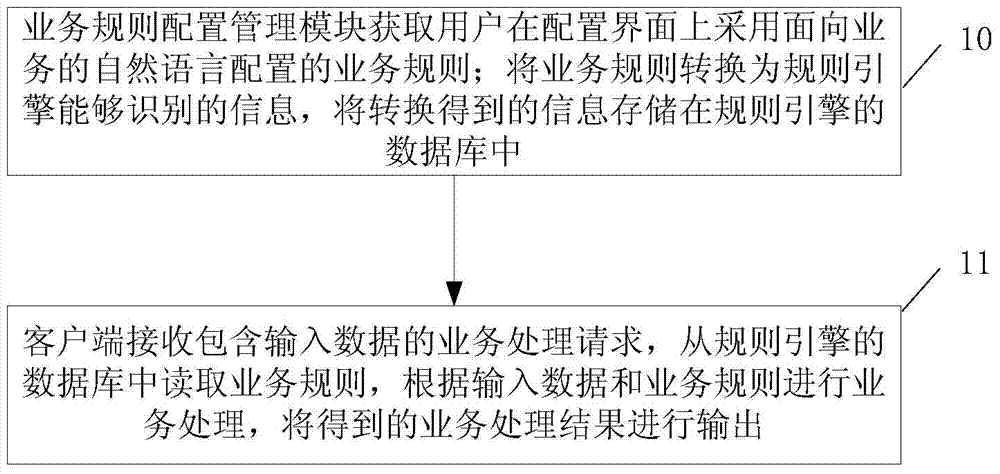

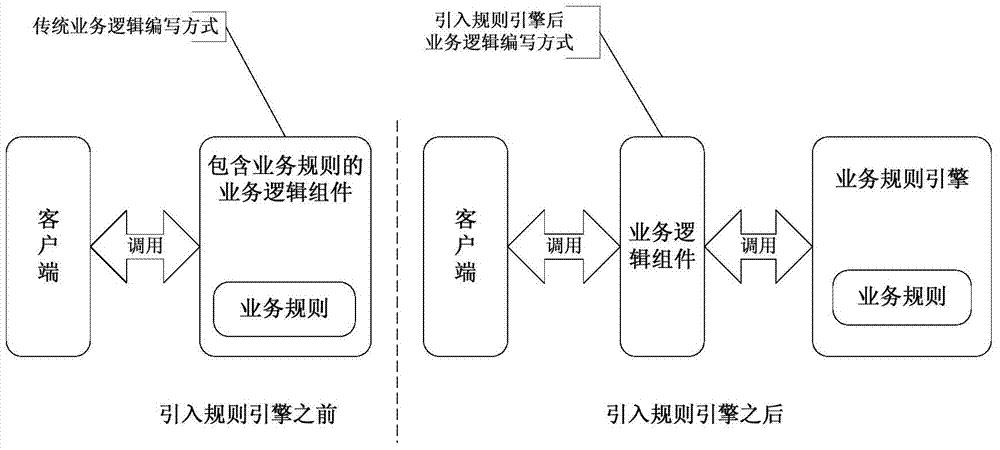

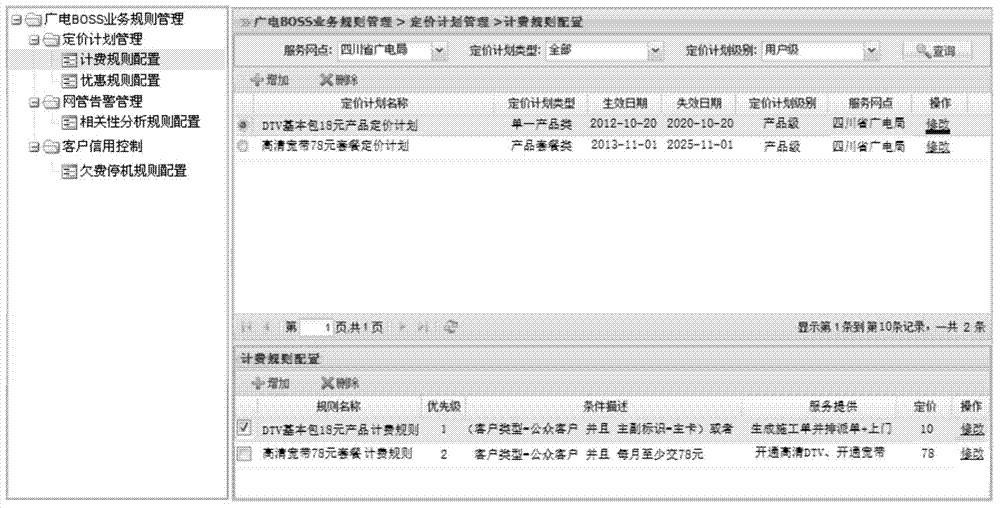

Service processing method and device

InactiveCN103927174AIncrease flexibilityHighly configurableTransmissionSpecific program execution arrangementsSupporting systemBroadcasting

The embodiment of the invention discloses a service processing method and device, and relates to the field of service processing. The service processing method and device are used for improving the processing efficiency of services in a radio and television integrated service operation support system. According to the service processing method and device, service-oriented natural language configuration service rules are adopted by a user on a configuration interface through a service rule configuration management module, the configuration service rules are converted into information capable of being identified by a rule engine through the service rule configuration management module, and the information obtained through conversion is stored in a database of the rule engine; after a client terminal receives a service processing request, service processing is carried out through the rule engine according to the stored service rules, and the processing result is output to obtain service processing results. By means of the service processing method and device, the processing efficiency of the services in the radio and television integrated service operation support system can be improved.

Owner:北京视博数字电视科技有限公司

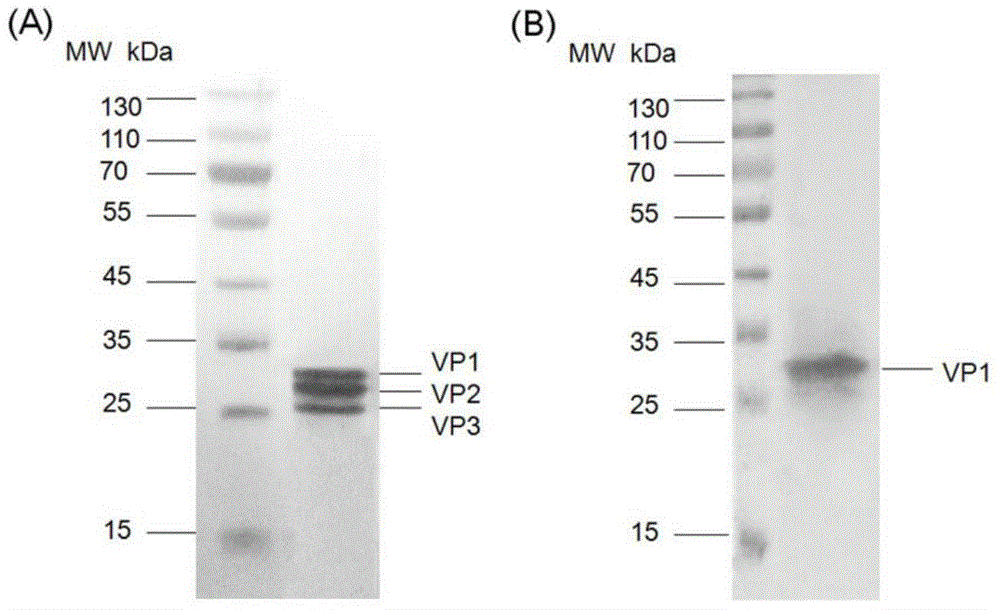

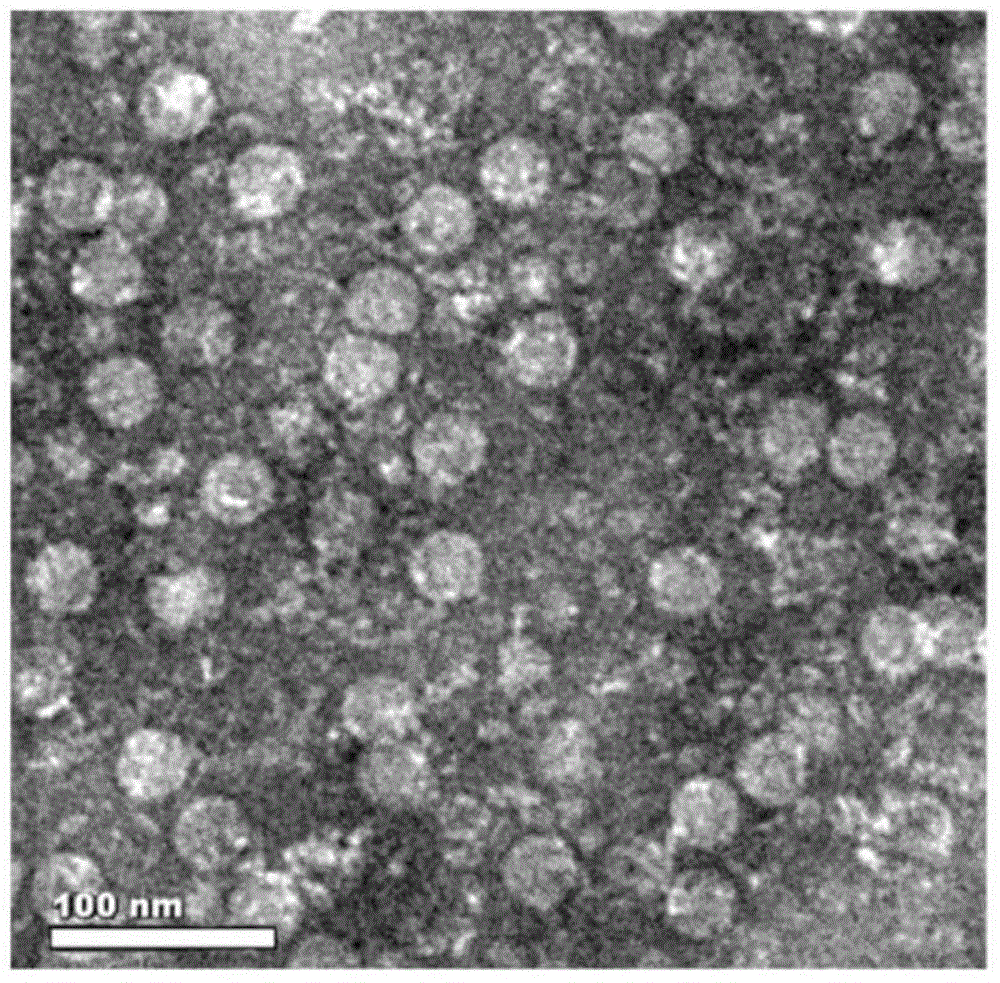

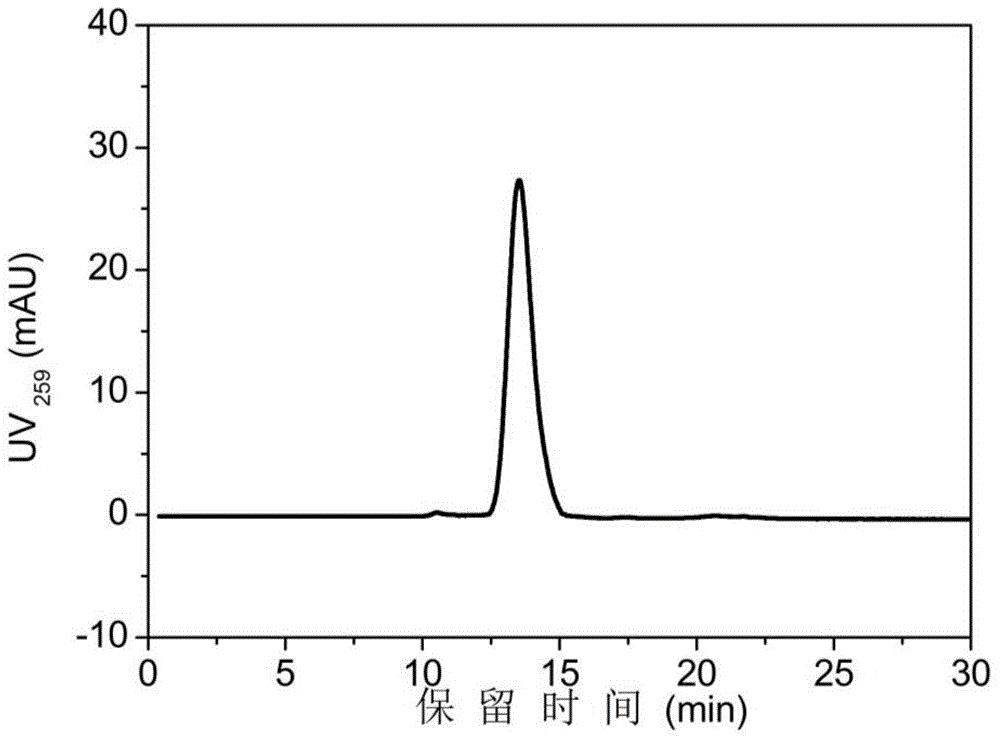

Method for rapidly, accurately and repeatedly determining foot-and-mouth disease vaccine antigen 146S

InactiveCN104634891AGood repeatabilityReduce mistakesComponent separationChromatographic separationPhosphate

The invention discloses a method for rapidly, accurately and repeatedly determining foot-and-mouth disease vaccine antigen 146S. A size exclusion high-efficiency liquid-phase chromatographic column in a molecular weight separation range of 2*10<4> to 1*10<7>Da is adopted to carry out the chromatographic separation on a detected sample on a high-efficiency liquid-phase chromatography. The operation pressure of the chromatography is 1.0MPa to 2.5MPa, the flow rate in the chromatographic column is 0.5 to 1.0 ml / min, a flow phase is phosphate buffer (pH 7.0 to 7.5) containing 0.1M sodium sulfate, and the column temperature is 15 to 25 DEG C. An ultraviolet and laser detector is used for detecting an optical signal of effluent at an outlet of the size exclusion high-efficiency liquid-phase chromatographic column, and a peak area of a sample can be analyzed by virtue of a computer software system of the high-efficiency liquid-phase chromatography. A standard curve of the absorption peak area and 146S concentration is established by virtue of a relation between the ultraviolet absorption peak and the concentration of different 146S standard products of different concentrations. Chromatograph is carried out on the detected sample through the size exclusion high-efficiency liquid-phase chromatographic column. The ultraviolet absorption peak area is measured, and the concentration of 146S in the detected sample can be acquired according to the standard curve.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

