Patents

Literature

904results about How to "Automate operations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing cordyceps militaris fermentation rice by utilizing solid state fermentation of rice

The invention provides a method for producing cordyceps militaris fermentation rice (cordyceps rice for short) by utilizing solid state fermentation of rice, and the method is characterized in that the rice is taken as a main fermentation substrate; and the cordyceps mycelia grows in the rice through a solid state fermentation manner so as to obtain the rice rich in the cordyceps mycelia. The method comprises the following steps: 1. preparing a cordyceps militaris liquid strain; 2. preparing a rice solid state fermentation culture medium; and 3. inoculating and fermenting. In the method, the medical effect of the cordyceps militaris is organically combined with the nutrition of the rice, thus the product contains various nutritive components and mineral elements, especially cordycepin andcordycepic acid, wherein, the content of the cordycepin is more than or equal to 600mg / 100g, and the content of the cordycepic acid is more than or equal to 3g / 100g, thereby improving the immunity ofthe organism, inhibiting tumours, preventing ageing, and satisfying the requirements of healthy eating of people.

Owner:王永显

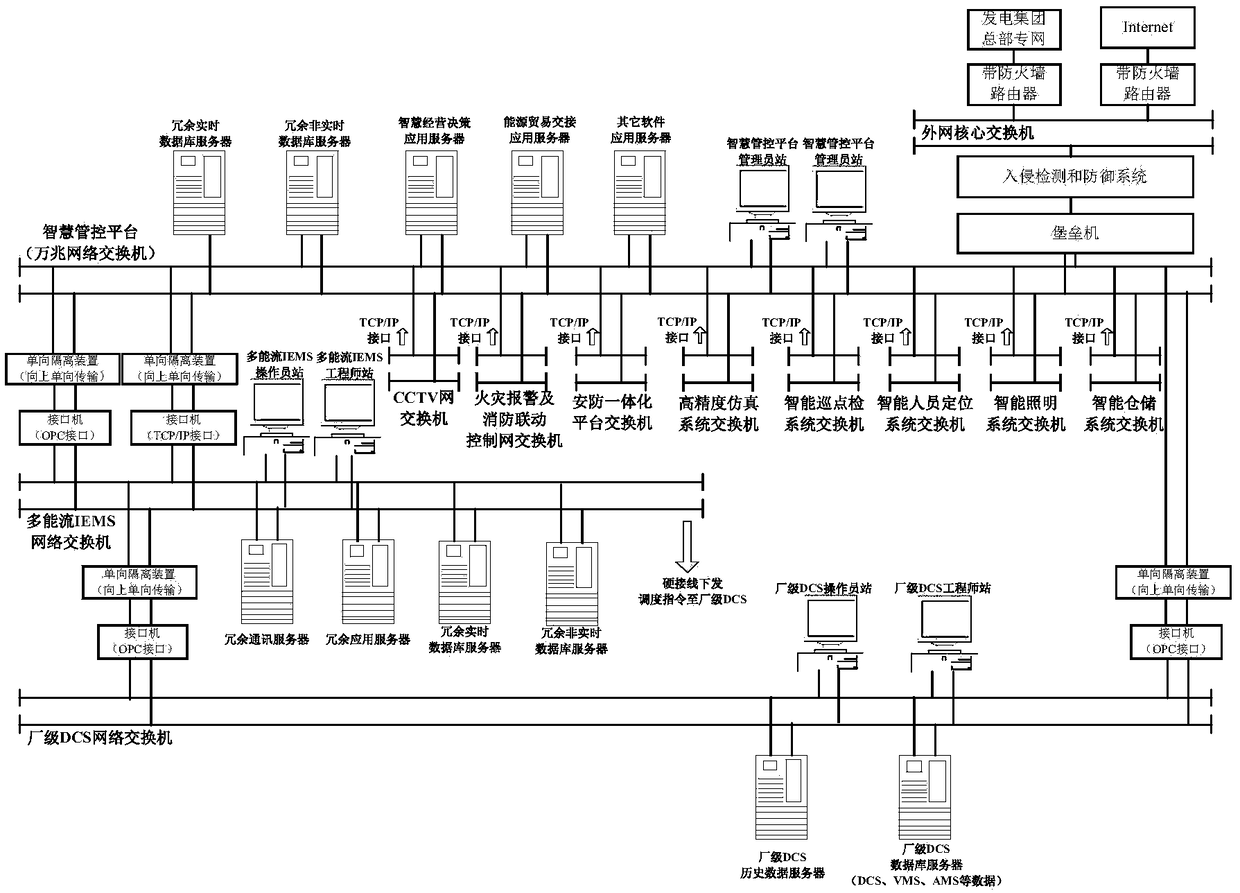

Smart power plant integrated monitoring and management system

PendingCN108762224AReal-timeRealize visualizationTotal factory controlProgramme total factory controlAutomatic controlSmart power

The invention discloses a smart power plant integrated monitoring and management system which comprises a smart management and control platform, a multi-energy flow IEMS network switch and a factory-level DCS; a smart management and control platform comprises a 10 Gigabit network switch, a server and a smart management and control platform administrator station; the server comprises a redundant real-time data server, a redundant non-real-time database server, a smart business decision-making application server, an energy trade transition application server and other software application servers; the server and the smart management and control platform administrator station are connected with the 10 Gigabit network switch; the factory-level DCS has two ways to upload externally; and the multi-energy flow IEMS network switch has two ways of upward interfaces. The system has the benefits that: a linkage application case after intelligent subsystems are accessed is planned, so that the design integrity of the smart power plant is stronger; combined with a DCS control system, the extension of automatic control range to the automatic control of the whole process operation is realized; and the smart power plant is endowed with the ability to integrate with the overall design of upper-level smart parks and smart cities.

Owner:SOUTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP CORP

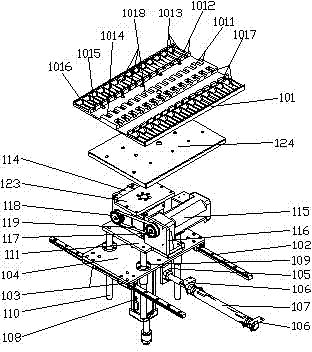

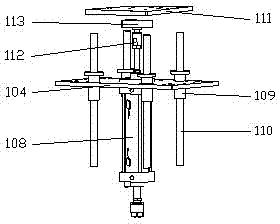

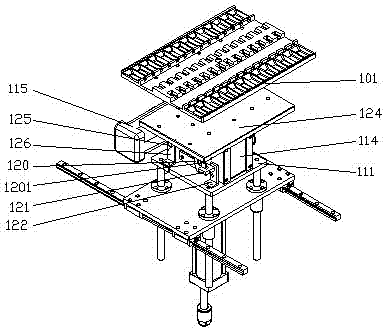

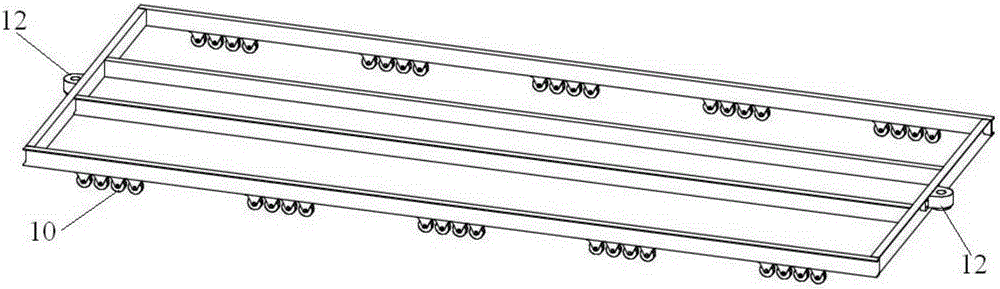

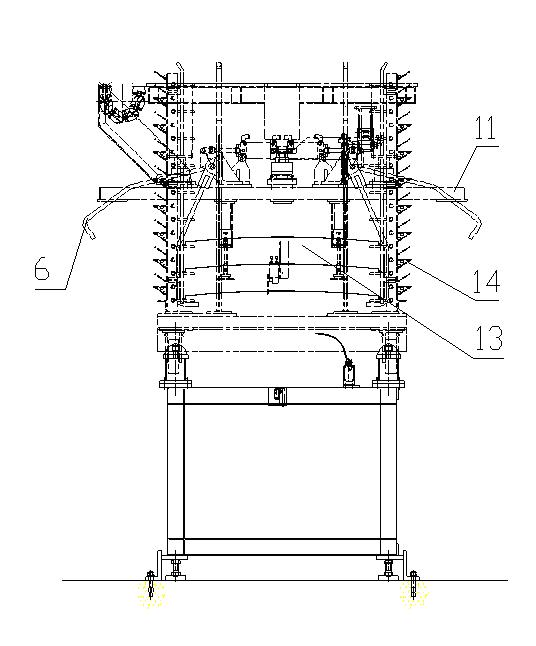

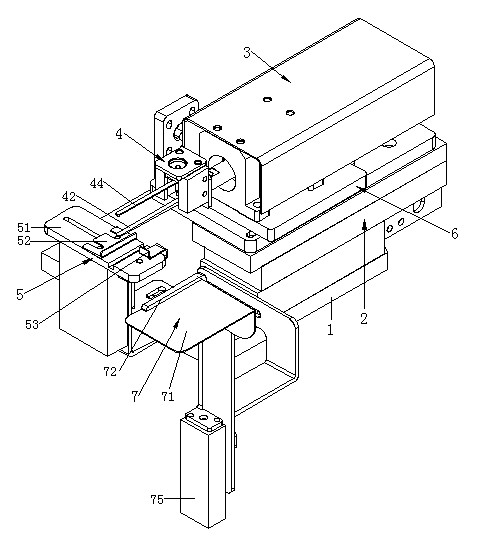

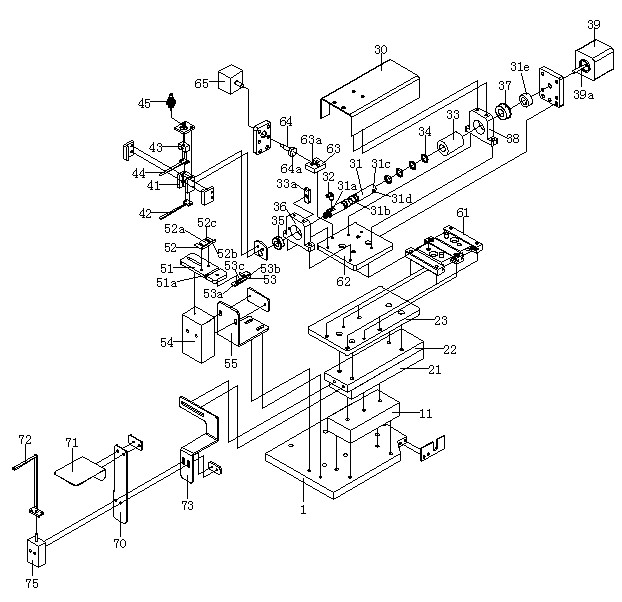

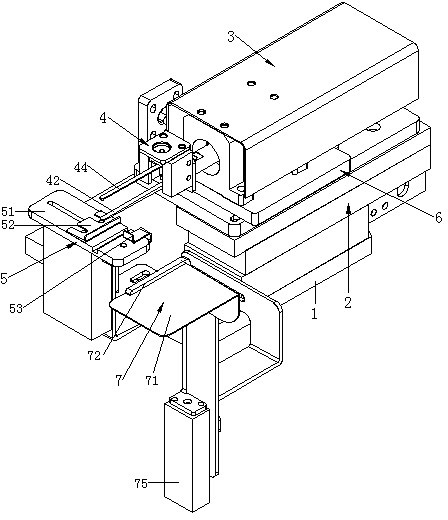

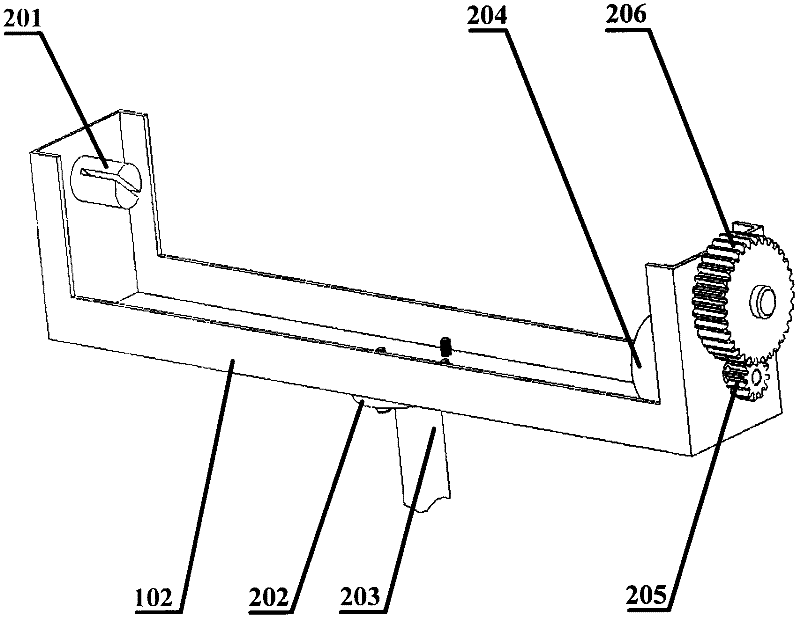

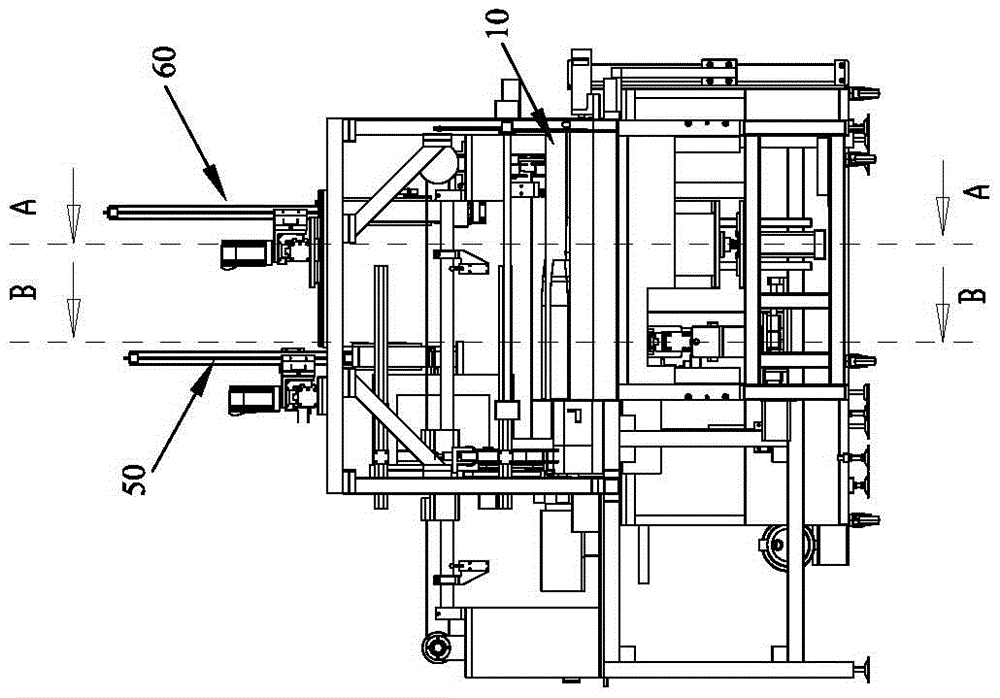

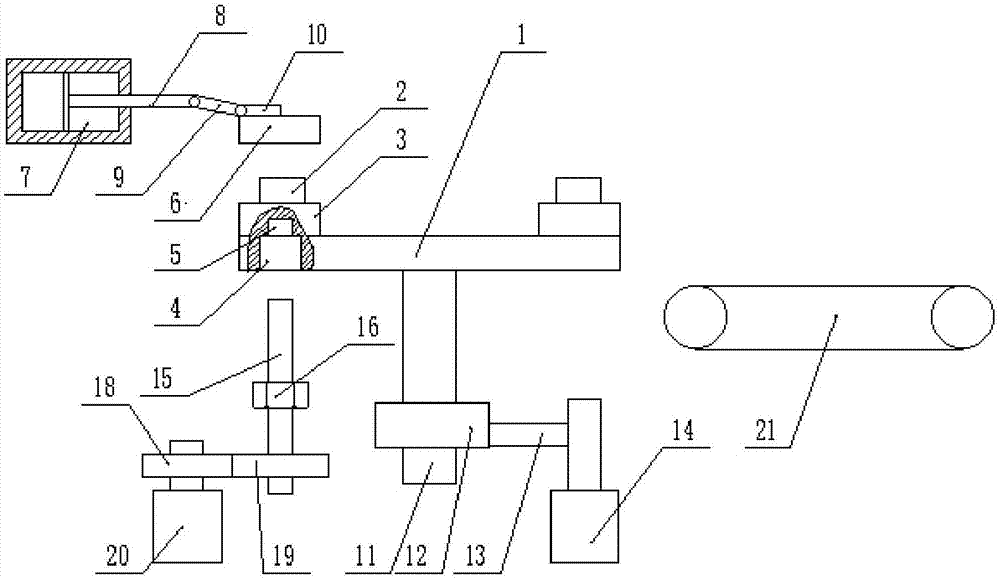

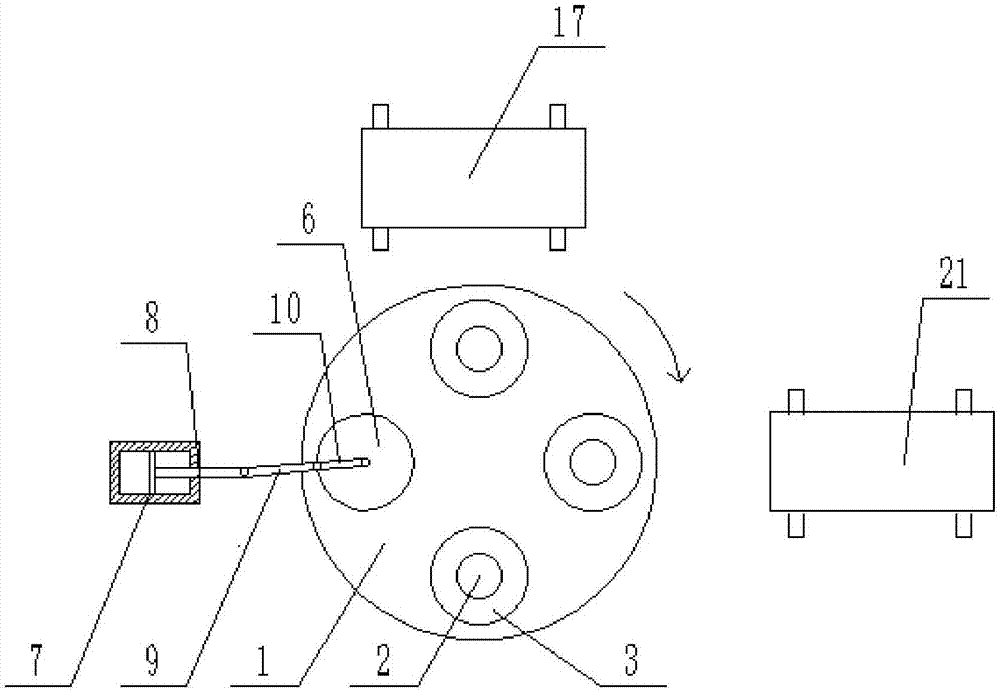

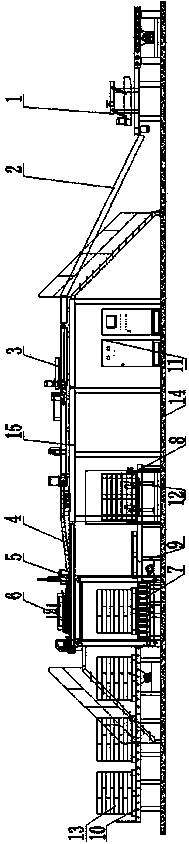

Packaging feeding machine of plastic injection molding products

InactiveCN103896061ARealize automatic controlImprove automationConveyorsControl devices for conveyorsMedical equipmentPlastic injection molding

The invention relates to a packaging feeding machine, in particular to a packaging feeding machine of plastic injection molding products. The packaging feeding machine comprises a machine frame, electrical equipment and a control program. The packaging feeding machine is characterized by further comprising a receiving mechanism, a first reclaiming mechanism, a distribution mechanism, a conveying mechanism and a second taking mechanism, wherein a feeding process is sequentially completed through the mechanisms arranged on the machine frame in a front and back connection mode, the packaging feeding machine can enable the agminate plastic injection molding products getting out of a mold of an injection molding machine in a monolithic mode to be separated from one another during packaging and conveyed to a packaging machine. By means of the packaging feeding machine, feeding work efficiency is greatly improved compared with manual operation, automatic operation is completely achieved in the whole production process, workers do not make contact with or pollute the products any longer, and the packaging feeding machine is applied to the fields of medical equipment, food utensils, tableware and the like and has great significance.

