Patents

Literature

159 results about "Bending actuator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

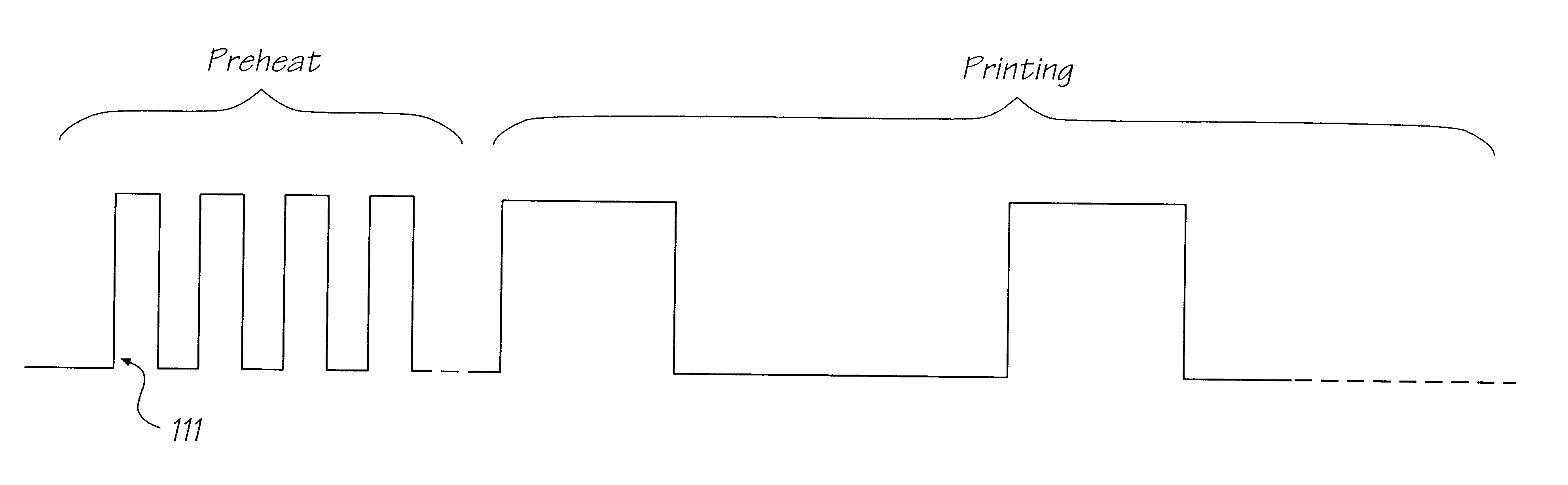

Temperature regulation of fluid ejection printheads

Owner:SILVERBROOK RES PTY LTD +1

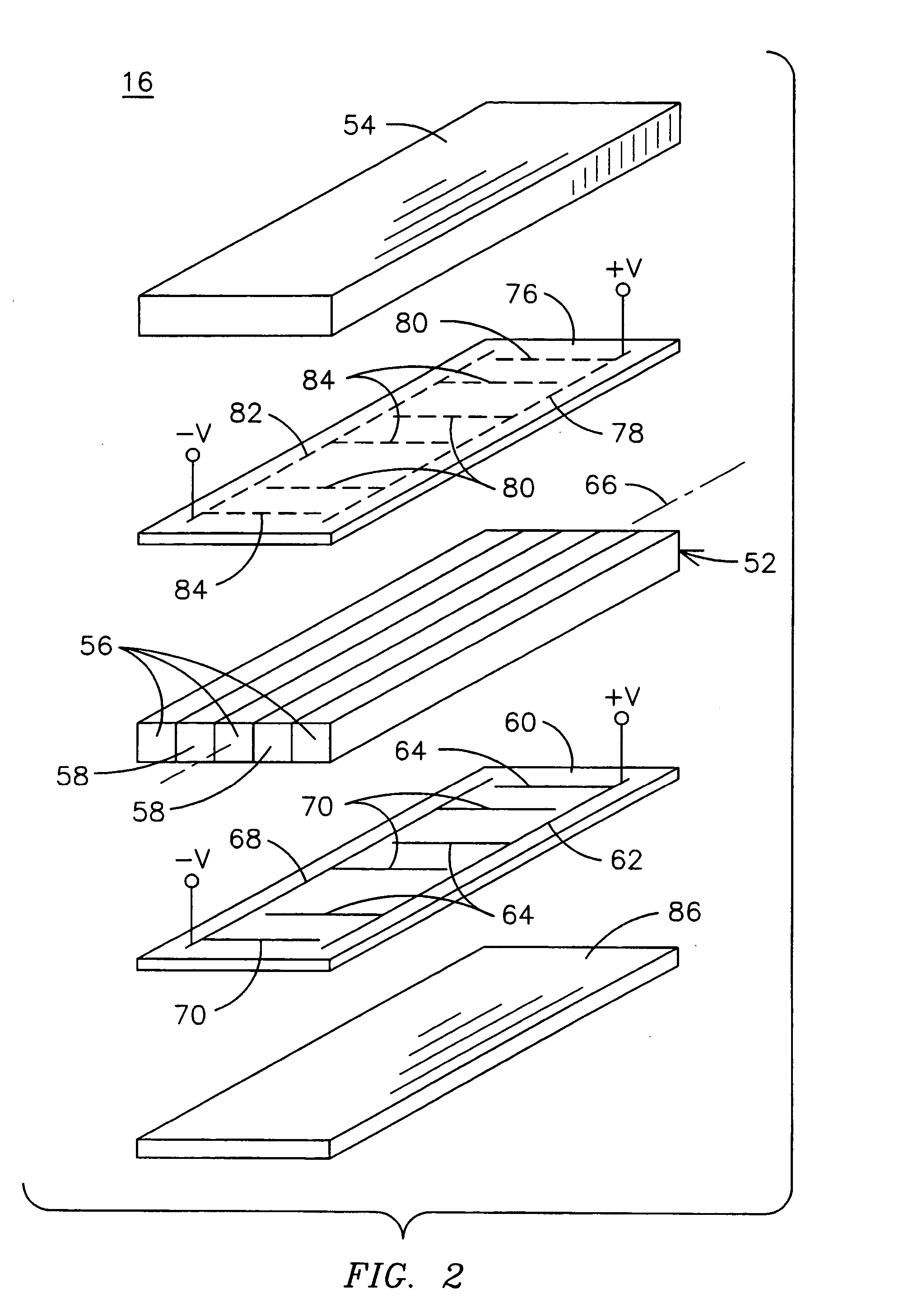

Piezoelectric actuator having minimal displacement drift with temperature and high durability

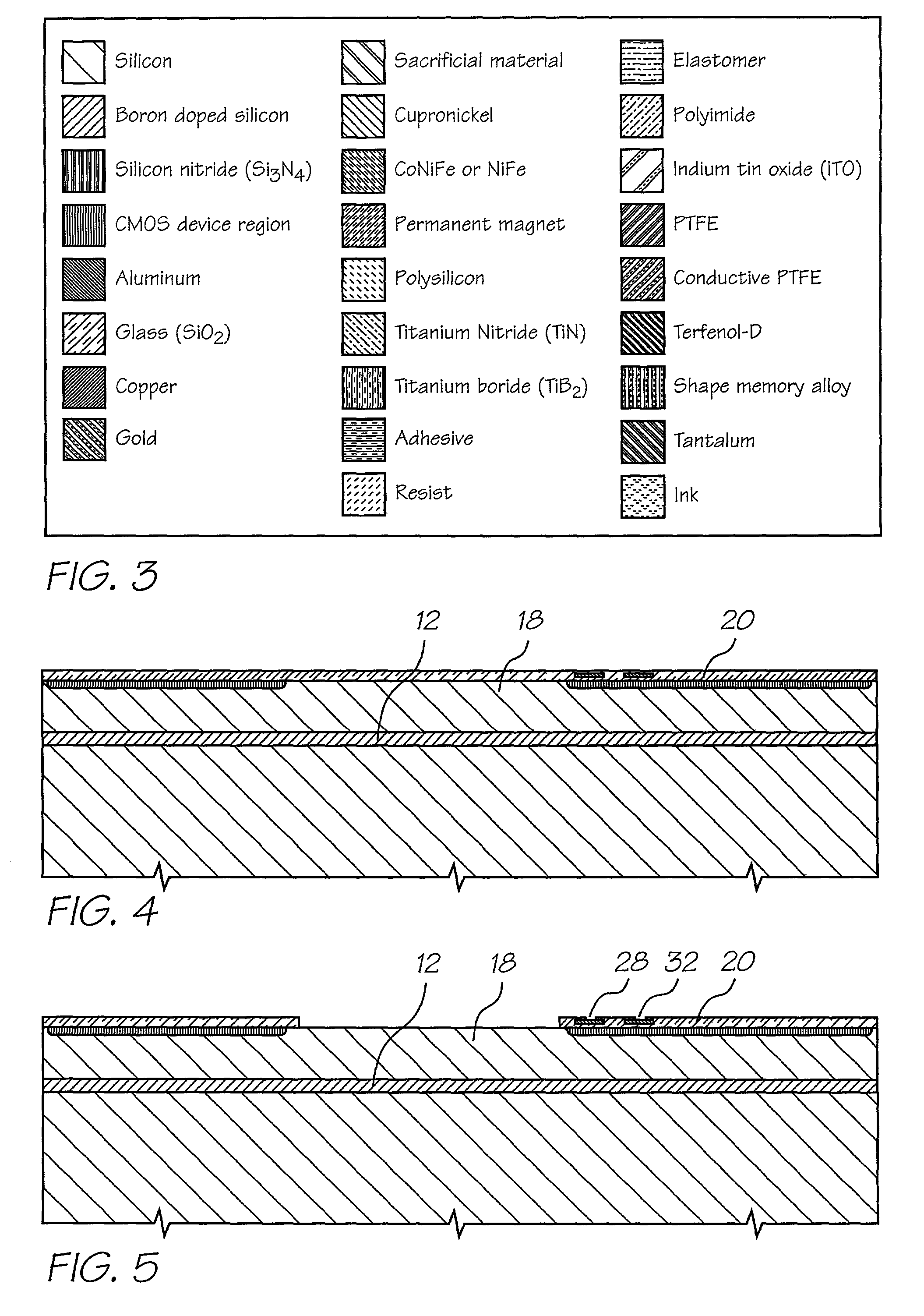

InactiveUS20050258715A1Piezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesPiezoelectric actuatorsControl theory

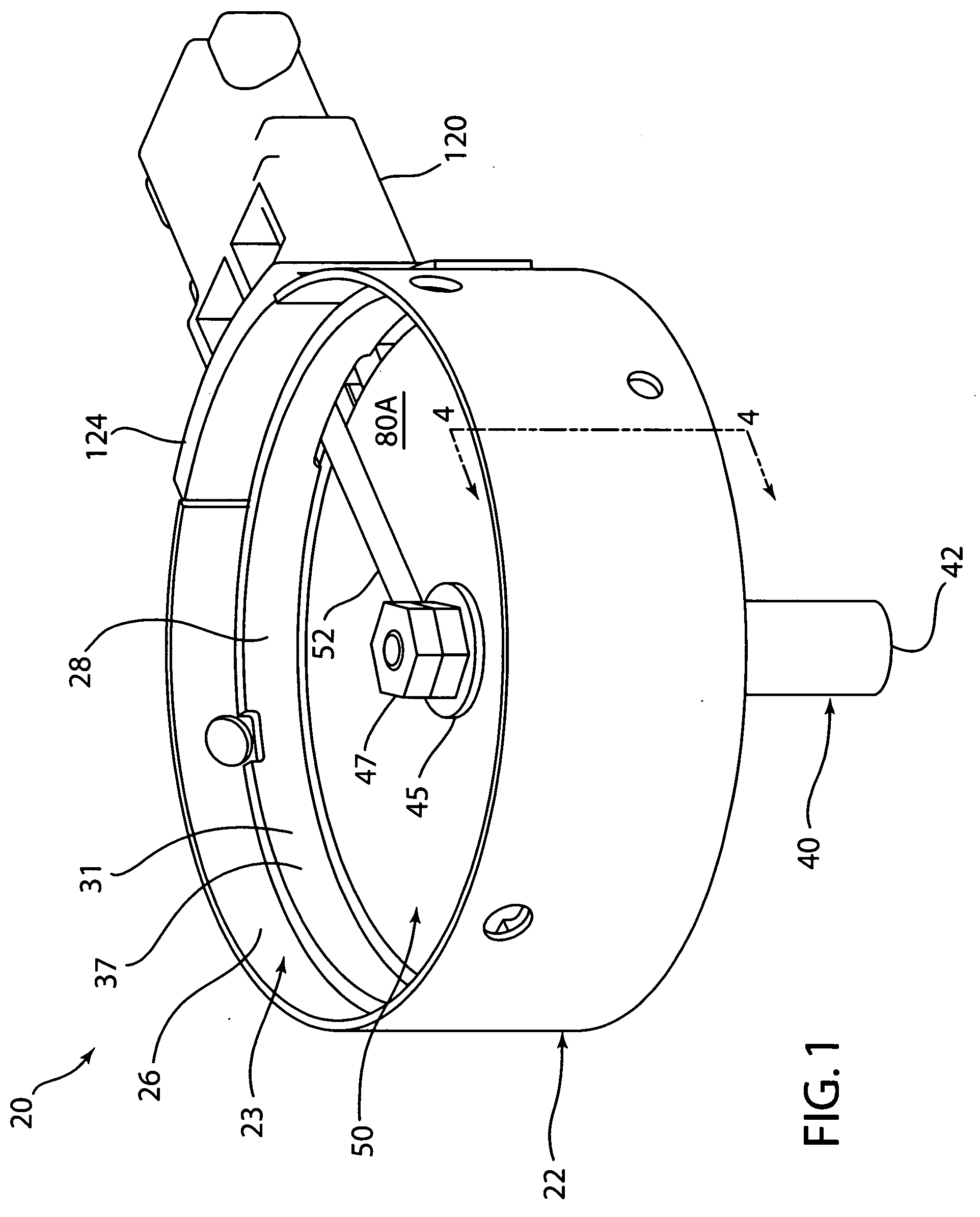

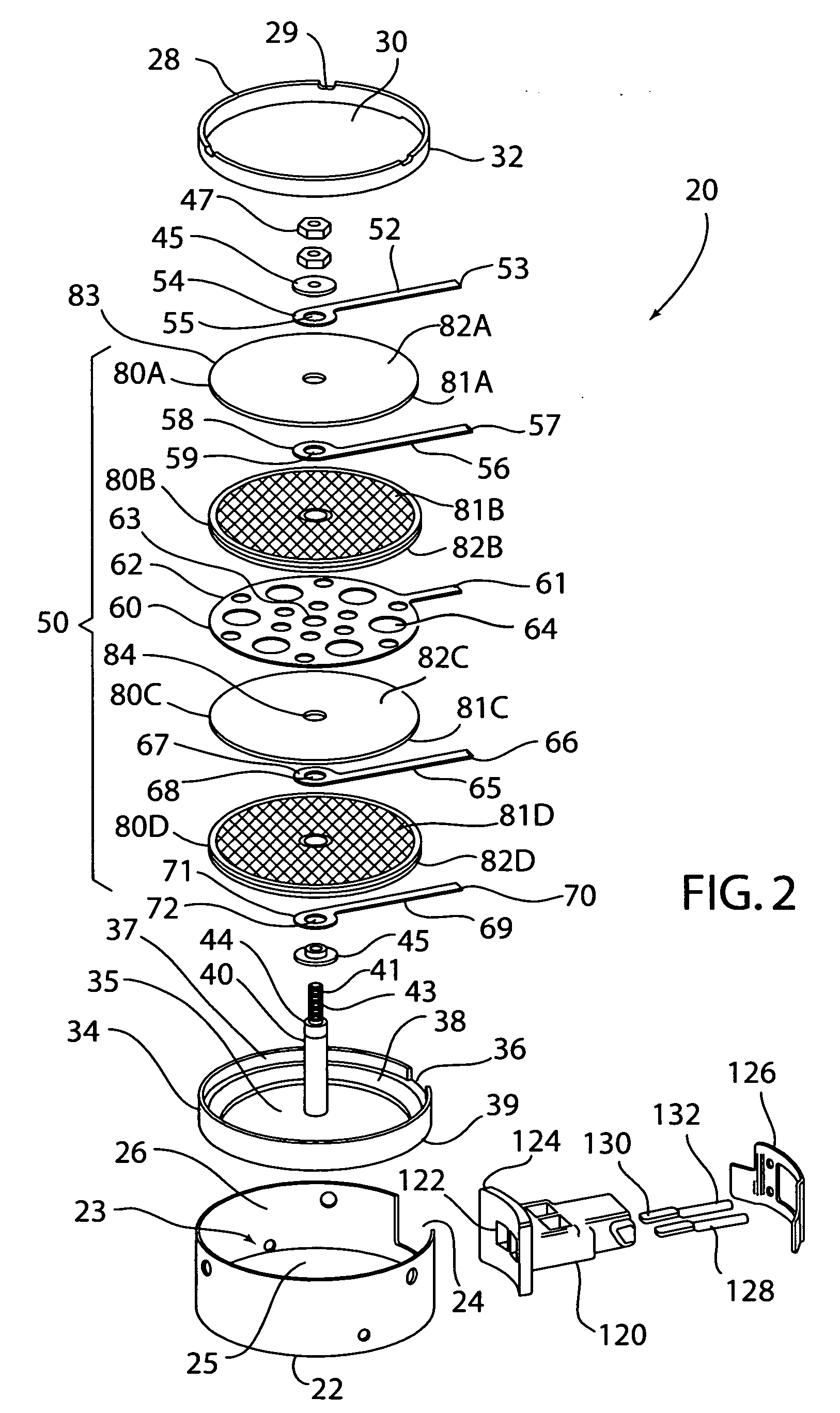

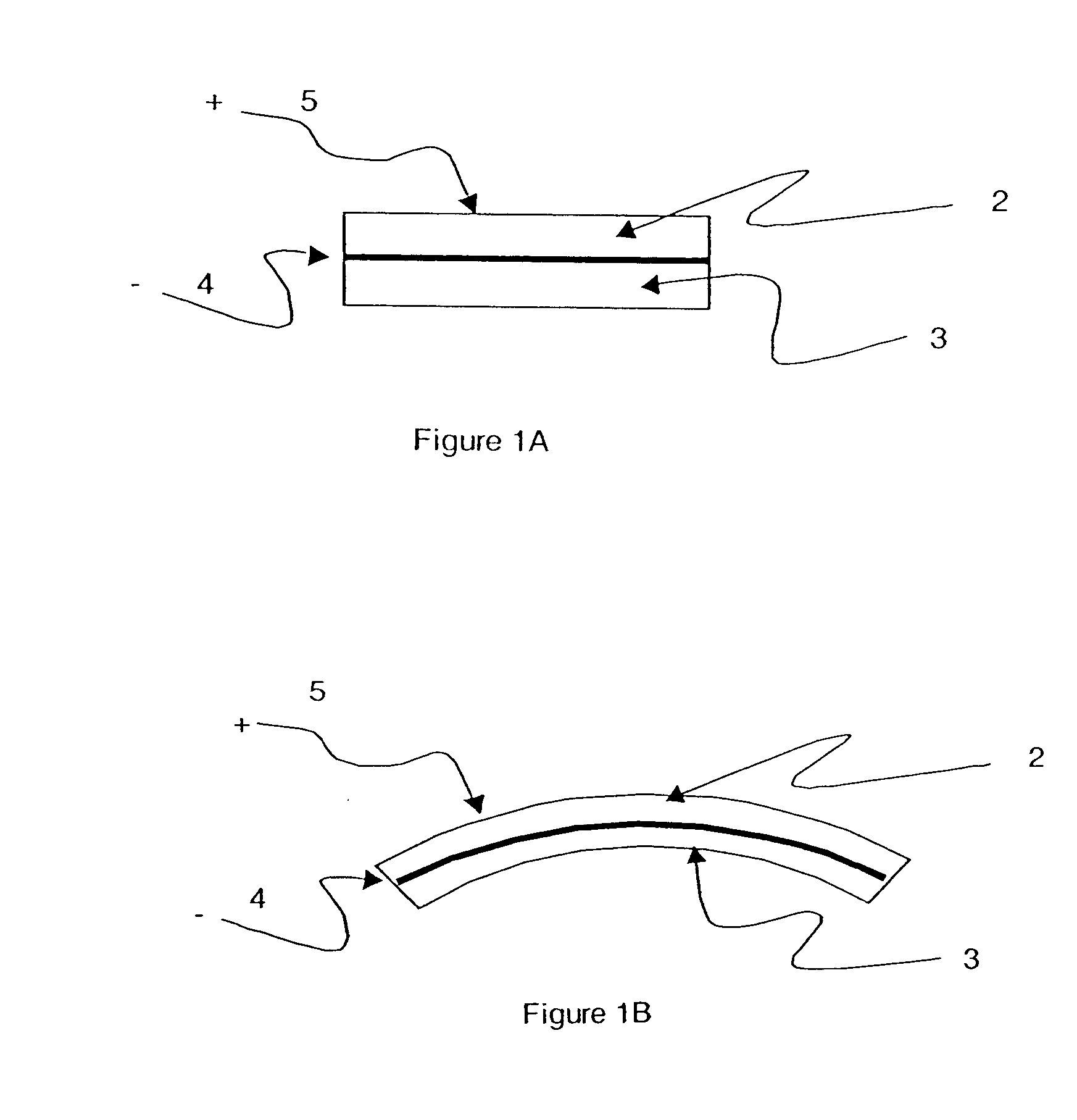

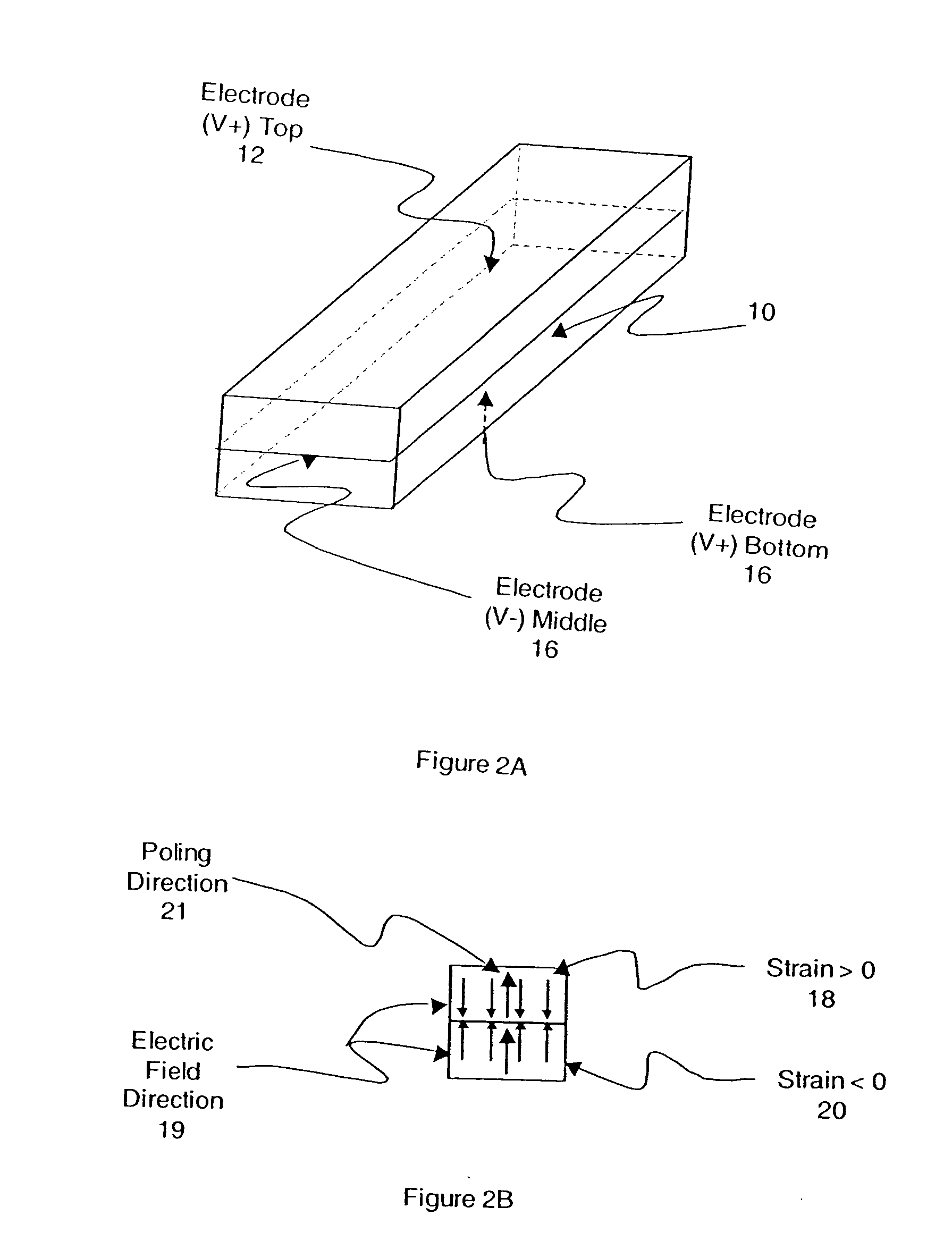

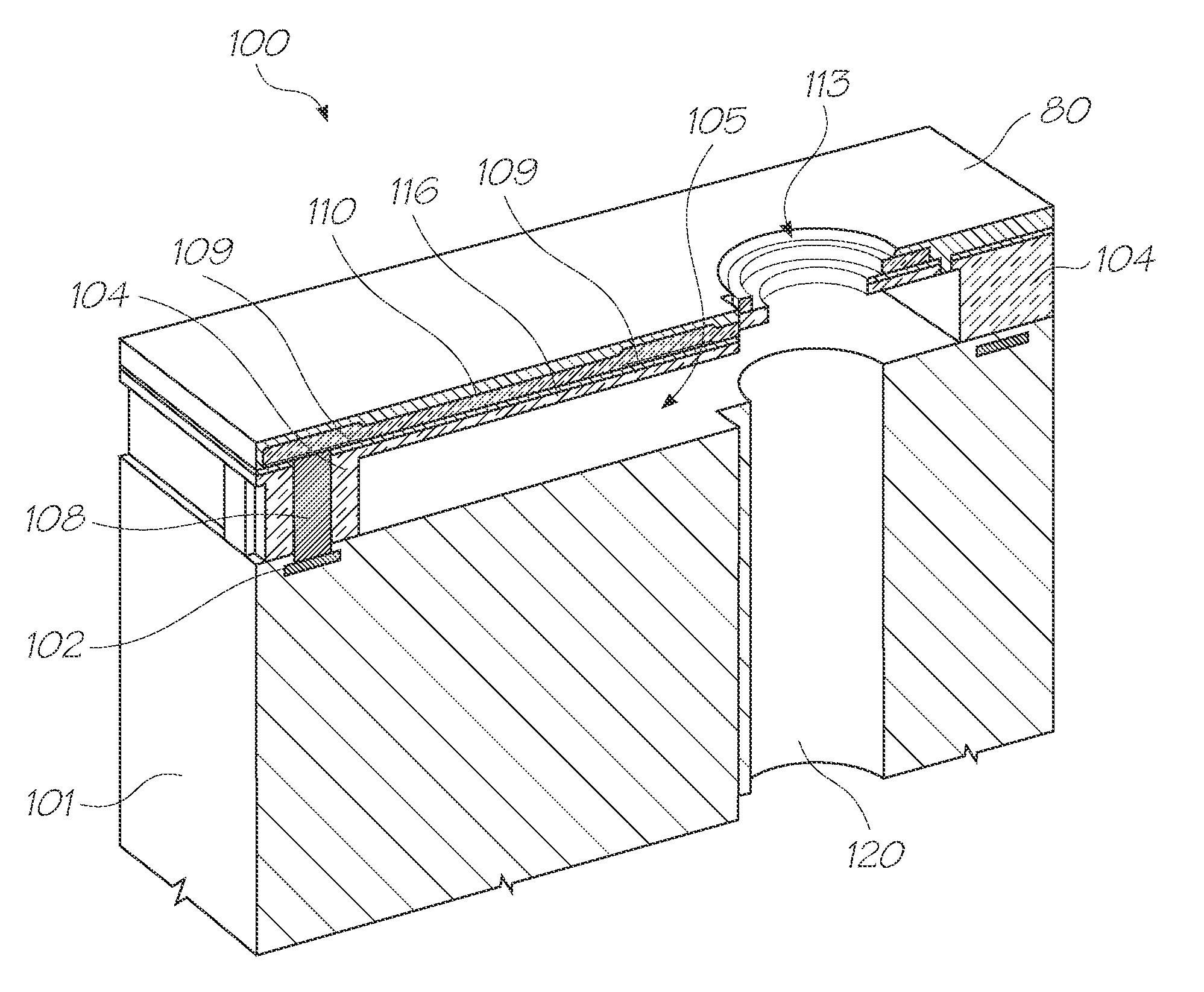

A piezoelectric bending actuator that is insensitive to temperature changes. The actuator includes a pair of piezoelectric layers. One of the layers bends in response to an applied voltage and the other piezoelectric layer flattens in response to an applied voltage. The piezoelectric layers are mounted adjacent to each other. The piezoelectric layers move opposite to each other in response to a change in temperature such that the piezoelectric bending actuator is stable over a range of temperatures. The piezoelectric layers are held in compression between a ring and a retainer. Compressing the piezoelectric layers allows the bending actuator to have a high stroke with improved durability because the discs are kept in compression.