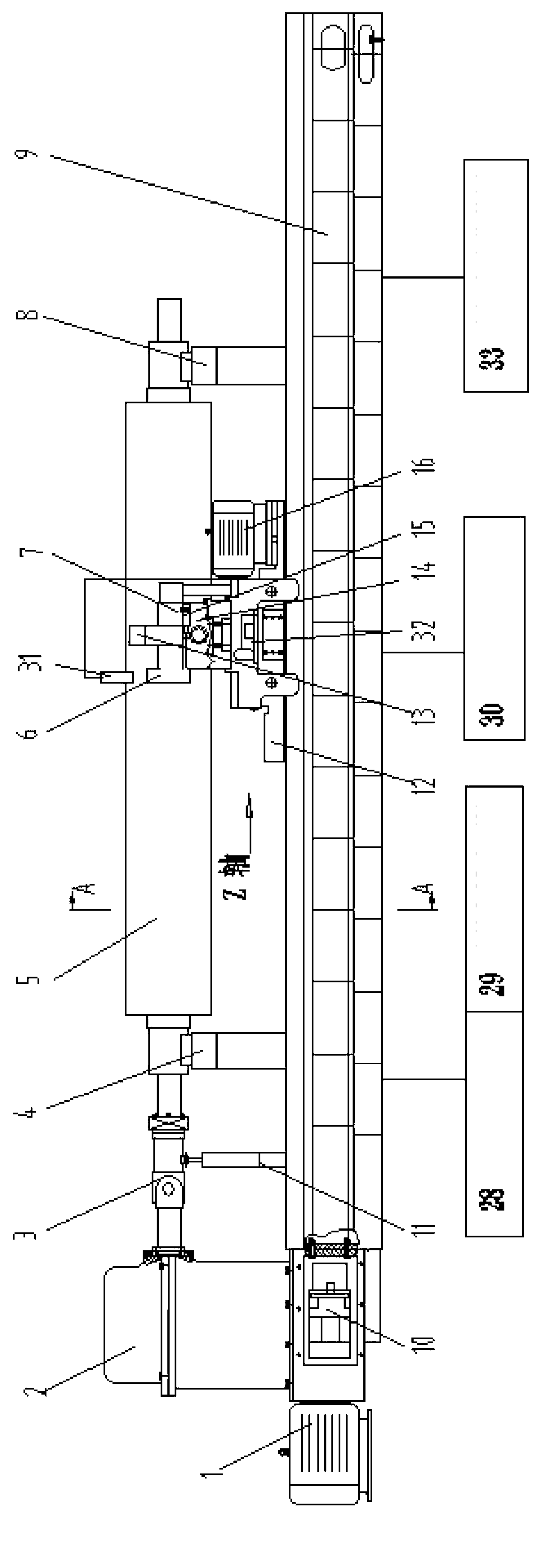

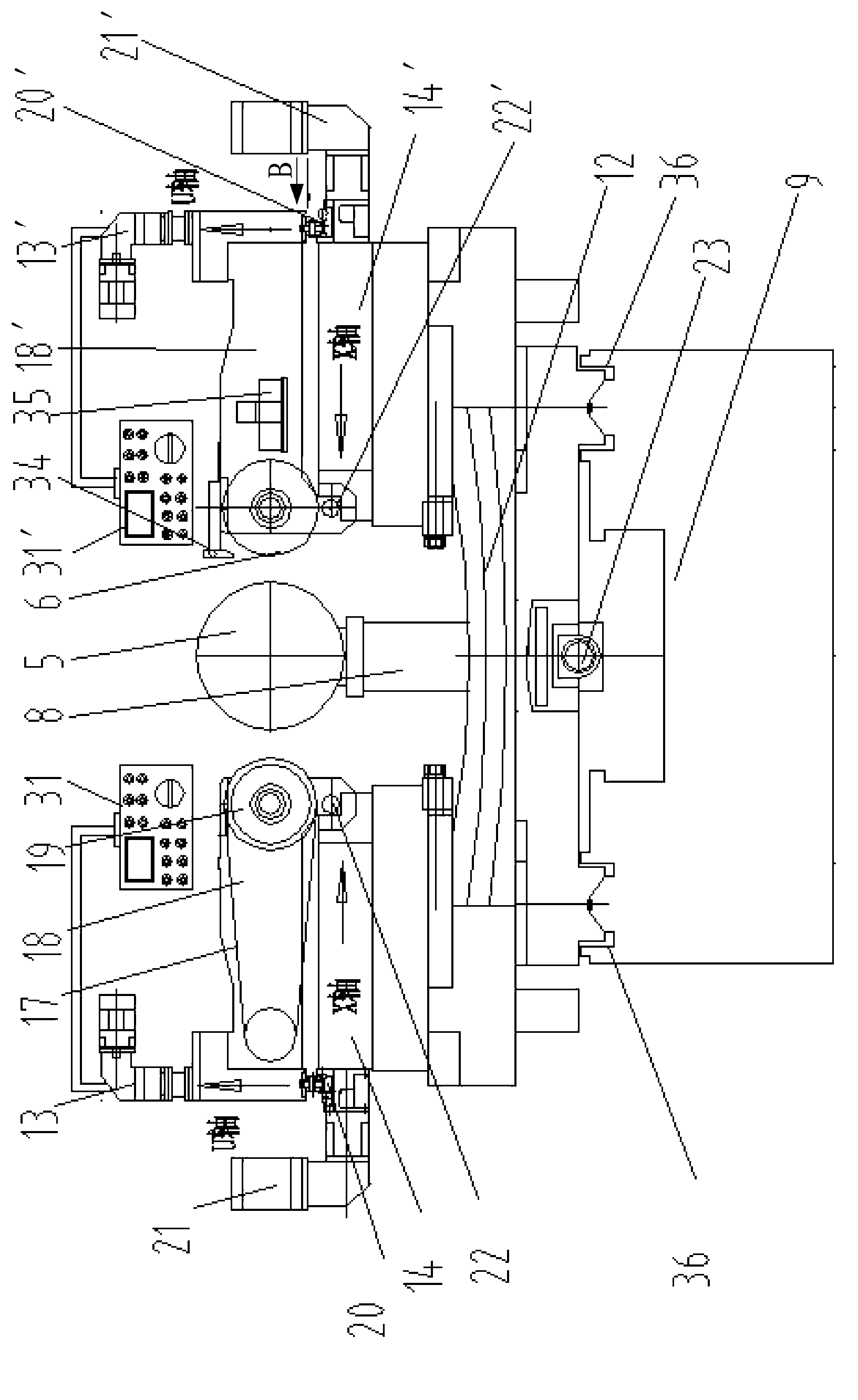

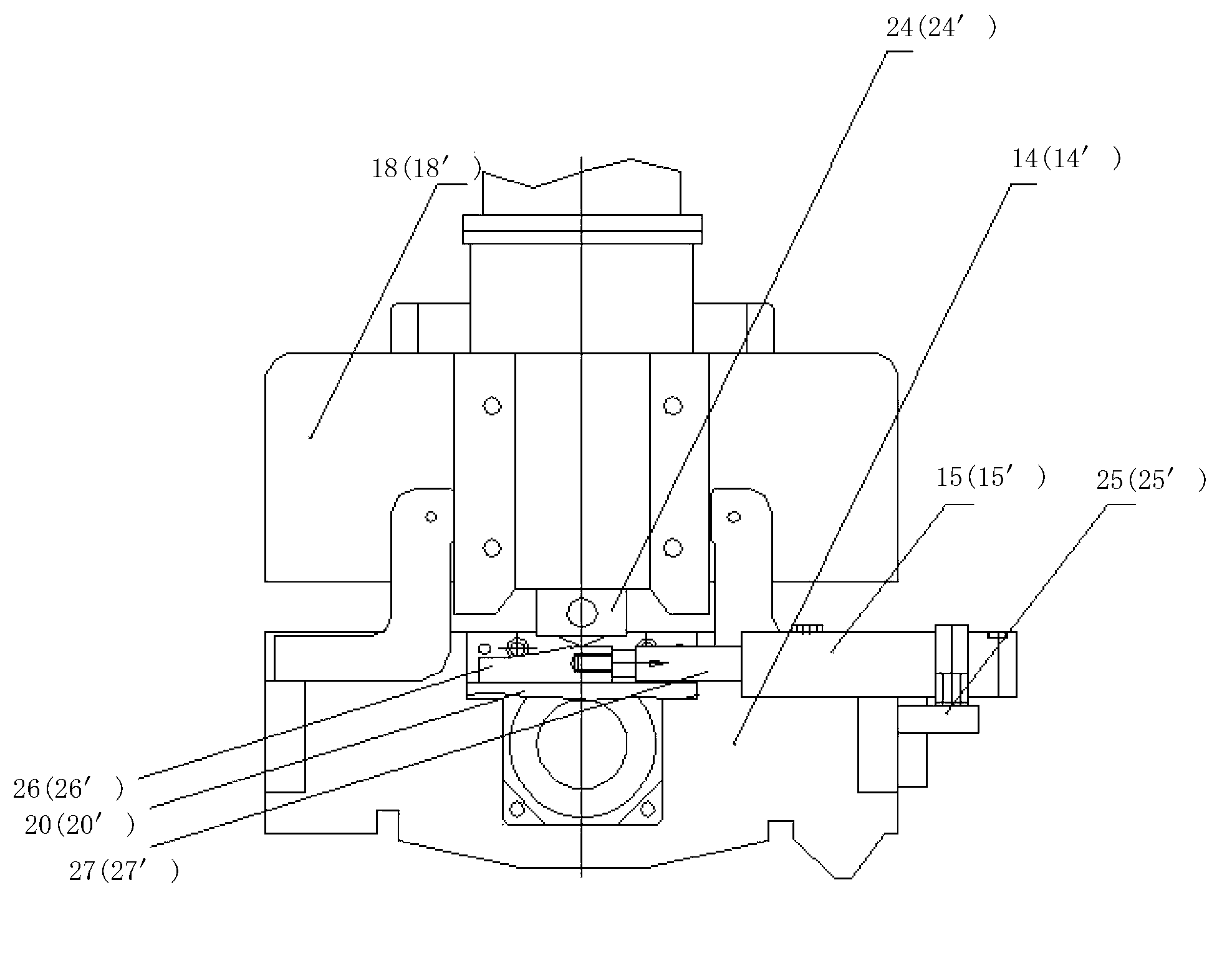

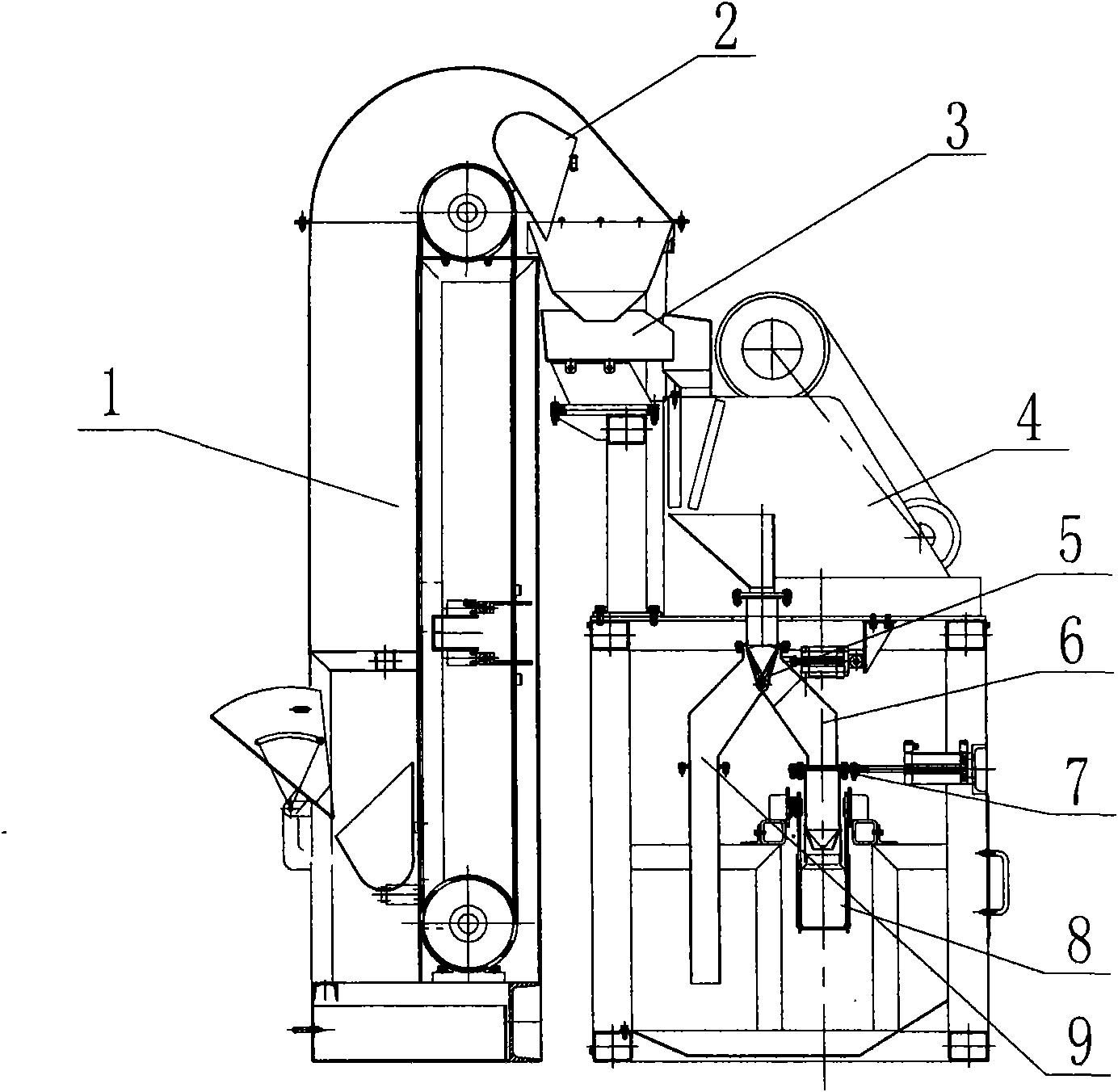

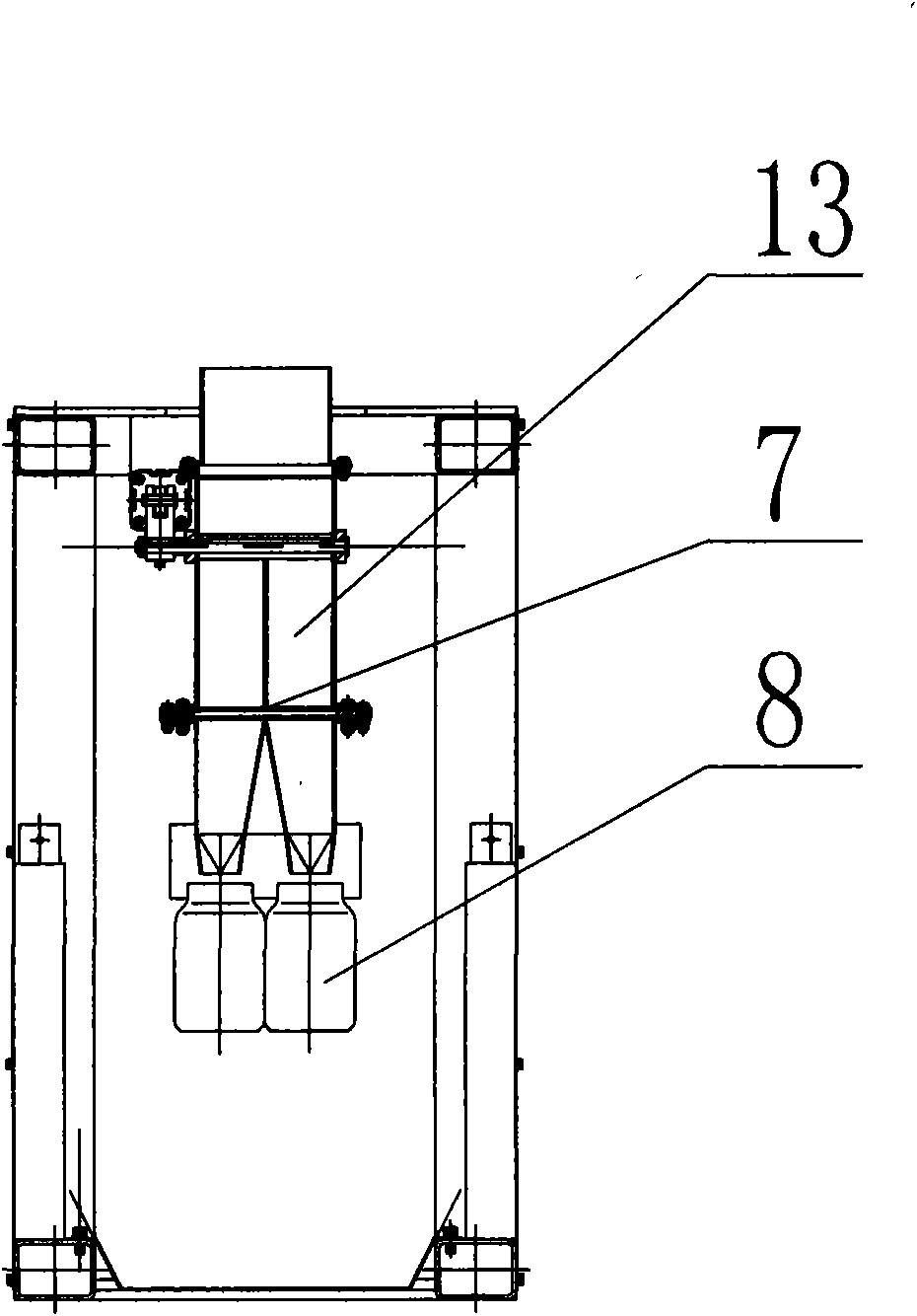

Two-wheeled numerical control roll grinder and numerical control method thereof

ActiveCN103009200ALow costSave energyRevolution surface grinding machinesBelt grinding machinesNumerical controlEngineering

The invention discloses a two-wheeled numerical control roll grinder and a numerical control method thereof. A small sliding frame of the double-wheeled numerical control roll grinder is provided with a U-axis micro-feeding mechanism, a main mechanical transmission case is lubricated by adopting an active lubricating loop, a cooling water purifying device is arranged on a grinder body, a large sliding frame guide rail is connected with a Z-axis guide rail hydraulic station through a lubricating oil tube, the Z-axis guide rail hydraulic station is subjected to dynamic pressure lubrication, a grinding wheel and an abrasive belt wheel are respectively connected with a shared mainshaft hydraulic station, a hybrid bearing and a capillary tube adjuster are respectively arranged at the front and the back of a main shaft of the grinding wheel and a main shaft of the abrasive belt wheel, and the mainshaft of the grinding wheel and the mainshaft of the abrasive belt wheel are subjected to dynamic and static pressure lubrication. According to the invention, due to adoption of a numerical-control setting manner, a roll curve is easy to change, ground workpieces are higher in quality and are easy to automatically control, the manual misoperation probability is lowered, a very excellent repeatable machining purpose is achieved and the quality of batch production can be ensured.

Owner:武汉宝德机电股份有限公司

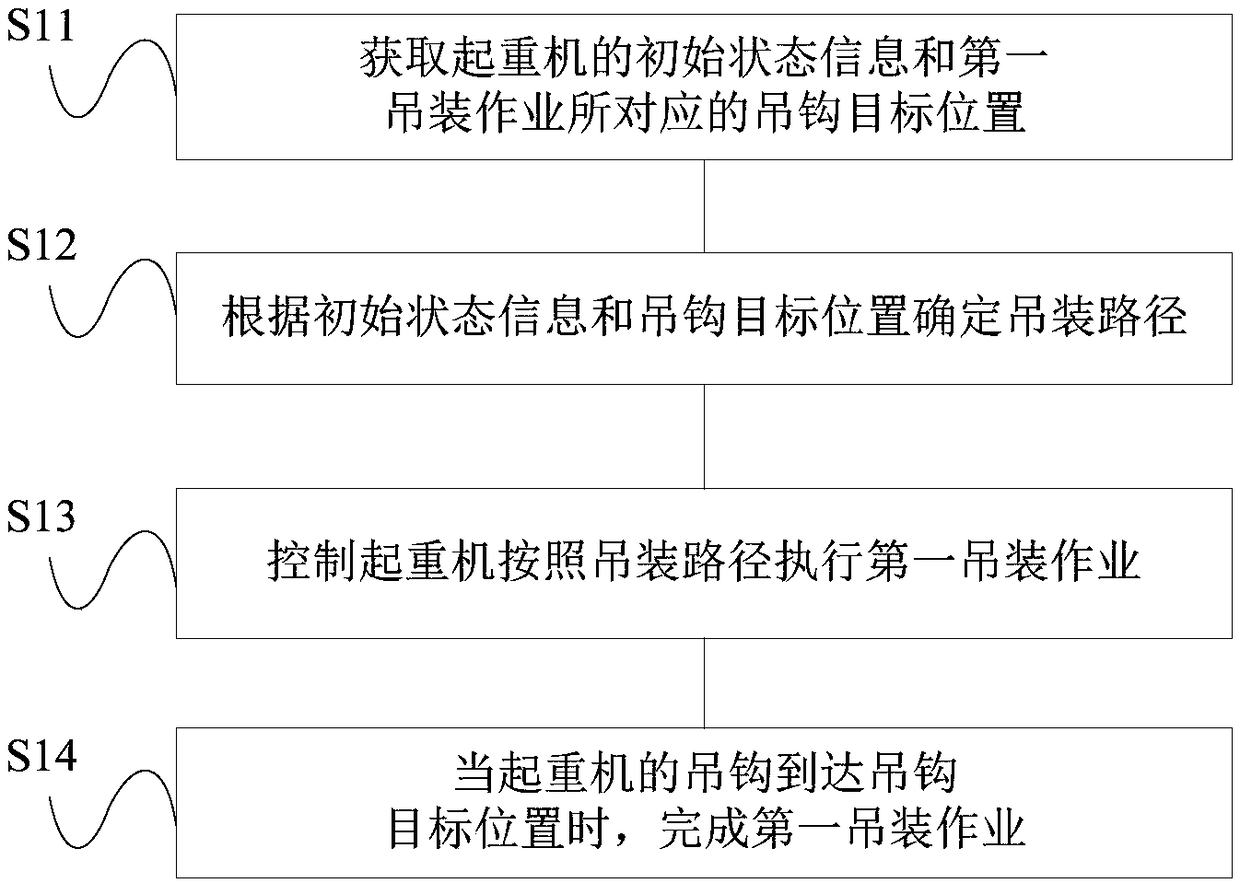

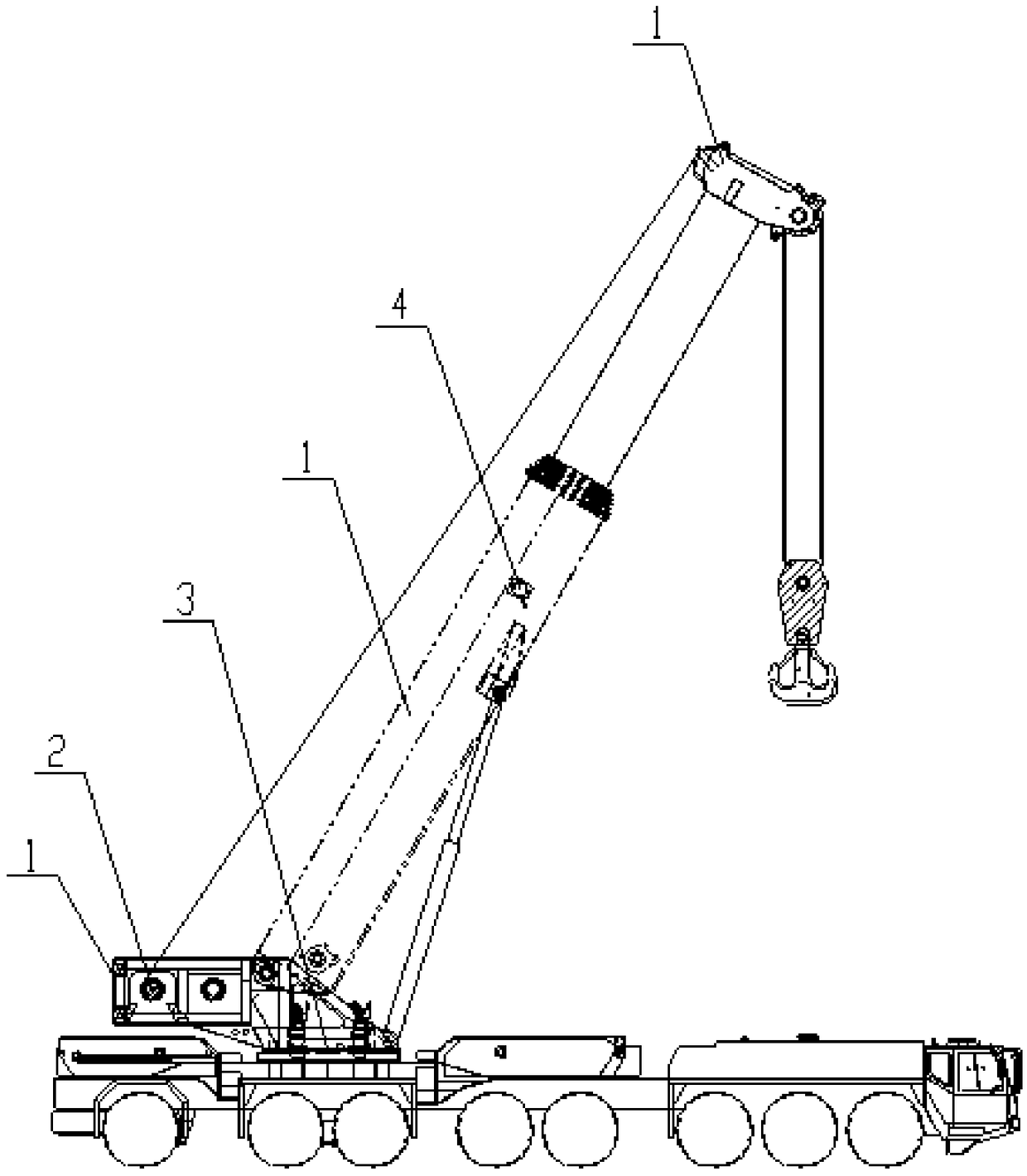

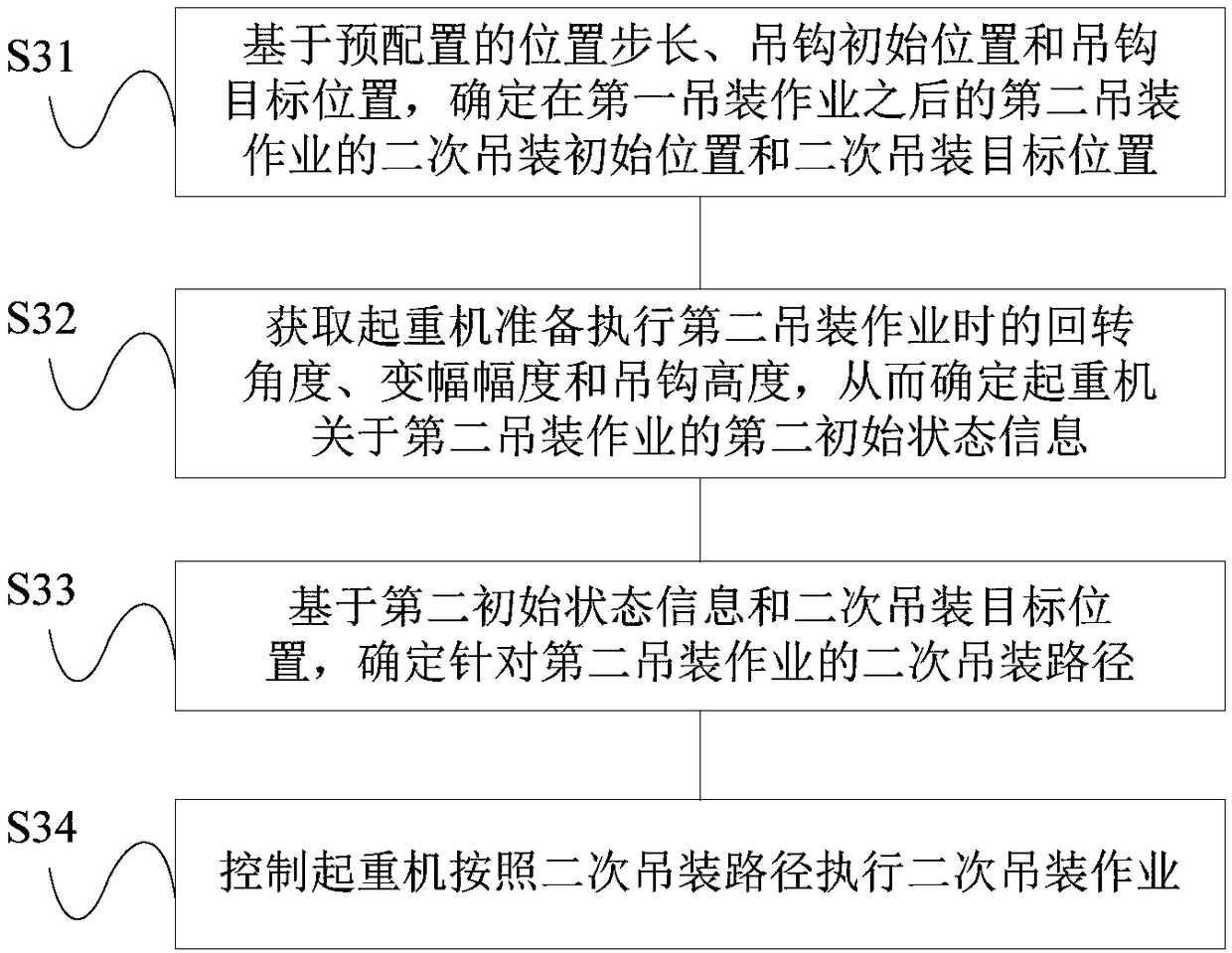

Crane hoisting control method and system

ActiveCN109279511ASafe and reliable automationReduce the intensity of manual operationLoad-engaging elementsCranesAutomatic controlSimulation

The invention relates to the technical field of crane automatic control and discloses a crane hoisting control method and system. The crane hoisting control method comprises the steps that initial state information of a crane and the lifting hook target position corresponding to first hoisting operation are obtained, wherein the initial state information comprises the initial rotary angle, the change amplitude and the lifting hook initial position of the crane with respect to first hoisting operation; a hoisting path is determined according to the initial state information and the lifting hooktarget position, wherein the hoisting path comprises the to-be-executed initial rotary angle, the to-be-executed change amplitude and the to-be-executed lifting hook height of the crane; and the crane is controlled to execute first hoisting operation according to the hoisting path and complete first hoisting operation when a lifting hook of the crane arrives at the lifting hook target position. Accordingly, it is guaranteed that hoisting operation can be conducted safely, reliably and automatically, the manual operation intensity can be lowered, and manual misoperation can be reduced.

Owner:ZOOMLION HEAVY IND CO LTD

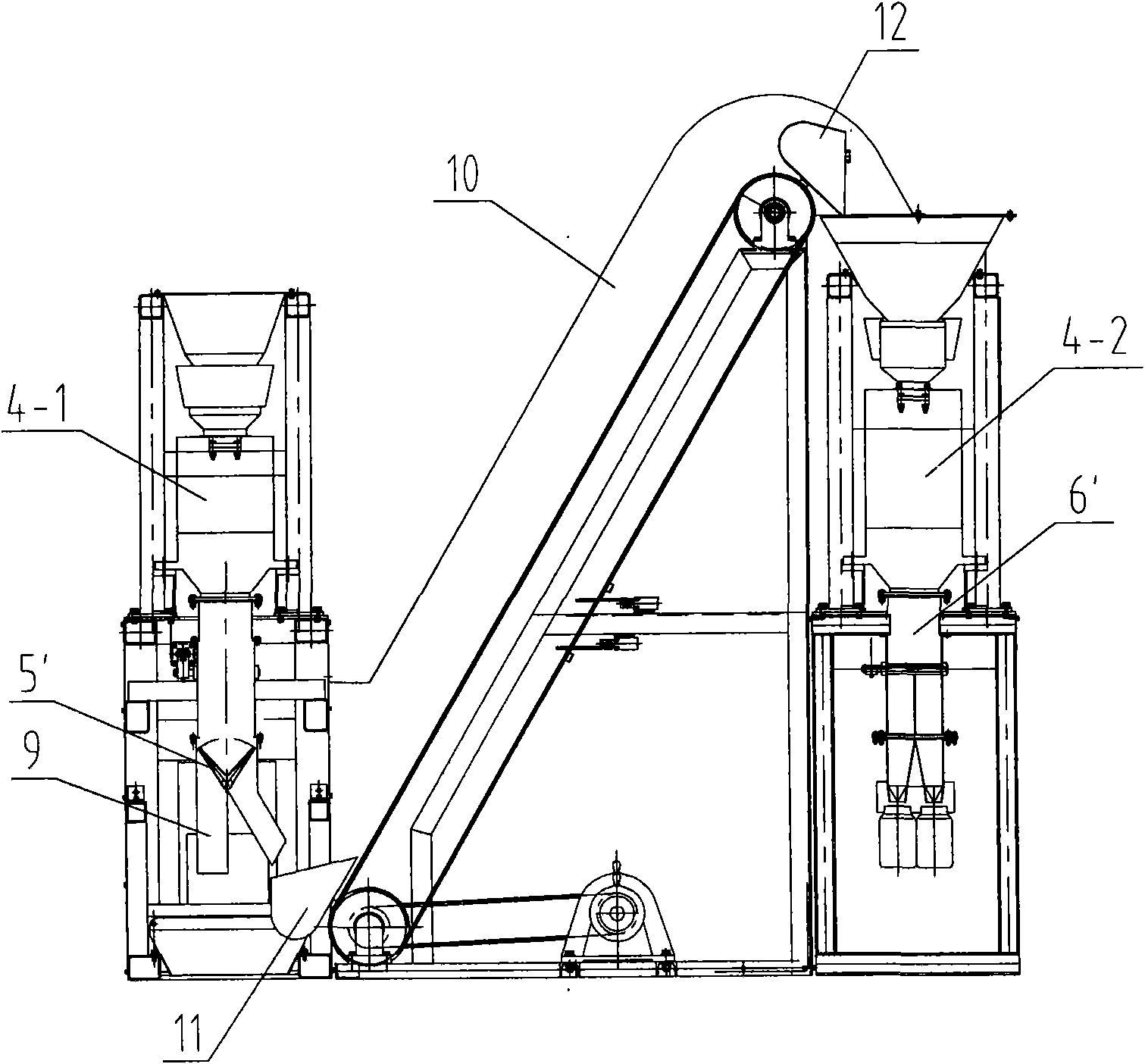

Coal coking automatic sample preparation system

InactiveCN101556221AGuarantee product qualityIncrease the level of automationPreparing sample for investigationComputer monitoringData acquisition

The invention relates to a coal coking automatic sample preparation system which comprises a sample-preparation working station, an automatic delivery unit, a discharging unit and a controlling unit, wherein the sample-preparation working station, the automatic delivery unit and the discharging unit are interlocked in sequence under the controlling action of the controlling unit, automatic feeding, crushing, shrinkage, canning, automatic delivery, sample sealing, information identification code spraying and rejected sample collection are performed to the raw material ore; and the controlling unit takes a PLC control system as a core part and comprises a data acquisition device, a system controller, an operating panel, a labelling machine controller, a jet printer controller, a packaging machine controller and a computer monitoring system, and the PLC control system is communicated with the seven parts through a filed bus. The invention has the advantages that the automatic feeding, the crushing, the shrinkage, the canning, the sample sealing, the information identification code spraying and the rejected sample collection automatization are finished for the raw material ore.

Owner:辽宁同辉科技发展有限公司

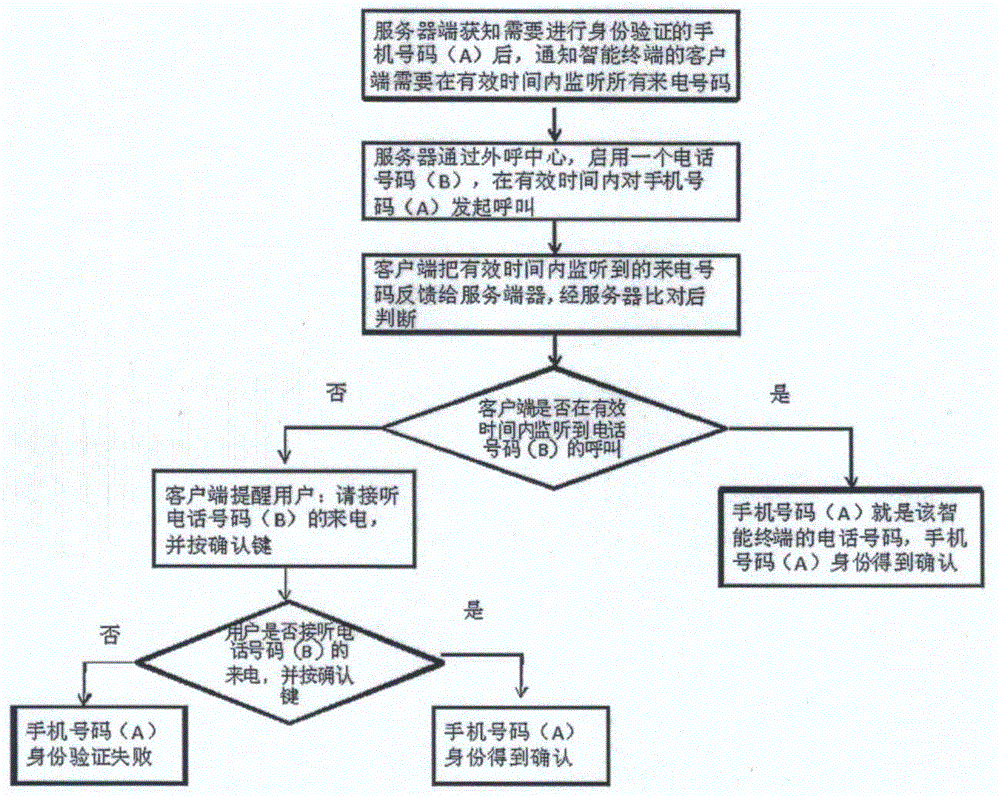

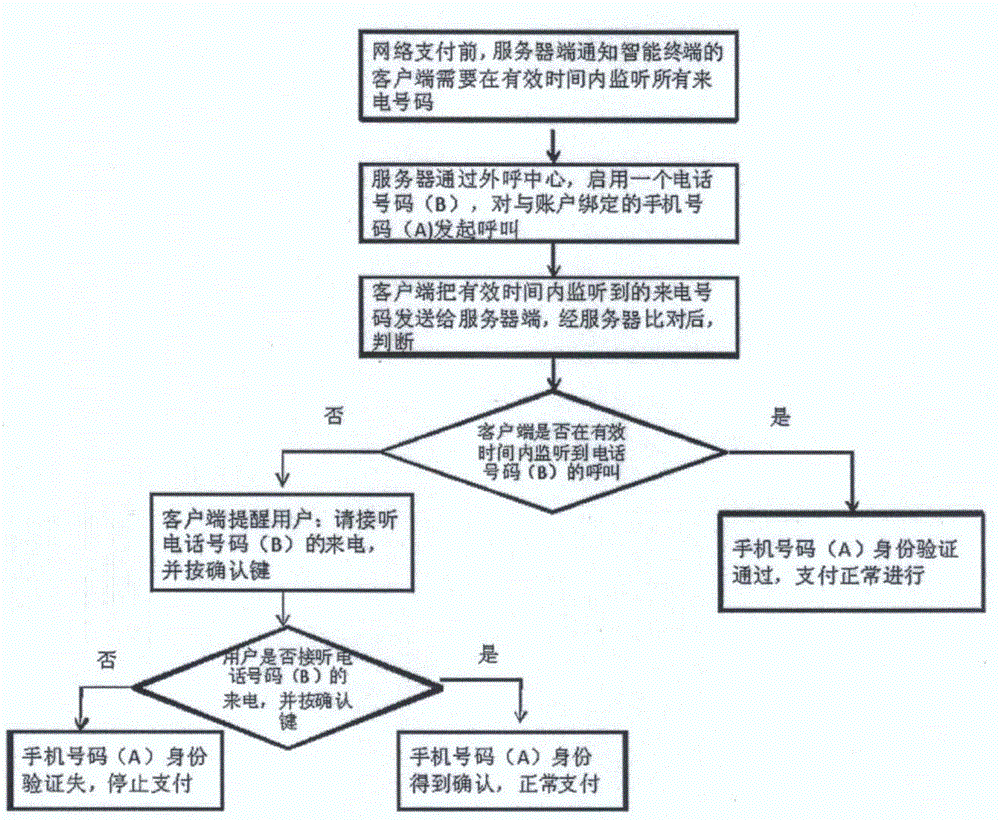

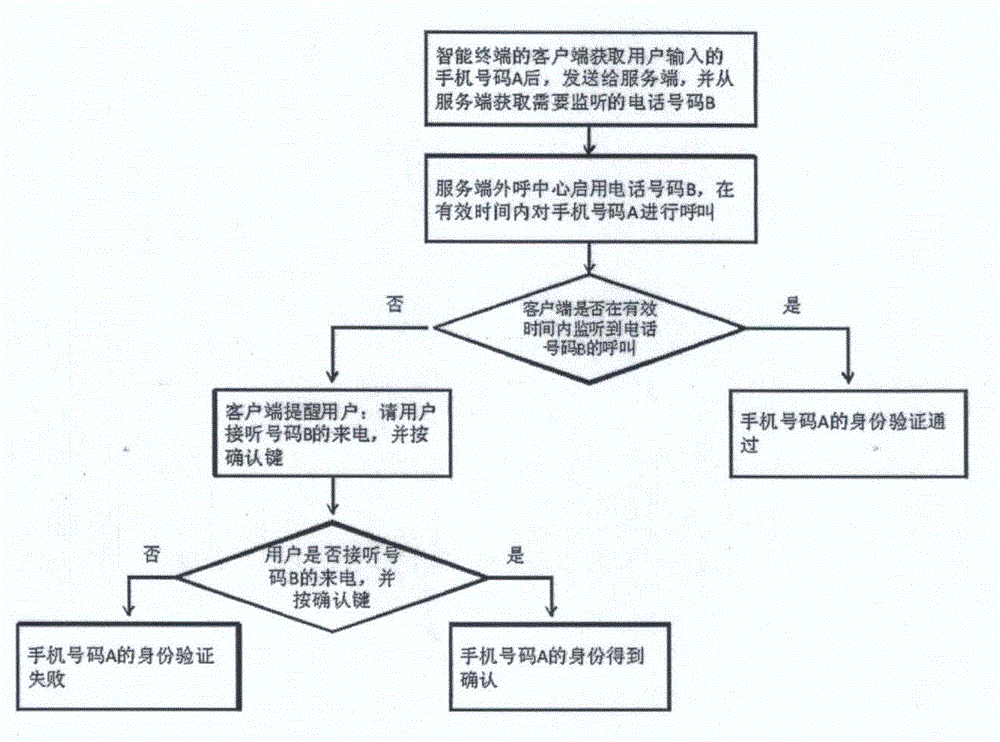

Identity verification method of mobile phone number of communication terminal

ActiveCN105307158AEasy to operateSave SMS costUser identity/authority verificationMessaging/mailboxes/announcementsClient-sideEffective time

