Patents

Literature

117results about "Digital marking by photographic/thermographic registration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System and method for digital bill presentment and payment

InactiveUS20050033690A1Reduce complexityEnhanced interactionFinancePayment architectureCredit cardDigital data

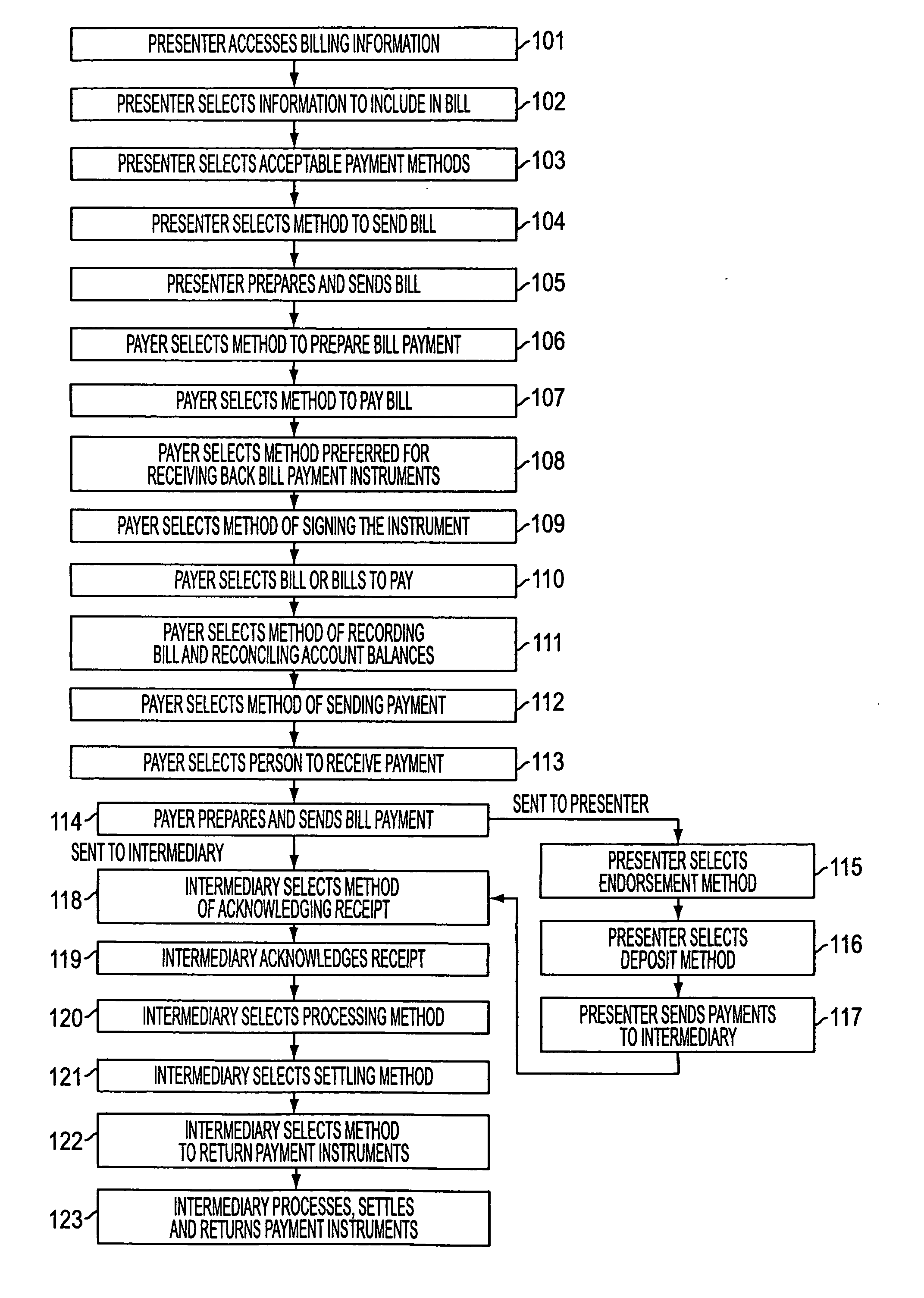

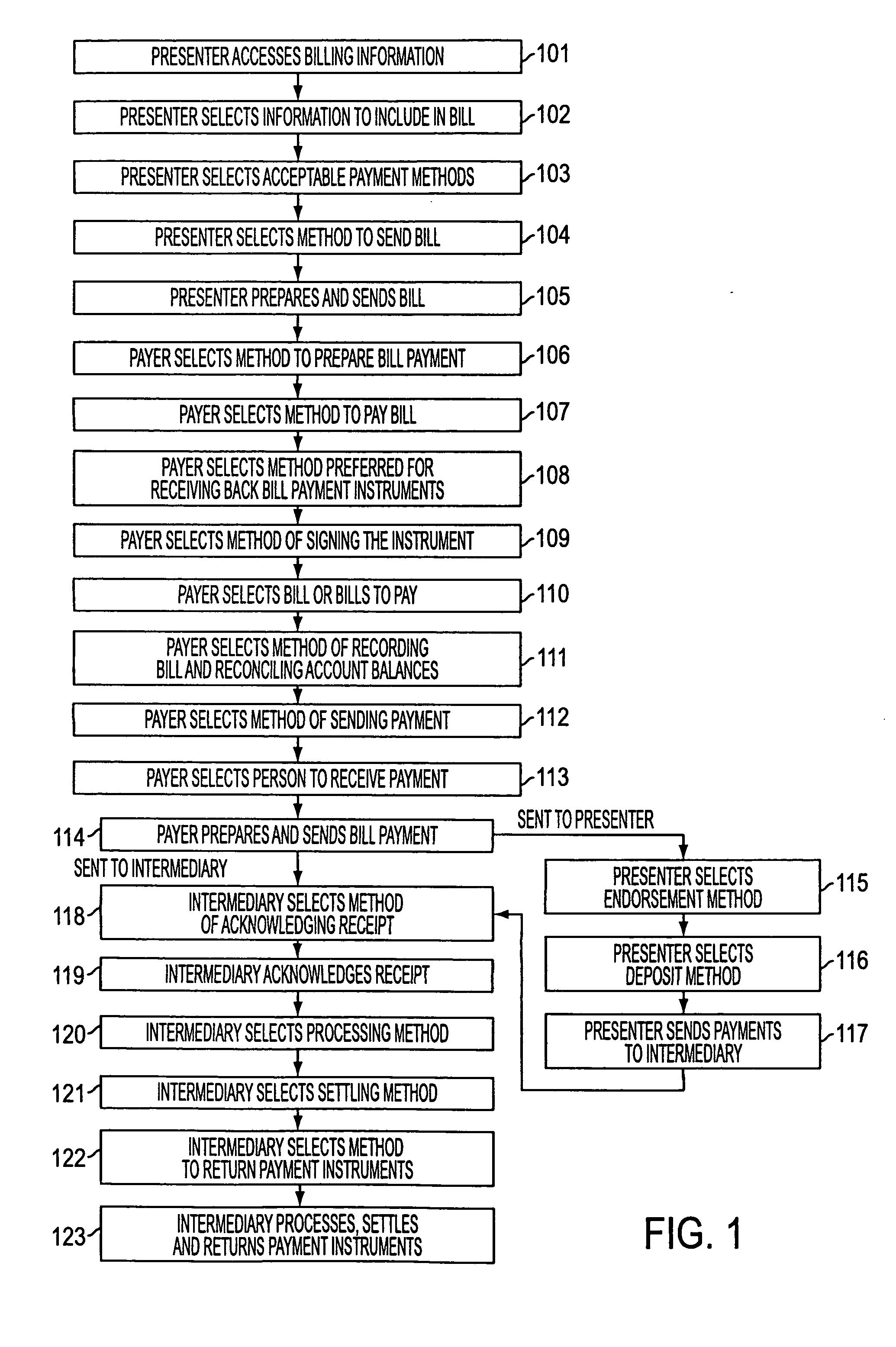

A system of bill presentment and bill payment. The parties to the process, which typically include the bill presenter, bill payer, and bank, credit card company or other intermediary, select from a number of choices in the selection of information to include in the bill, preparation of the bill, acceptable payment methods, means to send the bill and bill payment instrument, means of signing the bill, bill payment instrument, receipt acknowledging deposit and payment, method of recording and reconciling payments, and further actions. An accumulation of choices by the involved parties can include digital information in each step that represents all of the significant data accumulated up to and including that step. That digital data preferably includes digital signatures of each party at each step so as to provide an audit trail in purely digital form. Where digital data is chosen for each step, the digital data can be electronic or, using machine readable code, printed on paper, regardless of the form chosen in prior or later steps.

Owner:ANTOGNINI WALTER GERARD +1

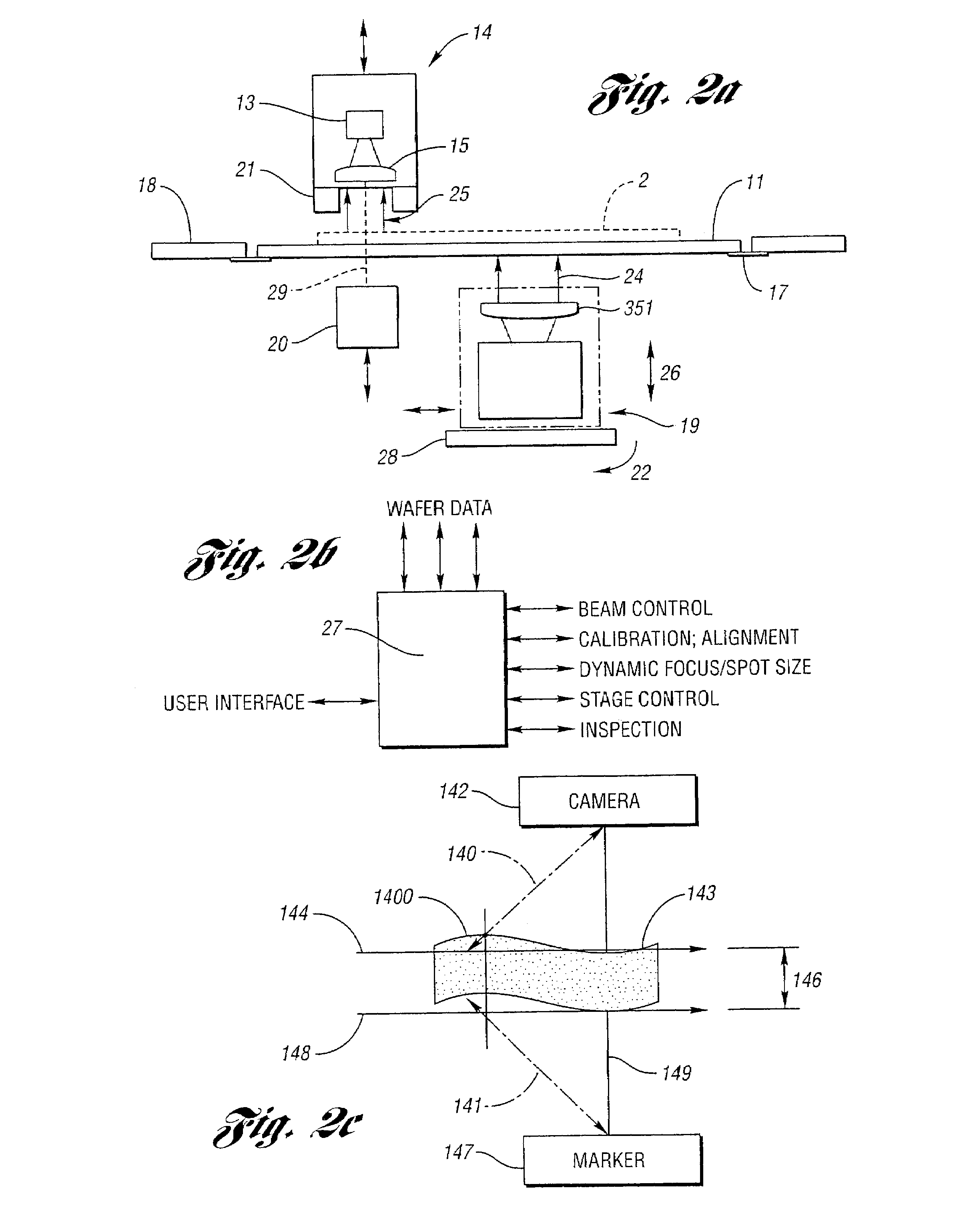

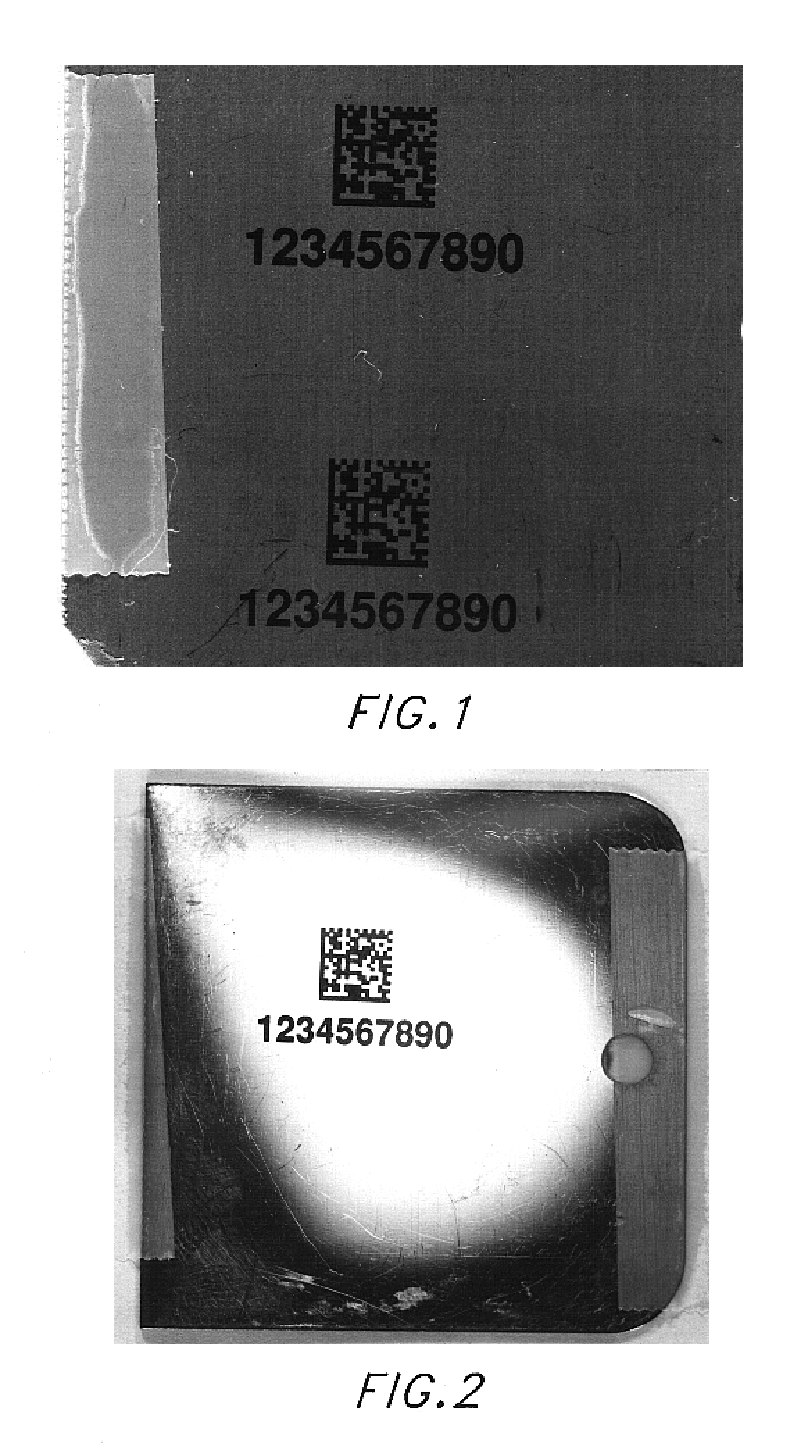

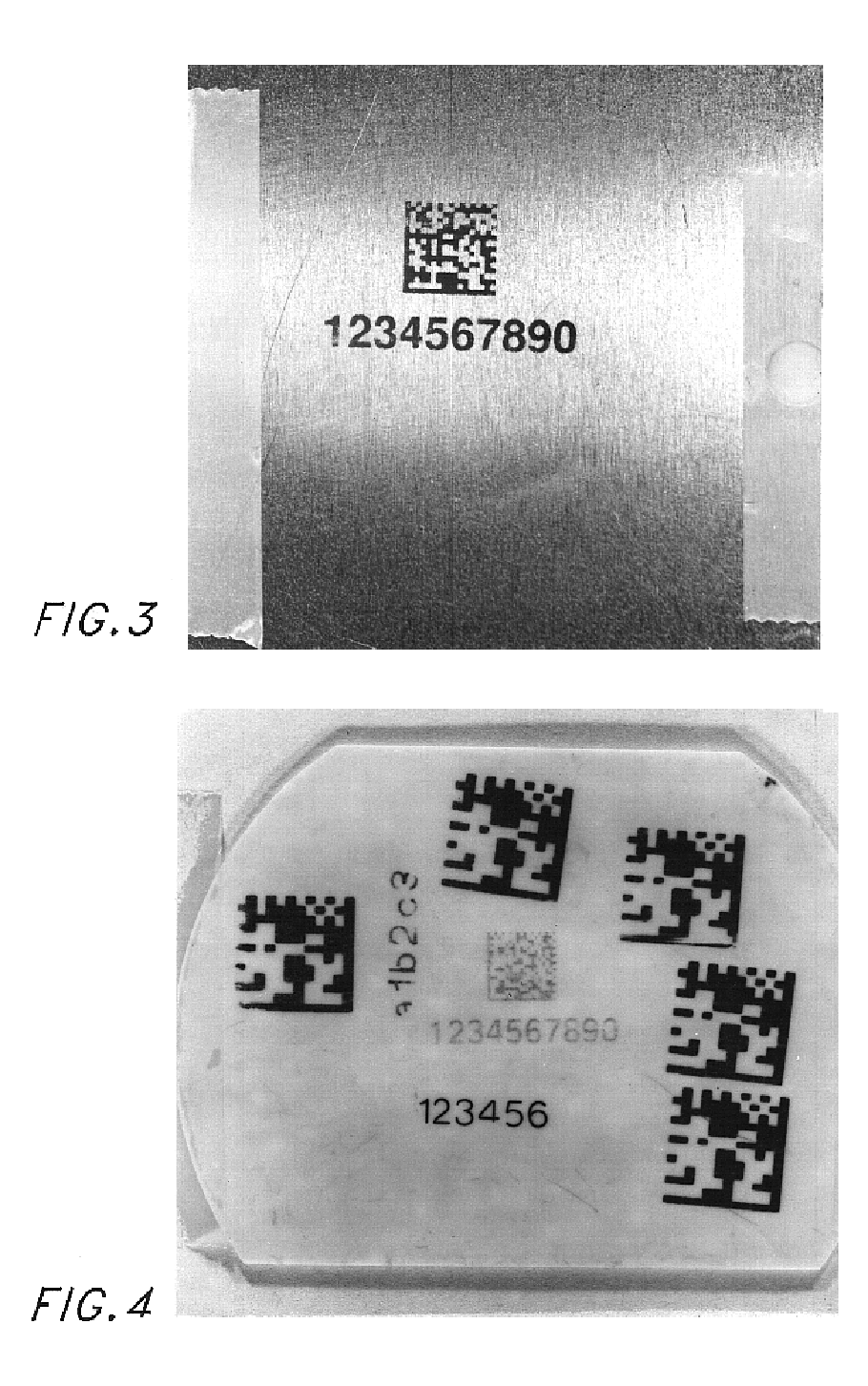

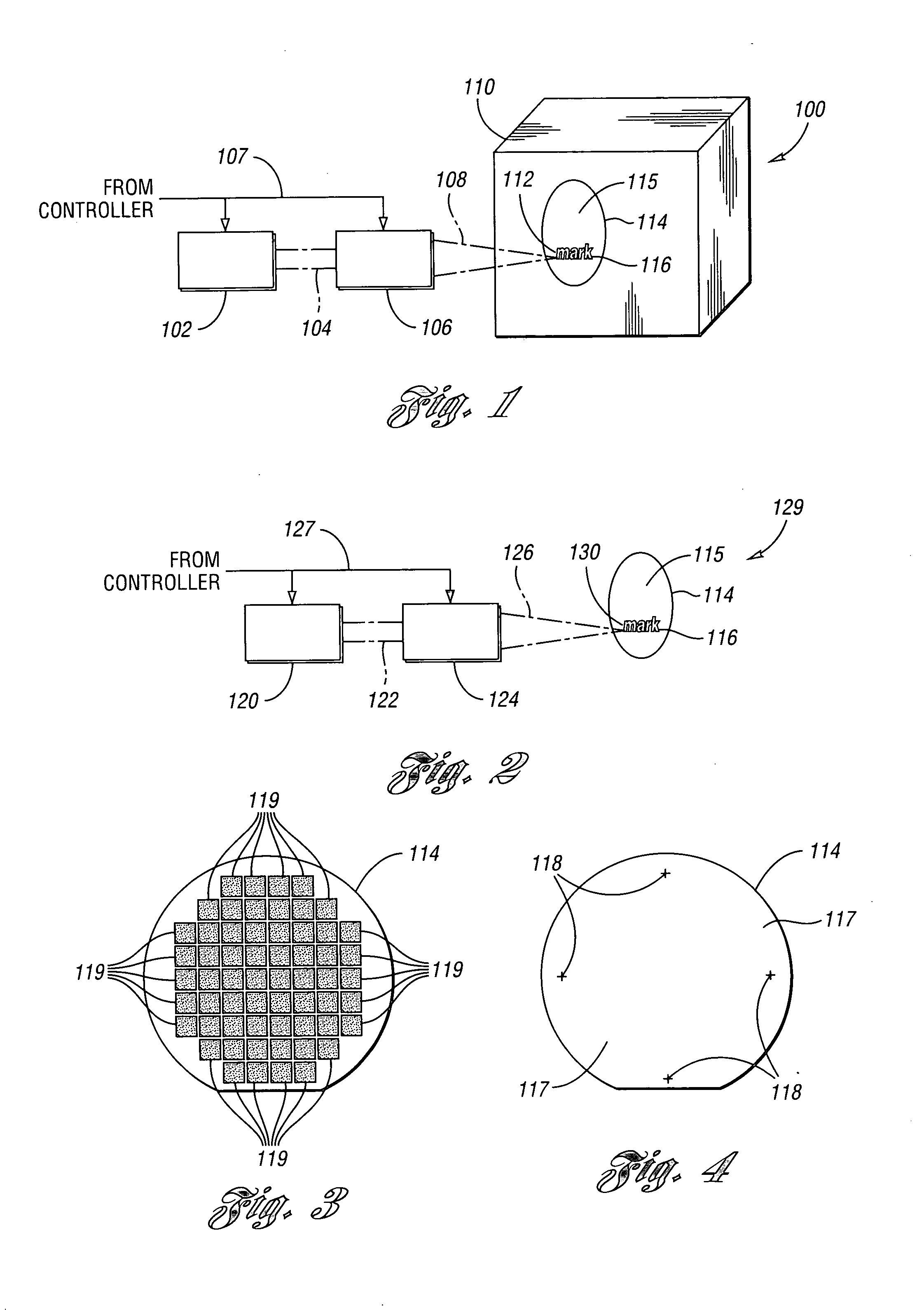

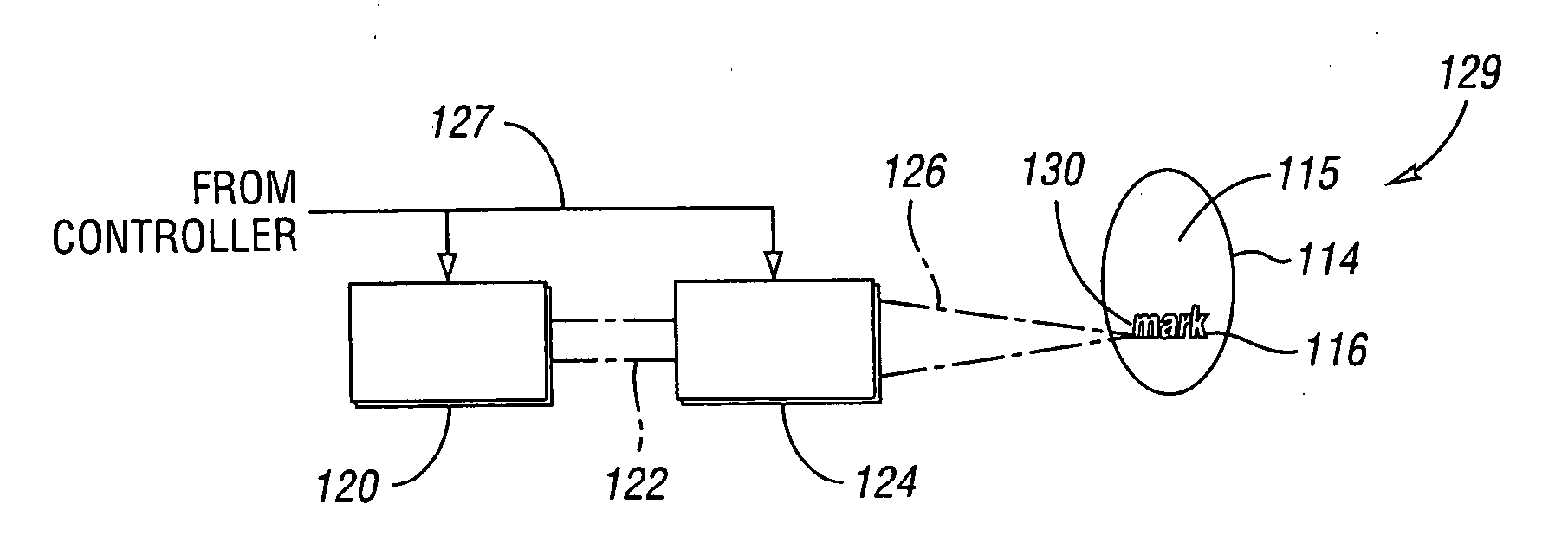

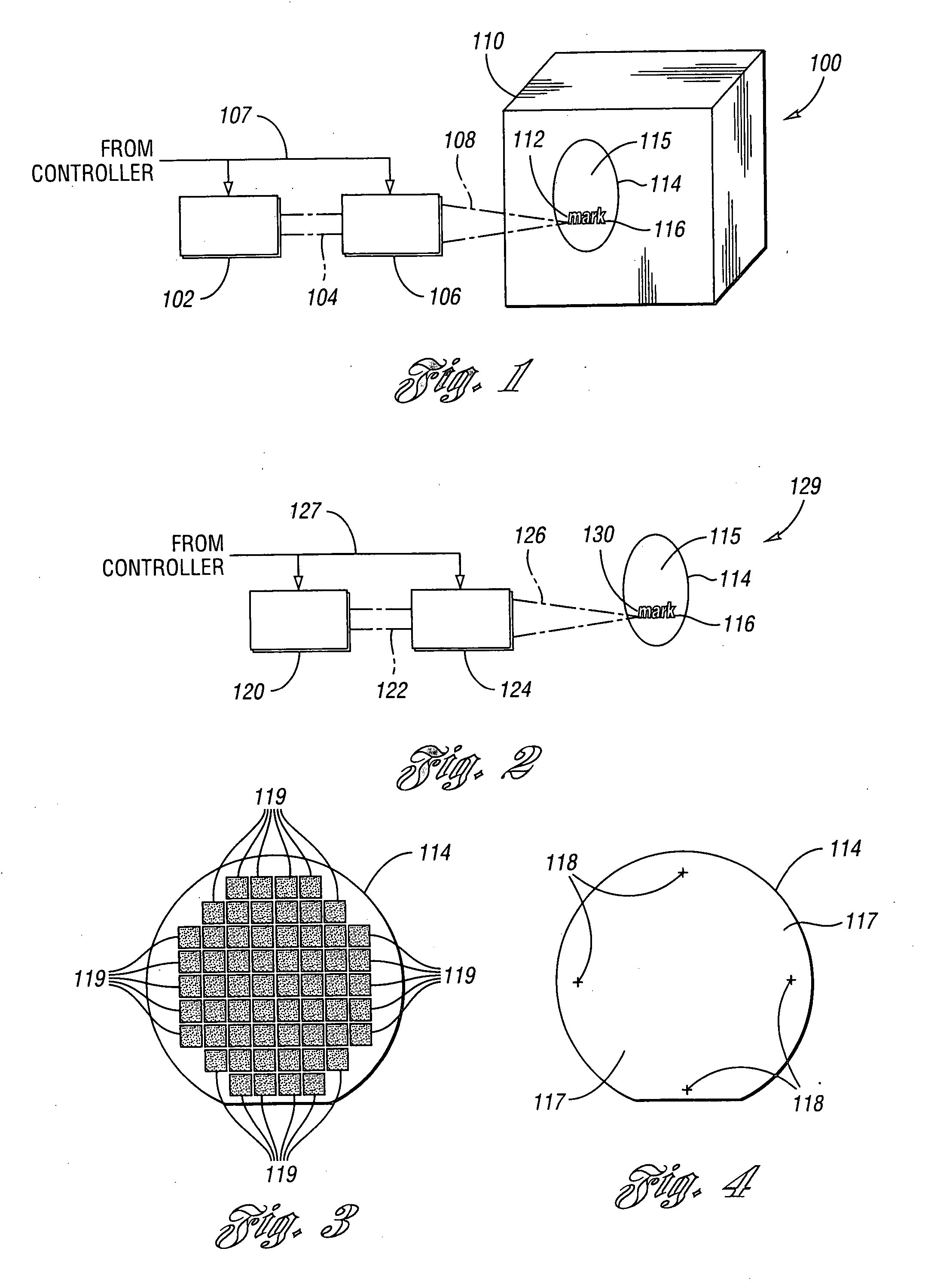

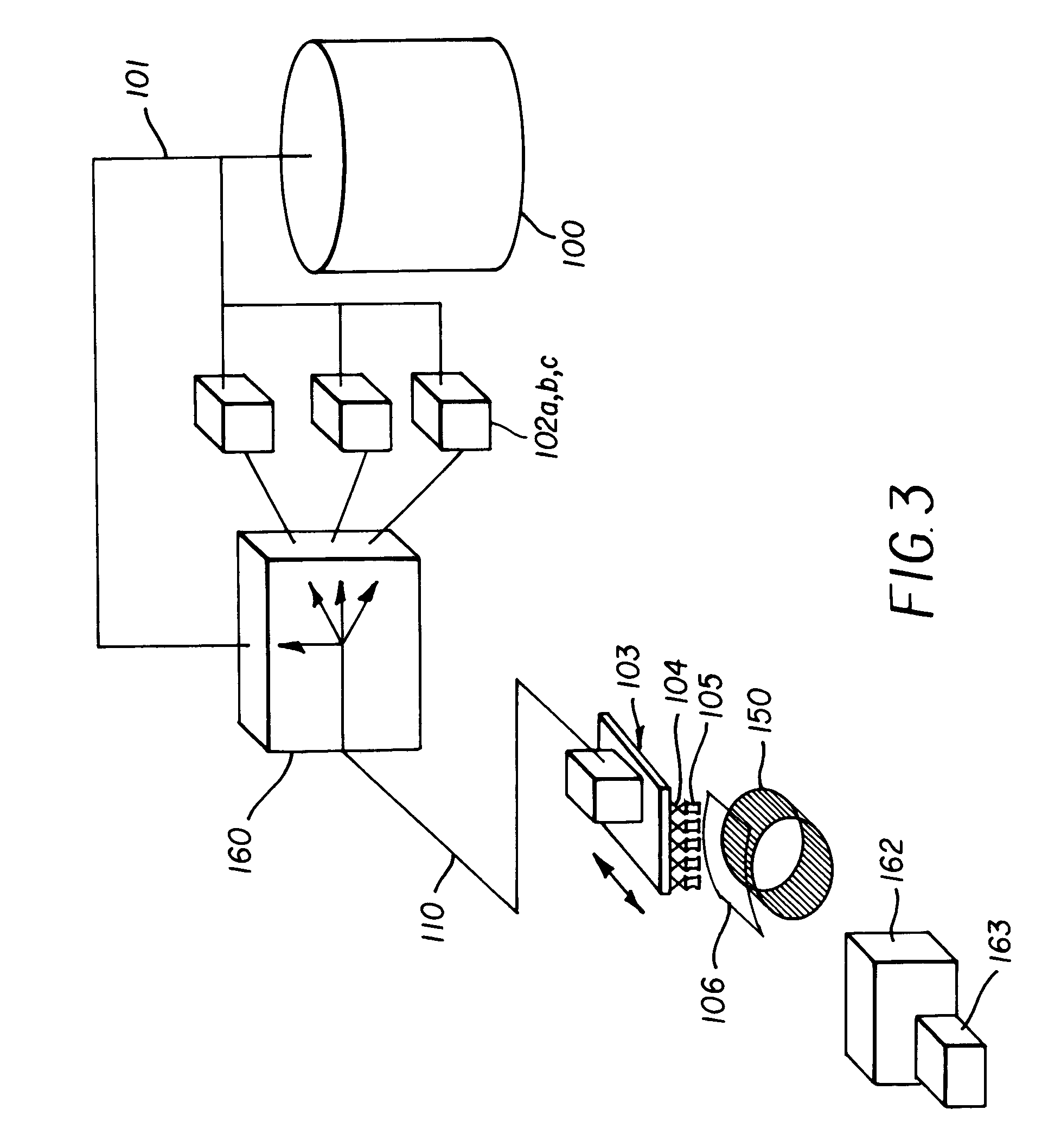

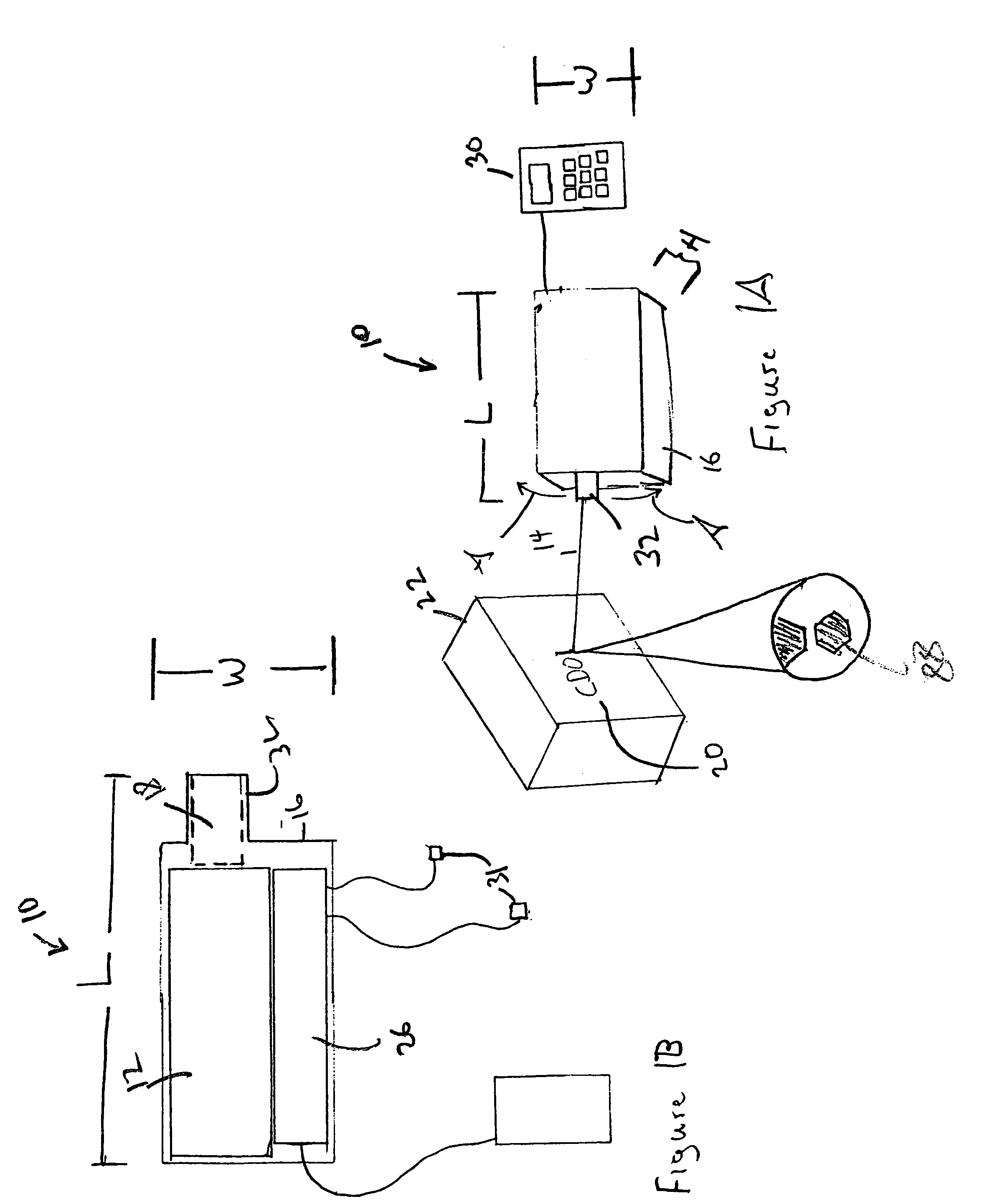

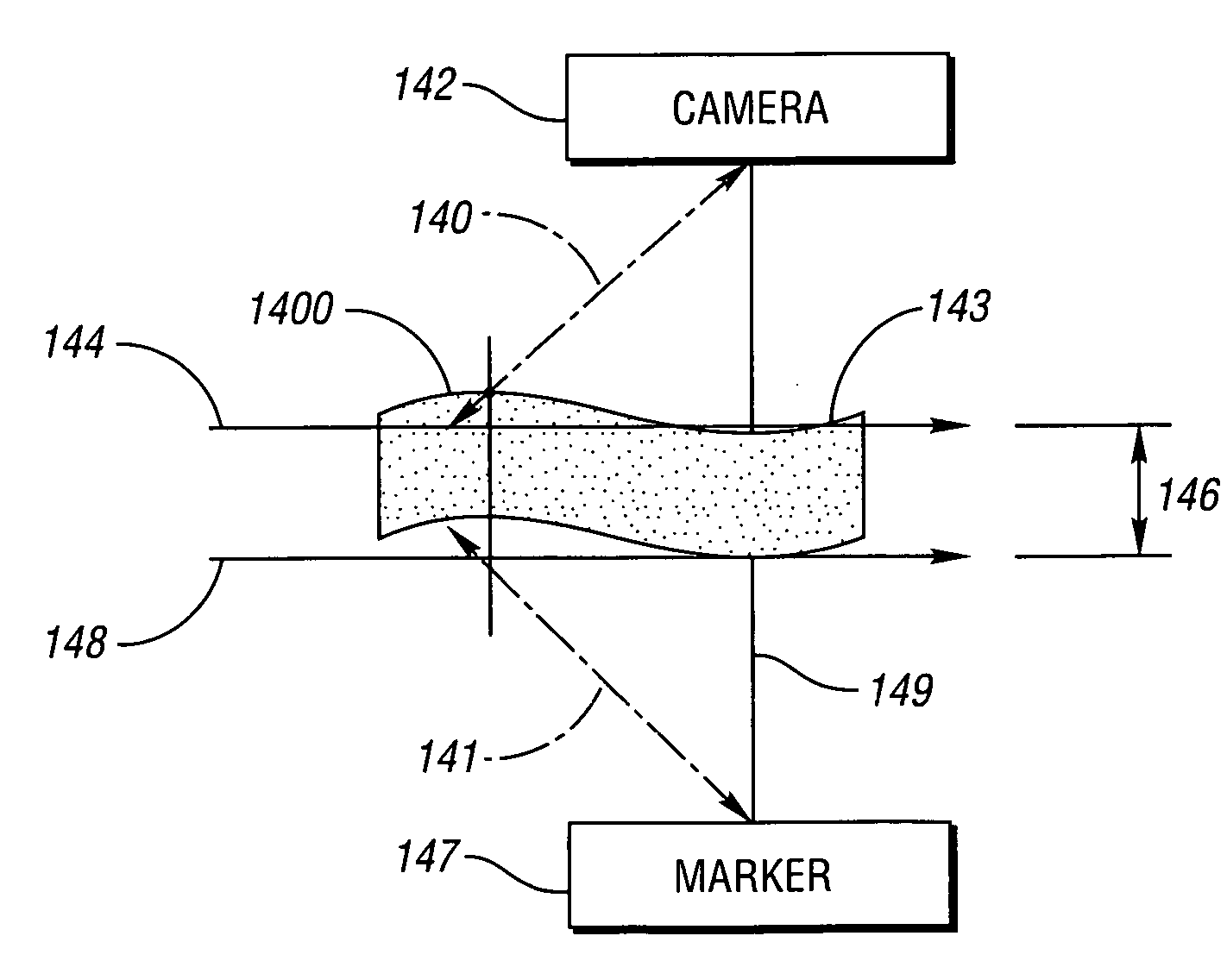

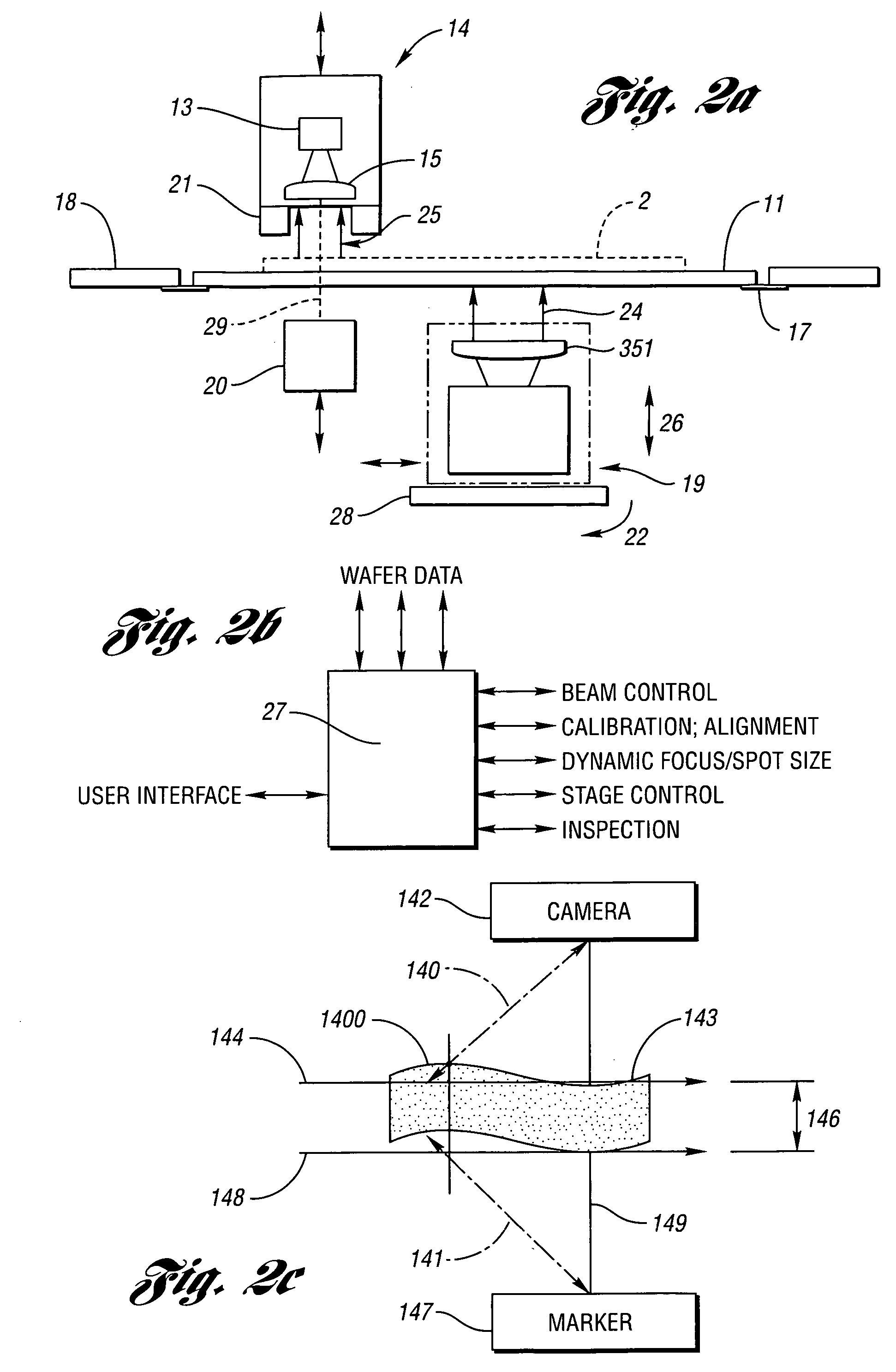

Method and system for calibrating a laser processing system and laser marking system utilizing same