Owner:台州华曙机械有限公司

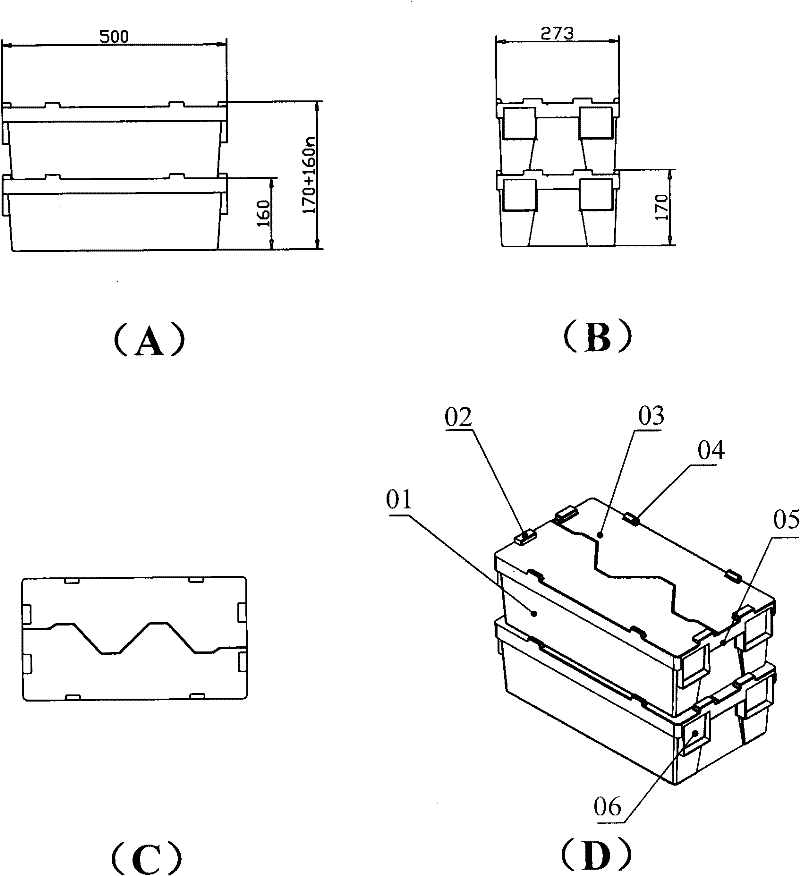

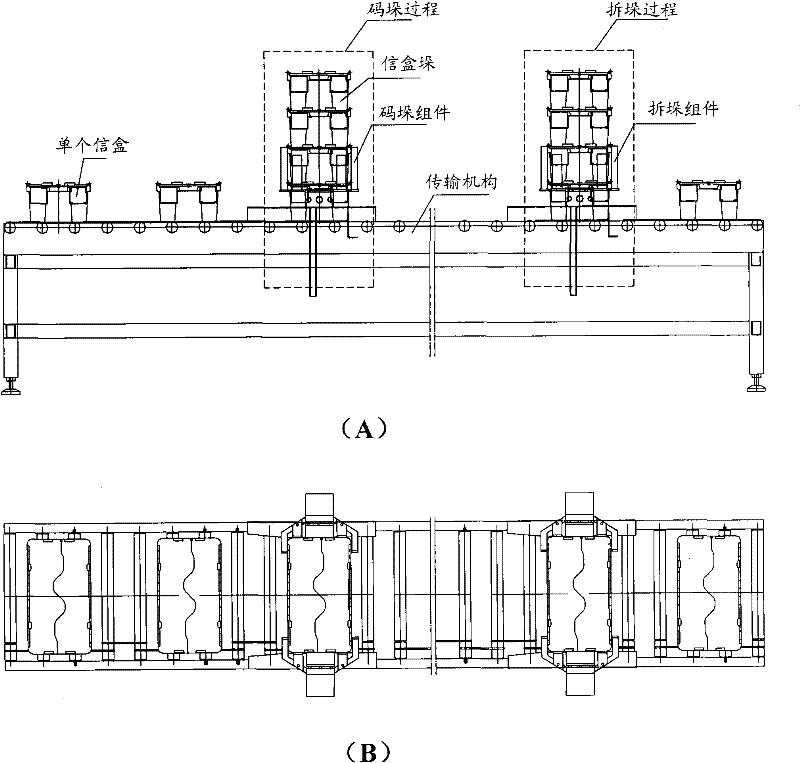

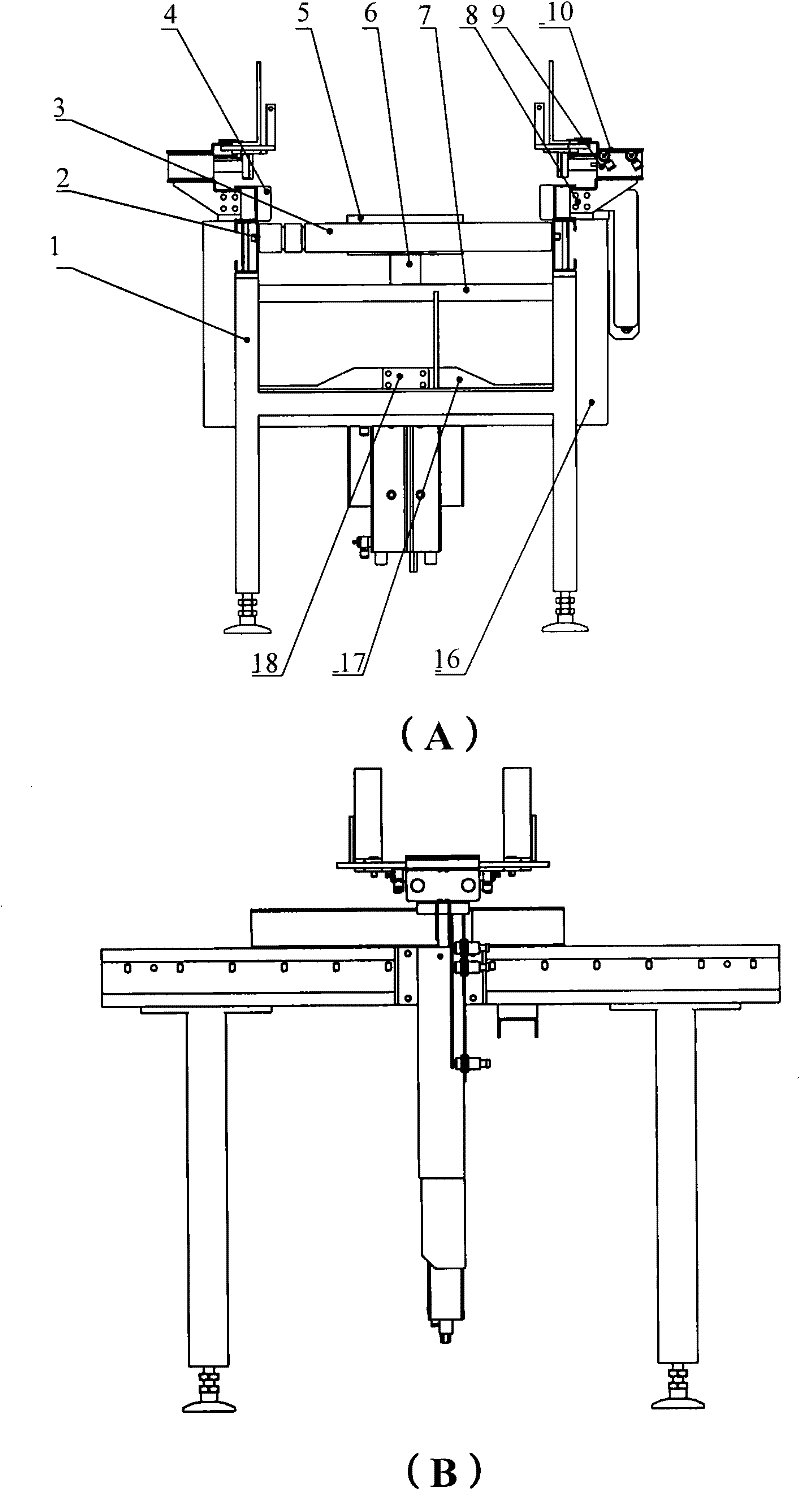

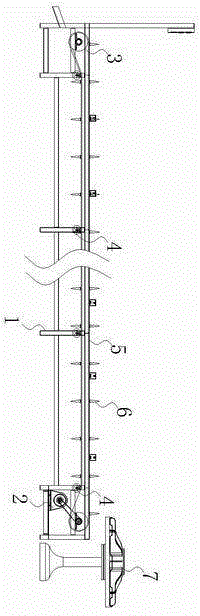

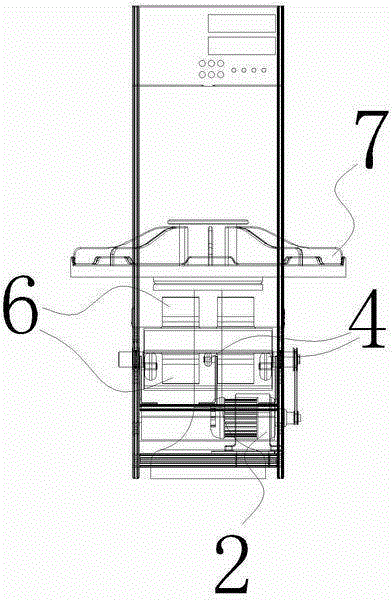

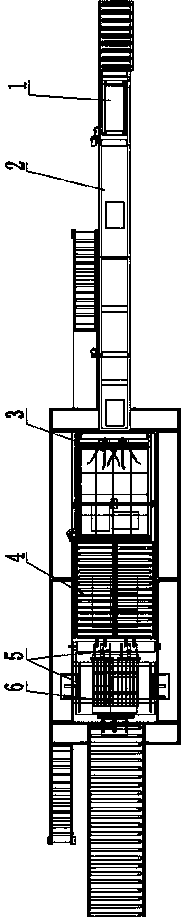

Stacking and unstacking conveying device and method for palletizing and storing postal container boxes

ActiveCN101746607AReduce the problem of occupying a large areaLess investmentStacking articlesDe-stacking articlesEngineeringMechanical engineering

The invention relates to a stacking and unstacking conveying device and a method for palletizing type conveying and storage of postal container boxes. The device comprises a conveying mechanism for transporting postal container boxes and stacking assemblies and unstacking assemblies which cooperate to control and carry out stacking or unstacking operations. Each stacking assembly and each unstacking assembly are respectively provided with a positioning mechanism for positioning the postal container boxes, a clamping mechanism for clamping the postal container boxes to carry out operations of stacking and unstacking and a lifting mechanism for lifting the postal container boxes to carry out operations of stacking and unstacking. The invention realizes stacking, unstacking, palletizing conveying and storage, solves the problem of a larger occupied area of postal boxes in transportation and storage, correspondingly reduces the investment of transporting lines, realizes automatic operation of the whole device, and has smart design, simple structure, easy operation and control, safe and reliable work, and broad popularization and application prospect.

Owner:邮政科学研究规划院有限公司

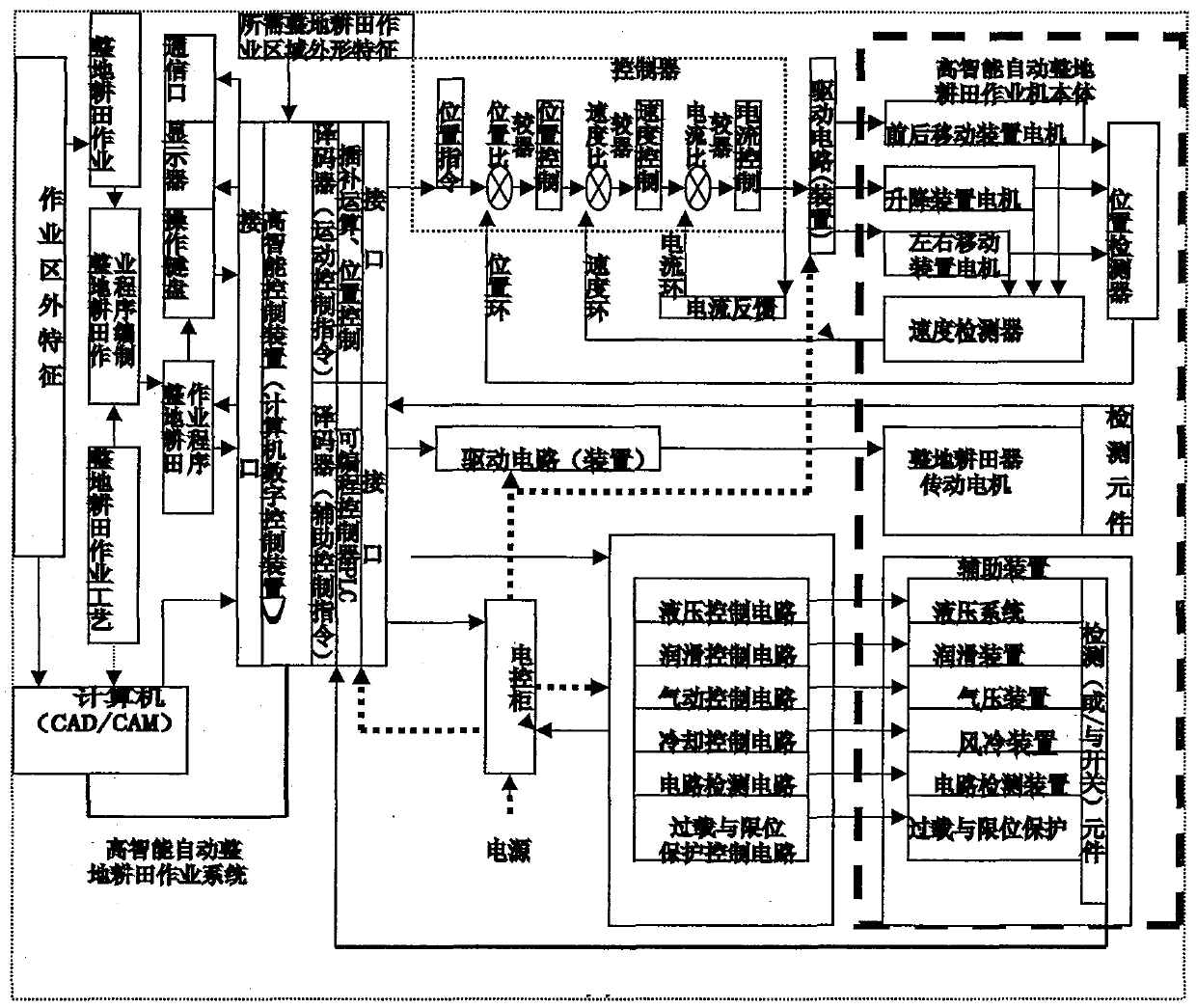

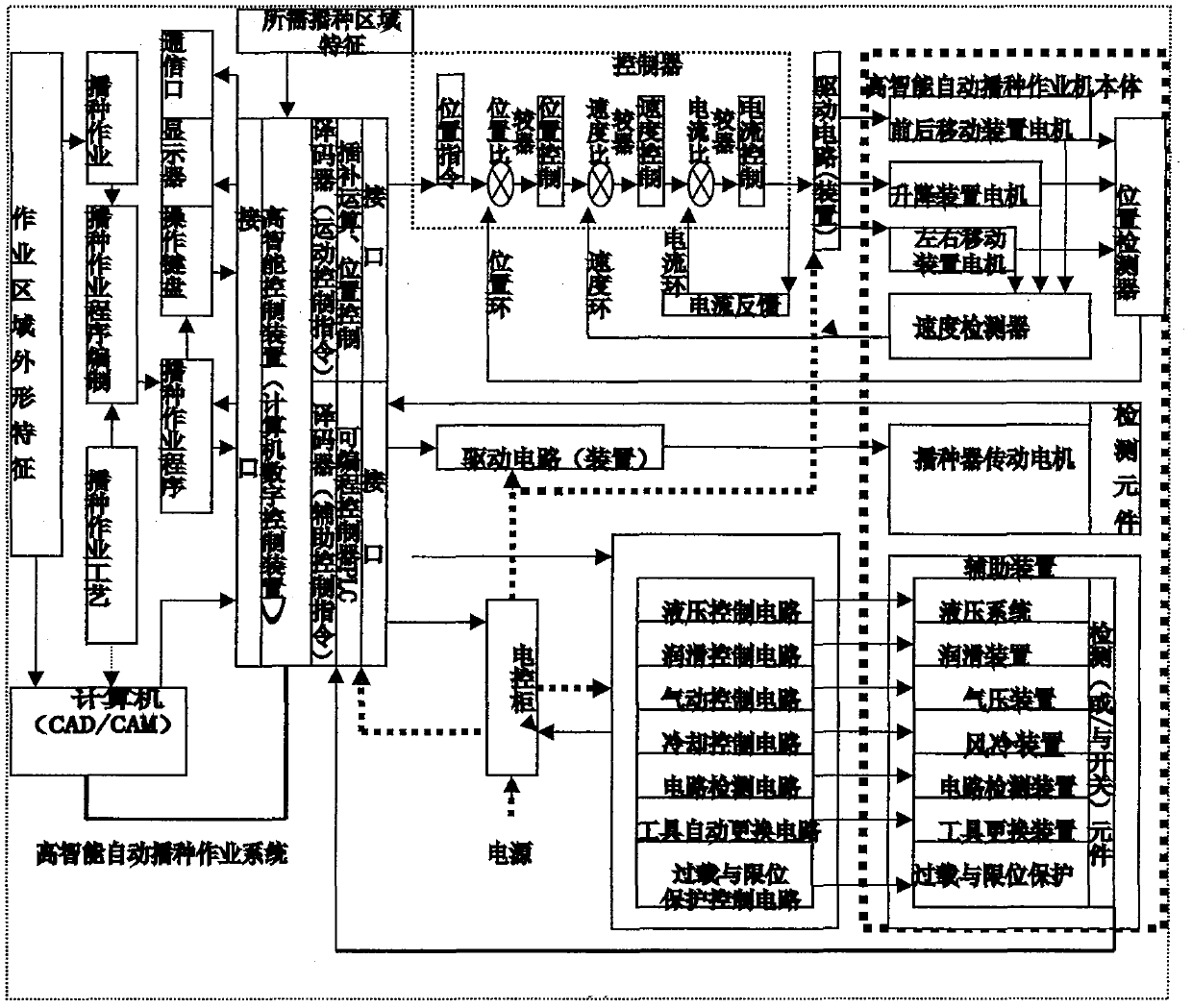

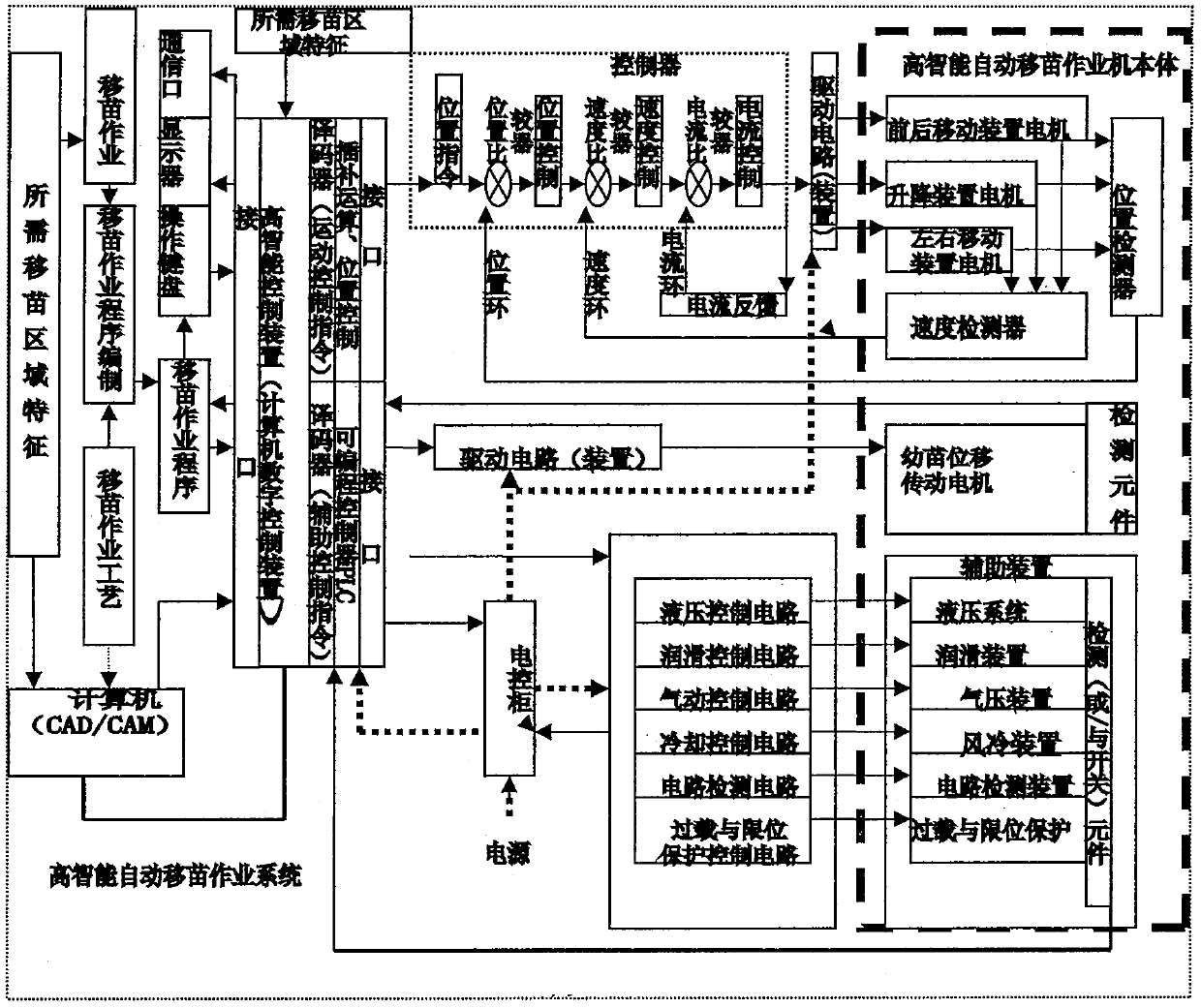

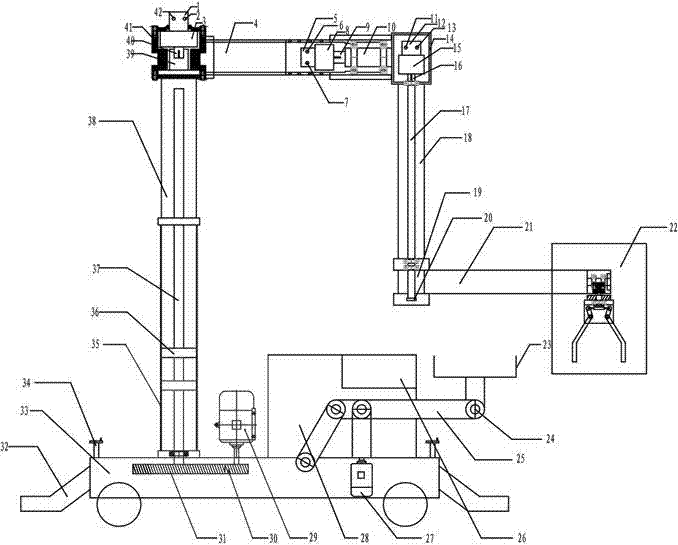

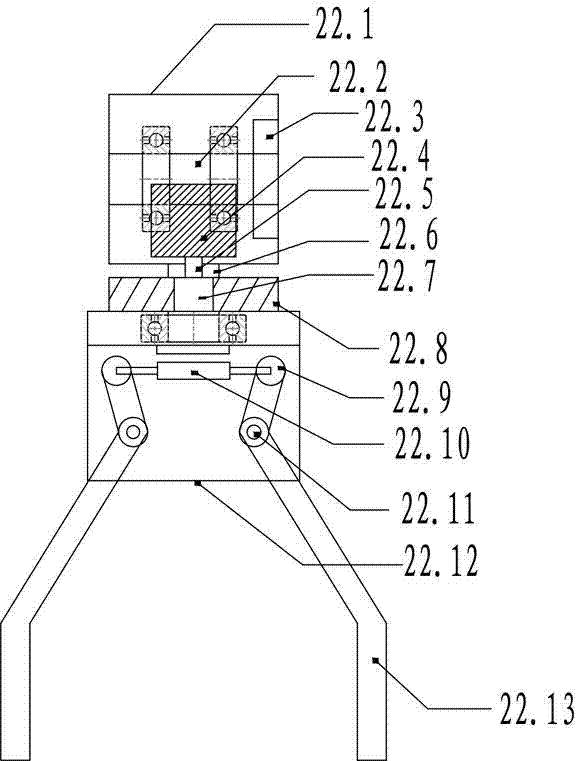

High-intelligence agricultural mechanical apparatus and system

InactiveCN108170104ARealize automated productionRealize zero emission at workAgricultural undercarriagesProgramme total factory controlElectric machineryAgricultural engineering

The invention belongs to the agricultural machinery field and relates to an agricultural mechanical apparatus and system. With the agricultural mechanical apparatus and system adopted, the problem that agricultural machinery cannot perform automatic operation can be solved. According to the agricultural mechanical apparatus and system, electric energy, motors and tracks are adopted to perform automatic operation; operation and work which are required by an operation area can be automatically and orderly completed according to the shape feature of the operation area or / and the crops of the operation area and an operation mode required by the operation area or / and the crops of the operation area; one such agricultural mechanical apparatus can be driven and controlled to complete various operation of the full-process management of plough, farming and harvest of the crops; and one or more agricultural mechanical apparatuses can be driven and controlled to complete various operation of thefull-process management of plough, farming and harvest of the crops.

