Document verification and tracking system for printed material

a technology of document verification and tracking system, applied in the field of printing system, can solve problems such as various technical problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

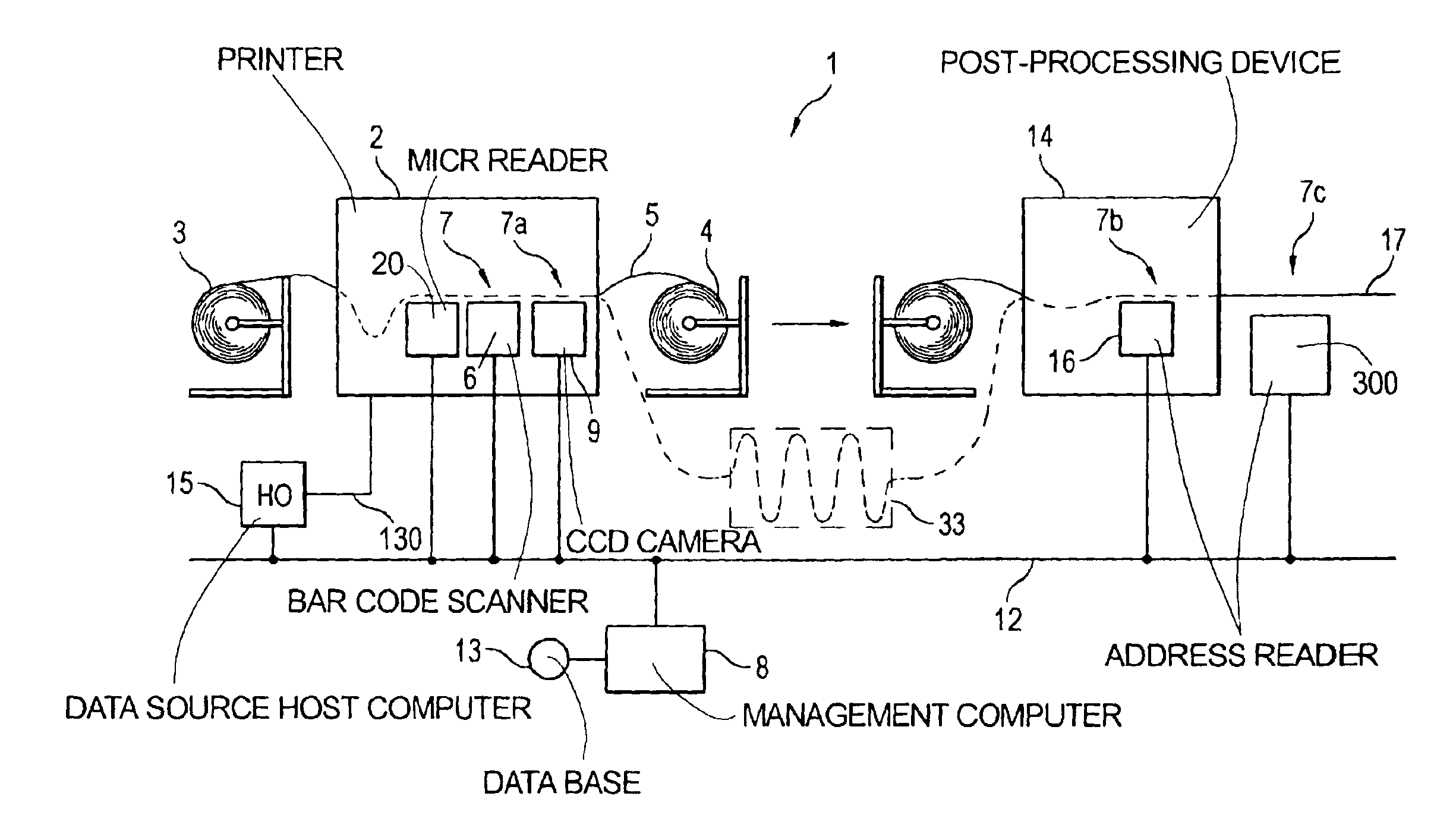

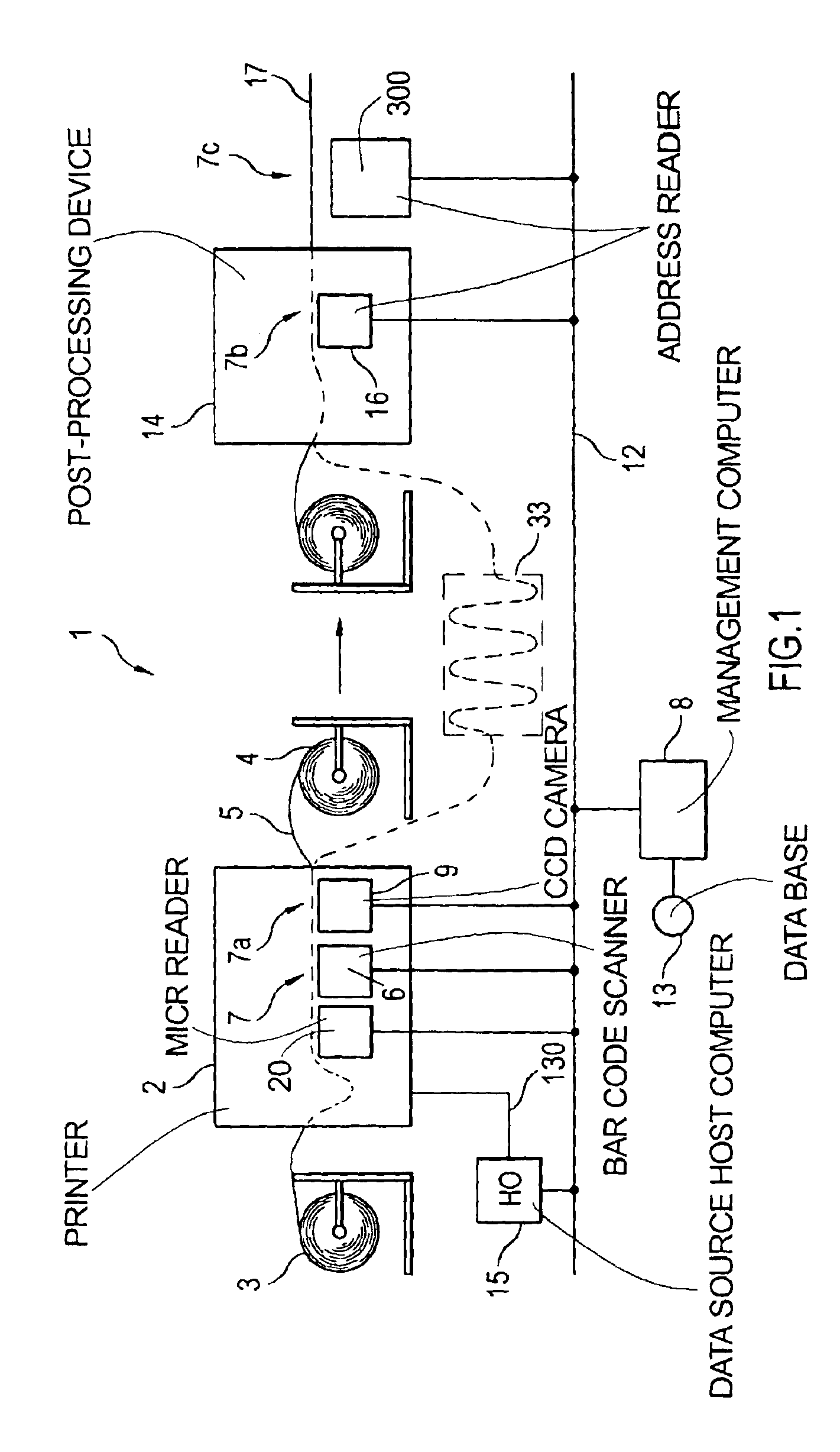

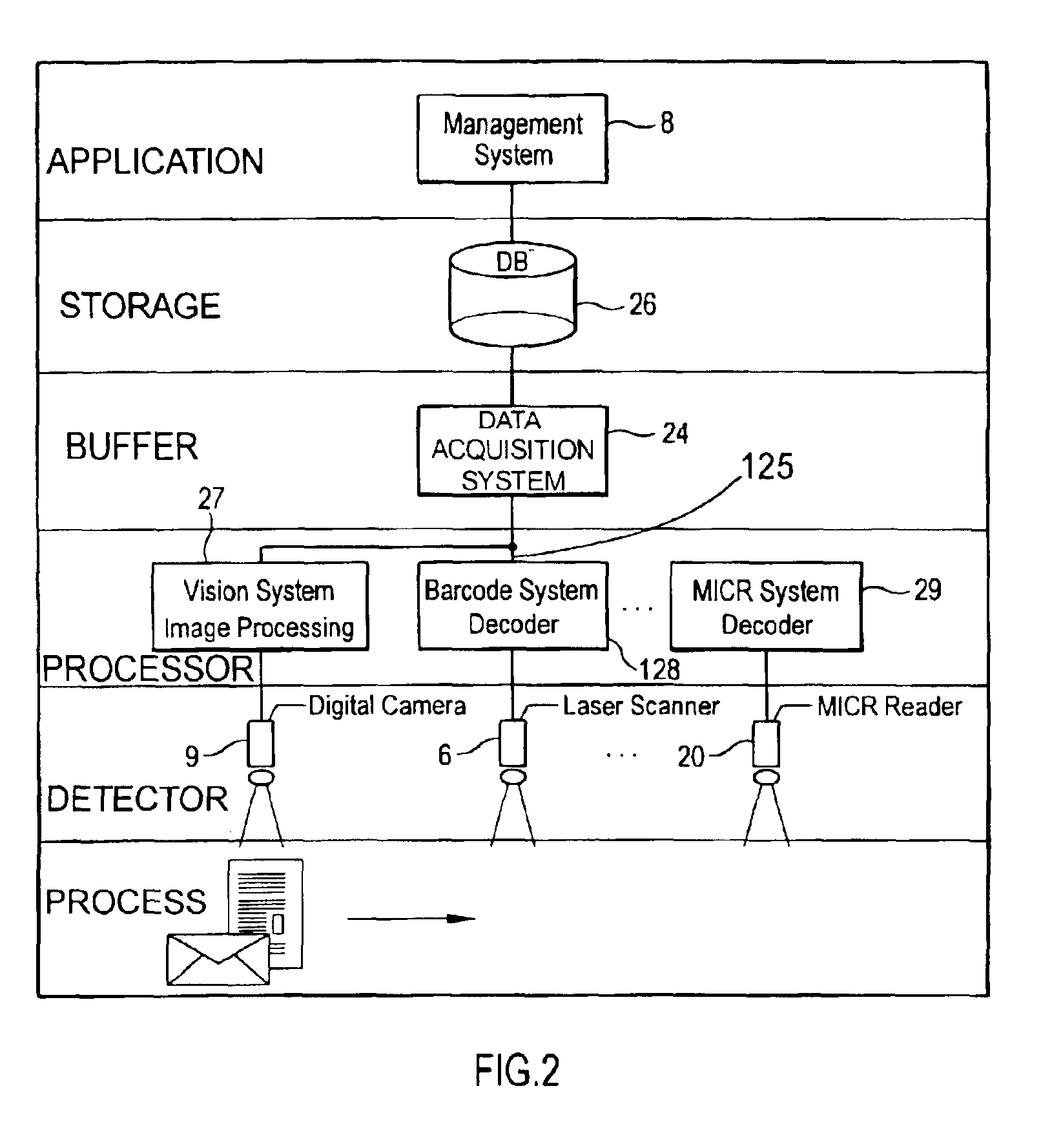

[0027]In FIG. 1, a printing line 1 is shown comprising an electrophotographic printer 2, which receives paper from an unwinding roll 3 and delivers documents printed on fanfold paper web 5 to a winding roll 4. The printer 2 receives a print data stream from a data source 15 (host computer) via a direct data line 130 or via a state-of-the-art computer network (LAN,WAN) 12. Documents printed in the printer 2 are provided with a bar code and / or magnetic characters. The bar code is read by a laser-based bar code scanner 6, which is located within the printer 2 or between printer 2 and winding roll 4. A MICR reader 20 may also be provided at printer 2 for reading the magnetic characters. Documents having passed the first checkpoint 7 are forwarded to a second checkpoint 7a, where optical information, that is, images or characters, printed on the paper web, are being checked by a CCD camera 9. Bar code scanner 6, CCD camera 9, and MICR reader 20 may exchange data with a workflow managemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com