InactiveUS7015418B2Mark accuratelyRecording apparatusSemiconductor/solid-state device detailsLaser processingThree degrees of freedom

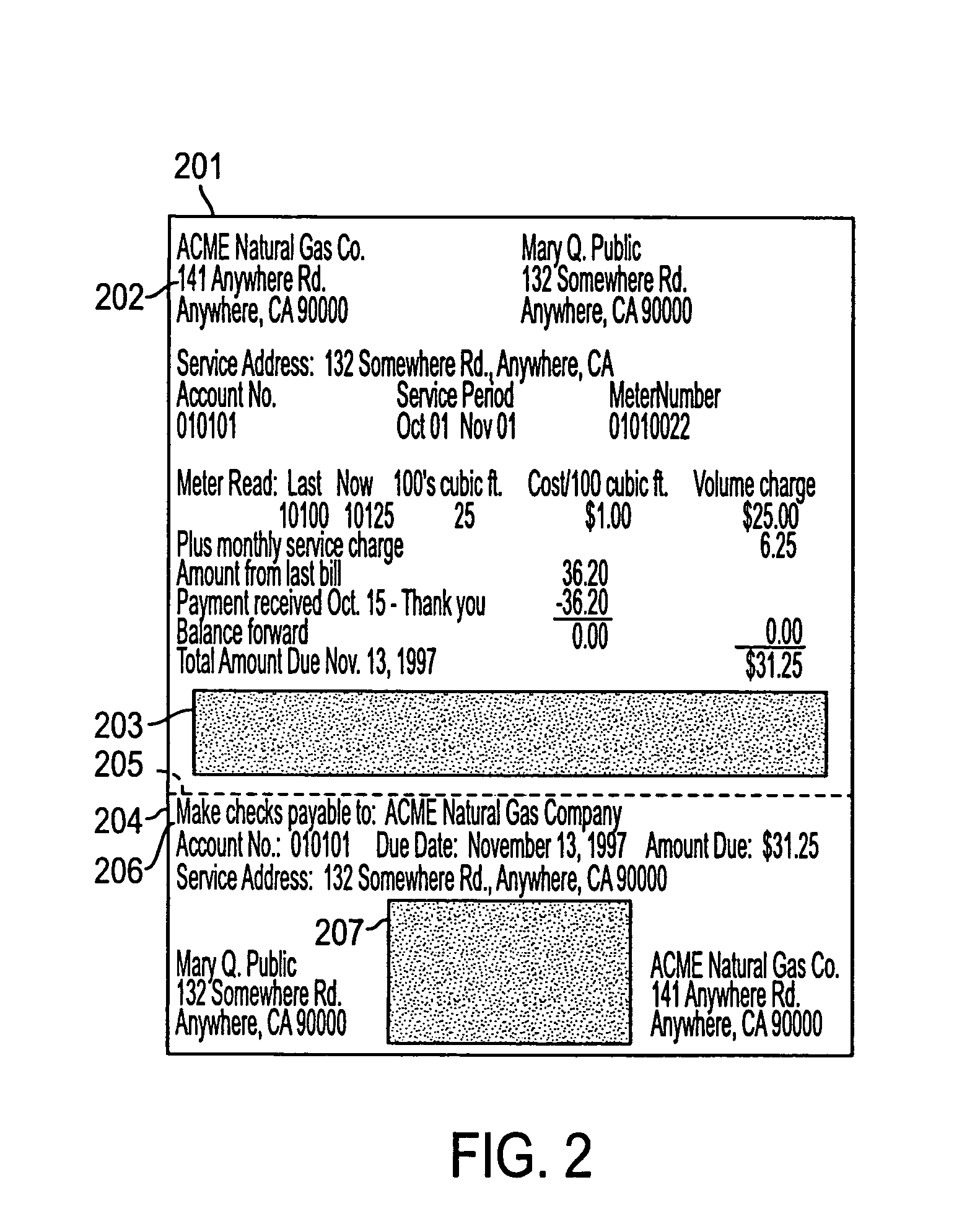

A method of calibrating a laser marking system includes calibrating a laser marking system in three dimensions. The step of calibrating includes storing data corresponding to a plurality of heights. A position measurement of a workpiece is obtained to be marked. Stored calibration data is associated with the position measurement. A method and system for calibrating a laser processing or marking system is provided. The method includes: calibrating a laser marker over a marking field; obtaining a position measurement of a workpiece to be marked; associating stored calibration data with the position measurement; relatively positioning a marking beam and the workpiece based on at least the associated calibration data; and calibrating a laser marking system in at least three degrees of freedom. The step of calibrating includes storing data corresponding to a plurality of positions and controllably and relatively positioning a marking beam based on the stored data corresponding to the plurality of positions.

Owner:ELECTRO SCI IND INC

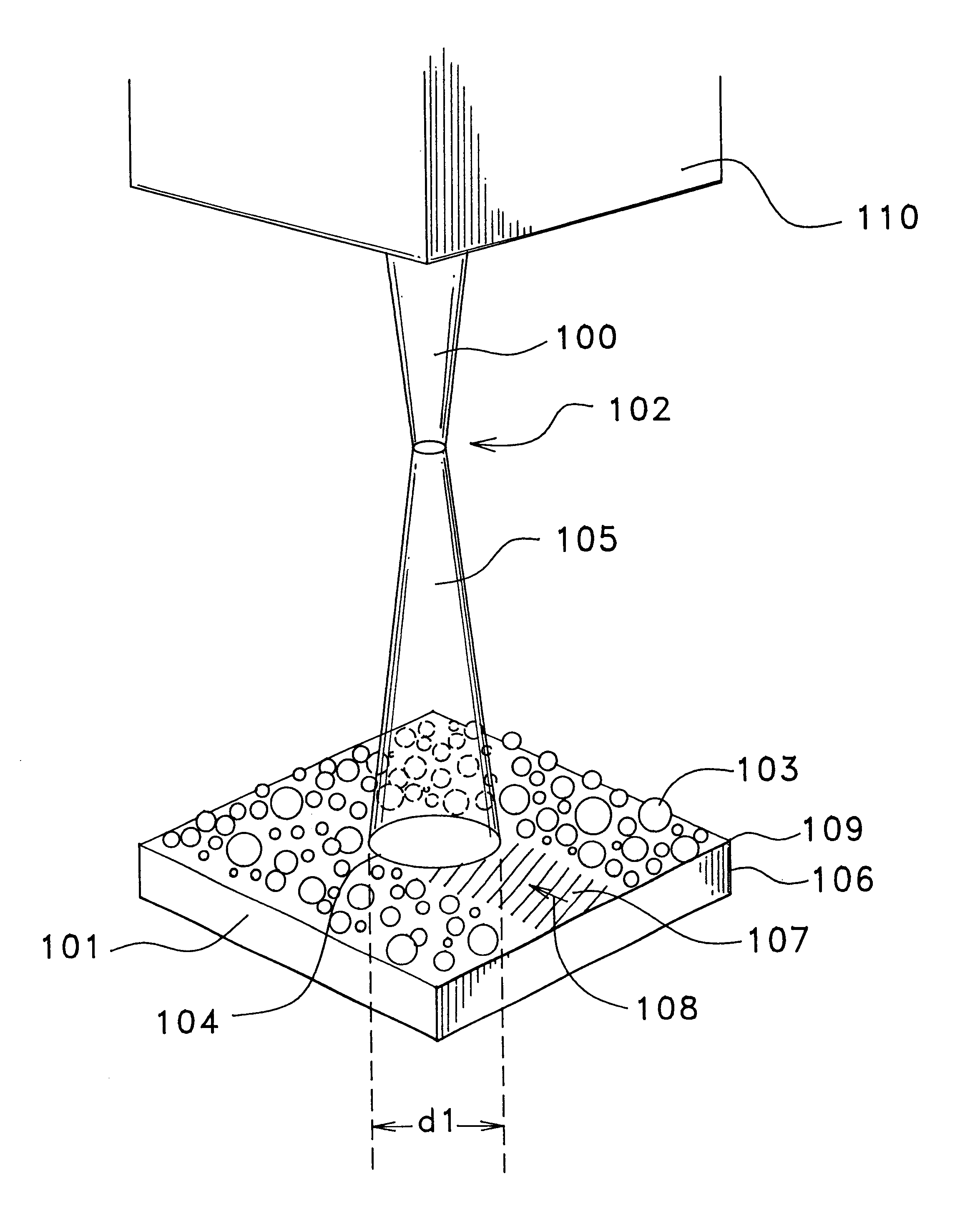

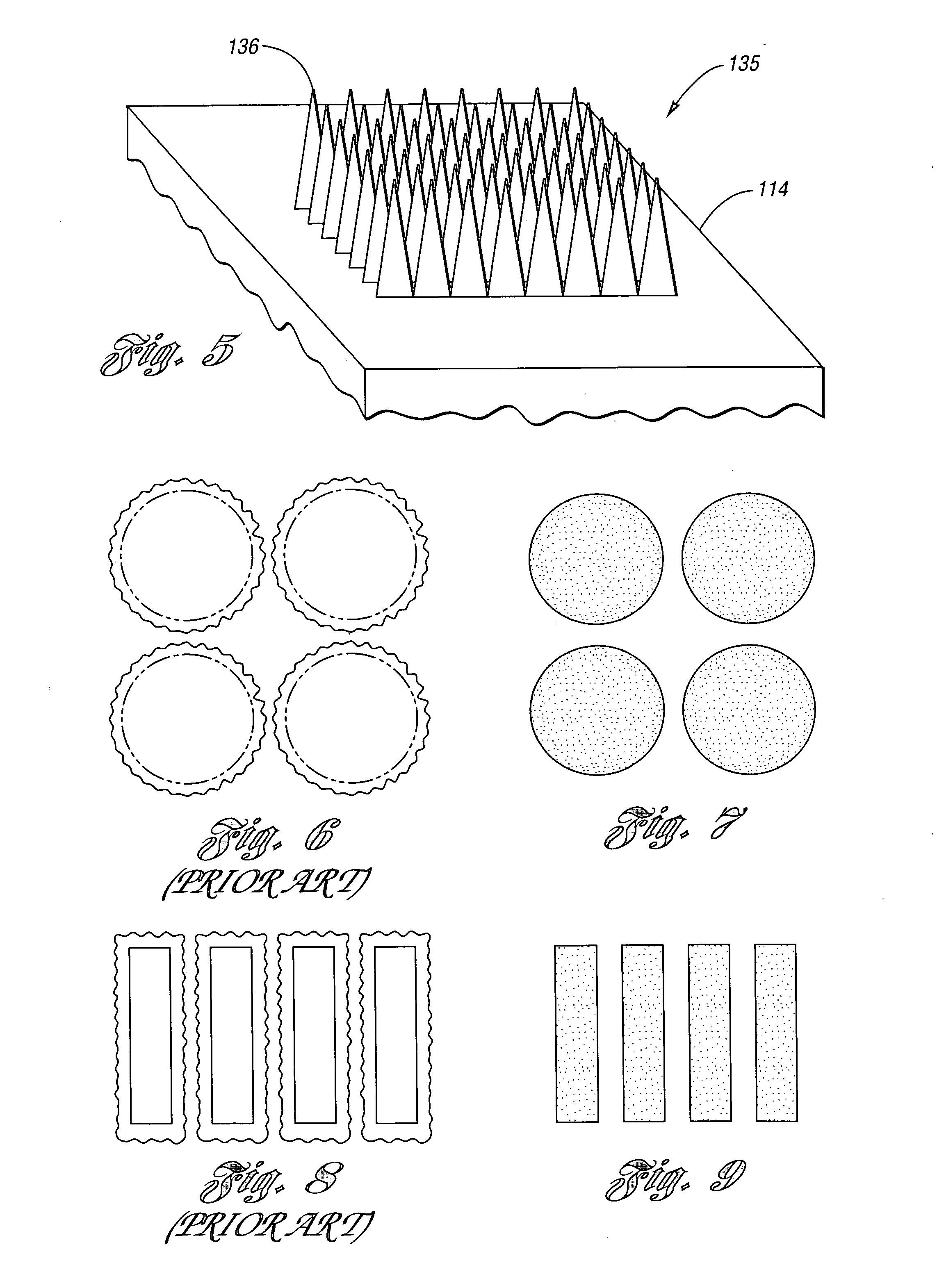

Laser-based method and system for processing targeted surface material and article produced thereby

InactiveUS20060000814A1Prevent unwanted changesSufficient total fluenceAdditive manufacturing apparatusSemiconductor/solid-state device detailsTarget surfaceSlag

A laser-based method and system for processing targeted surface material and article produced thereby are provided. The system processes the targeted surface material within a region of a workpiece while avoiding undesirable changes to adjacent non-targeted material. The system includes a primary laser subsystem including a primary laser source for generating a pulsed laser output including at least one pulse having a wavelength and a pulse width less than 1 ns. A delivery subsystem irradiates the targeted surface material of the workpiece with the pulsed laser output including the at least one pulse to texture the targeted surface material. The pulsed laser output has sufficient total fluence to initiate ablation within at least a portion of the targeted surface material and the pulse width is short enough such that the region and the non-targeted material surrounding the material are substantially free of slag.

Owner:ELECTRO SCI IND INC

High contrast surface marking using irradiation of electrostatically applied marking materials

InactiveUS6852948B1Quick tagSpeed up the processRecording apparatusRadiation applicationsVariable thicknessMaterials science

A method of radiantly marking substrates including metals, plastics, ceramic materials, glazes, glass ceramics, and glasses of any desired form, which comprises electrostatically applying to the material to be marked a variable thickness layer of marking material containing energy absorbing components and / or enhancers, then irradiating said layer with a radiant energy source such as a laser or diode based energy source such that the radiation is directed onto said layer, optionally in accordance with the form of the marking to be applied, preferably using a laser or diode based energy source of a wavelength which is sufficiently absorbed by the marking material so as to create a bonding of the marking material to the surface of the workpiece at the irradiated areas.

Owner:THERMAX LLC

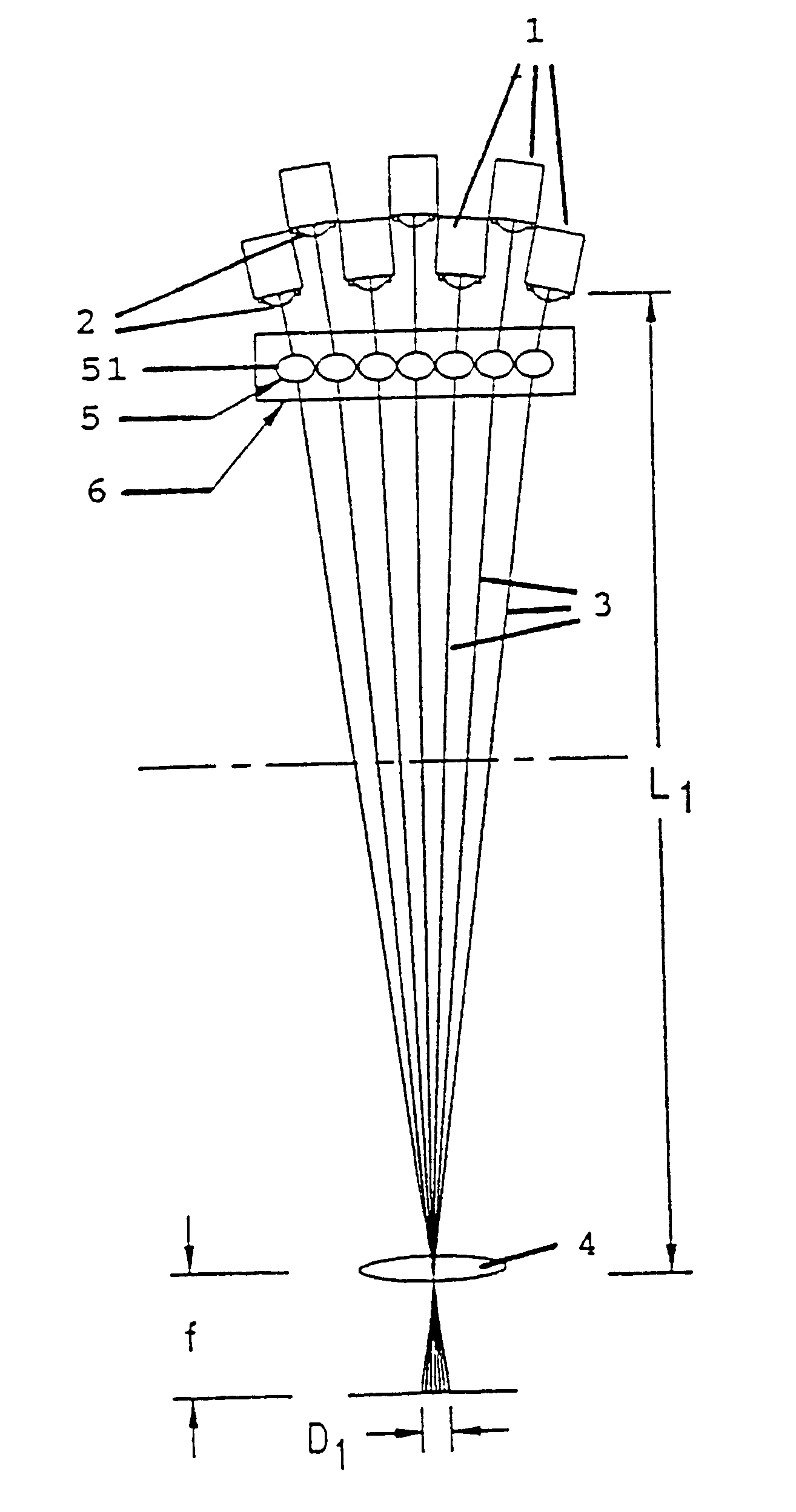

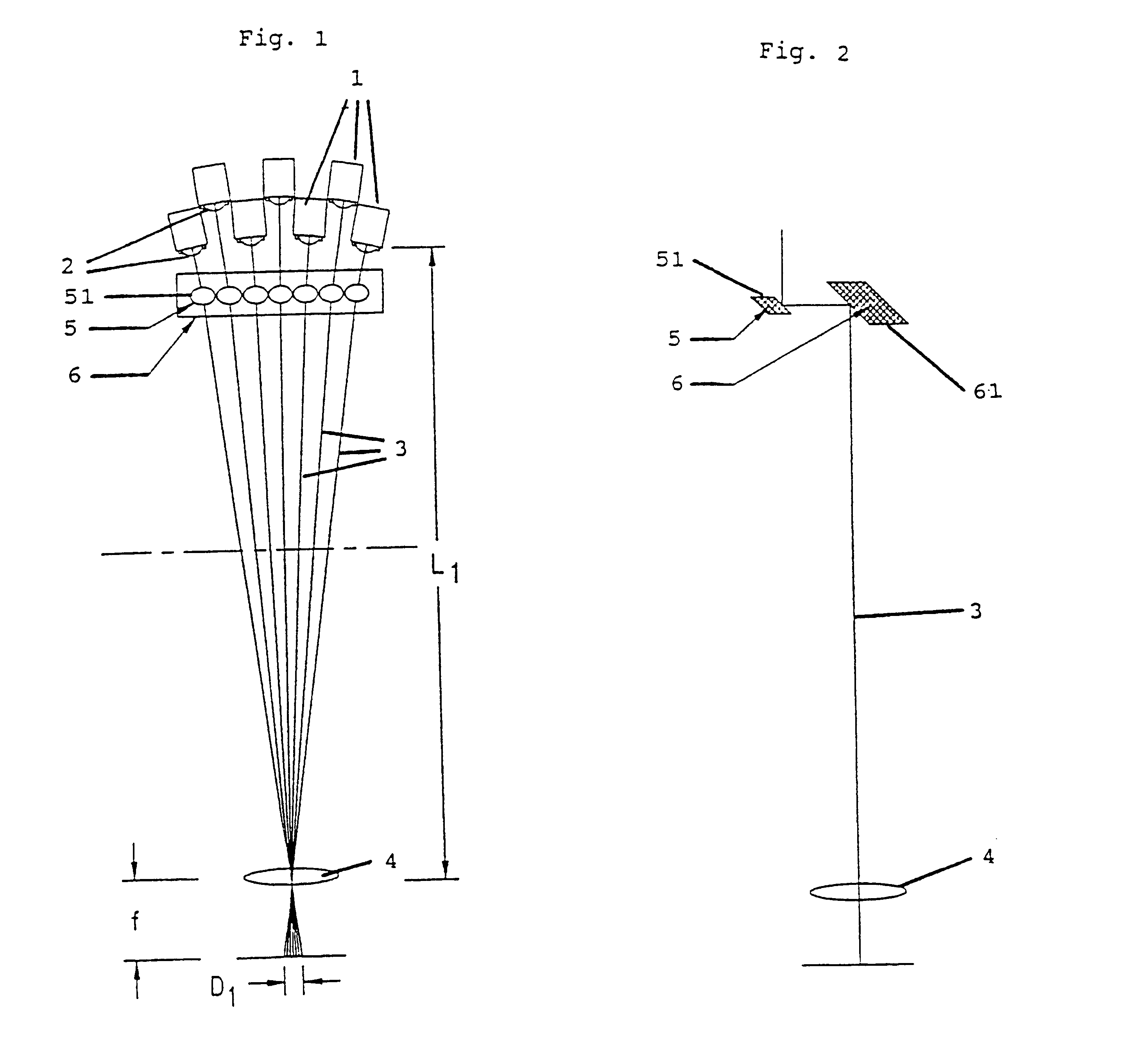

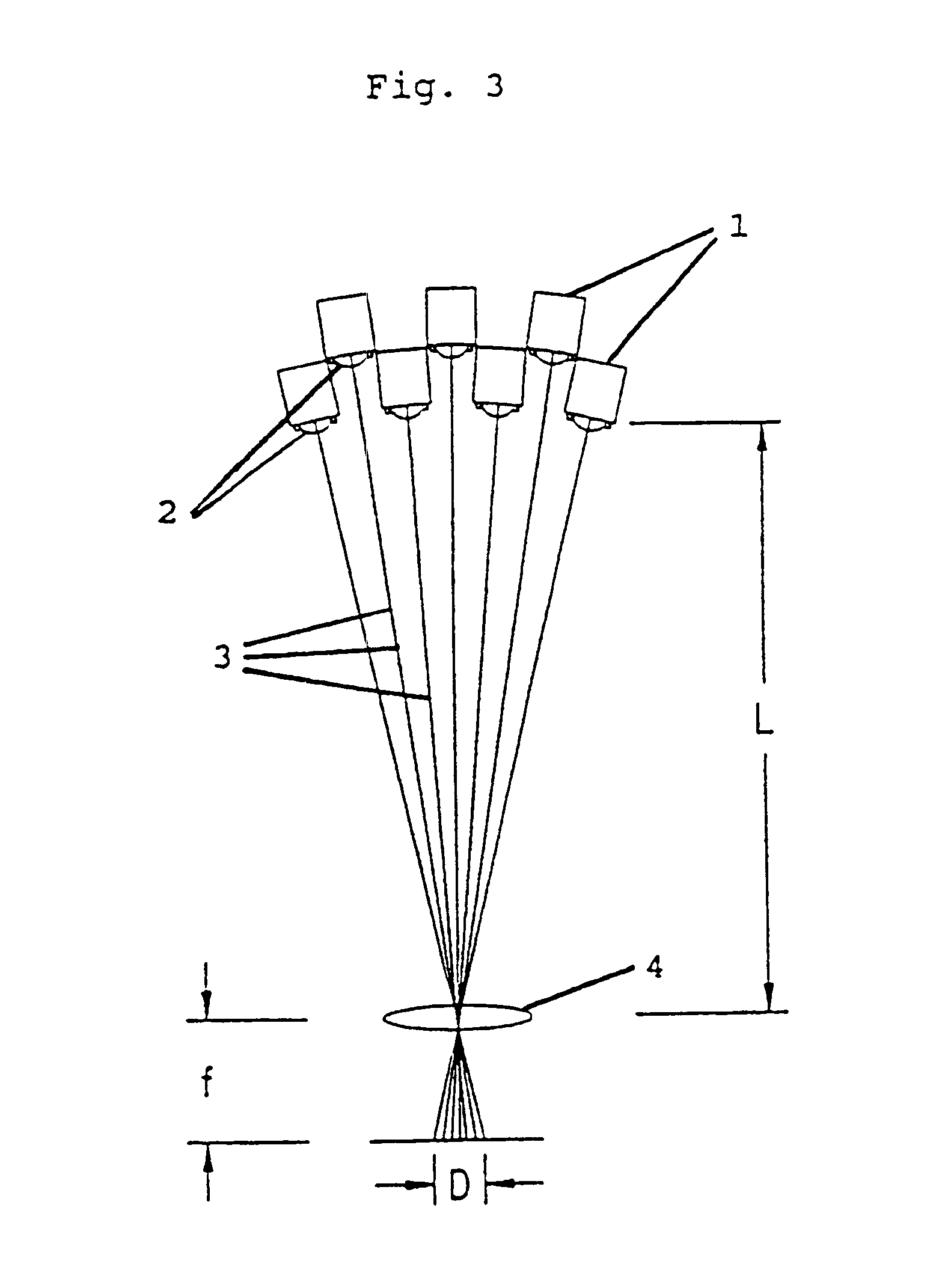

Multiple beam laser marking apparatus

InactiveUS6421159B1Space minimizationLaser detailsDigital marking by photographic/thermographic registrationLight beamOptoelectronics

A laser marking apparatus has a number of individual laser devices (1) mounted at angles to one another. The output ends (2) of the laser devices are disposed closely adjacent to one another and a number of laser beam redirectors (5) are disposed to intercept the laser beams (3) emitted from the laser output ends (2) so as to extend the length of the laser beam paths and to decrease the angle between said laser beams (3).

Owner:DOMINO THE

Laser-based method and system for processing targeted surface material and article produced thereby

ActiveUS20080011852A1Prevent unwanted changesSufficient total fluenceAdditive manufacturing apparatusSemiconductor/solid-state device detailsTarget surfaceSlag

Owner:ELECTRO SCI IND INC

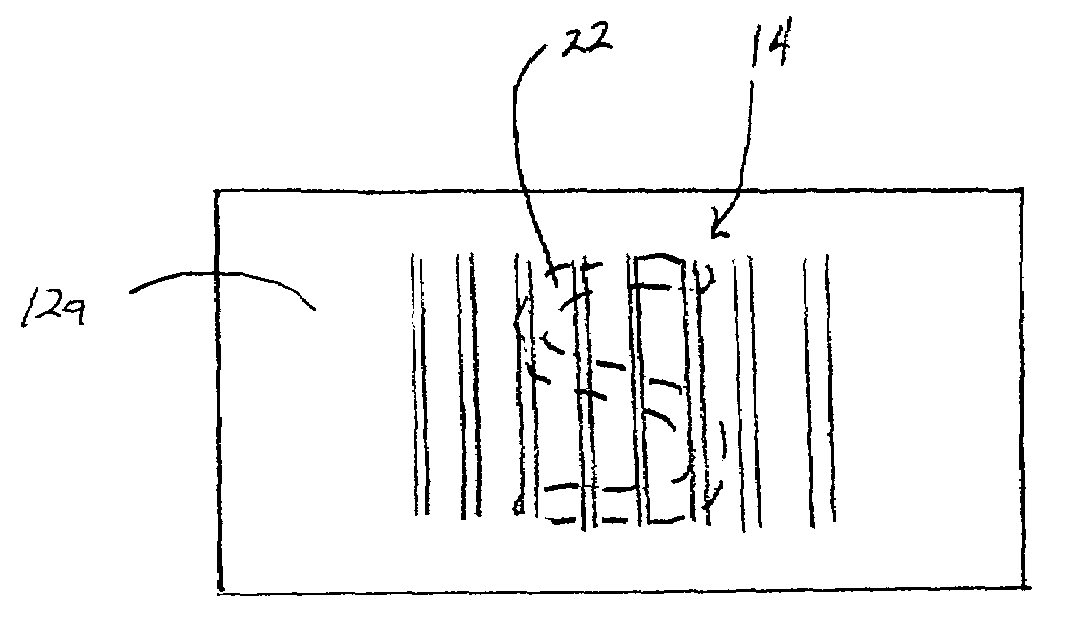

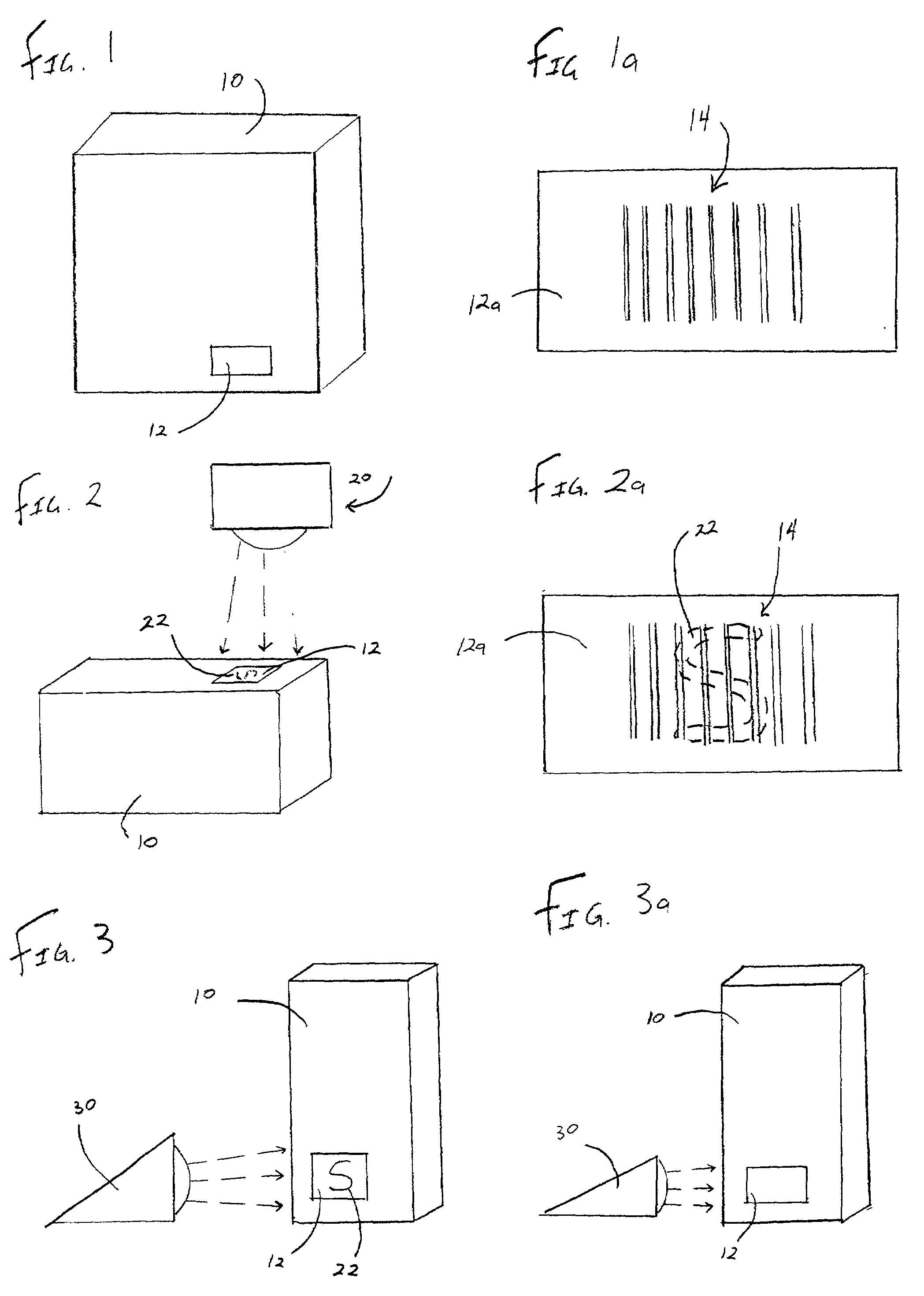

Verification system for the purchase of a retail item and method of using same

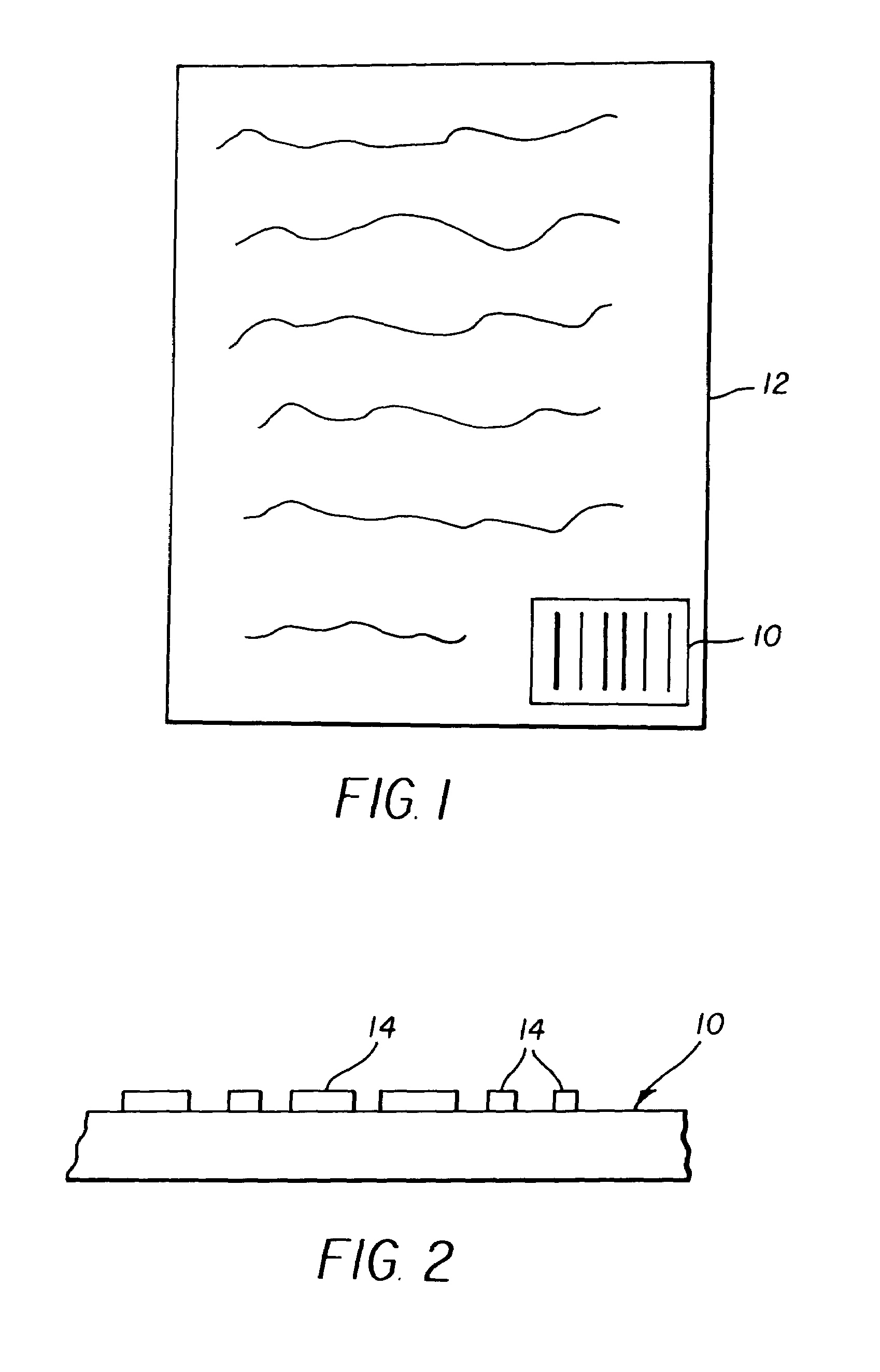

InactiveUS7108183B1Character and pattern recognitionDigital marking by photographic/thermographic registrationVerification systemLibrary science

The present invention provides a system and method for the verification of the purchase of a retail item wherein an encoding device provides a machine-readable post-purchase indicia on the label for a retail item at the point of sale of the retail item. When a customer returns the retail item for a refund or exchange, a detecting device analyzes the label for the presence of the post-purchase indicia. Presence of the post-purchase indicia indicates a legitimate exchange whereas the absence of the post-purchase indicia signifies a fraudulent exchange.

