Patents

Literature

568results about "Digital marking by printing code marks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

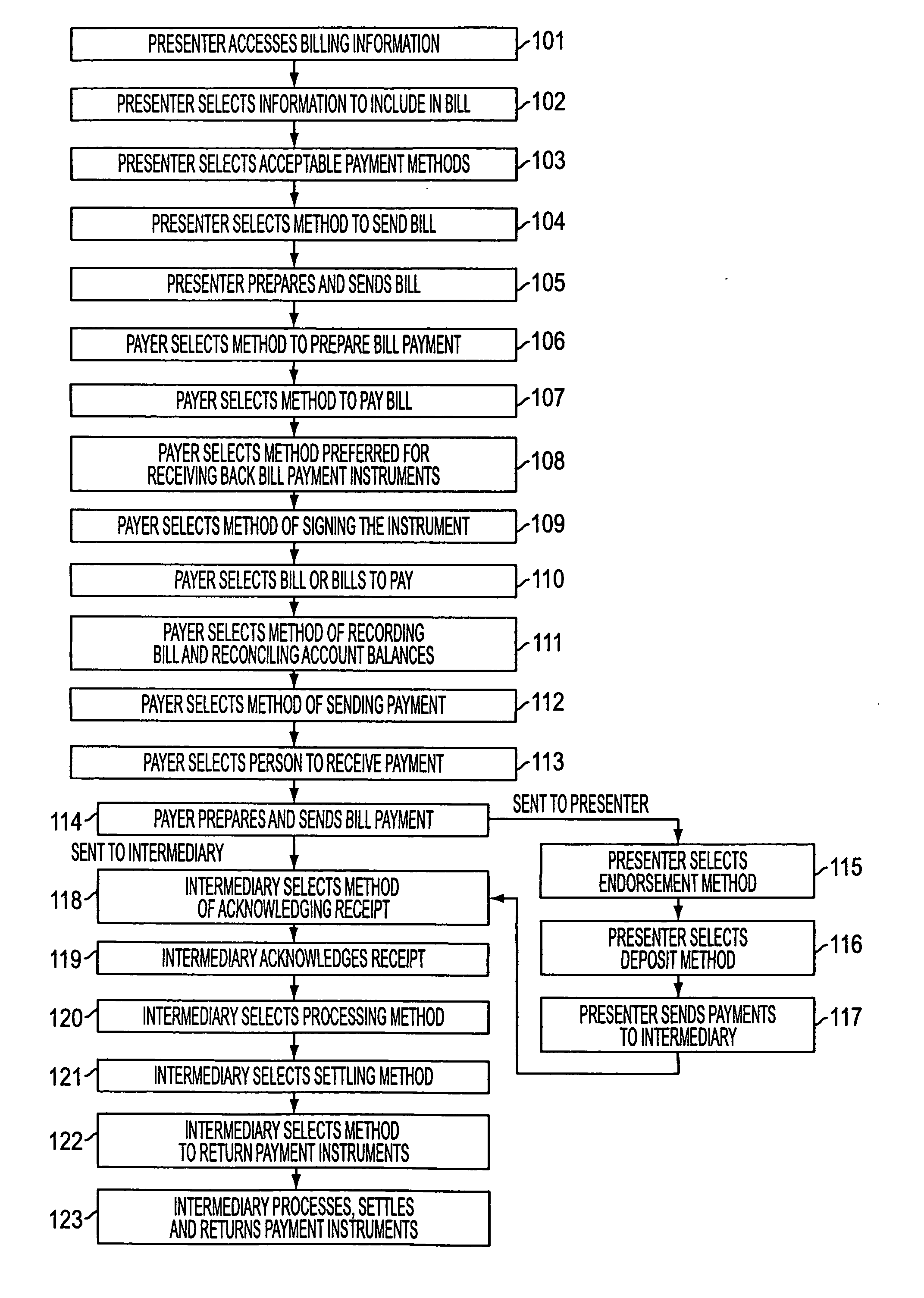

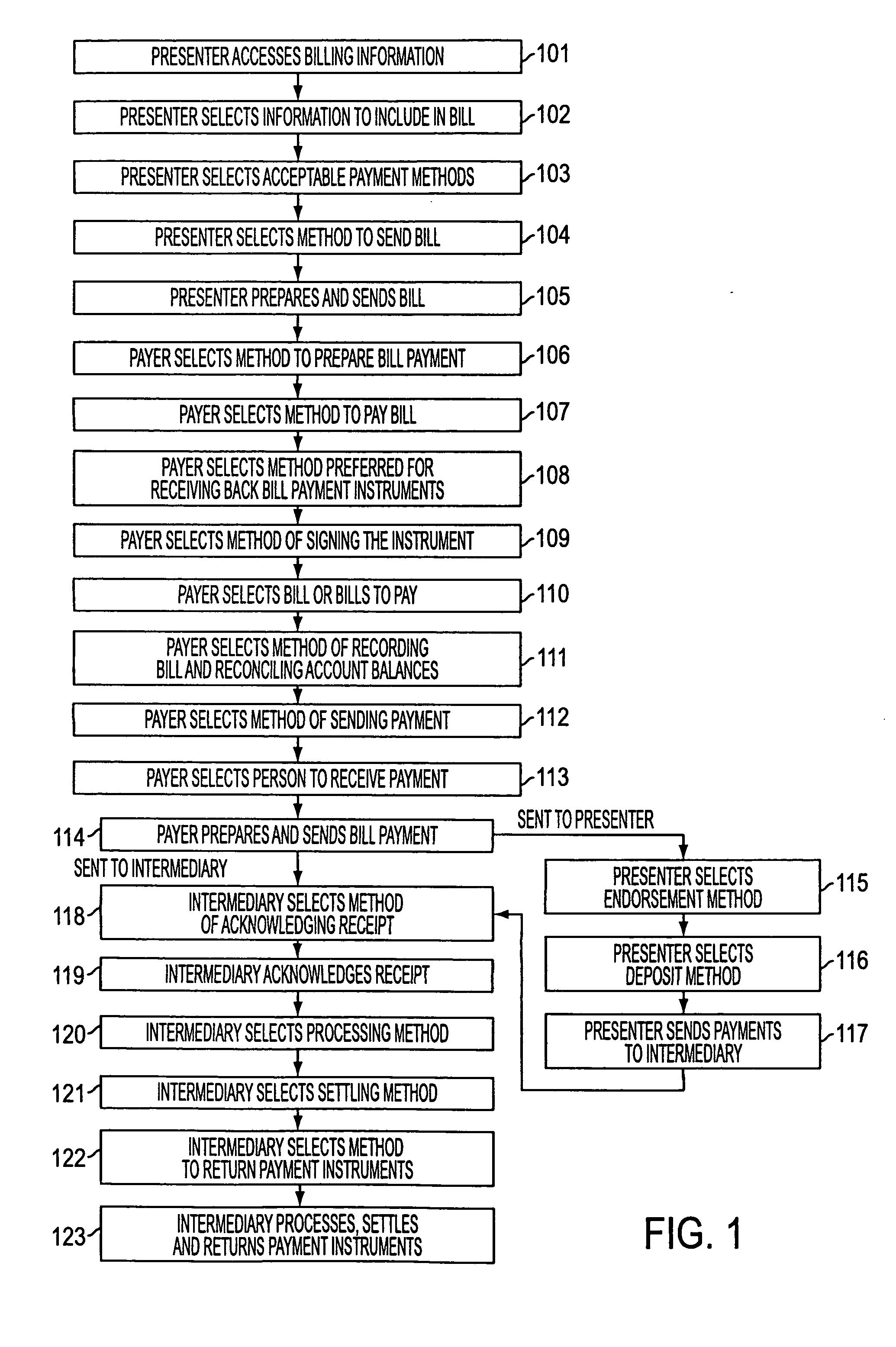

System and method for digital bill presentment and payment

InactiveUS20050033690A1Reduce complexityEnhanced interactionFinancePayment architectureCredit cardDigital data

A system of bill presentment and bill payment. The parties to the process, which typically include the bill presenter, bill payer, and bank, credit card company or other intermediary, select from a number of choices in the selection of information to include in the bill, preparation of the bill, acceptable payment methods, means to send the bill and bill payment instrument, means of signing the bill, bill payment instrument, receipt acknowledging deposit and payment, method of recording and reconciling payments, and further actions. An accumulation of choices by the involved parties can include digital information in each step that represents all of the significant data accumulated up to and including that step. That digital data preferably includes digital signatures of each party at each step so as to provide an audit trail in purely digital form. Where digital data is chosen for each step, the digital data can be electronic or, using machine readable code, printed on paper, regardless of the form chosen in prior or later steps.

Owner:ANTOGNINI WALTER GERARD +1

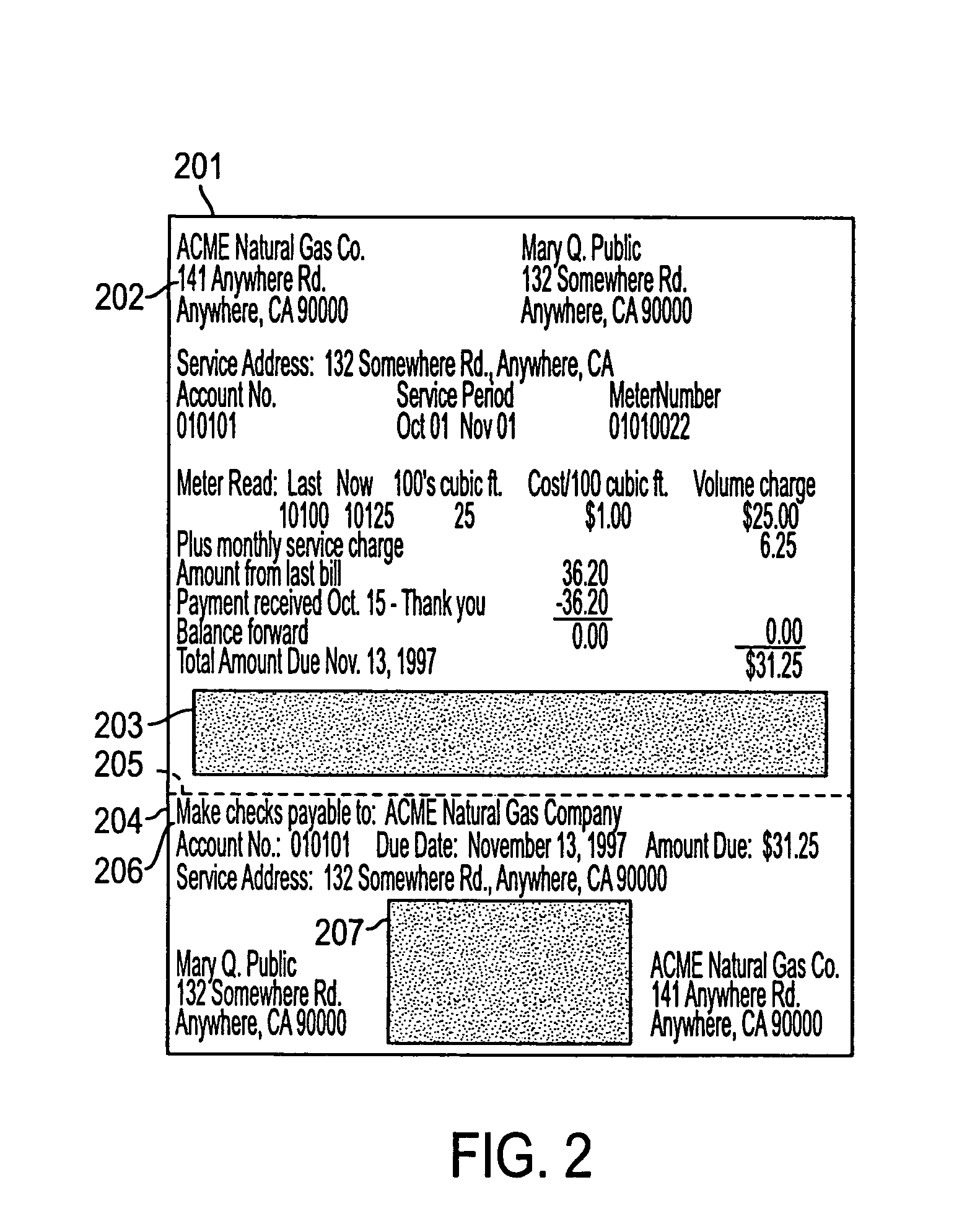

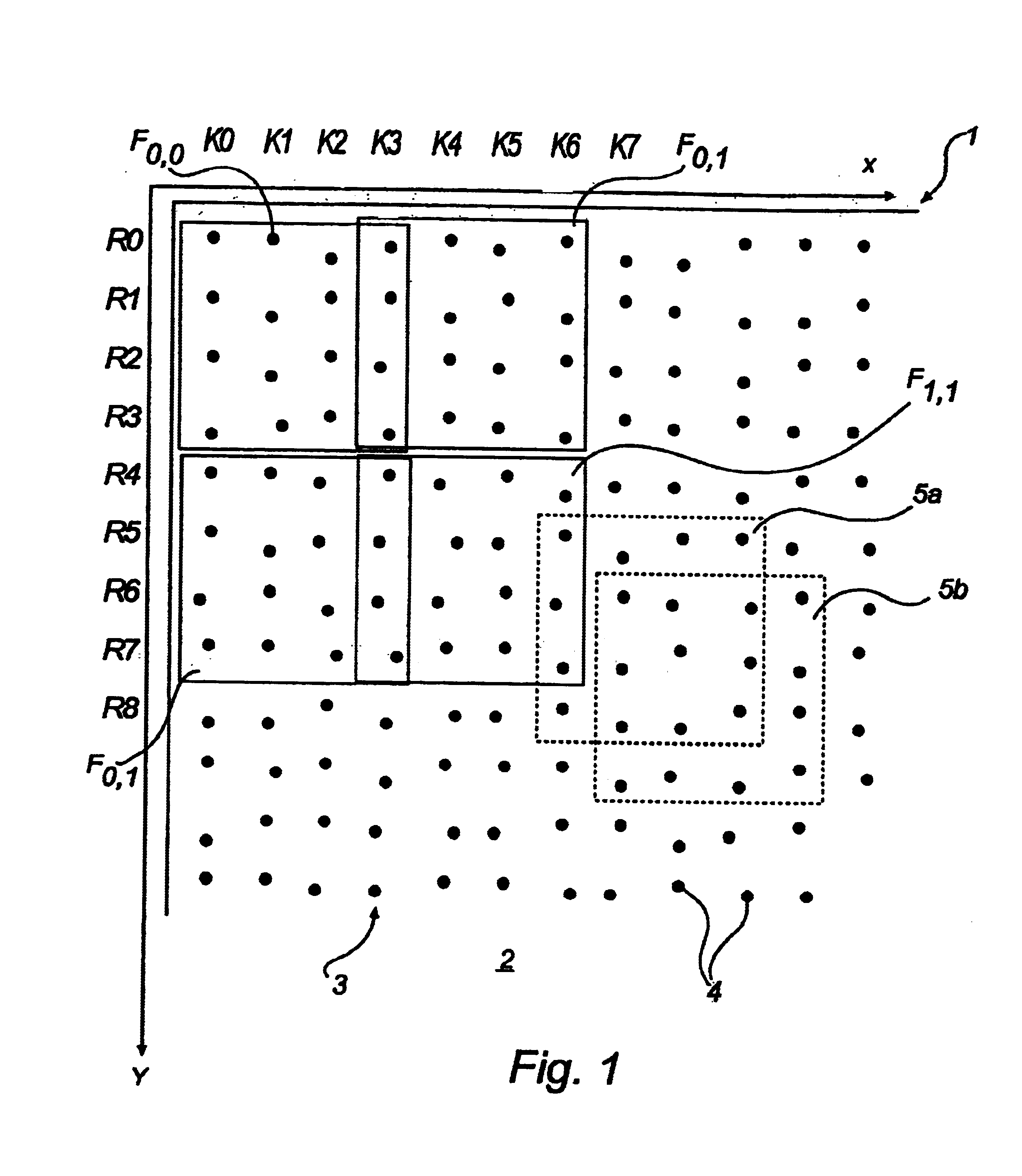

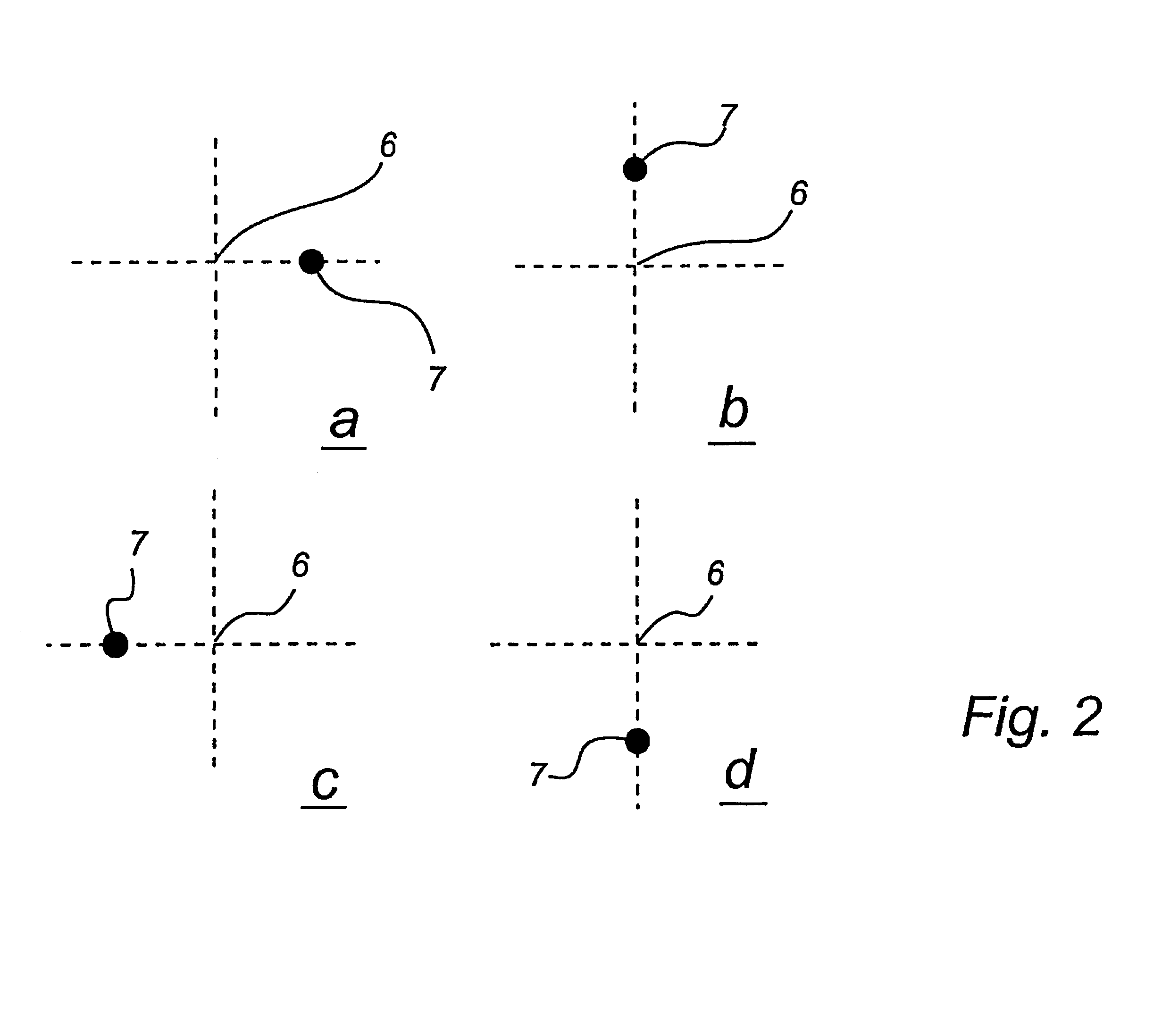

System and method for determining positional information

InactiveUS6689966B2Cost advantageInput/output for user-computer interactionTransmission systemsHandwritingGrating

A product has a surface having with a position-coding pattern that codes a plurality of positions on the surface. The position-coding pattern includes a plurality of symbols each having at least two different values. Each position on the surface being coded with a plurality of symbols. Each symbol including a raster point in a raster extending over the surface, and at least one marking, the location of which in relation to the raster point specifies the value of the symbol. The markings can include information representing more than one spatial resolution level and varying between different markings. The position-coding pattern can be used in different contexts for position determination such as digitizing handwriting.

