Crack-resistant thermal bend actuator

a thermal bend actuator and crack-resistant technology, applied in printing and other directions, can solve problems such as cracking and problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077]It will be appreciated that the present invention may be used in connection with any thermal bend actuator having an active beam fused to a passive beam. Such thermal bend actuators find uses in many MEMS devices, including inkjet nozzles, switches, sensors, pumps, valves etc. For example, the Applicant has demonstrated the use of thermal bend actuators in lab-on-a-chip devices as described in U.S. application Ser. No. 12 / 142,779, the contents of which are herein incorporated by reference, and a plethora of inkjet nozzles described in the cross-referenced patents and patent applications identified herein. Although MEMS thermal bend actuators find many different uses, the present invention will be described herein with reference to one of the Applicant's inkjet nozzle assemblies. However, it will, of course, be appreciated that the present invention is not limited to this particular device.

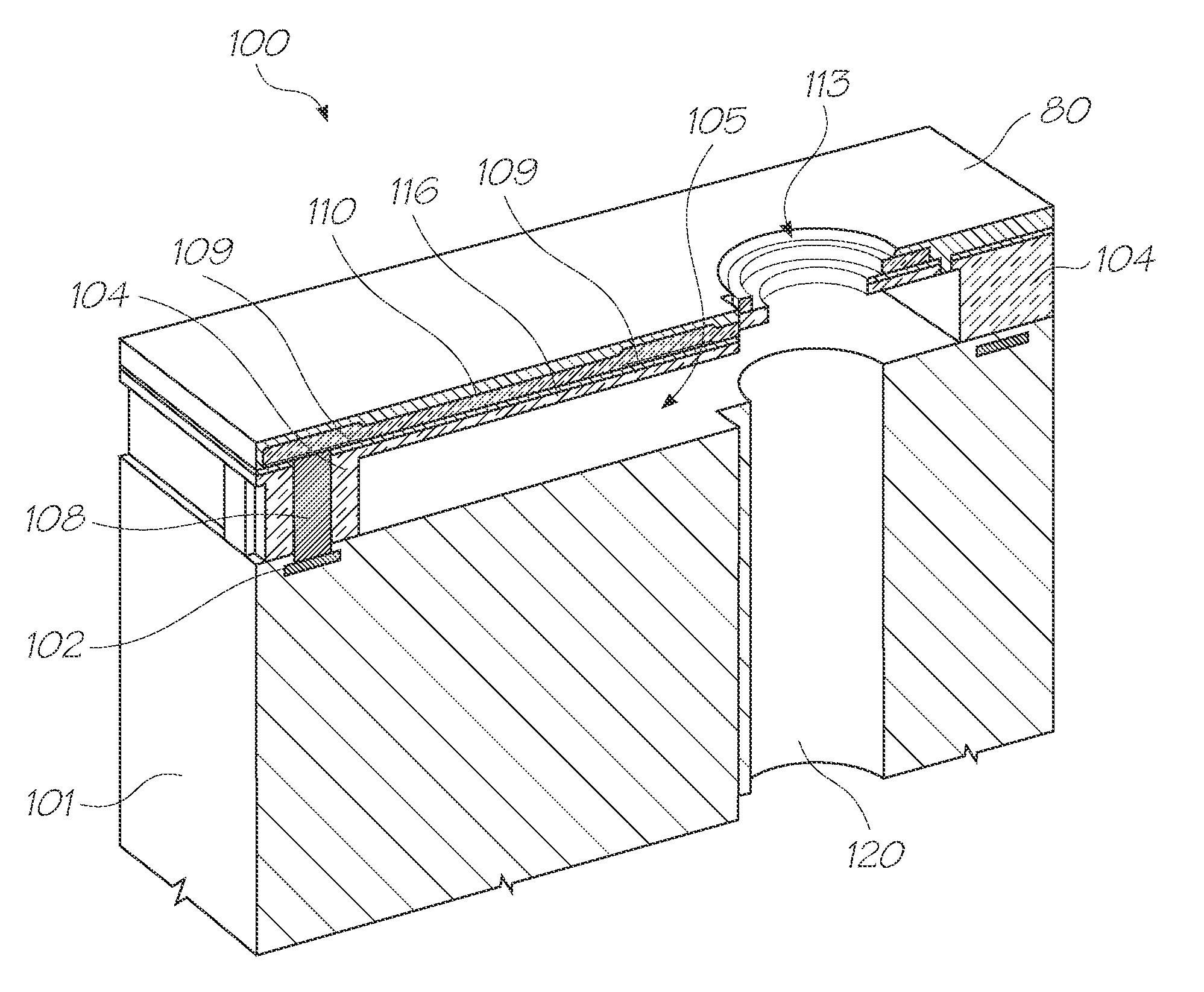

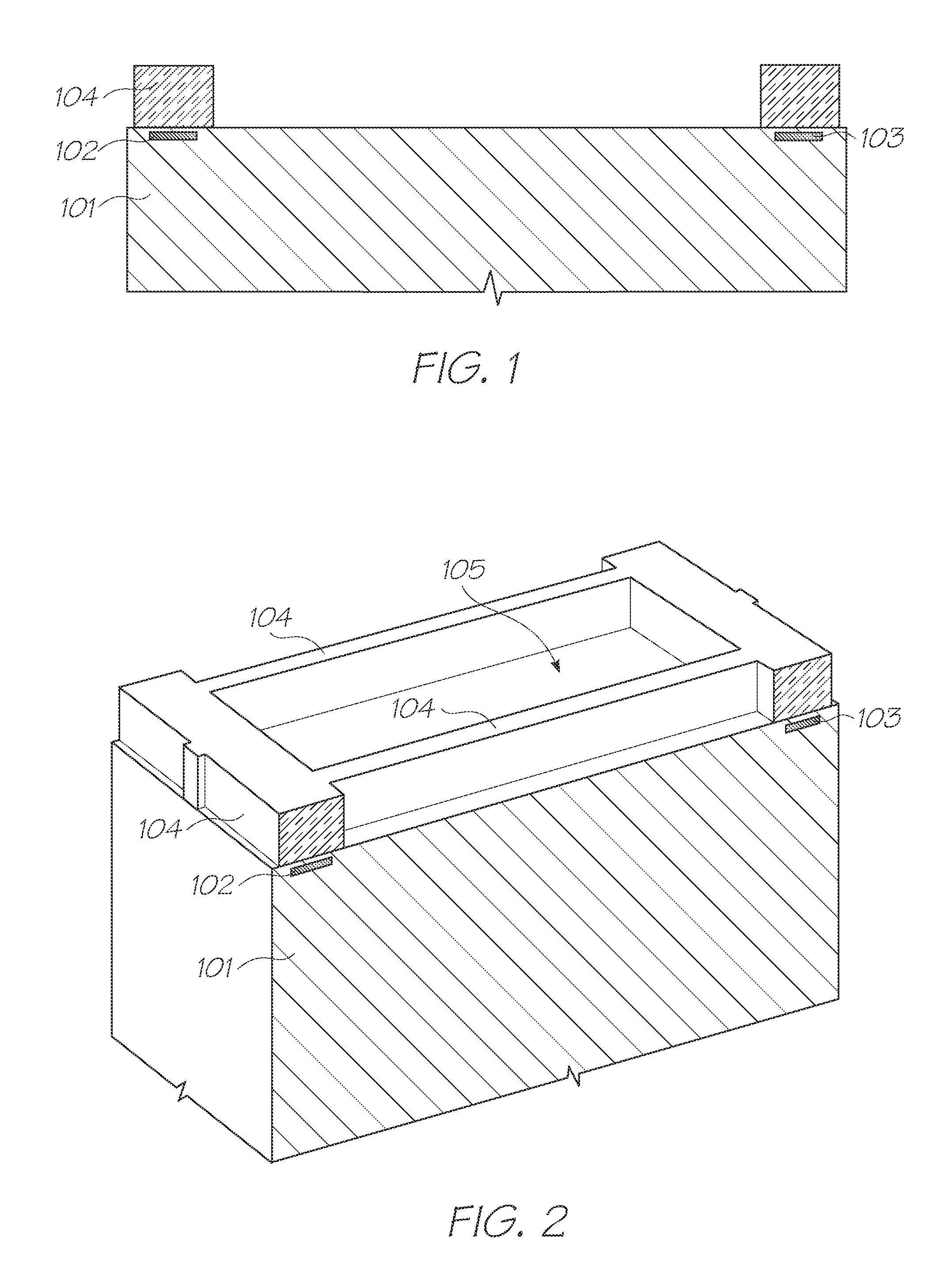

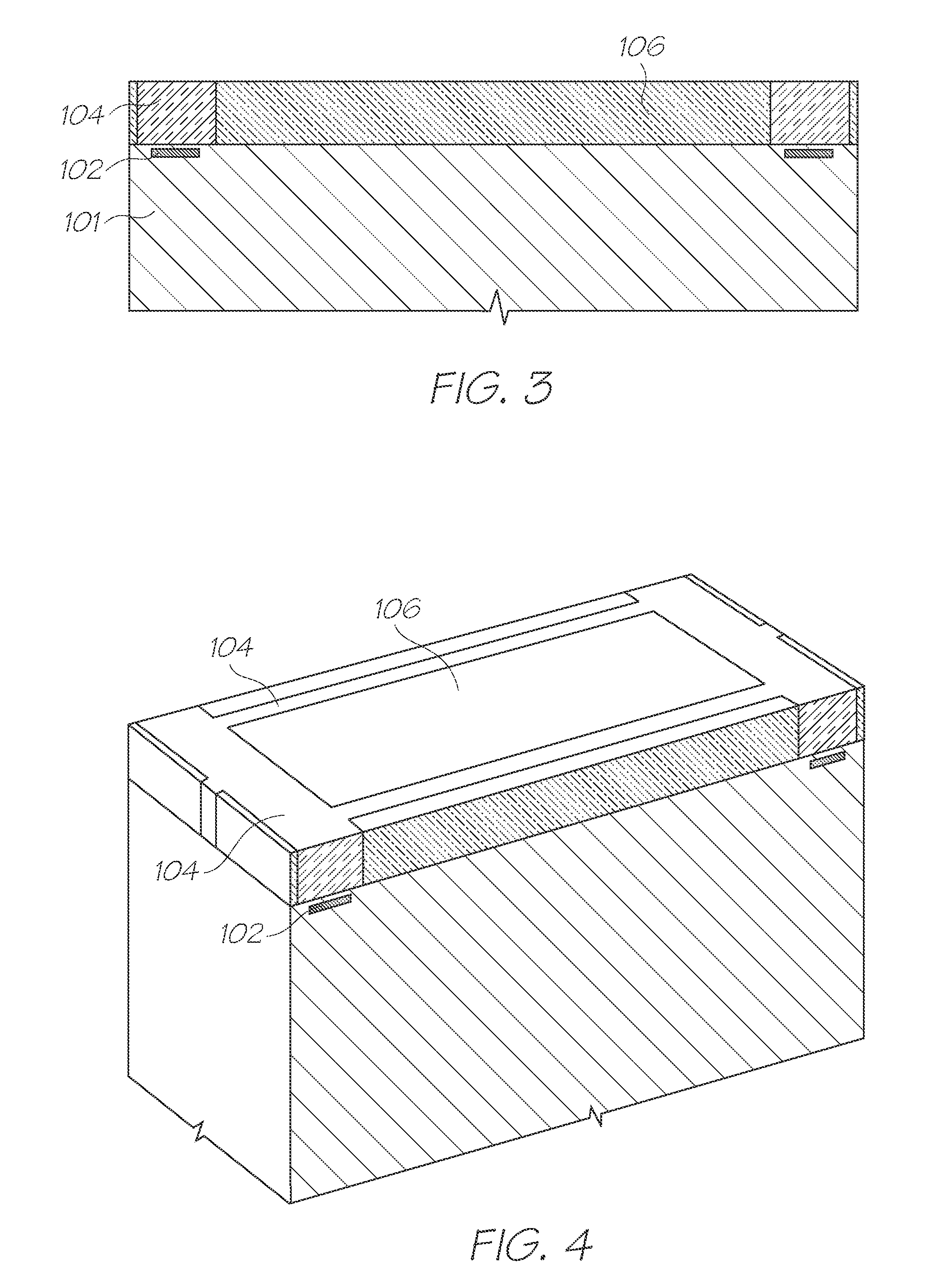

[0078]FIGS. 1 to 13 show a sequence of MEMS fabrication steps for an inkjet nozzle assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com