Cooling by-pass structure of electric appliance control box of frequency conversion type air conditioner outdoor unit

An air conditioner room and control box technology, applied in the direction of air conditioning system, space heating and ventilation, heating method, etc., can solve the problems of reducing the temperature of electrical control box, fuse burning, air conditioner shutdown, etc., to avoid fuse burning and shutdown. phenomenon, the effect of optimizing operating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

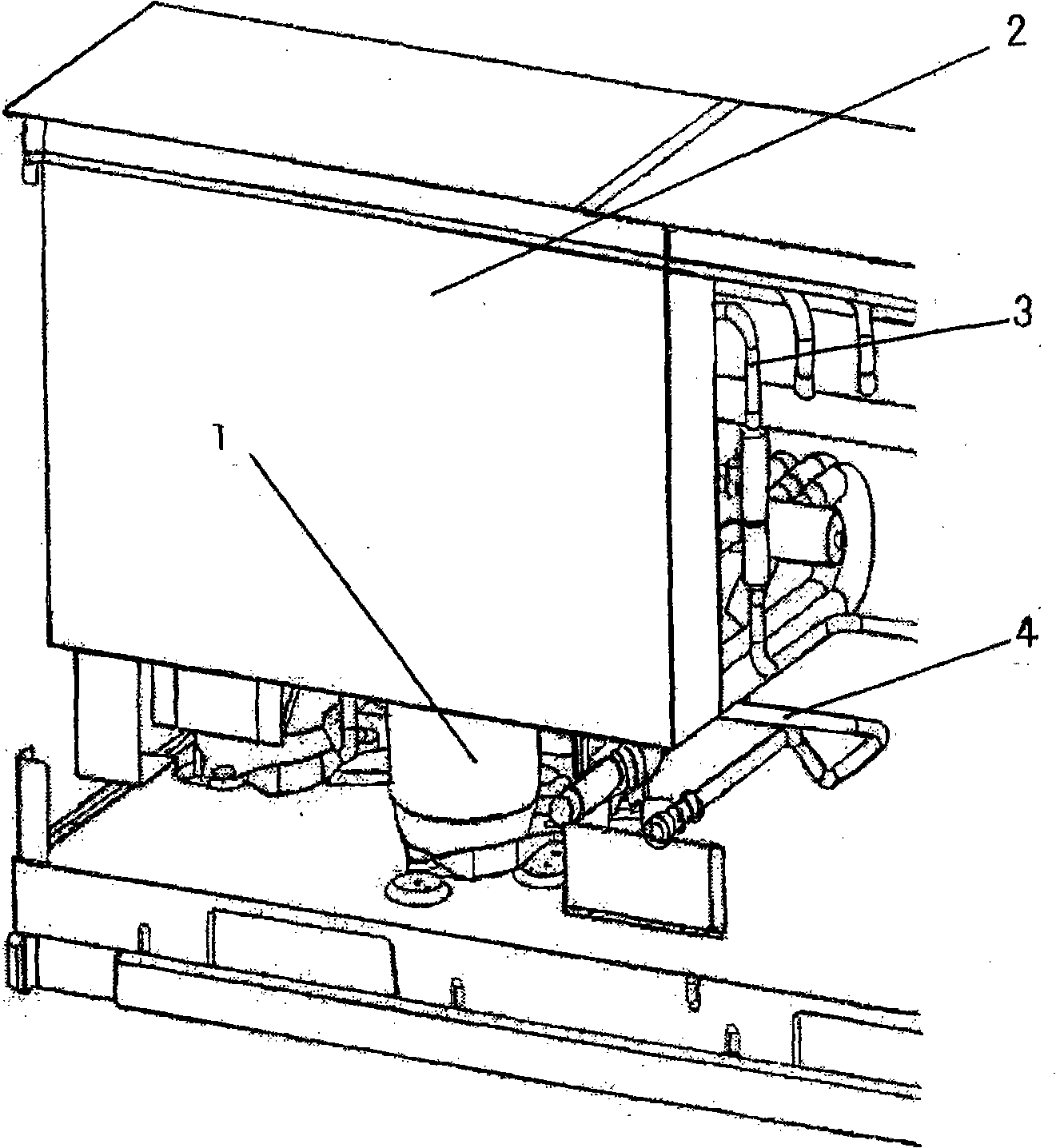