Owner:ANOTO AB

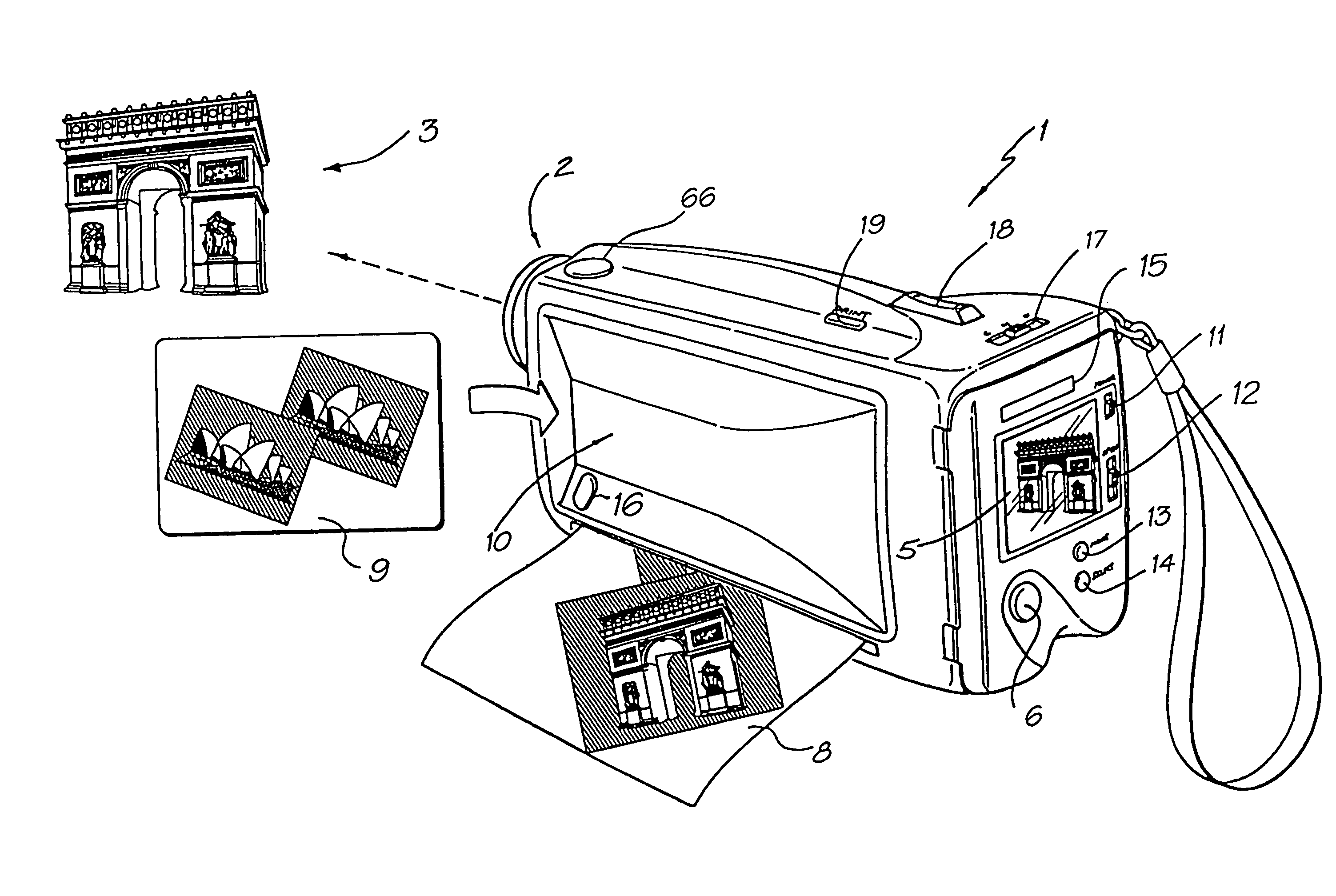

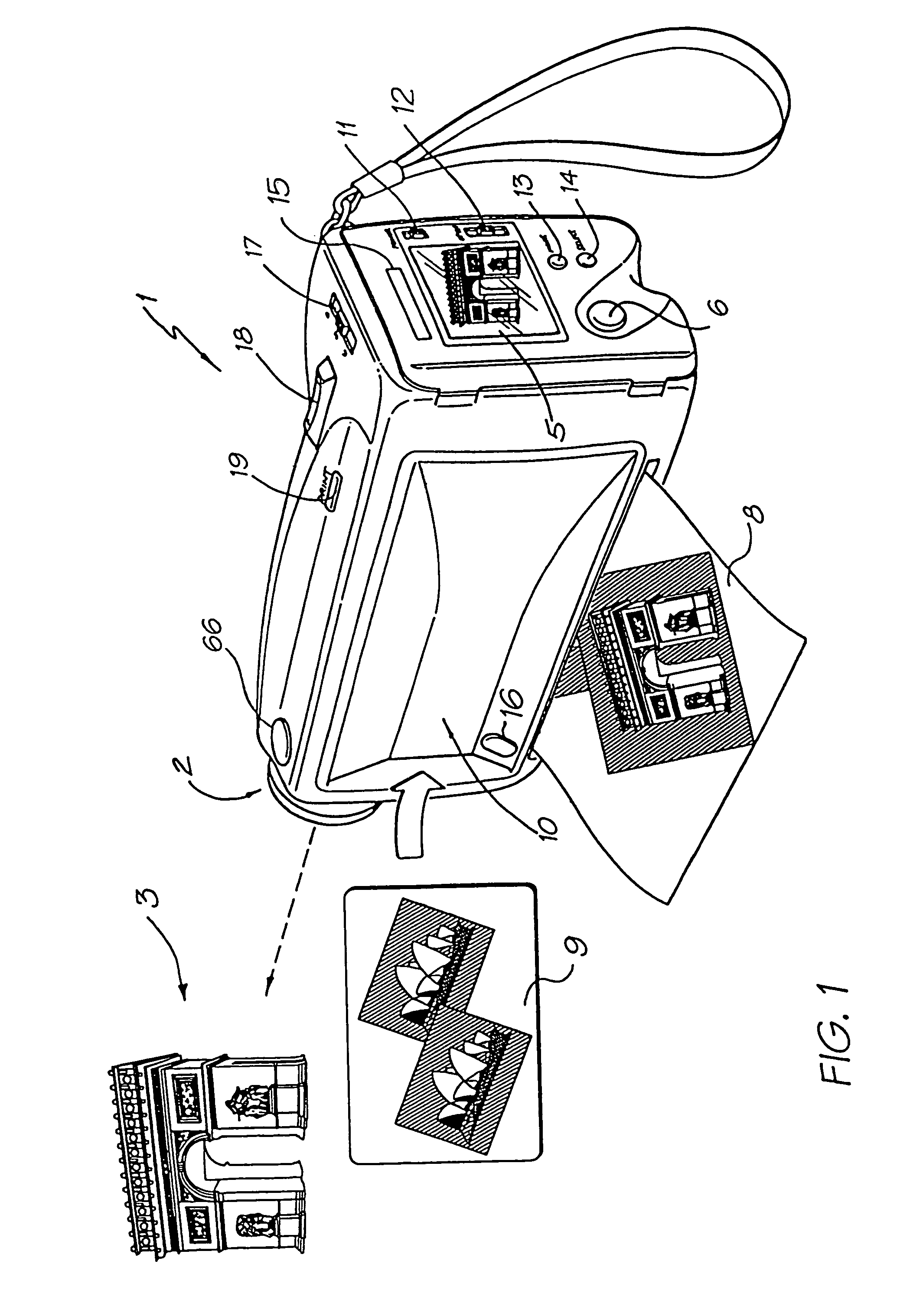

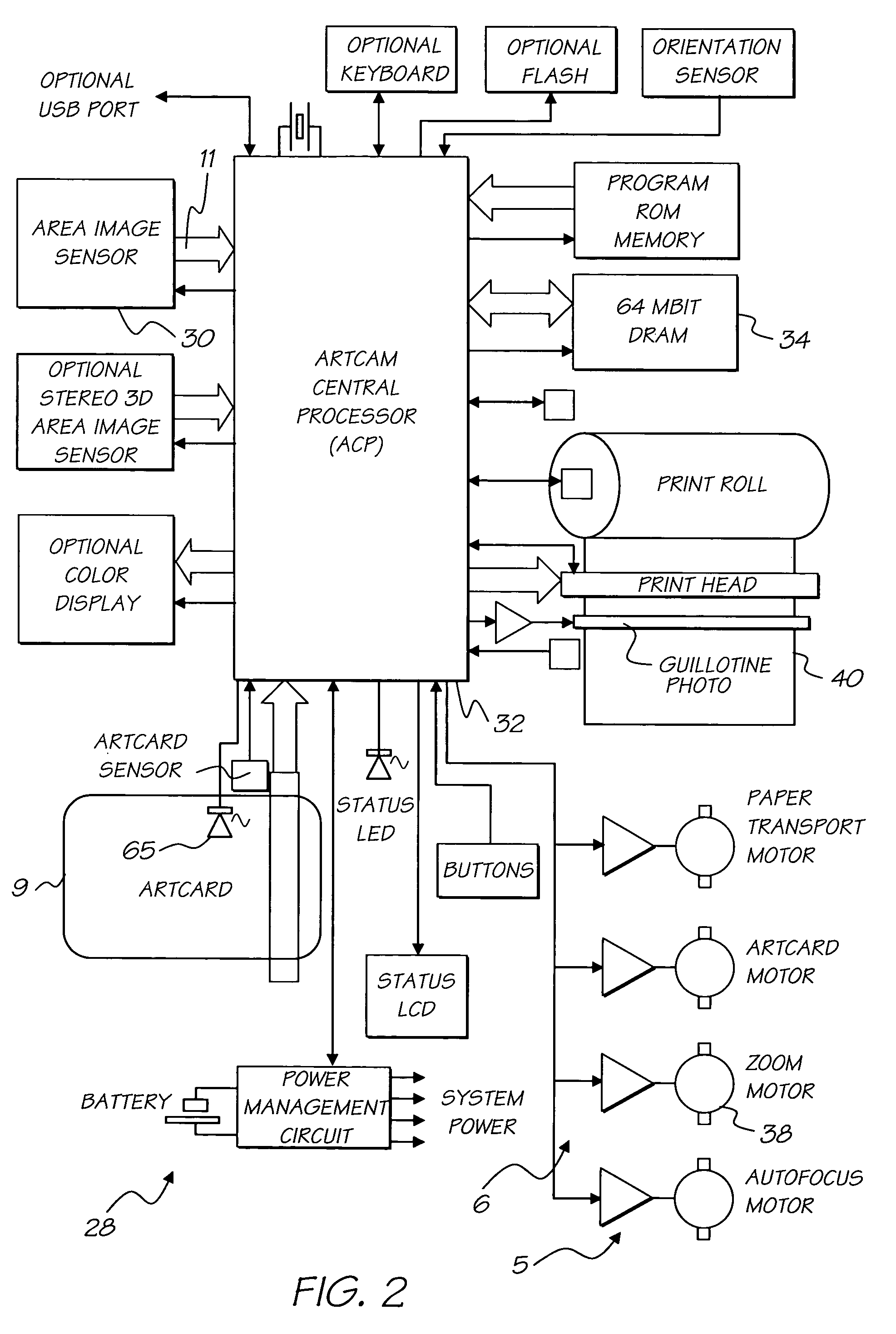

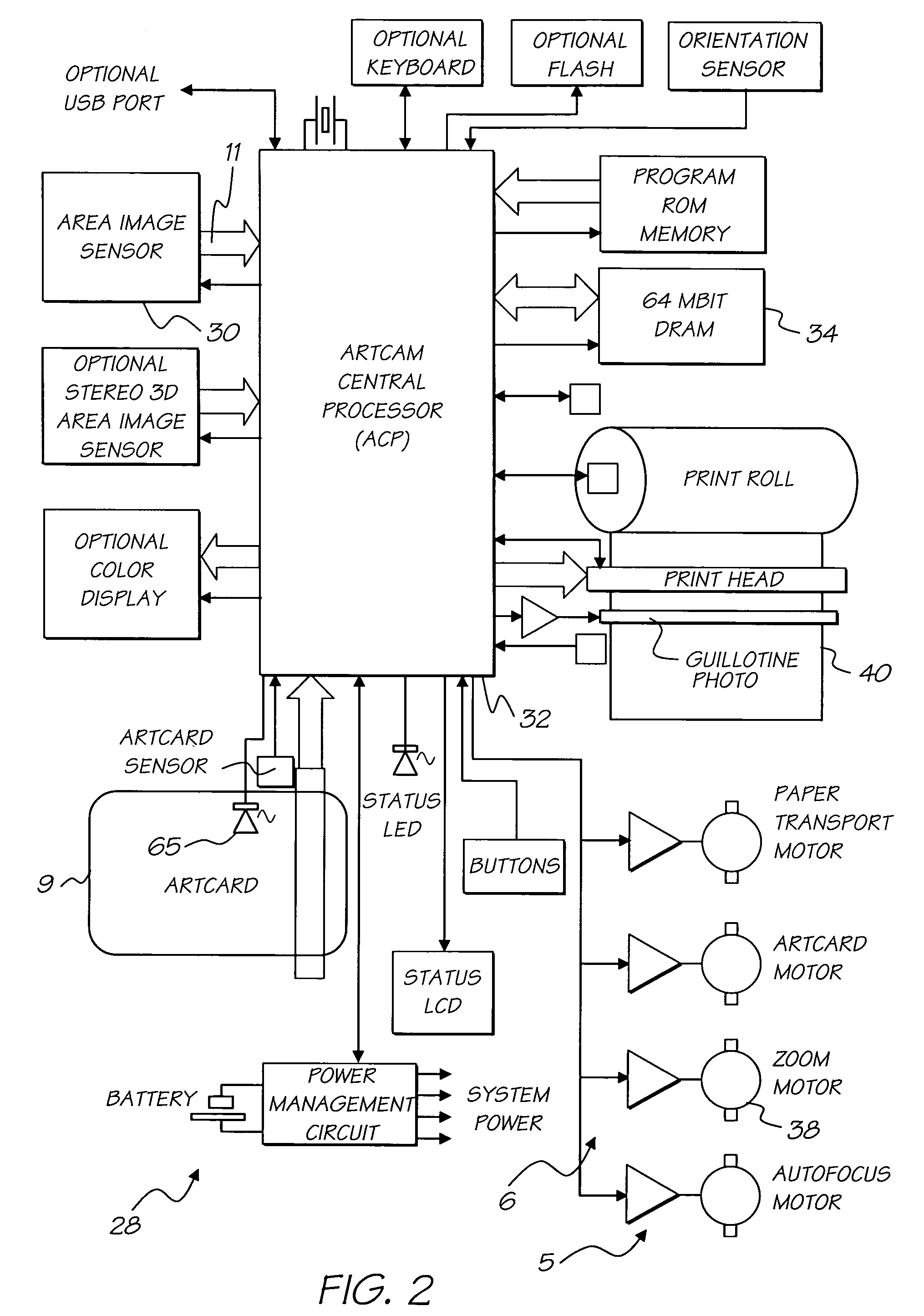

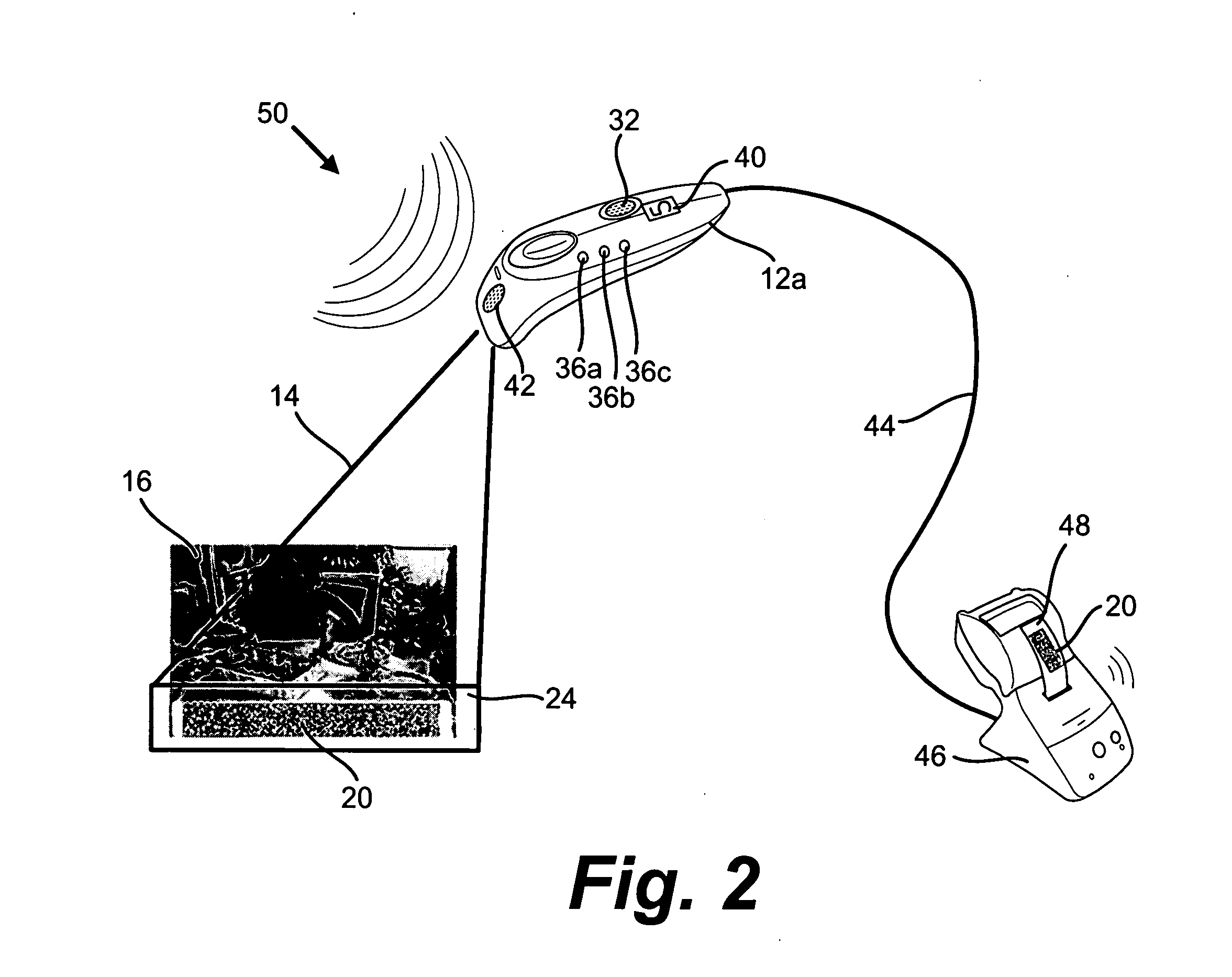

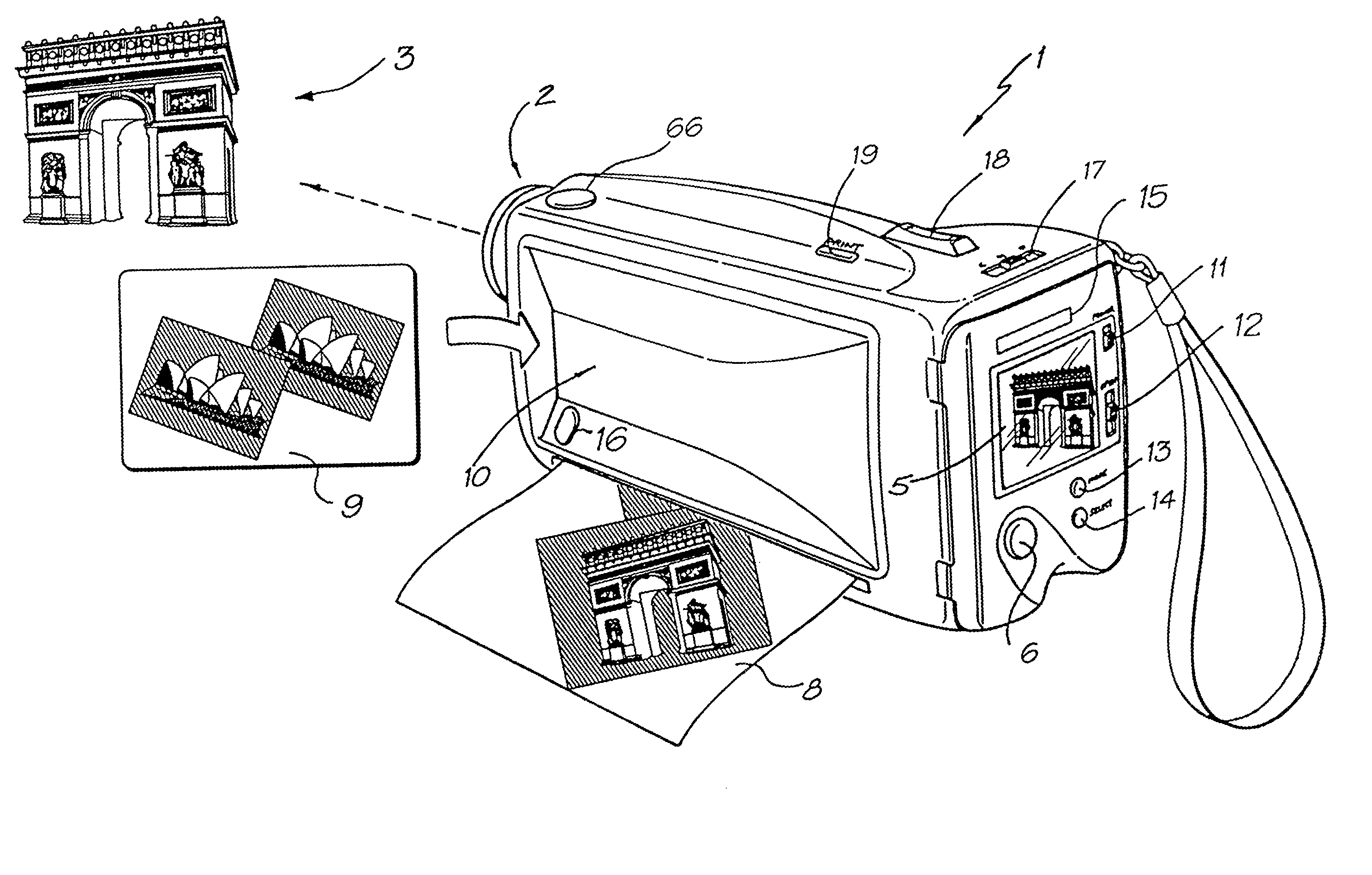

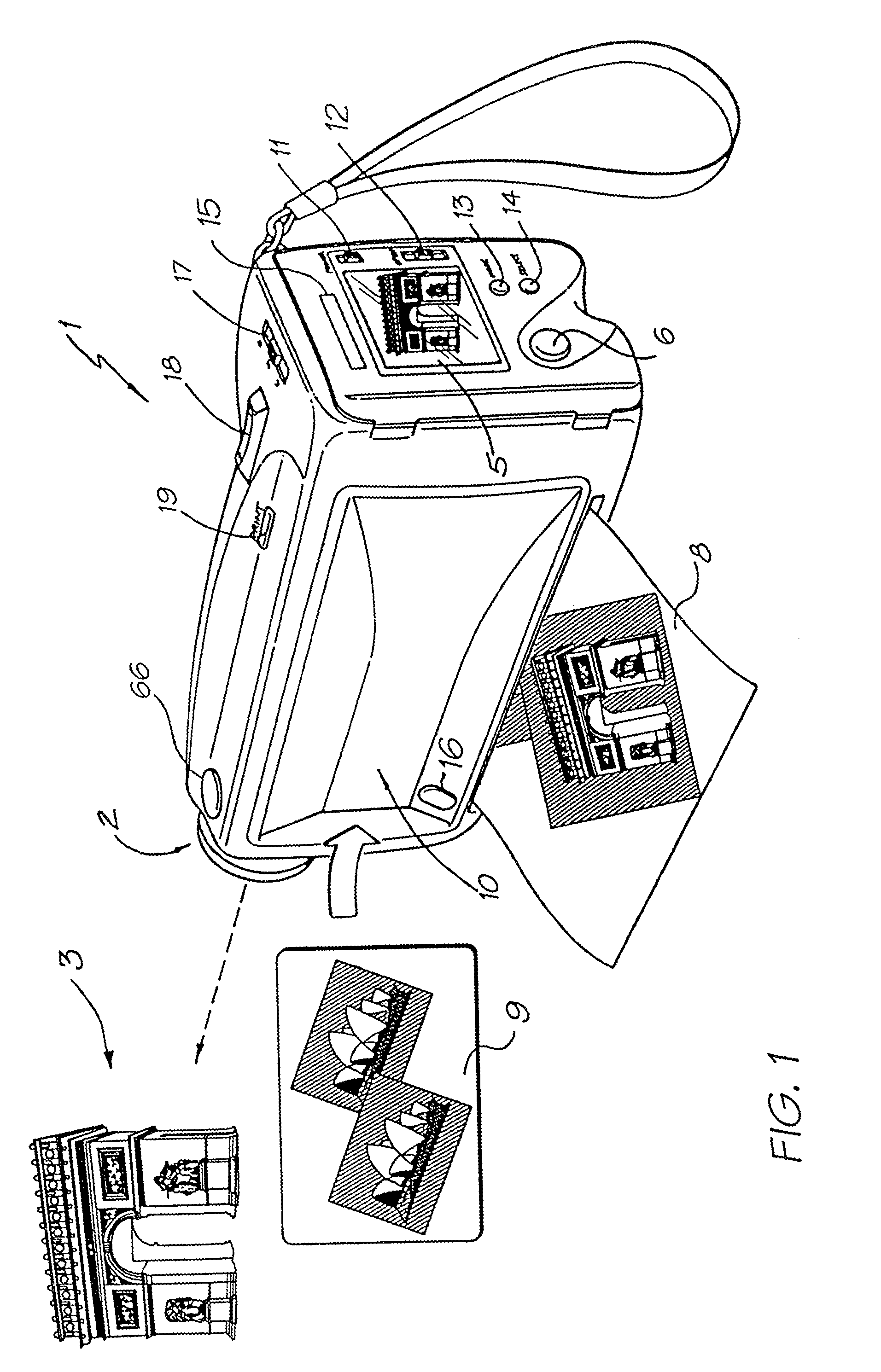

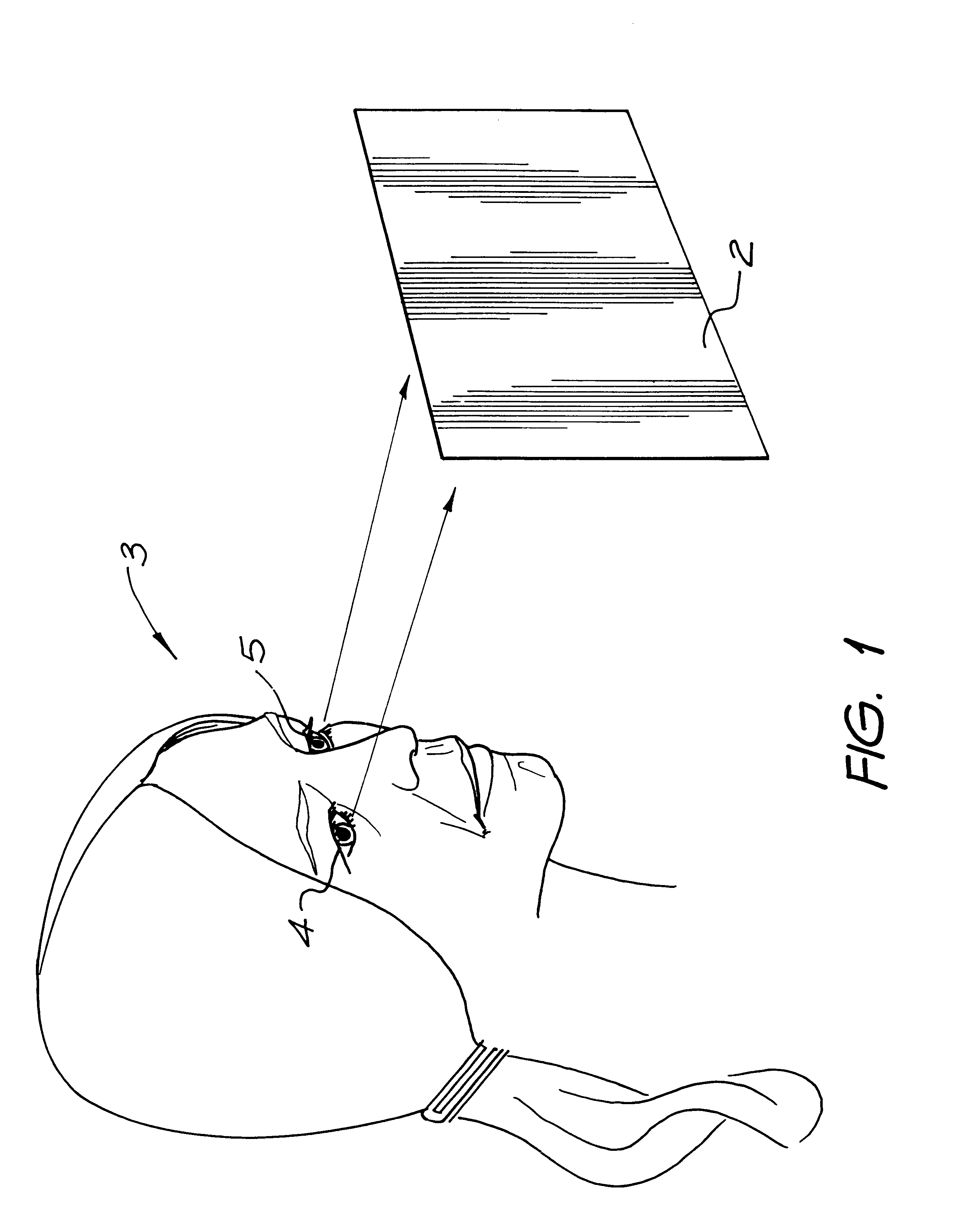

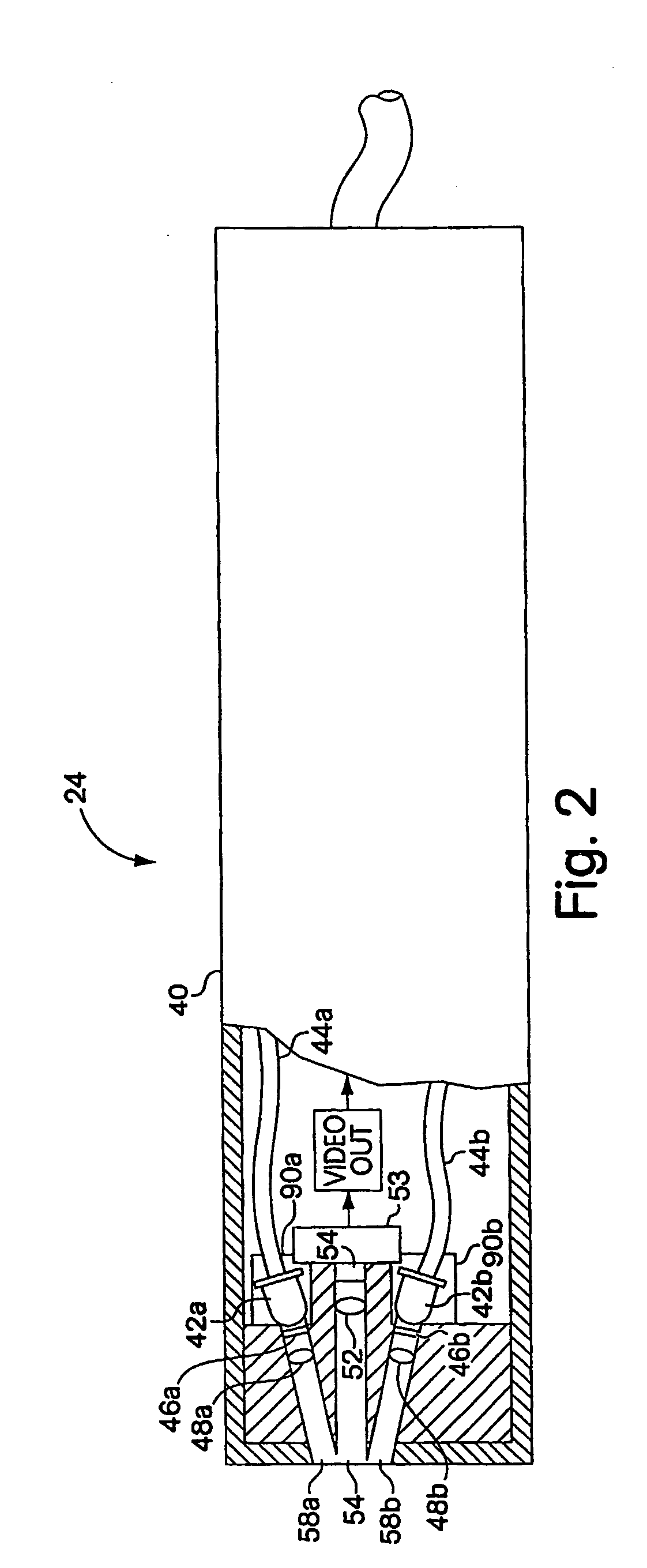

Portable hand held camera

InactiveUS7453492B2Increasing of apparent resolutionImprove graphicsTelevision system detailsInking apparatusPrint mediaHand held

A camera system comprising:at least one area image sensor for imaging a scene;a camera processor means for processing said image scene in accordance with a predetermined scene transformation requirement; anda printer for printing out said processed image scene on print media, utilizing printing ink stored in a single detachable module inside said camera system;said camera system comprising a portable hand held unit for the imaging of scenes by said area image sensor and printing said scenes directly out of said camera system via said printer.

Owner:GOOGLE LLC

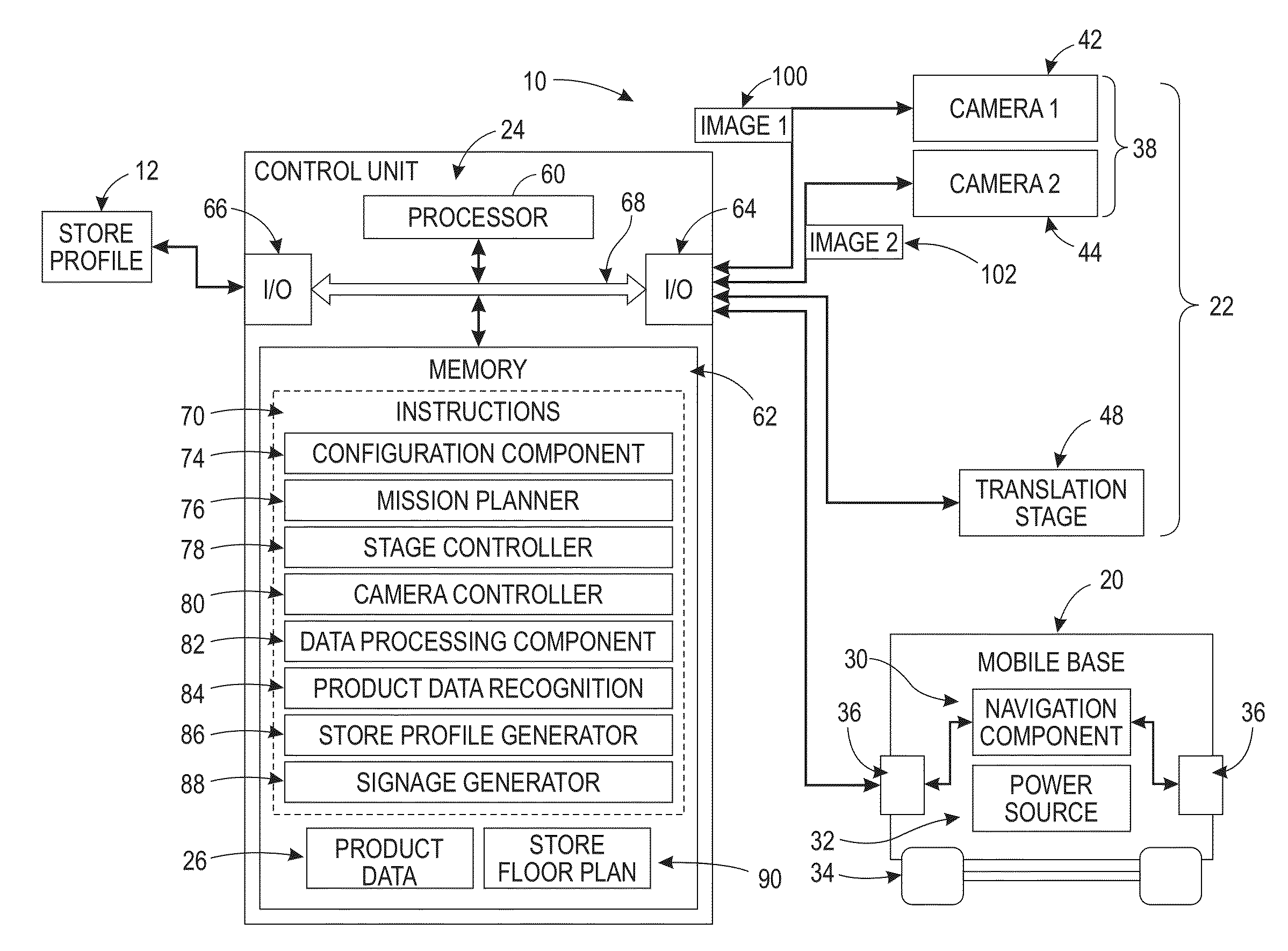

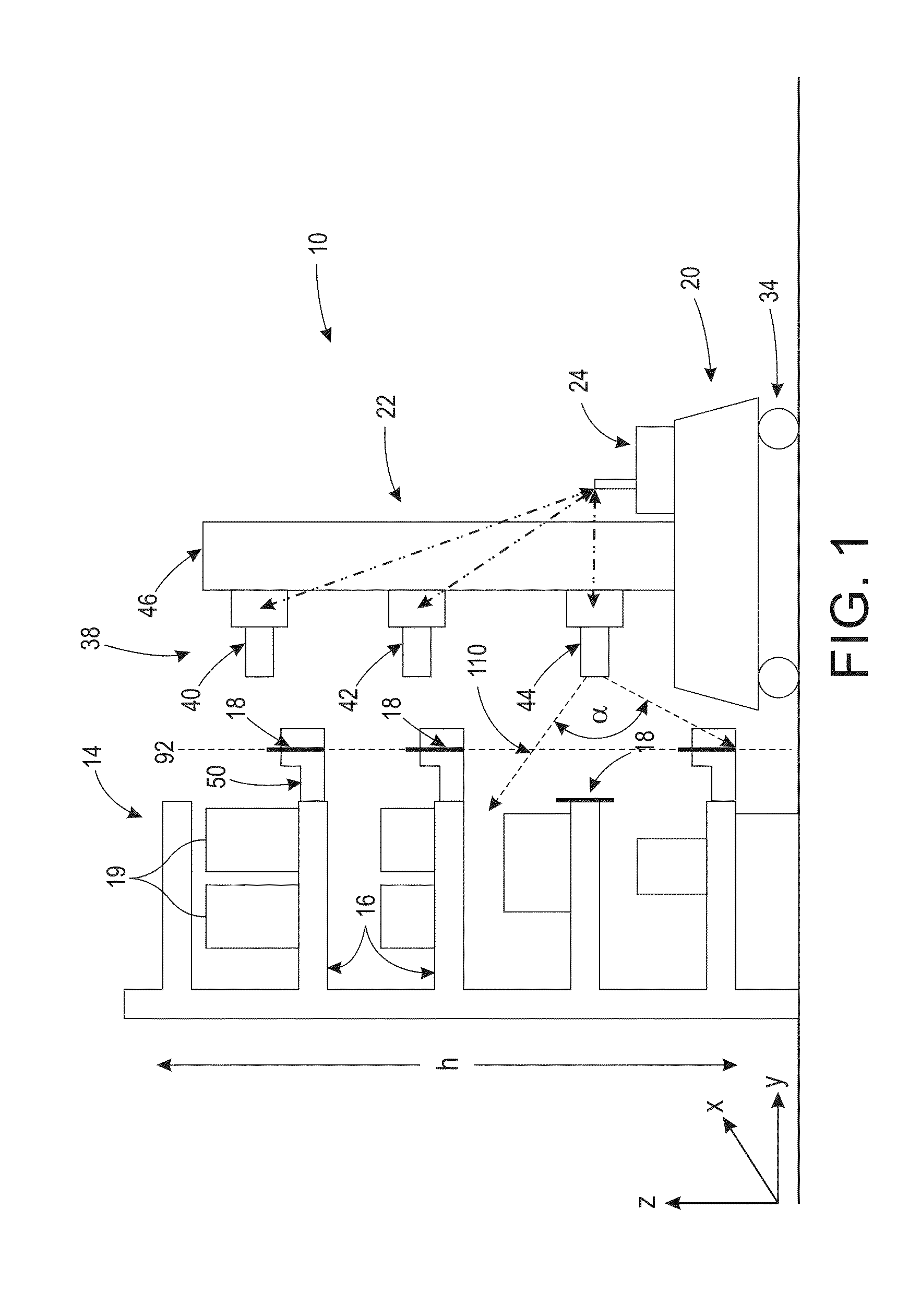

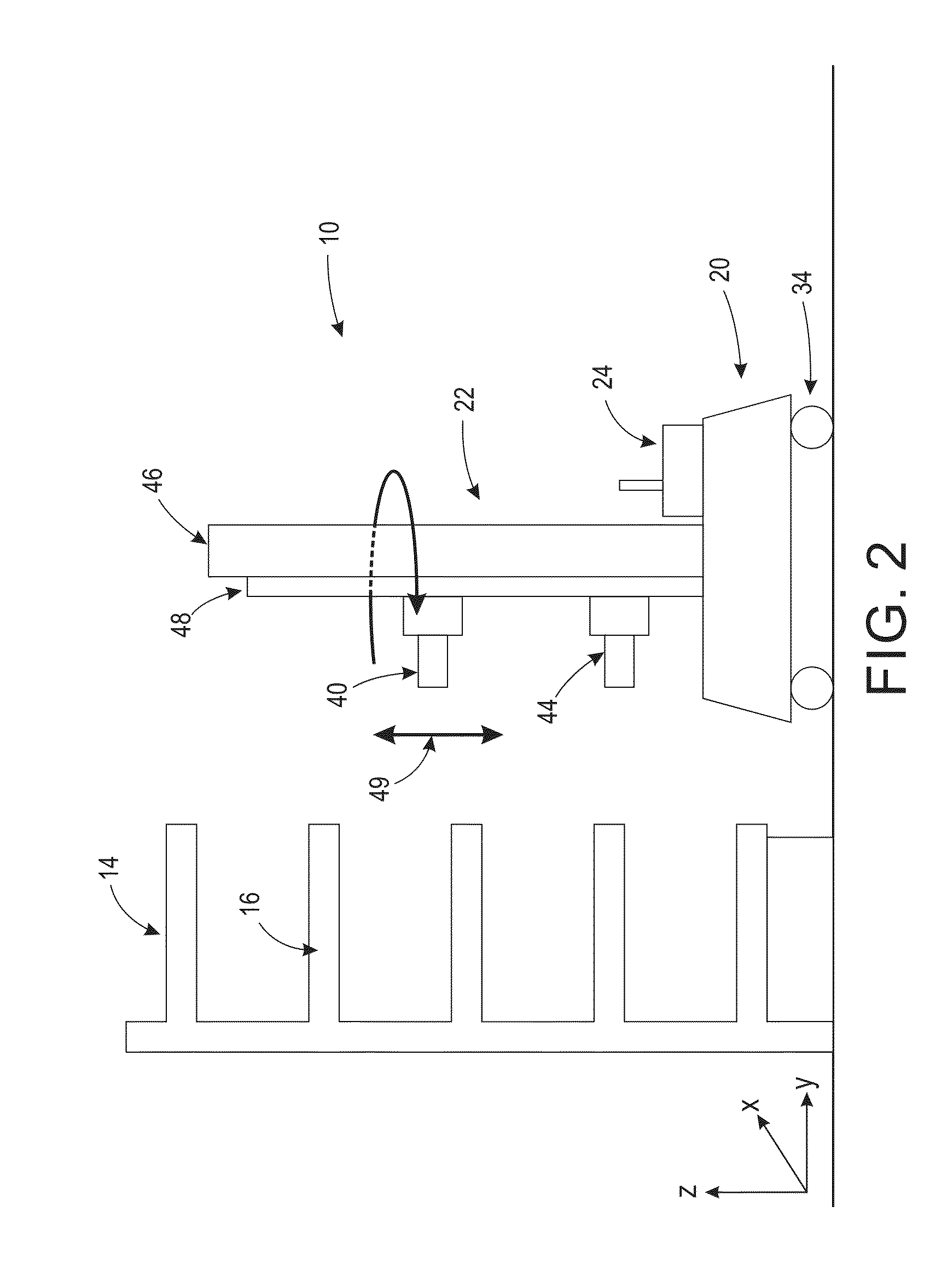

Store shelf imaging system

A store profile generation system includes a mobile base and an image capture assembly mounted on the base. The assembly includes at least one image capture device for acquiring images of product display units in a product facility, product labels being associated with the product display units which include product-related data. A control unit acquires the images captured by the at least one image capture device at a sequence of locations of the mobile base in the product facility. The control unit extracts the product-related data from the acquired images and constructs a store profile indicating locations of the product labels throughout the product facility, based on the extracted product-related data. The store profile can be used for generating new product labels for a sale in an appropriate order for a person to match to the appropriate locations in a single pass through the store.

Owner:CONDUENT BUSINESS SERVICES LLC

Apparatus and method for reading and decoding information contained in a barcode

ActiveUS7410099B2Efficient supplyRead operationDigital data information retrievalCharacter and pattern recognitionBarcodeOutput device

An image output device inputs content information, generates a barcode by encoding input content information, and outputs print data so that a sign visually indicating a property of the content information is printed adjacent to the generated barcode or by superimposing the sign on the generated barcode.

Owner:GOOGLE LLC

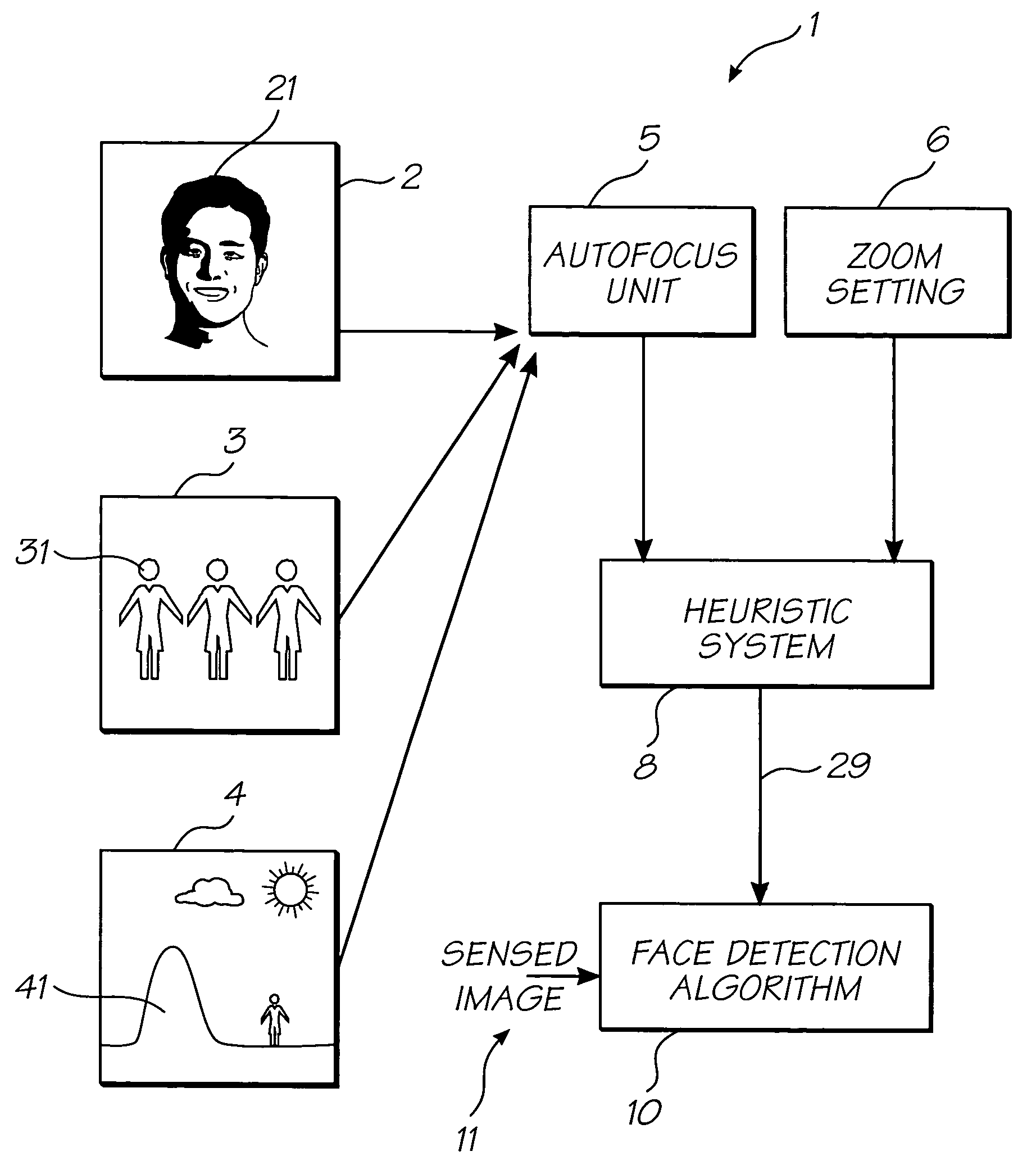

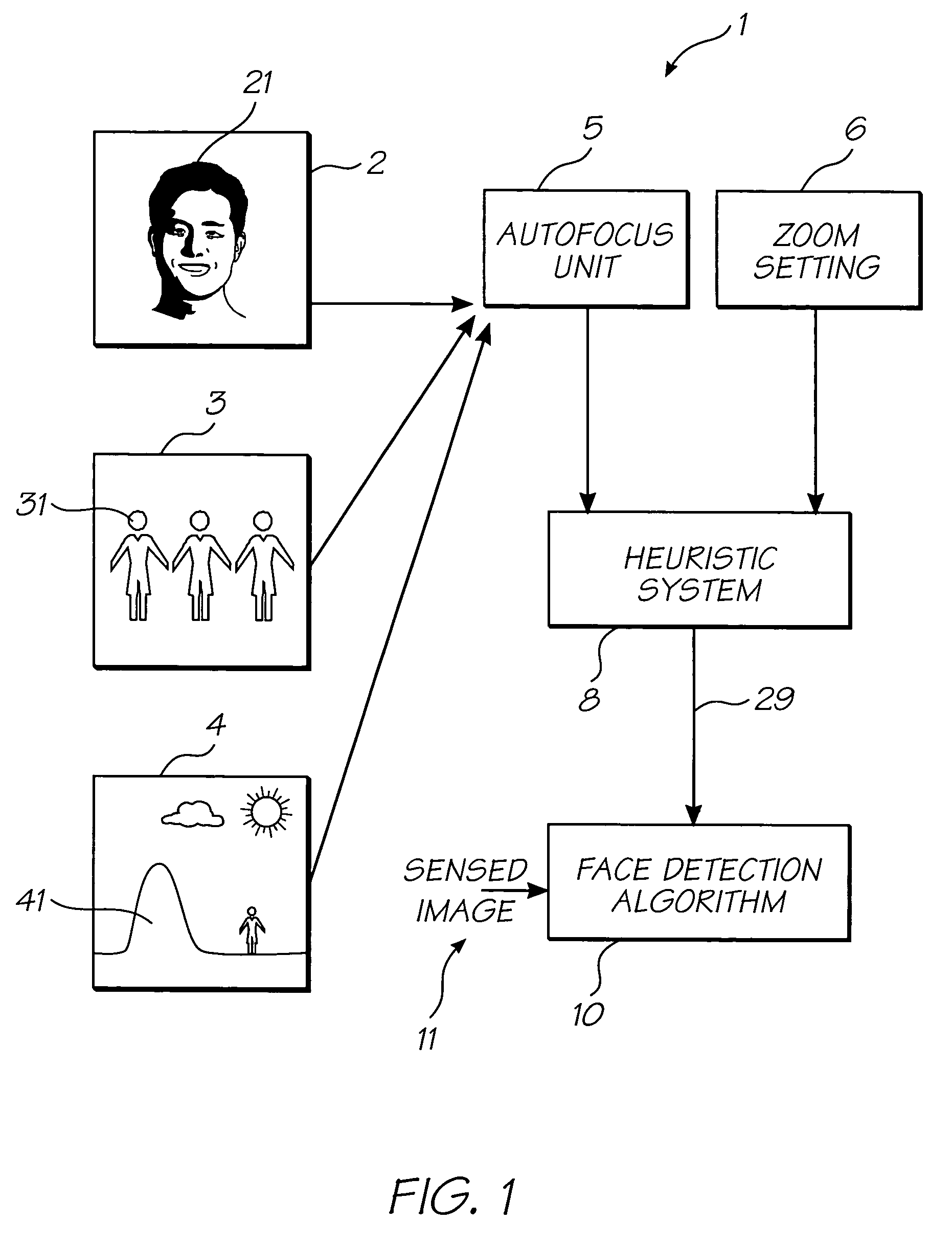

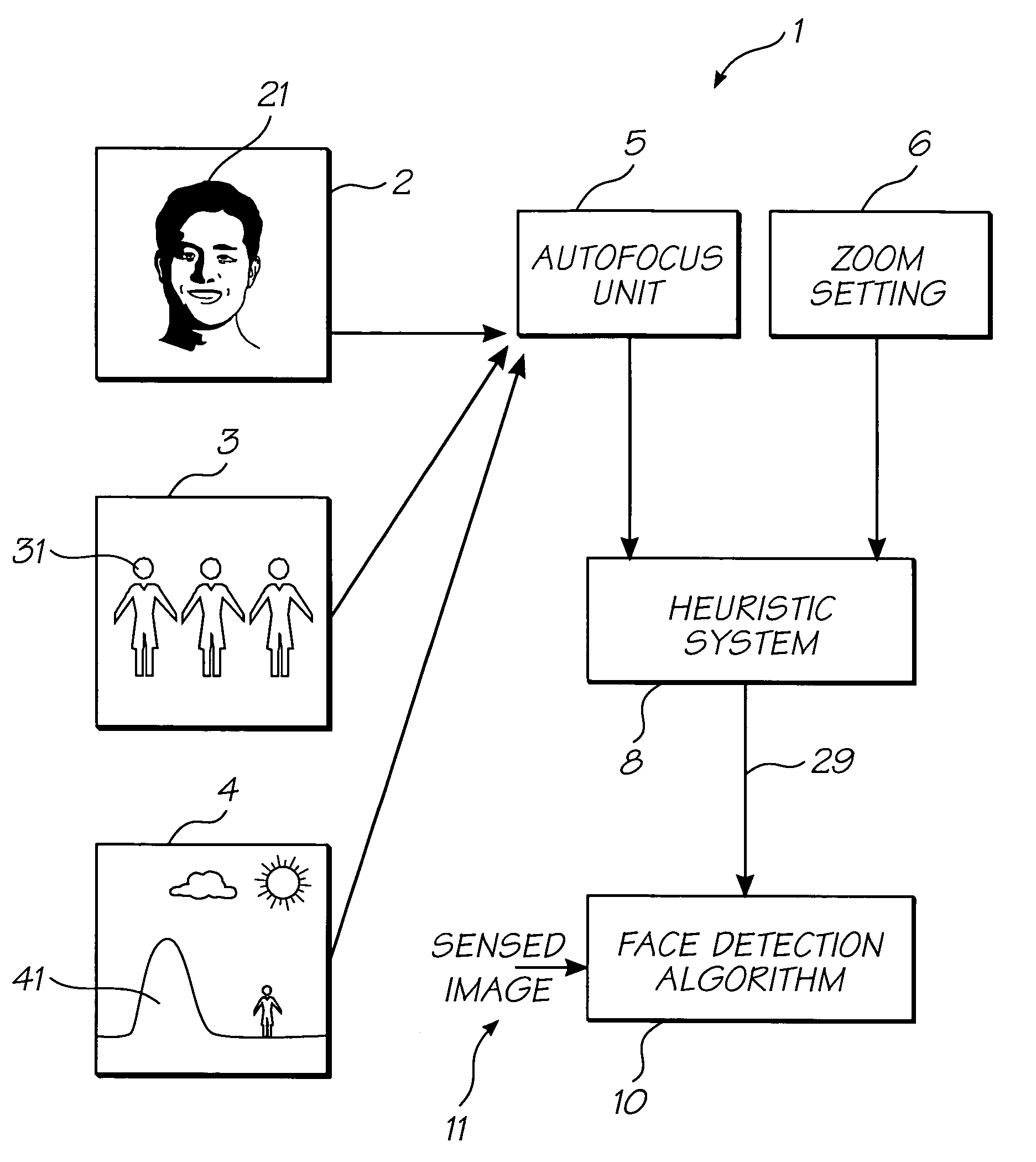

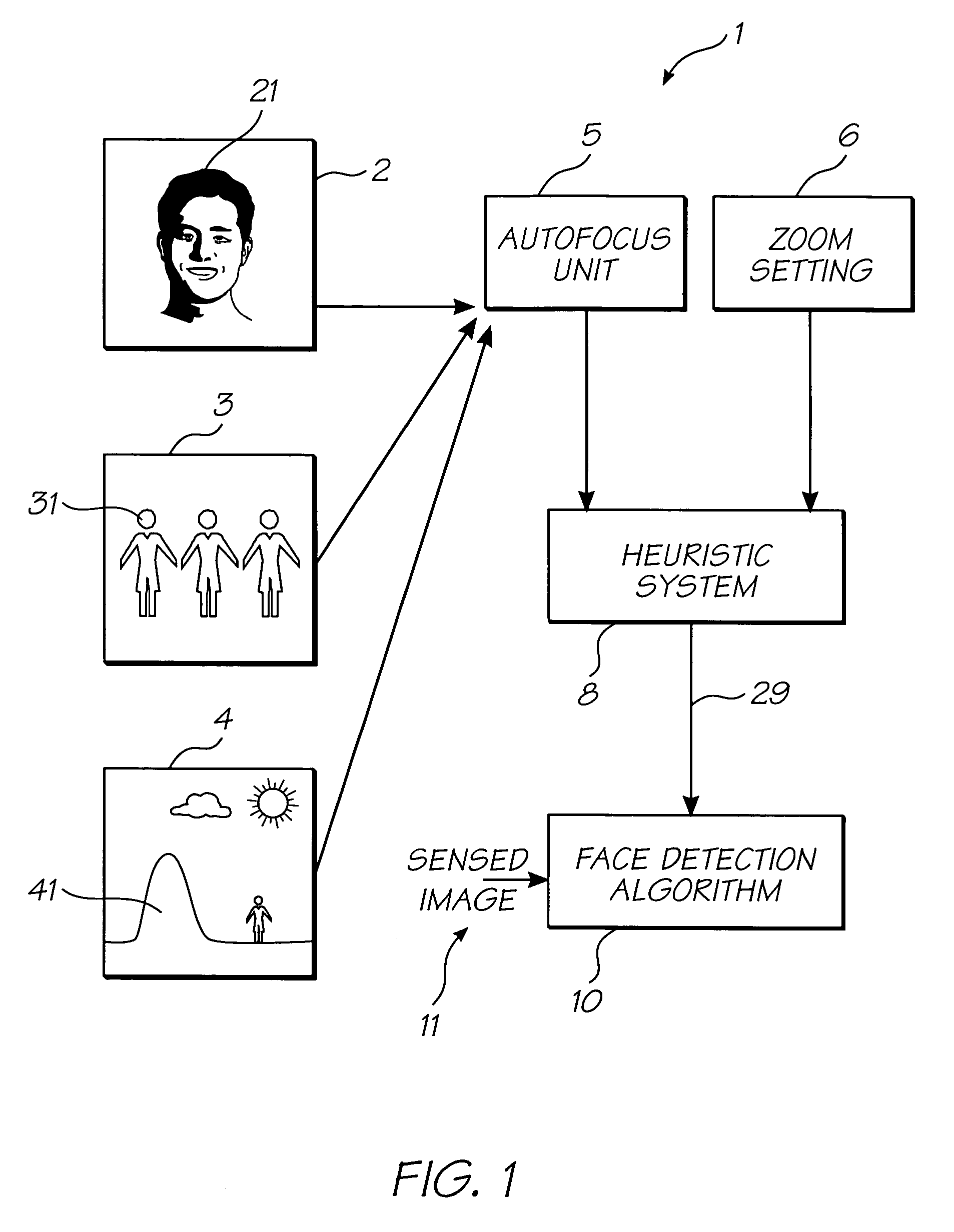

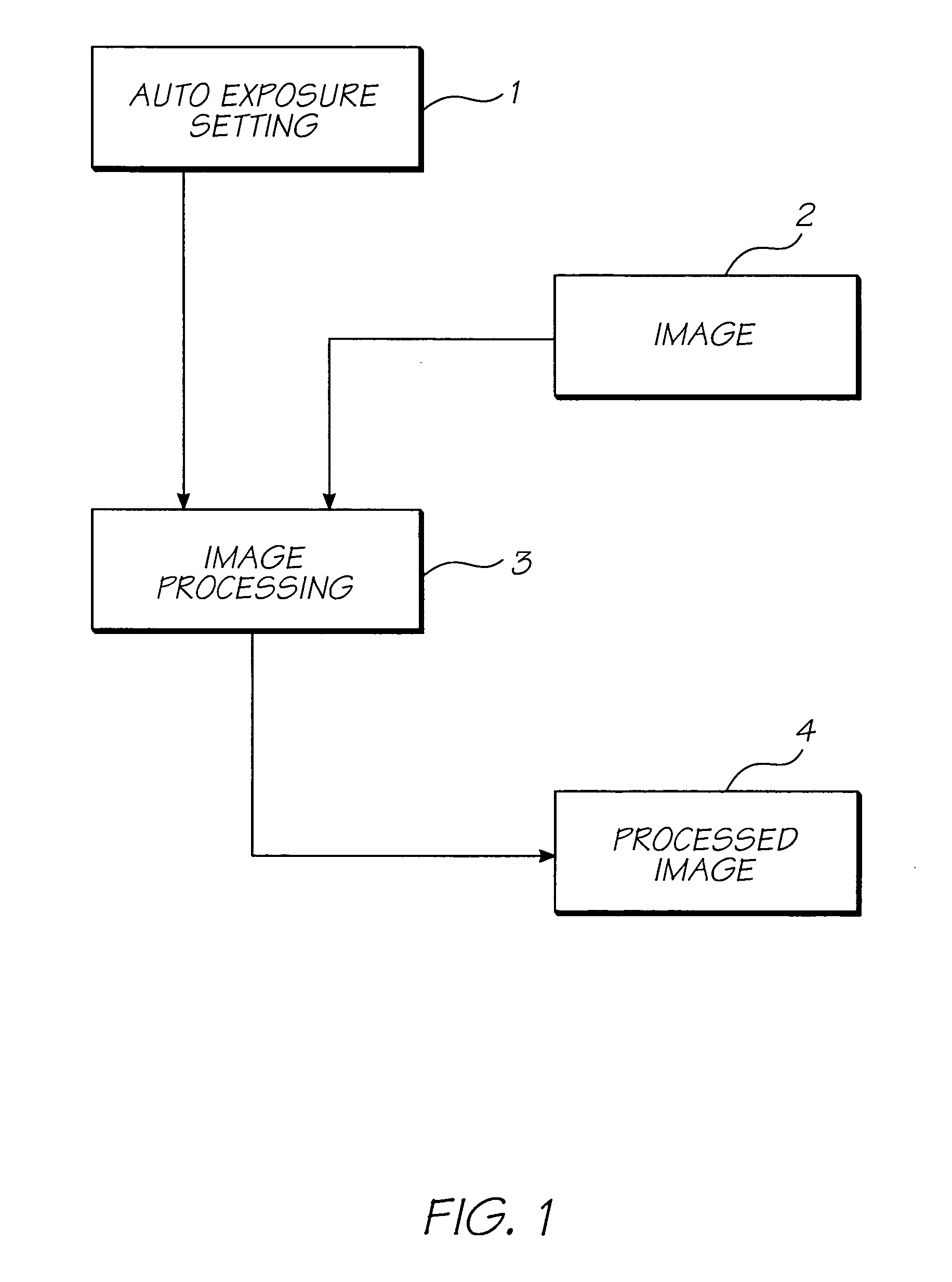

Digital camera utilizing autofocus settings for image manipulation

InactiveUS7385639B2Speed up the processImprove image processing capabilitiesTelevision system detailsMaterial nanotechnologyFace detectionAutofocus

A digital camera is provided for generating a manipulated output image. The camera focuses an image using an automatic focusing technique thereby generating focus settings. The focus settings are stored in a memory of the digital camera and used in manipulating the captured image to produce an enhanced image. The digital image manipulation process is selected from the group consisting of applying a face detection algorithm to the captured focussed image and producing a painting effect within the captured focussed image.

