Patents

Literature

207results about How to "Increase energy output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

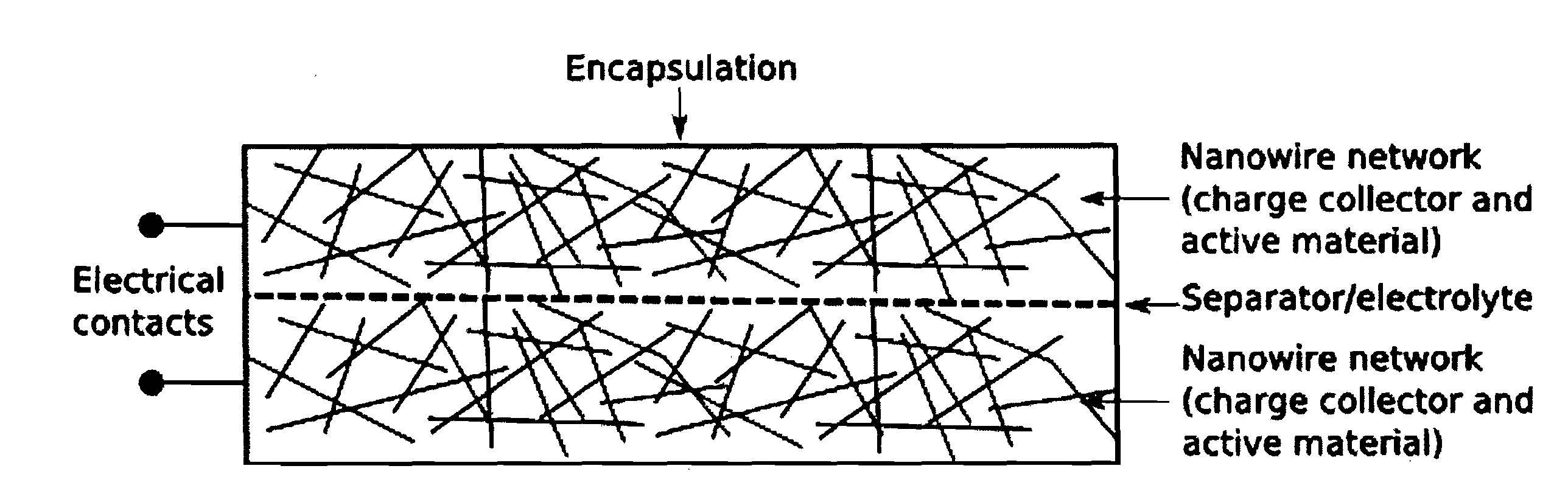

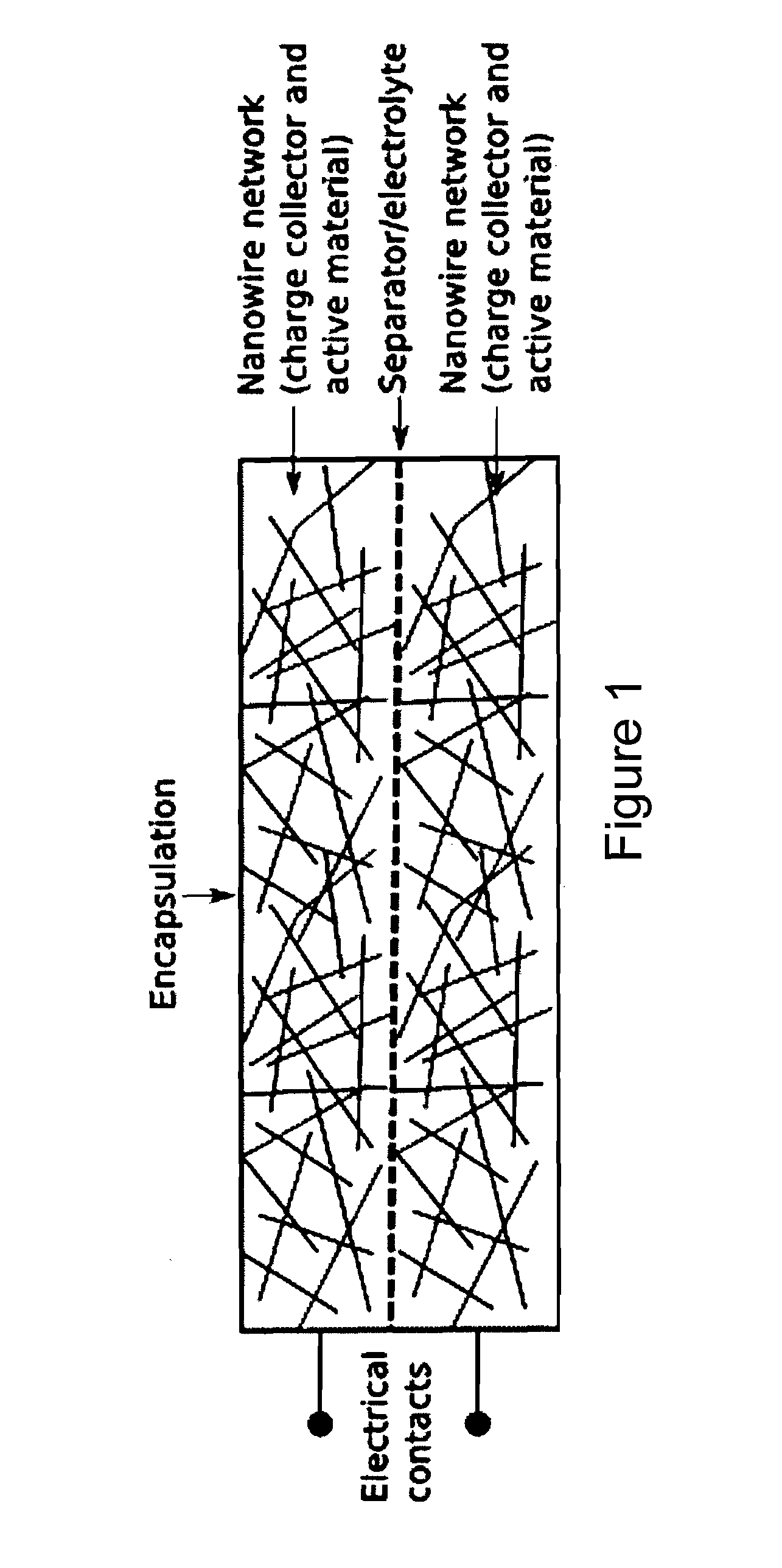

Charge storage devices containing carbon nanotube films as electrodes and charge collectors

ActiveUS20100178543A1Increasing total voltage outputIncrease energy outputMaterial nanotechnologyHybrid capacitor electrolytesElectrical energy storageCarbon nanotube

Owner:RGT UNIV OF CALIFORNIA

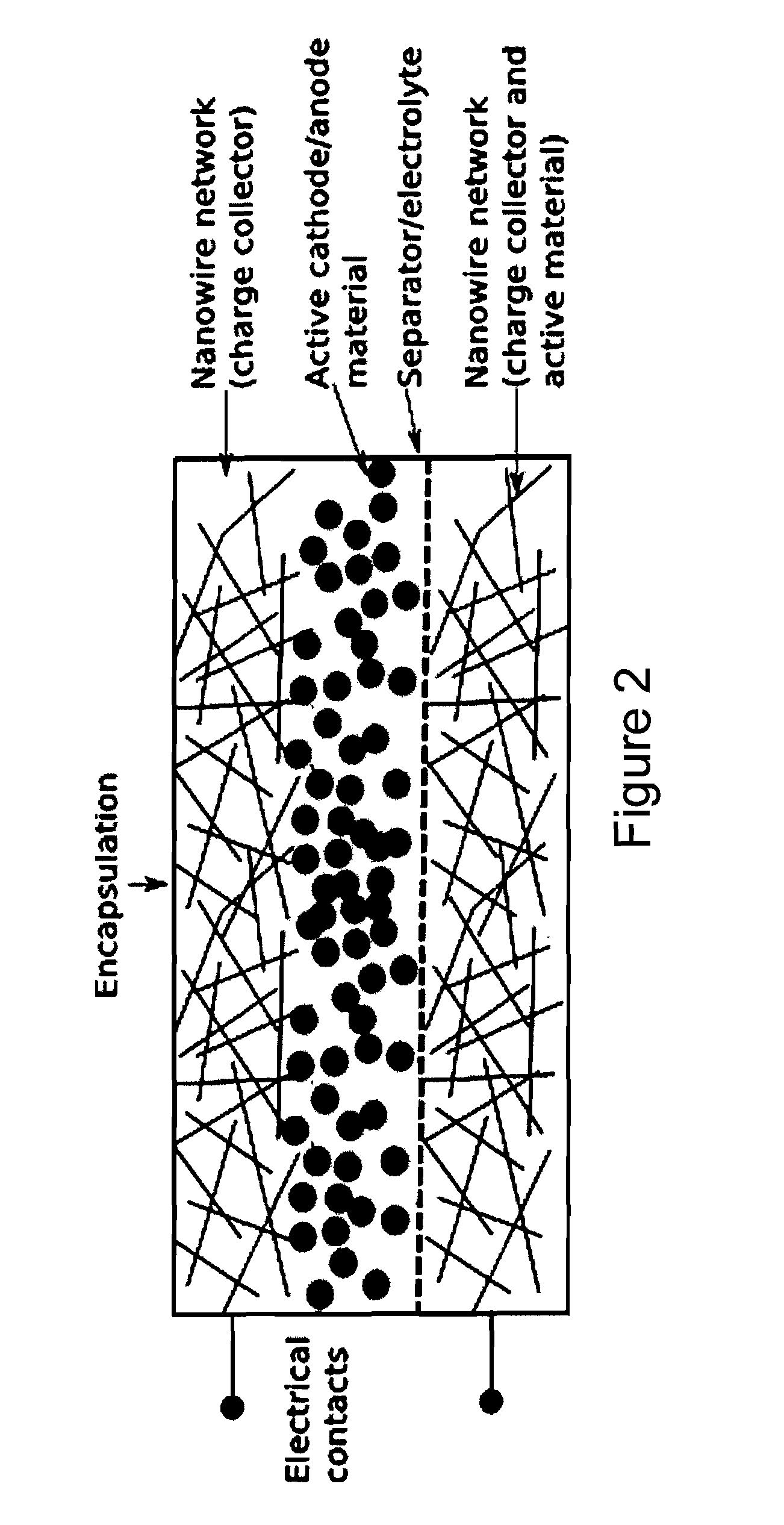

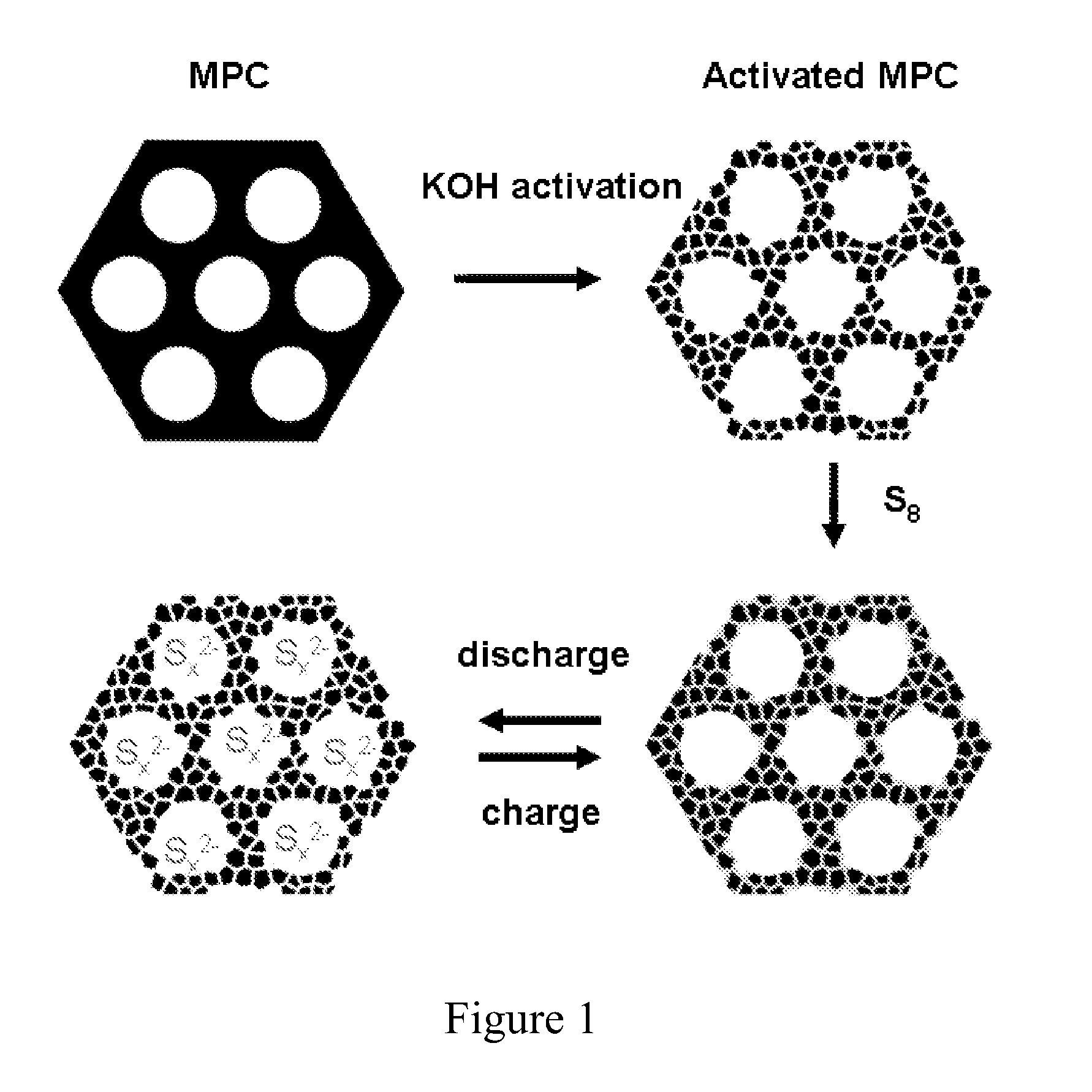

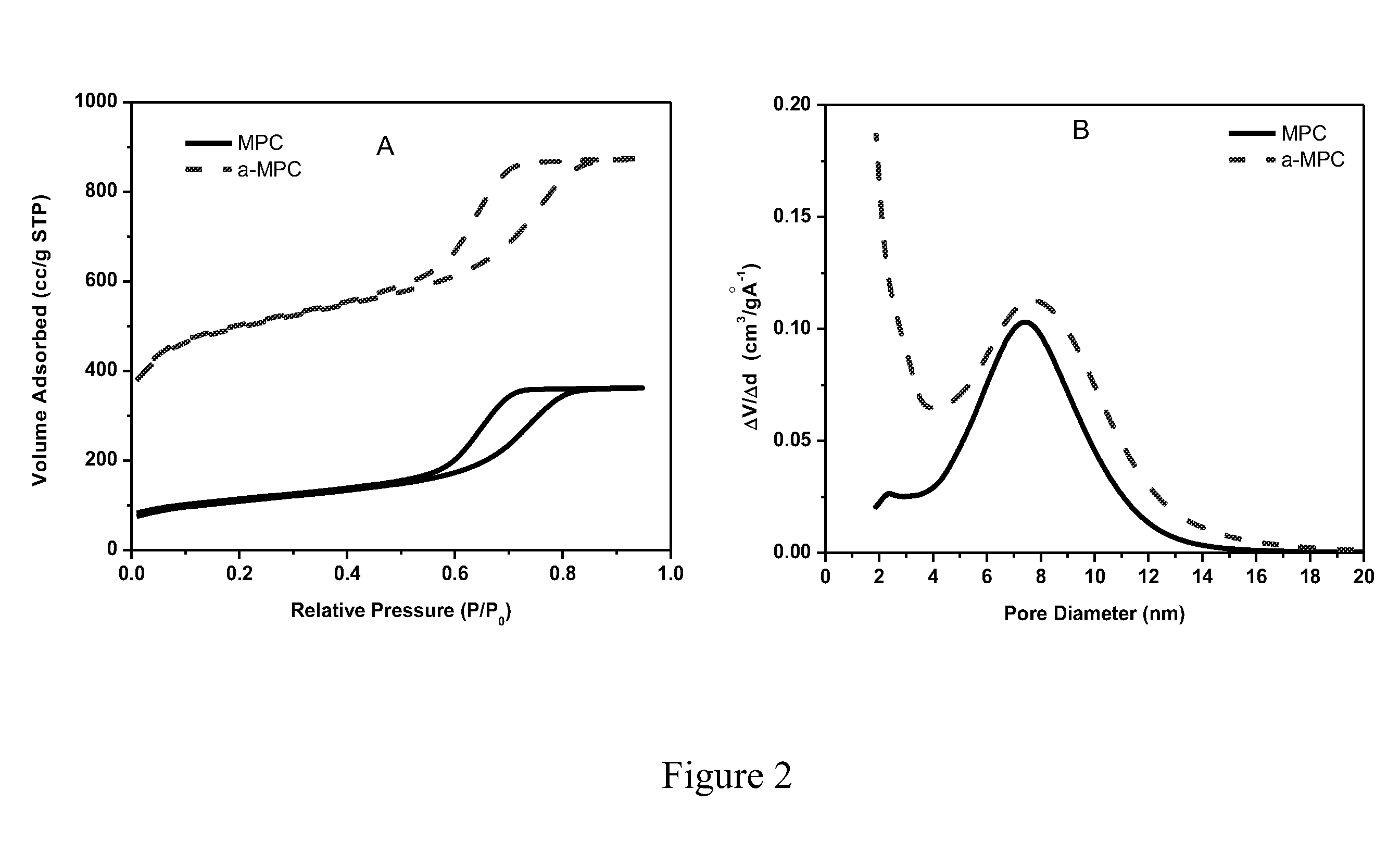

Sulfur-carbon nanocomposites and their application as cathode materials in lithium-sulfur batteries

ActiveUS20110052998A1Minimize formationEasy to transportAlkaline accumulatorsElectrode thermal treatmentCarbon compositesPorous carbon

The invention is directed in a first aspect to a sulfur-carbon composite material comprising: (i) a bimodal porous carbon component containing therein a first mode of pores which are mesopores, and a second mode of pores which are micropores; and (ii) elemental sulfur contained in at least a portion of said micropores. The invention is also directed to the aforesaid sulfur-carbon composite as a layer on a current collector material; a lithium ion battery containing the sulfur-carbon composite in a cathode therein; as well as a method for preparing the sulfur-composite material.