Owner:BARCODE SECURITY SYST

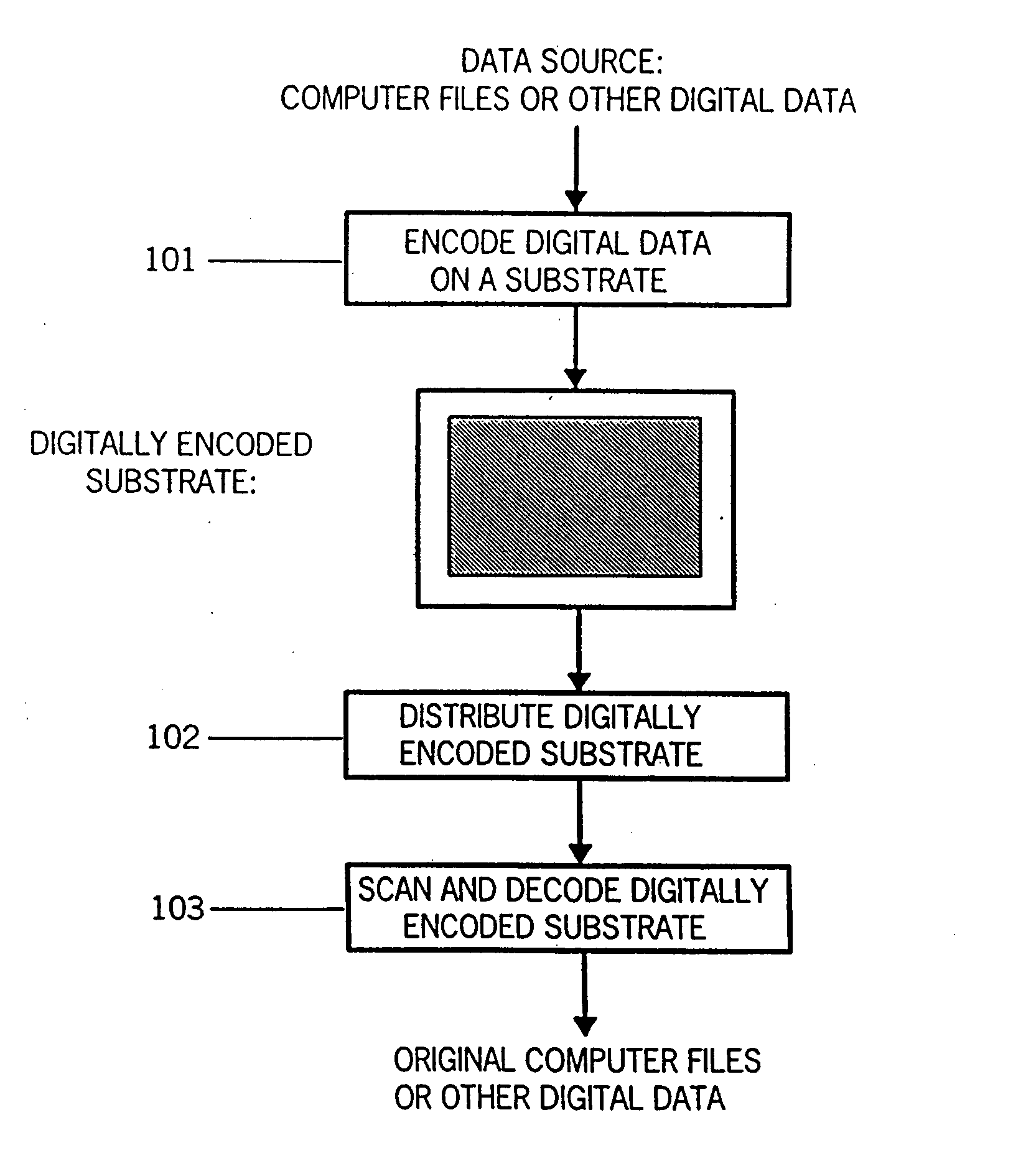

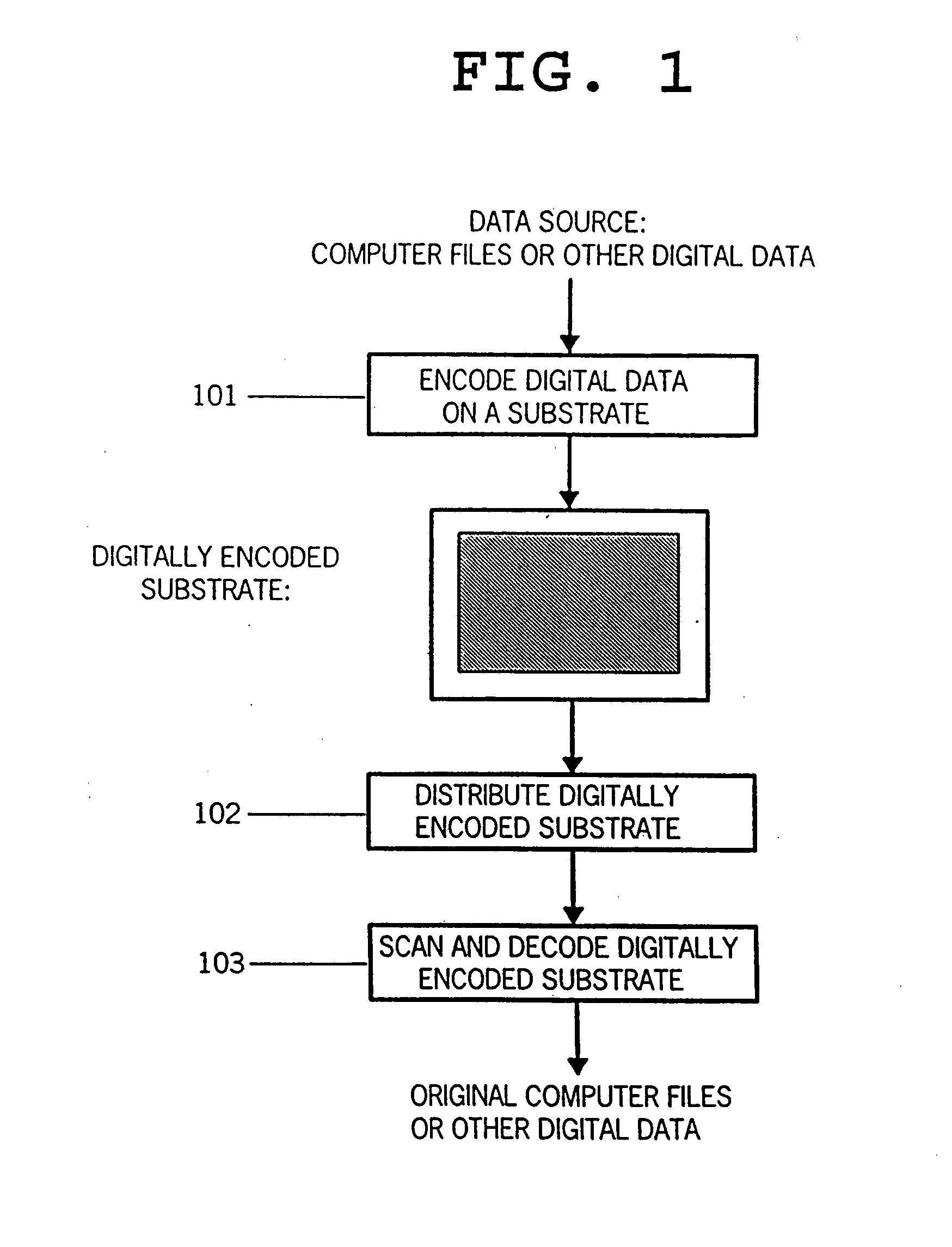

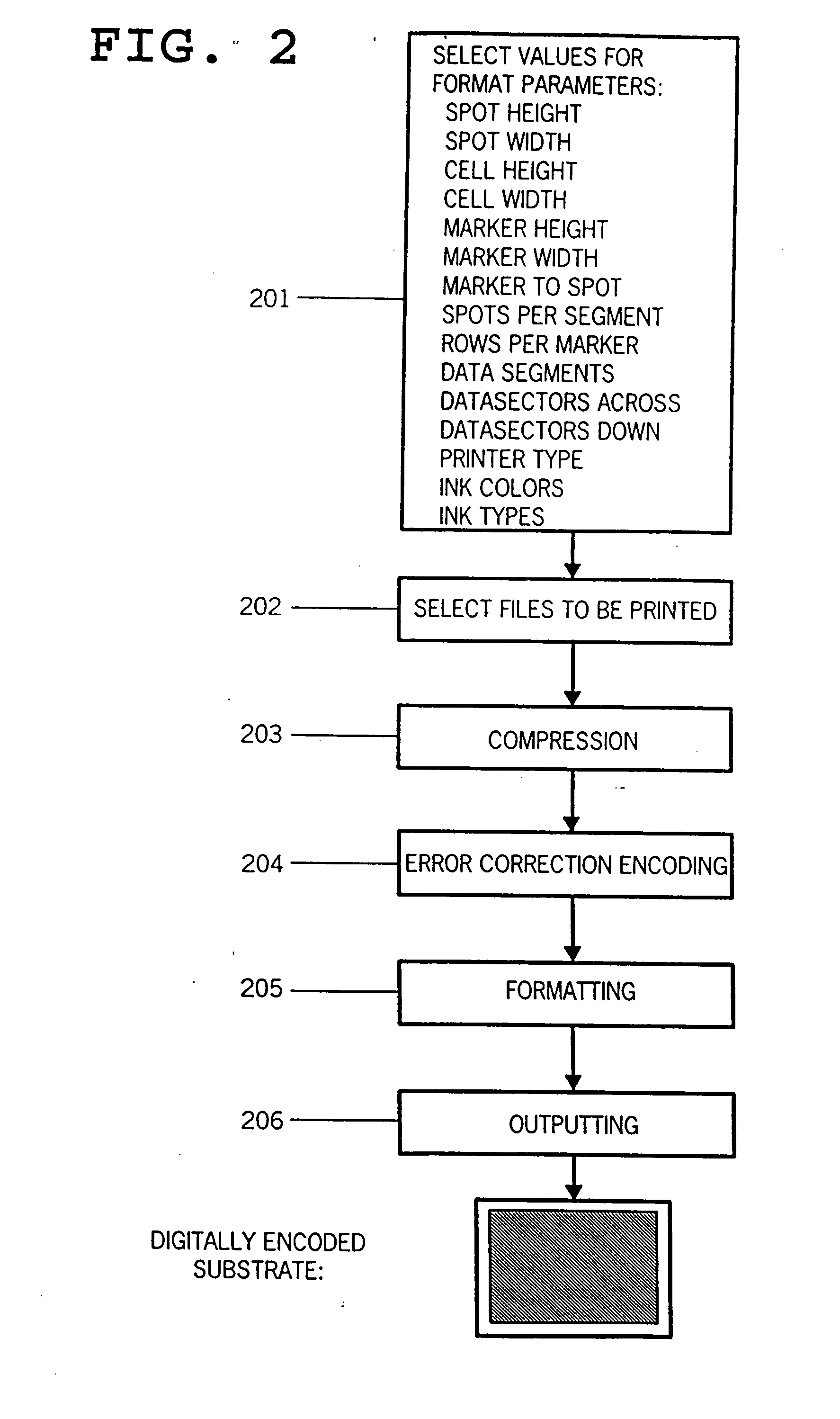

Variable formatting of digital data into a pattern

InactiveUS20050033724A1Maximization of overall densityEfficiently navigateDigital data processing detailsCharacter and pattern recognitionDigital dataComputer printing

A method of formatting digital data and a method of decoding the formatted digital data. User selectable format parameters vary the dimensions and other attributes of spots and the cells containing those spots as well as other features which the formatting process formats into a pattern. A method of encoding the formatted digital data using these format parameters allows for encoding a substrate optimally for any given printer or scanner. One embodiment provides for markers to facilitate determination of cell locations. In one embodiment the decoding process achieves a pyramid gain of knowledge by locating a landmark (801), which is located in a known position relative to a metasector (802), which contains information about the encoding process used to encode the main body of data (803), which the decoding process decodes to recover the original digital data. Further embodiments include encryption, transmission by facsimile, inclusion of human readable information, and automatic launches of computer files.

Owner:KALDREN LLC

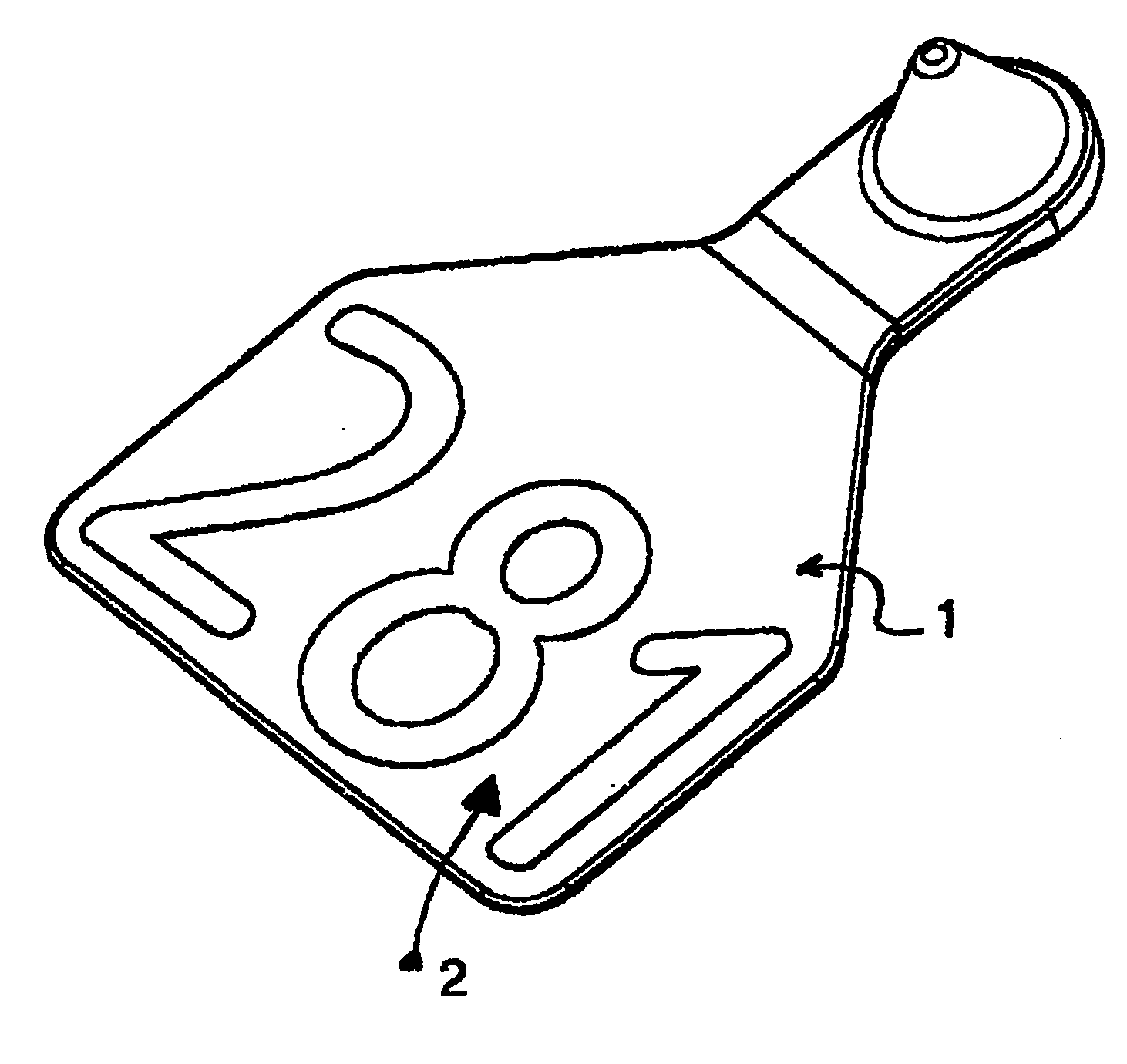

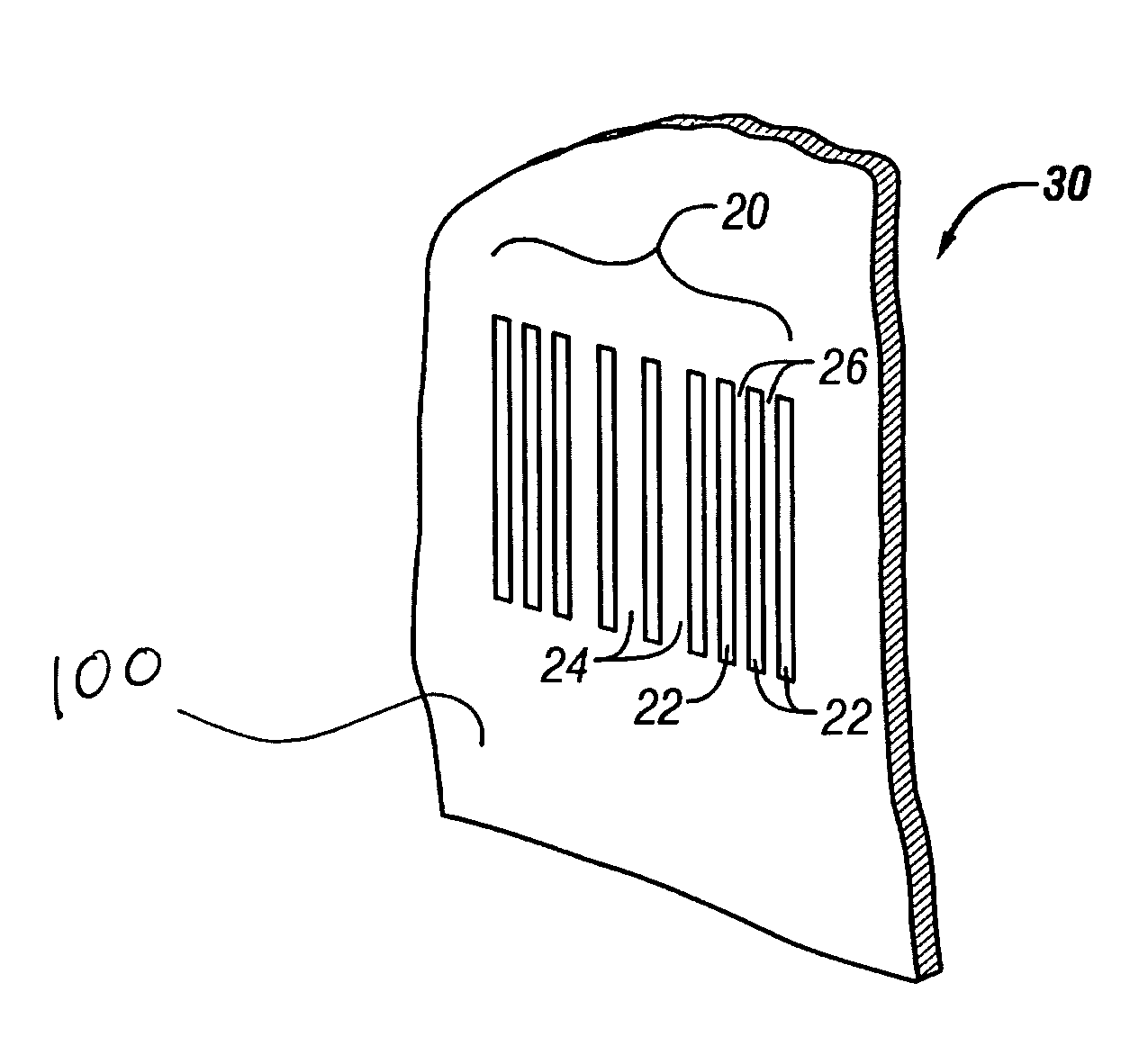

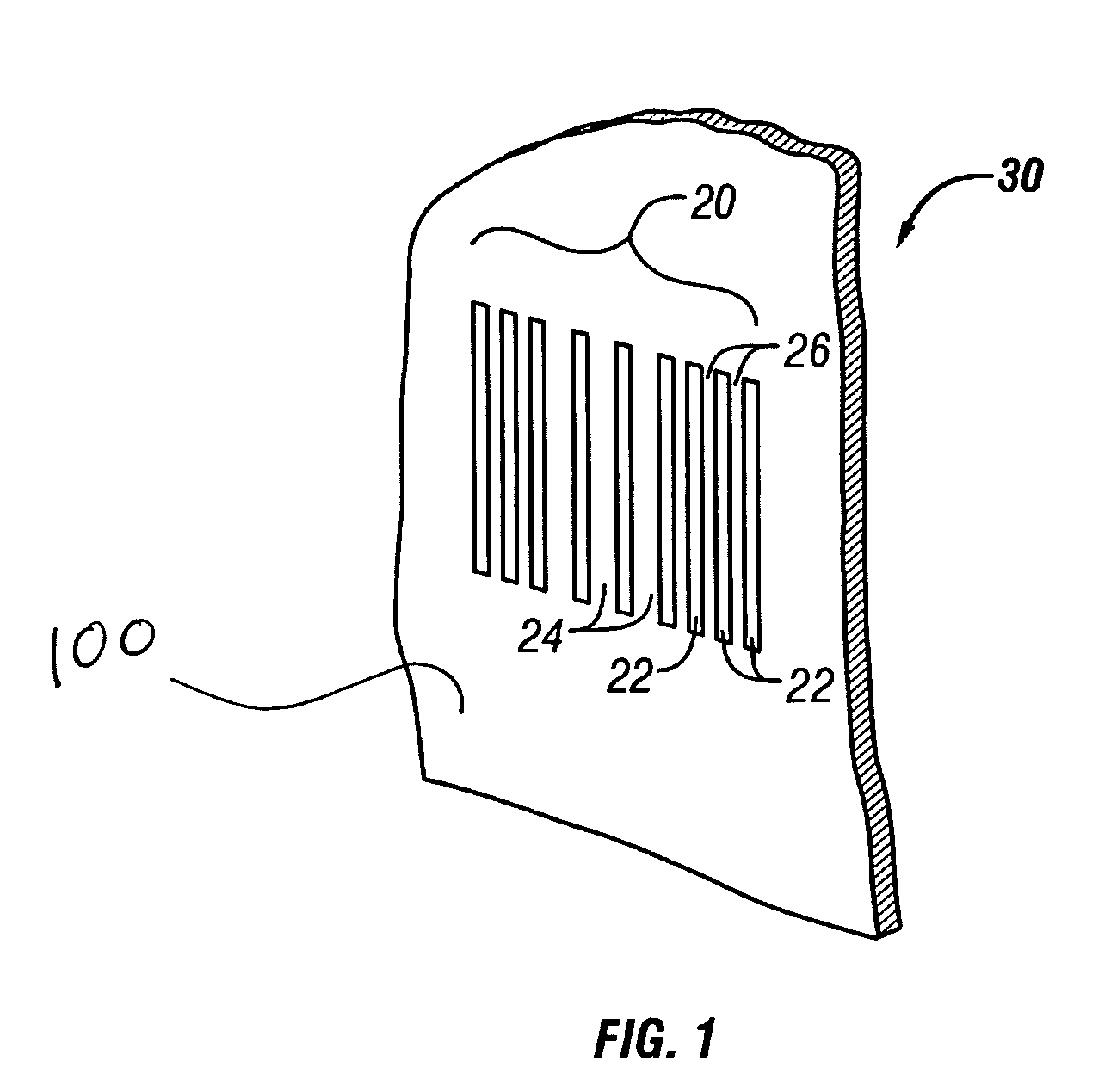

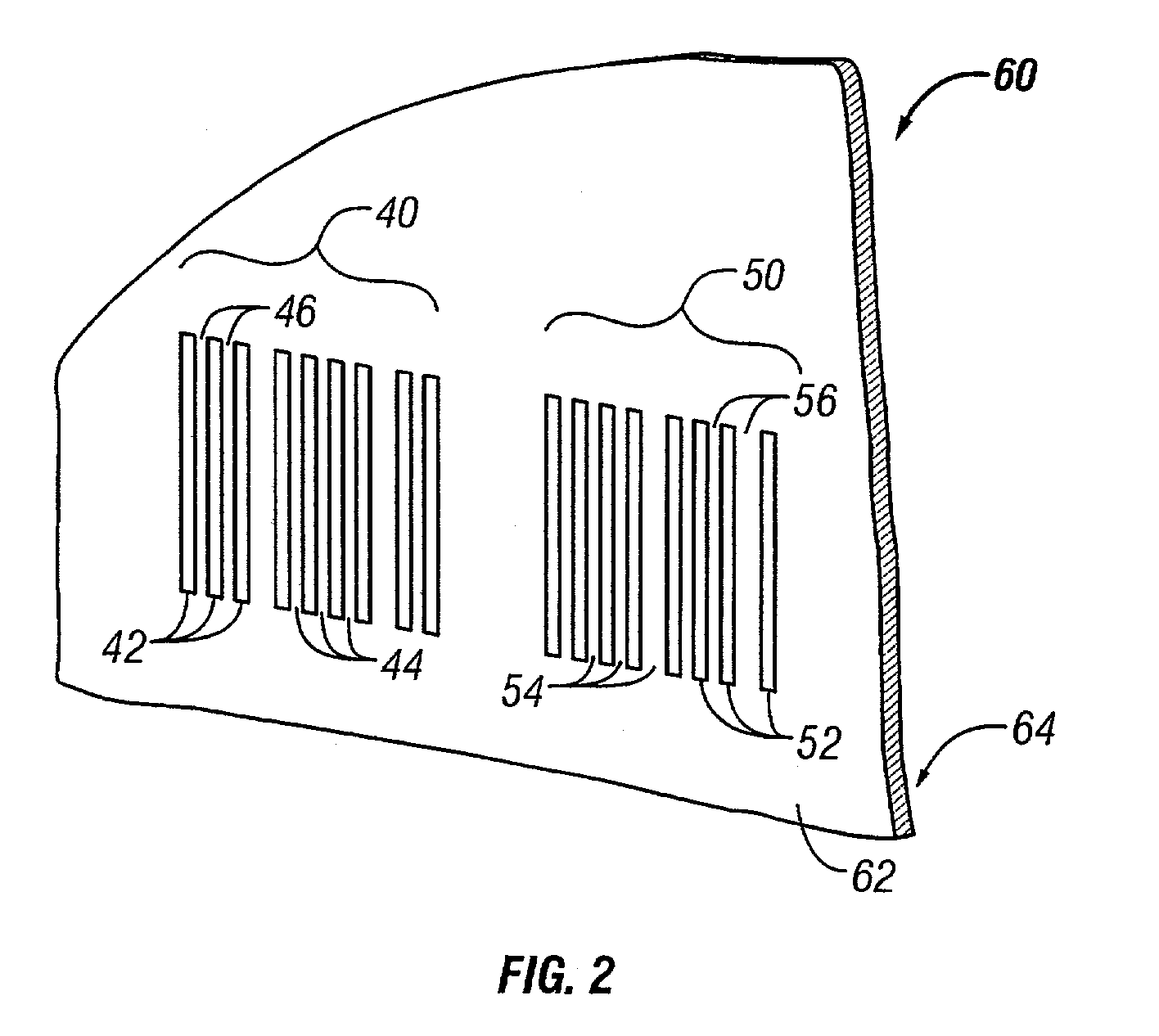

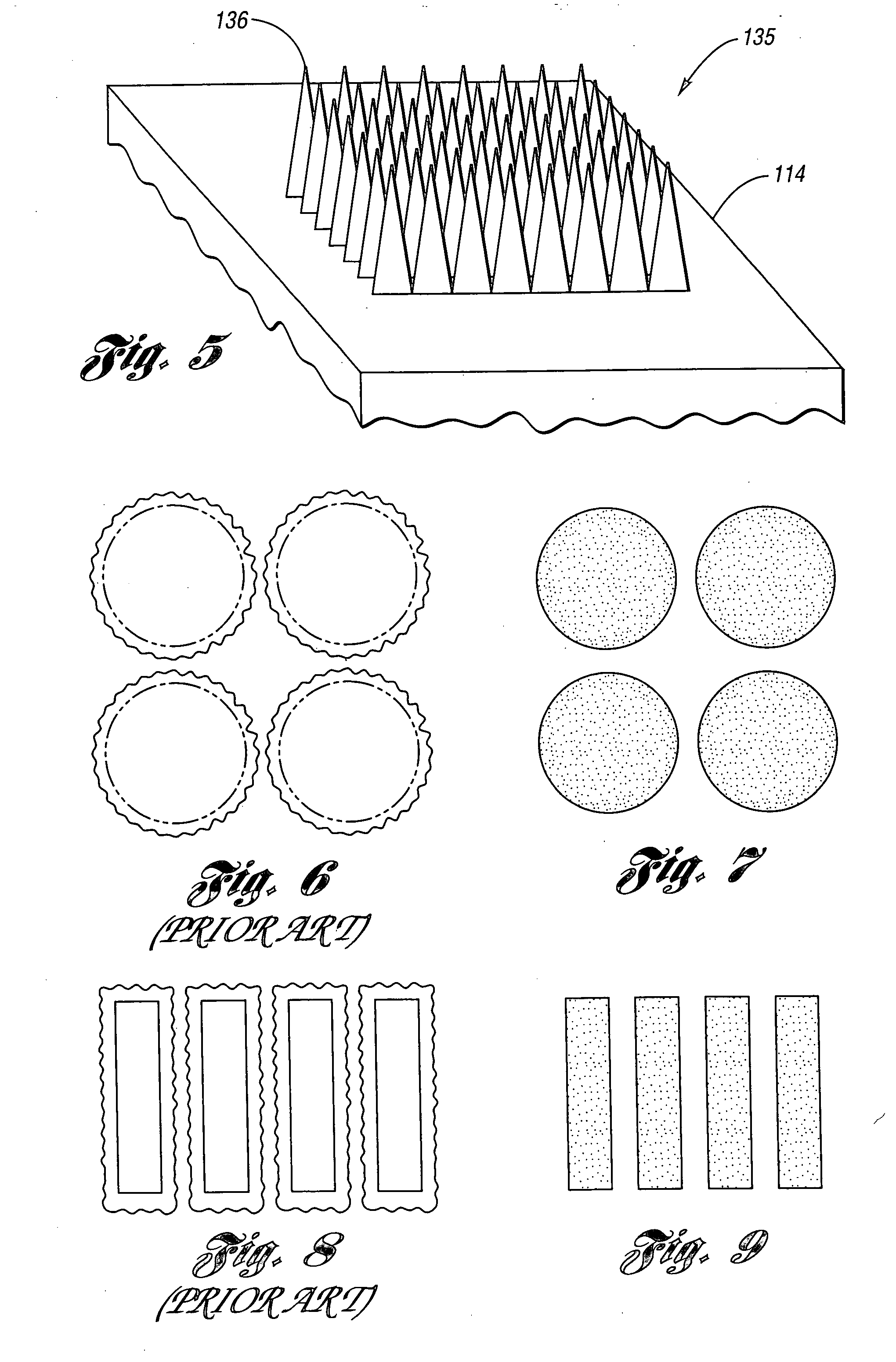

Tag marking

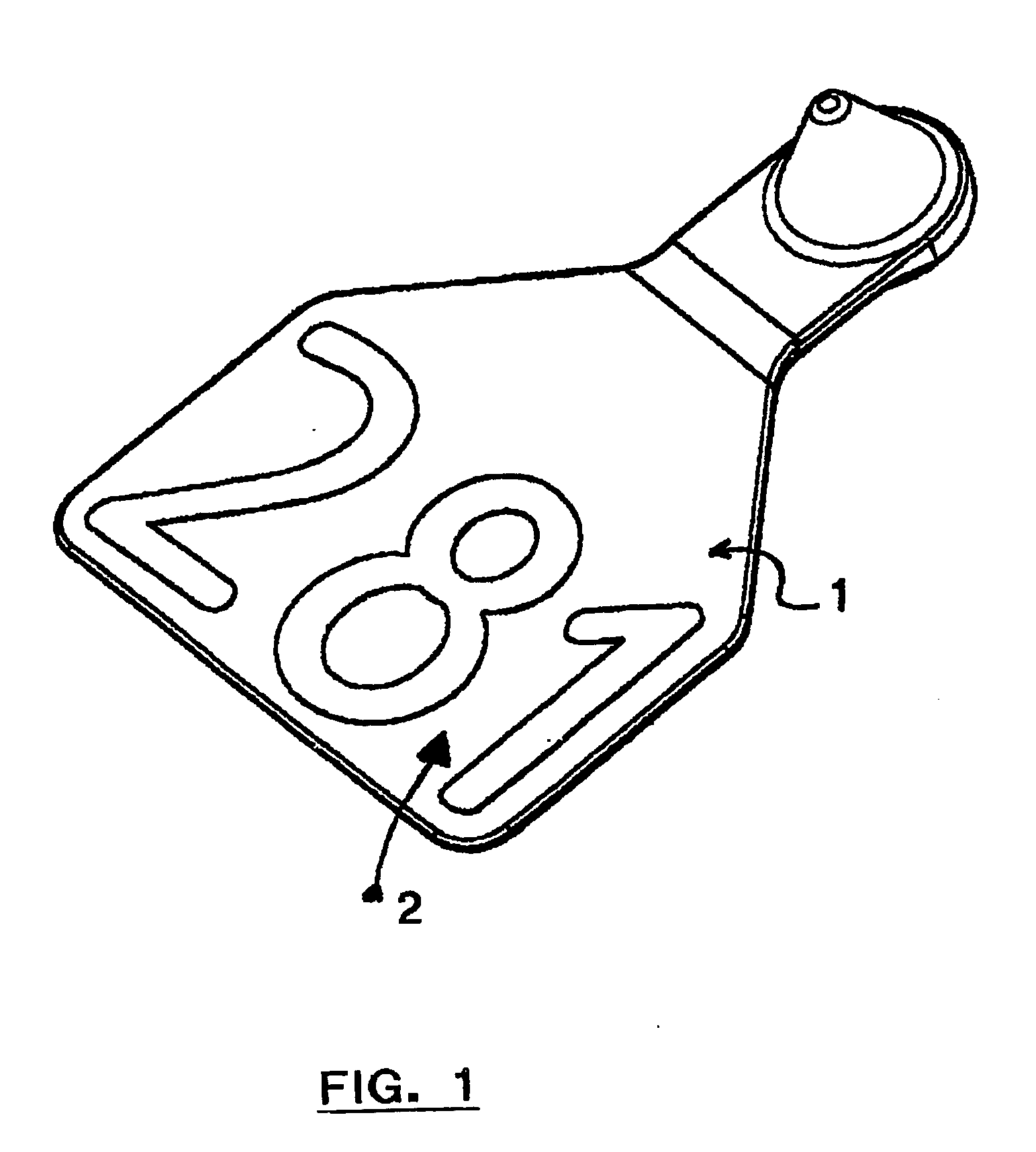

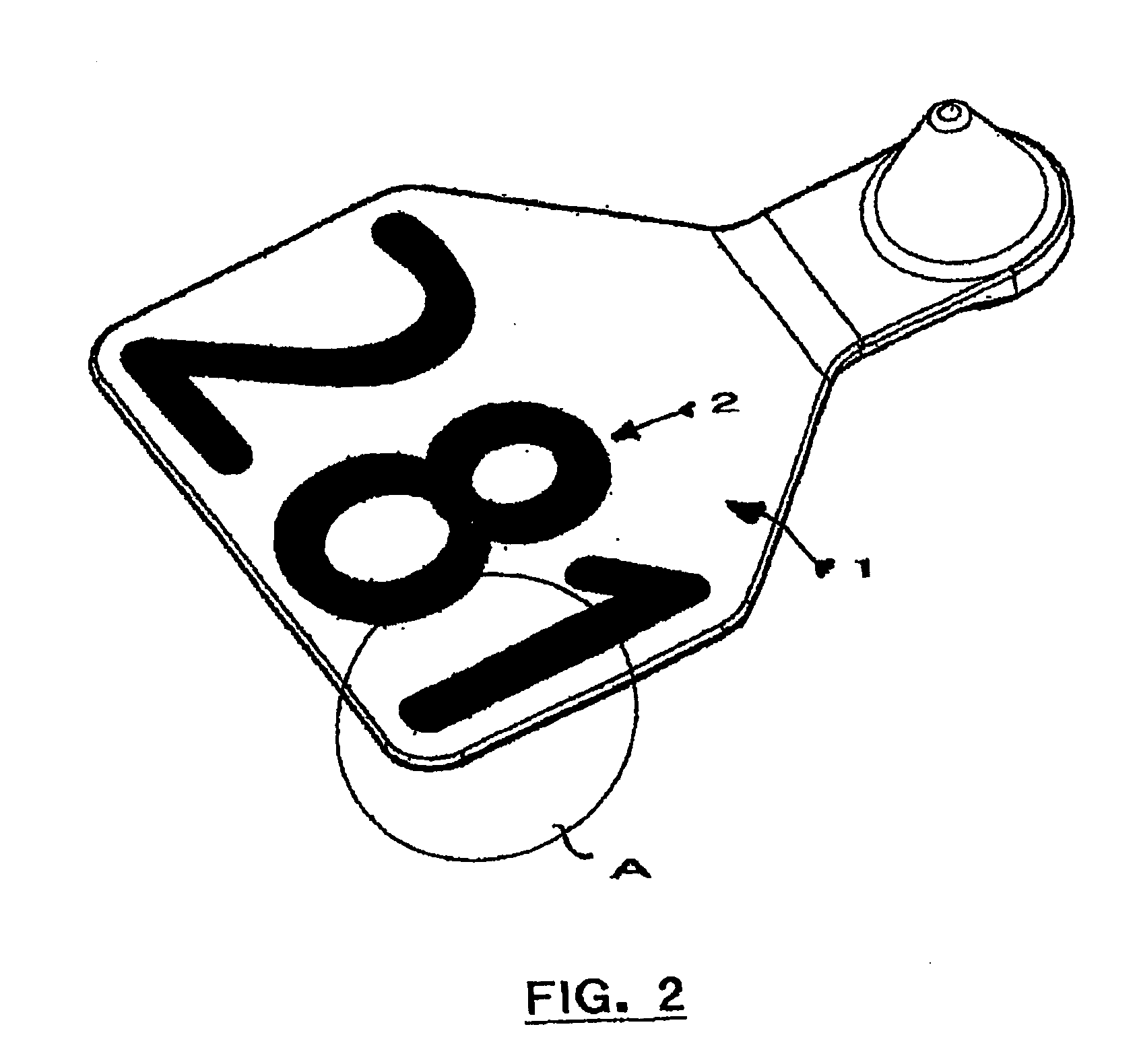

InactiveUS20040021313A1Overcome problemsContrastStampsOther printing matterEar tagBiomedical engineering

A plastic product such an animal ear tag (1) is laser marked with indicia (2). The contrast between the indicia (2) and the surrounding surface of the tag (1) is enhanced by the heated of the indicia following laser marking to a temperature at which the indicia and the surrounding surface have melted. In the preferred embodiment the indicia (2) is provided as a raised surface (3) and with a plurality of spaced apart peaks (4) with gaps (6) therebetween. The heating of the tag (1) is preferably by the application of a hot plate to the indicia surface of the tag and simultaneaouly or subsequently to the non-indicia surface of the tag.

