Wax deposition rate measuring device for crude oil

A measuring device and wax deposition technology, applied in the direction of material inspection products, etc., can solve the troublesome and time-consuming problems of measuring the thickness of wax deposition, and achieve the effect of small footprint and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

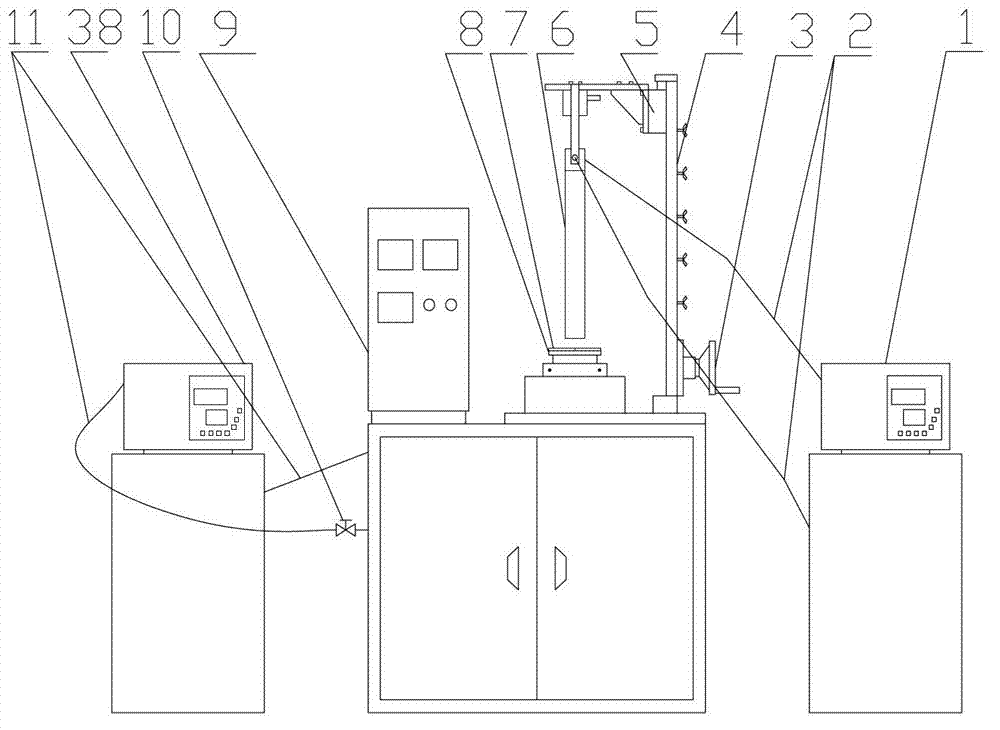

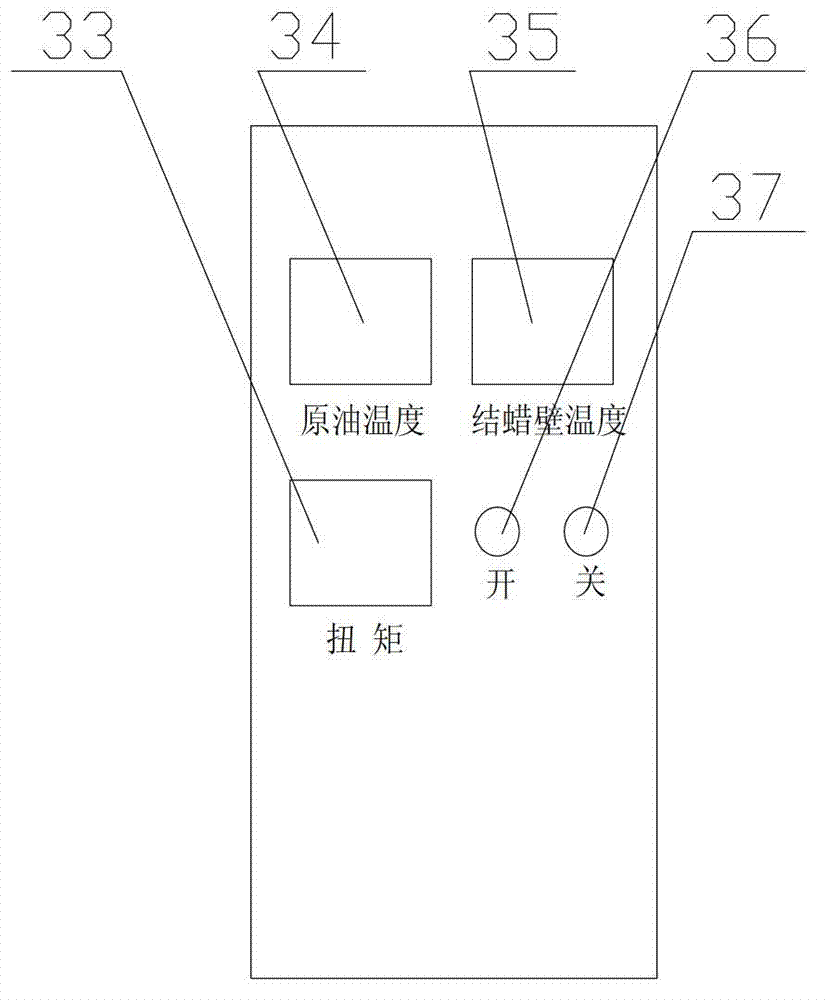

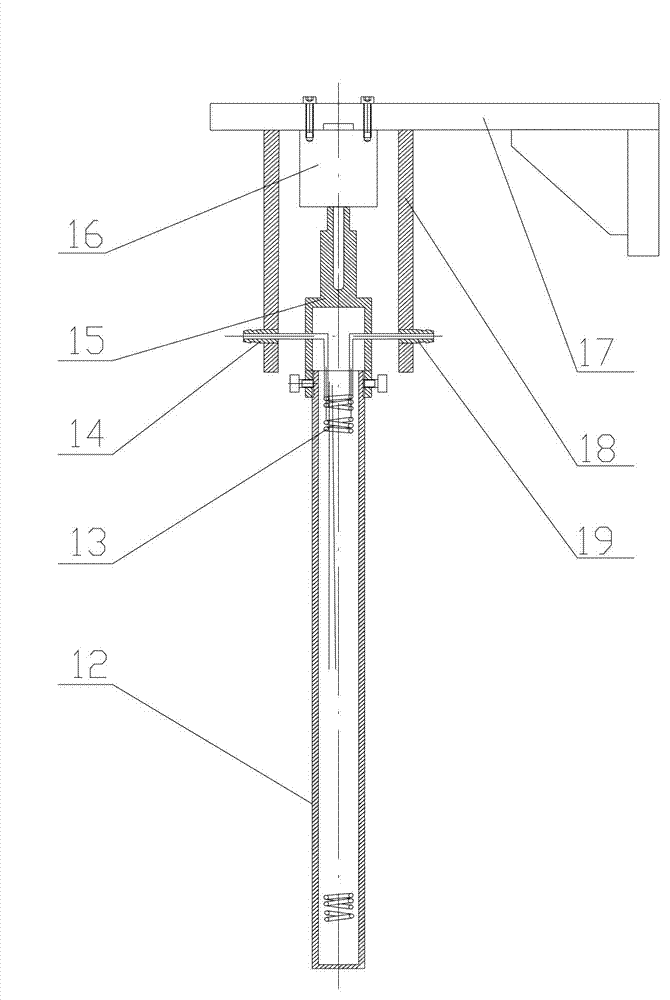

[0017] This embodiment is an experimental prototype, and its overall structure is as follows: figure 1 shown. The crude oil wax deposition rate measuring device of the present invention is composed of wax deposition cylinder 6, sample cylinder 8, low-resistance rotating mechanism, high-speed rotating mechanism, lifting mechanism 5, constant temperature oil bath 38, constant temperature water bath 1, measurement system, electric control system and Data acquisition and processing system and other components. A heat conduction oil tank 30 is installed in a box body 31, and the high-speed rotating mechanism positioned at the rear of the heat conduction oil tank 30 is fixed on the upper case plate. The AC servo motor 21 in the high-speed rotating mechanism is connected with the low-resistance rotating mechanism through the low-resistance bearing 22 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com