Patents

Literature

62results about How to "Uniform and stable feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

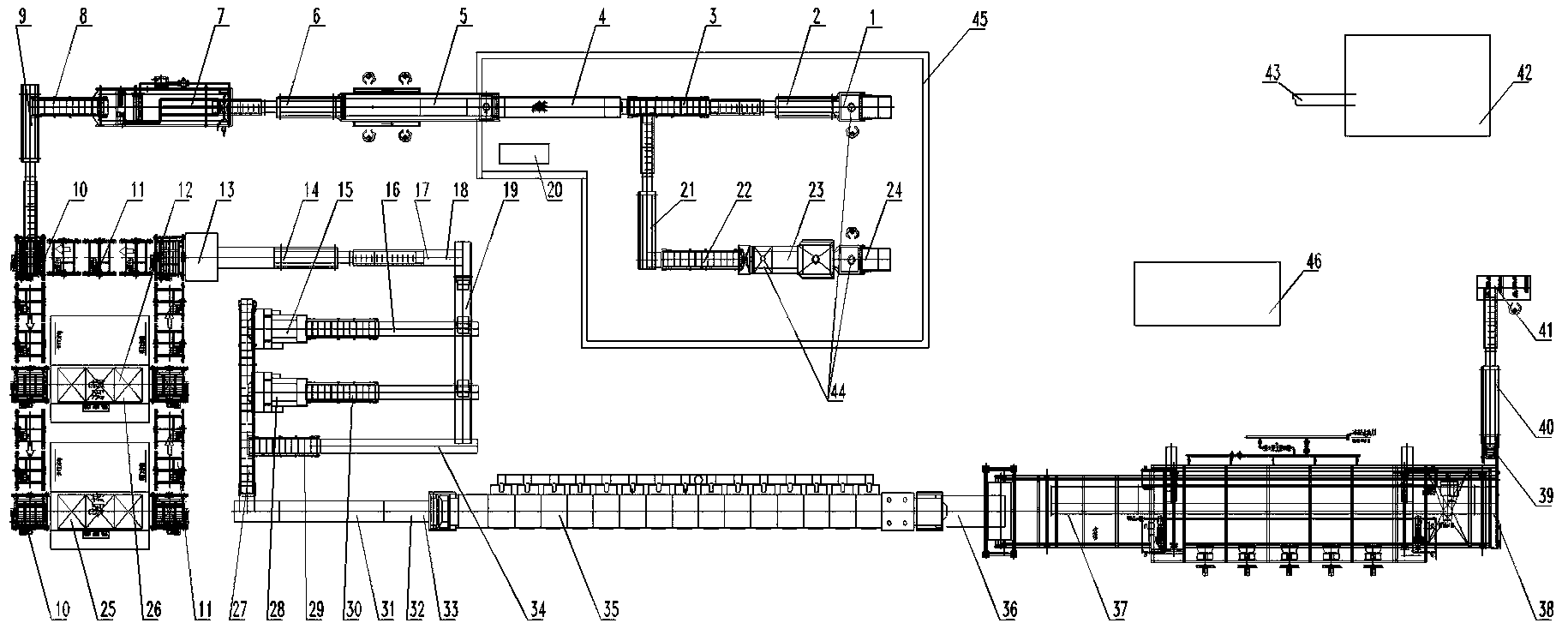

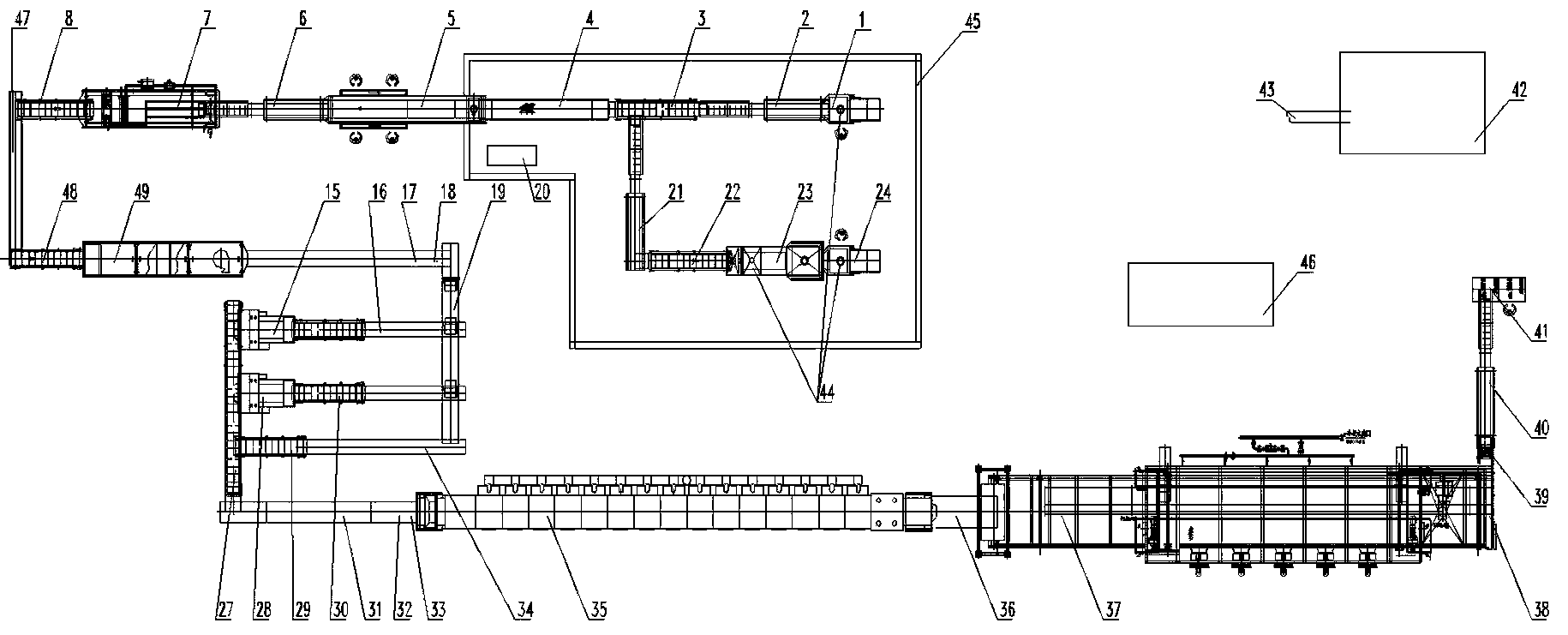

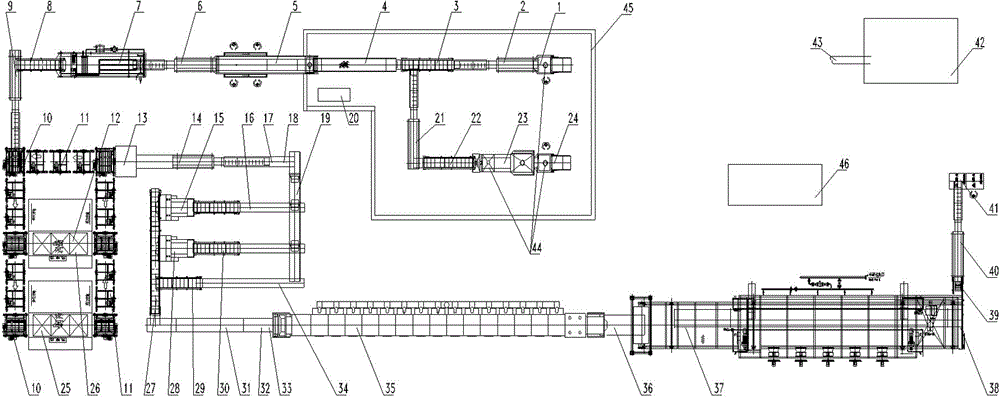

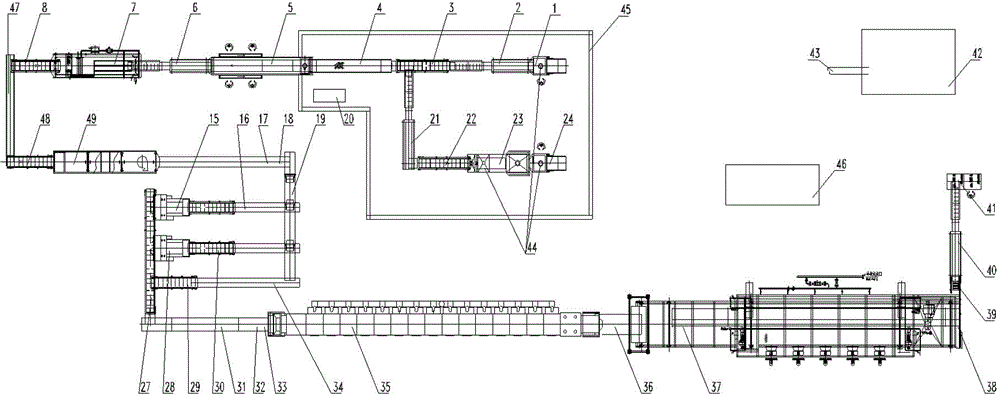

Automatic processing technology and system for traditional Chinese medicinal material pre-processing

ActiveCN103637911AUniform flowUniform and stable feedingPharmaceutical product form changeAutomatic controlControl system

Disclosed is an automatic processing technology and system for traditional Chinese medical material pre-processing. The processing technology sequentially comprises the procedures of unpacking, clean selecting, washing, medicine infiltrating, cutting, drying and box packaging or bagging. All the procedures are connected through a belt conveyor or a feeding machine or a vibration conveyor or material separating equipment. An automatic control system is used for controlling processing equipment in all links of the processing technology and automatic continuous production is realized. According to the automatic processing technology and system, an assembly line production mode is adopted, all main procedures in the current traditional Chinese medicine pre-processing process are connected organically through conveying equipment, caching conveying equipment and the material separating equipment, an automatic detecting technology and an automatic control technology are adopted to conduct real-time detection and control on the production process, the degree of automation of traditional Chinese medicine pre-processing is greatly improved, the labor intensity of workers can be lowered, the processing environment can be improved and the stability of the product quality can be maintained.

Owner:云南昆船电子设备有限公司

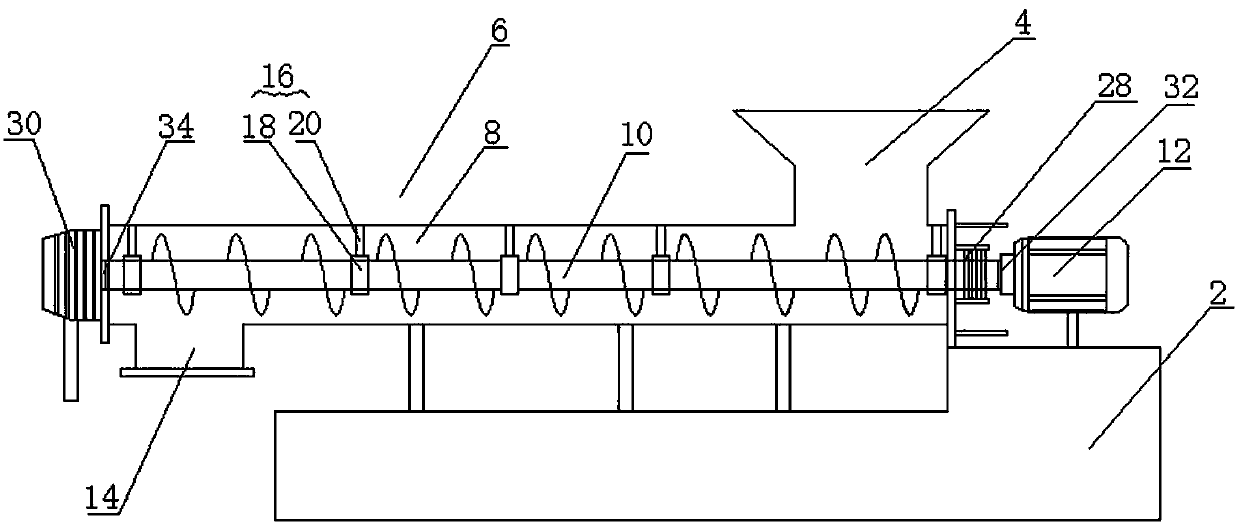

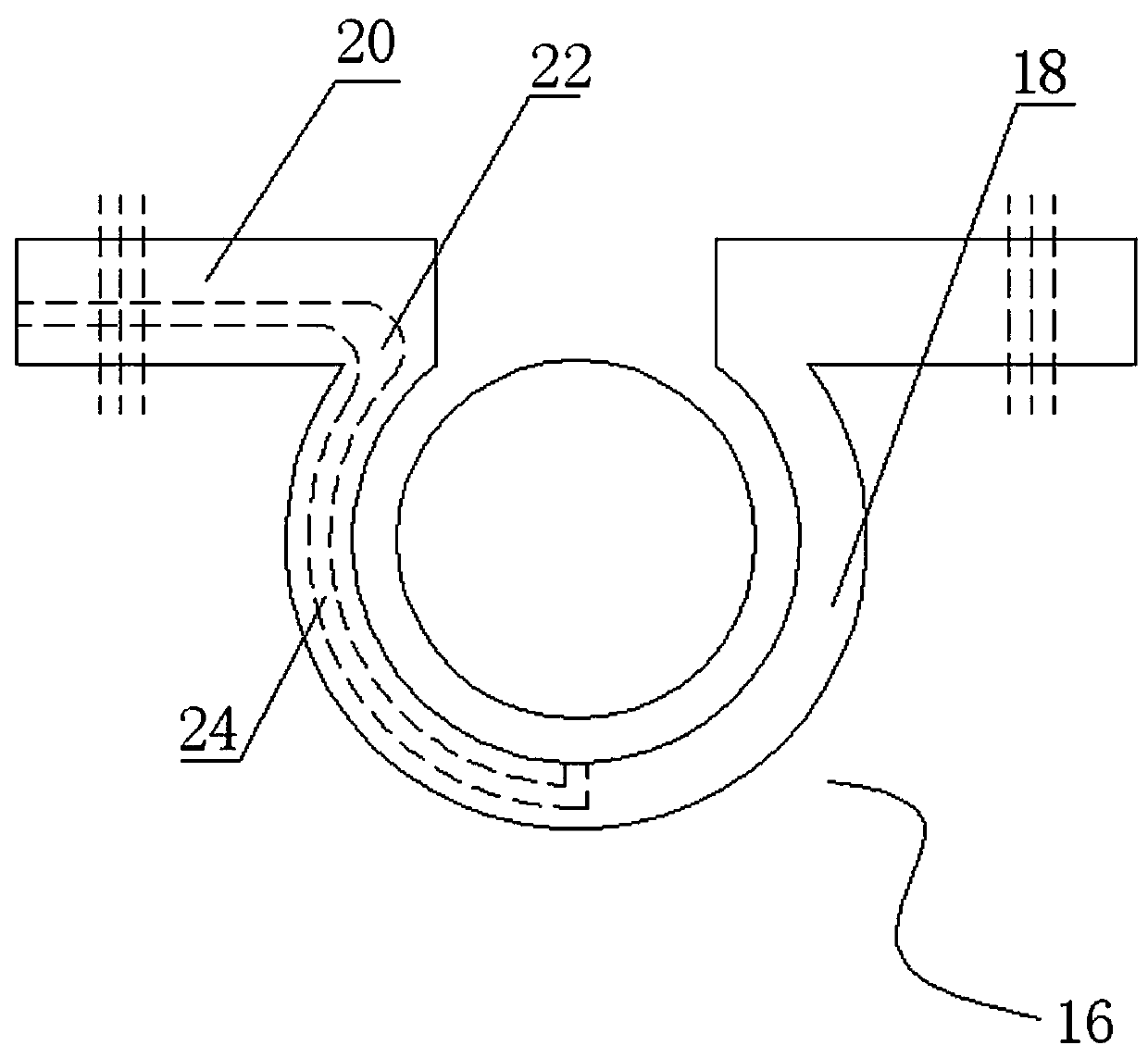

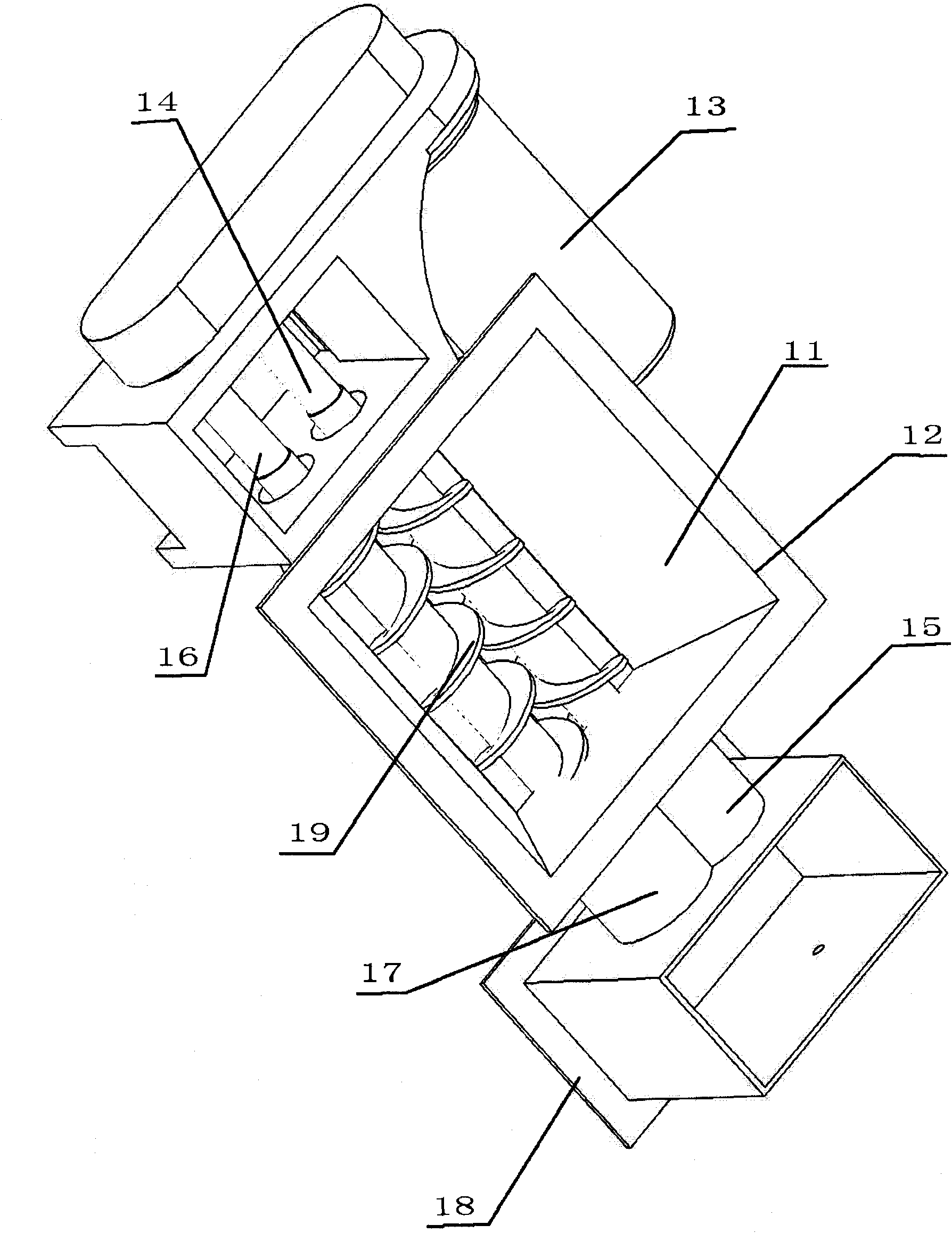

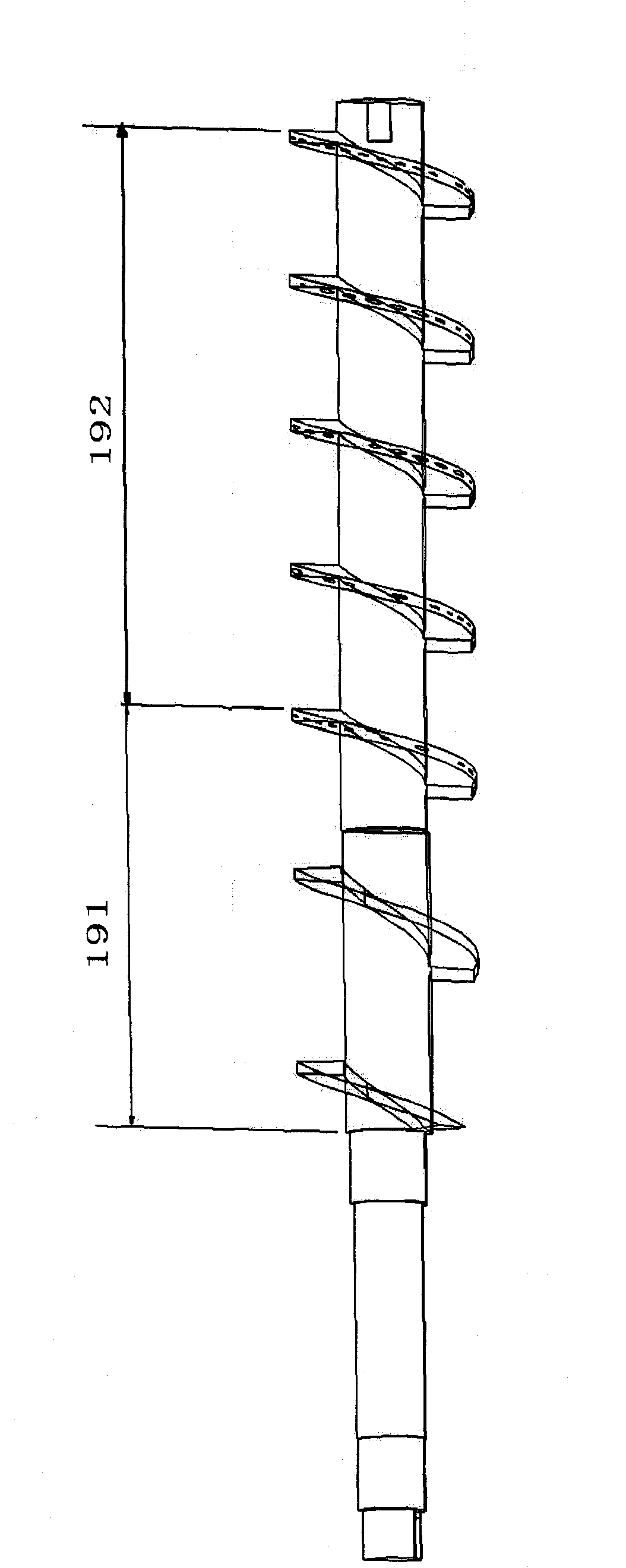

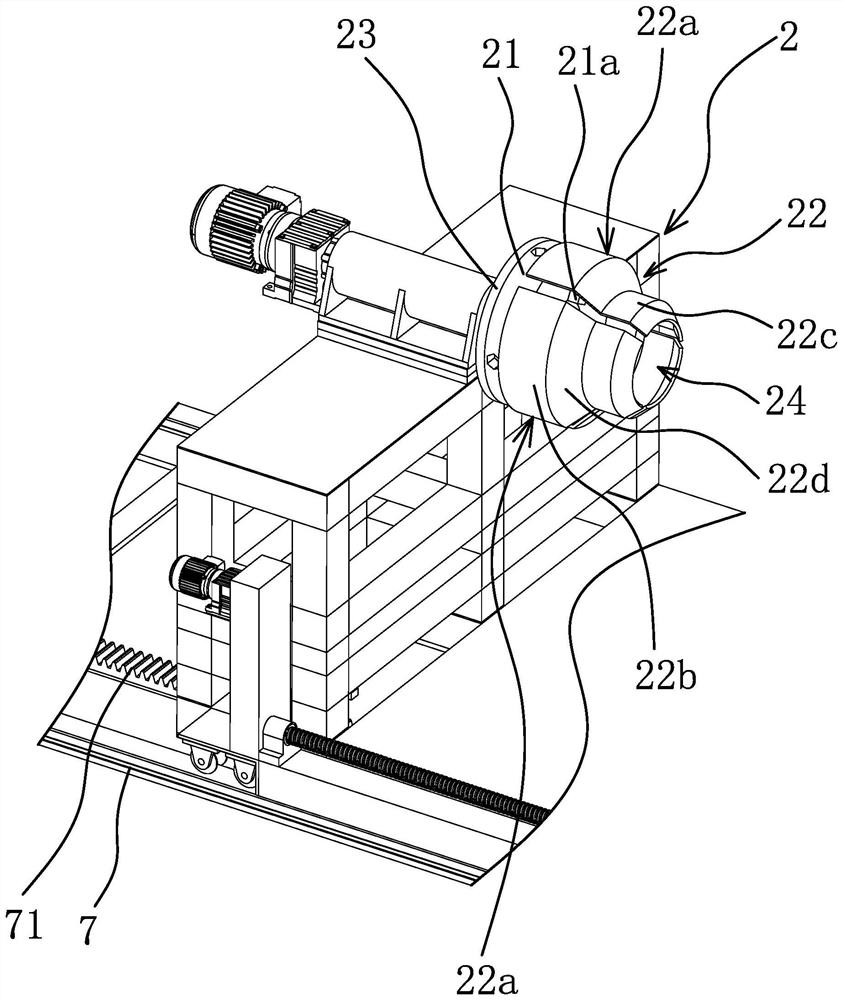

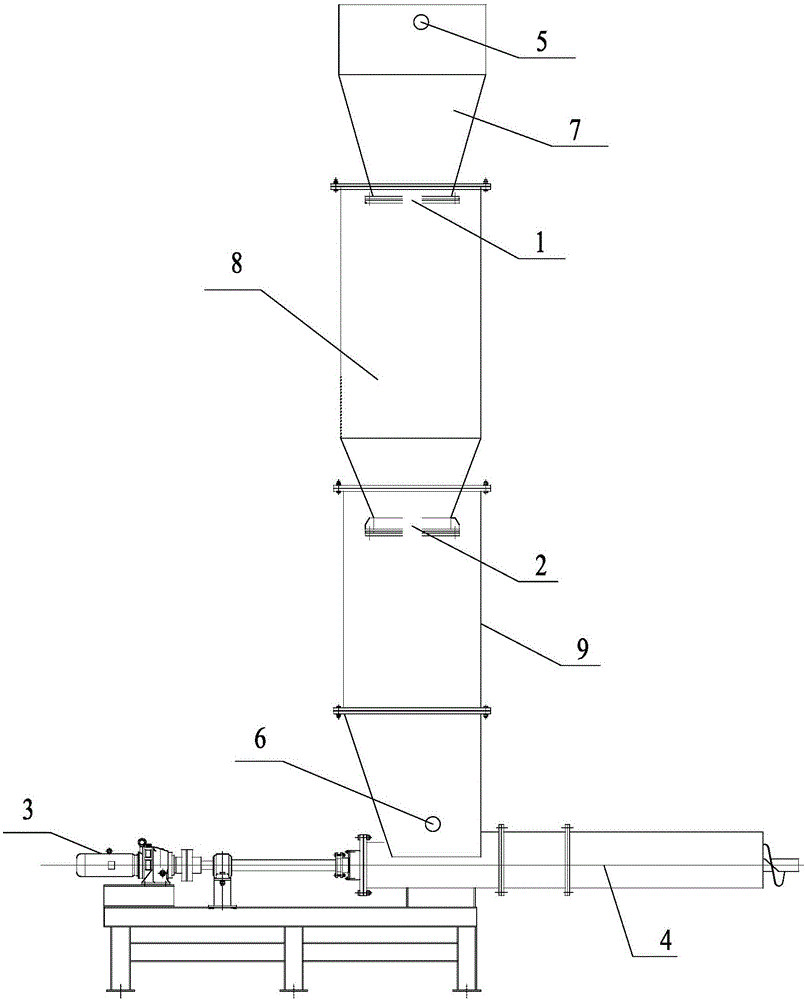

Tube type spiral feeder

InactiveCN103496563ASolve the problem of easy bending and deformationExtended service lifePackagingElectric machineryEngineering

The invention discloses a tube type spiral feeder which comprises a storage bin fixedly erected on a horizontal working table. The tube type spiral feeder further comprises a pushing device, wherein the pushing device is communicated with a feed port of the storage bin and is used for feeding materials in a pushing mode. The pushing device comprises a hollow feed tube body, a spiral pushing shaft and a variable frequency motor, the spiral pushing shaft is coaxially arranged in the feed tube body, the variable frequency motor drives the spiral pushing shaft to rotate around the axial line of the feed tube body, one end of the feed tube body is communicated with the feed port, and a discharge port is formed in the other end of the feed tube body. The tube type spiral feeder is characterized in that the spiral pushing shaft is sleeved with at least two hanging bearings, and the hanging bearings comprise shaft sleeves coaxially arranged on the spiral pushing shaft in a sleeved mode and hanging arms used for fixing the hanging bearings on the inner wall of the feed tube body in a hanging mode. The tube type spiral feeder solves the problem that the spiral pushing shaft is prone to bending and deformation in the long-distance material conveying process, and has the advantages of being simple in structure, long in service life and even and stable in material feeding.

