Patents

Literature

1814 results about "Wharf" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A wharf, quay (/kiː/, also /keɪ, kweɪ/), or staith(e) is a structure on the shore of a harbour or on the bank of a river or canal where ships may dock to load and unload cargo or passengers. Such a structure includes one or more berths (mooring locations), and may also include piers, warehouses, or other facilities necessary for handling the ships. Wharfs are often considered to be a series of docks in which boats are stationed.

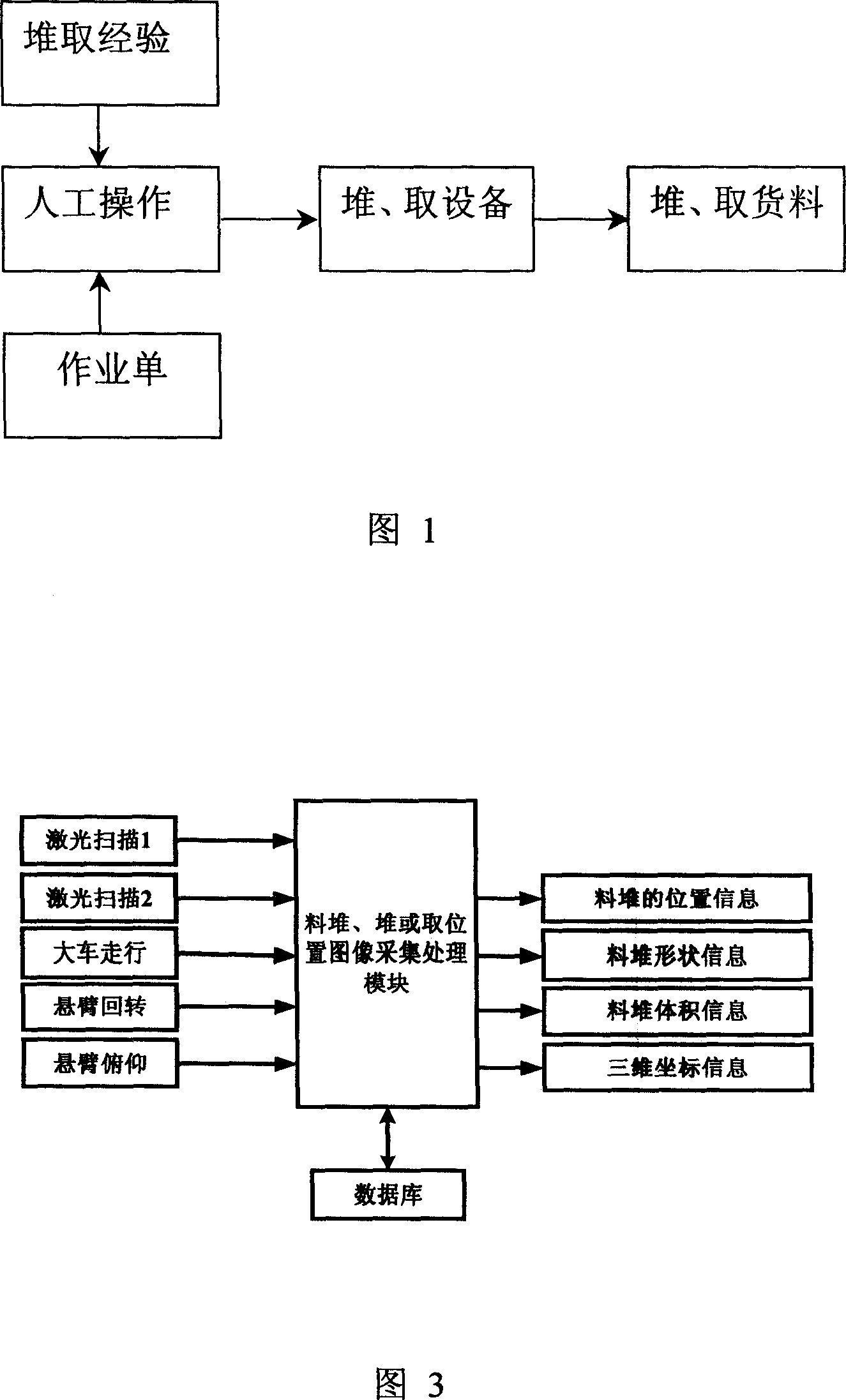

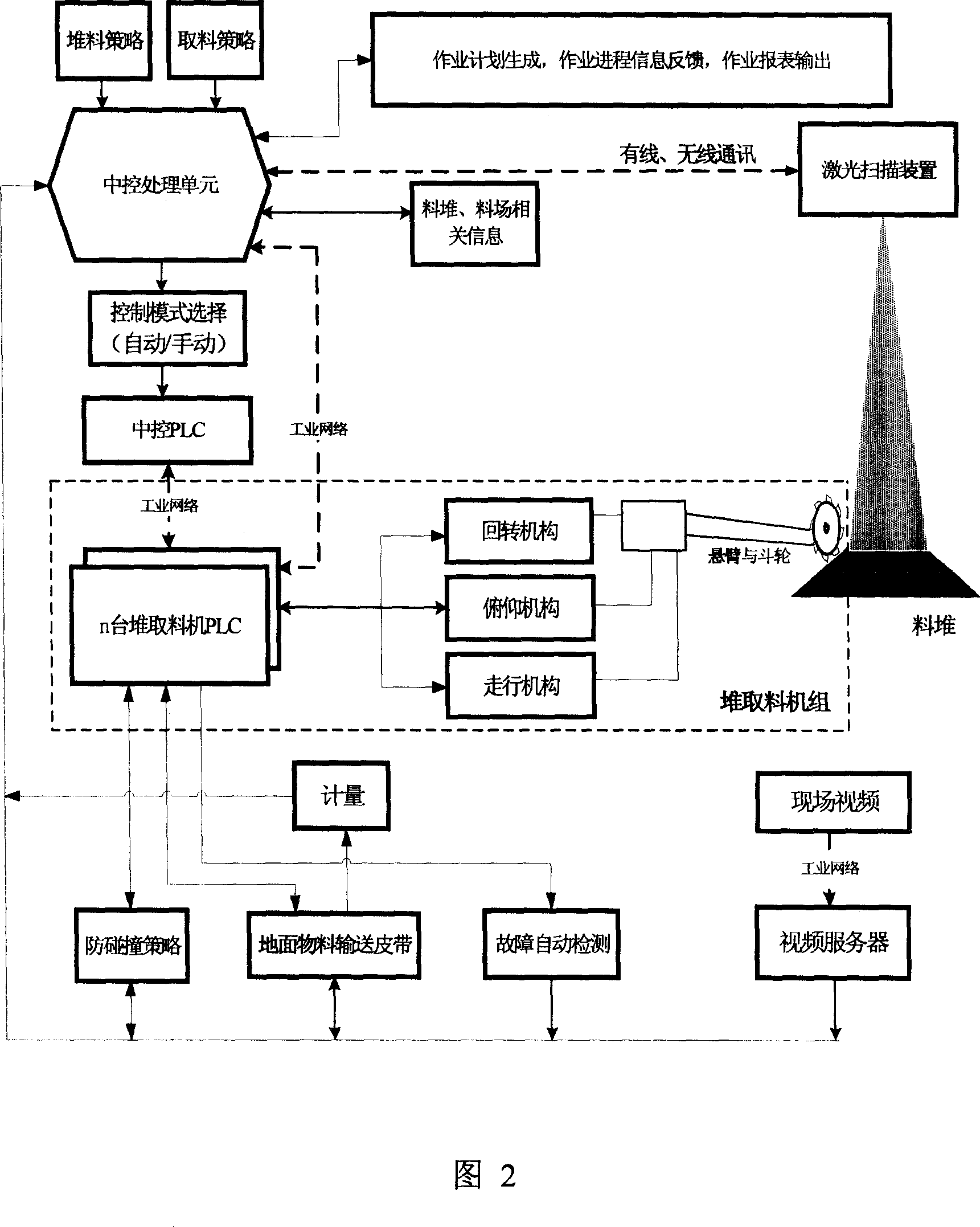

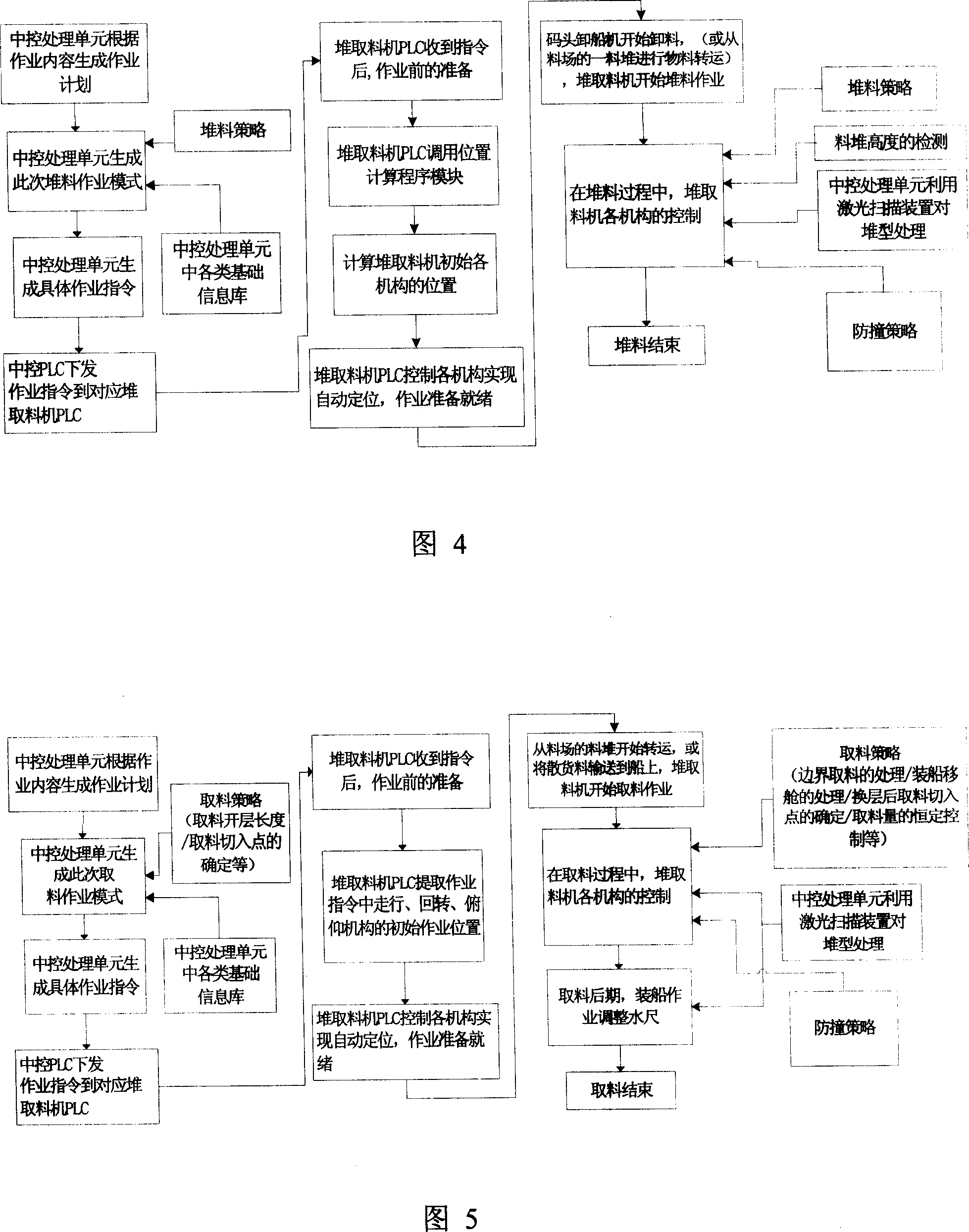

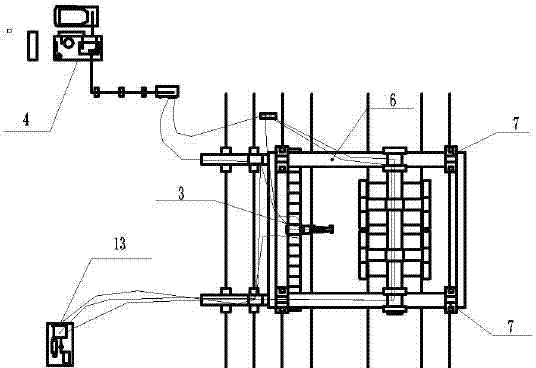

Unmanned piling and taking technique for bulk cargo stock yard

ActiveCN101104480AOvercoming automationOvercome labor intensityElectric programme controlLoading/unloadingBulk cargoLaser scanning

The invention relates to a port warehousing logistics technology, in particular to a bulk material yard unmanned stacking / reclaiming technology. Firstly, a database is established; secondly, operation instructions, automatic stacking / reclaiming operation modes and control instructions for automatic stacking / reclaiming operations are generated through input operation kinds of goods and the planning work amount; thirdly, the relevant instructions are sent to a central control PLC and then transmitted to the corresponding local stacker / reclaimer PLC through the industrial network; fourthly, the local PLC controls the operation of all components of the stacker / reclaimer to complete the local operation control. At the same time, a material stack laser scanning device is used to scan the material yard condition, and the scanned result will then be transferred to a central control processing unit through the industrial network; fifthly, the central control processing unit achieves the stack type scan data processing of the stacker / reclaimer to generate new instructions which will then be sent to the corresponding local stacker / reclaimer PLC; sixthly, a handle operating panel arranged inside a central control room can be taken as a backup means of manual operation under special circumstances. The invention can be applied to large-scale raw material yards, such as ports, wharfs, open warehouses, mine stacking yards, as well as iron and steel enterprises.

Owner:BAOSHAN IRON & STEEL CO LTD +1

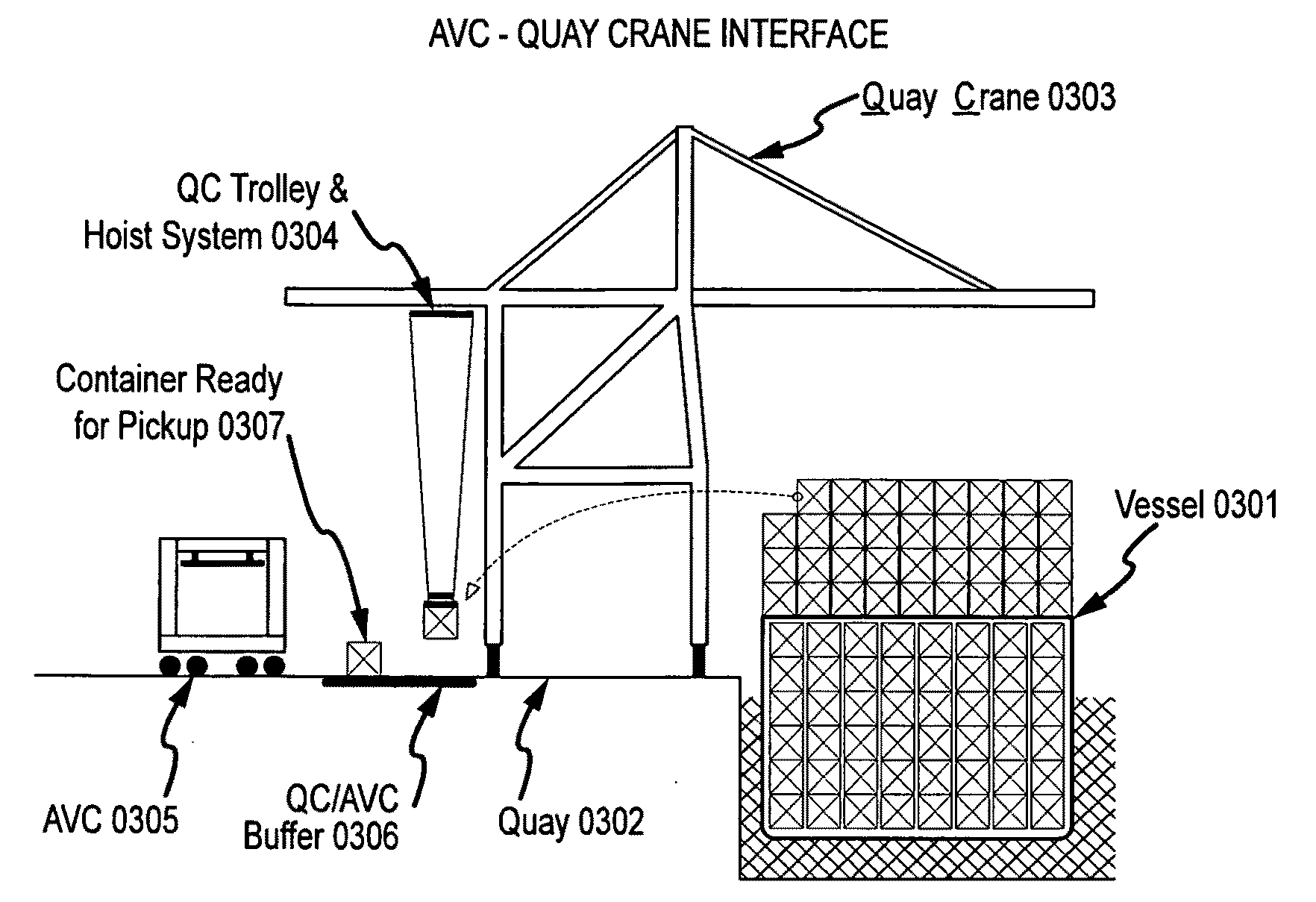

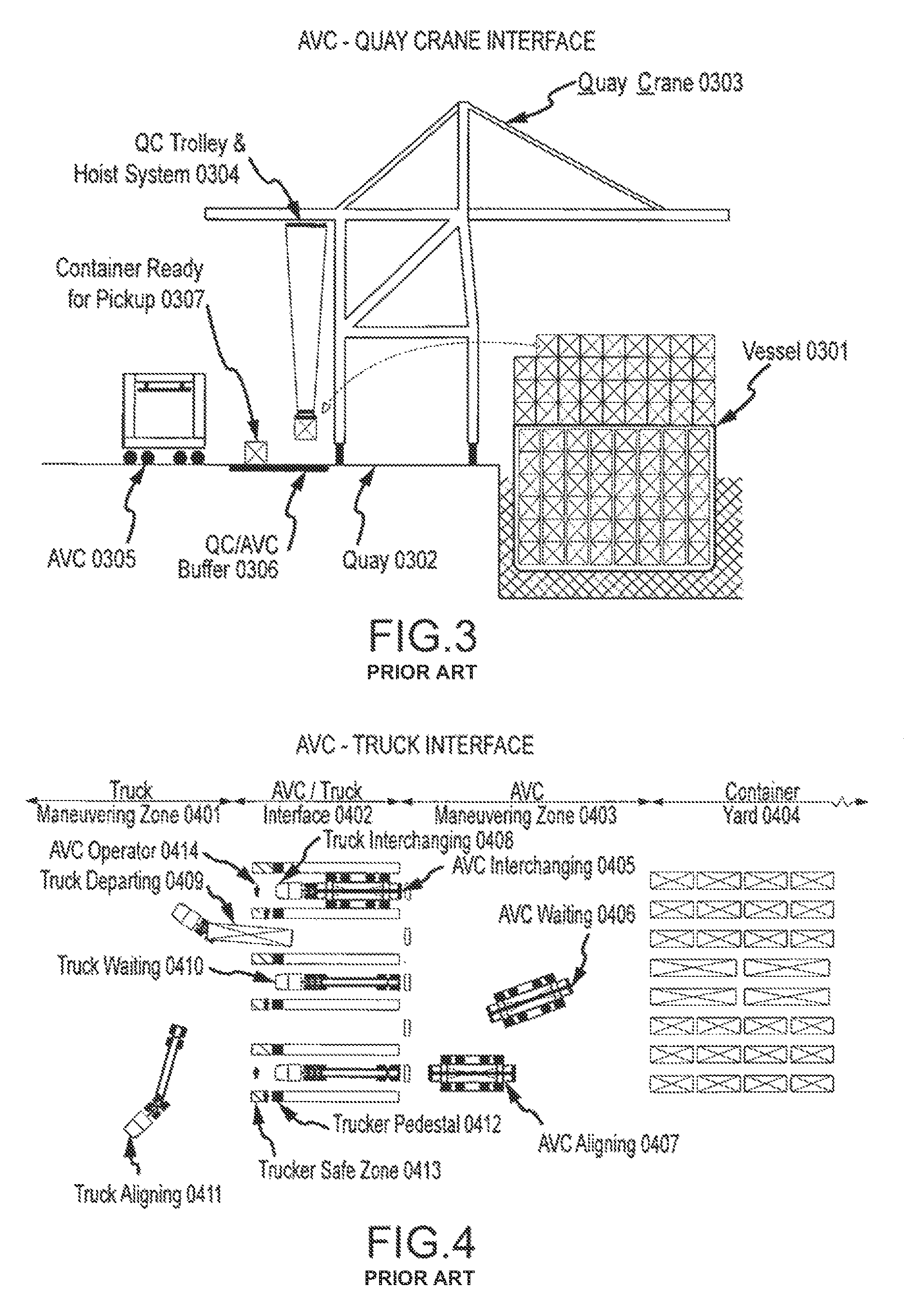

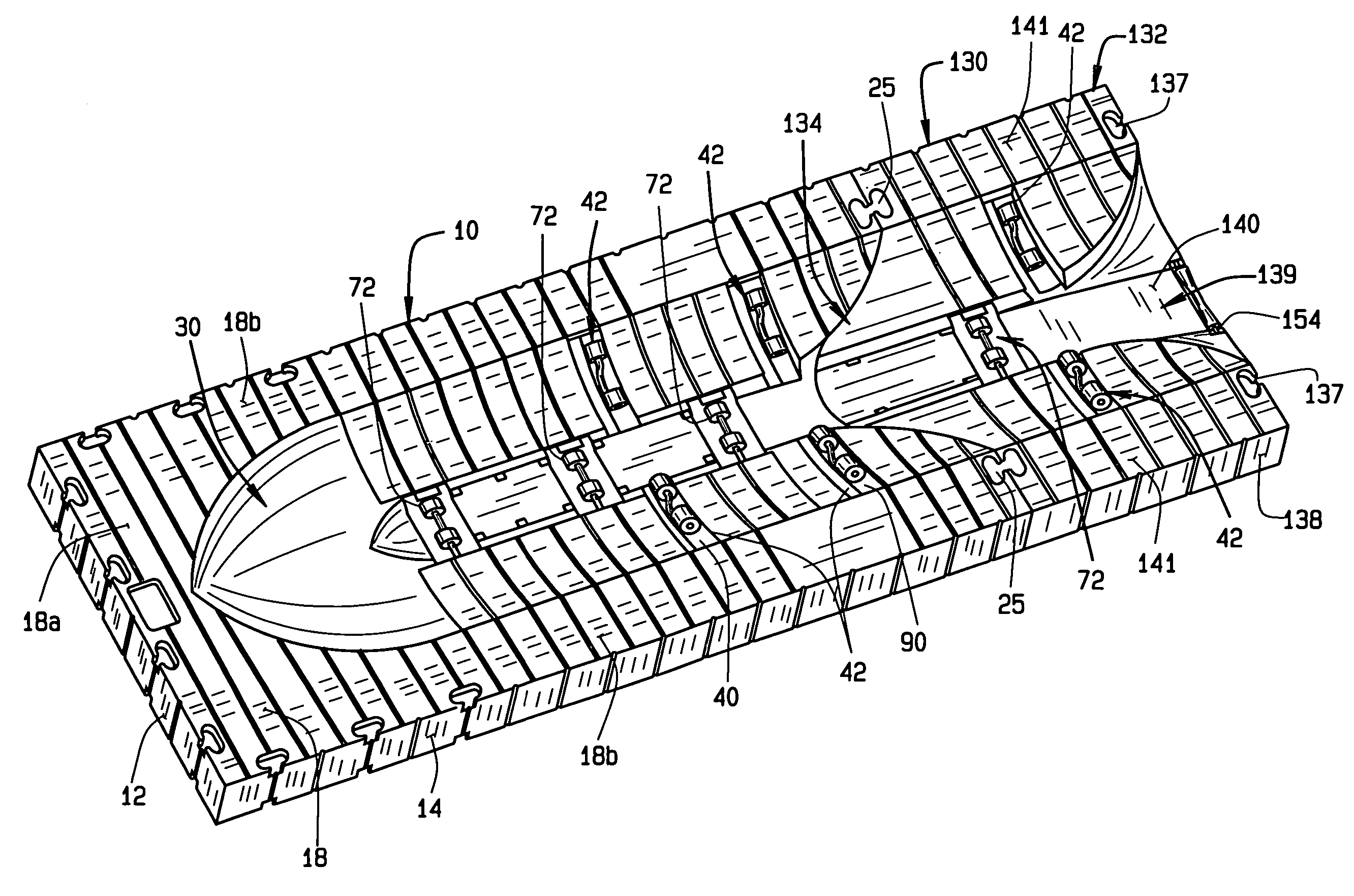

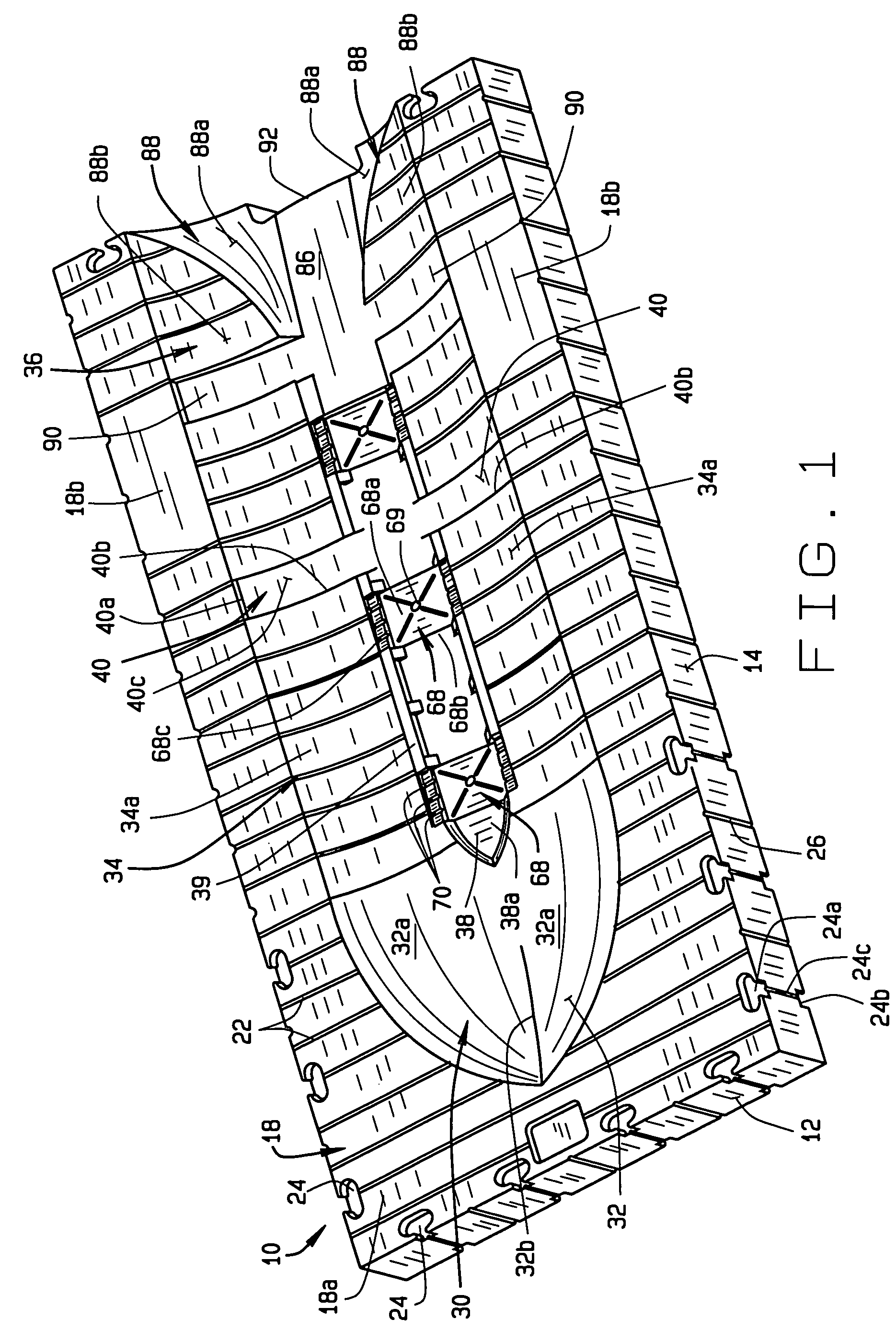

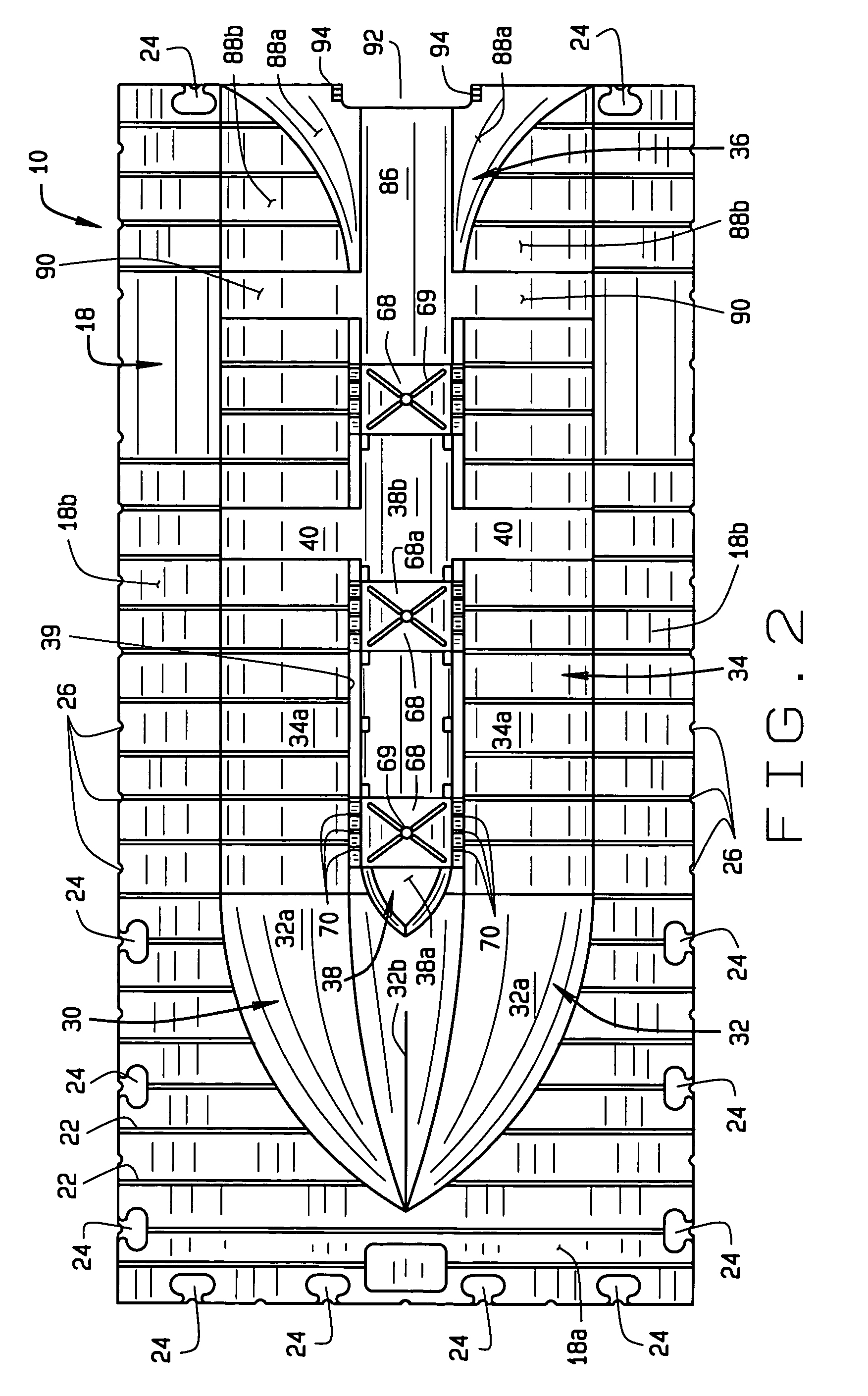

Automated marine container terminal and system

ActiveUS20100021272A1Isolation performanceReduce environmental footprintCargo handling apparatusDigital data processing detailsTruckRobot control

