Patents

Literature

173 results about "Wax deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

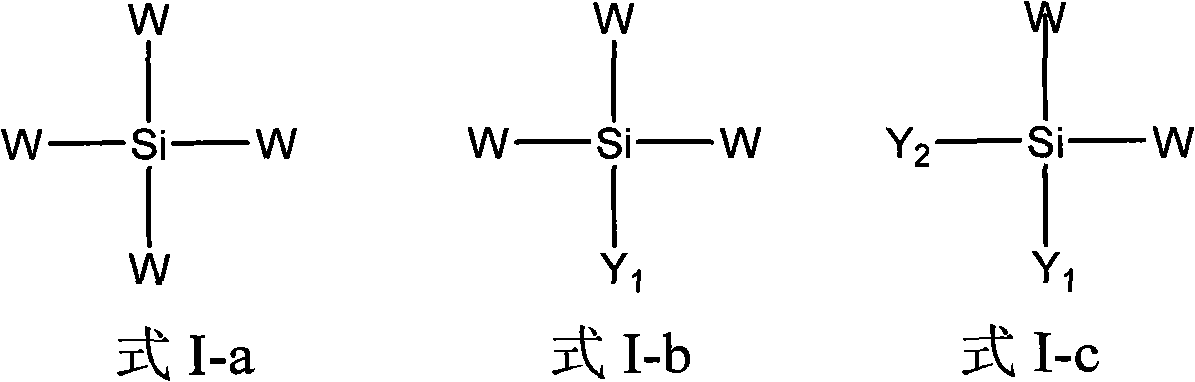

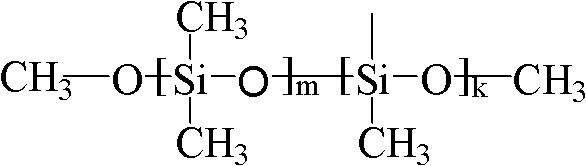

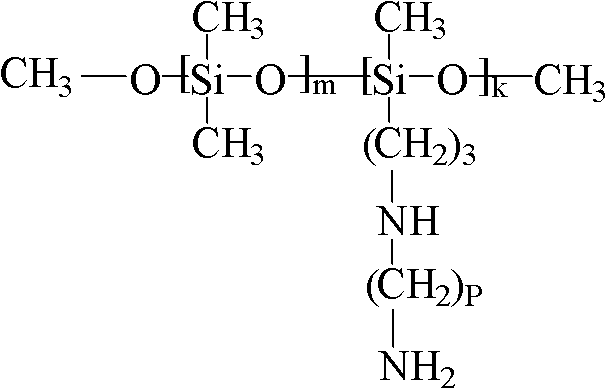

Mold release agent and preparation method and application thereof

The invention provides a mold release agent, which contains the following components: a silicon-hydrogen bond-containing polysiloxane compound, a cross-linking agent, a catalyst and a solvent, wherein the cross-linking agent is a silicon compound containing Si-OH groups and / or a silicon compound which can form the Si-OH groups through hydrolyzation. The mold release agent is a semi-permanent mold release agent, and has the advantages of rapid low-temperature solidification, less mold release agent transfer, less wax deposition, convenient construction, low cost and the like; the produced product has uniform openings; and the mold release agent particularly achieves major breakthrough in the field of producing polyurethane foam products. The invention also provides a method for preparing the mold release agent, and application of the mold release agent in producing polyurethane foam products, epoxy resin products, glass fiber reinforced epoxy resin products, rubber products, unsaturated polyester products and other polyurethane products.

Owner:HENKEL CORP

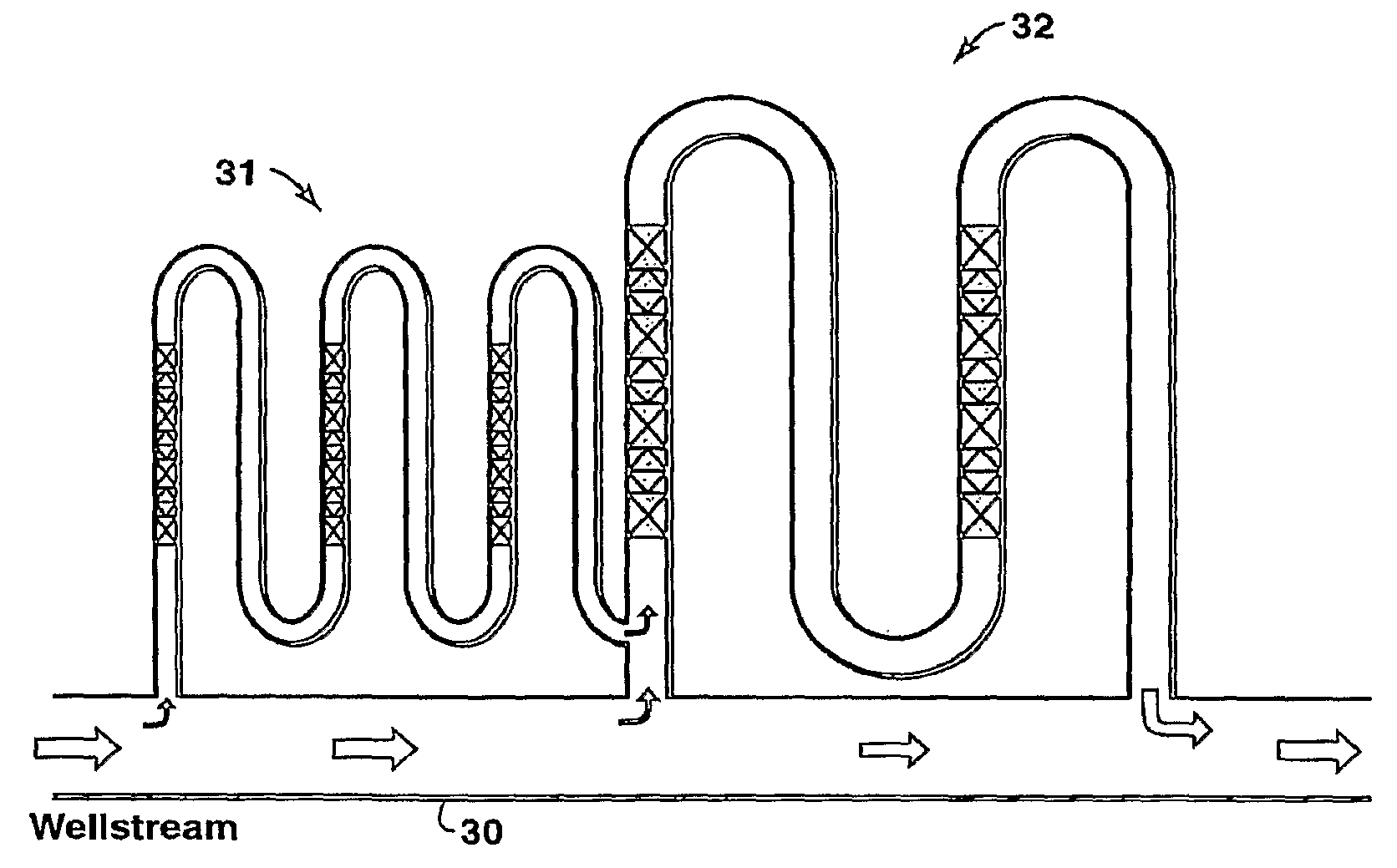

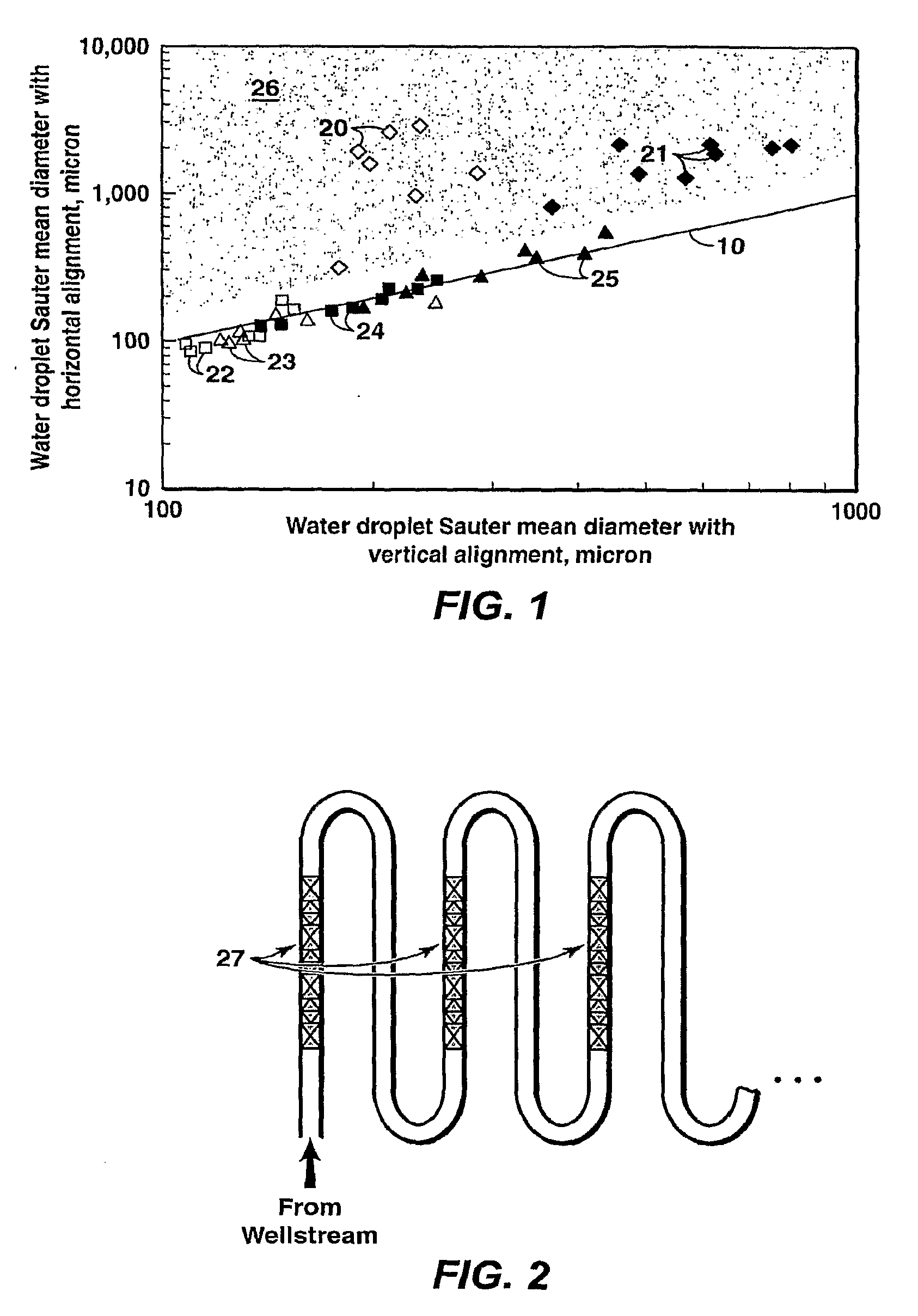

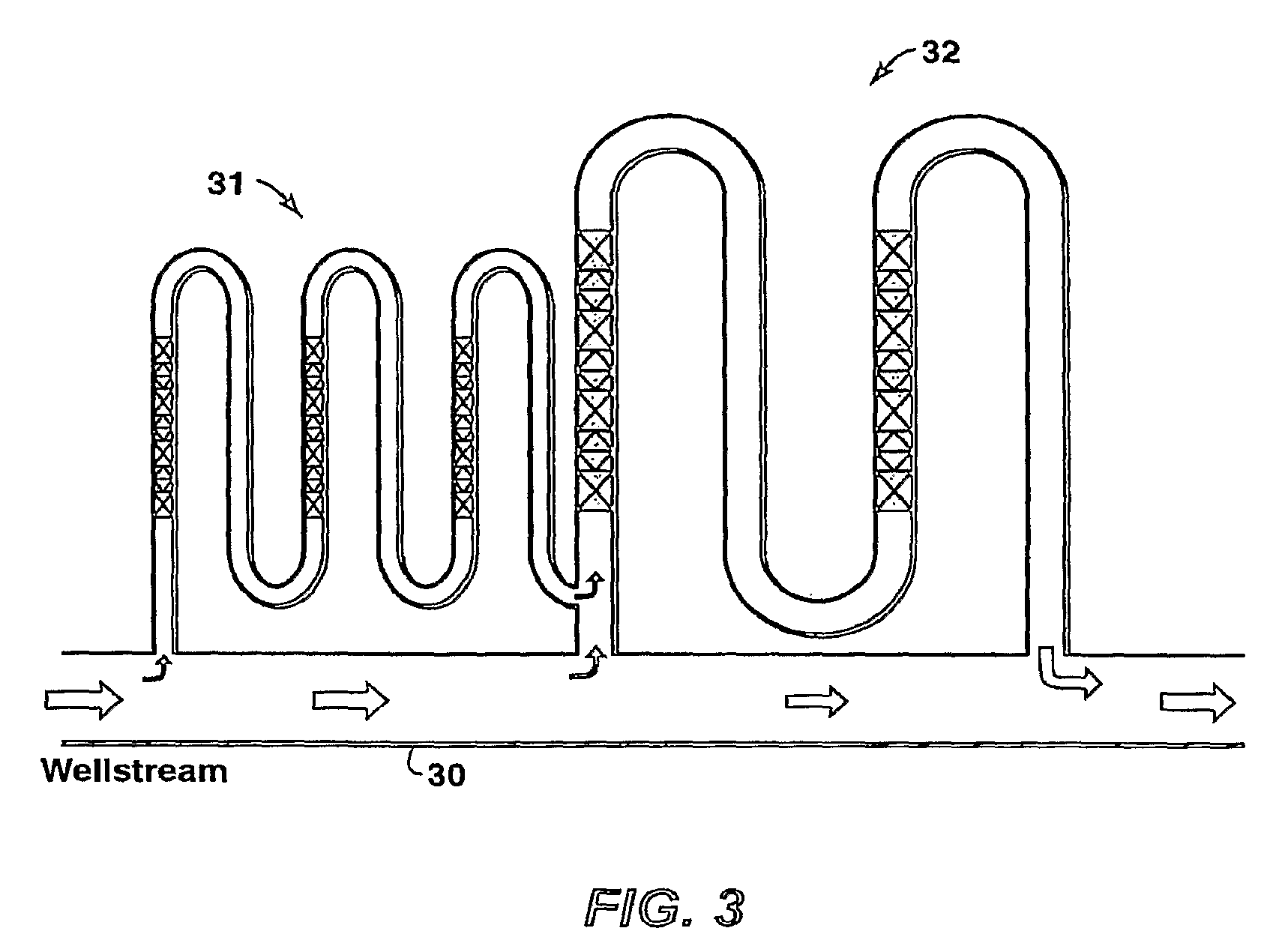

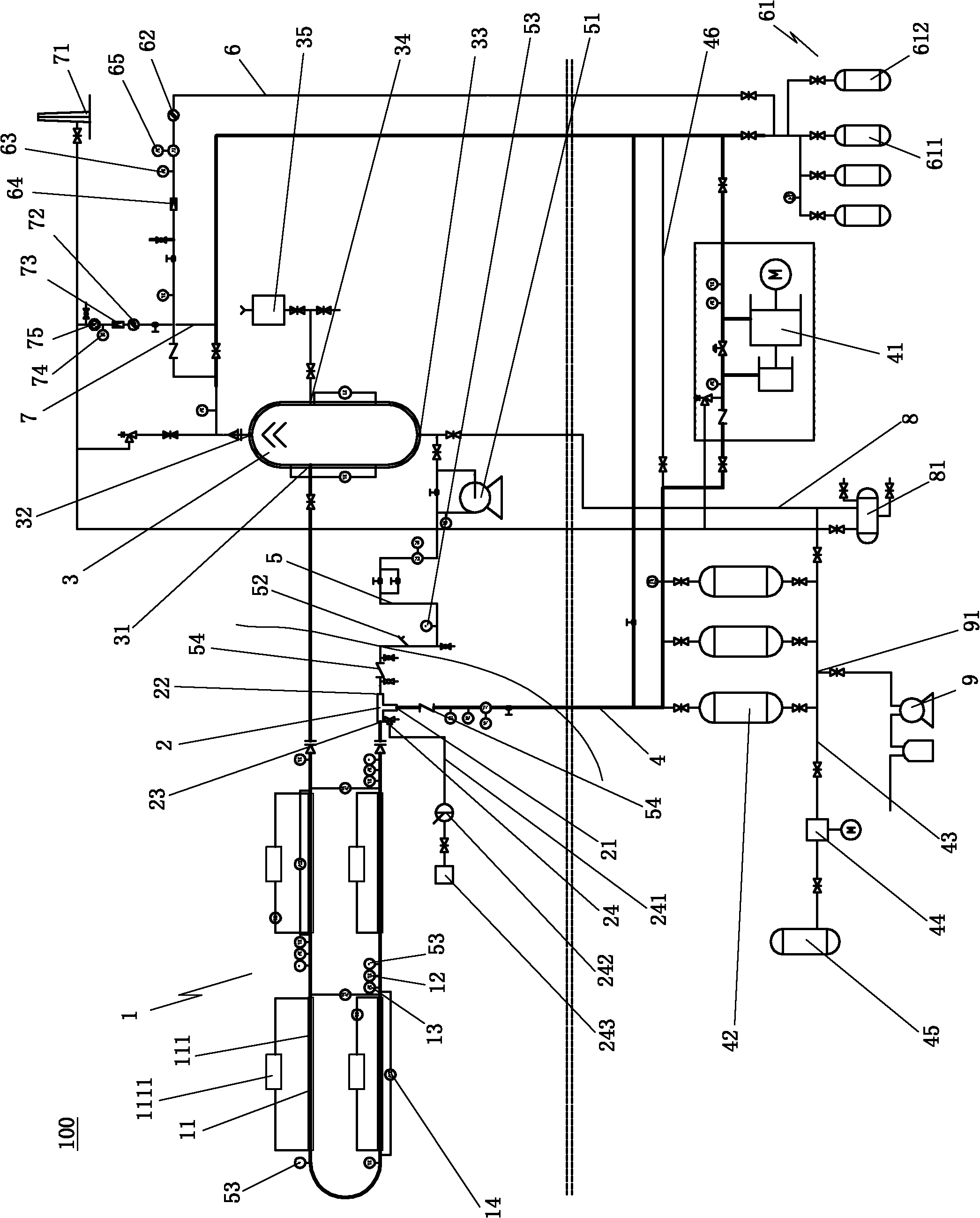

Method of Generating a Non-Plugging Hydrate Slurry

Method for reducing loss of flow due to hydrate solids deposits and wax deposition in a pipeline without the aid of chemicals and system for transporting a flow of wellstream hydrocarbons containing water, using a main pipeline and a cold-flow reactor connected to the main pipeline or within or forming a part of the pipeline, wherein at least a portion of the wellstream is fed to the cold-flow reactor. Also provided is a method for preventing hydrate nucleation and growth in a pipeline and preventing hydrate agglomeration as well as for preventing wax deposition. The provided method eliminates the use of energized equipment for melting, grinding or scraping hydrate solids from inside of pipelines or flowlines. Generating dry hydrates to be mixed with main flow of a wellstream is also described.