Owner:CTS CORP ELKHART

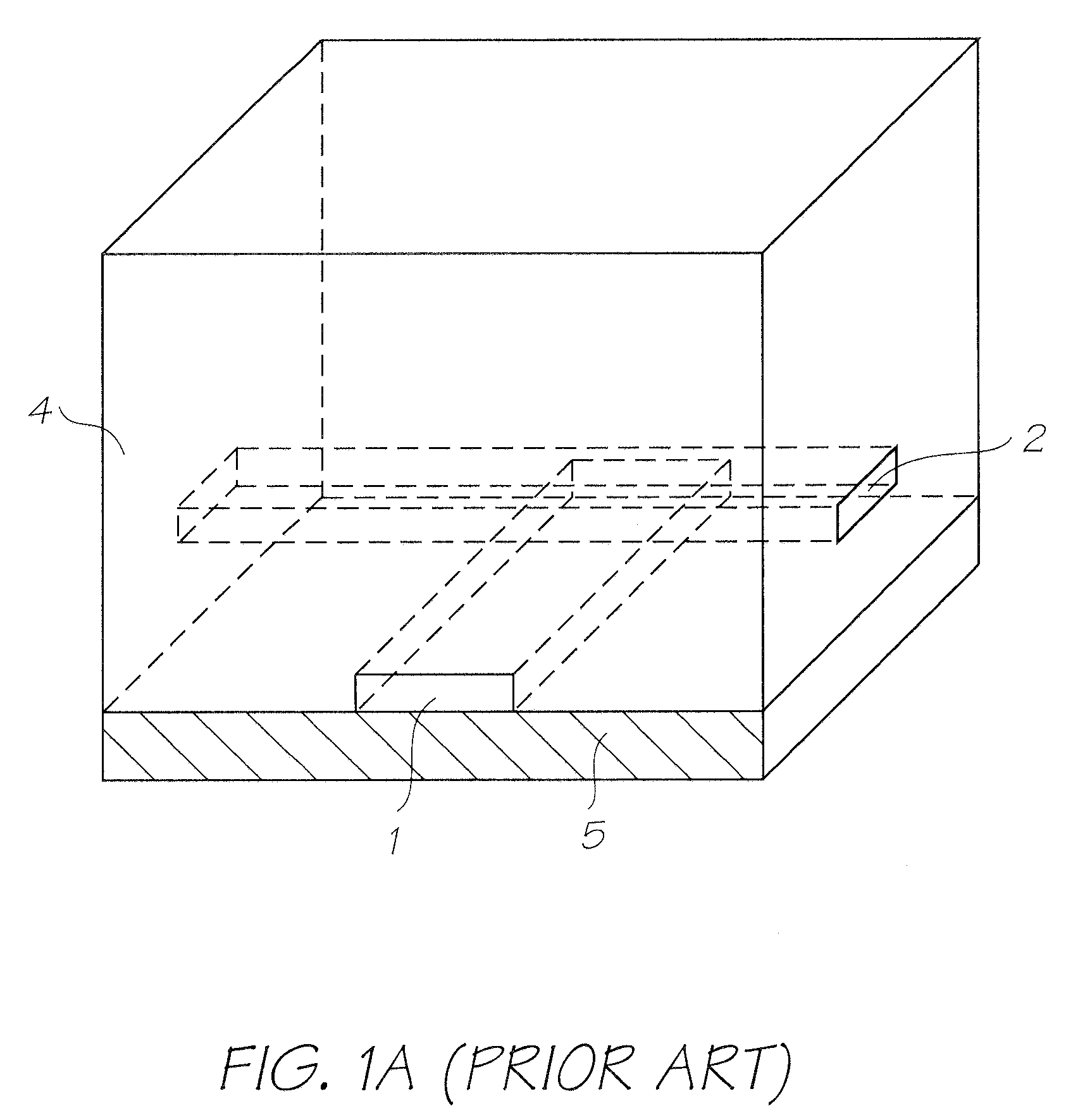

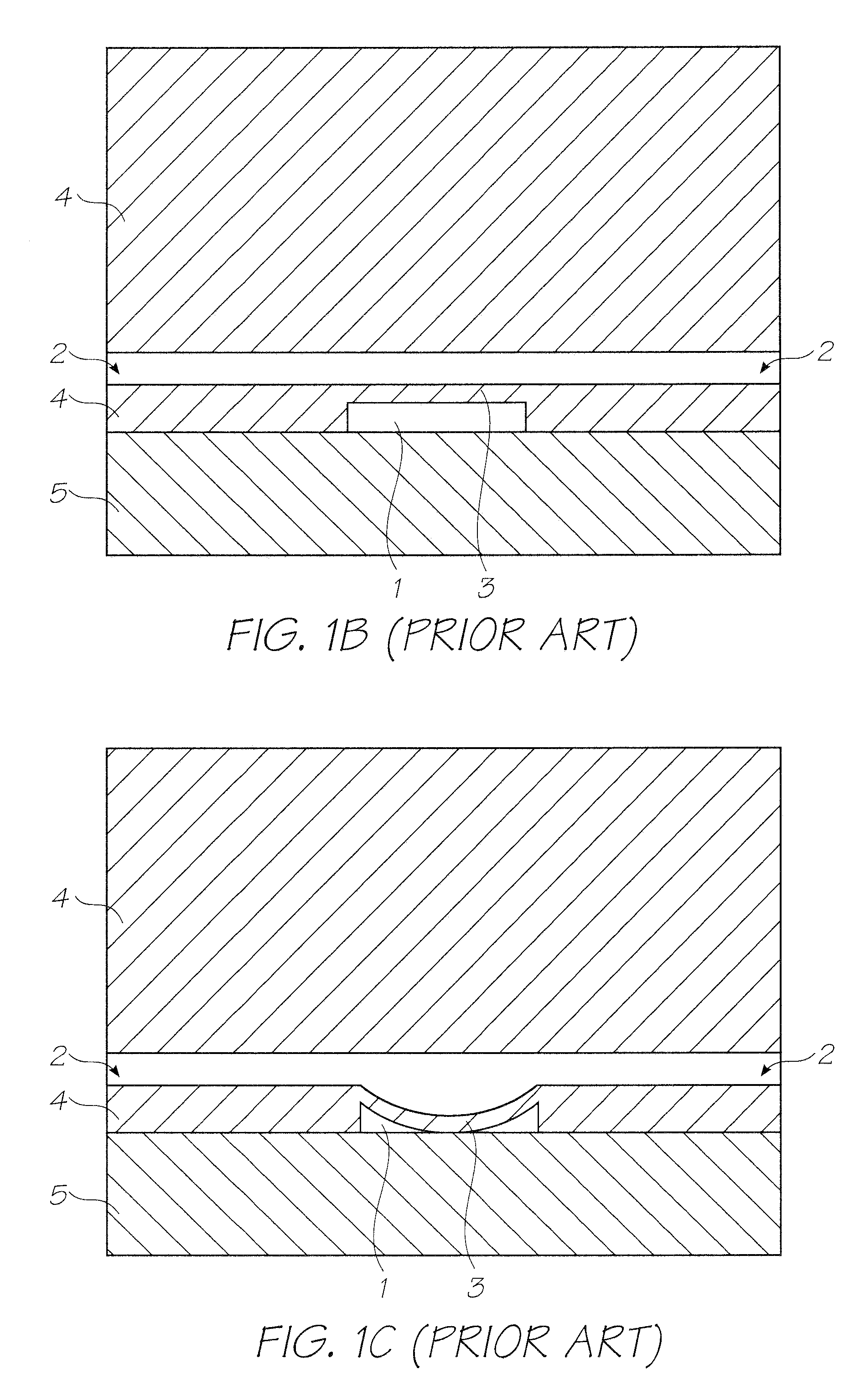

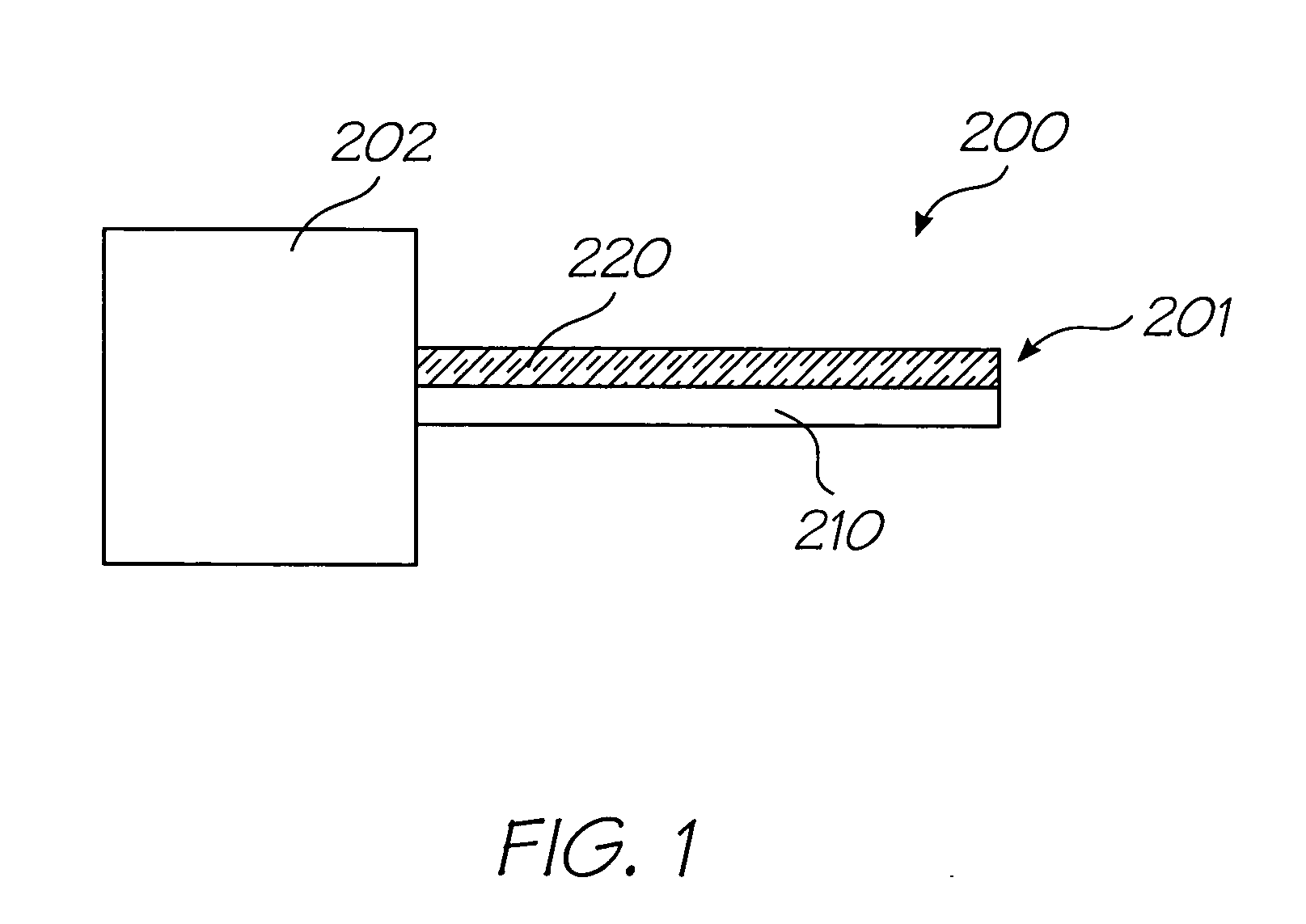

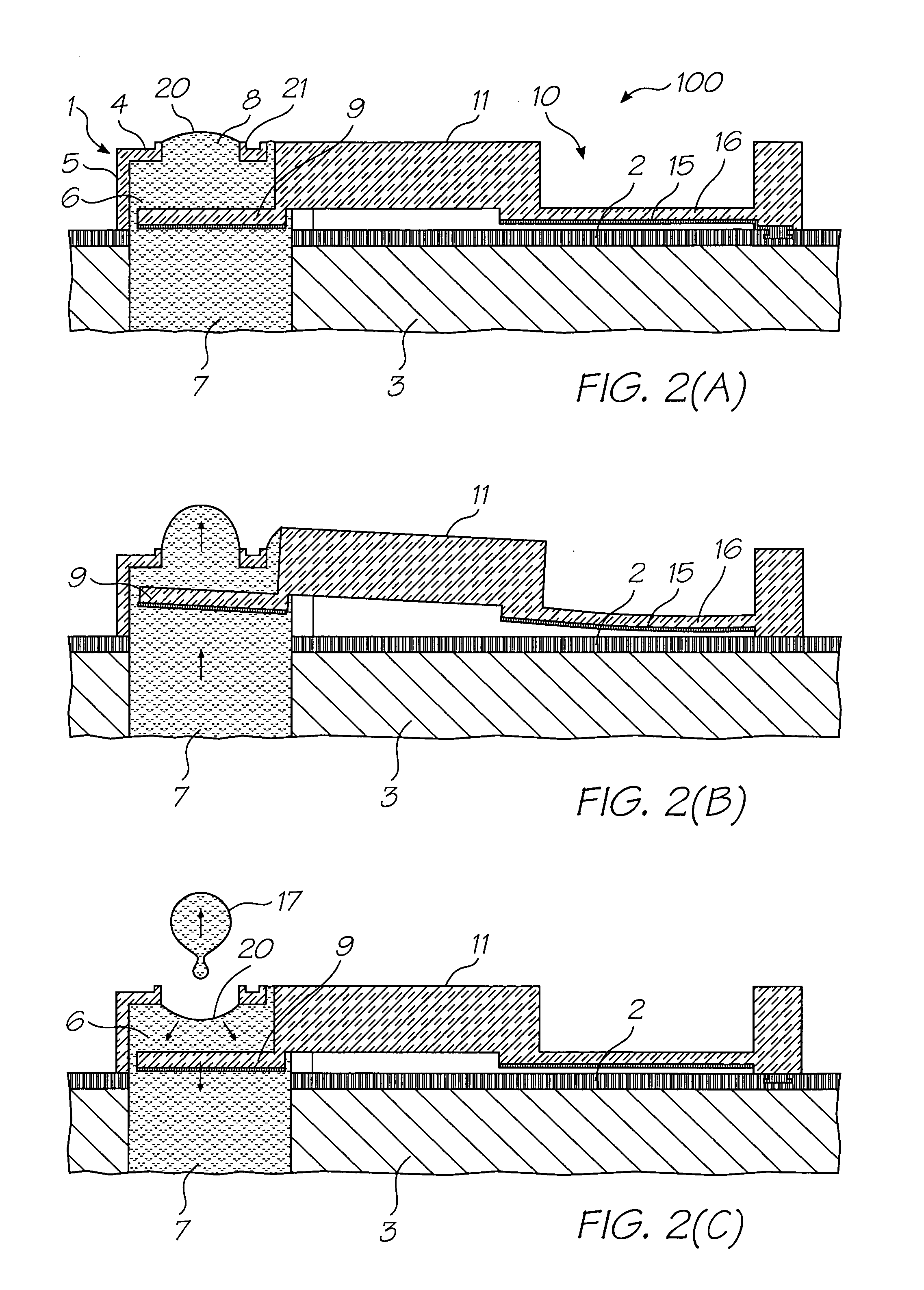

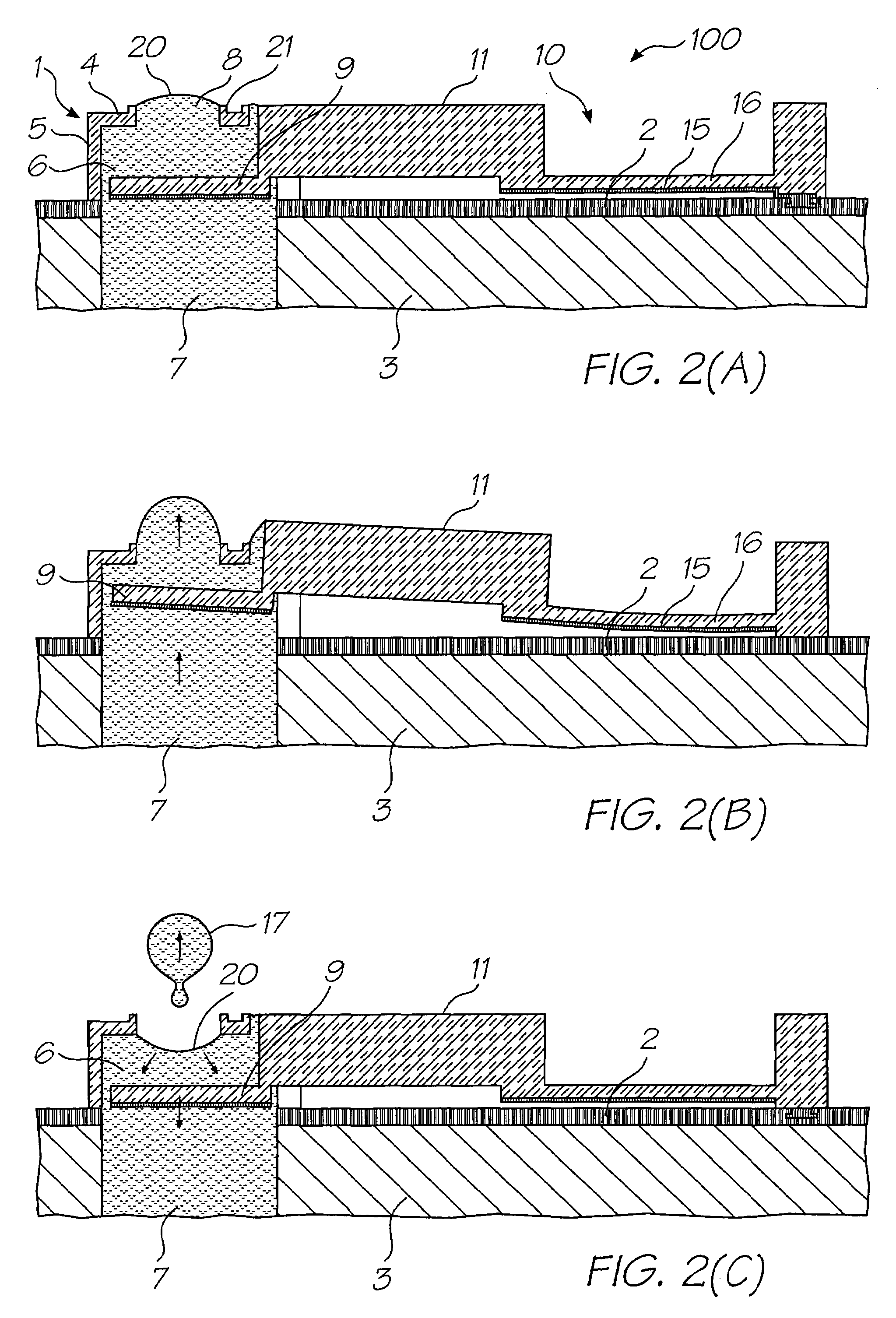

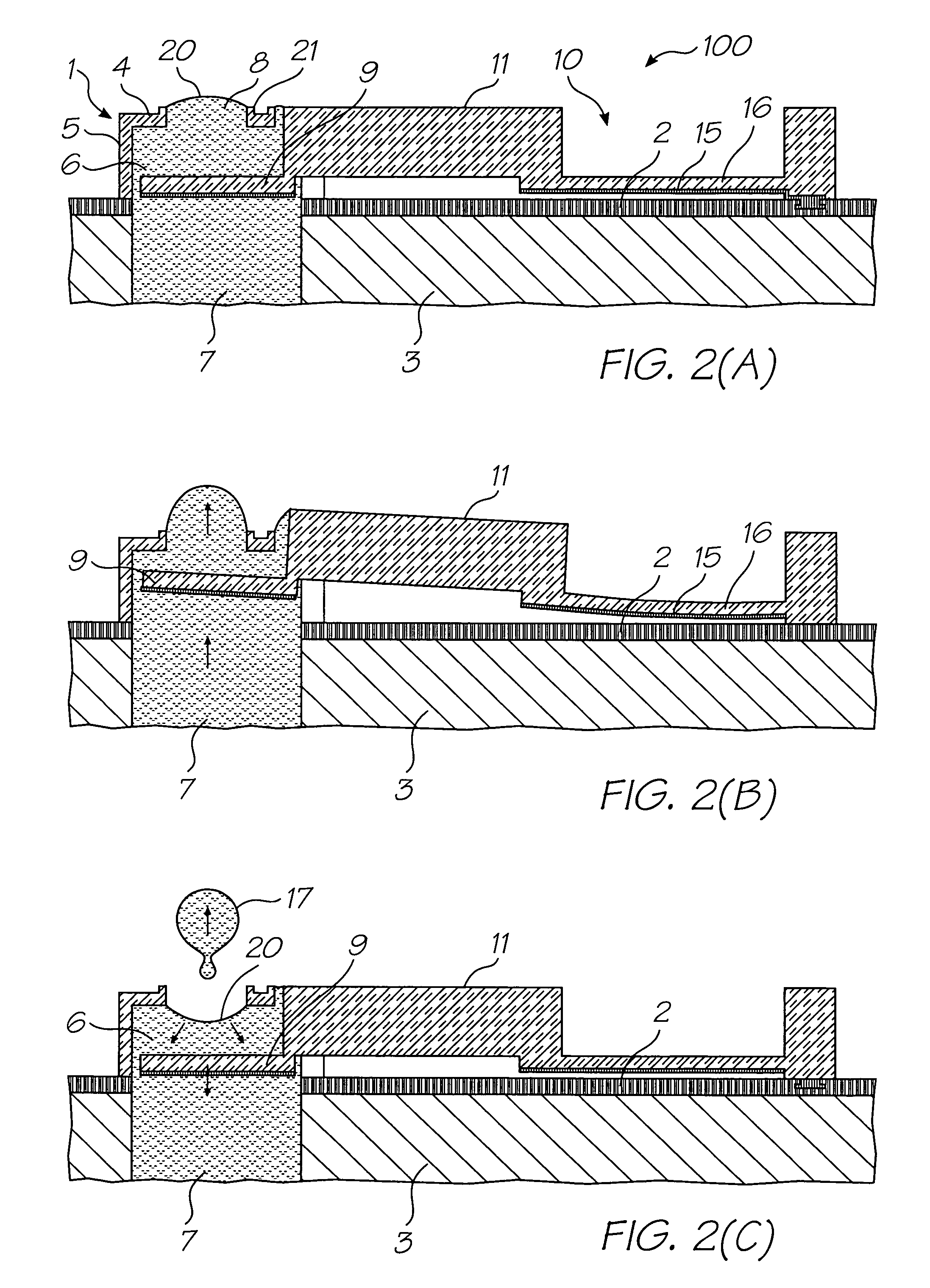

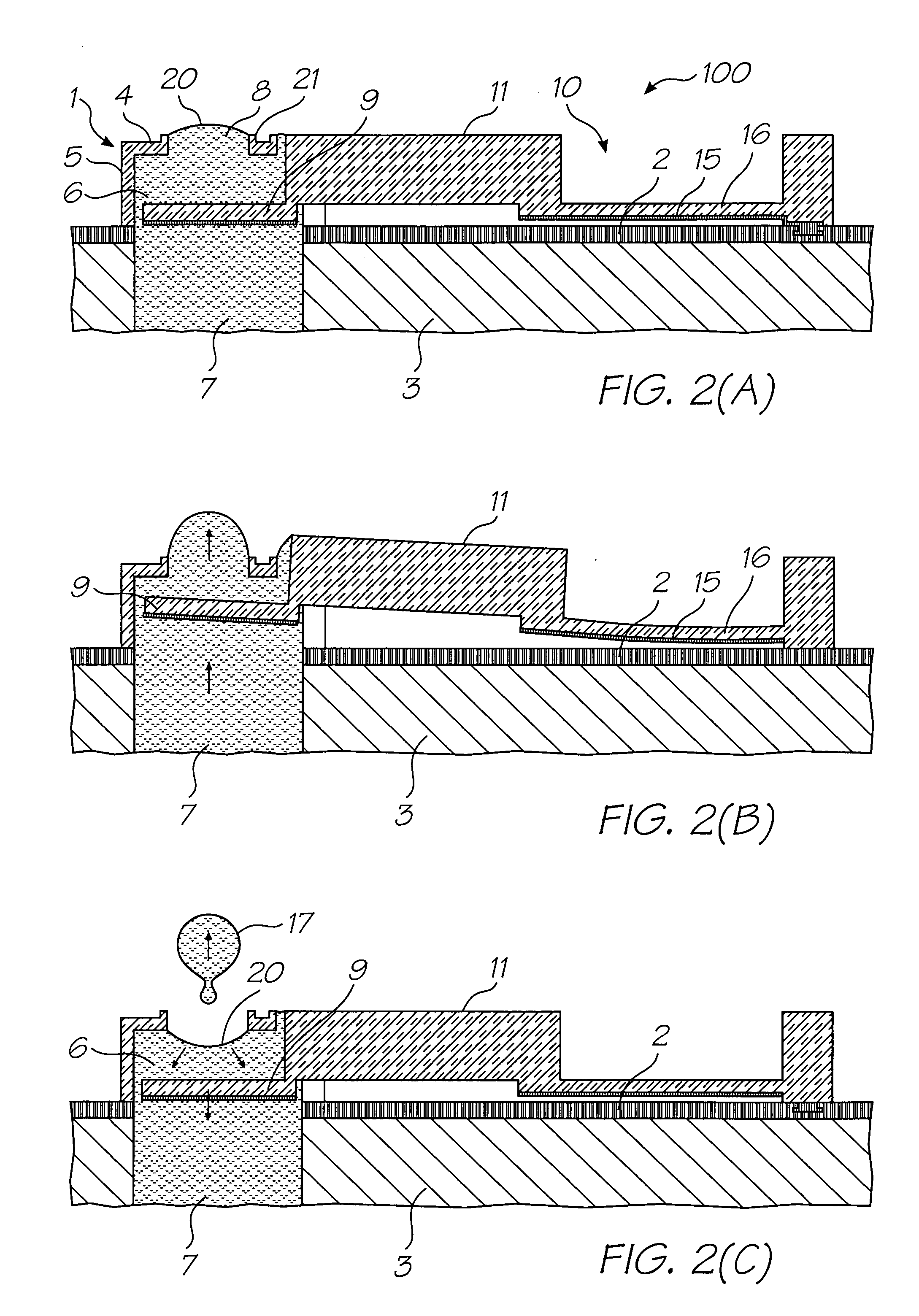

Ink jet mechanism with thermoelastic bend actuator having conductive and resistive beams

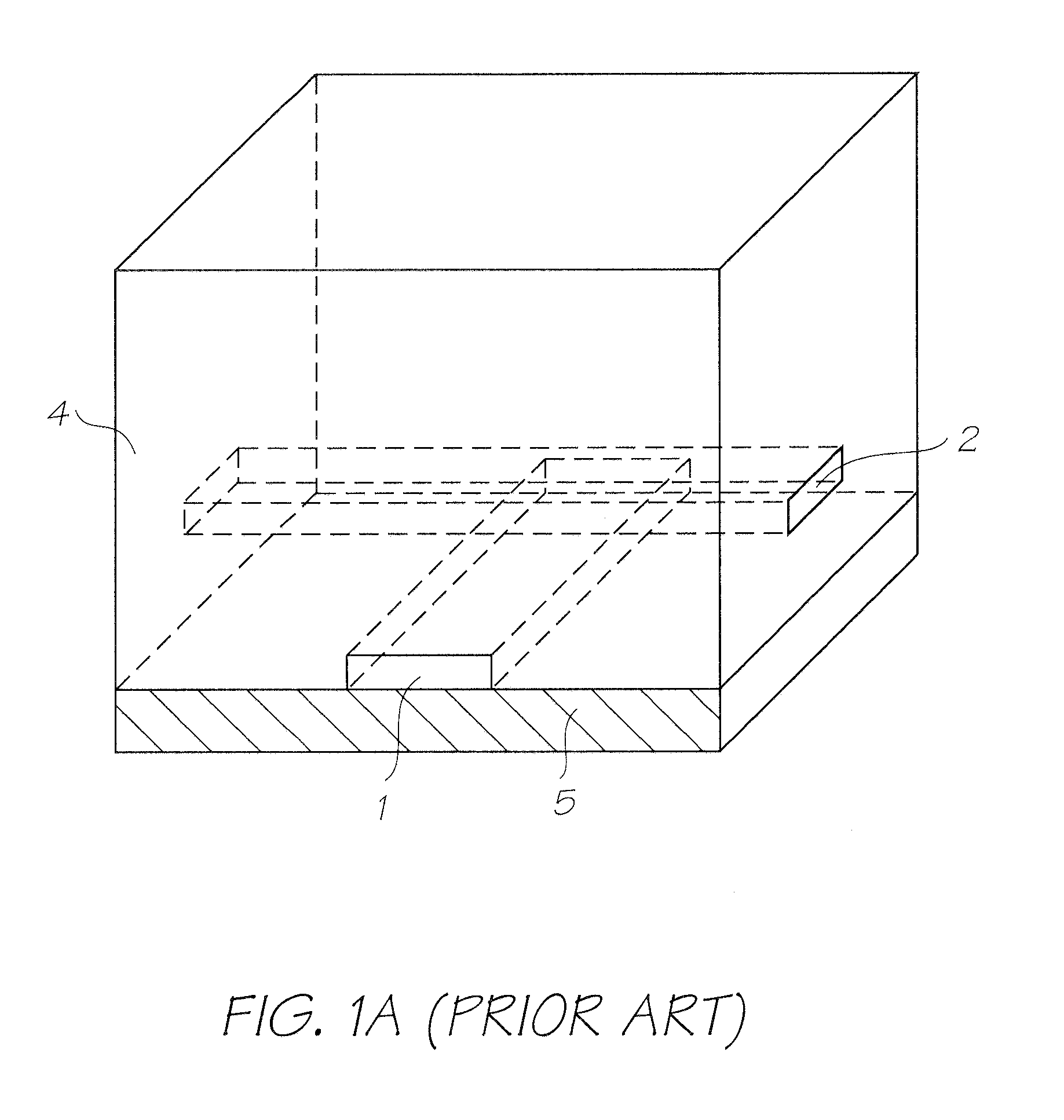

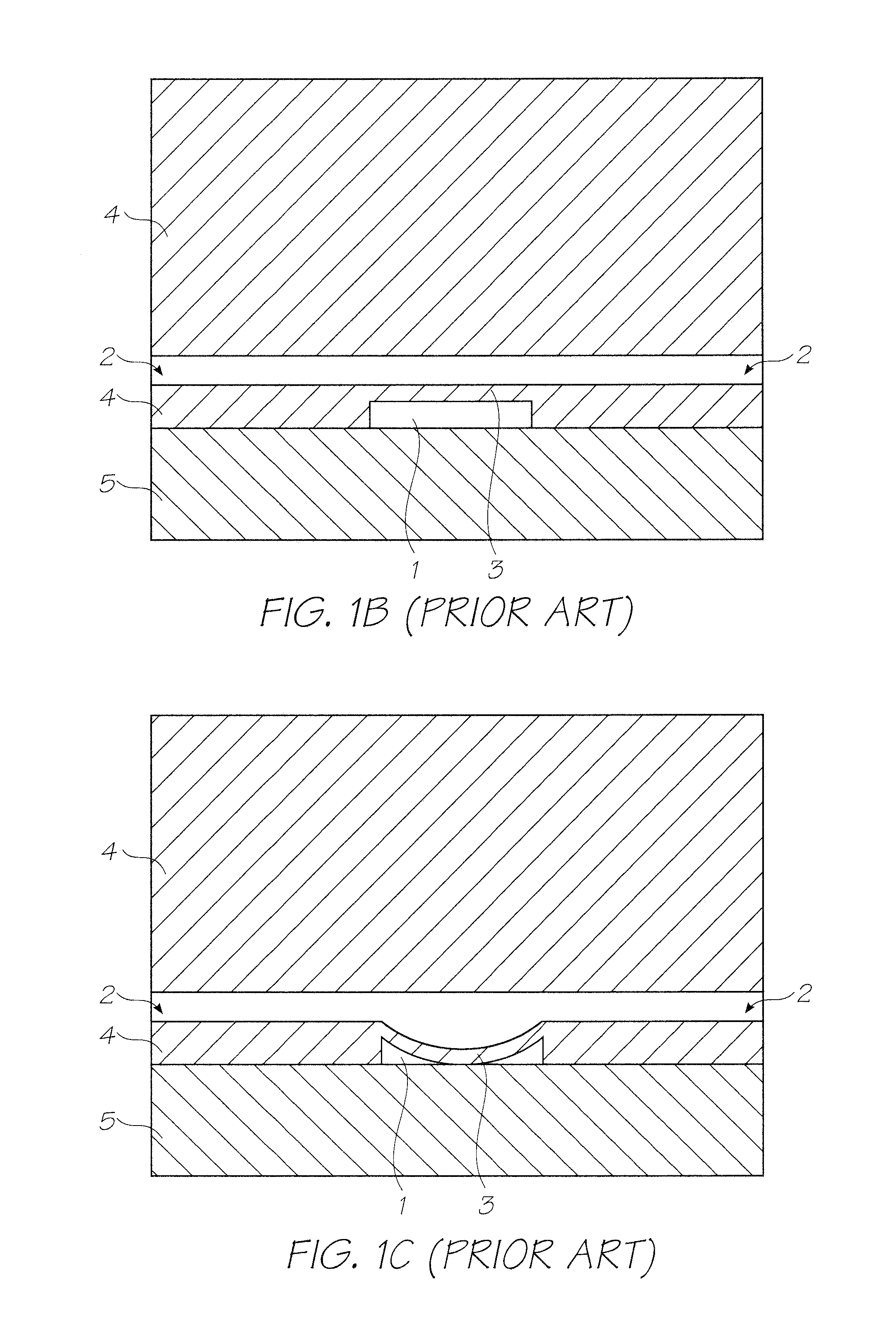

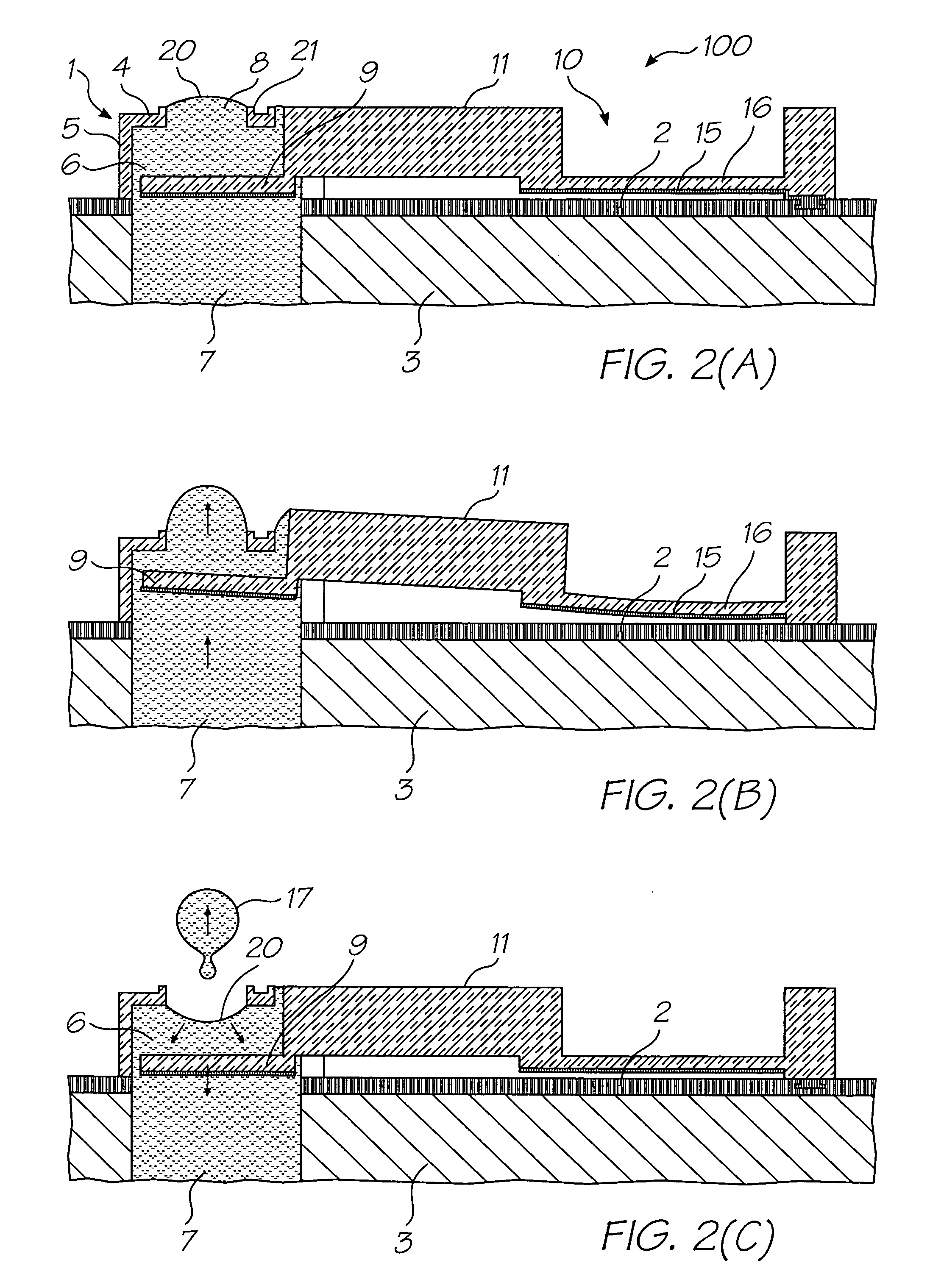

InactiveUS20010008406A1Effective volumeIncrease effective volumePrintingIndium tin oxideConductive materials

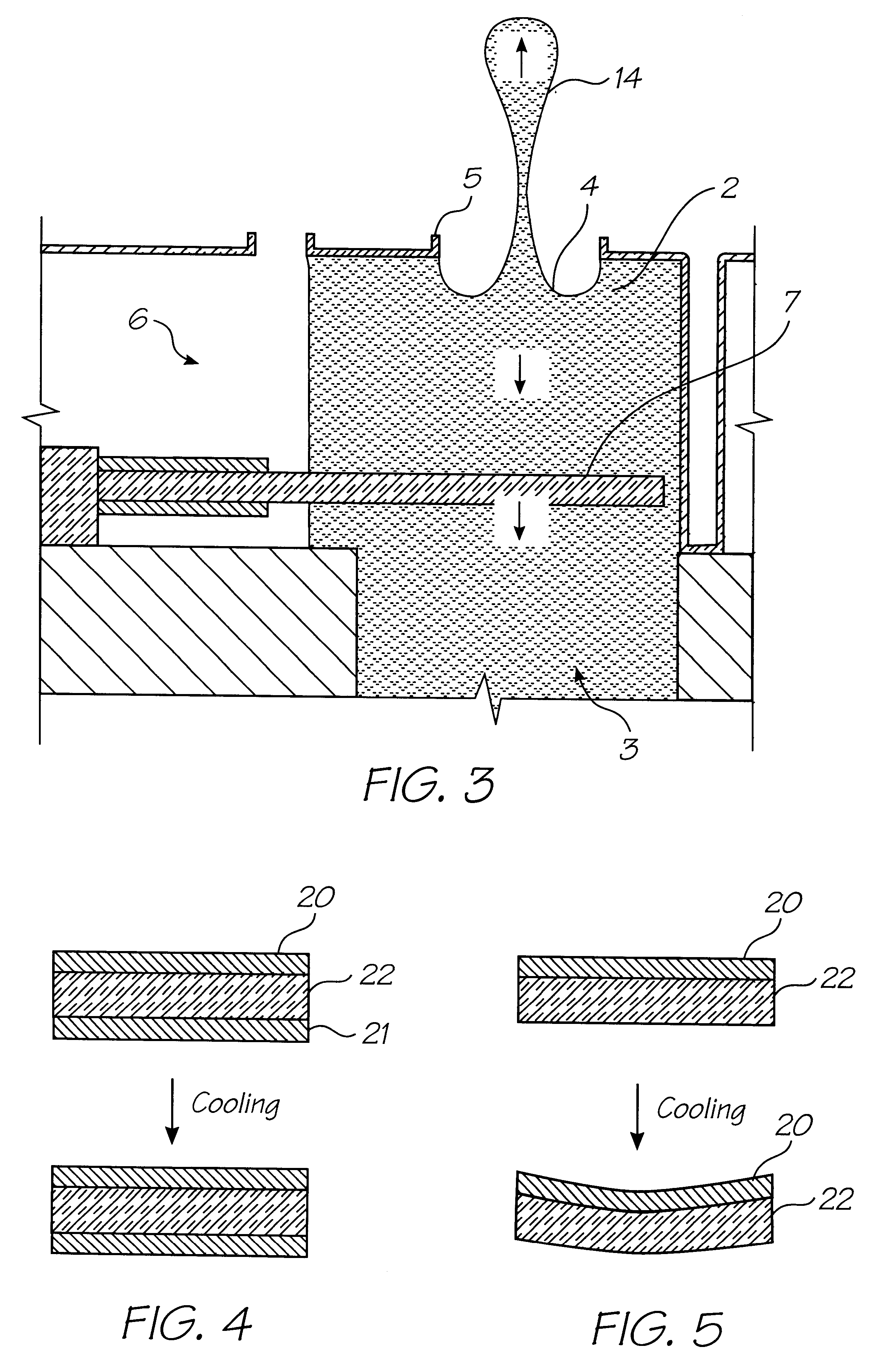

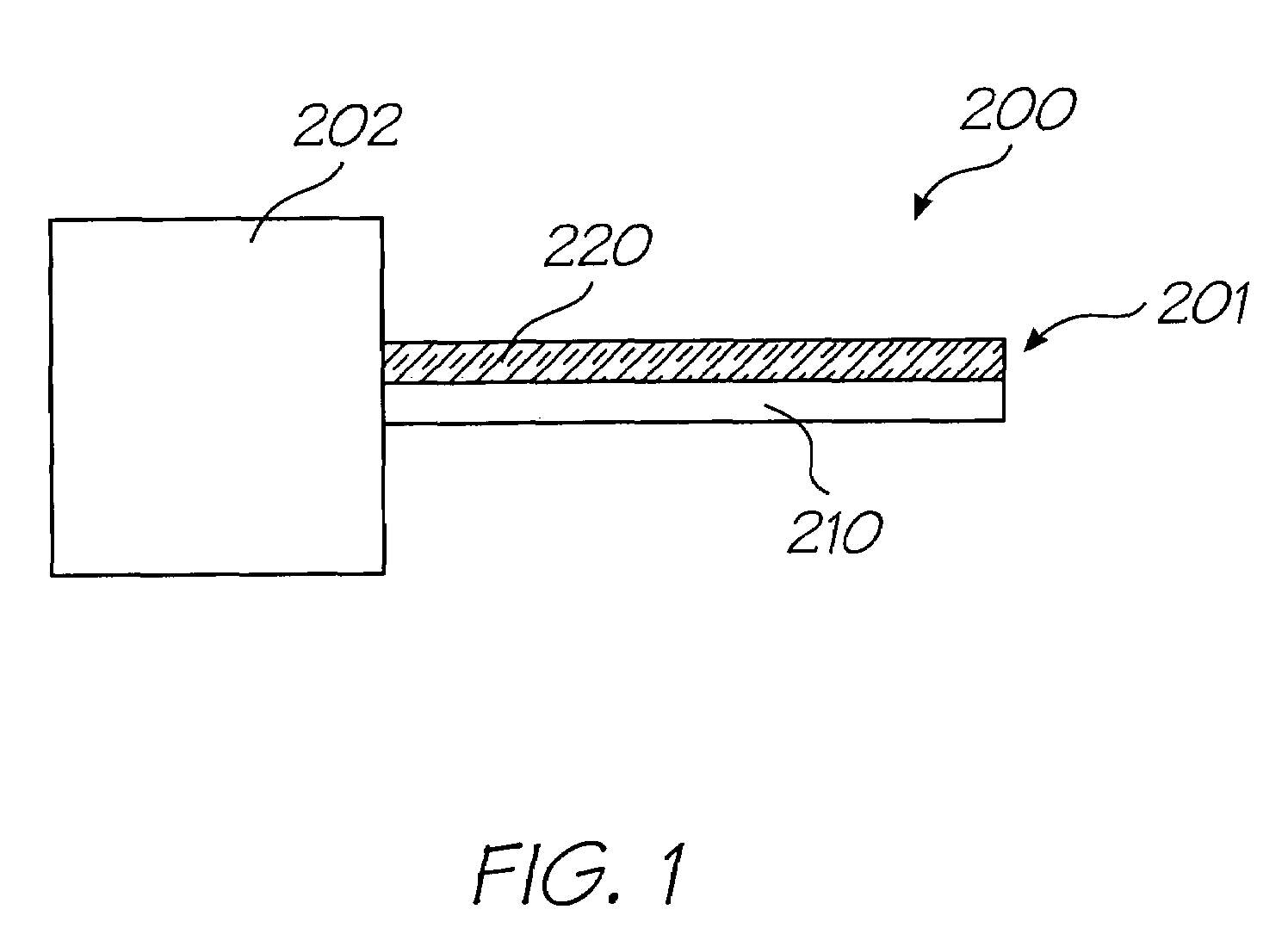

An ink jet printer uses a planar thermoelastic bend actuator to eject ink from a nozzle chamber. The thermal actuator includes a lower planar surface constructed from a highly conductive material such as a semiconductor metal layer interconnected to an upper planar surface constructed from an electrically resistive material such as Indium Tin Oxide (ITO), such that, upon passing a current between the planar surfaces, the thermal actuator is caused to bend towards an ink ejection port so as to thereby cause ejection of ink from the ink ejection port. The actuator is attached to a substrate and further includes a stiff paddle portion which increases the degree of bending of the actuator near the point where it is attached to the substrate. The surfaces are further coated with a passivation material as required.

Owner:SILVERBROOK RES PTY LTD +1

Ink jet nozzle assembly with a thermal bend actuator

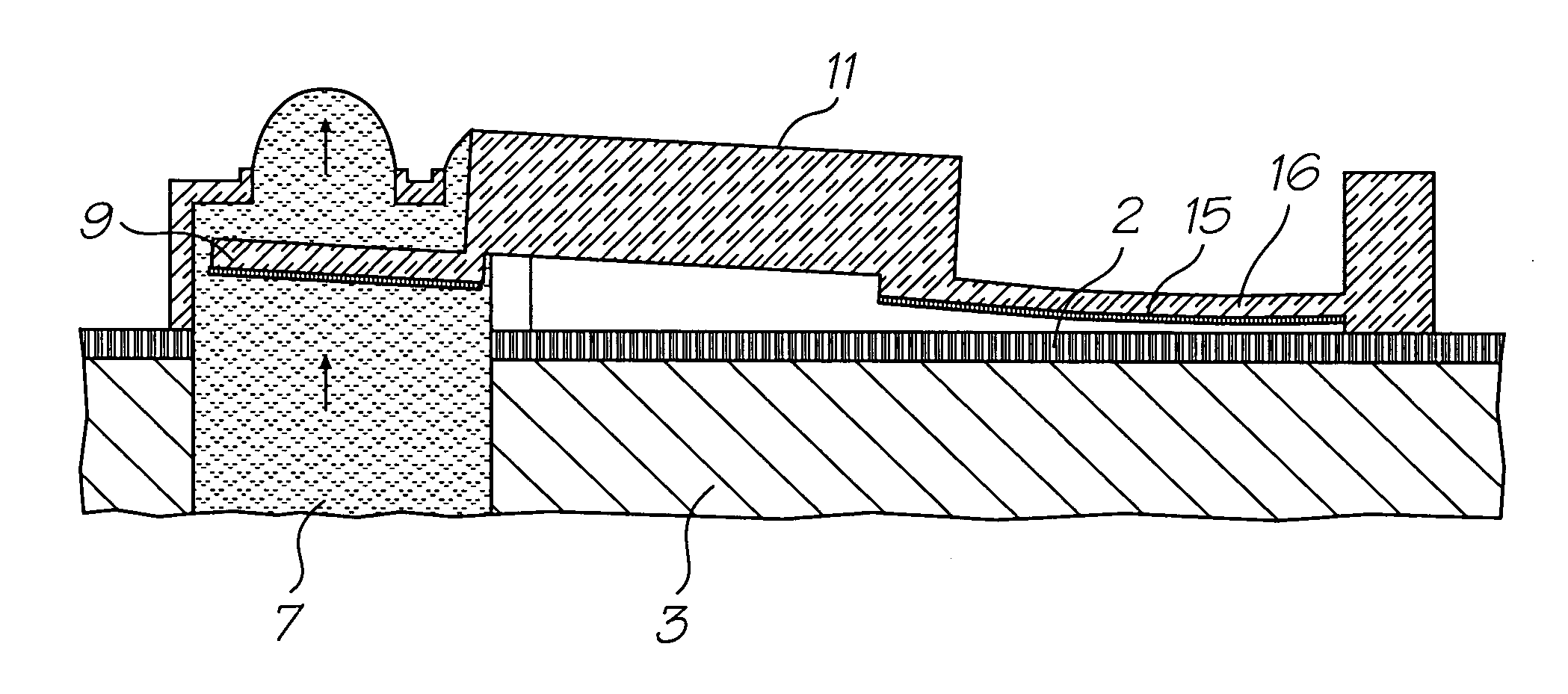

InactiveUS7195339B2Same thermal expansion and elasticity characteristicMaterial nanotechnologyTelevision system detailsThermal expansionBending actuator