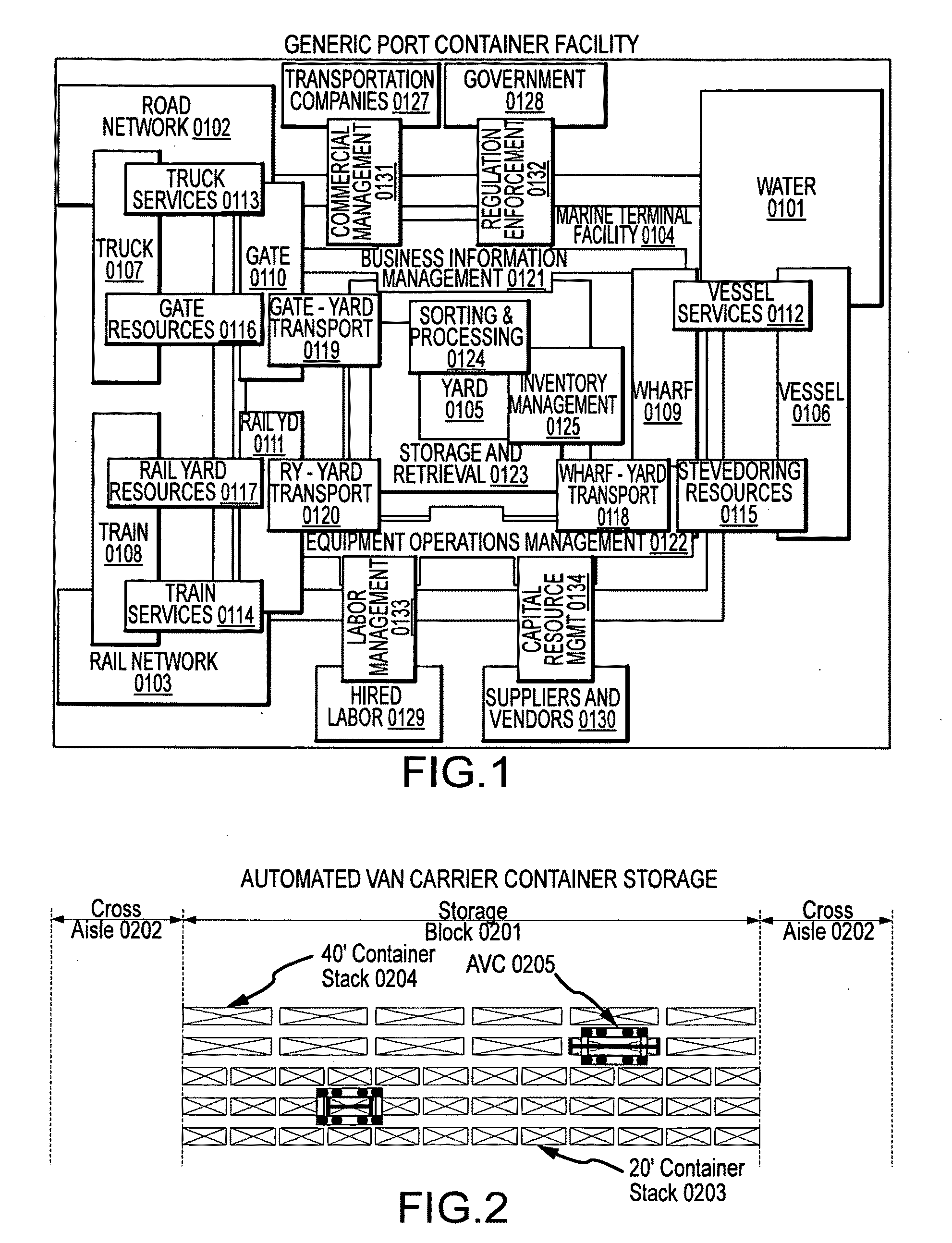

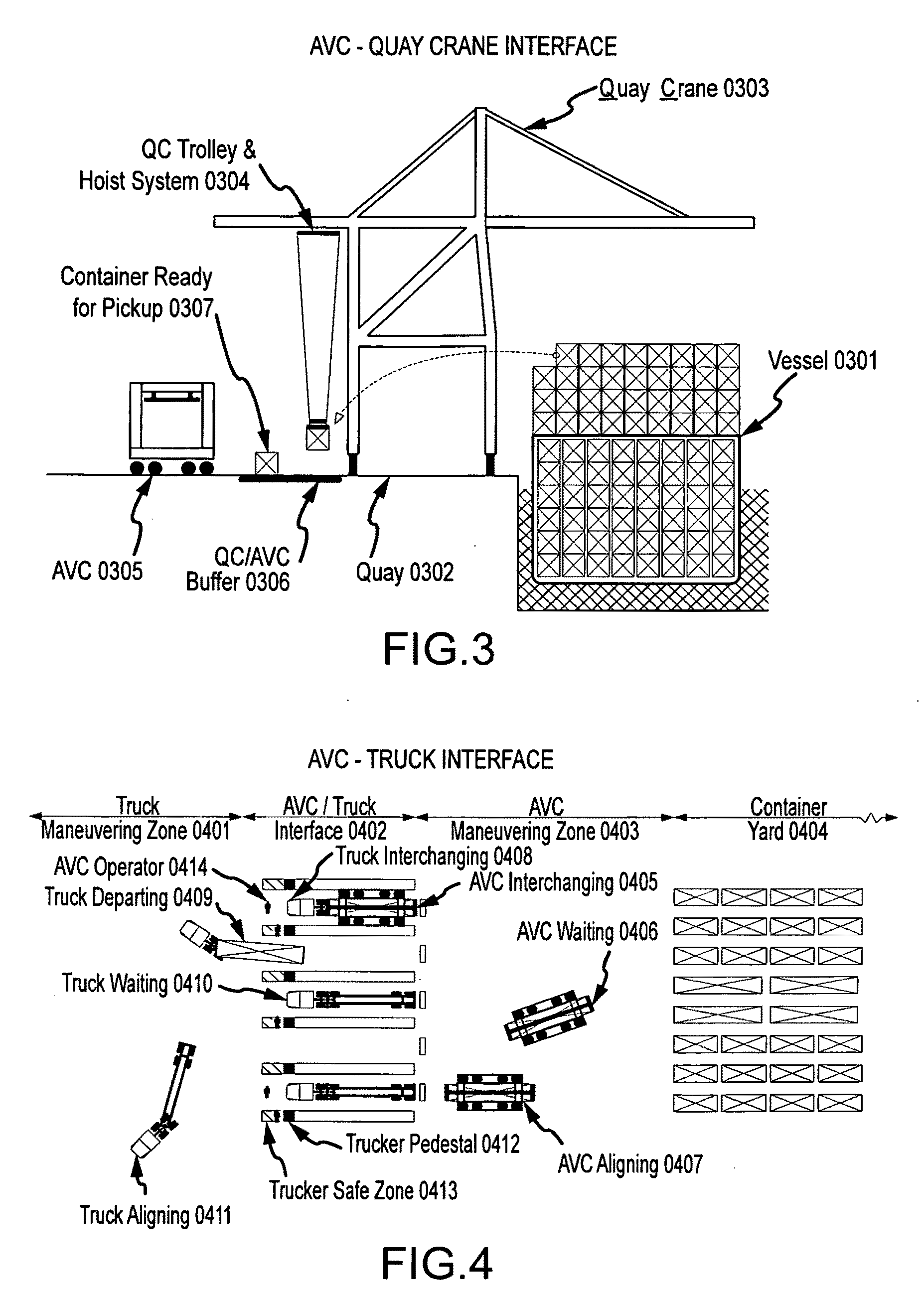

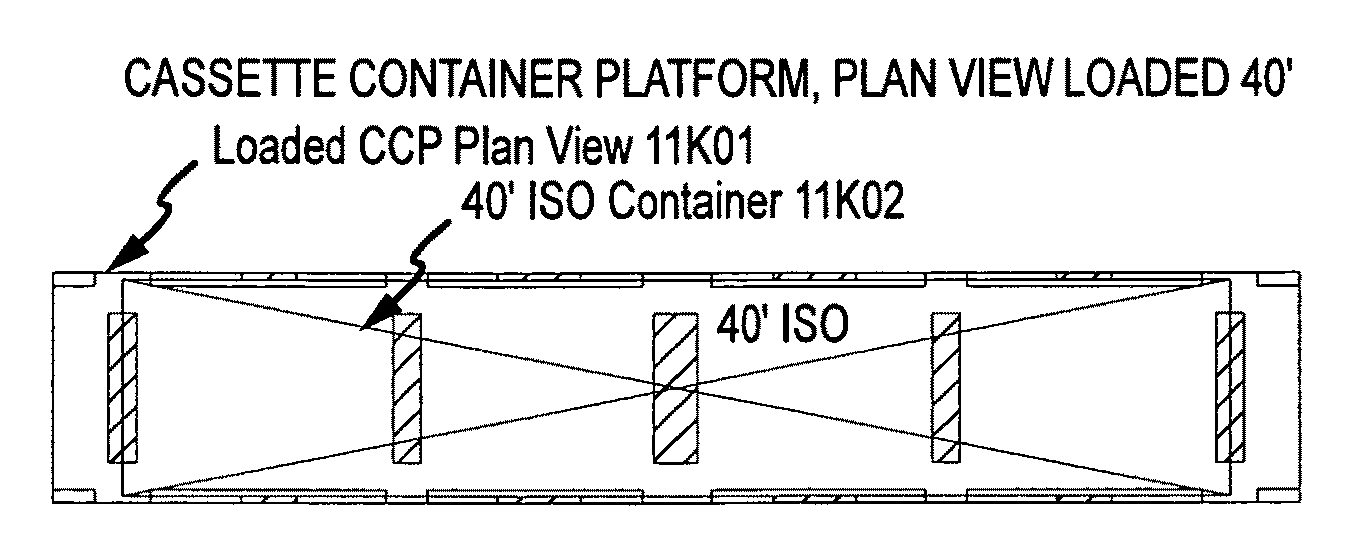

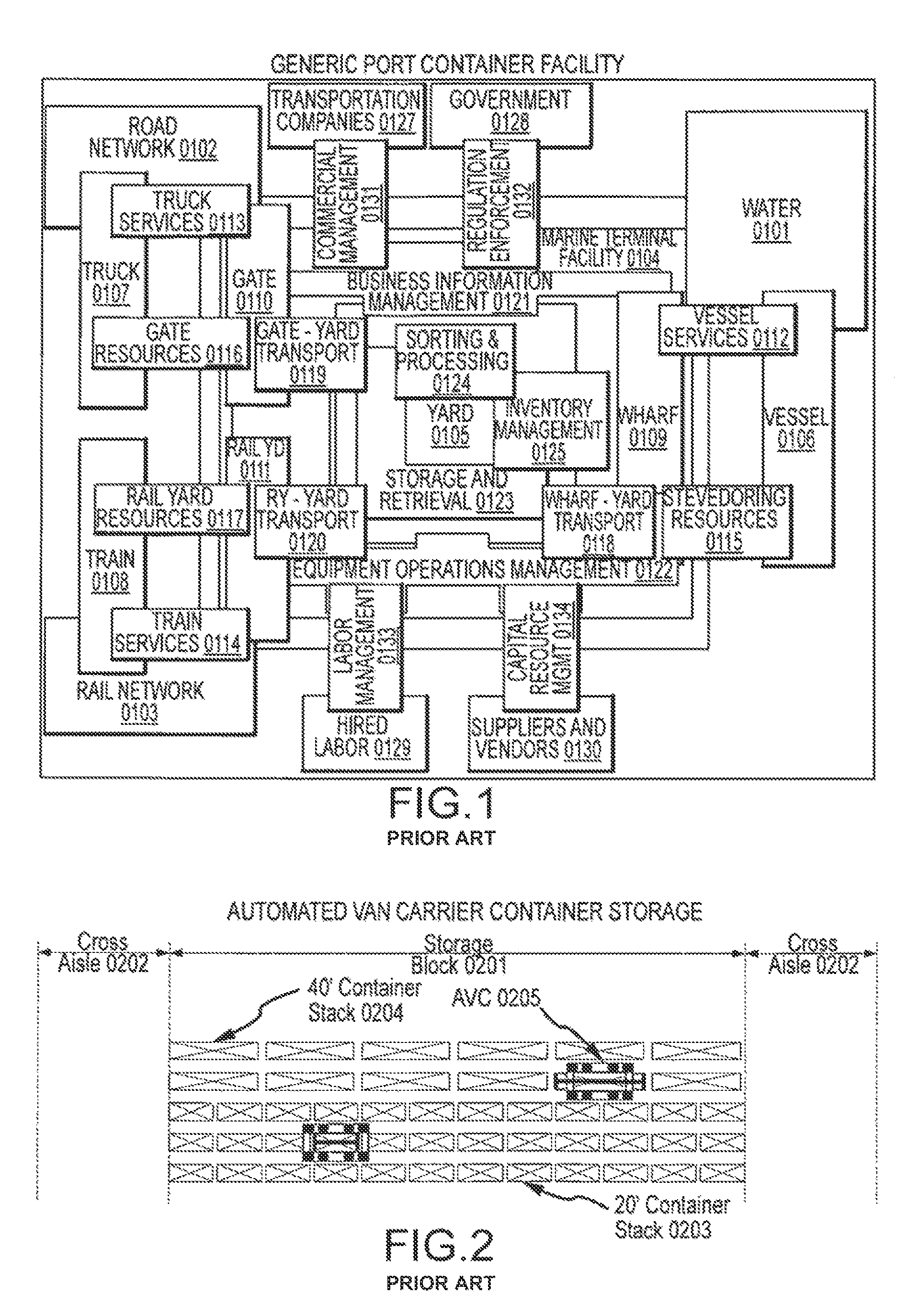

A system, equipment, and processes for extending the scope of automation in port container facilities, and thereby increasing port capacity within fixed land resources, increasing operational productivity, increasing safety, increasing the velocity and reliability of goods movement, increasing freight security, reducing negative environmental impacts, and reducing the overall cost of goods movement. A storage area is accessed by automated guided vehicles which receive and unload containerized loads. On the waterside, loads are exchanged between the vehicles and ships using quay cranes. On the ground transportation side, loads are exchanged between the vehicles and truck or rail carriers using semi automated or automated remote-controlled bridge cranes. Within the storage area, loads are exchanged between the vehicles and the storage facilities using automated stacking cranes. The vehicles are adapted to receive a cassette storage platform which in turn receives standard ISO containers. The vehicles also are adapted to receive one or more alternative platforms including a coning platform for workers to manage container coning, a reefer access and maintenance platform, and a worker transport platform. The use of a single vehicle type with interchangeable platforms allows for maximum flexibility and efficiency. The automation of the vehicle allows for complete contamination within the storage portion of the system.The system thus substantially extends the reach of automation to cover both landside and waterside intra-terminal transfer operations. By this extension, the interface of workers and machines is greatly reduced, increasing safety, productivity, security, and capacity. By this extension, the robotic control process can be fully optimized, increasing velocity and reliability while reducing the terminal's environmental footprint.

Owner:MARINE TERMINALS CORP

Automated marine container terminal and system

InactiveUS7972102B2Reduced footprintLow costCargo handling apparatusPassenger handling apparatusAutomated guided vehicleOverhead crane

A storage area is accessed by automated guided vehicles which receive and unload containerized loads. On the waterside, loads are exchanged between the vehicles and ships using quay cranes. On the ground transportation side, loads are exchanged between the vehicles and truck or rail carriers using semi automated or automated remote-controlled bridge cranes. Within the storage area, loads are exchanged between the vehicles and the storage facilities using automated stacking cranes. The vehicles are adapted to receive a cassette storage platform which in turn receives standard ISO containers. The vehicles also are adapted to receive one or more alternative platforms including a coning platform for workers to manage container coning, a reefer access and maintenance platform, and a worker transport platform.

Owner:MARINE TERMINALS CORP

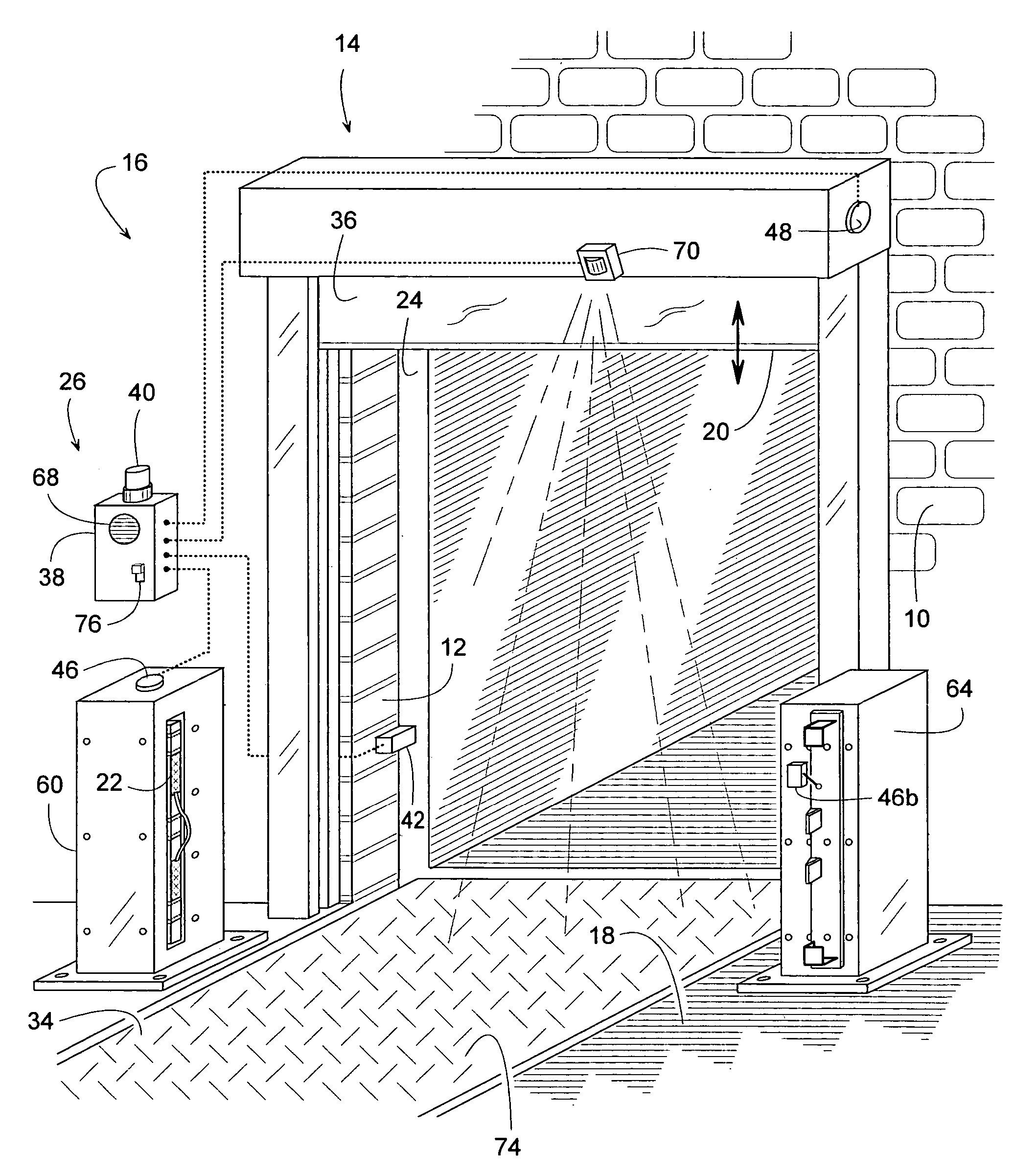

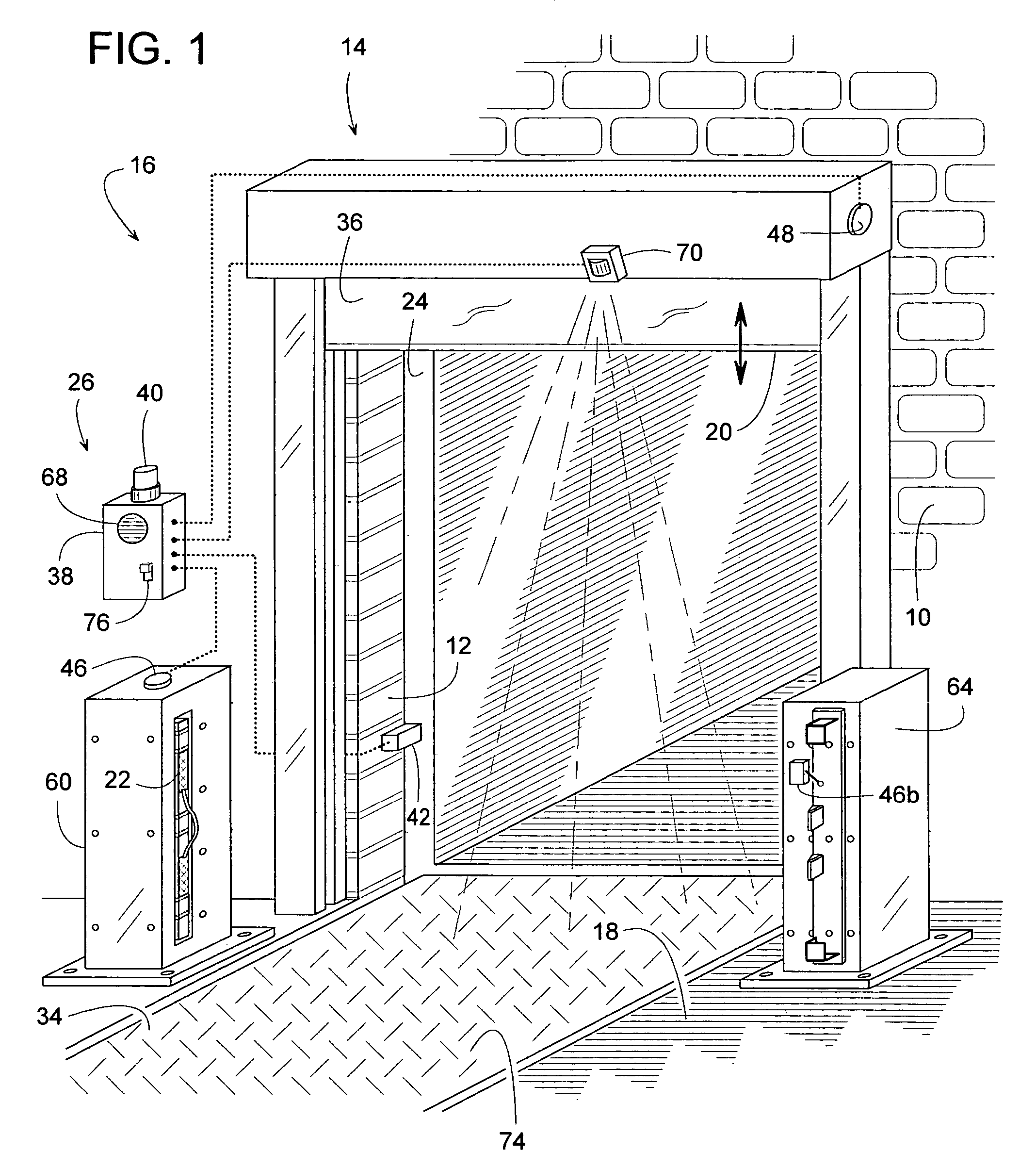

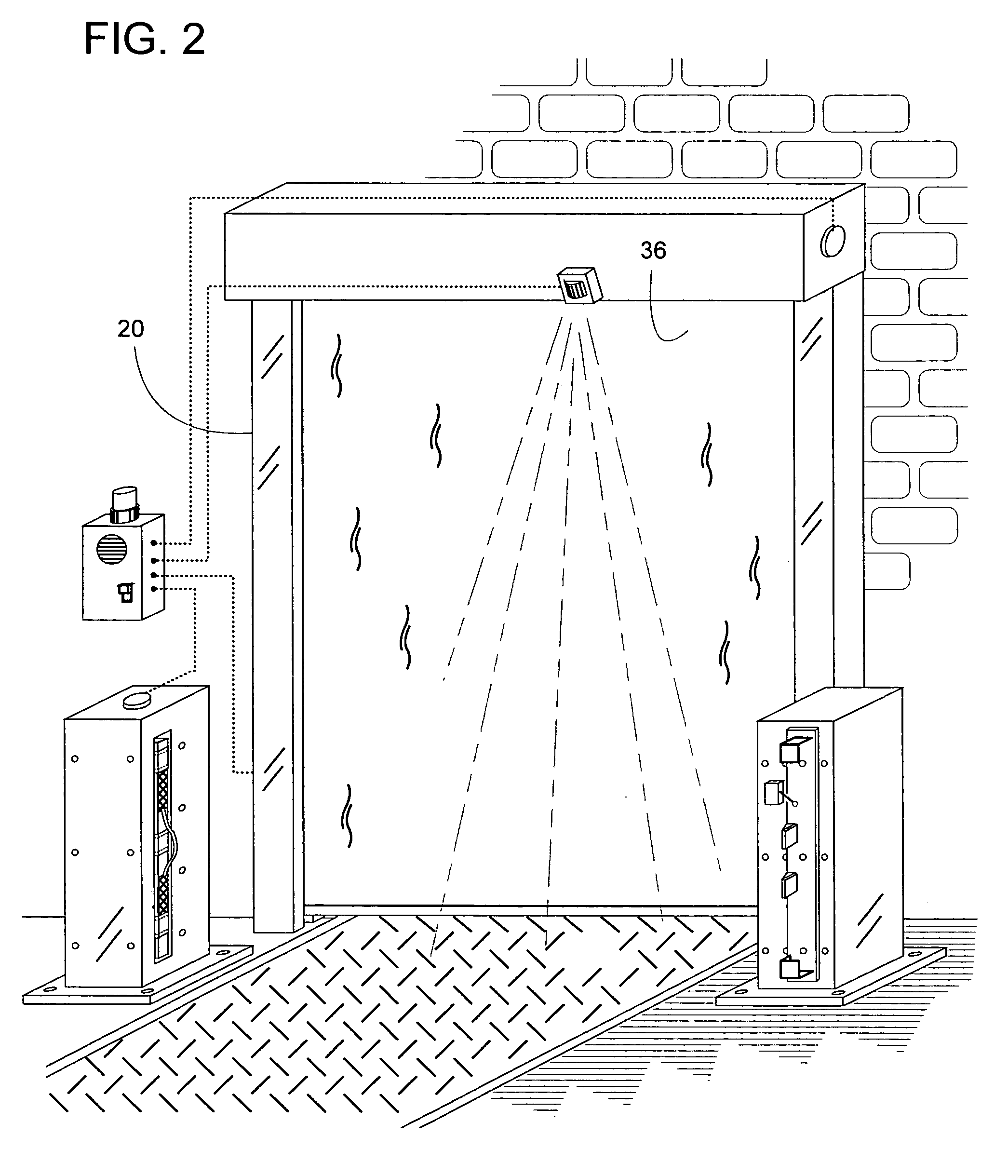

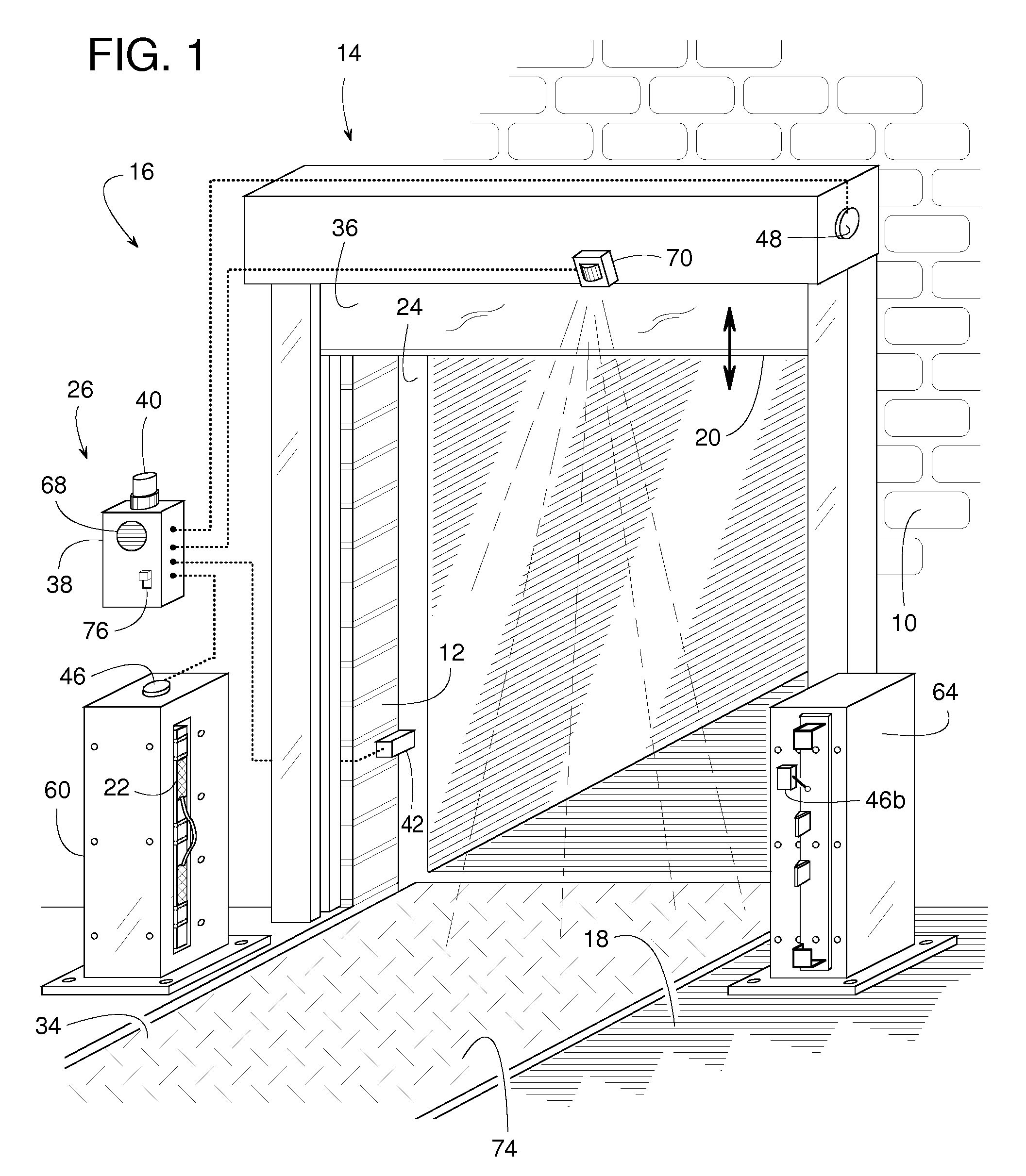

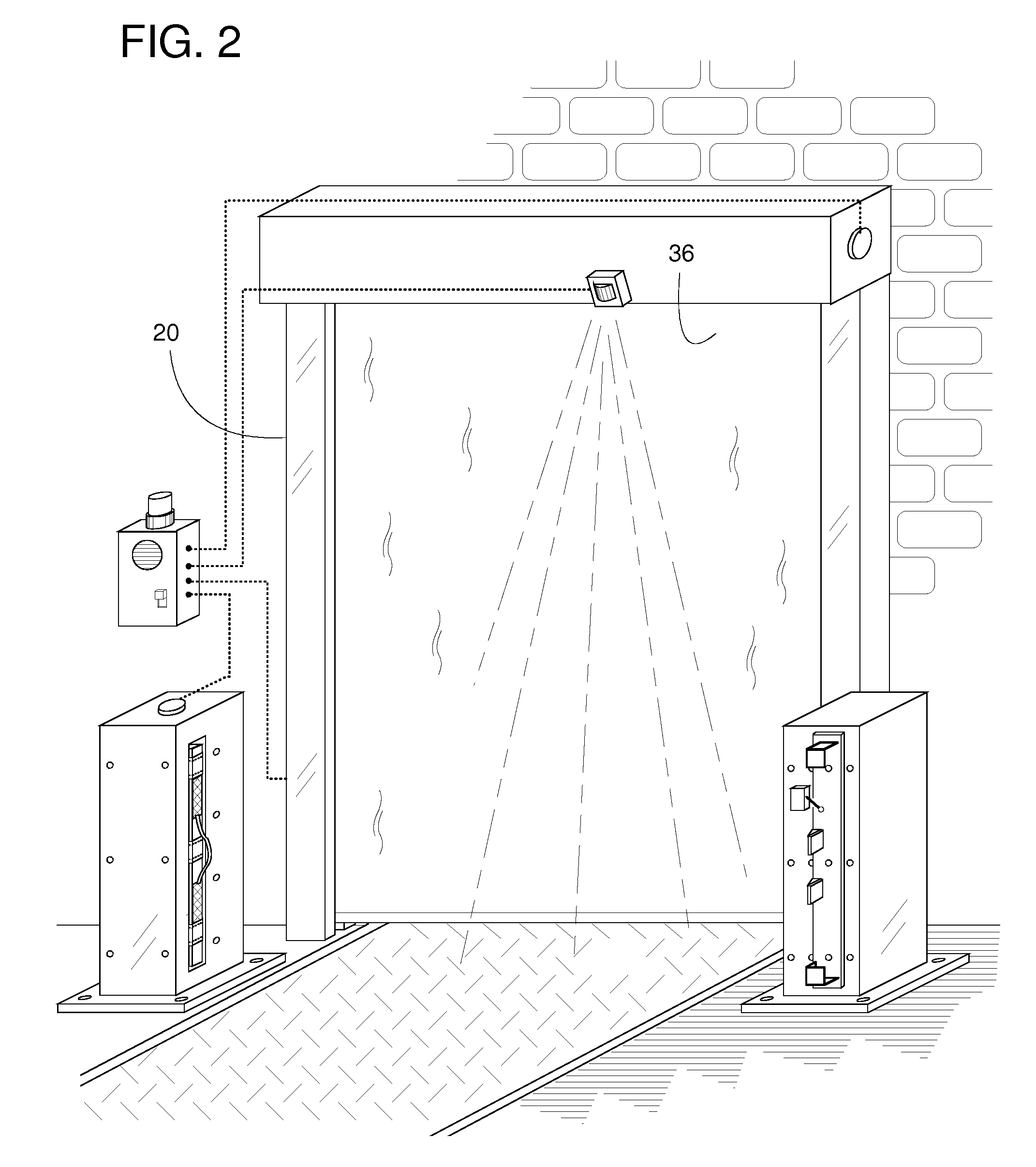

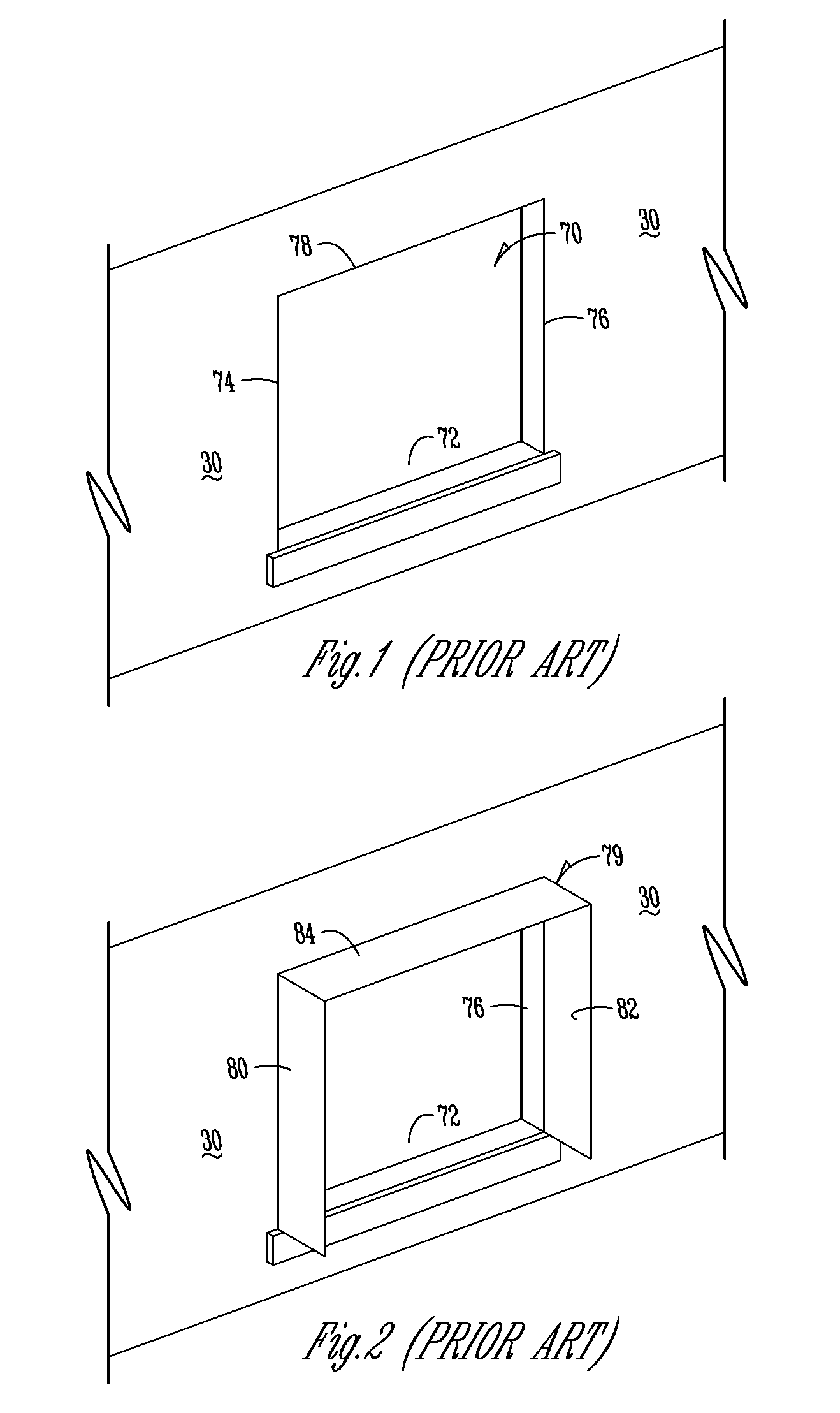

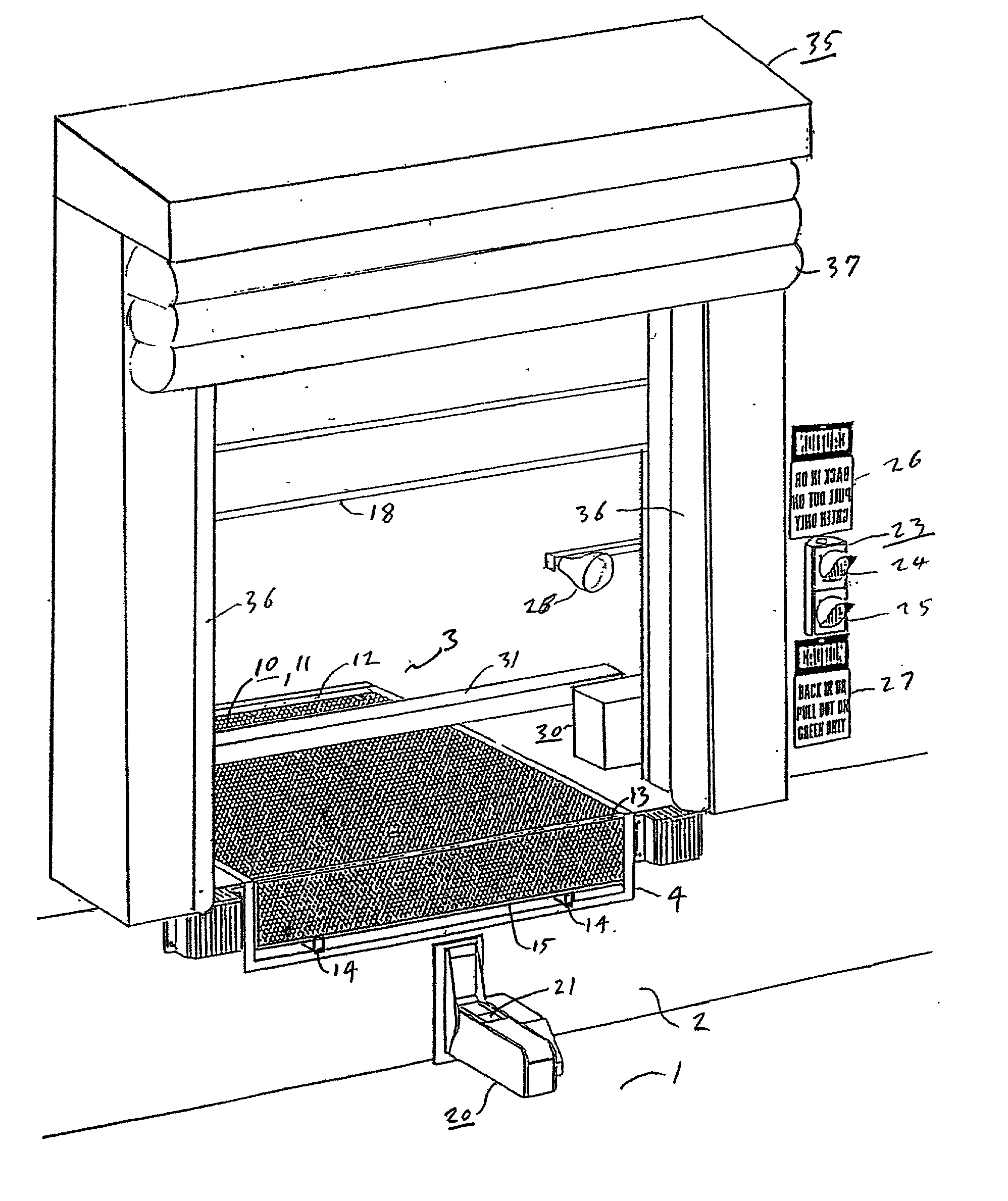

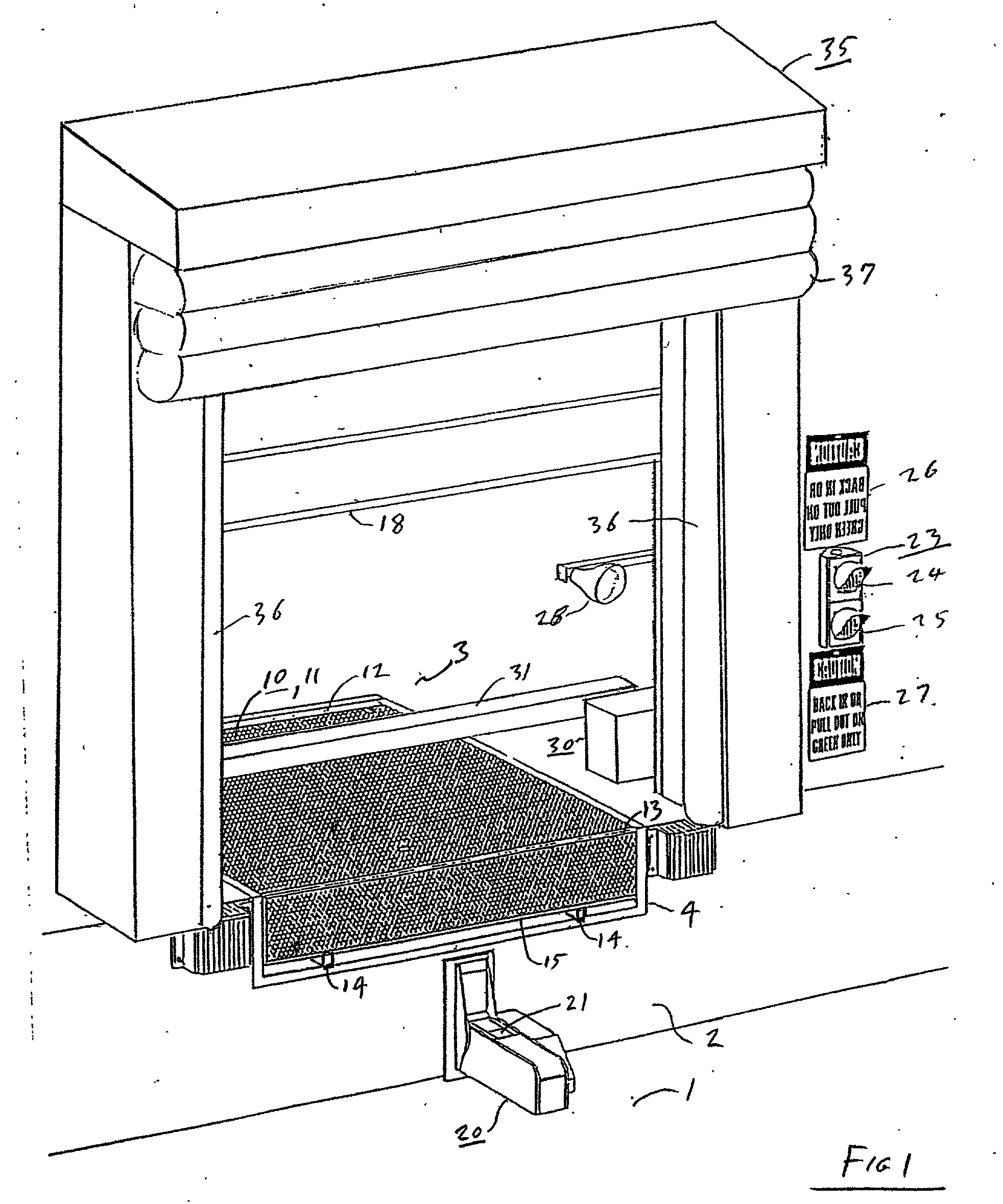

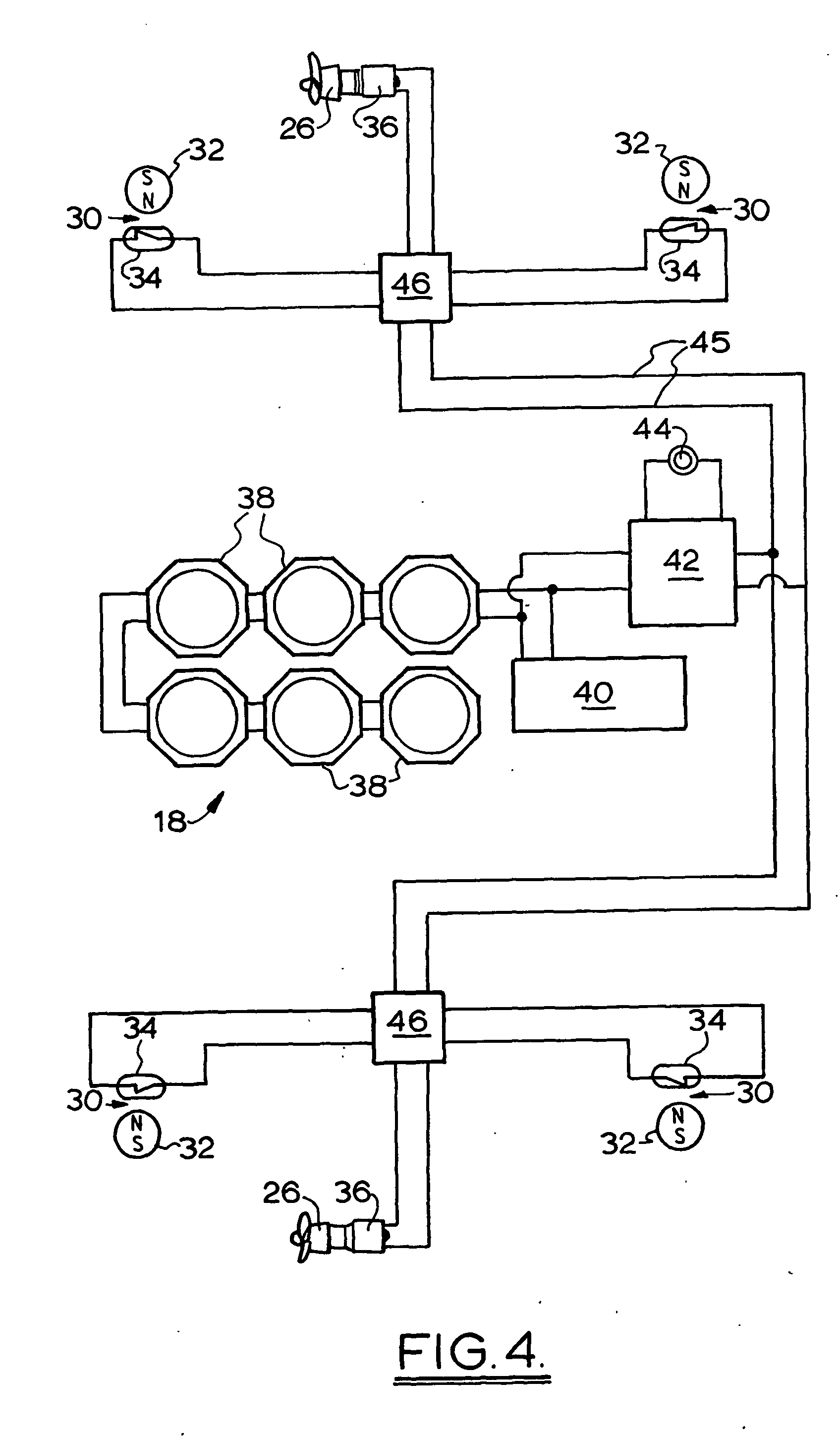

Alarm system for a loading dock

ActiveUS7380375B2Roof covering using slabs/sheetsRoof covering using tiles/slatesEngineeringBody sensors

A safety system for a truck doorway such as a loading dock with an elevated platform provides an alarm that warns of a falling hazard that may exist due to the dock door being open while a truck is not present at the dock. In cases where a dock's open doorway is protected by a barrier that can be opened or closed, the alarm can be de-activated by closing the barrier. In some embodiments, the safety system includes a remote body sensor that detects when someone or something is near the doorway. In response to the body sensor, a second, more pronounced alarm can warn of more imminent danger where someone on the platform may be too close to an open doorway when a truck is not present.

