Patents

Literature

226results about How to "Good grinding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

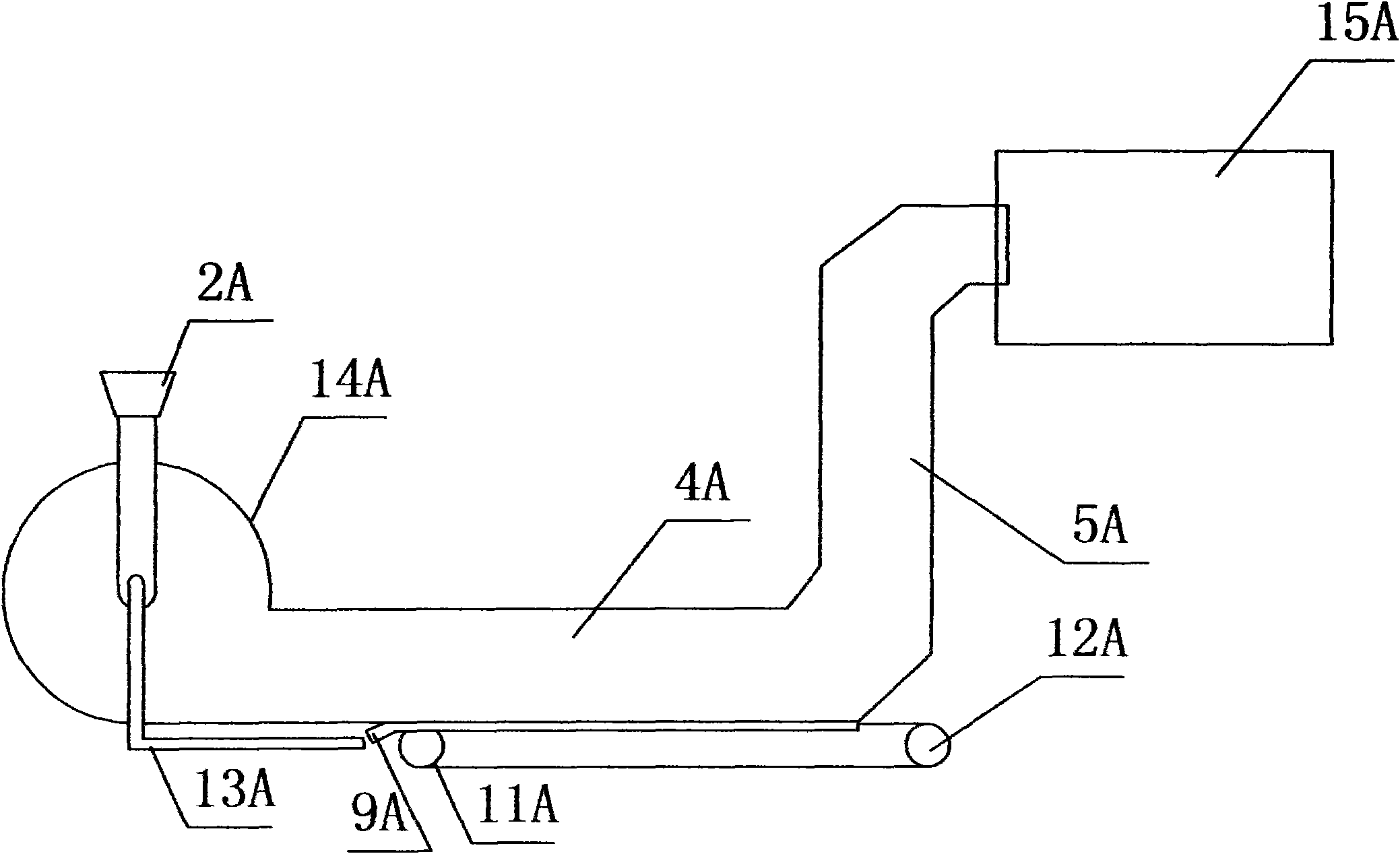

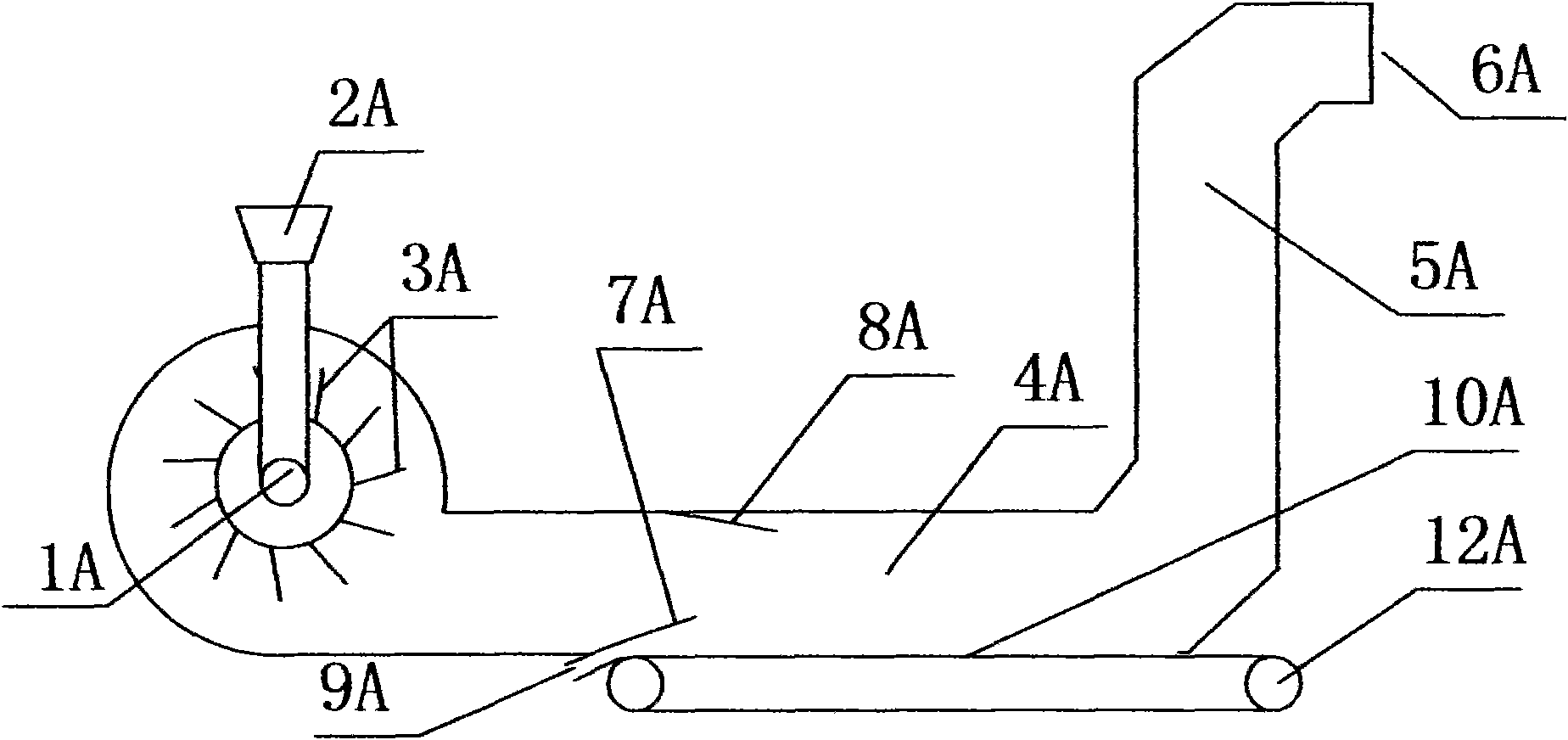

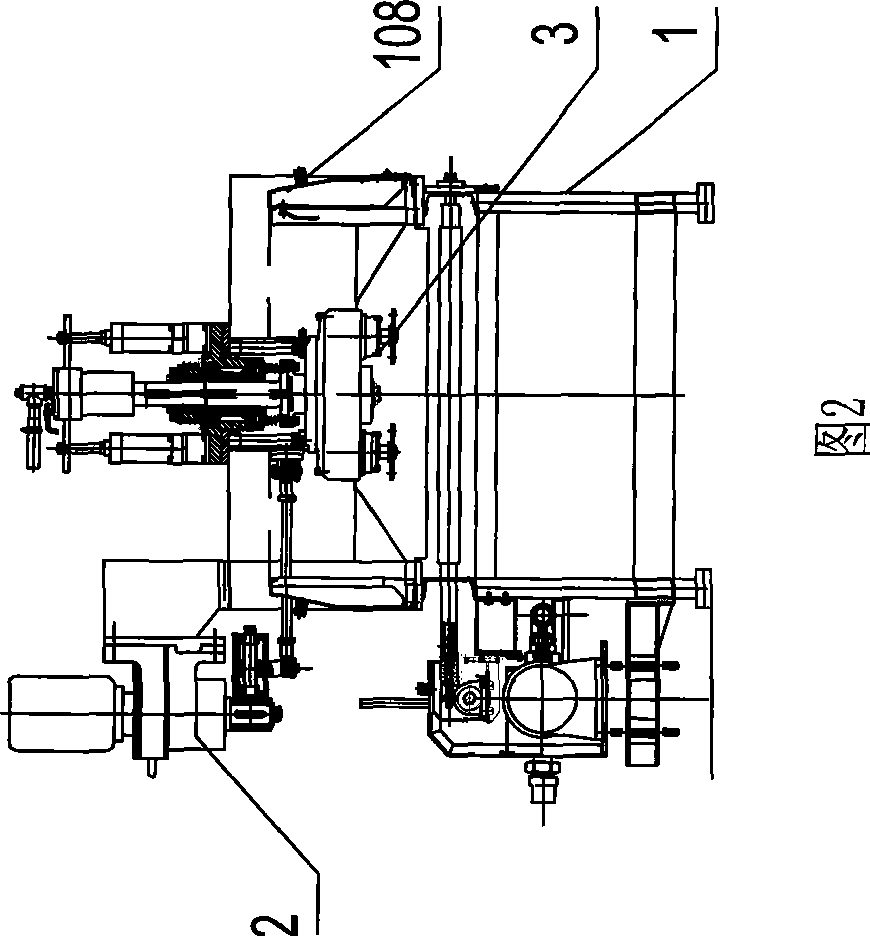

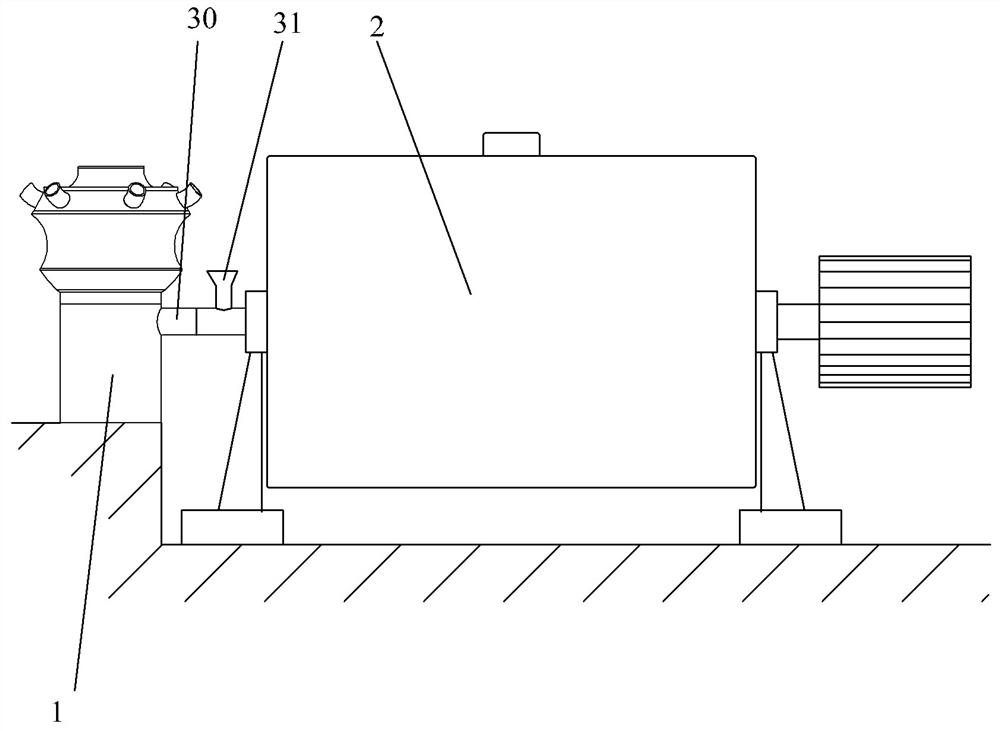

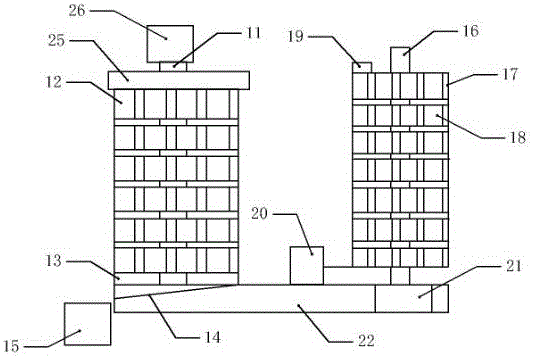

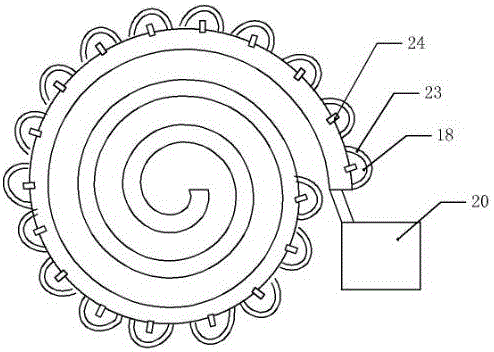

Method and equipment for preparing tea seed oil from tea seeds and extracting tea polyphenol from byproduct tea seed cake

InactiveCN102028042AEasy feedingEfficient separationSugar derivativesSteroidsAcetic acidCamellia oleifera

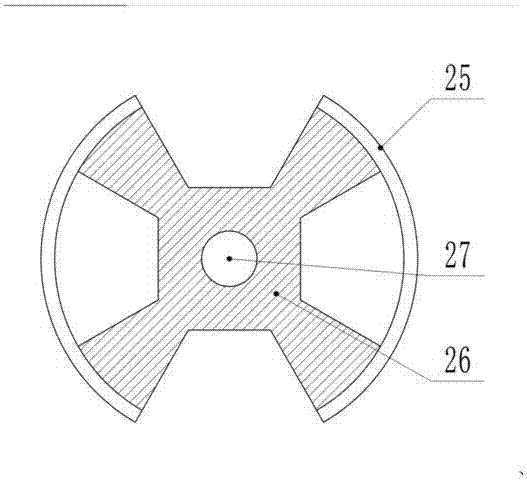

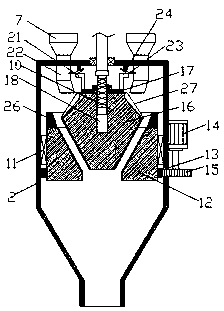

The invention discloses a method and equipment for preparing tea seed oil from tea seeds and extracting tea polyphenol from a byproduct tea seed cake. The method comprises the following steps of: screening; drying; husking, crushing, separating and grinding the tea seeds to obtain tea seed powder; cooking tea seed powder; wrapping a cake; squeezing a tea cake into tea seed oil and the byproduct tea seed cake; and extracting tea polyphenol and saponin from the byproduct tea seed cake. The method is characterized in that: petroleum ether or No.6 solvent oil is used for soaking the tea seed cakeso as to obtain a tea seed oil product; and a degreased tea seed cake is extracted by using solution of methanol or ethanol, concentrated solution is extracted by using ethyl acetate, extract liquor is evaporated and the solvent is recycled so as to obtain a tea polyphenol product. A piece of special equipment comprises a drier, a husking machine, a cooking machine, a squeezer and a tea seed cakegrinder. Good separation of kernels from shells is achieved by a special husking machine and the cooking degree of the tea seed powder can be controlled well by a special cooking machine. A special tea seed cake grinder is used, so that grinding efficiency is higher and the service life of the equipment is prolonged.