Owner:CHINA WEIGHING EQUIP SUZHOU FACTORY

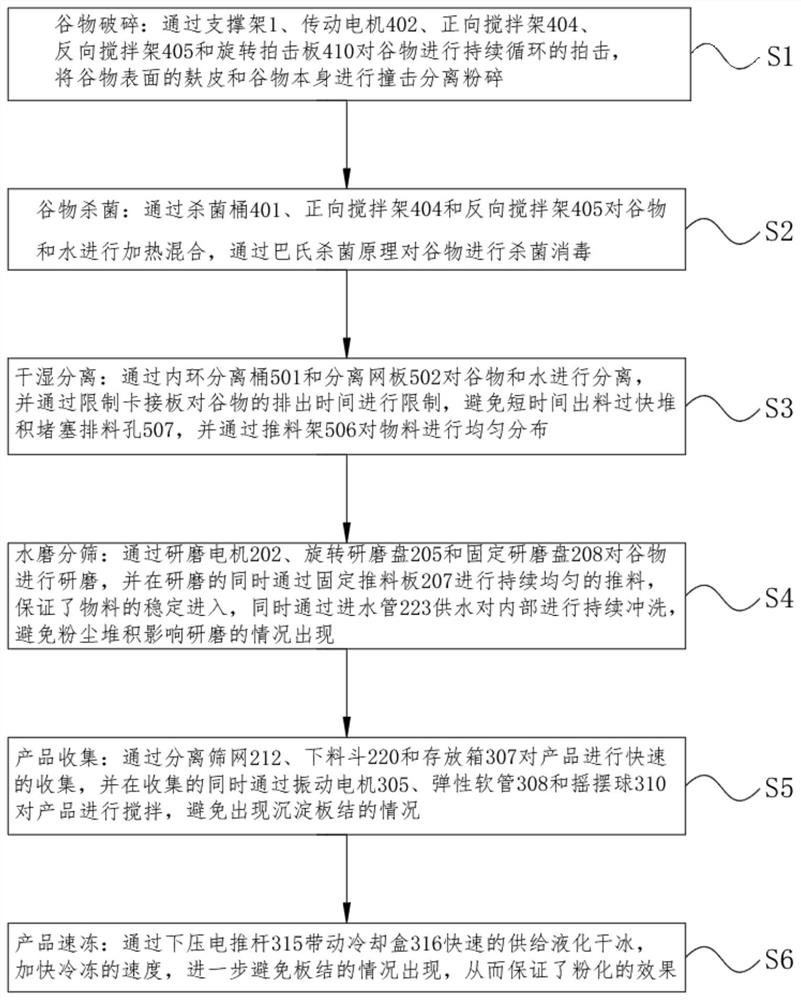

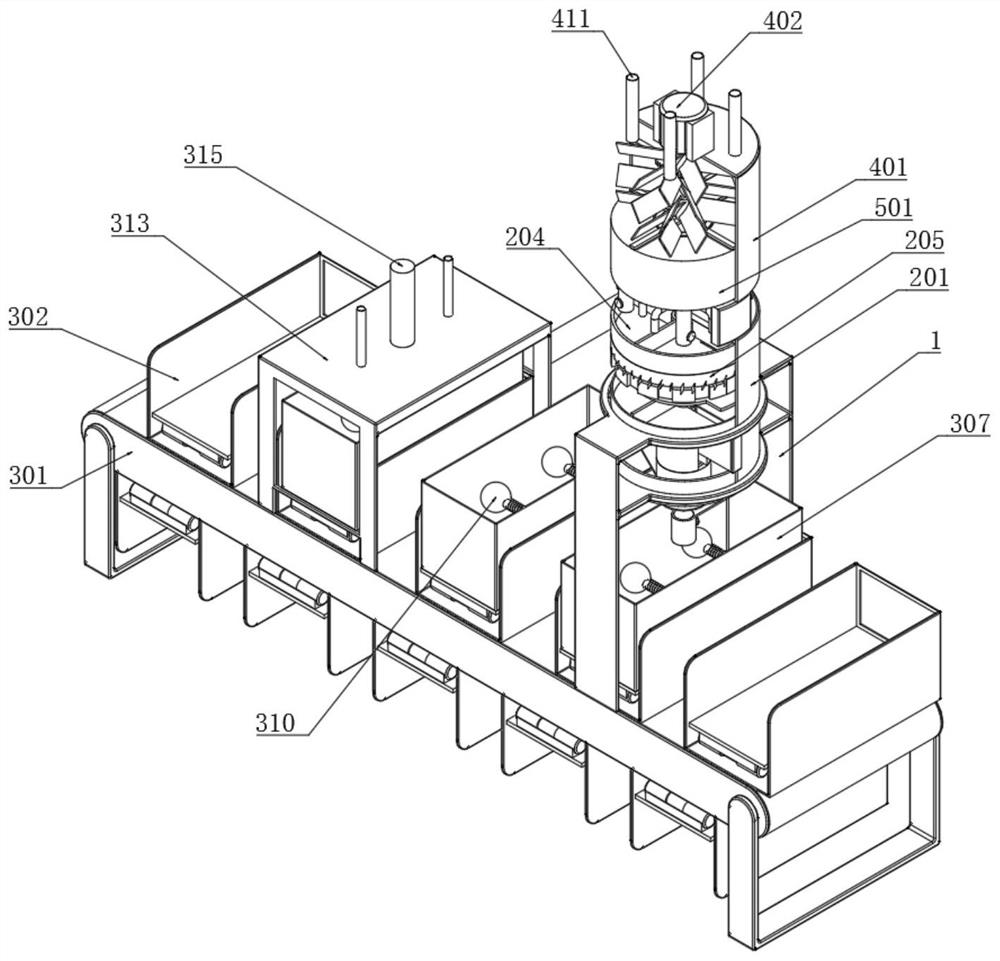

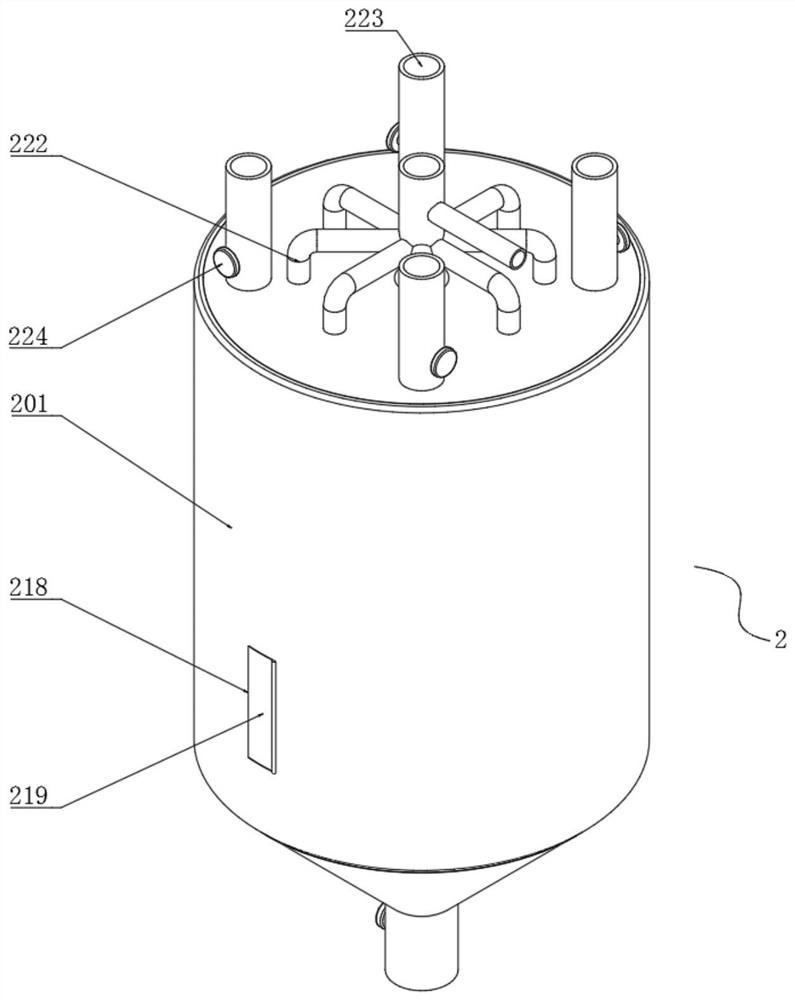

Preparation method of meal replacement powder

ActiveCN113198564AScientific and reasonable structureEasy to useGrain huskingGrain polishingMeal replacementProcess engineering

The invention discloses a preparation method of meal replacement powder. The preparation method comprises the steps of S1, cereal crushing; S2, cereal sterilization; S3, dry-wet separation; S4, water milling and screening; S5, product collection; S6, quick freezing of the product. The cereals are beaten and crushed, bran remaining on the surfaces of the cereals is removed, and large cereals are rapidly crushed, so that the surfaces of the cereals are clean. Meanwhile, the situation that a discharging port is blocked due to accumulation of large particles is avoided, the bacteria-free condition of subsequent production of the product is guaranteed through continuous sterilization, dry-wet separation is conducted on the sterilized product, a large amount of water is prevented from rapidly entering the grinding position, and therefore the concentration of a powder solution is guaranteed, and the situation that the drying efficiency is affected due to too low concentration is avoided. Dust raising and wet powder accumulation caused by too dry powder are avoided through water milling, normal production of the product is guaranteed, and in addition the production quality of the product is guaranteed.

Owner:东莞市霖鑫牛食品科技有限公司

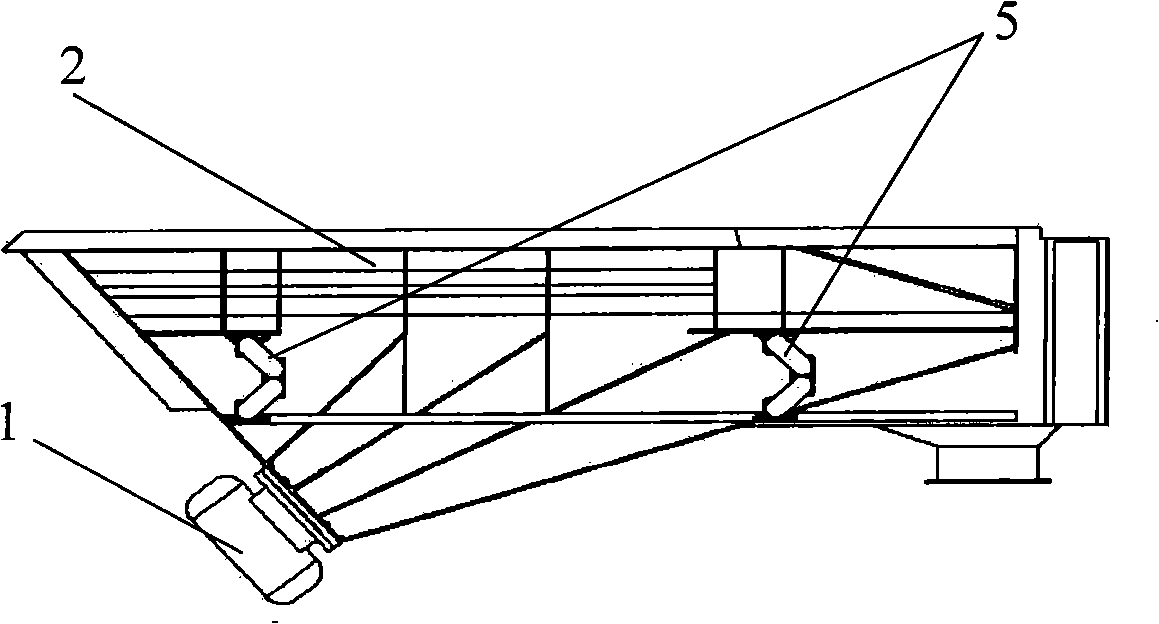

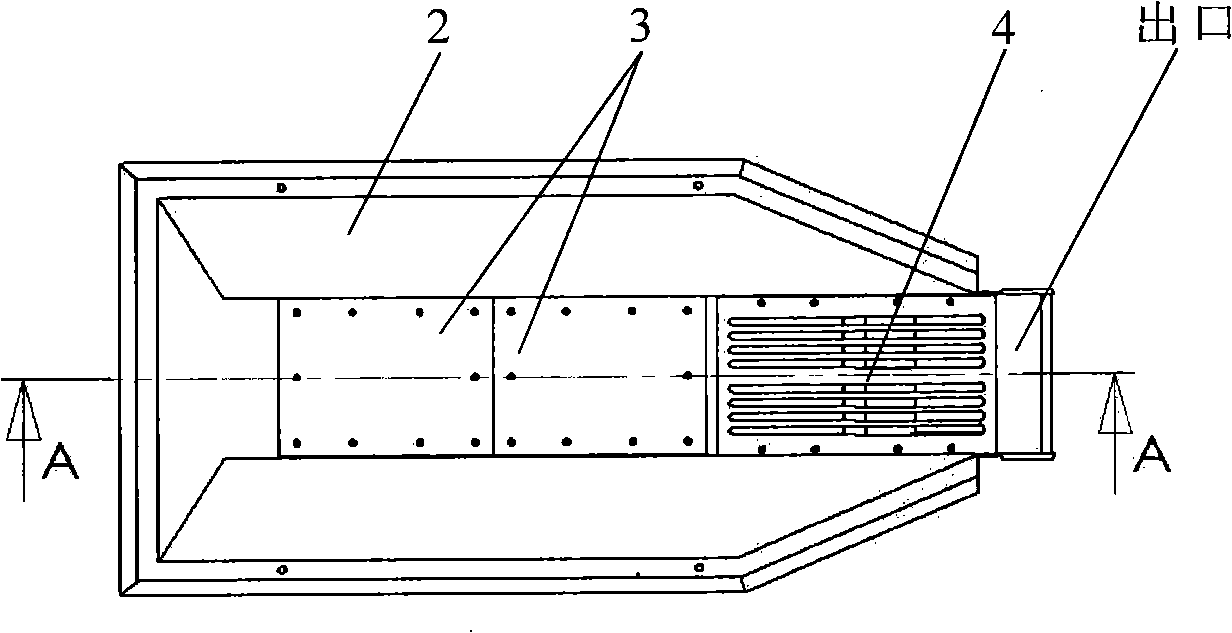

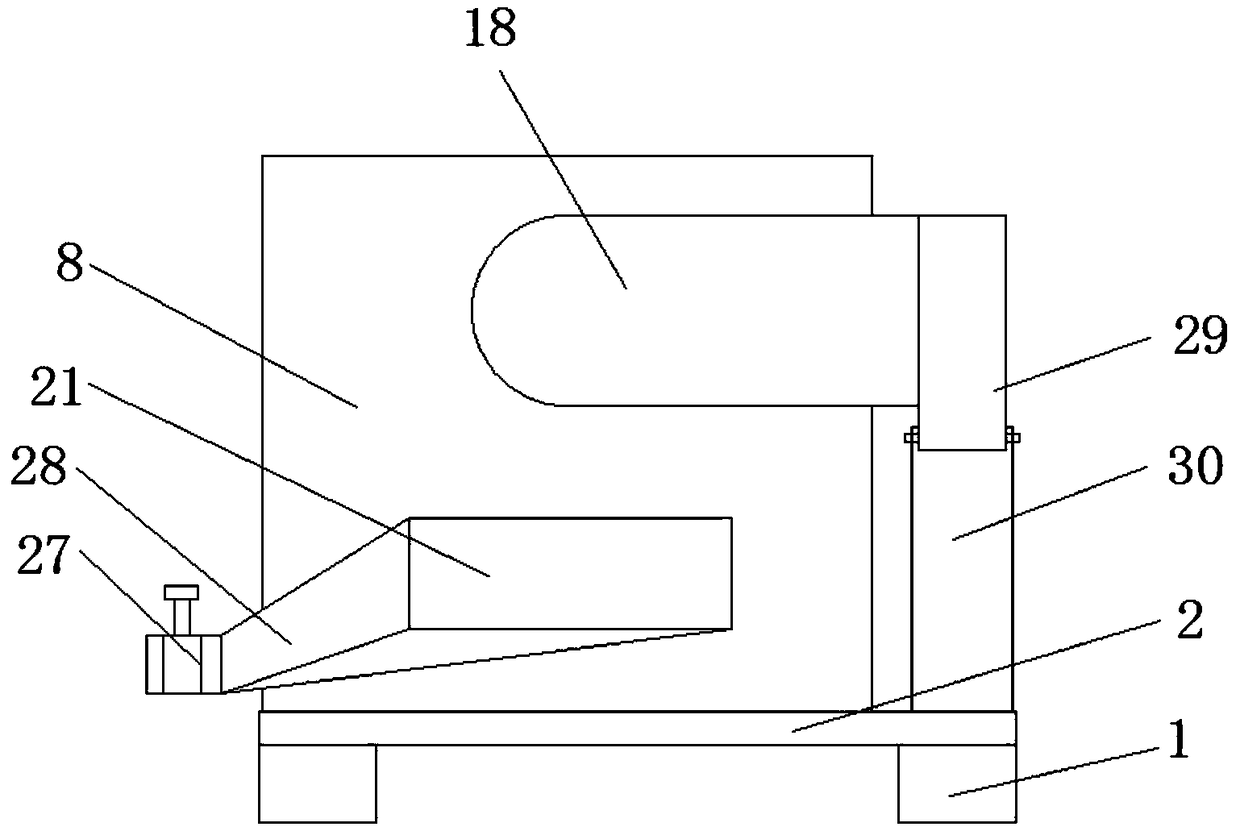

Pre-sifting vibrating material feeding device

The invention discloses a pre-screening vibratory feeding device. The bottom plate of the vibratory-bucket of the device is fixed on the bottom of the vibratory feeding bucket; a frequency-modulating motor is fixedly mounted on the rear wall plate of the vibratory feeding bucket, a pre-screening plate is fixedly mounted on the bottom plate at the front end of the vibratory feeding bucket, and a small material discharging opening is arranged under the pre-screening plate; a supporting device is fixedly mounted under the supporting-seat plate of the vibratory feeding bucket. The pre-screening plate can pre-screen the material during vibratory feeding, thereby, undersize materials are removed automatically; the frequency-modulating motor is taken as an exciting power source, the frequency-modulating motor is controlled to change the feeding amount so as to realize continuous and adjustable quantitative feeding; the bottom plate of the vibratory feeding bucket and the horizontal plane forms a relatively small angle, as a result, the material feeding becomes more even and stable; besides, the frequency-modulating motor can be adjusted to achieve zero delivery of material under a certain frequency.

Owner:WUXI XITONG ENG MACHINERY +1

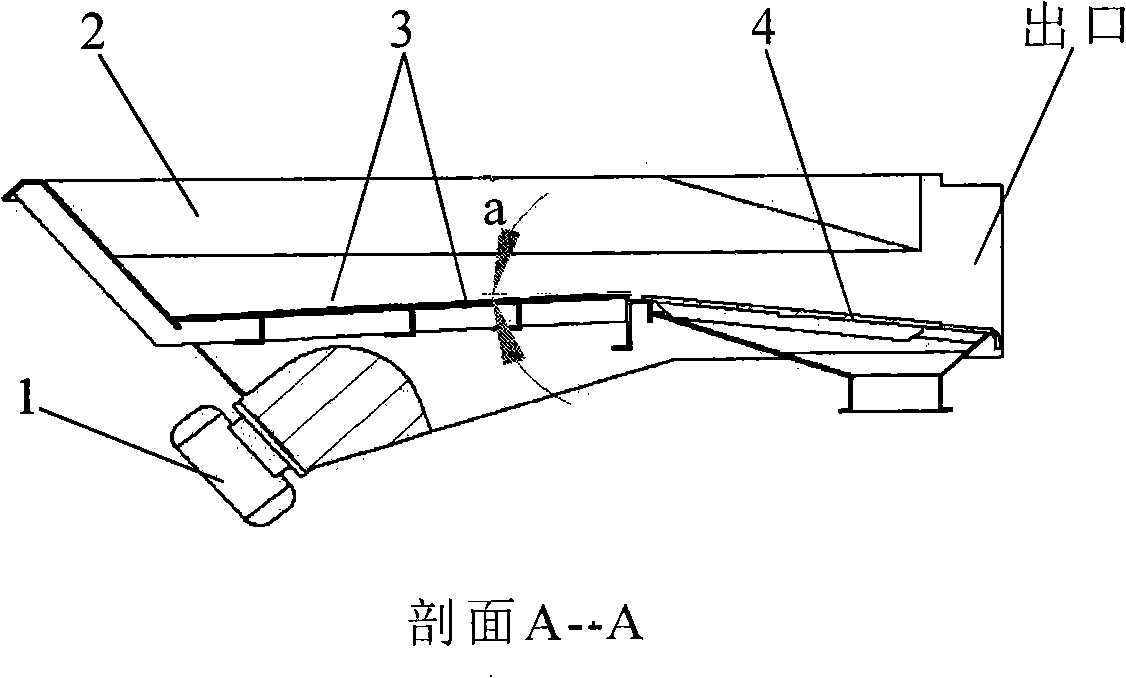

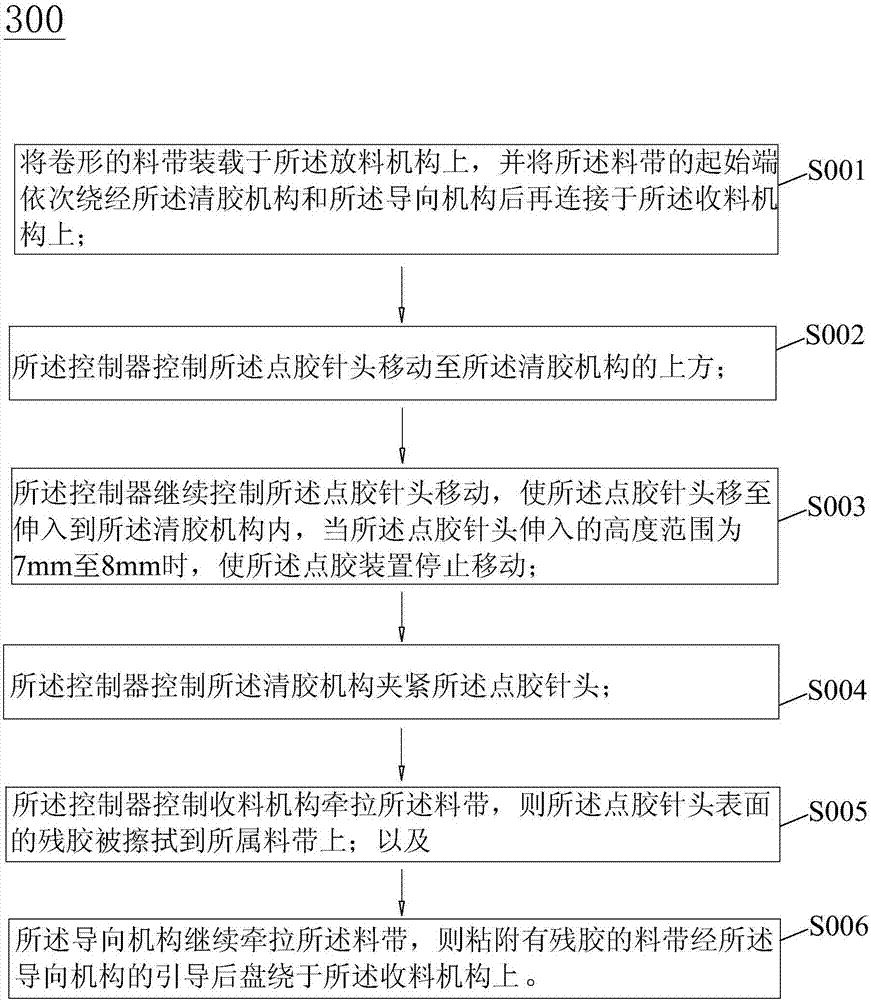

Automatic adhesive cleaning device and adhesive cleaning method thereof

ActiveCN106881241AAchieve cleanupEasy to cleanLiquid surface applicatorsSpraying apparatusAdhesiveEngineering

The invention provides an automatic adhesive cleaning device used for cleaning residual adhesives on a dispensing needle head. The automatic adhesive cleaning device comprises a fixed plate, material placing mechanisms, adhesive cleaning mechanisms, a guide mechanism and a material receiving mechanism, and the material placing mechanisms, the adhesive cleaning mechanisms, the guide mechanism and the material receiving mechanism are arranged on the fixed plate. Material belts are coiled into roll shapes and are loaded on the material placing mechanisms. The starting ends of the material belts are sequentially wound on the adhesive cleaning mechanisms and the guide mechanism and then are connected with the material receiving mechanism. In the process that the material receiving mechanism pulls the material belts, the material placing mechanisms, the guide mechanism and the material receiving mechanism act synchronously; the adhesive cleaning mechanisms clamp the dispensing needle head, so that the material belts are conveyed in the horizontal direction; the residual adhesives on the dispensing needle head are wiped on the material belts under matching of the material receiving mechanism and the adhesive cleaning mechanisms; and the material belts adhered with the residual adhesives are coiled on the material receiving mechanism under guiding of the guide mechanism. The automatic adhesive cleaning device and an adhesive cleaning method thereof are reasonable in design, high in efficiency, low in cost and high in automation degree.