Owner:MICHAEL STUART GARDNER

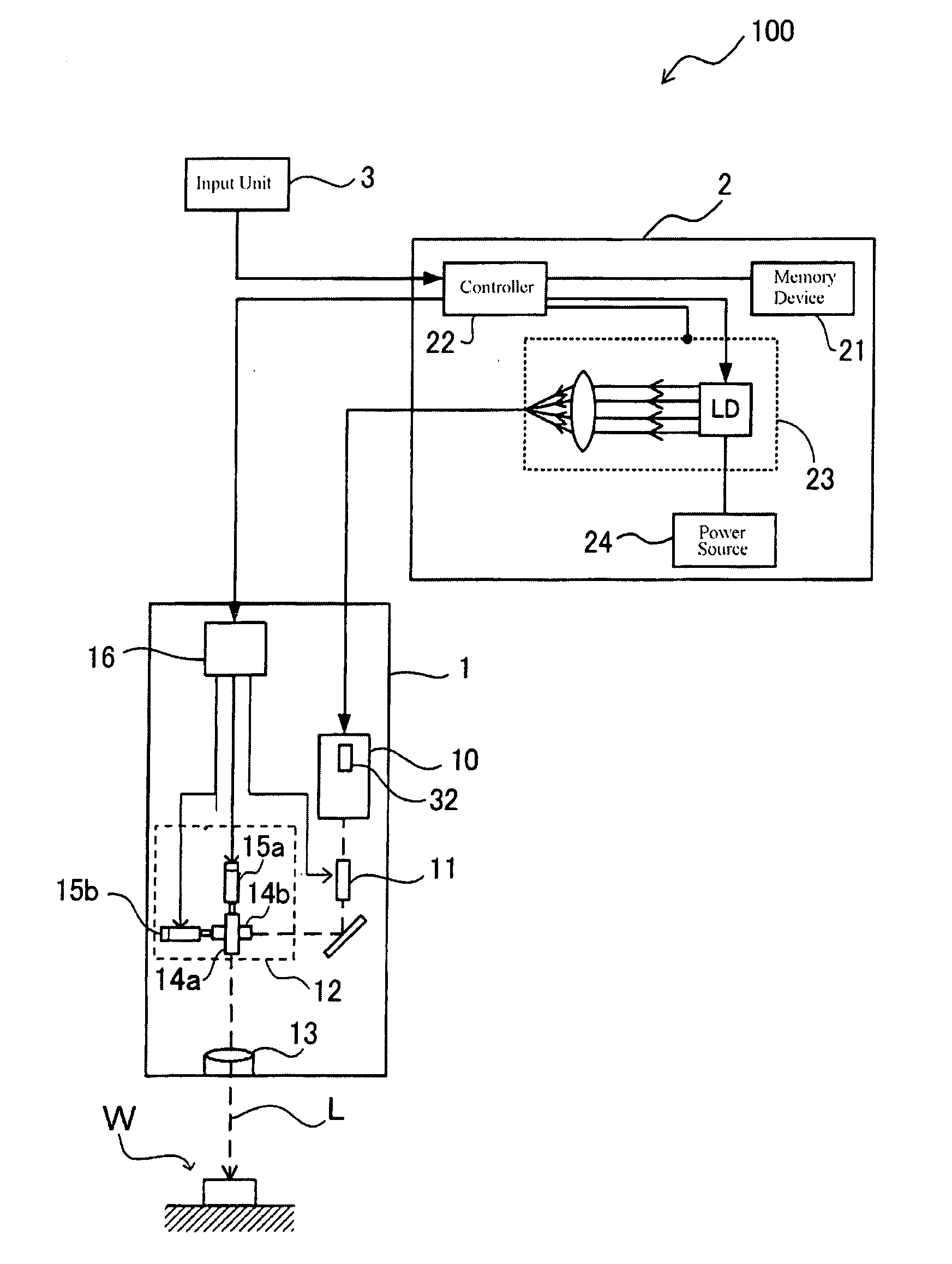

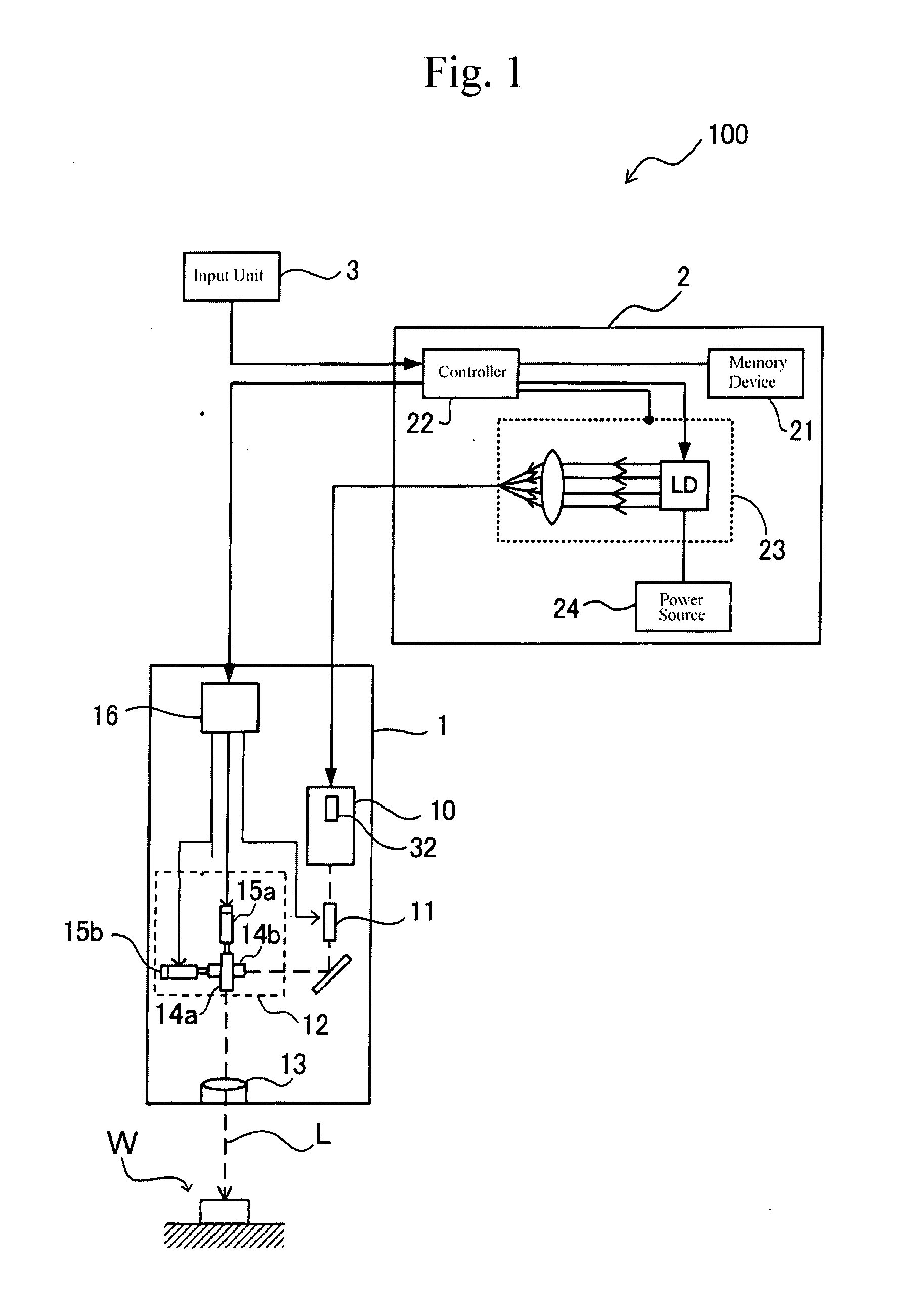

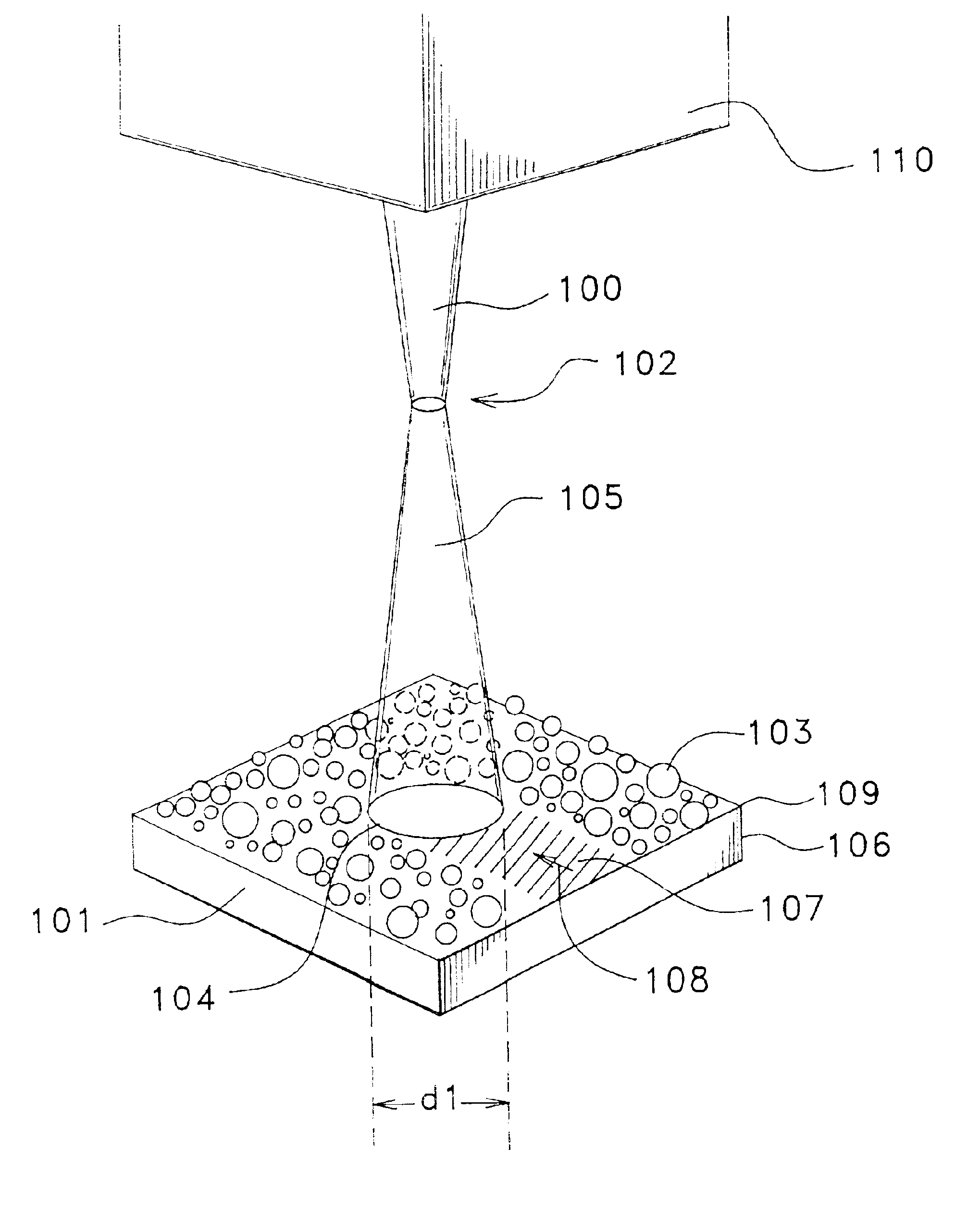

Laser marking device, laser marking method, and object to be marked

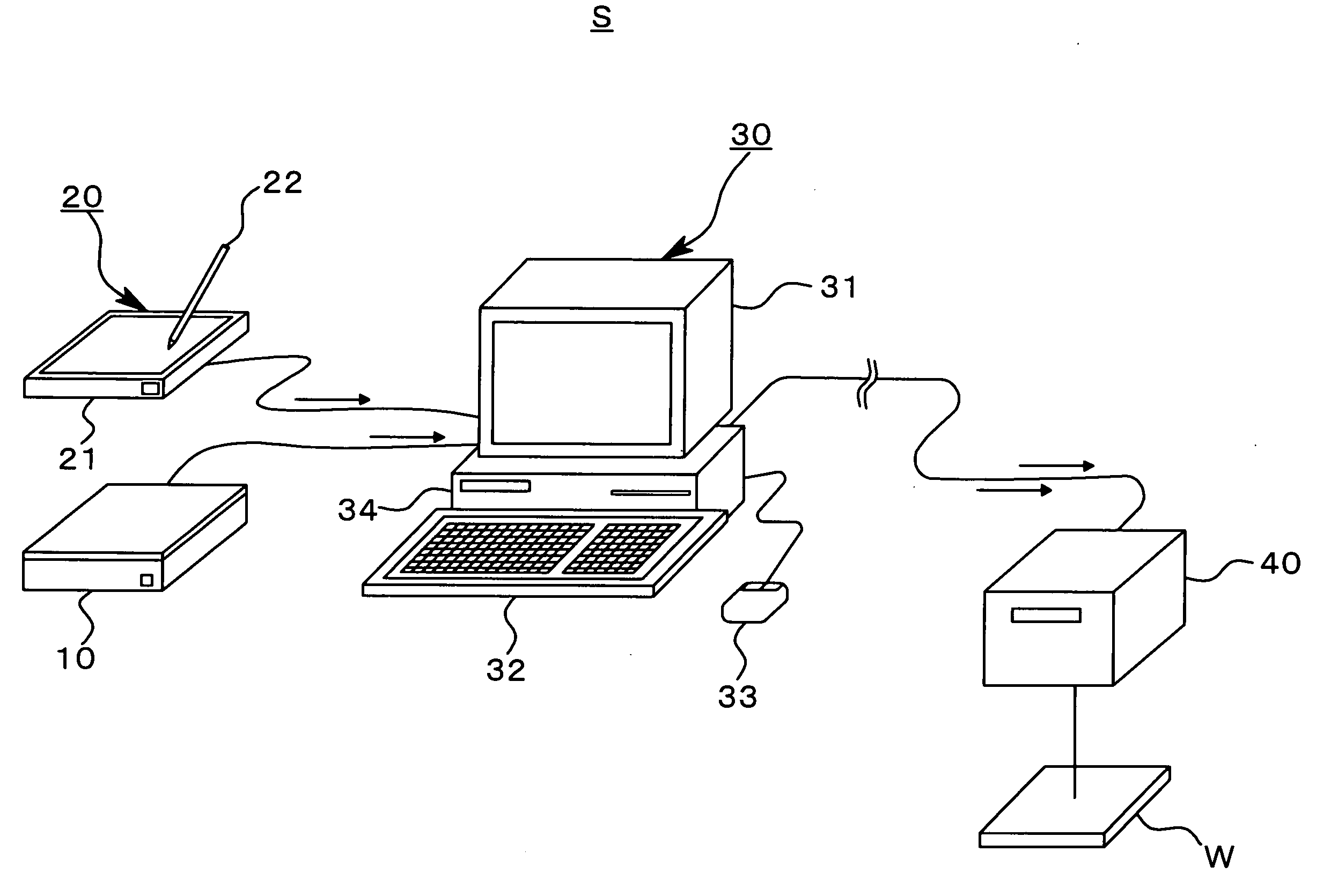

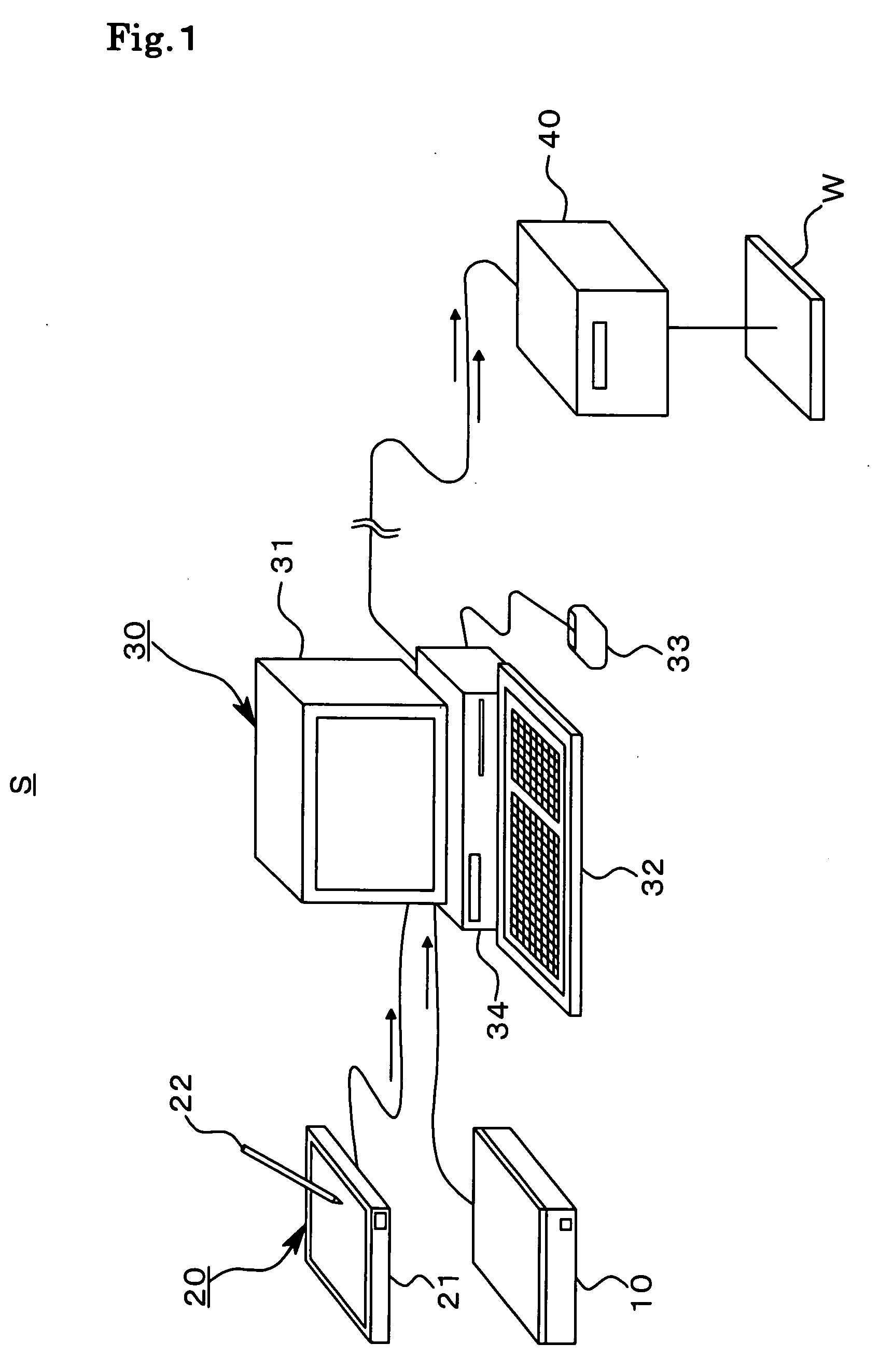

InactiveUS20070086822A1Adjustable densityEnhance the imageRecording apparatusDuplicating/marking methodsOptoelectronicsVolumetric Mass Density

The present invention relates to a laser marking device that irradiates a laser beam on a workpiece (W) to transform a portion inside the workpiece at a focal point of the laser beam, thus putting a dot in each predetermined area. The laser marking device includes acquiring means (10, 20) that acquires, as information on the dot, at least two-dimensional position information of an exposed section of the workpiece (W), and density information of the dot, coordinate setting means (30) that calculates, for each dot according to the density information, dot depth information showing the distance from the surface of the workpiece (W) to the dot in the thickness direction of the workpiece (W), and sets three-dimensional coordinates for each dot based on a position specified by the dot depth information and the two-dimensional position information, and laser marking means (40) that performs marking with the three-dimensional coordinates as a laser beam focal point.

Owner:ARAI HELMET LTD

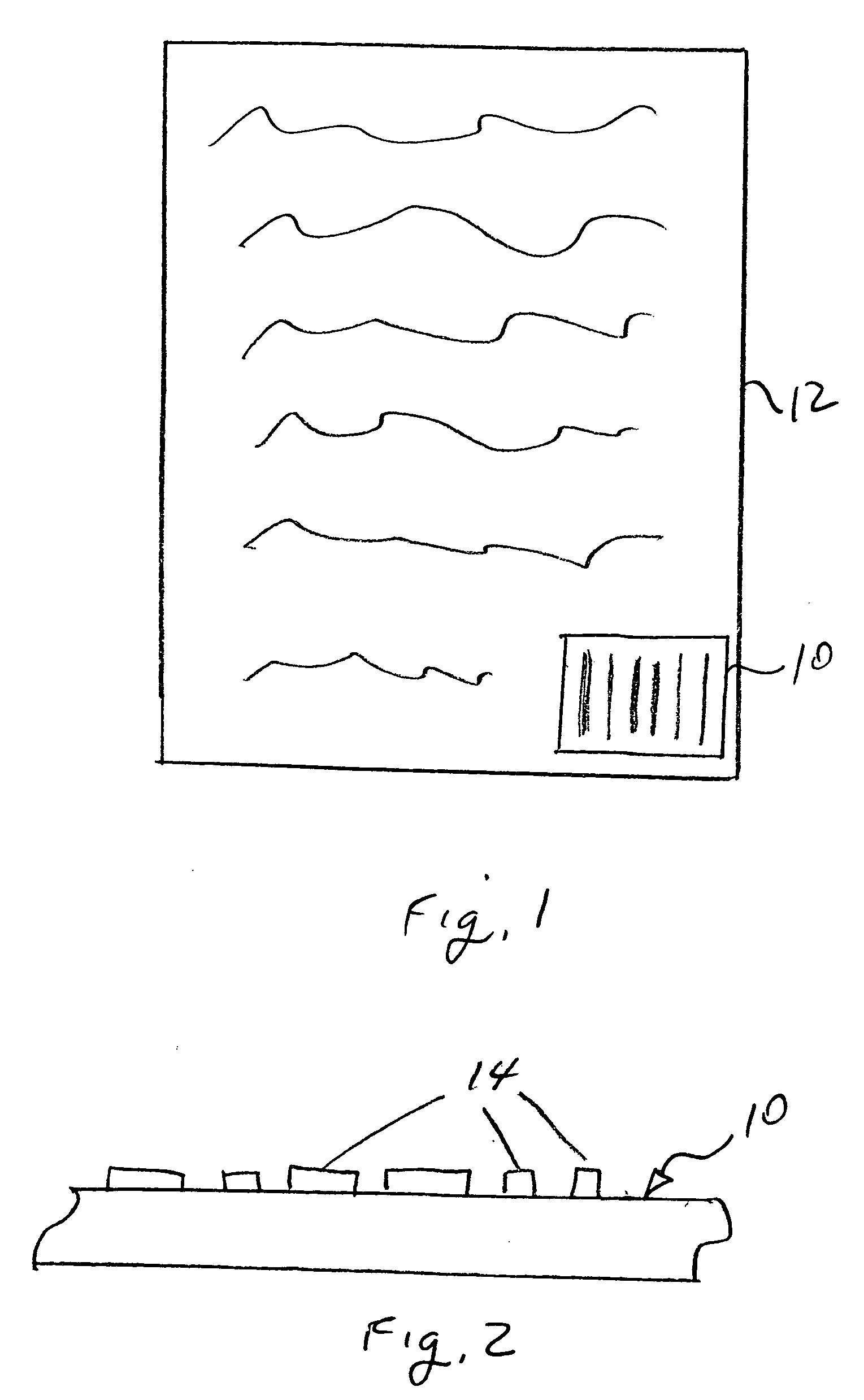

Coding symbology and a method for printing same

InactiveUS7108184B2Reduce potentially patient safety errorReduce errorsDuplicating/marking methodsPattern printingComputer science

Owner:BAXTER INT INC

Laser-based method and system for processing targeted surface material and article produced thereby

InactiveUS20080073438A1Prevent unwanted changesSufficient total fluenceAdditive manufacturing apparatusSemiconductor/solid-state device detailsTarget surfaceSlag

A laser-based method and system for processing targeted surface material and article produced thereby are provided. The system processes the targeted surface material within a region of a workpiece while avoiding undesirable changes to adjacent non-targeted material. The system includes a primary laser subsystem including a primary laser source for generating a pulsed laser output including at least one pulse having a wavelength and a pulse width less than 1 ns. A delivery subsystem irradiates the targeted surface material of the workpiece with the pulsed laser output including the at least one pulse to texture the targeted surface material. The pulsed laser output has sufficient total fluence to initiate ablation within at least a portion of the targeted surface material and the pulse width is short enough such that the region and the non-targeted material surrounding the material are substantially free of slag.

Owner:ELECTRO SCI IND INC

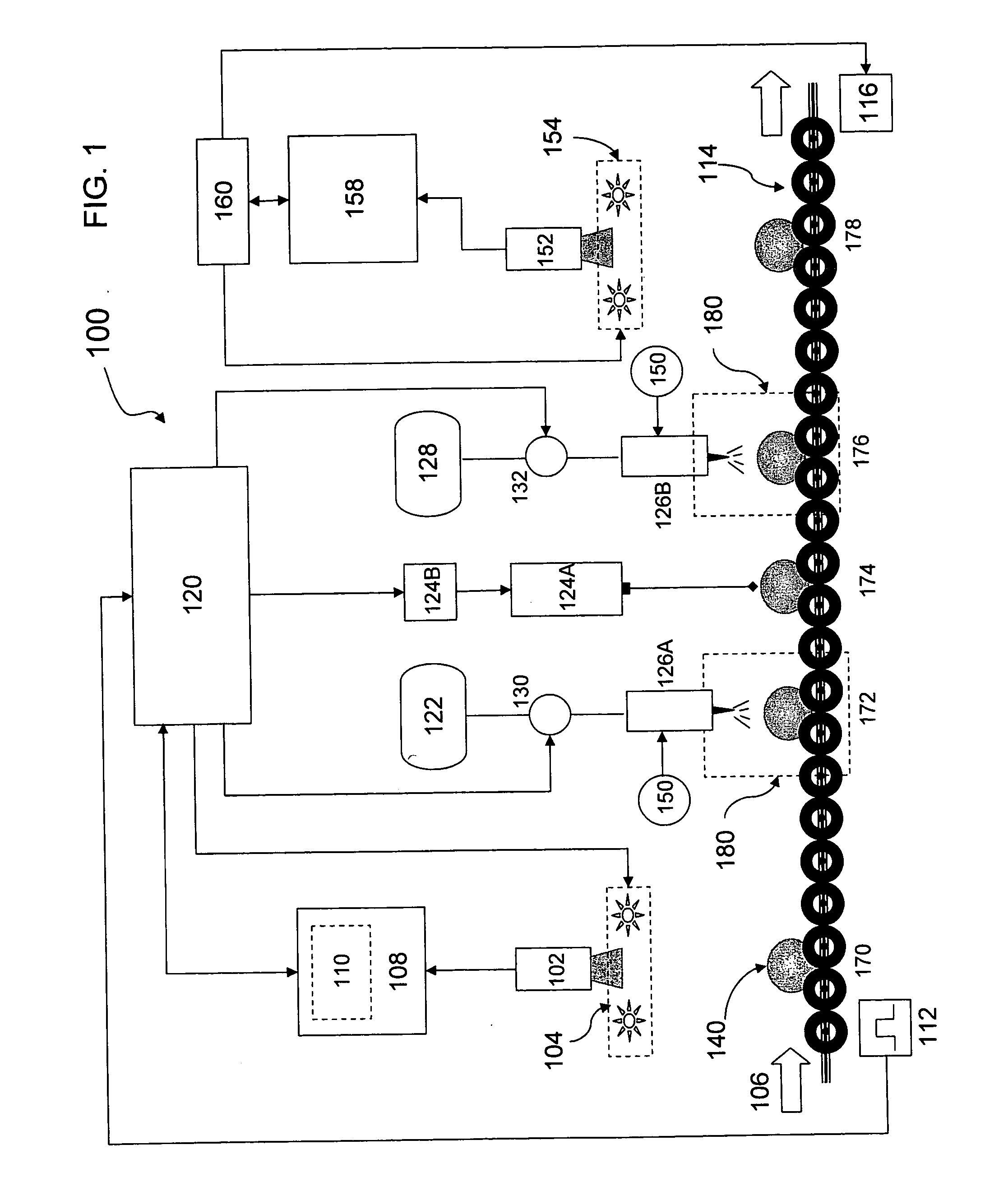

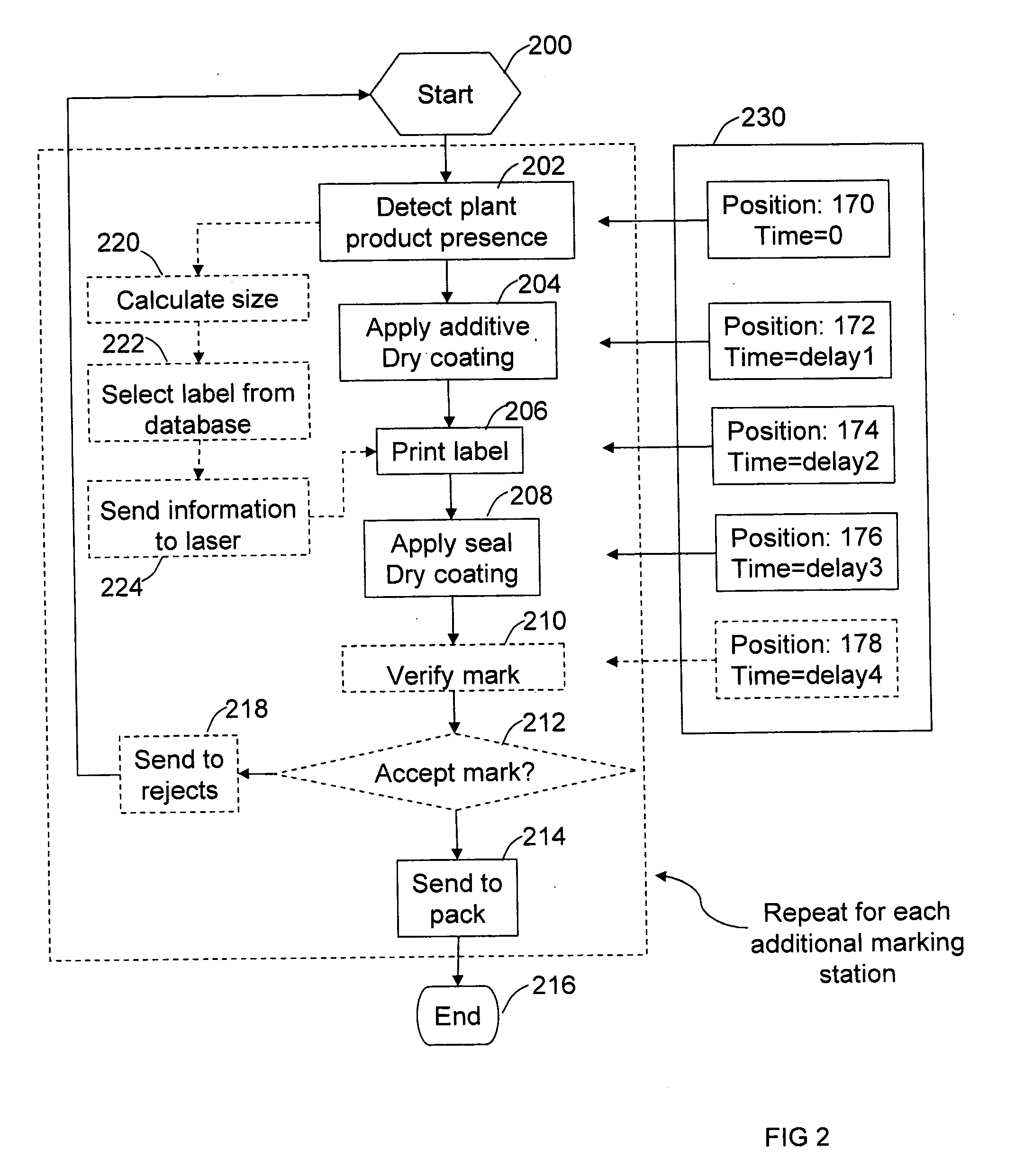

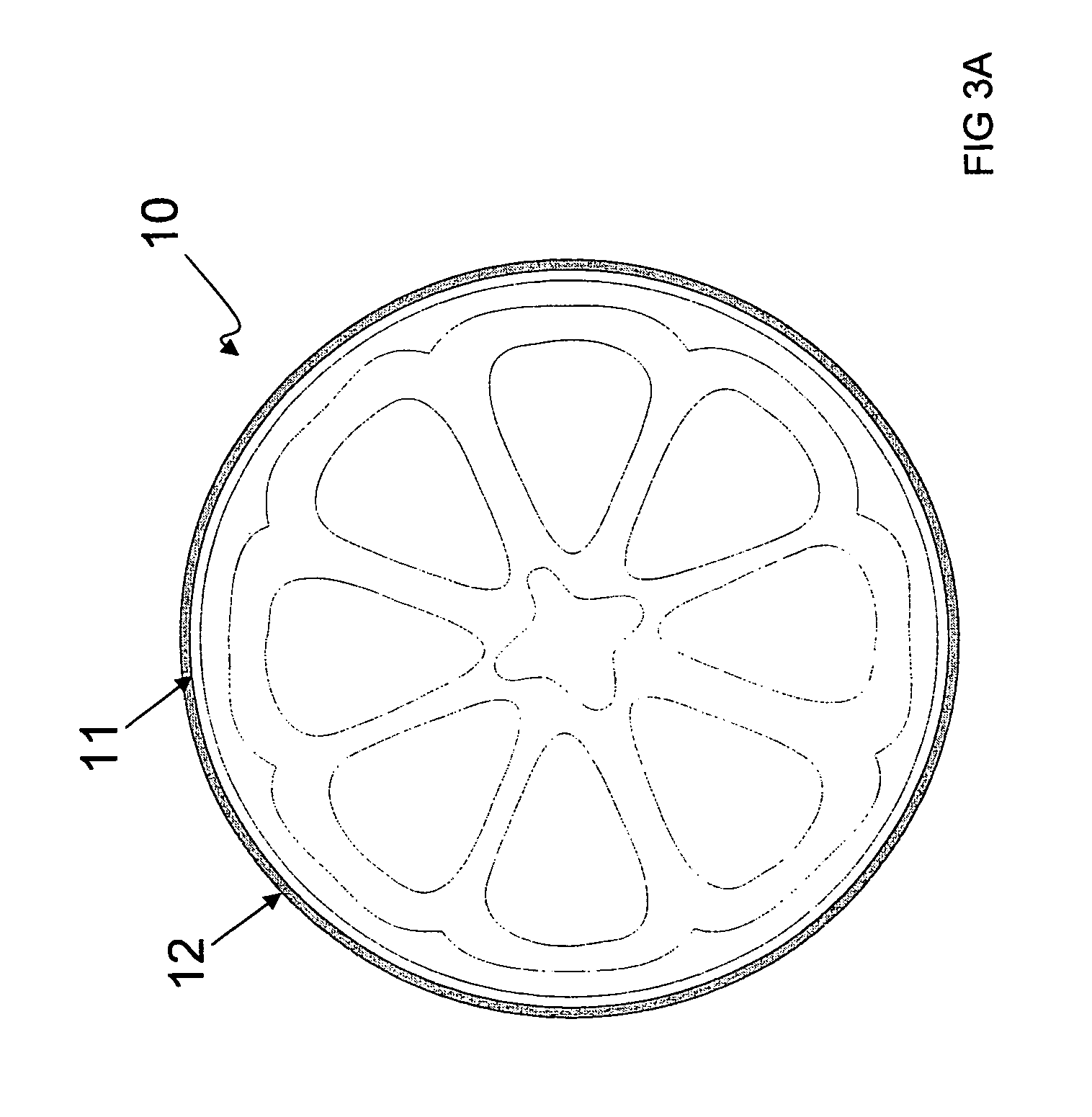

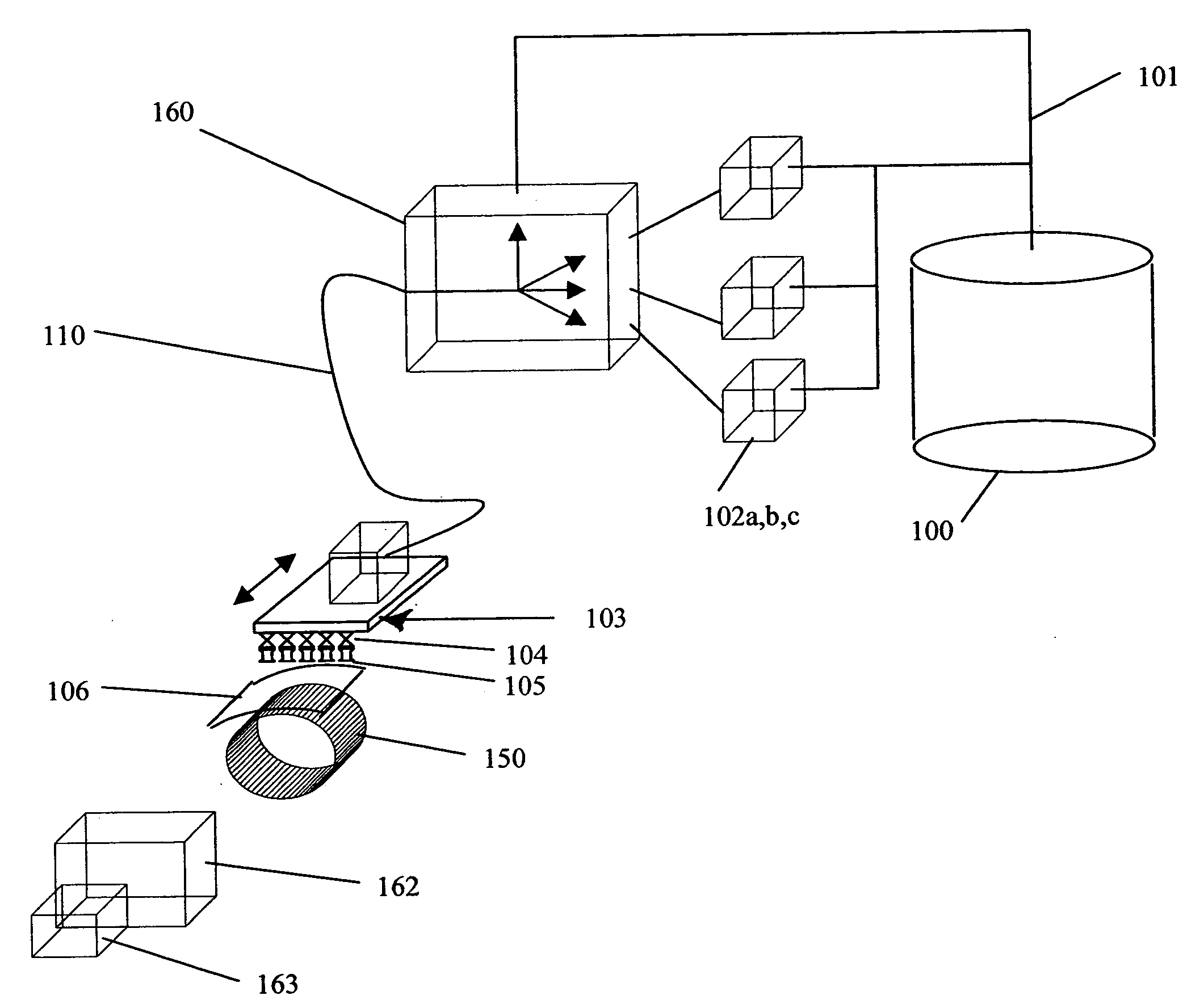

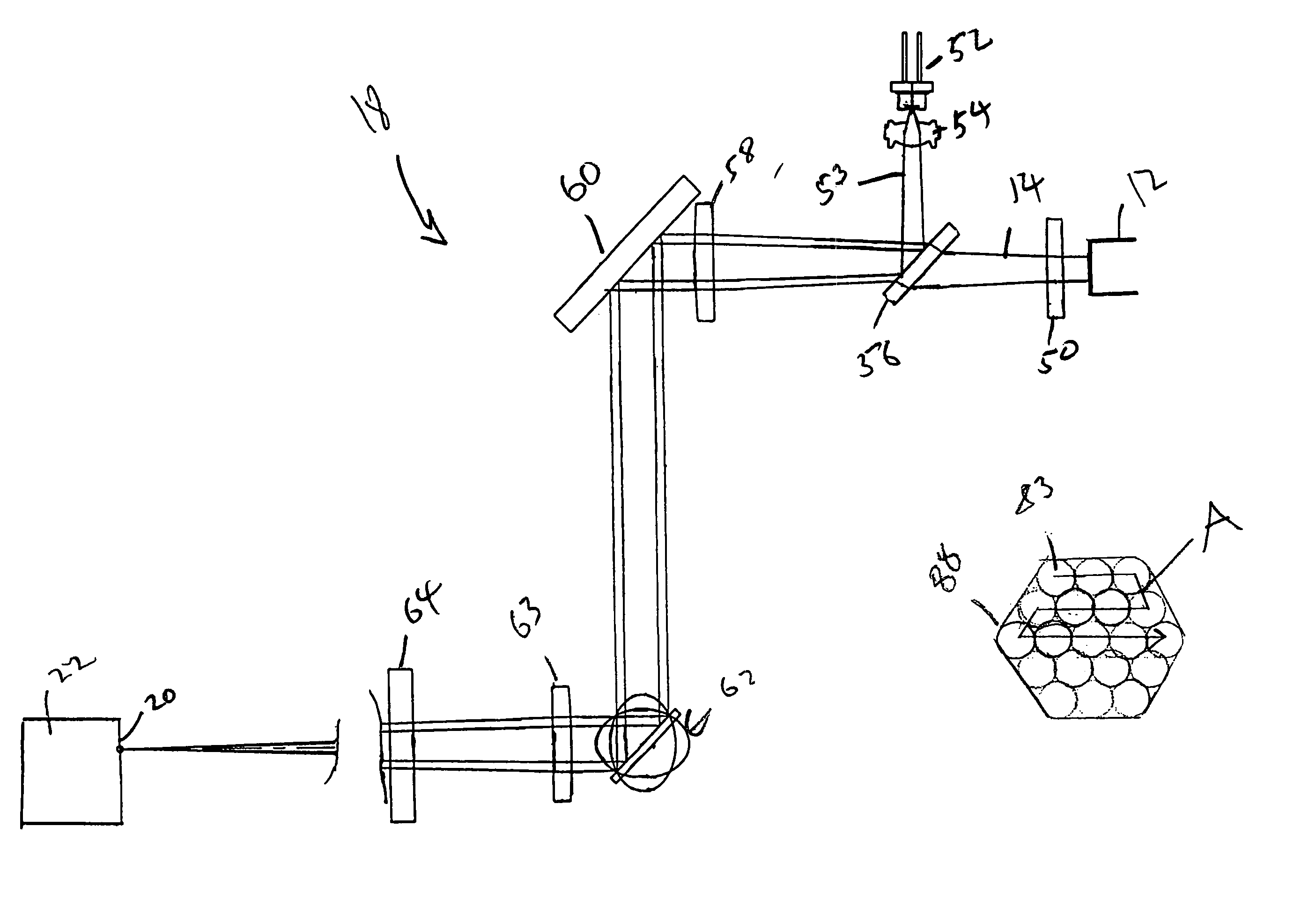

Method and apparatus for non-invasive laser based labeling of plant products

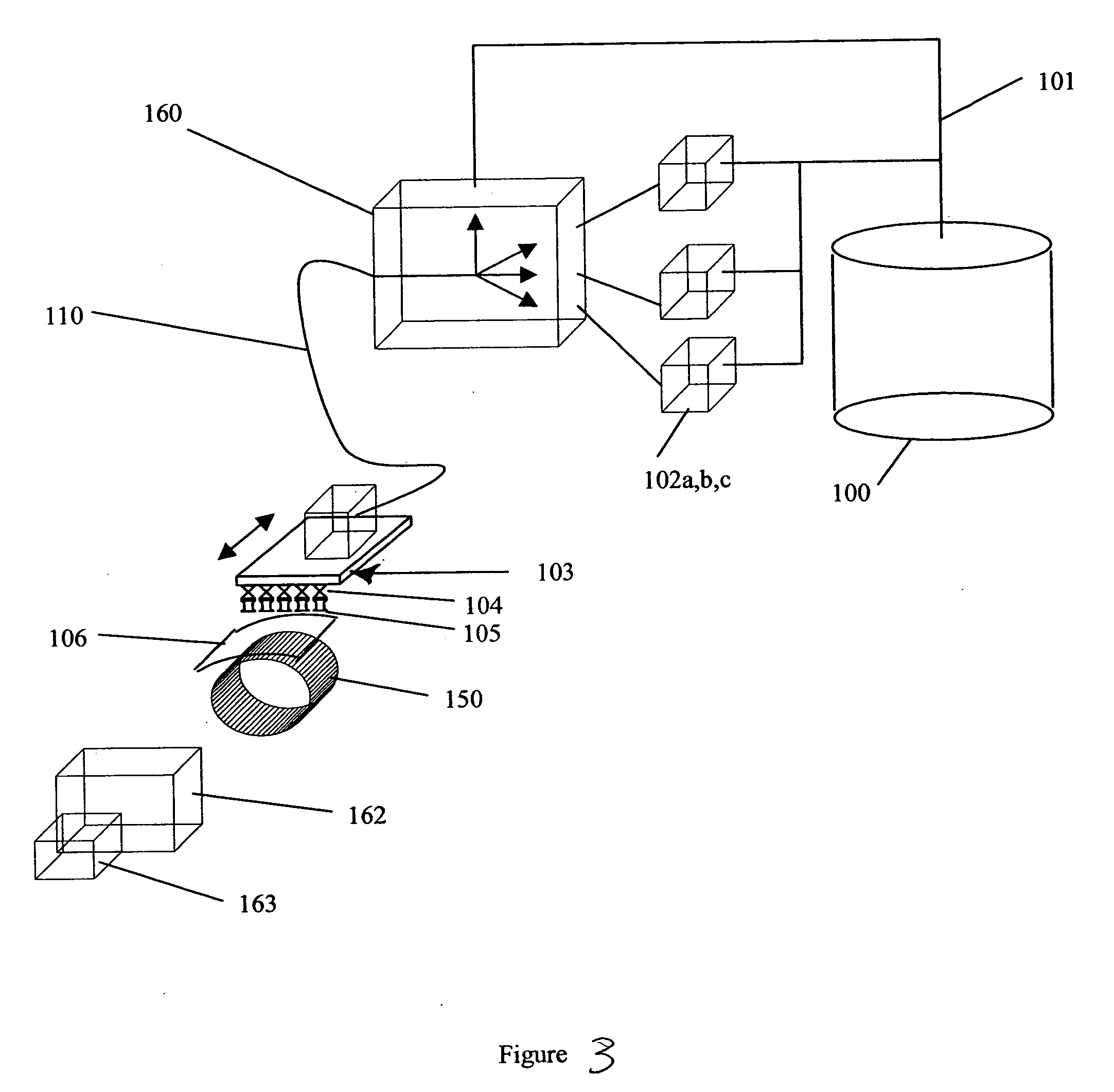

InactiveUS20070252006A1Simple stepsDigital marking by photographic/thermographic registrationSensing by electromagnetic radiationConfocalEngineering

A method and apparatus for labeling plant products based on laser activation of a color-changing compound is disclosed. In the preferred embodiment, a nozzle sprays a coating of photosensitive material containing color-changing chemical component. An optional drying station is set up to optimize homogeneity and adhesiveness of the color-changing coating. A laser equipped with beam steering optics is used to image the desired mark on the plant product by inducing a change of color in the photosensitive coating, without contacting the plant product skin and at a high speed. An optional nozzle sprays a sealant coating after printing, for extended durability of the imaged label. In addition, an optical sensor detects the incoming plant product, determines its size and sends information for selecting the proper label to be imaged. An additional optical sensor can be placed at the end of the process to verify the quality and legibility of the imaged label. The apparatus described can be extended to multiple marking stations, which can be controlled by a central computer to allow for dynamic updating of the desired label(s).