Owner:UT BATTELLE LLC

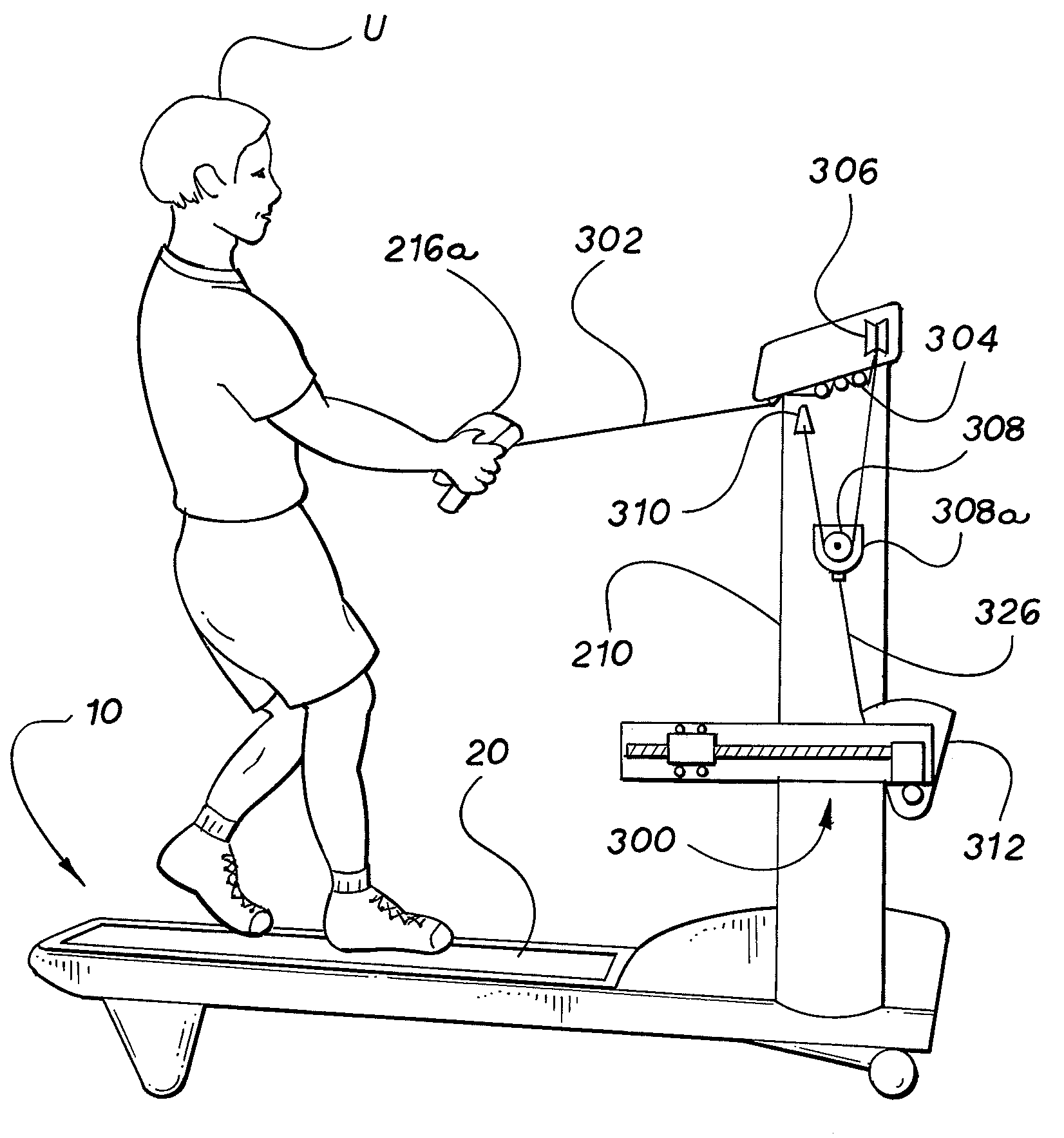

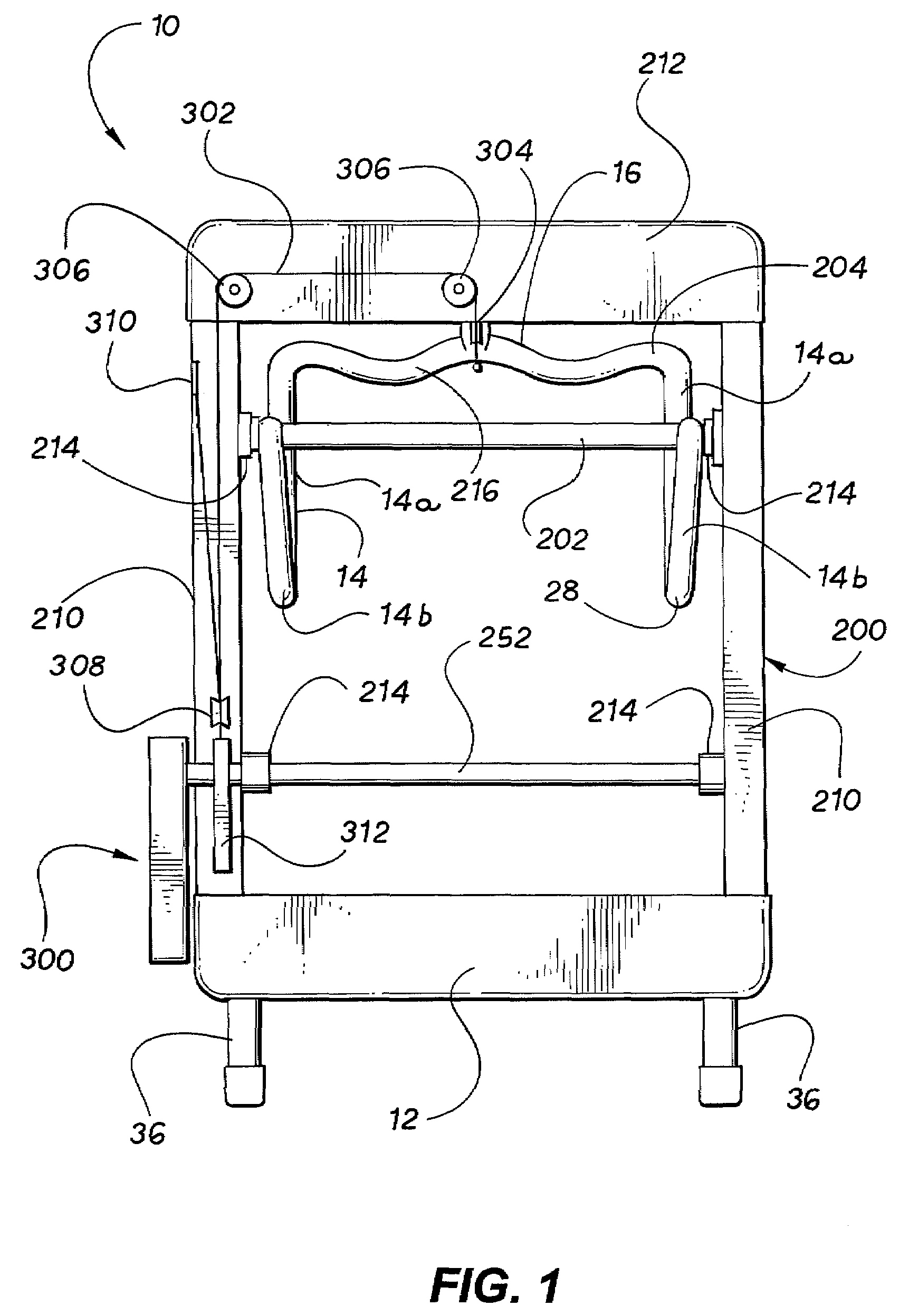

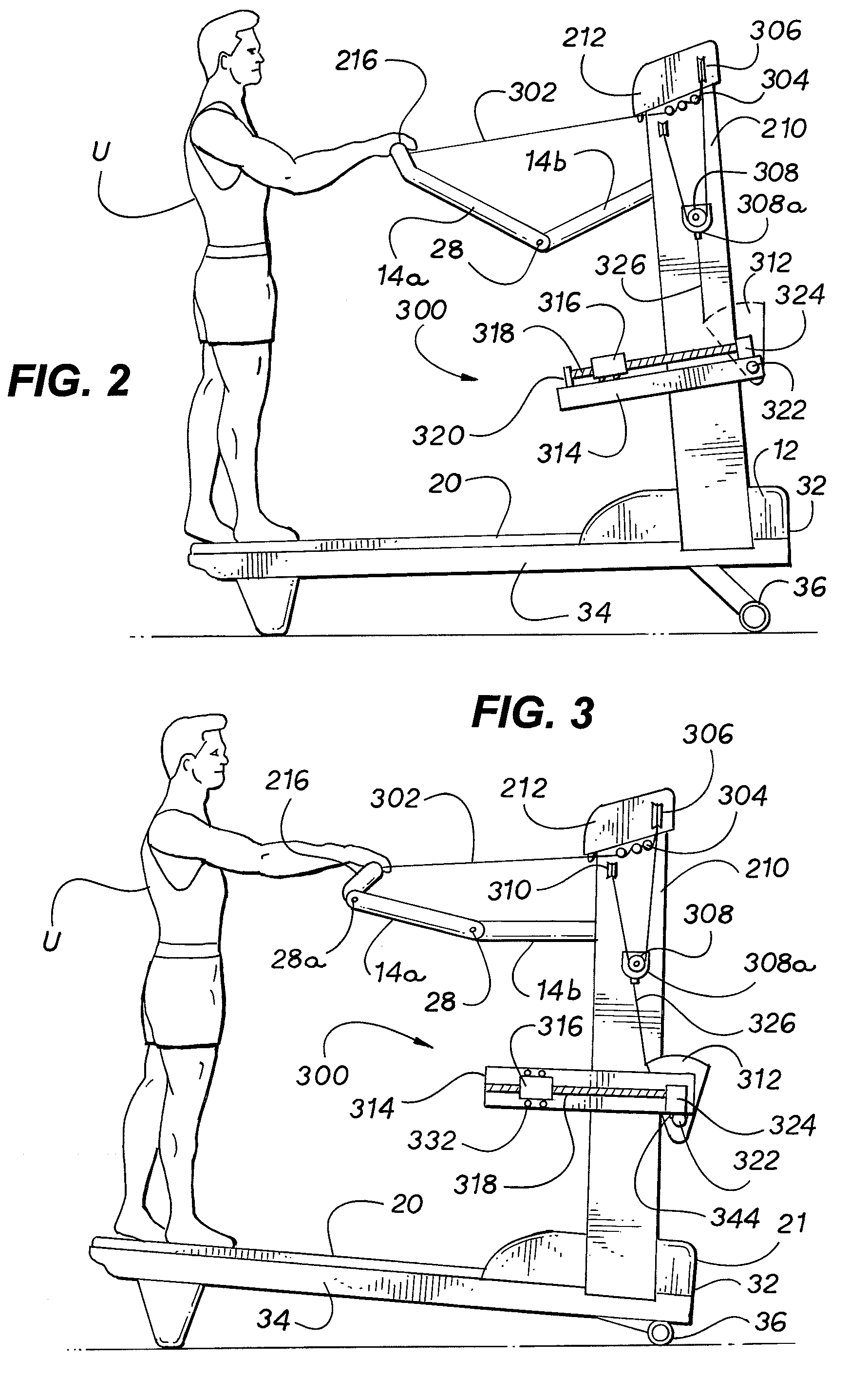

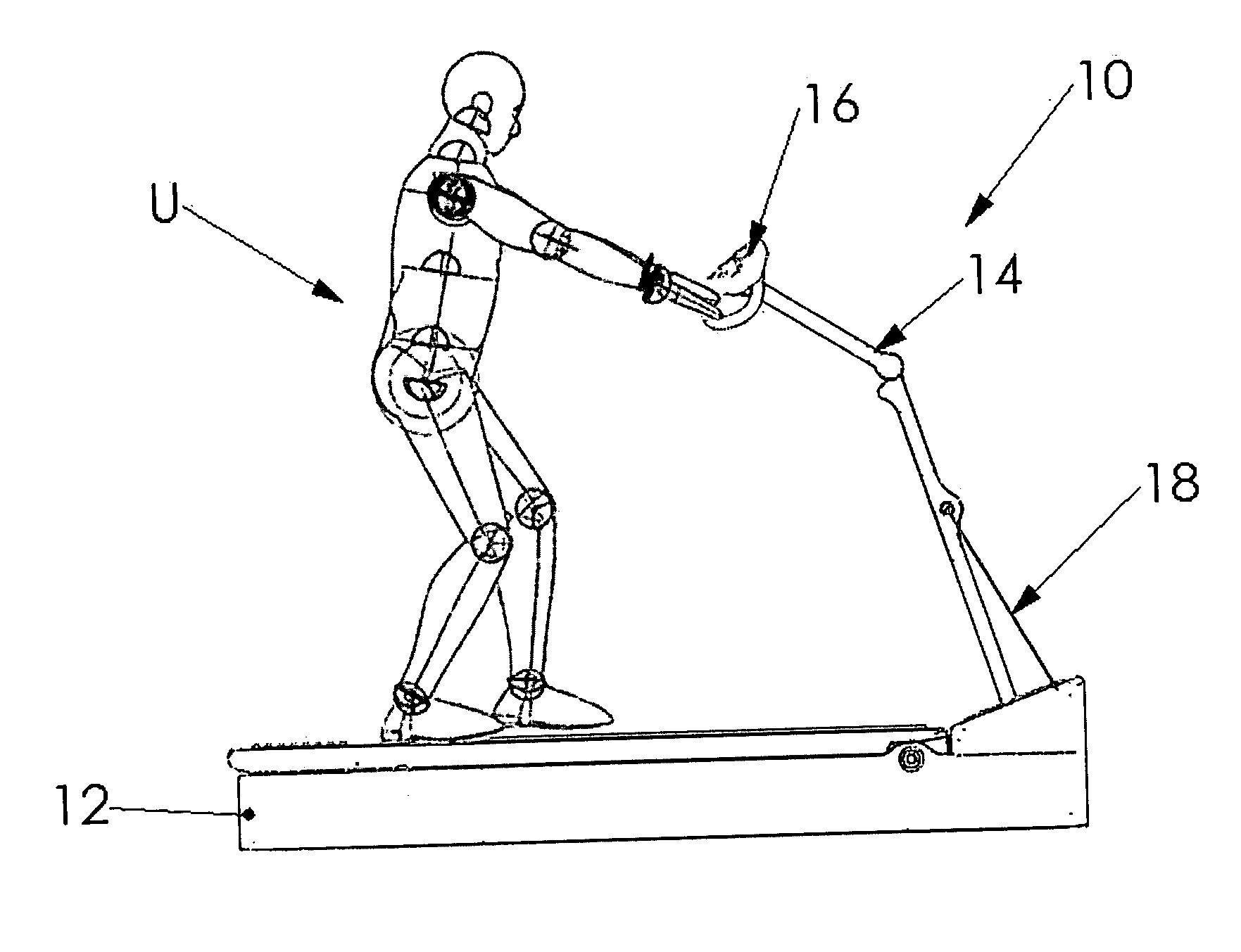

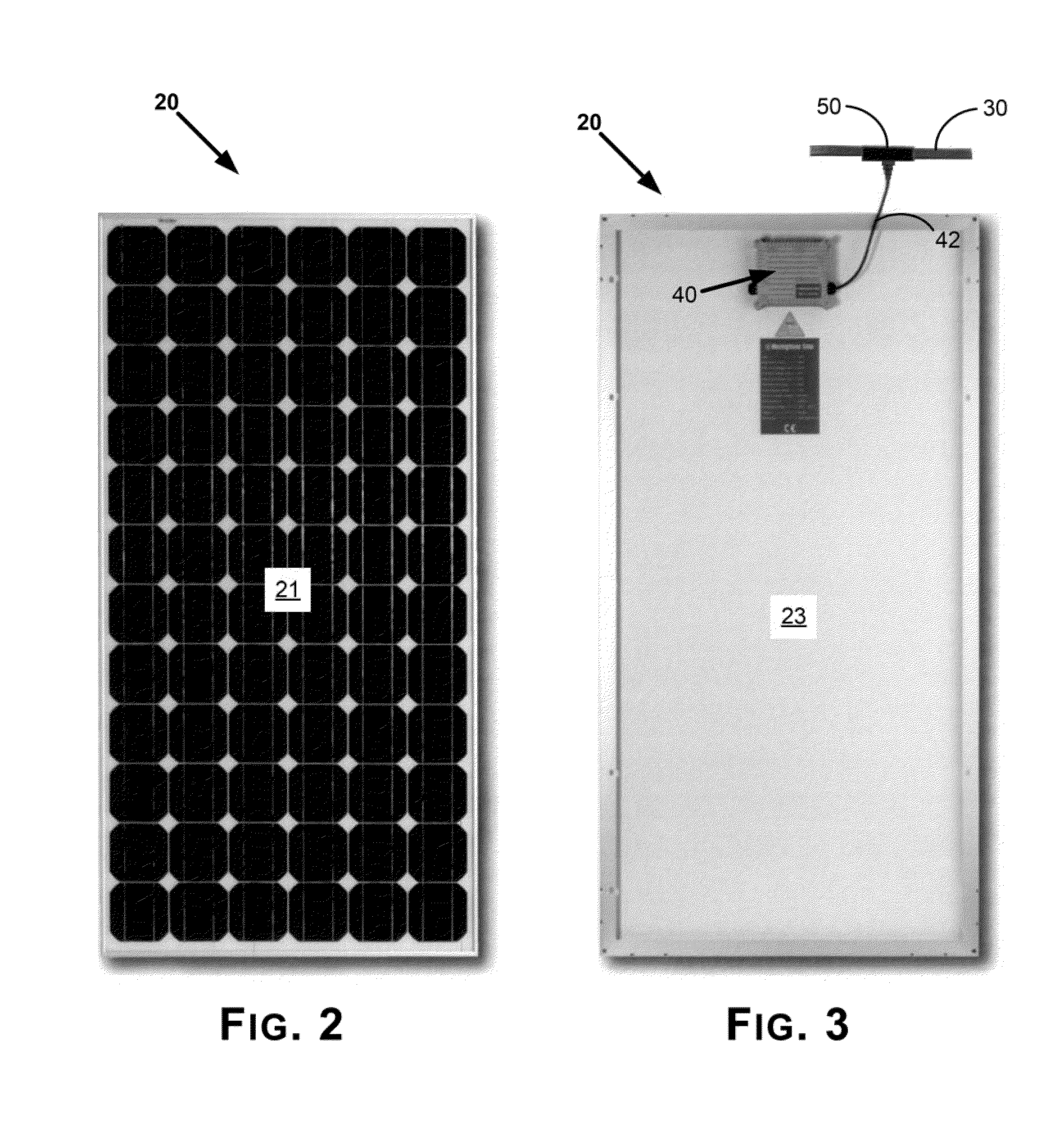

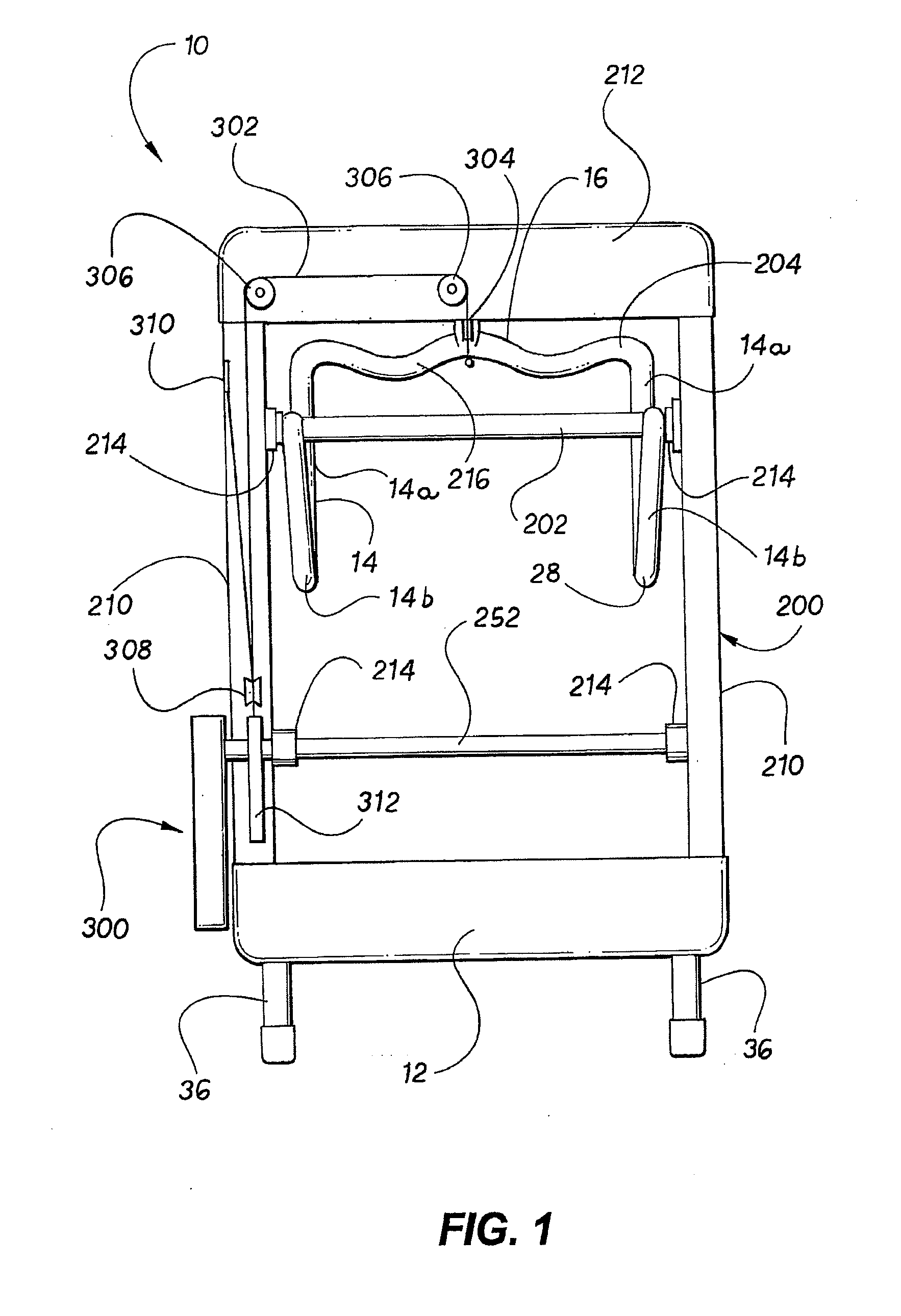

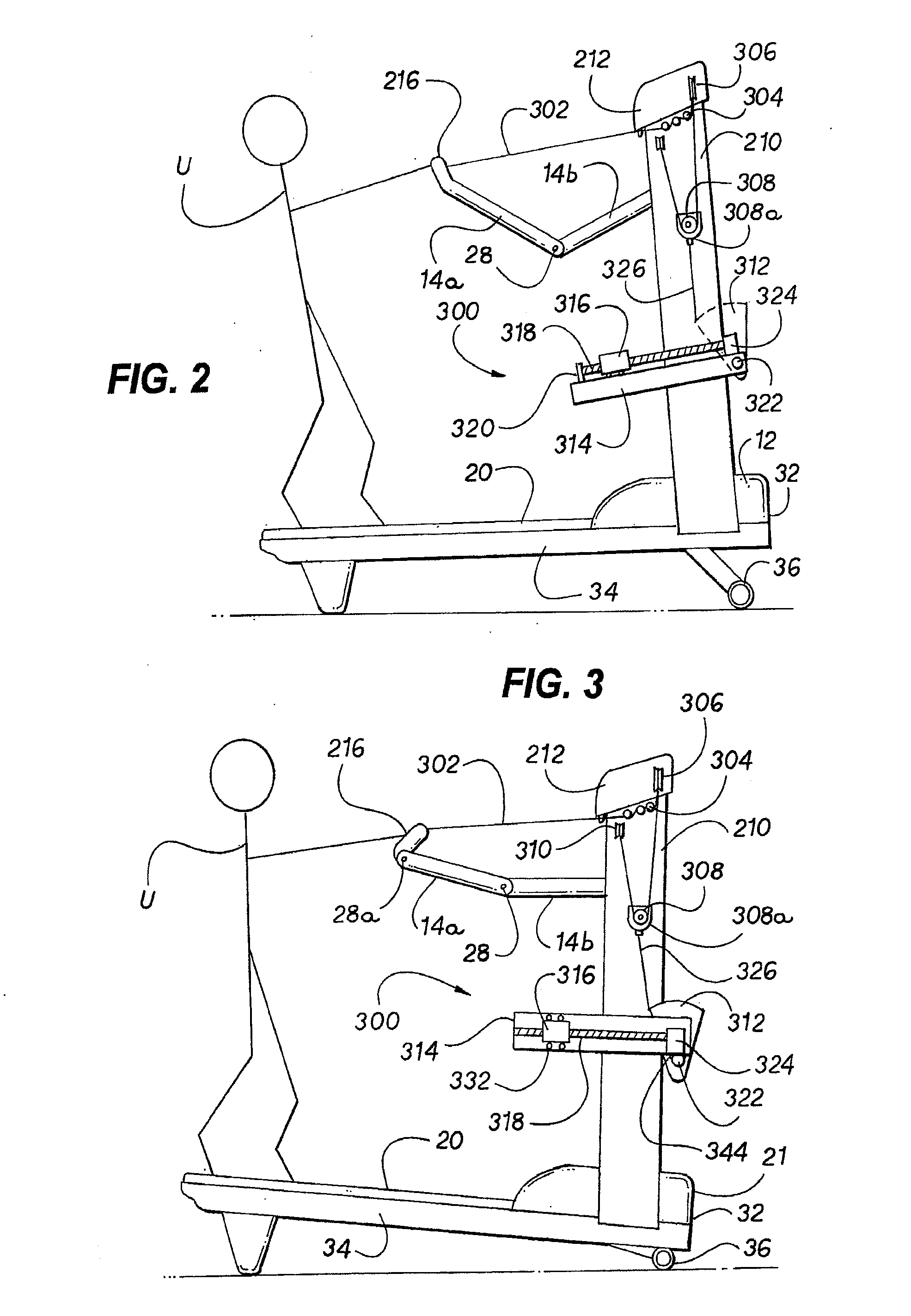

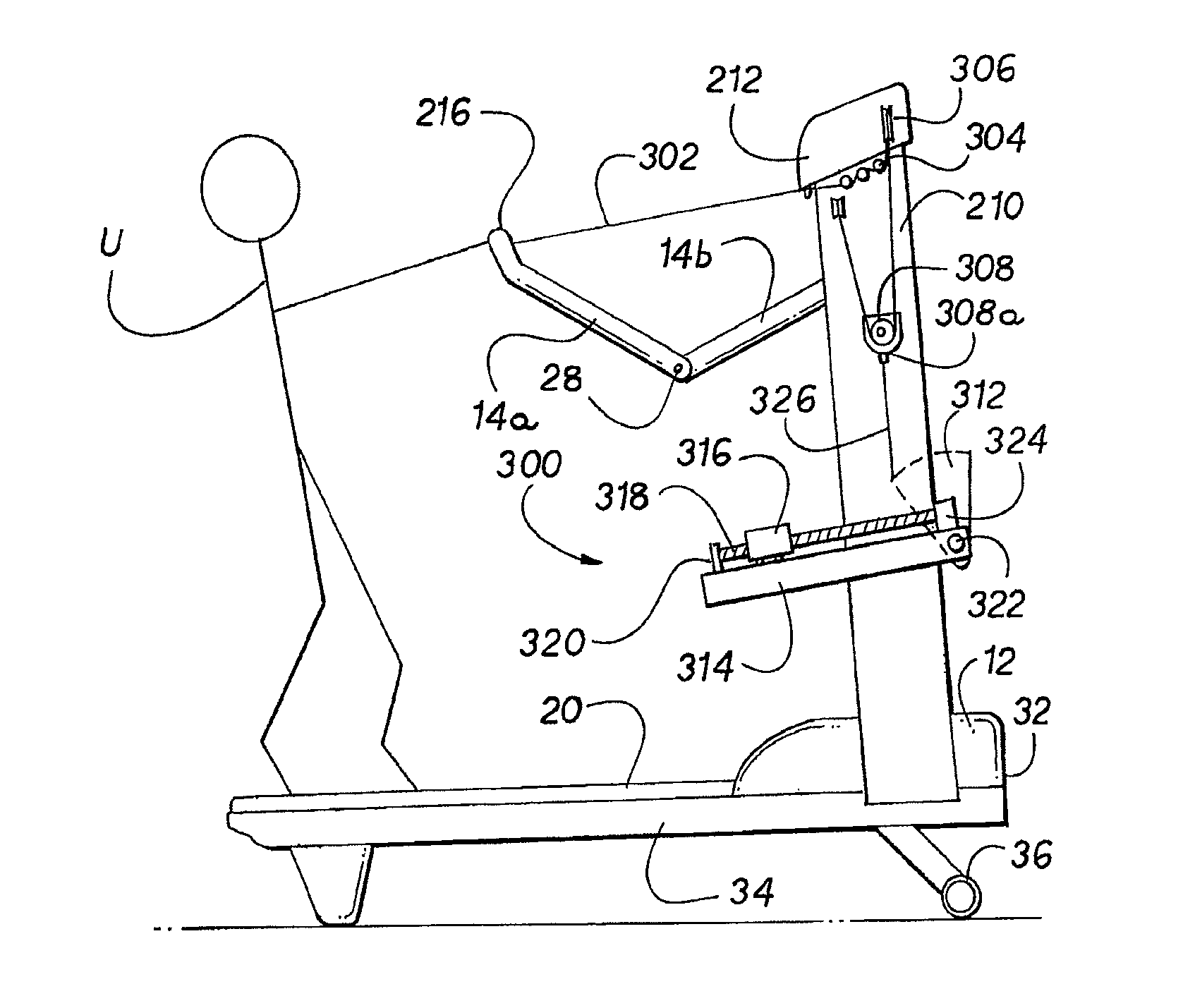

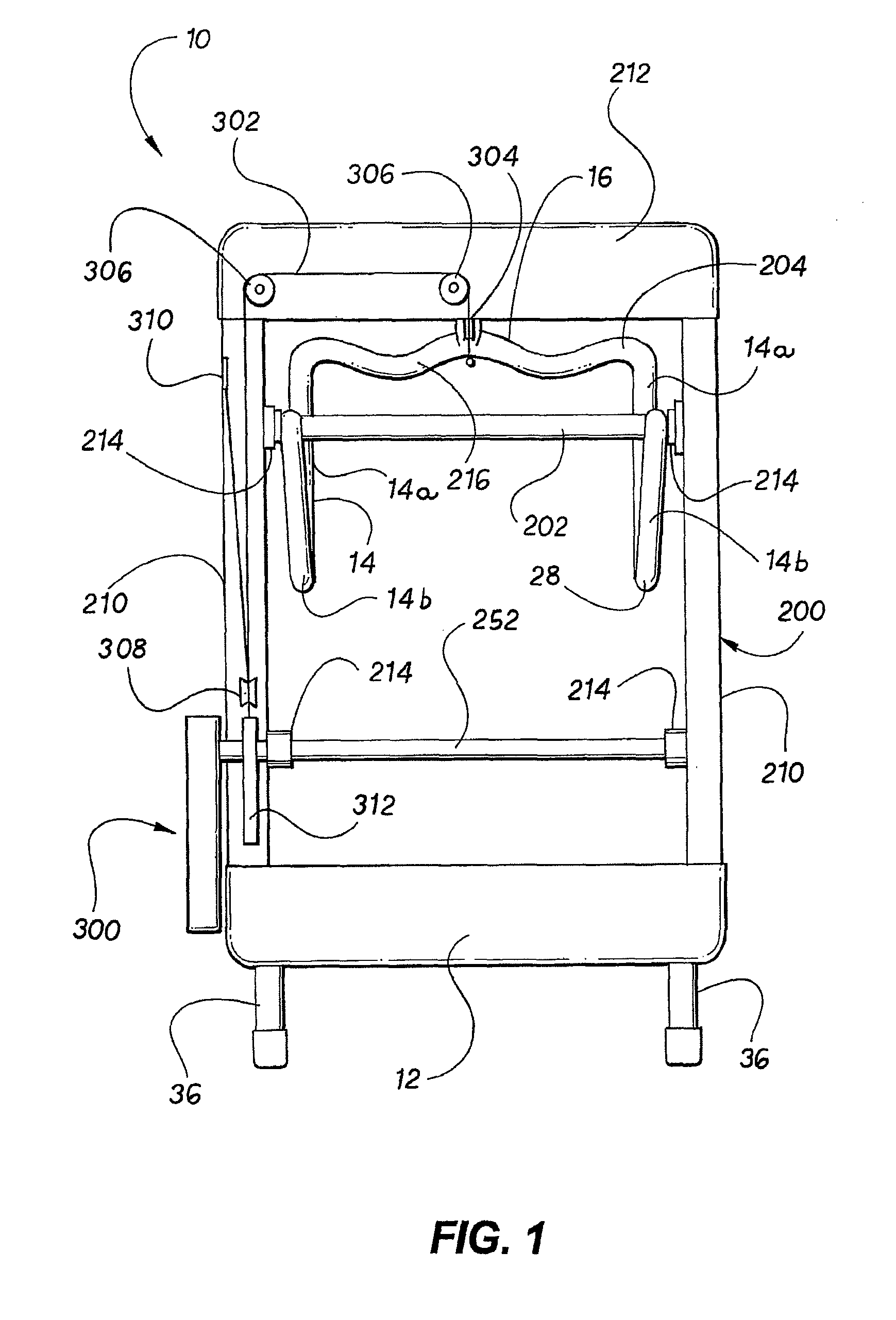

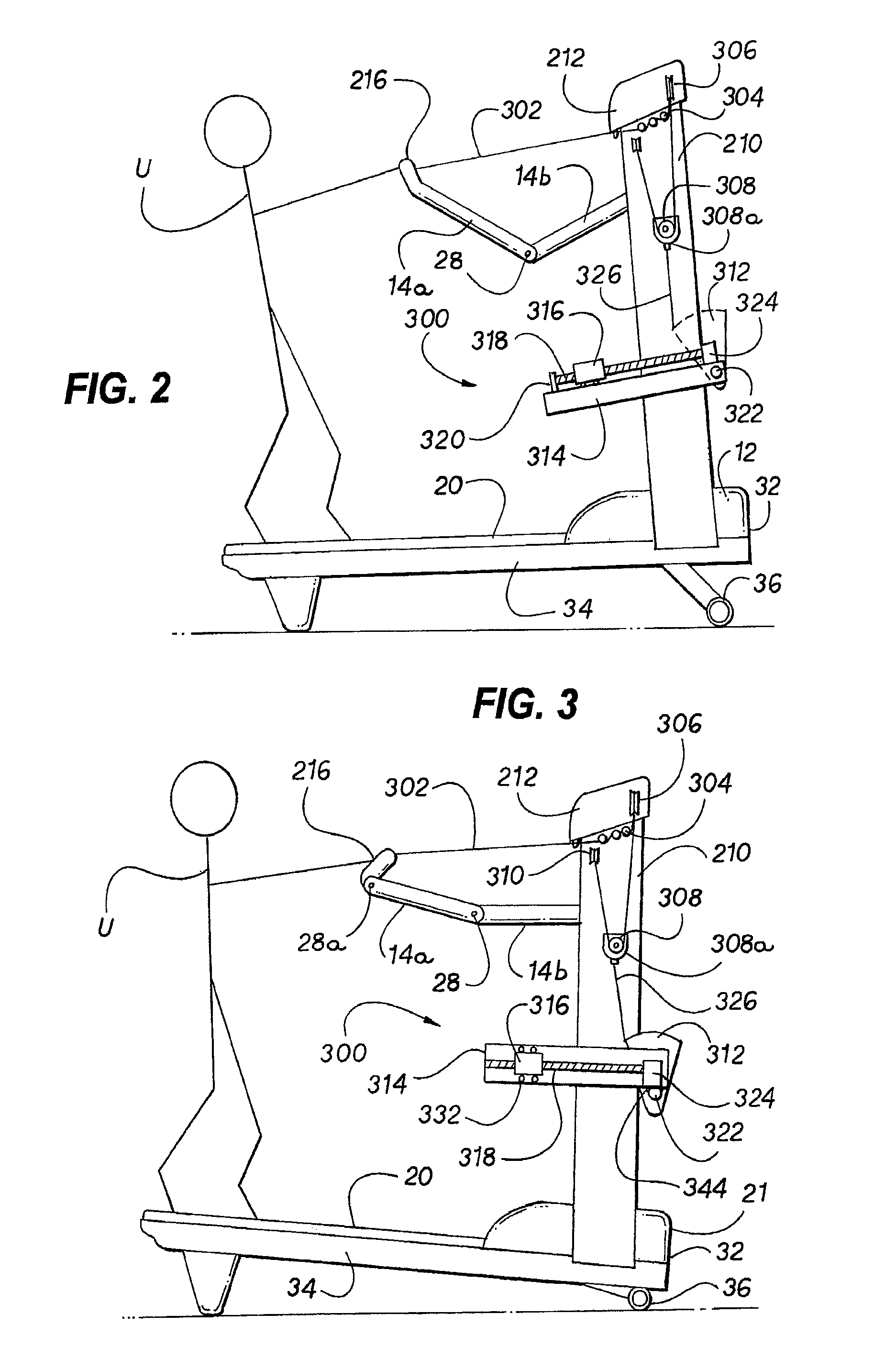

Dual direction exercise treadmill for simulating a dragging or pulling action with a user adjustable constant static weight resistance

InactiveUS7575537B2High activityIncrease ratingsMuscle exercising devicesMovement coordination devicesEngineeringTractor

An exercise treadmill having an endless moveable surface looped around rollers or pulleys to form an upper run and a lower run, the movable surface being rotated when one of the rollers or pulleys is rotated, and an exercise surface for walking or running while exercising, a weight resistance mechanism for providing a weight resistance for simulating the dragging or pulling of a load, wherein the weight resistance can be adjusted and set to a specific weight resistance setting; a movable hand controller operatively attached to the weight resistance mechanism for operating and controlling the exercise treadmill and the weight resistance mechanism, wherein the endless movable surface moves in a direction simulating walking or running backwards, and wherein the weight resistance mechanism applies a constant and static force to the hand controller generally only in the same as the direction the endless movable surface moves and opposite a pulling direction, whereby operation of the treadmill simulates the dragging or pulling of a load by a combination of the actuation of the weight resistance mechanism to simulate the load and the walking or running backwards to provide the dragging or pulling action.

Owner:FITNESS TOOLS

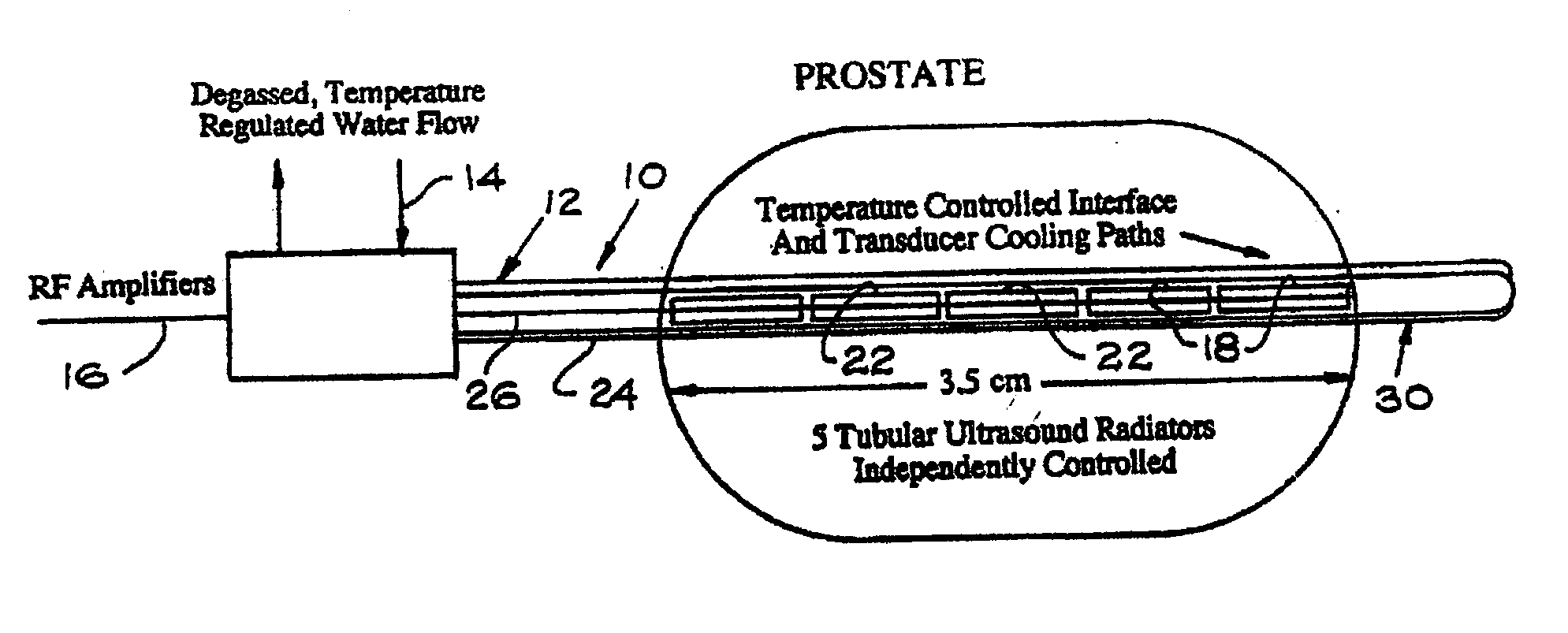

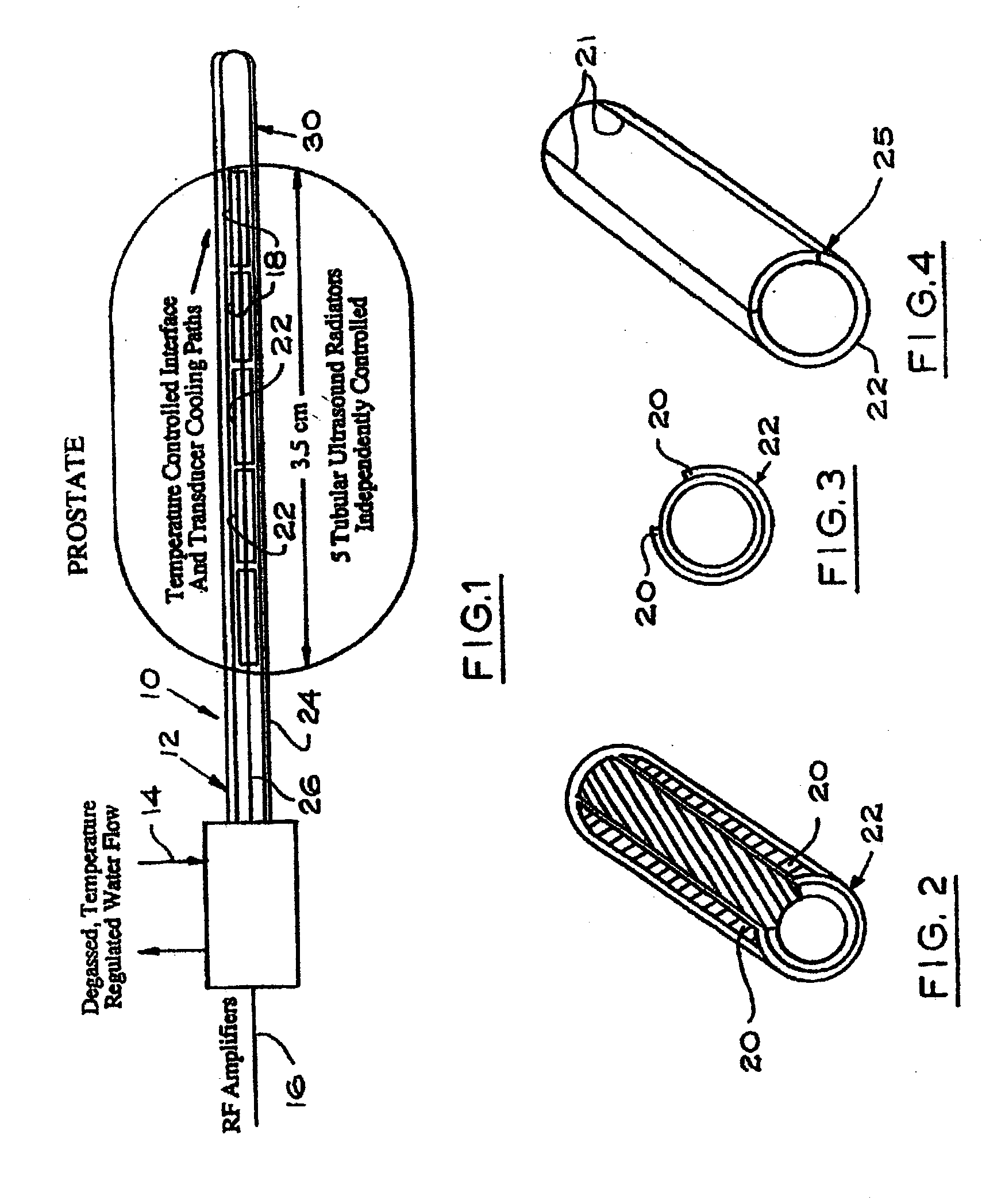

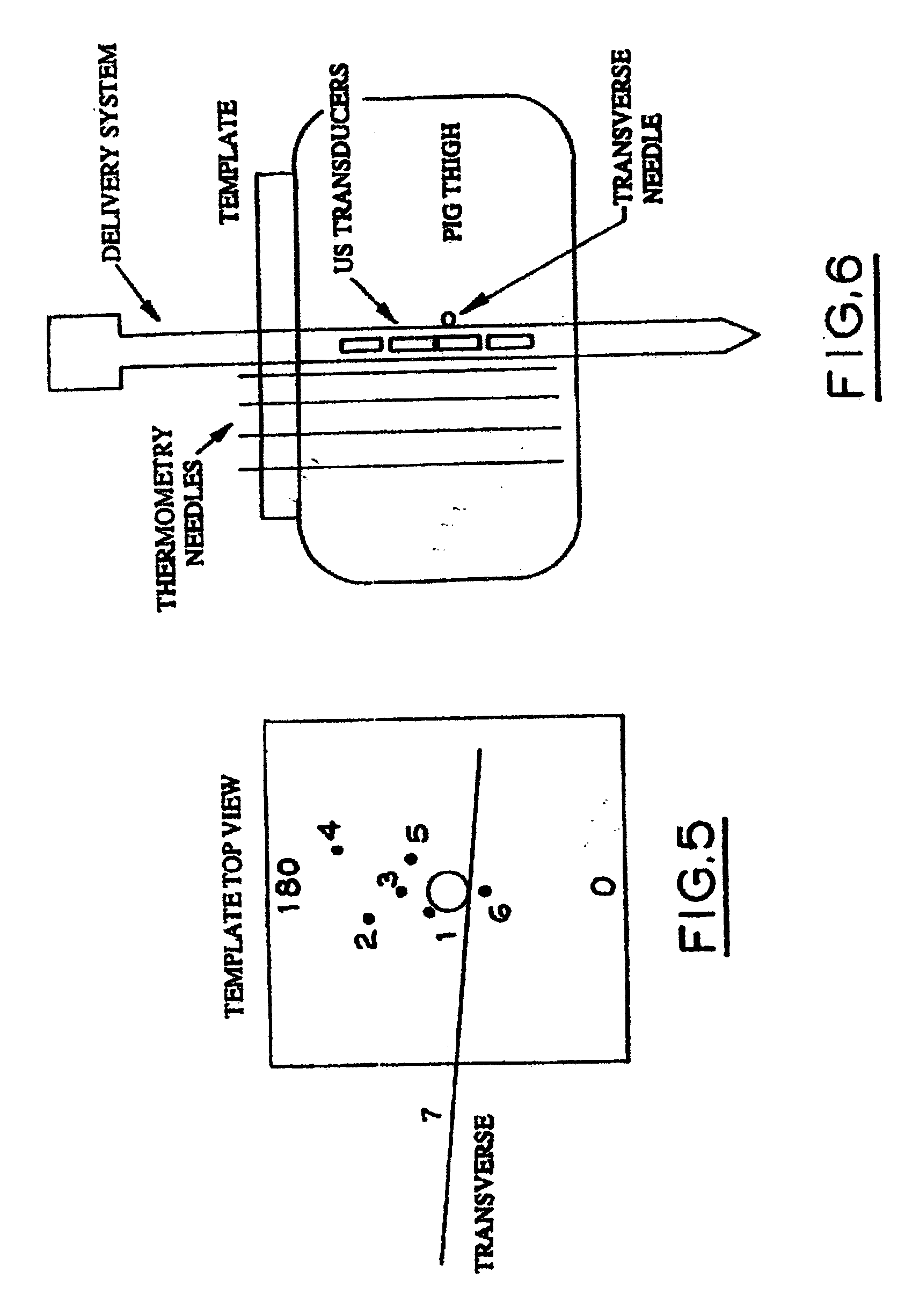

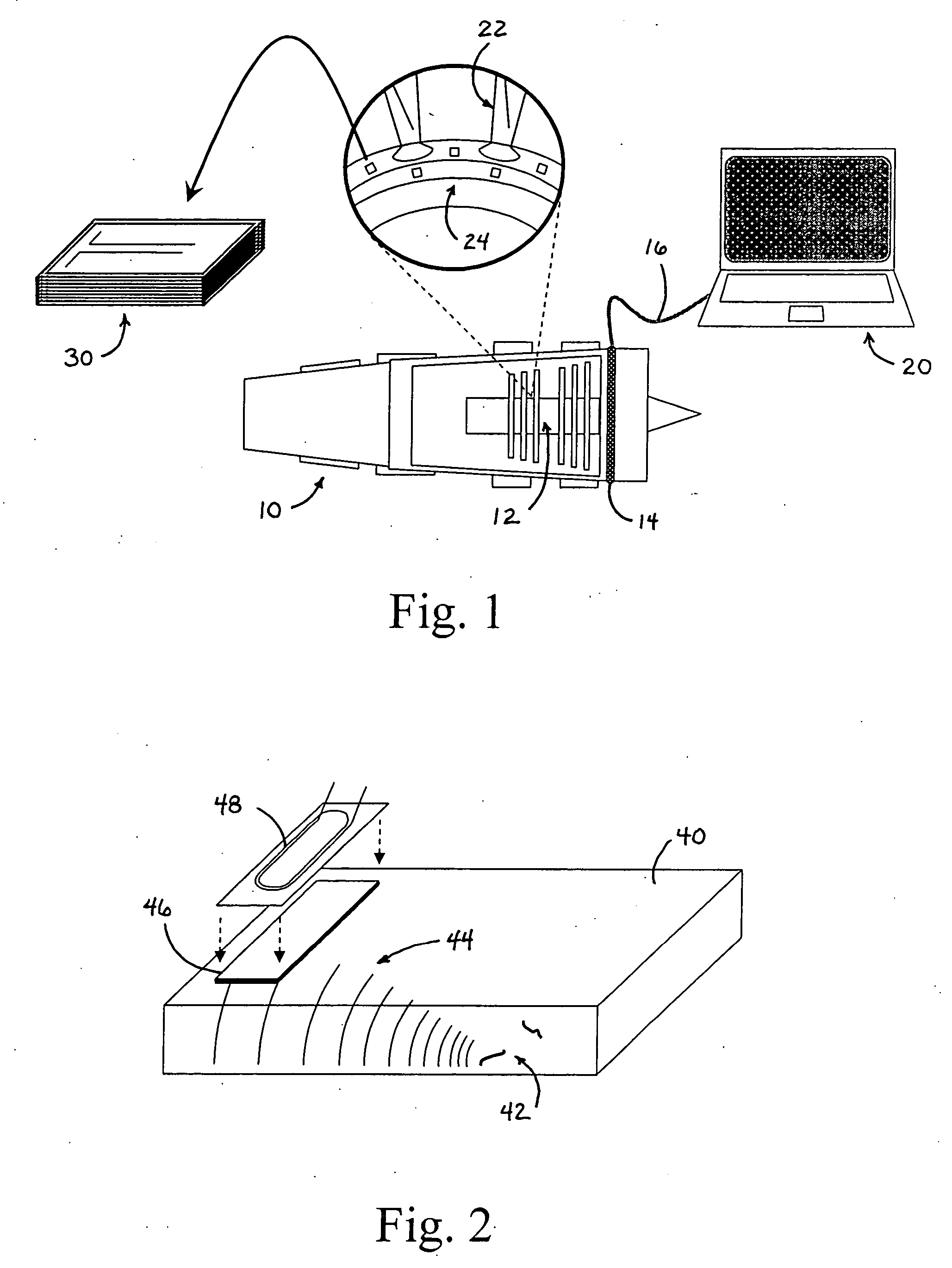

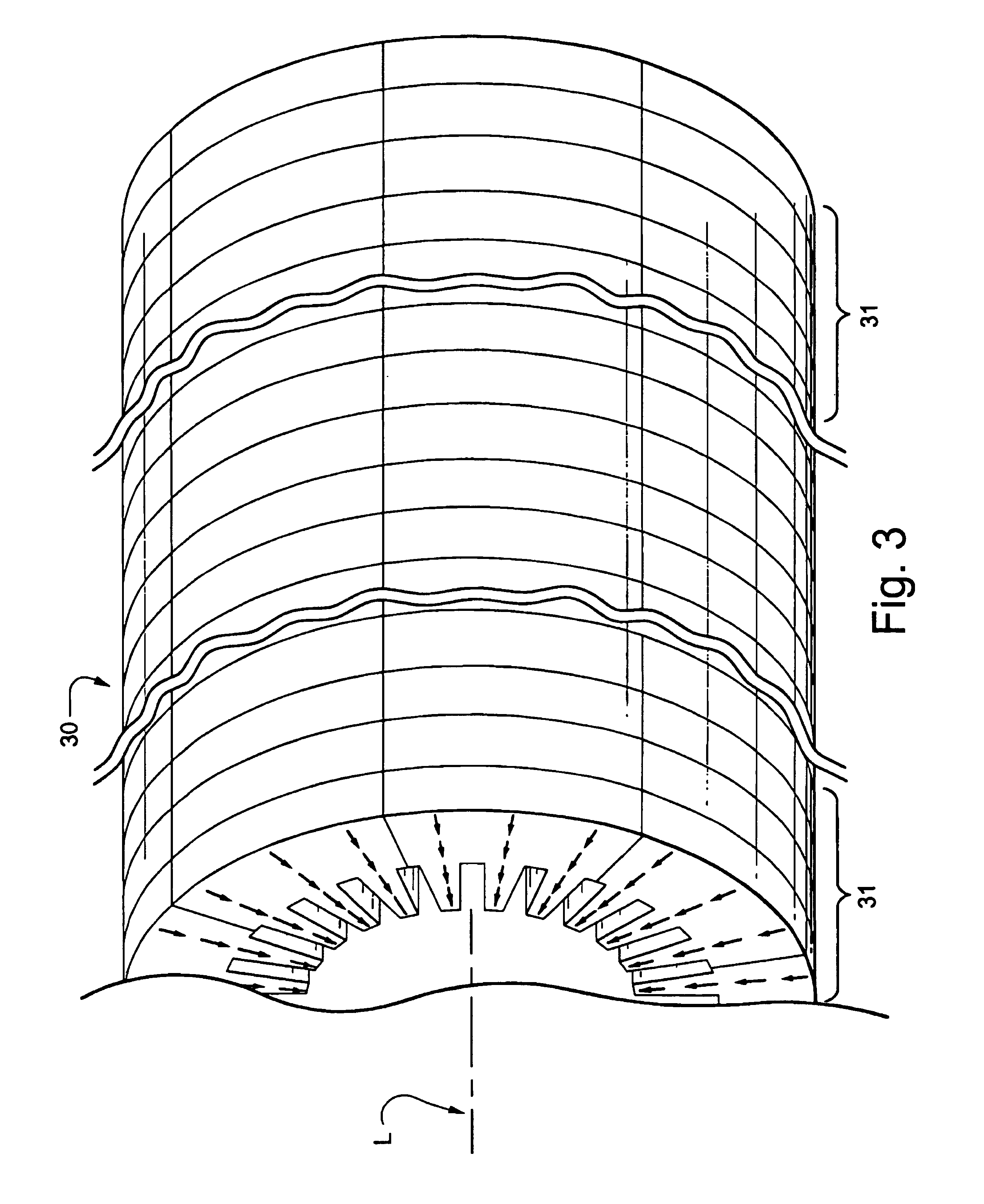

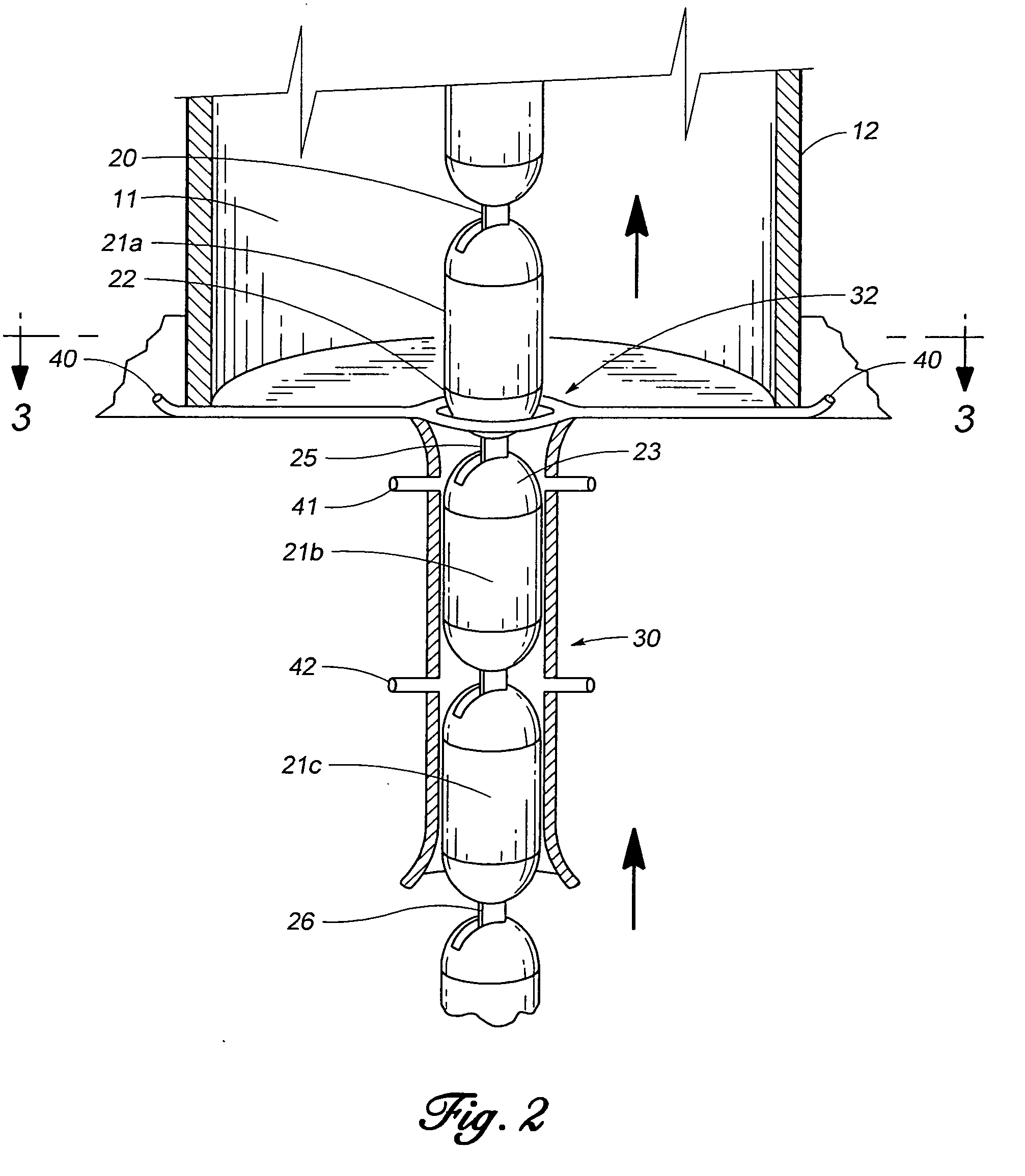

Method of manufacture of a transurethral ultrasound applicator for prostate gland thermal therapy

InactiveUS20040044375A1Increase energy outputEasy to controlUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyUrethraSealant

An apparatus for applying thermal therapy to a prostate gland, comprising a support tube having a longitudinal central passageway, a power lead channeled through the longitudinal central passageway and an ultrasound crystal disposed around at least part of the support tube. The ultrasound crystal is coupled to the power lead which provides the power to energize the ultrasound crystal and generate ultrasound energy providing thermal therapy to the prostate gland. The ultrasound crystal further includes inactivated portions for reducing ultrasound energy directed to the rectal wall of the patient. A sealant is disposed in contact with the ultrasound crystal allowing vibration necessary for efficient ultrasound energy radiation for the thermal therapy to the prostate gland.