Owner:FUJIAN YOUXI COUNTY SIN LONG EDIBLE OIL

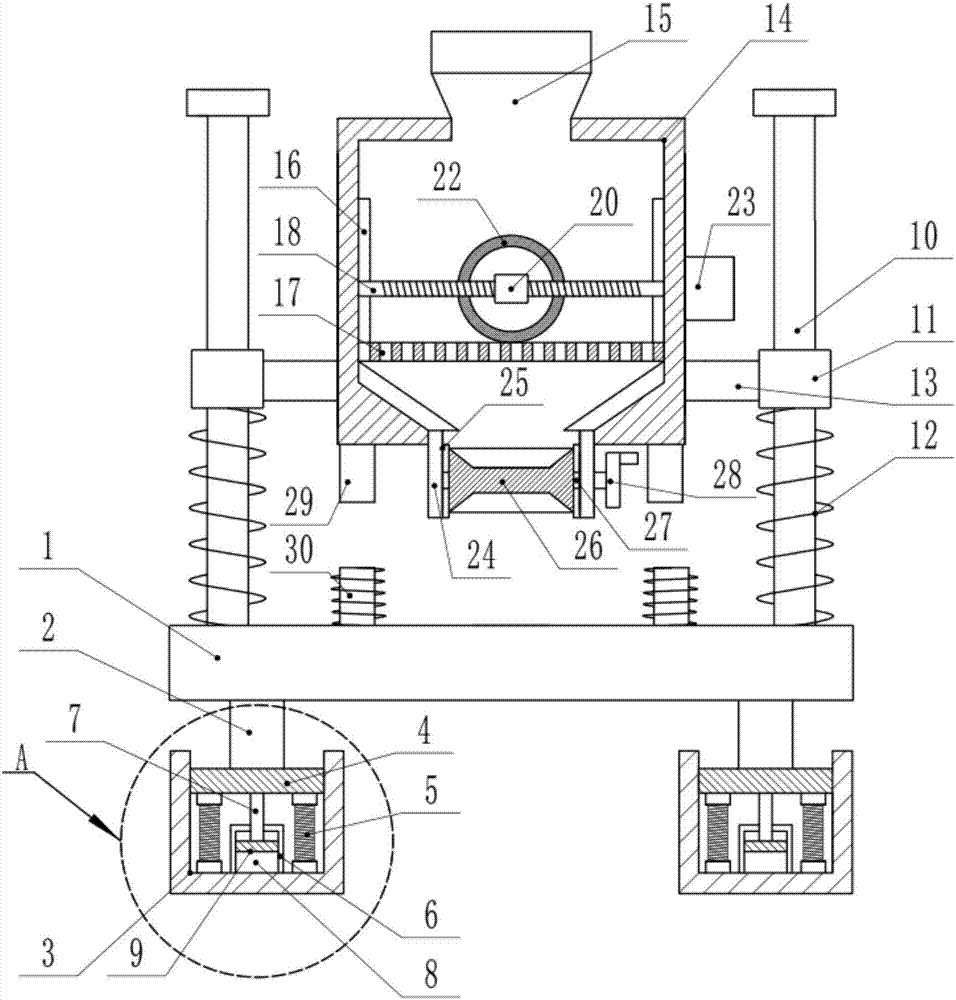

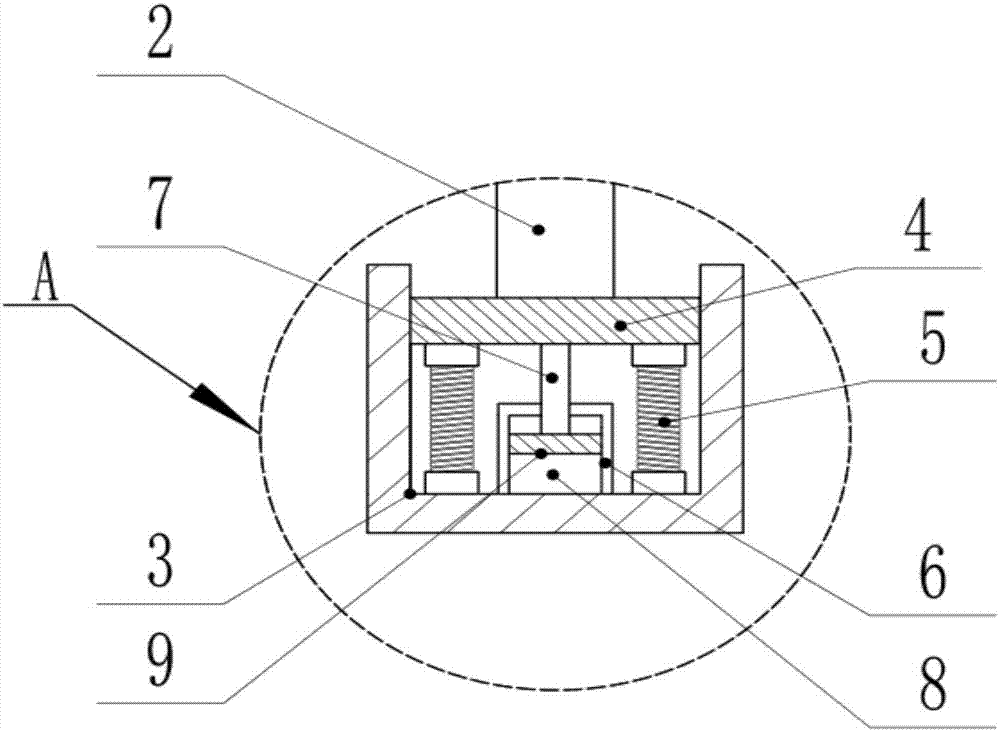

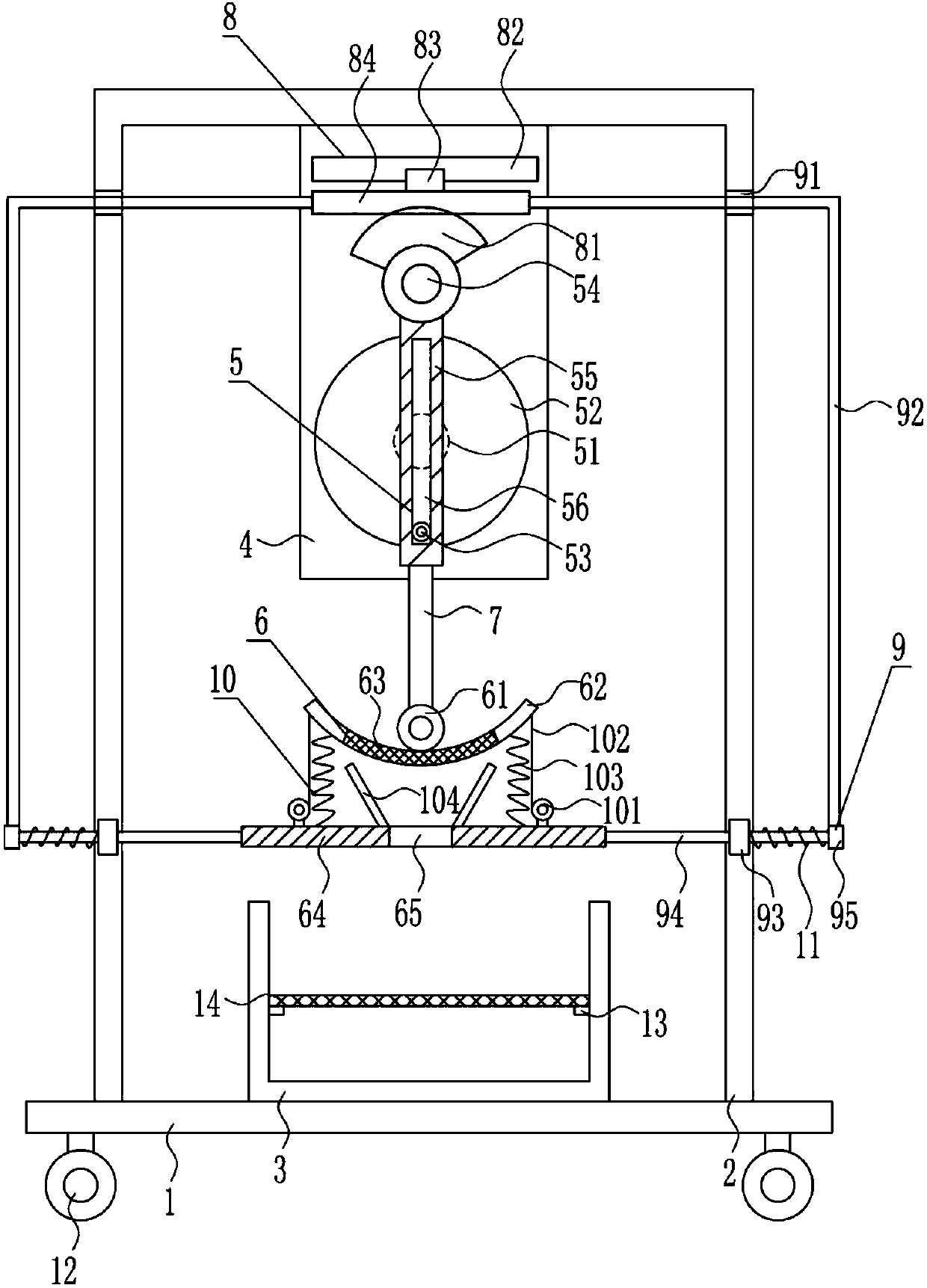

Fine feed grinding device for fry breeding

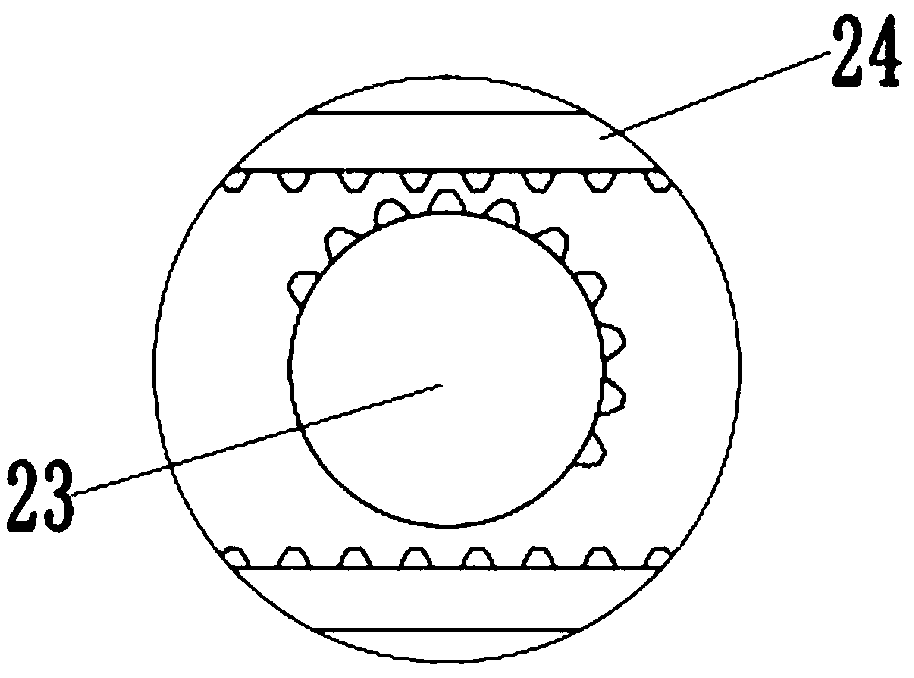

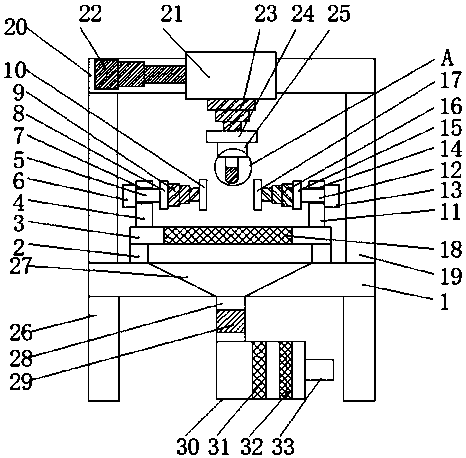

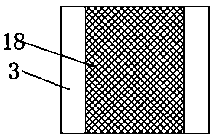

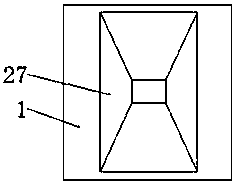

InactiveCN107377091AReduce noiseEffective shock absorptionFeeding-stuffNon-rotating vibration suppressionElectromagnet

The invention discloses a feed fine grinding device for fish fry cultivation, which comprises a shock absorbing spring, a shock absorbing cylinder, a grinding box, a grinding tank, a screening plate, a screw rod, a grinding roller, a grinding motor, a feeding trough, and a quantitative circular wheel and a magnet, the inside of the grinding box is provided with a grinding tank, a sieve plate is installed at the bottom of the grinding tank, a screw rod is installed on the front side of the grinding tank, and a guide rod is fixedly installed on the rear side of the grinding tank. Grinding rollers are also fixedly installed, and a quantitative round wheel is also rotatably installed inside the cutting trough; a magnet is fixedly installed on the lower side of the grinding box, and an electromagnet is also fixedly installed on the base. When it is necessary to grind the fish feed, the electromagnet is powered on and off intermittently, so that the grinding box moves up and down, thereby speeding up the speed of sieving the feed after grinding; after the sieving is completed, it is realized under the action of the quantitative round wheel Quantitative discharge, so as to accurately control the feeding amount of fish food, so as to achieve reasonable feeding.

Owner:YUYAO WANZHEN HARDWARE FACTORY

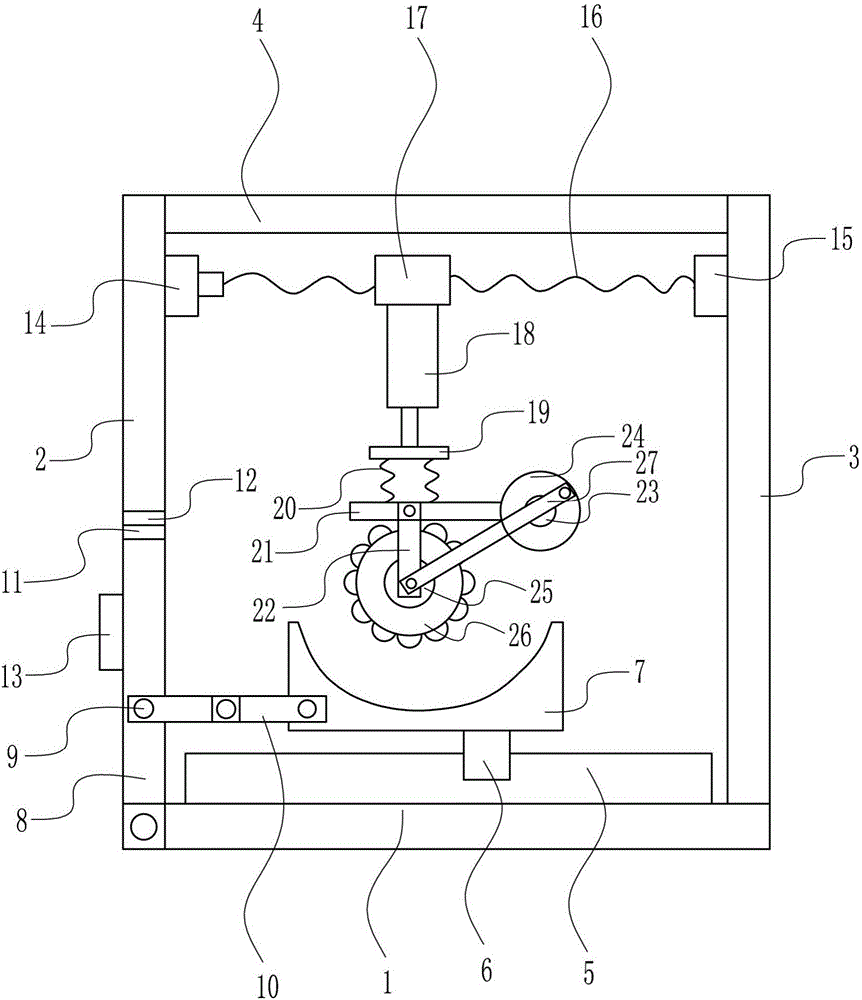

Rapid grinding device metal materials for 3D printing

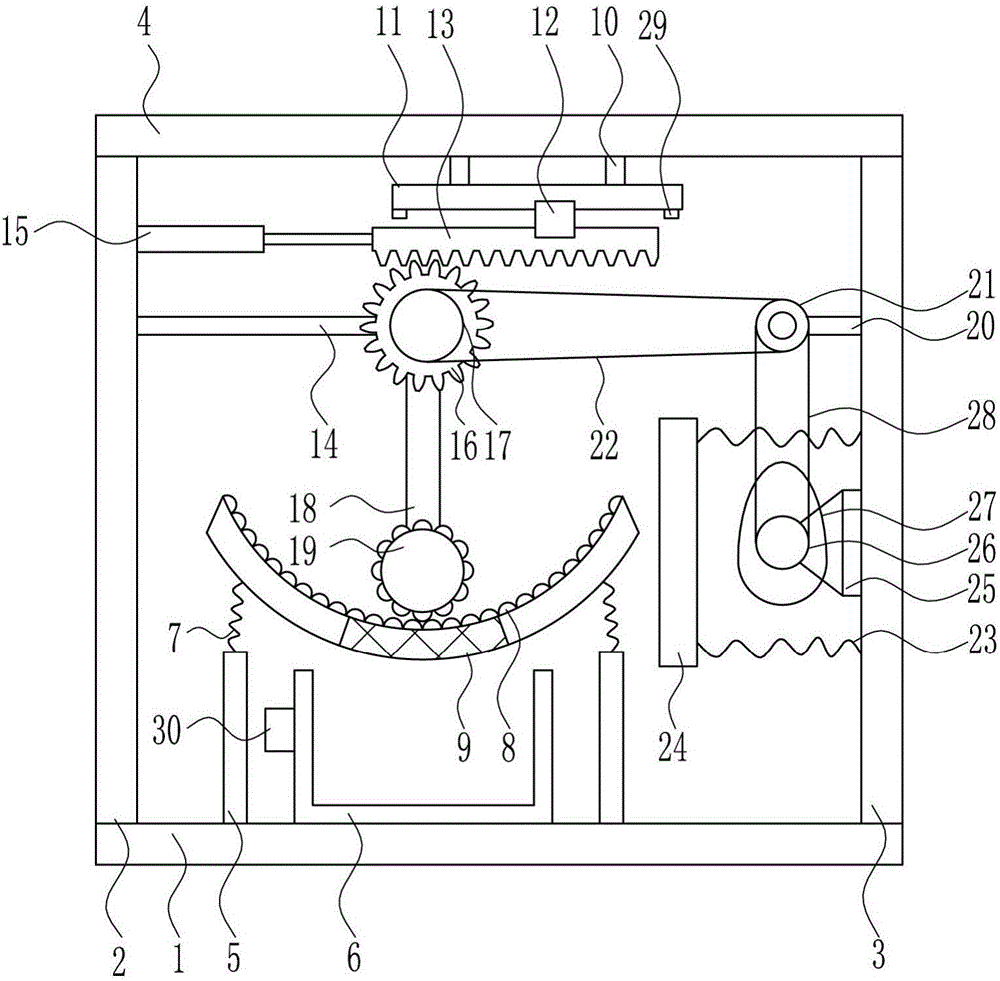

ActiveCN106180736AControl rotationControl swingAdditive manufacturing apparatusMetallic materialsPolymer chemistry

The invention relates to a grinding device for metal materials for 3D printing, in particular to a rapid grinding device for metal materials for 3D printing. By the adoption of the rapid grinding device for the metal materials for 3D printing, the technical purposes of excellent grinding effect, high work efficiency and simple structure are achieved. For achieving the technical purposes, the rapid grinding device for the metal materials for 3D printing comprises a bottom plate, a left support, a right support, a top plate, first supporting rods, a collection frame, first springs, a grinding cylinder, a screen plate, a supporting base, a sliding rail, a sliding block, a rack, a second supporting rod and the like. The left support is arranged at the left end of the top of the bottom plate. The right support is arranged at the right end of the top of the bottom plate. The first supporting rods are symmetrically arranged on the left side of the top of the bottom plate. By the adoption of the rapid grinding device for the metal materials for 3D printing, the effects of excellent grinding effect, high work efficiency and simple structure are achieved, the metal materials can be ground rapidly, the work benefits are increased for enterprises, and the rapid grinding device is reasonably provided with a reinforcing rib.

Owner:NANTONG DONGFANG PLASTIC CO LTD

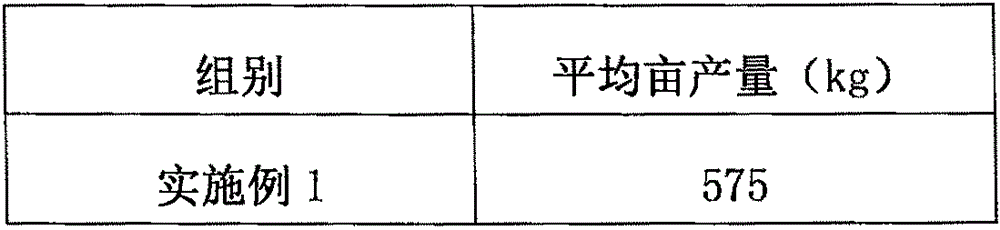

Novel graphene fertilizer and preparation method thereof

InactiveCN106008018AImprove the lubrication effectGood grinding effectBioloigcal waste fertilisersSolid/semi-solid fertilisersFertilizerFiber

The invention discloses a novel graphene fertilizer and a preparation method thereof. The fertilizer is mainly prepared from graphene, expanded vermiculite powder, soybean cake, distillers' grains, barnyard manure, straw, rapeseed oil, rice bran and water. The dispersion effect of graphene is improved by conducting ball-milling on the expanded vermiculite powder and graphene; meanwhile, due to the fact that the raw materials containing plant fiber are used in the fertilizer, the loss of effective ingredients in the fertilizer is greatly reduced, and the use effect of the fertilizer is improved; in the actual usage process, the use amount of the fertilizer can reduced by 50% or above, and the yield is increased by 15%-20%.