Owner:RITE HITE HLDG CORP

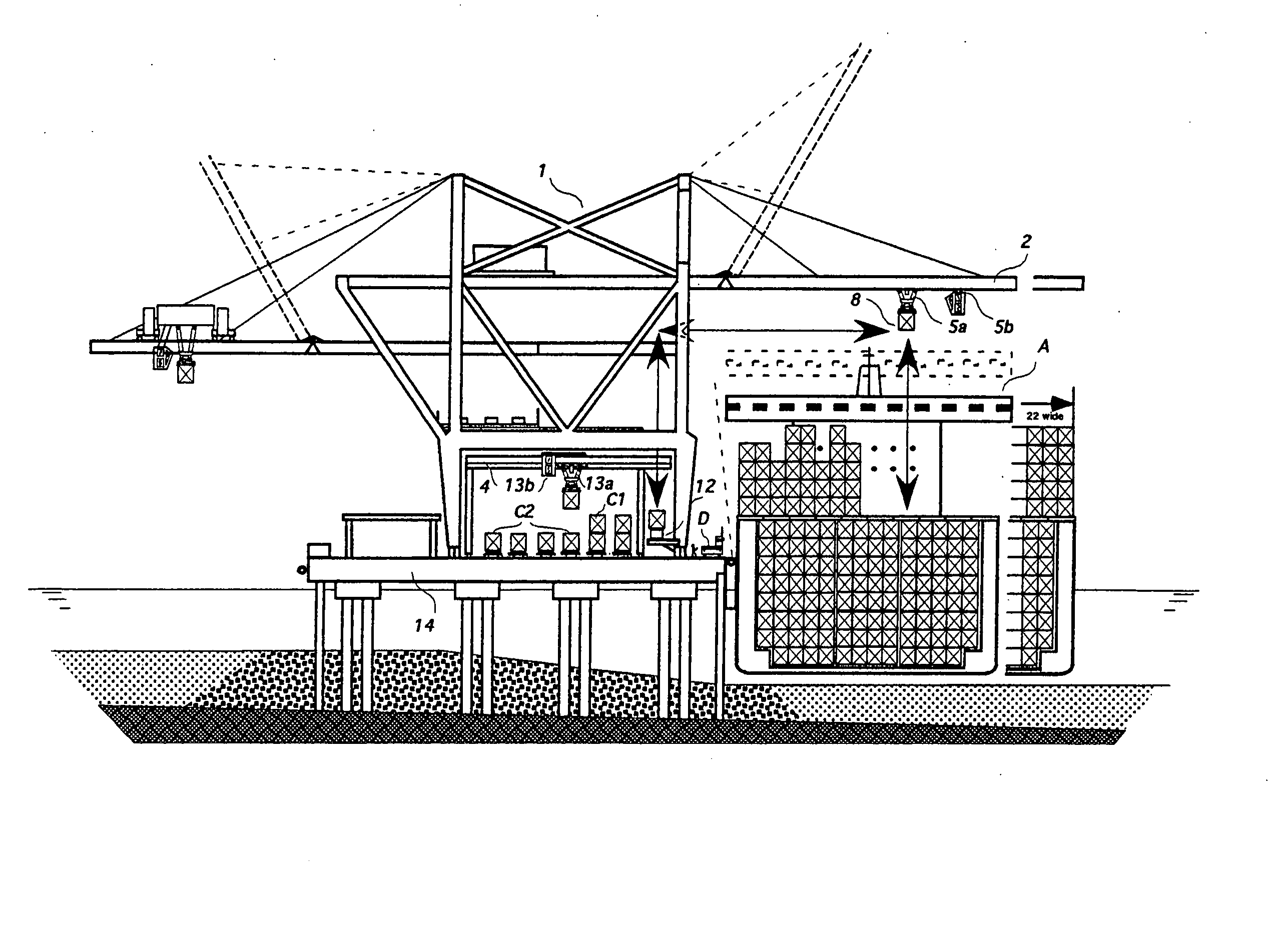

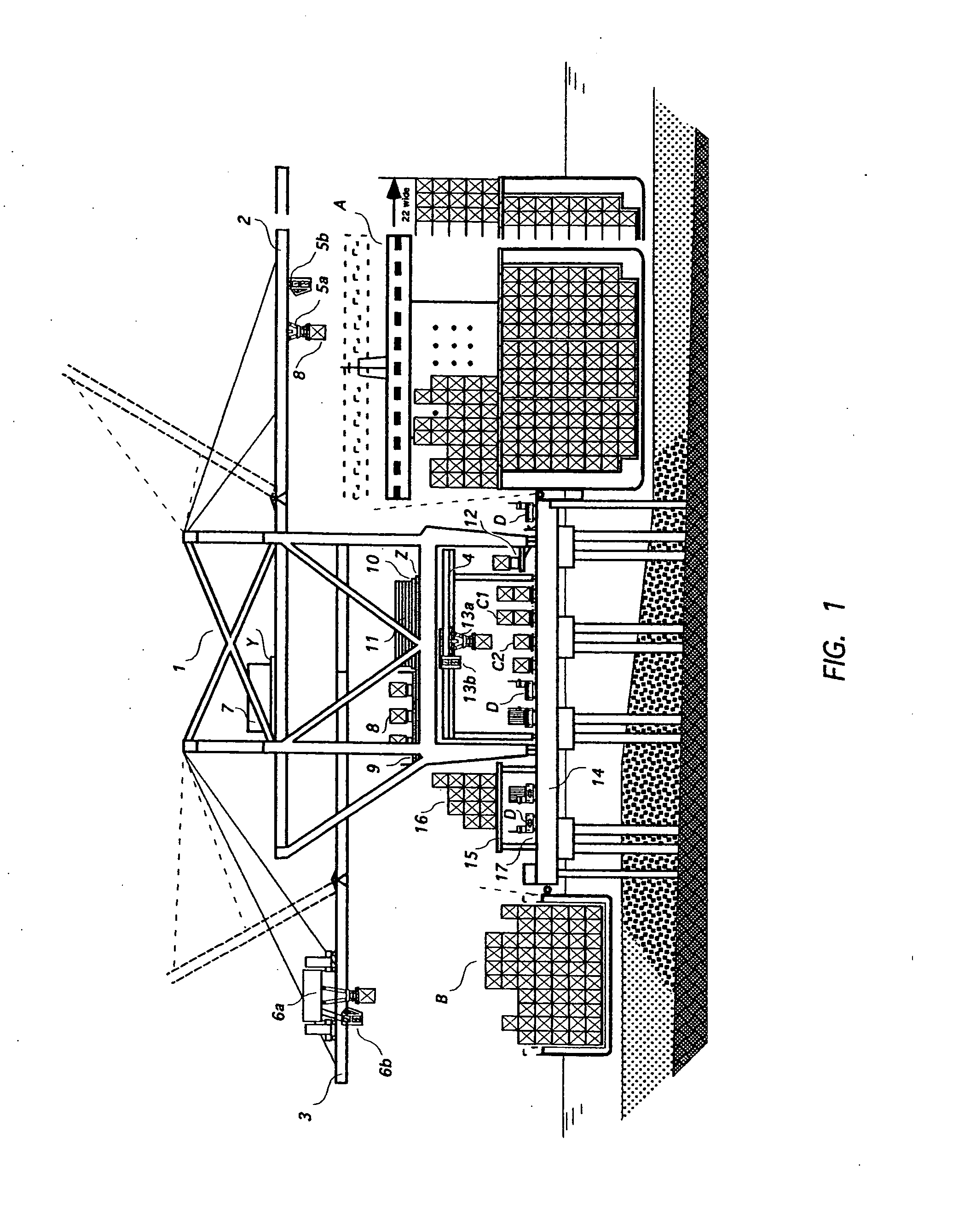

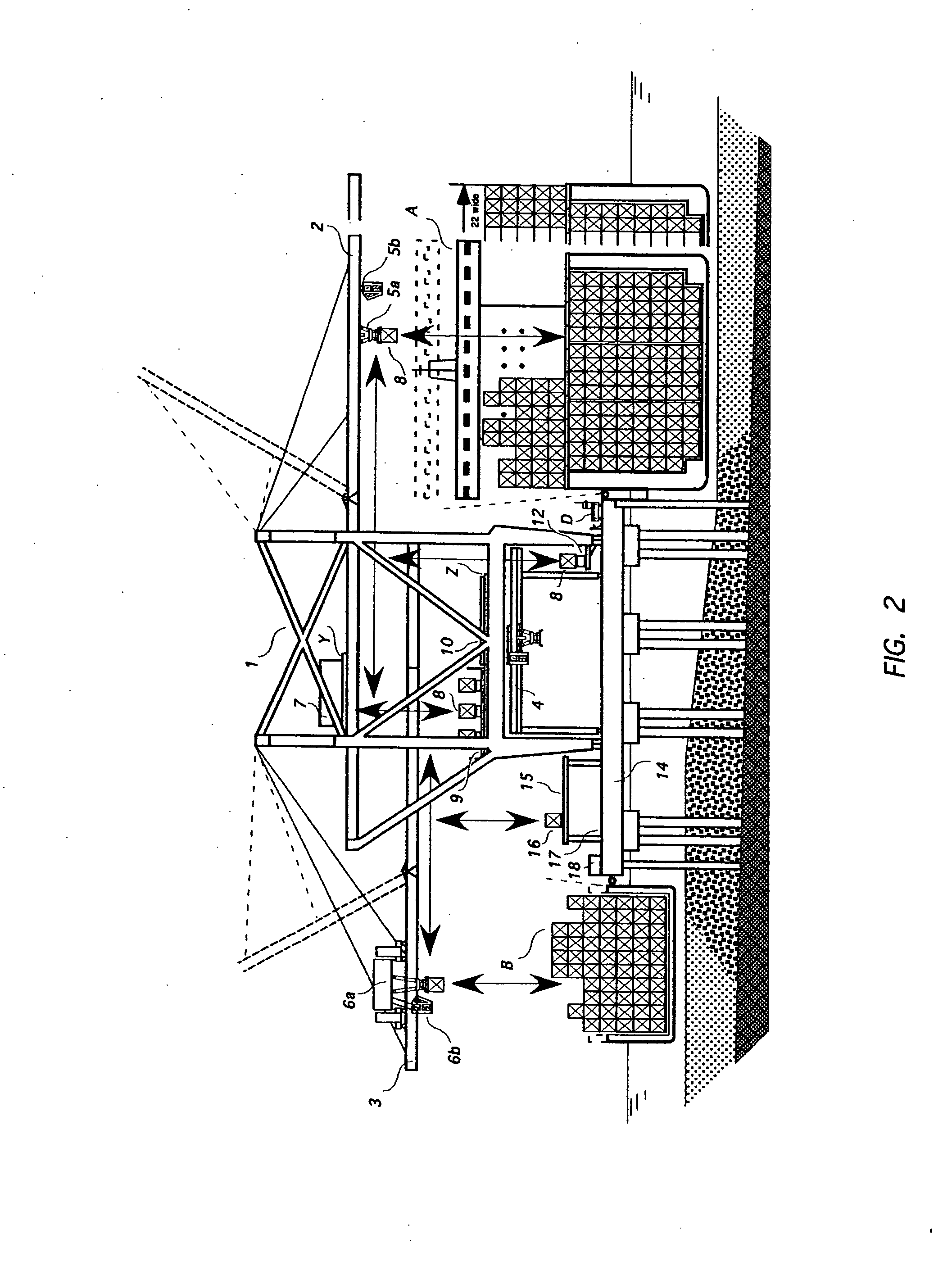

Container crane apparatus and method for container security screening during direct transshipment between transportation modes

InactiveUS20080219804A1Save a lot of costCargo handling apparatusBase supporting structuresContainer craneGround vehicles

A crane apparatus installed on a pier, wharf, bulkhead wharf or other foundation directly transships containers from a vessel moored alongside the foundation to another transportation mode without ground placement of the containers. The crane apparatus includes a parent crane displaceable along the foundation for unloading containers from the vessel and placing them on a first platform of the parent crane, and a sibling crane displaceable along the foundation independently of displacement of the parent crane for loading containers from the first platform directly onto over-the-ground vehicles or onto another vessel moored alongside the foundation. The parent crane has a first trolley-hoist-spreader movable along an outreach boom for unloading containers from the vessel and placing them on either the first platform or a second platform of the parent crane, and a second trolley-hoist-spreader movable along a backreach boom for loading containers from the second platform onto another vessel or onto over-the-ground vehicles. A container security scanning system may be provided on the second platform for scanning the containers while on the second platform to determine whether one or more preselected chemical, biological, explosive or nuclear materials are present in the containers.

Owner:CHATTEY NIGEL

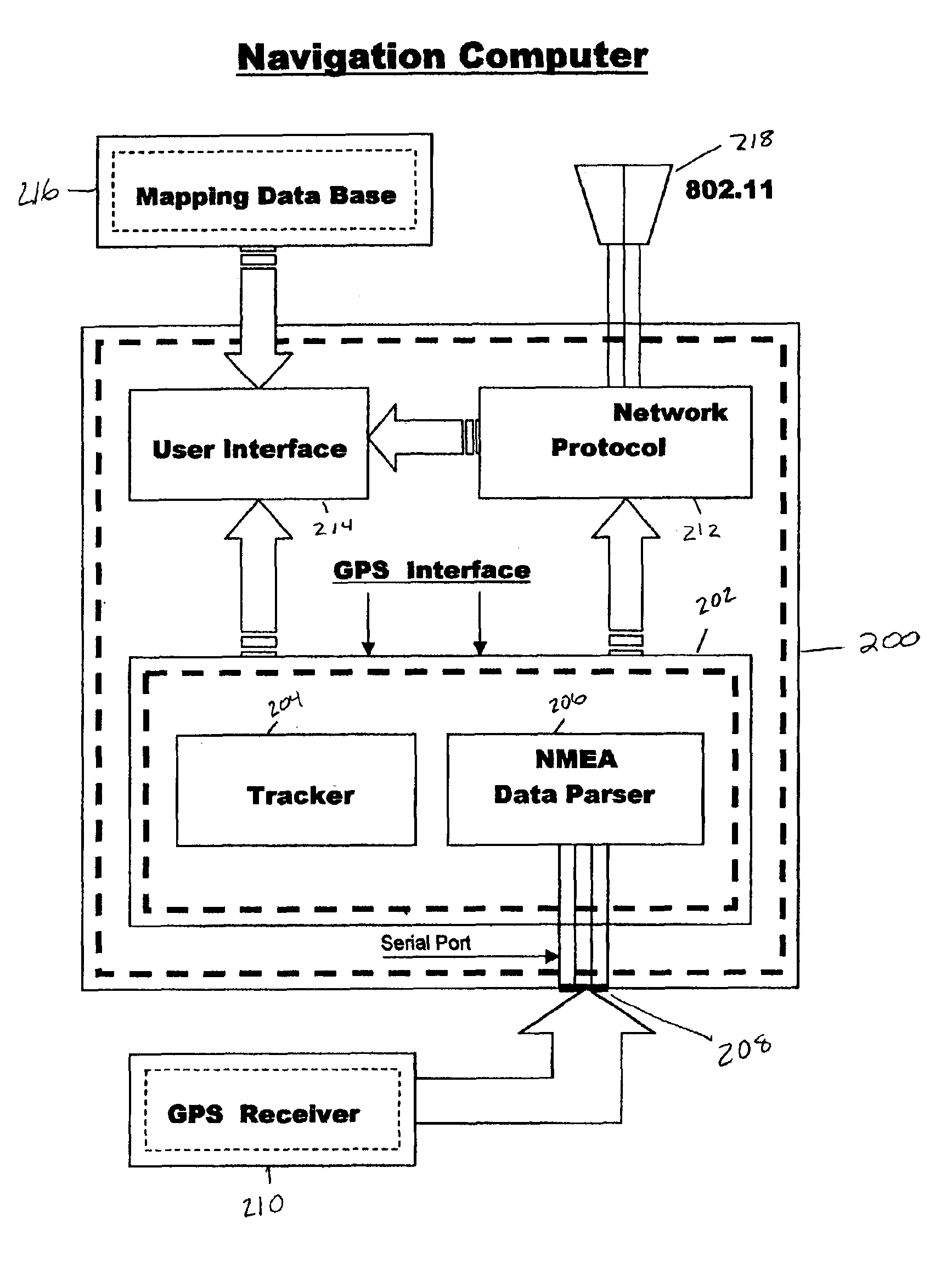

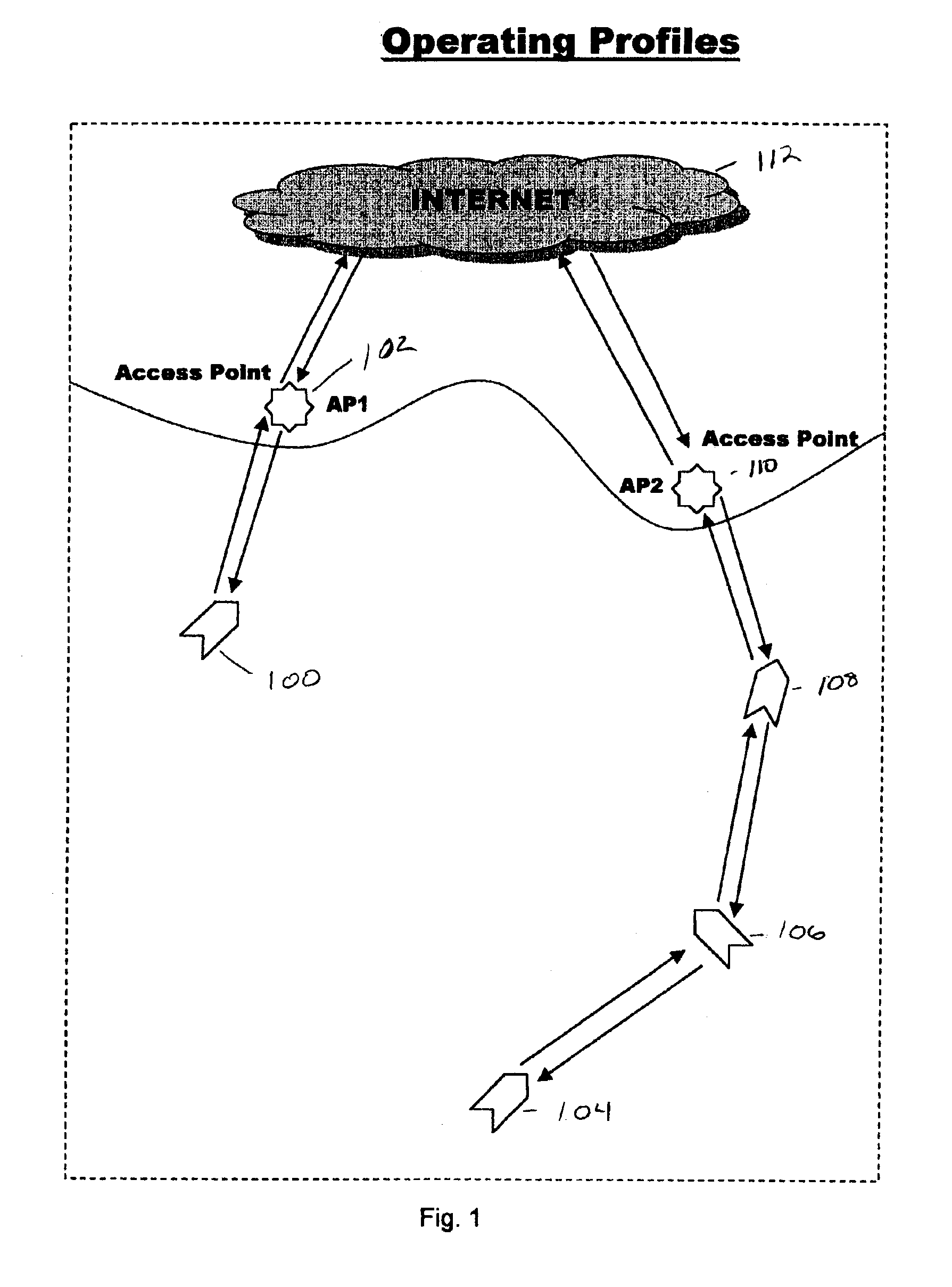

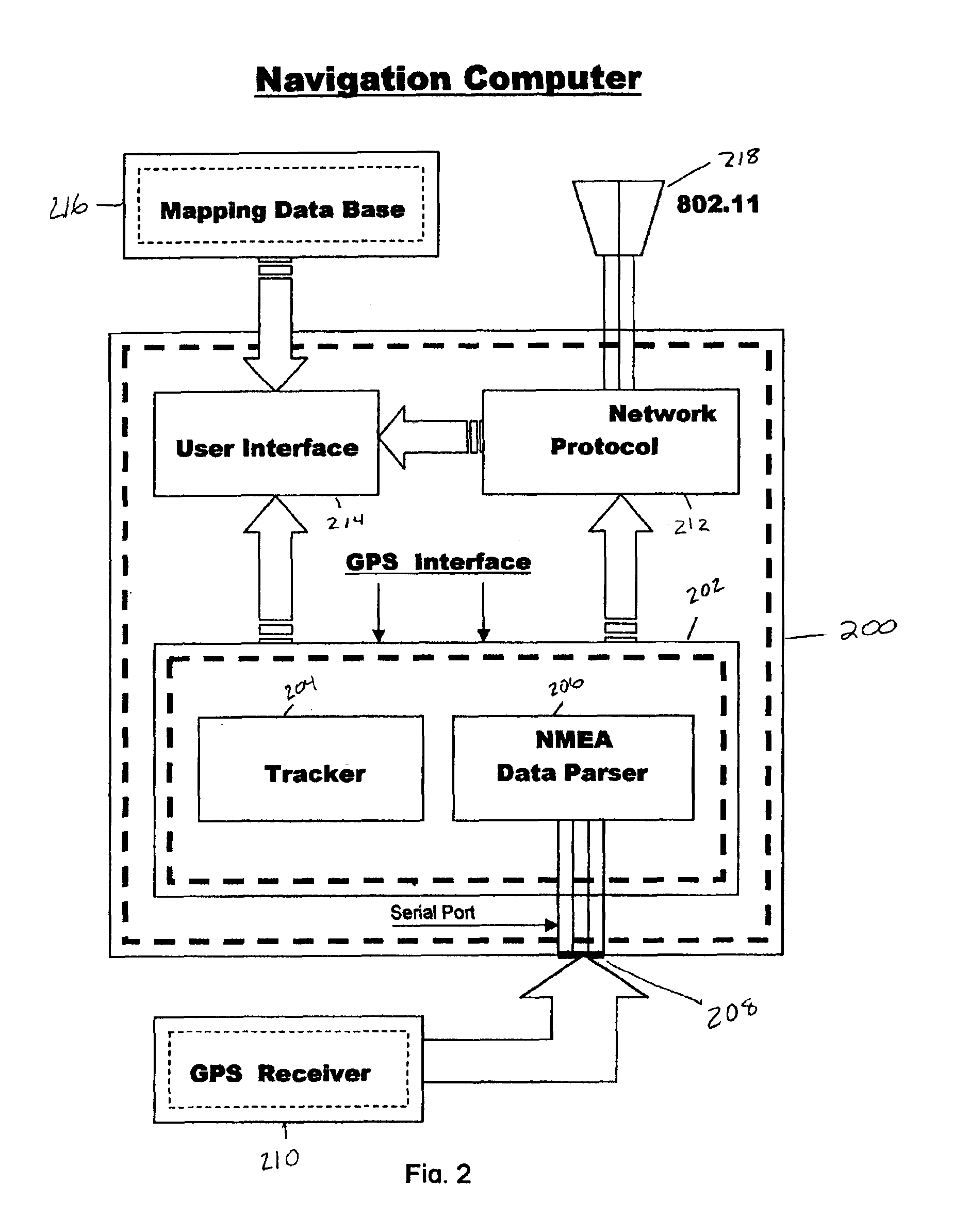

Navcell pier to pier GPS

InactiveUS6904364B2Improve navigation safetyHigh precisionError preventionFrequency-division multiplex detailsDisplay deviceGps receiver

The present invention is directed to, a navigation system comprising; a plurality of GPS-receivers having GPS antennas mounted thereto for receiving GPS signals, a data processing apparatus for processing GPS signals and determining location data, a wireless network transmitting and receiving apparatus connected to the data processing apparatus for transmitting and receiving the location data from the plurality of GPS-receivers, and a display device for displaying the location data.