Owner:GOOGLE LLC

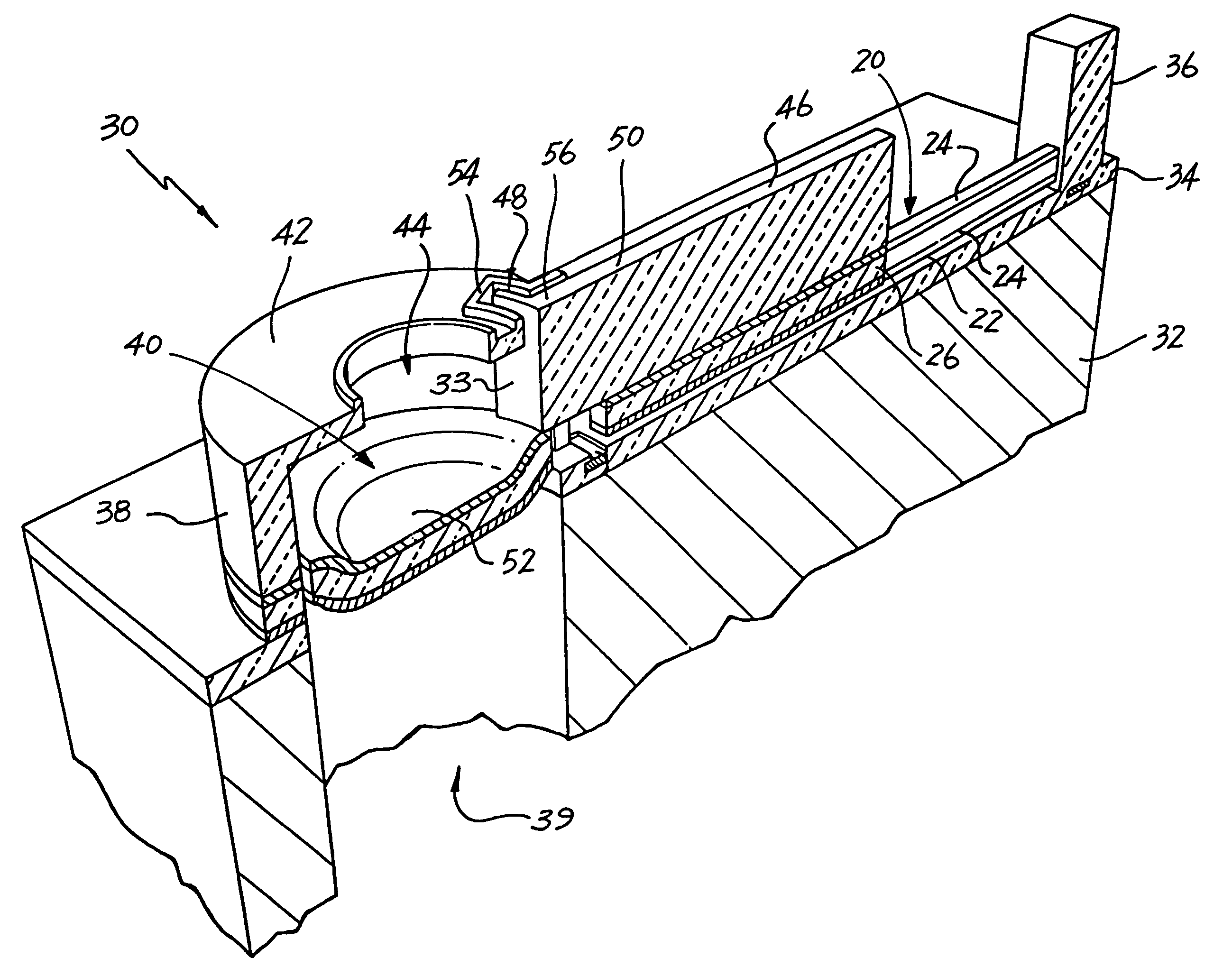

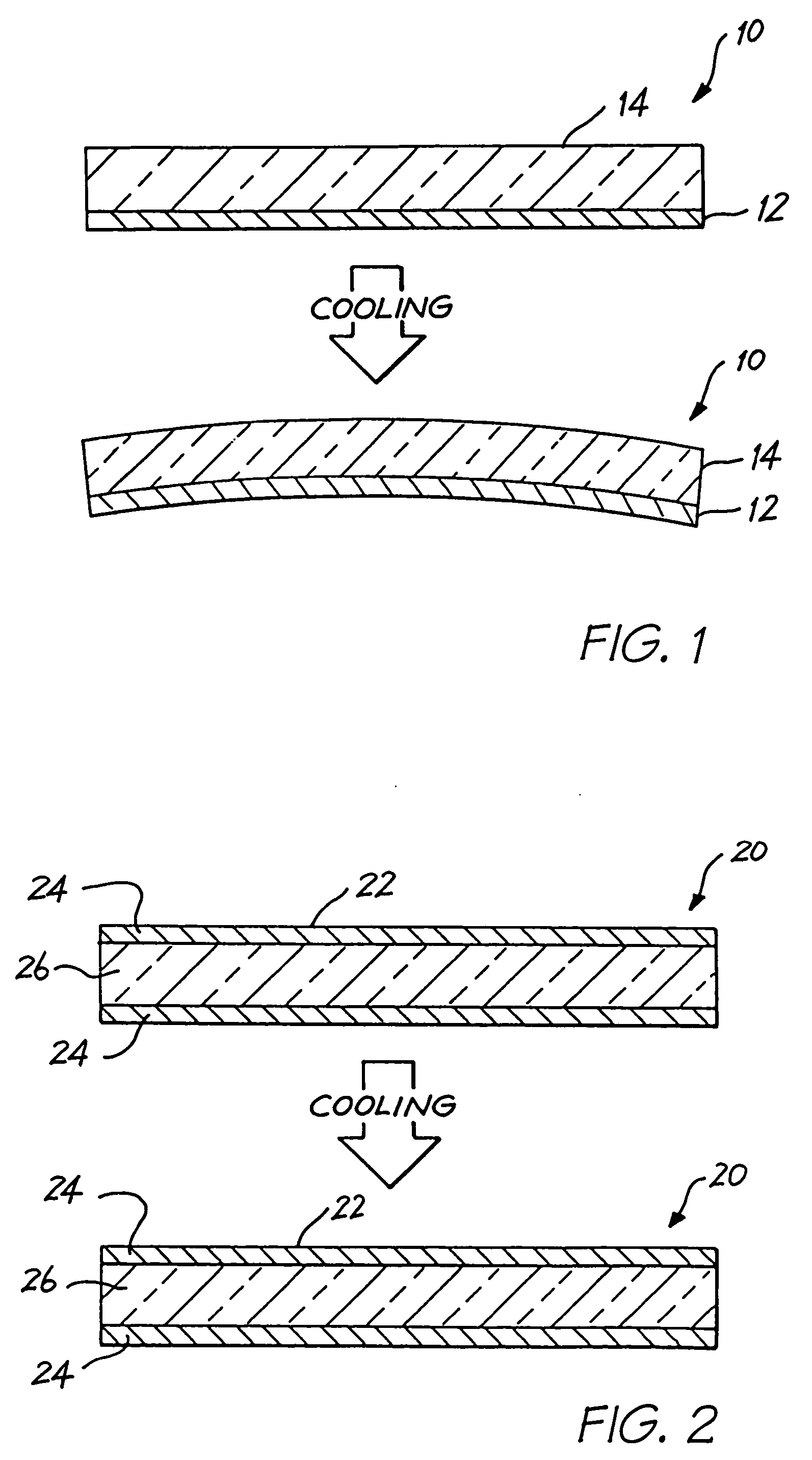

Method of manufacture of high Young's modulus thermoelastic inkjet printer

A method of manufacturing a thermally actuated ink jet printhead includes the step of initially providing a wafer having a circuitry layer including the electrical circuitry necessary for the operation of a thermal actuator. A first sacrificial layer is deposited on the wafer and is etched. A Young's modulus layer is deposited to form a first layer of a thermal actuator and a portion of a nozzle chamber wall. A conductive heater material layer is provided and has a portion interconnected to the circuitry layer. A second sacrificial layer is deposited and etched in preparation for nozzle chamber walls. A nozzle wall material layer is deposited to form the walls of the nozzle chamber. The nozzle wall material layer is etched to define a nozzle port for the ejection of ink. The sacrificial layers are etched away to release the thermal actuator. The nozzle chamber walls are formed to define a fulcrum for the thermal actuator.

Owner:SILVERBROOK RES PTY LTD +1

Processing of digital images using autofocus settings for image enhancement

InactiveUS7557853B2Improve image processing capabilitiesTelevision system detailsMaterial nanotechnologyAutofocusDigital image

A method of processing a digital image comprising: using a digital camera, capturing the image utilising an adjustable focusing technique; storing the focusing settings within a memory of the digital camera; utilising the focusing settings as an indicator of the position of structures within the image; processing the image within a processor of the camera utilising the said focus settings to produce a manipulated image having effects specific to said focus settings; and printing out the image using a printer inbuilt to the camera body.

Owner:GOOGLE LLC

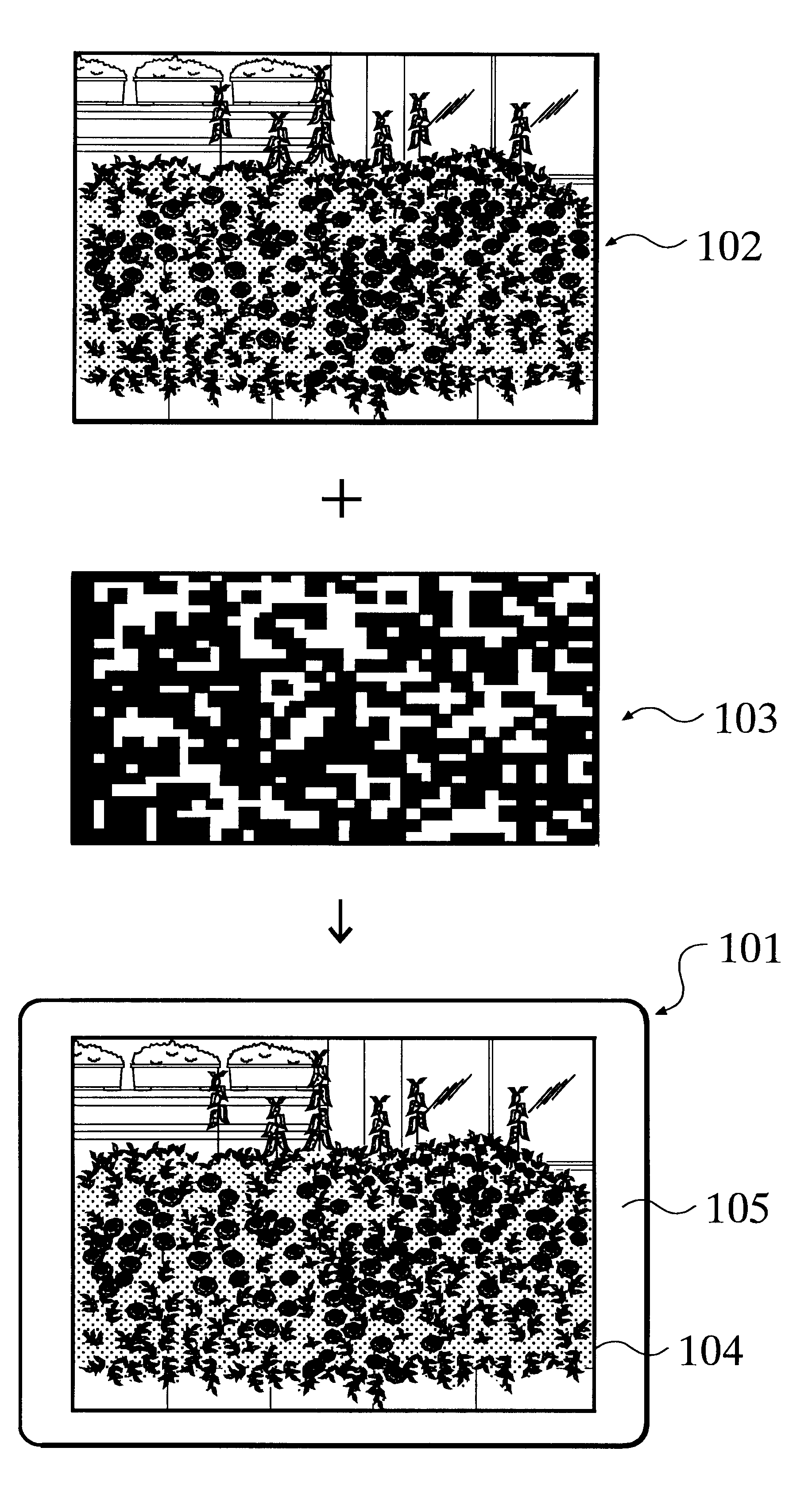

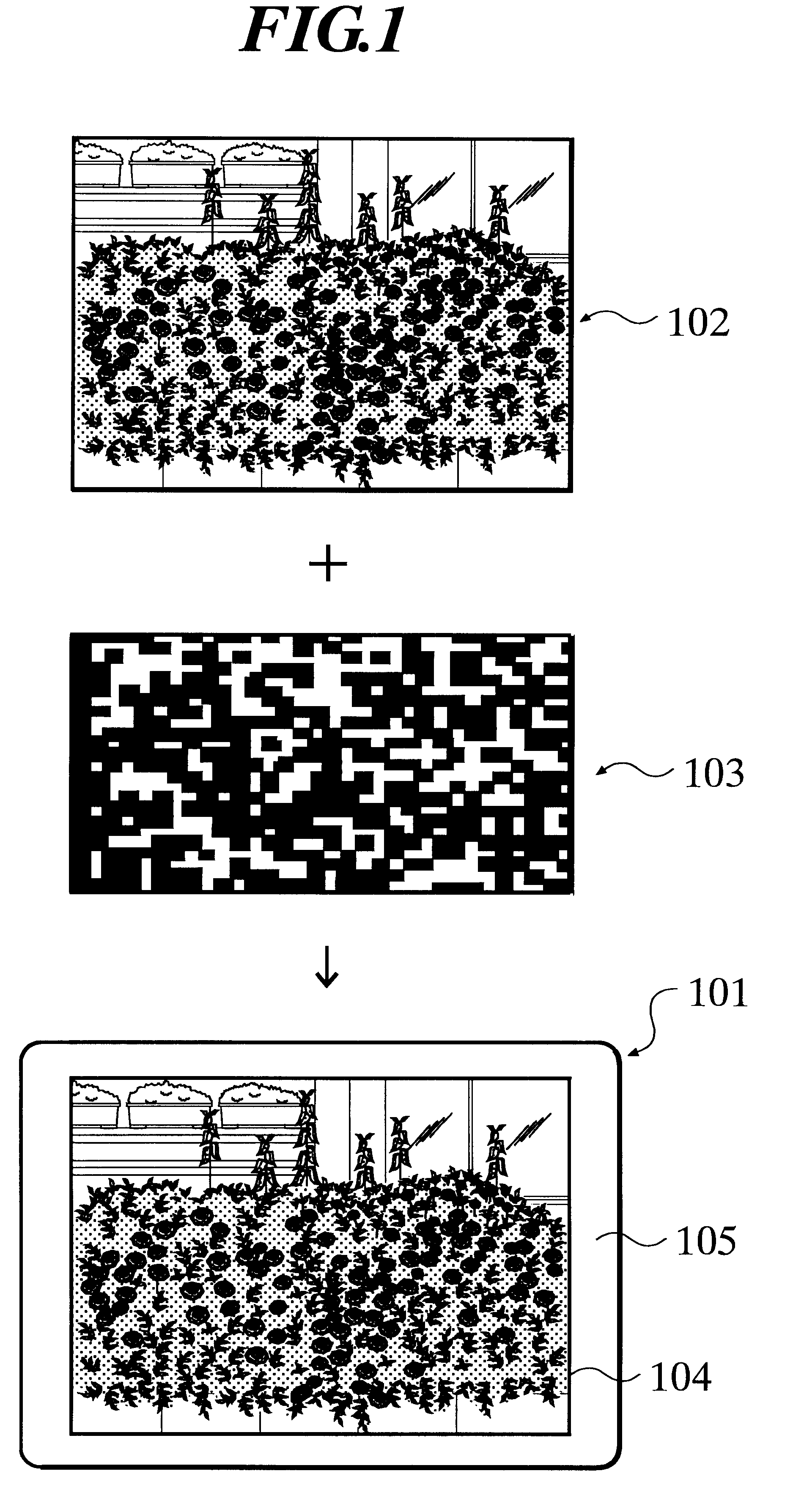

Information code product, manufacturing device and method for manufacturing the same, information code reading device, authentication system, authentication terminal, authentication server, and authentication method

InactiveUS6572025B1Improve securityAvoid Information LeakageCharacter and pattern recognitionPayment architectureComputer terminalAuthentication server

An information code product (101) comprising a body (105) having a code-including image (104) formed thereon which includes at least one unit of information codes (103) with one or more specific color, wherein the unit of information codes is adapted to be obtained by extracting an image with the specific color from the code-including image. A user is authenticated by an authentication system (301) which comprises an authentication terminal (302) for reading data included in the product (101) and an authentication server (303) which is interconnected to the authentication terminal through a network (304).

Owner:JAPAN GAIN THE SUMMIT

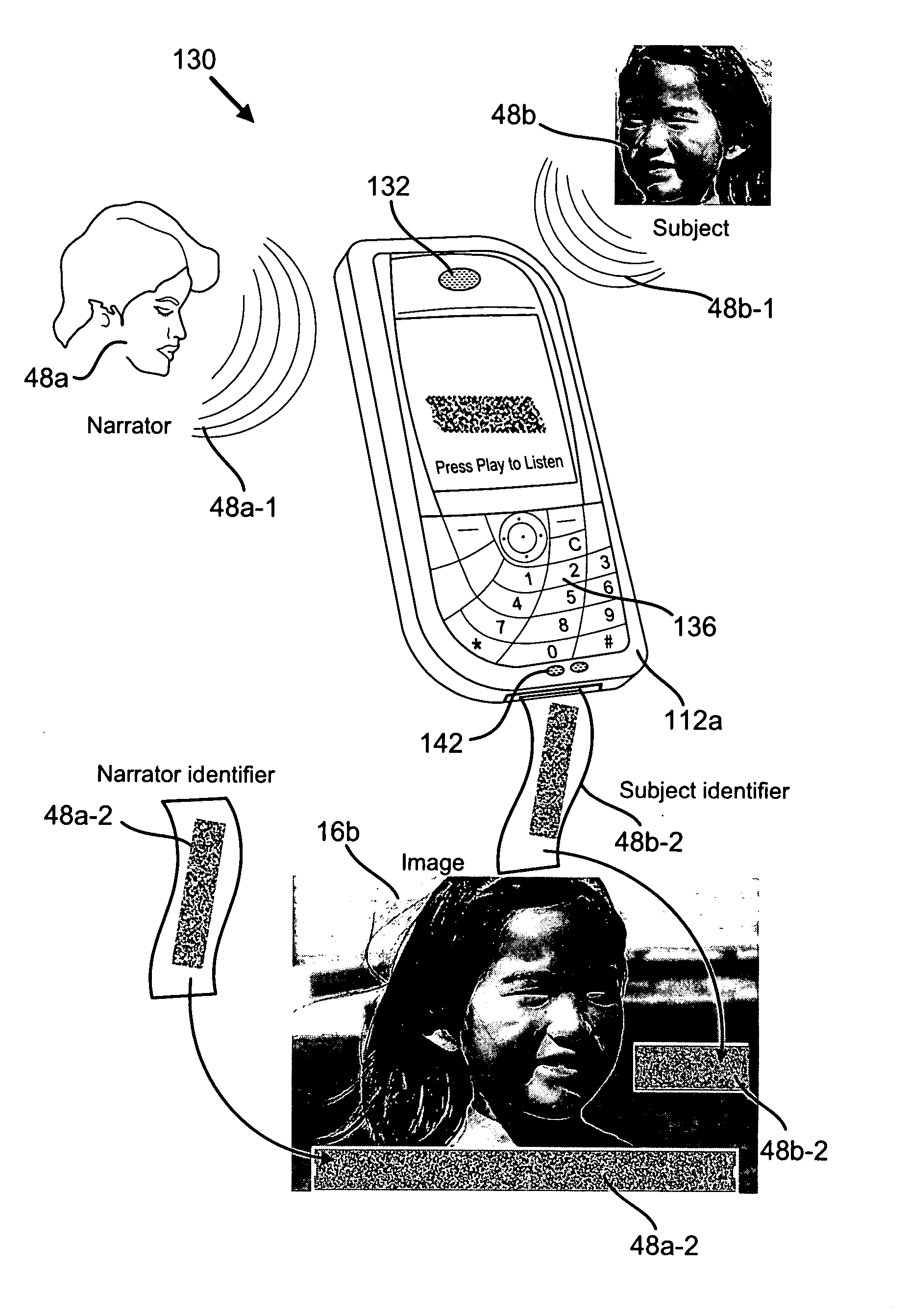

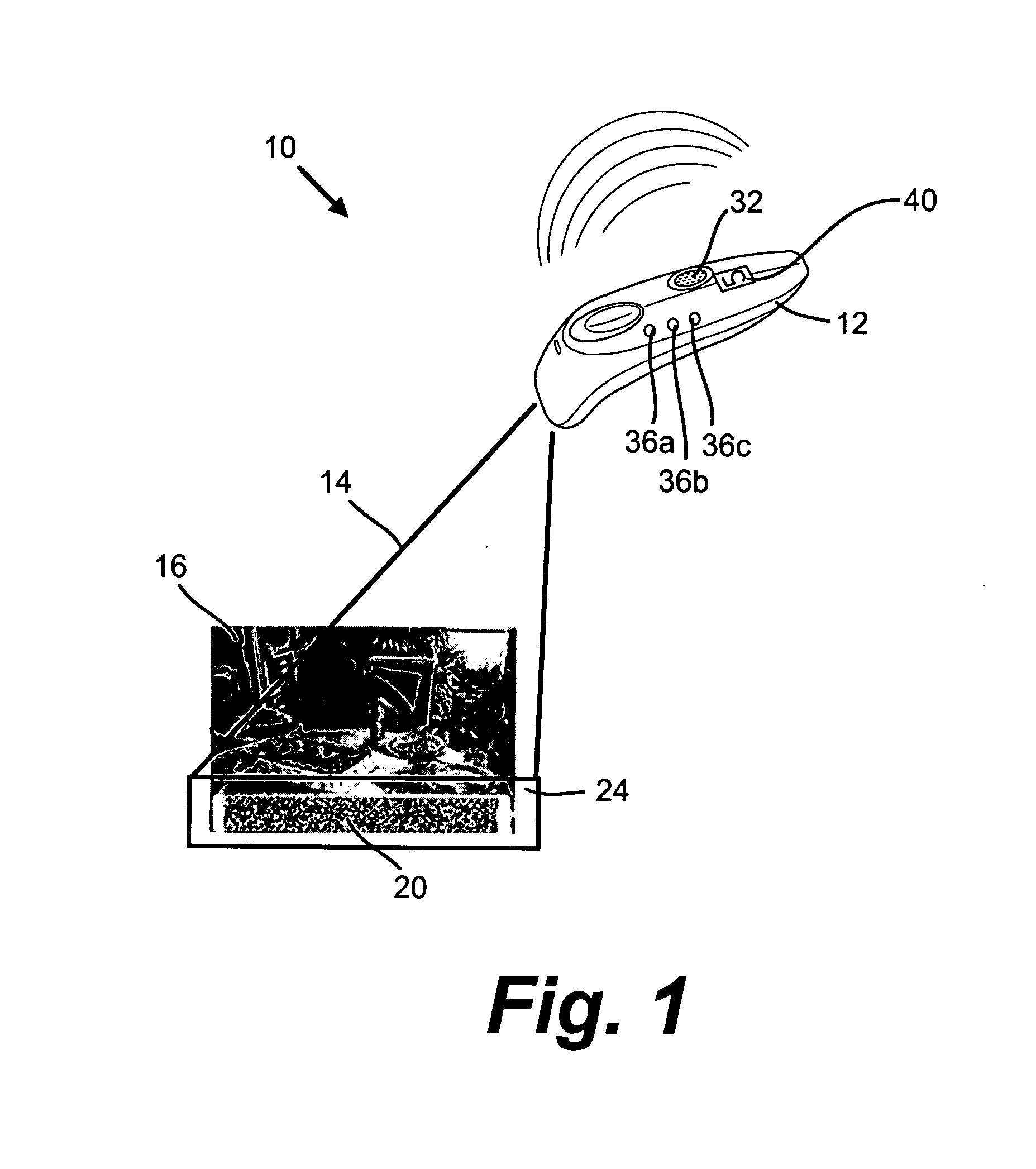

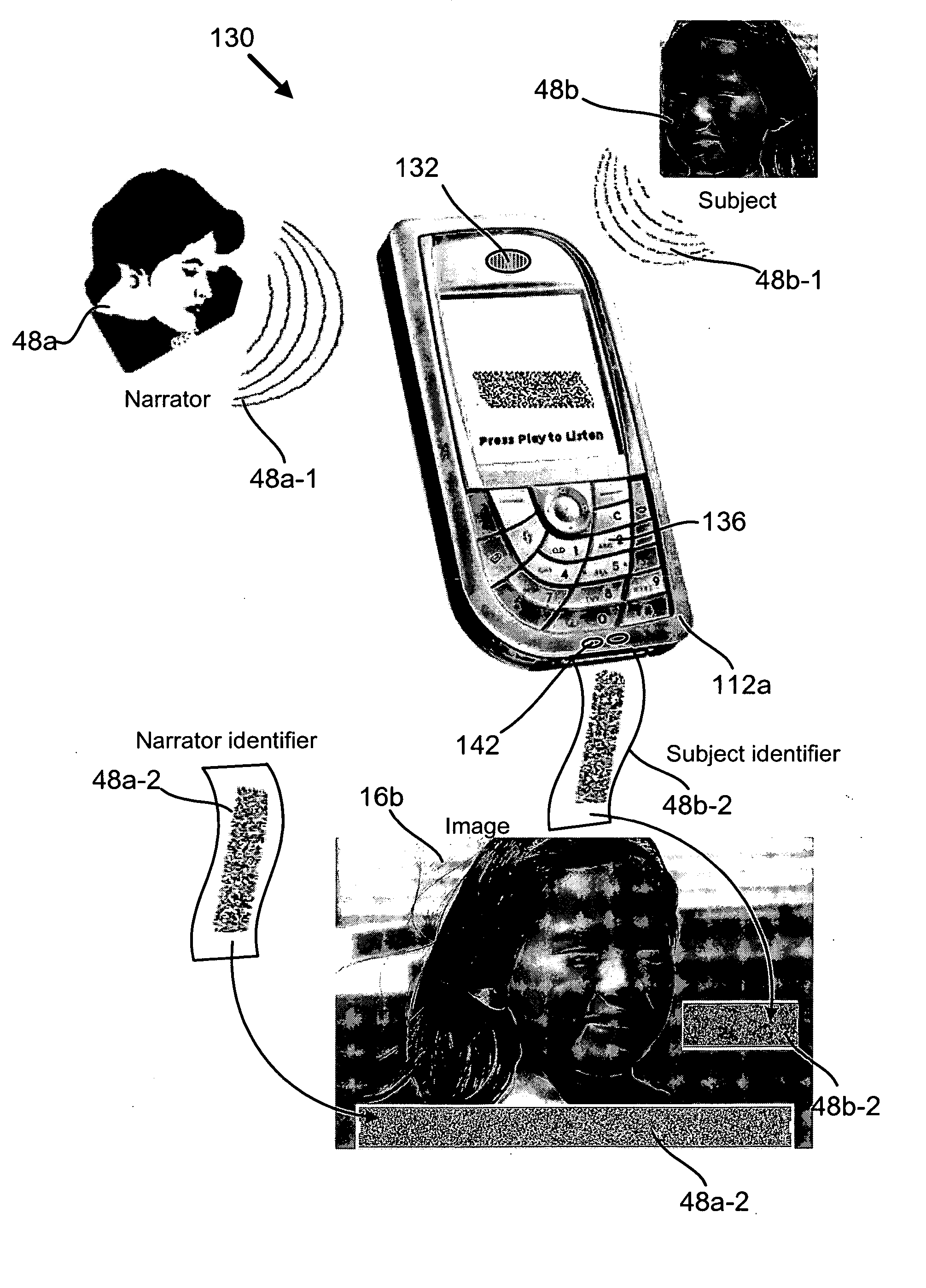

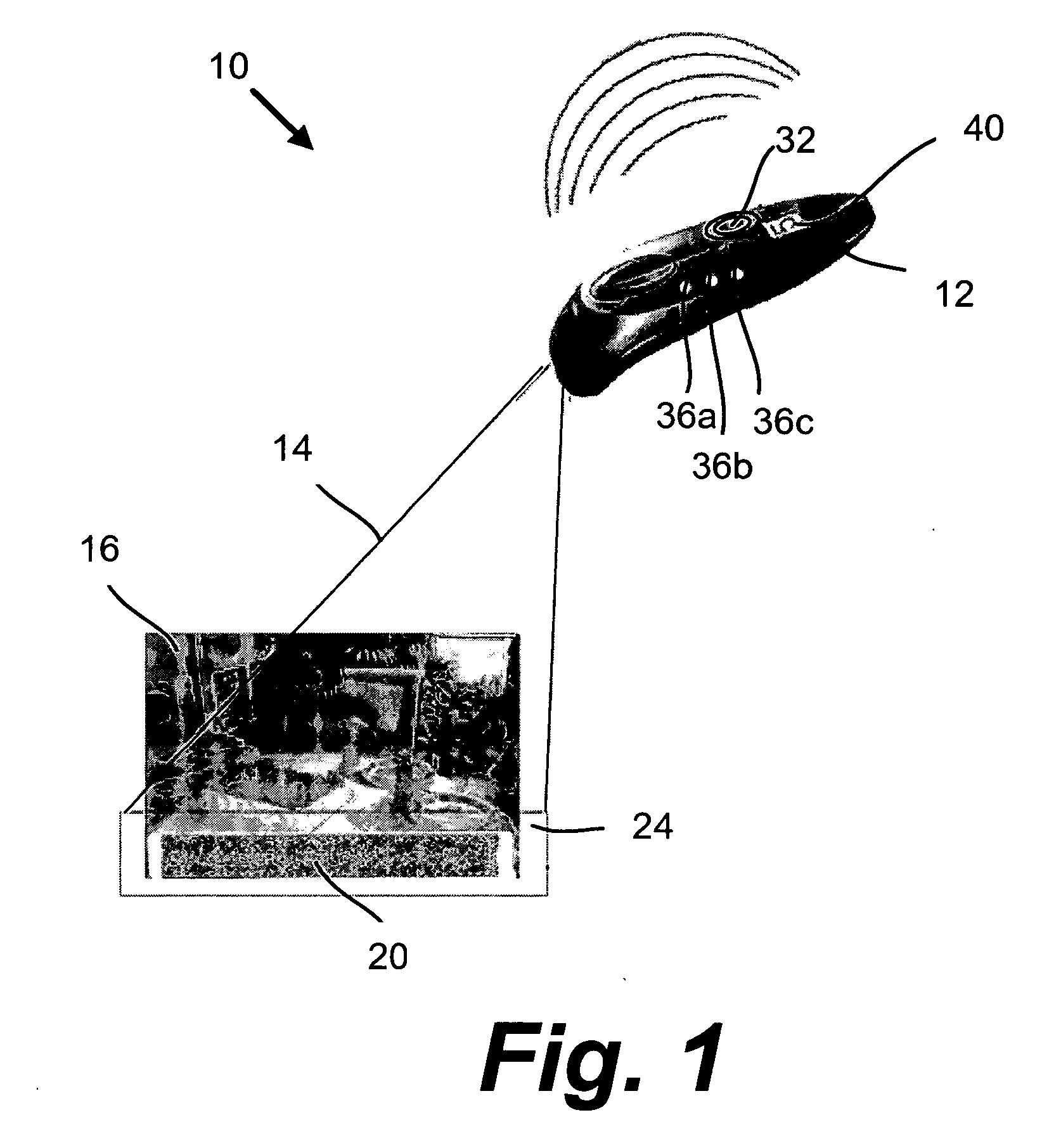

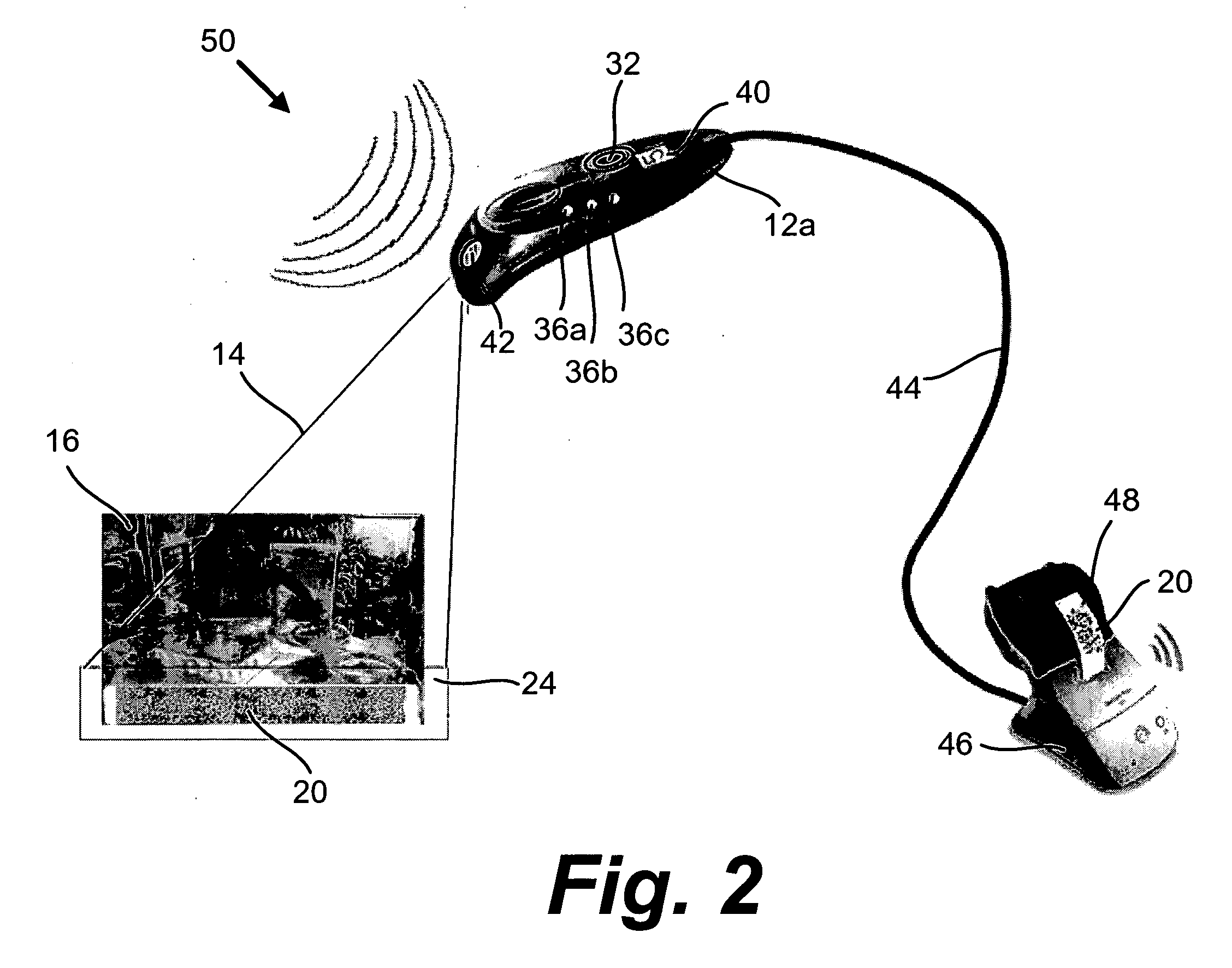

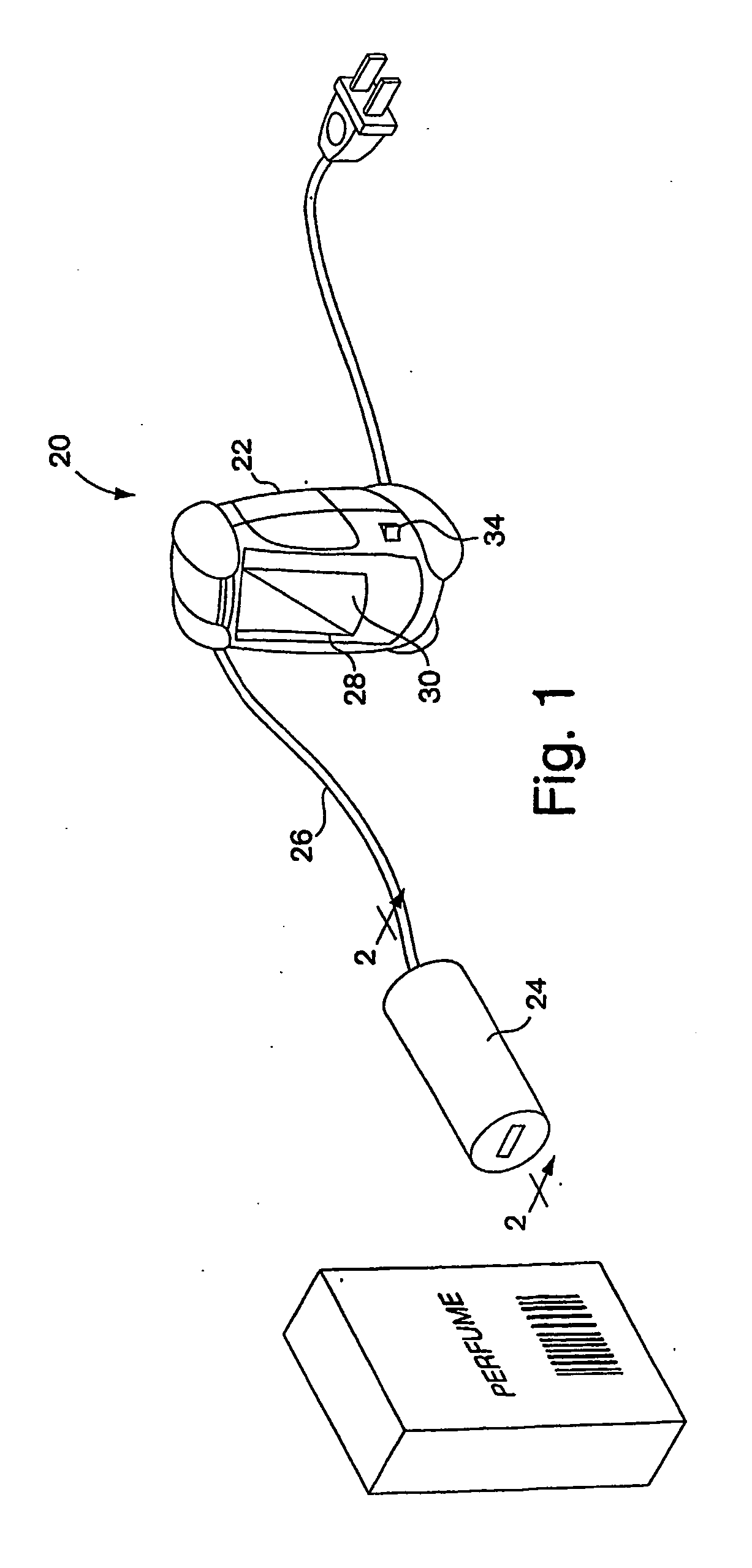

Systems and Methods for Generating, Reading and Transferring Identifiers

Systems and methods for generating, reading and transferring identifiers are disclosed. In one embodiment, a handheld system for associating a selected audio content with an object includes an identifier applied to a surface of the object and having a predetermined graphical format that is configured to encode the selected audio content, and a handheld device operable to encode the identifier and further operable to detect an audio content associated with the identifier.