Owner:EXXONMOBIL UPSTREAM RES CO

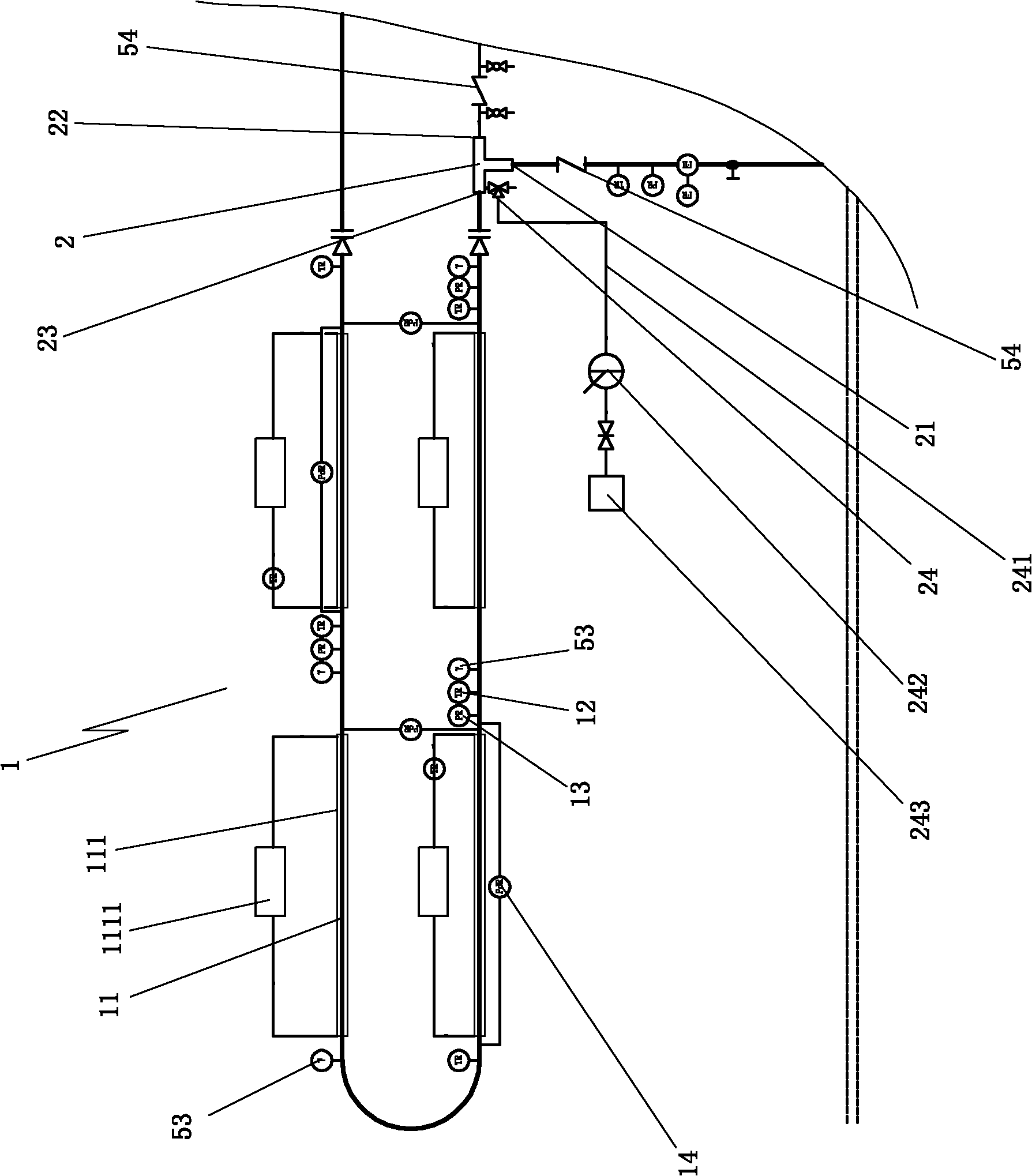

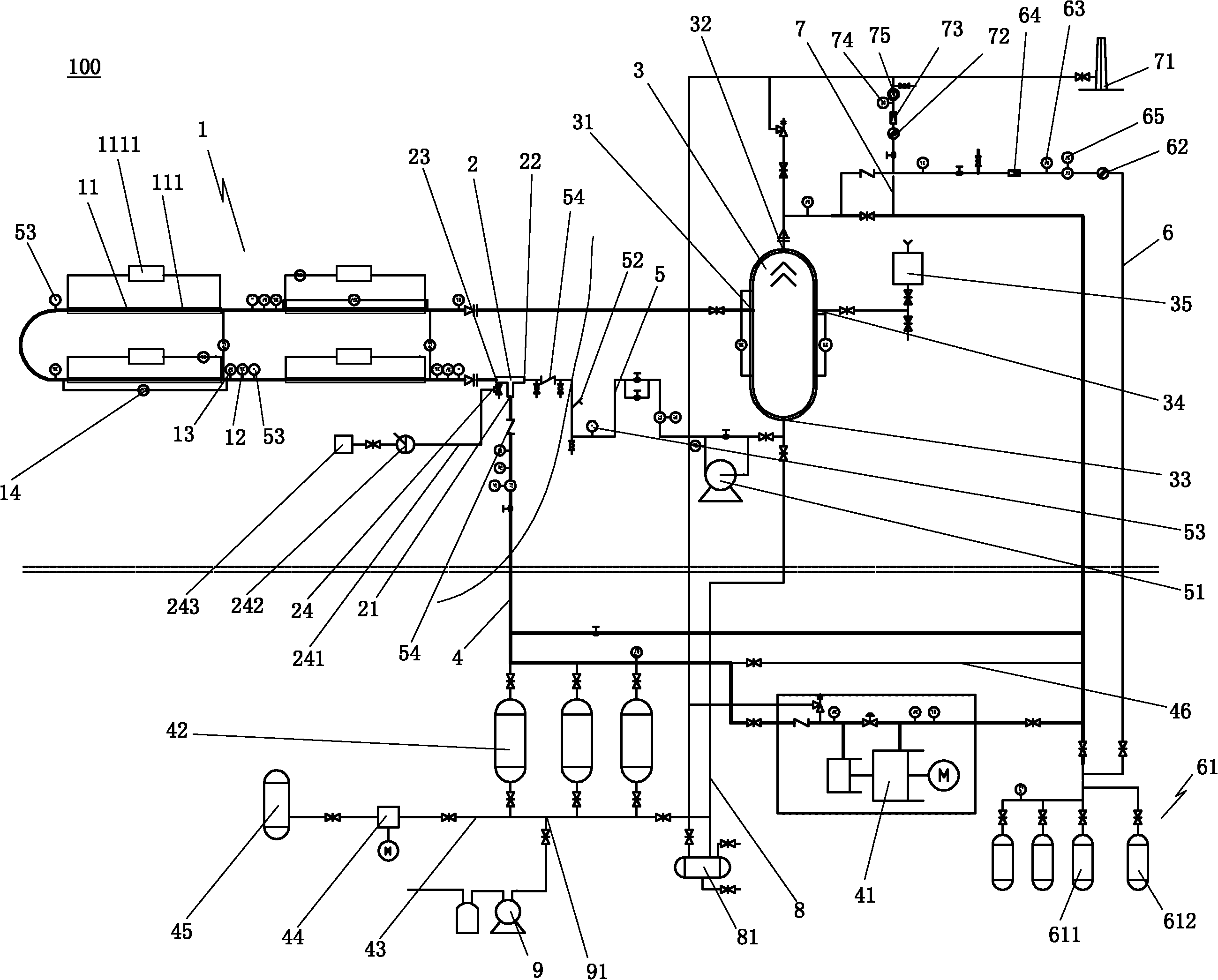

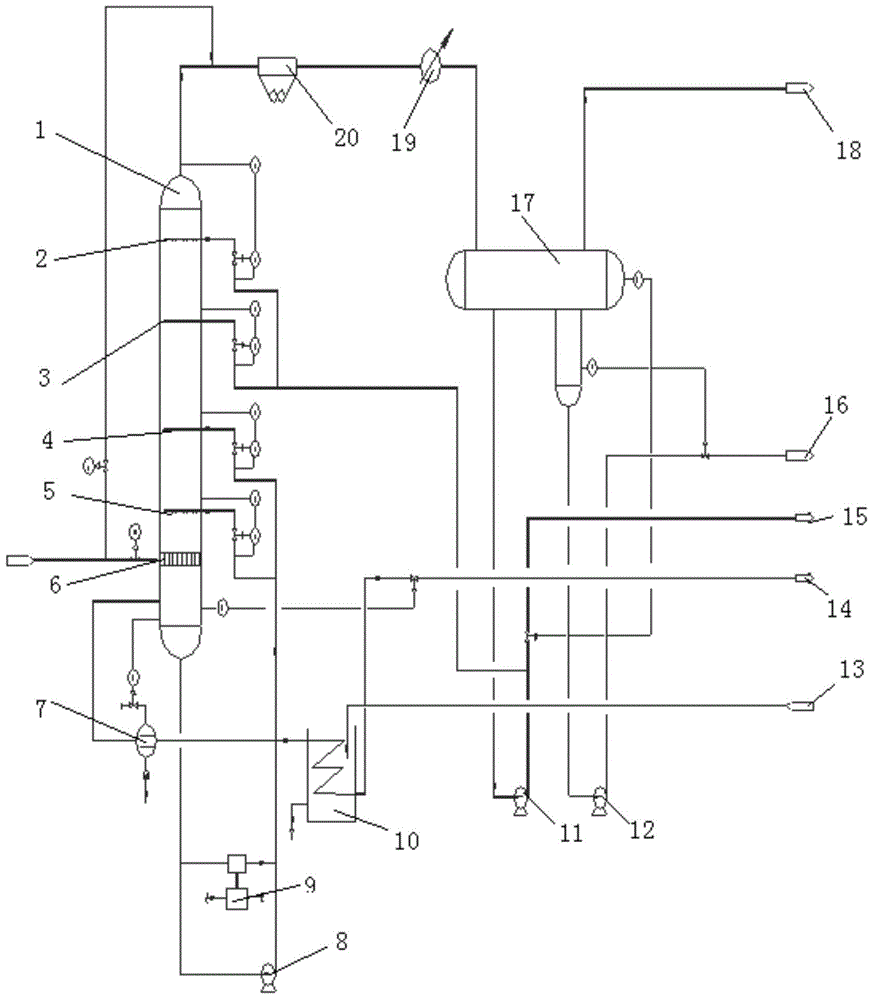

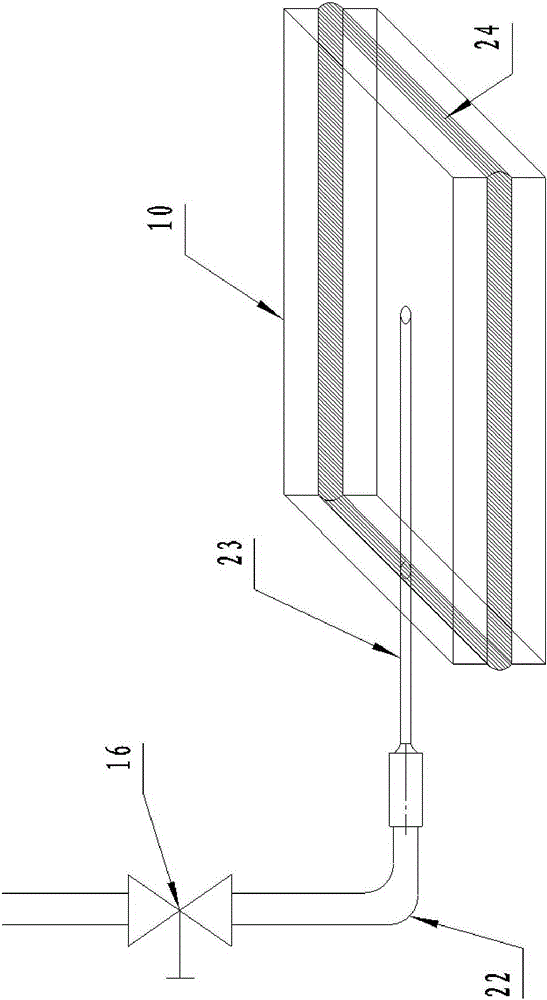

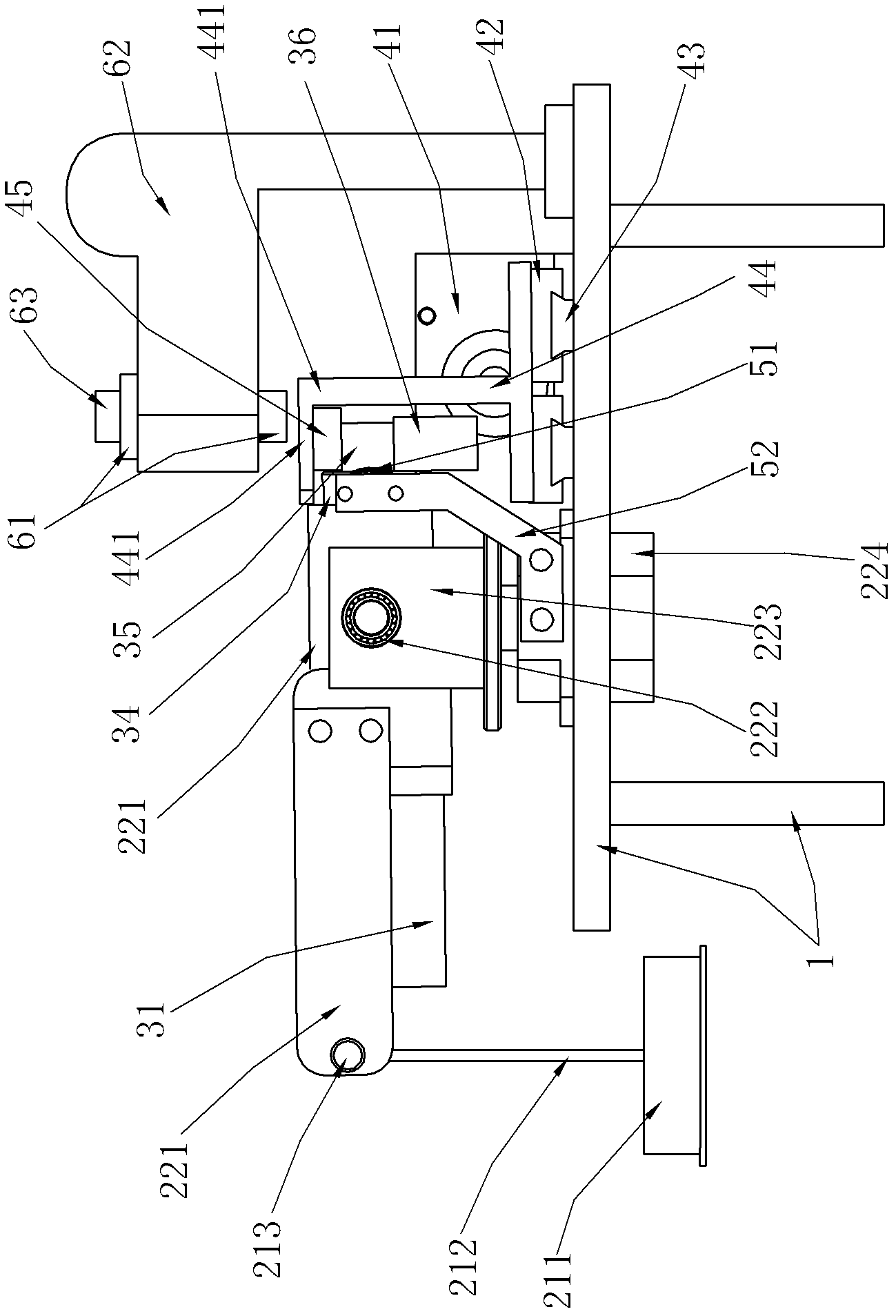

Wax deposition experimental device

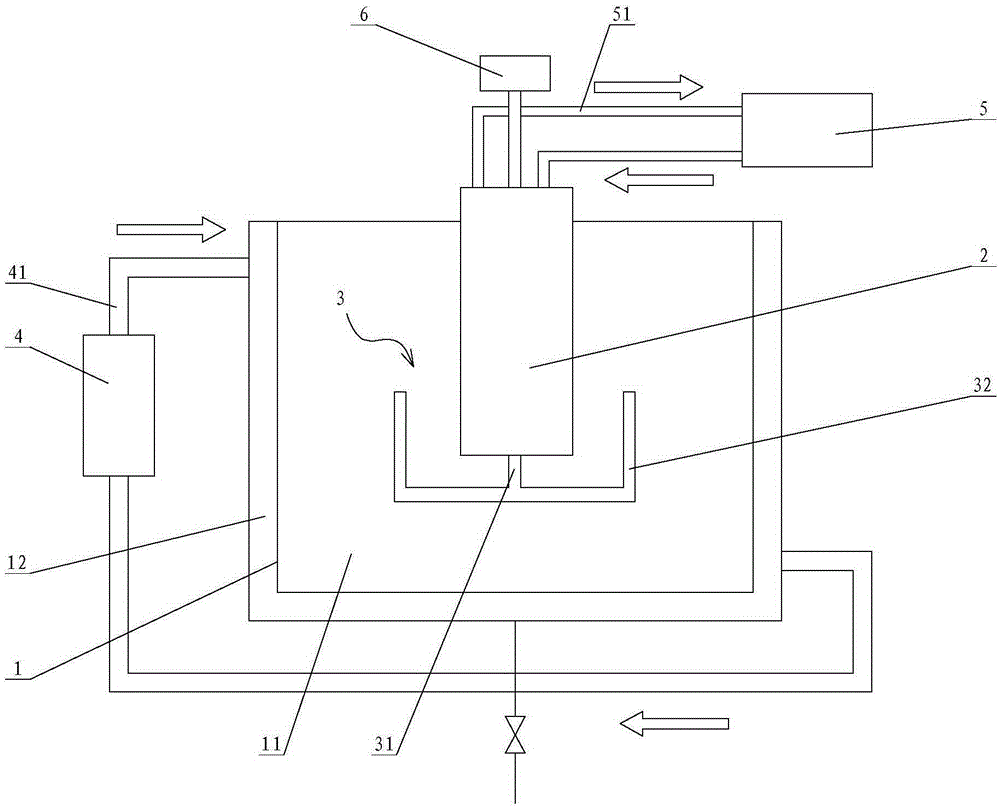

InactiveCN102062744AReasonable structureExquisite designParticle size analysisInvestigating phase/state changeWax depositionEngineering

The invention relates to a wax deposition experimental device. The experimental device comprises an experimental pipeline, wherein on end of the experimental pipeline is communicated to an outlet of a gas and liquid mixer; the other end of the experimental pipeline is communicated to a liquid return port of the gas and liquid separator; a gas inlet of the gas and liquid mixer is communicated to an exhaust port of the gas and liquid separator through a circulation compressor; a liquid inlet of the gas and liquid mixer is communicated to a liquid discharging port of the gas and liquid separator through a multiphase pump; a pipeline between the multiphase pump and the liquid inlet of the gas and liquid mixer is also provided with a laser particle size analyzer and an on-line gamma phase fraction instrument; the experimental pipeline is provided with a plurality of measuring sections at intervals; each measuring section can be detachably serially connected to the experimental pipe, the outer sides of the pipeline of all measuring sections are respectively provided with a temperature control water bath jacket; and the inlet end of each measuring section of the pipeline is respectively provided with one on-line gamma phase fraction instrument. The experimental device has the characteristics of reasonable structure, ingenious design, advanced experimental equipment, wide application range, accurate measurement and the like and can save the experimental cost and reduce emission of harmful gas.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

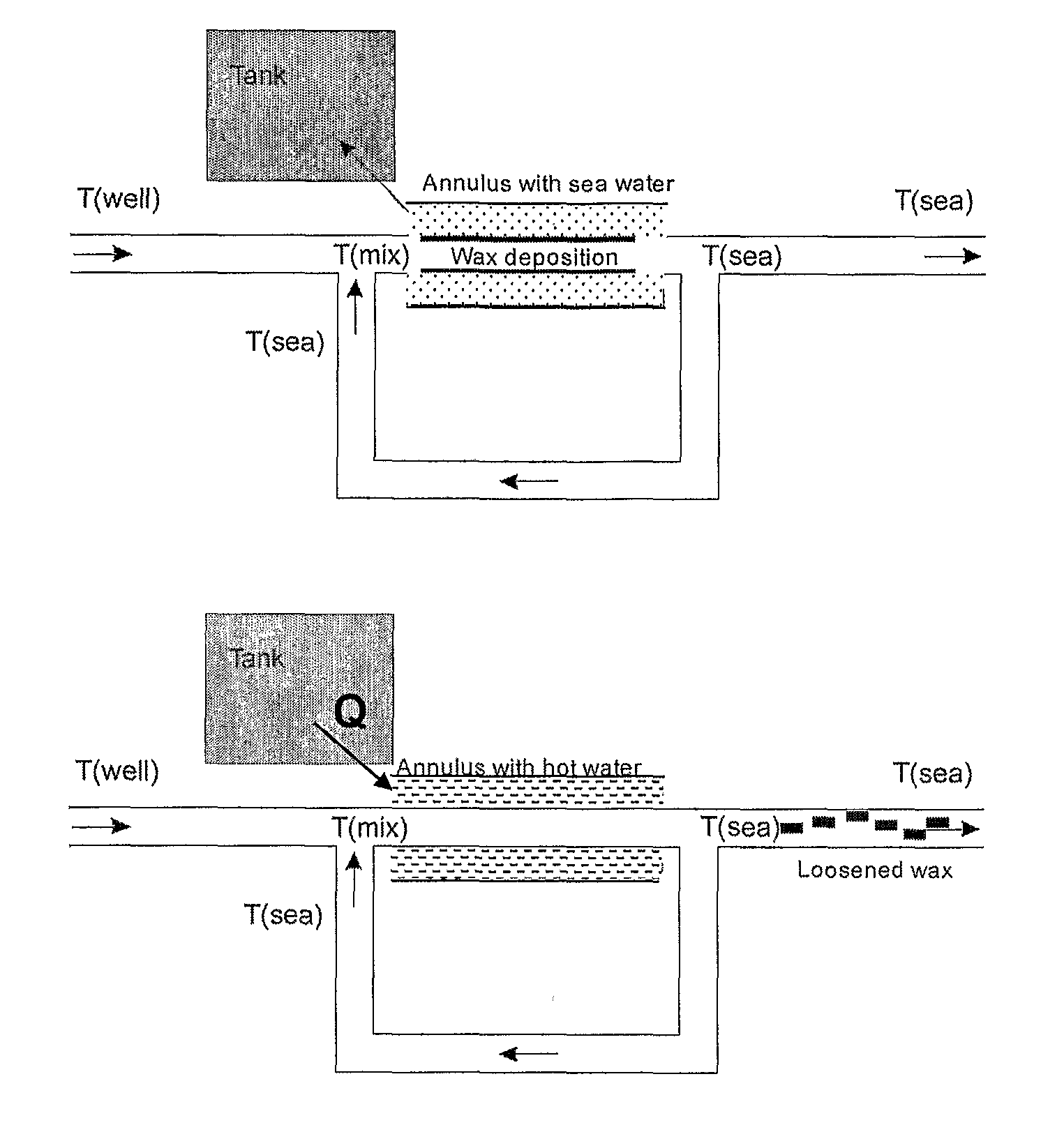

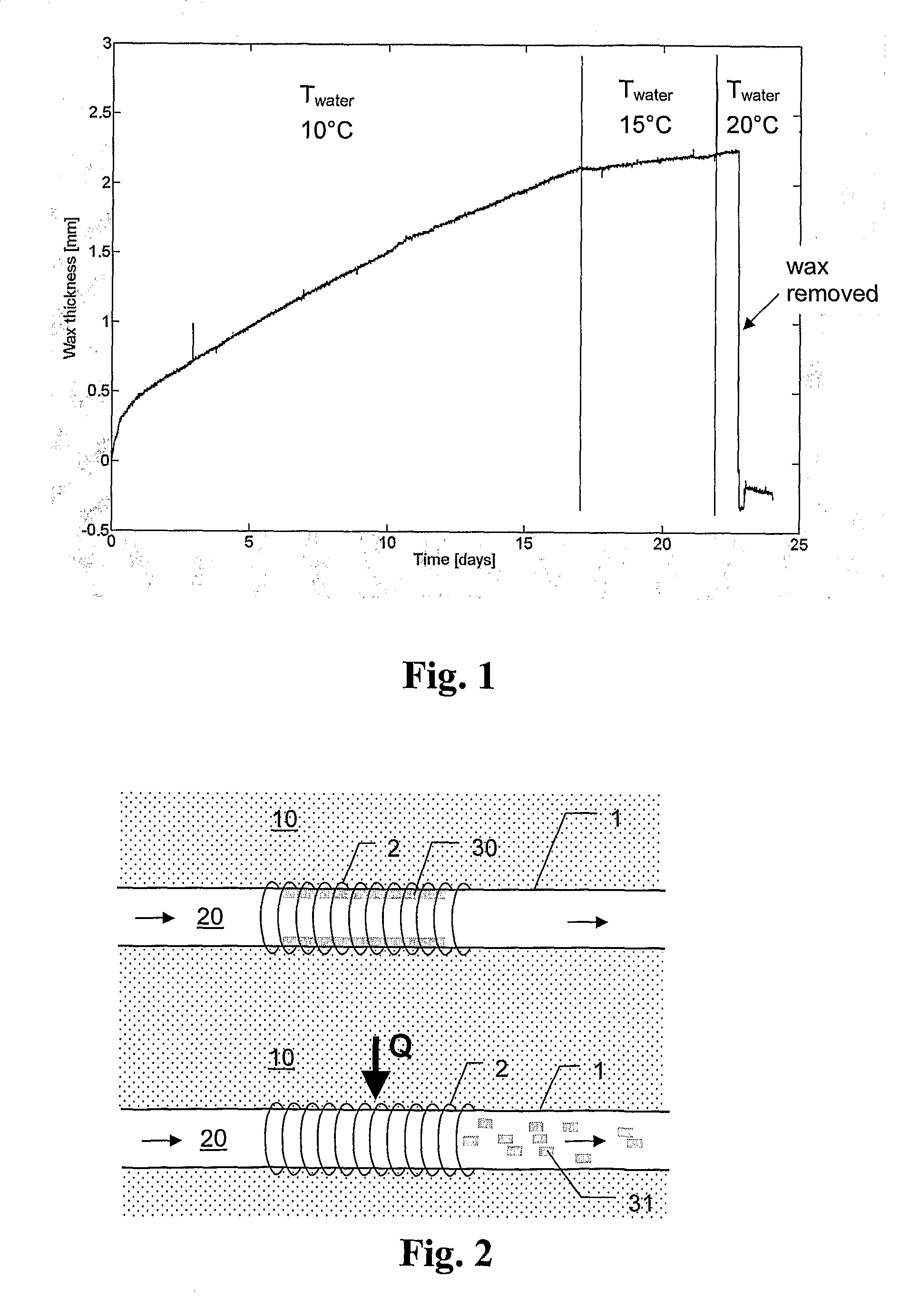

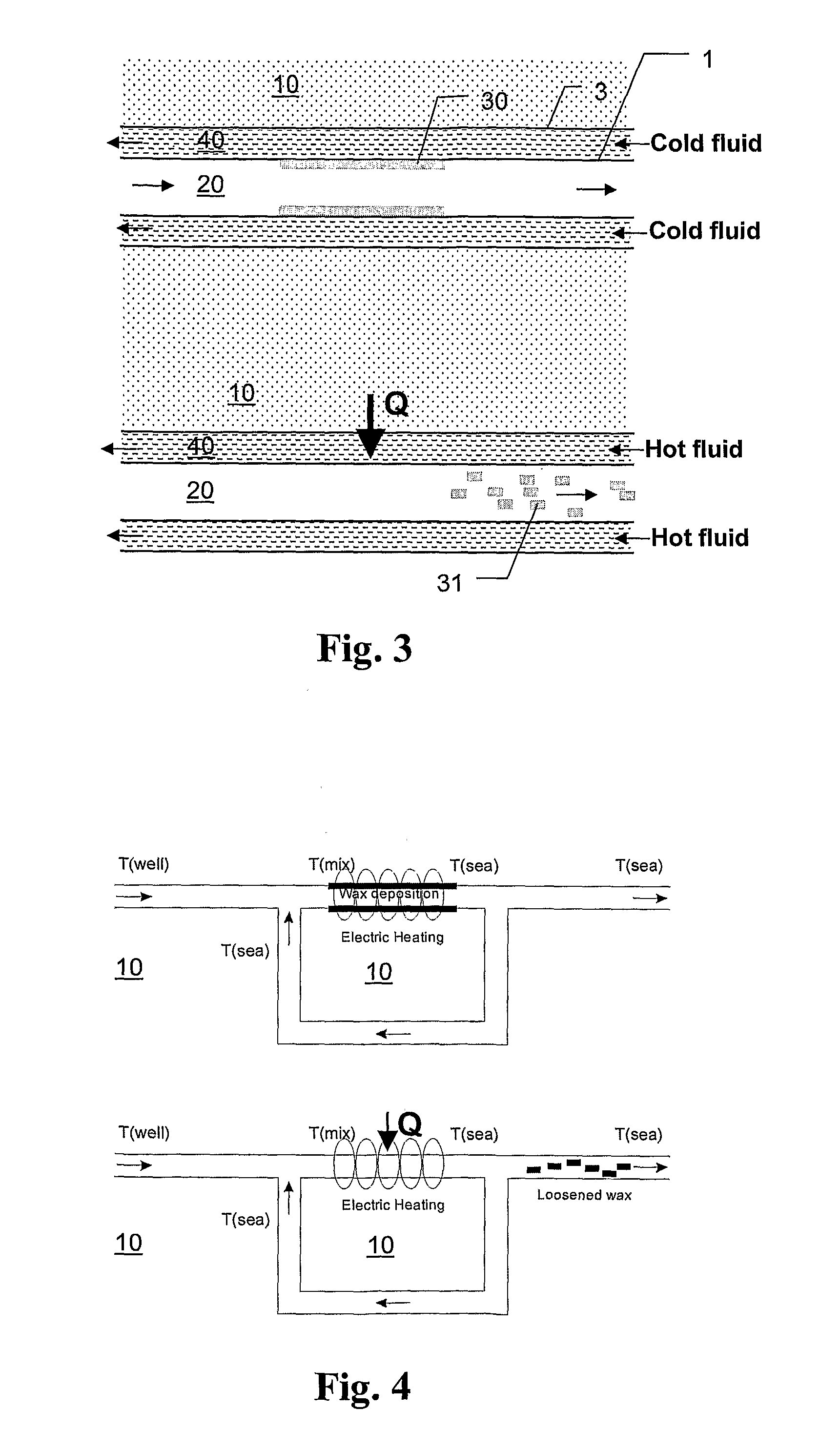

Method for wax removal and measurement of wax thickness

ActiveUS20100300486A1Situation is differentEffective installationCleaning heat-transfer devicesHollow article cleaningEngineeringWax removal

A method for removal of wax deposited on an inner wall in contact with a fluid stream. The method includes the steps of cooling the inner wall and the fluid stream to a temperature of or below the wax appearance temperature, enabling wax to dissolve and precipitate on the inner wall, and heating of the inner wall for a short period of time to release the deposited wax from the surface of the inner wall, mainly in the form of solid parts. The thickness of wax deposits in a pipe section can be determined by computing the temperatures obtained upstream and downstream in the said pipe section, before and after applying heat pulse.

Owner:DEN NORSKE STATS OLJESELSKAP AS

Composition and method for dispersing paraffins in crude oils

A composition of co-polymers, surfactants and solvents is provided for use in methods of reducing paraffin and wax deposition from crude oils in storage and transportation vessels.