Owner:S AQUA SEMICONDUCTOR LLC

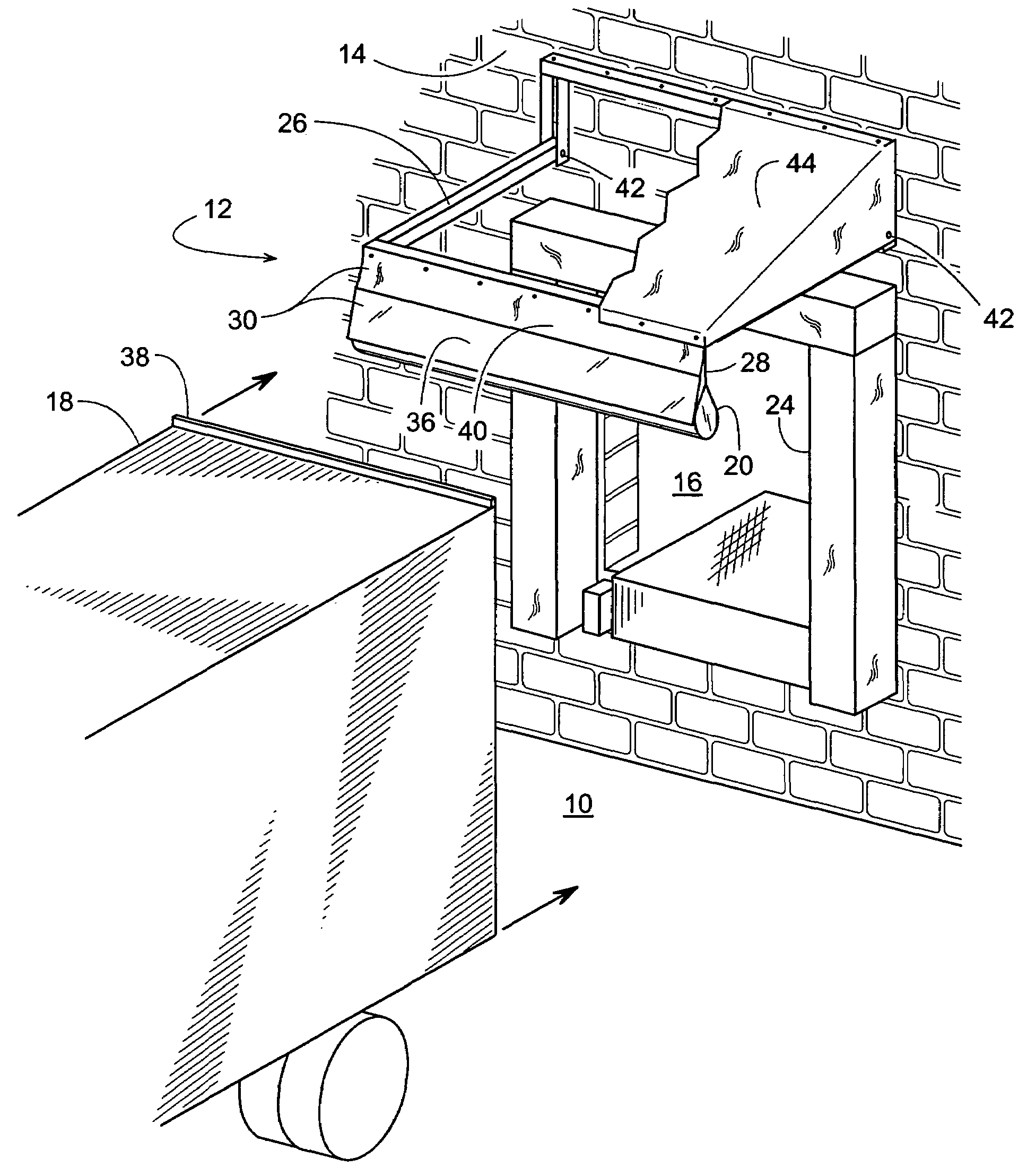

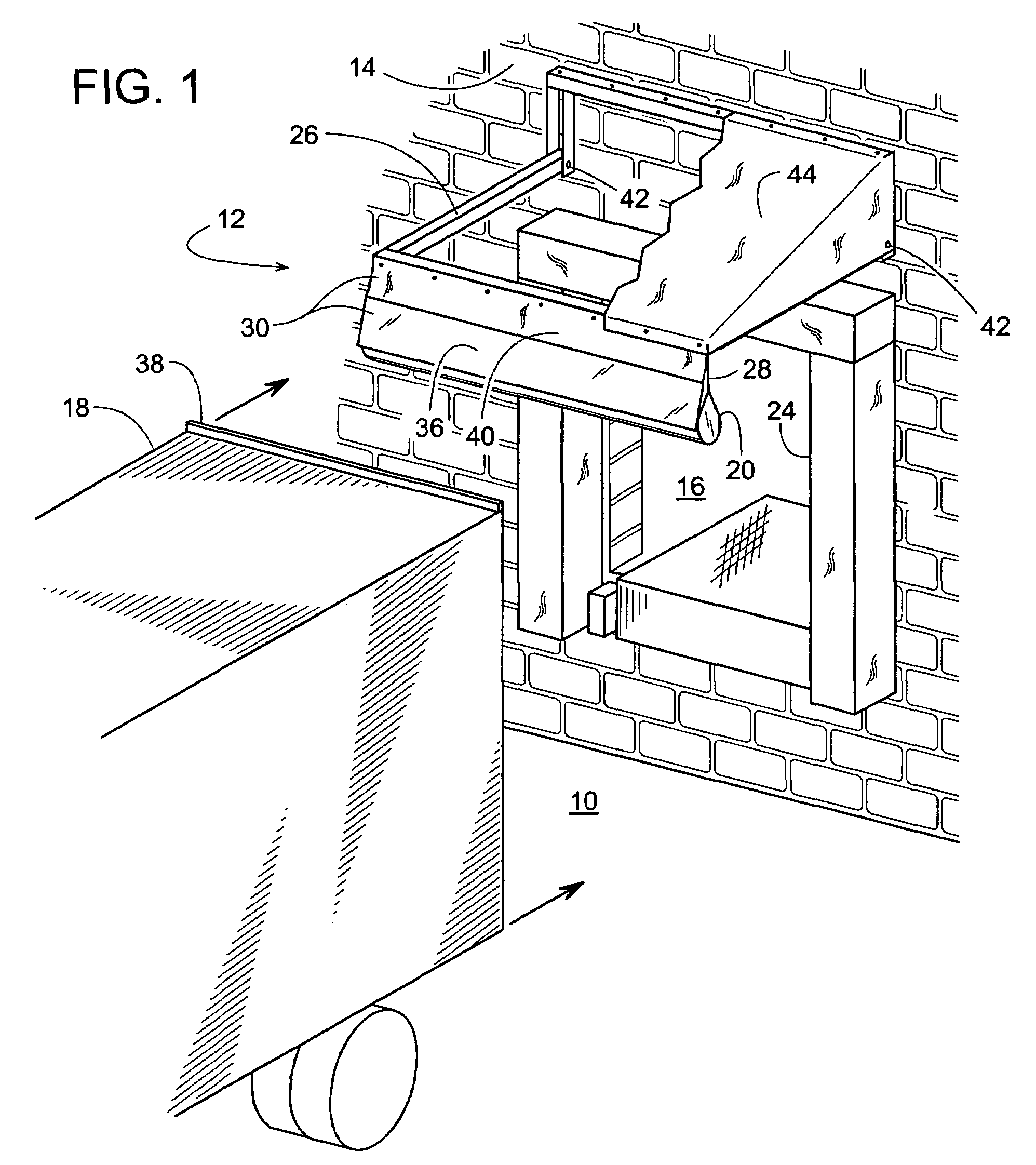

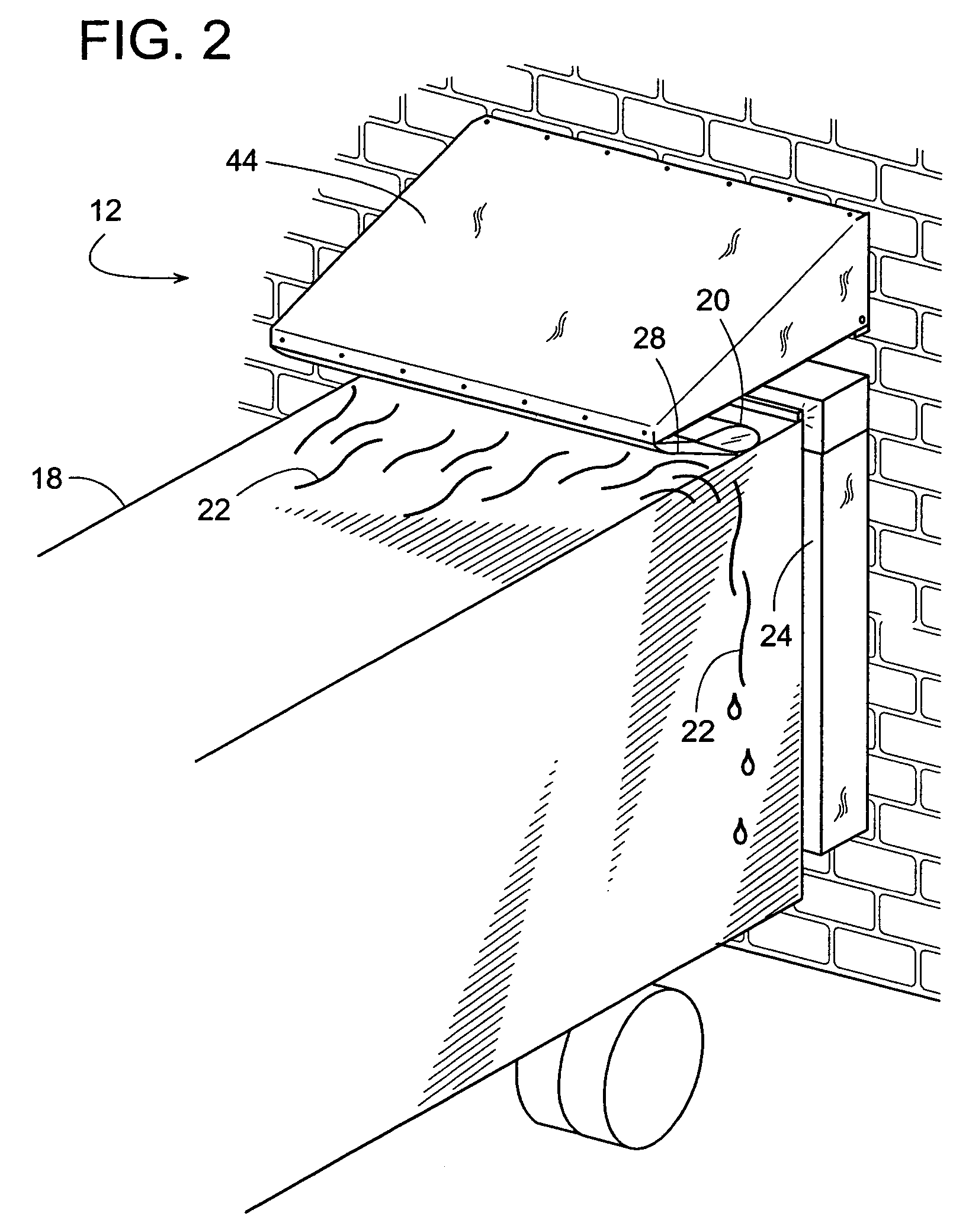

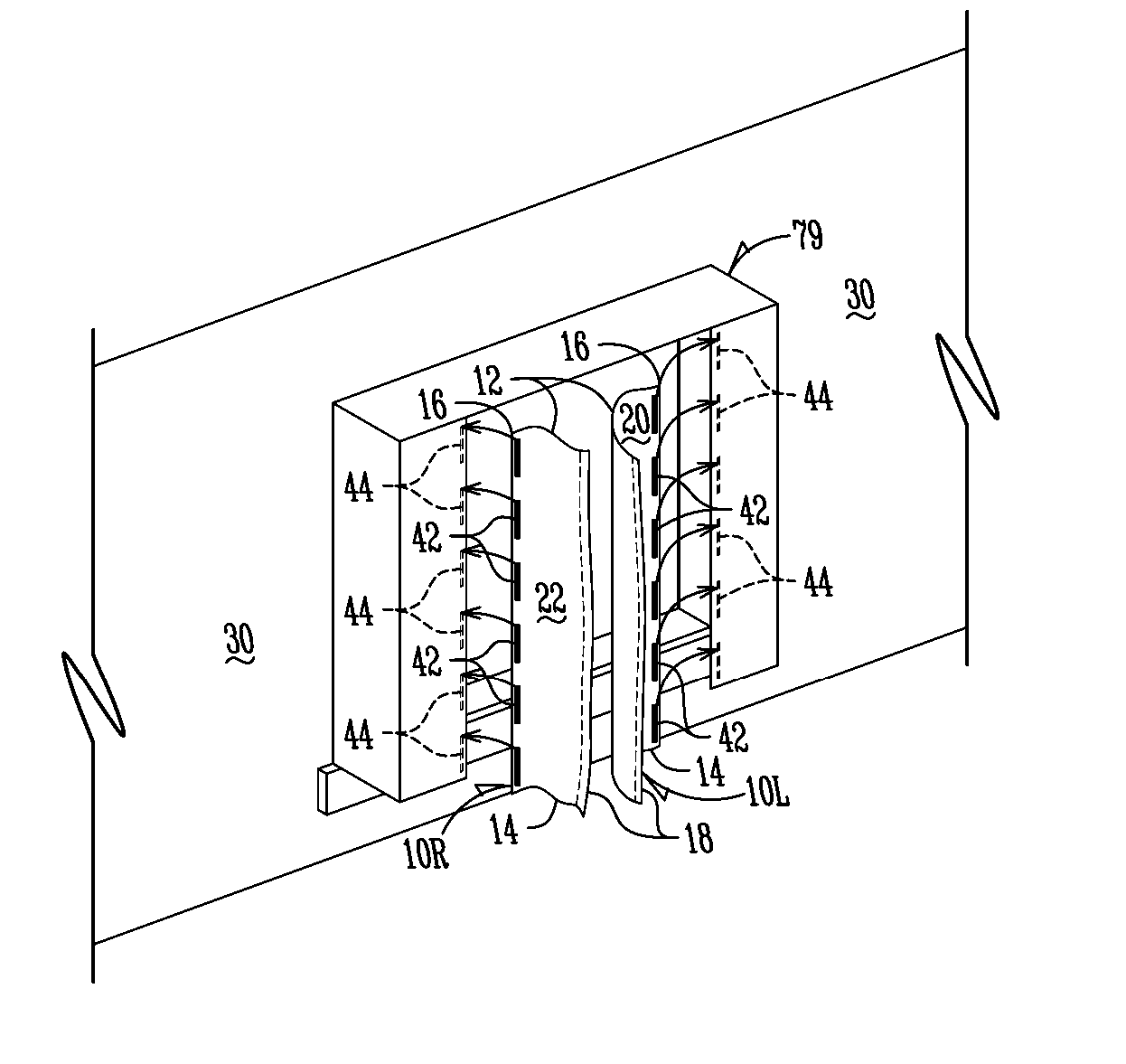

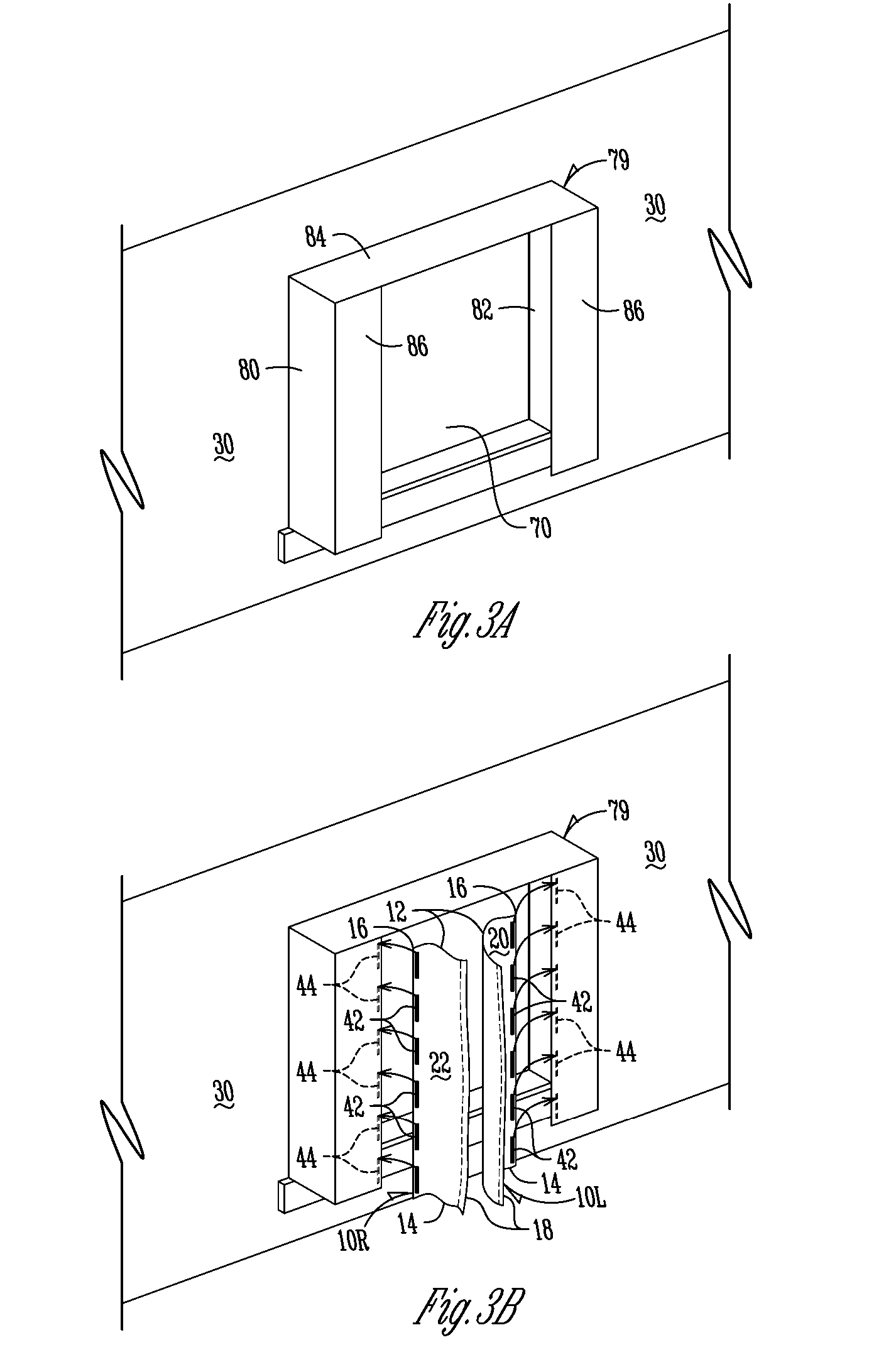

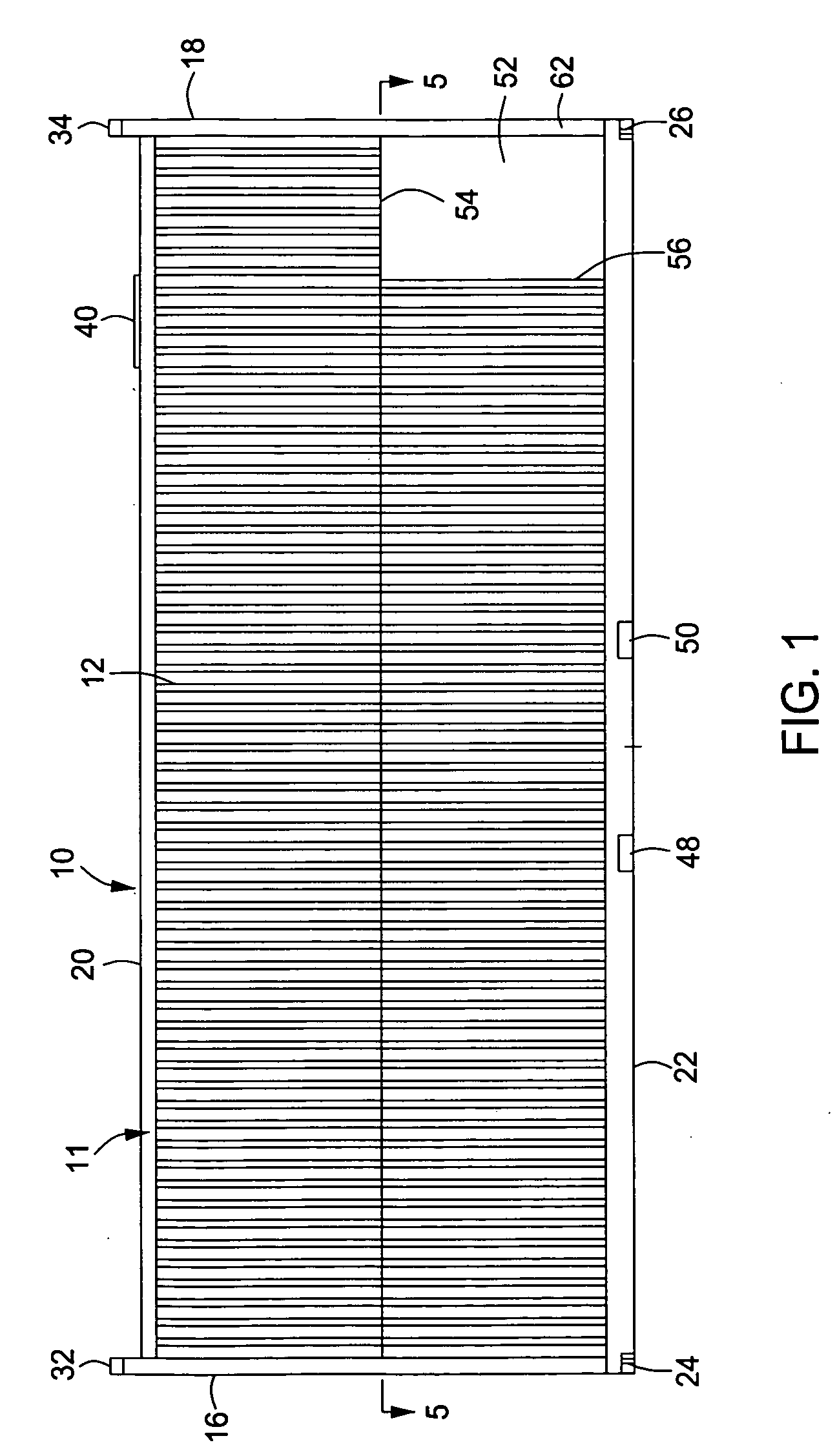

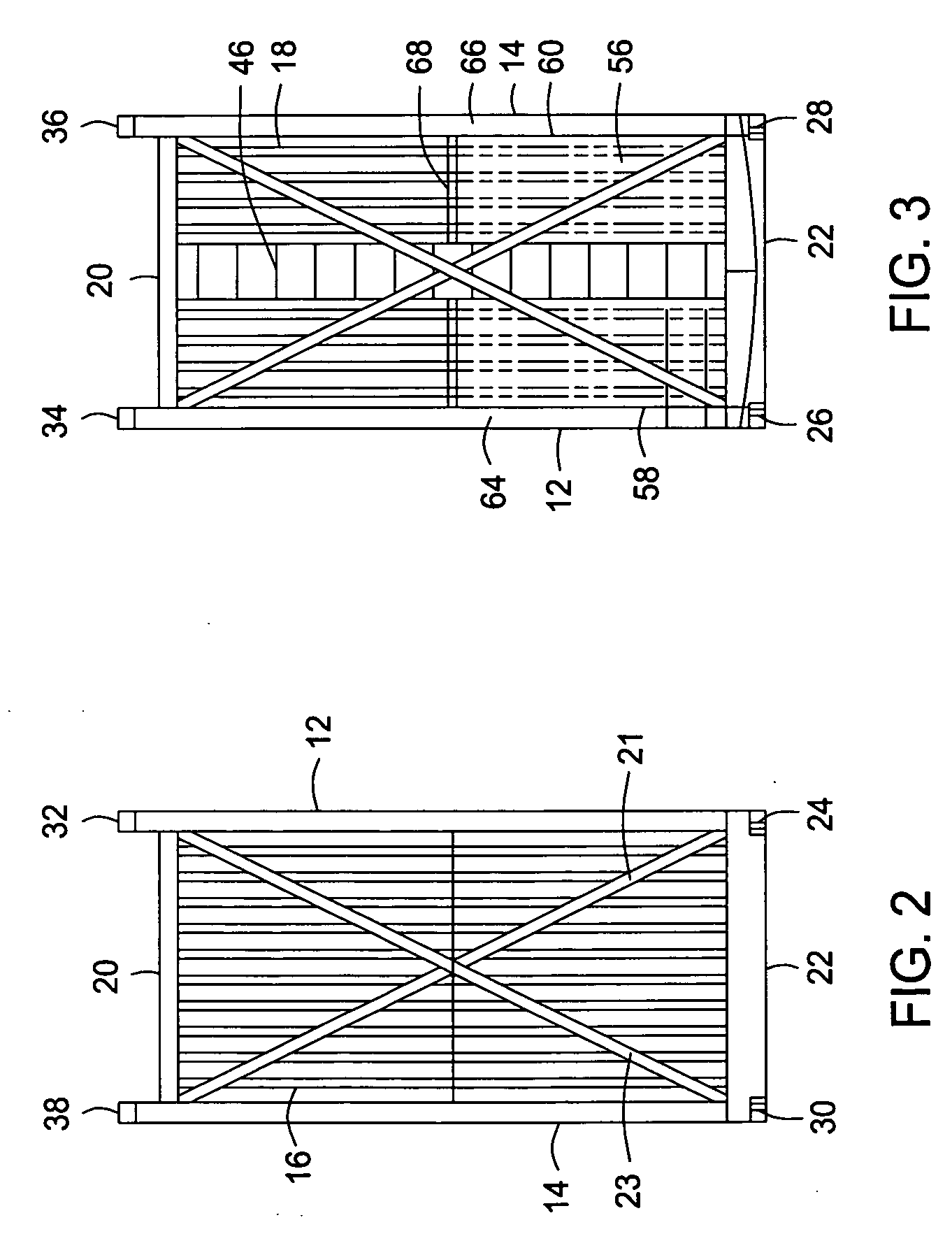

Water runoff deflector for a vehicle at a loading dock

ActiveUS7185463B2Easy to store and protectProtection from damageRoof covering using slabs/sheetsRoof covering using tiles/slatesWater flowTruck

A water runoff deflector for use at a loading dock includes a seal suspended from a wall-mounted frame. A truck can back underneath the deflector so that the seal rests atop the truck's roof. The seal helps prevent water (snow, rain, ice, slush, etc.) on the truck's roof from flowing off the back end of the truck and spilling into the building. The seal helps block any water flowing along the truck's roof toward the doorway of the dock and redirects the flow off to either side of the truck. The deflector can be used in conjunction with or without a conventional dock seal or dock shelter. Unique front and rear bumper designs along with a pivotally yieldable frame make the runoff deflector particularly useful in adapting to trucks of various heights. In some cases, the front bumper includes multiple panels of different rigidity to ensure smooth truck departures.

Owner:RITE HITE HLDG CORP

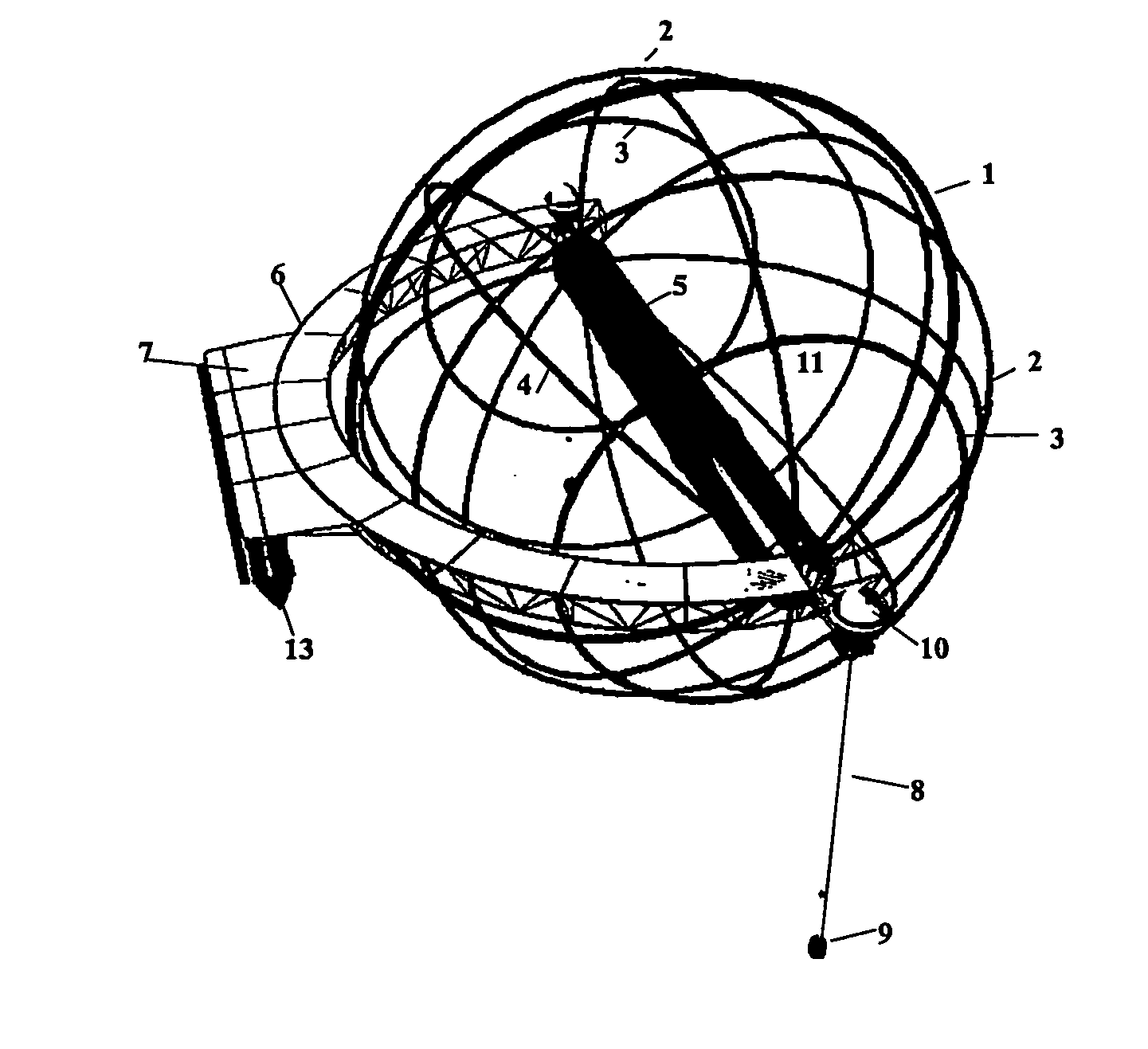

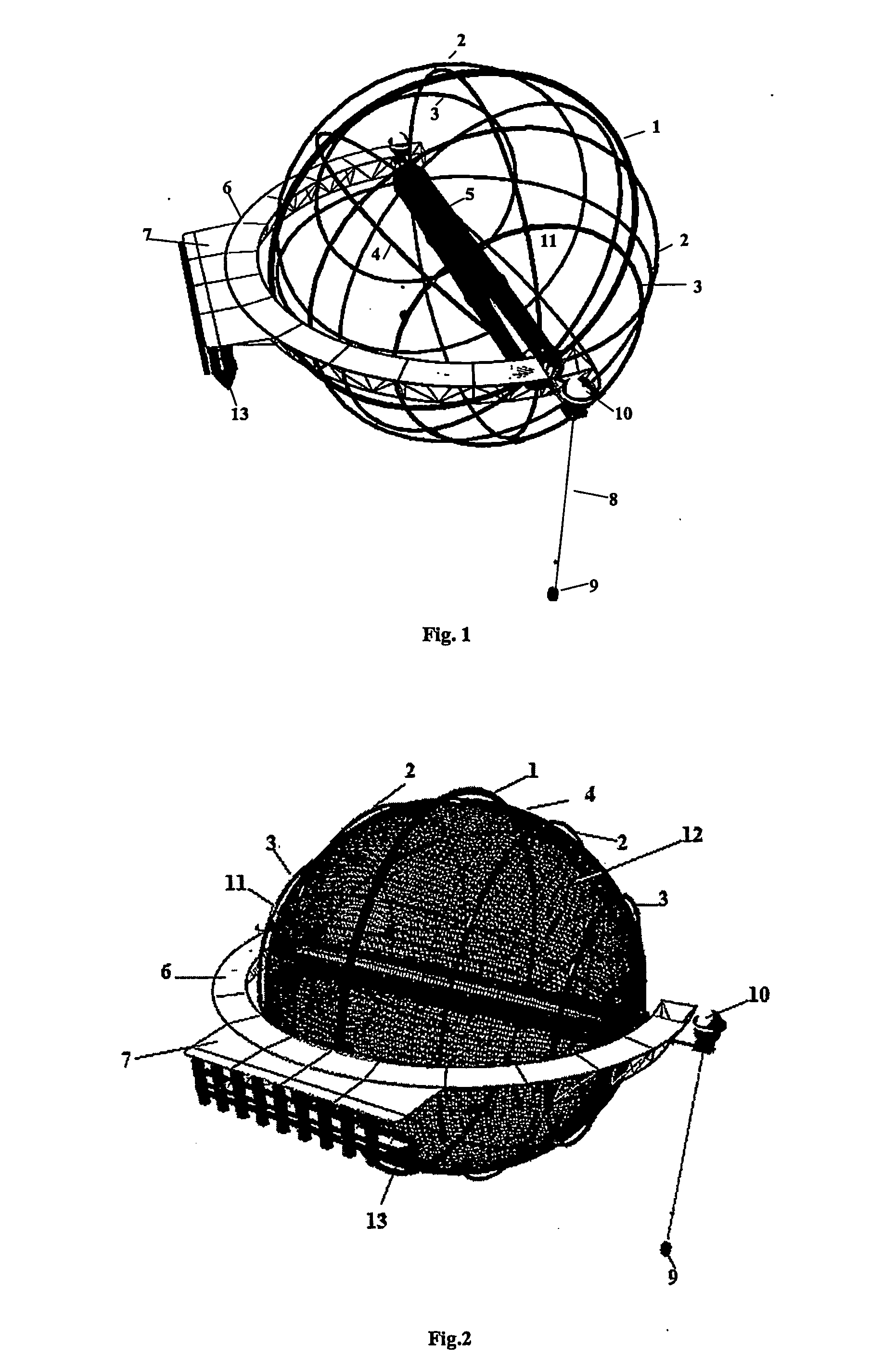

Submersible netpen

The present invention relates to a netpen for breeding, storage, or transport of fish in the sea, in particular completely or in part in open sea regions outside the skerries, wherein the netpen may be lowered in the sea to a desired depth when needed, wherein the netpen may be elevated to a half or approximately half submerged state for various work operations, such as maintenance and inspection of the netpen or harvesting, and wherein netpen has a substantially spherical geometry. The invention is characterized in that the netpen consists of a framework of stays (1, 2, 3, 4) mainly comprising polyethylene or polyethylene-like materials, such as PolyEthylene Low Density (PELD) or PolyEthylene High Density (PEHD), preferably PEHD, a horizontal through center pole (5) also serving as a buoyancy adjusting element for elevation and lowering of the netpen, a horseshoe-shaped working platform (6) having an integrated dock (7) for working vessels, the entire working platform including dock being liftable and lowerable through buoyancy adjustment by means of a designated element (13), and the working deck being mounted on an extended axle (15) on the center pole in such a manner that the netpen may be rotated inside said working deck. On said axle, through lines (8), there are also attached buoys (10) that gives the netpen sufficient reserve buoyancy in normal position as well as weighting organs (9) that, when the netpen is to be stabilized fully submerged at a desired depth, is landed on the sea floor; alternatively, the netpen is stabilized at the desired depth due to the reserve buoyancy in the floatation unit (30) and the floatation element (23), as shown in FIG. 30. Life-supporting functions, such as fodder, energy, and air, are being supplied to the netpen through a lifeline from a nearby floatation unit (30), preferably a platform being an integrated part of the anchoring for the netpen.

Owner:BYKS AS

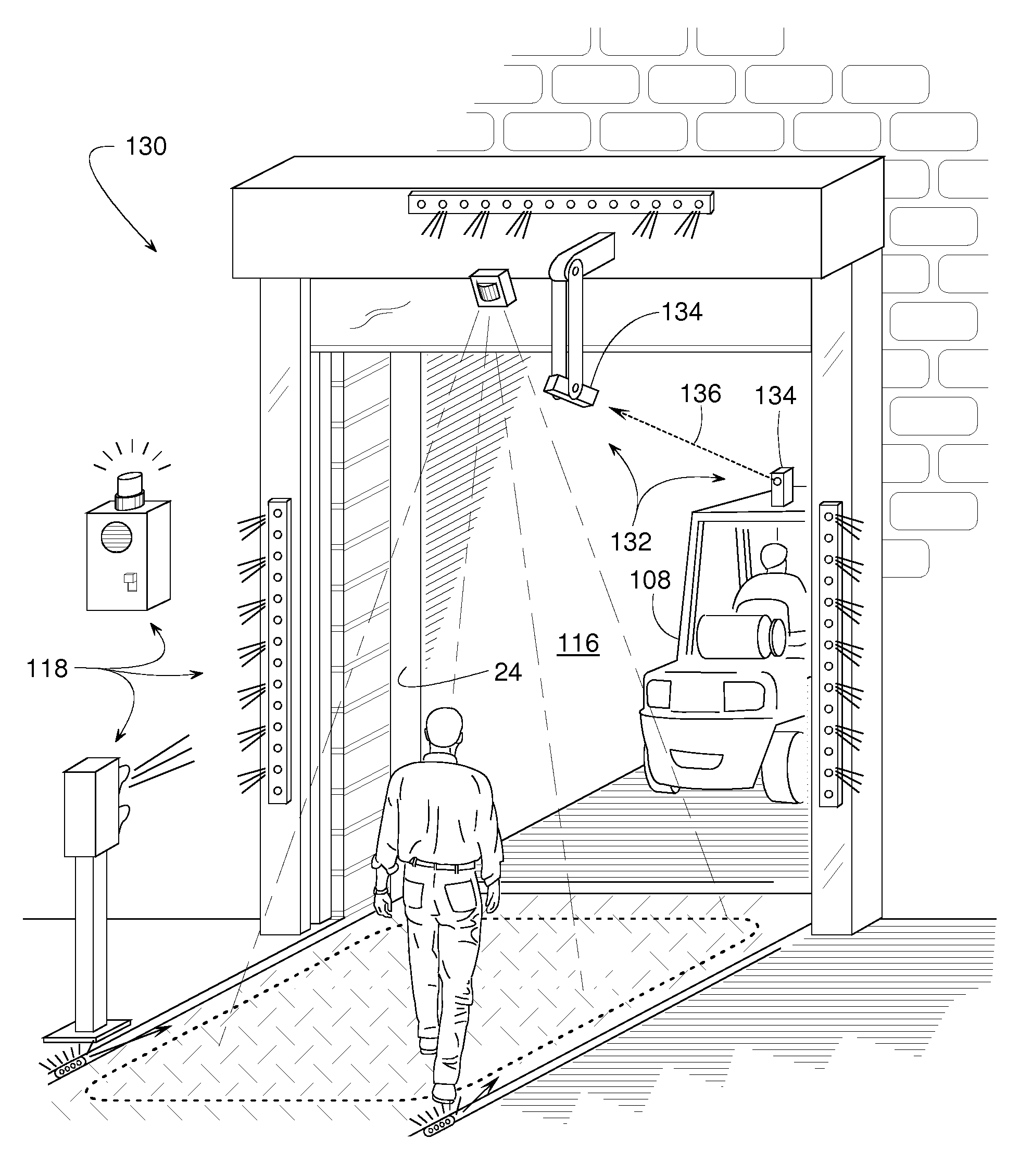

Alarm system for a loading dock

A safety system for a truck loading dock with an elevated platform provides an alarm that warns of a hazard at the loading dock such as a forklift operating inside the truck or a falling hazard that may exist due to the dock door being open while a truck is not present at the dock. In cases where a dock's open doorway is protected by a barrier that can be opened or closed, the alarm can be de-activated by closing the barrier. In some embodiments, the safety system includes a remote body sensor that detects when someone or something is near the doorway. In response to the body sensor, a second, more pronounced alarm can warn of more imminent danger where someone on the platform may be too close to an open doorway when a truck is not present.

Owner:RITE HITE HLDG CORP

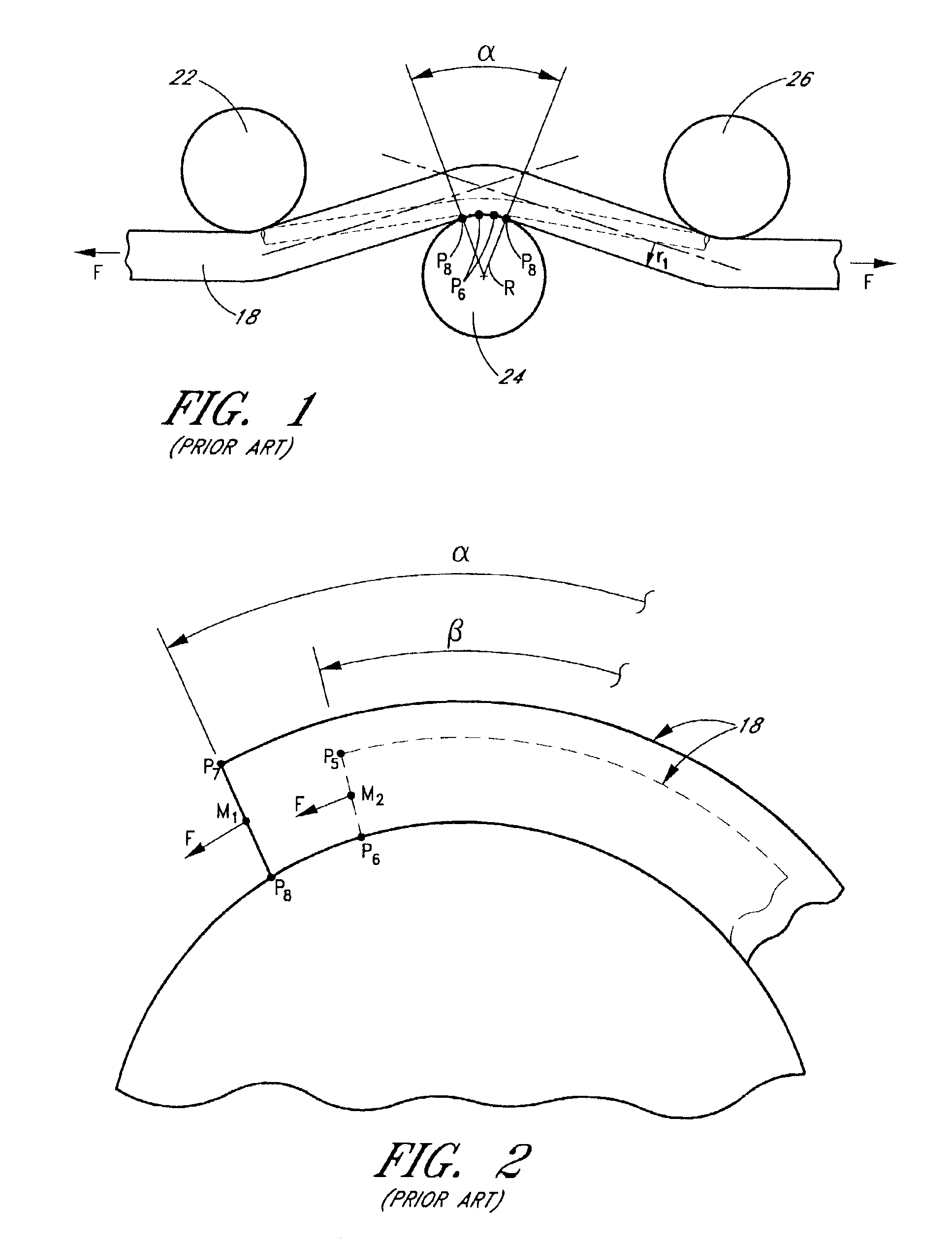

Loading dock seal

InactiveUS20070283636A1Easy to processSolve the complicated replacementRoof covering using slabs/sheetsRoof covering using tiles/slatesVertical edgeEngineering

The present invention relates generally to a loading dock seal. In one aspect it supplements an existing loading dock seal by attaching a flexible sheet vertically along vertical sides of the existing loading dock. The sheet wraps around the rear vertical edges of a truck body to seal any gaps that might exist, for example, between the opened rear door and the truck body wall caused by hinges.