Owner:SUNKIST GROWERS

Authentication method and apparatus for use with compressed fluid printed swatches

InactiveUS20050018013A1Digital marking by photographic/thermographic registrationPrintingCompressed fluidEngineering

Authentication systems, apparatus, and methods authenticate an identification marking including a nanocrystalline material. One or more properties of the marking are ascertained to provide a measured profile. The measured profile is compared to at least one member of a closed set of reference profiles. Each reference profile has predetermined values of one or more properties. Each reference profile is unique within the set. At least one reference profile is characteristic of an indicator material in a nanocrystalline morphology and non-characteristic of the same indicator material in a bulk morphology.

Owner:EAPEIRON SOLUTIONS INC

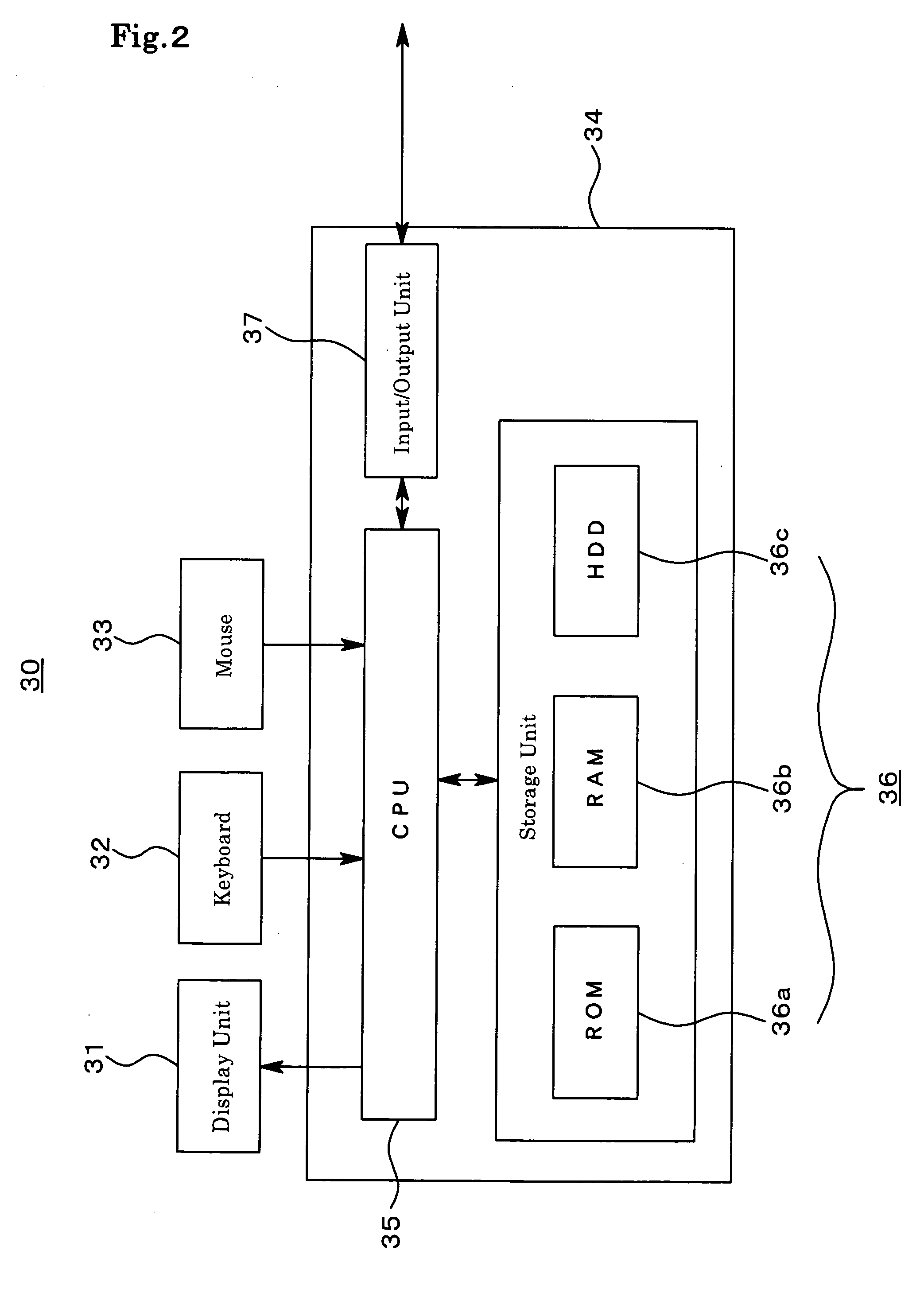

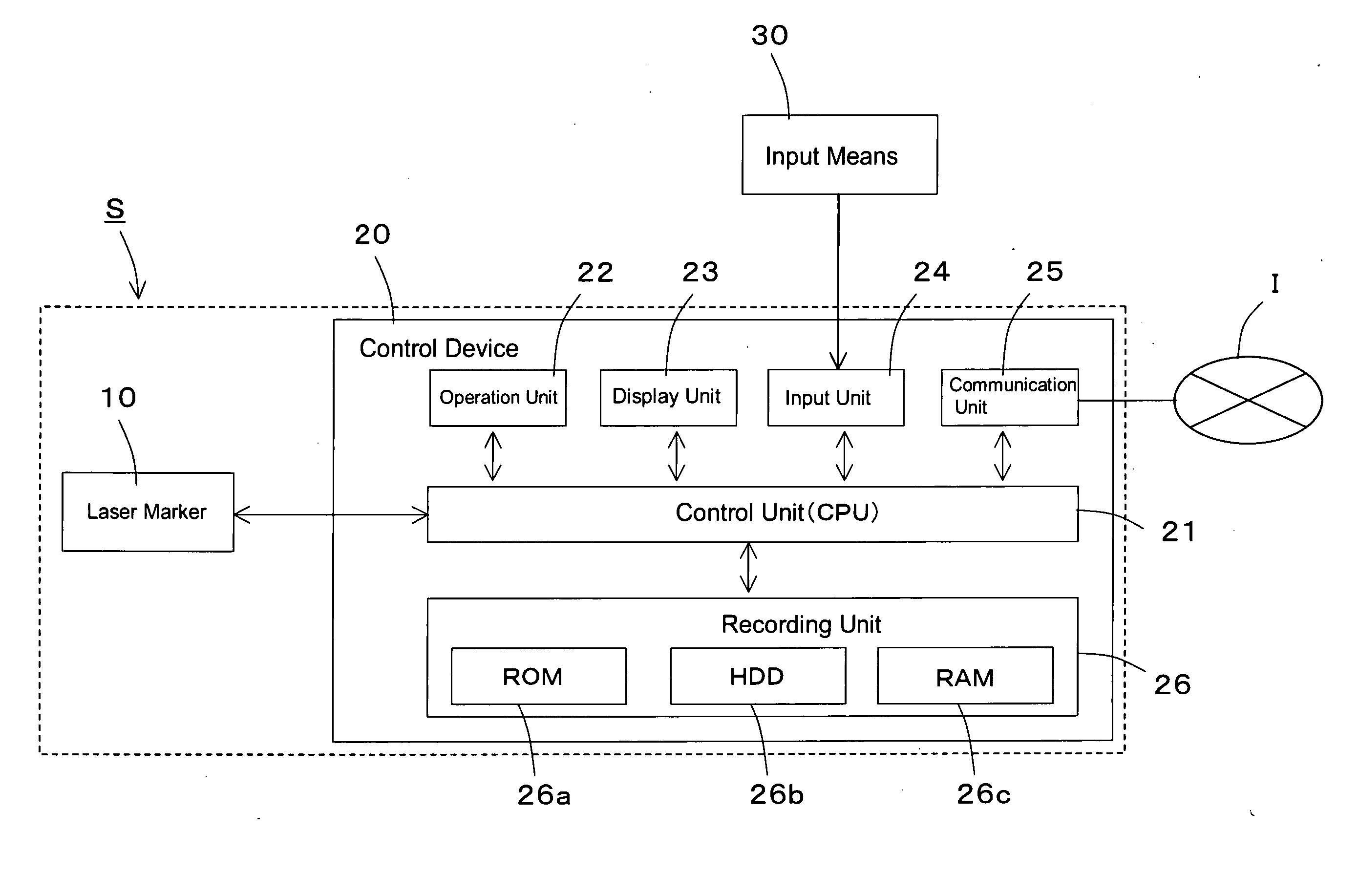

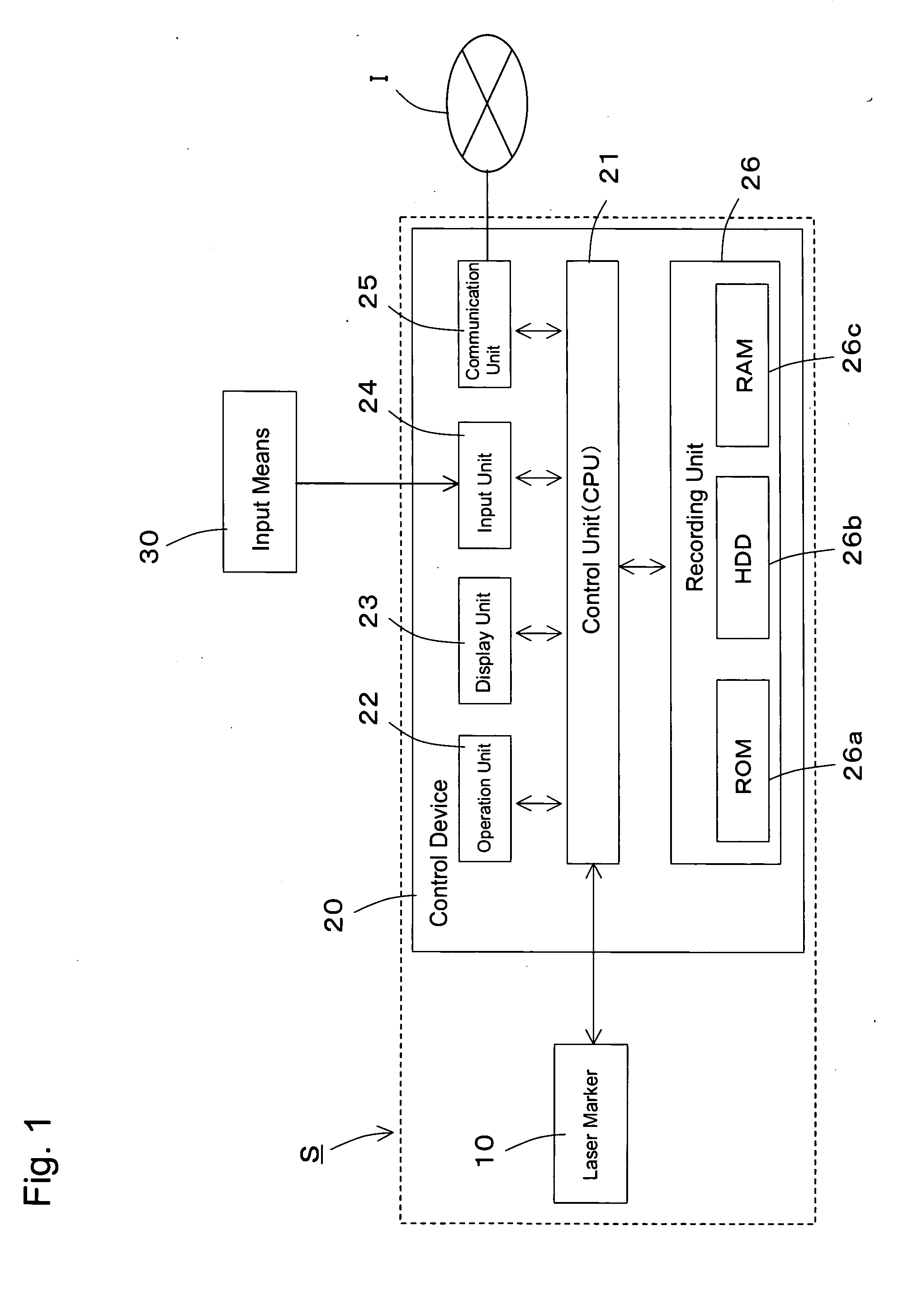

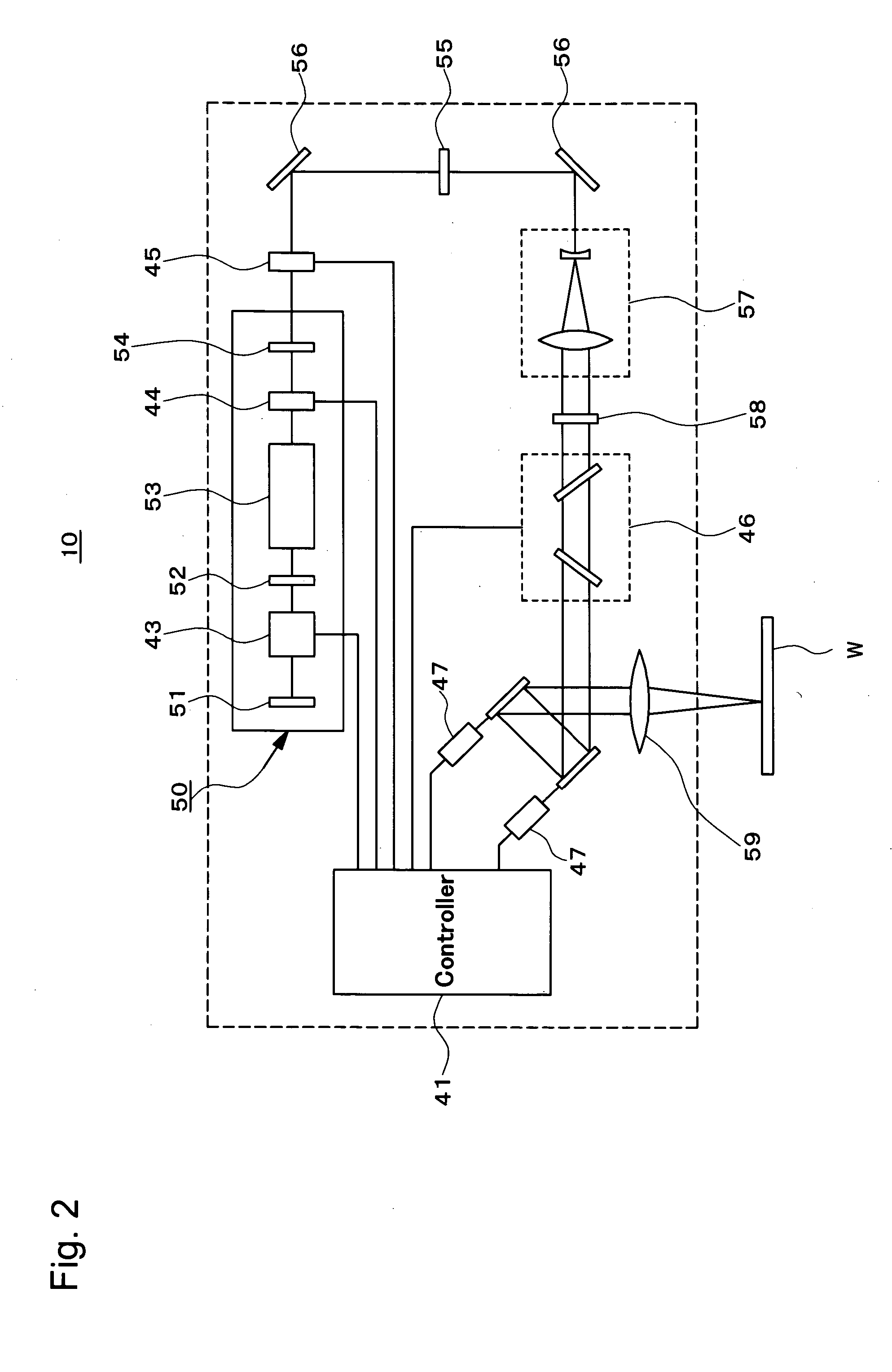

Method Of and System For Generating Laser Processing Data, Computer Program For Generating Laser Processing Data and Laser Marking System

InactiveUS20080067251A1Reduce overall man-hoursImprove accuracyDigital marking by photographic/thermographic registrationPrintingLaser processingSynchronism

Laser processing data based on which a laser processing system scans a work with a laser beam adjustable in focal distance in two dimensions is generate by specifying a two-dimensional pattern in an X-Y coordinate plane and a shift pitch at which the two-dimensional pattern is shifted in a Z-axis direction and repeatedly shifting the two-dimensional pattern at the shift pitch in the Z-axis direction in synchronism with the scan with the two-dimensional pattern.

Owner:KEYENCE

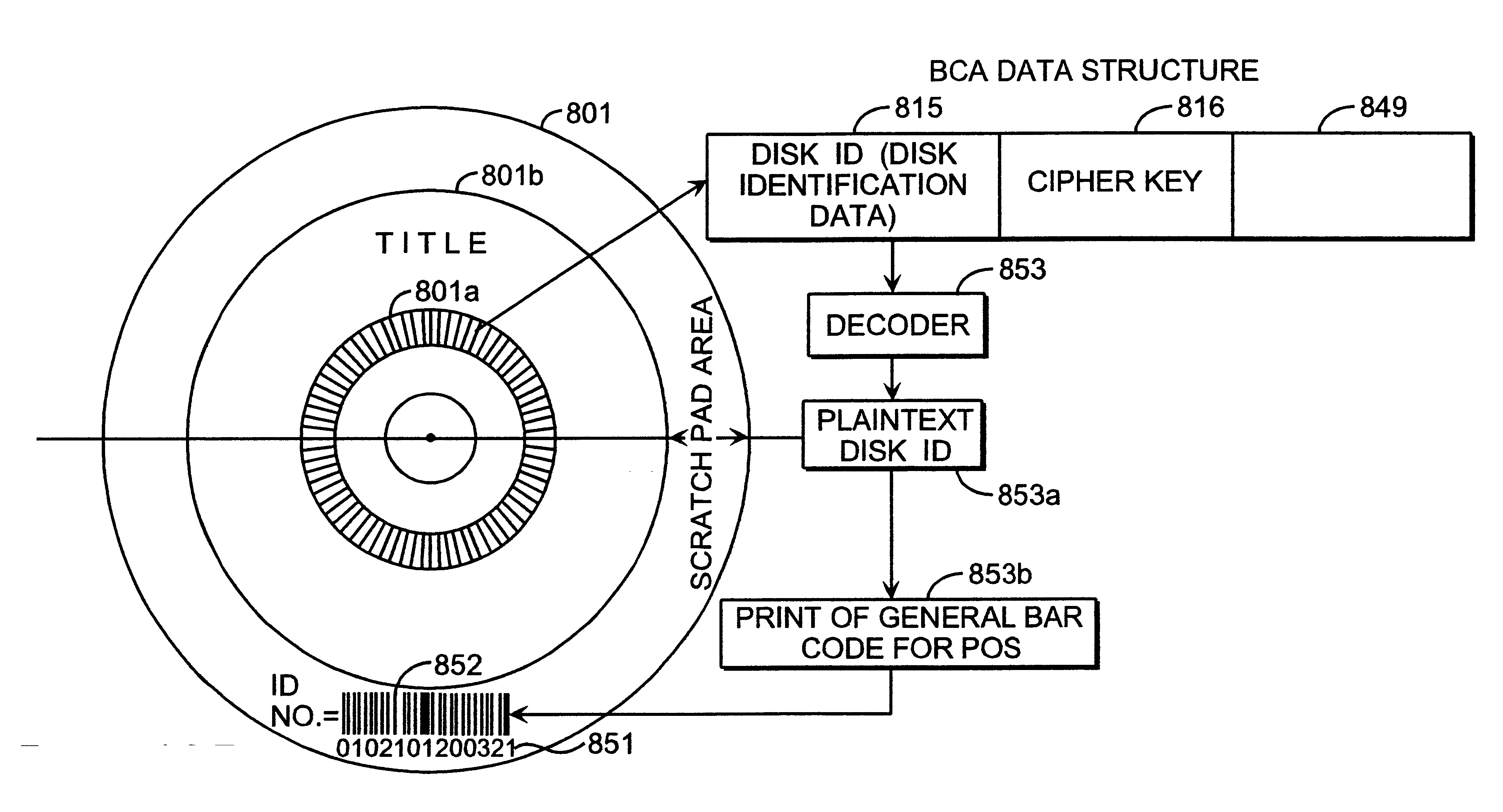

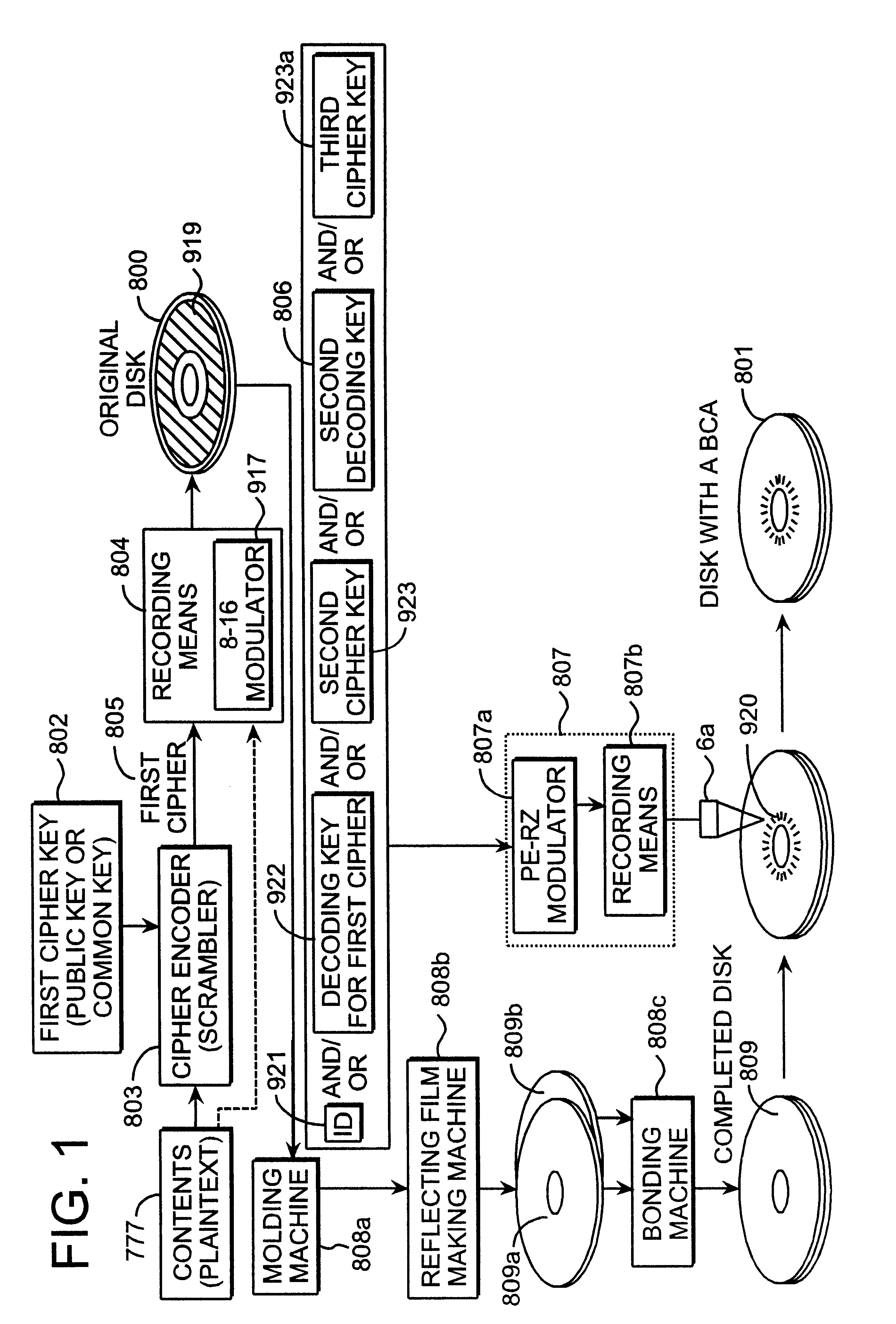

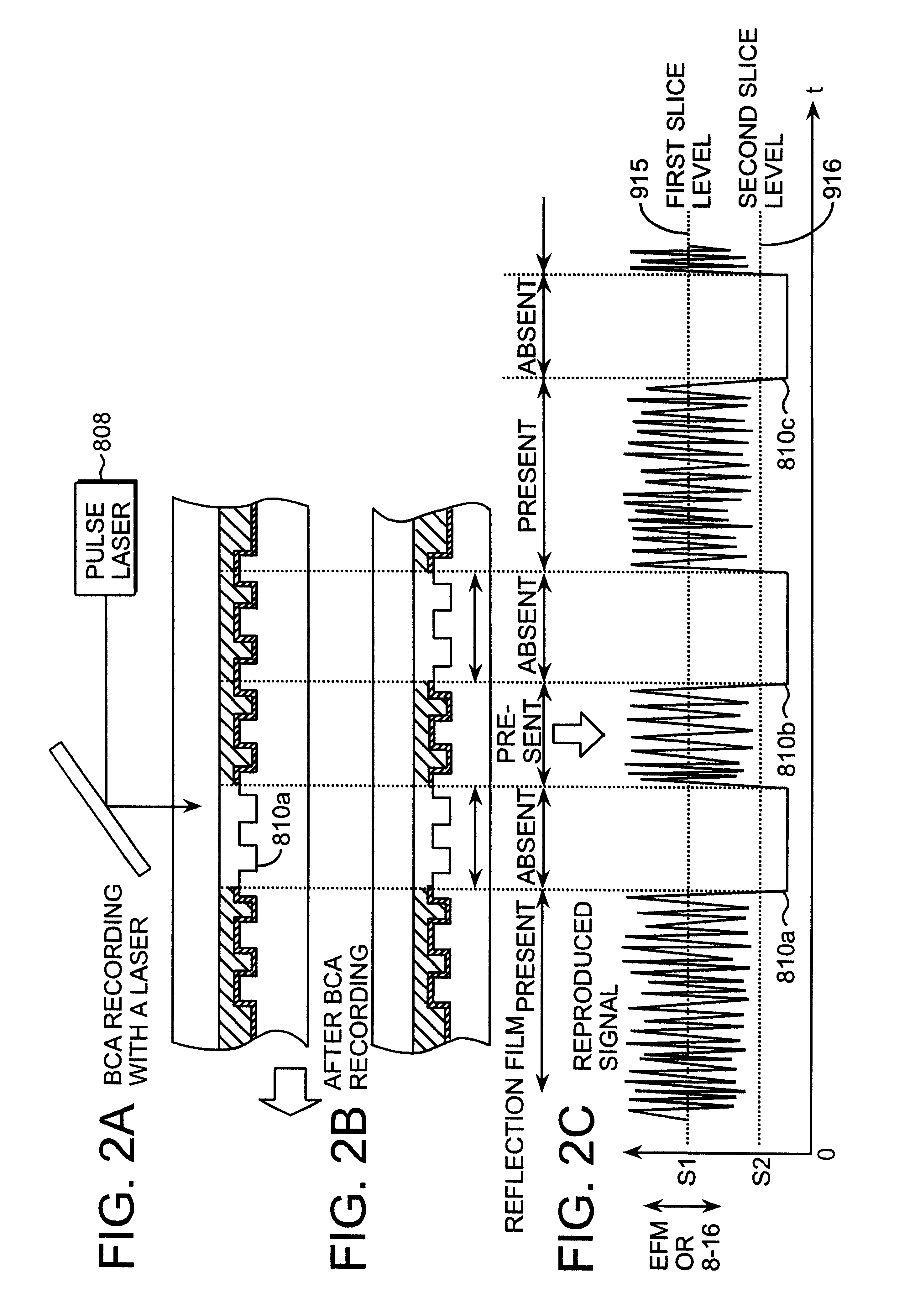

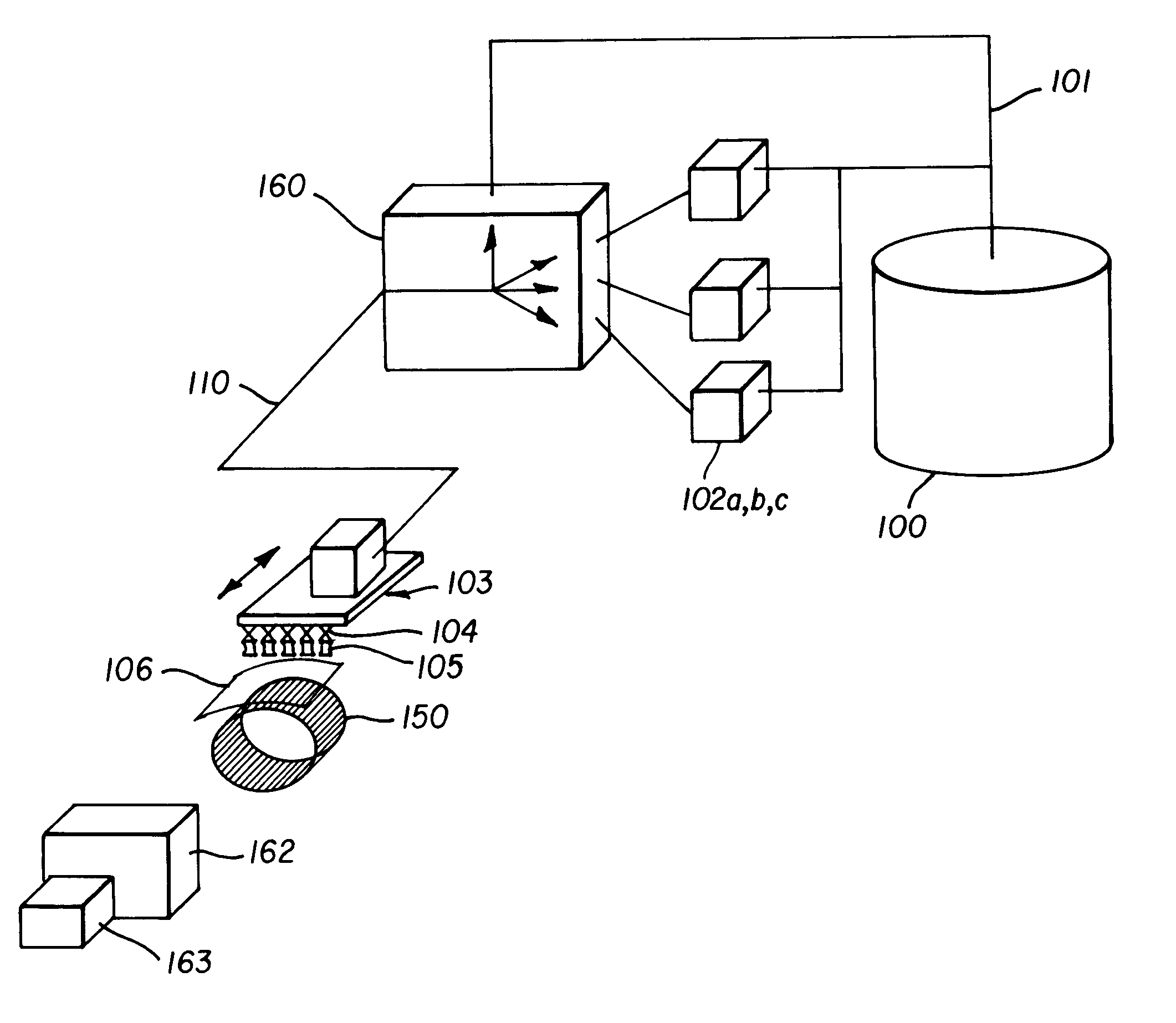

Recordable optical disk including an auxiliary information presence indicator

InactiveUS6885629B2Copyright protectionPrevent the software from being illegally installedAccessories for auxillary signalsDigital data processing detailsRecordable compact discComputer science

An optical disk having a first recording area for recording information; and a second recording area having auxiliary information including disk identification information unique to that optical disk recorded therein, wherein the second recording area including circumferentially arranged multiple stripe patterns each strip extending along a radius of the disk; and indicator indicating the presence of auxiliary information.

Owner:PANASONIC CORP

Authentication method and apparatus for use with compressed fluid printed swatches

InactiveUS7044376B2Digital marking by photographic/thermographic registrationPrintingCompressed fluidEngineering

Authentication systems, apparatus, and methods authenticate an identification marking including a nanocrystalline material. One or more properties of the marking are ascertained to provide a measured profile. The measured profile is compared to at least one member of a closed set of reference profiles. Each reference profile has predetermined values of one or more properties. Each reference profile is unique within the set. At least one reference profile is characteristic of an indicator material in a nanocrystalline morphology and non-characteristic of the same indicator material in a bulk morphology.

Owner:EAPEIRON SOLUTIONS INC

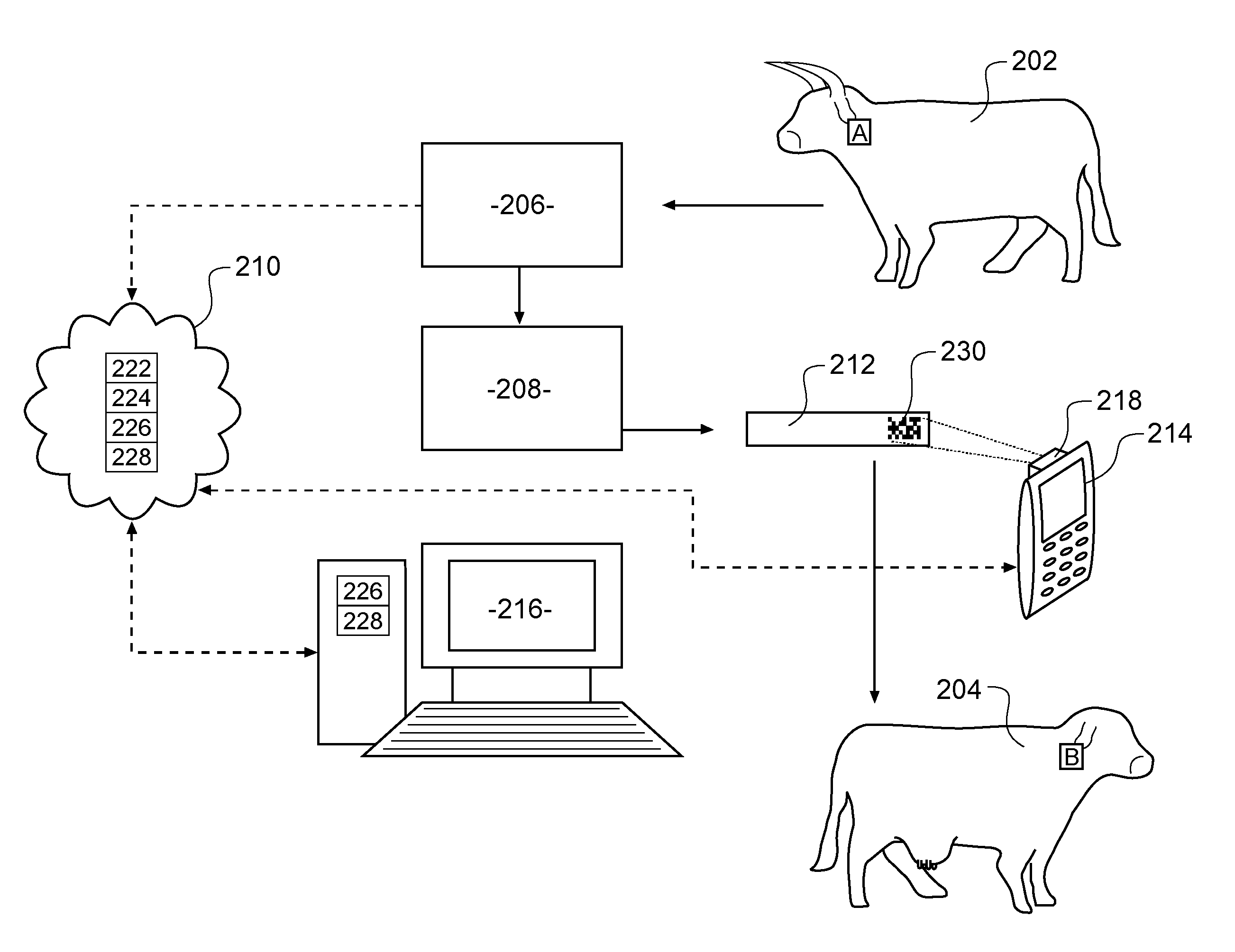

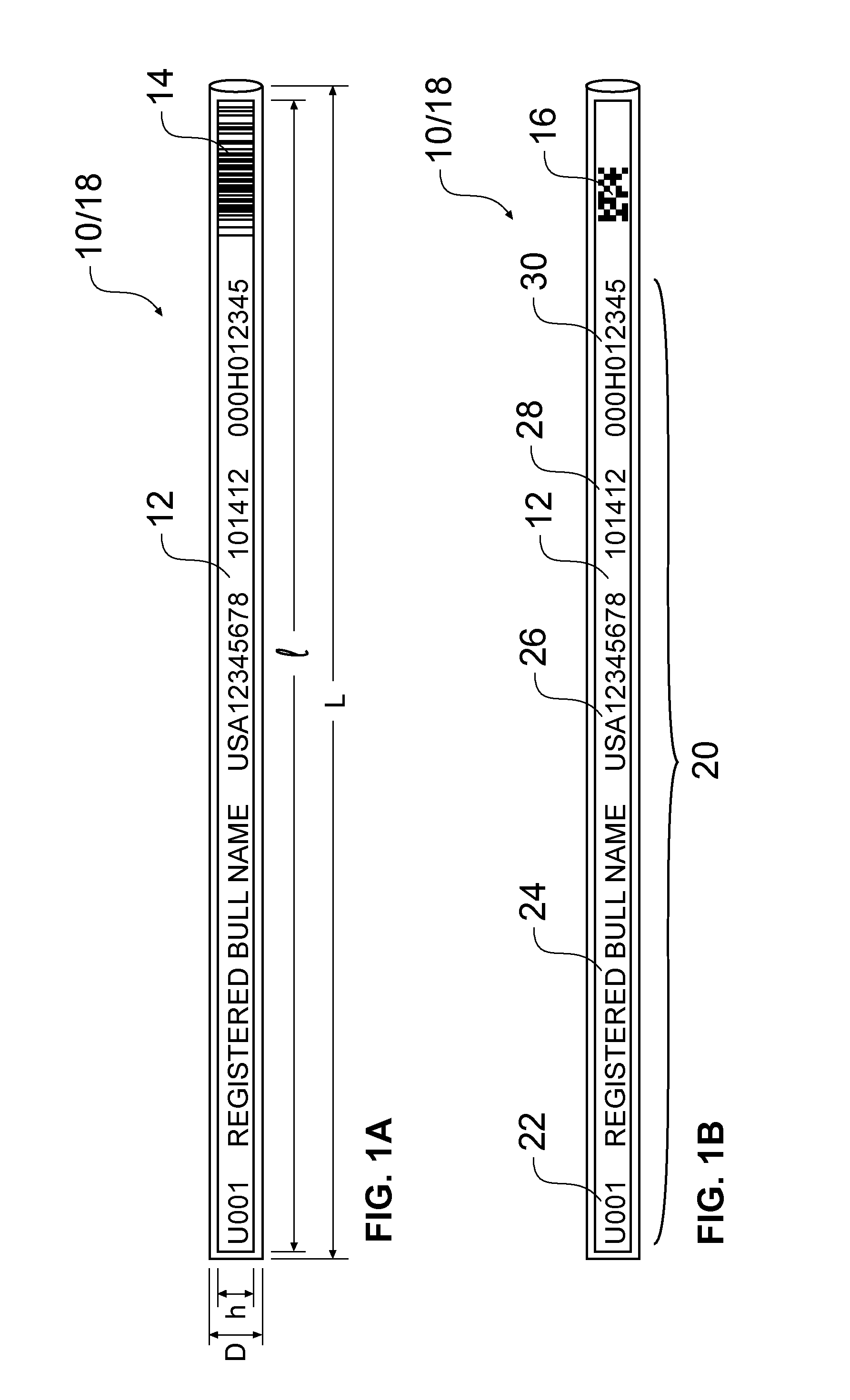

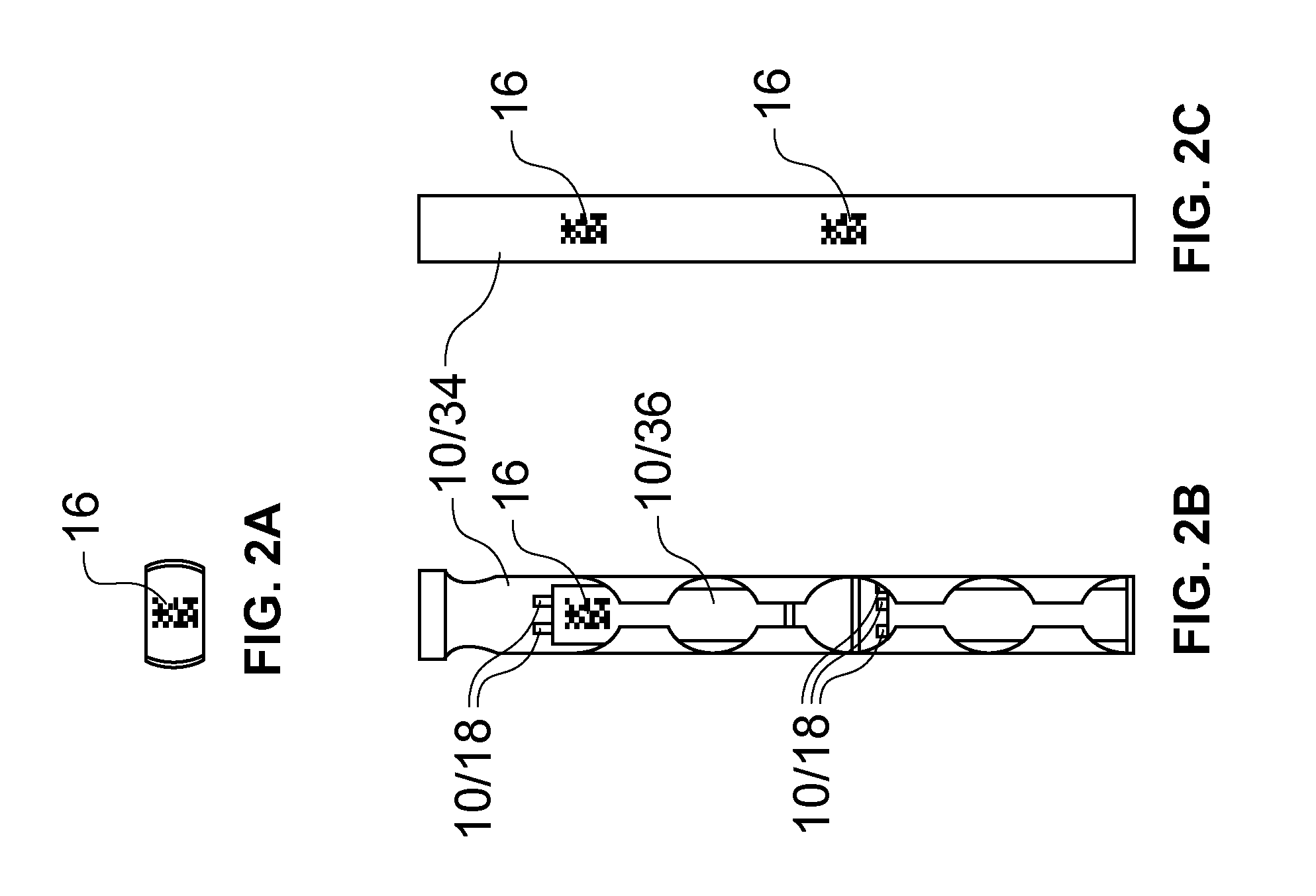

Two-dimensional bar codes in assisted reproductive technologies

A container suitable for storing biological material which is laser etched with a two-dimensional bar code and methods for producing the same. The container can be in the form of a straw having a thickness between about 0.1 mm and about 0.3 mm or can be in the form of another container that holds multiple straws. The laser etched mark can be in the form of a two-dimensional bar code may be located on an exterior surface of the container, and when the container is a straw, it remains unwarped and impermeable to fluids.