Owner:杨新高

Robot

ActiveCN104493810AAutomate operationsWorkability is goodProgramme-controlled manipulatorBuilding material handlingHydraulic motorArchitectural engineering

The invention discloses a robot. A hollow vertical rod is mounted in a vertical rod sleeve, a lead screw and nuts are mounted in the hollow vertical rod, a gear power motor and a gear mechanism connected with the lower end of the lead screw are mounted in a machine base, a first hydraulic motor inside a big-arm end is connected with a fixed shaft, the lower end of the fixed shaft is fixed on the hollow vertical rod, a second hydraulic motor is arranged inside a transverse swing arm connected with the big-arm end, a rotating arm end is further connected to a first rotating shaft connected with the second hydraulic motor, a longitudinal swing arm is connected to the rotating arm end, a second rotating shaft is connected to a third hydraulic motor inside the rotating arm end, a small-arm end is fixedly connected to the second rotating shaft, and a manipulator device is connected to the small-arm end. The robot has the advantages that the robot meets the requirements on multi-direction and multi-angle composite actions and can complete complex physical labor; when used for building construction, the robot is capable of building a wall, plastering and sticking bricks automatically, so that construction efficiency and quality of bricklaying projects are improved, labor intensity is reduced and construction cost is lowered.

Owner:苗健

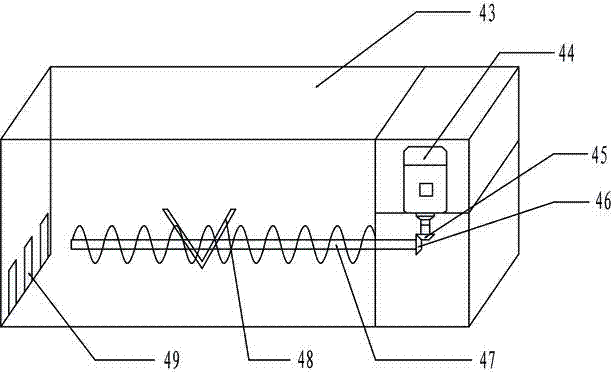

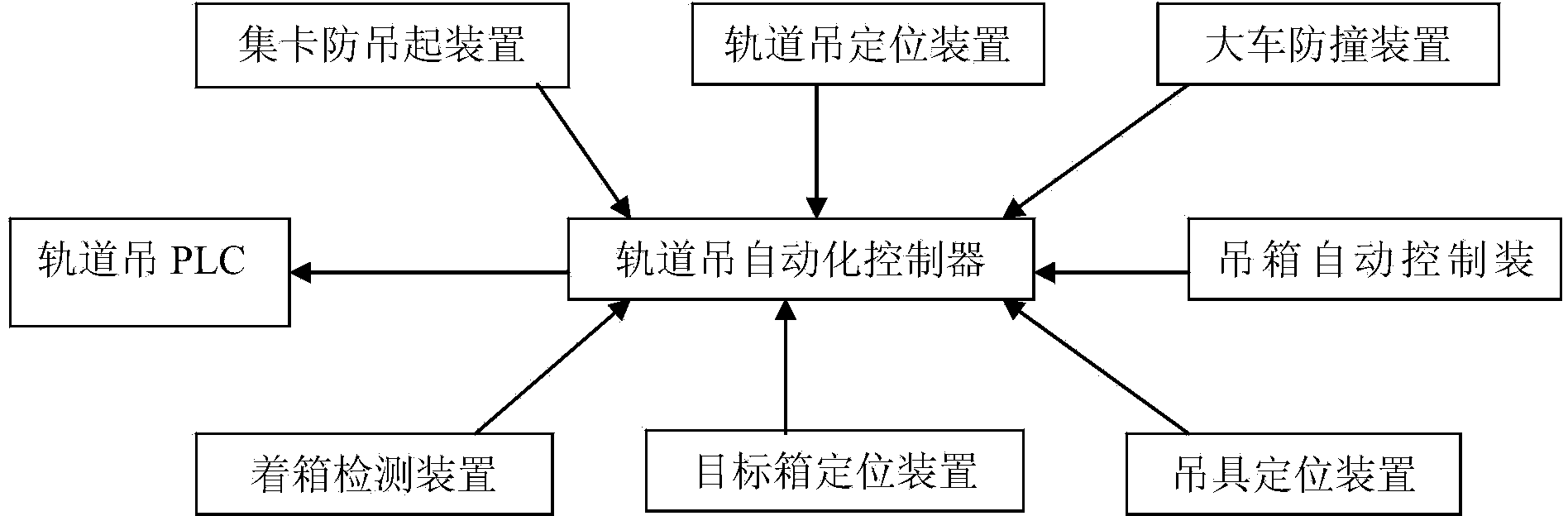

Rail-mounted gantry crane automatic yard operation control system and automatic loading and unloading method

ActiveCN103523675AImprove work efficiencyReduce labor costsSafety gearAutomatic controlControl system

The invention discloses a rail-mounted gantry crane automatic yard operation control system and an automatic loading and unloading method, and the control system and the automatic loading and unloading method can reduce investment for reconstruction and enables technological process to be simplified. The system comprises a rail-mounted gantry crane automatic controller, a rail-mounted gantry crane PLC controller, a hanger PLC controller, a container truck hoist-preventing device, a rail-mounted gantry crane positioning device, a container landing detection device, a hoisting box automatic control device, a target container positioning device and a hanger positioning device. The system refits a conventional rail-mounted gantry crane into an automatic rail-mounted gantry crane and can carry out container landing, locking, hanger rising, container dropping, unlocking, hanger rising and the like on containers through controlling by the automatic loading and unloading method, a cycle of operation can be automatically finished without intervention by a remote operator, so work efficiency is improved, labor cost is reduced and work cost is lowered down; moreover, equipment investment is small, and operation is simple and convenient.

Owner:TIANJIN PORT CONTAINER TERMINAL

Method for producing cordyceps militaris fermentation coarse cereals through solid-state fermentation

InactiveCN103271281ANutritiousEasy to eatFood preparationHorticultureAdditive ingredientCordyceps militaris

The invention discloses a method for producing cordyceps militaris fermentation coarse cereals through solid-state fermentation. According to the method, people can safely and conveniently eat and digest nutritional ingredients of cordyceps militaris, and simultaneously, problems of complicated production processes and high costs of cordyceps militaris products are solved. The method adopts a solid-state fermentation manner, and a fermentation substrate is strictly sterilized, so that in the process of fermentation, the microbial interference can be basically eliminated, the solid-state fermentation is easier to master when compared with liquid-state fermentation, and design requirements and costs of a biochemical reactor are low. The whole production process comprises three links as follows: manufacturing a liquid cordyceps militaris culture, manufacturing a solid-state fermentation medium of the coarse cereals, and performing inoculation and fermentation; and the three links can realize automatic operation, so that the human resource cost can be reduced.

Owner:食品行业生产力促进中心

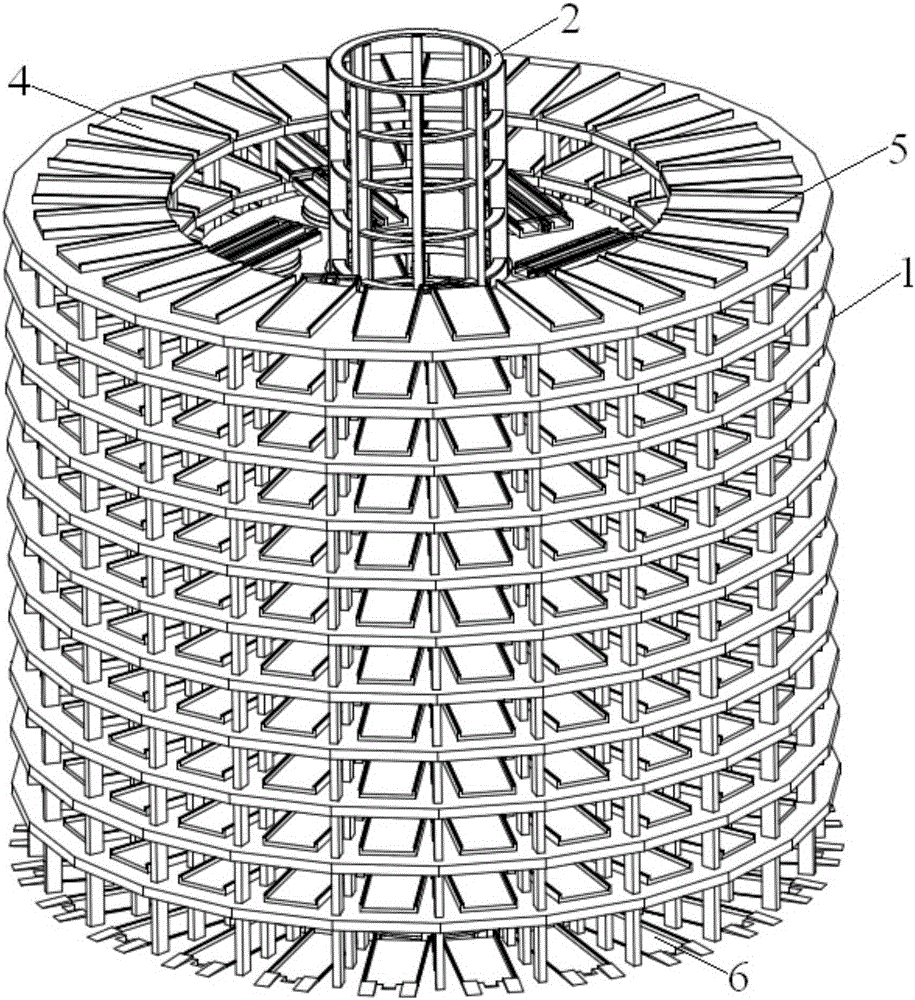

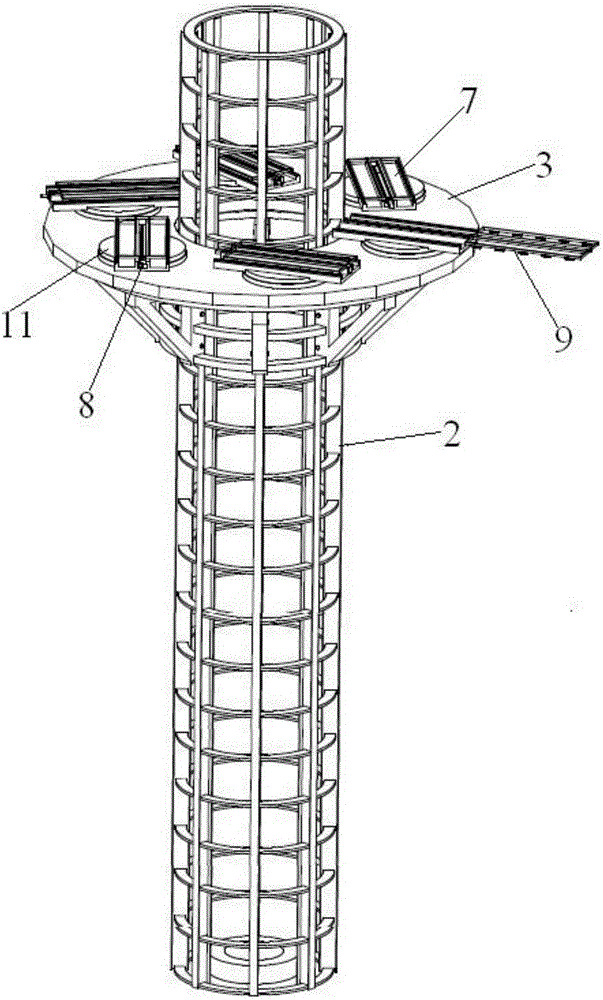

Turret type three-dimensional goods storage rack and automatic goods storing and taking method

ActiveCN105236063ALarge storage capacityAutomate operationsStorage devicesTraction frameTransport engineering

The invention provides a turret type three-dimensional goods storage rack and an automatic goods storing and taking method. The method includes the following steps that initialization is conducted firstly, a lifting platform moves and stops on a storing layer, and a tractor is started to work until traction frames are put on all transfer goods allocations; the lifting platform moves vertically and stops on an entering and exiting layer, and the tractor pushes all the traction frames to the transition goods allocations; goods to be stored are put on the transition goods allocations, and the tractor drags the traction frames to the transfer goods allocations at this moment; the lifting platform moves and stops on the storing layer, and the tractor pushes the traction frames and goods to a storage bin together; during goods taking, the tractor pulls the traction frames and drags the traction frames and the goods to the transfer goods allocations together; and the lifting platform moves to the entering and exiting layer, the tractor pushes all the traction frames to the transition goods allocations, and goods taking is completed. According to the automatic goods storing and taking method, automatic goods storing and taking can be achieved, no operation needs to be conducted by a goods owner in the process, efficiency of storing and taking goods is high, and the goods storing amount is large.

Owner:余小刚

Cyclic transport device

ActiveCN102807061BAutomate operationsSimple mechanical structureConveyorsConveyor partsProduction lineControl system

The invention provides a circumferentially cyclic transport device and a control and detection system thereof. The device includes clapboards uniformly mounted on the surface of the circumferential transport belt, a control system device for controlling the pulse transport of a motor, and a detection system for preventing the circumferential transport from deviating. According to the invention, the technical solution can achieve that objects to be transported are transported by means of imitating the garment production process as artificial driving of transport boxes in constant time and speed, and an automatic production line is obtained, so that the working efficiency is improved.

Owner:SUZHOU TRANSPARENT TECH CO LTD

Track sucking disk type gripping device

The invention relates to the technical field of automobile manufacturing equipment, in particular to a track sucking disk type gripping device for solving the problems of flexibility, safety and accuracy in gripping and feeding of large parts on an automobile welding line. The track sucking disk type gripping device comprises a fixed top beam, a cable assembly connected with the fixed top beam as well as a gripping bracket arranged in parallel to the fixed top beam. The track sucking disk type gripping device is characterized by further comprising a traveling mechanism positioned on the fixed top beam, a main air cylinder and at least one side air cylinder which are arranged between the fixed top beam and the gripping bracket as well as at least one driving mechanism positioned on the gripping bracket; and the driving mechanism is used for controlling a plurality of safe grabs; and at least one elastic gripping sucking disk is arranged below the gripping bracket. The track sucking disk type gripping device has the advantages of favorable stability for gripping workpieces, high gripping speed, sensitivity and accuracy, stability in operation, low noise and low possibility of wearing.