Owner:RGT UNIV OF CALIFORNIA +1

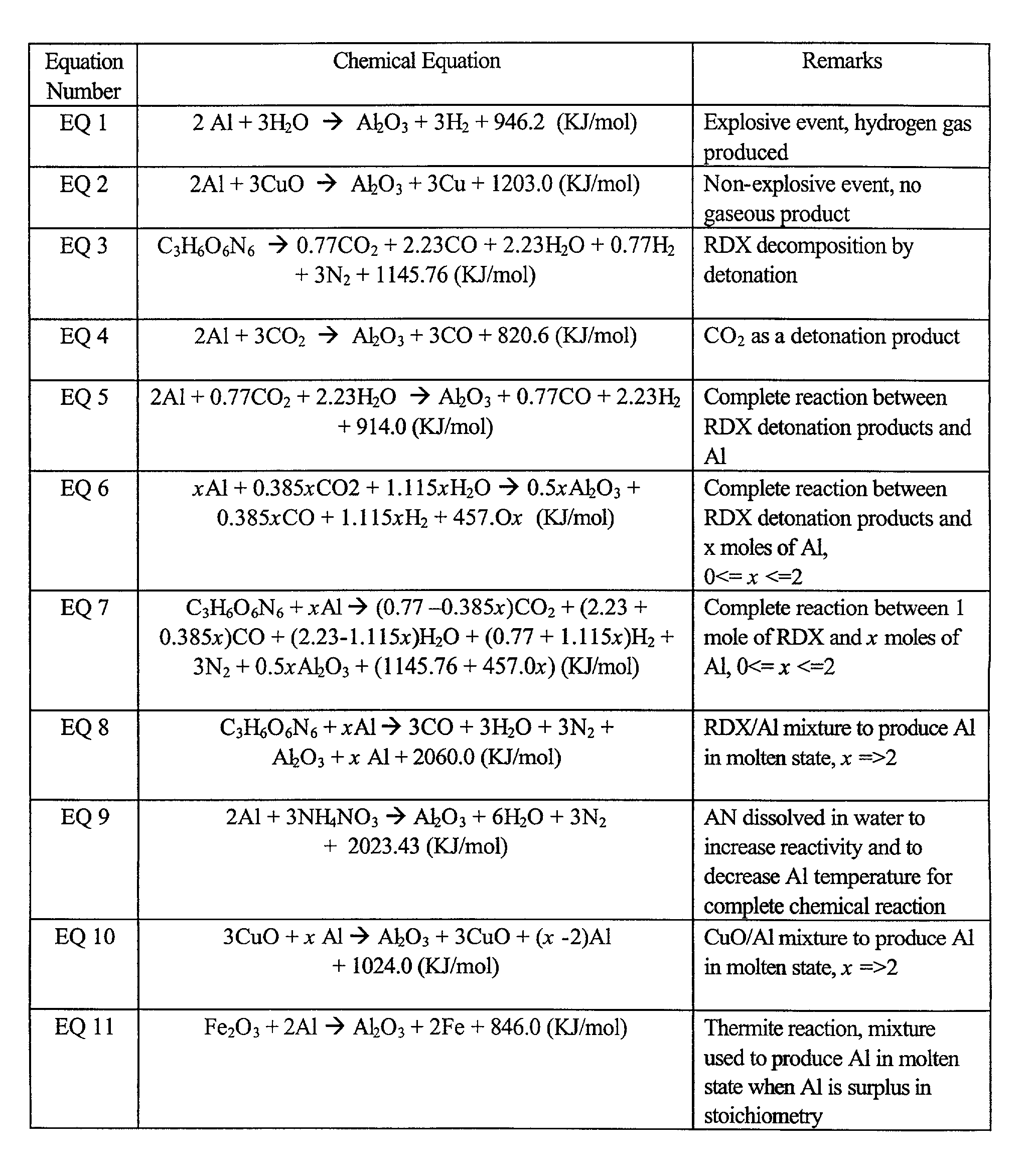

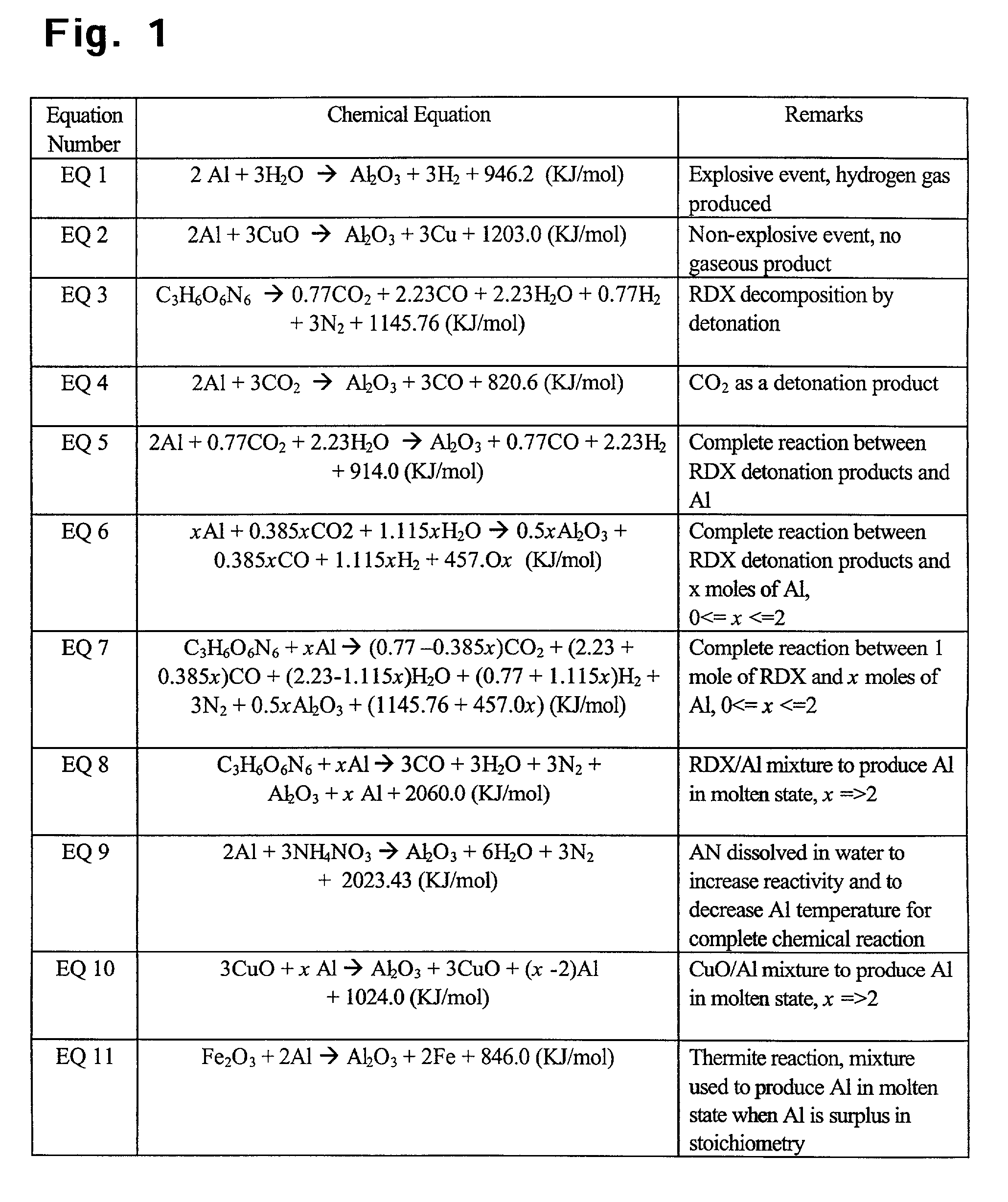

Use of aluminum in perforating and stimulating a subterranean formation and other engineering applications

InactiveUS7393423B2More energy outputImprove mechanical propertiesExplosive chargesBlasting cartridgesMolten stateThermal energy

A chemical reaction between molten aluminum and an oxygen carrier such as water to do useful work is disclosed, and in particular two chemical methods to obtain aluminum in its molten state. One is to detonate a HE / Al mixture with surplus Al in stoichiometry, and the other is to use an oxidizer / Al mixture with surplus Al in stoichiometry. Additionally, there is a physical method of shocking and heating Al using high temperature reaction products. The produced Al in its liquid form is forced to react with an oxygen carrying liquid (e.g. water), giving off heat and releasing hydrogen gas or other gaseous material. A water solution of some oxygen-rich chemicals (e.g. ammonium nitrate) can be advantageously used in place of water. A shaped charge is also disclosed having a liner that contains aluminum, propelled by a high explosive such as RDX or its mixture with aluminum powder. Some aluminum in its molten state is projected into the perforation and forced to react with water that also enters the perforation, creating another explosion, fracturing the crushed zone of the perforation and initializing cracks. Another shaped charge is shown having a liner of energetic material such as a mixture of aluminum powder and a metal oxide. Upon detonation, the collapsed liner carries kinetic and thermal energy. Also shown are methods to build and to detonate or fire explosive devices in an oxygen carrying liquid (e.g. water) to perforate and stimulate a hydrocarbon-bearing formation.

Owner:GEODYNAMICS

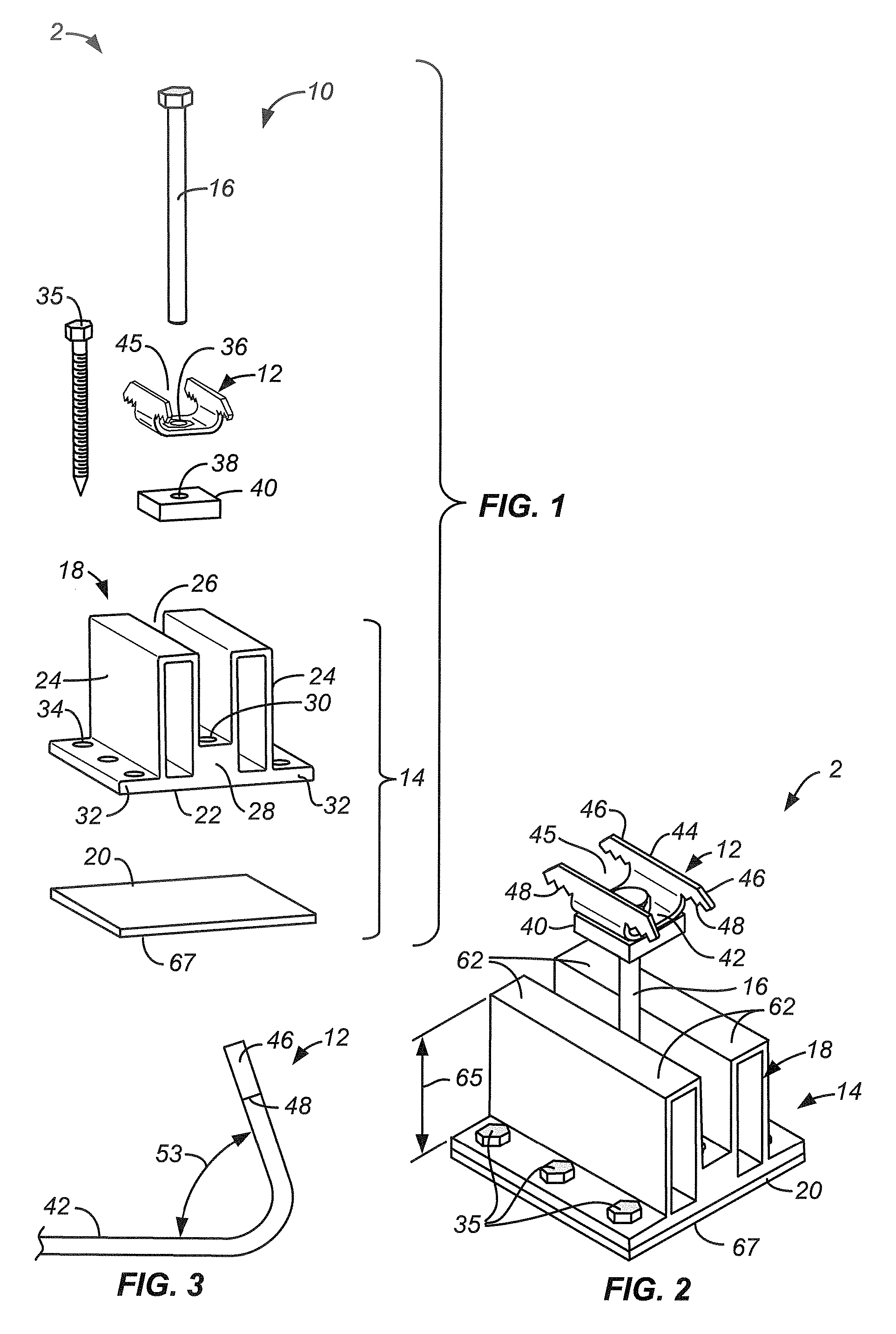

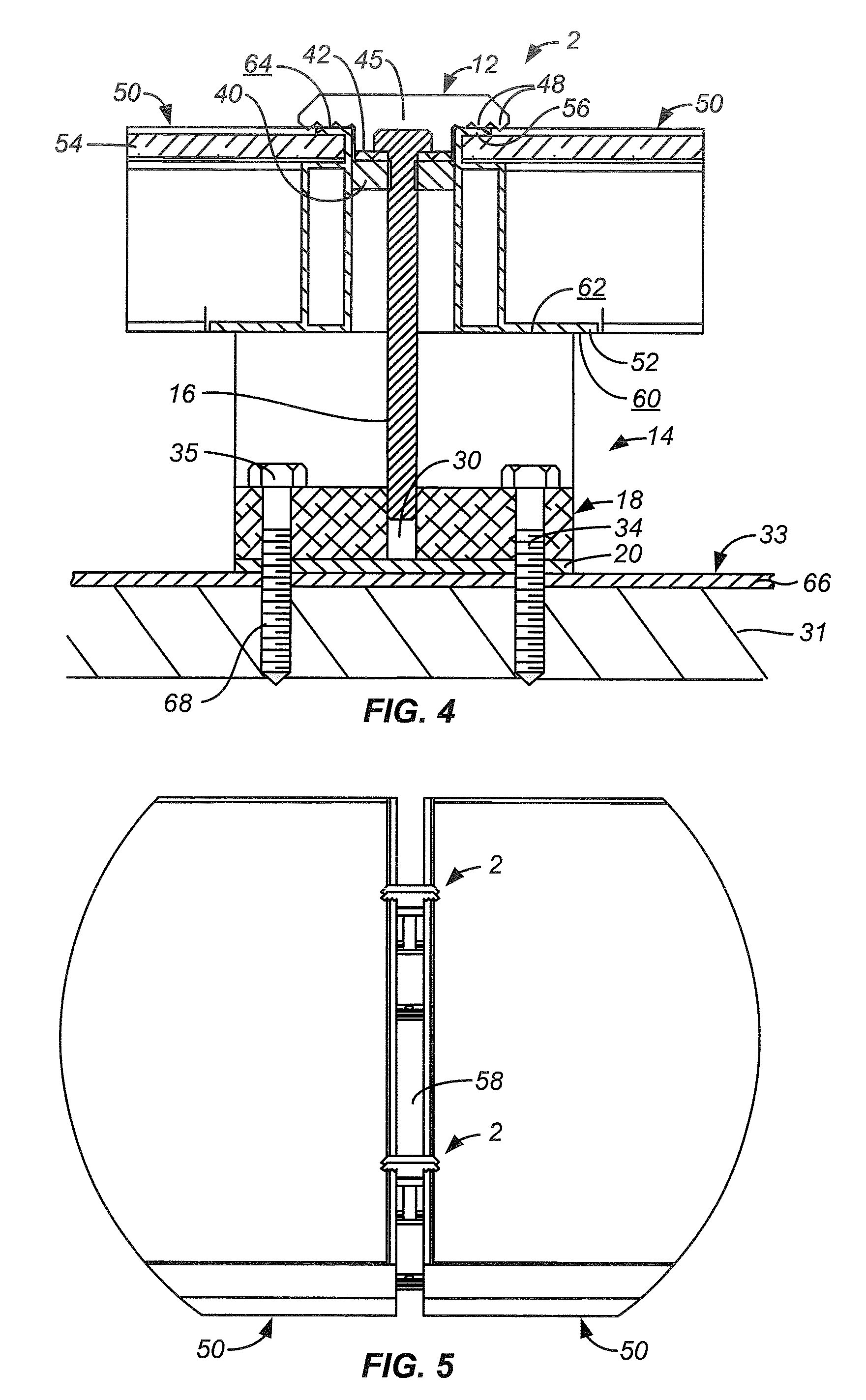

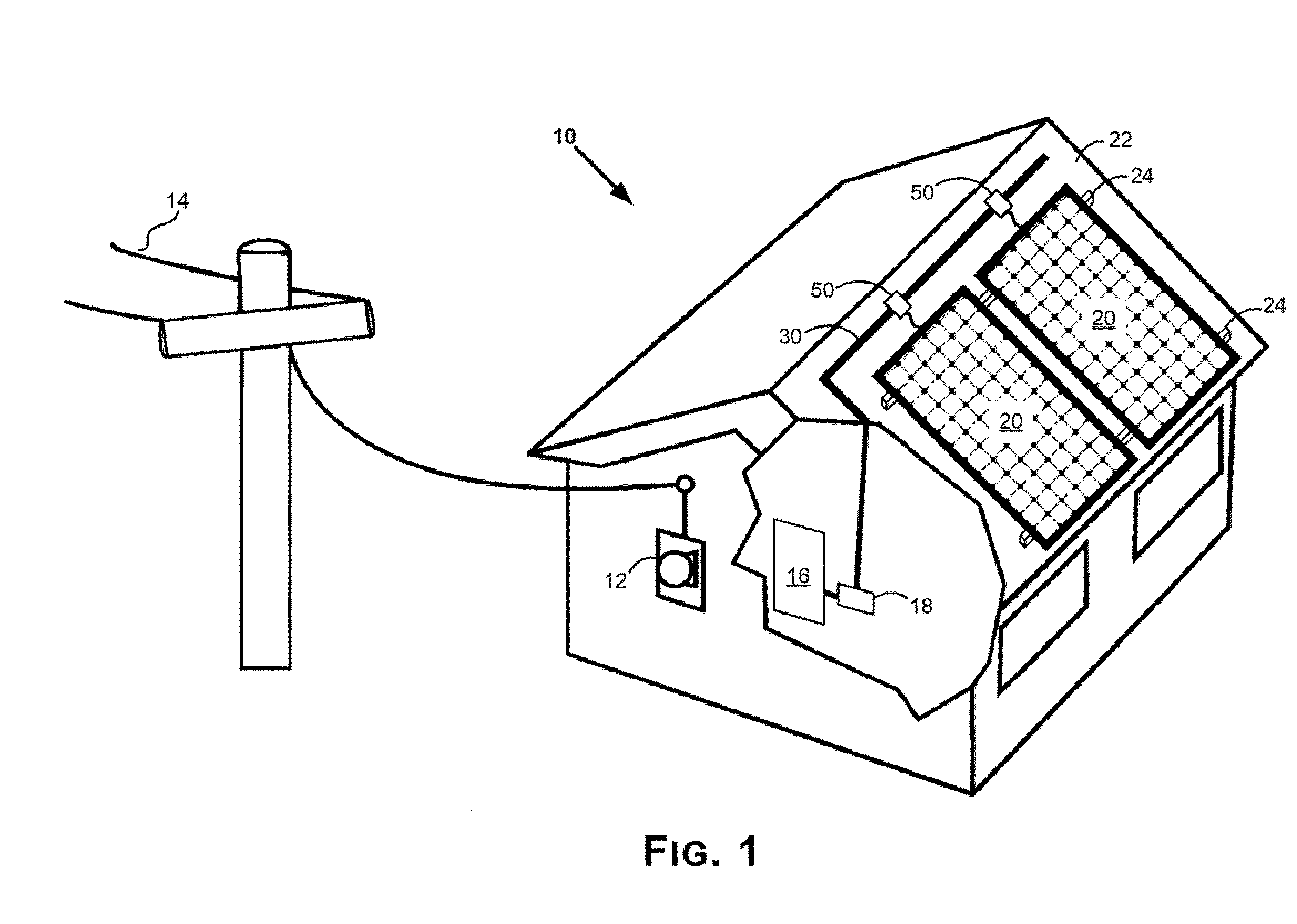

Connector with conductor piercing prongs for a solar panel

InactiveUS7824191B1Improve conversion efficiencyIncrease energy outputElectrically conductive connectionsPrinted circuitsElectricityElectrical conductor

The present invention comprises an electrical connector device for electrically connecting an alternating current (“AC”) photovoltaic (“PV”) solar panel device having an integral micro-inverter to the utility grid. The electrical connector device is a compression connector fitting that includes an upper and lower housing, which each include a channel for receiving the main electrical conductor line. The electrical connector device further includes three electrical prong, which are designed to pierce and penetrate the insulation of the main electrical conductor line to establish an electrical connection between the micro-inverter and the utility grid, when the electrical connector device is compressed about the main electrical conductor line. The shape of the channel formed in the electrical connector device has a distinctive cross-sectional shape that substantially corresponds to the shape of the main electrical conductor line to insure proper alignment and orientation of the main conductor line within the connector device.

Owner:SKY RICH STAR LTD

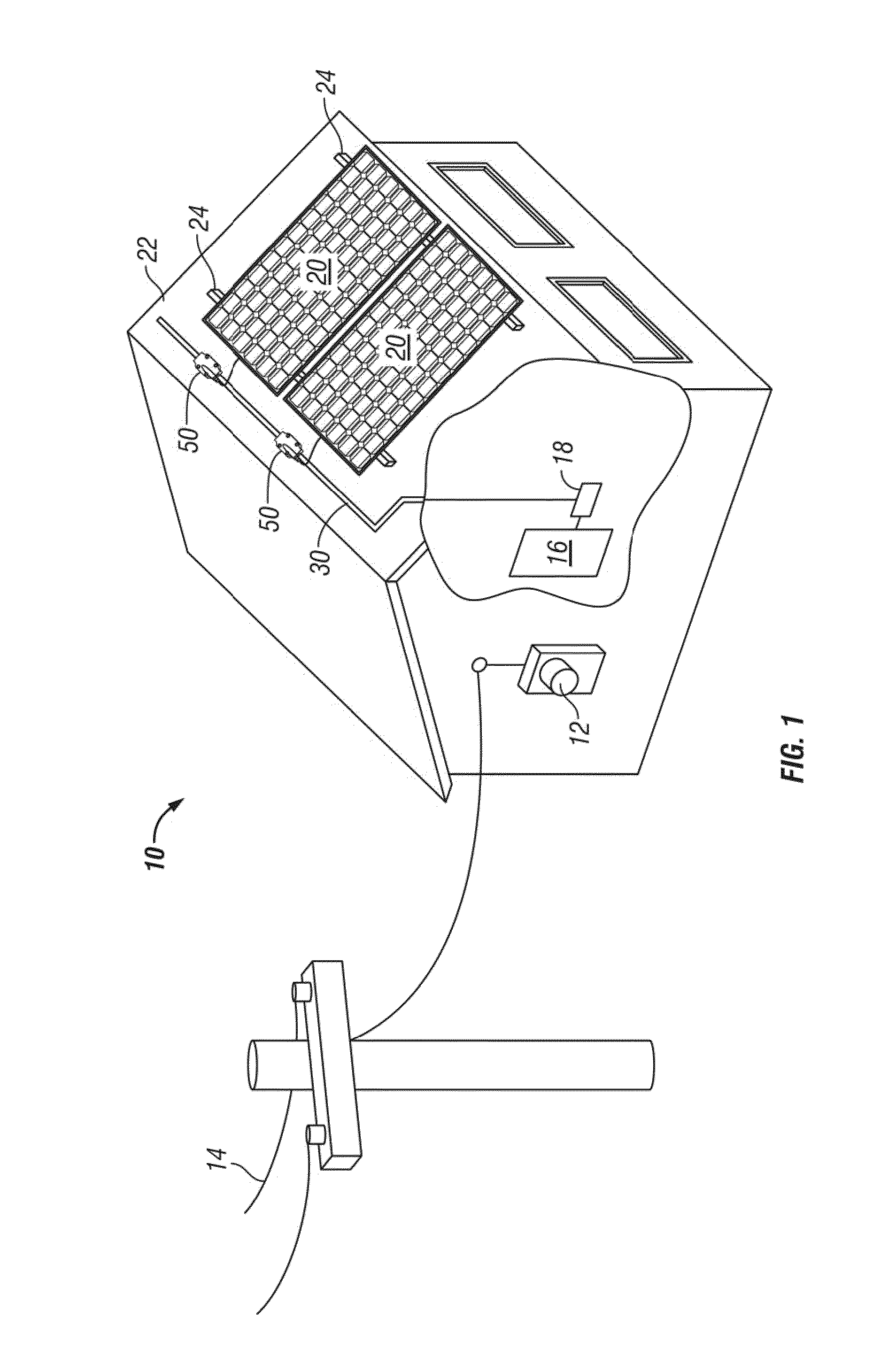

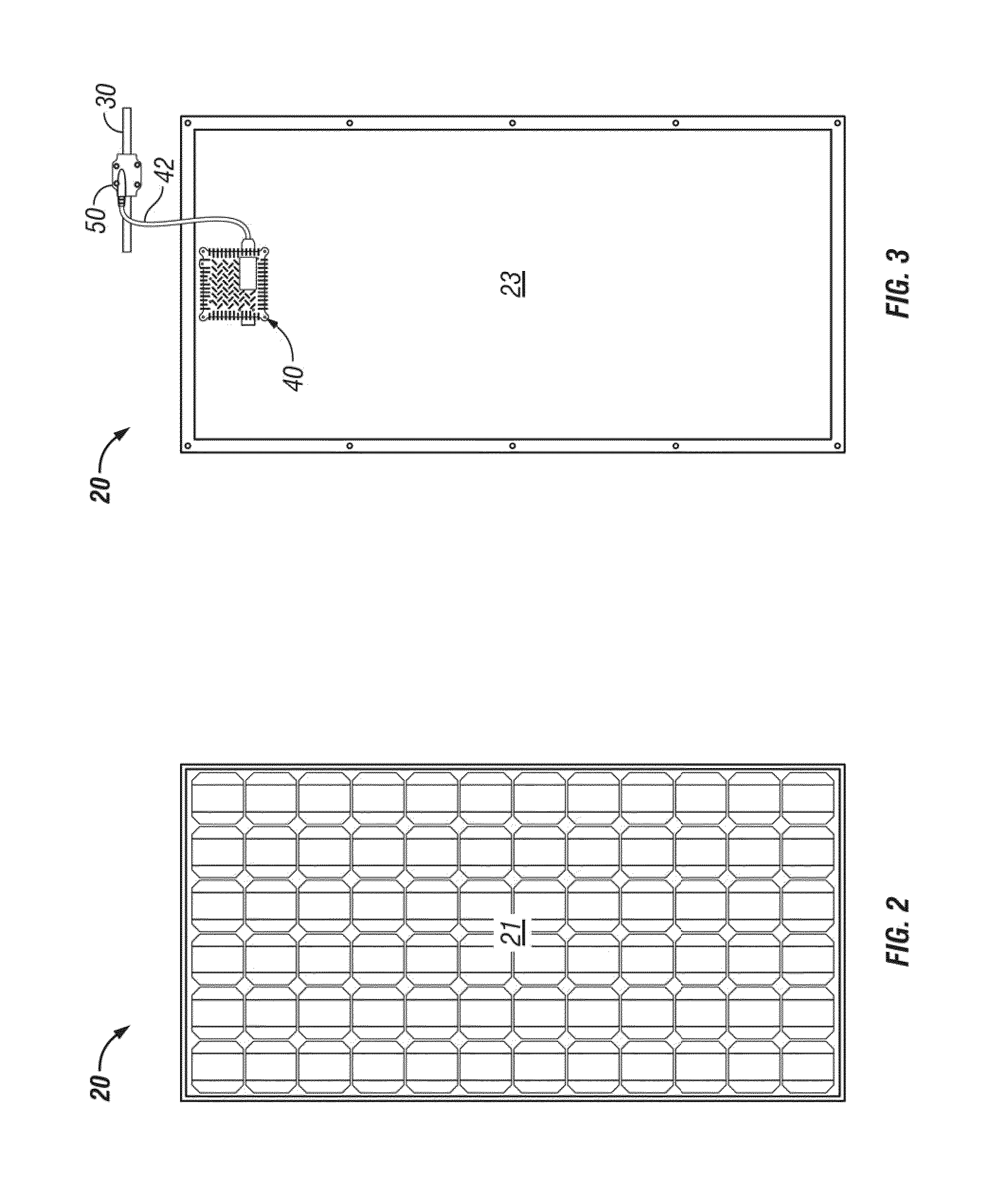

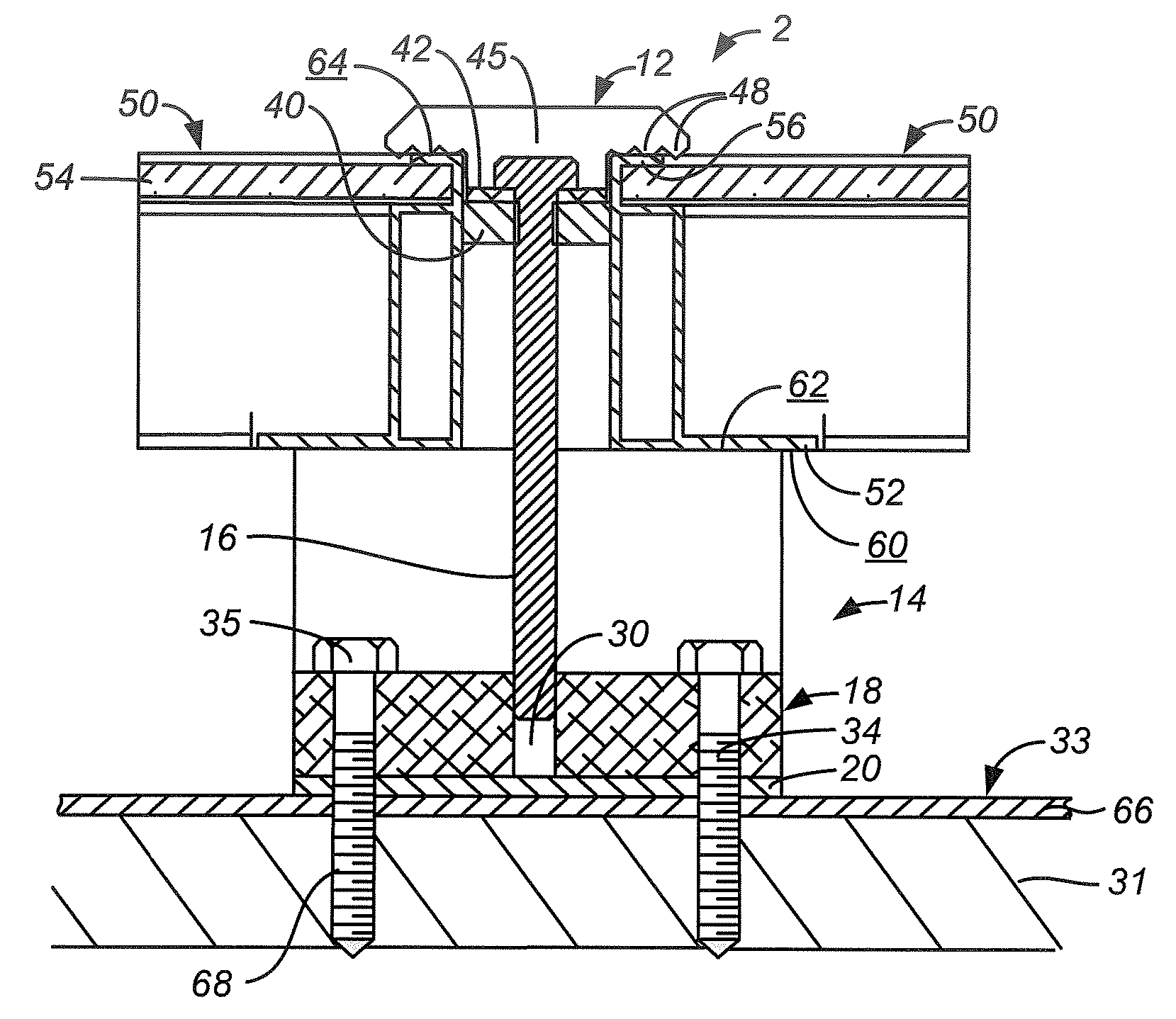

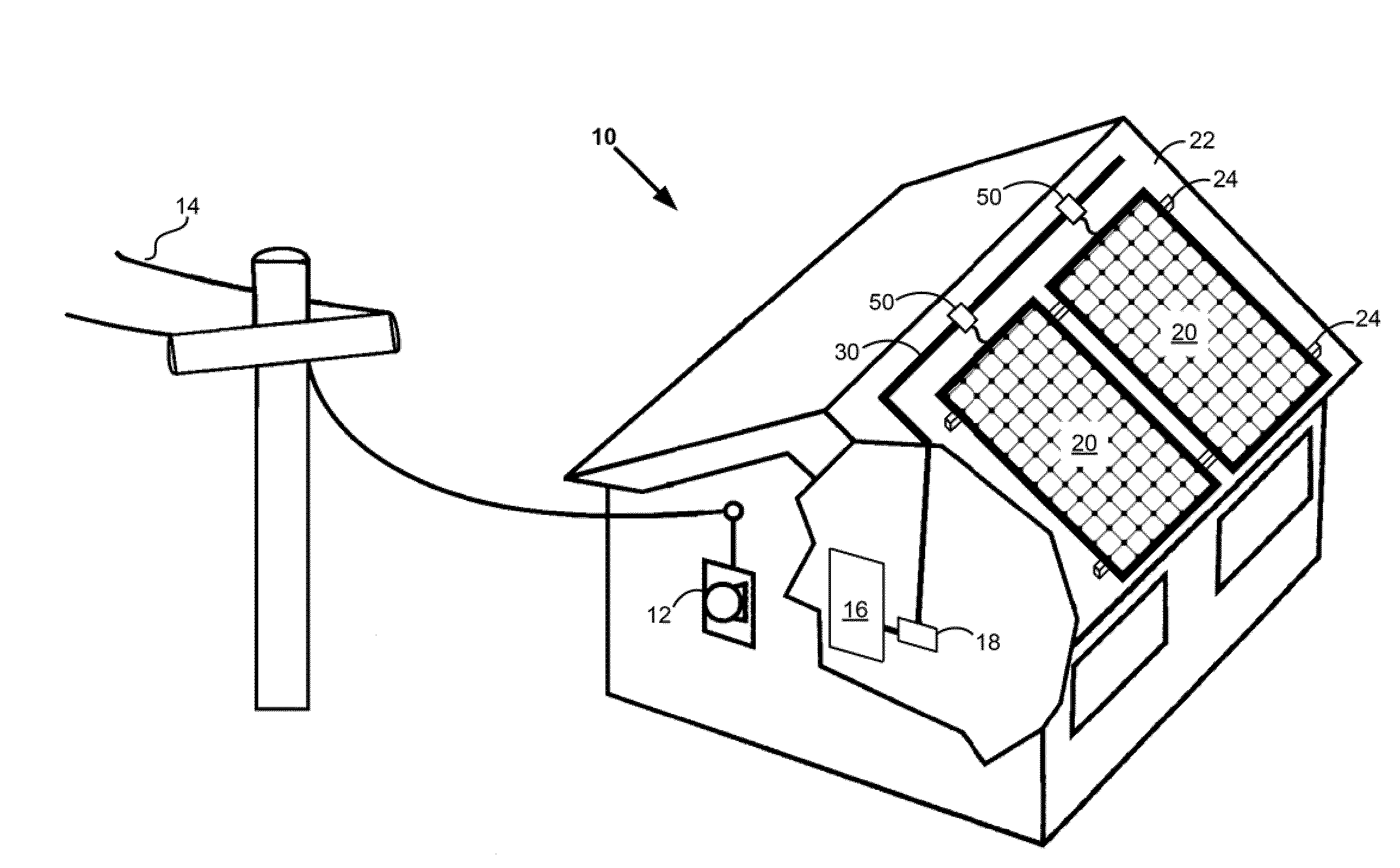

PV Module Mounting and Support Assembly and Installation

InactiveUS20070295391A1Reduce loadIncrease energy outputPhotovoltaic supportsSolar heating energyReady to useSupport surface

In some examples a PV module mounting and support assembly includes a base mountable to the deck, a deck-penetrating fastener for securing the base to the deck, and PV module mounting hardware. The PV module mounting hardware is used to secure an edge of a PV module on a PV module-support surface of the base with the edge of the PV module spaced apart from the deck. Flashing may be used between the lower surface and the deck. In some examples an internal PV mounting and support assembly is used to engage an internal lip of the PV module frame.