Owner:INGURAN LLC

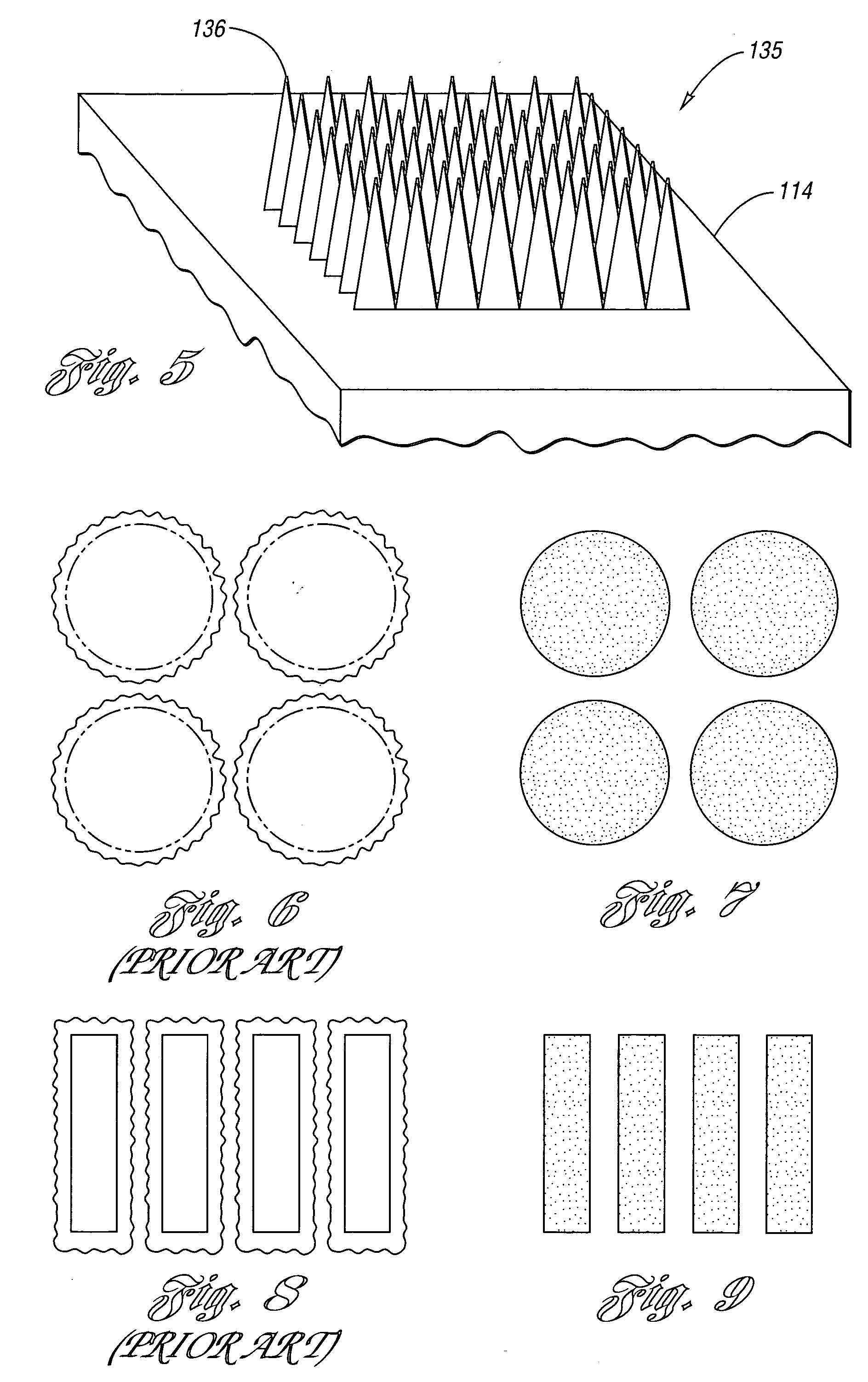

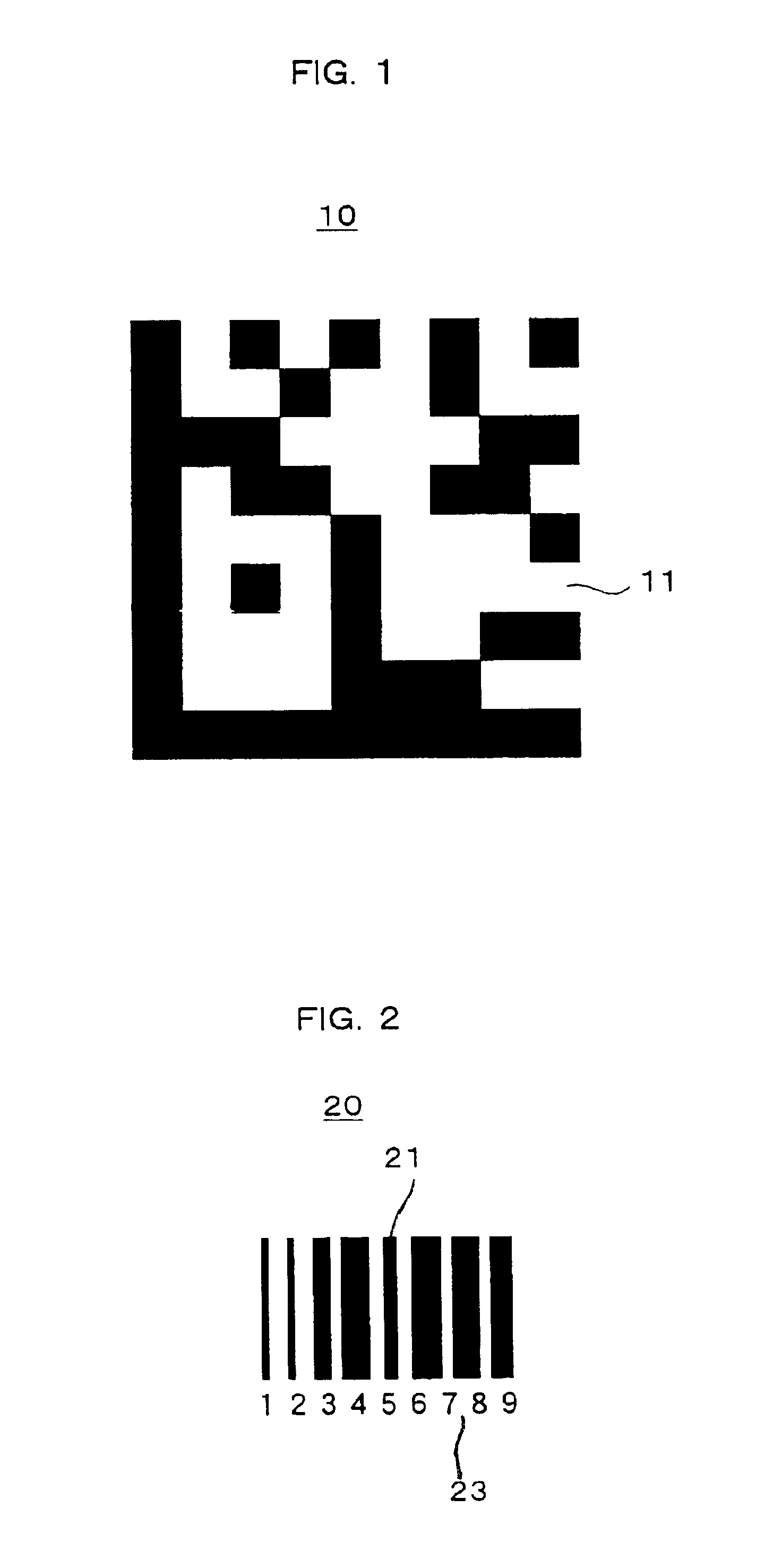

Method for Forming 2-Dimensional Code by Laser Marking and Laser Marking Device

InactiveUS20070279474A1Low costArea clearRecording apparatusMechanical apparatusLight beamOptoelectronics

It is judged whether a marking unit formed on a material becomes a bright mark or a dark mark. Based on this judgment, for the work W of a material in which the marking unit becomes a bright mark, the code symbol of the 2-dimensional code of the original image is bright / dark-reversed to generate a reversed code symbol 1R. By doing this, a laser marker 10 is controlled so as to apply a laser beam to the cell of the background portion without applying the laser beam on the cell of the code portion. On the other hand, in the case of the normal material in which the marking unit becomes a dark mark, the laser marker 10 is controlled to apply the laser beam to the cell of the code portion without applying the beam to the cell of the background portion.

Owner:ARAI HELMET LTD

Printing a code on a product

InactiveUS7167194B2Recording apparatusDigital marking by photographic/thermographic registrationData setComputer science

A method for printing is described. The method includes providing a printing system for printing a code on a product moving in a direction. The code is constructed from a plurality of pixels in a first data set indicating the positions of the pixels and generates a corrected data set indicating the position that each pixel would occupy if each pixel was moved at the velocity of the product until the pixel was printed. The method also includes printing the code according to the corrected data set.

Owner:MARKEM IMAJE CORP

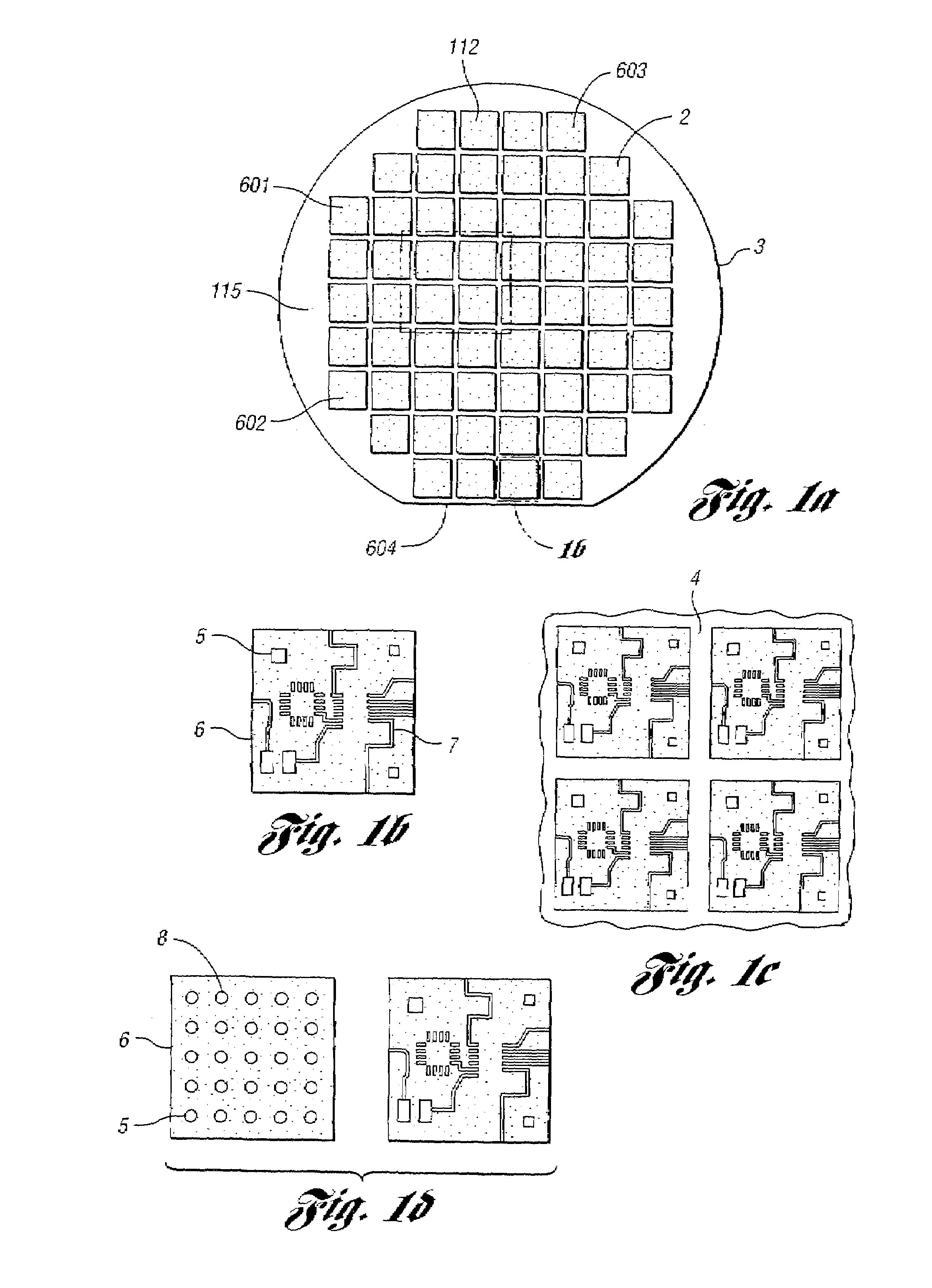

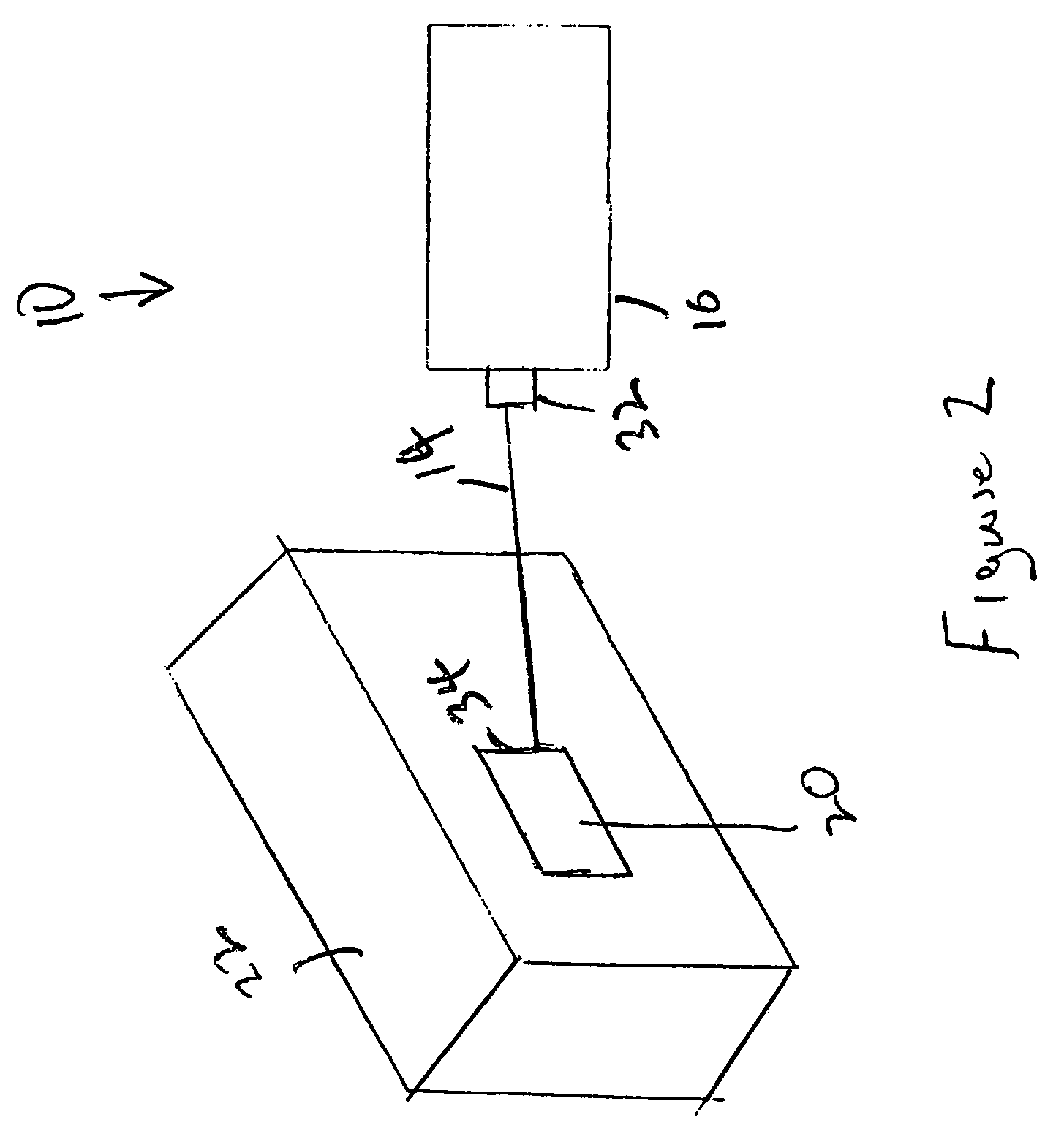

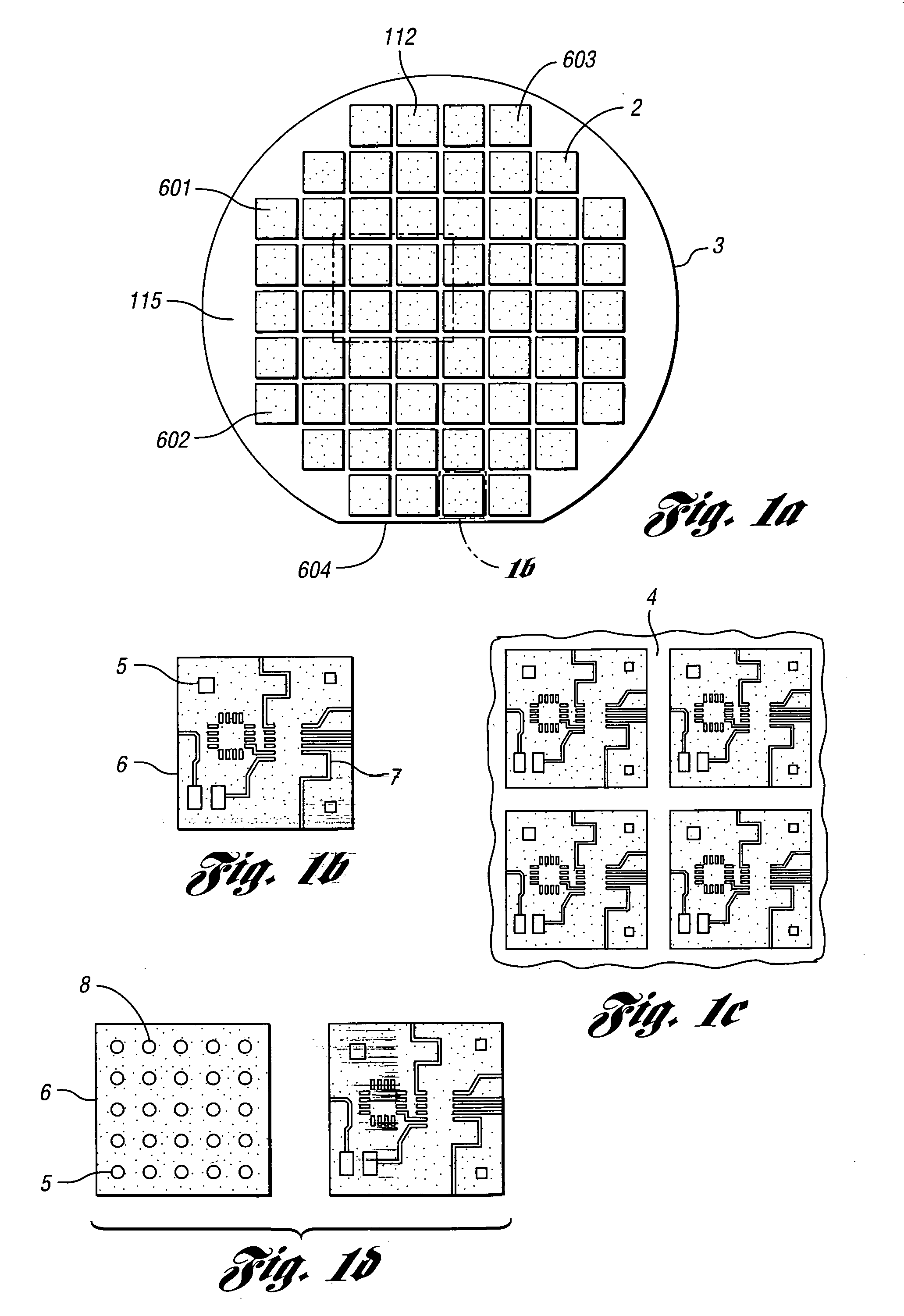

Semiconductor device and an information management system thereof

InactiveUS6896186B2Increase flexibilityAccurate and efficient distributionSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsBarcodeSemiconductor chip

Individual two-dimensional barcodes 30, 91 and 173 are provided for individual chips 31 arrayed on a wafer 50, individual lead frames 93 to each of which chips 92 are bonded and individual packaged products 171 constituted of resin sealed semiconductor chips based upon chip ID information to enable information management to be implemented separately for individual chips 31, individual frames 93 and individual chip products 171. Thus, a higher degree of efficiency and a higher degree of accuracy in the information management for semiconductor devices are achieved in all processes of semiconductor production including the individual manufacturing processes, the physical distribution process, the shipping process and the claim handling process.

Owner:HPLP TECH

Method and system for calibrating a laser processing system and laser marking system utilizing same

InactiveUS20060054608A1Mark accuratelySemiconductor/solid-state device detailsSolid-state devicesLaser processingThree degrees of freedom

A method of calibrating a laser marking system includes calibrating a laser marking system in three dimensions. The step of calibrating includes storing data corresponding to a plurality of heights. A position measurement of a workpiece is obtained to be marked. Stored calibration data is associated with the position measurement. A method and system for calibrating a laser processing or marking system is provided. The method includes: calibrating a laser marker over a marking field; obtaining a position measurement of a workpiece to be marked; associating stored calibration data with the position measurement; relatively positioning a marking beam and the workpiece based on at least the associated calibration data; and calibrating a laser marking system in at least three degrees of freedom. The step of calibrating includes storing data corresponding to a plurality of positions and controllably and relatively positioning a marking beam based on the stored data corresponding to the plurality of positions.

Owner:ELECTRO SCI IND INC

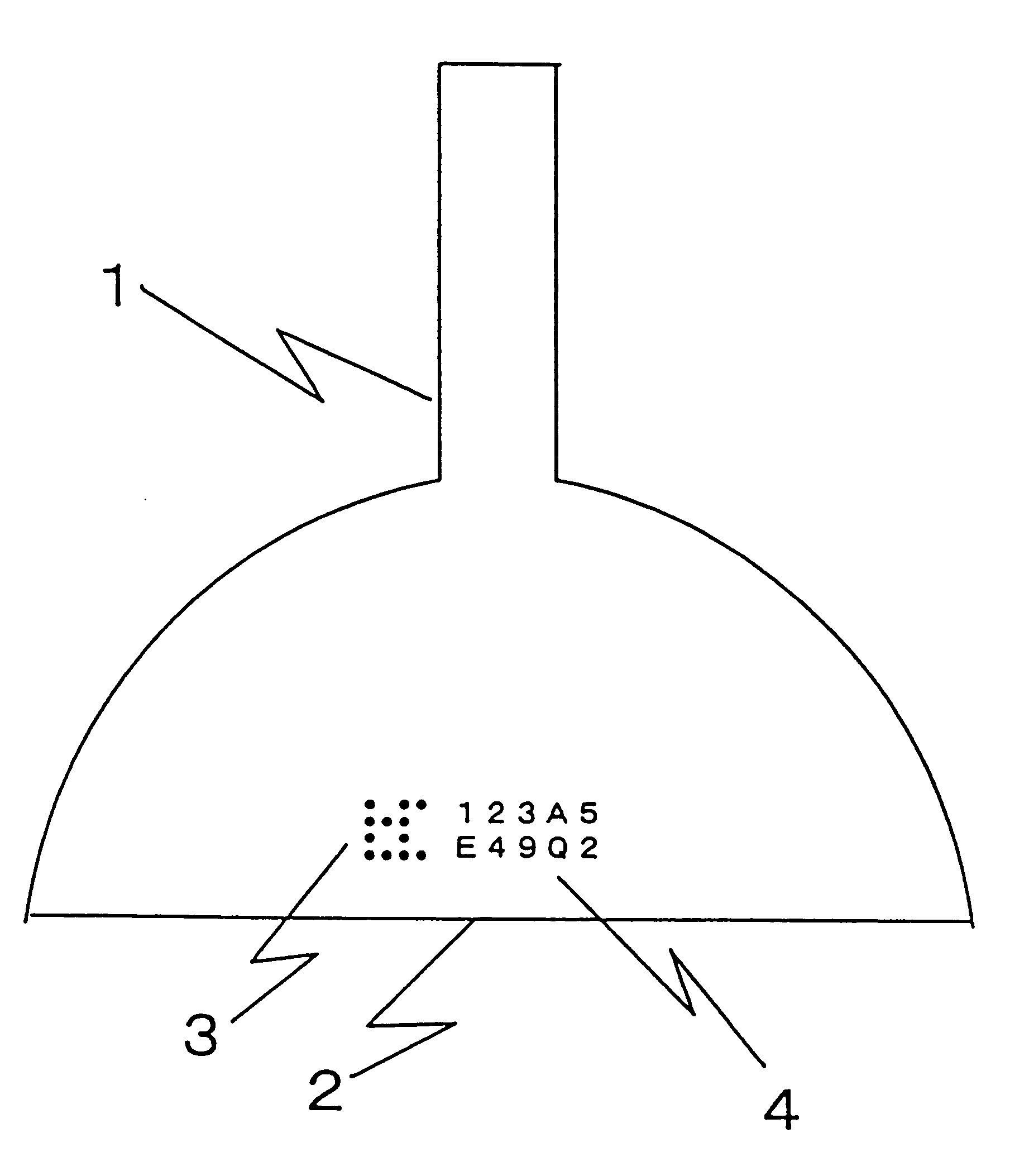

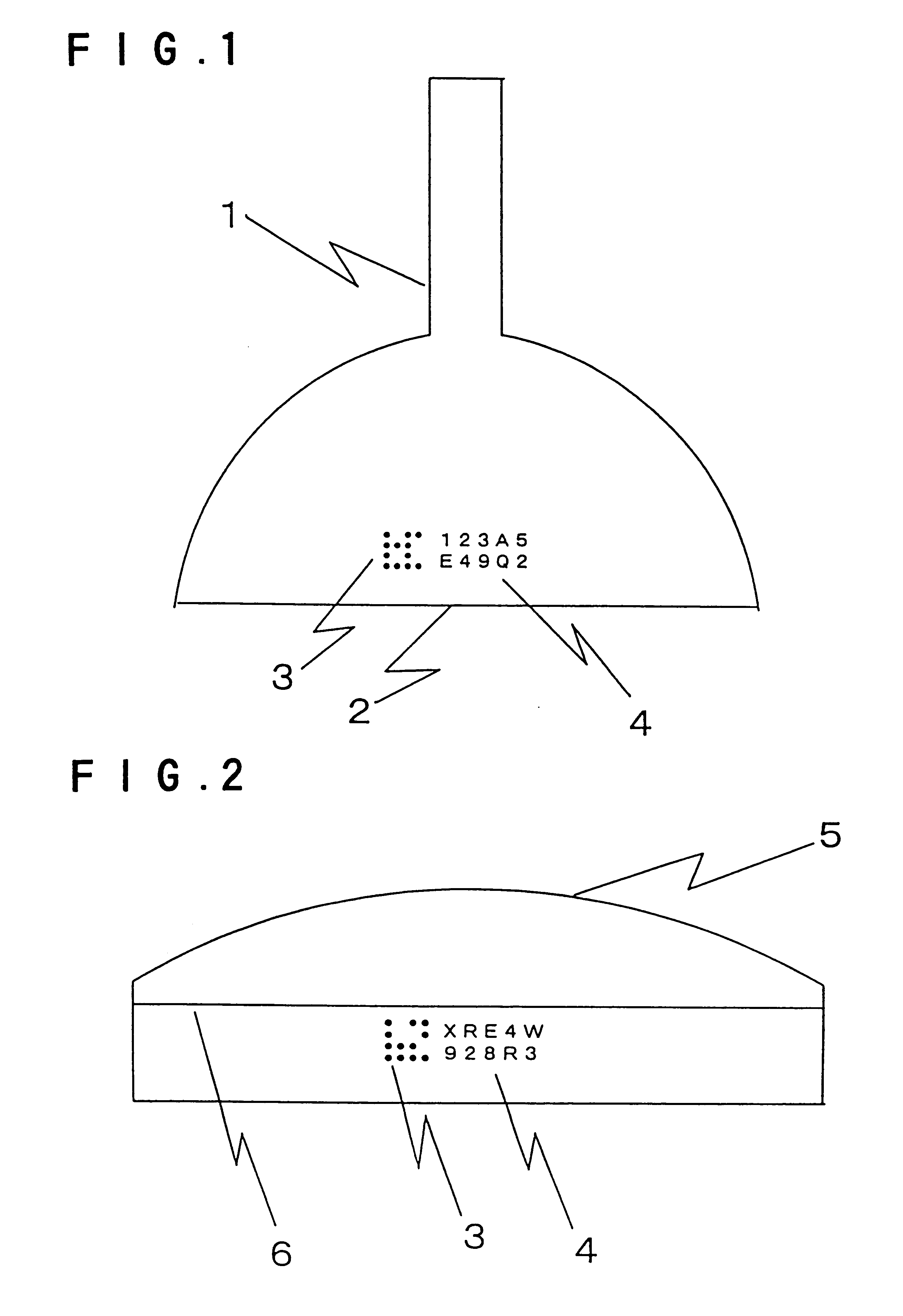

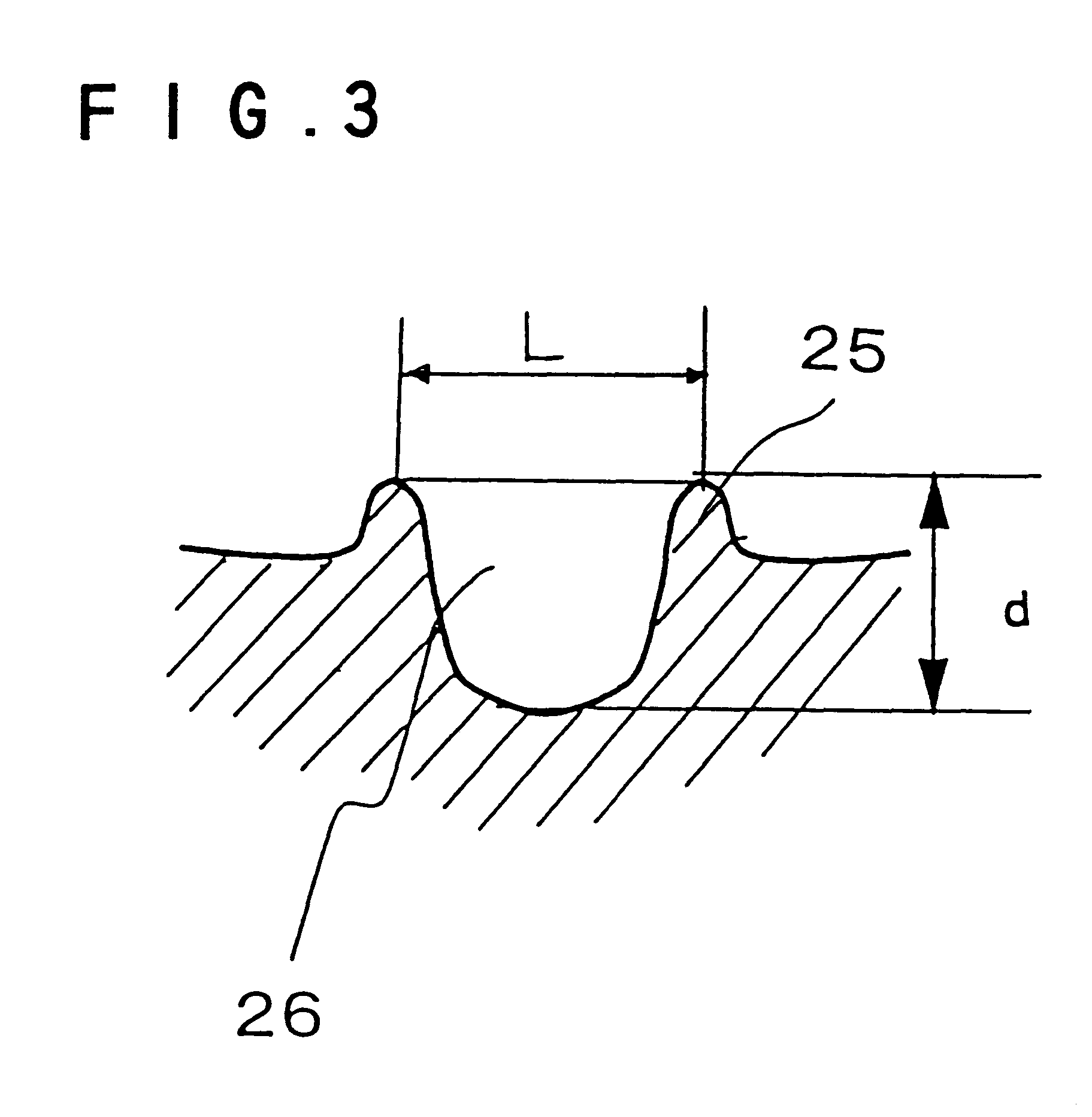

Glass bulb for a cathode ray tube and a method for producing a cathode ray tube

InactiveUS6227394B1Tube/lamp screens manufactureCathode-ray/electron-beam tube vessels/containersEngineeringCathode ray

Manufacturing steps for a cathode ray tube or a glass bulb for the cathode ray tube are controlled in such a manner that a two-dimensional matrix code 3 comprised of a plurality of dots is marked by laser in an outer side surface of a glass bulb 1, 5, the two-dimensional matrix code 3 containing the information which can identify individually glass bulbs, and the manufacturing steps are conducted by using a computer and the particulars specified by the serial information.

Owner:ASAHI GLASS CO LTD

High contrast surface marking using mixed organic pigments

InactiveUS6855910B2Quick tagRapid change of contentRadiation applicationsPretreated surfacesVariable thicknessMaterials science

A method of laser marking metals, plastics, ceramic materials, glazes, glass ceramics, and glasses of any desired form, which includes applying to the material to be marked a variable thickness layer of marking material containing energy absorbing enhancers then irradiating said layer with a laser or diode based energy source such that the radiation is directed onto said layer in accordance with the form of the marking to be applied, and using a laser or diode based energy source of a wavelength which is sufficiently absorbed by the marking material so as to create a bonding of the marking material to the surface of the workpiece at the irradiated areas.