Owner:郴州市通源生物科技有限公司

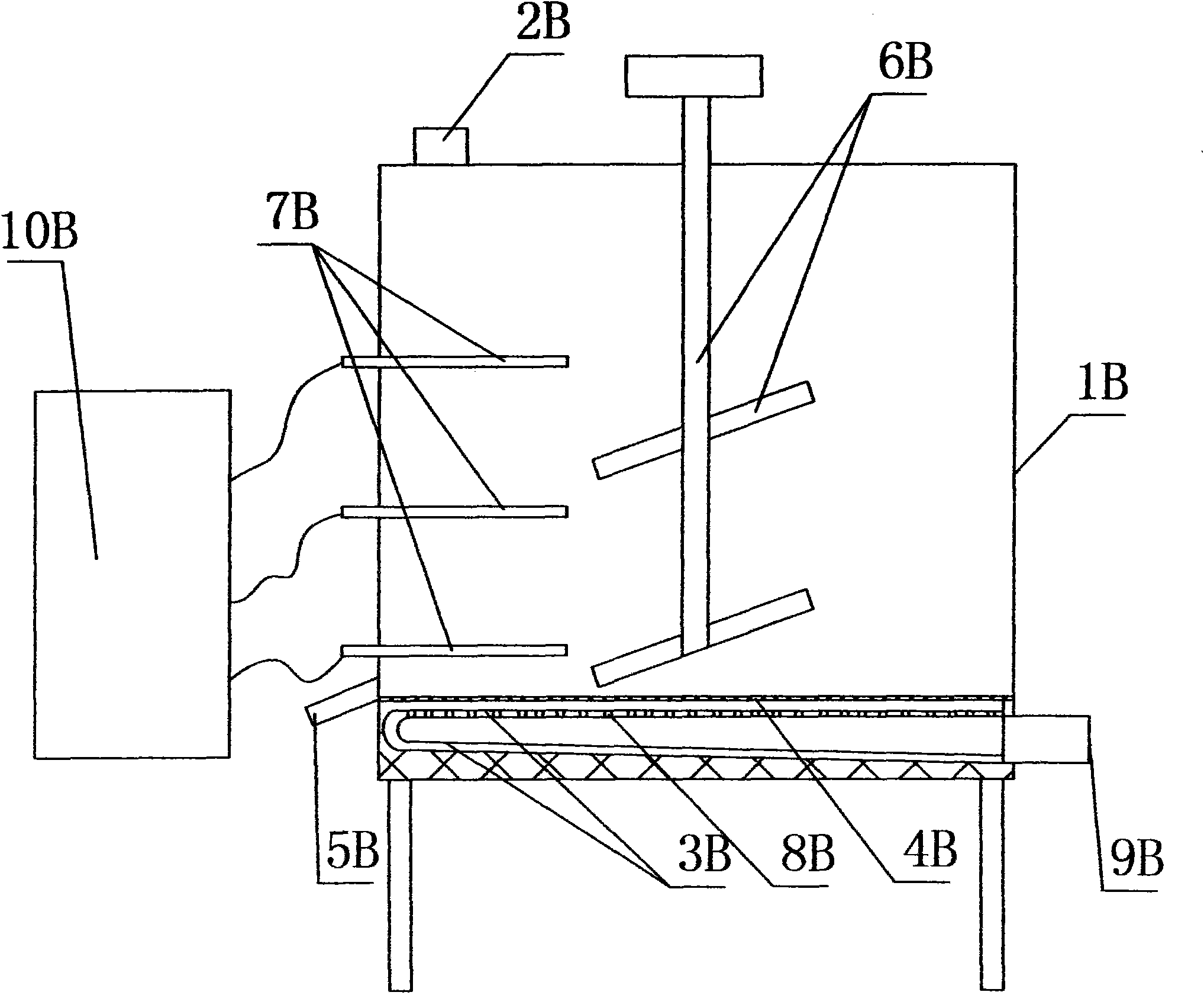

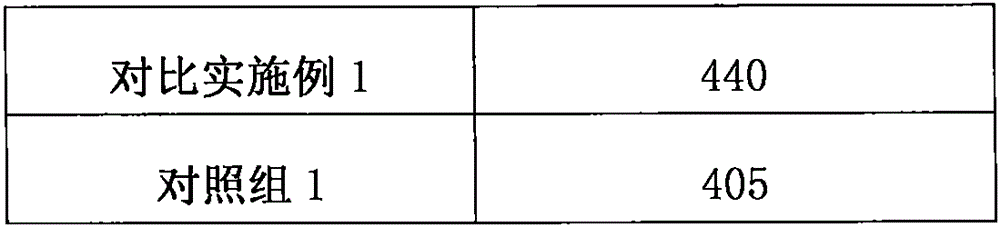

Ultra-fine grinding device for powder coating

InactiveCN110947447AFine and uniform particle sizeGood grinding effectGrain treatmentsElectric machineryEngineering

The invention relates to the technical field of coating grinding millers, in particular to an ultra-fine grinding device for powder coating. The ultra-fine grinding device comprises a fixing frame, agrinding cylinder and a storage bin. The lower end of the grinding cylinder is provided with supporting legs, the supporting legs are connected with the bottom of the fixing frame in a welded manner,the storage bin is arranged at the top end of the fixing frame, the left and right ends of the lower surface of the storage bin are connected with feed hoppers, the feed hoppers communicate with the upper surface of the grinding cylinder, a reduction motor is fixed to the lower surface at the top end of the fixing frame, and an output shaft of the reduction motor penetrates through the lower end at the center of the upper surface of the storage bin to be connected with a reciprocating lead screw. According to the ultra-fine grinding device for the powder coating, the reciprocating lead screw is driven by the reduction motor to rotate so as to realize the up-and-down movement of a movable round table grinding block, and the grinding gap is gradually reduced in the grinding process, so thatextremely fine grinding of the powder coating is realized, and the grinding effect of the ultra-fine grinding device for powder coating is excellent.

Owner:含山县领创新材料科技有限公司

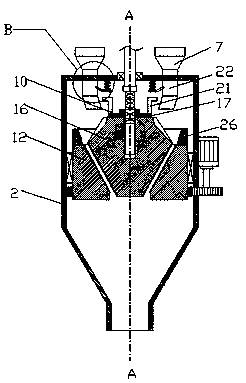

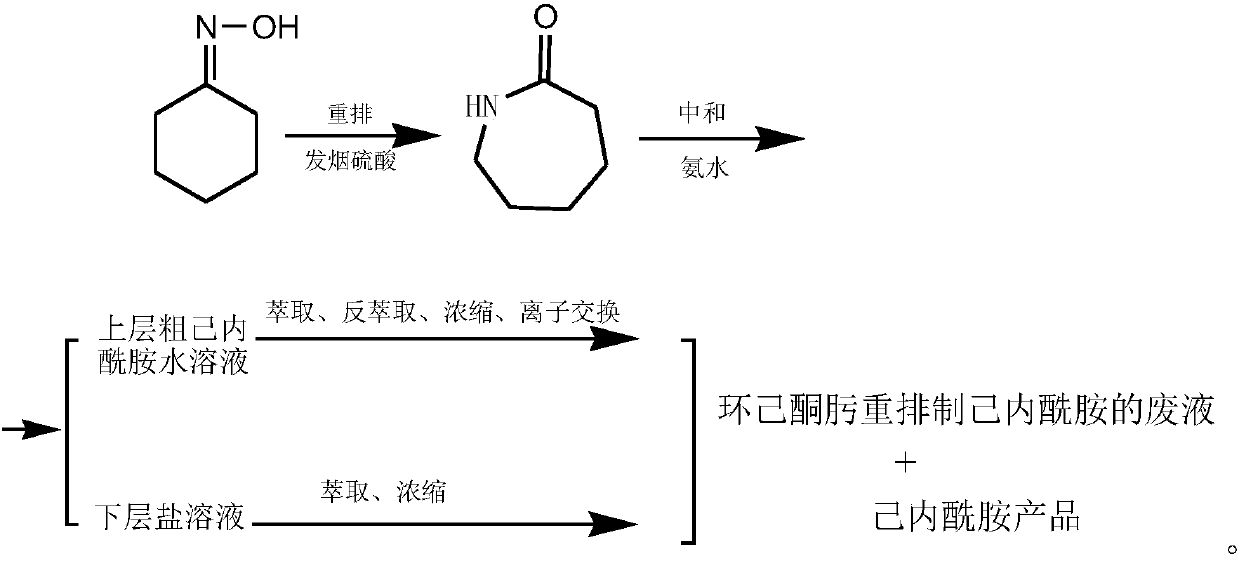

Activating grinding aid for steel slag micro-powder, and preparation method thereof

The invention relates to an activating grinding aid for steel slag micro-powder, and a preparation method thereof. The activating grinding aid comprises the following raw ingredients in parts by weight: 15-45 parts of an amide compound, 3-35 parts of alkanolamine, 5-20 parts of ethylene diamine or derivatives thereof, 0.1-0.5 part of a defoaming agent, and 15-70 parts of water. The preparation method for the activating grinding aid comprises the steps of: sequentially adding the 15-45 parts of amide compound, 3-35 parts of alkanolamine and 5-20 parts of ethylene diamine or derivatives thereof into 15-70 parts of water for mixing and stirring, and then adding the 0.1-0.5 part of defoaming agent to the mixture to obtain the activating grinding aid for the steel slag micro-powder. The activating grinding aid for the steel slag micro-powder is simple in preparation technique and less in usage amount, and is not only excellent in grinding aiding effect, but also capable of improving the activity index, especially 28d activity index, of the steel slag micro-powder; and the steel slag micro-powder does not contain chloride ions, thus meeting the national standard.

Owner:山东山铝环境新材料有限公司

Glazing machine

ActiveCN101362312AGood grinding effectEliminate cutting marksGrinding carriagesPolishing machinesCeramic tilesEngineering

The invention discloses a glazing machine for glaze. The glazing machine comprises a ceramic tile delivery mechanism, and also a polishing device arranged along the extending direction of the delivery mechanism, wherein, the polishing device comprises a swing grinding bench device and a grinding head device arranged on the swing grinding bench device, and a cooling system is arranged on the grinding head device. The glaze surface glazing machine is utilized for the glaze polishing on the basis of fine polishing of a fine polishing machine. The cutting marks are eliminated to the largest extent, and the surface glossiness required by the market is reached; the polishing efficiency is high, the polishing surface is wide, the surface quality of the ceramic tile product can be effectively improved, therefore, the requirement of consumers on high quality tiles can be met.

