Patents

Literature

1052 results about "Rotational rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

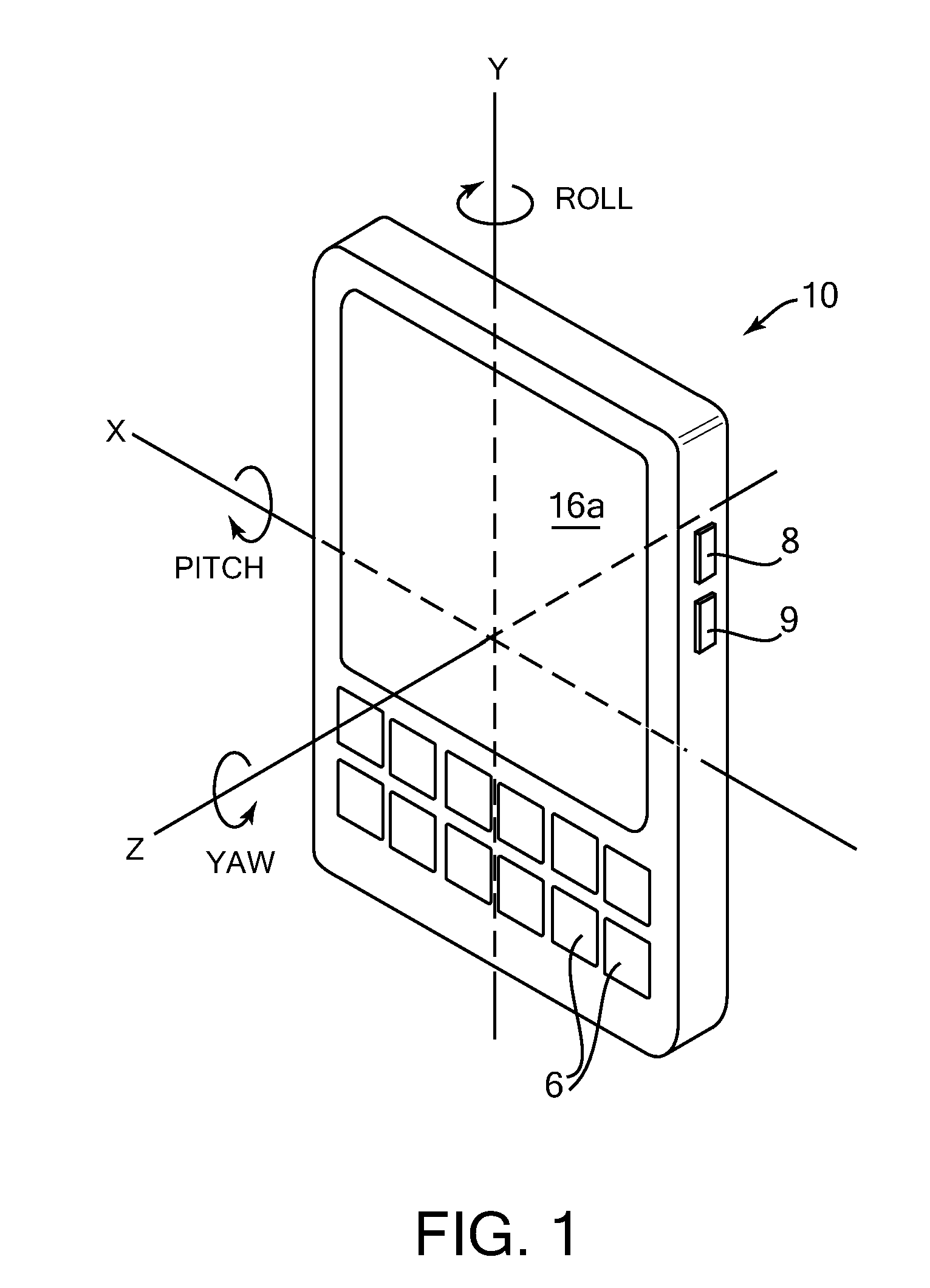

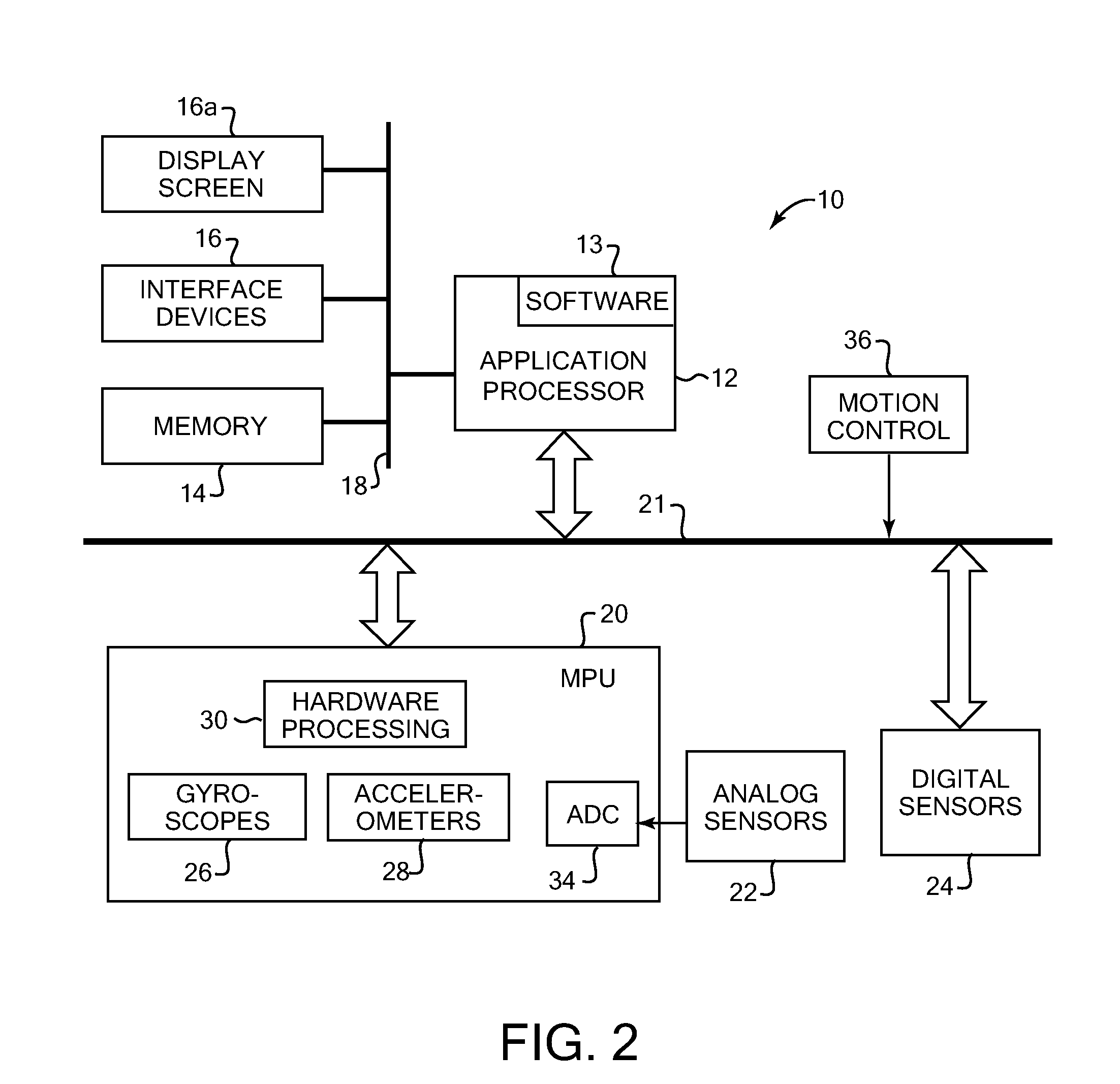

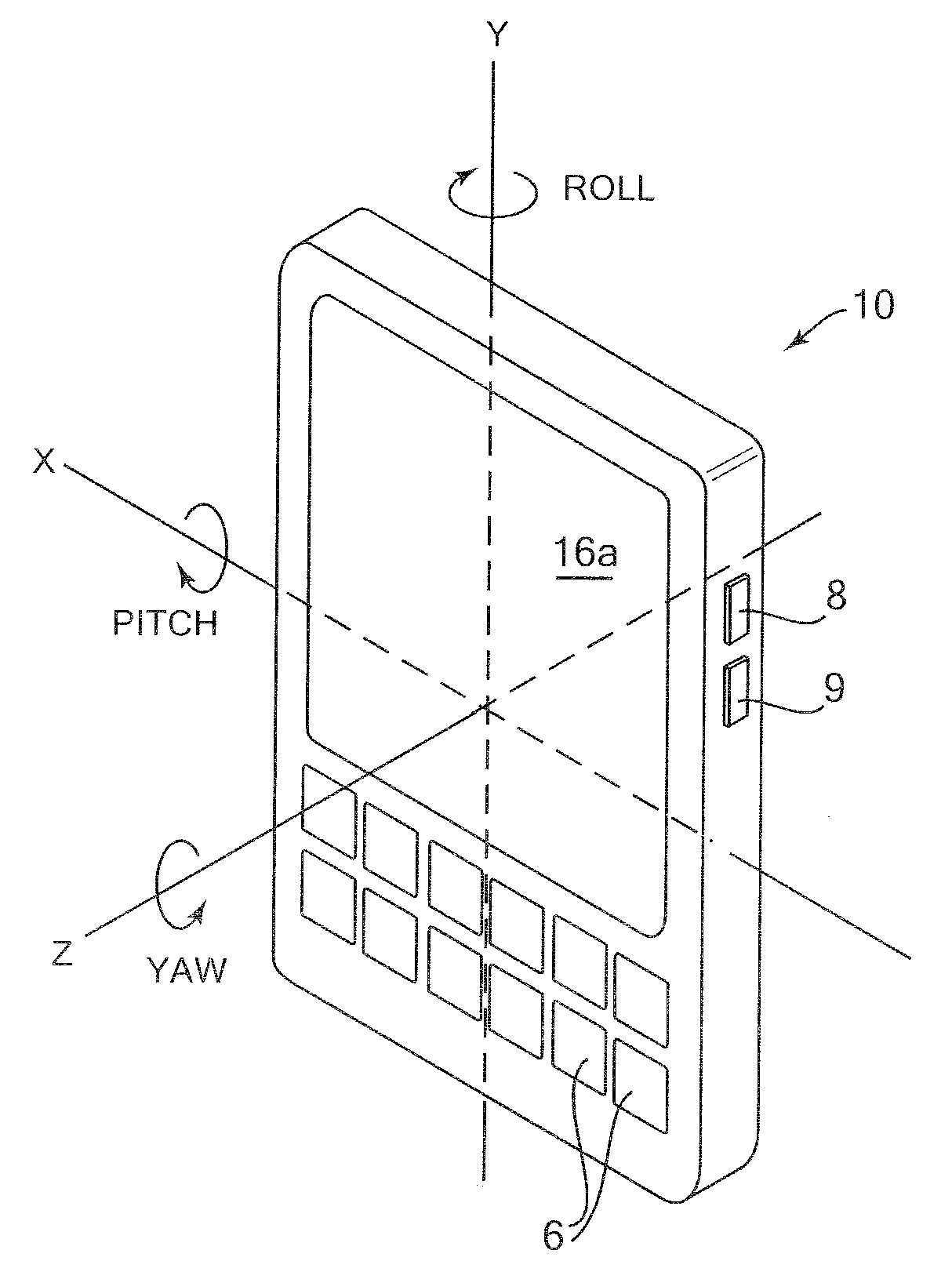

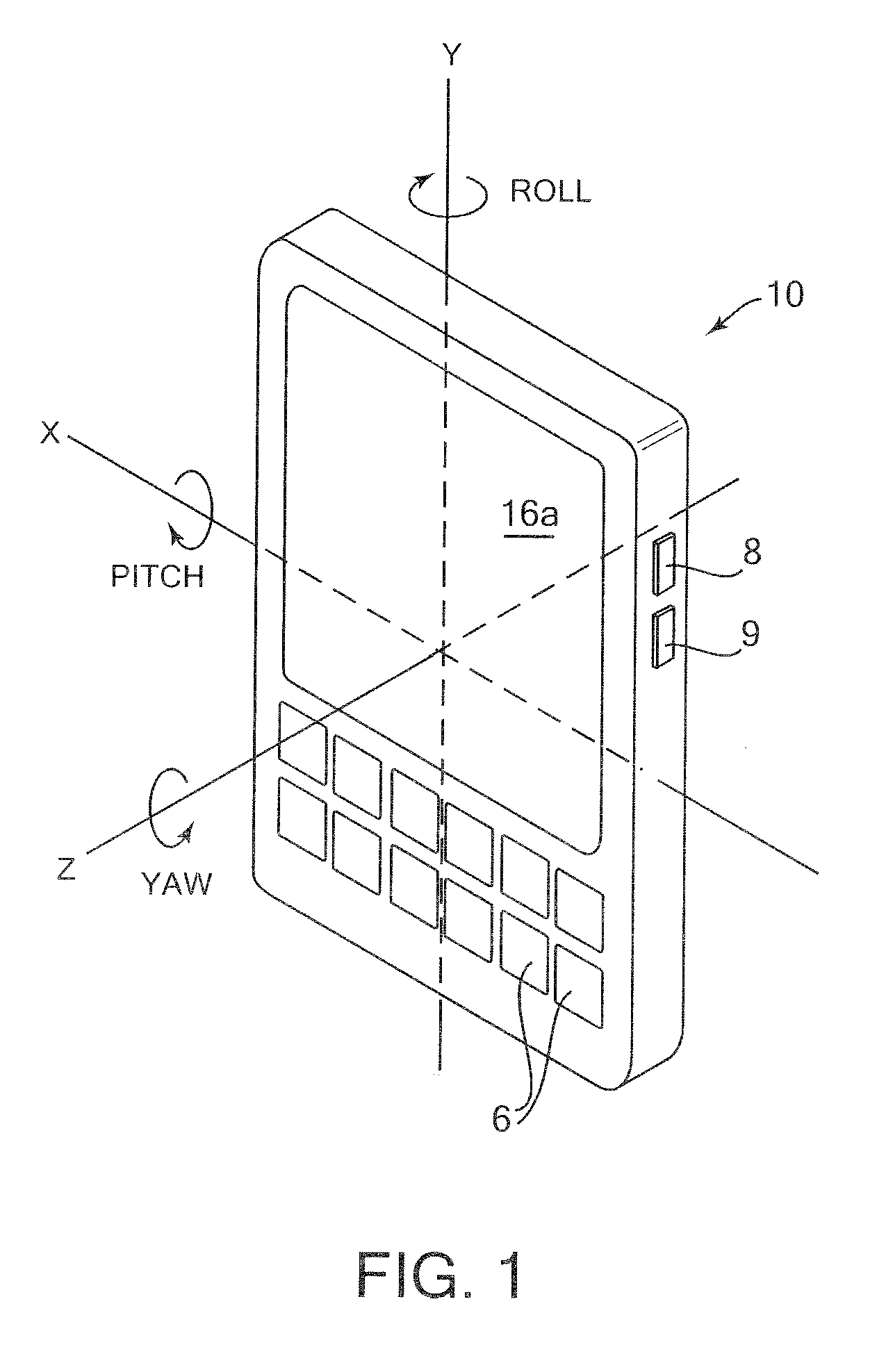

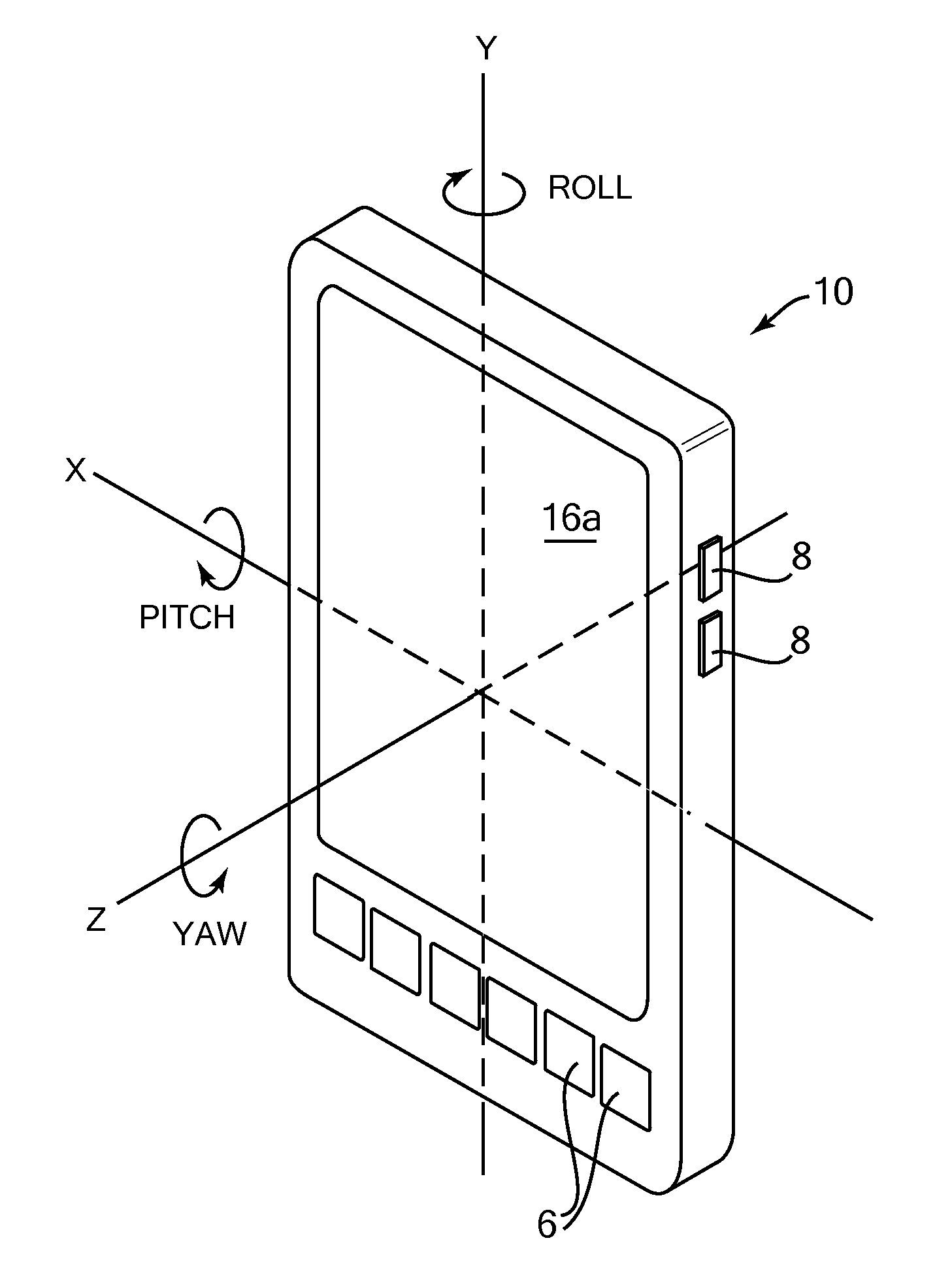

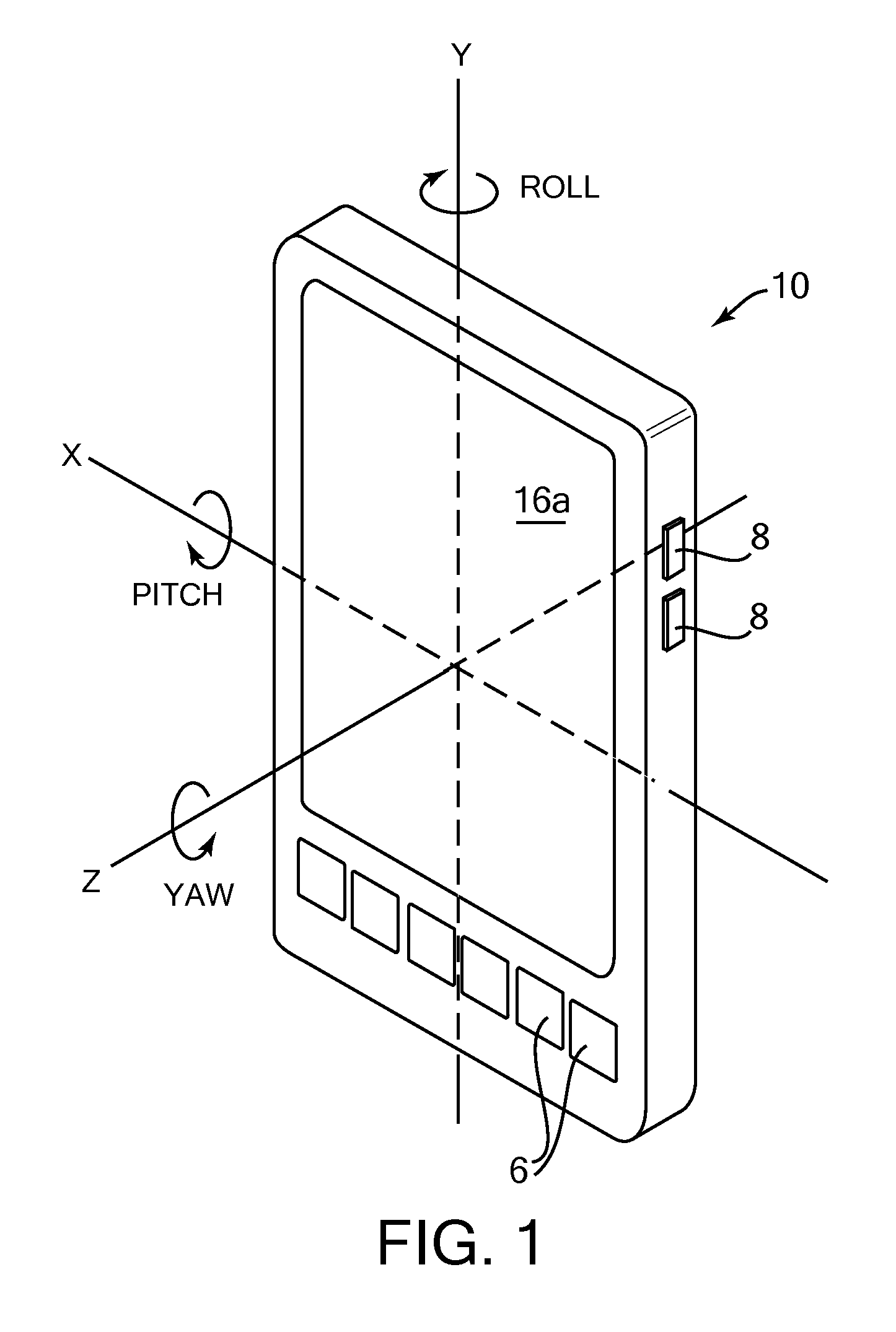

Controlling and accessing content using motion processing on mobile devices

ActiveUS20090303204A1Enhanced interactionAccurate motion dataInput/output for user-computer interactionDigital data processing detailsMotion processingAnimation

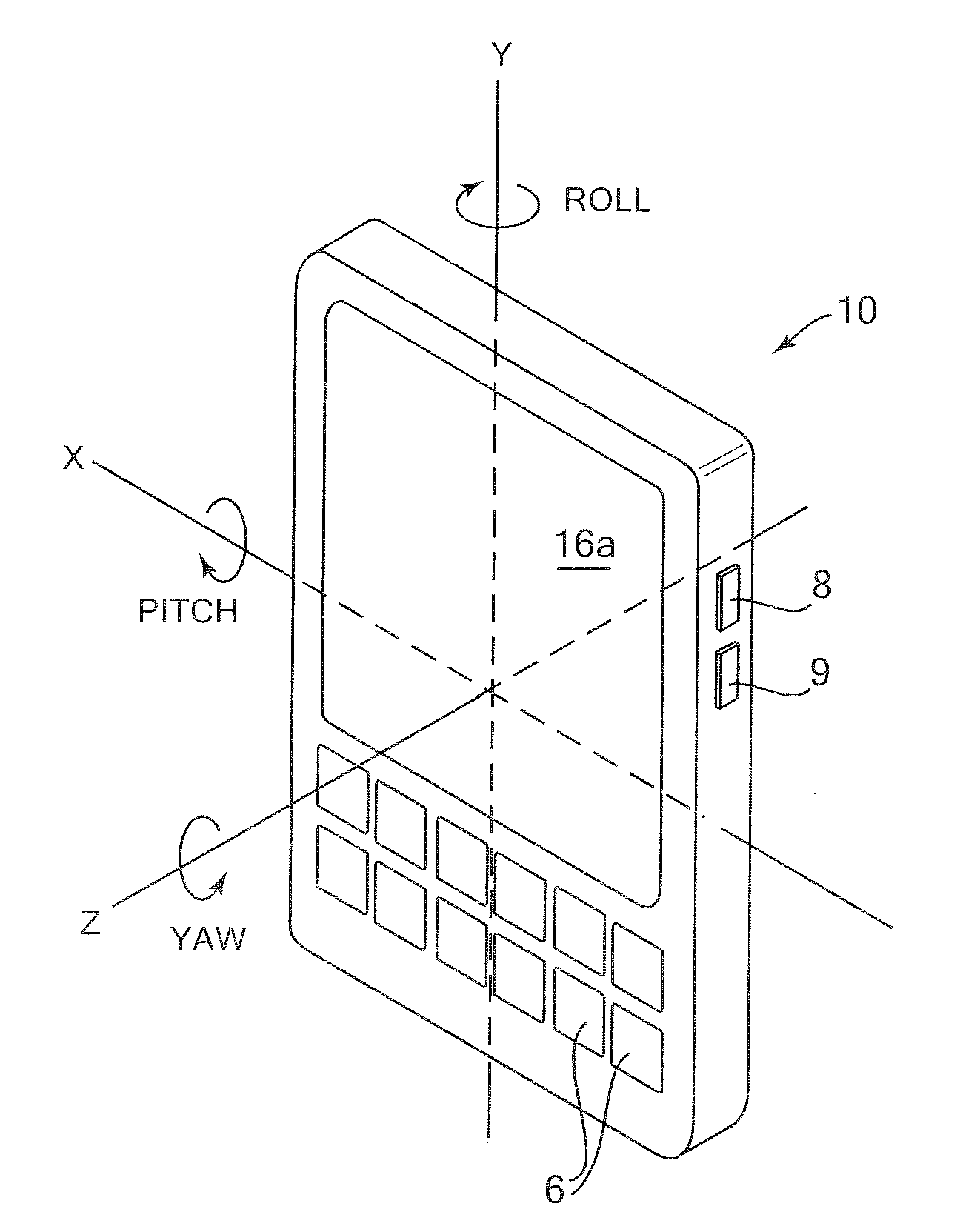

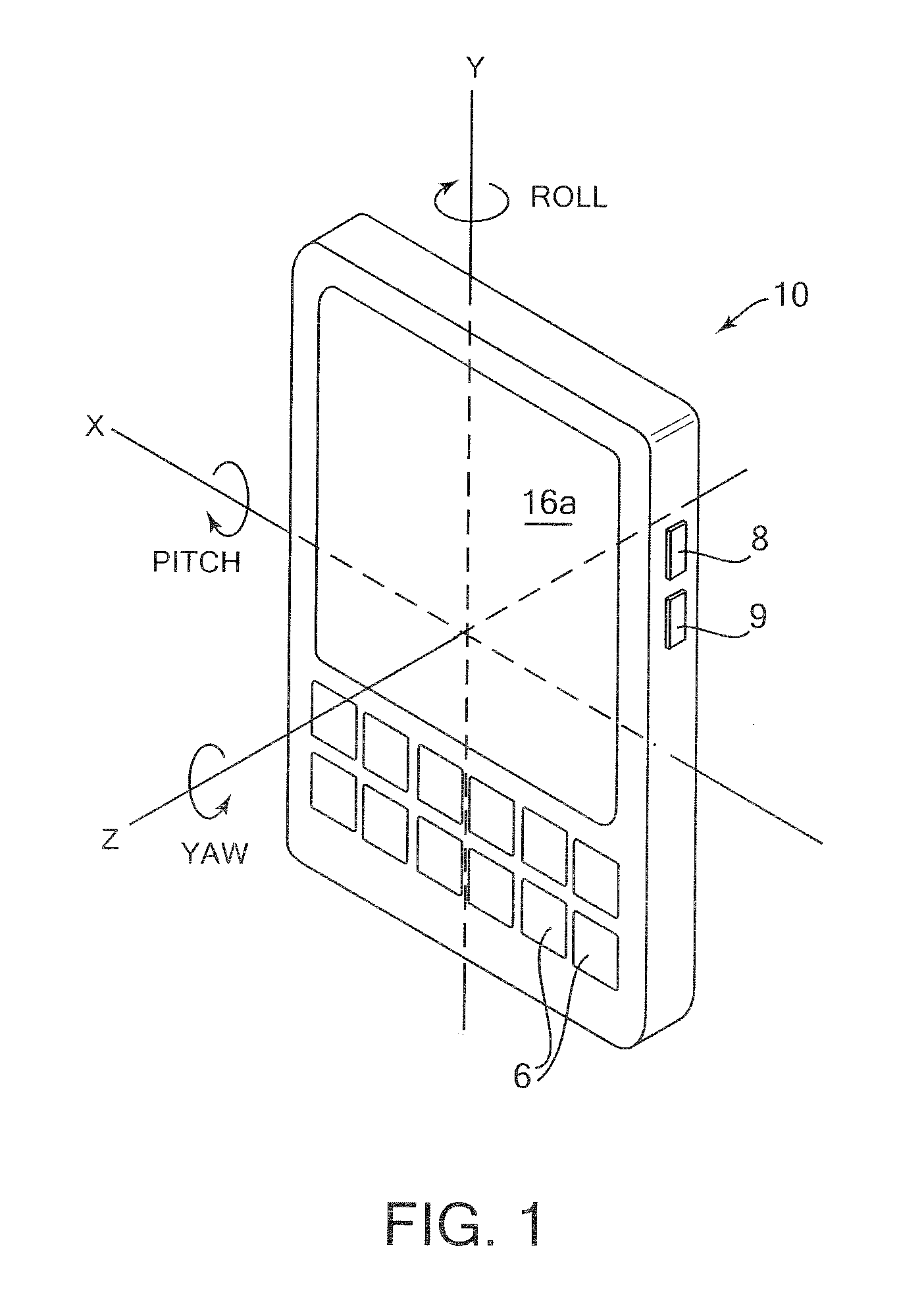

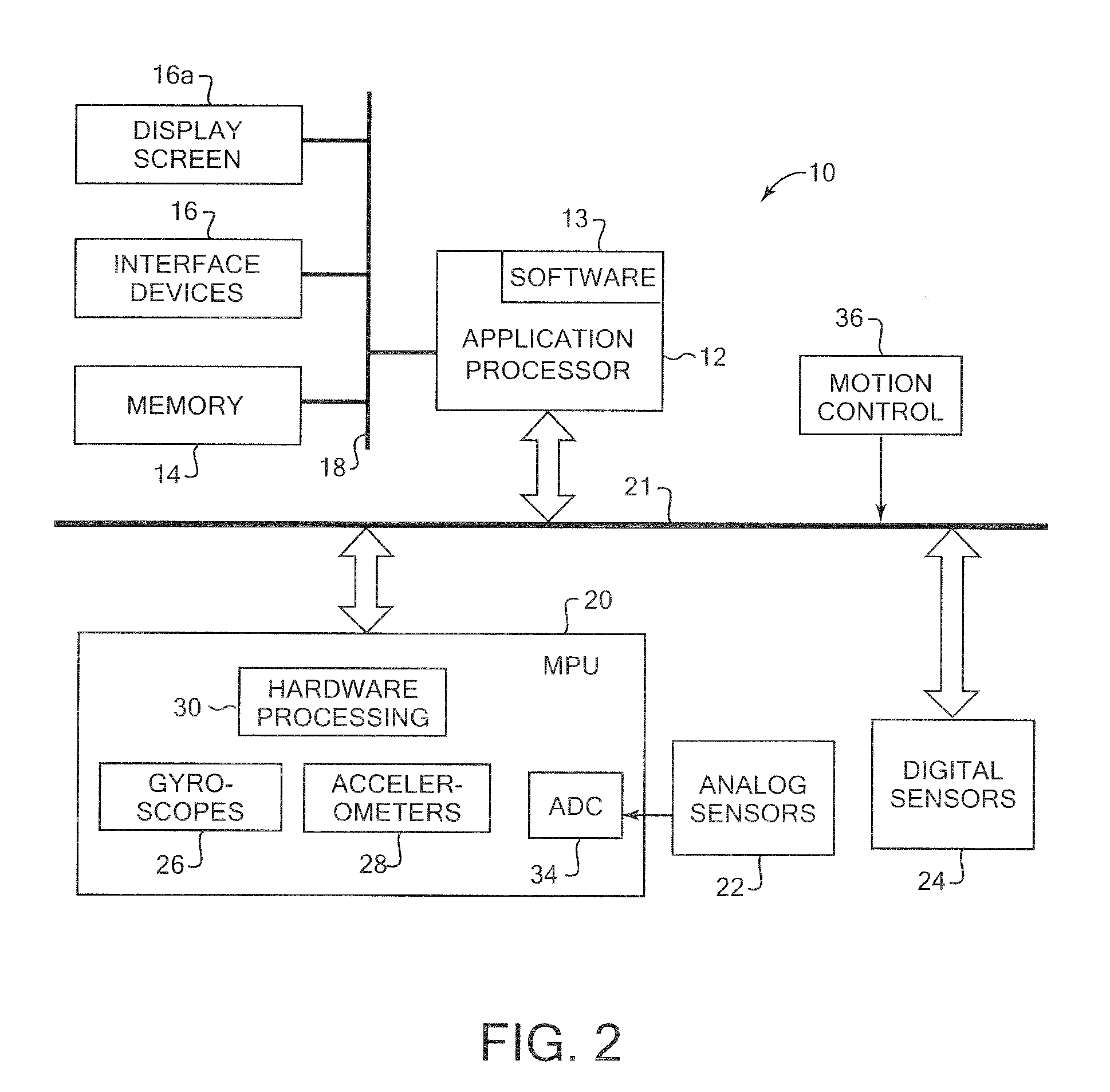

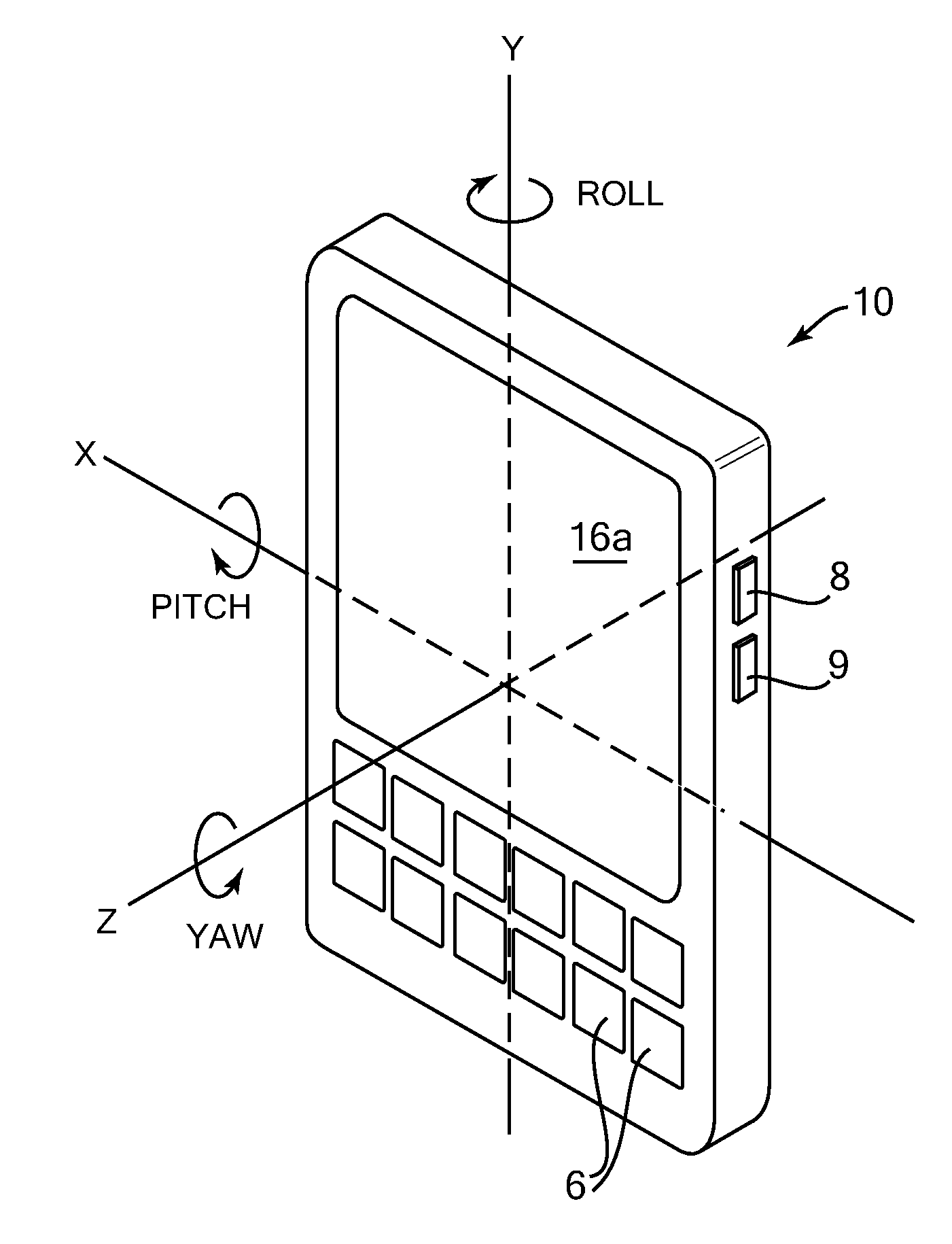

Various embodiments provide systems and methods capable of facilitating interaction with handheld electronics devices based on sensing rotational rate around at least three axes and linear acceleration along at least three axes. In one aspect, a handheld electronic device includes a subsystem providing display capability, a set of motion sensors sensing rotational rate around at least three axes and linear acceleration along at least three axes, and a subsystem which, based on motion data derived from at least one of the motion sensors, is capable of facilitating interaction with the device.

Owner:INVENSENSE

Controlling and accessing content using motion processing on mobile devices

InactiveUS20090262074A1Enhanced interactionAccurate motion dataDigital data processing detailsDevices with sensorMotion processingAnimation

Various embodiments provide systems and methods capable of facilitating interaction with handheld electronics devices based on sensing rotational rate around at least three axes and linear acceleration along at least three axes. In one aspect, a handheld electronic device includes a subsystem providing display capability, a set of motion sensors sensing rotational rate around at least three axes and linear acceleration along at least three axes, and a subsystem which, based on motion data derived from at least one of the motion sensors, is capable of facilitating interaction with the device.

Owner:INVENSENSE

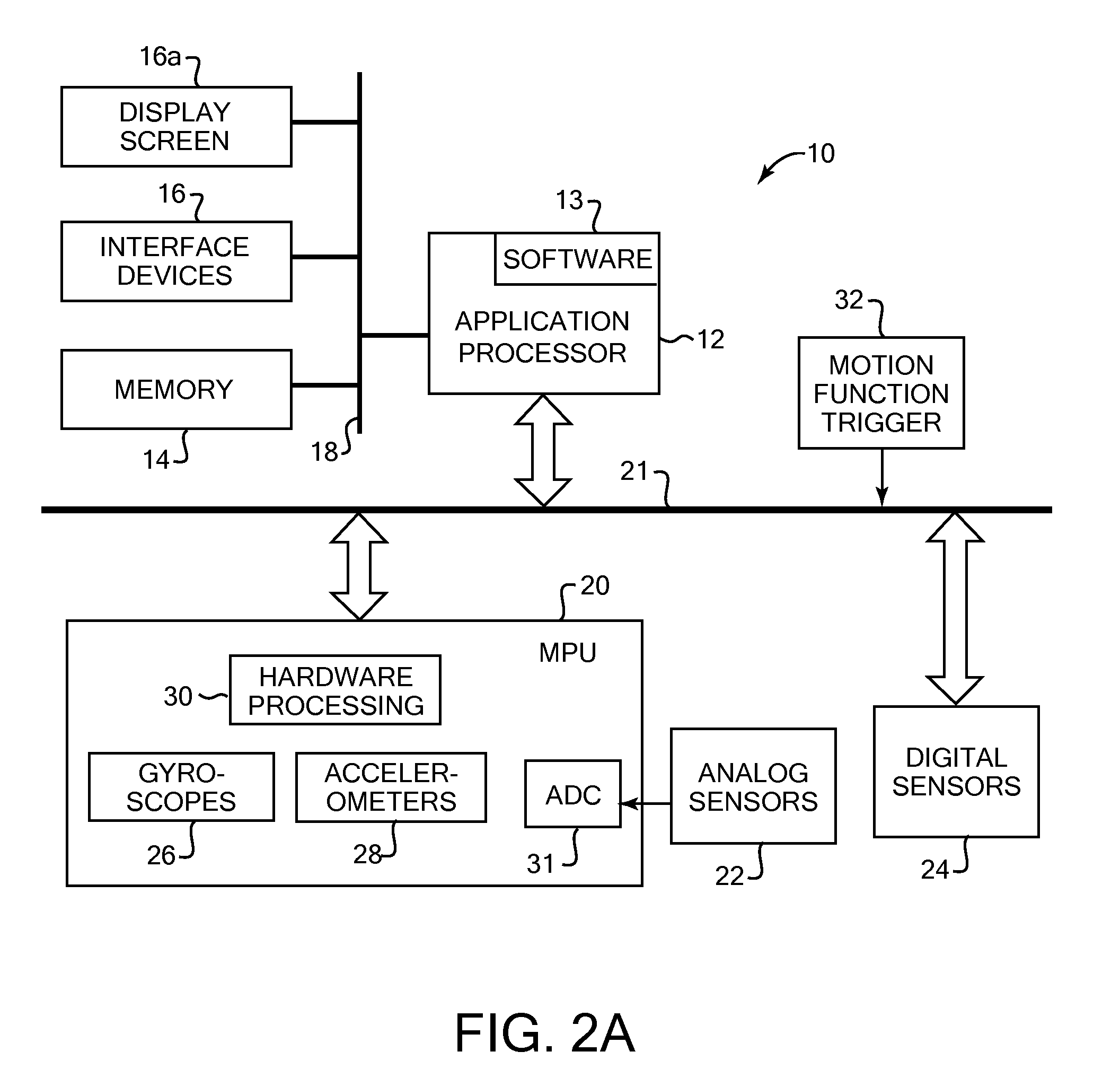

Motion sensing and processing on mobile devices

ActiveUS20100214216A1Accurate dataRobust intuitive accurate control of functionInput/output for user-computer interactionDigital data processing detailsAccelerometerGyroscope

Display devices including motion sensing and processing. In one aspect, a handheld electronic device includes a subsystem providing display capability and a set of motion sensors provided on a single substrate and including at least one gyroscope sensing rotational rate of the device around three axes of the device and at least one accelerometer sensing gravity and linear acceleration of the device along these axes. A computation unit is capable of determining motion data from the sensor data stored in the memory, the motion data derived from a combination of the sensed rotational rate around at least one of the axes and the sensed gravity and linear acceleration along at least one of the axes. The motion data describes movement of the device including a rotation of the device around at least one of the axes, the rotation causing interaction with the device.