Owner:THERMAX LLC

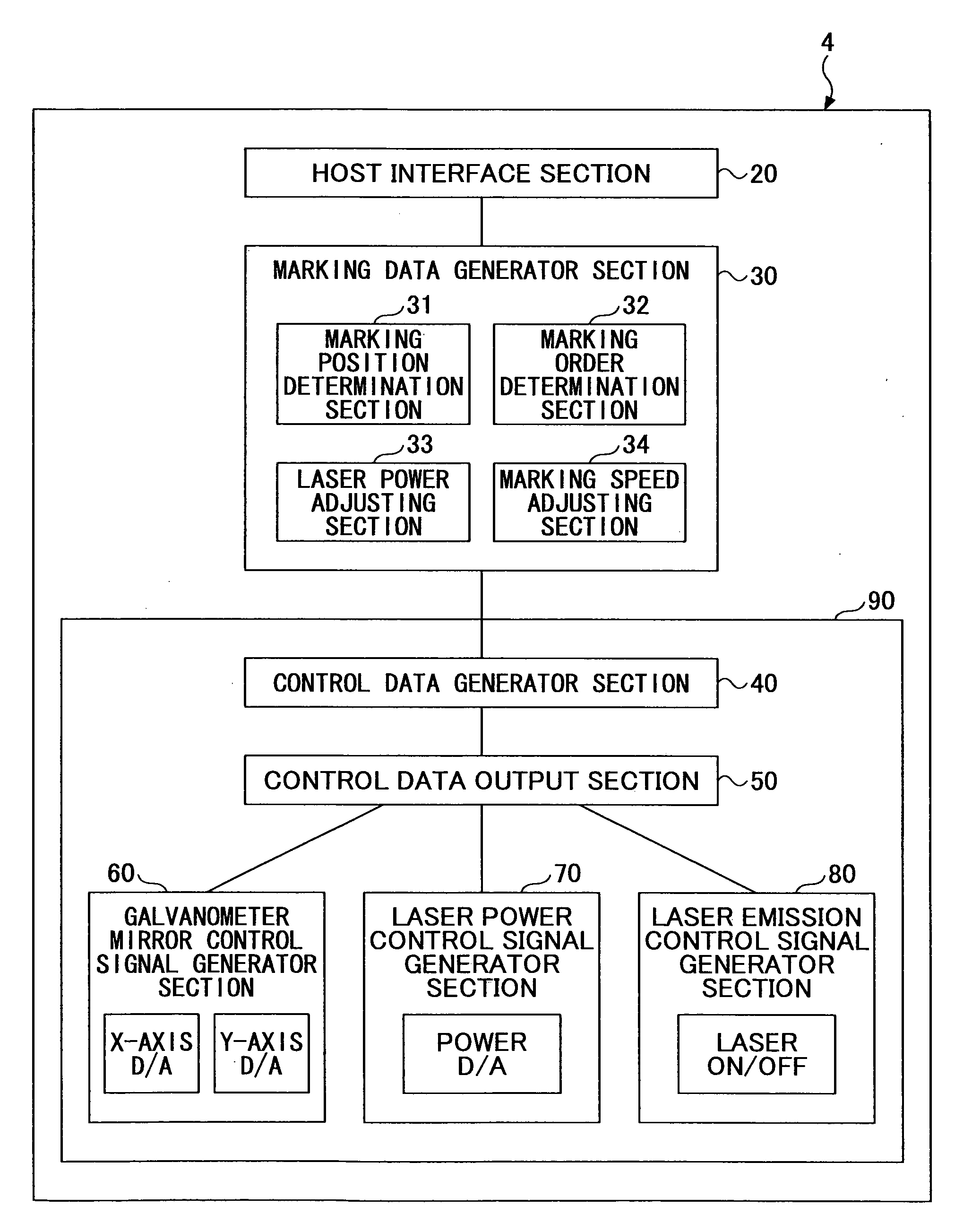

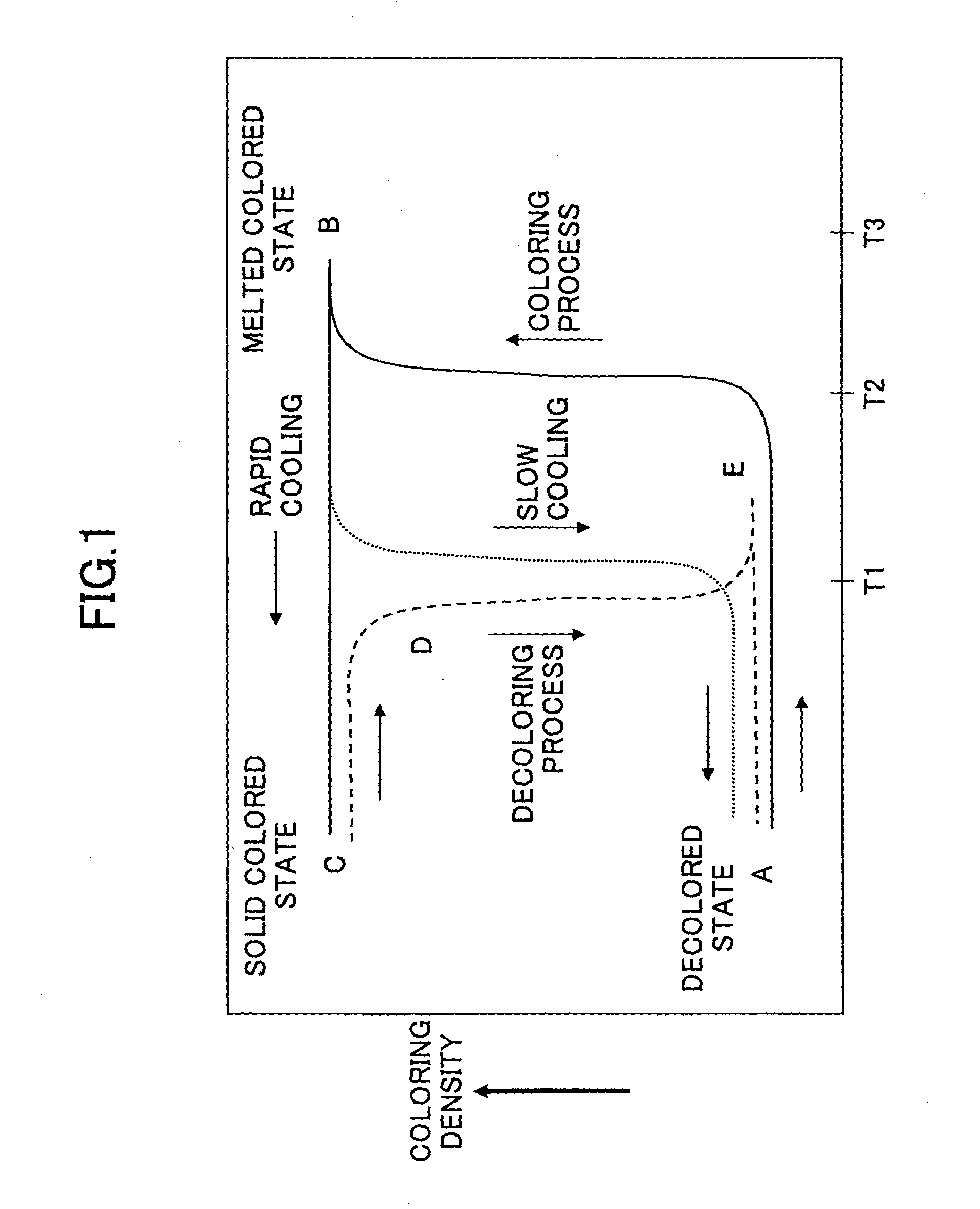

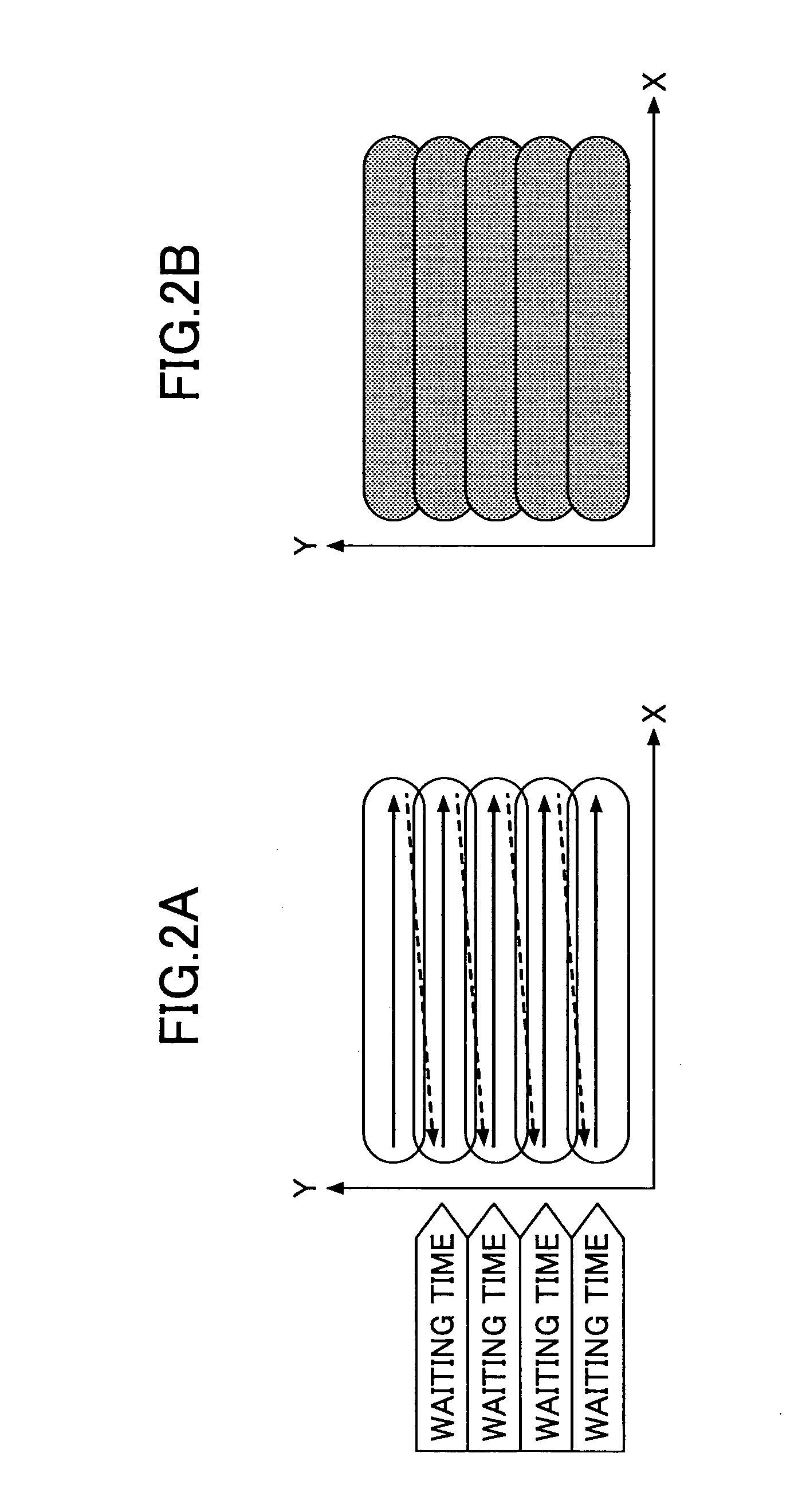

Marking control device, laser application device, marking control method, and computer-readable recording medium having marking control program

InactiveUS20120212564A1Quality improvementWide image erasable energy widthRecording apparatusVisual representation by thermal printersEngineeringLaser beams

A disclosed marking control device controls a marking device to mark a target image on a thermoreversible recording medium by applying a laser beam includes a marking position determination unit dividing the image into plural marking lines, and determining their marking positions; a marking order determination unit determining a marking order to mark the marking lines in mutually opposite directions; an adjusting unit adjusting a distance between a first ending point and a second starting point to be longer than a distance between a first starting point and a second ending point, or adjusting laser power applied to a second starting point side of the second marking line to be lower than the laser power applied to a second ending point side of the second marking line; and a marking instruction generator unit generating marking instructions including the marking positions of the marking lines and the marking order thereof.

Owner:RICOH KK

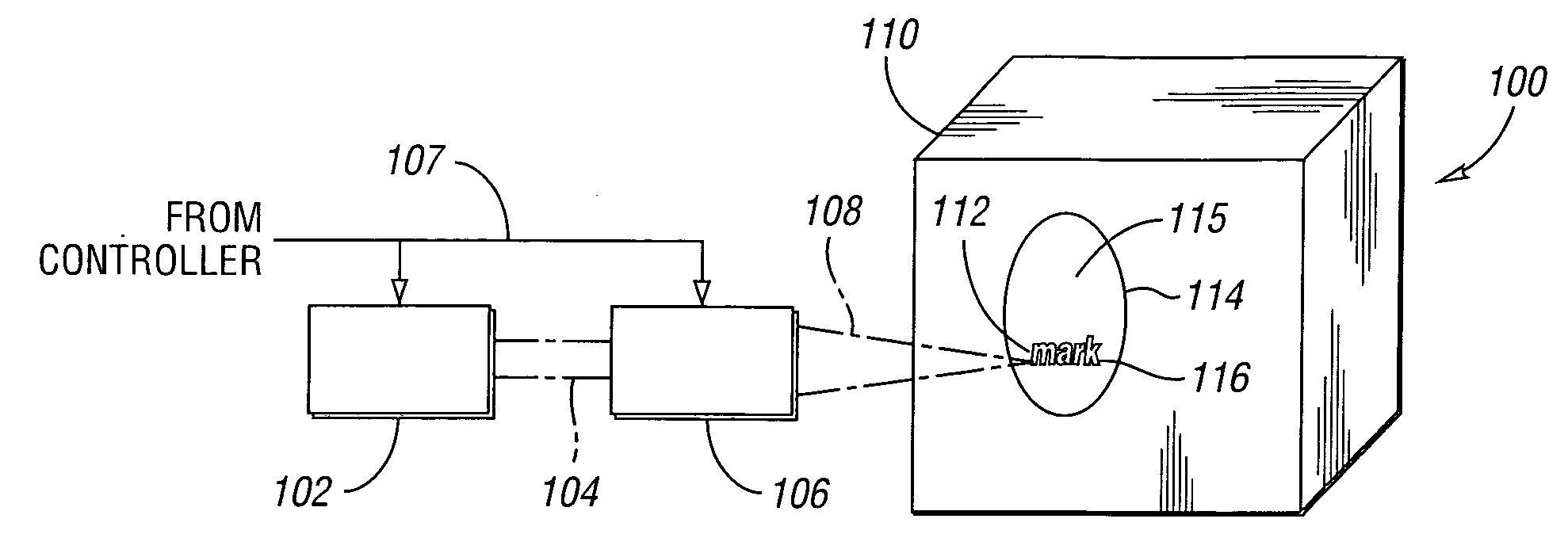

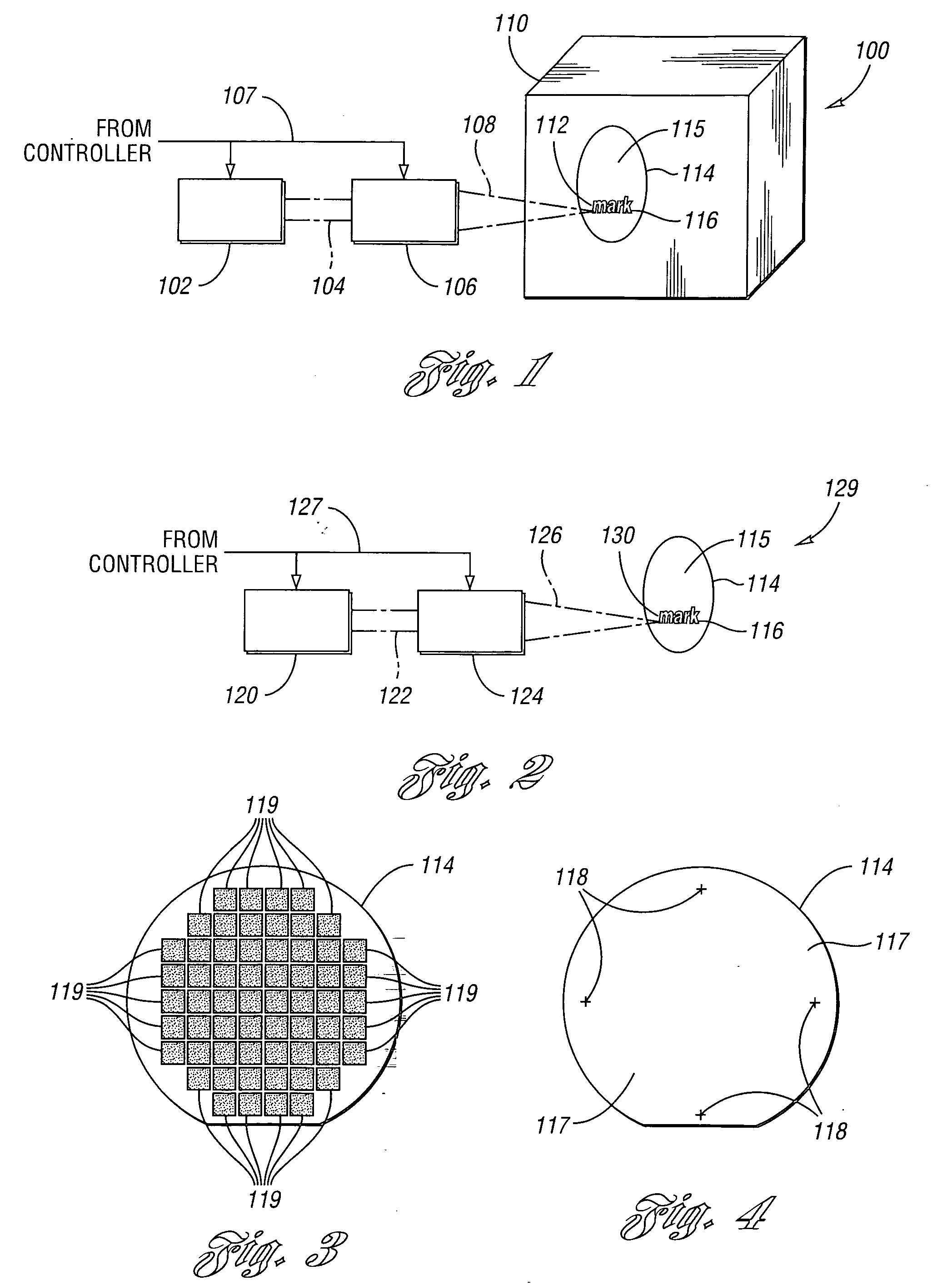

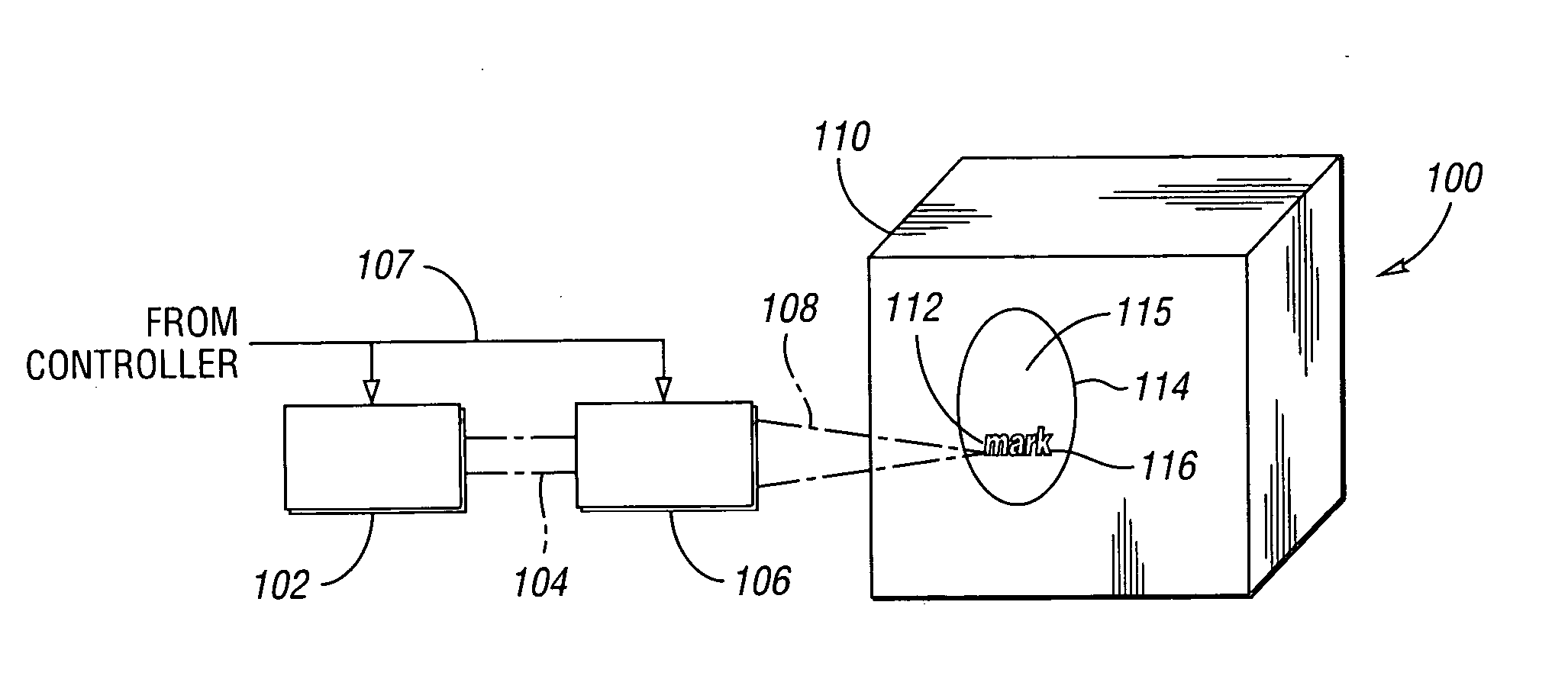

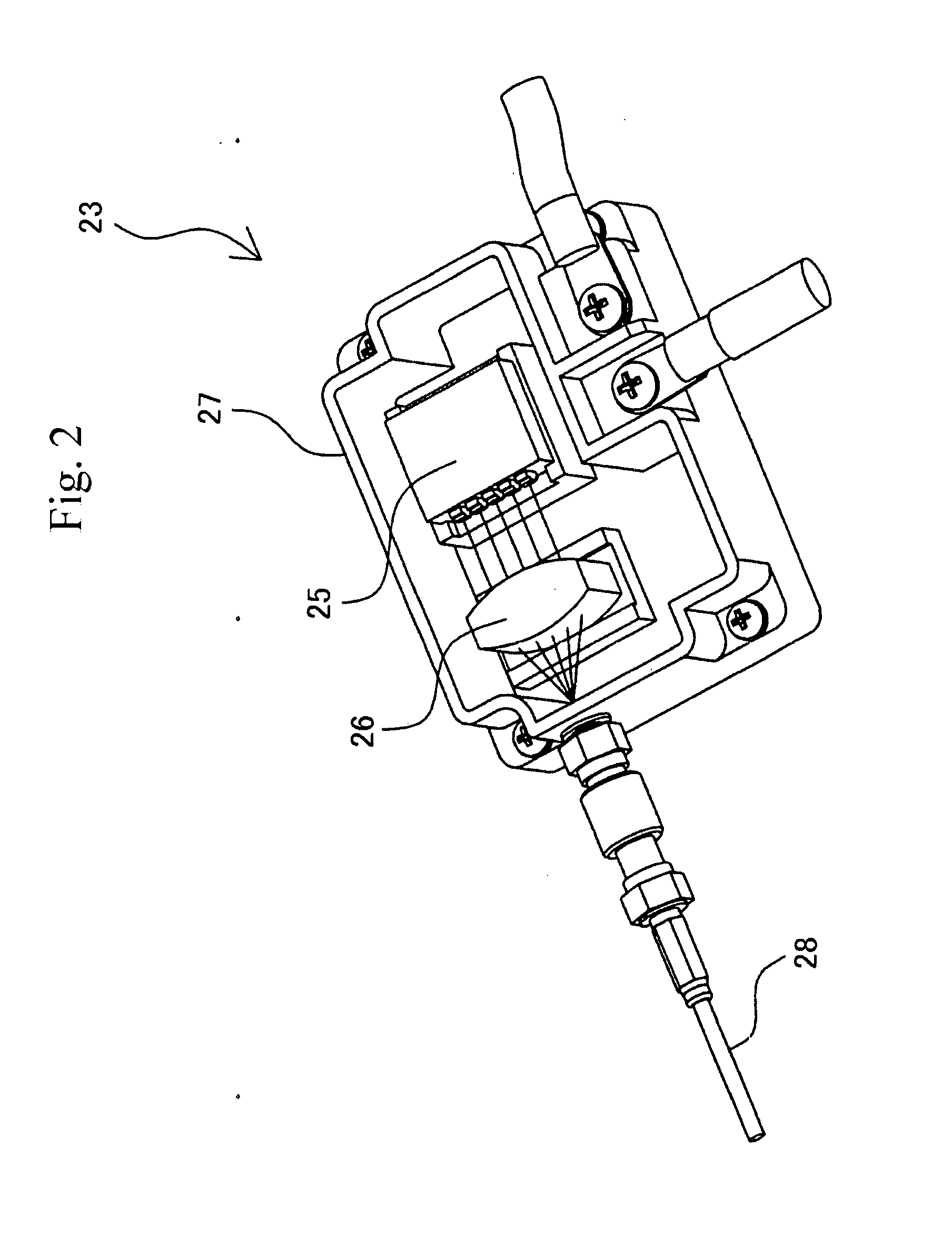

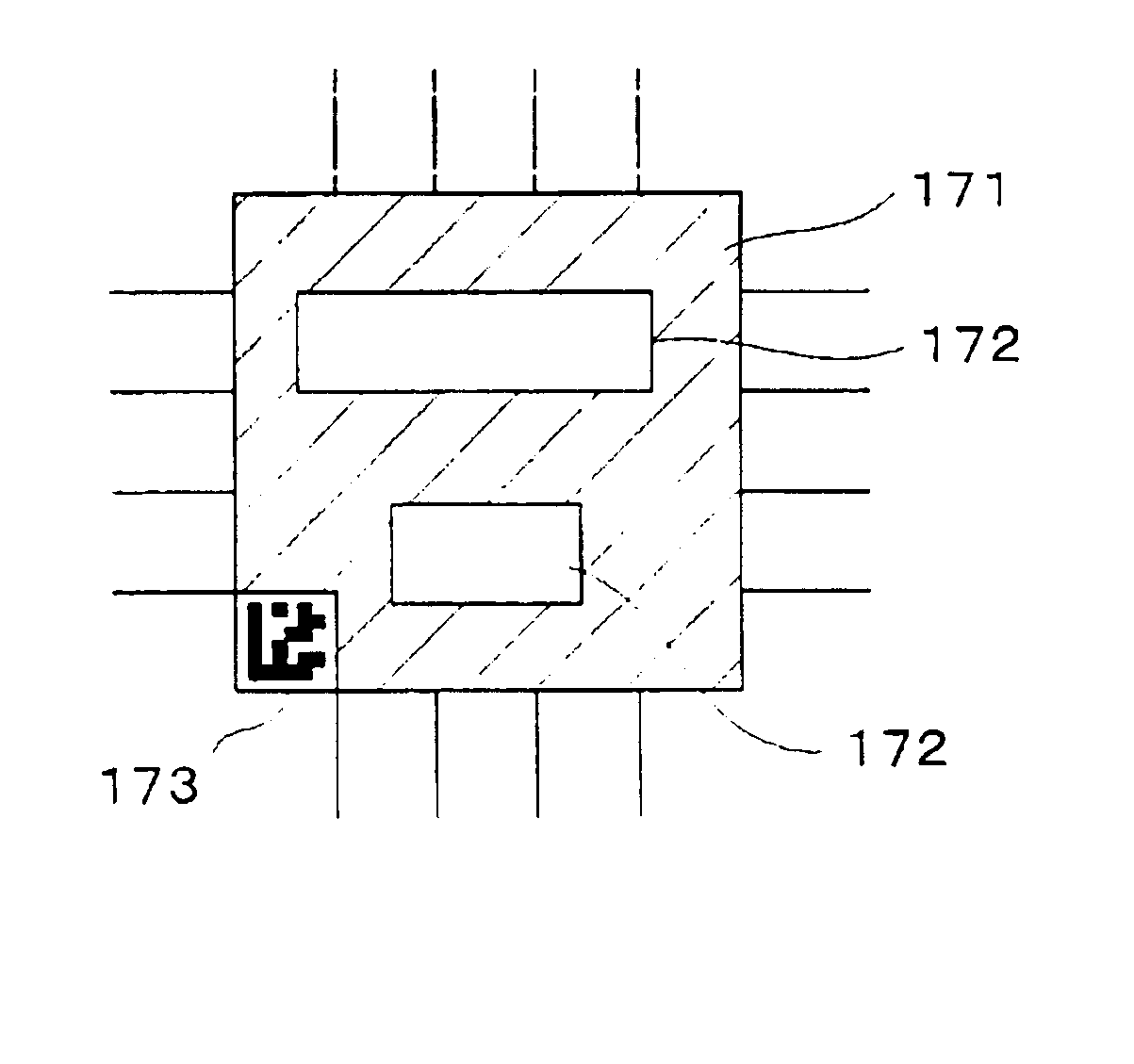

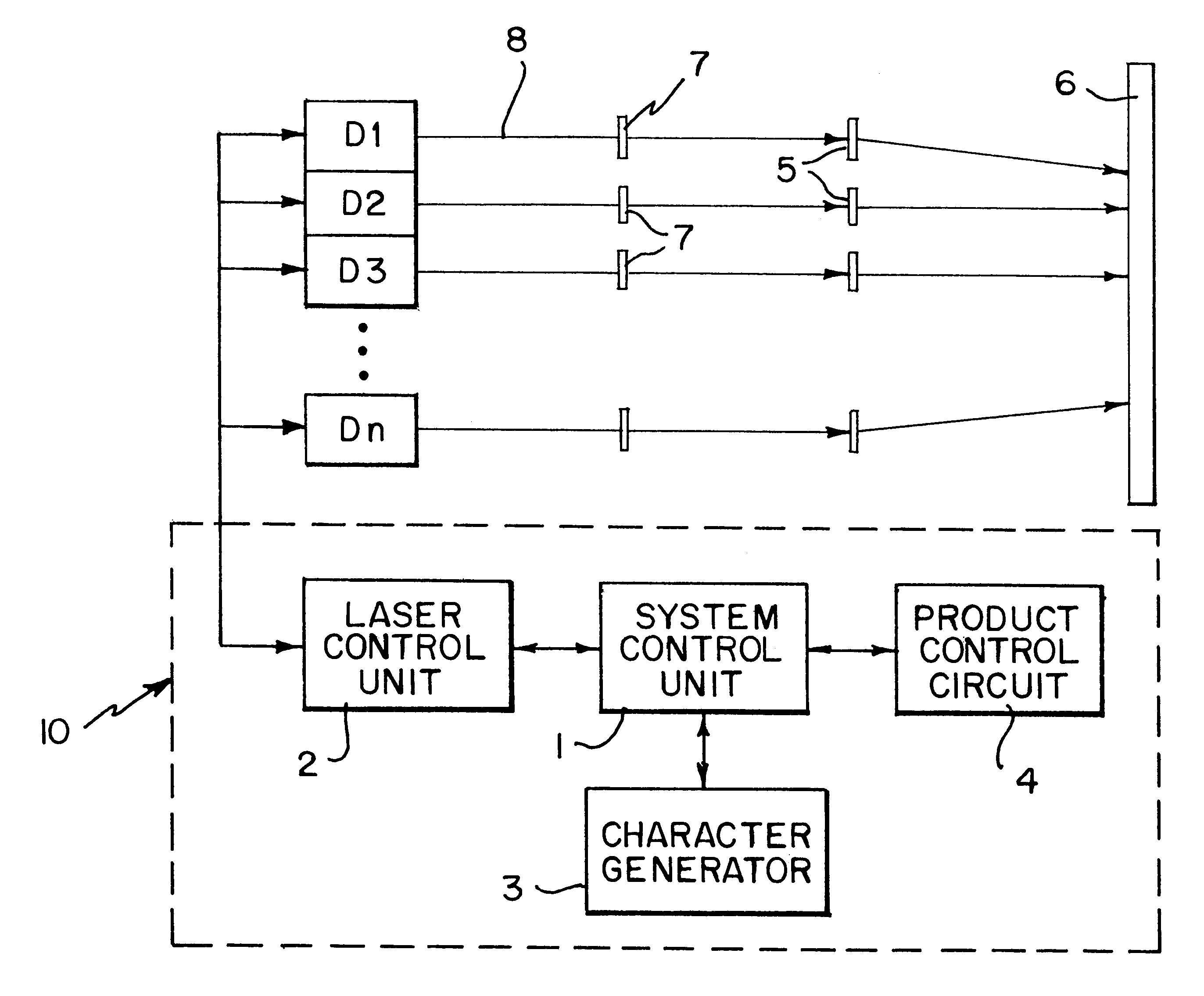

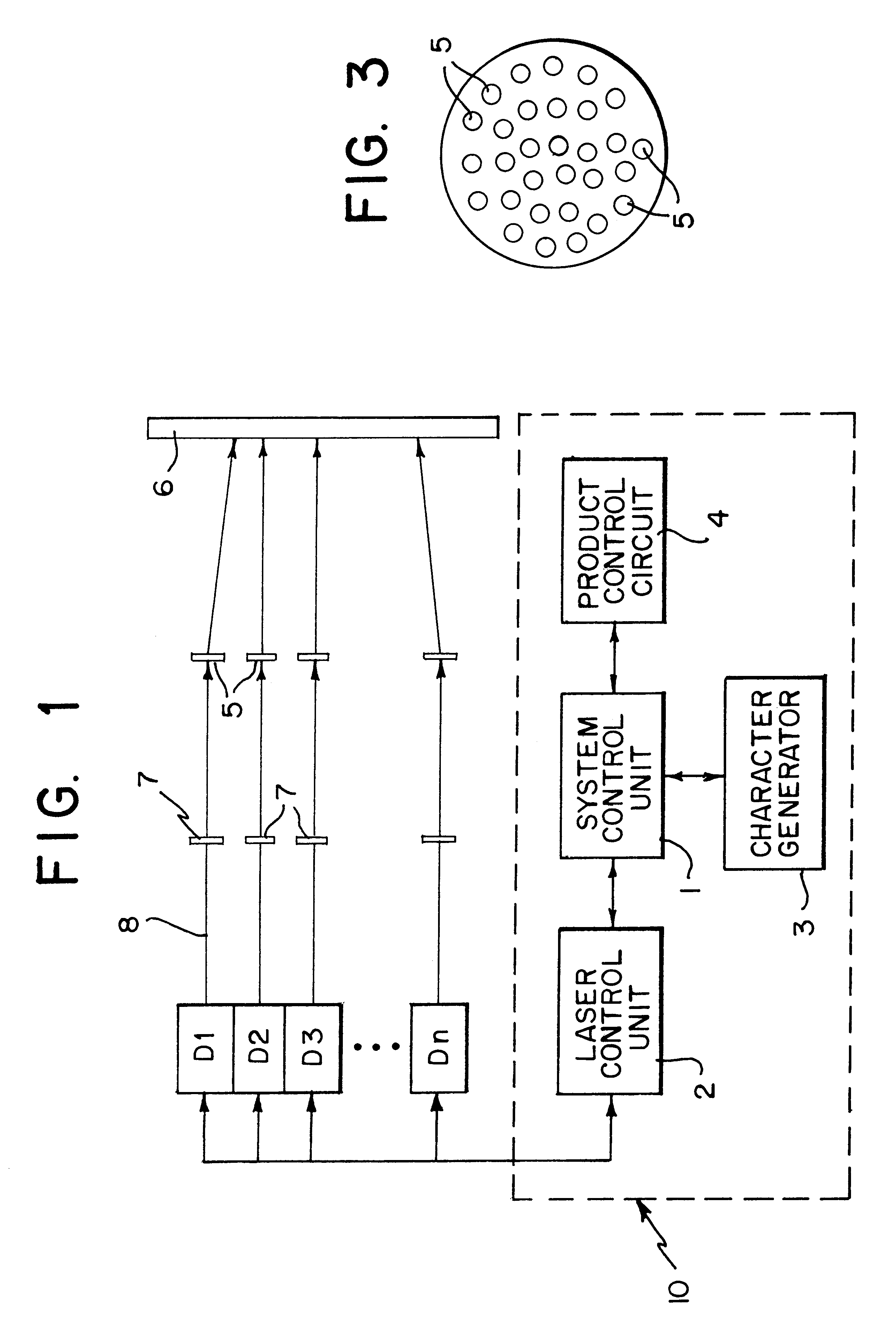

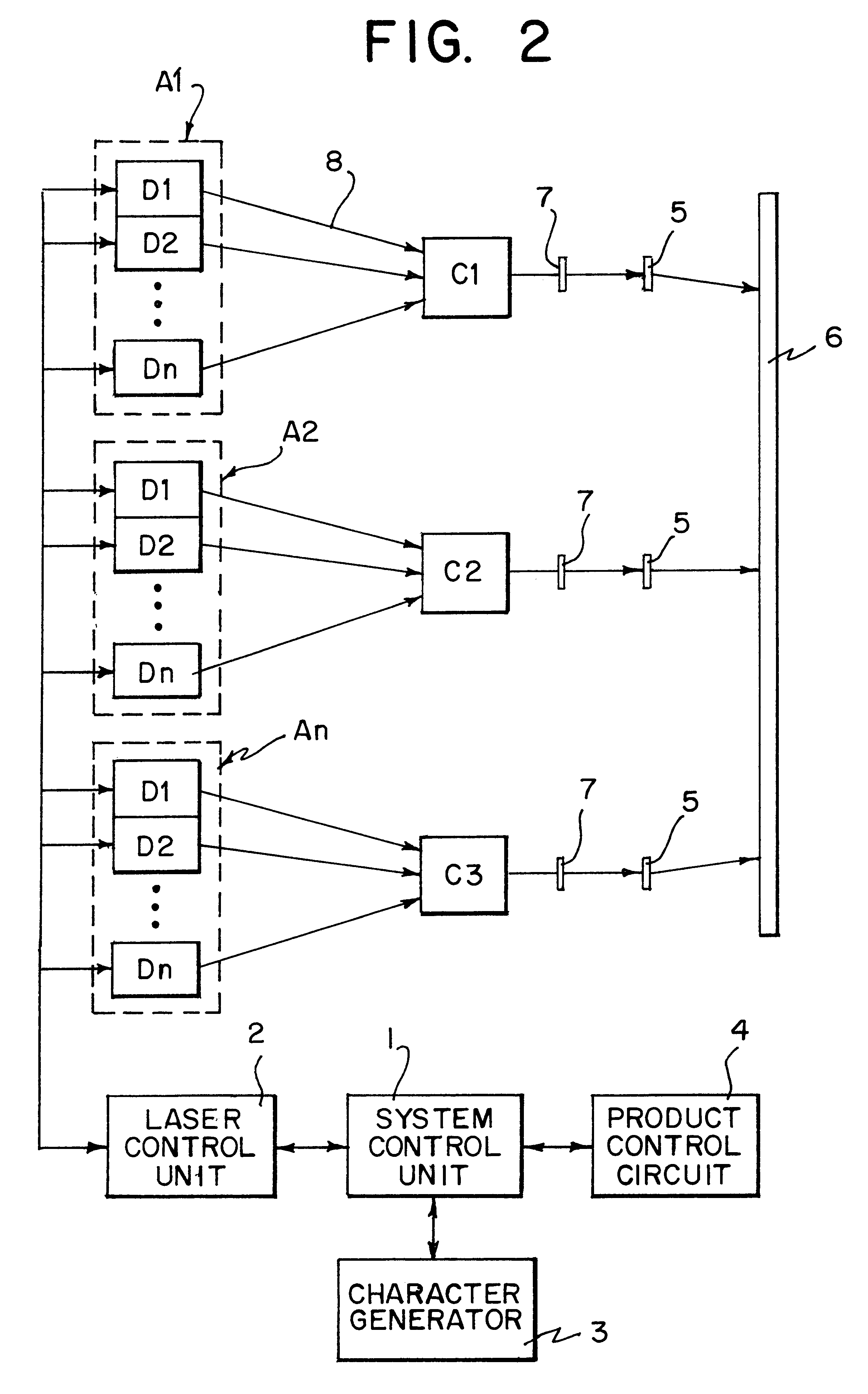

Laser marking apparatus with diode laser matrix

InactiveUS6201210B1Increase energy outputVisual presentationDigital marking by photographic/thermographic registrationLight beamLaser light

A laser marking system includes a means for generating a laser beam and a marking control unit which generates individual signals applied to a laser system for producing an NxM matrix of dots used to mark an object. Each dot is created from the laser light from at least one laser diode. If multiple lasers are used, their power can be combined with a concentrator to produce a single beam with a higher power and also provide for simplified control over the beam's power.