Owner:ECOLAB USA INC

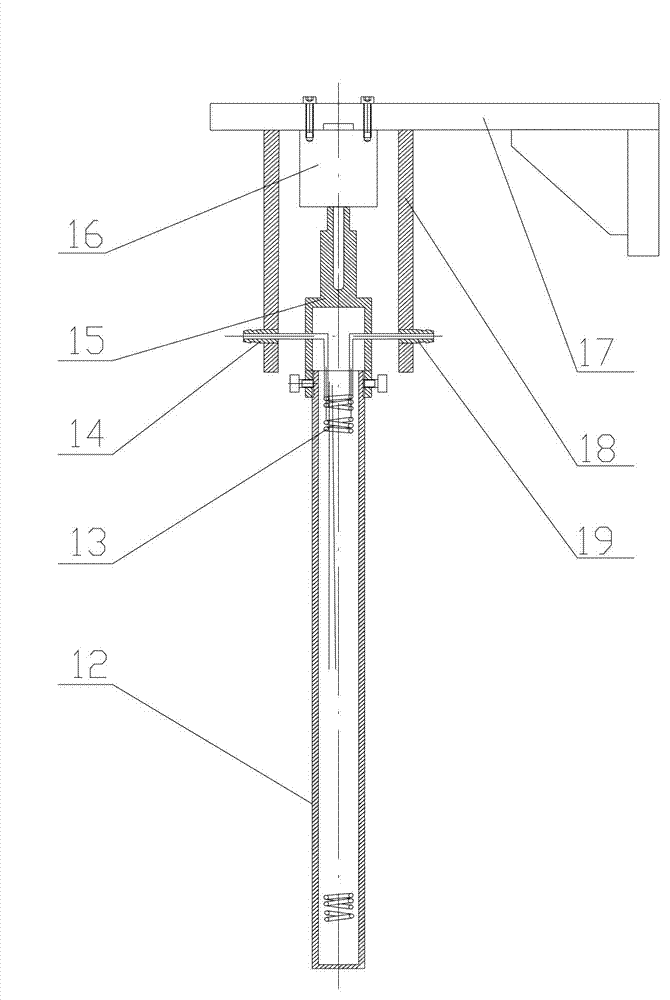

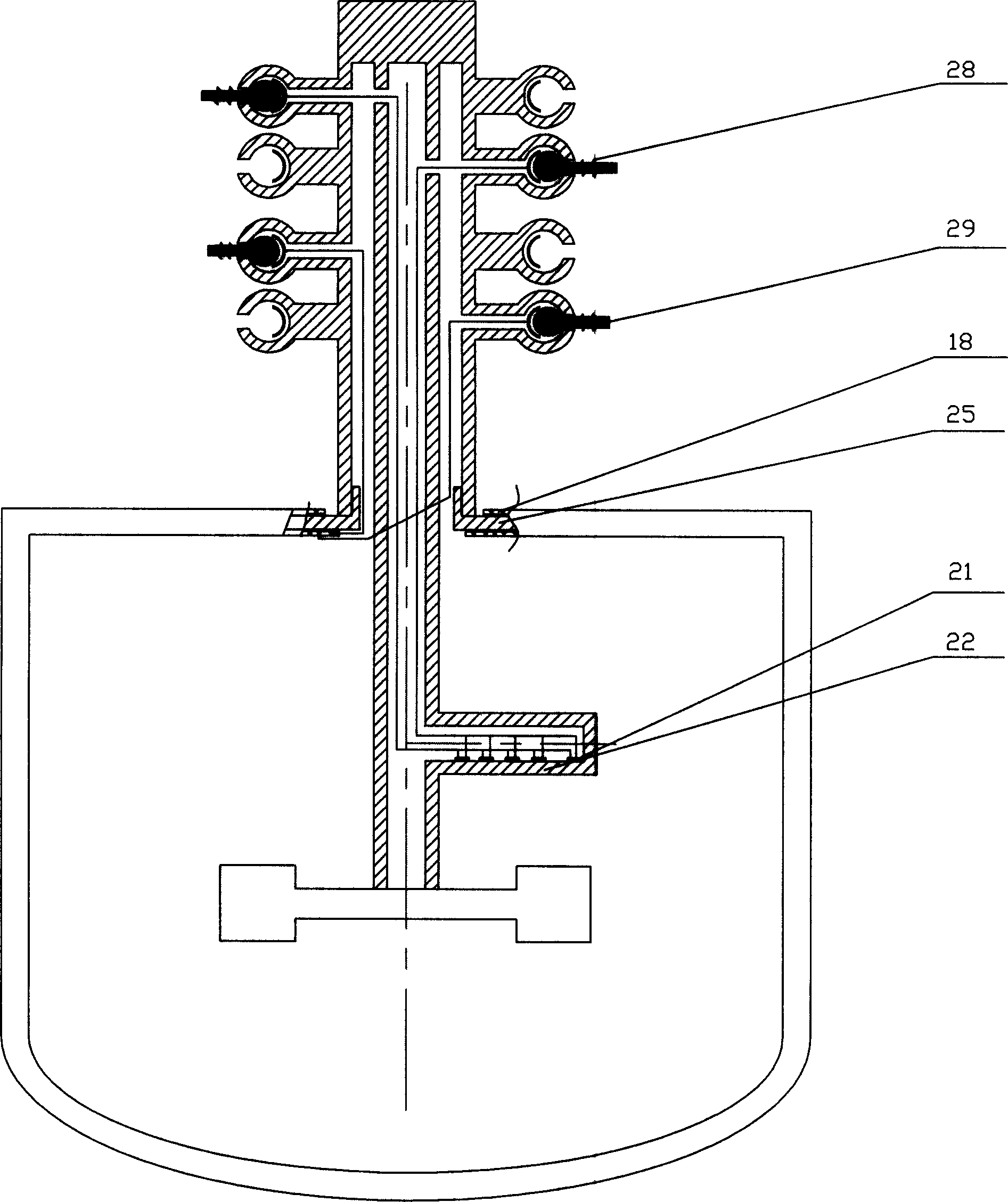

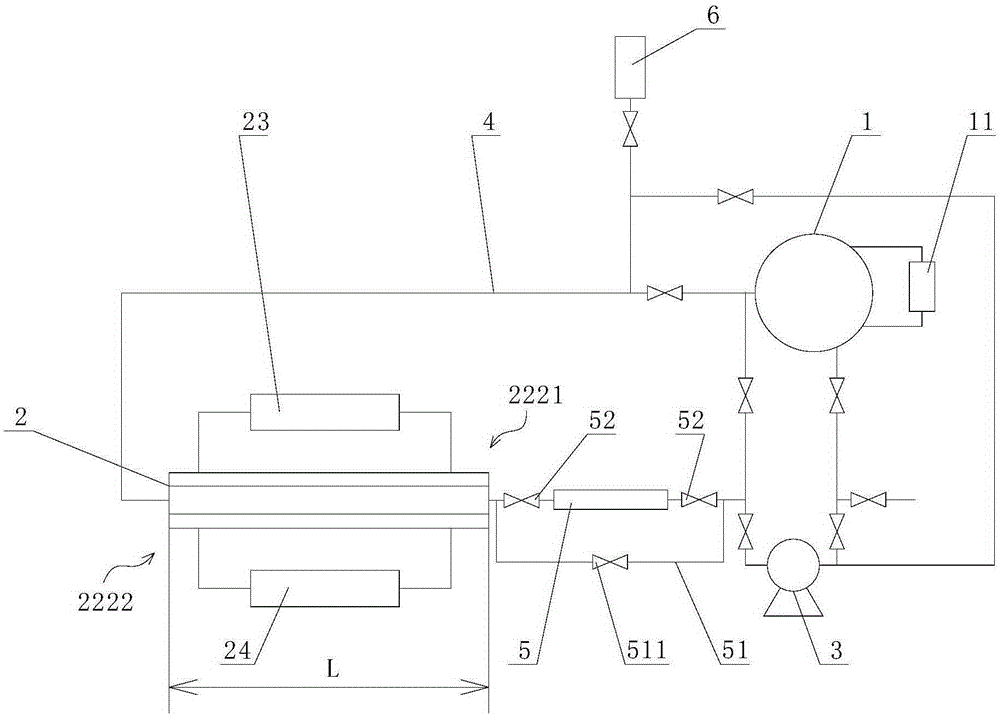

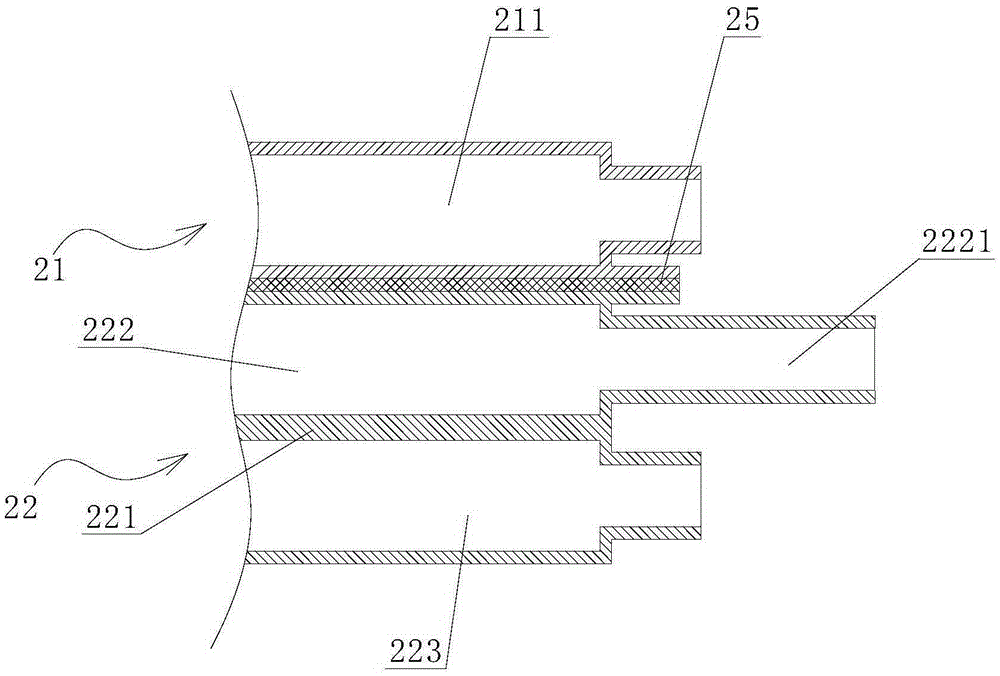

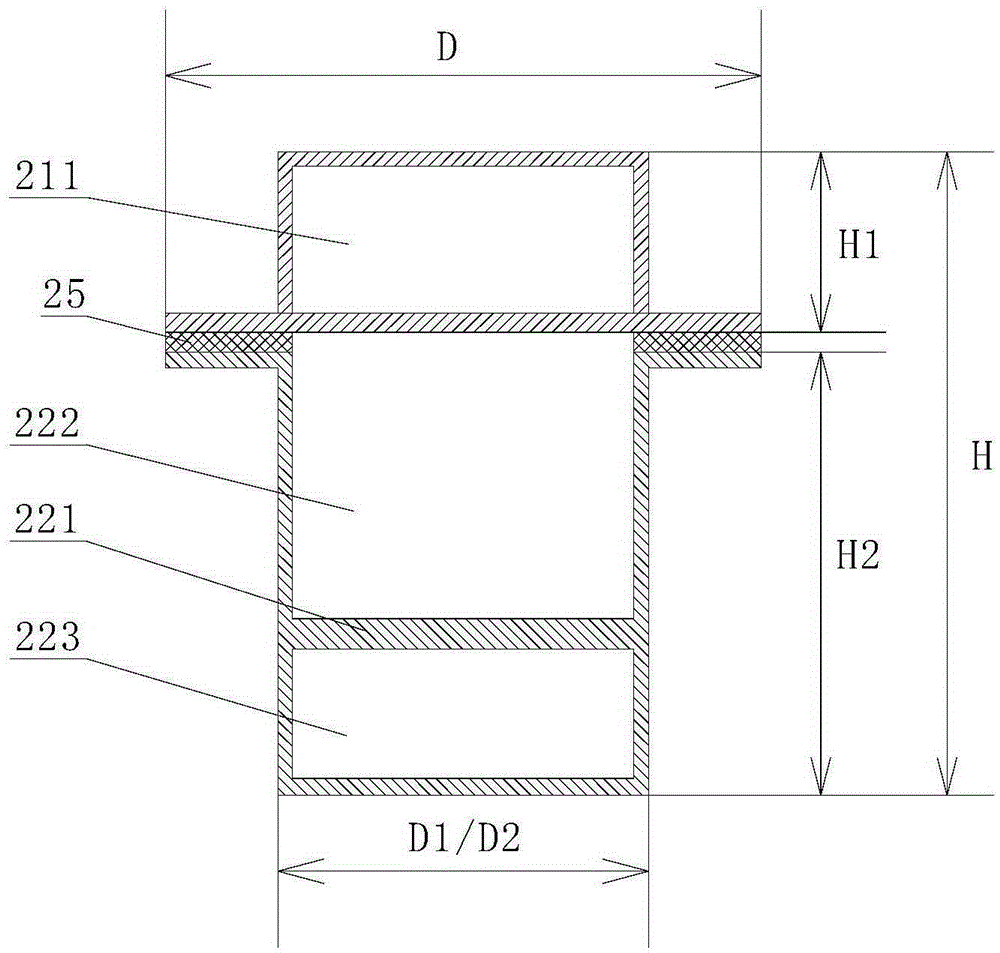

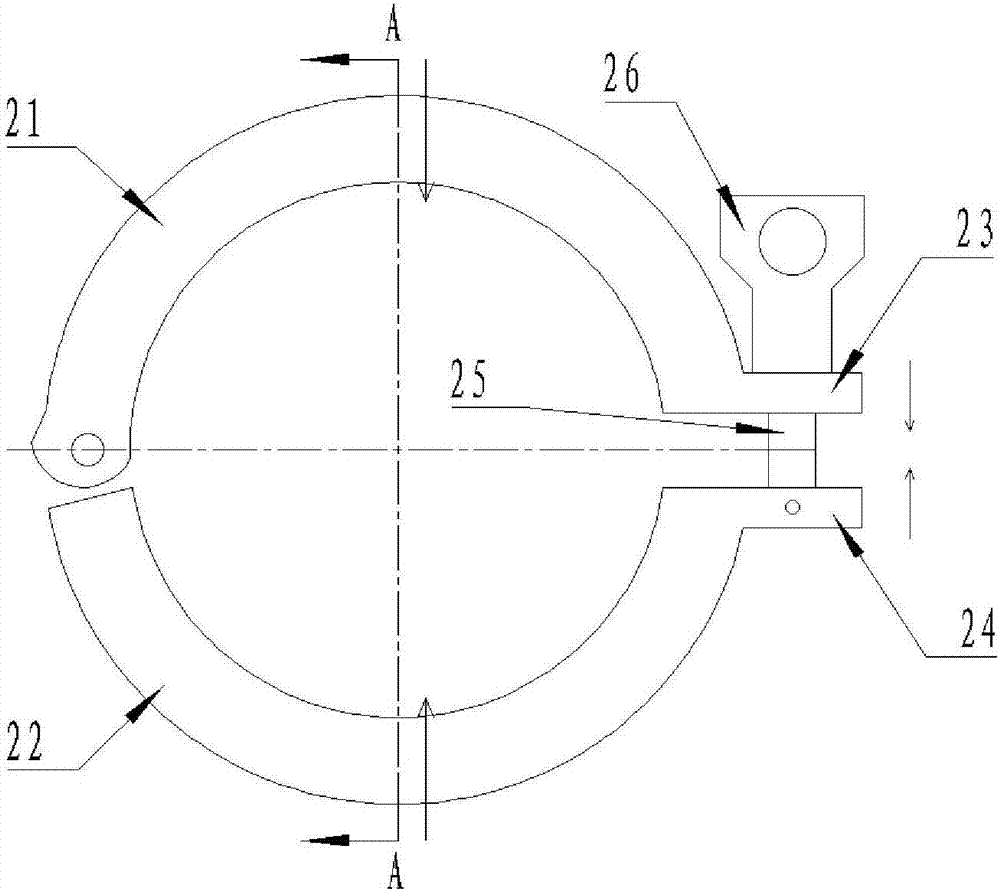

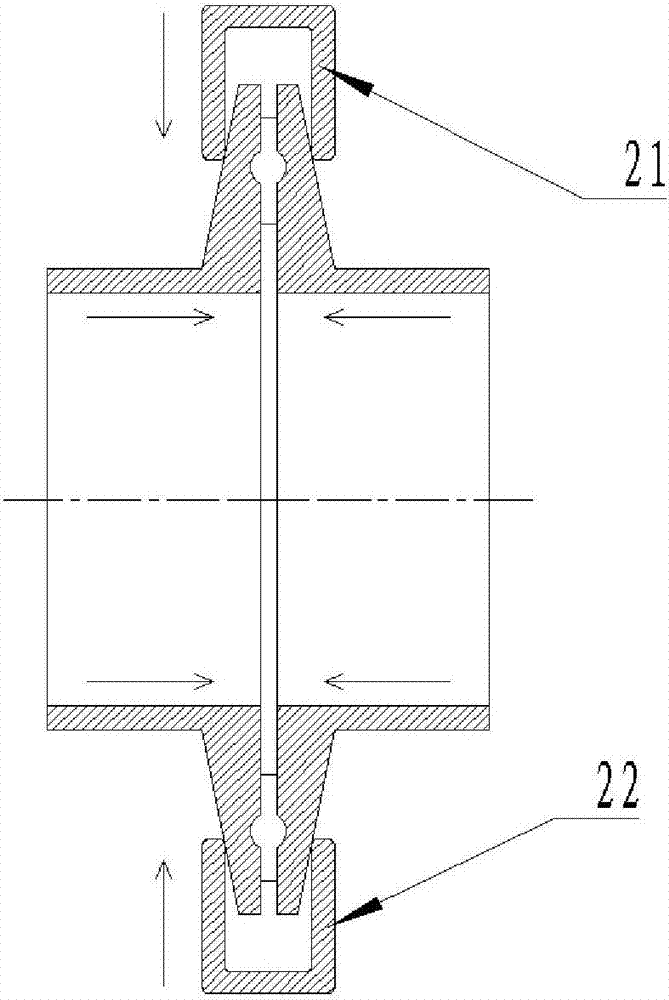

Wax deposition experimental device and method

InactiveCN105334145APromote precipitationChange the degree of blendingFlow propertiesTemperature controlExperimental methods

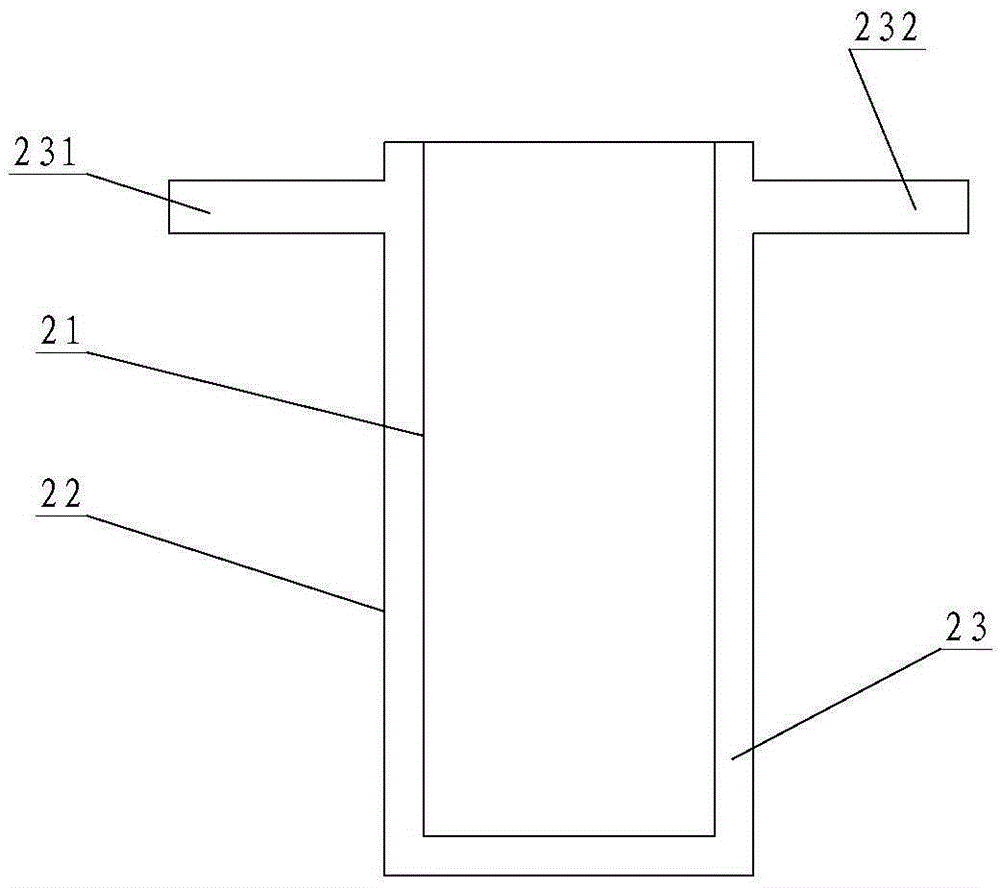

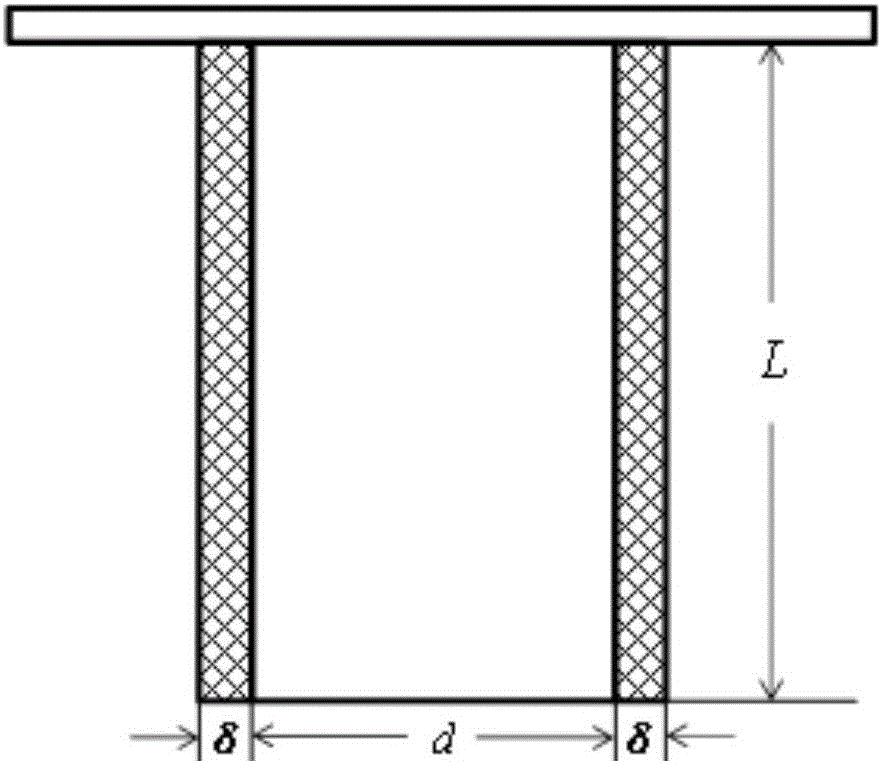

The invention provides a wax deposition experimental device and method. The wax deposition experimental device comprises an oil storage tank, a cold finger and a stirrer. The oil storage tank is provided with an oil storage cavity and sleeved with a water jacket interlayer, and the water jacket interlayer is connected with a first temperature control device. The cold finger is arranged in the oil storage cavity and is provided with an inner cylinder and an outer cylinder which is arranged outside the inner cylinder in a sleeving mode, an annular cavity is formed between the inner cylinder and the outer cylinder, and the annular cavity is connected with a second temperature control device. The stirrer is provided with a rotating shaft penetrating in the inner cylinder, and the end, penetrating out of the inner cylinder, of the rotating shaft is connected with a plurality of stirring paddles. The stirring paddles are located between the outer peripheral wall of the cold finger and the inner peripheral wall of the oil storage tank. According to the wax deposition experimental device and method, the wax deposition laws of crude oil and an oil-water mixture under the flowing condition can be determined, and it is of great significance to pipeline safety and economic operation.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

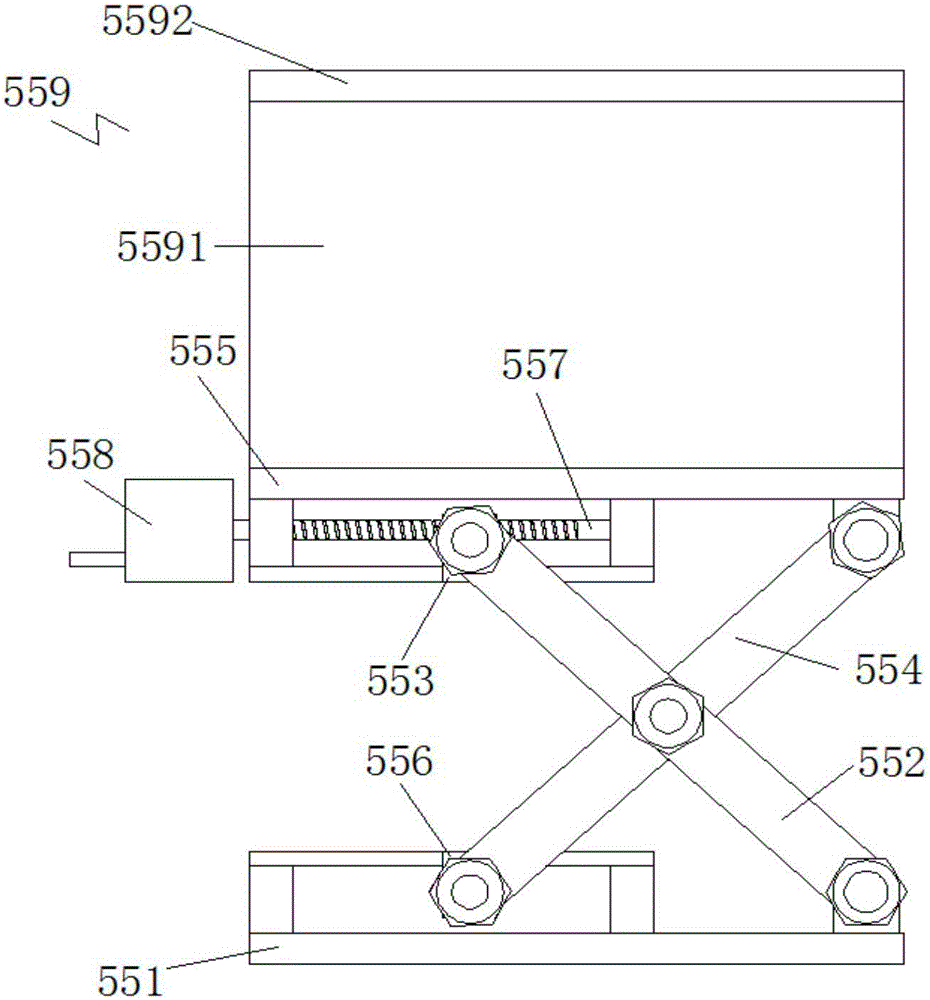

Wax deposition rate measuring device for crude oil

InactiveCN103116015AReduce volumeSmall footprintMaterial testing goodsWater bathsTemperature control

