Two-wheeled numerical control roll grinder and numerical control method thereof

A roll grinder and roll technology, which is applied to the double-wheel numerical control roll grinder and its numerical control field, can solve the problems of difficult-to-machine roll surface, mechanical transmission structure cannot reach numerical control machine tools, etc., and achieve material saving, excellent repeatability processing, and saving cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

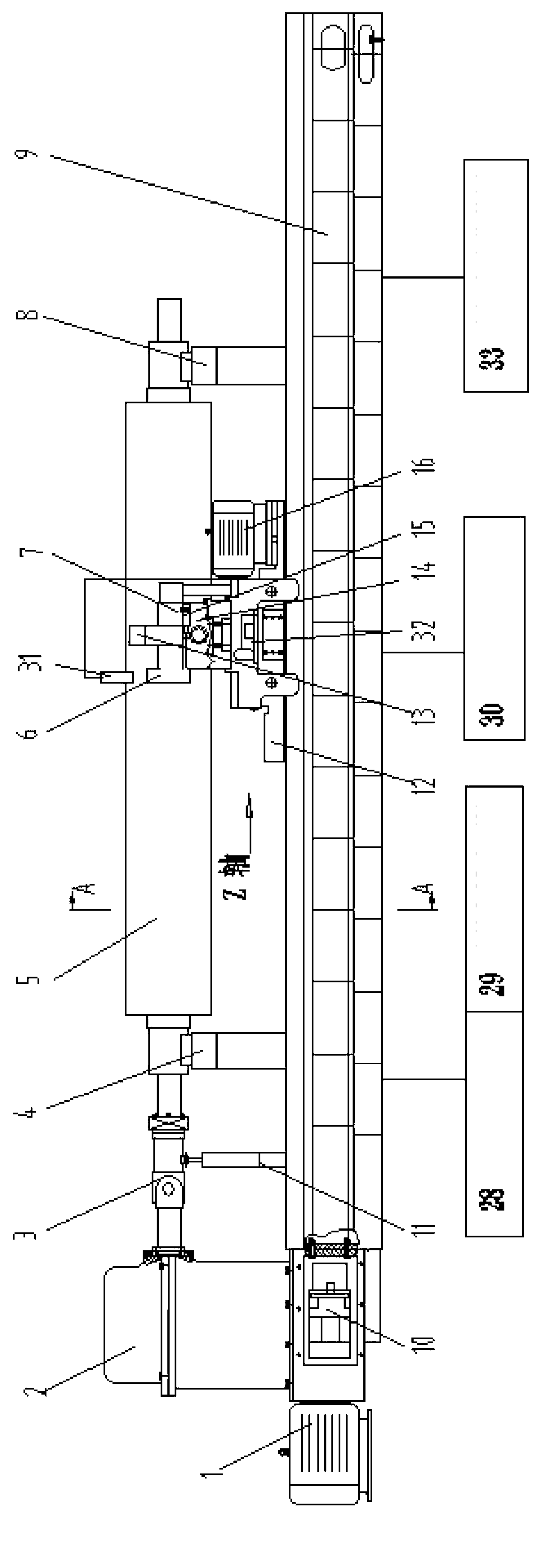

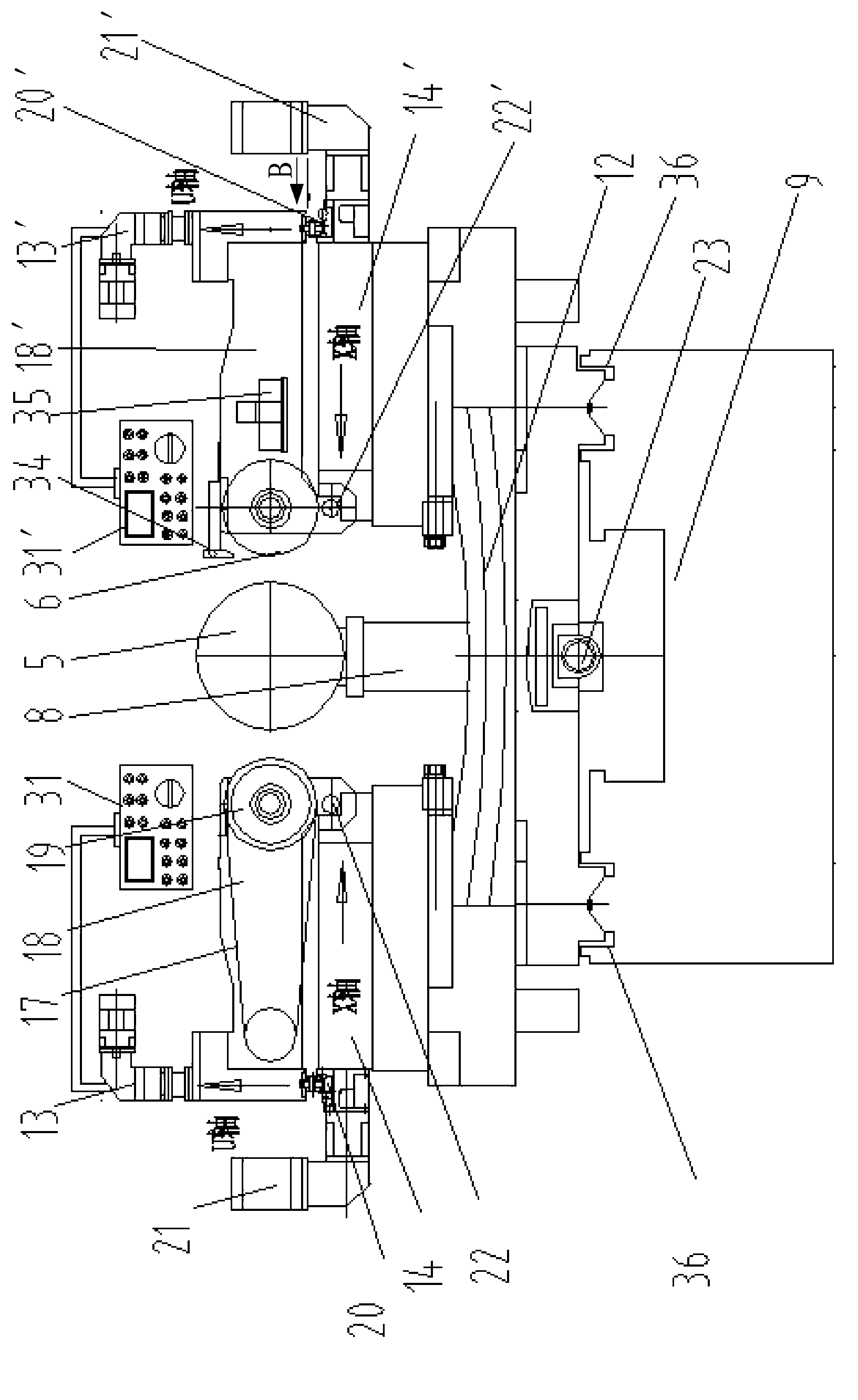

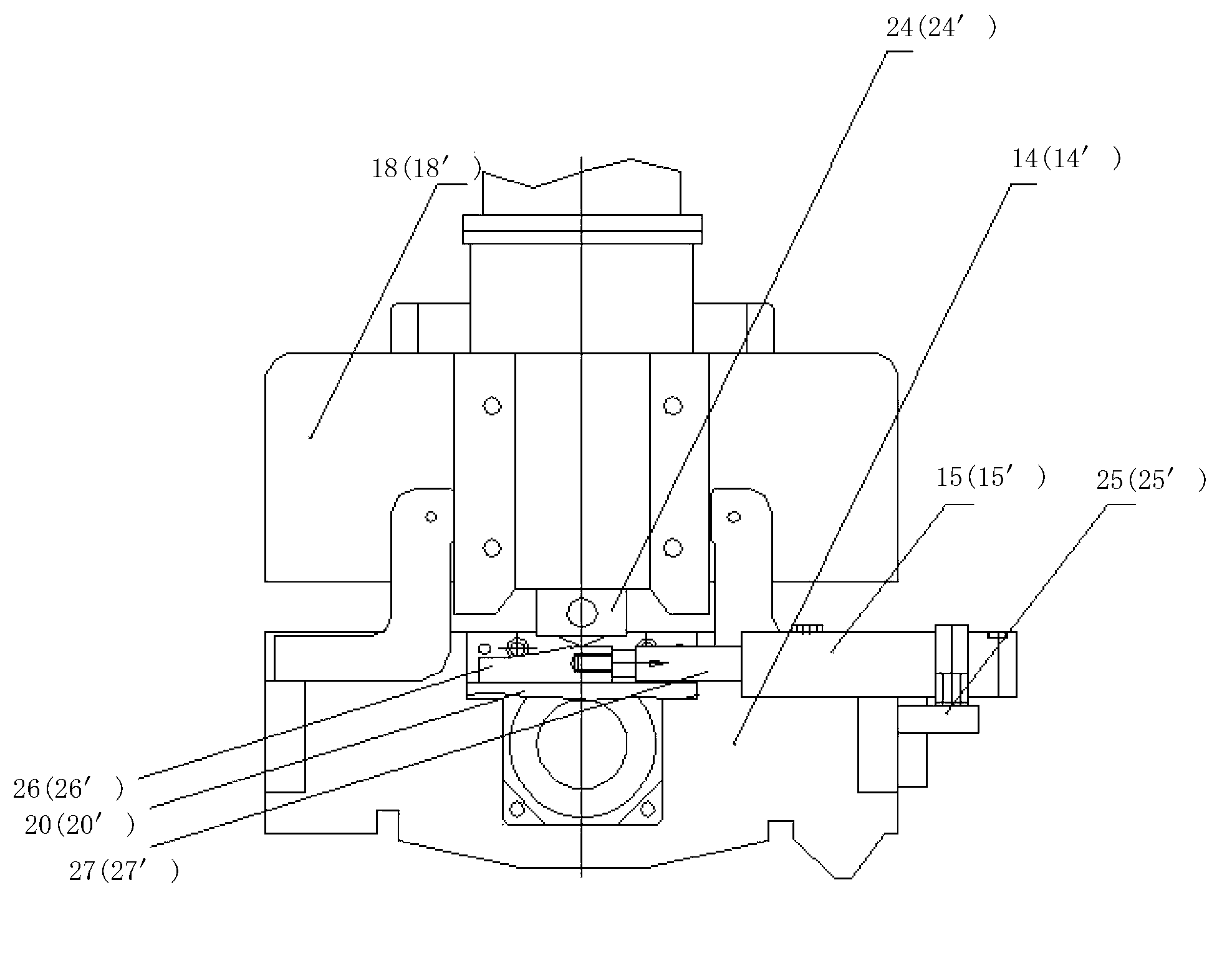

[0047] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

[0048] The present invention proposes a double-wheel CNC roll grinder and its numerical control method, which is an independent feed mechanism that can be designed to be suitable for the CNC machining curve of the double-wheel roll grinder, especially the CNC curve feed axis (U axis) and the grinding wheel compensation CNC The feed axis (X axis) enables it to cooperate with the CNC system to process the roll shape required by various processes; at the same time, in order to allow operators who do not understand CNC programming to select processing curves through concise text and graphics for automatic CNC processing , Design a good man-machine control interface. Wherein the large ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com