Owner:SUNPOWER CORPORATION

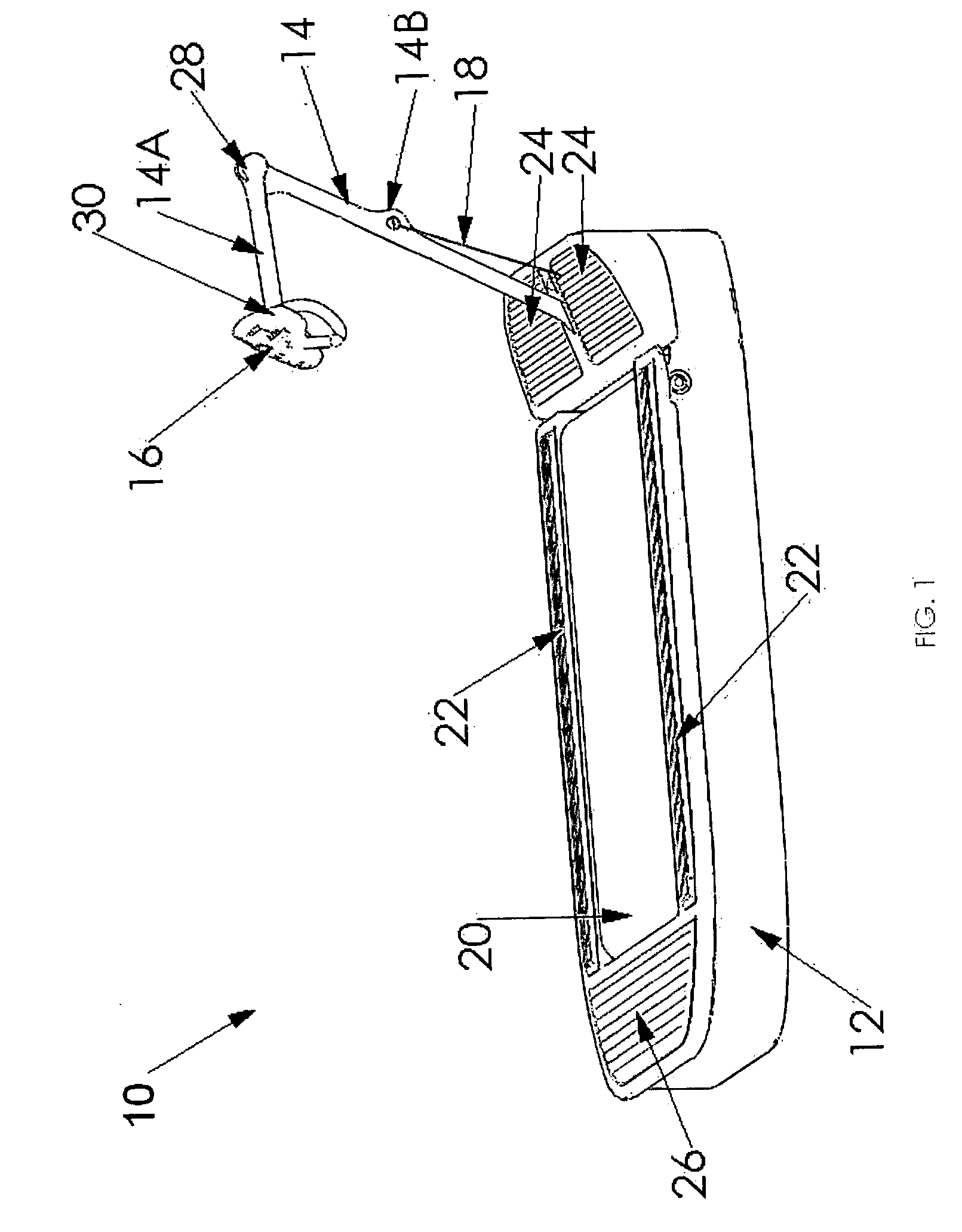

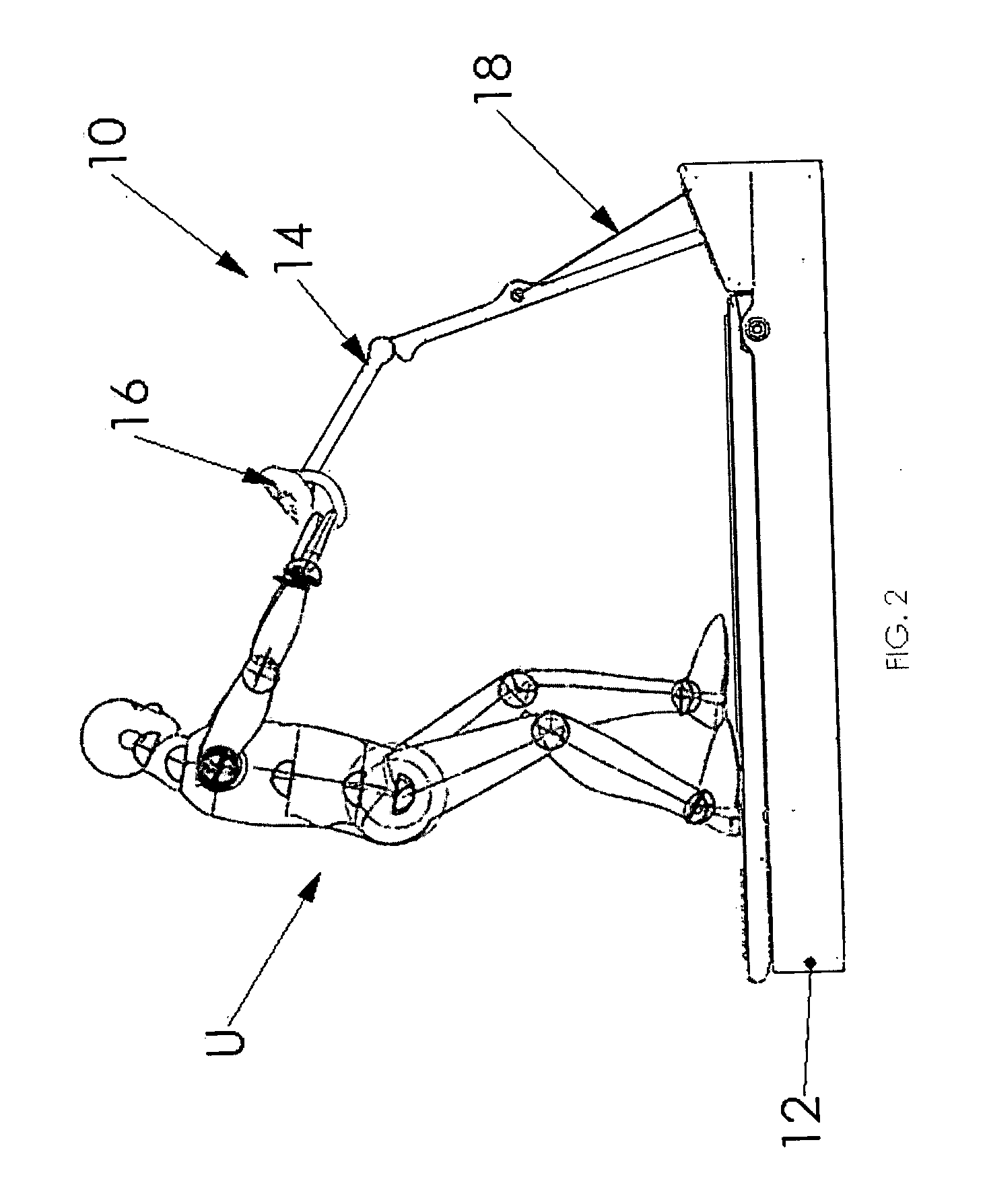

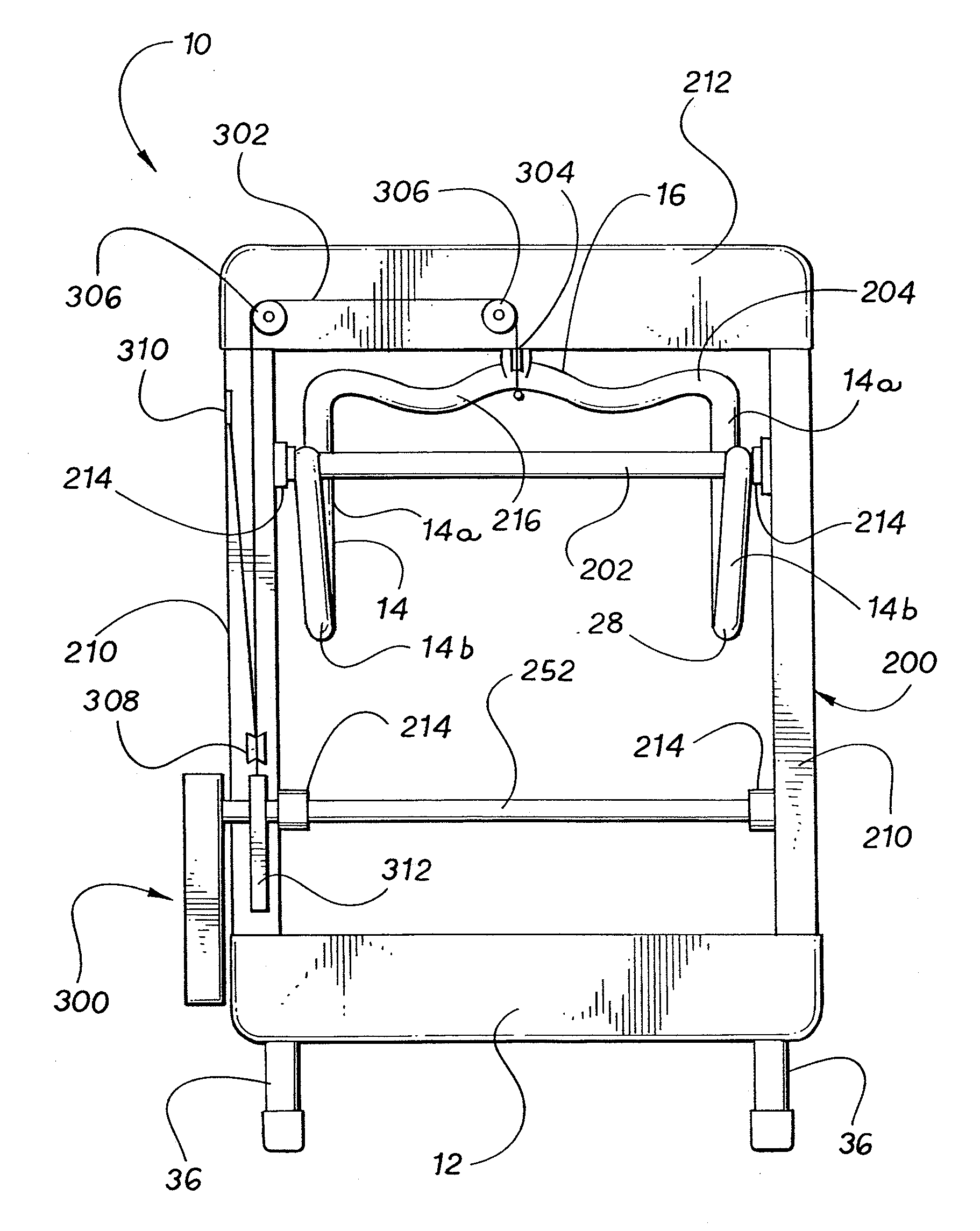

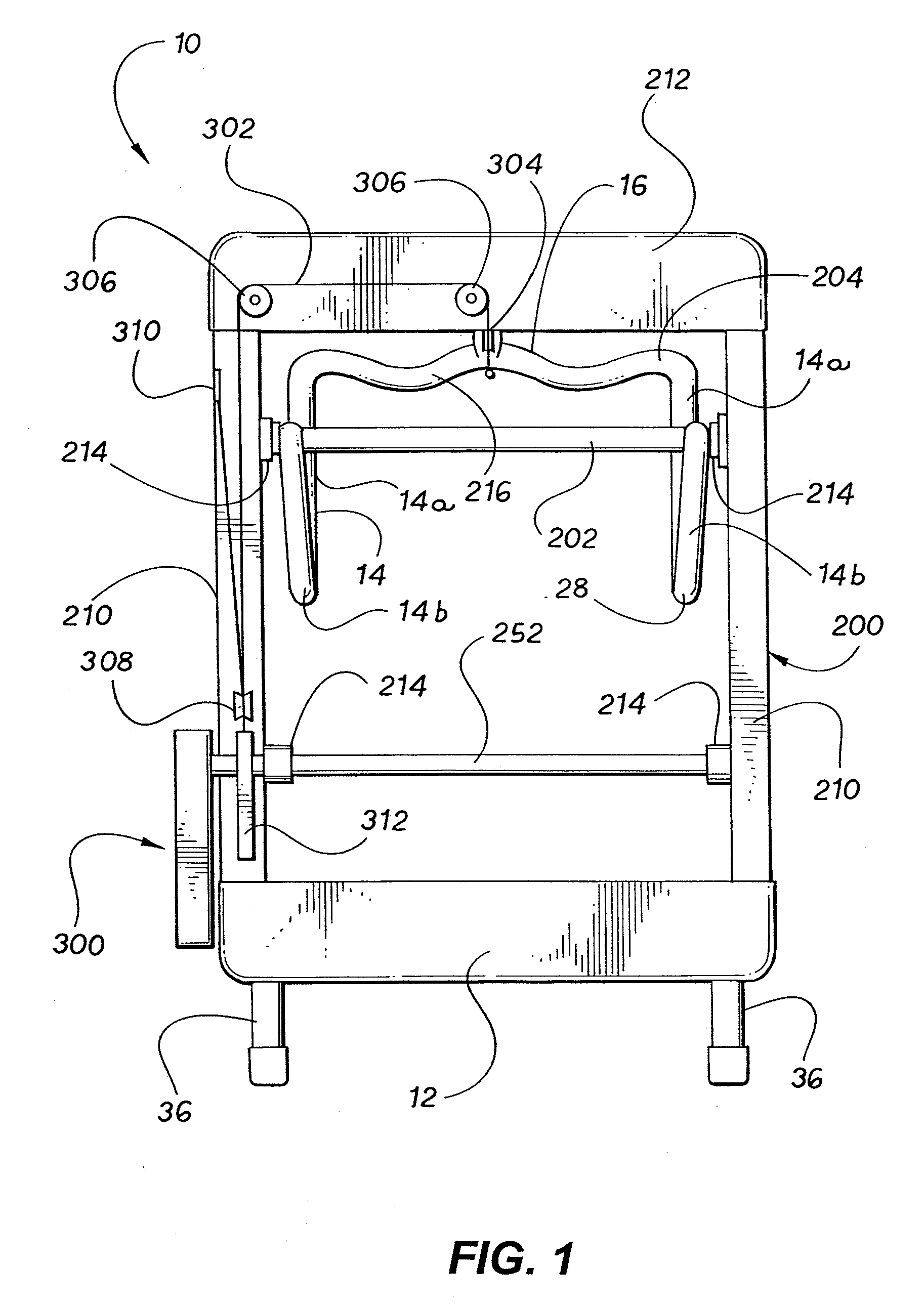

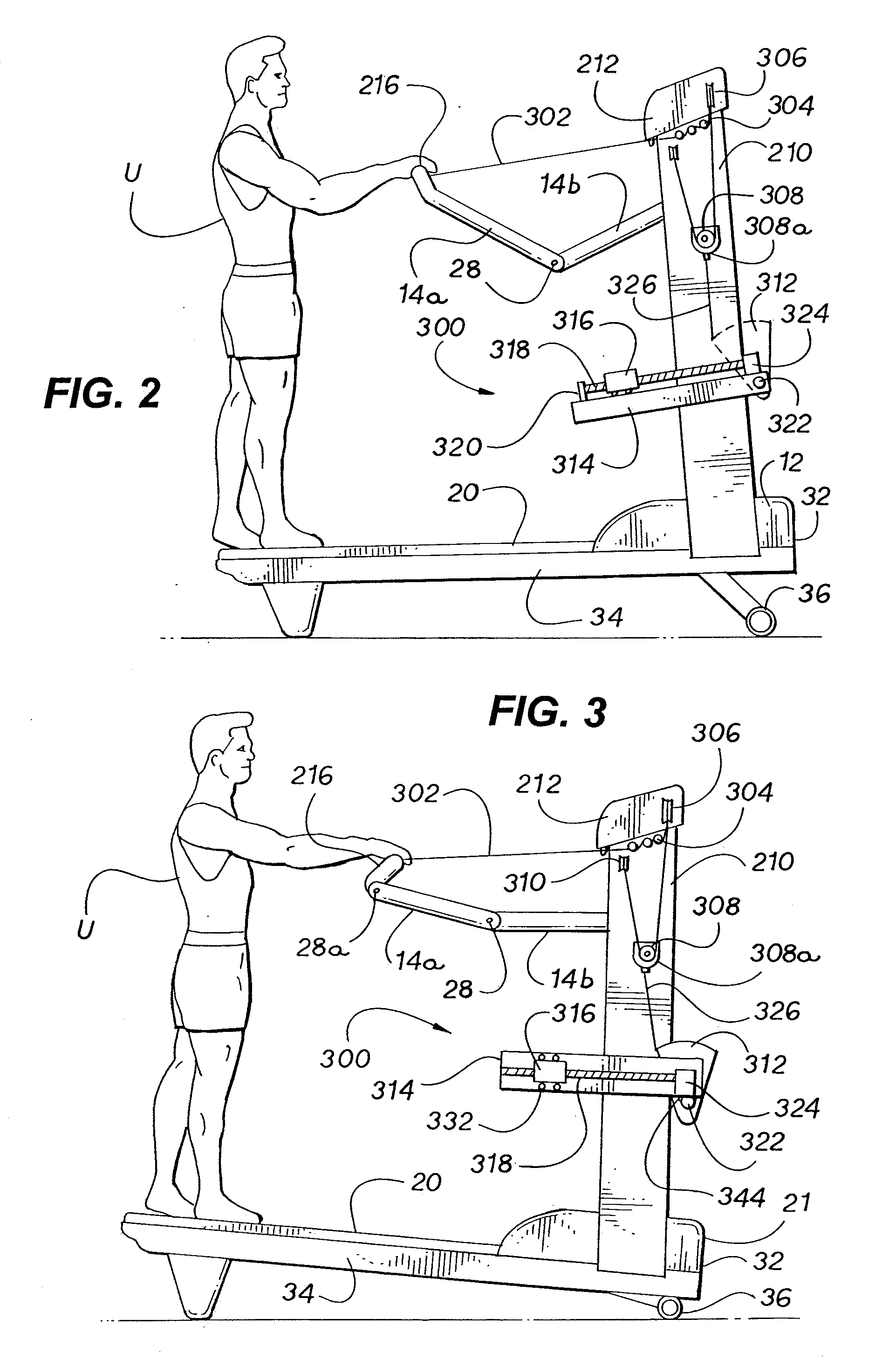

Exercise treadmill for pulling and dragging action

InactiveUS20070123396A1High activityIncrease ratingsMuscle exercising devicesMovement coordination devicesEngineeringPulley

An exercise treadmill of the type having an endless moveable surface looped around rollers or pulleys to form an upper run and a lower run, the movable surface being rotated when one of the rollers or pulleys is rotated, an exercise surface on for walking or running while exercising, and a weight resistance means for simulating the dragging or pulling of a load, wherein the endless movable surface moves in a direction simulating walking or running backwards.

Owner:ELLIS JOSEPH K

Solar panel with inverter

InactiveUS20110036386A1Improve conversion efficiencyIncrease energy outputPV power plantsPhotovoltaic energy generationPower inverterElectricity

The system of the present invention comprises a fully integrated and self-contained alternating current (“AC”) photovoltaic (“PV”) solar panel device, which features an integral micro-inverter having a compression connector fitting for electrically connecting to the utility grid. The compression connector fitting includes an upper and lower housing, which each include a cavity portion for receiving the main electrical conductor wire. The connector fitting further includes three electrical prong devices, which are designed to penetrate the insulation of the main electrical conductor wire, upon compression onto the main electrical conductor wire. Each micro-inverter converts DC power generated by its respective solar panel to grid-compliant AC power.

Owner:INT DEVMENT

Dual direction exercise treadmill with moment arm resistance

InactiveUS20110118089A1High activityIncrease ratingsResilient force resistorsMovement coordination devicesEngineeringPulley

An exercise treadmill for simulating a dragging or pulling action, having an endless moveable surface looped around rollers or pulleys to form an upper run and a lower run, with an exercise surface for walking or running on while operating the treadmill; and a moment arm weight resistance means for simulating the dragging or pulling of a load.

Owner:ELLIS JOSEPH K

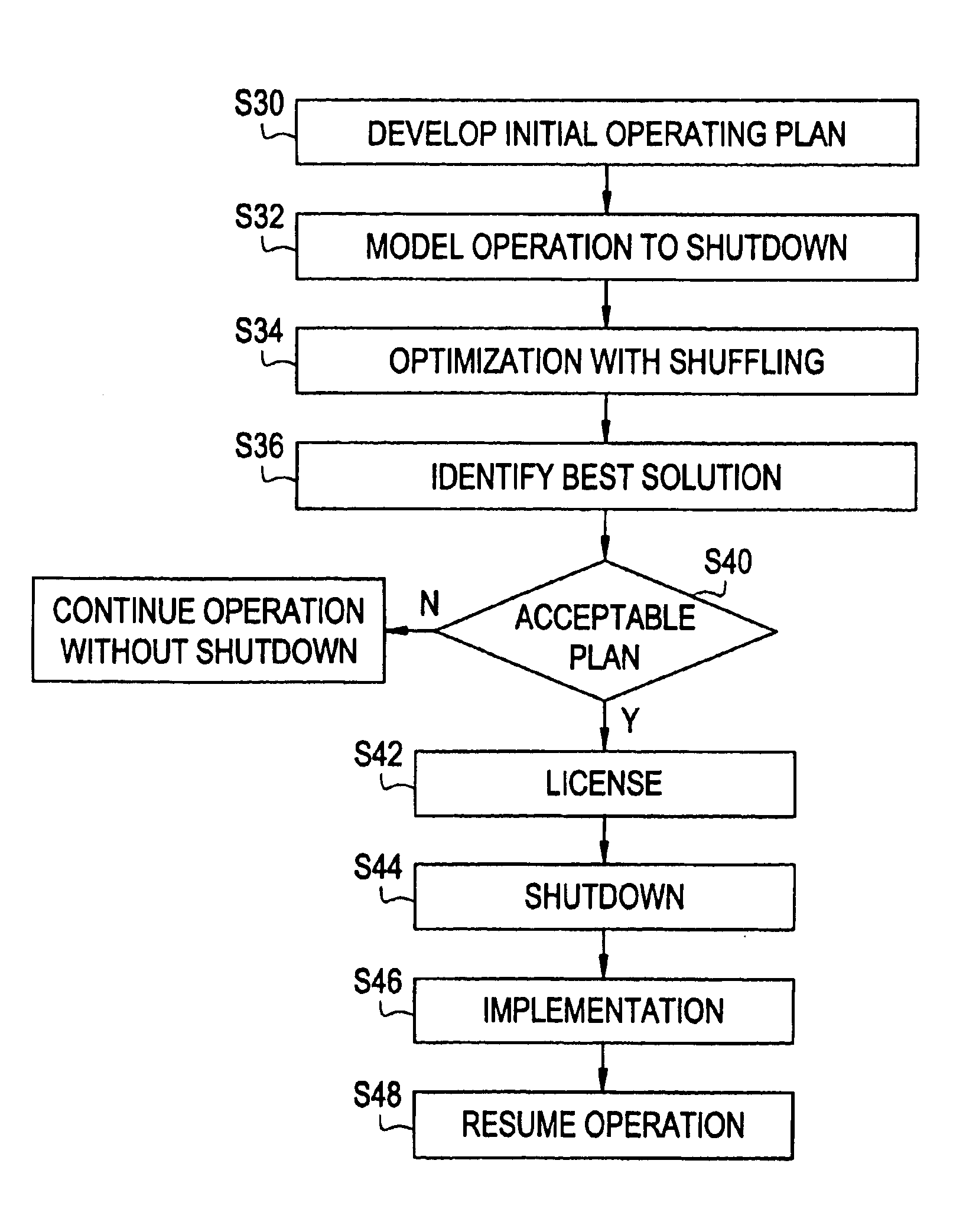

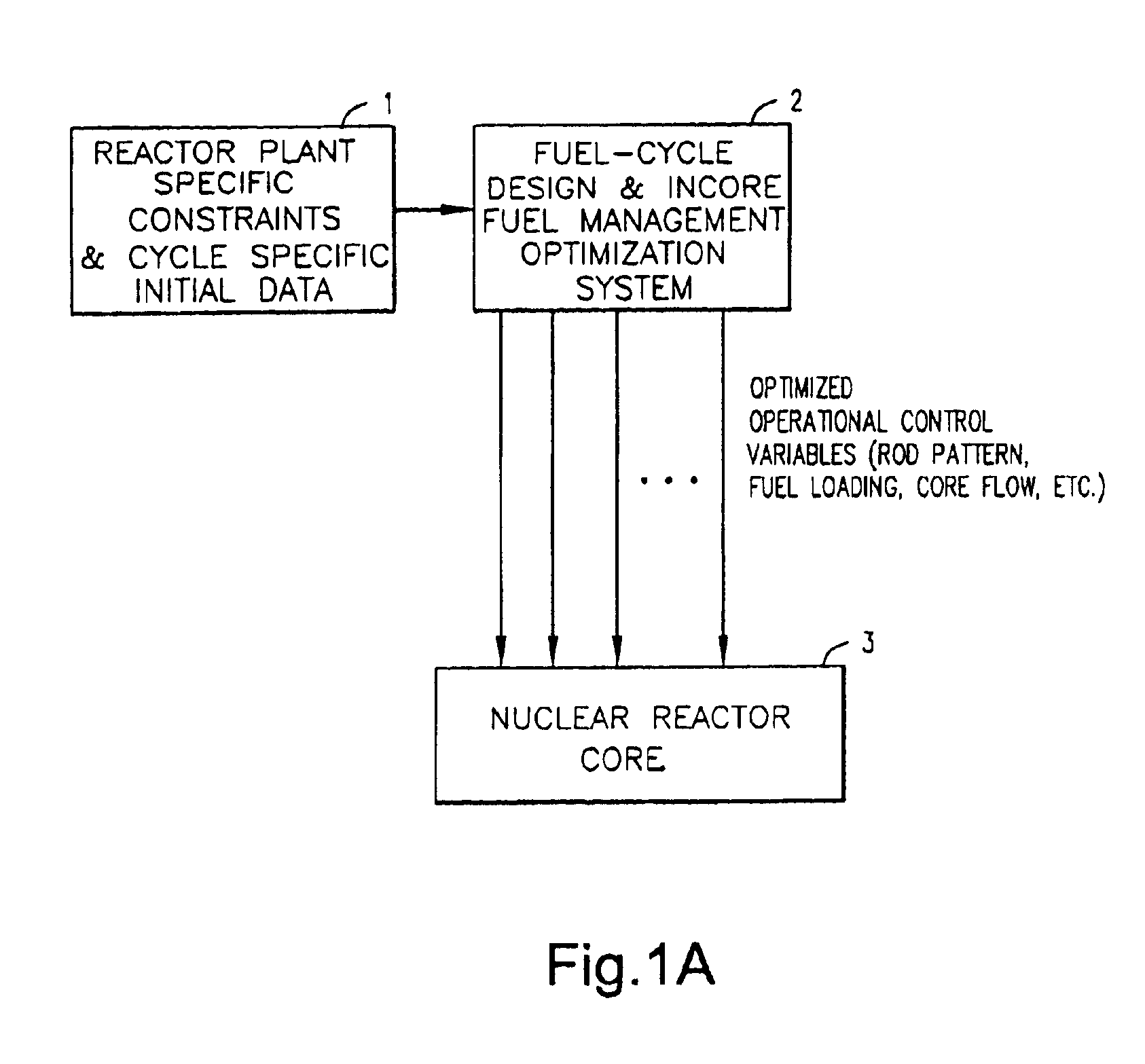

In-cycle shuffle

ActiveUS6862329B1Increase energy outputLimit thermal performanceNuclear energy generationNuclear monitoringNuclear engineeringTotal energy

According to the method, a reactor core is shut down during the operation cycle. One or more fuel bundles of the reactor core are then moved to new positions within the reactor core to increase a total energy, output of the reactor core as compared to continuing operation of the reactor core without the shutting down and moving steps.

