Rail-mounted gantry crane automatic yard operation control system and automatic loading and unloading method

An operation control and rail hoisting technology, applied in safety devices, transportation and packaging, load hoisting components, etc., can solve the problems of complicated operation and large equipment investment, and achieve the effect of simple operation, small equipment investment and labor cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

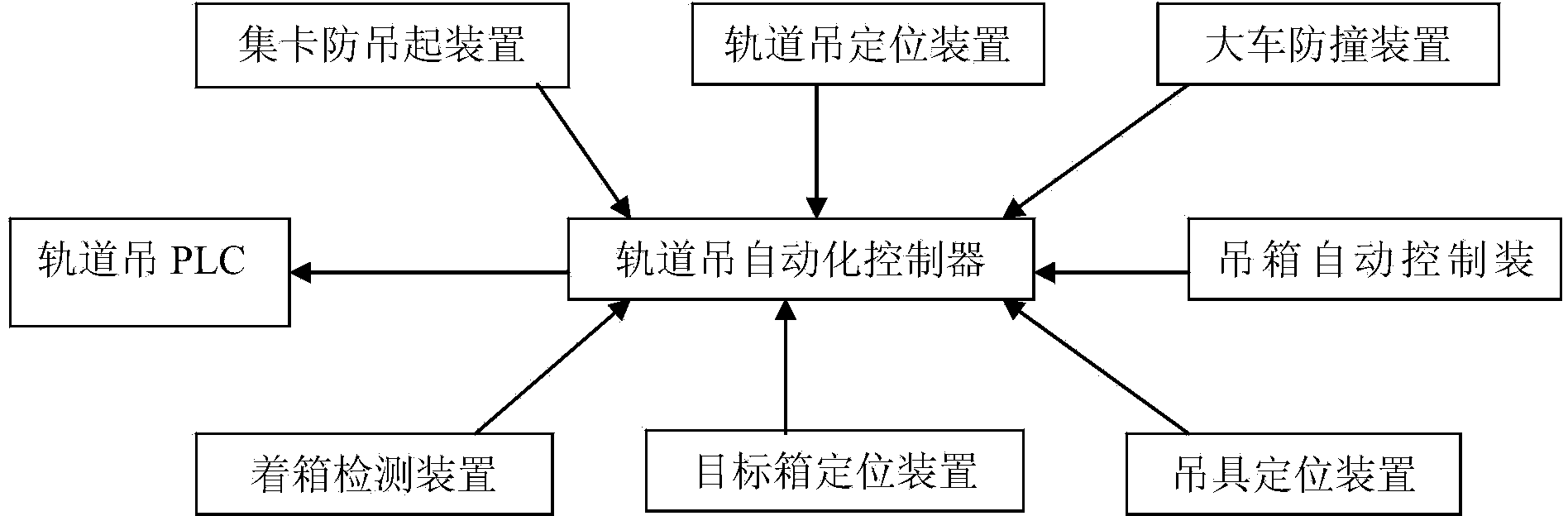

[0042] The principle diagram of the rail crane automatic yard operation control system of the present invention is as follows figure 1 As shown, it includes rail crane automation controller, rail crane PLC controller, spreader PLC controller, truck anti-lifting device, rail crane positioning device, box loading detection device, hanging box automatic control device, target box positioning device and Spreader positioning device.

[0043] The collection card anti-lifting device includes an anti-lifting detection infrared sensor installed on the rail suspension bottom beam, and the anti-lifting detection infrared sensor is used to detect the position of the container relative to the collection truck; the anti-lifting detection infrared The sensor is connected with the automatic controller of the rail crane, and the automatic controller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com