Owner:KEDA INDUSTRIAL GROUP CO LTD

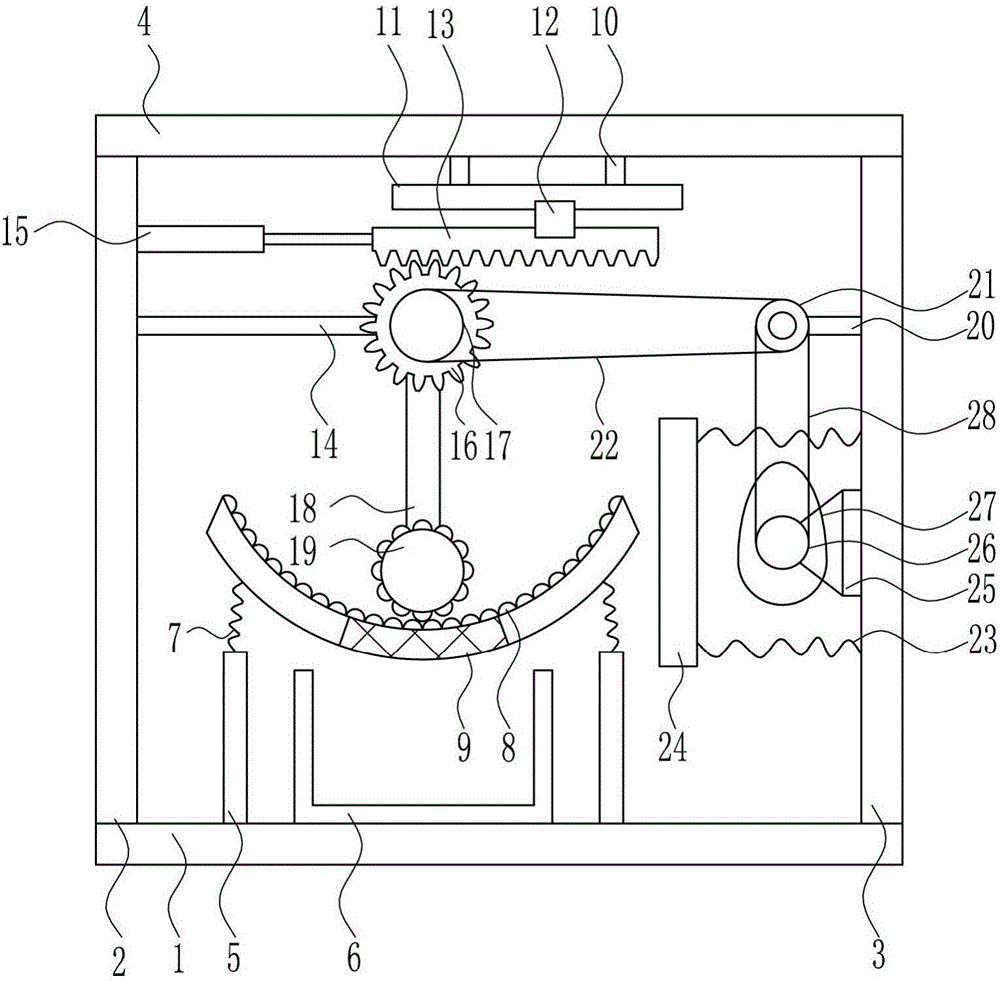

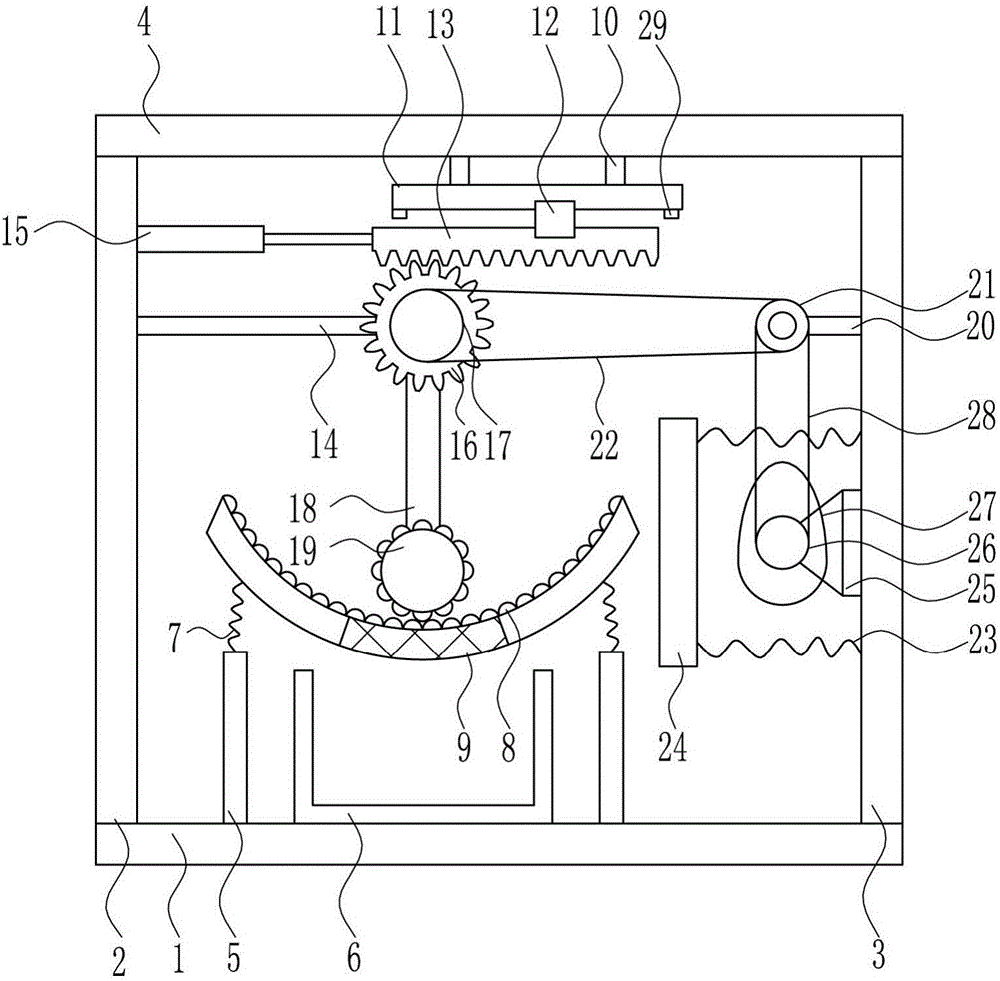

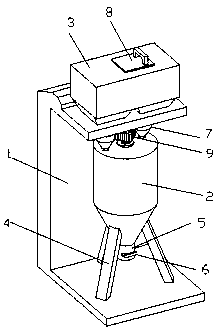

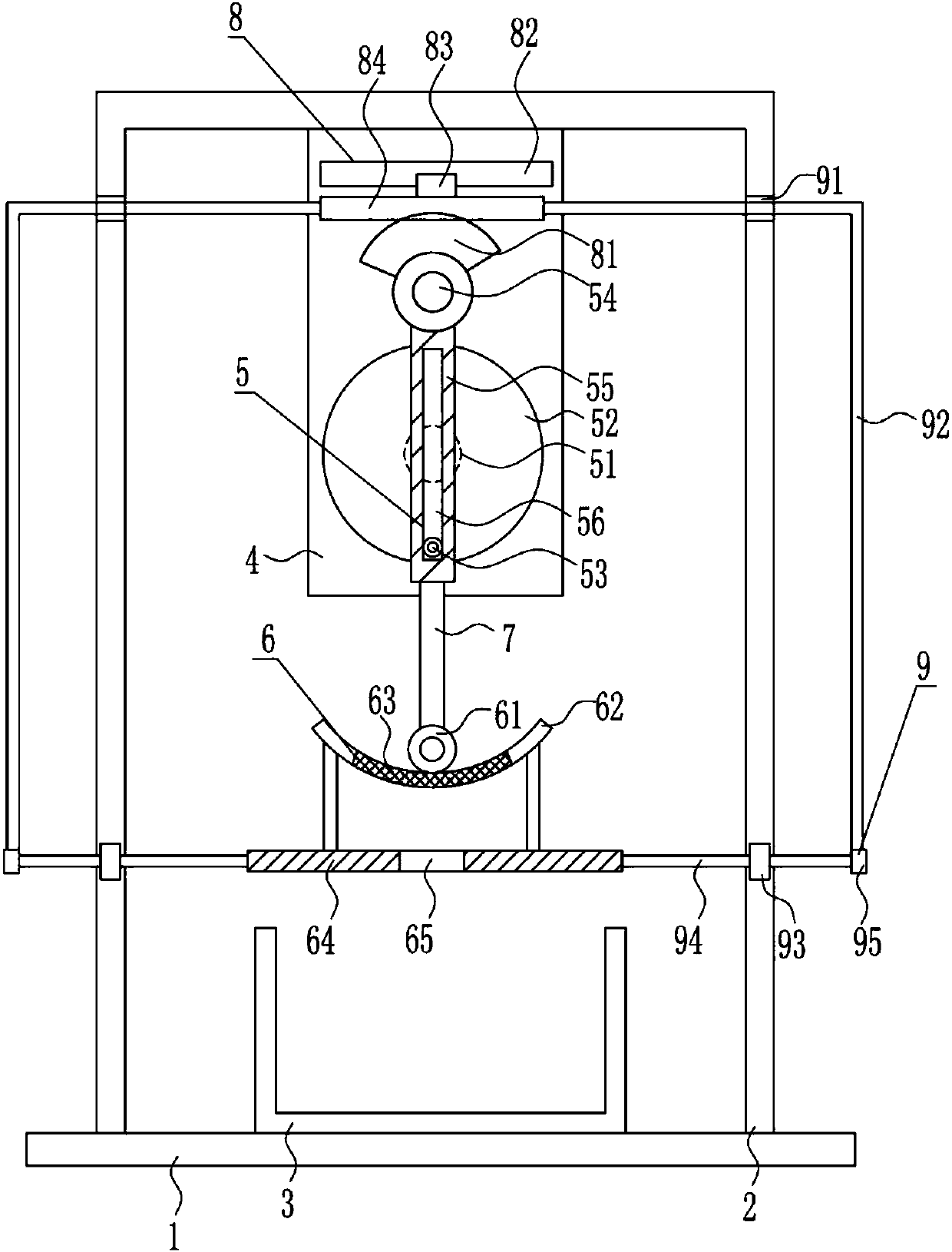

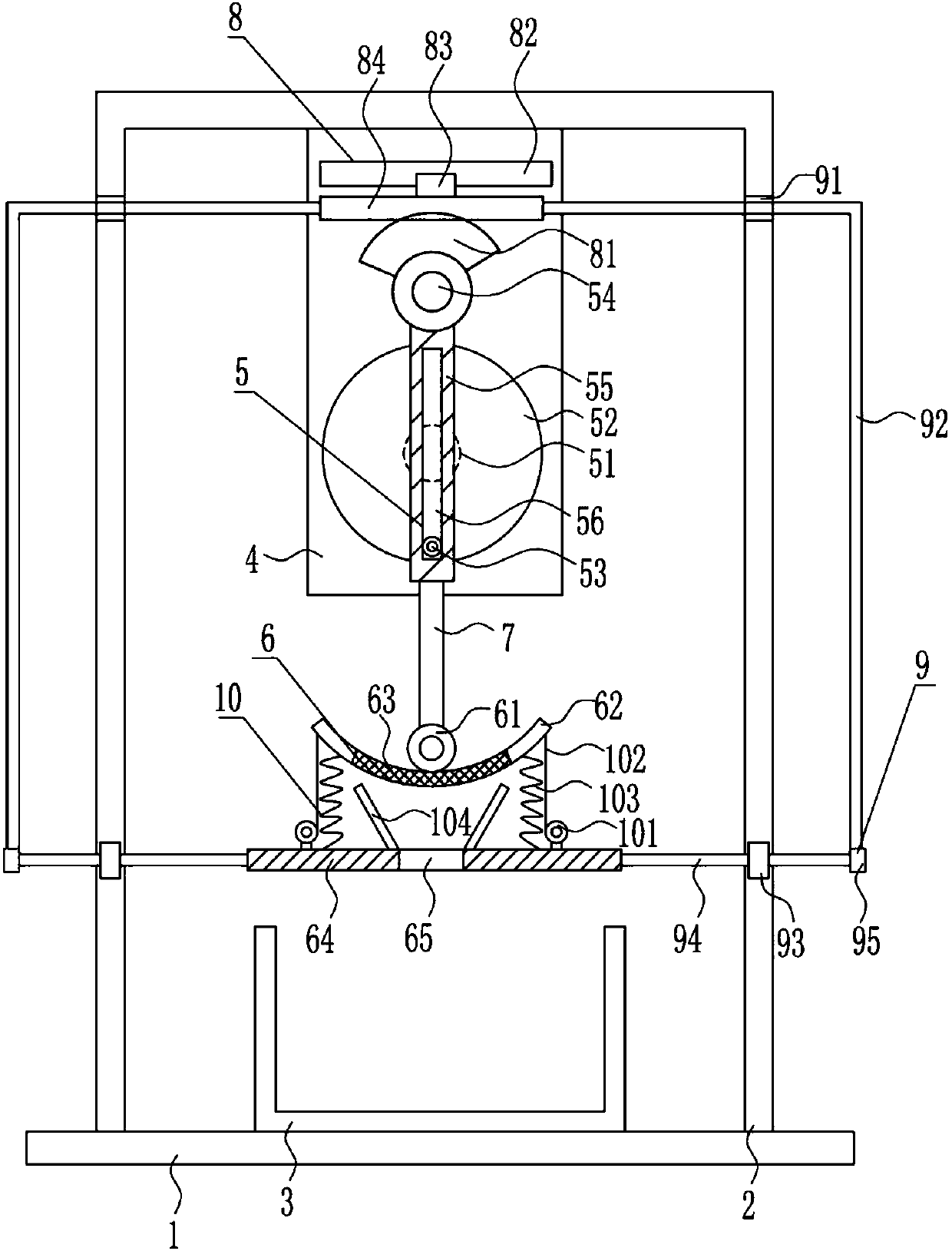

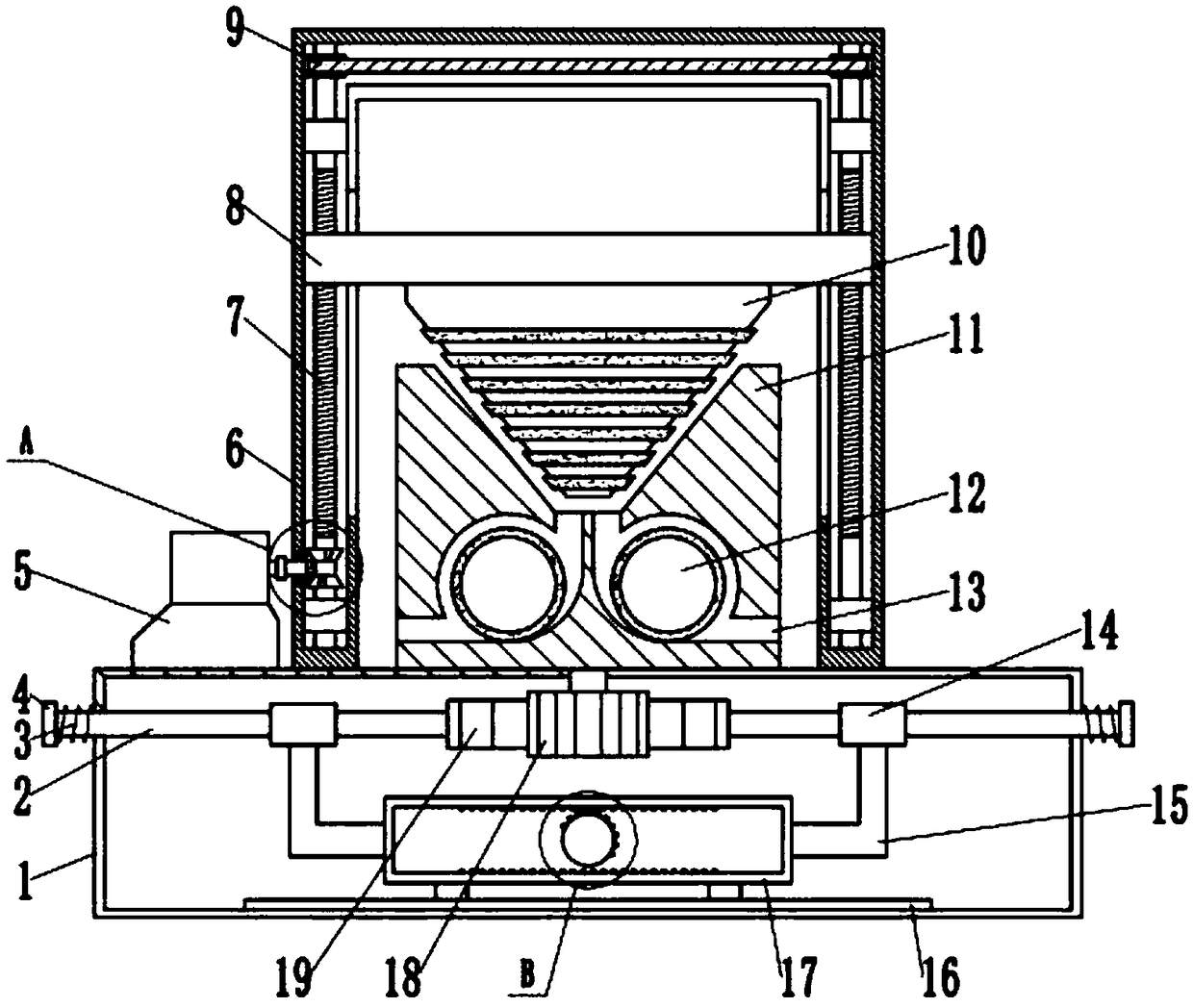

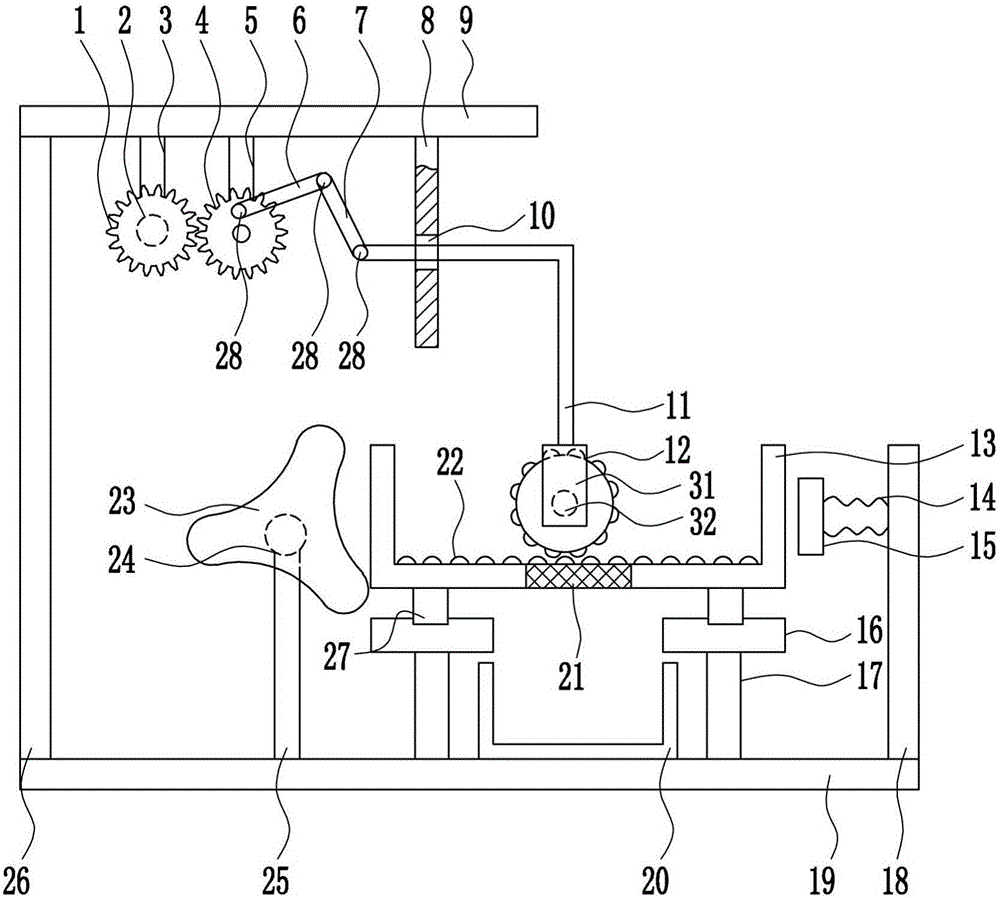

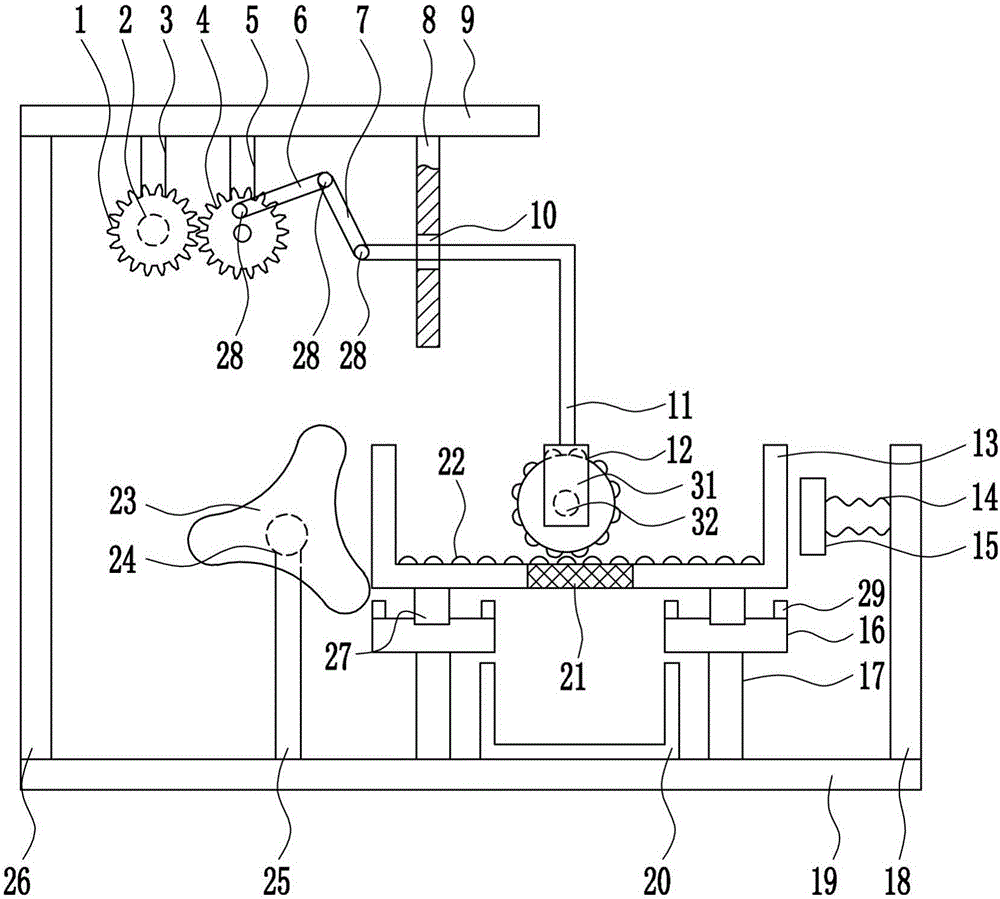

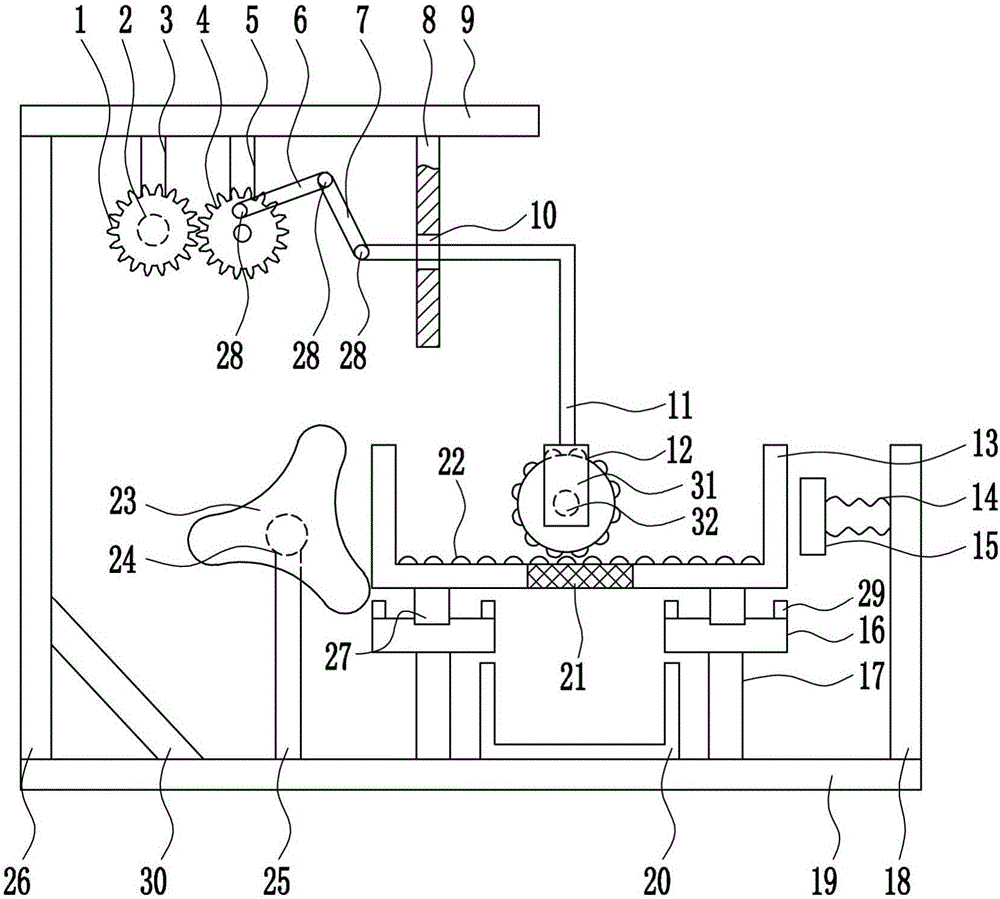

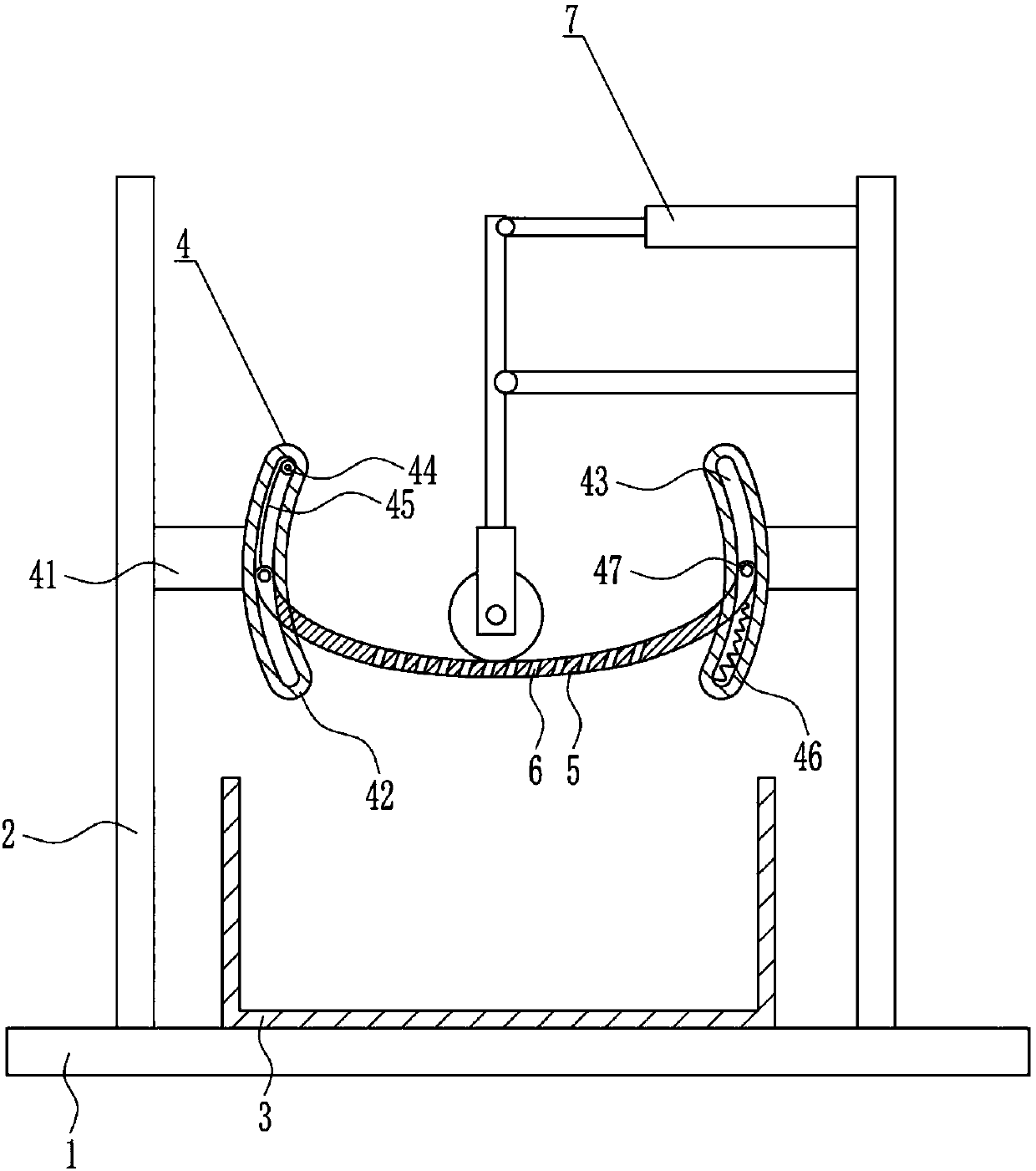

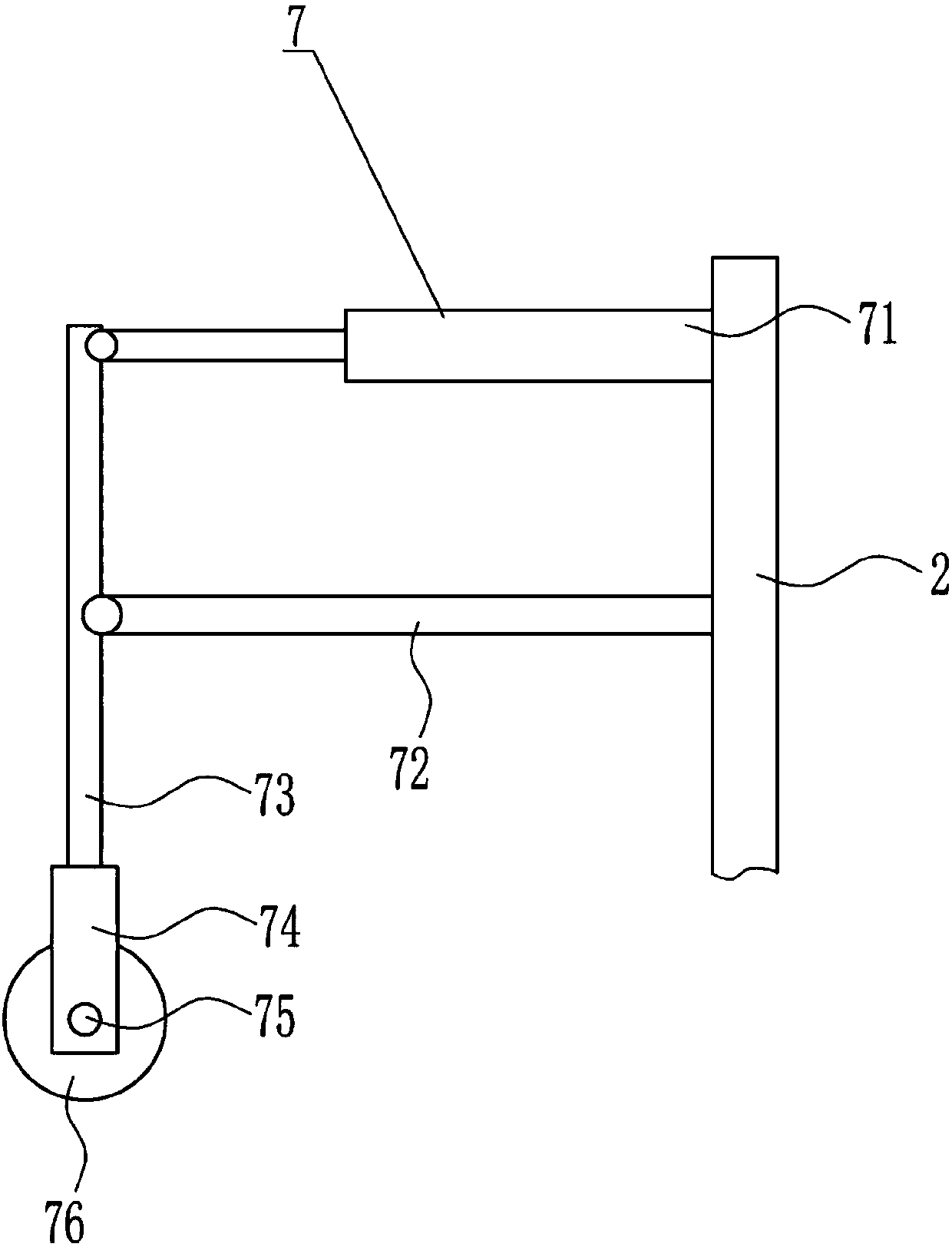

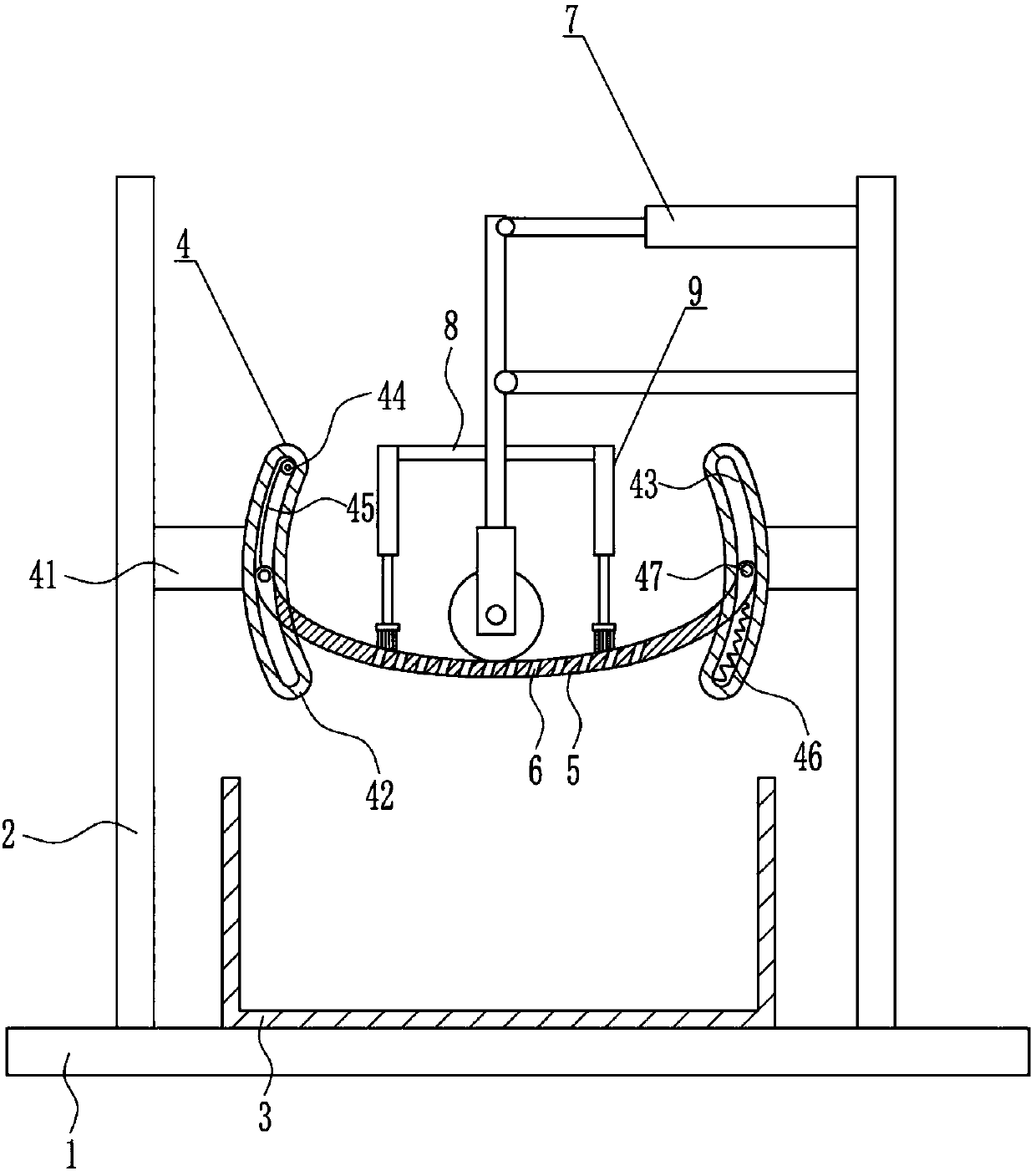

Plant liquid grinding and extracting equipment for medical cosmetology

InactiveCN107583307AGrinding speed is fastImprove grinding effectSolid solvent extractionGrain treatmentsEngineeringMedical treatment

The invention relates to plant liquid grinding and extracting equipment, in particular to plant liquid grinding and extracting equipment for medical cosmetology, which aims at solving the technical problem and providing the plant liquid grinding and extracting equipment for the medical cosmetology with the beneficial effects of high extracting efficiency, better grinding effect and simple operation. To solve the technical problem, the plant liquid grinding and extracting equipment for the medical cosmetology comprises a bottom plate, an n-shaped frame, a collecting box, a fixed plate, a driving mechanism, a grinding mechanism and the like, wherein the n-shaped frame is fixedly arranged at the top part of the bottom plate; the collecting box is arranged in the middle part of the top part ofthe bottom plate; the fixed plate is arranged at the top part of the interior of the n-shaped frame; the driving mechanism is arranged at the lower part of the front side of the fixed plate; a movement mechanism is arranged at the upper part of the front side of the fixed plate; a vertical rod is arranged at the bottom part of the driving mechanism. The plant liquid grinding and extracting equipment has the beneficial effects that the extracting efficiency is high, the grinding effect is better, and the operation is simple; by mutually matching the driving mechanism and the grinding mechanism, the plant liquid is ground, and the grinding speed is high.

Owner:钟光文

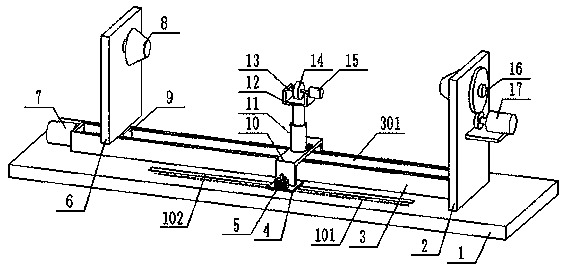

Polishing device for pipe fitting welding positions

ActiveCN110125756AReduce laborGood grinding effectEdge grinding machinesGrinding drivesArchitectural engineeringPipe fitting

The invention discloses a polishing device for pipe fitting welding positions. The polishing device comprises a fixed bottom plate, the upper end of the fixed bottom plate is provided with a guide rail and a fixed vertical plate, a fixed rotating shaft is mounted on the upper portion of the fixed vertical plate, a sliding groove is formed in the upper end surface of the guide rail, a movable seatand a driving assembly are mounted inside the sliding slot, a movable vertical plate is mounted at the upper end of the movable seat, a movable rotating shaft is mounted on the upper portion of the movable vertical plate, and the opposite ends of the movable rotating shaft and the fixed rotating shaft are provided with clamping columns; and