Owner:GLOBAL NUCLEAR FUEL -- AMERICAS

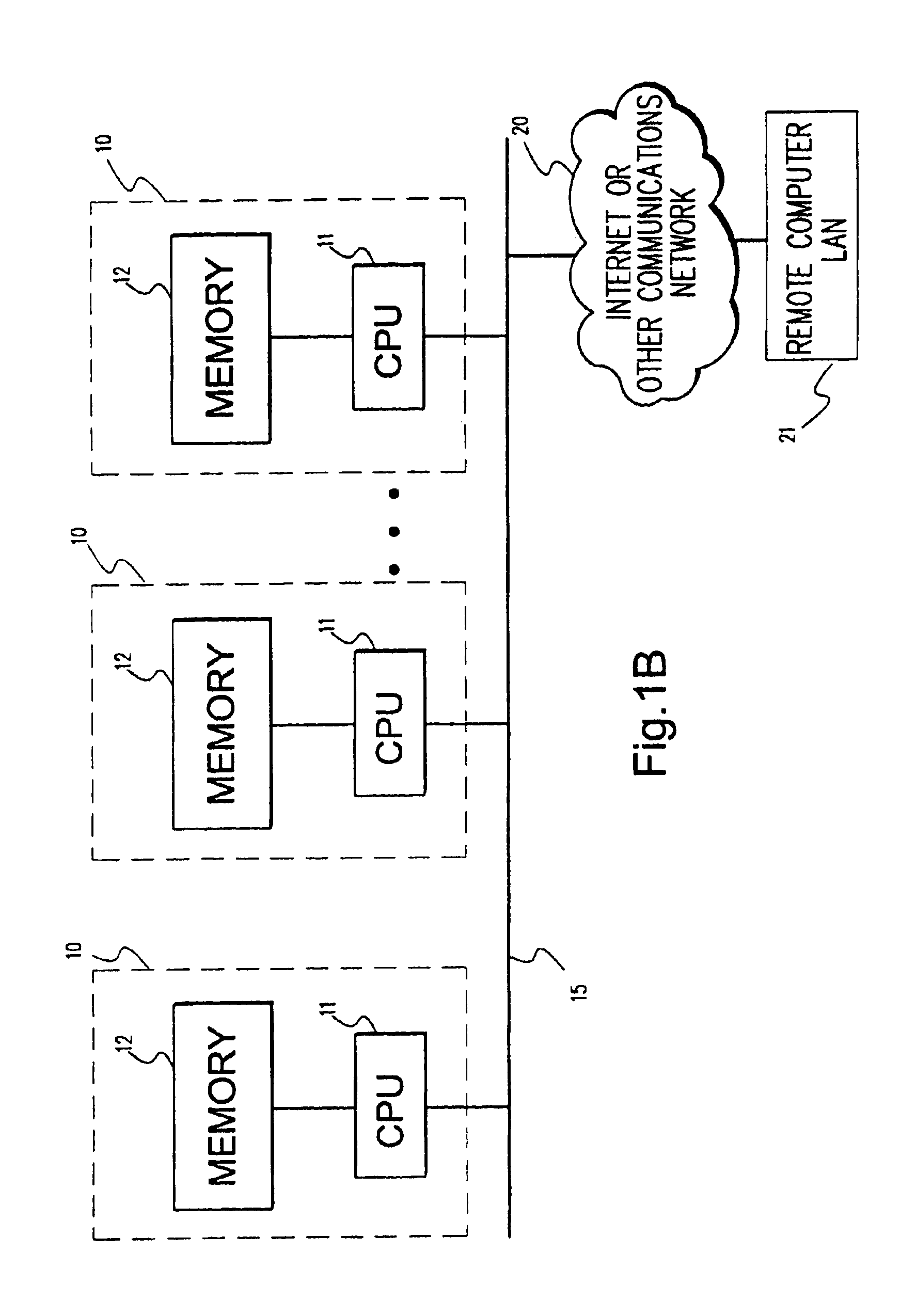

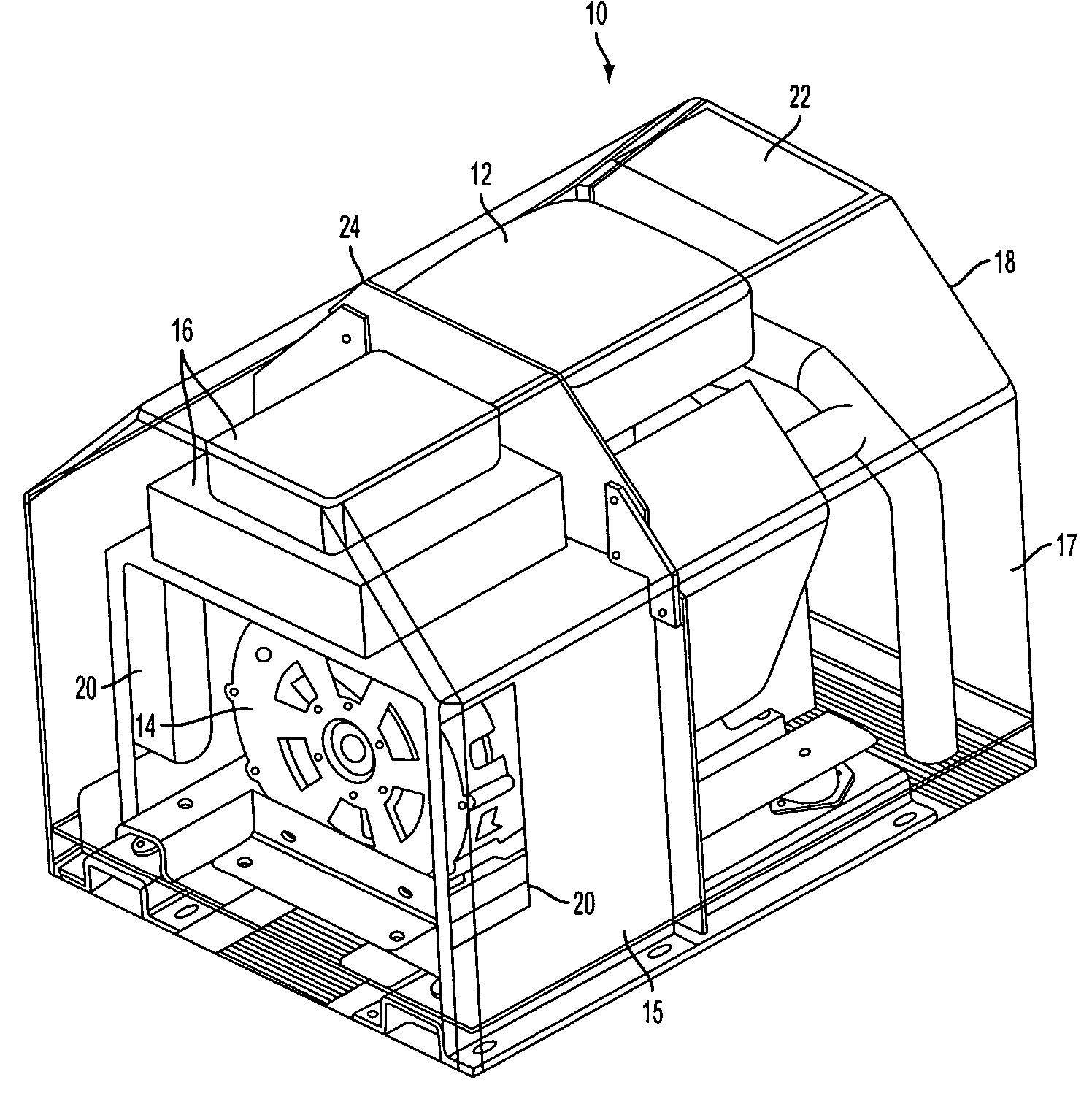

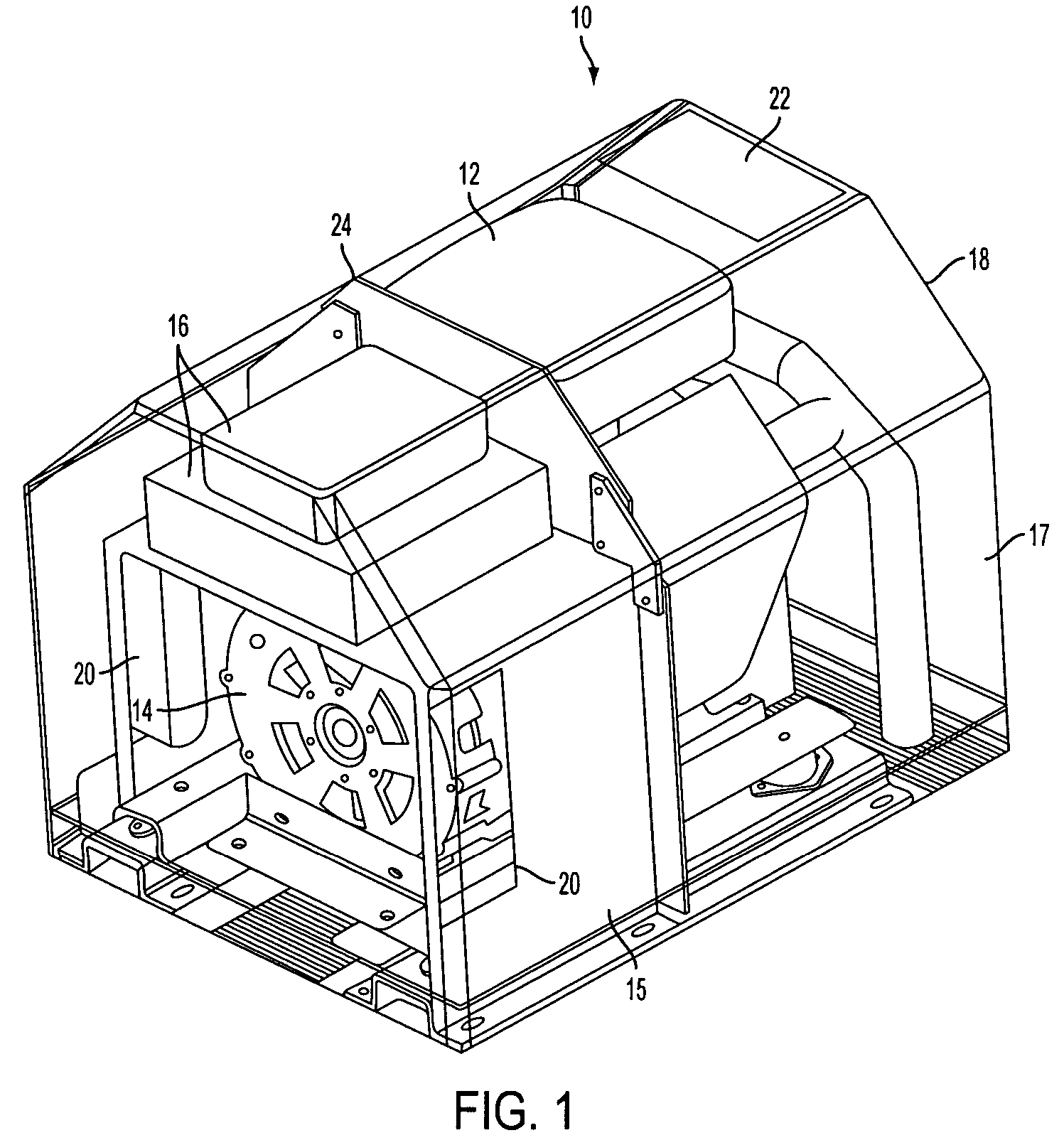

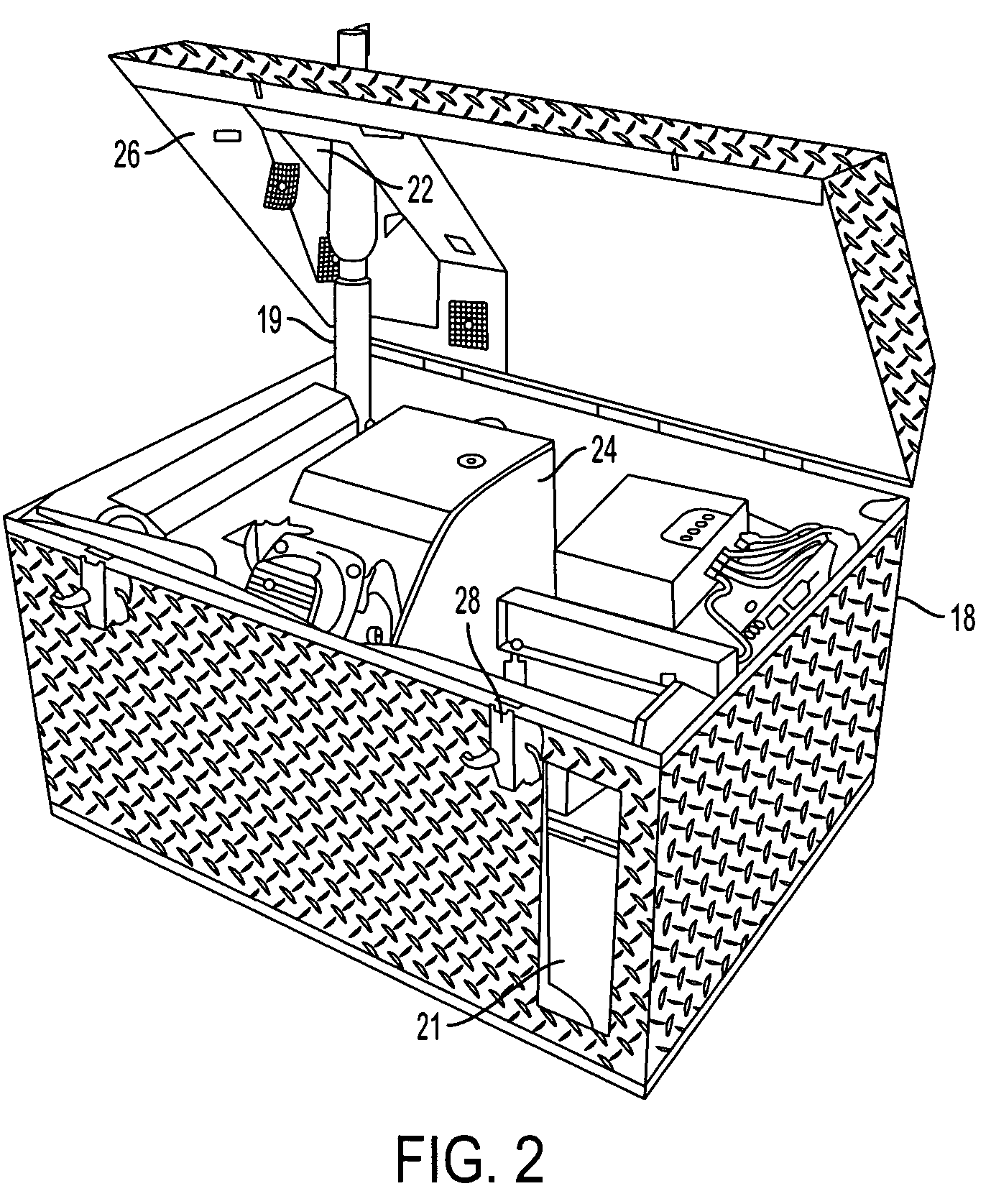

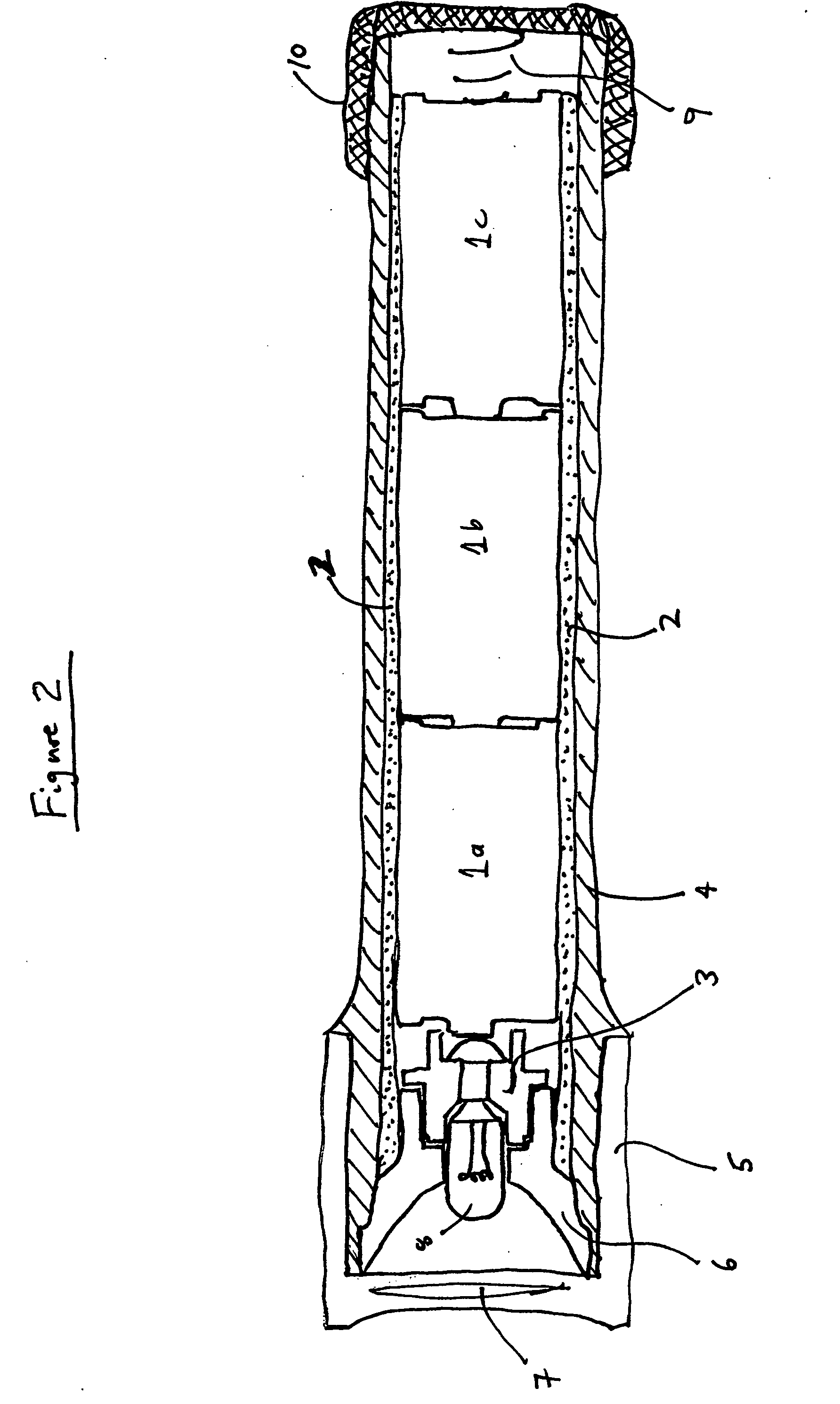

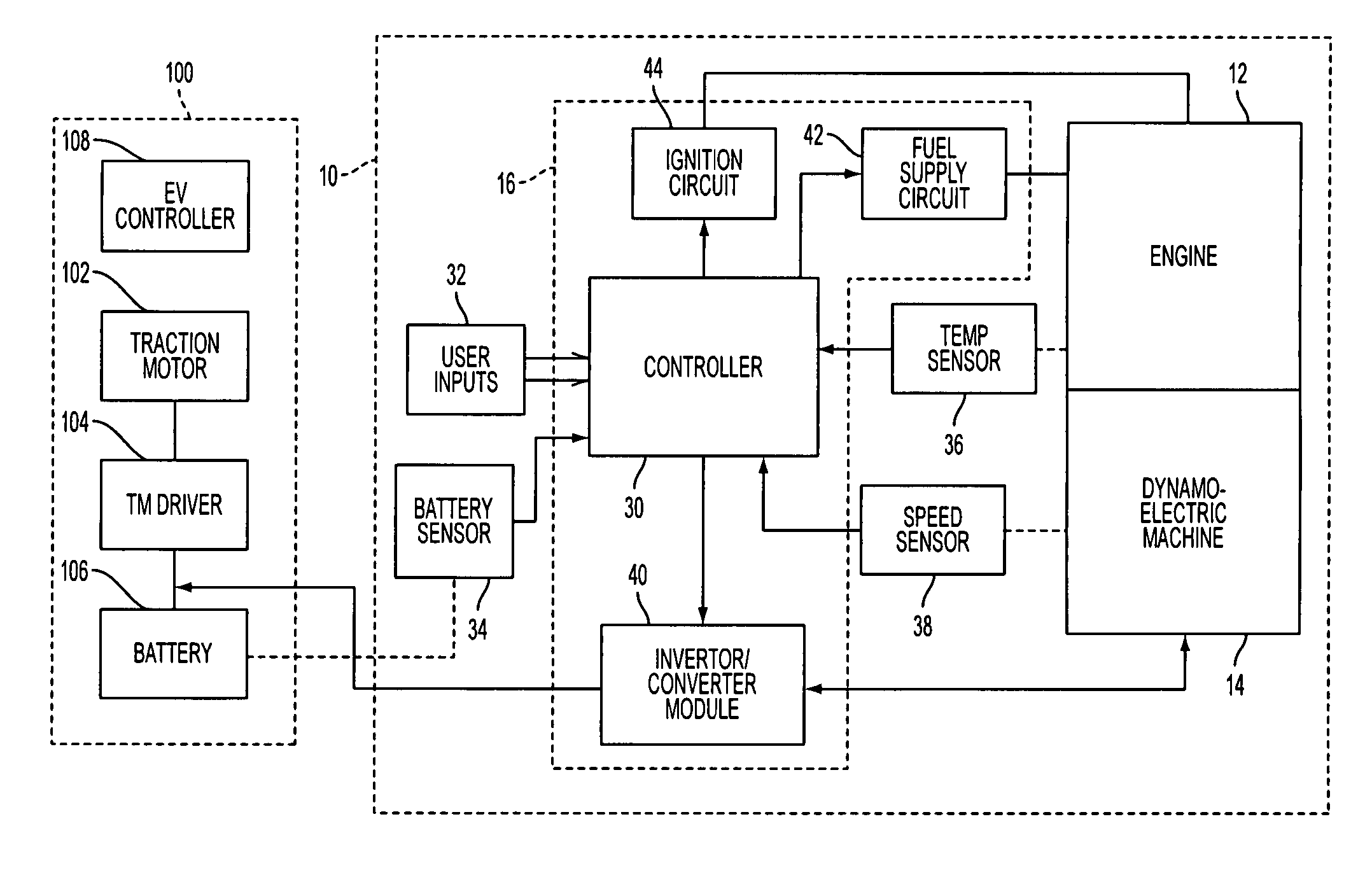

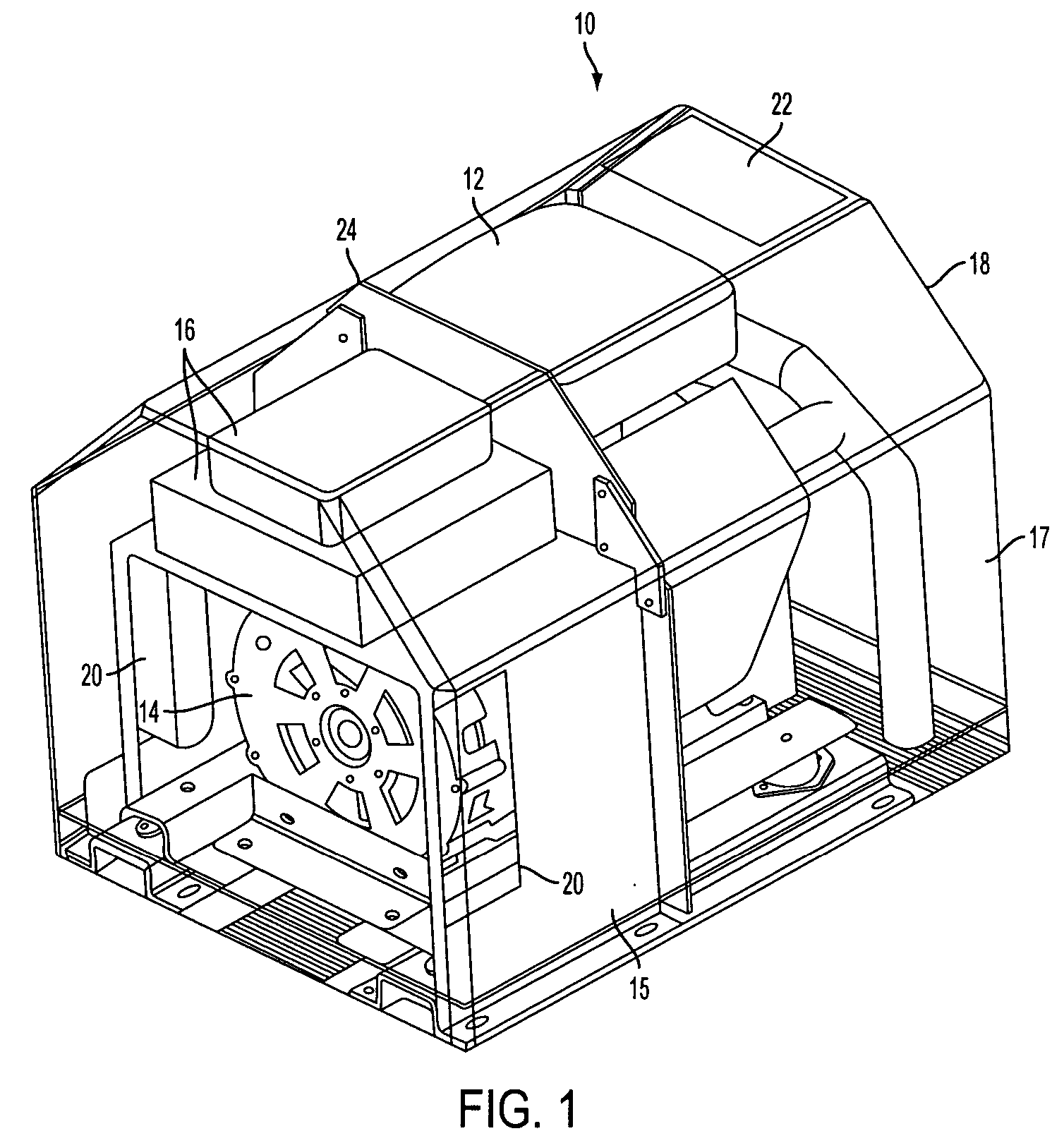

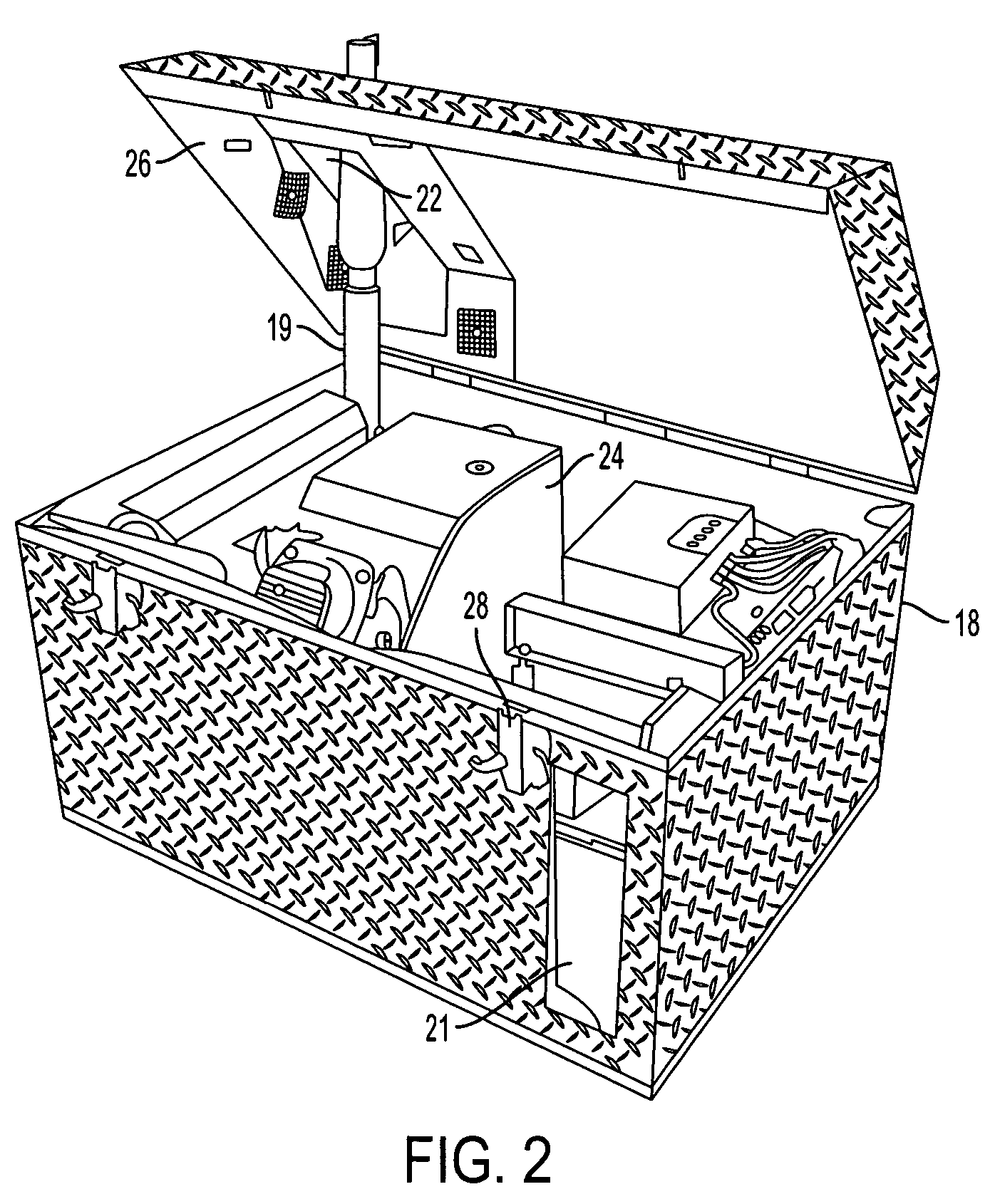

Autonomous portable range extender

InactiveUS7537070B2Increase concentrationIncrease torqueElectric propulsion mountingPropulsion using engine-driven generatorsElectricityEngineering

A portable range extender can be used to supply electrical power to an electric vehicle operable by an electric traction motor. The portable range extender includes an engine, a dynamoelectric machine coupled to the engine by a shaft, an autonomous range extender controller for controlling operations of the range extender independently of a controller for the vehicle, and circuitry associated with the engine and machine. The range extender and its controlling circuitry are self contained within an enclosure. The enclosure is partitioned to form two sections, a first section housing the dynamoelectric machine and the second section housing the engine. Windows in the enclosure provide a path for air cooling of the range extender components. Air cooling is facilitated by a first set of cooling fins mounted on the rotor of the dynamoelectric machine at an end proximate an air inlet window, a second set of cooling fins mounted on the rotor of the dynamoelectric machine in the vicinity of an opening in the partition, and a third set of cooling fins mounted on the engine at the opposite side of the partition opening.

Owner:BLUWAV SYST LLC

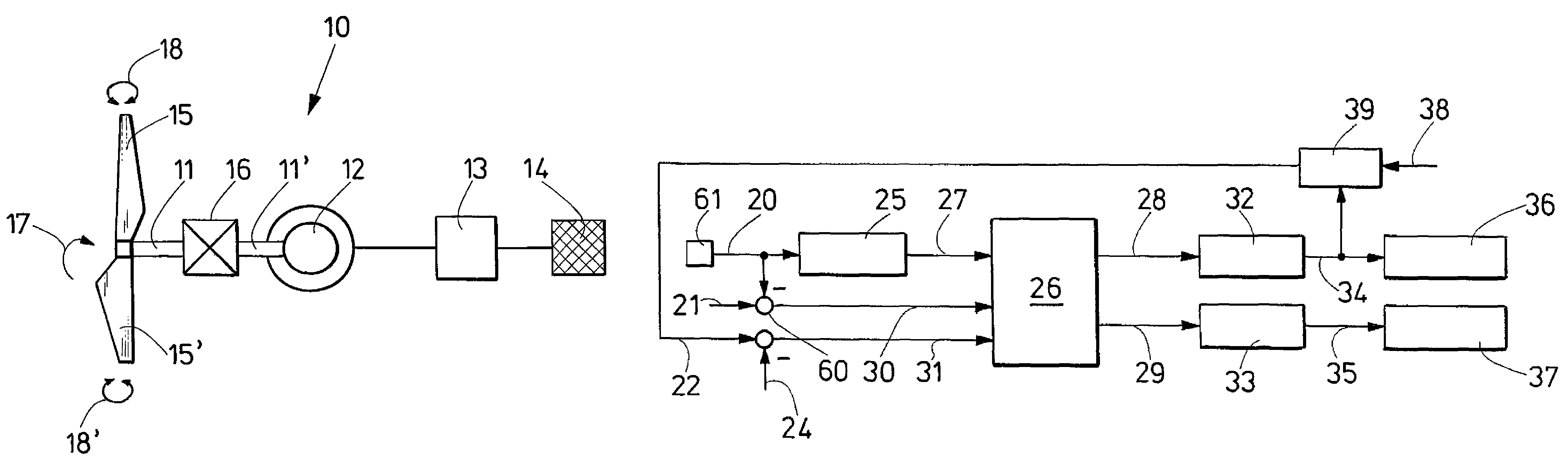

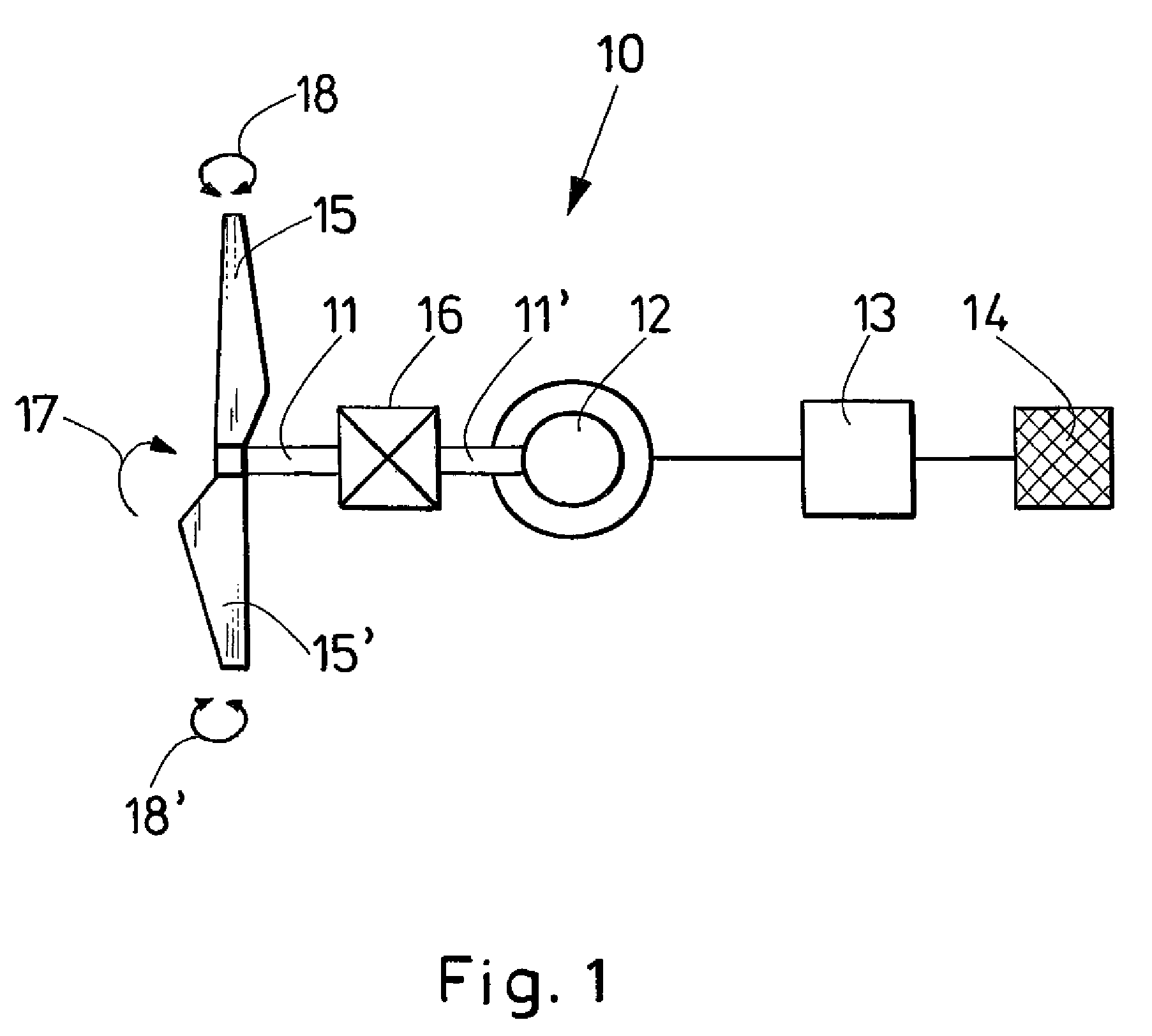

Method and system for regulation of the rotational speed of a rotor on a wind turbine

ActiveUS7586205B2Increase energy outputEfficient identificationOptimise machine performanceWind motor controlEngineeringTurbine

The invention relates to a method and a system for regulation of the rotational speed (52) of a rotor on a wind energy unit with a generator and a rotor blade. The first set parameter is a pitch angle (Pitch) of the rotor blade and the second set parameter is the torque of the generator. The system comprises a pitch angle control or regulation device (32), a torque control or regulation device (33), a first device for determination of a first rotational speed set value (28) (first rotational speed set value determination device (29)) and a second device (26) for determination of a second rotational speed set value (29) (second rotational speed set value determination device (26)). The first rotational speed set value (28) may be supplied to the pitch angle control or regulation device (32) and the second rotational speed set value (29) may be supplied to the torque control or regulation device (33), wherein the first and second rotational speed set value (28, 2)) may be different from each other.

Owner:SIEMENS GAMESA RENEWABLE ENERGY SERVICE GMBH

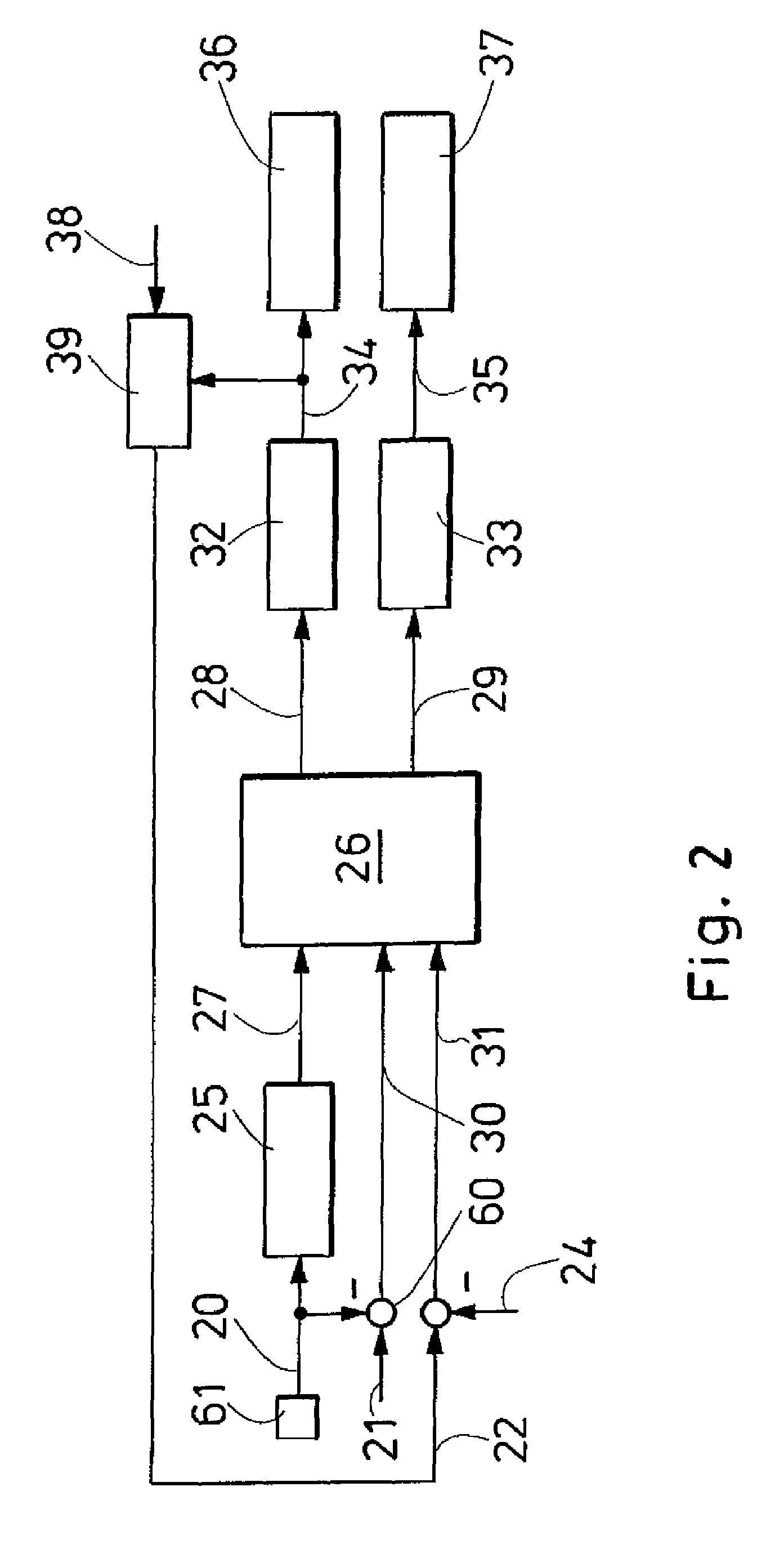

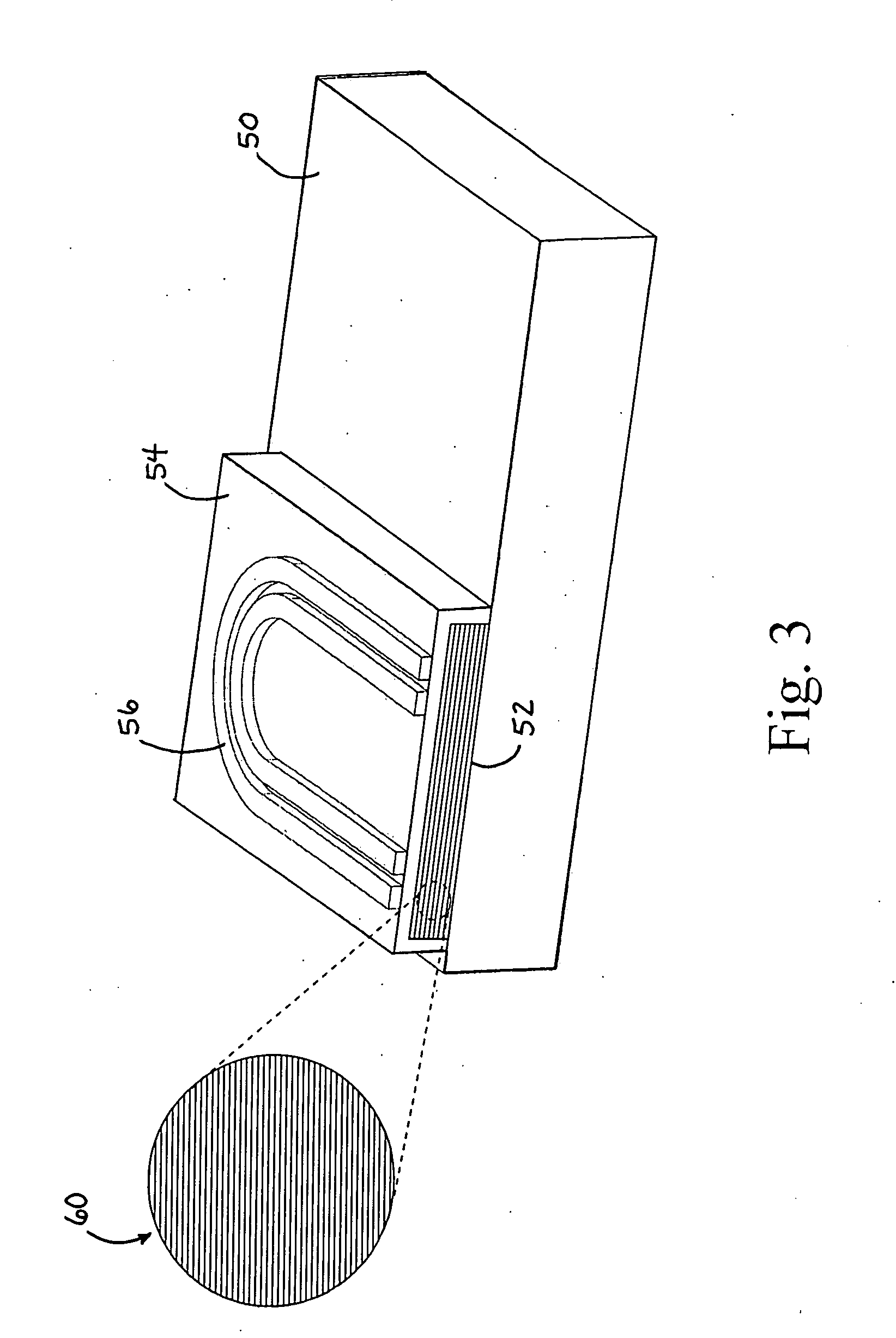

Systems & methods for flaw detection and monitoring at elevated temperatures with wireless communication using surface embedded, monolithically integrated, thin-film, magnetically actuated sensors, and methods for fabricating the sensors

ActiveUS20070108973A1Effective structural health managementEffective prognosisNanomagnetismVacuum evaporation coatingThin film sensorElectricity

Systems and methods for flaw detection and monitoring at elevated temperatures with wireless communication using surface embedded, monolithically integrated, thin-film, magnetically actuated sensors, and methods for fabricating the sensors. The sensor is a monolithically integrated, multi-layered (nano-composite), thin-film sensor structure that incorporates a thin-film, multi-layer magnetostrictive element, a thin-film electrically insulating or dielectric layer, and a thin-film activating layer such as a planar coil. The method for manufacturing the multi-layered, thin-film sensor structure as described above, utilizes a variety of factors that allow for optimization of sensor characteristics for application to specific structures and in specific environments. The system and method integrating the multi-layered, thin-film sensor structure as described above, further utilizes wireless connectivity to the sensor to allow the sensor to be mounted on moving components within the monitored assembly.