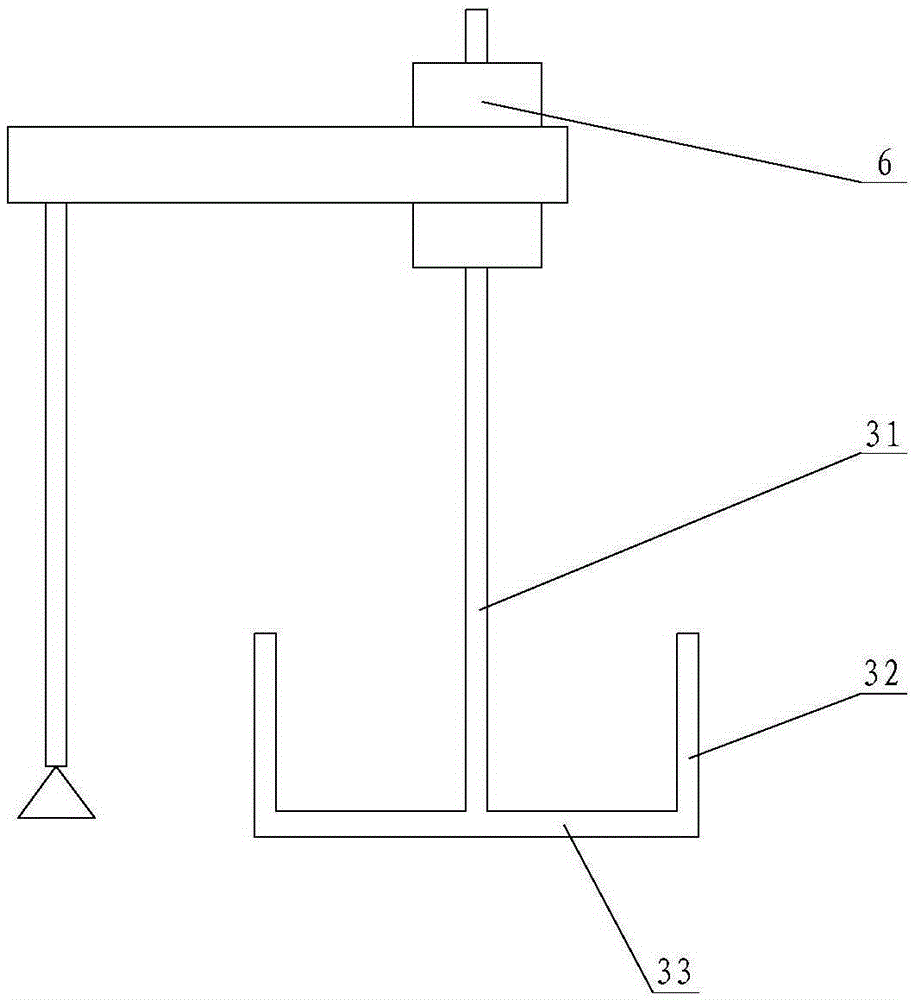

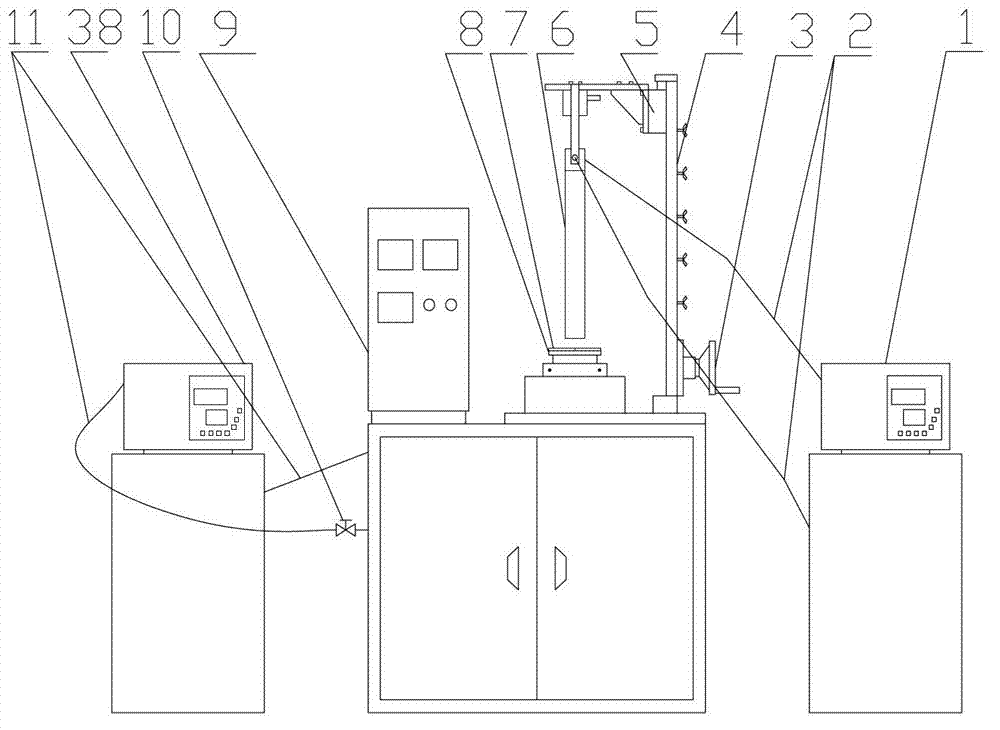

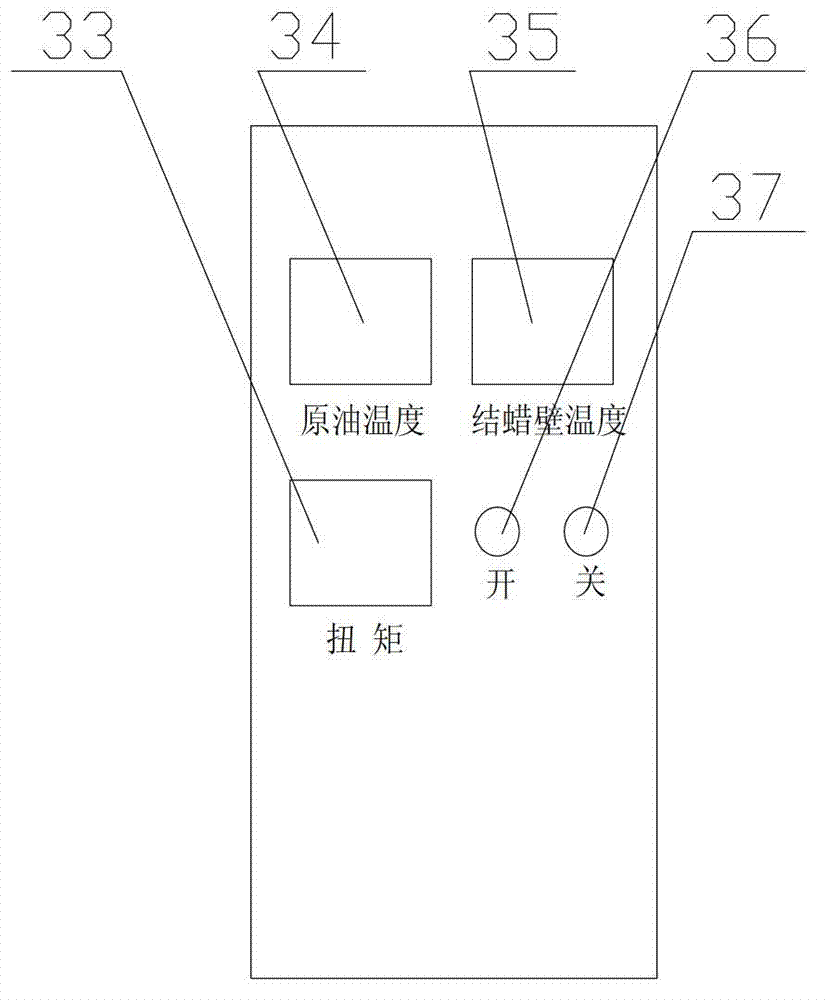

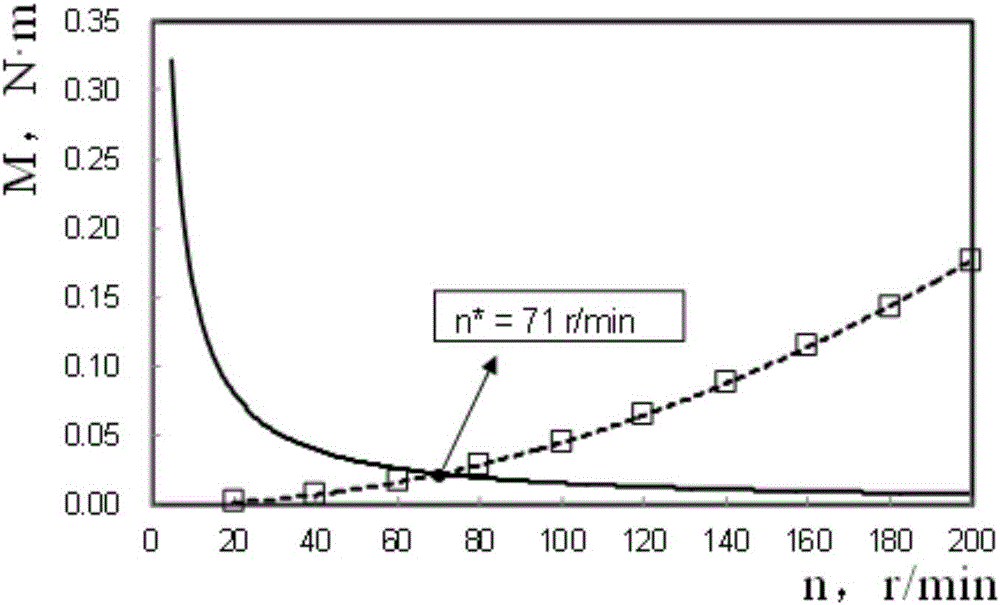

The invention provides a stress control type crude oil wax deposition device. The device comprises a wax deposition cylinder, a sample cylinder, a low-resistance rotating mechanism, a high-speed rotating mechanism, a constant-temperature oil bath, a lifting mechanism, a constant-temperature water bath, a measuring system, an electric control system and a data acquisition and processing system, the temperature control is performed on crude oil and the wall surface of the wax deposition cylinder through the constant-temperature oil bath and the constant-temperature water bath to achieve the required temperature; the sample cylinder can rotate through a computer data acquisition system, the low-resistance rotating mechanism and the high-speed rotating mechanism, and the rotational speed can be set; and the lifting of the wax deposition cylinder can be regulated through the lifting mechanism. Crude oil wax deposition regular experiments under different oil temperatures, wall temperatures and rotational speeds can be performed by changing the temperature of the constant-temperature oil bath and the constant-temperature water bath, as well as the rotational speed of the sample cylinder.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

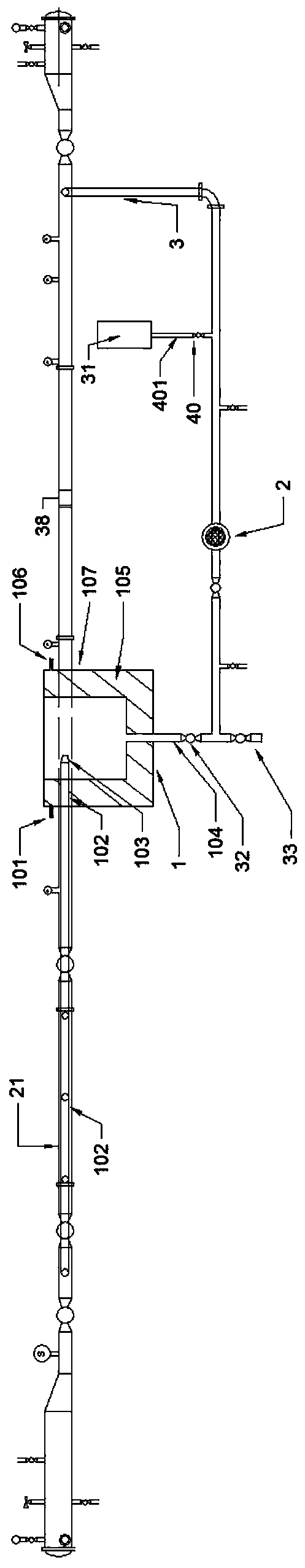

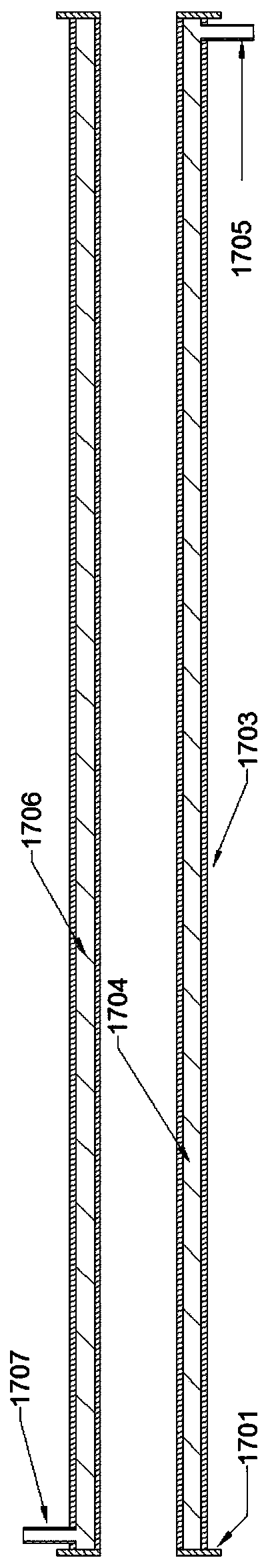

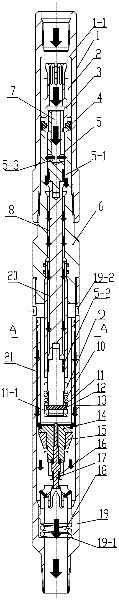

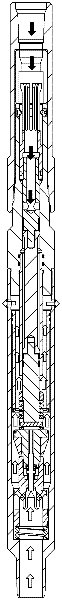

Deep well pitshaft wax-deposition analysis and testing device and analysis and testing method

The invention belongs to the field of oil development and specifically relates to a deep well pitshaft wax-deposition analysis and testing device and an analysis and testing method. The device and the method are used for analyzing and testing wax-deposition in a deep well pitshaft under different conditions so as to summarize corresponding laws. The deep well pitshaft wax-deposition analysis and testing device comprises a testing vertical pitshaft string, an oil tank, a controllable thermostatic water bath and a recycling tank. The testing vertical pitshaft string provides a wax deposition environment; the oil tank provides preset crude oil; and the recycling tank recycles crude oil after wax deposition. The crude oil enters the testing vertical pitshaft string from the oil tank to undergo wax deposition, and the crude oil after wax deposition then enters the recycling tank to be recycled. The controllable thermostatic water bath adjusts temperature of the outside environment during the wax-deposition process. In comparison with the prior art, wax deposition on the inner wall of the deep well pitshaft under different conditions can be simulated in the invention.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