Owner:LABELS THAT TALK

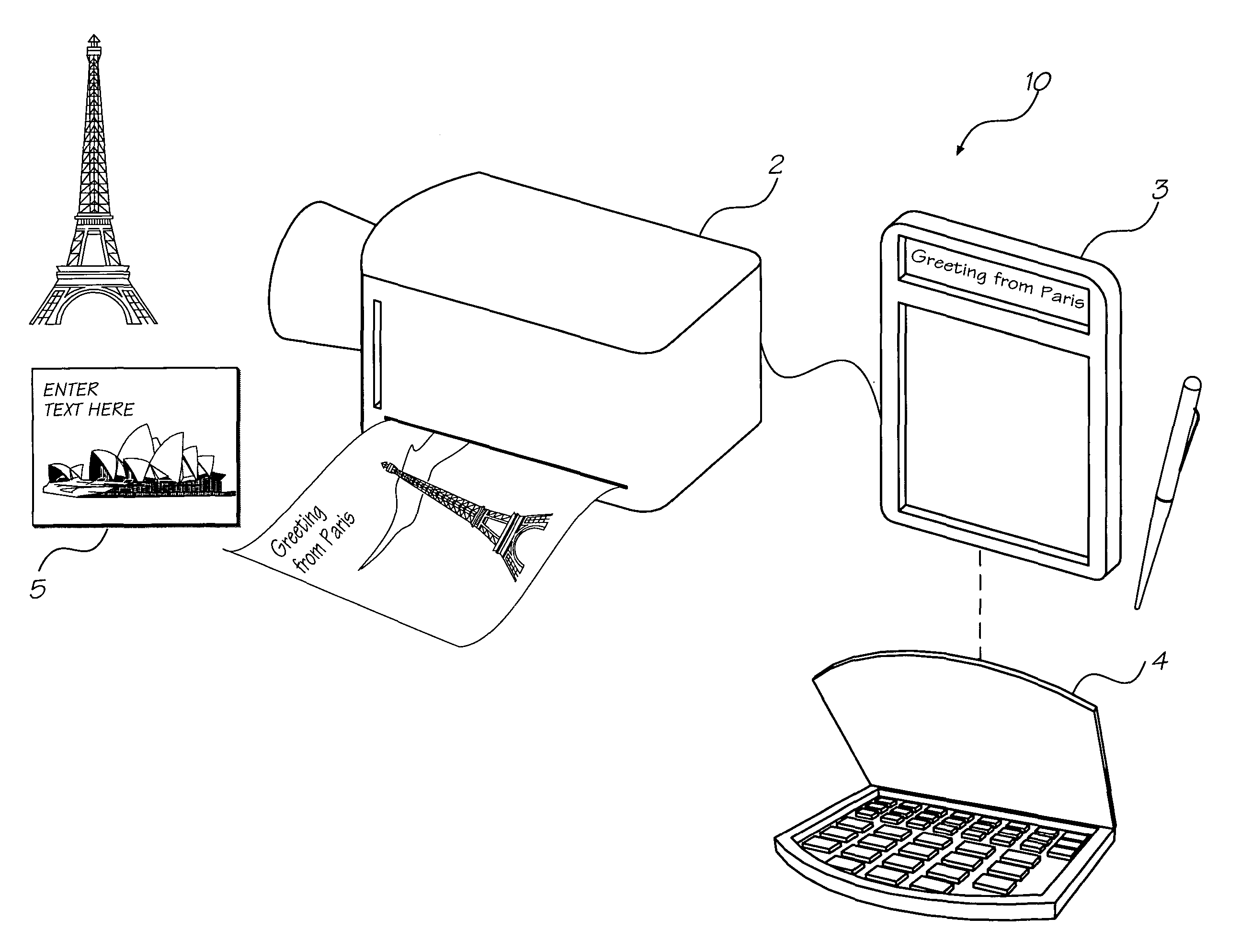

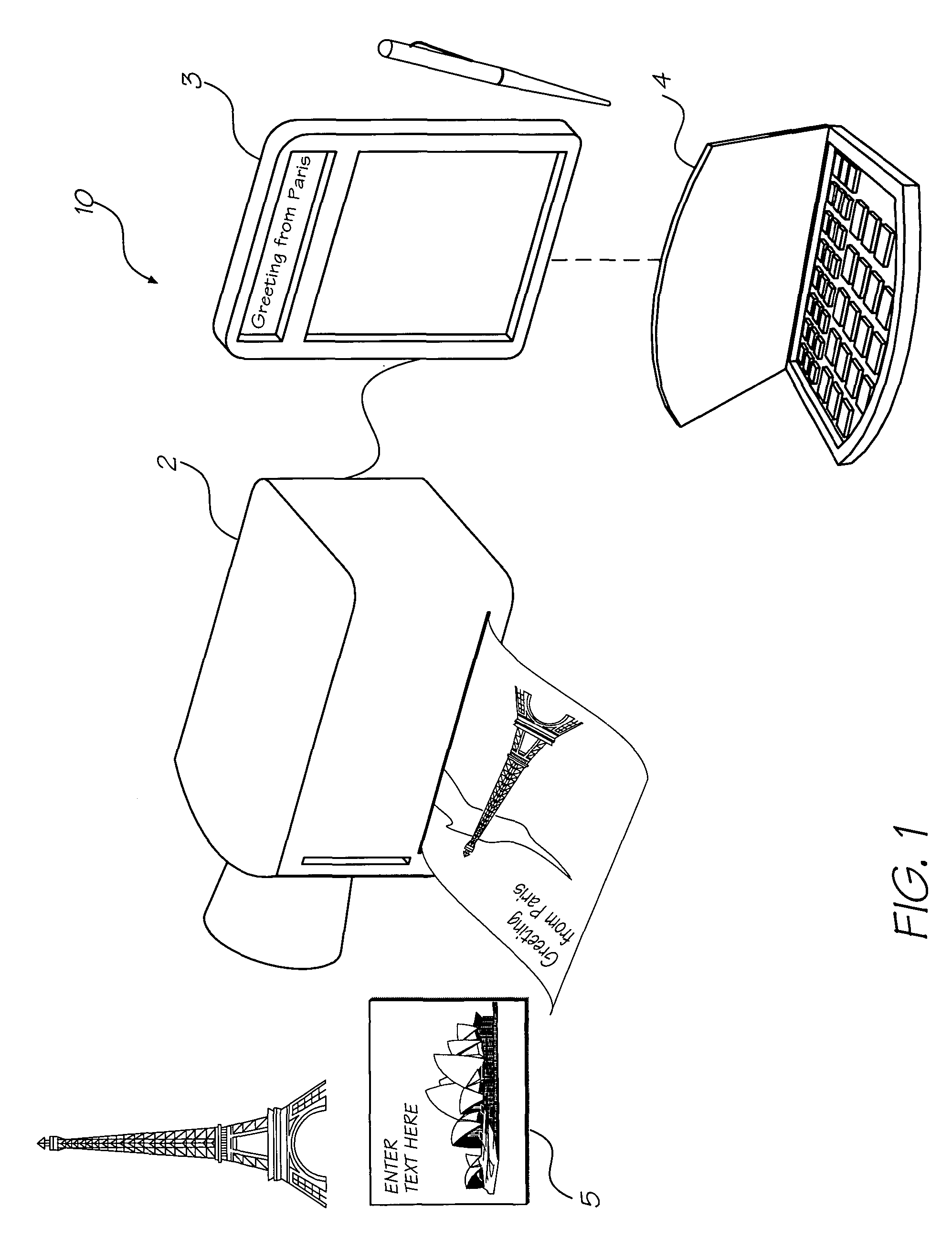

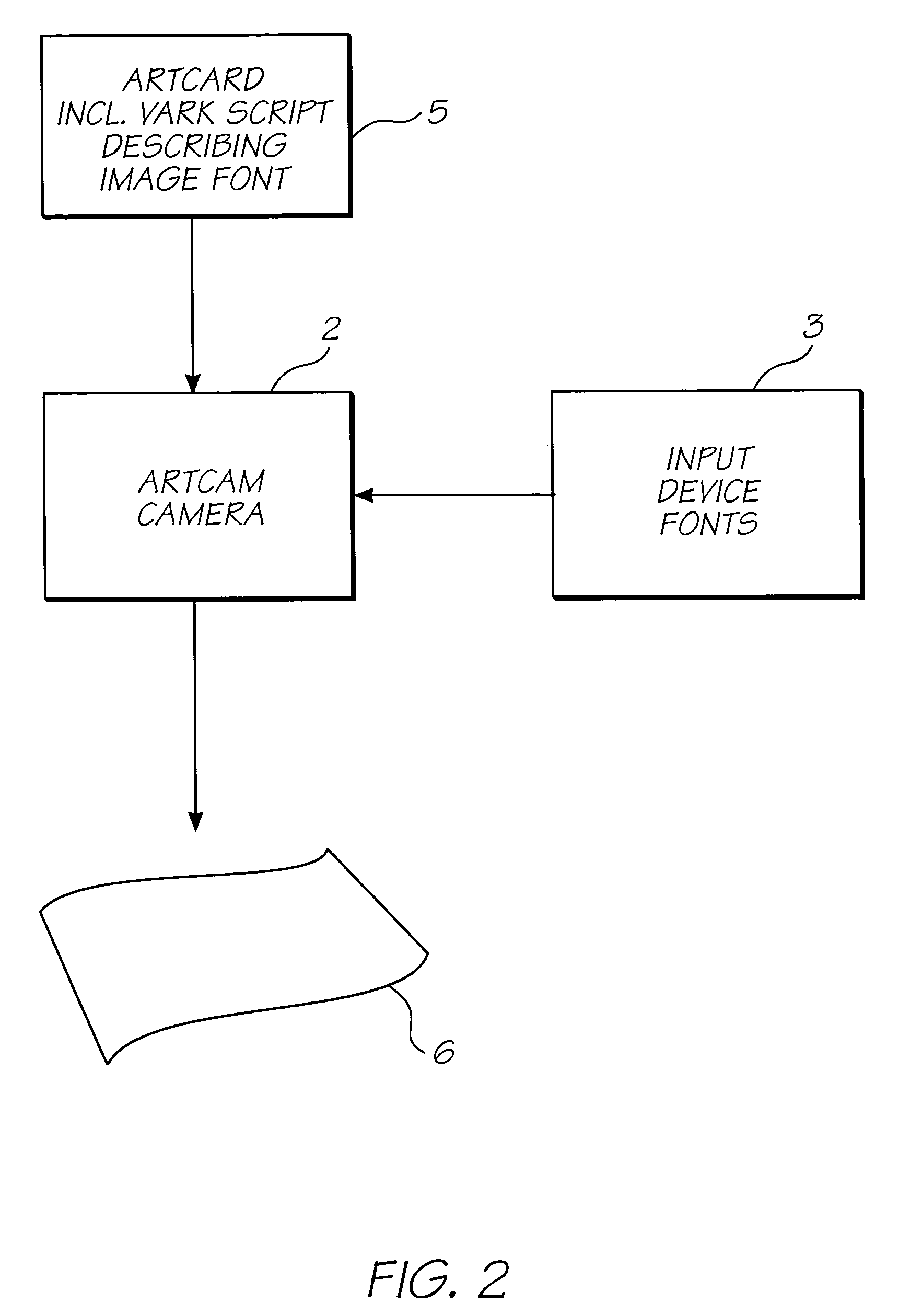

Apparatus for adding user-supplied text to a digital still image

InactiveUS7633535B2Television system detailsOther printing matterChinese charactersComputer graphics (images)

A convenient form of text editing in a camera device utilizing complex character sets is disclosed. The device includes a digital camera device able to sense an image; a manipulation data entry card adapted to be inserted into the digital camera device and to provide manipulation instructions for manipulating the image, including the addition of text to the image; a text entry device for the entry of the text which includes a series of non-roman font characters utilised by the digital camera device in conjunction with the manipulation instructions so as to create new text characters for addition to the image. The font characters are transmitted to the digital camera device when required and rendered by the camera in accordance with the manipulation instructions. The non-roman characters can include at least one of Hebrew, Cyrillic, Arabic, Kanji or Chinese characters.

Owner:GOOGLE LLC

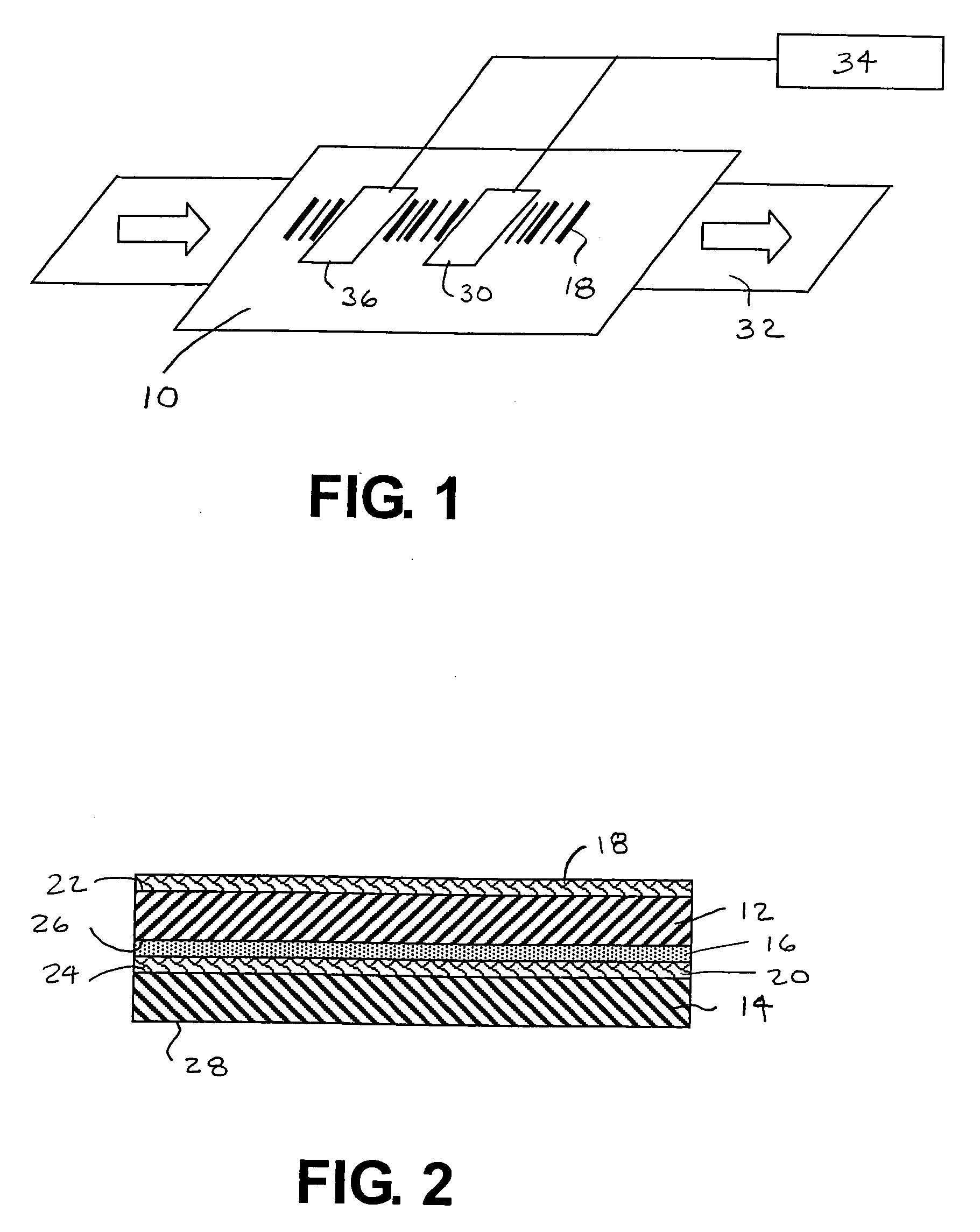

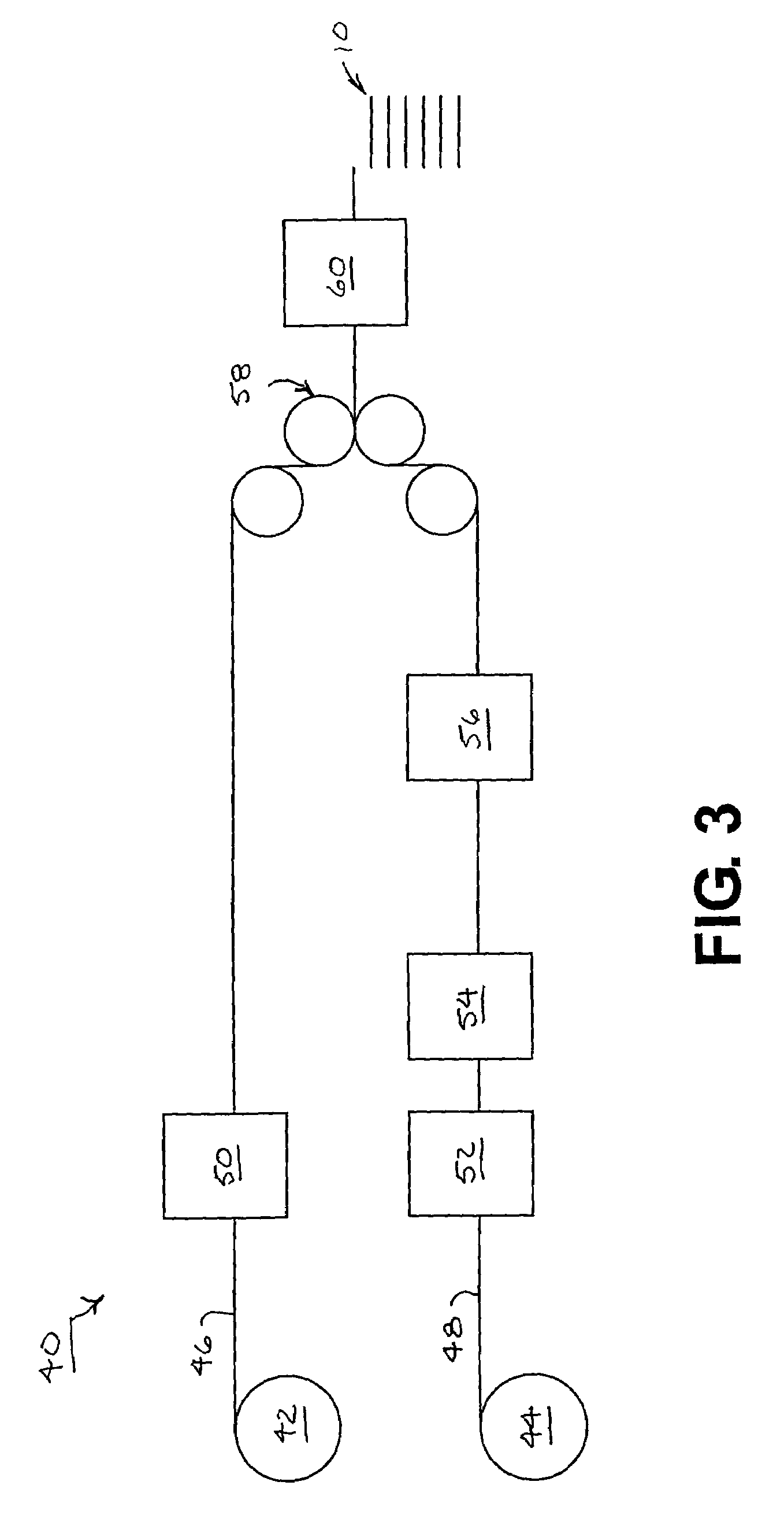

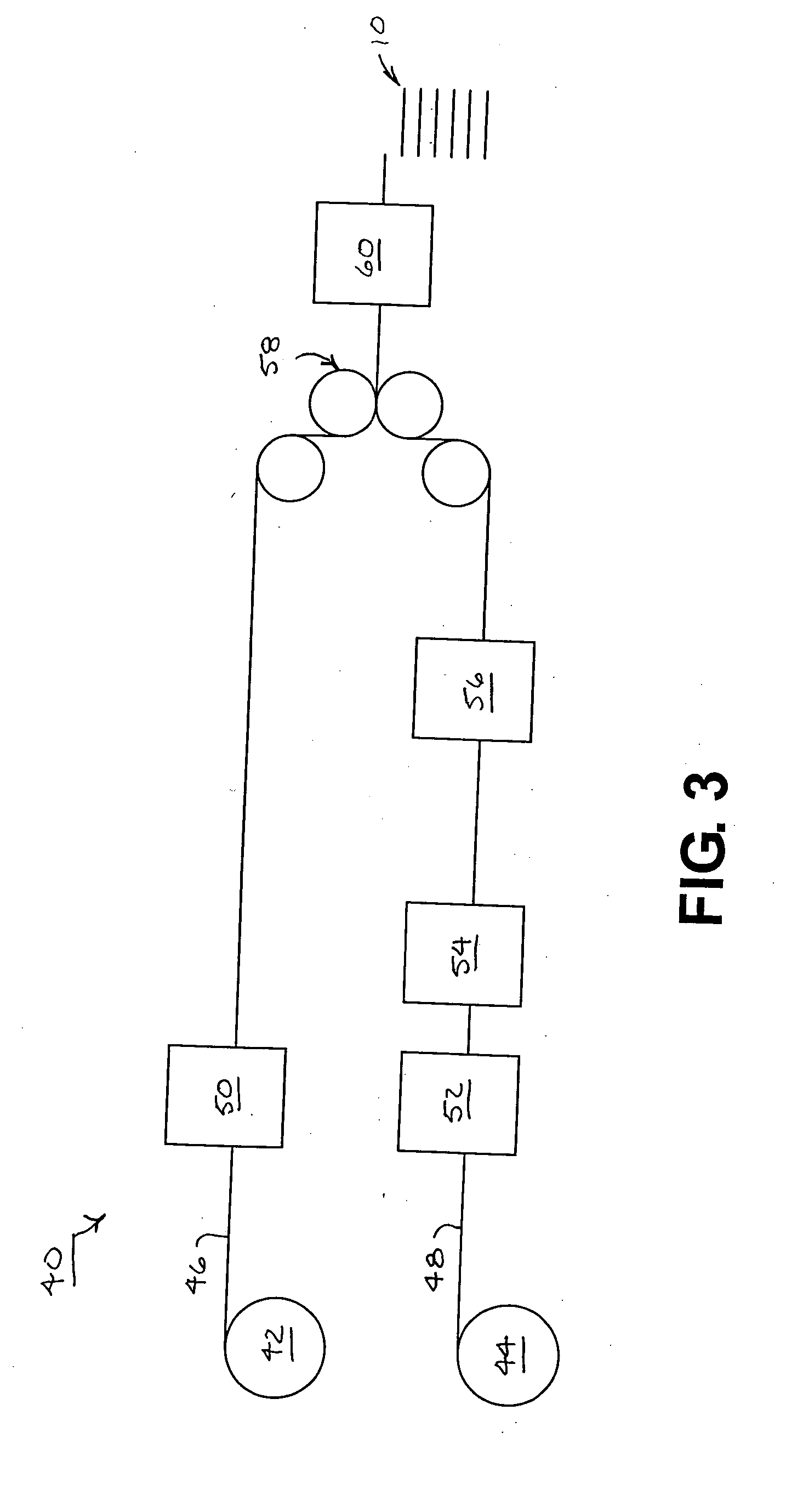

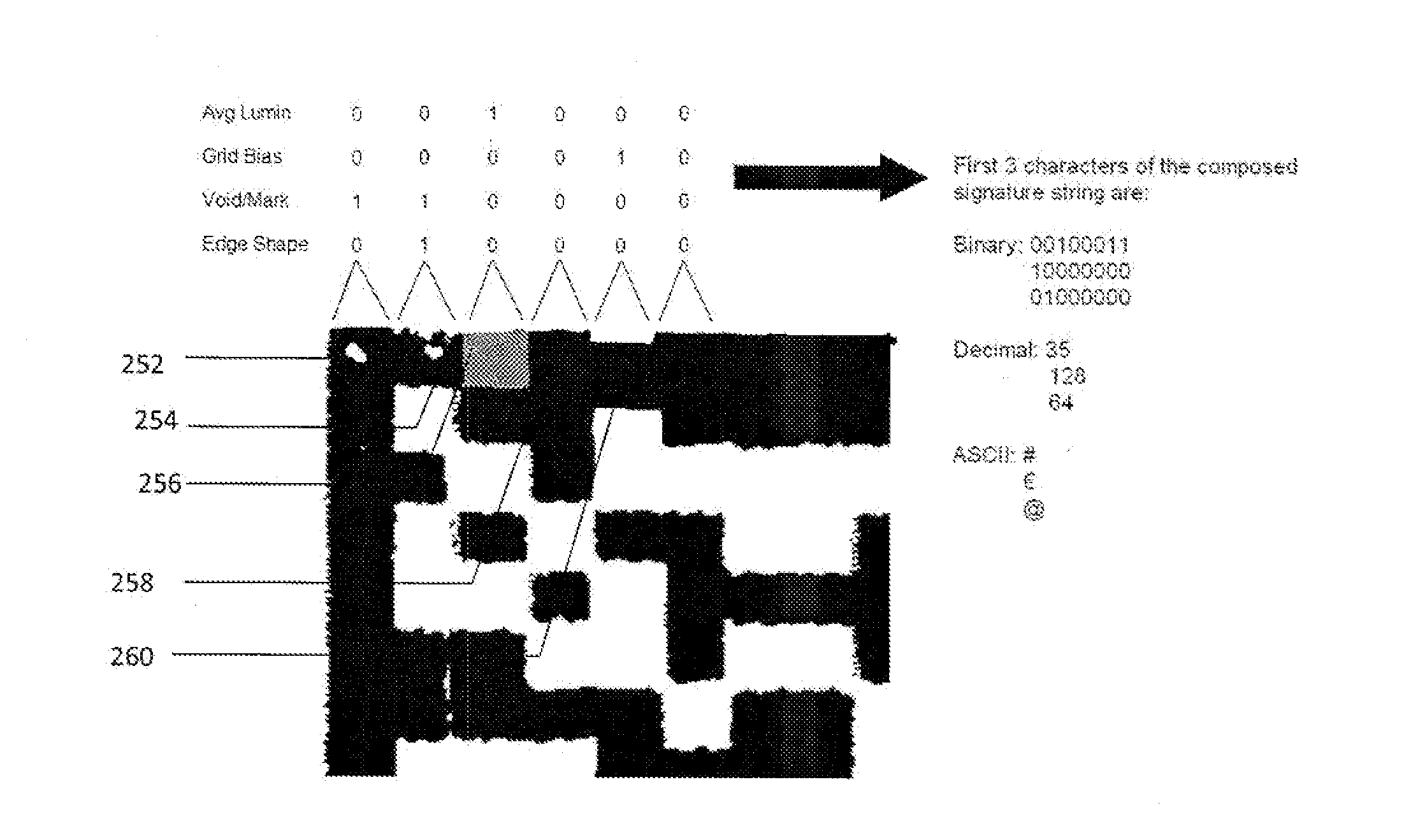

Media verification system

InactiveUS7077332B2Affect porosityAffect surfaceSensing record carriersRecord carriers used with machinesCapacitive sensingVerification system

A unique conductivity pattern is applied to printable articles to provide a “signature” for later verifying the authenticity of the printable articles. Preferably, the conductivity pattern is hidden from sight and differs from other conductivity patterns applied to other printable articles in an effectively random manner. Capacitive sensors read the conductivity patterns, and the resulting data for recording the signatures reflects not only details of the conductivity patterns themselves but also the characteristics of the capacitive sensors and their use.

Owner:WISCONSIN LABEL CORP CORP

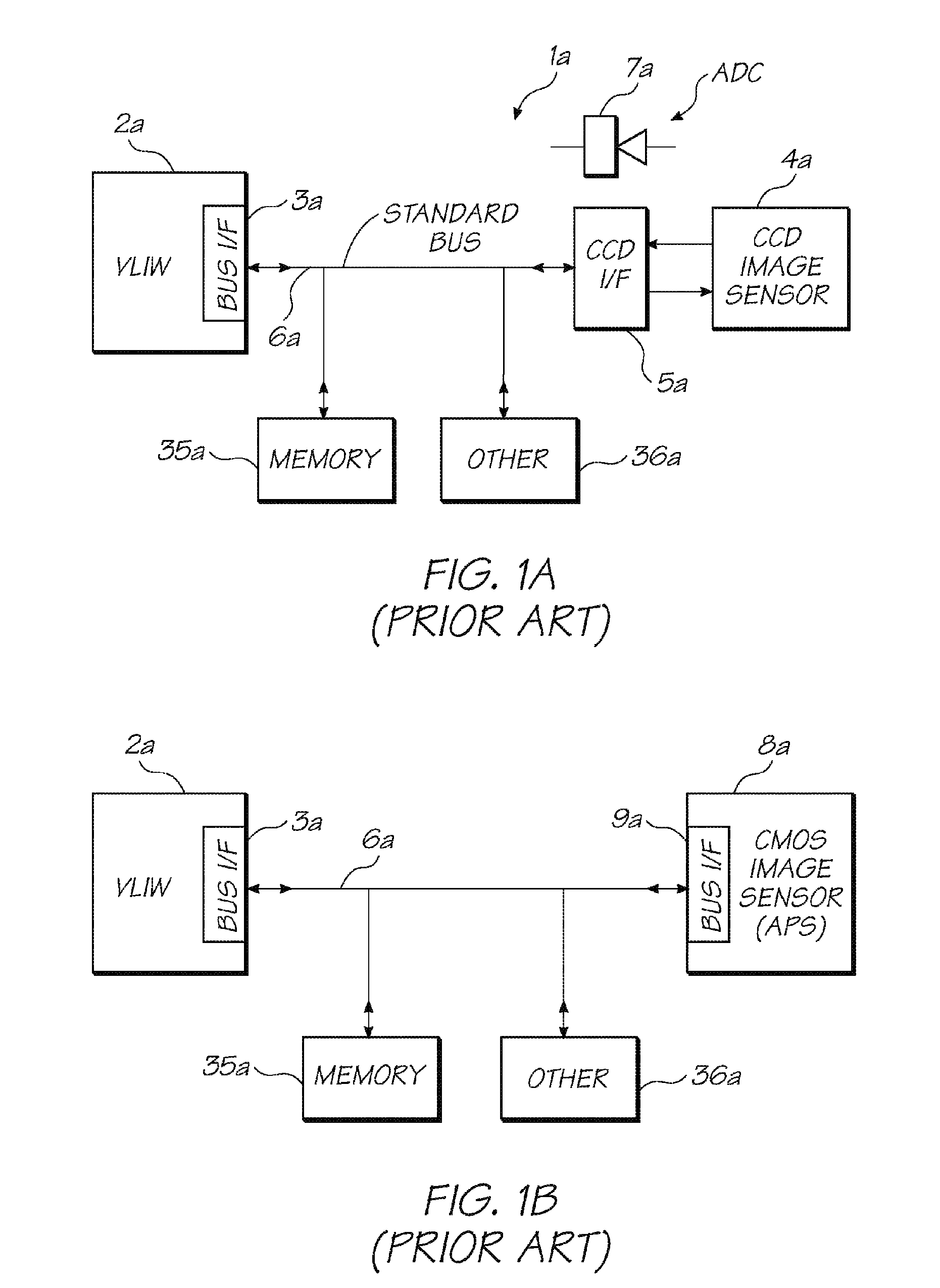

VLIW image processor

A microcontroller for an image sensing and processing apparatus is provided. The microcontroller has VLIW processor circuitry, image sensor interface circuitry connected between the VLIW processor circuitry and the image sensor, bus interface circuitry connected between the VLIW processor circuitry and a bus connectable with devices other than the image sensor, and buffer memory and queuing circuitry intermediate the image sensor and bus interface circuitry and the VLIW processor to control delivery of information to the VLIW processor.