Owner:SOUTHWEST RES INST

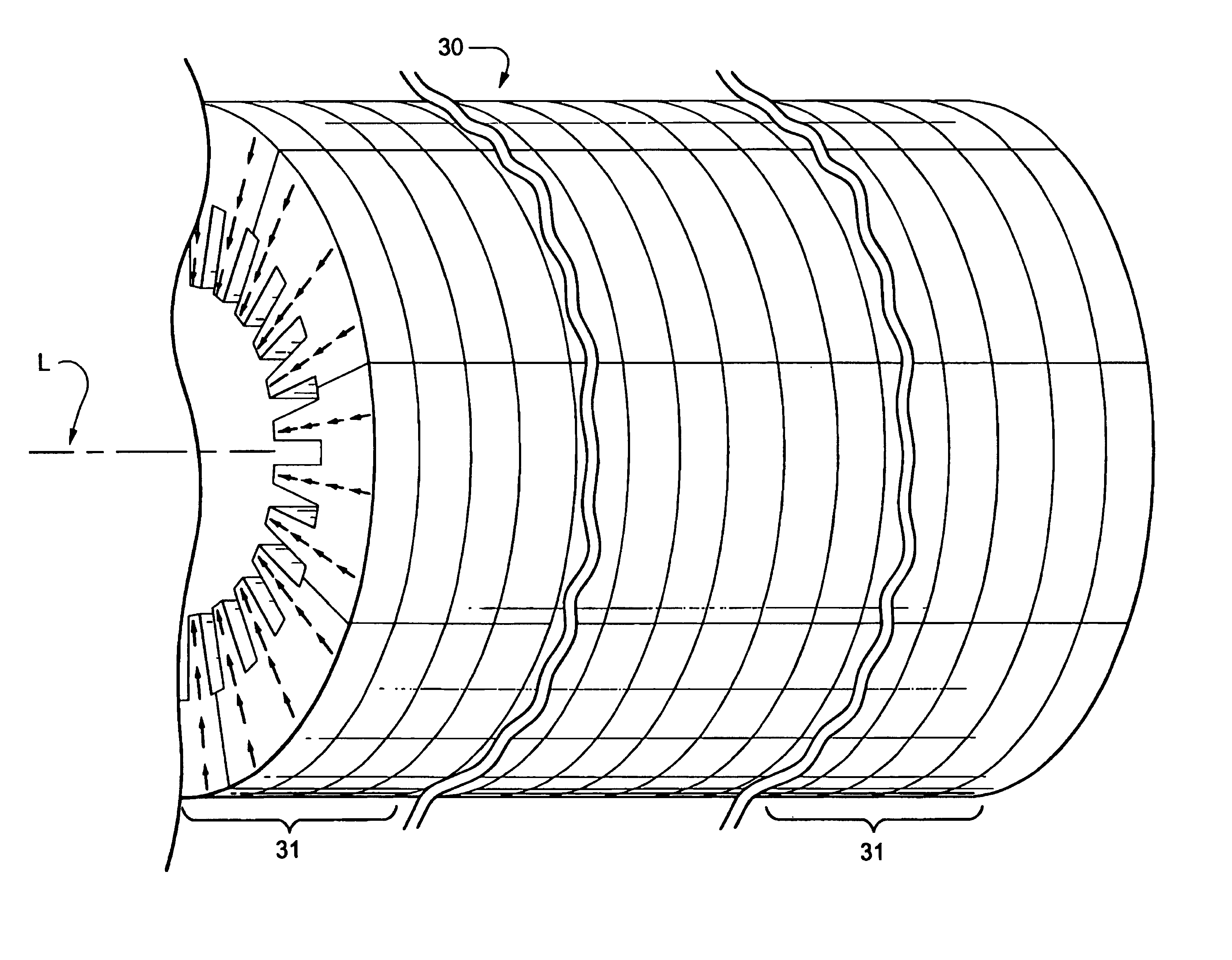

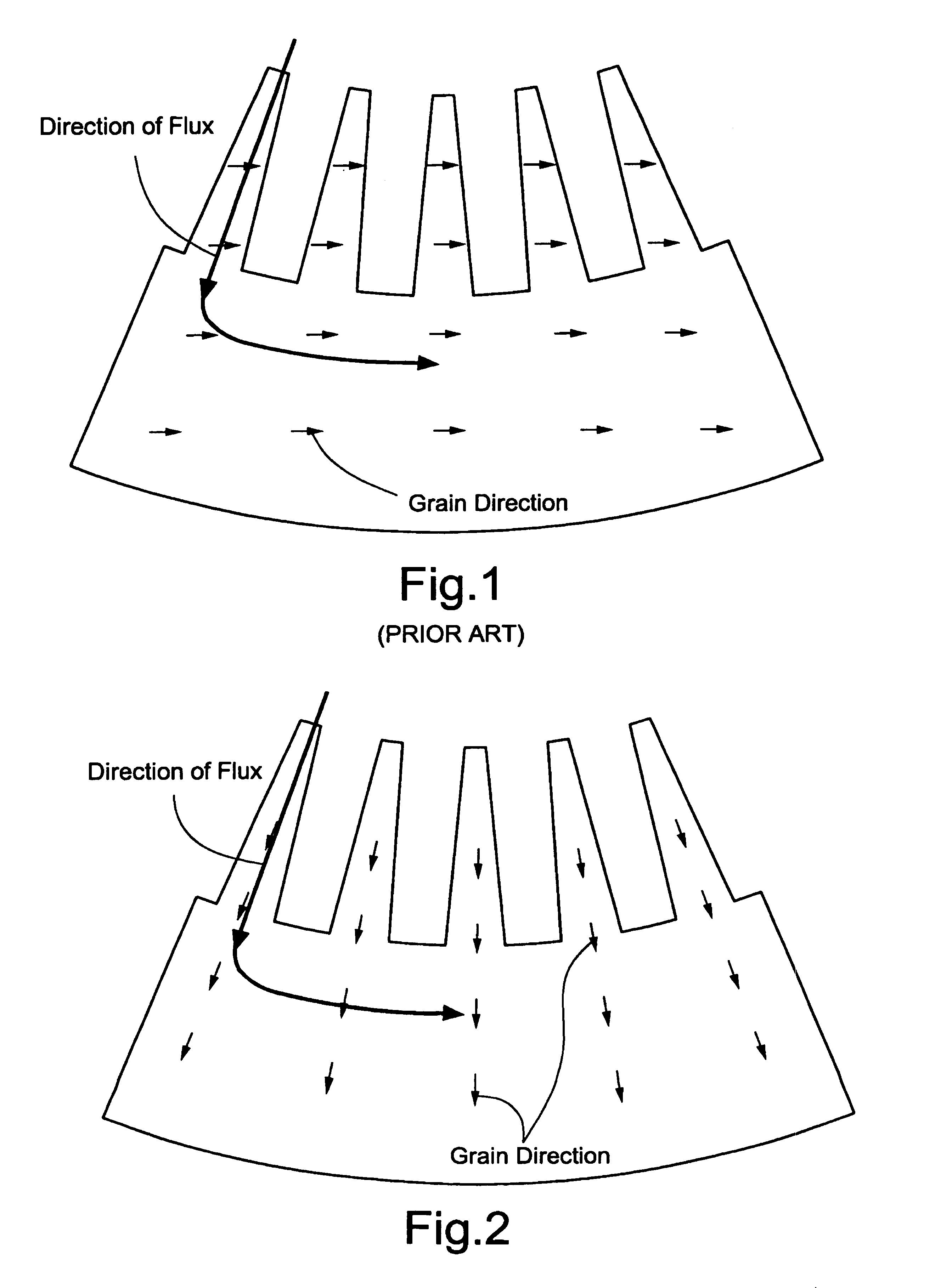

Silicon steel punching orientation modifications to lower eddy current losses at the stator core end of dynamoelectric machines

InactiveUS7057324B2High saturationLower saturation levelMagnetic circuit stationary partsMagnetic circuit characterised by magnetic materialsEddy currentMagnetic flux

The invention involves orienting the metal laminations that form a stator core end in such a way so as to reduce eddy current losses in the finger portions of the metal laminations. The metal laminations are positioned so that the grain orientation is parallel to the magnetic flux lines generated in the finger portions.

Owner:GENERAL ELECTRIC CO

Porous film

ActiveUS20100092754A1Improve heat resistanceImprove featuresHybrid capacitor separatorsFinal product manufactureChemistryHeat resistant

Provided is a porous film comprising a heat-resistant resin and two or more fillers, wherein a value of D2 / D1 is 0.15 or less where among values each obtained by measuring the average particle diameter of particles that constitute one of the two or more fillers, the largest value is let be D1 and the second largest value is let be D2.

Owner:SUMITOMO CHEM CO LTD

Dual direction exercise treadmill with moment arm resistance

InactiveUS8398529B2High activityIncrease ratingsResilient force resistorsMovement coordination devicesClassical mechanicsEngineering

An exercise treadmill for simulating a dragging or pulling action, having an endless moveable surface looped around rollers or pulleys to form an upper run and a lower run, with an exercise surface for walking or running on while operating the treadmill; and a moment arm weight resistance means for simulating the dragging or pulling of a load.

Owner:ELLIS JOSEPH K

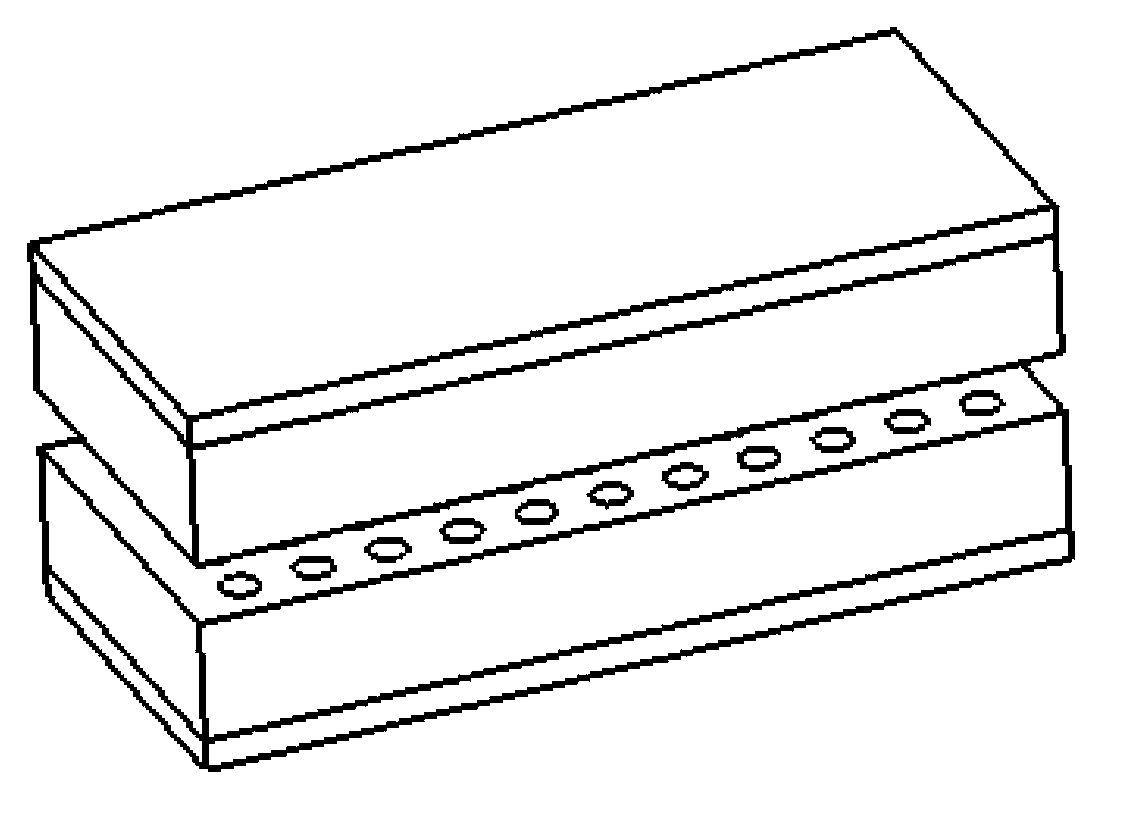

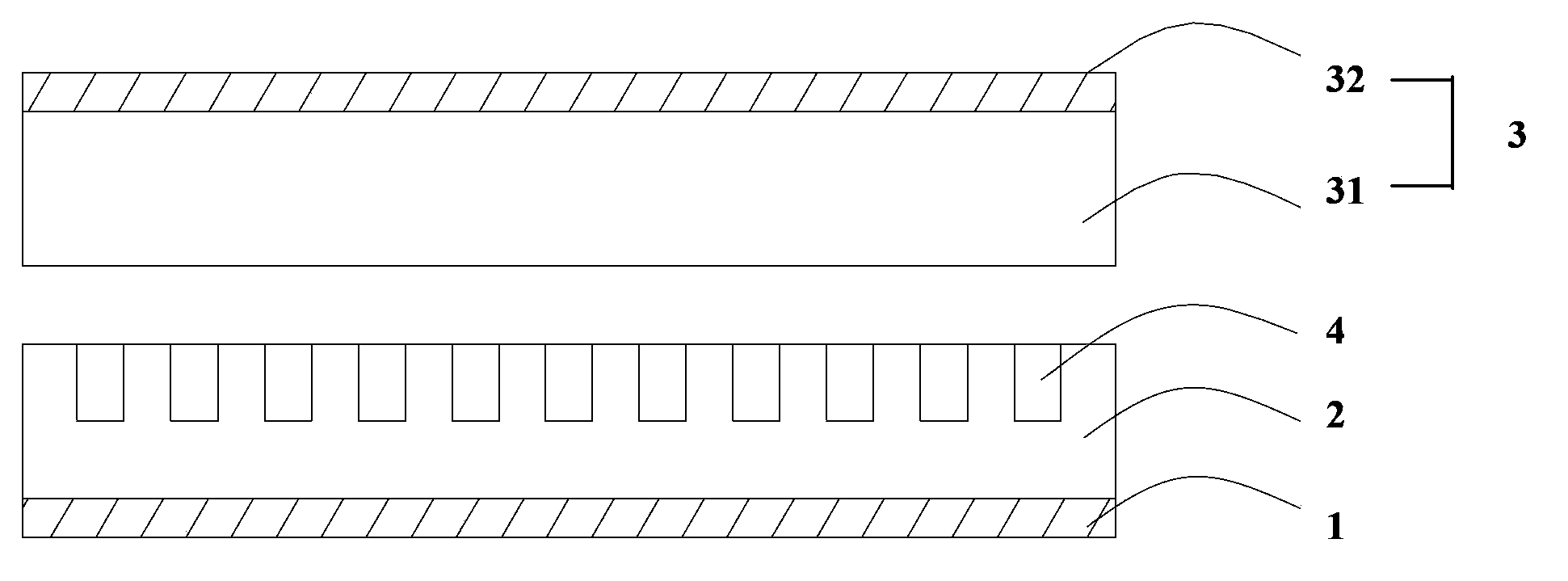

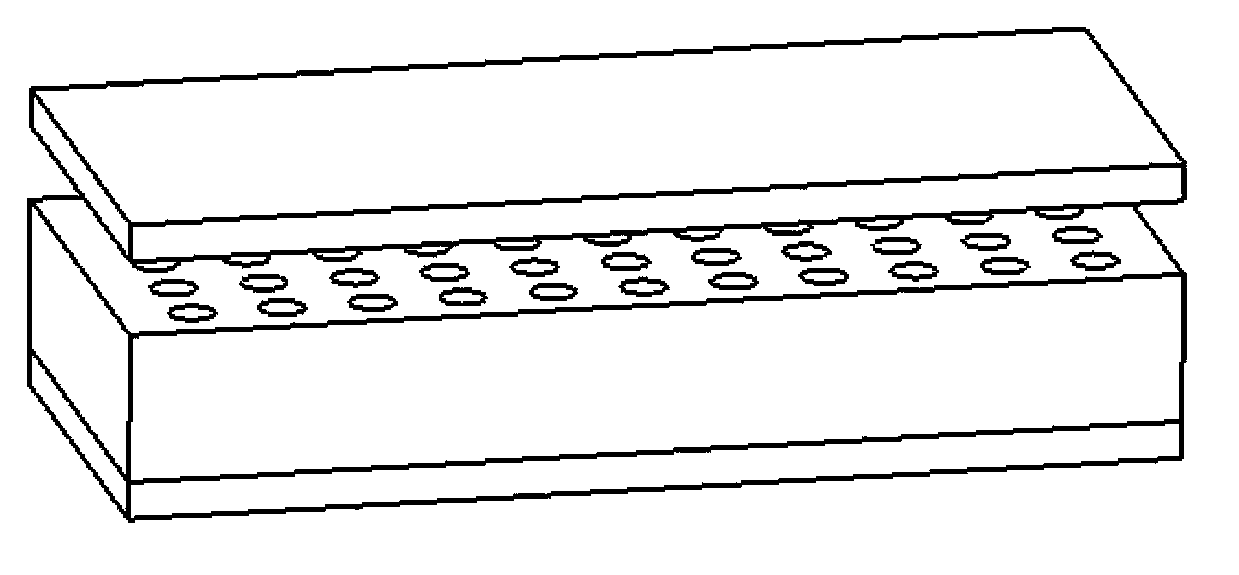

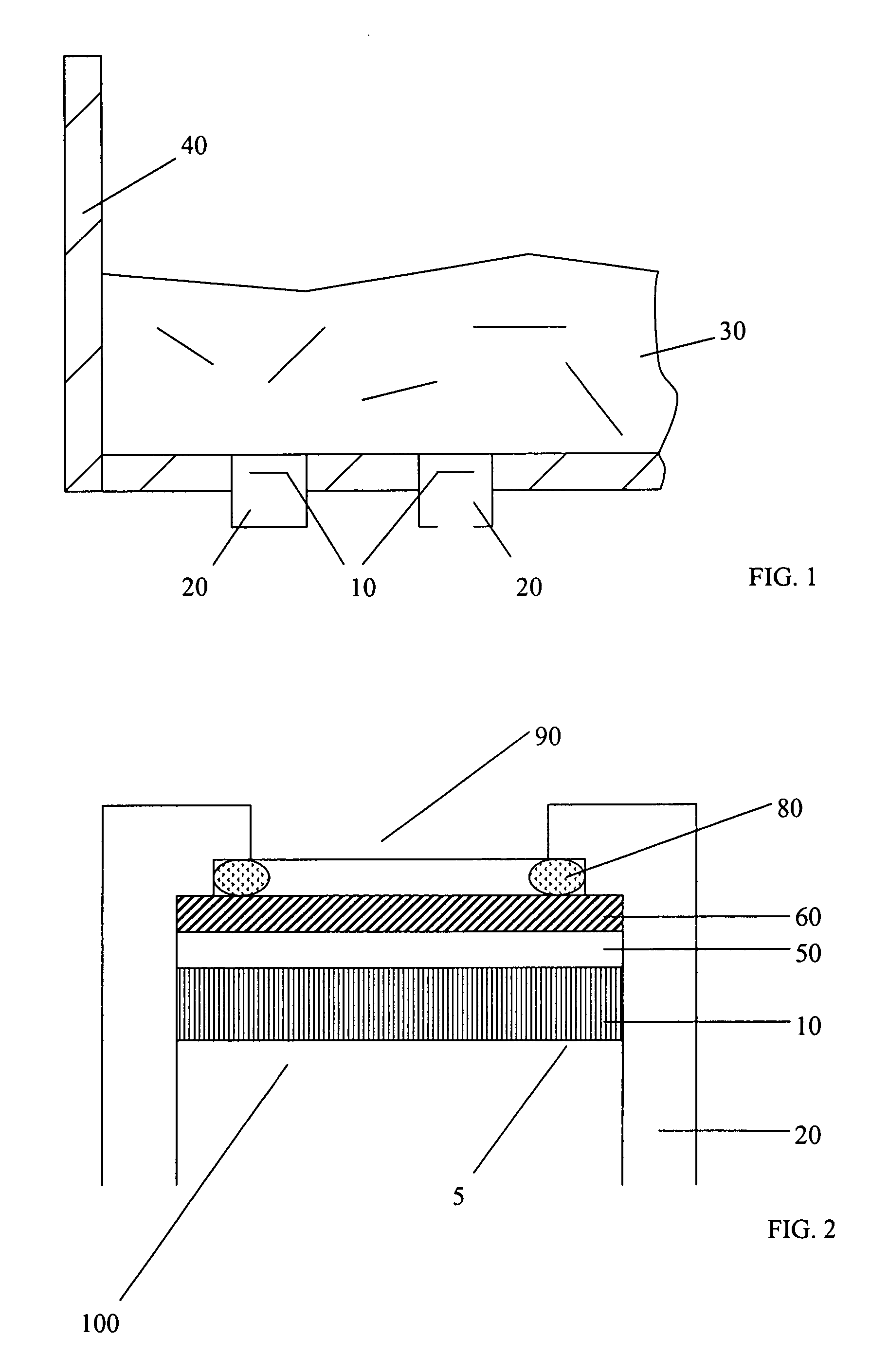

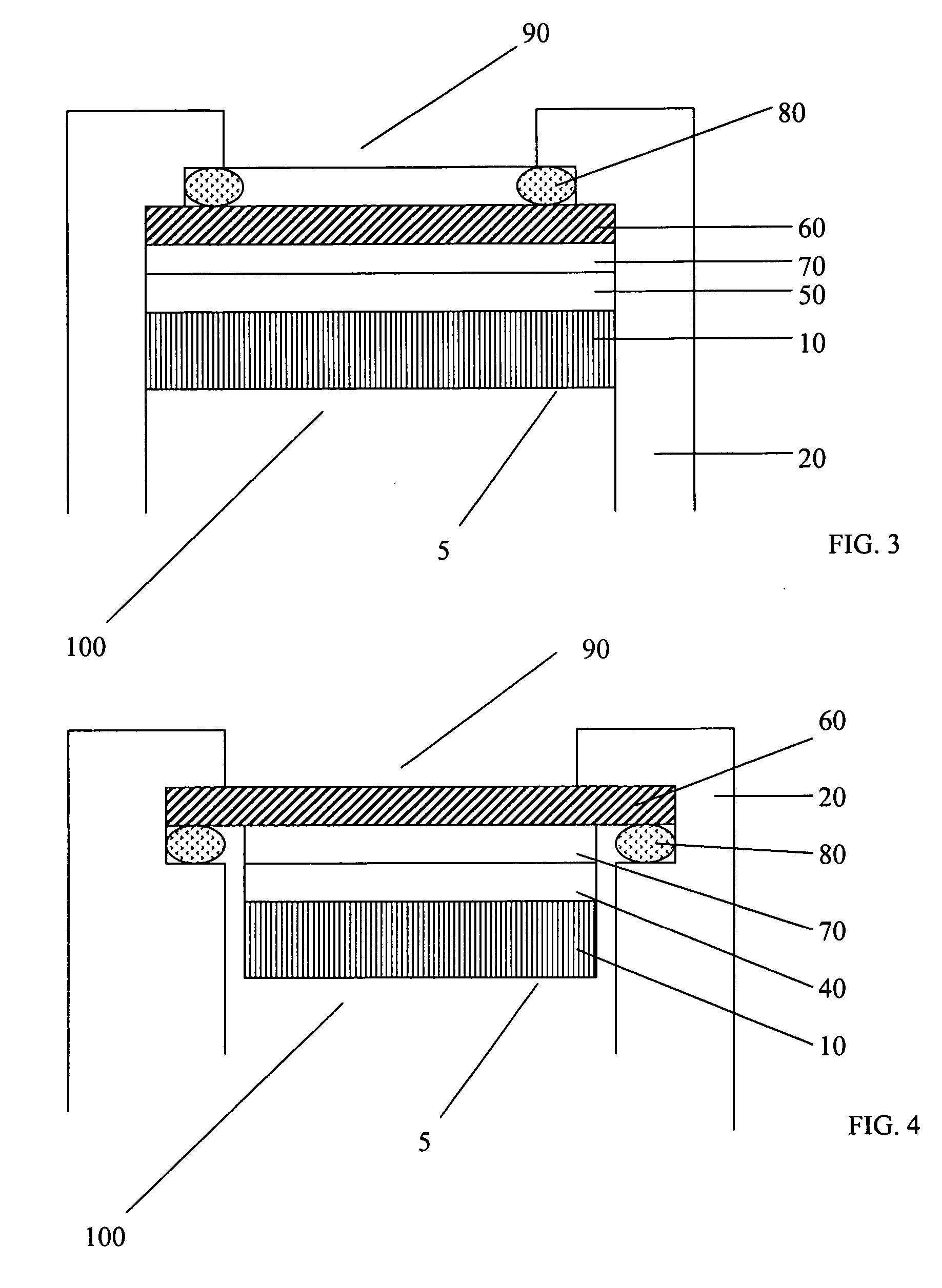

High-power nanometer friction generator and manufacturing method thereof

ActiveCN103856096AIncrease energy outputImprove friction performanceFriction generatorsFriction effectHigh energy

The invention provides a high-power nanometer friction generator and a manufacturing method thereof. The high-power nanometer friction generator comprises a first electrode layer, a macromolecule polymer layer and a friction electrode layer which are sequentially overlaid; the surface, opposite to the friction electrode layer, of the macromolecule polymer layer is provided with a plurality of nanometer holes; the first electrode layer and the friction electrode layer are voltage and current output electrodes of the friction generator. Polyvinylidene fluoride provided with the nanometer holes serves as the macromolecule polymer layer for friction, the friction effect is good, voltage and current output is high, and high-energy output of the friction generator is achieved.

Owner:NEWNAGY TANGSHAN

Battery-powered devices

InactiveUS20070002559A1Easy to operateReduce the temperaturePoint-like light sourceLighting support devicesElectrical conductorElectrical battery

Battery-powered devices in which an energy consumption unit is associated with a heat conductor coupled to the battery-based power supply are described. A portion of the waste heat generated during operation of the energy consumption unit is transferred to the power supply, particularly to the one or more batteries that comprise the energy source of the power supply. The power supply may contain a housing composed of heat-insulating material. Heating of the batteries or battery housing warms the battery(ies), mitigating functional problems associated with battery operation at low temperatures.

Owner:UNDERWATER KINETICS

Autonomous portable range extender

InactiveUS20050279542A1Increase flux concentrationHigh torqueElectric propulsion mountingGas pressure propulsion mountingHeat sinkElectric vehicle

A portable range extender can be used to supply electrical power to an electric vehicle operable by an electric traction motor. The portable range extender includes an engine, a dynamoelectric machine coupled to the engine by a shaft, an autonomous range extender controller for controlling operations of the range extender independently of a controller for the vehicle, and circuitry associated with the engine and machine. The range extender and its controlling circuitry are self contained within an enclosure. The enclosure is partitioned to form two sections, a first section housing the dynamoelectric machine and the second section housing the engine. Windows in the enclosure provide a path for air cooling of the range extender components. Air cooling is facilitated by a first set of cooling fins mounted on the rotor of the dynamoelectric machine at an end proximate an air inlet window, a second set of cooling fins mounted on the rotor of the dynamoelectric machine in the vicinity of an opening in the partition, and a third set of cooling fins mounted on the engine at the opposite side of the partition opening.

Owner:BLUWAV SYST LLC

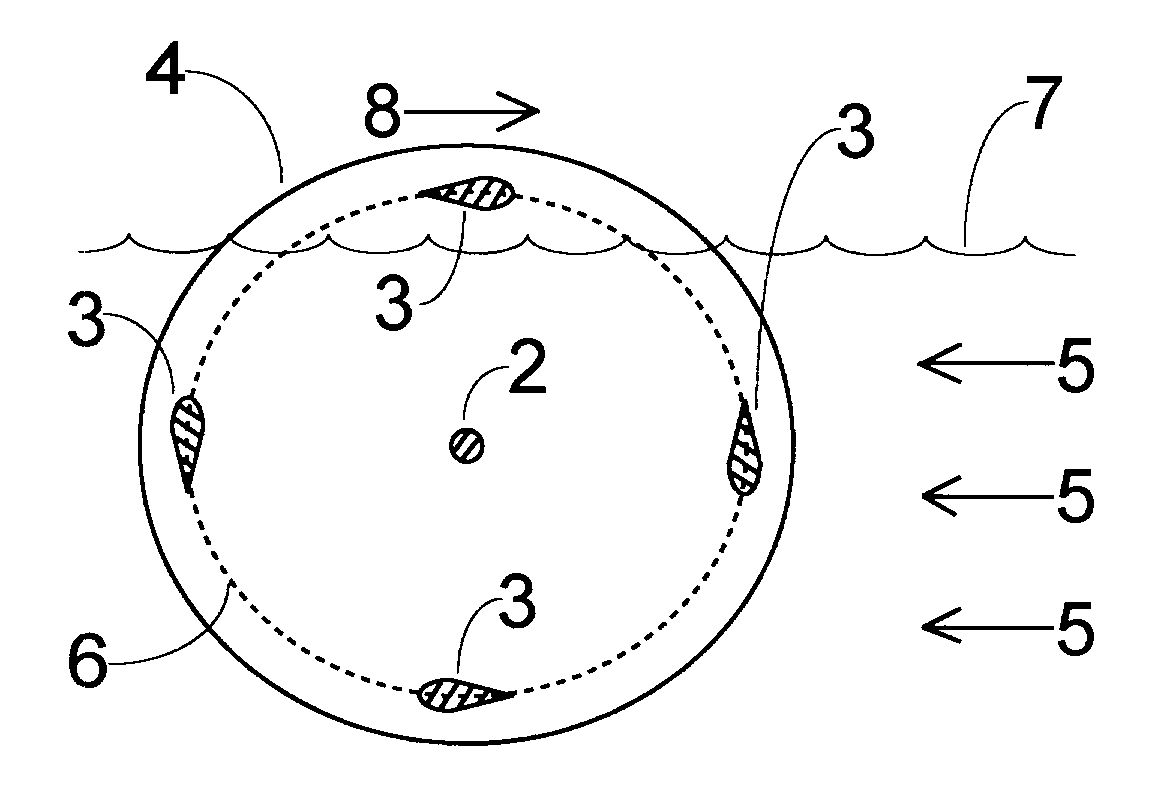

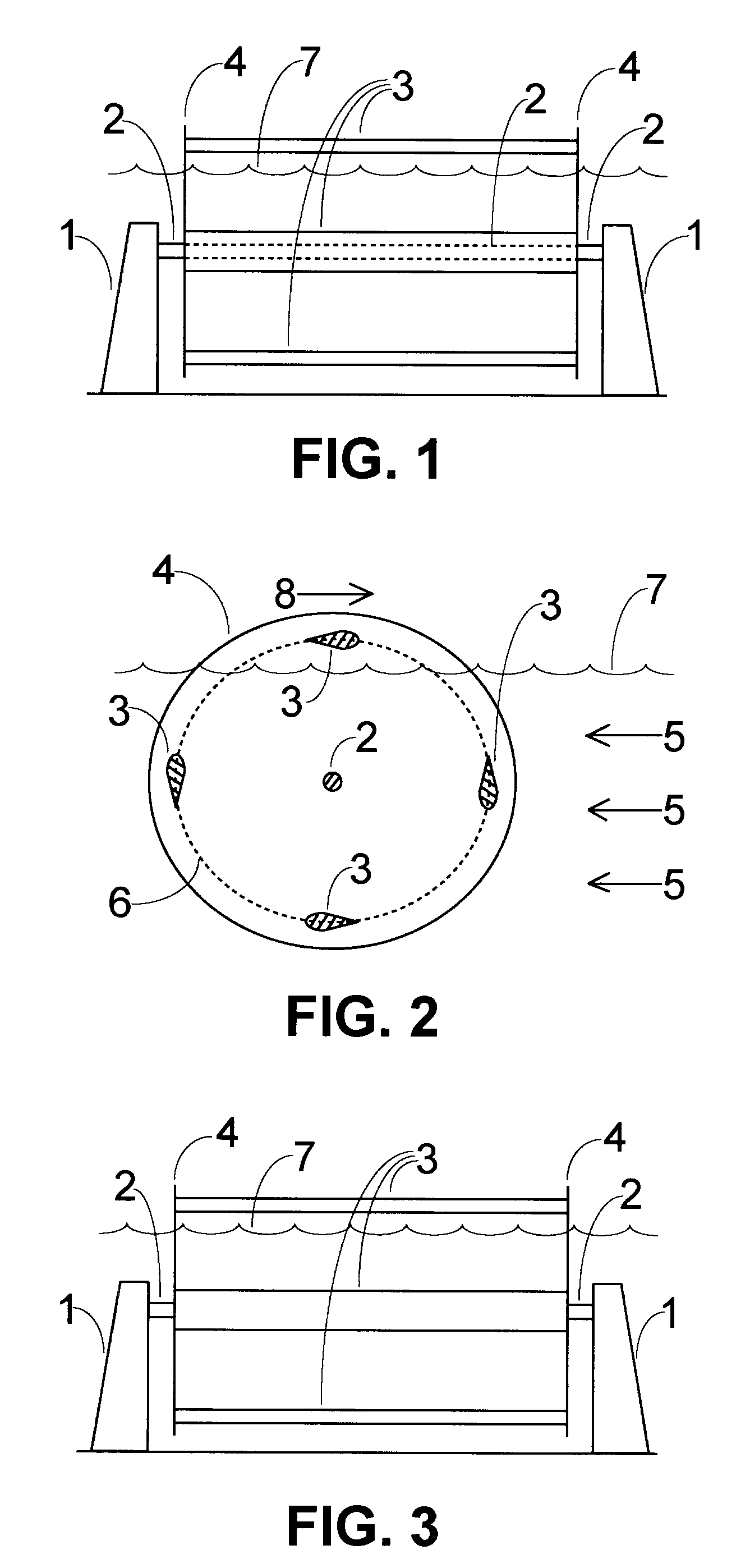

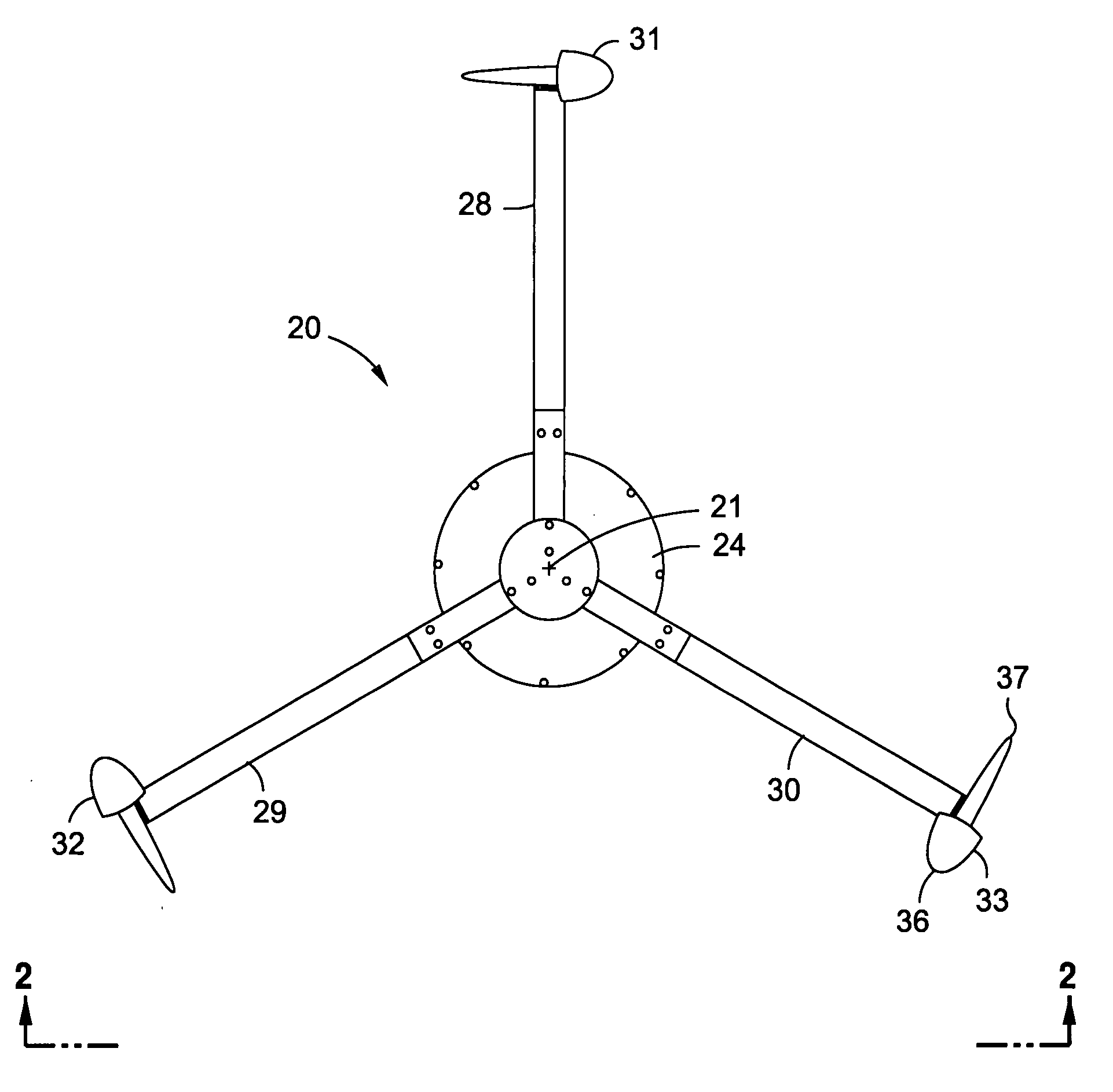

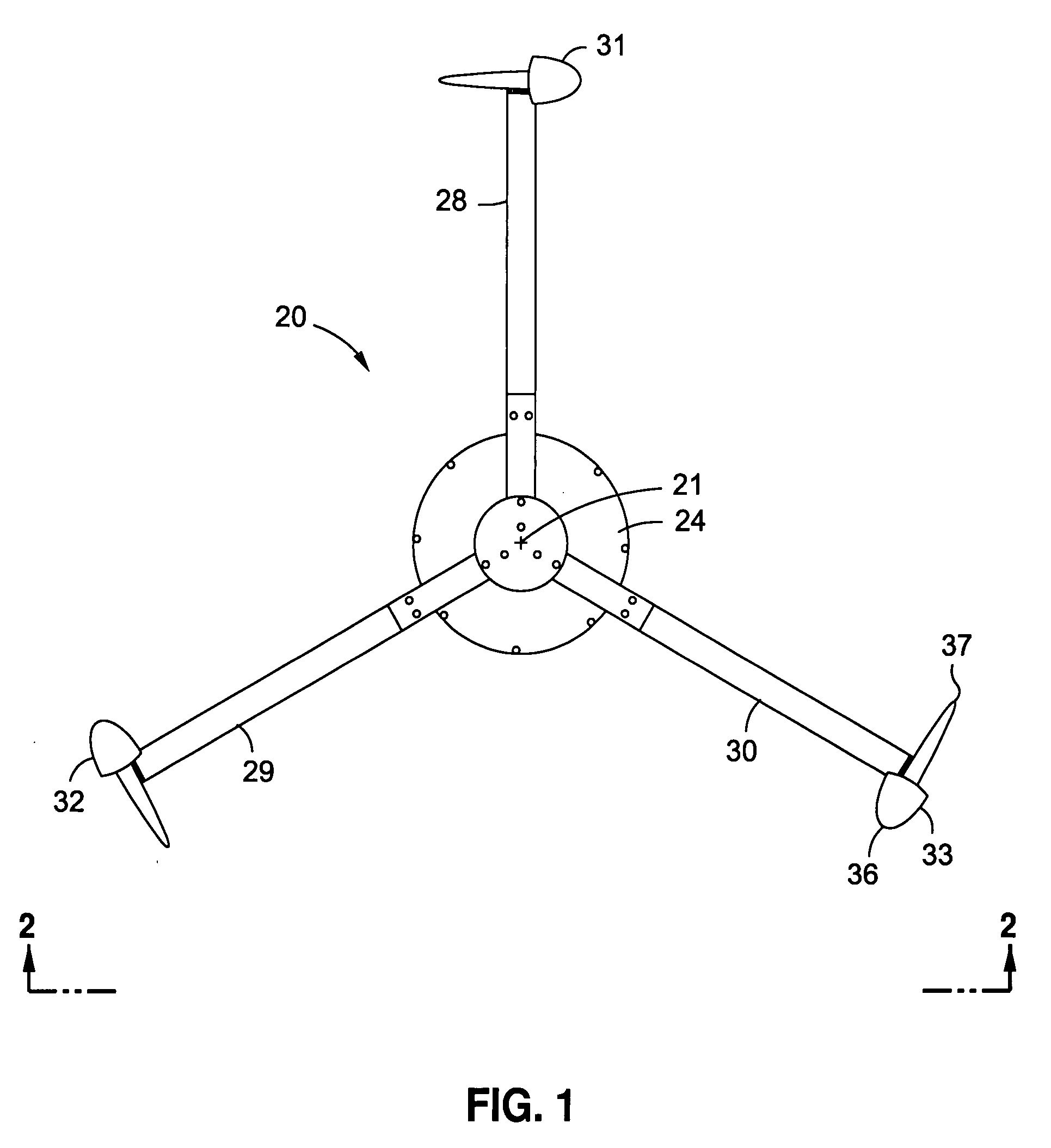

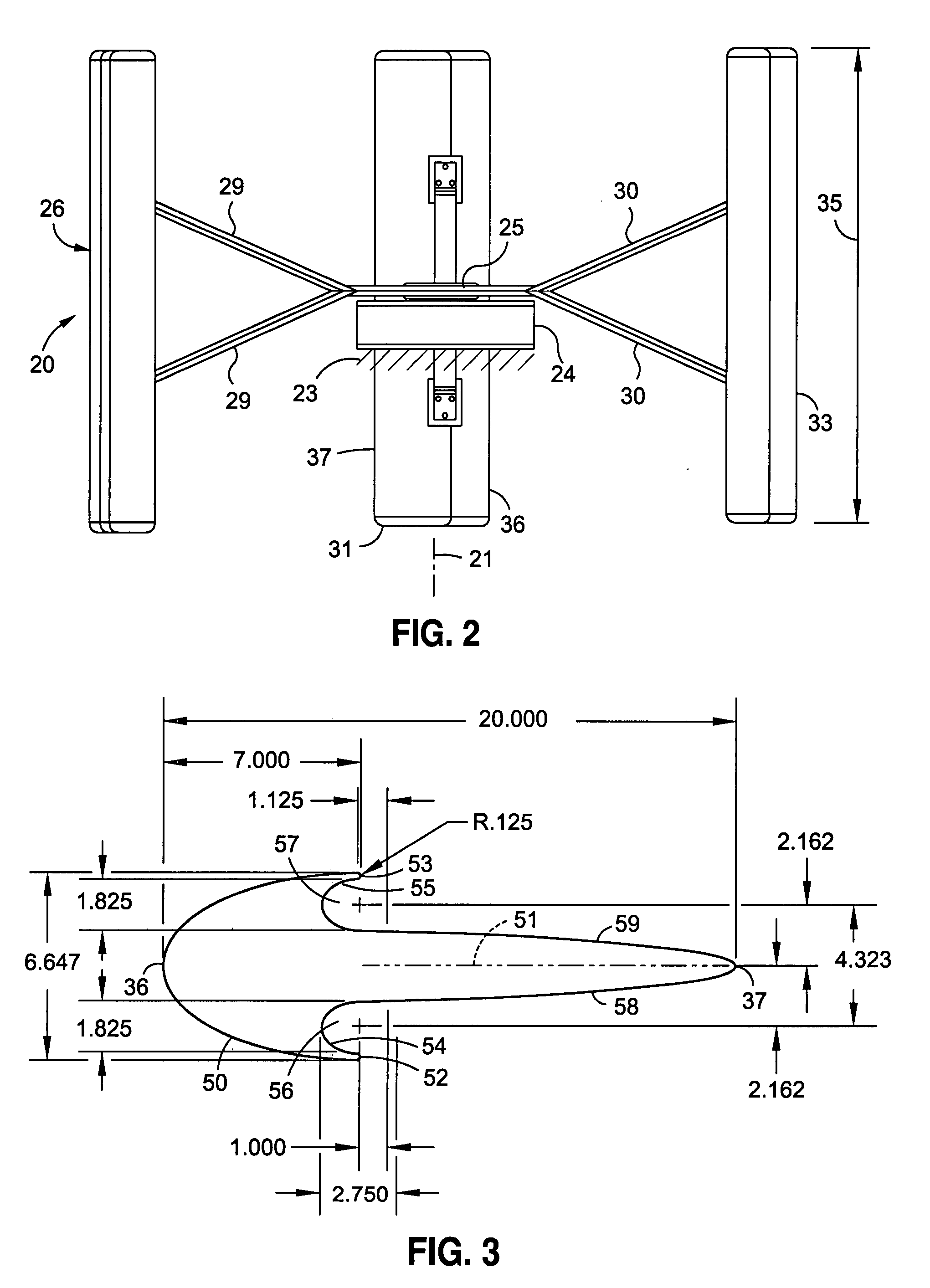

Darrieus water wheel turbine

ActiveUS20090194997A1Simple and reliable processEliminate the effects ofWind motor controlHydro energy generationWater wheelWater flow

A reaction turbine system for the generation of hydroelectricity is disclosed. It consists of a Darrieus type turbine with a horizontal axis of rotation. The blades may be straight or helical, and are held equidistant from the central rotating shaft by blade support members. The blades are oriented so that a blade at its rotational apex moves directly opposite to the direction of water flow. The turbine is elevated such that the top portion, where blades travel directly against the direction of water flow, is in the air and above the water level. This design greatly reduces stresses on the system and increases energy output relative to a Darrieus turbine fully immersed in water flow. This design also enables the turbine to self-start.