The invention provides an identity verification method of a mobile phone number of a communication terminal. The identity verification method comprises: a step 1, after obtaining the mobile phone number of the communication terminal requiring identity verification, a server notifies a client of an intelligent terminal to monitor all incoming call numbers within an effective time and send the monitored telephone numbers to the server; a step 2, the server starts a pre-selected target telephone number by an external call center to call the mobile phone number of the communication terminal; and a step 3, the client sends the telephone numbers monitored within the effective time to the server, the server compares the telephone numbers to judge whether the client of the intelligent terminal monitors the call of the target telephone number within the effective time, if judges that the client monitors the call of the target telephone number, confirms the mobile phone number of the communication terminal as the telephone number of the intelligent terminal, and the client hangs up the call and notifies the server that the identity verification corresponding to the mobile phone number is passed. According to the method provided by the invention, a communication device can complete the identity verification of the mobile phone number without receiving or inputting a verification code, in this way, the operation efficiency is further improved, and the possibility of manual wrong operations is reduced.

Owner:北京科能腾达通信技术有限公司

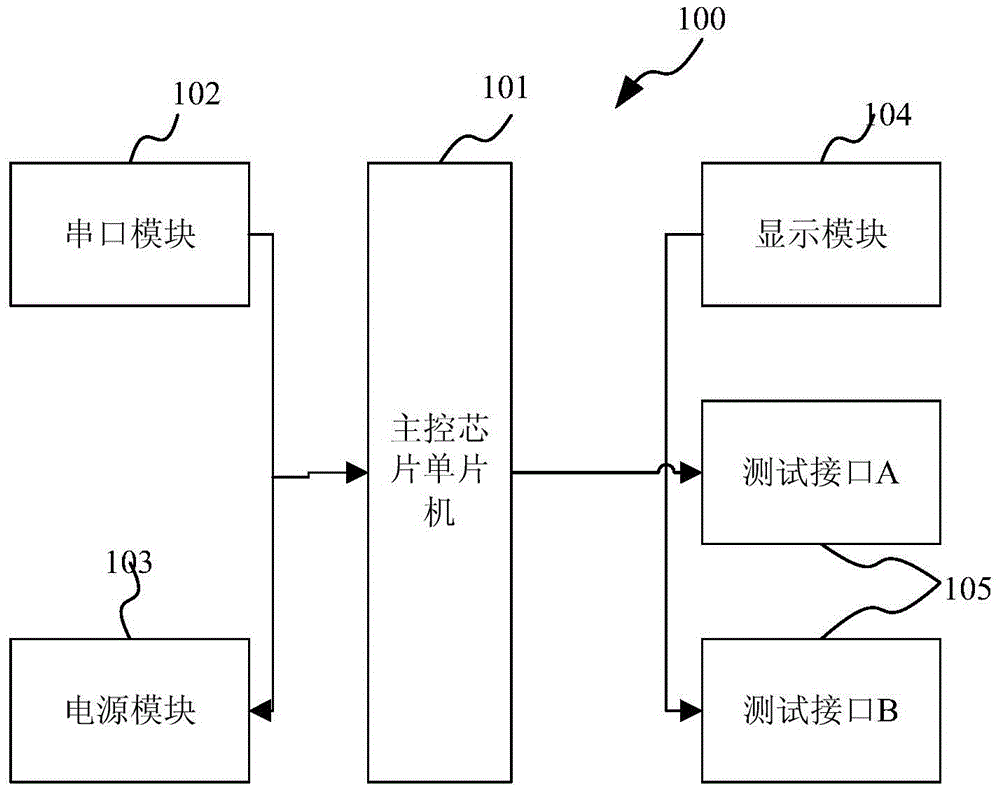

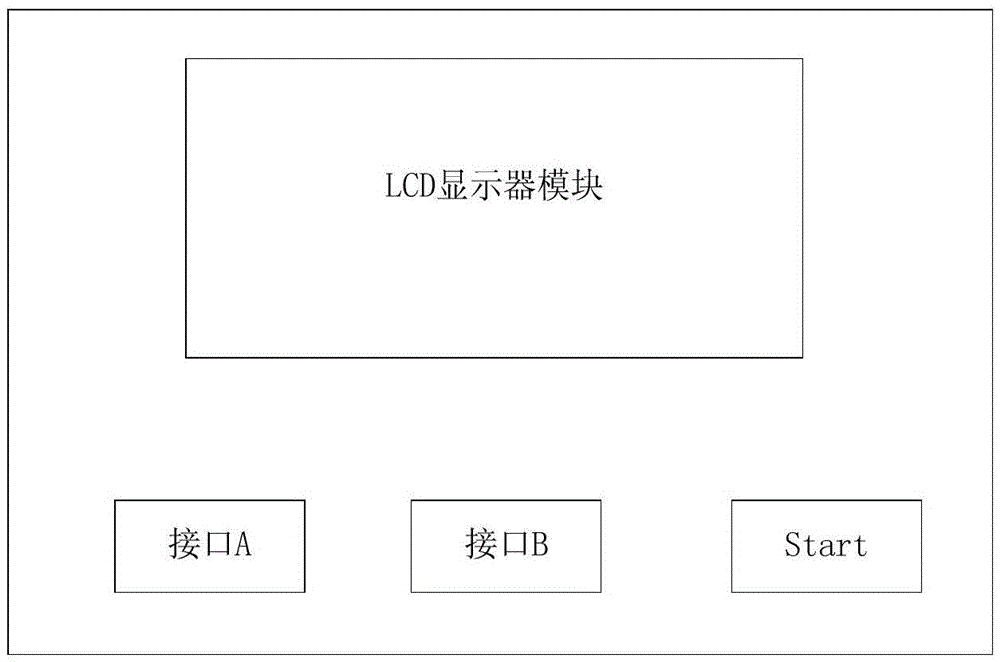

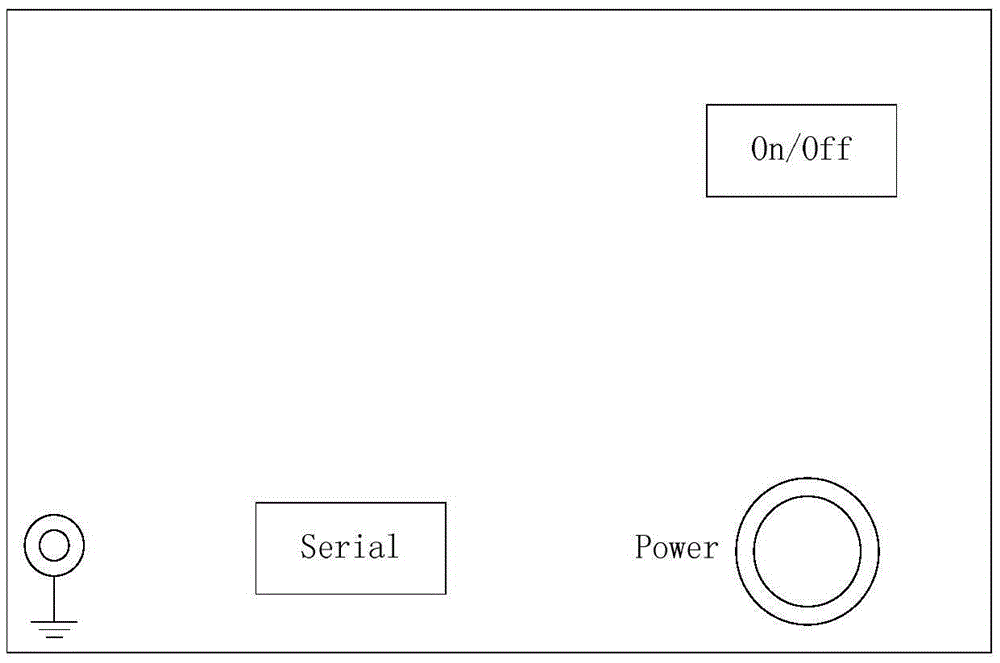

USB3.1 Type-C cable automatic testing method and system

The invention provides a USB3.1 Type-C cable automatic testing method and system, and the system at least comprises a main control part which comprises a main control CPU, carries out the testing of a USB3.1 Type-C cable through the operation of a program, enables a testing result to be displayed on a display screen, and determines whether the testing result is transmitted to a PC or not according to the needs; a serial port module which comprises a serial port on the main control CPU and an external drive chip, and is used for communicating with a computer; and an interface module which is an independent pluggable module and comprises two USB3.1 Type-C testing interface male seat modules. The system can effectively test a signal of the USB3.1 Type-C cable and test whether short circuit or circuit break happens to a power line or not. Meanwhile, the system cannot damage testing equipment, reduces the error of manual operation, improves the testing efficiency and first pass yield, improves the testing efficiency, and reduces the damages to USB Type-C cable rate testing equipment.

Owner:深圳市易通电子科技有限公司

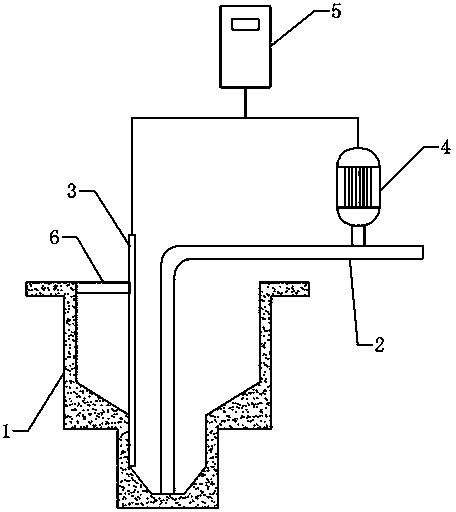

Grit removal device for grit chamber

InactiveCN103505913AExtended service lifeEasy to fixSettling tanks feed/dischargeSedimentation settling tanksProgrammable logic controllerInductor

The invention discloses a grit removal device for a grit chamber. The grit removal device comprises a grit chamber main body, a grit discharge pump, an inductor and a motor, wherein one end of the grit discharge pump is arranged on the inner bottom surface of the grit chamber main body, the other end of the grit discharge pump is arranged on one side of the top end of the grit chamber main body, the inductor is arranged above the inner bottom surface of the grit chamber main body, the motor is connected with the grit discharge pump, and a PLC (Programmable Logic Controller) cabinet is connected with the inductor and the motor respectively through a data line. The grit removal device is simple in structure, convenient to install and free of manual operation errors in traditional grit removal work, the manual operations can be reduced, the labor cost can be lowered, the sewage treatment efficiency can be improved, and the service life of the grit chamber can be prolonged.

Owner:吴佳倩

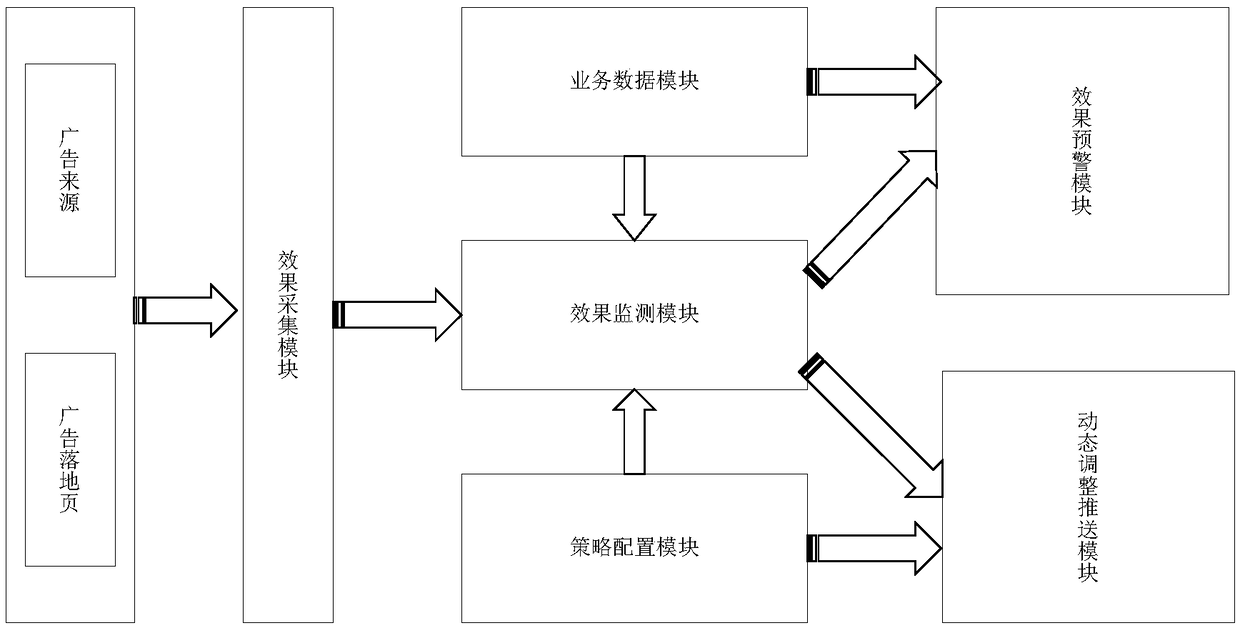

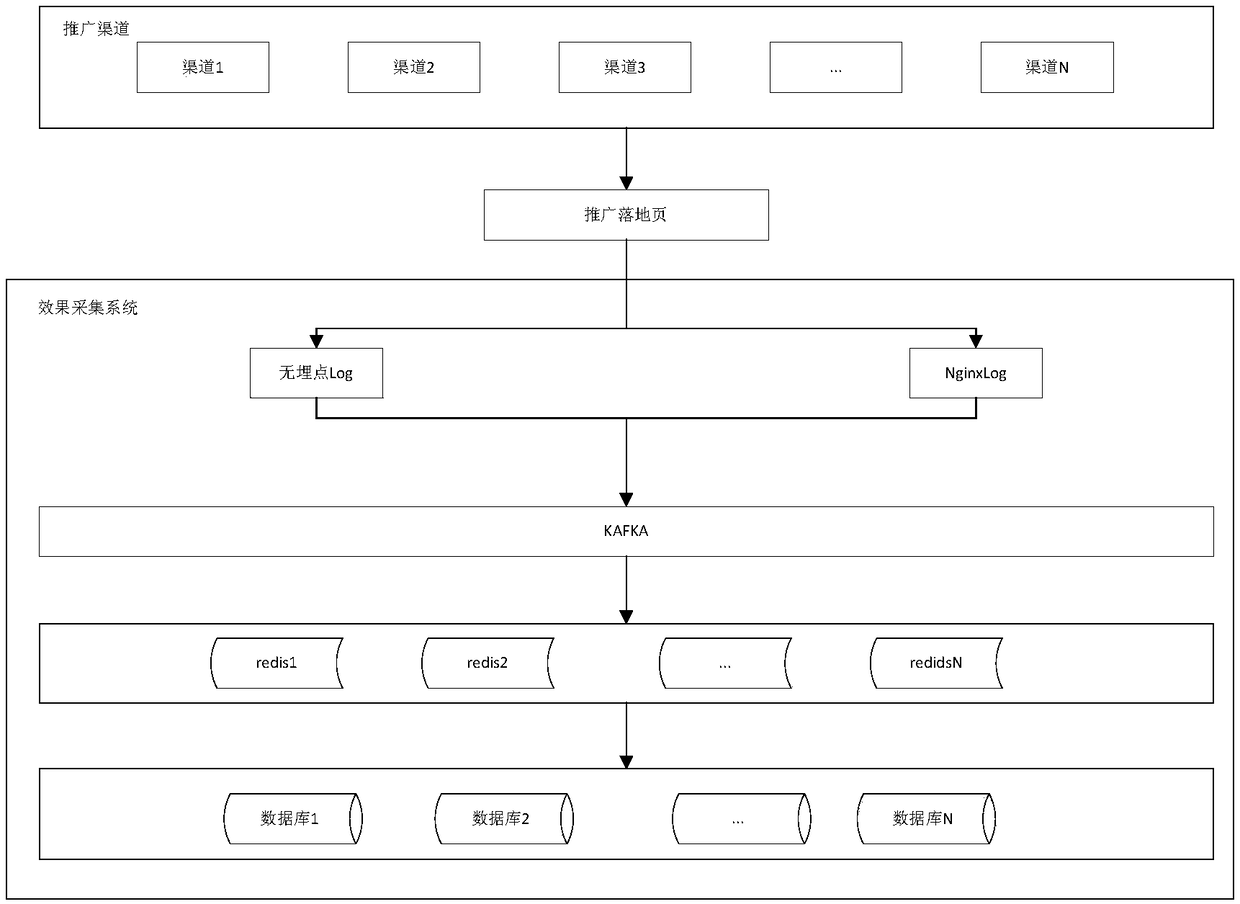

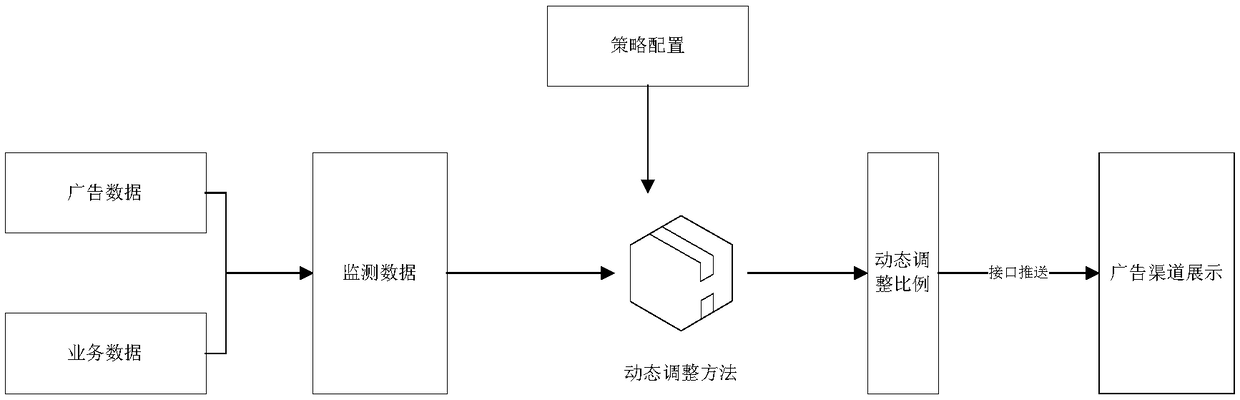

An advertisement delivery dynamic adjustment system based on big data

InactiveCN109191183ASolve integration troublesSolve problems such as possible intrusionAdvertisementsTraffic capacityThird party

The invention discloses an advertisement delivery dynamic adjustment system based on big data. The system mainly comprises: an effect collection module responsible for collecting different advertisingchannel source data, an effect monitoring moduel responsible for combining the source data with the business data, an effect early warning module for real-time pushing of abnormal data or data exceeding an early warning threshold in the effect monitoring module, a strategy configuration module for presetting a placement proportion and a placement cost, and a dynamic adjustment pushing module forrealizing dynamic adjustment of advertisement placement. By adopting the five-level subsystem structure, the invention can realize the full monitoring of the advertisement source without relying on the third party, form a monitoring report based on the advertisement flow data and the service data, dynamically adjust the advertisement investment proportion and the cost and the like, and can achievethe beneficial effects of improving the data security, facilitating operation, saving the human cost and the like.

Owner:优赛恒创科技发展(北京)有限公司 +1

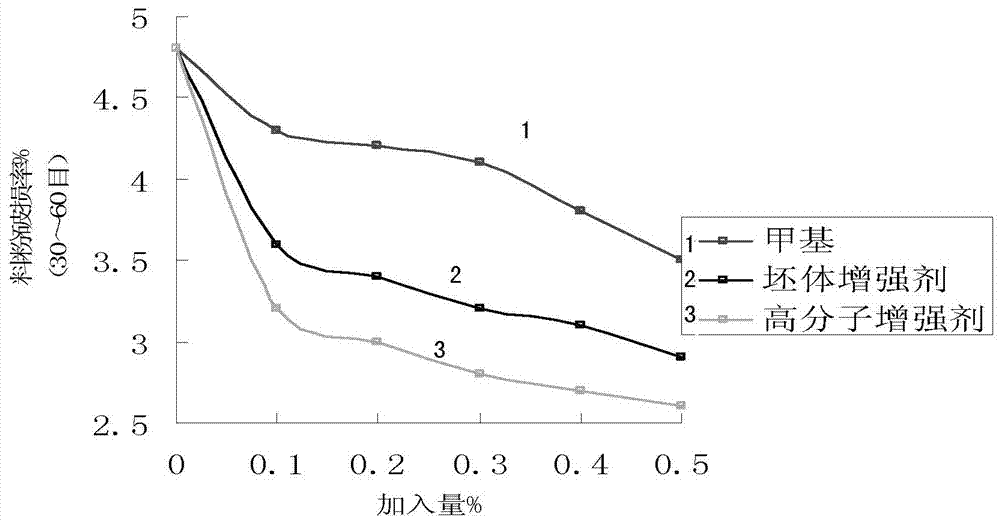

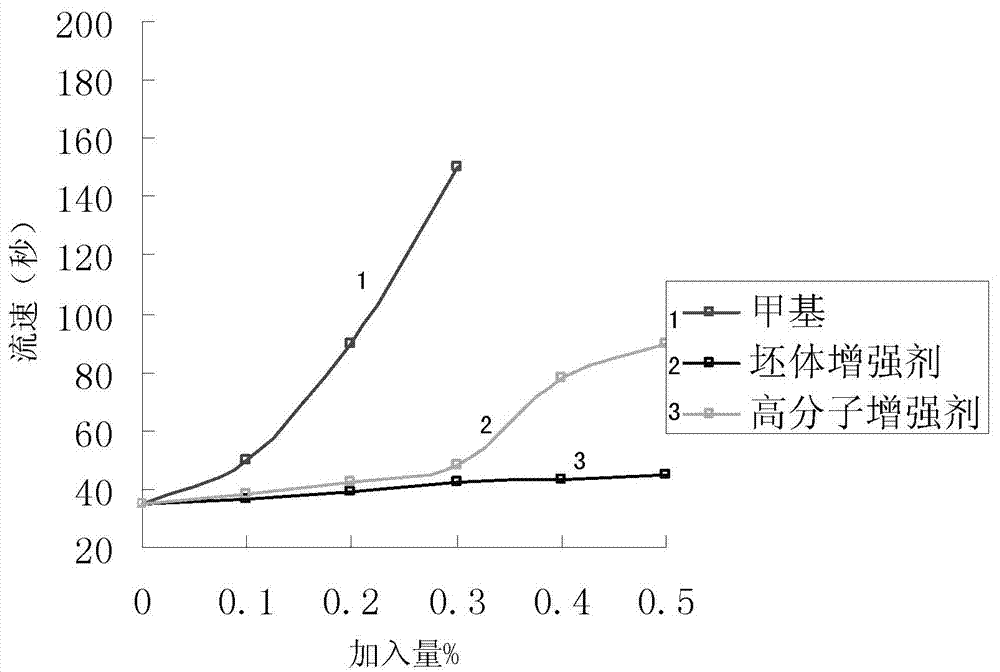

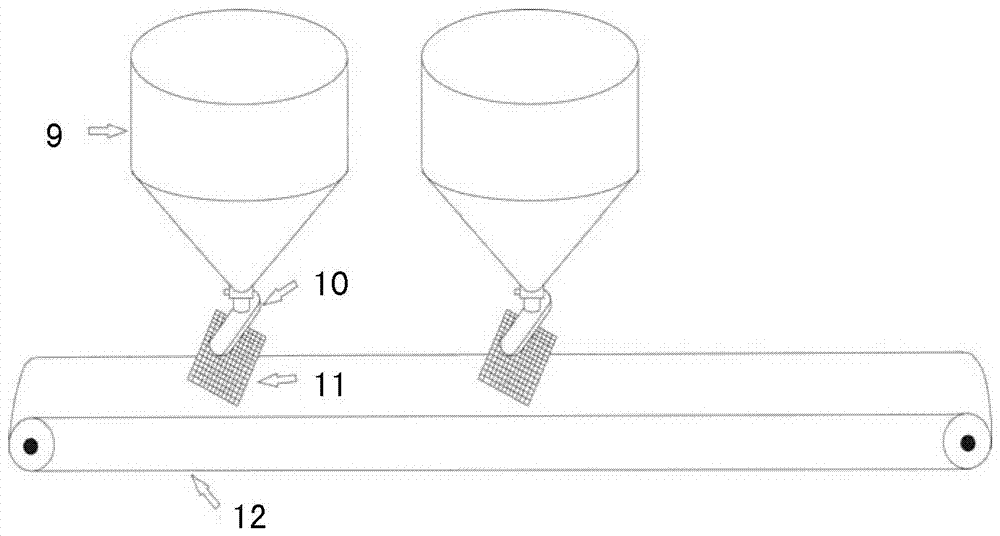

Ceramic tile decorated by dry lamination of colorful particles and micro powder and preparation method of ceramic tile

ActiveCN107116675AEasy to shapeExcellent color richnessMixing operation control apparatusCeramic shaping plantsPrillBrick

The invention provides a ceramic tile decorated by dry lamination of colorful particles and micro powder and a preparation method of the ceramic tile which are improved on floral designs, hues, and production technologies. The preparation method of the ceramic tile includes the steps that basic powder materials and colored materials are dry-mixed to prepare toner; the toner is prilled to form colored particles in different shapes; the colored particles and the toner with different colors are conveyed to and stirred in a plurality of stirrers correspondingly according to set proportions; the powder materials which are stirred in the multiple stirrers are conveyed through a plurality of feeding belts correspondingly and blanked into a vertical material loading machine according to a preset material loading procedure, and the powder materials naturally stack to form a flower shape; and the formed flower-shaped powder is conveyed to a press mold frame, pressed and formed.