Owner:BERNACKI DANIEL R +1

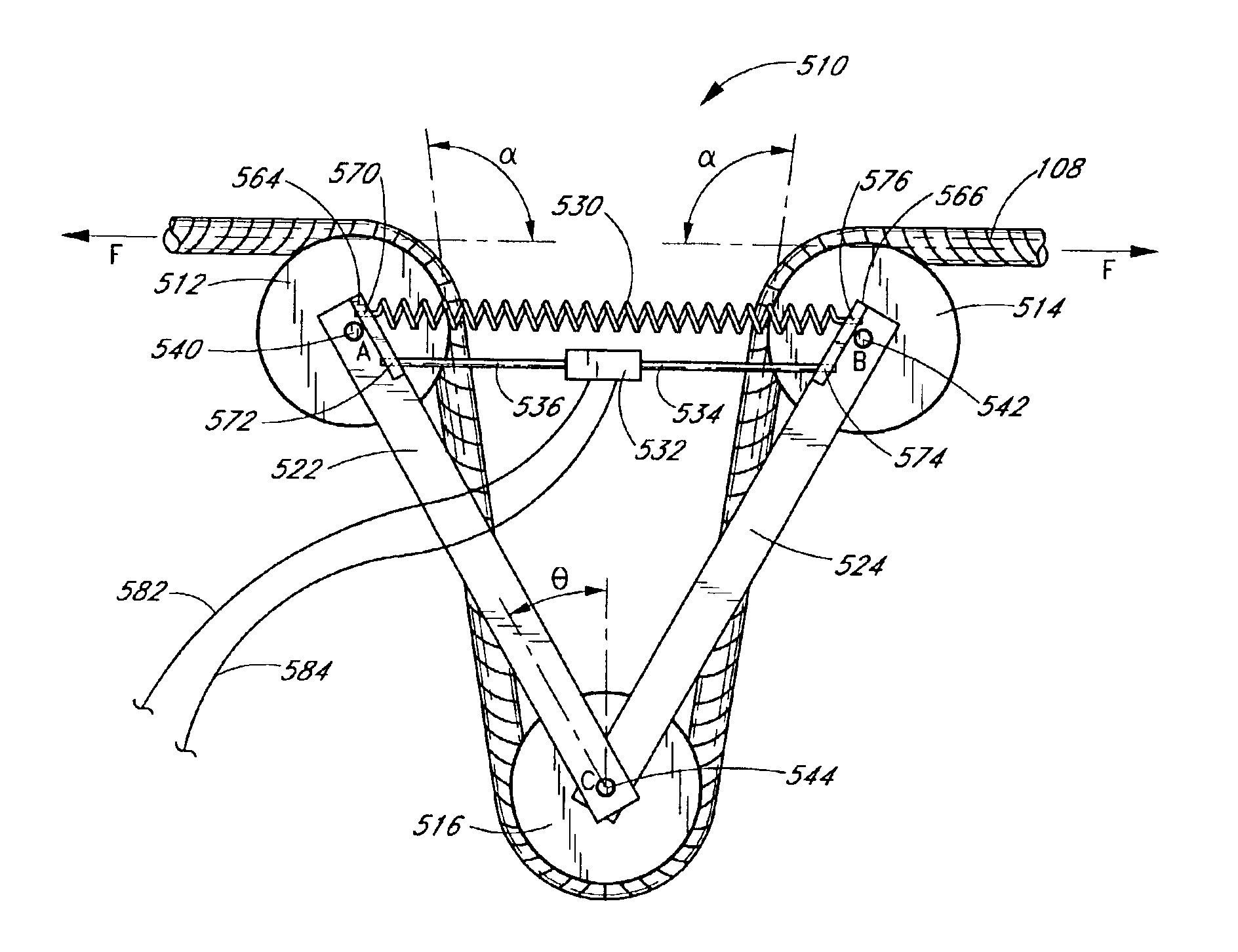

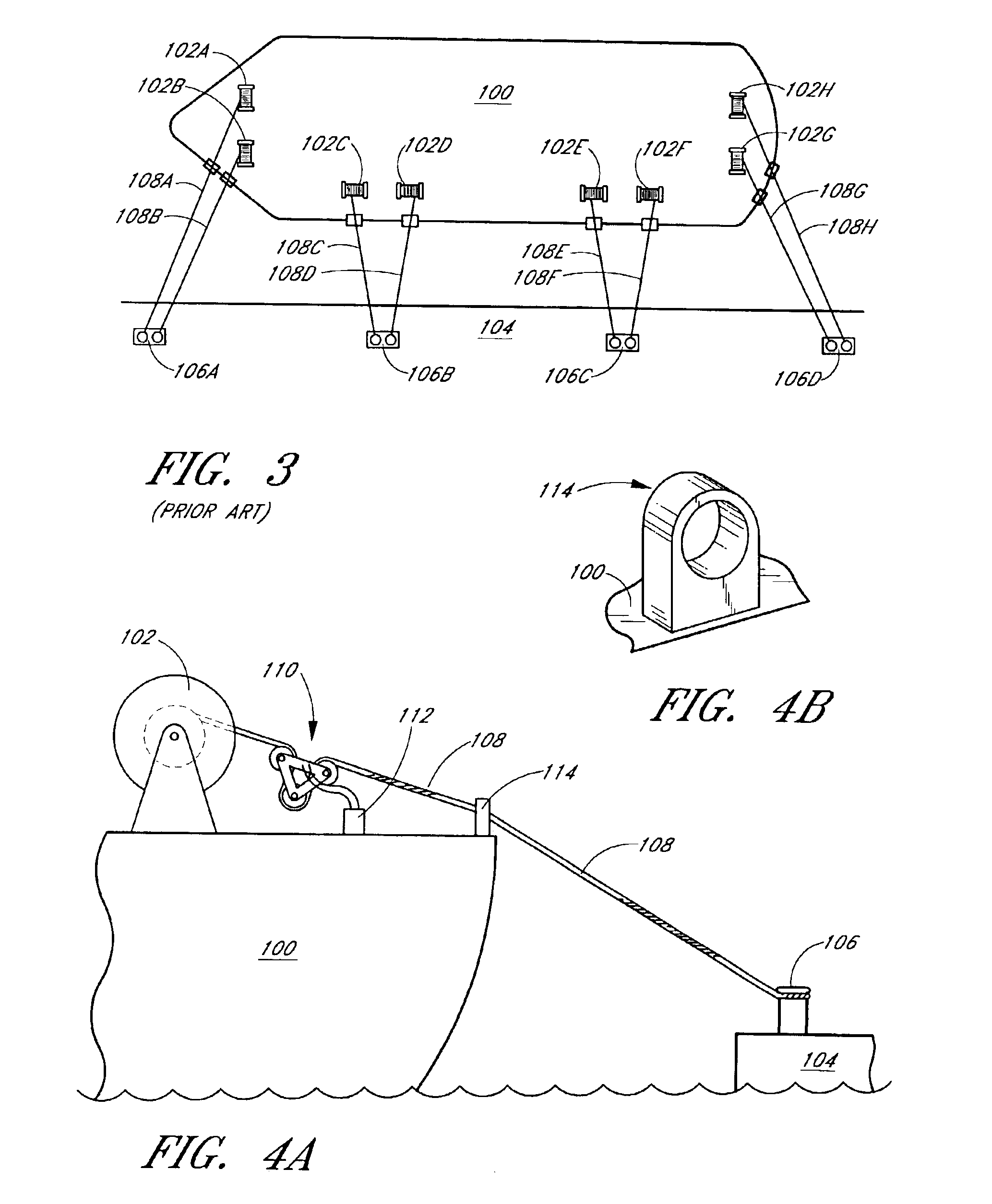

Tension measuring device for mooring line

A device for measuring tension in a line for mooring a ship to a dock or an anchor. The device includes three pulleys secured to rigid frames or springs. Sensors are placed on rigid frames, springs or shafts for securing the pulleys. Portions of the mooring line extending from a center pulley to the other two pulleys are approximately perpendicular to portions of line extending from the two pulleys to a winch or a mooring post or hook. The springs between the pulleys may provide resilience in the mooring line which may obviate a need for a pendent line between the mooring line and the winch. The sensors communicate with a signal-processing unit which transmits amplified sensor signals to a monitor which is accessible to personnel aboard the ship. The monitor may display the tension in the mooring line in text or graphic formats.

Owner:CHEUNG MAXWELL C

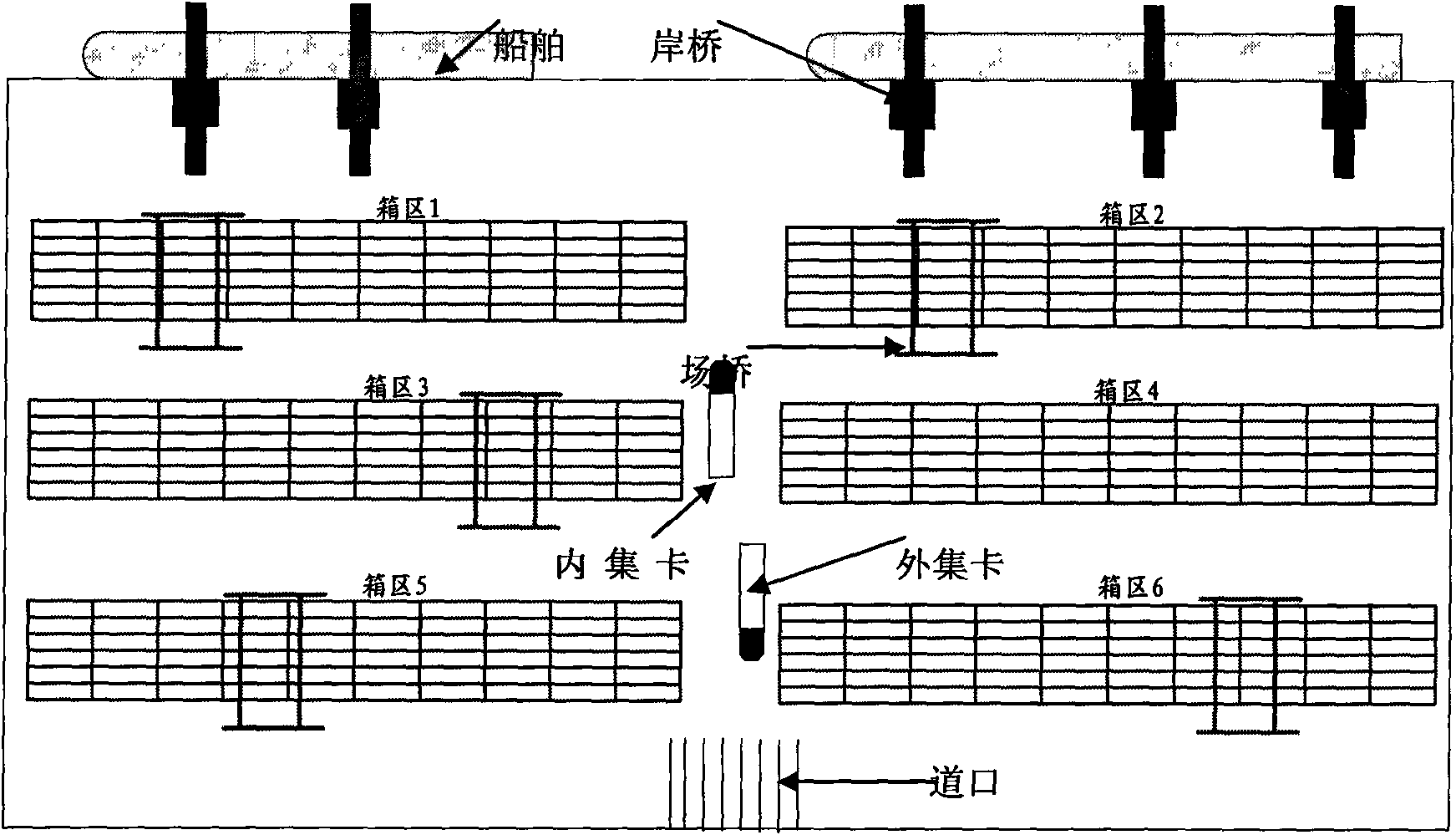

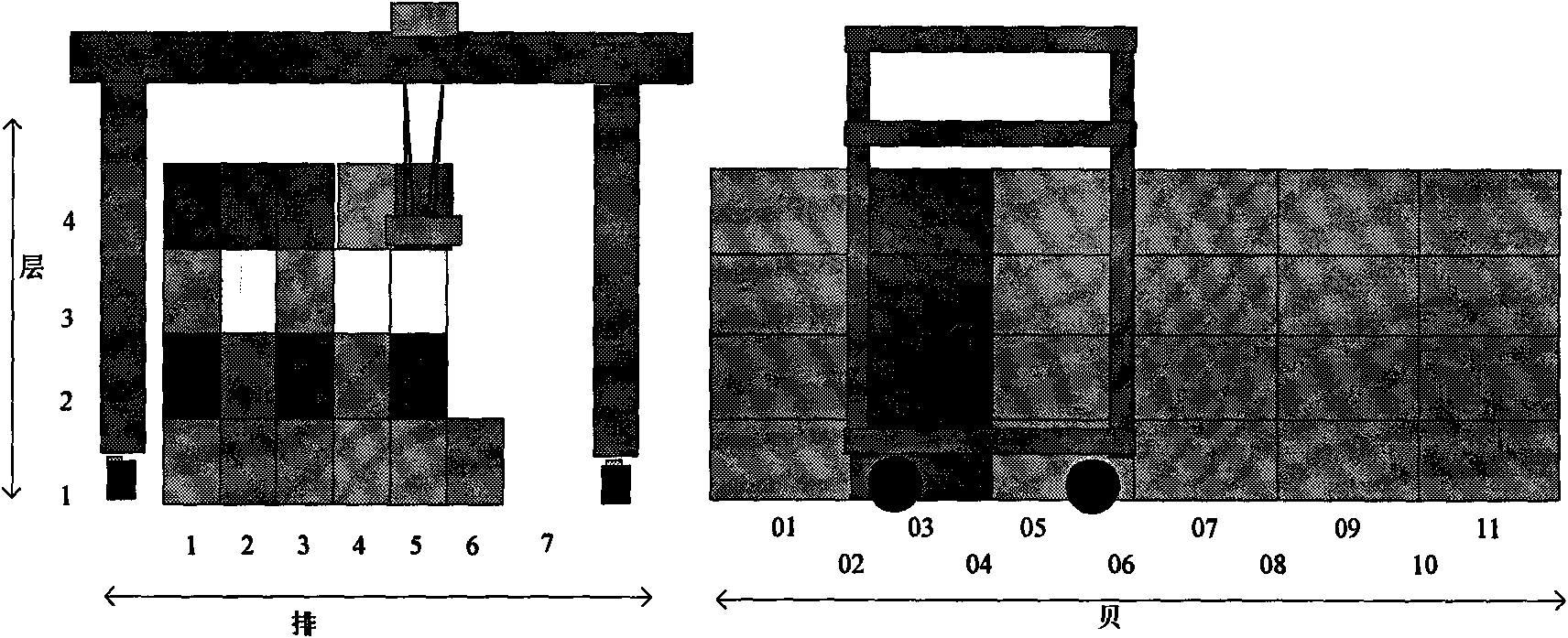

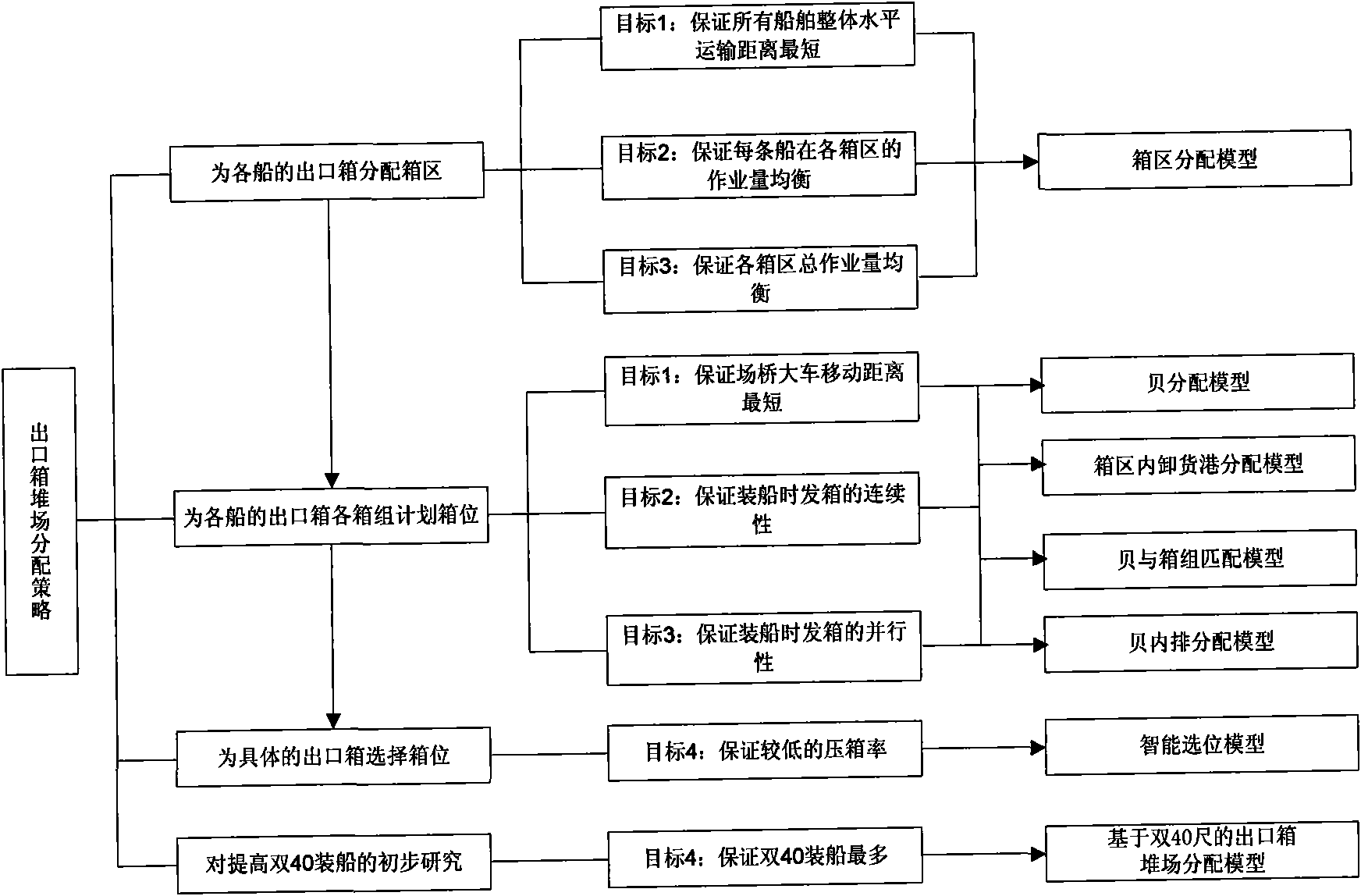

Distribution Method for export container yard of container wharf

InactiveCN101585453AReduce loading and unloading costsImprove service qualityData processing applicationsStorage devicesDistribution methodVolumetric Mass Density

The invention discloses a automatic distribution method for an export container yard of a container wharf, which comprises the following steps: firstly, distributing a container region for export containers of each ship; then, planning a container slot for each container set of the export containers of each ship; and finally, selecting the container slot for specific export containers. The method carries out deep research on the distribution of the export container regions, the planning of the container slots and the automatic slot selection of approach and preliminary consideration for improving the proportion of double 40 shipping, is favorable for improving the orderliness of the export container stacking under the predetermined yard density and has important significance in establishing good basis for the ordered organization of subsequent shipping operation.

Owner:SHANGHAI MARITIME UNIVERSITY

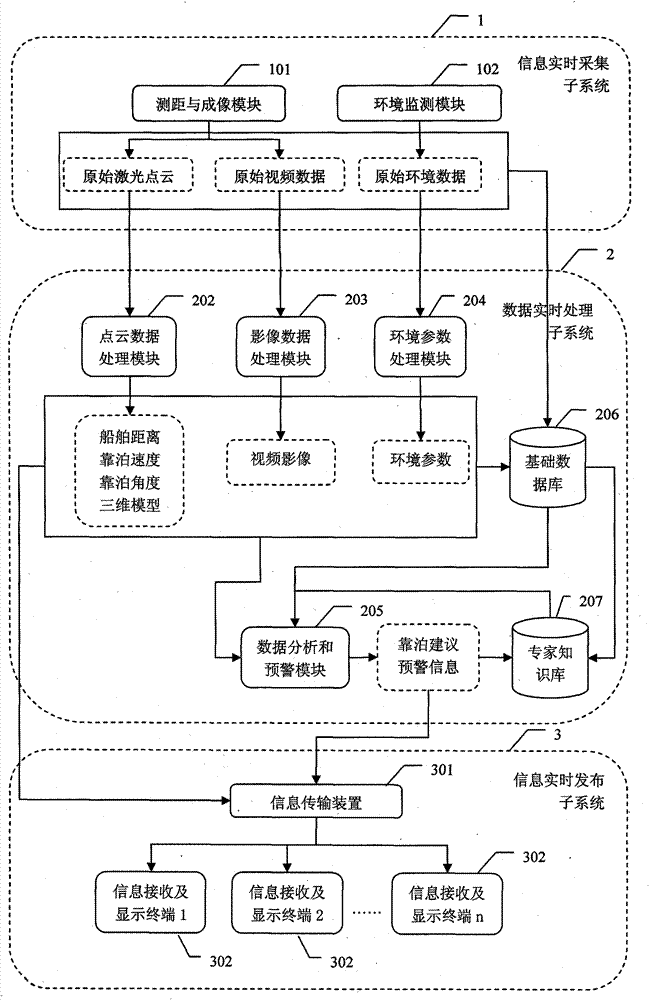

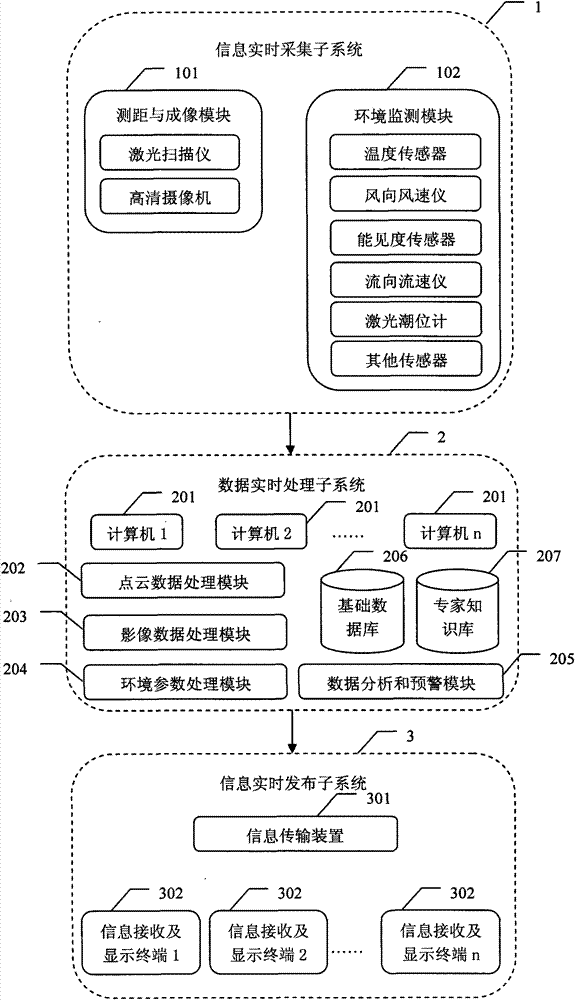

Intelligent ship berthing assistance system and method

InactiveCN103901806AAvoid limitationsAvoid monotonyProgramme controlComputer controlPoint cloudNavigation safety

The invention relates to the field of ship navigation safety, in particular to an intelligent ship berthing assistance system and method based on various sensors. According to the method, the intelligent ship berthing assistance system formed by an information real-time acquisition subsystem (1), a data real-time processing subsystem (2) and an information real-time issue subsystem (3) is adopted, data such as three-dimensional laser-point cloud, video images and environment parameters are acquired in real time through the information real-time acquisition subsystem (1), data real-time processing is carried out through the data real-time processing subsystem (2), the real-time ship distance, the berthing speed, the berthing angle, a wharf and ship three-dimensional model, the video images, the environment parameters, berthing suggestions, warning information and the like needed by ship berthing are acquired and are then issued to a user terminal through the information real-time issue subsystem (3), and therefore intelligent ship berthing assistance is achieved. The intelligent ship berthing assistance system and method are suitable for all sizes of berths and all types of ships and effectively solve the problems of limitation and simplicity of various other existing methods and systems.

Owner:唐粮 +1

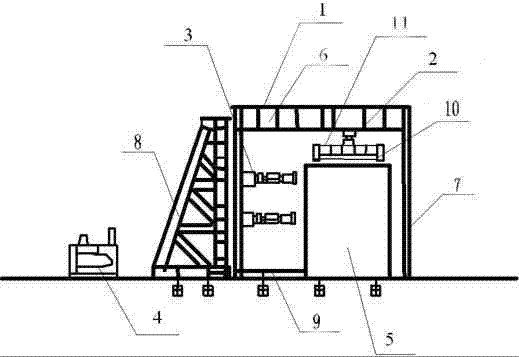

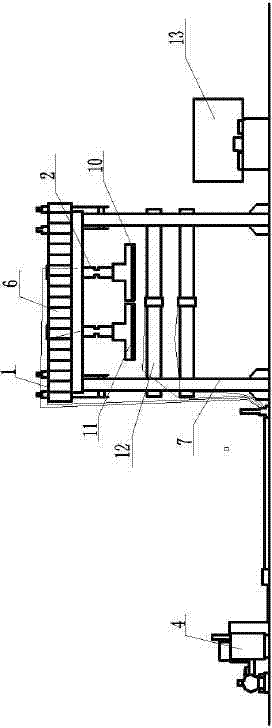

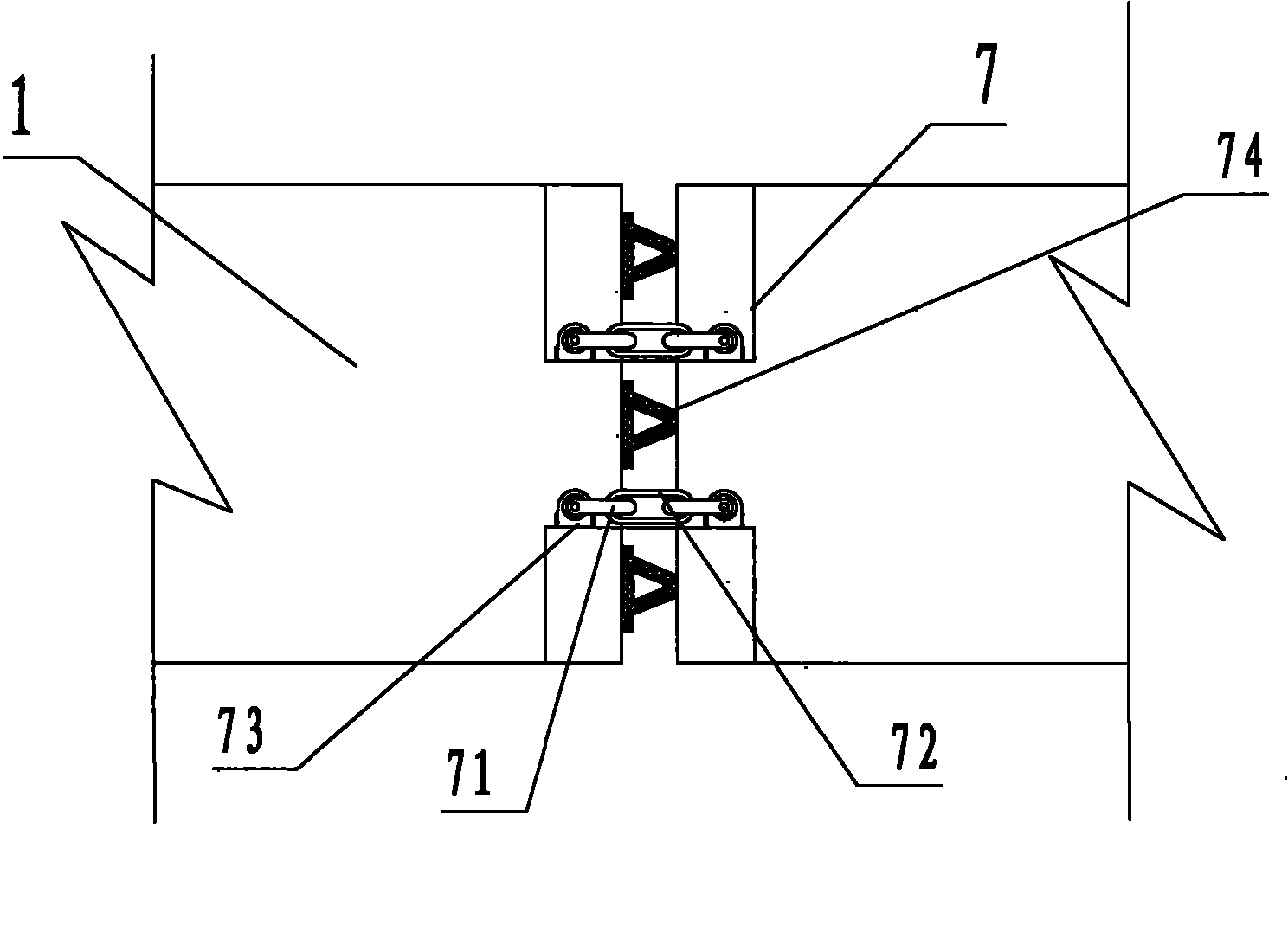

Dynamic and static testing system and method for multifunctional wharf structure

InactiveCN102928293AEasy to assembleStable structureMachine part testingMaterial strength using tensile/compressive forcesActuatorShip load

The invention discloses a dynamic and static testing system for a multifunctional wharf structure. The dynamic and static testing system comprises a detachable large-rigidity bearing frame, a vertical loading actuator, a horizontal loading actuator, a multi-channel controller, an electro-hydraulic servo oil source system, a data collecting system as well as a displacement and force sensor. The maximum clearance size of the loading frame is 4.5m* 4.5m*4.5m (L*W*H); a testing space can be randomly adjusted according to test sample requirements; a loading mode is that vertical and horizontal combined loading can be finished through two 10-100 t static vertical actuators and 3-20t dynamic horizontal actuators; integral or member stress performance tests of the high pile frame wharf structure with large water level difference under a combined effect of various complicated working conditions such as gantry crane load, piling load and ship load are simulated. The invention further provides a dynamic and static testing method for the wharf structure, which can be used for really simulating the stressed deformation performances of the wharf structure under various complicated stressed conditions and can be also used in stress experiments of similar structures.

Owner:CHONGQING JIAOTONG UNIVERSITY

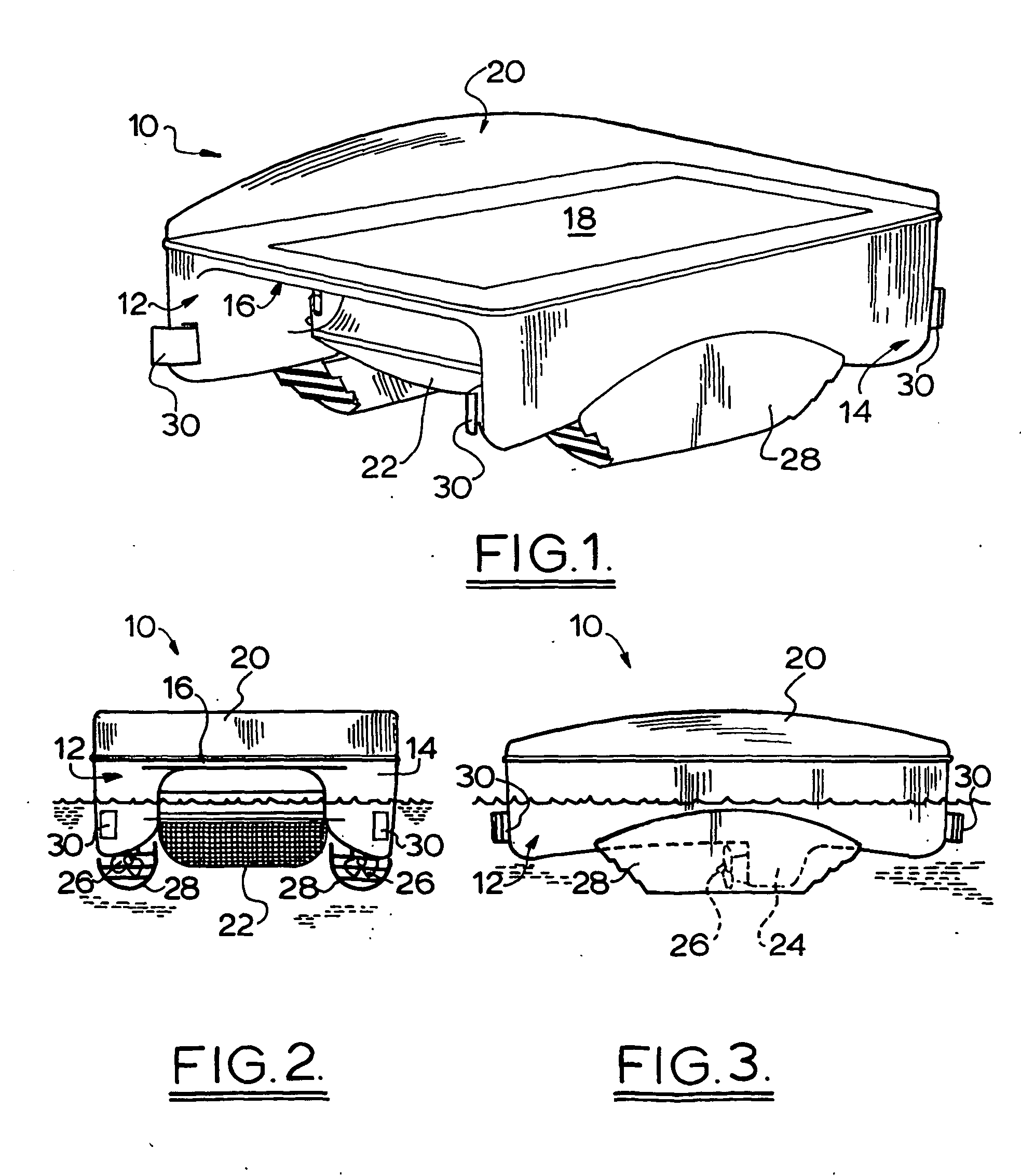

Floating drive-on-watercraft dock

A floating drive-on watercraft dock comprises a one-piece molded body defining a watercraft receiving area. The watercraft receiving area includes roller assemblies on the bottom of the watercraft receiving area and glide assemblies on the sides of the watercraft receiving area. The roller and glide assemblies can be easily removed and replaced for servicing of the watercraft dock. An extension unit is provided which can be connected to the watercraft dock body. The extension unit includes an extension body and a tongue extending from the extension body. The tongue is sized and shaped to have a bottom surface complementary to the entrance to the watercraft receiving area of the watercraft dock body. The extension unit also includes a watercraft receiving area, which, when the extension unit is connected to the watercraft dock, increases the length of the watercraft receiving area.

Owner:E Z DOCK

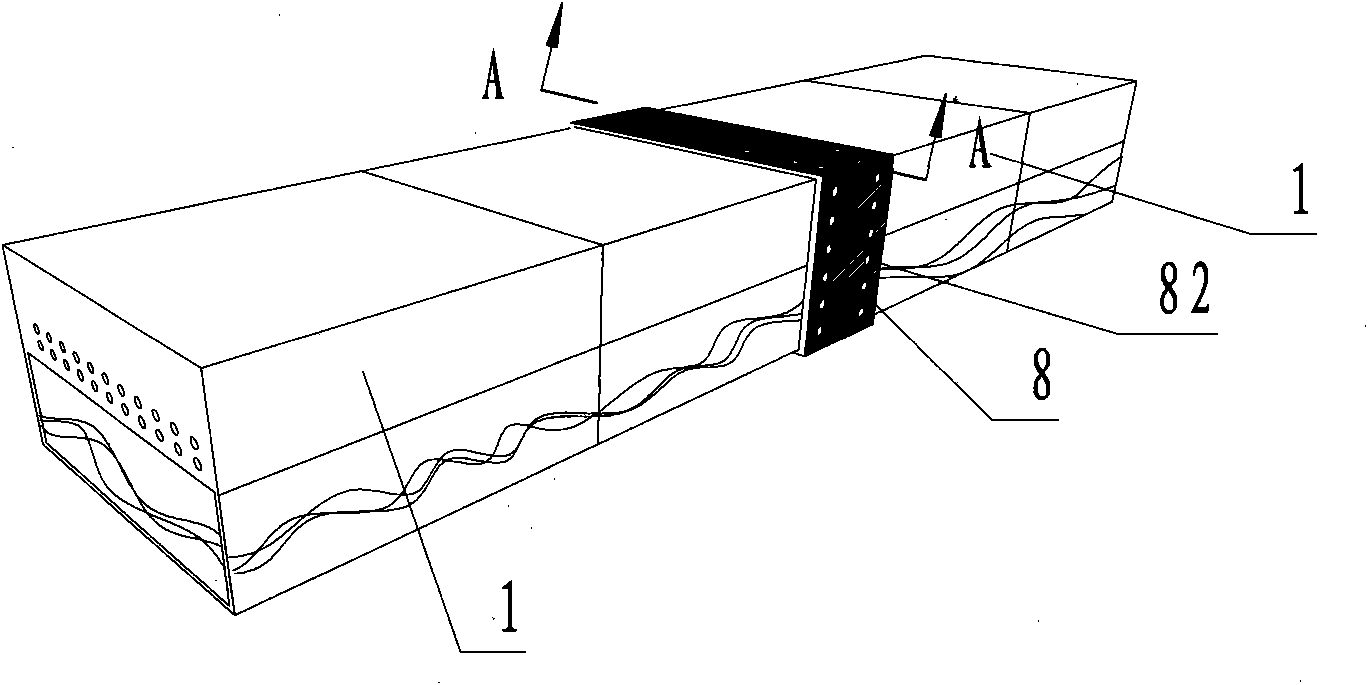

Semi-submersible type multifunctional jetty

InactiveCN101850834AExpand to benefit the societyGood sea living environmentBreakwatersQuaysEngineeringFishing

The invention discloses a semi-submersible type multifunctional jetty, comprising one or more semi-submersible type steel box bodies mutually connected together. The lower part of each box body is provided with an anchoring locating device, and a wave wall is arranged in the longitudinal direction at the upper part of the box body. The box body is internally provided with an intermediate deck dividing the box body into an upper layer and a lower layer, wherein the upper layer is a functional box, and the lower layer is a snorkeling box. The lower layer of the box body is provided with a snorkeling device, and one end part of the box body is also provided with a shore coupling device. The invention has the advantages that the adopted semi-submersible type jetty has low manufacturing cost, short construction period, convenient construction and safe use, can effectively prevent geological disasters and avoid the damage caused by earthquakes and surge, does not change the ocean attribute and can utilize a platform on the surface of the box body as a floating dock and a hydrophilic leisure and entertainment occasion for fishing and the like.

Owner:许是勇

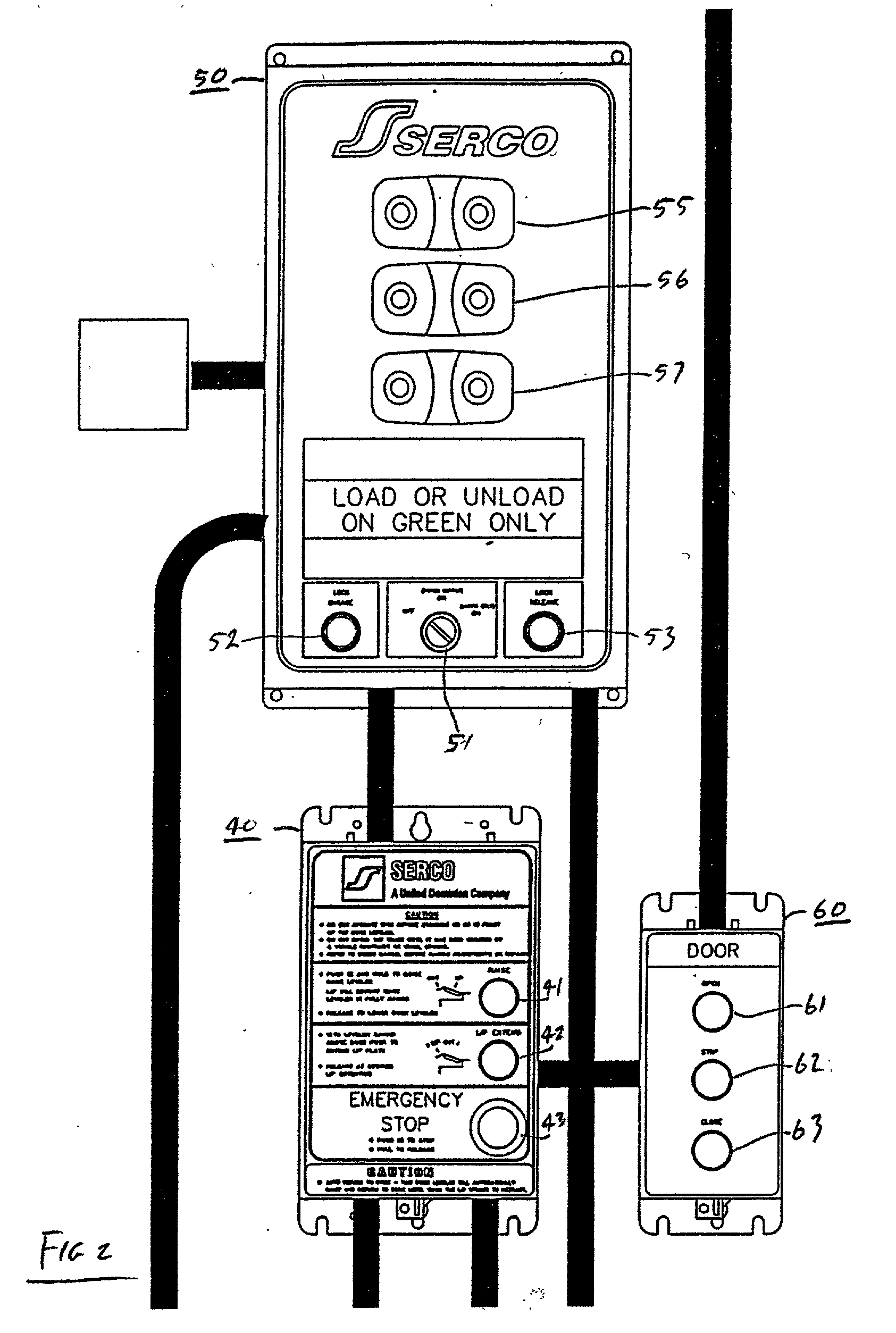

Master control panel for loading dock equipment

InactiveUS20030199996A1Electric devicesPedestrian/occupant safety arrangementSoftware engineeringMechanical engineering

Owner:4FRONT ENGINEERED SOLUTIONS

Dual direction water surface skimmer and pool side docking device

A water skimmer vessel has two hulls (12, 14) between which a debris collection net or basket-like catcher (22) is arranged. Hinged flaps (68) are provided at each end of the catcher and operate to allow inflow but block outflow of debris from the catcher. Each hull of the vessel is equiped with amoter covered by a guard (28). The vessel may move in either direction and is equipped with sensors (30) on each hulll for effecting the turning and reversing of the vessel upon contact with pool skimmer box inlet (206) and the vessel can be controlled to enter the dock and permit the contents of the catcher to be discharged into the current of pool water flowing into the skimmer box.