Owner:STABINS PETER ANDREW

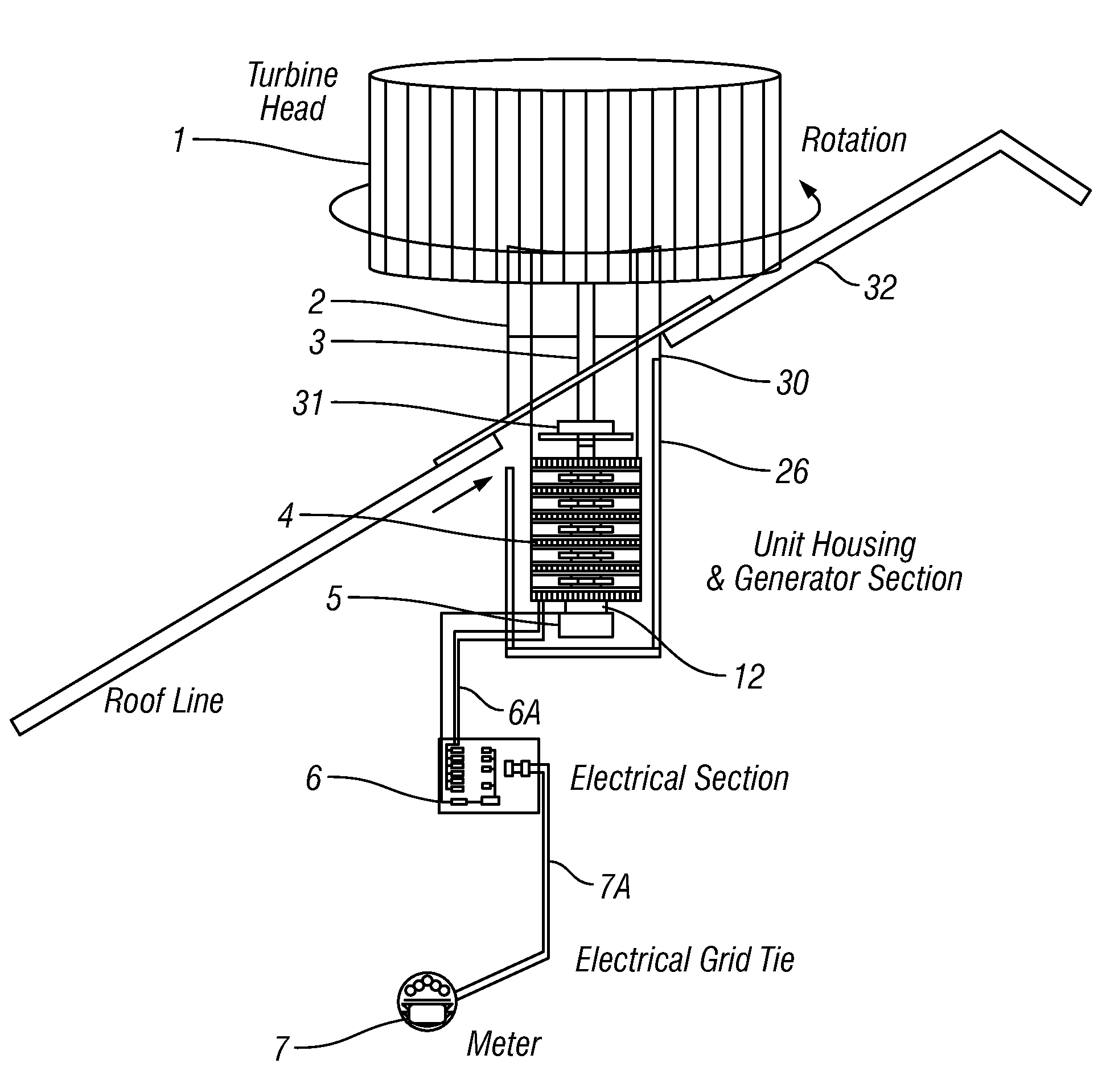

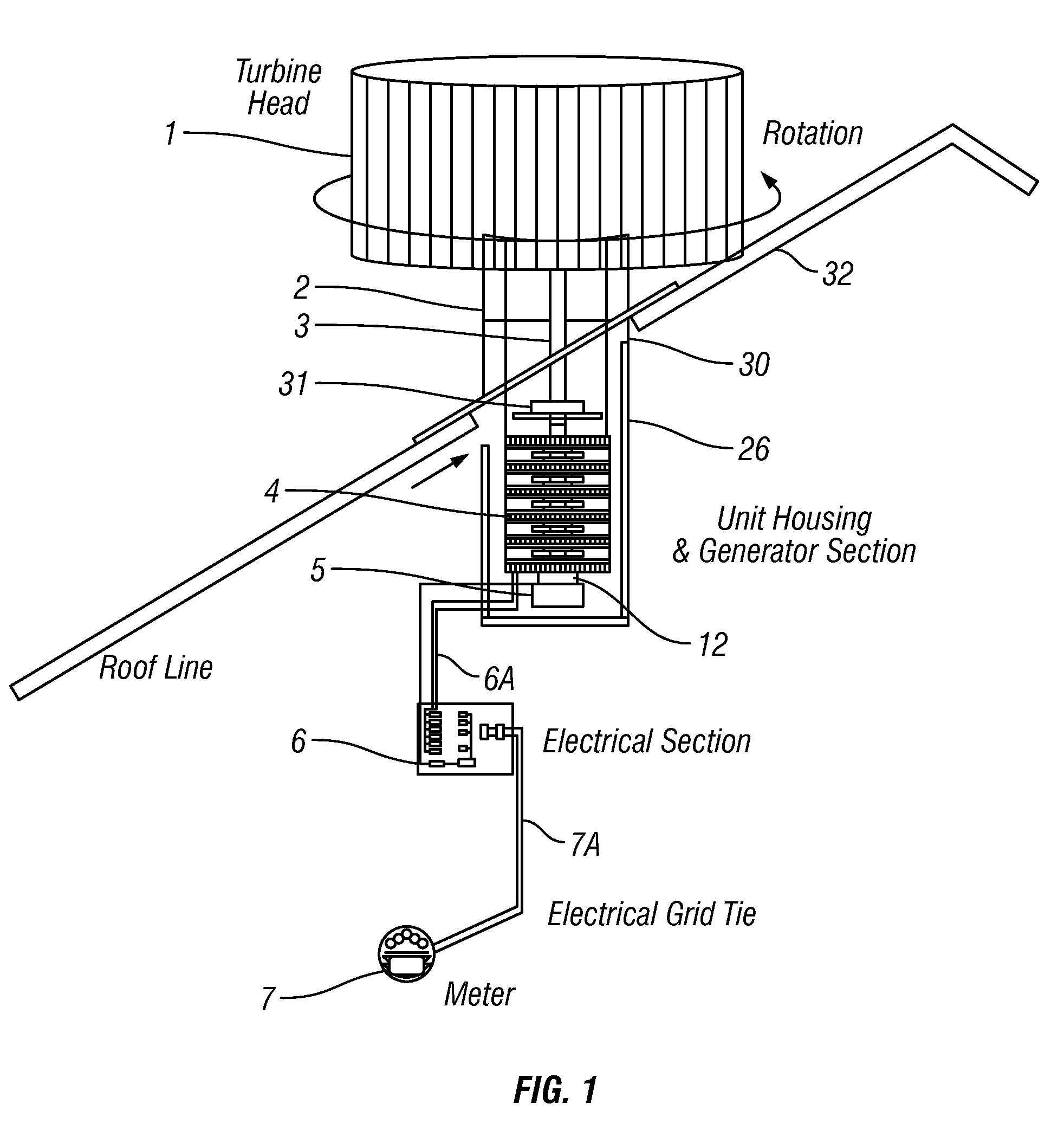

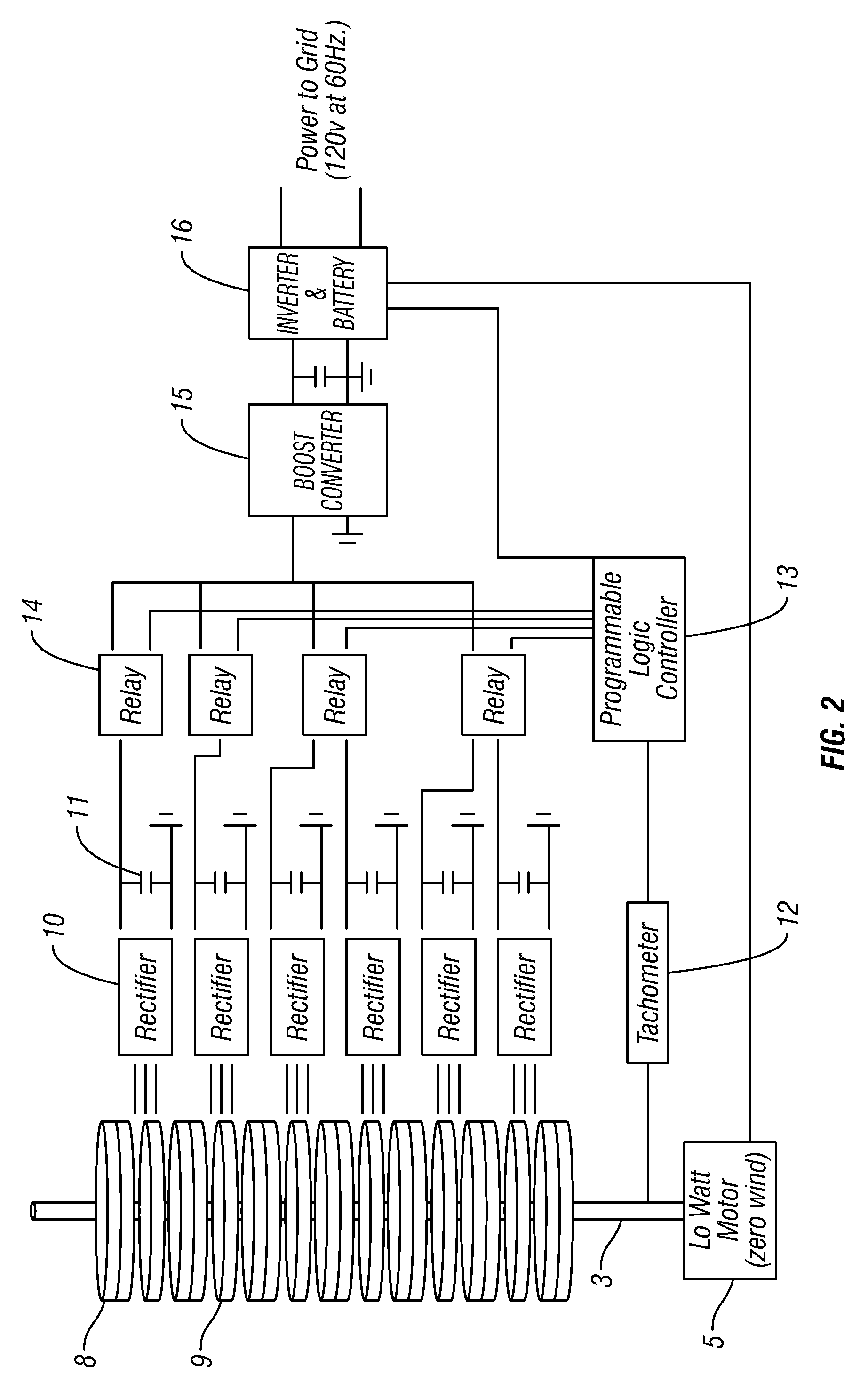

Multistage electric power generating and ventilating device

InactiveUS20110121576A1Reduce torqueIncrease energy outputEngine fuctionsWind motor supports/mountsWind drivenWind force

An electric generator include a plurality of magnet disks coupled to a rotating shaft at longitudinally spaced apart locations. The magnet discs are formed on each face of a substantially flat, cylindrical rotor from magnetic material and are polarized in a selected direction. A plurality of stators is disposed between pairs of the magnet discs. A wire coil is disposed in each stator. In one aspect, a wind driven turbine rotates the generator.

Owner:BAYKO JOHN W

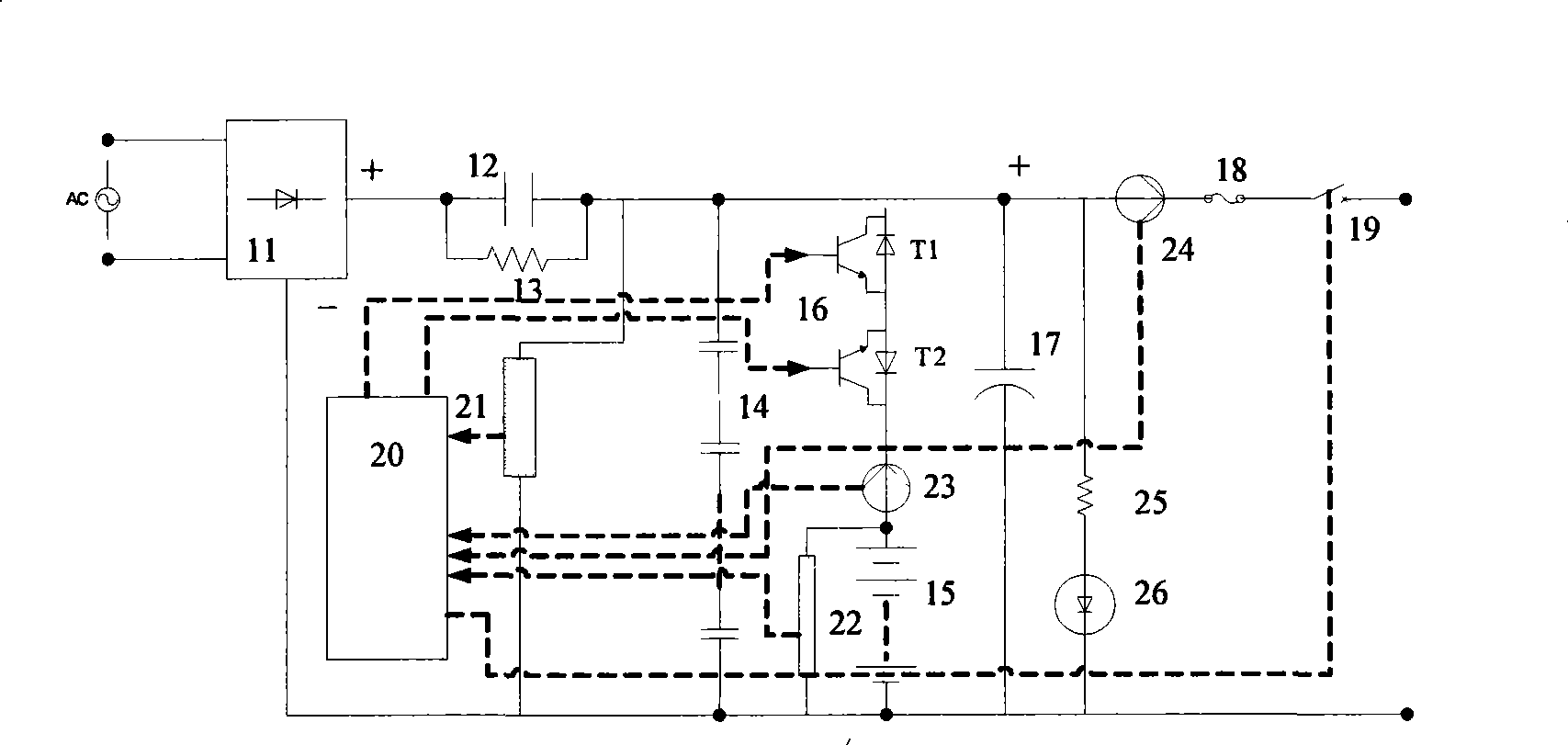

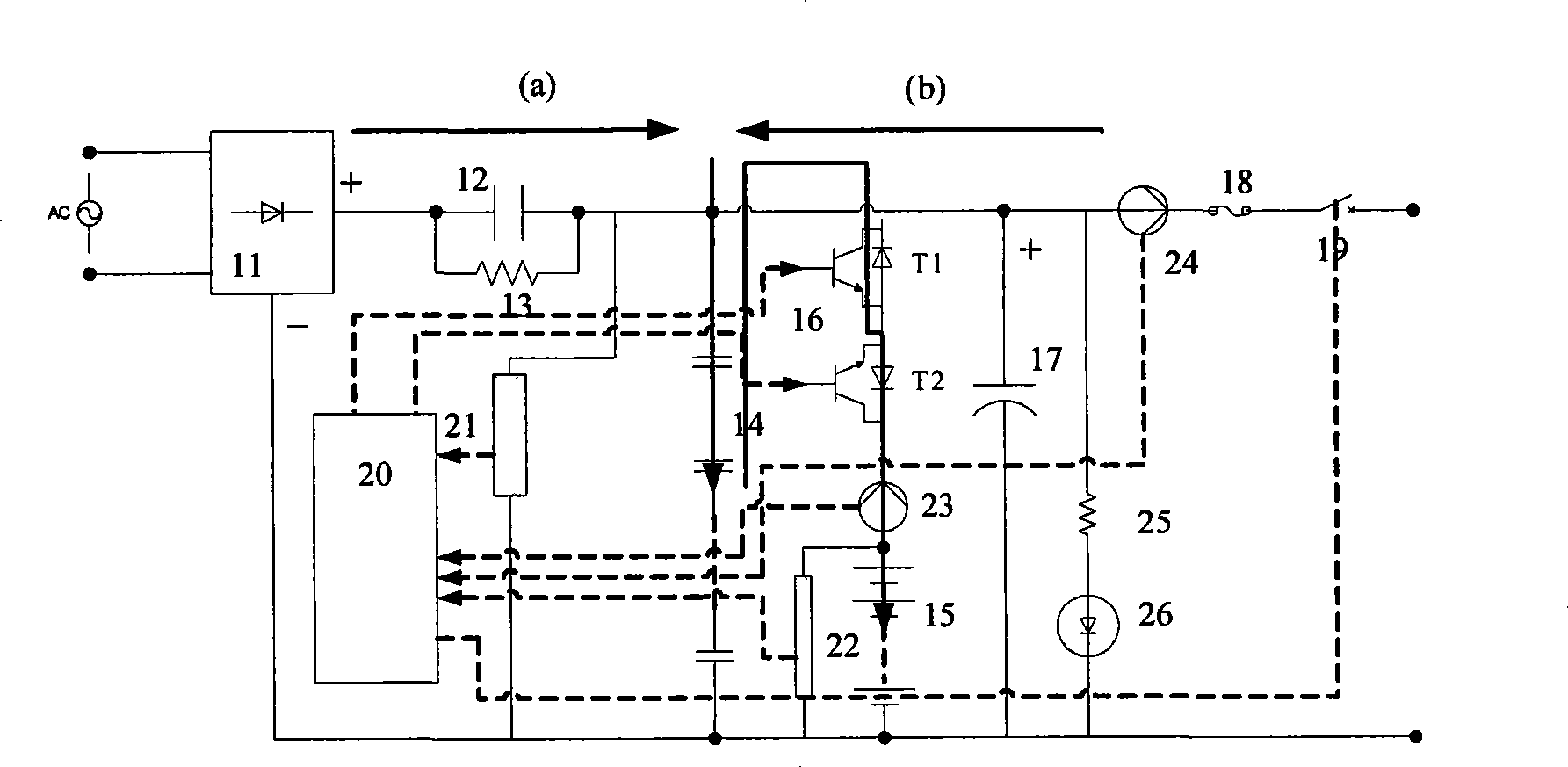

Mixed battery pack comprising lithium power cell and super capacitor

InactiveCN101399452AGood powerExtend cycle lifeElectrical storage systemBatteries circuit arrangementsCharge voltageCapacitance

The invention discloses a mixing battery group consisting of a lithium power battery group and a super capacitor group. The mixing battery group comprises a rectifying circuit, a charging buffer circuit, a lithium power battery group consisting of a plurality of lithium power batteries, a super capacitor group consisting of a plurality of super capacitors, a main circuit of bilateral switch, an output switch and a signal collection and control circuit; the outer current or DC electrical source is connected with the input terminal of the main circuit by the rectifying circuit and the charging buffer circuit, and the output terminal of the main circuit is connected with the electric equipment by the output switch; the signal collection and control circuit comprises a controller, a bus bar voltage transducer, a lithium battery group voltage transducer, a lithium battery electric current transducer and an output current transducer. The invention can provide output of electric energy with high power and high energy stably, guarantee to be effectively connected with 220V effective value of electric equipment, and bear a certain degree of fluctuation of charging voltage and current, and guarantee the stability and convenience for electric energy supply and invisibility of power supply. The mixing battery group is characterized by small volume and convenient carrying.

Owner:刘云海 +2

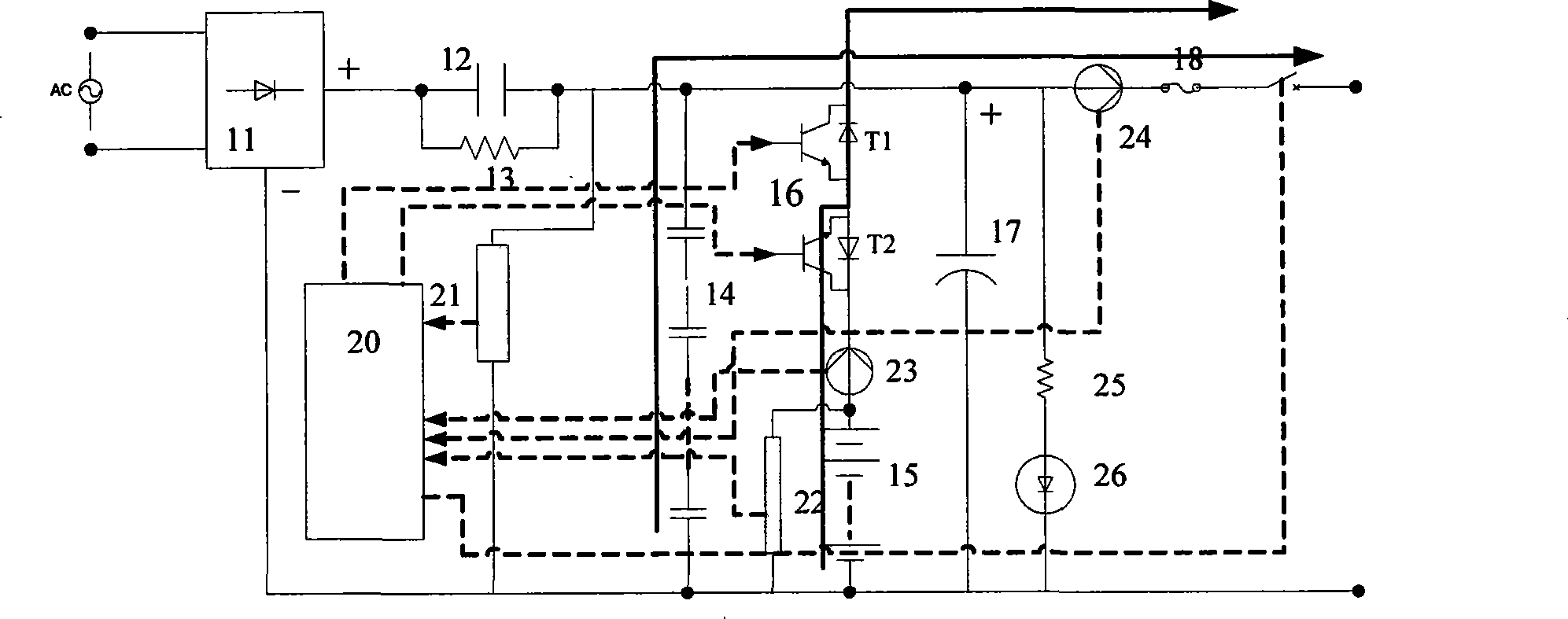

Method and apparatus for optimizing aerosol generation with ultrasonic transducers

ActiveUS20070053789A1Reduced effectivenessIncrease energy outputMovable spraying apparatusSpray nozzlesChemical reactionUltrasonic sensor

The invention is an apparatus and methods for optimizing the performance and protecting one or more aerosol generating transducers from deterioration while operating in a chemically reactive aqueous solution by utilizing one or more protective barrier techniques to eliminate chemical interaction between the aqueous solution and the transducers. The method of the present invention produces an aerosol producing transducer with the transducer housing and assembly to be constructed in such a way as to assure its efficient and effective long-term and problem free operation in an aqueous solution that is chemically reactive.

Owner:ALTAPURE

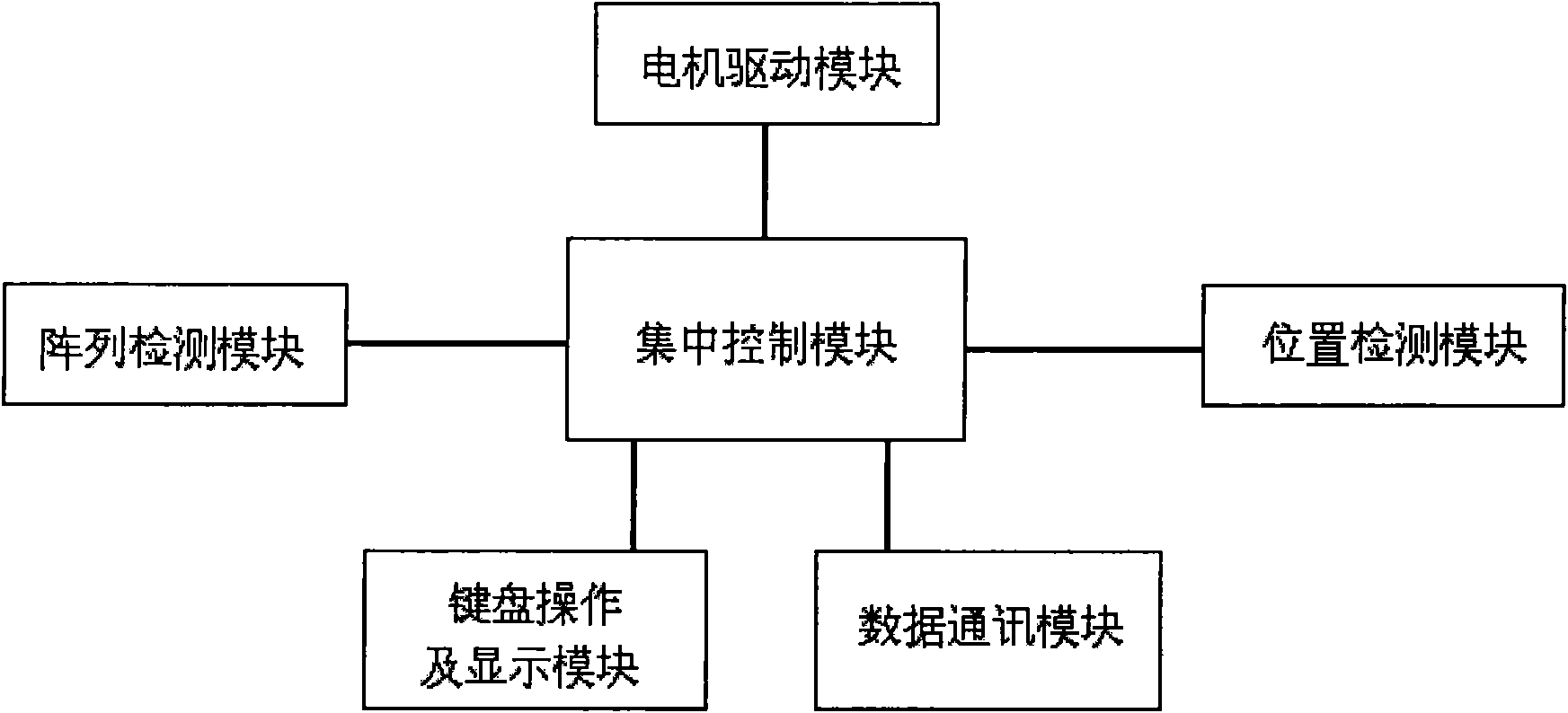

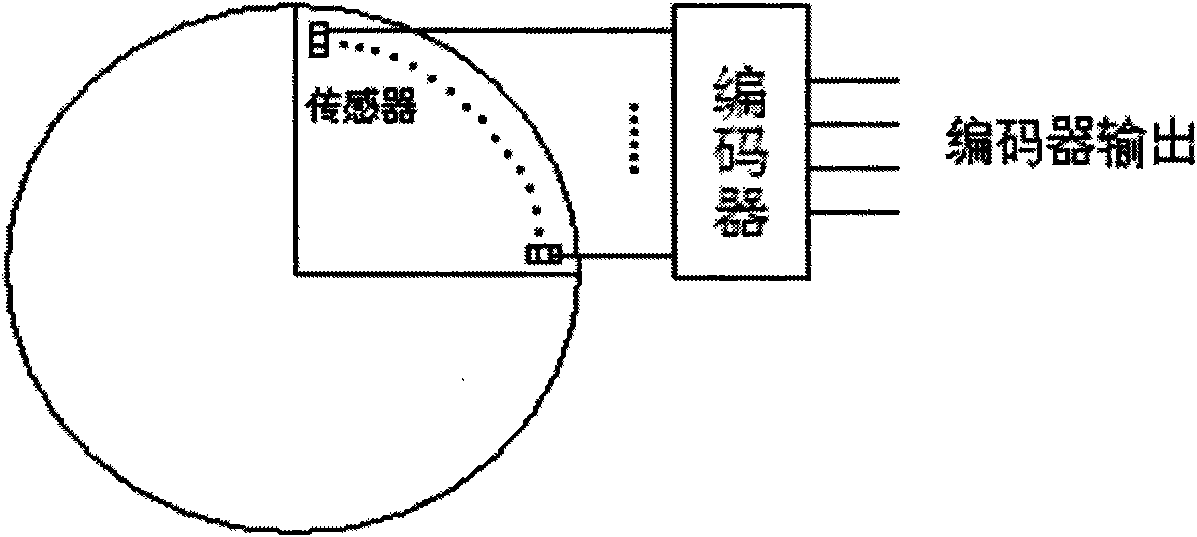

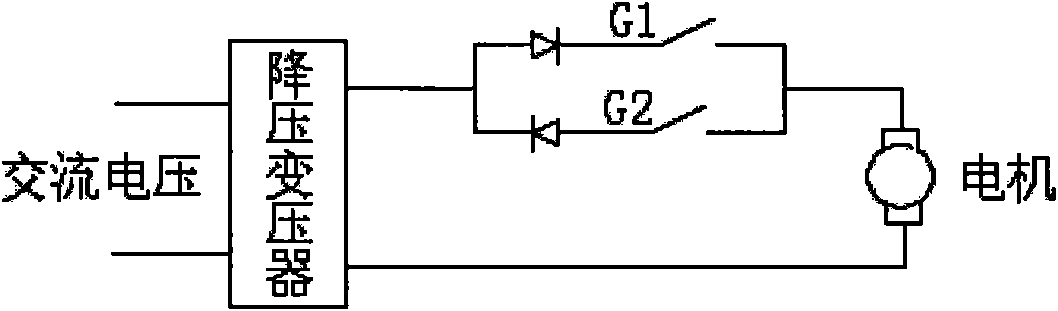

Method and device for tracking control of solar electrical energy generation

InactiveCN101592969AIncrease energy outputImprove photoelectric conversion efficiencyPhotovoltaic supportsControl using feedbackLocation detectionAutomatic control

The invention discloses a method and a device for tracking control of solar electrical energy generation. The method comprises the following steps: automatically selecting a maximum power tracking mode or a timed tracking mode according to the level of the real-time output power of a solar battery; when the timed tracking mode is run, controlling tracking according to the current time and the detected current position signal of a solar panel; and when the maximum power tracking mode is run, determining the tracking direction of a mechanical structure according to the changing condition of the output power of the solar battery. The device comprises a centralized control module, a position detecting module for detecting the actual rotating position of the solar panel, and an array detecting module for detecting the real-time output power of the solar battery. The invention has the advantages of simple and convenient operation, accurate rotating position, realization of automatic control, simple structure, high detecting accuracy and low cost.

Owner:SHENZHEN NENGLIAN ELECTRONICS +1

Vertical axis omni-directional wind turbine

InactiveUS20080273978A1Increase energy outputRenewable energy generationMachines/enginesElectricityLow speed

A vertical axis wind turbine with a rotor driven by a group of vanes that assure starting at low speeds, efficiently generates electricity at all wind speeds, especially under circumstances that include abrupt increases in the wind velocity.