Owner:DONGGUAN WORLD PRECISION MACHINERY

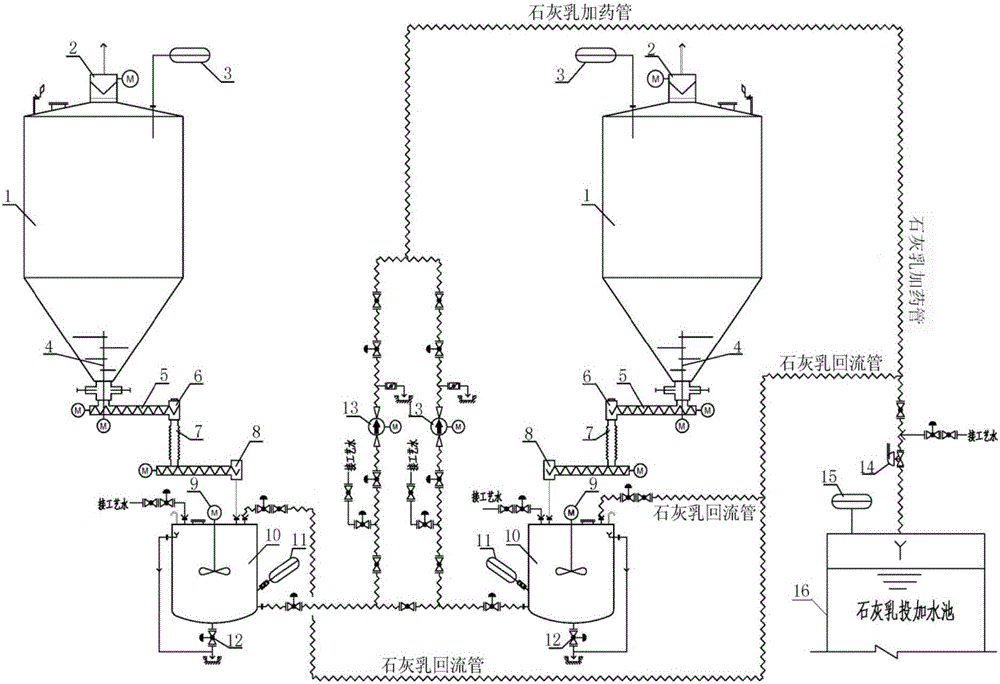

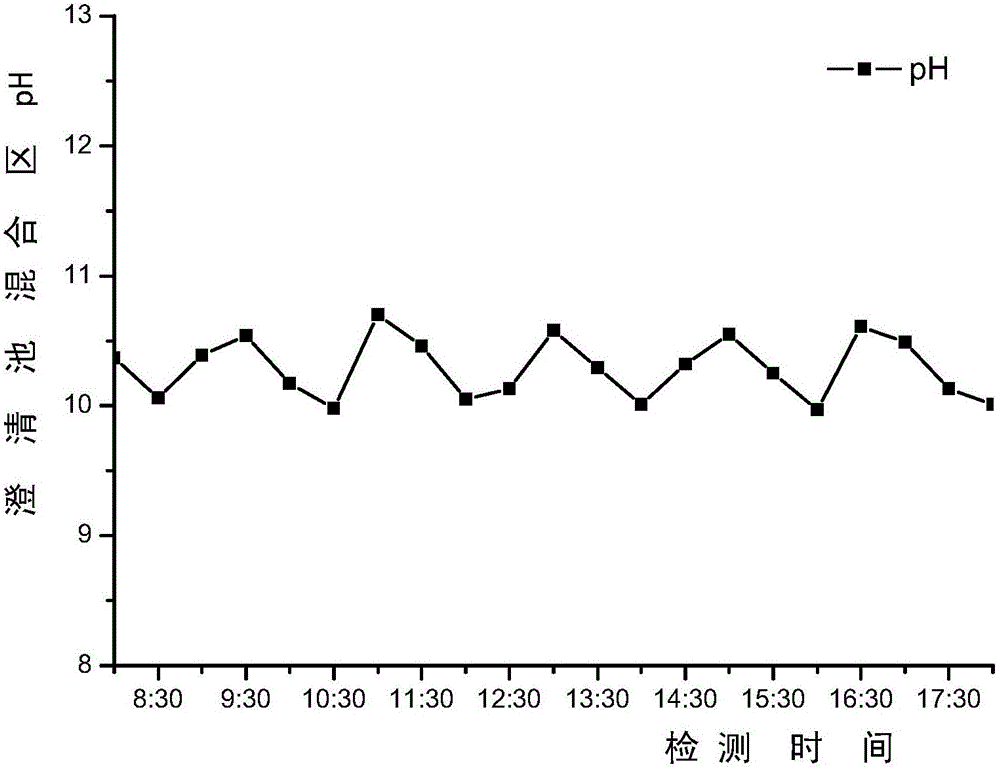

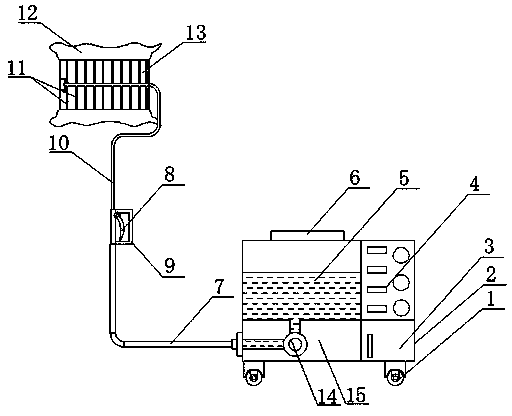

Slaked lime feeding system in water processing system

InactiveCN104986845AReduce labor intensityReduce fouling and cloggingWater/sewage treatment by neutralisationWater treatment systemEngineering

The invention provides a slaked lime feeding system in a water processing system. The slaked lime feeding system comprises a lime powder bin. An outlet of the lower end of the lime powder bin is provided with a feeding machine. The feeding machine is connected with a metering conveying machine. The metering conveying machine is connected with a feeder though a pipeline made of transparent materials. The feeder is connected with a lime milk solution. The lime milk solution tank is provided with an automatic sand draining valve and communicated with a lime milk feeding water tank through a lime milk chemical feeding pipe. According to the slaked lime feeding system, through the pipeline made of the transparent materials, the whole process of material conveying and flowing can be observed, and dredging can be conducted conveniently and timely once blocking is found; due to the fact that the automatic sand draining valve is arranged, automatic sand draining can be conducted regularly; the labor intensity of workers is lowered, deposition and blocking caused by sand grains are reduced, the concentration of a lime agent prepared through a limb chemical feeding device keeps stable, the error does not exceed + / -0.5%, precise control over the PH value of feeding points can be guaranteed, and the error does not exceed + / -0.3.

Owner:XIAN TPRI WATER & ENVIRONMENTAL PROTECTION

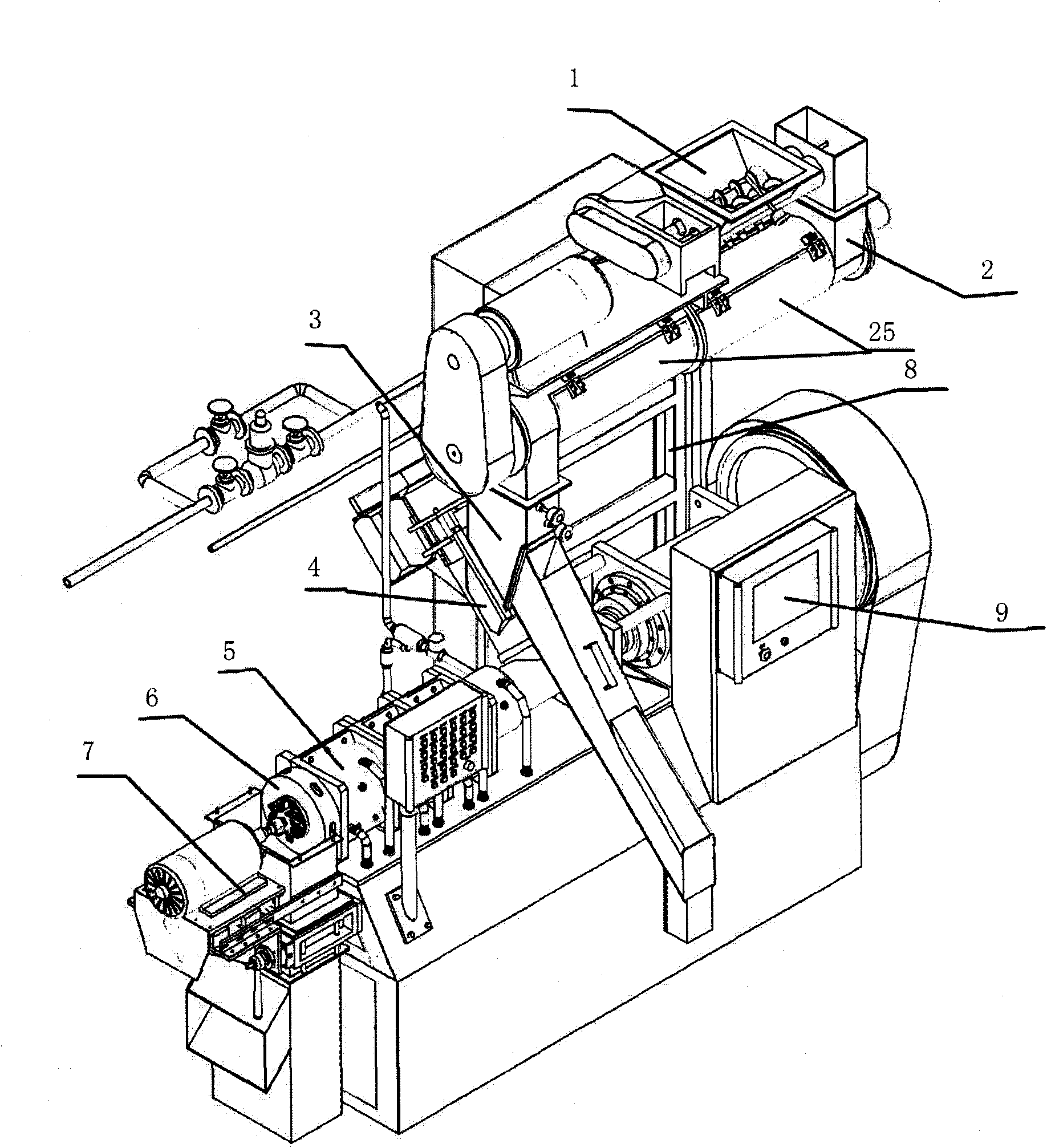

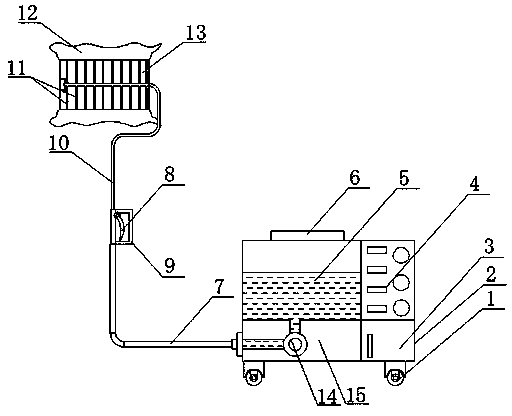

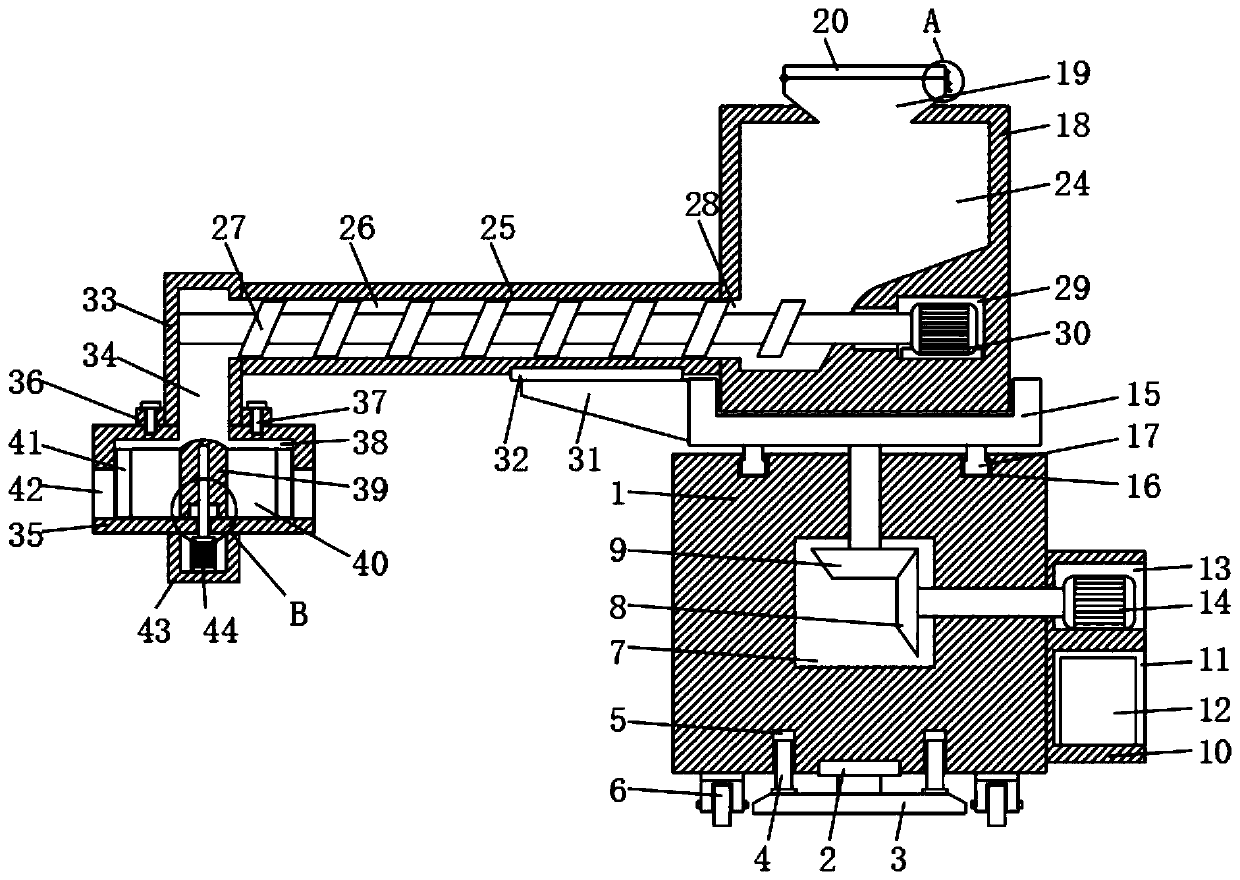

Single-screw low-temperature wet-process puffing machine

ActiveCN101773278AUniform and stable feedingReduce volumeFeeding-stuffFood shapingElectrical controlElectric machinery

The invention relates to a novel single-screw low-temperature wet-process puffing machine belonging to the field of puffing devices. The novel single-screw low-temperature wet-process puffing machine comprises a rack body and a motor, wherein the top of the rack body is provided with a double-screw feeder; the upper middle part of the rack body is provided with a conditioner connected with the double-screw feeder; the middle of the rack body is provided with a secondary feeder connected with the conditioner through a conditioner outlet tee joint; a low-temperature extrusion puffing device driven by the motor is connected with the secondary feeder; the tail end of the low-temperature extrusion puffing device is connected with an extrusion die device; and the outer side of the extrusion die device is also provided with a gap self-regulating cutter device connected with the rack body and an electrical control system. The invention is automatically controlled by a programmable logic controller (PLC) and realizes the production of puffed products, i.e. puffed foods, puffed pet foods, puffed aquatic feeds, puffed livestock and poultry feeds, puffed urea, and the like, under a low-temperature condition.

Owner:常州市宏寰机械有限公司 +1

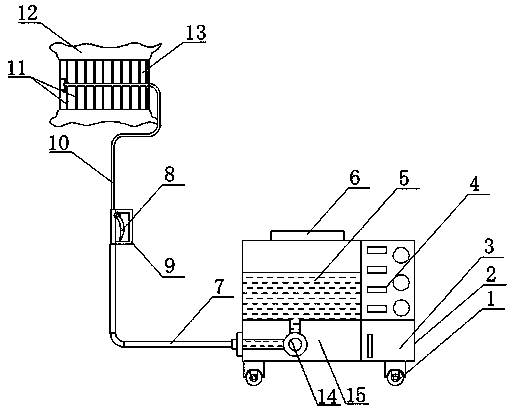

Continuous paint feeding roller brush

InactiveCN103726644ASimple structureEasy to useBuilding constructionsEngineeringMechanical engineering

The invention discloses a continuous paint feeding roller brush which comprises traveling wheels, a feeding vehicle, a delivery pipe, a delivery switch, a handle, a roller brush support and a brush body. The traveling wheels are arranged at the bottom of the feeding vehicle and are fixedly welded to the bottom of the feeding vehicle, a pump box is arranged on the lower portion of the feeding vehicle, a power box is arranged at the side, closely adjacent to the pump box, of the lower portion of the feeding vehicle, a control box is arranged on the upper portion of the power box, a storage cabin is arranged the side, close to the control box, of the power box, the bottom of the storage cabin is communicated with a pump through a pipeline, a cabin cover is arranged on the upper portion of the storage cabin, the delivery pipe is inserted in one side outside the pump box, one end of the delivery pipe is communicated with the pump in the pump box, the other end of the delivery pipe is provided with the handle, the delivery switch is arranged on the upper portion of the handle, the upper portion of the delivery switch is connected with the roller brush support in an inserting mode, a roller wheel is fixed to the roller brush support in a sleeved mode, liquid outlet pipes are arranged in the roller wheel, and the brush body is fixed to the outer portion of the roller wheel in a sleeved mode. The continuous paint feeding roller brush has the advantages of being simple in structure, convenient to use, high in strength, even and stable in paint feeding and capable of saving time and labor, reducing secondary pollution and saving raw materials.

Owner:刘成涛

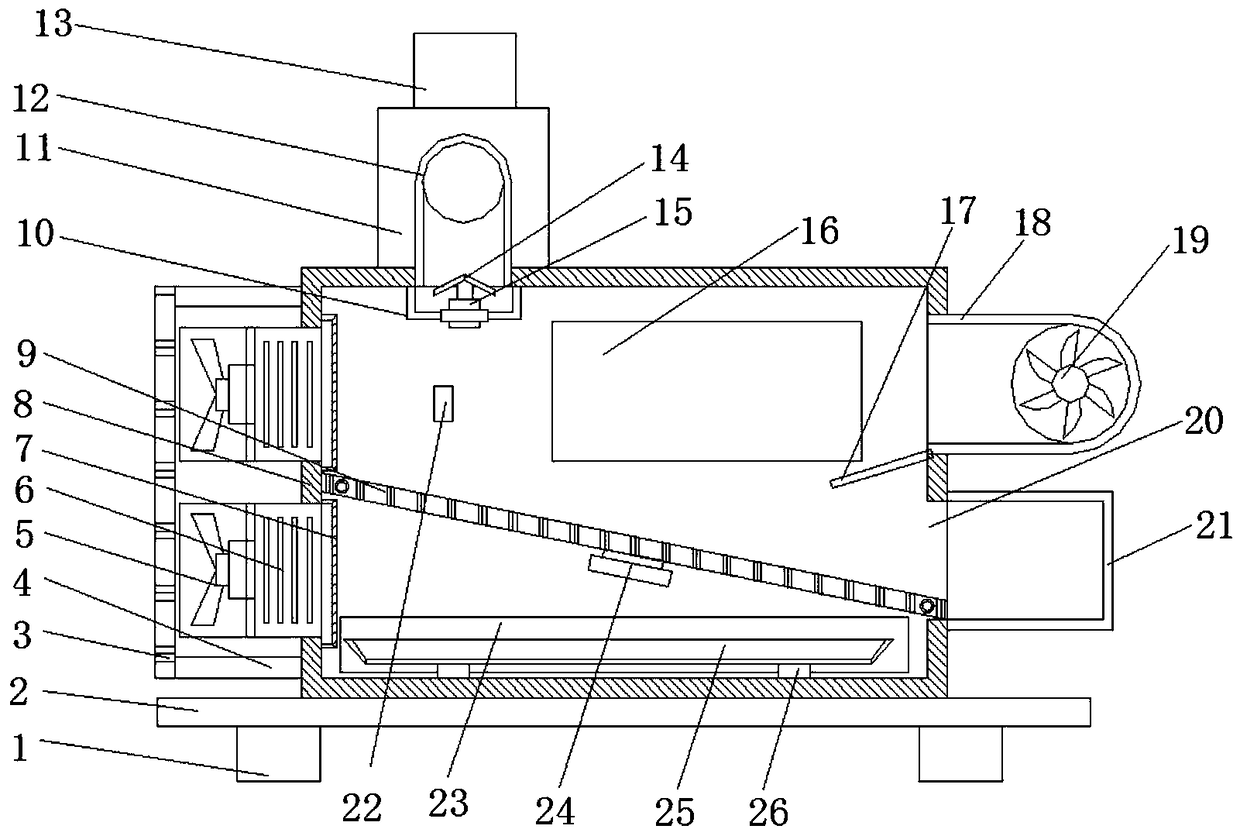

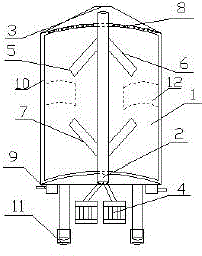

Convenient feeding type drying device for agricultural byproduct processing

InactiveCN109059516AFeeding is simple and convenientAvoid damageSievingScreeningAgricultural engineeringImpurity

The invention belongs to the technical field of agricultural byproduct processing and particularly relates to a convenient feeding type drying device for agricultural byproduct processing. In order tosolve the problems, such as single function, low drying efficiency and inconvenient feeding, of the existing drying device, the following technical scheme is provided. According to the technical scheme, the drying device comprises a base, wherein one side of the top of the base is connected with a drying box through bolts, one side of the drying box is connected with a conveying box through bolts, two round through holes are formed in one end of the drying box, the inner parts of both round through holes are connected with an air heater through bolts, and the inner wall of one side of the drying box is connected with a temperature sensor through bolts. In the invention, crops can be pushed into a feeding pipe through a rotating conveying paddle and dispersed in the drying box through a rotating dispersing rod, so that the feeding of the drying device is simple, convenient, uniform and stable; and at the same time, impurities can be cleared, the labor force is saved, further impurity clearing can be carried out on the crops during drying, and the quality of agricultural byproducts is ensured.