Owner:广东清远蒙娜丽莎建陶有限公司 +1

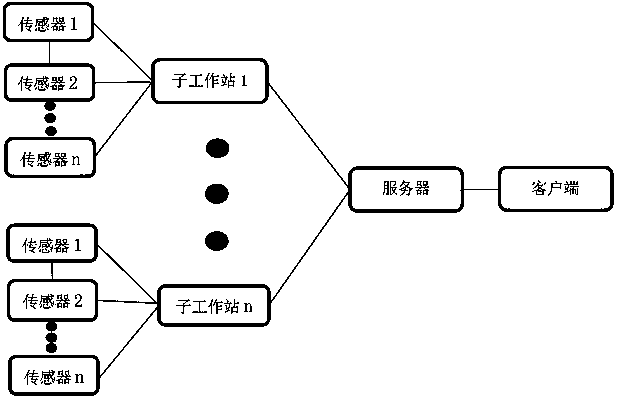

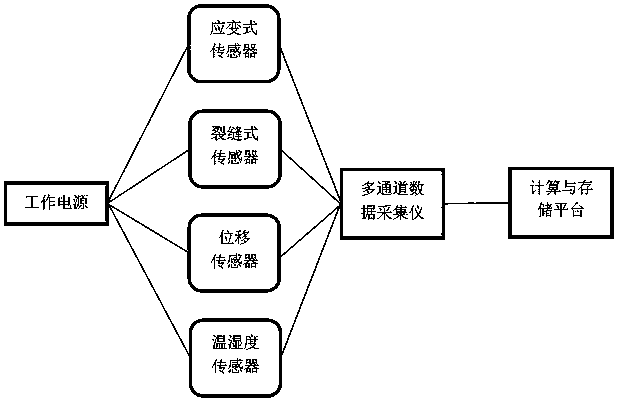

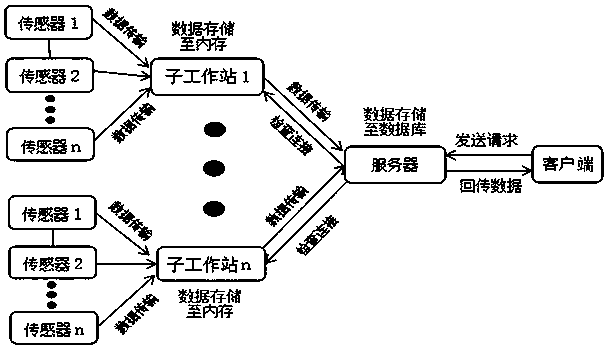

Building structure health monitoring system

PendingCN109099975AReduce manual operation errorsImprove work efficiencyMeasurement devicesProgramme total factory controlClient-sideData transmission

The invention relates to a building structure health monitoring system for carrying out remote real-time monitoring on a health condition of a building through various sensors installed on main components of a building structure. The system comprises a plurality of sensors, a plurality of sub-workstations, a server and a client, wherein the sensors are connected to the sub-workstations, the sub-workstations are connected to the server through a local area network, and the server is connected to the client through Internet; and the sub-workstations are used for preprocessing data collected by the sensors, transmitting and storing the data in a database of the server, and carrying out modelling, analysis and processing on the data in the database on the client through a building informationmodelling (BIM) in order to monitor the health condition of the building structure in real time. According to the system, the building structure is remotely and comprehensively monitored, the monitoring data is transmitted in real time, and the health condition of the building structure is comprehensively mastered, so that the reliable basis is provided for the work such as construction guidance,operation management, safety maintenance, reliability evaluation and the like of the building.

Owner:SHANGHAI UNIV

A method for directly importing BOM into a production system

InactiveCN109325730AImprove efficiencyReduce the chance of human errorOffice automationManufacturing computing systemsModularityDevice type

The invention discloses a method for directly importing BOM into a production system. The method comprises the following steps of S100, setting PCB design software, inputting material key informationinto a schematic diagram, and deriving an initial BOM; step S200, automatically merging, counting, classifying and sorting the material information in the initial BOM to generate a final BOM, whereinthe material information comprises a device type, a material code, an encapsulation and a value; step S300, directly importing the final BOM into the production system. The method of the invention adopts a script program to realize automatic classification, merging and sorting, which can effectively improve the efficiency of outputting final BOM. By reducing the comparison of complicated information of materials, and only inputting useful information, the probability of manual error can be reduced, and by the operation of PCB schematic diagram, the reuse of circuit module or unit can be realized and the labor cost is reduced.

Owner:SICHUAN JIUZHOU ELECTRONICS TECH

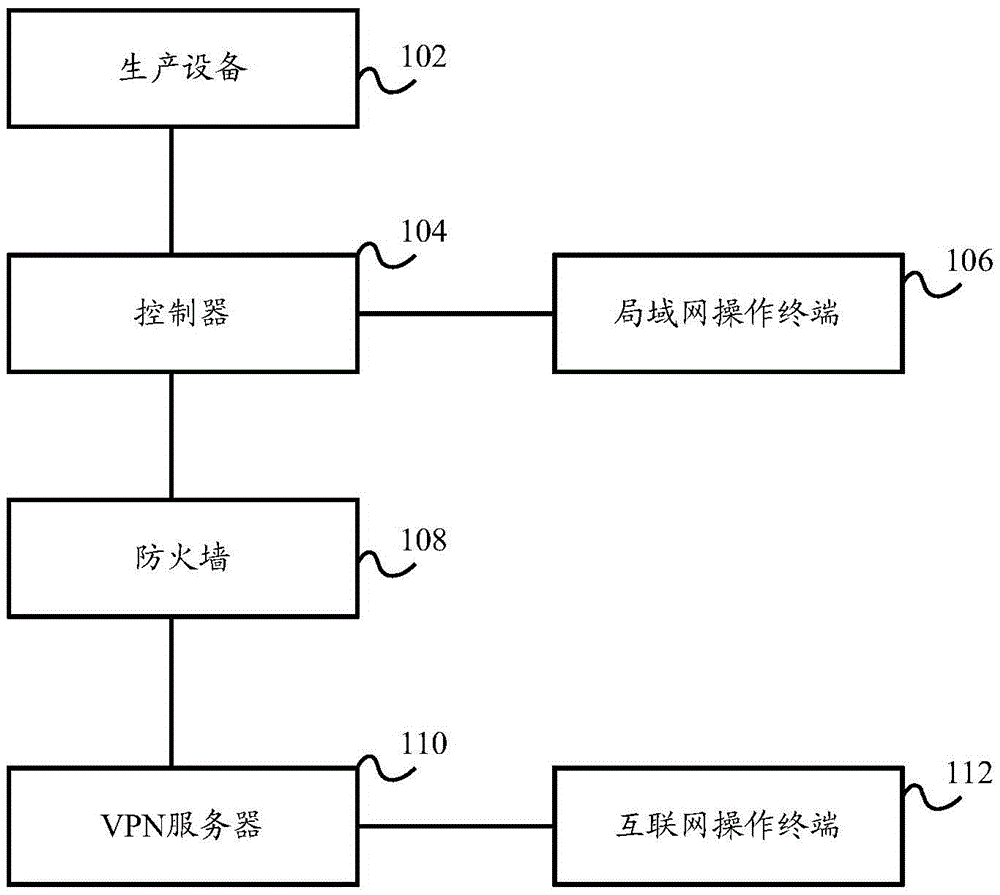

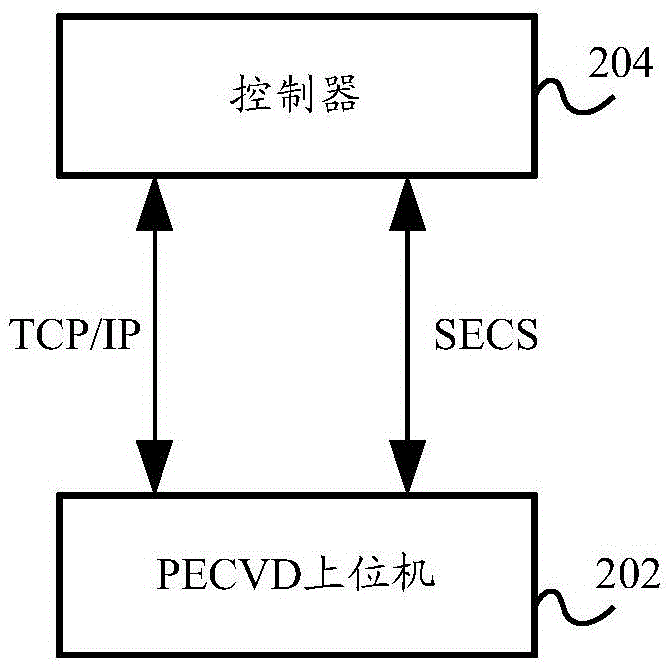

Solar battery production line and remote control method and system thereof

InactiveCN105491144ARealize remote controlImprove work efficiencyTransmissionRemote controlLocal area network

The invention discloses a solar battery production line and a remote control method and system thereof, for remotely controlling production devices in a solar battery production line so as to improve the work efficiency, decreases the labor cost and reduces the probability of manual maloperaiton. The remote control system of the solar battery production line comprises a controller, multiple production devices in the solar battery production line and an operation terminal, wherein the controller is used for adjusting the work states of the production devices according to the indication of the operation terminal; each production device comprises a host computer and an interface, the host computers and the controller carry out information interaction through the interfaces, and the interfaces are used for performing protocol conversion on information interacted between the host computers and the controller; and the operation terminal comprises a local area network operation terminal, and the local area network operation terminal is in signal connection with the controller for remotely controlling the production devices in a local area network.

Owner:ENN SOLAR ENERGY

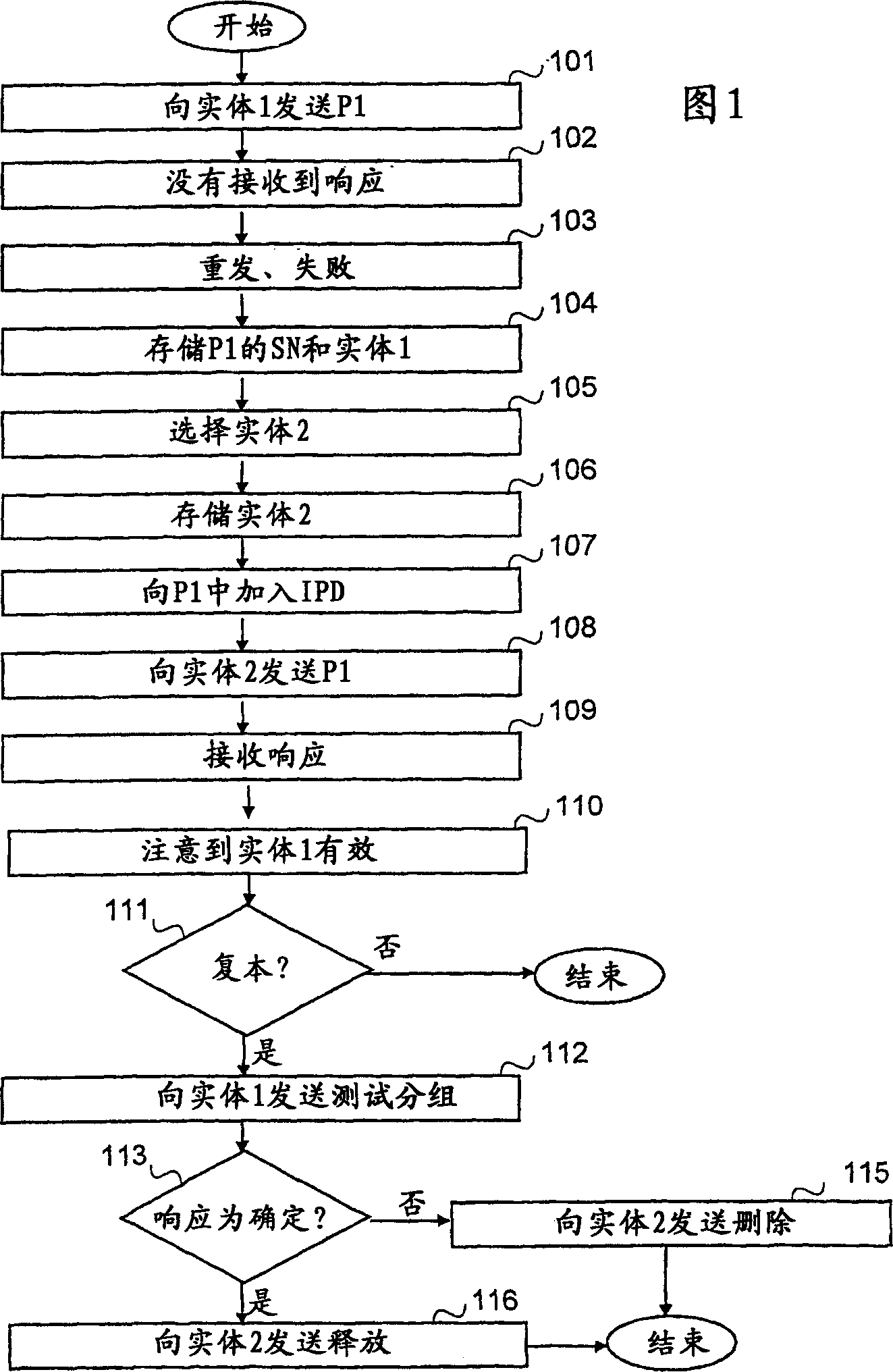

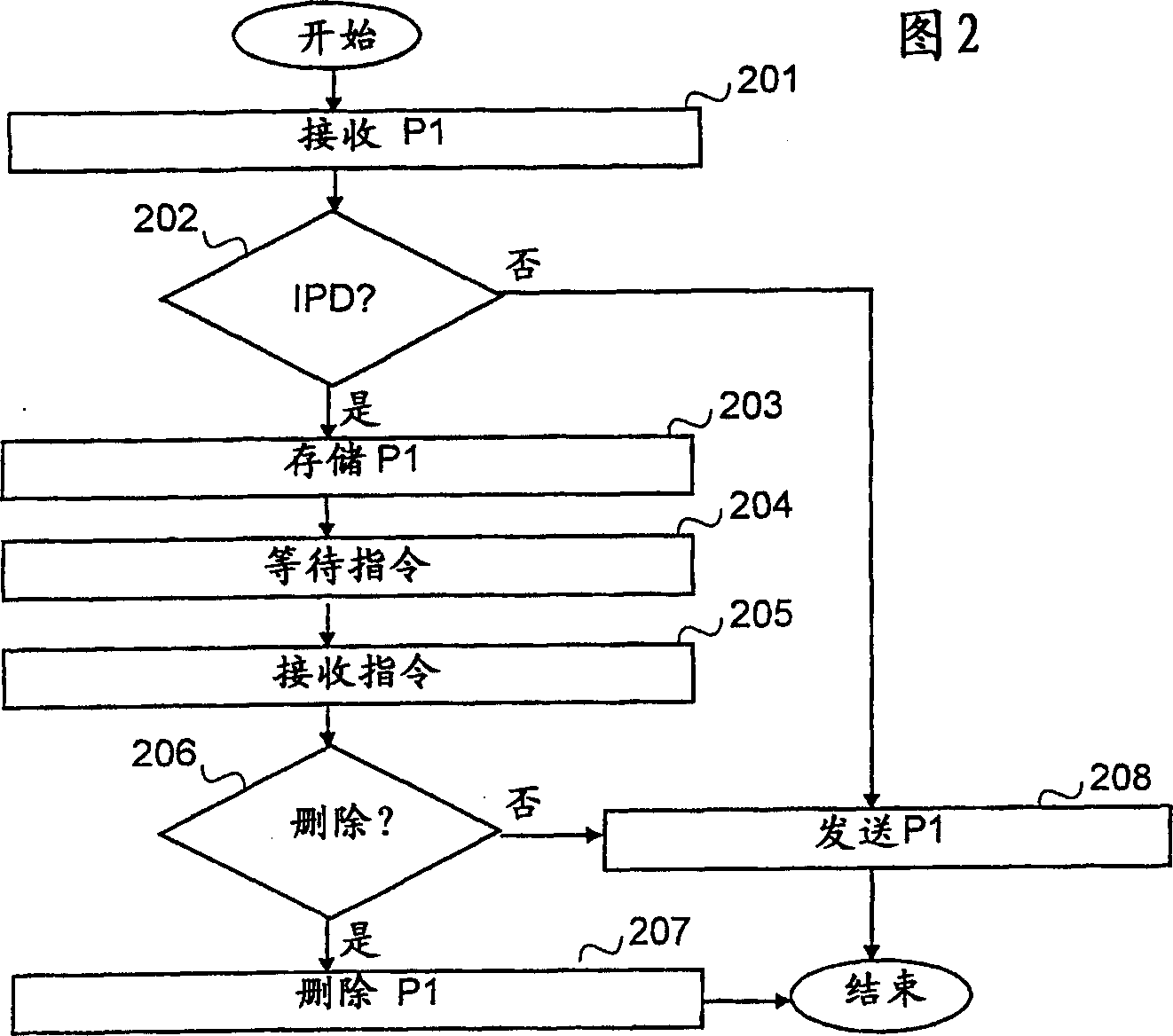

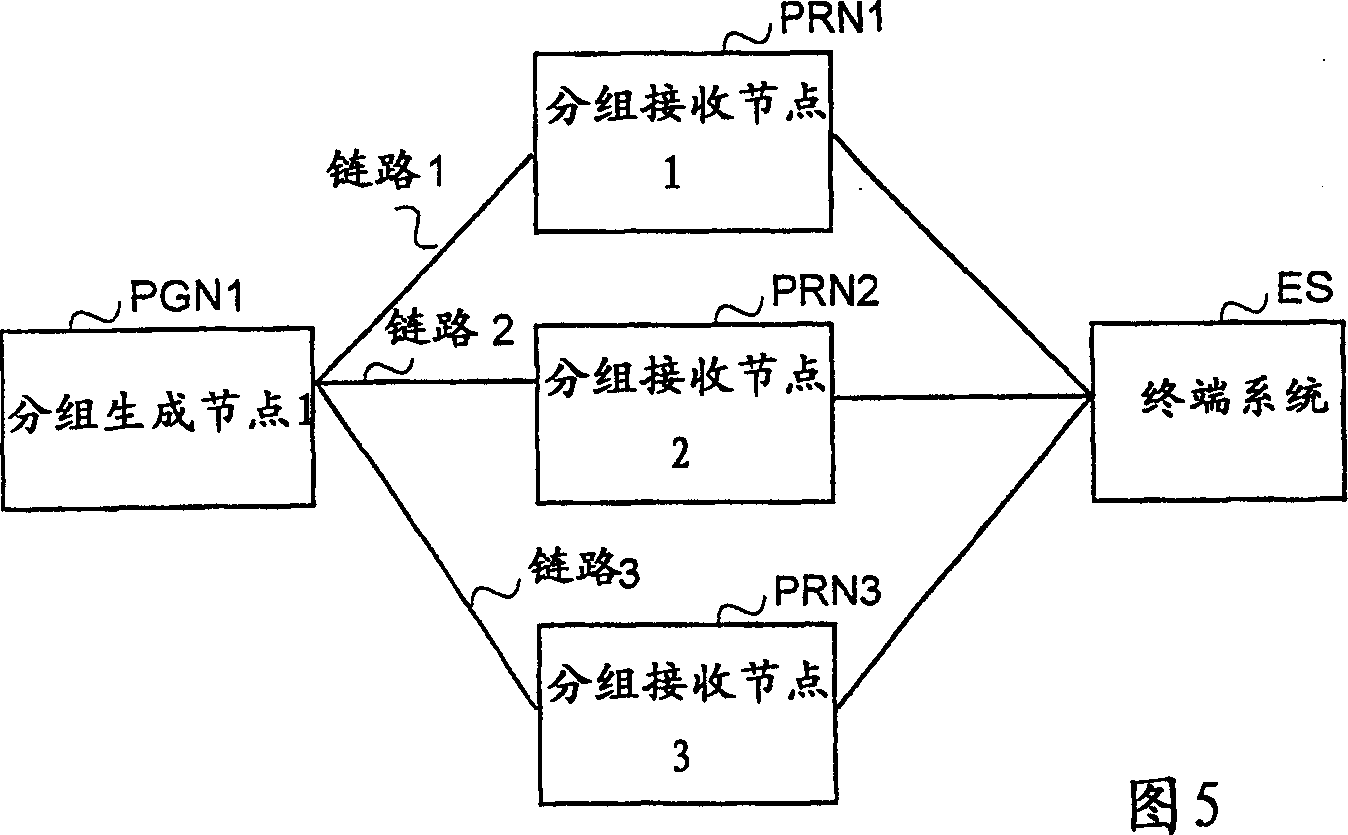

Controlled data network error recovery

InactiveCN1341308AImprove reliabilityReduce manual errorsError prevention/detection by using return channelData switching networksControl dataNetwork error

A method, a system and network nodes using indication of possible duplicates (IPD) of units, so that these units can be handled differently than other units. The unit is indicated to be a possible duplicate to the entity to which it is resent because no response was received from the entity it was sent to.

Owner:MICROSOFT TECH LICENSING LLC

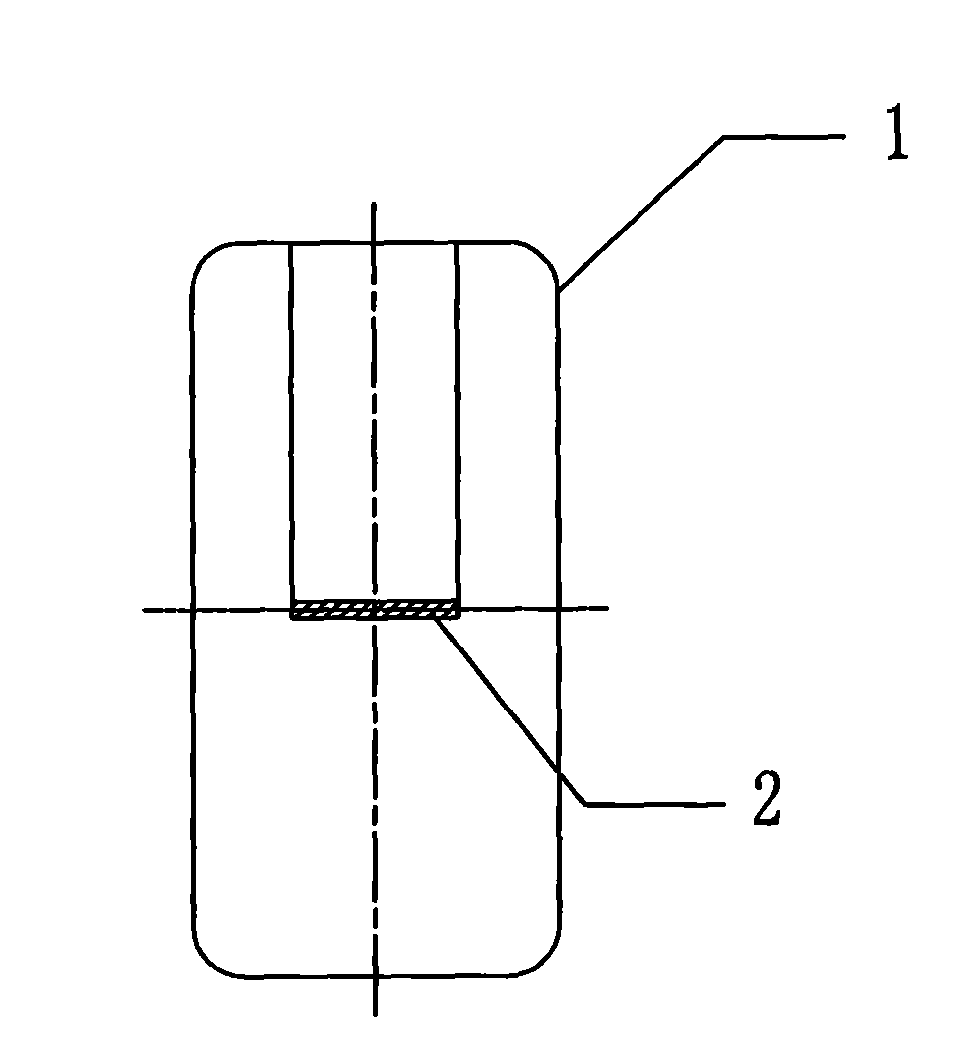

Intelligent counterfeiting bottle stopper

ActiveCN101927862APrevent tamperingAvoid swappingClosure using stoppersClosure stoppersMicrowave frequency rangeEngineering

The invention relates to an intelligent counterfeiting bottle stopper which comprises a bottle stopper body and a radio frequency identification chip, wherein the chip is selected from chips with different working frequencies including low frequency, high frequency, ultrahigh frequency or microwave frequency range; and the radio frequency identification chip is encapsulated inside the bottle stopper body. The intelligent counterfeiting bottle stopper leads the information of wine to be stored in the bottle stopper, and utilizes radio frequency identification (RFID) technology to read the related information of the wine in the bottle stopper, thus leading the bottle stopper to become an identification carrier of the wine and having the intelligent counterfeiting function.

Owner:潘国平

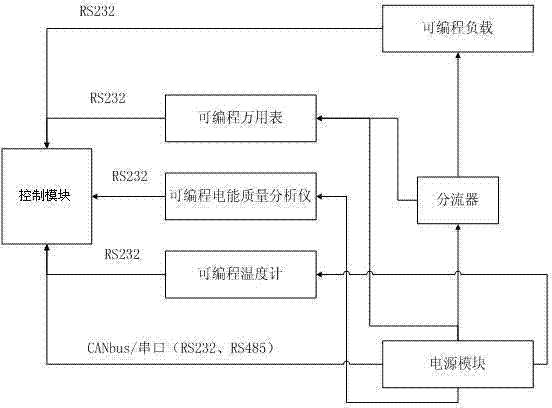

Automatic calibration device for power module and calibration method

InactiveCN103760498AReduce manual errorsImprove efficiencyPower supply testingPower qualityProgrammable load

The invention discloses an automatic calibration device for a power module and a calibration method. The automatic calibration device comprises the power module, a control module, a programmable universal meter, a programmable power quality analyzer, a programmable thermometer, a programmable load and a shunt, wherein the control module is connected with the power module. An output end of the power module is connected with an input end of the programmable load and an input end of the programmable universal meter through the shunt respectively. The output end of the power module is further connected with the input end of the programmable universal meter, an input end of the programmable power quality analyzer and an input end of the programmable thermometer. An output end of the programmable load, an output end of the programmable universal meter, an output end of the programmable power quality analyzer and an output end of the programmable thermometer are connected with the control module. Compared with traditional manual calibration, the automatic calibration device for the power module reduces manual operation errors and greatly improves efficiency and accuracy.