Owner:INVENSENSE

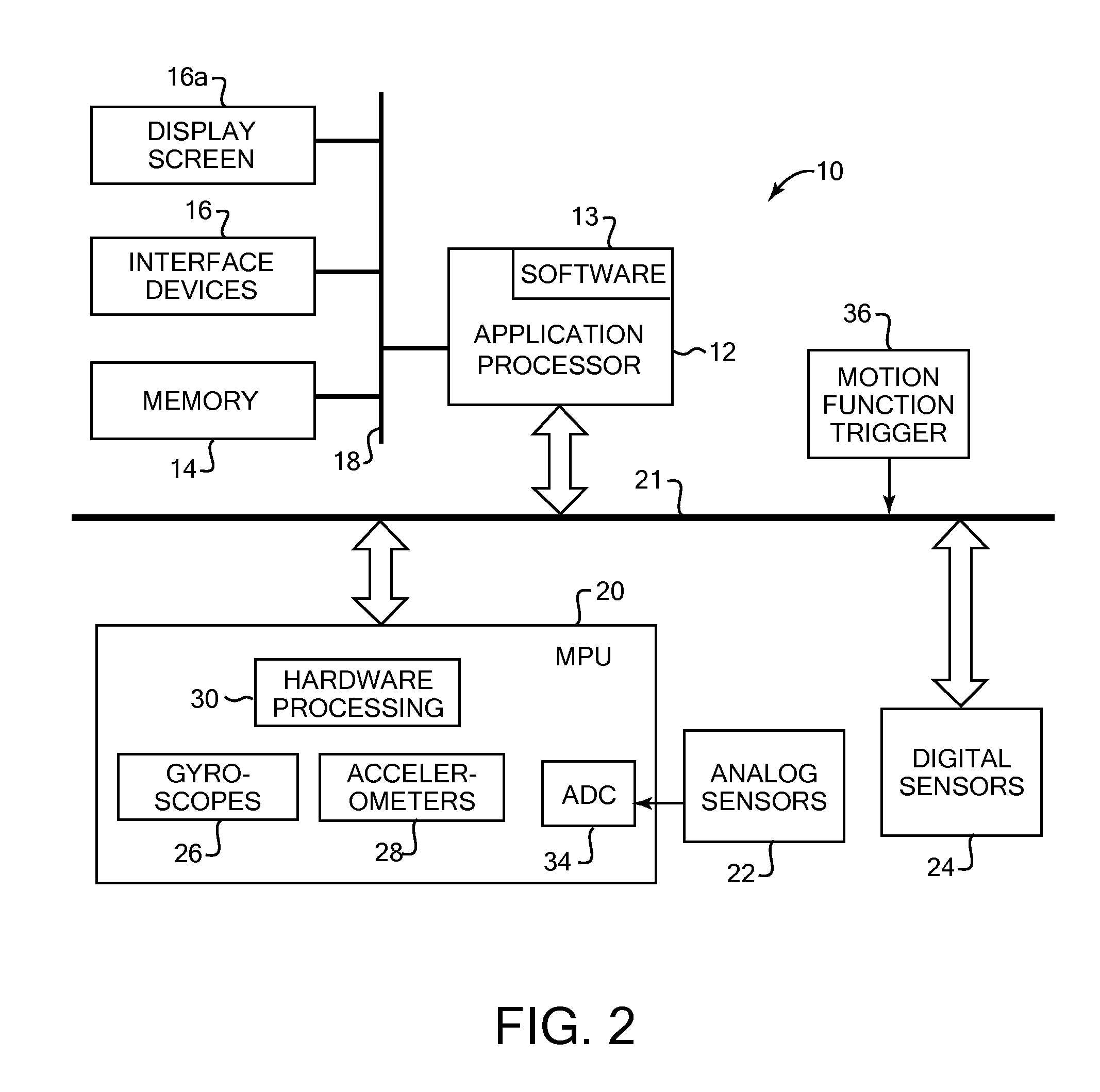

Mobile device user interface combining input from motion sensors and other controls

InactiveUS20110316888A1Intuitive fast accurate control of functionIntuitive fast accurate controlDigital data processing detailsCathode-ray tube indicatorsDisplay deviceInput control

Various embodiments provide user interfaces for mobile devices which combine input from motion sensors and other input controls. In one aspect, a handheld electronic device includes a display operative to display an image, an input control operative to sense a contact motion of the user with the device, a set of motion sensors sensing rotational rate of the device around at least three axes of the device and linear acceleration along at least three axes of the device, and a subsystem capable of facilitating interaction with the device based on combined sensor data. The combined sensor data includes motion data derived from at least one of the motion sensors and contact data derived from the contact motion sensed by the input control.

Owner:INVENSENSE

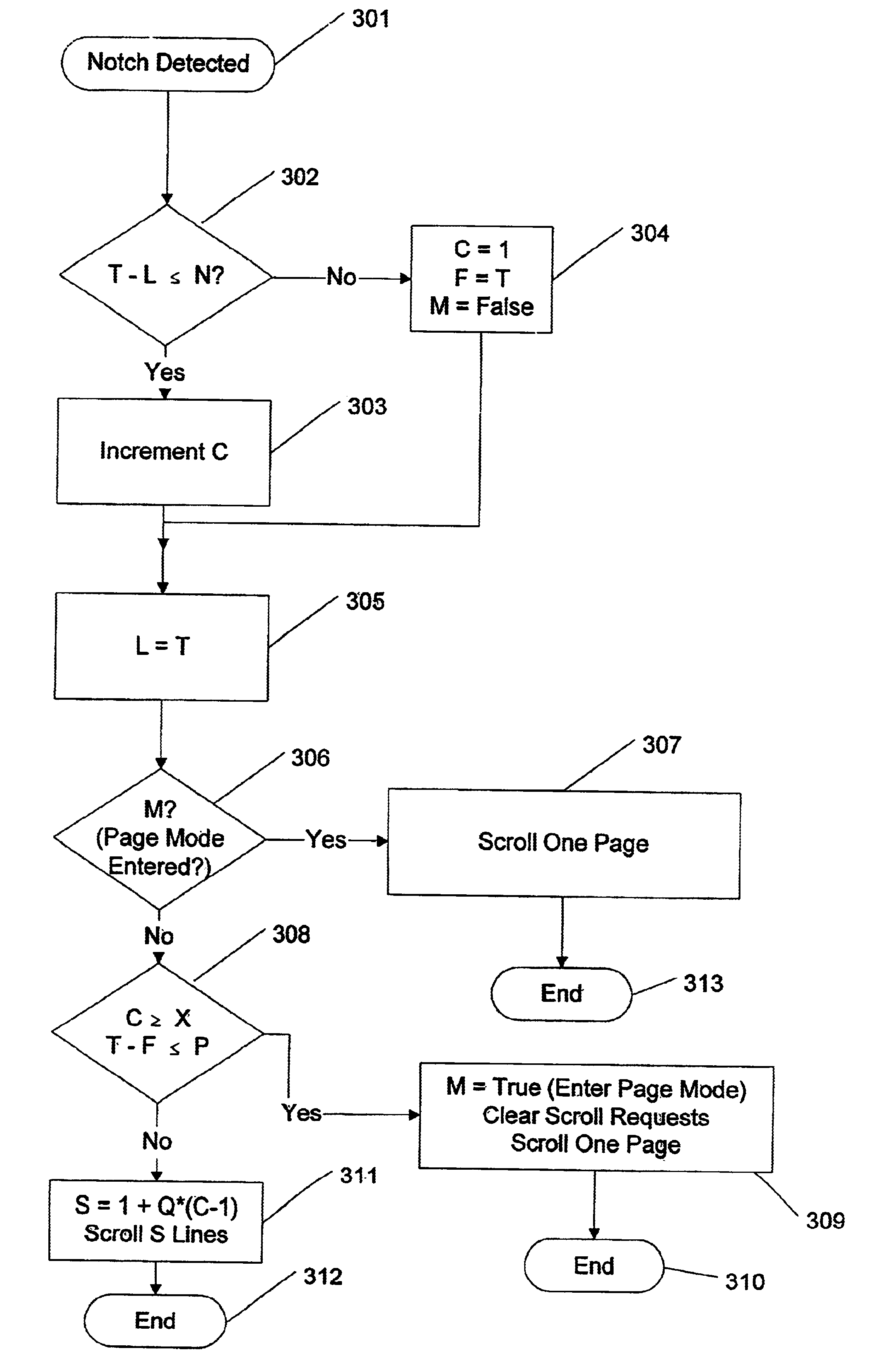

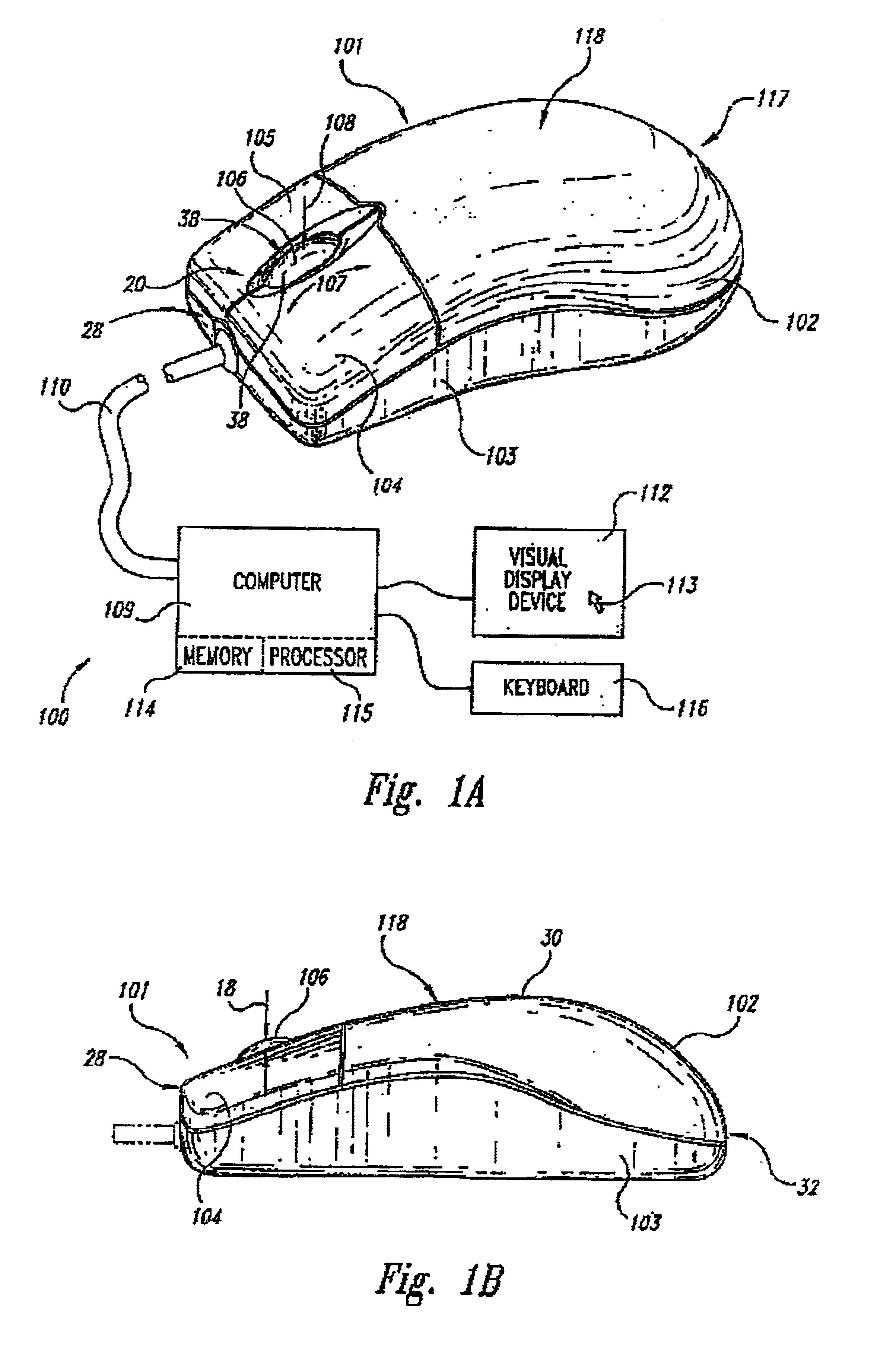

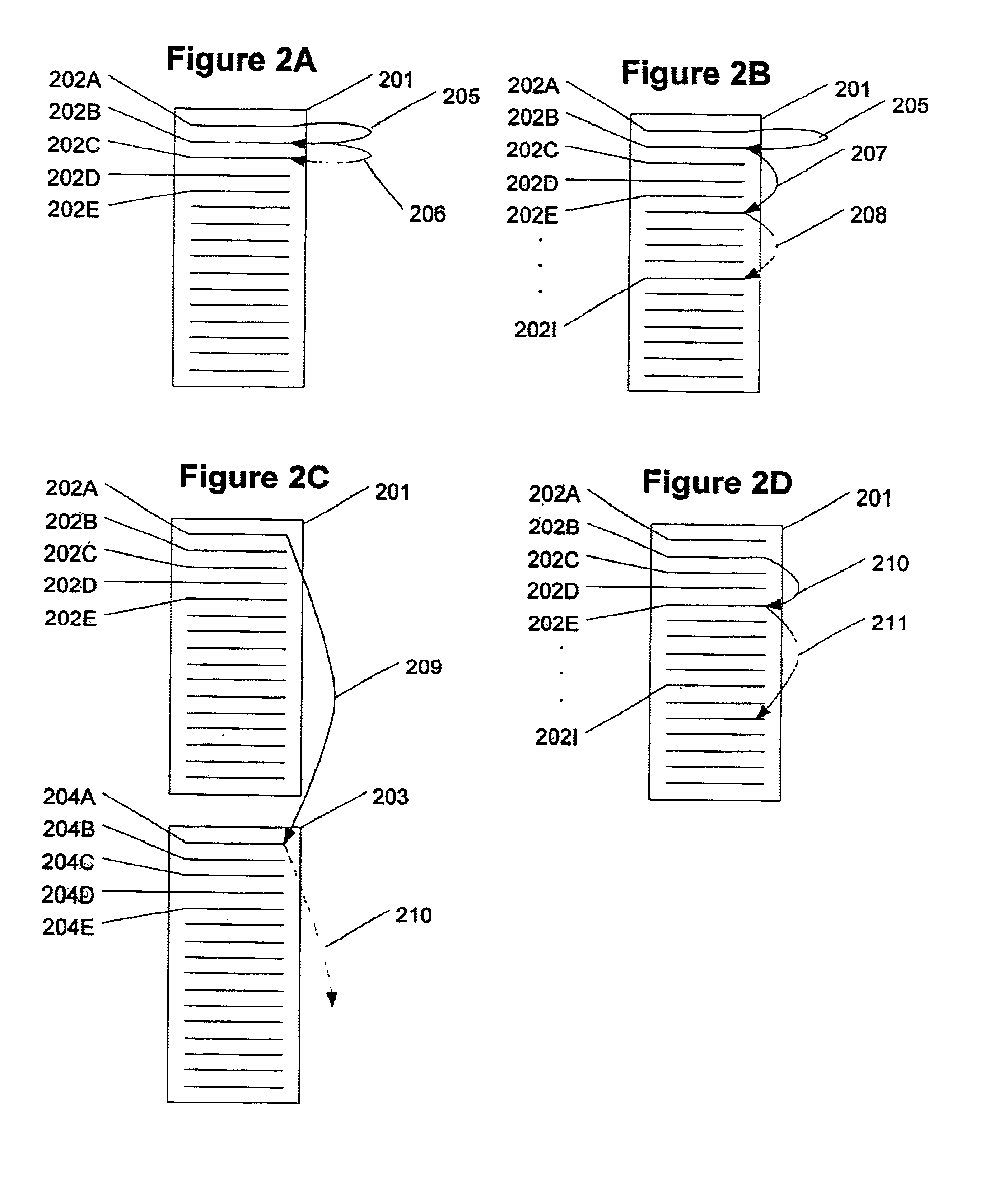

Accelerated scrolling

InactiveUS6865718B2Simple technologyCathode-ray tube indicatorsInput/output processes for data processingDisplay deviceScrolling

A system and method for accelerating scrolling of a display is disclosed. When a wheel of a wheeled pointing device is actuated by a user at a first rotational rate, the display in a window scrolls up or down one line at a time. When the wheel is rotated at a second rotational rate, the display in the window scrolls up or down multiple lines at a time. In additional embodiments, the scrolling technique shifts from one line at a time / multiple lines at a time to a page or pages at a time when the wheel is rotated for at a rotational rate for a minimum period of time.

Owner:MICROSOFT TECH LICENSING LLC

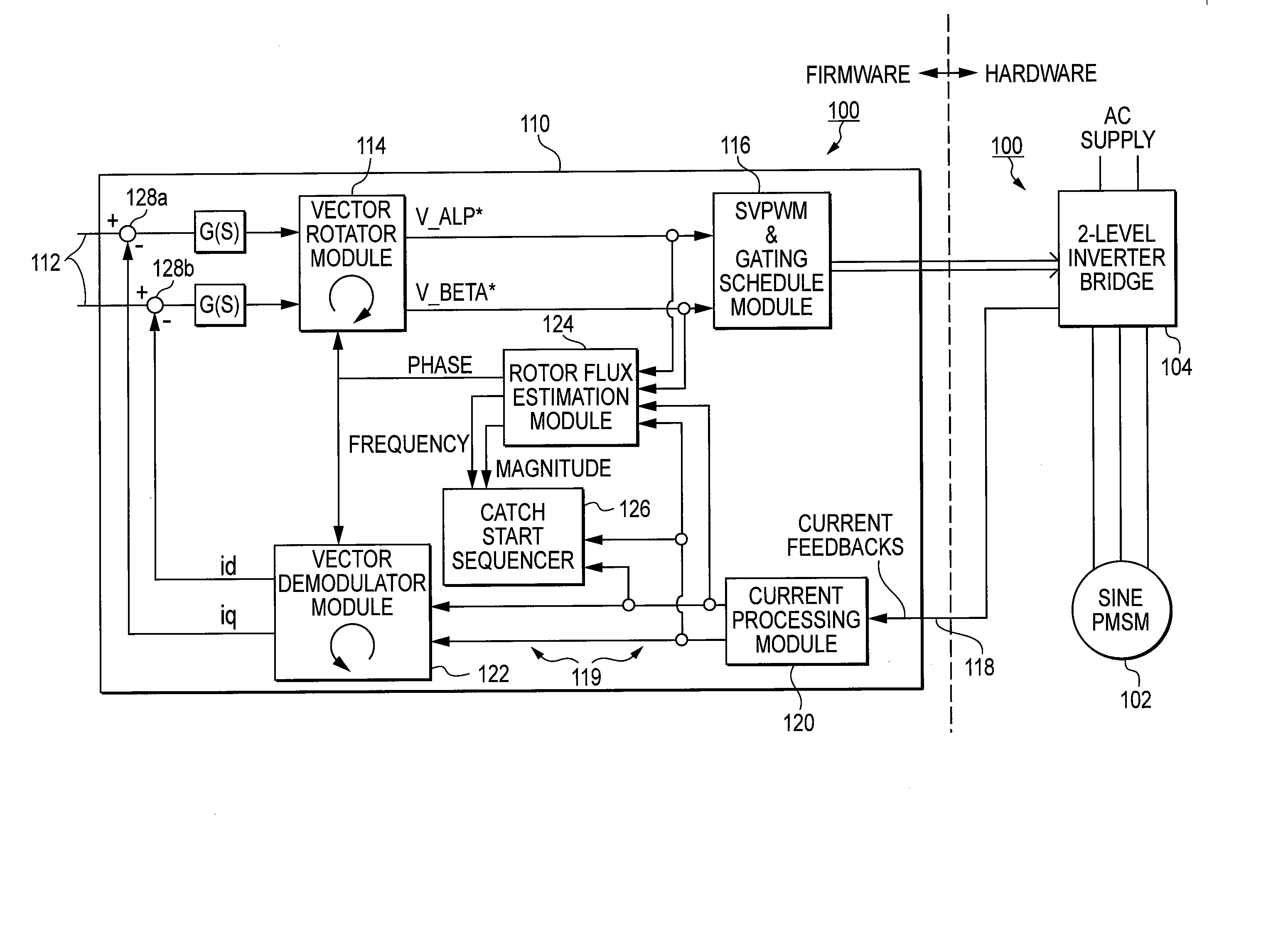

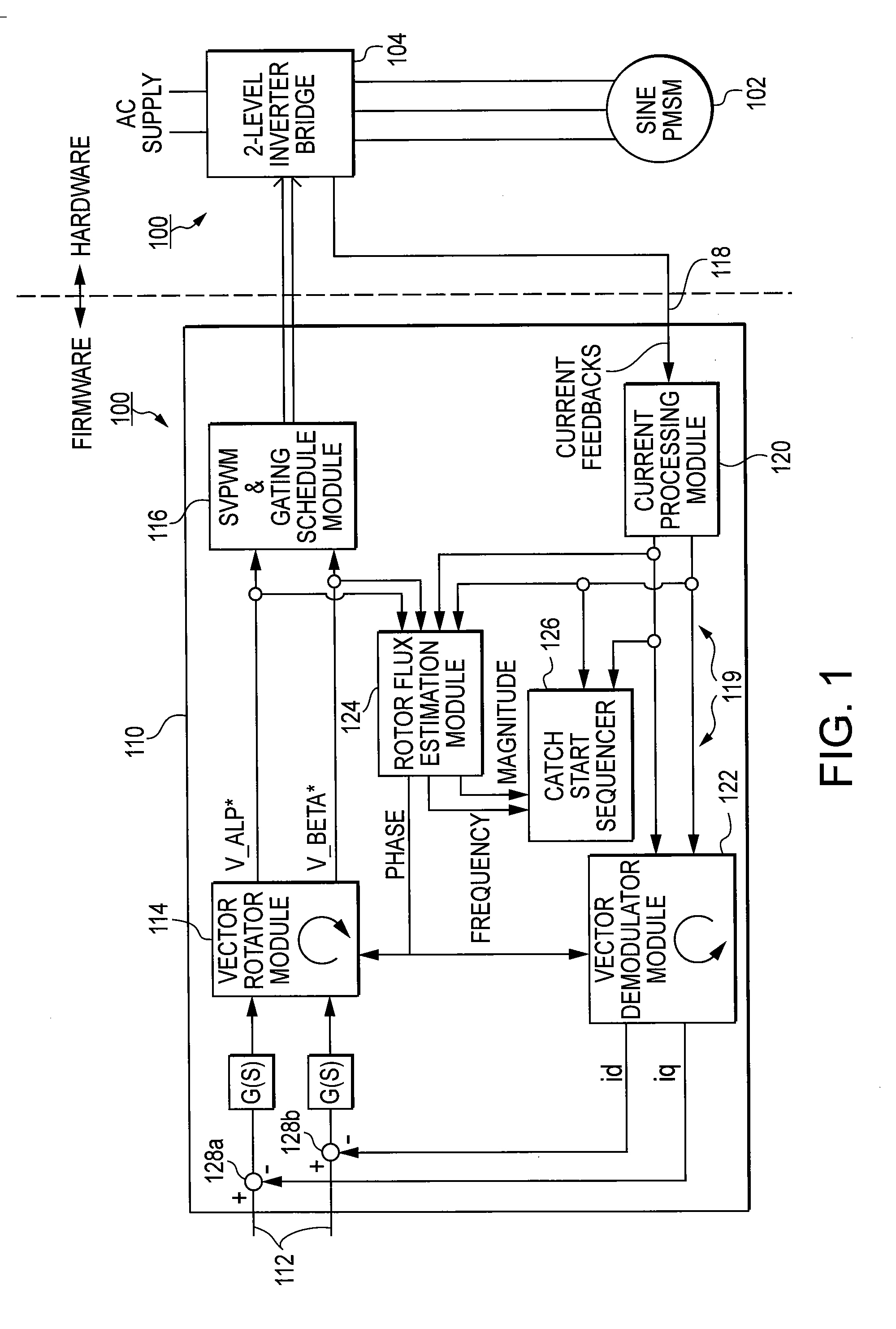

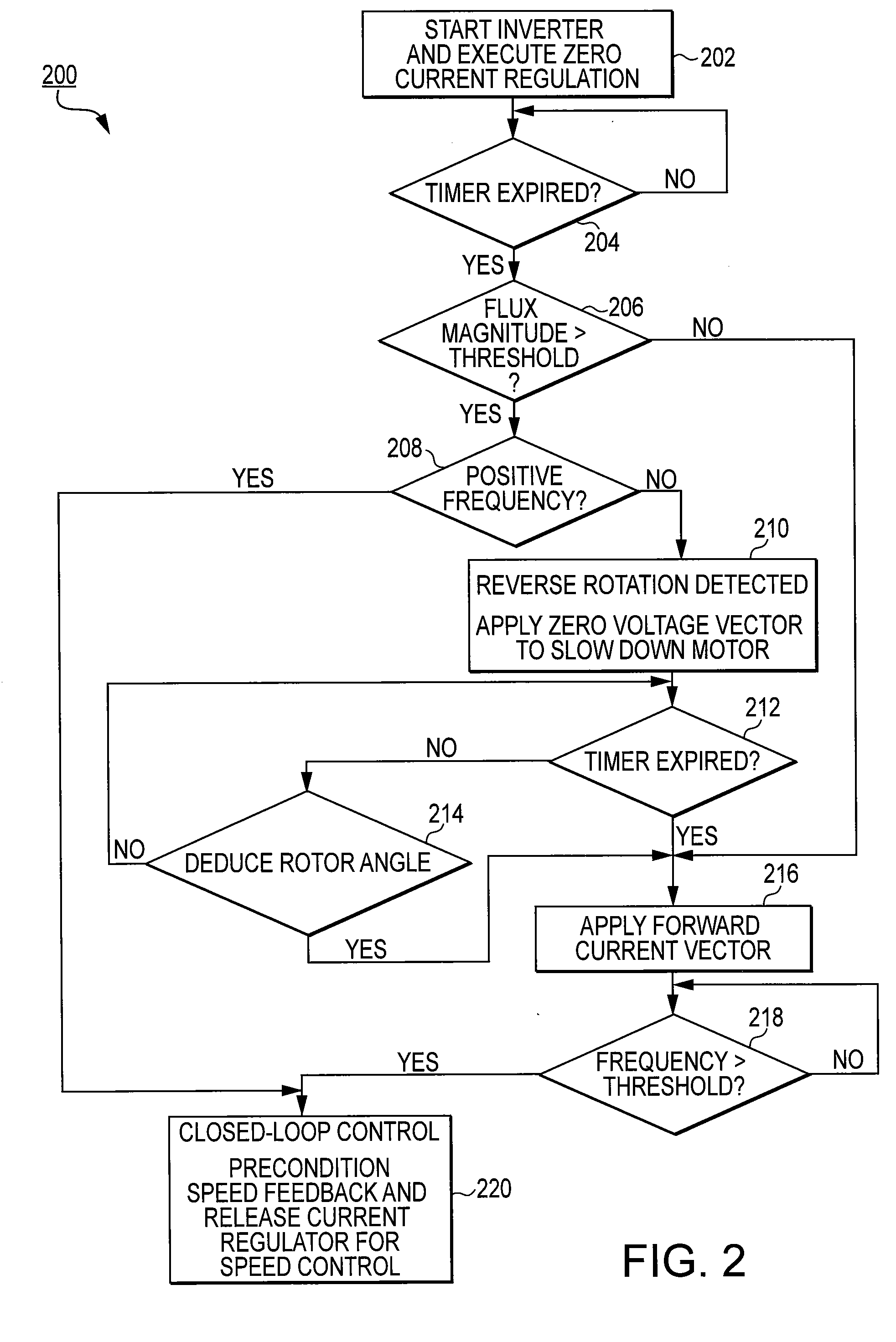

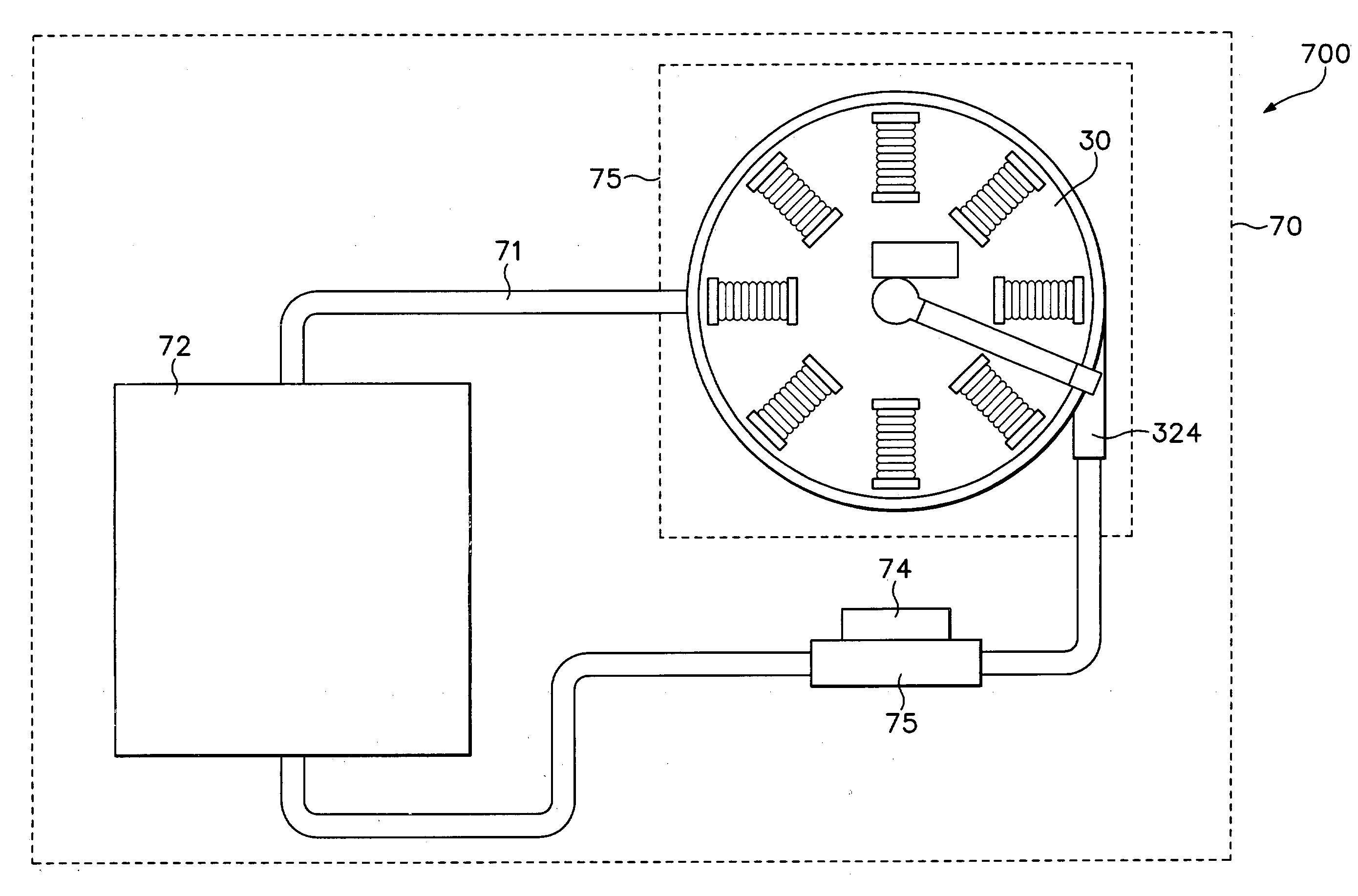

Method and system for starting a sensorless motor

ActiveUS20070001635A1Preventing over current shutdownHigh currentAC motor controlSynchronous motors startersMotor driveEngineering

A motor drive system for a sensorless motor includes a catch start sequencer that controls the motor drive system to robustly start the motor in the event the motor rotor is rotating in forward or reverse direction prior to activating the motor drive system. In particular, the catch start sequencer causes the motor drive system to initially find and track the rotor position, and then determines the speed and possibly the direction of rotation of the rotor. If the rotor is rotating in the reverse direction, the catch start sequencer controls the motor drive system to slow the speed of rotation and to then start the rotor rotating in the forward direction.

Owner:INFINEON TECH AMERICAS CORP

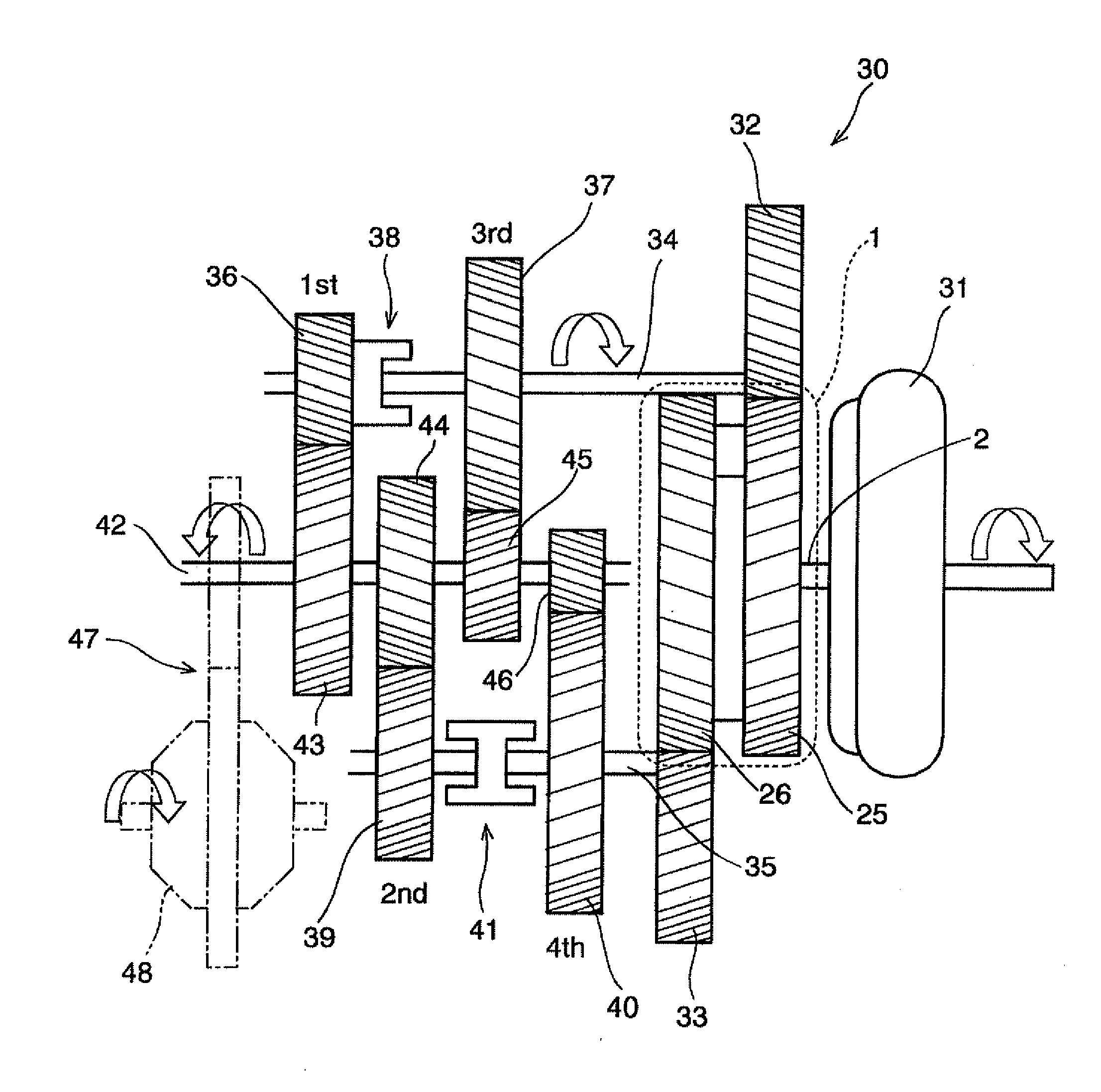

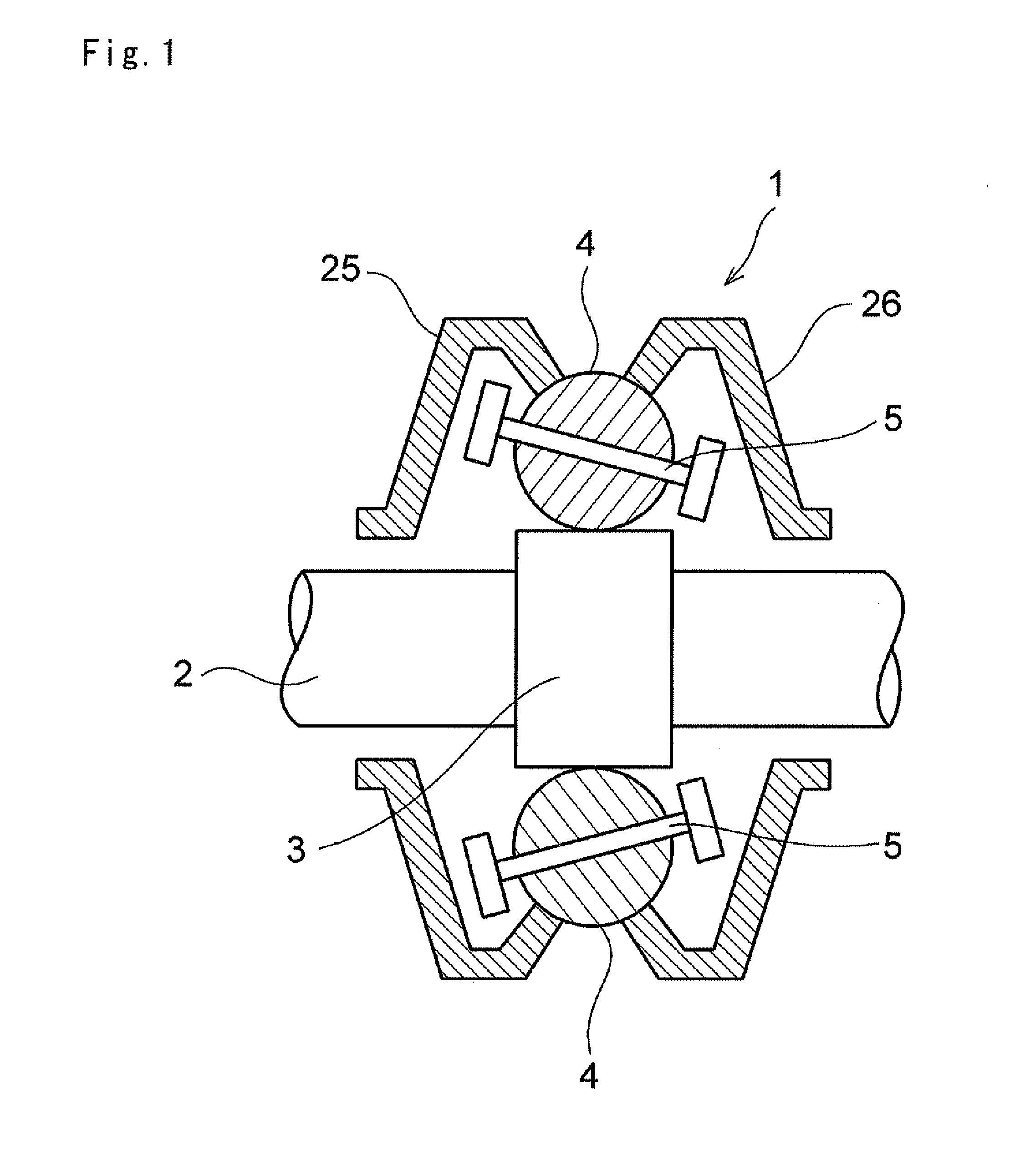

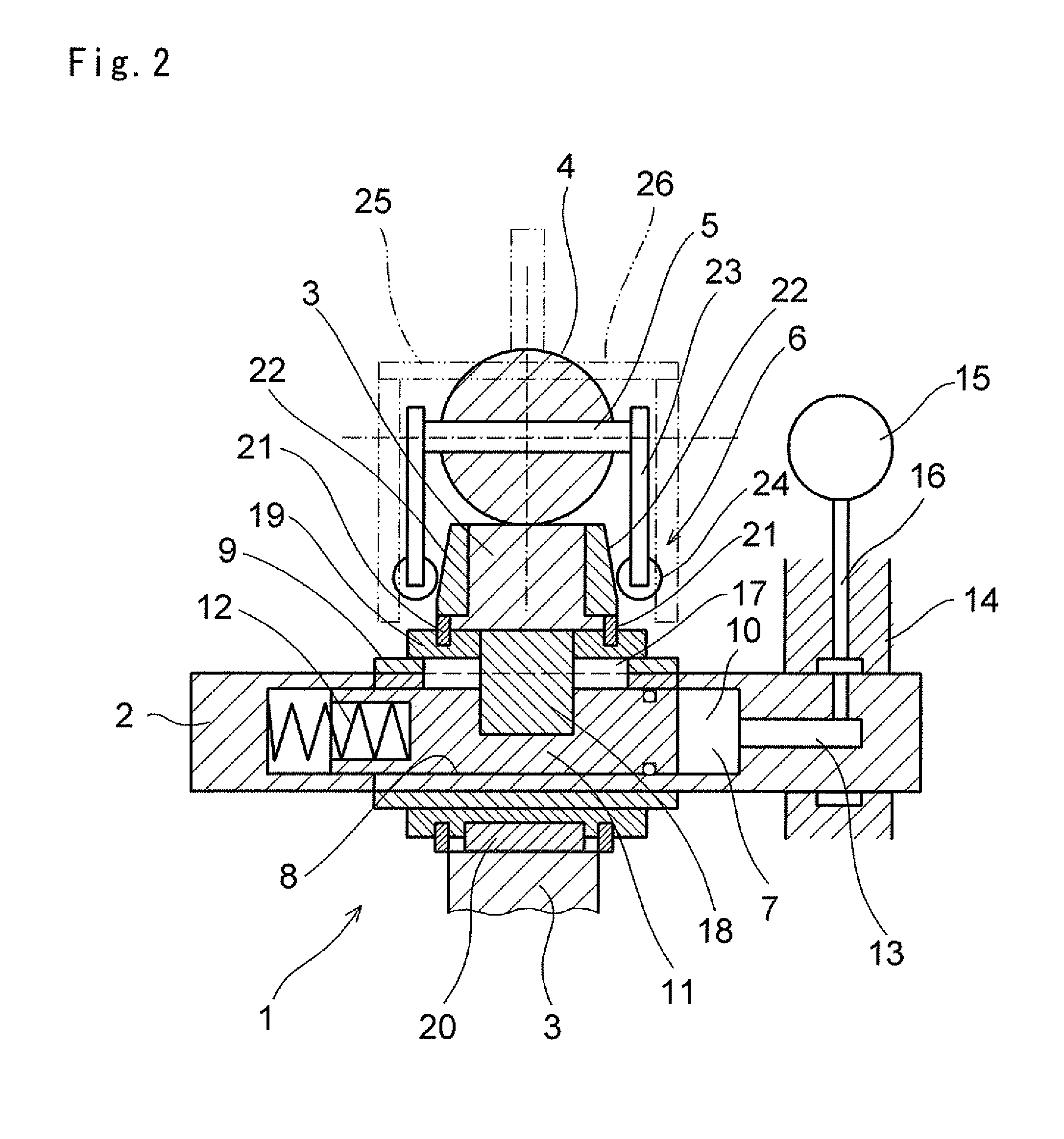

Continuously variable transmission mechanism and transmission using the same

InactiveUS20110319222A1Increase rotation speedRotational radiusFriction gearingsRotation velocityControl theory

A continuously variable transmission adapted to set a speed change ratio in accordance with a tilt angle of a rolling member mediating a torque being transmitted, and to transmit a torque among three elements. The transmission mechanism is provided with a rolling member having a smooth outer face and capable of tilting a rotational center axis thereof, and a rotary member arranged to be contacted with a predetermined portion of the outer face of the rolling member in a torque transmittable manner. Specifically, the continuously variable transmission mechanism is configured to vary a rotational speed of the rotary member by changing a rotation radius of a contact point between the rolling member and the rotary member by tilting the rotational center axis of the rolling member.

