Container automated wharf loading and unloading system and method

A loading and unloading system and container technology, applied in storage devices, transportation and packaging, two-dimensional position/channel control, etc., can solve problems such as high transportation costs, low loading and unloading efficiency, and no precedent for automatic navigation of trucks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

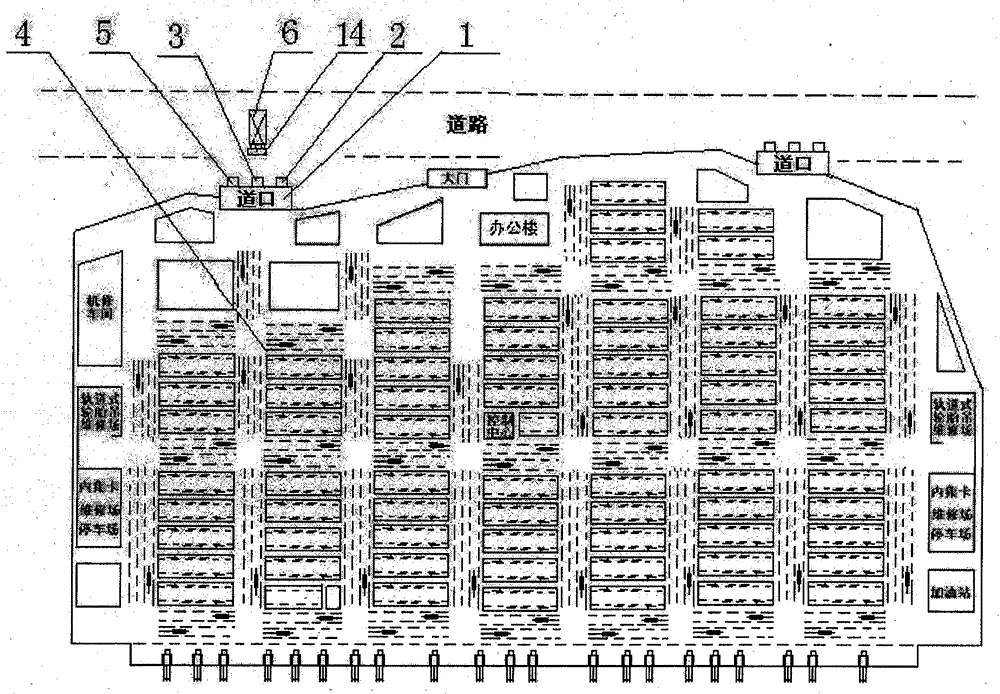

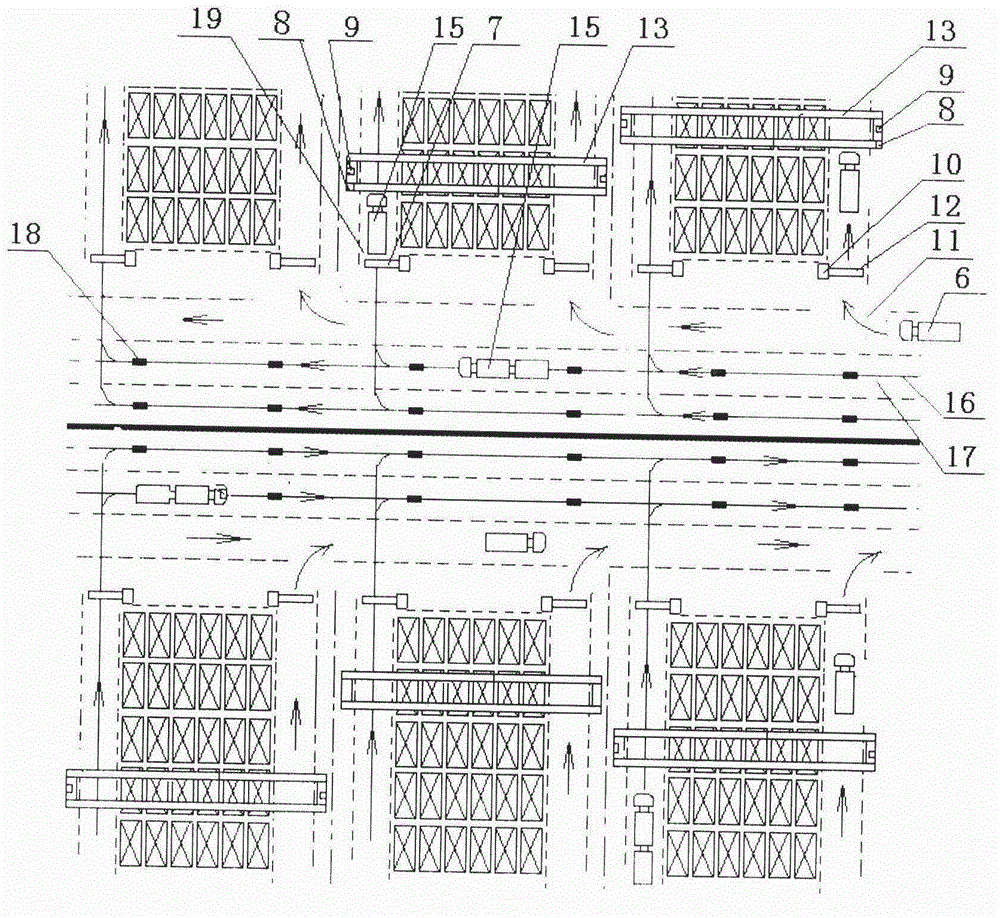

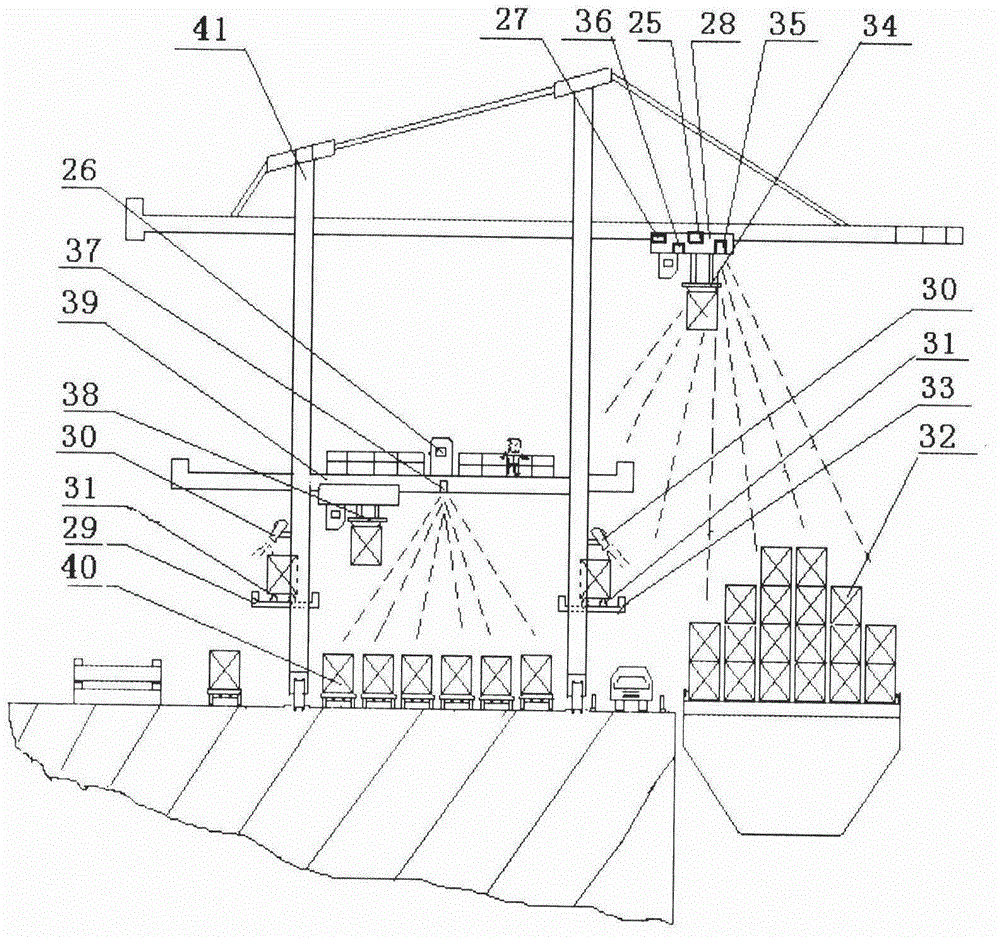

[0025] Below in conjunction with accompanying drawing, the utility model will be further described:

[0026] In the figure, the crossing (1), the box number recognition system (2), the license plate recognition system (3), the field crossing (4), the radio frequency reader (5), the external collection card (6), the crossing gate lever (7) , radio frequency reader (8), laser scanning positioning system (9), crossing radio frequency reader (10), outer truck lane (11), crossing gate lever (12), rail tire crane (13), outer Collector truck GPS reader (14), automatic guided vehicle (15), metal enamel navigation line (16), navigation vehicle lane (17), ground radio frequency card (18), yard crossing (19), image recognition system ( 20), laser scanner (21), metal magnetic detector (22), GPS reader (23), wireless terminal (24), image camera (25), bridge crane control center (26), driving encoder ( 27), height encoder (28), rear platform (29), container number identification system (30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com