Owner:JIANGSU JIAYU NEW POWER TECH

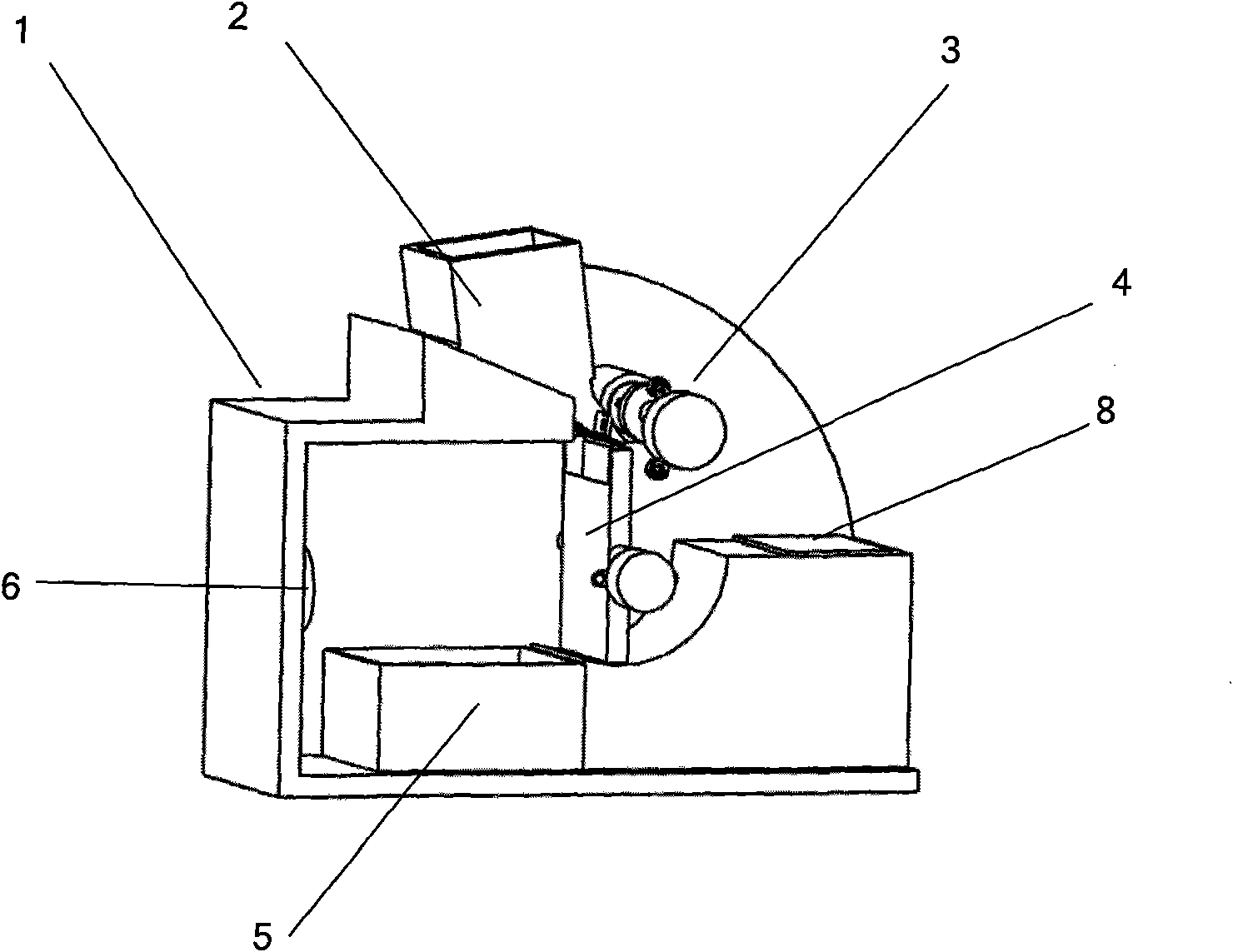

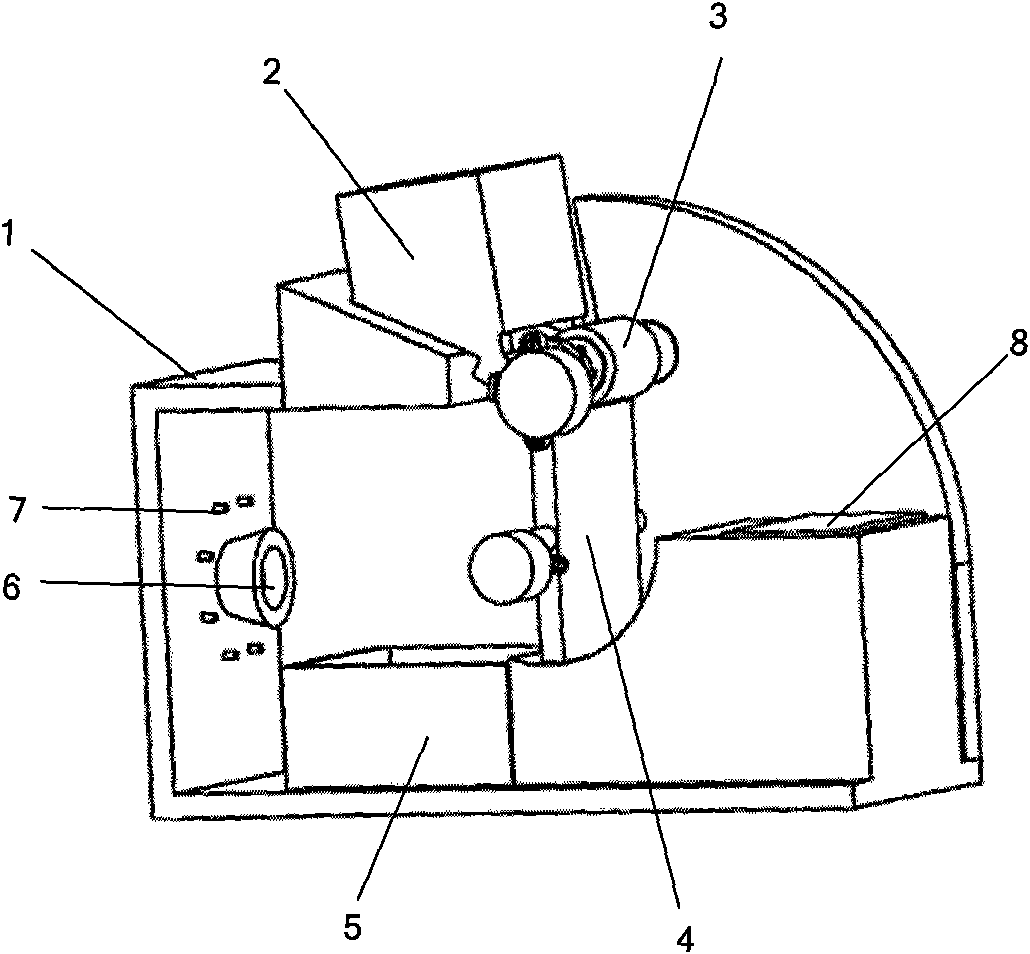

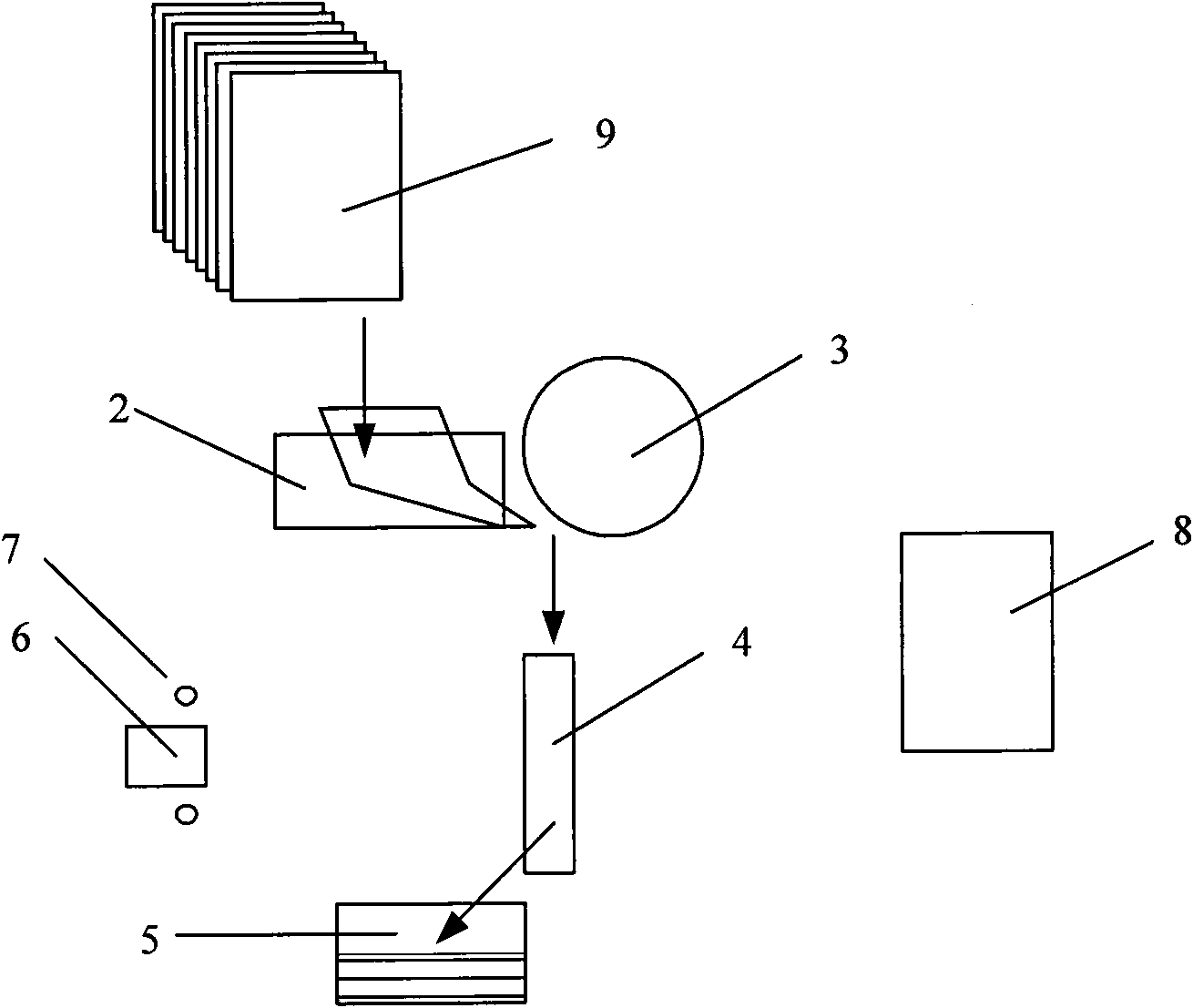

Batch business card shooting device

InactiveCN101848295AImplement batch processingAvoid manual operationPictoral communicationBusiness cardDigitization

The invention relates to a batch business card shooting device, belonging to the field of computer peripheral input devices. The batch business card shooting device comprises a machine frame, a business card transport unit, a shooting unit and a control unit. The business card transport unit arranged on the machine frame is used for carrying out batch inputting, advancing, overturning and outputting on the business cards; the shooting unit arranged on the machine frame is used for shooting the input business cards; and the control unit is used for controlling the business card transport unit to transport the business cards and controlling the shooting unit to shoot the business cards. In the invention, the batch business cards automatically enter the shooting area of the shooting module one by one through the above modules, the shooting module automatically shoots the front and opposite faces of the business cards, and then the shot pictures are transported to a computer to be subject to business card processing, identification and management. The invention solves the problem of digitalized storage of the business cards for people, and can realize digitalized management, thus saving labor force cost and improving office efficiency.

Owner:HANVON CORP

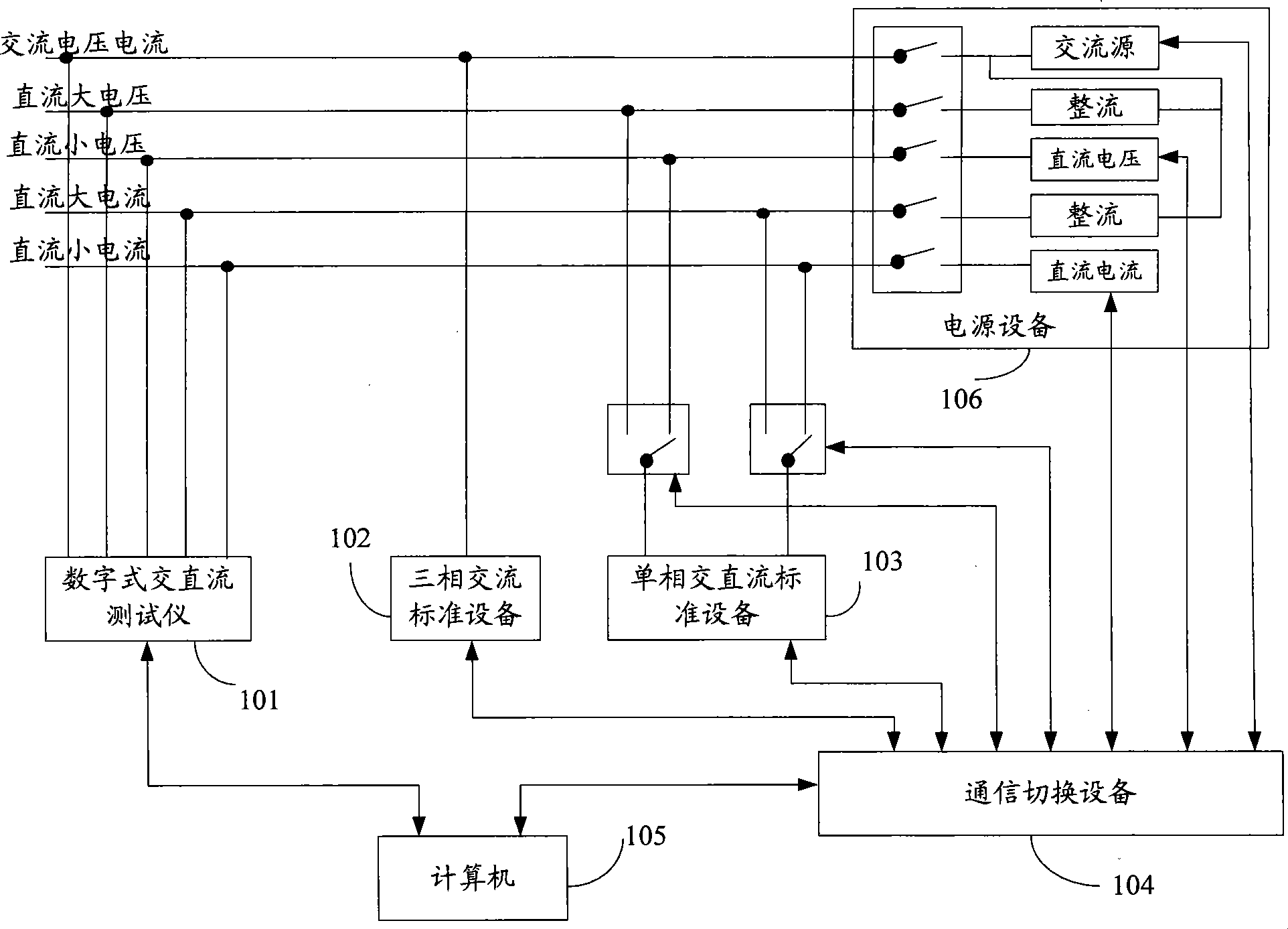

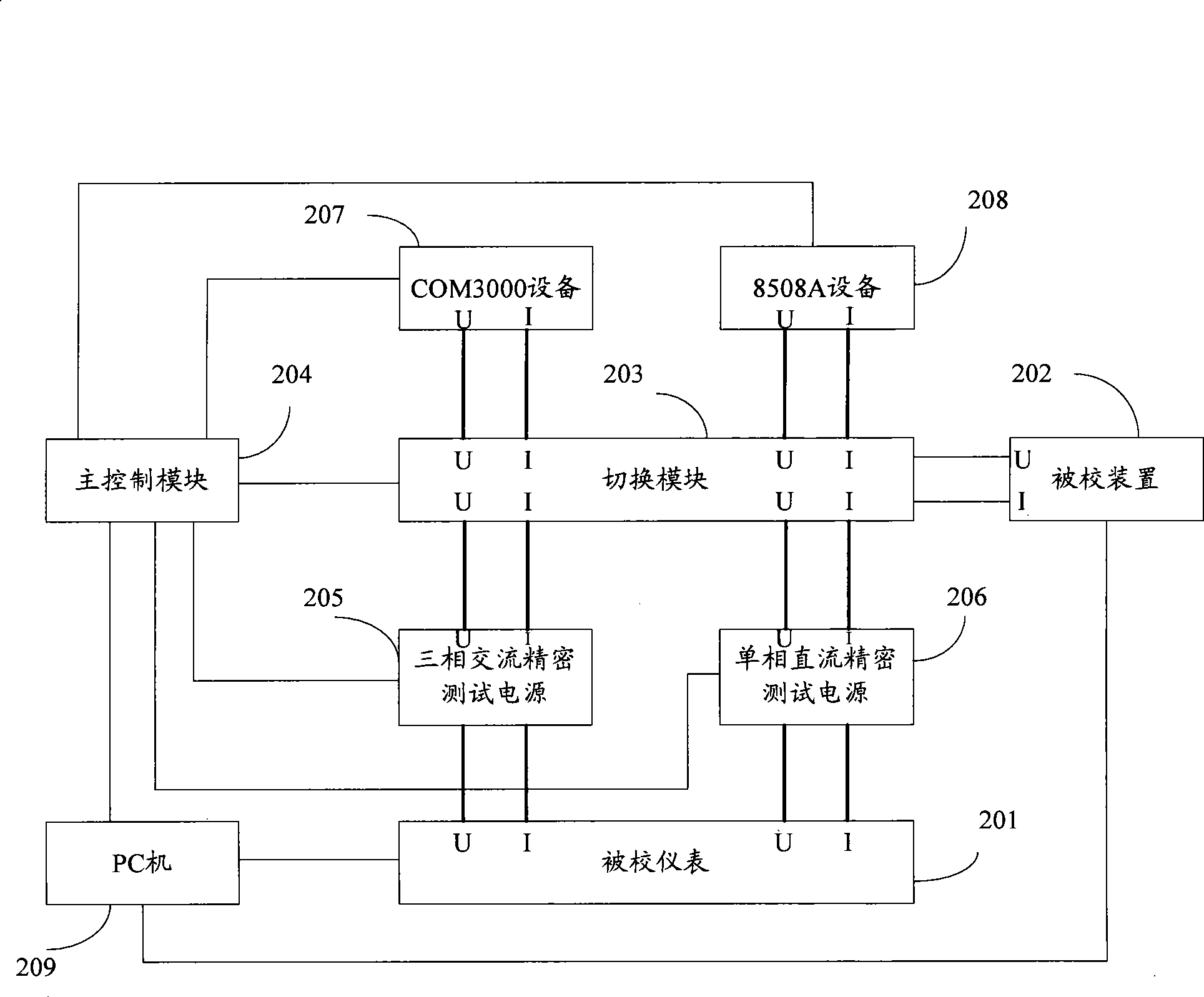

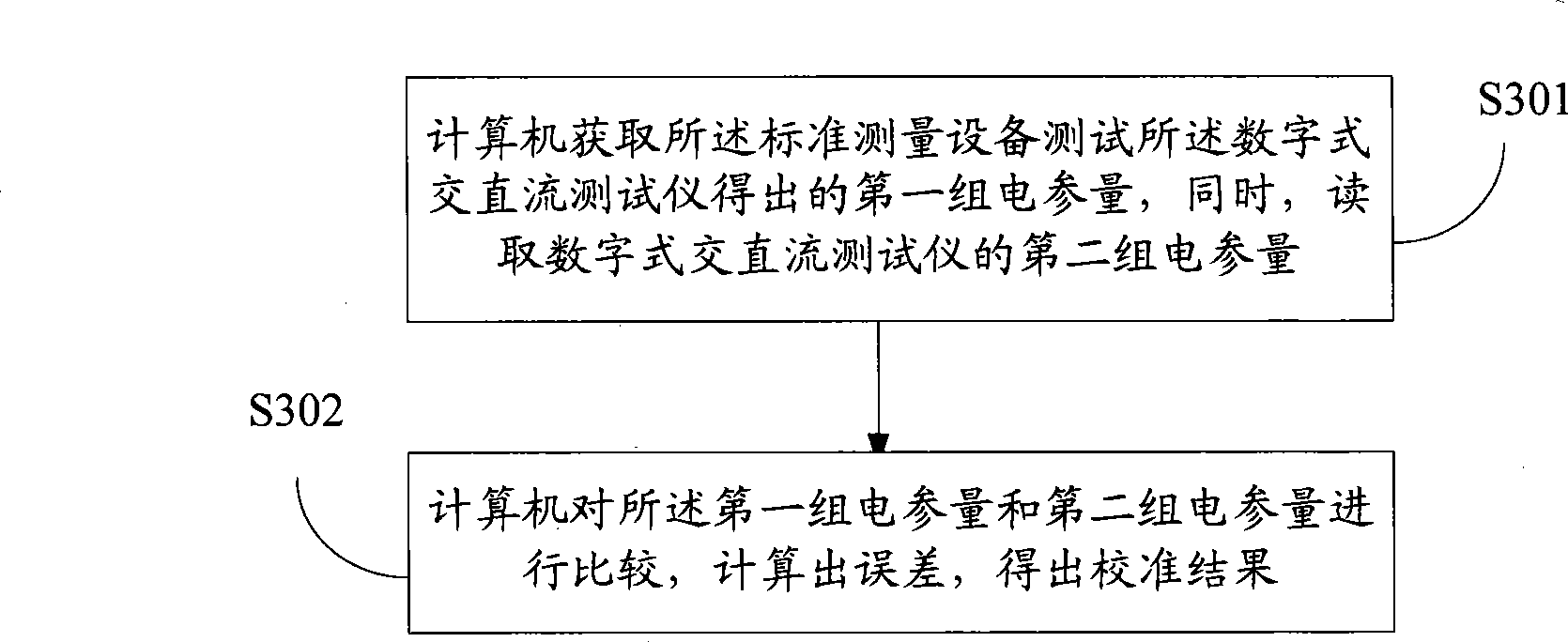

Calibration system and method for digital alternating current-direct current tester

InactiveCN101387696AFully automatedReduce manual errorsElectrical measurementsElectricityCalibration result

The invention discloses a correction system for digital alternative-direct current tester and a method. The correction system comprises a digital alternative-direct current tester, a standard measurer, a communication switcher and a computer, wherein the standard measurer can measure the digit alternative-direct current tester and read out a first electric parameter group; the communication switcher can obtain a first electric parameter group from the standard measurer, the computer obtains a first electric parameter group from the communication switcher, reads a second electric parameter group from the digital alternative-direct current tester, and compares the first and the second electric parameter groups to calculate the error and obtain the corrected result of the digital alternative-direct current tester. The invention can avoid the problems of the manual correction such as large error and low efficiency.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST

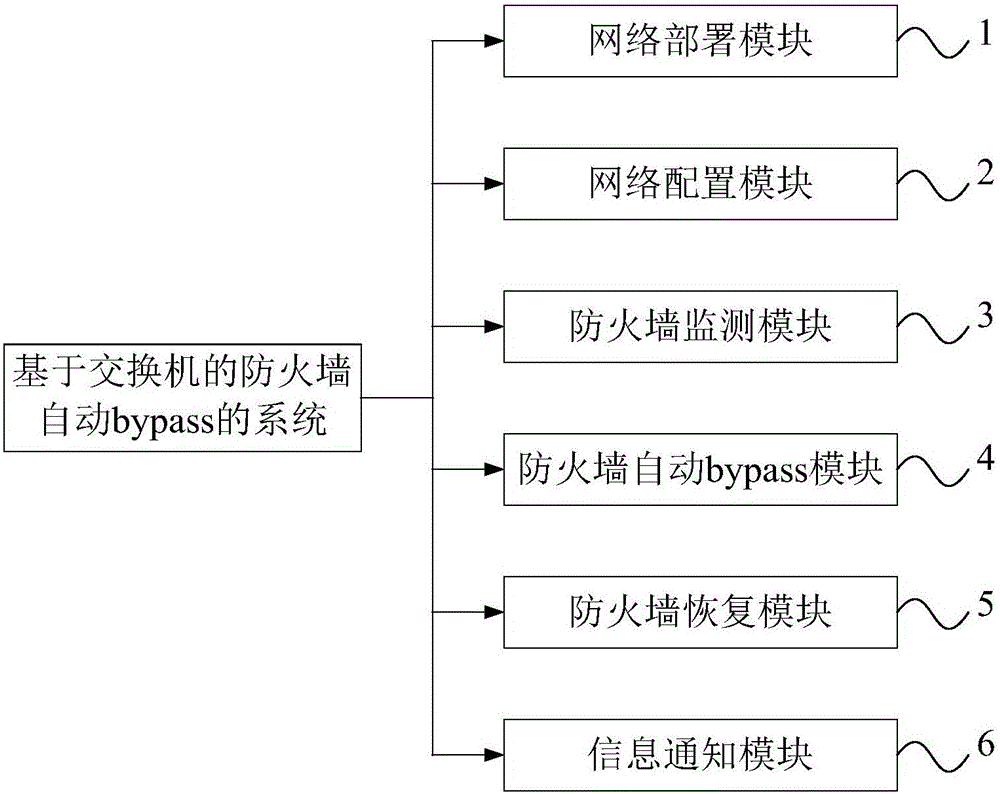

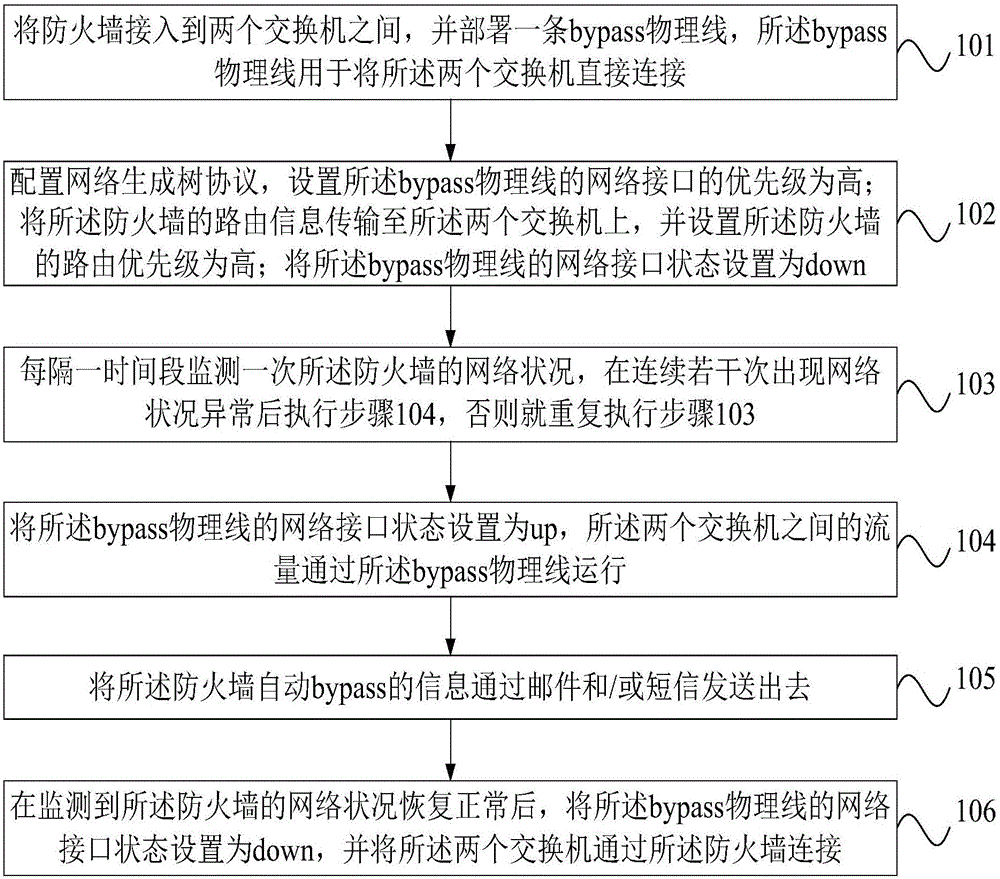

Method and system for firewall automatic bypass based on switches

InactiveCN106209425AShorten the timeReduce manual errorsData switching networksTraffic capacitySpanning Tree Protocol

The invention discloses a method and a system for firewall automatic bypass based on switches. The method comprises steps: S1, the firewall is connected between two switches, and a bypass physical line is deployed for directly connecting the two switches; S2, a network spanning tree protocol is configured, the network interface of the bypass physical line is set to have a high priority, the routing information of the firewall is transmitted to the two switches, the routing priority is set to be high, and the network interface state of the bypass physical line is set to be down; S3, the network state of the firewall is monitored at each time interval, and after abnormal network states appear at several times continuously, S4 is executed; and S4, the network interface state of the bypass physical line is set to be up, and the flow between the two switches is operated through the bypass physical line. The bypass function is automatically executed in the case when fault happens to the firewall, and the time for trouble shooting and change is saved.