Owner:HASKI ROBERT R

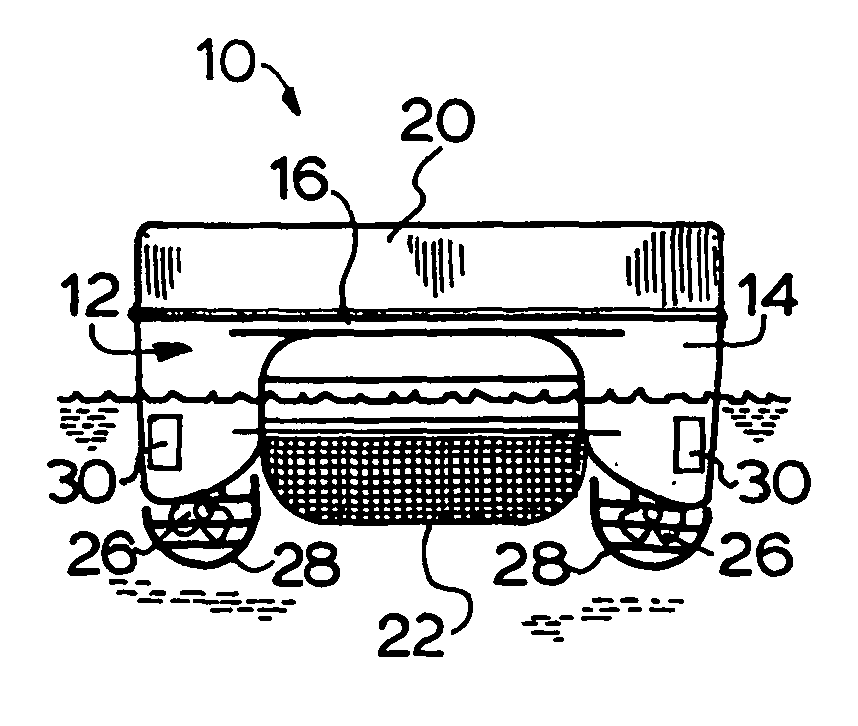

Modular floating dock with inflatable pontoons

InactiveUS20060153643A1Simple modular configurationEasy to installDry-dockingSlipwaysModularityPontoon bridge

A modular buoyant support apparatus is comprised of buoyant support modules of inflatable pontoons. The pontoons comprise inflatable tubular chambers, typically fabricated of polymer coated fabric sheet material. A buoyant support module comprises a rigid frame connected to an inflatable pontoon. A means is provided to interconnect buoyant support modules to form a modular buoyant support apparatus of varied support area and configuration. Means are provided to attach an appropriately configured dock surface to the modular buoyant support apparatus.

Owner:BASTA SAMUEL T

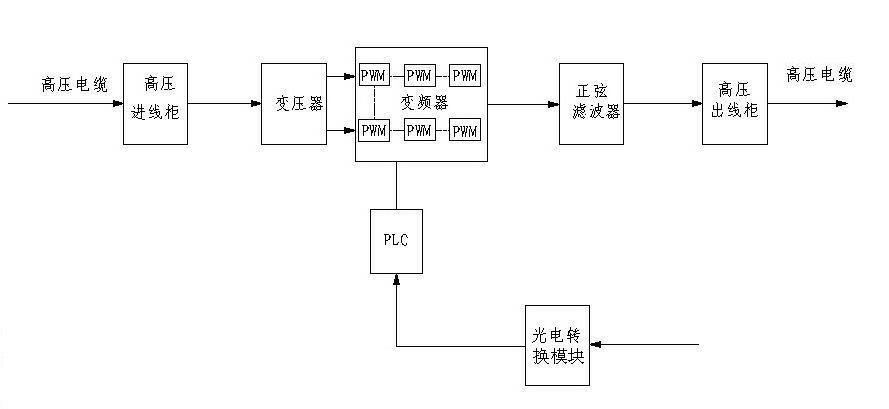

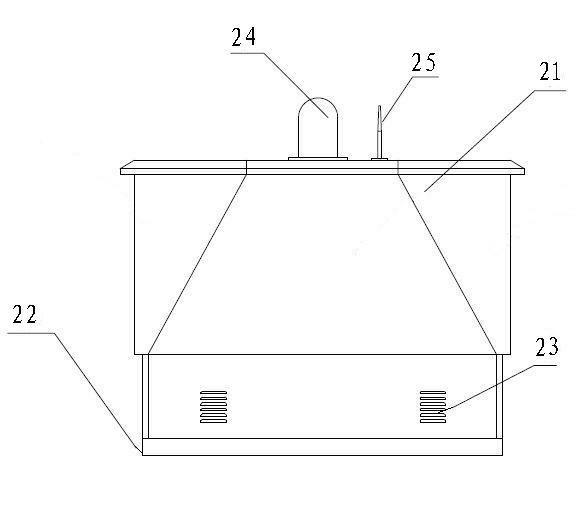

Wharf marine shore power system

ActiveCN102497110ASave on paymentSave energyAuxillariesConversion with intermediate conversion to dcTransformerTransverter

The invention relates to a wharf marine shore power system which is characterized by comprising a high-voltage variable-frequency power supply device, a high-voltage junction box, a high-voltage cable reel and an onboard transformer substation. The high-voltage variable-frequency power supply device comprises a high-voltage incoming line cabinet and a transformer, a high-voltage cable is connected into the high-voltage incoming line cabinet and is connected to the transformer, the high-voltage incoming line cabinet is provided with multiple levels of current-limiting resistors, the transformer is connected with a frequency converter through the high-voltage cable, the frequency converter consists of a plurality of PWM (Pulse Width Modulation) power units connected in series and in parallel and is connected with a sine filter through the high-voltage cable, and the sine filter is connected with a high-voltage outgoing line cabinet through the high-voltage cable. The wharf marine shore power system disclosed by the invention is a power supply system applied to a wharf and used for supplying power to in-harbor ships, and has the advantages of saving energy source, realizing emission reduction and environment protection, and having wide application range; and the wharf marine shore power system can supply power of various systems, such as 400V, 415V, 440V, 690V, 6.6kV, 50 / 60Hz andthe like, to parked ships.

Owner:JIANGSU XINHANG ELECTRICAL

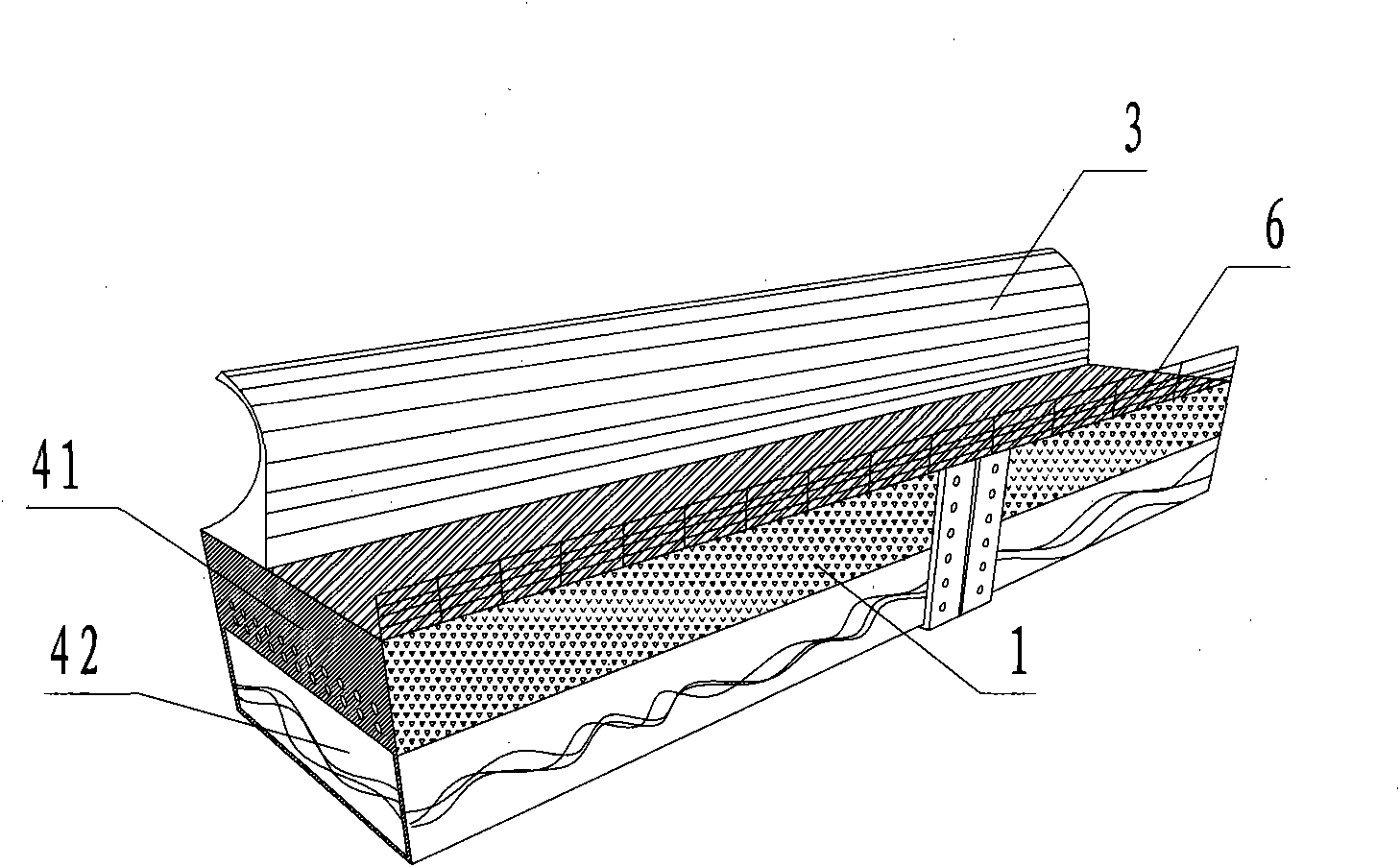

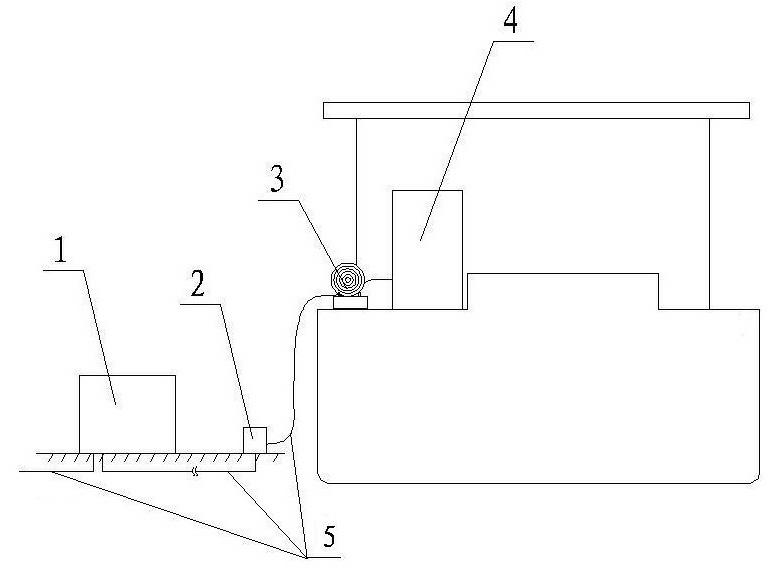

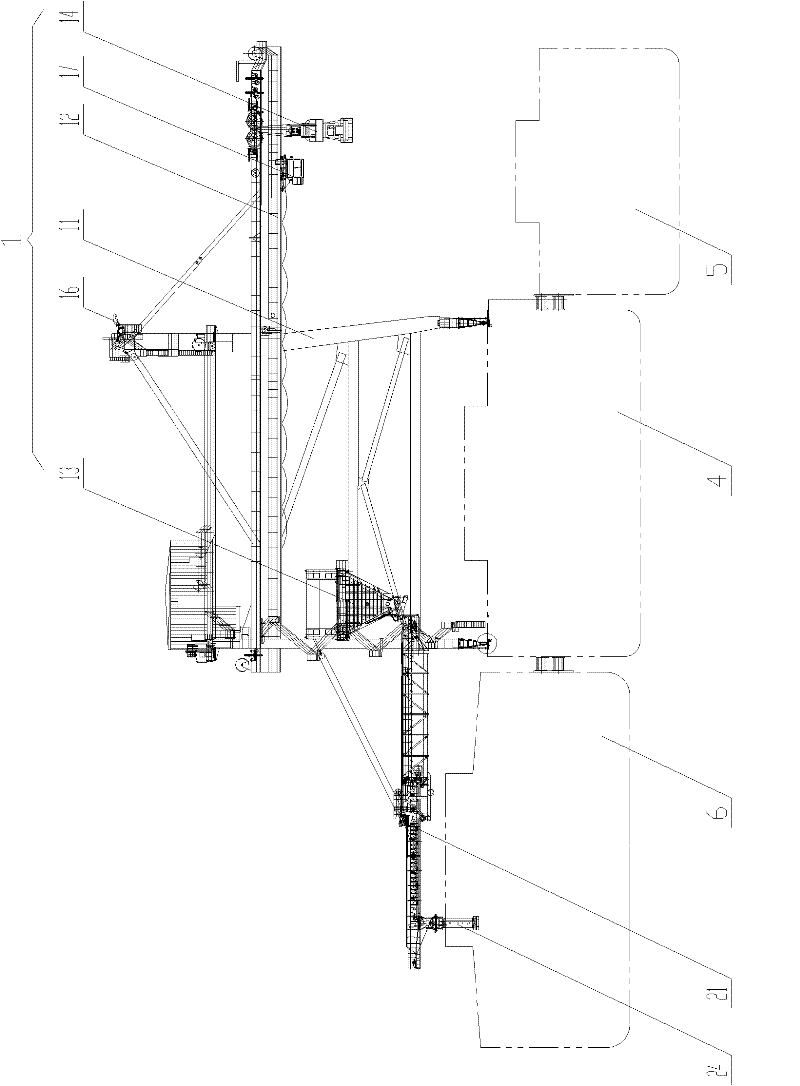

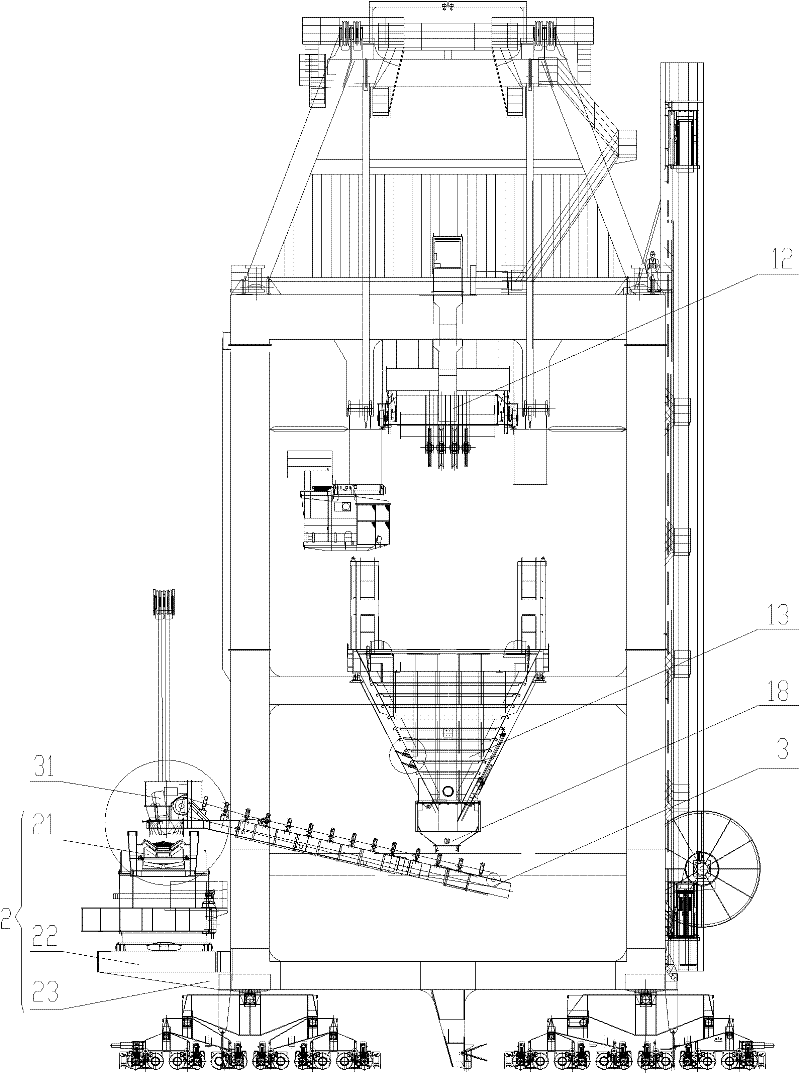

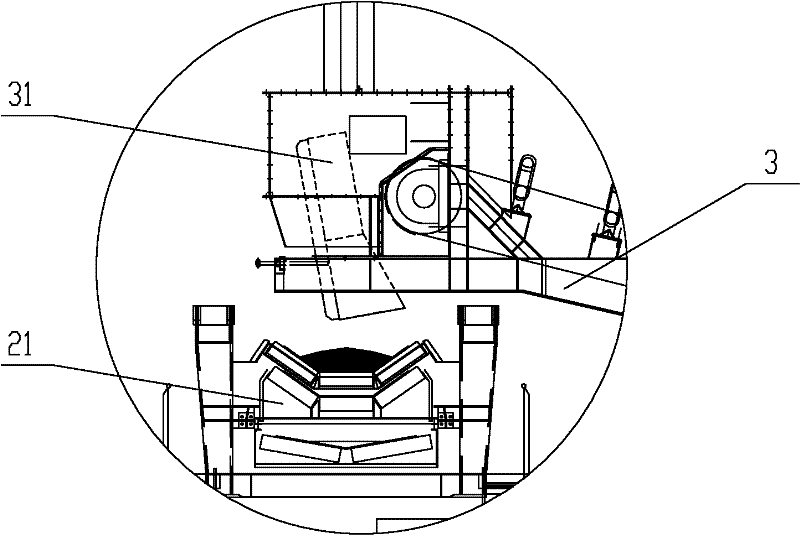

Lighterage operation bridge type loading and unloading ship machine

InactiveCN102229392AIncrease flexibilityImprove convenienceCargo handling apparatusPassenger handling apparatusBridge typeBelt conveyor

The invention discloses a lighterage operation bridge type loading and unloading ship machine (1), which comprises three parts, namely an unloading ship machine (1), a loading ship machine (2) and a middle belt conveyor (3), wherein the loading ship machine is arranged on the lower side of the unloading ship machine (1); a rotary and pitchable telescopic arm frame belt conveyor (21) is arranged above a wharf boat (4) and a ship (6) to be loaded on the other side; the middle belt conveyor (3) is arranged between the unloading ship machine (1) and the loading ship machine (2); one end of the middle belt conveyor (3) is arranged below a discharge hole of a hopper (13) of the unloading ship machine (1), and the other end of the middle belt conveyor (3) is connected with the telescopic arm frame belt conveyor (21) of the loading ship machine (2); and the loading ship machine (2) and the middle belt conveyor (3) are supported on a supporting frame (11). Due to a three-in-one loading and unloading ship machine, a large number of tail vehicles, metal structures and other parts are saved, so that the weight of the machine is lightened, the whole system has a simple and compact structure and small occupied space, and the cost of a lighterage operation system is reduced.

Owner:SANY GRP

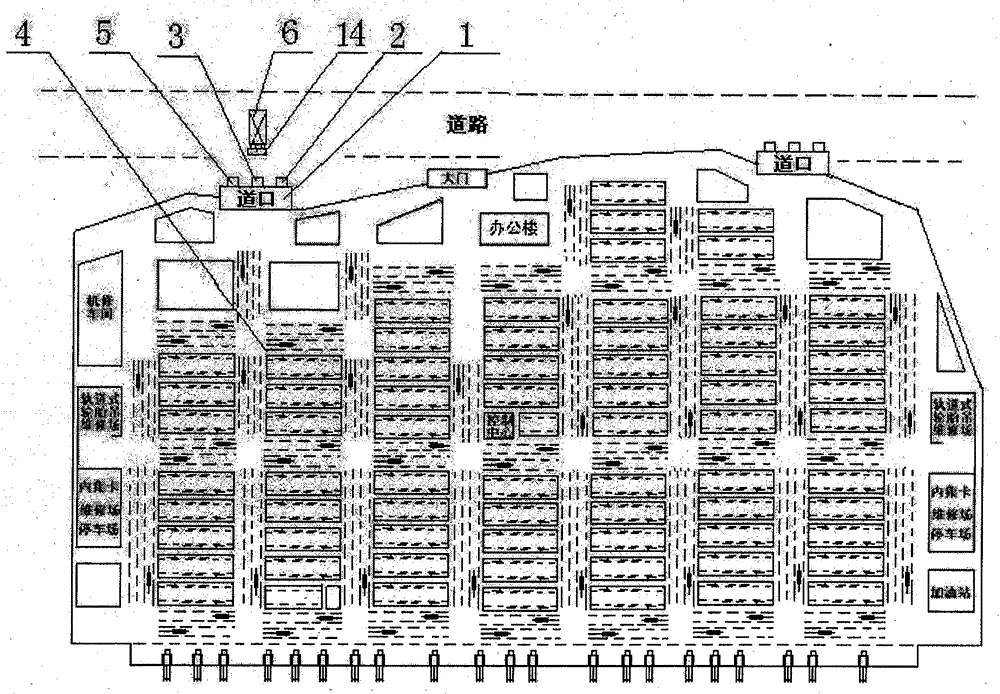

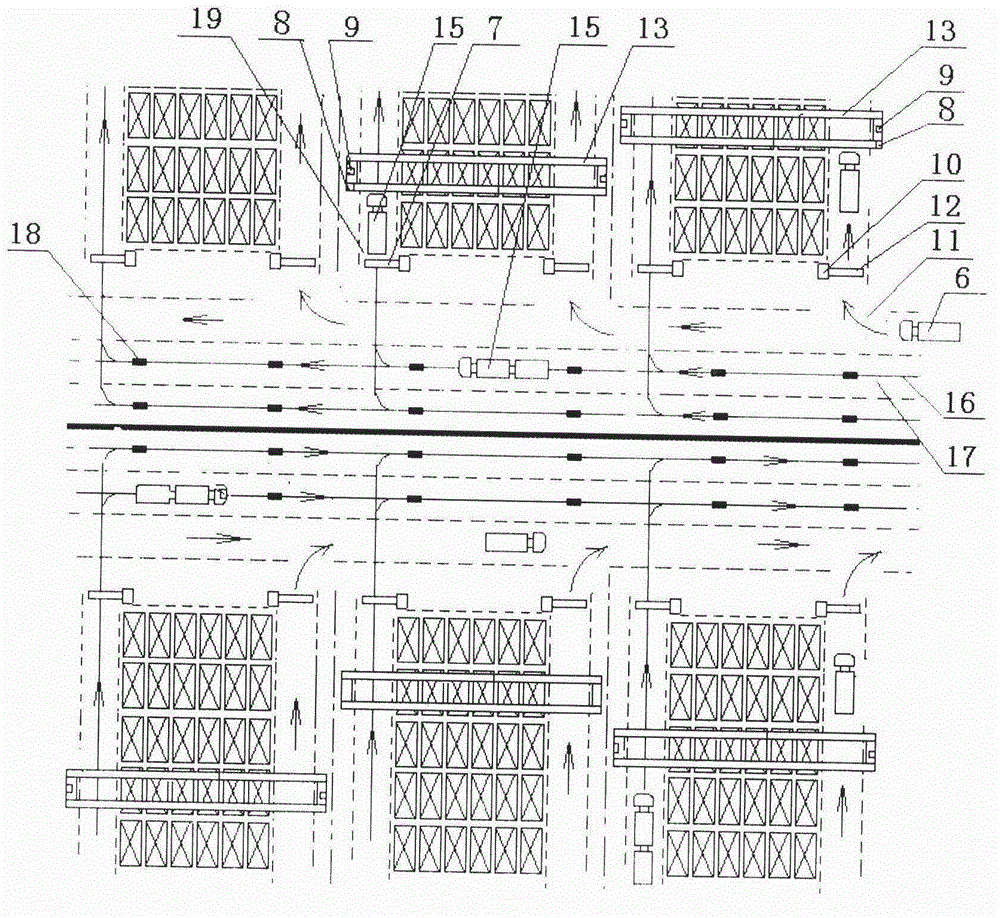

Container automated wharf loading and unloading system and method

InactiveCN104058261AAnti-collisionAvoid collisionStorage devicesPosition/course control in two dimensionsOn boardAutomated guided vehicle

The invention discloses a container automated wharf loading and unloading system and method. Containers on board are loaded or unloaded through a double-trolley and double-platform bridge crane; an automated guided vehicle refitted by a common truck, on which a metal magnetic detector, a GPS (global positioning system) reader-writer, a laser collision avoidance system and an image display system are arranged, travels along a metal enamel leading line through the metal magnetic detector; the GPS reader-writer reads radio frequency card address positions on the ground; the laser collision avoidance system and the image display system measure collision avoidance functions of people and objects; a rail tyre crane travels through rails when conveying the containers and travels through tyres during site changing; guide vehicle and outer truck lanes exist in a site and do not disturb each other; an outer truck is guided through the GPS reader-writer when entering a wharf; a common container wharf is transformed into a full-automatic container loading and unloading wharf through the equipment improvement.

Owner:NANTONG TONGLEI SOFTWARE

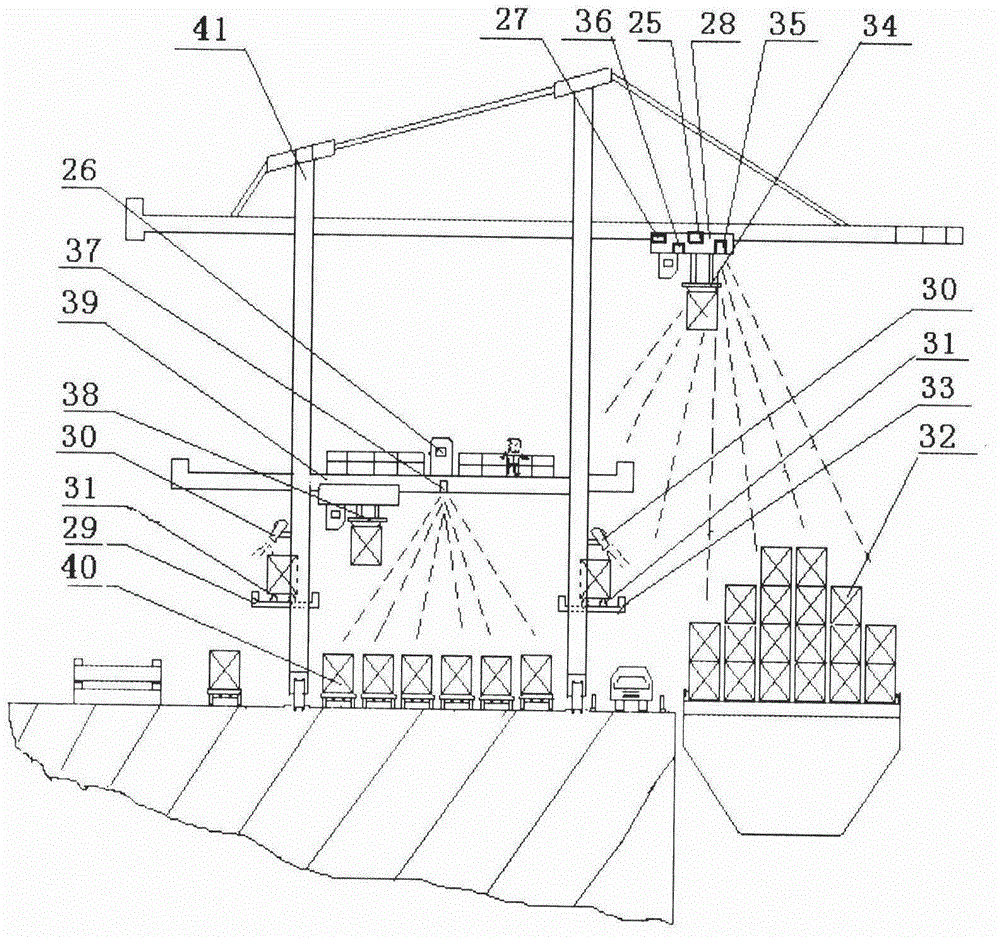

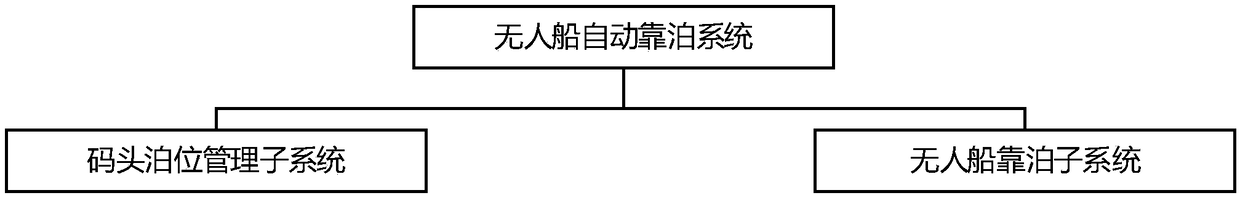

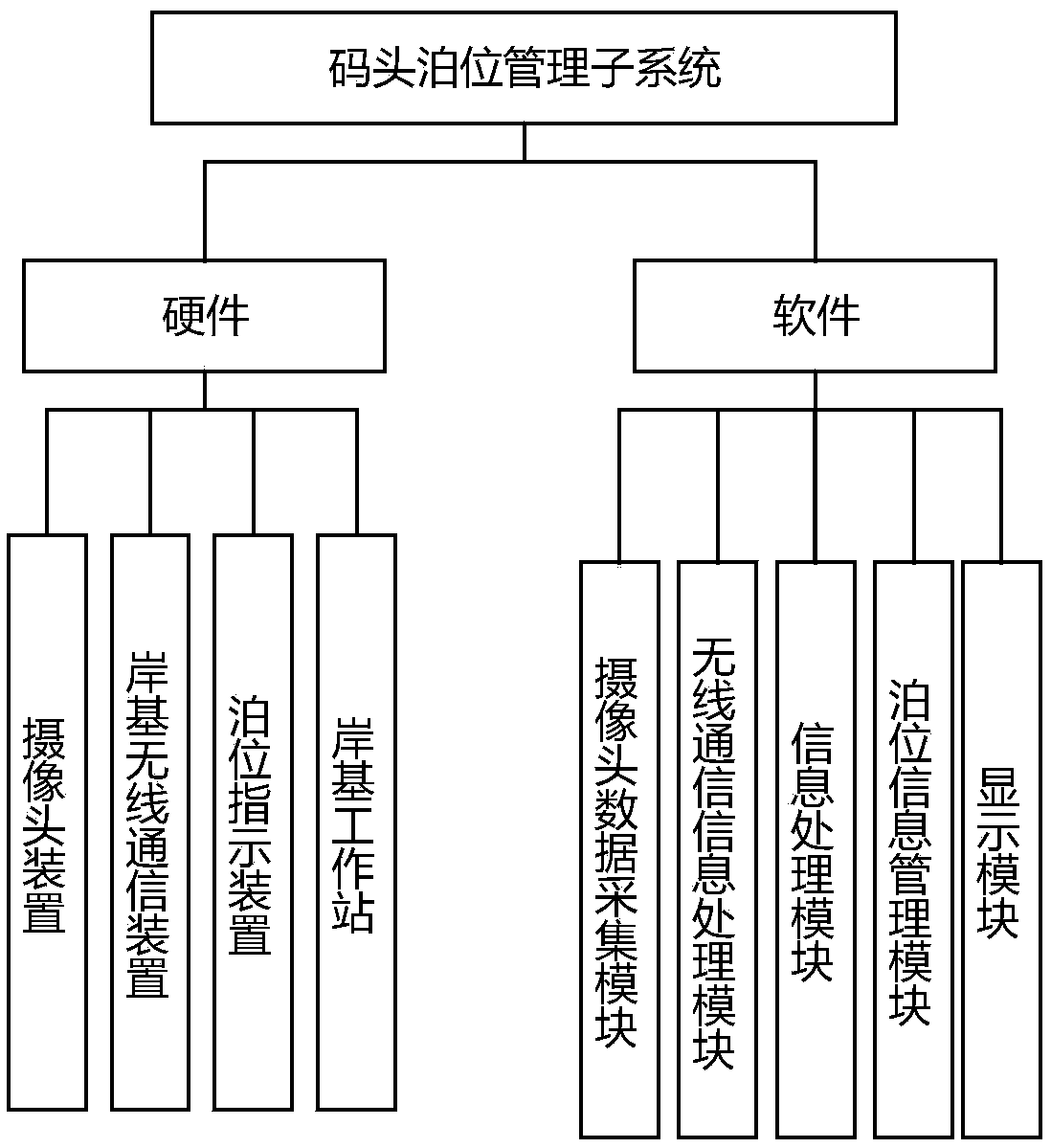

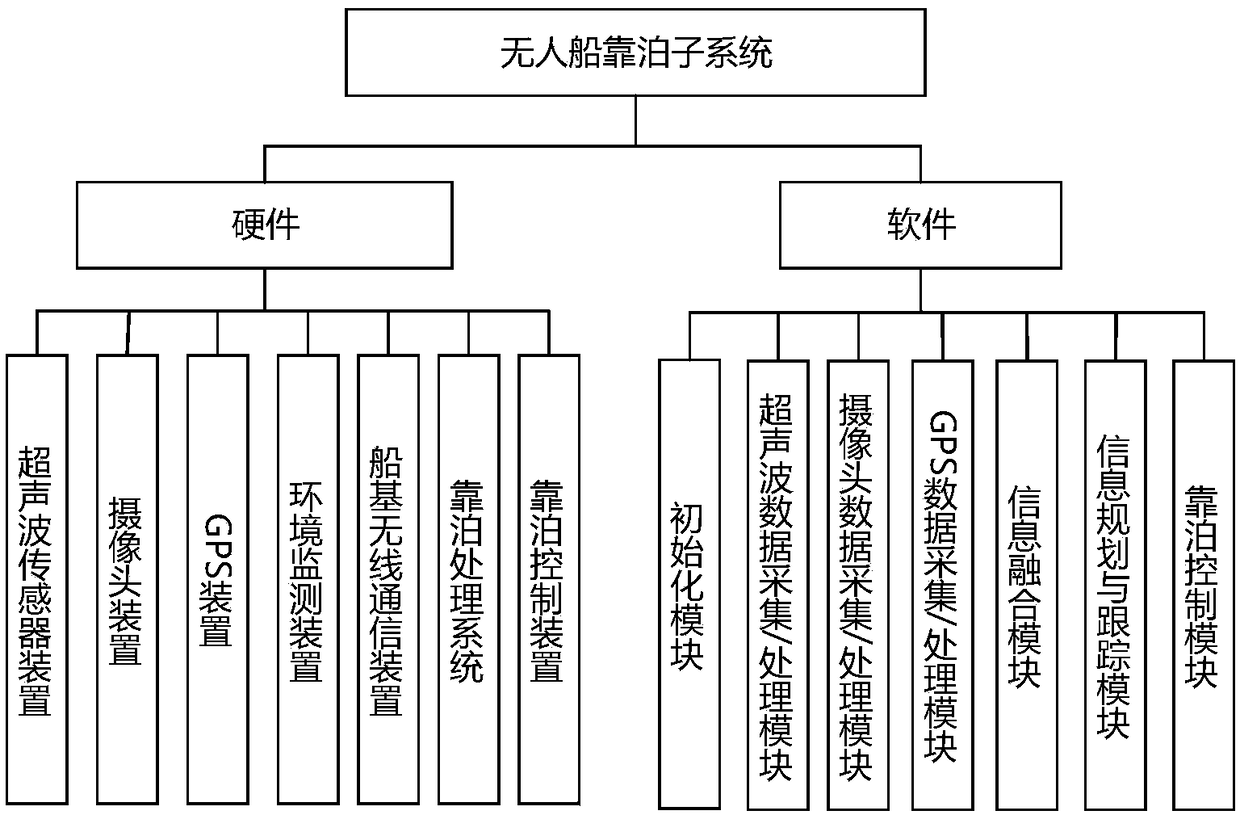

Automatic berthing system and method of unmanned vessel

ActiveCN109285389AEnsure safetyChange motion status in real timeMarine craft traffic controlInformation integrationAutomatic testing

The invention discloses an automatic berthing system and method of an unmanned vessel. The automatic berthing system comprises a quay berth management subsystem and an unmanned vessel berthing subsystem, wherein the quay berth management subsystem carries out automatic identification and management on berths according to image information collected by a camera, and performs data interaction with the unmanned vessel on the automatic berthing process through a wireless communication device; and the unmanned vessel berthing subsystem carries out information fusion processing on camera data, ultrasonic data, GPS data and environment monitoring data, and completes the automatic berthing process of the unmanned vessel by combining berth information received by a vessel-based wireless communication device. The automatic berthing system realizes automatic berthing of the unmanned vessel, has important significance for realizing the unmanned island-reef replenishment process, can effectively improve the safety of the island-reef replenishment process and the replenishment efficiency, and reduces the replenishment cost.