Owner:GOOGLE LLC

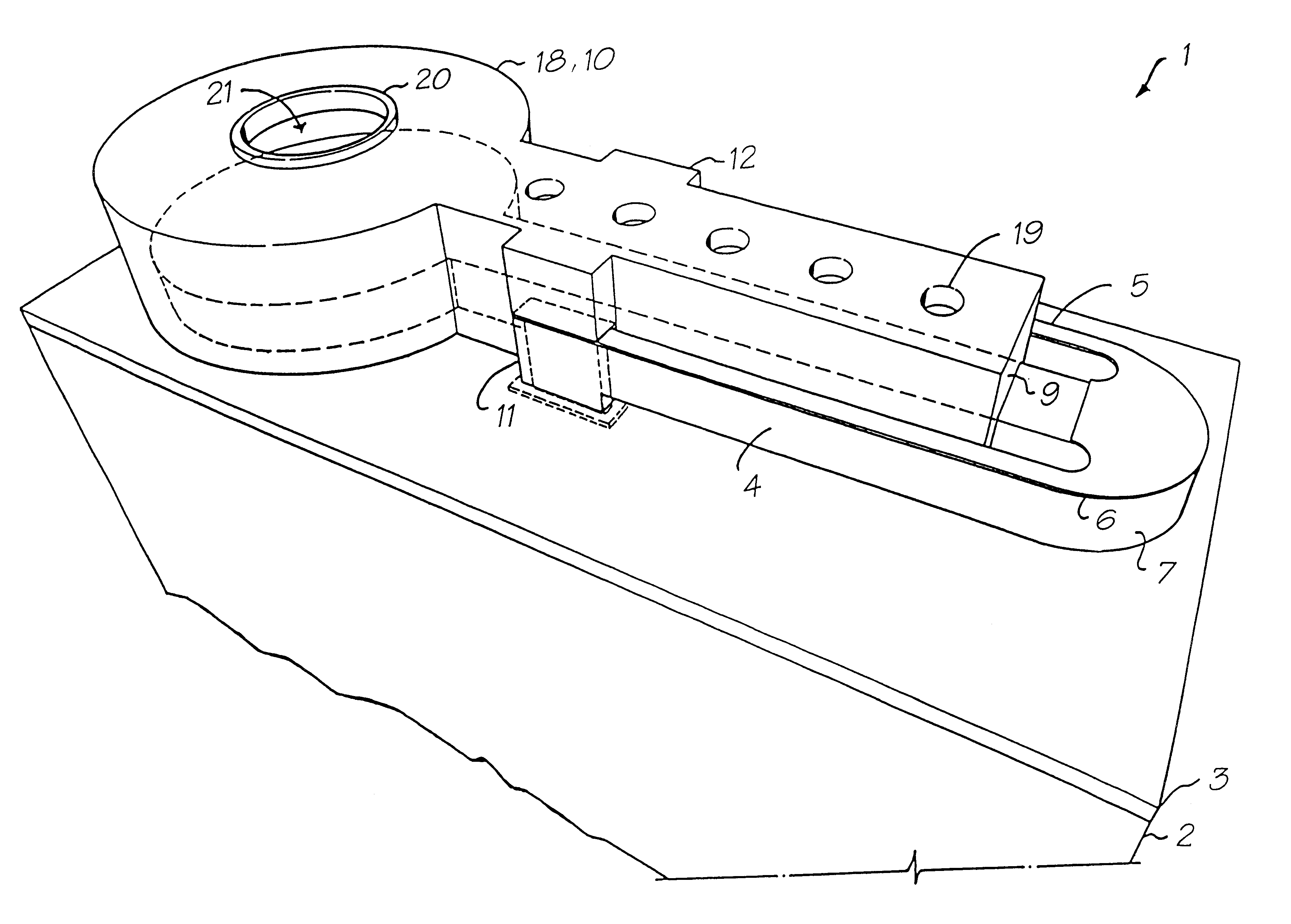

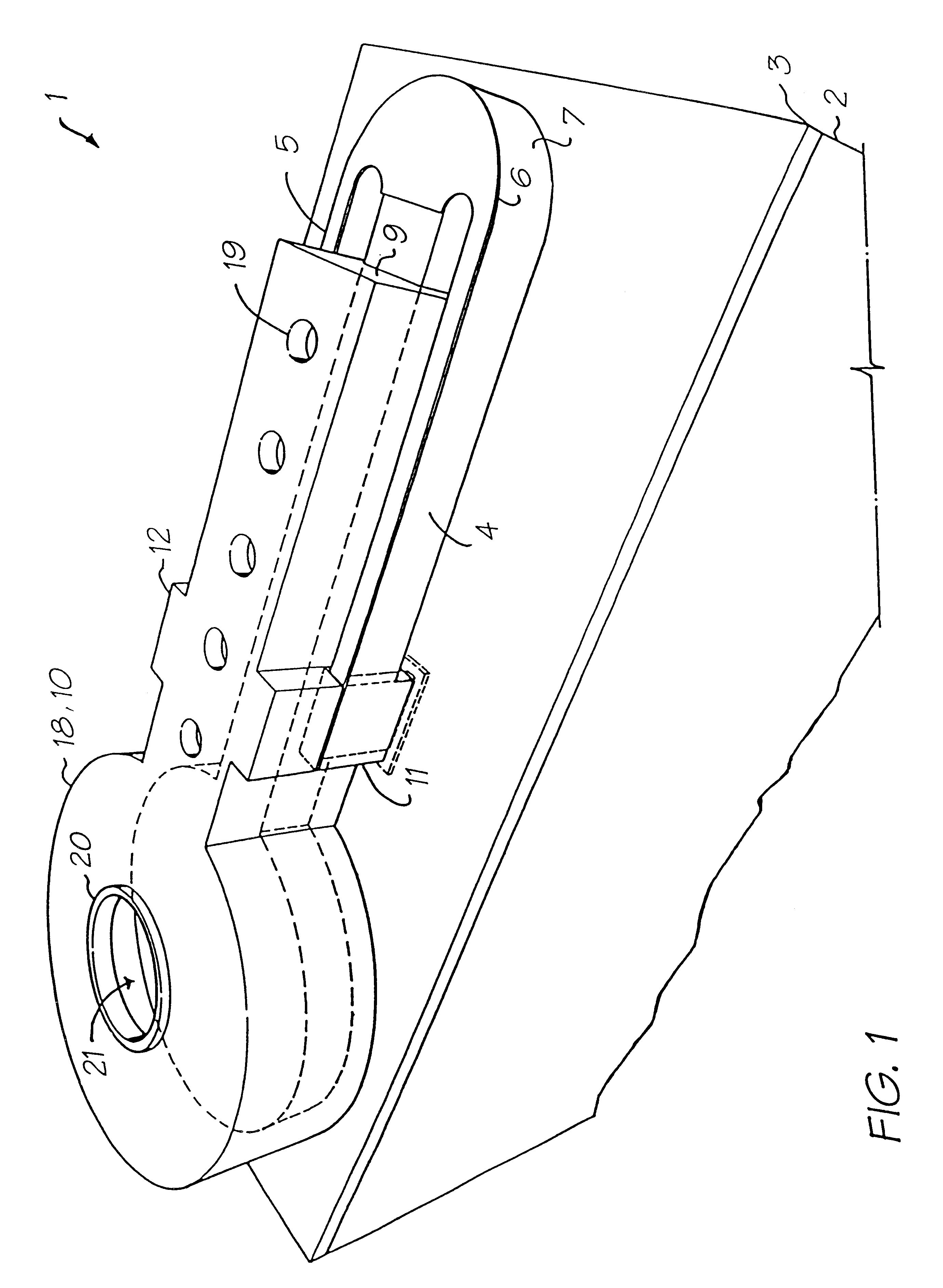

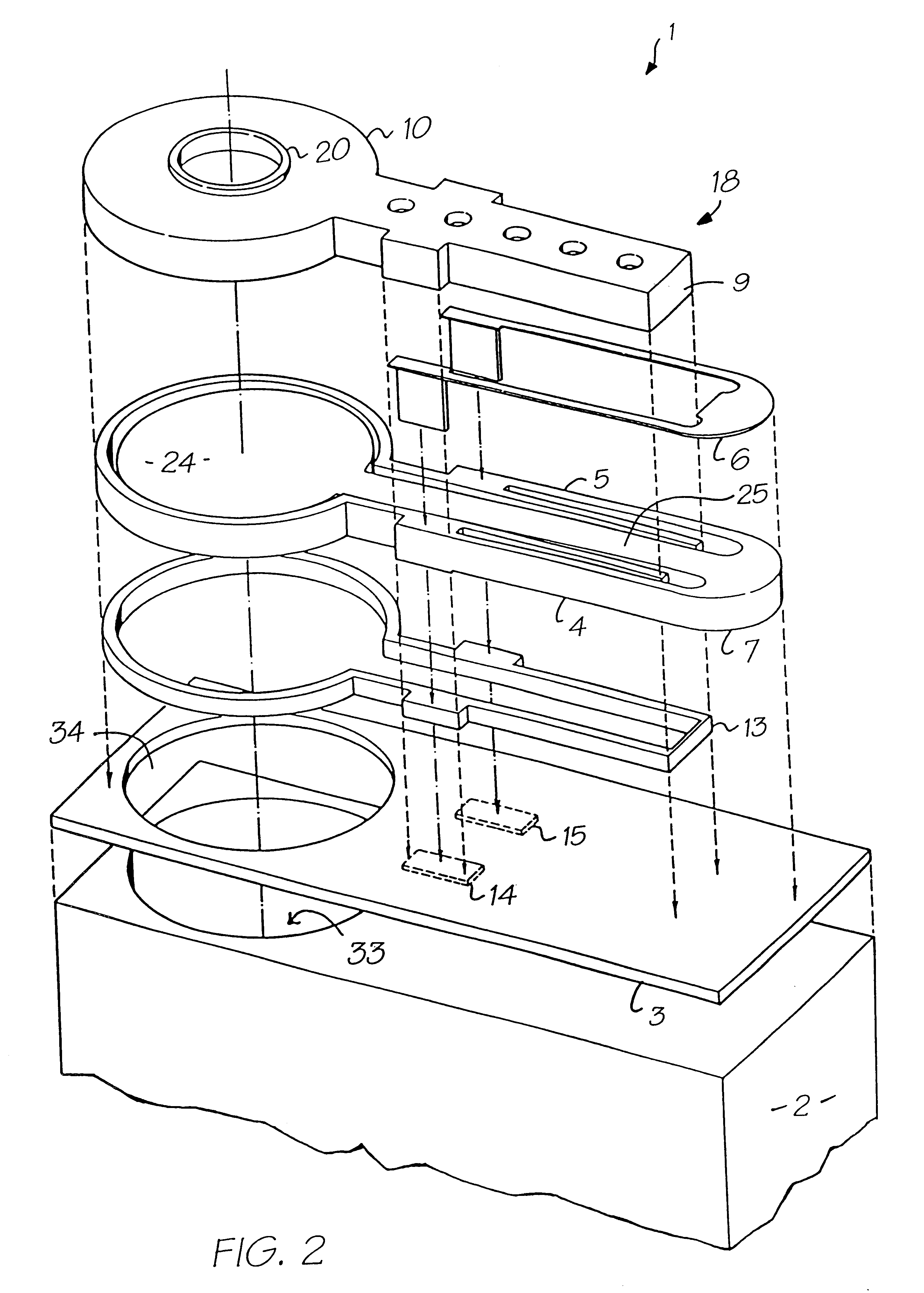

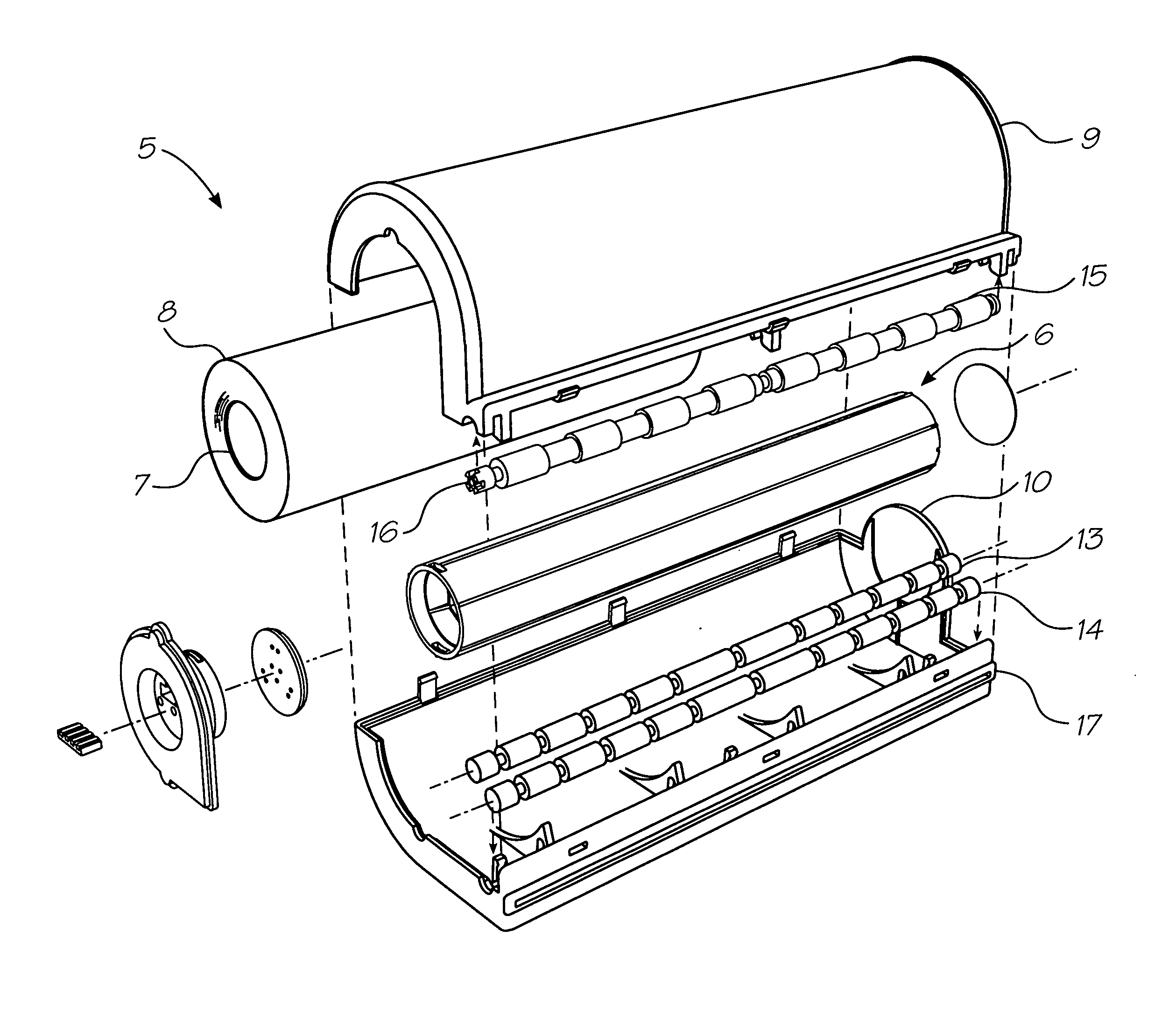

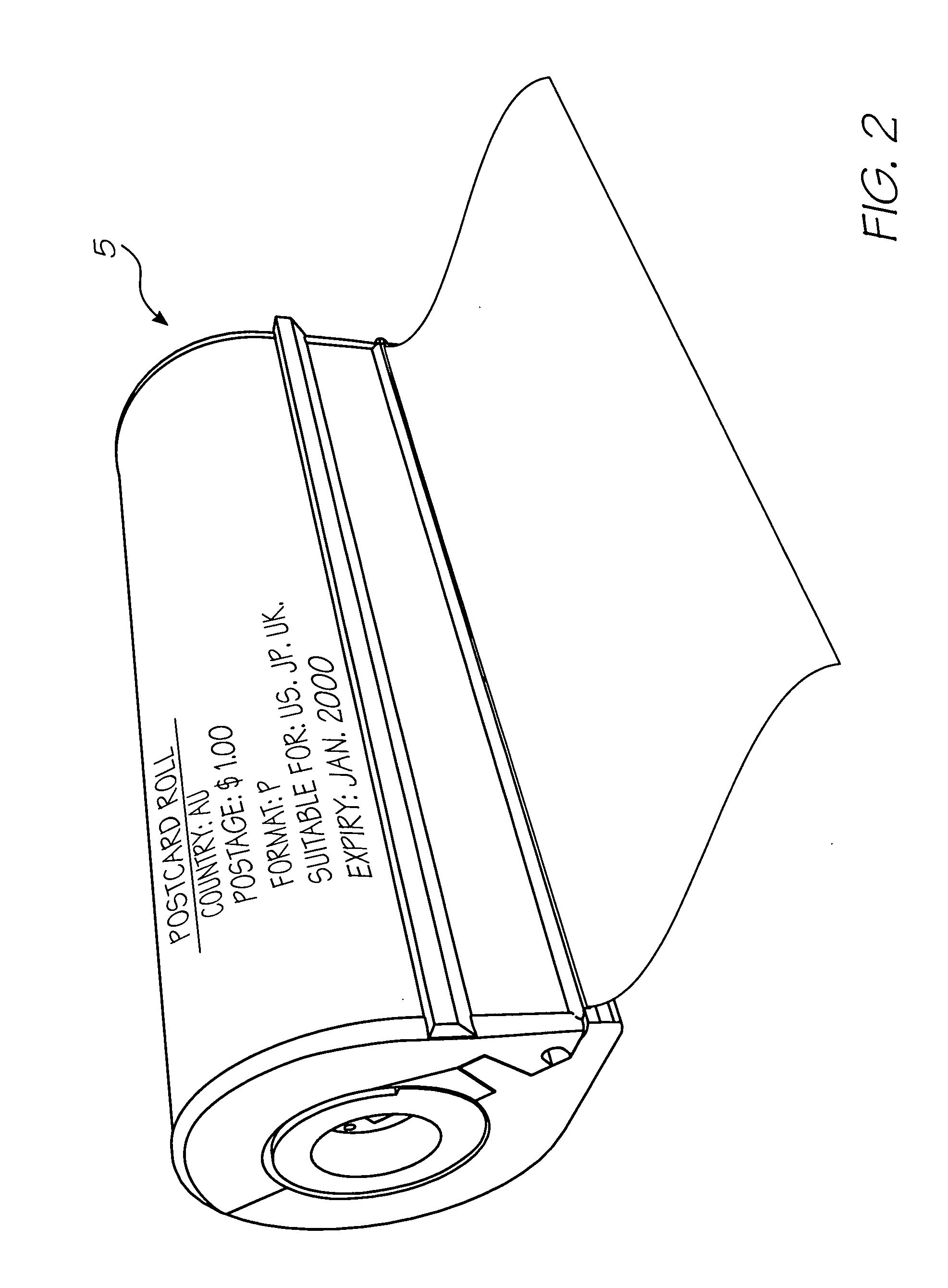

Inkjet cartridge with ink reservoir core and releasable housing

InactiveUS20070046754A1Quality improvementTelevision system detailsInking apparatusPrint mediaEngineering

A print roll unit includes an elongate ink reservoir core defining a plurality of ink chambers which each extend along the core. The chambers are isolated to store respective inks. A roll of print media includes a tubular former in which the core can be received and a length of print media which is wound upon the former. A housing includes a pair of molded covers which can be fastened together in a releasable manner to house the roll of print media.

Owner:SILVERBROOK RES PTY LTD +1

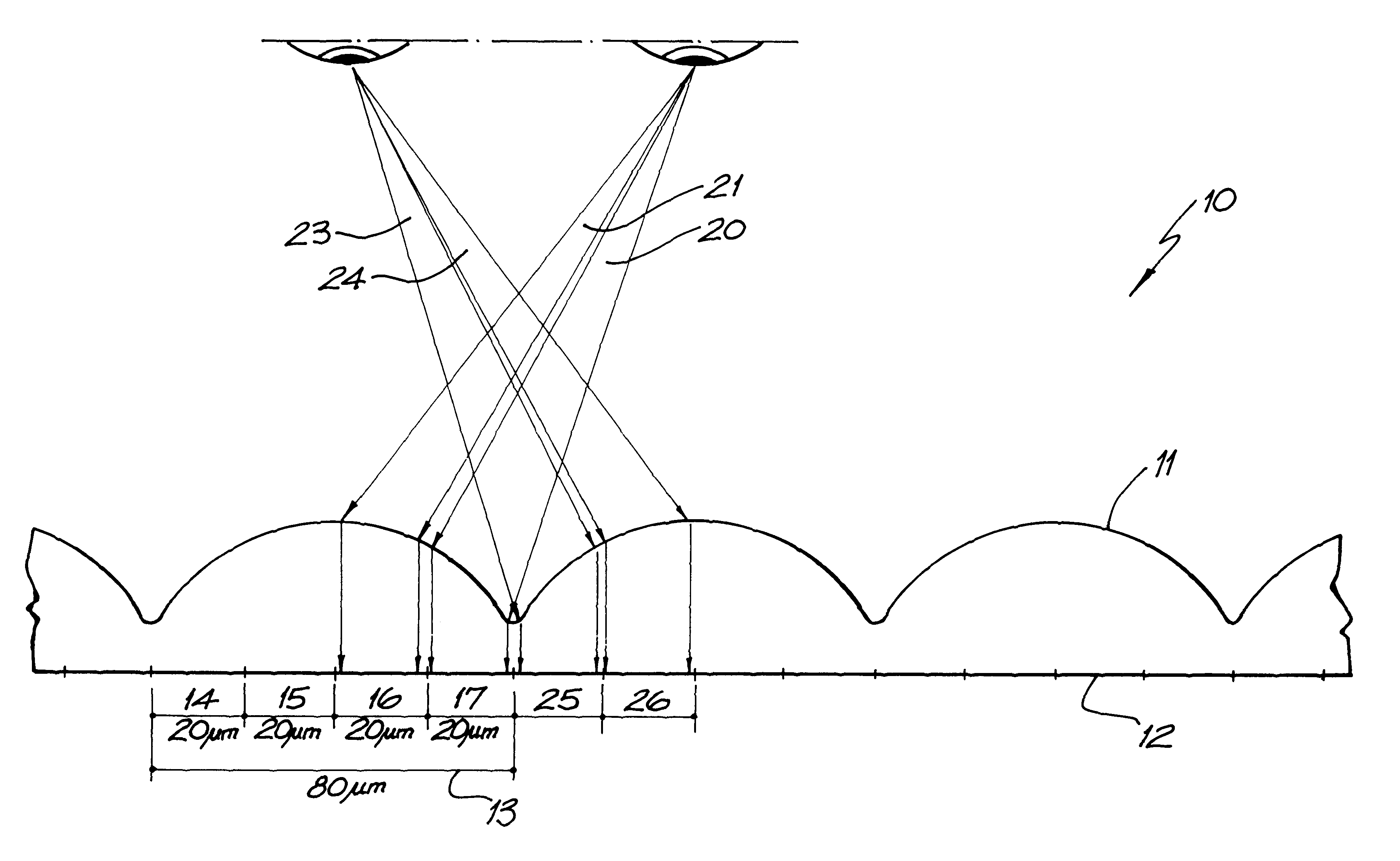

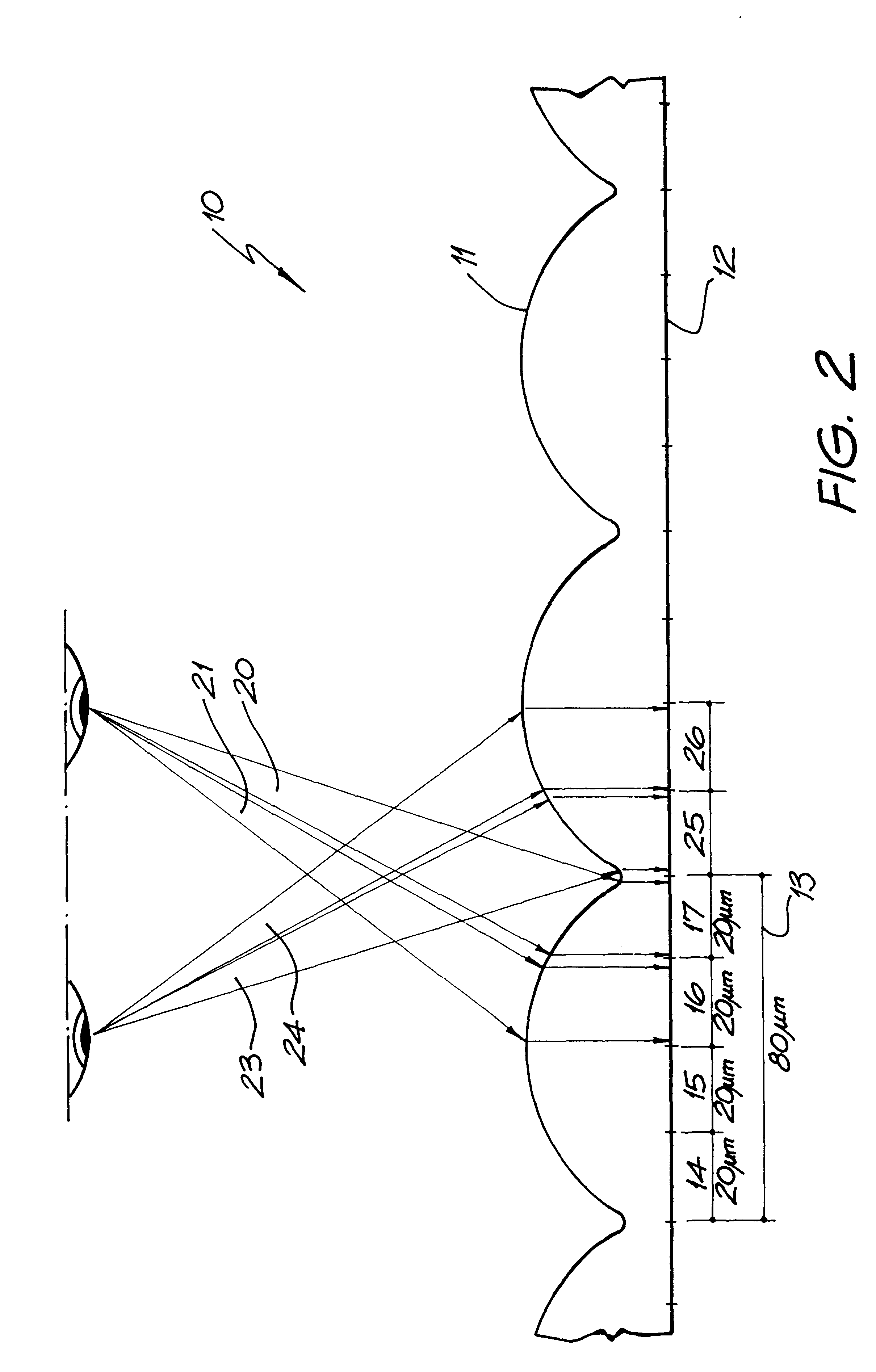

Pseudo-3D stereoscopic images and output device

A transparent print media comprising a first surface having a polarity of lenticular portions adapted to image left and right stereo images printed on an opposing surface to the first surface so as to produce a stereo photographic image when viewed from the first surface.

Owner:GOOGLE LLC

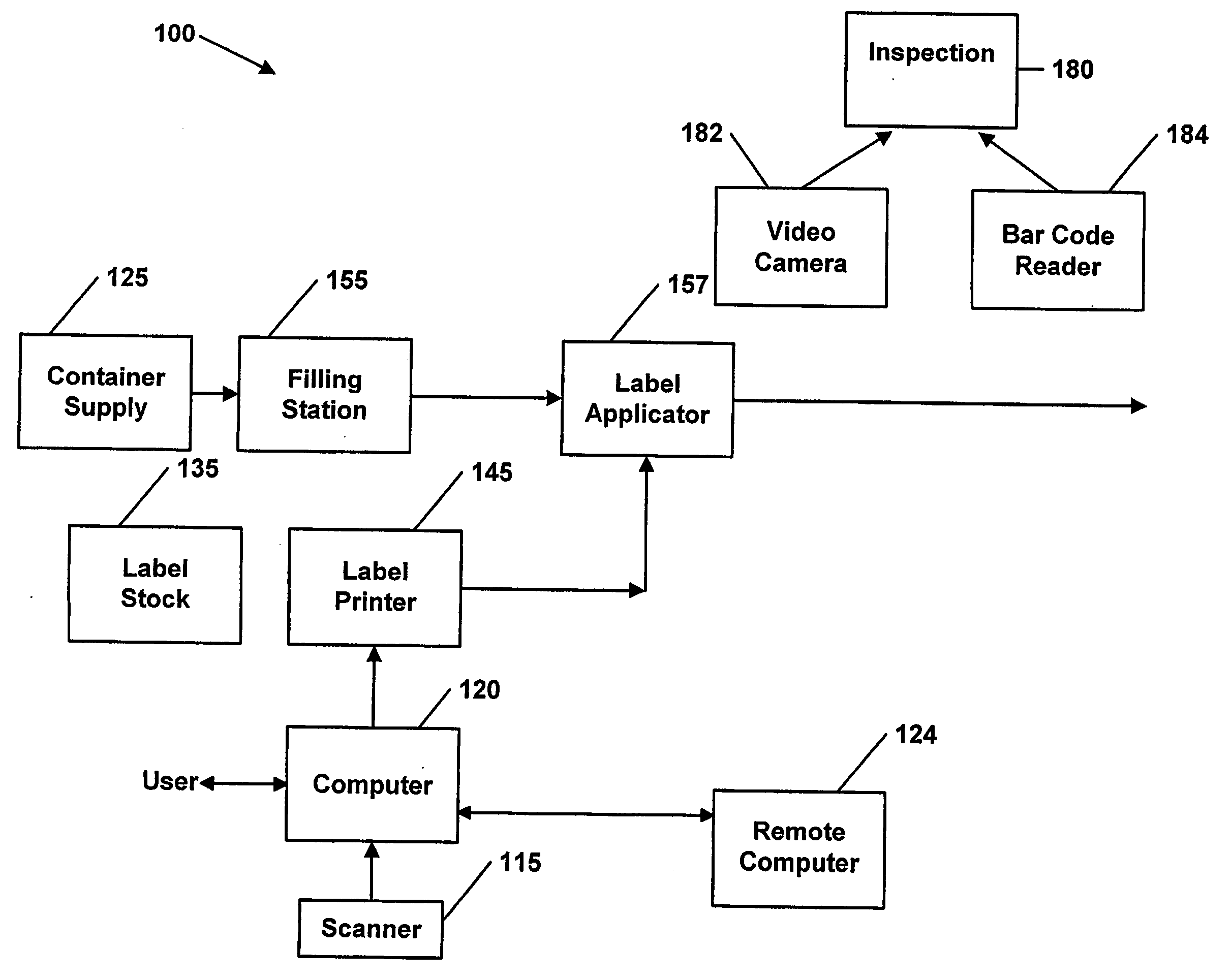

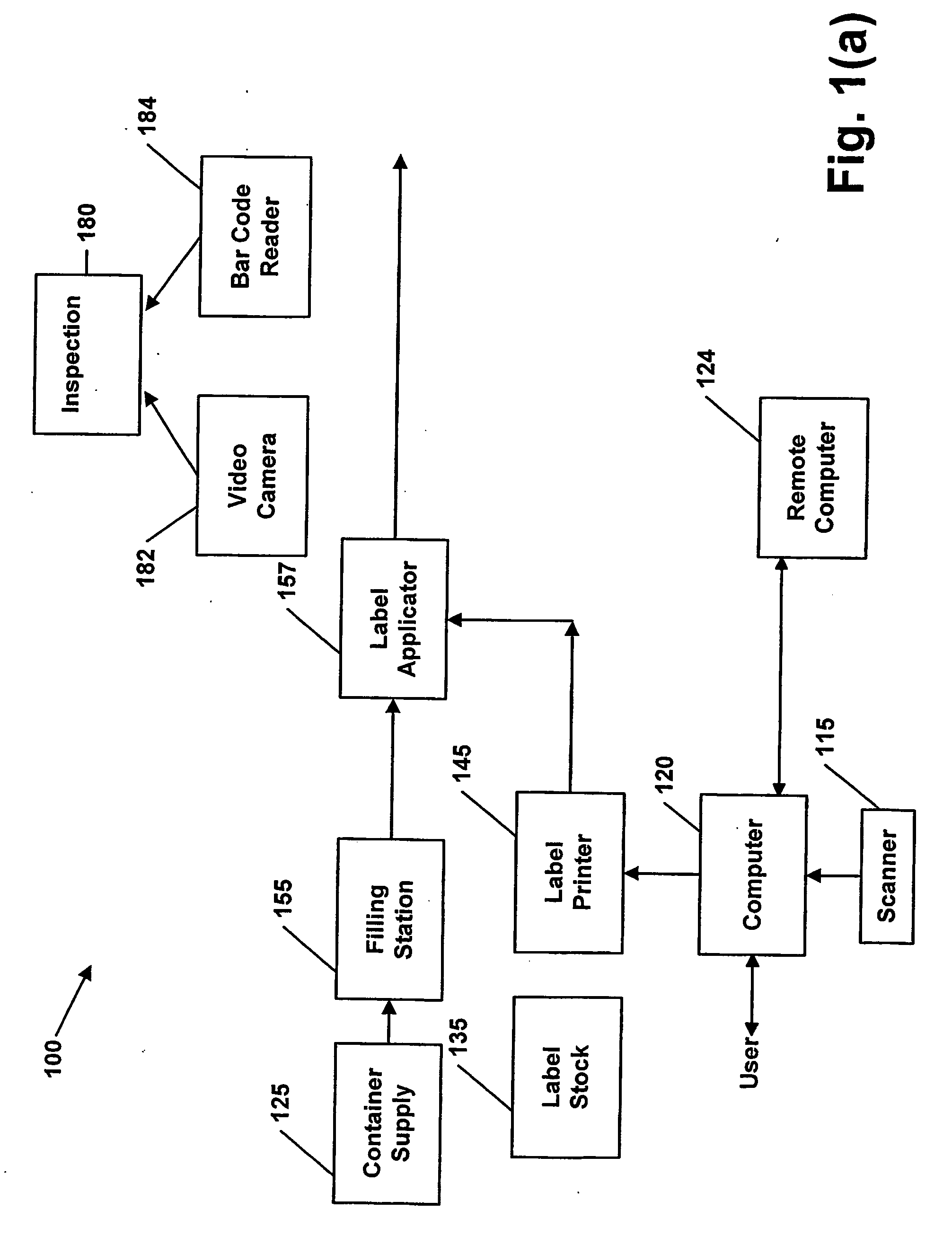

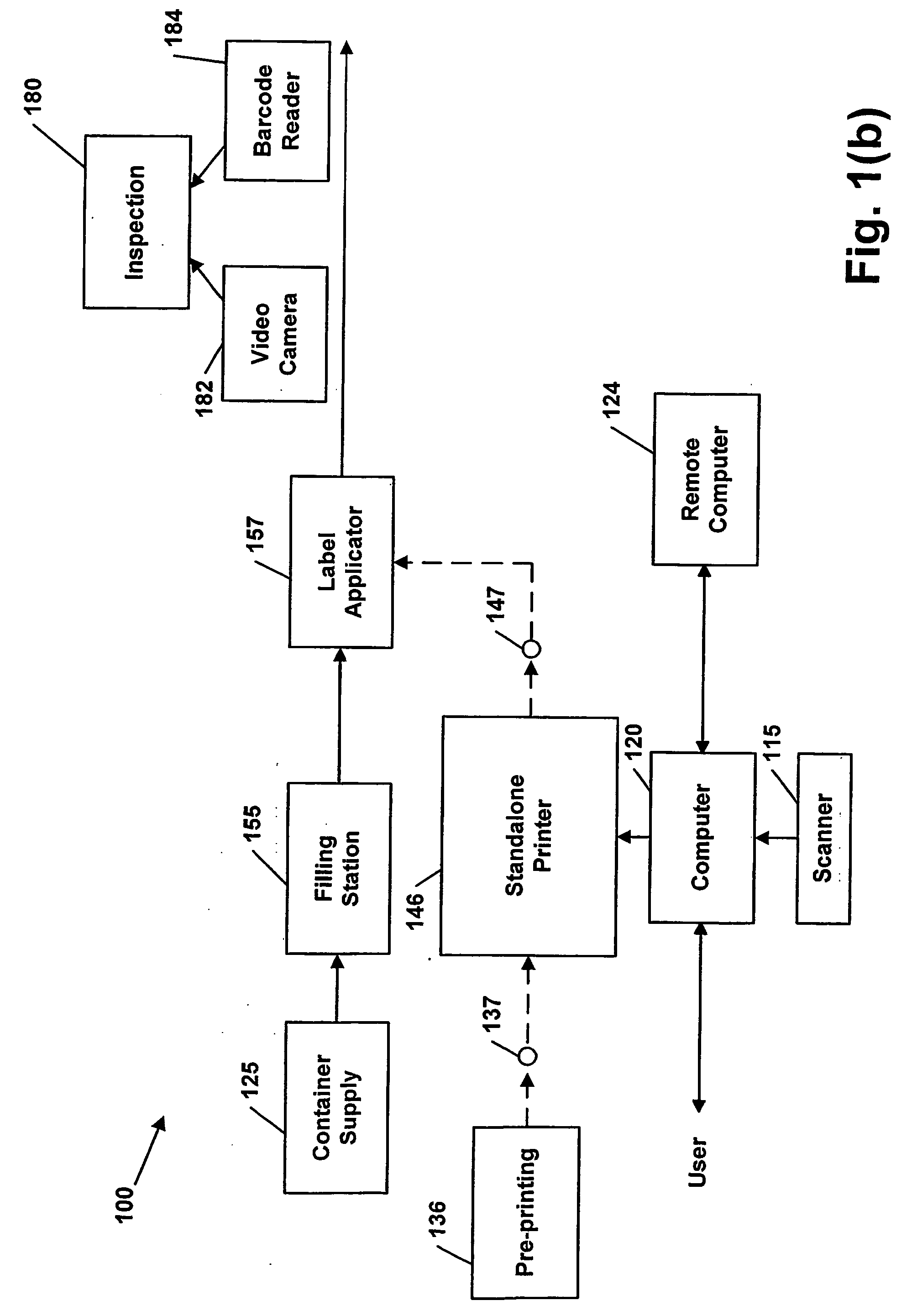

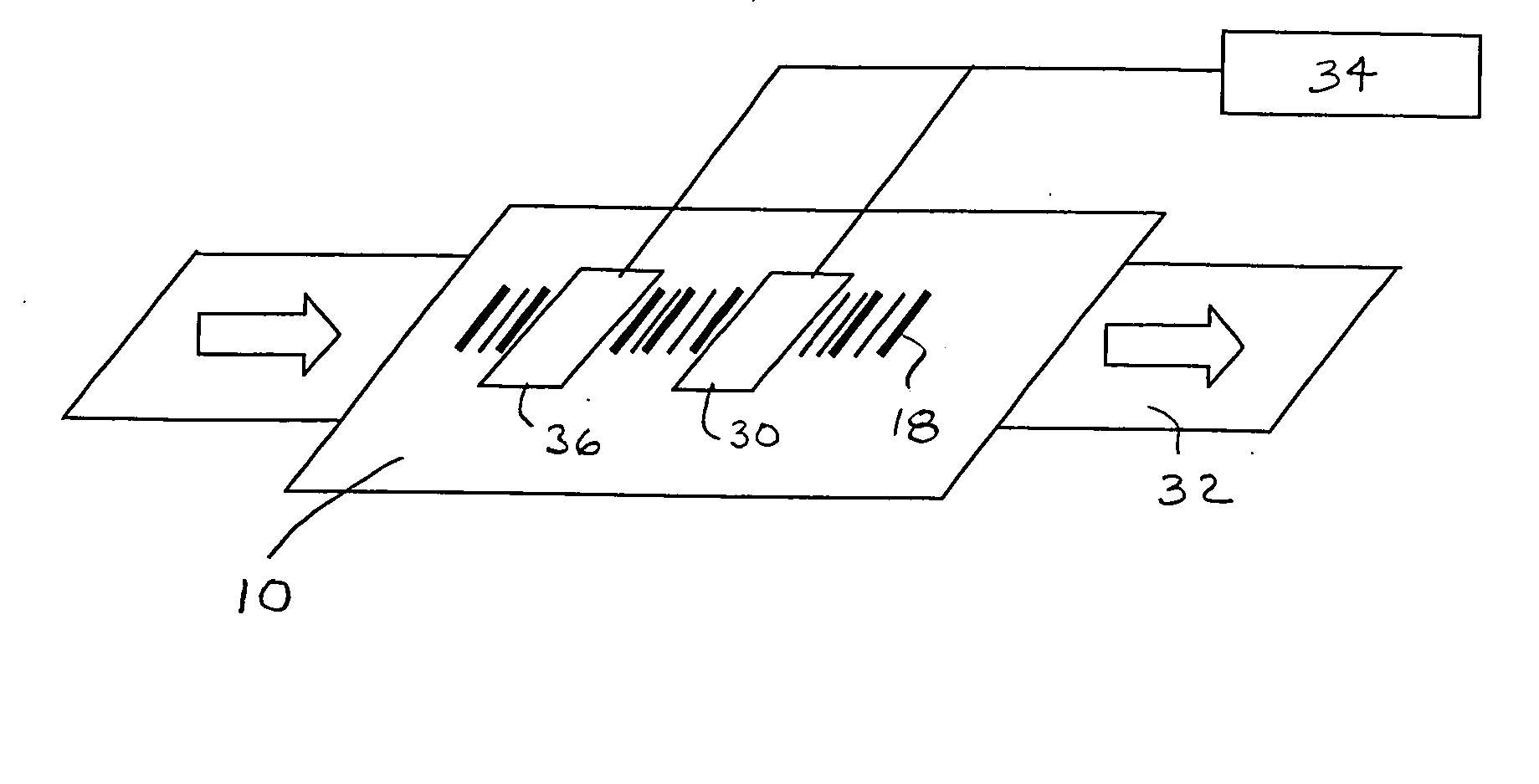

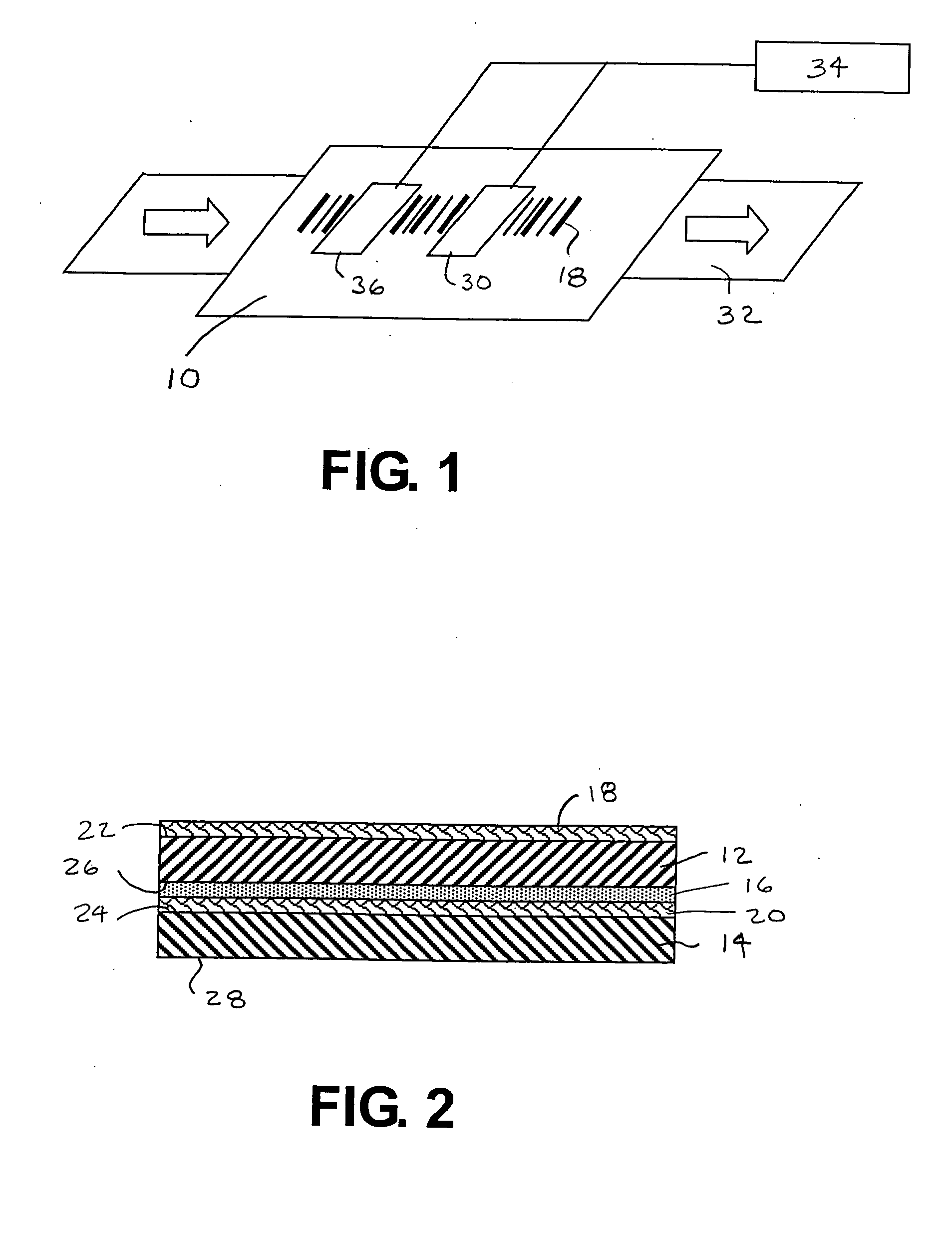

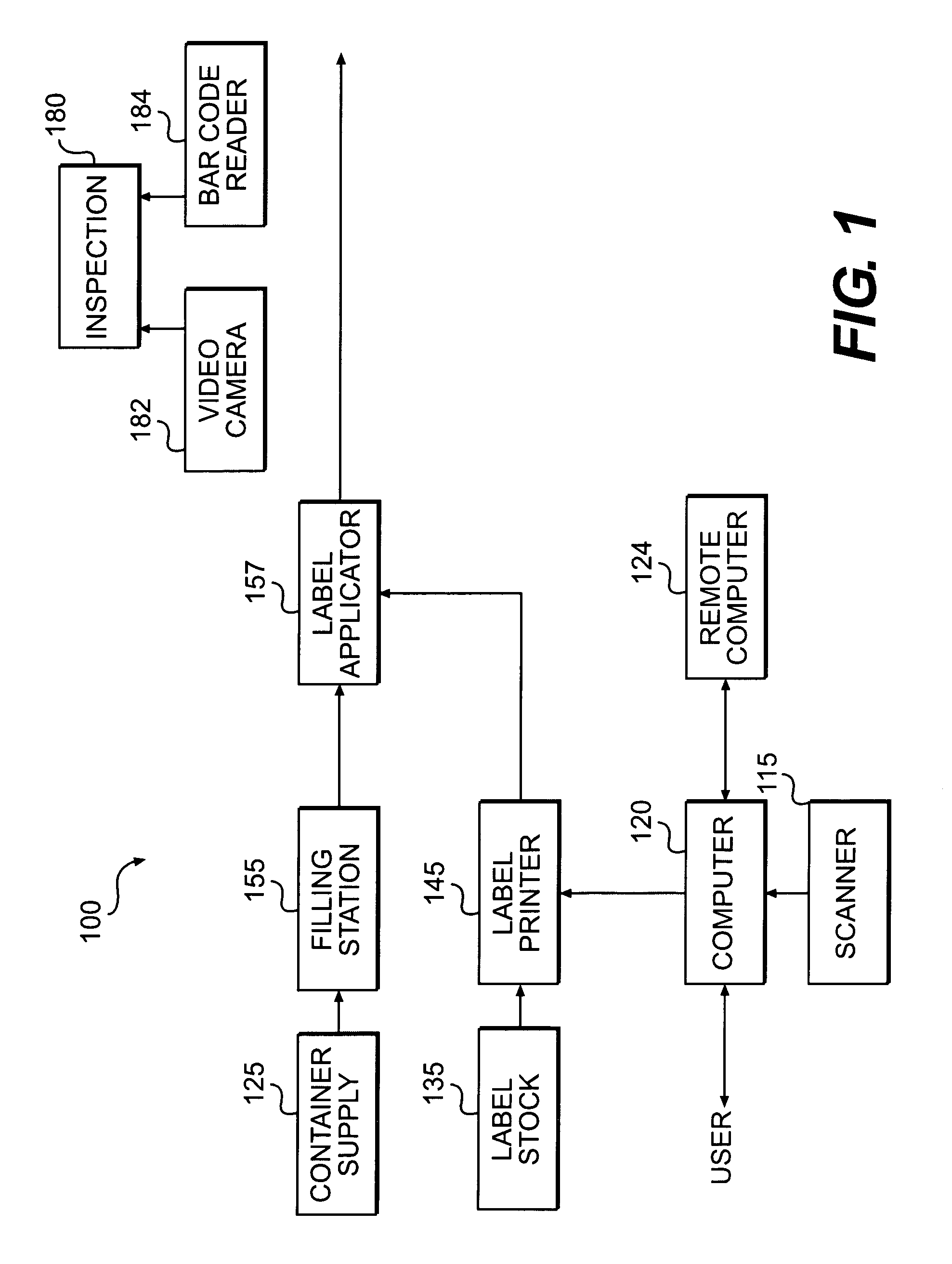

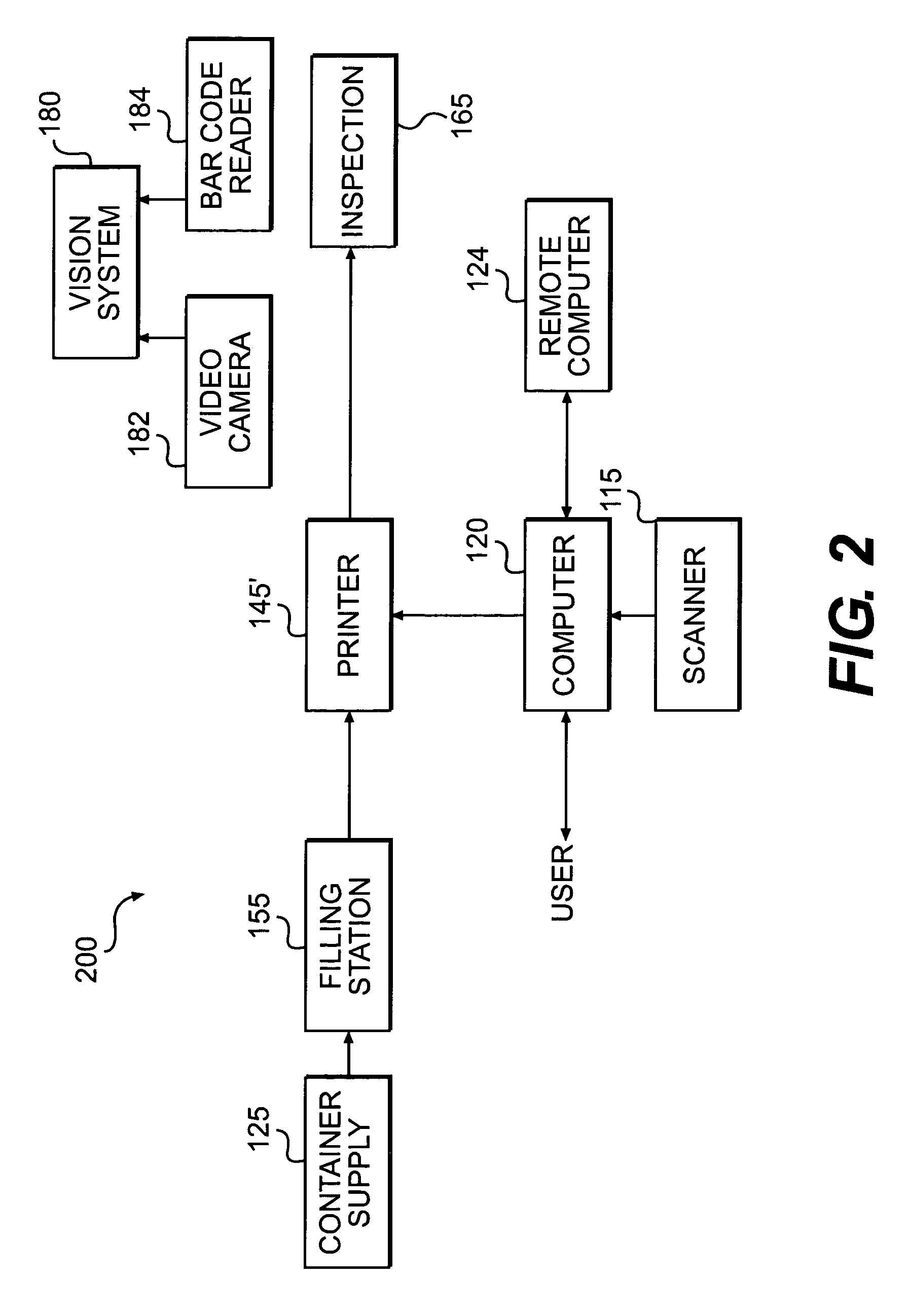

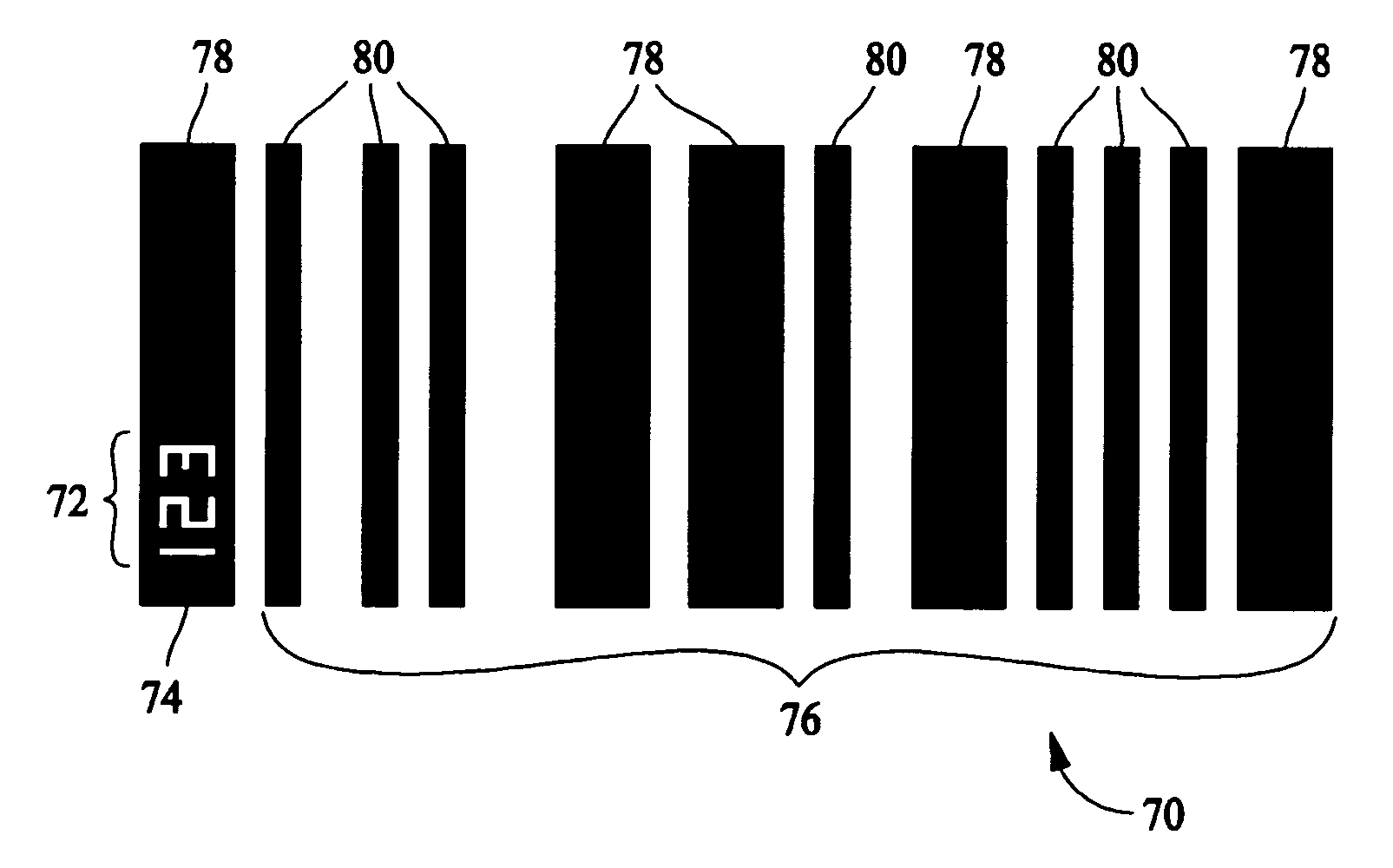

Method and apparatus for applying bar code information to products during production