Owner:SHANGHAI CTRIP COMMERCE CO LTD

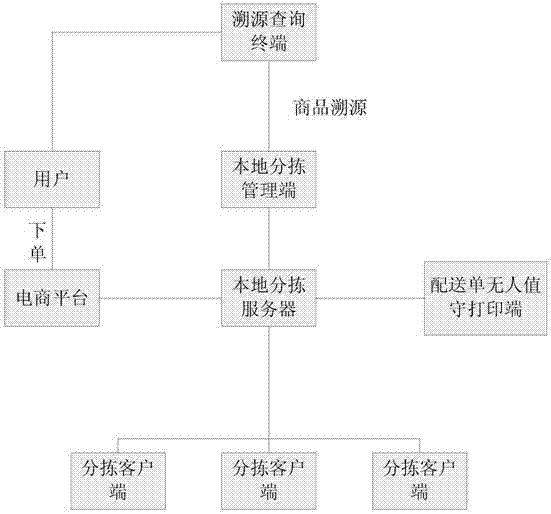

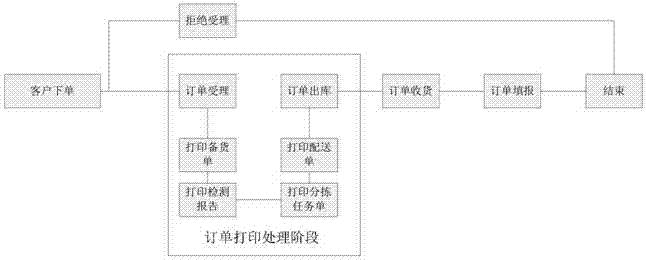

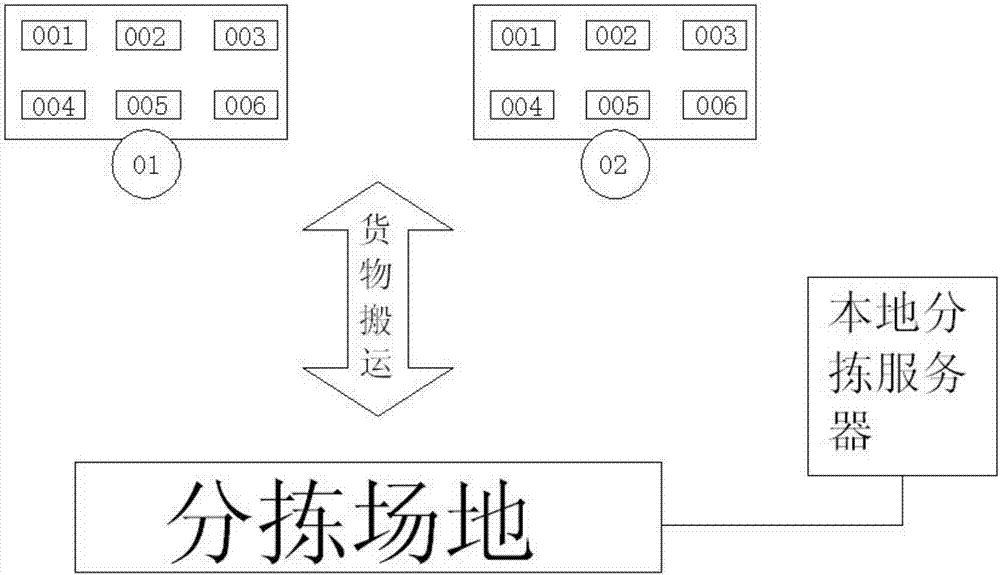

Transaction-based food circulation traceability system

InactiveCN107146093AReduce manual errorsAvoid overpackingBuying/selling/leasing transactionsE-commerceClient-side

A transaction-based food circulation traceability system disclosed by the present invention comprises an e-commerce platform, a local sorting server, a management terminal, a delivery terminal and a sorting client, the e-commerce platform enables the transaction commodities to be numbered via a commodity numbering module and transmits the information to the local sorting server, the local sorting server carries out the trading area numbering on the regions of a city, numbers the commercial tenants of purchasing the commodities in the numbered trading areas and sends the commodity information, the trading area information and the commercial tenant information to the sorting client, and the sorting client determines the types and weights of the commodities via the commodity information, sorts according to the trading area information and the commercial tenant information, updates the weights of the sorted commodities real-timely, transmits the actual weighing weights to the local sorting server, at the same time, prints the sorting information.

Owner:成都顺点科技有限公司

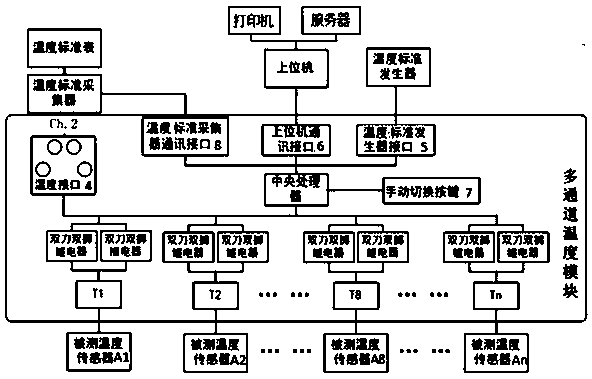

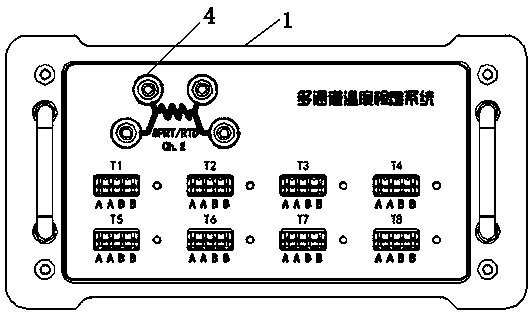

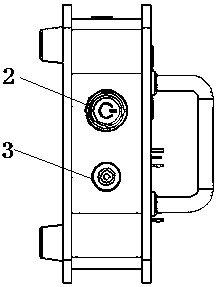

Device and method for multi-channel temperature calibration

PendingCN109269680AMeet the needs of different conditions of useRealize verification workThermometer testing/calibrationTechnical standardData acquisition

The invention relates to a device and a method for multi-channel temperature calibration. The method comprises the steps that: a calibration personnel controls an upper computer, and when a set temperature value is reached, a temperature indicating value of a calibrated sensor A1 and indicating value data of a temperature standard meter at the same time are uploaded to the upper computer; after aset time S1 arrives, a central processor of a multi-channel temperature module controls a plurality of pairs of double-pole double-throw relays to switch off, a channel interface T2 end is conducted by switching on double-pole double-throw relays A1, and a temperature indicating value of a calibrated sensor A2 and indicating value data of the temperature standard meter at the same time are uploaded to the upper computer, so as to complete calibration of the calibrated sensors in sequence; the obtained data is compared according to rules, a calibration certificate is generated according to thesensor determined to be qualified, and the calibration certificate is printed, output and uploaded to a server; and for the sensor determined to be unqualified, the calibration personnel switches theunqualified calibrated sensor to a current data acquisition state through manually switching buttons for reexamination and debugging. The invention can simultaneously realize the verification work ofthe 8-way tested temperature sensor and improve the verification efficiency. The device and the method can realize the calibration of 8 channels of tested temperature sensors, and improve the calibration efficiency.

Owner:ZHONGHUAN TIG TIANJIN METEOROLOGICAL INSTR +1

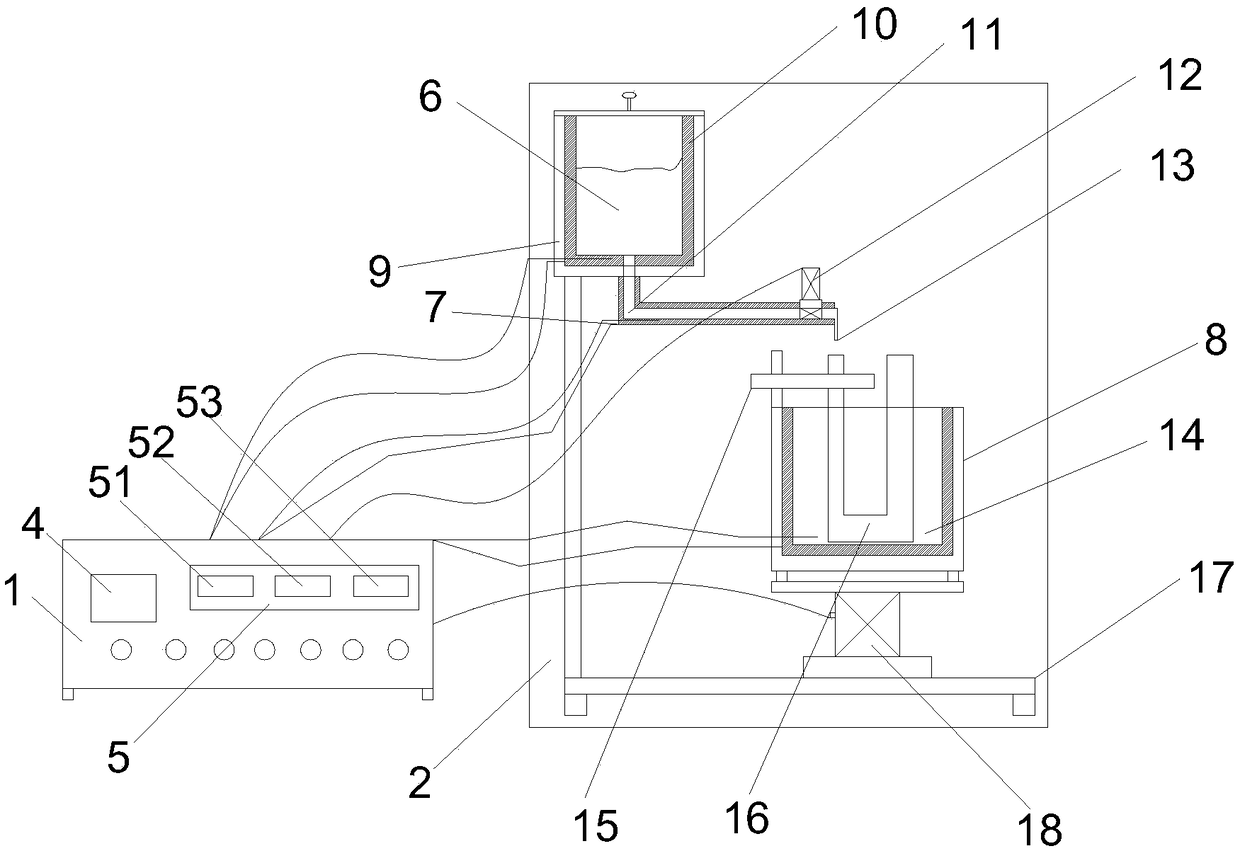

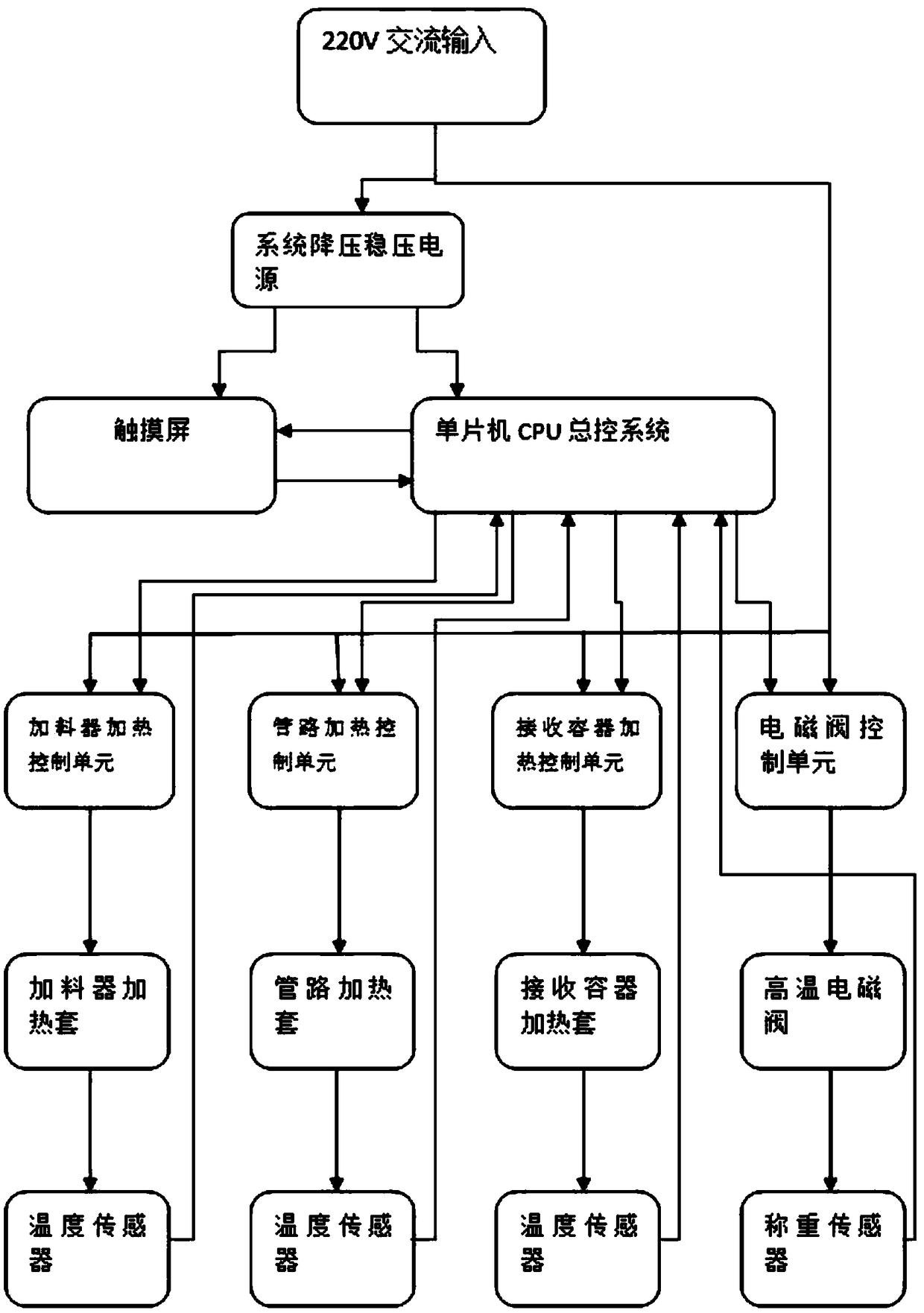

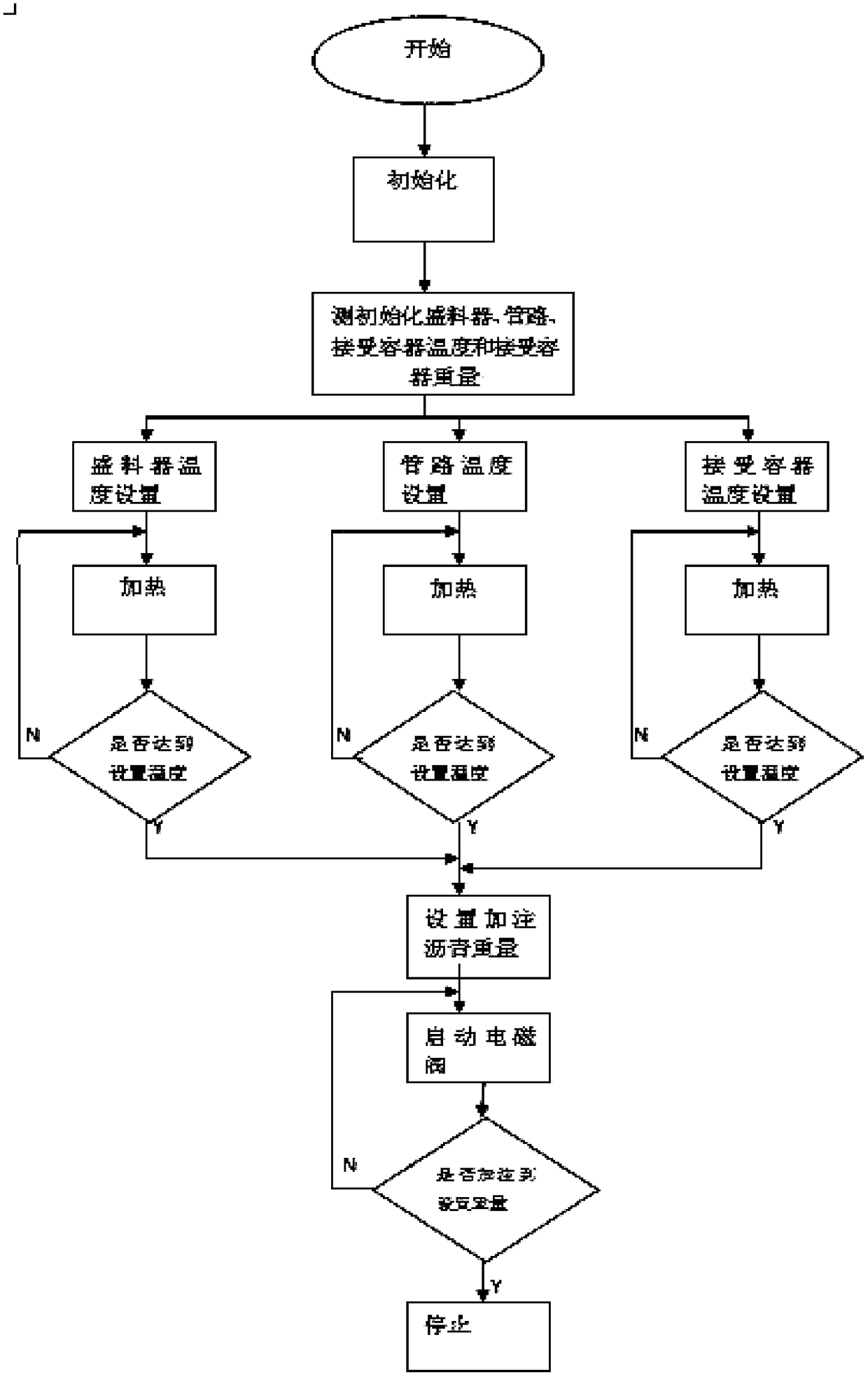

Automatic laboratory asphalt filling device

PendingCN109251760AMeet the requirements of automatic filling precision controlReasonable structural designPreparing sample for investigationWorking-up pitch/asphalt/bitumen by meltingAutomatic controlBottle

The invention discloses an automatic laboratory asphalt filling device. The device comprises a control mechanism and an execution mechanism connected with the control mechanism, wherein the control mechanism comprises a crate and an internal control system, the execution mechanism comprises a charging mechanism, a feeding mechanism and a storing mechanism, temperature sensors and heaters are arranged on the charging mechanism, the feeding mechanism and the storing mechanism respectively, a high temperature electromagnetic valve and a flowing nozzle are arranged on a feeding pipeline, a receiving insulating container is arranged on the storing mechanism, a clamp holder is arranged on the receiving insulating container, and the clamp holder is connected with a receiving bottle or a viscometer pipe. A laboratory asphalt filling process is automatically controlled, manual operation is not needed, through the temperature sensors and an automatic control device, heating temperature control is directly completed, through the electromagnetic valve and a weighing sensor, the weight of filled asphalt is controlled, by means of multiple control units in combination with a general control system, temperature control and heating process control are achieved separately, the efficient control requirements are met, and by setting the weighing sensor to control the filling weight, the requirements of automatically filling and measuring the laboratory asphalt are effectively met in the whole process.