the surface of the fixed bottom plate is provided with anadjusting groove, a sliding block is slidably mounted inside the adjusting groove, a moving plate is mounted at the upper end of the sliding block, a door frame is mounted at the upper end of the moving plate, a height adjusting rod is mounted at the upper end of the door frame, a fixing frame is mounted at the upper end of the height adjusting rod, and a polishing wheel is installed inside the fixing frame. The polishing device has the beneficial effects that the device can automatically polish the pipe fitting welding positions, the labor of an operator is greatly reduced, the polishing effect is good, and the efficiency is high.

Owner:SINOPEC JIANGHAN OILFIELD CONSTR ENG

Steel slag grinding aid and preparation method thereof

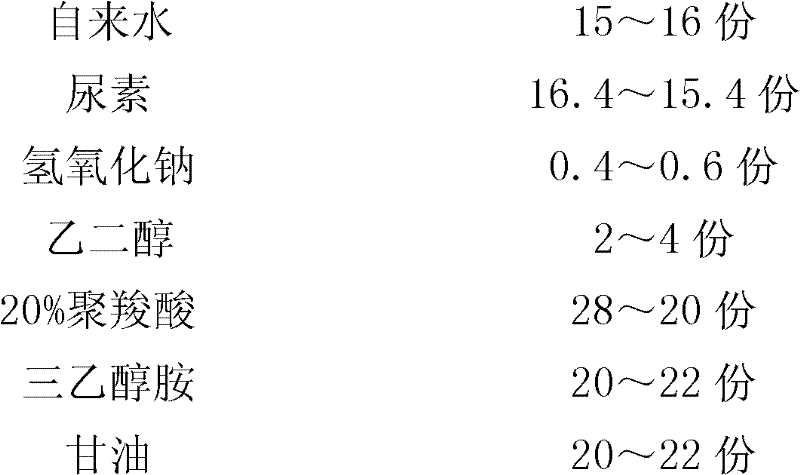

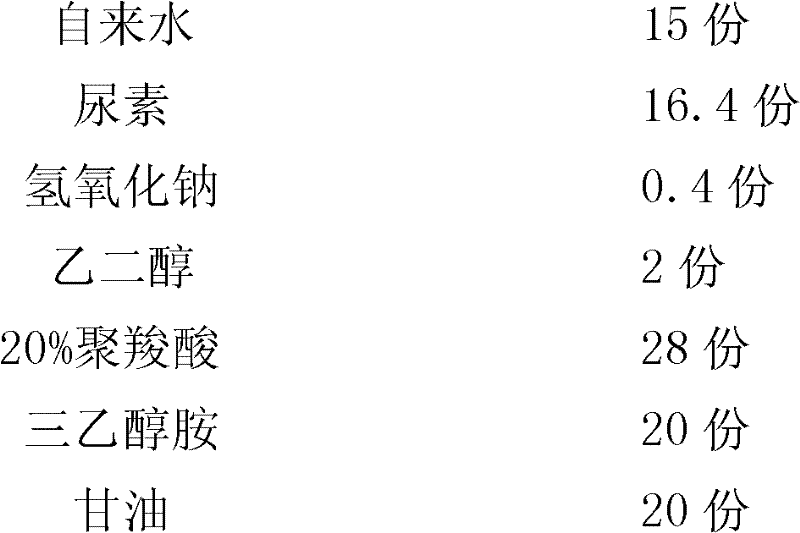

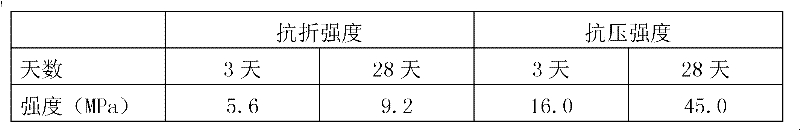

The invention discloses a steel slag grinding aid, comprising the following ingredients: 15-16 weight portions of tap water, 16.4-15.4 weight portions of urea, 0.4-0.6 weight portions of sodium hydroxide, 2-4 weight portions of glycol, 28-20 weight portions of 20% polycarboxylic acid, 20-22 weight portions of triethanolamine, and 20-22 weight portions of glycerin. The steel slag grinding aid is prepared by mixing the raw material according to the order, uniformly stirring, wherein, the ambient temperature of the mixing process is no lower than 20 DEG C, and the system temperature of the raw material solution in the mixing process is controlled to 40 DEG C. The preparation method is simple, and the steel slag grinding aid has excellent aid-grinding effect with small dosage and can well activate the activity of the steel slag powder because of no chloride ion included. According to the invention, the yield of the steel slag powder is increased by more than 30 %, and the quality of the steel slag powder meets the national quality standard, thus the steel slag grinding aid is an auxiliary agent with advantages of high efficiency and environmental protection.

Owner:孙贤文

Ceramic bond and preparation method thereof

ActiveCN105150122ALower firing temperatureImprove gripAbrasion apparatusGrinding devicesChromium sesquioxideLithium carbonate

The invention relates to a ceramic bond and a preparation method thereof, and belongs to the technical field of grinding wheel bonds. The ceramic bond is prepared from, by weight, 20%-40% of borosilicate glass, 22%-43% of feldspar, 10%-35% of nepheline syenite, 5%-13% of clay, 2%-5% of lithium carbonate and 3%-13% of chromium sesquioxide. According to the ceramic bond, all the components are subjected to a synergistic effect within a limited dosage range, the firing temperature of the ceramic bond is lowered to be 1000 DEG C, high-temperature burning loss of ceramic microcrystal grinding materials is avoided, the revolving strength of a grinding wheel manufactured through the bond is improved, and the grinding linear velocity reaches 80 m / s maximally. The preparation method is easy and convenient to operate, easy to control and suitable for industrial application and popularization.