Owner:ZHEJIANG HAOQING AUTOMOBILE MFG CO LTD +1

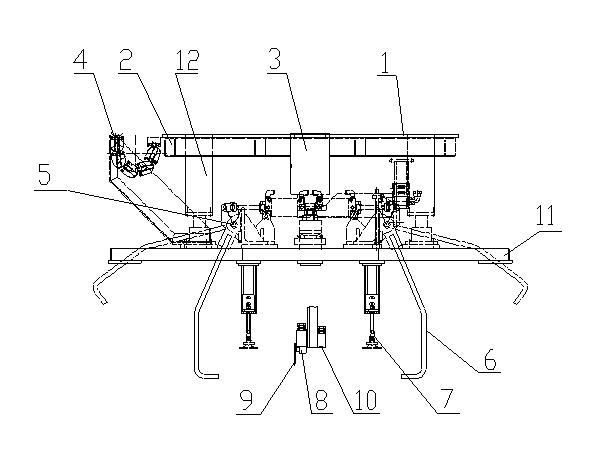

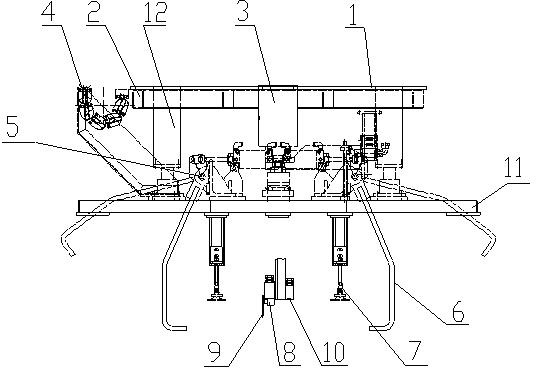

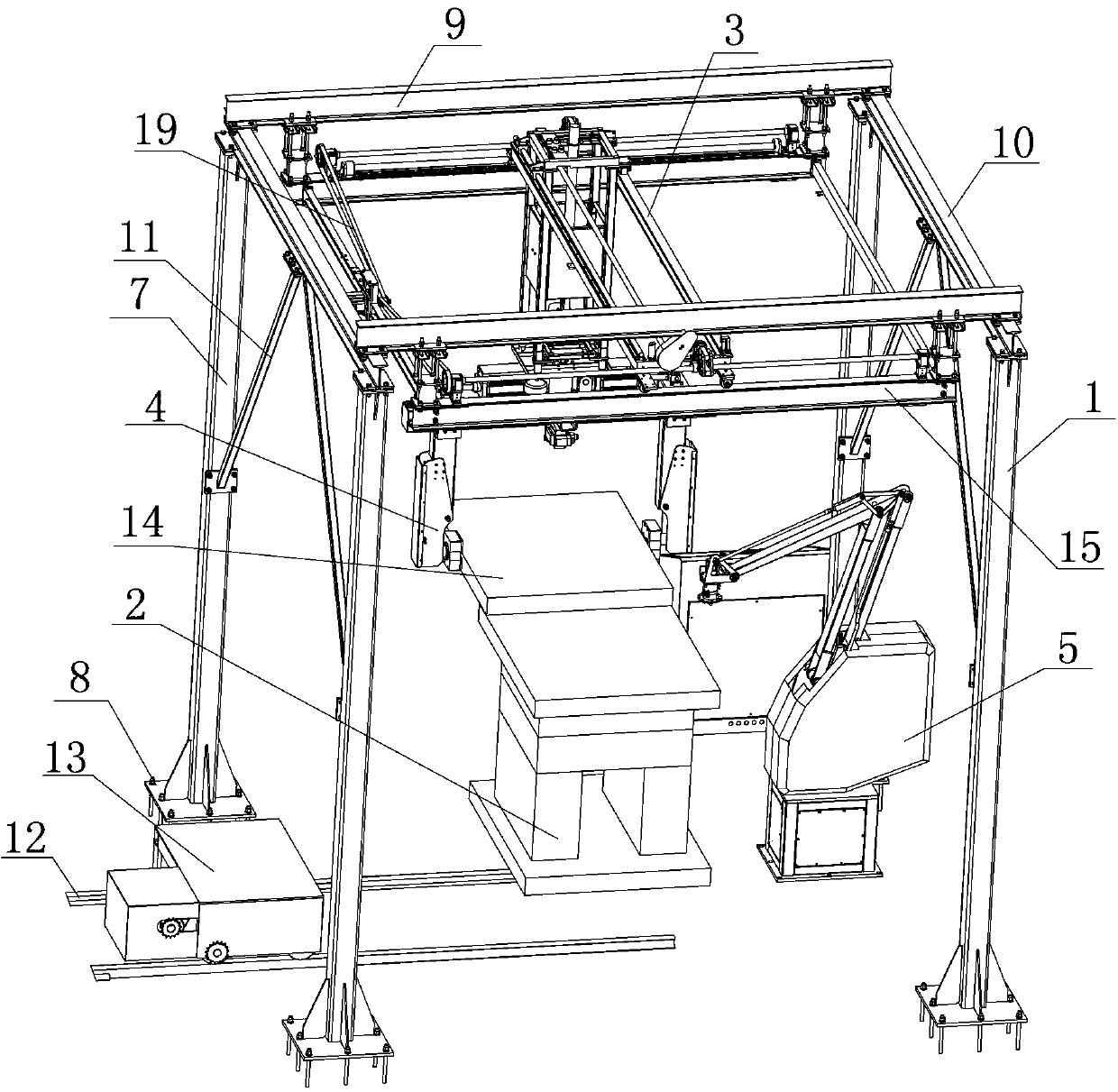

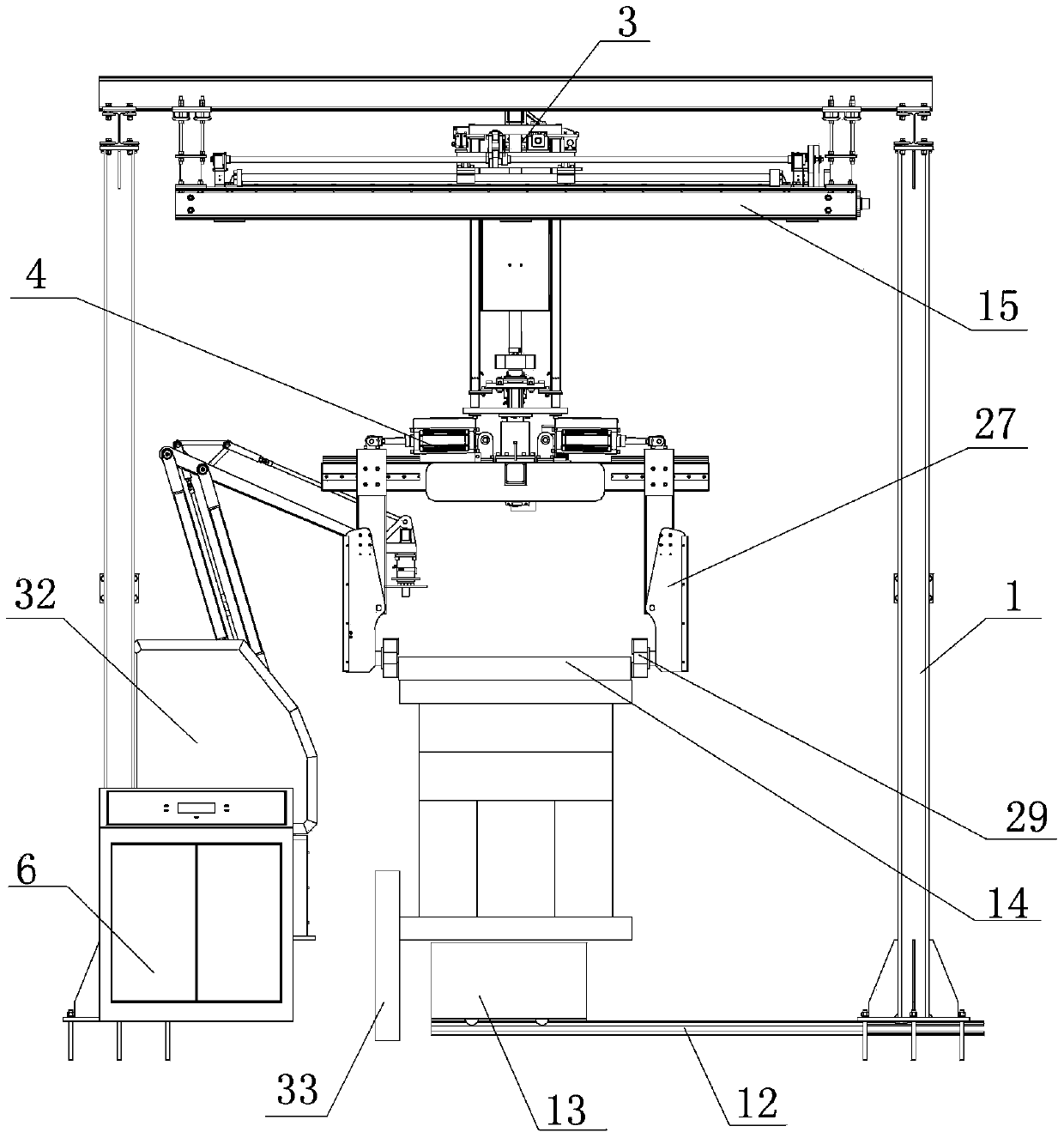

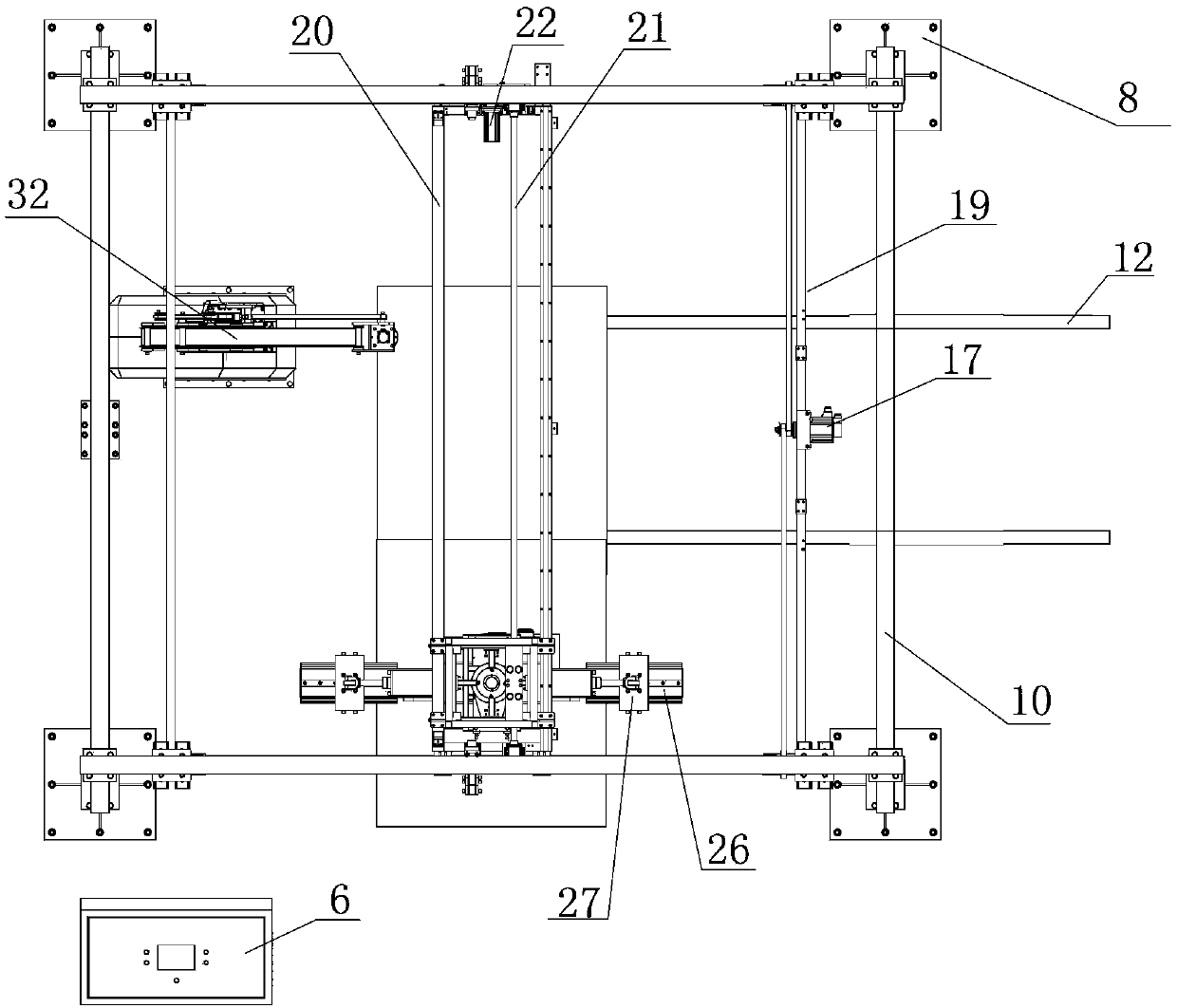

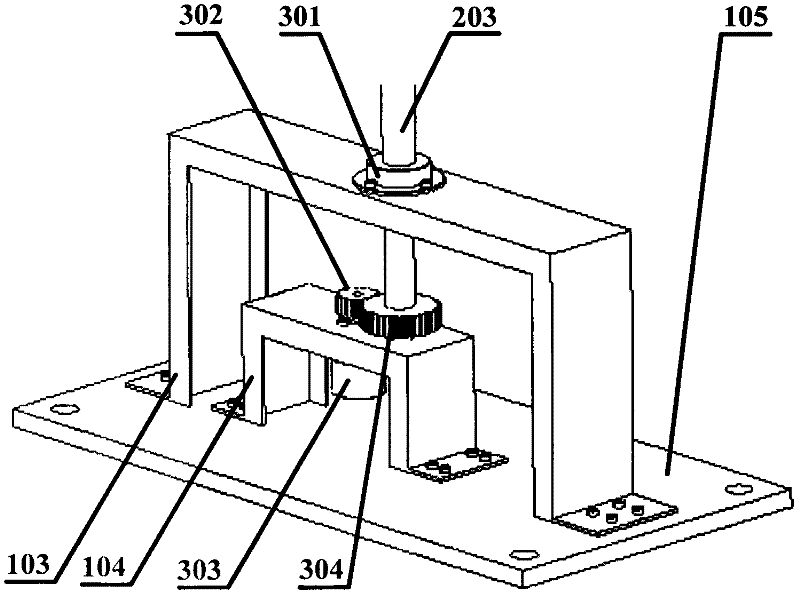

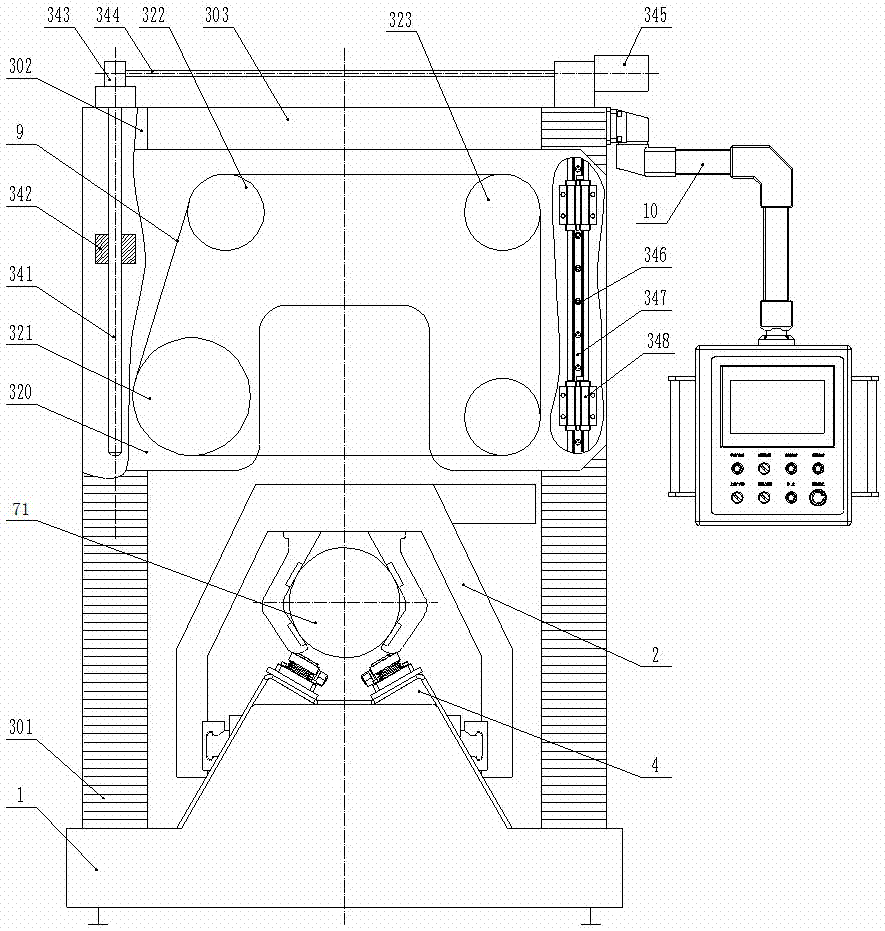

Injection mold automatically-disassembling device

The invention relates to an injection mold automatically-disassembling device. The injection mold automatically-disassembling device comprises a portal frame, a workbench for bearing a mold, a travelling mechanism for driving the mold to travel in the X-axis direction, the Y-axis direction and the Z-axis direction, a clamping and turnover mechanism for clamping and turning over the mold, a disassembling mechanism for disassembling the mold, and a control cabinet. The traveling mechanism is mounted on the portal frame, the clamping and turnover mechanism is mounted on the travelling mechanism, and the travelling mechanism, the clamping and turnover mechanism and the disassembling mechanism are connected with the control cabinet. The disassembling mechanism achieves disassembly of screws on the mold, and the clamping mechanism and the travelling mechanism achieves turnover, automatic hoisting and transportation of the mold, so that the injection mold automatically-disassembling device achieves automatic process of mold disassembly, facilitates mass assembly line operation, greatly improves the production efficiency, achieves safe production, reduces the labor intensity and labor costs, and meanwhile, by disassembling the mold through mechanical force, avoids damage to the mold and is safe and reliable.

Owner:QINGDAO HAIER MOLDS

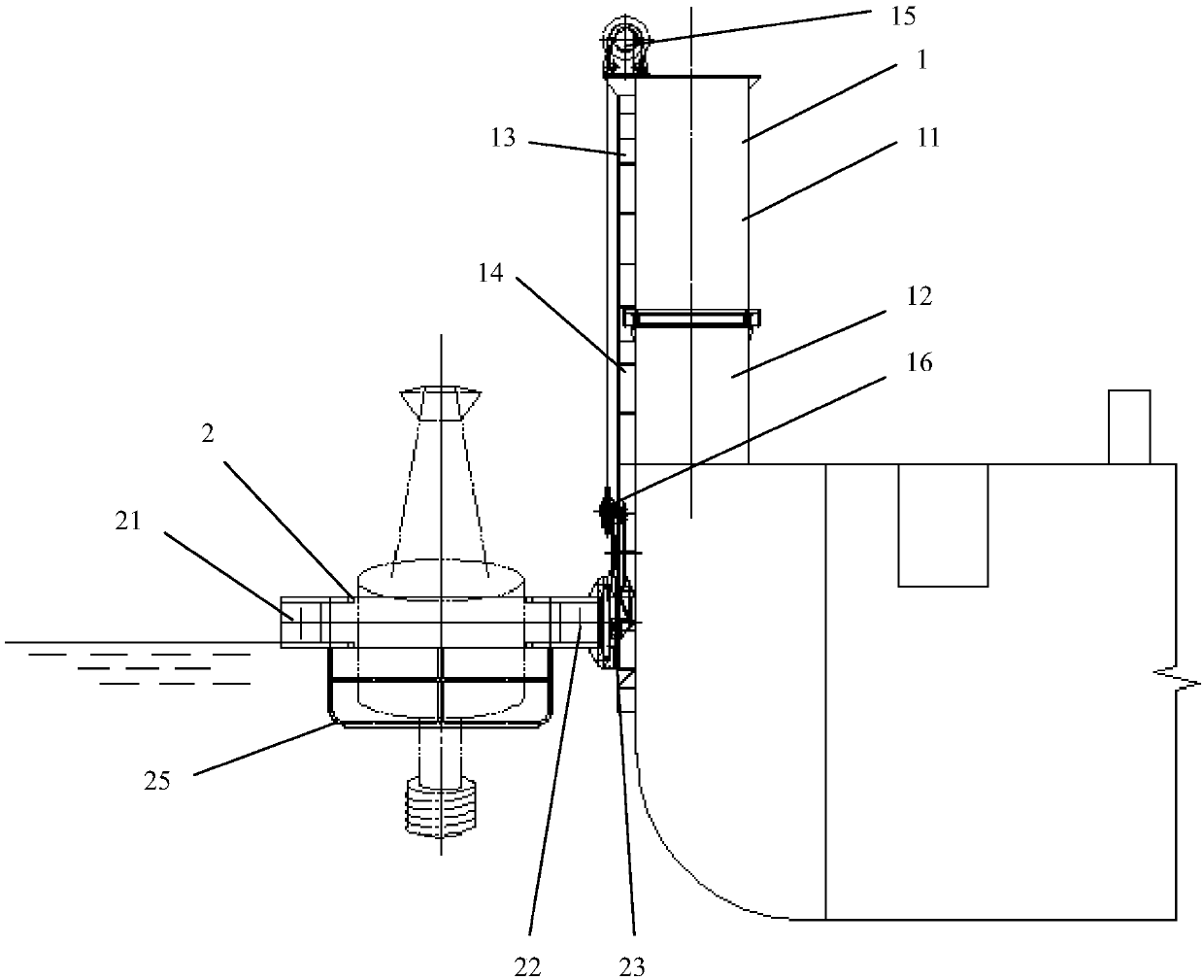

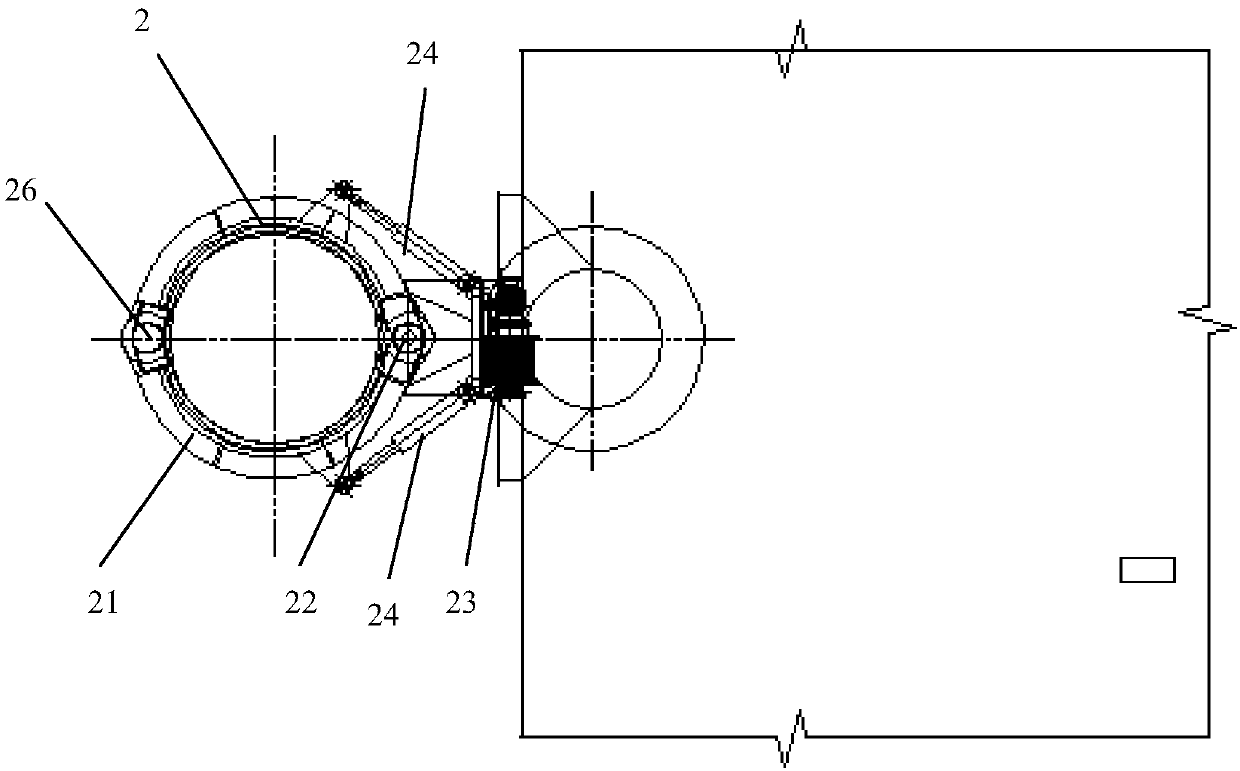

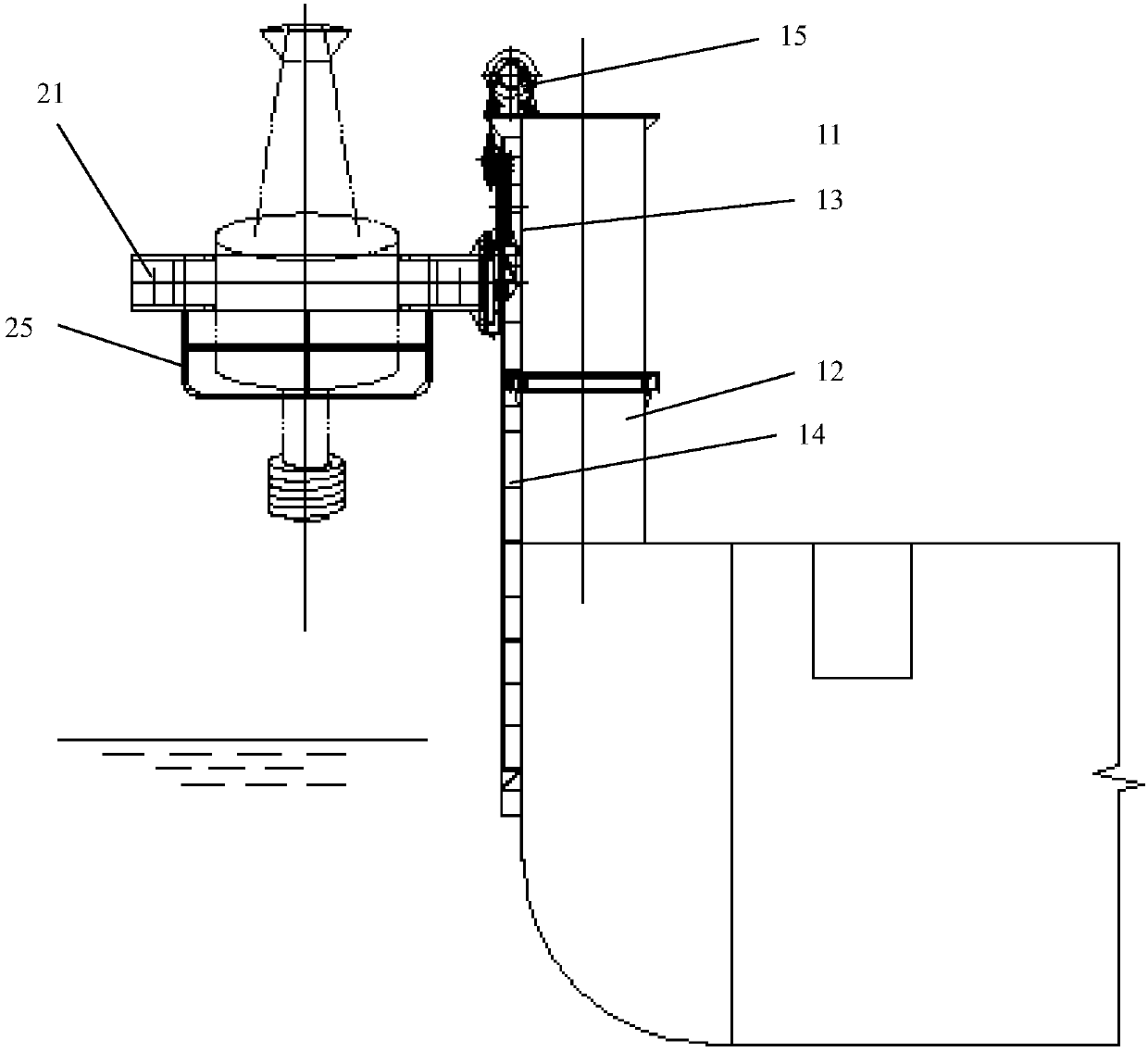

Automated buoy recycling and laying device

ActiveCN107697242AIncrease the window periodImprove work efficiencyBuoysVessel salvagingBuoyAutomated control system

The invention discloses an automated buoy recycling and laying device. The automated buoy recycling and laying device comprises a buoy hoisting and slewing device, a buoy clamping device and a power and automated control system, wherein the buoy hoisting and slewing device is used for hoisting a buoy and slewing the buoy to a deck face of a hull, a sliding chute guide rail is arranged on the buoyhoisting and slewing device, the buoy clamping device is used for clamping the buoy and slidably connected with the sliding chute guide rail, and the power and automated control system is used for providing power for the buoy hoisting and slewing device and the buoy clamping device and controlling the buoy hoisting and slewing device and the buoy clamping device. According to the automated buoy recycling and laying device, the operating efficiency is high, the safety and the reliability are better, dangerous operation of hooking and the like which need to be participated in directly by personnel is not needed, operation can be conducted under a higher sea condition, the window period of the buoy operation is prolonged, and greater benefits are obtained.