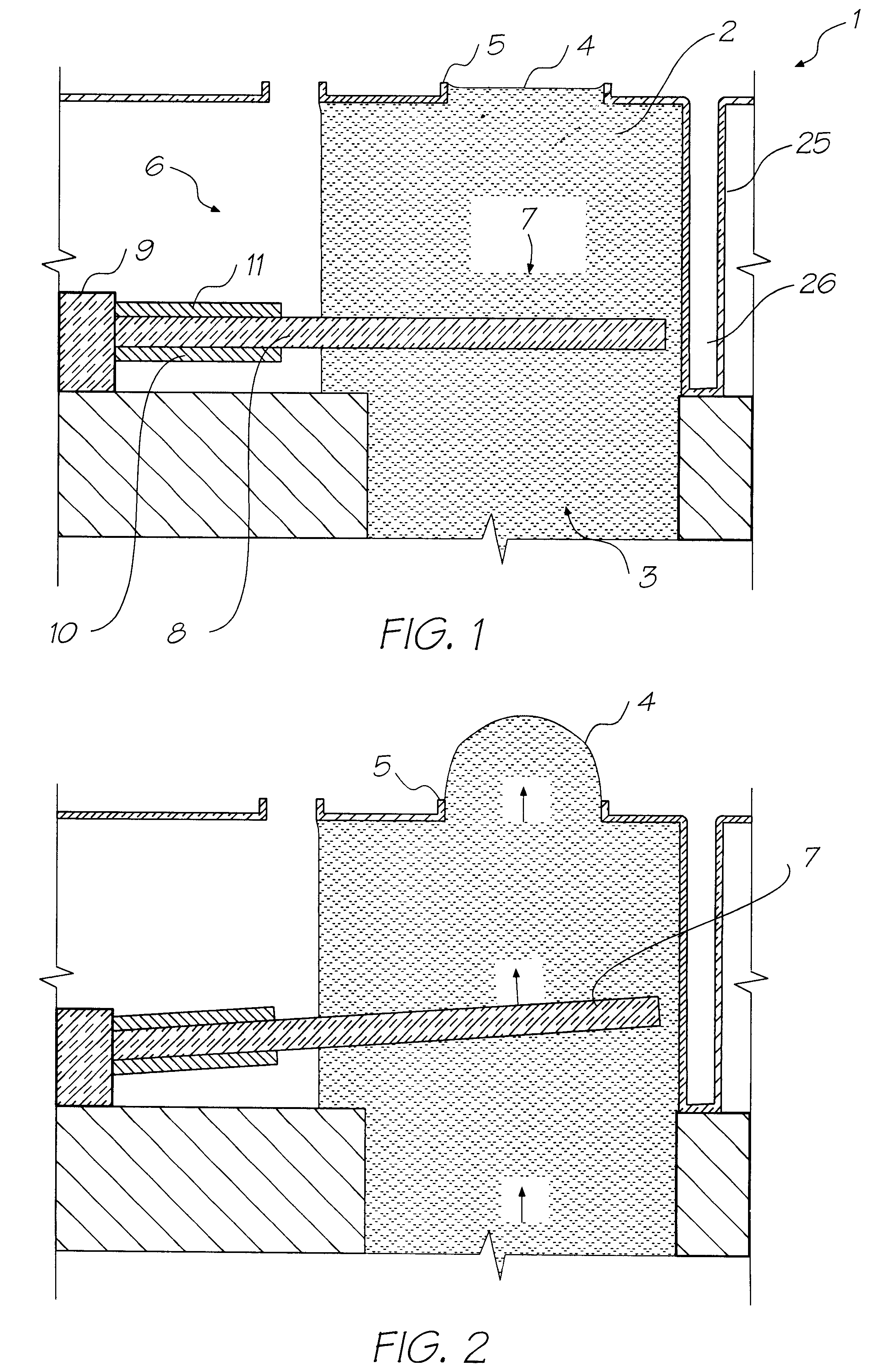

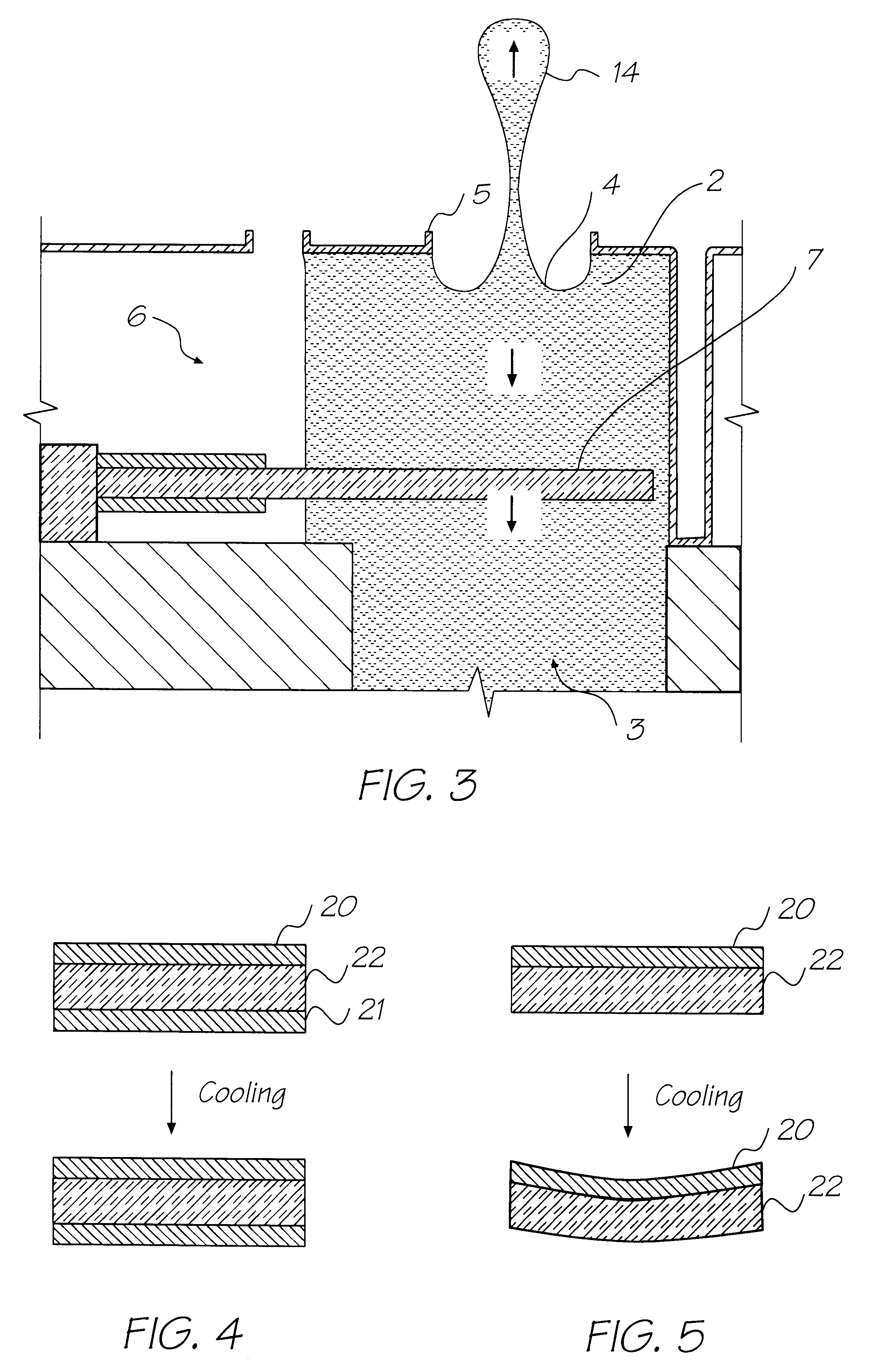

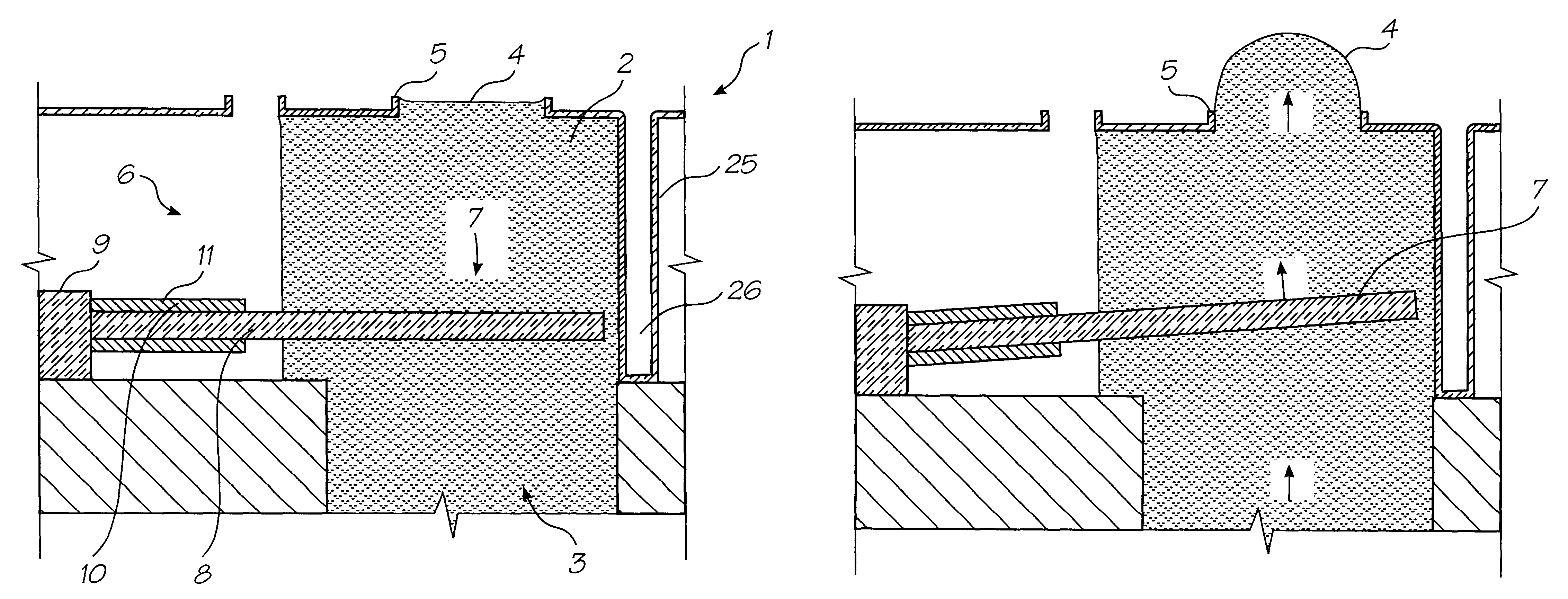

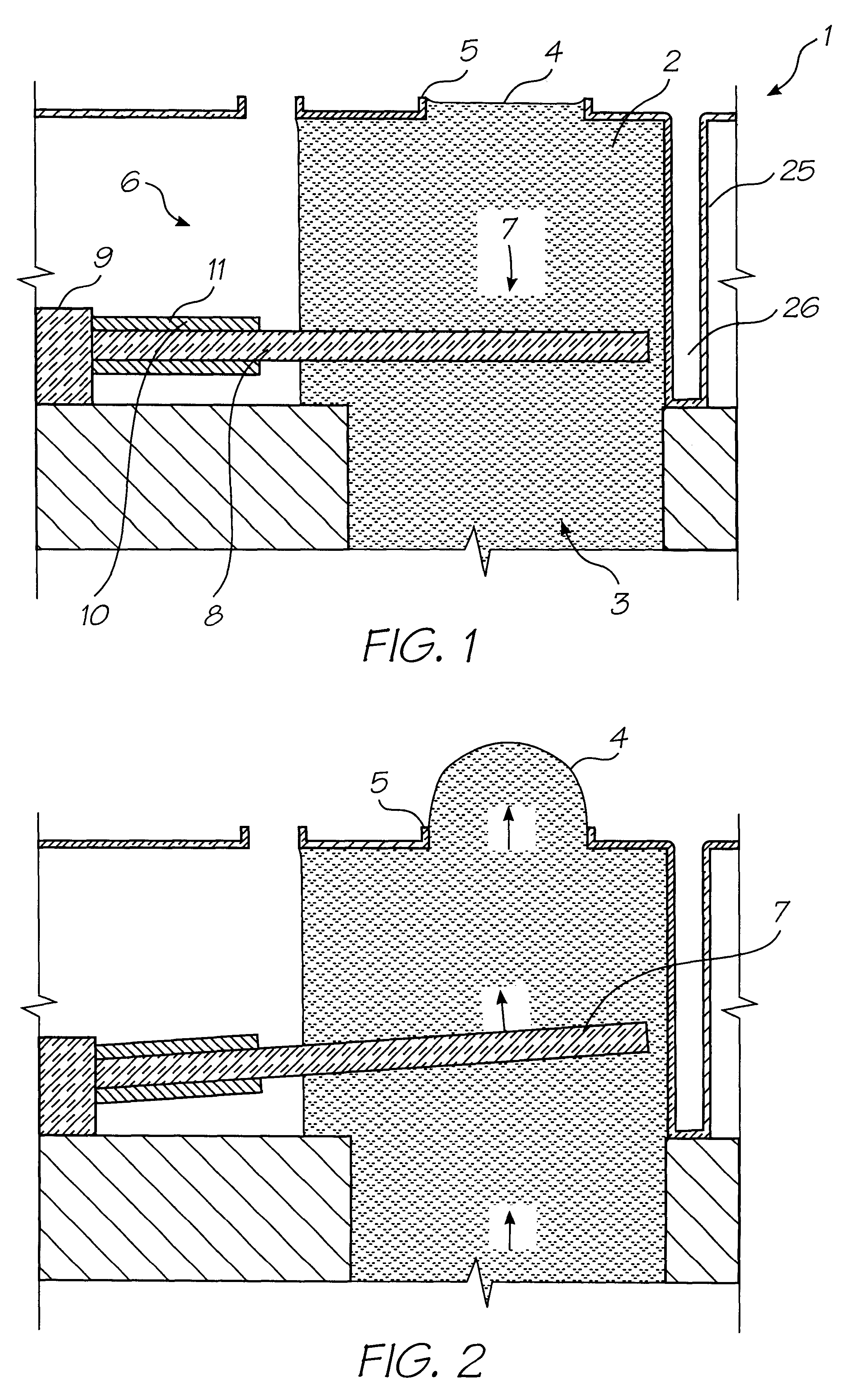

An ink jet nozzle assembly for an inkjet printer includes a wafer substrate defining an ink supply passage. A drive circuitry layer is formed on the wafer substrate. A nozzle is formed on the drive circuitry layer and defines an ink chamber in fluid communication with the ink supply passage, a side aperture in fluid communication with the ink chamber and an ink ejection port in fluid communication with the ink chamber. A support extends from the drive circuitry layer. A thermal bend actuator extends from the support, through the side aperture and terminates in a free end within the ink chamber. The actuator includes a first layer having a first co-efficient of thermal expansion, and a second layer deposited on the first layer which has a second co-efficient of thermal expansion. The first layer is coupled to the drive circuitry layer so that, in use, the drive circuitry layer can actuate bending of the thermal bend actuator so as to move the free end and thereby eject ink from the ink ejection port.

Owner:ZAMTEC +1

Mechanically-Actuated Microfluidic Pinch Valve

A microfluidic pinch valve. The valve comprises a microfluidic channel defined in a compliant body; a valve sleeve defined by a section of the microfluidic channel, the valve sleeve having a membrane wall defining part of an outer surface of the body; a compression member for pinching the membrane wall against an opposed wall of the valve sleeve; and a thermal bend actuator for moving the compression member between a closed position in which the membrane wall is sealingly pinched against the opposed wall, and an open position in which the membrane wall is disengaged from the opposed wall.

Owner:SILVERBROOK RES PTY LTD

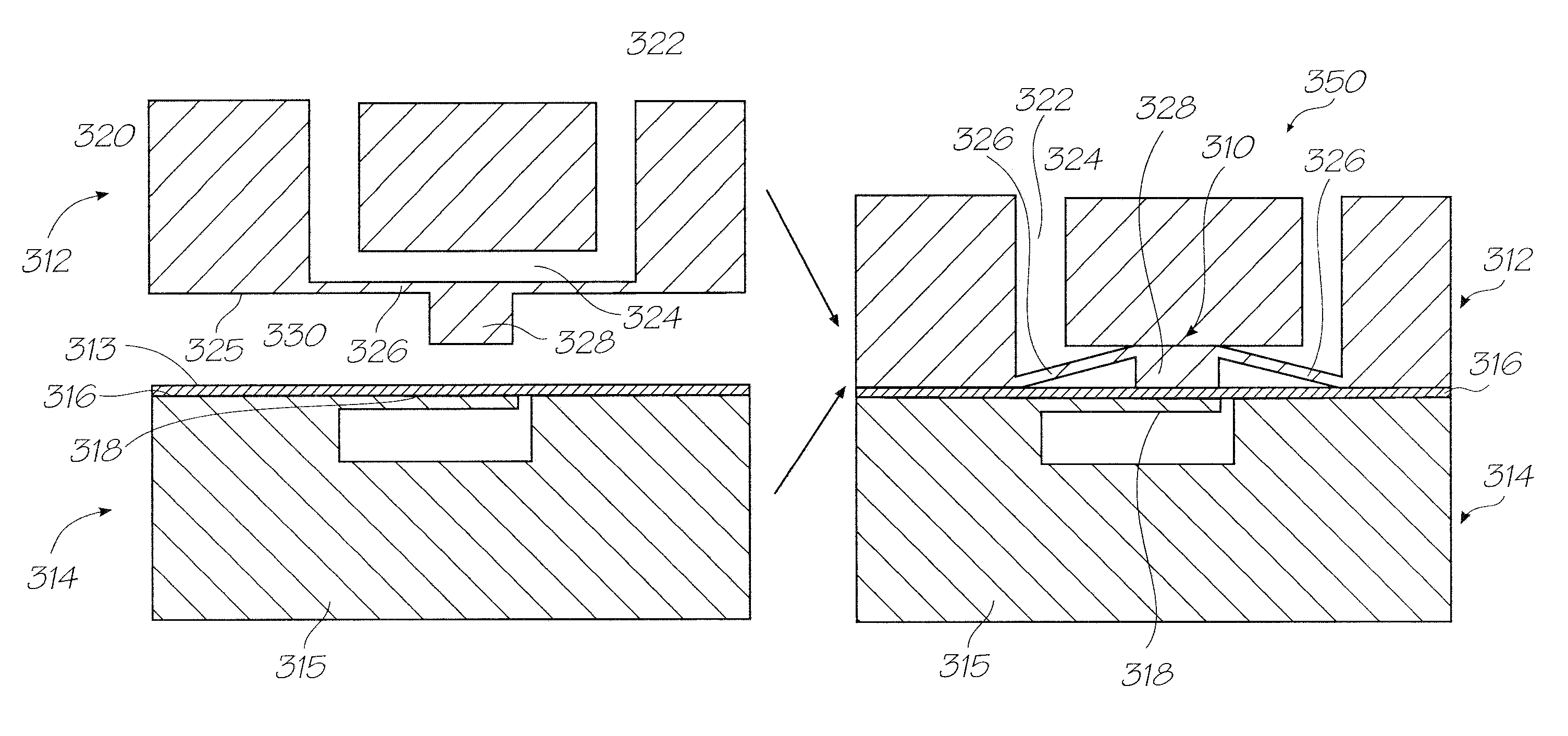

Inkjet printhead having thermal bend actuator with separate heater element

An ink jet nozzle arrangement formed on a substrate comprising: a nozzle chamber having an ink ejection aperture in one wall thereof and an actuator interconnection aperture in a second wall thereof; an external thermal bend actuator interconnected at one end with an internal ink ejection paddle through the actuator interconnection aperture and, at a second end, affixed to the substrate; and a moveable internal ink ejection paddle, moveable under the control of the external thermal bend actuator for the ejection of ink out of the ink ejection aperture; wherein the external thermal actuator further can comprise a series of layers and preferably can include a planar conductive heating circuit layer which preferably can include a first portion adjacent the second end which forms a conductive circuit of heating the thermal bend actuator, and a second portion forming a portion of the ink ejection paddle, the second portion being electrically isolated from the first portion by means of a slot traversing the planar conductive heating circuit layer external to the nozzle chamber.

Owner:MEMJET TECH LTD +1

Ink jet printhead having thermal bend actuator heating element electrically isolated from nozzle chamber ink

An ink jet printhead includes a number of nozzle devices formed on a substrate. Each nozzle device has a nozzle chamber, a nozzle opening through which ink from the nozzle chamber is ejected, a movable element in contact with ink in the nozzle chamber to cause the ejection of ink and thermal bend actuator. The thermal bend actuator has a proximal end anchored to the substrate and a distal end connected to the movable element. The actuator includes a first portion adjacent the proximal end and having a conducting heating circuit layer for heating the actuator. A second end portion of the actuator extends to the movable element and is in contact with ink in the chamber. A dielectric slot electrically isolates the first and second portions so that electric energy in the heating circuit layer is not conducted by the actuator to the ink in the chamber.

Owner:MEMJET TECH LTD +1

Bending actuators and sensors constructed from shaped active materials and methods for making the same

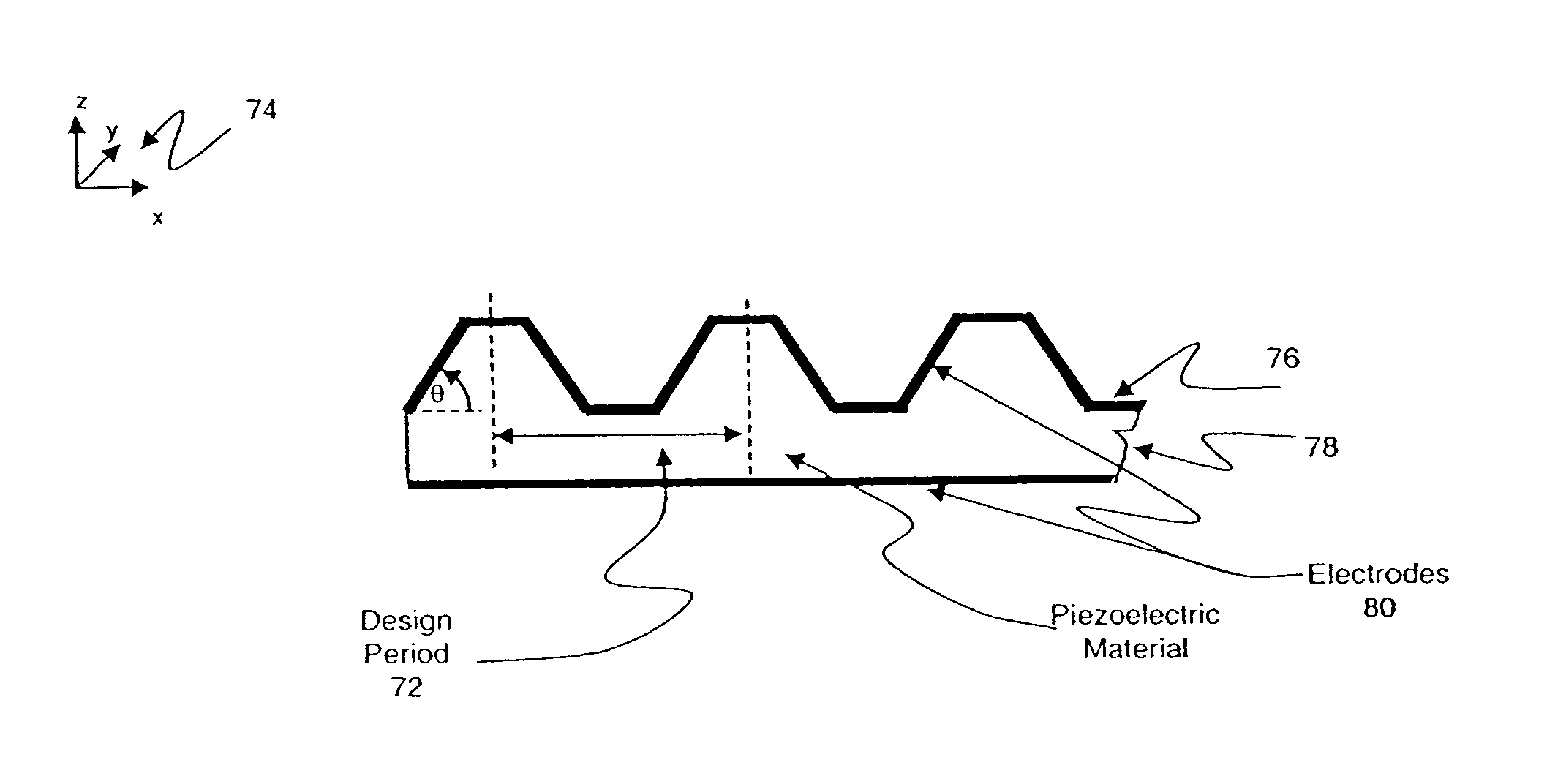

InactiveUS20040056567A1Increase stiffnessMagnetostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElectrode placementUniform field

Bender devices are demonstrated by developing non-uniform fields within a homogeneous, non-planar single slab active member material of non-uniform thickness through geometrical constraints and electrode placement. Single slab actuators are demonstrated for semiconductor designs including MEMS applications. Single slab bender periodic designs are demonstrated to be well suited for MEMS fabrication. Shaped actuators having a topological pattern formed across at least one portion are demonstrated to induced strain at the patterned portion of the actuator, causing the patterned portion to flare into open and close positions upon application of an external field. Voltage transformers, spark generators, power sources, and sensors are developed using the non-planar, homogeneous, single slab active member material of non-uniform thickness. Last, semiconductor process design techniques are demonstrated for periodic and other non-planar single slab actuators.

Owner:MONODRIVE

Mechanically-Actuated Microfluidic Diaphragm Valve

InactiveUS20090314972A1Operating means/releasing devices for valvesCircuit elementsDiaphragm valveEngineering

A microfluidic diaphragm valve. The valve comprises: an inlet port; an outlet port; a weir positioned between the inlet and outlet ports, the weir having a sealing surface; a diaphragm membrane for sealing engagement with the sealing surface; and a thermal bend actuator for moving the diaphragm membrane between a closed position in which the membrane is sealingly engaged with the sealing surface and an open position in which the membrane is disengaged from said sealing surface.

Owner:SILVERBROOK RES PTY LTD

Thermal bend actuator comprising aluminium alloy

A thermal bend actuator, having a plurality of elements, is provided. The actuator comprises a first active element for connection to drive circuitry a second passive element mechanically cooperating with the first element. When a current is passed through the first element, the first element expands relative to the second element, resulting in bending of the actuator. The first element is comprised of an aluminium alloy.

Owner:SILVERBROOK RES PTY LTD +1

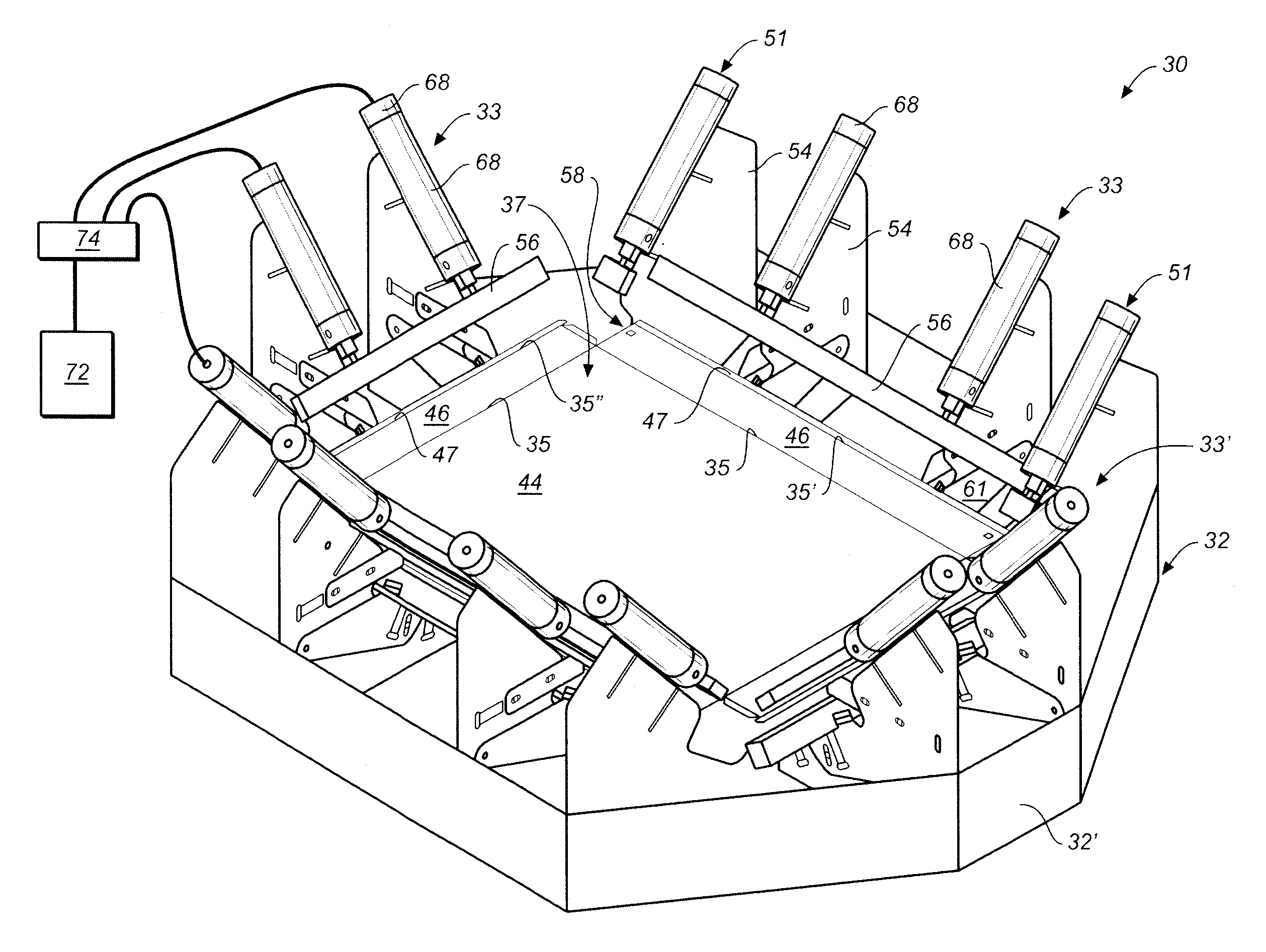

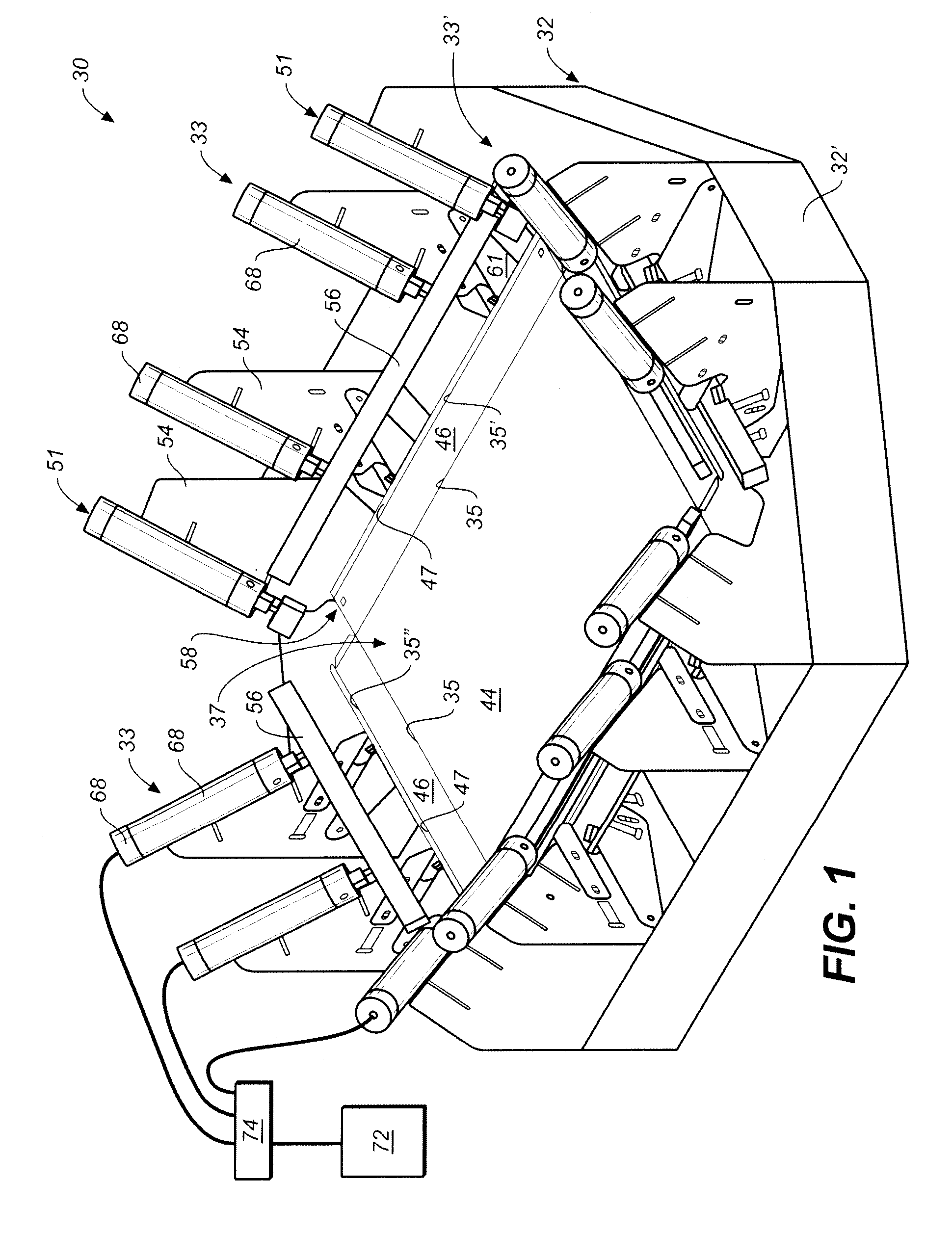

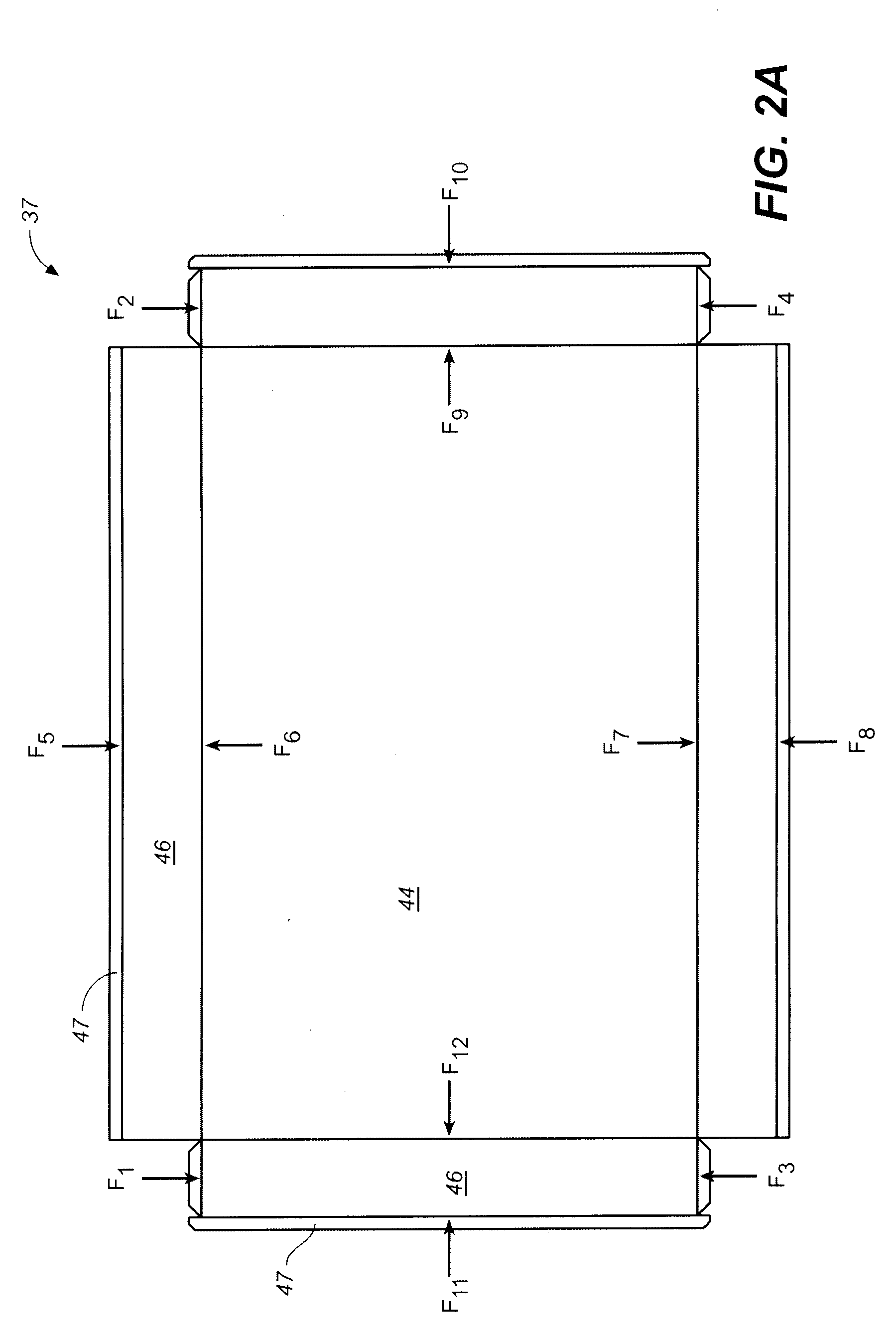

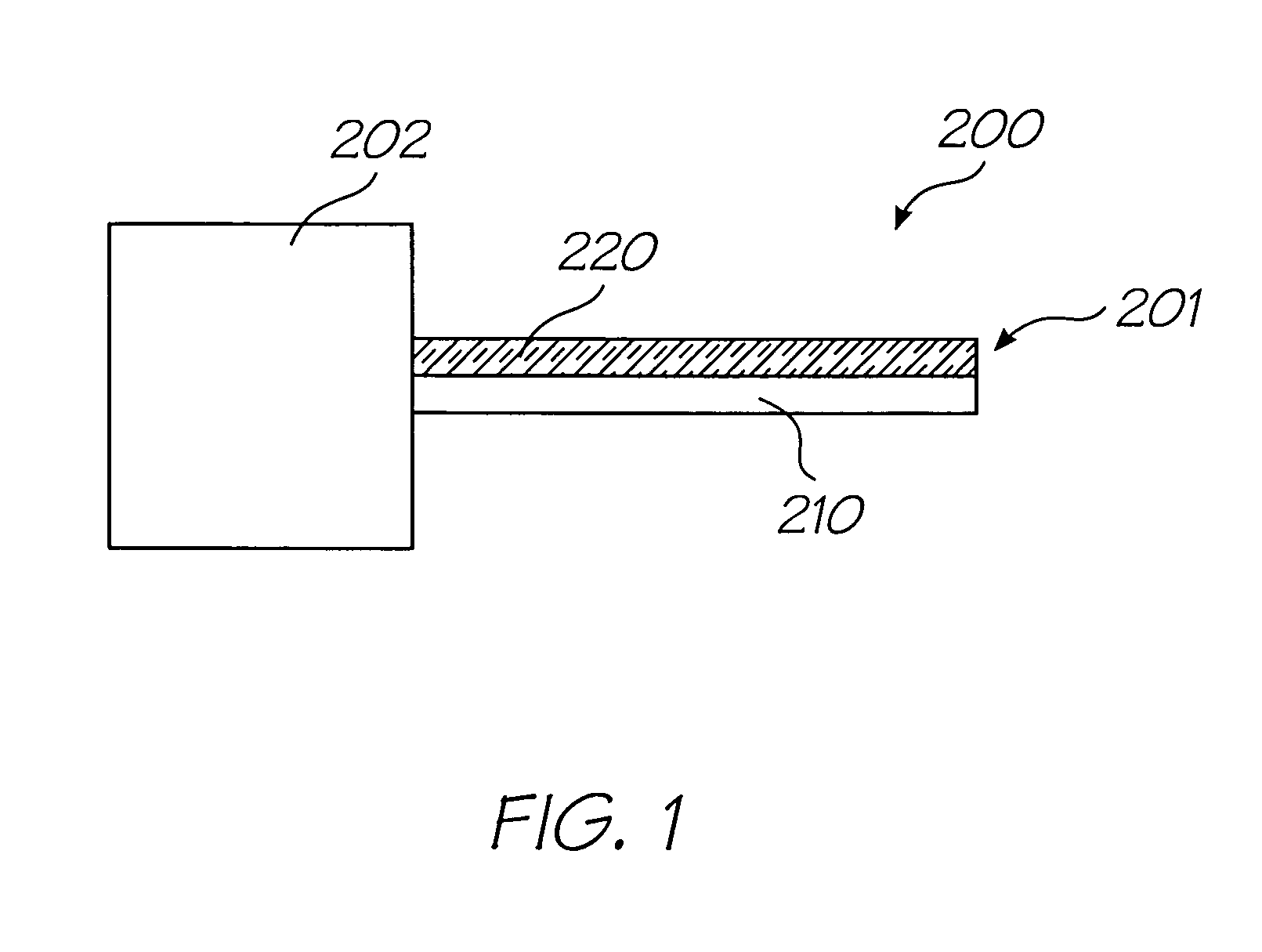

Method and Apparatus For Imparting Compound Folds on Sheet Material

A method and apparatus for imparting compound folds on sheet materials includes a tool base for receiving and supporting the sheet material, a locator for positioning the sheet material relative to the work base, and a bend actuator mounted on the tool base. The bend actuator has an actuator member movable between an initial retracted position and a deployed extended position for applying a force against an unsecured portion of sheet material to effect bending of the sheet material about the first fold line as the actuator member moves from the initial retracted position and contacts the unsecured portion. The bend actuator also has a contact member positioned to abut against an outer portion of the unsecured portion as the actuator member continues to bend the sheet material about the first fold line, wherein the contact member effects bending of the sheet material along the second fold lines as the actuator member continues moving toward the deployed extended position. A method of using the method and apparatus for imparting compound folds on sheet materials is also disclosed.