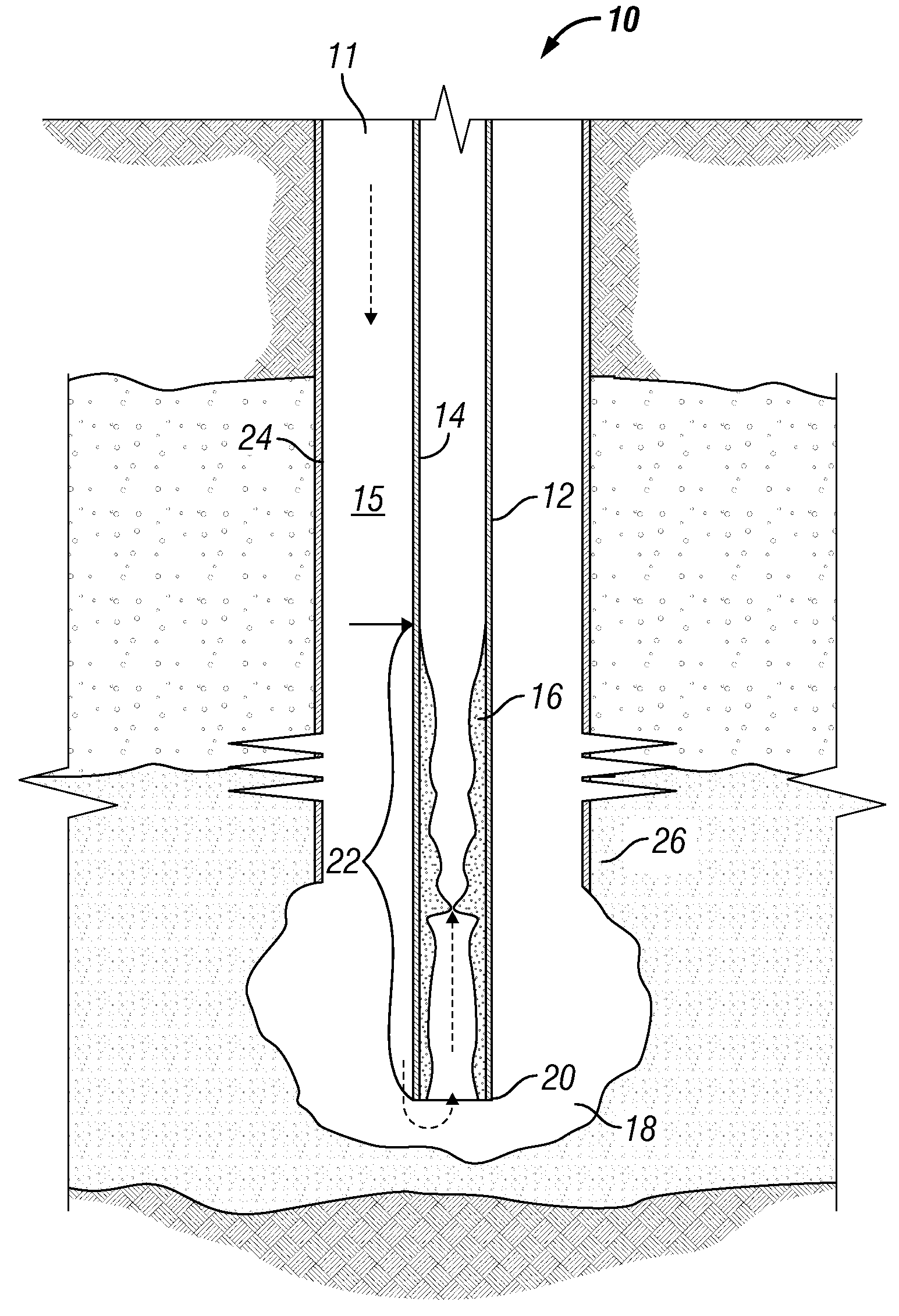

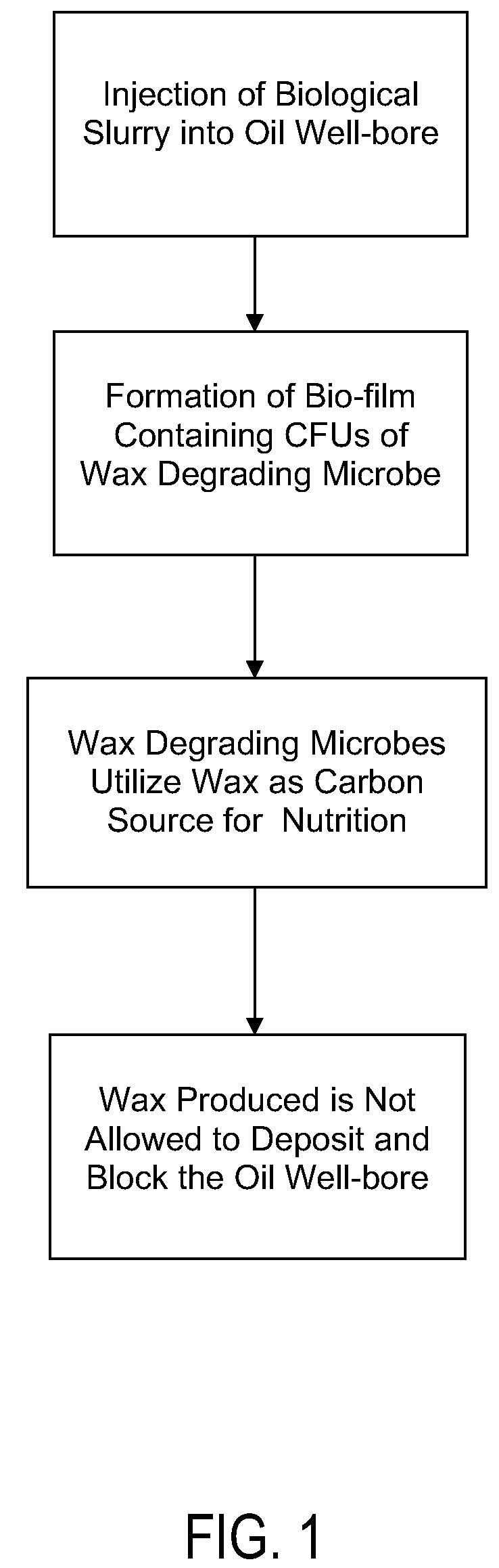

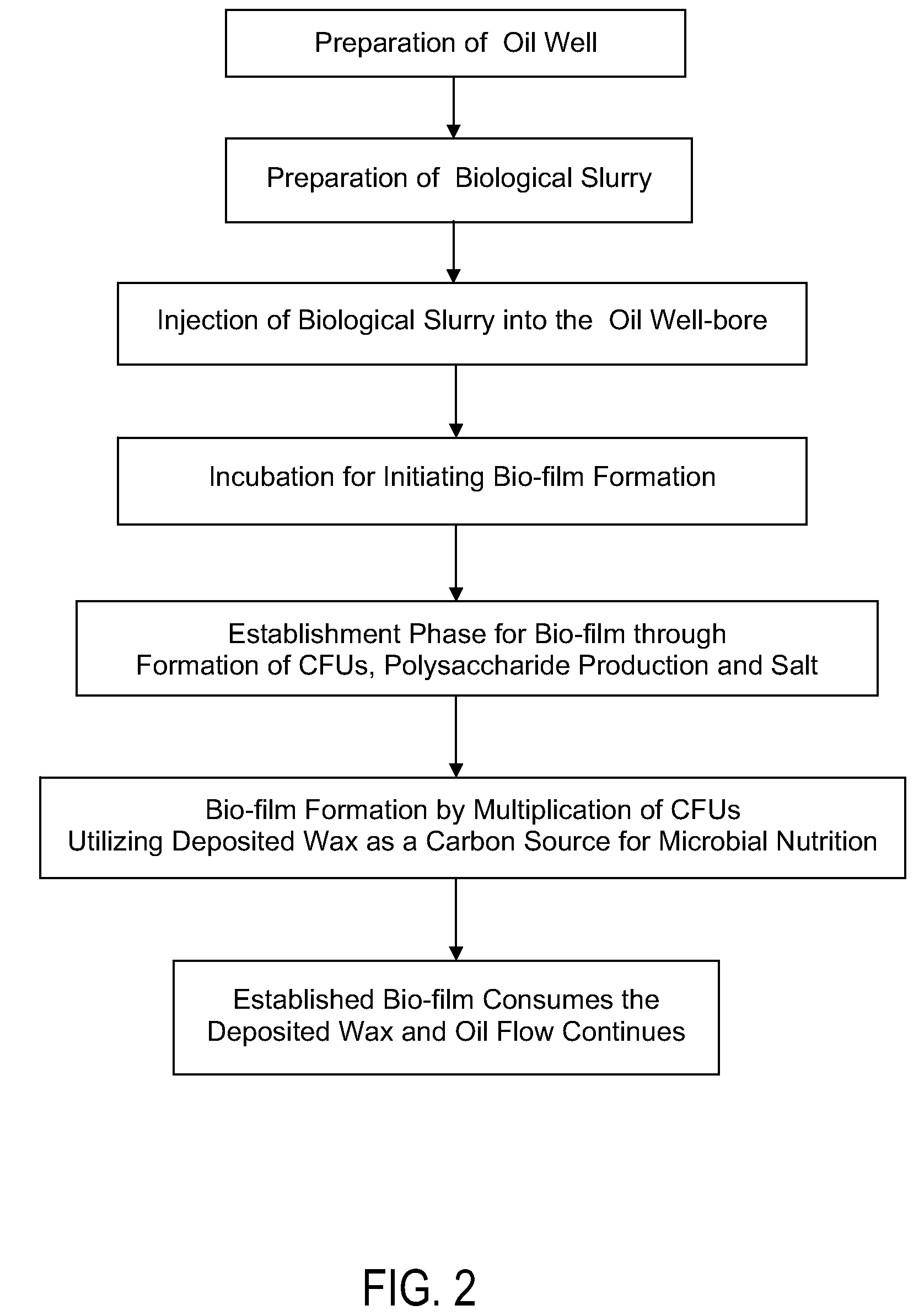

Wellbore treatment for reducing wax deposits

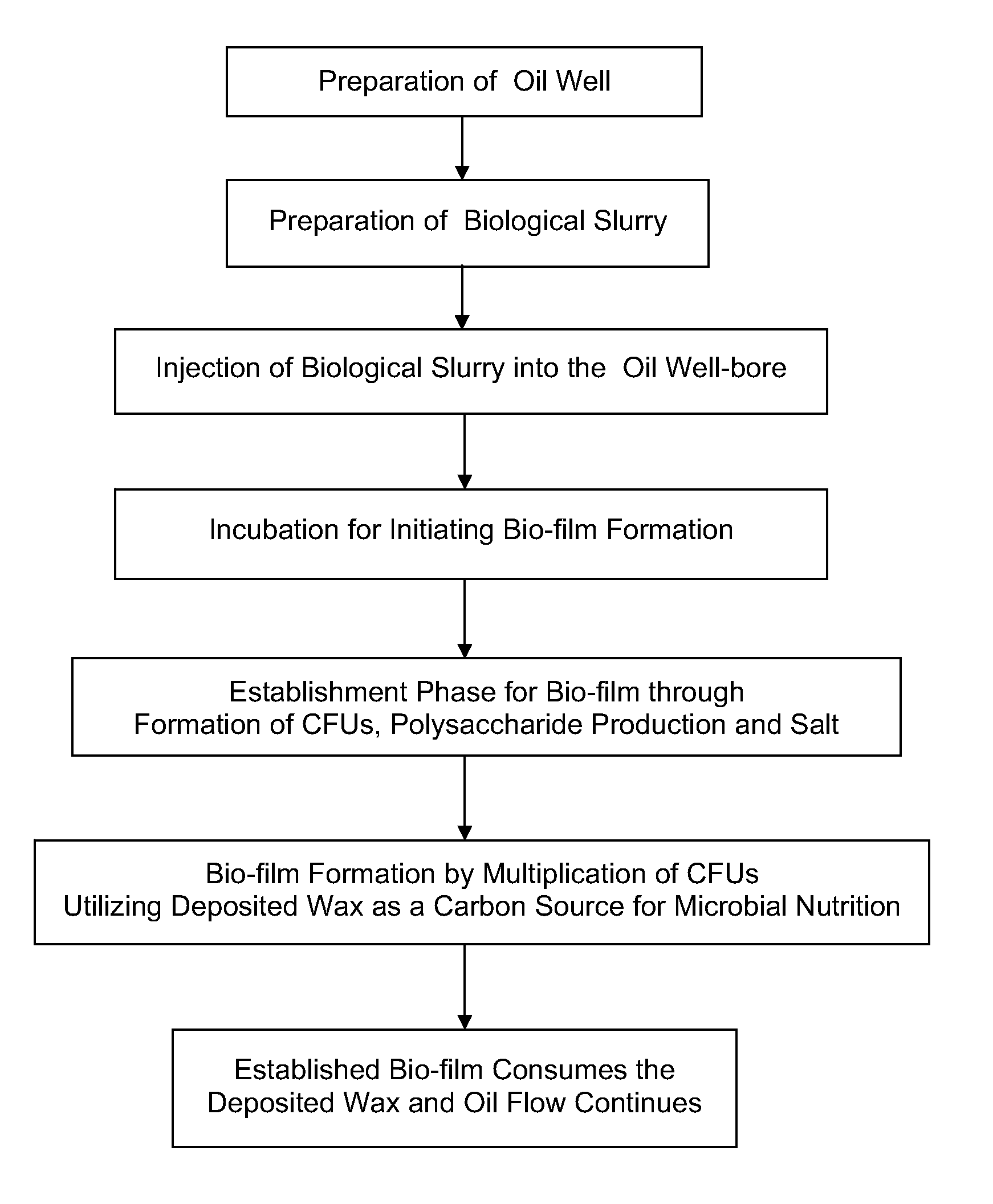

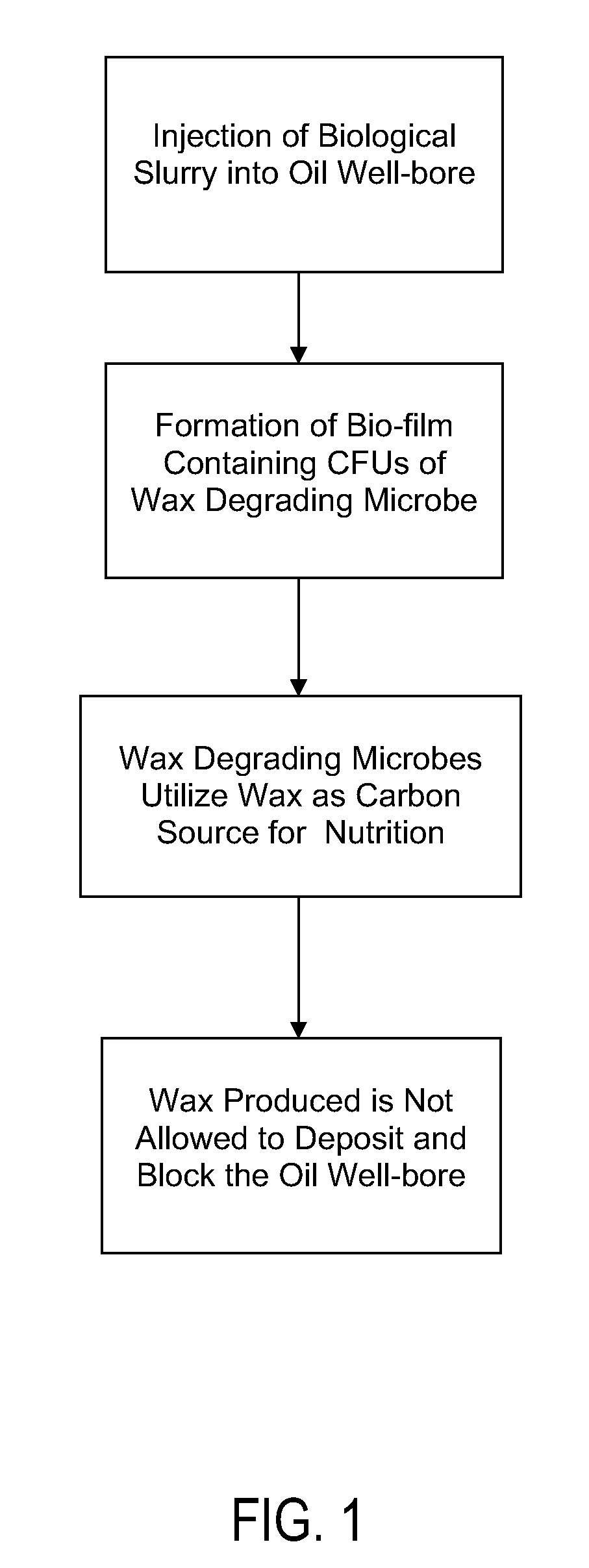

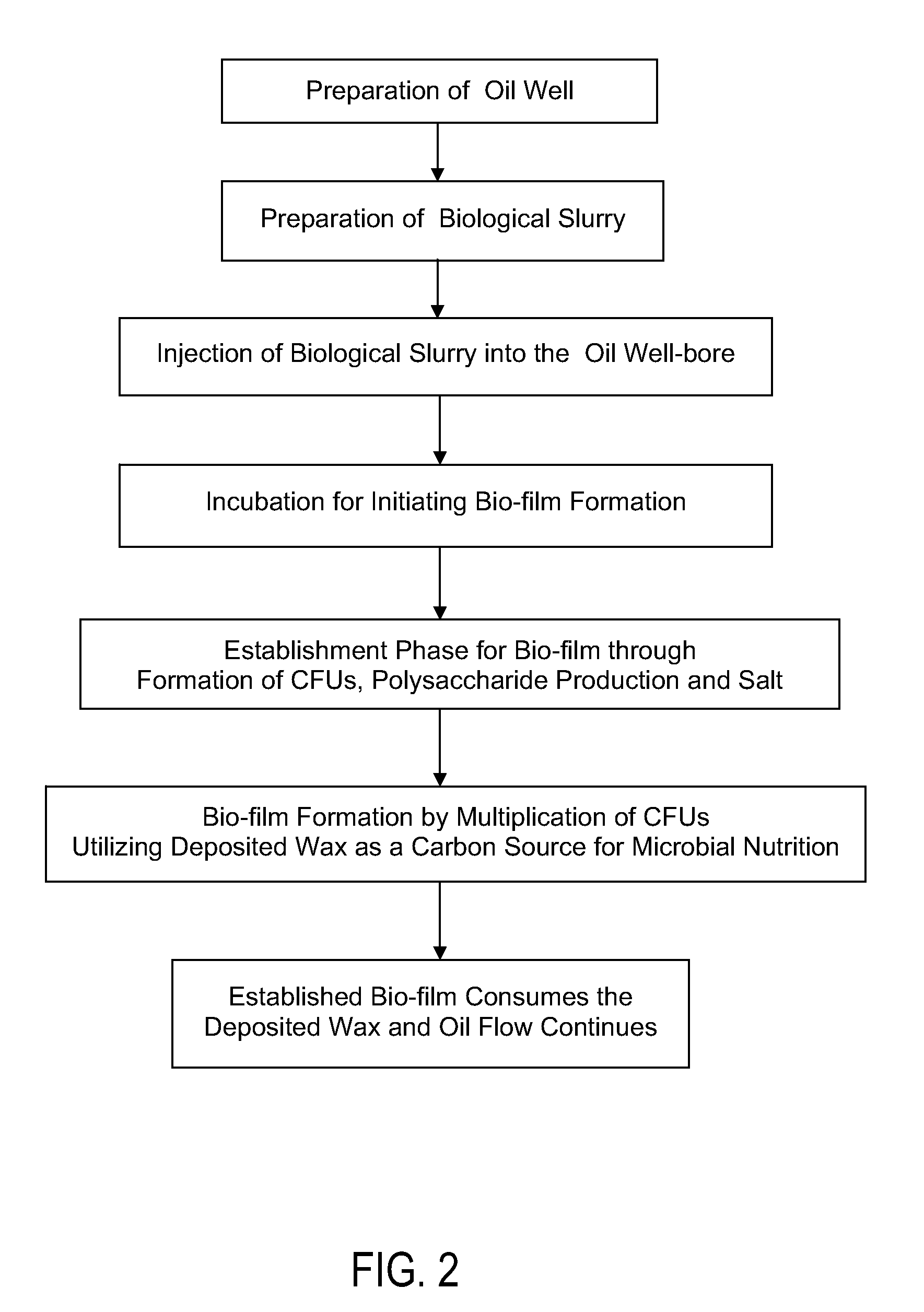

InactiveUS20090025931A1Improve convenienceImprove utilizationCleaning apparatusFluid removalParaffin waxBiofilm

A method of reducing wax deposition in an oil wellbore tubing are disclosed which comprise providing an aqueous bioslurry comprising at least one microbe capable of degrading paraffin wax at about 20-45° C. and a nutrient medium containing one or more carbon source and a source of O2. The method further includes providing an oil wellbore completion having a production tubing with an interior surface including a zone that is susceptible to wax deposition when the well is operated to produce oil. The method further includes, while oil production from the well is stopped, incubating the biological slurry in the wax-deposition zone tubing for a sufficient time to multiply the microbe(s) and form a biofilm on at least the wax-susceptible zone

Owner:GLORI OIL

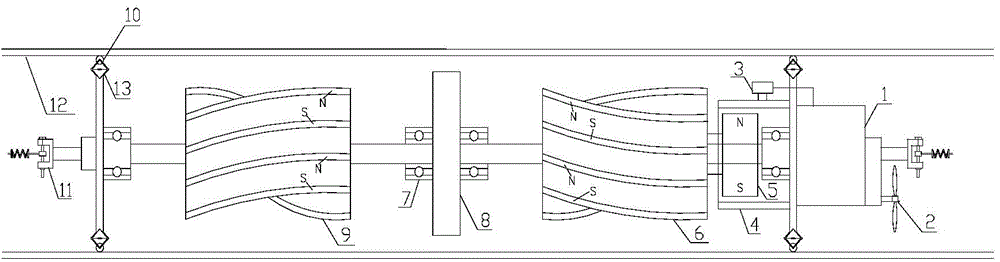

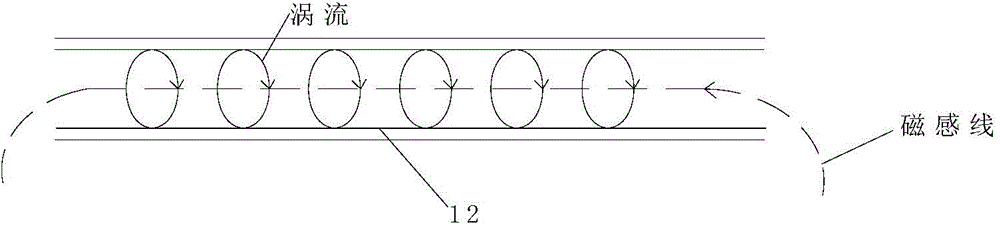

Non-contact type pipe wall wax deposition removing device and pipe wall wax deposition removing system

The invention relates to the technical field of crude oil pipeline removing, in particular to a non-contact type pipe wall wax deposition removing device and a pipe wall wax deposition removing system. The non-contact type pipe wall wax deposition removing device comprises a magnetic impeller, a center rotating shaft and at least two sets of clamping pulley assemblies. Each clamping pulley assembly comprises a pulley rack and a plurality of clamping pulleys which are fixed on the edge of the pulley rack. The clamping pulleys and a pipe wall are attached, when the removing device operates, the inner wall of an oil pipe can not be damaged, crude oil in the pipe penetrates through the pulley racks and then impacts the magnetic impeller, the magnetic impeller rotates along with the center rotating shaft under the effect of fluid pressure, accordingly, an alternating magnetic field is formed in the pipe, and induced eddy currents are formed on the pipe wall. The pipe wall achieves self heating, deposited wax is made to be peeled and cracked, and the wax removing effect is good. The non-contact type pipe wall wax deposition removing device and the pipe wall wax deposition removing system are simple in structure, do not need an external power source in the magnetoelectricity conversion process, and have the advantage of being low in energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

Wellbore treatment for reducing wax deposits

InactiveUS7681638B2Improve convenienceImprove utilizationCleaning apparatusFluid removalParaffin waxBiofilm

A method of reducing wax deposition in an oil wellbore tubing includes providing an aqueous bioslurry comprising at least one microbe capable of degrading paraffin wax at about 20-45° C. and a nutrient medium containing one or more carbon source and an oxygen slow-releasing compound. The method further includes providing an oil wellbore completion having a production tubing with an interior surface including a zone that is susceptible to wax deposition when the well is operated to produce oil. The method further includes, while oil production from the well is stopped, incubating the biological slurry in the wax-deposition zone tubing for a sufficient time to multiply the microbe(s) and form a biofilm on at least the wax-susceptible zone.