Owner:ANHUI HUARUI PHARMA TECH DEV CO LTD

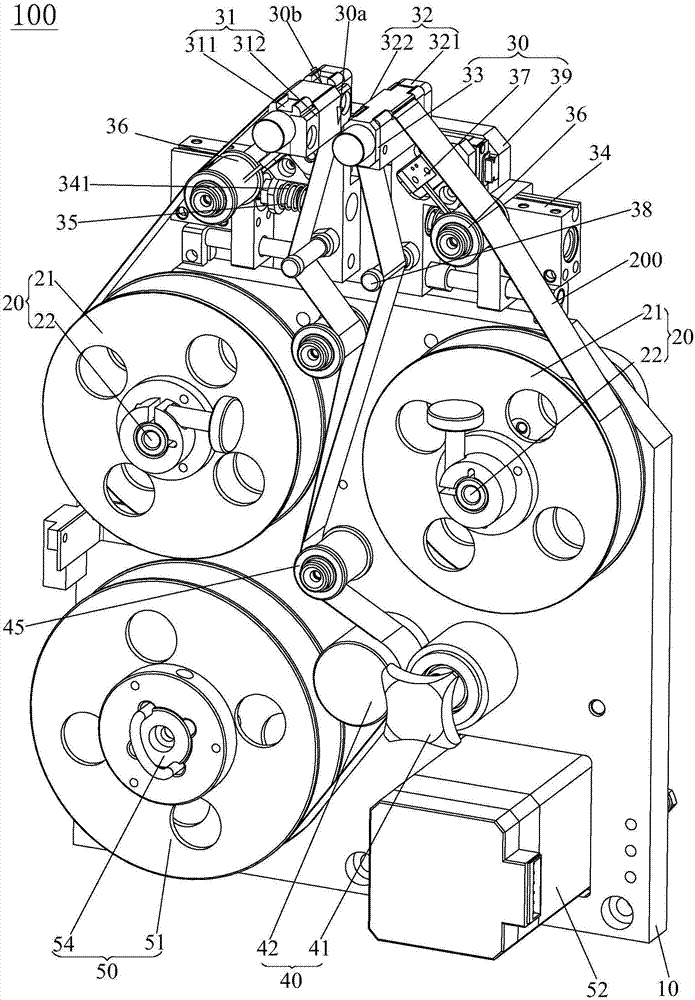

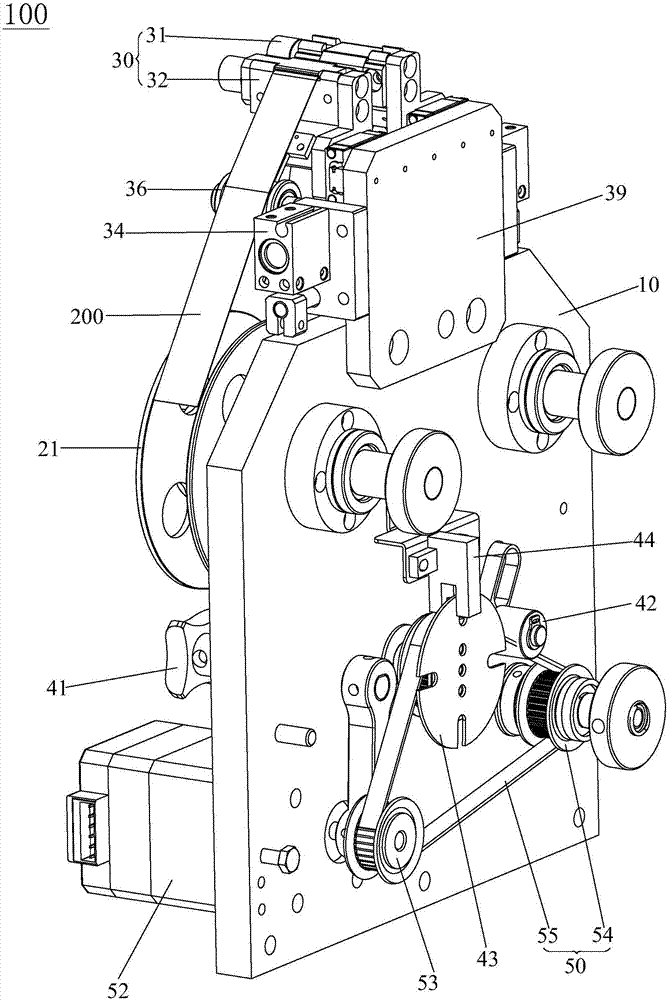

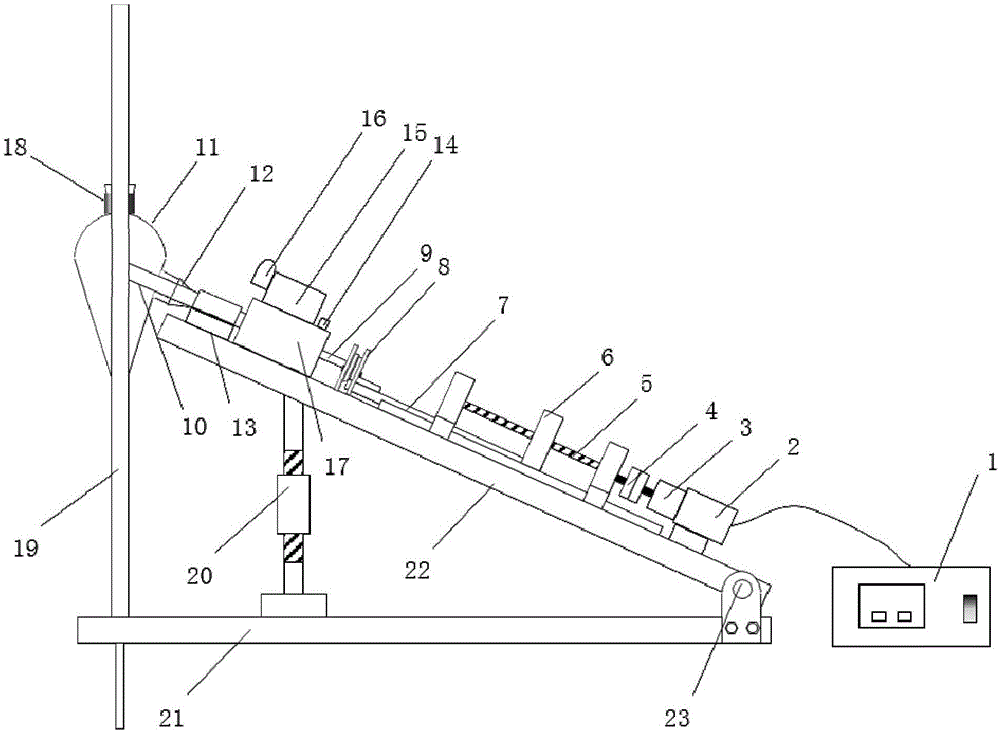

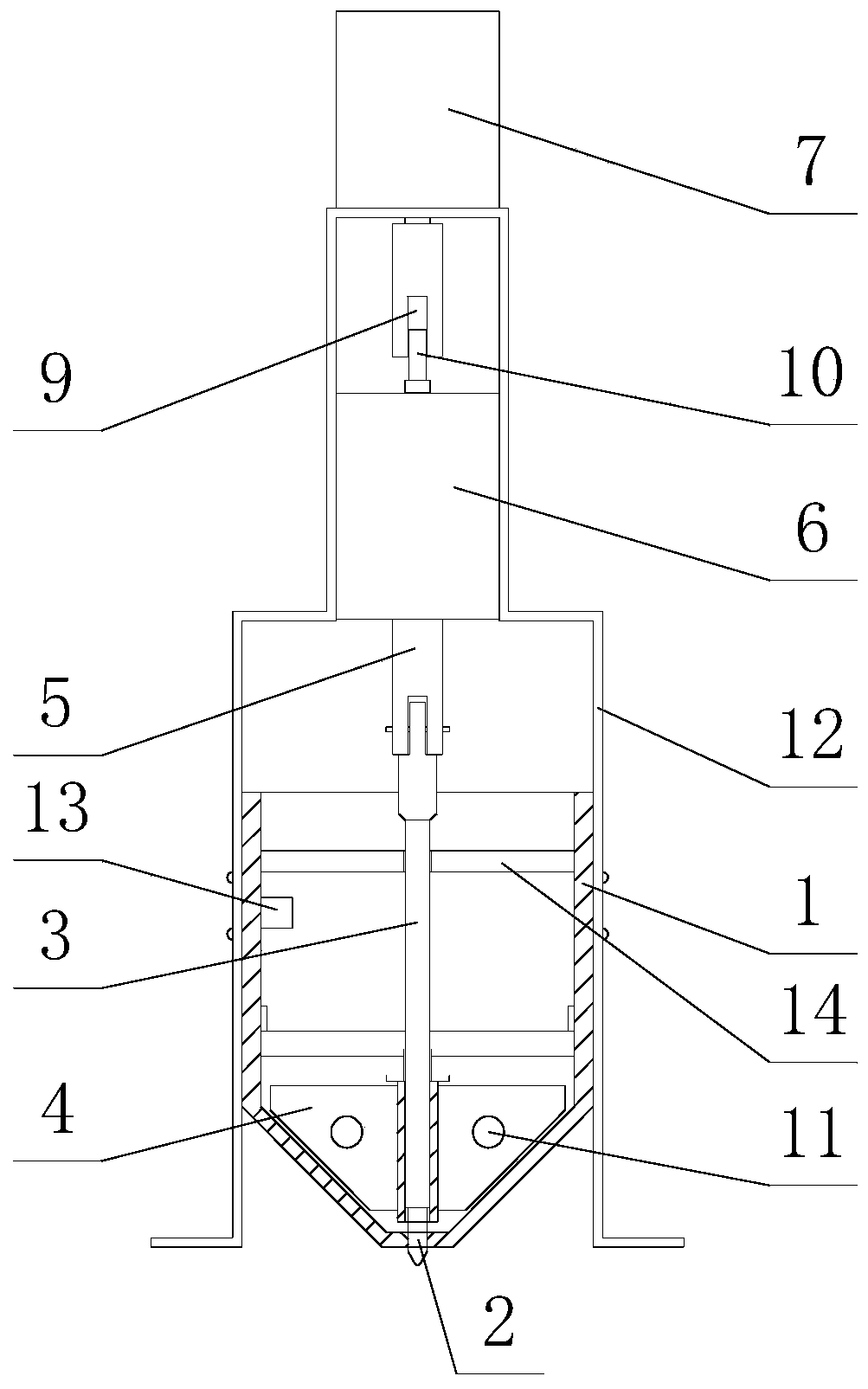

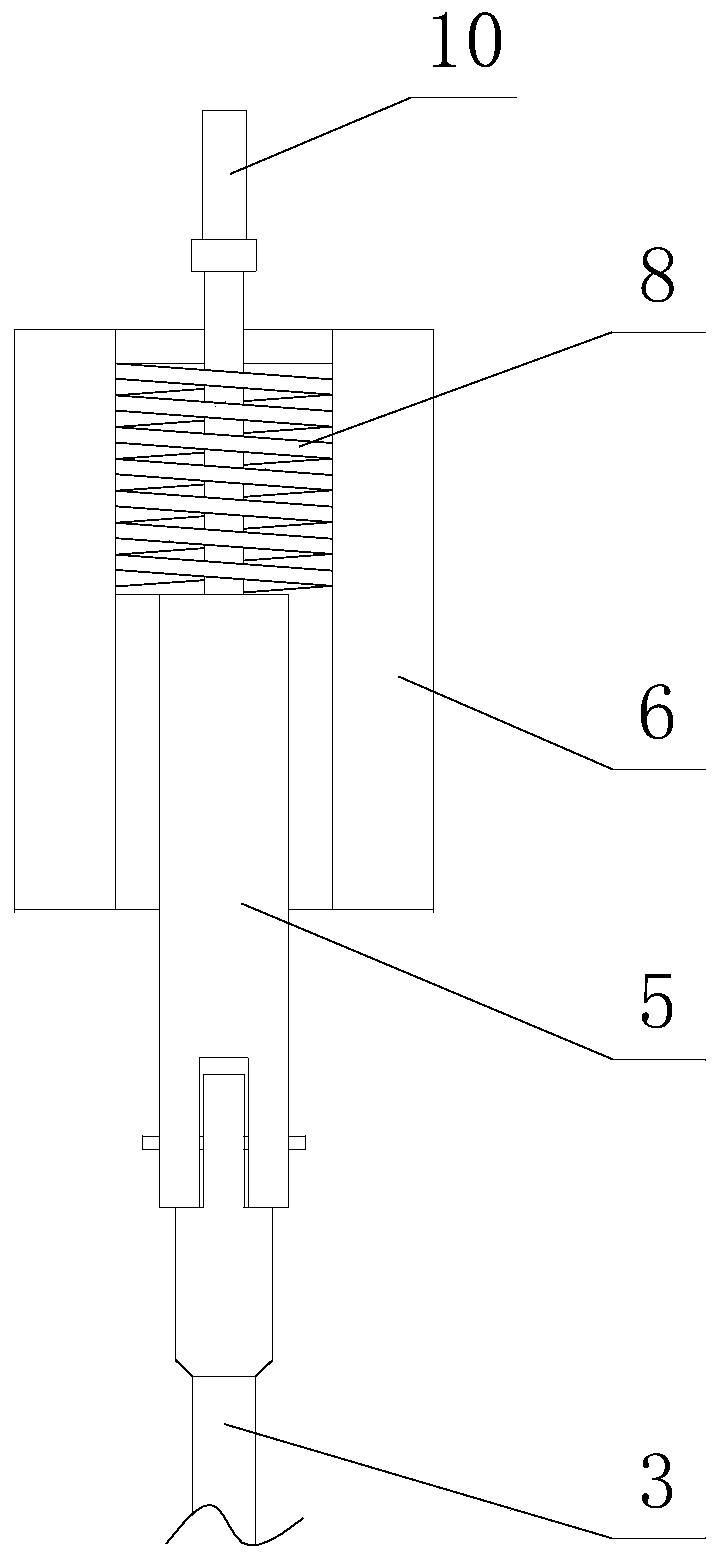

Propulsion type trace feeder

ActiveCN106743511AContinuous, stable and uniform dispersionUniform and stable dispersionLoading/unloadingConveyor partsLower limitCoupling

The invention provides a propulsion type trace feeder and relates to the trace feeder. The propulsion type trace feeder solves the problems that an existing trace feeder is high in feeding lower limit, feeding is nonuniform and the feeding amount is not easy to adjust. A reducer is coaxially connected with a sliding rail through a coupling. A sliding block is in threaded connection with the sliding rail. One end of a push rod is fixedly connected with the sliding block. A slope support plate is mounted on the upper end face of a horizontal support plate through a spiral adjusting support. The lower portion of the slope support plate is hinged to one end of the horizontal support plate. A fixed stand column is vertically arranged at the other end of the horizontal support plate. A storage pipe is fixed to the upper portion of the slope support plate through a storage pipe fixing clamp. The other end of the push rod is fixedly connected with one end of a rubber tight fit push rod. The other end of the rubber tight fit push rod is inserted into one end of the storage pipe, and the rubber tight fit push rod and the storage pipe are tightly connected. The other end of the storage pipe is inserted into the center of a falling bottle. The storage pipe is wrapped with a support fixing frame, and the support fixing frame is fixed to the slope support plate. The propulsion type trace feeder is used for trace feeding.

Owner:HARBIN INST OF TECH

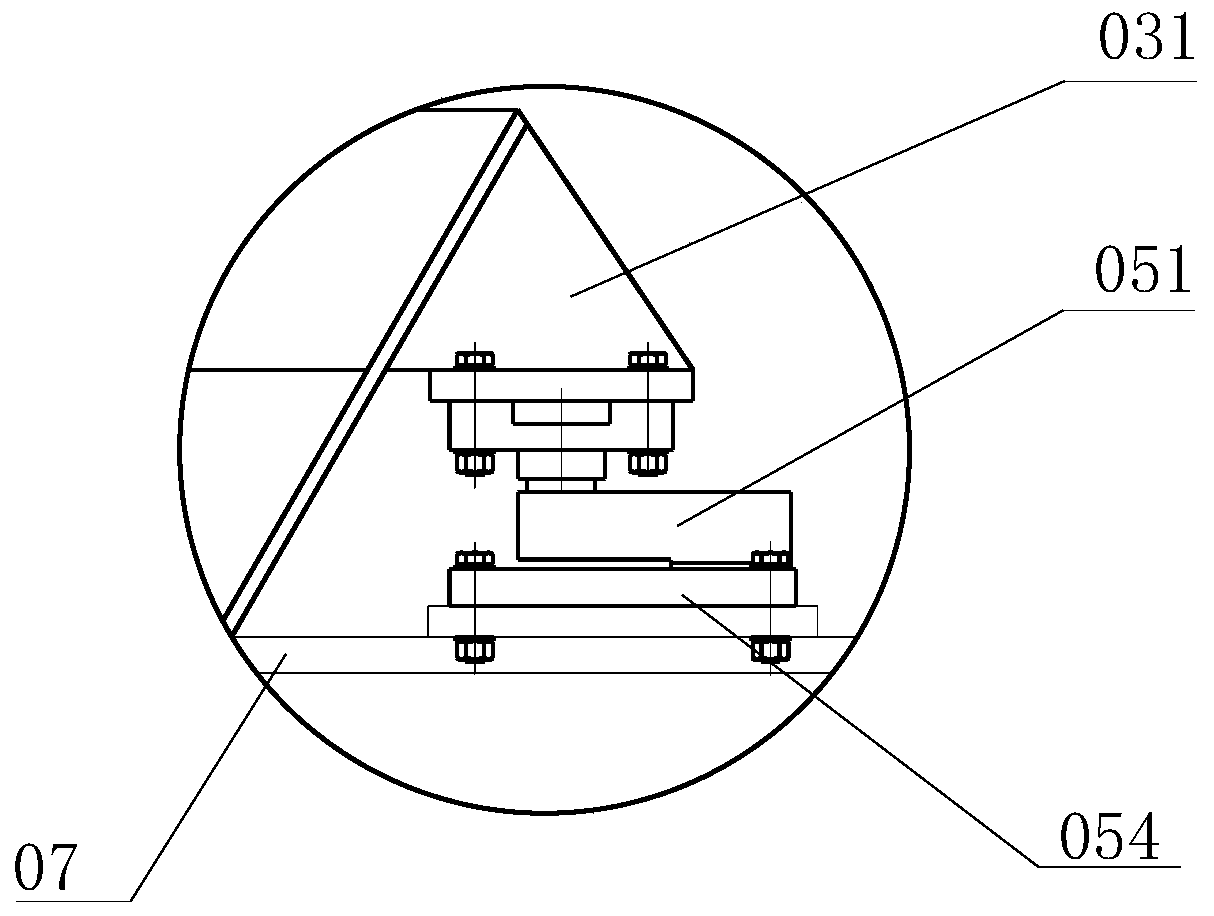

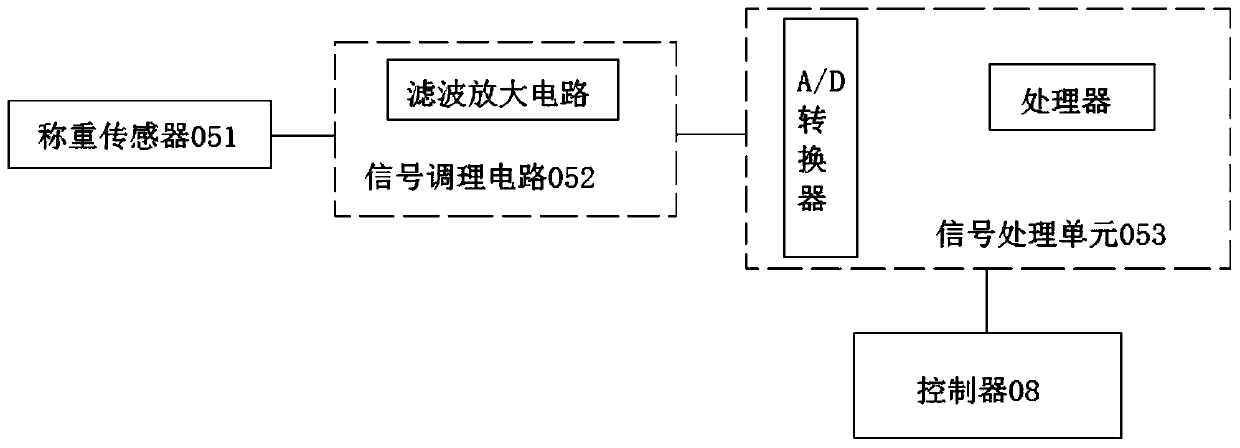

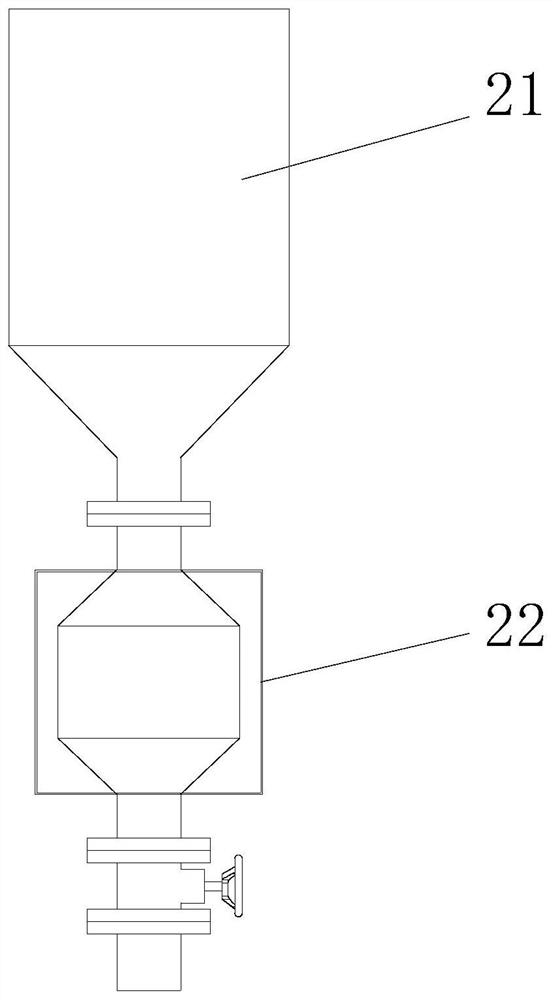

Feeding device and method with automatically-adjusted feeding amount

PendingCN110091428AFeed amount is constantAutomatic adjustment of feeding amountFeeding arrangmentsAuxillary shaping apparatusProduction lineImpeller

The invention provides a feeding device and method with automatically-adjusted feeding amount. The feeding device is installed above a mold conveying rail of a prefabricated plate production line, thefeeding device comprises a machine frame, a material bin, a hopper, a load device, a rotary feeding valve and a controller, wherein the material bin, the hopper and the rotary feeding valve are in sequential communication from top to bottom, the load device is arranged on the machine frame, the material bin, the hopper, the rotary feeding valve and a built-in thick-liquid material weight are allapplied to a load end of the load device, and a data interface of the load device is electrically connected to the controller. According to the feeding device, the feeding amount in one feeding periodmonitored online by the load device is acquired by the controller, the rotating speed of an impeller of the rotary feeding valve is adjusted online, so that the purpose of automatically adjusting thefeeding amount is achieved; an on-line sliding filter can eliminate field mechanical vibration interference and pulse interference, so that the precision of feeding amount detection is improved, andthe on-line monitoring real-time performance requirement is met; and the device is compact in structure and high in automation degree, and the working efficiency and the product quality can be improved.

Owner:BEIJING TRIUMPH INT ENG

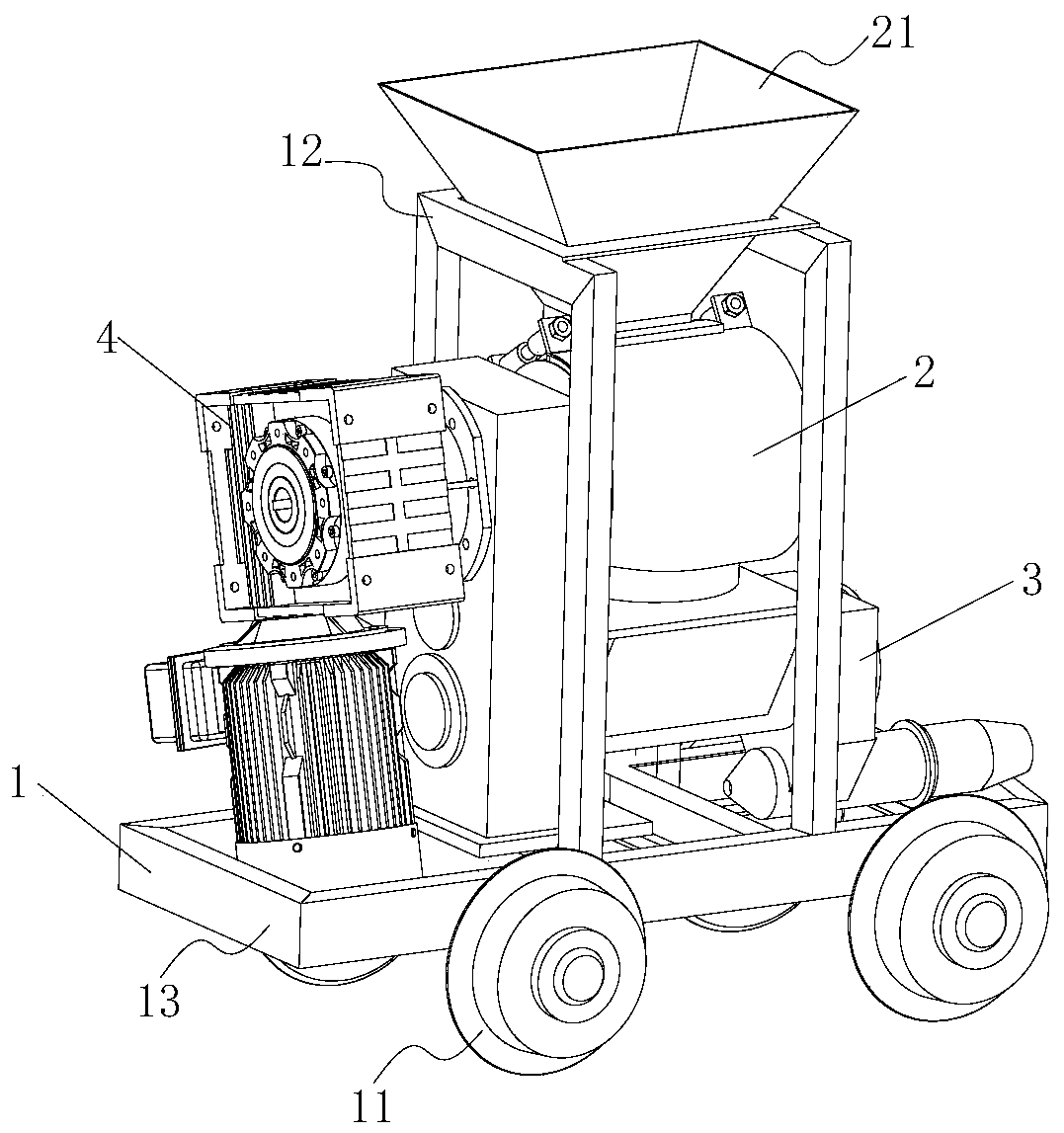

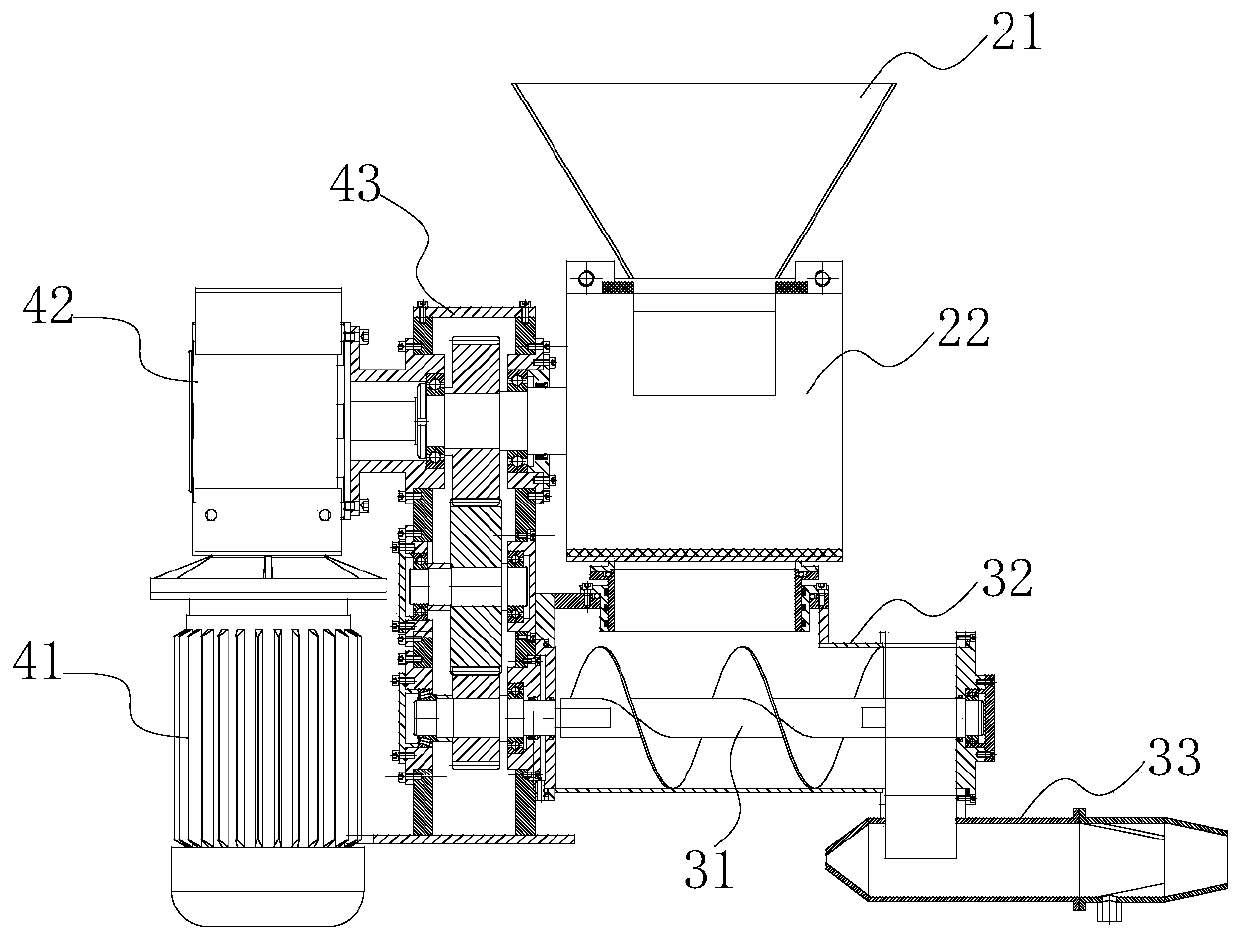

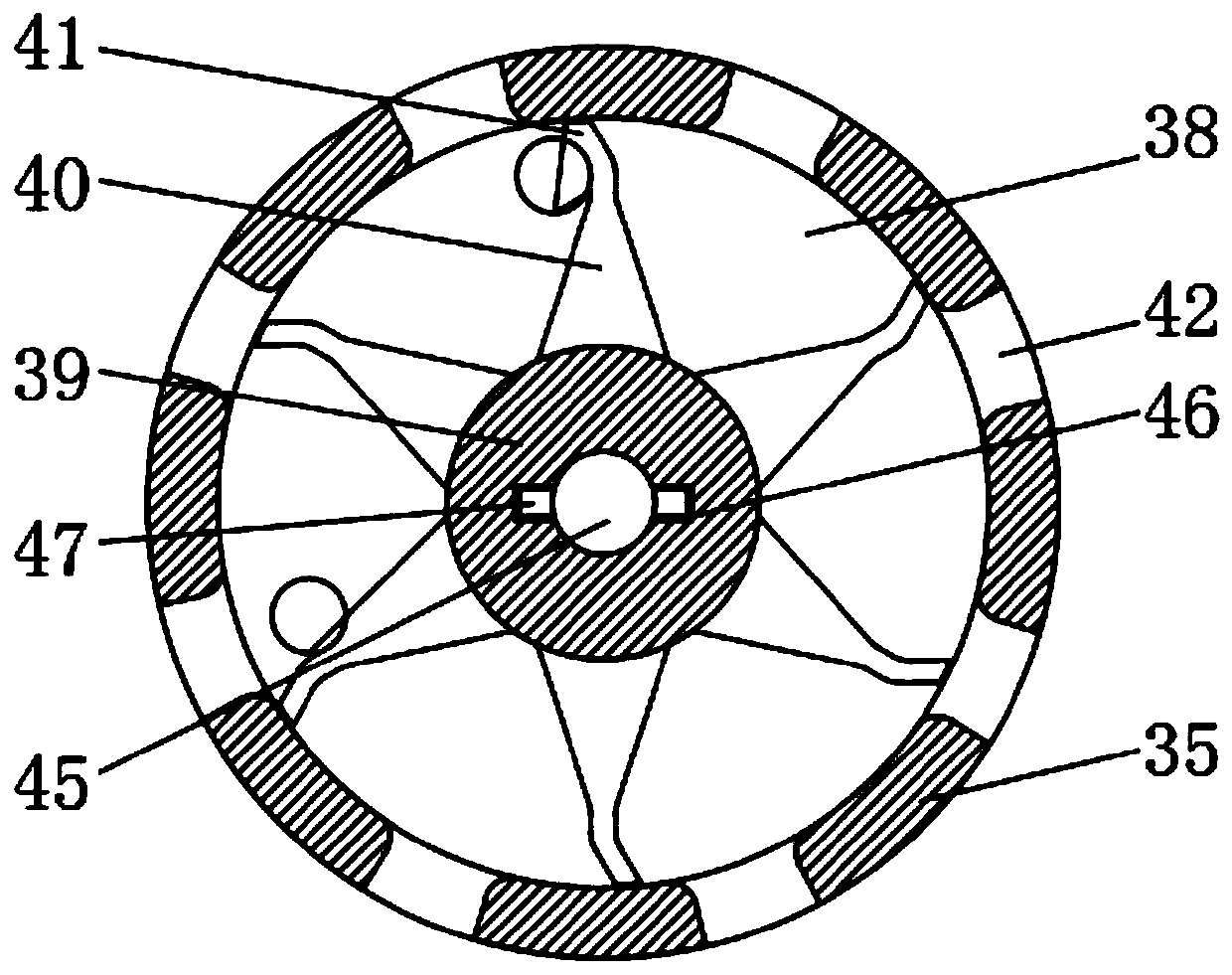

Long-distance dust-free shotcrete machine

ActiveCN109899090AReduce deliveryLong conveying distanceUnderground chambersTunnel liningReducerEngineering