Owner:TOYOTA JIDOSHA KK

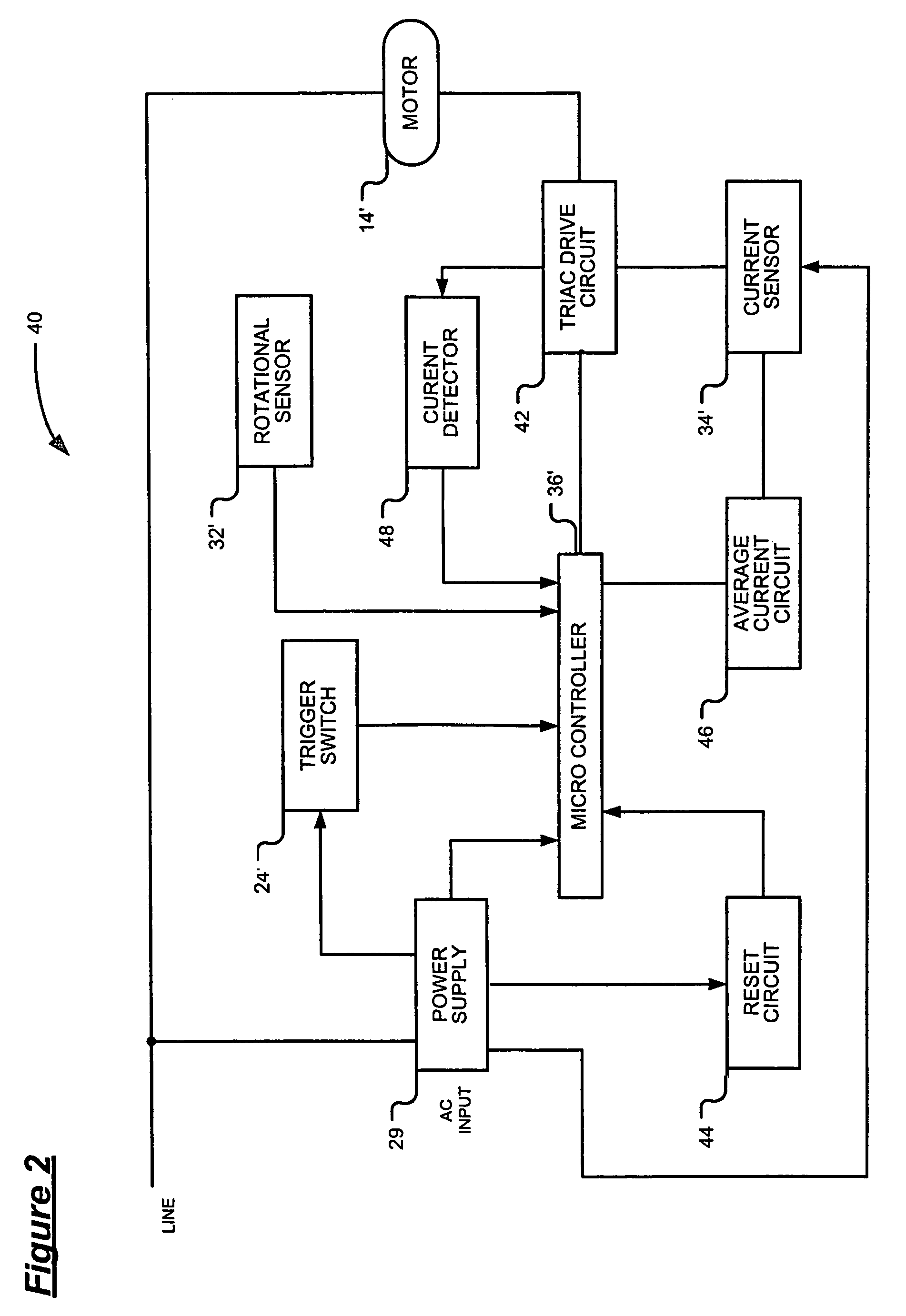

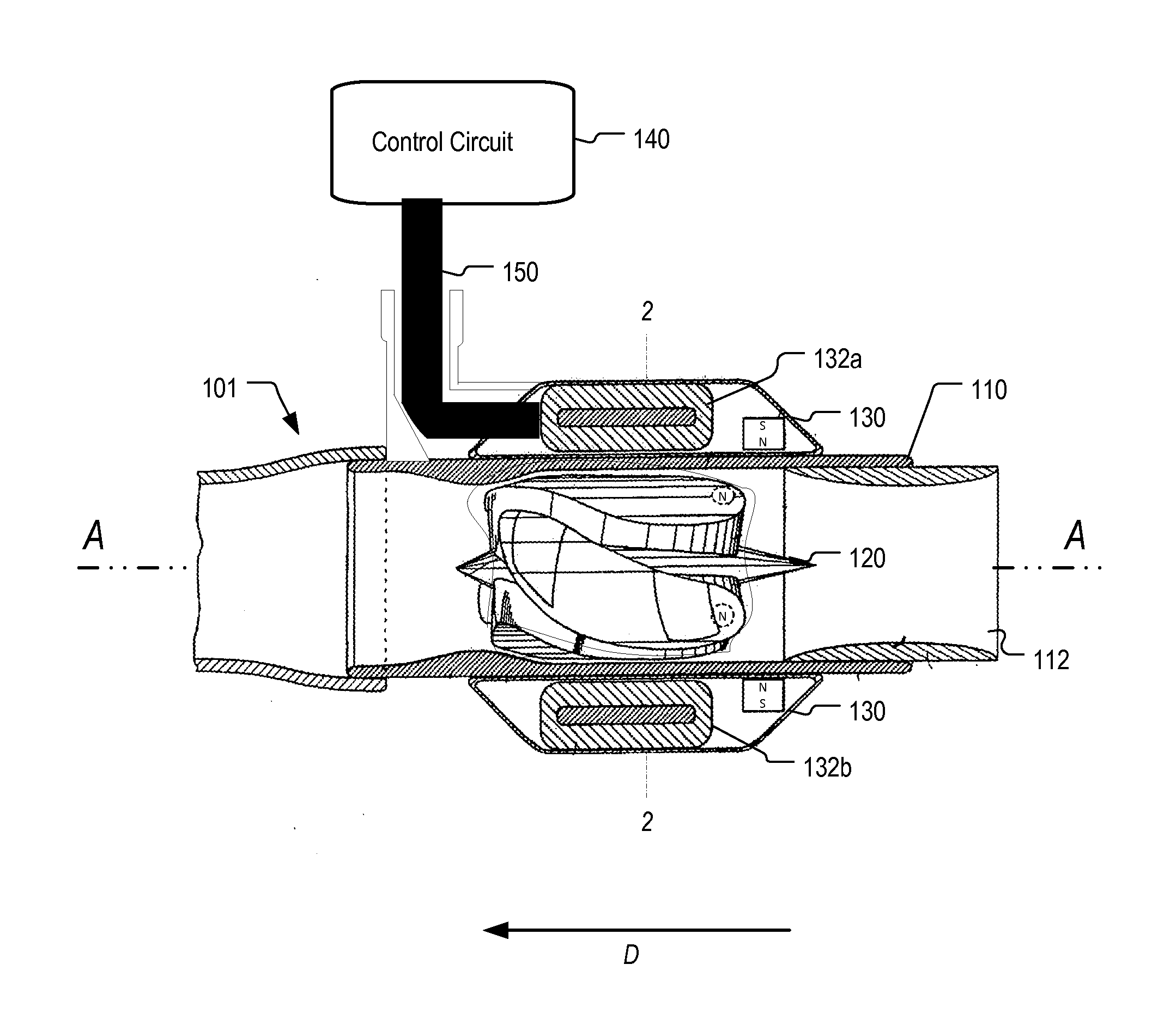

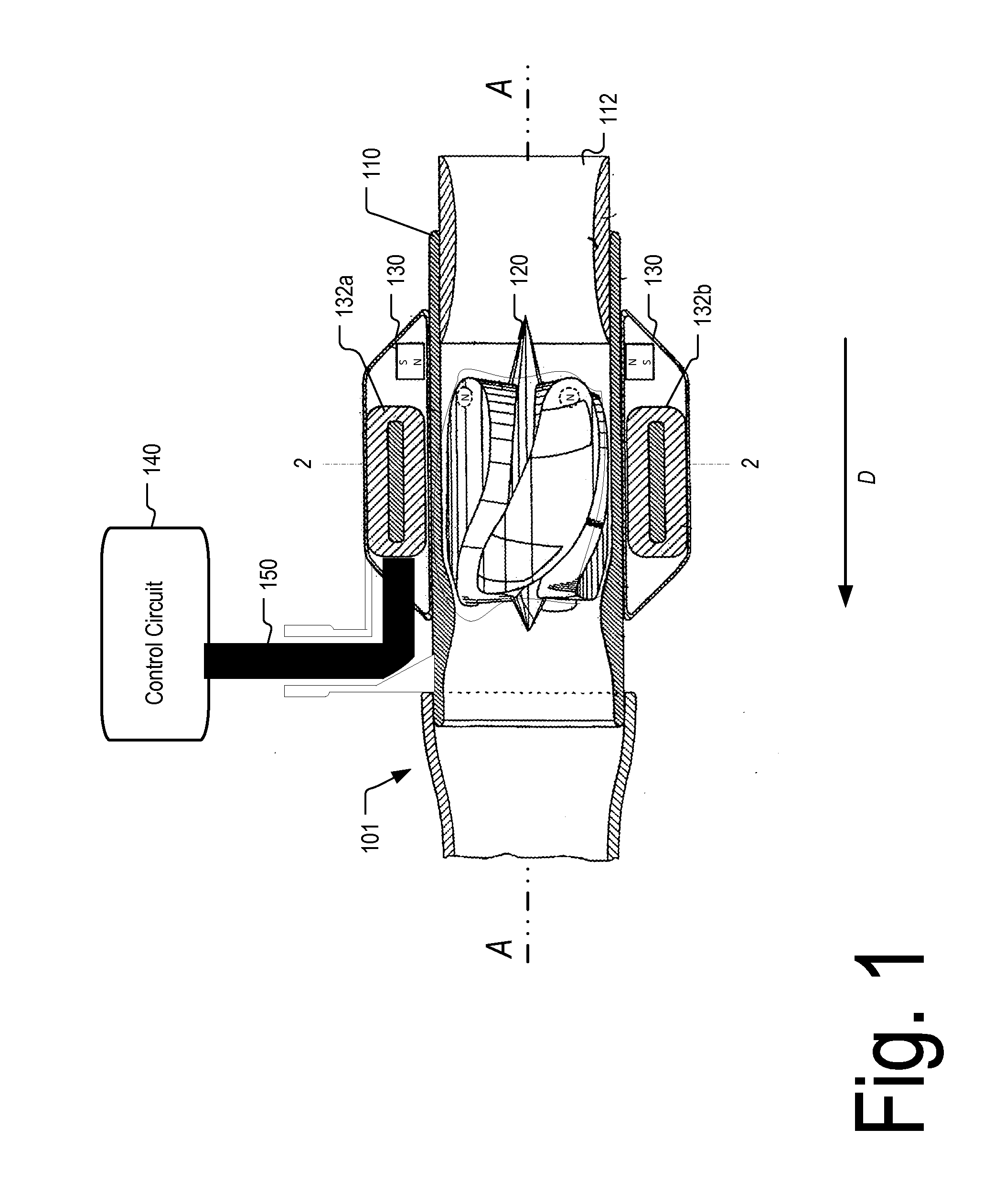

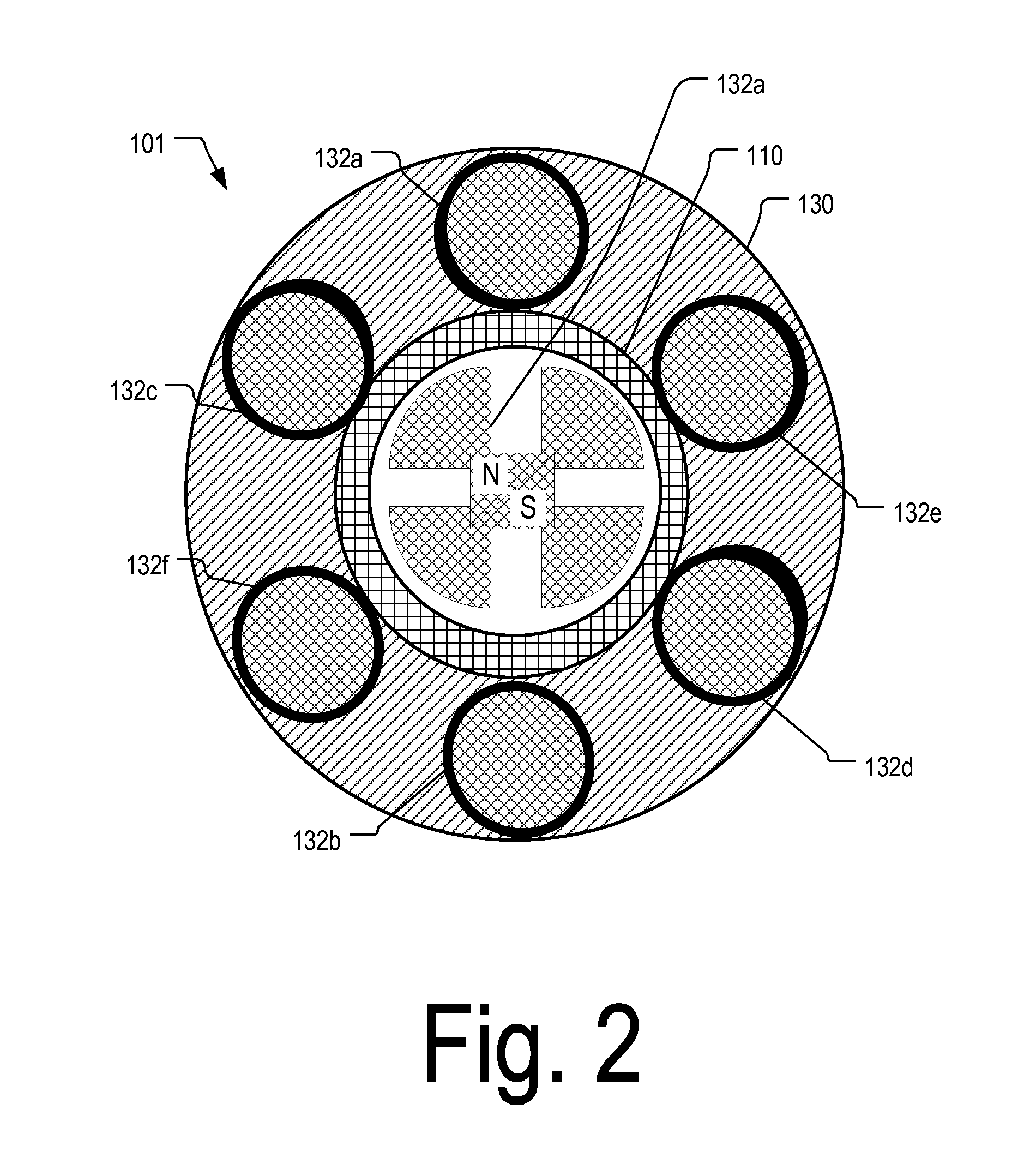

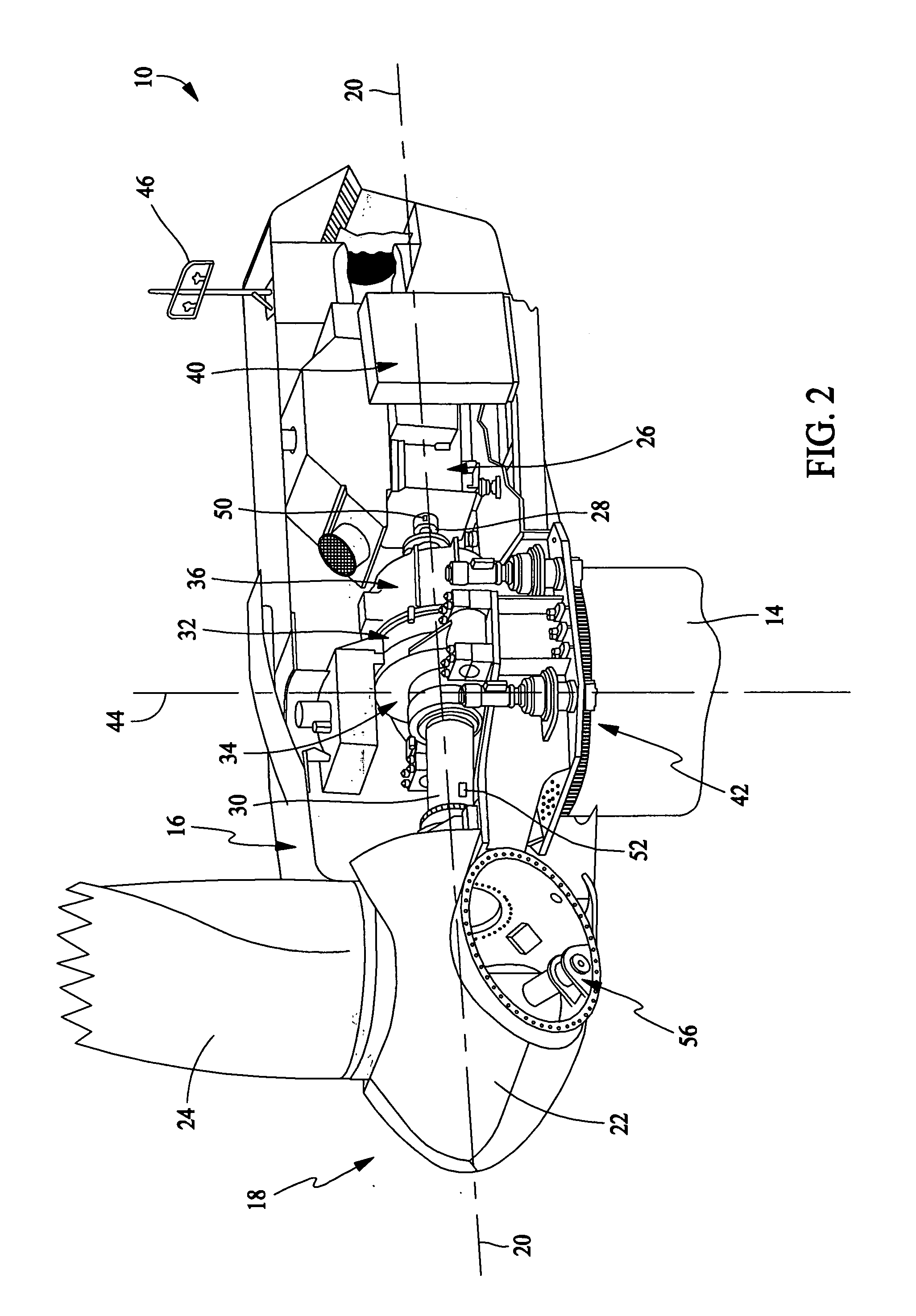

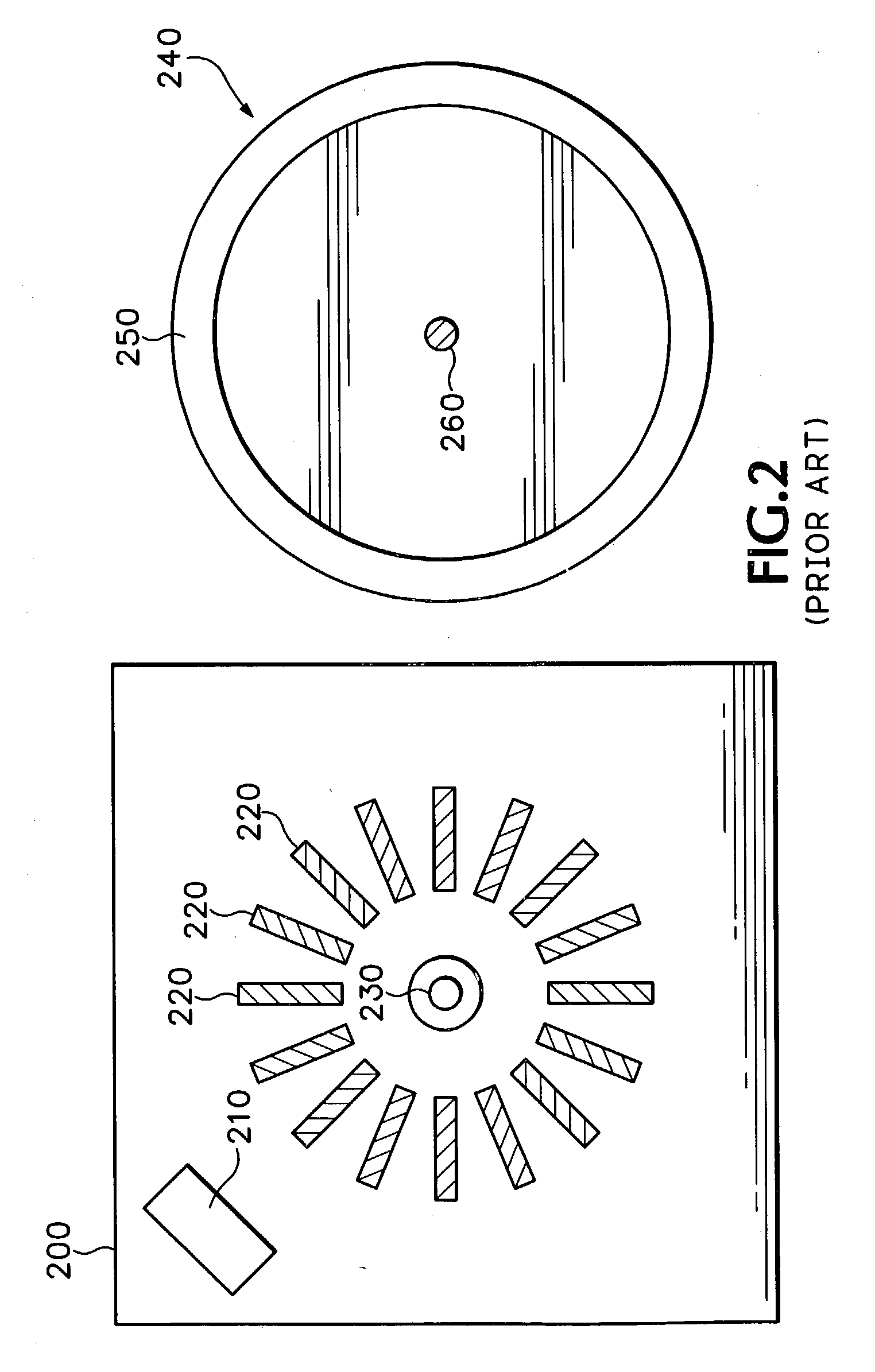

Power tool anti-kickback system with rotational rate sensor

A control system is provided for use in a power tool. The control system includes: a rotational rate sensor having a resonating mass and a controller electrically connected to the rotational rate sensor. The rotational rate sensor detects lateral displacement of the resonating mass and generates a signal indicative of the detected lateral displacement, such that the lateral displacement is directly proportional to a rotational speed at which the power tool rotates about an axis of the rotary shaft. Based on the generated signal, the controller initiates a protective operation to avoid further undesirable rotation of the power tool. The control scheme employed by the power tool may initiate different protective operations for different tool conditions.

