Powdery material metering and feeding device

A feeding device and powdery material technology, applied in the field of chemical equipment, can solve problems such as powdery material escape, impeller stuck, device failure shutdown, etc., to increase service life, prevent powder from escape, and strengthen the shaft end The effect of tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

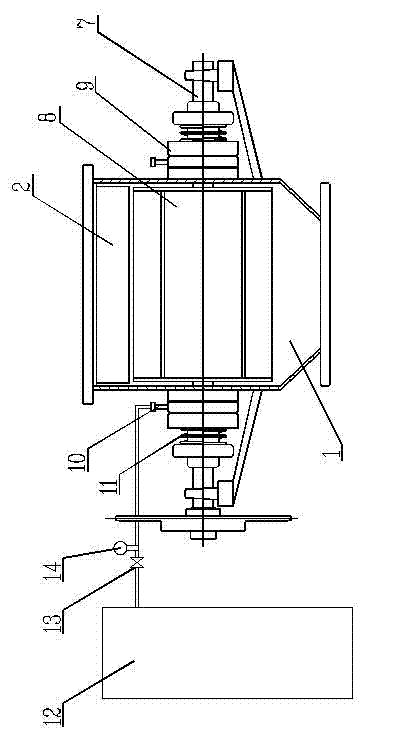

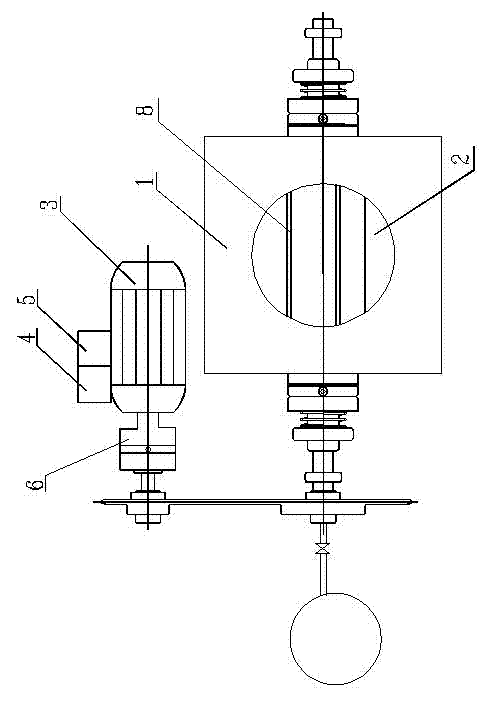

[0017] as attached figure 1 As shown: the powder material metering and feeding device of the present invention includes a housing 1, the housing is provided with an anti-blocking baffle 2, and the upper right of the housing is provided with a motor 3, and the motor is equipped with a frequency conversion The device 4 and the forward and reverse switching device 5, the motor linkage reducer 6, the reducer drives the chain to drive the rotating shaft 7, and the rotating shaft is equipped with an impeller 8.

Embodiment 2

[0019] In the metering and feeding device for powdery materials, the rotating shaft includes smooth mirror end caps 9 at both ends, and the smooth mirror end caps are equipped with an air inlet pipe 10, and the air inlet pipe is connected to a compressed air cylinder 12, and the Compress the air to prevent the powder from entering the shaft gap, ensure continuous operation without being affected by the powder, and enhance the service life. A spring 11 is installed on the outside of the smooth mirror end cover. In this way, the problem of poor sealing of the shaft end and the leakage of powder is solved.

[0020] The metering and feeding device for powdery materials has a pressure gauge 13 and a regulating valve 14 on the air inlet pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com