Automatic rail transport system of container wharf and operation method

A rail transportation and container technology, applied in the directions of transportation and packaging, conveyors, storage devices, etc., can solve the problems of increased cost, can only travel at both ends, and low horizontal transportation efficiency, and achieves improved work efficiency, high work efficiency, and practicality. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

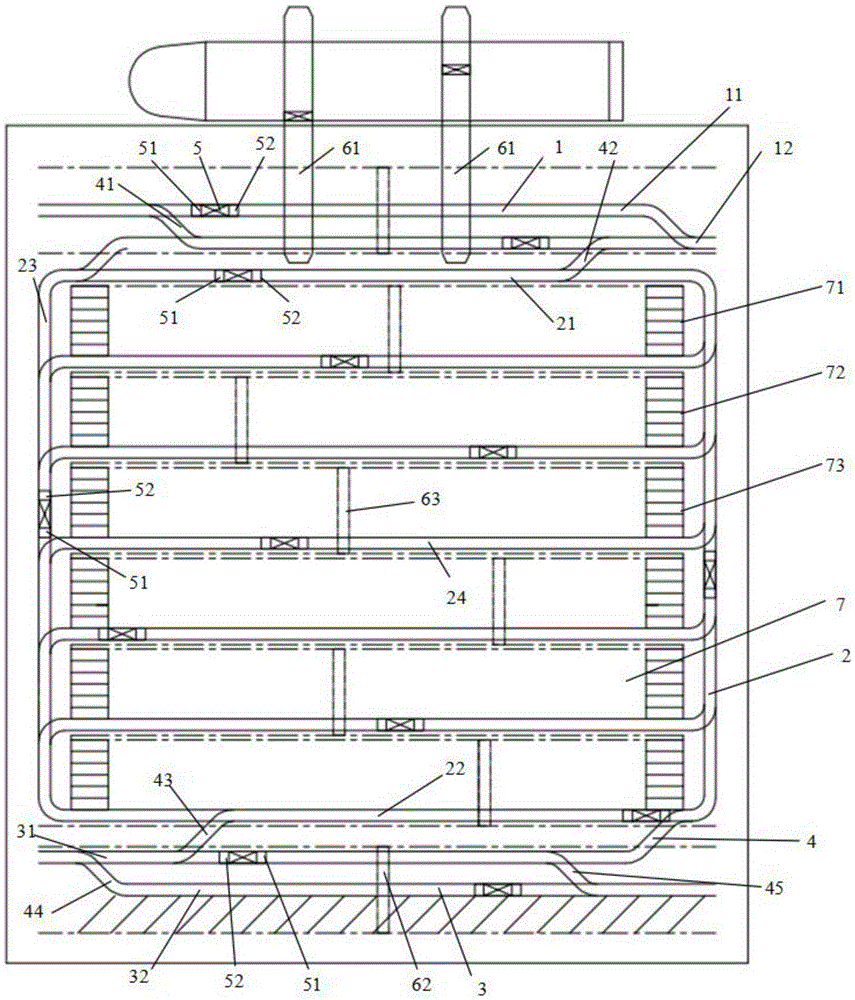

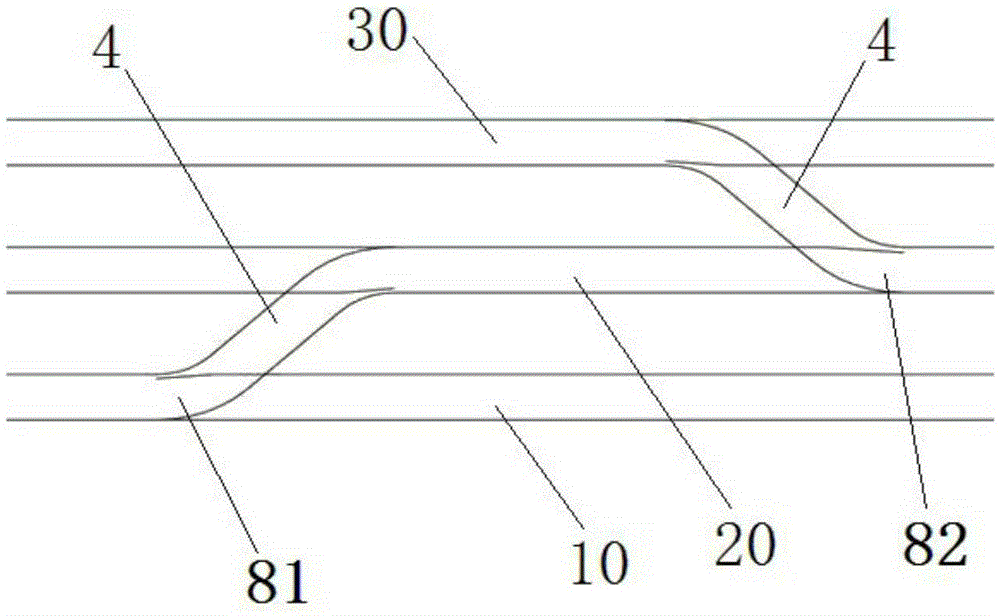

[0051] refer to figure 1, a structural schematic diagram of Embodiment 1 of the container terminal automated rail transportation system of the present invention. As shown in the figure, the transportation system includes at least one shore rail 1 parallel to the shore, at least one set of orbiting rails 2 arranged around the container yard, at least one dredging rail 3 behind the yard, at least A track shuttle car 5 and a plurality of transfer rails 4, and the shore rail and the surrounding rail 2 are connected through the transfer rail 4, and the surrounding rail 2 and the distribution rail 3 are connected through the transfer rail 4;