Owner:GLORI OIL

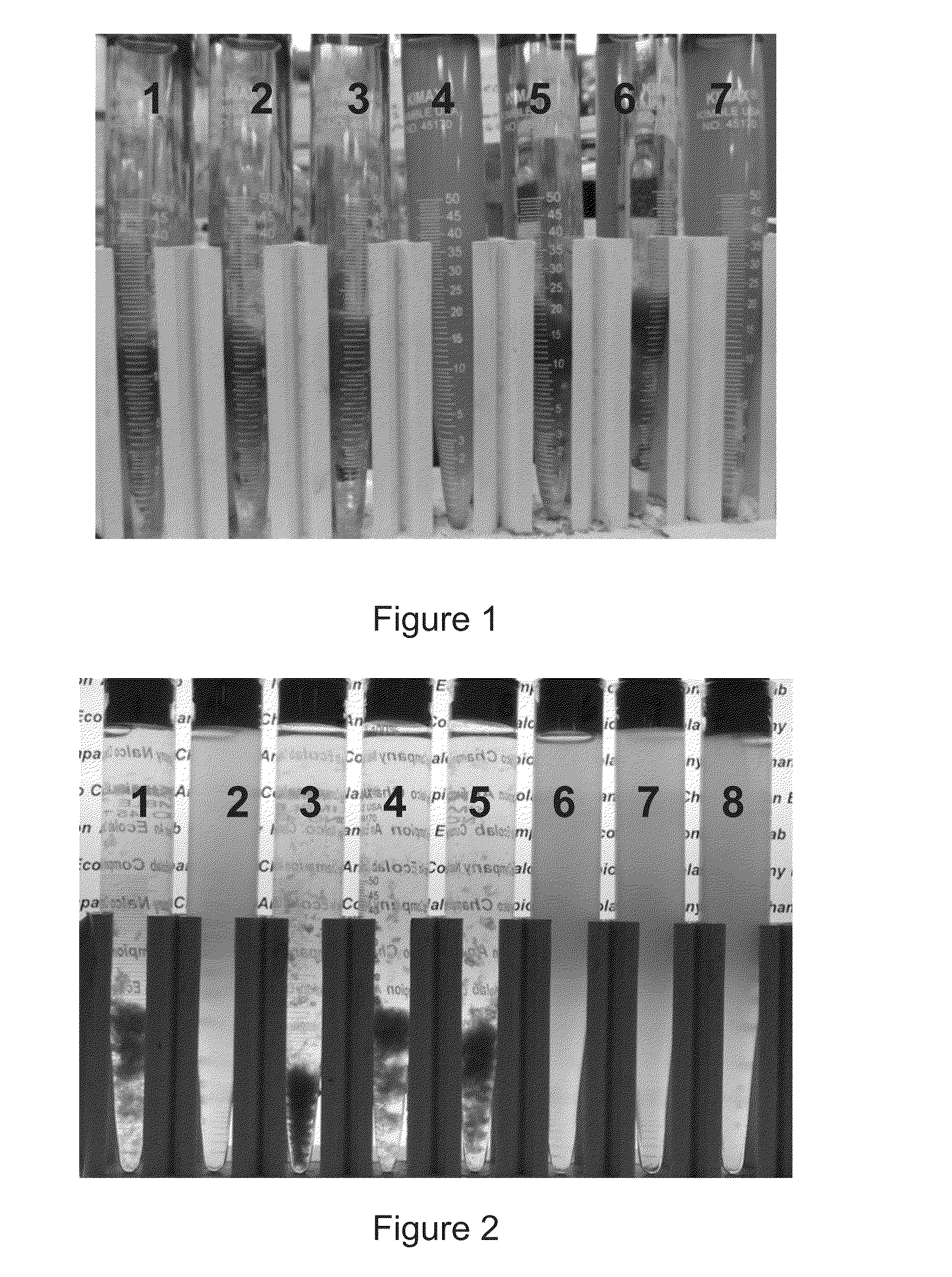

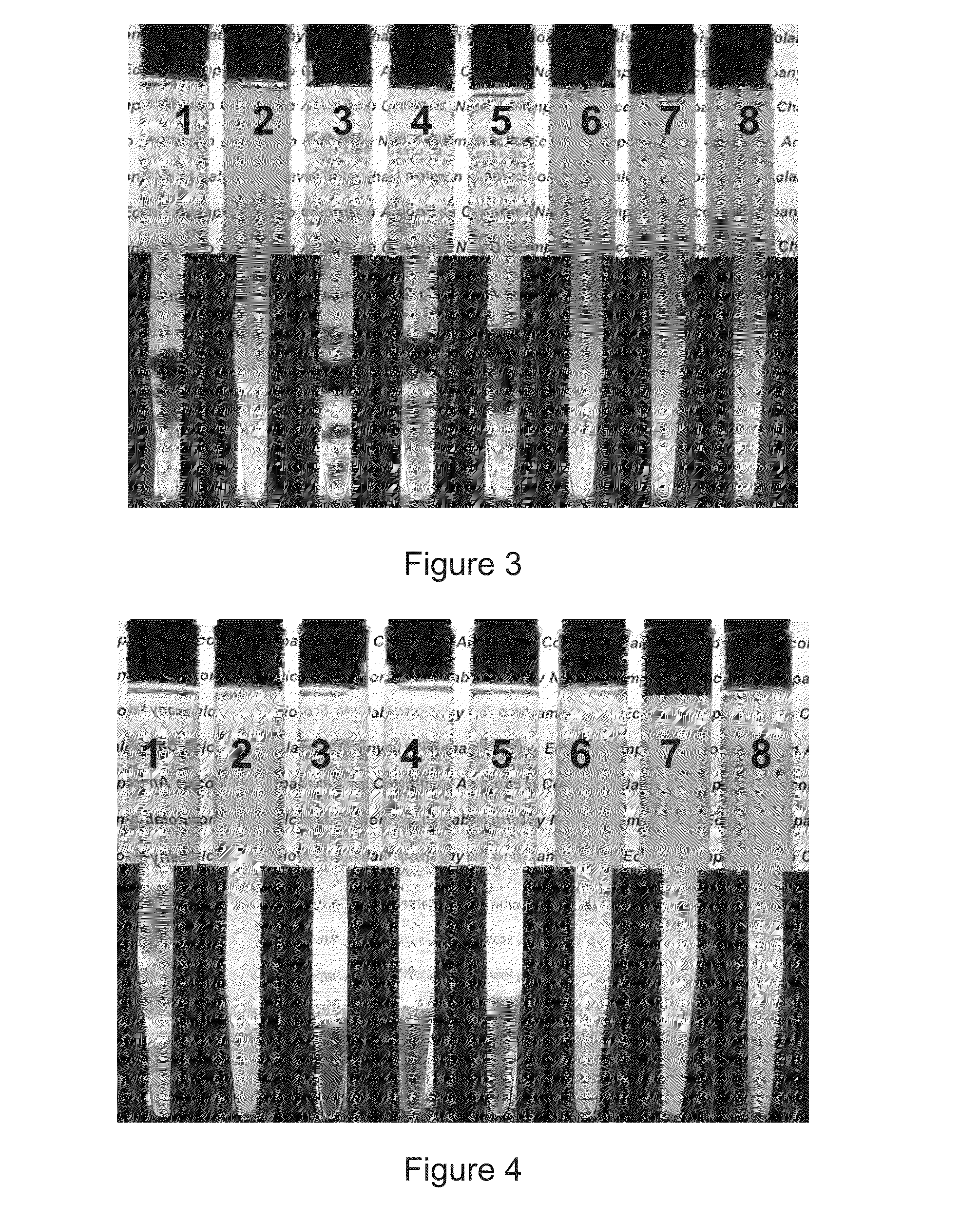

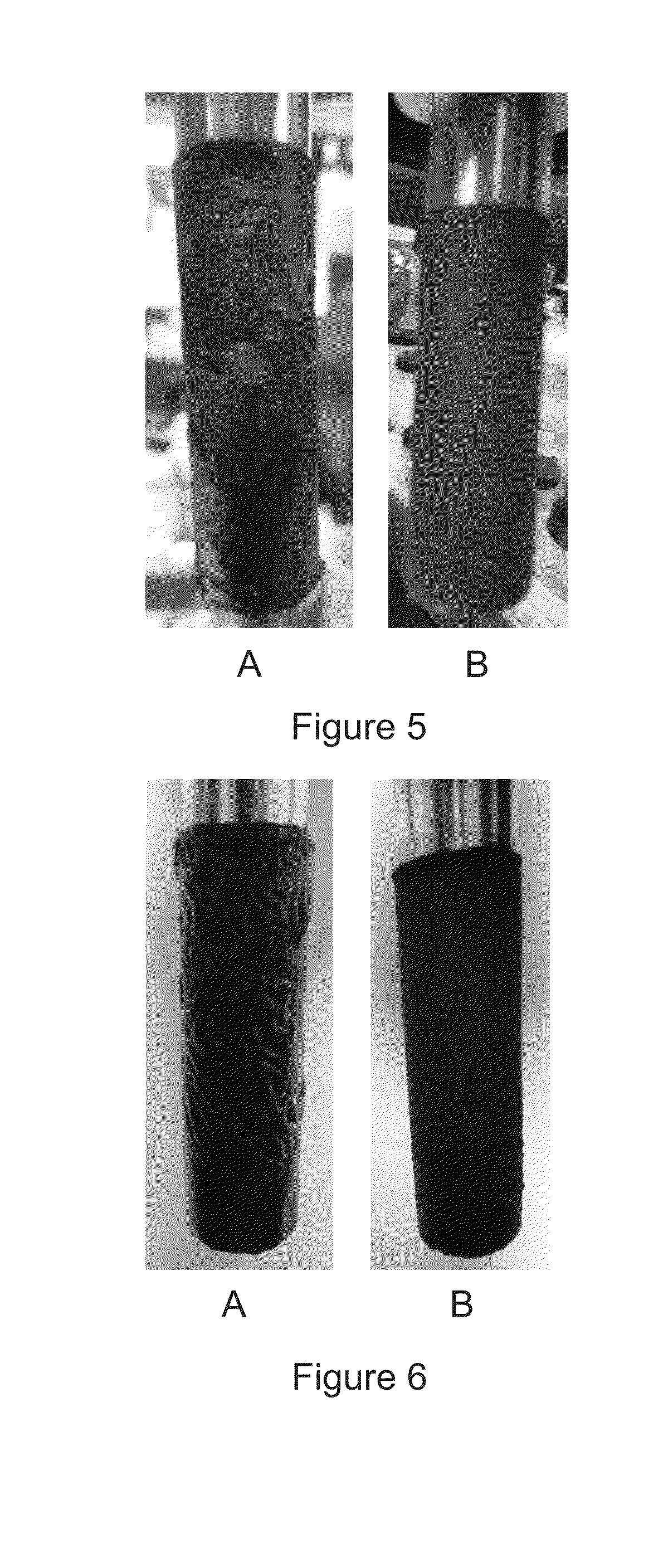

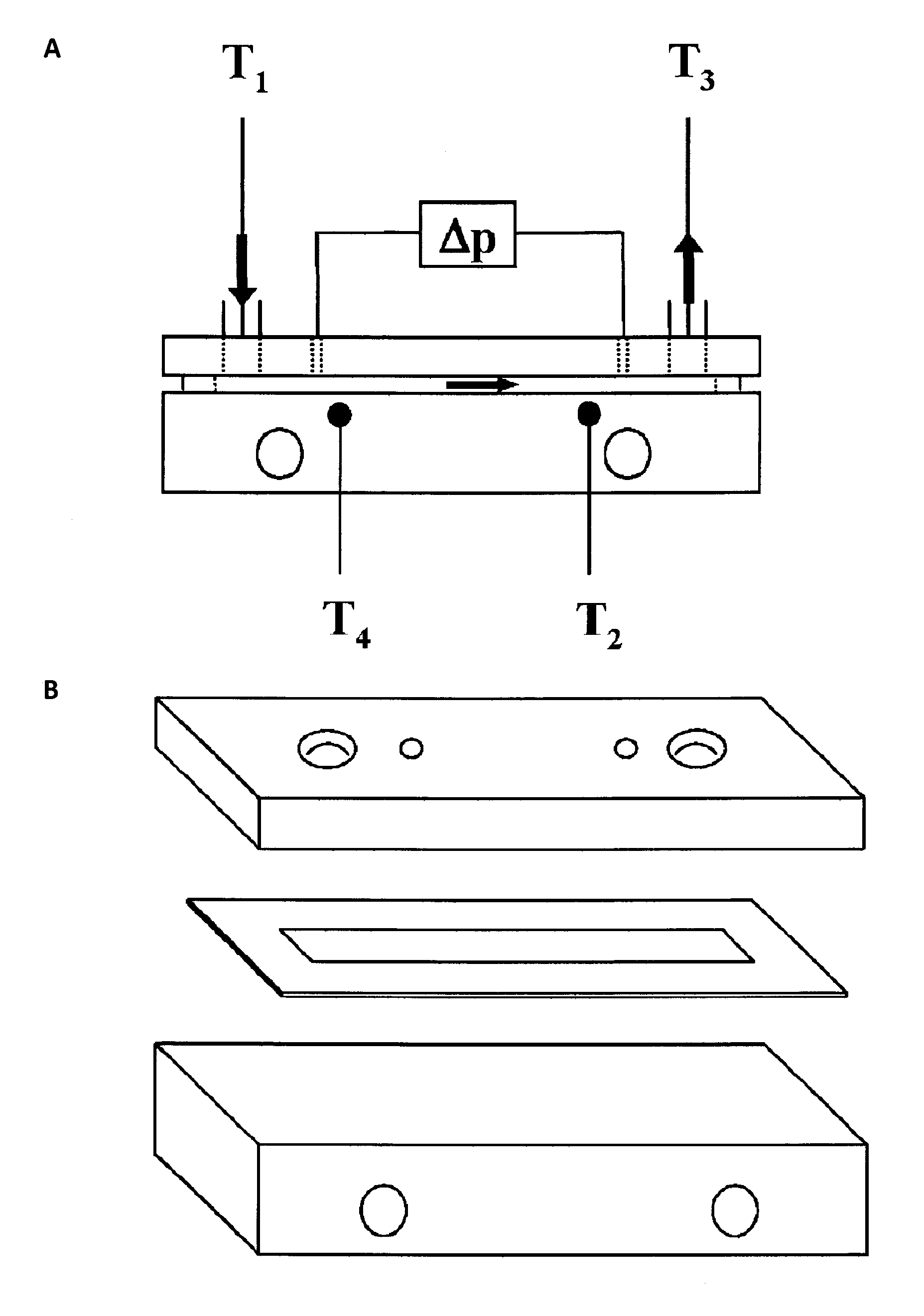

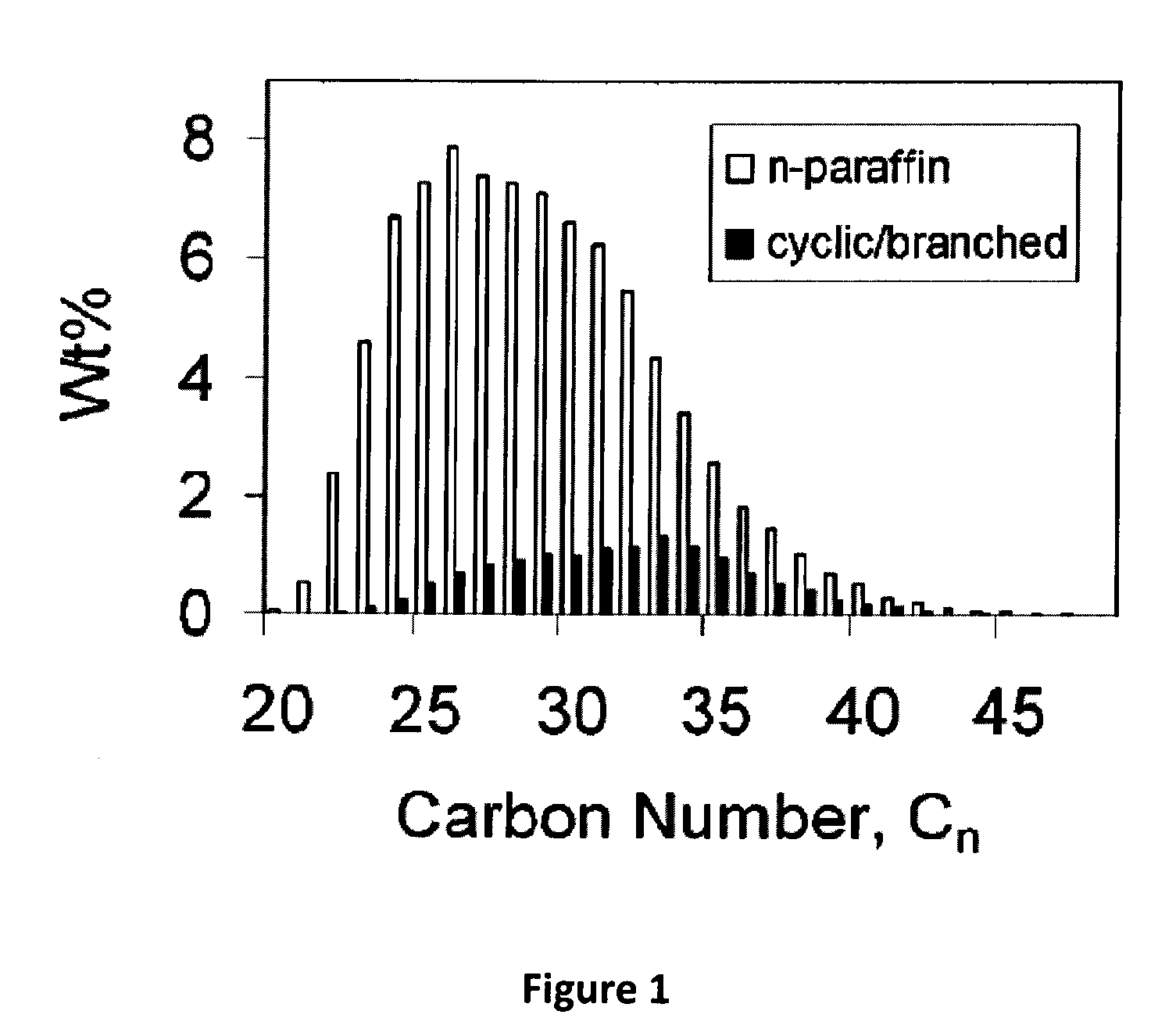

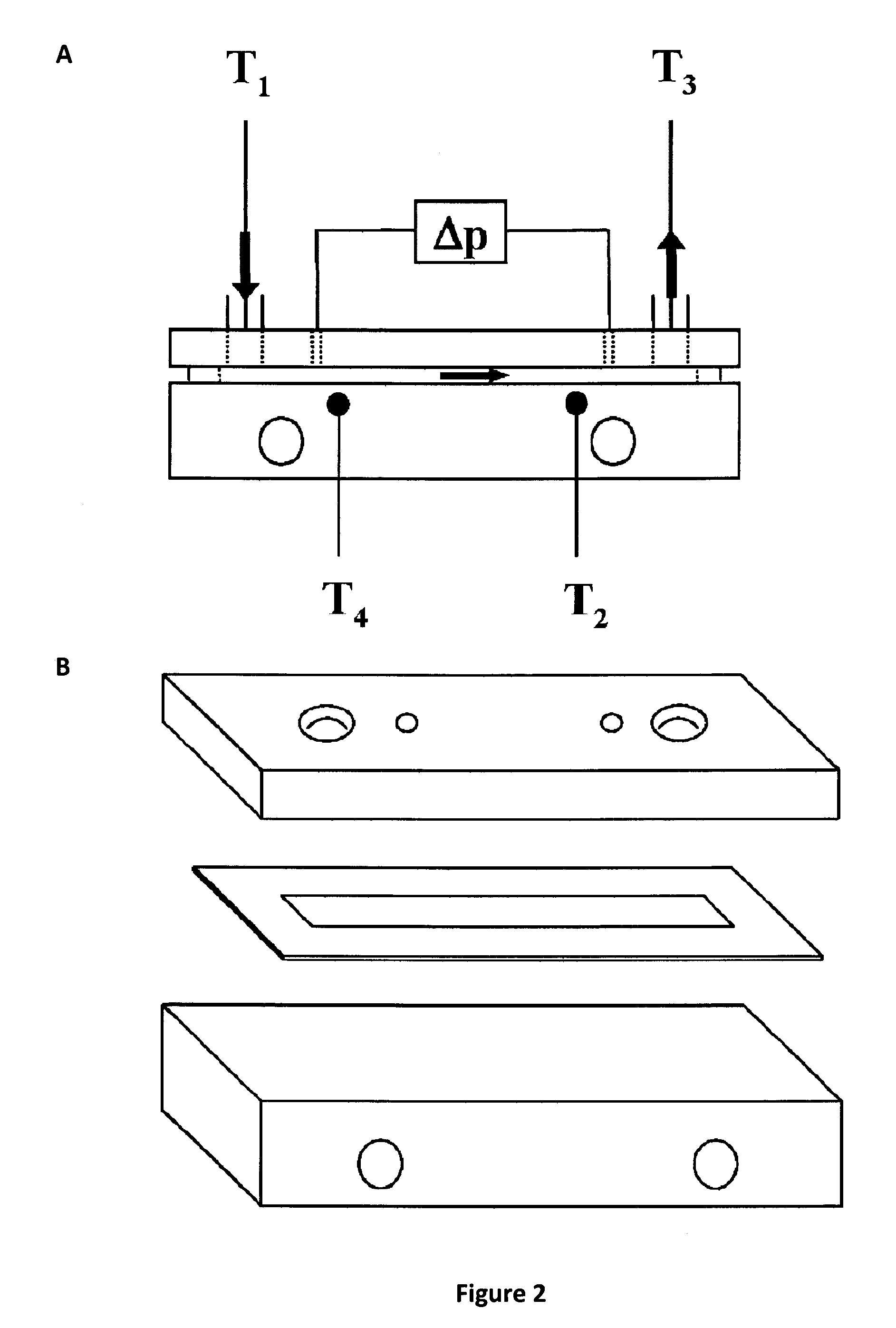

Methods for Testing the Effect of Polymer Additives on Wax Deposition from Crude Oils and Reducing Wax Deposition from Crude Oil During Pipeline Transmission

Owner:KRIEGEL ROBERT M +4

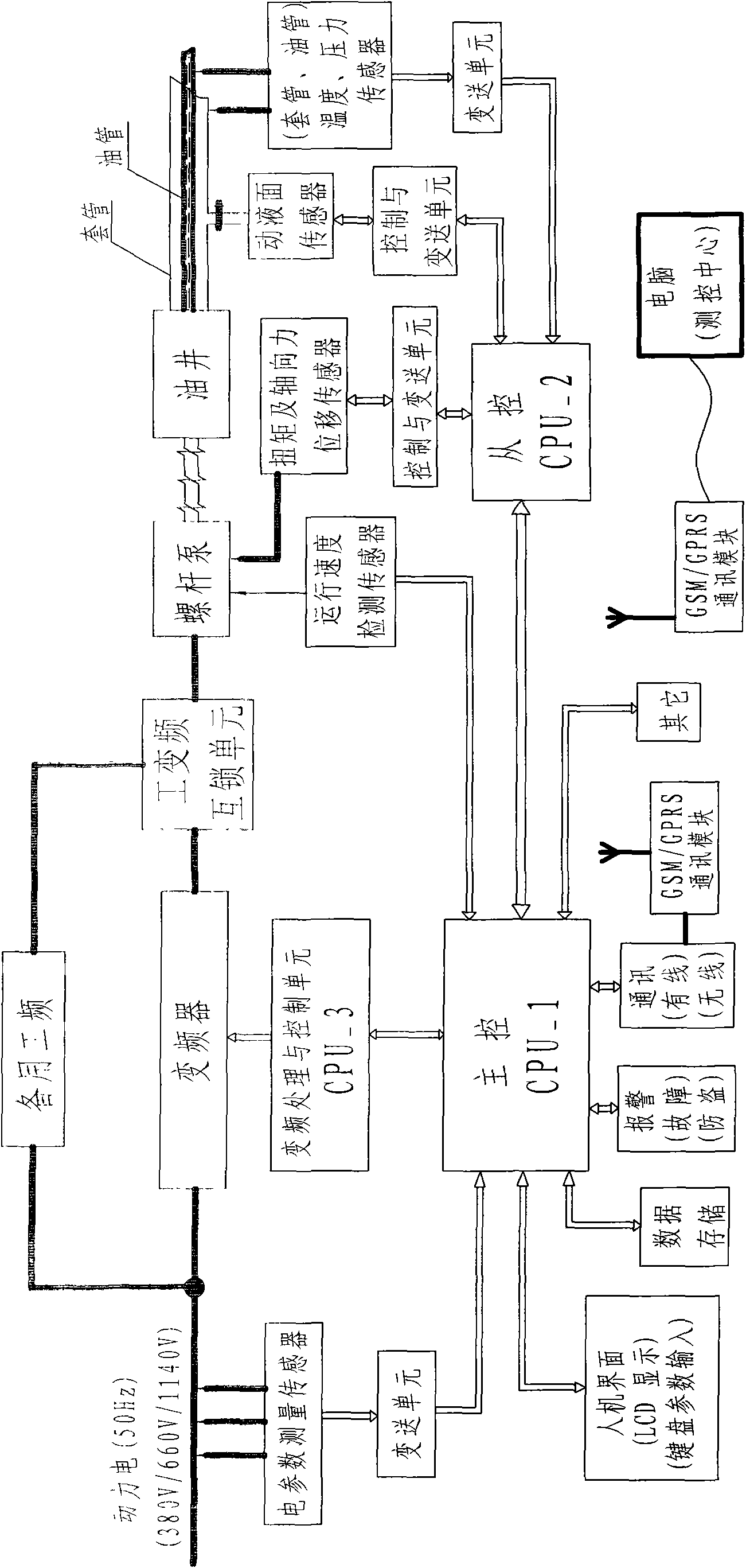

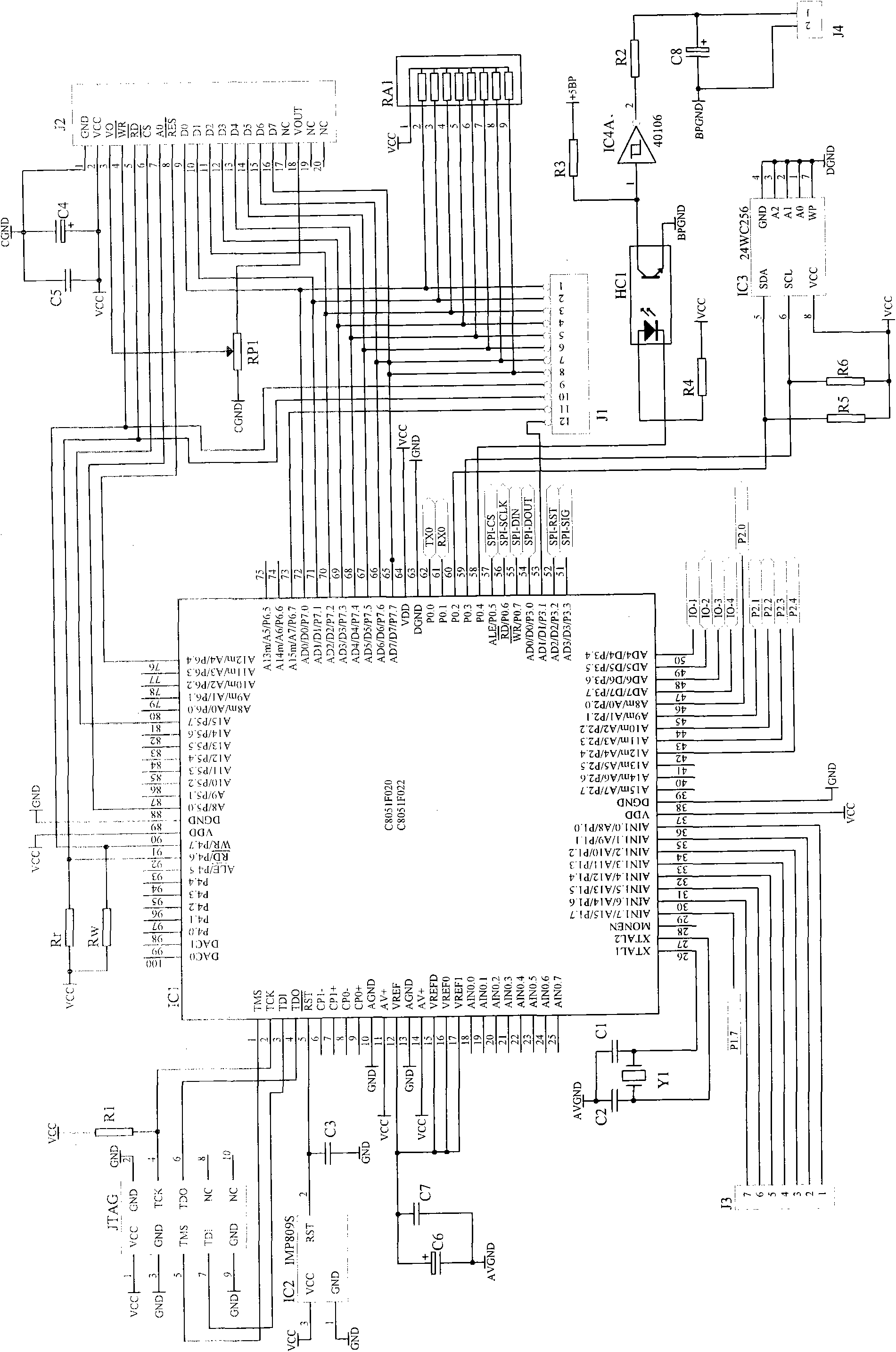

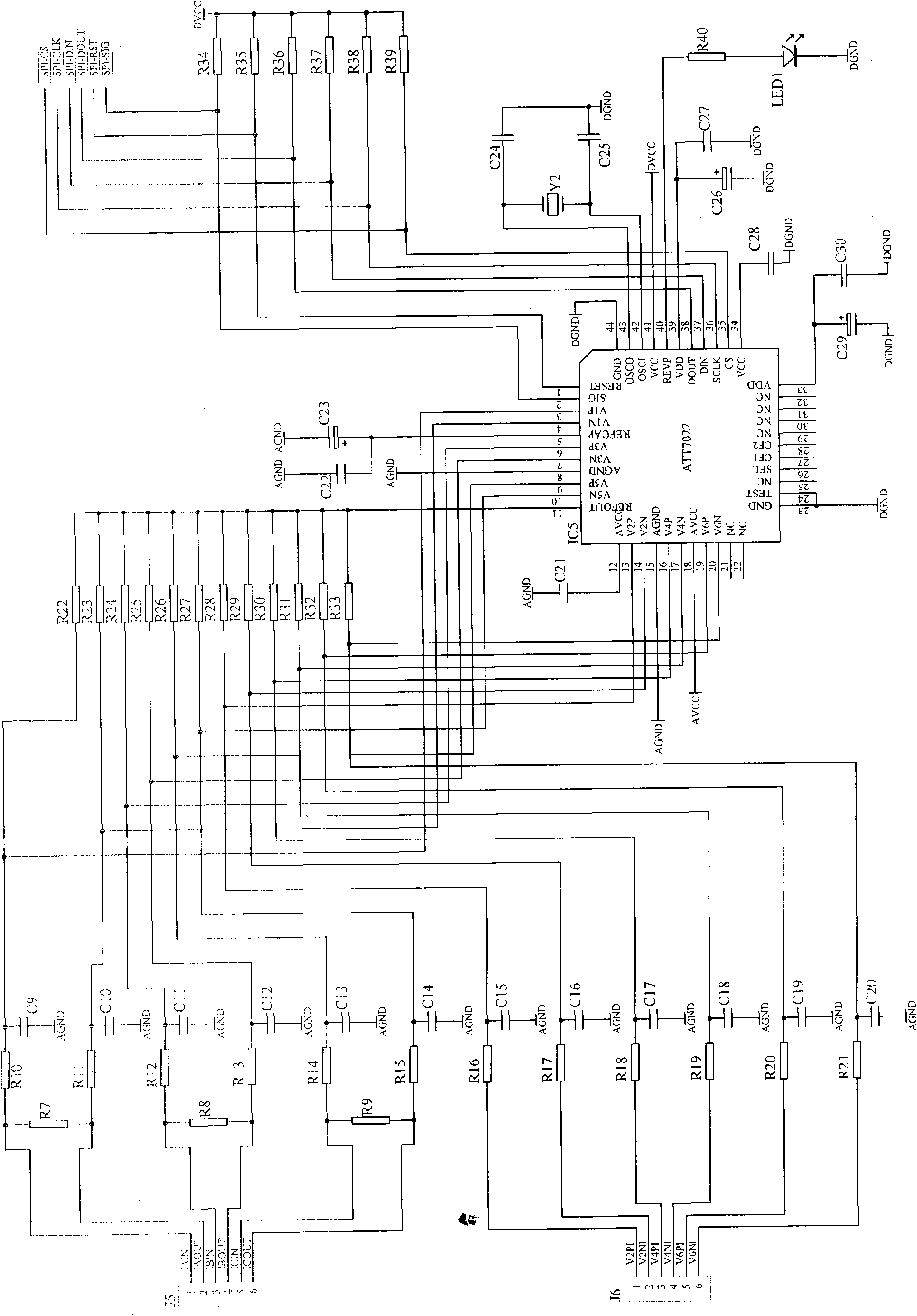

Intelligent monitoring device for screw pump well

InactiveCN101539135AMonitor work dataExtended service lifeFlexible member pumpsElectric controllersClosed loopEngineering

The invention relates to an intelligent monitoring device for a screw pump well, which is a high-performance industrial control device combined with optical, mechanical and electronic integration and electronic information and communication technology, and is mainly used for intelligently monitoring oil extraction of the screw pump well in oil field. The intelligent monitoring device mainly comprises a light current part and a strong current part, and is characterized in that the intelligent monitoring device takes connection of parts such as a sensor capable of measuring dynamic liquid level of the screw pump well on line, a sensor capable of measuring the torque and axial force of the screw pump well on line, a sensor capable of measuring electricity using parameters such as running current constantly and a remote wireless communication device and the like with a CPU as a core to realize the effective measurement and intelligent closed-loop control of the screw pump well. The intelligent monitoring device can avoid pump burning phenomenon of a screw pump caused by evacuation through accurate measurement and effective monitoring and dispatching, scientifically make a hot washing system according to wax deposition cause and the like to avoid phenomena such as rod breakage and the like, find eccentric wear problem in time to prolong pump detection cycle, and optimize design of the screw pump well to reasonably determine working parameters and reduce potential safety hazard and the like.

Owner:王洪亮 +1

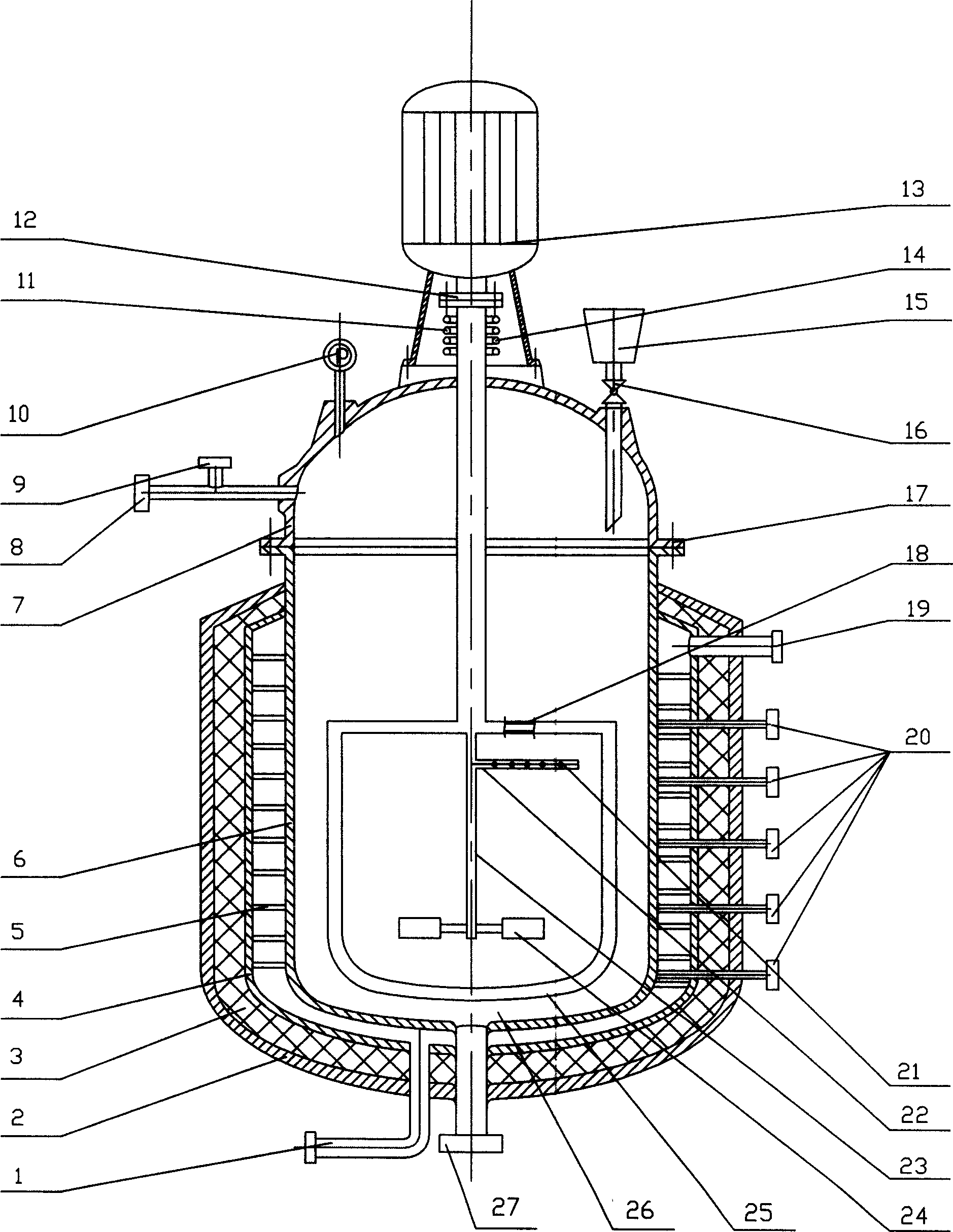

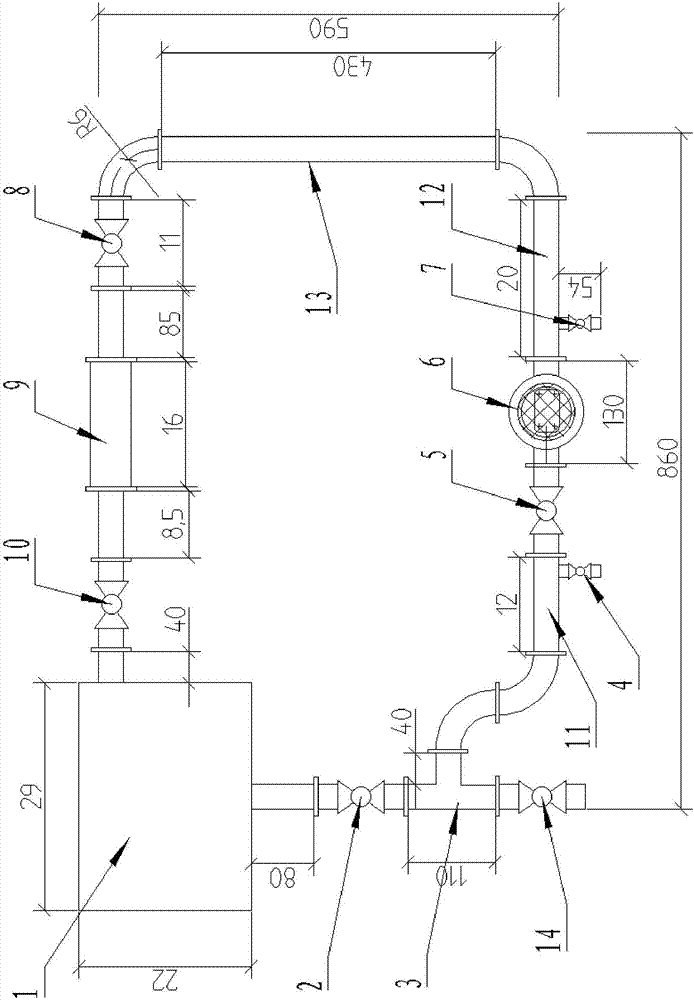

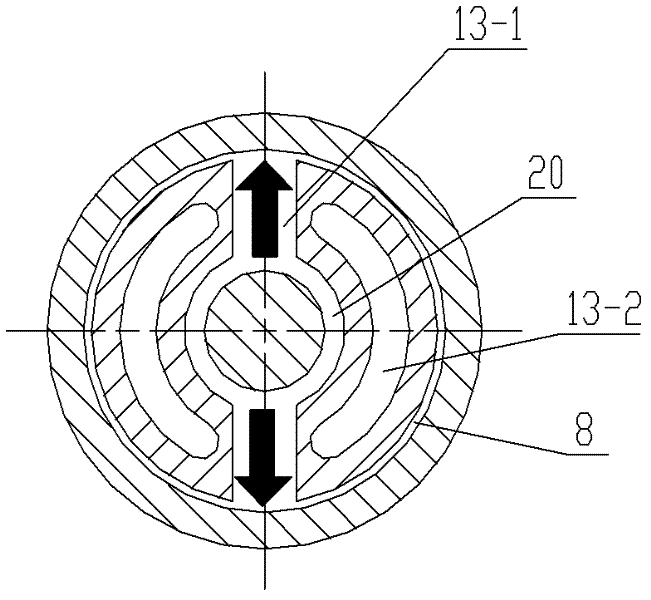

High pressure sealing ring current type crude oil wax deposition simulating device

The invention provides a high-pressure sealing circulatory imitating wax deposition device for wax deposition imitation in long petroleum pipeline. It comprises a sealing kettle (26) which has an oil inlet (15) and an oil outlet (27), an electric stirrer (23) inserted in kettle (26), a temperature-control and a detector. The temperature-control has an inner heater which is fixed on the stirrer (23) and inserted in the kettle (26), a clamping sheath (4) which covers the inner container (6), a heat-insulating layer (3) and an outer cover (2). The detector comprises a piezometer (10) which is inserted in the kettle (26) through the kettle cover (7), a plurality of temperature sensor (21-2) in the kettle (26), a temperature sensor slideway (14), a plurality of temperature sensor drive pipe (20) which is through the outer cover (2), heat-insulating layer (3), clamping sheath (4) and close to the outer wall of inner container (6). Said simulator has small structure, volume, little apparatuses, large experiment space of oil sample, while the equivalent sheared intensity of oil sample equals the intensity of on-site oil of channel in the simulating experiment that the geometrical and dynamical condition is close to the on-site reality. The experiment has real simulating course, accurate data, and lower cost.