Owner:BLACK & DECKER INC

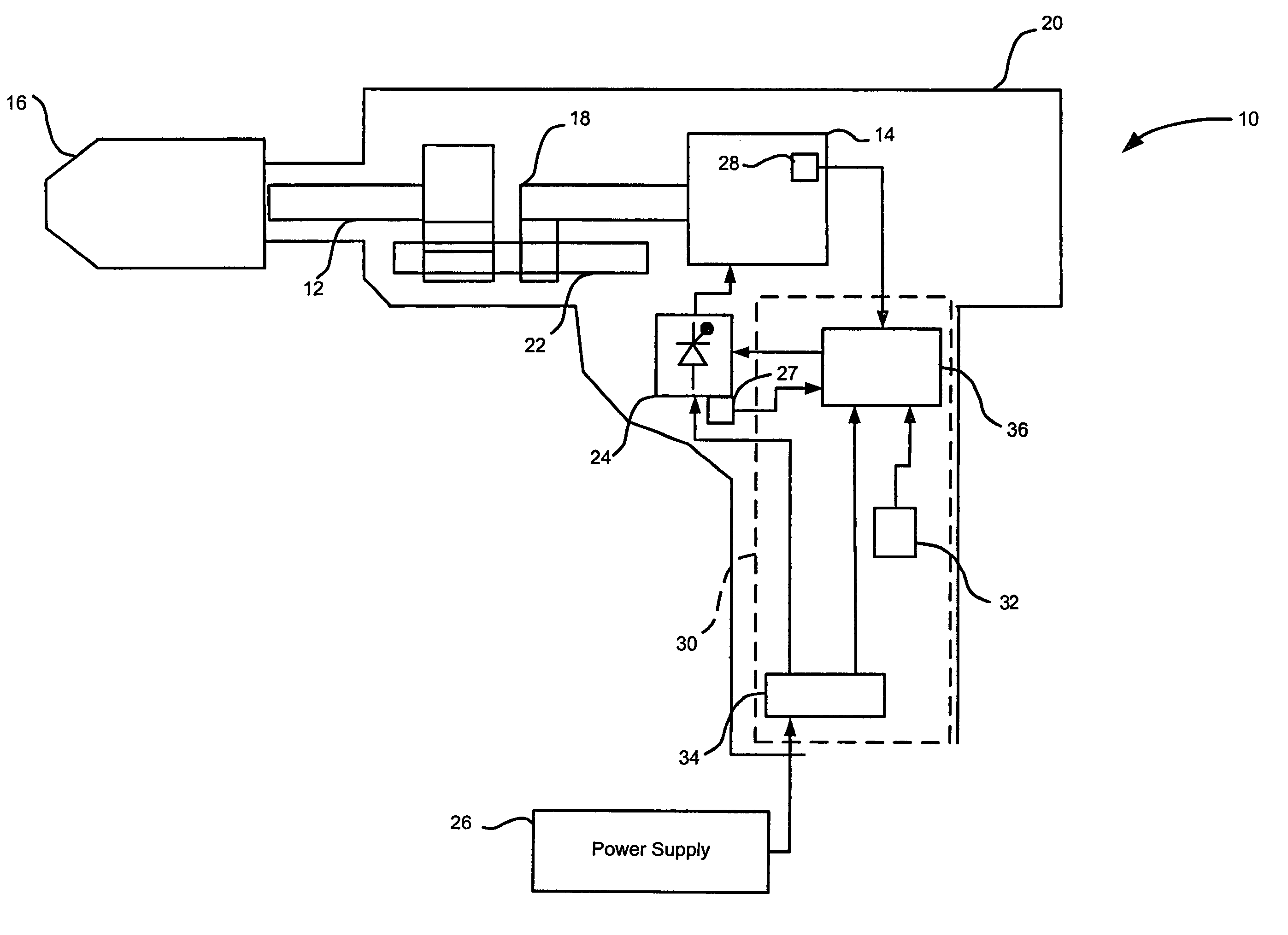

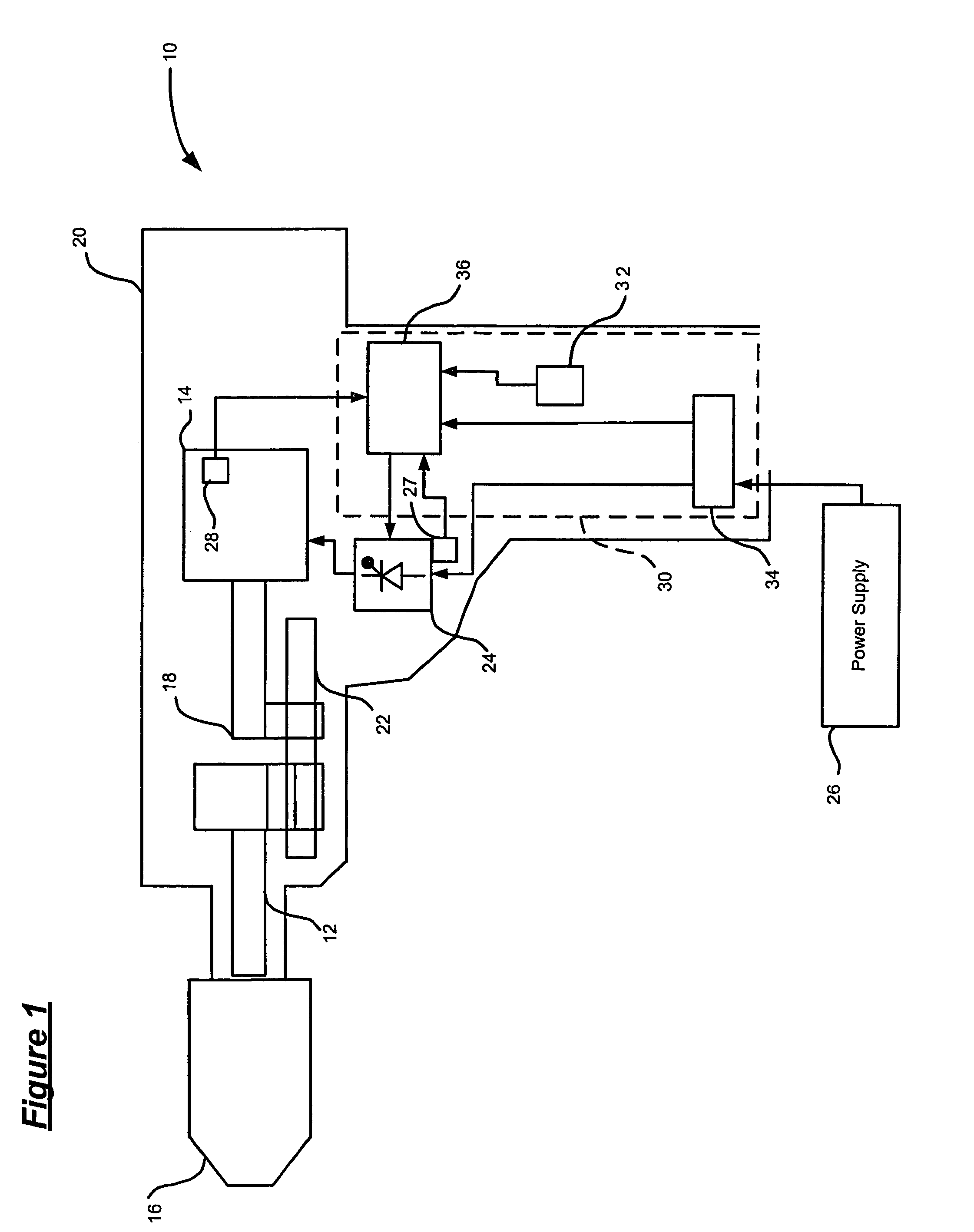

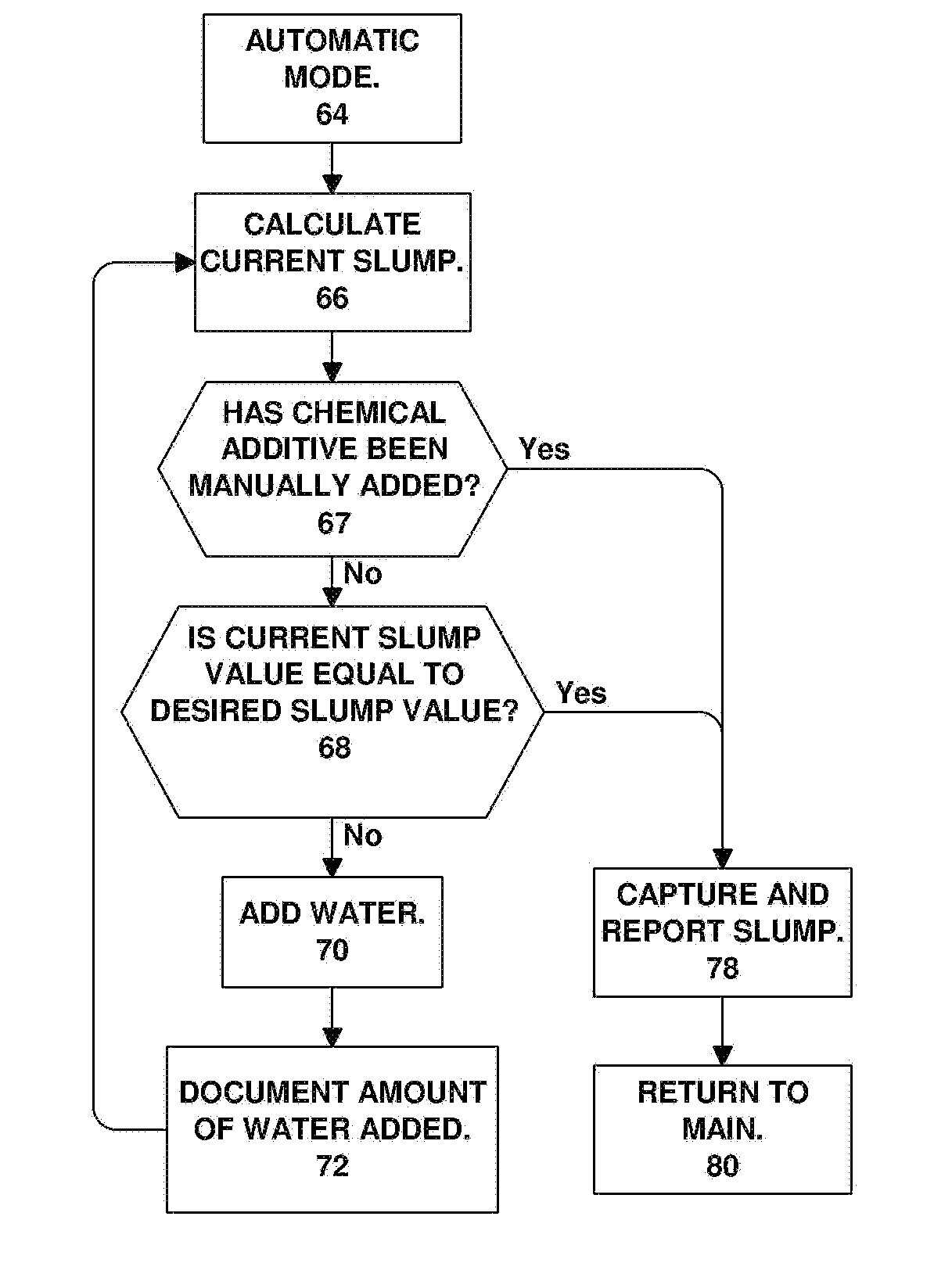

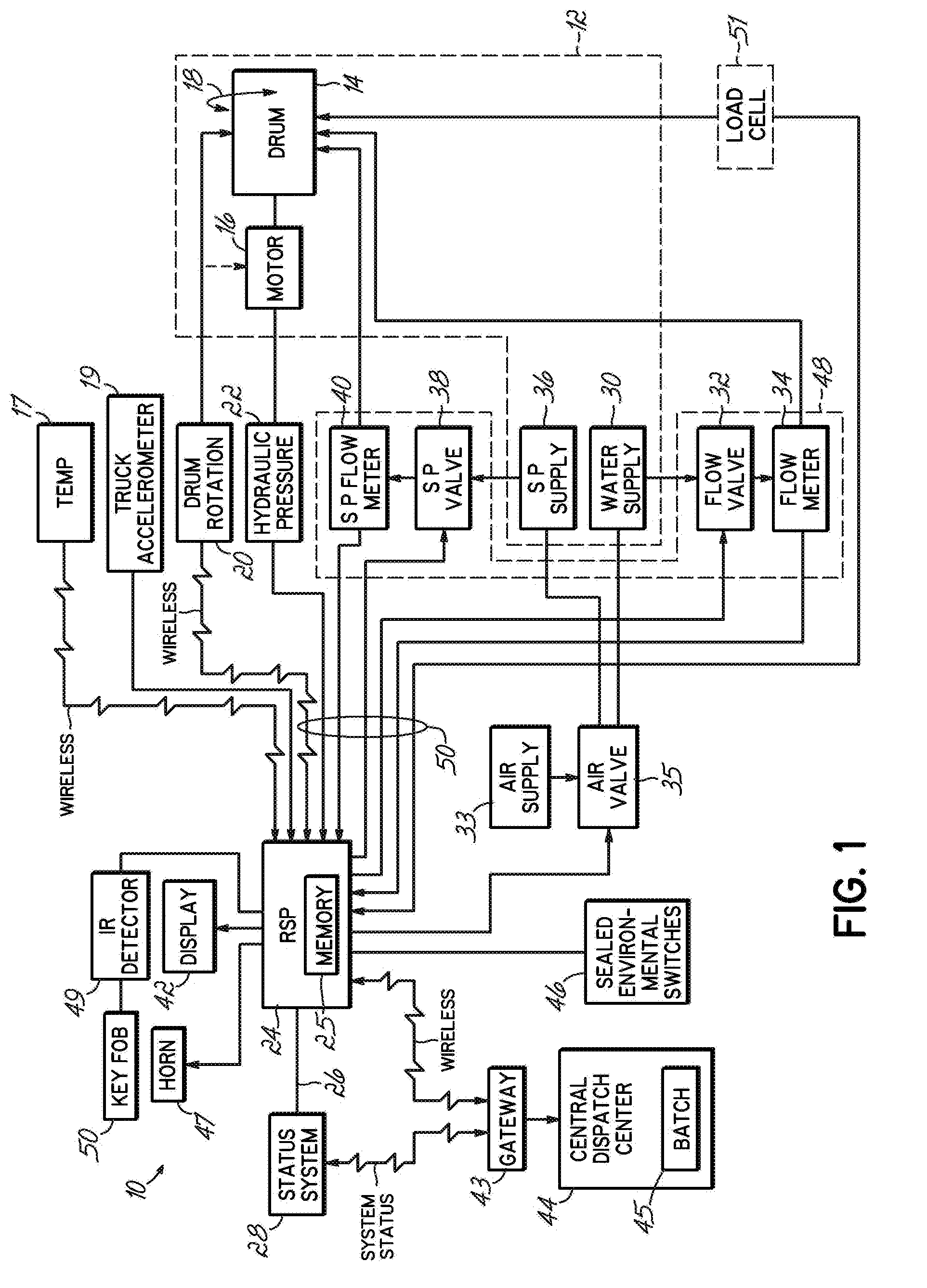

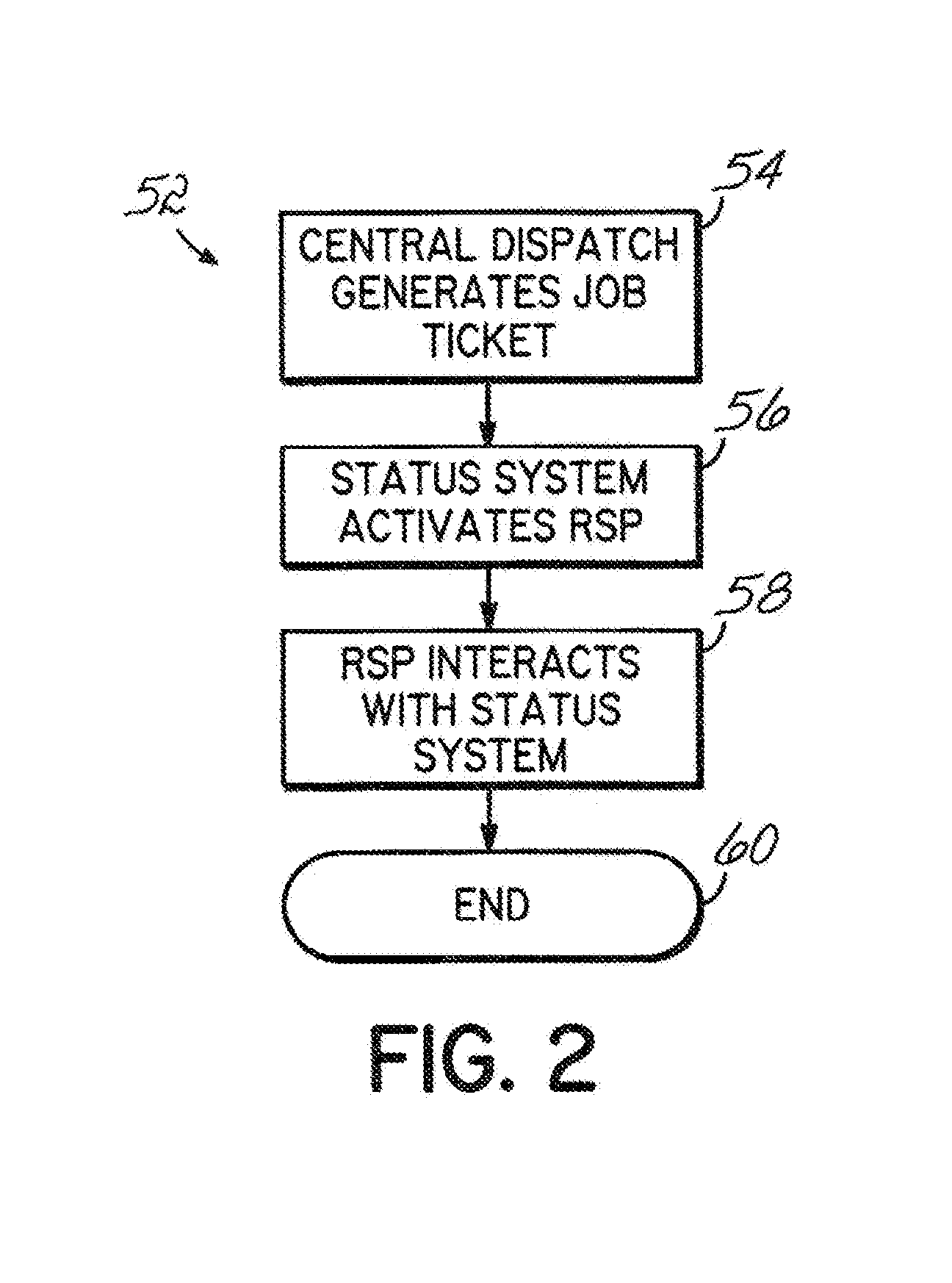

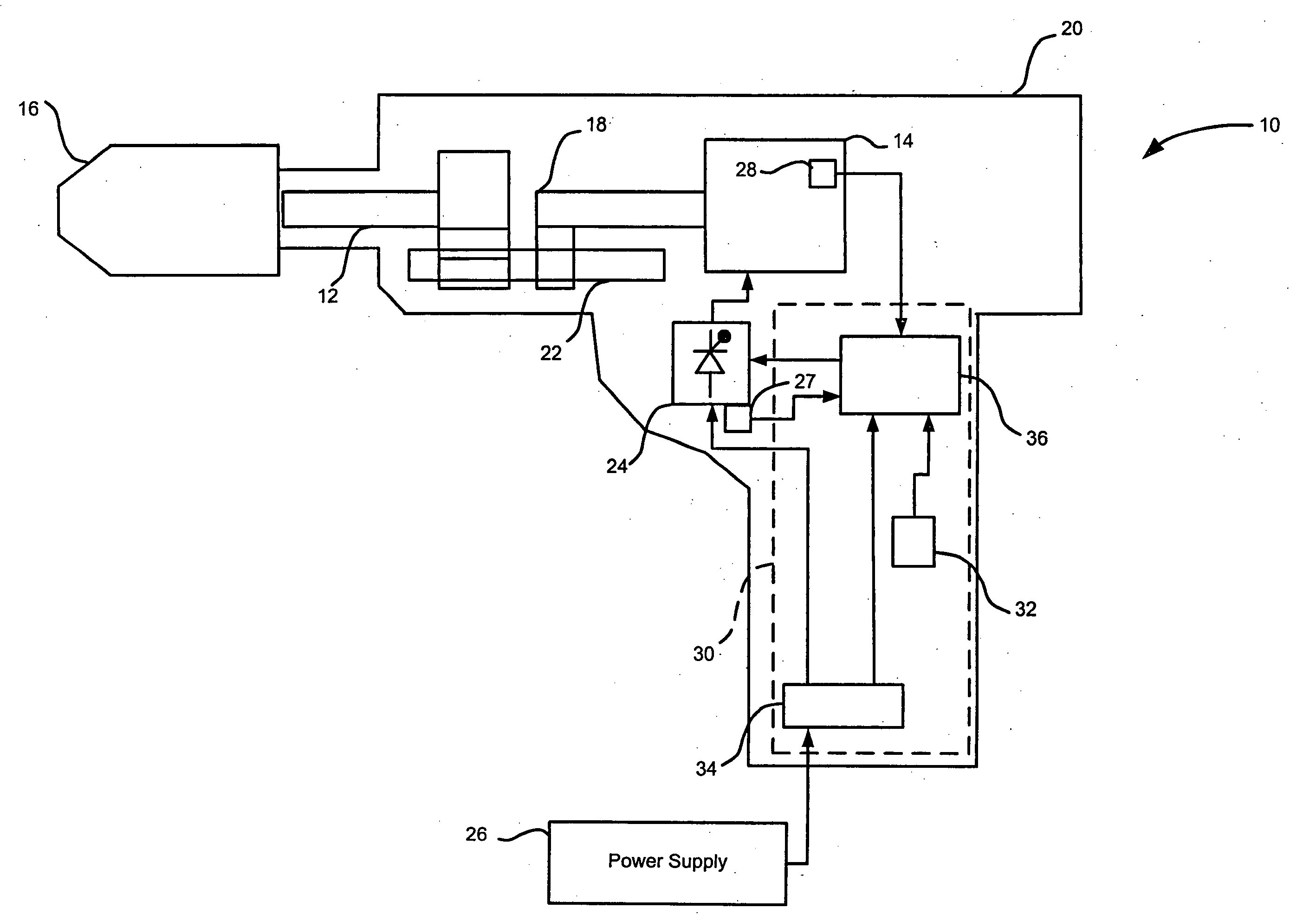

Method and System for Calculating and Reporting Slump in Delivery Vehicles

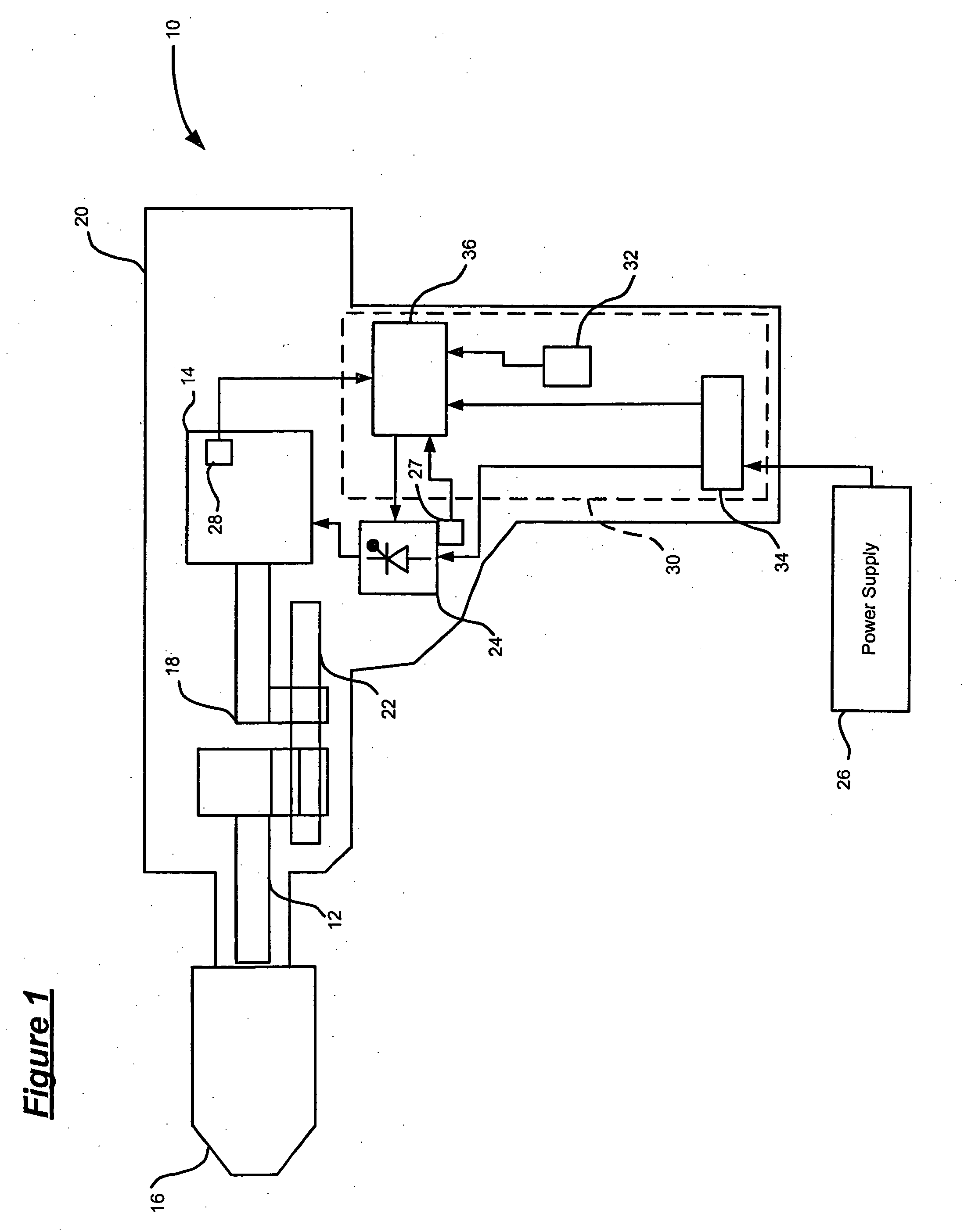

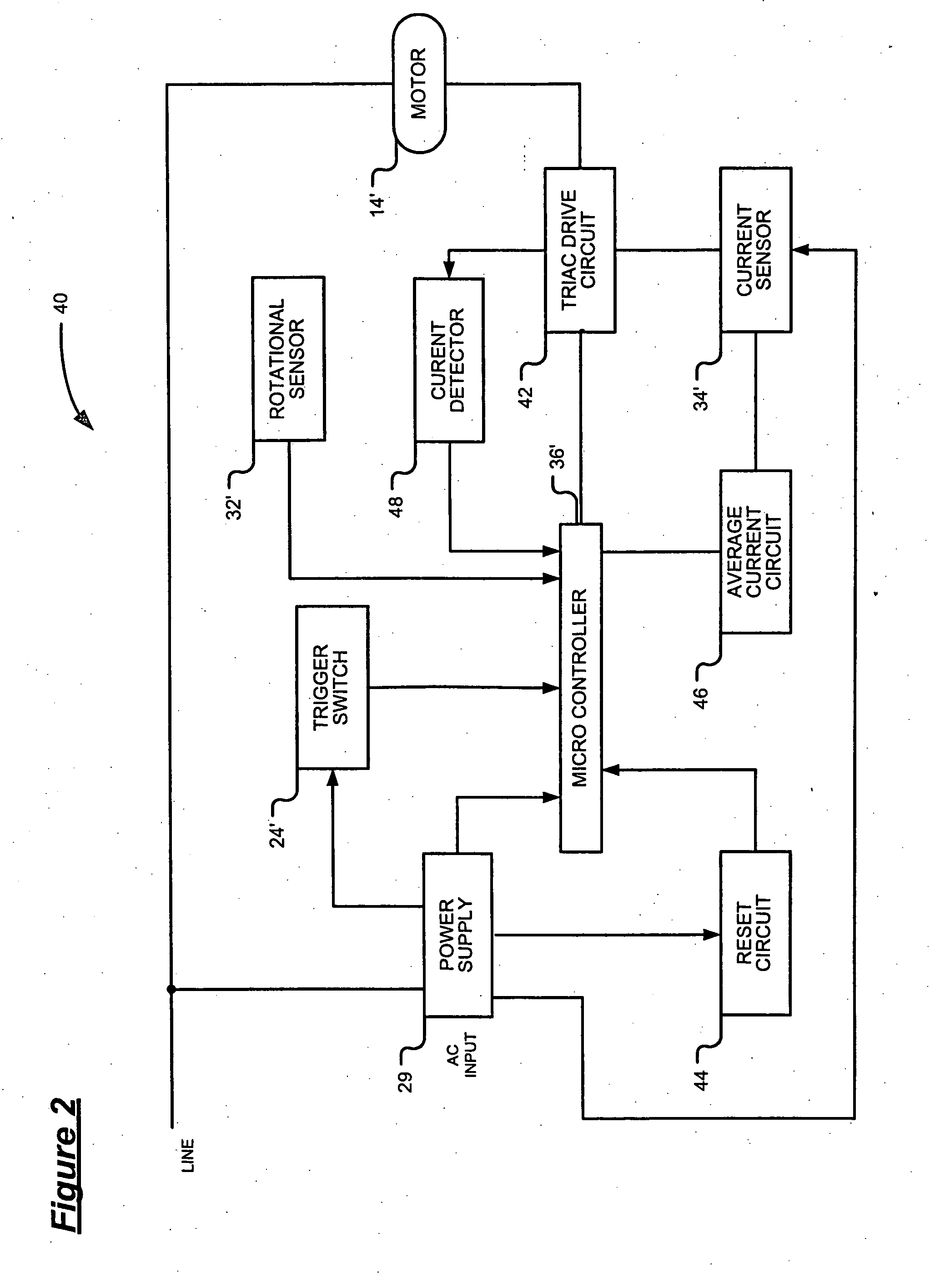

ActiveUS20090037026A1Easy to useThermometer detailsSampled-variable control systemsDelivery vehicleCold weather

A system for managing a concrete delivery vehicle having a mixing drum 14 and hydraulic drive 16 for rotating the mixing drum, including a rotational sensor 20 configured to sense a rotational speed of the mixing drum, a hydraulic sensor 22 coupled to the hydraulic drive and configured to sense a hydraulic pressure required to turn the mixing drum, a temperature sensor for sensing temperature of the drum, and a communications port 26 configured to communicate a slump calculation to a status system 28 commonly used in the concrete industry, wherein the sensing of the rotational speed of the mixing drum is used to qualify a calculation of current slump based on the hydraulic pressure required to turn the mixing drum. Temperature readings are further used to qualify or evaluate a load. Also, water purge connections facilitate cold weather operation.

Owner:VERIFI

Power tool anti-kickback system with rotational rate sensor

A control system is provided for use in a power tool. The control system includes: a rotational rate sensor having a resonating mass and a controller electrically connected to the rotational rate sensor. The rotational rate sensor detects lateral displacement of the resonating mass and generates a signal indicative of the detected lateral displacement, such that the lateral displacement is directly proportional to a rotational speed at which the power tool rotates about an axis of the rotary shaft. Based on the generated signal, the controller initiates a protective operation to avoid further undesirable rotation of the power tool. The control scheme employed by the power tool may initiate different protective operations for different tool conditions.

Owner:BLACK & DECKER INC

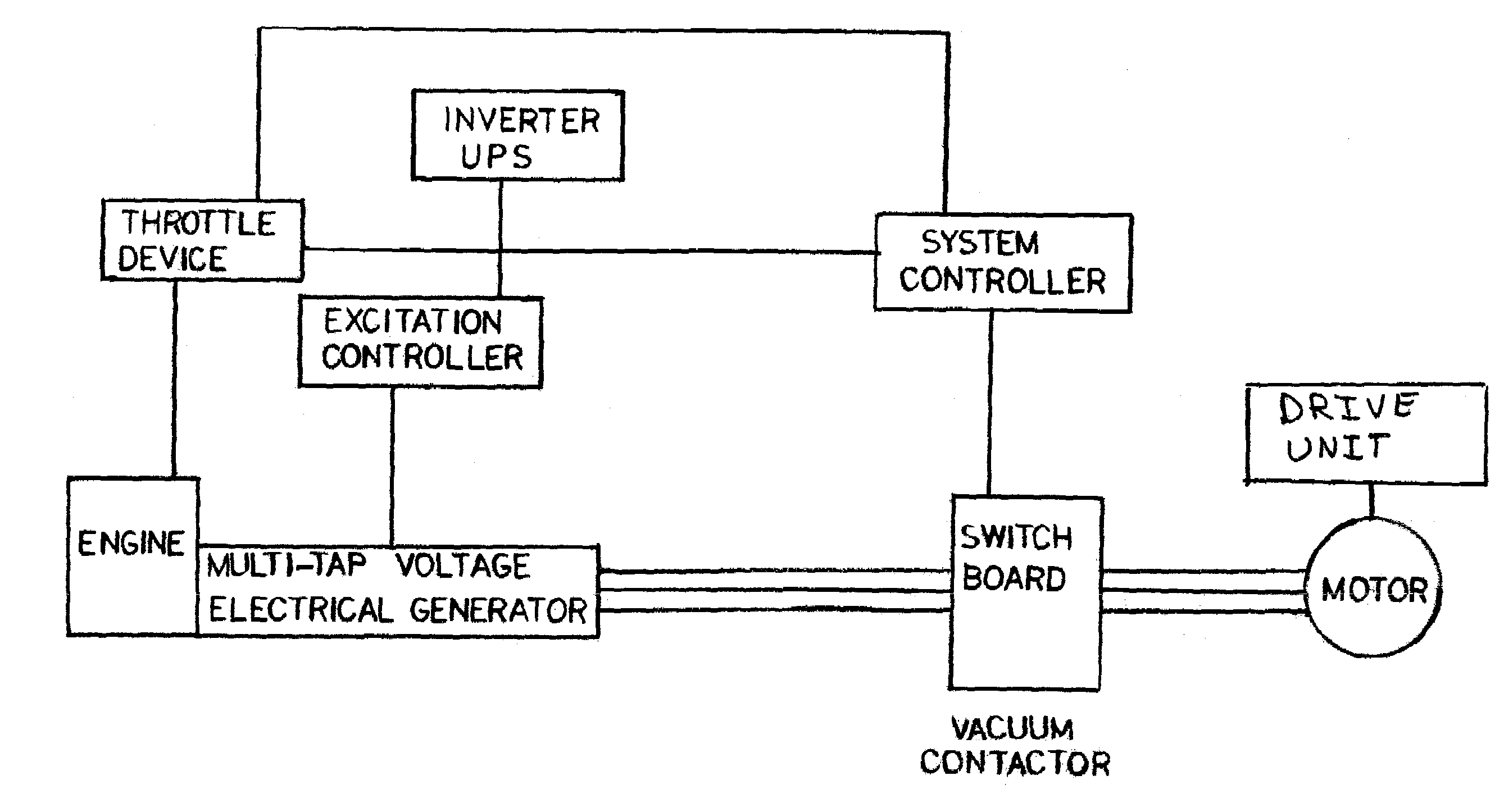

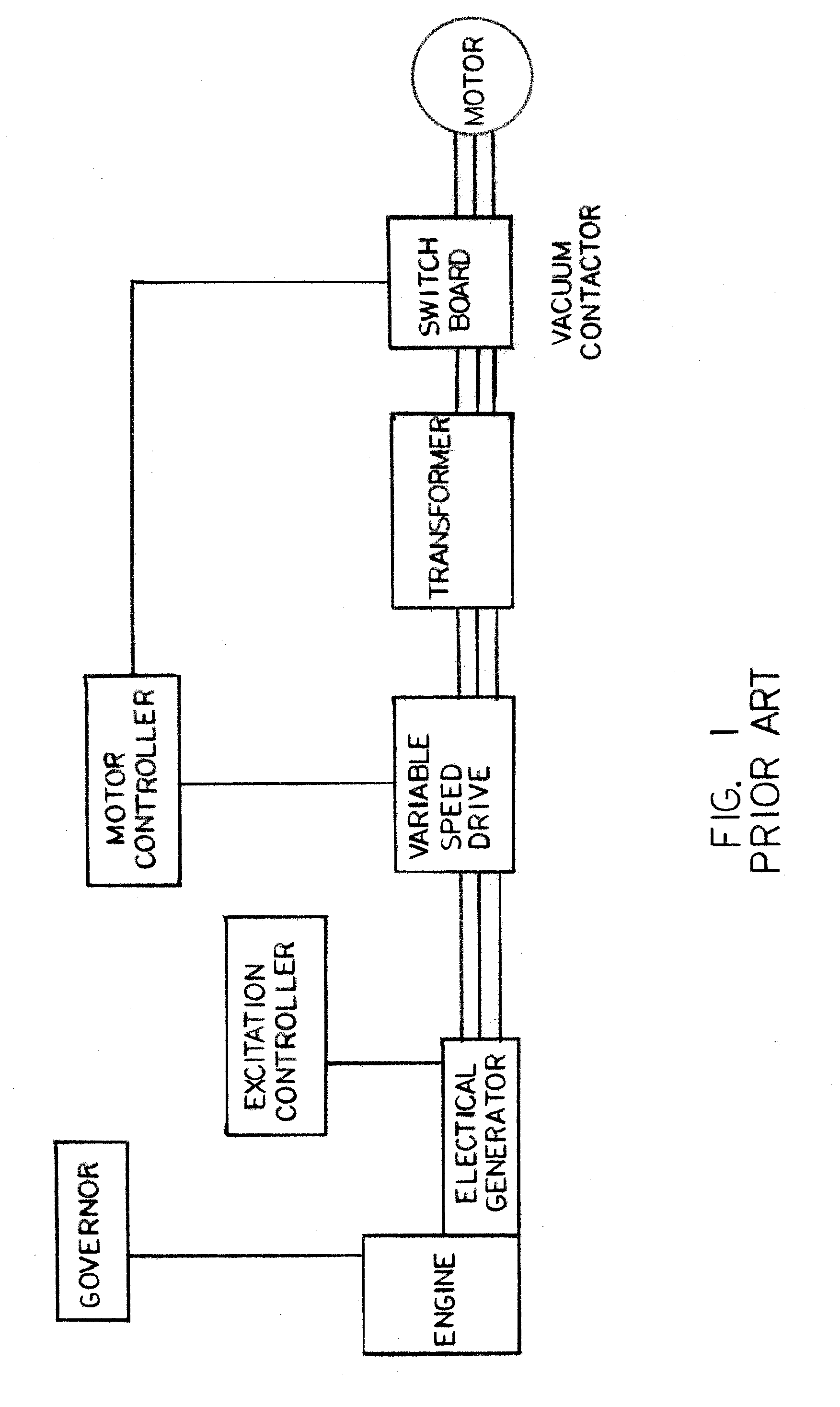

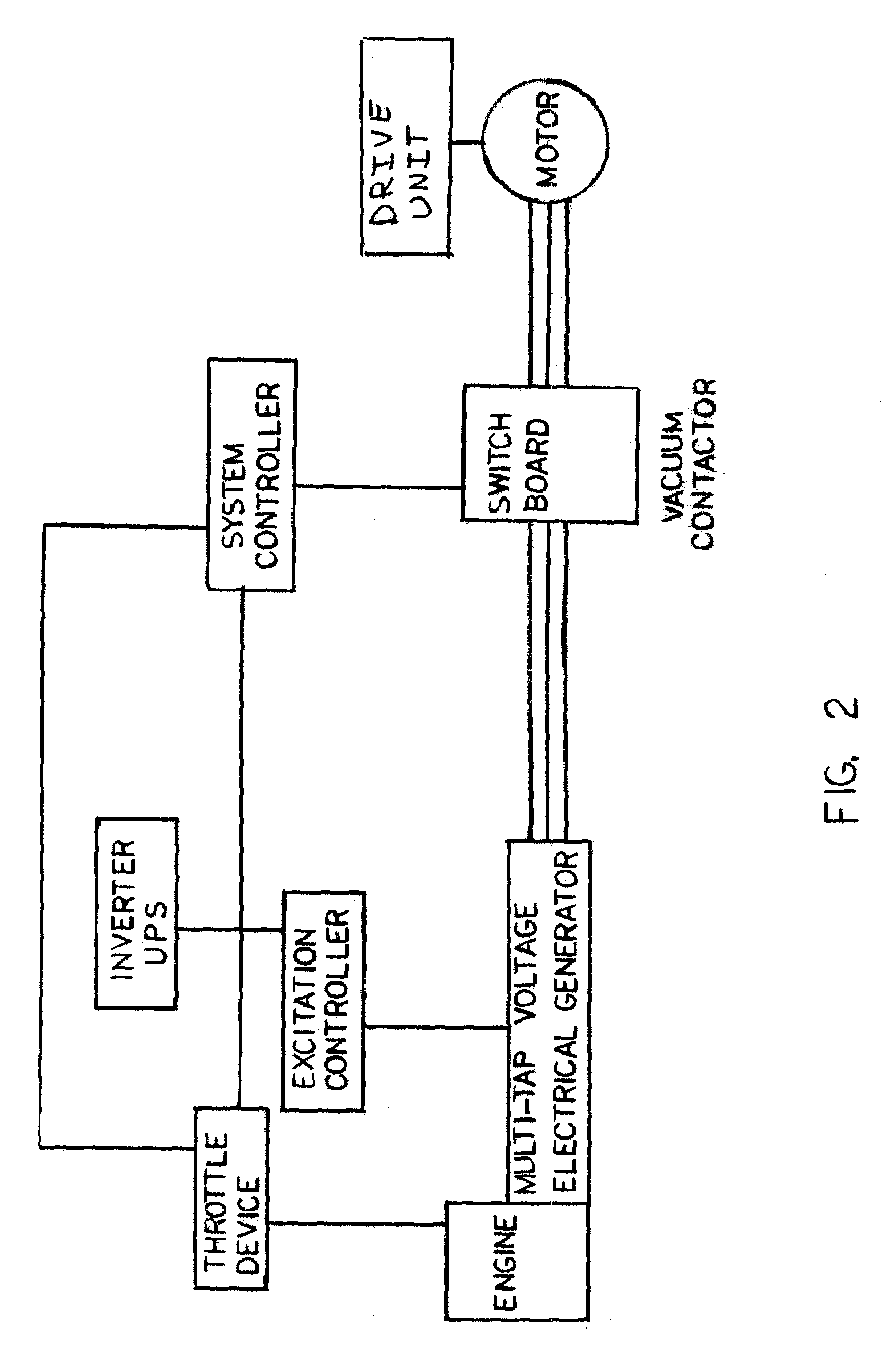

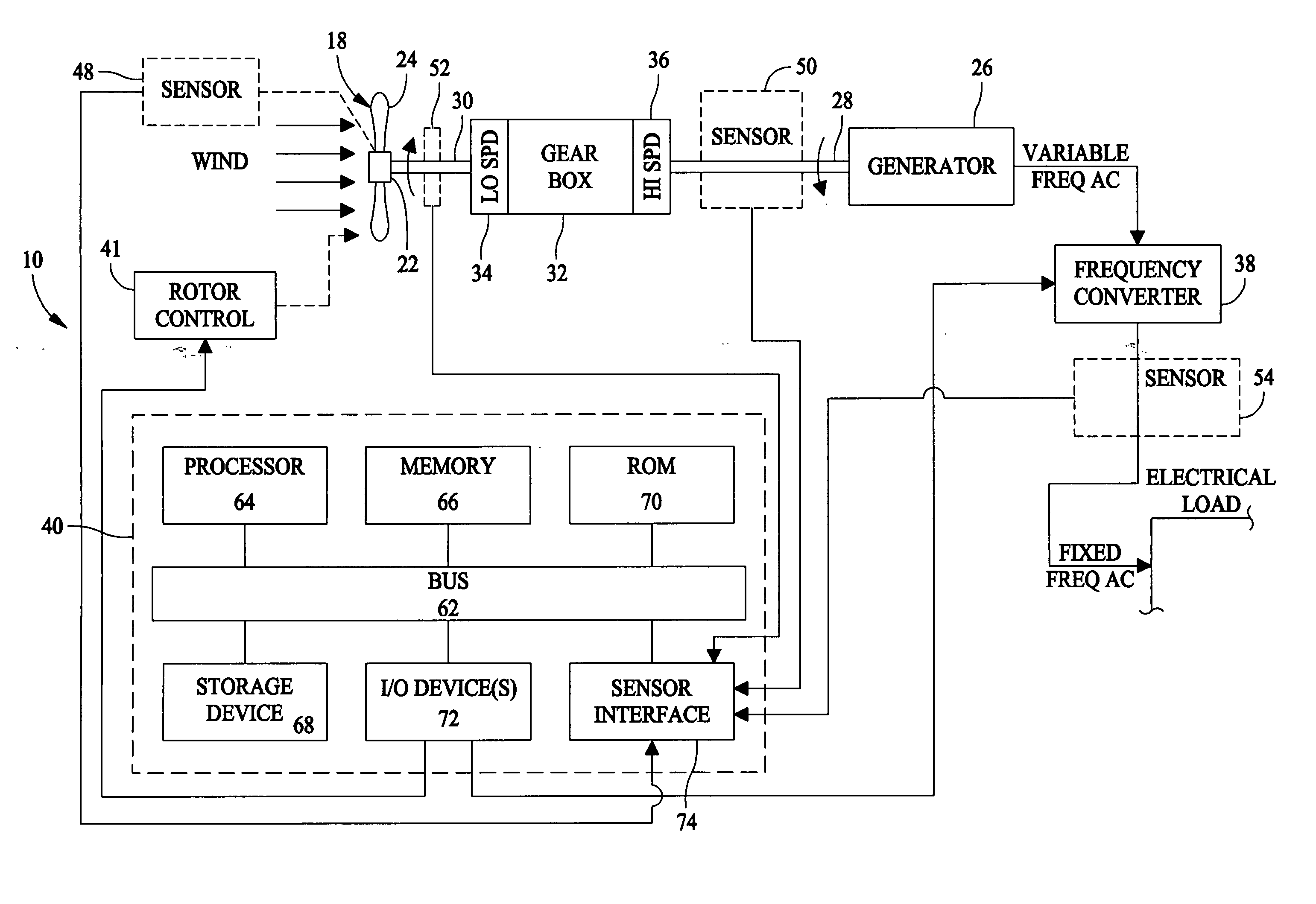

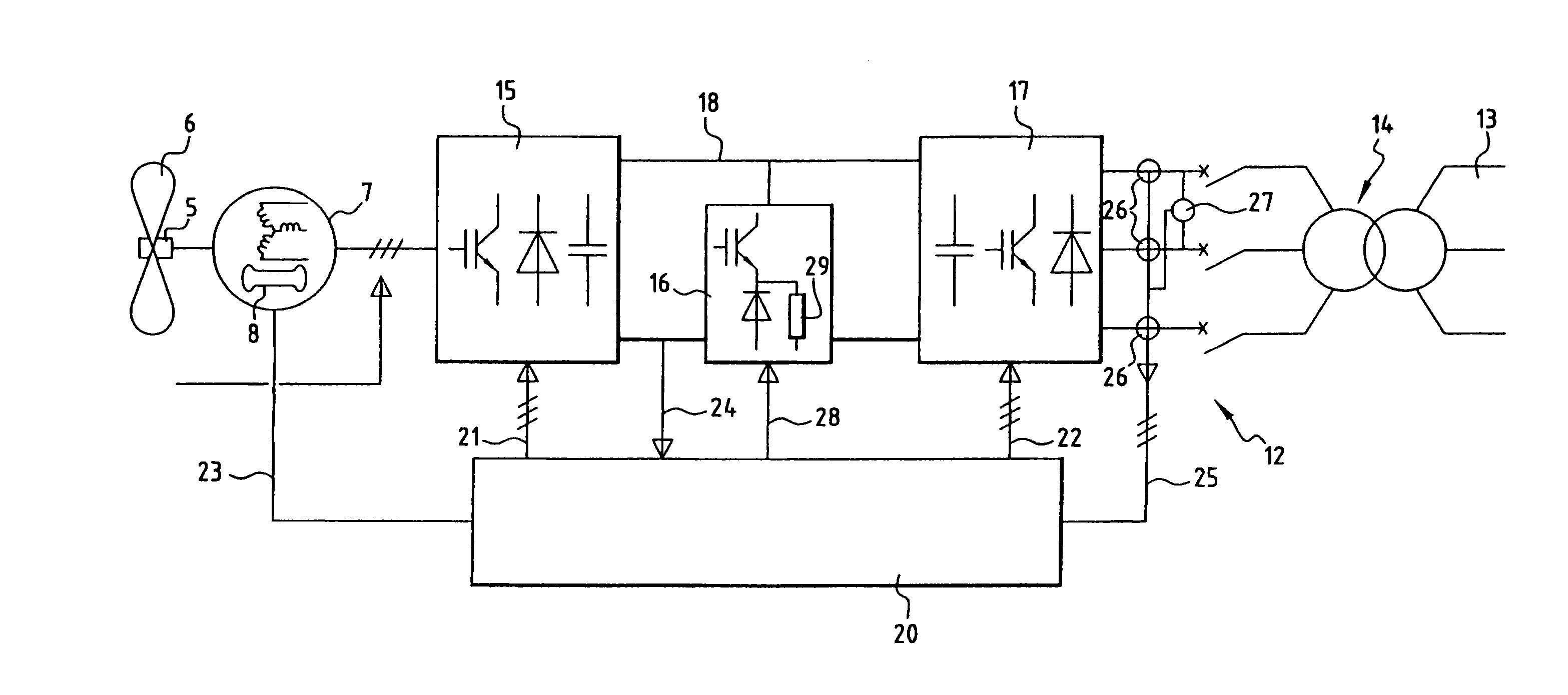

Variable frequency power system and method of use

A variable frequency power system with a power source having a rotating output and a speed control to regulate rotational speed of the rotating output. A generator coupled to and driven by the rotating output of the power source, whereby the speed control of the power source directly controls output power frequency of the generator due to control of rotational frequency of the rotating output. A voltage regulator connected between the generator and the motor regulates output voltage from the generator to the electrical motor load. A system controller controls output power frequency of the generator. The system controller interfaces with the speed control of the power source and configured to monitor generator output and operational conditions of the electrical motor load. The system controller adjusts the speed control based on generator output and operational conditions of the electrical motor load.

Owner:FOUND ENTERPRISES

Axial flow pump pressure algorithm

ActiveUS20140357937A1Shorten speedIncrease speedControl devicesBlood pumpsAxial-flow pumpDifferential pressure

The presence or absence of a high pressure condition in an implantable blood pump is determined at least in part based on a comparison between a determined amount of differential pressure across the pump and a pressure threshold value. The amount of differential pressure parameter may be determined based at least in part on a parameter related to flow, such as a parameter related to thrust on the rotor of the pump. In response to determining the presence of a high pressure condition, an updated speed of rotation of the rotor that is less than the rotor's initial speed may be determined. The rotor's speed may be increased when the flow rate of blood is determined to be at least equal to a flow recovery threshold value.

Owner:HEARTWARE INC

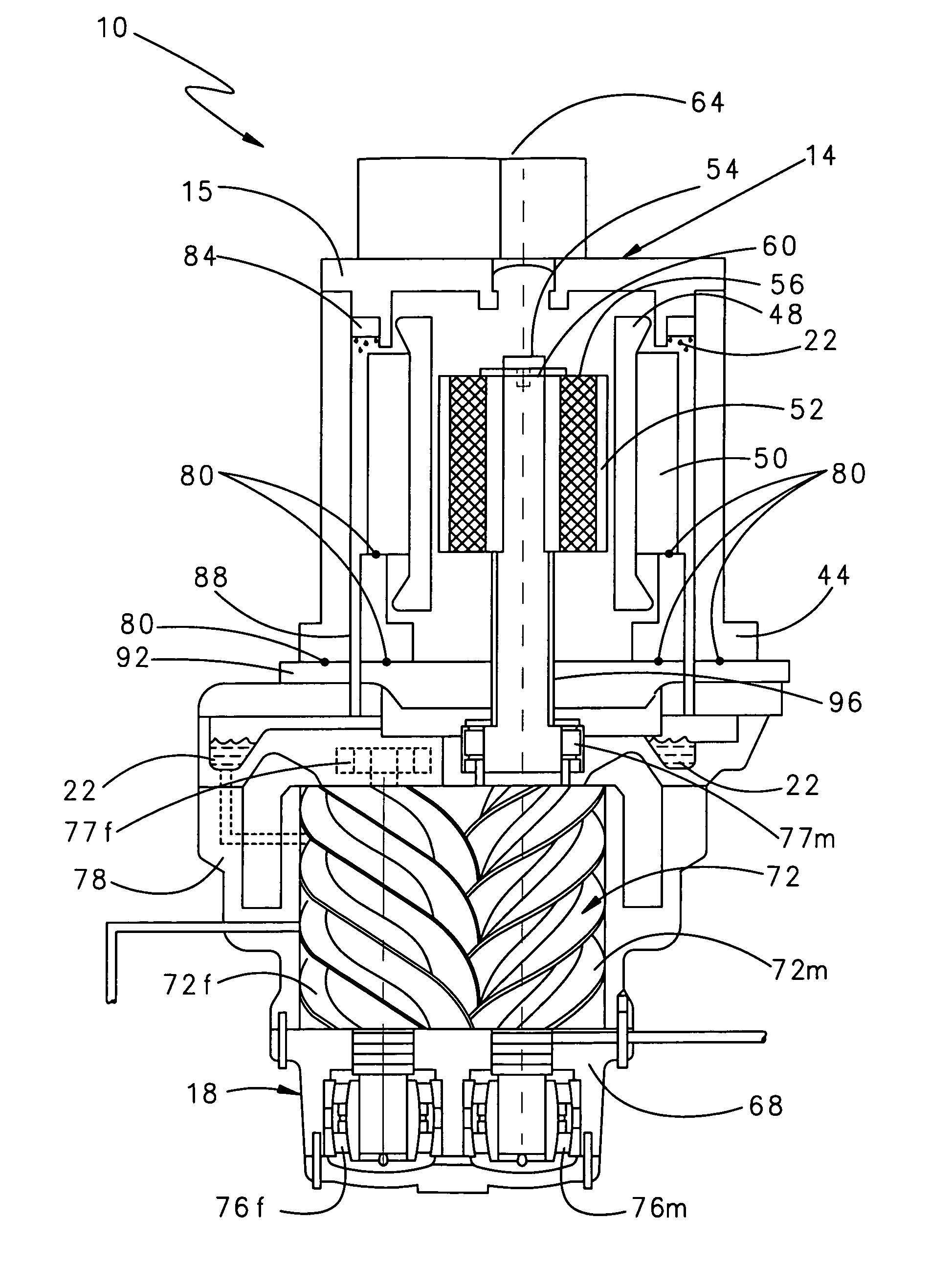

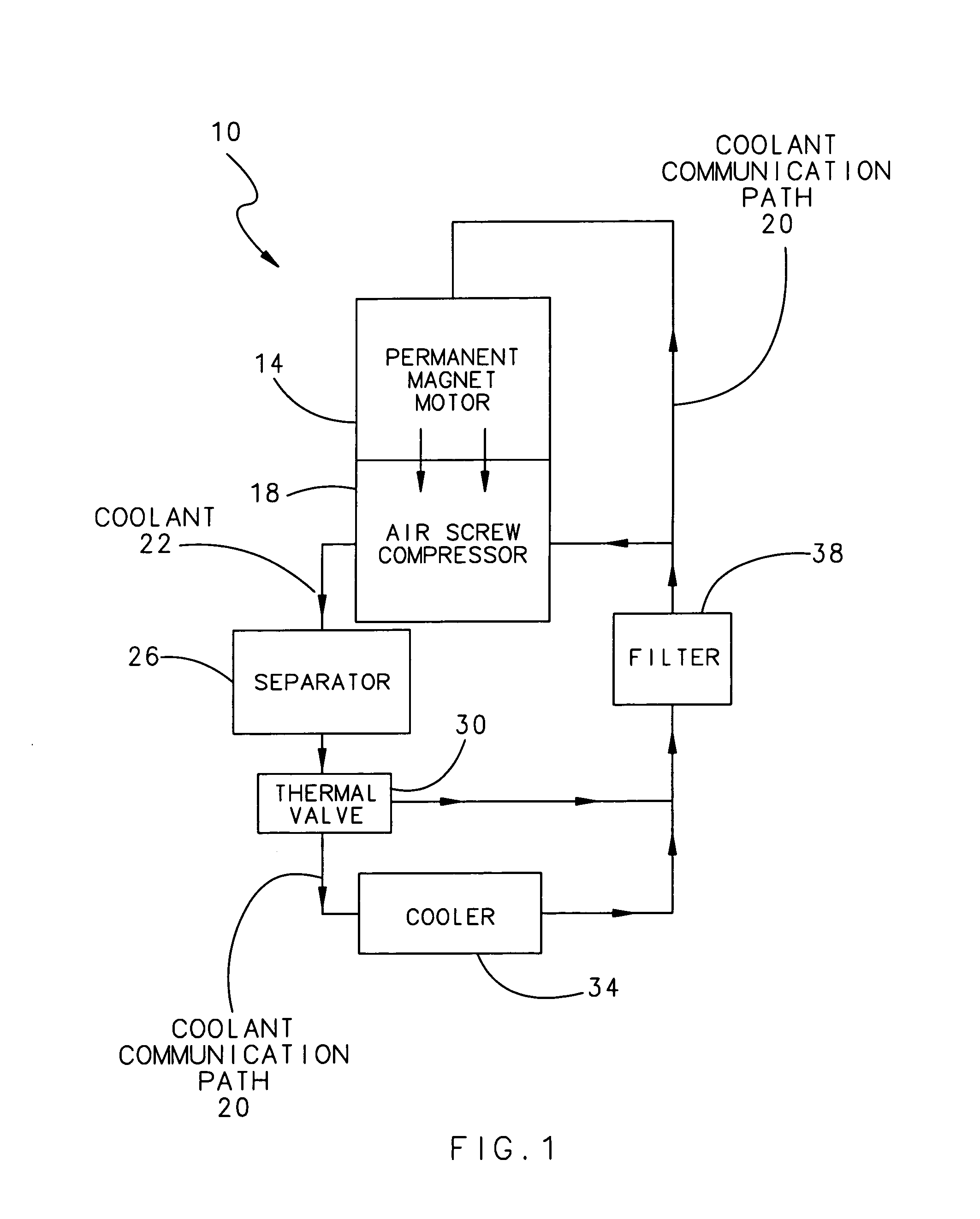

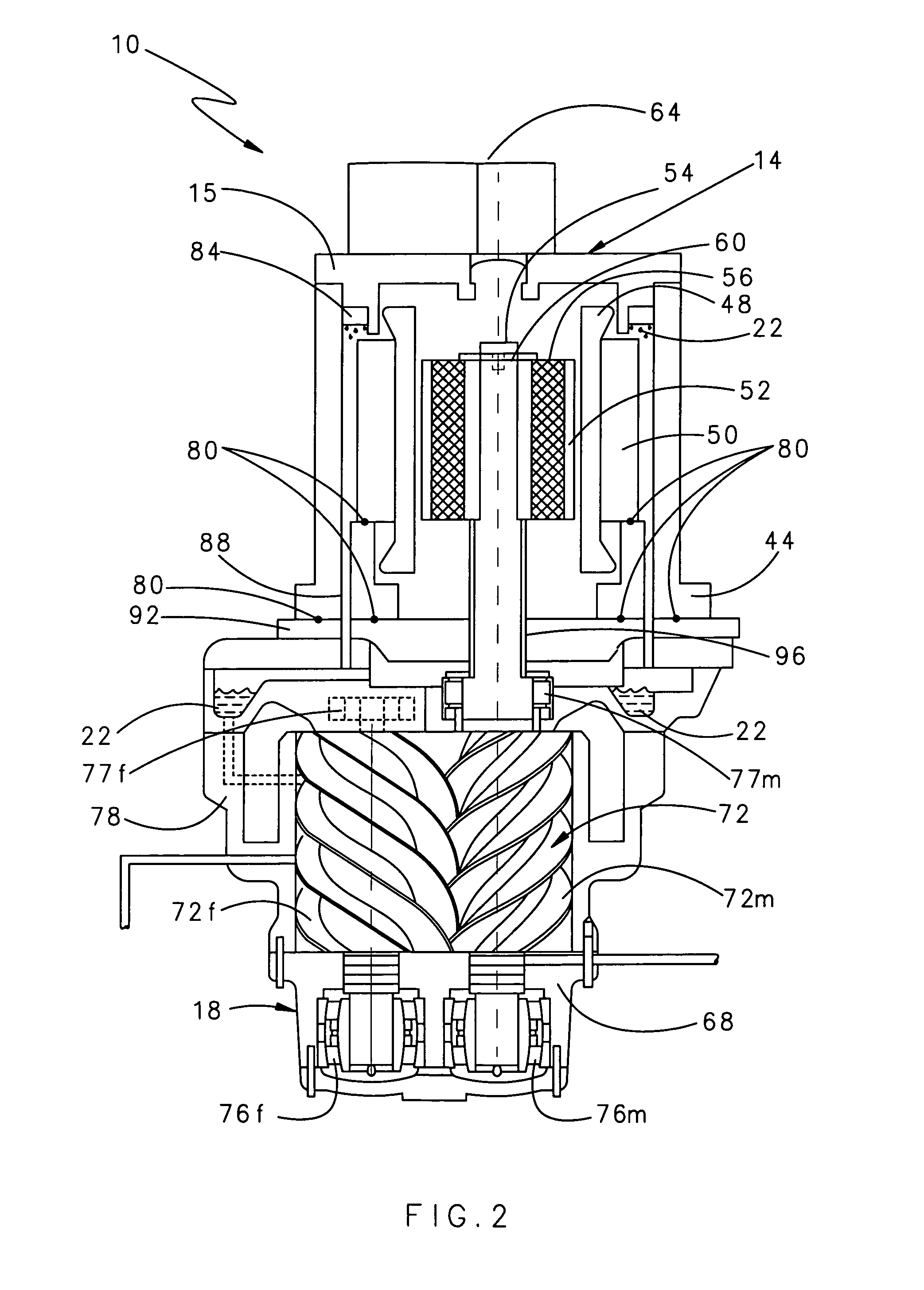

Lubricant cooled integrated motor/compressor design

InactiveUS20070241627A1Prevent overboard leakageThe process is compact and efficientRotary/oscillating piston combinations for elastic fluidsEngine of counter-engagement typePermanent magnet motorGear train

A compressor system according to the present invention utilizes direct rotational input from a permanent magnet motor to generate compressed air. The permanent magnet motor is mounted directly to an air screw compressor. The rotational input is provided by the permanent magnet motor to the air screw compressor without a gear train. The permanent magnet motor and associated variable speed drive controls the rotational speed of the permanent magnet motor and hence the screw compressor. Differing motors may selectively mount, and provide rotational input to, the air screw compressor.