Owner:WEPOWER

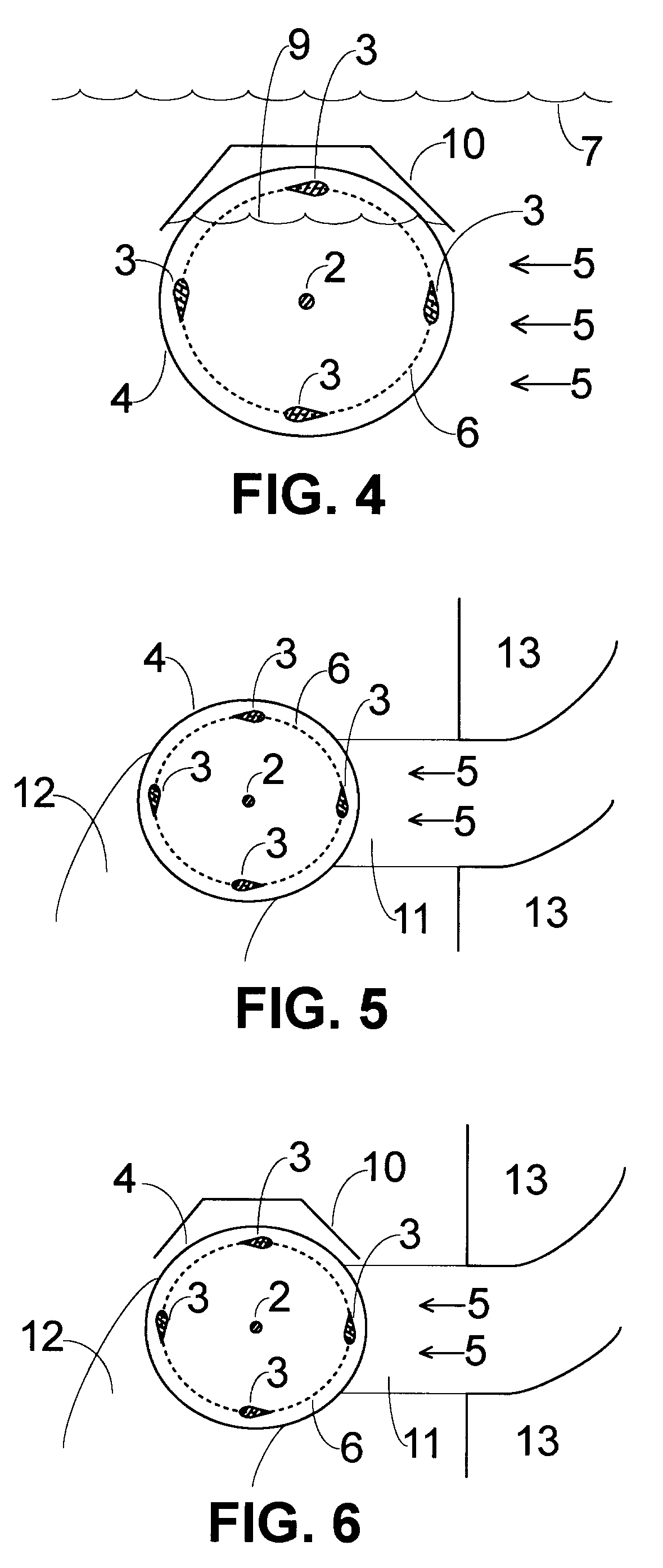

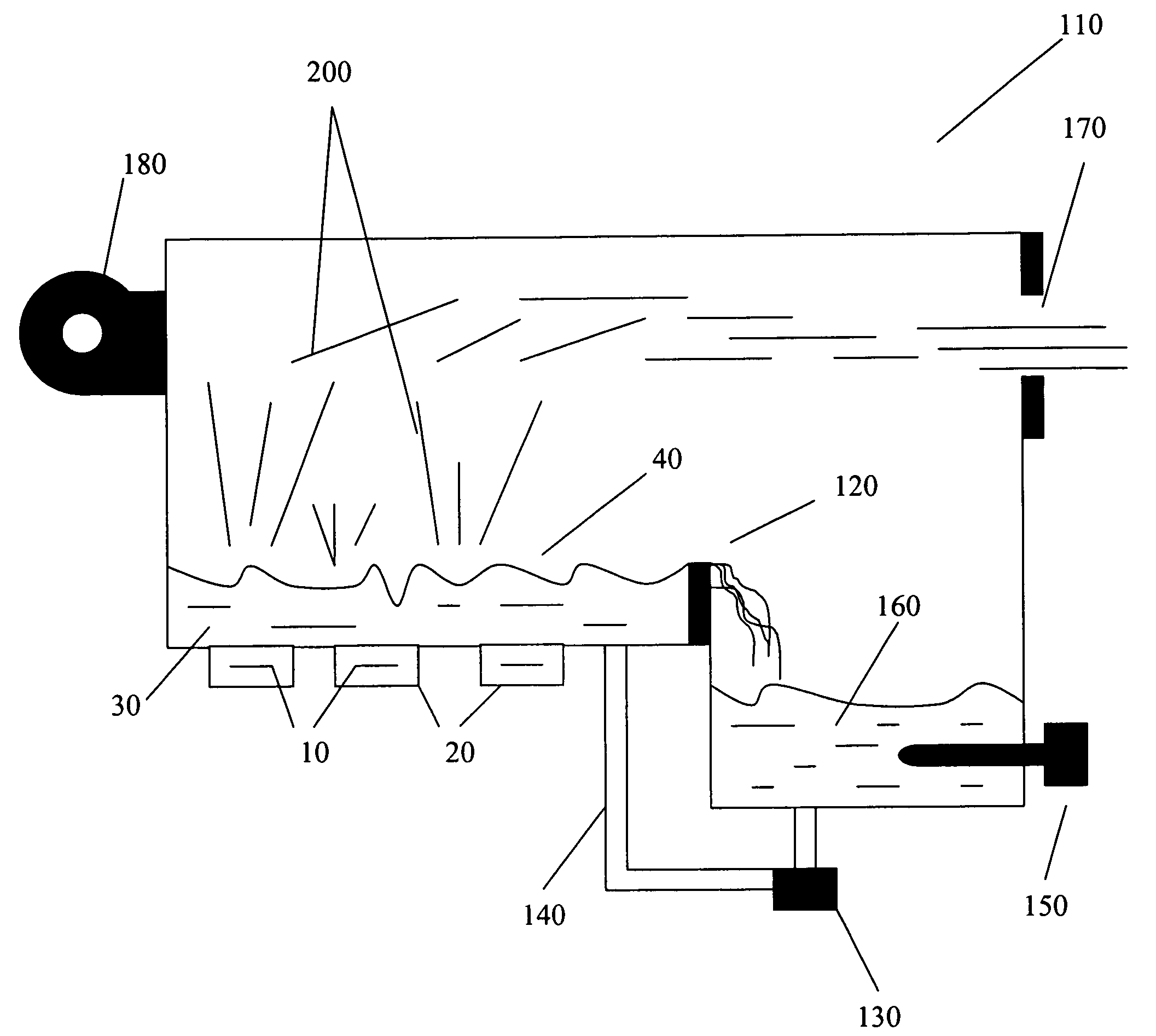

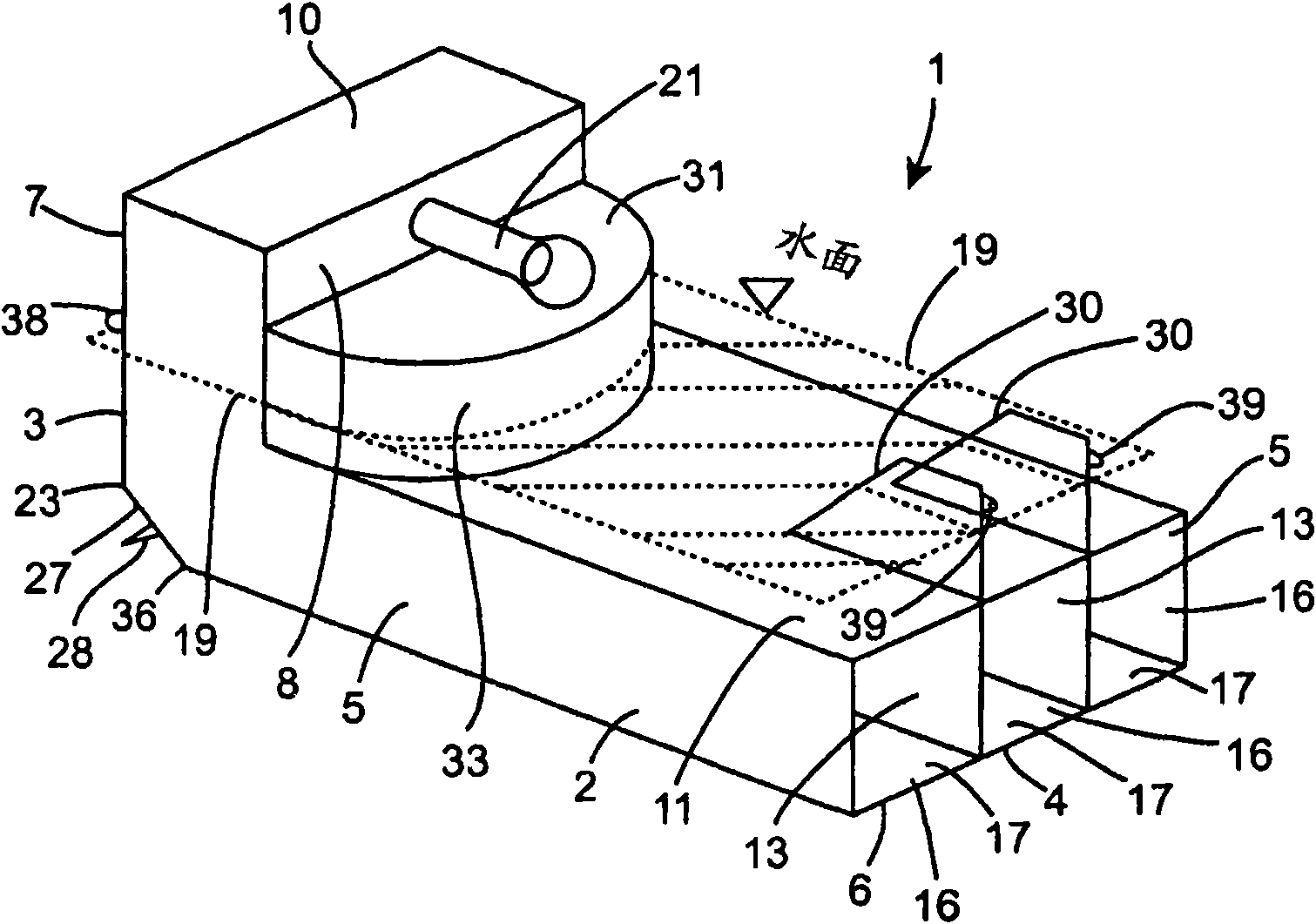

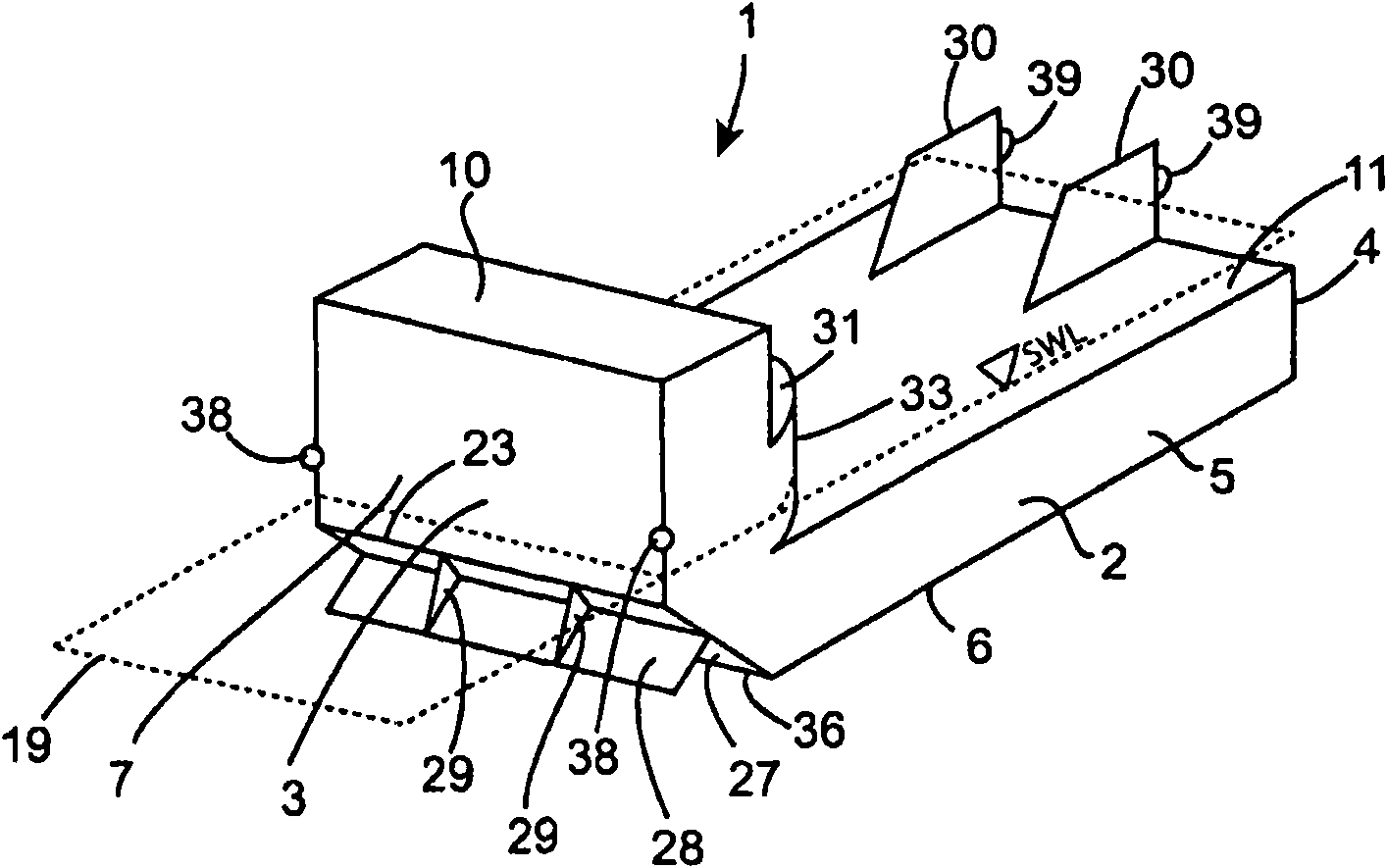

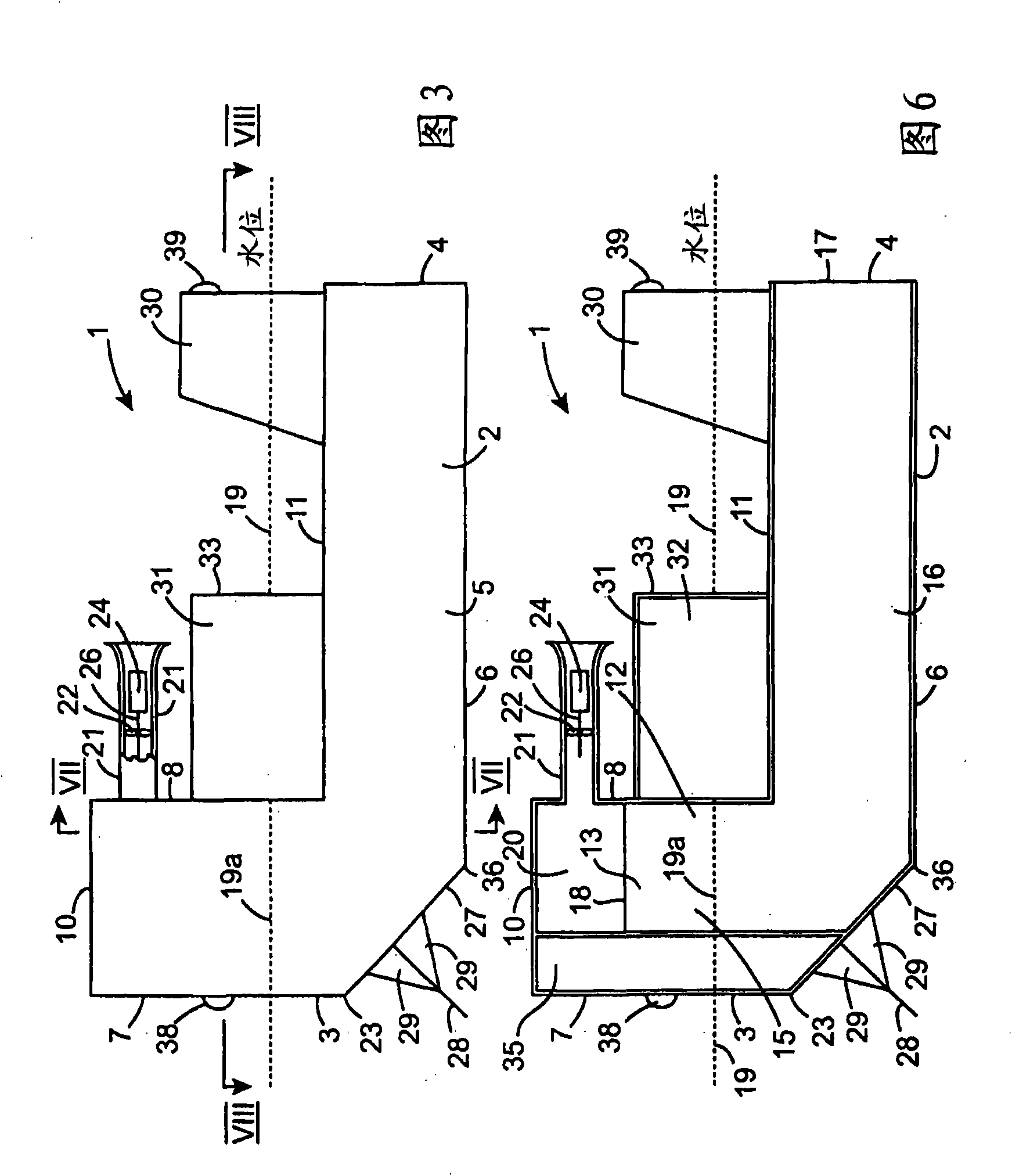

A floatable wave energy converter and a method for improving the efficiency of a floatable wave energy converter

ActiveCN101568720AImprove efficiencyHigh outputMachines/enginesEngine componentsElectricityAir conditioning

A wave energy converter (1) comprises a housing (2) extending between a forward end (3) and an aft end (4). Three upstanding air chambers (15) are located in the housing (2) and three corresponding water accommodating ducts (16) extend aft from the air chambers (15) and terminate in aft water accommodating openings (17) for accommodating water into and out of the air chambers (15) as the housing (2) oscillates by pitching in response to passing waves. An air accommodating duct (21) communicates with the air chambers (15) through a manifold (20) for accommodating air into and out of the air chambers (15) as the water level (19a) falls and rises within the air chambers (15) as the housing (2) oscillates. A self-rectifying turbine (22) located in the air accommodating duct (21) powers an electrical generator (24) for generating electricity. A buoyancy tank (31) is located on the housing (2) above the water accommodating ducts (16) aft of the air chambers (15) for maintaining the housing (2) floating in the water. A first stabilising plate (28) extending in a generally forwardly downwardly direction extends from a lower sloping portion (27) at the forward end (3) of the housing (2) for controlling the pitching oscillating motion of the housing (2) relative to wave motion for in turn enhancing the power output produced by the converter (1). A forward ballast tank (31) and a pair of second stabilising plates (30) extending upwardly from the housing (2) enhance the stability of the converter (1).

Owner:MARITIME TECH LTD

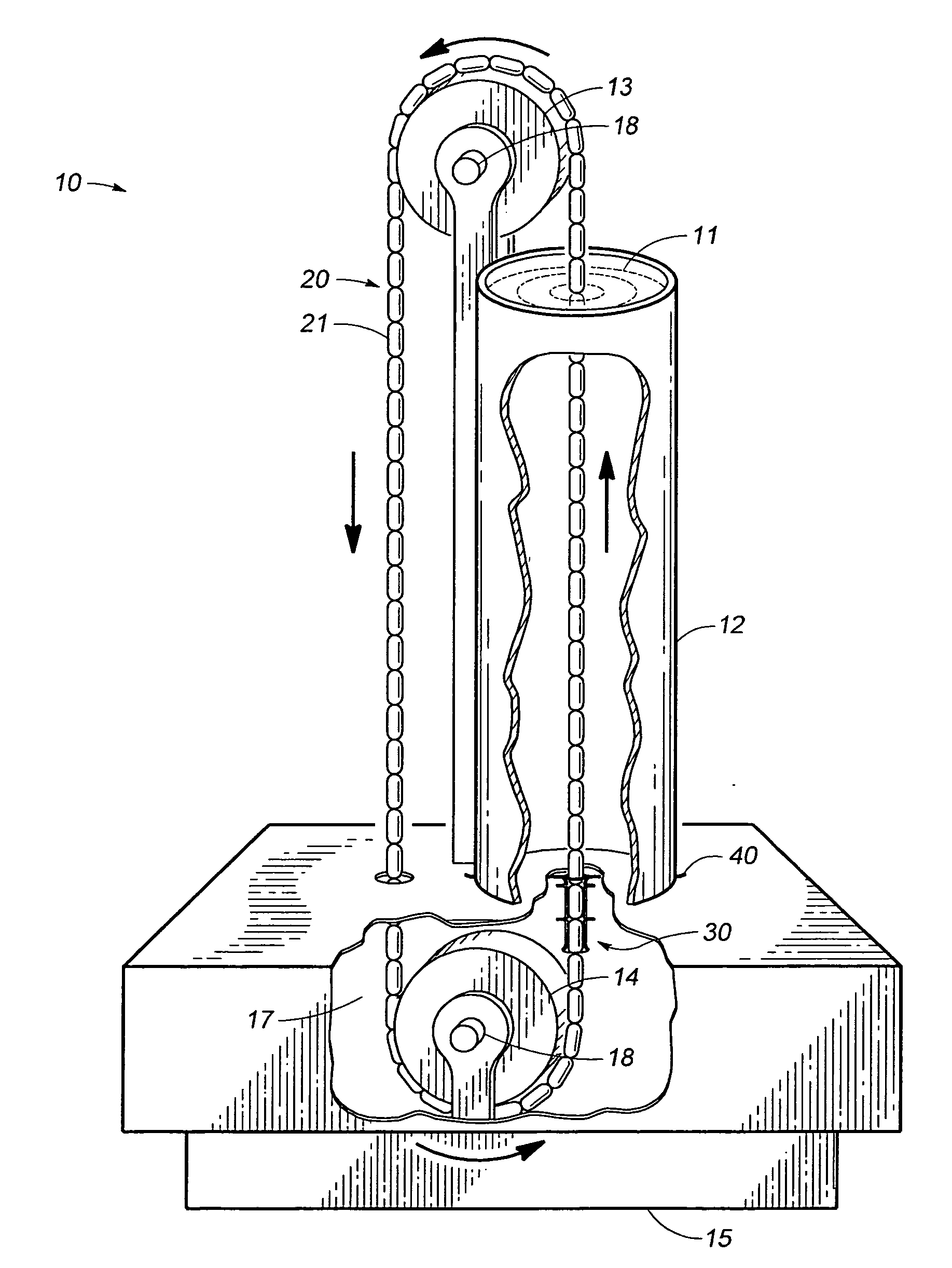

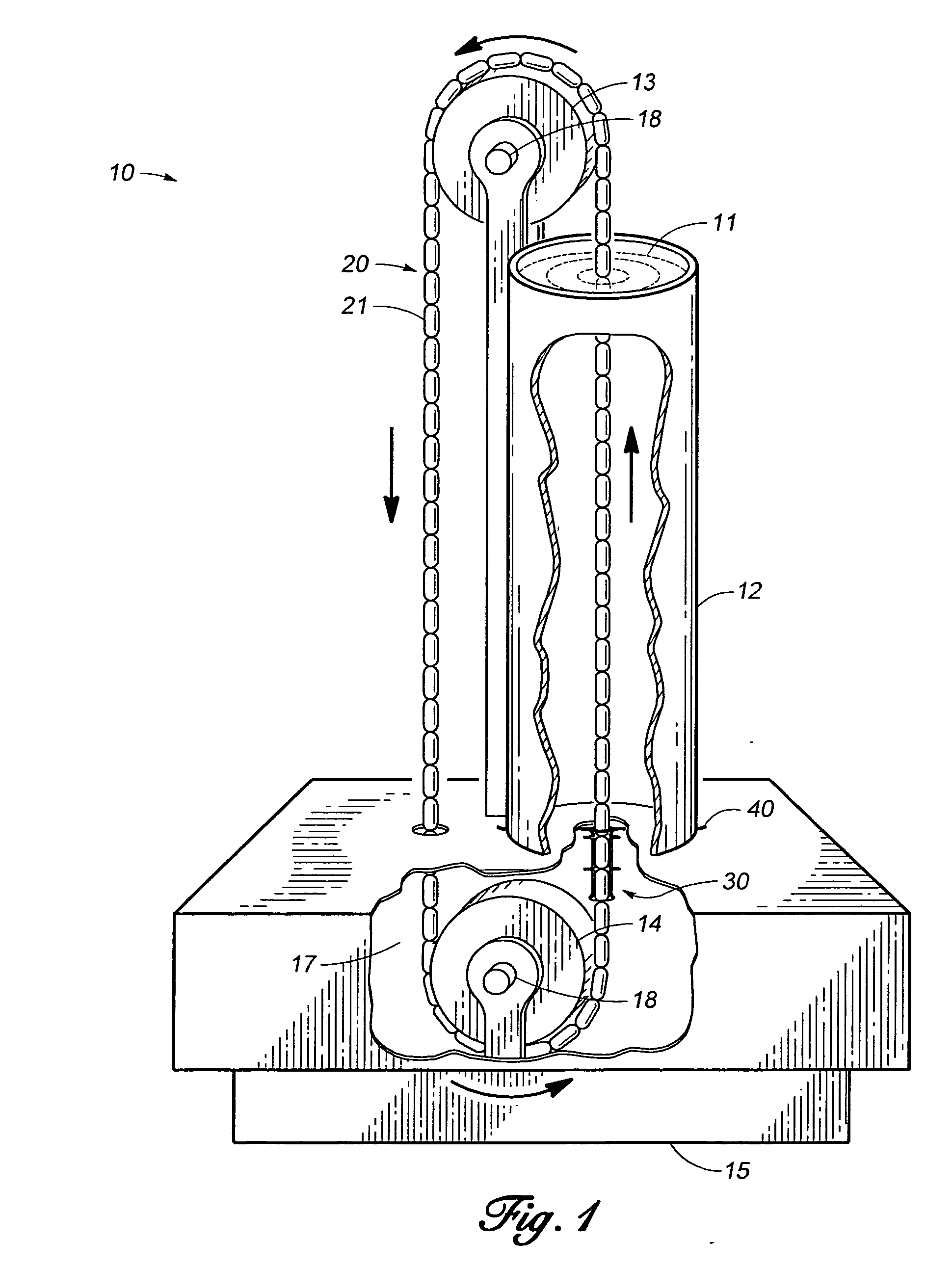

"Closed Loop" Economy of Motion Machine

InactiveUS20100223922A1Preventing working fluid lossIncrease power generationHydro energy generationMachines/enginesDifferential pressureMechanical wear

A means and apparatus for fluid containment providing for closed loop operation of an apparatus within a column of liquid. The apparatus extracts power from a buoyant source within the contained column of liquid and is comprised of an endless chain of movable buoyant objects, a means to convert the movement of the chain into useful work and a tank filled with a constant volume column of liquid. The buoyant objects comprising the chain sequentially enter the bottom of the liquid column through an airlock seal of the current invention, move up through the column and emerge at the surface. The emerging buoyant objects leave the tank and are directed to the tank bottom where each buoyant object repeats the cycle. As the chain of buoyant objects cycles through the displaced column of liquid, the volume of liquid remains constant, with one buoyant object of the chain entering the bottom of the liquid column as one is exiting at the top surface. The invention provides for closed loop operation of the apparatus and increased control fluid flow rates within the apparatus to addresses liquid leakage due to mechanical wear at seals and to provide a controlled method for removal of friction generated heat within the apparatus. Chambered sections within the apparatus create fluid flow restriction zones where differential pressure can be controlled to further reduce the force requirement for injecting each buoyant object (a.k.a. displacing element) into the bottom of the contained column of liquid.

Owner:MCGAHEE VINCENT DEPAUL

Dual direction exercise treadmill for simulating a dragging or pulling action

InactiveUS20080287267A1Reduced strengthNeed can be addressedMuscle exercising devicesMovement coordination devicesEngineeringPulley

An exercise treadmill having an endless moveable surface looped around rollers or pulleys to form an upper run and a lower run, the movable surface being rotated when one of the rollers or pulleys is rotated, and an exercise surface for walking or running while exercising, a weight resistance mechanism for providing a weight resistance for simulating the dragging or pulling of a load, wherein the weight resistance can be adjusted and set to a specific weight resistance setting; a movable hand grip controller operatively attached to the weight resistance mechanism for operating and controlling the exercise treadmill and the weight resistance mechanism, wherein the endless movable surface moves in a direction simulating walking or running backwards, and wherein the weight resistance mechanism applies an approximately constant and static force to the hand grip controller generally only in the same as the direction the endless movable surface moves and opposite a pulling direction, whereby operation of the treadmill simulates the dragging or pulling of a load by a combination of the actuation of the weight resistance mechanism to simulate the load and the walking or running backwards to provide the dragging or pulling action.

Owner:FITNESS TOOLS

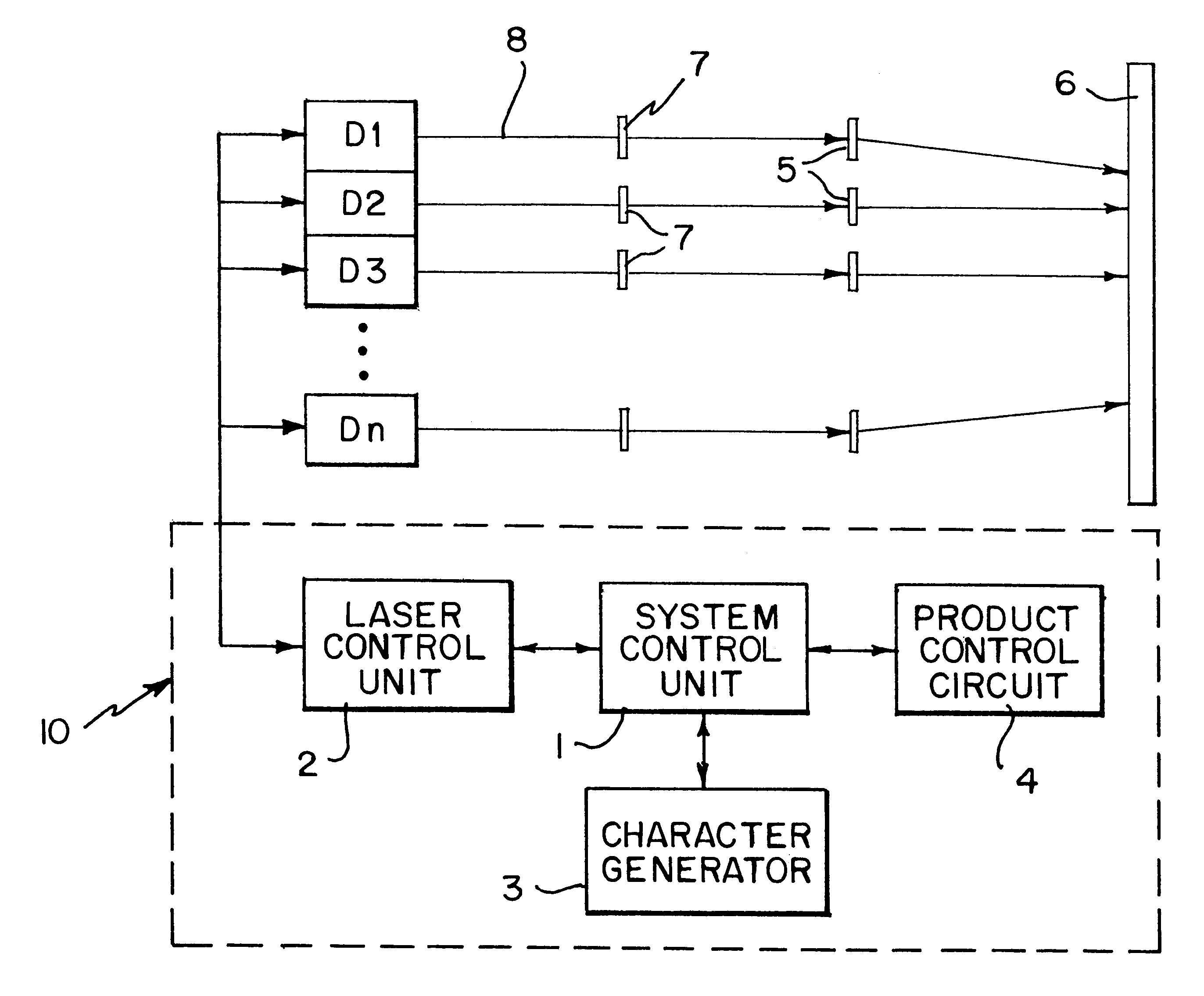

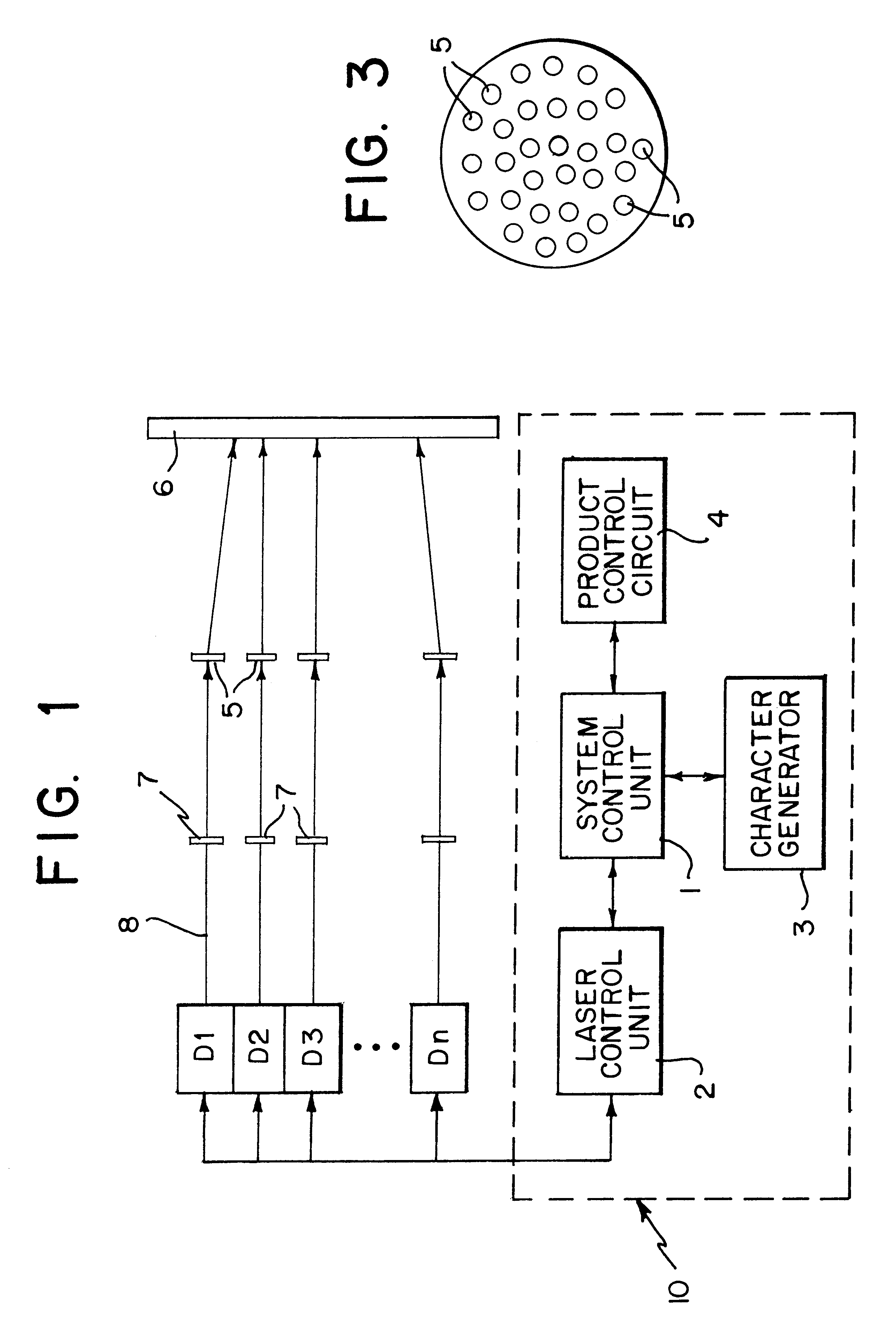

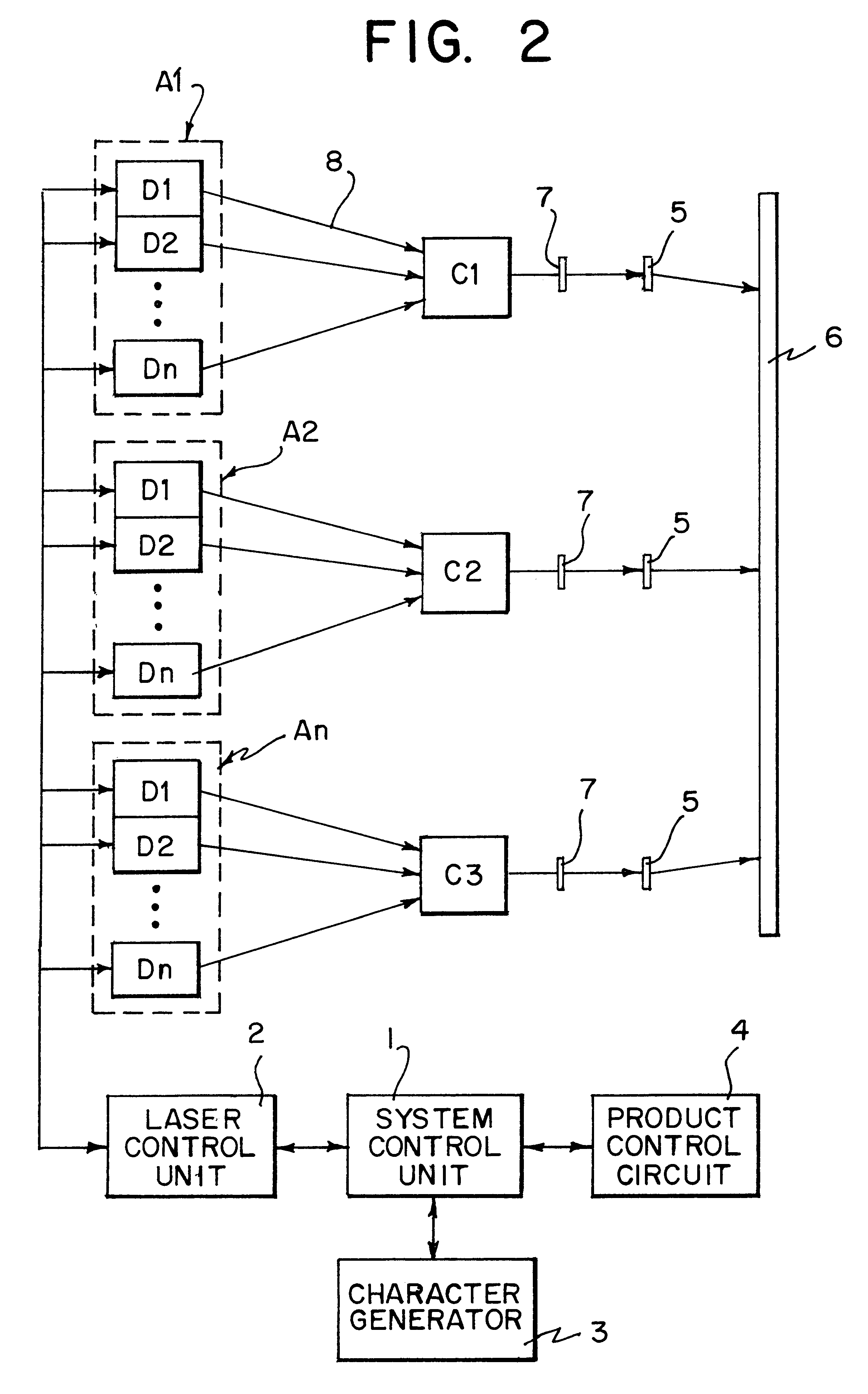

Laser marking apparatus with diode laser matrix

InactiveUS6201210B1Increase energy outputVisual presentationDigital marking by photographic/thermographic registrationLight beamLaser light

A laser marking system includes a means for generating a laser beam and a marking control unit which generates individual signals applied to a laser system for producing an NxM matrix of dots used to mark an object. Each dot is created from the laser light from at least one laser diode. If multiple lasers are used, their power can be combined with a concentrator to produce a single beam with a higher power and also provide for simplified control over the beam's power.

Owner:MACSA ID

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com