The invention provides a long-distance dust-free shotcrete machine, and relates to the technical field of concrete spraying equipment. The long-distance dust-free shotcrete machine includes a machinebody, a feeding mechanism, a spraying mechanism and a driving mechanism, the machine body includes wheels and a chassis, the feeding mechanism includes a hopper, a feeding shell and a feeding shaft, the hopper is connected with the feeding shell, the feeding shaft is arranged in the feeding shell, a pressure relief port is formed in the feeding shell, a plurality of feeding cabins are arranged onthe feeding shaft in central symmetry, the spraying mechanism includes a feeding screw, a feeding box and a swirl injector, the feeding screw is arranged in the feeding box, the swirl injector is connected with the feeding box, the driving mechanism includes a motor, a reducer and a gearbox, the motor is connected with the reducer, the reducer is connected with a gear in the gearbox, and the driving mechanism drives the feeding shaft and the feeding screw to rotate. According to the long-distance dust-free shotcrete machine, the technical problems that the pressure of long-distance conveying of concrete is insufficient and dust is prone to being generated at the hopper are solved, and the advantages of compact structure and good sealing effect are further achieved.

Owner:SHANDONG UNIV OF SCI & TECH +1

Feeding equipment capable of uniformly spraying feed for aquatic product breeding

PendingCN111528159AEasy to moveEasy to carry mobile workClimate change adaptationPisciculture and aquariaHydraulic cylinderAnimal science

The invention provides feeding equipment capable of uniformly spraying feed for aquatic product breeding, and relates to the technical field of feed feeding. The feeding equipment capable of uniformlyspraying the feed for aquatic product breeding comprises a fixed seat, wherein a hydraulic cylinder is embedded in the bottom of the fixed seat; a supporting seat is fixedly connected to the drivingend of the hydraulic cylinder; a first inner groove is formed in the fixed seat, and a first bevel gear is rotatably connected into the first inner groove; a second bevel gear is connected to the first bevel gear in an engaged mode; a containing box is fixedly connected to one side of the outer surface of the fixed seat; and a second groove is formed in the position, close to the top, in the containing box. The whole feeding equipment is convenient to move and fix through the arranged supporting seat matched with a universal wheel structure, operation is convenient, use is flexible, feed is conveyed through an arranged packing auger, the situation that the feed blocks a conveying pipe can be prevented, and even and stable conveying can be achieved; and meanwhile, some large lump or caked feed can be crushed and dispersed, and the use very convenient.

Owner:南京慧昌生物科技有限公司

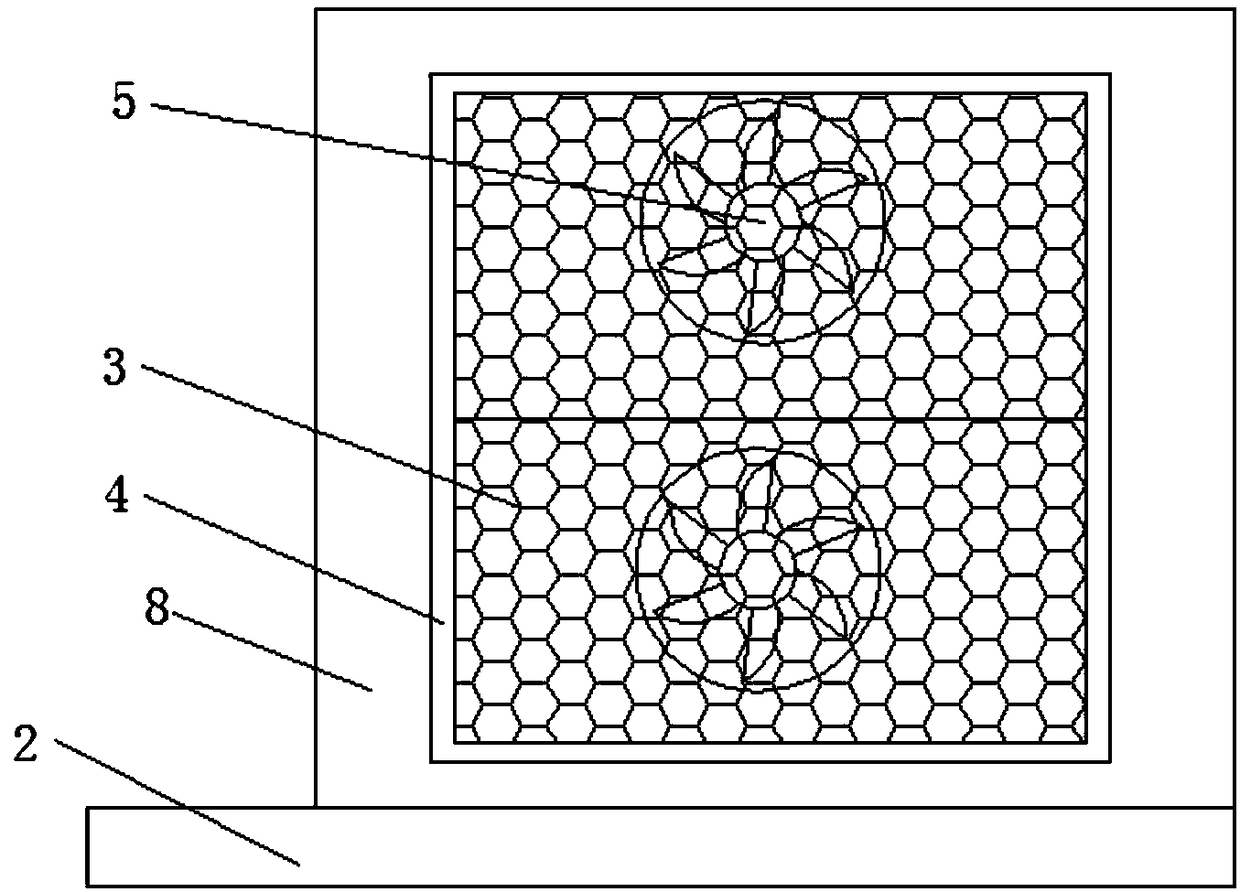

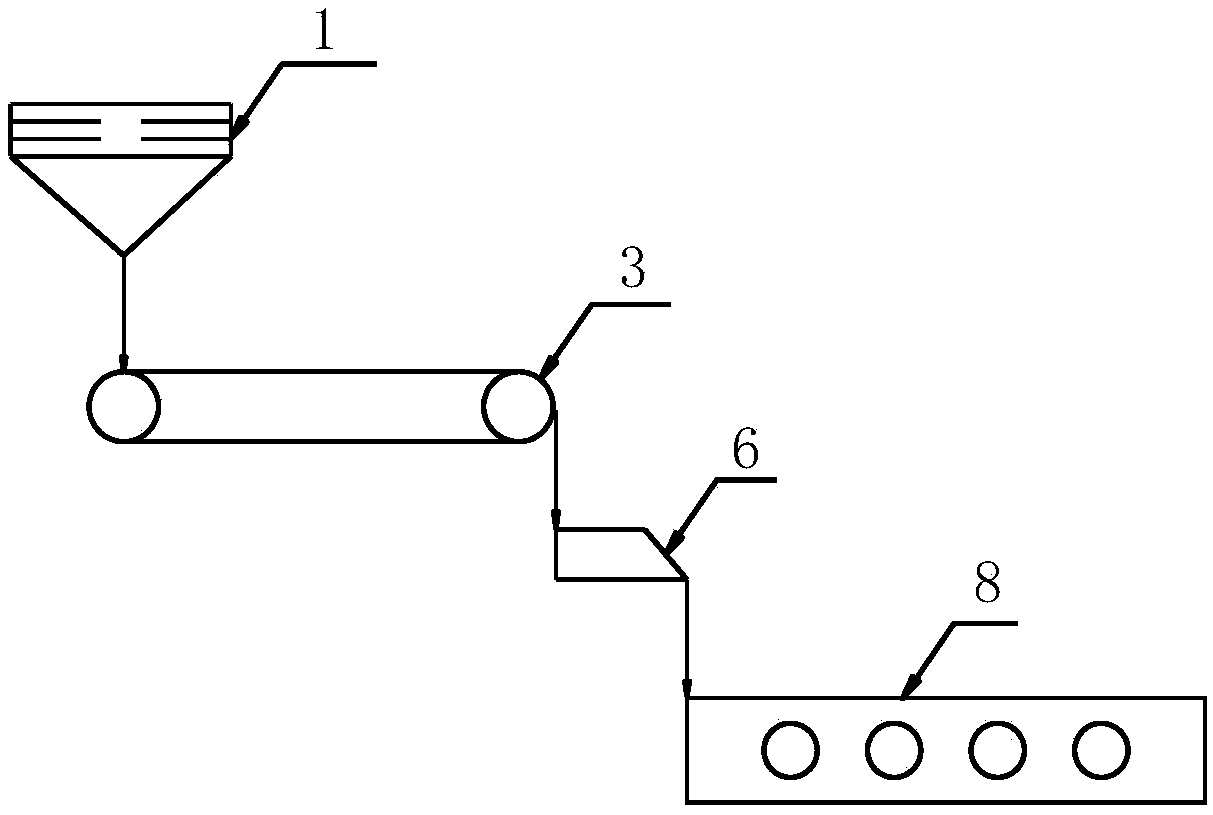

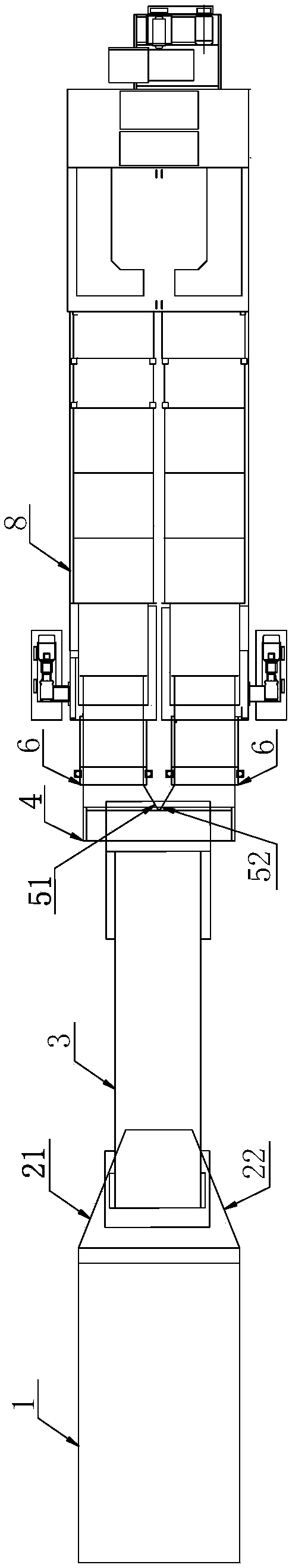

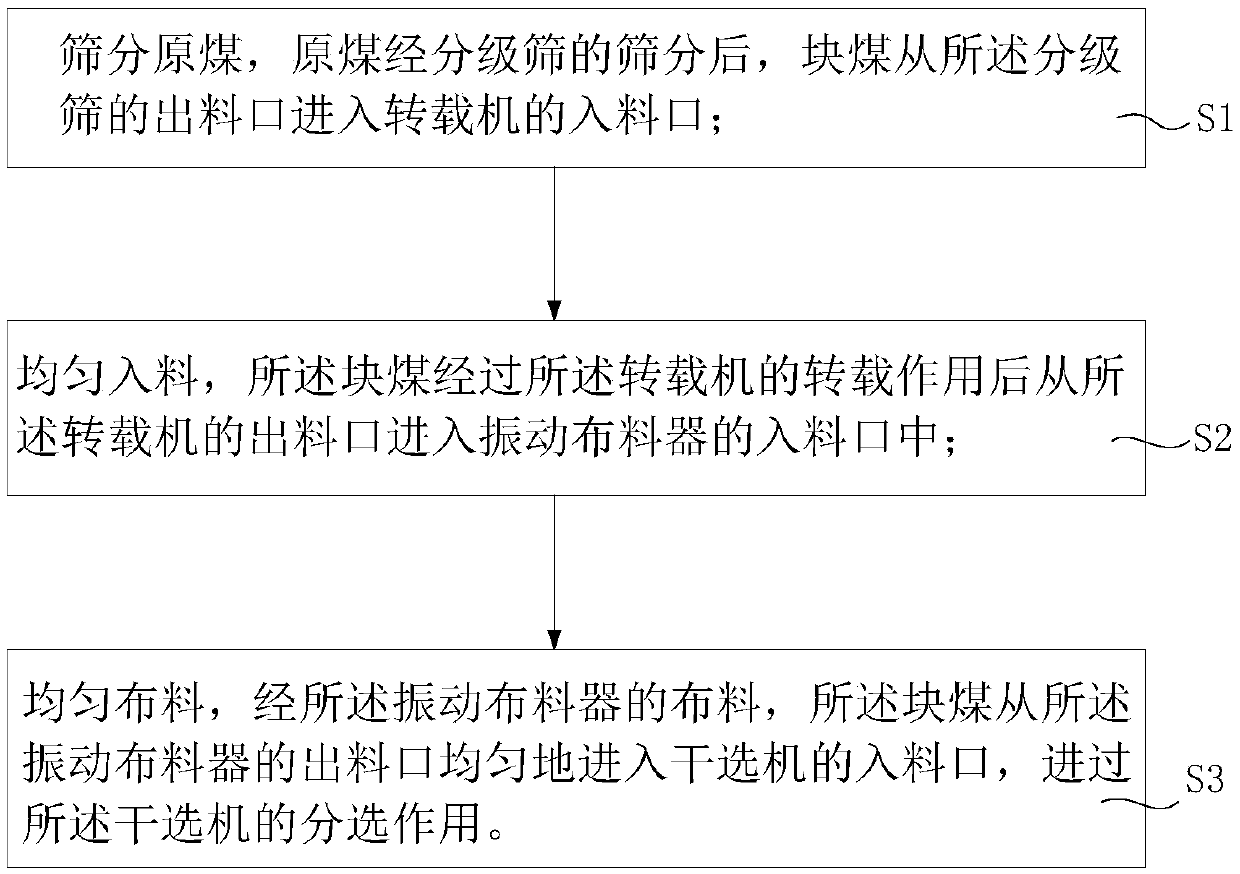

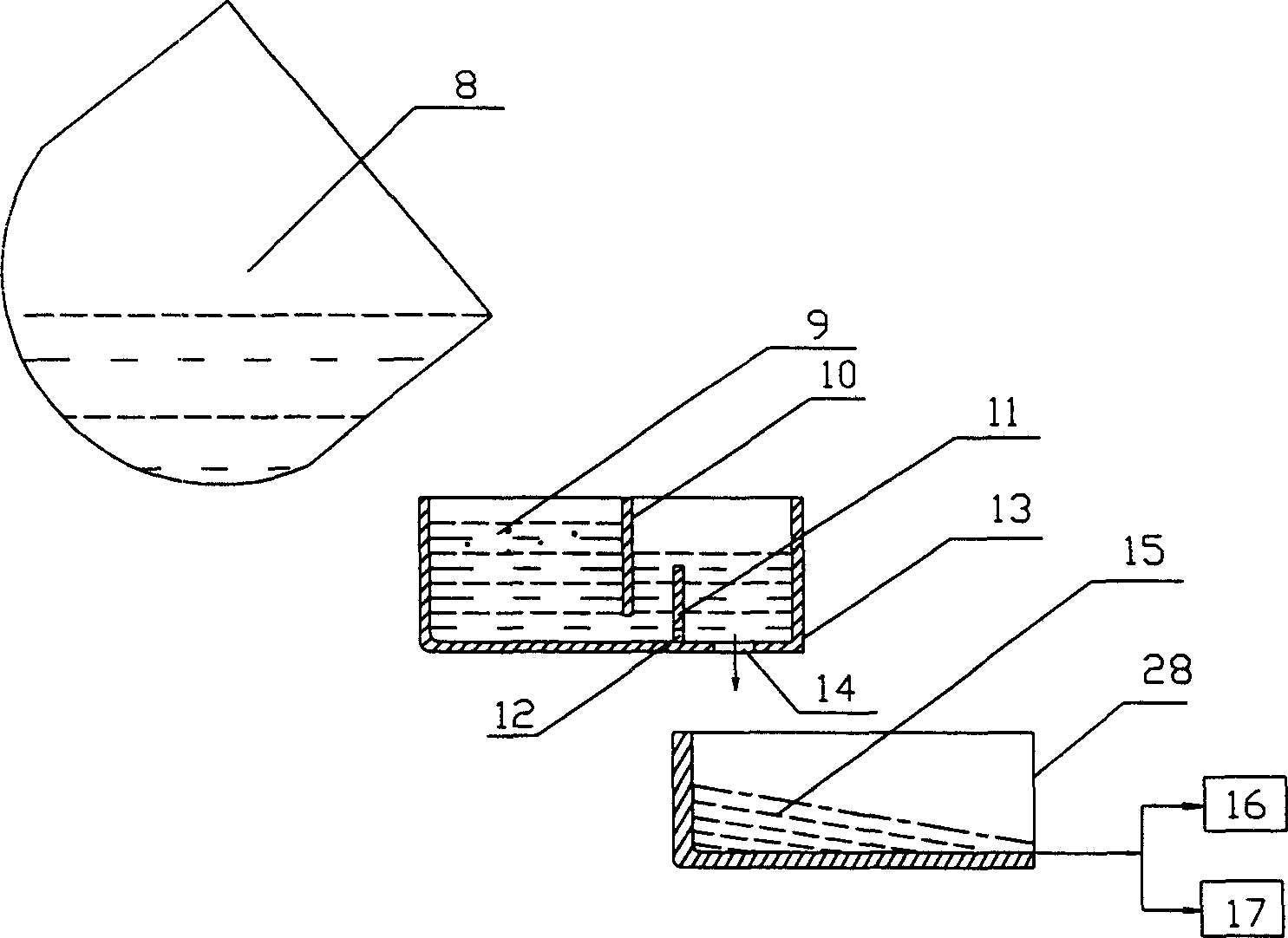

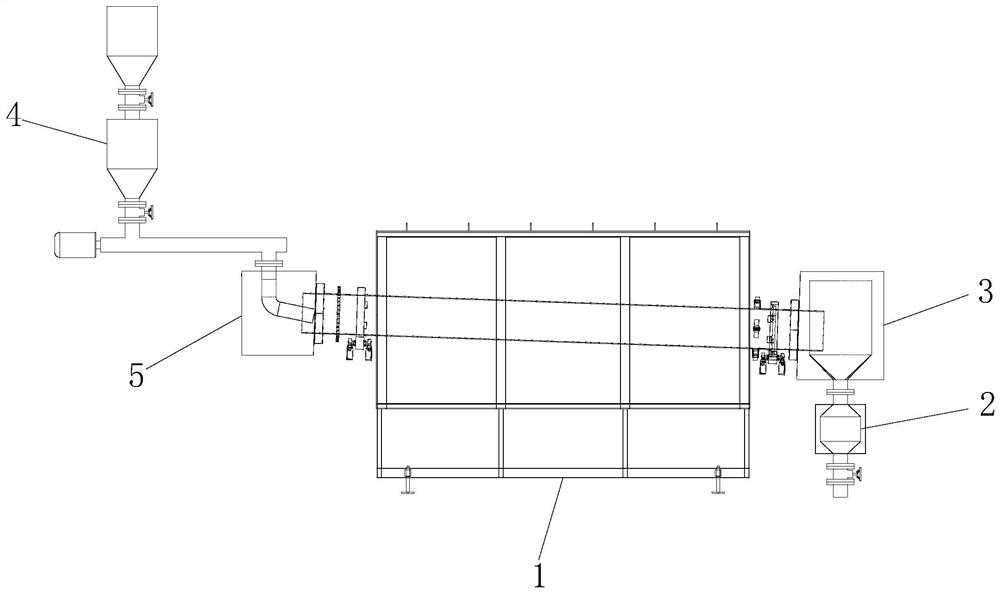

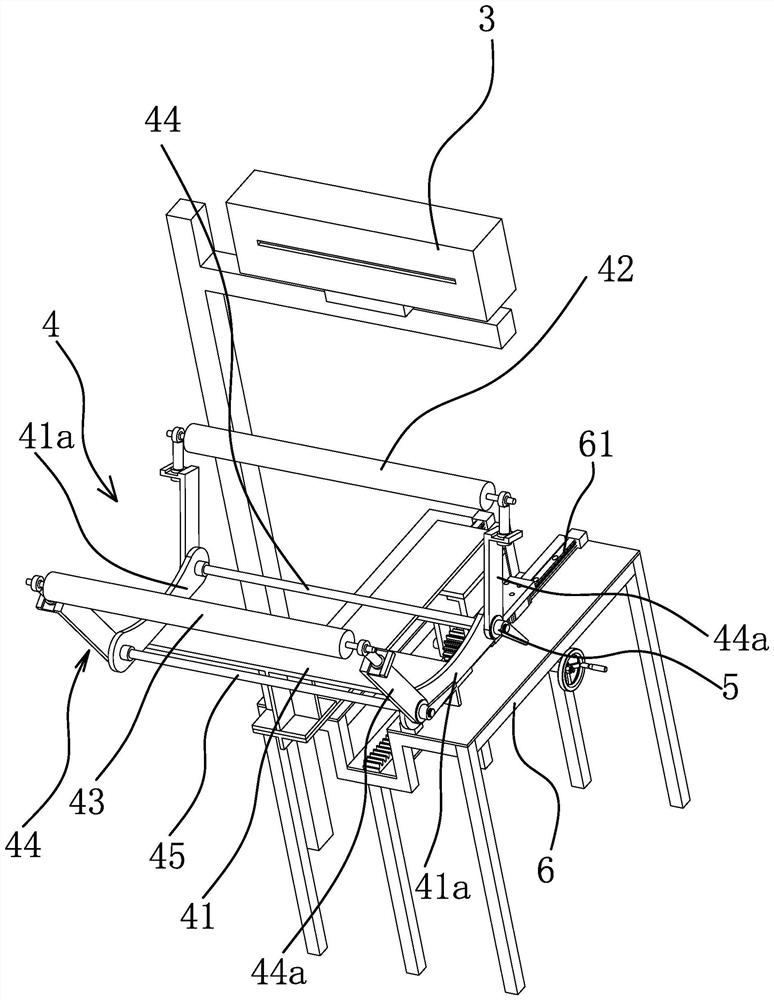

Dry separator feeding device and feeding method

InactiveCN109675792AFlexible feedingUniform and stable feedingSievingScreeningEngineeringMechanical engineering

The invention discloses a dry separator feeding device and feeding method. The dry separator feeding device comprises a grading sieve, and further comprises a reversed loader and a vibrating distributing device. A feeding opening of the reversed loader communicates with a discharging opening of the grading sieve. A feeding opening of the vibration distributing device communicates with a discharging opening of the reversed loader. A discharging opening of the vibrating distributing device is used for communicating with a feeding opening of a dry separator. The dry separator feeding method is used for feeding by the dry separator feeding device. By means of the dry separator feeding device and feeding method, the arrangement flexibility of the grading sieve and dry separator is improved, rawcoal is uniformly laid on the dry separator, and the sorting precision and sorting effect of the dry separator are improved.