Owner:SULLAIR CORP

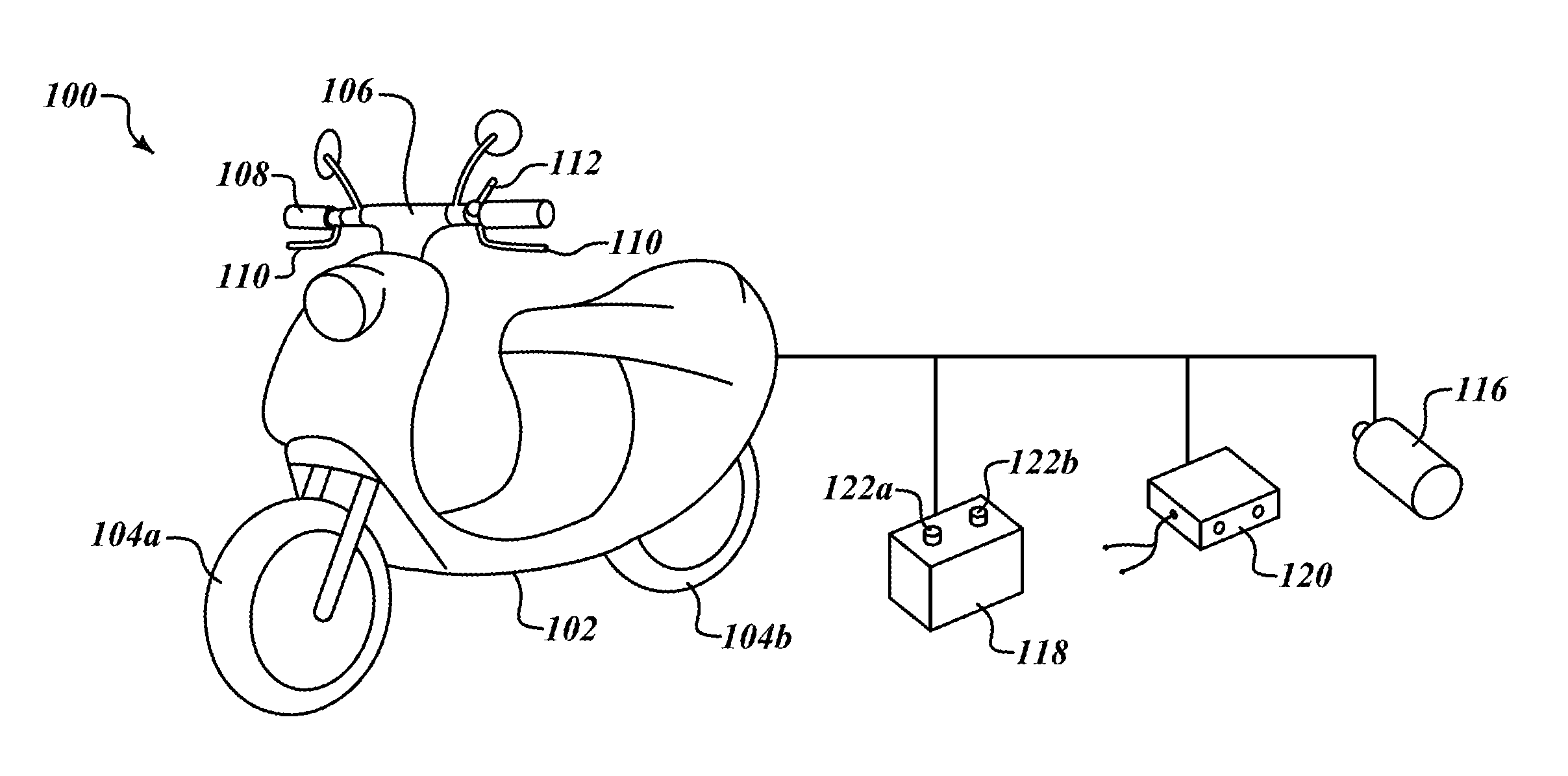

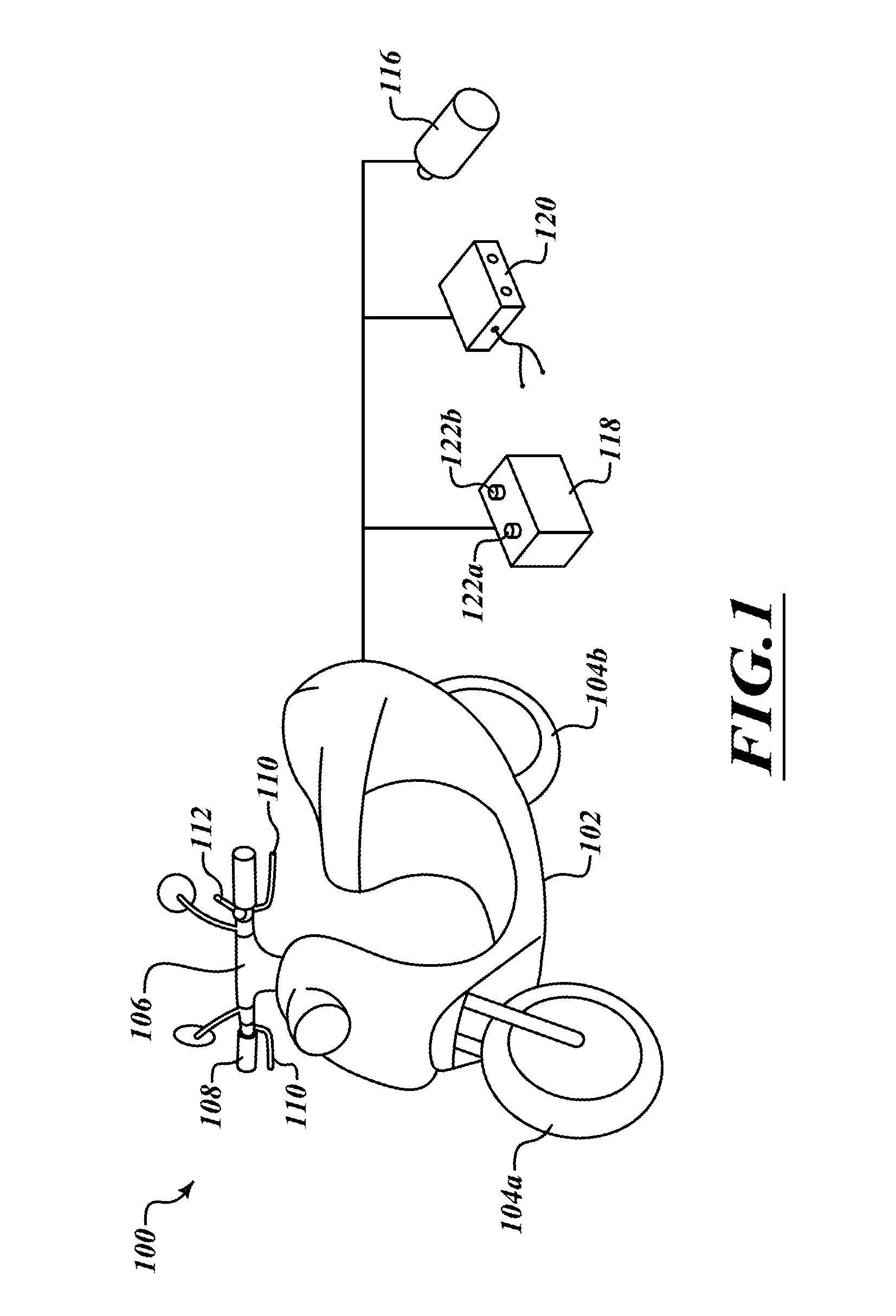

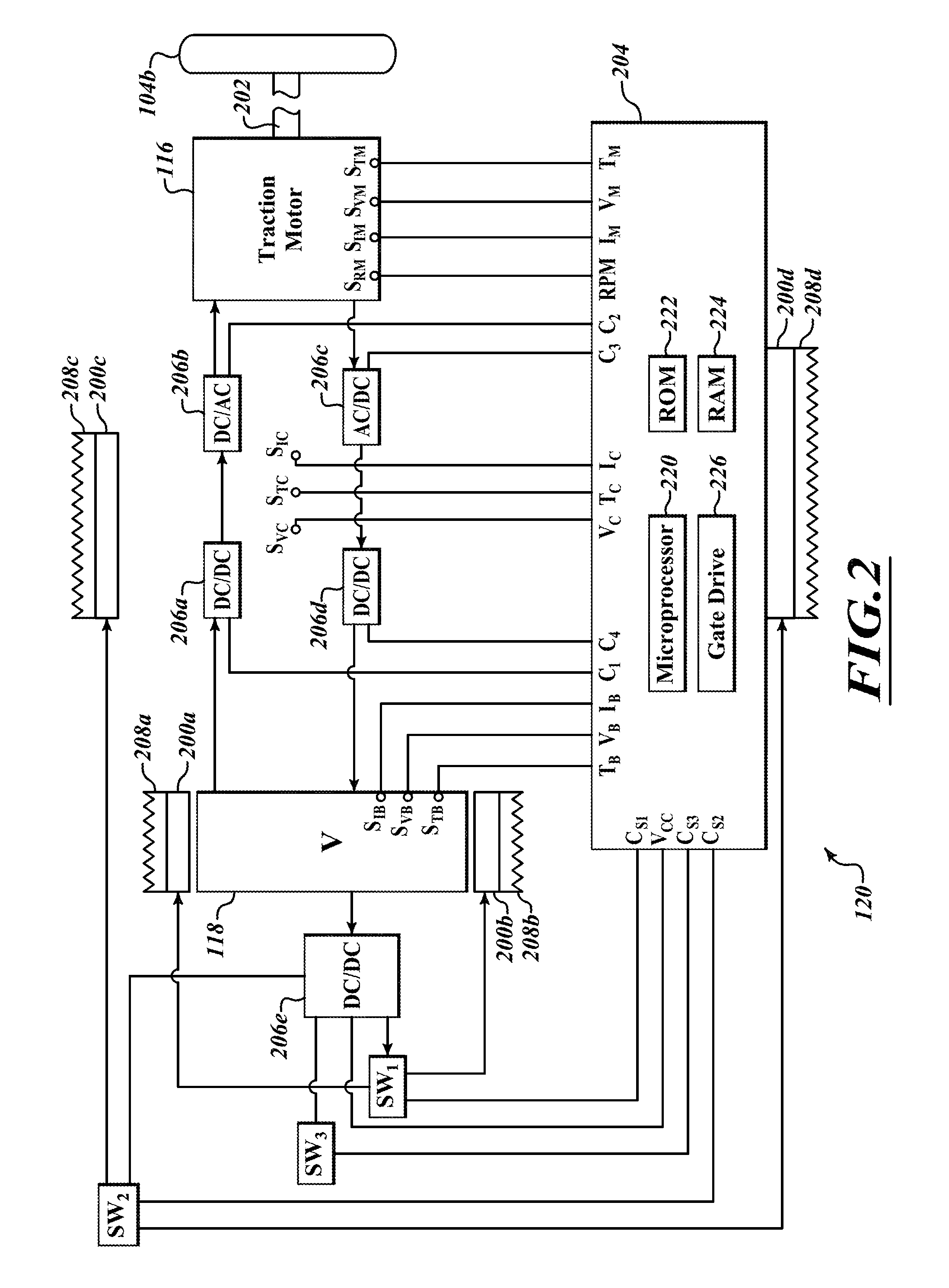

Thermal management of components in electric motor drive vehicles

ActiveUS20130033203A1Registering/indicating working of vehiclesNavigation instrumentsRegenerative brakeSupercapacitor

Thermal management of various components such as electrical energy storage devices (e.g., batteries, super- or ultracapacitors), power converters and / or control circuits, in electrically powered vehicles may employ active temperature adjustment devices (e.g., Peltier devices), which may advantageously be powered using electrical energy generated by the traction electric motor during regenerative braking operation. Temperature adjustment may include cooling or heating one or more components. The adjustment may be based on a variety of factors or conditions, for instance sensed temperature, sensed current draw, sensed voltage, sensed rotational speed.

Owner:GOGORO

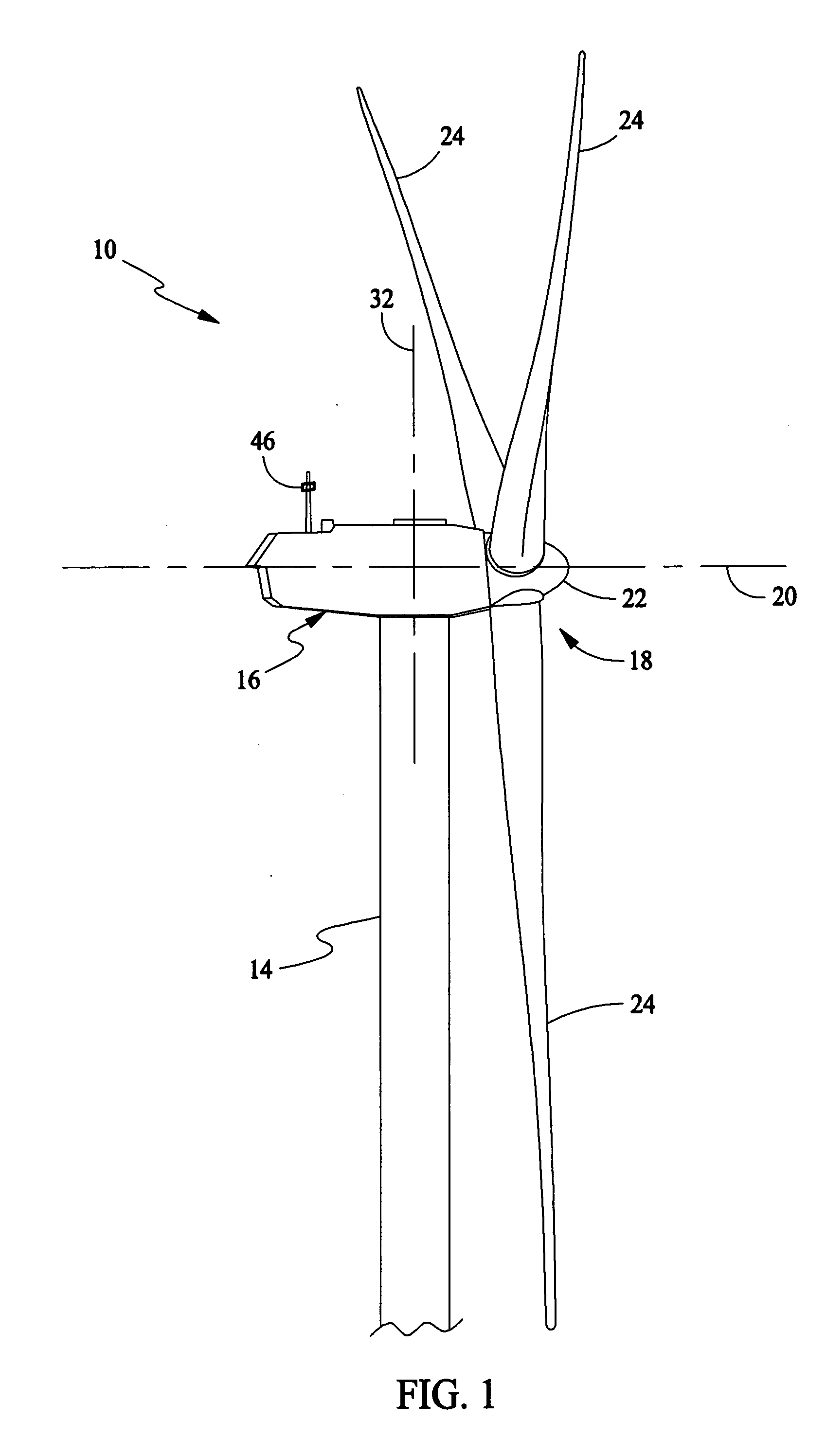

Methods and apparatus for controlling rotational speed of a rotor

A method for controlling a rotational speed of a rotor having at least one rotor blade, a rotor shaft, and an electrical generator coupled thereto. The method includes controlling a torque of the rotor shaft by controlling a torque of the electrical generator, alternating between changing an angle of pitch of the at least one rotor blade and maintaining the angle of pitch of the at least one rotor blade substantially constant, and maintaining a substantially constant rotational speed of the rotor during variable wind speeds above a predetermined rated wind speed.

Owner:GENERAL ELECTRIC CO

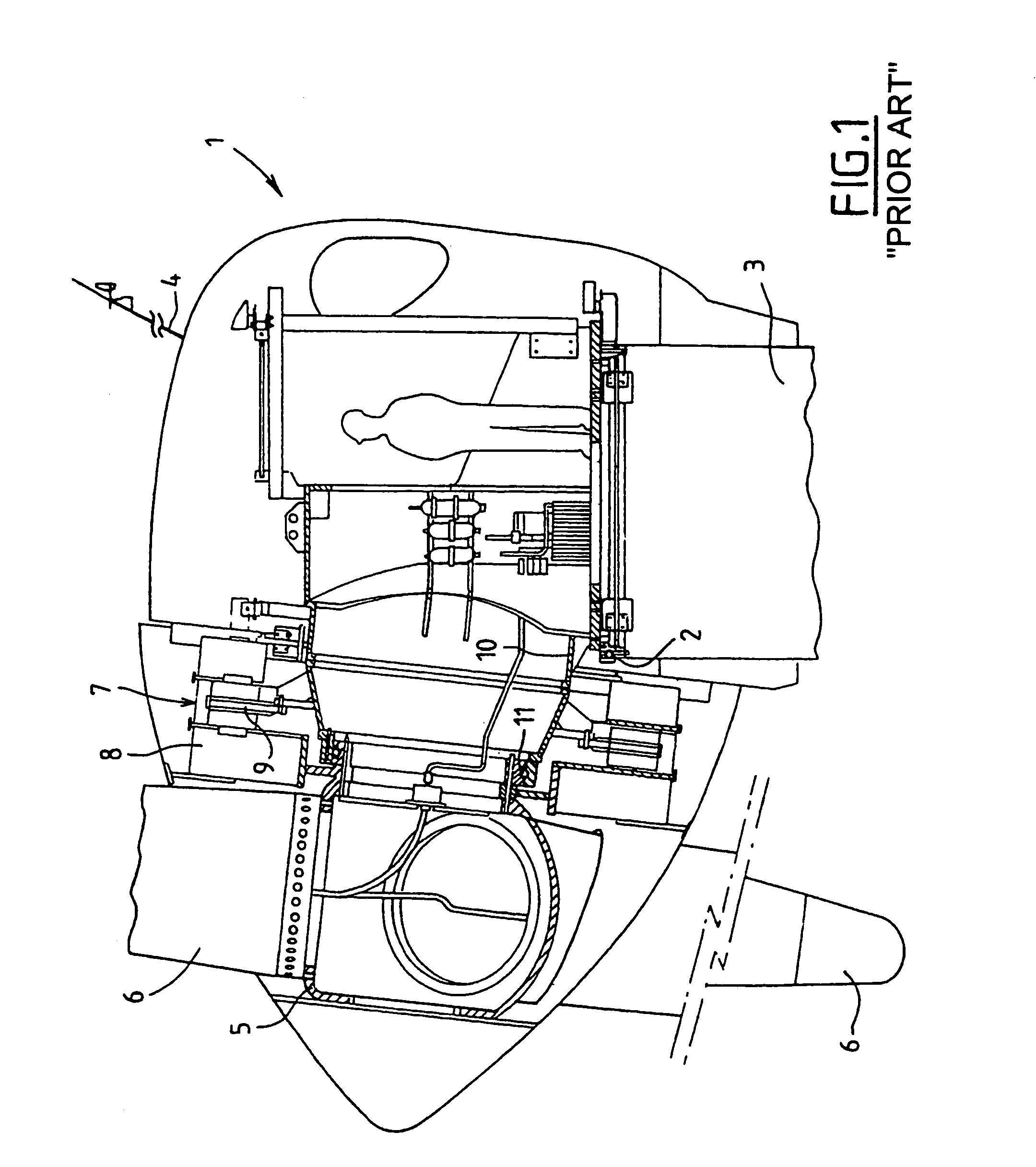

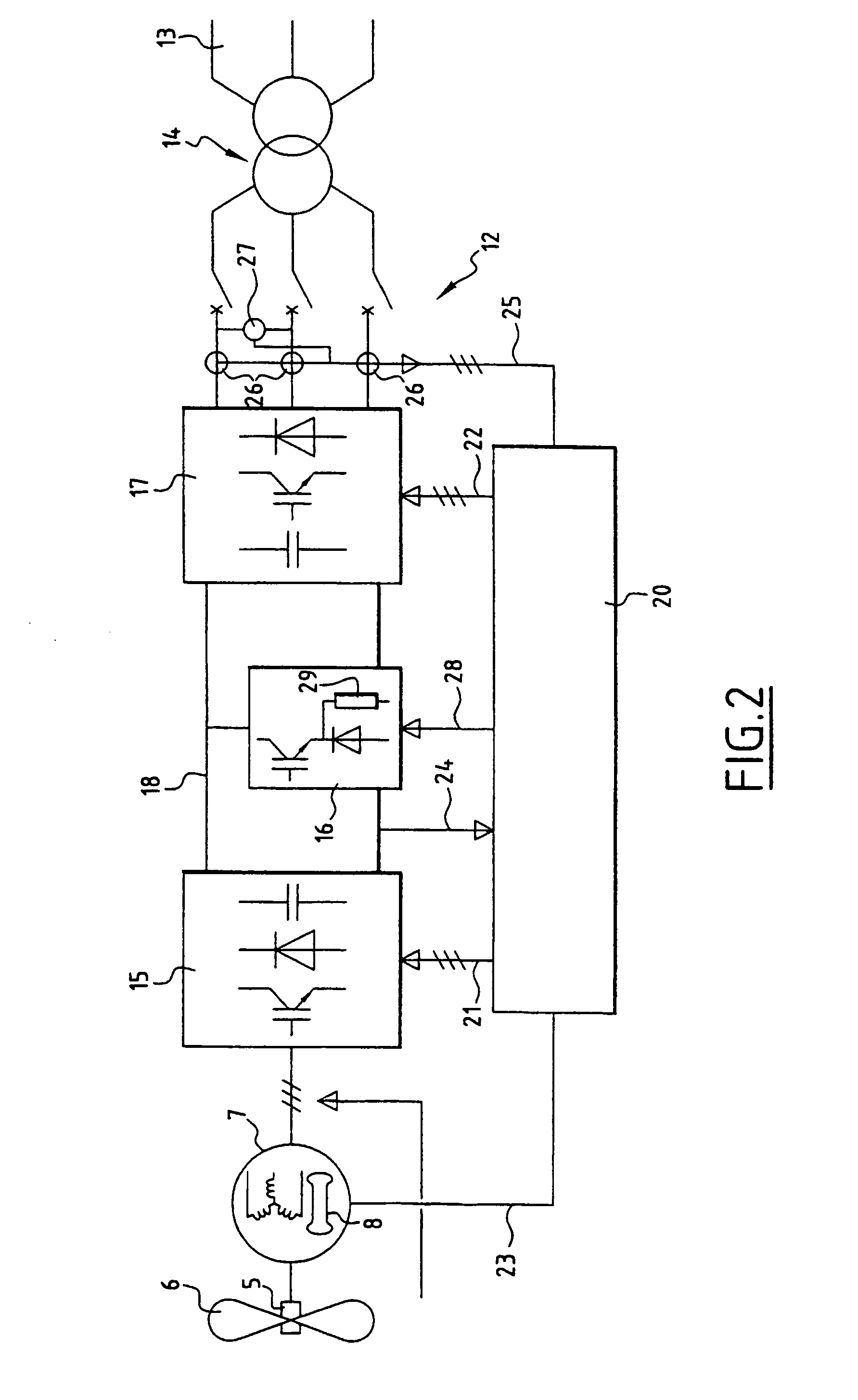

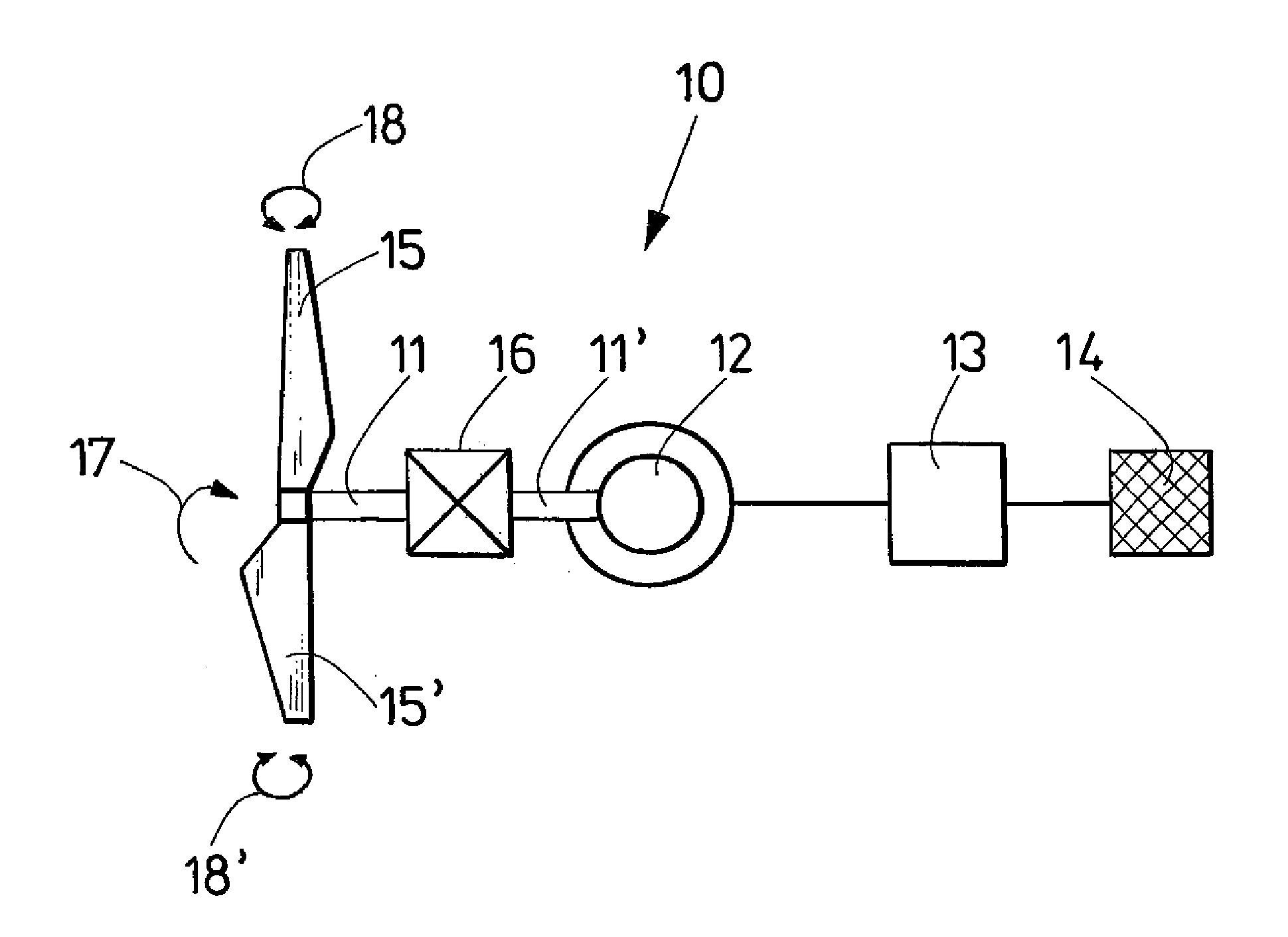

Method and device for regulating a wind machine

A method and corresponding apparatus for regulating a system that produces electric power, the system including an electric alternator having a rotor integral with a rotating part of a wind machine to form a rotary assembly, and a power electronics module, the method including the steps of: producing an alternating current at output terminals of the alternator; converting the alternating current produced by the alternator into modulated pulses of direct current. Alternating electric current produced by the alternator is regulated by controlling the speed of rotation of the rotary assembly by resisting torque imposed by the alternator in response to modulating the pulses of continuous current produced by the converted the alternating current.

Owner:JEUMONT

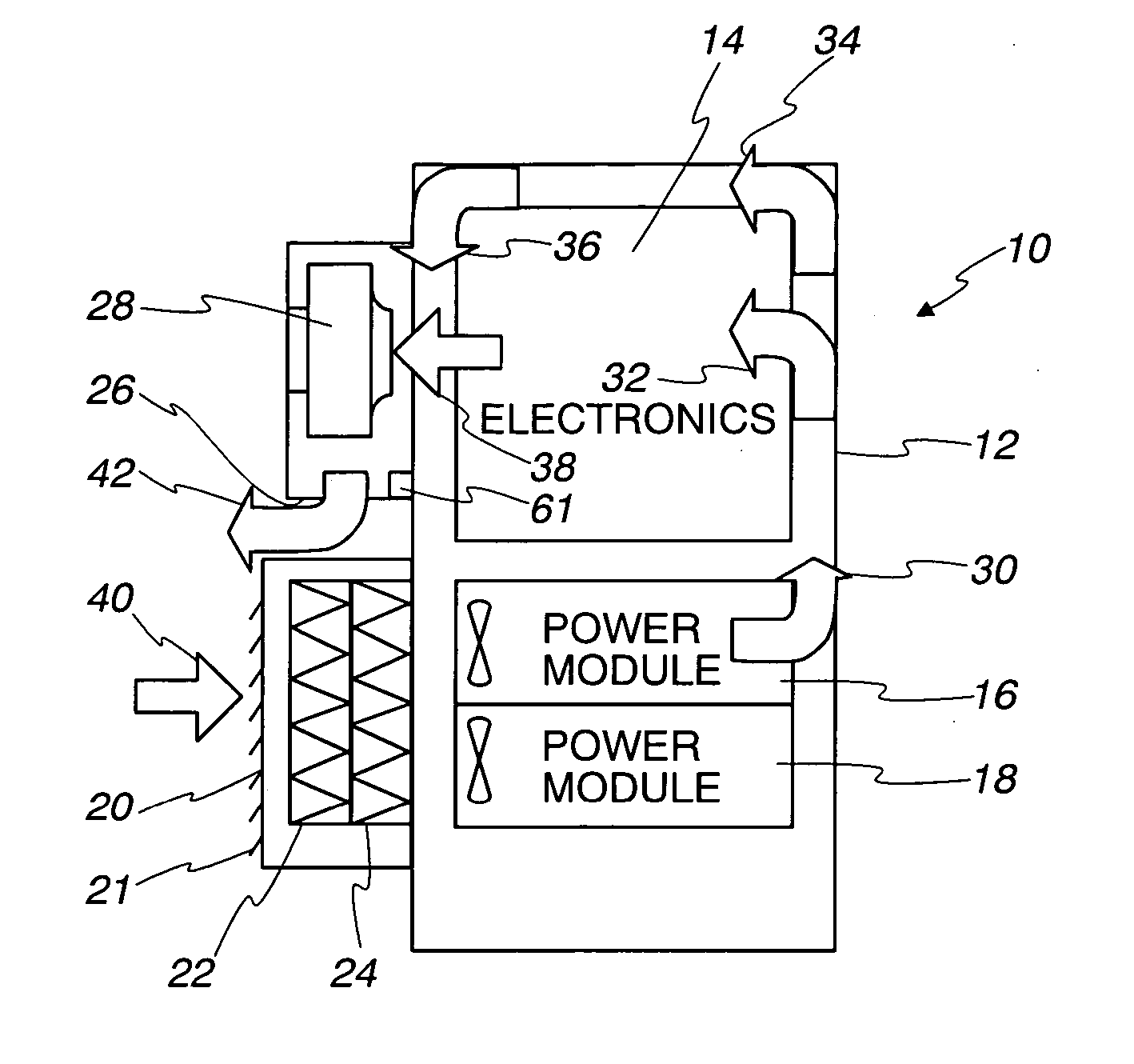

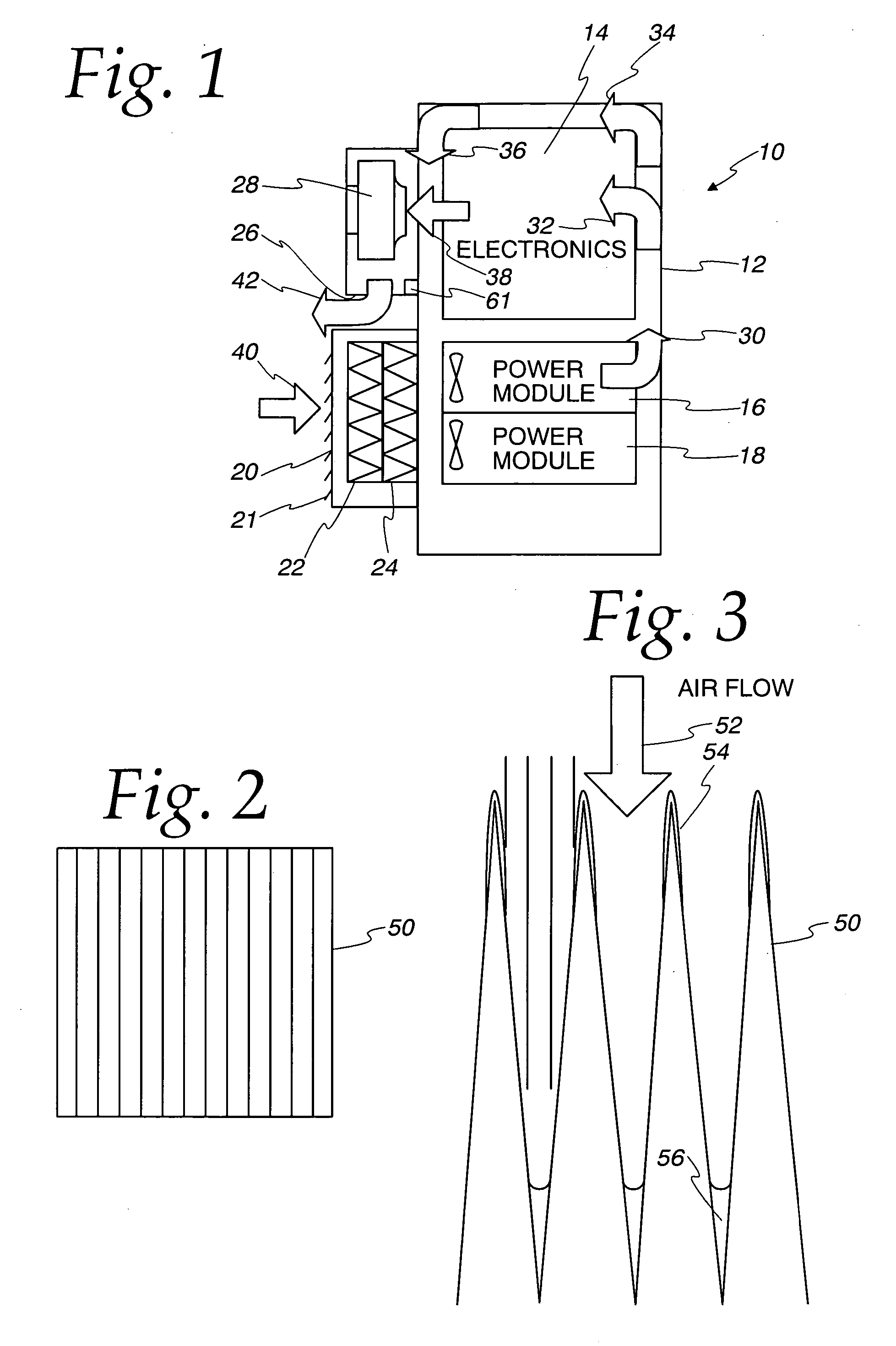

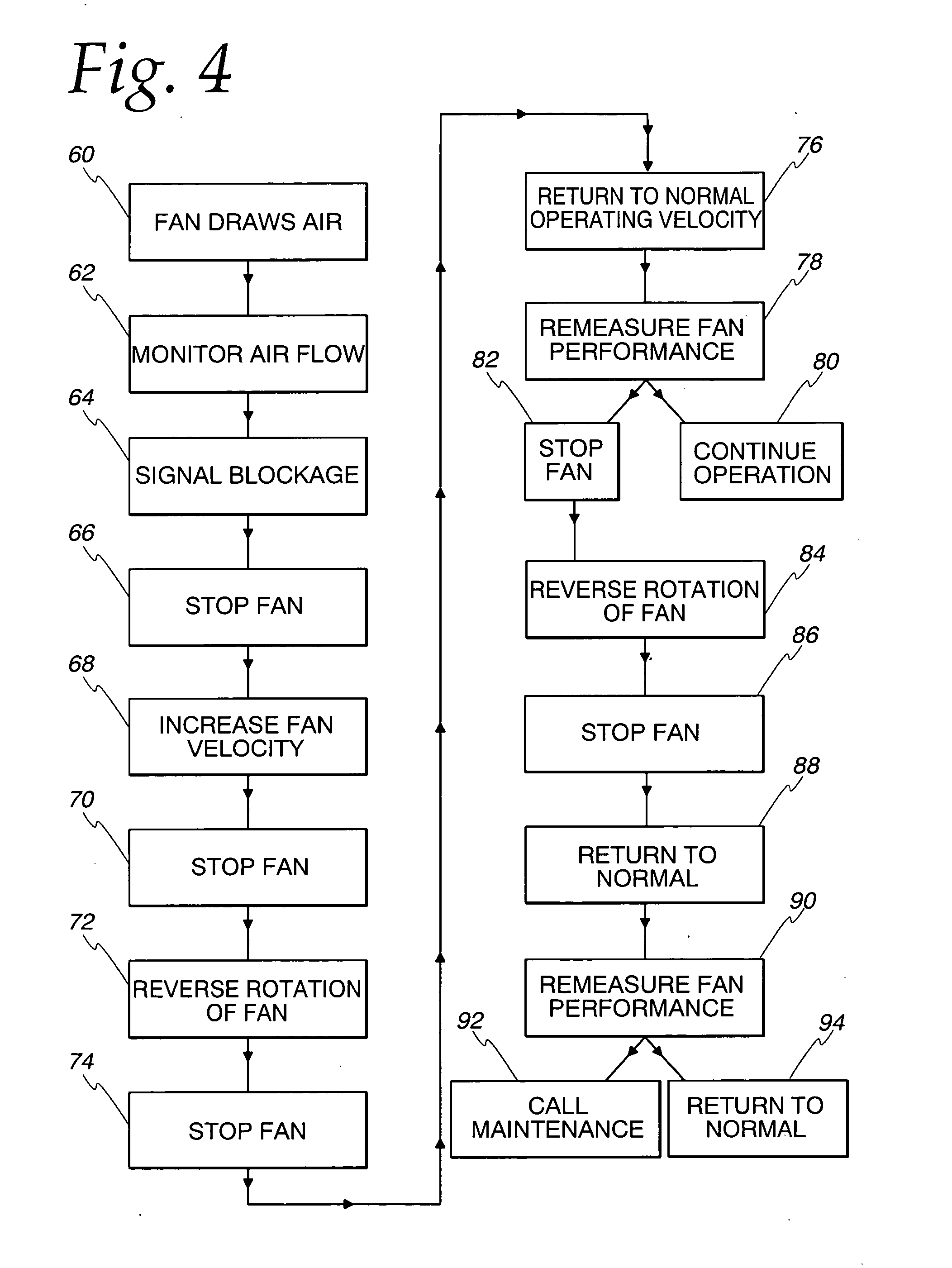

Filter system for an electronic equipment enclosure

InactiveUS20050108996A1Expensive and harder to cleanLess expensiveCombination devicesDispersed particle filtrationHEPAParticulates

A filter system including a method for self cleaning the filter system of an electronic equipment enclosure where air flow is monitored either by monitoring fan performance or air flow velocity through the enclosure. The system includes two filters elements, an upstream ASHRAE or HEPA filter element to block particulate matter and a downstream PTFE filter element to block water vapor. The ASHRAE or HEPA filter element is relatively inexpensive and easy to clean. The PTFE filter element is more expensive and difficult to clean. Thus, the cheaper filter is used to protect the more expensive filter from contaminants and to increase its useful life. The method of self cleaning includes stopping the fan when a signal is received indicating a predetermined resistance to air flow which is a function of blockage of the filter elements, thereafter operating the fan at an increased rotational velocity to determine whether the fan itself is malfunctioning, thereafter slowing and stopping the fan to allow the fan to be reversed, rotating the fan in reverse for a predetermined period of time, such as five minutes, thereafter slowing and stopping the fan and returning the fan to its usual rotational velocity and direction. If the resistance to air flow is still above a predetermined level, the fan is again slowed, stopped and reversed and then returned to normal operation. The reversal operation can be conducted a multiple number of times, however, after a predetermined number, a signal is sent requesting maintenance.

Owner:MARCONI INTPROP RINGFENCE +1

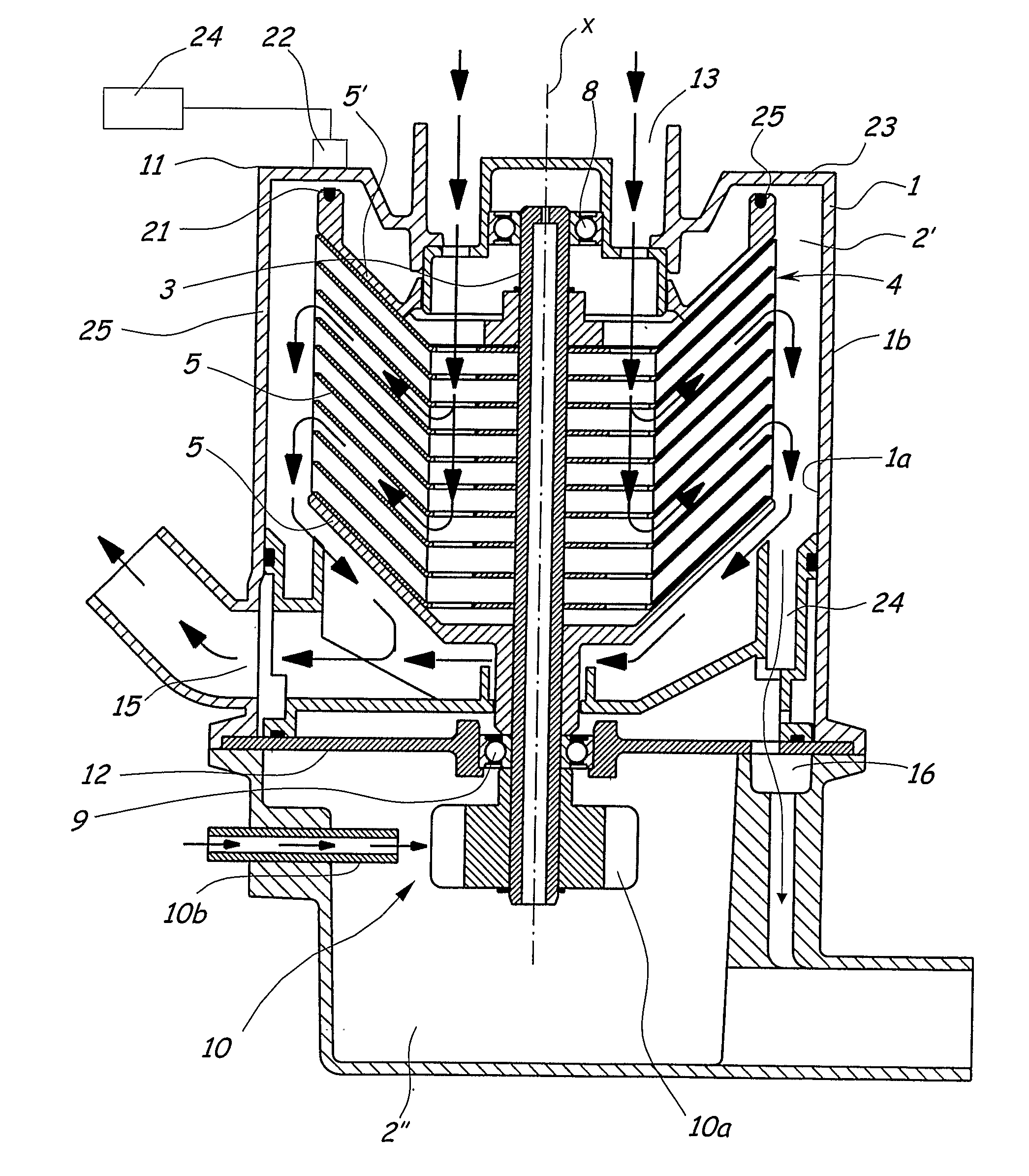

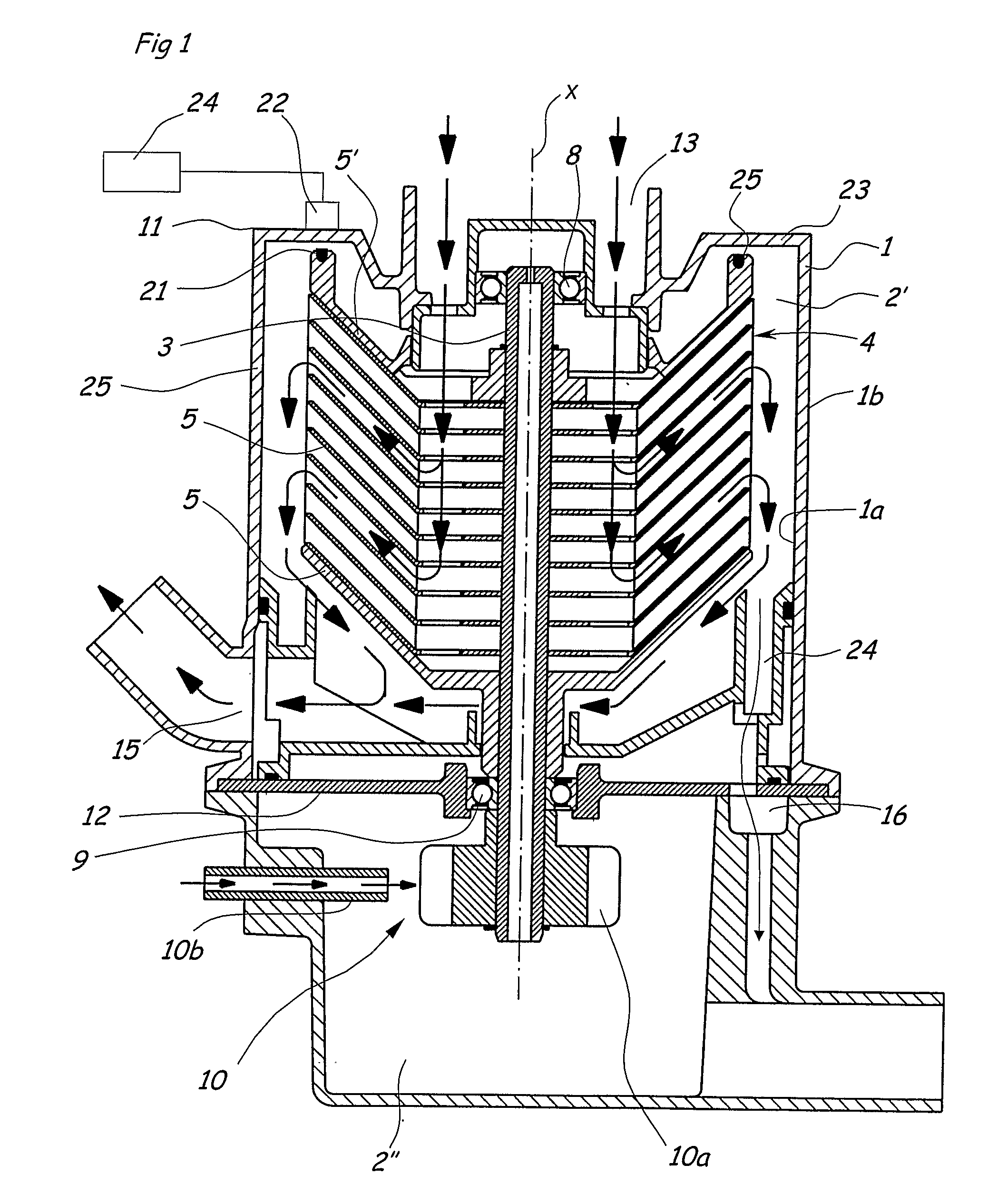

Centrifugal separator for cleaning of gas

ActiveUS20090025562A1Reliable and secure determinationReliable readCombination devicesAuxillary pretreatmentInterior spaceEngineering

The invention refers to a centrifugal separator comprising a stationary casing defining an inner space, a spindle and a rotating member, which is attached to the spindle and arranged to rotate around an axis of rotation with a rotary speed. The rotating member comprises a number of separating discs which are provided in the inner space. A drive member drives the spindle and the rotating member with said rotary speed. A sensor device senses the rotation of the rotating member in relation to the casing. The sensor device comprises at least one transmitter element which is provided in the inner space on the rotating member and a receiver element which is provided at the casing and arranged to sense the transmitter element. The receiver element is provided on the casing outside the inner space.