Owner:CHANGSHA LUSHENG INSTR EQUIP

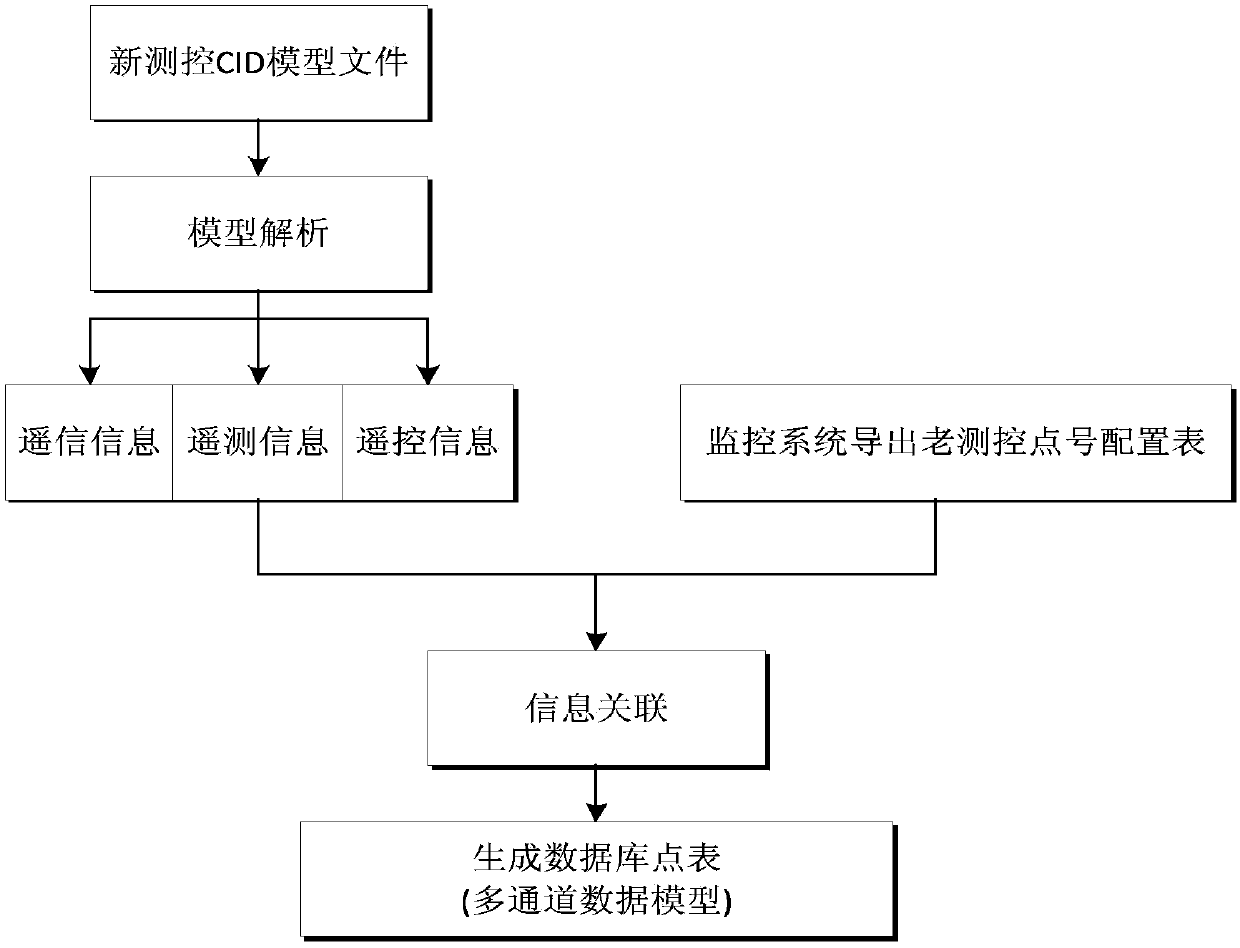

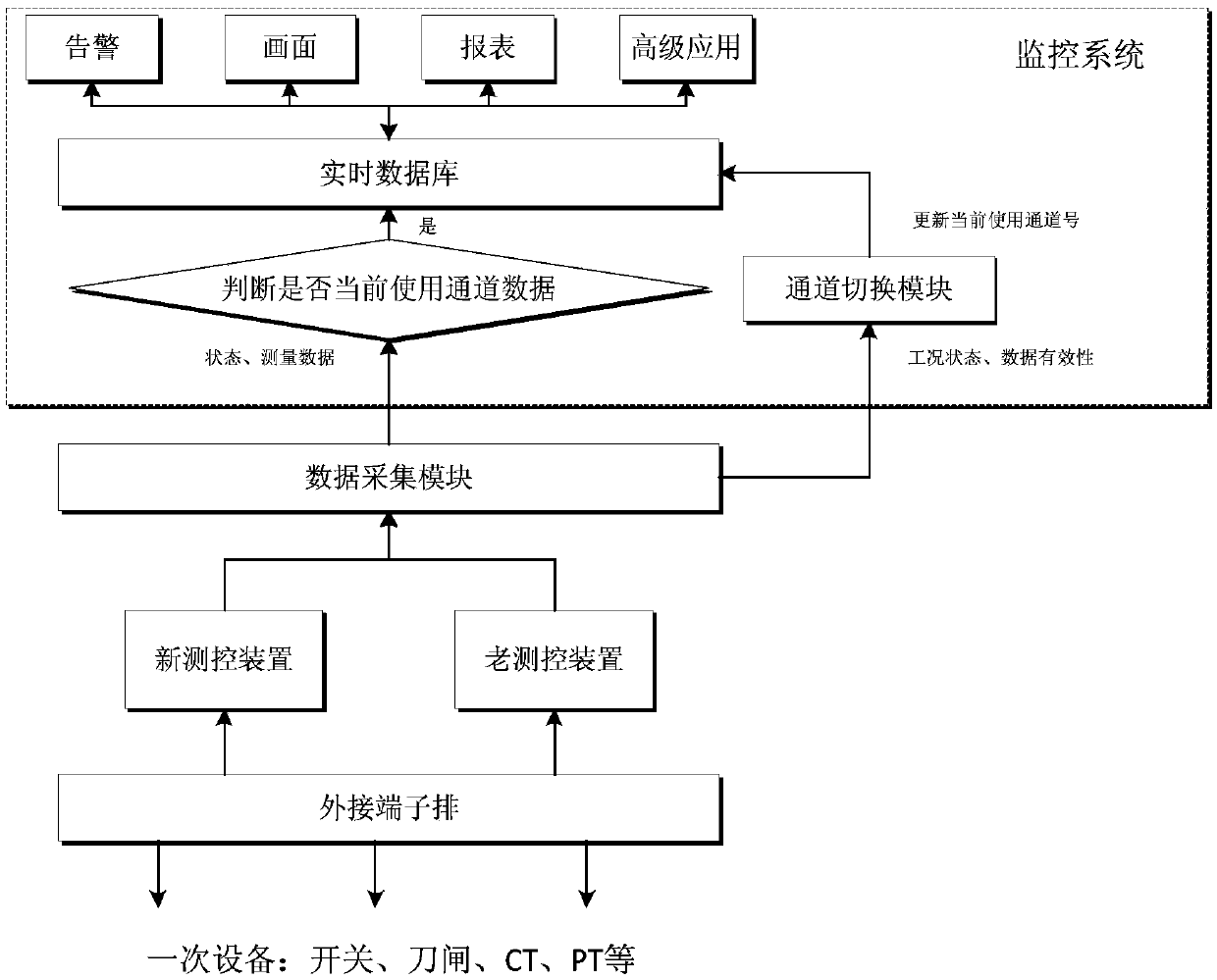

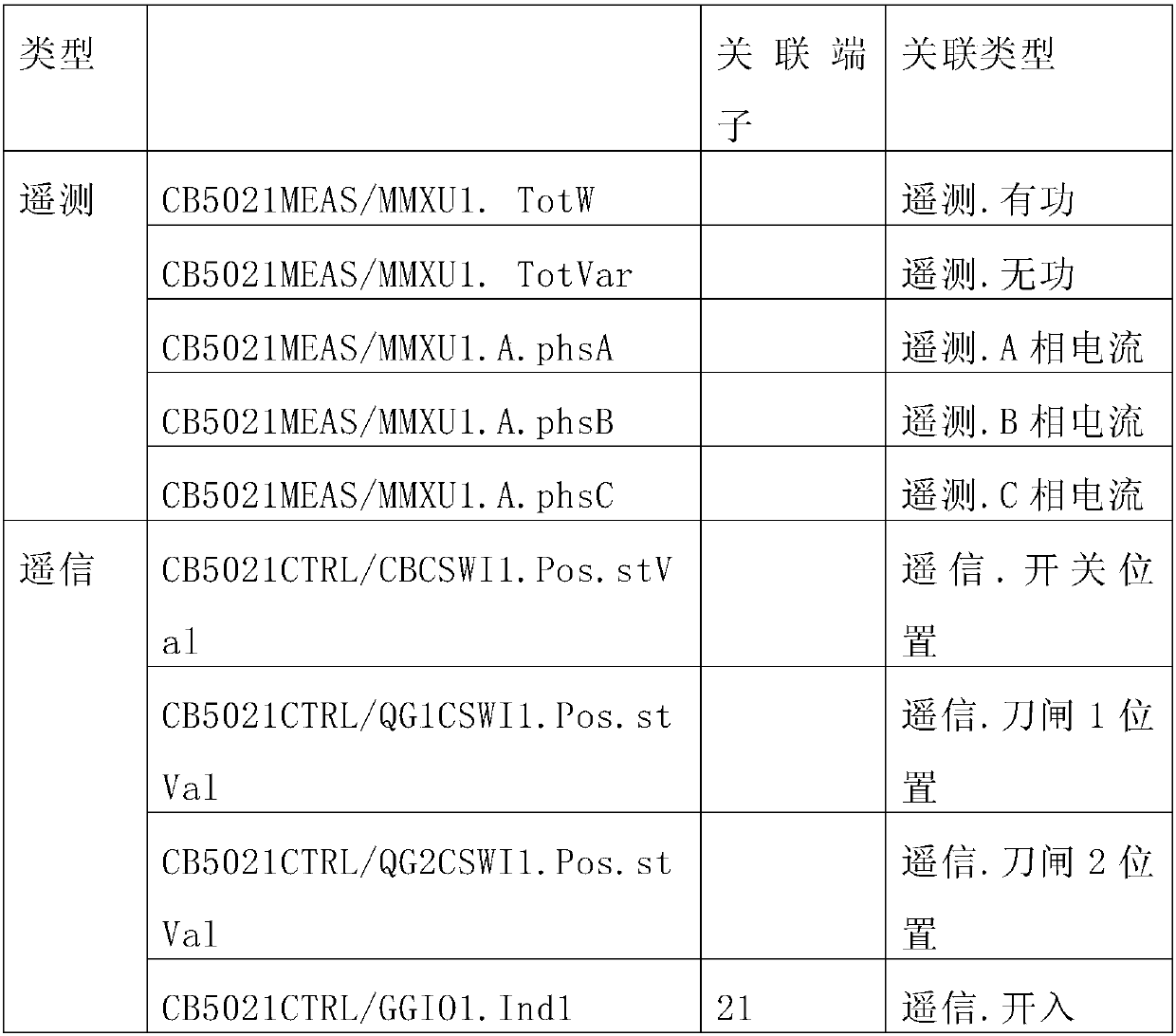

Rapid replacement method in case of failure of transformer substation measuring and control device

ActiveCN107565690AAddressing Accuracy and Reliability IssuesReduce the probability of manual errorsCircuit arrangementsSpecial data processing applicationsDatabase maintenanceData model

The invention discloses a rapid replacement method in case of a failure of a transformer substation measuring and control device. The method comprises the following steps: analyzing an IEC61850 modelof a new measuring and control device to acquire a three-remote data model, exporting a three-remote data model of the original measuring and control device from a monitoring system database, and carrying out automatic matching and generating a database point table according to mapping relationships between the data models and association types and association terminals; virtualizing the new and the original measuring and control devices into different data source channels, and establishing channel association between the data source channels and the generated database point table; and achieving rapid measuring and control device replacement through the multi-channel switching technology. The method provided by the invention has the advantages that the measuring and control device is addedthrough the additional data source channel, original monitoring system and telecontrol database configurations are not changed, and all the association is automatically achieved through programs, sothat high accuracy and reliability during database maintenance are effectively achieved, the probability of manual errors and the debugging workload are reduced, and technical guarantees are providedfor the rapid measuring and control device replacement.

Owner:NARI TECH CO LTD +1

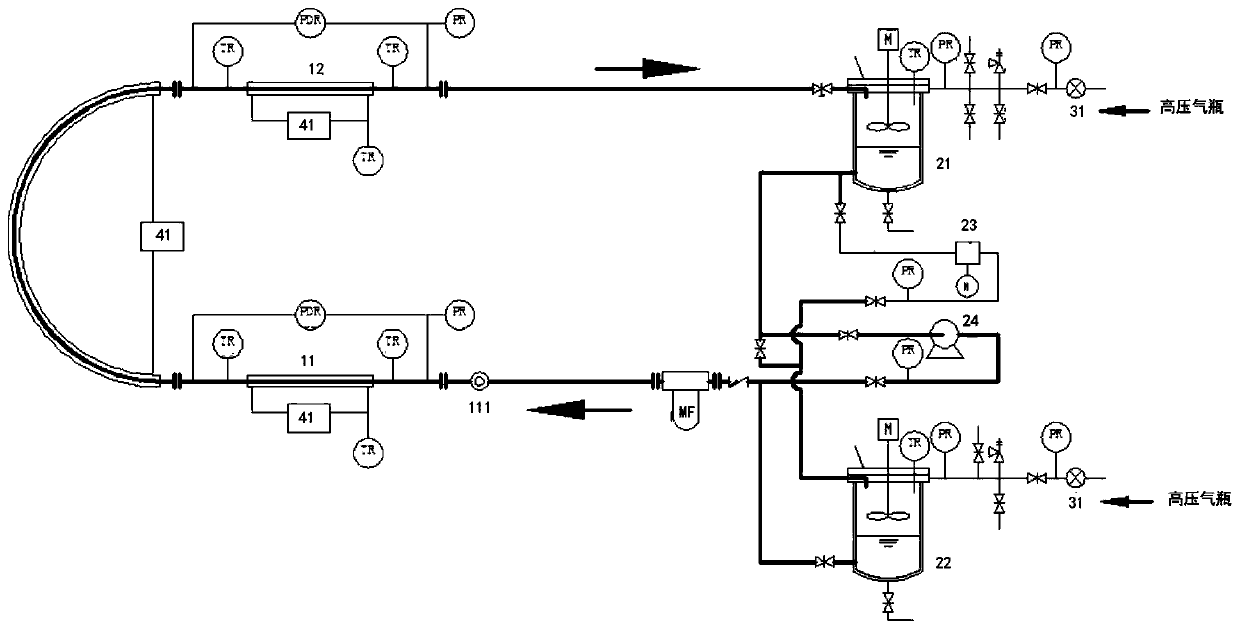

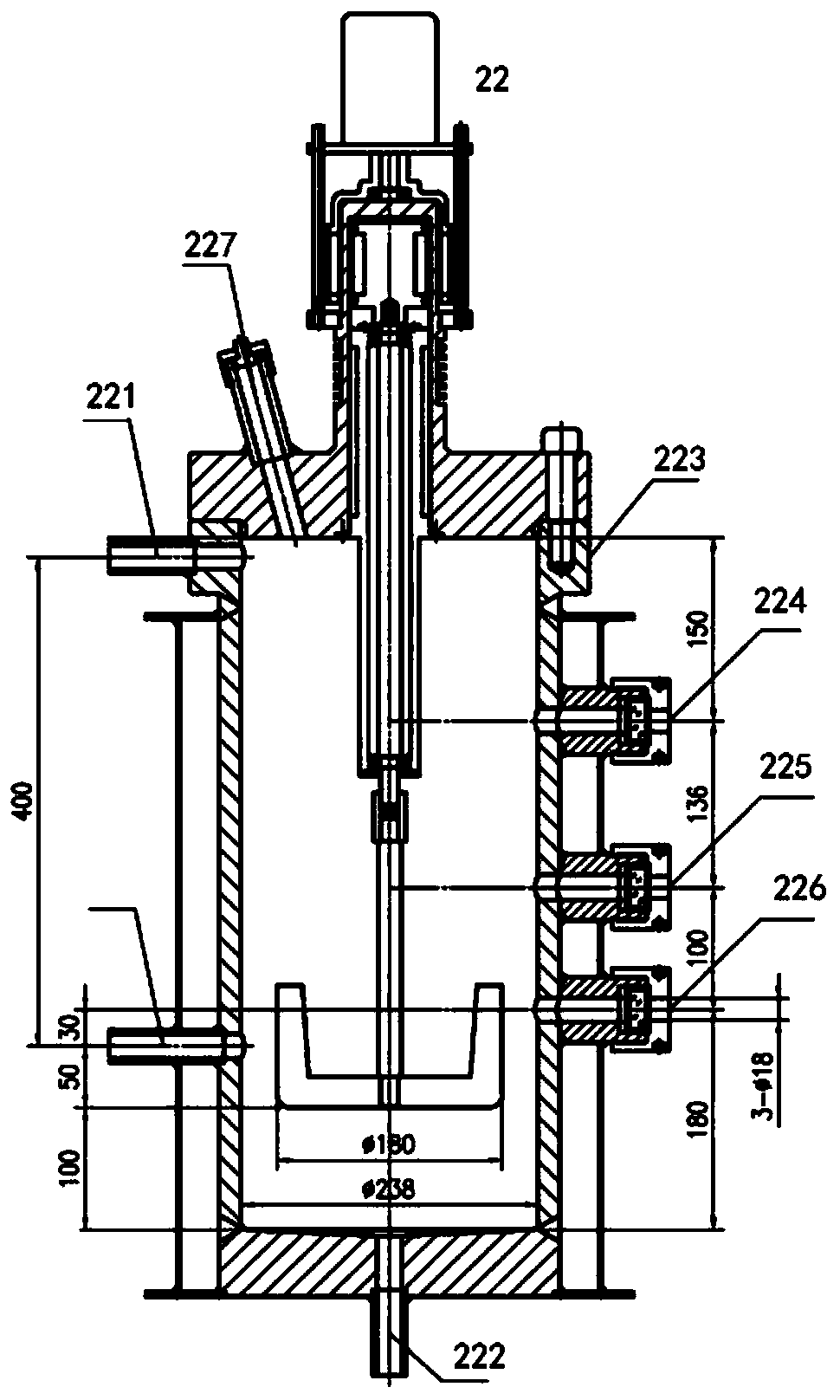

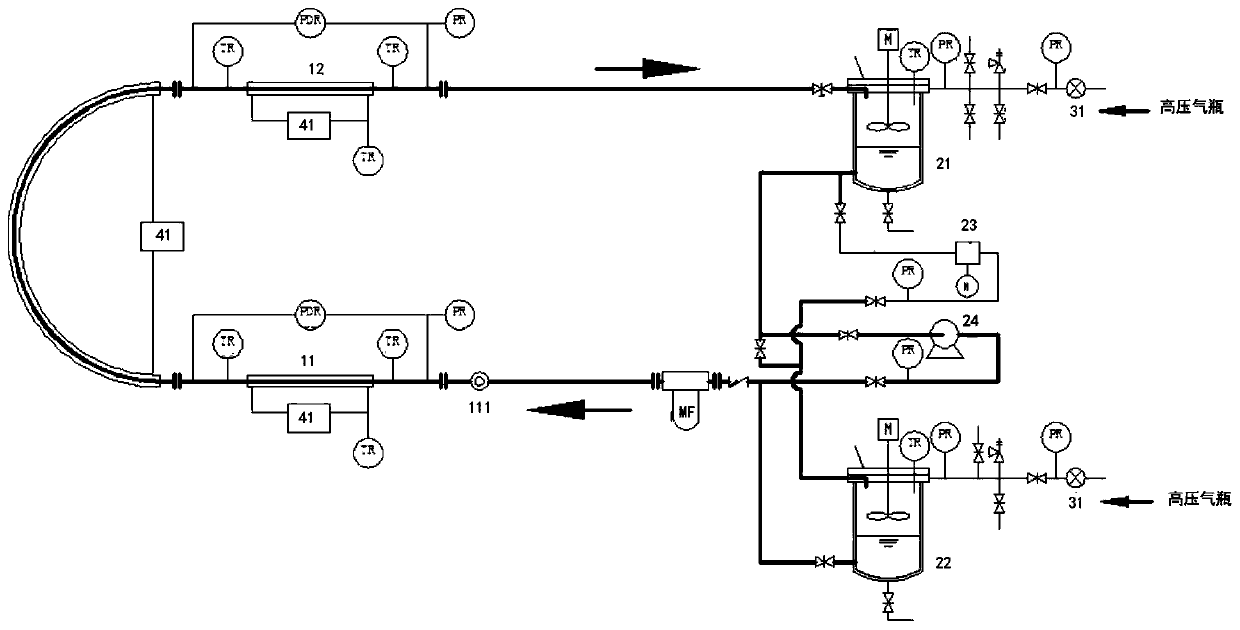

High-pressure oil-gas-water pipe wax-flowing deposition simulation experimental device

The invention relates to a high-pressure oil-gas-water pipe wax-flowing deposition simulation experimental device, which includes a loop system, an oil supplying system, a gas supplying system, a measurement system, a temperature controlling system and a data collecting system. The loop system comprises a test section and a reference section, and is used for a wax deposition experiment; the oil supplying system is used for providing testing oils for the loop system; the gas supplying system is used for providing high-pressure gases for the oil supplying system; the measurement system is used for testing status data of all pipelines; the temperature controlling system is used for controlling temperatures of the loop system and the oil supplying system; and the data collecting system is usedfor collecting and dealing the status data, computing a pipe diameter of a pipe after inner pipe wax deposition in the test section, and obtaining the average thickness of wax deposition layers and the wax deposition rate.

Owner:CHINA NAT OFFSHORE OIL CORP +1

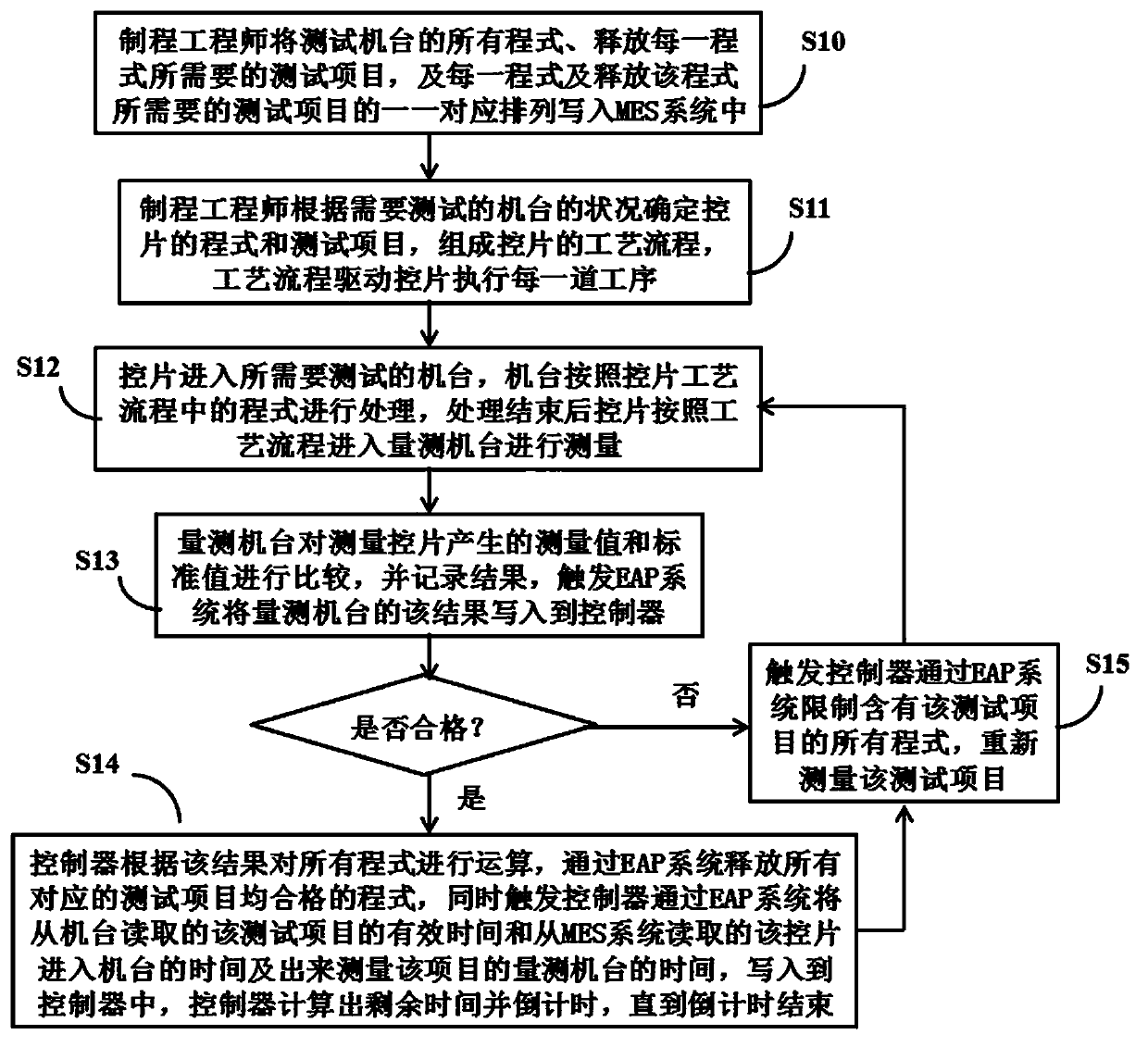

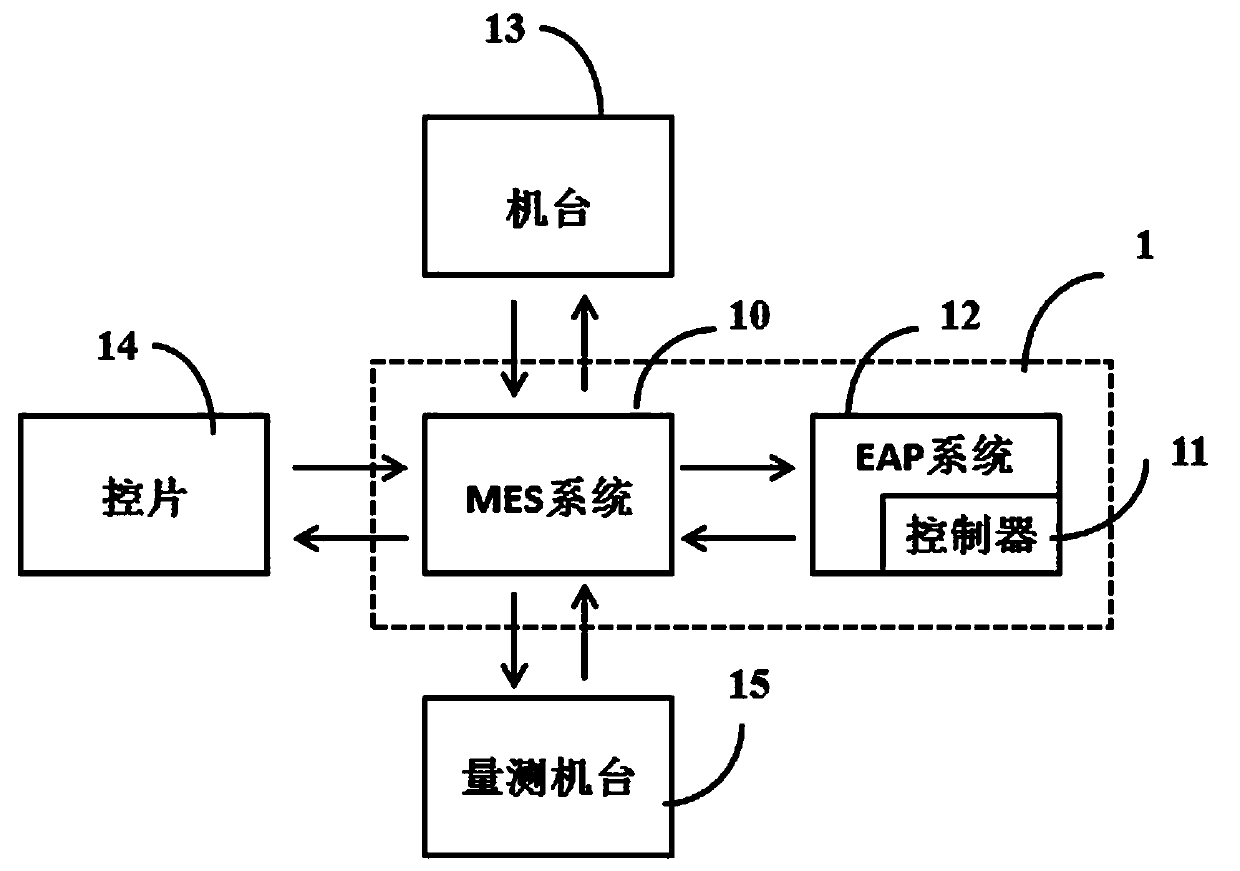

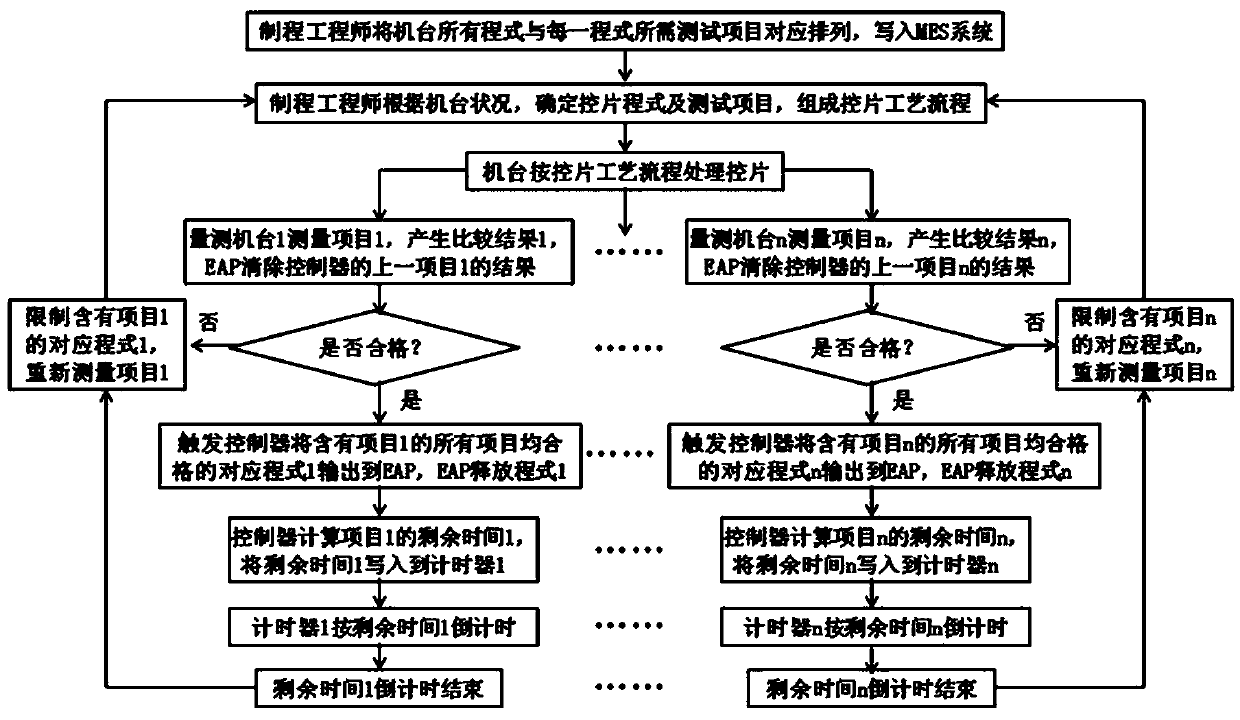

Method for releasing machine program and system

ActiveCN110164803ARealize monitoringGuaranteed normal processingSemiconductor/solid-state device manufacturingSoftware engineeringTest item

The invention relates to a method for releasing a machine program and a system. The method comprises the steps that programs and required test items of the machine for processing a control wafer are determined according to the condition of the machine so as to form a process flow of the control wafer; all programs of the machine are arranged corresponding to the test items required for releasing each program; the control wafer executes procedures according to the process flow, a measurement machine measures the processed test items of the control wafer, the measured value of each test item iscompared with a standard value, and the comparison result is recorded; and if all test items corresponding to a program are qualified, the program corresponding to the all qualified test items is released. The release of the program can be controlled more effectively according to the invention.