Owner:IND ORIGAMI INC CA US

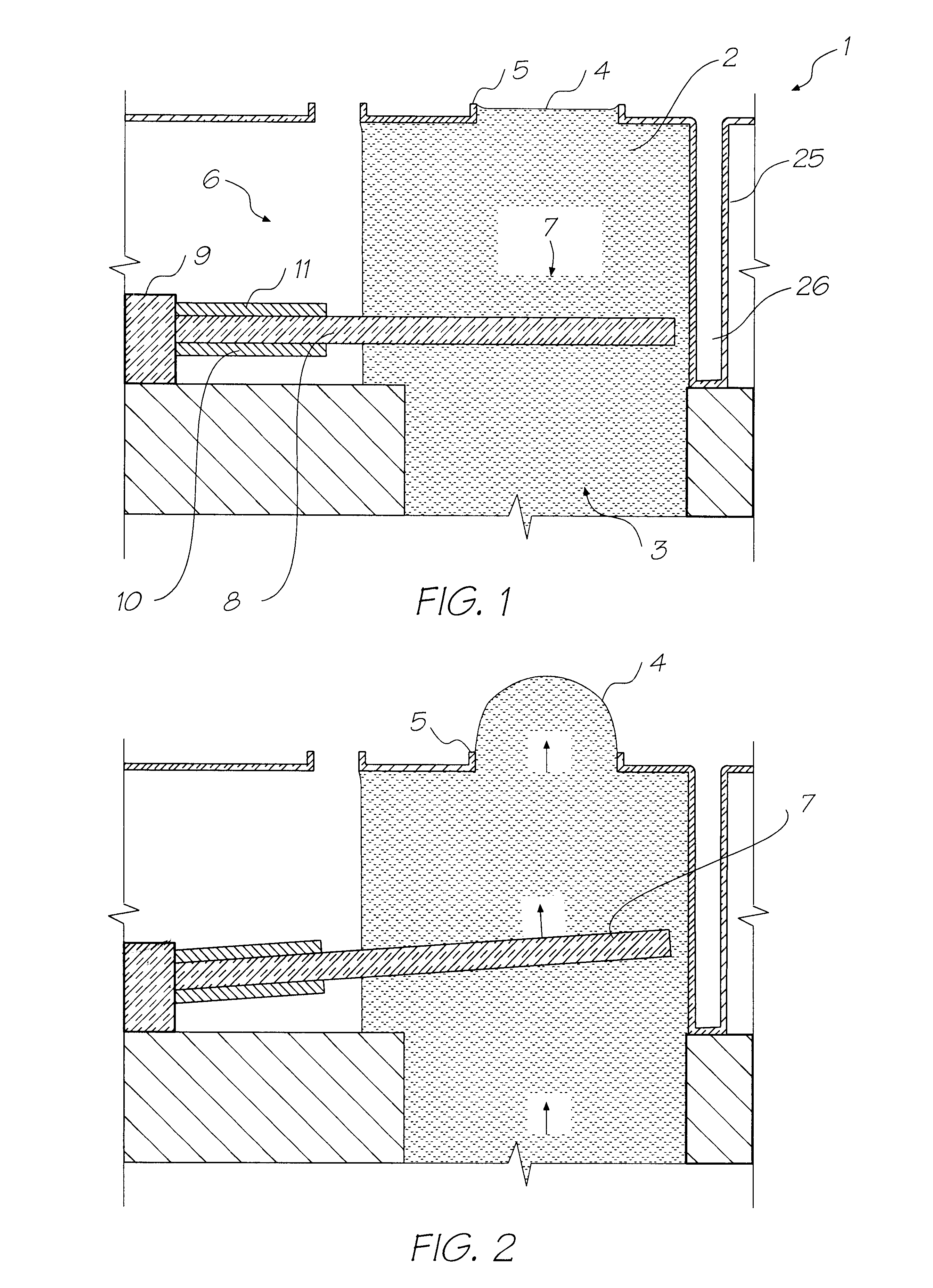

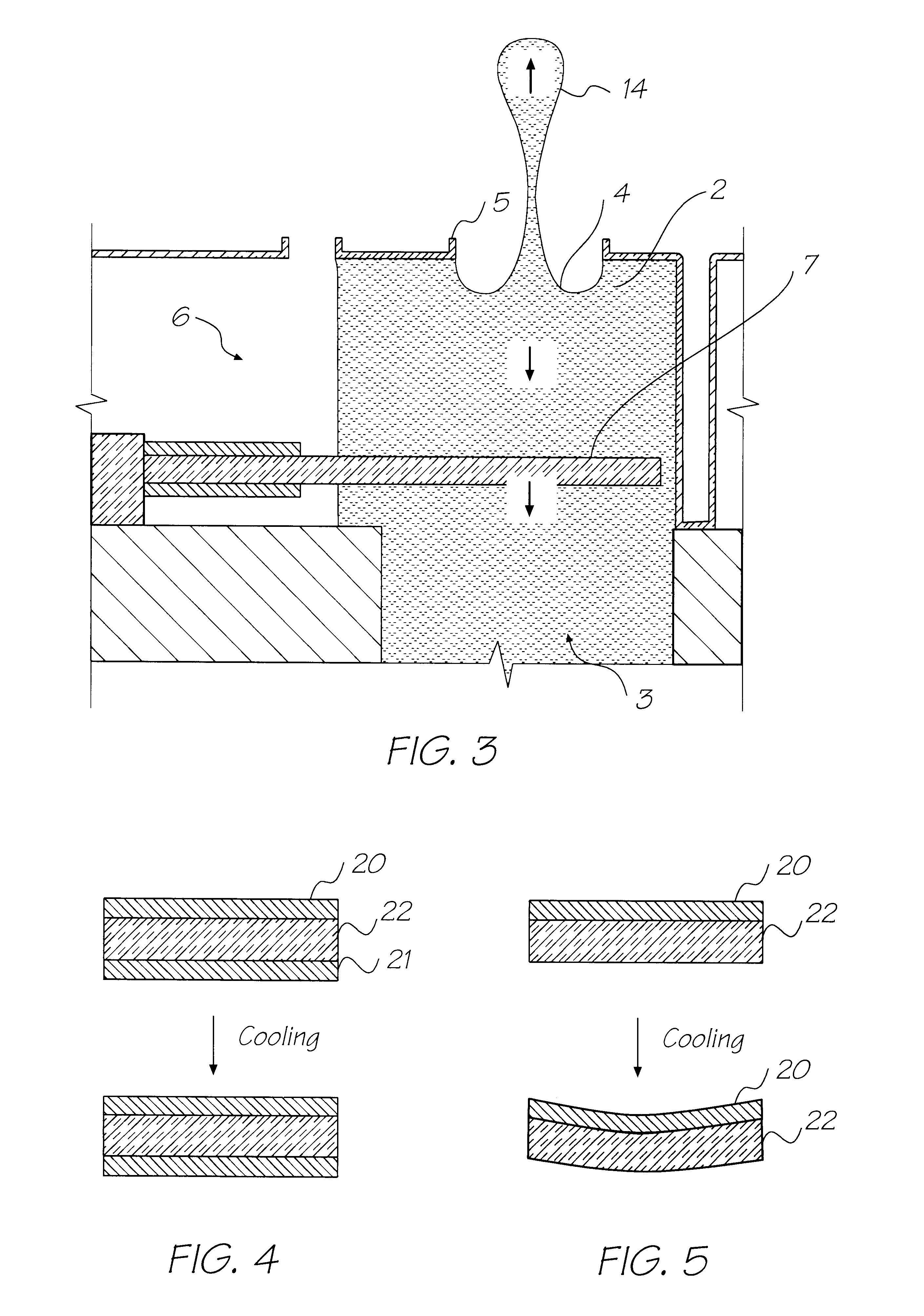

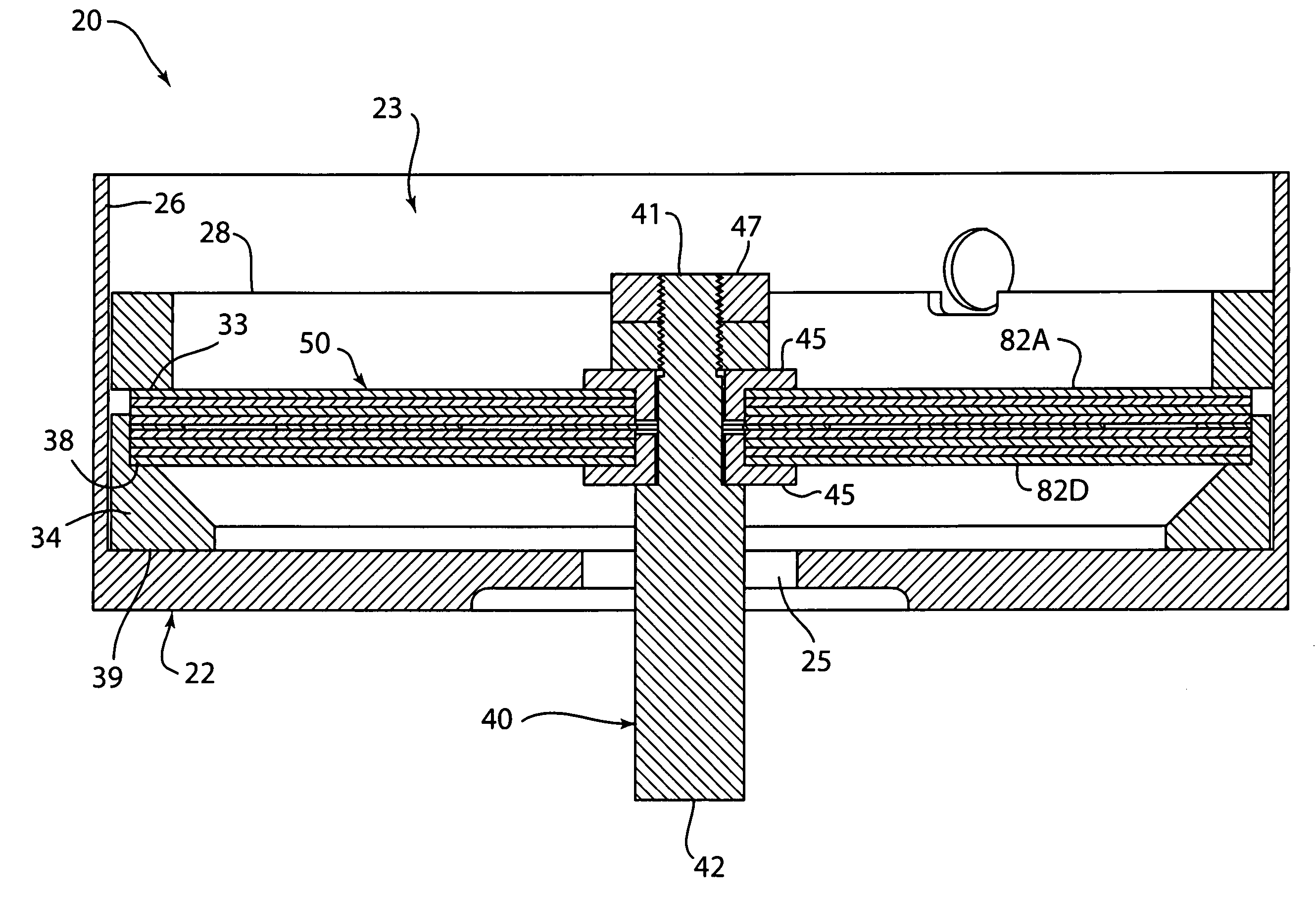

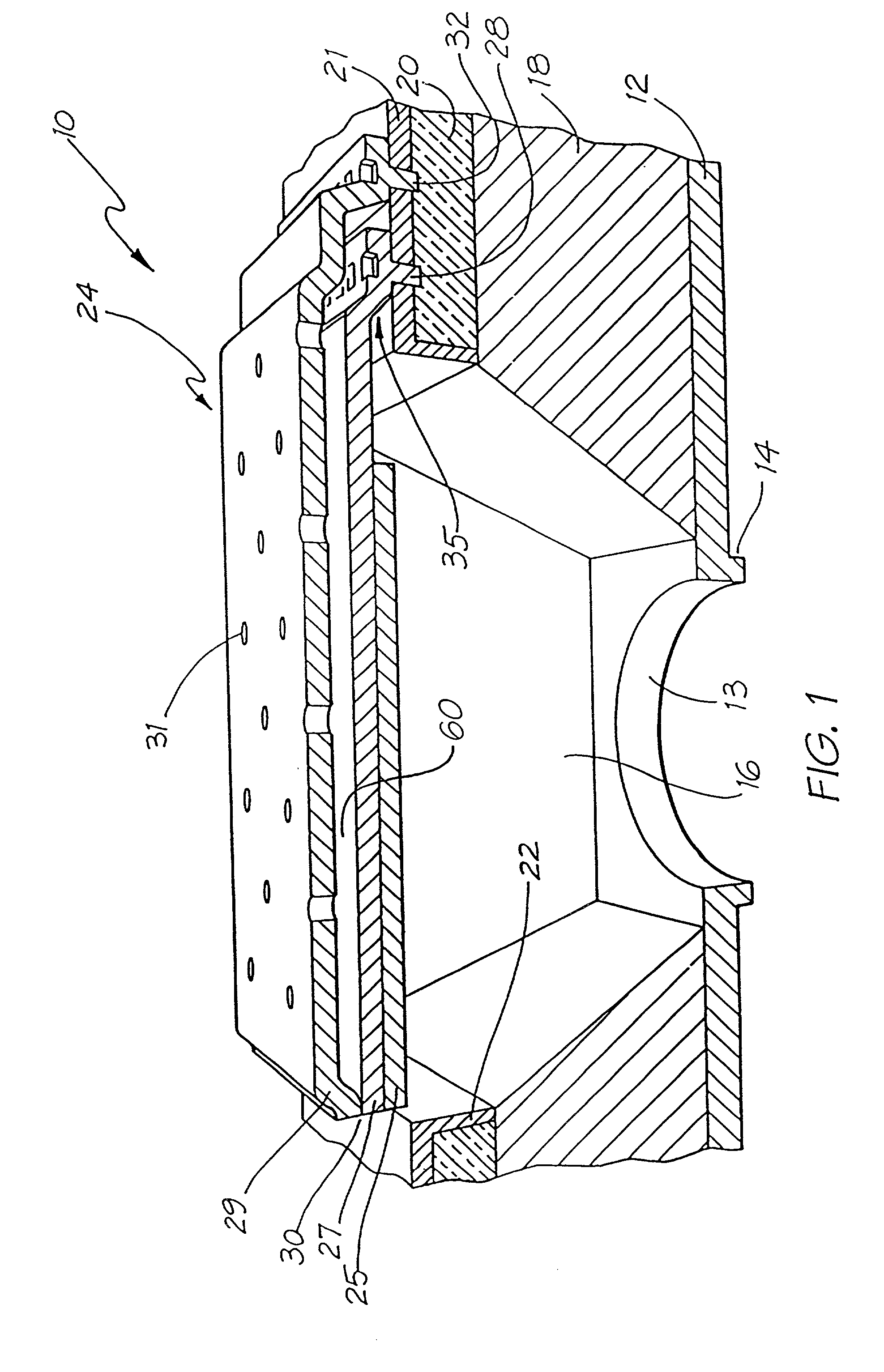

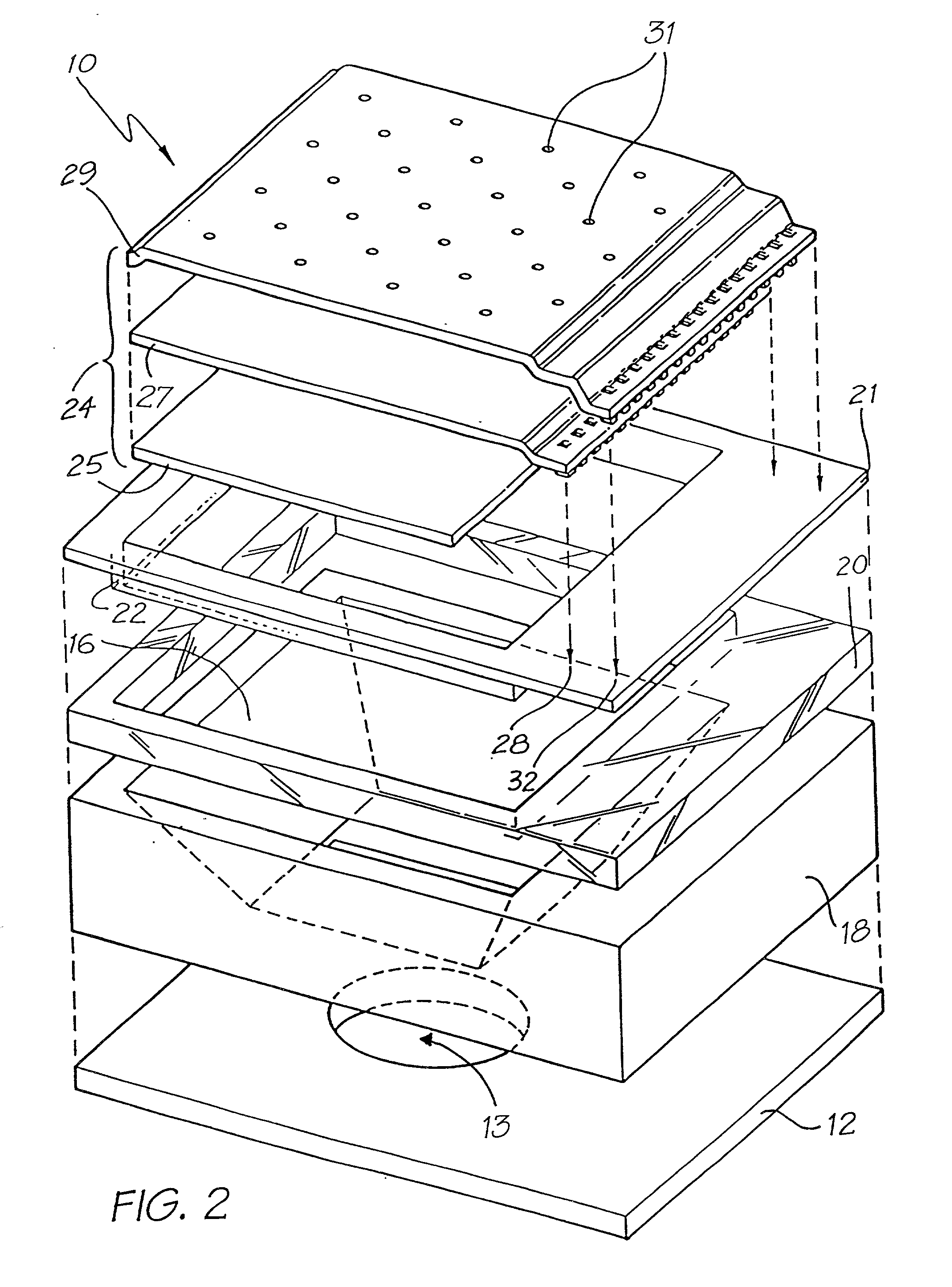

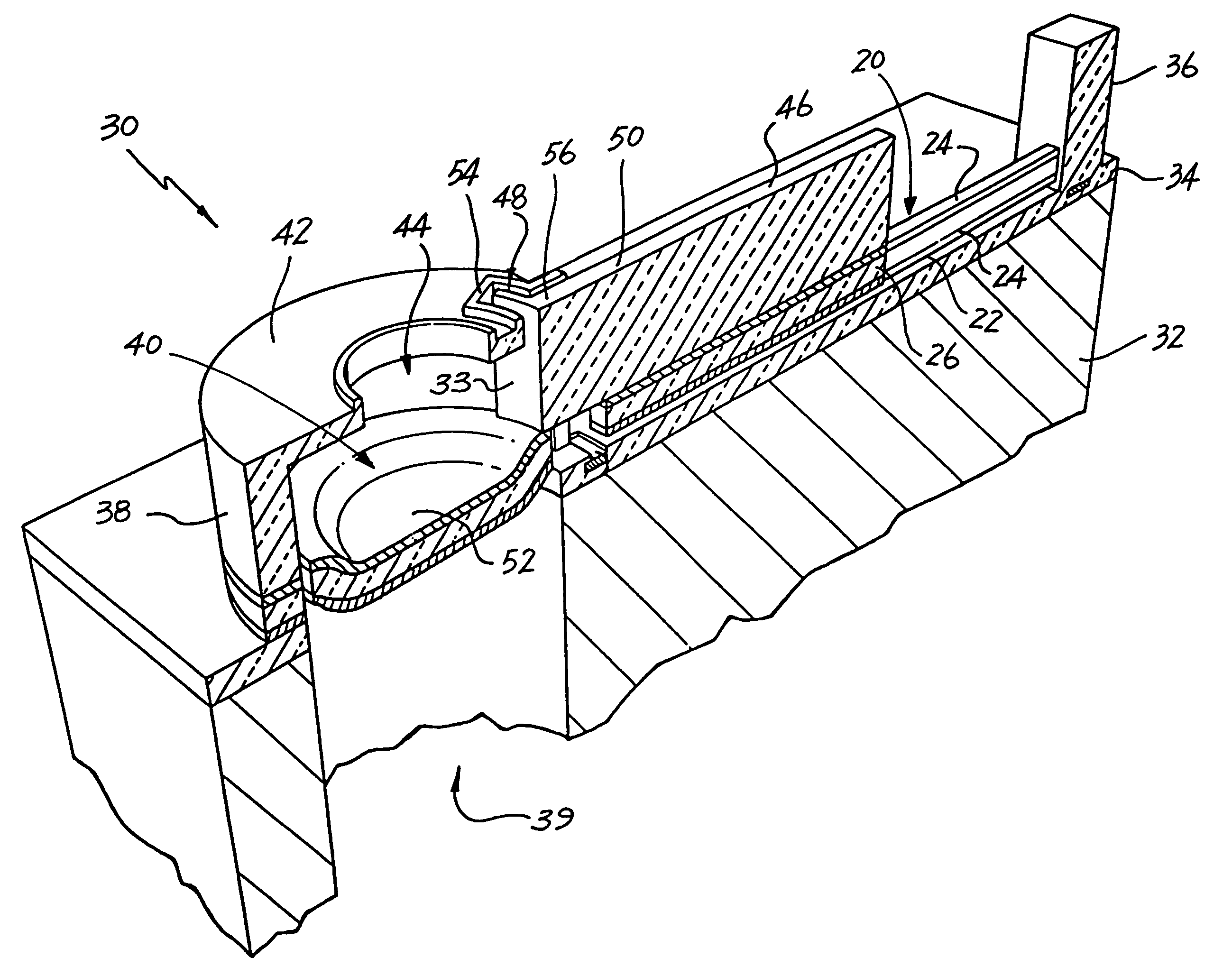

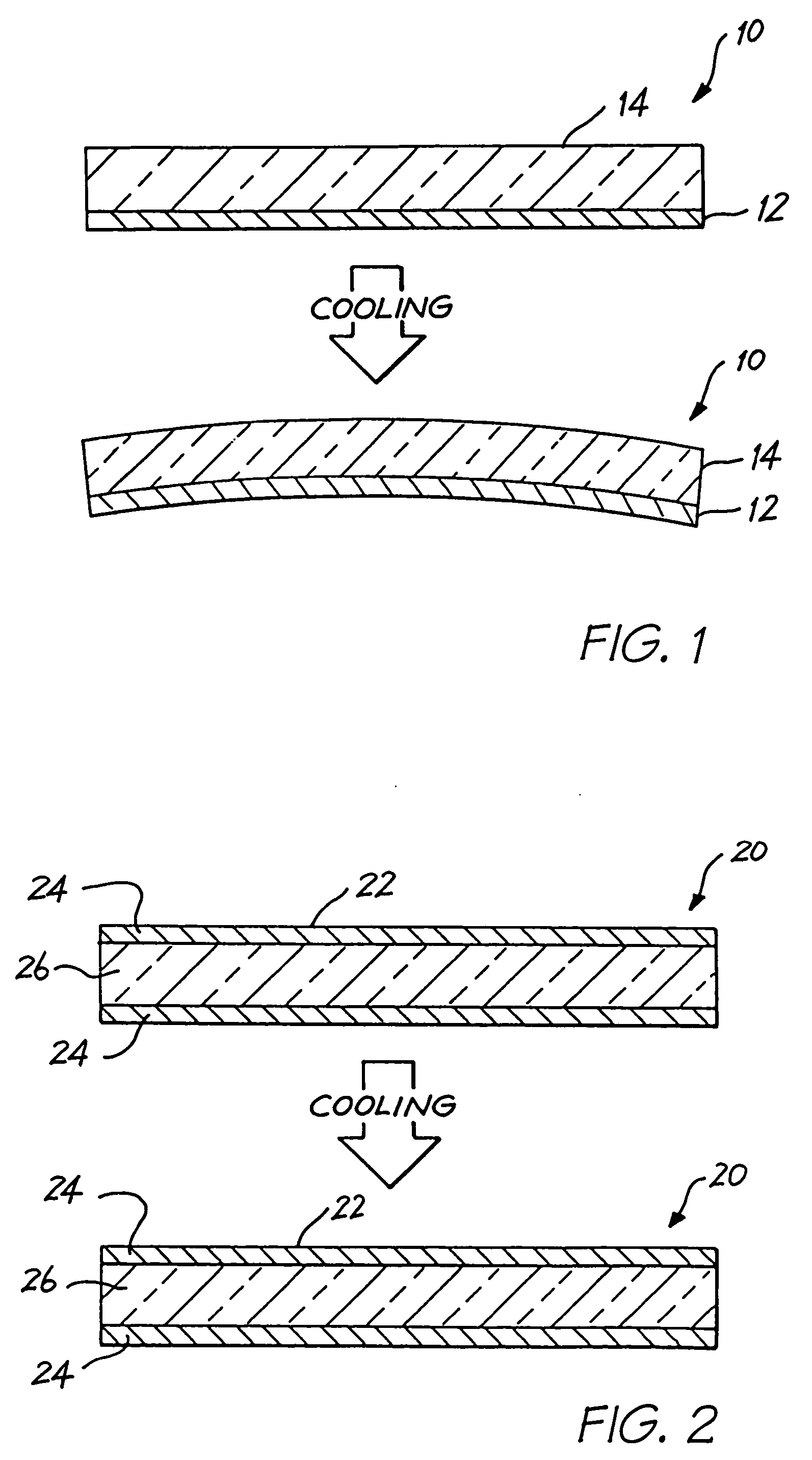

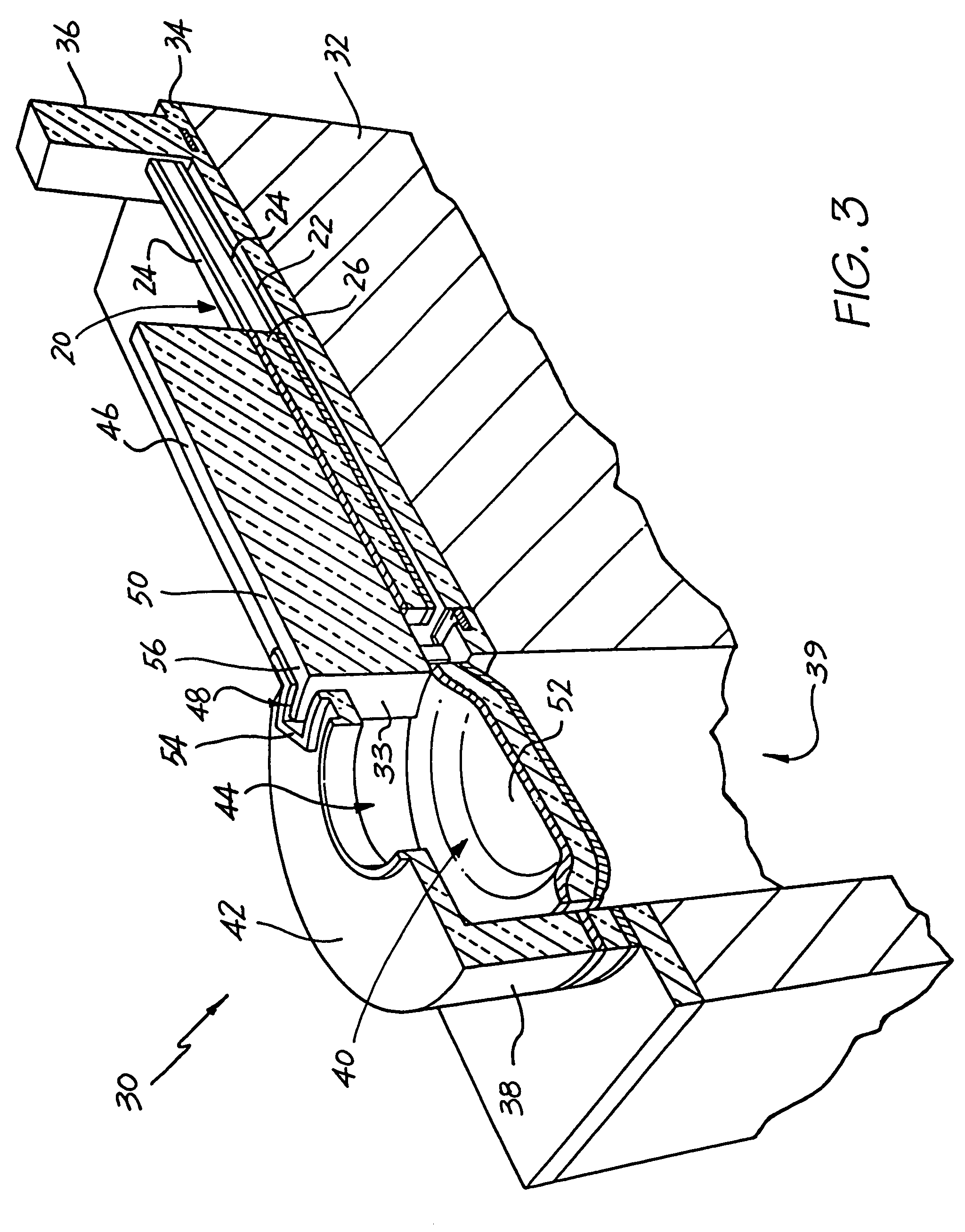

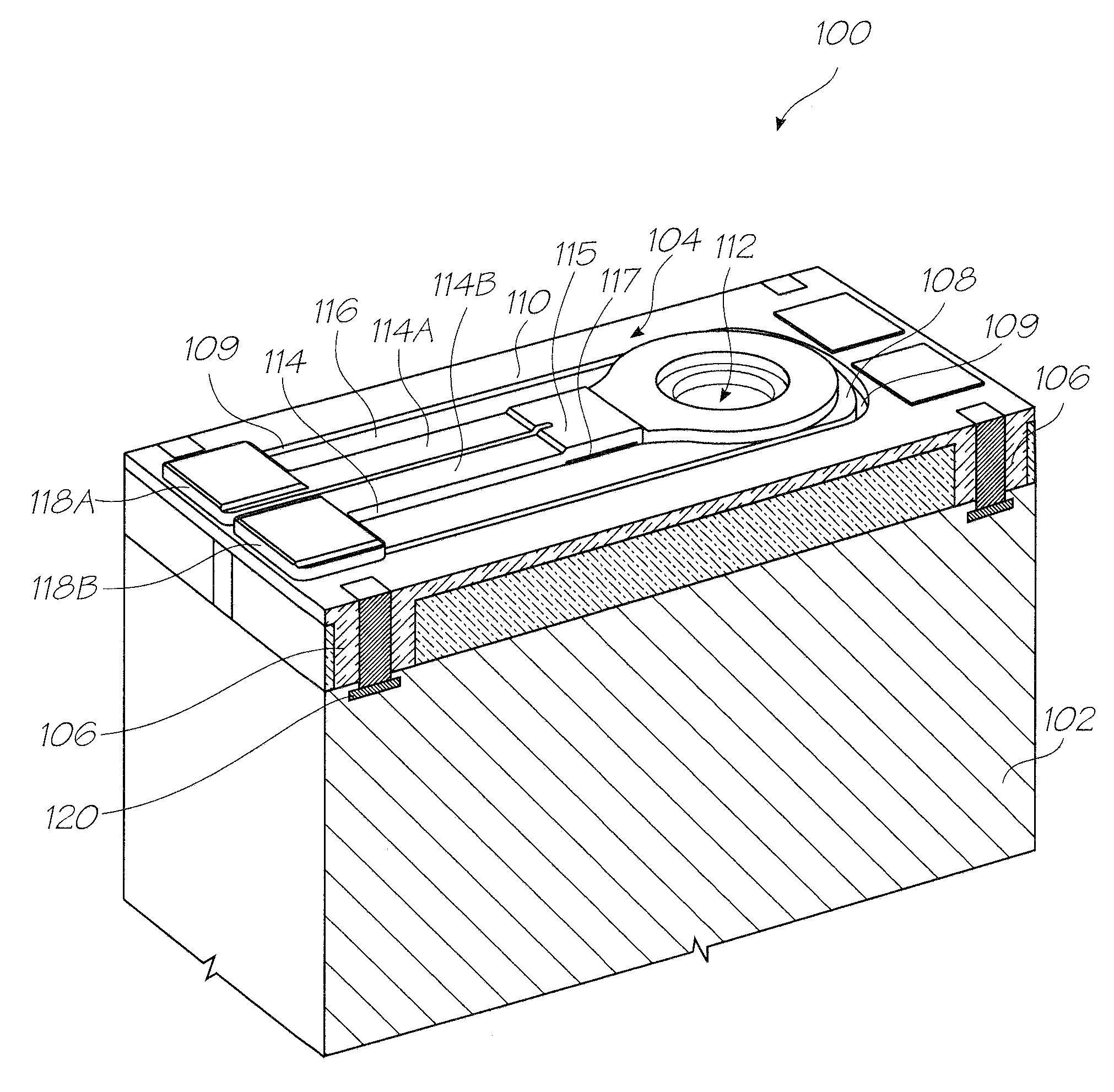

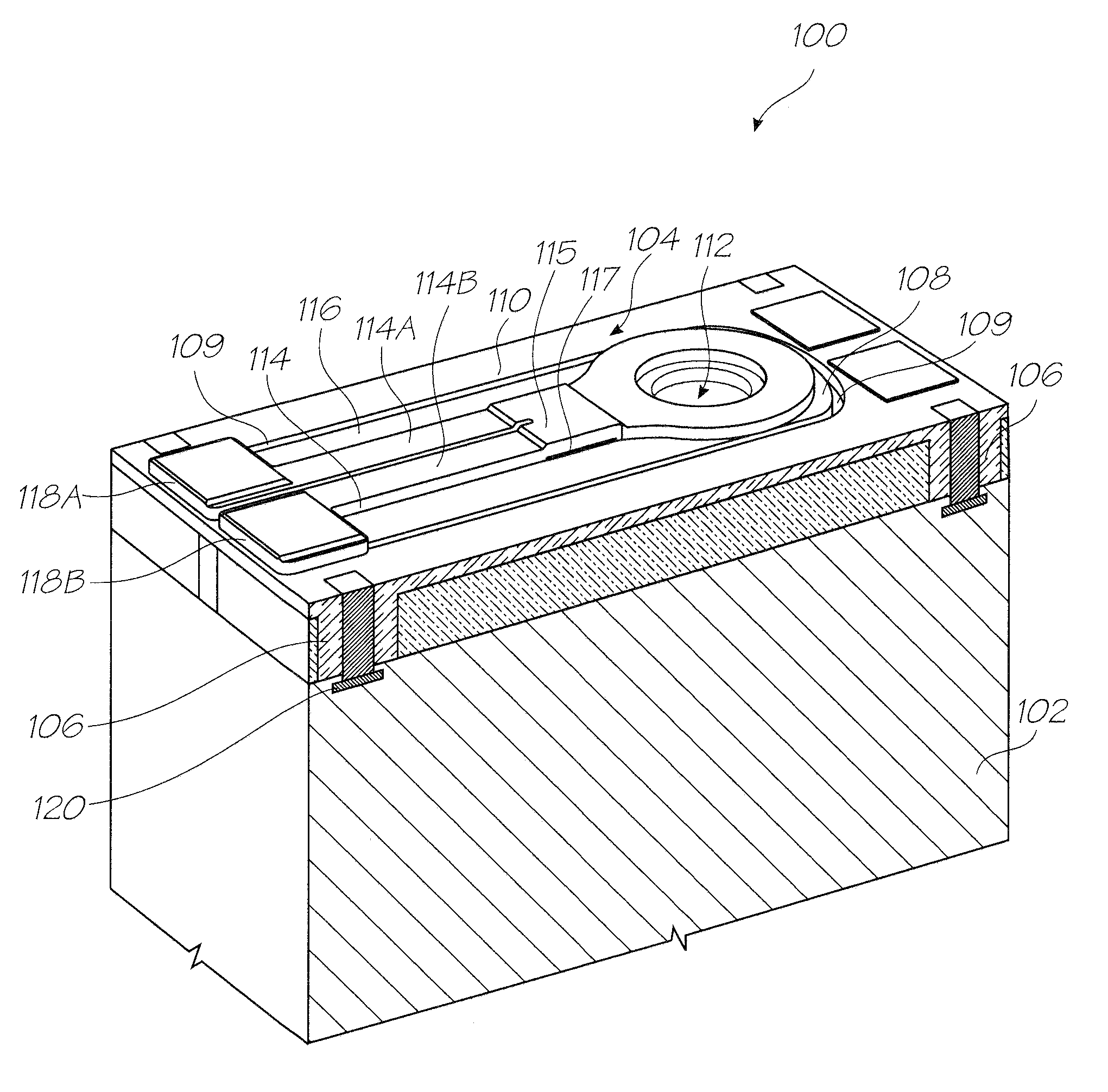

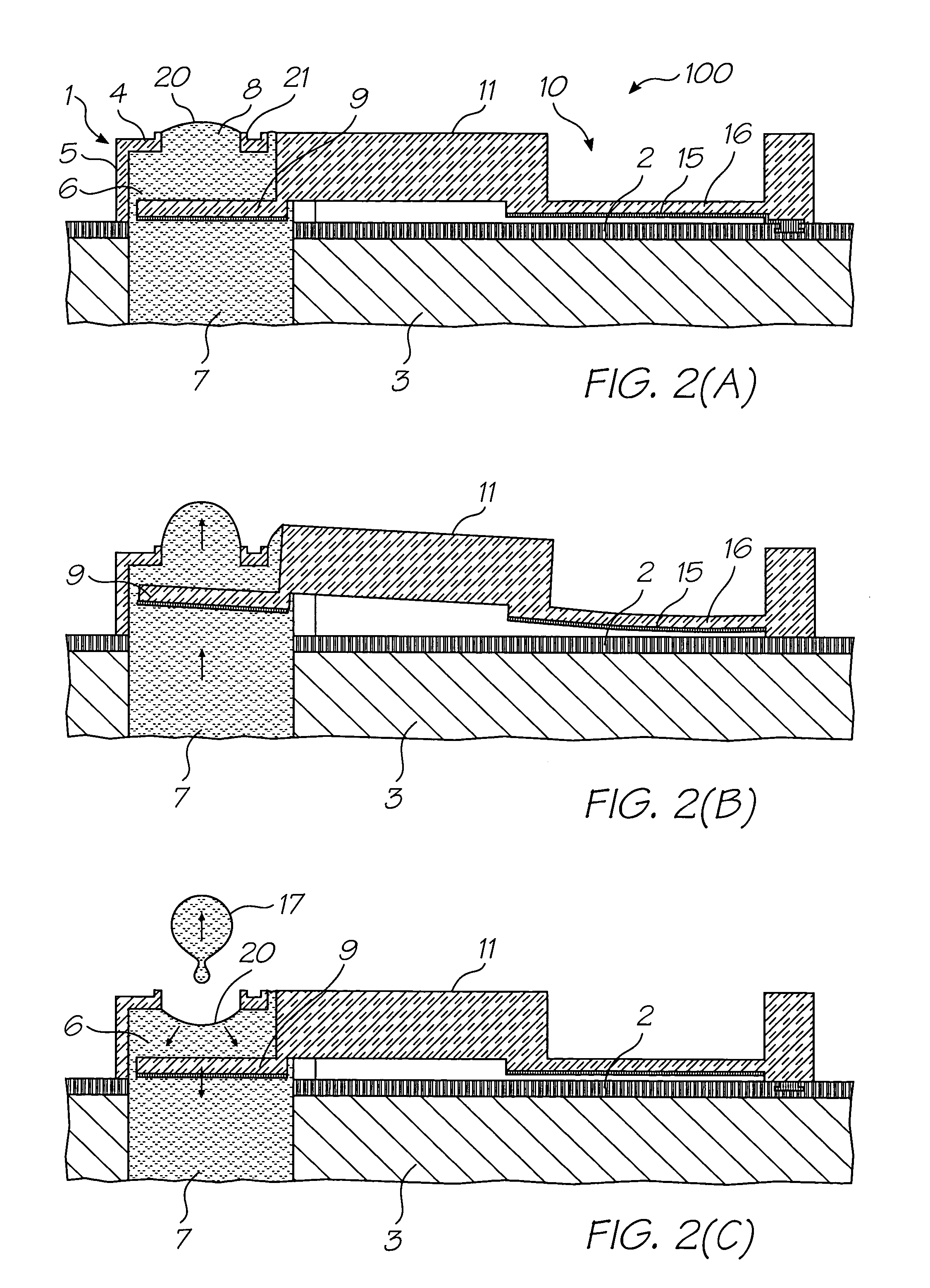

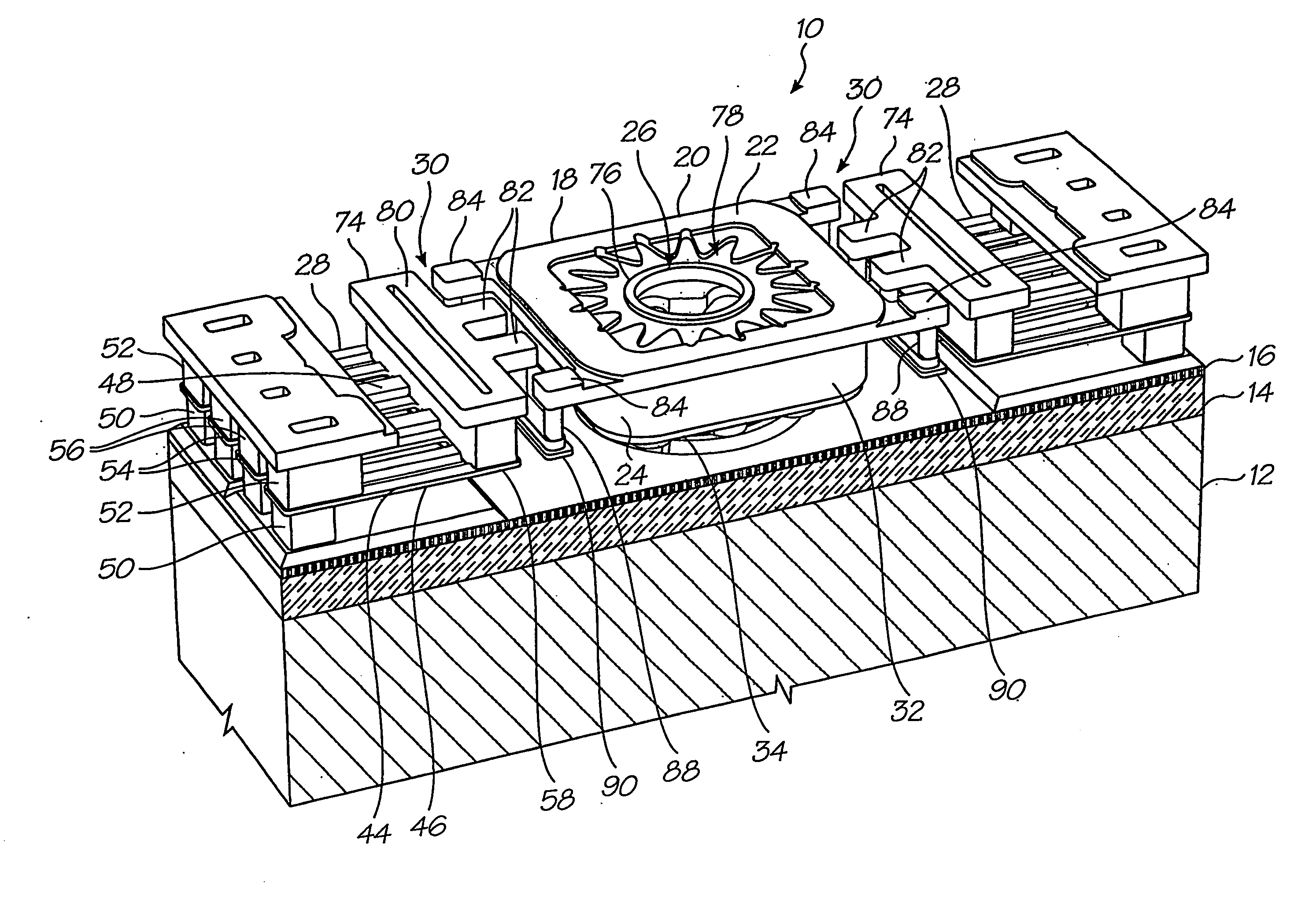

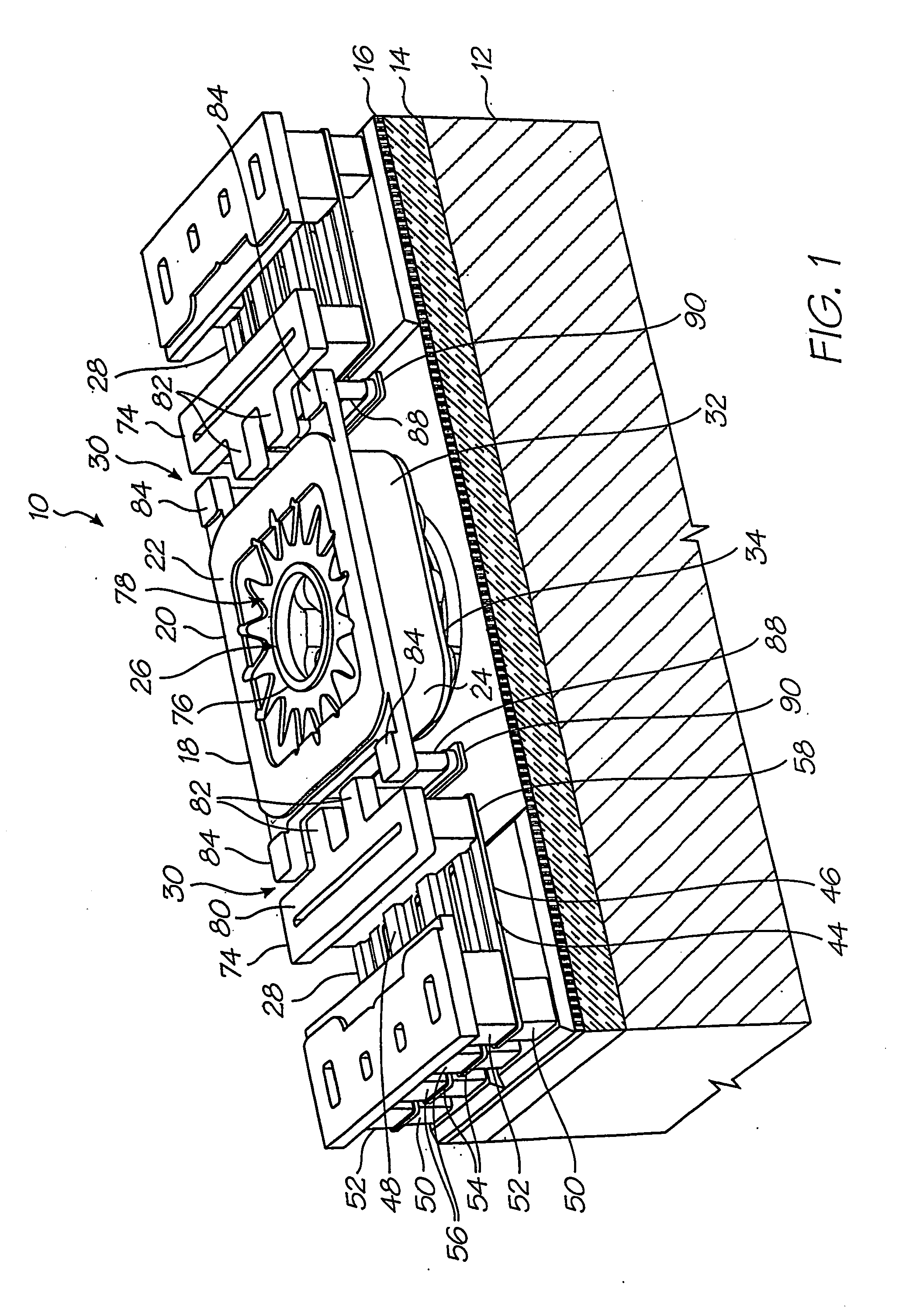

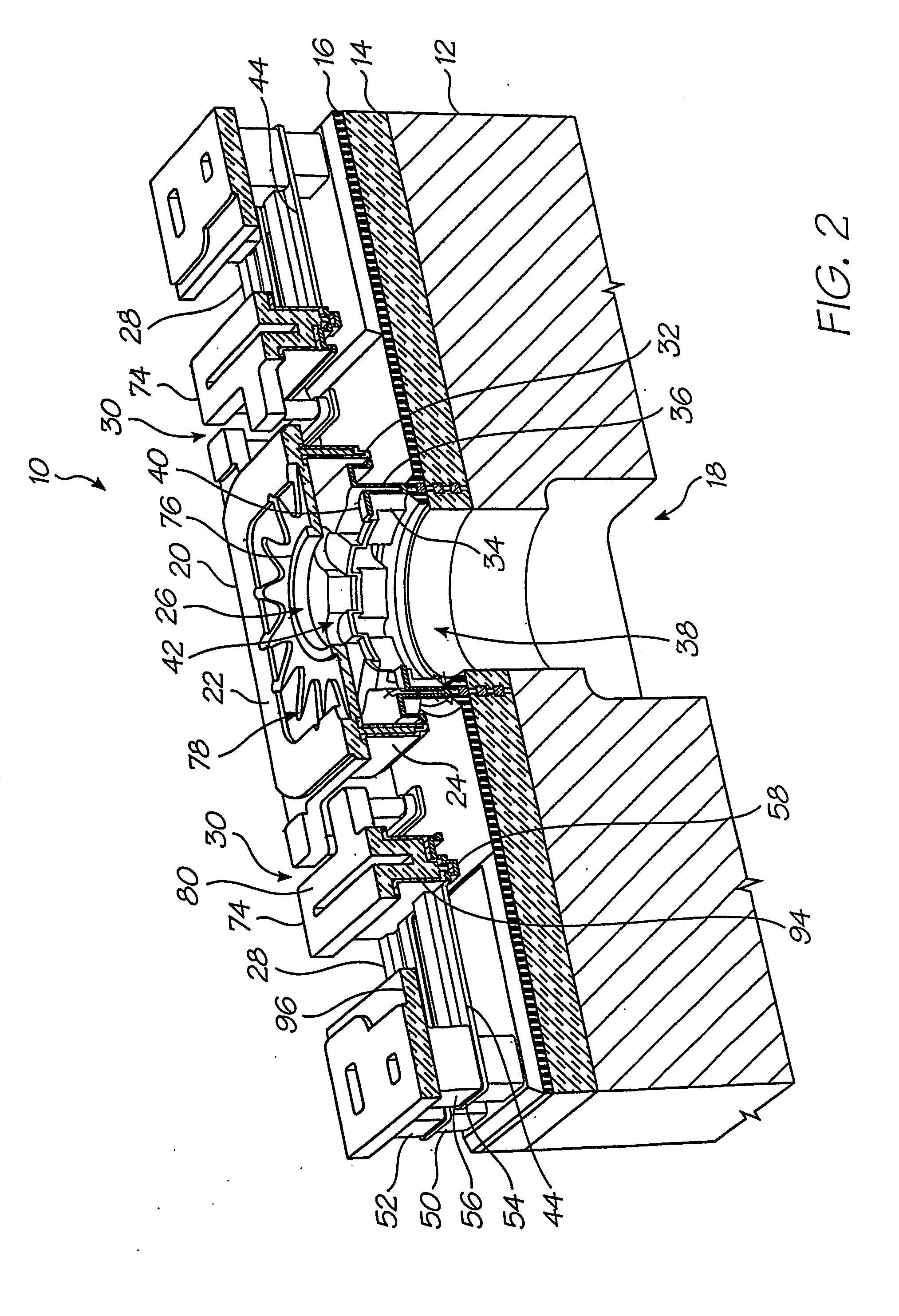

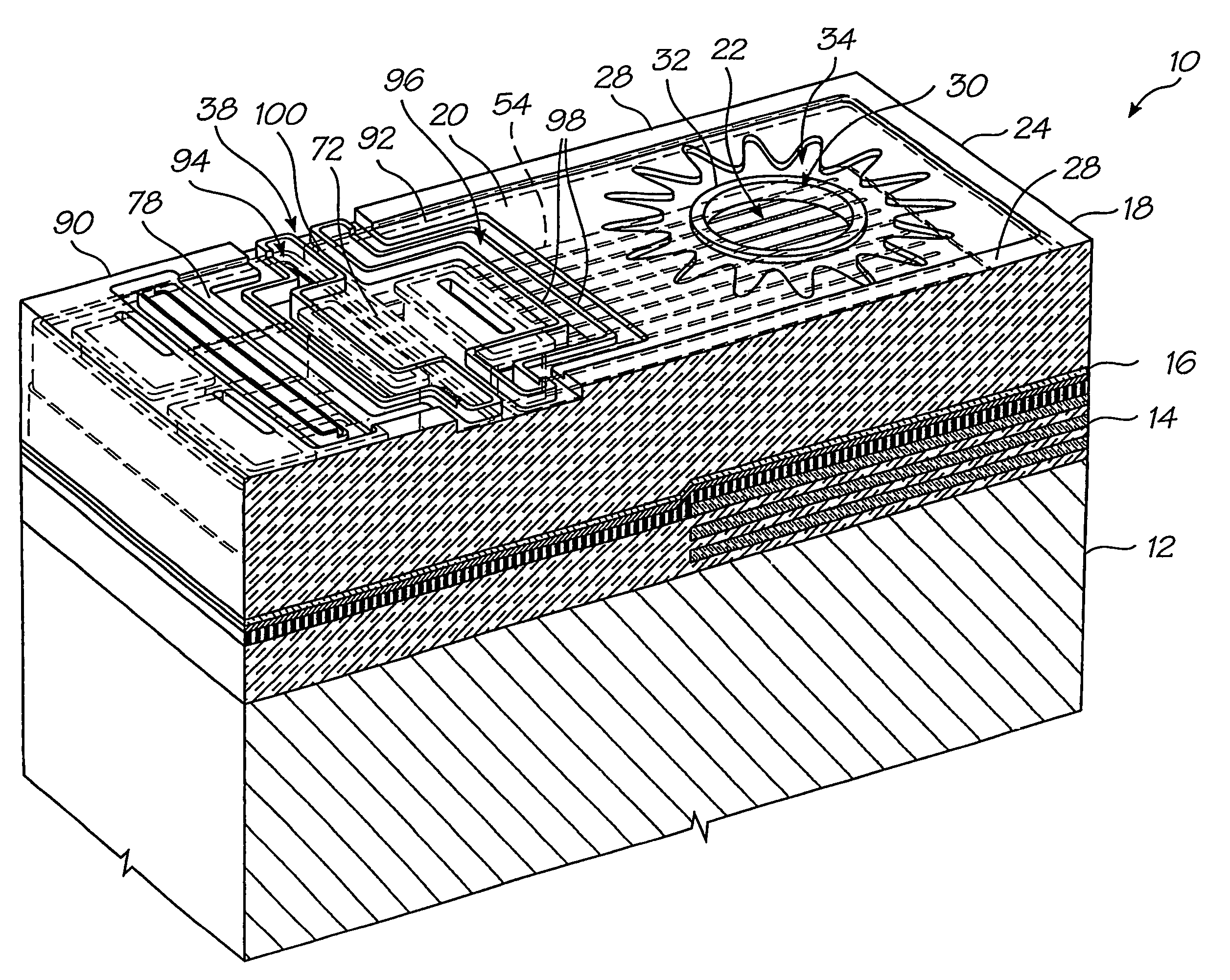

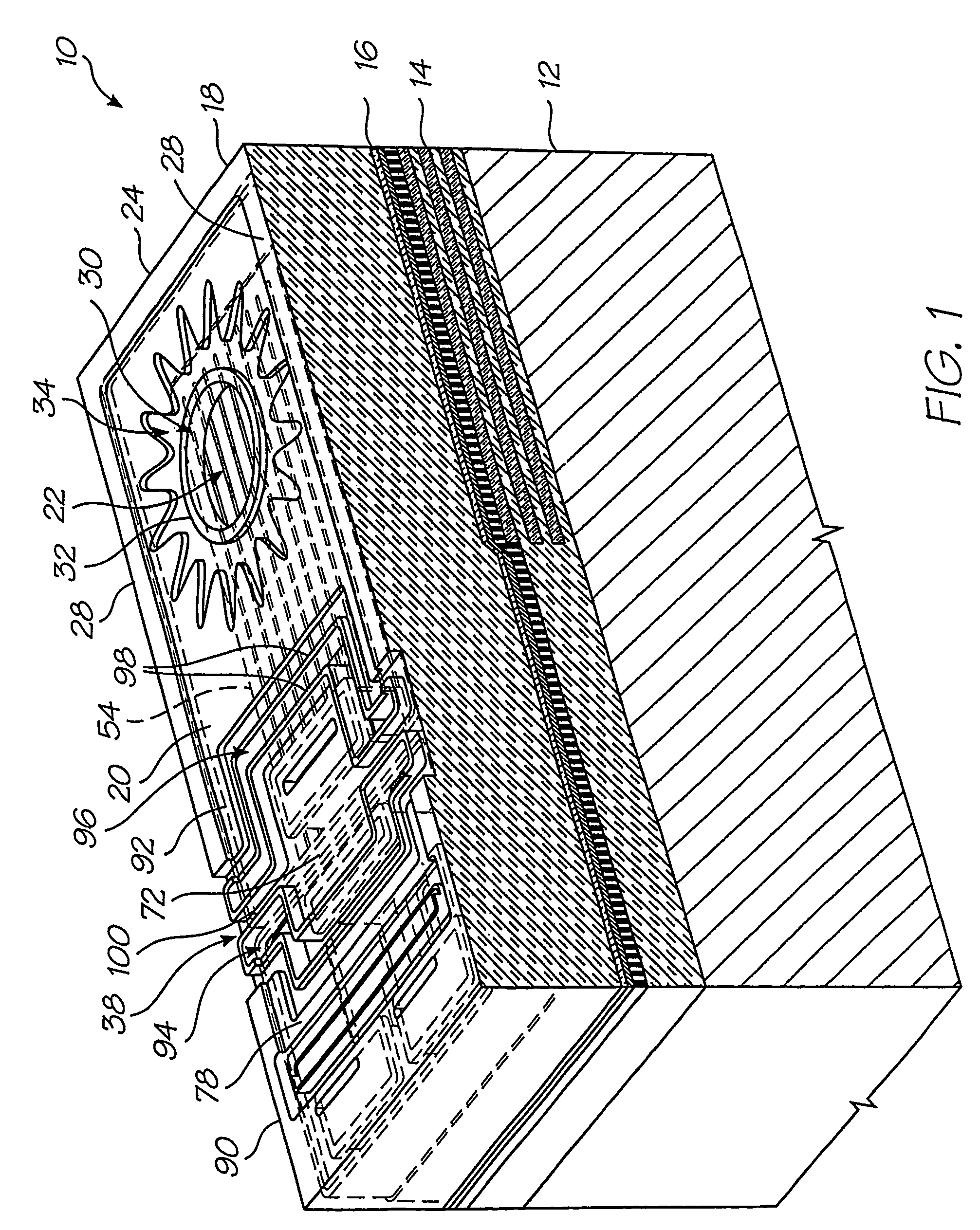

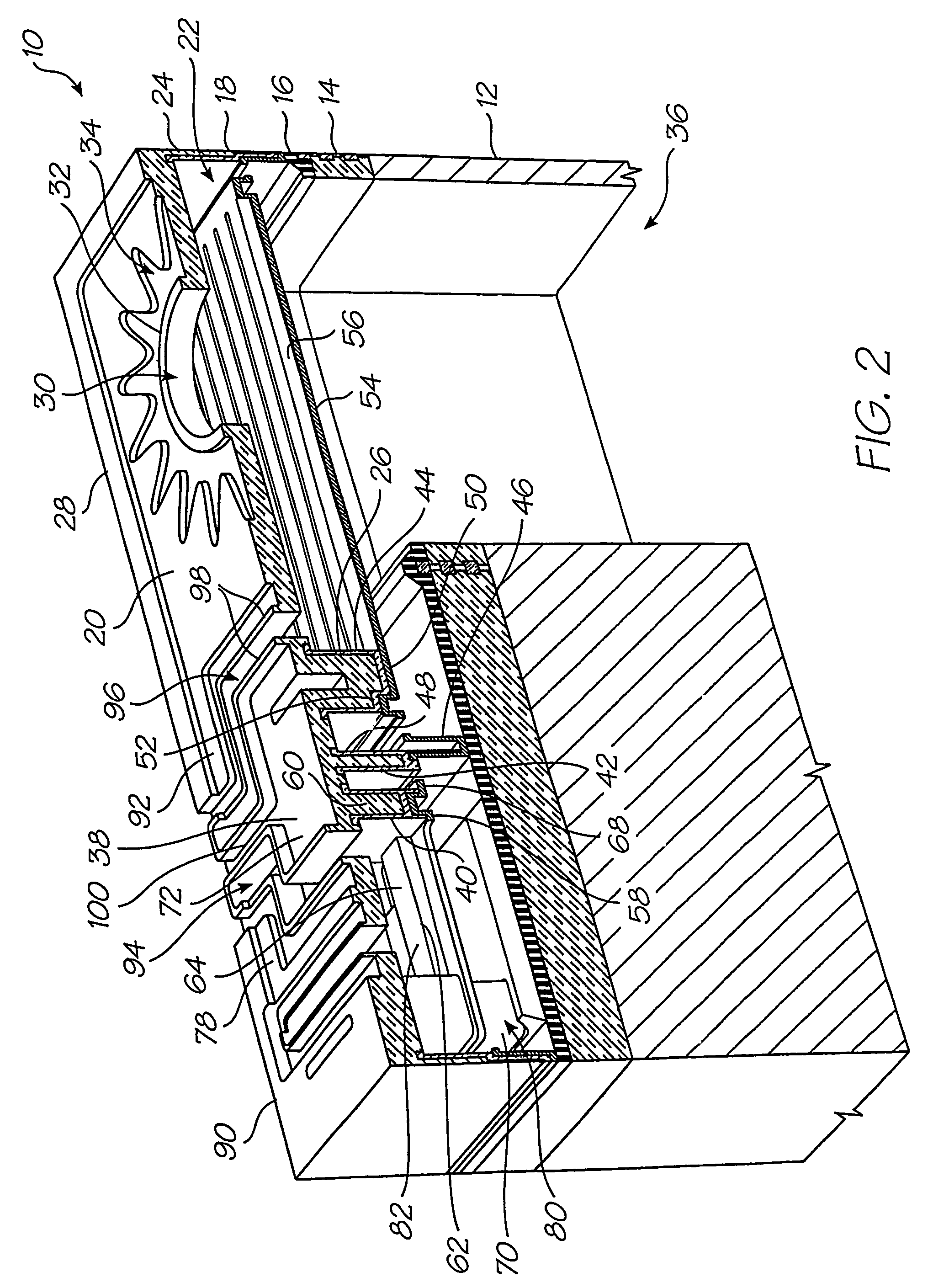

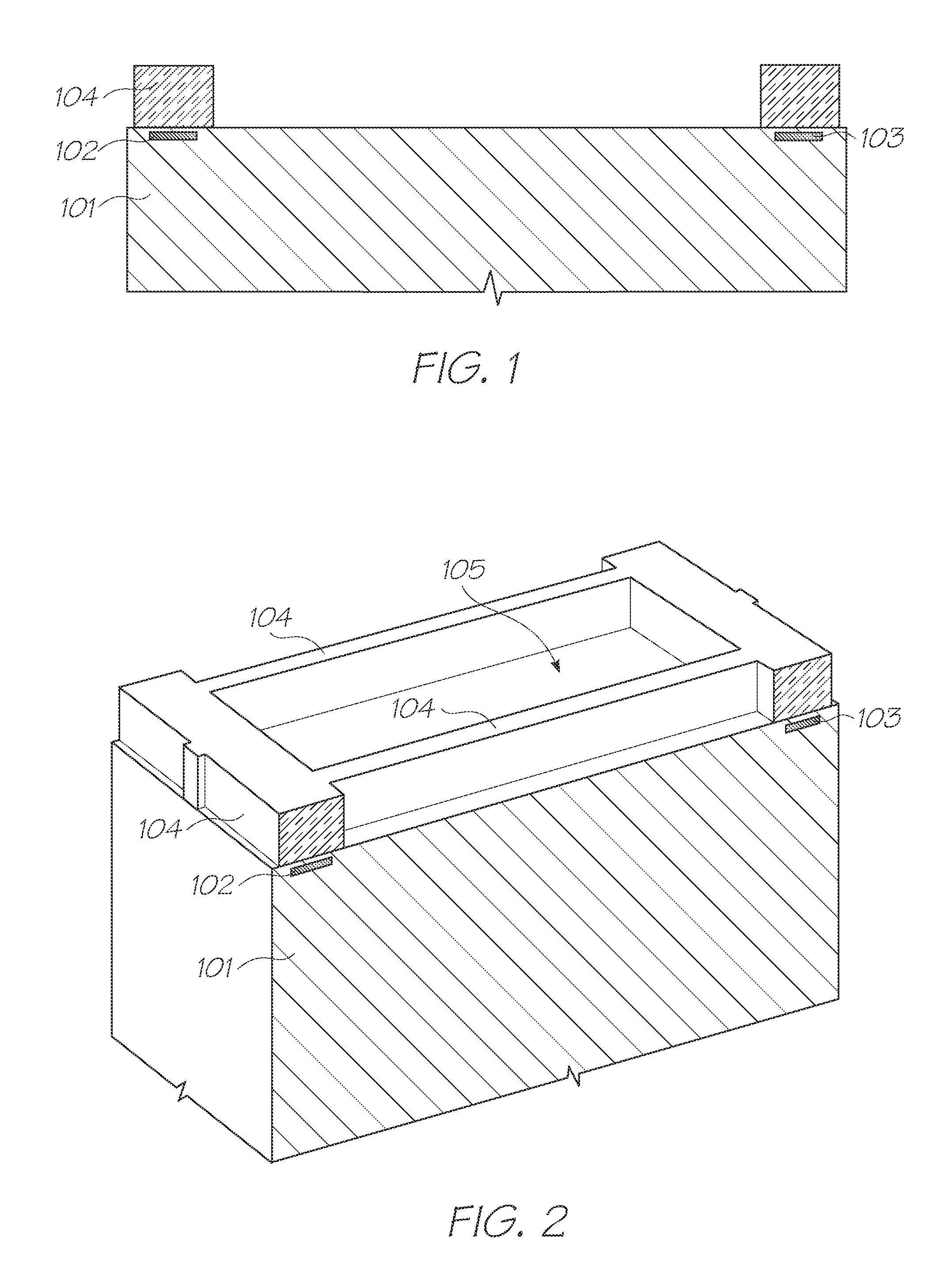

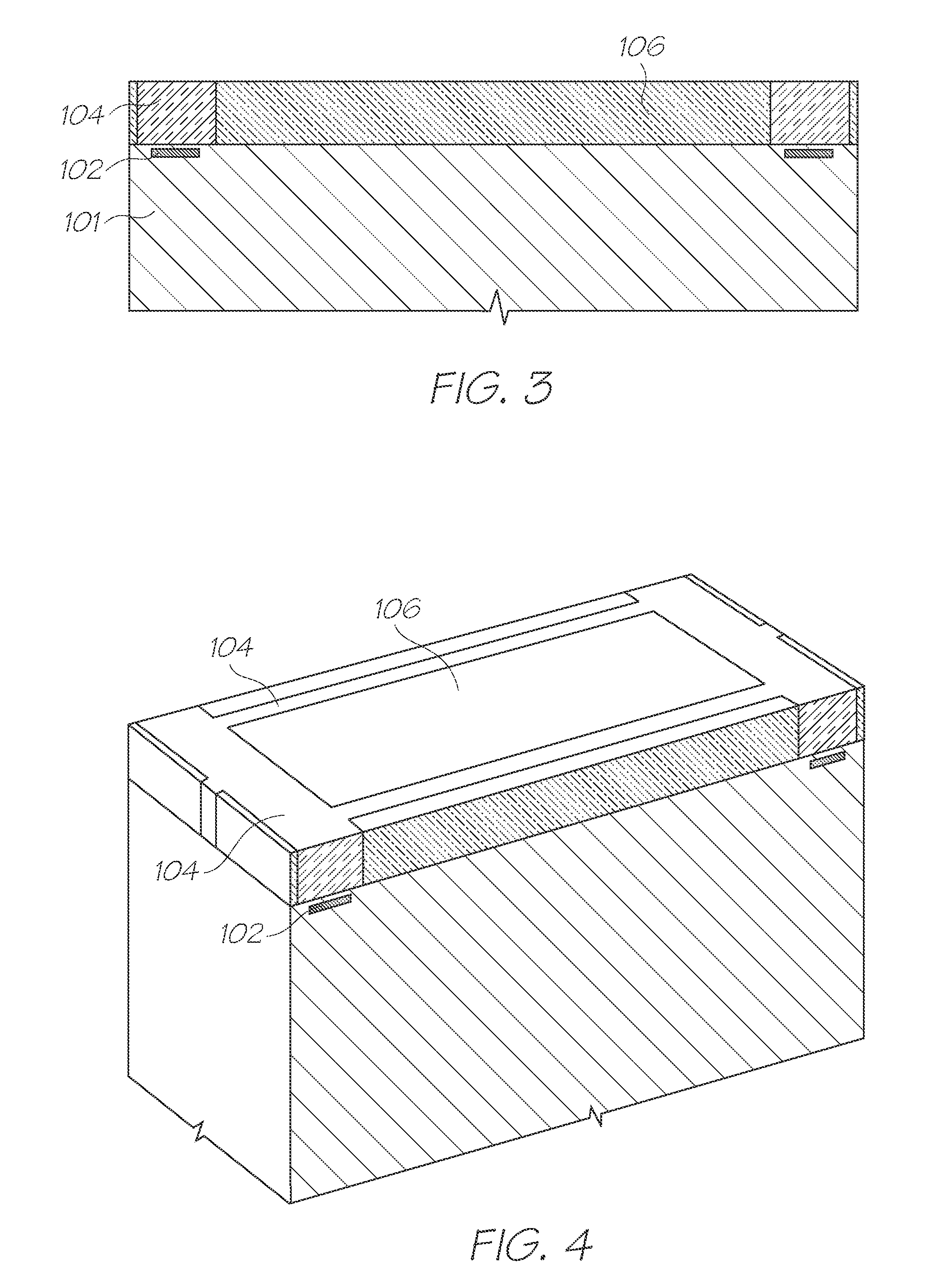

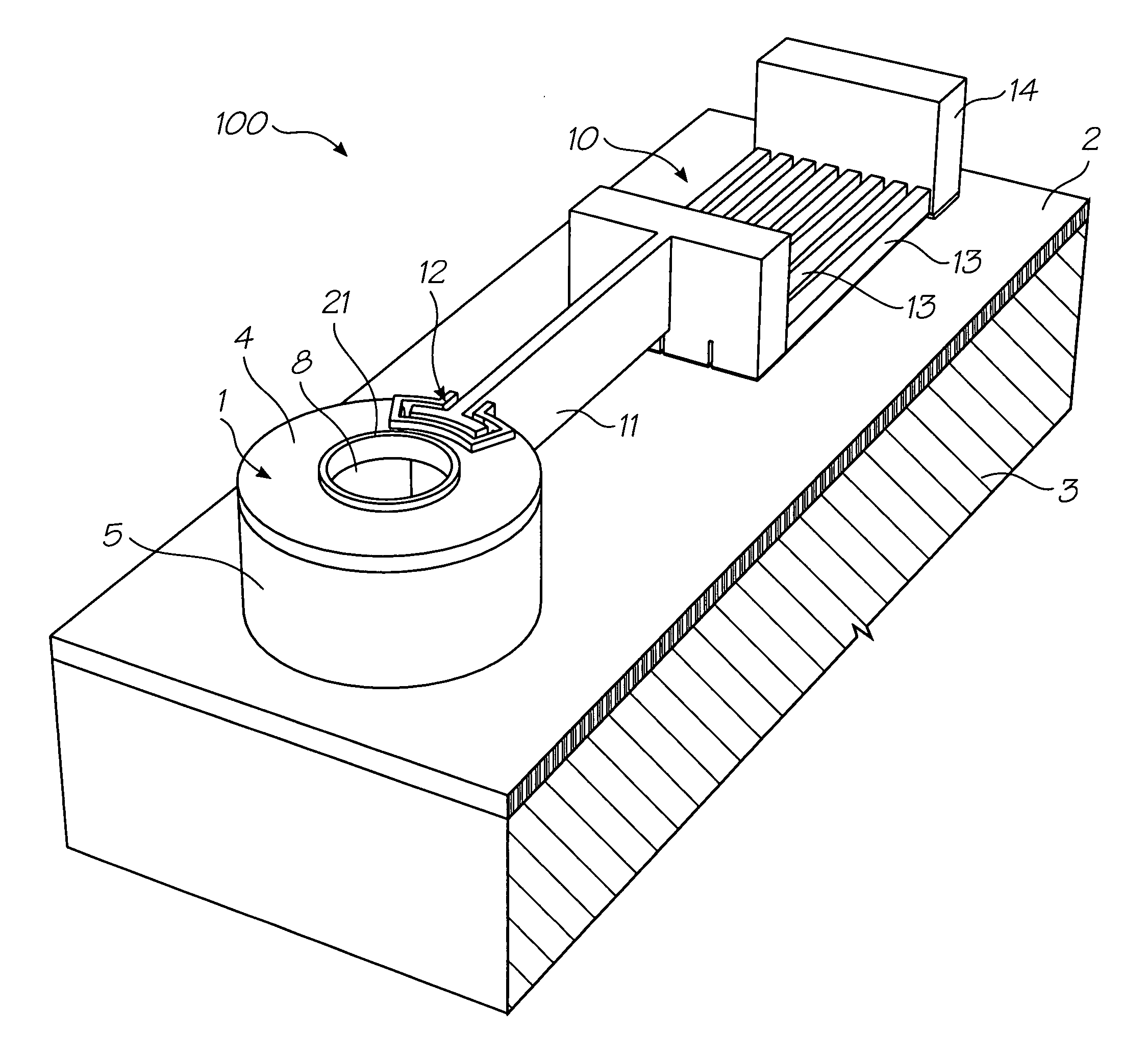

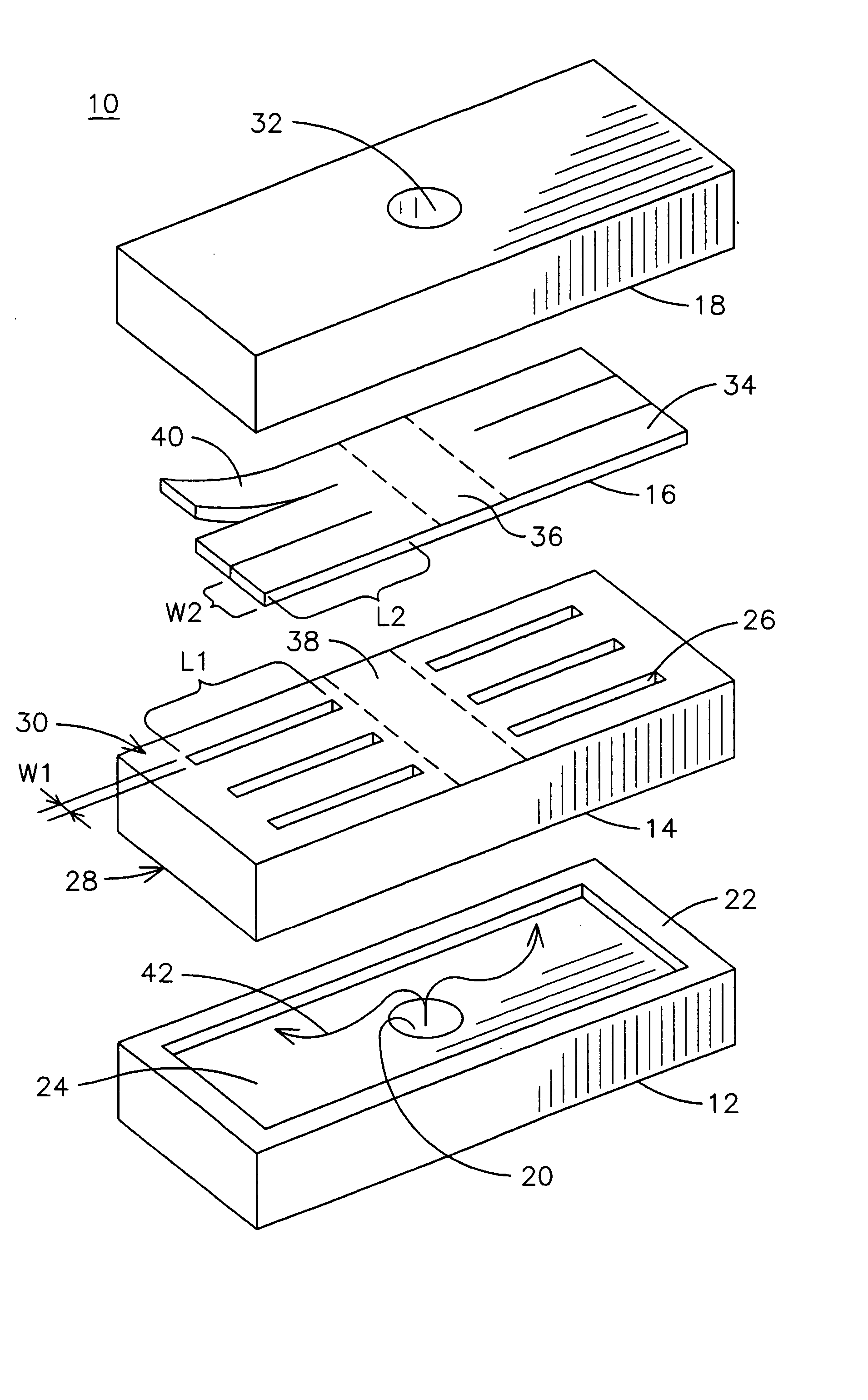

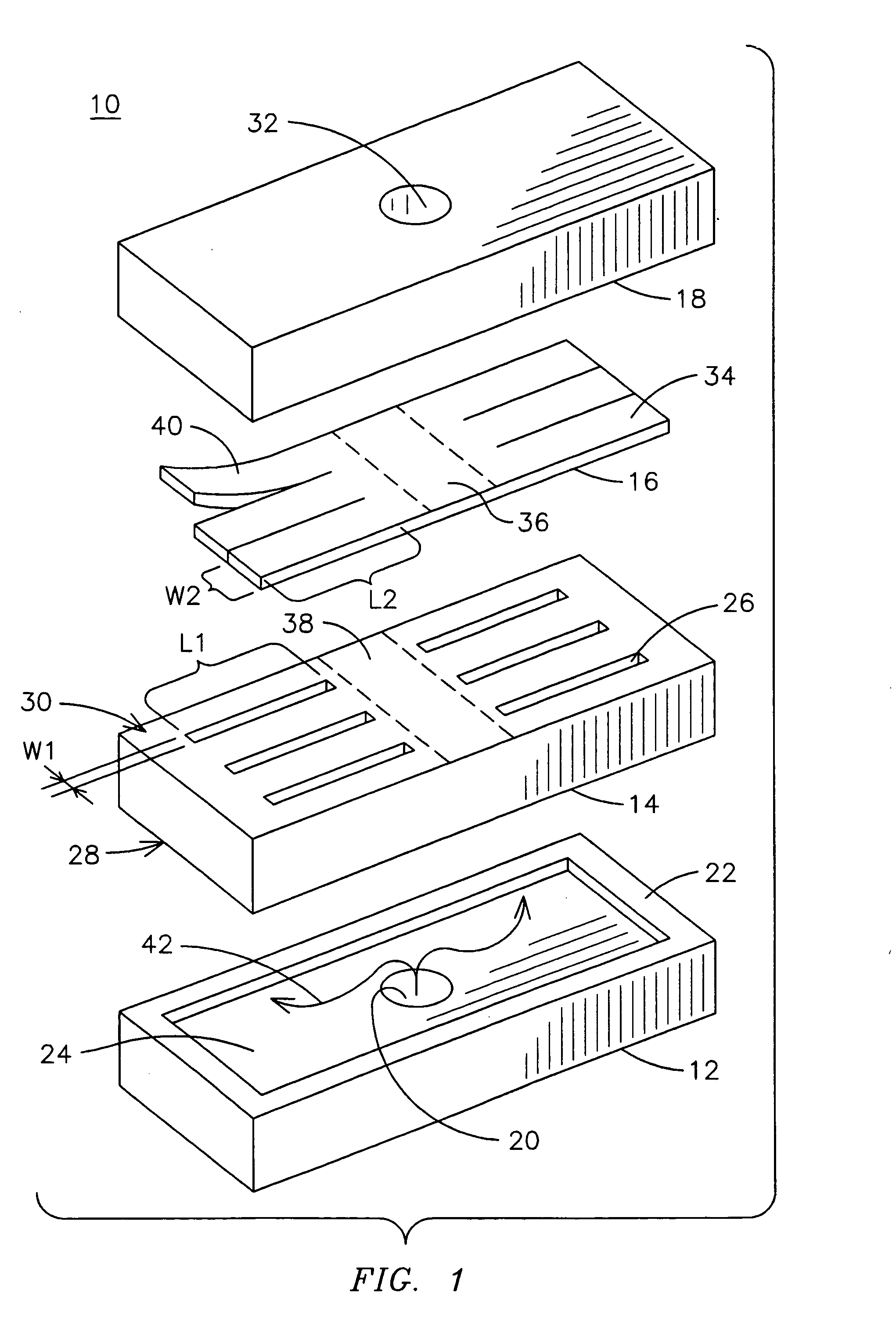

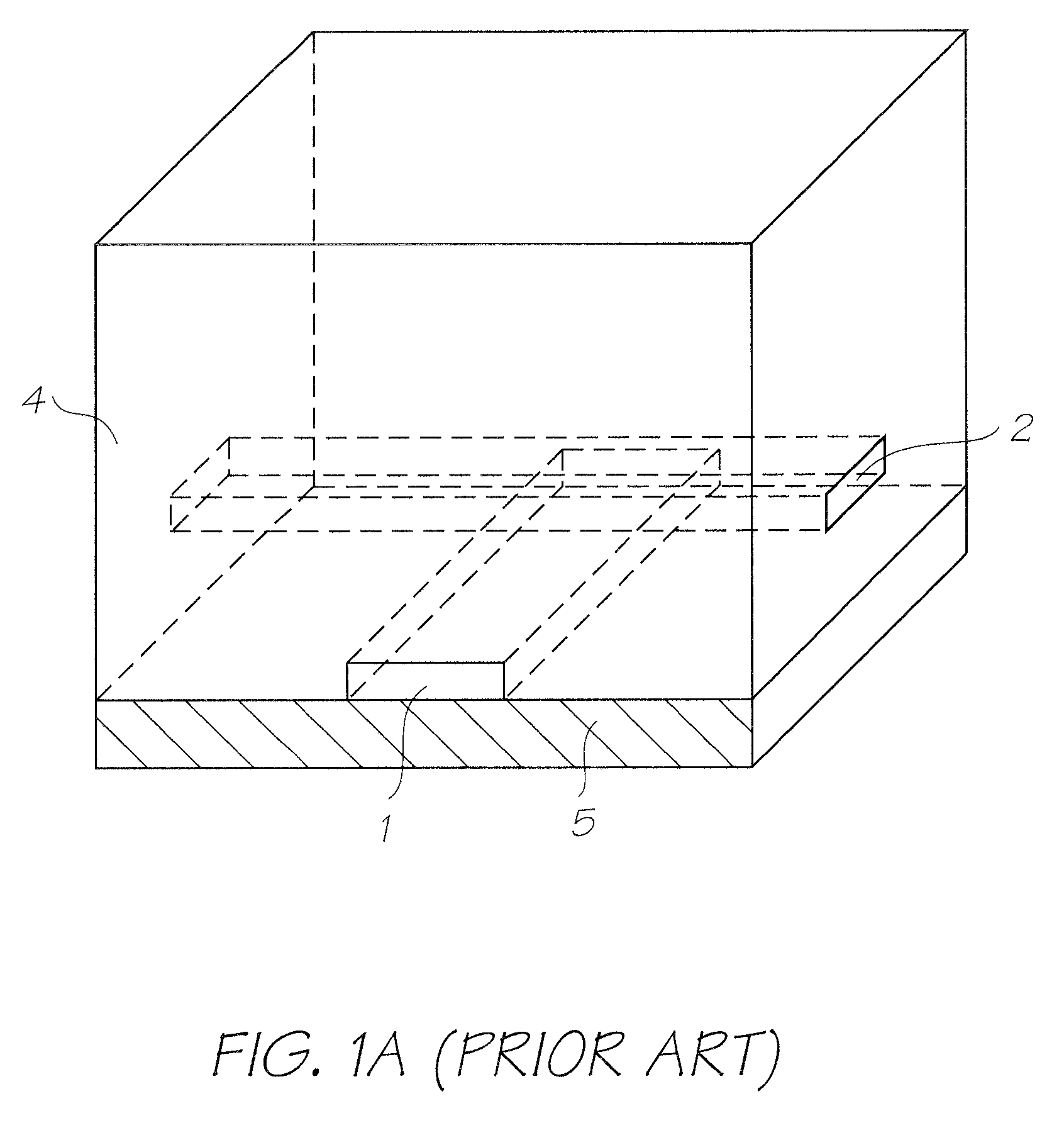

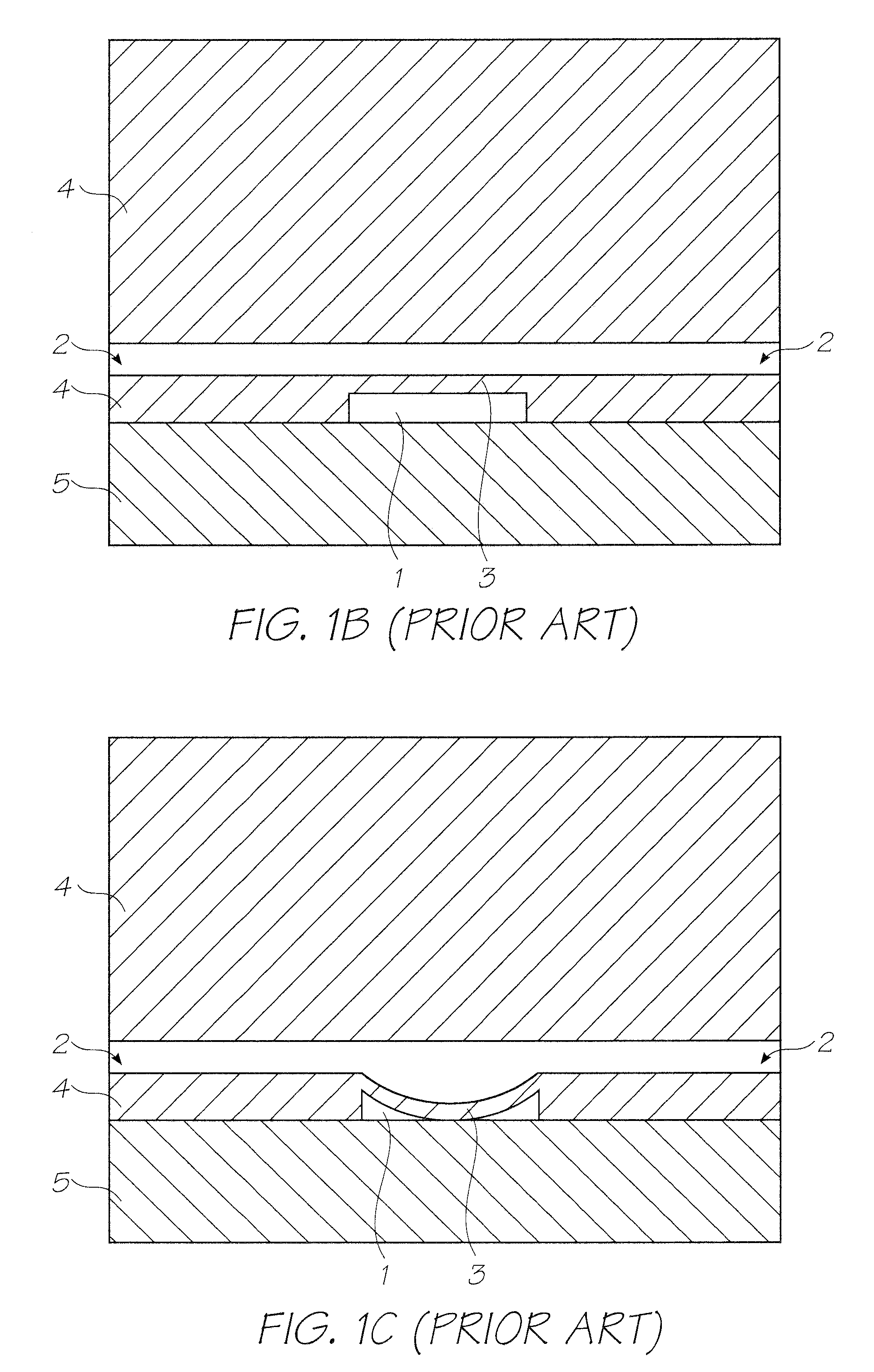

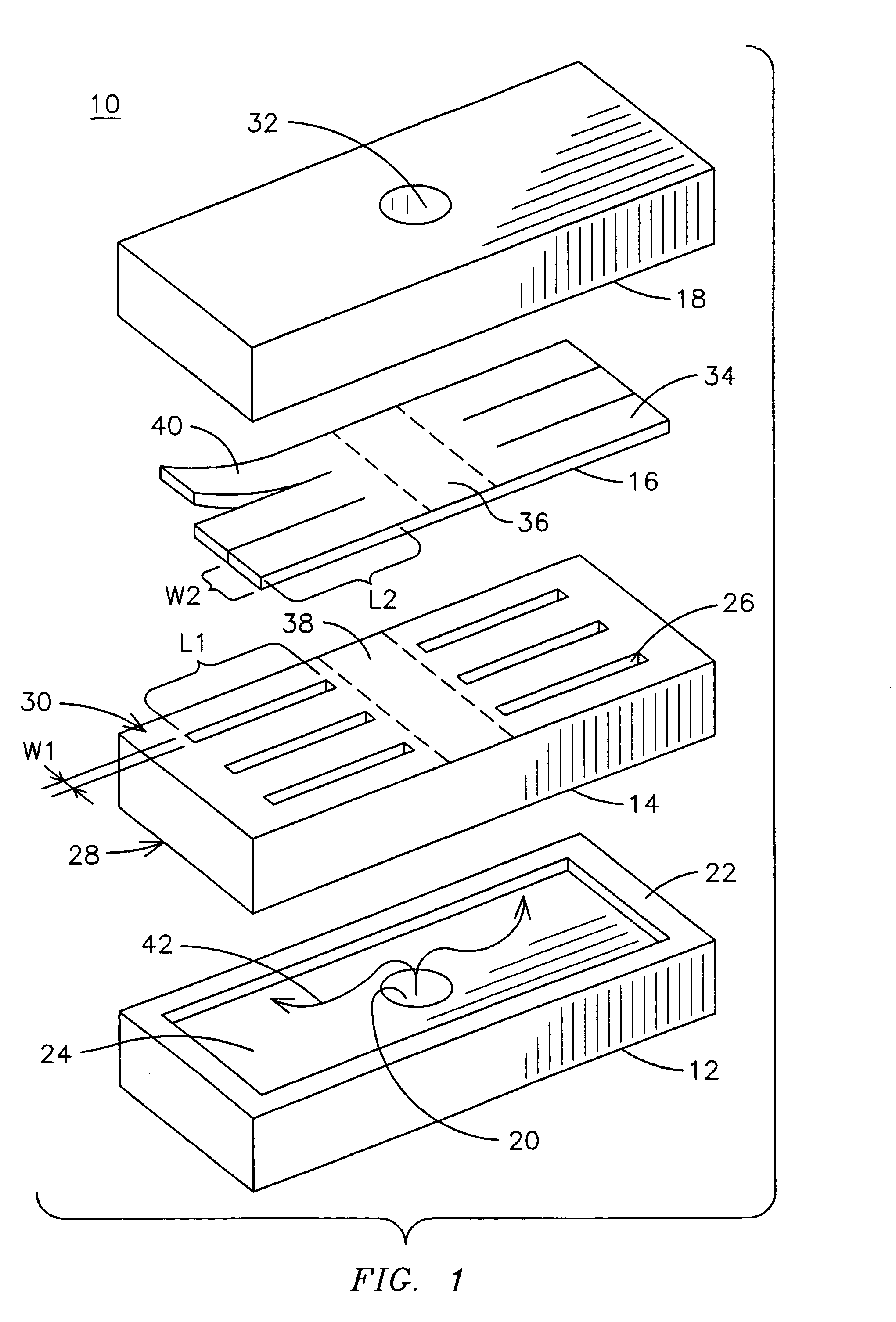

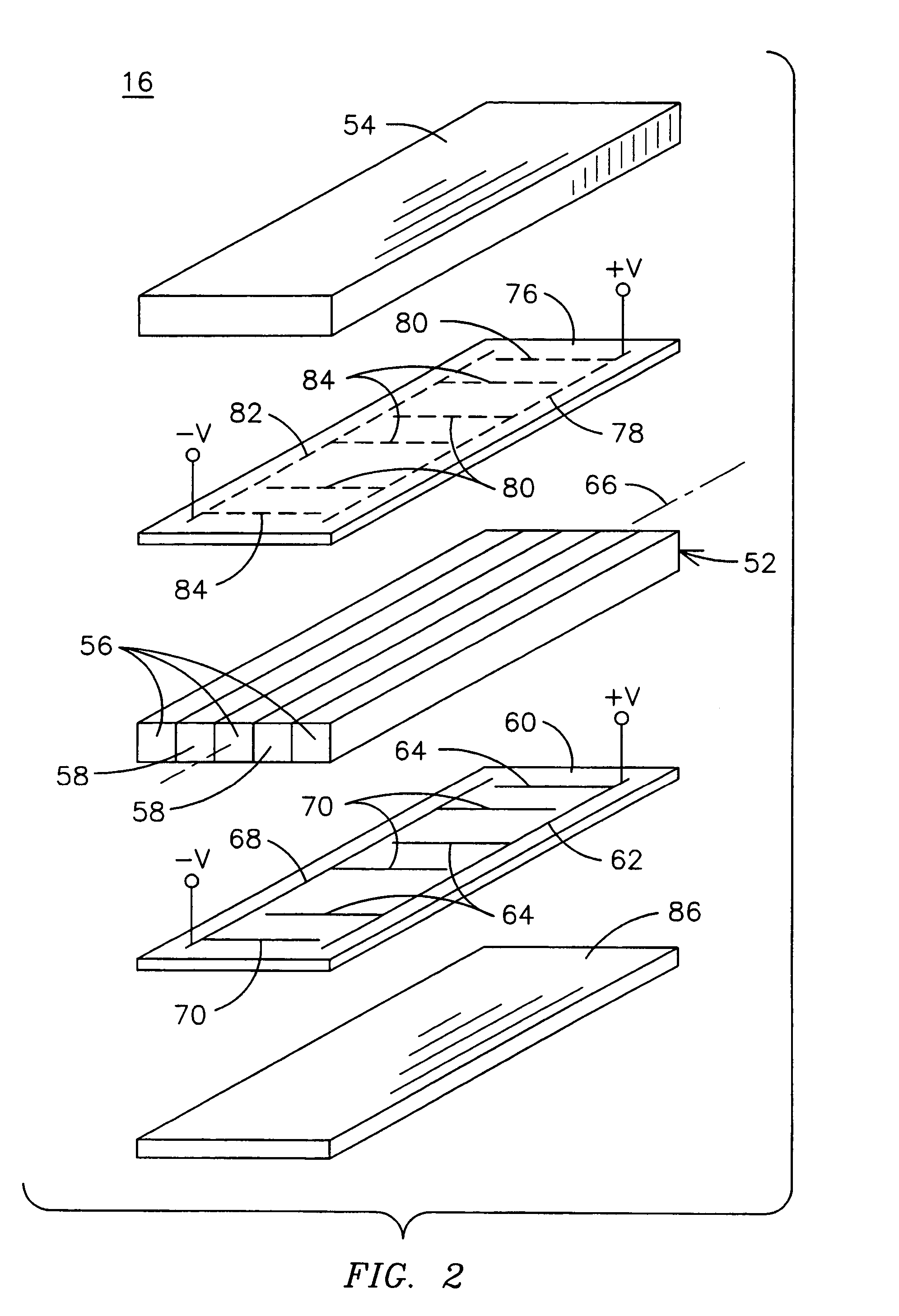

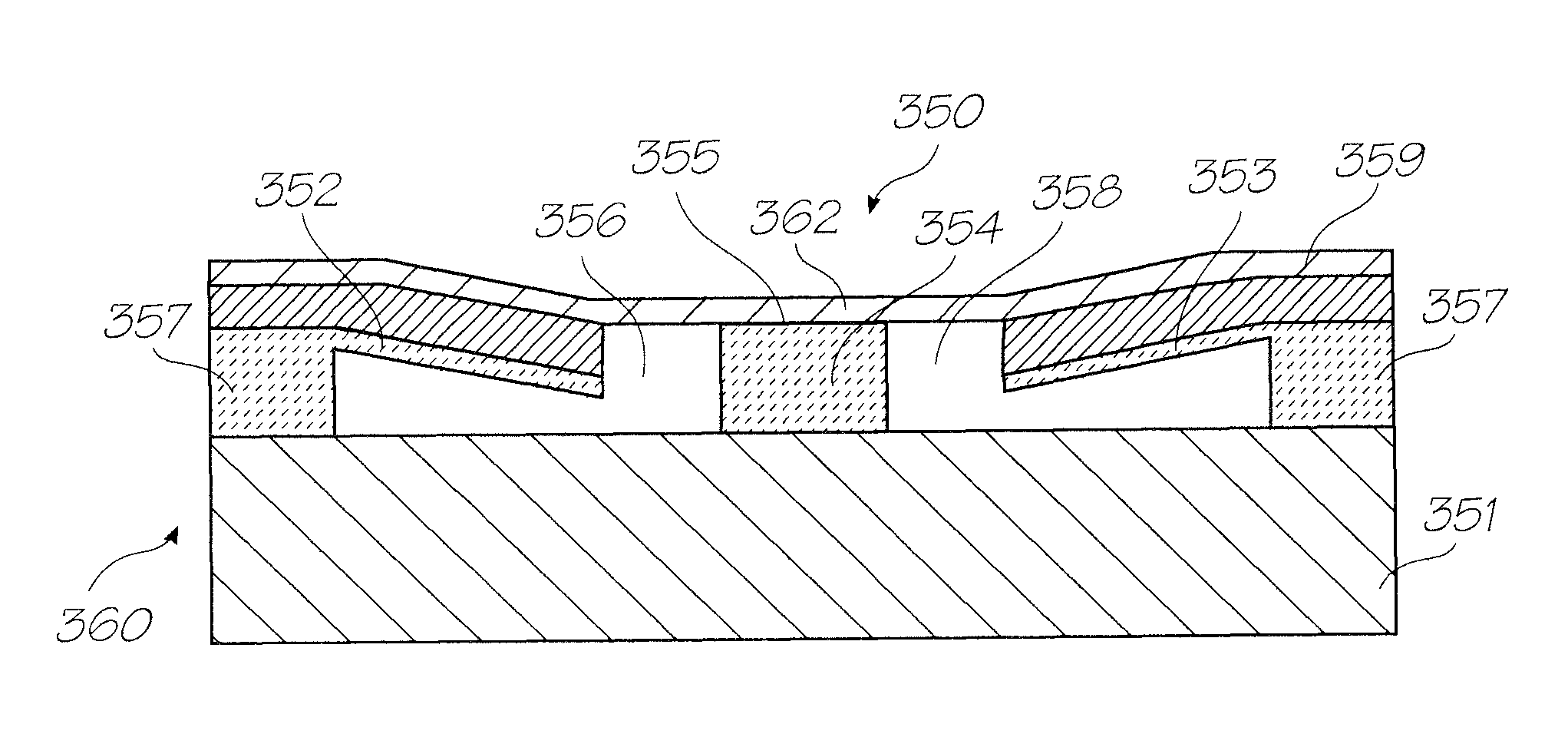

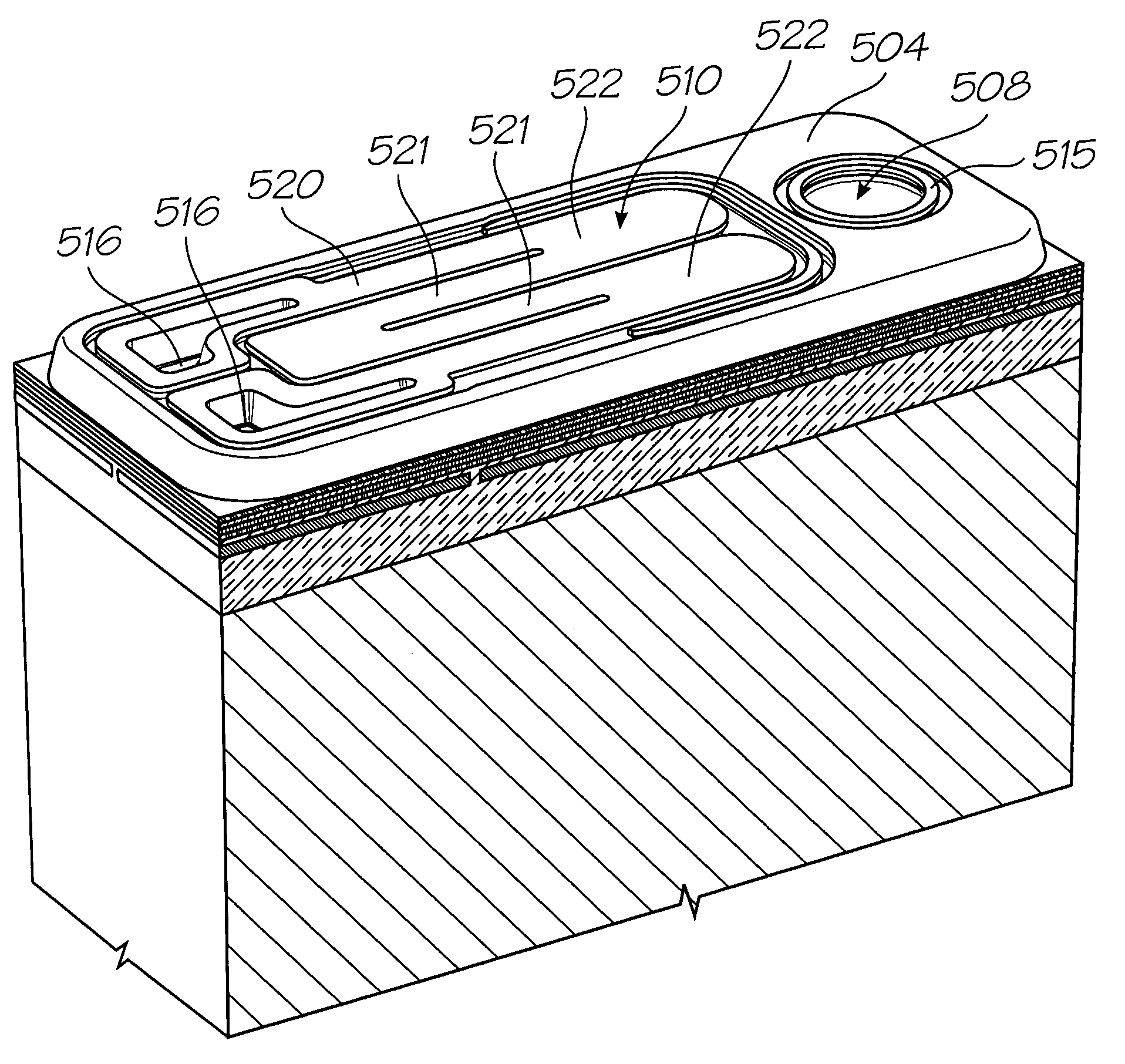

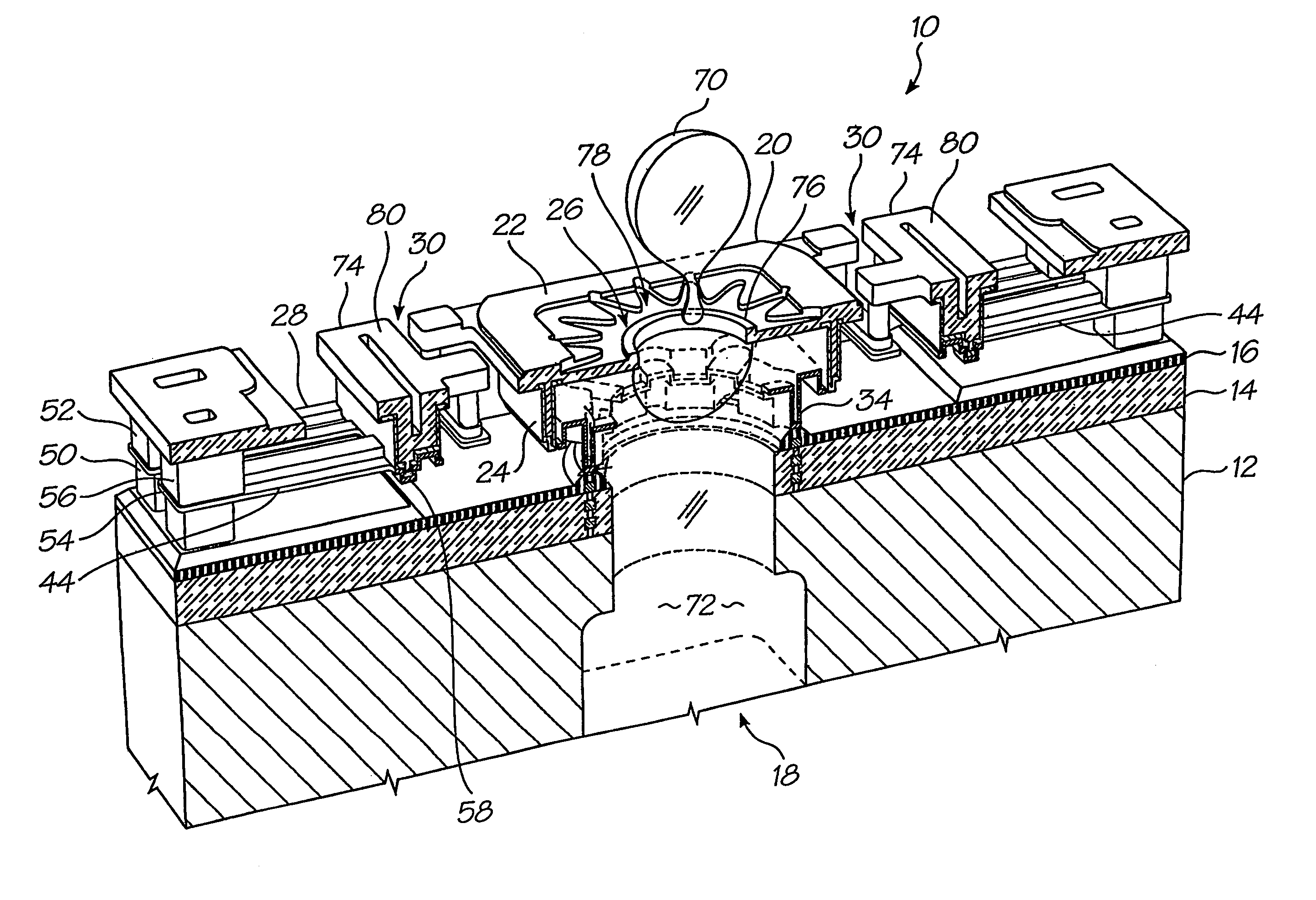

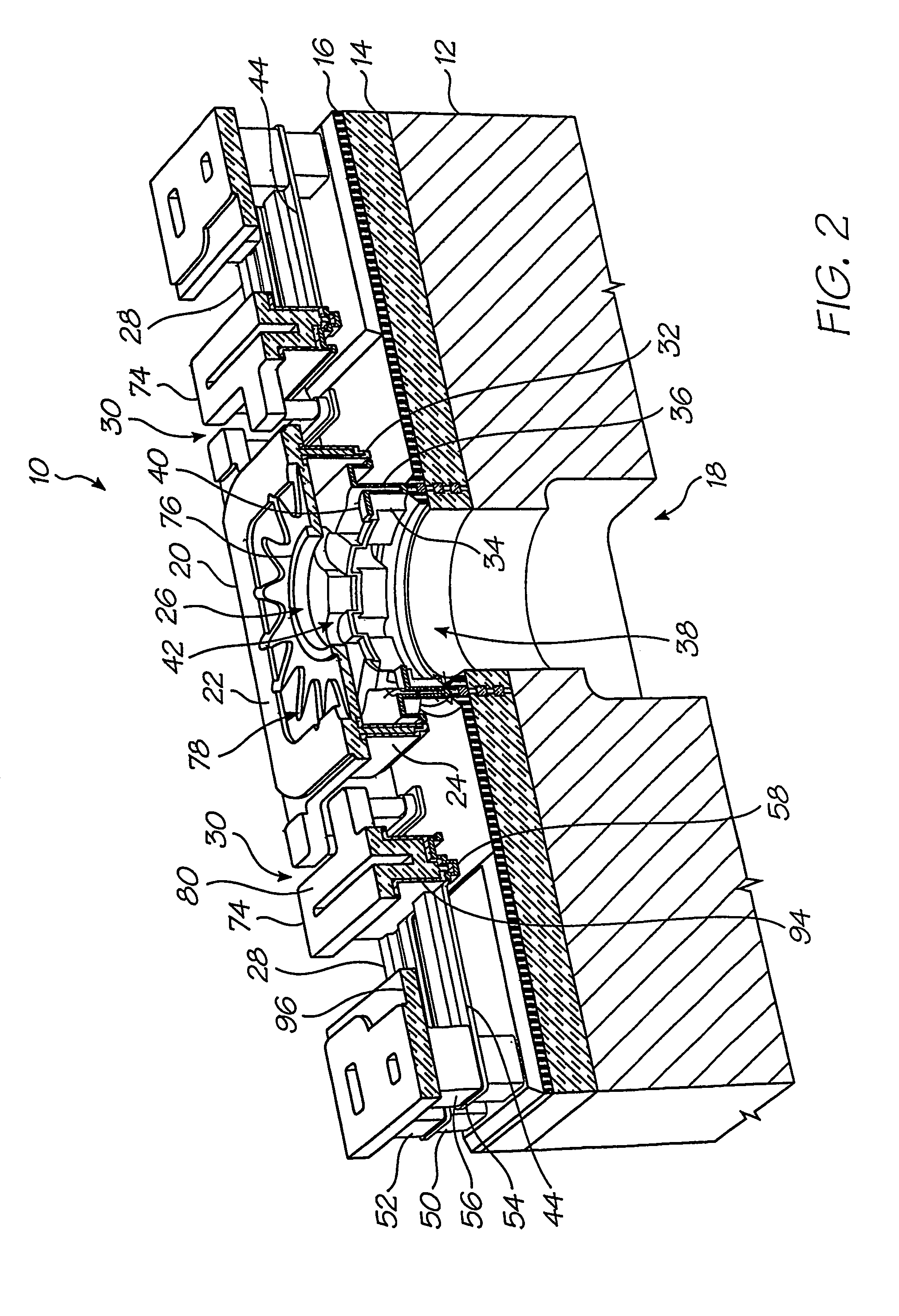

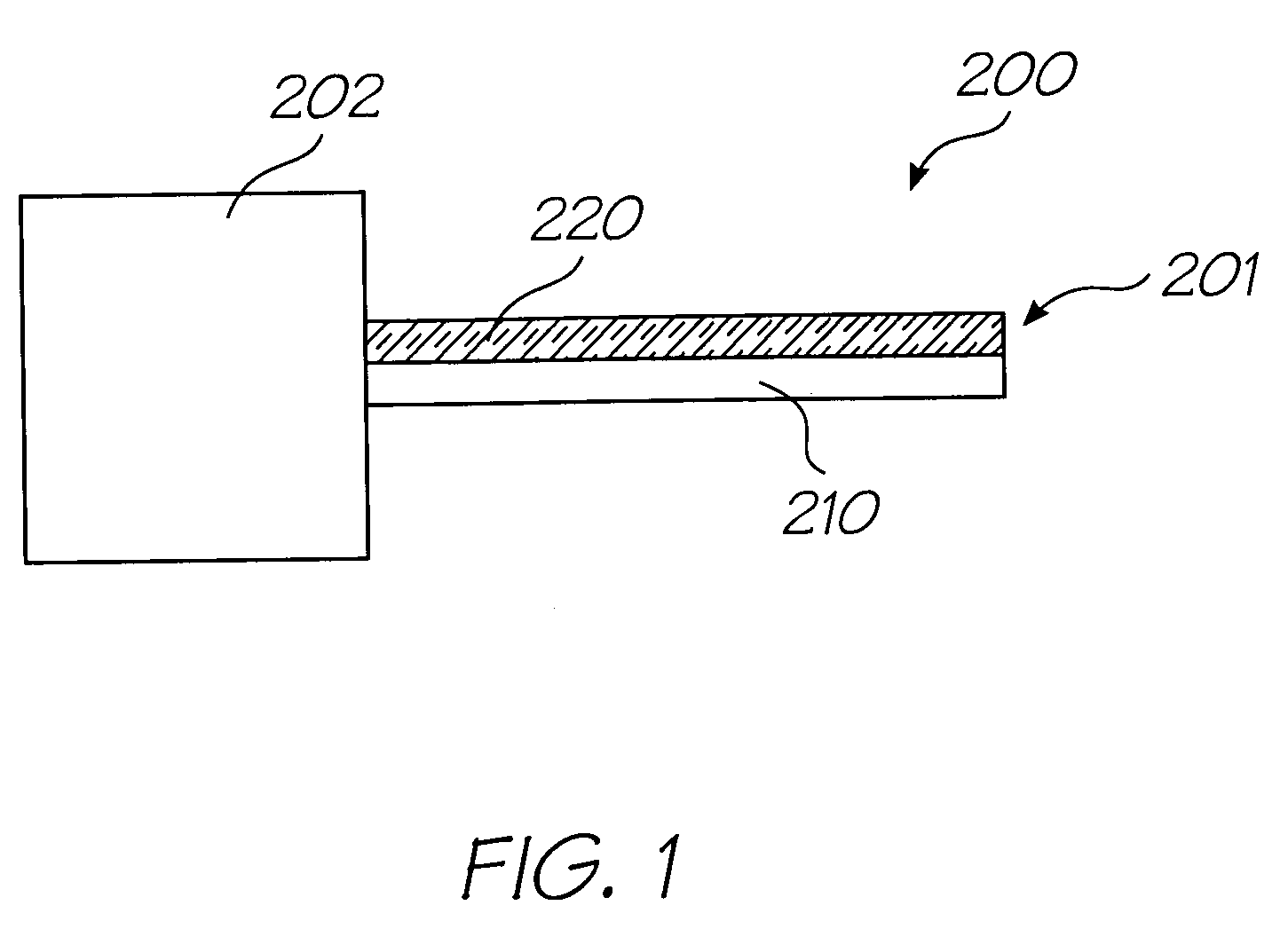

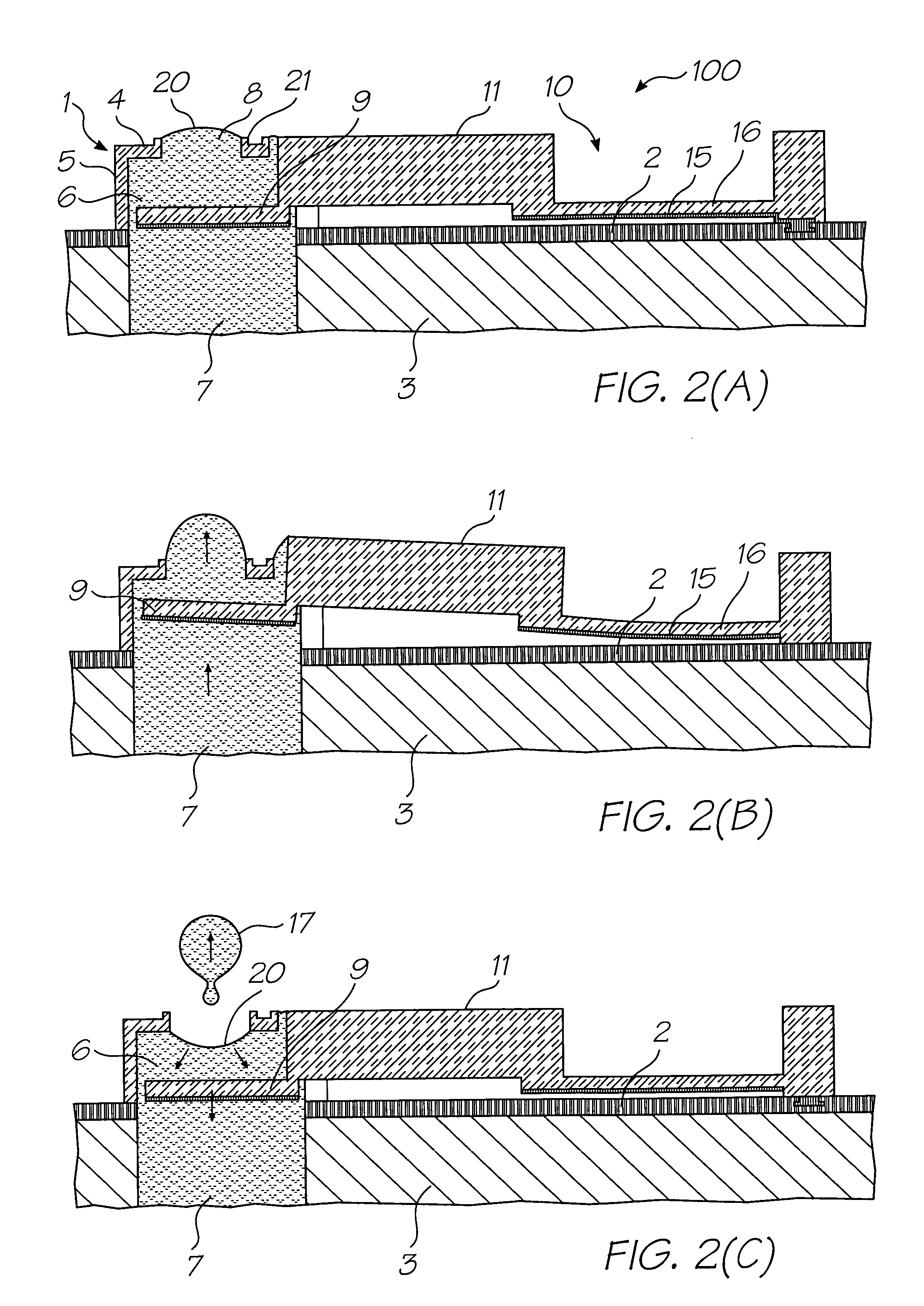