Owner:PIPECHINA SOUTH CHINA CO

Delayed coking steam evacuating and cooling system and application thereof

The invention relates to a delayed coking steam evacuating and cooling system and application thereof. A gas-phase distributor, a tower bottom reflux distributor B, a tower bottom reflux distributor A, a tower top reflux distributor B and a tower top reflux distributor A are arranged in an evacuation cooling tower in sequence from an inlet; the tower top reflux distributor B and the tower top reflux distributor A are connected with a light distillate oil storage tank; the tower bottom reflux distributor B and the tower bottom reflux distributor A are connected with an outlet at the bottom of the evacuation cooling tower; a heavy distillate oil storage tank is connected with an inlet at the lower part of the evacuation cooling tower; an outlet at the top of the evacuation cooling tower is connected with a tower top three-phase separator; a gas-phase outlet of the tower top three-phase separator is connected with a low-pressure gas tank; a bottom oil-phase outlet of the tower top three-phase separator is connected with the light distillate oil storage tank, the tower top reflux distributor A and the tower top reflux distributor B; and a bottom liquid-phase outlet of the tower top three-phase separator is connected with a sewage treatment system. The system can be used for improving the separation accuracy and washing effect of light and heavy condensed oil, the gas phase at the top of the evacuation cooling tower is clean, and accidents caused by a wax deposition phenomenon are avoided.

Owner:PETROCHINA CO LTD +1

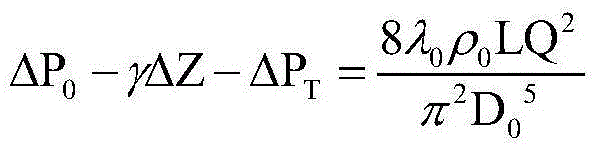

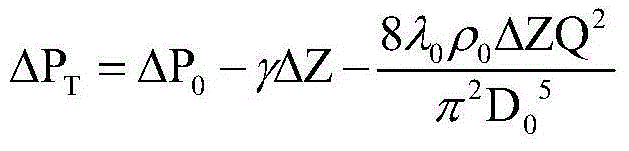

Crude-oil pipeline wax deposit pigging simulation experiment method

PendingCN110208500AAchieving on-site pigging conditionsReal-time monitoring of pressure changesWeighing by removing componentHollow article cleaningPiggingEngineering

The invention discloses a crude-oil pipeline wax deposit pigging simulation experiment method. By controlling the temperature difference between an oil flow and a pipe wall, a wax deposition experiment is carried out in a wax removal testing pipe section; after a preset deposition time arrives, pressure at two ends is measured through pressure sensors at two ends, the thickness of the deposition layer is further obtained in the wax removal testing section, a pigging process is then carried out, a pig is sent by a launcher, pigging operation is carried out in the wax removal testing stage underpushing by the oil flow, the process of pushing ball ahead wax blocking or oil wax slurry by the pig is observed through a transparent testing section, the quality before wax deposition and after waxremoval in the wax removal testing stage is obtained, and the wax removal efficiency during a one-time pigging process is measured. Through analyzing the thickness of the deposition layer in the waxremoval testing stage and the wax removal efficiency of different pigs during the one-time pigging process, teh wax removal mechanism in the actual pigging process is studied, the problems of ball clamping, wax blocking and the like during the actual pipeline ball passing wax removal process are solved, and more scientific guidance is provided for actual pigging operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

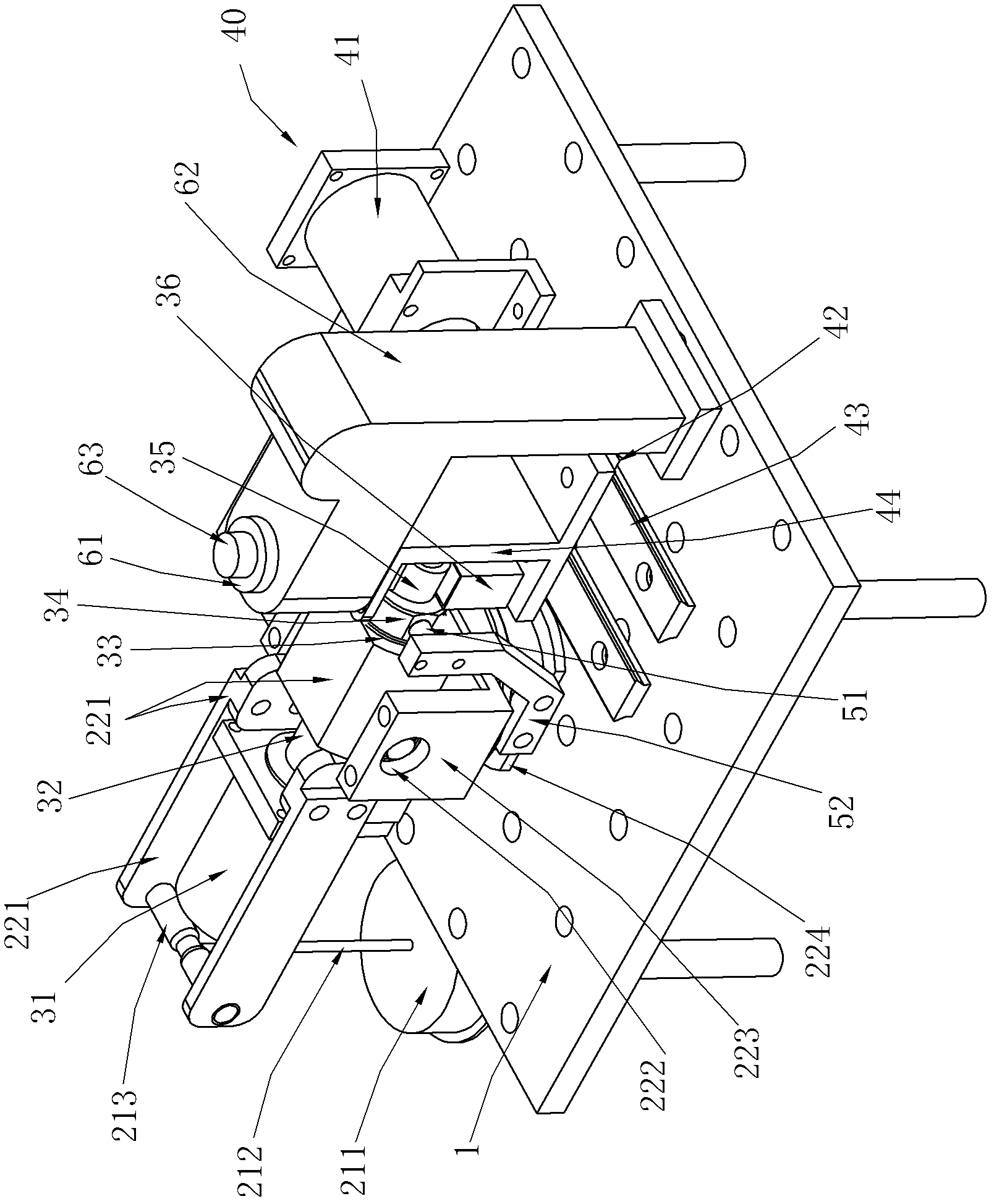

Qualitative wax deposition experimental device and method under pipeline transportation conditions

ActiveCN105301039ARealize deposition dynamic simulationInvestigating phase/state changeExperimental methodsWater flow

The invention provides a qualitative wax deposition experimental device and a qualitative wax deposition experimental method under pipeline transportation conditions. The qualitative wax deposition experimental device under pipeline transportation conditions comprises an oil storage tank, a wax deposition main body and a pump, wherein a water jacket interlayer is formed in the outer side of the oil storage tank in a sleeved manner and is connected with a first temperature controller; the wax deposition main body comprises an upper tank body and a lower tank body; the upper tank body is provided with an upper water flow chamber; the upper water flow chamber is connected with a second temperature controller; the lower tank body is a tank body of which the upper end is open; the upper tank body is connected to the opening of the lower tank body in a sealed manner; a clapboard is arranged in the lower tank body; the lower tank body above the clapboard is an experimental cavity; the lower tank body below the clapboard is a lower water flow chamber; the lower water flow chamber is connected with a third temperature controller; the inlet end of the experimental cavity and the outlet end of the experimental cavity are respectively communicated with the oil storage tank; and the pump is connected between the inlet end of the experimental cavity and the oil storage tank. The device disclosed by the invention is capable of measuring the wax deposition rule of crude oil and oil-water mixtures under simulated pipeline transportation conditions and has significance on pipeline safety and economic operation.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Anti-wax anti-scaling anti-corrosion alloy material

The invention provides an anti-wax anti-scaling anti-corrosion alloy material. The alloy material is used for a protective device of a pipeline or equipment in industrial production, such as an anti-wax anti-scaling anti-corrosion device, and is prepared by smelting the following nine components in percentage by weight: more than 52 percent and less than 65 percent of Cu, more than 14.2 percent and less than 20 percent of Zn, more than 15 percent and less than 19 percent of Ni, more than 2 percent and less than 3 percent of Pb, more than 3 percent and less than 5 percent of Sn, more than 0.23 percent and less than 0.43 percent of Fe, less than 0.005 percent of Sb and the balance of S and Mn. By the anti-wax anti-scaling anti-corrosion device made of the alloy material, the corrosion resistance and scaling prevention and wax deposition prevention functions of metallurgical equipment and oil extraction equipment are greatly improved, the maintenance period and replacement period of industrial equipment are prolonged, and production cost is reduced.

Owner:恩曼自动化技术(上海)有限公司

Wax deposition resistant coating for oil pipeline

InactiveCN1865370ASolve anti-waxPolyurea/polyurethane coatingsEpoxy resin coatingsPolyvinylidene difluoridePolyvinylidene fluoride

Disclosed is an anti-waxing paint for internal surfaces of oil pipes, which comprises modified polyurethane 20-50%, polyvinylidene fluoride 5-30%, epoxy resin 5-20%, molybdenum sulfide 2-20%, Disclosed is an anti-waxing paint for internal surfaces of oil pipes, which comprises modified polyurethane 20-50%, polyvinylidene fluoride 5-30%, epoxy resin 5-20%, molybdenum sulfide 2-20%, cerium fluoride 2-10%.

Owner:ZHONGBEI UNIV

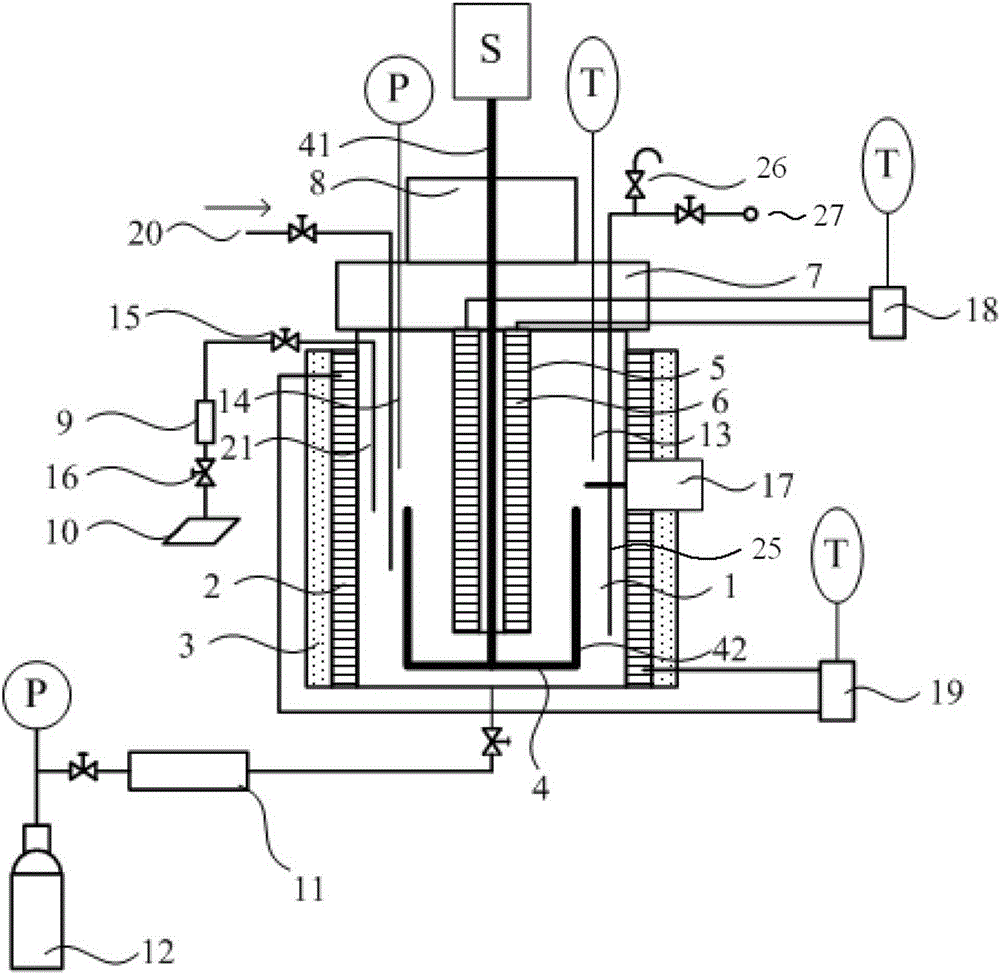

High-pressure wax deposition simulation device and method

ActiveCN105223227AGuaranteed stabilityDeposition experiment went wellInvestigating phase/state changeTemperature controlControl system

The invention provides a high-pressure wax deposition simulation device and method. The high-pressure wax deposition simulation device comprises a high-pressure kettle (1), wherein the high-pressure kettle (1) is internally provided with a cold finger (5) used for wax deposition; the temprature of the cold finger (5) is controlled by a first temperature control system (18); the temperature in the high-pressure kettle (1) is controlled by a second temperature system (19); the high-pressure wax deposition simulation device further comprises a sampling pipe (9), a sampling device (21) and a visible window (10), which can be used for sampling and observing under a high-pressure environment in the high-pressure kettle (1); and the high-pressure wax deposition simulation device further comprises a viscosity detection device (17). The high-pressure wax deposition simulation device and method provided by the invention can realize wax deposition simulation experiment, viscosity online detection and visualization processes under the high-pressure environment.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

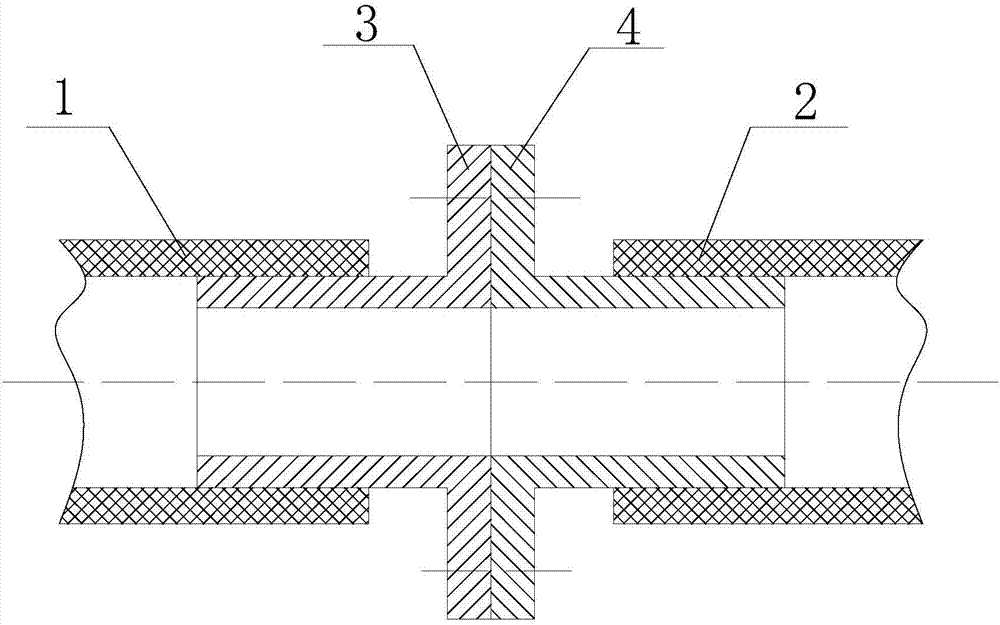

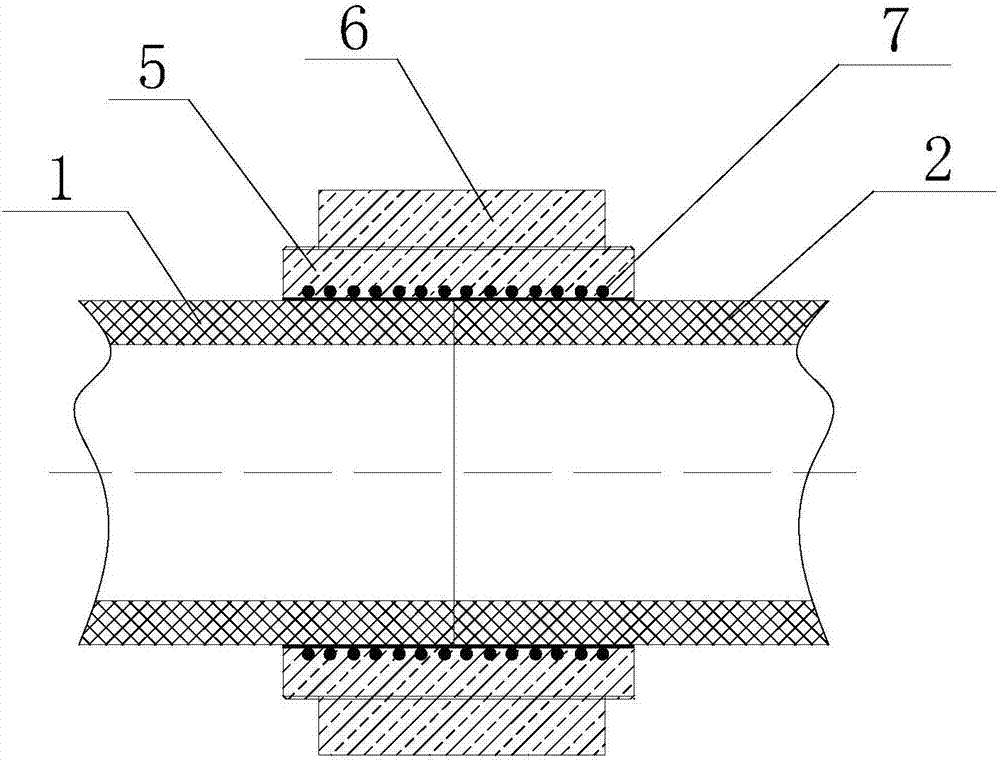

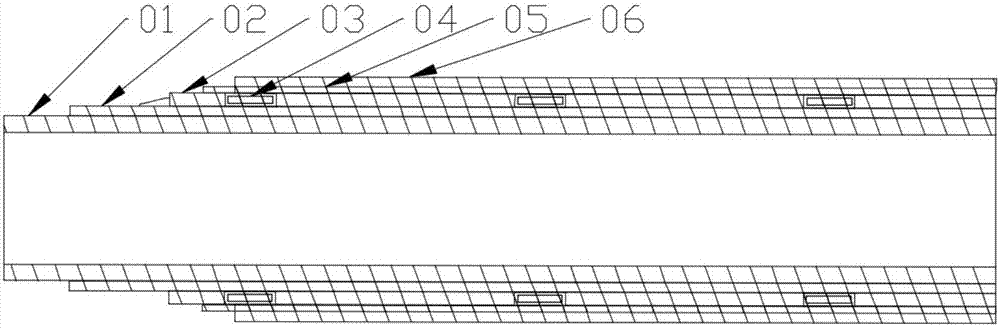

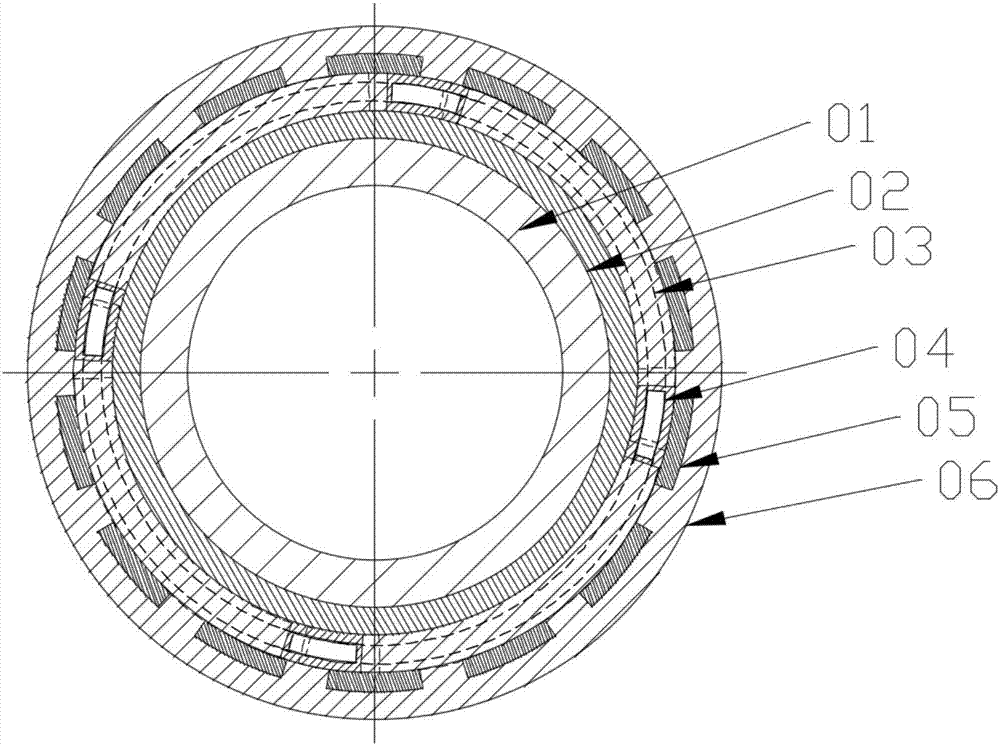

Reinforced thermoplastic pipe (RTP) joint structure and connection method thereof

PendingCN107228248AEffective protectionImprove pressure resistancePipe connection arrangementsButt jointHigh pressure

The invention provides a reinforced thermoplastic pipe (RTP) joint structure and a connection method thereof. The RTP joint structure comprises a first RTP, a second RTP, a PE electric melting joint and a GRE reinforced pipe hoop. The first RTP and the second RTP have the same external diameter, and the butt joint end faces of the first RTP and the second RTP are subjected to thermofusion welding. The internal diameter of the PE electric melting joint is matched with the external diameter of the first RTP, and a heating wire is preset and wound inside the PE electric melting joint. The outer wall of the PE electric melting joint is provided with an external thread. The PE electric melting joint simultaneously sleeves the first RTP and the second RTP and is subjected to electric fusion welding to the first RTP and the second RTP through the heating wire, the inner wall of the GRE reinforced pipe hoop is provided with an internal thread matched with the external thread of the PE electric melting joint, and the GRE reinforced pipe hoop is screwed on the external thread of the PE electric melting joint. According to the RTP joint structure, problems that in the prior art, an RTP connection part corrodes easily, is low in high pressure resistance and is subjected to wax deposition and blockage easily can be effectively solved.

Owner:曹如锋

Pipe cleaning experimental facility suite for crude oil pipeline

The invention provides a pipe cleaning experimental facility suite for a crude oil pipeline. The pipe cleaning experimental facility suite comprises a circuit system and a pipe cleaning experimental system, wherein the circuit system includes an oil tank (1), a wax deposition pipe section (9) and a gear oil pump (6), which are connected into a closed loop in sequence; the wax deposition pipe section (9) can simulate a wax deposition process of crude oil in a transportation process; the wax deposition pipe section (9) can be demounted; the pipe cleaning experimental system can measure the strength and the wax cleaning resistance of a wax deposit on the inner wall of the wax deposition pipe section (9). According to the pipe cleaning experimental facility suite for the crude oil pipeline, the true wax deposit in an oil conveying pipeline is obtained by adopting the circuit system; the indoor simulation of the ball running wax cleaning of the crude oil pipeline is carried out by adopting the pipe cleaning experimental system. A wax deposition law of wax-containing crude oil in a pipe conveying condition, the property of a wax layer and a failure law of the wax layer in a pipe cleaning process can be researched; further, the internal relation among the pipe cleaning process, the wax deposition process and the property of the wax deposit is explored.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Sliding-rolling combined type soft friction test apparatus

InactiveCN102519868AImprove cleaning efficiencyEnsure safety and efficiencyUsing mechanical meansMaterial analysisHardnessPetroleum

The invention relates to a sliding-rolling combined type soft friction test apparatus, which comprises a test bed and a loading mechanism which can rotatably support on the test bed, an upper sample mounting rack is arranged on the test bed, and enables linear movement on a plane, an upper sample is fixed on the upper sample mounting rack; a lower sample is arranged at the lower part of the uppersample, and is rotatably butted with the upper sample through the loading mechanism; a frictional force detection mechanism is arranged on the test bed, and is connected with the loading mechanism; the lower sample is an elastic sample, the hardness of the upper sample is stronger than that of the lower sample; the lower sample is butted with the upper sample through the loading mechanism, when the operation is carried out, the lower sample enables rotary movement, the upper sample enables sliding movement, thereby a sliding-rolling combined type soft friction contact couple is formed. The apparatus of the present invention can be used for simulating a residue distribution rule of a petroleum natural gas pipeline inner wall wax deposition after pipe cleaning operation, and provides basis for raising pipeline cleaning efficiency and soft friction research in the petroleum natural gas industry.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

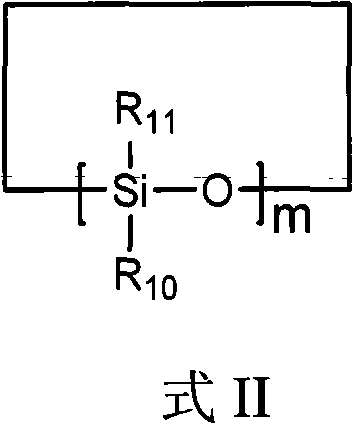

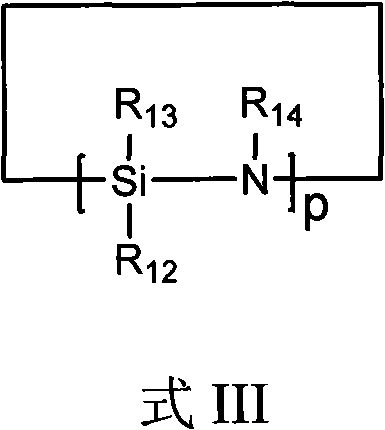

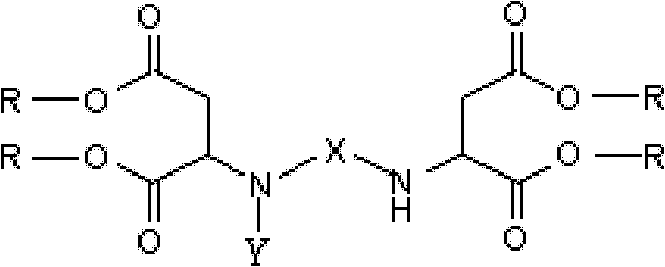

Wax deposition preventing organic paint and preparation method of organic coating containing it

The invention discloses wax deposition preventing organic paint and a preparation method of an organic coating containing it. The wax deposition preventing organic paint comprises an organosilicon polyaspartic ester with a structure shown in formula (1) and isocyanate. In formula (1), R is an alkane group, and when X represents -R'-[SiR"20] nSiR"2-R'-, Y represents H; or, when X is -(CH2)P-, Y represents the wax deposition preventing organic paint provided in the invention. With reduced raw material cost and shortened curing time during the forming of an organic coating from organic paint, the wax deposition preventing organic paint of the invention can form an organic coating with good stability and low surface energy. And the surface of a sucker rod and the inner walls of an oil pipeline and an oil container in crude oil extraction can be coated with the wax deposition preventing organic coating, so that the oil delivery capacity of an oil well can be improved during crude oil extraction and the service life of an oil pumping unit is prolonged. Structural formula (1) is shown below.