Owner:MACSA ID

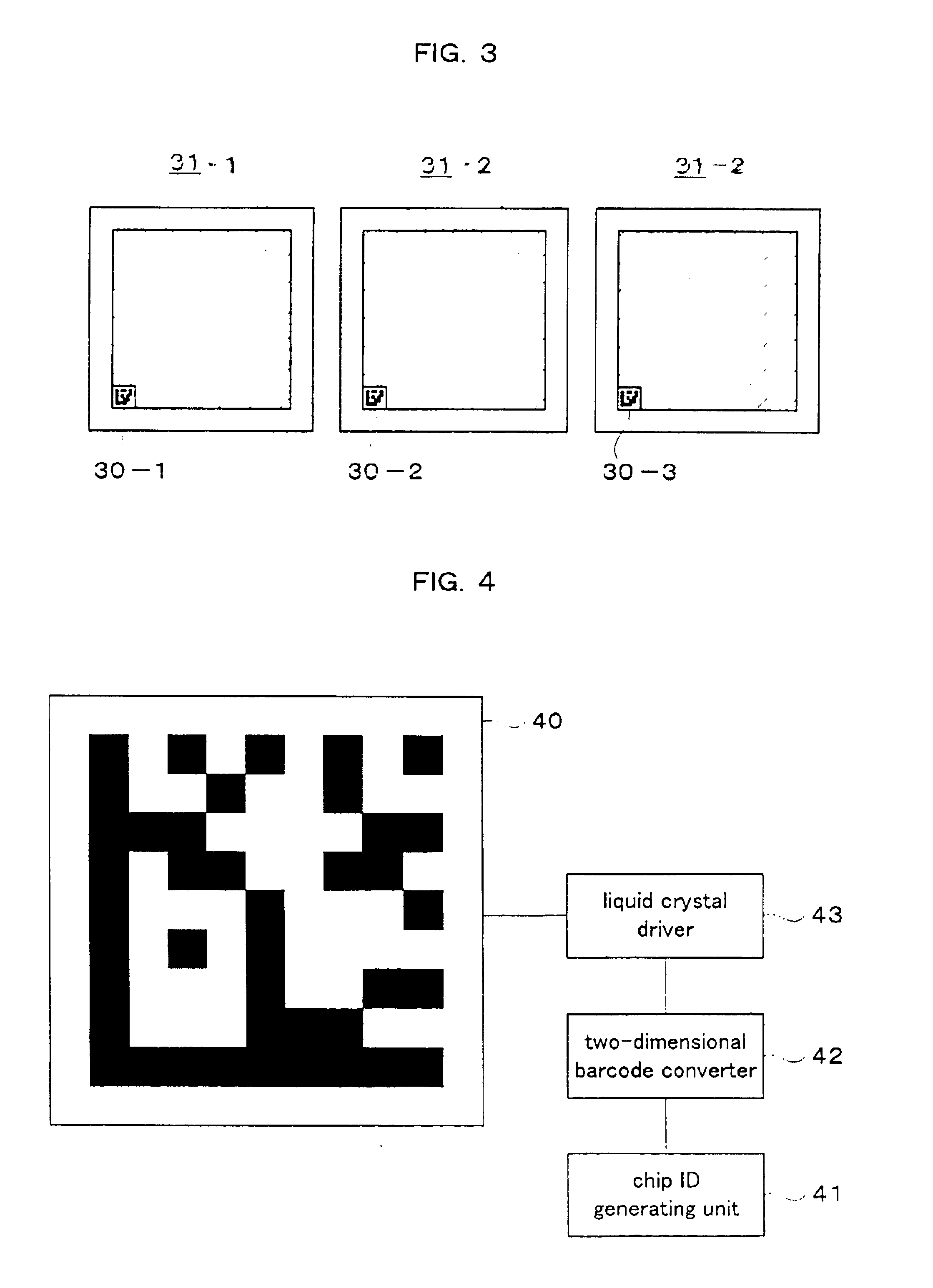

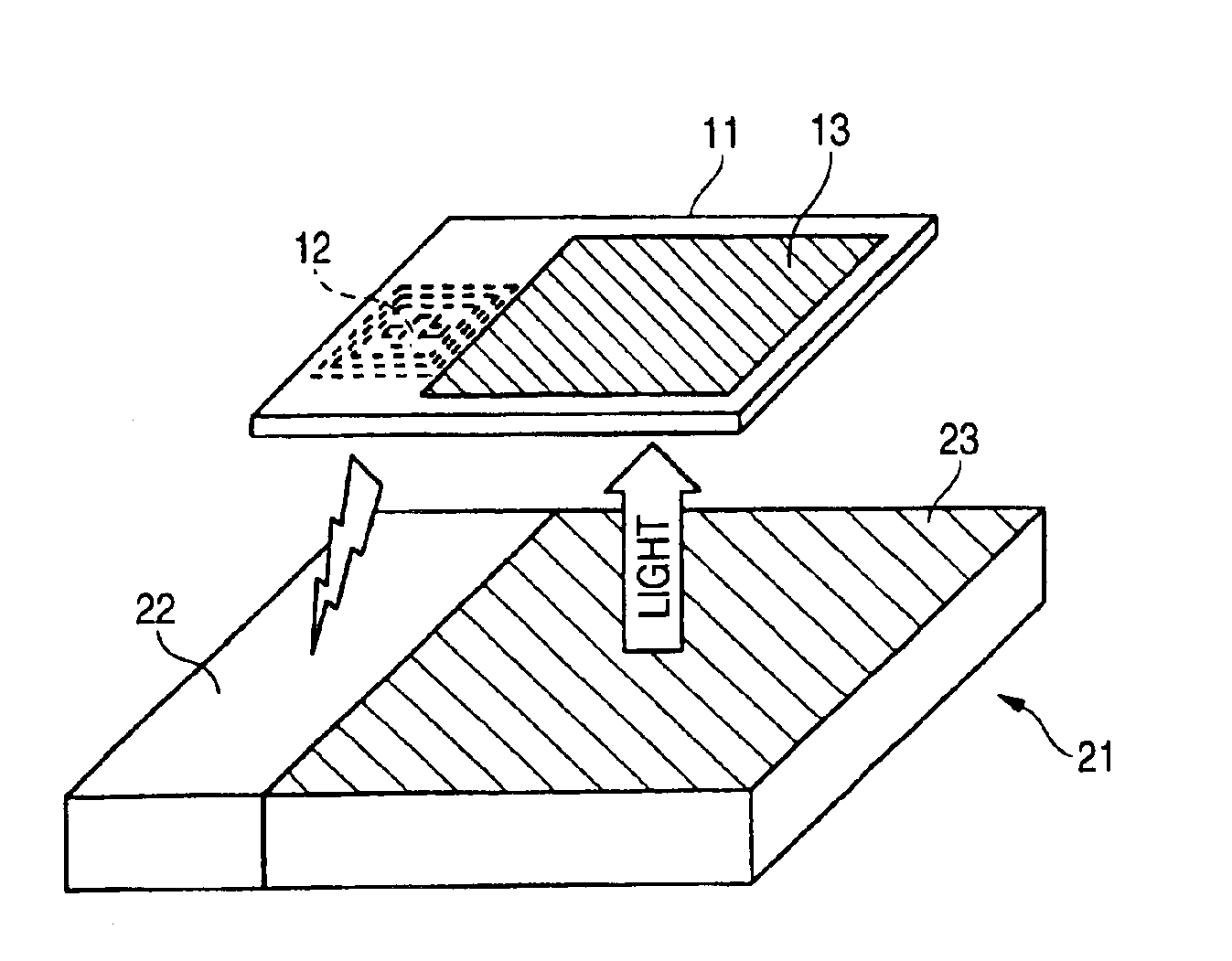

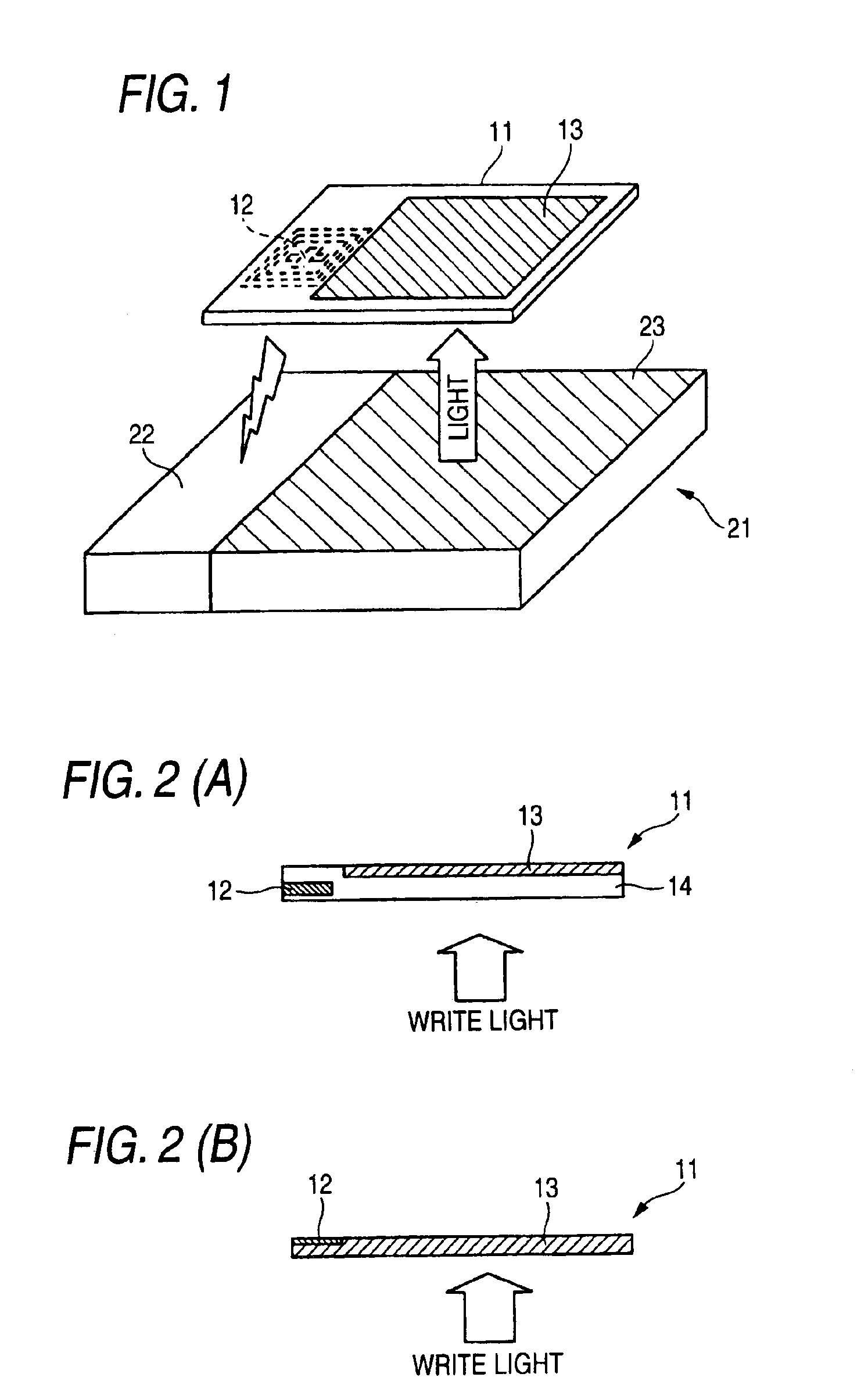

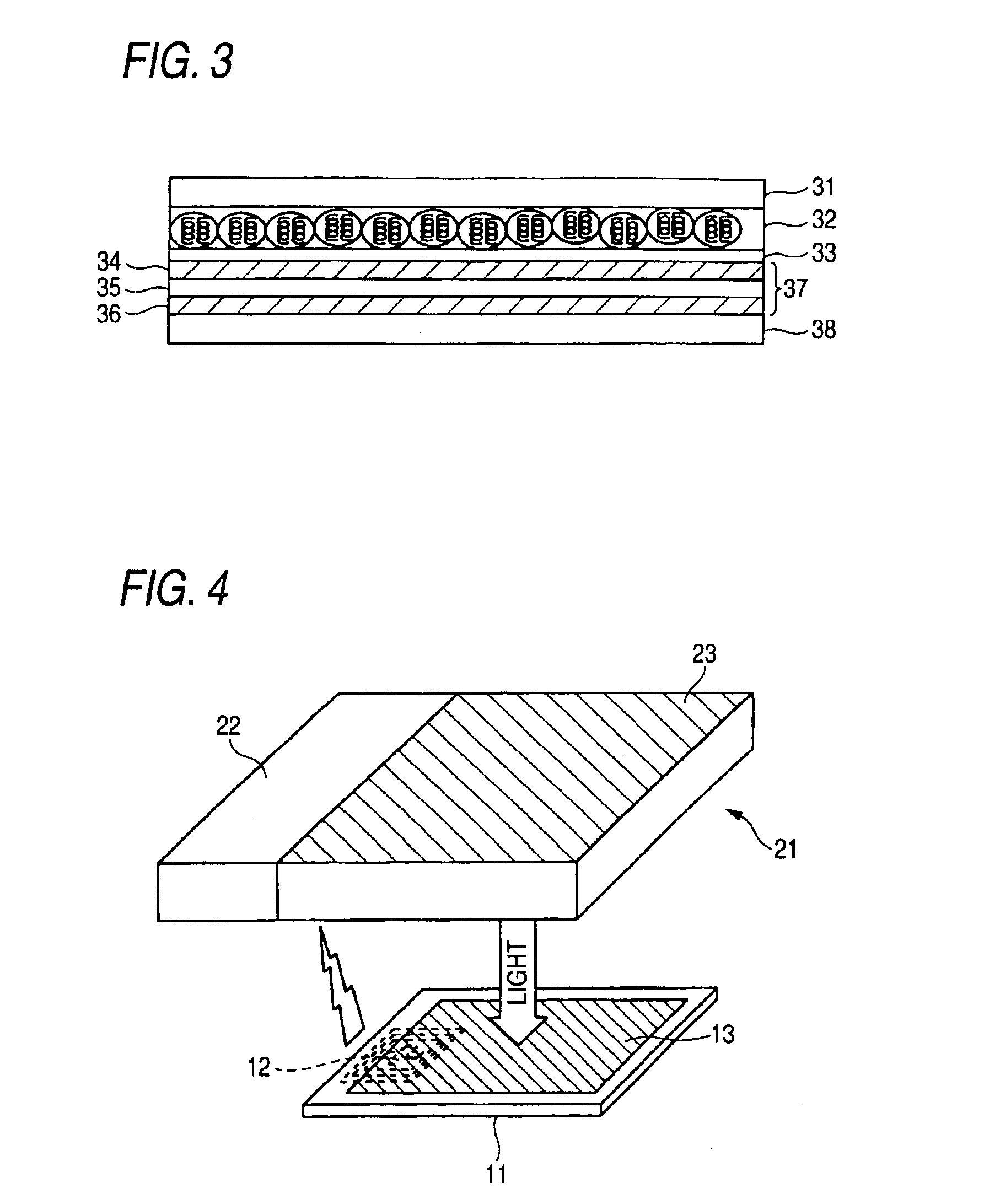

Display and record medium and information writer

InactiveUS6908036B2MiniaturizationIncreased durabilityOther printing matterRead-only memoriesLiquid-crystal displayComputer science

A display and record medium includes a digital information record section, which is implemented as an IC memory and can record record information in noncontact, and an information display section implemented as a liquid crystal display medium of light write type into which display information can be written. A digital information rewrite section of an information writer communicates with the digital information record section of the display and record medium by electromagnetic waves to rewrite record information as required. A display information rewrite section of the information writer irradiates an optical pattern to the information display section of the display and record medium to rewrite display information. It is possible to rewrite both digital information and display information concurrently in noncontact.

Owner:FUJIFILM BUSINESS INNOVATION CORP

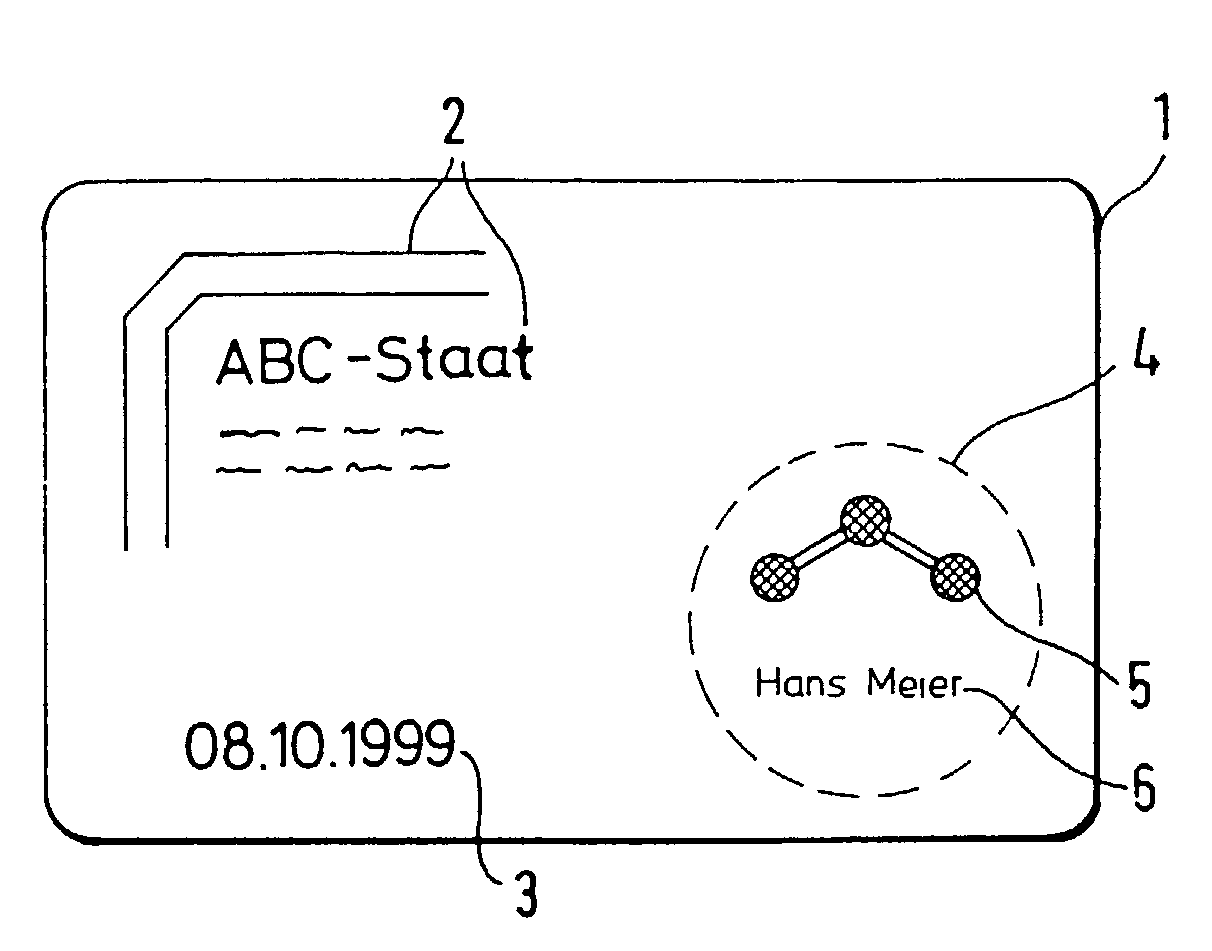

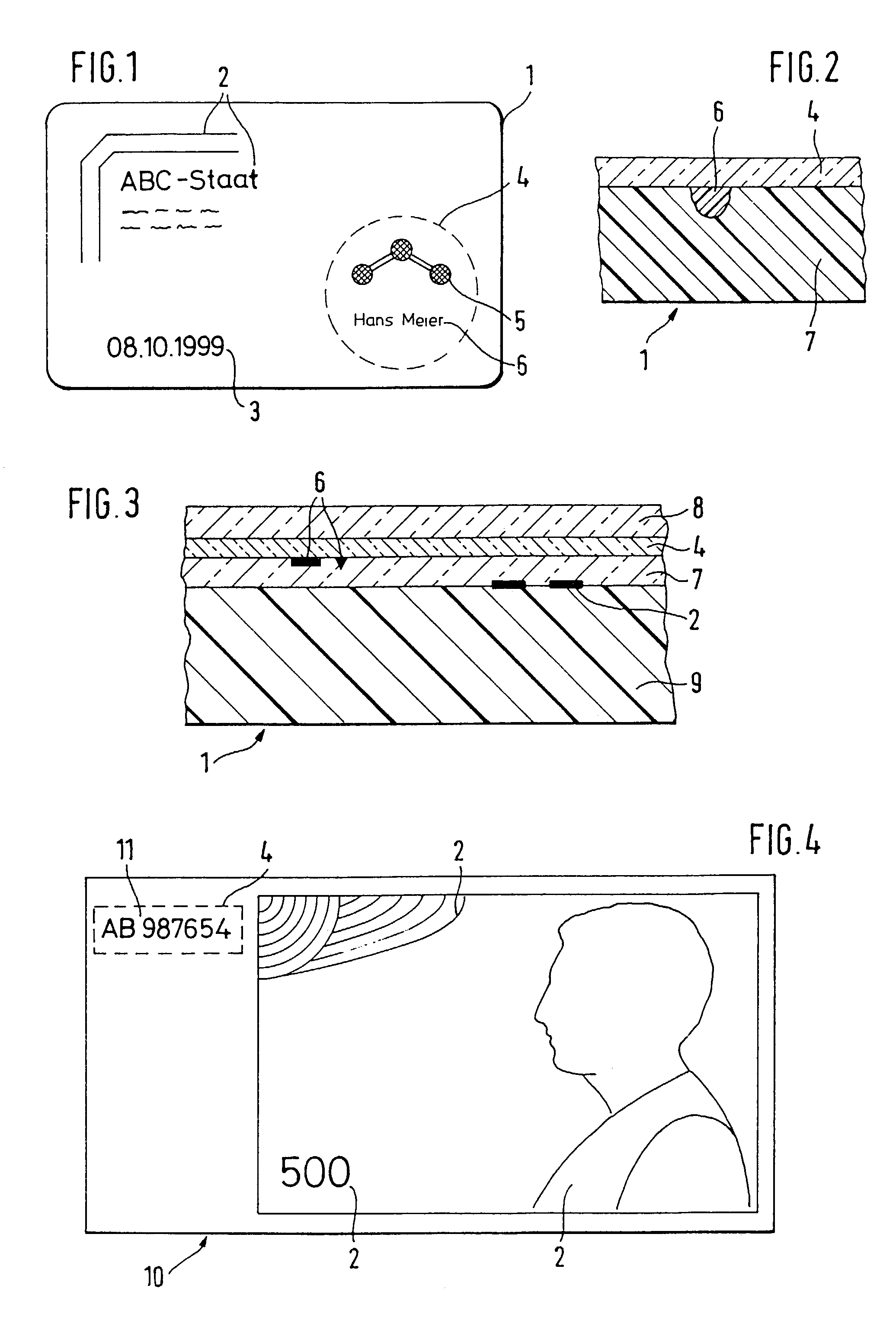

Method for producing laser-writable data carriers and data carrier produced according to this method

InactiveUS7252239B2Simpler andElevated protection against forgery and manipulationNon-fibrous pulp additionPattern printingWork in processManufacturing data

The invention relates to a method for producing a data carrier having a laser-markable layer and a transparent optically variable layer overlapping therewith at least in certain areas, wherein visually visible markings that at least partly overlap with the optically variable layer are produced in the laser-markable layer after the application of the optically variable layer. The invention further includes a data carrier produced by the method and a semifinished product, such as a data carrier blank, that is provided for processing by the method.

Owner:GIESECKE & DEVRIENT GMBH

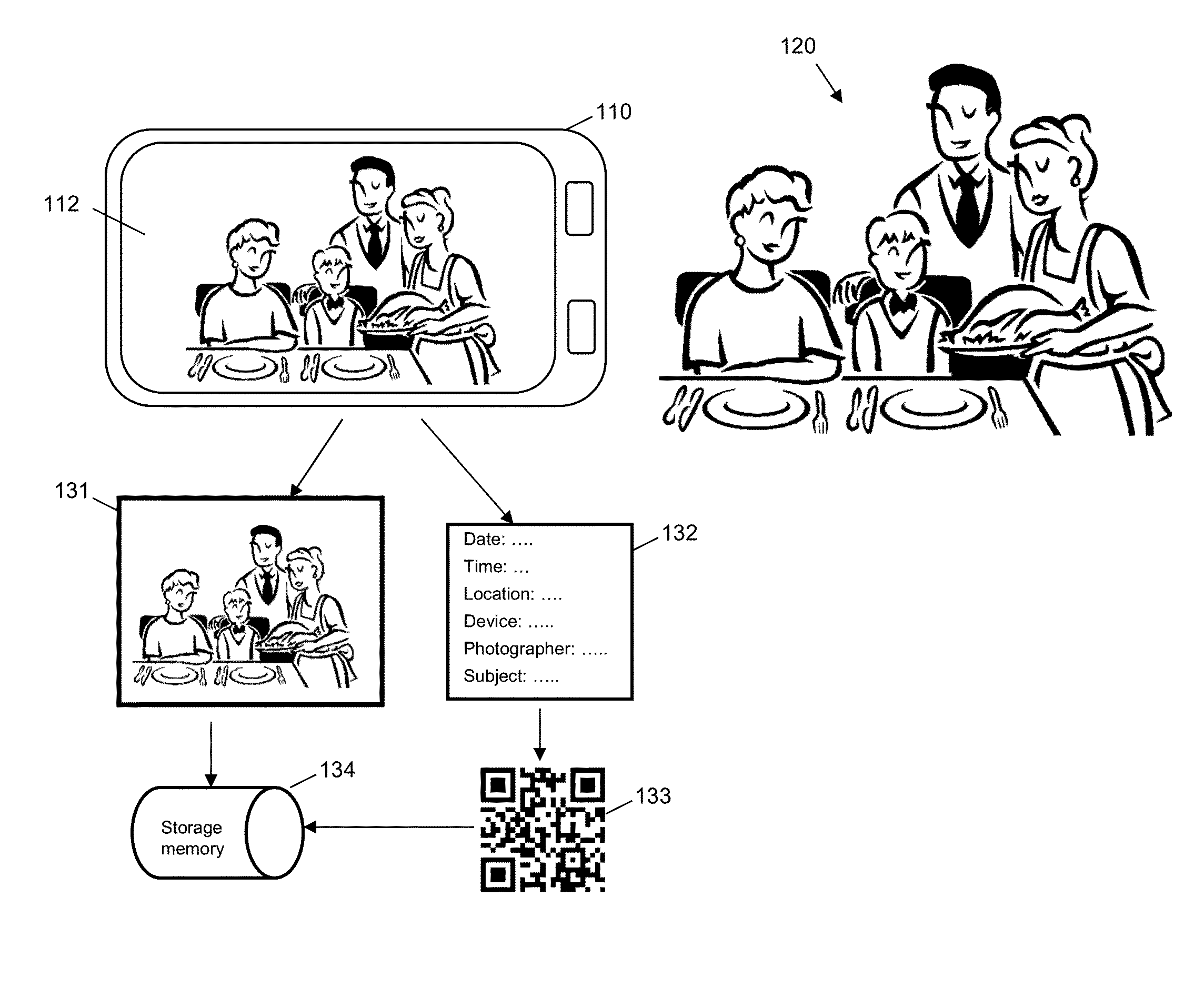

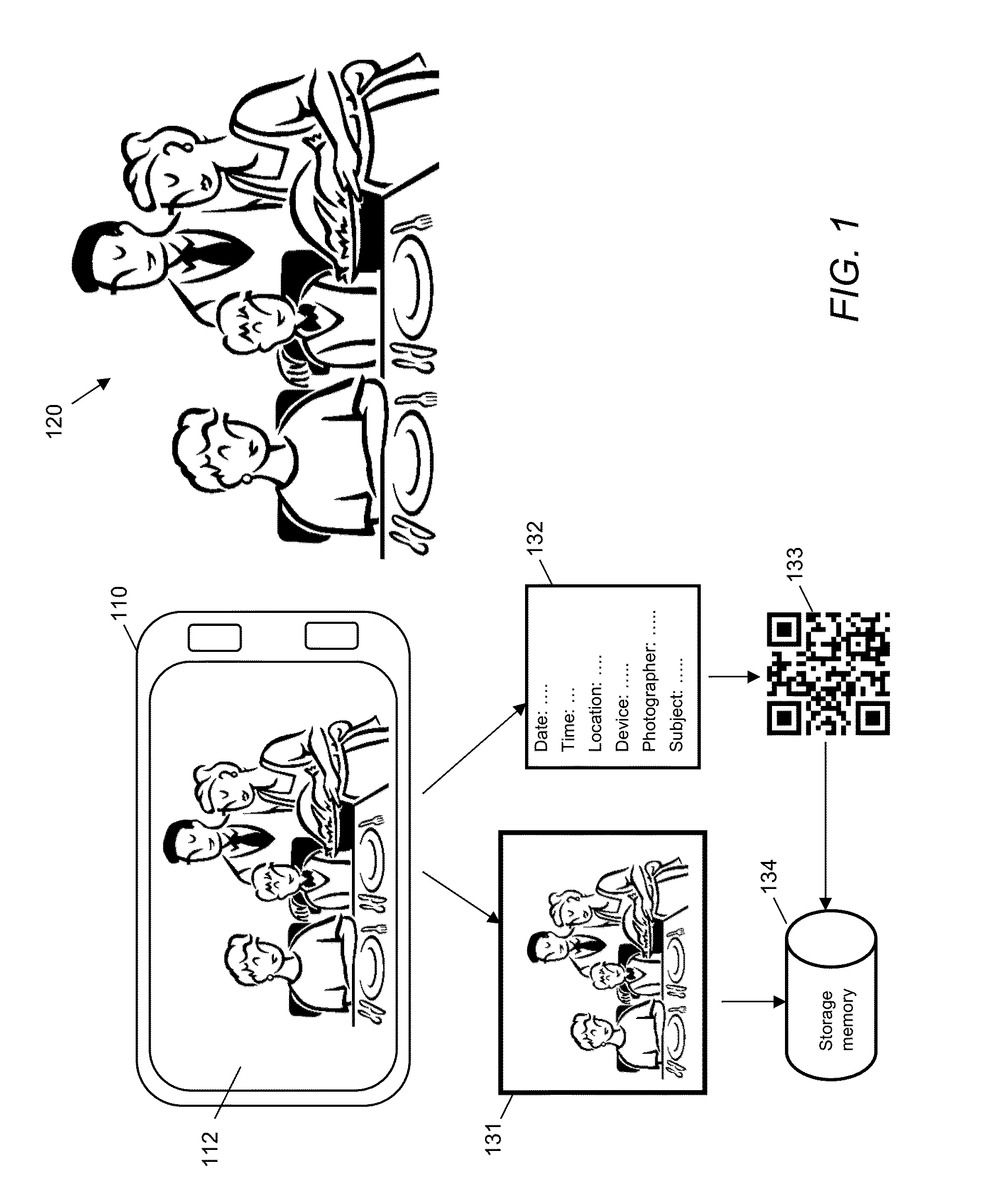

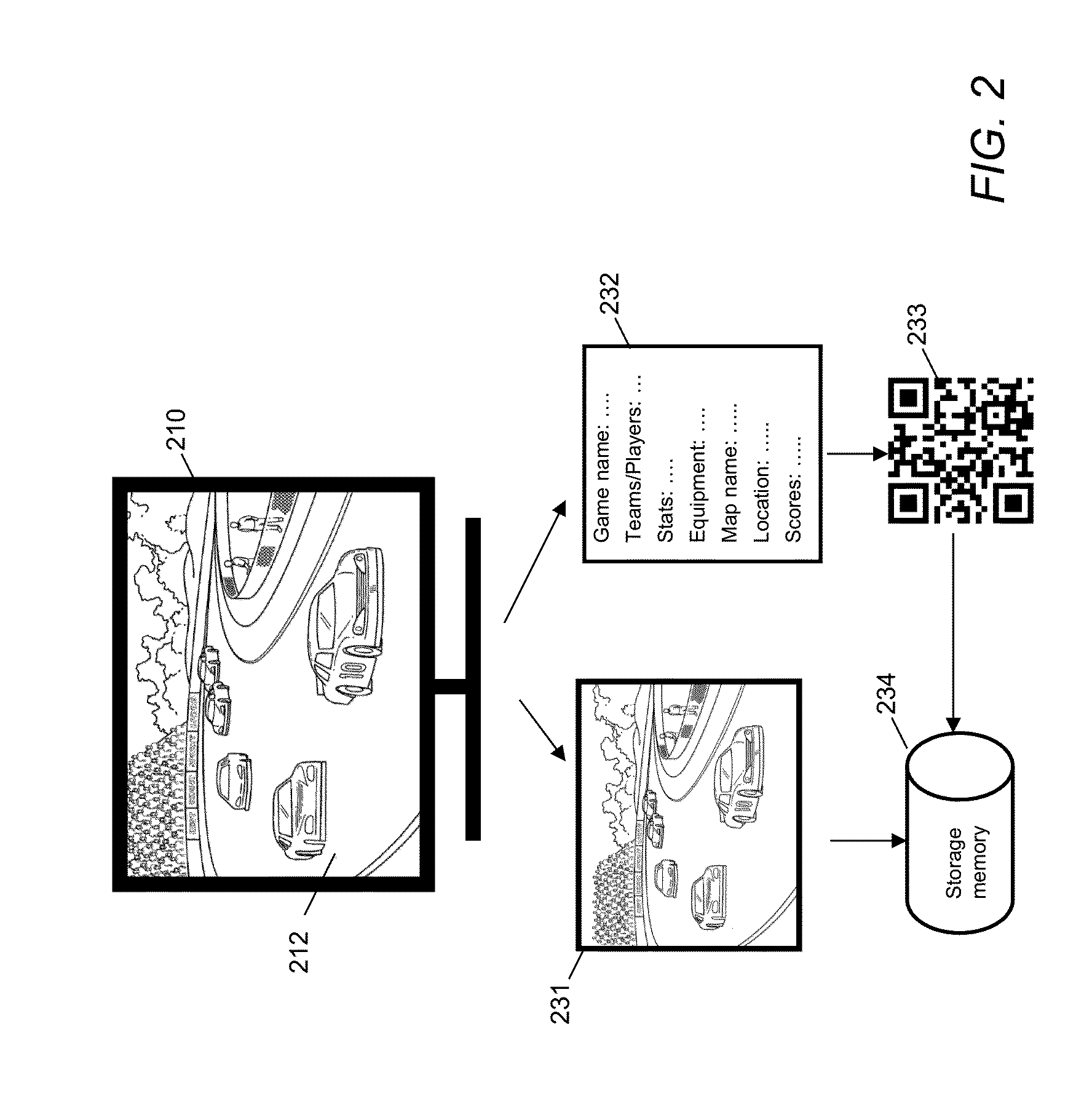

Apparatus and method for automatically generating an optically machine readable code for a captured image

A method for generating optically machine readable code is provided. The method includes capturing an image with a user device, automatically generating, by the user device, an optically machine readable code comprising information about the image recorded during the capturing of the image, and associating the optically machine readable code and the image. A computer readable storage medium storing one or more programs and an apparatus are also provided.

Owner:SONY COMPUTER ENTERTAINMENT INC

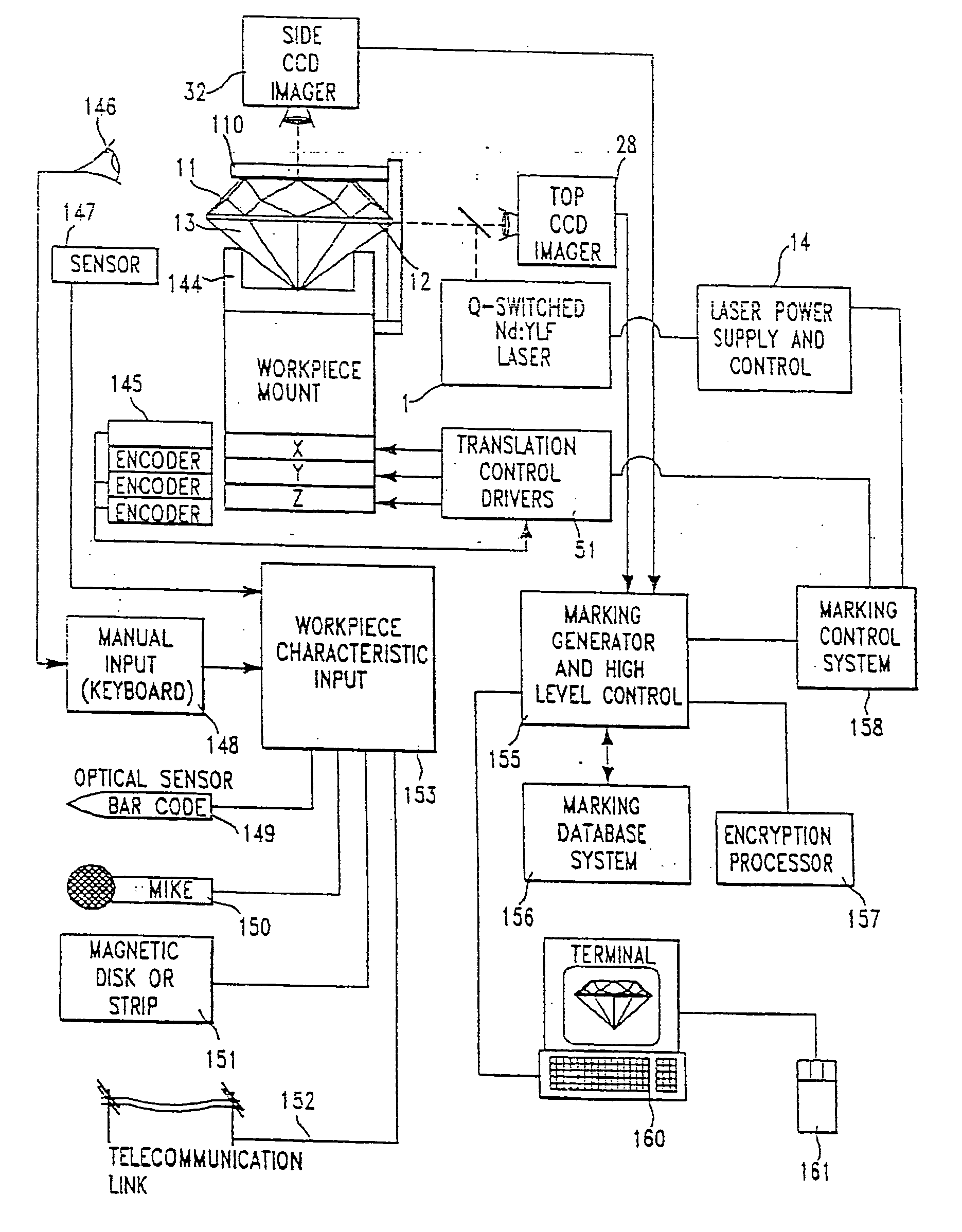

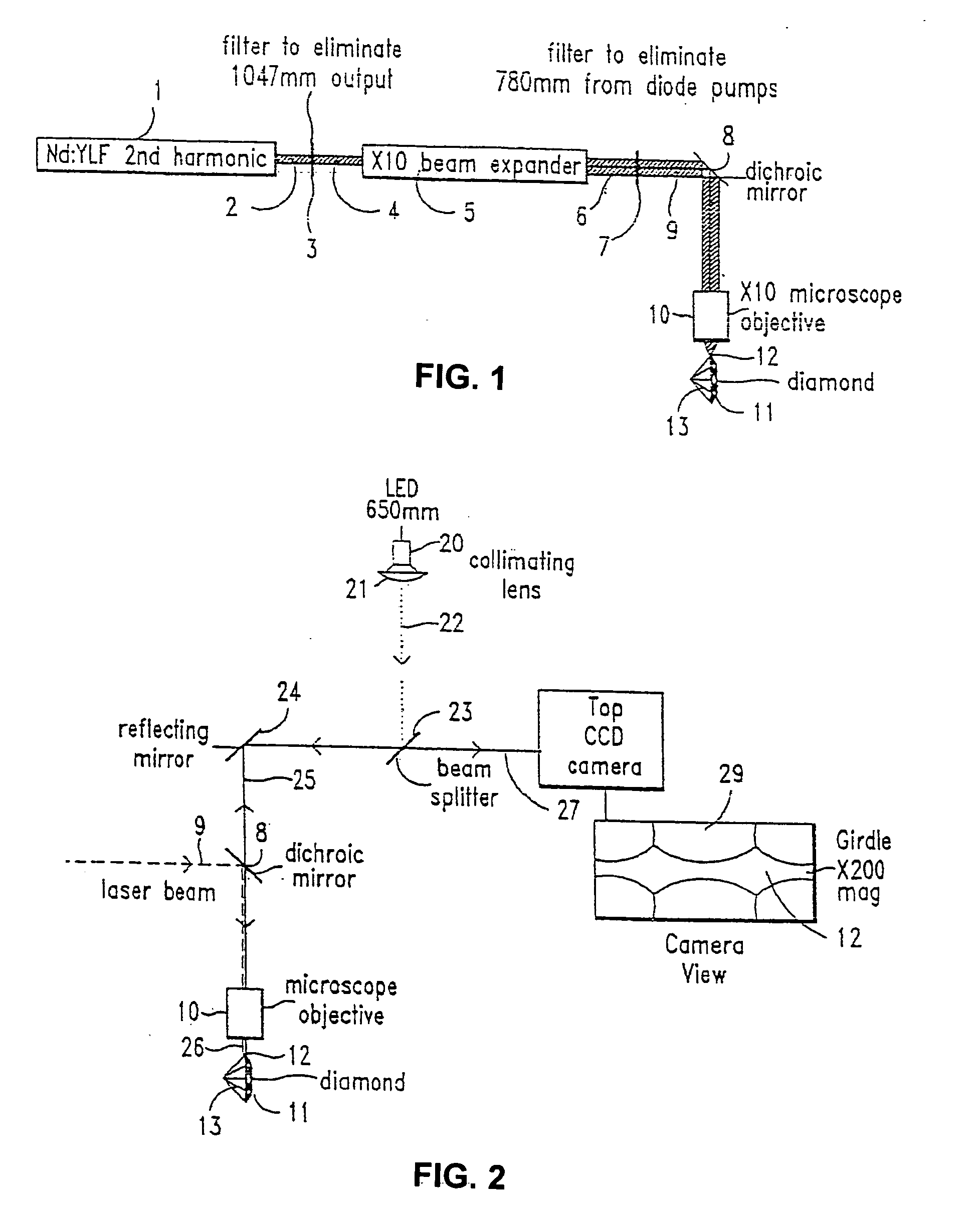

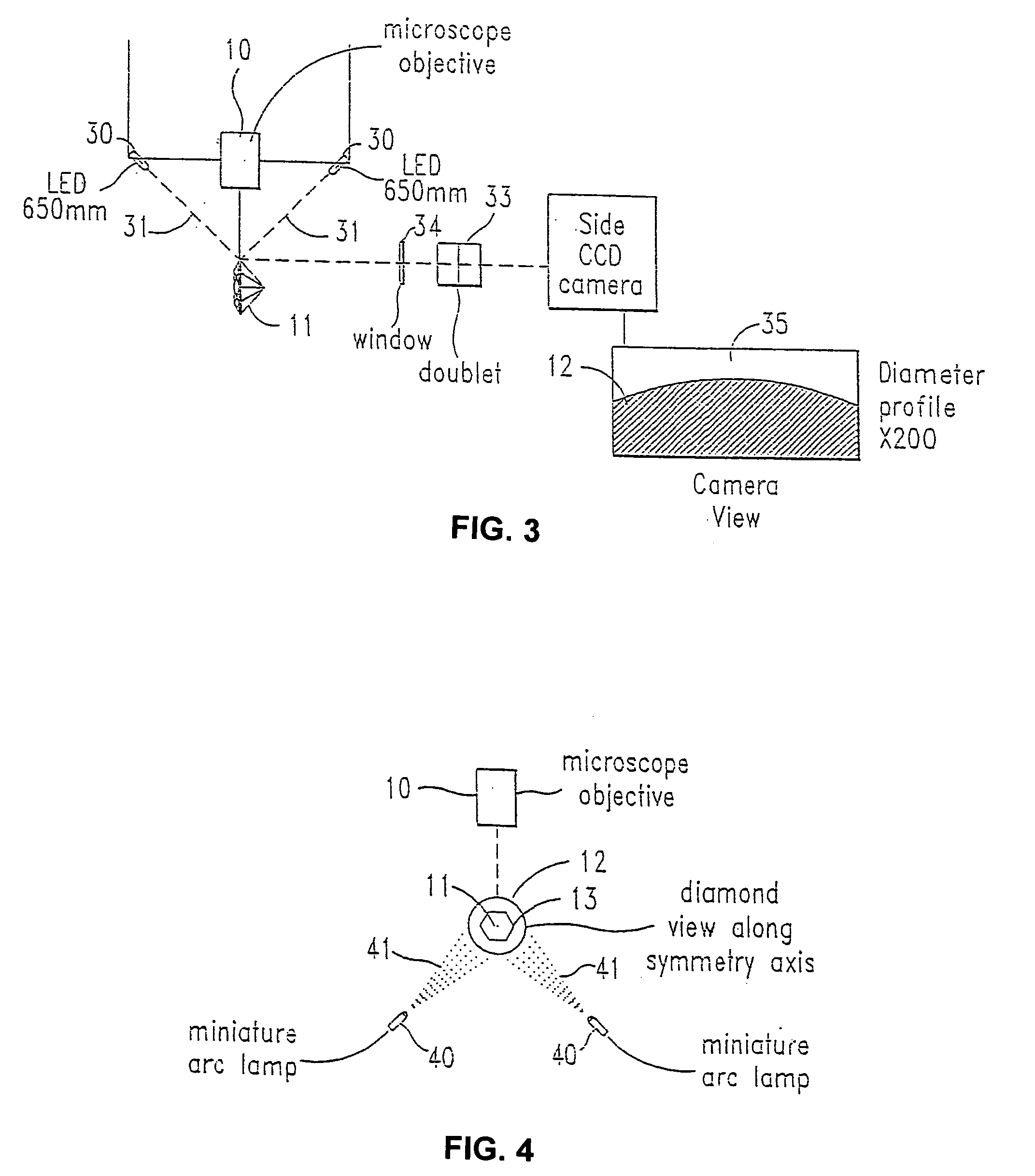

Laser marking system

InactiveUS20050103760A1Improve immunityBranding equipmentDecorative surface effectsGemstoneElectron storage

A laser energy microinscribing system, comprising a semiconductor excited Q-switched solid state laser energy source; a cut gemstone mounting system, allowing optical access to a mounted workpiece; an optical system for focusing laser energy from the laser energy source onto a cut gemstone; a displaceable stage for moving said gemstone mounting system with respect to said optical system so that said focused laser energy is presented to desired positions on said gemstone, having a control input; an imaging system for viewing the gemstone from a plurality of vantage points; and a rigid frame supporting said laser, said optical system and said stage in fixed relation, to resist differential movements of said laser, said optical system and said stage and increase immunity to vibrational misalignments. The laser energy source is preferably a semiconductor diode excited Q-switched Nd:YLF laser with a harmonic converter having an output of about 530 nm. The system may further comprise an input for receiving marking instructions; a processor for controlling said displaceable stage based on said marking instructions and said imaging system, to selectively generate a marking based on said instructions and a predetermined program; and a storage system for electronically storing information relating to images of a plurality of workpieces. A secure certificate of authenticity of a marked workpiece is also provided.

Owner:KAPLAN GEORGE R +3

Popular searches

Sensing record carriers Record carriers used with machines Special data processing applications Digital marking by printing code marks Semiconductor/solid-state device manufacturing Ablative recording Resistor manufacture Welding/soldering/cutting articles Metal working apparatus Laser beam welding apparatus

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com