Symmetrically actuated ink ejection components for an ink jet printhead chip

A printhead chip for an ink jet printhead that includes a plurality of nozzle arrangements on a silicon wafer substrate (12). Each nozzle arrangement (10) has an active and static ink ejection structures positioned on the substrate. The active ink ejection structure (20) has a roof (22) with an ink ejection port (26) defined in the roof. The active ink ejection structure (20) and the static ink ejection structure (34) together define a nozzle chamber (42) in fluid communication with an ink supply. At least two thermal bend actuators (28) are operatively arranged with respect to the active ink ejection structure to displace the active ink ejection structure with respect to the static ink ejection structure towards and away from the substrate to reduce and increase a volume of the nozzle chamber to eject an ink drop from the nozzle chamber. The actuators (28) are configured and connected to the active ink ejection structure to impart substantially rectilinear movement to the active ink ejection structure.

Owner:MEMJET TECH LTD +1

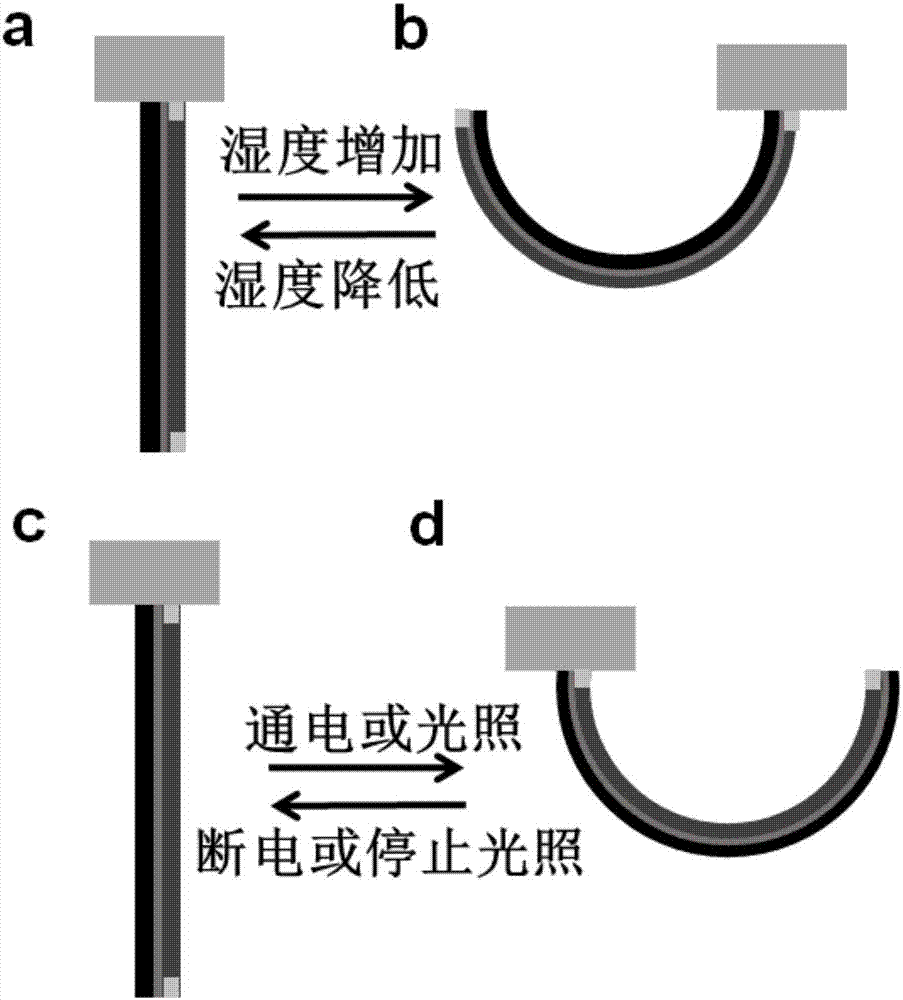

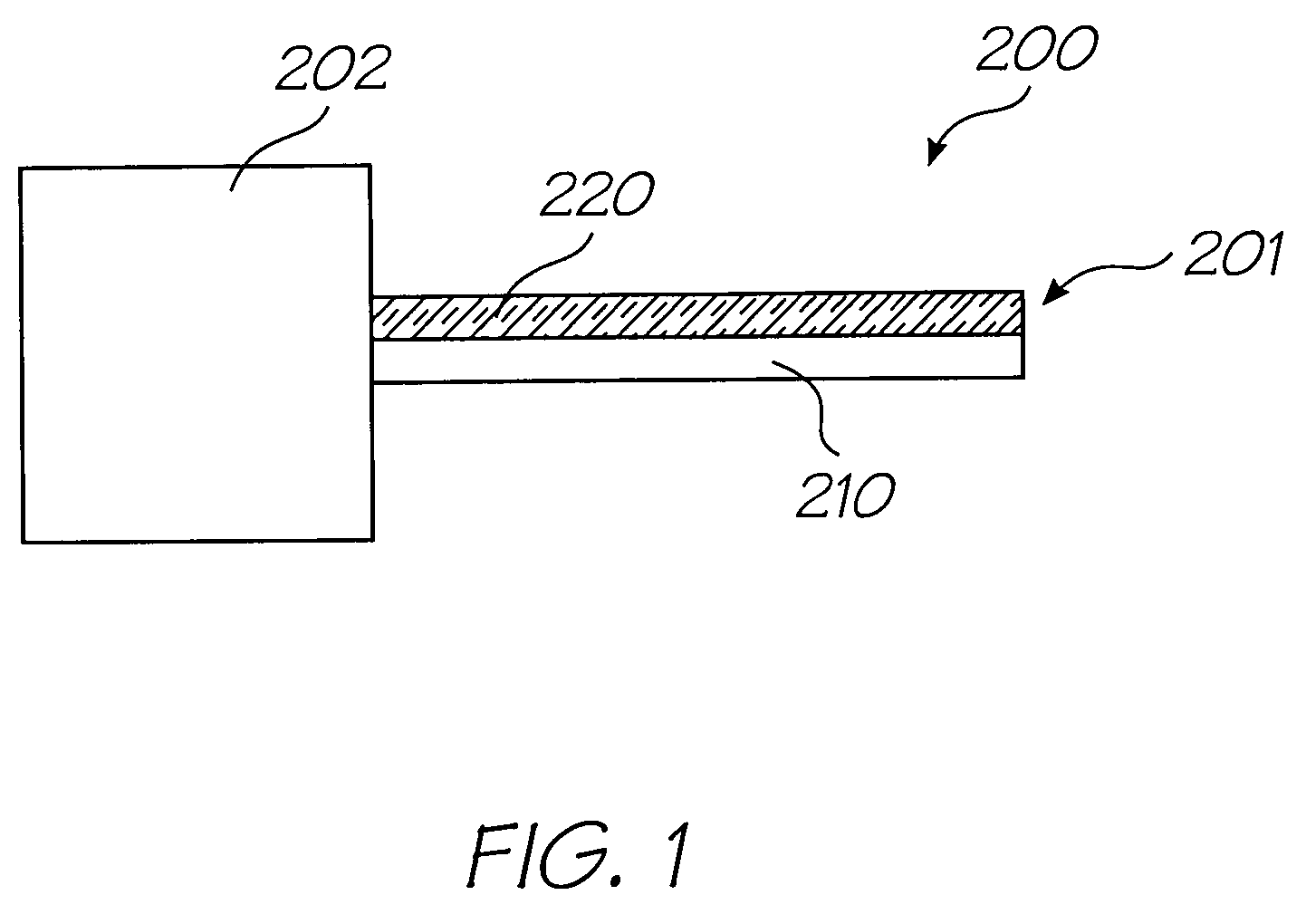

Actuation material, bidirectional bending actuator and preparation method of bidirectional bending actuator

ActiveCN107297929AFlexibleImprove mechanical propertiesMaterial nanotechnologySynthetic resin layered productsThermal dilatationElectrical connection

The invention discloses an actuation material, a bidirectional bending actuator and a preparation method of the bidirectional bending actuator. The actuation material comprises a first material layer and a second material layer which are arranged in an overlap manner, wherein an adhesive layer is arranged between the first material layer and the second material layer; the humidity expansion coefficient of the first material layer is greater than that of the second material layer; the thermal expansion coefficient of the first material layer is smaller than that of the second material layer; the first material layer is a carbon-based cellulose composite material layer; and the second material layer is a polymer material layer. The actuator comprises the actuation material and at least two electrodes, wherein the two electrodes are arranged at an internal and are electrically connected with the actuation material; and the two electrodes are fixed on the surface of the first material layer of the actuation material at an interval. The actuator is capable of responding to multiple types of stimulation, can be driven through light, electricity and humidity, and can achieve bidirectional bending deformation.