Owner:708TH RES INST OF CSSC

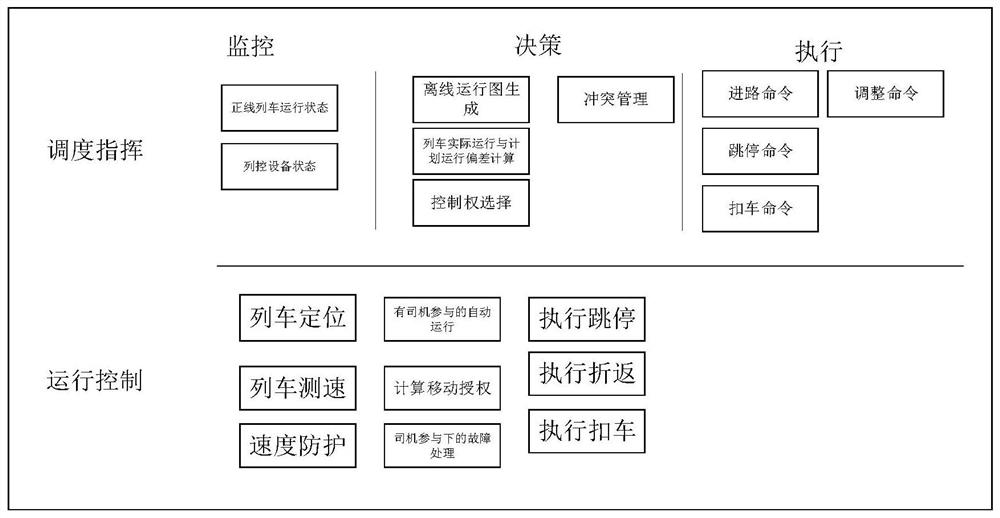

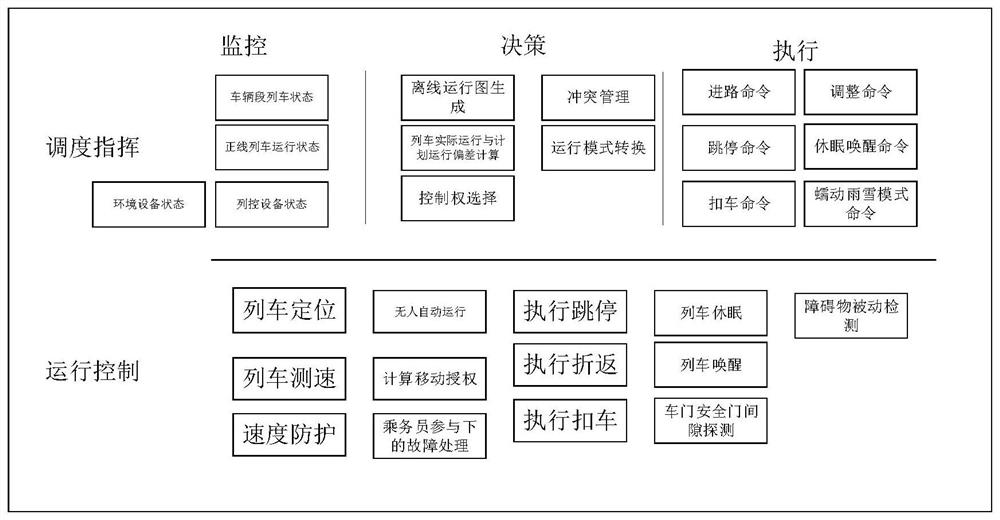

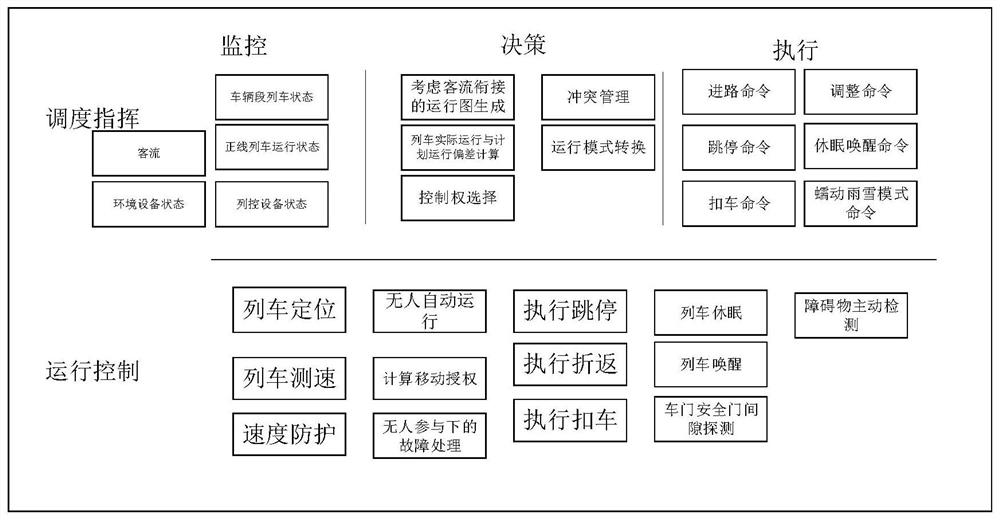

Urban rail transit train operation control system oriented to different intelligent levels

ActiveCN111923966AAutomate operationsRailway traffic control systemsControl systemControl engineering

The invention provides an urban rail transit train operation control system oriented to different intelligent levels. The system comprises an operation control unit and a dispatching and commanding unit. The operation control unit functionally comprises train speed measurement and positioning, starting, speed protection, interval protection, pull-in parking, automatic opening / closing of a train door and a safety door, movement authorization calculation, obstacle detection, fault processing and the like according to the whole process of a train; and the dispatching and commanding unit has the functions of generating a running chart, issuing various control commands, displaying and monitoring the real-time state of the train, monitoring the state of environmental equipment, giving a fault alarm and the like. The system provided by the invention controls the operation of the train operation control system and dispatches and commands the train operation control system; functions of the train operation control system are improved from manual implementation or participation of a driver or a dispatcher to automatic and autonomous operation of the whole train process, and technical supportis provided for intelligent construction of the urban rail transit train operation control system.

Owner:BEIJING JIAOTONG UNIV +1

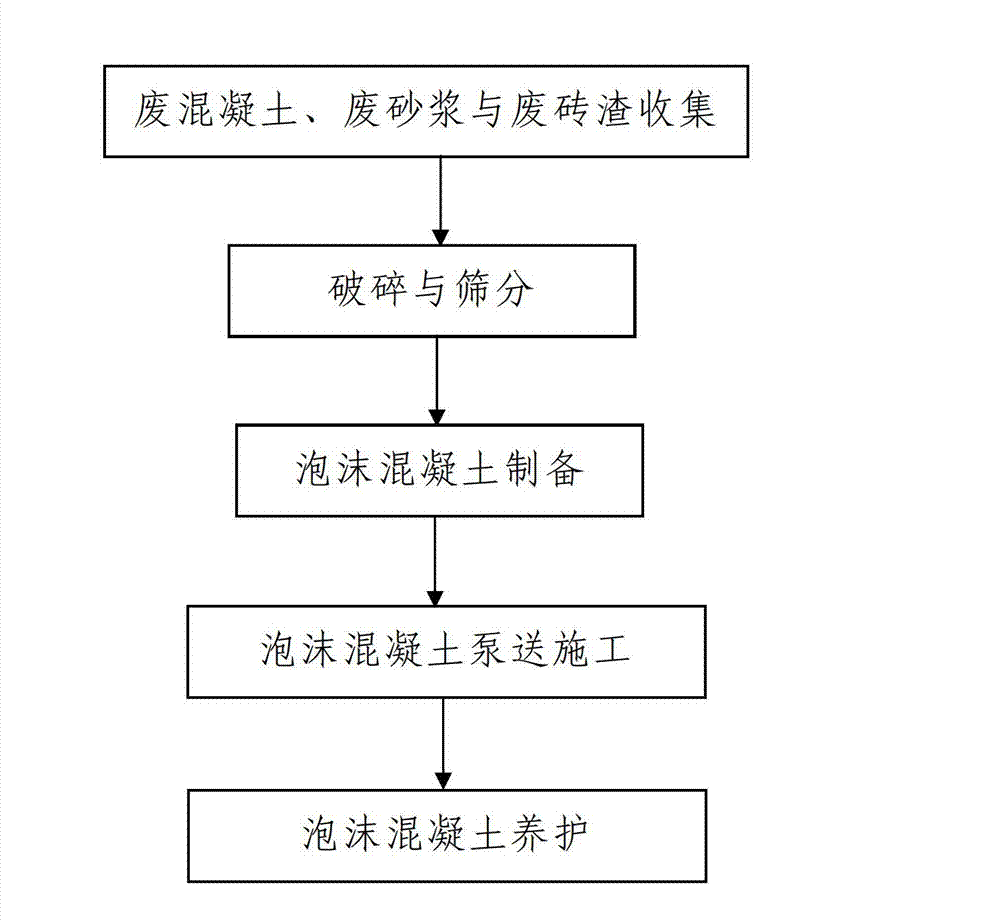

Construction waste recycling and reusing process

InactiveCN102815964AThe method steps are simpleReasonable designSolid waste managementBuilding material handlingFoam concreteBrick

The invention discloses a construction waste recycling and reusing process, which comprises the following steps of: 1, collecting waste concrete, waste mortar and waste brick slag; 2, smashing and screening, namely smashing and screening the collected waste concrete, the collected waste mortar and the collected waste brick slag to obtain regenerative rough aggregates and regenerative fine aggregates; and 3, preparing foam concrete, namely firstly preparing cement slurry, namely uniformly stirring concrete, water, the regenerative rough aggregates and the regenerative fine aggregates to obtain the cement slurry, and secondly adding a foam dilution solution, namely adding the foam dilution solution formed by uniformly mixing a foaming agent and water into the cement slurry, and uniformly stirring to obtain the foam concrete. The steps of the process are simple; the investment cost is low; the process is simple, feasible and high in operability; the waste concrete, the waste mortar and the waste brick slag can be effectively reused; the economical benefit is outstanding; the produced foam concrete material is high in heat preservation performance; and the problems that the construction waste is abandoned and stacked randomly and occupies the land, the waste of resources is severe, and the environment pollution is severe are solved.

Owner:陕西建工集团有限公司

The coil feeding device of the automatic elastic head machine and the automatic elastic head machine

InactiveCN102286854AFully automaticEnsure high quality and uniformWork-feeding meansEngineeringMechanical engineering

The invention discloses a coiling and feeding device of an automatic rubber band head coiling machine and the automatic rubber band head coiling machine. The device comprises a mounting plate, wherein a guide sliding table is fixedly arranged on the mounting plate and comprises a base with a travel sensor and a sliding table glidingly arranged on the base; a rotation mechanism is fixedly arrangedon the sliding table and comprises a bracket and a rotary shaft driven by a first driving mechanism; the rotary shaft is connected with a clamping mechanism; the clamping mechanism comprises a slide rail fixed at the end of the rotary shaft; a fixed pressing plate is fixed on the slide rail; a slider is glidingly arranged in the slide rail; a movable pressing plate is fixedly arranged on the slider; and the slide rail is fixedly connected with a foot pressing cylinder for driving the slider to reciprocate. The coiling and feeding device of the automatic rubber band head coiling machine and the automatic rubber band head coiling machine integrate the functions of automatic coiling and feeding, thereby realizing automatic operation, improving the production efficiency and ensuring high quality and uniform coiling of a rubber band head.

Owner:NINGBO SUPREME ELECTRONIC MASCH INC

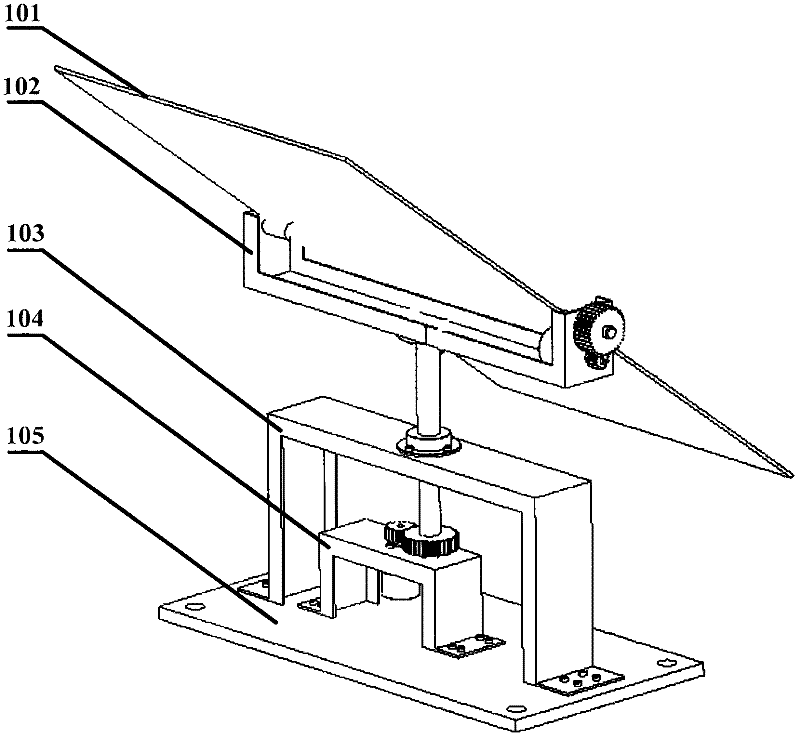

Sun auto-tracking device and tracking method thereof

InactiveCN102411377AExtended TrackingRealize three-dimensional omni-directional trackingControl using feedbackMotor driveAutomatic control

The invention discloses a sun auto-tracking device and a tracking method thereof. The device comprises a solar energy pole plate, a horizontal fixed shaft, a horizontal bracket, an upright shaft, a pedestal, an upright direct current motor, a horizontal direct current motor and an automatic control circuit, wherein the horizontal bracket is used for fixing the solar energy pole plate and the horizontal fixed shaft, the upright shaft is used for supporting the horizontal bracket, the upright direct current motor is used for driving the upright shaft to rotate, the horizontal direct current motor is used for driving the horizontal fixed shaft to rotate, and the automatic control circuit is composed of STC (Sensitivity-Time Control) single chip machine, a GPS (Global Positioning System) chip, a tilt sensor module, an electronic compass and a direct current motor driving module. The sun auto-tracking device provided by the invention has the characteristics of large tracking range, automation and wide applicable area and the like.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

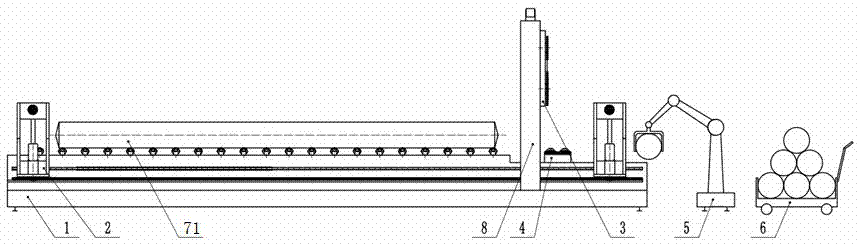

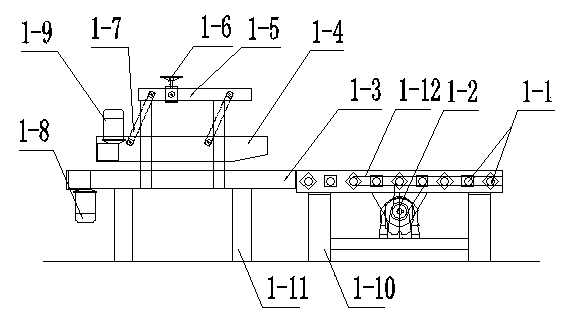

Grinding, cleaning and drying integrated machine for baseball bats

ActiveCN106737053AAutomate operationsReduce labor costsRevolution surface grinding machinesDrying machines with progressive movementsEngineeringCleaning station

The invention discloses a grinding, cleaning and drying integrated machine for baseball bats. An automatic feeding device, a grinding device, a cleaning device and a drying device are arranged. The automatic feeding device is used for feeding the baseball bats into the grinding device; the surfaces of the baseball bats are ground with abrasive paper after the baseball bats reach the grinding station; after the surfaces are ground, the baseball bats are conveyed to the cleaning station of the cleaning device, and water is sprayed to the baseball bats so as to remove impurities generated on the surfaces after grinding; and finally, the baseball bats are conveyed to the drying station of the drying device for drying treatment and then discharged. The whole process does not require manual intervention, automatic operation is achieved, and the purposes of reducing labor cost and improving production efficiency are achieved.

Owner:QUEST COMPOSITE TECH CORP

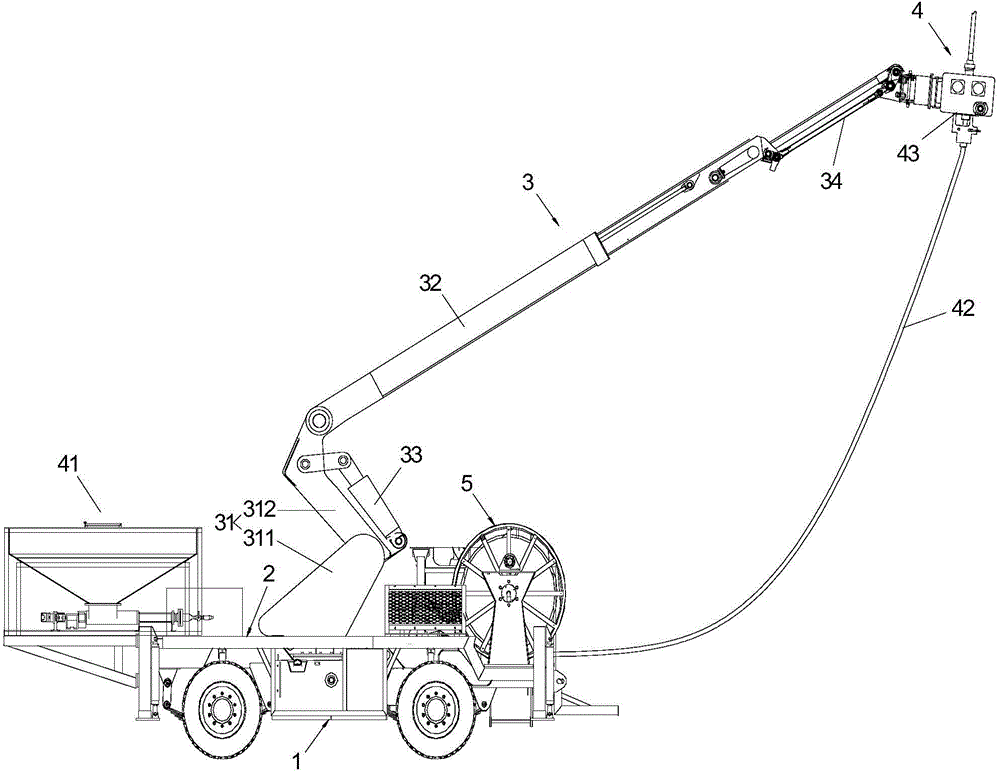

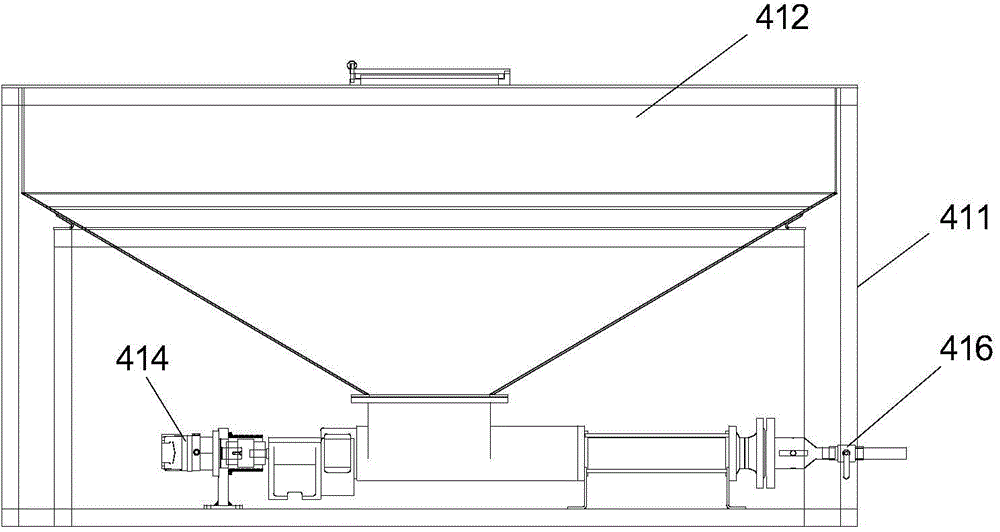

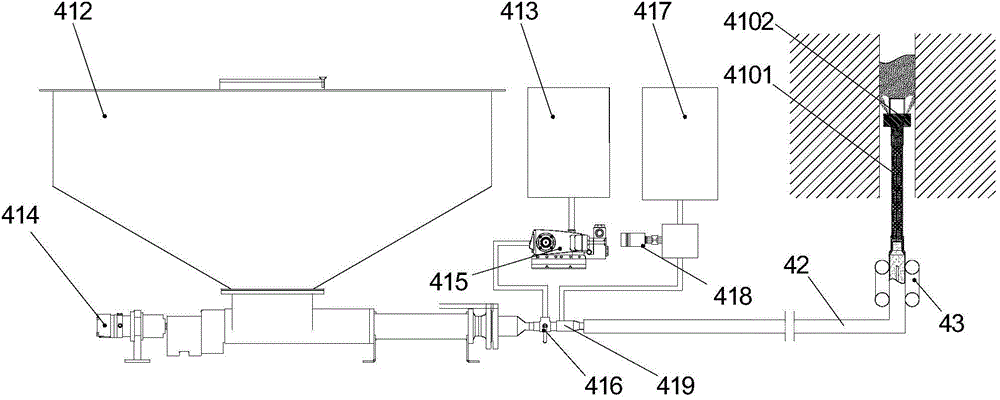

Underground on-site explosive dosing and charging truck

ActiveCN104949593AReduce labor intensityImprove safety conditionsBlastingControl systemEmulsion explosive

The invention relates to the technical field of underground explosive trucks and discloses an underground on-site explosive dosing and charging truck. The underground on-site explosive dosing and charging truck comprises a truck body, a chassis disposed on the truck body, a mechanical arm automatic hole finding mechanism and a charging conveying mixing mechanism which are disposed on the chassis, and a hydraulic system and an electric control system which are matched with the mechanical arm automatic hole finding mechanism and the charging conveying mixing mechanism, wherein the charging conveying mixing mechanism comprises an automatic charging module used for mixing and charging emulsion matrix to form emulsion explosives, a charging tube which is connected with the automatic charging module and used for conveying the emulsion explosives, and an automatic tube conveyor for automatically conveying the charging tube; the mechanical arm automatic hole finding mechanism is matched with the automatic tube conveyor and used for performing blast hole position alignment on the head end of the charging tube. The underground on-site explosive dosing and charging truck has the advantages that mechanical hole finding, automatic tube collecting and conveying and automatic blast hole filling are achieved, charging efficiency is increased, operator labor intensity is lowered, and operator safety conditions are improved effectively.

