Preparation method of meal replacement powder

A production method and technology of meal replacement powder, which is applied in food science, food preservation, grain germ removal, etc., can solve the problem of inability to effectively ensure the fineness and quality of the ground dust, affect the efficiency of production, product quality, and feed in and out The problem of unequal speed achieves the effect of stable fit, safe and convenient use, and guaranteed concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

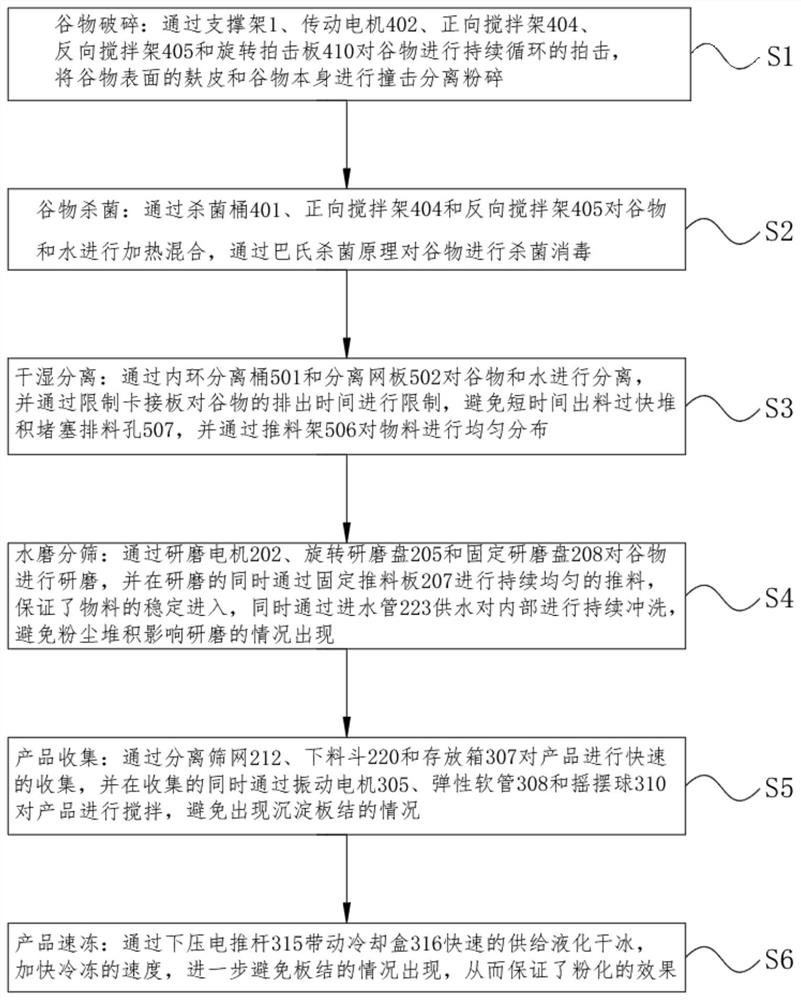

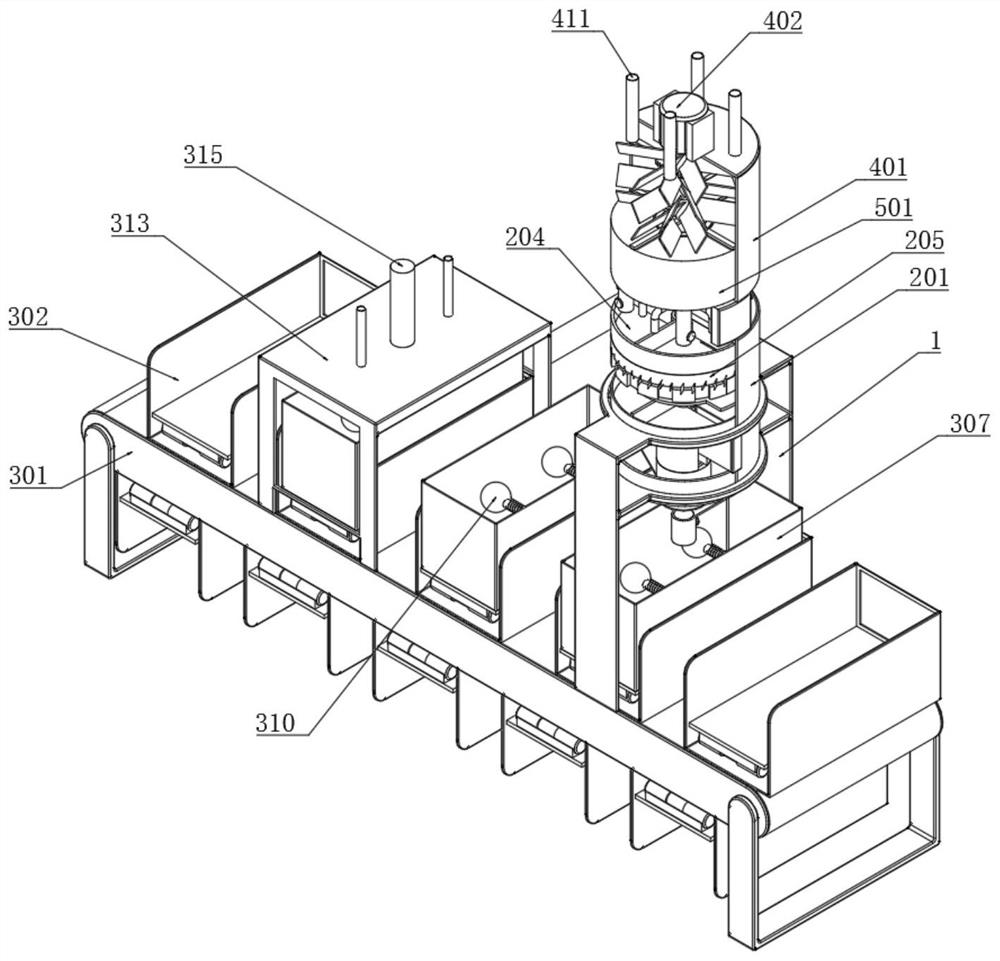

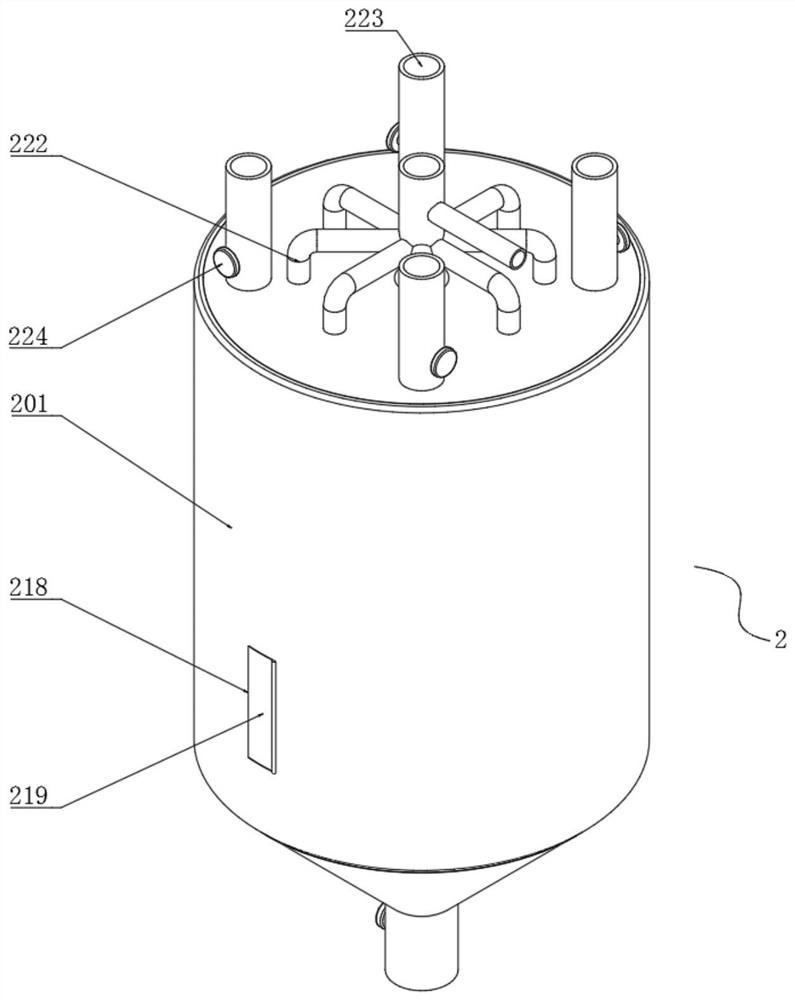

[0044] Example: such as Figure 1-15 Shown, the present invention provides a kind of technical scheme, 1. a kind of preparation method of meal replacement powder, it comprises the following steps;

[0045] S1: Grain crushing: through the support frame 1, the transmission motor 402, the forward stirring frame 404, the reverse stirring frame 405 and the rotating clapping plate 410, the grain is continuously slapped, and the bran on the surface of the grain and the grain itself are crushed. Impact separation and crushing;

[0046] S2: Grain sterilization: heat and mix the grain and water through the sterilization barrel 401, the forward stirring frame 404 and the reverse stirring frame 405, and sterilize the grain through the pasteurization principle;

[0047] S3: Dry and wet separation: separate the grain and water through the inner ring separation barrel 501 and the separation net plate 502, and limit the discharge time of the grain by limiting the clamping plate, so as to avo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com