Owner:ALFA LAVAL CORP AB

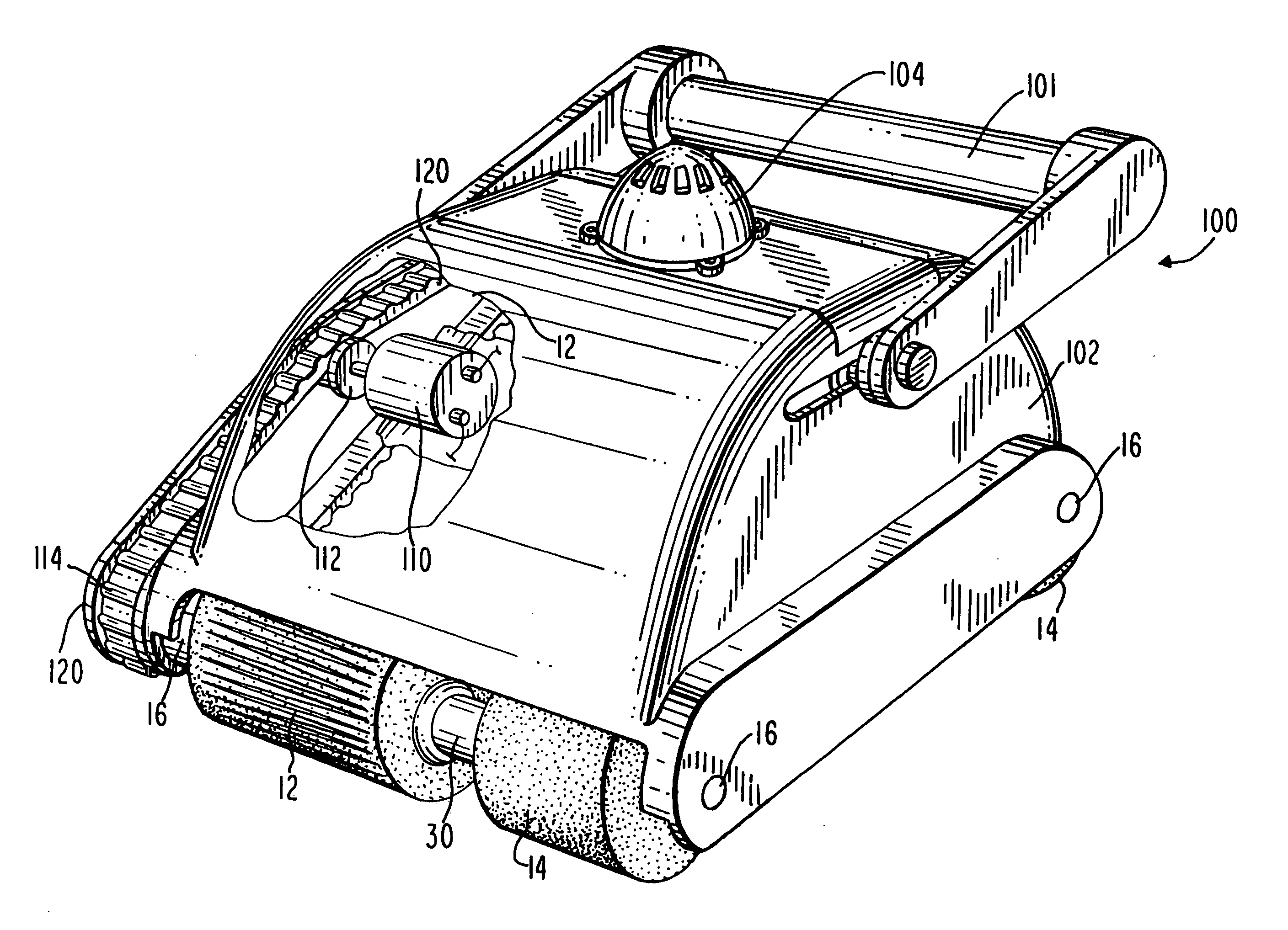

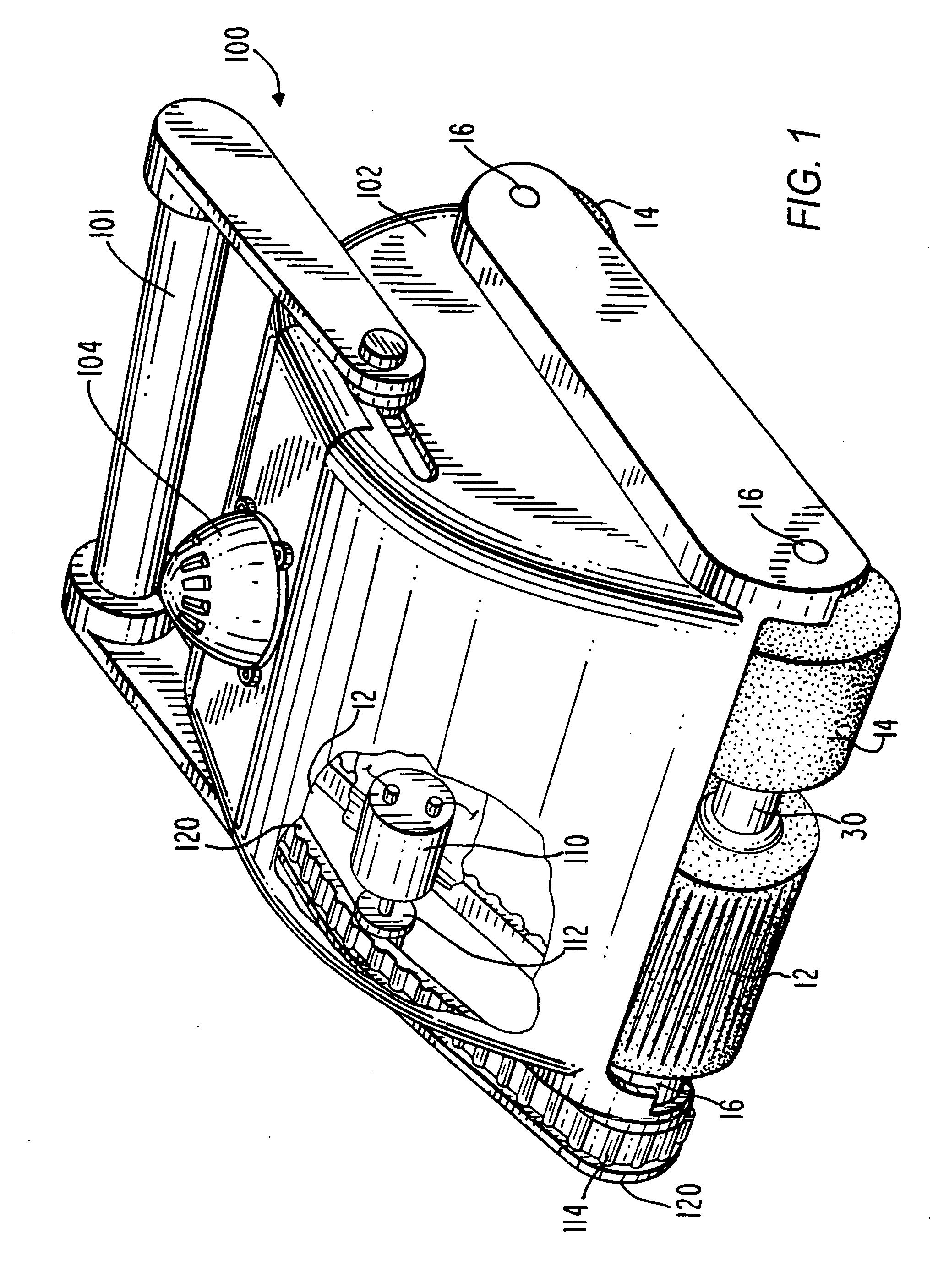

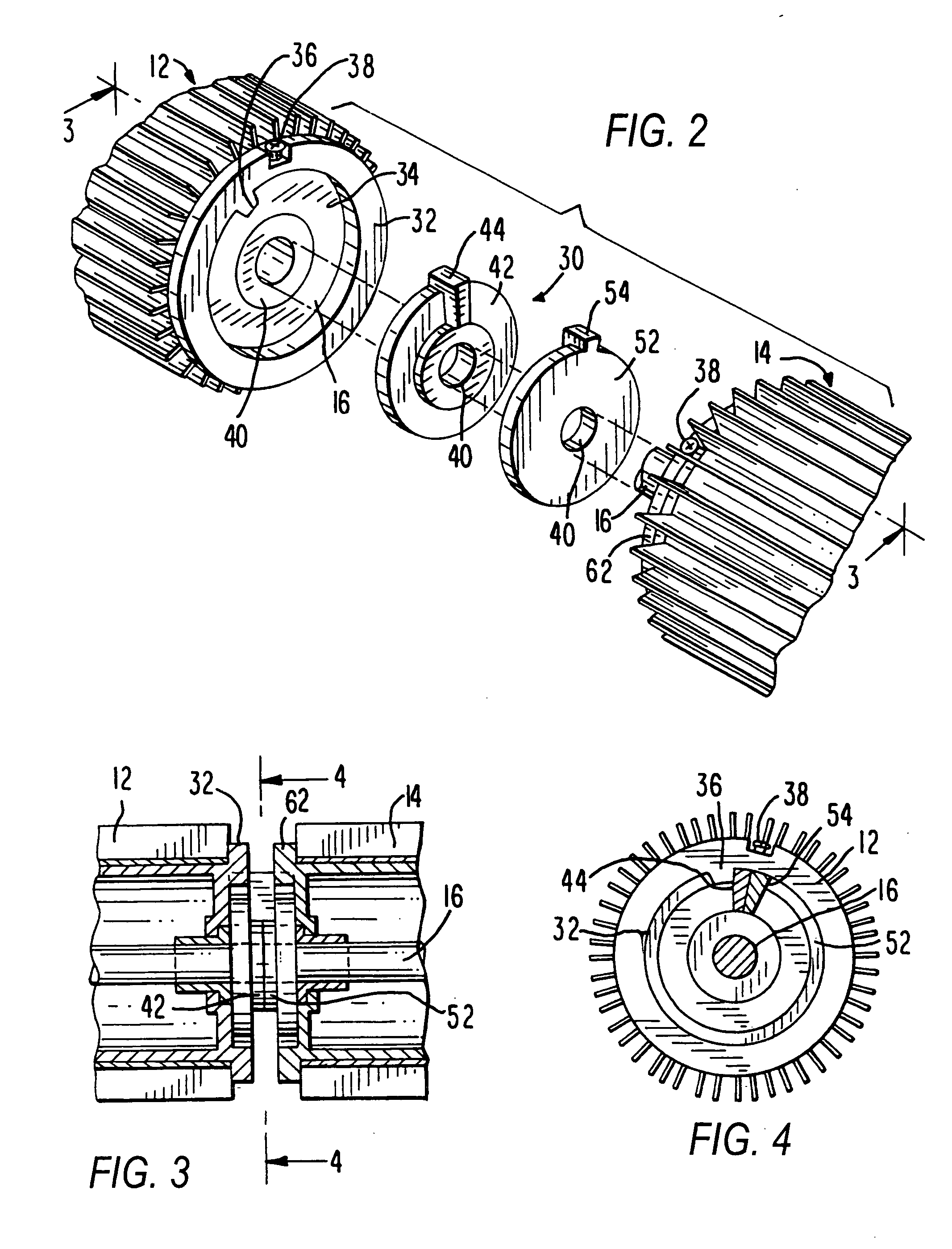

Directional control for dual brush robotic pool cleaners

A method and apparatus for accurately controlling the directional and turning movement of a self-propelled robotic pool cleaner having at least one pair of rotational support members for propelling and cleaning along a surface of a pool or tank include accelerating at least one pair of the rotational support members from a stopped position to a first predetermined rotational rate for a first predetermined time period to propel the pool cleaner in a first direction along the pool surface, continuing the rotation at the first rotational rate for a second predetermined time period; and increasing to a second higher rotational rate, such that the cleaner is propelled at a maximum normalized rate during straight-line movement for cleaning the pool. The duration of straight-line movement is incrementally advanced by a signal that is manually generated by a user switch or a magnet that is brought into proximity of a reed switch mounted inside the cleaner's housing.

Owner:ZODIAC POOL SYST LLC

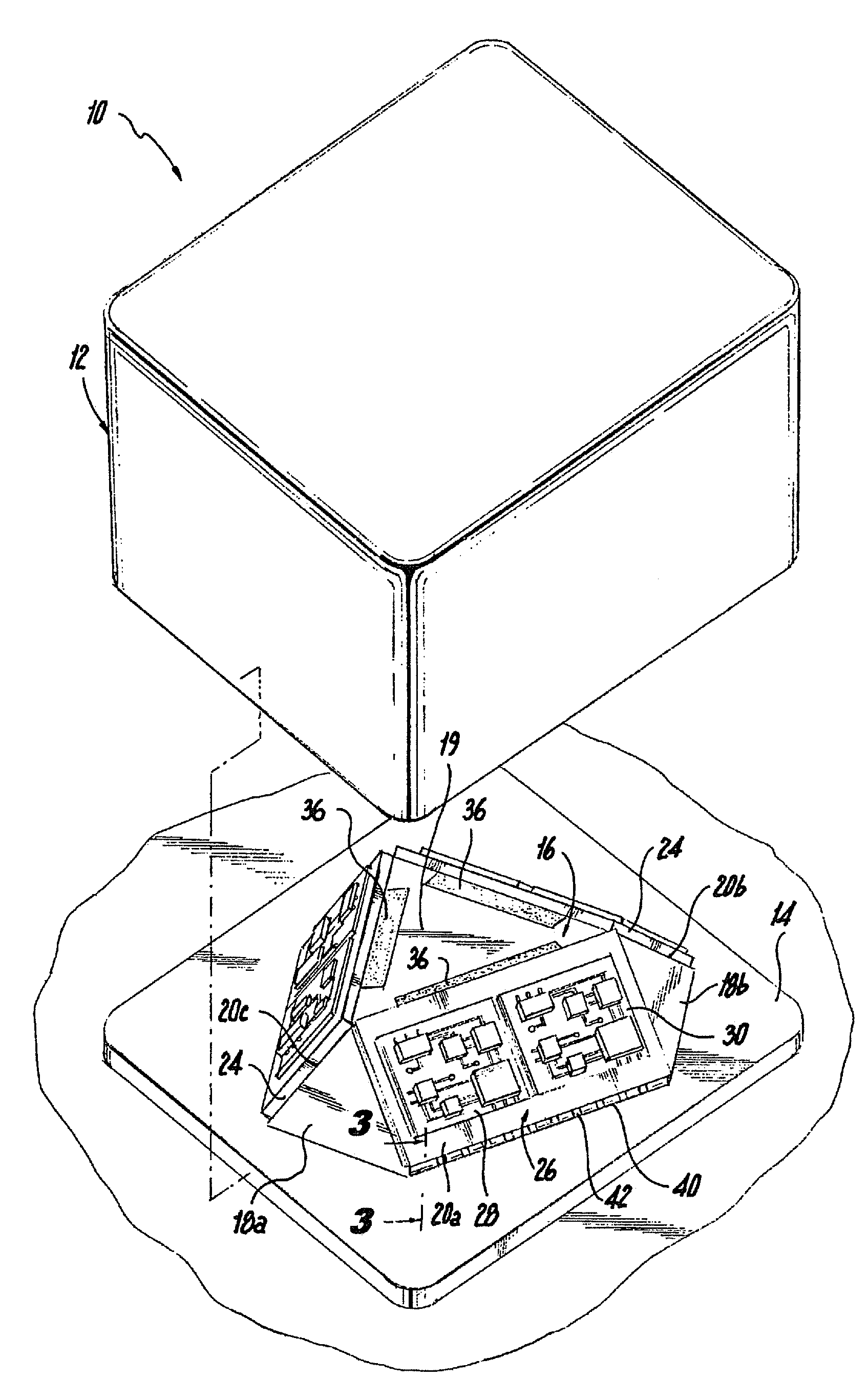

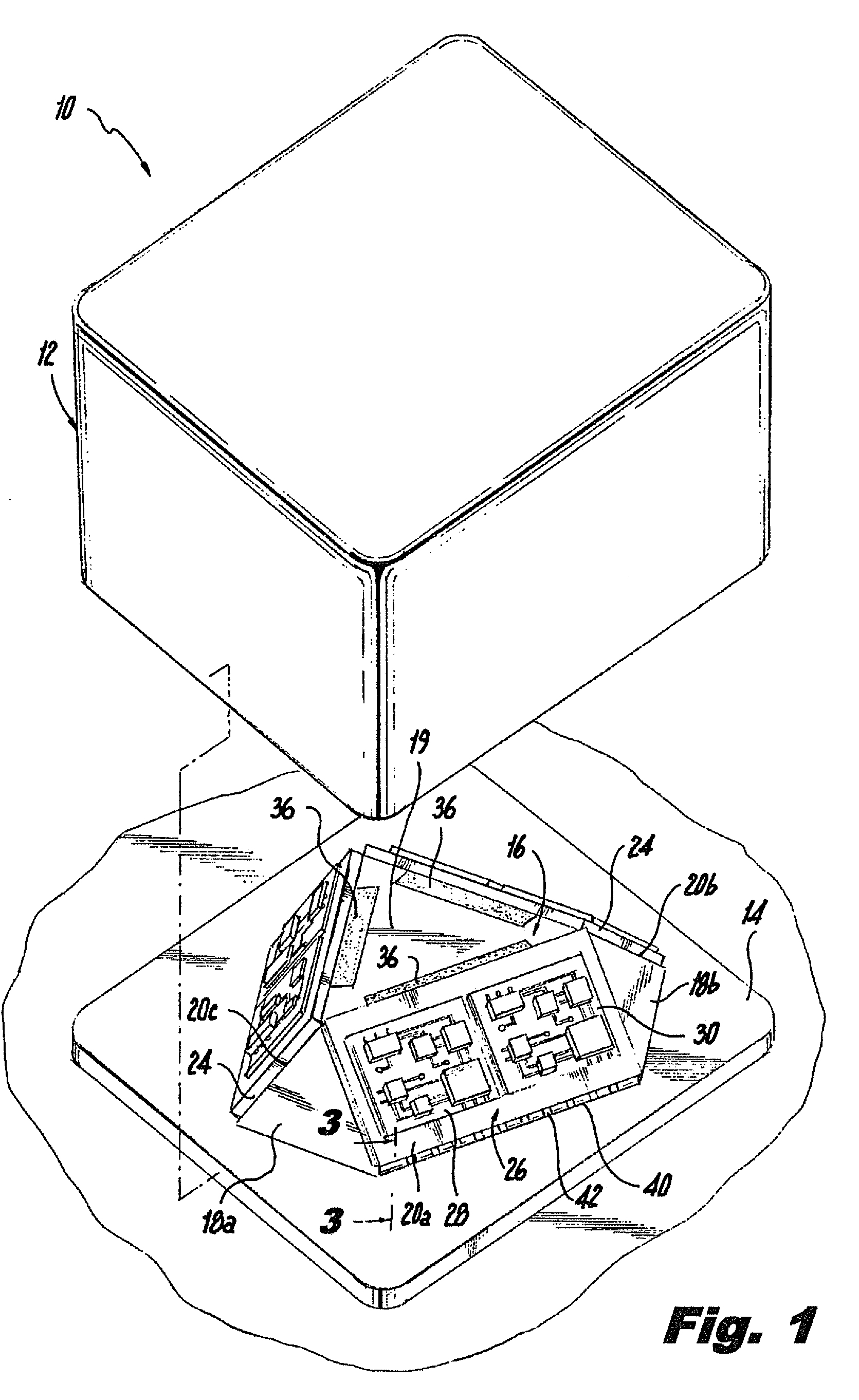

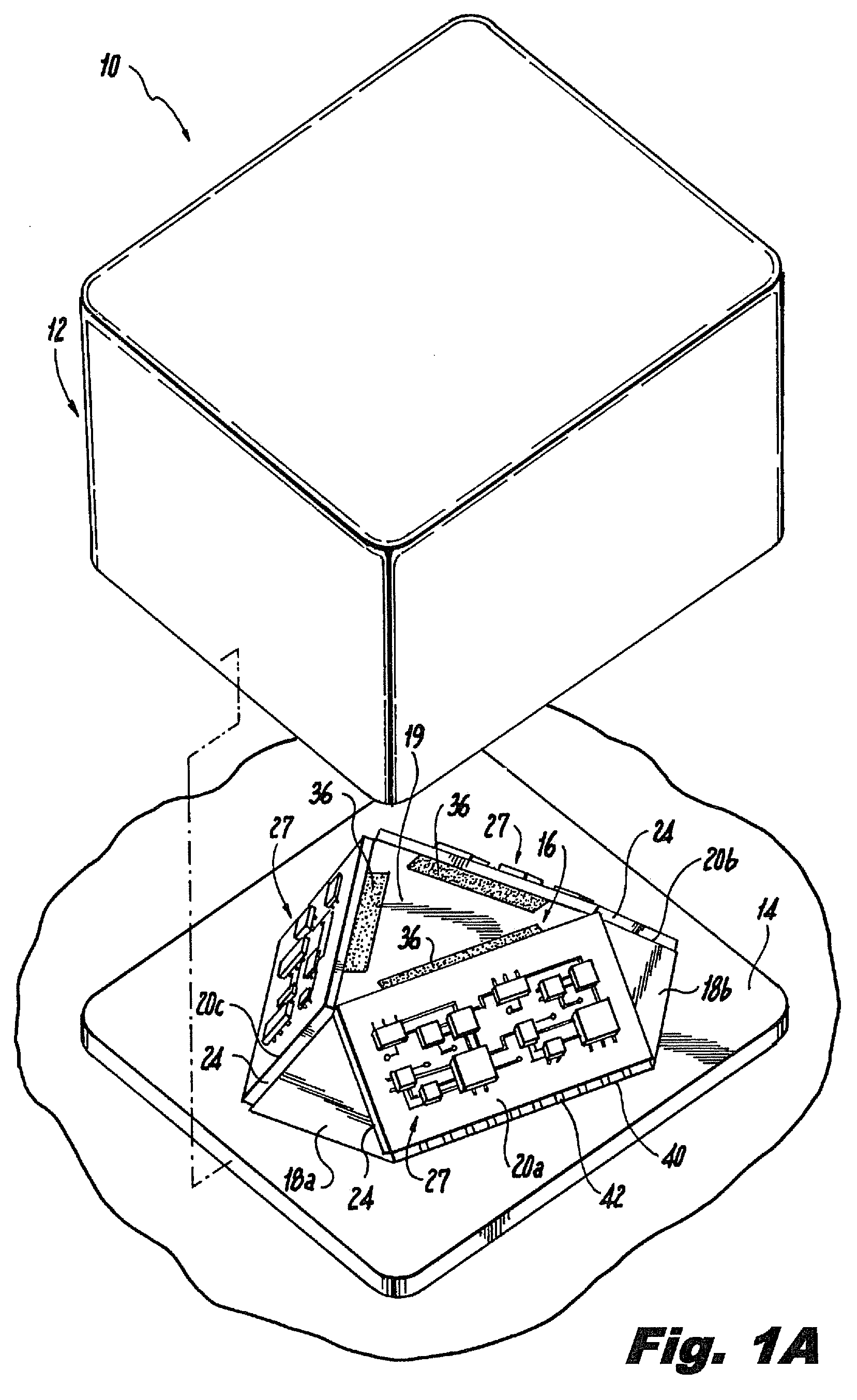

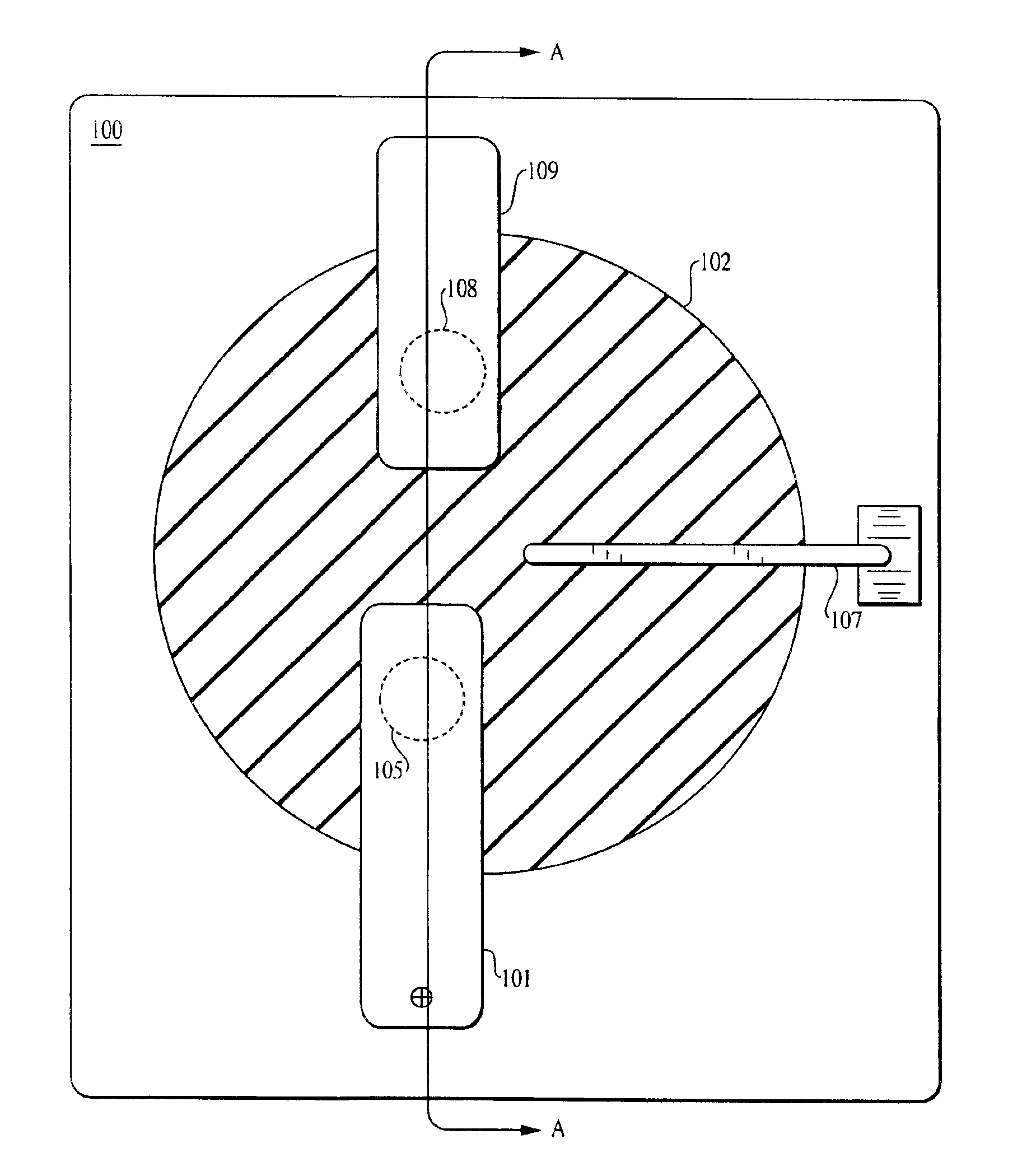

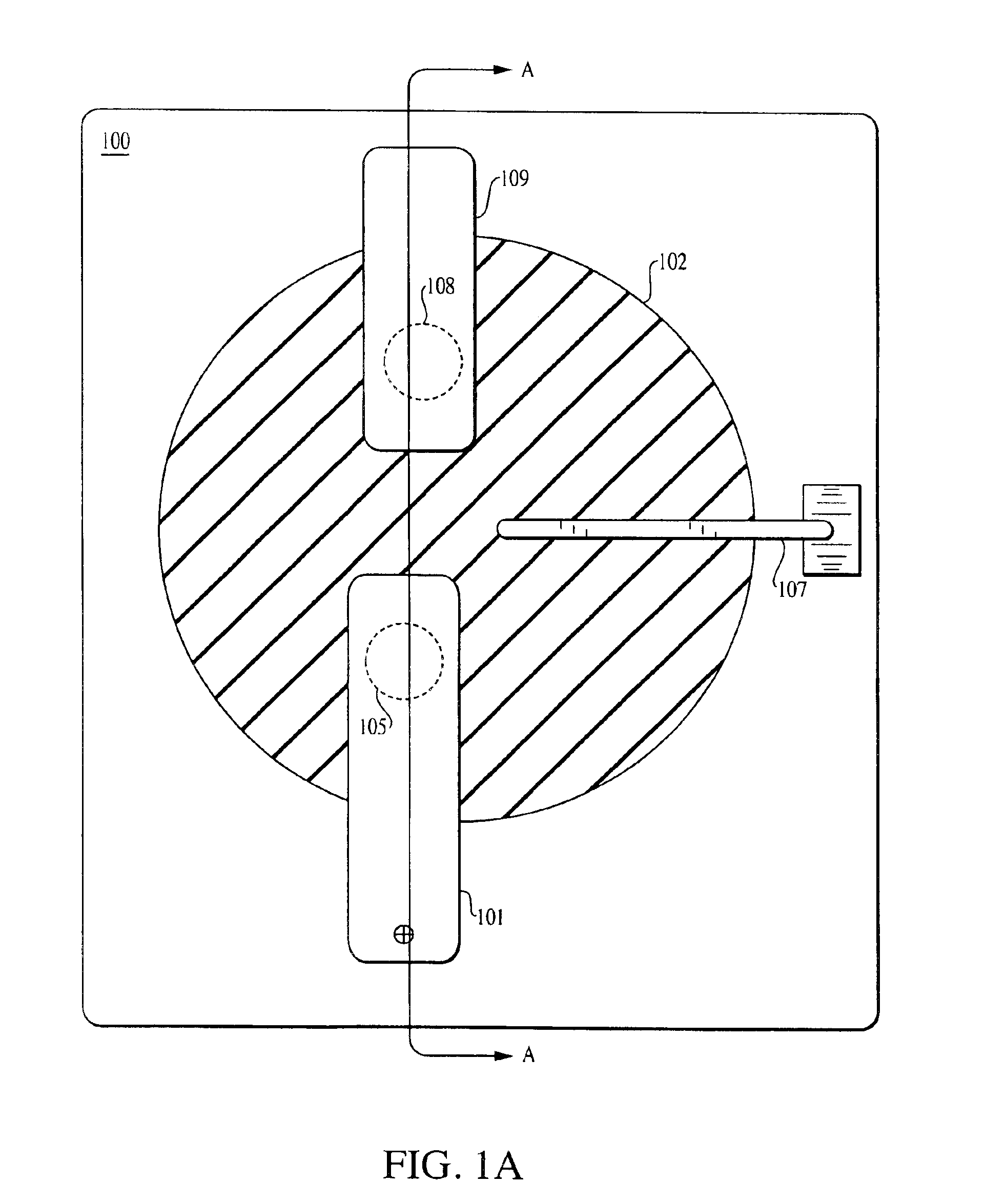

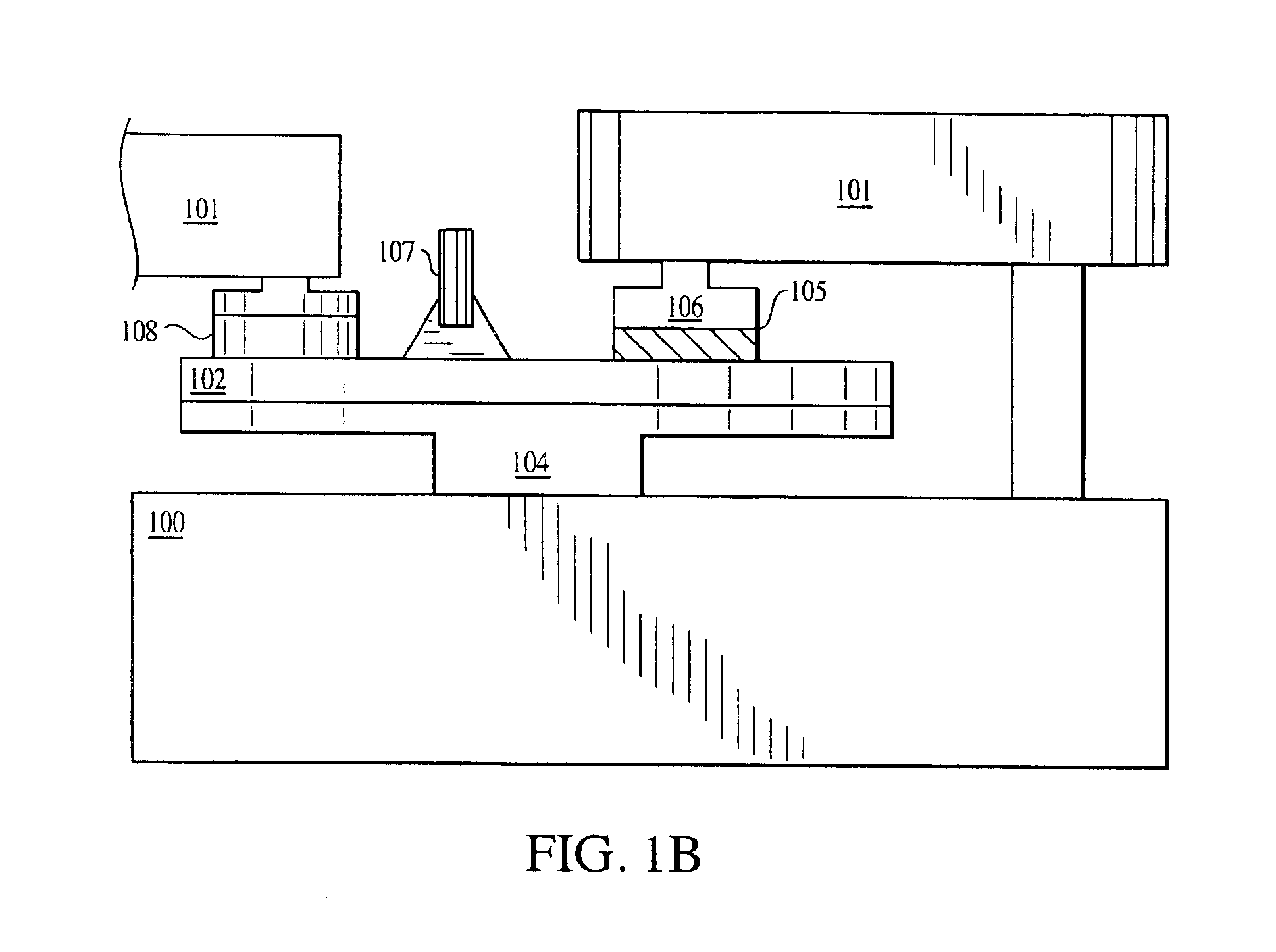

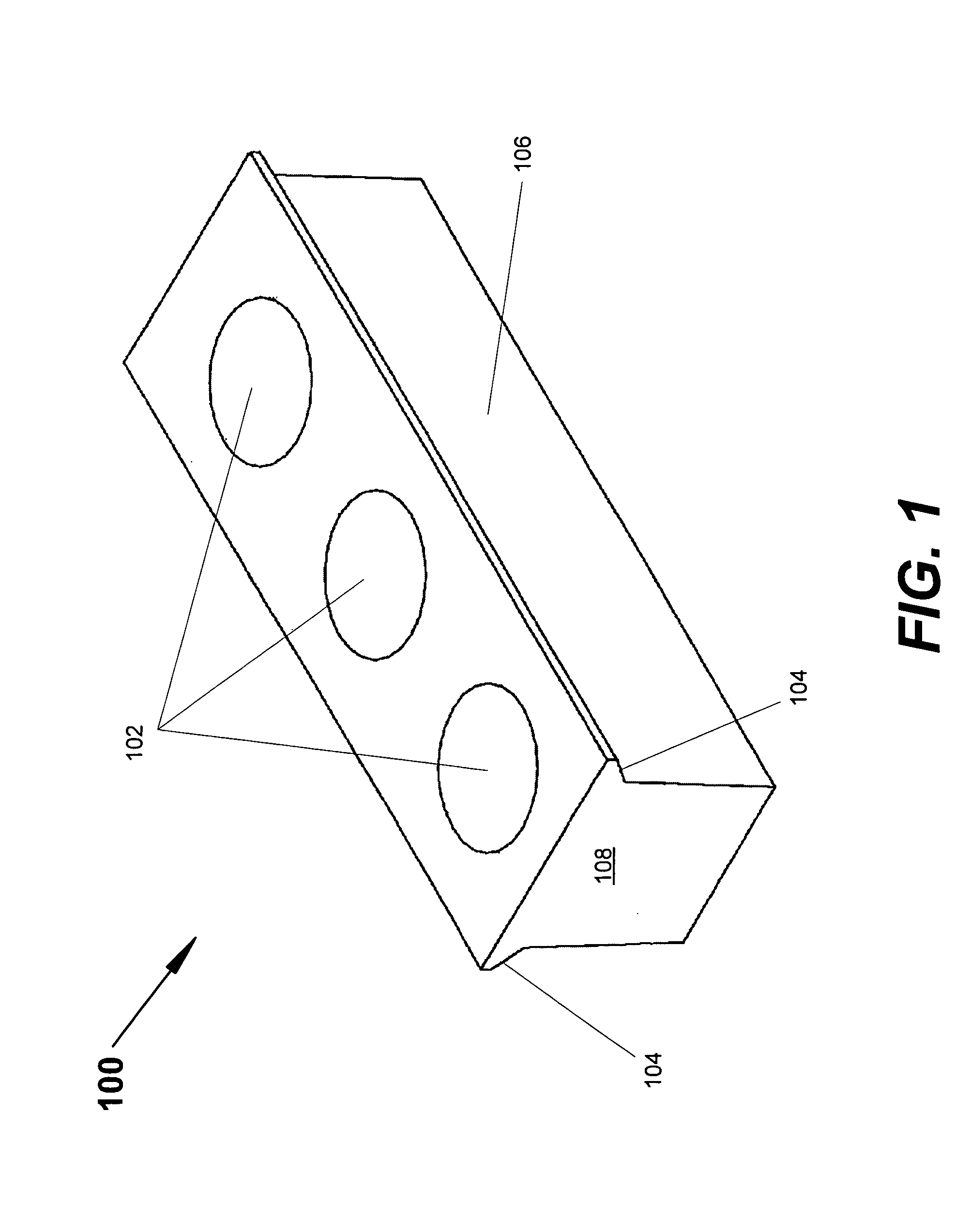

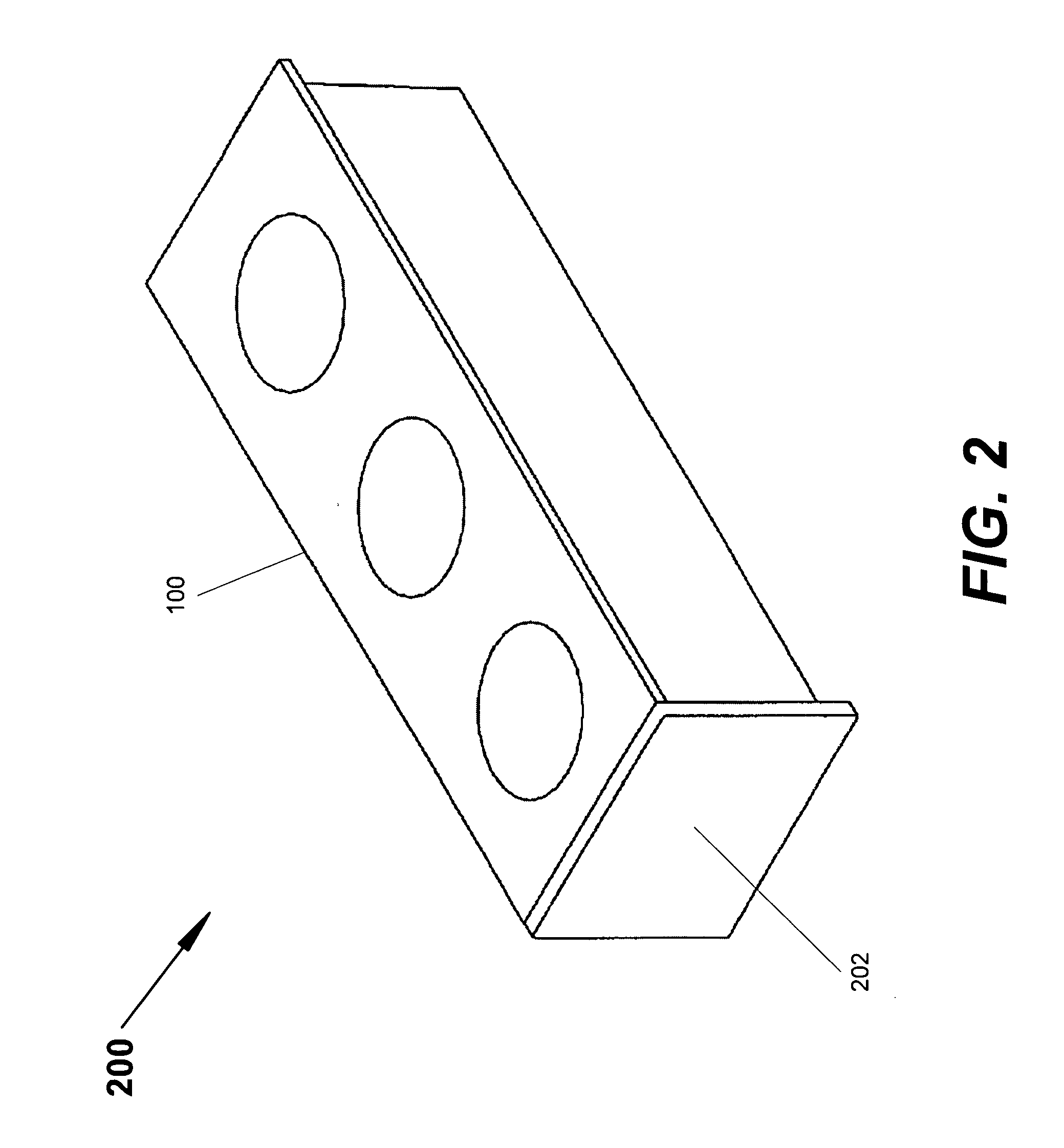

Integrated inertial measurement system and methods of constructing the same

InactiveUS20090308157A1Easy to fixAcceleration measurement using interia forcesSoldering apparatusGyroscopeAccelerometer

An inertial measurement system having a triangular cupola shaped base structure with three mutually orthogonal sides and a bottom surface surrounding a hollow core. The bottom surface includes an aperture providing access to the hollow core. An inertial module is mounted on each of the sides and includes a gyroscopic rotational rate sensor and a linear accelerometer connected to a circuit board. The inertial measurement system also includes a motherboard and a plurality of metallization elements. The metallization elements extend from the bottom surface to the sides of the base structure and conductively connect the inertial module to the motherboard. The inertial measurement system may also include a non-conductive adhesive underfill positioned between the inertial module and the base structure.