Owner:SHENYANG INST OF AUTOMATION GUANGZHOU CHINESE ACAD OF SCI +1

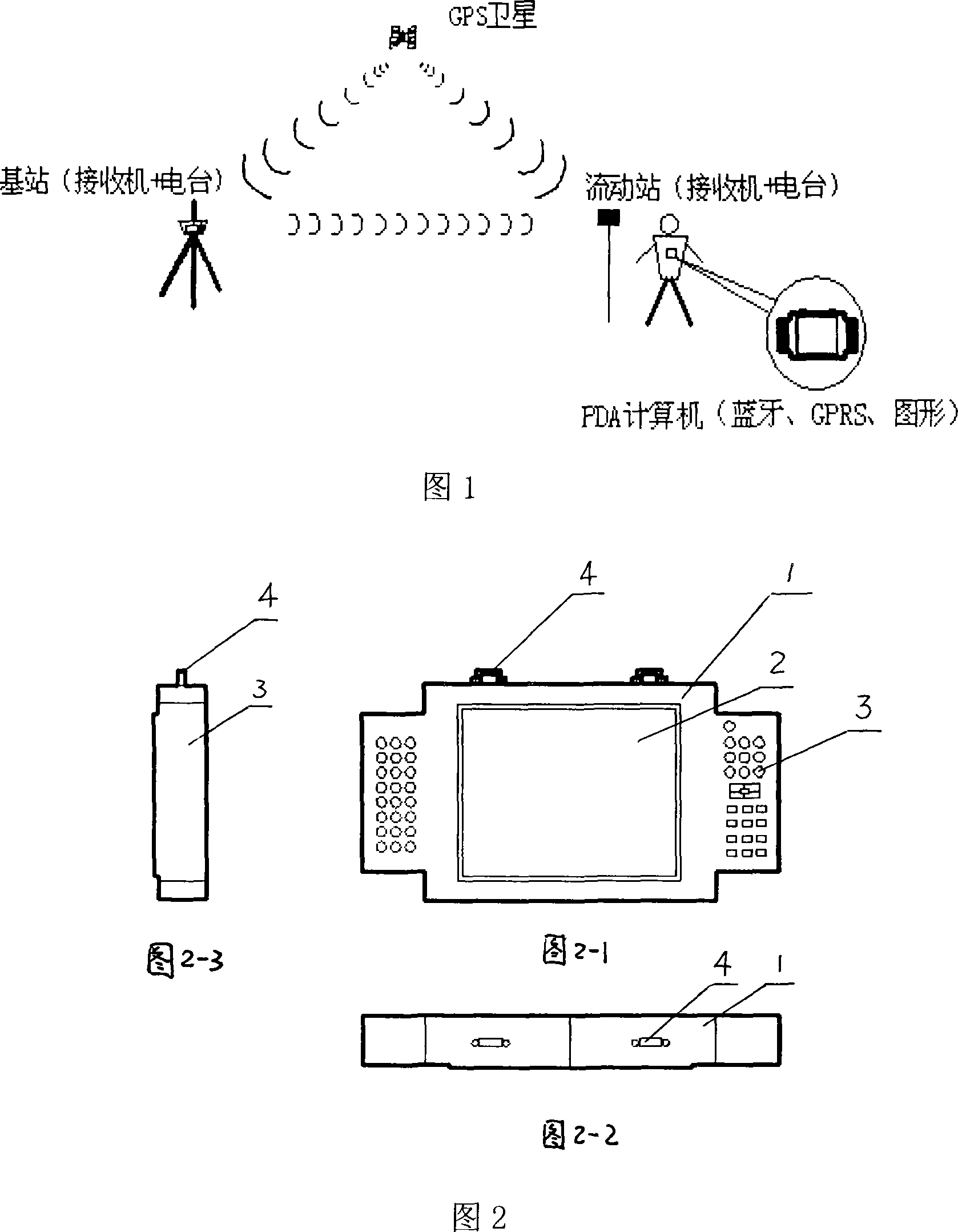

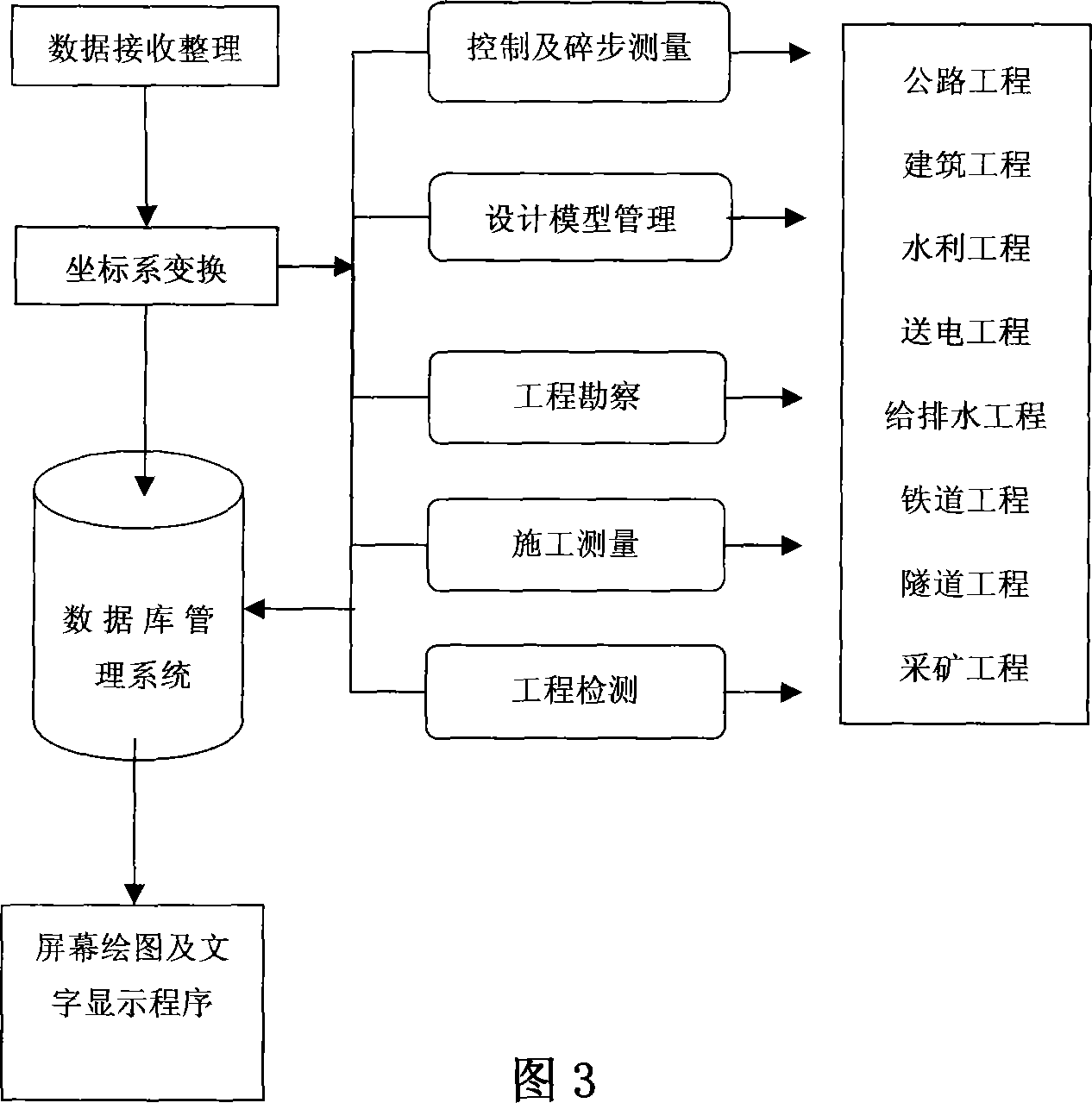

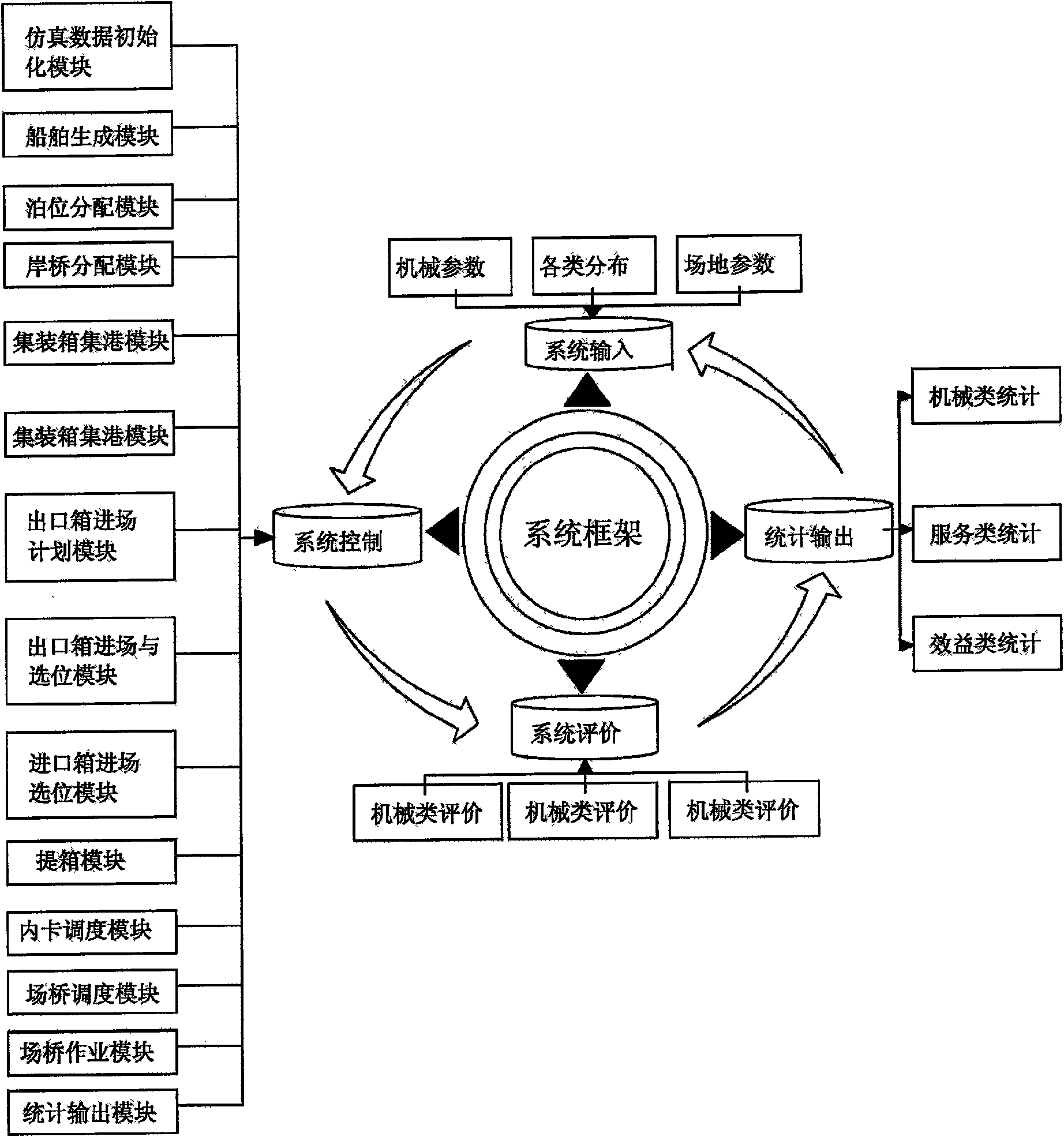

Civil construction engineering GPS-RTK measurement integrated PDA device

InactiveCN101158993AAvoid wasteful situationsImprove work efficiencyTransmission systemsPosition fixationSoftware systemData acquisition

The invention discloses a PDA device of civil and architectural engineering GPS-RTK measurement integration, which is a PDA computer used for GPS-RTK data collection and processing and applied to civil and architectural engineering. The hardware in the PDA computer comprises a display, press keys and hanging parts, a host chip equipped inside the body with a dominant frequency above 400MHz, a bluetooth module and a GPRS module, a built-in data transmission antenna and a power supply; a built-in software system in the PDA computer integrates the data collection, processing, application and transmission of GPS-RTK, which greatly enhances operation efficiency and reliability, directly accomplishes the tasks like design and survey, construction survey, and geometric detection etc. of normal civil engineering (including highways, railways, port terminals, city roads and pipe network, hydropower project and so on), does not need the prior fractional work such as data downloading, indoor processing, outdoor surveying and designing etc., and obviously enhances the operation efficiency of civil engineering measurement.

Owner:CHONGQING JIAOTONG UNIVERSITY

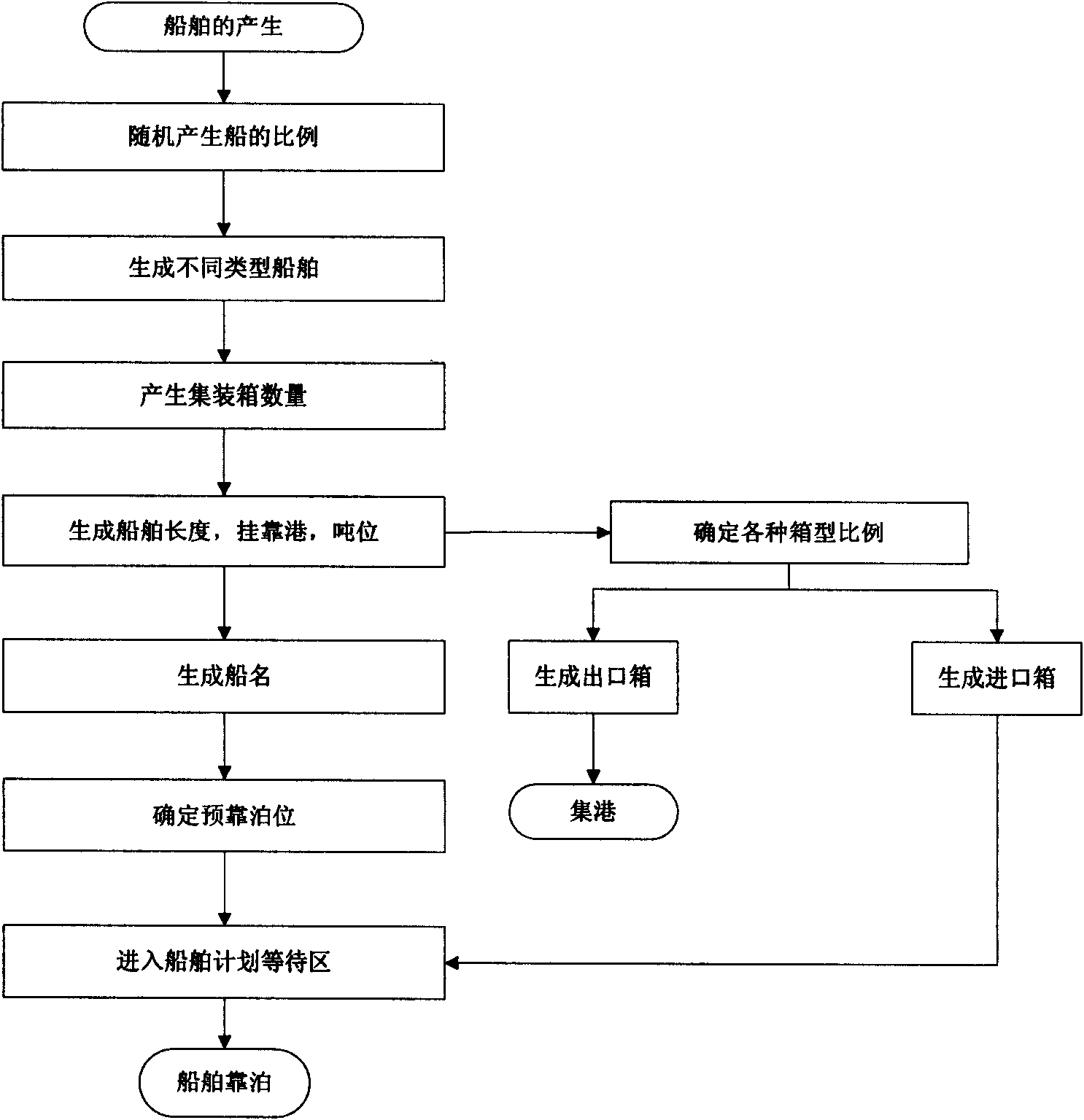

Container terminal yard optimization system

The invention discloses a container terminal yard optimization system. The system consists of a system input module, a system control module, a system evaluation module and a statistics output module, wherein the system control module performs all production scheduling of container terminals according to mechanical parameters and various types of distribution / site parameters input by the system input module, and transmits various produced data into the system evaluation module for machinery evaluation, service evaluation and effectiveness evaluation, and the data are also subjected to machinery statistics, service statistics and effectiveness statistics through the statistics output module. The system solves the problems that operation conflict causes uneven busy / idle degrees of machinery and low efficiency of the terminals, and the like, and realizes the smallest number of overstock containers in yards, the lowest container turnover rate and high working efficiency.

Owner:SHANGHAI MARITIME UNIVERSITY

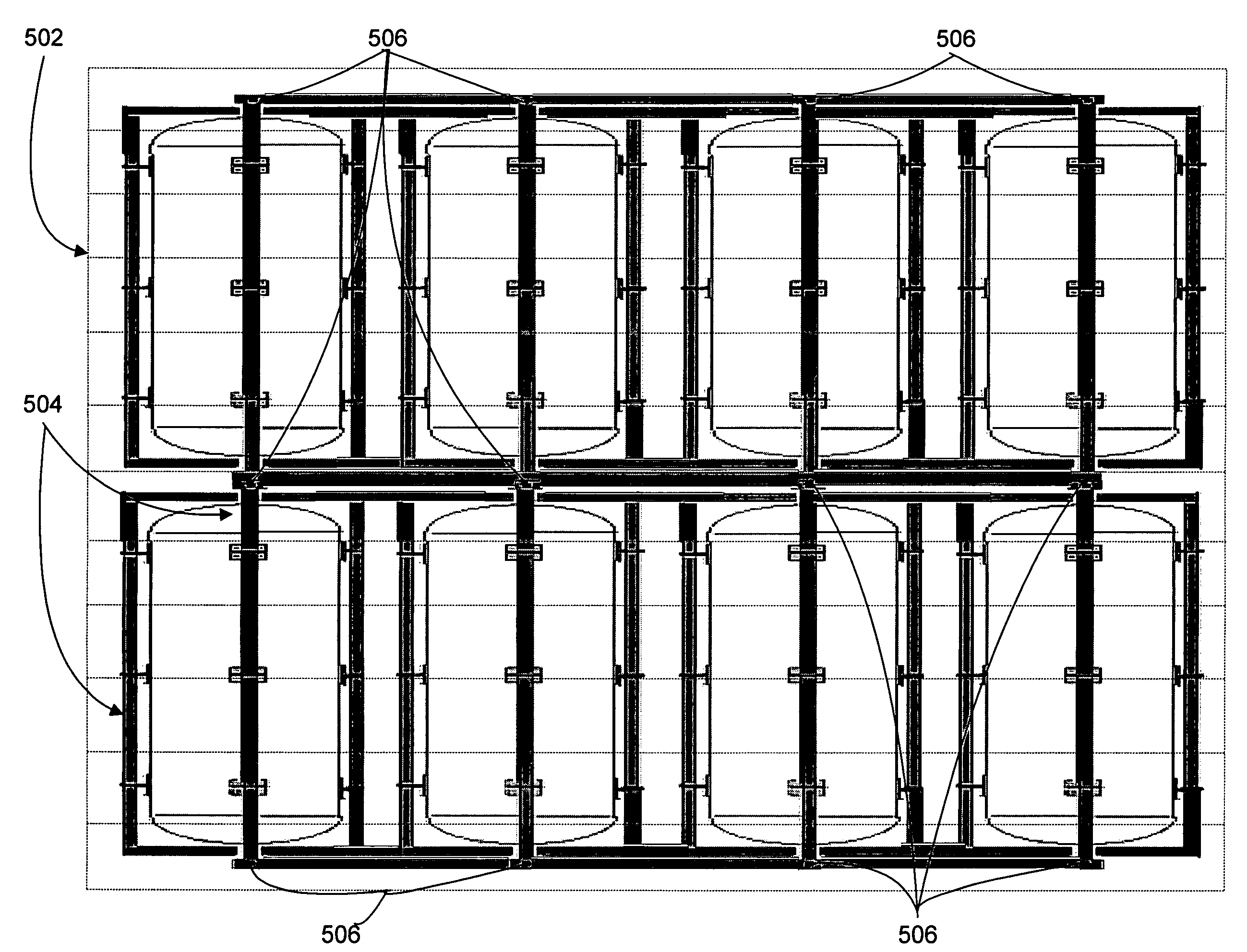

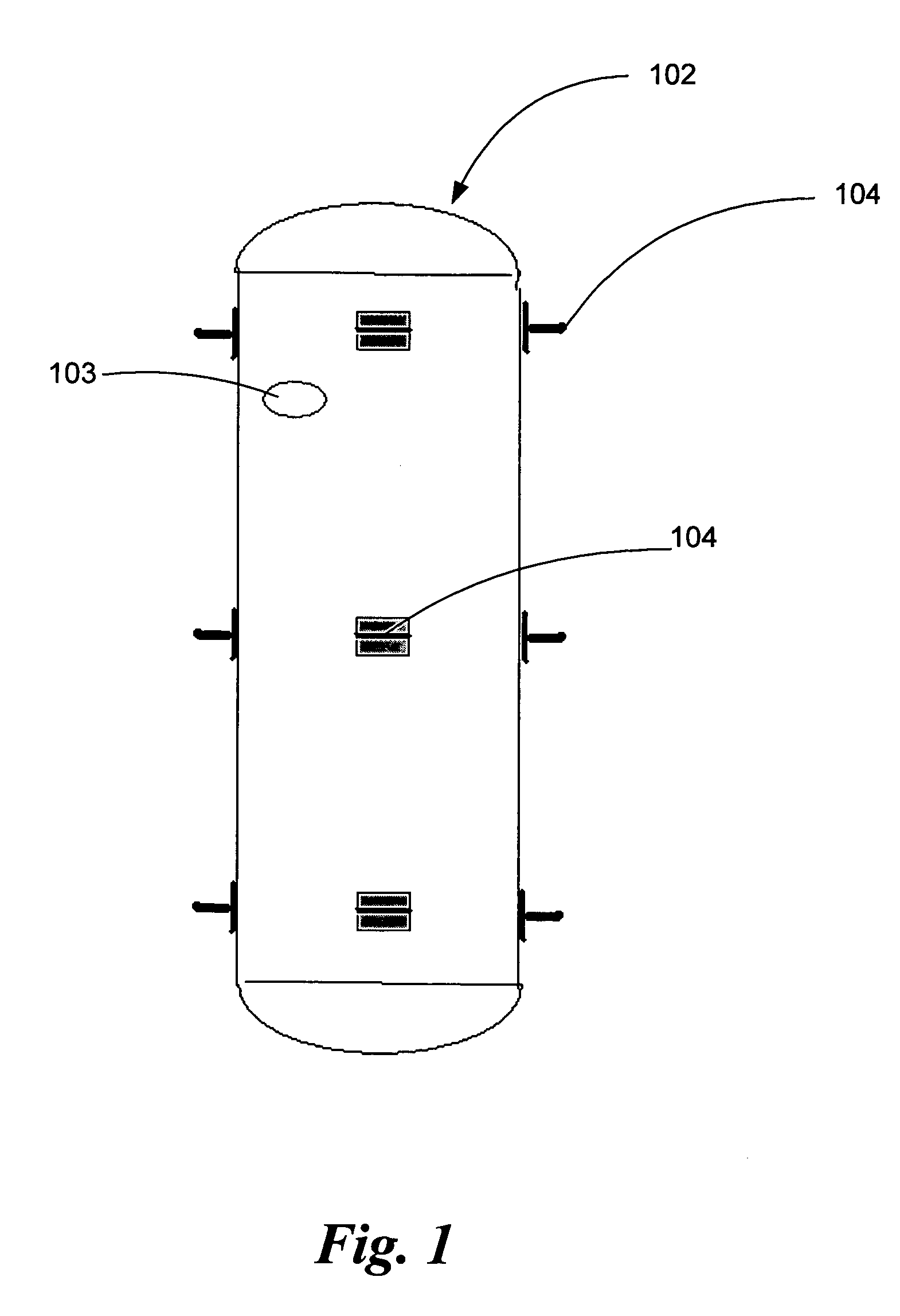

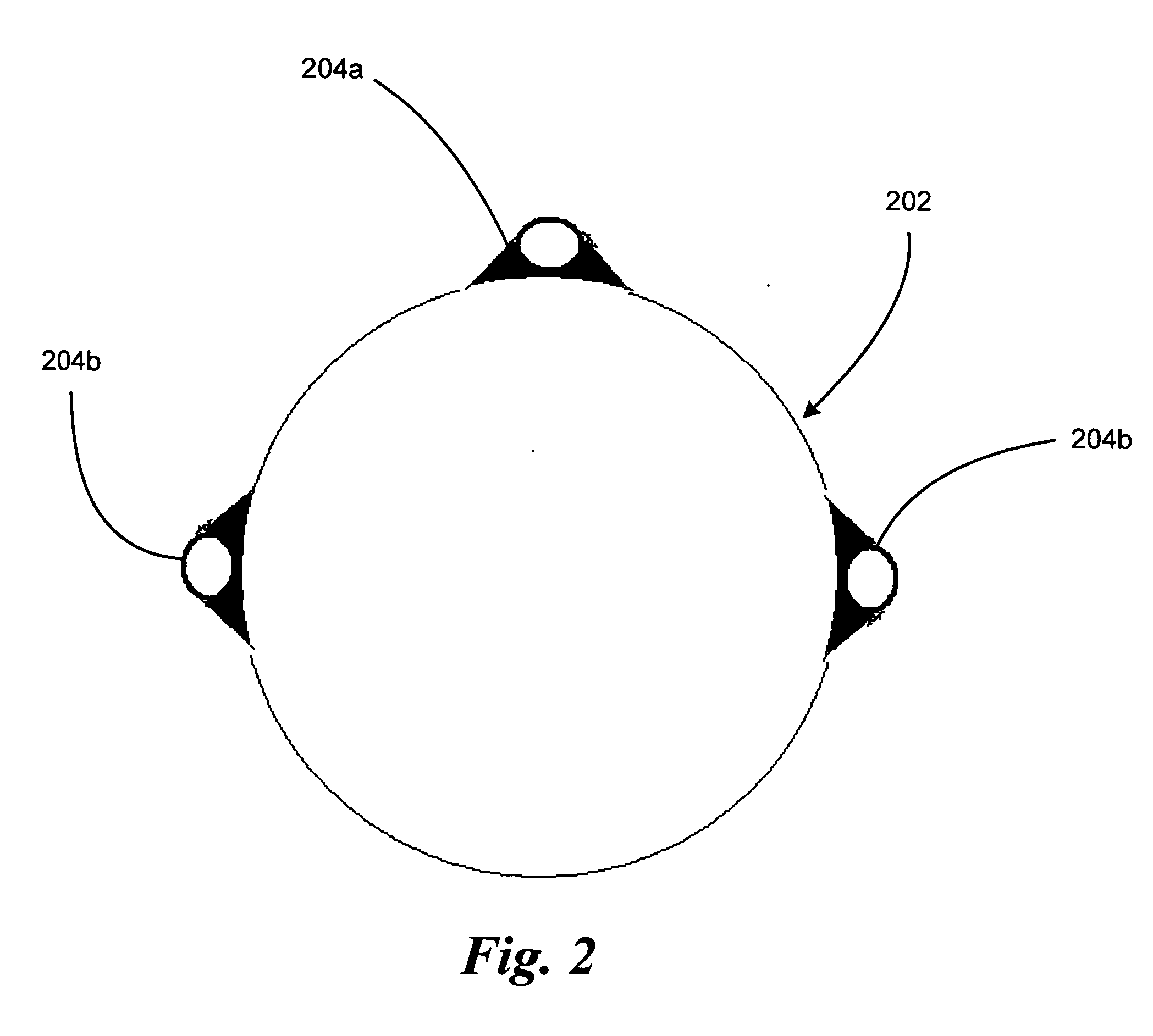

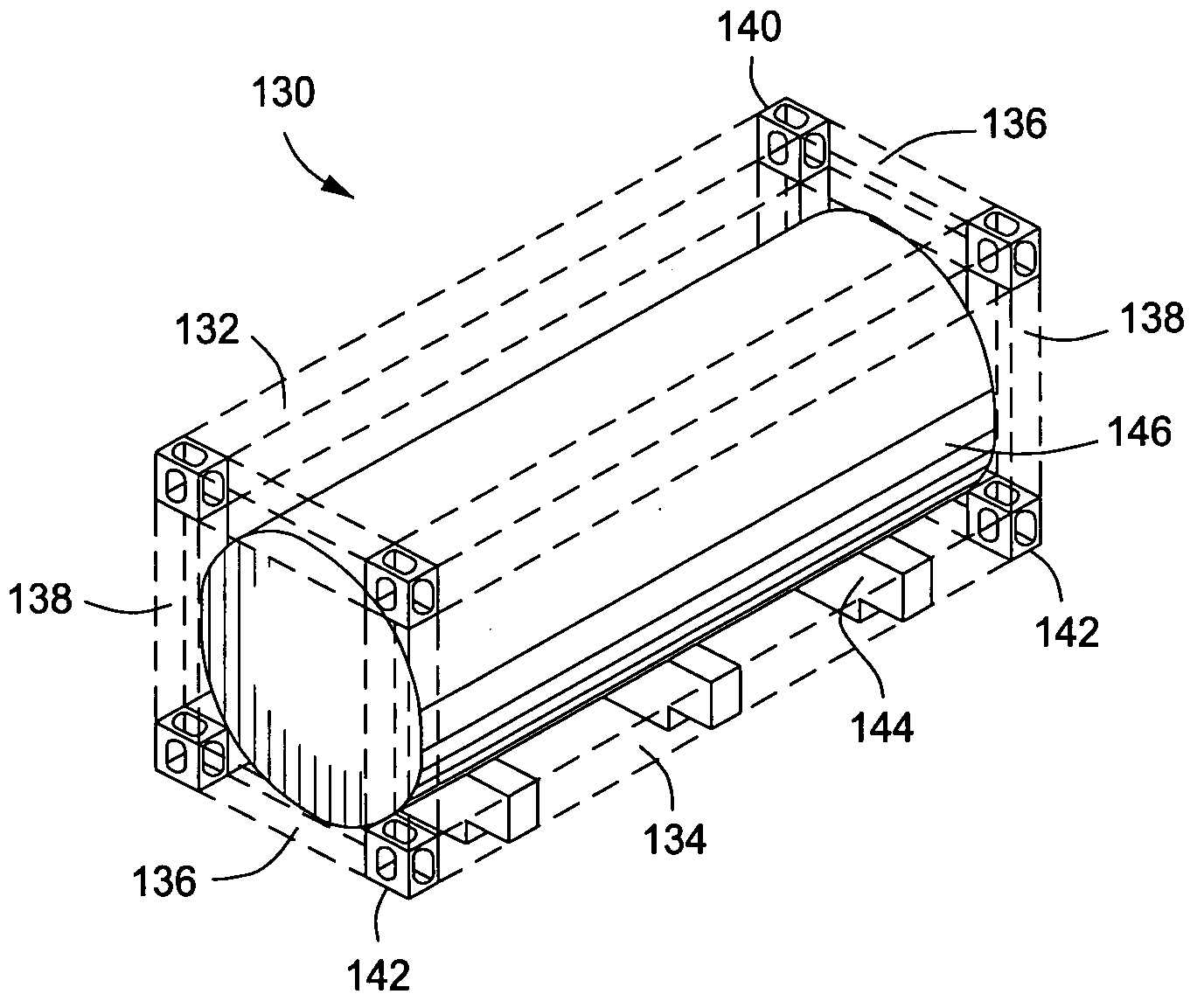

Modular tank unit for ship, barge and rail transportation

InactiveUS20090134171A1Easily and simply installedEasily and simply and removedLarge containersClosures to prevent refillingParticulatesReceiving facility

A modular tank unit for utilizing vessels of opportunity to serve as carriers for transportation and handling of specialty liquids or flowable particulate products or to serve as a terminal ashore receiving and dispensing to truck, rail, barge or other receiving facilities. The modular tank unit has a rectangular intermodal framework of predetermined dimension and tare weight permitting its transportation by cargo vessel, hopper barge and by rail for positioning inland or at shore facilities. A tank may be adapted for other modes of transportation and may be removably secured within the rectangular framework. The modular tank unit in its smaller dimension can be transported empty by rail and can be positioned in the field by portable crane. The modular tank unit defines a pump compartment having a pumping and draining manifold and portable pump and valve assembly for fluid handling, enabling the modular tank unit to be “active” for power energized pumping or “passive” for gravity discharge.

