On-line verification method for processing cassegrain two-mirror optics system

A Cassegrain double mirror and optical system technology, which is applied in the direction of optical instrument testing, optical performance testing, measuring devices, etc., can solve problems such as online inspection, and achieve the effect of ensuring processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

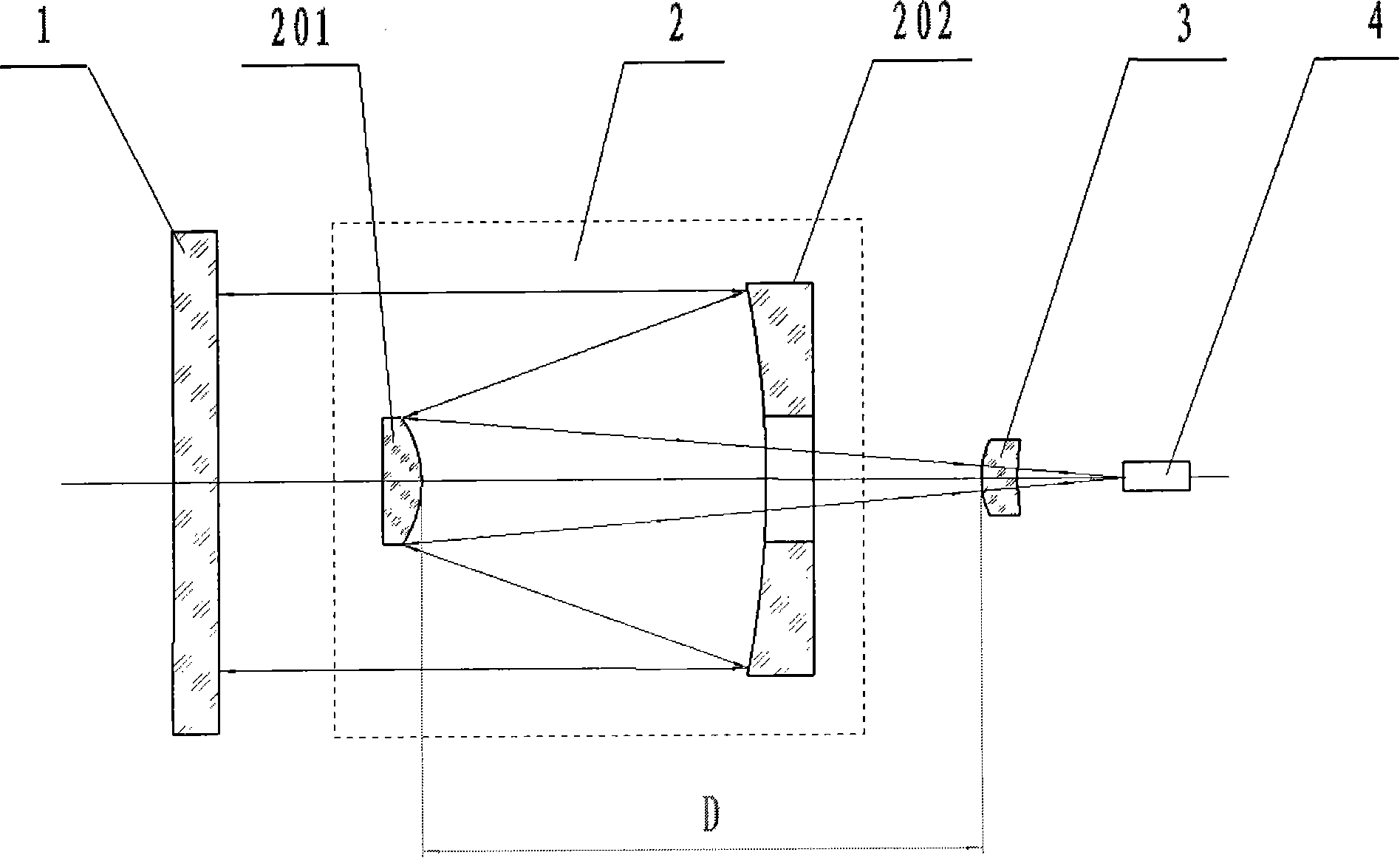

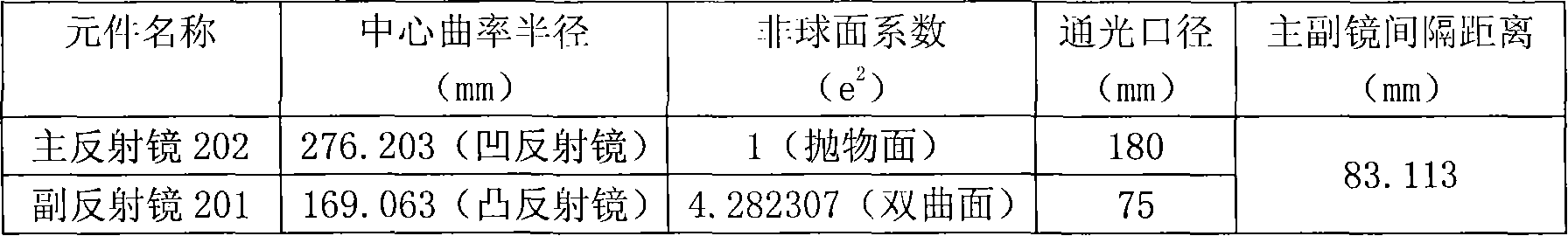

[0013] According to attached figure 1 The processing and inspection optical path diagram of the sub-mirror 201, we designed a paired processing and inspection optical path for a Cassegrain two-mirror optical system 2 with an on-axis point imperfect imaging. The optical parameters of this Cassegrain two mirror optical system 2 are shown in Table 1:

[0014] Table 1

[0015]

[0016] The inspection light path design is as follows:

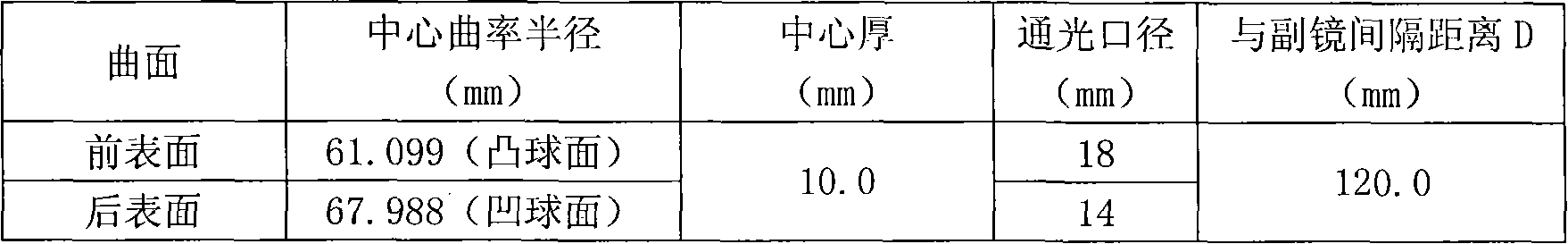

[0017] The standard self-collimating plane mirror 1 adopts a plane mirror with a diameter of 250mm and a surface accuracy of one-tenth of the wavelength; the compensation lens 3 adopts BK7 optical glass, and the specific optical design parameters are shown in Table 2:

[0018] Table 2

[0019]

[0020] After the compensation lens 3 is added, the Cassegrain two-mirror optical system forms a perfect image on the 2-axis point, and the wave aberration of the point on the axis is close to one-fiftieth of the wavelength; the detection instrument 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com