Owner:FUJIAN NORMAL UNIV

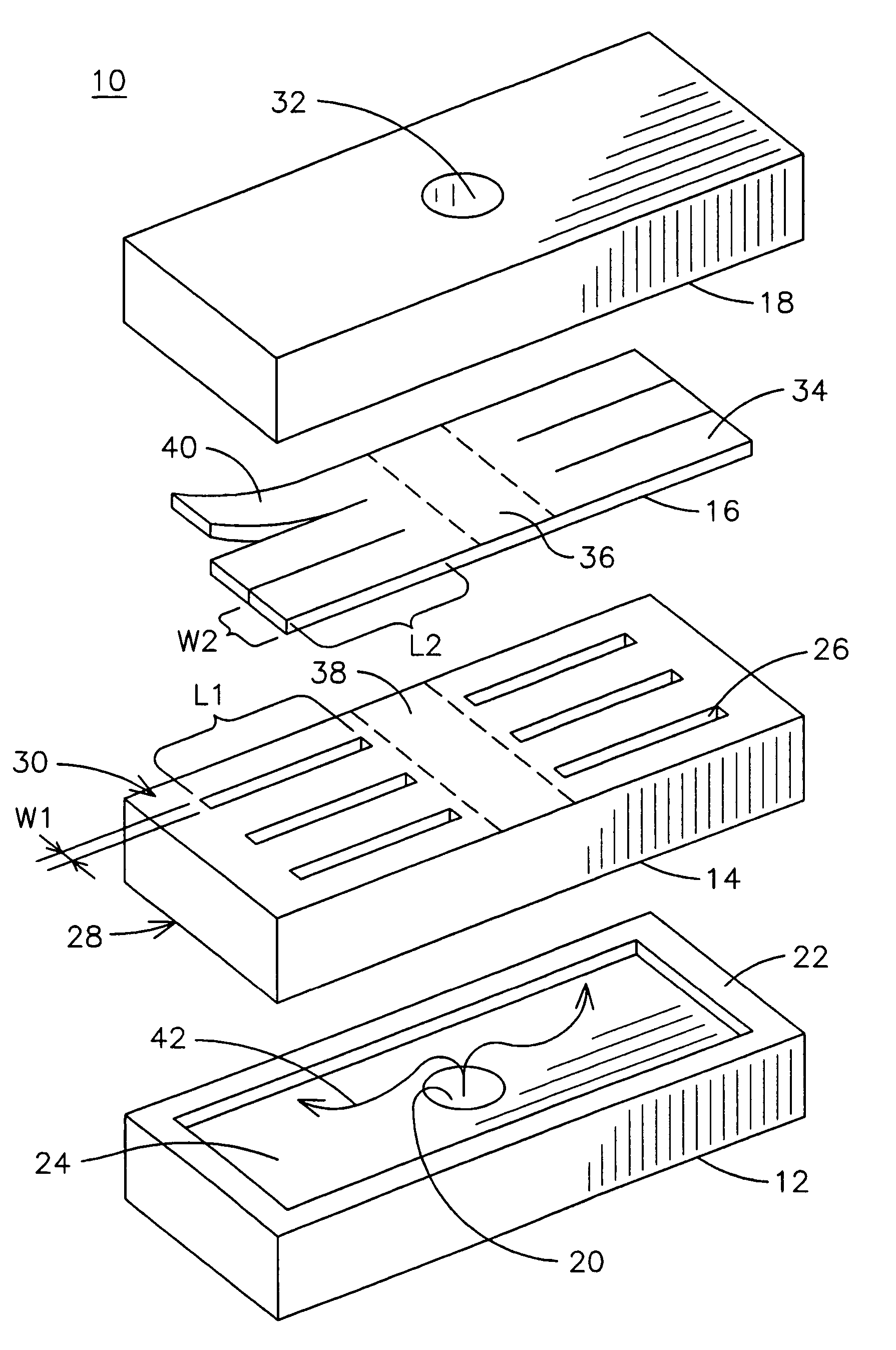

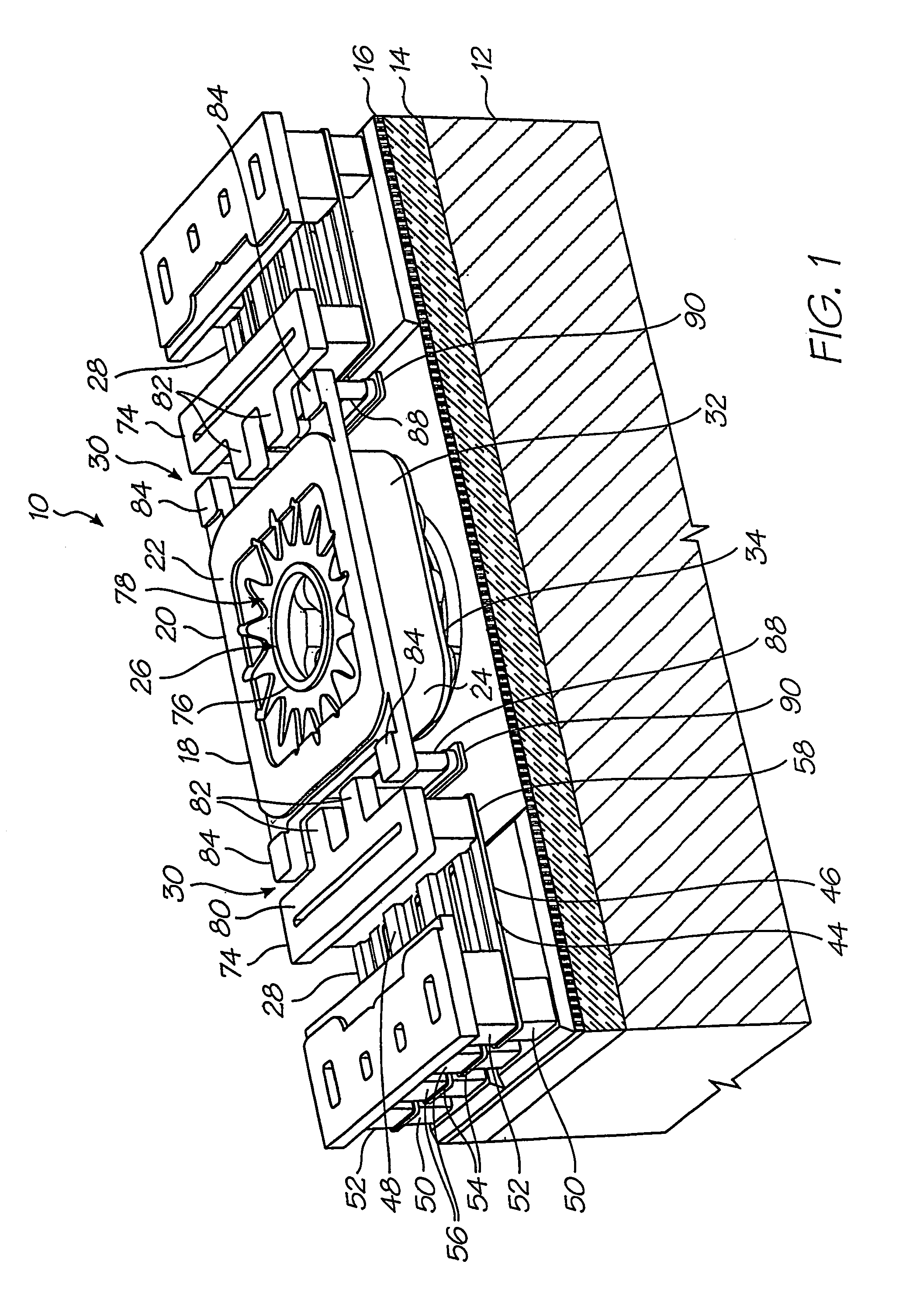

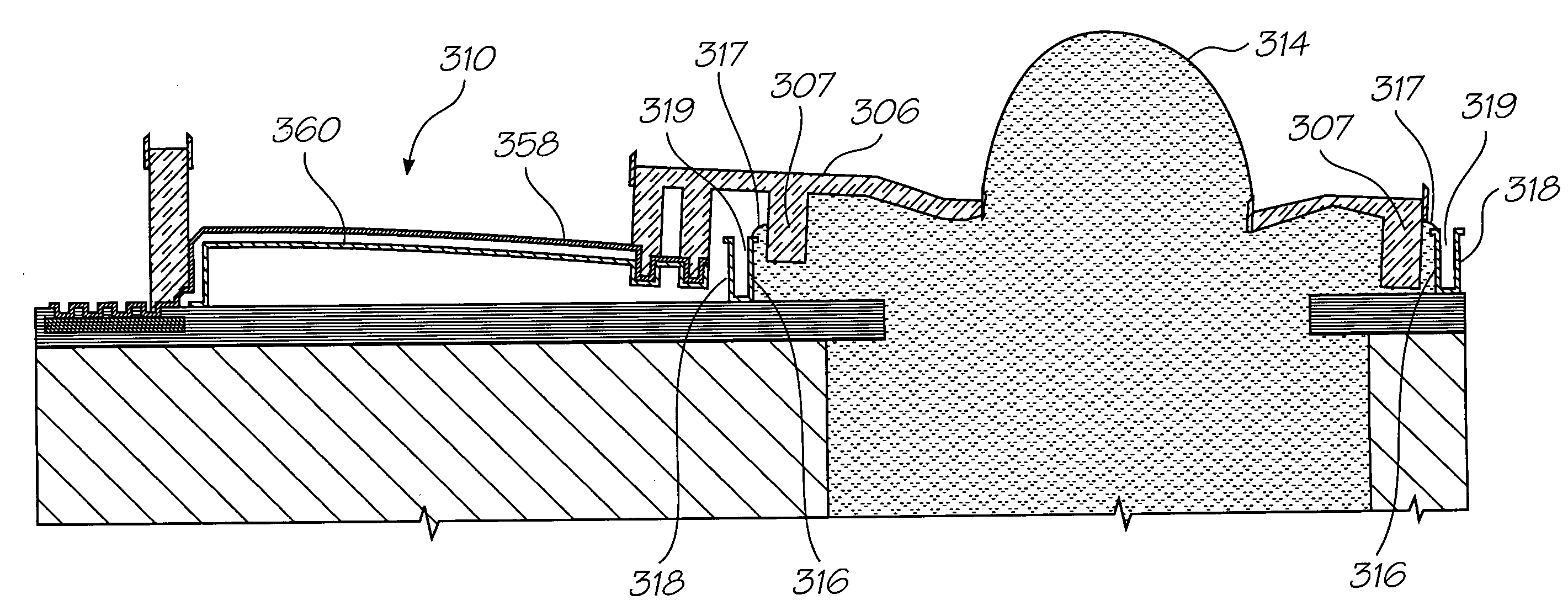

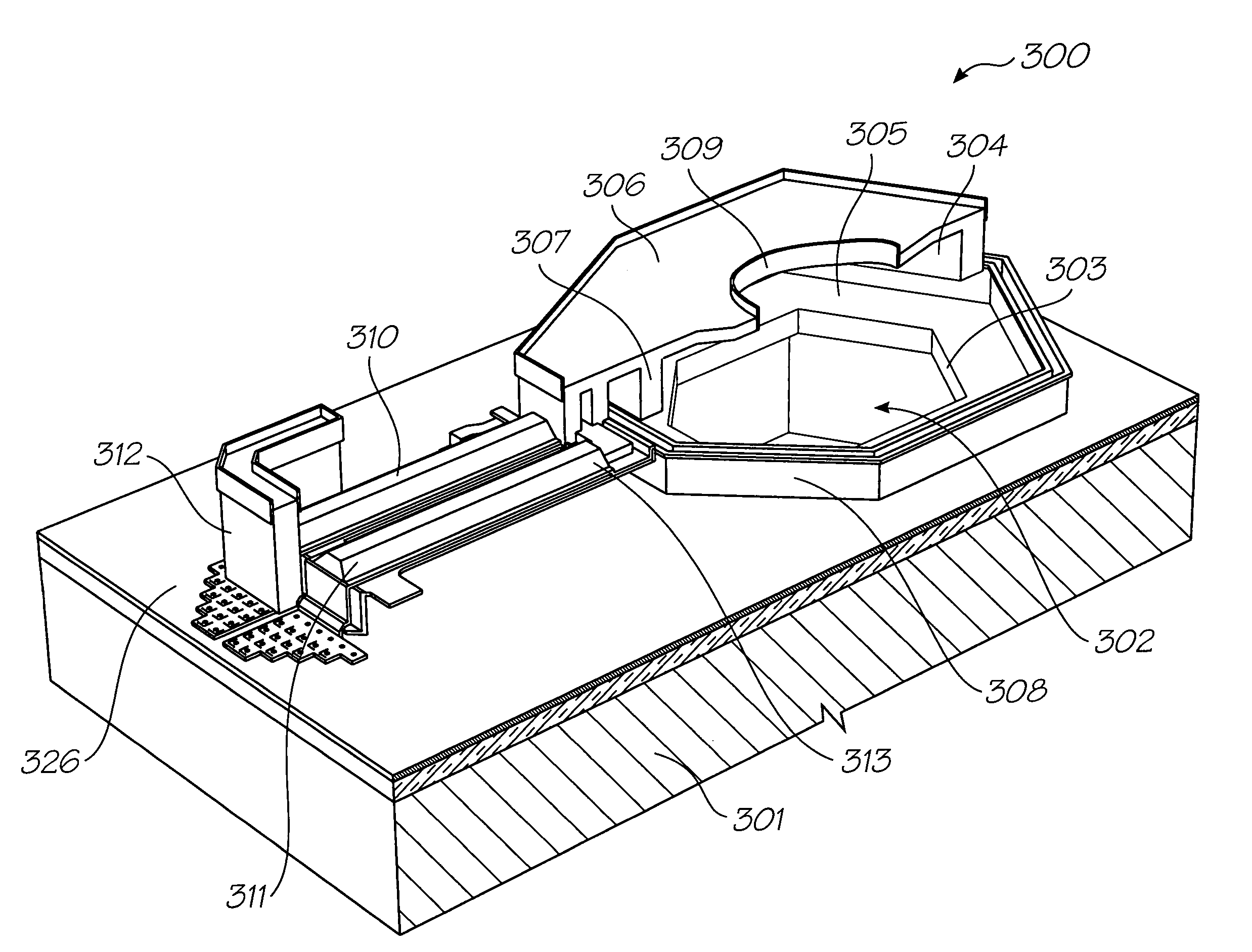

Discrete air and nozzle chambers in a printhead chip for an inkjet printhead

A printhead chip for an inkjet printhead includes a plurality of nozzle arrangements on a substrate. Each nozzle arrangement includes nozzle chamber walls and a roof that define a nozzle chamber with the roof defining an ink ejection port in fluid communication with the nozzle chamber. An ink-ejecting member or paddle is positioned in the nozzle chamber and displaceable towards and away from the ink ejection port so that a resultant fluctuation in ink pressure within the nozzle chamber results in an ejection of ink from the ink ejection port. At least one work transmitting structure of a lever mechanism is displaceable with respect to the substrate results in displacement of the ink-ejecting member. A thermal bend actuator is capable of displacing the structure upon receipt of an electrical drive signal. An air chamber defined by walls and a covering formation are positioned over the actuator to protect the component from ingress of microscopic detritus such as paper dust.

Owner:MEMJET TECH LTD +1

Crack-resistant thermal bend actuator

ActiveUS20110050806A1Improve thermal efficiencyRobust and resistant to crackingPrintingPower flowThermal insulation

A thermal bend actuator comprises an active beam for connection to drive circuitry and a passive beam mechanically cooperating with the active beam. When a current is passed through the active beam, the active beam expands relative to the passive beam resulting in bending of the actuator. The passive beam comprises a first layer comprised of silicon nitride and a second layer comprised of silicon dioxide. The second layer is sandwiched between the first layer and the active beam to provide thermal insulation for the first layer.

Owner:SILVERBROOK RES PTY LTD

Inkjet nozzle assembly having thermal bend actuator with an active beam defining part of an exterior surface of a nozzle chamber roof

An inkjet nozzle assembly is provided. The assembly comprises a nozzle chamber comprising a floor and a roof. The roof has a nozzle opening defined therein, and a moving portion moveable towards the floor. The assembly further comprises a thermal bend actuator, having a plurality of cantilever beams, for ejecting ink through the nozzle opening. A first active beam of the actuator defines at least part of an exterior surface of the roof

Owner:MEMJET TECH LTD +1

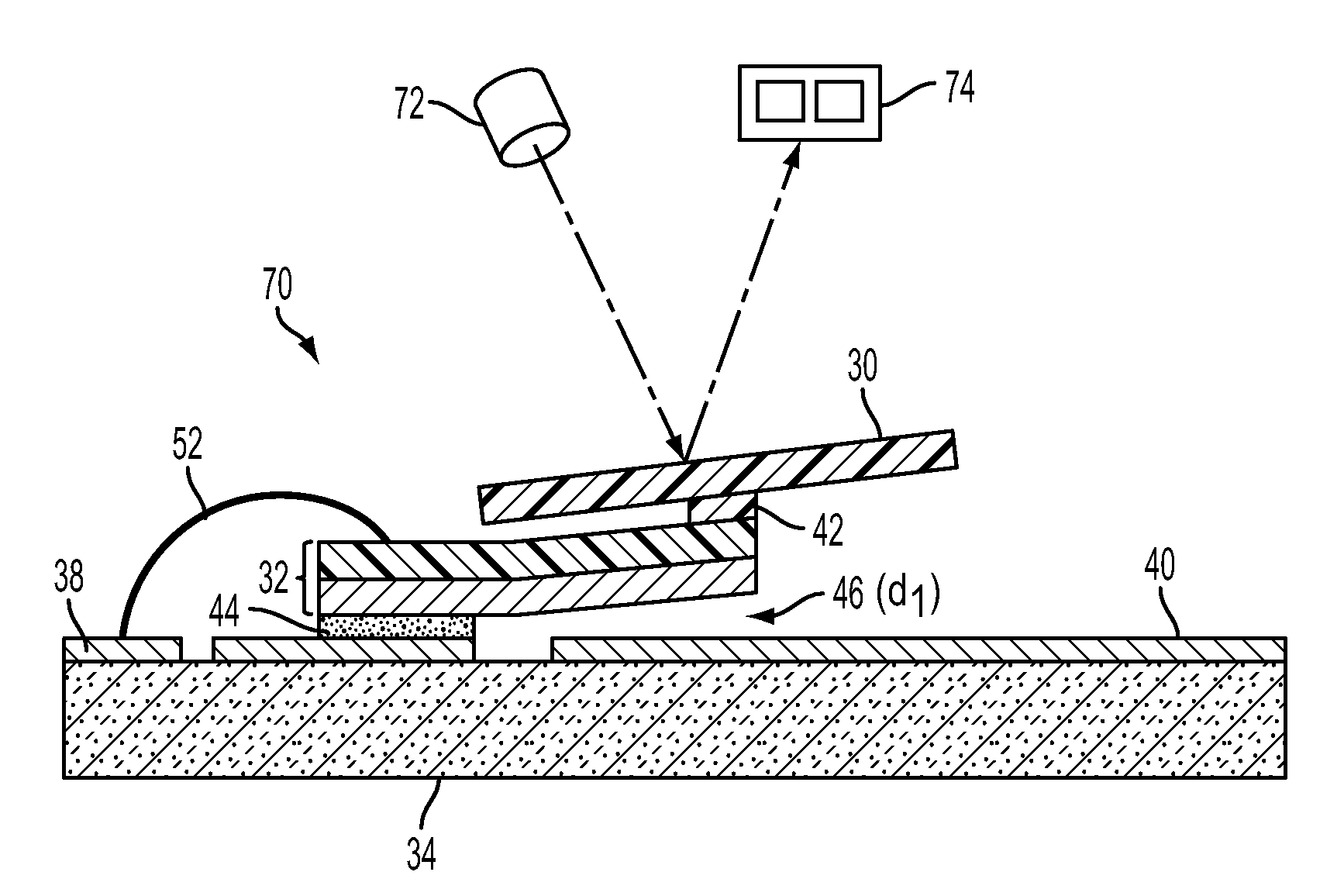

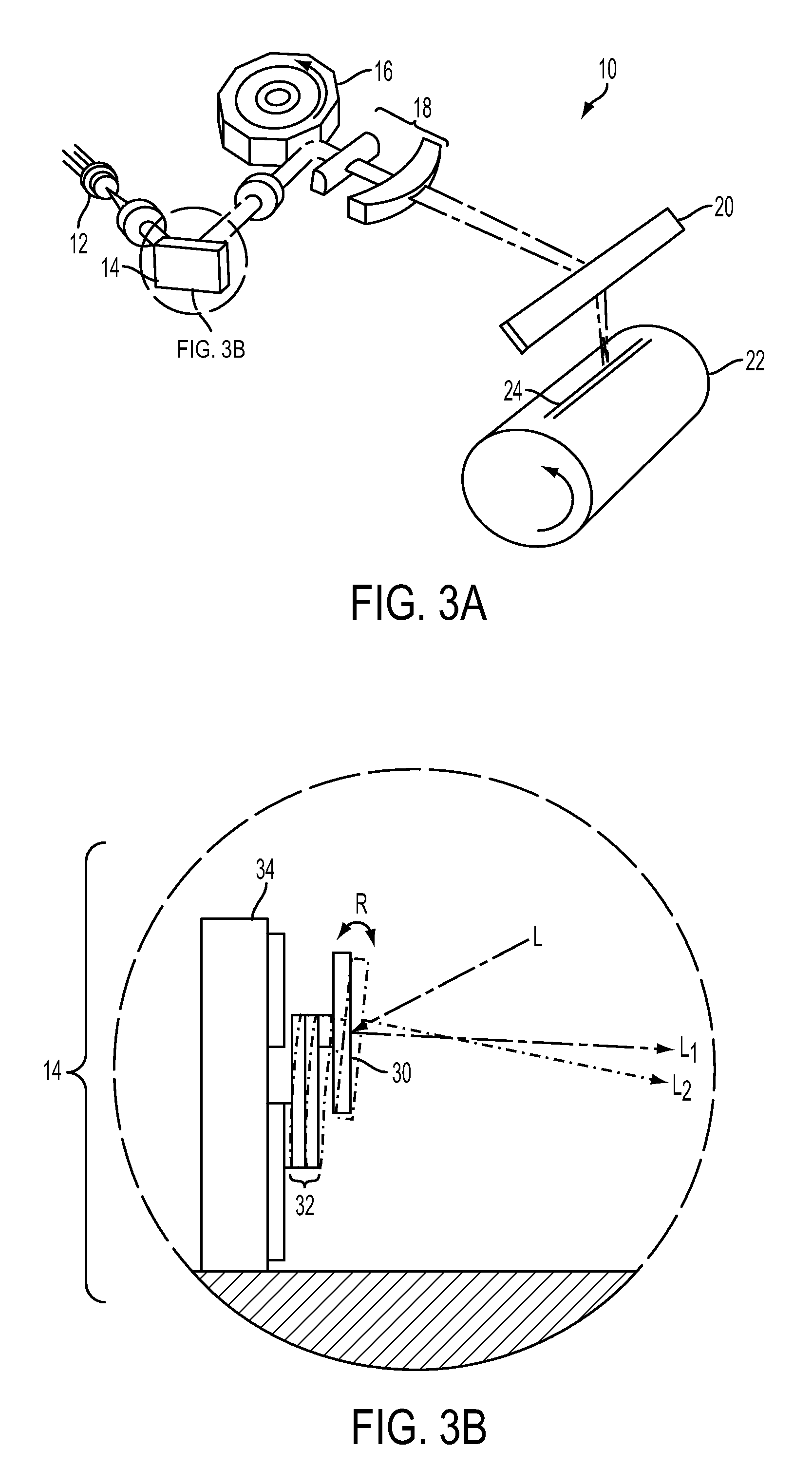

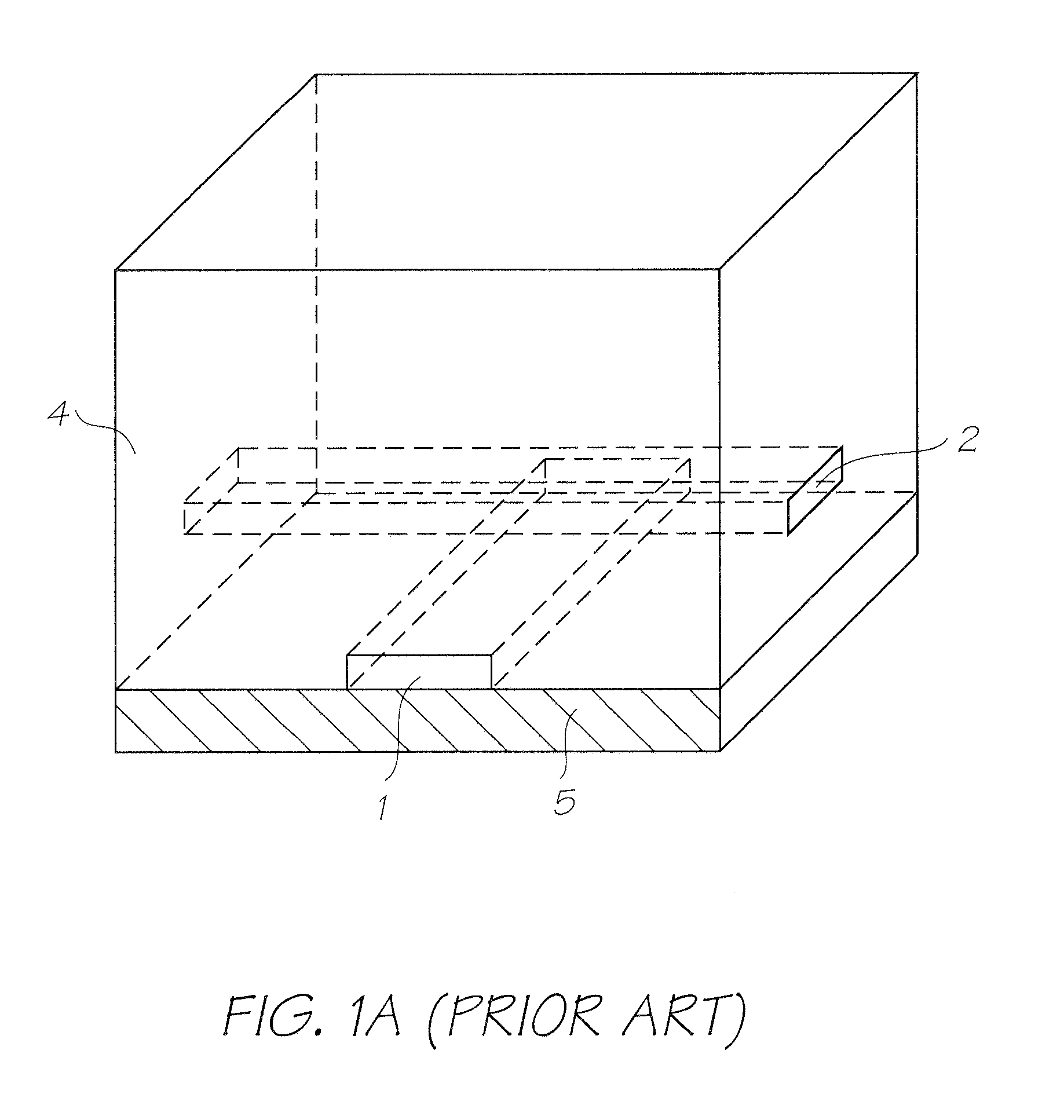

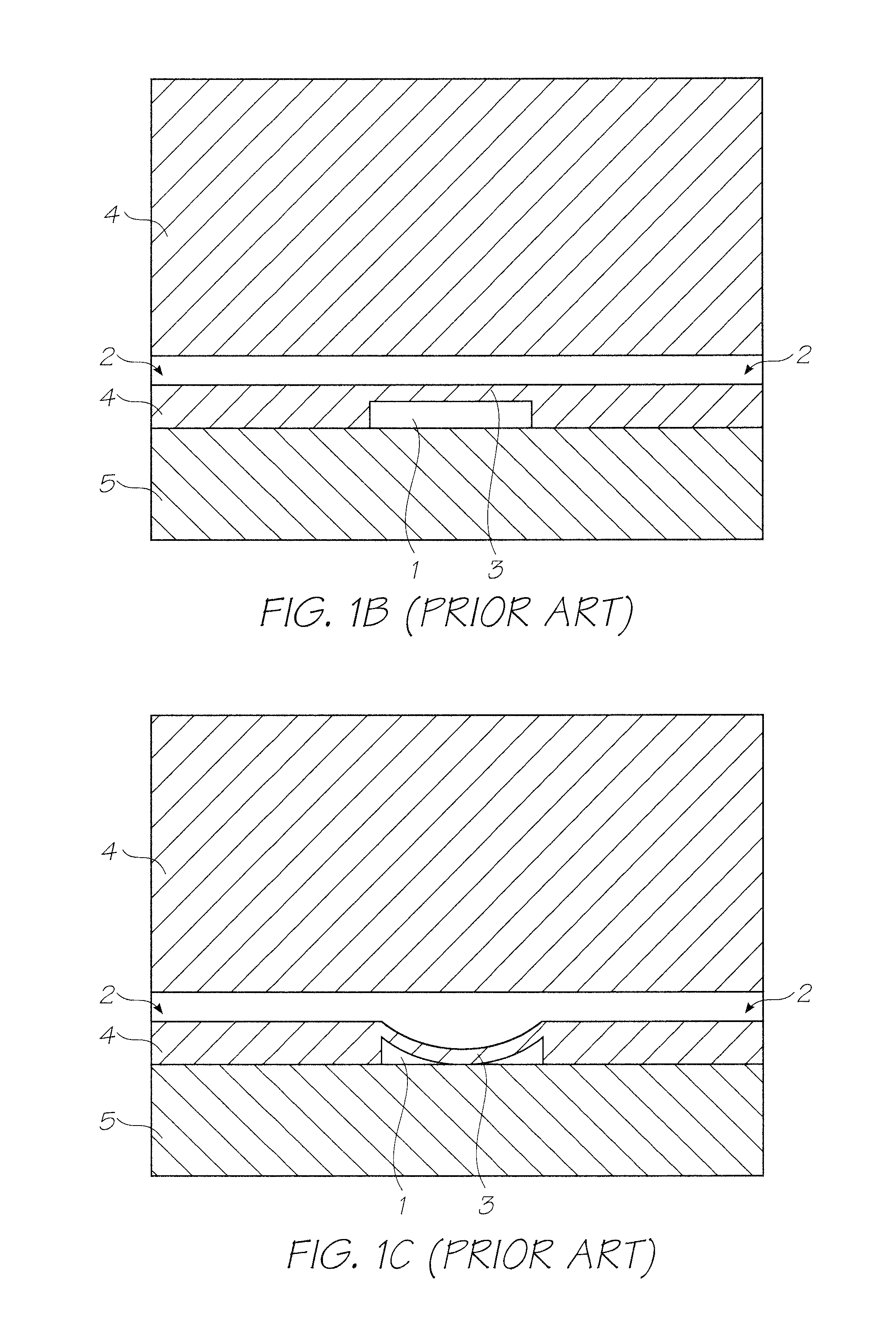

Agile beam steering mirror for active raster scan error correction

Scan line position error resulting in banding, bow, skew, etc. is corrected by way of an agile beam steering mirror assembly in a ROS printing system and the like. The agile beam steering mirror system comprises a piezoelectric bending actuator fixedly mounted to a substrate at a proximate end thereof. A mirror structure is mounted at a free distal end of the bending actuator. Voltage applied to the bending actuator causes rotation of the mirror to thereby correct for positional errors of the scan line. Correction waveforms may be stored in control memory associated with the agile beam steering mirror assembly. A capacitive sensing circuit using a sensing electrode located beneath the free end of the bending actuator may be used in a feedback arrangement to determine and control mirror position.

Owner:XEROX CORP

Piezoelectric microvalve

InactiveUS20050133751A1Operating means/releasing devices for valvesCircuit elementsElectricityEngineering

A piezoelectric microvalve and method for controlling a fluid flow through a piezoelectric microvalve are provided. The microvalve includes an inlet plenum and a flow directing structure for directing a fluid flow, wherein a first side of the structure is in fluid communication with the inlet plenum. The microvalve also includes a piezoelectric bending actuator comprising a flap portion responsive to a command signal for controlling a fluid flow through the flow directing structure. The microvalve further includes an outlet plenum in fluid communication with a second side of the flow directing structure.

Owner:GENERAL ELECTRIC CO

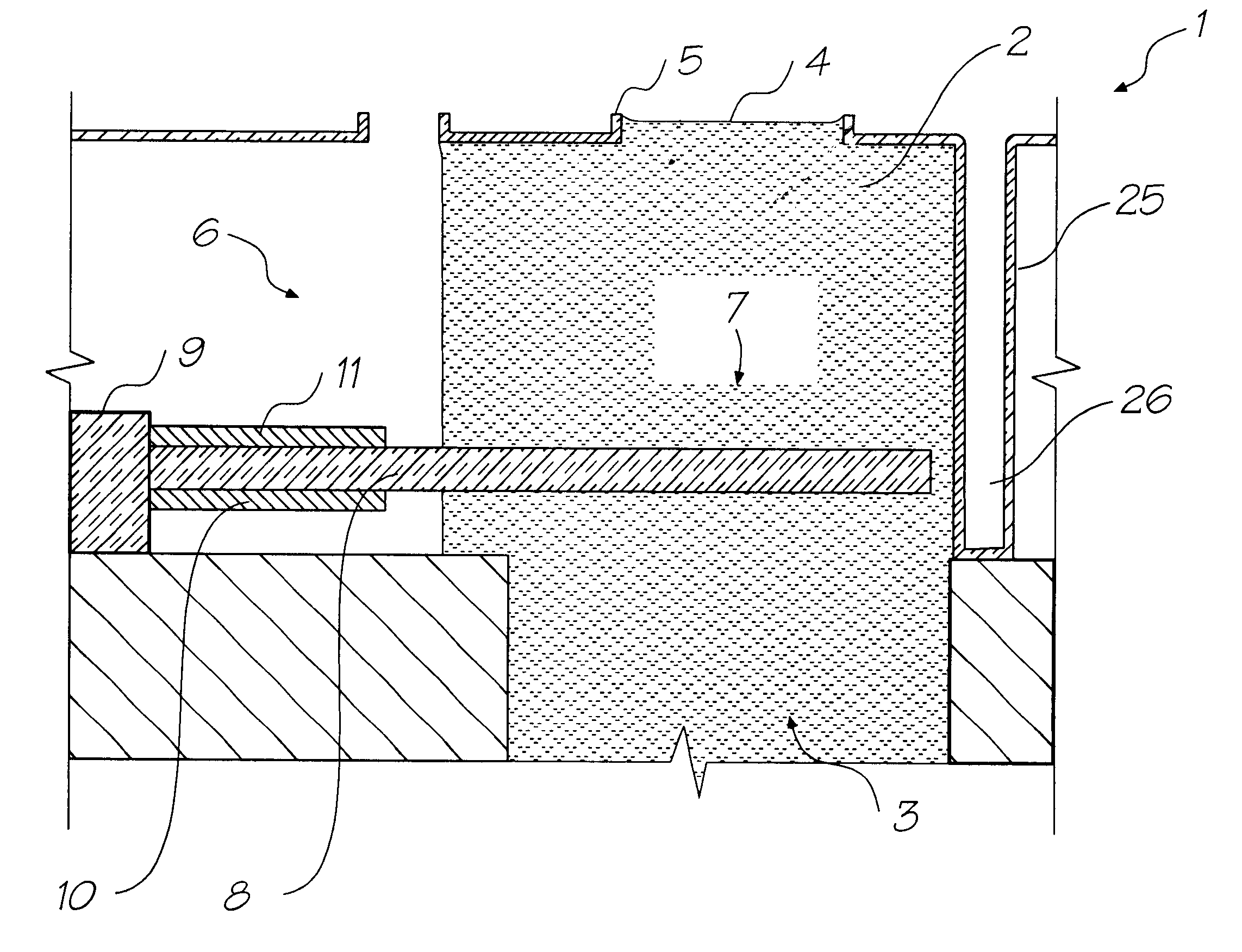

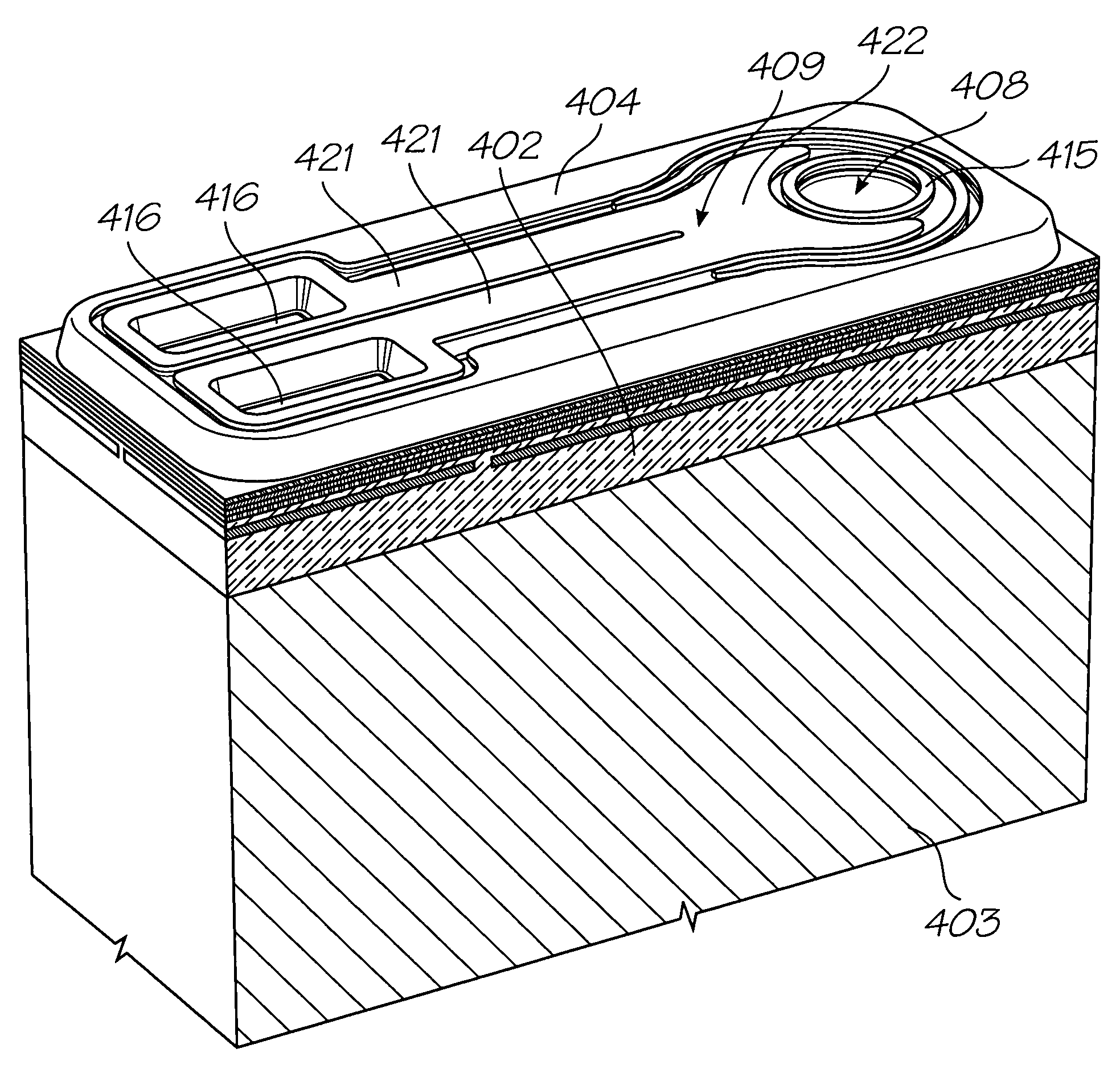

Microfluidic system comprising microfluidic pump, mixer or valve

InactiveUS7842248B2Shaking/oscillating/vibrating mixersTransportation and packagingEngineeringMicrofluidic channel

A microfluidic system. The system comprises: (A) a microfluidics platform comprising: a compliant body having a microfluidic channel defined therein; an elongate chamber defined by a section of the microfluidic channel, the chamber having a membrane wall defining part of an outer surface of the body; and a plurality of compression members spaced apart along the membrane wall, each compression member being configured for pinching a respective part of the membrane wall against an opposed wall of the chamber; and (B) a MEMS integrated circuit bonded to the outer surface of the body, the MEMS integrated circuit comprising: a plurality of moveable fingers, each finger engaged with a respective compression member, each finger being configured to urge the respective compression member between a closed position in which the respective part of the membrane wall is sealingly pinched against the opposed wall, and an open position in which the respective part of the membrane wall is disengaged from the opposed wall; a plurality of thermal bend actuators, each associated with a respective finger for controlling movement of the respective finger, and control circuitry for controlling actuation of the actuators.

Owner:SILVERBROOK RES PTY LTD

Piezoelectric microvalve

InactiveUS6988706B2Operating means/releasing devices for valvesCircuit elementsEngineeringMicro valve

A piezoelectric microvalve and method for controlling a fluid flow through a piezoelectric microvalve are provided. The microvalve includes an inlet plenum and a flow directing structure for directing a fluid flow, wherein a first side of the structure is in fluid communication with the inlet plenum. The microvalve also includes a piezoelectric bending actuator comprising a flap portion responsive to a command signal for controlling a fluid flow through the flow directing structure. The microvalve further includes an outlet plenum in fluid communication with a second side of the flow directing structure.

Owner:GENERAL ELECTRIC CO

Inkjet nozzle assembly having thermal bend actuator with an active beam defining substantial part of nozzle chamber roof

An inkjet nozzle assembly is provided. The assembly comprises a nozzle chamber comprising a floor and a roof. The roof has a nozzle opening defined therein, and a moving portion moveable towards the floor. The assembly further comprises a thermal bend actuator, having a plurality of cantilever beams, for ejecting ink through the nozzle opening. A first active beam of the actuator defines at least 30% of a total area of the roof.

Owner:MEMJET TECH LTD +1

Mechanically-actuated microfluidic diaphragm valve

A microfluidic diaphragm valve. The valve comprises: an inlet port; an outlet port; a weir positioned between the inlet and outlet ports, the weir having a sealing surface; a diaphragm membrane for sealing engagement with the sealing surface; and a thermal bend actuator for moving the diaphragm membrane between a closed position in which the membrane is sealingly engaged with the sealing surface and an open position in which the membrane is disengaged from said sealing surface.

Owner:SILVERBROOK RES PTY LTD

Thermal bend actuator comprising aluminium alloy

A thermal bend actuator, having a plurality of elongate cantilever beams, is provided. The actuator comprises: a first active beam for connection to drive circuitry, the first beam being defined by a tortuous beam element, the tortuous beam element having a plurality of contiguous beam members; and a second passive beam mechanically cooperating with the first beam. When a current is passed through the first beam, the first beam expands relative to the second beam, resulting in bending of the actuator. The plurality of contiguous beam members comprises a plurality of longer beam members extending along a longitudinal axis of the first beam, and at least one shorter beam member extending across a transverse axis of the first beam and interconnecting longer beam members.