Owner:ROSEMOUNT AEROSPACE

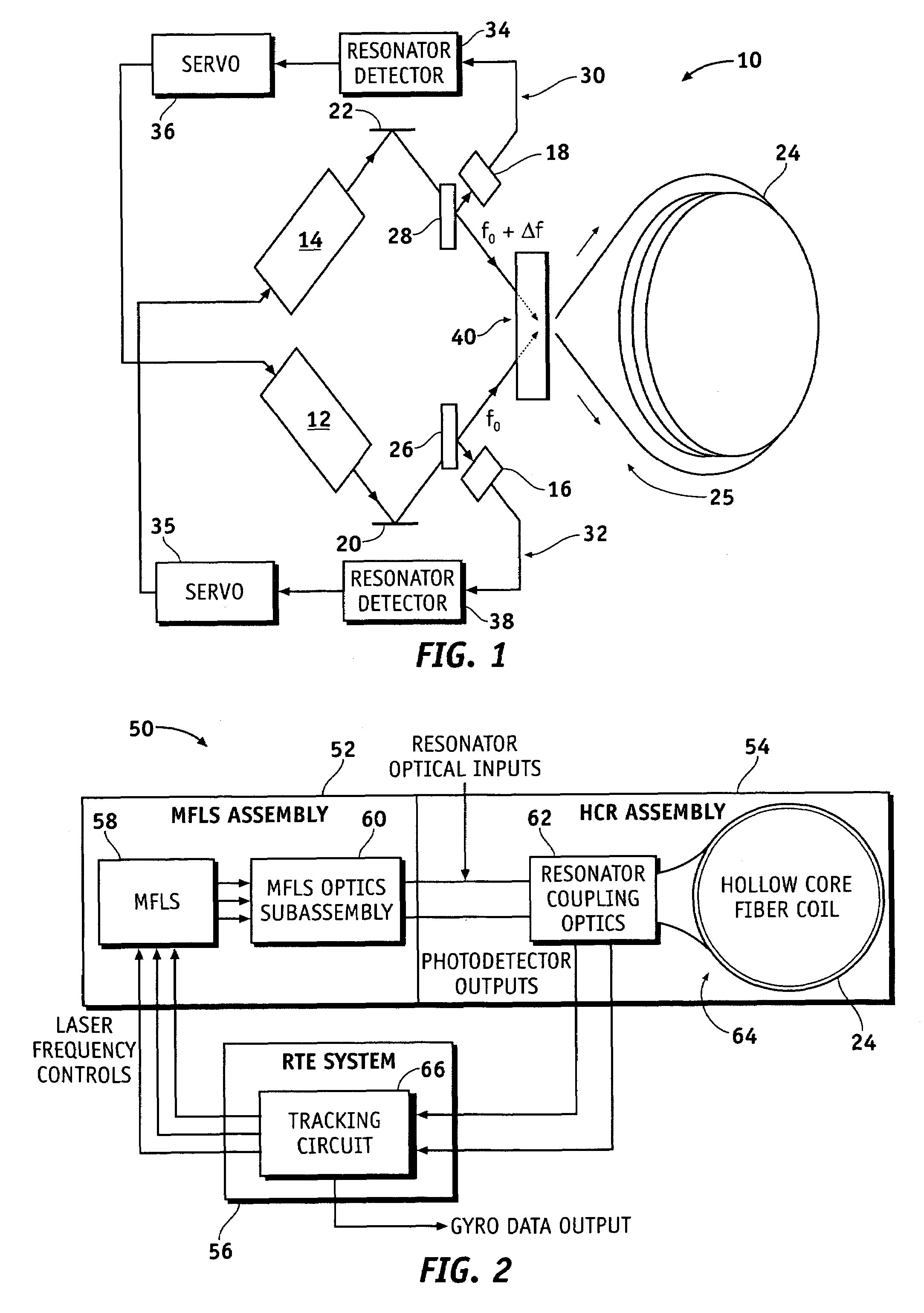

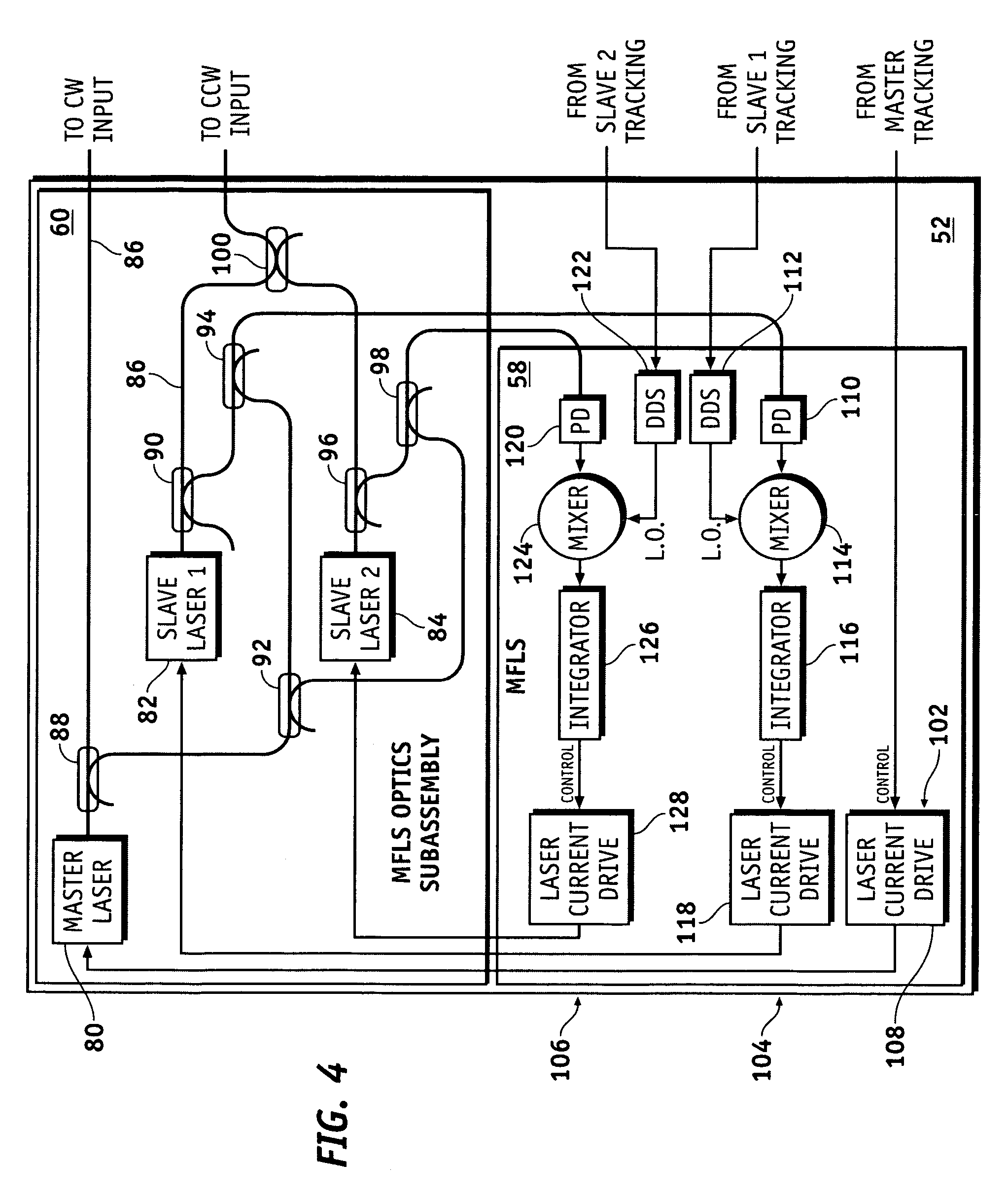

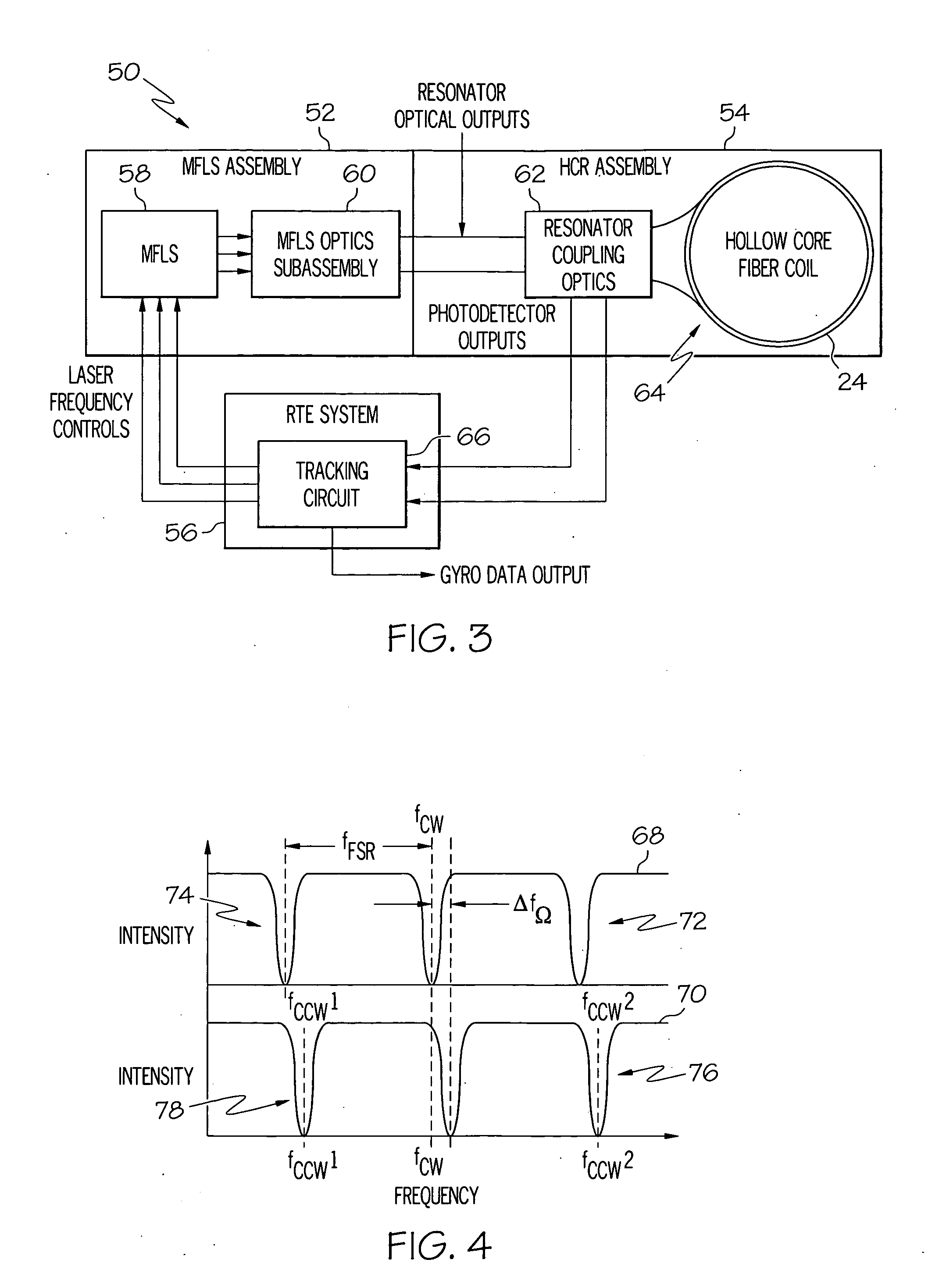

System and method for stabilizing light sources in resonator gyro

ActiveUS7372574B2Speed measurement using gyroscopic effectsSagnac effect gyrometersResonanceLaser light

Methods and apparatus are provided for stabilizing laser light sources of a resonator gyro. A resonator gyro comprises a first light source configured to produce a first input light, a second light source configured to produce a second input light, a resonator coupled to the first and second light sources, a resonance detection circuit coupled to the resonator, and a controller coupled to the resonance detection circuit and the first and second light sources. The resonance detection circuit detects a resonance frequency for each of the counter-propagating directions of the resonator. The controller tunes the first input light to a clockwise resonance frequency, and tunes the second input light to a counter-clockwise resonance frequency. A difference between the resonance frequencies is proportional to a rotational rate of the resonator gyro.

Owner:HONEYWELL INT INC

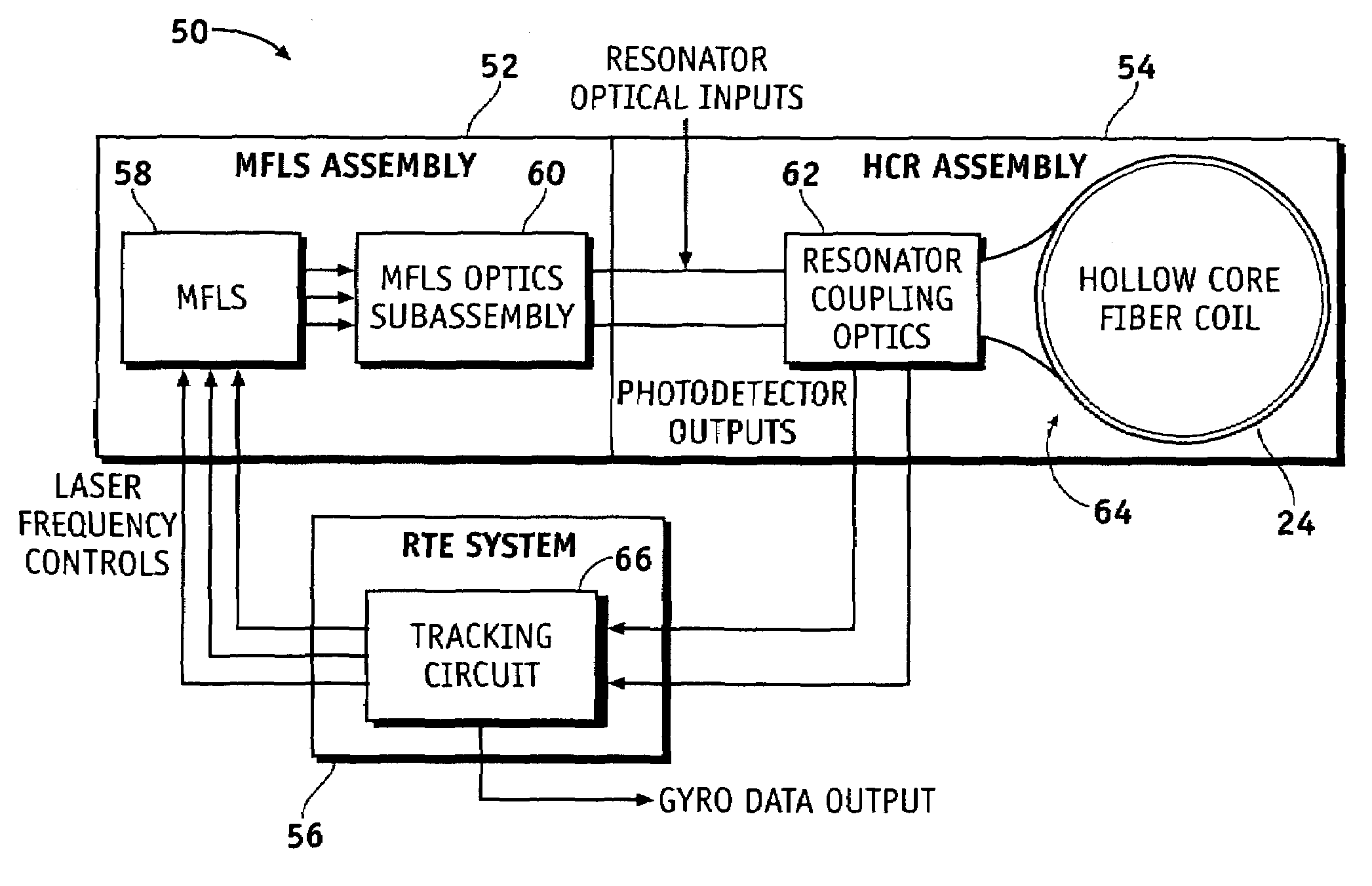

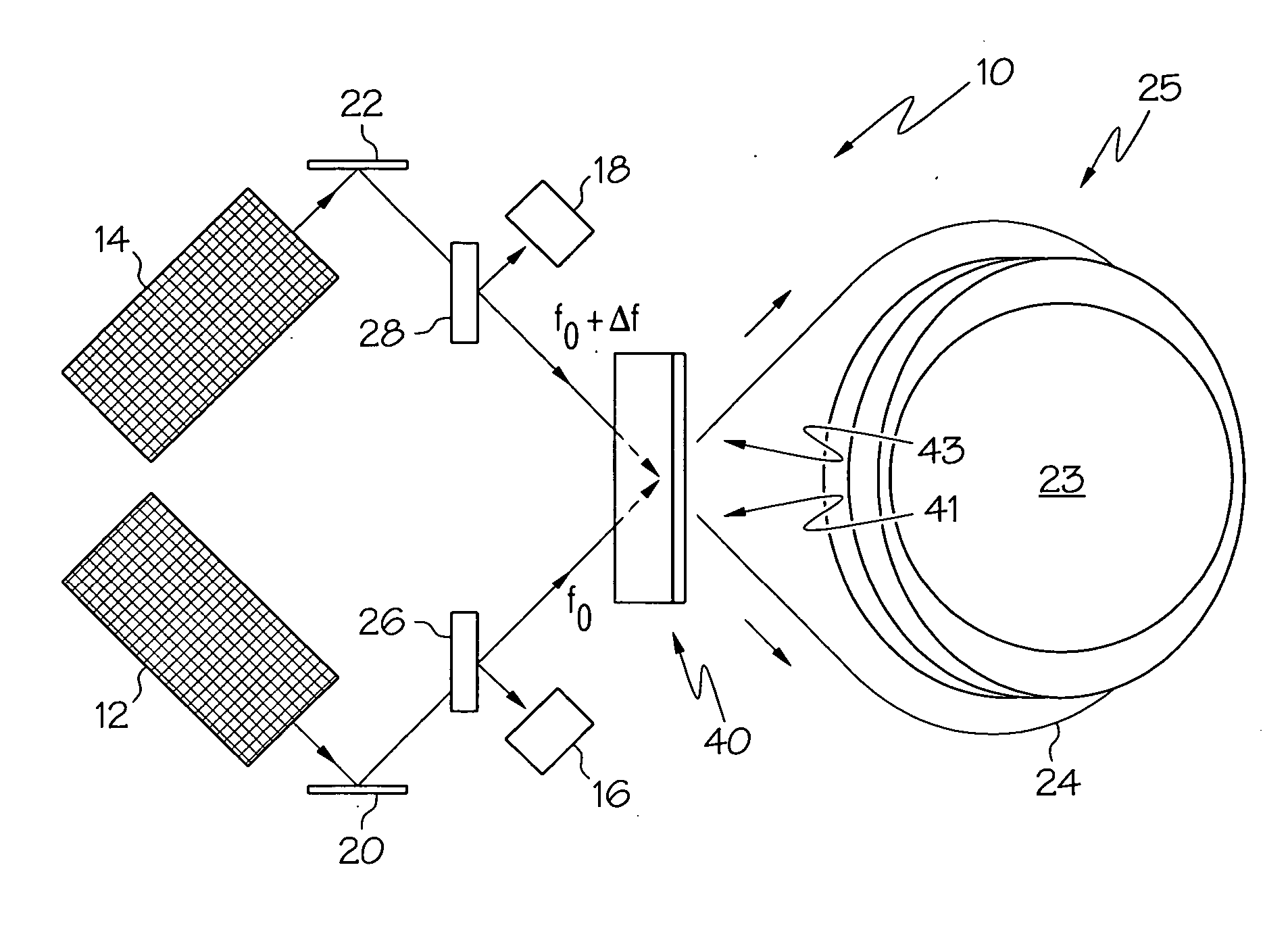

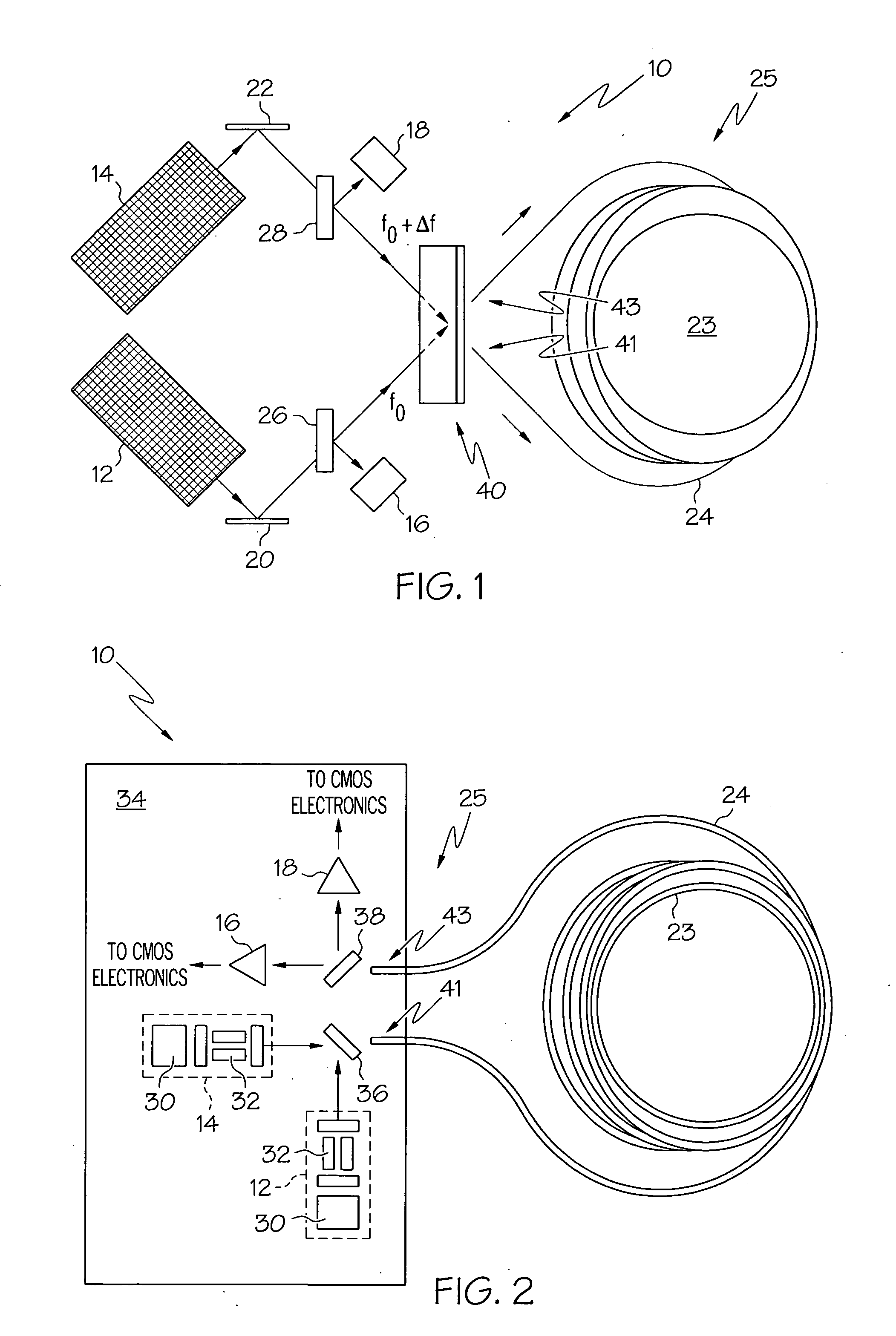

Optical resonator gyro with external cavity beam generator

ActiveUS20070242276A1Sagnac effect gyrometersSpeed measurement using gyroscopic effectsOptical gyroscopeLight beam

Methods and apparatus are provided for determining the rotational rate of an optical gyro. An optical gyro comprises at least one substrate, a multi-frequency light source (MFLS) mounted on the substrate, and a resonator coupled to the MFLS. The MFLS is configured to produce a first light beam having a first frequency and a second light beam having a second frequency and phase locked with the first light beam. The resonator comprises an optical fiber coil having a hollow core. The resonator is configured to circulate a portion of each of the first and second light beams through the hollow core. The portion of the first light beam propagates in a first counter-propagating direction, and the portion of the second light beam propagates in a second counter-propagating direction. A measured difference between the first and second frequencies indicates a frequency shift proportional to the rotation rate of the optical gyro.

Owner:HONEYWELL INT INC

Control of chemical mechanical polishing pad conditioner directional velocity to improve pad life

InactiveUS6910947B2Extend working lifeIncrease the number ofSemiconductor/solid-state device testing/measurementComputer controlMaterial removalEngineering

A method, apparatus and medium of conditioning a planarizing surface includes installing a wafer to be polished in a chemical mechanical polishing (CMP) apparatus having a polishing pad and a conditioning disk, polishing the wafer under a first set of pad conditioning parameters selected to maintain wafer material removal rates with preselected minimum and maximum removal rates, determining a wafer material removal rate occurring during the polishing step, calculating updated pad conditioning parameters to maintain wafer material removal rates within the maximum and minimum removal rates, and conditioning the polishing pad using the updated pad conditioning parameters, wherein the updated pad conditioning parameters are calculated by a pad wear and conditioning model that predicts the wafer material removal rate of the polishing pad based upon the rotational speed and direction of the conditioning disk.

Owner:APPLIED MATERIALS INC

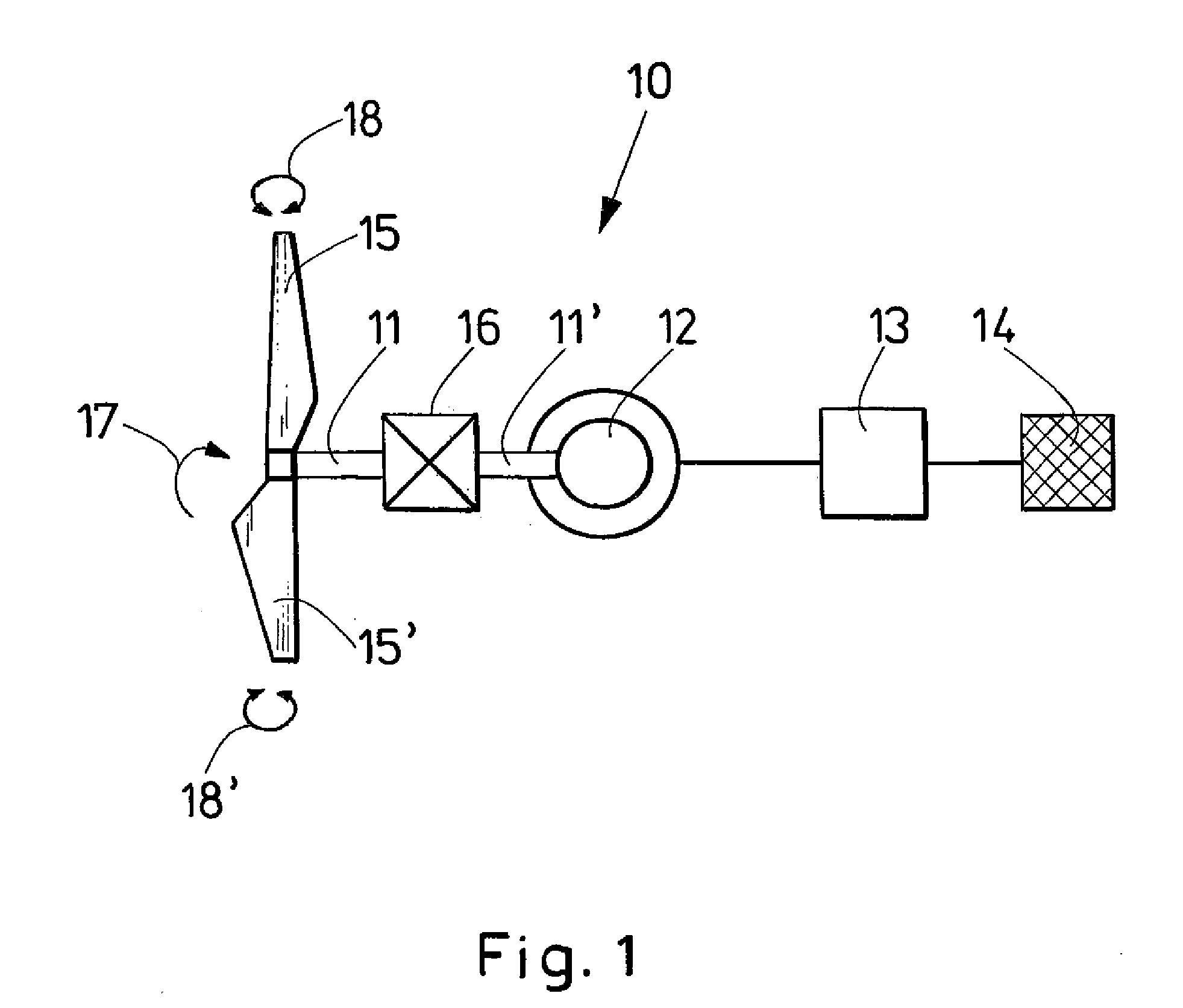

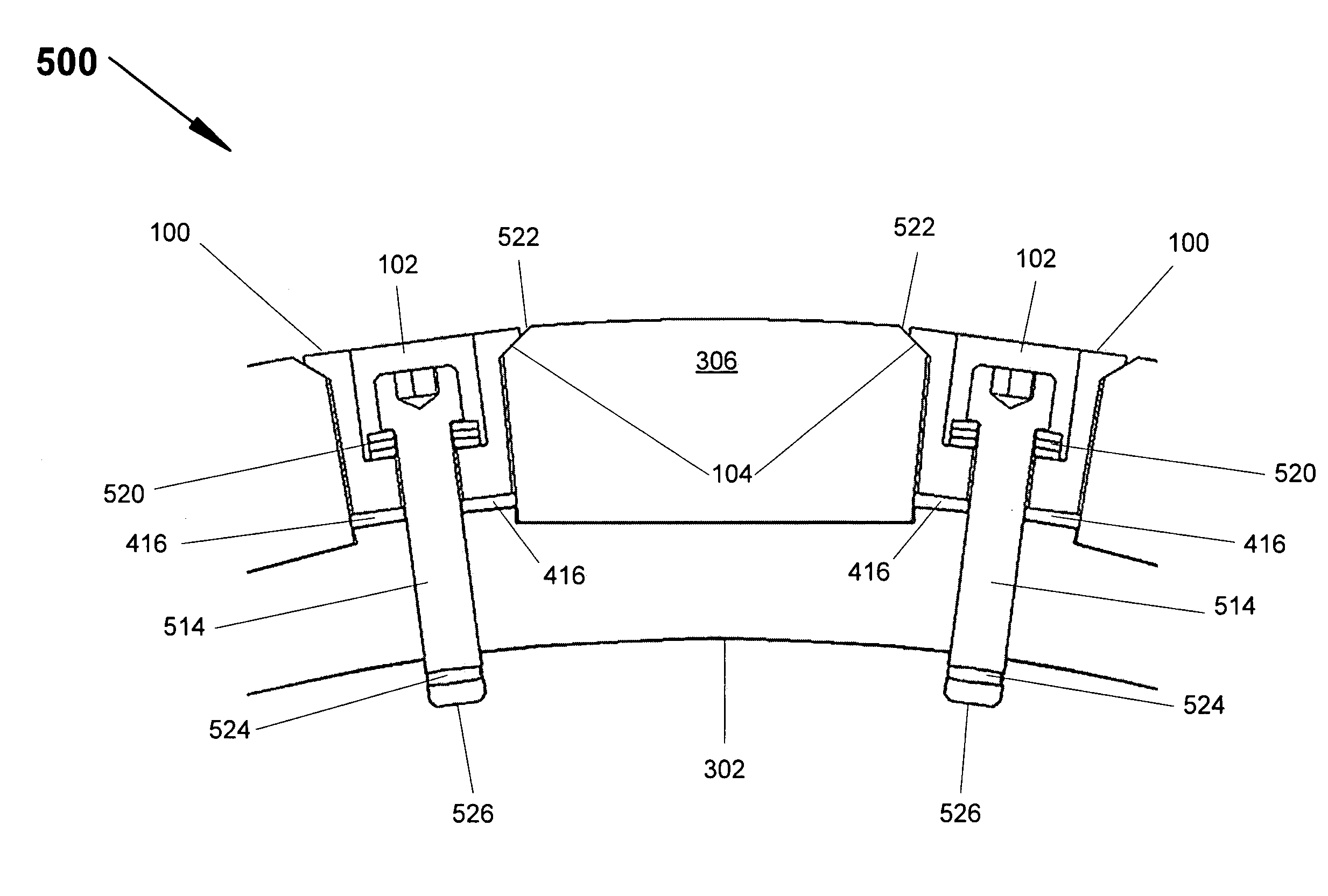

Method and system for regulation of the rotational speed of a rotor on a wind turbine

ActiveUS20080136188A1Increase energy outputEfficient identificationOptimise machine performanceWind motor controlTurbineControl theory

The invention relates to a method and a system for regulation of the rotational speed (52) of a rotor on a wind energy unit with a generator and a rotor blade. The first set parameter is a pitch angle (Pitch) of the rotor blade and the second set parameter is the torque of the generator. The system comprises a pitch angle control or regulation device (32), a torque control or regulation device (33), a first device for determination of a first rotational speed set value (28) (first rotational speed set value determination device (29)) and a second device (26) for determination of a second rotational speed set value (29) (second rotational speed set value determination device (26)). The first rotational speed set value (28) may be supplied to the pitch angle control or regulation device (32) and the second rotational speed set value (29) may be supplied to the torque control or regulation device (33), wherein the first and second rotational speed set value (28, 2)) may be different from each other.

Owner:SENVION DEUT GMBH

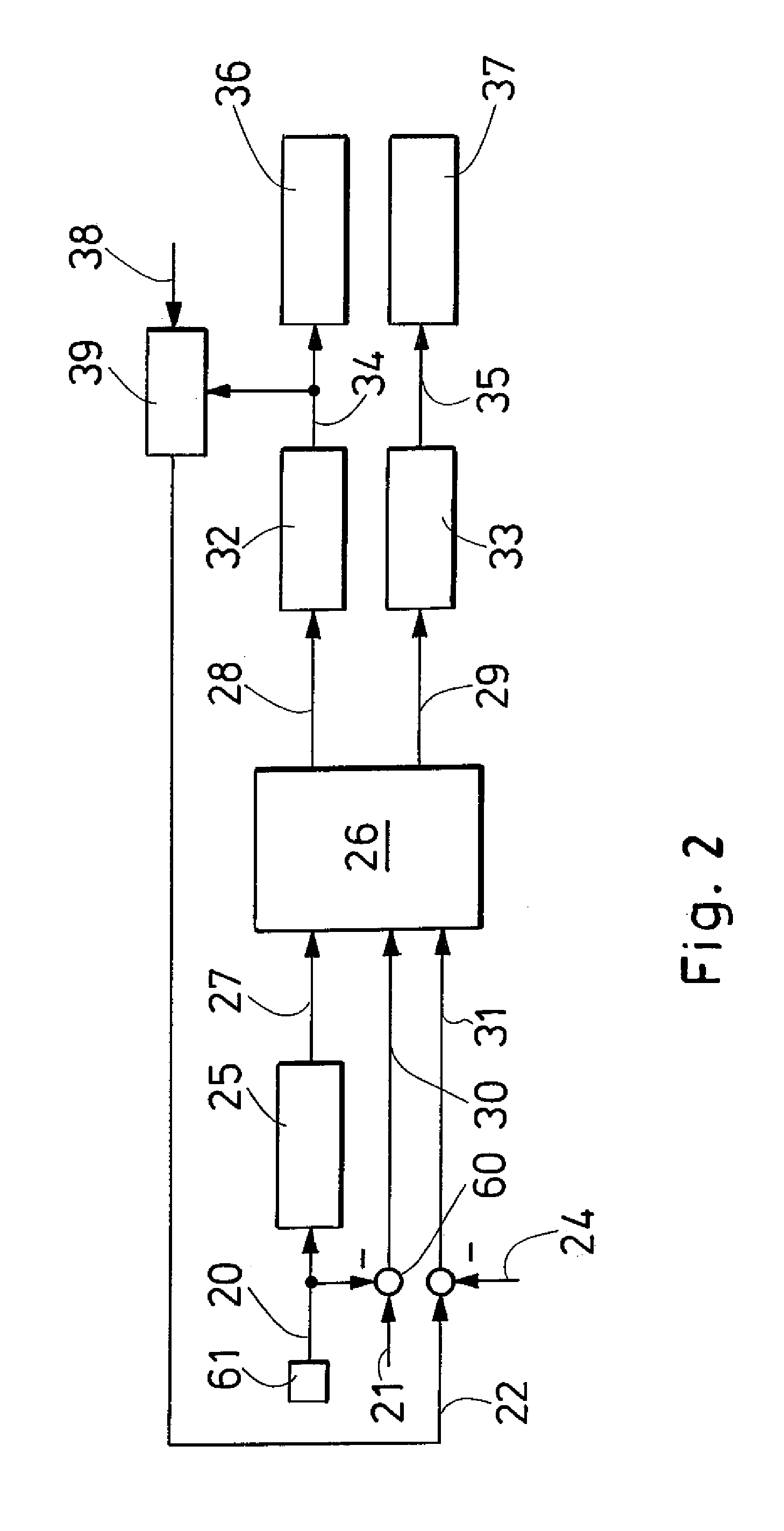

Magnet retention on rotors

ActiveUS20060220483A1Magnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsEngineeringRotational rate

Permanent magnets are mounted on a rotor of an electrical motor by an apparatus that keeps an adhesive bonding layer between the magnet and rotor in compression over wide variations in temperature and speed of rotation. The mechanical stresses on the magnets are controlled using compliant layers and spacers. The apparatus allows the removal and replacement of individual magnets.

Owner:MOOG INC

Centrifugal liquid pump with perimeter magnetic drive

InactiveUS20040123614A1Reducing temperature influence on carrierDomestic cooling apparatusMagnetic tension forceEngineering

Embodiments of the invention provide a compact, seal-less, centrifugal liquid pump with a perimeter magnetic drive that is substantially smaller than a conventional centrifugal liquid pump having magnets attached directly to the impeller shaft. Because rotational force is applied at the perimeter of the impeller, rather than at the shaft, embodiments of the invention have lower torque requirements and rotational speed, increasing the life of the pump bearings. Additionally, embodiments of the invention may suspend the pump bearings by using a redirected flow of liquid coolant, further increasing the bearing life.