Owner:CHINA SHENHUA ENERGY CO LTD +2

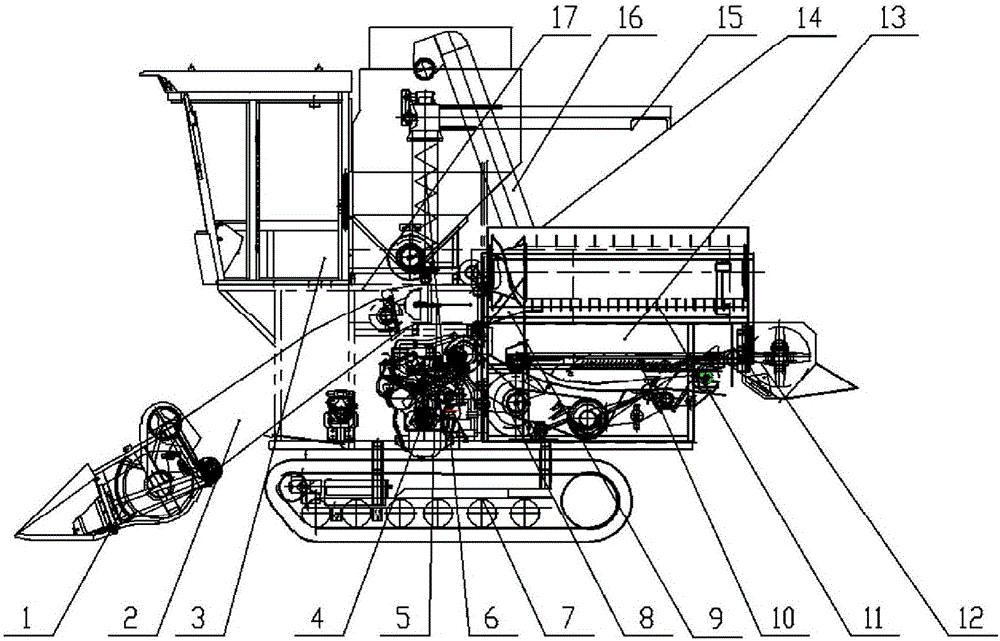

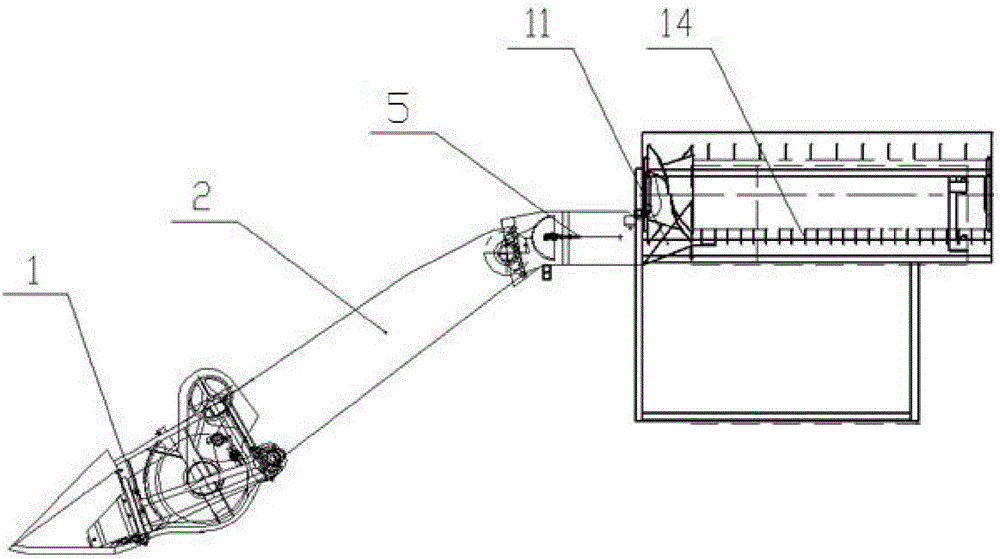

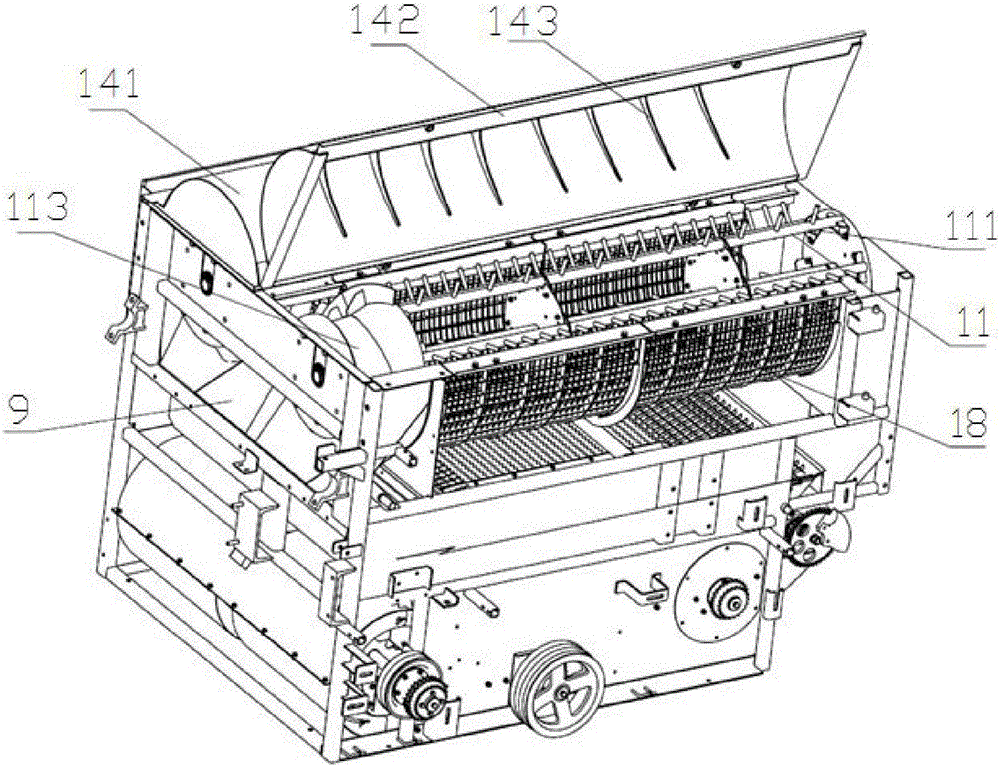

Grain combine harvester

The present invention provides a grain combine harvester comprising a header body, a chassis, a first bridge, a threshing chamber and threshing rollers. The header body is arranged at the front end of the chassis, the threshing chamber is arranged at the rear end of the chassis, the header body communicates with the threshing chamber by the first bridge, the threshing rollers are arranged in the threshing chamber, the first bridge is connected with the threshing rollers by a second bridge, and the first bridge is hinged to the second bridge. The grain combine harvester adopts double bridges and double threshing rollers and combines a crawler chassis to provide the grain combine harvester with large feed amount, fast harvesting speed, high efficiency of threshing and selection and good universality by reasonable layout and matching.

Owner:ZOOMLION HEAVY MASCH CO LTD

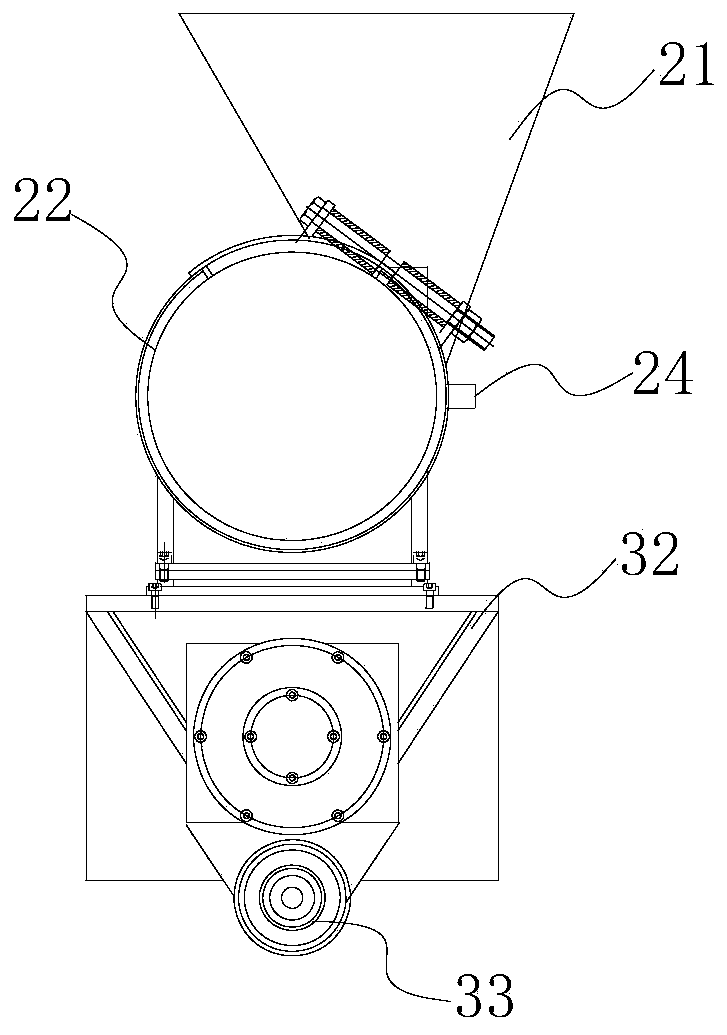

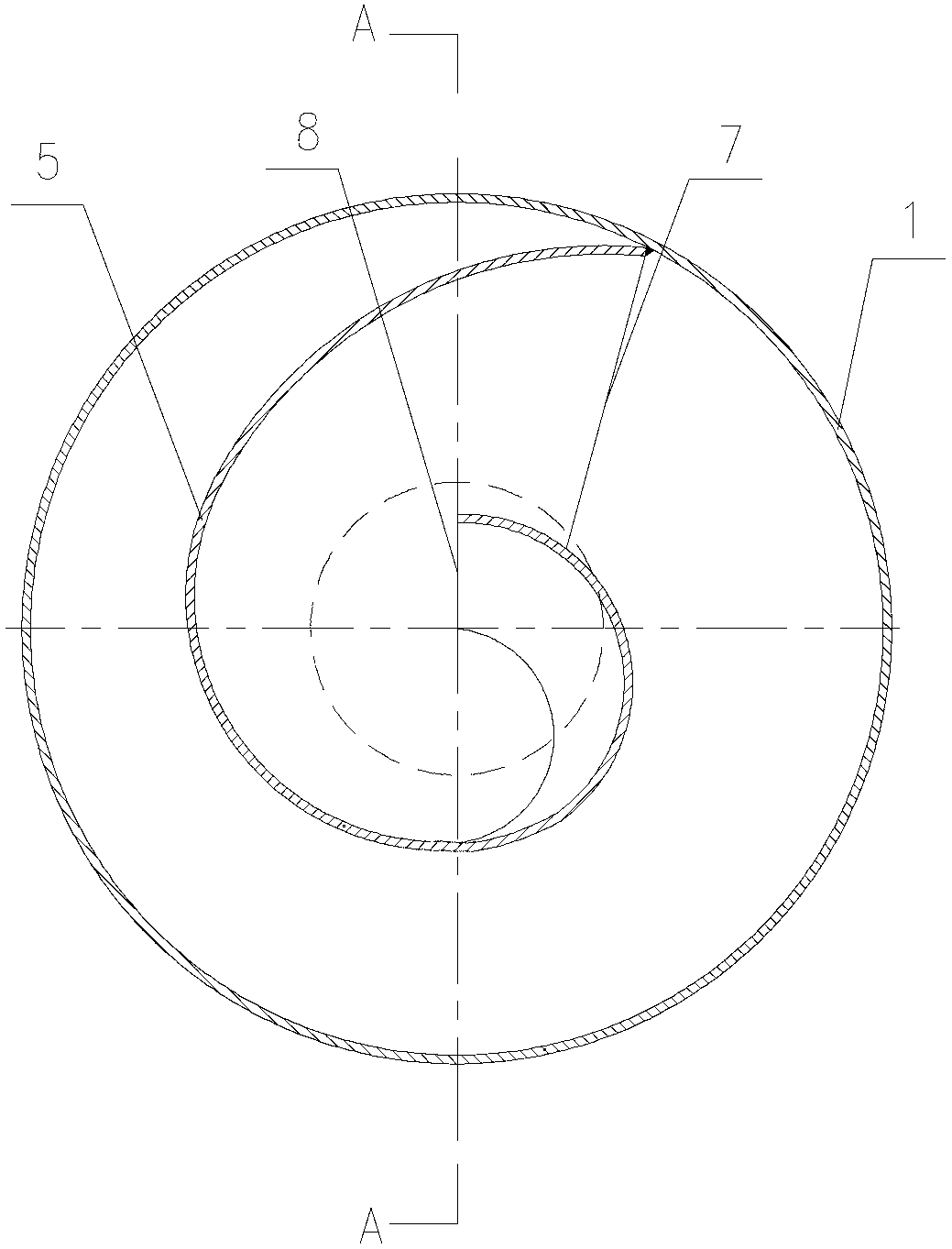

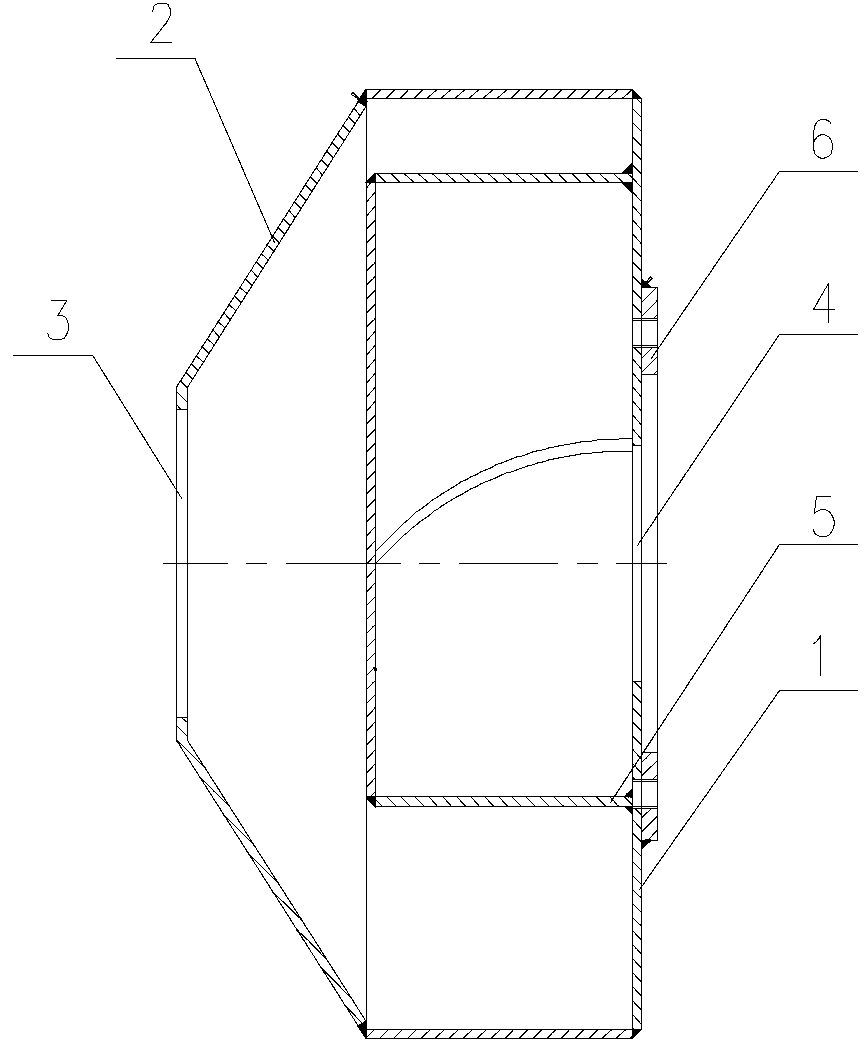

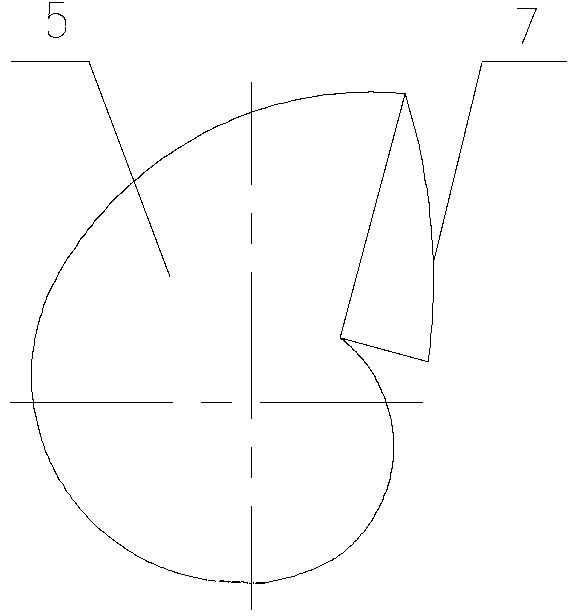

Drum-shaped material feeder for center transmission ball grinder

The invention relates to a drum-shaped material feeder for a center transmission ball grinder. The drum-shaped material feeder comprises a material feeding body, wherein a material feeding cover is fixed on the top of the material feeding body; a material inlet is formed in the material feeding cover; a material outlet is formed in the bottom of the material feeding body; a drum-shaped material feeding plate is arranged between the material inlet and the material outlet; the start end of the drum-shaped material feeding plate is internally tangent to the inner wall of the material feeding body; the tail end of the drum-shaped material feeding plate is connected with the material outlet; a channel between the start end and the tail end is helical, and the size is gradually reduced. According to the drum-shaped material feeder for the center transmission ball grinder, the drum-shaped material feeding plate is arranged in the material feeding body, so that the design is unique and novel; the manufacturing is simple and convenient and low in cost; the ore feeding amount is large; materials are uniformly and steadily fed; impact to the ball grinder is low; the service life of the ball grinder is prolonged.

Owner:CHANGZHOU KEYE MINING MACHINERY

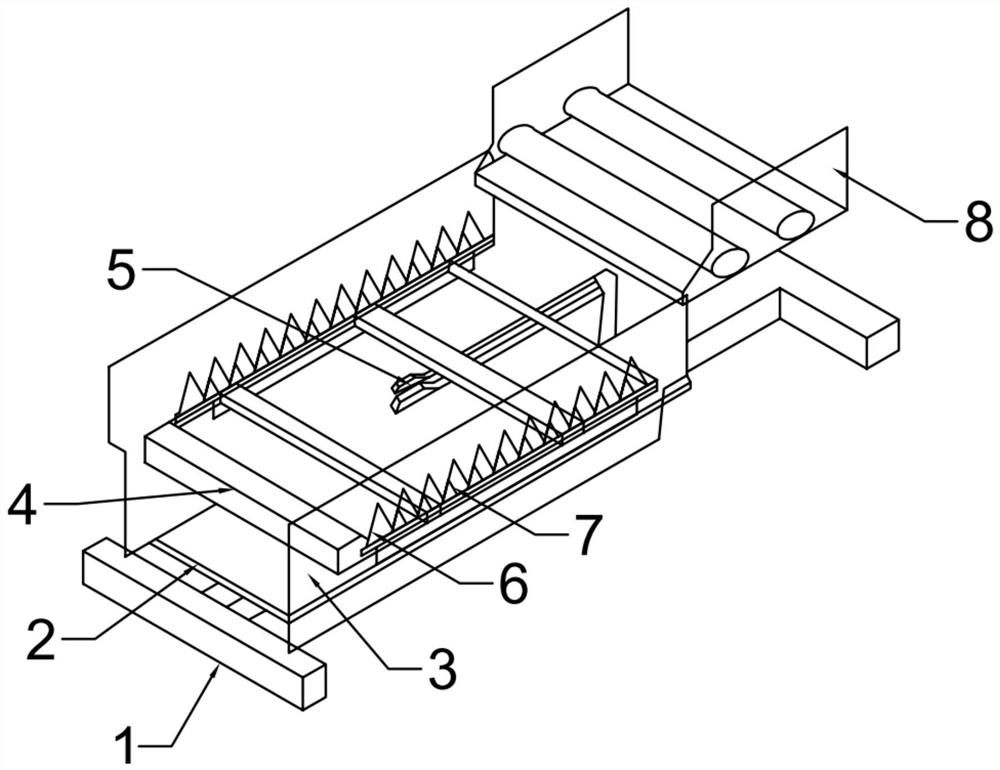

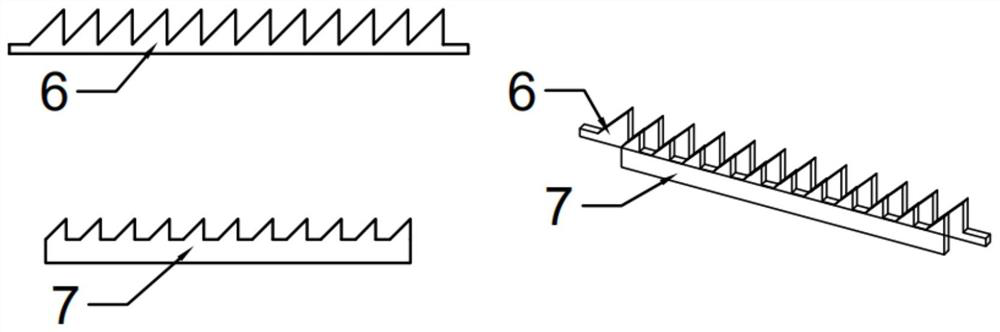

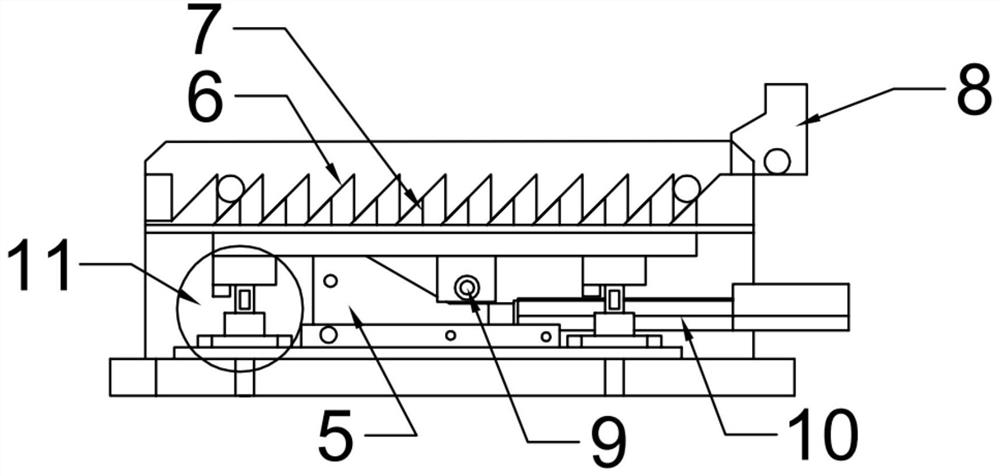

Stepping type feeding device for machining

The invention relates to the technical field of machining conveying, and discloses a stepping type feeding device for machining. The stepping type feeding device comprises a base and a bottom plate, wherein baffles are fixedly connected to the left side and the right side of the bottom plate; supporting frames are fixedly connected to the inner sides of the baffles and are located above the bottomplate; first rack plates are fixedly connected to the left ends and the right ends of the supporting frames; second rack plates are connected to the inner sides of the first rack plates in a slidingmode; a driver is movably connected to the rear end of the bottom plate; a material table is fixedly connected to the upper parts of the rear parts of the baffles; sliding blocks are fixedly connectedto the middle parts of the lower ends of the second rack plates; a transmission shaft is connected to the right end of the driver in a sliding mode; and an air cylinder is arranged at the lower endsof the second rack plates. According to the feeding device, workpieces can be uniformly and stably fed; and in the moving, feeding and conveying process of the workpieces, the workpieces cannot collide with one another, so that the damage to the surfaces of the workpieces is avoided, and the influence on the next step of machining of the workpieces is avoided.

Owner:徐江涛

Manufacturing method of roller brush capable of supplying coating continuously

InactiveCN103721910AEasy to prepareSimple structureLiquid surface applicatorsCoatingsPlastic materialsPolyvinyl chloride

The invention discloses a manufacturing method of a roller brush capable of supplying coating continuously. The method comprises the steps as follows: A, a plurality of steel angle iron and stainless steel plates are selected and welded into a feed trolley body, the stainless steel plates are welded to the upper part of the feed trolley body to produce a material storage bin, a control box is arranged on one side of the material storage bin, a power supply box is arranged at the lower part of the control box, a pump case is arranged at the lower part of the material storage bin, travelling wheels are welded to the bottom of the feed trolley, and a bin cover is in threaded connection with the upper part of the storage bin; and B, a material convey pipe is inserted and connected to one side outside the pump case, a handle is inserted and connected to the other end of the material convey pipe, a material convey switch is mounted at the upper part of the handle, a roller brush frame is inserted and connected to the upper part of the material convey switch, a rolling wheel is nested and fixed on the roller brush frame and adopts any of rubber, PVC (polyvinyl chloride) or a plastic material, a liquid outlet pipe is arranged in the rolling wheel, and a brush is nested and fixed outside the rolling wheel. The manufacturing method of the roller brush capable of supplying coating continuously has the advantages that the manufacturing method is simple; and a manufactured product is simple in structure, high in strength, uniform and stable in material supplying, time-saving and labor-saving, secondary pollution is reduced, and raw materials are saved.