Owner:白鸽磨料磨具有限公司

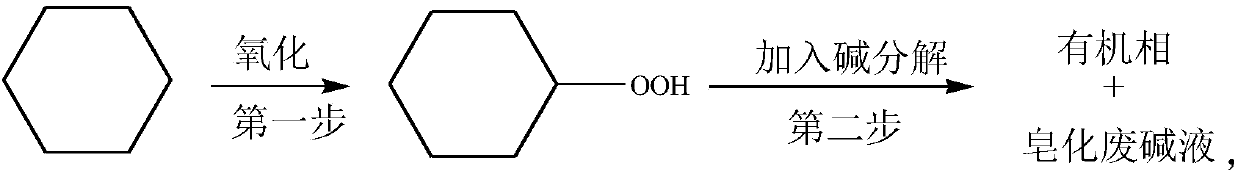

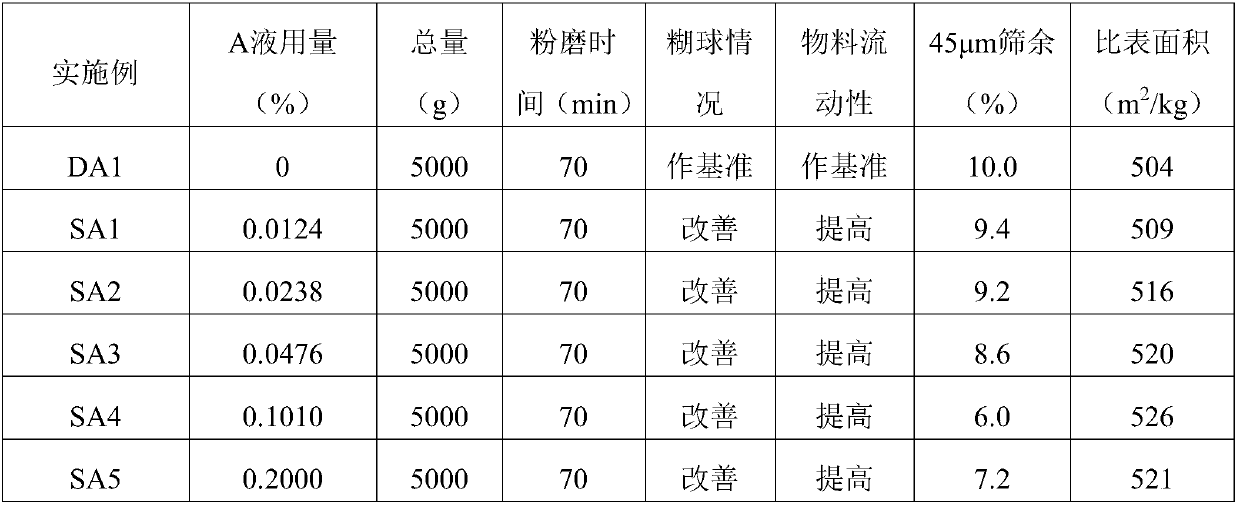

Grinding aid and application thereof

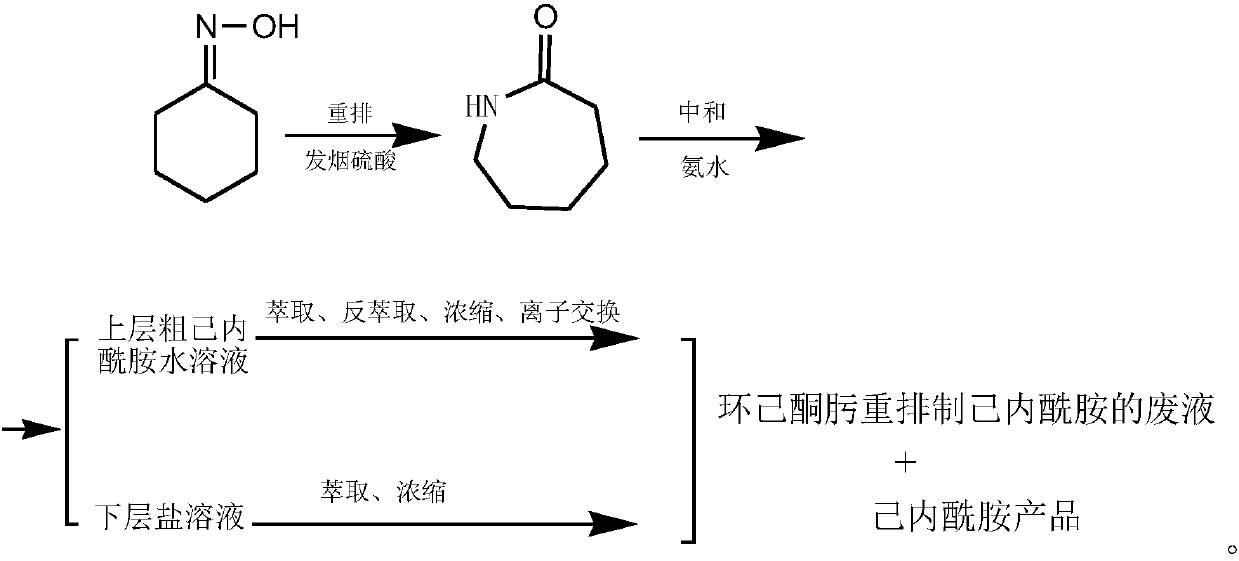

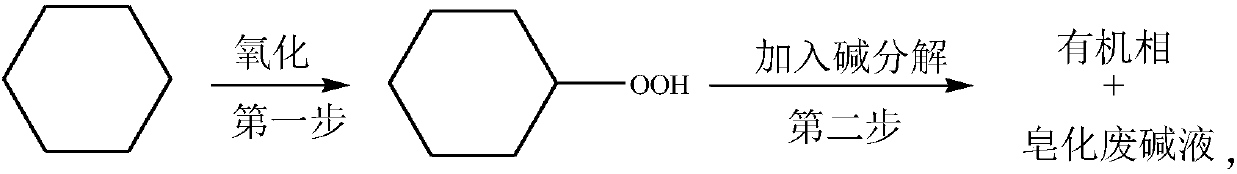

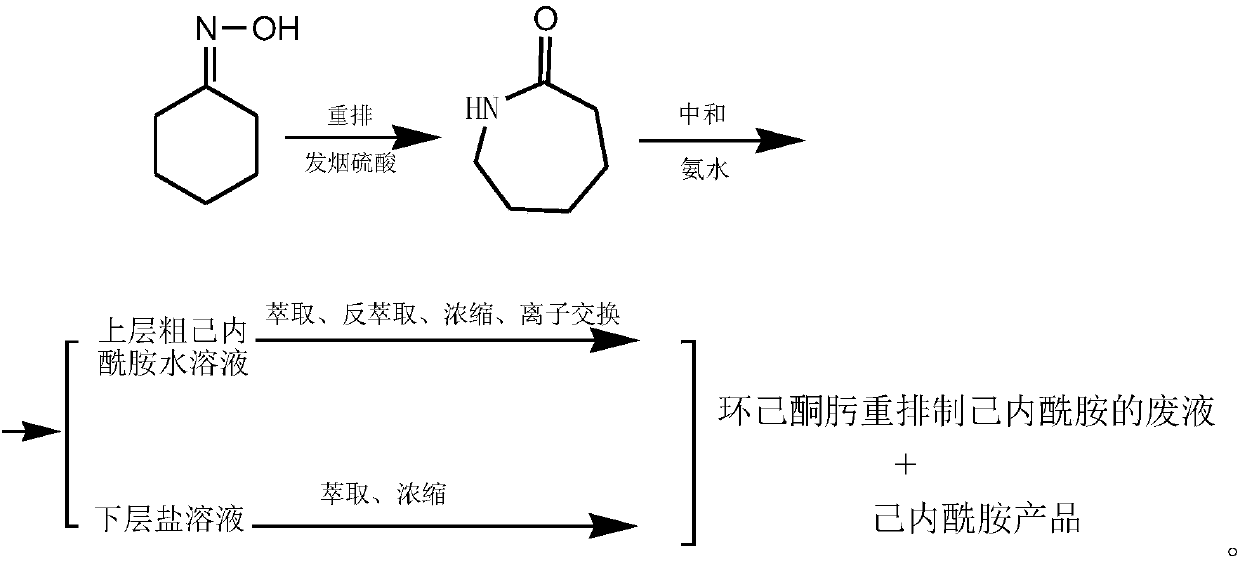

ActiveCN108017299ASolve the problem of reasonable handlingImprove liquidityLiquid wasteCyclohexanone

The invention provides a grinding aid and an application thereof. The grinding aid contains a waste liquid obtained after production of caprolactam from cyclohexanone. The grinding aid recycles the waste liquid obtained after production of caprolactam from cyclohexanone, and has a good grinding aiding effect.

Owner:湖南昌迪环境科技有限公司

Cement grinding method and cement grinding aid

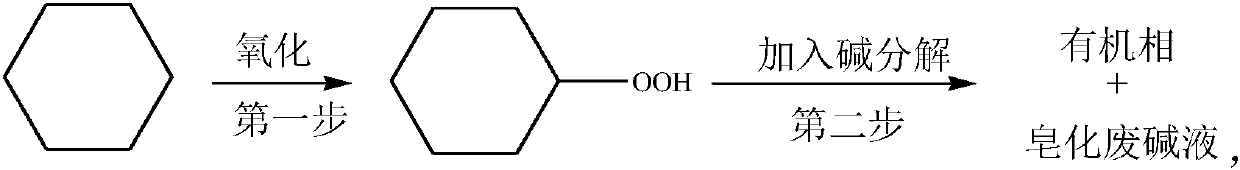

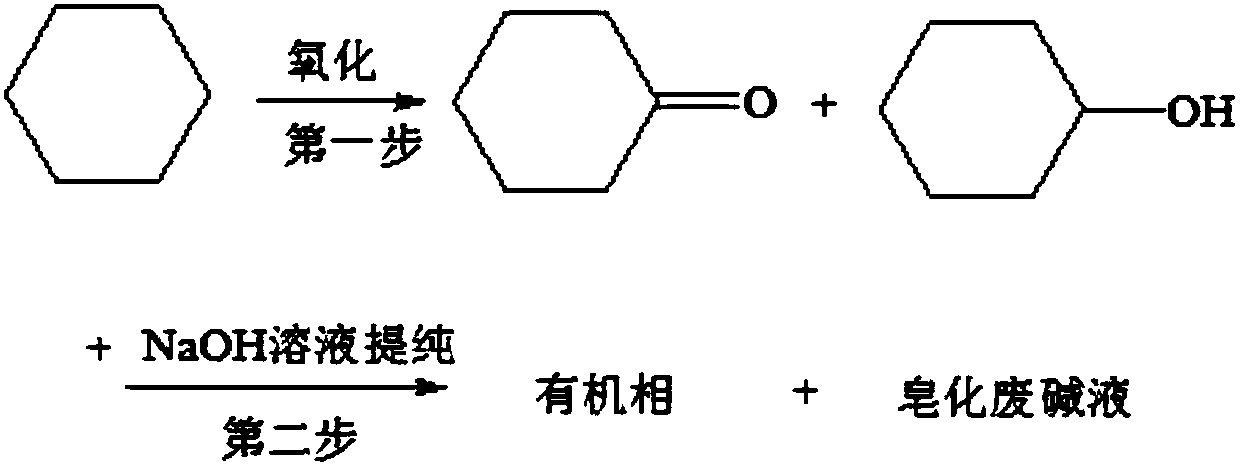

ActiveCN108017297ASolve the problem of reasonable handlingDoes not affect construction performanceCyclohexanoneCement grinding

The invention provides a cement grinding method and a cement grinding aid. The method includes: subjecting a to-be-grinded cement material and a cement grinding aid to grinding treatment together; wherein the cement grinding aid contains waste saponification lye generated in preparation of cyclohexanone by cyclohexane oxidation. The cement grinding method provided by the invention can take the waste saponification lye generated in preparation of cyclohexanone by cyclohexane oxidation as the grinding aid for cement grinding.

Owner:湖南昌迪环境科技有限公司

Waterproof emery cloth for grinding of car industry and manufacturing method thereof

ActiveCN105415211AGood grinding effectFlat surfaceAbrasion apparatusGrinding devicesAdhesive cementMechanical engineering

The invention discloses a waterproof emery cloth for grinding of the car industry. The waterproof emery cloth comprises a base abrasive cloth, a base material reinforcing layer, abrasive particles and an adhesive, wherein the surface of the base abrasive cloth is divided into a plurality of areas; the abrasive particles attached in the same area have the different size, and the abrasive particles attached in different areas are different in size; the size of the abrasive particles attached to each area of the base material reinforcing layer gradually increases from the center of the base abrasive cloth to the side edge of a base material; the abrasive particles are compound abrasive particles and prepared by compounding nanometer cerium dioxide particles and silicon dioxide particles; the adhesive comprises a component A and a component B. The invention further designs a manufacturing method of the waterproof emery cloth for grinding of the car industry. The method comprises the following processes: coating the adhesive; pre-curing; arranging sand; post-curing; flexing with water; cutting with laser; performing anti-deformation treatment for the base material; storing. The manufacturing method is simple and easy to carry out, and low in manufacturing cost; the manufactured waterproof emery cloth for grinding is resistant to ageing, resistant to fatigue, resistant to high temperature, resistant to abrasion, and long in service life.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

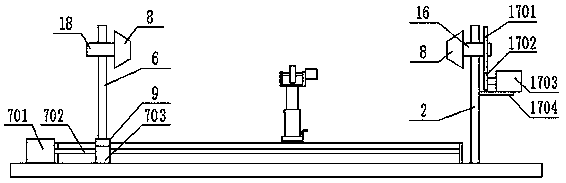

Traditional Chinese medicinal material grinding device for medical treatment

The invention relates to a traditional Chinese medicinal material grinding device and particularly relates to a traditional Chinese medicinal material grinding device for medical treatment. The invention aims to provide the traditional Chinese medicinal material grinding device for medical treatment good in grinding effect, high in grinding efficiency and labor-saving and time-saving. In order to solve the technical problem, the invention provides the traditional Chinese medicinal material grinding device for medical treatment. The traditional Chinese medicinal material grinding device for medical treatment comprises a bottom plate, a left side plate, a right side plate, a top plate, a slide rail, a slide block, a grinding groove, a baffle plate, a first connecting rod, a second connecting rod, a magnet, an iron block, a handle, a first motor and the like; the left side plate, the slide rail and the right side plate are successively arranged on the upper portion of the bottom plate from left to right; a top plate is connected between the tops of the left side plate and the right side plate; the slide block is slidably arranged on the upper portion of the side rail; the grinding groove is formed in the upper portion of the slide block; the baffle plate is arranged on the lower portion of the left side plate; and the bottom of the baffle plate is connected to the bottom of the left side plate in a hinged manner. The traditional Chinese medicinal material grinding device for medical treatment provided by the invention achieves effects of good grinding effect, high grinding efficiency and labor and time saving.

Owner:PINGHU RUIYANG PRECISION MACHINERY

Multistage grinding device for traditional Chinese medicinal materials

The invention discloses a multistage grinding device for traditional Chinese medicinal materials. The device comprises a base and a rack. A lifting rack is arranged on the inner side of the rack, a grinding cone is fixedly mounted at the bottom of the lifting rack, a grinding table is arranged on the base, the lower side of the grinding table is rotatably mounted on the base through a rotating shaft, and a grinding groove matched with the grinding cone is formed in the upper side of the grinding table; two grinding cavities are symmetrically formed in the inner side of the lower part of the grinding table, grinding rollers are rotatably mounted in the grinding cavities, the upper sides of the grinding cavities are communicated to the inner parts of the grooves and the lower sides of the grinding cavities are communicated to the outer side. The device grinds the traditional Chinese medicinal materials primarily by matching the grinding cone which moves up and down continuously with thegrinding table which rotates intermittently clockwise and anticlockwise and further grinds the traditional Chinese medicinal materials through the grinding rollers, so that the device is not only is high in grinding efficiency, but also is excellent in grinding effect.

Owner:石俊杰

Grinding device for precise part machining

InactiveCN109108777AEasy to polishGood grinding effectGrinding drivesGrinding machinesControl engineering

The invention discloses a grinding device for precise part machining. The grinding device comprise a worktable, a moving rod is arranged at the upper end of the worktable, a supporting plate is arranged on the moving rod, a first fixed rod and a second fixed rod are arranged on the supporting plate, a first rotating shaft is arranged on the first fixed rod, a first mounting plate is arranged at the right end of the first rotating shaft, a first electric telescopic rod is arranged at the right end of the first mounting plate, a first clamping plate is arranged at the right end of the first electric telescopic rod, a second rotating shaft is arranged on the second fixed rod, a second mounting plate is arranged at the left end of the second rotating shaft, a second electric telescopic rod isarranged at the left end of the second mounting plate, a second clamping plate is arranged at the left end of the second electric telescopic rod, a fourth electric telescopic rod is arranged at the lower end of a moving table, a fixed plate is arranged at the lower end of the fourth electric telescopic rod, a third rotating motor is arranged on the lower end of the fixed plate, a third rotating shaft is arranged at the lower end of the third rotating motor, a connecting rod is arranged at the lower end of the third rotating shaft in a threaded manner, and a grinding head is arranged at the lower end of the connecting rod. The grinding device is good in grinding effect, high in efficiency and capable of preventing environment pollution.