InactiveUS20060118631A1Easy to reconfigureEfficient processingData processing applicationsDigital data processing detailsProduction lineComputer printing

Bar code infomiation (310, 330) is printed on a printable surface (300) of a product (125), such as a label (300) or container of the product, or the product itself, during a production run. A first component (310) of a composite bar code symbol, which may identify a product carried in the containers, is either pre-printed or printed during a production run, and a second component (330), which may identify a lot, batch, expiration date or commodity number, is printed during the production run. Check data may be used to confirm the accuracy of information that is used by a printer computer (120). A database (188) may be accessed to determine if recovered information from first and second bar code symbols portions (610, 620) is consistent. A standalone printer (146) may supply labels (147) to one or more production lines (100) on an as-needed basis.

Owner:LUBOW ALLEN +1

Media verification system

InactiveUS20050006472A1Save storage apaceImprove access speedTicket-issuing apparatusSensing record carriersVerification systemComputer science

A unique conductivity pattern is applied to printable articles to provide a “signature” for later verifying the authenticity of the printable articles. Preferably, the conductivity pattern is hidden from sight and differs from other conductivity patterns applied to other printable articles in an effectively random manner. Capacitive sensors read the conductivity patterns, and the resulting data for recording the signatures reflects not only details of the conductivity patterns themselves but also the characteristics of the capacitive sensors and their use.

Owner:WISCONSIN LABEL CORP CORP

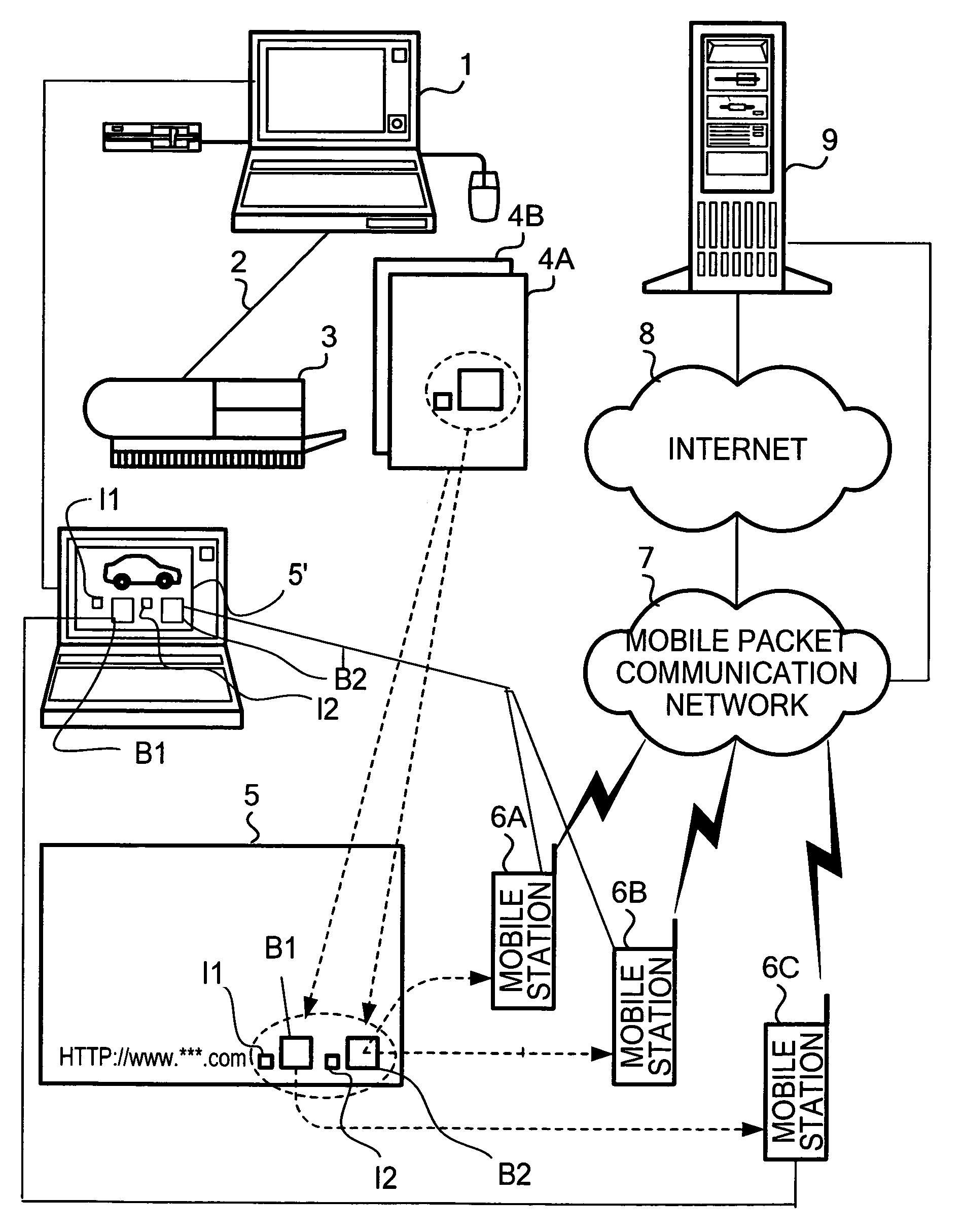

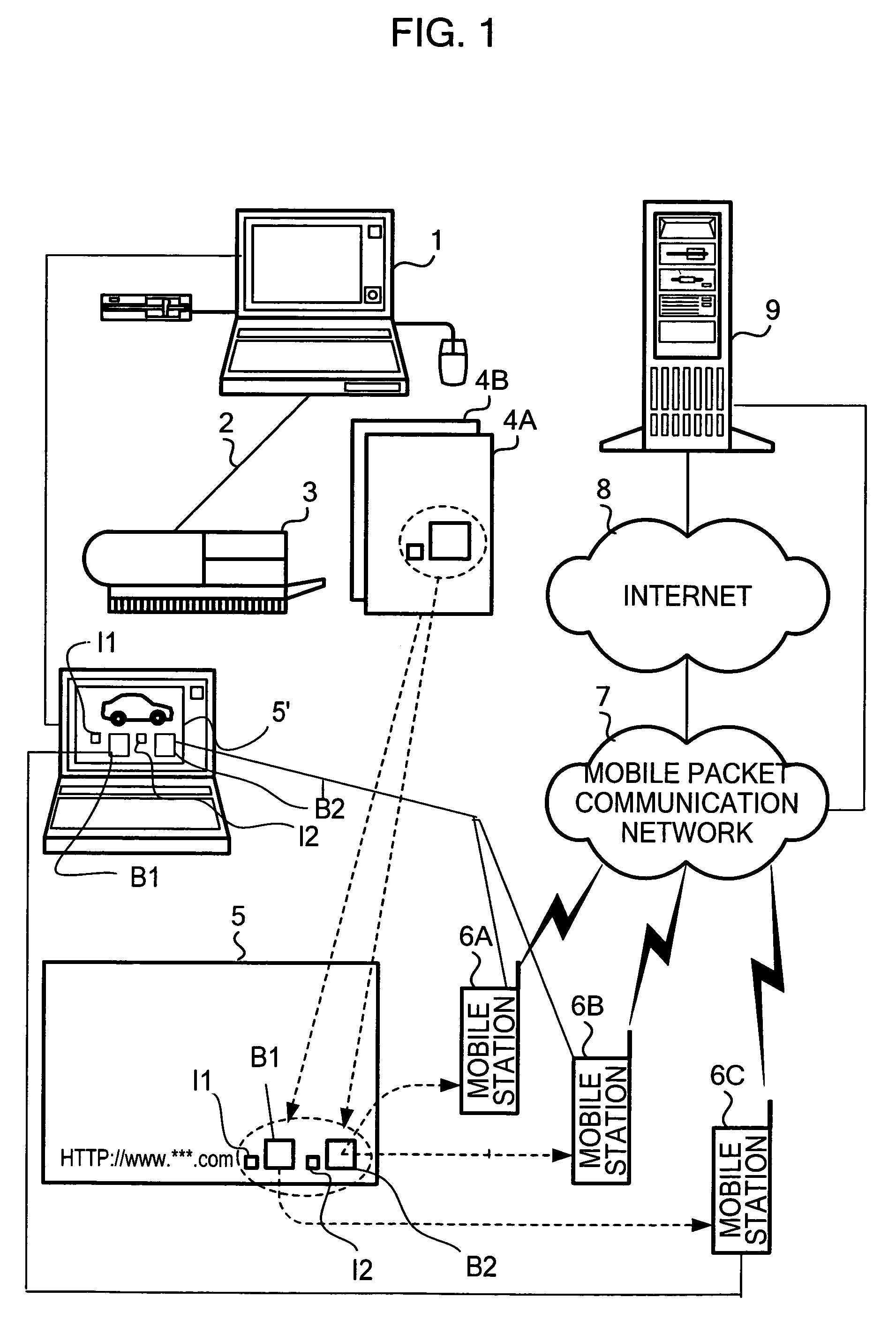

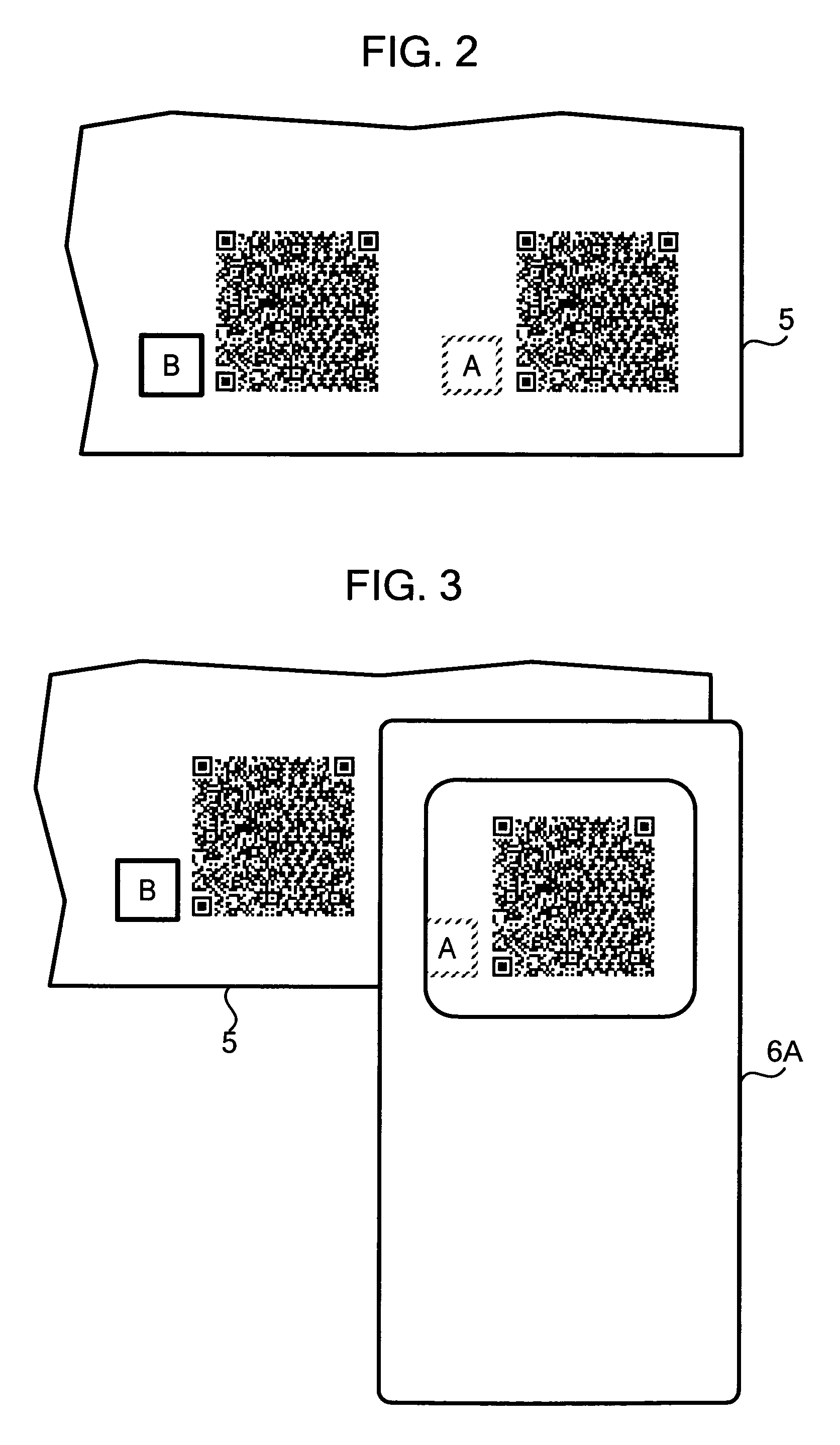

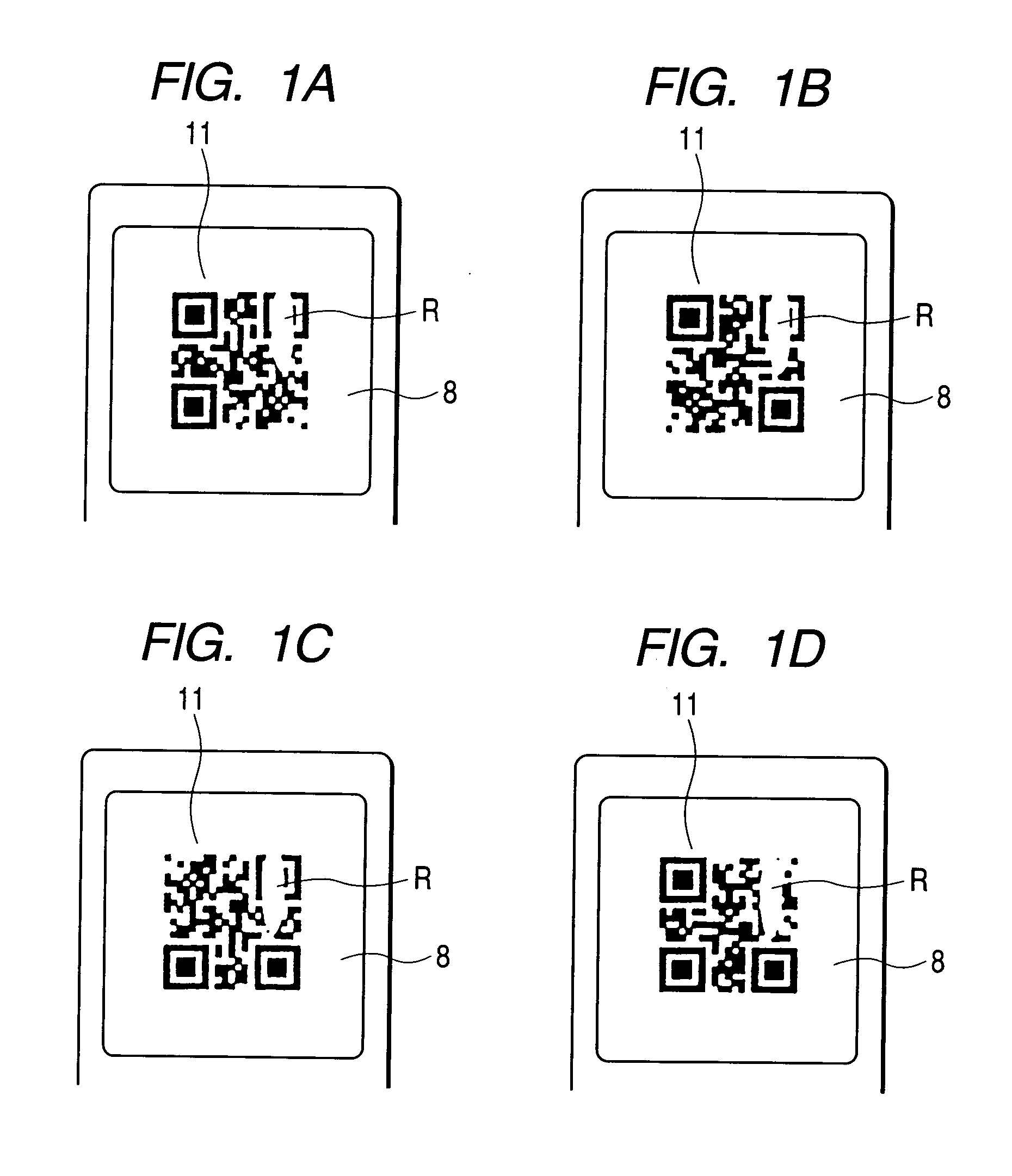

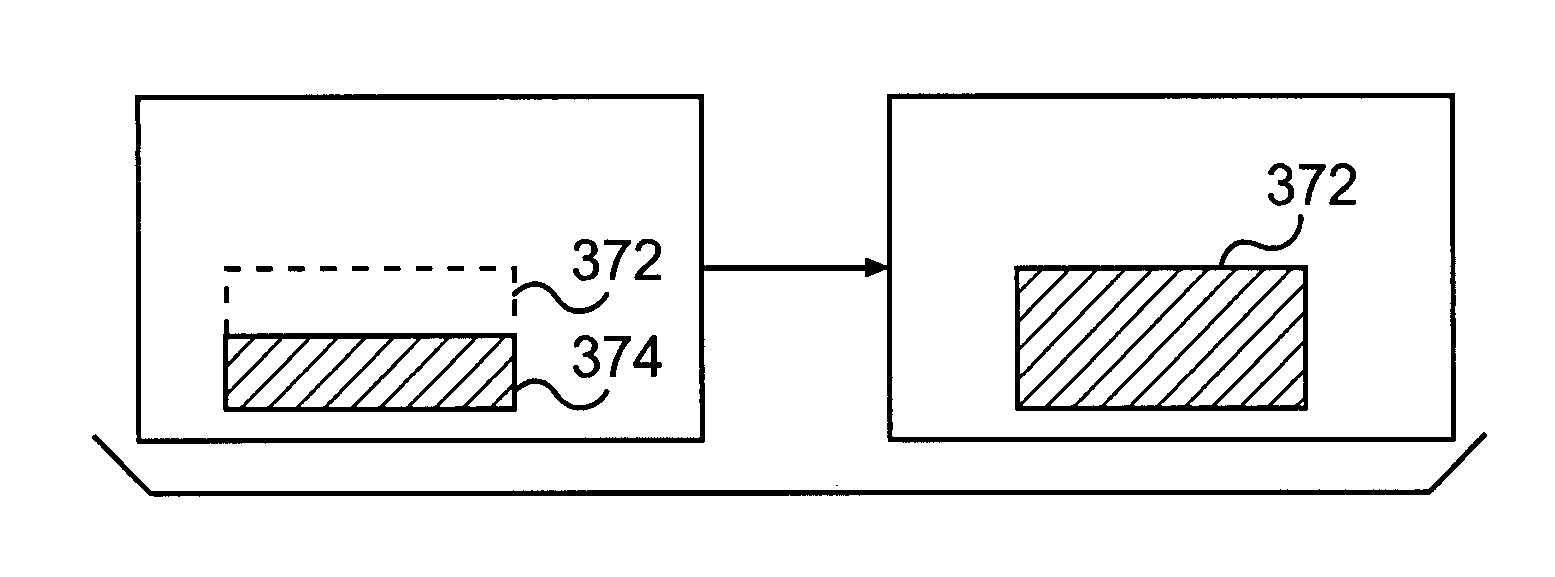

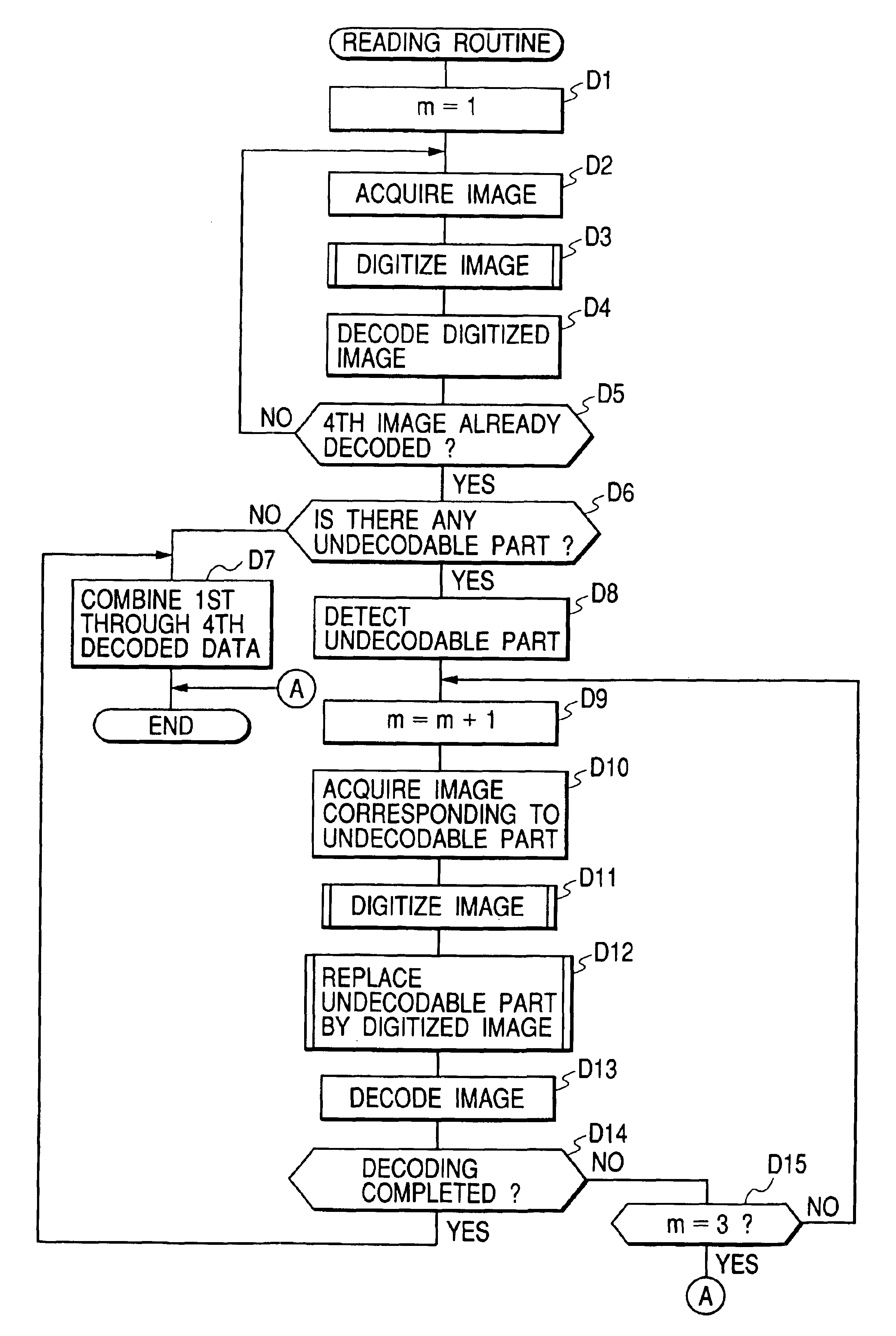

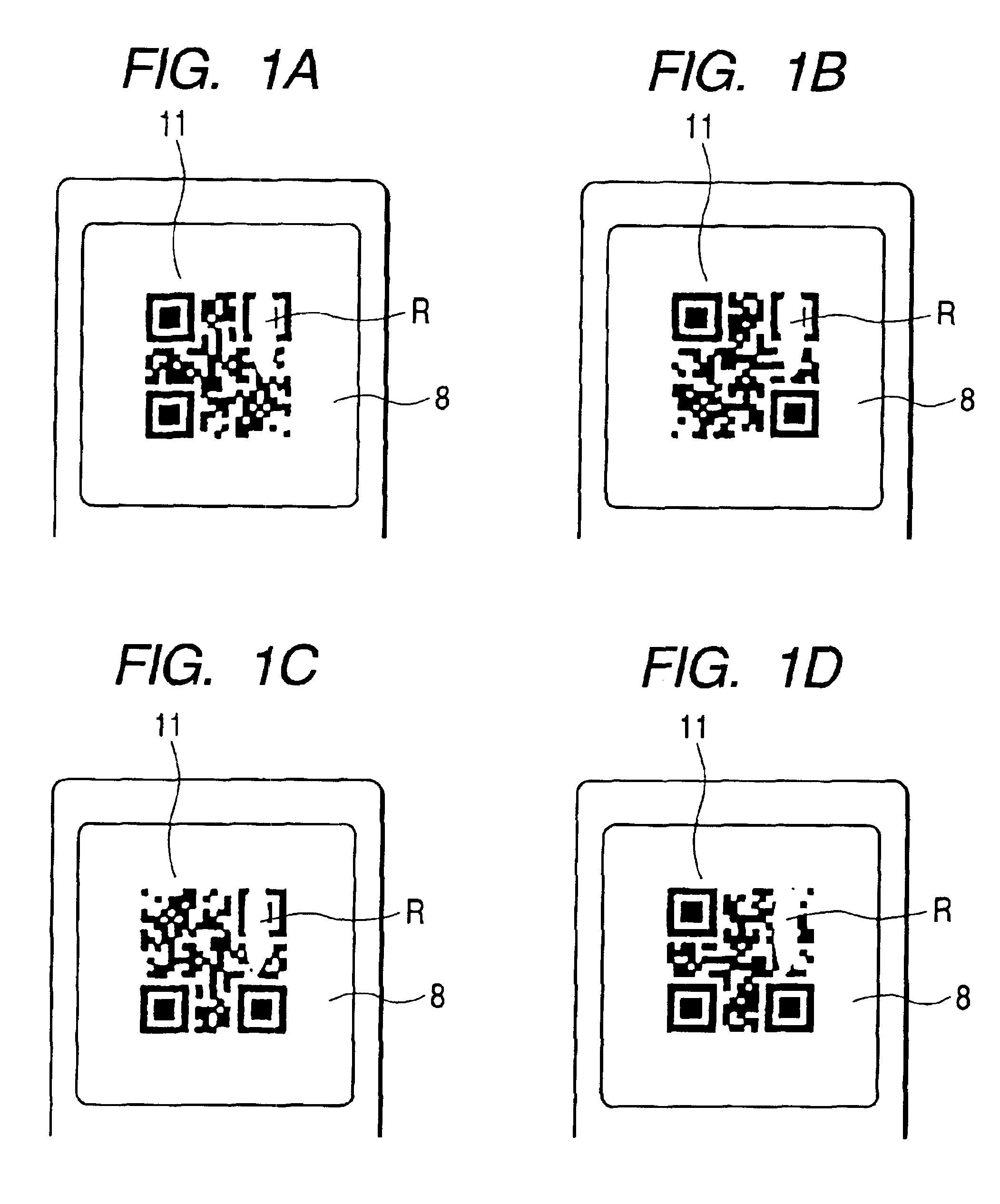

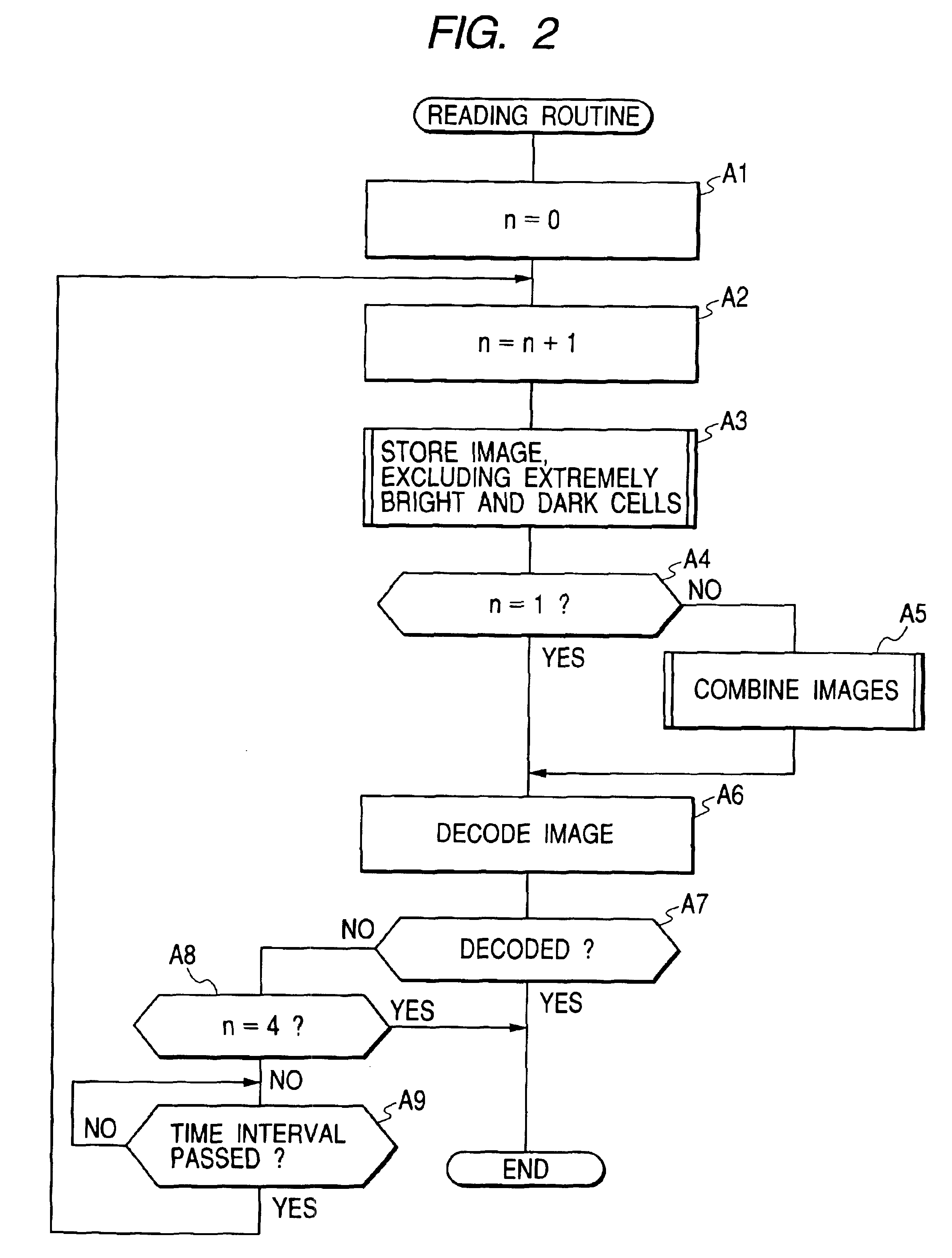

Method for displaying and reading information code for commercial transaction

ActiveUS20040012569A1Easy to combineInput/output for user-computer interactionCharacter and pattern recognitionMirror reflectionDisplay device

An object of the present invention is for an optical information reader for settling a commercial transaction to read and decode with certainty a quick response (QR) code displayed on a buyer's mobile telephone display. A QR code 11 is displayed on the display a plurality of times at a prescribed time interval. The QR code is rotated by 90□ every time. Therefore, a part of the QR code which could not have been decoded due to a mirror reflection, stains or scratches on the display can be decoded at the second, third or fourth display, because the QR code 11 is displayed four times at different angles.

Owner:DENSO WAVE INC

Method and apparatus for applying bar code information to products during production

InactiveUS7182259B2Reduce in quantityEasy to identifyCo-operative working arrangementsCharacter and pattern recognitionBarcodeEngineering

Bar code information is printed on a printable surface associated with a product, such as a label or container of the product, or the product itself, during a production run under the control of a printer computer. The bar code information may include two components of a composite bar code symbol, where the first component is either pre-printed or printed during a production run, and the second component is printed during the production run. The first component may identify a product that is carried in the containers, while the second component identifies a lot, batch, expiration date or commodity number. In another aspect, check data is used to confirm the accuracy of information that is used by a printer computer to control a printer. In another aspect, first and second bar code symbols portions are read to recover information, and a database is accessed to determine if the recovered information is consistent.

Owner:INT BARCODE CORP

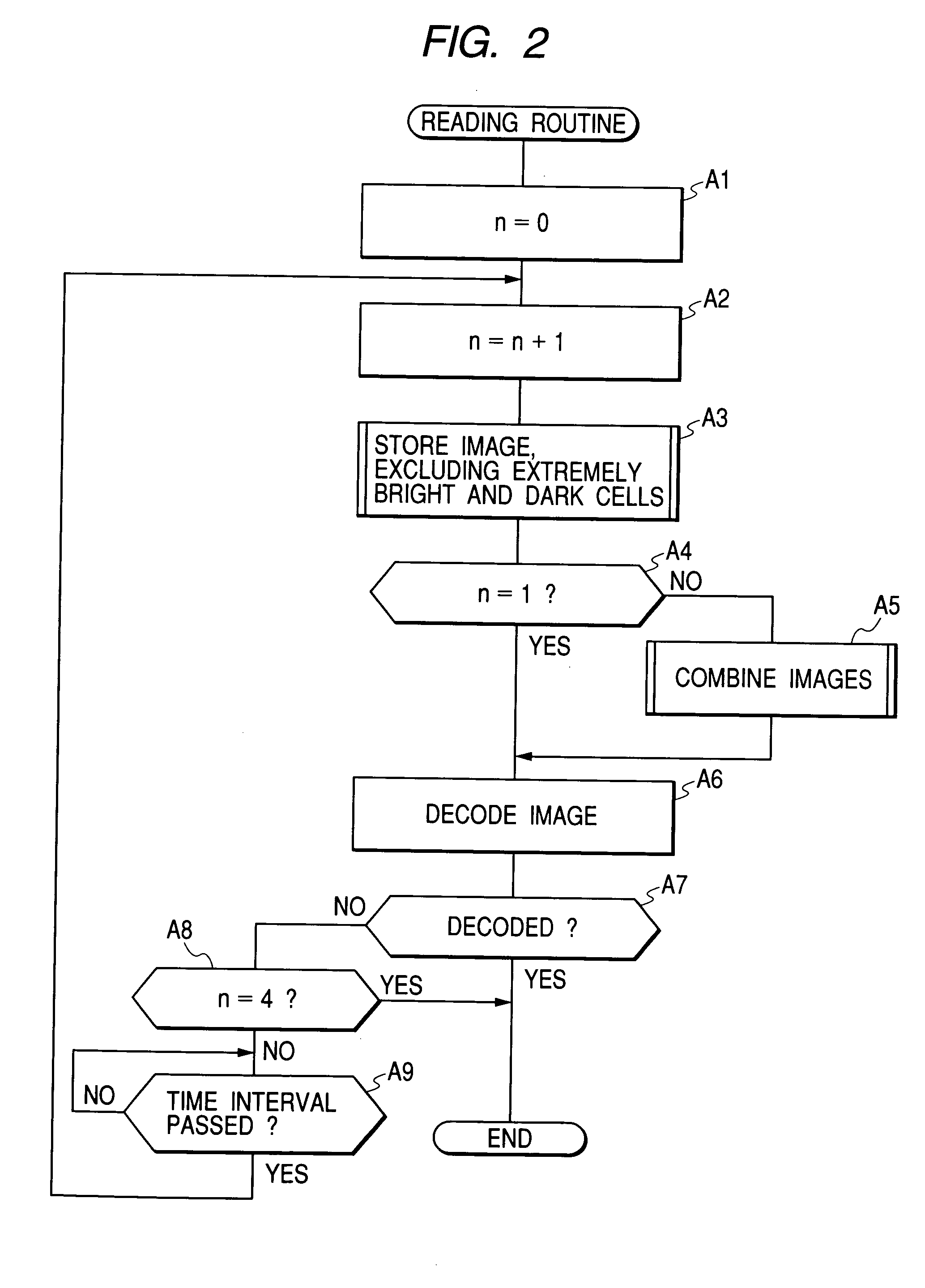

Method for displaying and reading information code for commercial transaction

ActiveUS6997384B2PickedEasy to combineInput/output for user-computer interactionCharacter and pattern recognitionMirror reflectionDisplay device

An optical information reader for settling a commercial transaction reads and decodes with certainty a quick response (QR) code displayed on a buyer's mobile telephone display. A QR code 11 is displayed on the display a plurality of times at a prescribed time interval. The QR code is rotated by 90° every time. Therefore, a part of the QR code which could not have been decoded due to a mirror reflection, stains or scratches on the display can be decoded at the second, third or fourth display, because the QR code 11 is displayed four times at different angles.