Owner:北京碧海云智新材料技术有限公司

Inner corrosion-resistant high wear-resistant powdery coating specifically for oil field producing well pipe

InactiveCN106978040AImprove anti-corrosion performanceImprove temperature resistanceFireproof paintsAntifouling/underwater paintsEpoxyWear resistant

The invention discloses an inner corrosion-resistant high wear-resistant powdery coating specifically for an oil field producing well pipe. The coating is prepared from 50 to 60 parts by weight of epoxy resin, 25 to 35 parts by weight of silicone resin, 15 to 20 parts by weight of phenolic resin, 10 to 15 parts by weight of polyester resin, 18 to 22 parts by weight of a phenol polymer curing agent, 5 to 10 parts by weight of an acrylate copolymer leveling agent, 2 to 5 parts by weight of a methacrylate copolymer sensitizer, 0.5 to 2 parts by weight of imidazole, 0.5 to 2 parts by weight of defoamer benzoin, 10 to 15 parts by weight of titanium dioxide, 40 to 50 parts by weight of a ultra-wear resistant material, 3 to 5 parts by weight of graphene and 25 to 40 parts by weight of wollastonite powder. The inner corrosion-resistant high wear-resistant powdery coating has excellent wear resistance and high temperature resistance, has a flat and smooth surface, prevents wax deposition and scaling and is a good oil field pipe inner wall corrosion-resistant coating.

Owner:孟鋆辉

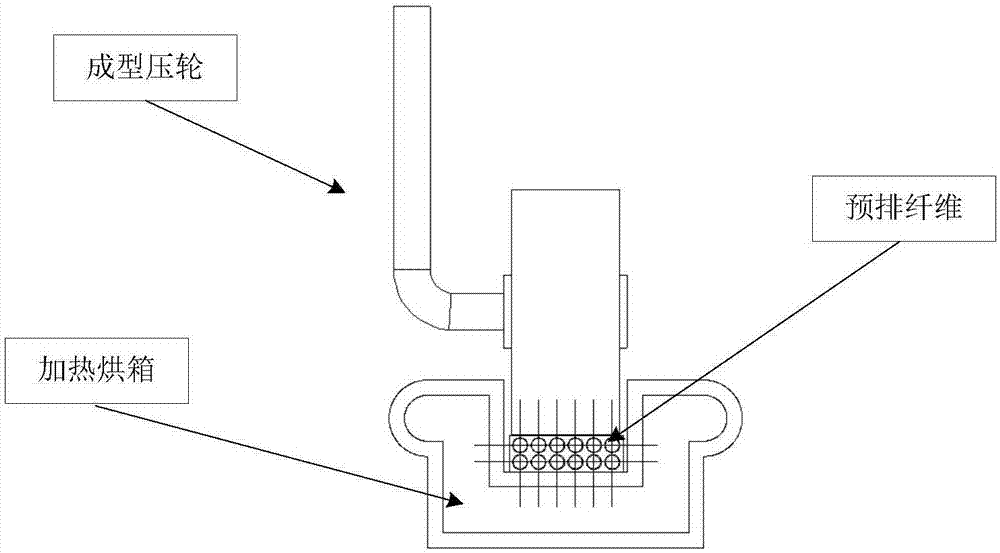

Intelligent flexible composite constant oil pipe for underground and manufacturing technology thereof

PendingCN107355187AAvoid corrosionAvoid security issuesDrilling rodsDrilling casingsFiberManufacturing technology

The invention discloses an intelligent flexible composite constant oil pipe for underground and a manufacturing technology thereof. The intelligent flexible composite constant oil pipe for the underground replaces a traditional oil extraction method of steel oil pipes along with external applying cables, avoids the corrosion damage of a pipeline and related safety accidents on the basis of solving the problems of corrosion, scale formation and wax deposition, and meanwhile, an oil-submerged electric cable is internally arranged in a pipe body and plays a protective function on the pipe body so as to prevent the pipe body from being corroded by outside oil gas and being worn and damaged by rountrip operation. A related sensor which is internally arranged in the pipe body conducts collecting and monitoring on underground information, and back-feeds the information to a ground control system. According to the intelligent flexible composite constant oil pipe for underground and the manufacturing technology thereof, a multi-row and multi-bundle fiber dip forming technology is adopted to achieve the manufacturing technology, after resin impregnating and forming are conducted on fiber dried silk, a multi-row fiber strip with certain toughness and high strength is formed, the fiber strip is applied to various kinds of function layers, such as compressive armored and tensile armored of the pipeline, therefore the structural strength of the pipeline is improved, and meanwhile, a resin substrate further has the properties of being swelling resistant, hydrolyzing resistant, oil and gas corrosion resistant and high temperature resistant to chemical agents, and a better protection for fiber is facilitated.

Owner:浙江恒安泰石油工程有限责任公司

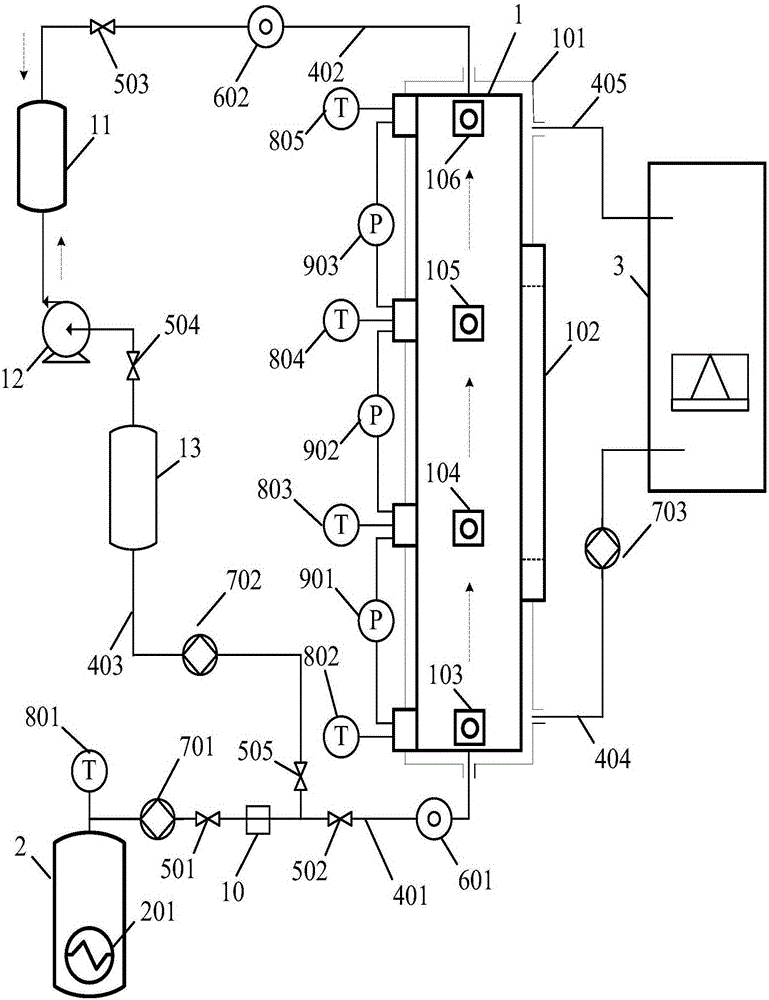

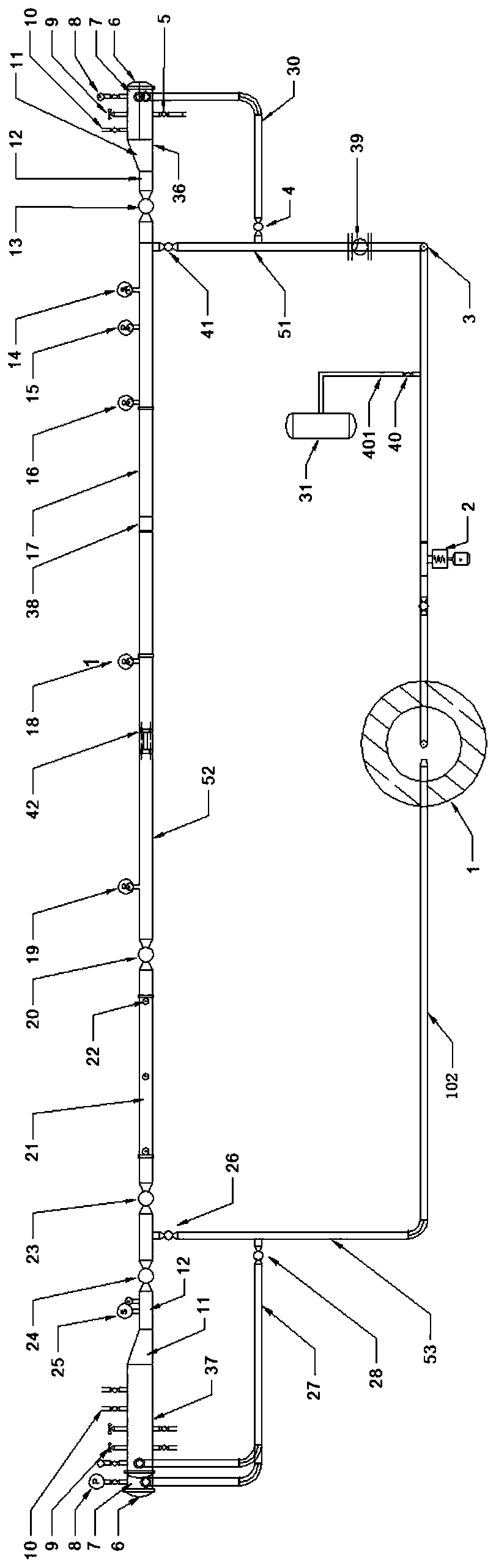

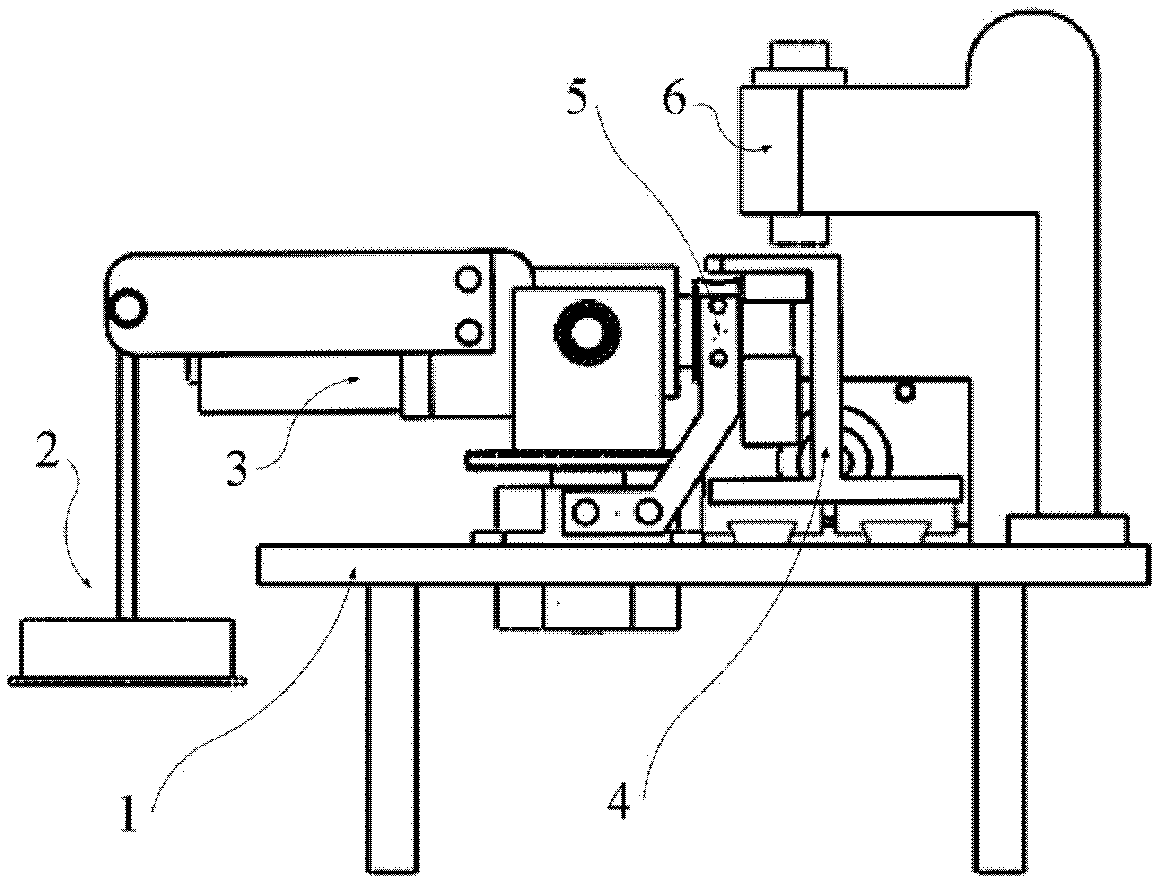

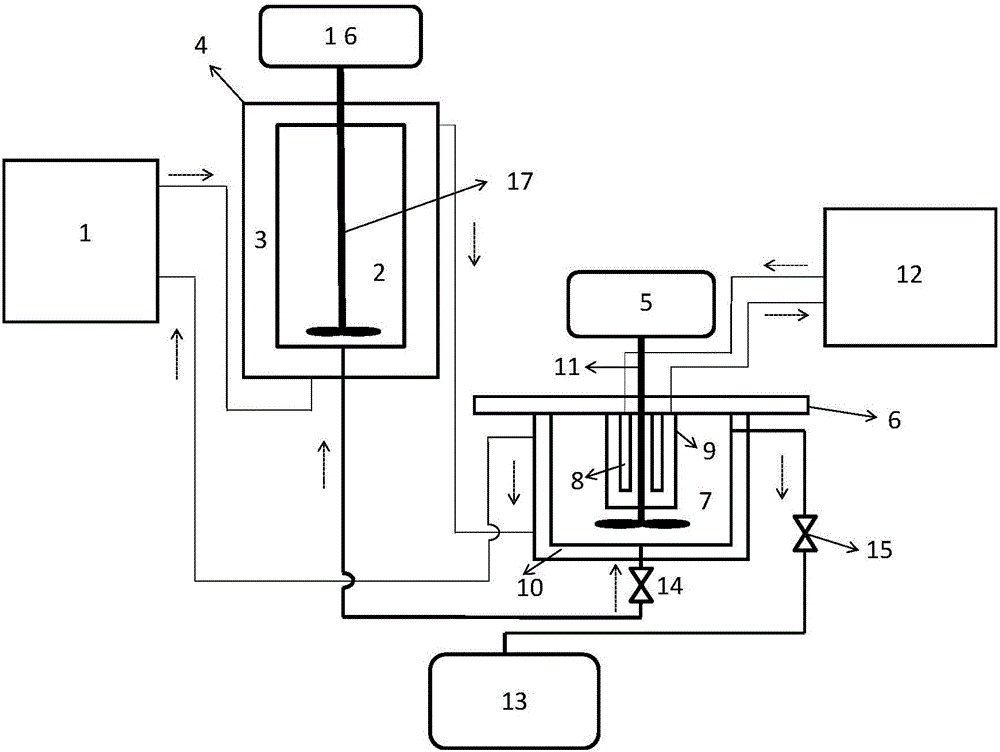

Detection method and system for simulating wax deposition in crude oil pipeline conveying process

InactiveCN105699415AImprove the mixing effectRealize continuous updateInvestigating phase/state changeWeighing by absorbing componentWater bathsTemperature control

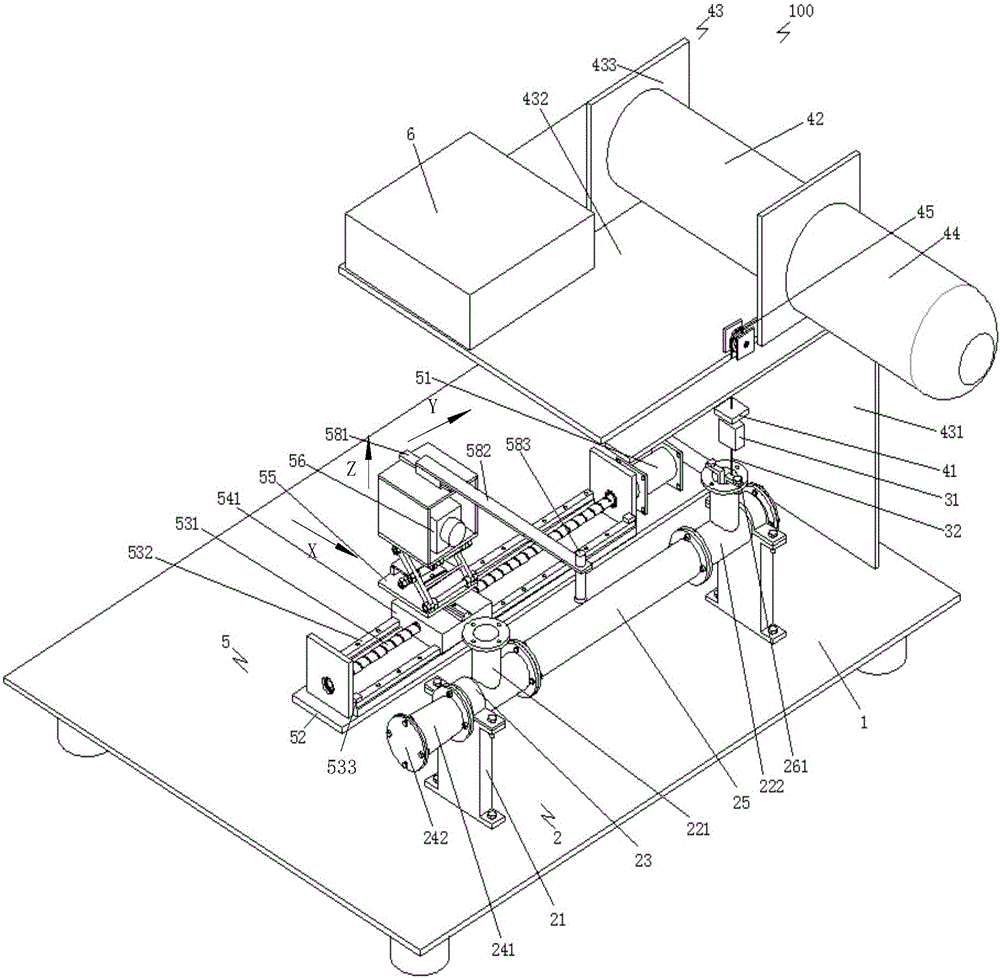

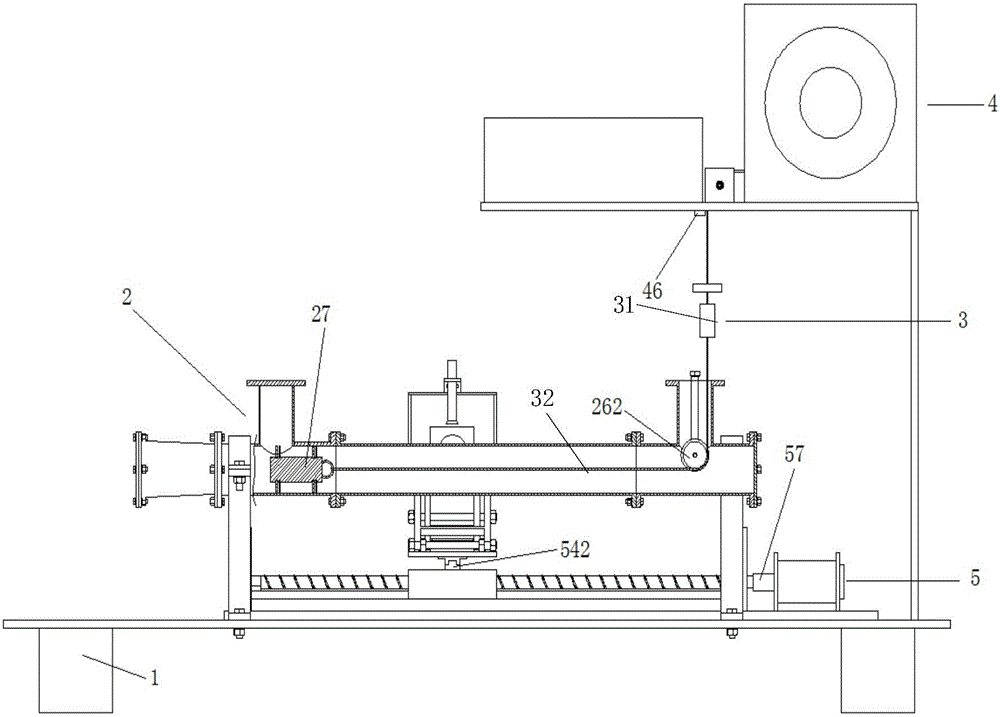

The invention provides a detection method and system for simulating wax deposition in a crude oil pipeline conveying process. The method comprises the steps that a high level storage tank, an oil sample container and a low level storage tank are installed in a sequentially lowered mode; a first water bath, a temperature control interlayer of the high level storage tank and a temperature control interlayer of the oil sample container form a first closed loop; a second water bath and a hollow interlayer of a cold finger form a second closed loop; a stirrer is arranged in a hollow part of the cold finger, the stirring rate of the stirrer is changed, and the stirring rate corresponding to the shear rate under the simulated pipeline conveying condition is obtained; stirring is maintained, sediment is stripped away from the surface of the cold finger after an experiment is over, and weighing and calculating are conducted to obtain the increase rate of a wax deposition layer. The system at least comprises the high level storage tank, the oil sample container, the low level storage tank, the cold finger, the temperature control water baths and a connecting pipe. By constructing an oil sample passageway and establishing a wax deposition temperature field, continuous update of oil samples in the sample container is realized, pipe flow shear is simulated quantitatively in a stirring mode, and the wax deposition detection process is more approximate to the actual pipeline conveying condition.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Multiphase flow pipeline mechanical wax removal simulated test device and mould to manufacture wax deposit

InactiveCN106643868AImprove safety and reliabilitySimple structureMeasurement devicesHollow article cleaningThermodynamicsControl system

The invention provides a multiphase flow pipeline mechanical wax removal simulated test device and a mould to manufacture wax deposit. The multiphase flow pipeline mechanical wax removal simulated test device comprises a testing station. The testing station is fixedly provided with a multiphase flow pipeline component. The multiphase flow pipeline component comprises a main pipeline. The main pipeline is provided with a wax deposit arranged in the axial direction and having a crescent-shaped cross section. The main pipeline is provided with a pipeline cleaner. The pipeline cleaner is connected with a rope. One end of the rope penetrates the main pipeline. The upper part at one end of the main pipeline is provided with a wax cleaning resistance detection mechanism. The wax cleaning resistance detection mechanism comprises a measured force sensor. One end of the upper part of the measured force sensor is connected with an electric winch drive mechanism. Observation mechanisms are parallelly arranged at intervals on one side of the main pipeline and can observe pipeline cleaning. The multiphase flow pipeline mechanical wax removal simulated test device further comprises a control system. The test device is capable of simulating the use of a mechanical mode to clean the wax in a multiphase flow pipeline and can find applications in the research on the wax removal of an oceanic petroleum transporting pipeline.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Acrylic copolymers as additives for inhibiting paraffin deposit in crude oil, and compositions containing same

Owner:INST FR DU PETROLE +1

Safety valve in pipe

InactiveCN102337864AHigh production temperatureThoroughly remove waxCleaning apparatusWell/borehole valve arrangementsUpper jointSafety valve

The invention discloses a safety valve in a pipe, comprising an upper joint, a safety valve body and a lower joint which are sequentially connected from top down, wherein the upper joint, the safety valve body and the lower joint form a main perforating hollow structure; a piston assembly, a valve plate assembly and a first spring are sequentially arranged between an upper step and a lower step in the main hollow structure from the top down; a liquid injection channel is formed over the piston assembly in the main hollow structure; a bridge channel is formed at the periphery of the piston assembly; and the valve plate assembly is sealed at the lower end of the bridge channel. In the invention, the piston assembly is pushed by hydraulic pressure by forming the central liquid injection channel at the upper end part, and the piston assembly pushes the valve plate assembly, and then a production oil side output channel is opened, so that the production oil enters the space between a large-diameter oil pipe and a small-diameter oil pipe to form an oil extracting channel; while extracting the oil, high-temperature liquid is cycled in the mall-diameter oil pipe for transferring heat to the production oil through heat conduction, so that the temperature of the production oil is higher than wax deposition temperature so as to achieve the purpose of removing the wax and preventing the deposition of wax.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com