Owner:SHENZHEN KING EXPLORER SCI & TECH CORP

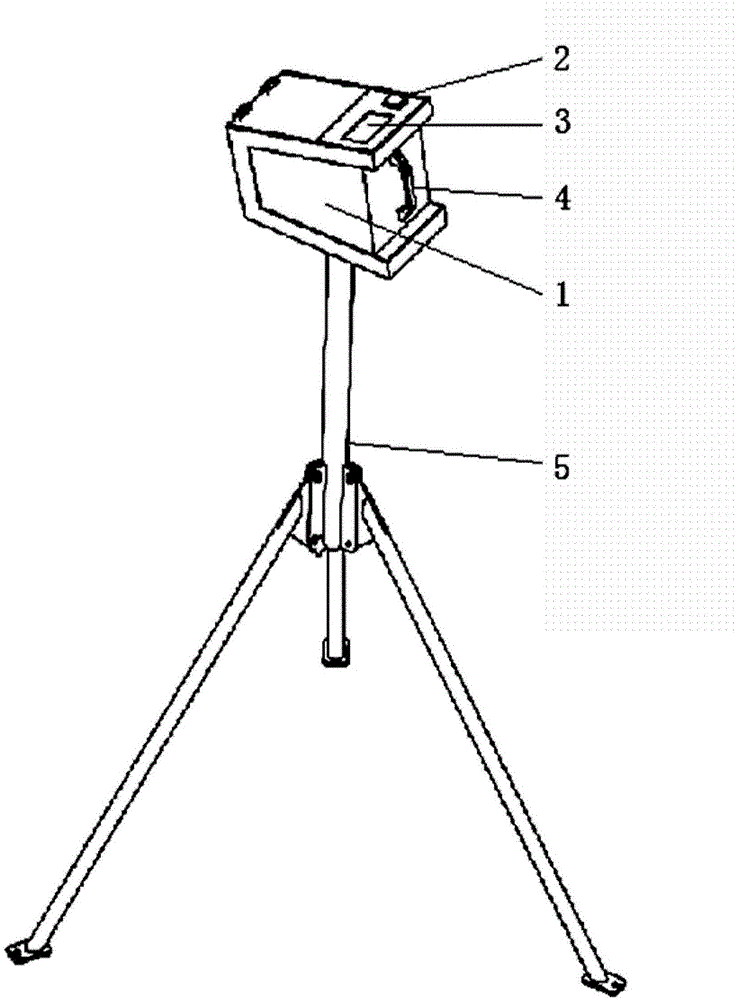

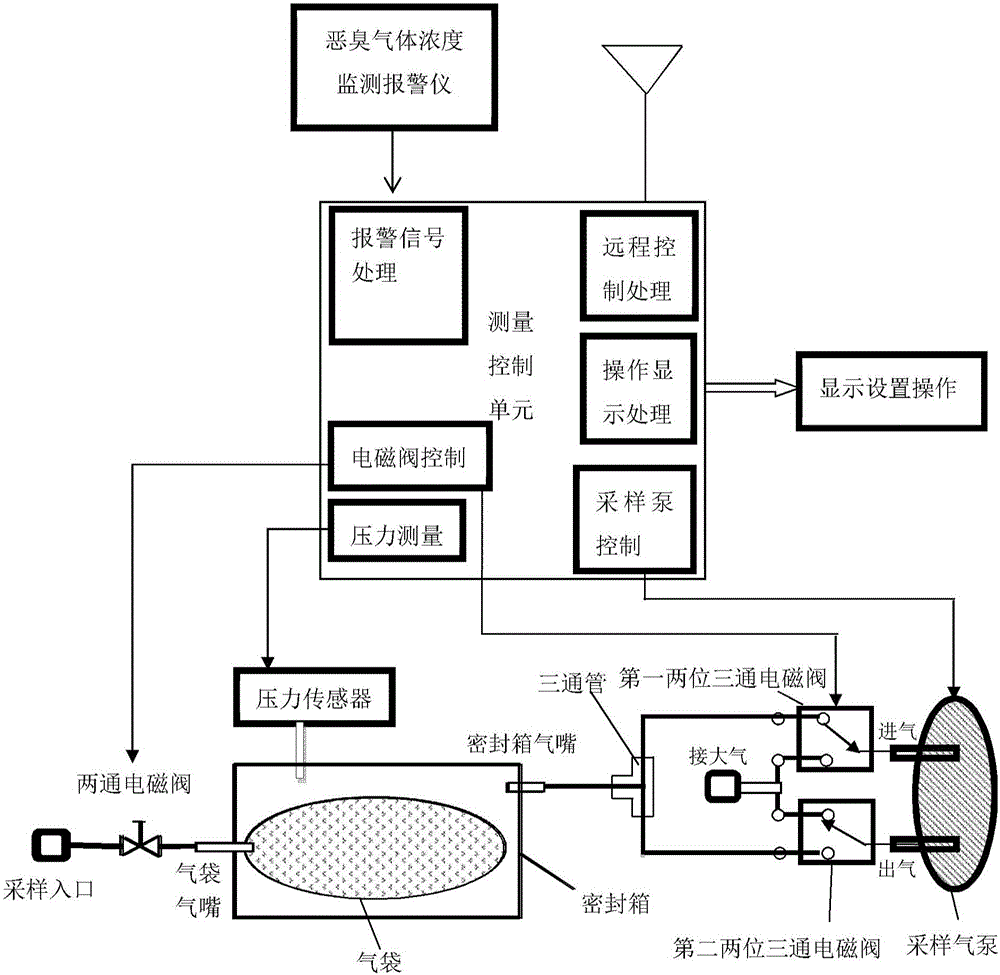

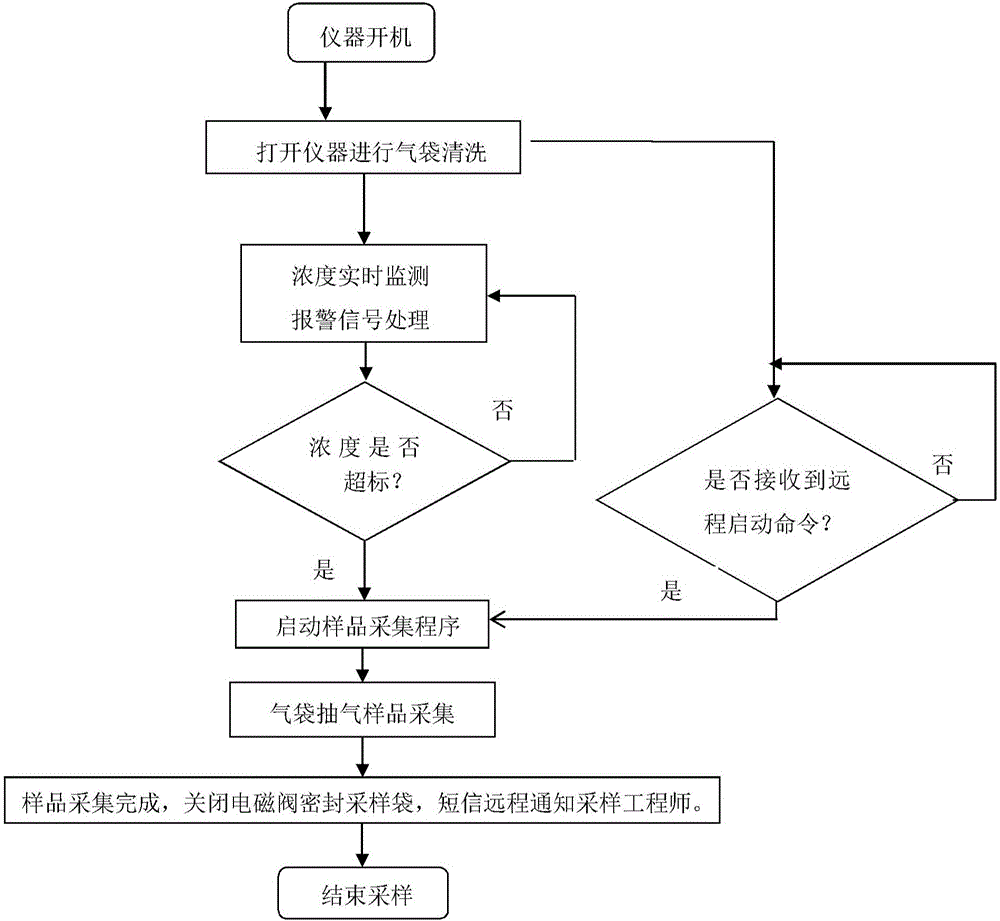

Automatic sampling device for malodorous gas

PendingCN106442031AAvoid mixingRepresentativeWithdrawing sample devicesAlarmsSolenoid valveArtificial olfaction

Provided is an automatic sampling device for malodorous gas. The automatic sampling device comprises a seal box, a measurement control unit and a gas concentration monitoring and alarming unit; the gas concentration monitoring and alarming unit comprises a concentration measurement module and an alarming module, and the alarming module sends an alarming signal to the measurement control unit after the odor concentration exceeds the set threshold value concentration; the seal box is internally provided with a gas bag collecting sampling gas, the gas bag is provided with a gas bag gas nipple which penetrates through the seal box to be connected to one end of a two-way solenoid valve, and the other end of the two-way solenoid valve is connected with a sampling inlet; the measurement control unit comprises a monitoring and alarming signal processing module receiving the alarming signal, a solenoid valve control module and a sampling pump control module, and the solenoid valve control module is electrically connected with the two-way solenoid valve so as to control switching-on and switching-off of the two-way solenoid valve. The sampling device is used for achieving on-site automatic identifying and sampling of the malodorous gas, and the problem that the best opportunity of sampling is missed due to the fact that a traditional method depends on artificial olfaction is solved.

Owner:BEIJING MUNICIPAL ENVIRONMENTAL MONITORING CENT

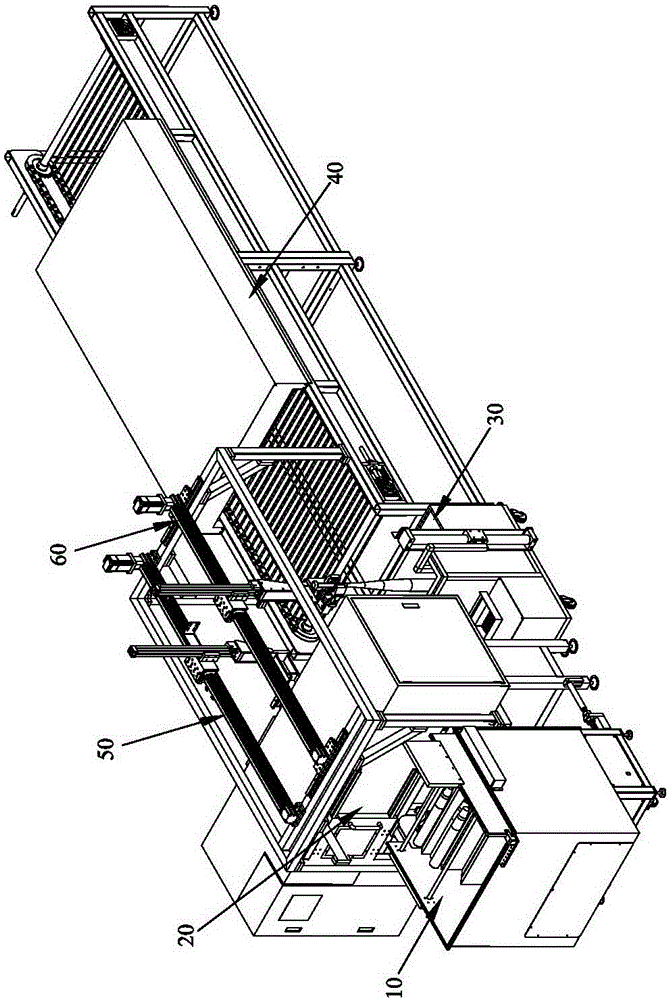

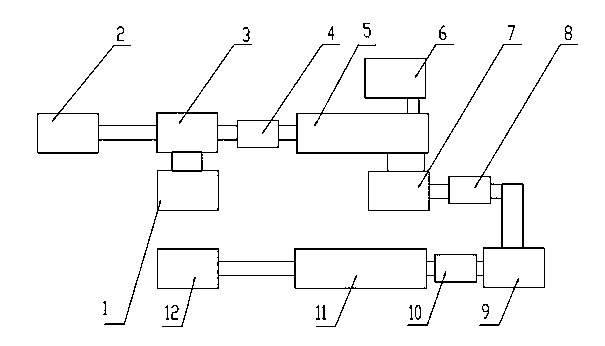

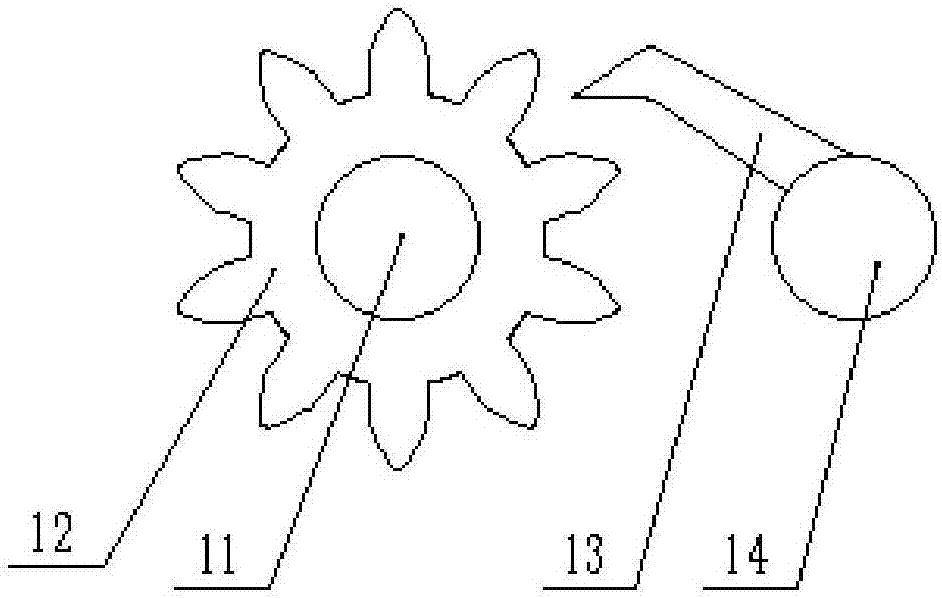

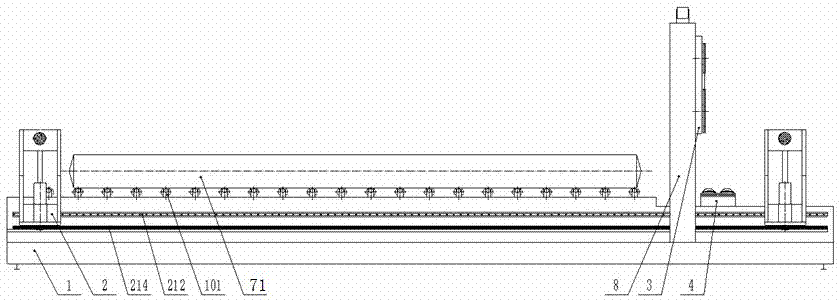

Automatic production line for saw blade heat treatment

InactiveCN103146902AGuarantee the environmentGuaranteed atmosphereFurnace typesHeat treatment furnacesProduction lineEngineering

The invention discloses an automatic production line for saw blade heat treatment, and belongs to the technical field of work piece heat treatment. The automatic production line for the saw blade heat treatment is characterized by comprising a feed mechanism, a feeding tray stepping advancing mechanism, a heat preserving furnace, a carbon-nitrogen furnace, a quenching mechanism, a cleaning machine, a tempering furnace and feeding tray conveying mechanisms, wherein the feed mechanism, the feeding tray stepping advancing mechanism, the heat preserving furnace, the carbon-nitrogen furnace, the quenching mechanism, the cleaning machine, the tempering furnace are sequentially arranged according to a manufacturing process order, and the feeding tray conveying mechanisms are arranged between each two adjacent devices. The feeding tray conveying mechanisms comprise a transition cylinder, a carbon-nitrogen furnace discharging advancing device, a quenching discharging advancing device, a tempering furnace feeding advancing device and a tempering furnace discharging advancing device, wherein the transition cylinder is arranged between the heat preserving furnace and the carbon-nitrogen furnace, the carbon-nitrogen furnace discharging advancing device is arranged on one side of the carbon-nitrogen furnace, the quenching discharging advancing device is arranged between the quenching mechanism and the cleaning machine, the tempering furnace feeding advancing device is arranged between the cleaning machine and the tempering furnace, and the tempering furnace discharging advancing device is arranged at an outlet of the tempering furnace. The automatic production line for the saw blade heat treatment has the advantages of improving production efficiency and energy use rates of the devices, ensuring heat treatment quality of saw blades due to continuous production, achieving automation operation of the whole production line and being small in number of employed workers and good in labor environment.

Owner:烟台金都锯业有限公司

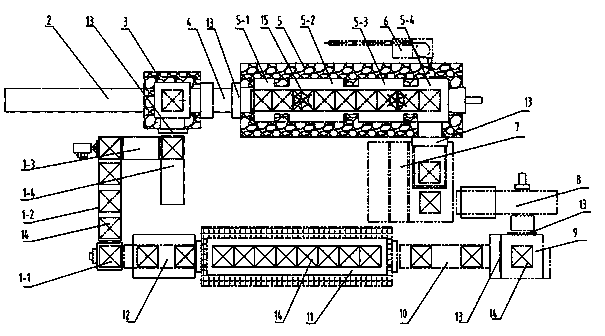

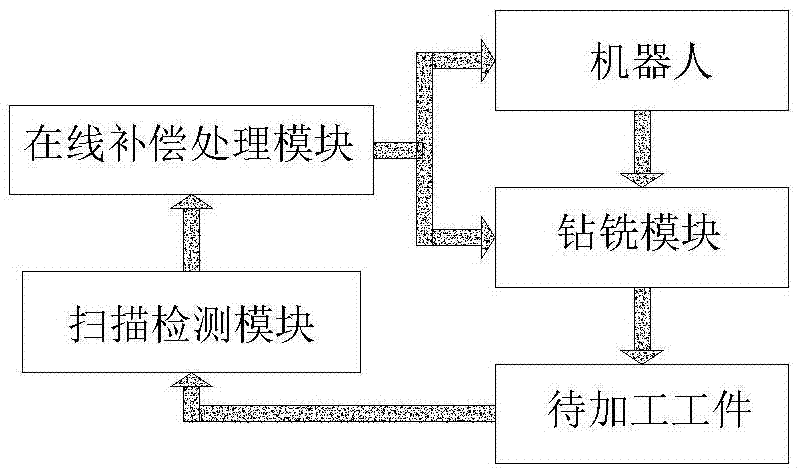

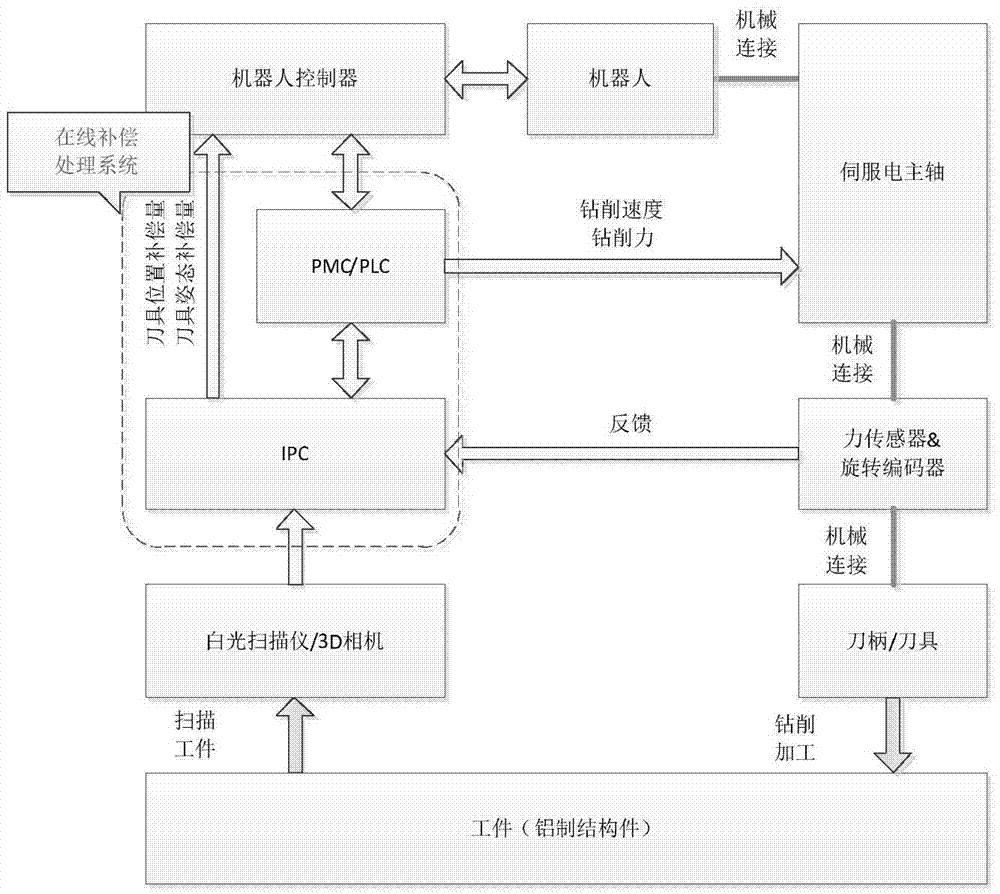

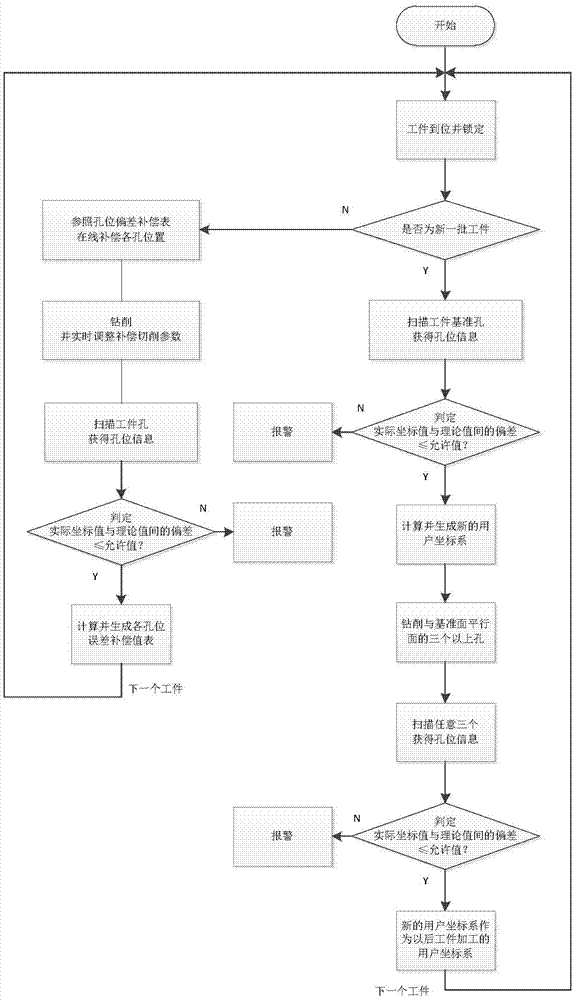

Automatic drilling and milling system and method and drilling and milling production line