Owner:温惠青

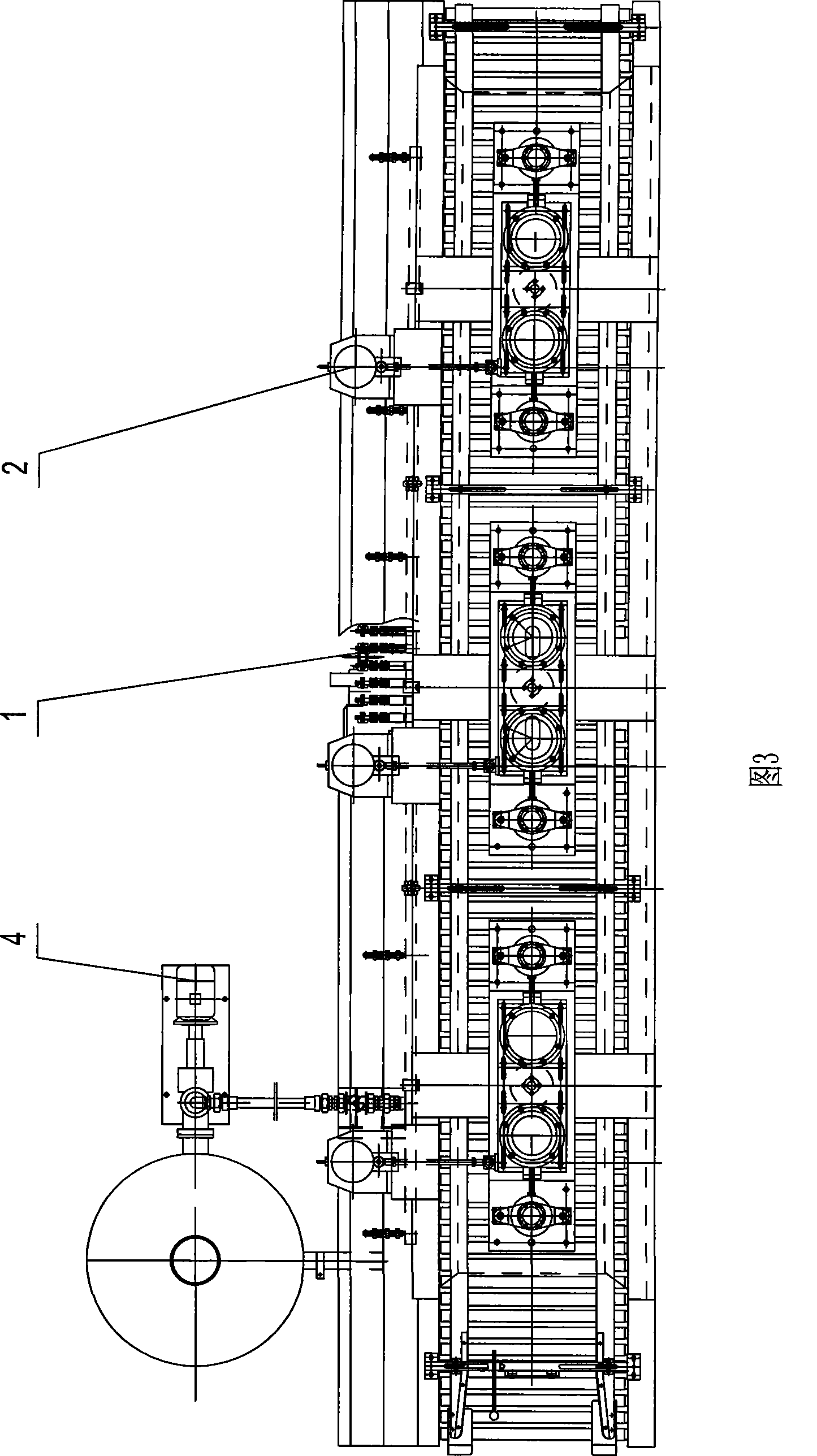

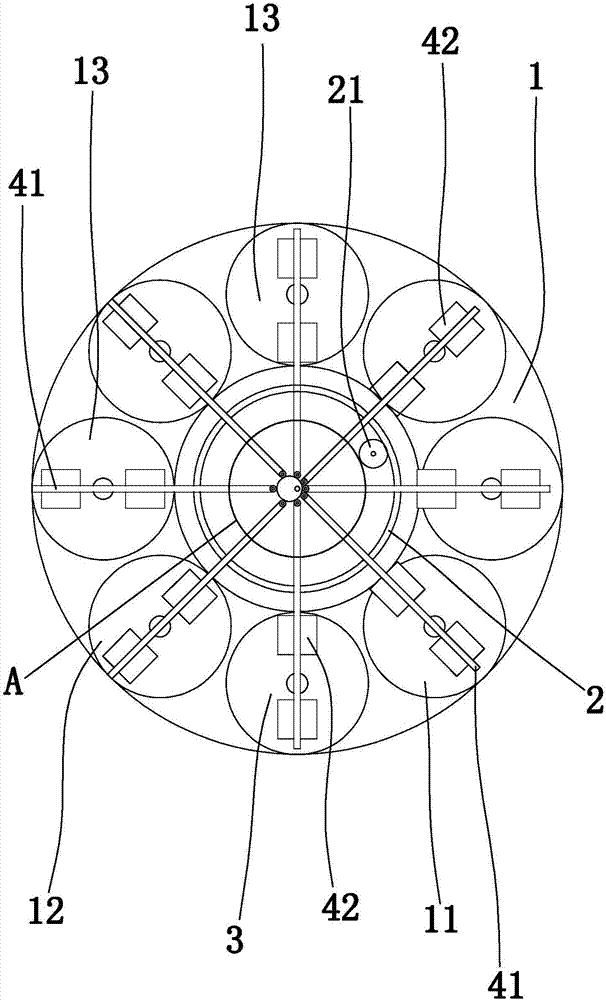

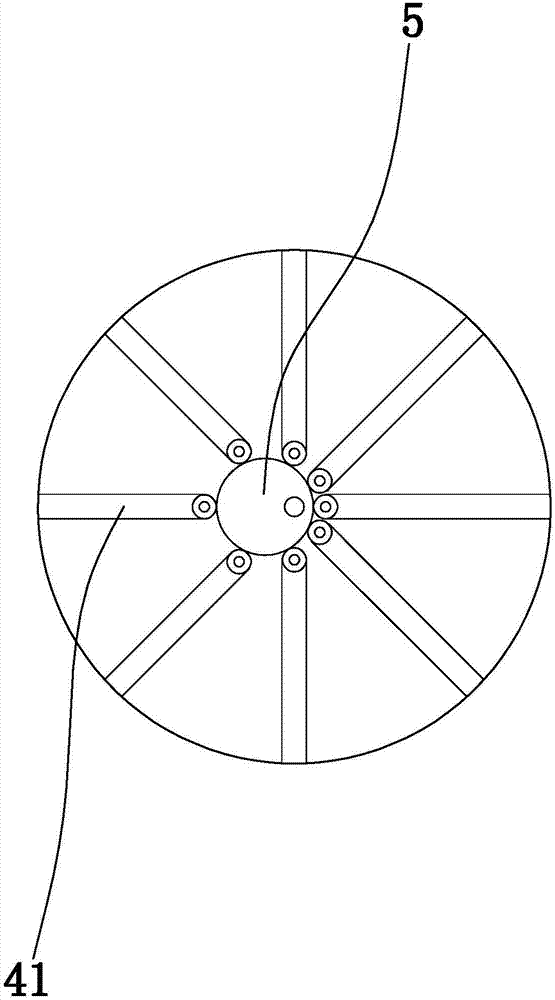

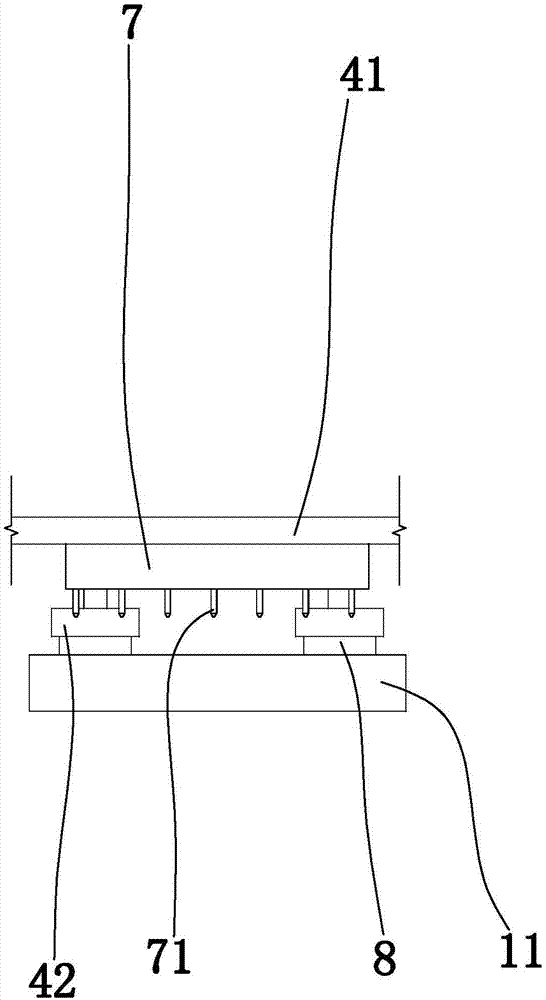

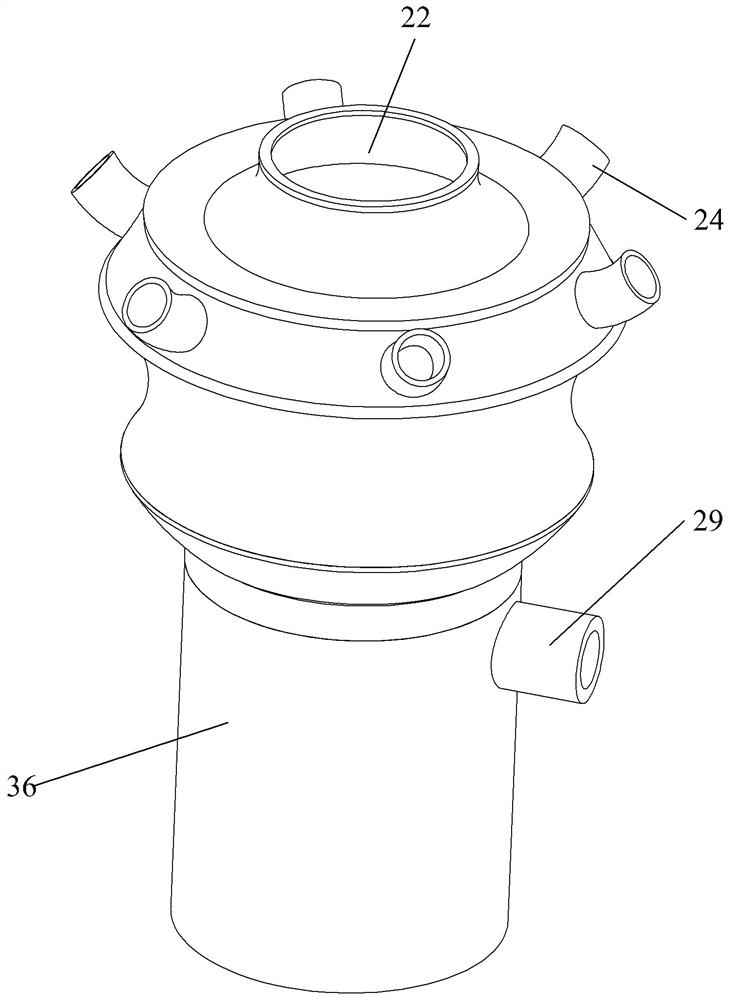

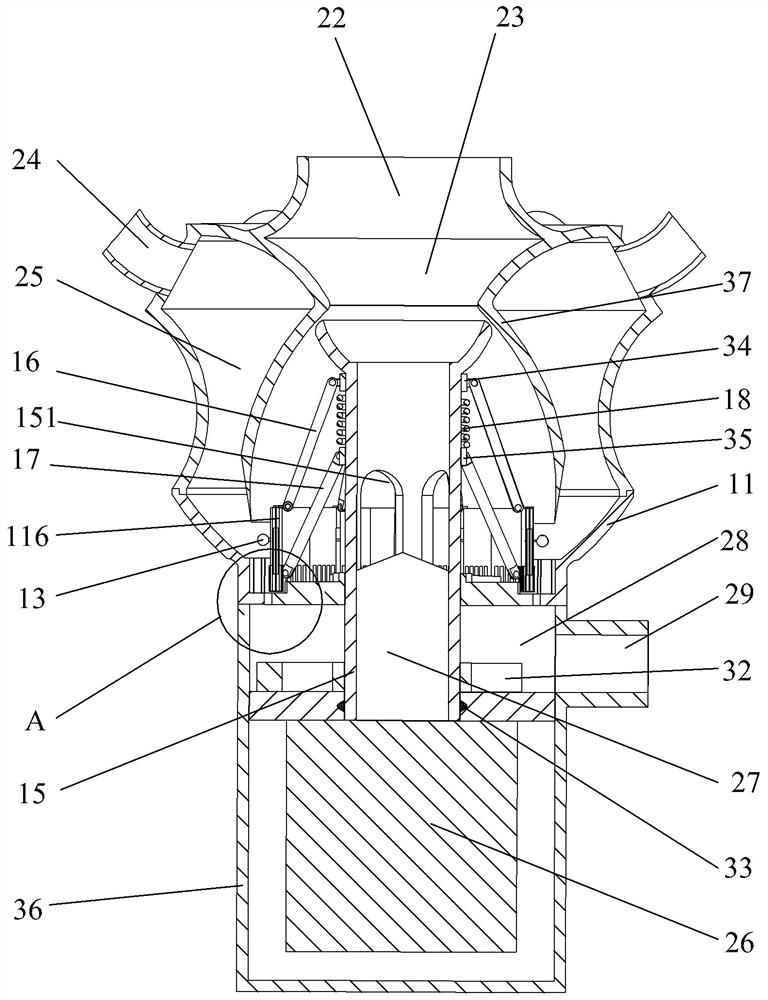

Planet continuous mill

InactiveCN107398808AEffective continuous grindingStrong automatic cleaning abilityGrinding machinesGrinding work supportsEngineeringMachining process

The invention discloses a planet continuous mill which comprises a main rack, empty stations, a drive gear ring and a main motor. A starting mill, a terminal mill and multiple middle mills are arranged on the main rack. Each empty station comprises a supporting table. A starting mill disc, middle mill discs, a terminal mill disc and the supporting tables are sequentially distributed in the circumferential direction of the drive gear ring. The drive gear ring is rotationally connected with the main rack. Multiple workpiece locating structures are arranged on the drive gear ring. A workpiece locating groove is formed in the bottom of each gravity press block. At least one vertical sliding rod is arranged on each transverse sliding rail rod. The vertical sliding rods are connected with the transverse sliding rail rods through locating pins. A vertical sliding groove is formed in each gravity press block. The vertical siding rods are in sliding fit with the vertical sliding grooves in the corresponding gravity press blocks. The planet continuous mill has the beneficial effects that workpieces can be effectively ground continuously, grinding machining from rough to fine can be achieved through one-time grinding, and the machining process is convenient, fast and efficient; and the automatic clearing capacity of grinding waste is high, the grinding furnaces can be cleared in advance before the workpieces arrive, and the grinding effect is good.

Owner:义乌市台荣超硬制品有限公司

Chlorine-free highly effective composite enhanced solid cement grinding aids and production method

The invention provides a chlorine-free high-efficiency composite reinforcing type solid cement grinding aid and production method, the grinding aid is composed of inorganic substrate material, organic material and water, strong antifreeze and antirust; the inorganic substrate material is composed of powder coal ash, sodium carbonate and sodium silicate, the mixing solution of any three or four among triethanolamine, glycol, propanediol, glycerolor paper pulp waste liquid is selected as the organic material, the inorganic strong antifreeze is composed of aluminum sulfate, calces or sodium hydrogen, sodium acetate or carbamide, and the antirust is sodium dihydrogen phosphate. The production method is the following: first the inorganic strong antifreeze is utilized to perform the complexation and modification of the organic material solution, and then the obtained mixing solution and the inorganic substrate material are furthermore compounded, reacted, blended and crushed. The invention has simple process, low cost, wide application range, good anti-freezing anti-rusting functions, and can improve later strength of cement obviously without disadvantage influence, and also obviously reduce the using amount of cement clinker by 20 percent, thereby having outstanding economical benefit.

Owner:DALIAN UNIV OF TECH

High efficiency cement composite grinding aid

An efficient composite grinding aid used for production of cement contains proportionally triethanolamine, acetic aid, aluminium sulfate solution, waste paper pulp liquid, salt of low-molecular fatty acidand water. Its advantages are low cost, high effect and high quality of cement.

Owner:沈阳建筑工程学院

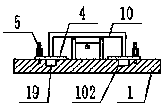

Processing technology and processing device for anti-deformation corundum-mullite high-temperature load bearing board

ActiveCN112934438ASave time and energyGood grinding effectTransportation and packagingMixersBall millMachining process

The invention relates to the technical field of load bearing board processing, and particularly relates to a processing technology and a processing device for an anti-deformation corundum-mullite high-temperature load bearing board. The processing device for the anti-deformation corundum-mullite high-temperature load bearing board comprises grinding and mixing equipment and a dry-method ball mill. The grinding and mixing equipment comprises a grinding device and a driving device. The grinding device comprises a grinding ring groove, a grinding cylinder and an expansion return device. According to the processing device for the anti-deformation corundum-mullite high-temperature load bearing board, when raw materials of the load bearing board are processed, the large raw materials are preliminarily ground firstly, the ground raw materials in an inner cavity and an outer cavity pass through the same position, and the raw materials can be fully mixed; and the particle size of the raw materials is smaller than a preset numerical value, the raw materials can be mixed and ground in advance before being fully ground, all the raw materials can be further mixed and ground conveniently, and a large amount of time and energy are saved. In addition, the grinding cylinder is in a dynamic change process in the grinding process, and therefore the grinding cylinder cannot be stuck.