Owner:MEMJET TECH LTD +1

Photoinduced bending flexible electro-conductive baseplate and preparation method thereof

InactiveCN103029355ARealize integrationMiniaturizationConductive layers on insulating-supportsLaminationEngineeringArtificial muscle

The invention discloses a photoinduced bending flexible electro-conductive baseplate and a preparation method thereof. The photoinduced bending flexible electro-conductive baseplate comprises a photoinduced bending flexible substrate and an electro-conductive layer, wherein the photoinduced bending flexible substrate is made of a photoinduced bending polymer material, and the electro-conductive layer is attached onto the surface of the photoinduced bending flexible substrate. The flexible baseplate simultaneously having the photoinduced bending capability and the electro-conductive capability is prepared, so that the integration and the microminiaturization of a photoinduced bending actuator and a light source can be realized, and the wide application and the quick development of a photoinduced bending material in the field of artificial muscles can be accelerated.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

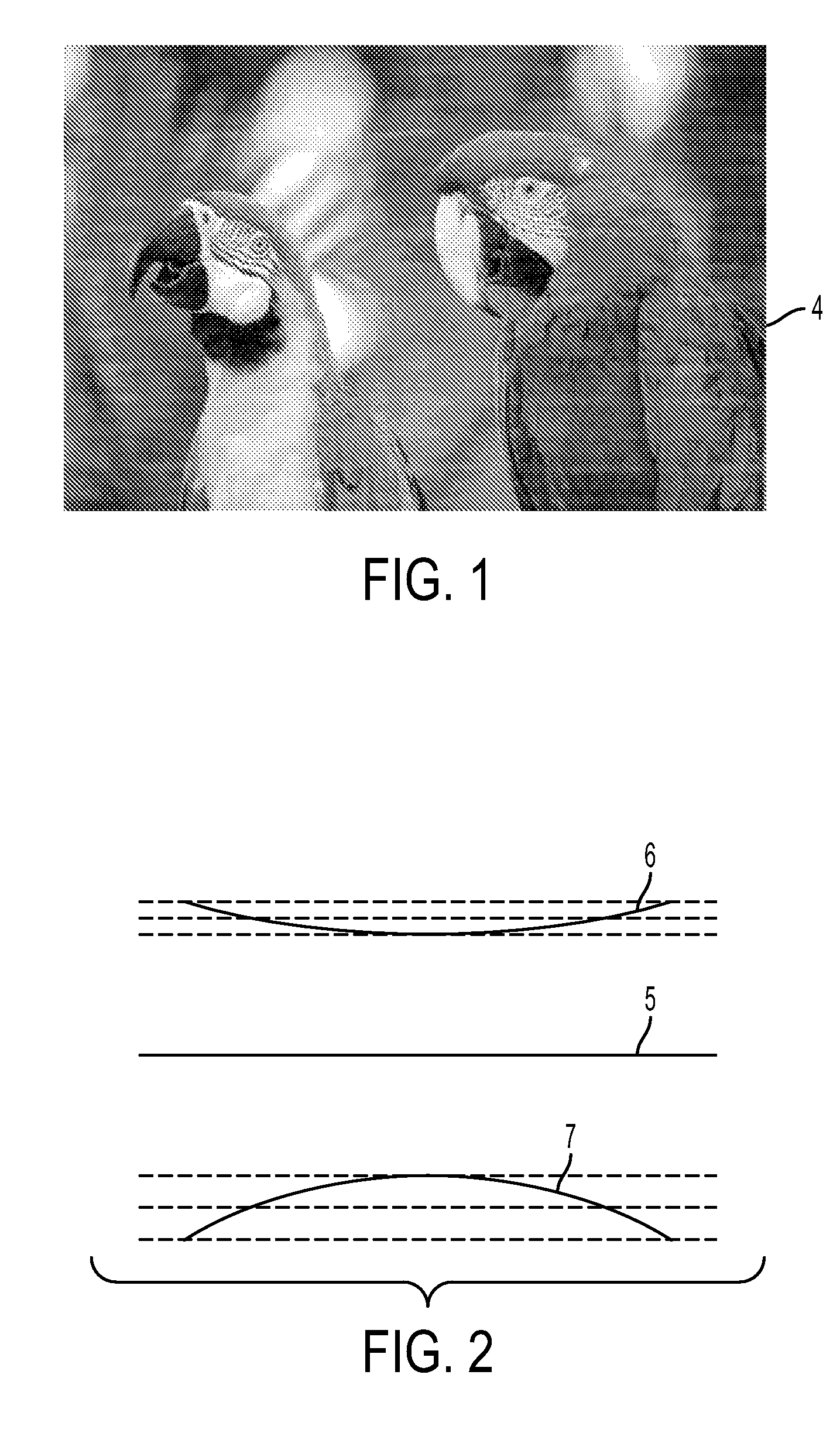

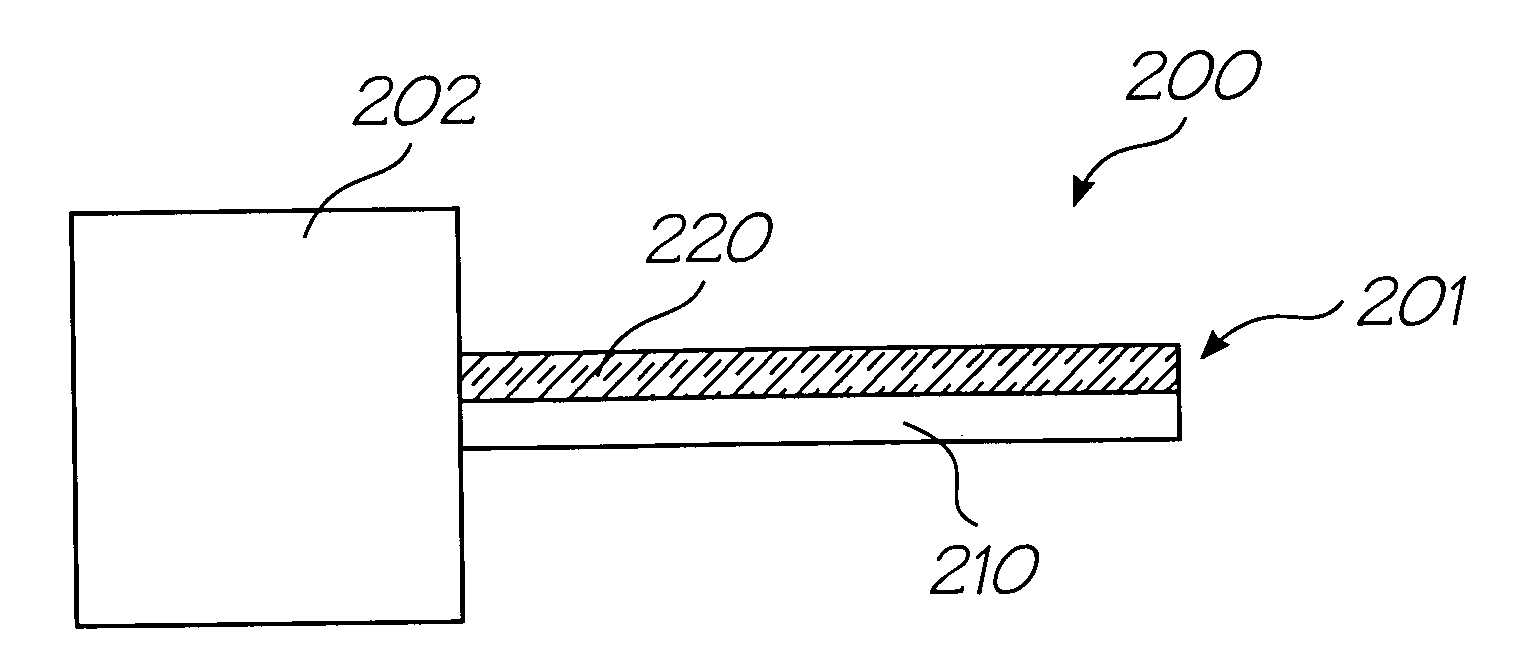

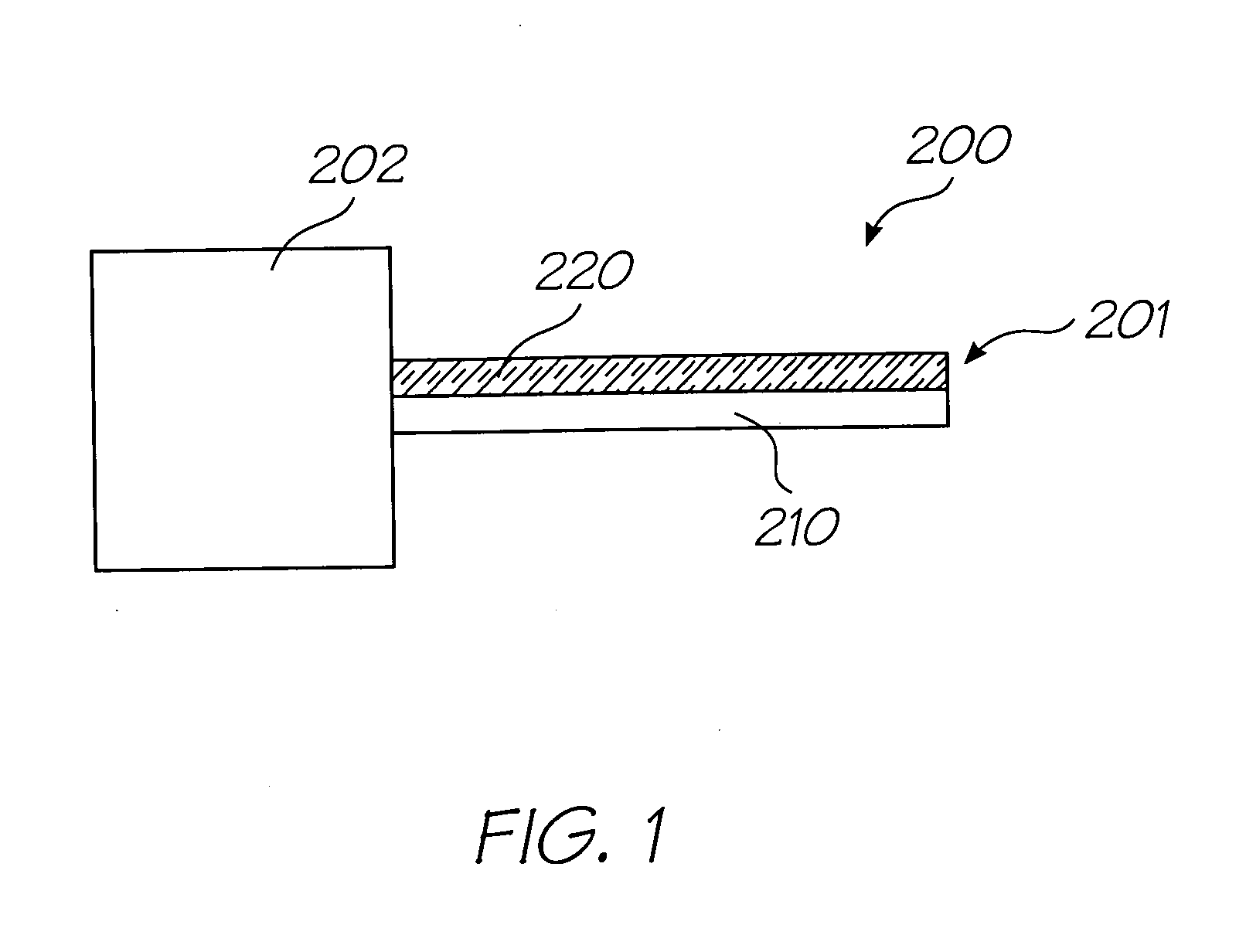

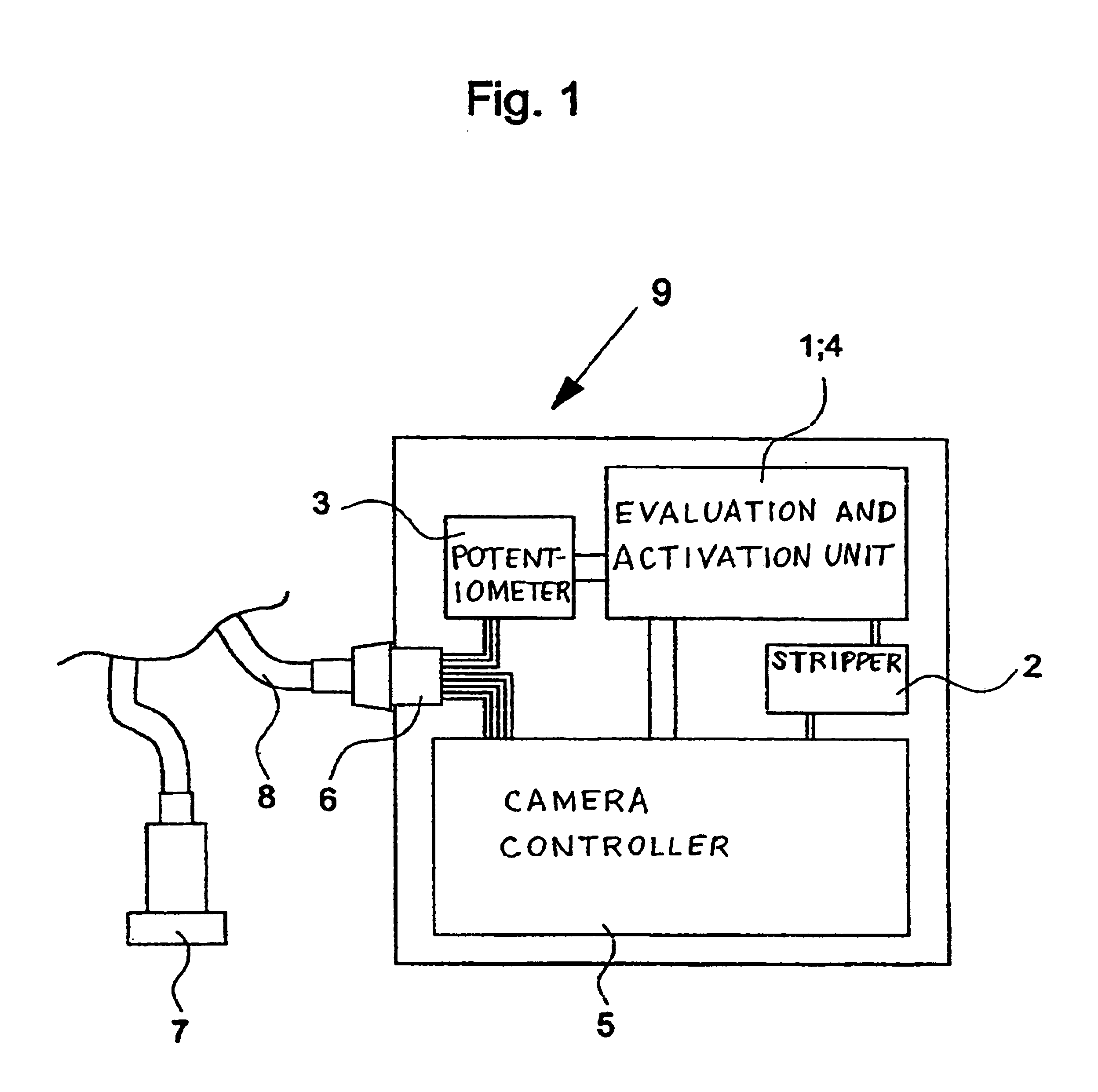

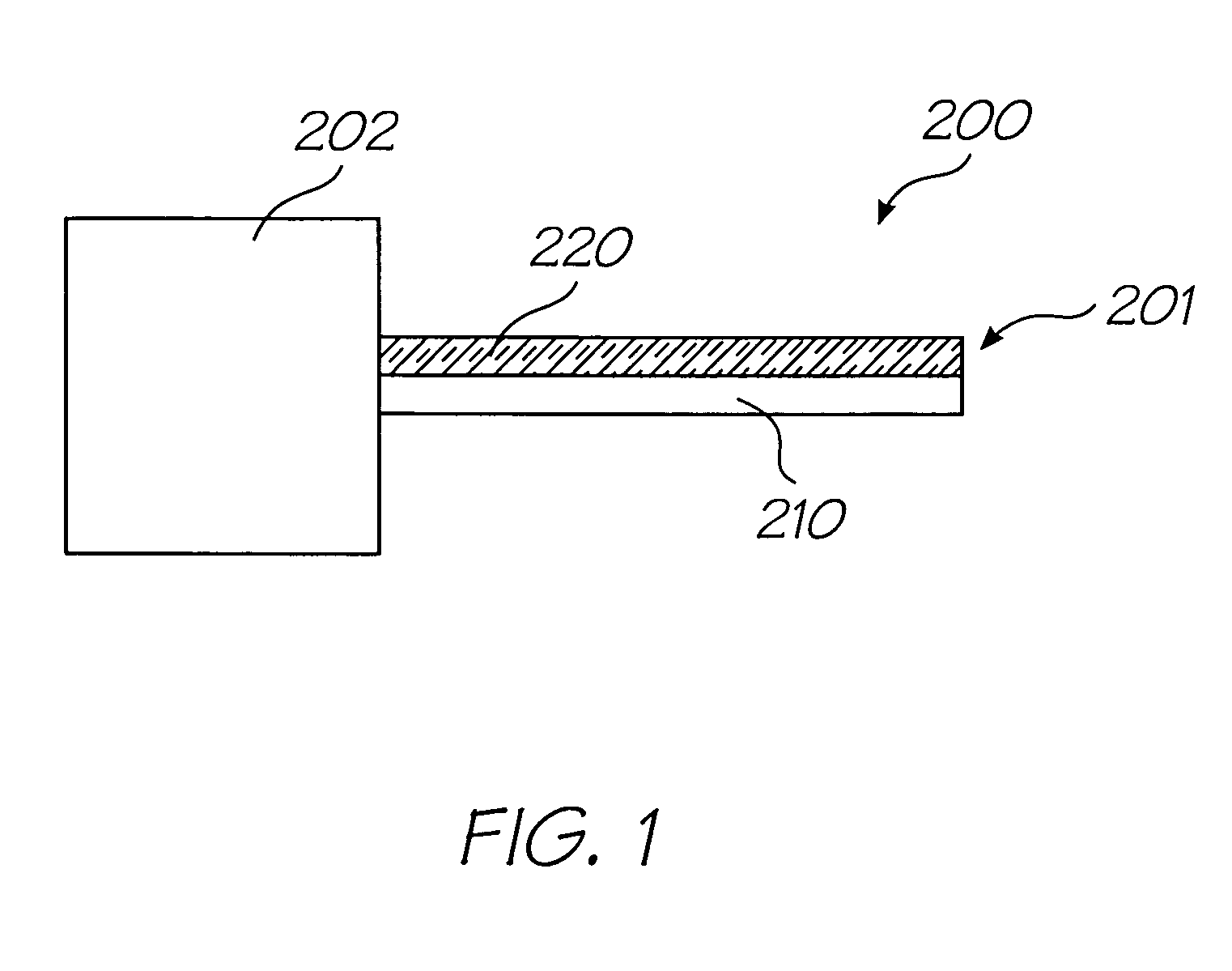

Method and System for Image Stabilization

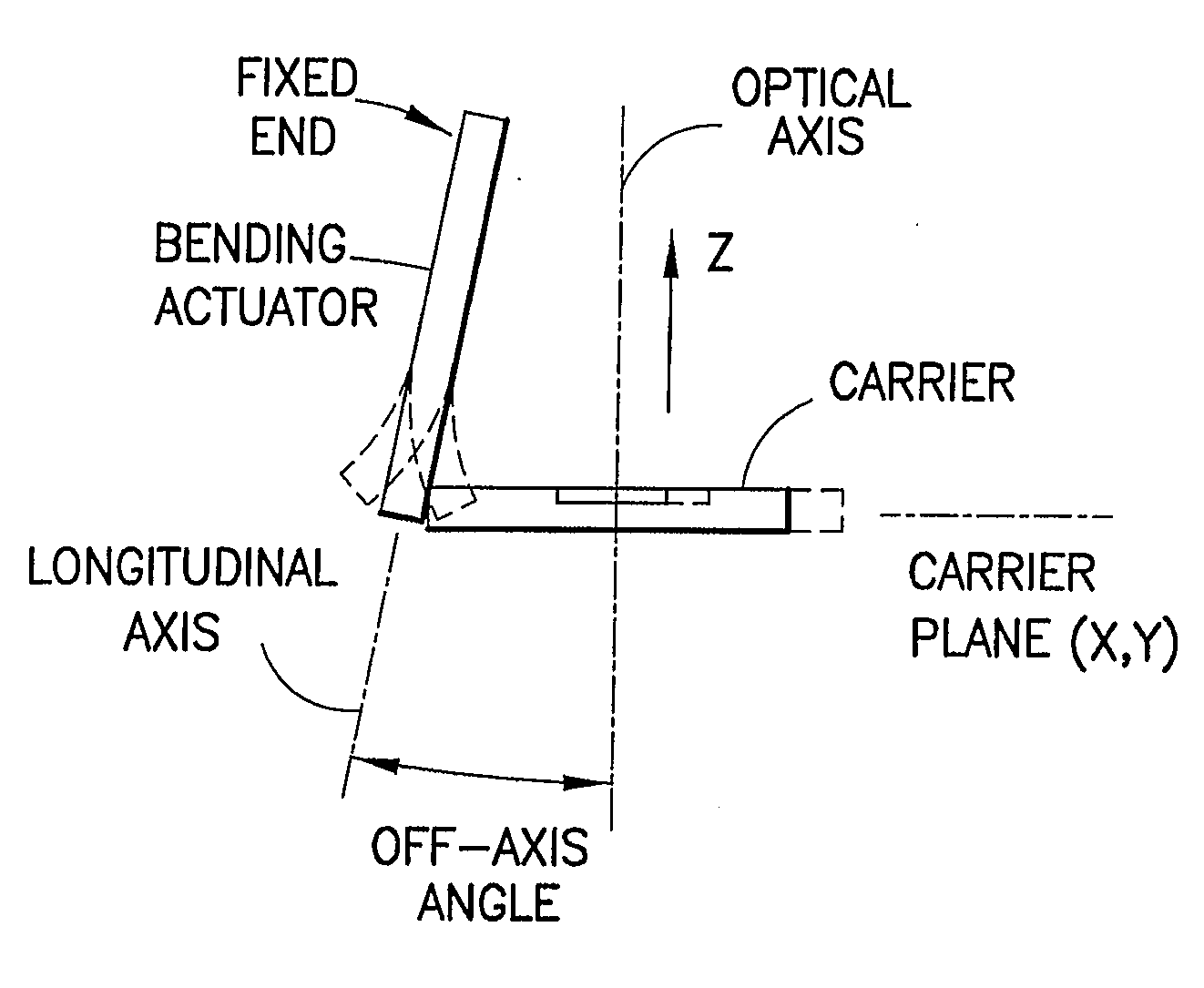

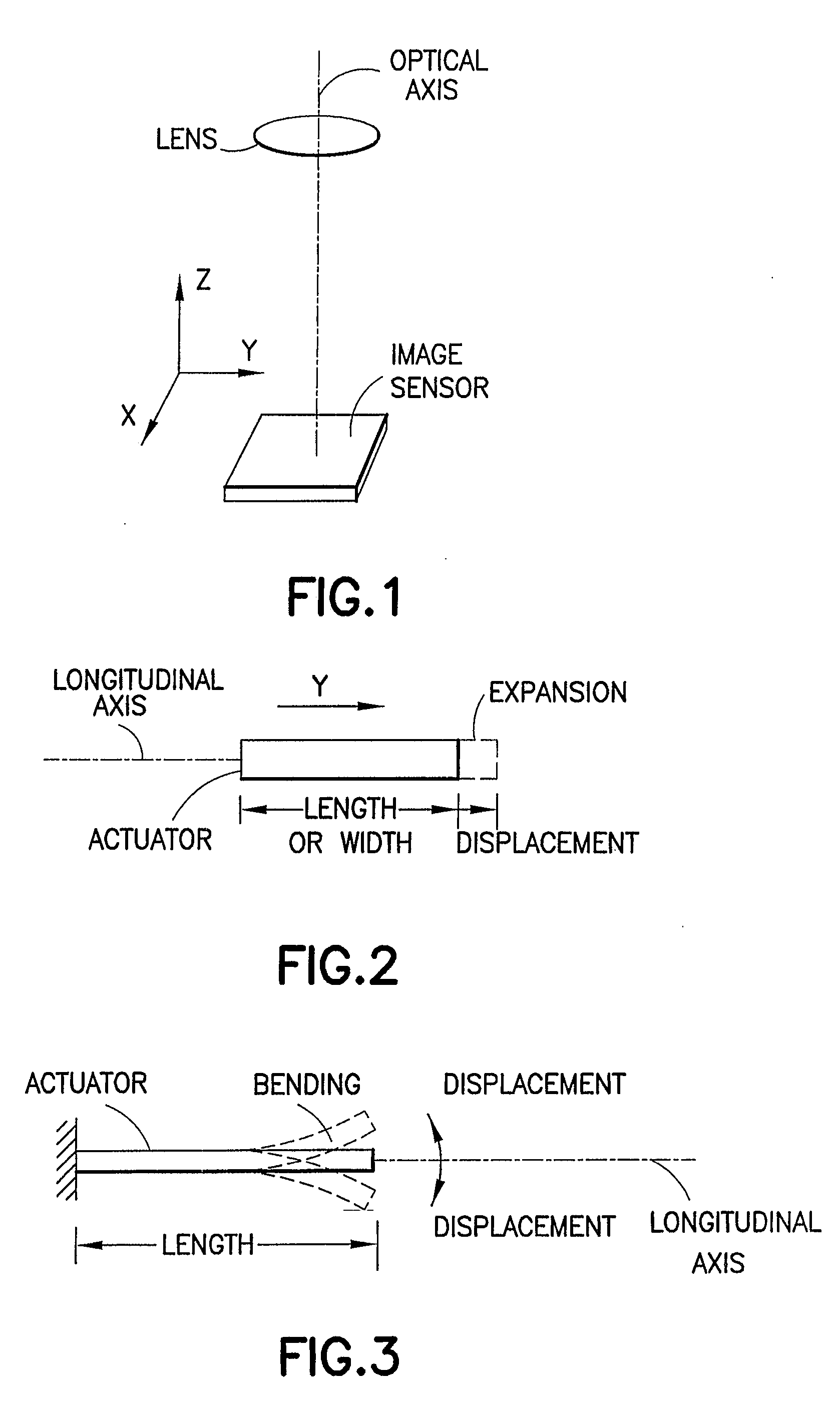

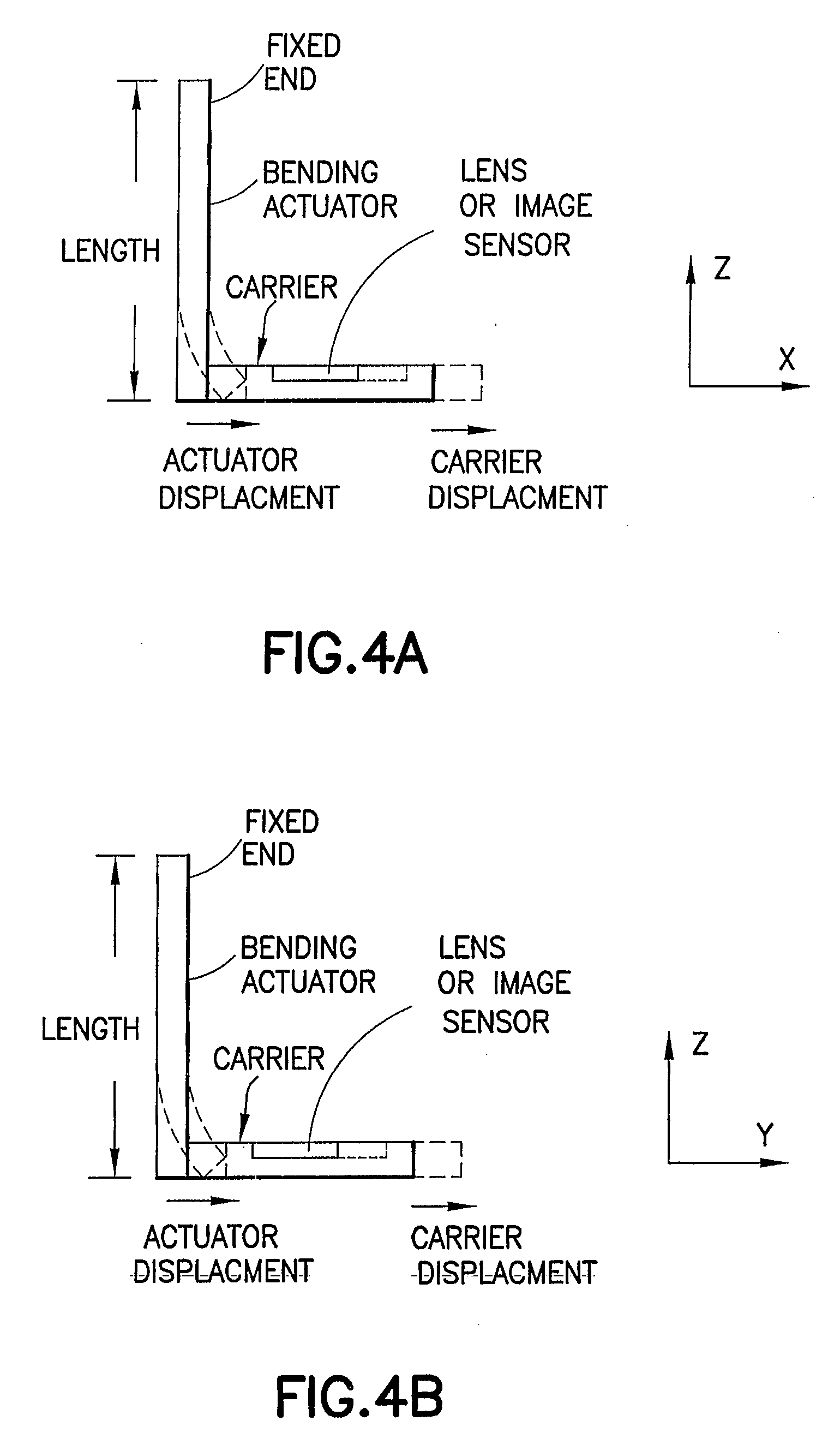

An optical image stabilizer for use in a camera to compensate for an unwanted movement of camera, wherein two bending actuators are used to shift a lens element or the image sensor in different directions in a plane so as to shift a projected image on the image sensor in response to the unwanted camera movement. The plane is substantially perpendicular to the optical axis of camera, and longitudinal axis of each bending actuator is substantially parallel to the optical axis. The actuator can be fixedly mounted on one end so that the other end is allowed to bend. The actuator can be fixedly mounted on both ends so that the middle section is allowed to bend. Alternatively, the middle section is fixedly mounted and both ends can be used for shifting an imaging component.

Owner:NOKIA CORP

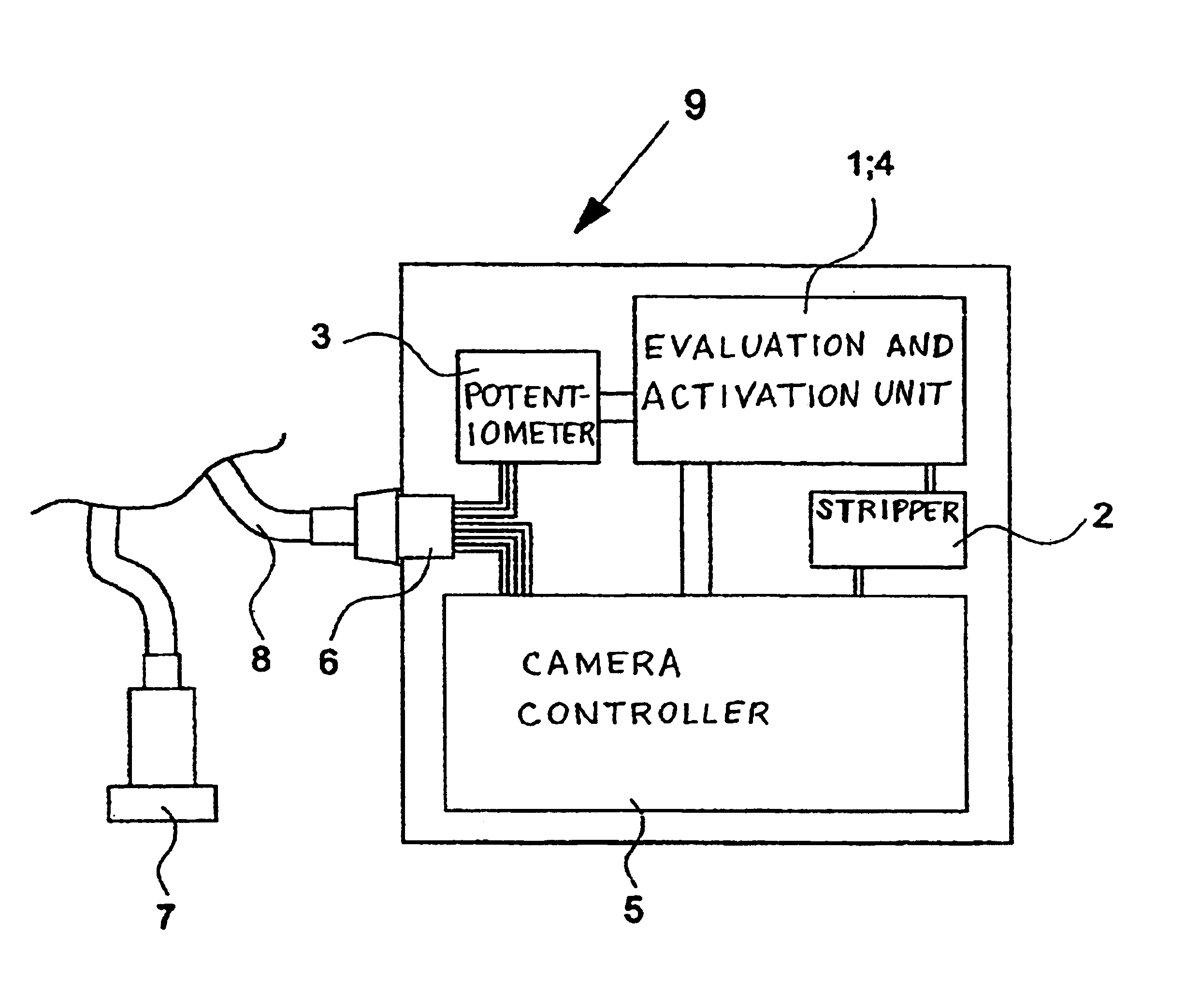

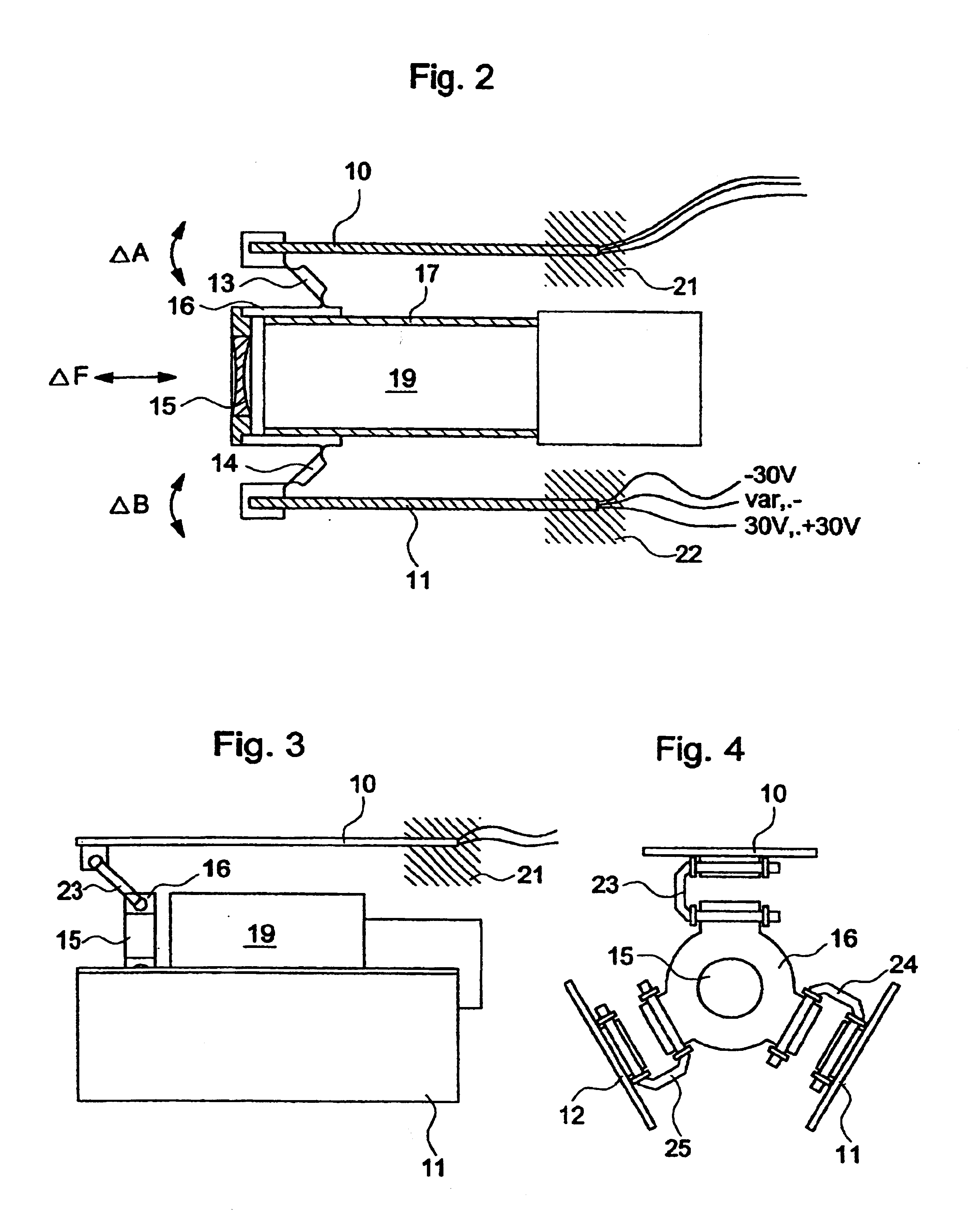

Focussing and focal length adjusting device for a video camera

InactiveUS6947091B1Minimize forceShort focusTelevision system detailsColor television detailsVertical blanking intervalEngineering

A focussing and focal length adjusting device for an optical lens system in the camera head of an endoscope. This device includes a focussing device which has several piezoelectric bending actuators attached along and symmetrically to the optical axis of the focussing lens. The piezoelectric bending actuators are via in each case one joint member connected to a sleeve encompassing the focussing lens in a manner such that with voltage impingement bending movements carried out by the bending actuators are converted into a linear focussing movement for the focussing lens. Furthermore a zoom drive adjusting the focal length of a zoom lens system includes a stepper motor whose stepped rotation via a grooved roller and a pin linearly moved by the helical groove of this roller is converted into a linear movement of a zoom lens sleeve for the focal length adjustment. The activation of the stepper motor for the zoom operation, and the production of the focus adjusting signal for the piezoelectric actuators of the focussing device are effected during the vertical blanking interval of the video signal, this interval being extracted by an extraction circuit from the video signal and being led to a respective focussing circuit and a zoom control circuit in the form of a time window.

Owner:RICHARD WOLF GMBH

Symmetrically actuated ink ejection components for an ink jet printhead chip

A printhead chip for an ink jet printhead that includes a plurality of nozzle arrangements on a silicon wafer substrate (12). Each nozzle arrangement (10) has an active and static ink ejection structures positioned on the substrate. The active ink ejection structure (20) has a roof (22) with an ink ejection port (26) defined in the roof. The active ink ejection structure (20) and the static ink ejection structure (34) together define a nozzle chamber (42) in fluid communication with an ink supply. At least two thermal bend actuators (28) are operatively arranged with respect to the active ink ejection structure to displace the active ink ejection structure with respect to the static ink ejection structure towards and away from the substrate to reduce and increase a volume of the nozzle chamber to eject an ink drop from the nozzle chamber. The actuators (28) are configured and connected to the active ink ejection structure to impart substantially rectilinear movement to the active ink ejection structure.

Owner:MEMJET TECH LTD +1

Inkjet nozzle assembly having thermal bend actuator with an active beam defining part of an exterior surface of a nozzle chamber roof

An inkjet nozzle assembly is provided. The assembly comprises a nozzle chamber comprising a floor and a roof. The roof has a nozzle opening defined therein, and a moving portion moveable towards the floor. The assembly further comprises a thermal bend actuator, having a plurality of cantilever beams, for ejecting ink through the nozzle opening. A first active beam of the actuator defines at least part of an exterior surface of the roof.

Owner:MEMJET TECH LTD +1

Inkjet nozzle assembly having thermal bend actuator with an active beam defining substantial part of nozzle chamber roof

An inkjet nozzle assembly is provided. The assembly comprises a nozzle chamber comprising a floor and a roof. The roof has a nozzle opening defined therein, and a moving portion moveable towards the floor. The assembly further comprises a thermal bend actuator, having a plurality of cantilever beams, for ejecting ink through the nozzle opening. A first active beam of the actuator defines at least 30% of a total area of the roof.

Owner:MEMJET TECH LTD +1

Inkjet nozzle assembly having moving roof portion defined by a thermal bend actuator having a plurality of cantilever beams

An inkjet nozzle assembly is provided. The assembly comprises a nozzle chamber comprising a floor and a roof. The roof has a nozzle opening defined therein, and a moving portion moveable towards the floor. The assembly further comprises a thermal bend actuator, having a plurality of cantilever beams, for ejecting ink through the nozzle opening. The moving portion of the roof comprises the actuator.

Owner:MEMJET TECH LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com