Owner:DEBERARDINIS NICHOLAS W

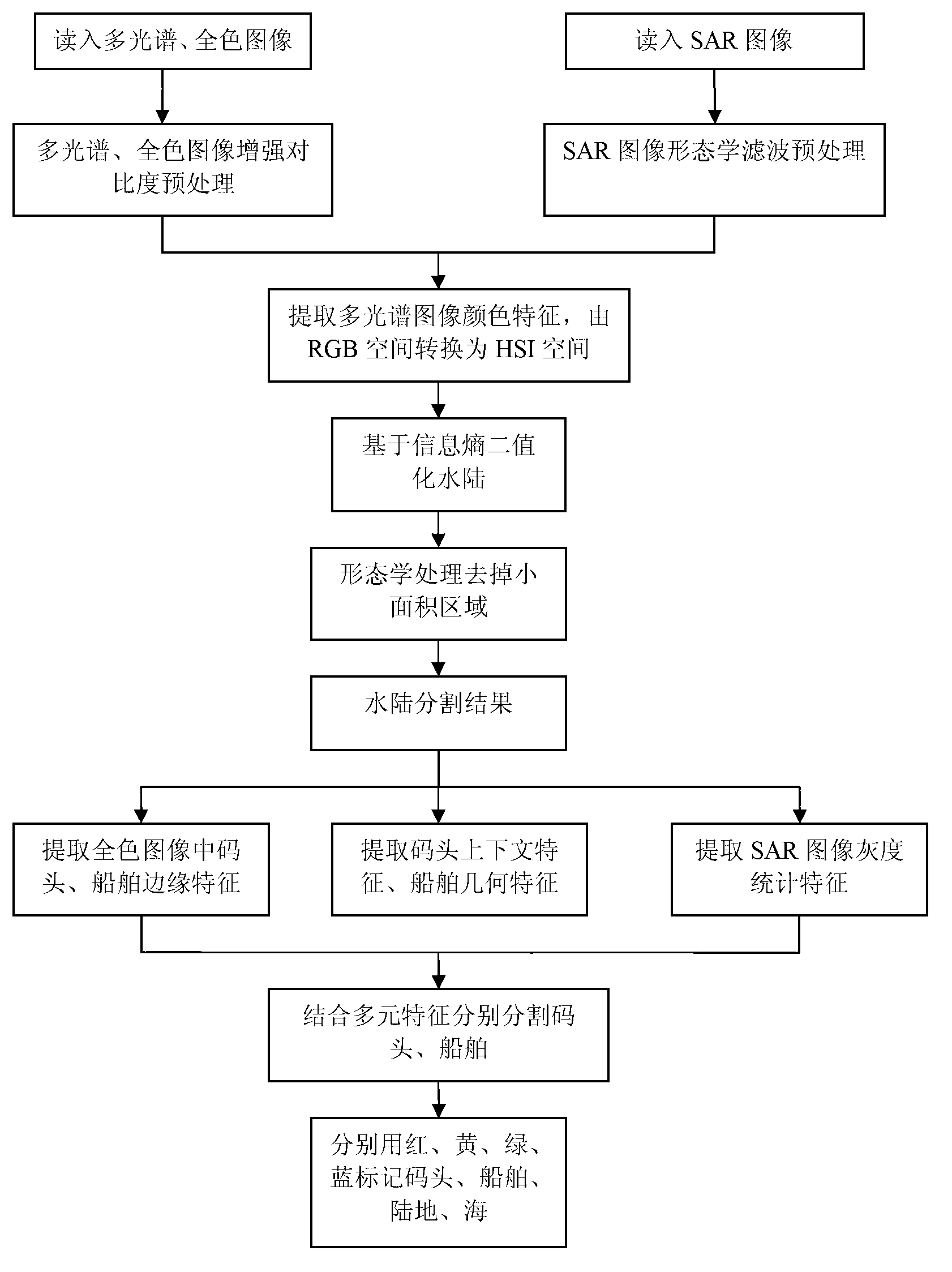

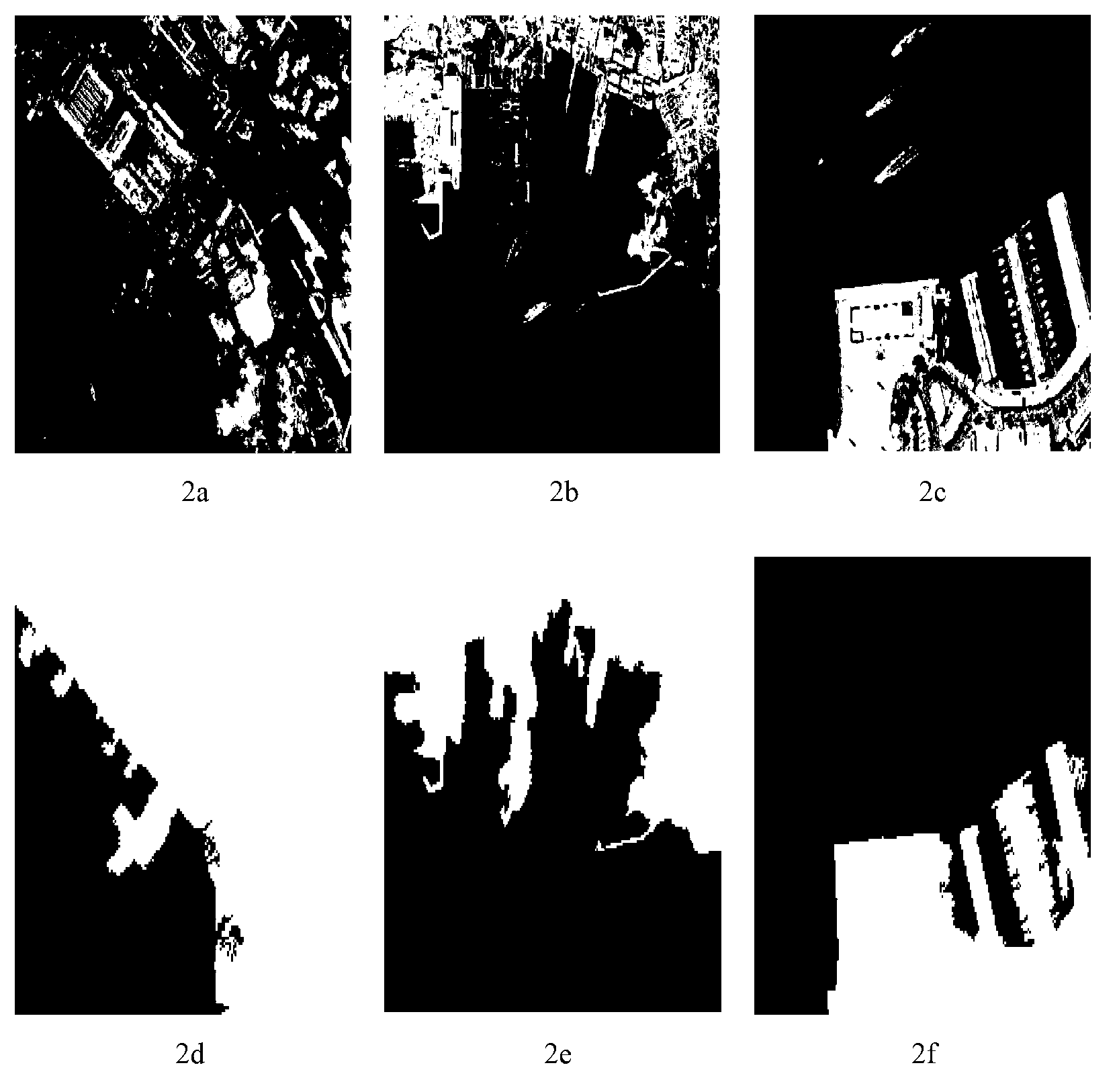

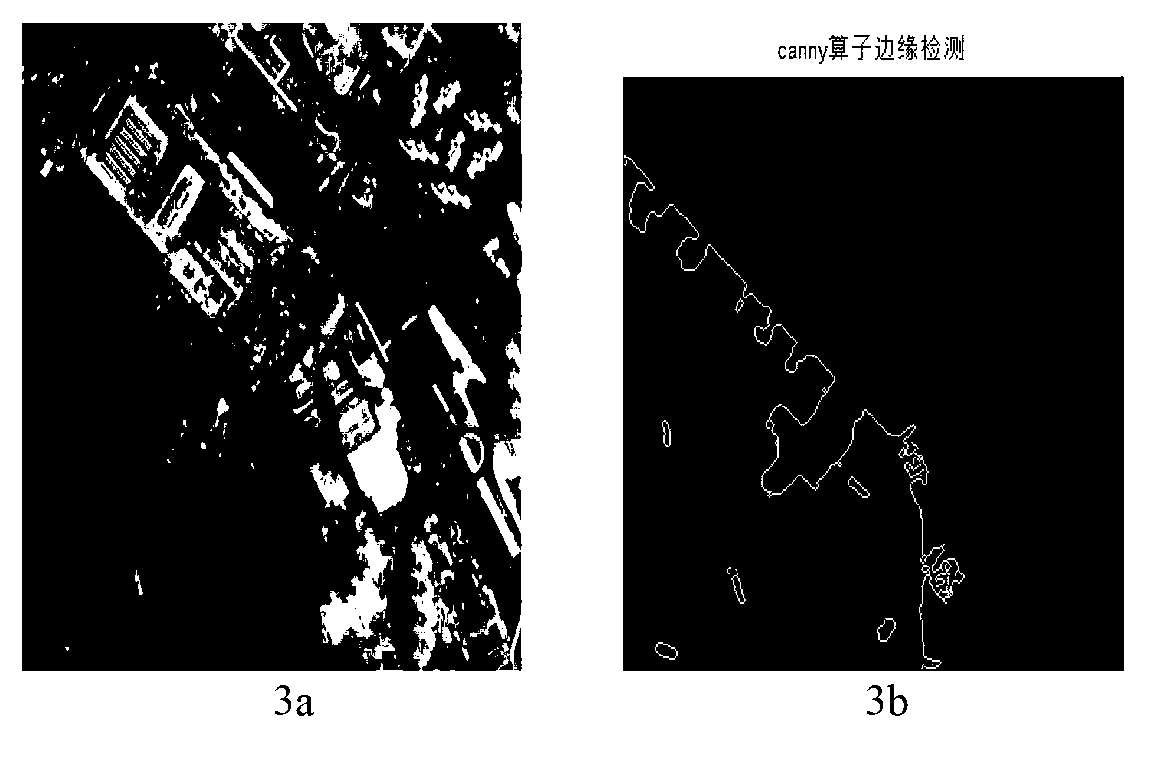

Multisource remote sensing image characteristic combined wharf and ship partition method

InactiveCN103020975AImprove universalitySimple procedureImage analysisGray levelSynthetic aperture radar

The invention discloses a multisource remote sensing image characteristic combined wharf and ship partition method. The method includes the steps: reading a multispectral image, a full-color image and an SAR (synthetic aperture radar) image; preprocessing the three images; converting the multispectral image from an RGB (red, green and blue) space into an HIS (hue, saturation and intensity) space, and subjecting land and water to binarization based on information entropy; morphologically processing to remove a small area to obtain a water and land partition result, wherein the white portion is the land, and the black portion is the water area; for the full-color image, extracting edge features of the wharf and the ship, and extracting context features of the wharf and geometric features of the ship; for the SAR image, extracting gray level statistical characteristics of the wharf and the ship; partitioning the wharf and the ship according to the multi-element characteristics extracted from the SAR image; and subjecting the final partitioned image to color marking. The wharf and the ship are partitioned by making full use of the multi-element characteristics of the multi-source images, more target information is obtained by the aid of complementarity of the different types of remote sensing images, and consequently, accuracy in partition of the wharf and the ship is improved.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY +1

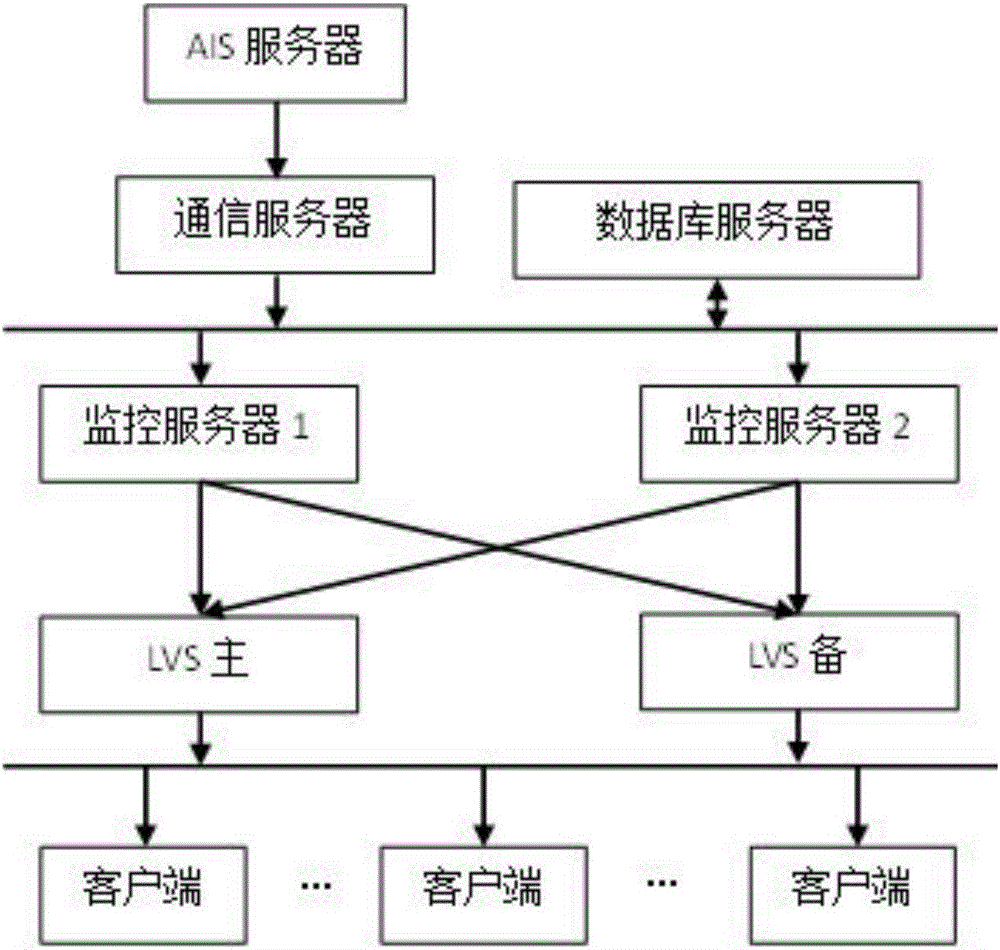

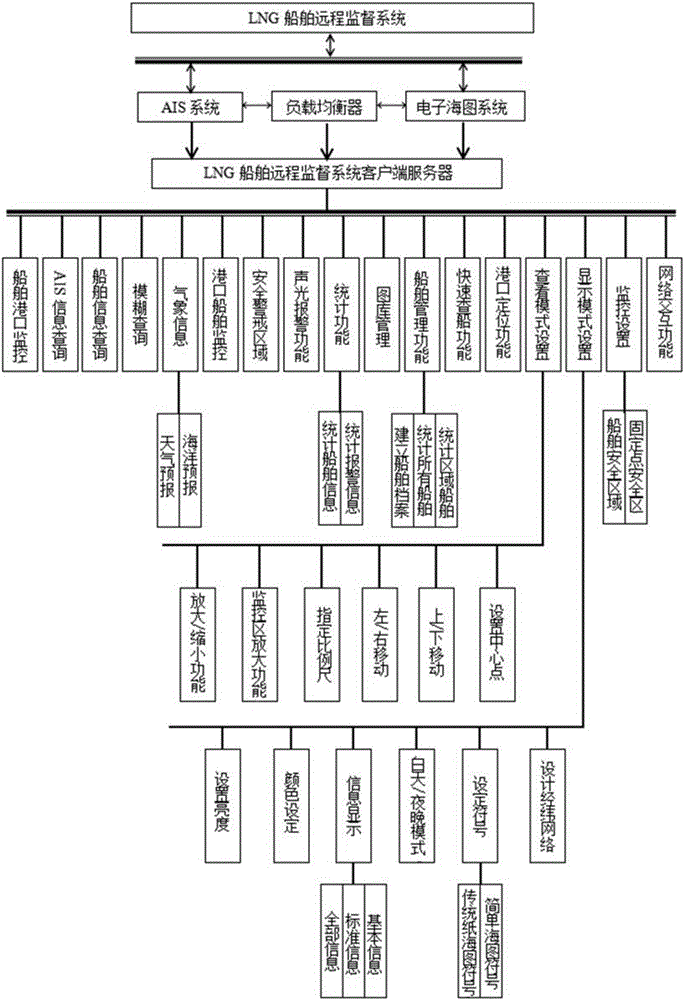

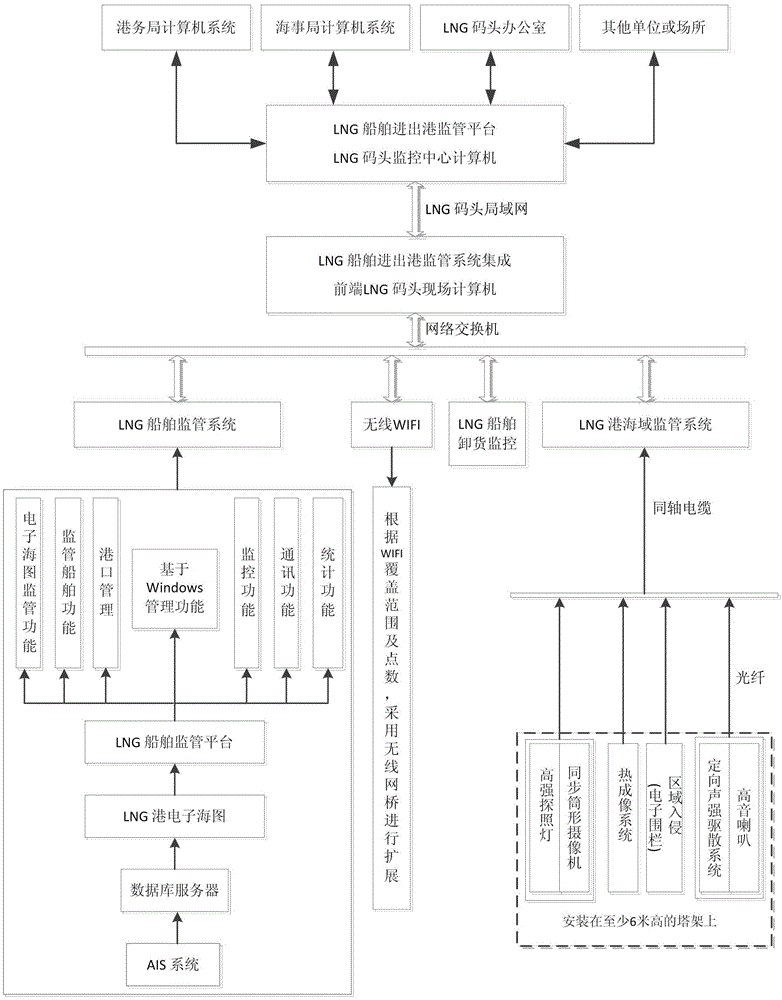

LNG ship remote monitoring system

PendingCN106845875ARealize real-time dynamicCollaborateSatellite radio beaconingResourcesMonitoring systemRights management

The invention discloses an LNG ship remote monitoring system. An AIS system of an LNG ship supervision platform is used for analyzing an AIS message to obtain information of a supervised ship so as to position the supervised ship, and a ship position is displayed through an electronic chart system; corresponding supervision data and query statistical information of the ship are displayed for people with different permissions at a client based on the permission management. The system disclosed by the invention integrates an information technology, a networking technology, an intelligent technology and a visualization technology, can cover the whole LNG ship and a sea area in an LNG wharf to perform the remote monitoring on the LNG ship, thereby achieving aims of remote visualization monitoring, information acquisition, paperless office, and all-weather supervision; the problems of insufficient functions of traditional monitoring equipment, difficulty in performing automatic evaluation on navigation safety of the LNG ship, the risk source certification and analytic hierarchy method of LNG ship berthing and departing and unloading job, and fuzzy comprehensive evaluationare solved, and the interconnection and intercommunication among port and waterway, pilotage, port control and maritime affairs departments, an LNG receiving station and the like can be effectively realized.

Owner:中华人民共和国青岛海事局 +1

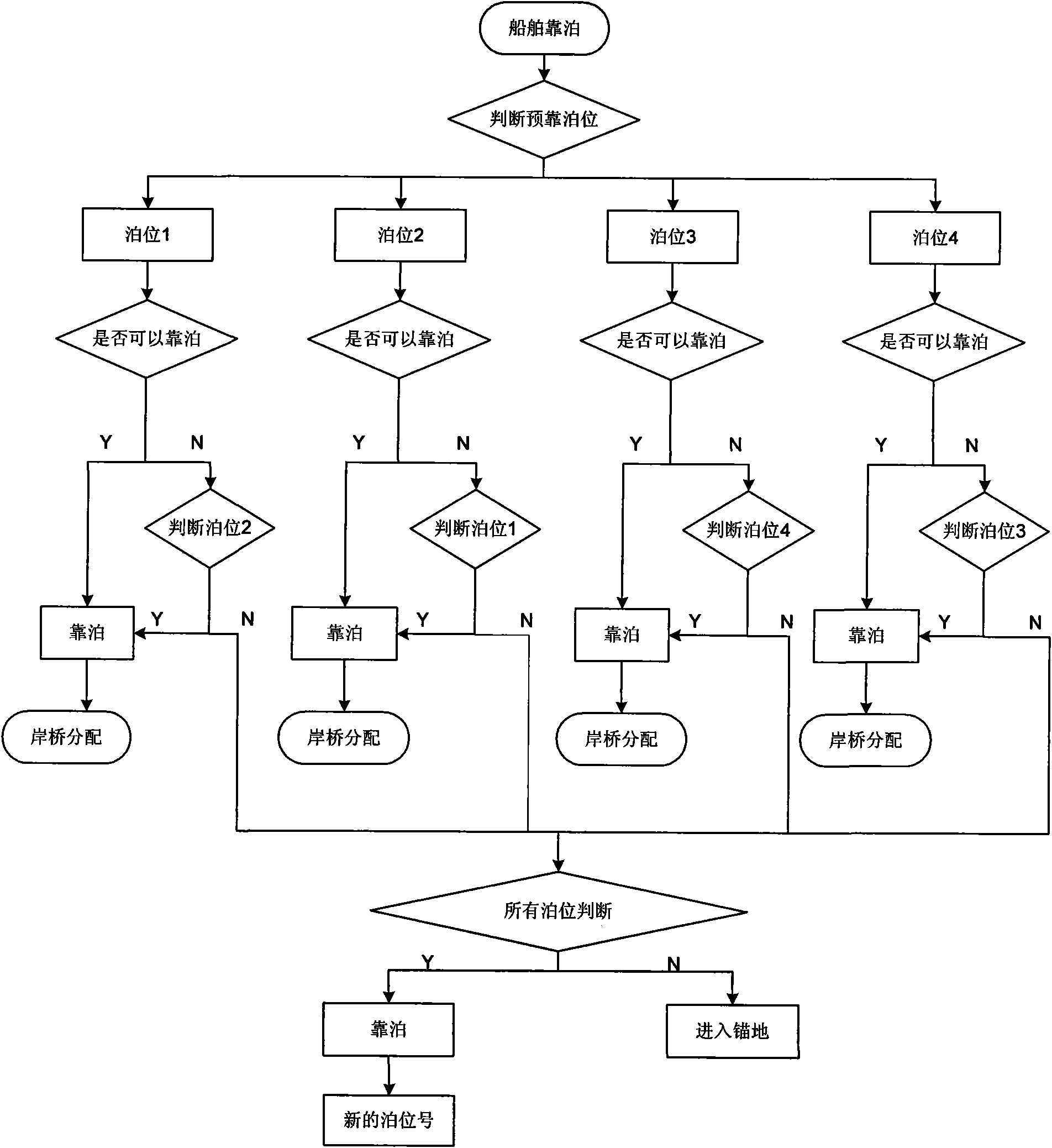

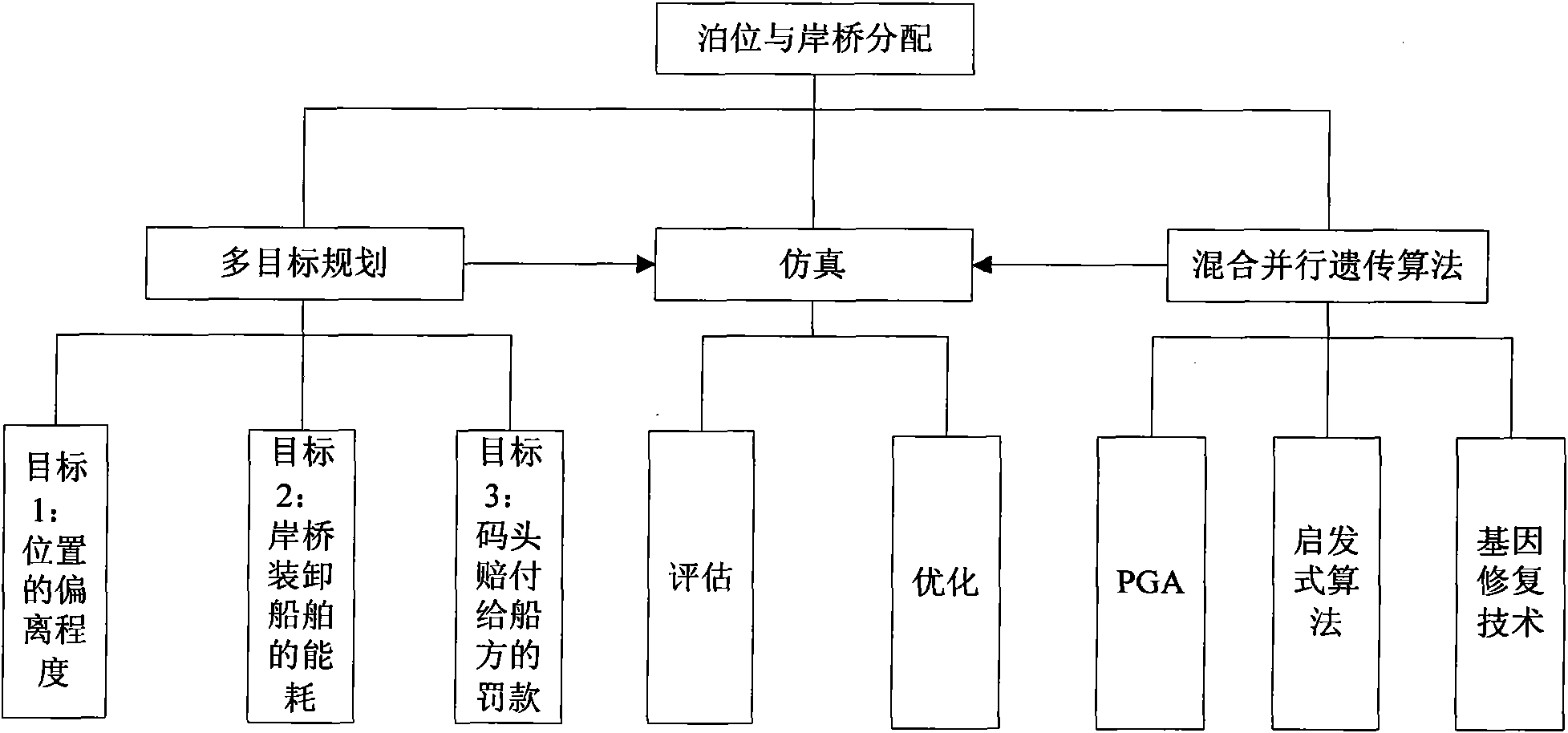

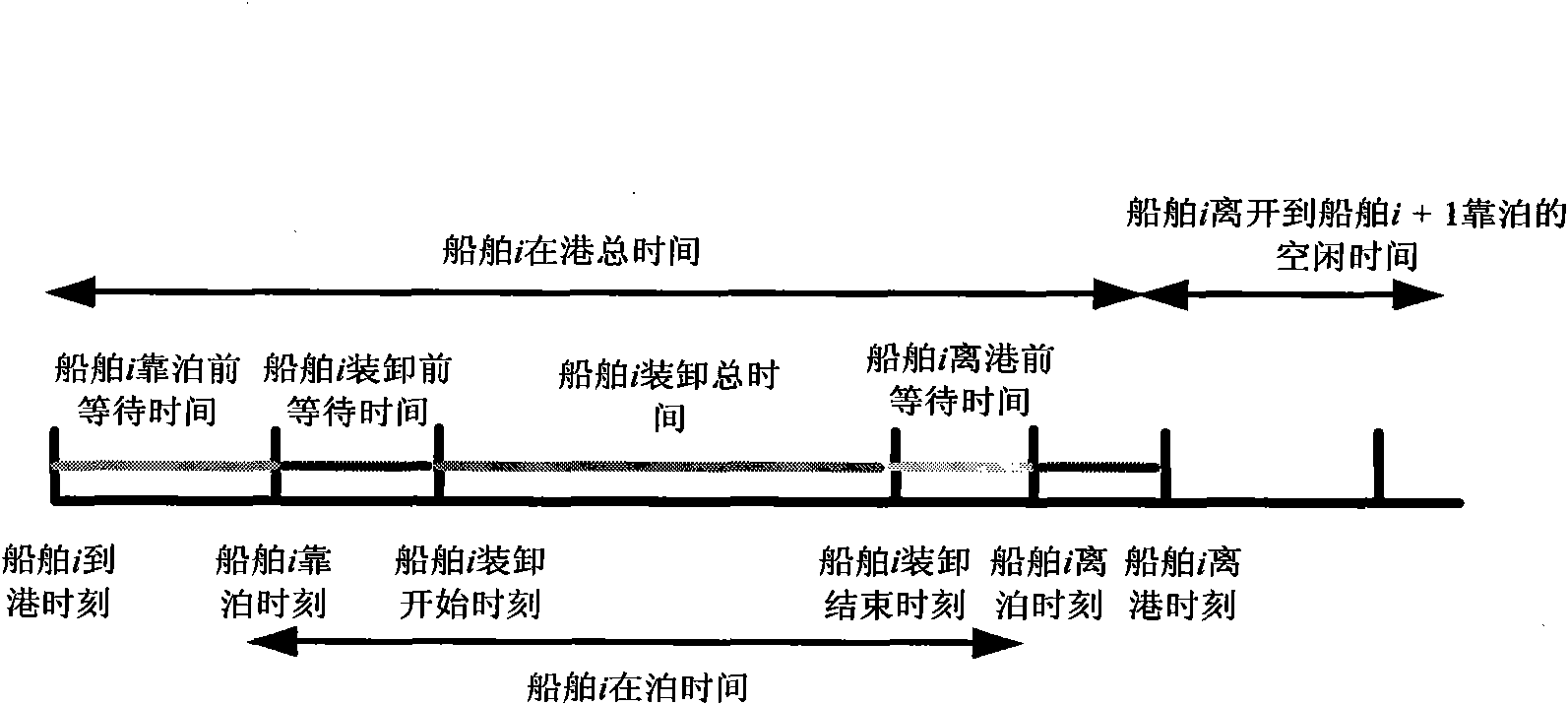

Distribution method of container quay berths and shore bridges

InactiveCN101789093AGlobal optimization is beneficialReduce loading and unloading energy consumptionForecastingDistribution methodPerformance index

The invention provides a distribution method of container quay berths and shore bridges. By adopting a rolling type plan distribution method, berth and shore bridge distribution models based on multi-objective planning are constructed; the models are based on a continuous quay wall line and are more closer to the actual berth conditions of a quay; a hybrid algorithm on the basis of combining a heuristic algorithm and a parallel genetic algorithm is adopted, and the performance of the hybrid algorithm is evaluated by a distribution simulation system of the container quay berths and the shore bridges; when a berth and shore bridge distribution scheme is generated, the simulation system simulates the distribution scheme, acquires corresponding performance indexes, compares with other schemes, and determines whether the scheme is better; and a method combining simulation and a gene repair technology is adopted to repair infeasible schemes, thereby being favorable for reducing the time in port of a ship, and reducing the horizontal transport distance when the ship is loaded or unloaded, the energy consumption of the shore bridges, and the fine that the quay pays to a ship owner, and further reducing the loading and unloading cost on the quay, improving the service quality of the quay and realizing the purpose of the invention.

Owner:SHANGHAI MARITIME UNIVERSITY

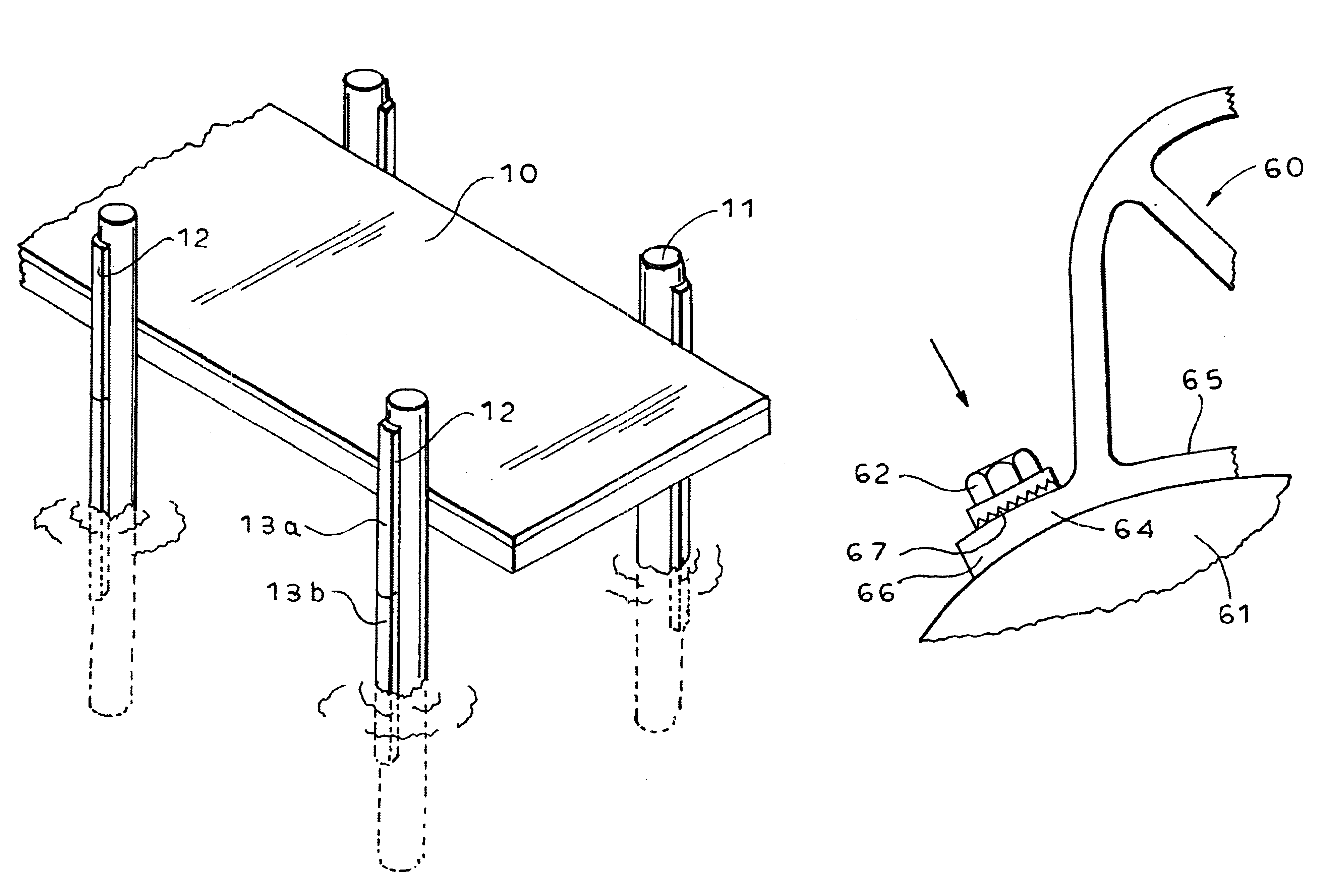

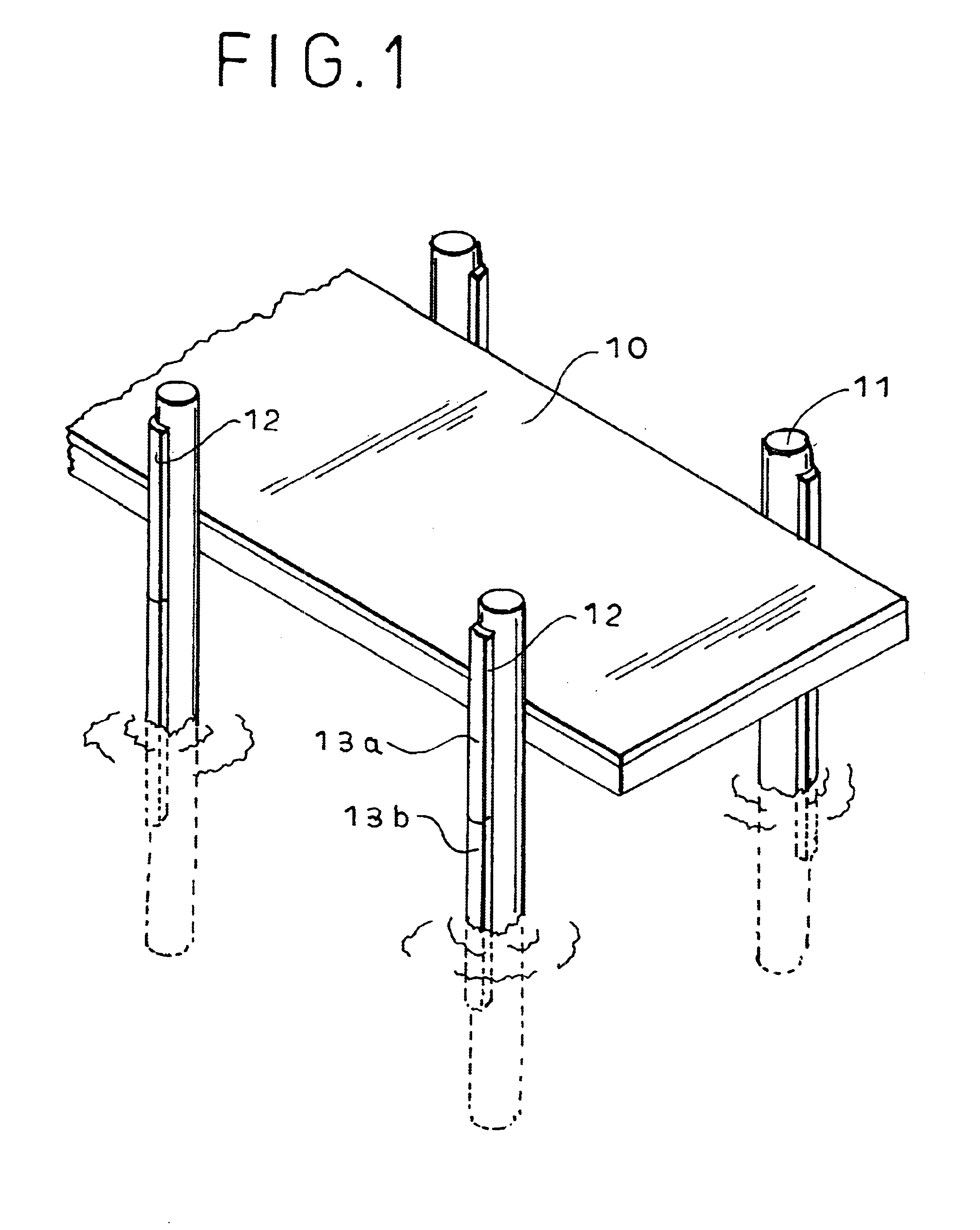

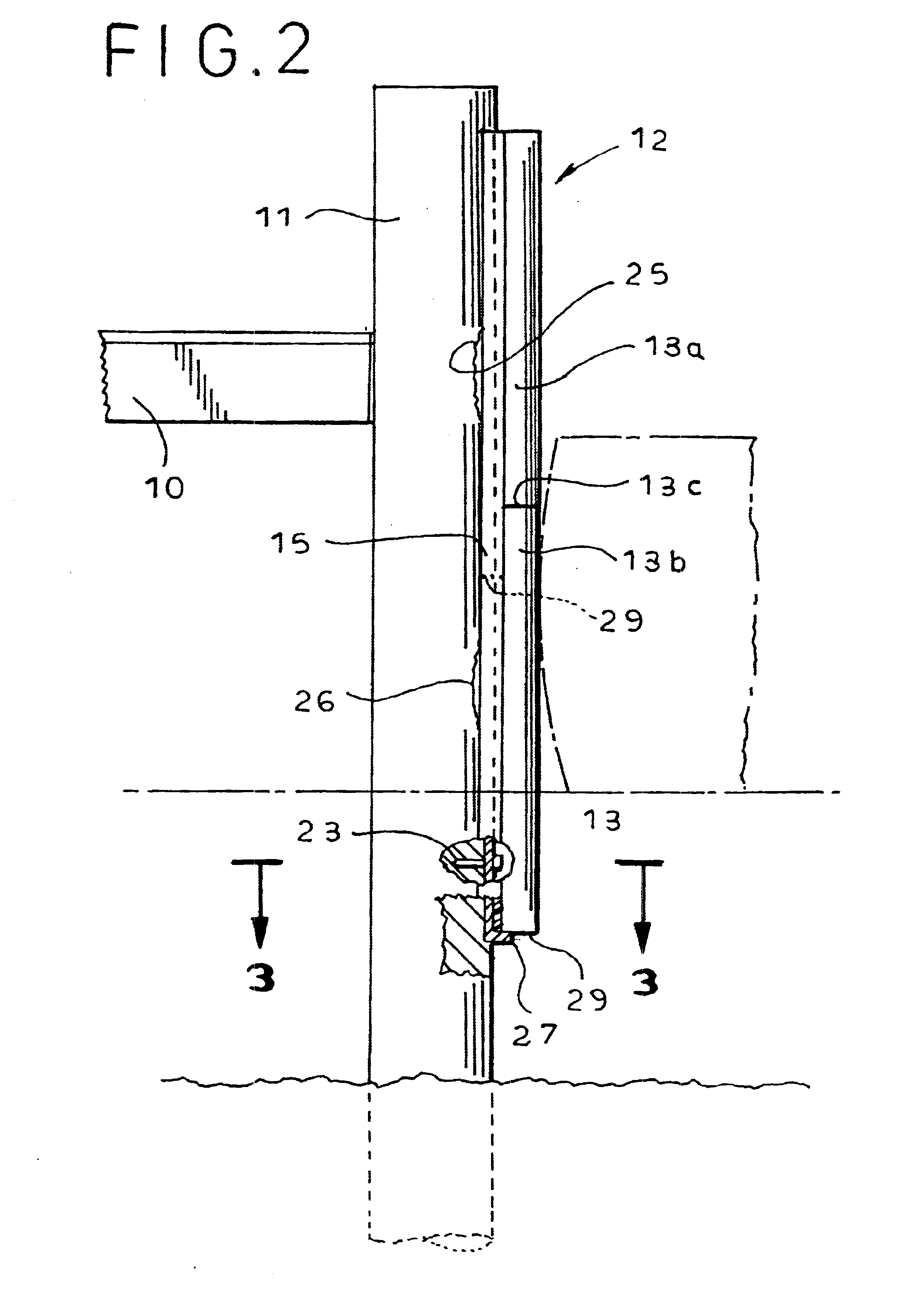

Piling fender

InactiveUS6685395B1Neat and clean and uniform appearanceVessel cleaningClimate change adaptationCushioningEngineering

A dock fender, particularly for attachment to the outer face of a dock piling for cushioning vessels attached to the dock. The fender is of extruded construction, having laterally extending flanges which are conformable to the surface of the pilings. The fender is attached to the piling by lag screws applied to the flanges. Special washers, of rectangular configuration, are provided to underlie the heads of the lag screws. The washers are formed with anti-rotation means such that, after initial proper alignment of the washers with the fender flanges, the washers will retain such orientation during rotational tightening of the lag screws. In one form, the anti-rotation means comprises bent corners of individual washers. In another form, the washers are of a length to engage more than one lag screw.

Owner:PAWLING ENGINEERED PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com