Owner:河南蚂蚁新材料有限公司

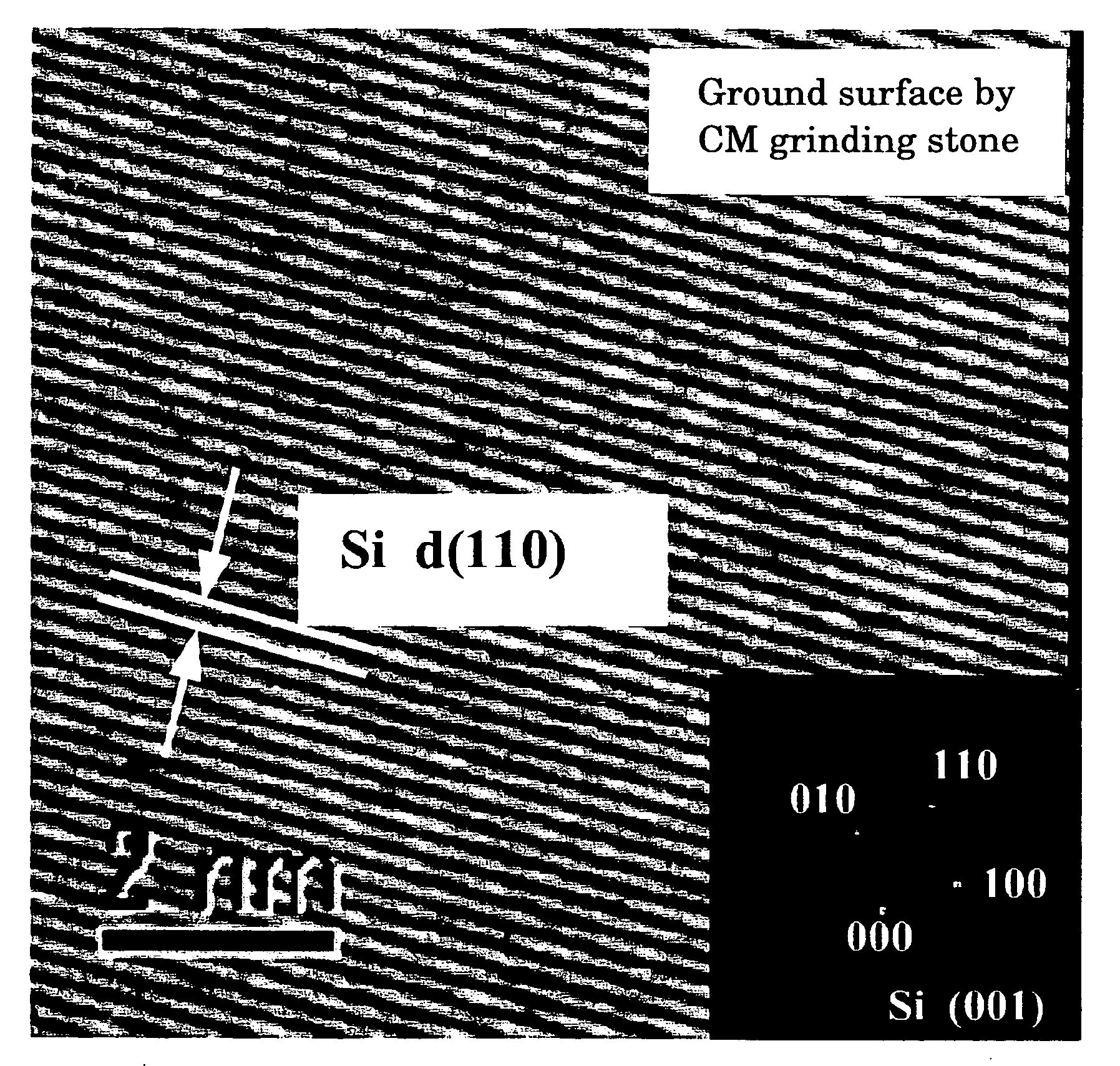

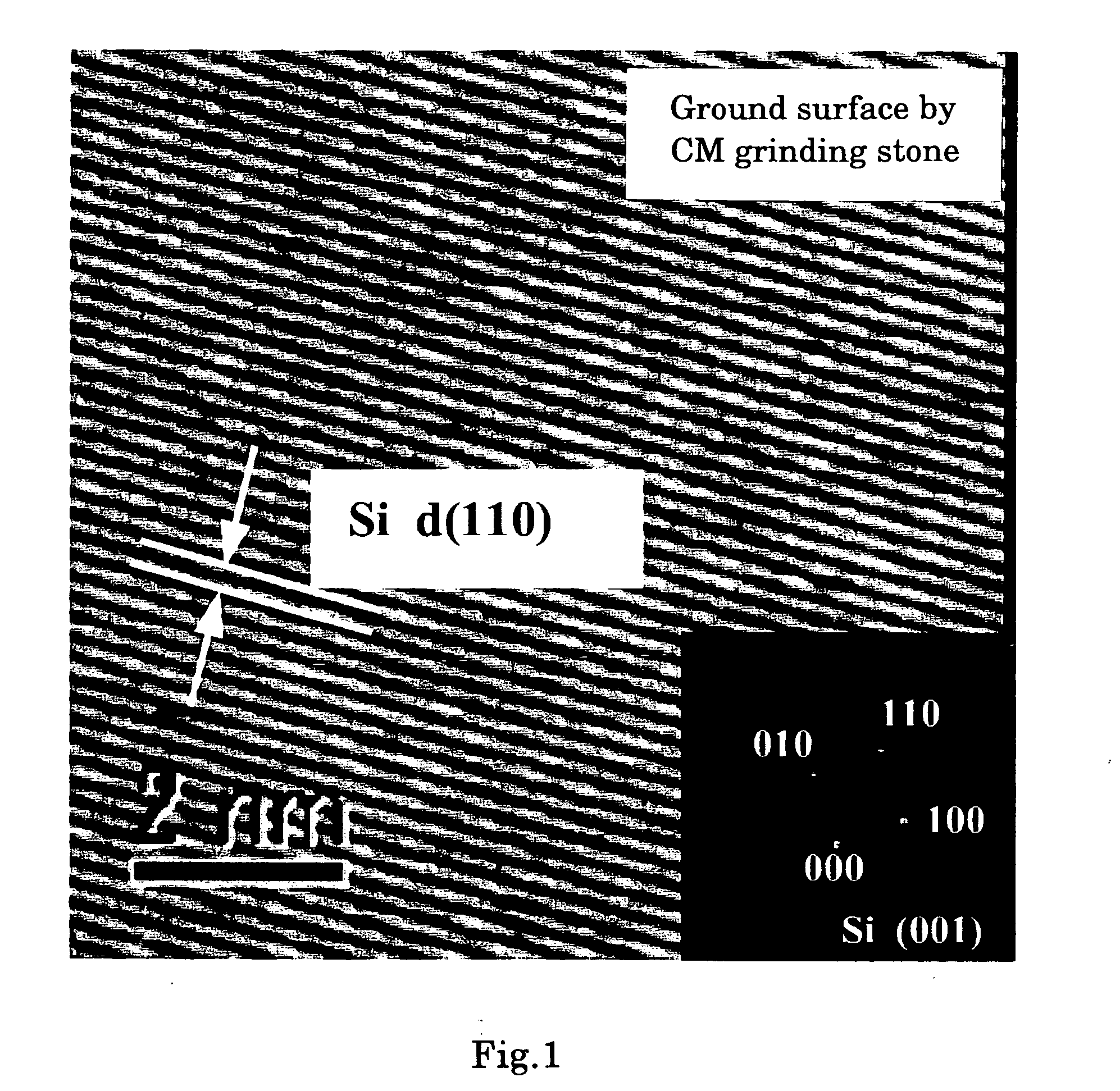

Synthetic grinding stone

ActiveUS20100037530A1Good grinding effectImprove grinding forcePigmenting treatmentOther chemical processesCerium oxideAdamite

Owner:TOKYO DIAMOND KOGU +1

Petroleum coke high-efficiency grinding plant for battery production

The invention relates to a petroleum coke grinding plant, particularly a petroleum coke high-efficiency grinding plant for battery production. The invention aims to provide a petroleum coke high-efficiency grinding plant for battery production, which has the advantages of uniform grinding and low workload and is convenient to operate. In order to solve the technical problems, the invention provides a petroleum coke high-efficiency grinding plant for battery production. The petroleum coke high-efficiency grinding plant for battery production comprises a first gear, a first motor, a first bracket, a second gear, a second bracket, a first connecting rod, a second connecting rod, a guide plate, a top plate, an L-shaped bracket and the like, wherein the left end of the top of the bottom plate is welded with a left rack; the left side of the top of the bottom plate is welded with a support rod; and the top end of the support rod is fixedly connected with a second motor through screws. The petroleum coke high-efficiency grinding plant for battery production has the advantages of uniform grinding and low workload, is convenient to operate, and performs the important function of favorable grinding effect, higher work efficiency and high safety.

Owner:冠县泰荣房地产开发有限公司

Cement mixture grinding method and cement mixture grinding aid

ActiveCN108017298ASolve the problem of reasonable handlingDoes not affect construction performanceCyclohexanoneSaponification

The invention provides a cement mixture grinding method and a cement mixture grinding aid. The method includes: subjecting a to-be-grinded cement mixture and the cement mixture grinding aid to grinding treatment together; specifically, the cement mixture grinding aid contains waste saponification lye generated in preparation of cyclohexanone by cyclohexane oxidation. The cement mixture grinding method provided by the invention can take the waste saponification lye generated in preparation of cyclohexanone by cyclohexane oxidation as the grinding aid for cement mixture grinding.

Owner:湖南昌迪环境科技有限公司

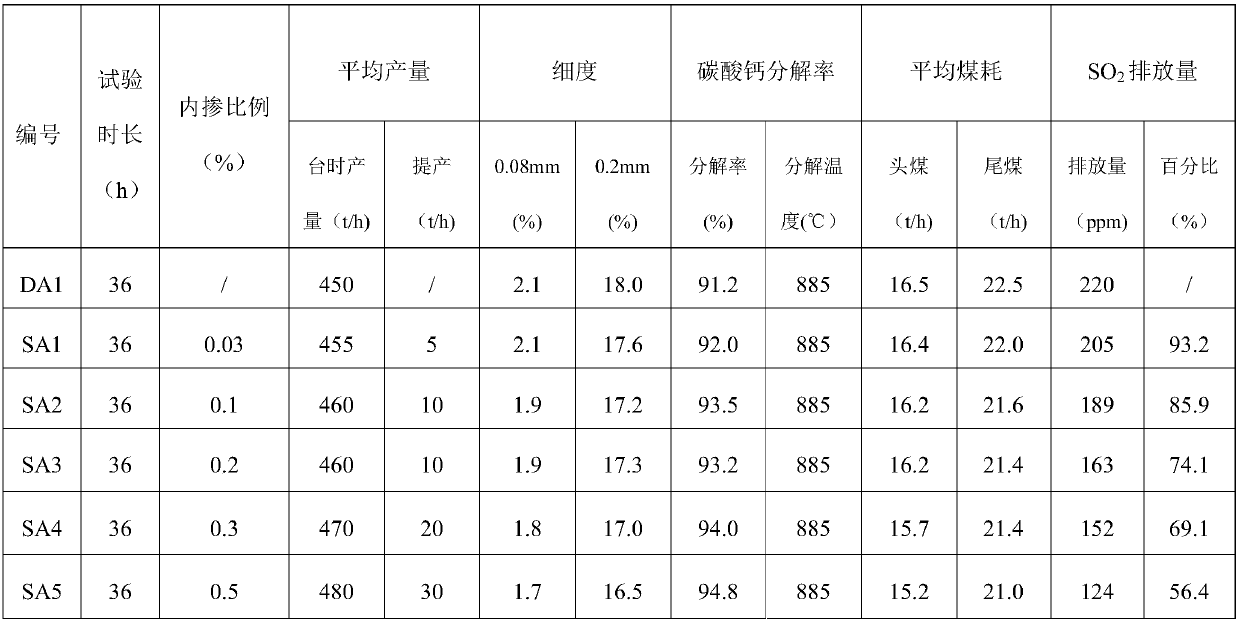

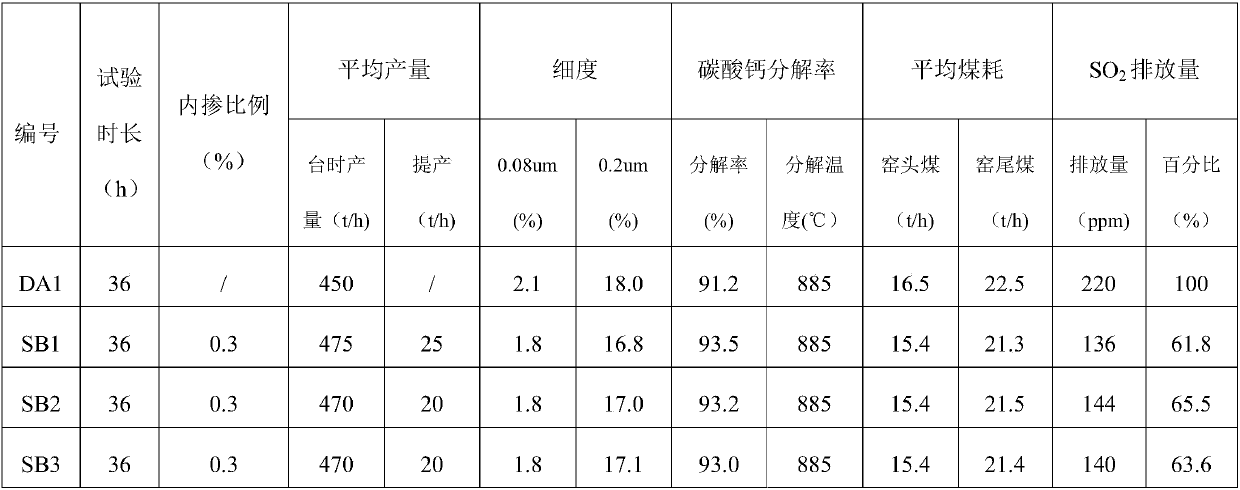

Cement raw material additive, application thereof and cement production process

ActiveCN109824284ASolve the problem of reasonable handlingDoes not affect mechanical propertiesCement productionToxic industrial wasteCoal

The invention relates to a cement raw material additive, application thereof and a cement production process. The cement raw material additive comprises industrial waste alkali liquid and an alkalineimprover. The cement raw material additive can recycle the industrial waste alkali liquid during cement raw material grinding and cement production and has good comprehensive effects of increasing yield, lowering coal consumption, improving raw material burnability and desulfurizing.

Owner:湖南昌迪环境科技有限公司

Optical fiber grinding method

The invention relates to an optical fiber grinding method. The method includes: stripping and cleaning an optical fiber coating layer, cleaning a clamp, solidifying peregal O to clamp optical fibers,removing photoresist, performing coarse grinding, performing medium grinding, performing fine grinding, polishing, cleaning, detecting and the like, wherein a photoresist-removing grinding piece is grinding paper of 30 micrometers, a coarse grinding piece is grinding paper of 9 micrometers, a medium grinding piece is grinding paper of 3 micrometers, a fine grinding piece is grinding paper of 1 micrometer, and a polishing piece is grinding paper of 0.02 micrometer; a vegetable adhesive solution is used for cleaning after each grinding step, and the adhering feature and good water solubility ofthe vegetable adhesive solution is beneficial to the removing of end-face impurities and do not have adverse effects on the optical fibers. The method is simple to operate and good in grinding effect.

Owner:SUZHOU TABINUO ELECTROMECHANICAL

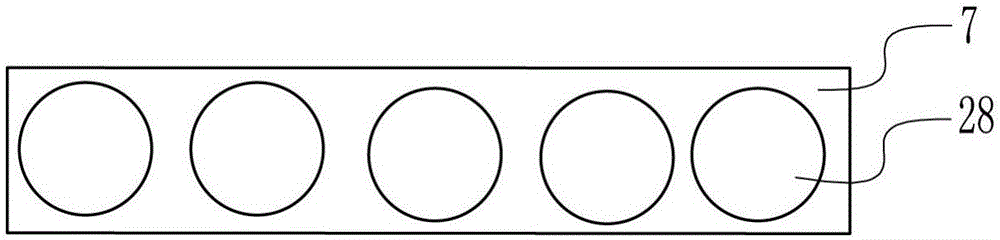

Wheat grinding device for food processing

ActiveCN107899669AFully groundedGood grinding effectGrain treatmentsEngineeringMechanical engineering

The invention discloses a wheat grinding device for food processing, and belongs to the technical field of food processing. The wheat grinding device is capable of being simple in operation, comprehensive in grinding and high in working efficiency. The grinding device for food processing comprises a bottom plate, supports, a collecting frame, a swing device, a loading plate and a grinding device body; the supports are symmetrically and vertically arranged on two ends of the bottom plate, and the collecting frame is arranged on the position, between the two supports, of the bottom plate; the swinging device is fixedly arranged on the supports, the loading plate is arranged on swinging parts of the swinging device and is located above the collecting frame, and multiple discharging holes areformed in the loading plate; and the grinding device body is fixed on the support on one side, and a grinding part of the grinding device body is in contact with the upper surface of the loading plate. The wheat grinding device has the advantages that the grinding effect is good, and the effects of simple operation, comprehensive grinding and the high working efficiency are achieved.

Owner:SHAANXI UNIV OF SCI & TECH

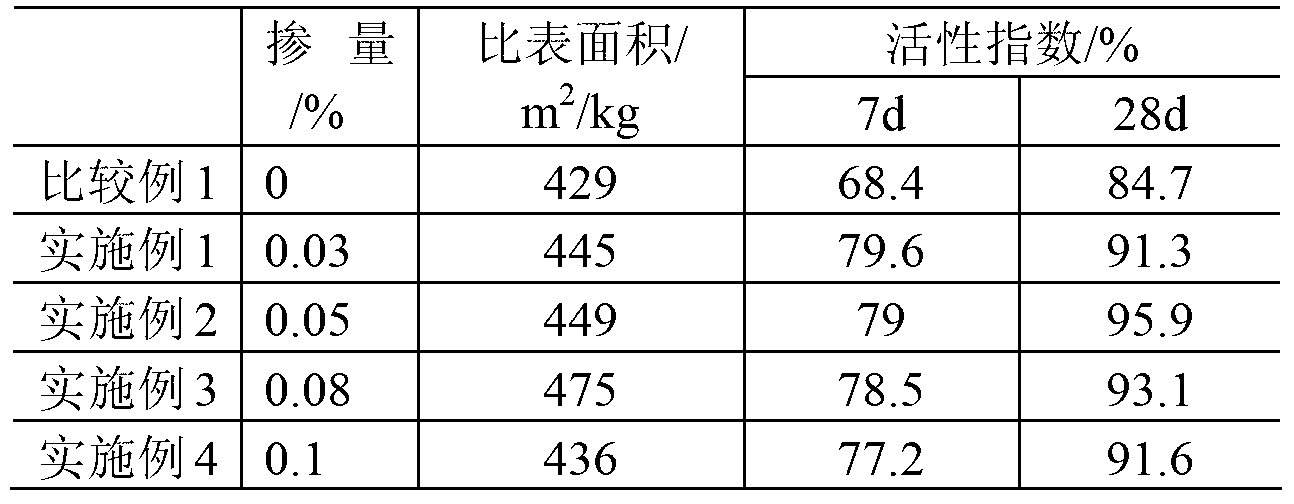

Process flow for automatically producing fiber optic connector

The invention discloses a process flow for automatically producing a fiber optic connector, comprising the steps of: a part assembling process of assembling the parts into a connector joint, and injecting glue into the connector joint to keep the glue from solidifying; an automatic curing process of heating a connector for solidification on a curing device and performing constant-temperature cooling; an automatic grinding process of using a manipulator to automatically grind the front end surface of a fiber connector joint by means of 8-shaped grinding; a test process of using a virtualizationtest to individually test three indexes by segment, namely, geometric size, insertion loss and return loss, and setting insertion loss and return loss to automatic discrimination; and an automatic packaging process of using an assembly line of automatic winding, bundling, certificate sticking, and bagging. The process flow provided by the invention greatly saves the labor cost by adopting an automated production mode instead of the post requiring lots of the front-end personnel, and also improves the stability, reliability, excellent rate and production efficiency of the product.

Owner:SICHUAN TIANYI COMHEART TELECOM

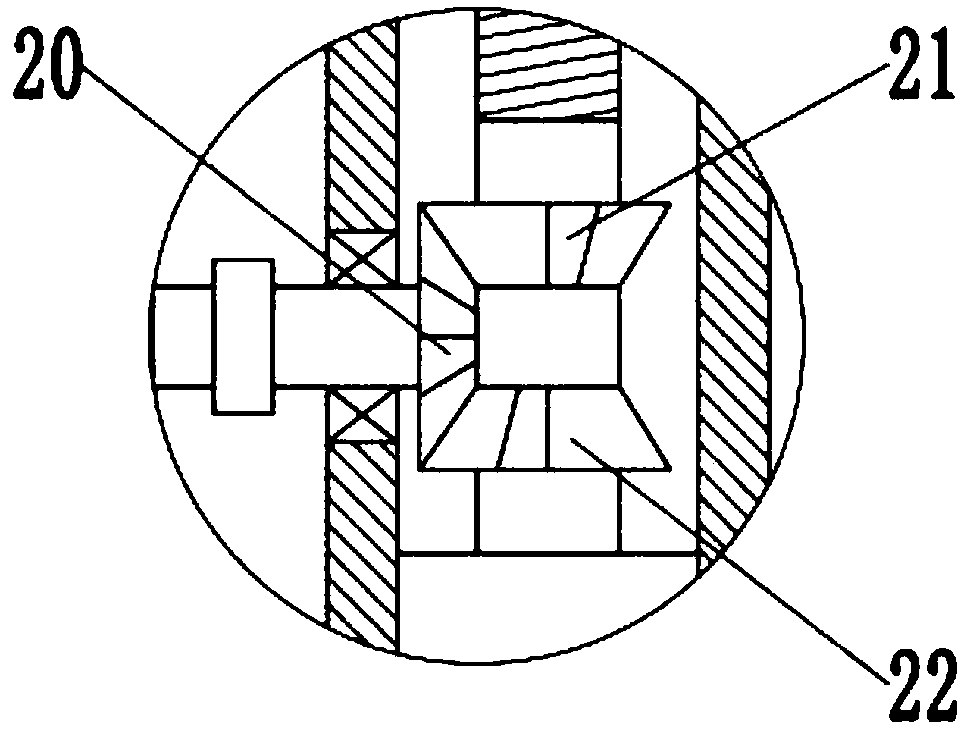

Gear deburring device

ActiveCN106695487AImprove work efficiencyGood grinding effectEdge grinding machinesGrinding drivesEngineeringGear tooth

The invention relates to the technical field of gear machining, in particular to a gear deburring device. The gear deburring device comprises a hollow base. A first rotation shaft and a second rotation shaft are arranged on the two sides of the base correspondingly. A plurality of same to-be-machined gears penetrate the first rotation shaft. Tooth grooves of the gears on the first rotation shaft are opposite in the longitudinal direction. The first rotation shaft is provided with a motor. A winding belt is wound around the second rotation shaft, and longitudinal strip-shaped grooves and transverse strip-shaped grooves are evenly formed in the winding belt and divide the winding belt into the grid shape. Air bags are arranged in grids on the winding belt and externally provided with elastic fine abrasive paper. A hollow interlayer is arranged on the winding belt. One-way air inlet holes communicating with the hollow interlayer are formed in the connecting positions of the air bags and the winding belt. The hollow interlayer of the winding belt is connected with an air blower. The lower end of the second rotation shaft is connected with an air cylinder. The problems that the process of deburring between teeth of the gears is not uniform, consequently, dull polish patterns exist between the gears obtained after being deburred, and the tooth profile of the gears is damaged are solved.

Owner:重庆和烁精密锻造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com