Owner:刘成涛

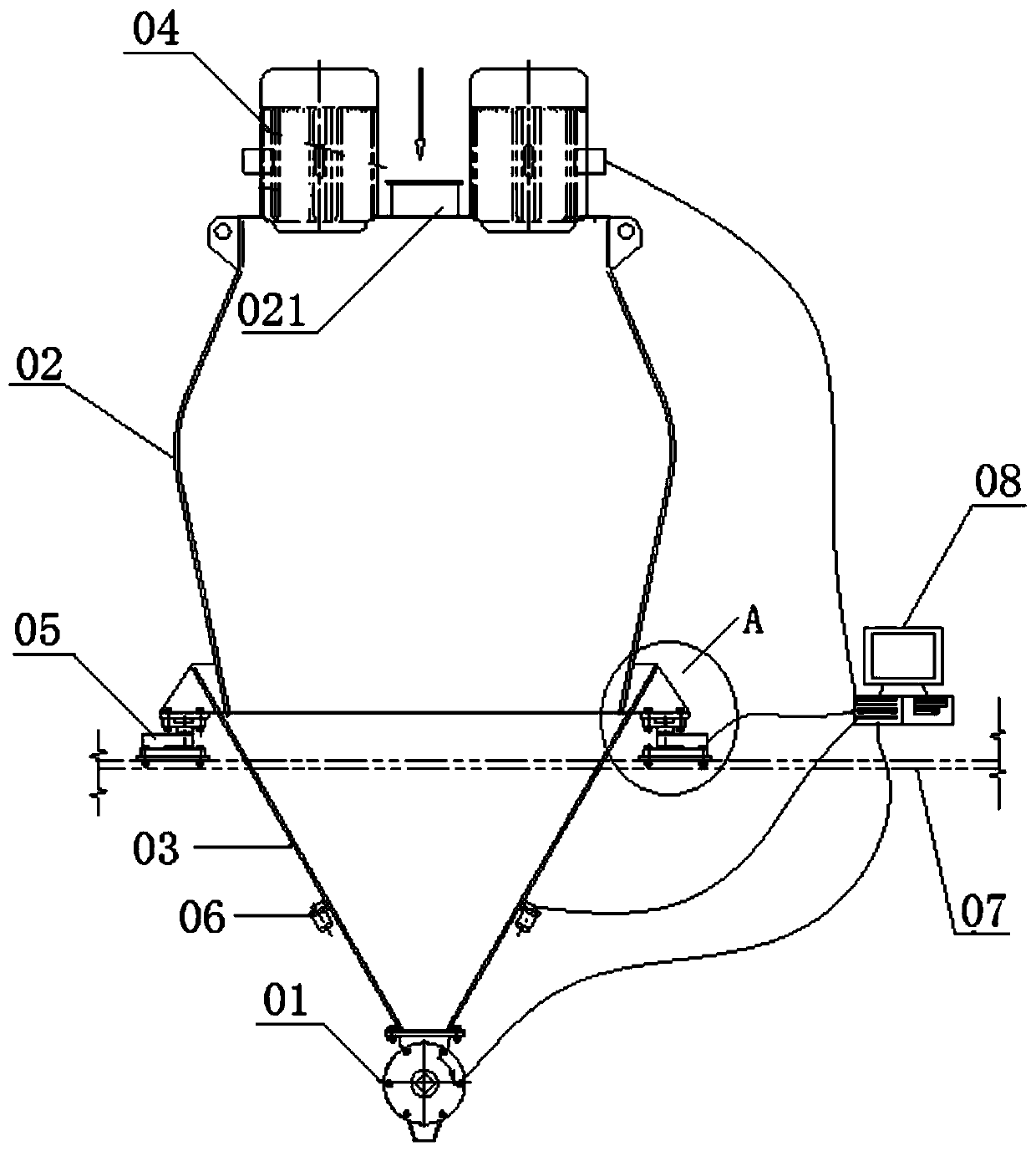

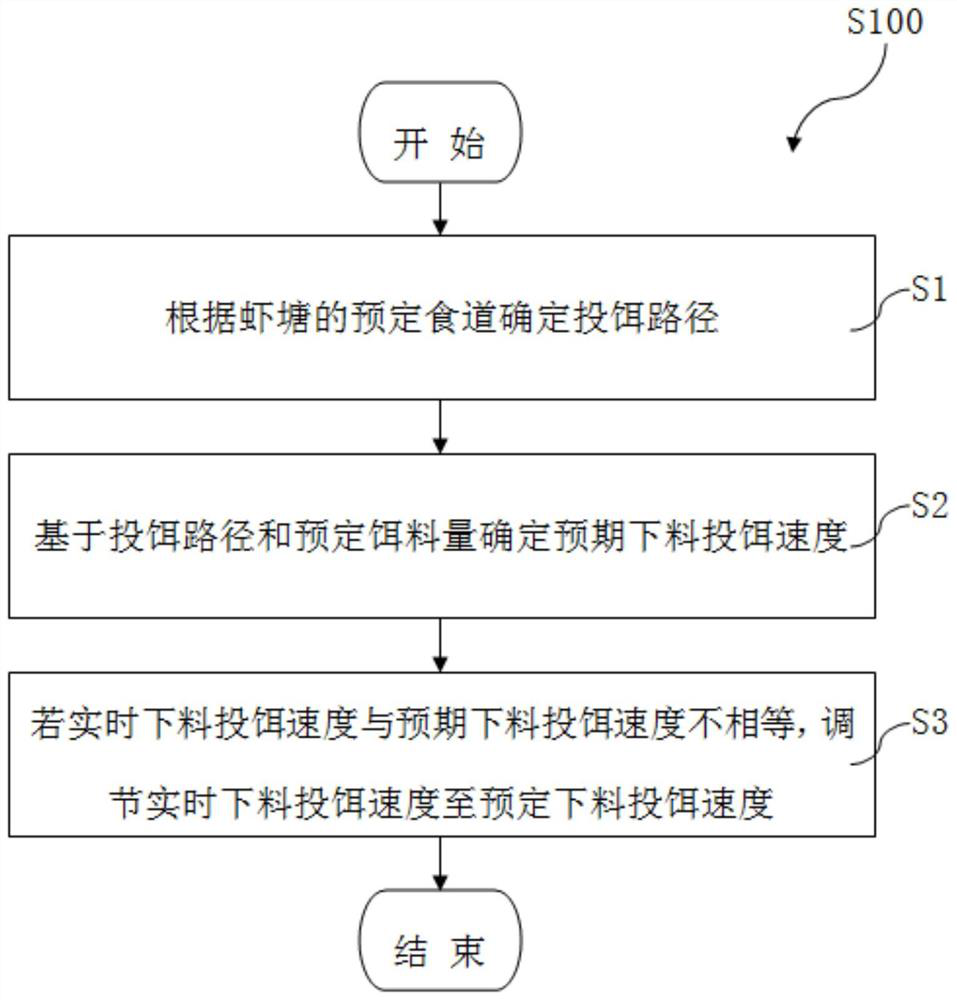

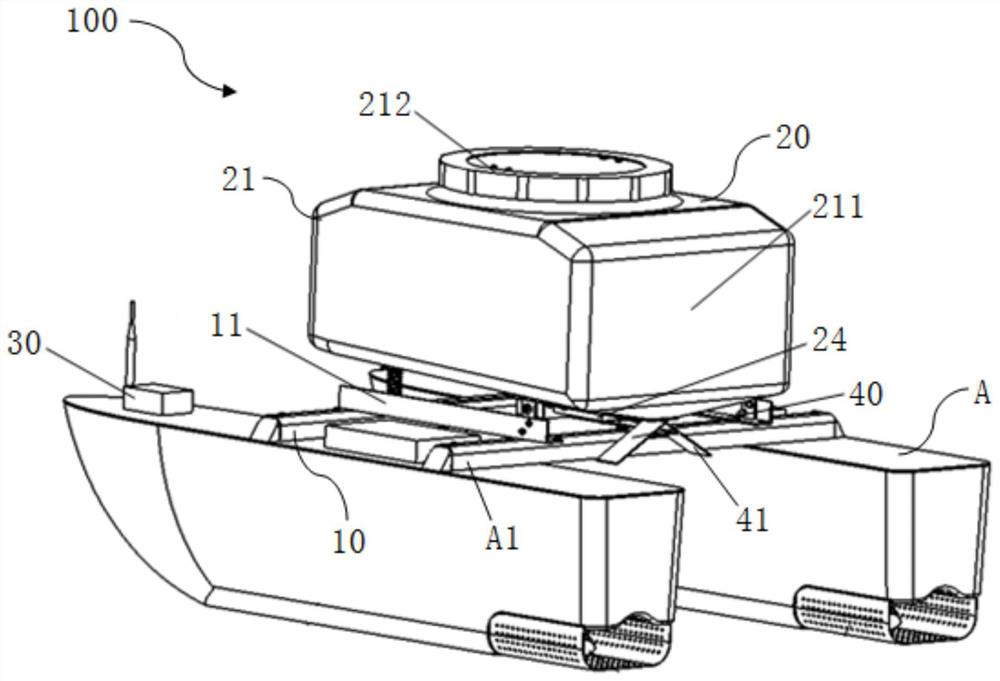

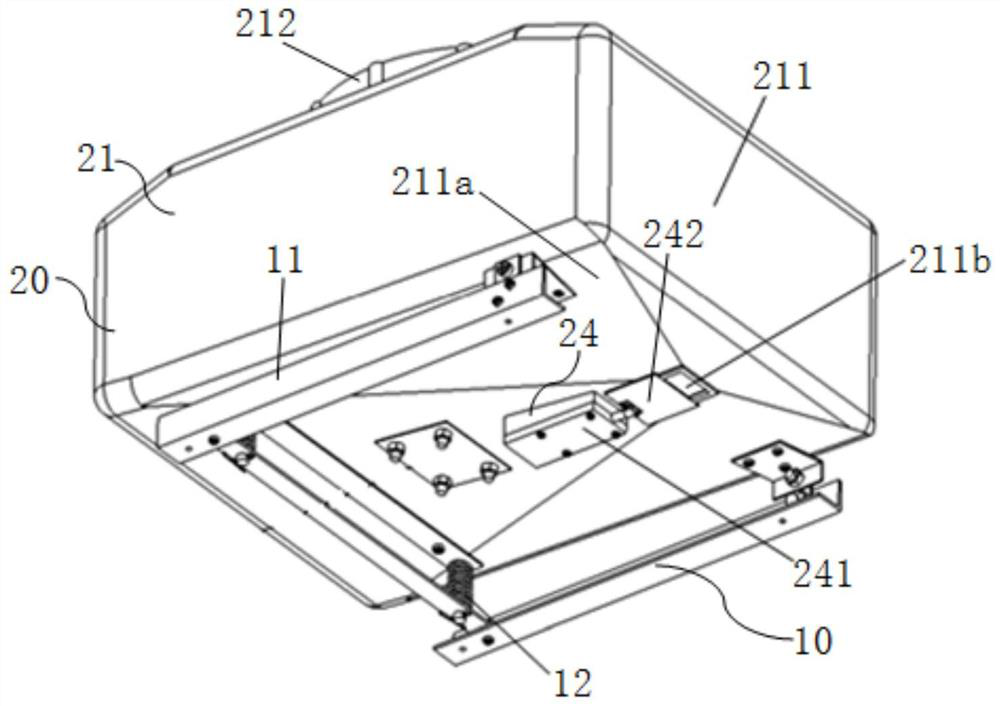

Shrimp pond bait feeding method, control module and device

PendingCN113261523ASimple structureReduce broken rateClimate change adaptationPisciculture and aquariaMechanical engineeringShrimp culture

The invention belongs to the field of shrimp culture, and discloses a shrimp pond bait feeding method. The feeding method can realize uniform and accurate bait feeding in a shrimp pond, monitors whether the real-time discharging and feeding speed on a feeding path is equal to the expected discharging and feeding speed or not, and adjusts the real-time discharging and feeding speed to the preset discharging and feeding speed if the real-time discharging and feeding speed is not equal to the expected discharging and feeding speed. The invention further discloses a shrimp pond bait feeding control module and device, in particular to a shrimp pond bait feeding device. The shrimp pond bait feeding method can be well and automatically implemented, the structure is simple, use is convenient, the shrimp pond bait feeding device is arranged on a catamaran and comprises a connecting assembly, a bait feeding unit and a bait feeding control module, the bait feeding unit comprises a bait box, an electric push rod and an opening plate, the bottom of the bait box is of a bucket-shaped structure, a bait feeding opening is formed in the bottommost part of the bait box, the electric push rod is arranged on the outer surface of the bottom of the bait box, and when the electric push rod acts, the opening plate closes or opens the bait feeding opening.

Owner:SHANGHAI OCEAN UNIV

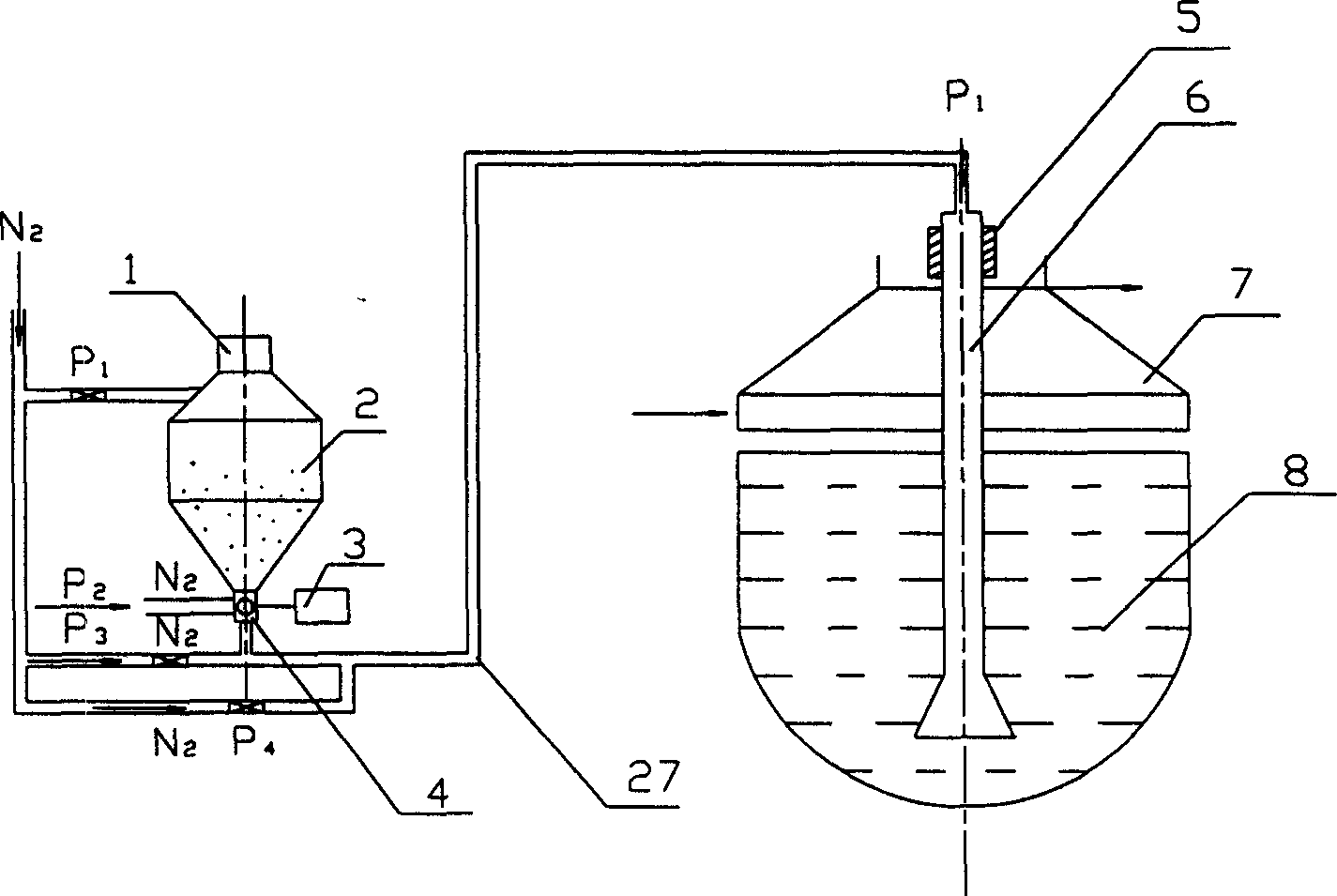

Molten iron desulfurizing method

The improved molten iron desulfurizing process outside blast furnace includes spraying deactivated magnesia grains as desulfurizing agent via high-precision automatically regulating material feeding mode; desulfurizing in the molten iron ladle with water cooling hood to prevent adhesion of desulfurizing dross and molten iron; slag-iron separation in the same separator and feeding pure molten ironinto pig iron mixer or molten iron ladle. The said process has the features of less investment, simple process, low production cost and easy maintenance.

Owner:NANJING NANGANG IND DEV CO LTD

Quantitative feeder for powdery or micro-granular solids

ActiveCN110937415AControl the dosageAvoid cloggingRotary stirring mixersLoading/unloadingElectric machineProcess engineering

The invention discloses a quantitative feeder for powdery or micro-granular solids. The feeder comprises a raw material container, wherein discharging holes are formed in the lowest end of the raw material container, a rotating shaft is arranged at the axial line of the raw material container, a stirring blade is connected at the lower part of the rotating shaft, an electromagnet is arranged at the upper part of the rotating shaft, the top of the rotating shaft is fixedly connected with an iron core rod extending from the lower part of the electromagnet, the electromagnet is connected with a power supply, a motor is arranged above the electromagnet, the protruding part at the top of the iron core rod is movably connected with an output shaft of the motor, and the iron core rod drives the rotating shaft to move up and down under the magnetic force action of the electromagnet. The feeder can realize the control over the feeding quantity of raw materials only by controlling the power to be on and off and can keep the raw materials in a loose state all the time due to the introduction of the stirring effect, the discharging is uniform and stable, and the situations of caking and material blocking cannot occur; and meanwhile, the phenomenon of blocking, caused by moisture, of the discharging holes can also be prevented, in this way, the adding quantity of the raw materials can be controlled by controlling the length of the adding time, and by means of the mode, the control is more accurate and convenient, and the practical popularization is facilitated.

Owner:陈之中

Method for using continuous paint feeding roller brush

The invention discloses a method for using a continuous paint feeding roller brush. The method comprises the following steps that A, a cabin cover is firstly opened, mixed paint raw materials are poured in a storage cabin, and the cabin cover is closed; B, a power source on a control box is started, so that the power source in a power box supplies electricity to a pump in a pump box, the pump starts to operate, the paint raw materials in the storage cabin are pumped to a delivery pipe; C, a delivery switch on a handle is controlled, the paint raw materials are pumped into a cavity in a roller brush support, made to reach a cross bar at the top of the roller brush support along the roller brush support and enter liquid outlet pipes in a roller wheel and guided to the inner portion of a brush body by the liquid outlet pipes and the brush body is made to be soaked by the paint; D, the roller brush support is controlled by the handle so that the brush body outside the roller wheel can be tightly attached to a painted wall. The method has the advantages that the method is simple, the used products are simple in structure, the strength is high, material feeding is even and stable, time and labor are saved, secondary pollution is reduced, and raw materials are saved.

Owner:刘成涛

Atmosphere-controllable rotary kiln and implementation method thereof

PendingCN112146433AEvenly heatedAvoid lumpsRotary drum furnacesMaintainance of heating chambersProcess engineeringContinuous flow

The invention discloses an atmosphere-controllable rotary kiln which comprises a rotary kiln body. The rotary kiln body comprises a furnace tube; stirring strips are arranged on the inner wall of thefurnace tube; a feeding mechanism is arranged at the feeding end of the rotary kiln body; a discharging mechanism is arranged at the discharging end of the rotary kiln body; the joint of the rotary kiln body and the feeding mechanism is sleeved with a kiln opening inert gas protection device; and the joint of the rotary kiln body and the discharging mechanism is sleeved with a kiln tail inert gasprotection device. The invention further discloses an implementation method of the controllable-atmosphere rotary kiln. According to the atmosphere-controllable rotary kiln and the implementation method thereof provided by the invention, the stirring strips are arranged on the inner wall of the furnace tube and can indirectly drive powder to be stirred along with the rotation of the furnace tube,so that the powder is in a continuous flowing state in the furnace tube, the whole powder is heated more uniformly, the agglomeration of the powder is avoided, the contact surface of the powder and reaction gas in the kiln is increased, the reaction is more sufficient, and the reacted powder has high purity and few impurities.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

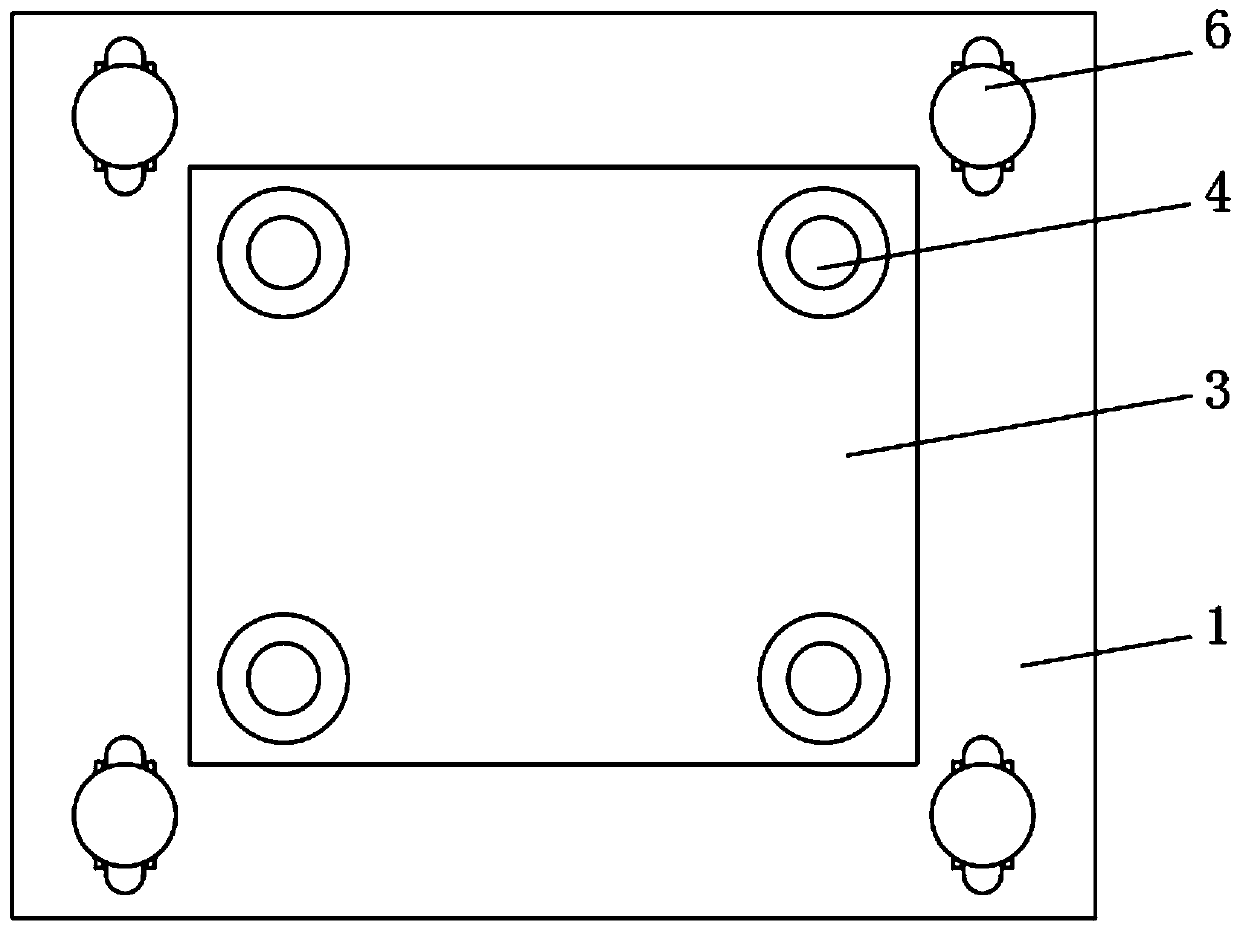

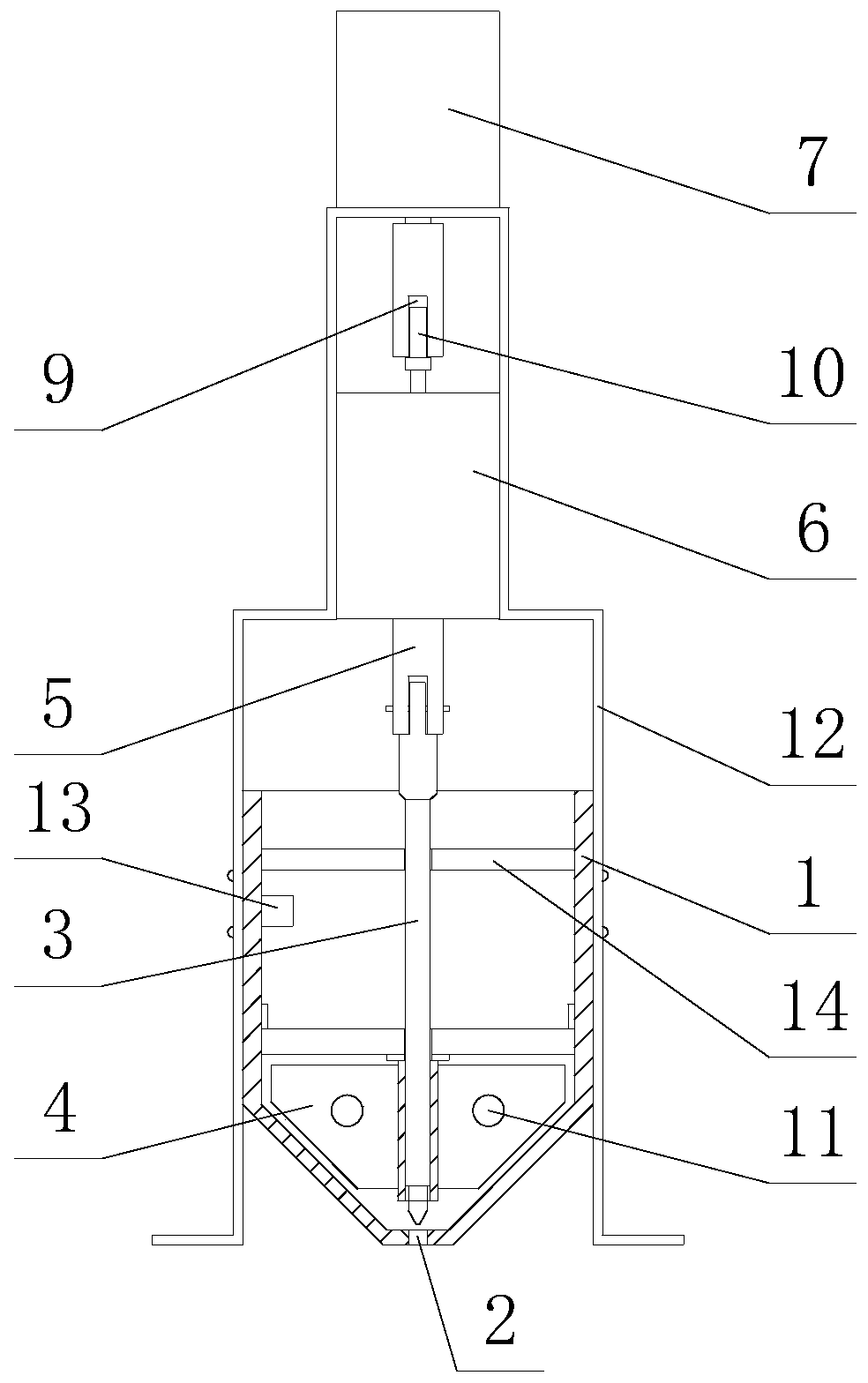

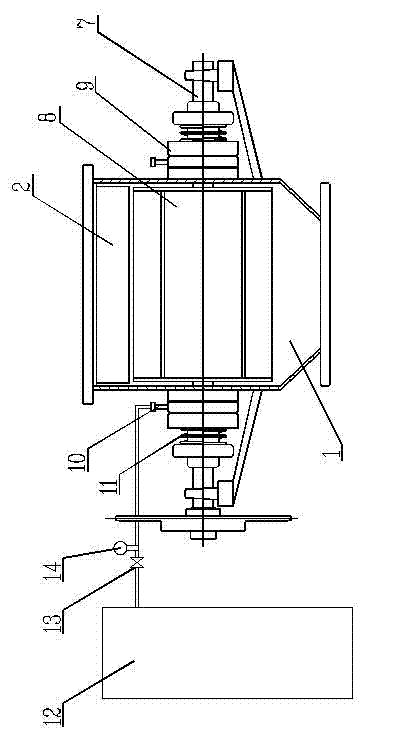

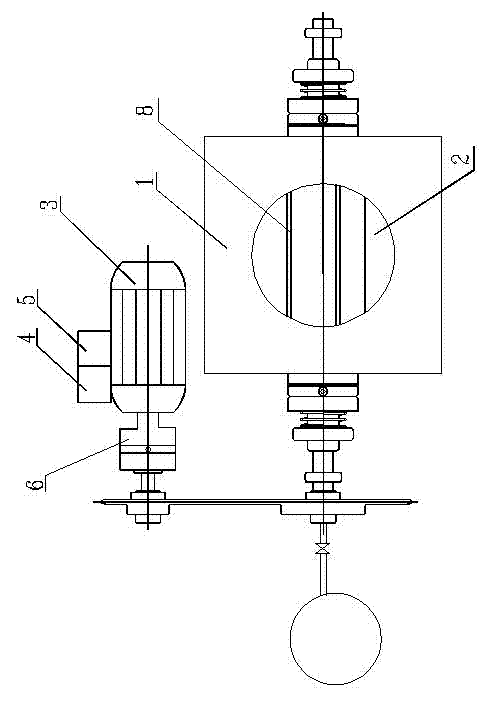

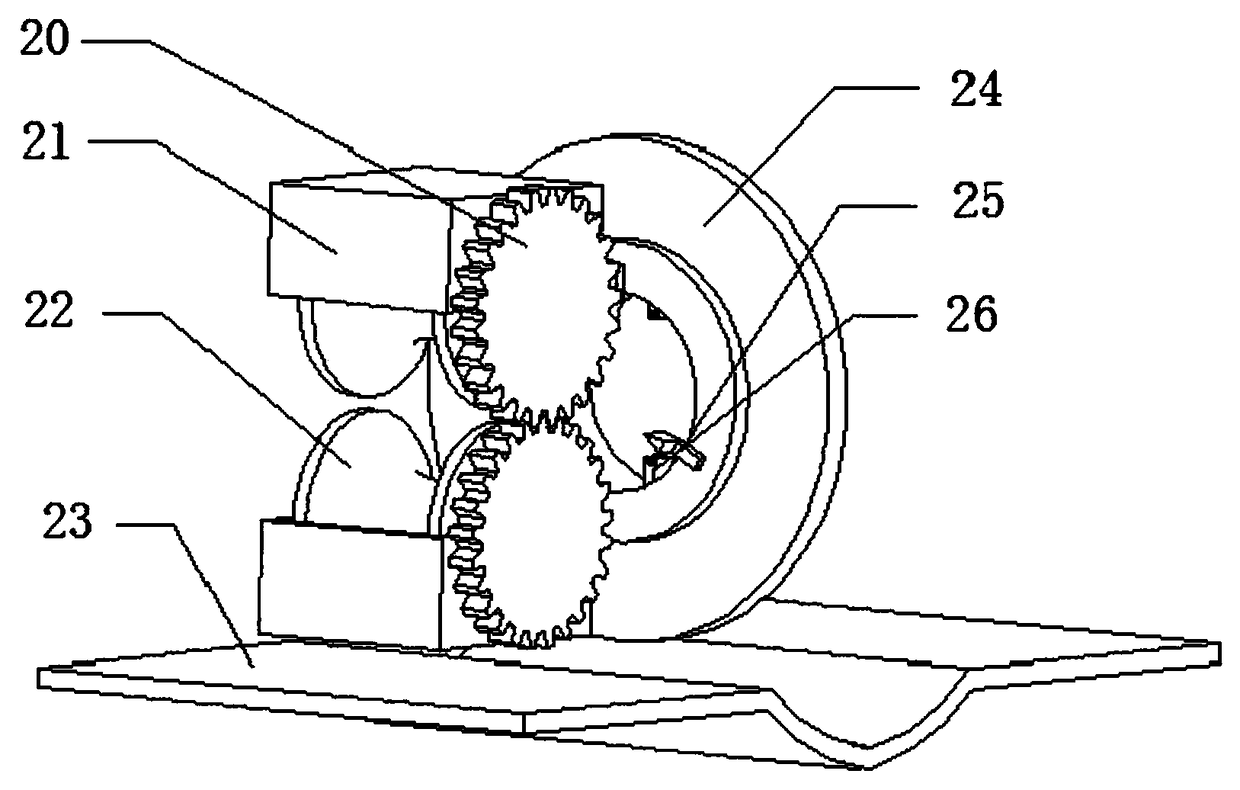

Powdery material metering and feeding device

The invention provides a powdery material metering and feeding device. In the chemical production process, a powdery material feeding device has the problems that an impeller of the device is usually deadly blocked in the running process of a system, so that the device is stopped by failure, the sealing property of a shaft end of a rotating shaft is poor, and the like. The powdery material metering and feeding device comprises a shell (1) which is internally provided with an anti-blocking baffle (2); a motor is arranged above the shell at the right side; the motor is provided with a frequency converter (4) and a positive and negative rotation switching device (5); the motor is linked with a speed reducer (6); the speed reducer is used for driving a rotating shaft (7) by driving a chain; and the rotating shaft is provided with an impeller (8). The powdery material metering and feeding device is used for feeding during chemical production.