Owner:DENSO WAVE INC

Unique Identification Information From Marked Features

Owner:SYS TECH SOLUTIONS

Ink jet nozzle assembly with a thermal bend actuator

InactiveUS7195339B2Same thermal expansion and elasticity characteristicMaterial nanotechnologyTelevision system detailsThermal expansionBending actuator

An ink jet nozzle assembly for an inkjet printer includes a wafer substrate defining an ink supply passage. A drive circuitry layer is formed on the wafer substrate. A nozzle is formed on the drive circuitry layer and defines an ink chamber in fluid communication with the ink supply passage, a side aperture in fluid communication with the ink chamber and an ink ejection port in fluid communication with the ink chamber. A support extends from the drive circuitry layer. A thermal bend actuator extends from the support, through the side aperture and terminates in a free end within the ink chamber. The actuator includes a first layer having a first co-efficient of thermal expansion, and a second layer deposited on the first layer which has a second co-efficient of thermal expansion. The first layer is coupled to the drive circuitry layer so that, in use, the drive circuitry layer can actuate bending of the thermal bend actuator so as to move the free end and thereby eject ink from the ink ejection port.

Owner:ZAMTEC +1

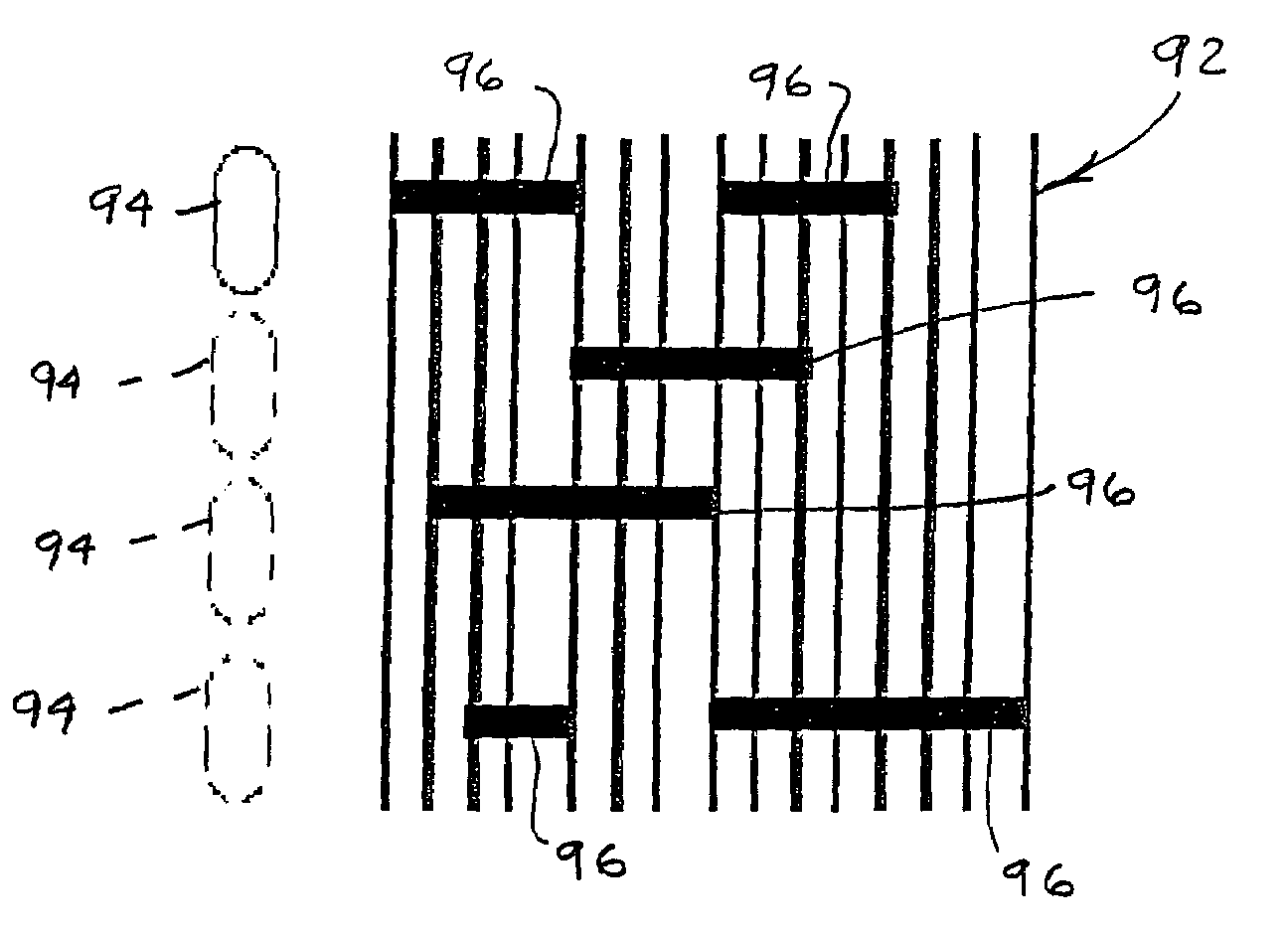

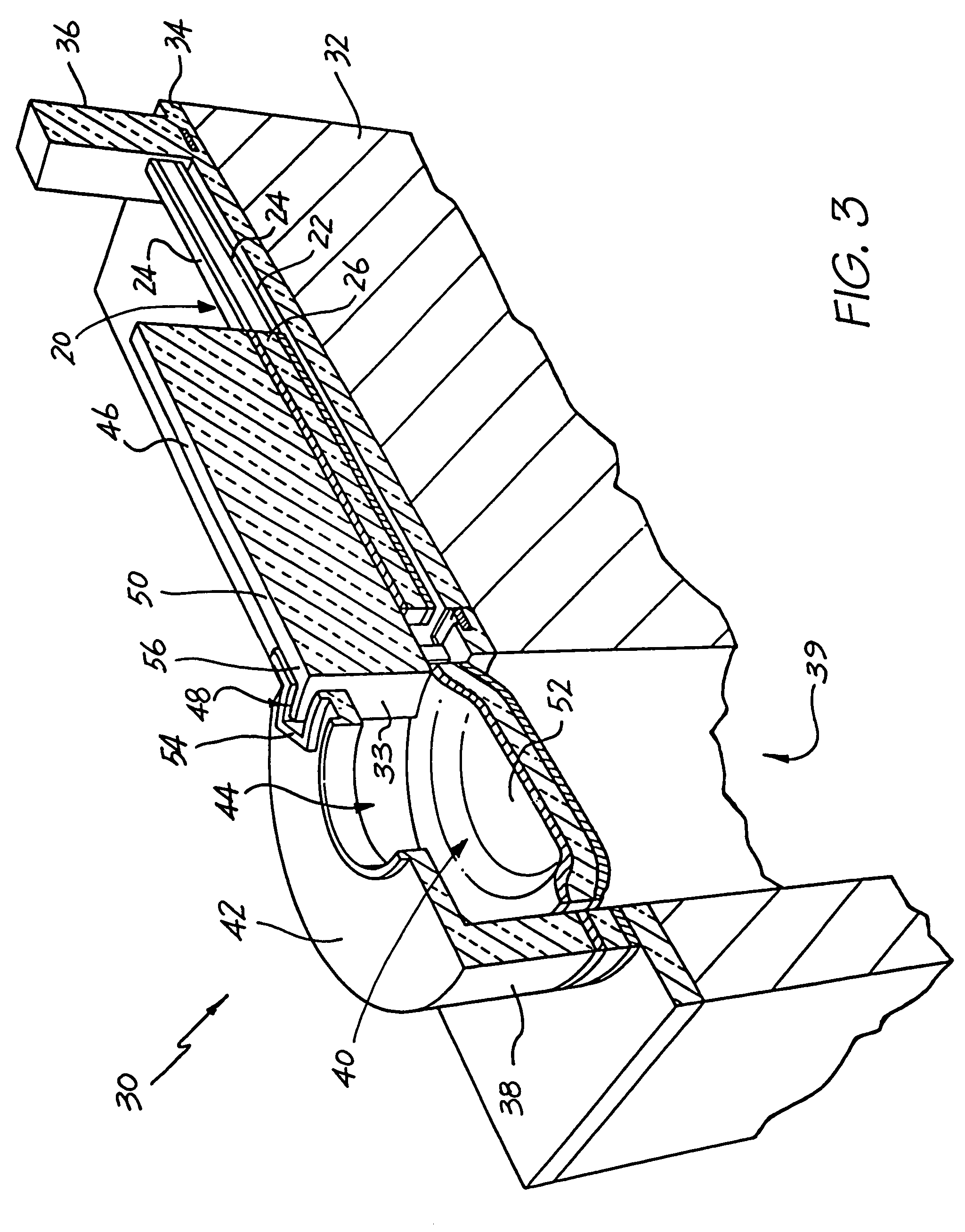

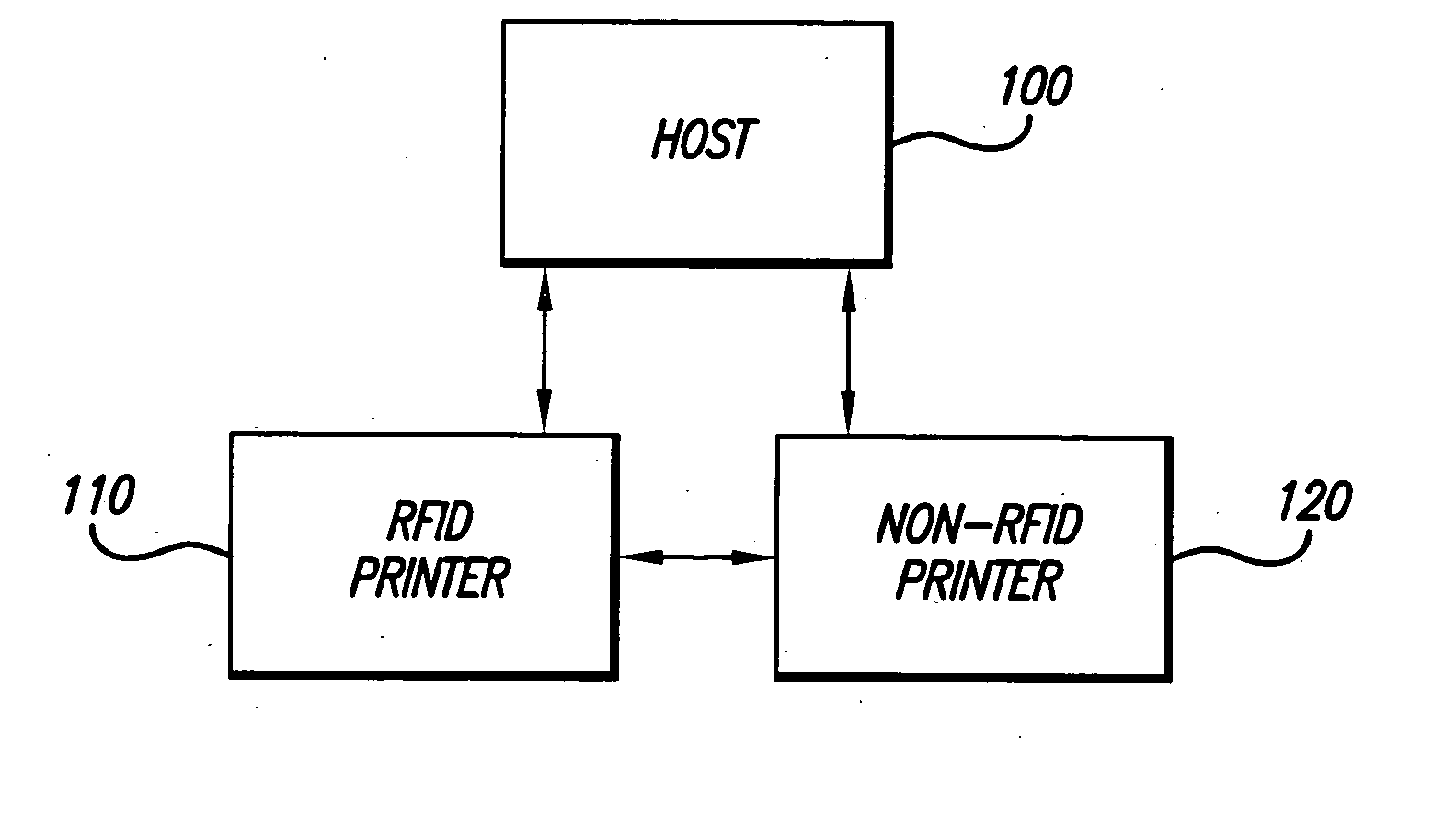

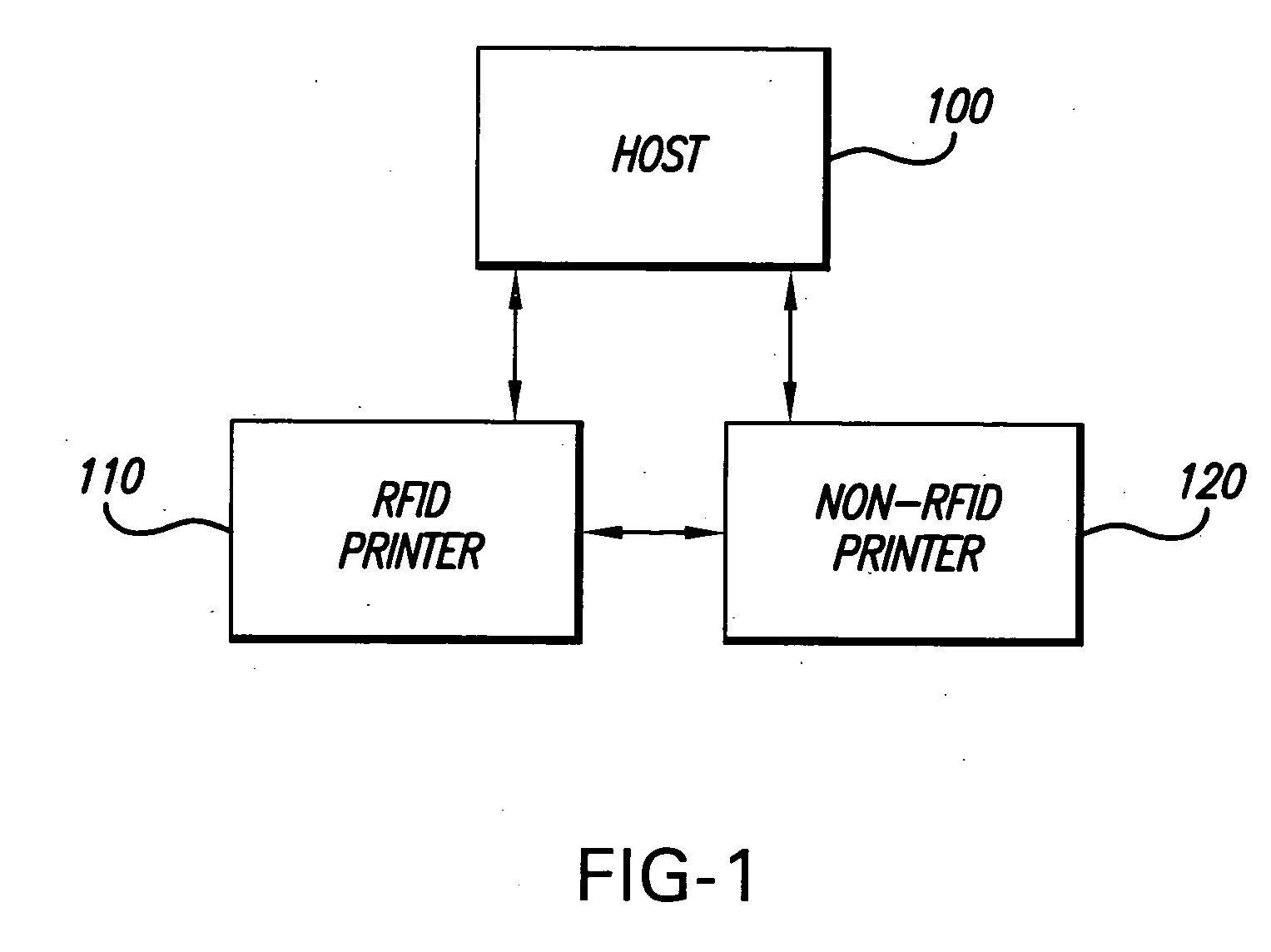

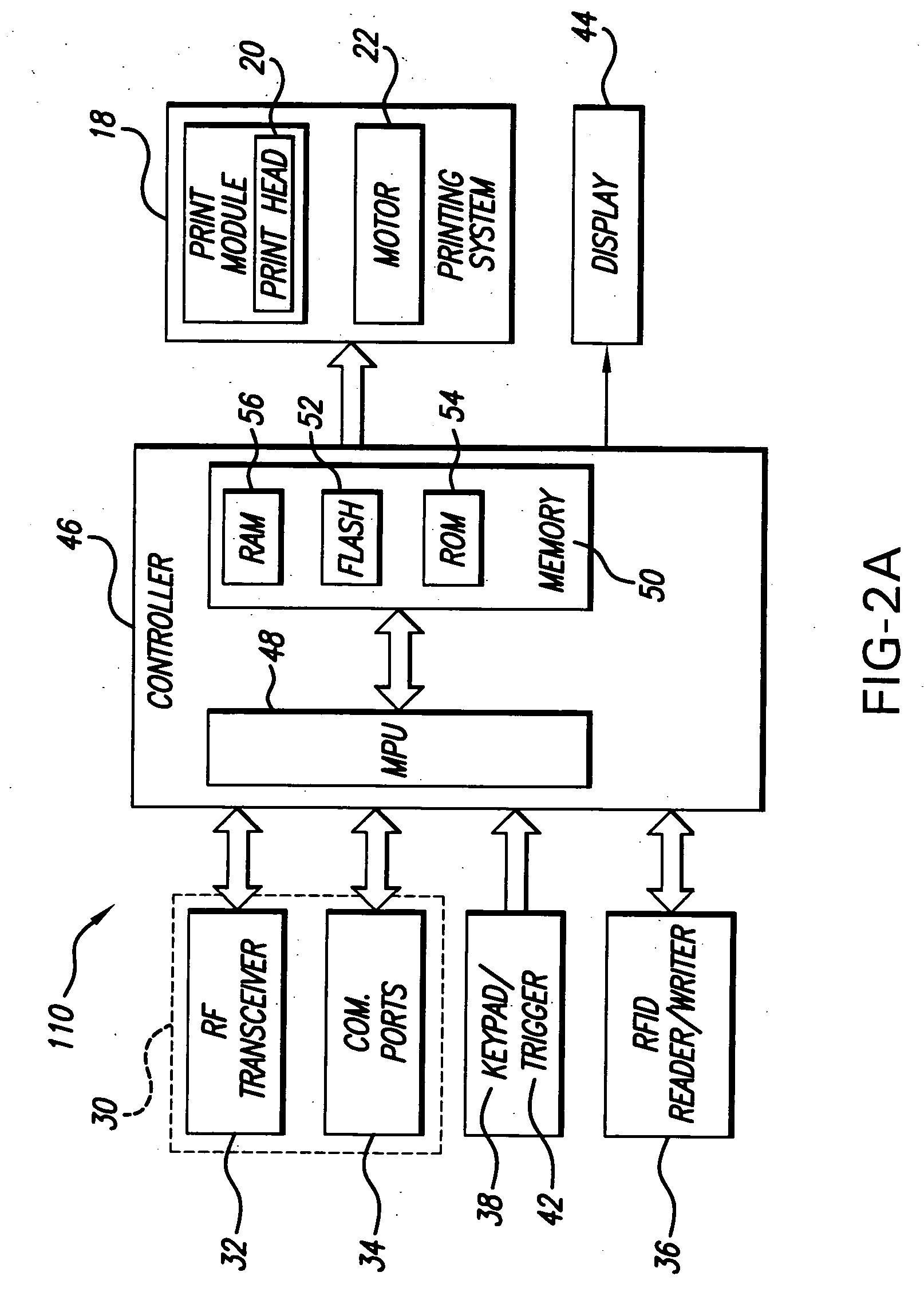

RFID printer system, method of printing and sets of record members

InactiveUS20060071063A1Not possibleInking apparatusTesting sensing arrangementsEngineeringTransponder

A system and method for printing both record members having RFID transponders disposed thereon and record members not having RFID transponders disposed thereon. In one embodiment, a RFID printer receives data to be printed on a record member and determines if the data includes RFID data to be written to a RFID transponder embedded on a record member. If the received data includes RFID data, the RFID printer prints a RFID record member according to the received data. If the received data does not include RFID data, the RFID printer transmits the data to a non-RFID printer for printing. In another embodiment, a non-RFID printer receives data to be printed on a record member and determines if the data includes RFID data to be written to a RFID transponder embedded on a record member. If the received data does not include RFID data, the non-RFID printer prints a record member according to the received data. If the received data does include RFID data, the non-RFID printer transmits the data to a RFID printer for printing. At least one set of RFID record members in a RFID web is written to and printed with data. At least one set of non-RFID record members in a non-RFID web is printed with the same data. The set(s) of RFID record members are associated with the set(s) of non-RFID members by the same indicium which is printed on at least one RFID record member and in at least one non-RFID record member having related data. When there are plural sets of RFID record members, wherein the sets of RFID record members have different data, and there are plural sets of non-RFID record members, wherein the sets of non-RFID record members have different data, and the data of the sets of RFID record members and the sets of non-RFID record members have related data, differing indicia are printed on at least one record member of each set to associate the sets of RFID and non-RFID record members.

Owner:AVERY DENNISON CORP

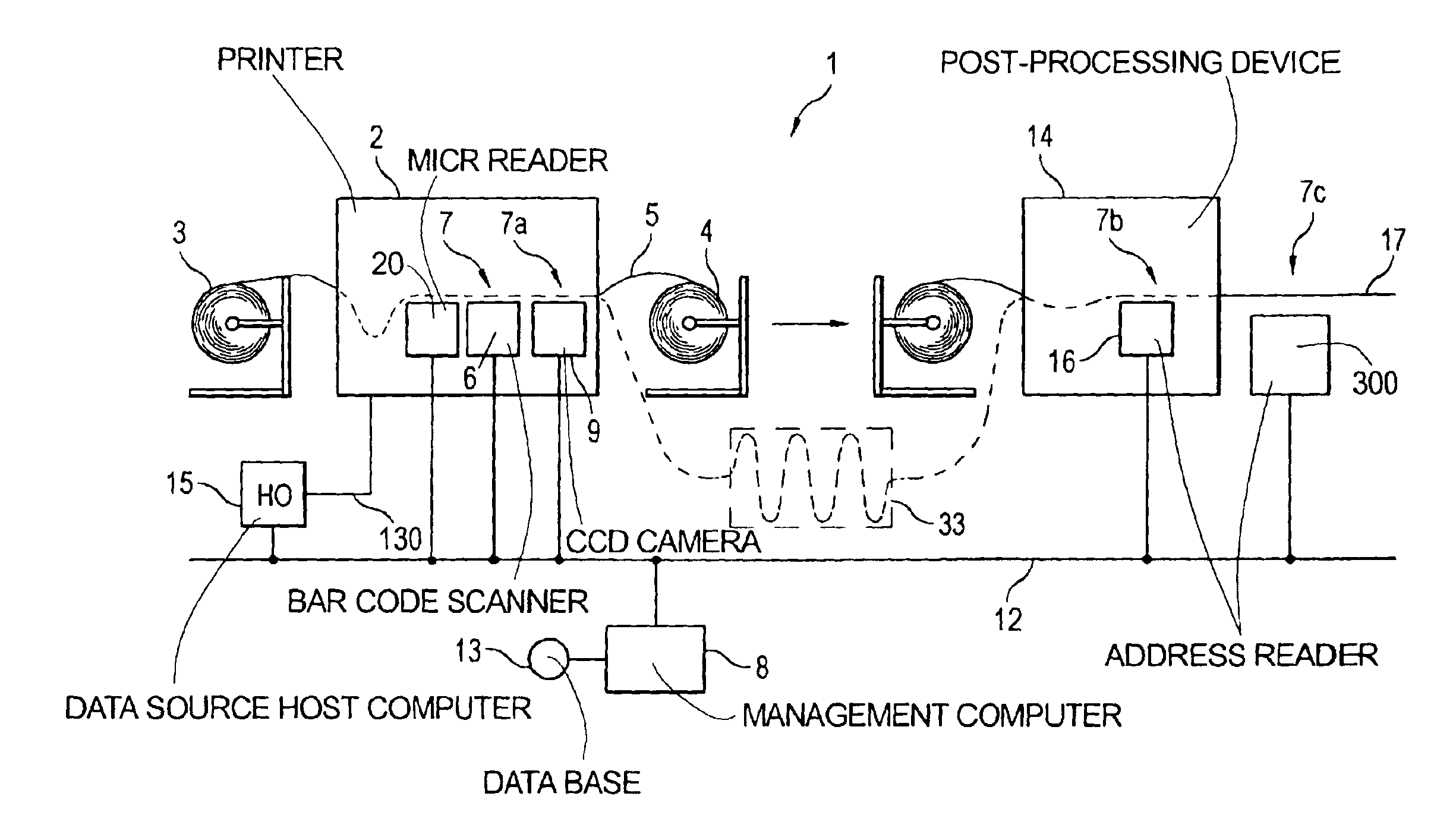

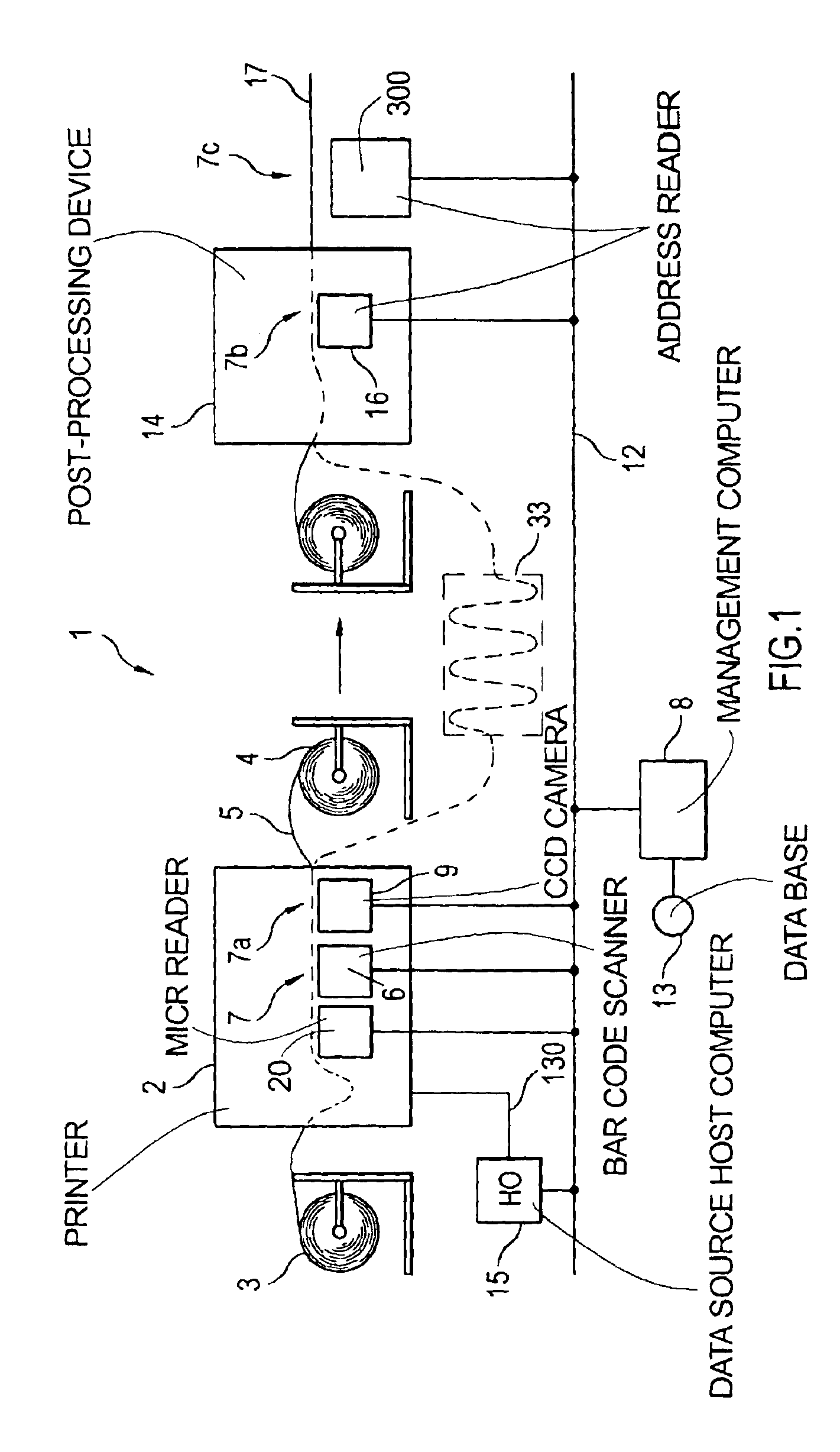

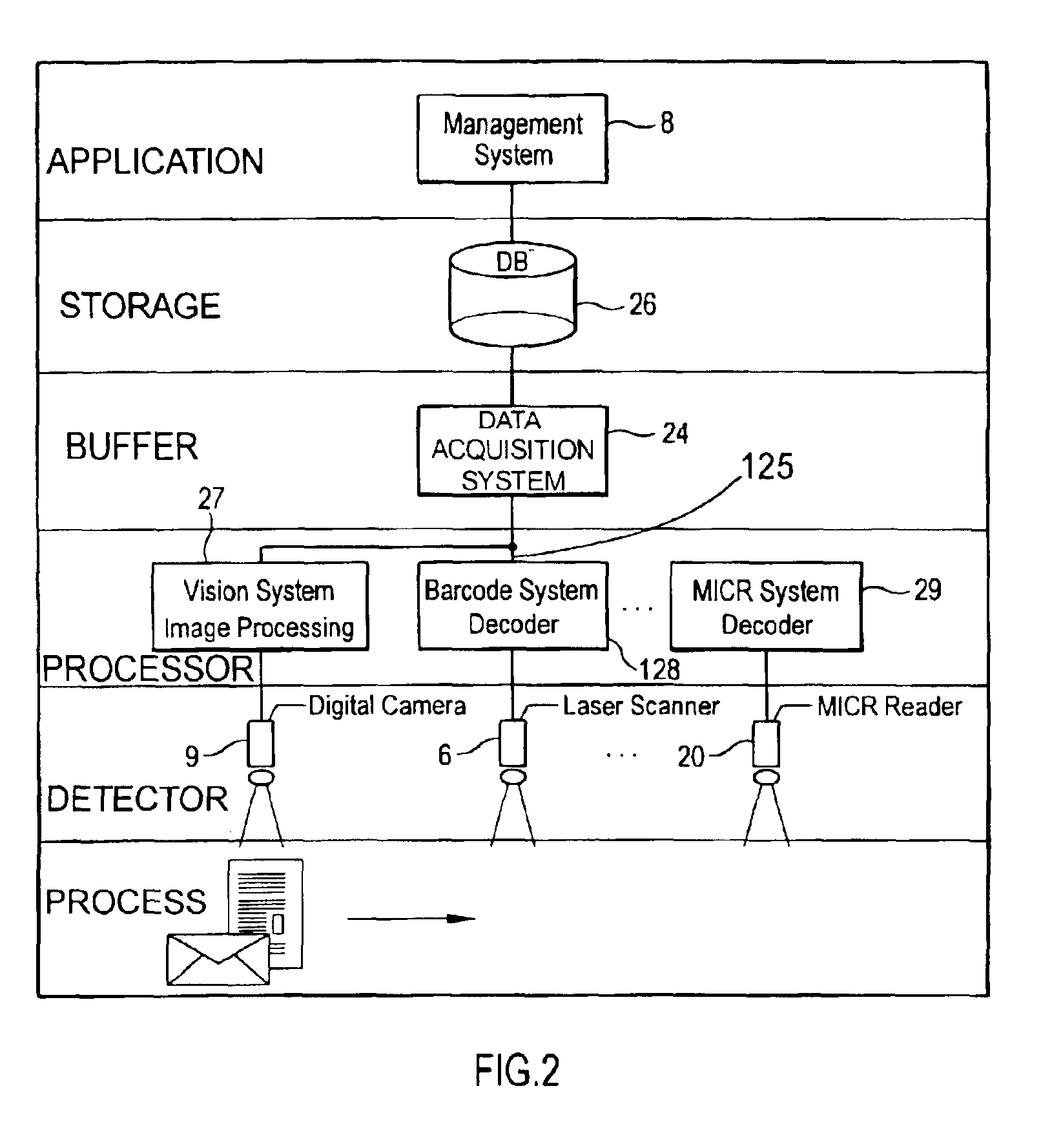

Document verification and tracking system for printed material

InactiveUSRE38957E1Co-operative working arrangementsCharacter and pattern recognitionOptical testBarcode

In a multifunctional printing method and printing system, printed material is checked, verified and tracked. For that purpose different test equipments are located in-line with a printing line. Magnetic information being printed by a printing station onto the recording carrier using magnetic ink character readable toner may be in-line tested by a magnetic test equipment, which reads information from the magnetic recording zone on the carrier. Optical information may be tested by an in-line mounted optical test equipment, respectively. Further in-line test equipment is proposed such as a leaser bar code scanner and an address reader. The printing line may have additional devices such as print preprocessing unwinders or print postprocessing stackers, folders or cutters.

Owner:OCE PRINTING SYST

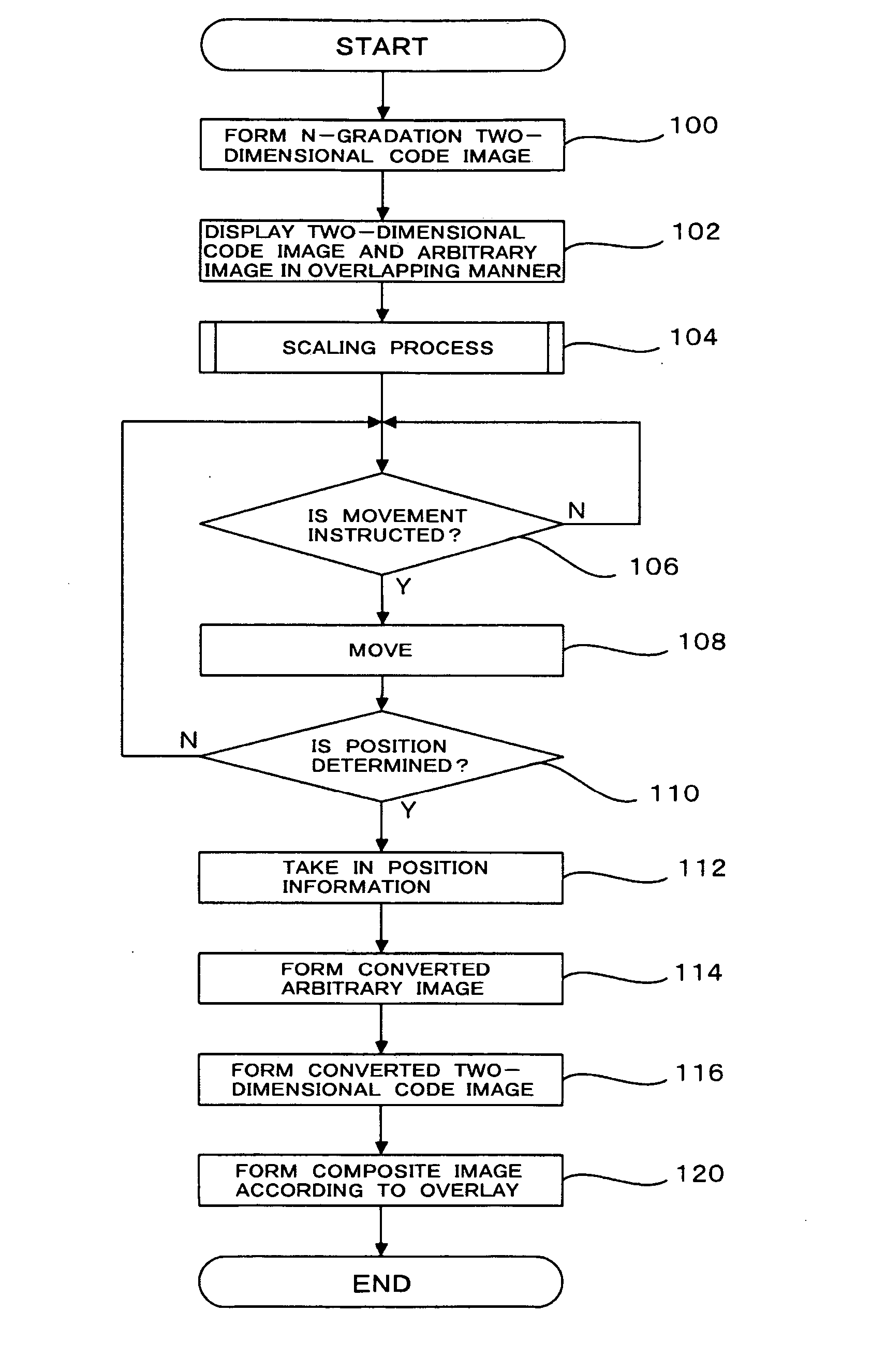

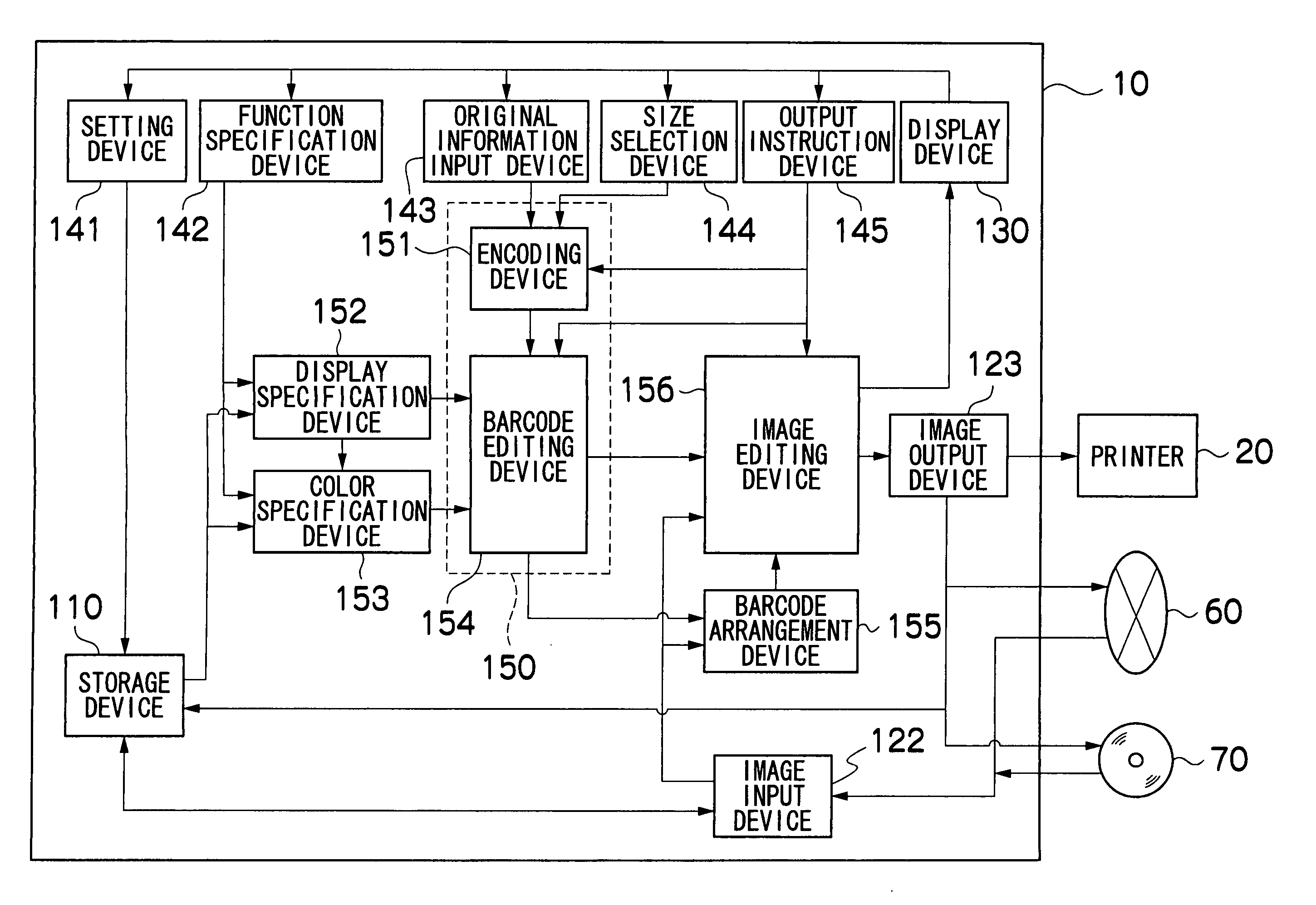

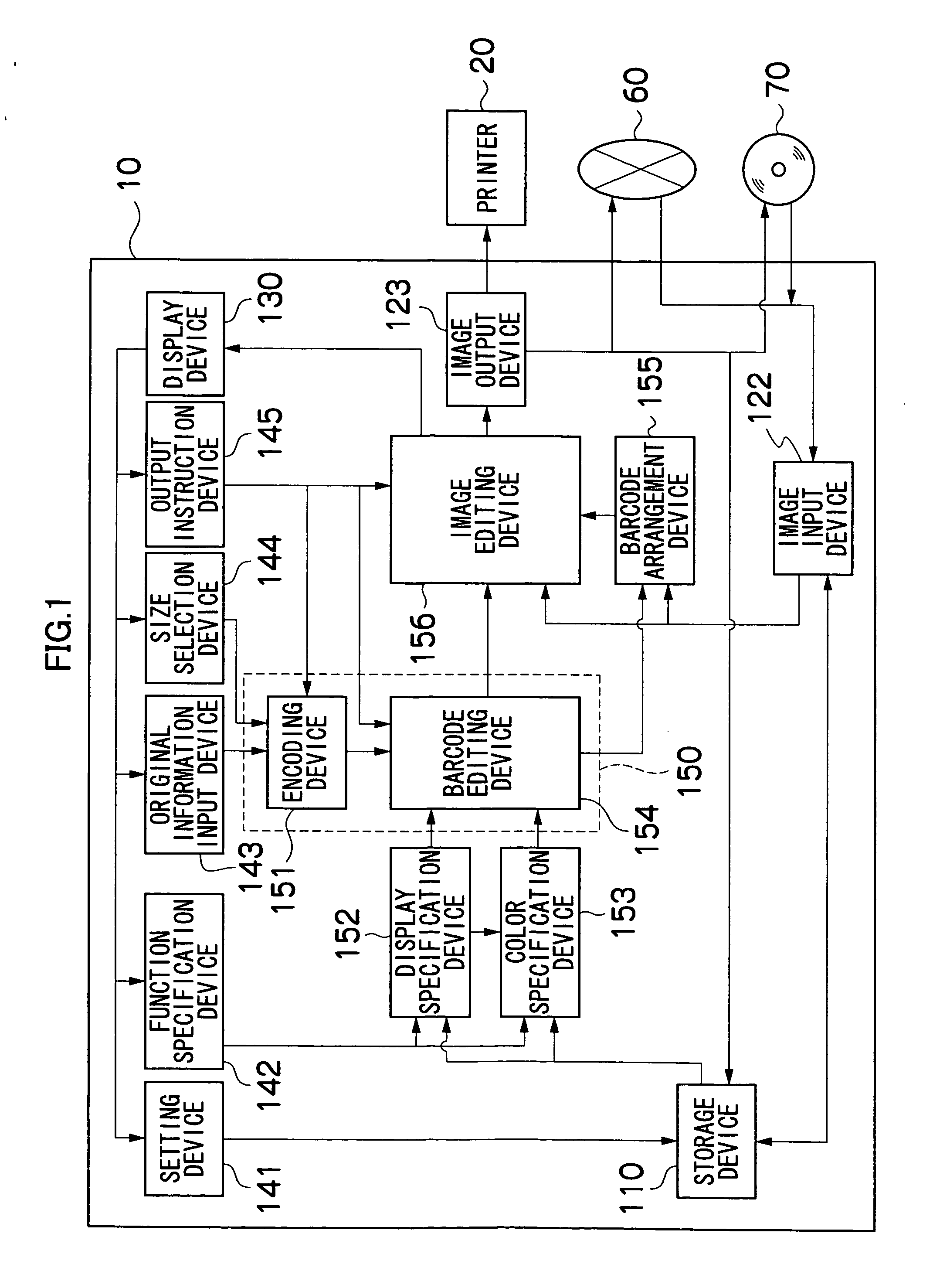

Image forming apparatus and computer readable medium

InactiveUS20060215931A1Easily causedReliable readCharacter and pattern recognitionRecord carriers used with machinesComputer graphics (images)Image formation

