System for testing optical axis of broadband multi-sensor electro-optic apparatus

A multi-sensor and photoelectric instrument technology, applied in the field of optical systems, can solve the problem that the mechanical reference axis of the instrument installation cannot be completely consistent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

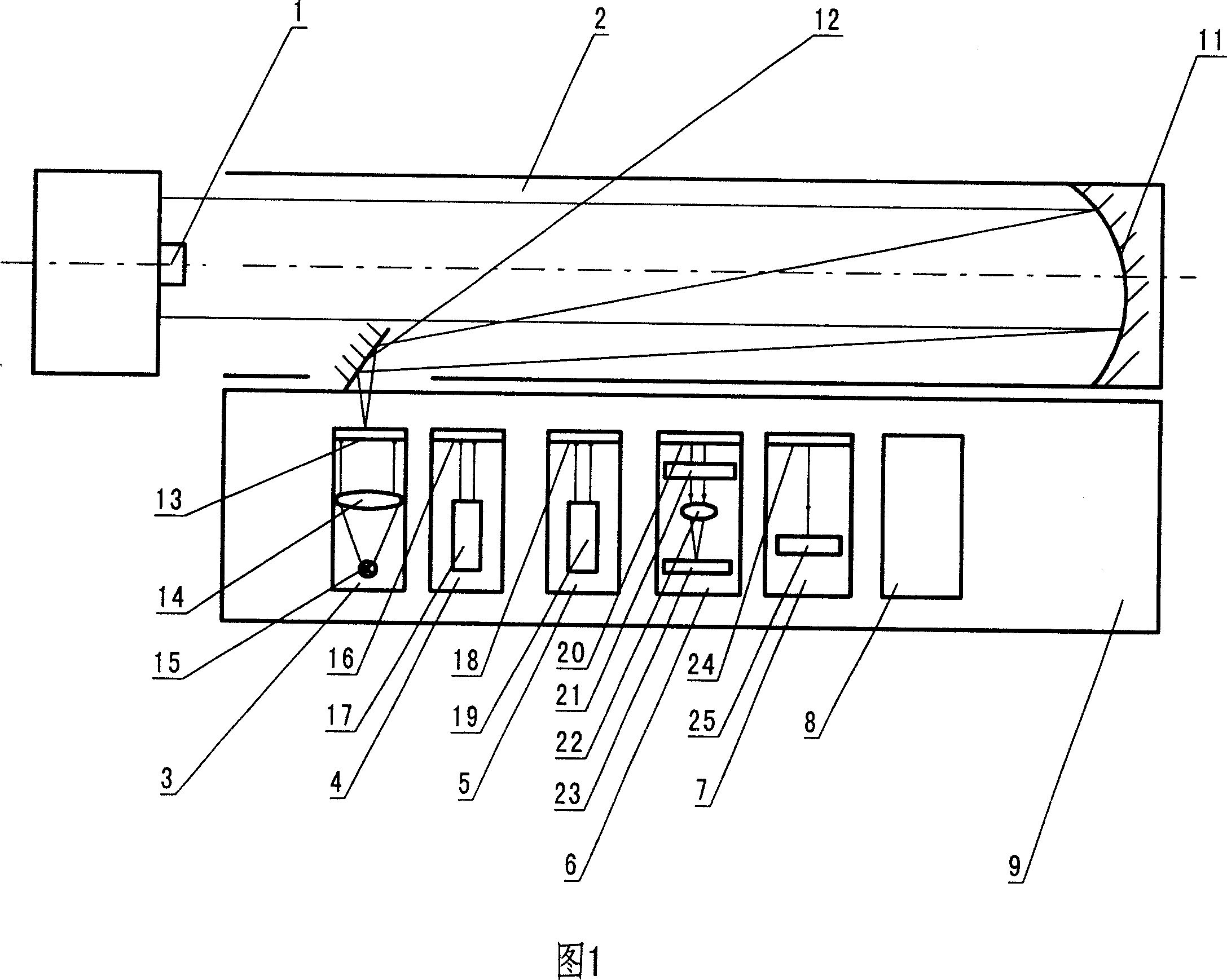

[0007] The reference plane mirror 1 adopts a high-quality plane mirror.

[0008] The collimator 2 adopts a reflective collimator, and its main mirror is an off-axis parabolic reflector 10, and a plane reflector 11 is added near the image plane of the off-axis parabolic reflector 10 to refract the convergent focus of the off-axis parabolic reflector 10. Turning to the image plane, the image plane is parallel to the optical axis of the collimator 2, so as to eliminate stray light interference. The size of the off-axis parabolic reflector 10 is φ400mm and focal length f=4000mm.

[0009] Visible light self-collimating aiming optical system 3 is made up of first target board 12, condenser lens 13, halogen lamp 14; axis, the first target plate 12 can be a cross-hair plate or a star point orifice plate, etc.

[0010] The far-infrared optical system 4 is composed of a second target plate 15 and a 9-13 μm blackbody light pipe 16 , and the optical axis of the 9-13 μm blackbody light p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com