PendingCN106925997AImprove processing efficiencyImprove flexibilityAutomatic control devicesMeasurement/indication equipmentsProduction line3d scanning

The invention discloses an automatic drilling and milling system and method and a drilling and milling production line, and relates to the technical field of electromechanical machining. The automatic drilling and milling system and method and the drilling and milling production line can be applied to the process of machining to-be-machined aluminum workpieces and the like through a milling machining center and / or an automatic robot drilling and milling system and the like; and in other words, 3D scanning and other surveillance technologies are utilized for conducting online surveillance and compensation on the robot track, and accordingly accurate machining of the to-be-machined workpieces is achieved.

Owner:SHANGHAI FANUC ROBOTICS

Automobile casting paint spraying device

ActiveCN107999313AImplement bulk transferRealize paintingLiquid spraying apparatusElectric machineryEngineering

The invention belongs to the field of automobile part manufacturing, and particularly discloses an automobile casting paint spraying device. The automobile casting paint spraying device comprises a machine frame, wherein the machine frame is provided with a paint spraying unit, a conveying unit and a driving unit from top to bottom; the conveying unit comprises a rotating shaft and a rotating table, and a plurality of fixtures are uniformly distributed on the rotating table; the rotating table is provided with a first connecting hole, a base is provided with a second connecting hole, and the inner wall of the second connecting hole is provided with an internal spline; the paint spraying unit comprises a piston cylinder, the interior of the piston cylinder is in sliding connection with a piston, the piston is fixedly provided with a piston rod, the piston rod is in hinge joint with a first connecting rod, and the first connecting rod is in hinge joint with a second connecting rod; the two end faces of the piston cylinder are sealed, the end face of one side of the piston cylinder is provided with a liquid inlet hole and a liquid discharge hole, the end face of the other side of thepiston cylinder is provided with an air inlet hole and an air outlet hole, the liquid outlet hole is connected with a liquid discharge pipe, and the liquid discharge pipe is connected with a spray head; the air outlet hole is connected with a guide cover; and the driving unit comprises a first rotating motor and a second rotating motor. By adopting the scheme, batch paint spraying work of automobile castings can be carried out.

Owner:宁波高新区新柯保汽车科技有限公司

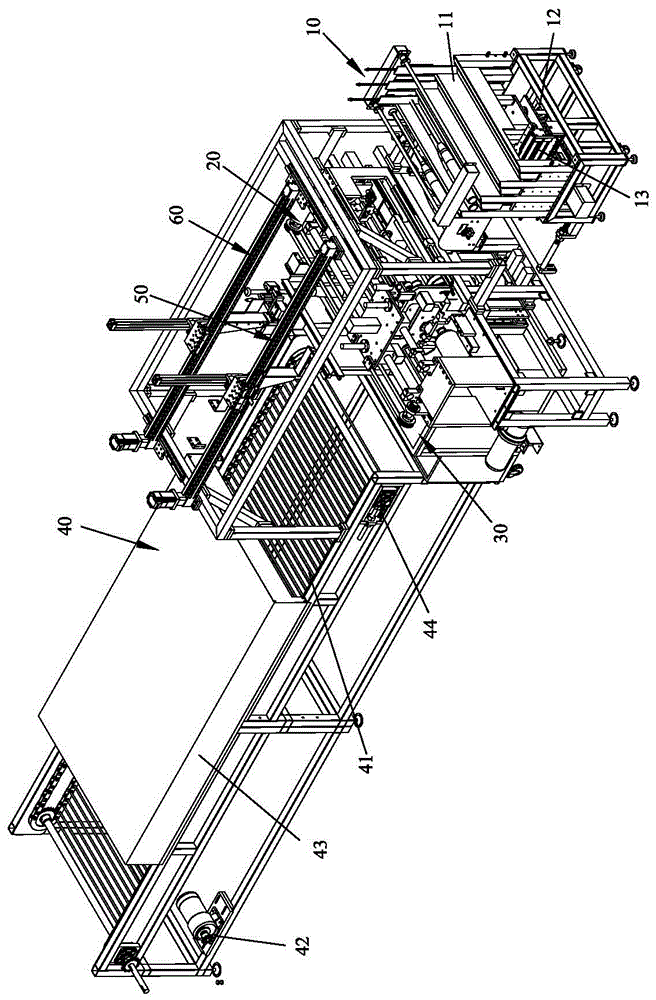

Single-crystal bar disconnection cutting equipment

PendingCN107443601AOperational securityReduce labor intensityWorking accessoriesGrinding machinesElectric machineryServo

The invention discloses single-crystal bar disconnection cutting equipment. The single-crystal bar disconnection cutting equipment comprises a machine frame, a single-crystal bar feeding device, a cutting machine frame, a wire saw cutting mechanism, a single-crystal bar jacking device, a material collecting and conveying robot and a skip car, wherein the single-crystal bar feeding device can slide on an undercarriage for operation; the cutting machine frame is installed on the undercarriage; the wire saw cutting mechanism is installed on the cutting machine frame; and the single-crystal bar jacking device, the material collecting and conveying robot and the skip car can slide on the undercarriage. The single-crystal bar disconnection cutting equipment is characterized in that supporting roller assemblies are fixed to a base; clamping jaws of two movable clamping units are located above supporting rollers, and the clamping units can penetrate through the space below the cutting machine frame; the wire saw cutting mechanism achieves single-section cutting; servo motors drive speed reducers to drive gears to be engaged with racks so that a bar flotation jacking device can move; and the material collecting robot is located on the side face of the bar flotation jacking device. The single-crystal bar disconnection cutting equipment has the advantages that the clamping units and the single-crystal bar jacking device can be driven to move automatically through matching of the motors, the gears and the racks, the labor intensity of operators is low and the degree of automation is high; and diamond wires can be replaced conveniently, wire breaking cannot happen easily and the failure rate is low.

Owner:福州天瑞线锯科技有限公司

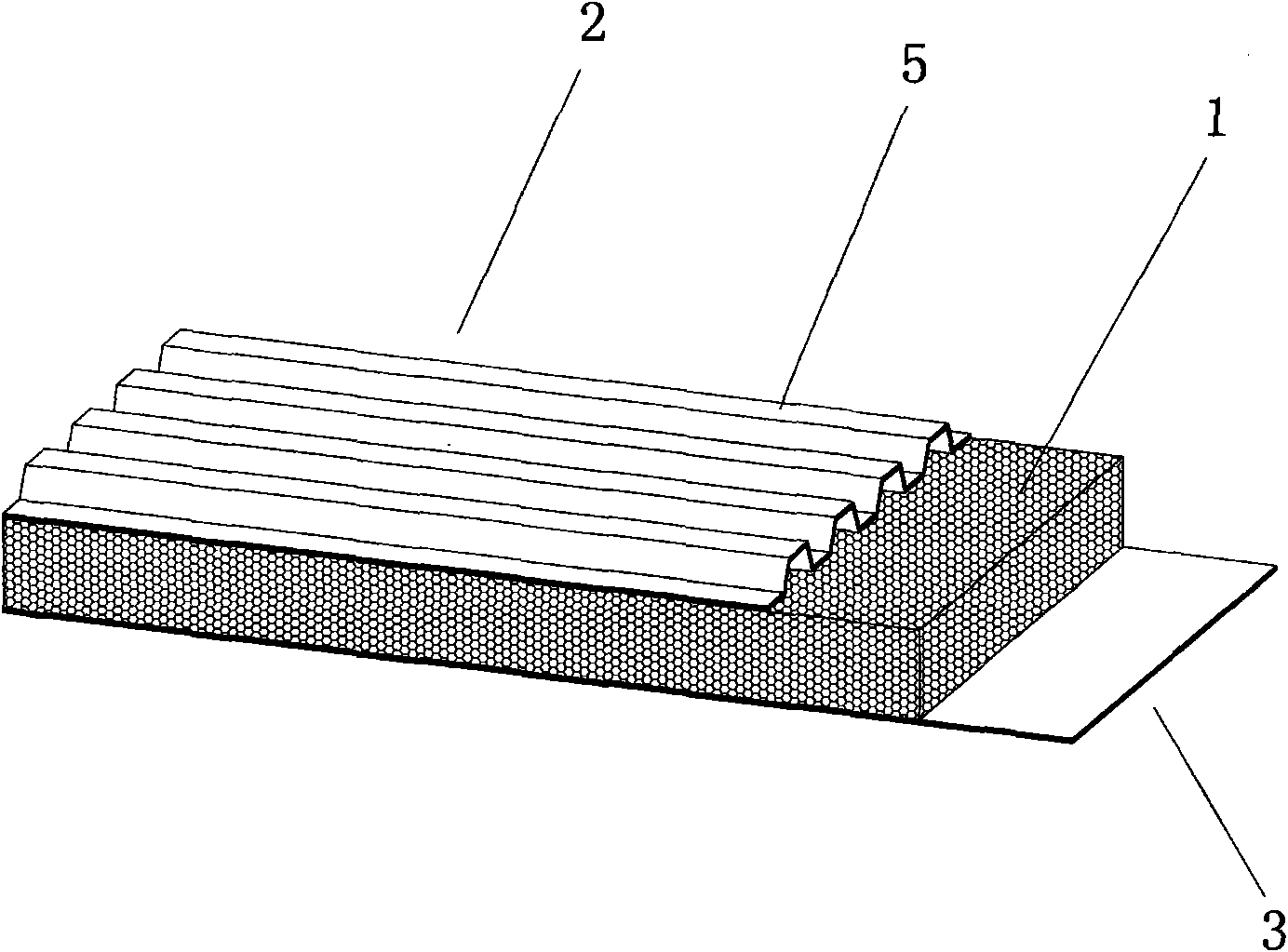

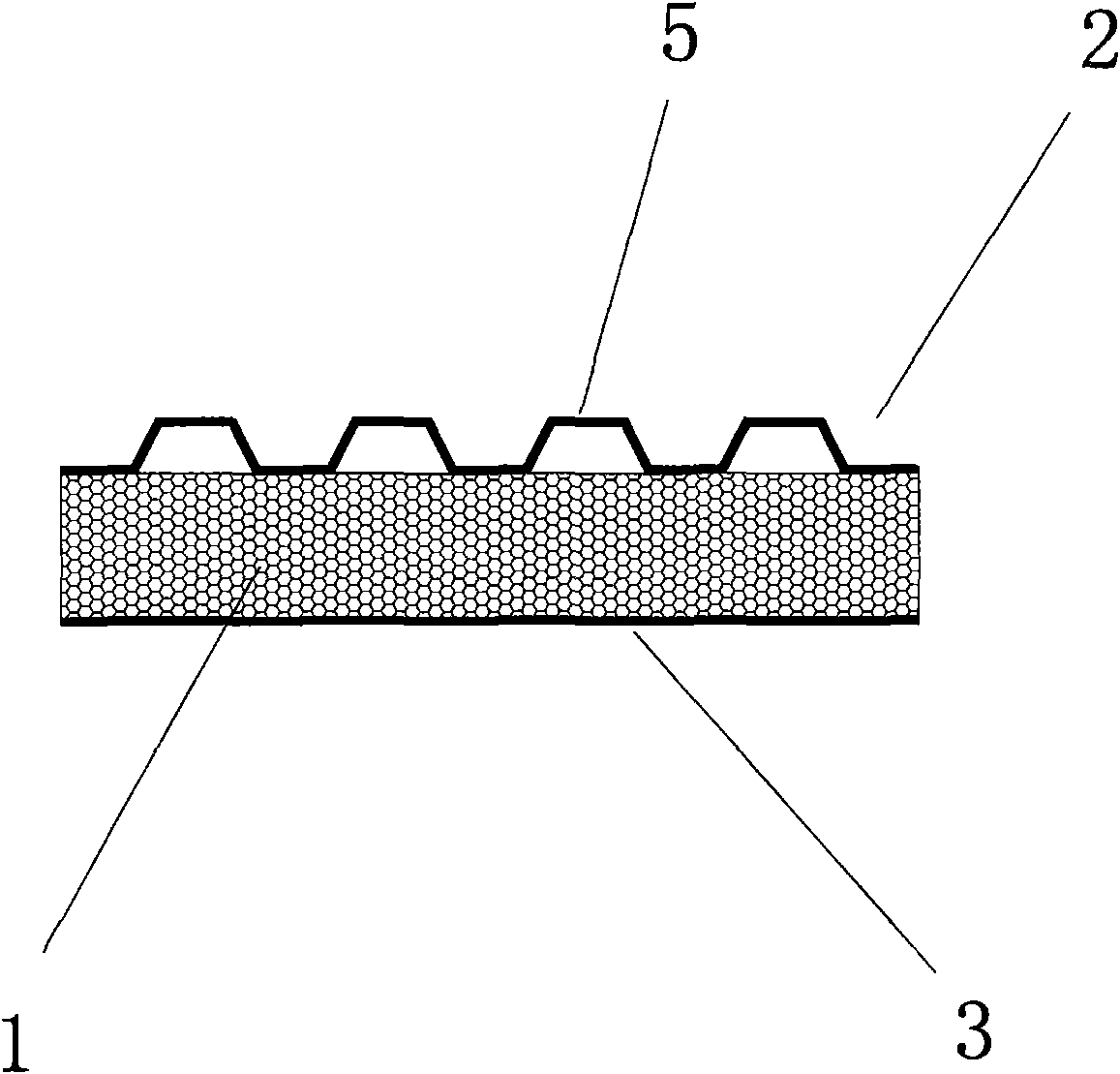

Light foaming concrete composite heat insulation plate

InactiveCN102535660ALow densityRelieve pressureHeat proofingWater-setting substance layered productPolystyreneSurface plate

The invention discloses a light foaming concrete composite heat insulation plate, which comprises an outer panel, an inner panel and a foam concrete slab heat insulation layer, wherein the foam concrete slab heat insulation layer is clamped and arranged between the outer panel and the inner panel. A foam concrete plate used as a middle heat insulation layer has the advantages and properties that the weight is light, the heat insulation and sound isolation effects are realized, the foam concrete plate does not combust, the service life is long, the intensity is high, and the like, so the light-weight foam concrete composite heat insulation plate has the advantages that the weight is light, the heat insulation performance, the sound isolation effect and the inflaming retarding and fireproof performance are good, the durability is realized, the intensity is high, the anti-impact performance is good, the construction is simple and convenient, and the like. The light-weight foam concrete composite heat insulation plate can replace color plates using high molecular materials such as polystyrene foam, polyurethane and the like as heat insulation layers, can be used as heat insulation materials for buildings, and can be particularly used as roof materials.