Owner:INTEL CORP

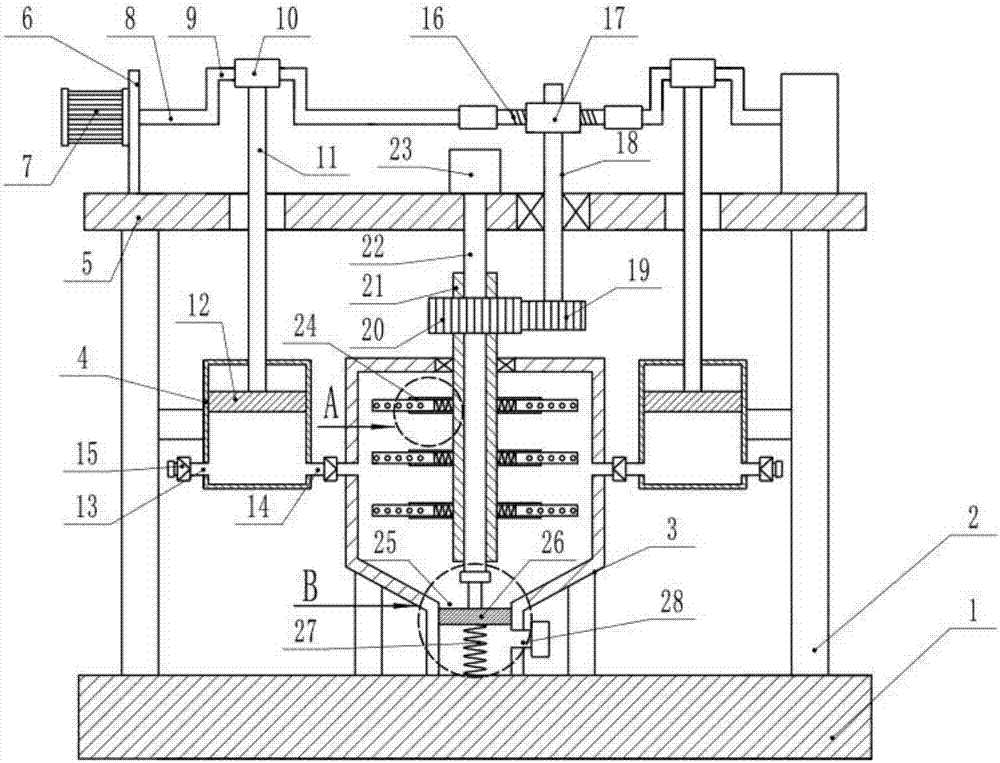

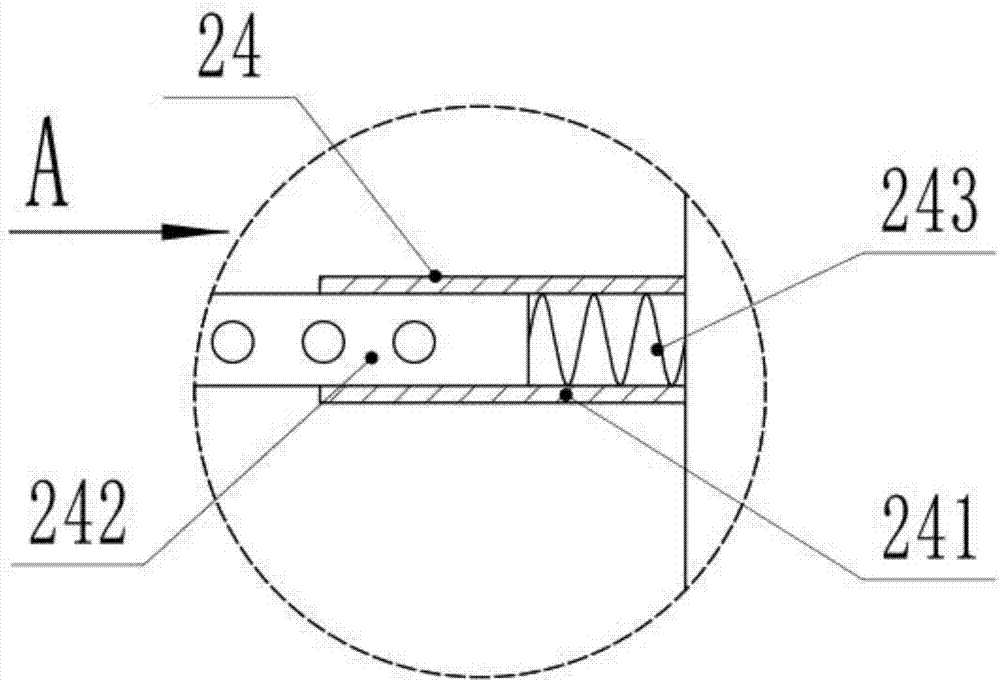

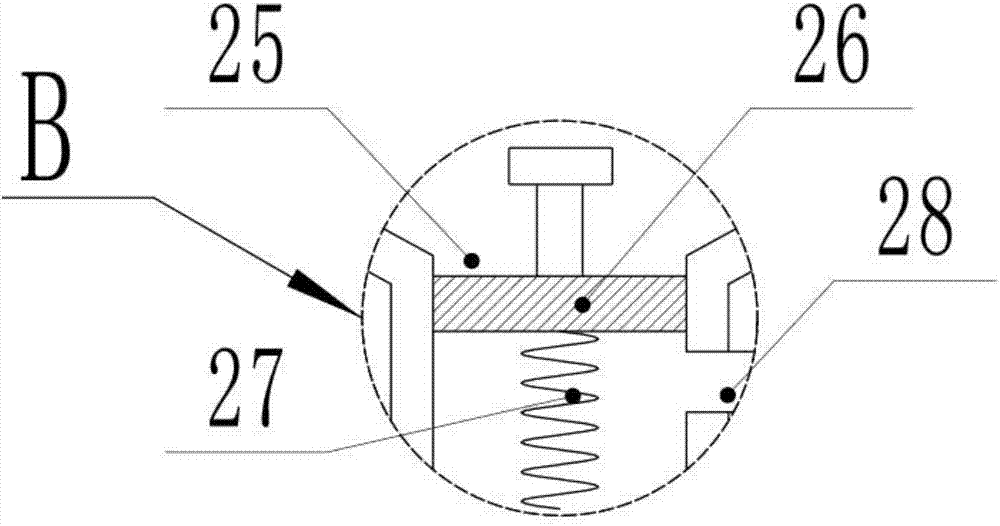

Industrial liquid chemical raw material efficient mixing device

InactiveCN107321230AAvoid inadequate mixingDifferent mixing rangeRotary stirring mixersTransportation and packagingCouplingCompound (substance)

The invention discloses an industrial liquid chemical raw material efficient mixing device, which comprises a base, a mixing device, charging devices, a main driving motor, crankshafts, a connecting rod, a worm, a worm gear, a stirring device and a plugging head, wherein the mixing device is fixedly installed at the central position of the upper surface of the base, the charging devices are arranged on both sides of the mixing device, two sets of crankshafts are connected onto the connecting shaft through couplings, shaft sleeves are rotationally mounted on the crankshafts, the connecting rod is welded on the lower sides of the shaft sleeves, and the lower end of the connecting rod is connected with a piston; the stirring shaft is fixedly provided with the stirring device inside the mixing device. The device can realize simultaneous mixing and material charging; the fact that too much raw materials are added at one time, resulting in insufficient mixing of the raw materials is avoided; meanwhile, the rotation speed of the main driving motor can be adjusted, so that the stirring shaft has different rotating speeds, further resulting in the difference of the size of stirring blades suffered centrifugal force, different blade stirring ranges of the stirring blades are realized and the mixing effect is improved.

Owner:HUIAN KELIAN AGRI TECH CO LTD

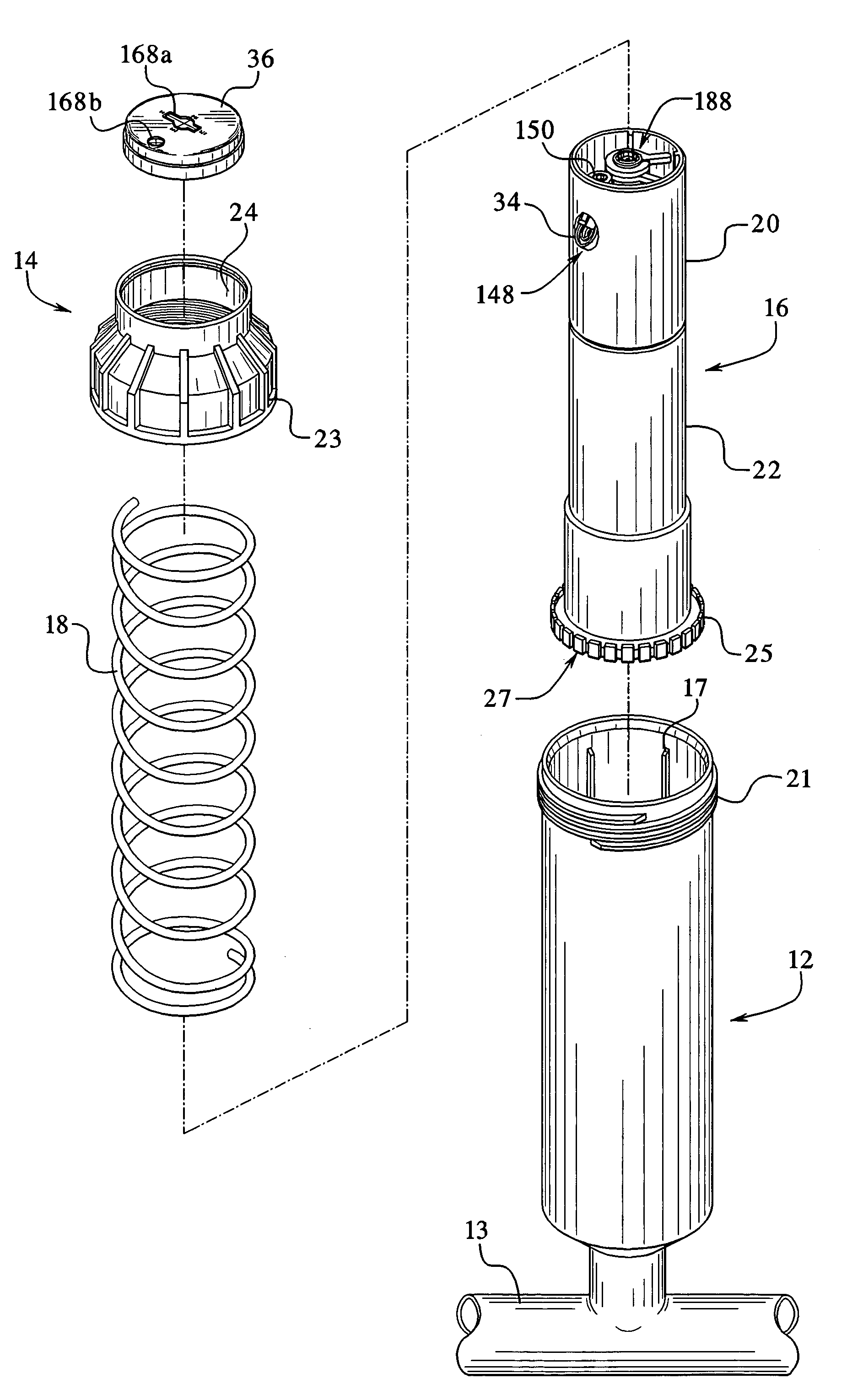

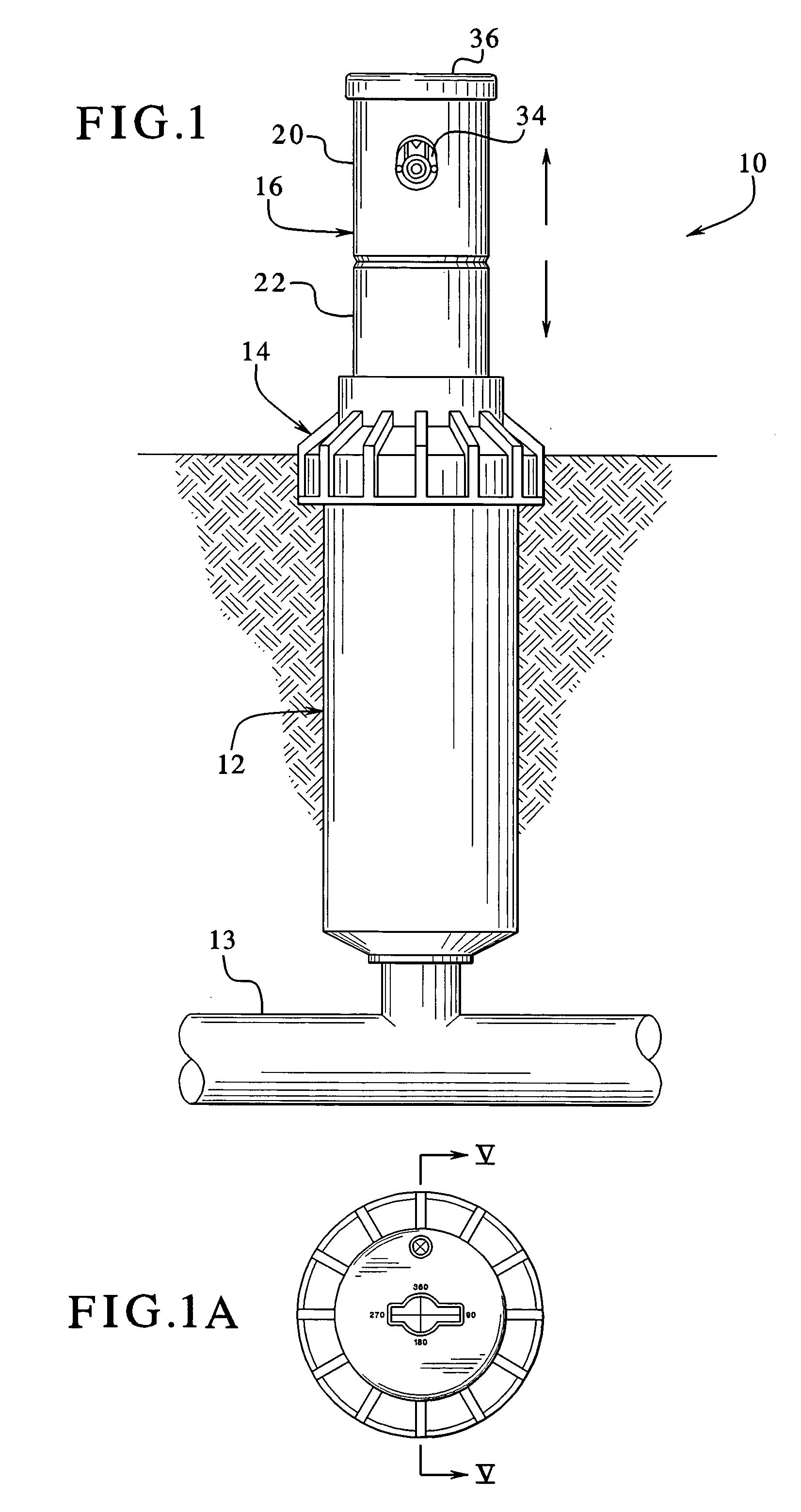

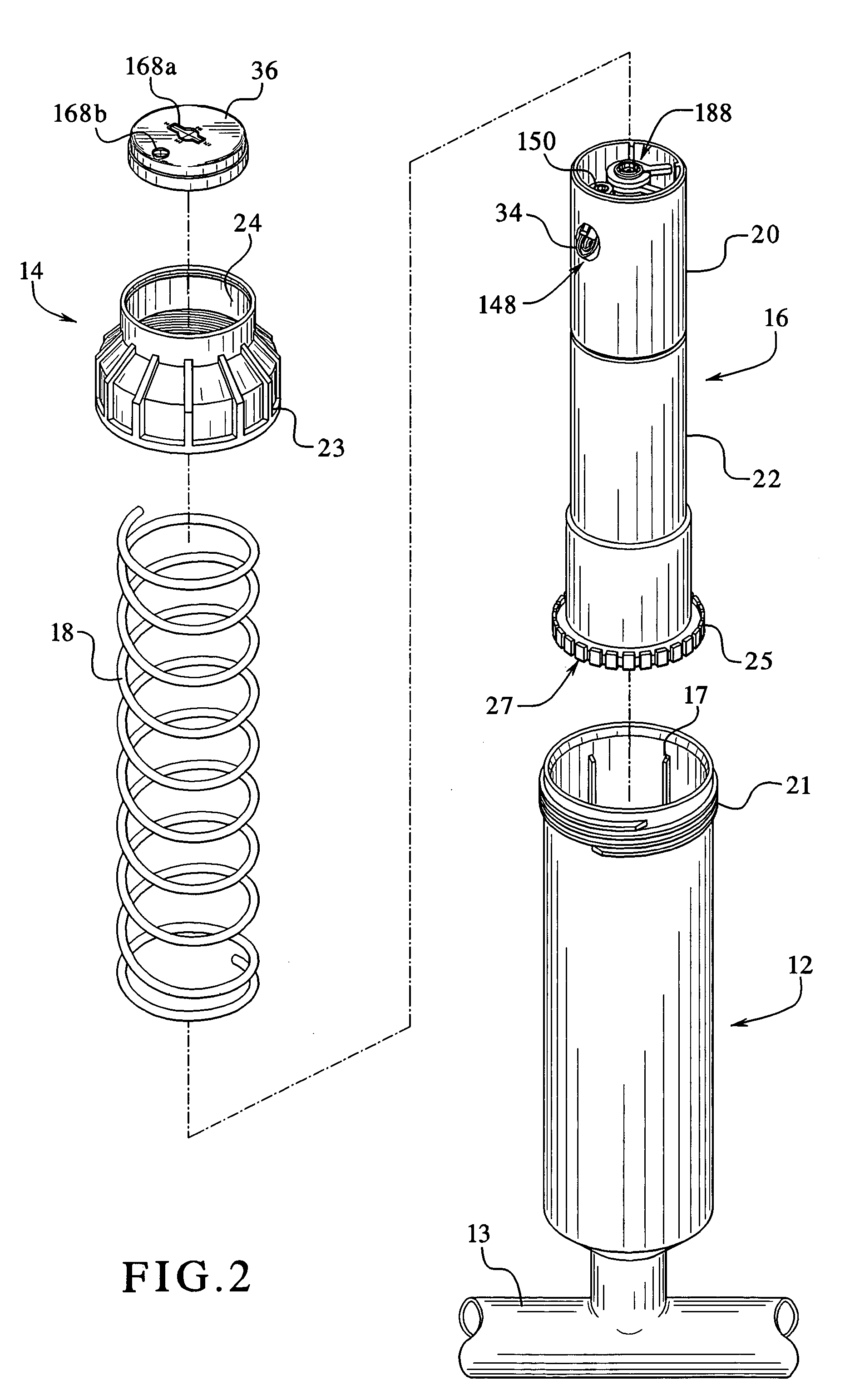

Adjustable sprinkler

InactiveUS20050194464A1Quickly and efficiently setEliminate needSelf-acting watering devicesWatering devicesImpellerReduction drive

An adjustable sprinkler including an inner housing slideably engaged with an outer housing. The inner housing includes a head rotatably mounted to a body. The outer housing includes an inlet which receives pressurized water and transfers the pressurized water to a nozzle attached to the head. The inner housing includes a reverser for selectively driving an impeller in two different directions. The impeller is connected to a reducer which reduces the rotational rate transferred from the impeller to the head and also enables the head to be manually rotated without causing damage to the internal components of the adjustable sprinkler. The head includes a click set and a cap. The cap defines at least one opening to enable a user to insert a tool through the cap to adjust and set the boundaries of the spray pattern using the click set.

Owner:BRUNINGA KENNETH

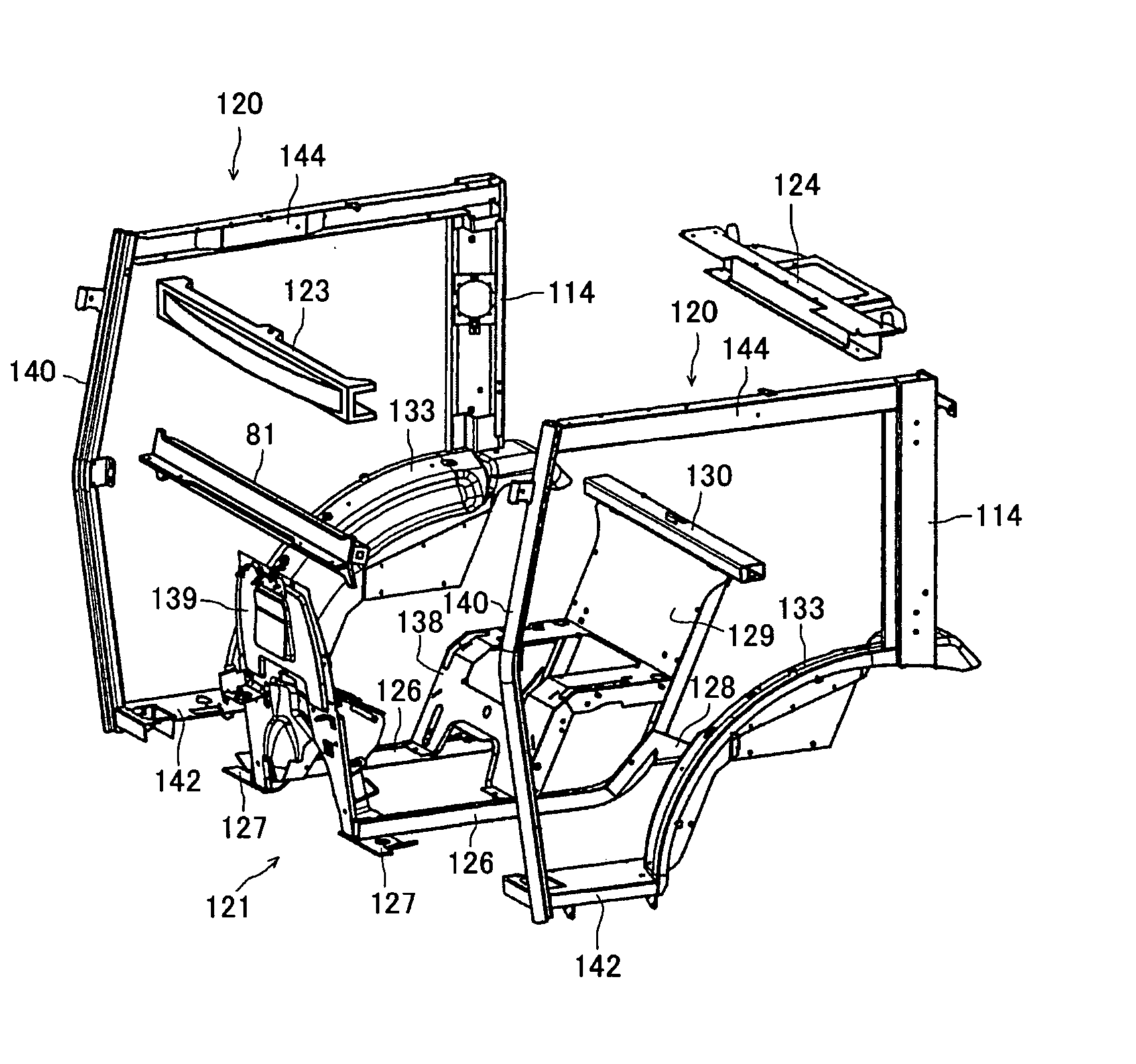

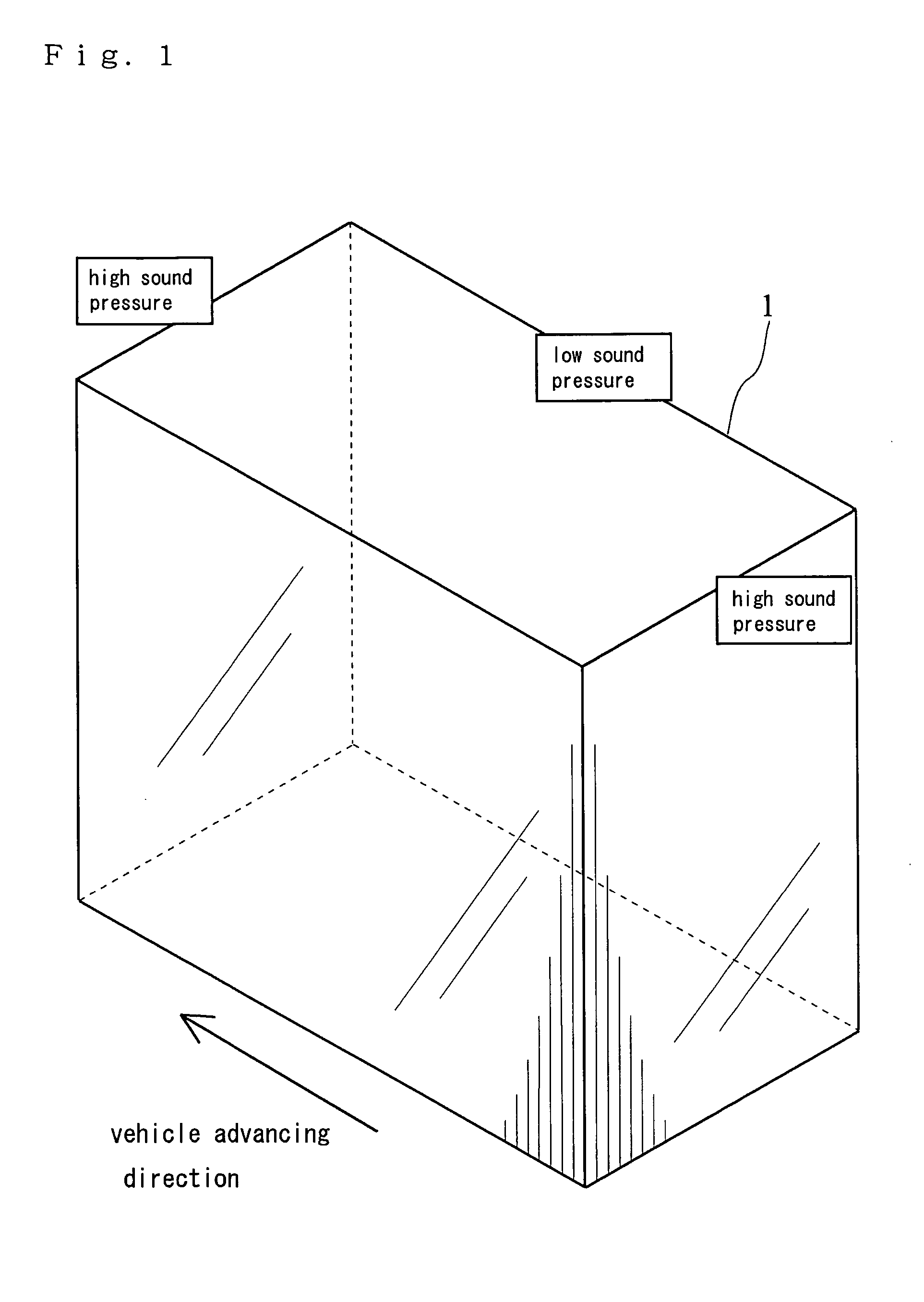

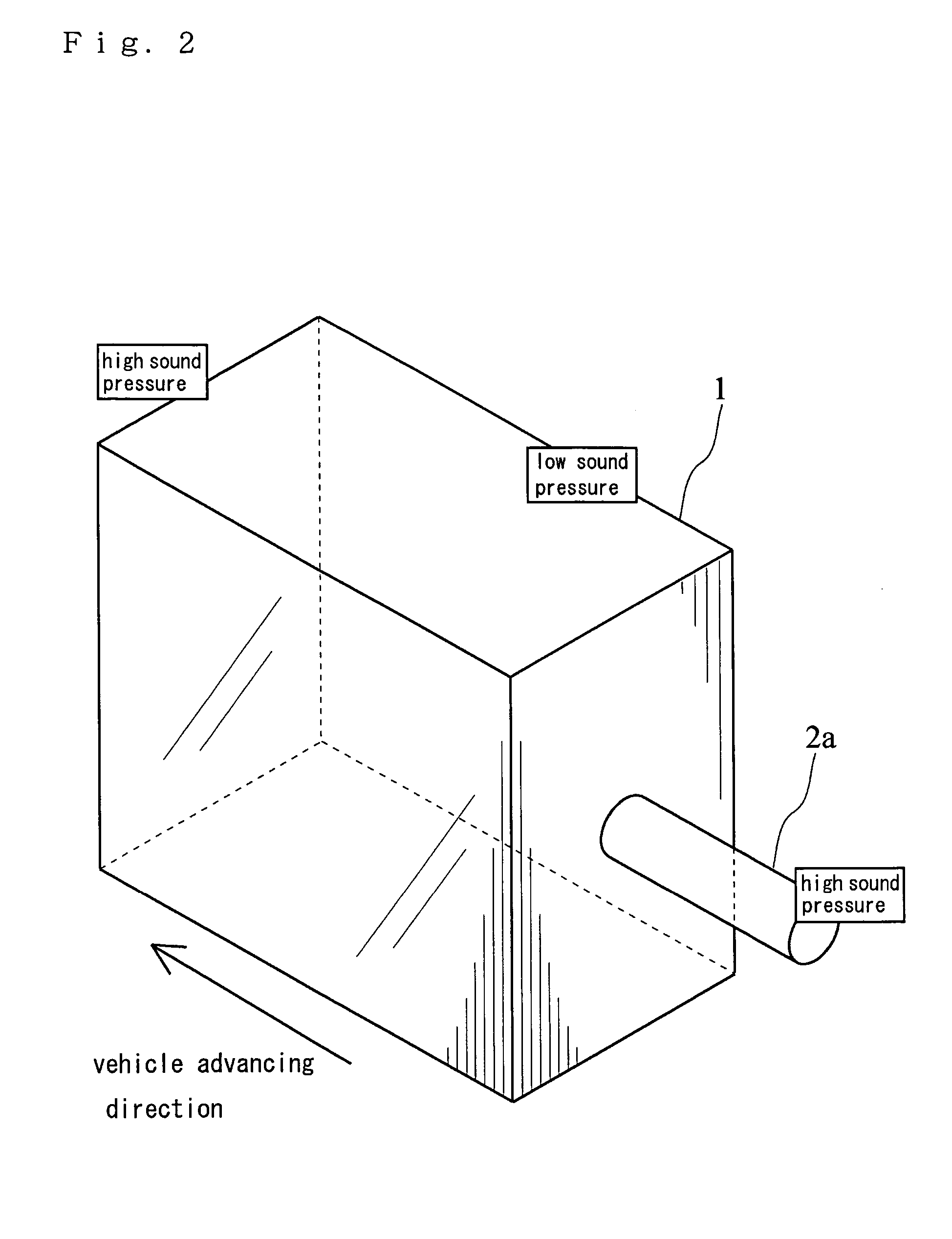

Noise Proof Structure of Cabin

InactiveUS20080023261A1Improve noiseReduce noiseMachines/enginesSuperstructure subunitsNacelleResonance

The purpose of the present invention is to change hollow resonance frequency in a cabin without changing the dimensions of the cabin and not providing any partition in the cabin. The present invention provides noise proof structure of a cabin reducing furry noise so as to improve livability and comfortability for an operator. A resonator resonating at frequency of hollow resonance is provided at a position at which sound pressure is high when the hollow resonance occurs. A rotary sensor measuring rotary speed of an engine of the working machine or the like having the cabin, an actuator opening and closing a partition at the opening, and a controller controlling the partition through the actuator corresponding to the rotary speed measured by the rotary sensor are provided.

Owner:YANMAR CO LTD

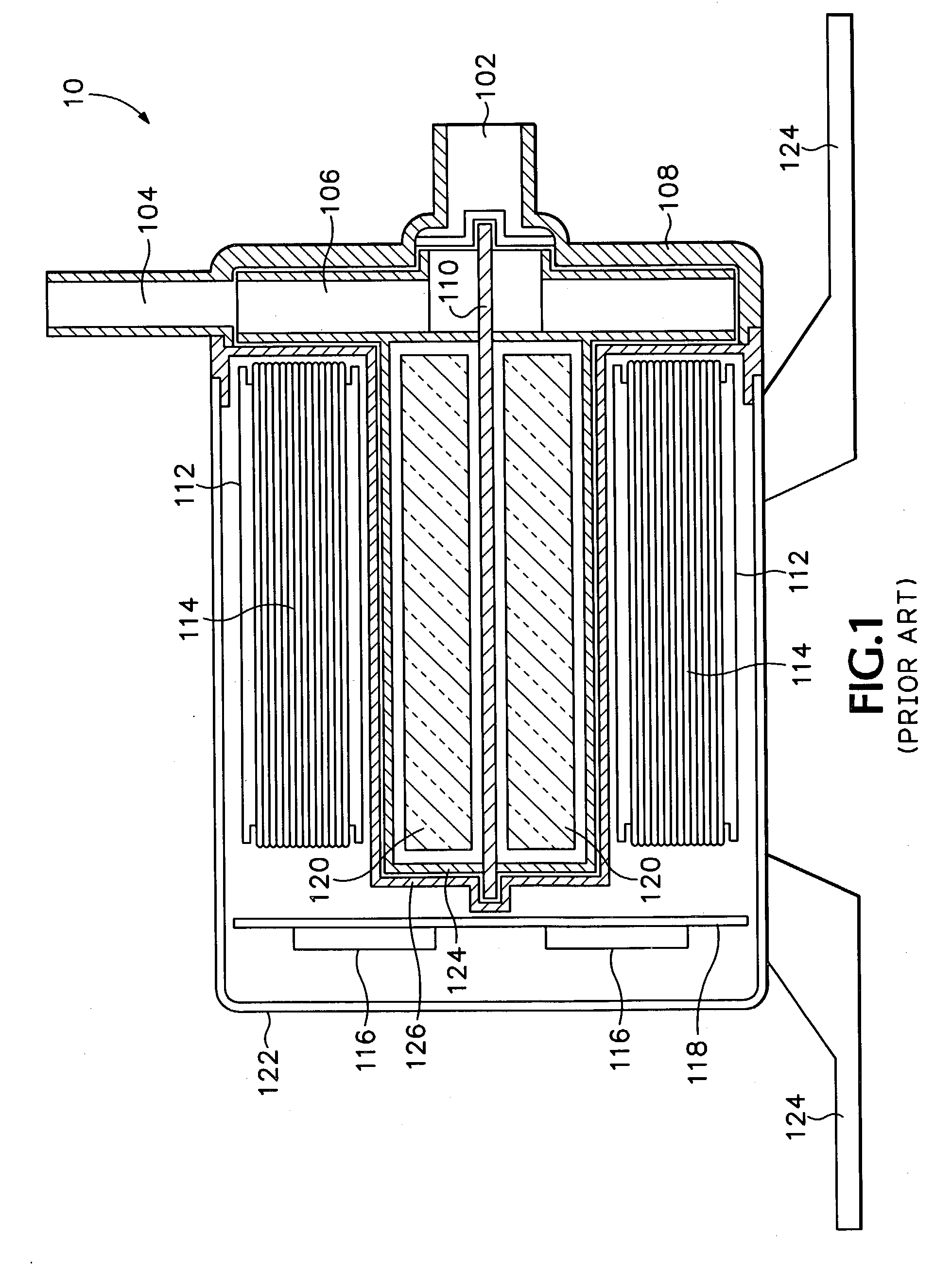

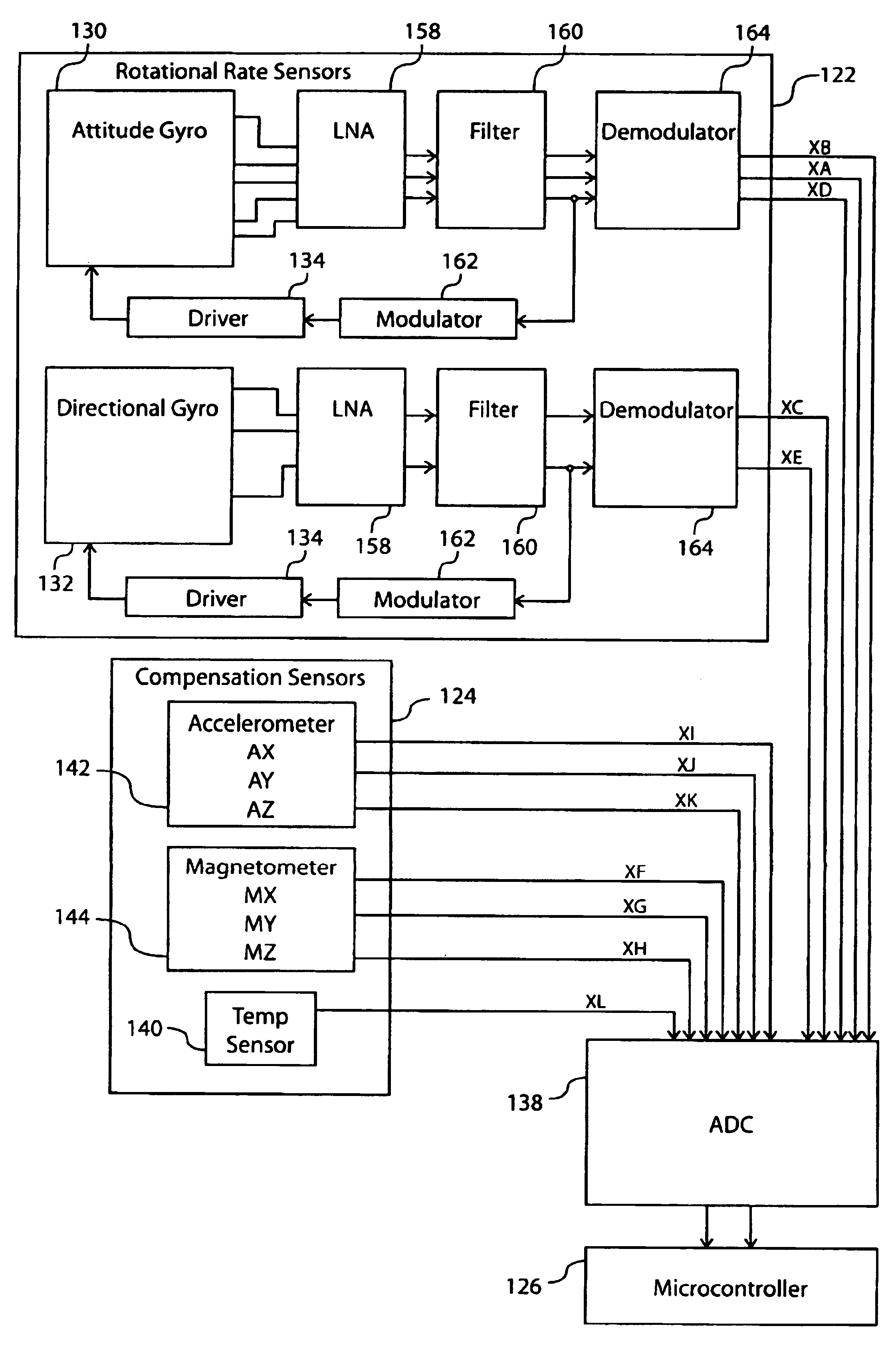

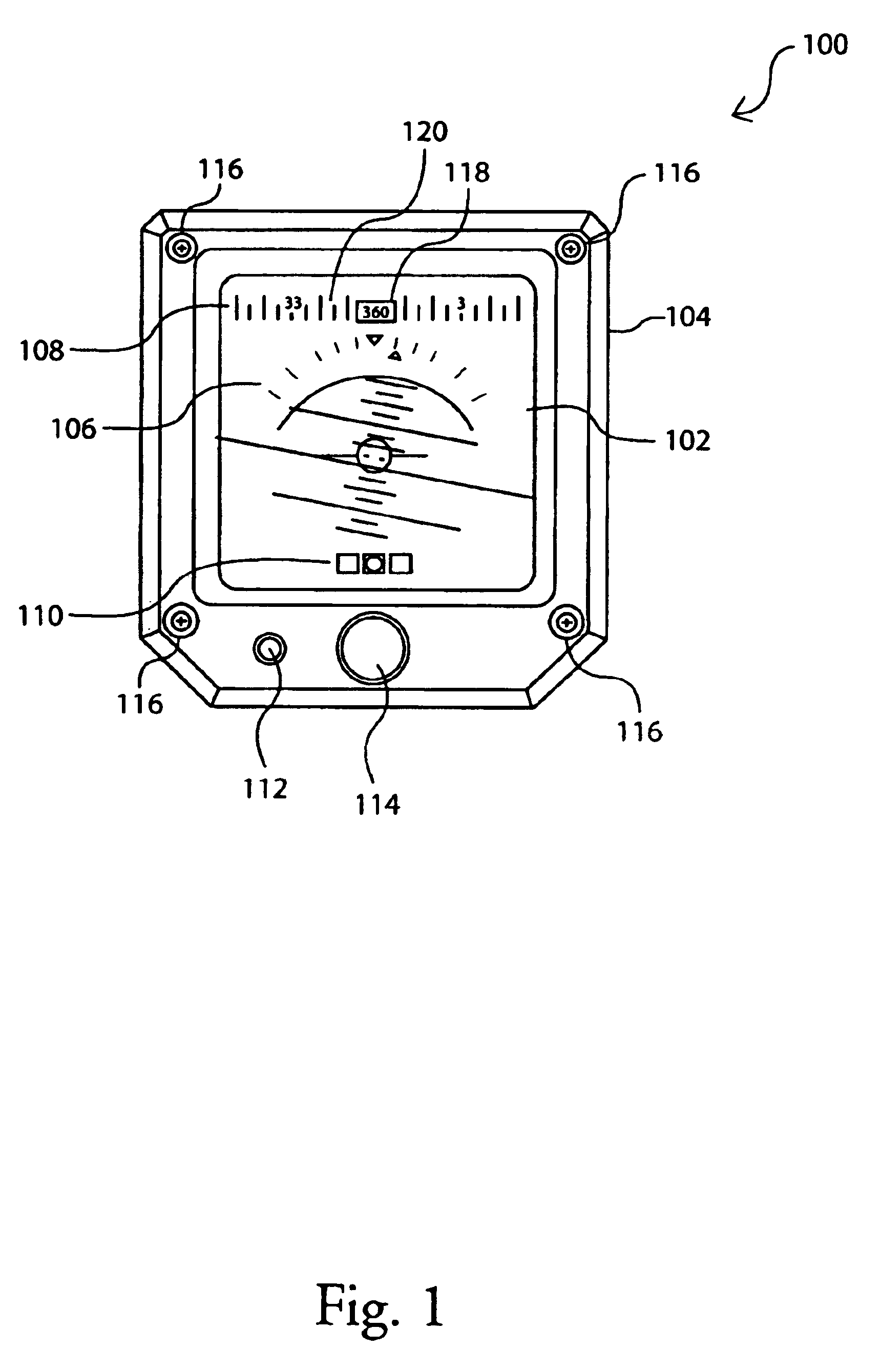

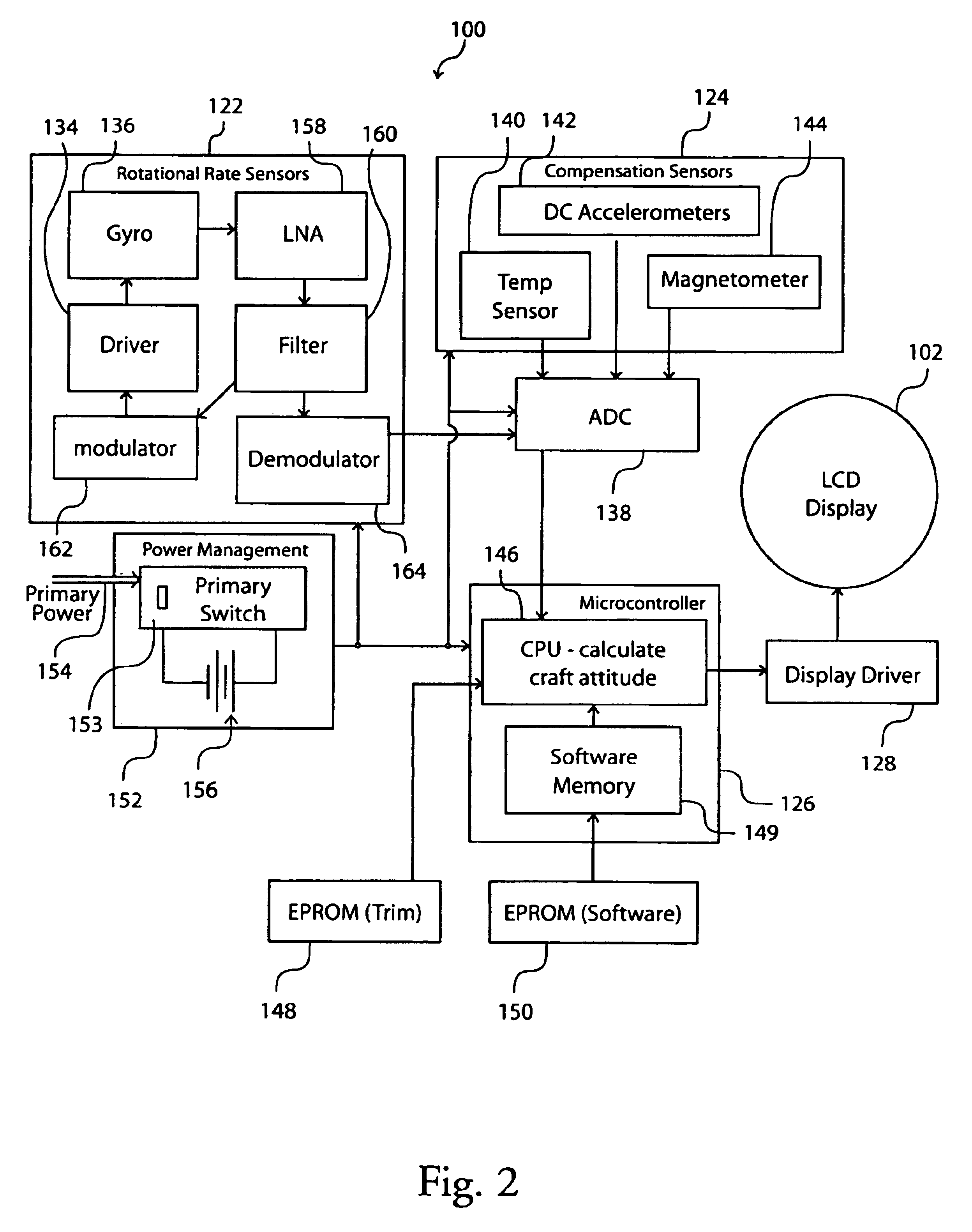

Piezoelectric rate sensor system and method

InactiveUS6853315B2Low costSolution to short lifeSpeed measurement using gyroscopic effectsNavigation instrumentsMicrocontrollerDisplay device

A compact, lightweight, cost effective, self-contained standby electronic navigation system with high signal-to-noise ratio and good dynamic stability is provided. The system includes a first sensor module for providing a plurality of rotational rate signals, a second sensor module for providing a plurality of compensation signals, and a microcontroller module for processing the rotational rate signals and the compensation signals and sending the signals to a display for displaying attitude information, directional information, and turn coordinate information on a single screen simultaneously. In one embodiment, the first sensor module includes a plurality of rotational sensors made of piezoelectric elements. The piezoelectric elements are made from a single sheet of piezoelectric material so that the elements possess uniform characteristics, and are arranged to reduce systematic drift and random noise normally present in a rotational rate sensor. The sensors can be configured on a single multi-sensor chip.

Owner:TRIAD SENSORS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com