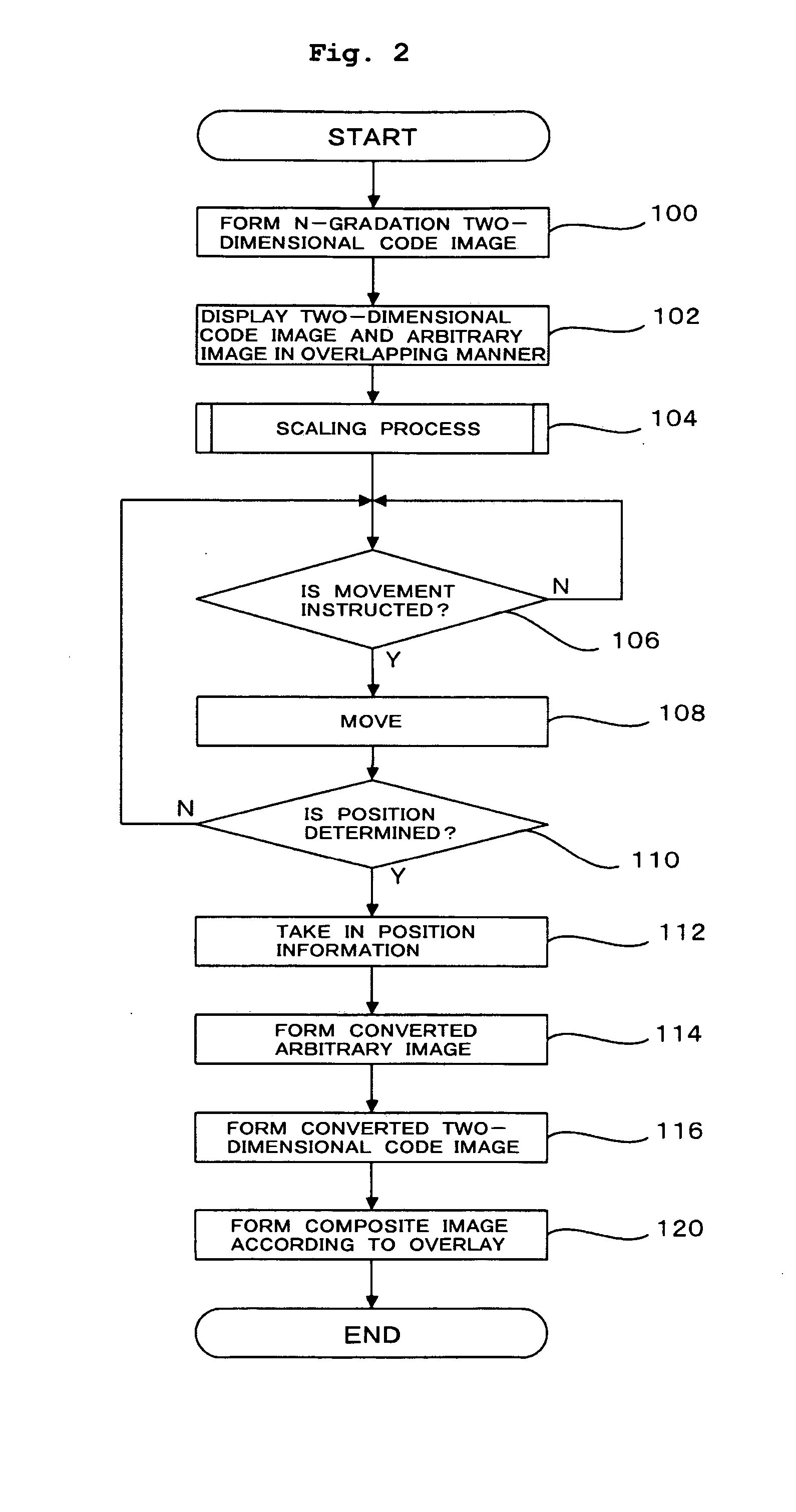

The present invention provides an image forming apparatus which forms a composite image obtained by combining a two-dimensional code image and an arbitrary image and having high discrimination. In an image forming routine executed by a CPU in the image forming apparatus, a converted arbitrary image is formed from a 256 gradation arbitrary image (S114) and a converted 256 gradation QR code image is formed from a QR code image (S100), a converted QR code image is formed from the QR code image (S116), and a composite image 40 obtained by combining the converted arbitrary image and the converted QR code image according to overlay at a position designate by an operator is formed (S120). Regarding first to fifth regions obtained by dividing 256 gradations from a shadow side to a highlight side, the converted arbitrary image and the converted QR code image are formed by converting gradations of pixels on the images to gradations in the second region.

Owner:UNKNOWN +1

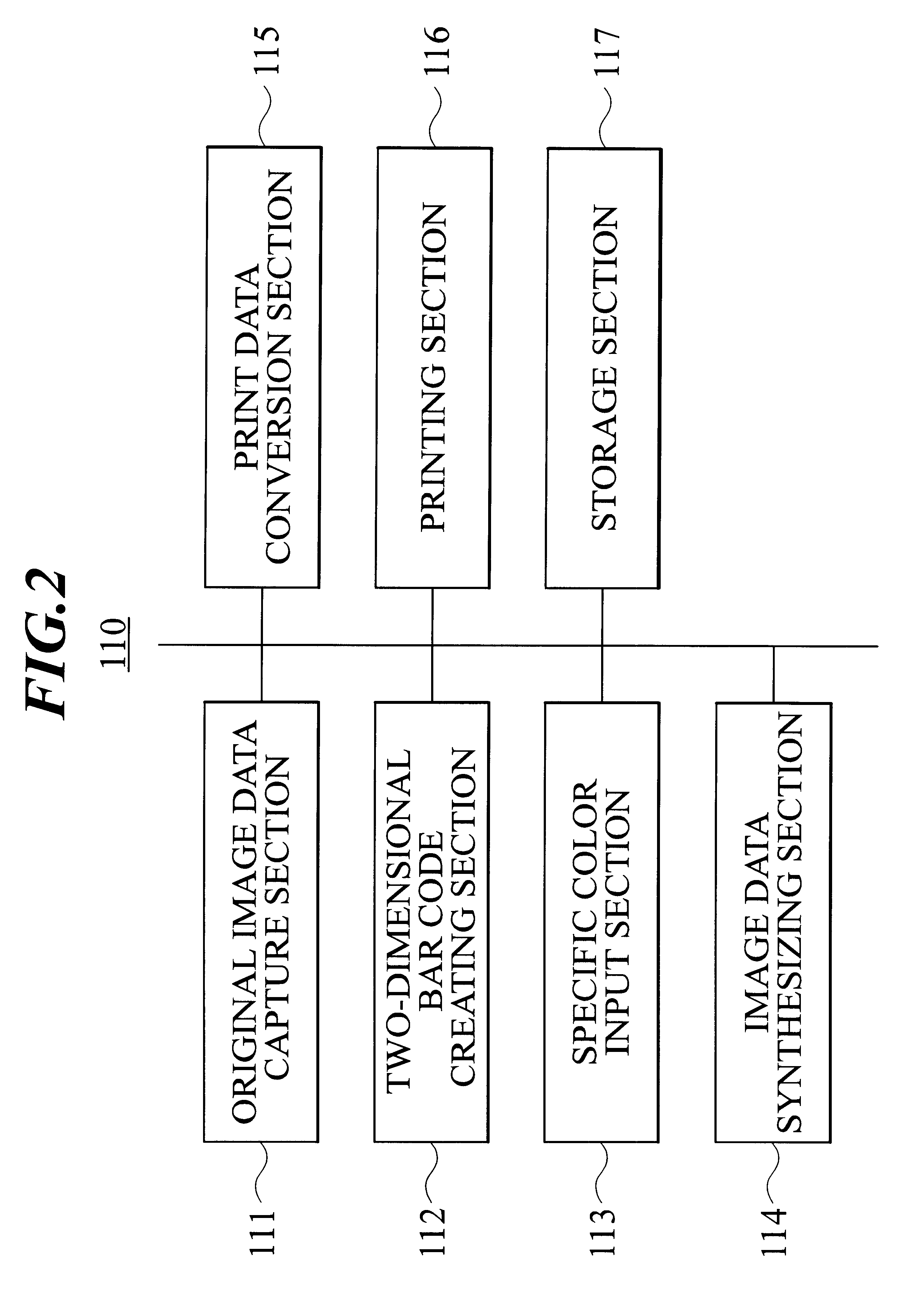

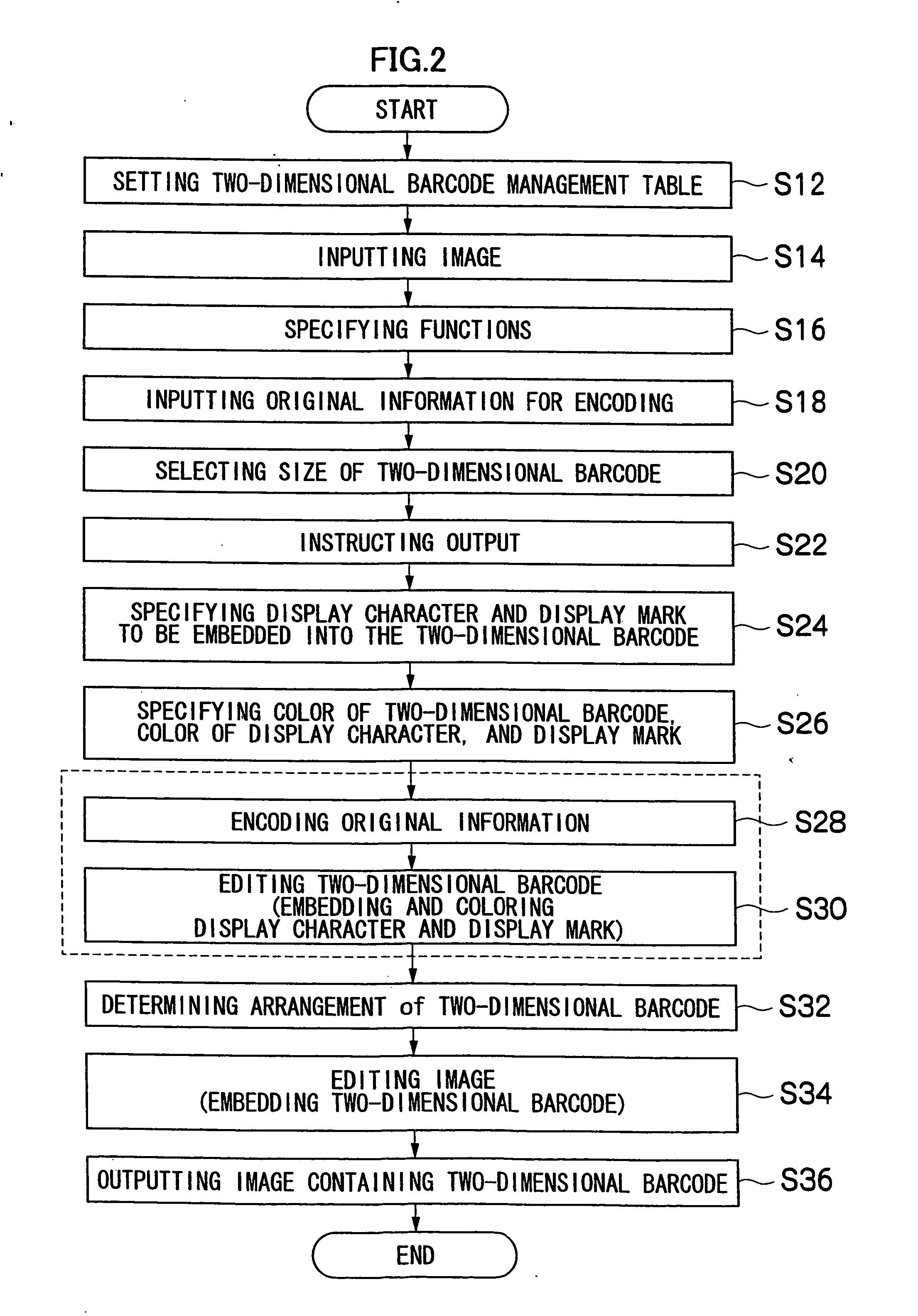

Barcode creation apparatus, barcode creation method and program

ActiveUS20050274804A1Without creating a sense of discomfort in the userCharacter and pattern recognitionRecord carriers used with machinesBarcodeTerminal equipment

The barcode creation apparatus which creates a barcode read in by a prescribed terminal device, comprises: a function specification device which specifies a function which allows the terminal device to startup when the barcode is read in, from a plurality of functions that the terminal device has; a color specification device which specifies a color of the barcode, the color representing the function specified by the function specification device; and a barcode creation device which creates the barcode in the specified color.

Owner:FUJIFILM CORP +1

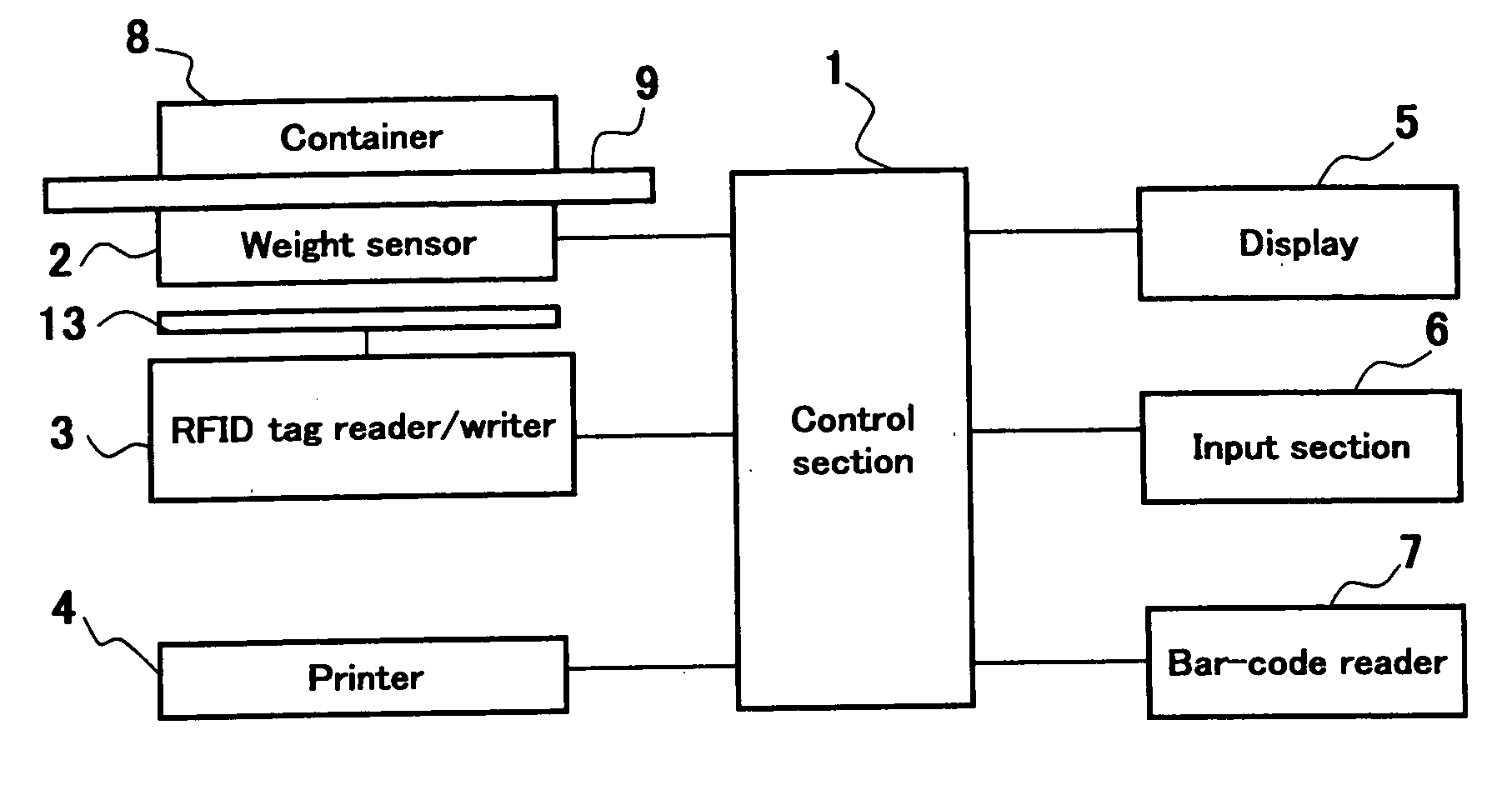

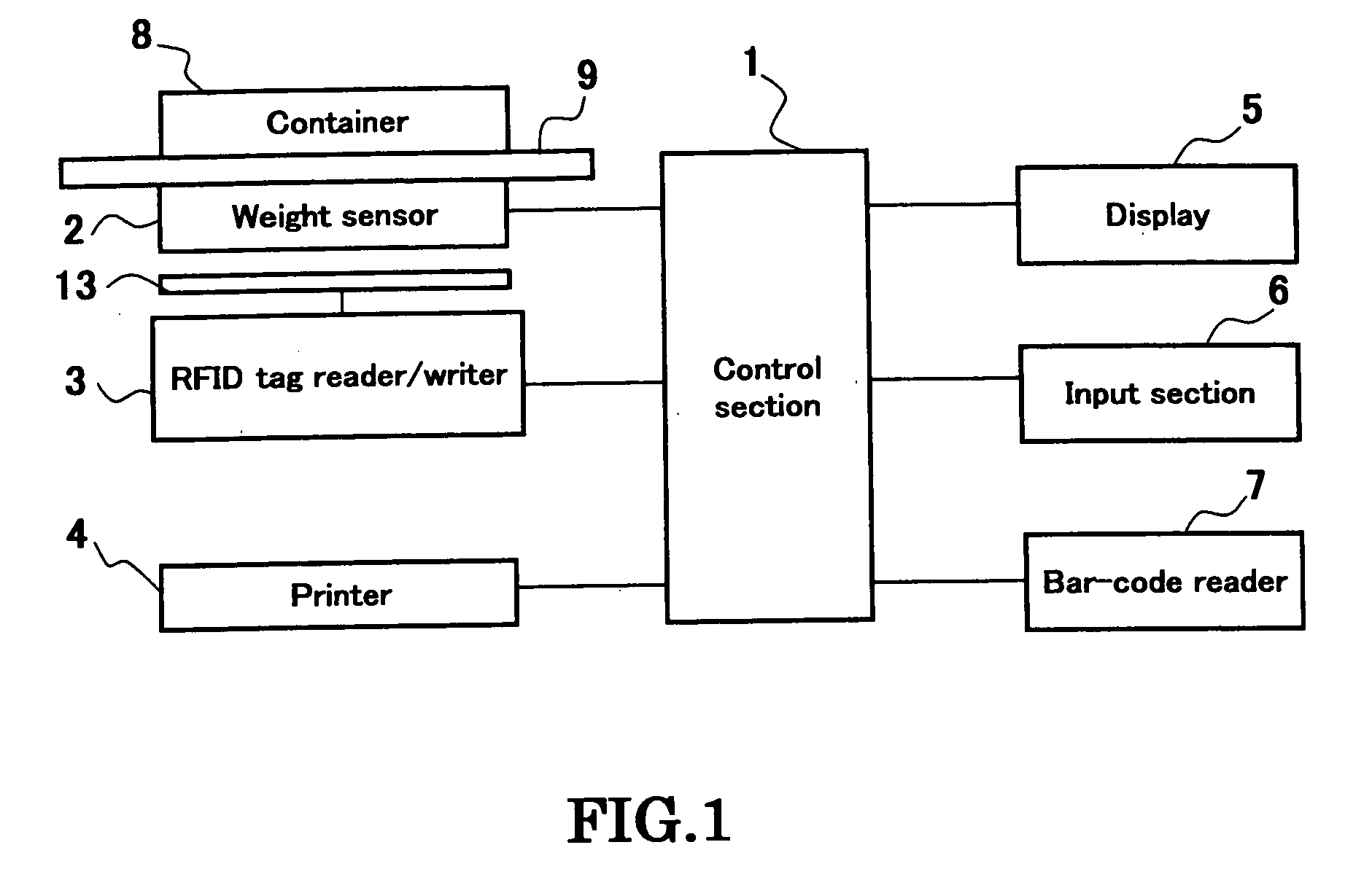

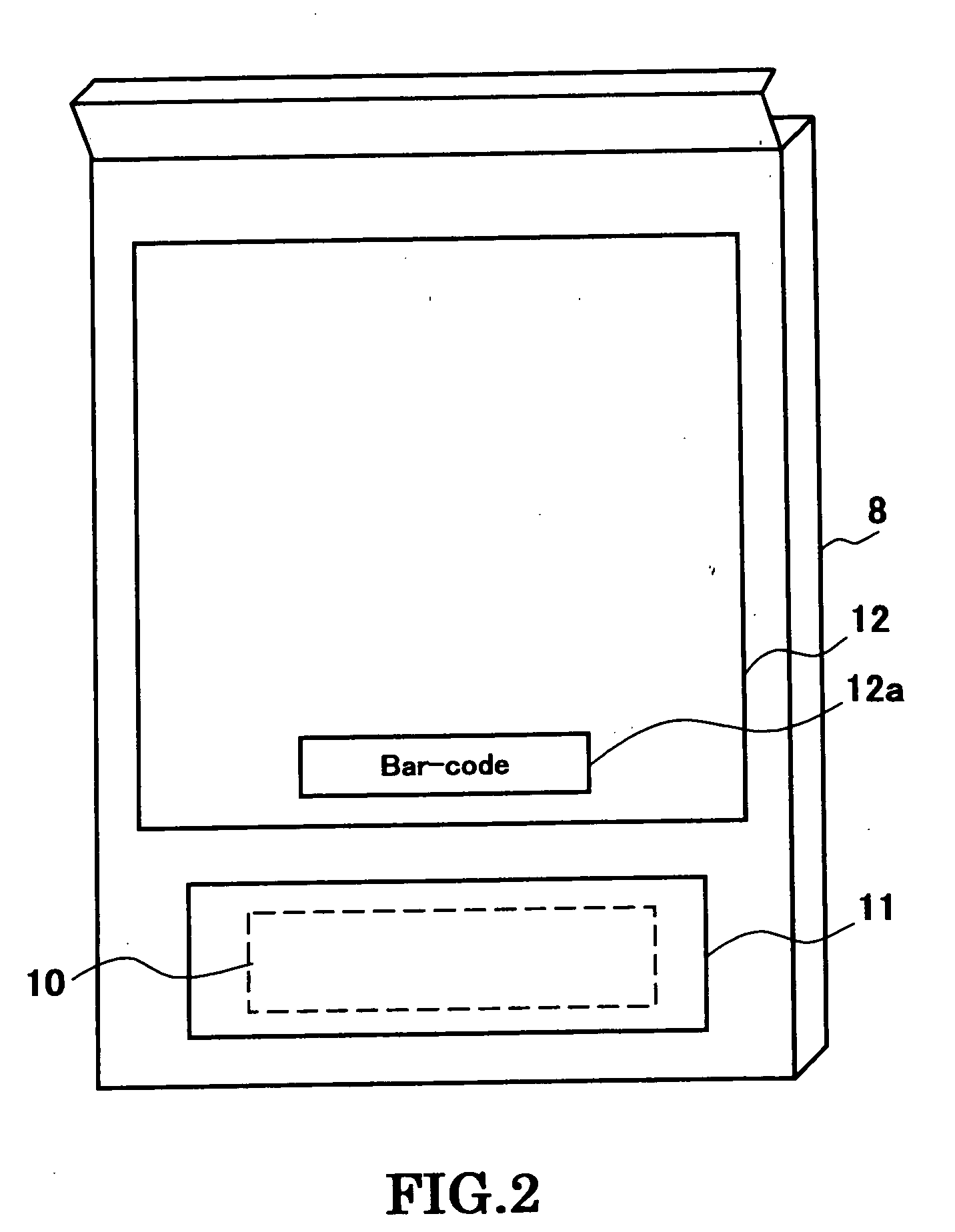

Label and RFID tag issuing apparatus

ActiveUS20050218219A1Co-operative working arrangementsCharacter and pattern recognitionBarcodeDatabase

A label and RFID tag issuing apparatus comprises a recording apparatus that records information on a production label and an RFID tag reader / writer that writes and reads part of the recorded information to / from an RFID tag. This label and RFID tag issuing apparatus writes a production number to the RFID tag attached to the container if a container for containing an article or articles carrying the production label and RFID tag is judged to be on the container loading plate. The apparatus, subsequently confirming presence of the container on the container loading plate, records on the production label production information including bar-code data corresponding to the production number that has been written to the RFID. Thus, information recorded on the production label and information stored in the RFID tag are tied, and thereby accidental affixing of a wrong production label onto the container can be prevented.

Owner:TOSHIBA TEC KK

Systems and methods for generating, reading and transferring identifiers

ActiveUS20060249573A1Record carriers used with machinesSpecial data processing applicationsGraphicsHand held devices

Systems and methods for generating, reading and transferring identifiers are disclosed. In one embodiment, a handheld system for associating a selected audio content with an object includes an identifier applied to a surface of the object and having a predetermined graphical format that is configured to encode the selected audio content, and a handheld device operable to encode the identifier and further operable to detect an audio content associated with the identifier.

Owner:LABELS THAT TALK

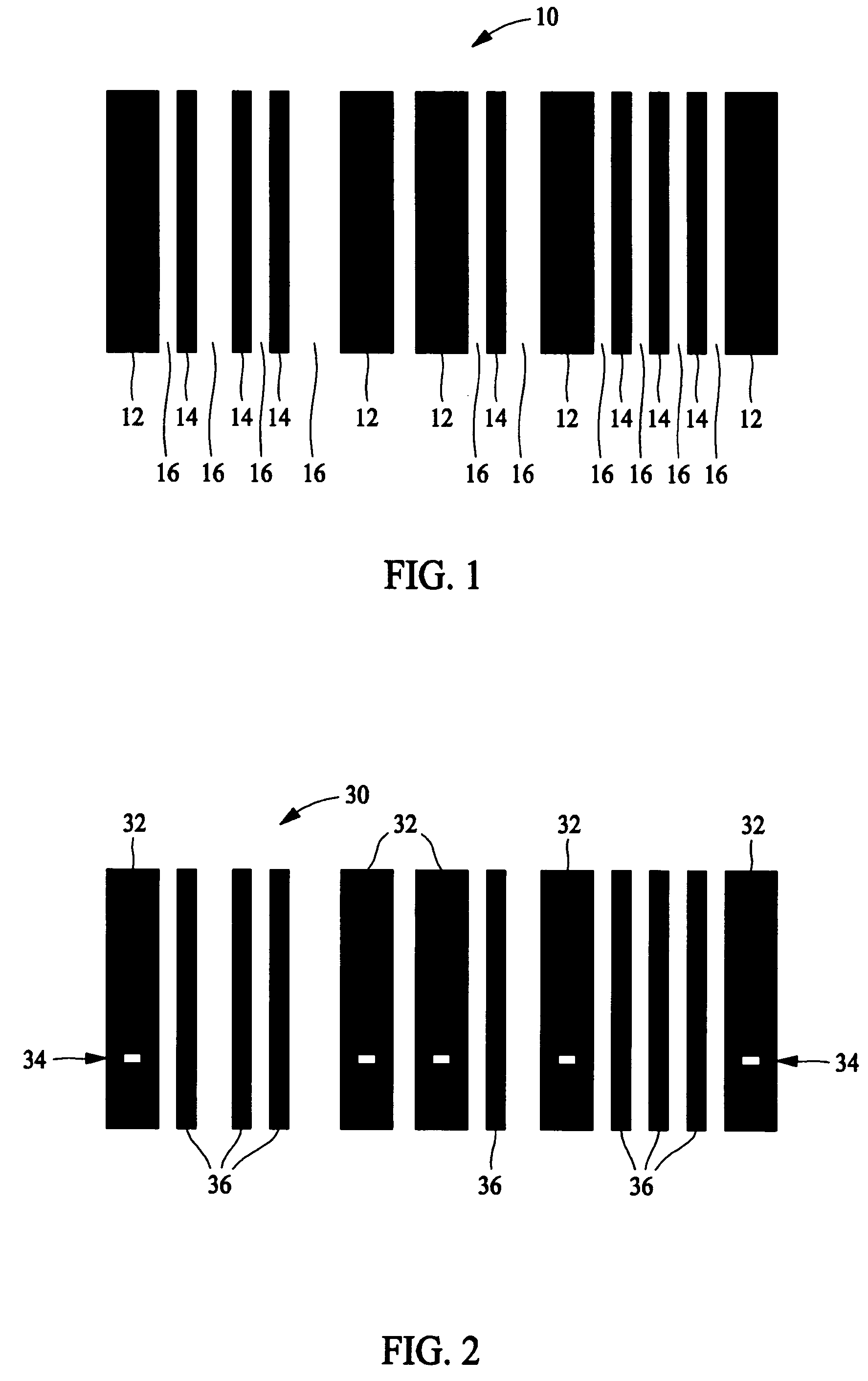

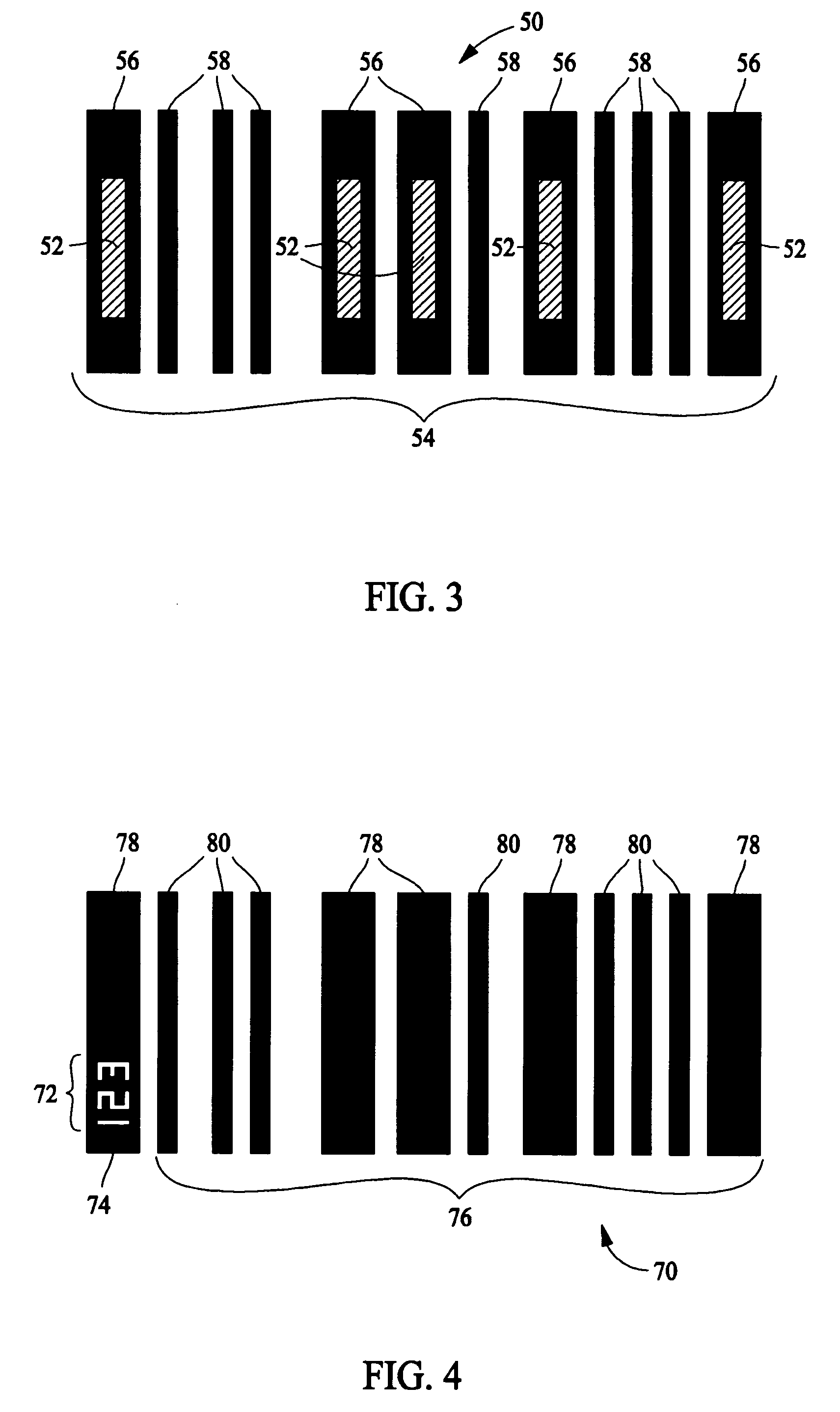

Barcodes including embedded security features and space saving interleaved text

InactiveUS7025269B2Character and pattern recognitionRecord carriers used with machinesEmbedded securityPattern recognition

A method for adding authentication features to a barcode is described. The barcode includes a plurality of printed parallel bars and the method includes embedding printed security features within the printed barcode. The parallel bars of the bar code are of varying width and at least one of the parallel bars has security features printed within that are printed in a color that is different than a color of the parallel bars.

Owner:WATSON LABEL PRODS CORP

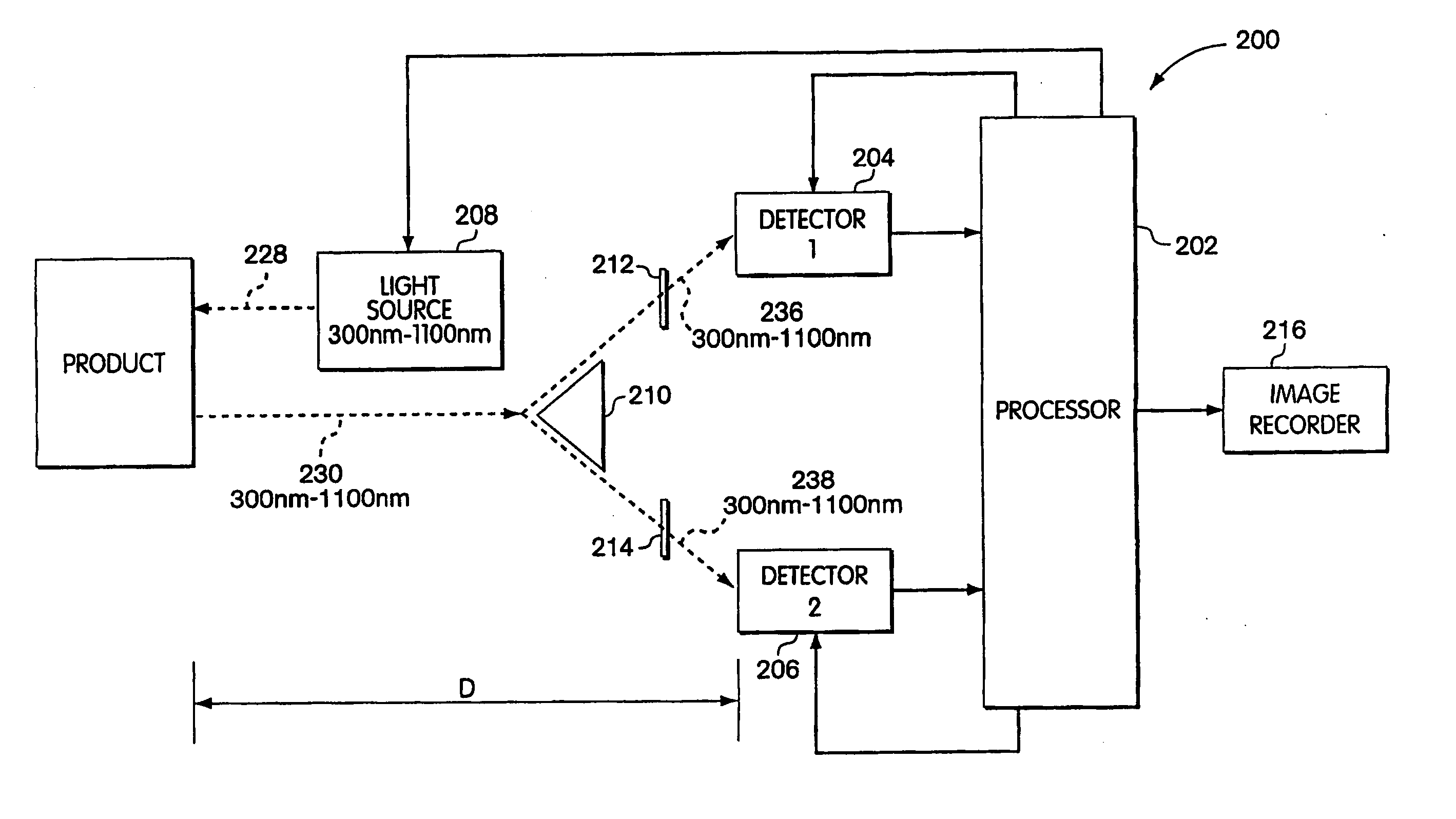

Tamper-resistant authentication mark for use in product or product packaging authentication

InactiveUS20050243305A1Prevent inadvertent removalPrevent removalPattern printingCharacter and pattern recognitionAdditive ingredientMarking out

A method of authenticating products or packaging by analyzing key ingredients on products or on product packaging is disclosed. Light-sensitive compounds can be used to identify the product or product packaging. The product or product package may include visible or invisible ink containing a particular light-sensitive compound. One or more light-sensitive compounds and ink, if used, may be printed in one or more locations on the product or product packaging to produce an authentication mark to inhibit inadvertent or intentional removal of the mark, thereby rendering the mark tamper-resistant. The mark is sealed to isolate the mark from the environment. A device may be used to irradiate the mark and read light absorption or emission. A controller determines the authenticity of the mark by comparing the emitted or absorbed properties to a standard.

Owner:VIG RAKESH +1

Popular searches

Digital marking by photographic/thermographic registration Digital marking by printing code marks Graph reading Mechanical pattern convertion Typewriters Internal/peripheral component protection Sensing by electromagnetic radiation Still video cameras Picture signal generators Other printing apparatus

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com