Owner:南京荣欣化工有限公司

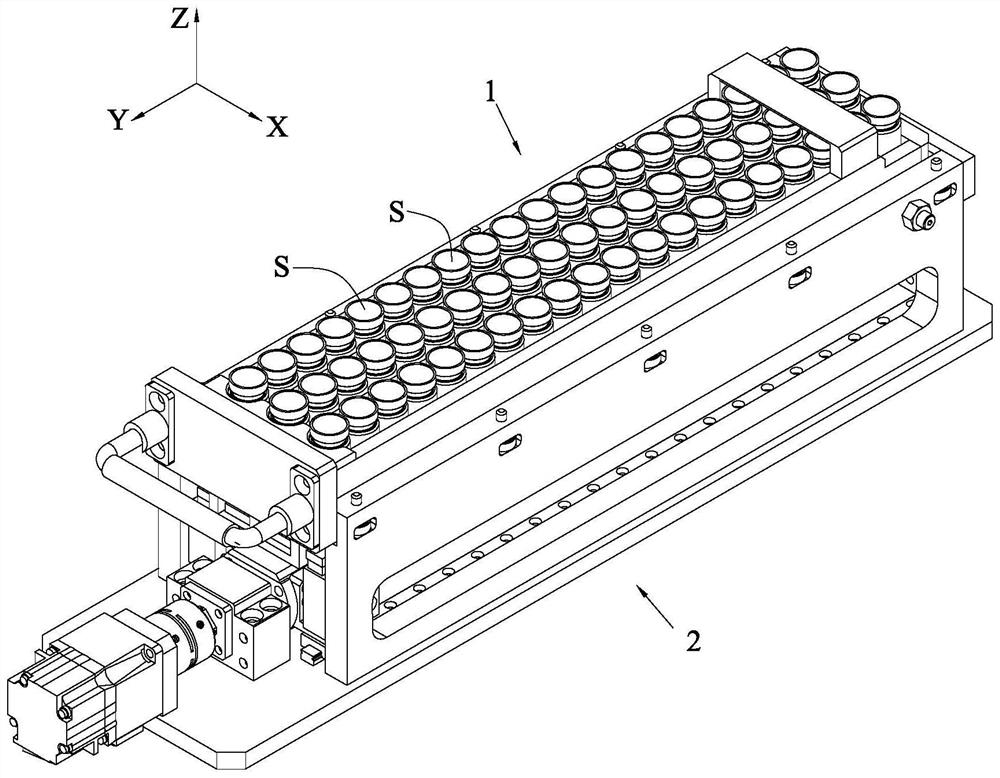

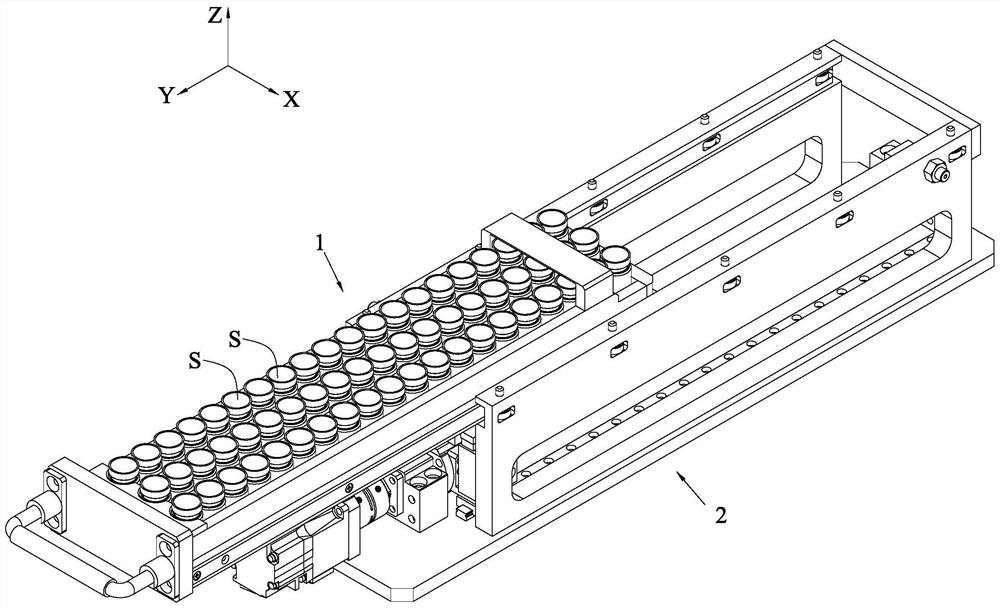

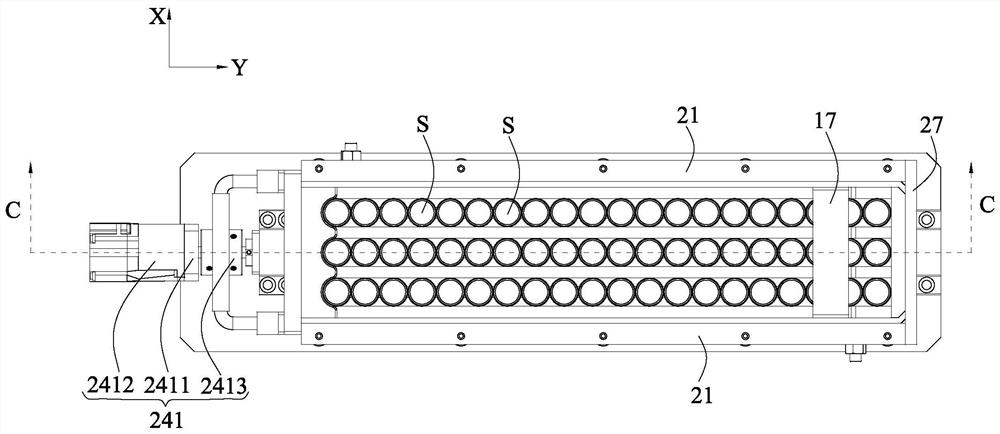

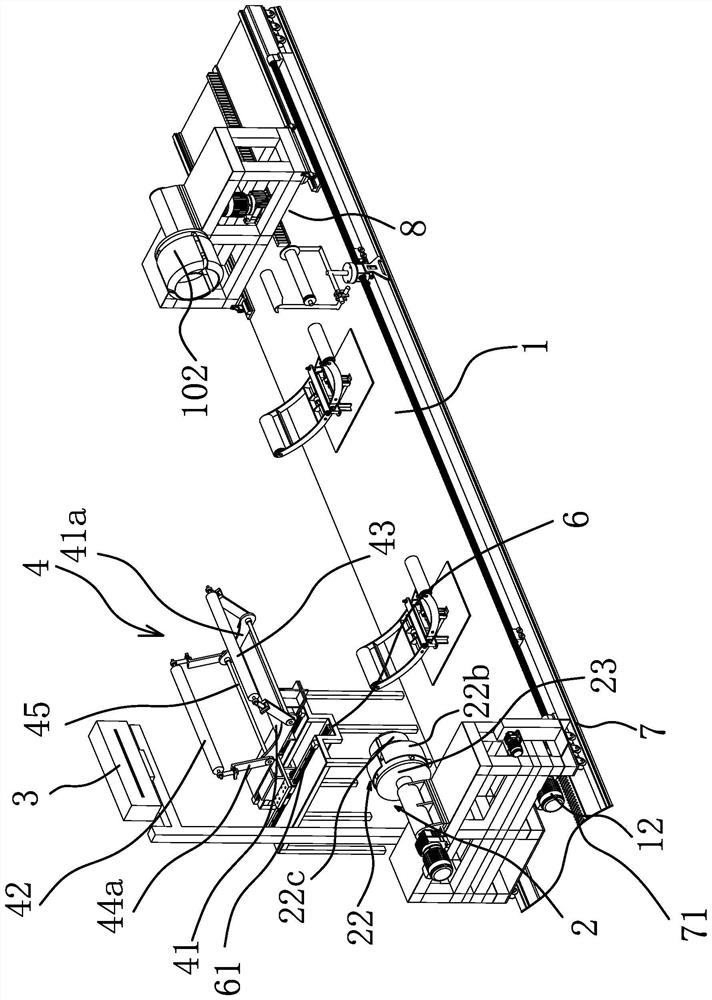

Full-automatic feeding device

ActiveCN113415617AUniform and stable feedingEfficient feeding processConveyor partsClassical mechanicsStructural engineering

Owner:华科智谷(上海)科技发展有限公司

Outer coating layer feeding mechanism of FRPP three-layer wall reinforced pipe production equipment

The invention provides an outer coating layer feeding mechanism of FRPP three-layer wall reinforced pipe production equipment, and belongs to the technical field of FRPP three-layer wall reinforced pipe production equipment. The problem that an outer coating layer of an existing three-layer-wall reinforced pipe is not uniform in coating is solved. The outer coating layer feeding mechanism of the FRPP three-layer wall reinforced pipe production equipment comprises a dragging plate capable of transversely moving, a movable die head and a fixed die head which directly face each other in the transverse direction and can be located with the two ends of a pipe blank respectively are arranged on the dragging plate, an extruder is arranged on one side of the dragging plate, and the fixed die head comprises a rotatable seat body and a cylindrical supporting piece connected to the seat body. The supporting piece is provided with a small-caliber end capable of supporting the inner wall of the pipe blank and a large-caliber end capable of containing the outer coating layer, the diameter of the large-caliber end is larger than that of the small-caliber end, and the small-caliber end is located at the end close to the movable die head. According to the outer coating layer feeding mechanism of the FRPP three-layer wall reinforced pipe production equipment, the feeding uniformity and stability of the outer coating layer are improved, and the feeding quality of the outer coating layer is further improved.

Owner:YONGGAO CO LTD +1

Automatic processing technology and system for pretreatment of Chinese herbal medicines

ActiveCN103637911BUniform flowUniform and stable feedingPharmaceutical product form changeAutomatic controlControl system

Disclosed is an automatic processing technology and system for traditional Chinese medical material pre-processing. The processing technology sequentially comprises the procedures of unpacking, clean selecting, washing, medicine infiltrating, cutting, drying and box packaging or bagging. All the procedures are connected through a belt conveyor or a feeding machine or a vibration conveyor or material separating equipment. An automatic control system is used for controlling processing equipment in all links of the processing technology and automatic continuous production is realized. According to the automatic processing technology and system, an assembly line production mode is adopted, all main procedures in the current traditional Chinese medicine pre-processing process are connected organically through conveying equipment, caching conveying equipment and the material separating equipment, an automatic detecting technology and an automatic control technology are adopted to conduct real-time detection and control on the production process, the degree of automation of traditional Chinese medicine pre-processing is greatly improved, the labor intensity of workers can be lowered, the processing environment can be improved and the stability of the product quality can be maintained.

Owner:云南昆船电子设备有限公司

High efficiency reaction tank

InactiveCN104437305AFlow restrictionWeight increaseChemical/physical/physico-chemical stationary reactorsImpellerBiochemical engineering

The invention discloses a high efficiency reaction tank, which comprises a tank body and a rotating shaft. The side of the tank body is provided with a feed inlet, the rotating shaft is arranged at inside the tank body, the rotating shaft is connected to at least 2 motors, the rotating shaft is provided with an impeller, the impeller consists of an upper impeller and a lower impeller, and the upper impeller and the lower impeller are 15-20cm away from the tank body. The feed inlet is provided with a distributing pipe, and the tank bottom is equipped with at least two discharge ports. During reaction operation, the rotating shaft rotates driven by the at least 2 motors simultaneously, the stirring efficiency is high, the upper impeller and the lower impeller work at the same time, so that the reaction liquid is fully stirred and mixed between the two impellers, the reaction is complete, the distributing pipe enables even and smooth feeding, thus being conducive to proceeding of reaction. With the advantages of reasonable structure, convenience and simplicity, the high efficiency reaction tank is suitable for popularization and use.

Owner:上海伟阳纸业有限公司

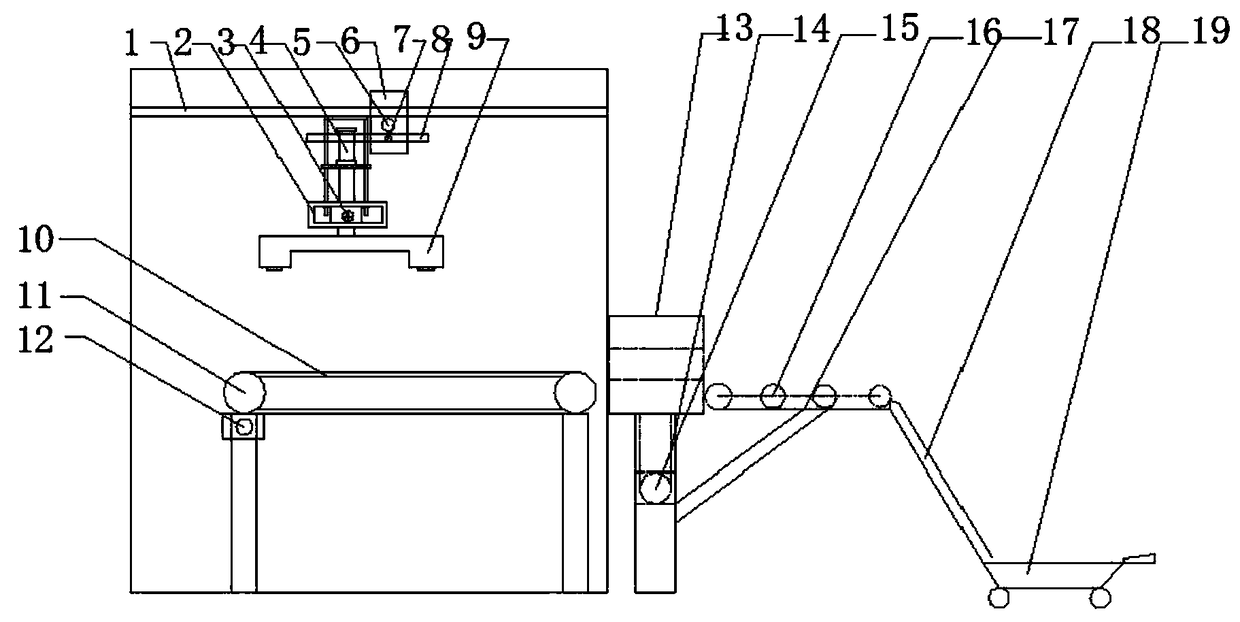

Steel pipe picking, cleaning and conveying device

ActiveCN108163539AFlexible and accurate movementUniform and stable feedingConveyorsHollow article cleaningEngineeringSteel tube

The invention relates to a steel pipe picking, cleaning and conveying device, and belongs to the field of building construction. The steel pipe picking, cleaning and conveying device is composed of apicking device, a cleaning device and a river transporting device. The picking device is provided with a fixed guide rail, a fixed guide rail sliding block, a sliding guide rail support, a sliding guide rail, a sliding guide rail sliding block, a limiting switch, an electromagnetic tong air cylinder, an electromagnetic tong servo motor, a fixed support and an electromagnetic tong structure, the cleaning device is provided with a conveying belt, a conveying belt driving wheel, a conveying belt driving motor, a cleaning main box, a transmission chain, a cleaning device driving motor, a rolling wheel and a cleaning device support mechanism, and the transporting device is provided with a trolley mechanism used for automatically stacking steel pipes. The steel pipe picking, cleaning and conveying device is scientific and reasonable in design, and automation is basically achieved.

Owner:浙江国高钢品科技有限公司

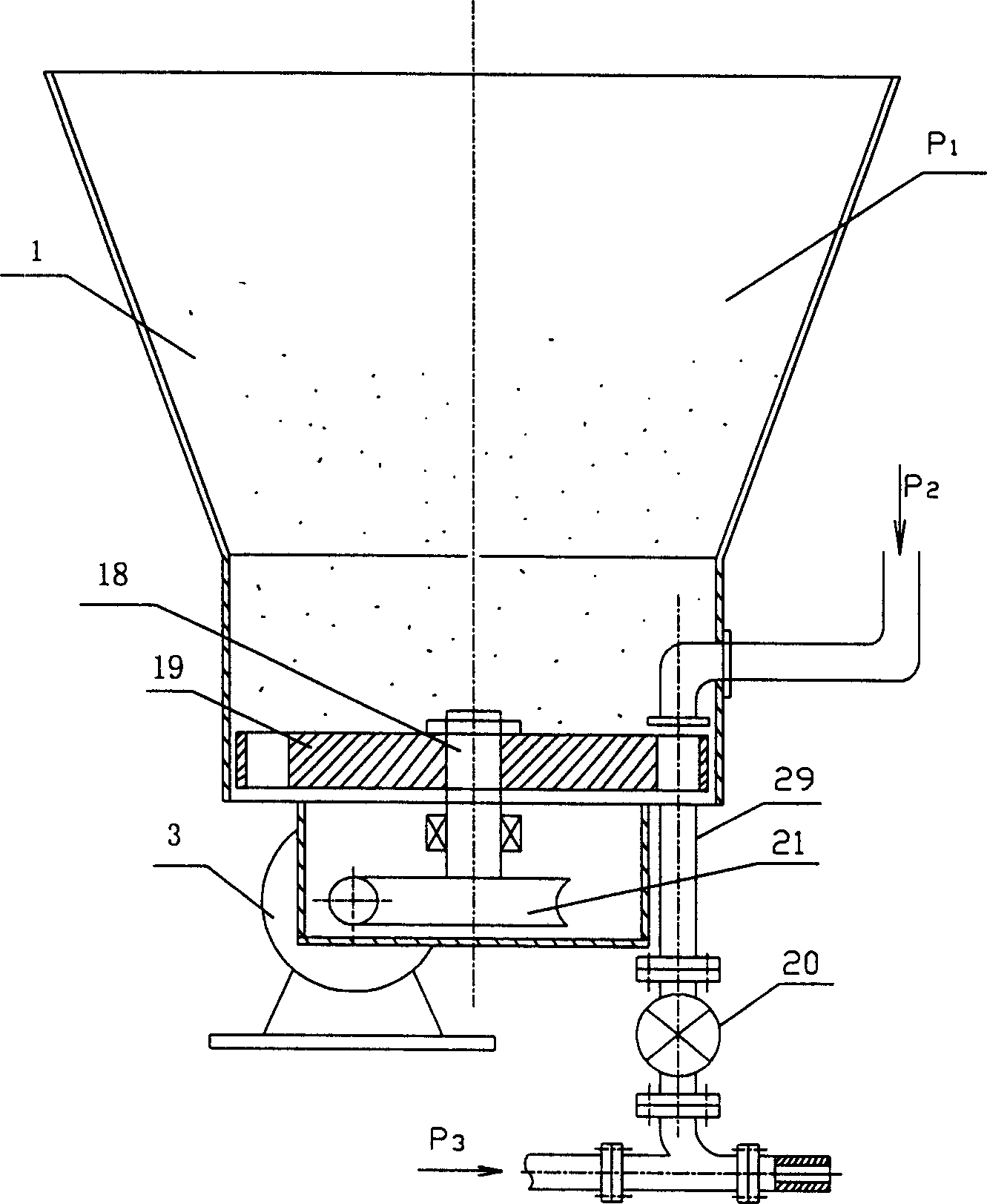

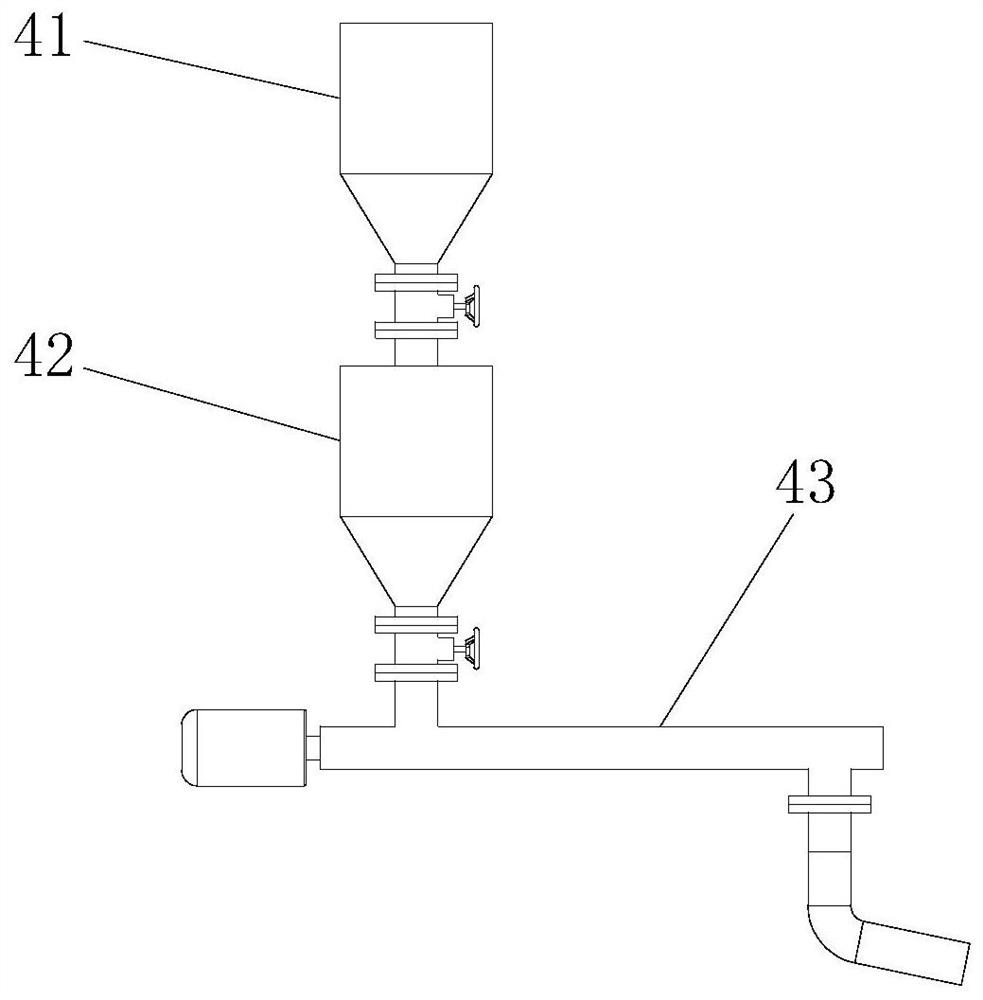

Double-layered turning plate type feeding mechanism

InactiveCN106147872AImproved gas stabilityImprove stabilityGasification processes detailsLiquid carbonaceous fuelsEngineeringMechanical engineering

The invention belongs to the technical field of gasification furnaces and relates to a double-layered turning plate type feeding mechanism. The double-layered turning plate type feeding mechanism comprises a No.1 bucket, a No.2 bucket and an opening type packing auger; a discharging hole of the No.1 bucket is in sealed connection with a feeding hole of the No.2 bucket; a discharging hole of the No.2 bucket is connected with an upper part bucket of the opening type packing auger; a No.1 valve is arranged at the lower end of the No.1 bucket, and a No.2 valve is arranged at the lower end of the No.2 bucket; a second material level monitor is arranged at the lower part of an inner cavity of the upper part bucket of the opening type packing auger; a first material level monitor is arranged at the upper part of the No.1 bucket. The feeding mechanism is reliably sealed and can be used for quantitatively and effectively feeding materials.

Owner:无锡湖光工业炉有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com