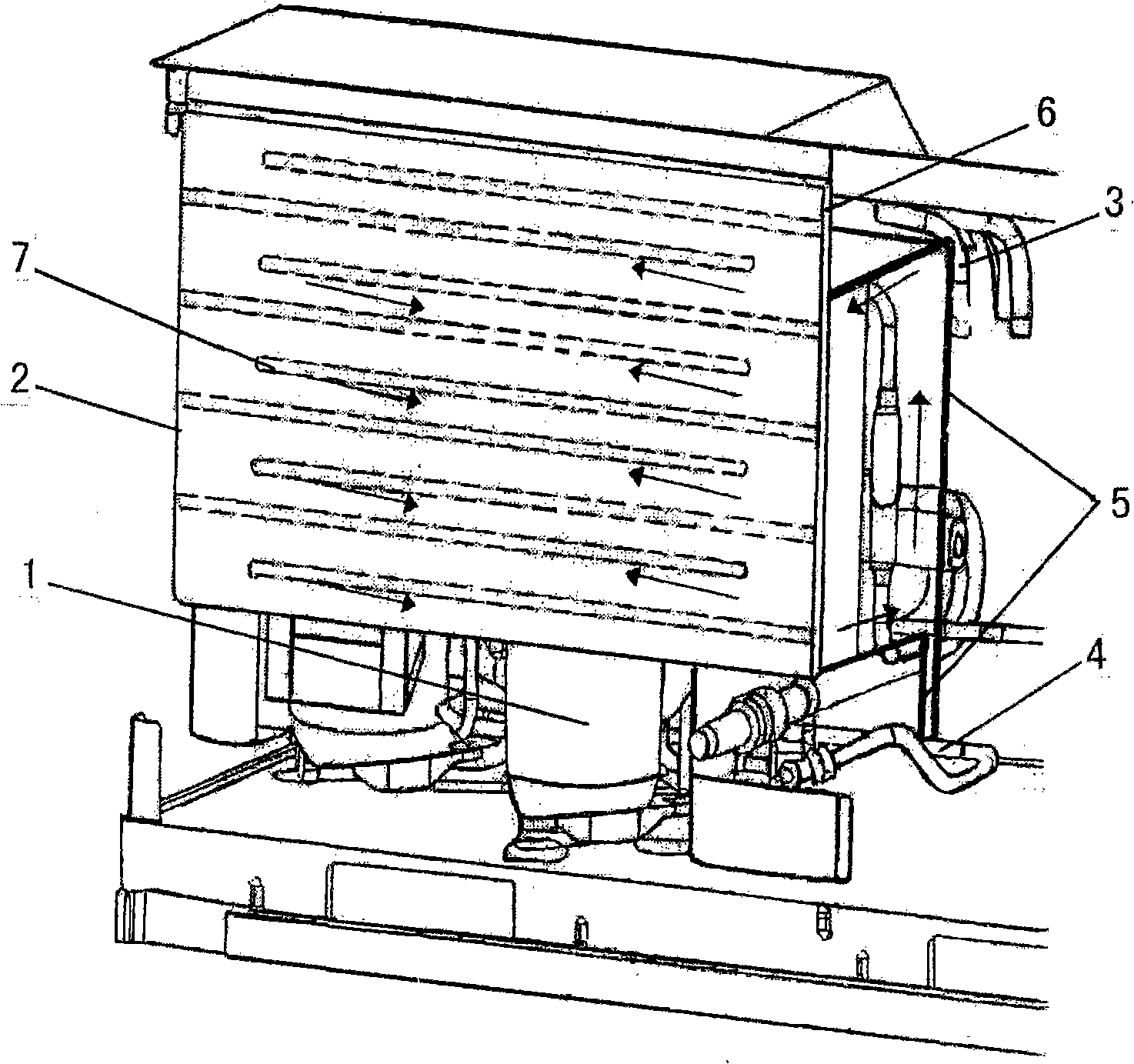

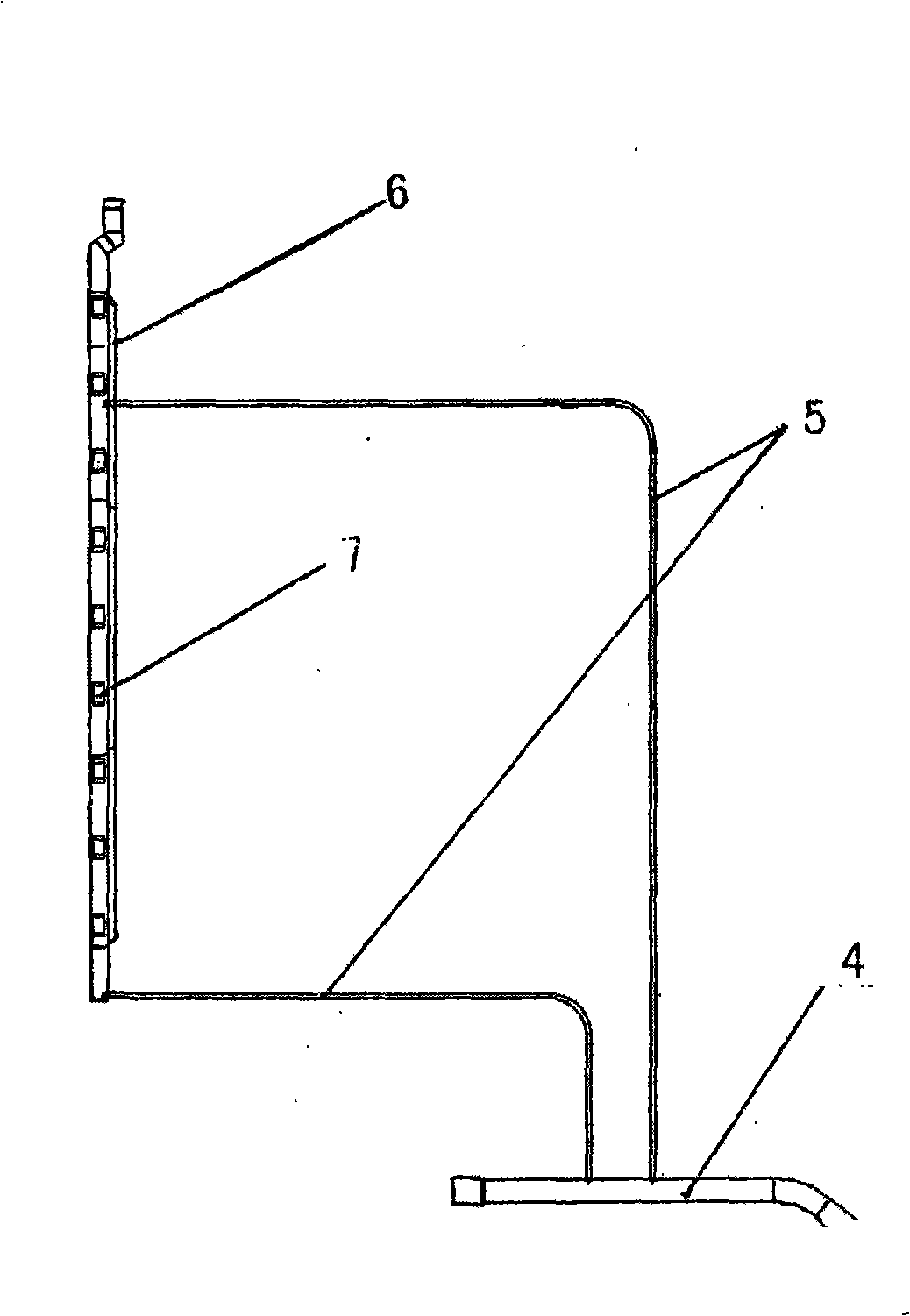

[0023] The present invention will be further described now in conjunction with accompanying drawing. Figure 2 shows the internal structure of the outdoor unit of the frequency conversion air conditioner involved in the present invention, and Figure 3 shows a schematic diagram of the communication between the capillary, the control box panel and the low-temperature refrigerant pipe in the cooling bypass structure of the present invention.

[0024] As shown in the figure, the cooling bypass structure of the outdoor unit and electrical control box of the inverter air conditioner according to the present invention includes a thickened control box panel 6 and a capillary tube 5 connecting the inside of the panel with the low-temperature refrigerant pipe 4 . In the cavity of the thickened control box panel, deflectors 7 arranged in parallel up and down are arranged, so that a "rotary" upper and lower flow channel is formed in the control box panel 6 . The upper and lower parts of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com