Owner:BEIJING SIFANGRUGANG CONCRETE PROD

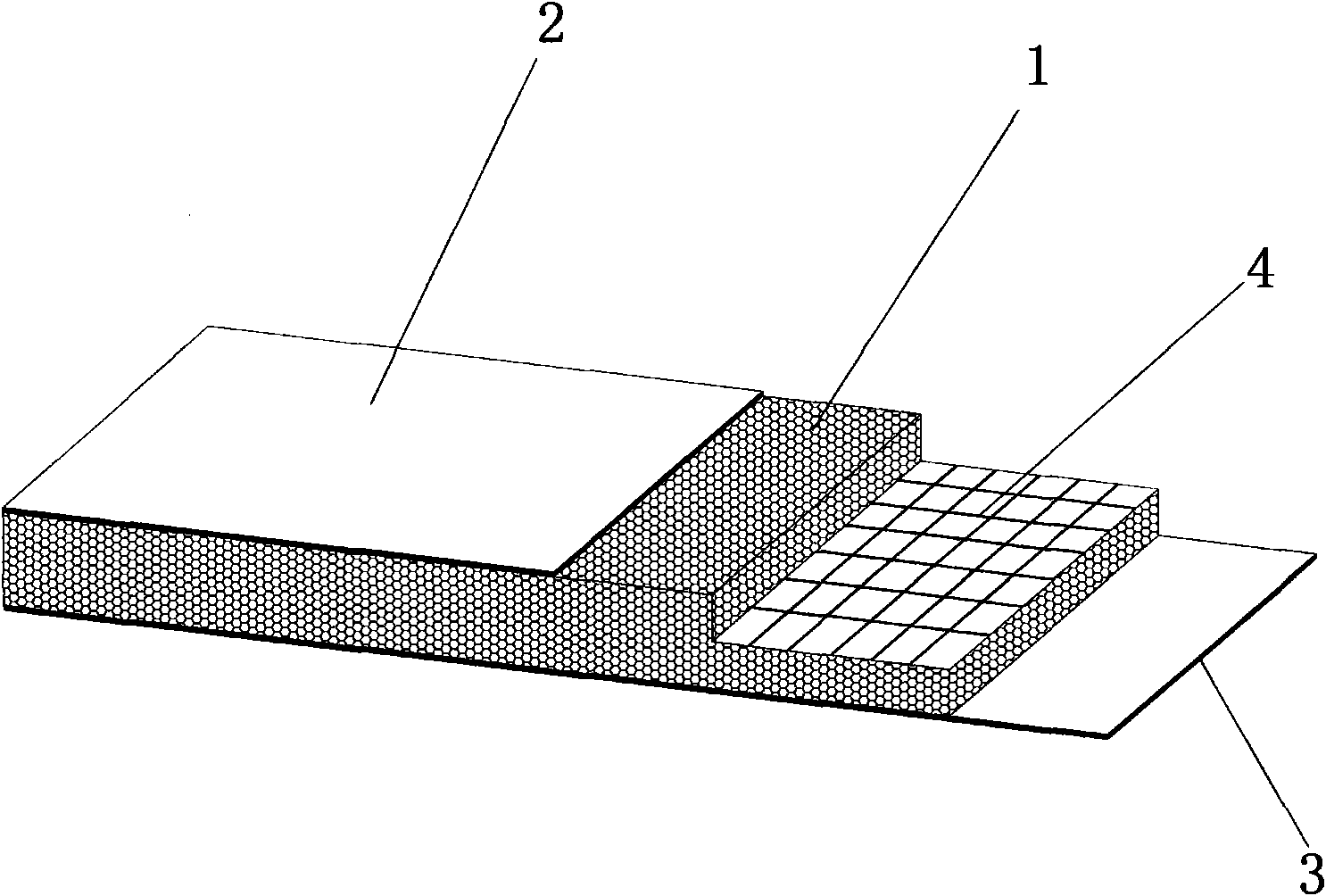

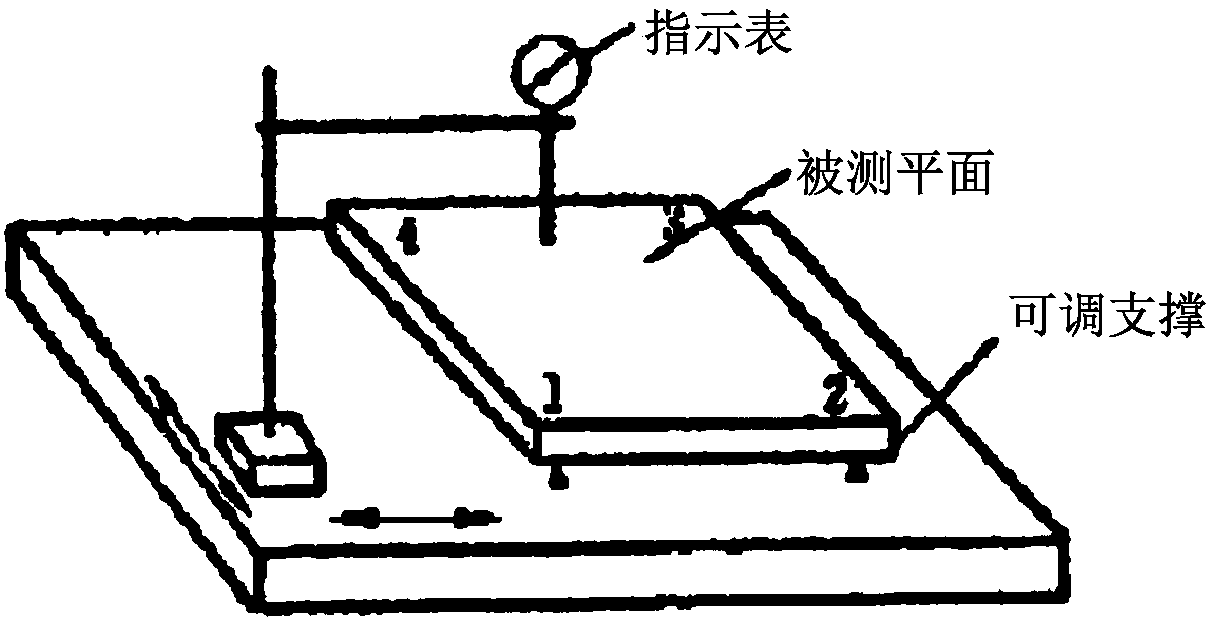

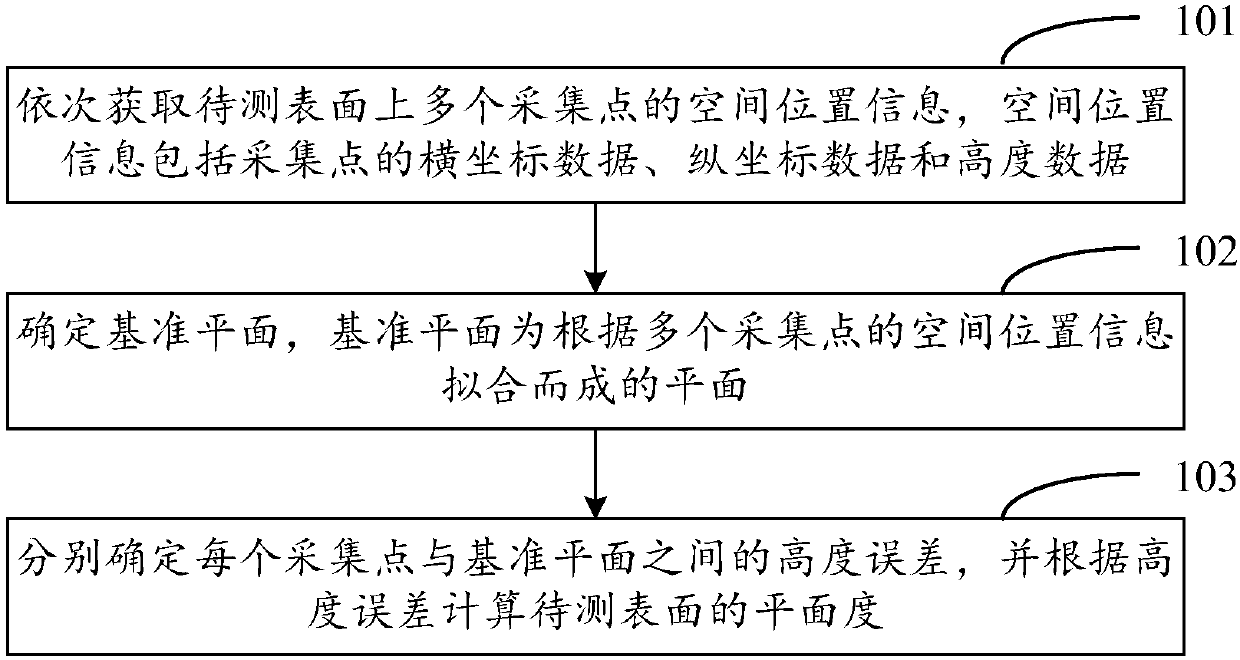

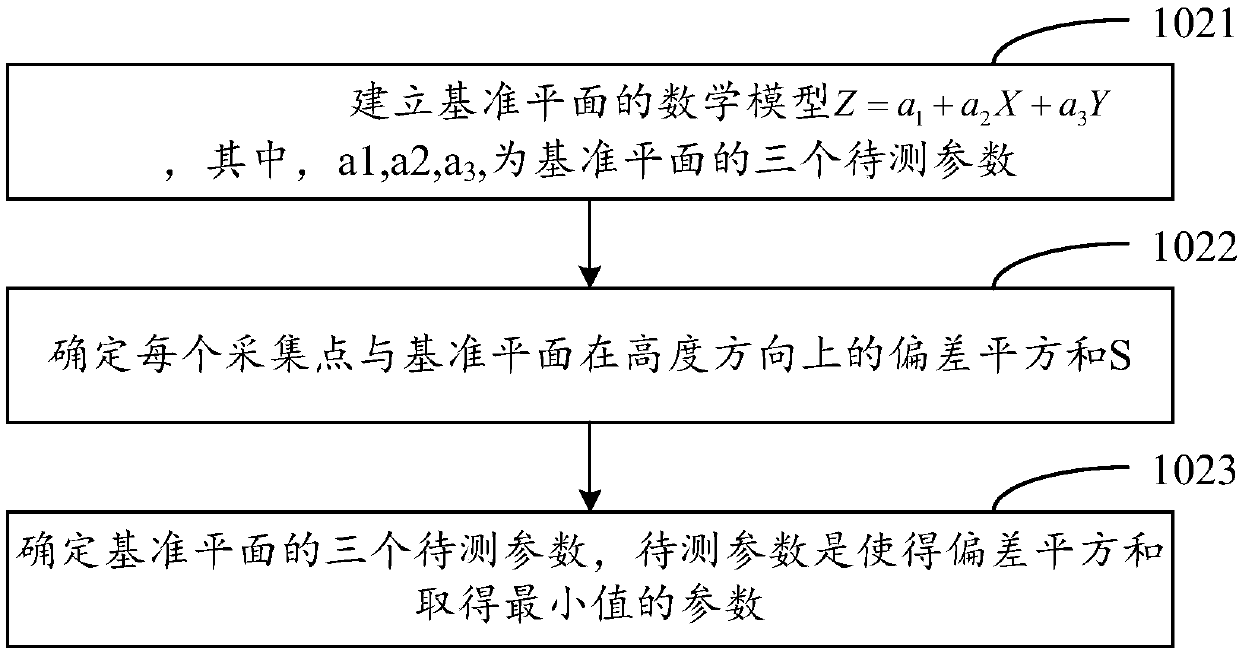

Method and device for determining flatness of surface

InactiveCN107063060AImprove detection accuracyEasy to determineMechanical roughness/irregularity measurementsProduction lineAlgorithm

The invention discloses a method and a device for determining the flatness of a surface. The method comprises the following steps: acquiring spatial position information of multiple collection points on a to-be-measured surface in turn, wherein the spatial position information includes horizontal coordinate data, longitudinal coordinate data and height data of the collection points; determining a datum plane, wherein the datum plane is a plane formed through fitting according to the spatial position information of the multiple collection points; and determining the height error between each collection point and the datum plane, and calculating the flatness of the to-be-measured surface according to the height error. As the datum plane matching the collection points most is determined through fitting, error generated when an actual plane is used as a datum plane is avoided, potential error caused by manual intervention is eliminated, and the precision of flatness detection is improved greatly. Moreover, the method can run automatically, improves the repeatability and reproducibility of detection, and is suitable for automatic production lines.

Owner:北京正木激光设备有限公司

Stacker crane

ActiveCN103350906AThe pile shape is beautiful and neatAutomate operationsCharge manipulationStacking articlesControl systemClassical mechanics

The invention relates to a stacker crane which is especially suitable for automatically stacking fluid materials which are contained in bags. The stacker crane comprises a bag-direction guiding mechanism, a ranking and group organizing mechanism, a layering bag pushing mechanism and a pressing and exhausting mechanism all of which are located on an upper layer platform, comprises a vibration compaction mechanism, a stacking plate lifting mechanism, a tray bin, a tray output mechanism, a stacking plate output mechanism and an all-line electrical control system all of which are located on a lower layer platform, and comprises a climbing and conveying mechanism. The bag-direction guiding mechanism is used for automatically guiding products, the ranking and group organizing mechanism is used for automatically ranking and integrating the products, the layering bag pushing mechanism is used for integrating the products for the second time, and the pressing and exhausting mechanism is used for exhausting the air in the products for the second time. The vibration compaction mechanism is used for vibrating and compacting the products evenly, the stacking plate lifting mechanism is used for lifting stacking plates, the tray bin is used for storing trays, the tray output mechanism is used for automatically outputting the trays, the stacking plate output mechanism is used for automatically outputting the stacking plates, and the all-line electrical control system is used for controlling executive components. Under the premise that the stacker crane is suitable for conventional automatic stacking of ordinary materials, the stacker crane is more suitable for automatically stacking the fluid materials, safe and reliable, environment-friendly effects can be achieved, the stacking appearance is attractive and orderly, and full automation is achieved.

Owner:烟台圣元自动化设备有限公司

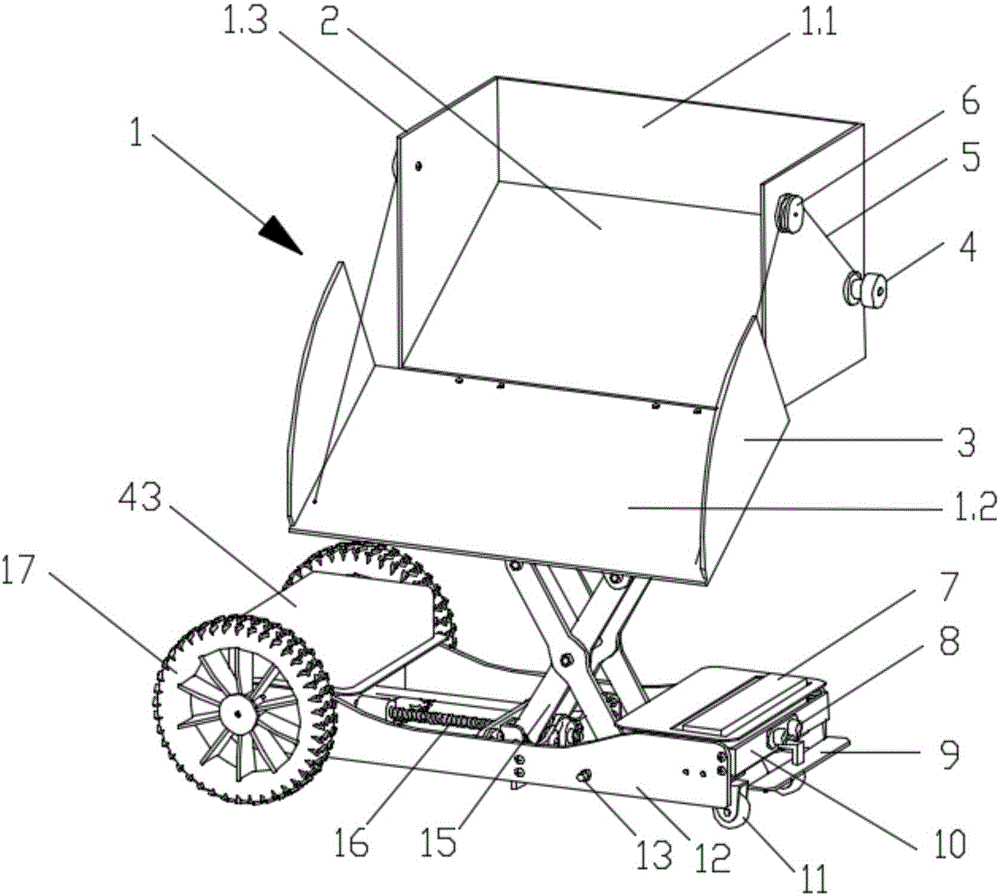

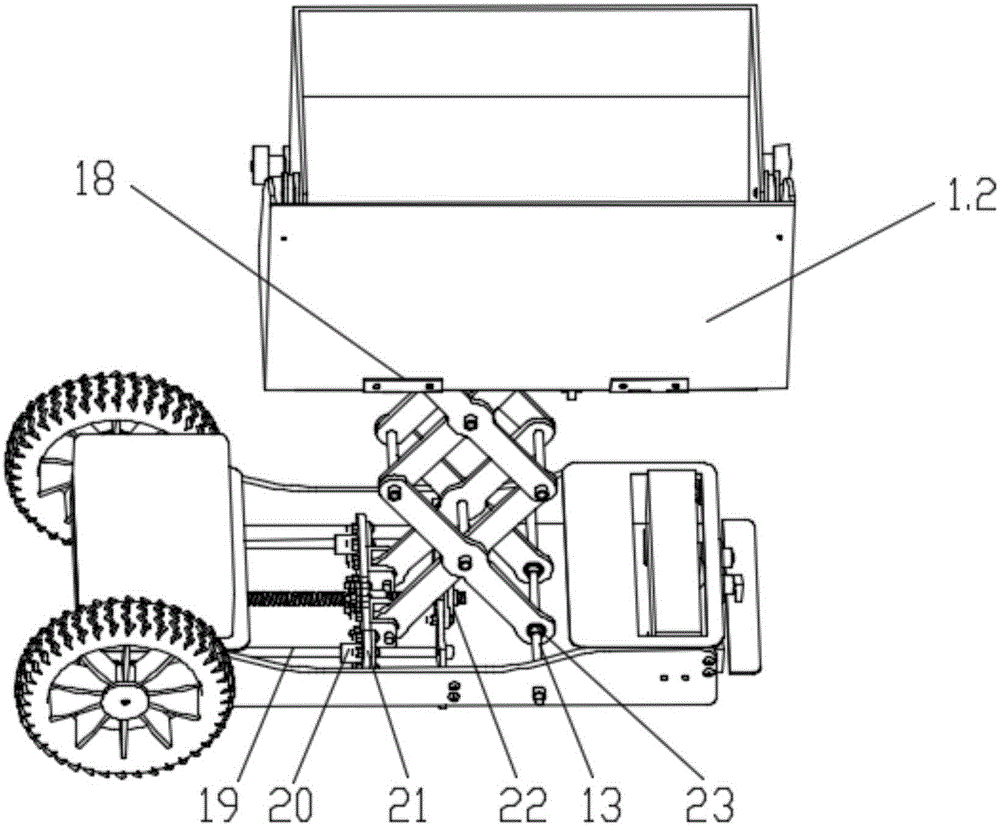

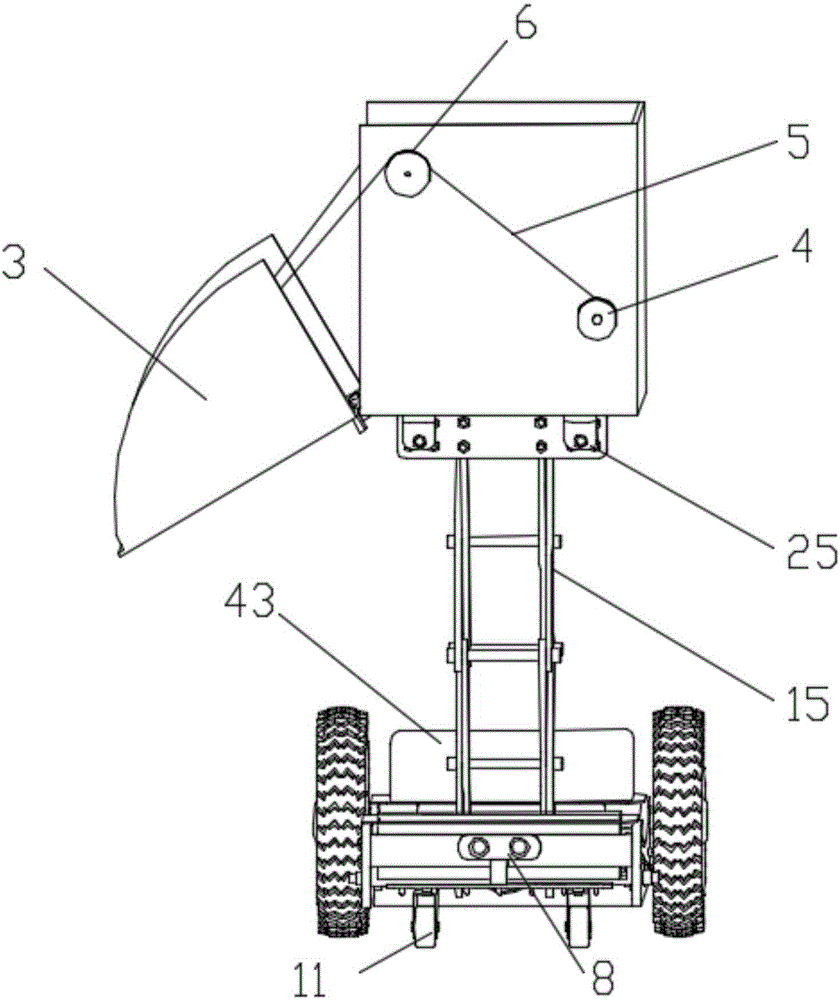

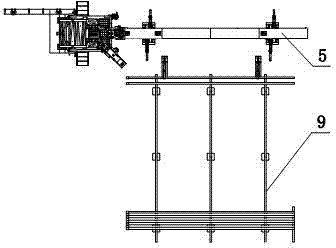

Intelligent carrier vehicle for loading, unloading and carrying goods

ActiveCN106080713AEasy to operateSave human effortSupporting partsPosition/course control in two dimensionsVehicle frameIntegrated circuit

The invention discloses an intelligent carrier vehicle for loading, unloading and carrying goods. The intelligent carrier vehicle for loading, unloading and carrying the goods comprises a driving device, a jacking device, a material bearing device and a control device, wherein the driving device comprises a frame driven by a motor A; the jacking device comprises a motor B, a lead screw, a sliding rod I, a sliding block I, a sliding rod II, a sliding block II and at least two 'X'-shaped foldable support frames; the material bearing device comprises a container and an opening and closing mechanism driven by a motor C; the control device comprises an ultrasonic sensor, a gray level sensor and an integrated circuit controller; the bottom of the material bearing device is connected with the support frames; the bottoms of the support frames are connected with a sliding mechanism on the frame; and the control device controls traveling of the carrier vehicle. The intelligent carrier vehicle integrally has functions of automatic tracking, carrying and unloading, labors and time are saved, labor intensity of carrying workers is reduced, goods transfer efficiency is greatly improved, and the number of damaged articles is reduced.

Owner:广州仪速安电子科技有限公司

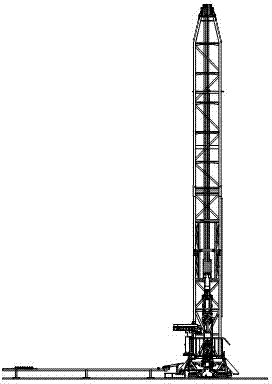

Numerical-control petroleum workover line

ActiveCN102877802AAutomate operationsReduce harmDrilling rodsDrilling casingsManipulatorPetroleum oil

The invention discloses a numerical-control petroleum workover line mainly applied to the process of petroleum tubing maintenance. The numerical-control petroleum workover line comprises a derrick disposed on a platform. A tubing rack is disposed on the side of the derrick. The numerical-control petroleum workover line is characterized in that a tube conveying chute is arranged at the end of the tube rack, a trolley for pushing tubing to move is arranged on the tube conveying chute, a hydraulic pipe clamp manipulator capable of lifting up one end of a tube and a tube-conveying manipulator capable of gripping the tube which is lifted and lifting and conveying the tube to a next procedure are disposed at the end of the tube conveying chute, main and auxiliary elevators which are used for regulating the tube to the upper middle of the platform and capable of moving up and down are arranged on the derrick, and a hydraulic slip is disposed below the main and auxiliary elevators at the center of the platform. The numerical-control petroleum workover line has the advantages that the whole process of tube mounting and demounting is automated and is fast and stable, and the tube is minimally damaged during mounting and demounting.

Owner:胜利油田胜兴集团有限责任公司

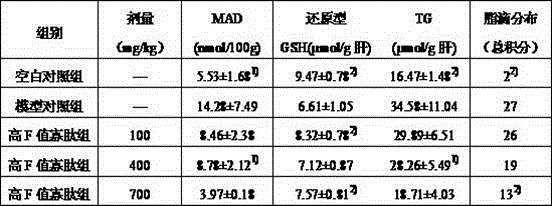

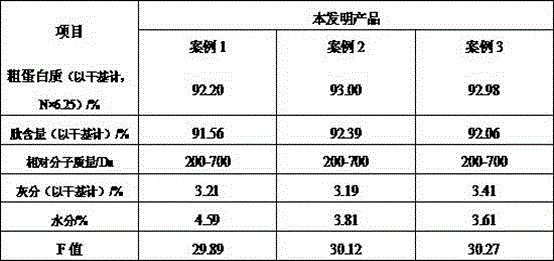

Industrial production method of high-F-value corn oligopeptide with alcohol dispelling and liver protection activities

InactiveCN105639048ARealize industrial productionSimple production processVegetable proteins working-upBiotechnologyUltrafiltration

The invention discloses an industrial production method of high-F-value corn oligopeptide with alcohol dispelling and liver protection activities. The production method comprises the following steps: carrying out high-speed shearing emulsification on corn gluten meal (CGM), carrying out enzymolysis by combining basic protein with compound flavored proteinase, carrying out enzyme deactivation and frame filtering, carrying out activated carbon adsorption to remove bitterness, colors and aromatic amino acid, carrying out separation and purification by virtue of ultrafiltration equipment, carrying out desalination by virtue of nanofiltration, and carrying out spray drying, so as to obtain the high-F-value corn oligopeptide. According to the high-F-value corn oligopeptide produced by virtue of the production method, the fatty degeneration index of liver cells of mice with alcoholic hepatic injury can be decreased, meanwhile, the contents of triglyceride (TG) and malondialdehyde (MDA) in the livers can be reduced, and the content of reduced glutathione (GSH) can be increased; and a result shows that the high-F-value corn oligopeptide produced by virtue of the production method has the effect of preventing the alcoholic hepatic injury of the mice.

Owner:乳山市华隆生物科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com