[0052] The rail shuttle car 5 has a container placement platform, which can run along the rails on the shore rail 1, the surrounding rail 2, the dredging rail 3, and the transfer rail 4, and the rail shuttle car 5 is provided with a control device (the Not shown), the control device accepts and transmits wireless command signals, controls the...

Embodiment 2

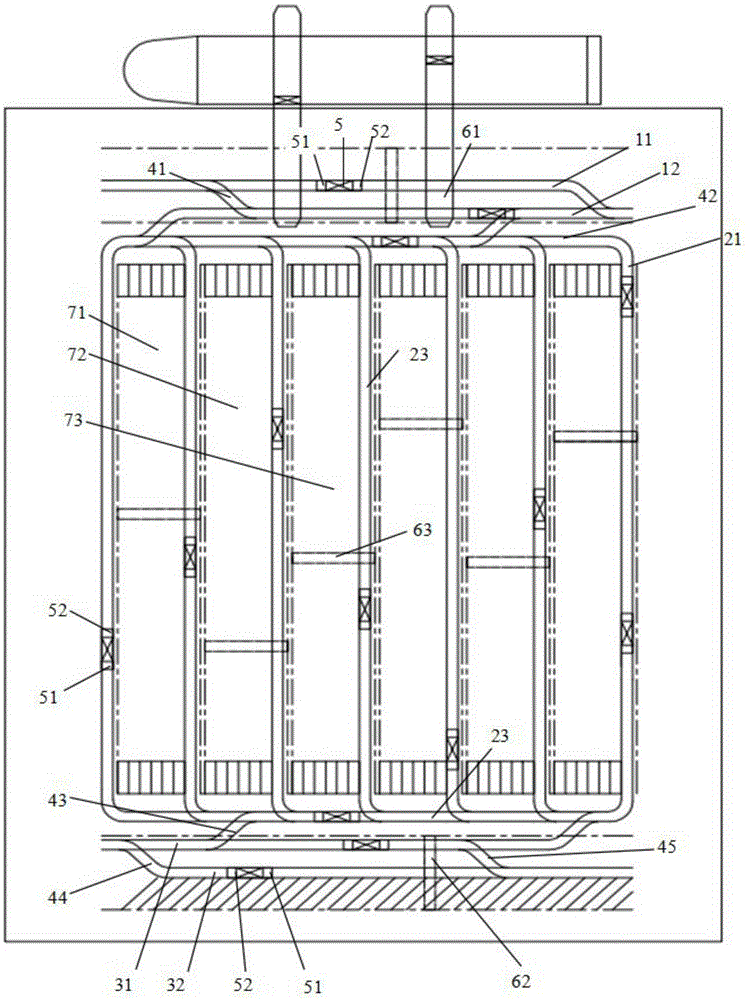

[0068] refer to figure 2 , a structural schematic diagram of Embodiment 2 of the container terminal automated rail transportation system of the present invention. As shown in the figure, the structure and content of the transportation system in this embodiment are basically the same as those in the first embodiment above, the only difference is that the storage yard is a vertical storage yard,

[0069] And there are a plurality of stack areas, each of which includes a plurality of stacking positions 7; the rail transportation system includes multiple sets of the surrounding tracks 2, and each set of the surrounding tracks 2 includes two vertical tracks and a plurality of Parallel tracks, and a stacking position 7 is arranged between every two parallel tracks, and each stack area is correspondingly provided with a set of surrounding tracks; the loading and unloading equipment 63 provided in the stockyard can travel to the parallel track. The rail shuttle car 5 on the track ca...

Embodiment 3

[0072] The present invention also proposes an operation method of the transportation system, comprising the following steps:

[0073] The process of transporting the container from the loading and unloading position on the shore to the unloading and unloading position behind the yard for unloading:

[0074] 1) The rail shuttle car 5 travels to the shore side loading and unloading position of the shore side track 1 to load and unload the container;

[0075] 2) The rail shuttle car 5 changes the track by exchanging the direction mode, and travels into the orbiting track 2 via the transfer track 4;

[0076] 3) The track shuttle car 5 travels unidirectionally along the orbital track 2 to a position where it connects with the transport track 3 through the transfer track 4;

[0077] 4) track shuttle car 5 is changed track by exchanging described direction mode, travels into dredging and transporting track 3 via transfer track 4;

[0078] 5) The track shuttle car 5 travels along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com