Owner:ZHENGZHOU UNIV OF IND TECH

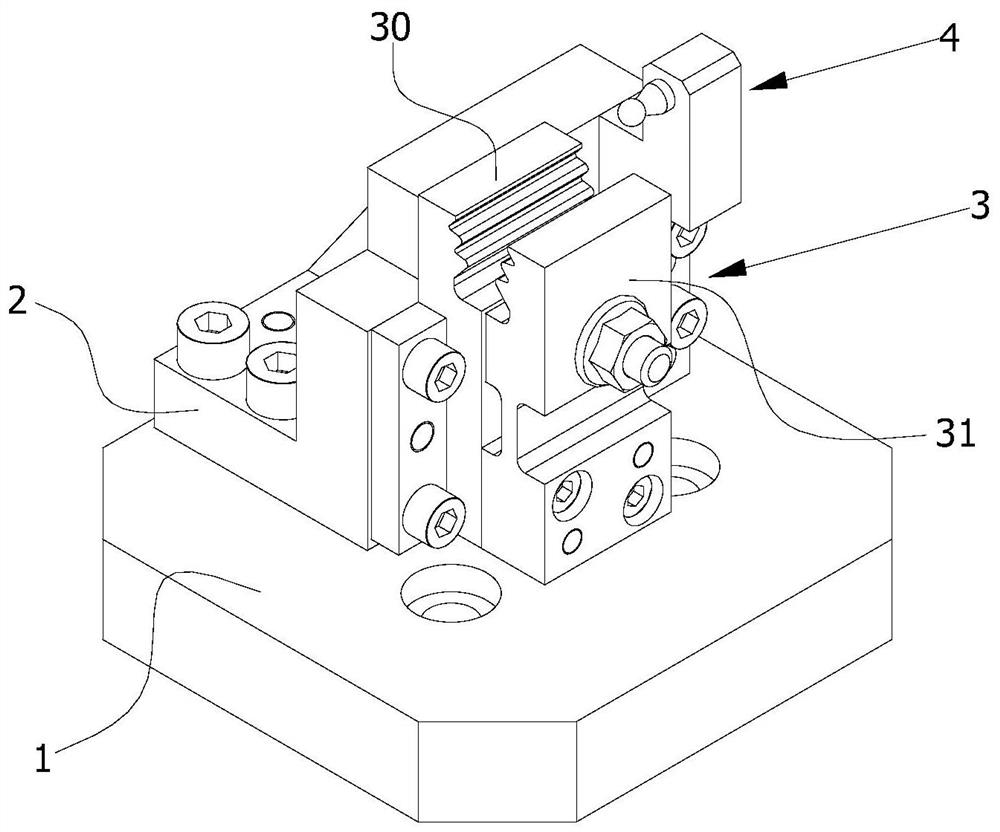

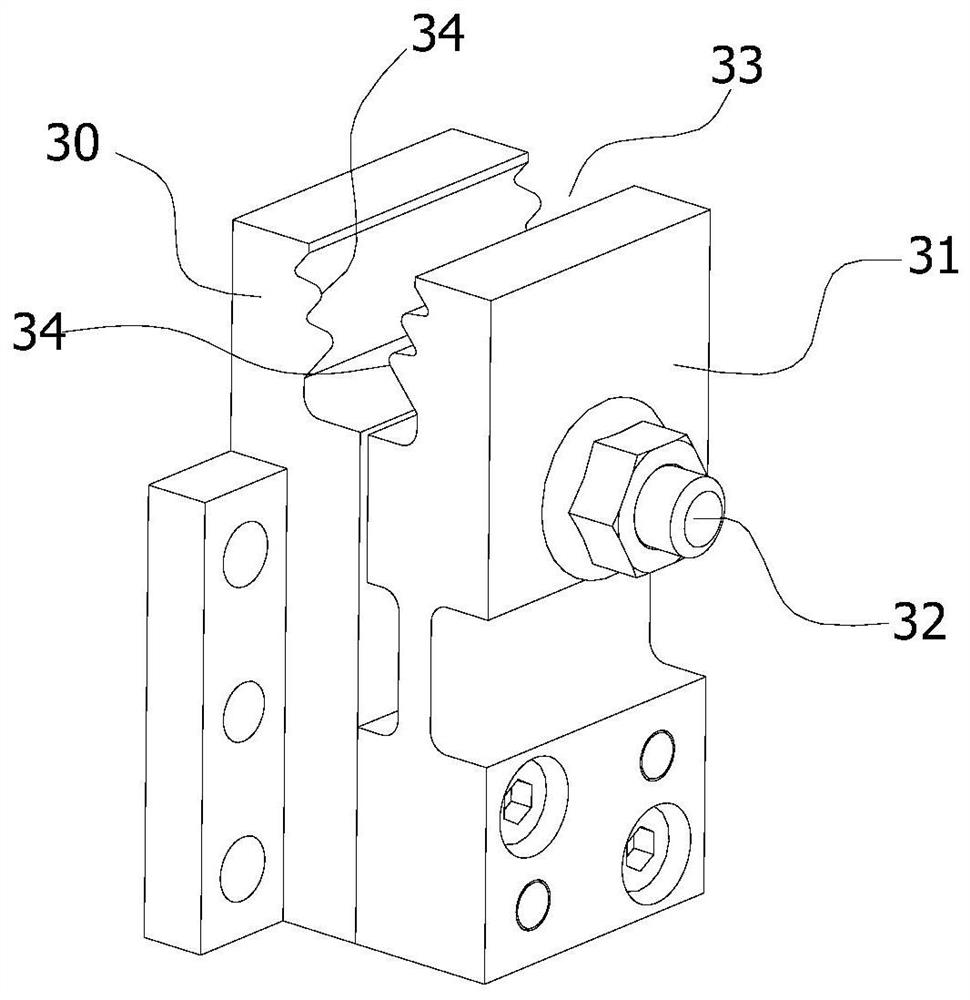

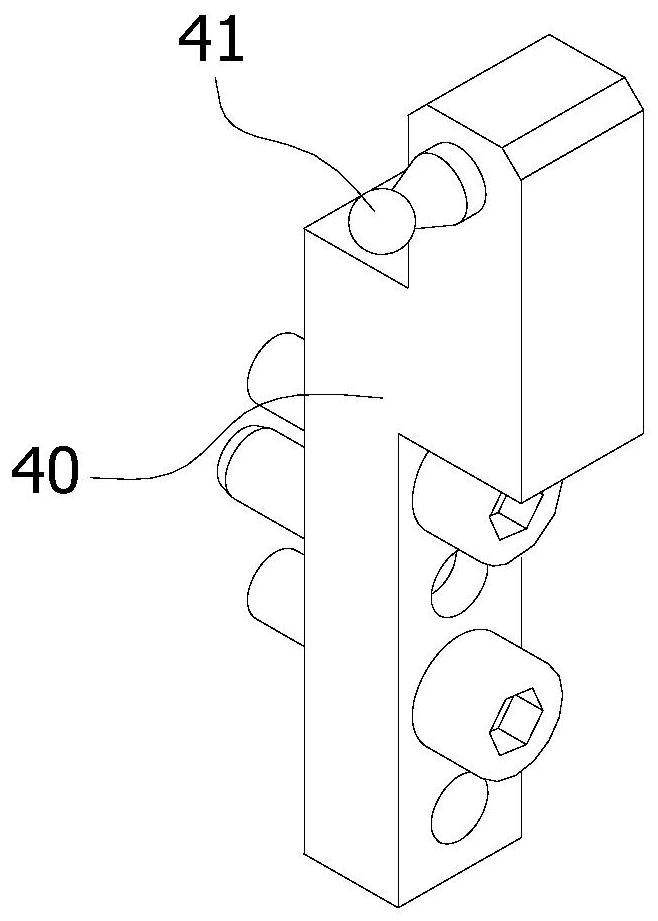

Novel integrated machining clamp and process for aero-engine turbine blade

PendingCN113681466AStable structureEasy to useGrinding machinesGrinding work supportsNumerical controlTurbine blade

The invention discloses a novel integrated machining clamp and process for an aero-engine turbine blade. The novel integrated machining clamp comprises a base, a support arranged on the base, a chuck assembly and an end face positioning assembly, wherein the chuck assembly and the end face positioning assembly are arranged on the support. The chuck assembly comprises a tenon tooth positioning block arranged on the support, a tenon tooth clamping block connected with the tenon tooth positioning block in a matched mode and a locking part arranged on the tenon tooth clamping block, and a tenon tooth groove used for clamping the blade is formed between the tenon tooth positioning block and the tenon tooth clamping block. The end face, close to the tenon tooth clamping block, of the tenon tooth positioning block and the end face, close to the tenon tooth positioning block, of the tenon tooth clamping block are both provided with teeth. The machining clamp is reliable in structure and good in use performance, and machining and positioning accuracy is improved. Grinding is convenient. According to the machining process, the design principle of process concentration is adopted, machining surfaces with the same positioning mode are concentrated in one working procedure for machining, and the machining precision is guaranteed through the precision of numerical control powerful grinding equipment. Repeated clamping errors are reduced, and the tool manufacturing cost is reduced.

Owner:AECC AERO SCI & TECH CO LTD

Method for correcting multi-screen connected wall

InactiveCN100589583CSimple structureLow costPicture reproducers using projection devicesCathode-ray tube indicatorsComputer graphics (images)Correction method

The apparatus comprises a correction unit composed of a video camera module for capturing the color information of the screen, an image data buffer module, and a main control module used for receivingand executing the computer command. Said video camera module and image data buffer module are respectively connected to the multi-screen display wall and computer via the main control module. The method comprises: appointing the image displayed by each display unit on the multi-screen display wall; said video camera module shoots at least one picture and saves it in the image data buffer module;the computer extracts the color information from each display unit; according to the color of each display unit, the computer corrects the difference between said display units.

Owner:GUANGDONG VTRON TECH CO LTD

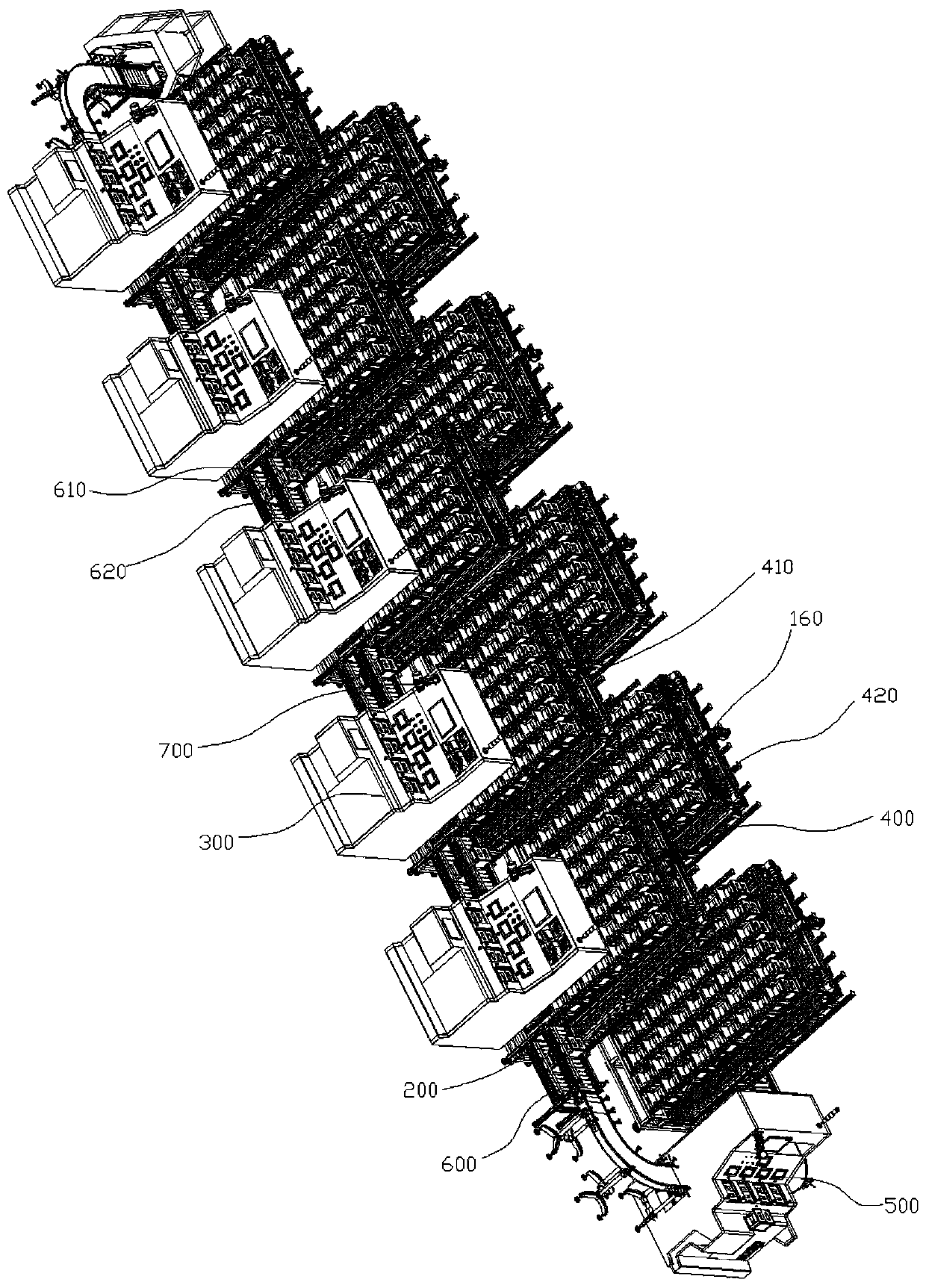

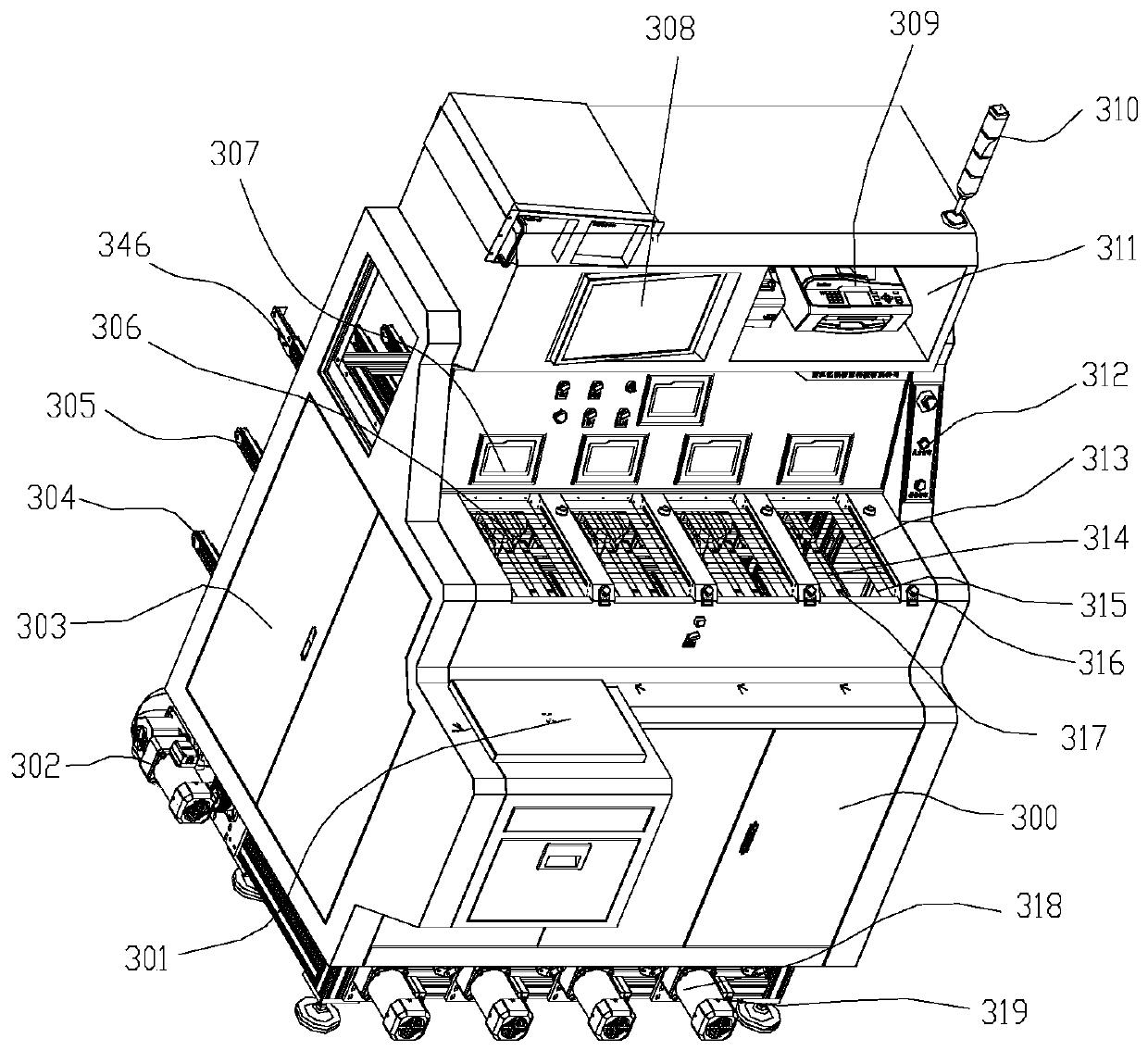

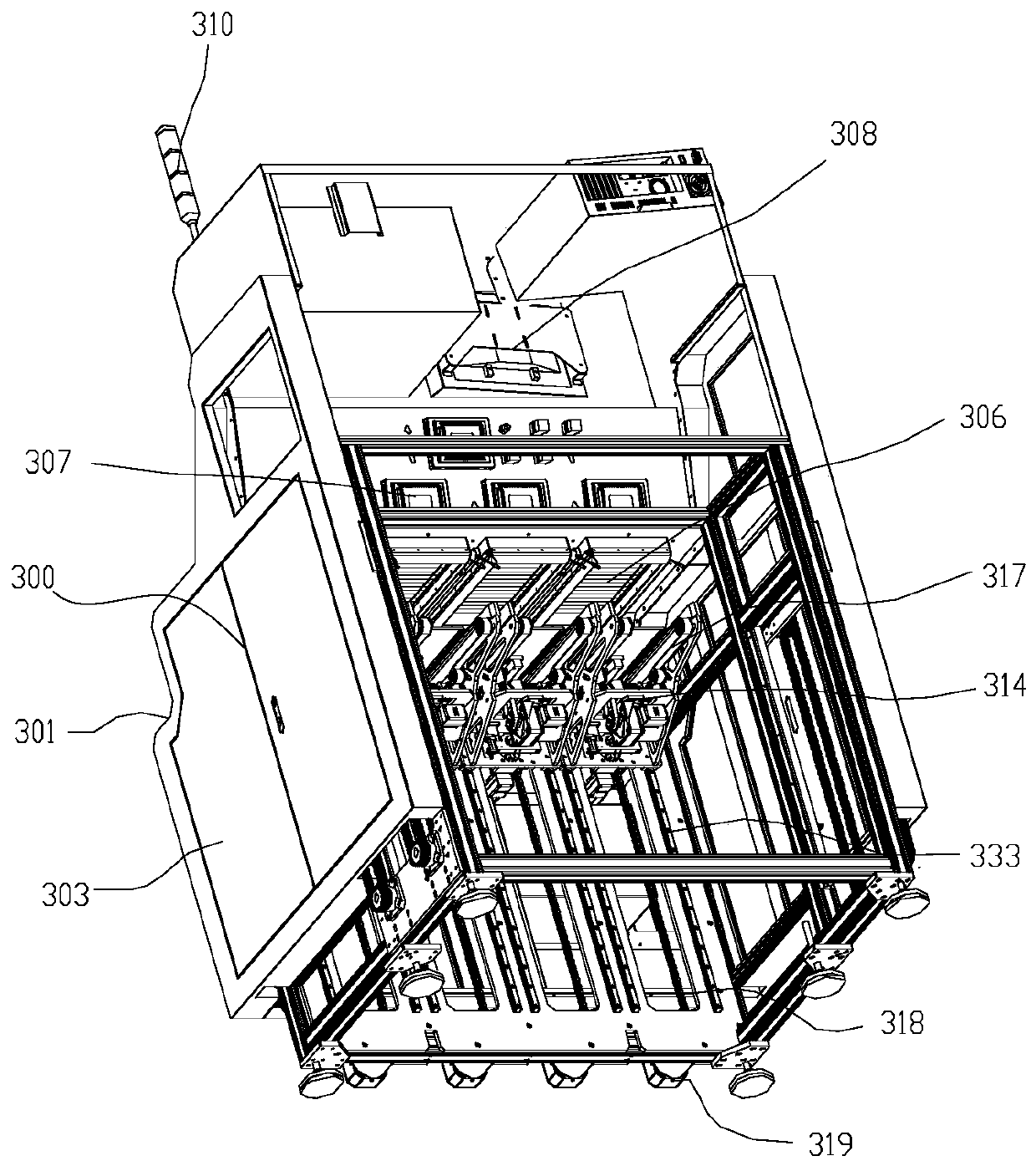

Automatic traditional Chinese medicine prescription dispensing system

The invention discloses an automatic traditional Chinese medicine prescription dispensing system. The automatic traditional Chinese medicine prescription dispensing system comprises a plurality of three-dimensional medicine storages and a dispensing table, wherein a medicine box moving mechanism is arranged between the three-dimensional medicine storages and the dispensing table, a medicine box switching device is arranged between the dispensing table and the medicine box moving mechanism, each three-dimensional medicine storage is composed of a storage rack and a plurality of medicine boxes,identification marks capable of storing and reading information are arranged on the medicine boxes, the three-dimensional medicine storages are provided with stacking mechanisms, and the dispensing table comprises a rack, a control table arranged on the rack, a plurality of taking windows, a general weighing platform for weighing medicines, a main display for receiving prescriptions and displayingrelated information, and a medicine box information display for reading and then displaying medicine box information in the current taking window. Automatic operation is adopted in the whole feedingprocess, so that personnel requirements are less, and personnel quality requirements are lower; the working environment is improved, and the mobility of personnel is reduced; the operation difficultyis low, the mastering speed is high, the manual error and the loss of medicinal materials are reduced, and the traceability of prescription dispensing is improved.

Owner:药鲁班(杭州)医疗科技有限公司

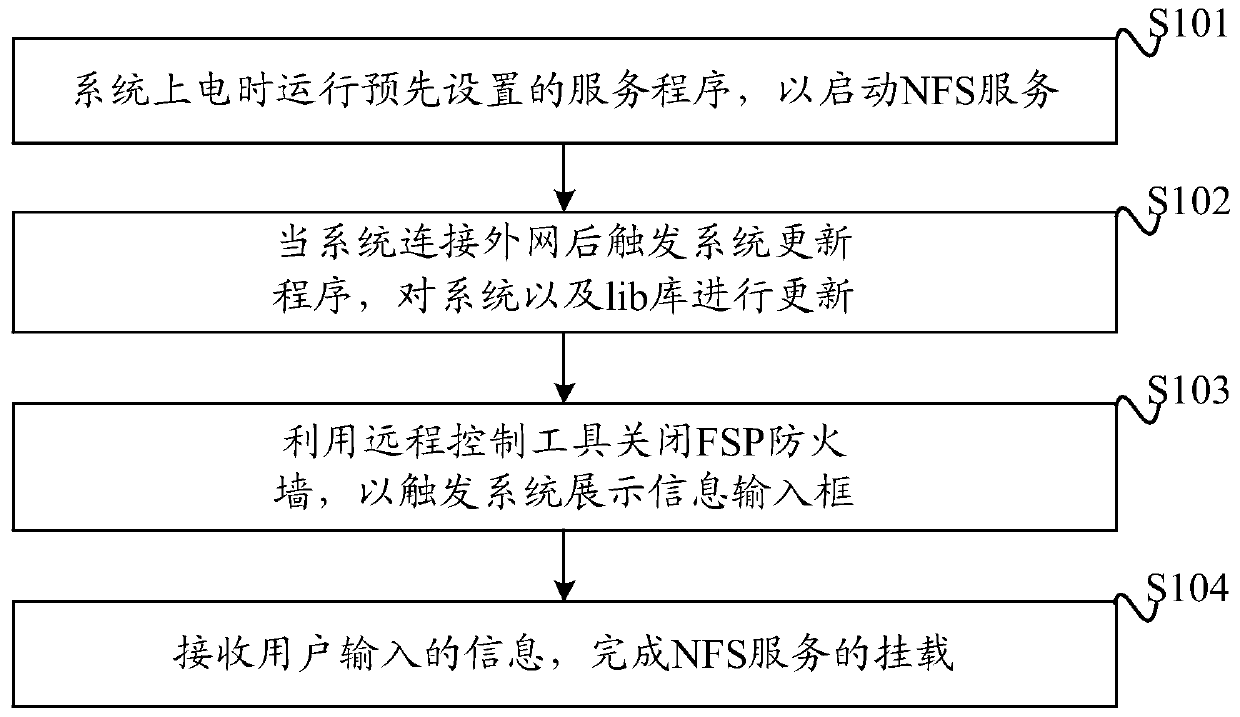

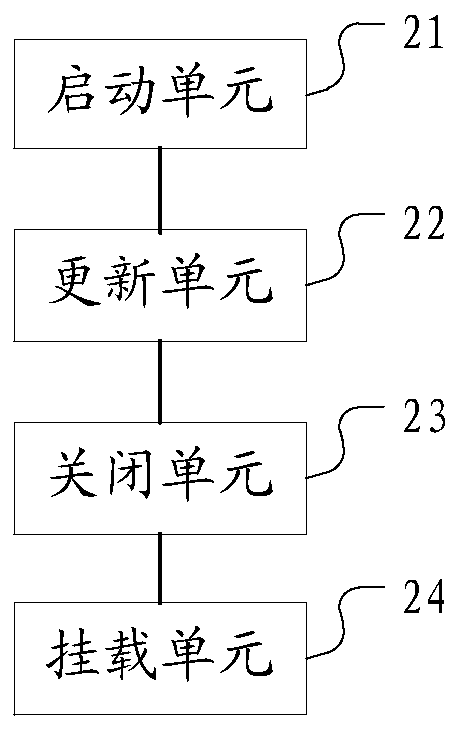

Method and device for building LCB server and medium

InactiveCN109976814AImprove construction efficiencyReduce labor costsBootstrappingProgram loading/initiatingElectricityRemote control

The embodiment of the invention discloses a method and a device for building an LCB server and a computer readable storage medium, and the method comprises the steps: operating a preset service program when a system is powered on, so as to start an NFS service; after the system is connected with the external network, triggering a system updating program, and updating the system and the lib library; automatically closing the FSP firewall by using a remote control tool so as to trigger a system display information input box; and the user fills information required for mounting the NFS service into the information input box, and the system completes mounting of the NFS service according to the information. Various steps are integrated into one script program, automatic installation and mounting of the NFS service can be achieved by operating the script program after the system is powered on, a user only needs to input information related to NFS service mounting in the whole operation process, the labor cost is greatly reduced, and the building efficiency of the LCB server is improved. And through an automatic building mode, the possibility of manual operation errors is reduced.

Owner:INSPUR BUSINESS MACHINE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com